Patents

Literature

288results about How to "Improve manufacturing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

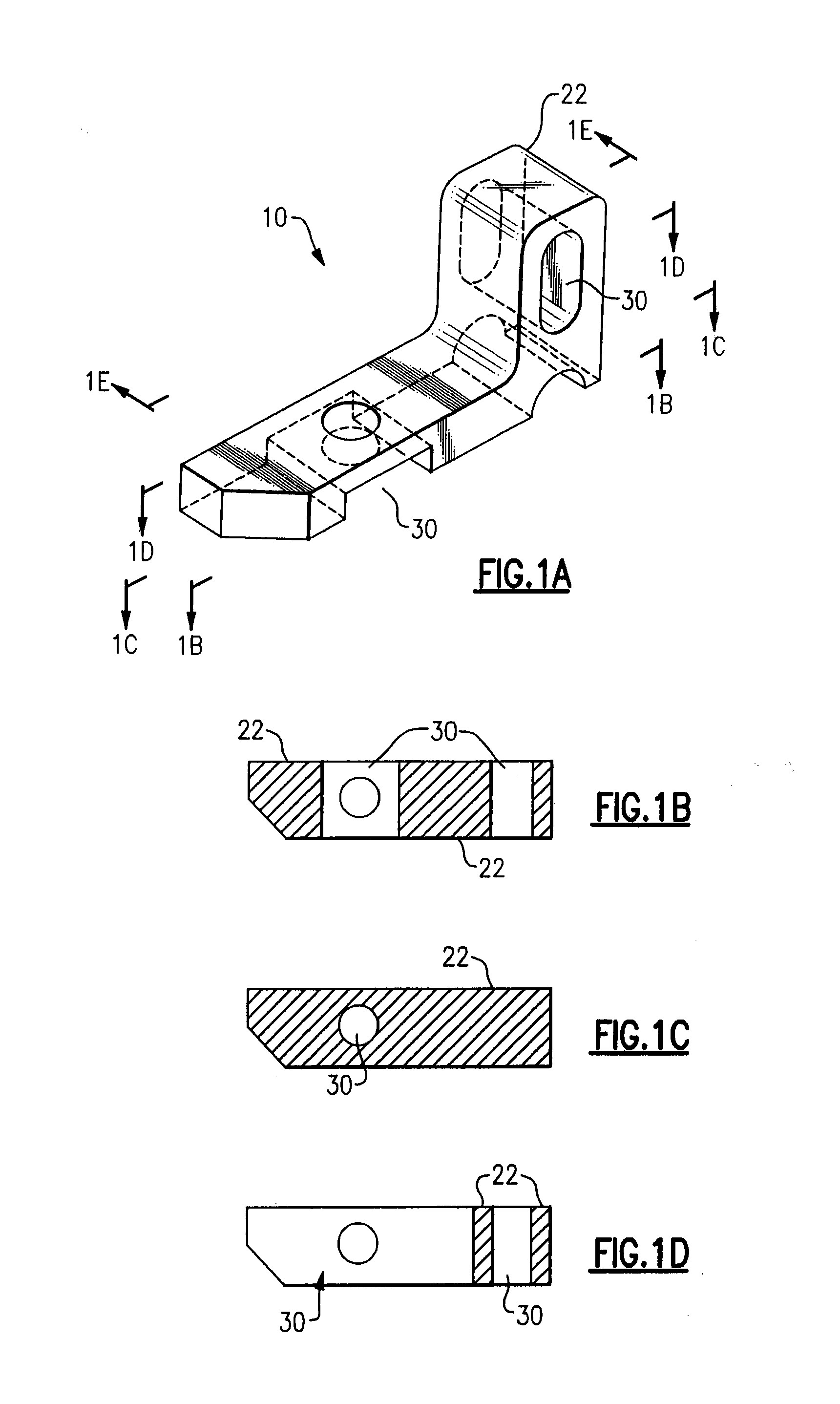

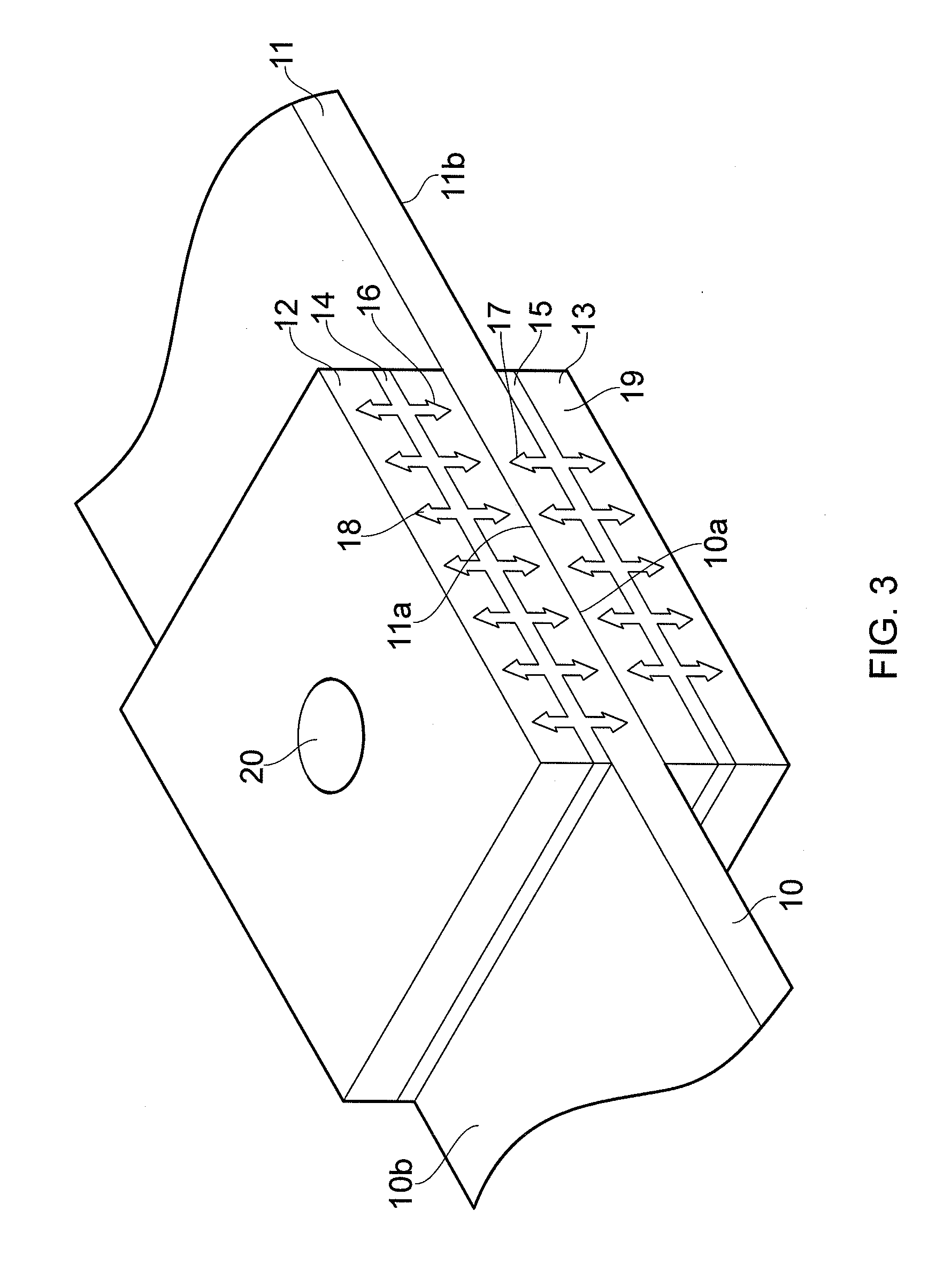

Flexible 3D Freeform Techniques

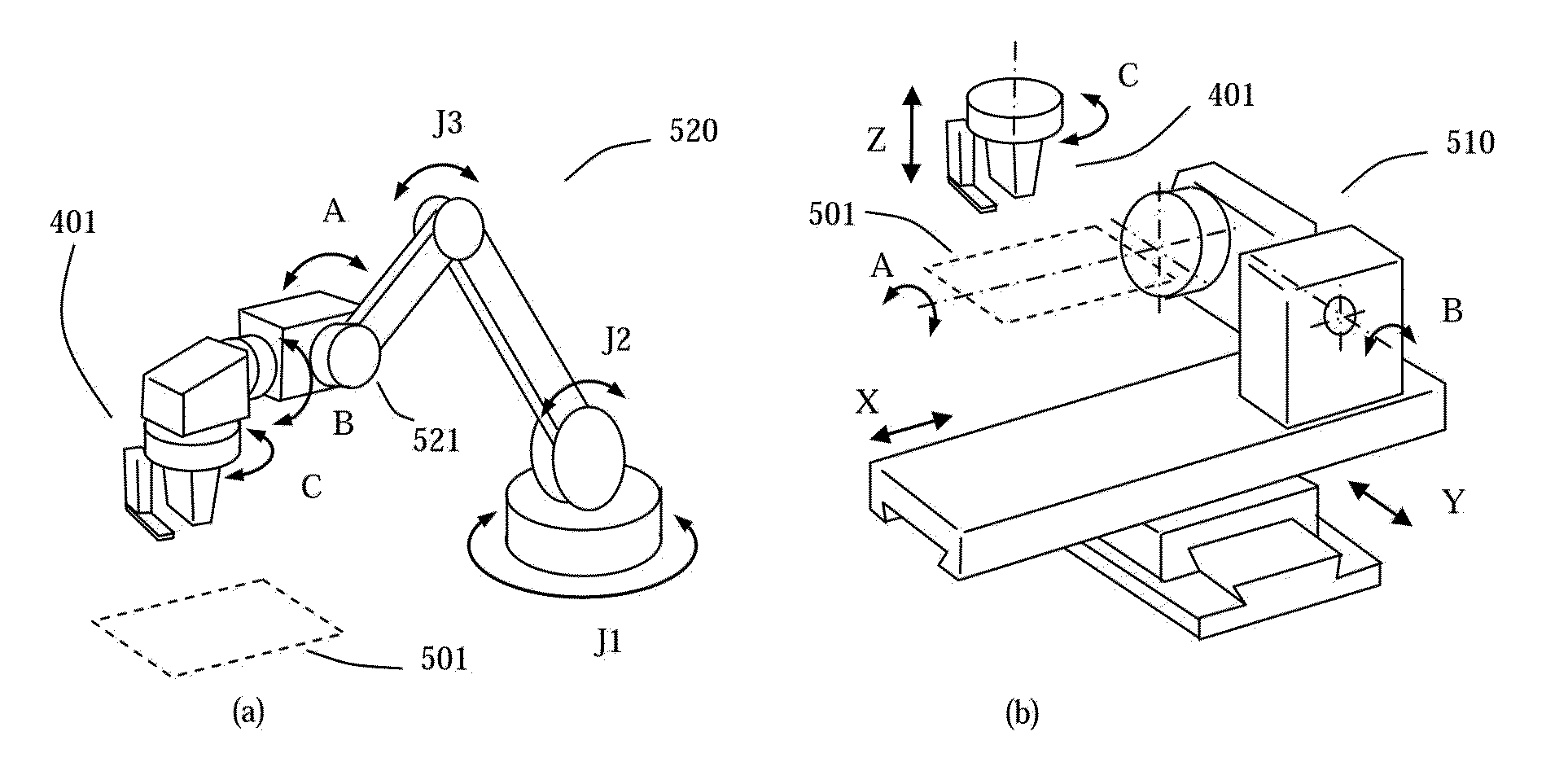

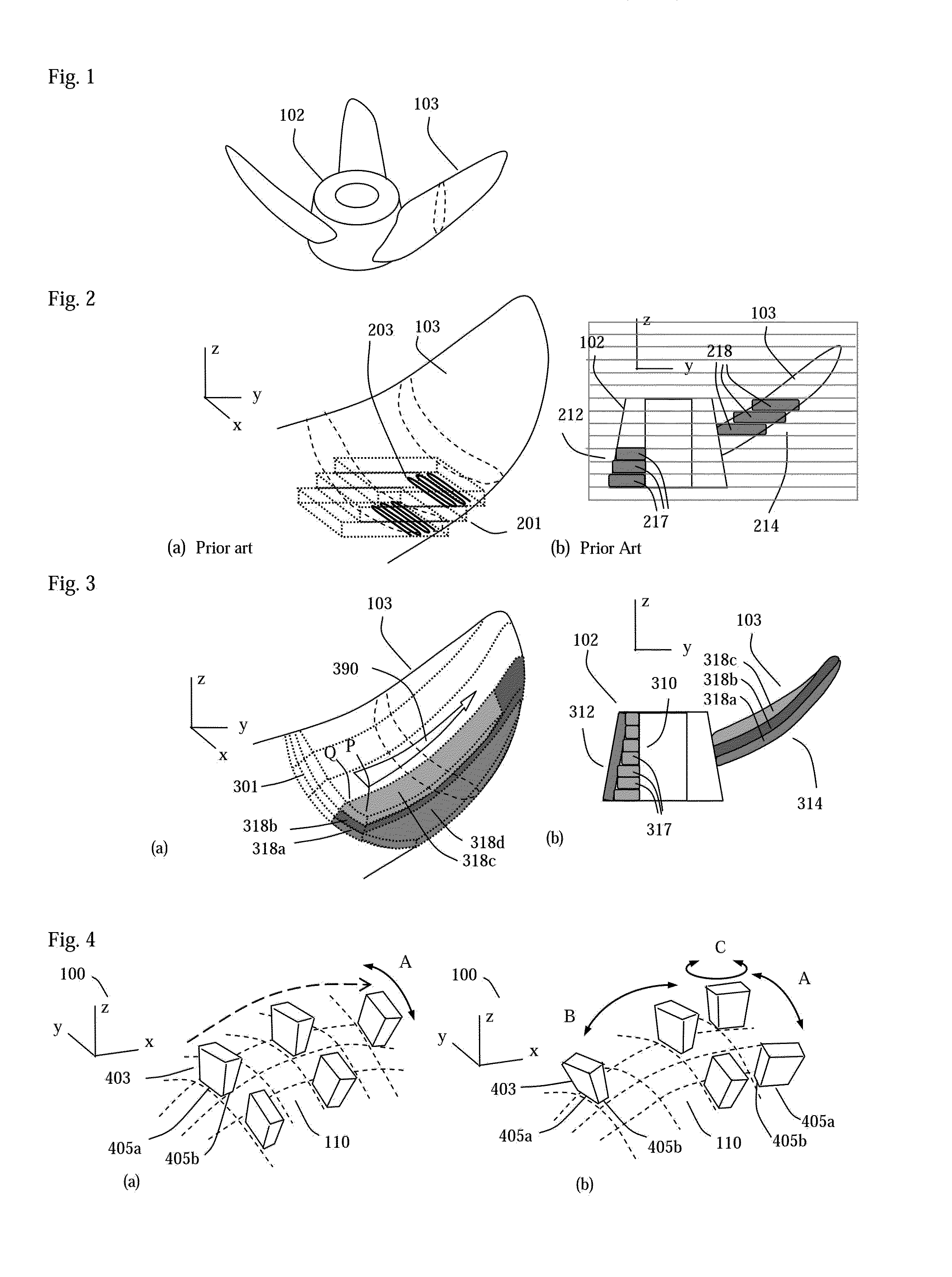

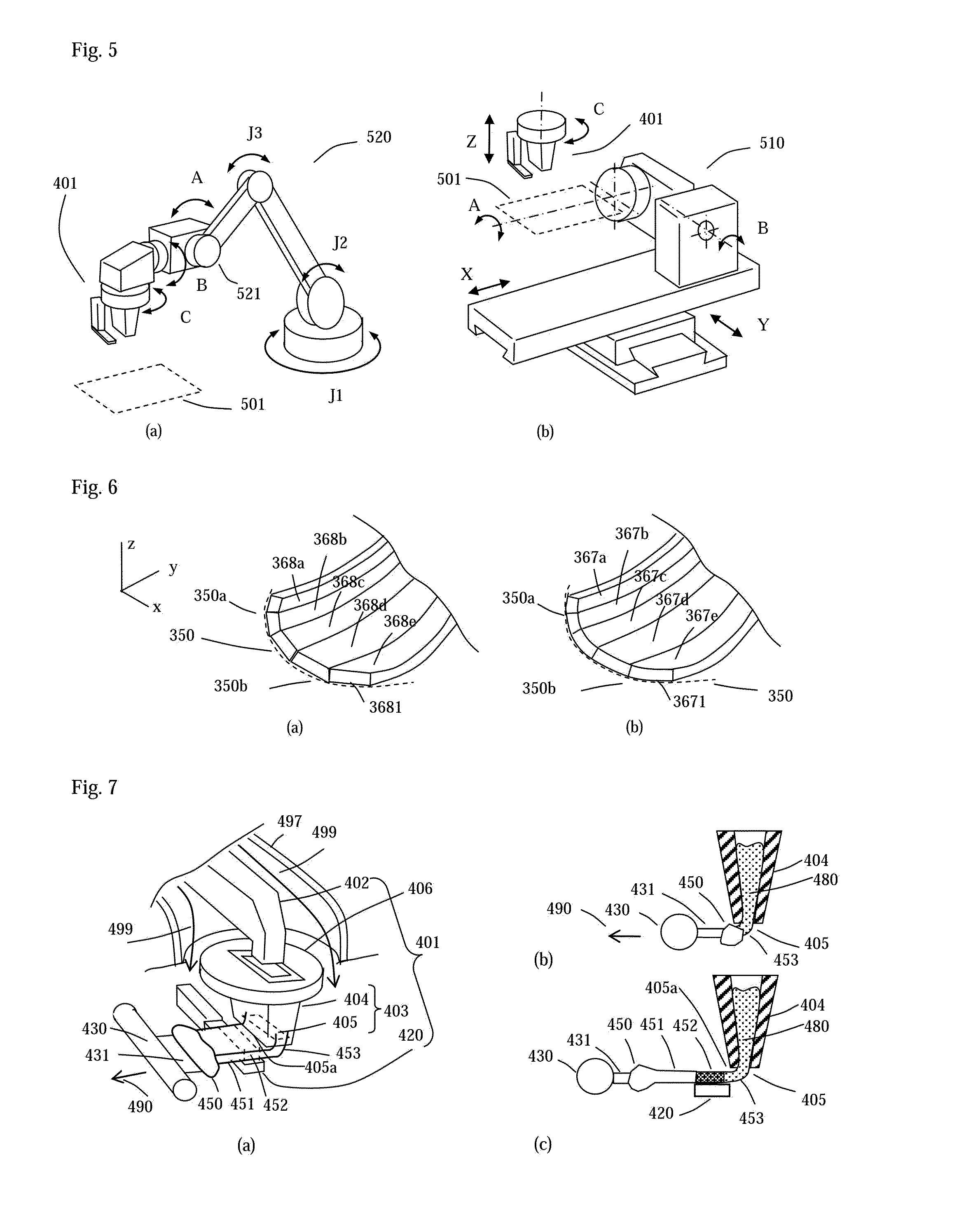

ActiveUS20160151833A1Improve manufacturing speedBuild fine and complexConfectioneryGlass forming apparatusEngineeringInjection molding machine

This invention relates to processes and systems of rapid prototyping and production. Its features includes flexible material deposition along tangential directions of surfaces of a part to be made, thereby eliminating stair-shape surface due to uniform horizontal layer deposition, increasing width of material deposition to increase build up rate, applying the principles of traditional forming / joining processes, such as casting, fusion welding, plastic extrusion and injection molding in the fabrication process so that various industrial materials can be processed, applying comparatively low cost heating sources, such as induction heating and arc-heating. Additional features include varying width and size of material deposition in accordance with geometry to be formed and applying a differential molding means for improved shape formation and surface finishing.

