Patents

Literature

155results about "Preparation by carbon oxide reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

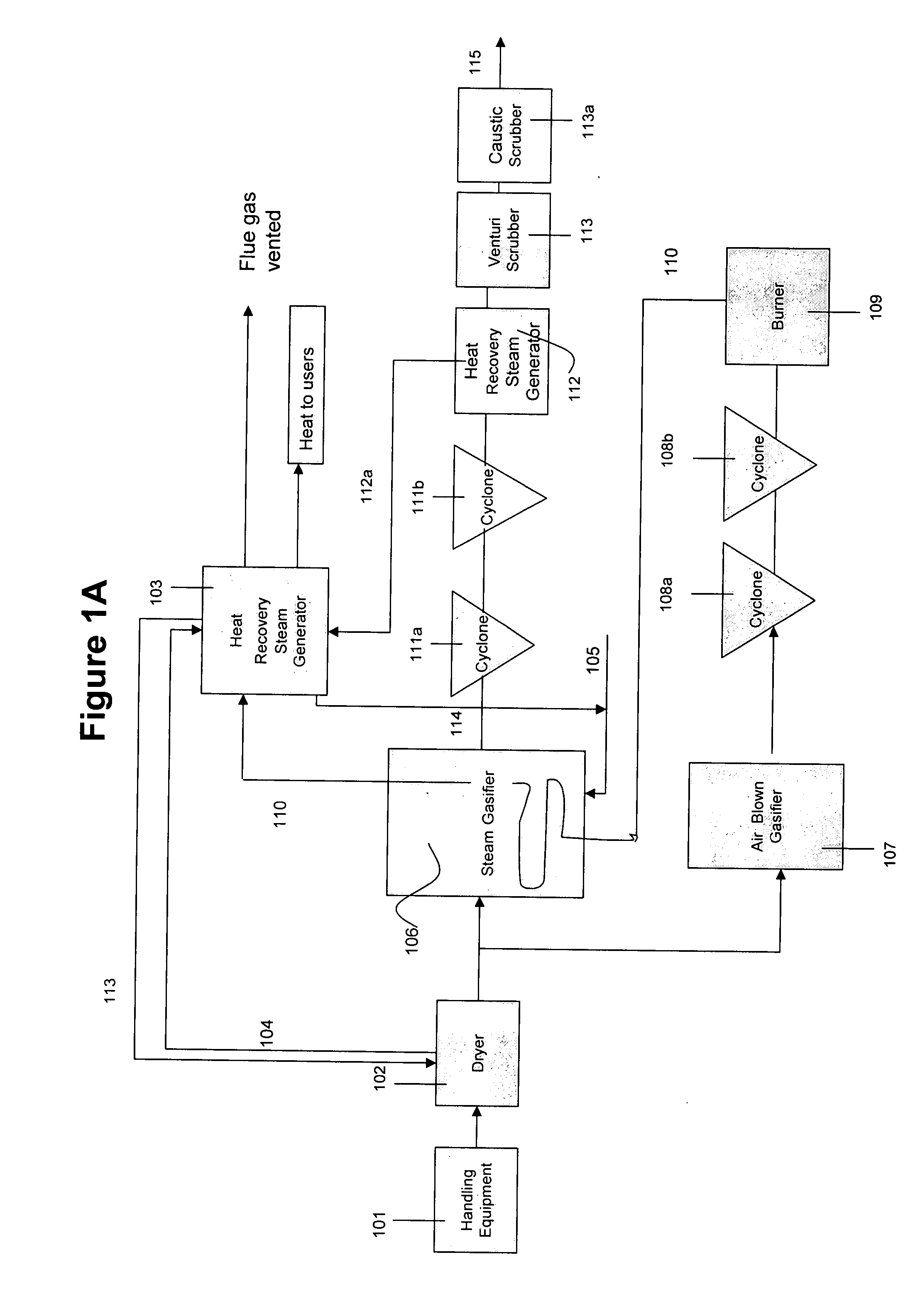

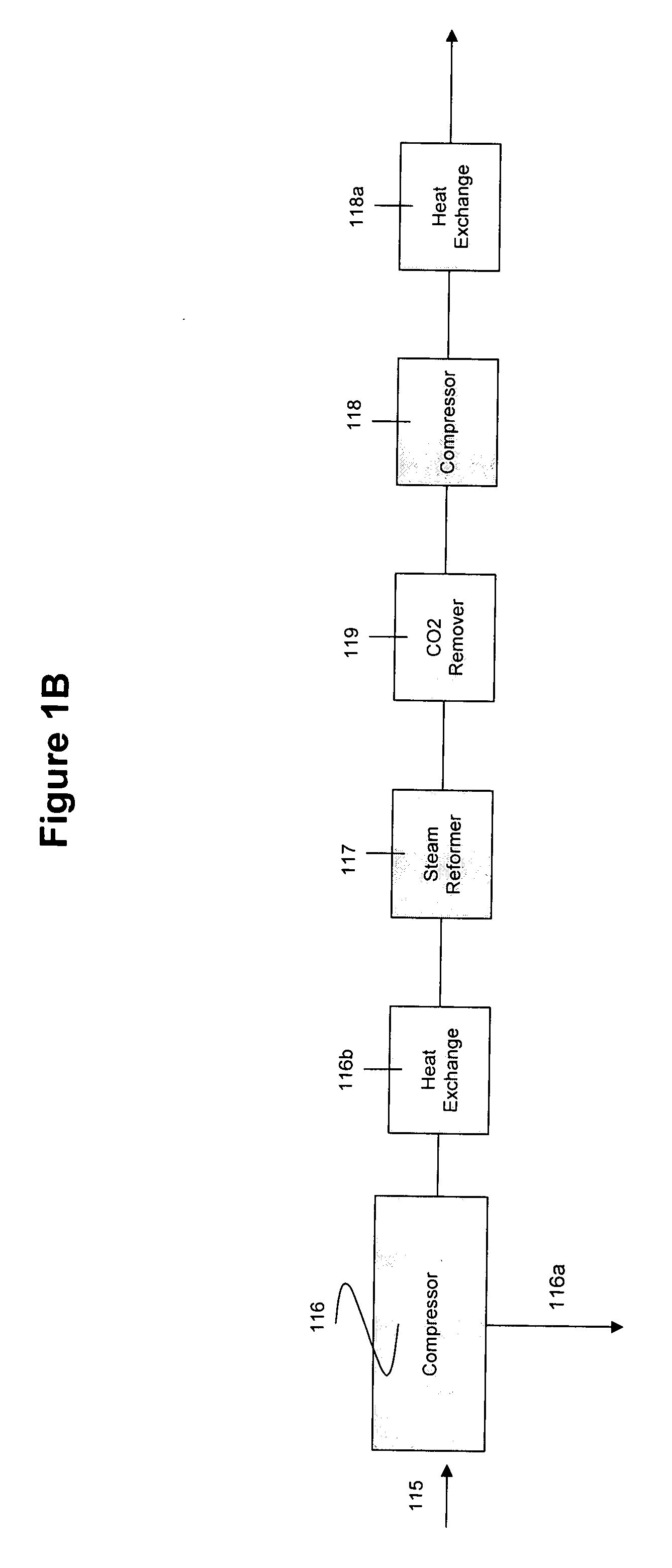

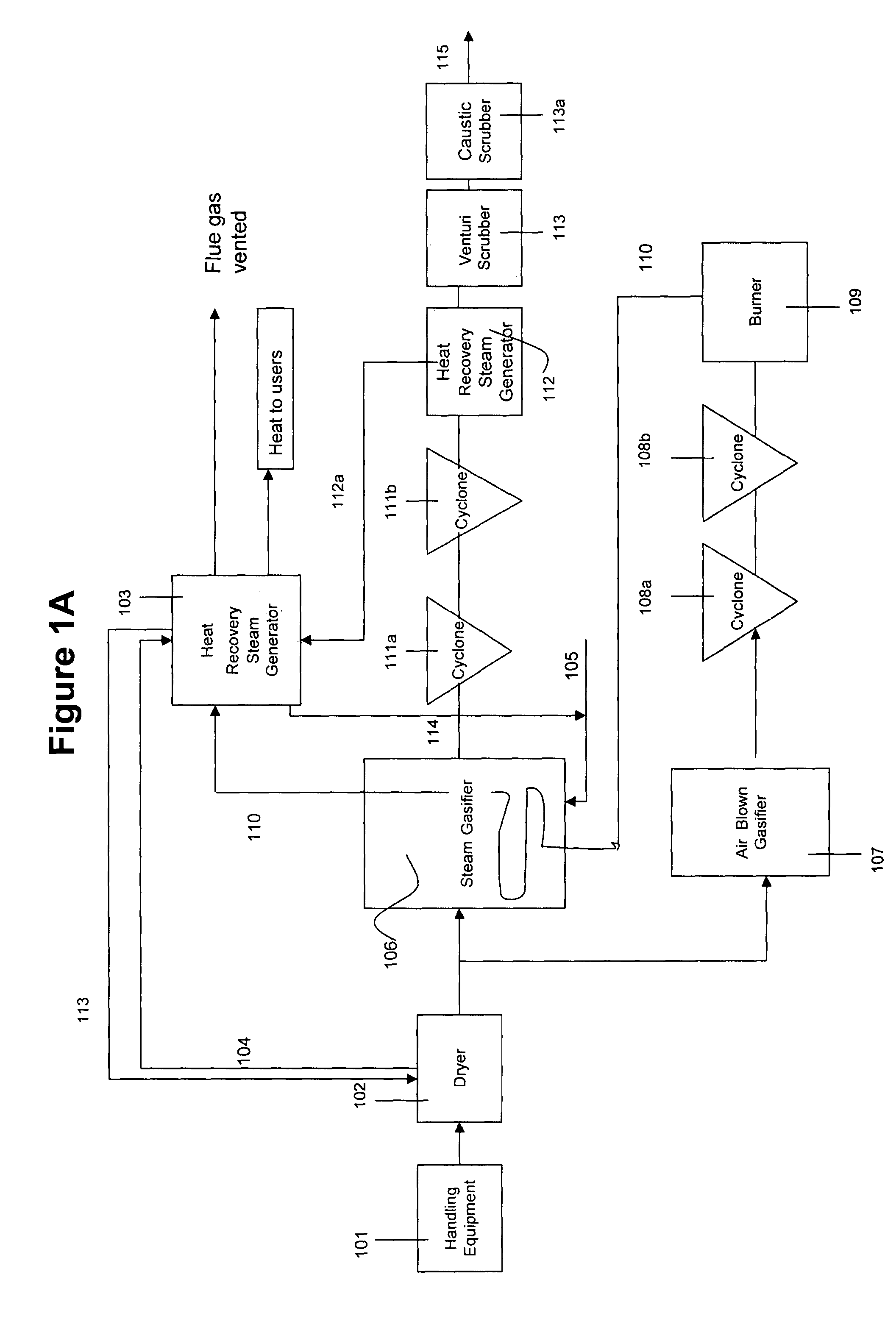

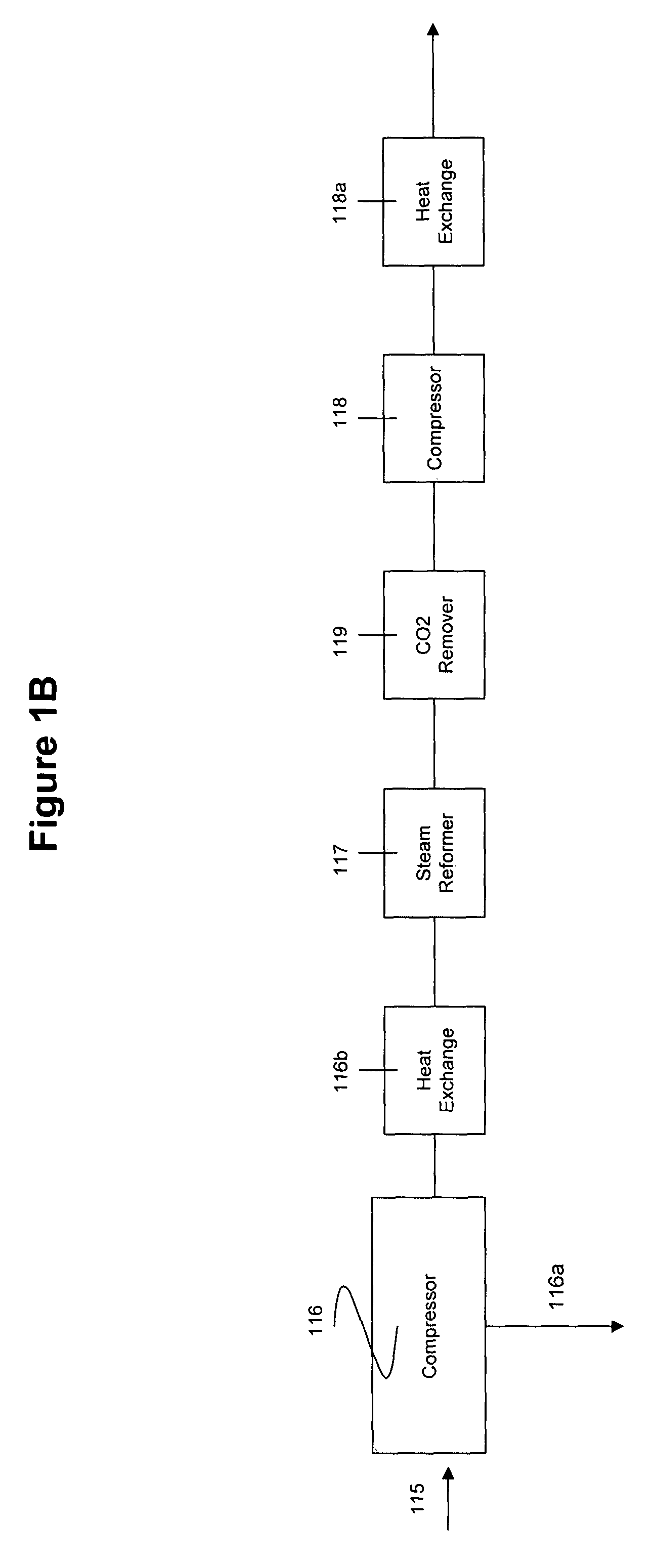

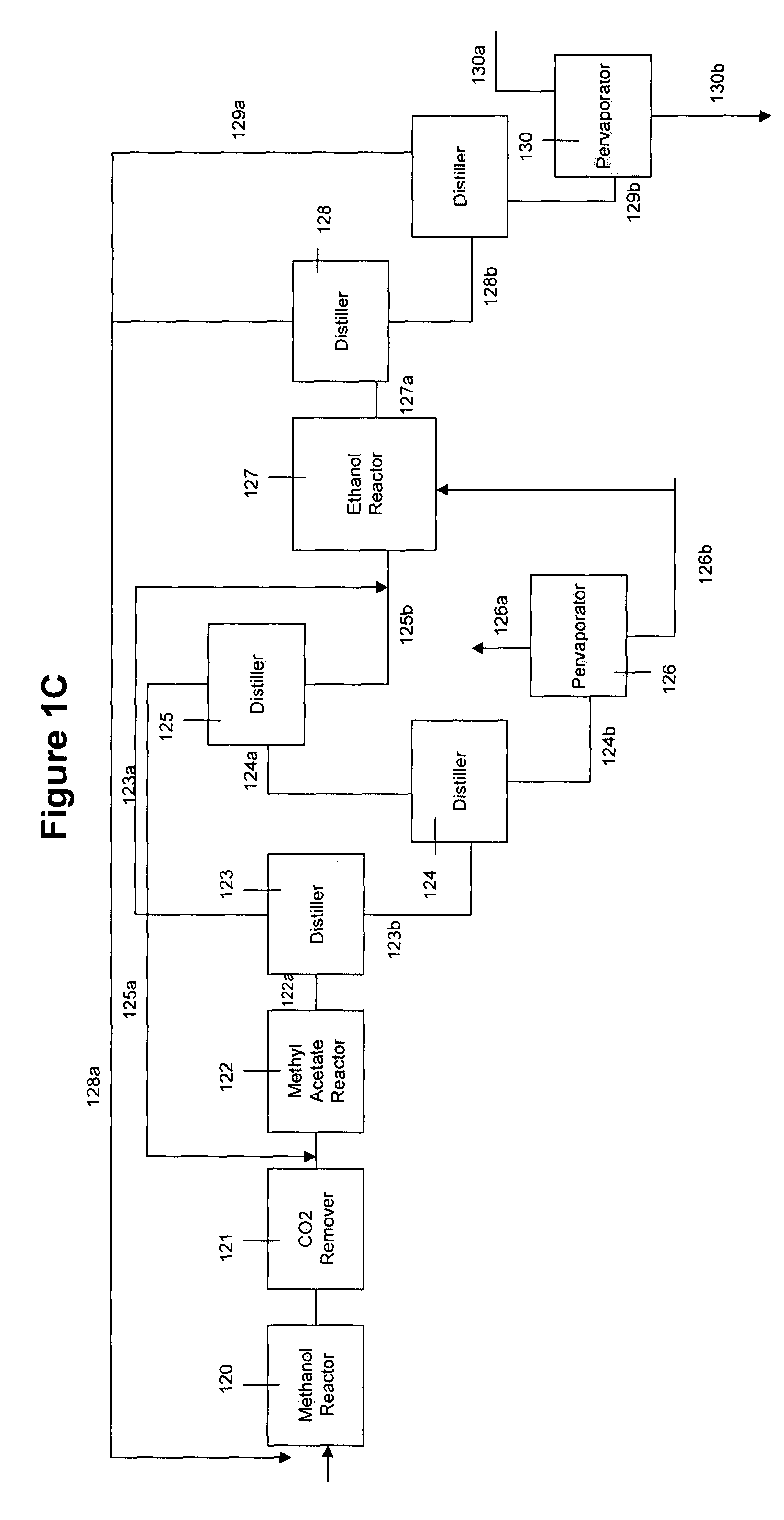

System and method for converting biomass to ethanol via syngas

A method and apparatus for synthesizing ethanol using synthetic routes via synthesis gas are disclosed. A method and apparatus for gasifying biomass, such as biomass, in a steam gasifier that employs a fluidized bed and heating using hot flue gases from the combustion of synthesis gas is described. Methods and apparatus for converting synthesis gas into ethanol are also disclosed, using stepwise catalytic reactions to convert the carbon monoxide and hydrogen into ethanol using catalysts including iridium acetate.

Owner:WOODLAND BIOFUELS

Integrate chemical processes for industrial utilization of seed oils

ActiveUS20050154221A1Easy to operateHigh olefin conversionFatty oils/acids recovery from wasteOxygen-containing compound preparationPolyesterAmino esters

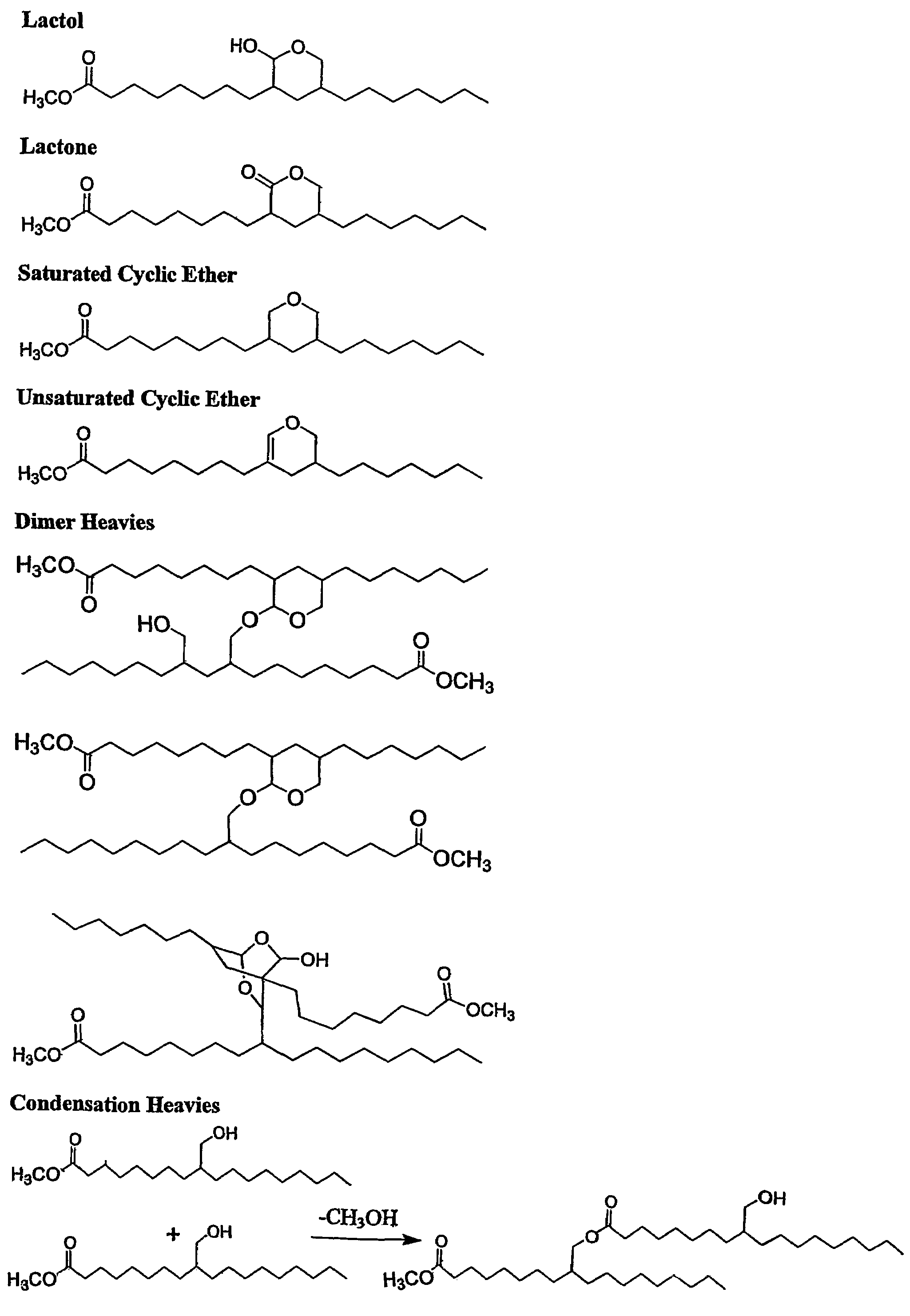

Integrated processes of preparing industrial chemicals starting from seed oil feedstock compositions containing one or more unsaturated fatty acids or unsaturated fatty acid esters, which are essentially free of metathesis catalyst poisons, particularly hydroperoxides; metathesis of the feedstock composition with a lower olefin, such as ethylene, to form a reduced chain olefin, preferably, a reduced chain α-olefin, and a reduced chain unsaturated acid or ester, preferably, a reduced chain α,Ω-unsaturated acid or ester. The reduced chain unsaturated acid or ester may be (trans)esterified to form a polyester polyolefin, which may be epoxidized to form a polyester polyepoxide. The reduced chain unsaturated acid or ester may be hydroformylated with reduction to produce an α,Ω-hydroxy acid or α,Ω-hydroxy ester, which may be (trans)esterified with a polyol to form an α,Ωpolyester polyol. Alternatively, the reduced chain unsaturated acid or ester may be hydroformylated with reductive amination to produce an α,Ω-amino acid or α,Ω-amino ester, which may be (trans)esterified to form an α,Ωpolyester polyamine.

Owner:DOW GLOBAL TECH LLC

Dimerized alcohol compositions and biodegradible surfactants made therefrom having cold water detergency

InactiveUS6222077B1Good cold water detergencyOrganic detergent compounding agentsOther chemical processesDouble bondCarboxylic acid

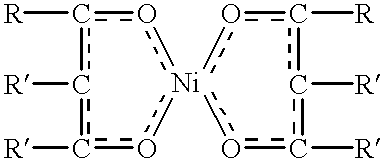

There is provided an alcohol composition obtained by dimerizing an olefin feed comprising C6-C10 linear olefins to obtain C12-C20 olefins, followed by conversion to alcohols, such as by hydroformylation. The composition has an average number of branches ranging from 0.9 to 2.0 per molecule. The linear olefin feed preferably comprises at least 85% of C6-C8-olefins. The primary alcohol compositions are then converted to anionic or nonionic surfactants, preferably sulfated or oxyalkylated or both. The sulfated compositions are biodegradable and possess good cold water detergency. The process for making the dimerized primary alcohol comprises dimerizing, in the presence of a homogeneous dimerization catalyst under dimerization conditions, an olefin feed comprising C6-C10 olefins and preferably at least 85 weight % of linear olefins based on the weight of the olefin feed, to obtain a C12-C20; optionally double bond isomerizing said C12-C20 olefins; and converting the C12-C20 olefins to alcohols, preferably through hydroformylation. The process is preferably a one-step dimerization. The homogenous catalyst comprises a mixture of a nickel carboxylate or a nickel chelate, with an alkyl aluminum halide or an alkyl aluminum alkoxide.

