Microchannel plate with fractal structure, photocatalytic reactor and application thereof

A technology of photocatalytic reactor and photocatalytic reaction, applied in chemical/physical/physical chemical reactor, chemical instrument and method, chemical/physical/physical chemical process of energy application, etc., can solve difficult industrial amplification, uneven , Low and other problems, to achieve the effect of controlling the residence time, controlling the light penetration rate, and controlling the lighting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

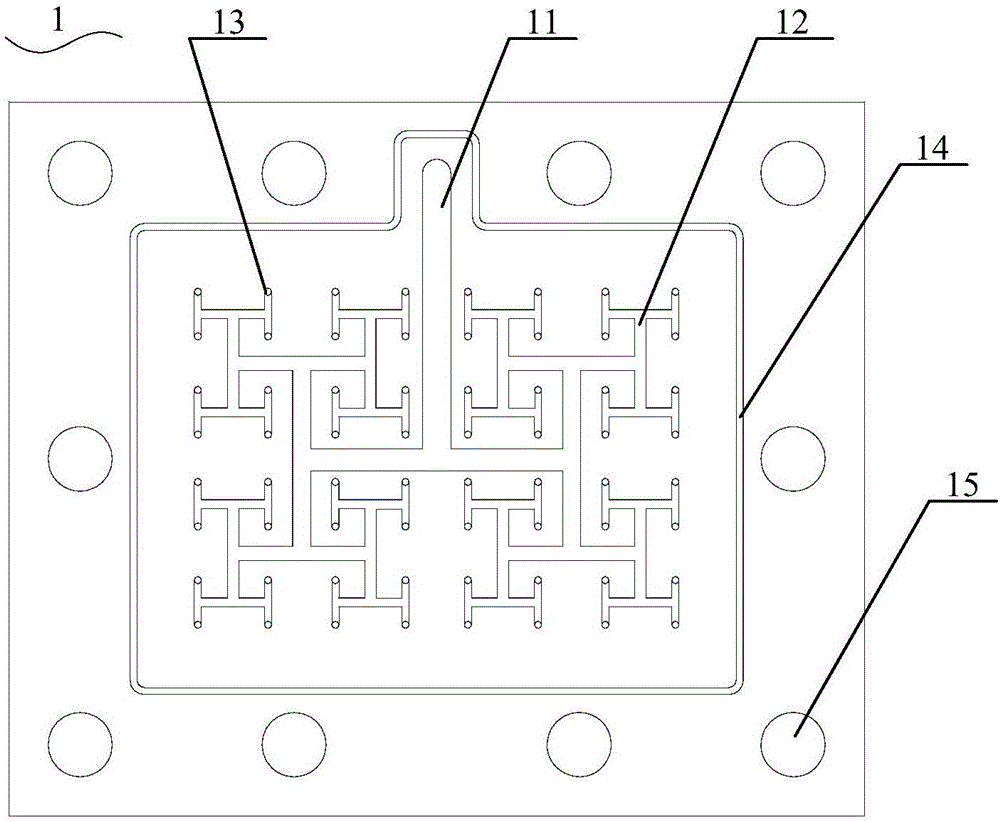

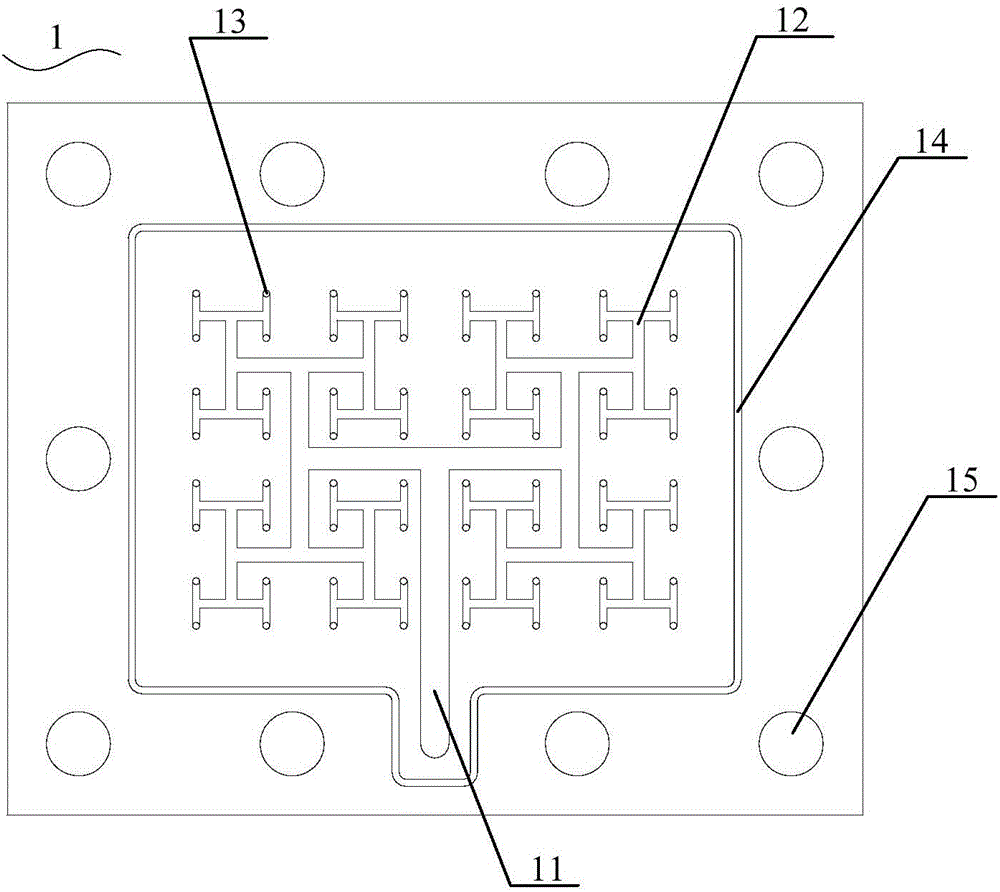

[0058] see Figure 1 to Figure 2 , the present invention provides a microchannel plate 1 with a fractal structure, the microchannel plate 1 with a fractal structure includes opposite first surfaces and second surfaces, wherein, figure 1 It is a structural schematic diagram of the top view of the first surface of the microchannel plate 1 with a fractal structure, figure 2 It is the second surface top view structure schematic diagram of the microchannel plate 1 with fractal structure; the first surface and the second surface of the microchannel plate 1 with fractal structure are all provided with main pipeline microchannel 11 and with the main pipe A multistage H-type fractal bifurcated microchannel 12 connected to one end of the road microchannel 11, and the H-type fractal bifurcated microchannel 12 on the first surface of the microchannel plate 1 with a fractal structure is connected to the described microchannel with a fractal structure The H-shaped fractal bifurcated micro...

Embodiment 2

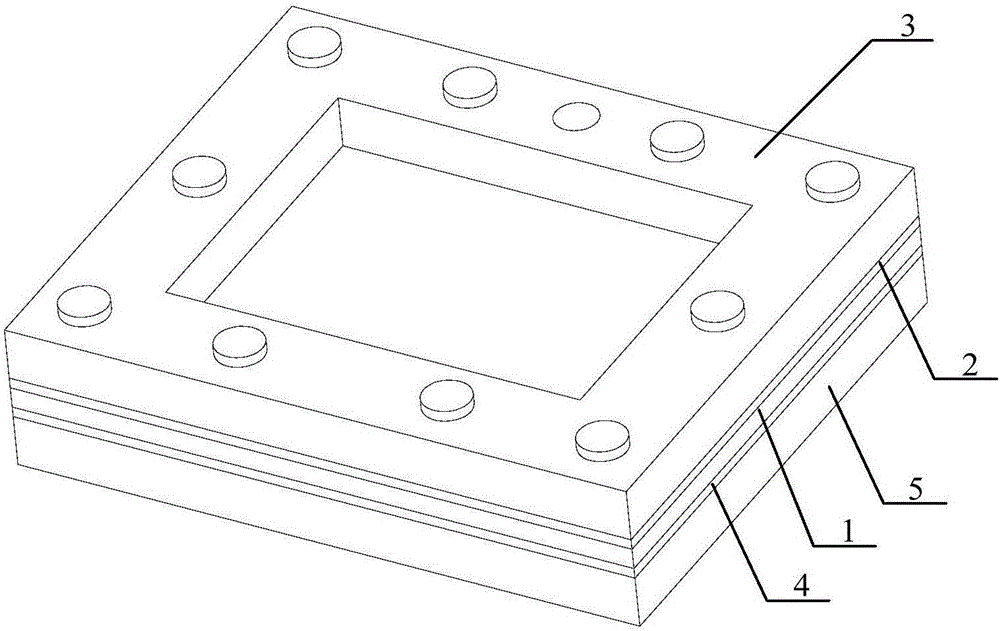