Owner:NATIONAL TSING HUA UNIVERSITY

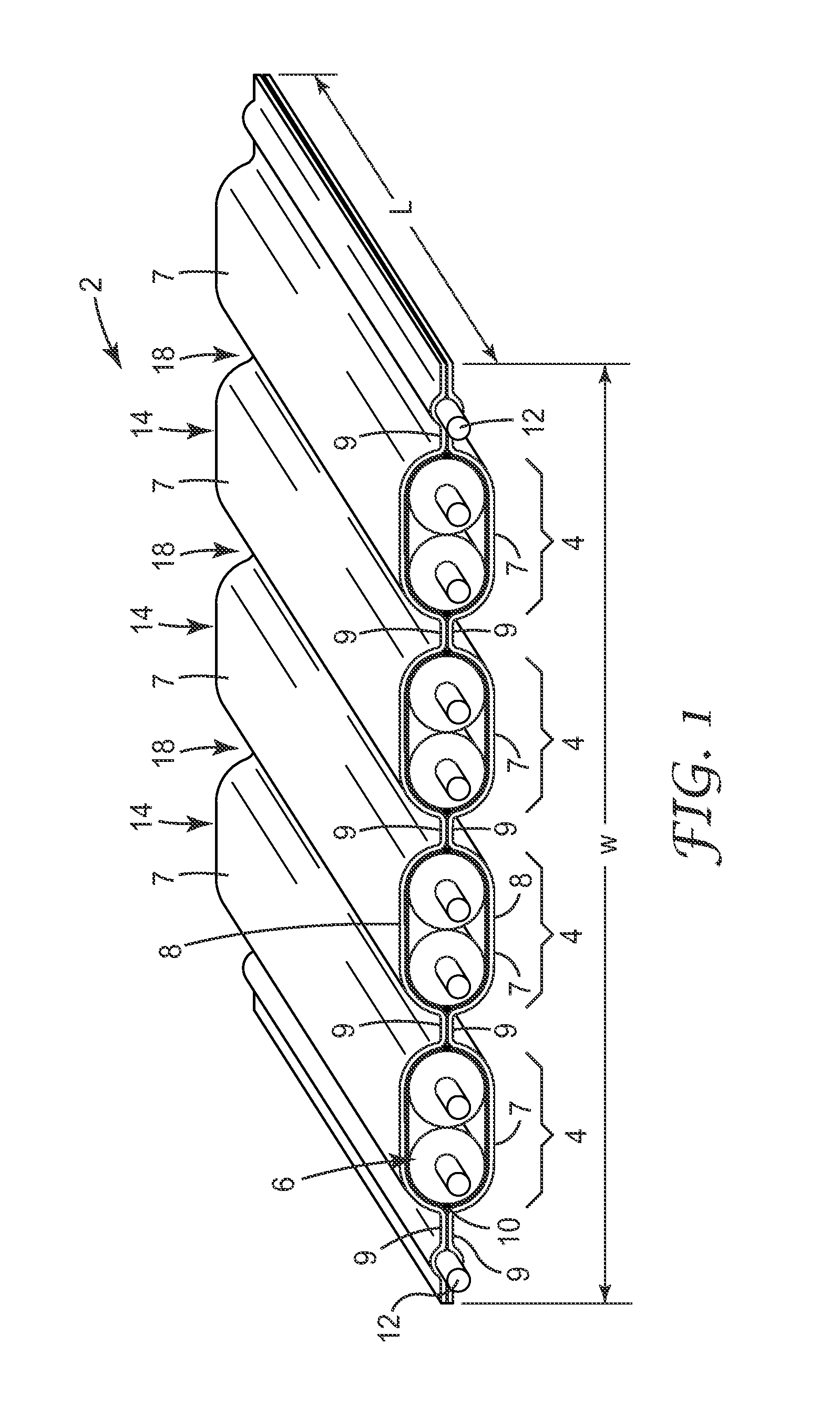

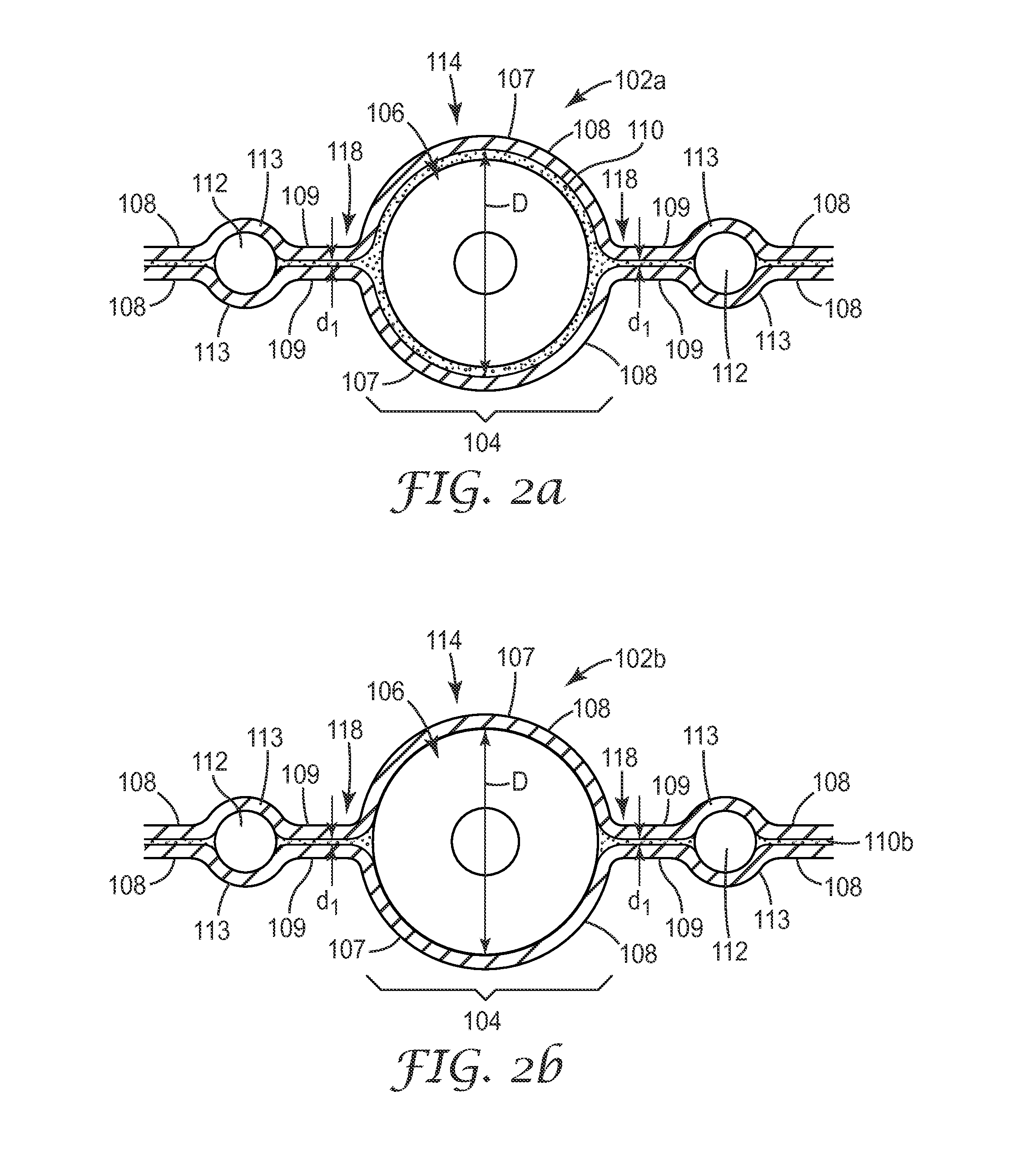

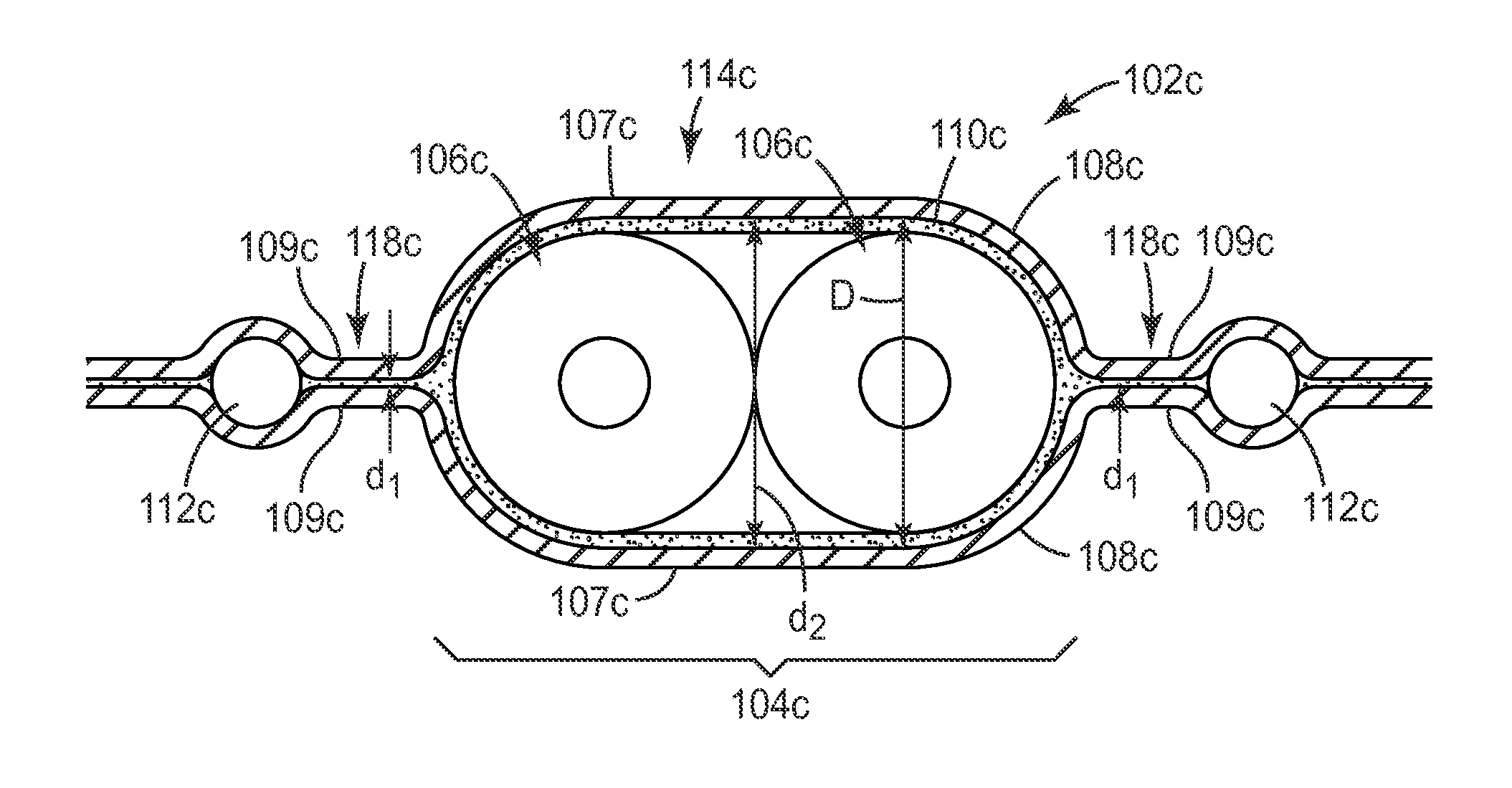

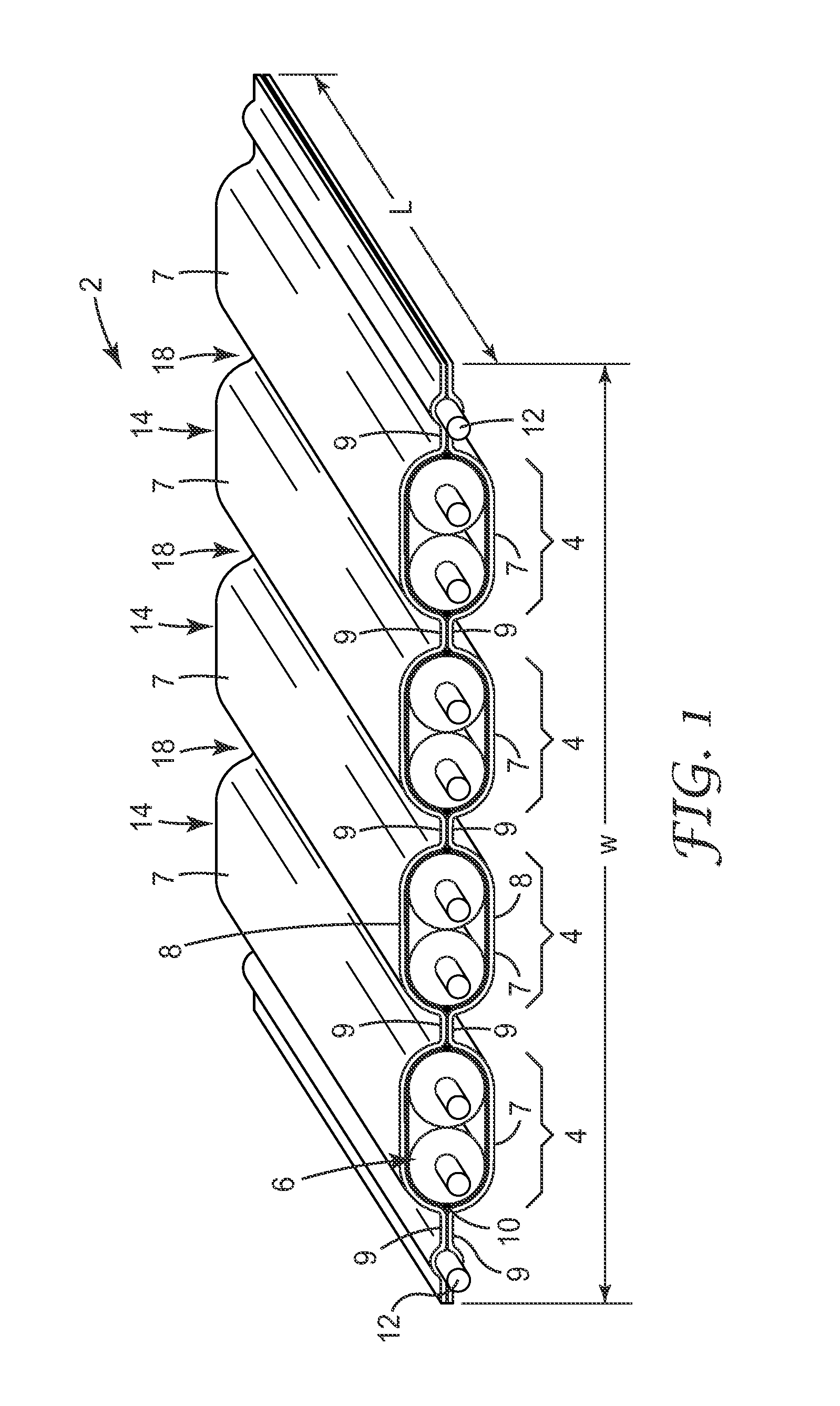

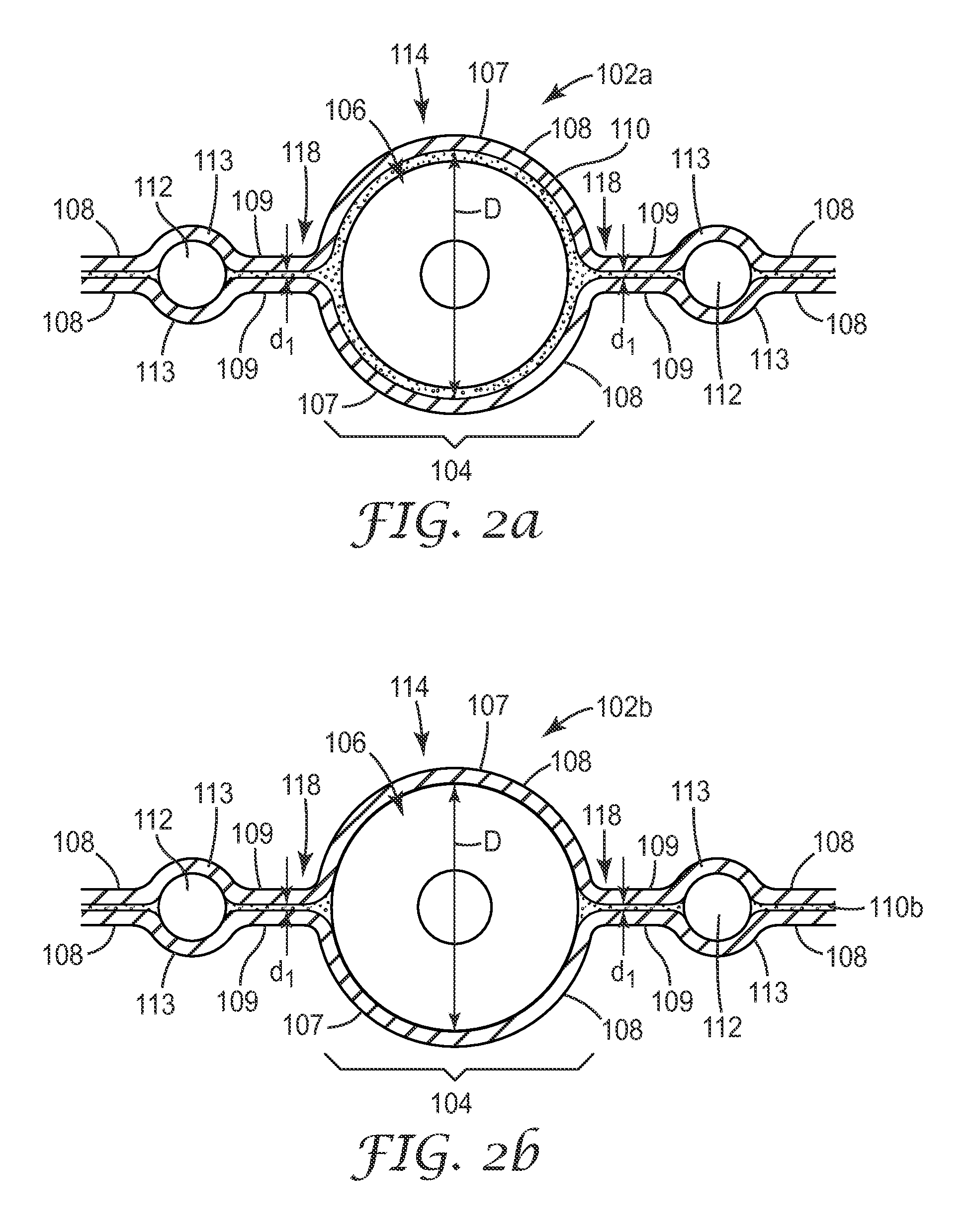

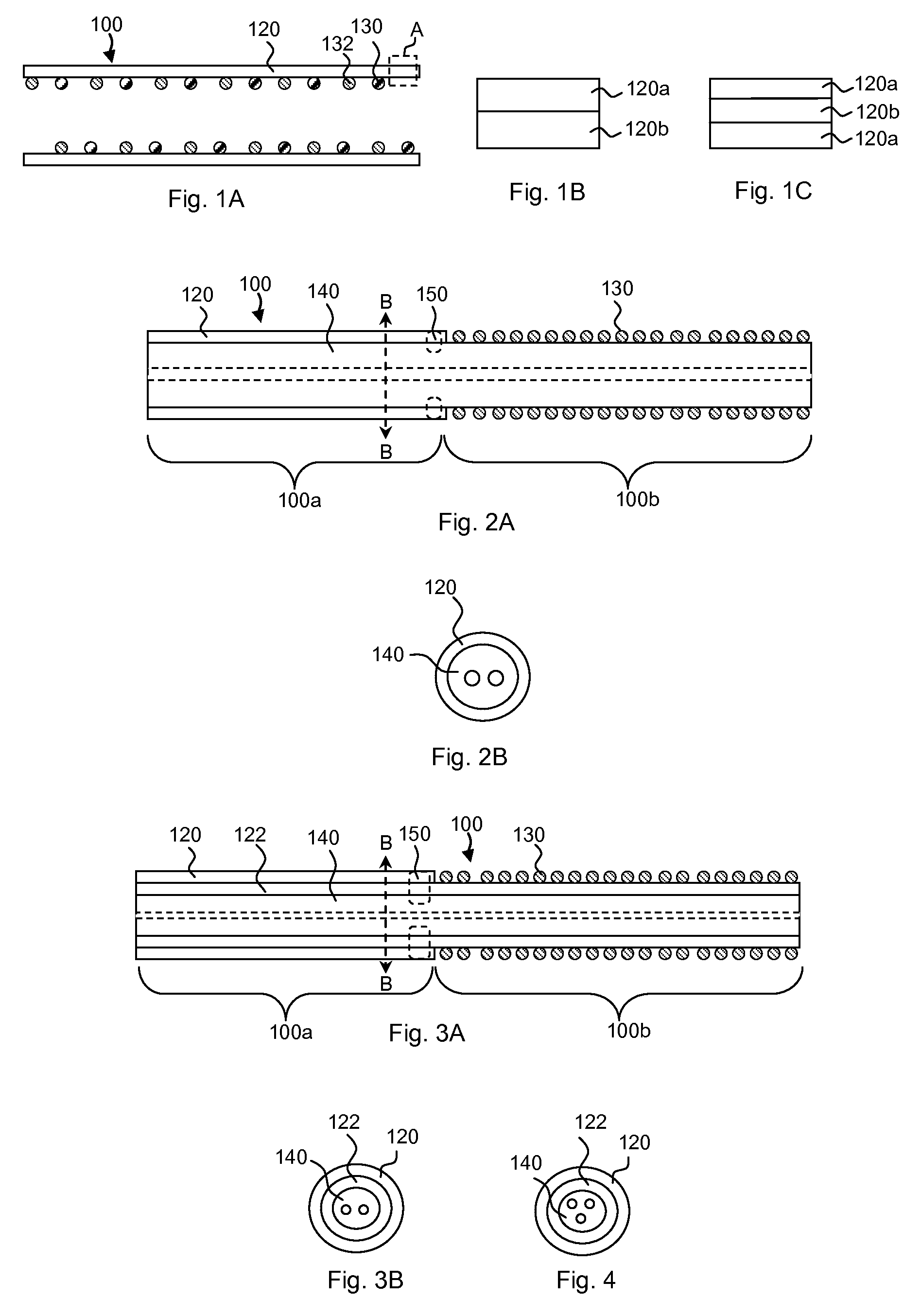

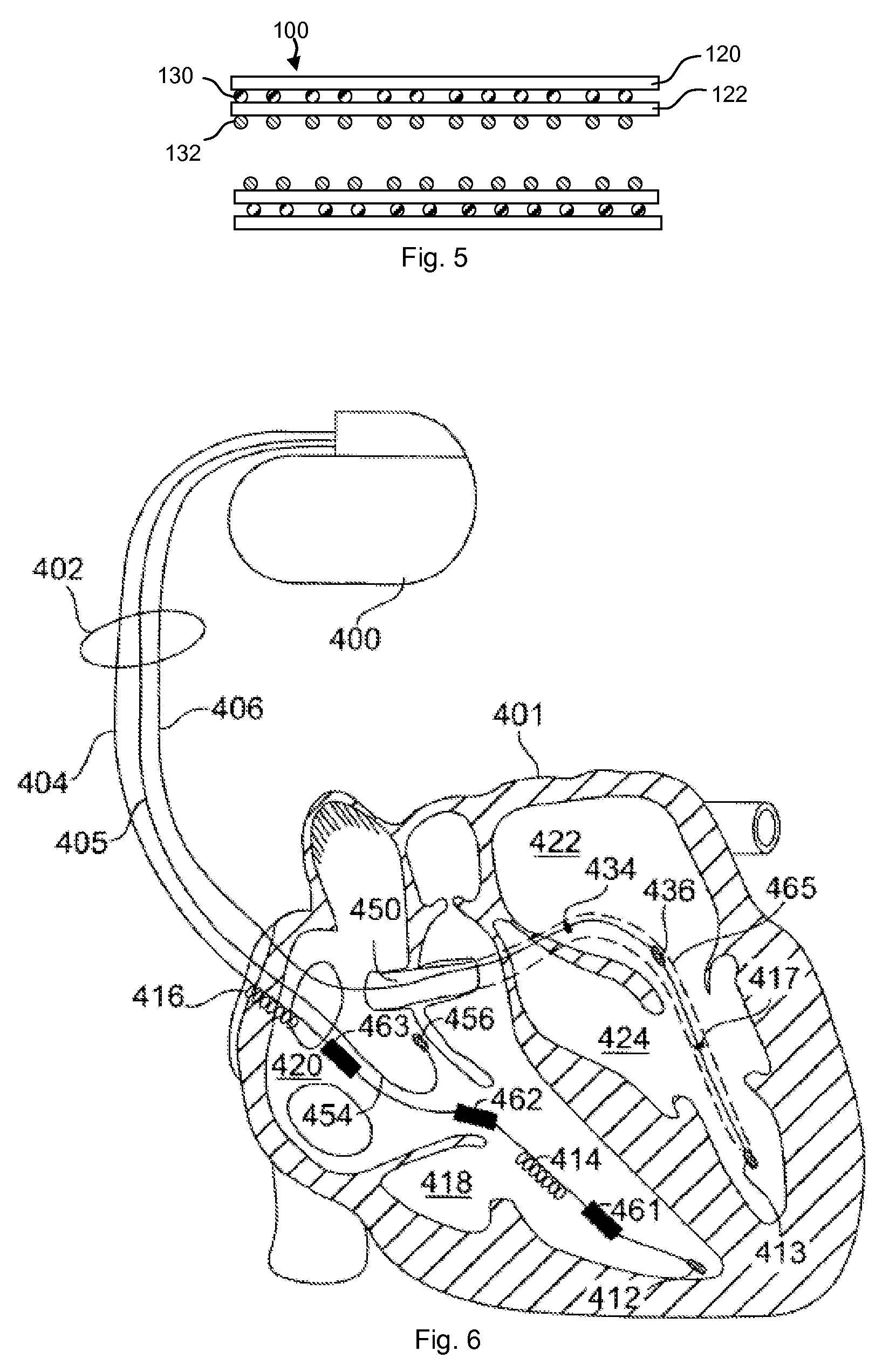

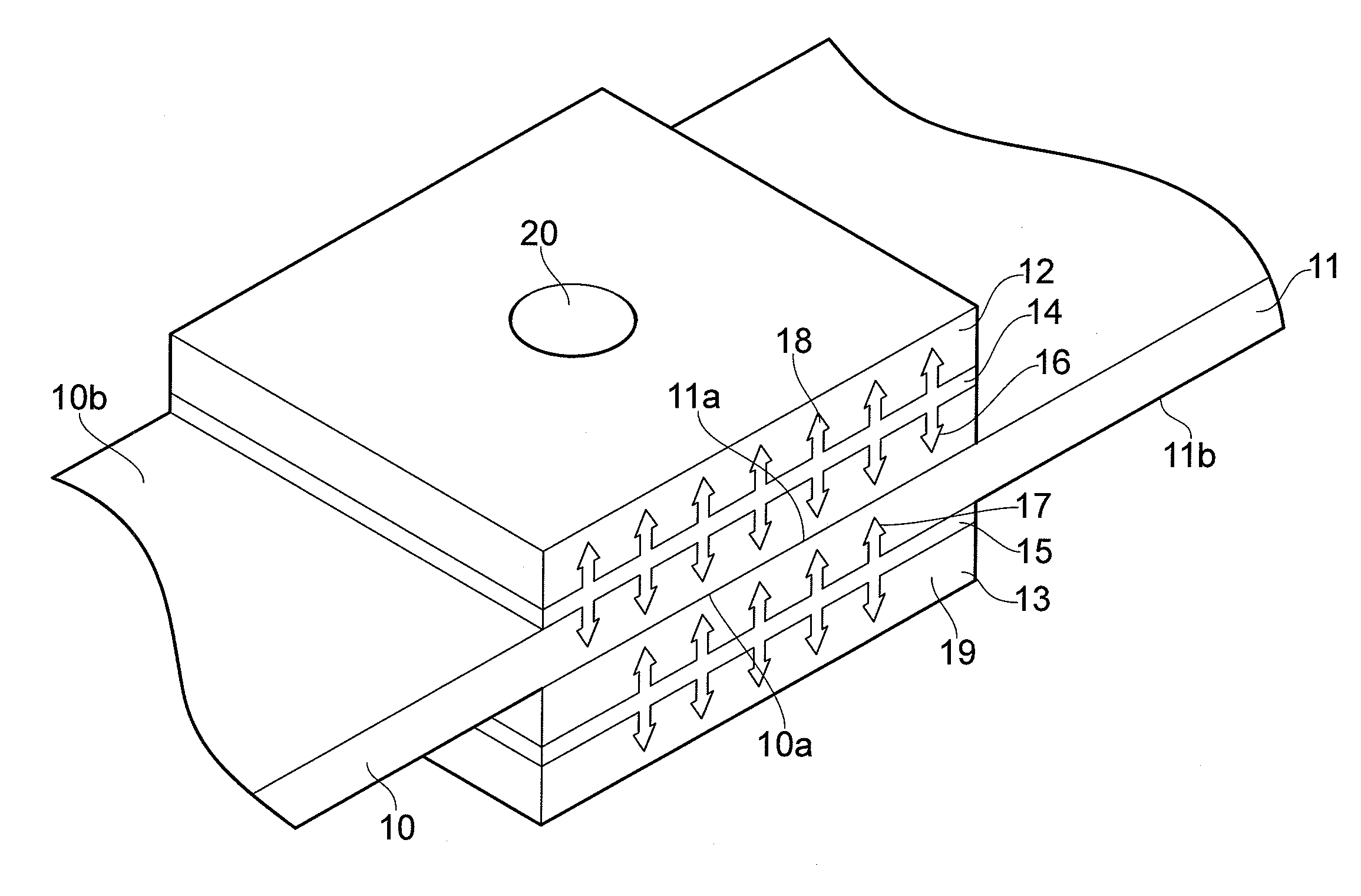

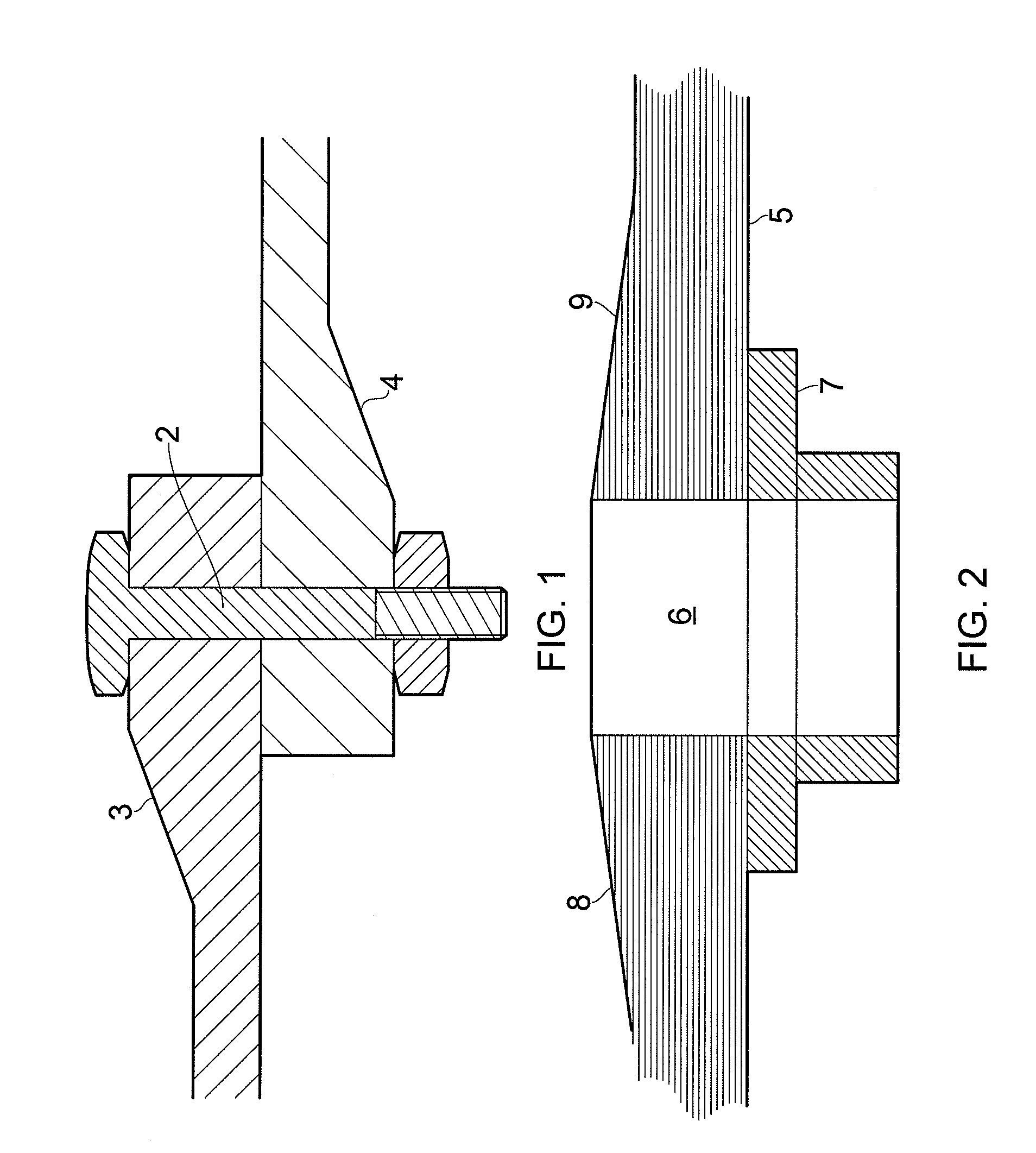

High density shielded electrical cable and other shielded cables, systems, and methods

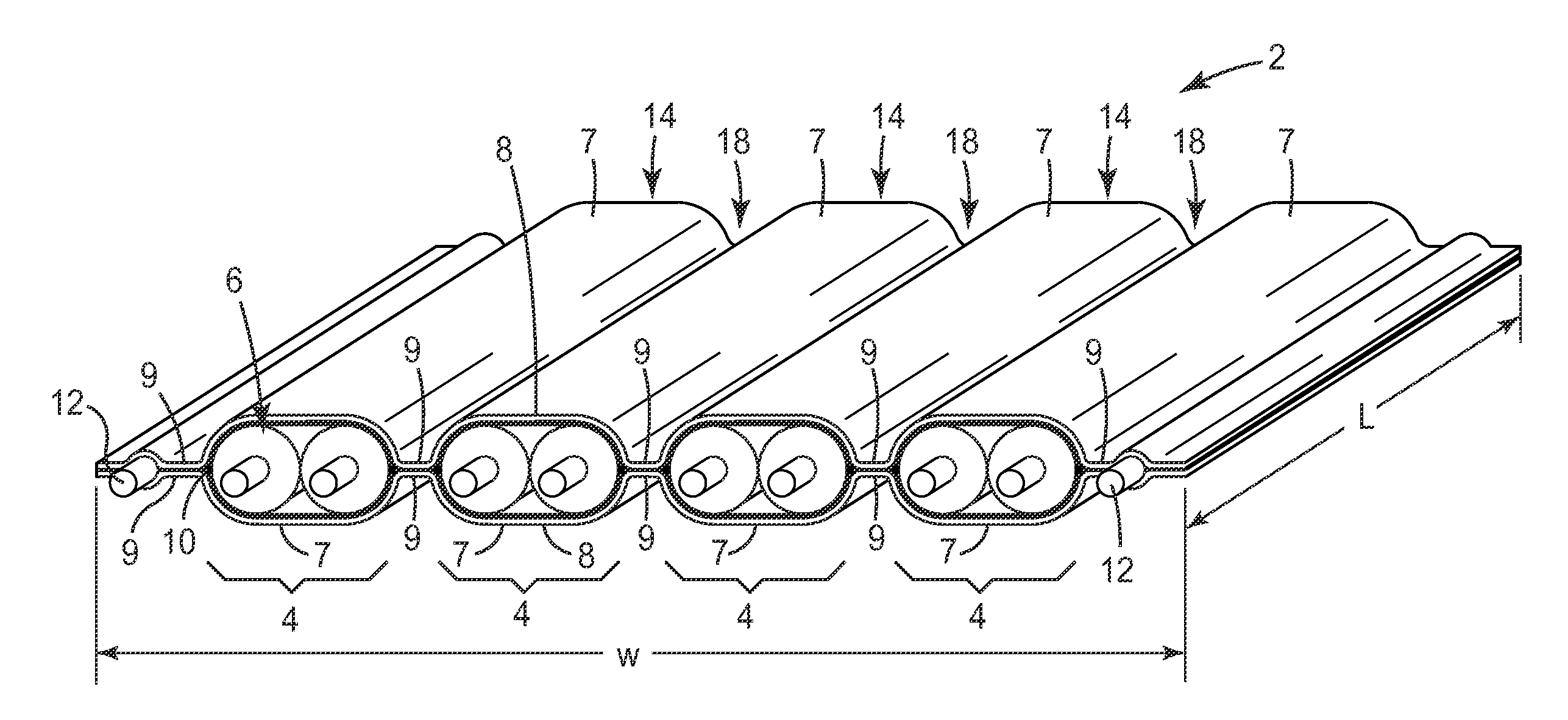

ActiveUS20130146326A1Improve manufacturing speedReduce complexityQuad constructionsPower cables with screens/conductive layersShielded cableHigh density

A shielded electrical ribbon cable (2) includes conductor sets (4) each including one or more insulated conductors (6), and a first and second shielding film (8) on opposite sides of the cable. In transverse cross section, cover portions (7) of the shielding films (8) substantially surround each conductor set (4), and pinched portions (9) of the films (8) form pinched portions of the cable on each side of each conductor set (4). Dense packing is achieved while maintaining high frequency electrical isolation between conductor sets (4). When the cable (2) is laid flat, a quantity s / Dmin is in a range from 1.7 to 2, where S is a center-to-center spacing between nearest insulated conductors (6) of two adjacent conductor sets (4), and Dmin is the lesser of the outer dimensions of such