Owner:SHELL OIL CO

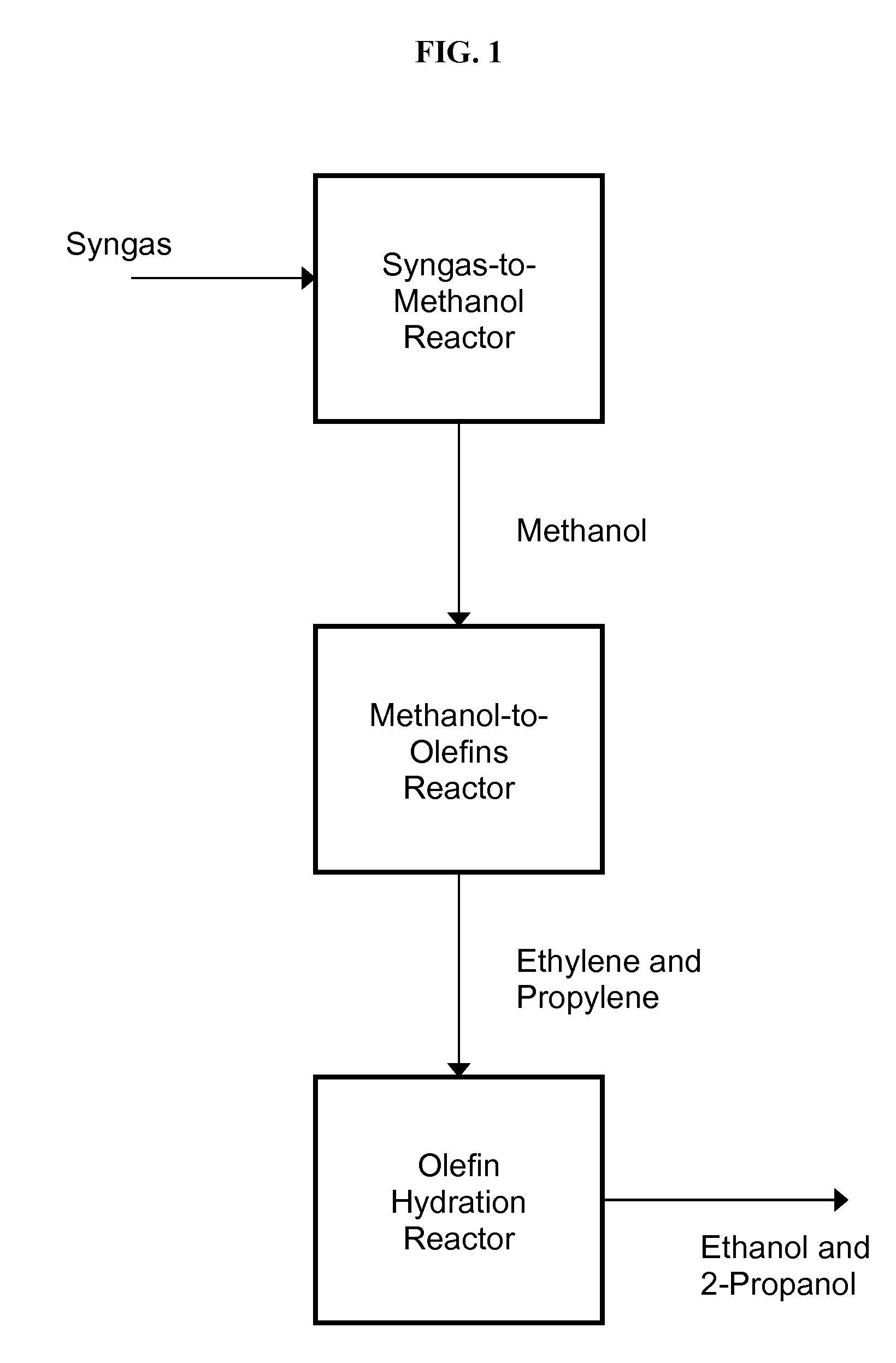

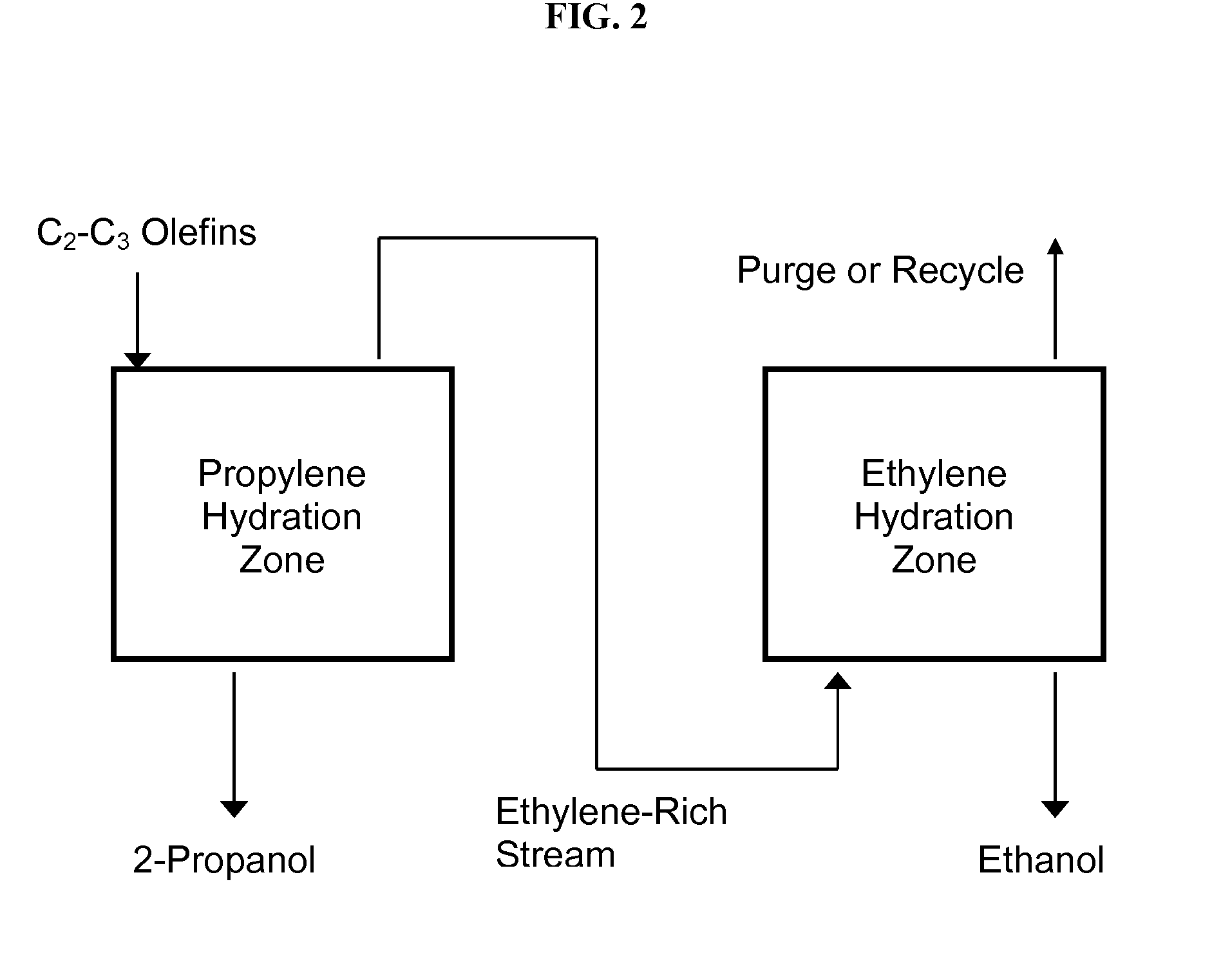

Methods and apparatus for synthesis of alcohols from syngas

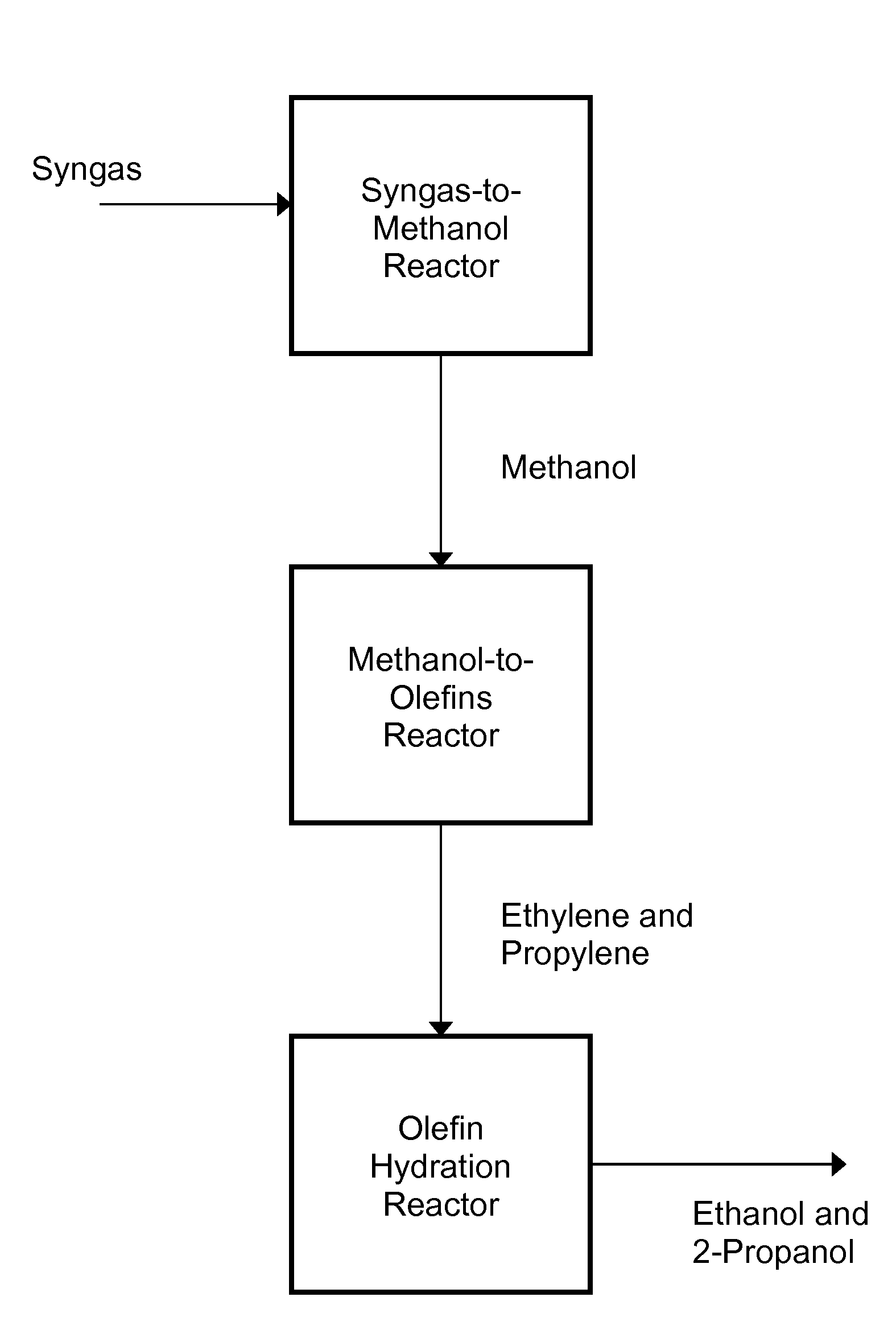

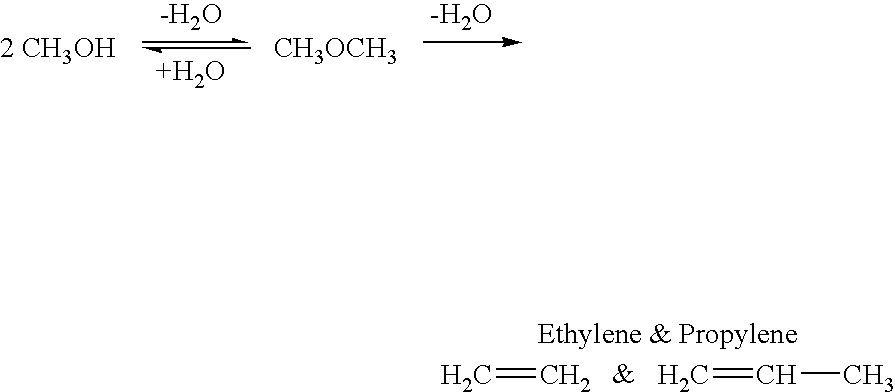

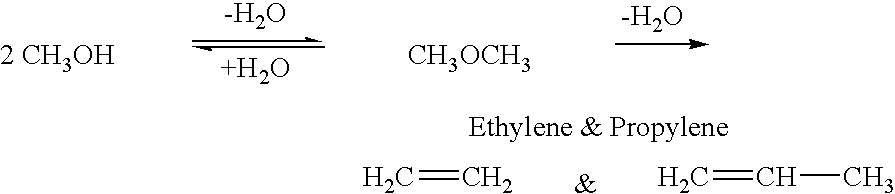

This invention provides a method for producing ethanol and 2-propanol from syngas, the method comprising: (a) converting syngas into methanol using a methanol-synthesis catalyst; (b) converting methanol into ethylene and propylene using a methanol-to-olefins catalyst; and (c) hydrating ethylene into ethanol and propylene into 2-propanol. As taught herein, the combined yield of the ethanol and the 2-propanol from biomass can be at least 100 gallons per dry ton biomass. In certain embodiments, the yield of ethanol is at least 100 gallons per dry ton biomass. In some embodiments, the yield of 2-propanol is at least 50 gallons per dry ton biomass.

Owner:ALBEMARLE CORP +1

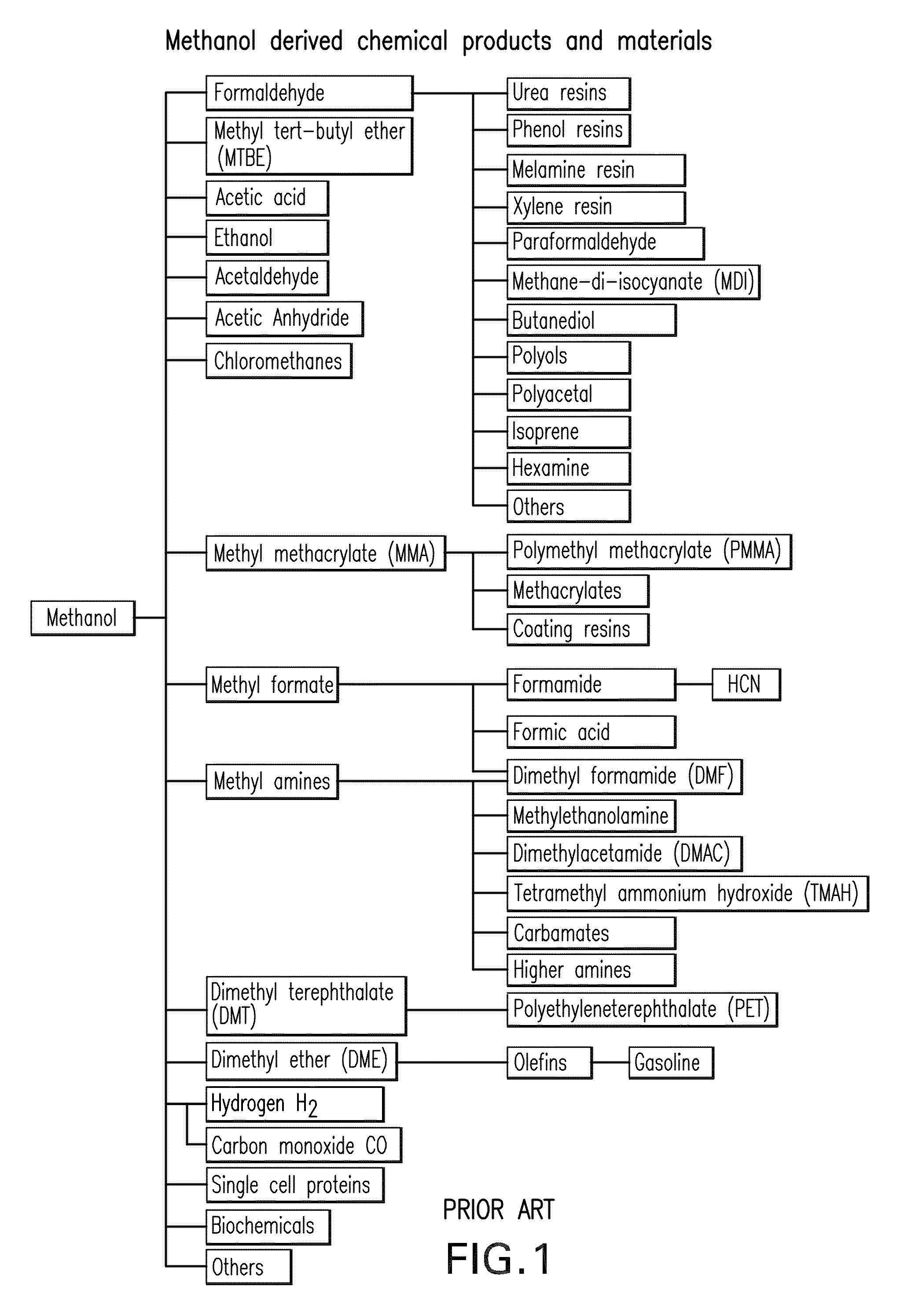

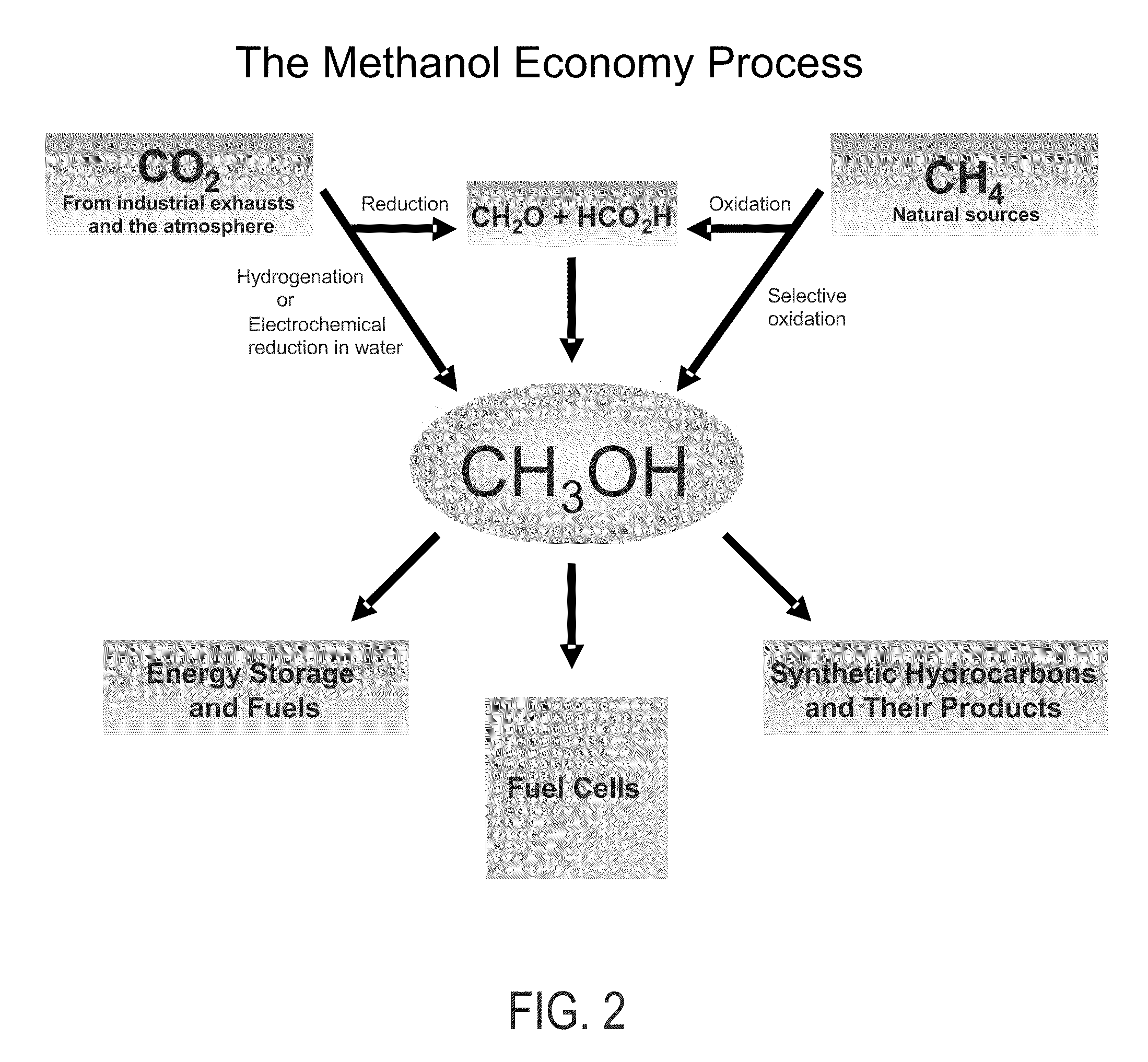

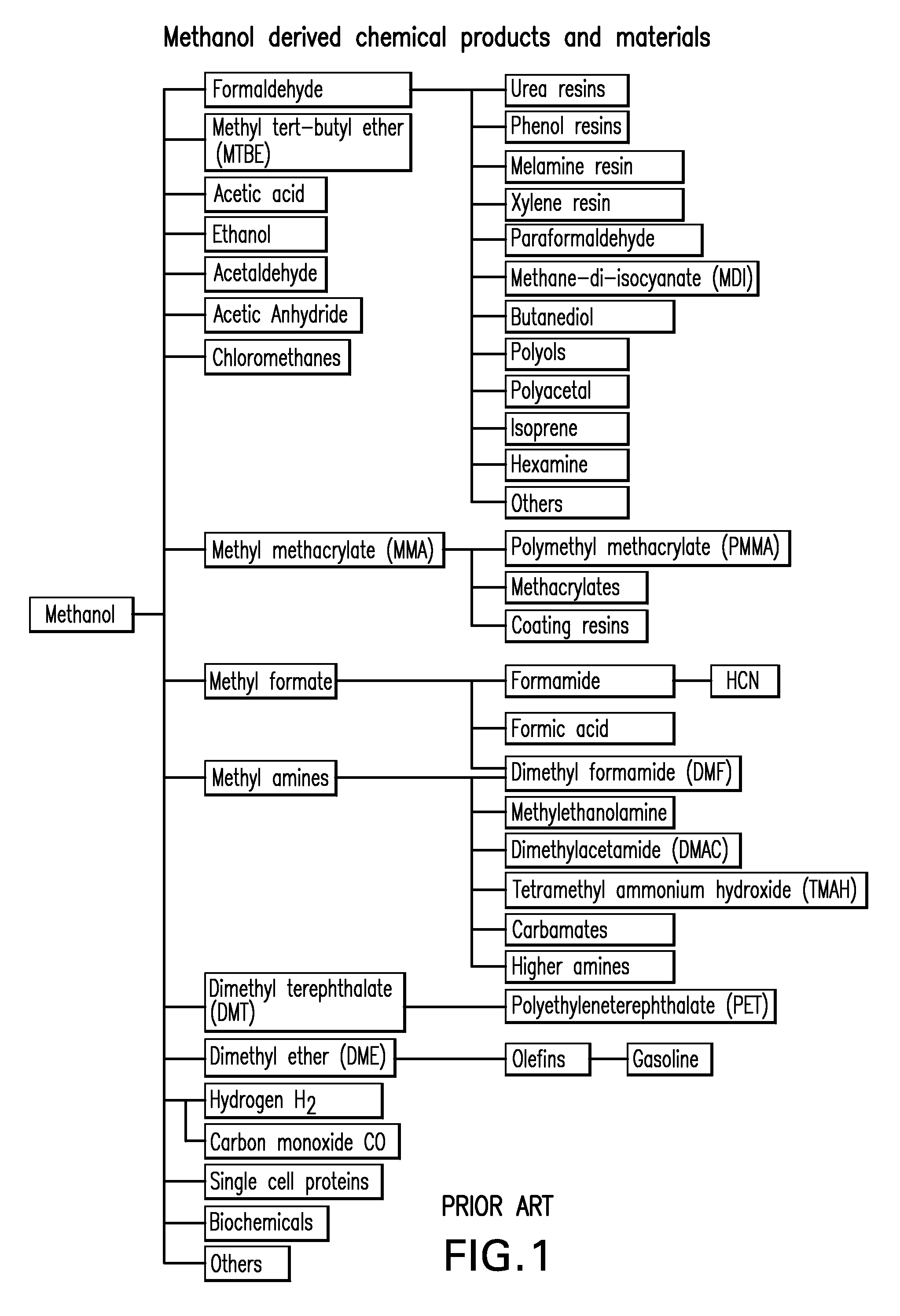

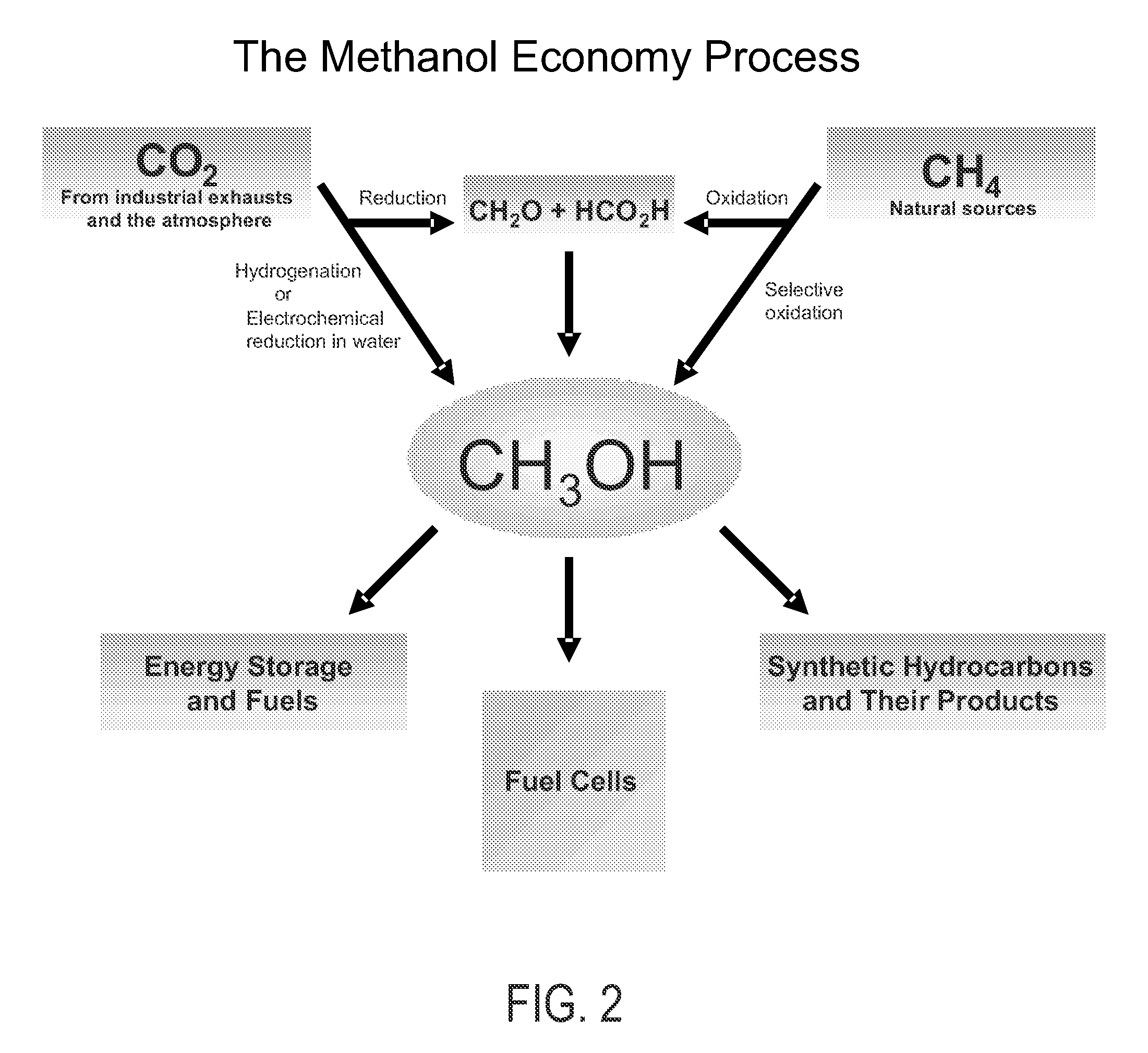

Method for producing methanol, dimethyl ether, derived synthetic hydrocarbons and their products from carbon dioxide and water (moisture) of the air as sole source material

InactiveUS7378561B2High activityImprove surface activityOrganic compound preparationOrganic chemistry methodsNano structuringWater source

A method for producing methanol and dimethyl ether using the air as the sole source of materials is disclosed. The invention relates to a method for separating the water (i.e., the moisture in the air) and carbon dioxide content of atmospheric air for their use in the subsequent production of methanol, dimethyl ether and derived synthetic hydrocarbons as products. The method includes the conversion of carbon dioxide and water under conditions sufficient to produce methanol and / or dimethyl ether. Methanol and / or dimethyl ether can be used as fuel or fuel additives or further converted to synthetic hydrocarbons and their products. Carbon dioxide is captured on a suitable absorbent, preferentially polyethyleneimine supported on nano-structured fumed silica. The process can also involve hydrogenation with hydrogen produced by electrolysis of water obtained from the air or from any other water source. Methanol can be dehydrated to produce dimethyl ether or further processed to produce synthetic hydrocarbons, polymers, and products derived from them by other known methods.