[0070] see Figure 3 to Figure 7 , the present invention also provides a kind of photocatalytic reactor, described photocatalytic reactor comprises: the microchannel plate 1 with fractal structure as described in embodiment one, the specific structure of described microchannel plate 1 with fractal structure Please refer to Embodiment 1, which will not be repeated here; the first quartz cover plate 2, the first quartz cover plate 2 is located on the first surface of the microchannel plate 1 with a fractal structure, the first quartz cover plate The plate 2 is provided with the first outlet through hole 22 corresponding to the position of the main pipeline microchannel 11; the first metal cover plate 3, and the first metal cover plate 3 is located on the surface of the first quartz cover plate 2; The first metal cover plate 3 is an annular cover plate, and the inner area of the first metal cover plate 3 is similar to the distribution area of the H-type fractal bifurcated mic...

Embodiment 3

[0081] The present invention also provides a photocatalytic reaction system, which includes: the photocatalytic reactor, gas supply system, liquid supply system, tee, light source, cooling circulating water system and Power system; the photocatalytic reactor communicates with the gas supply system and the liquid supply system through the tee; the light source is located on the upper and lower sides of the photocatalytic reactor; the cooling circulating water system It includes a water supply device and a quartz water tank connected with the water supply device, the photocatalytic reactor is located in the quartz water tank; the power system is connected with the liquid supply system and the cooling circulating water system, suitable for Drive the flow of reaction liquid and cooling water.

[0082] As an example, the gas supply system may include a gas cylinder, a pressure reducing valve, and a gas mass flowmeter. The flow meter is connected to the tee; the light source can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com