nearest insulated conductors (6). Alternatively, a first and second conductor set each having only one pair of insulated conductors can satisfy a condition that Σ / σ1 is in a range from 2.5 to 3. Other shielded cables, systems, and methods, which may or may not utilize the dense packing, are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

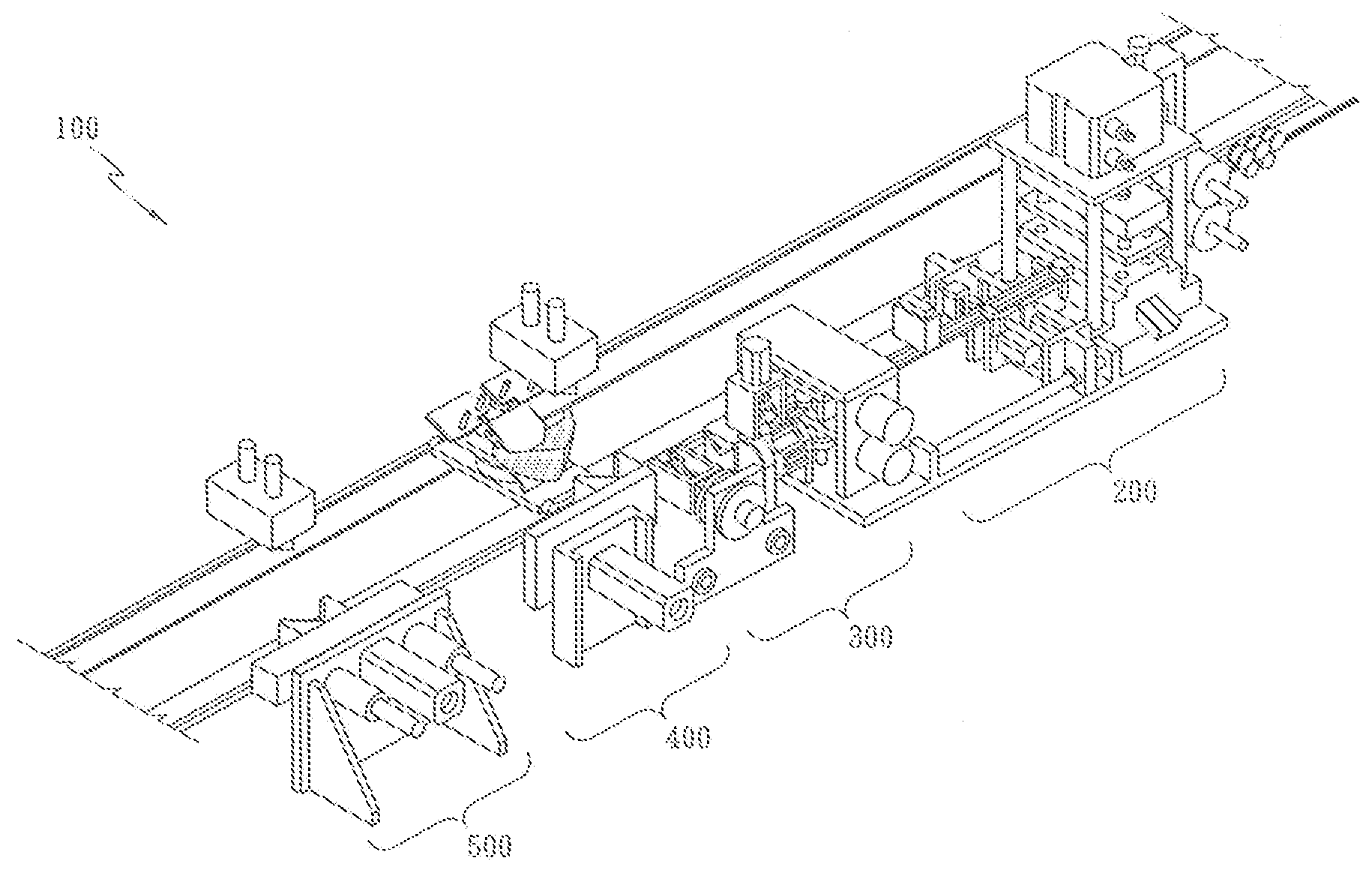

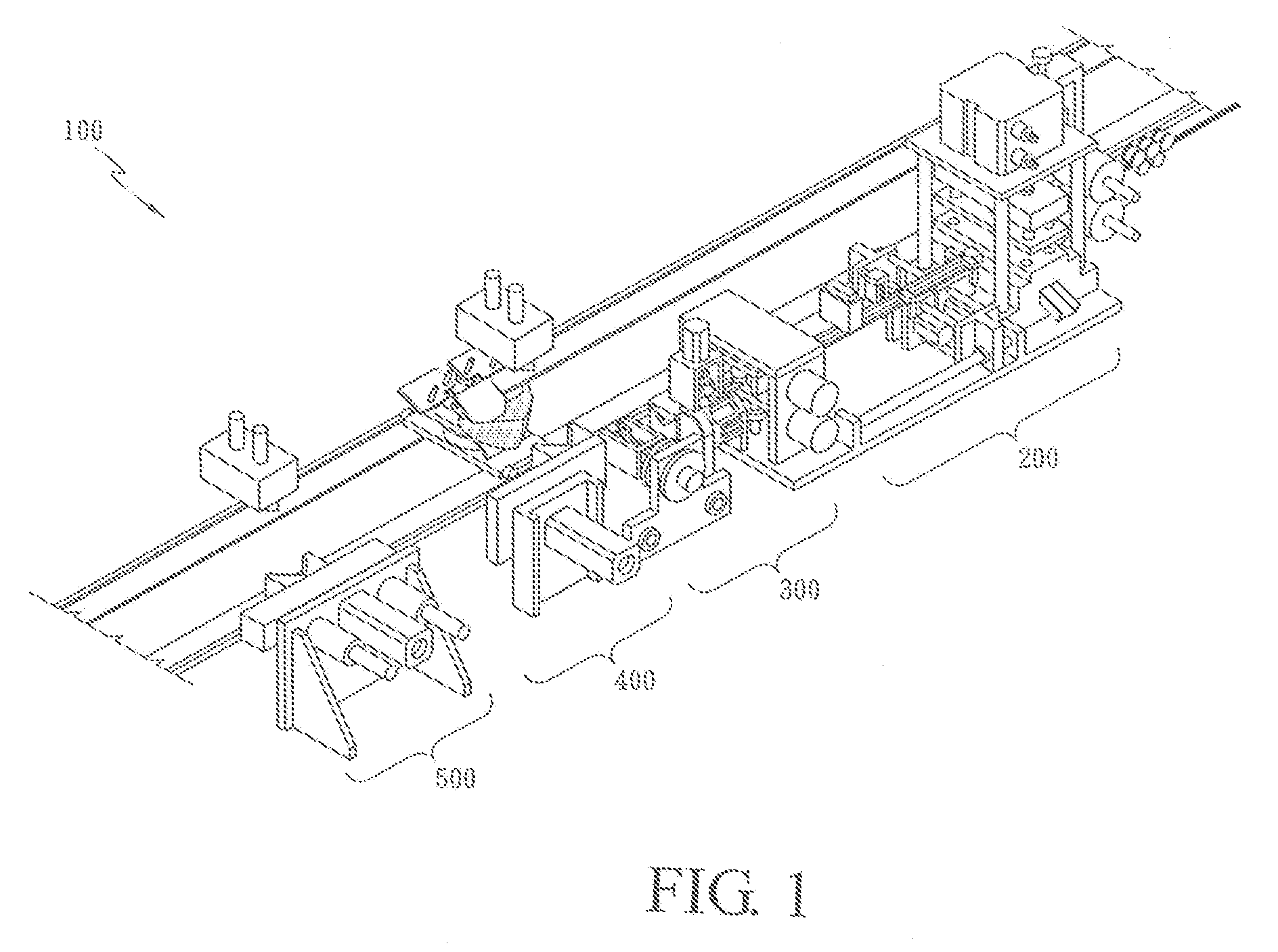

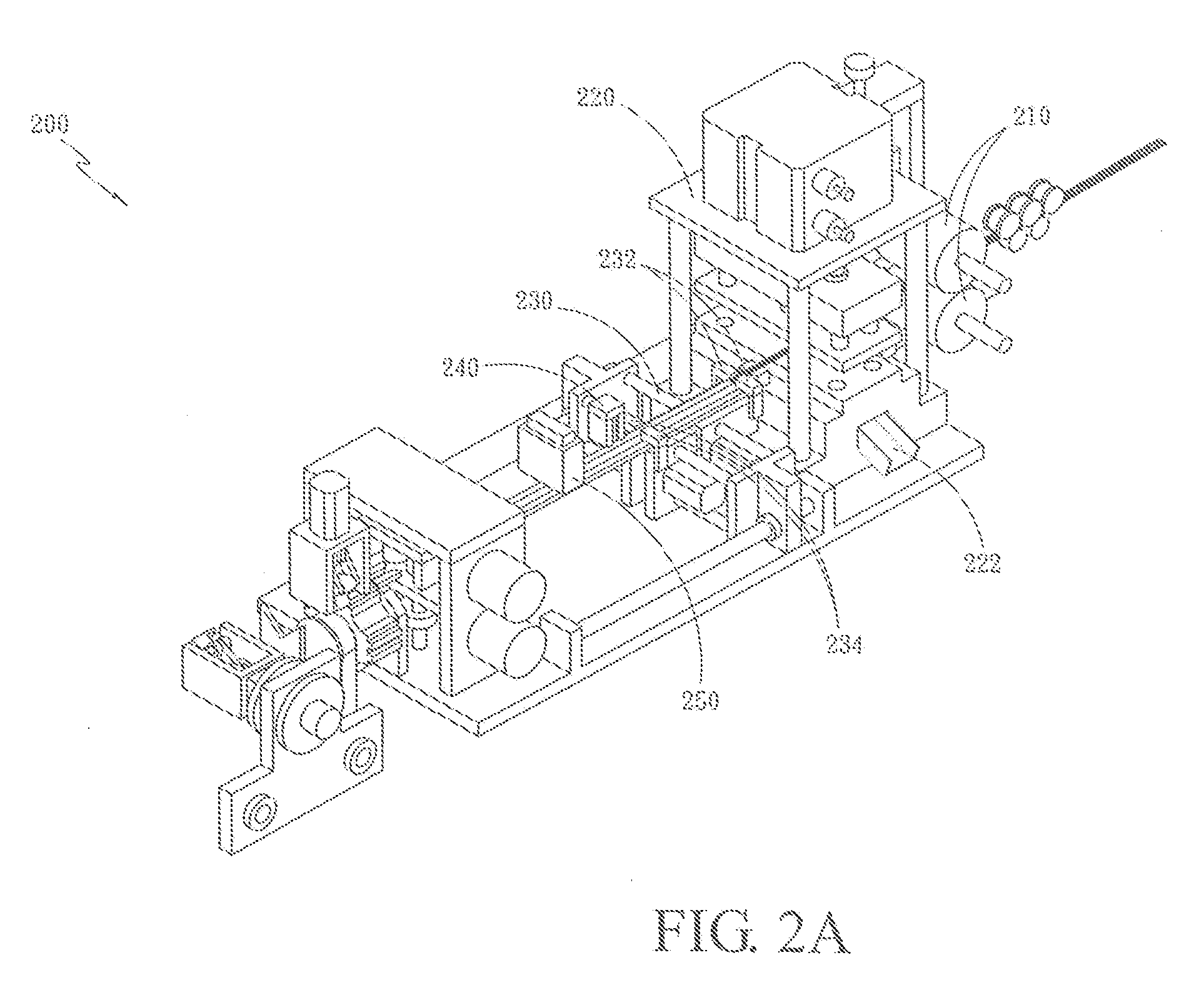

Automatic nose strip bonding apparatus for face mask

InactiveUS20080251210A1Improve manufacturing speedImprove product qualityLiquid surface applicatorsLamination ancillary operationsNoseSecondary bonding

An automatic nose strip bonding apparatus for a face mask is disclosed, including a nose strip providing mechanism, a nose strip turnover mechanism, and a press-to-bond device. The nose strip providing mechanism drives a nose strip forward and carries out stamping operation on the nose strip, and applies a bonding agent to the nose strip. The nose strip turnover mechanism serves to turn over the nose strip that has already been applied with the bonding agent to allow the surface of the nose strip on which the bonding agent is applied to face a face mask. The press-to-bond device includes a first bonding device and a second bonding device to attach the nose strip to the face mask and to carry out a secondary bonding operation, respectively, to ensure firm bonding of the nose strip to the face mask.