Owner:UNIV OF SOUTHERN CALIFORNIA

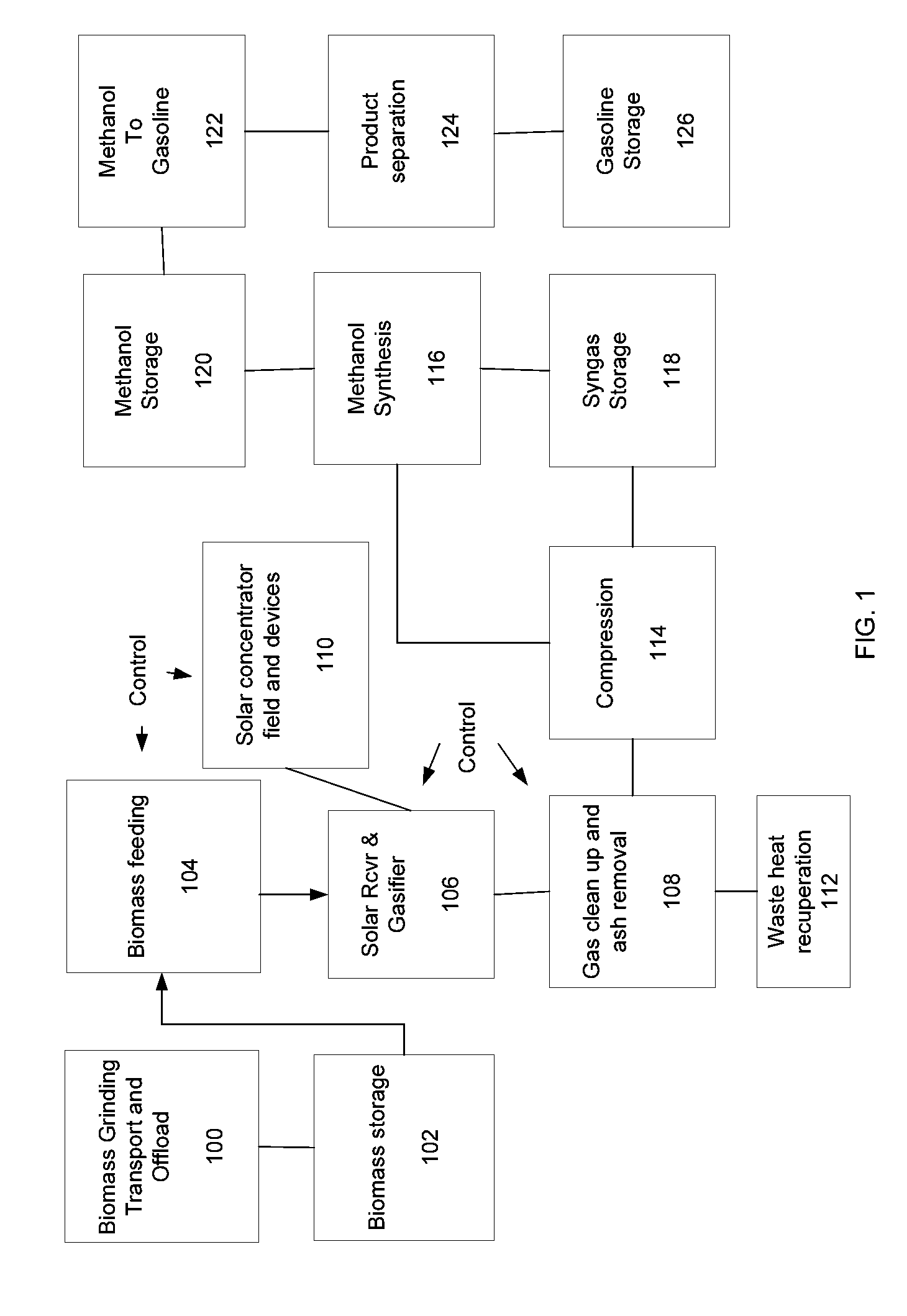

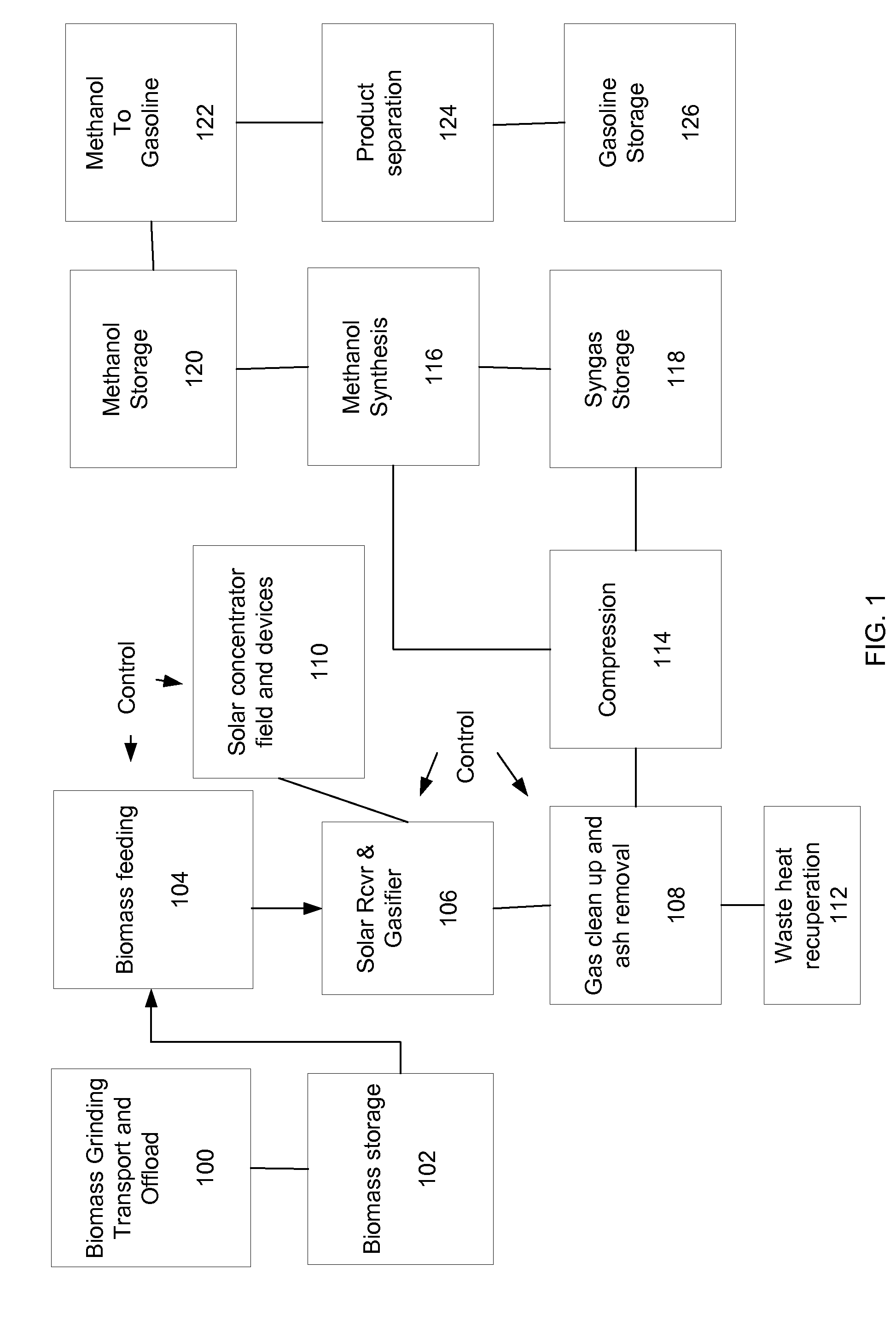

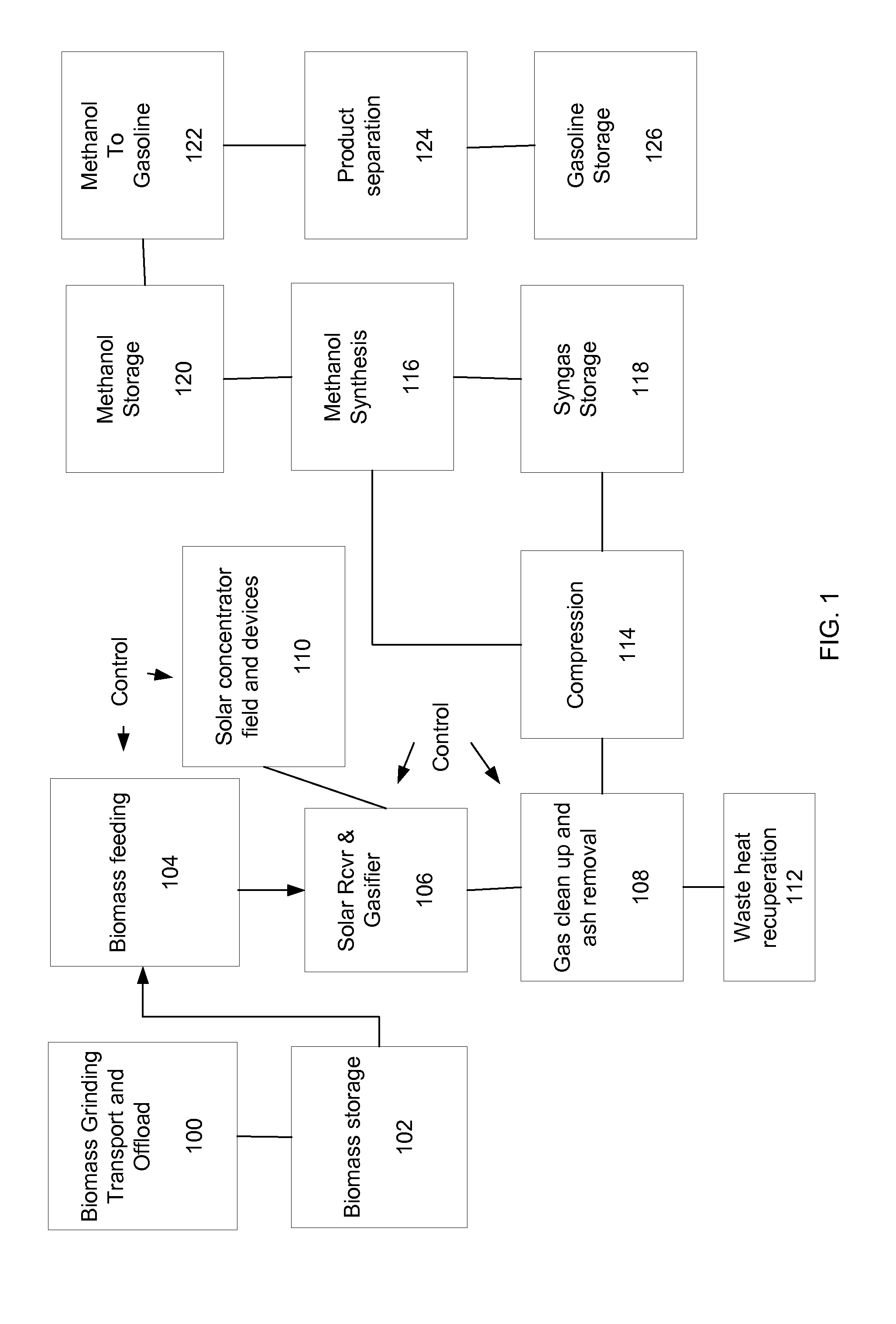

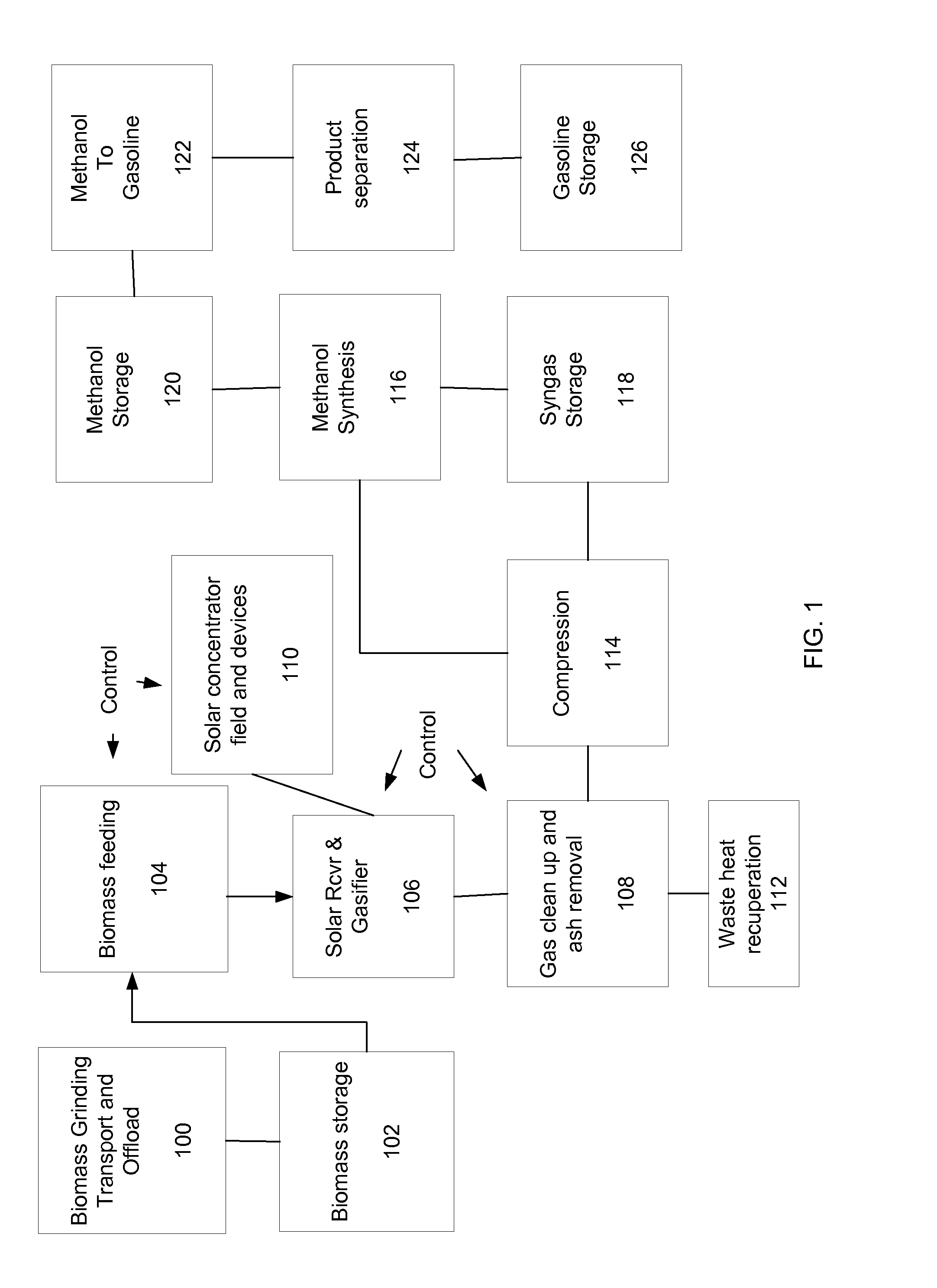

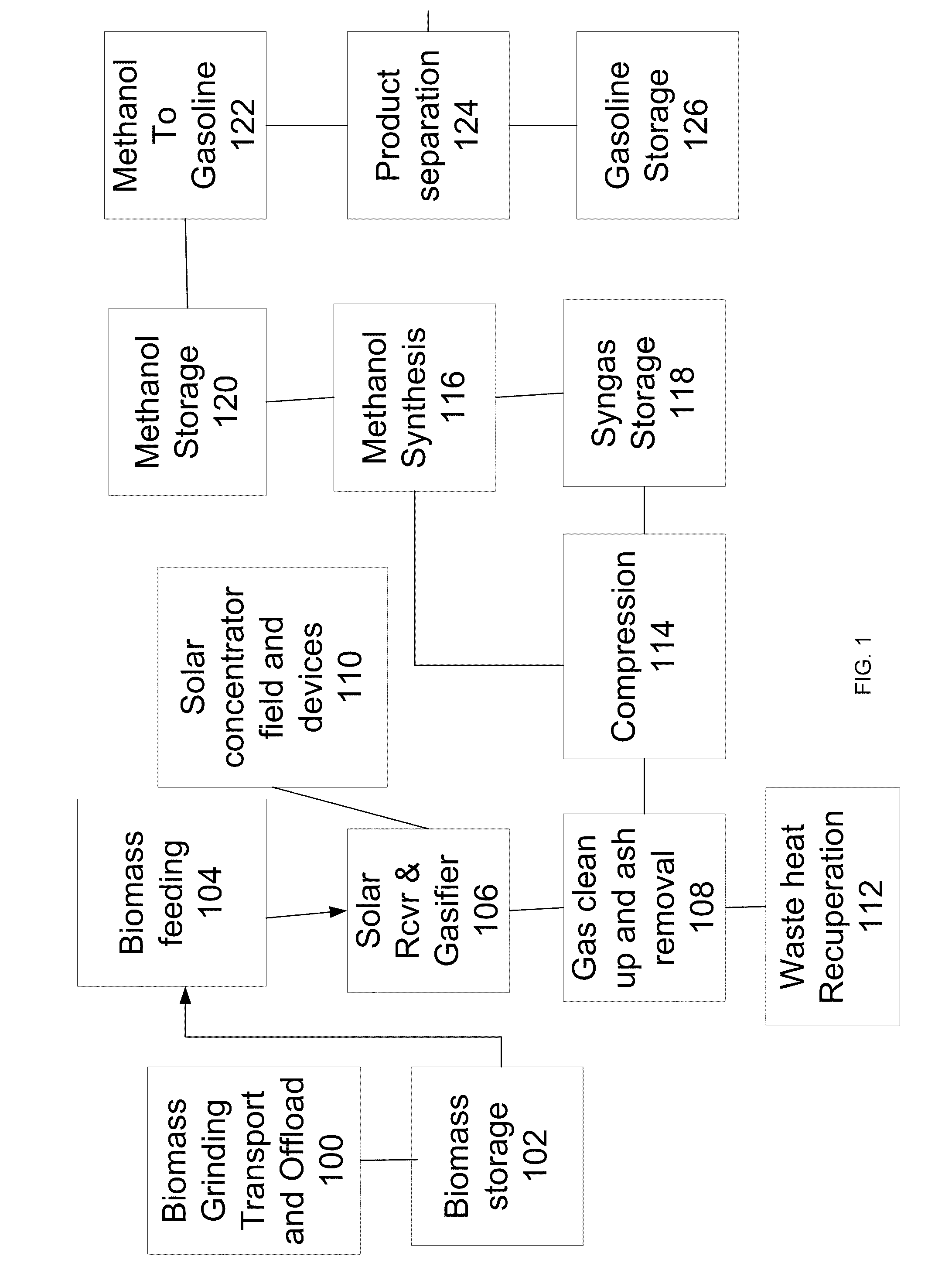

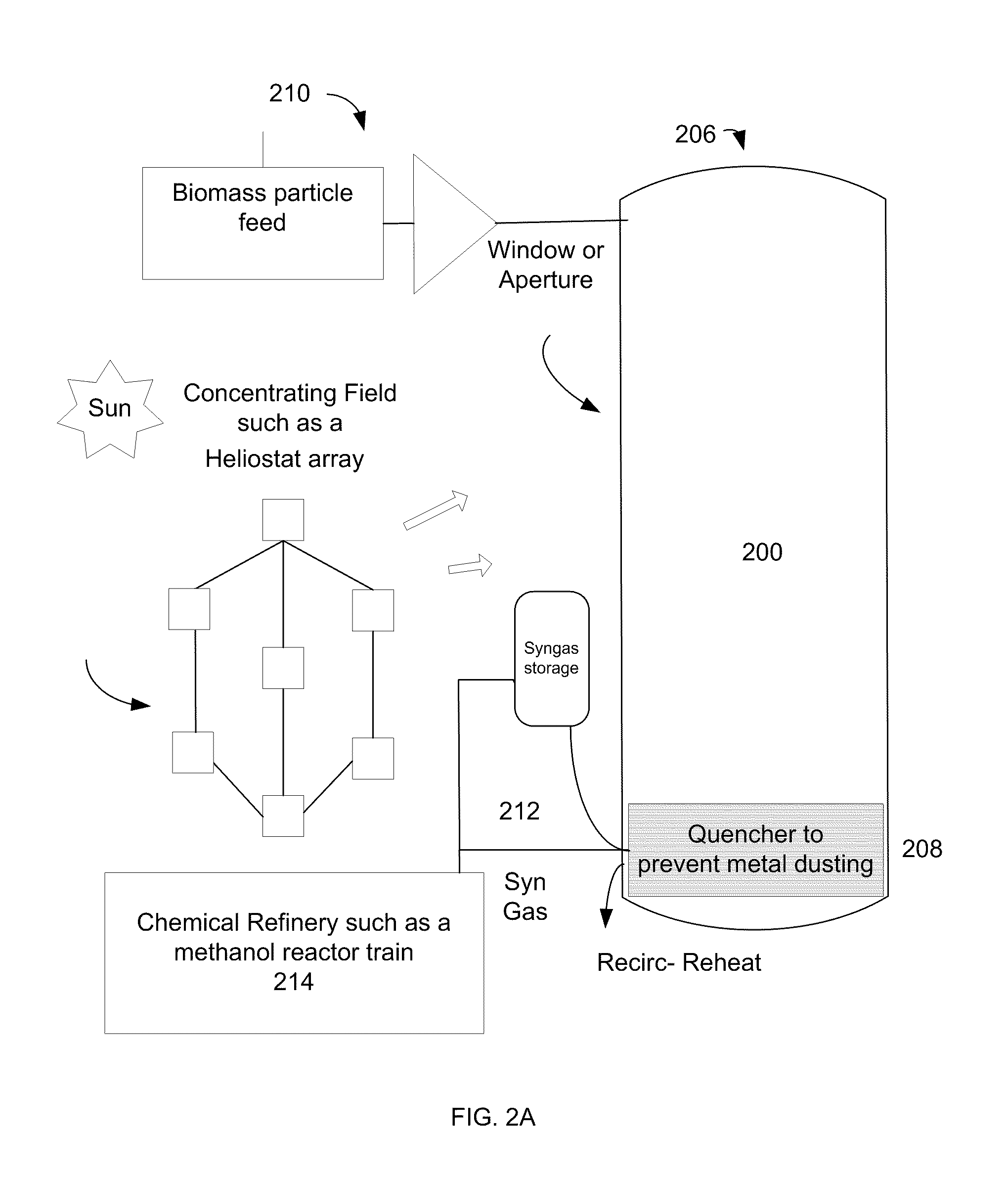

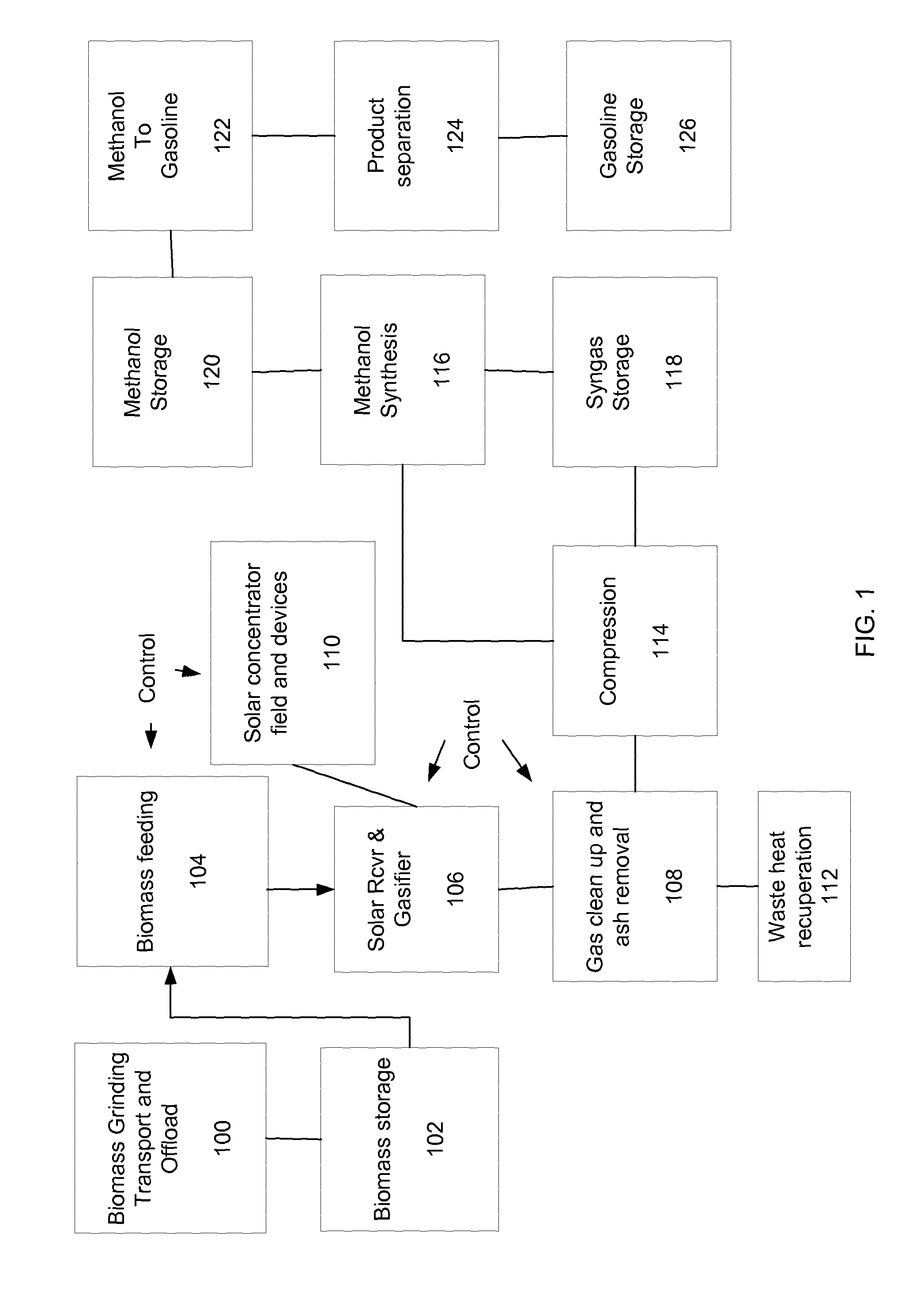

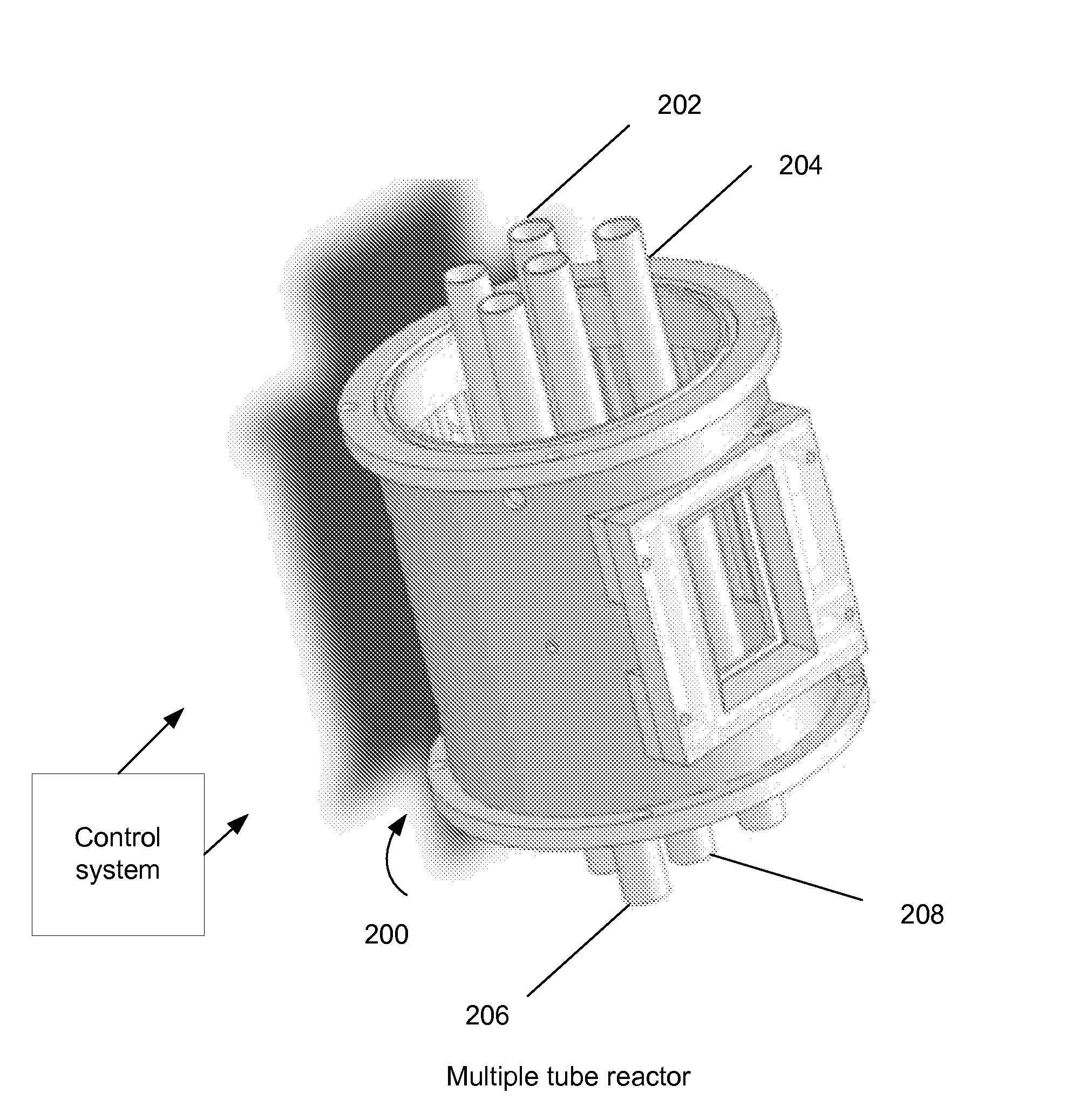

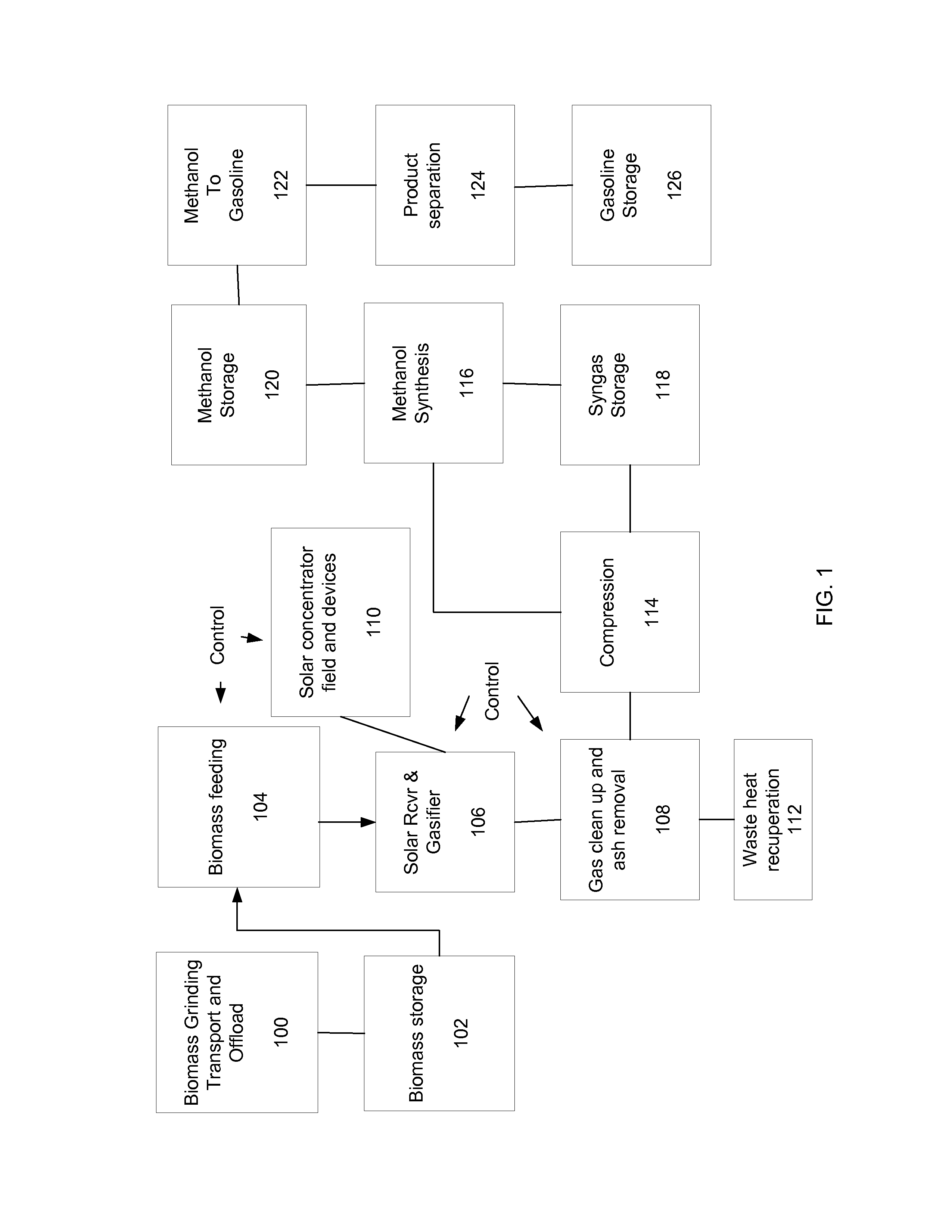

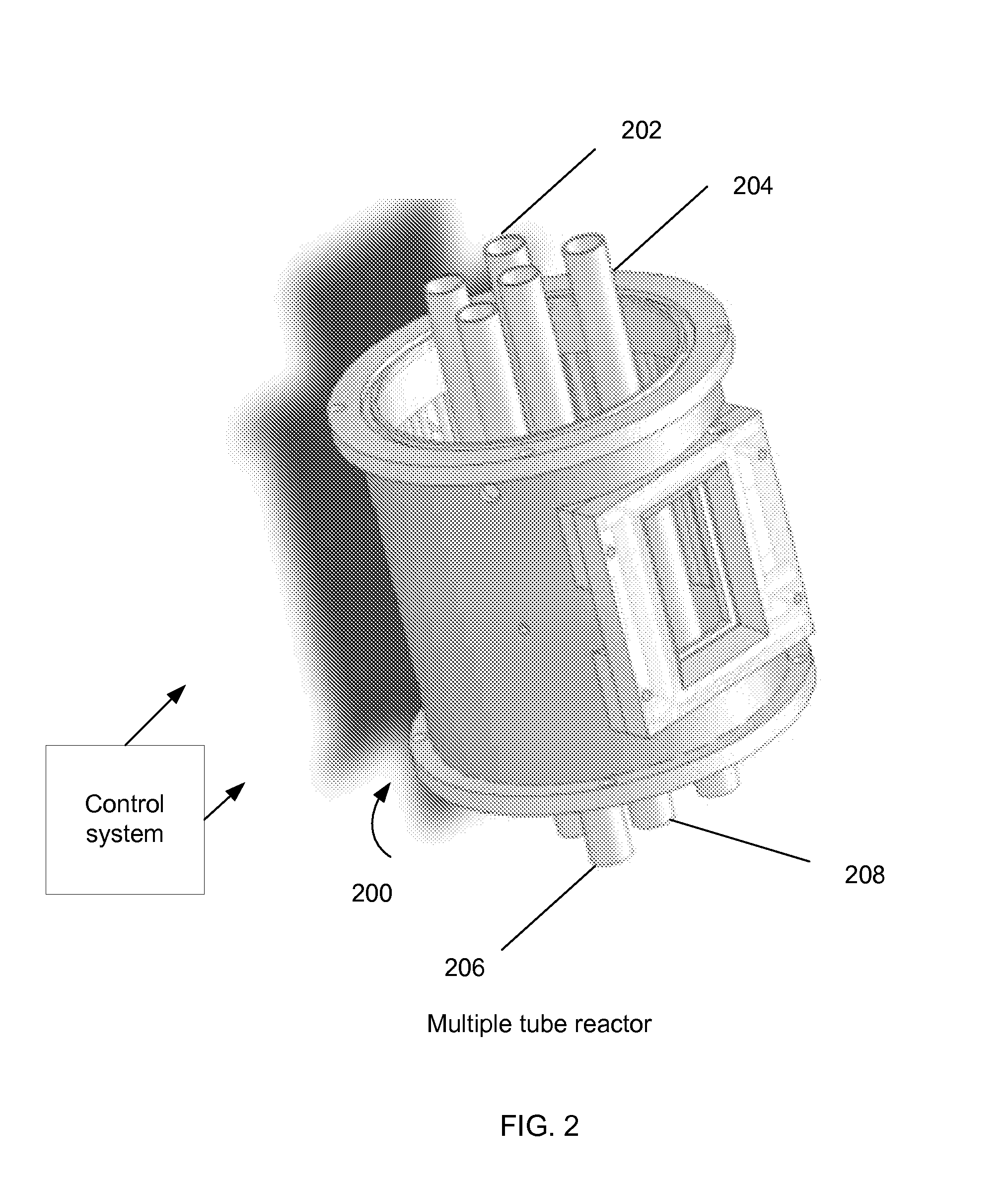

Systems and methods for solar-thermal gasification of biomass

InactiveUS20100237291A1Process control/regulationSolar heating energySteam reformingChemical reaction

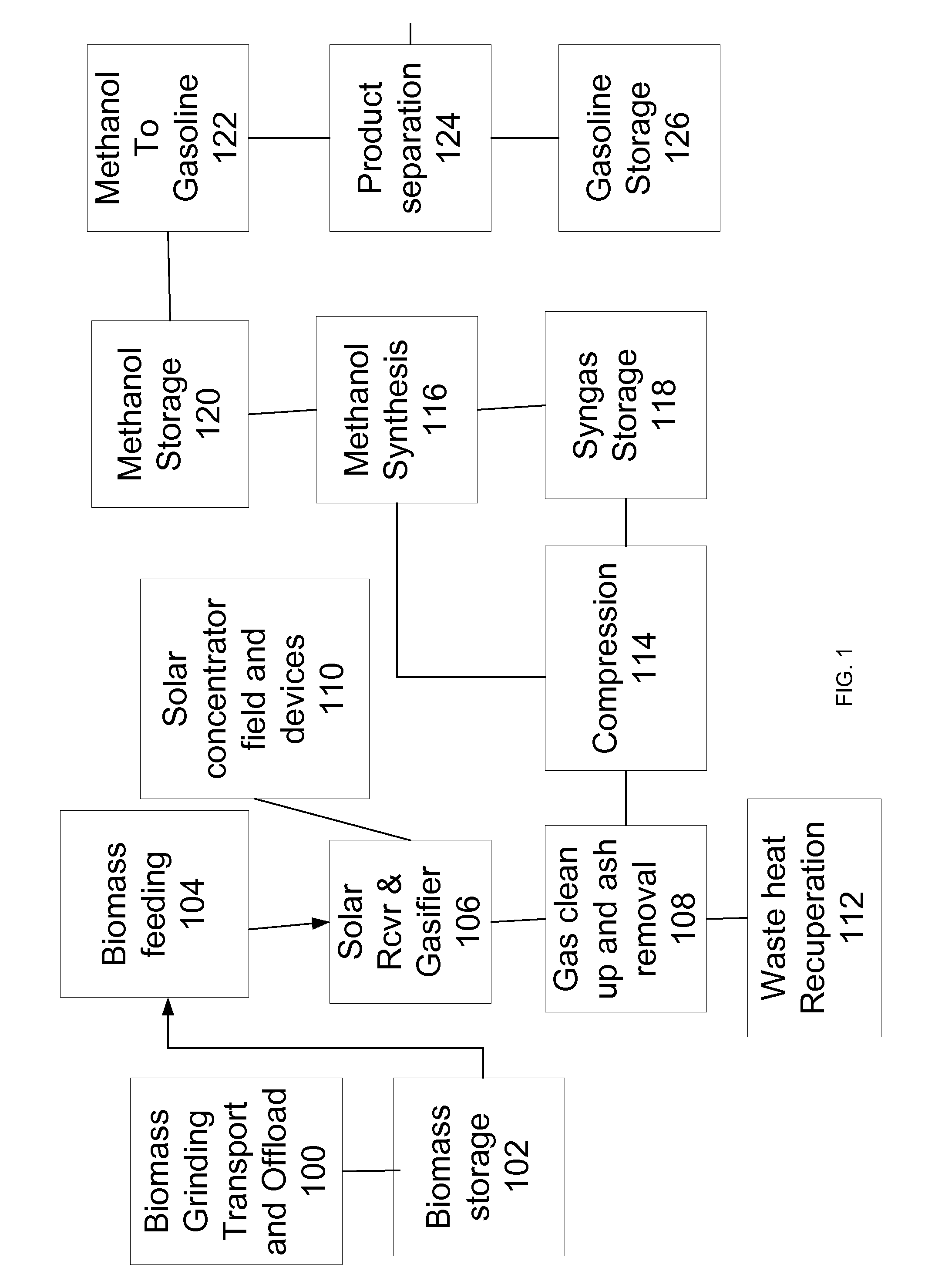

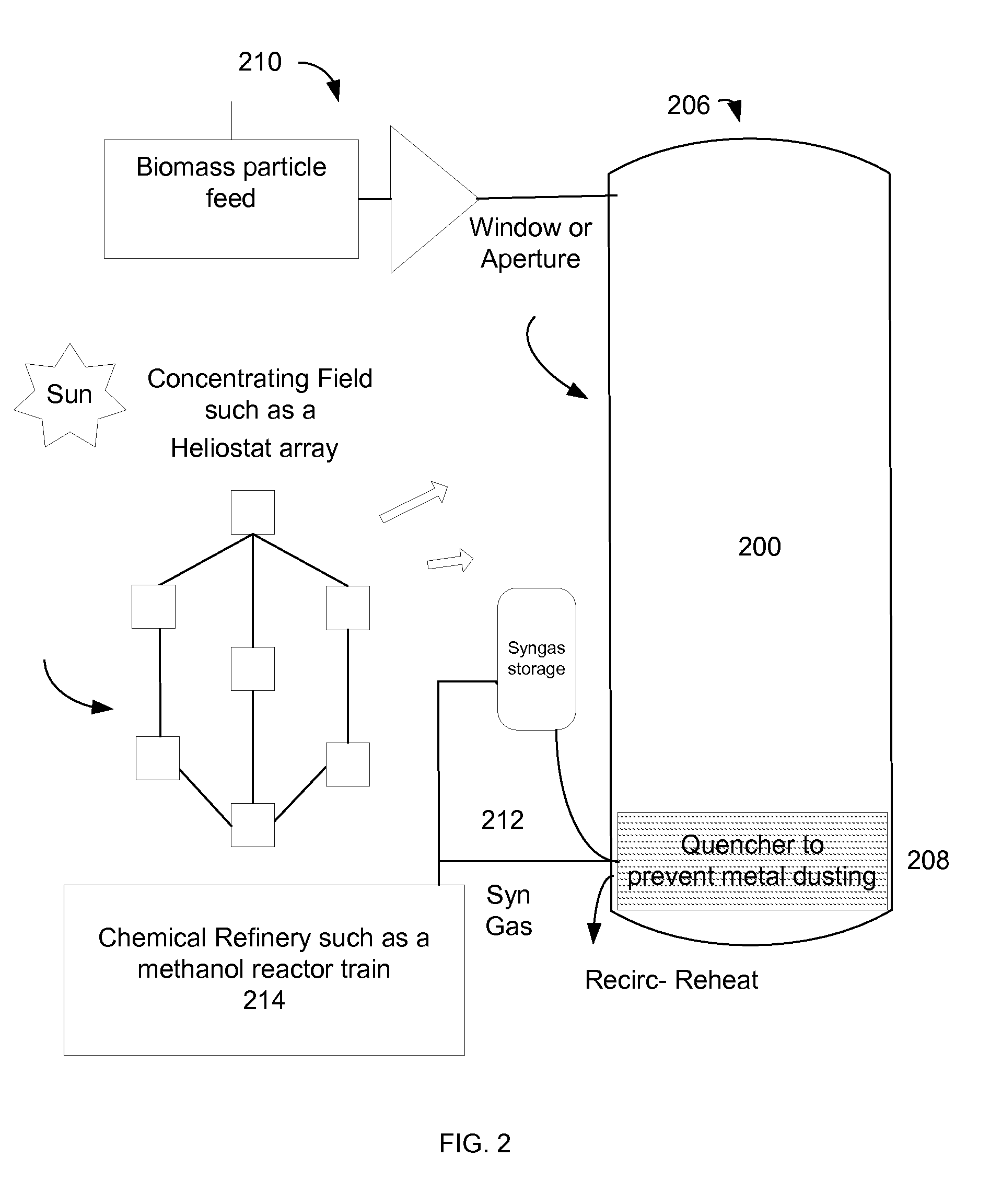

A method, apparatus, and system for a solar-driven chemical plant that may include a solar thermal receiver having a cavity with an inner wall, where the solar thermal receiver is aligned to absorb concentrated solar energy from one or more of 1) an array of heliostats, 2) solar concentrating dishes, and 3) any combination of the two. Some embodiments may include a solar-driven chemical reactor having multiple reactor tubes located inside the cavity of solar thermal receiver, wherein a chemical reaction driven by radiant heat occurs in the multiple reactor tubes, and wherein particles of biomass are gasified in the presence of a steam (H2O) carrier gas and methane (CH4) in a simultaneous steam reformation and steam biomass gasification reaction to produce reaction products that include hydrogen and carbon monoxide gas using the solar thermal energy from the absorbed concentrated solar energy in the multiple reactor tubes.

Owner:SUNDROP IP HLDG LLC

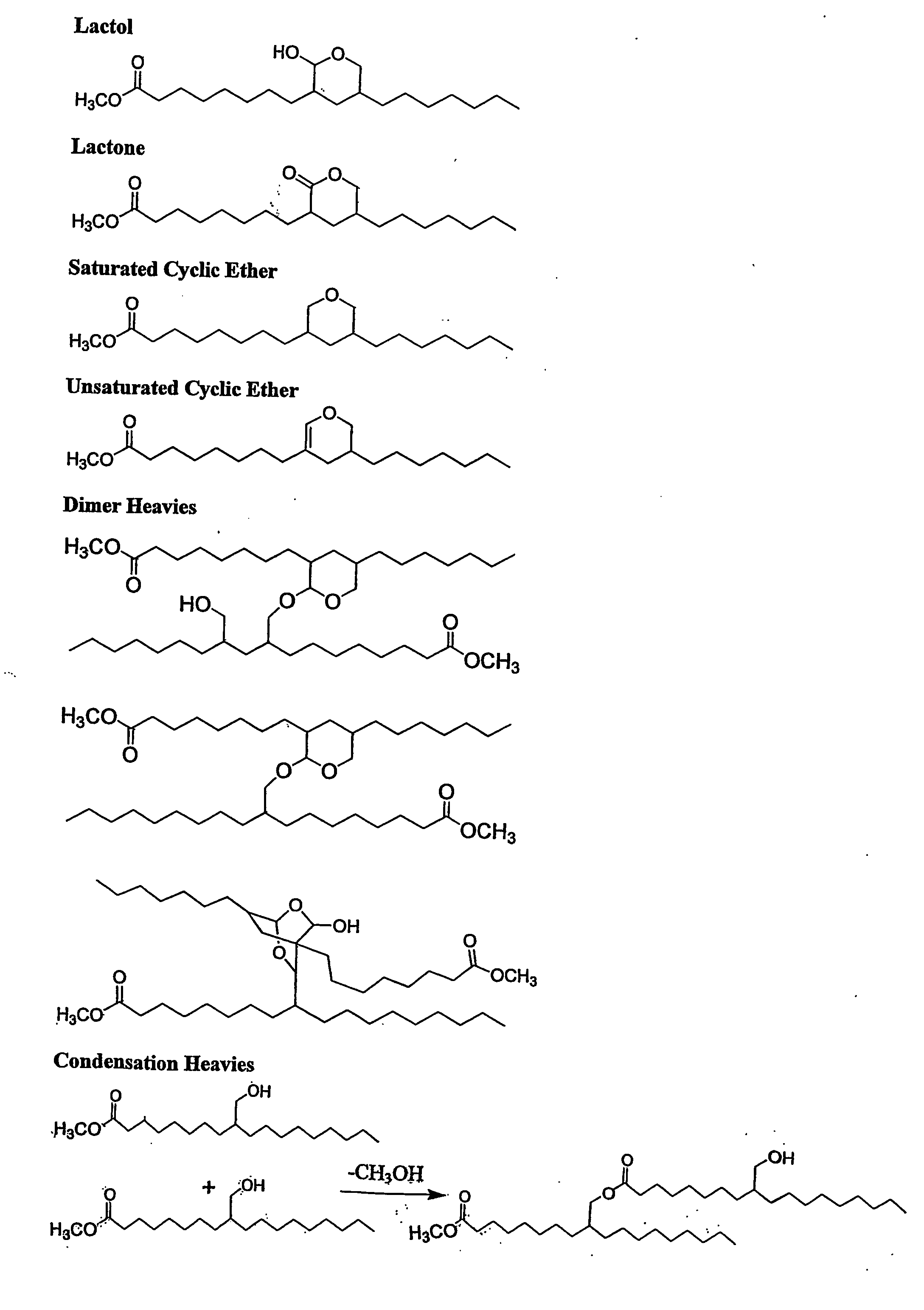

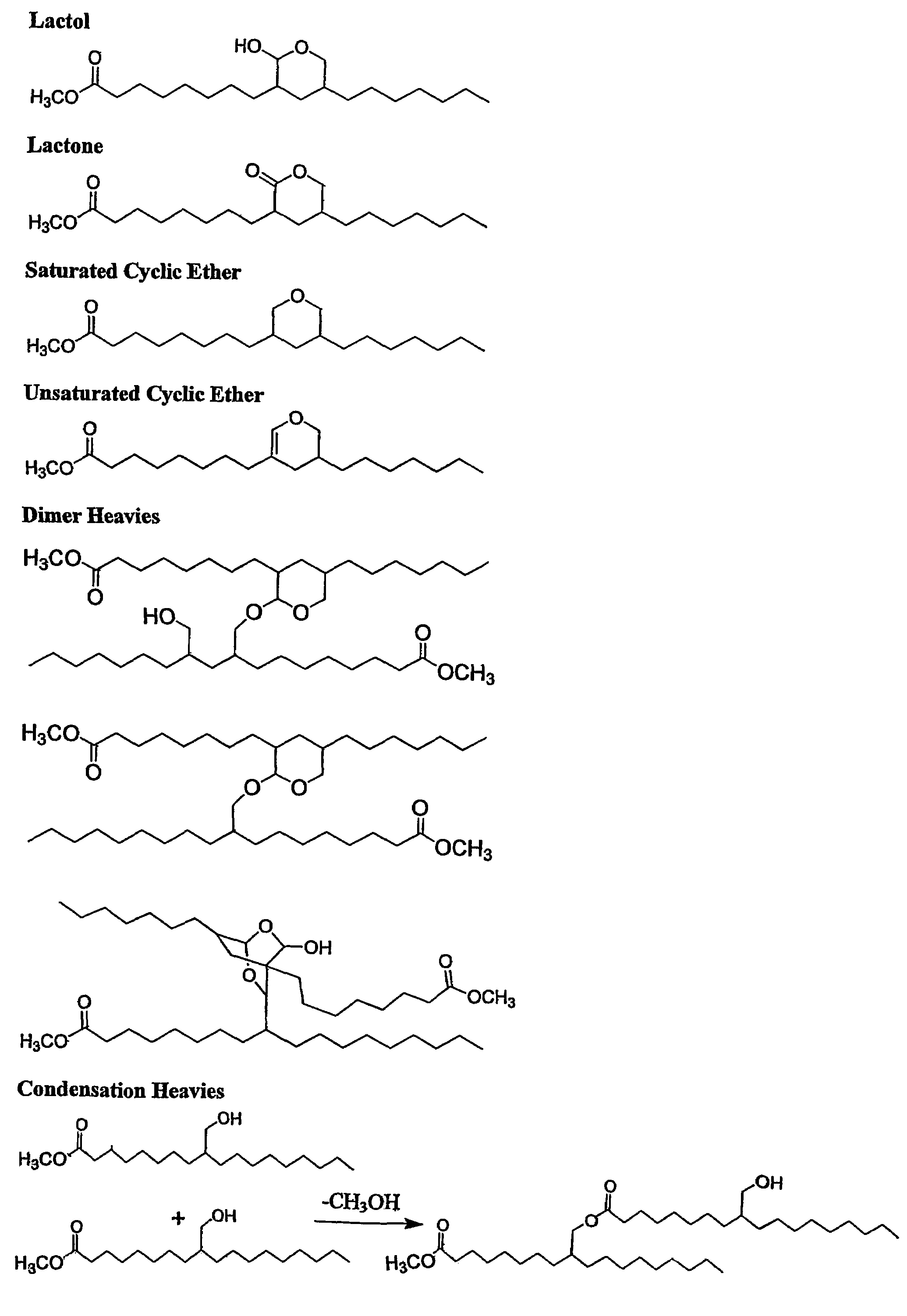

Aldehyde and alcohol compositions derived from seed oils

An aldehyde composition derived by hydroformylation of a transesterified seed oil and containing a mixture of formyl-substituted fatty acids or fatty acid esters having the following composition by weight: greater than about 10 to less than about 95 percent monoformyl, greater than about 1 to less than about 65 percent diformyl, and greater than about 0.1 to less than about 10 percent triformyl-substituted fatty acids or fatty acid esters, and having a diformyl to triformyl weight ratio of greater than about 5 / 1; preferably, greater than about 3 to less than about 20 percent saturates; and preferably, greater than about 1 to less than about 20 percent unsaturates. An alcohol composition derived by hydrogenation of the aforementioned aldehyde composition, containing a mixture of hydroxymethyl-substituted fatty acids or fatty acid esters having the following composition by weight: greater than about 10 to less than about 95 percent monoalcohol {mono(hydroxymethyl)}, greater than about 1 to less than about 65 percent diol {di(hydroxymethyl)}, greater than about 0.1 to less than about 10 percent triol, tri(hydroxmethyl)-substituted fatty acids or fatty acid esters; preferably greater than about 3 to less than about 35 percent saturates; and preferably, less than about 10 percent unsaturates. The alcohol composition can be converted into an oligomeric polyol for use in the manufacture of polyurethane slab stock flexible foams.

Owner:DOW GLOBAL TECH LLC

Systems and methods for quenching, gas clean up, and ash removal

A method, apparatus, and system for a solar-driven chemical plant are disclosed. An embodiment may include a solar thermal receiver aligned to absorb concentrated solar energy from one or more solar energy concentrating fields. A solar driven chemical reactor may include multiple reactor tubes located inside the solar thermal receiver. The multiple reactor tubes can be used to gasify particles of biomass in the presence of a carrier gas. The gasification reaction may produce reaction products that include hydrogen and carbon monoxide gas having an exit temperature from the tubes exceeding 1000 degrees C. An embodiment can include a quench zone immediately downstream of an exit of the chemical reactor. The quench zone may immediately quench via rapid cooling of at least the hydrogen and carbon monoxide reaction products within 0.1-10 seconds of exiting the chemical reactor to a temperature of 800 degrees C. or less.

Owner:SUNDROP IP HLDG LLC

Efficient and selective conversion of carbon dioxide to methanol, dimethyl ether and derived products

ActiveUS7605293B2Minimize or eliminate the disadvantages or dangers inherentElectrolysis componentsCarbon compoundsHydrogenFlue gas

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning powerplants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by electrochemical reduction produces formic acid acid and some formaldehyde and methanol mixtures. The formic acid can be used as source of carbon as well as hydrogen to produce methanol, dimethyl ether and other products.