Owner:CHEN HUNG HO

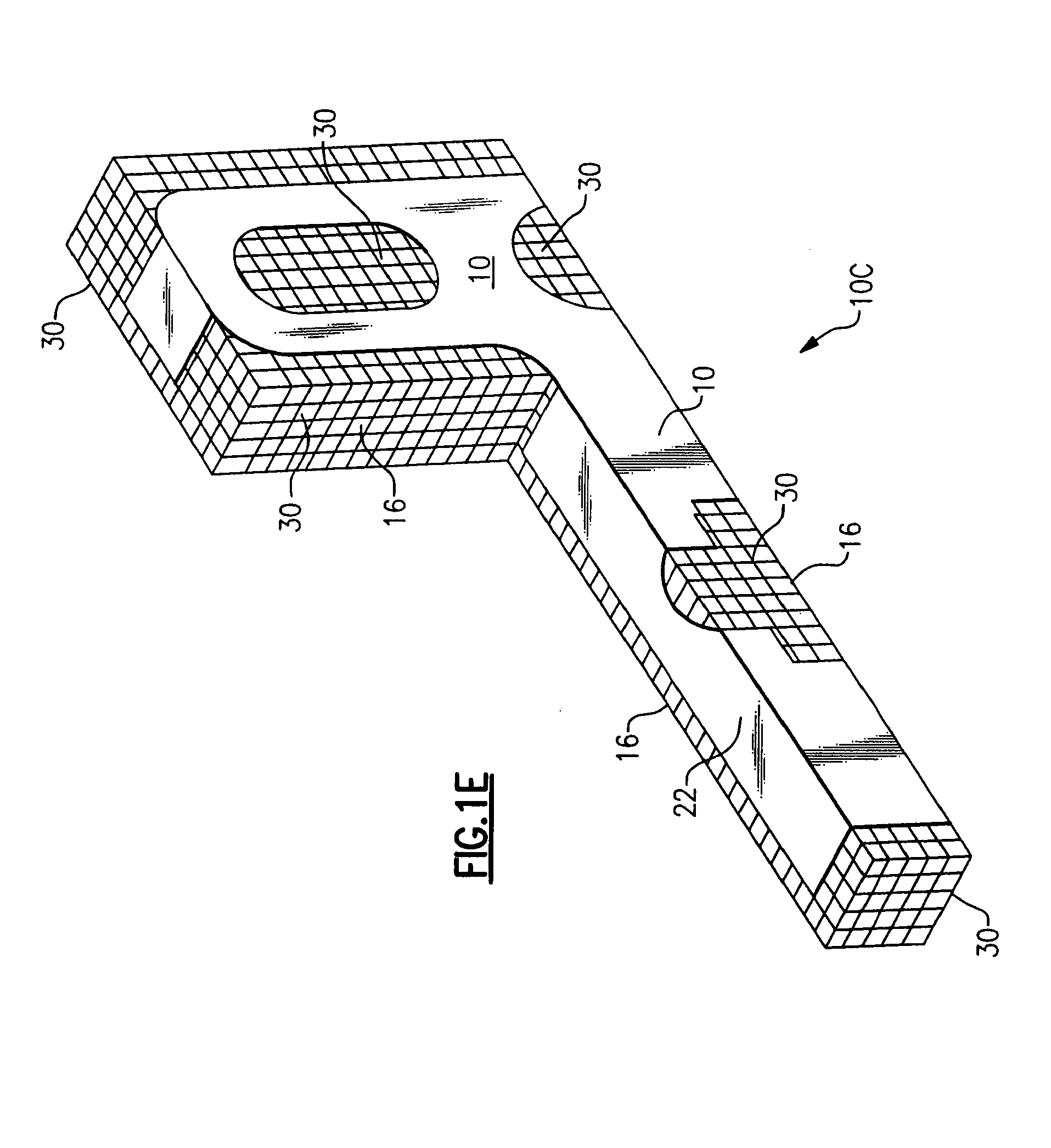

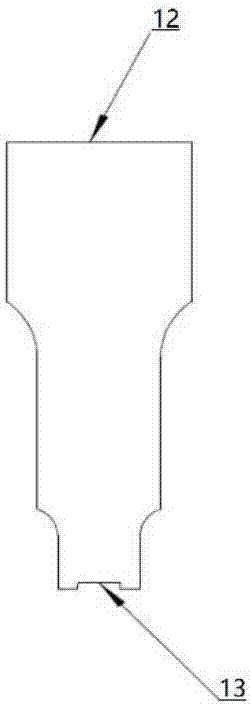

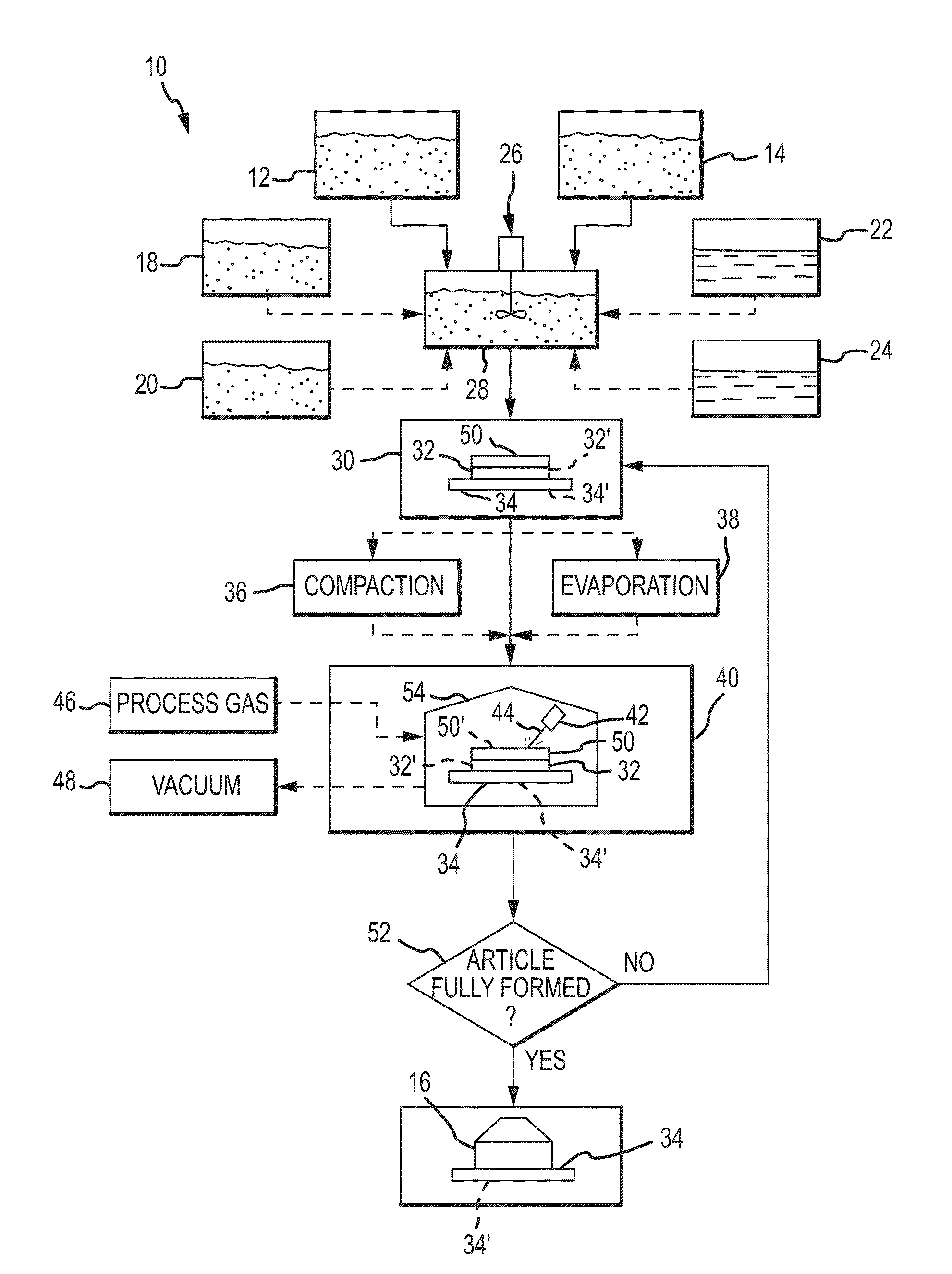

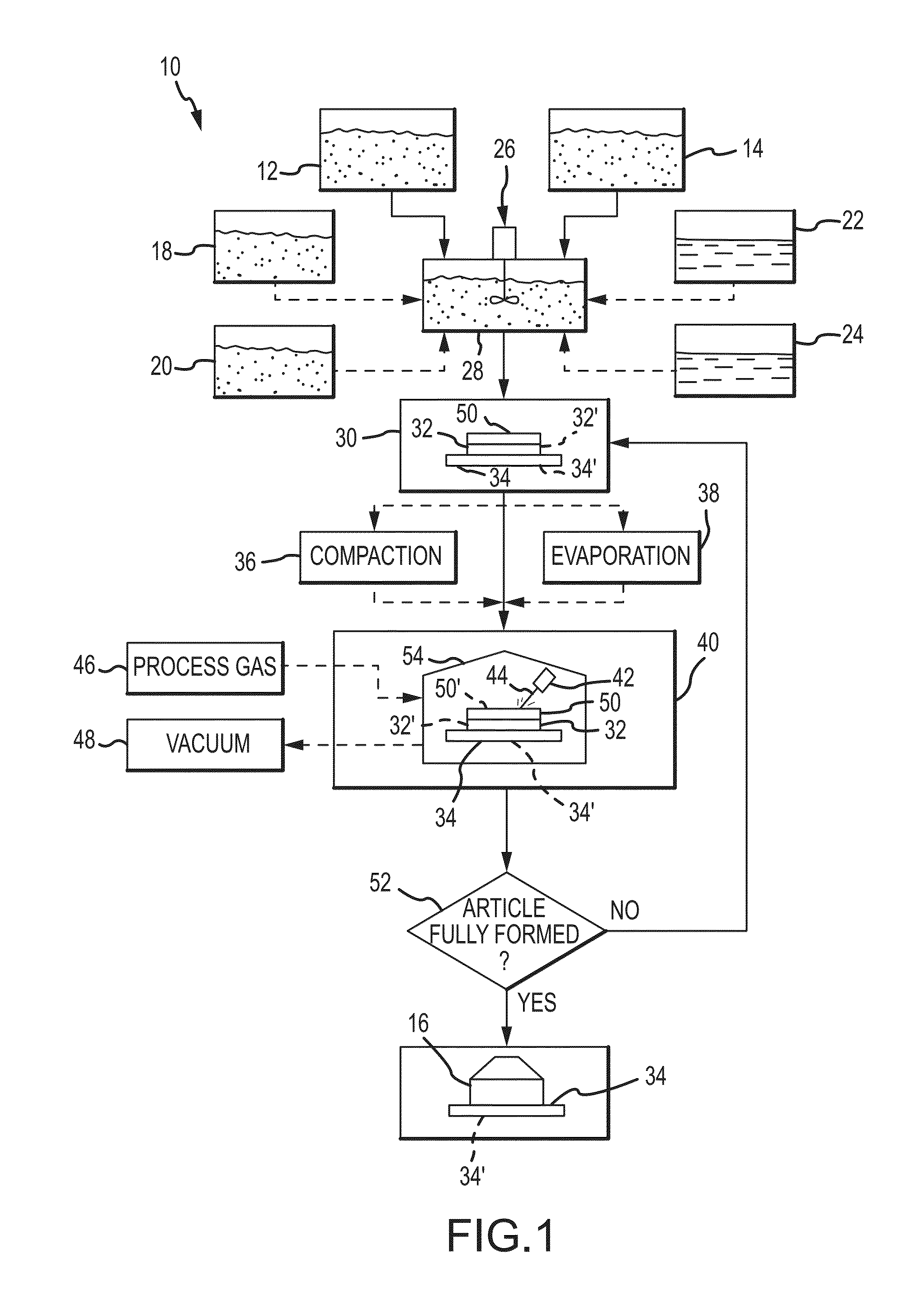

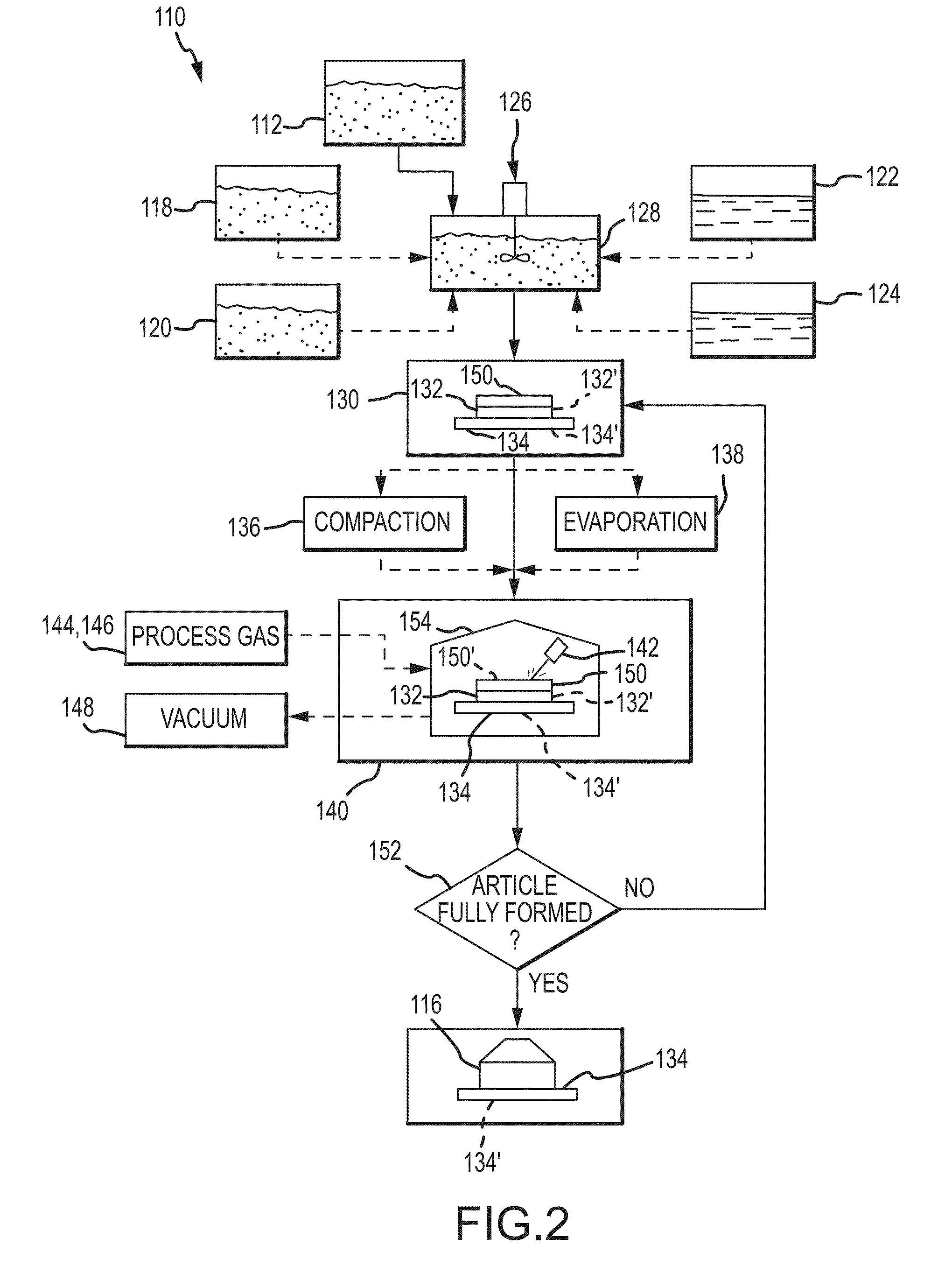

Method for fabricating three dimensional models

InactiveUS20100021638A1Improve manufacturing speedReduce the amount requiredAdditive manufacturing apparatusPretreated surfacesMulti materialMethod selection

A method for fabricating a three dimensional model by fabricating a composite model formed of a plurality of successive layers comprised of one or more materials wherein each successive layer is formed by depositing at least first material delineating boundaries of at least one first area of the layer by a drop-by-drop deposition and depositing at least a second material over the layer by a rapid deposition method, and may include the deposition of a third material by a drop-by-drop or rapid deposition method and will include planing the layer to a uniform thickness and selectively removing the first and second materials, and third material if present, by successive removal methods, each of which effects only one of the materials.