Owner:UNIV OF SOUTHERN CALIFORNIA

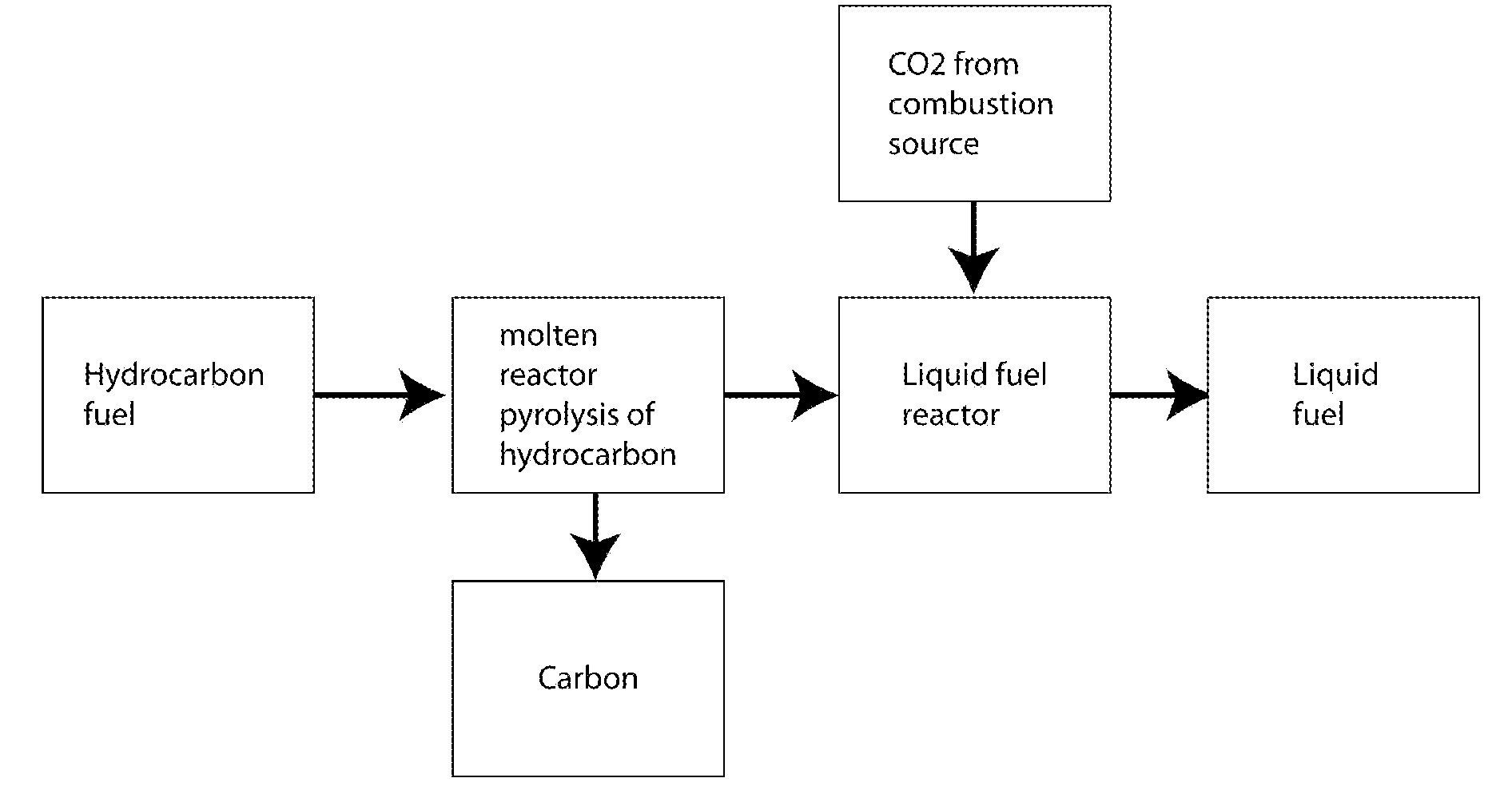

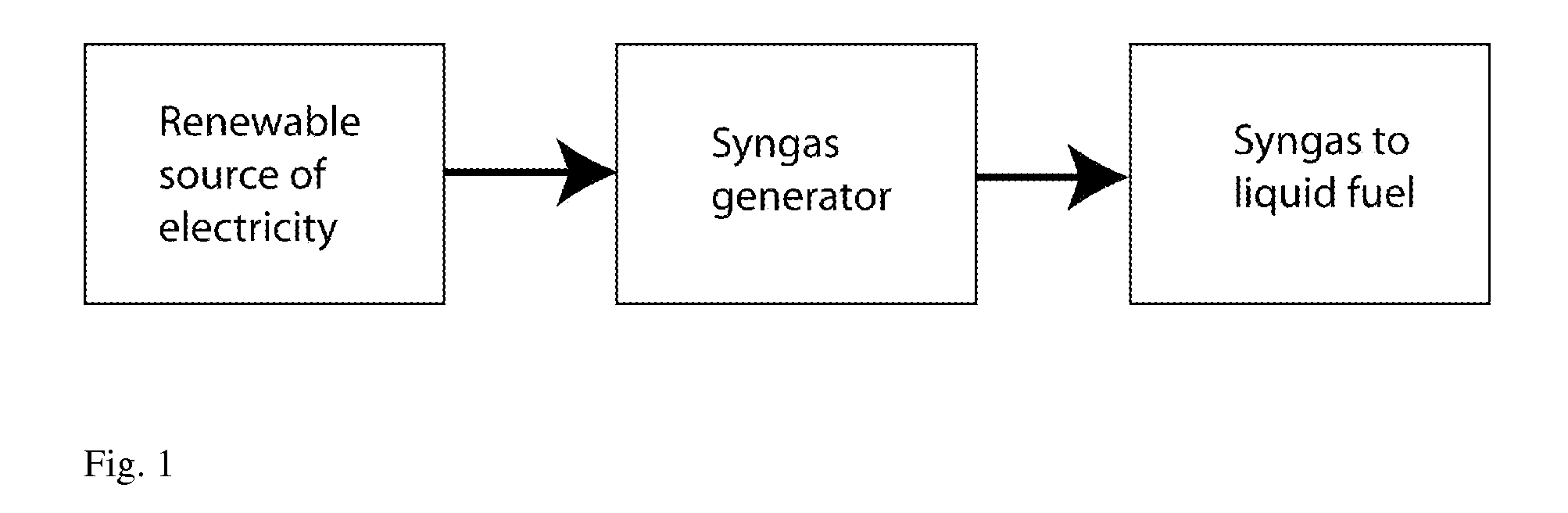

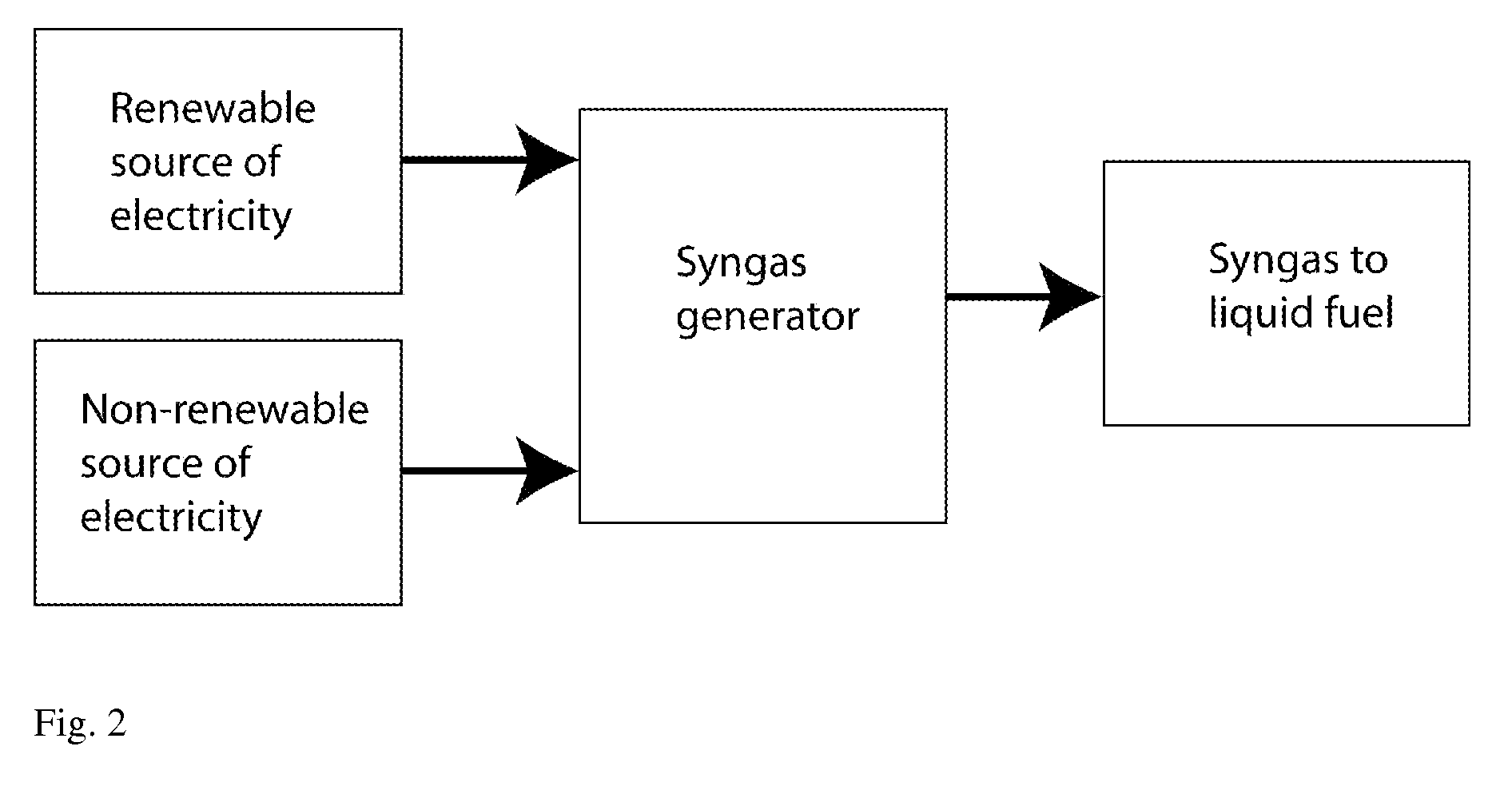

Renewable electricity conversion of liquid fuels from hydrocarbon feedstocks

The present invention includes a method for converting renewable energy source electricity and a hydrocarbon feedstock into a liquid fuel by providing a source of renewable electrical energy in communication with a synthesis gas generation unit and an air separation unit. Oxygen from the air separation unit and a hydrocarbon feedstock is provided to the synthesis gas generation unit, thereby causing partial oxidation reactions in the synthesis gas generation unit in a process that converts the hydrocarbon feedstock into synthesis gas. The synthesis gas is then converted into a liquid fuel.

Owner:INENTEC

System and method for converting biomass to ethanol via syngas

A method and apparatus for synthesizing ethanol using synthetic routes via synthesis gas are disclosed. A method and apparatus for gasifying biomass, such as biomass, in a steam gasifier that employs a fluidized bed and heating using hot flue gases from the combustion of synthesis gas is described. Methods and apparatus for converting synthesis gas into ethanol are also disclosed, using stepwise catalytic reactions to convert the carbon monoxide and hydrogen into ethanol using catalysts including iridium acetate.

Owner:WOODLAND BIOFUELS

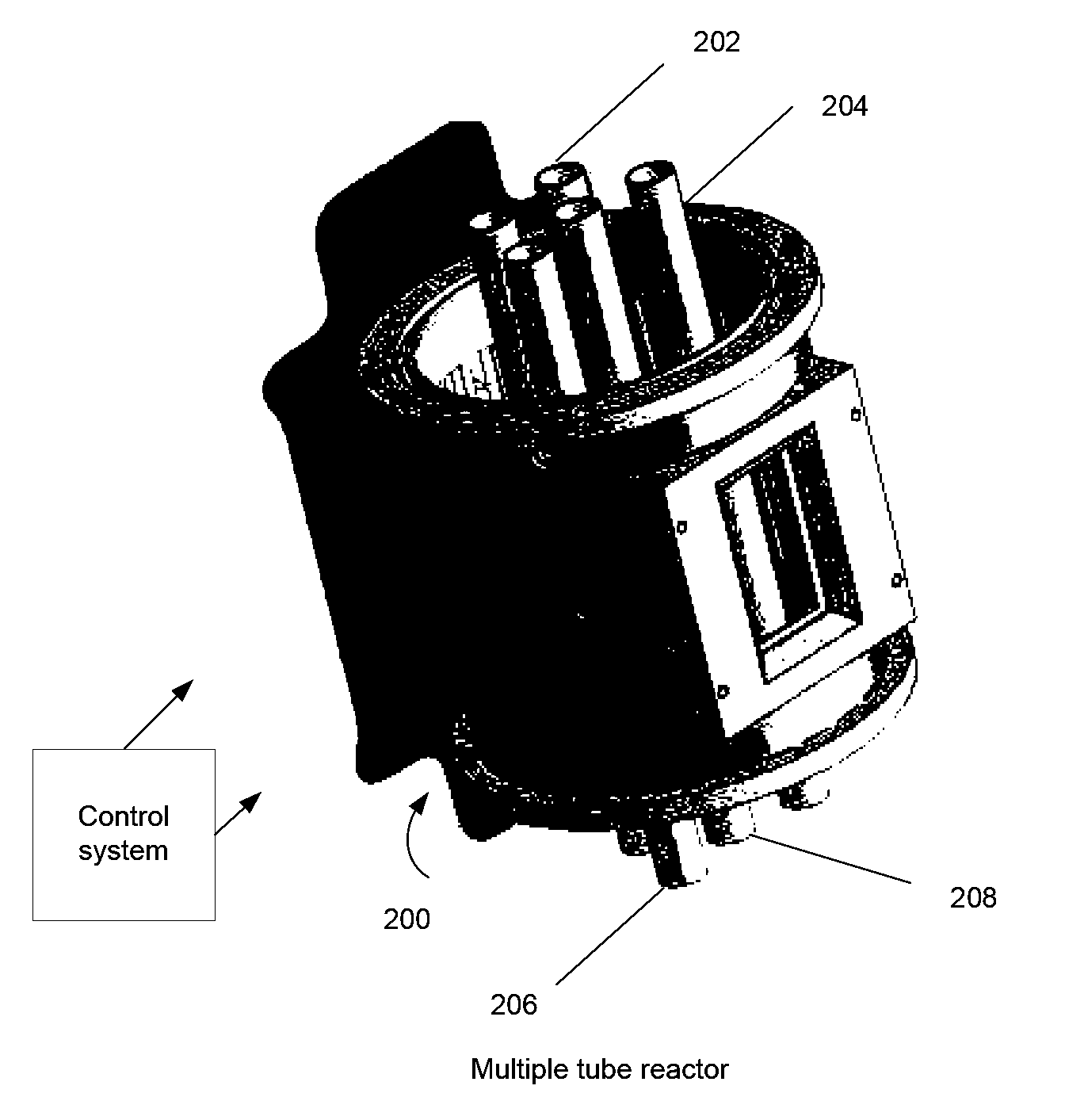

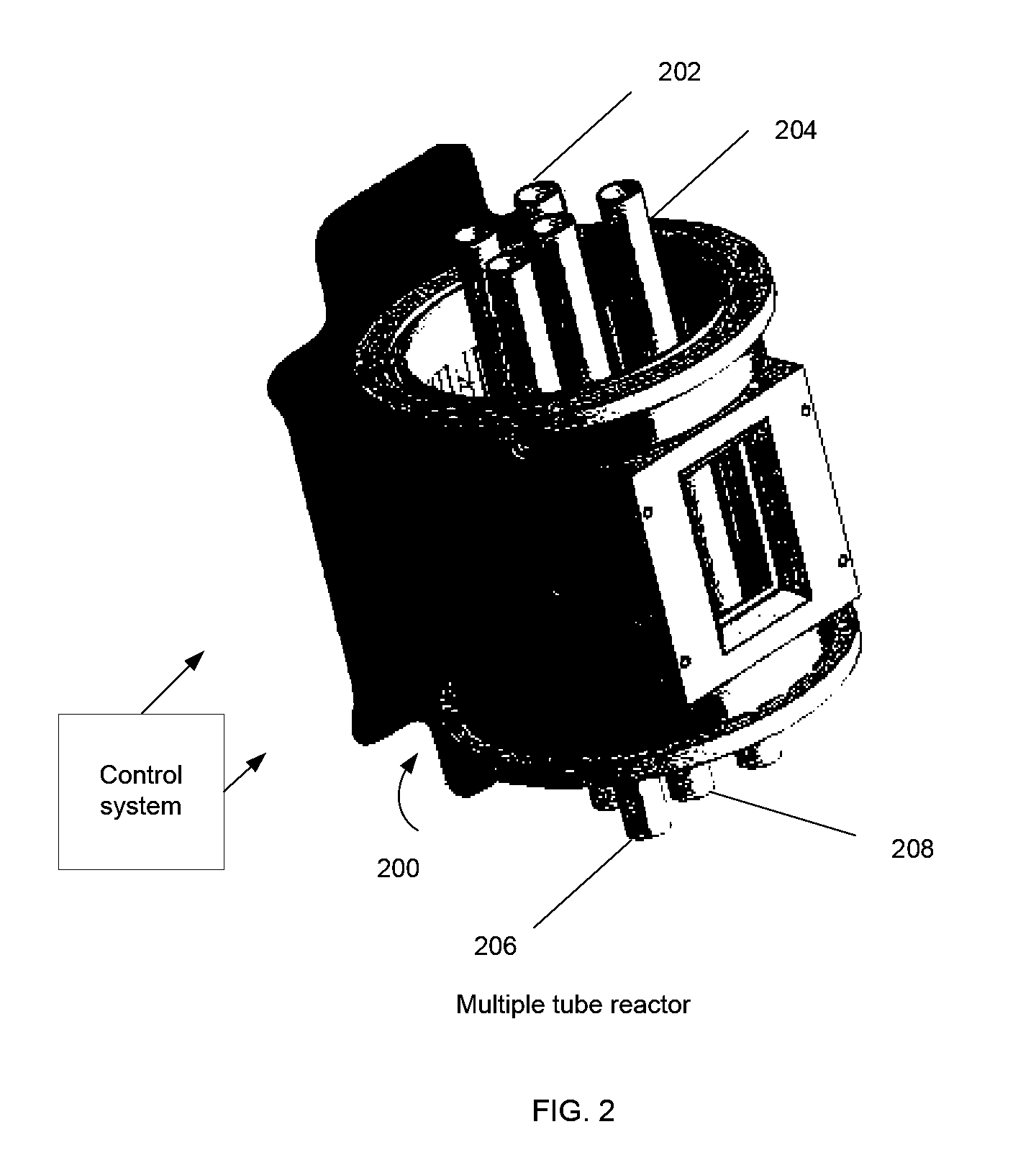

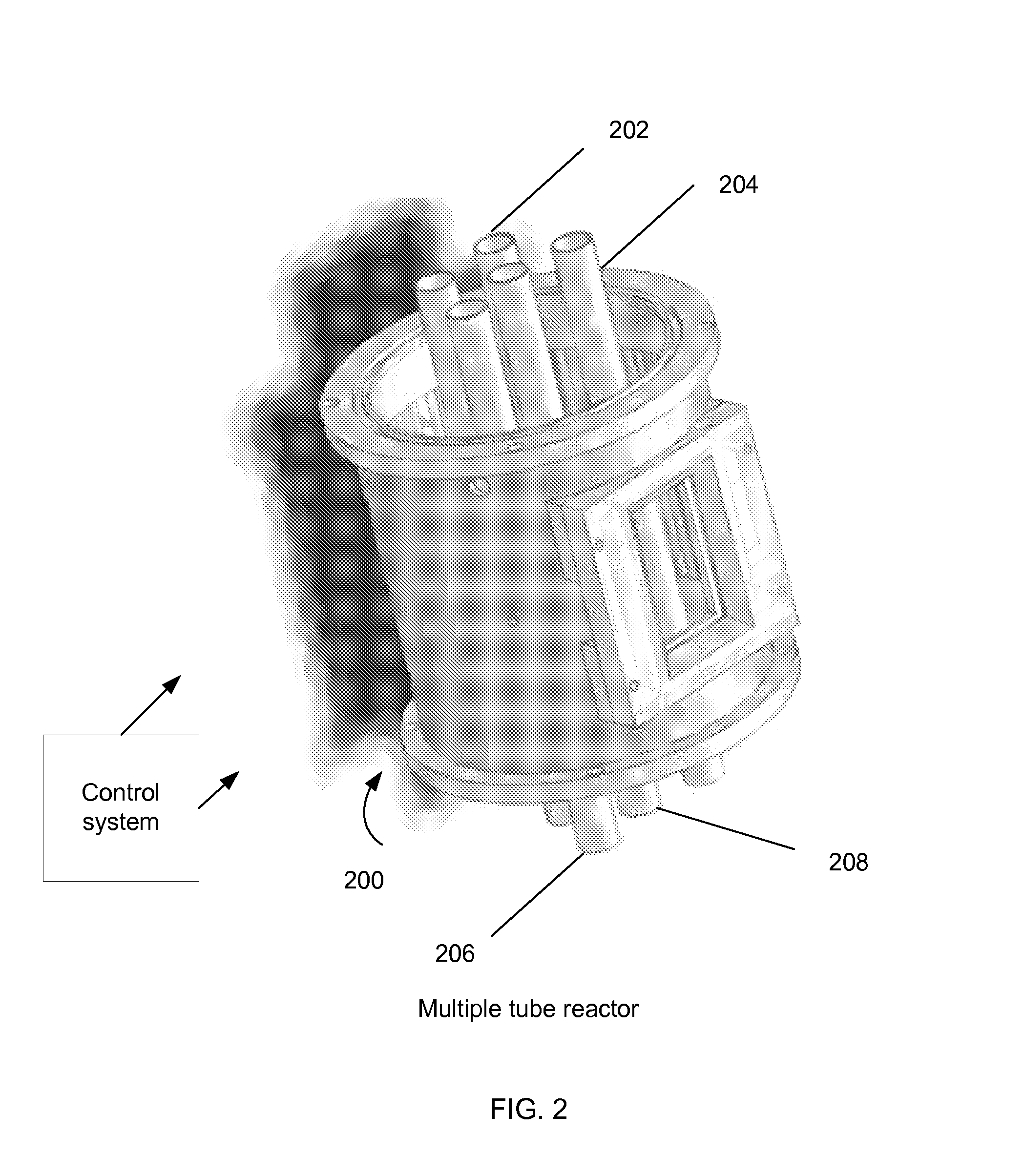

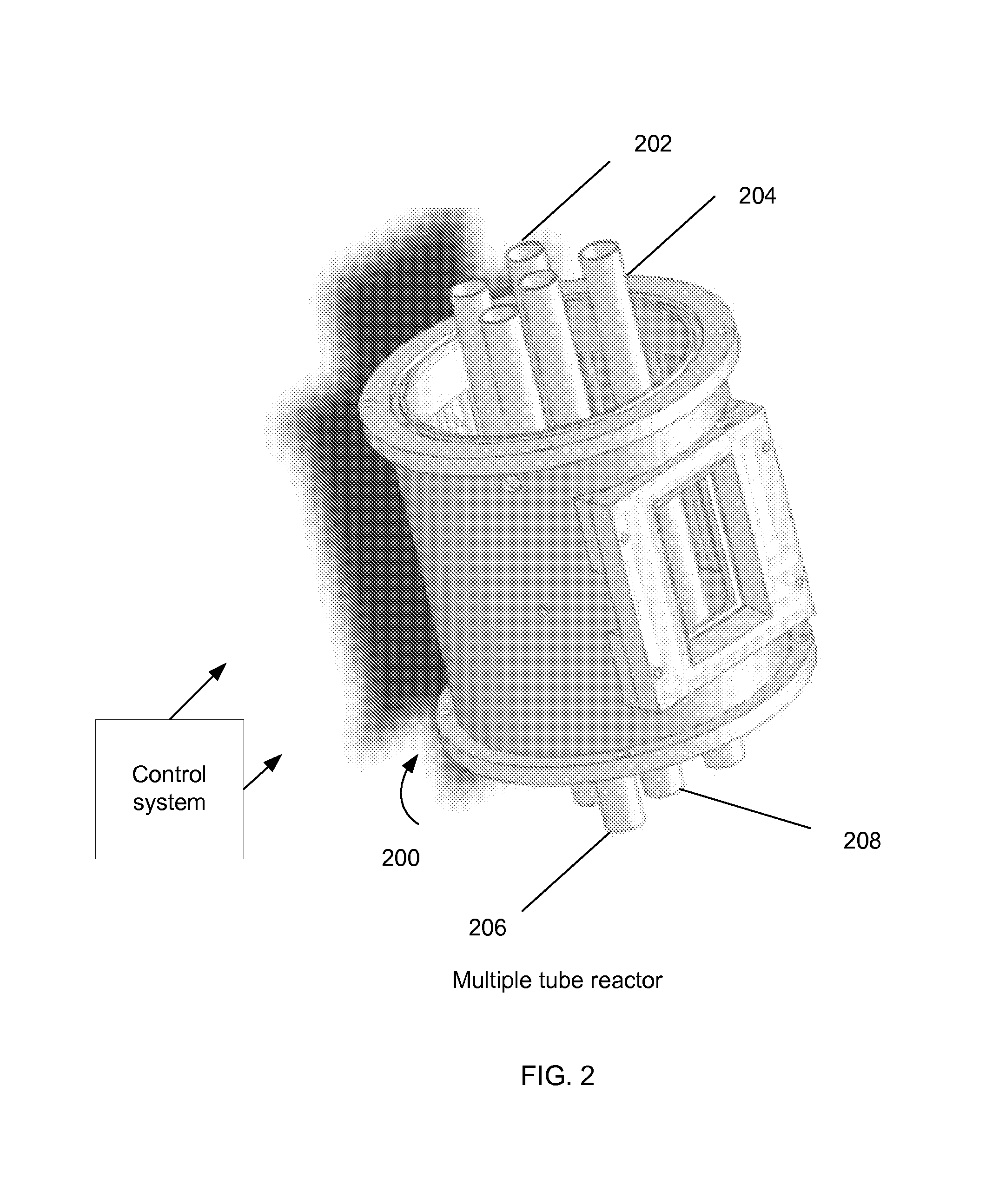

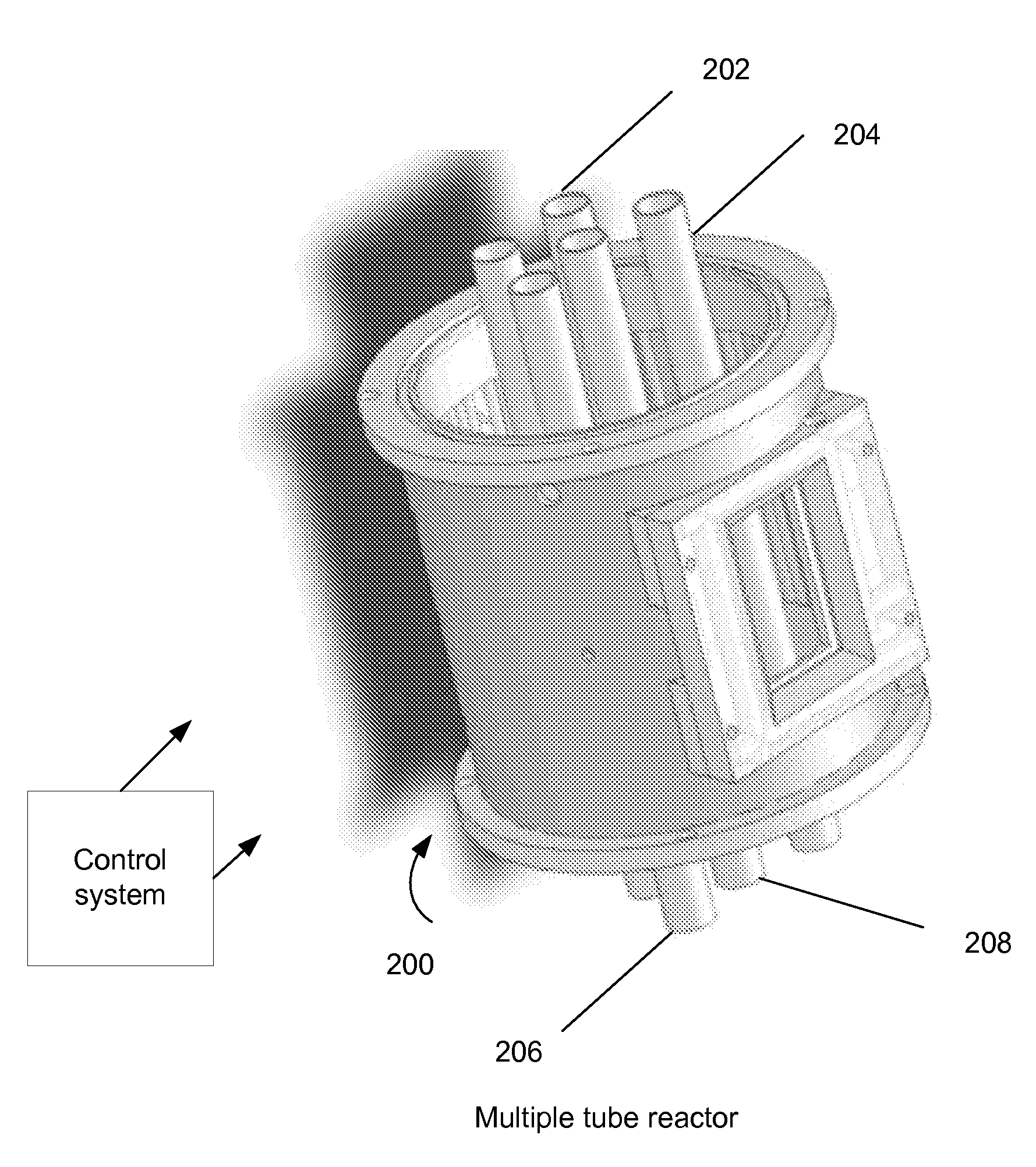

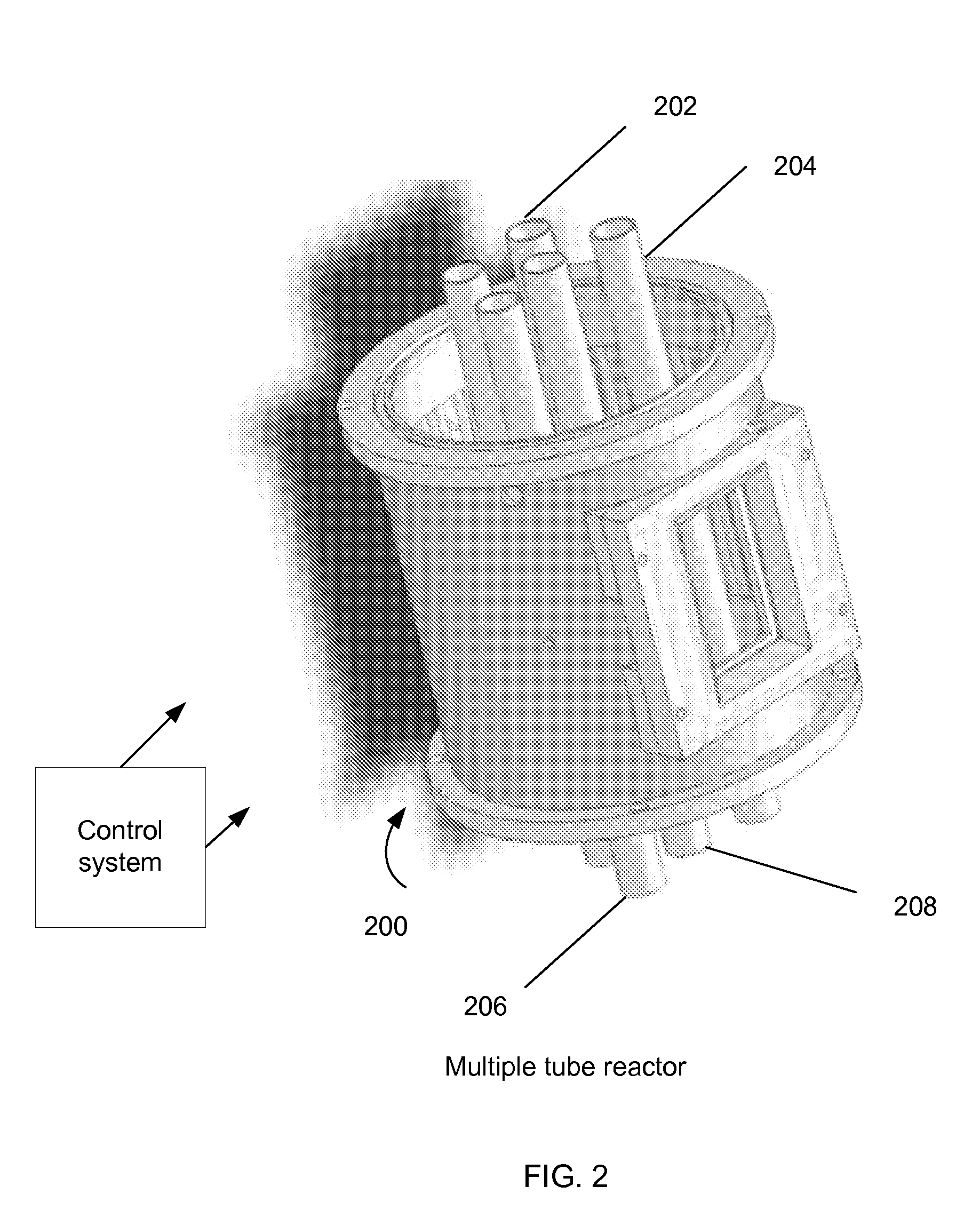

Systems and methods for reactor and receiver control of flux profile

InactiveUS20100242352A1Improve availabilityProcess control/regulationSolar heating energyChemical reactionChemical reactor

A method, apparatus, and system for a solar-driven chemical reactor are disclosed, including a solar thermal receiver aligned to absorb concentrated solar energy. Some embodiments include a solar driven chemical reactor that has multiple reactor tubes. Some embodiments include one of 1) one or more apertures open to an atmosphere of the Earth or 2) one or more windows, to pass the concentrated solar energy into the solar thermal receiver. This energy impinges on the multiple reactor tubes and cavity walls of the receiver and transfer energy by solar radiation absorption and heat radiation, convection, and conduction. In this way, the energy causes reacting particles to drive the endothermic chemical reaction flowing in the reactor tubes. The design of the multiple reactor tubes and solar thermal receiver can be adapted per a solar flux profile to take advantage of variations in the concentrations of solar flux in the profile.

Owner:SUNDROP FUELS

Systems and methods for reactor chemistry and control

InactiveUS20100242354A1Process control/regulationSolar heating energyChemical reactionChemical reactor

A method, apparatus, and system for a solar-driven chemical plant that manages variations in solar energy are disclosed. Some embodiments include a solar thermal receiver to absorb concentrated solar energy, a solar driven chemical reactor contained within the solar thermal receiver, and an entrained gas biomass feed system that uses an entrainment carrier gas and supplies a variety of biomass sources fed as particles into the solar driven chemical reactor. Inner walls of the solar thermal receiver and the chemical reactor can be made from materials selected to transfer energy. Some embodiments include a control system that may be configured to balance the gasification reaction of biomass particles with the available concentrated solar energy and additional variable parameters including, but not limited to, a fixed range of particle sizes, temperature of the chemical reactor, and residence time of the particles in a reaction zone in the chemical reactor.

Owner:SUNDROP FUELS

Efficient and selective chemical recycling of carbon dioxide to methanol, dimethyl ether and derived products

ActiveUS7608743B2Avoid emissionsElectrolysis componentsOxygen compounds purification/separationFlue gasExhaust fumes

An efficient and environmentally beneficial method of recycling and producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning powerplants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by chemical or electrochemical reduction secondary treatment to produce essentially methanol, dimethyl ether and derived products.

Owner:UNIV OF SOUTHERN CALIFORNIA

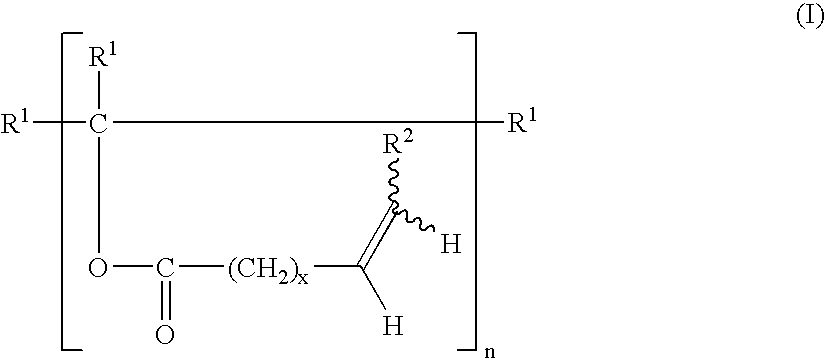

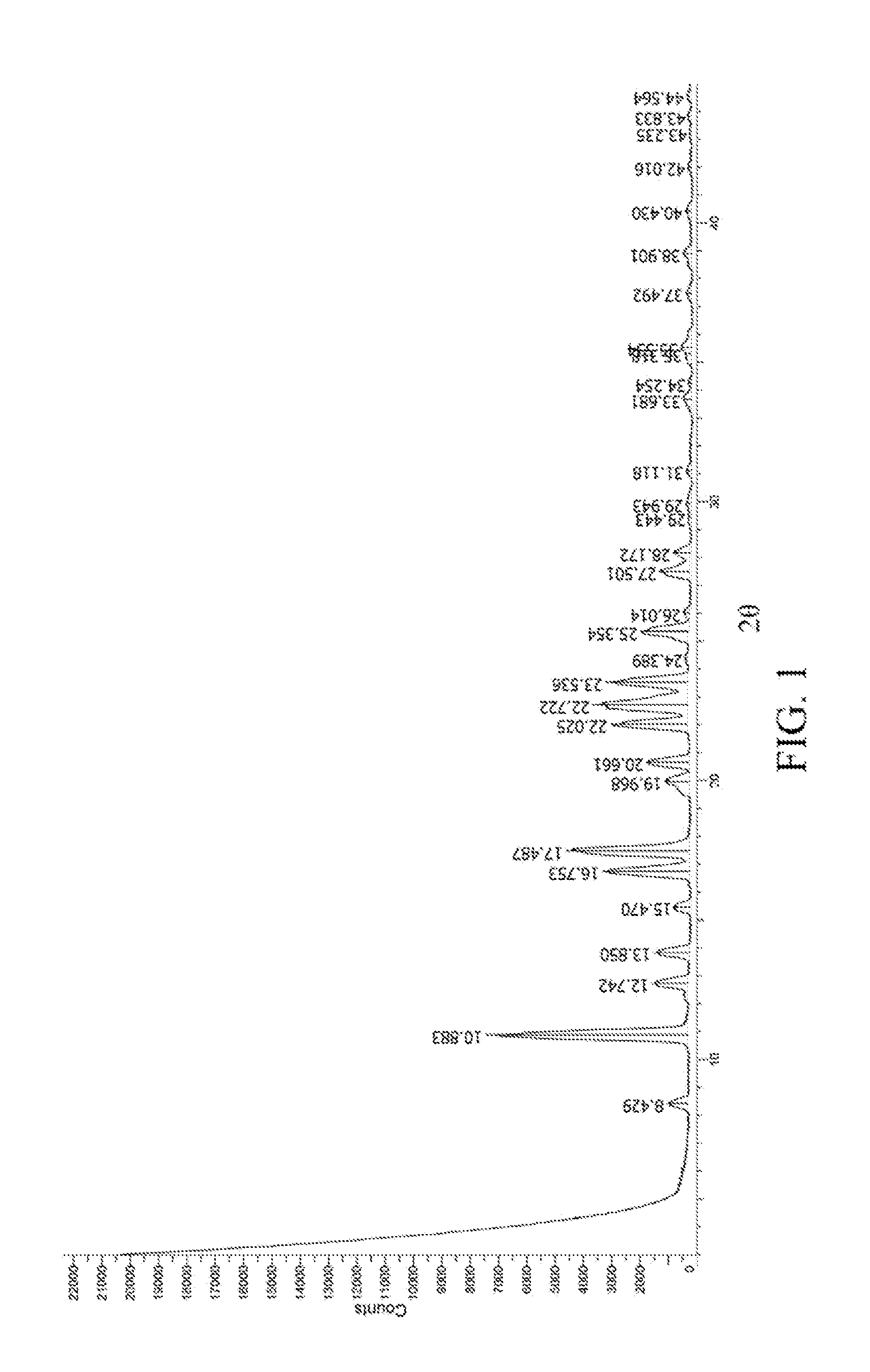

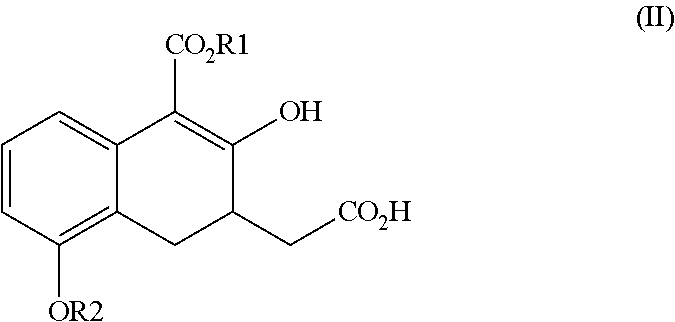

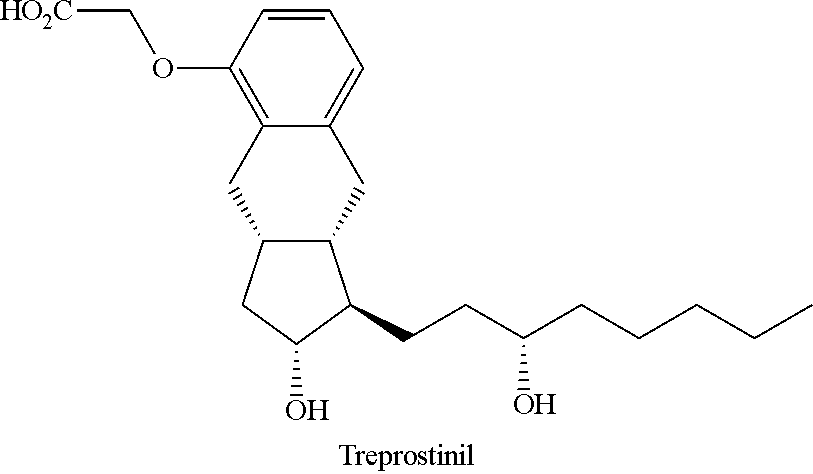

Novel intermediate for synthesizing treprostinil diethanolamine and method for preparing the same

ActiveUS20160152548A1High optical purityHigh purityOrganic compound preparationPreparation by ester-hydroxy reactionCombinatorial chemistryEthanolamine synthesis

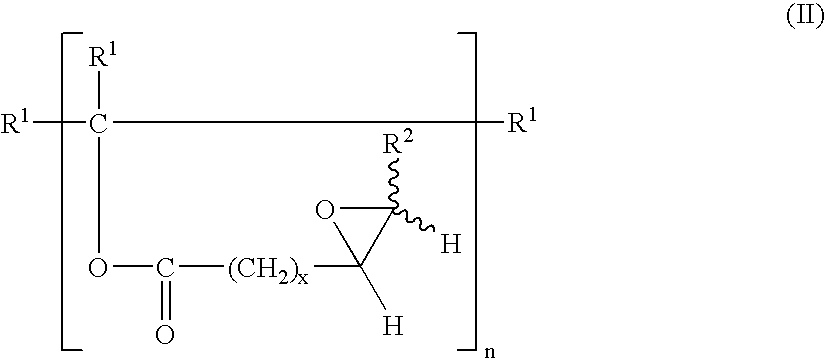

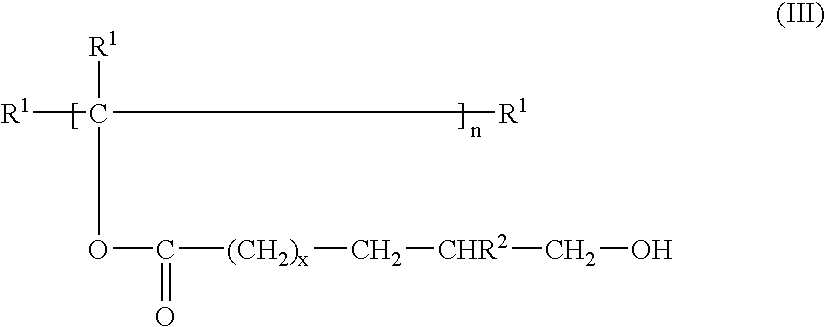

The present invention relates to a method for treprostinil diethanolamine synthesis. The present invention also relates to a novel intermediate used in the method for treprostinil diethanolamine synthesis. The novel intermediate is shown in the following formula (II):wherein R1 and R2 are described in the description.

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

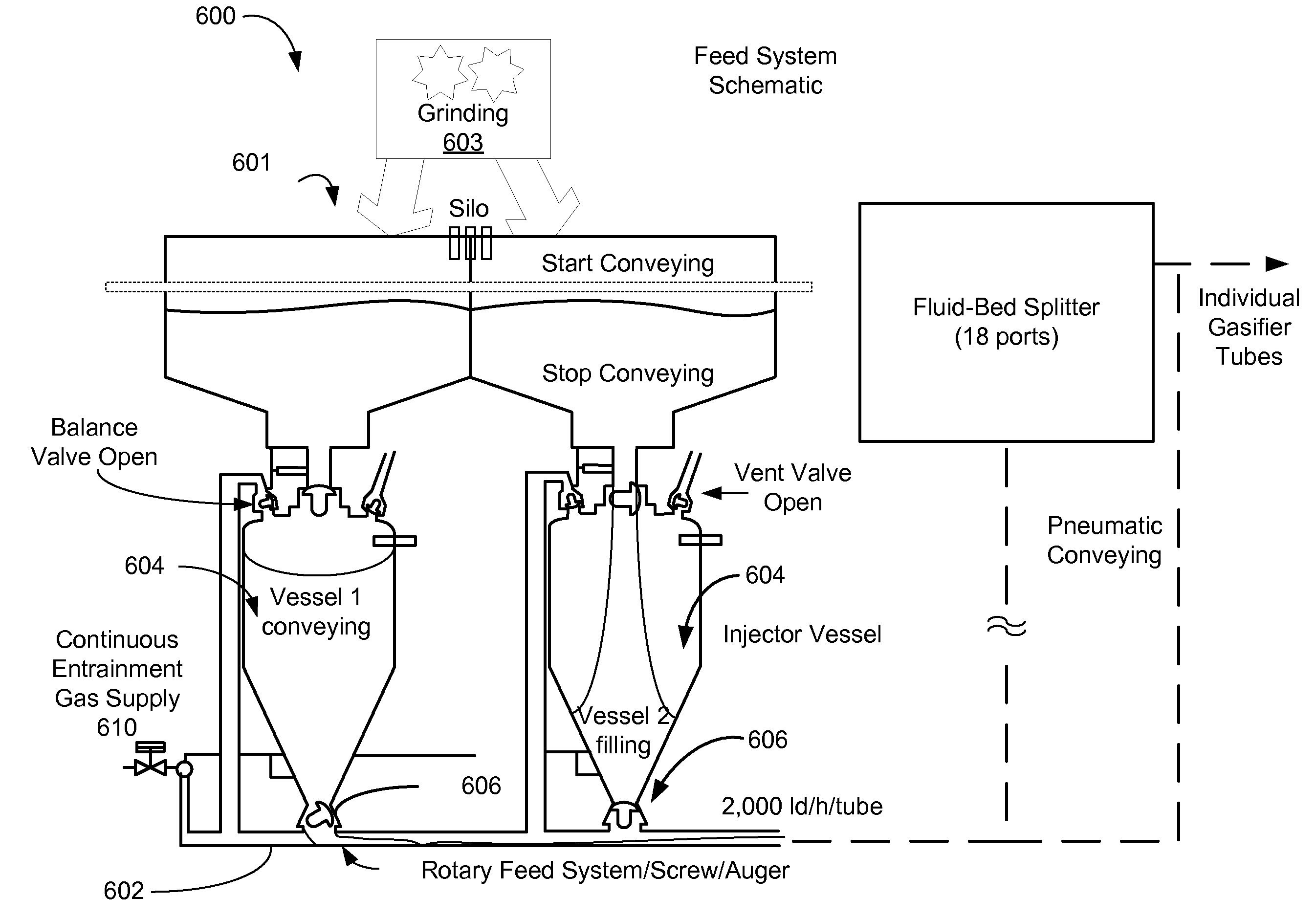

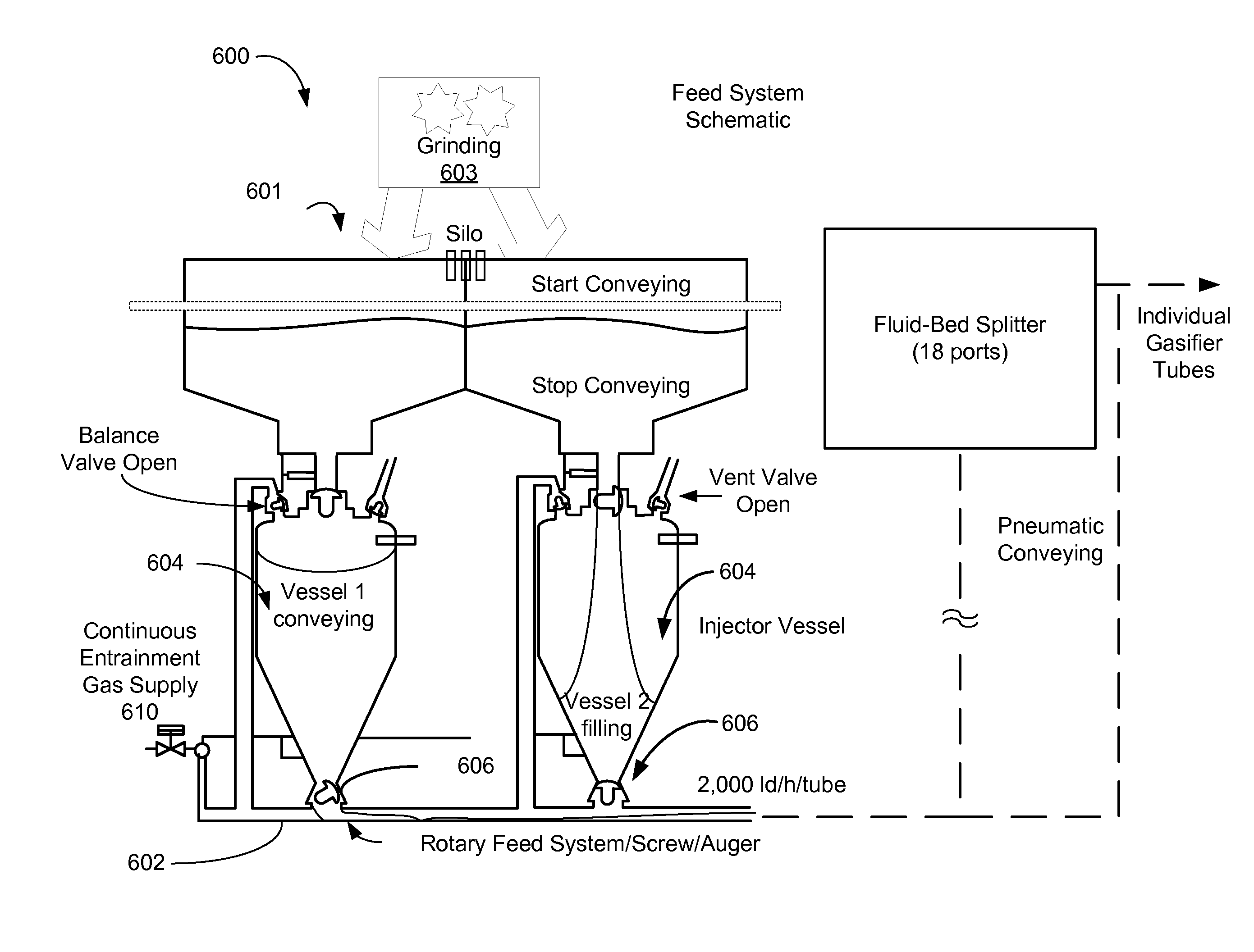

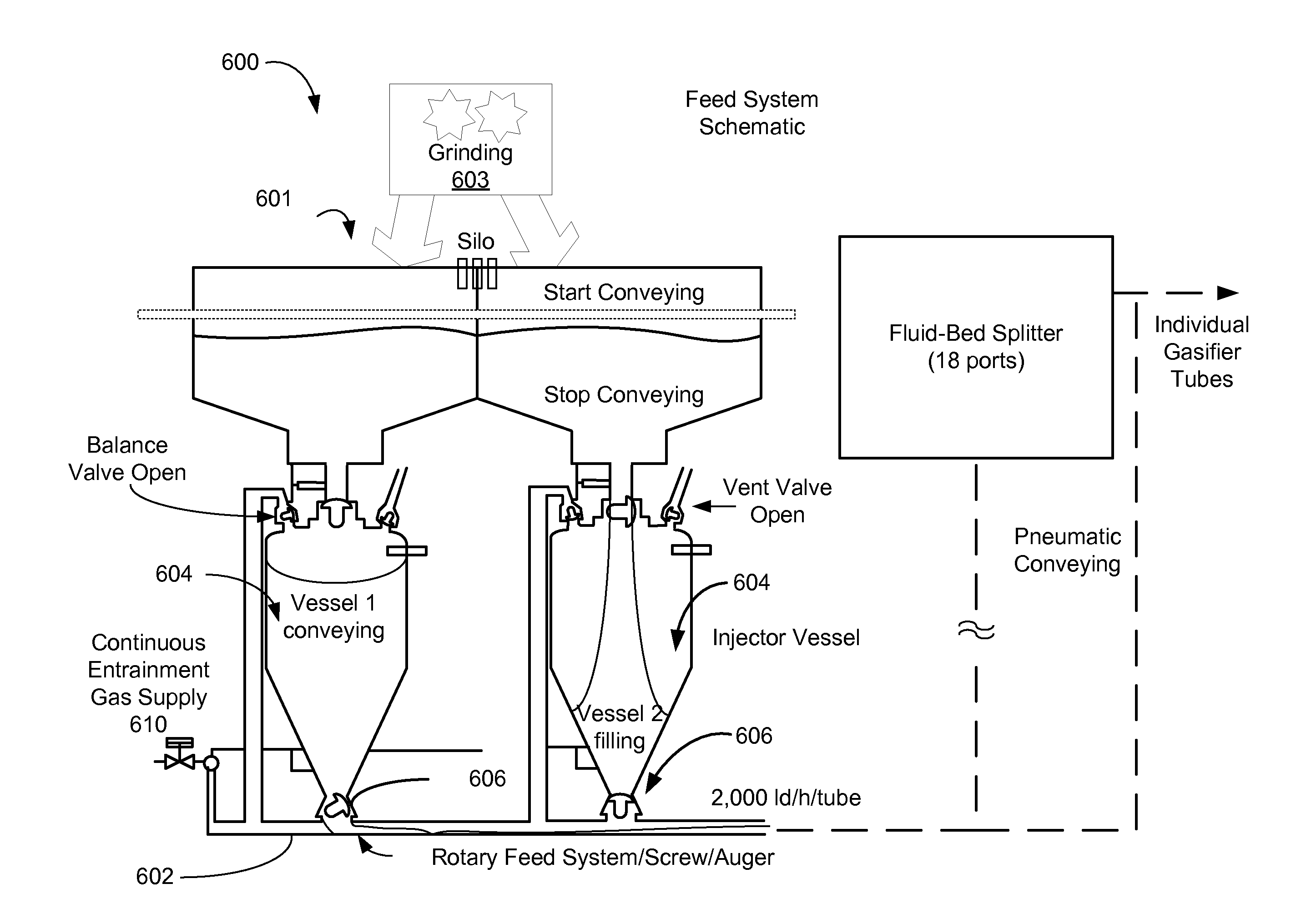

Systems and methods for biomass grinding and feeding

InactiveUS20100242353A1Process control/regulationSolar heating energyChemical reactorLiquid hydrocarbons

A method, apparatus, and system for a solar-driven bio-refinery that may include a entrained-flow biomass feed system that is feedstock flexible via particle size control of the biomass. Some embodiments include a chemical reactor that receives concentrated solar thermal energy from an array of heliostats. The entrained-flow biomass feed system can use an entrainment carrier gas and supplies a variety of biomass sources fed as particles into the solar-driven chemical reactor. Biomass sources in a raw state or partially torrified state may be used, as long as parameters such as particle size of the biomass are controlled. Additionally, concentrated solar thermal energy can drive gasification of the particles. An on-site fuel synthesis reactor may receive the hydrogen and carbon monoxide products from the gasification reaction use the hydrogen and carbon monoxide products in a hydrocarbon fuel synthesis process to create a liquid hydrocarbon fuel.

Owner:SUNDROP IP HLDG LLC

Aldehyde and alcohol compositions derived from seed oils

An aldehyde composition derived by hydroformylation of a transesterified seed oil and containing a mixture of formyl-substituted fatty acids or fatty acid esters having the following composition by weight: greater than about 10 to less than about 95 percent monoformyl, greater than about 1 to less than about 65 percent diformyl, and greater than about 0.1 to less than about 10 percent triformyl-substituted fatty acids or fatty acid esters, and having a diformyl to triformyl weight ratio of greater than about 5 / 1; preferably, greater than about 3 to less than about 20 percent saturates; and preferably, greater than about 1 to less than about 20 percent unsaturates. An alcohol composition derived by hydrogenation of the aforementioned aldehyde composition, containing a mixture of hydroxymethyl-substituted fatty acids or fatty acid esters having the following composition by weight: greater than about 10 to less than about 95 percent monoalcohol {mono(hydroxymethyl)}, greater than about 1 to less than about 65 percent diol {di(hydroxymethyl)}, greater than about 0.1 to less than about 10 percent triol, tri(hydroxymethyl)-substituted fatty acids or fatty acid esters; preferably greater than about 3 to less than about 35 percent saturates; and preferably, less than about 10 percent unsaturates. The alcohol composition can be converted into an oligomeric polyol for use in the manufacture of polyurethane slab stock flexible foam.

Owner:DOW GLOBAL TECH LLC

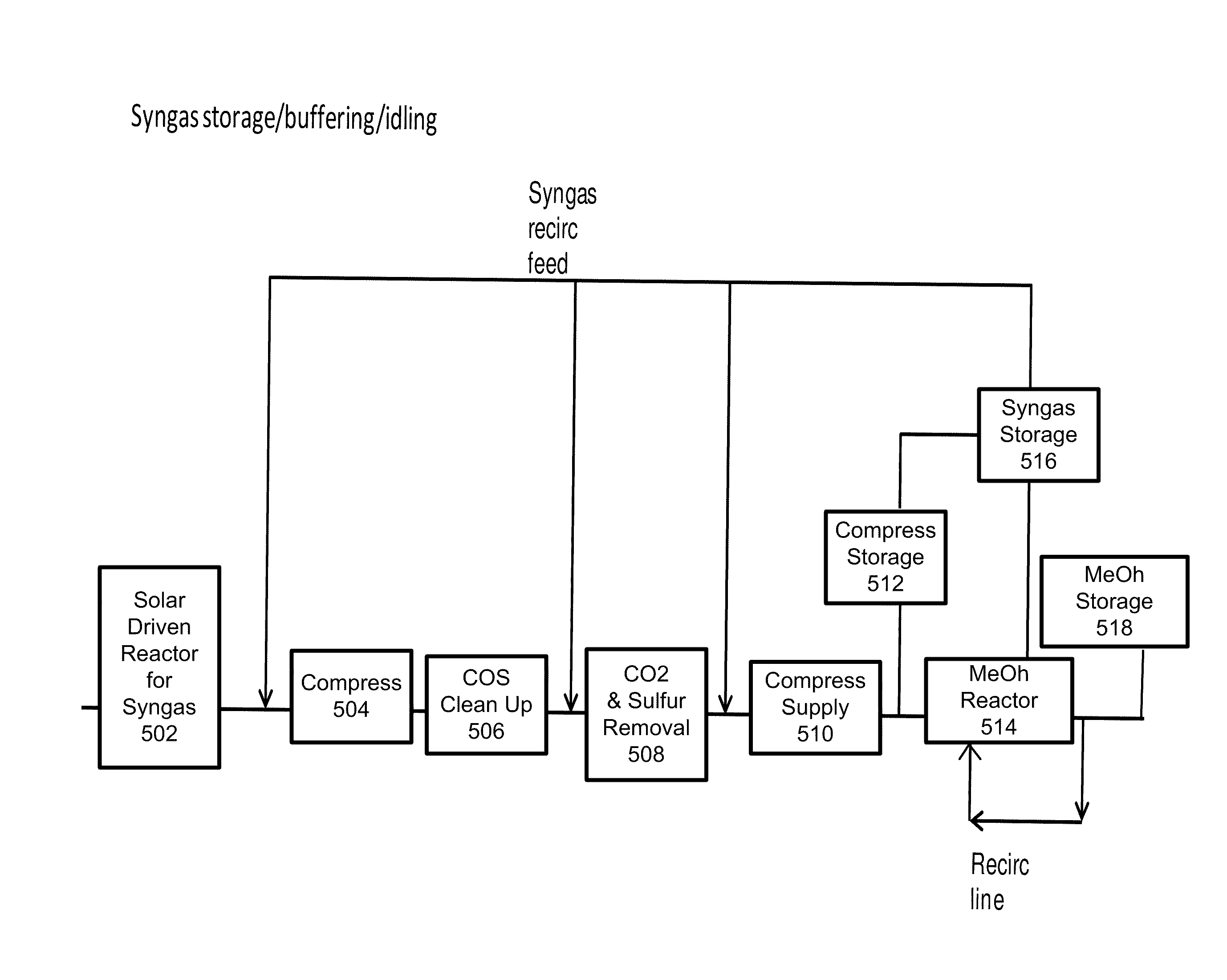

Systems and methods for cyclic operations in a fuel synthesis process

InactiveUS20100249251A1Increase productionReduce outputProcess control/regulationSolar heating energyChemical reactorProduct gas

A method, apparatus, and system for a fuel synthesis system including a multiple methanol reactor train, operated in parallel from a common input of 1) synthesis gas from a solar driven chemical reactor and 2) synthesis gas from a storage tank. In some embodiments, the multiple methanol reactor trains are idled as needed based on a variable amount of synthesis gas fed into the process. Additionally, some embodiments may include a controller to control operation of the multiple methanol trains by potentially idling one or more of the methanol reactor trains, switching to an operational state, or altering the output from the reactor trains, based on the amount of synthesis gas being generated by the solar driven chemical reactor, which is subject to marked variations in volume of synthesis gas output based on a seasonal, diurnal and weather effects.