Owner:SOLIDSCAPE

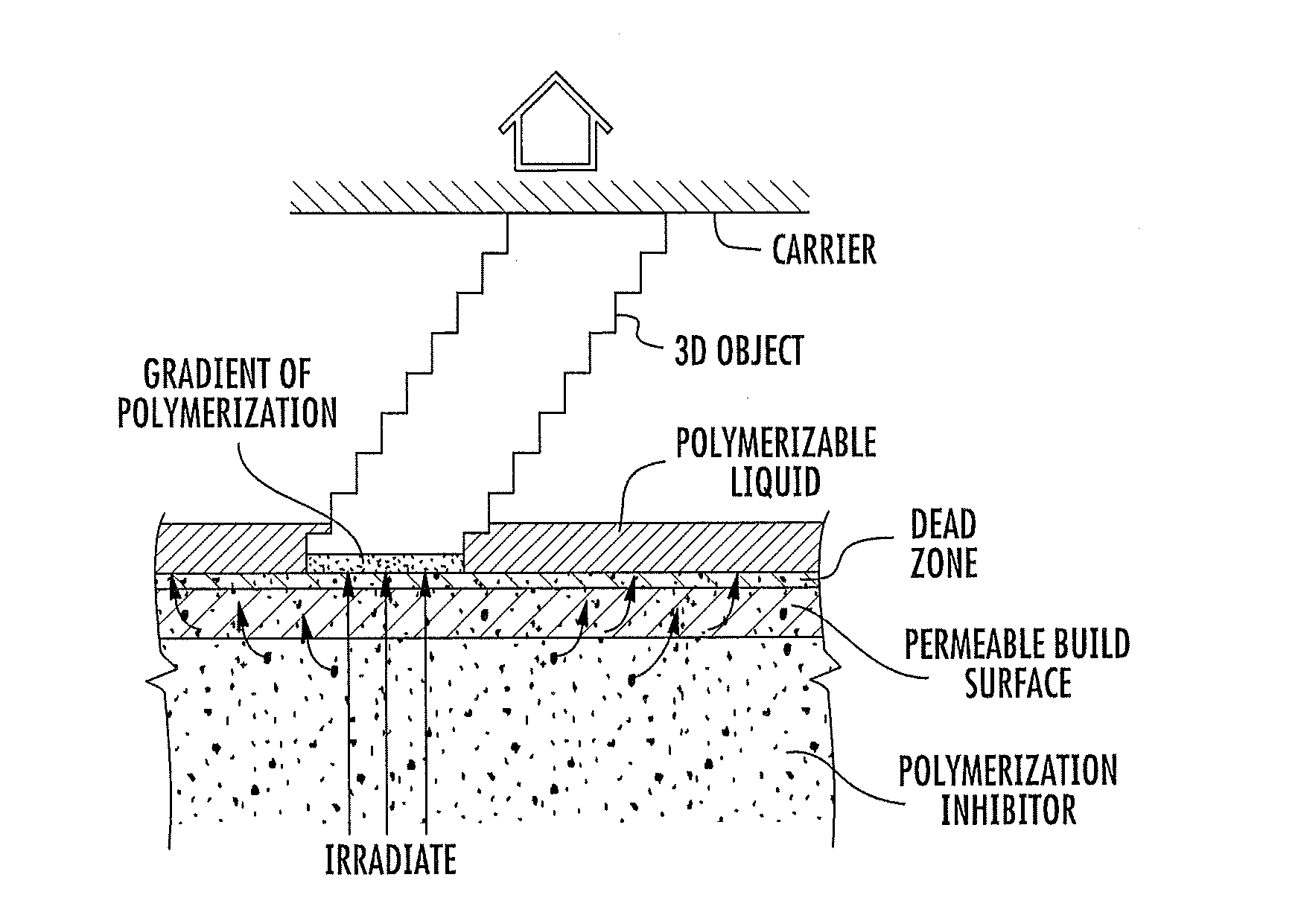

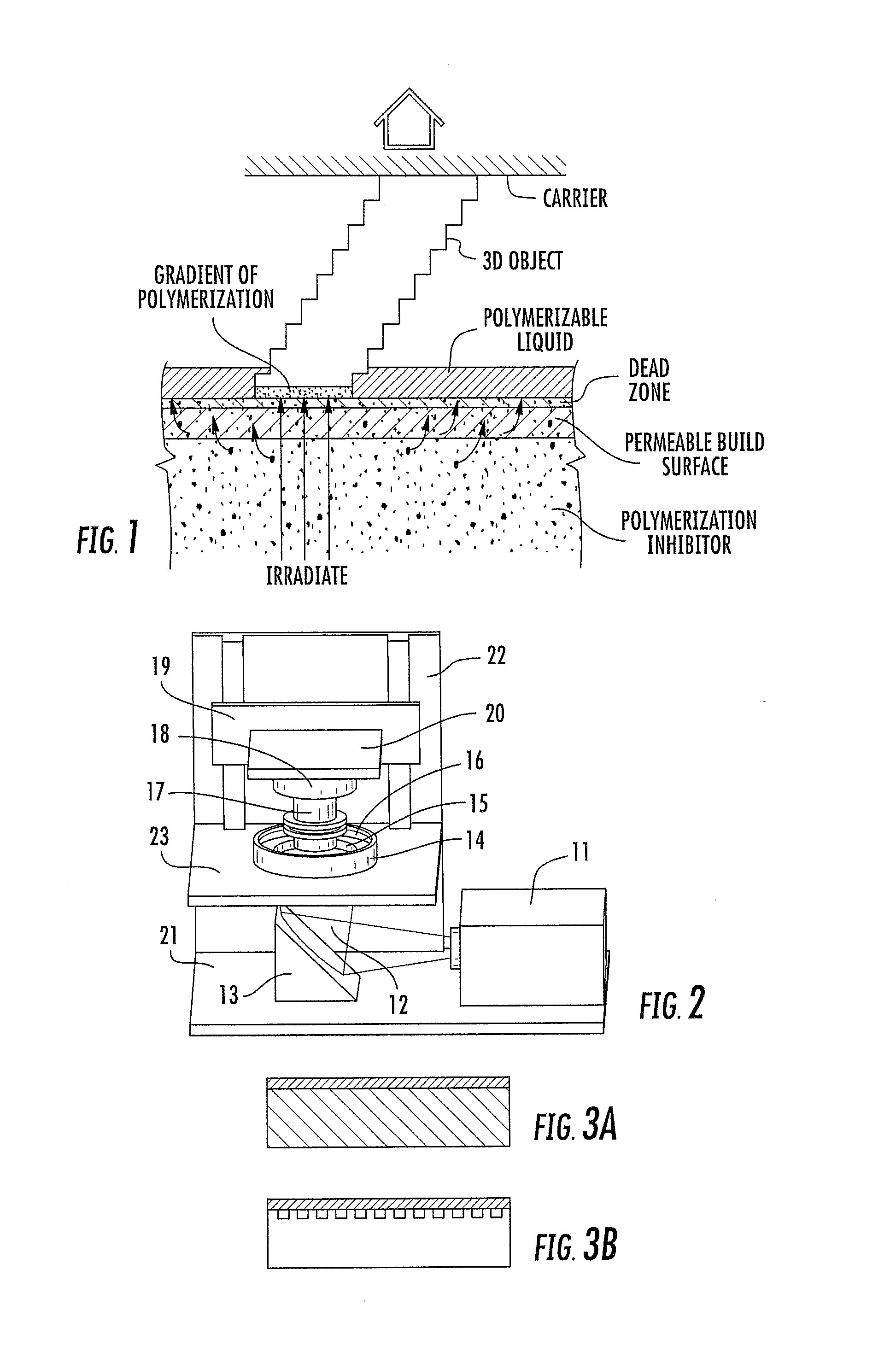

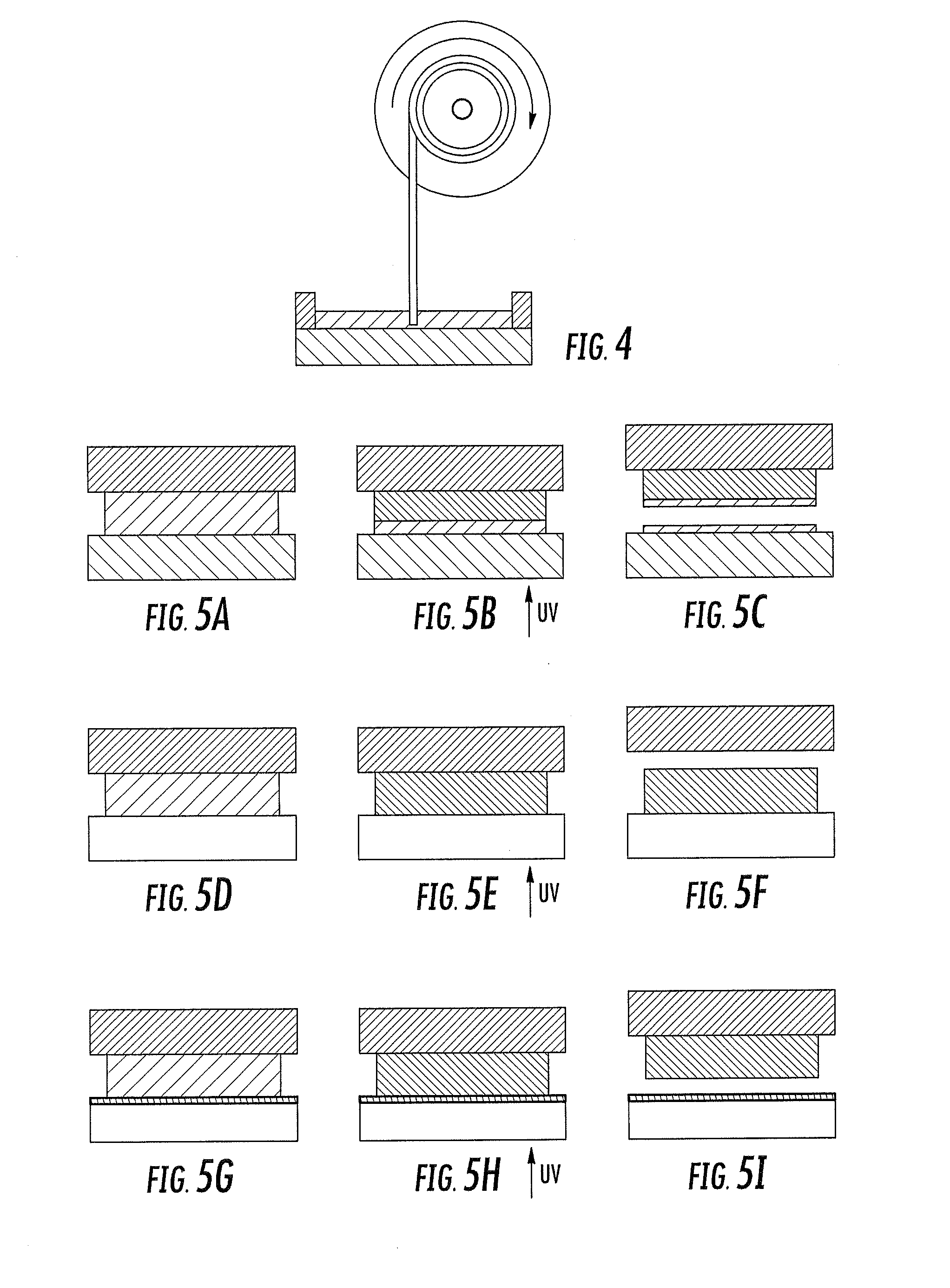

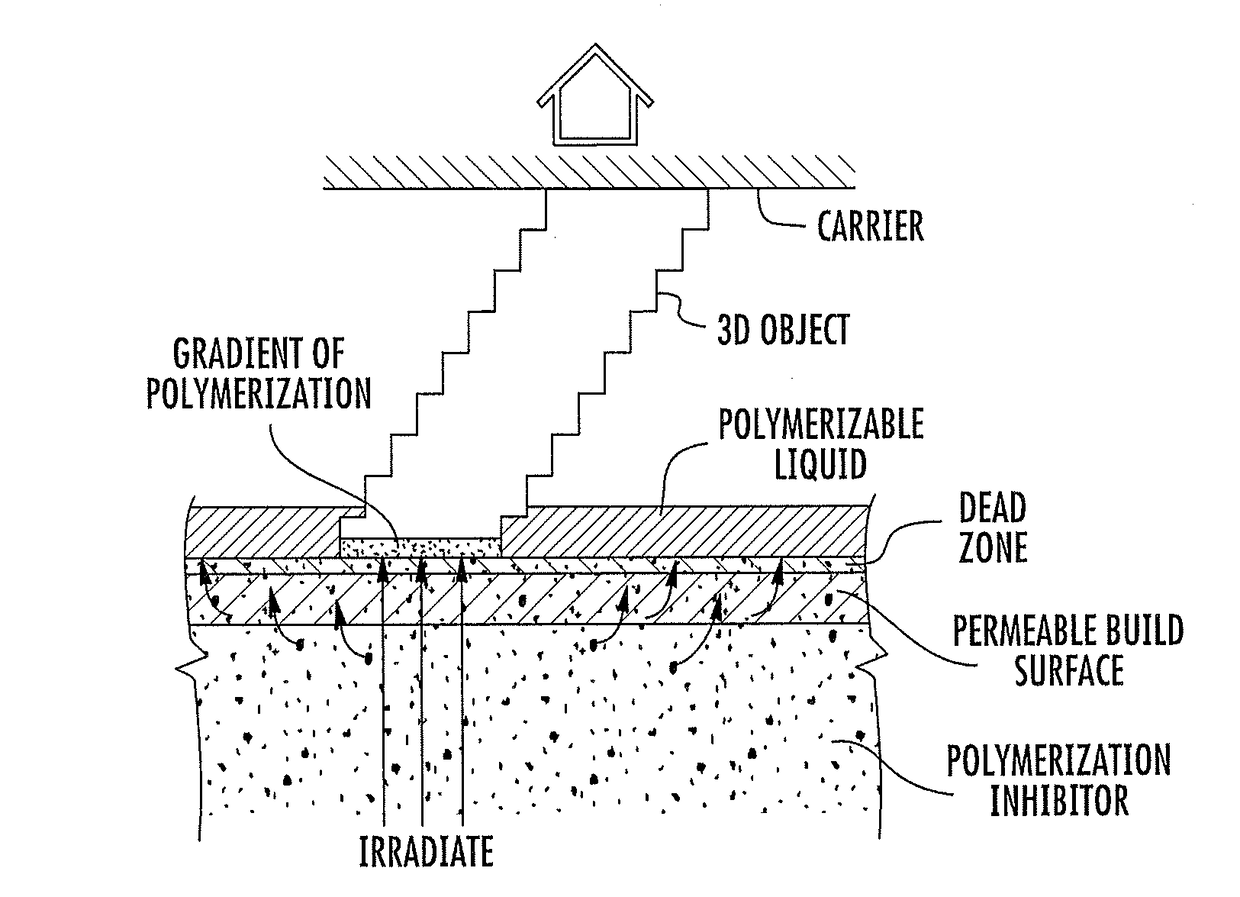

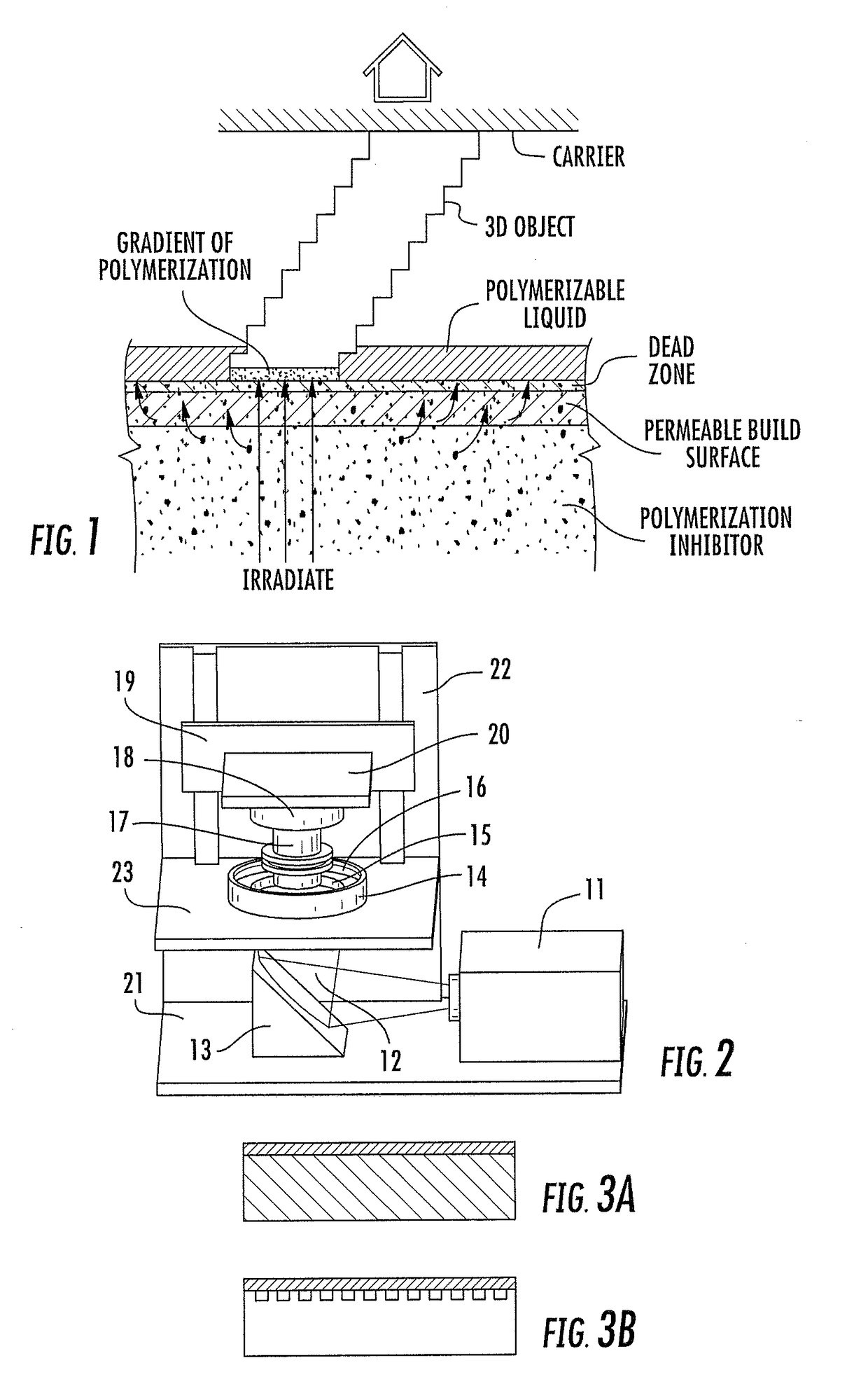

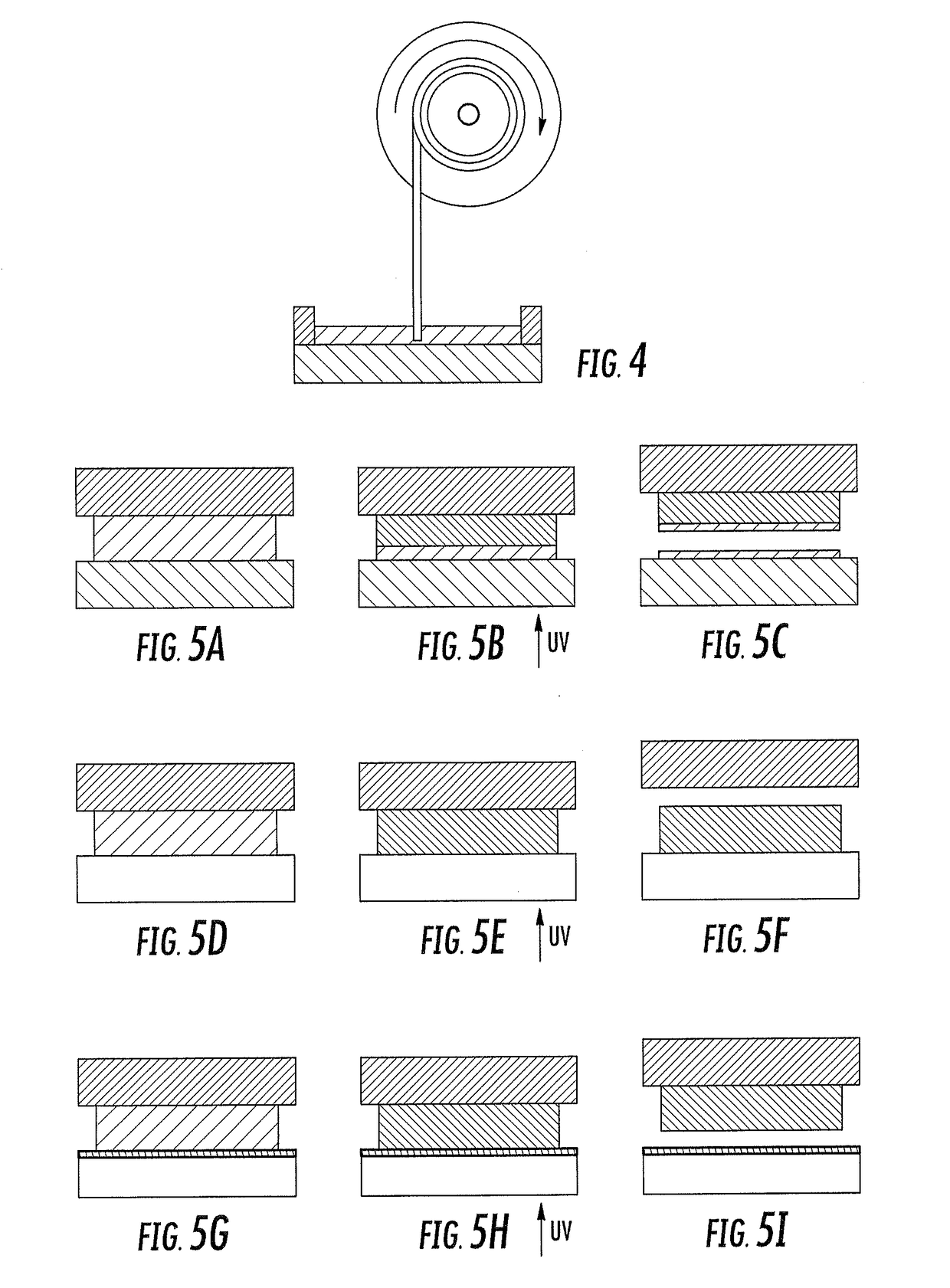

Acceleration of stereolithography

ActiveUS20160046072A1Facilitate re-fillingReduce decreaseManufacturing platforms/substrates3D object support structuresTinAcceleration Unit

A method of forming a three-dimensional object by bottom-up three-dimensional fabrication by irradiating a polymerizable liquid to produce the three-dimensional object, is described. In the method: (i) a Lewis acid or an oxidizable tin salt (e.g., stannous octoate) is included in said polymerizable liquid in an amount effective to accelerate the formation of said three-dimensional object during said fabrication; and / or (i) the three-dimensional object is irradiated after forming to further polymerize unpolymerized material remaining in the three-dimensional object.