Owner:SUNDROP FUELS

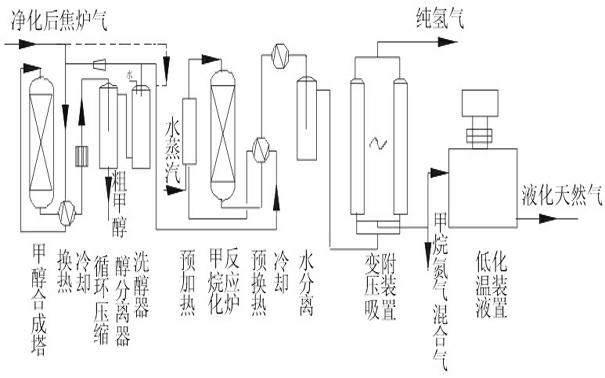

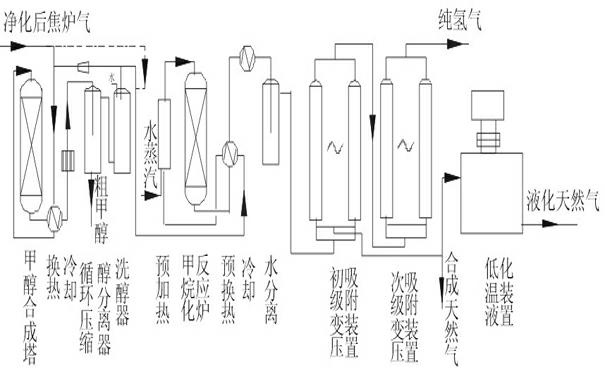

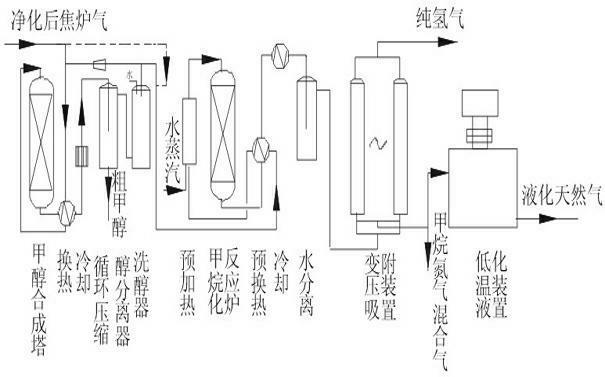

Novel process for co-production of liquefied synthesis gas, pure hydrogen and methanol from coke-oven gas

InactiveCN102585951AReduce contentLow carbon oxide contentGaseous fuelsHydrogen productionMethanationMethanol

The invention discloses a process for co-production of liquefied synthesis gas, pure hydrogen and methanol from coke-oven gas. The process comprises the steps of: (a) firstly, purifying and compressing the coke-oven gas, then enabling the gas after being subjected to the heat exchange of a heat exchange device to enter into a methanol synthesis tower for a methanol synthesis catalytic reaction, exchanging heat of discharged gas by a heat exchanger, and enabling the gas after being cooled by a cooler to enter into a methanol separator so as to obtain crude methanol; and (b) preparing refined methanol, enabling the gas to enter into a methanol washing machine, washing away trace methanol in the gas with water, enabling partial gas after being compressed by a circular compressor to turn back to the heat exchanger for methanol synthesis and enabling other gas to enter into a heat exchanger for methanation, enabling the gas to enter into a pre-heater after heat energy is recycled, adding a small amount of aqueous vapor in the pre-heater and then enabling the gas to enter into a methanation reaction furnace. According to the process disclosed by the invention, content of oxycarbide in the gas is reduced and the methanol product is obtained through resource recycling, residual small amount of oxycarbide is removed thoroughly and hydrogen resource with high value is recycled, and the obtained liquefied natural gas is convenient to transport.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

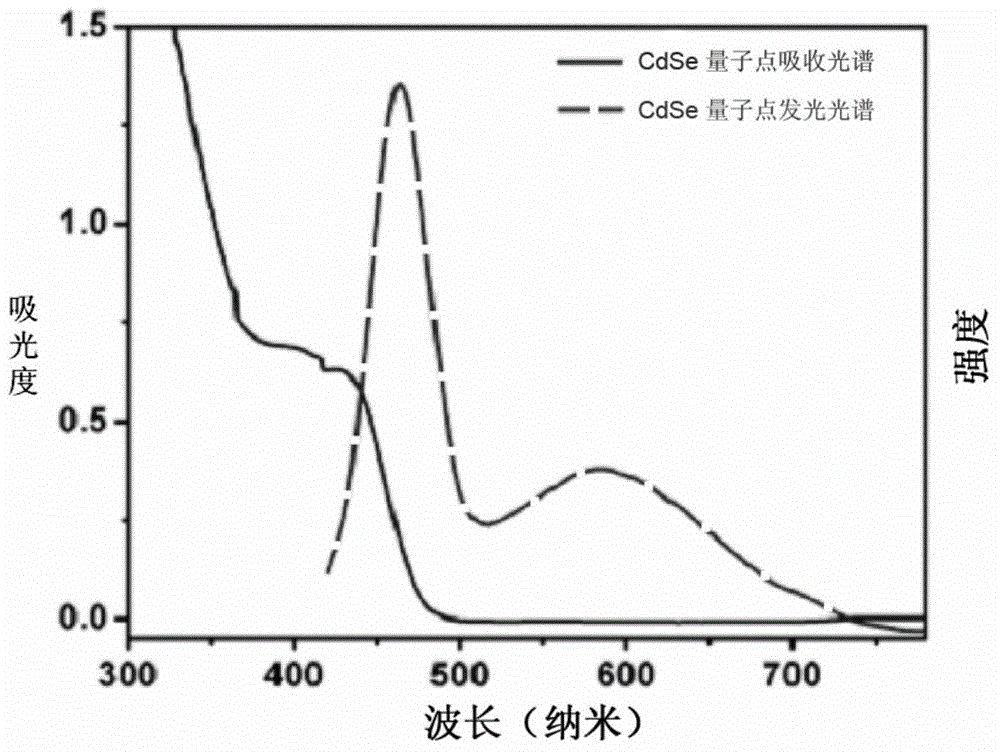

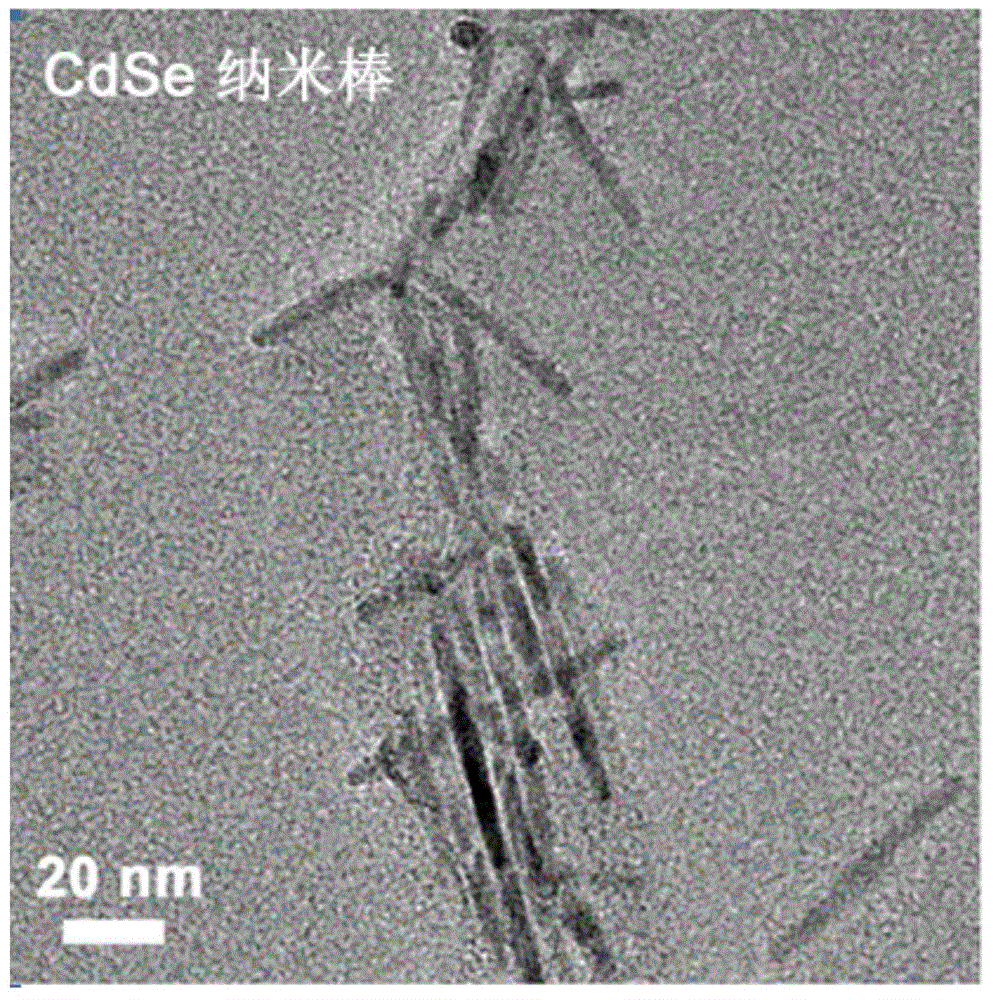

Carbon dioxide reduction method

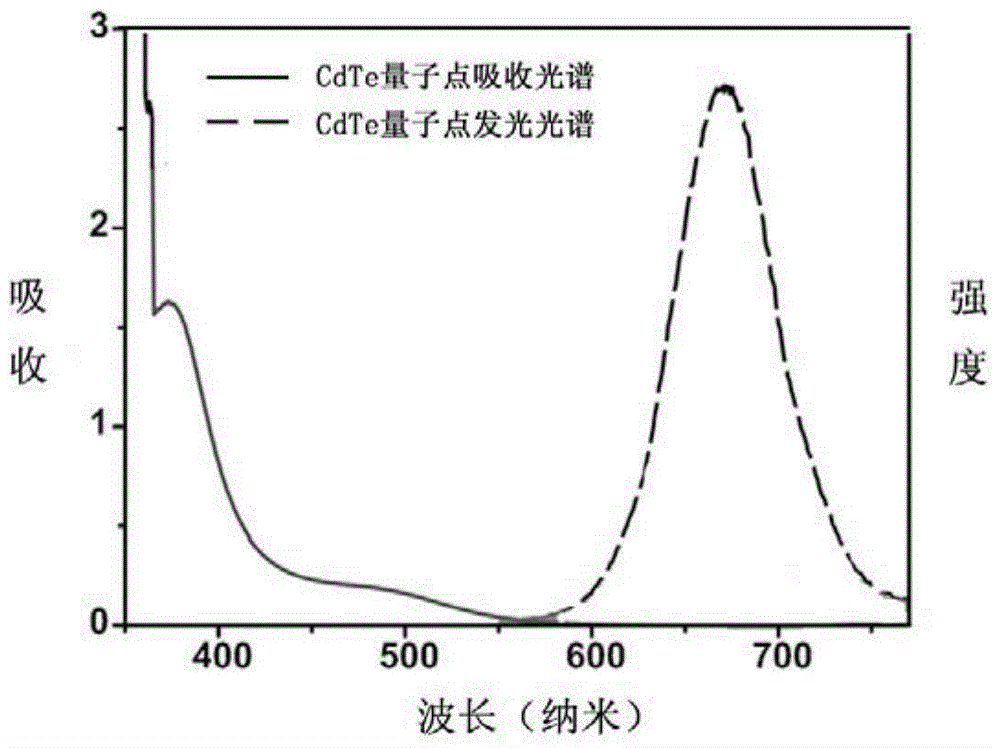

ActiveCN104478656ANo pollution in the processWide variety of sourcesProductsHydrocarbon from carbon oxidesPhotocatalytic reactionExternal irradiation

The invention discloses a carbon dioxide reduction method which comprises the following steps: by using carbon dioxide as a raw material and a NaOH, Na2CO3 or Na2SO3 water solution with a certain concentration as a reaction solution and adding 0.2-5.0 g / L composite photocatalyst of oxide of Ti, Bi, W, V, Mo or Y, putting in an internal irradiation, external irradiation, suspension or liquid-film photocatalytic reactor, and introducing carbon dioxide at 10-60 mL / minute to carry out photocatalytic carbon dioxide reduction reaction at normal temperature for 0.5-5 hours by using a mercury lamp, xenon lamp or sunlight as a light source, thereby obtaining formic acid, methanol, methane and other carbon dioxide reduction products. The method has the advantages of simple technique and green reaction process, can catalytically convert the carbon dioxide into useful chemical products, and thus, has favorable economic benefit and environmental benefit.

Owner:GUANGXI UNIV

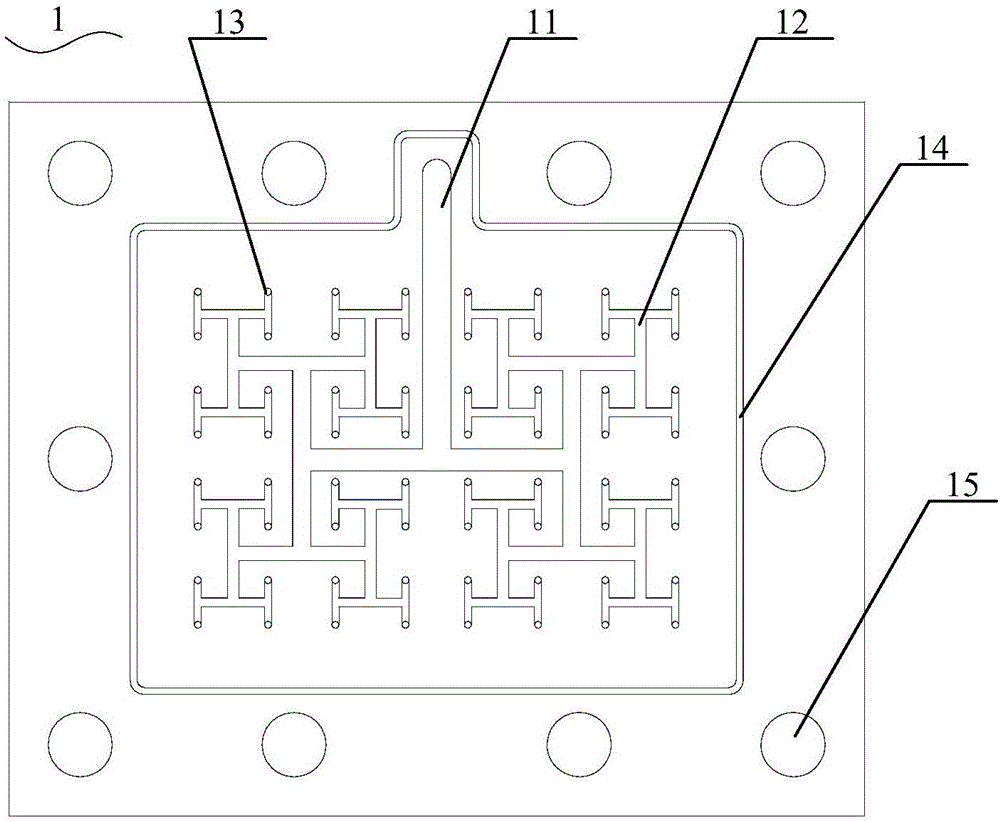

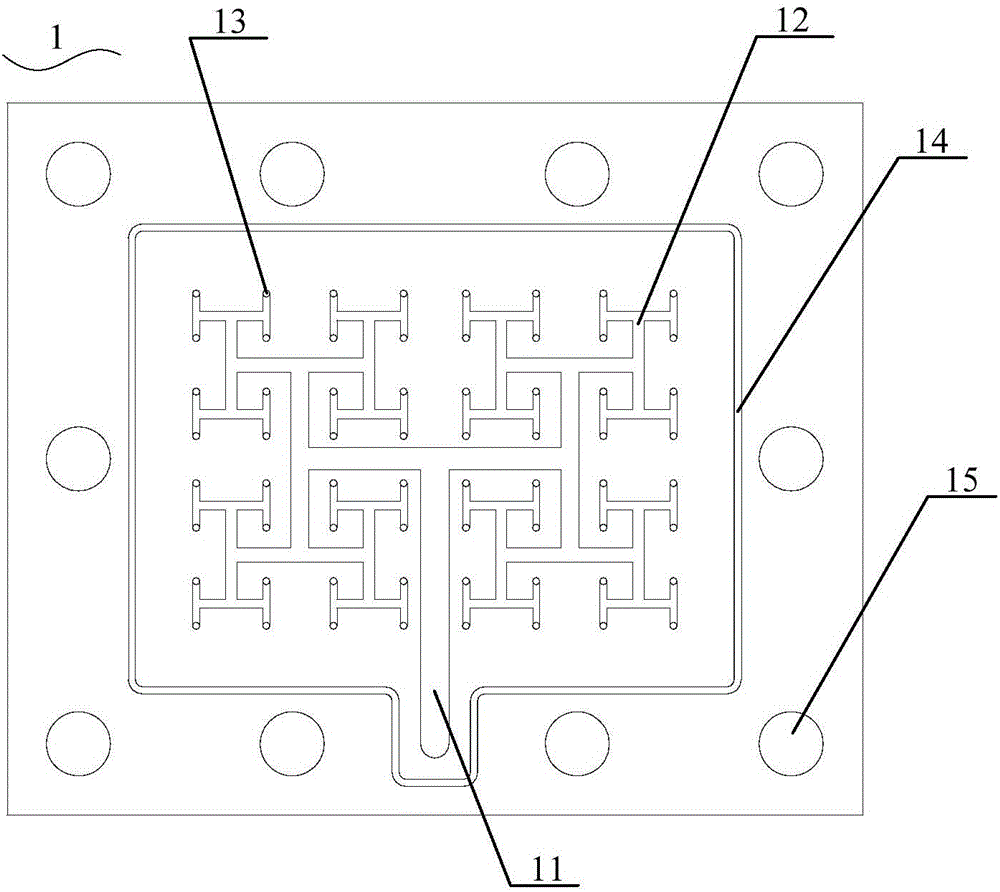

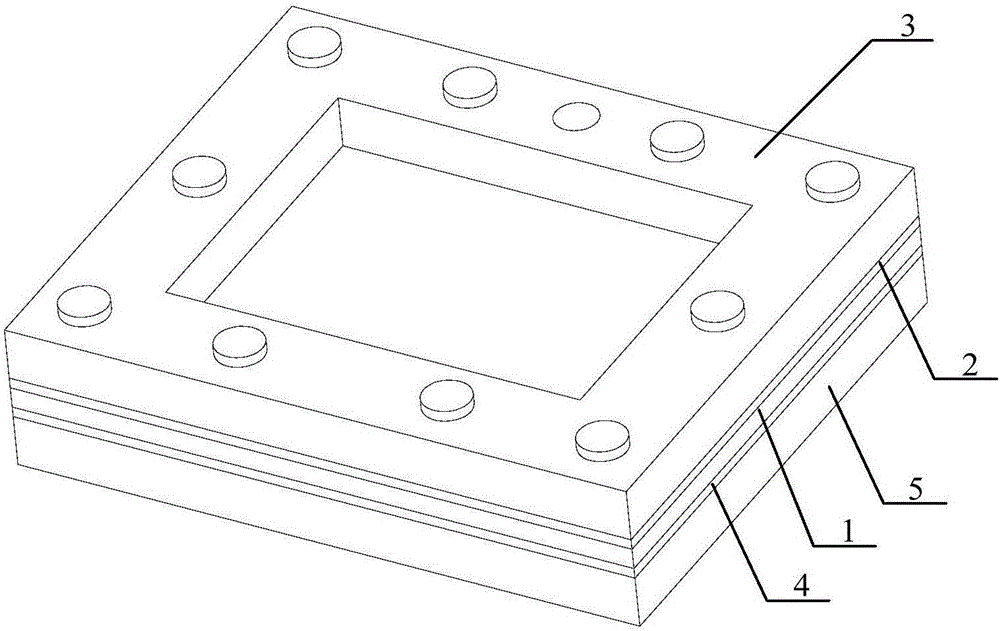

Microchannel plate with fractal structure, photocatalytic reactor and application thereof

InactiveCN106311110AControl flowControl dwell timeChemical/physical/physico-chemical microreactorsEnergy based chemical/physical/physico-chemical processesPhotocatalytic reactionThree-phase

The invention provides a microchannel plate with a fractal structure, a photocatalytic reactor and an application thereof. The microchannel plate with the fractal structure comprises a first surface and a second surface which are opposite; the first surface and the second surface of the microchannel plate with the fractal structure each is provided with a main pipeline microchannel and multistage H-shaped fractal bifurcated microchannels which are connected with one end of the corresponding main pipeline microchannel, and the H-shaped fractal bifurcated microchannels of the first surface of the microchannel plate with the fractal structure communicate with those of the second surface of the microchannel plate with the fractal structure through connecting through holes. According to the microchannel plate with the fractal structure, the photocatalytic reactor and the application thereof, through forming fractal-structured microchannels in the upper and lower surfaces of the microchannel plate with the fractal structure, three phases, i.e., gas, liquid and solid phases can be effectively distributed, heat transfer and mass transfer are strengthened, the problem in collection of reactants of fractal distribution can be effectively solved, meanwhile, the length of the microchannels can be increased, and the control on reaction flux and reactant residence time is better facilitated.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

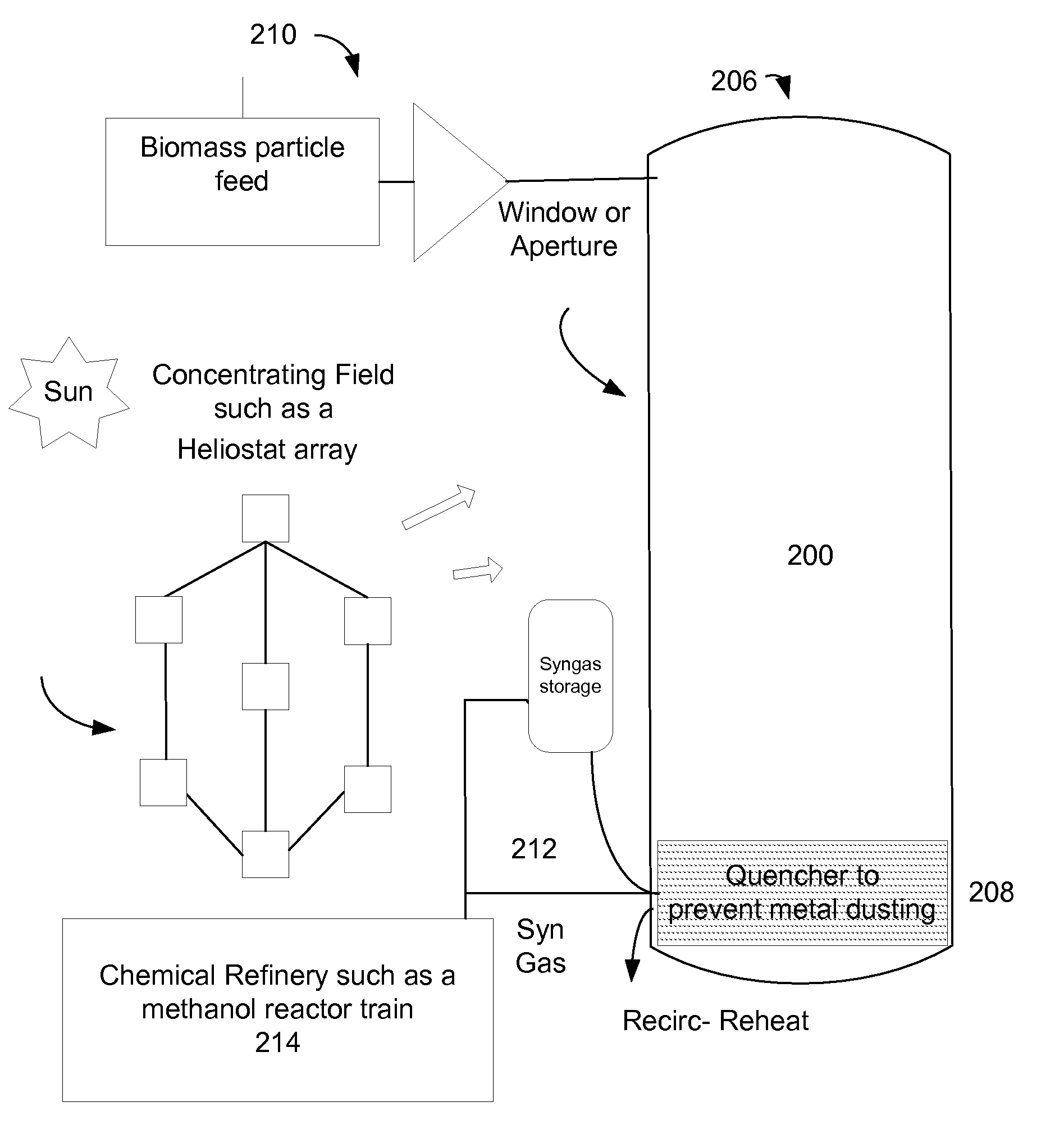

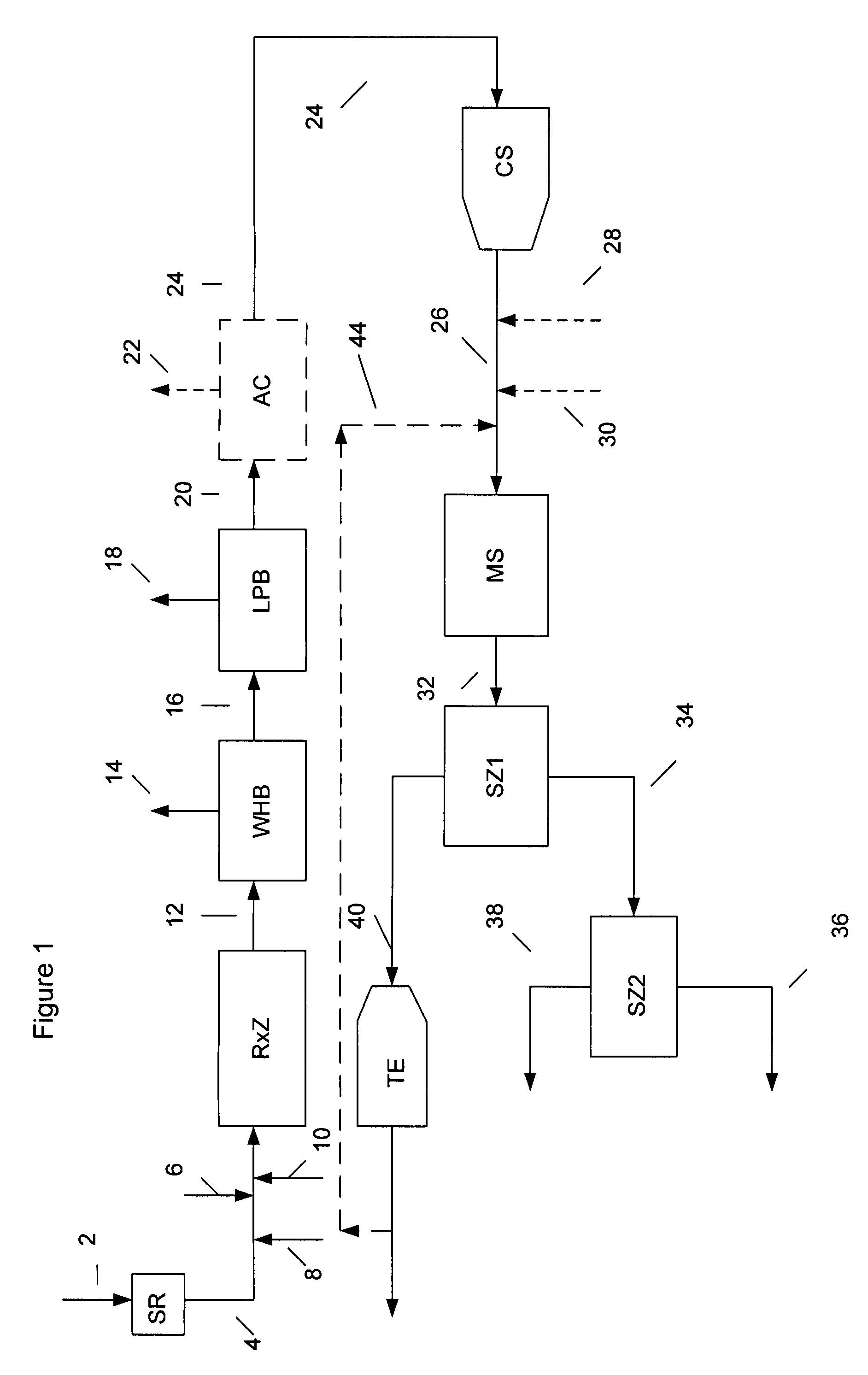

Systems and methods for an integrated solar driven chemical plant

A method, apparatus, and system for an integrated solar-driven chemical plant that manages variations in solar energy are disclosed. In some embodiments, a chemical reactant, including particles of biomass, are converted in a solar driven chemical reactor into synthesis gas containing carbon monoxide and hydrogen using concentrated solar energy to drive the conversion of the chemical reactant. The synthesis gas is supplied for a catalytic conversion of the synthesis gas in a methanol synthesis plant to methanol. Cycling occurs between an operational state and an idle state for a number of methanol trains in the methanol synthesis plant depending upon an amount of synthesis gas generated in the solar driven chemical reactor. A control system for the chemical reactor sends control signals to and receives feedback from a control system for the methanol synthesis plant.