Owner:CARBON INC

Method of making fasteners by three-dimensional printing

Owner:A RAYMOND & CO

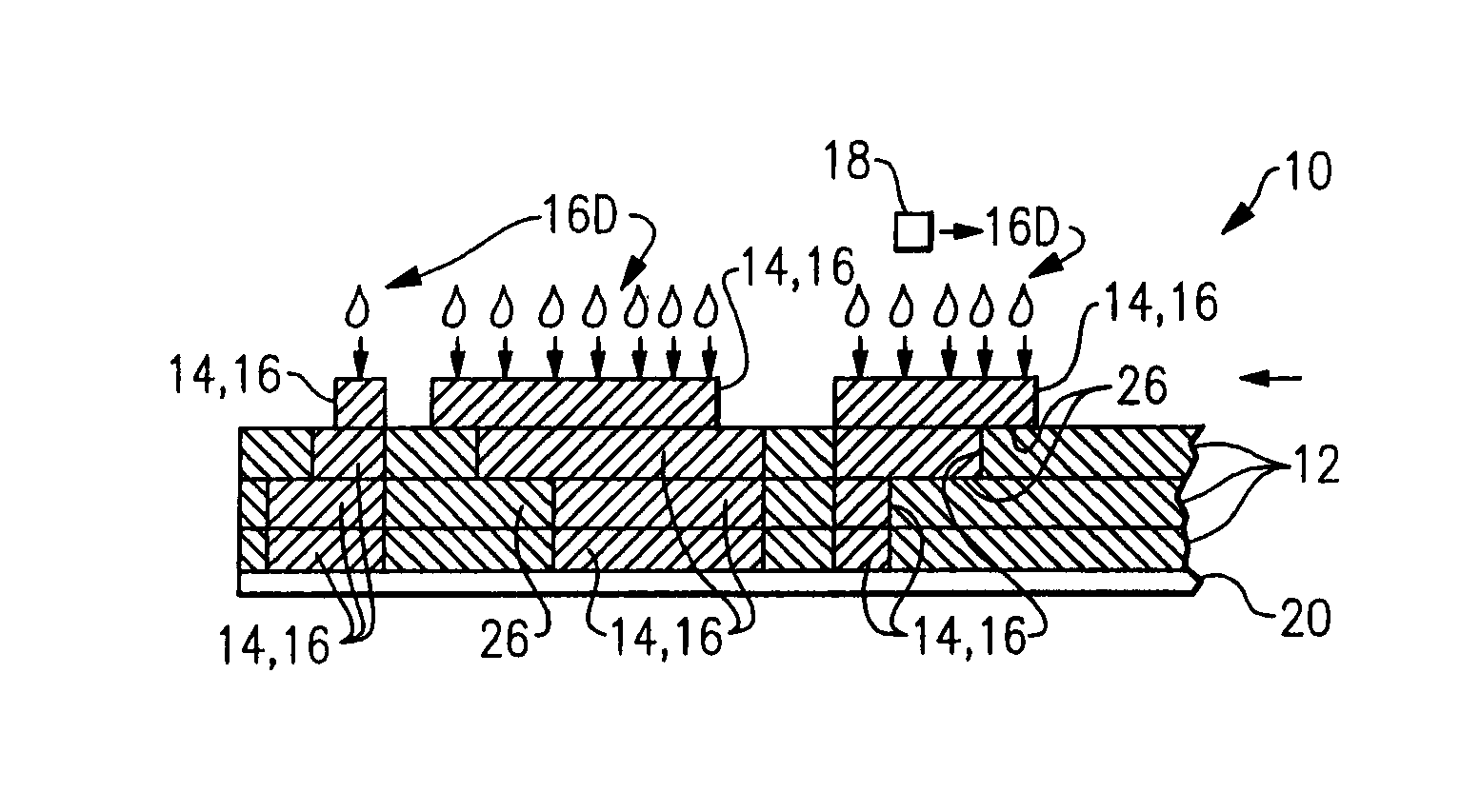

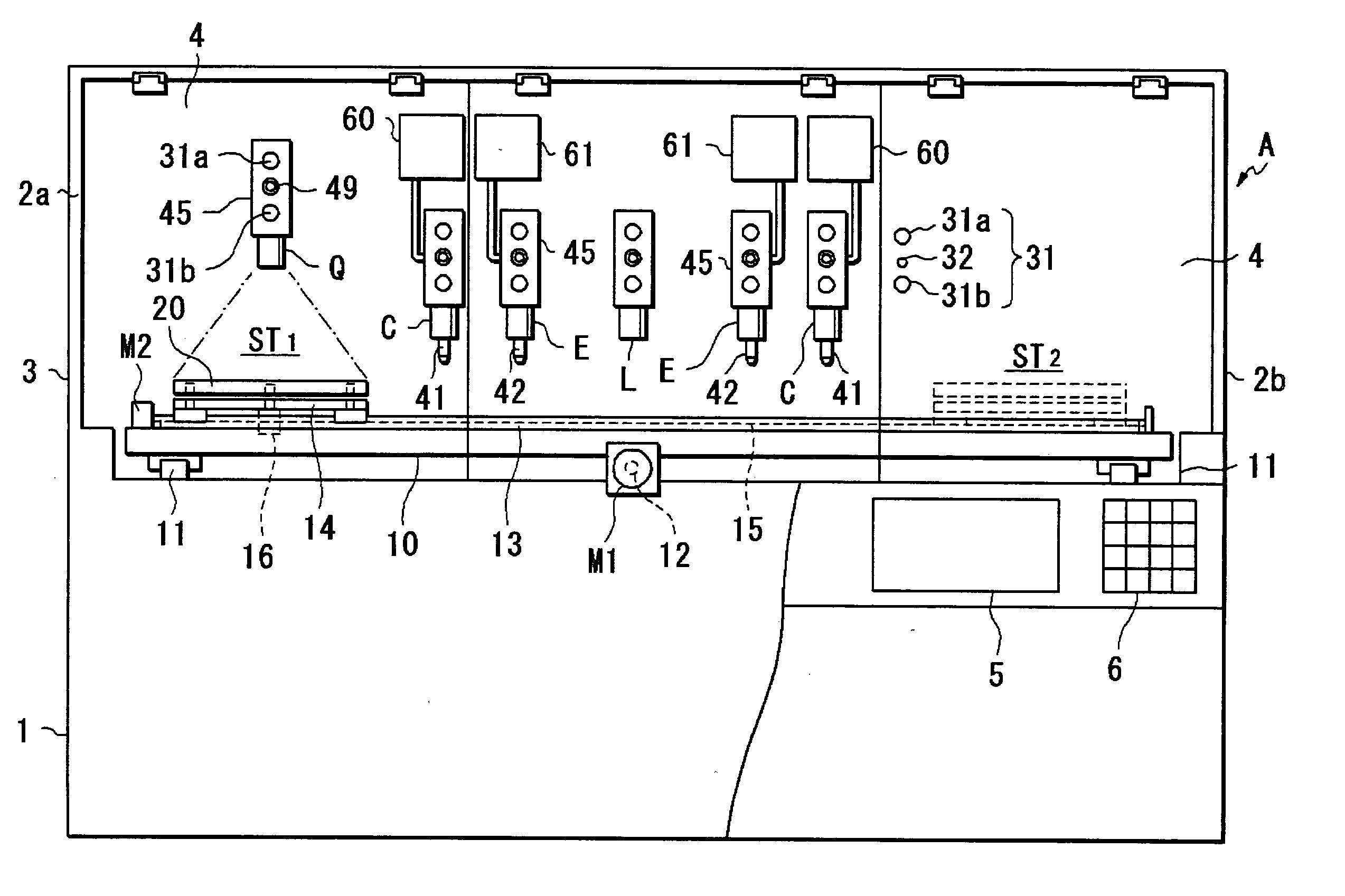

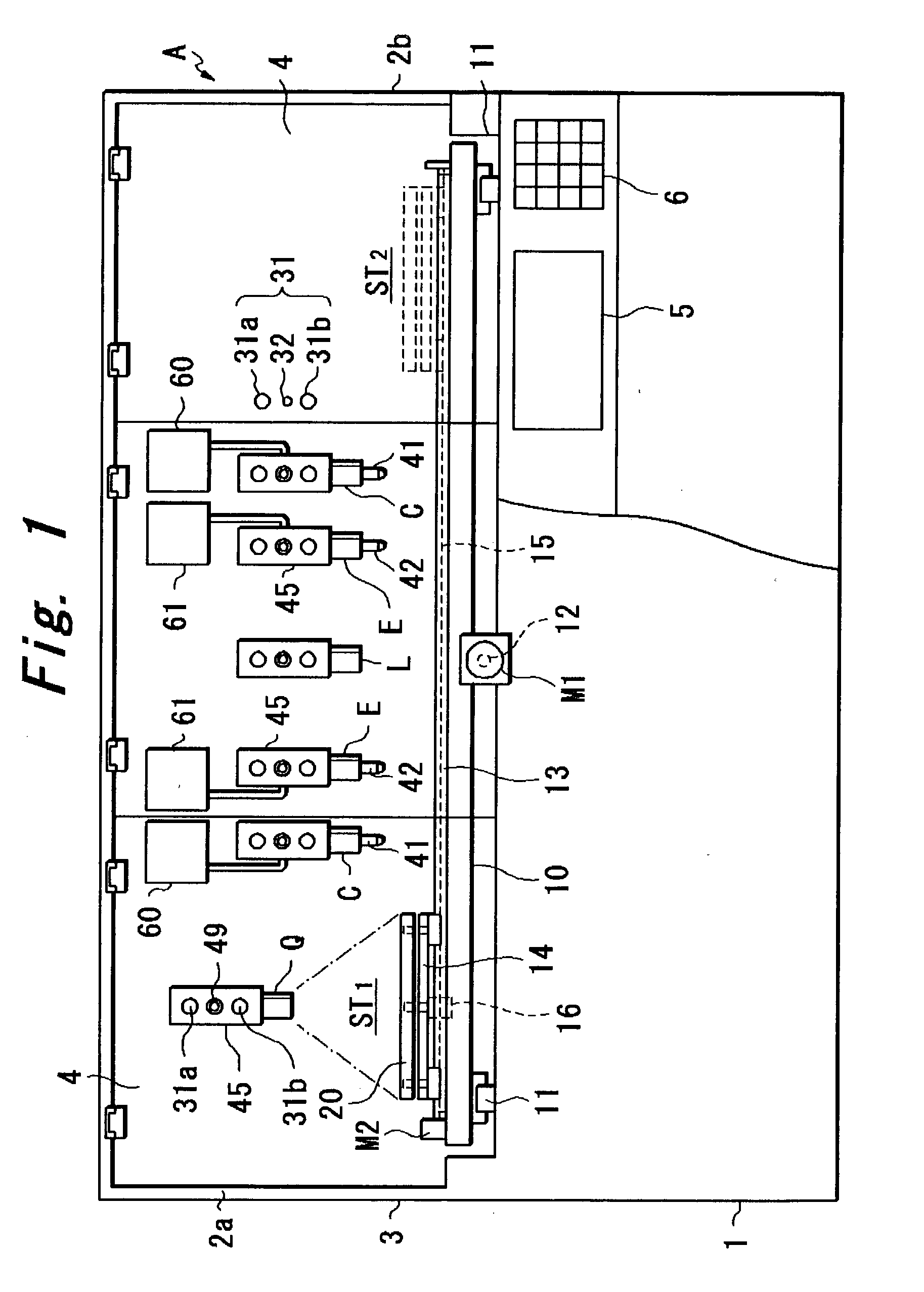

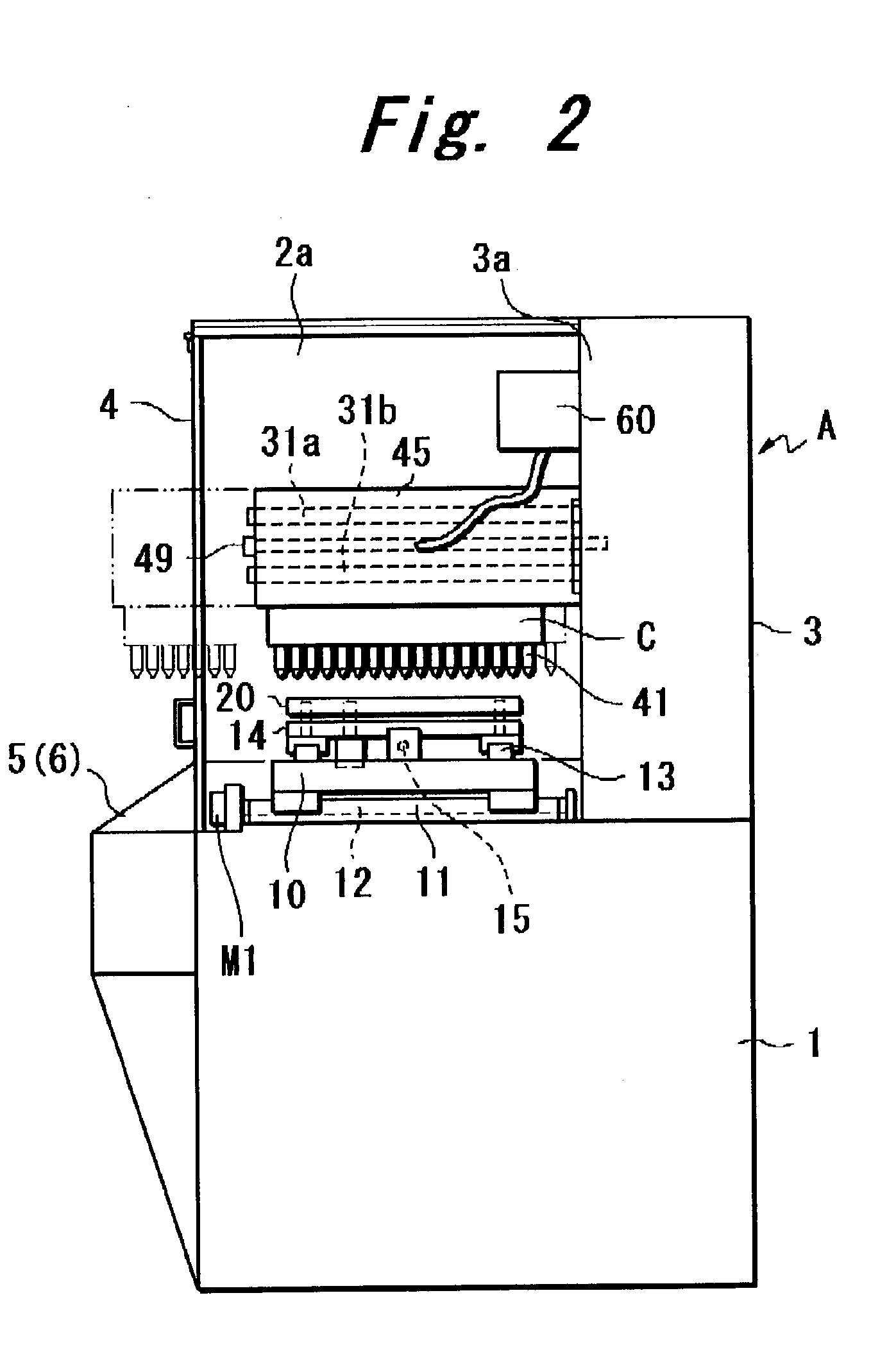

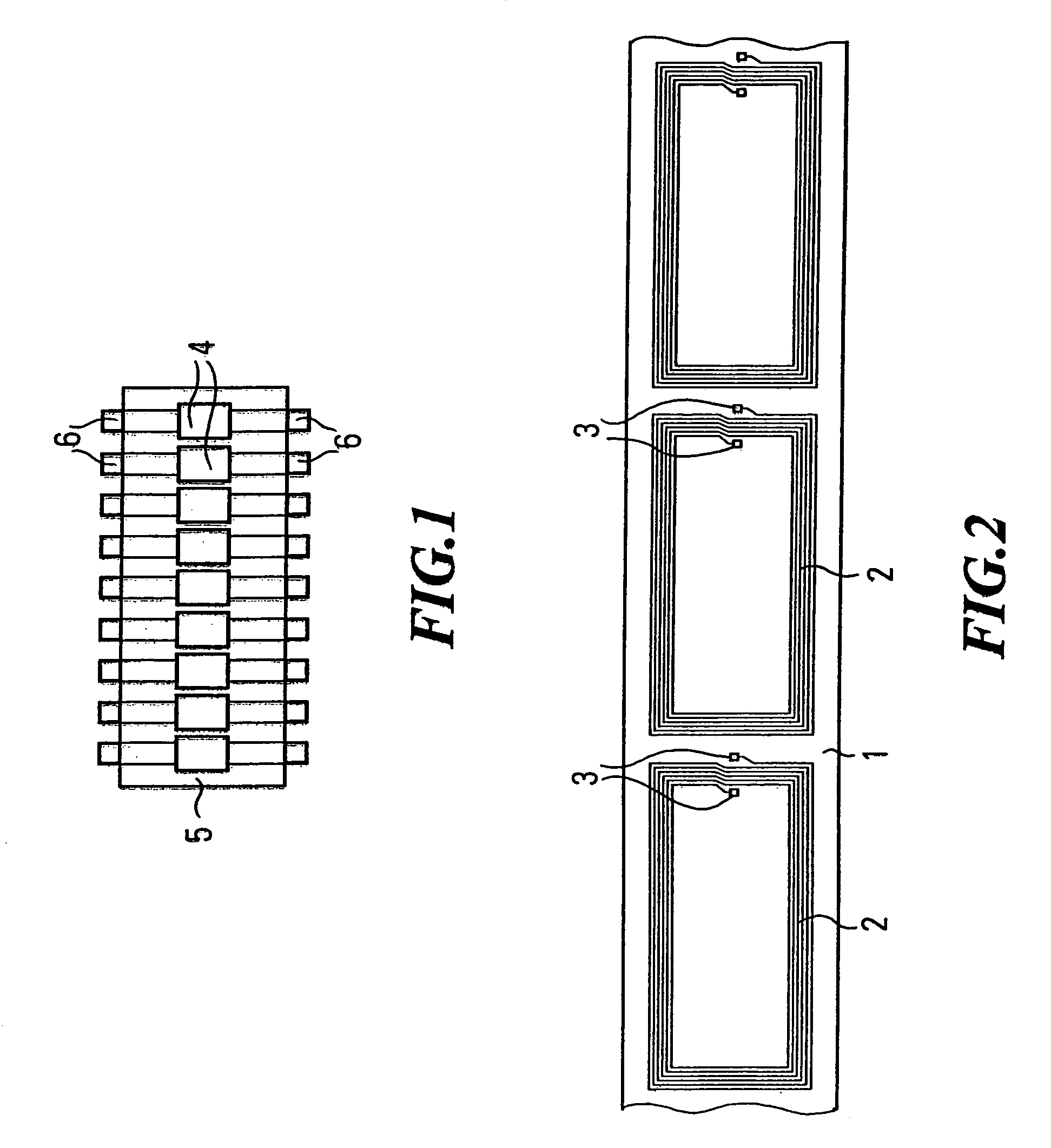

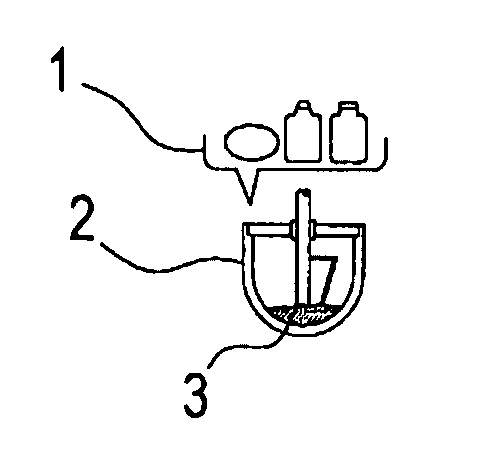

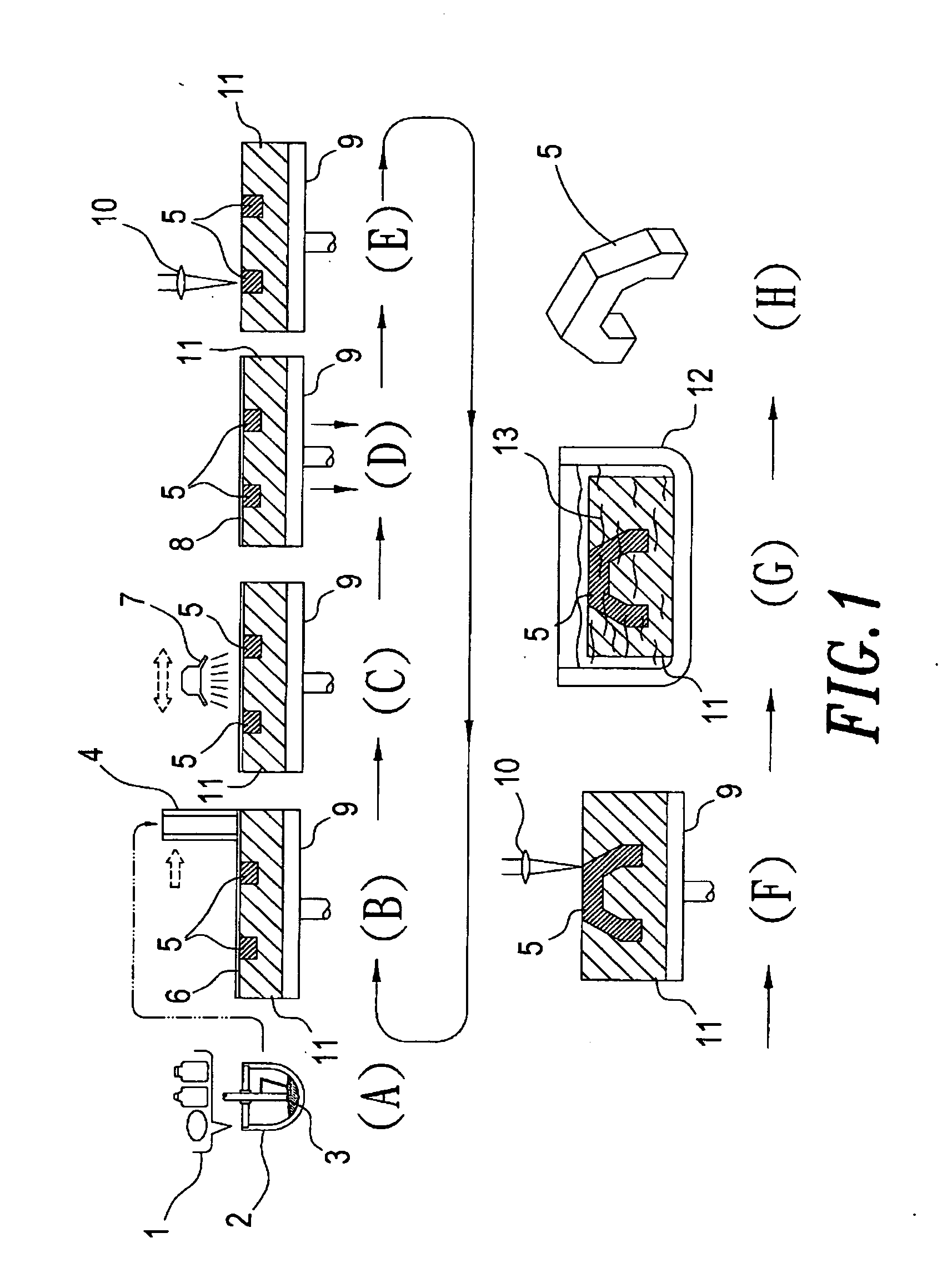

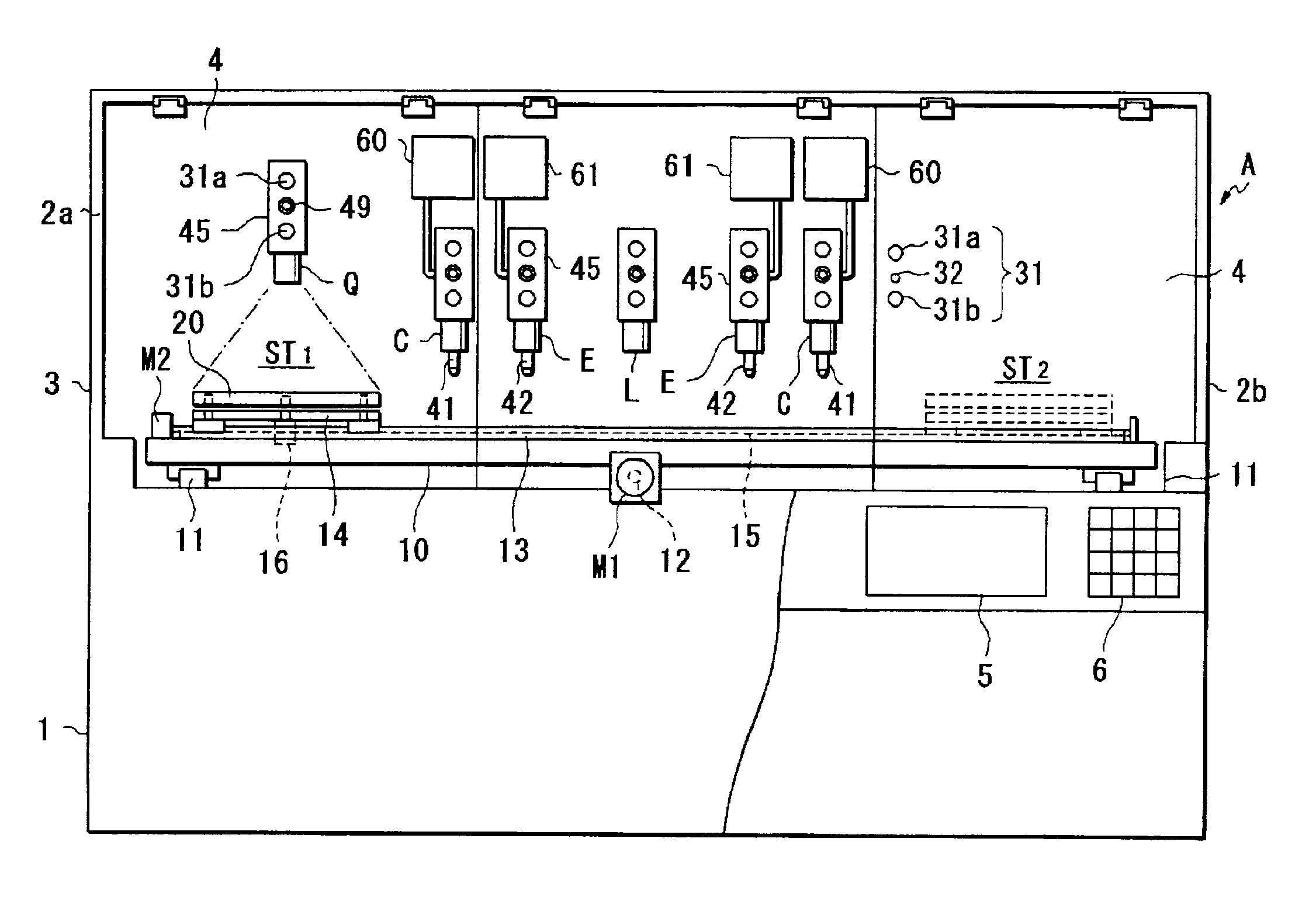

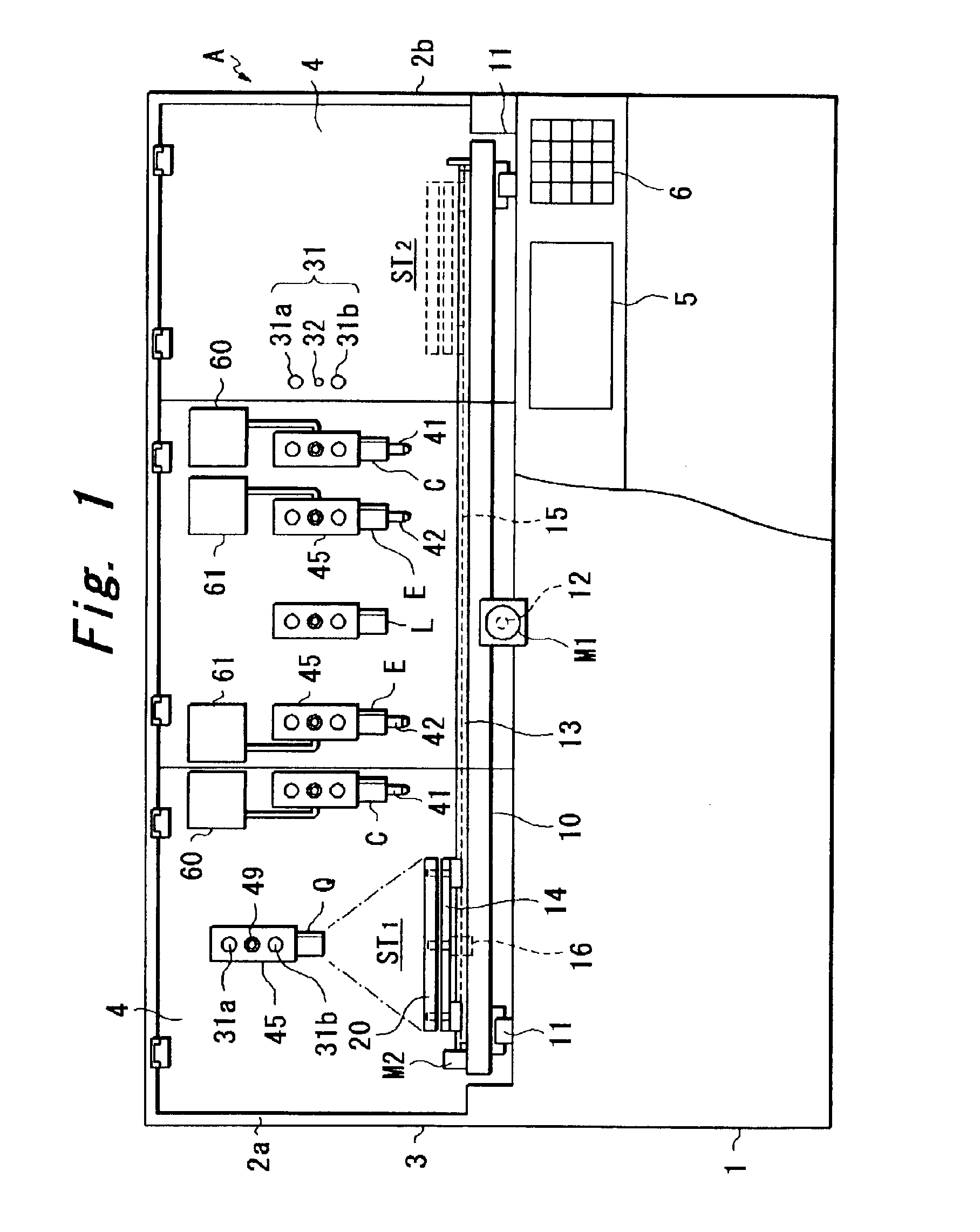

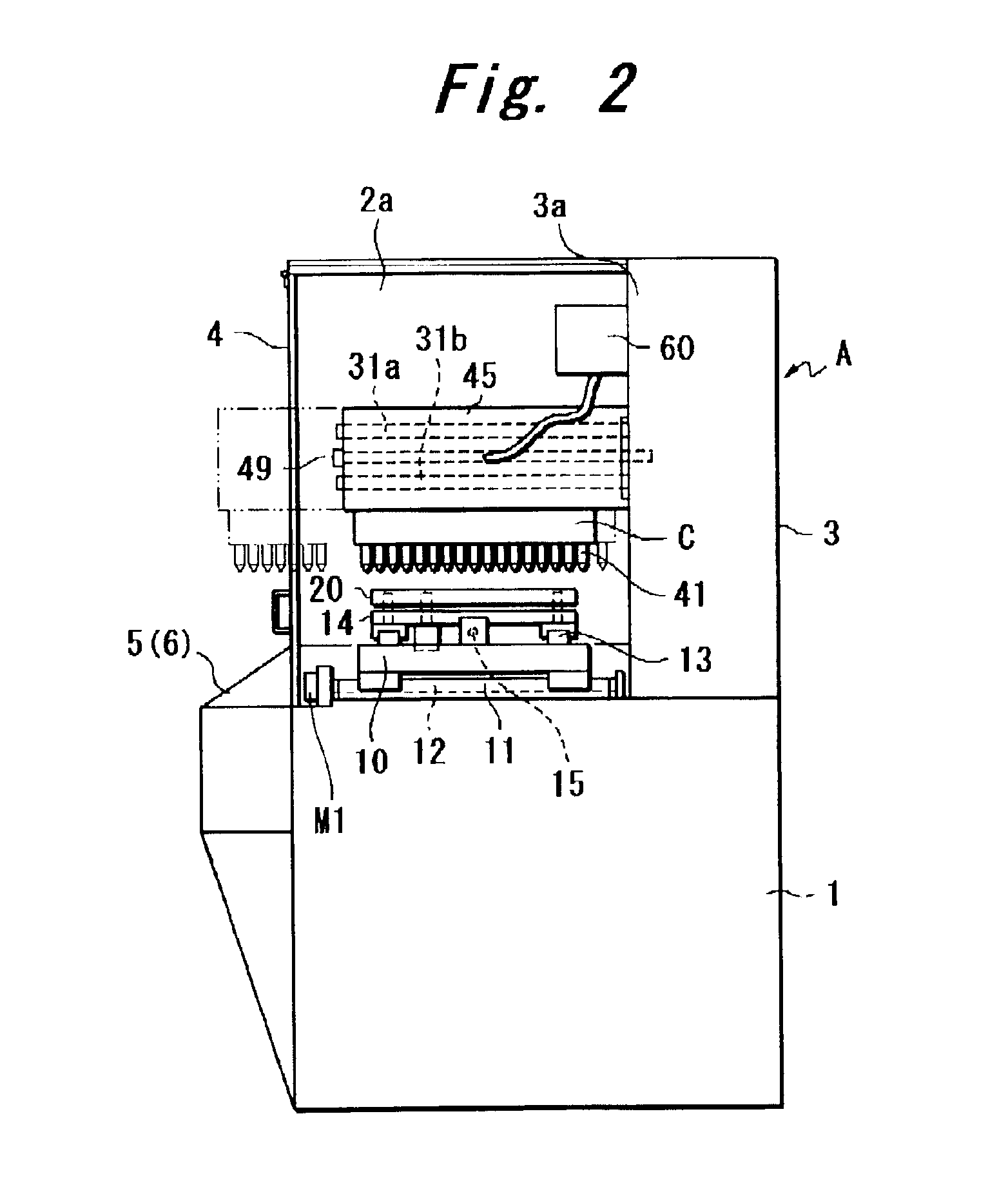

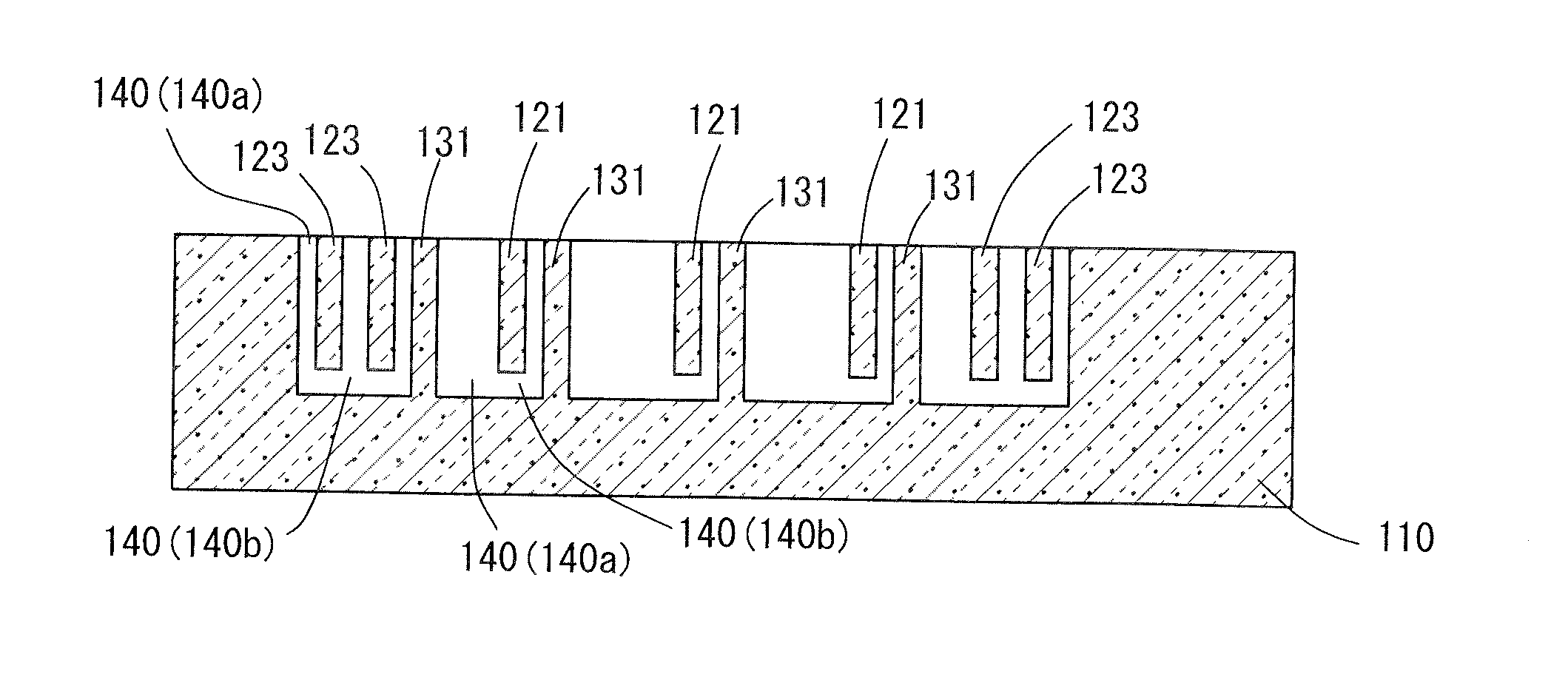

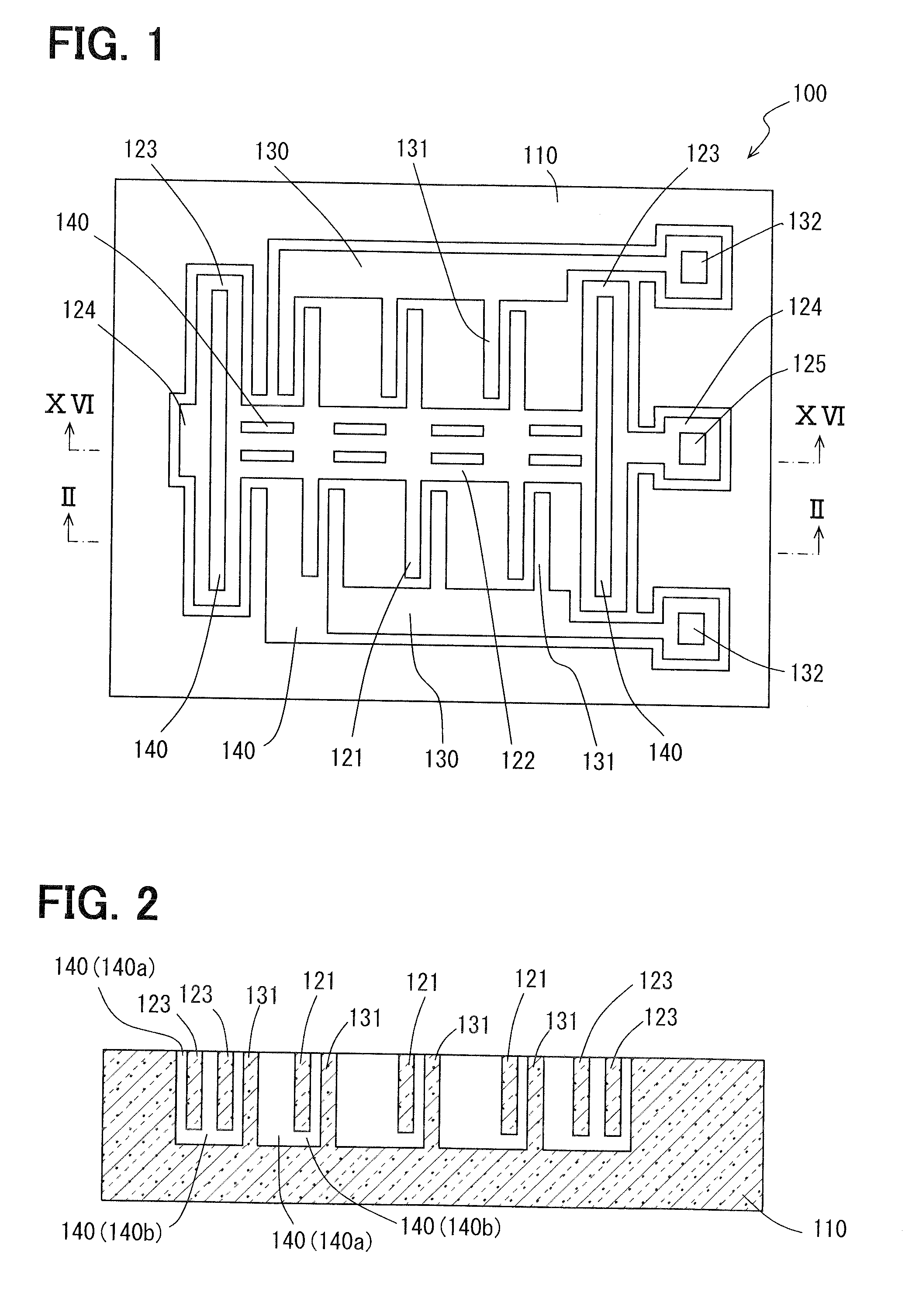

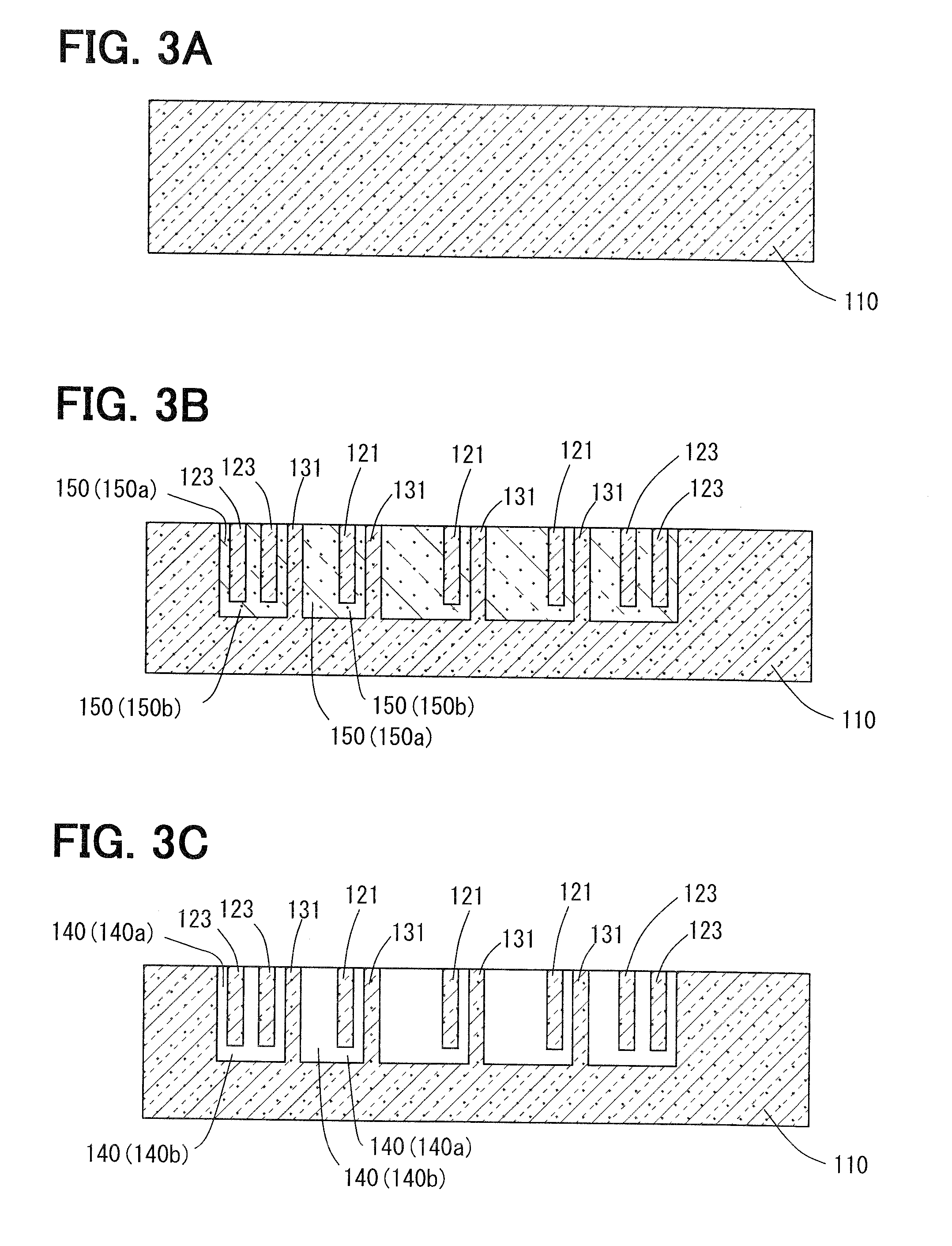

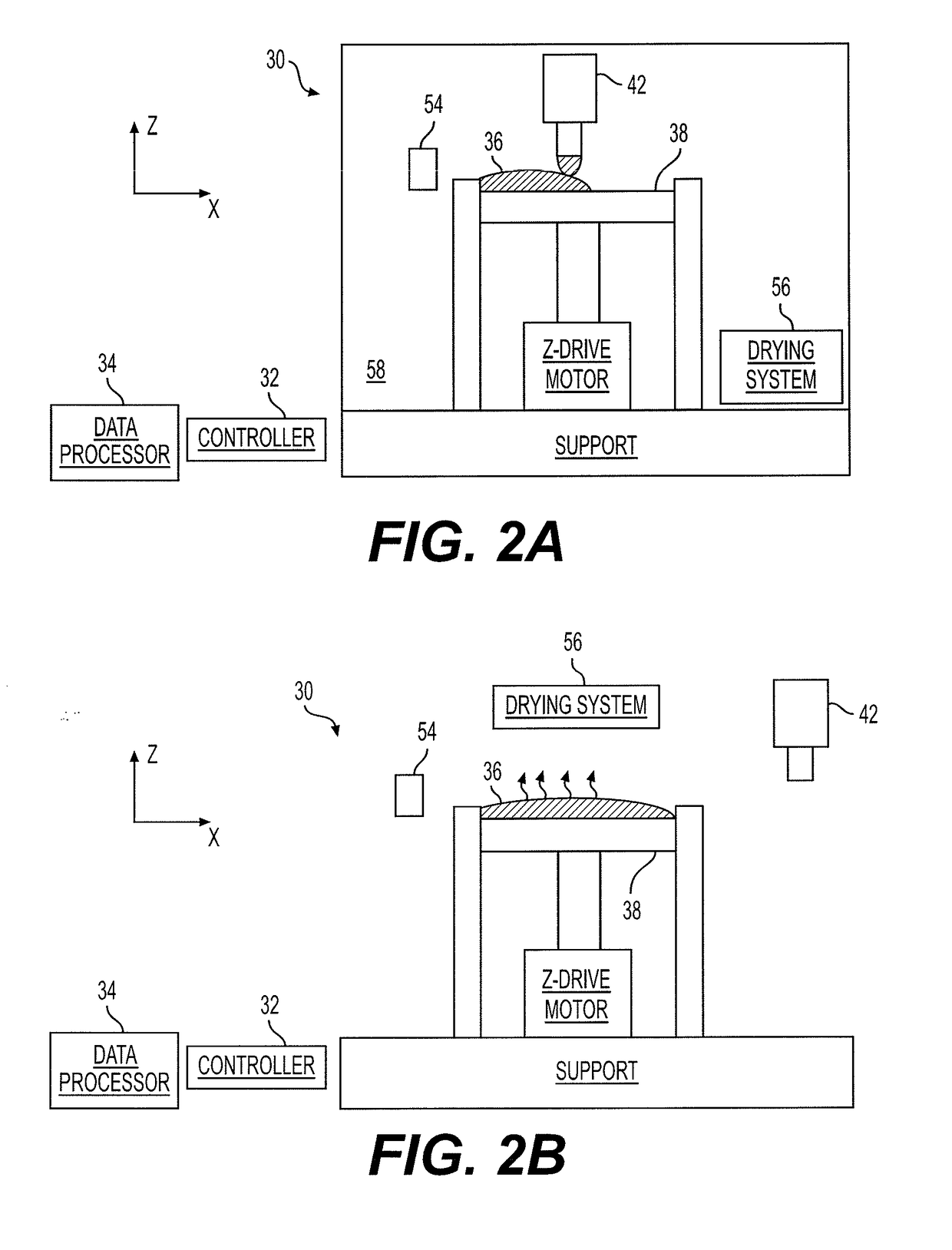

Apparatus for manufacturing stacked type electronic part

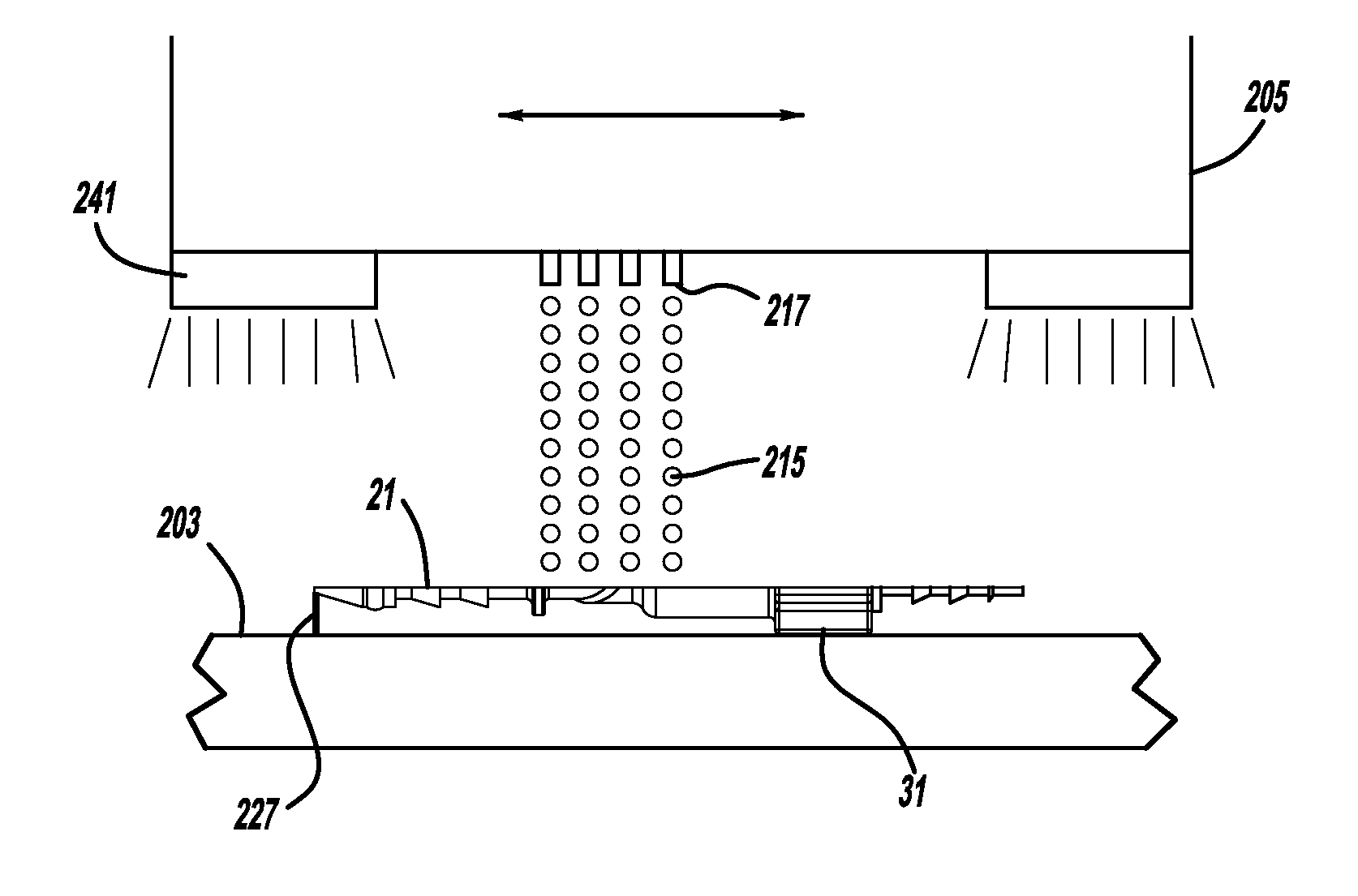

ActiveUS20030183165A1Improve manufacturing speedEasily practically used and smallerLiquid surface applicatorsPrinted electric component incorporationBackplaneEngineering

An object of the present invention is to provide an apparatus for manufacturing a stacked type electronic part which can manufacture a stacked type electronic part dried at low temperature for a product by increasing a manufacturing speed. A base plate is placed in a predetermined linear section path to be moved back and forth and be moved vertically. Above the section path are juxtaposed one or more insulator layer forming means discharging an insulating resin paste, conductor layer forming means jetting a conductor paste by an ink jet system and drying means drying the pastes. A thin film layer having a predetermined conductor pattern placed on an insulator layer while the base plate is moved back and forth one or more times. Those steps are repeated to form a stacked type electronic part.