Owner:SUNDROP IP HLDG LLC

Method for preparing formic acid, methanol and methane by using metal hydro-thermal to reduce CO2

InactiveCN101265148ARealize resourcesReduce operating energy consumptionHydrocarbon from carbon oxidesOrganic compound preparationReaction temperaturePollution

Owner:TONGJI UNIV

Method for reducing carbon dioxide through inorganic semiconductor photocatalysis system

InactiveCN105983420AAchieve restorationSimple compositionHydrocarbon from carbon oxidesPhysical/chemical process catalystsSolventSemiconductor

The invention discloses a system for reducing carbon dioxide through an inorganic semiconductor photocatalysis system, and a reduction method thereof. The system for reducing carbon dioxide through the inorganic semiconductor photocatalysis system comprises an inorganic semiconductor photocatalyst, a solvent, an electron sacrificing body and an illuminator. The method for reducing carbon dioxide by using the system comprises the following steps: 1, adding the inorganic semiconductor photocatalyst to a photoreactor, carrying out aggregating precipitation by using an acid or a solvent greatly different from a semiconductor raw solution in polarities, centrifuging the obtained solution, and dispersing the obtained precipitate by using a solvent to obtain a catalyst solution; 2, adding the electron sacrificing body to the catalyst solution to obtain a mixed solution; 3, adjusting the pH value of the mixed solution to 2.0-14.0 in order to obtain a reaction solution; 4, introducing carbon dioxide to the reaction solution, and sealing the reaction solution and 5, irradiating the final mixed solution with a light source to carry out a reduction reaction. The system disclosed in the invention has the advantages of simple com position, simplicity in operation, low price, easy obtaining, and high visible light utilization rate.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

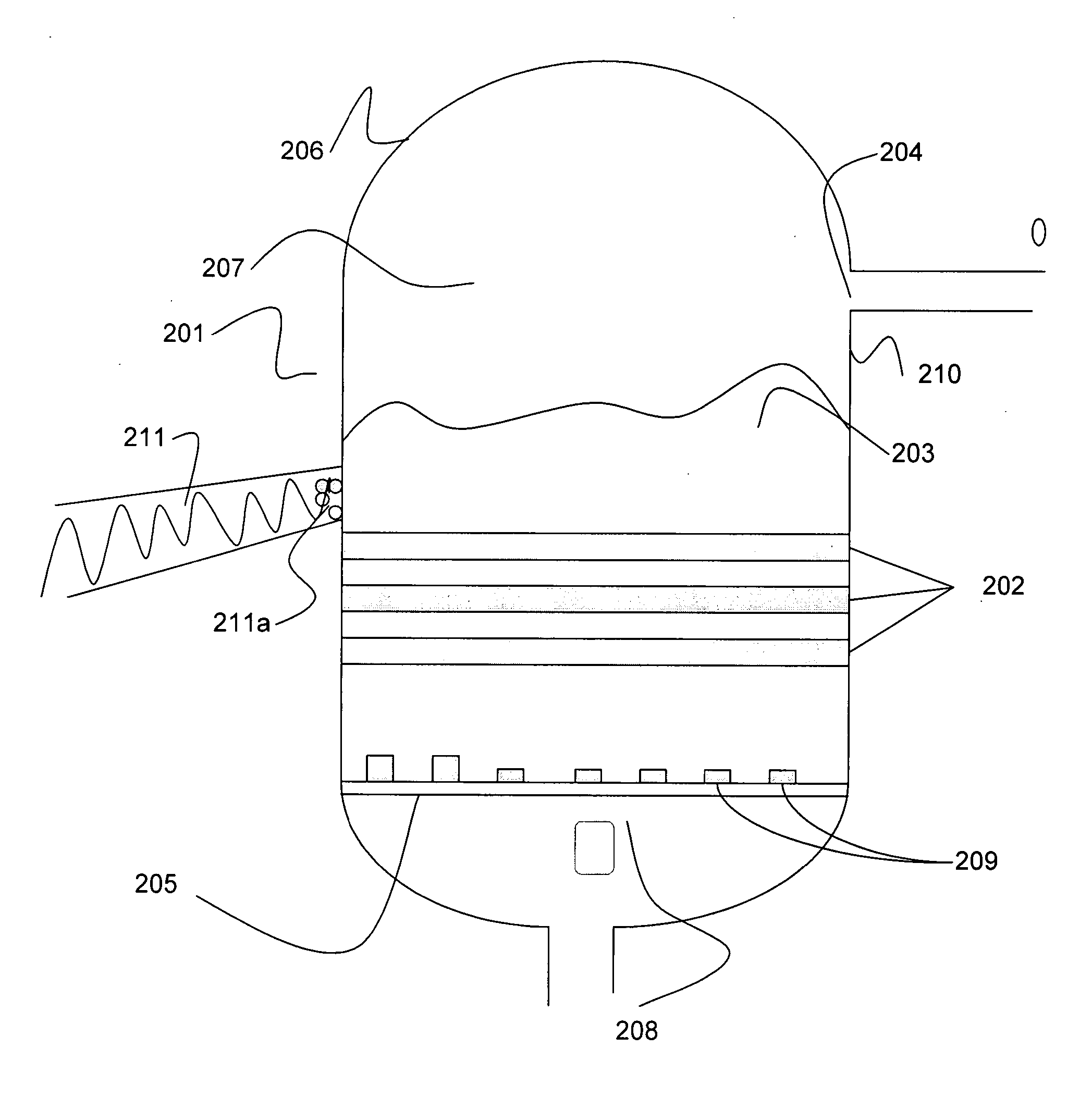

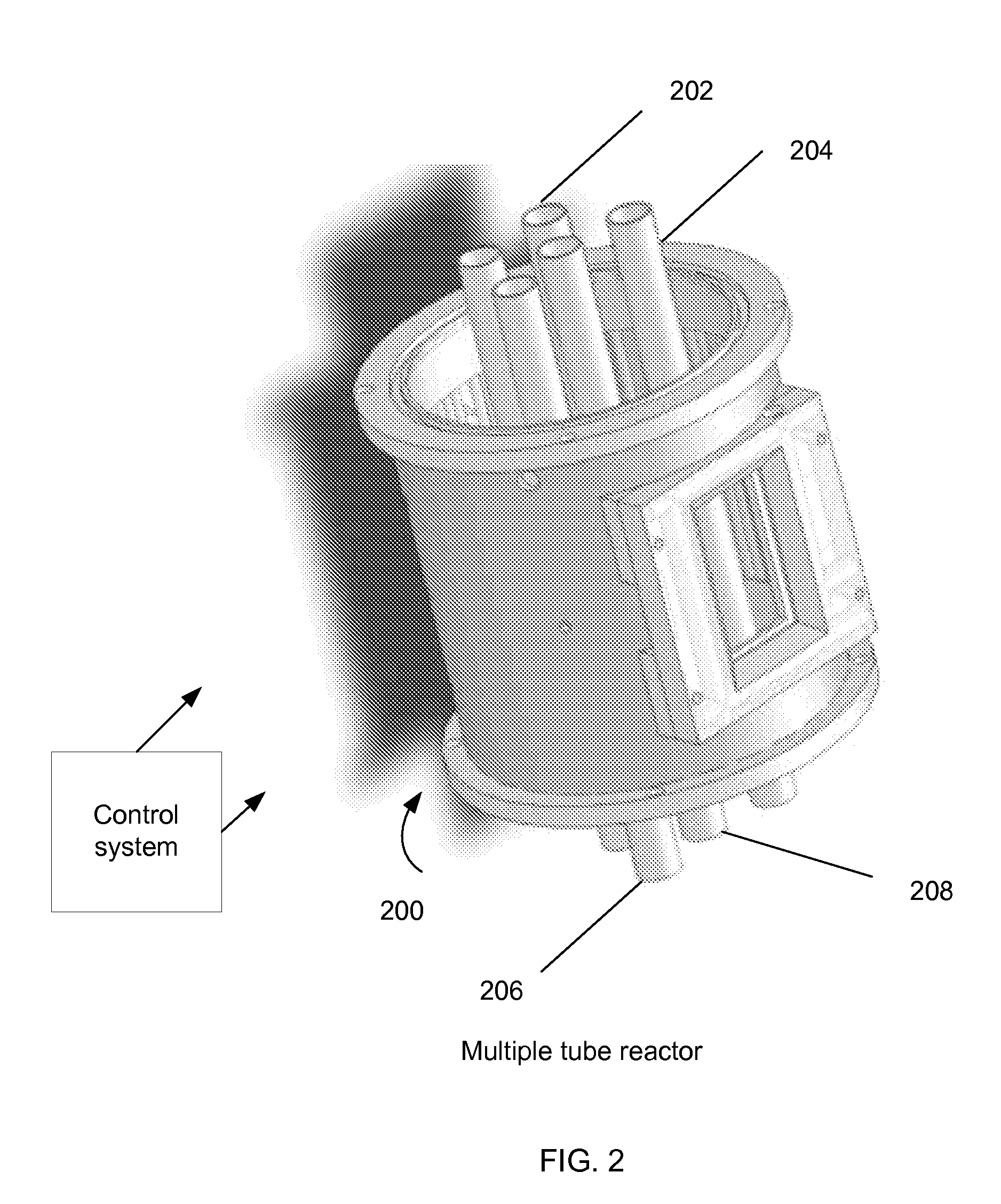

Systems and methods for biomass gasifier reactor and receiver configuration

InactiveUS20100247387A1Complete gasificationProcess control/regulationSolar heating energyHydrogenHeliostat

A method, apparatus, and system for solar-driven chemical plant may include a solar thermal receiver to absorb concentrated solar energy from an array of heliostats. Additionally, some embodiments may include a solar driven chemical reactor that has multiple reactor tubes. The concentrated solar energy drives the endothermic gasification reaction of the particles of biomass flowing through the reactor tubes. Some embodiments may also include an on-site fuel synthesis reactor that is geographically located on the same site as the chemical reactor and integrated to receive the hydrogen and carbon monoxide products from the gasification reaction.

Owner:SUNDROP IP HLDG LLC

Catalyst composition, a process for preparing the catalyst composition and a use of the catalyst composition

ActiveUS20080306289A1High selectivityImprove performanceBiocideOxygen-containing compound preparationRheniumNitrate

A catalyst composition comprising a support having a surface area of at least 500 m2 / kg, and deposited on the support:silver metal,a metal or component comprising rhenium, tungsten, molybdenum or a nitrate- or nitrite-forming compound, anda Group IA metal or component comprising a Group IA metal having an atomic number of at least 37, and in addition potassium, wherein the value of the expression (QK / R)+QHIA is in the range of from 1.5 to 30 mmole / kg, wherein QHIA and QK represent the quantities in mmole / kg of the Group IA metal having an atomic number of at least 37 and potassium, respectively, present in the catalyst composition, the ratio of QHIA to QK is at least 1:1, the value of QK is at least 0.01 mmole / kg, and R is a dimensionless number in the range of from 1.5 to 5, the units mmole / kg being relative to the weight of the catalyst composition.

Owner:SHELL USA INC

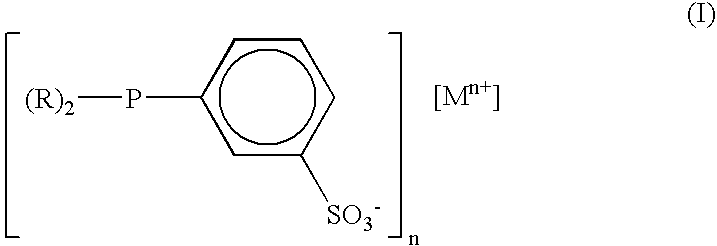

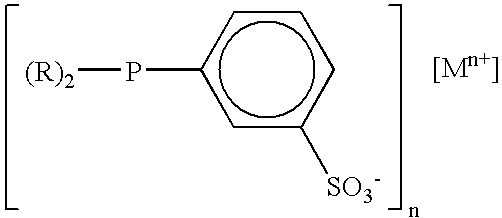

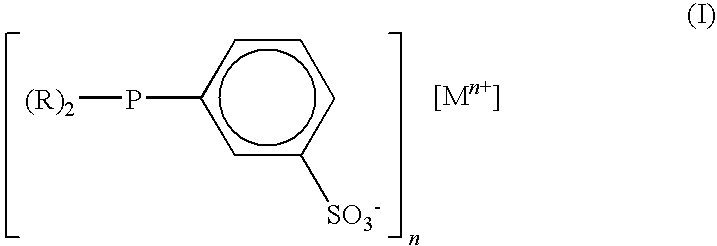

Nonaqueous ionic ligand liquids, process for preparing them and their use as catalyst constituents

InactiveUS6103908AHigh yieldSuitable for preparationOxygen-containing compound preparationOrganic compound preparationPhosphoniumAmmonium

Nonaqueous ionic ligand liquids of the formula (Q(+))a Aa-, where Q(+) is a singly charged quaternary ammonium and / or phosphonium cation or the equivalent of a multiply charged ammonium and / or phosphonium cation and Aa- is a sulfonated triarylphosphine, a process for preparing them and their use as catalyst constituents.

Owner:CELANESE CHEM EURO GMBH

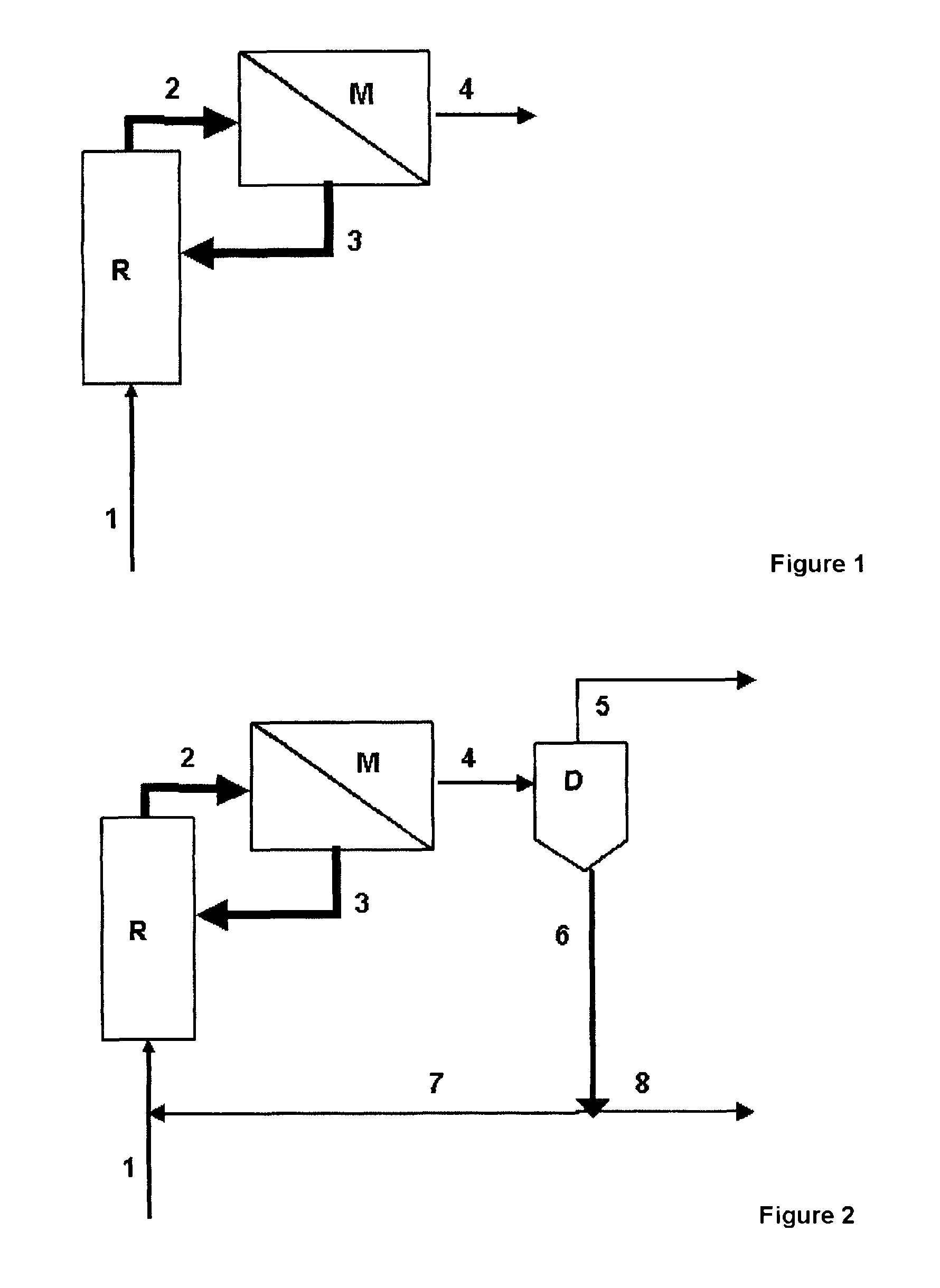

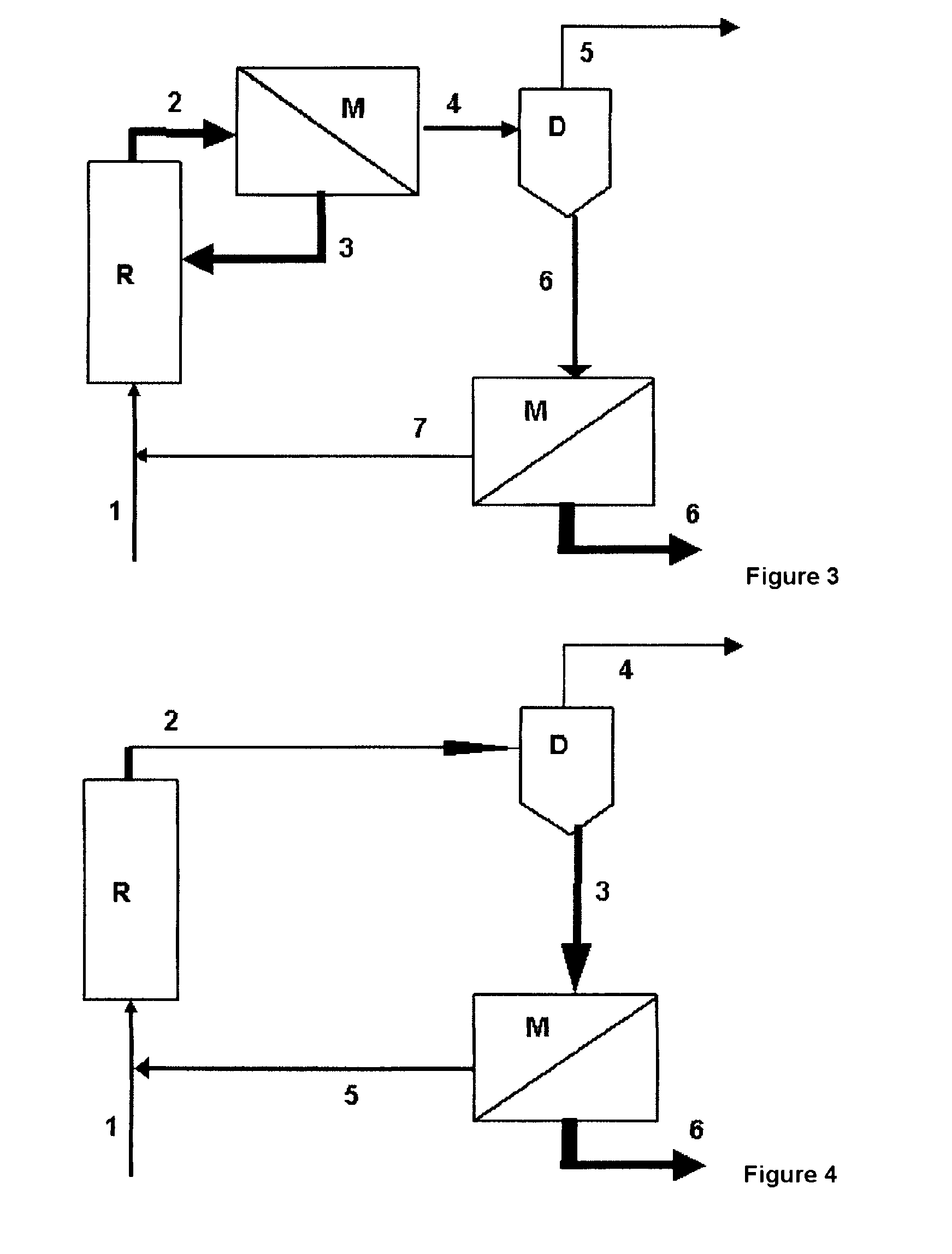

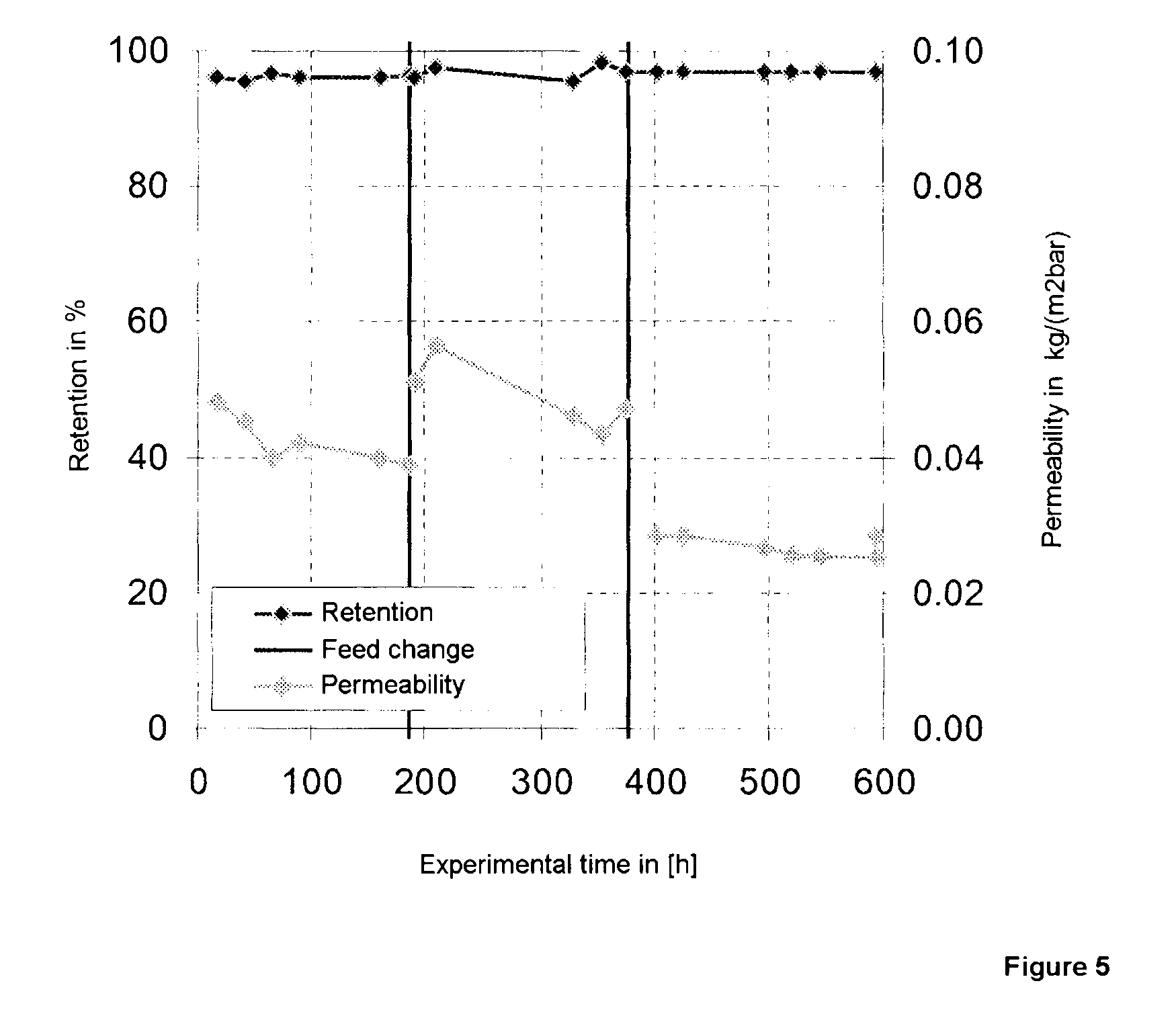

Method for enriching a homogeneous catalyst from a process flow

InactiveUS8969628B2Oxygen-containing compound preparationSemi-permeable membranesPolymer scienceHomogeneous catalysis

The invention relates to a method for enriching a homogenous catalyst from a process flow comprising said homogenous catalyst as a component, wherein the process flow is conducted over at least one membrane and wherein the membrane wholly or partially comprises a polymer that has planar polymer units connected to one another via a rigid link and wherein the linker is contorted, such that at least one planar polymer unit is connected to at least one second planar polymer unit via the link, in a non-co-planar arrangement. The invention furthermore relates to a method for producing tridecanal.

Owner:EVONIK DEGUSSA GMBH

Production of methanol from the crude glycerol by-product of producing biodiesel

InactiveUS7388034B1Improve flowOrganic compound preparationOxygen compounds preparation by reductionBiodieselVegetable oil

Production of methanol from a stream of crude glycerol. The crude glycerol is preferably a side product (waste product) that results from the production of biodiesel from vegetable oils and animal fats. The crude glycerol stream is combined with superheated steam and oxygen to produce a synthesis gas that is then passed to a methanol synthesis reaction zone to produce methanol.

Owner:GD SPA

Process for treating a carrier, a process for preparing a catalyst, the catalyst, and use of the catalyst

A process for treating a carrier, or a precursor thereof, to at least partly remove impurities comprising contacting the carrier, or the precursor thereof, with a treatment solution comprising a salt; a process for preparing a catalyst; the catalyst; a process for preparing an olefin oxide by reacting an olefin with oxygen in the presence of the catalyst; and a process for preparing a 1,2-diol, a 1,2-diol ether or an alkanolamine.

Owner:SHELL USA INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com