Owner:UHT CORP

High density shielded electrical cable and other shielded cables, systems, and methods

ActiveUS8841554B2Improve manufacturing speedReduce complexityCoaxial cables/analogue cablesQuad constructionsShielded cableElectricity

Owner:3M INNOVATIVE PROPERTIES CO

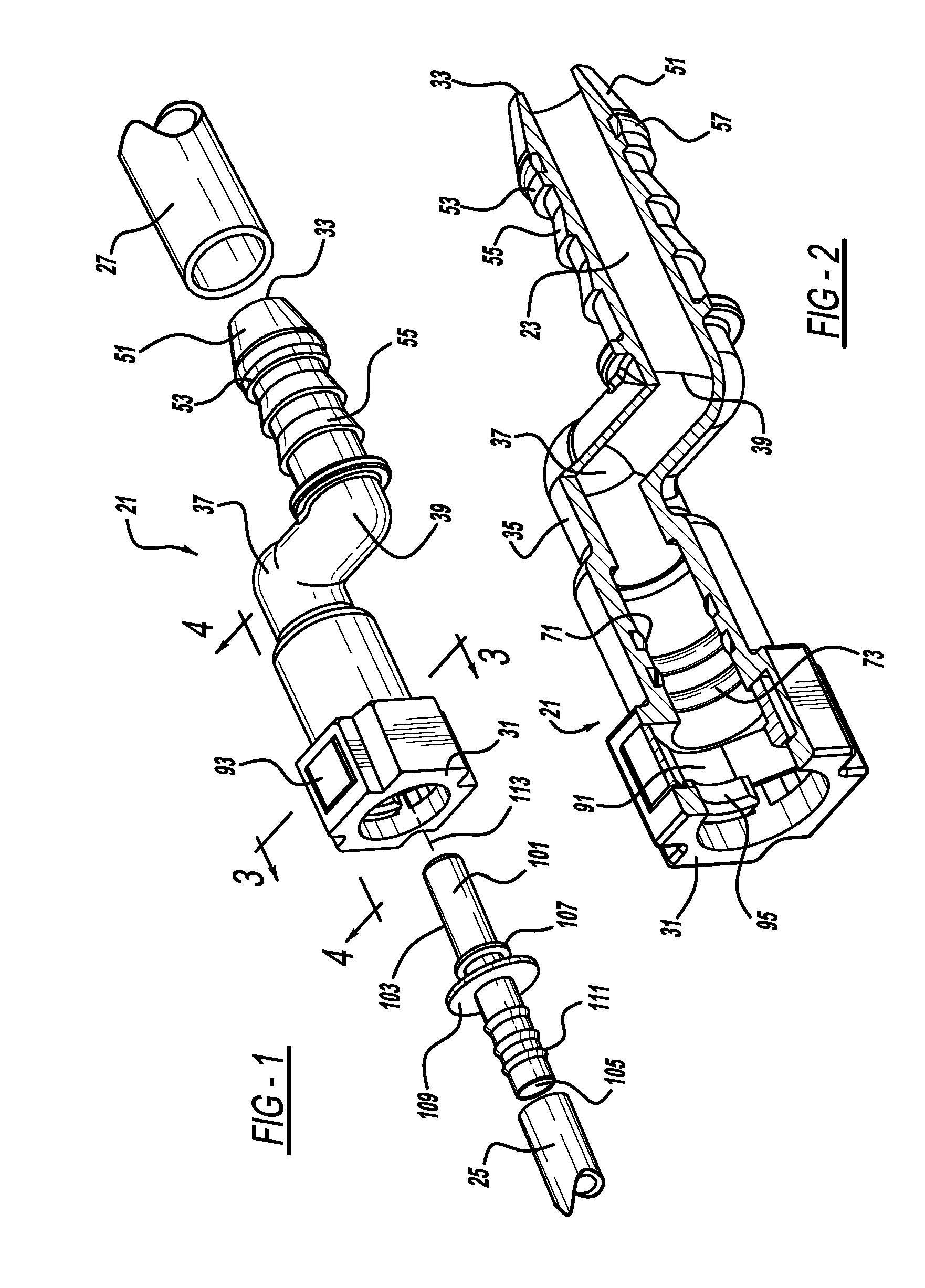

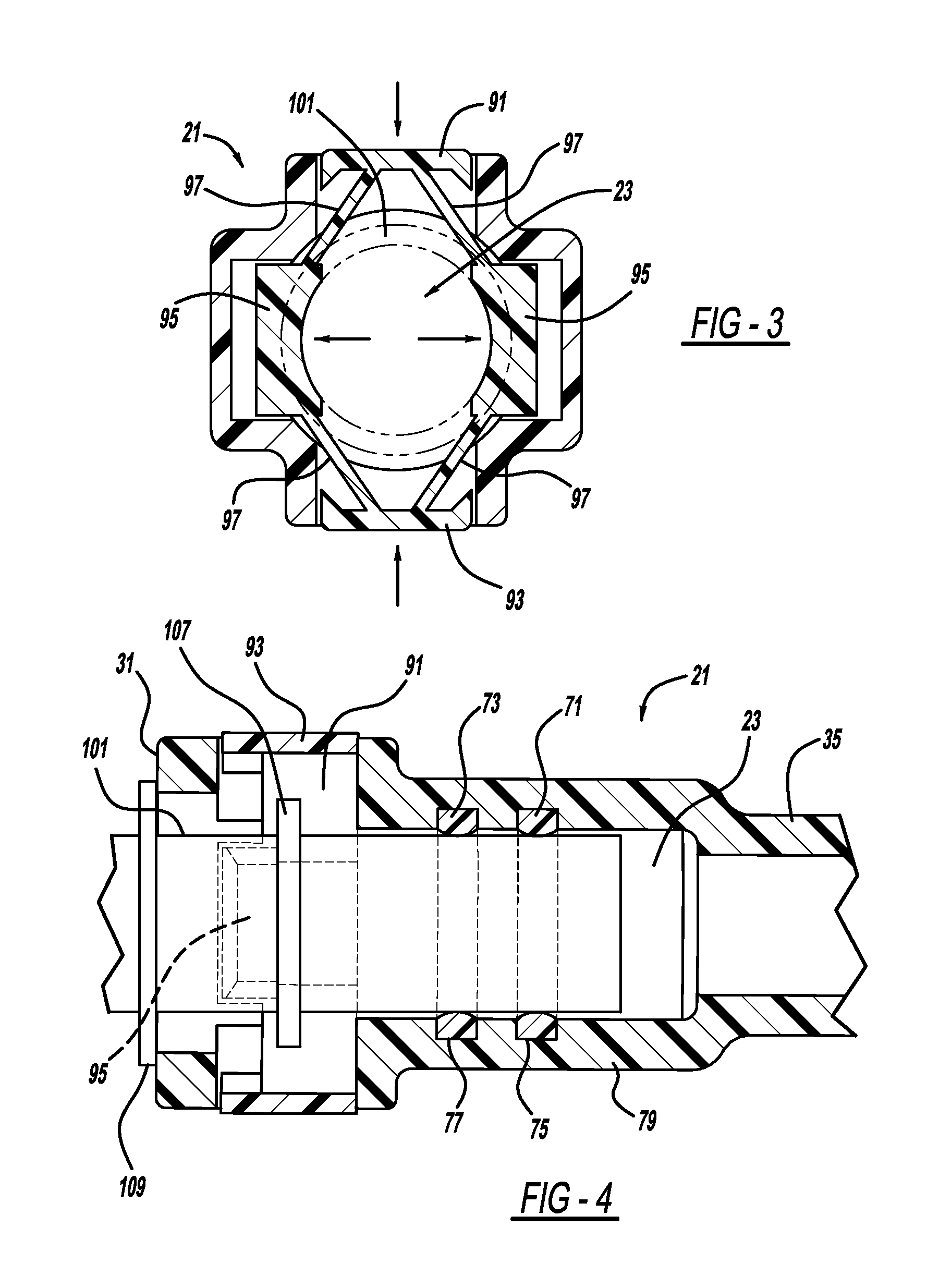

Connectors manufactured by three-dimensional printing

InactiveUS20140084583A1Increase manufacturing speedSave timeSleeve/socket jointsAdditive manufacturing apparatusEngineeringPrinting press

A hollow conduit is provided. In another aspect, a quick connector, suitable to carry fluid therethrough, is made of layers of material, a light curable material and / or multiple built-up materials. Another aspect uses a three-dimensional printing machine to emit material from an ink jet printing head to build up a conduit.

Owner:A RAYMOND & CO

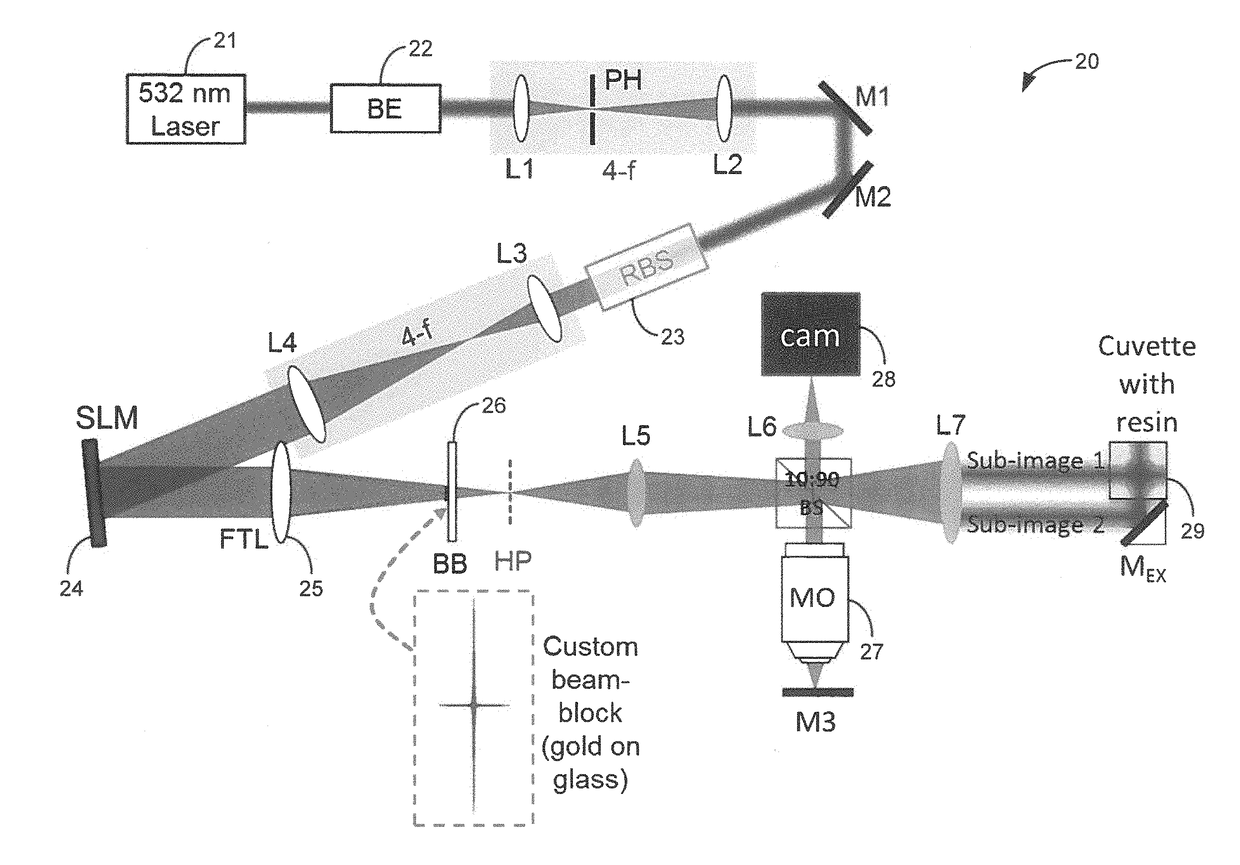

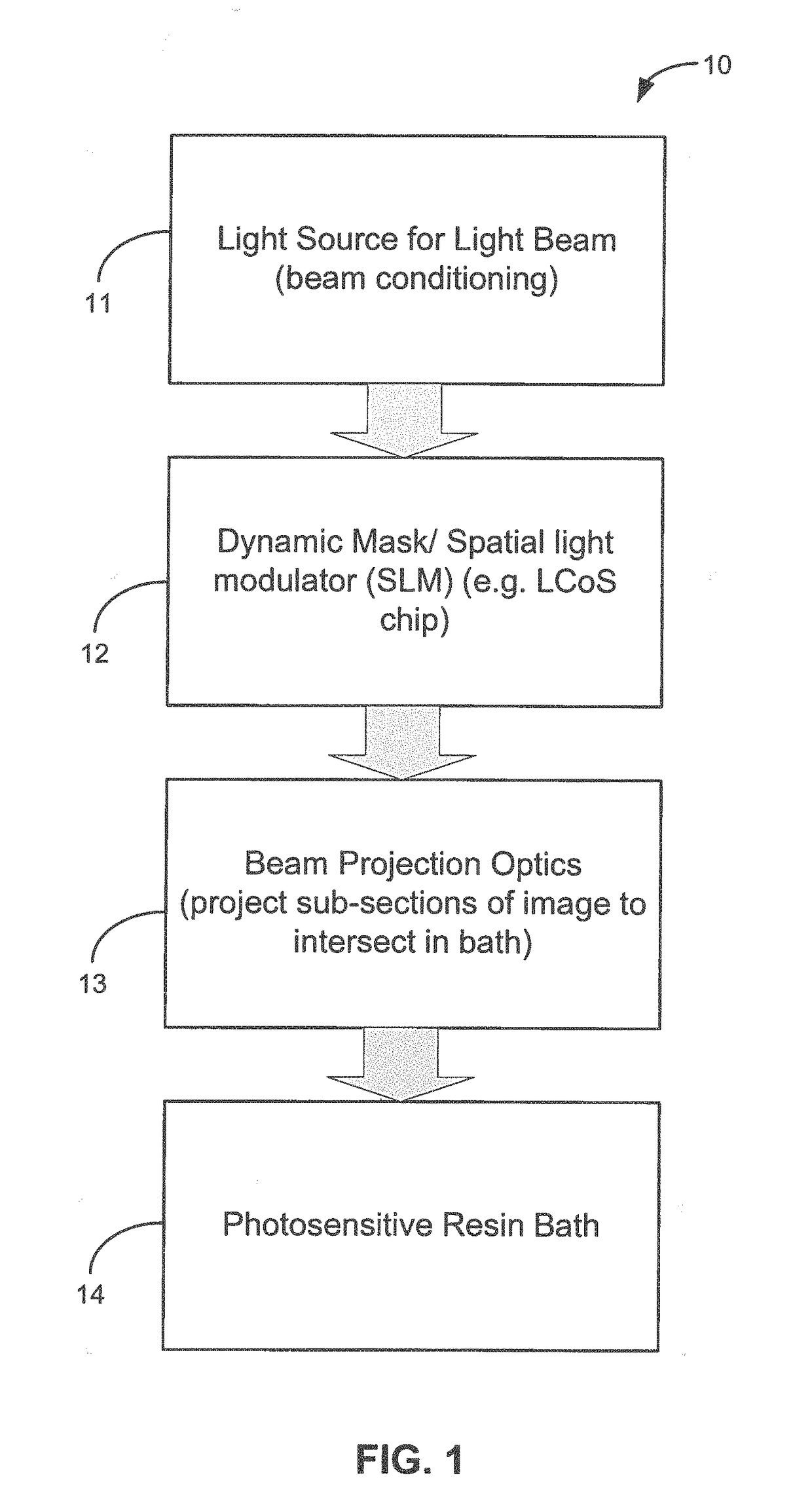

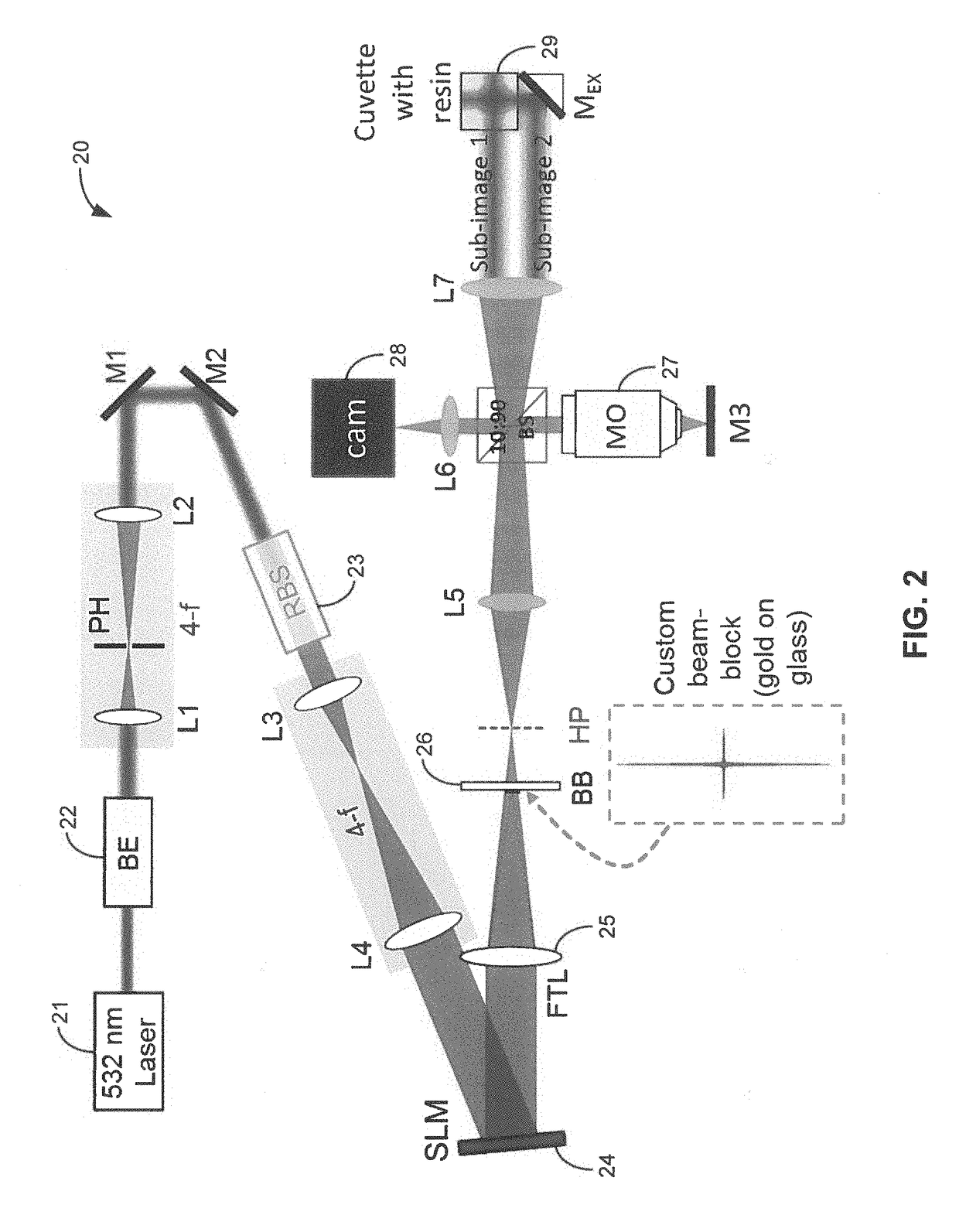

Multi-beam resin curing system and method for whole-volume additive manufacturing

ActiveUS20180015672A1High surface finishIncrease ratingsAdditive manufacturing apparatusActive addressable light modulatorProjection opticsSpatial light modulator

A multi-beam volumetric resin curing system and method for whole-volume additive manufacturing of an object includes a bath containing a photosensitive resin, a light source for producing a light beam, and a spatial light modulator which produces a phase- or intensity-modulated light beam by impressing a phase profile or intensity profile of an image onto a light beam received from the light source. The system and method also include projection optics which then produces multiple sub-image beams from the modulated light beam which are projected to intersect each other in the photosensitive resin to cure select volumetric regions of the resin in a whole-volume three-dimensional pattern representing the object.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

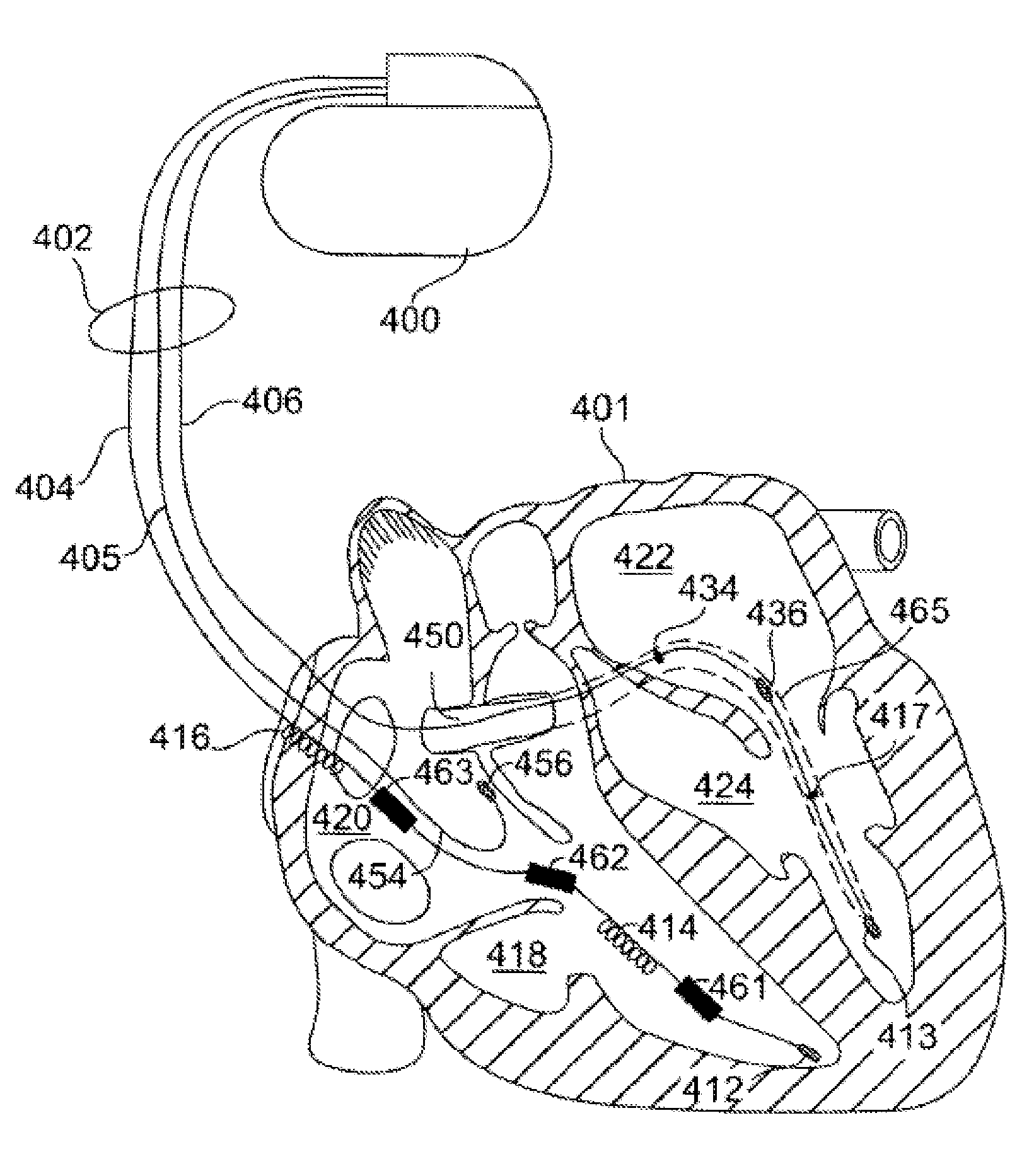

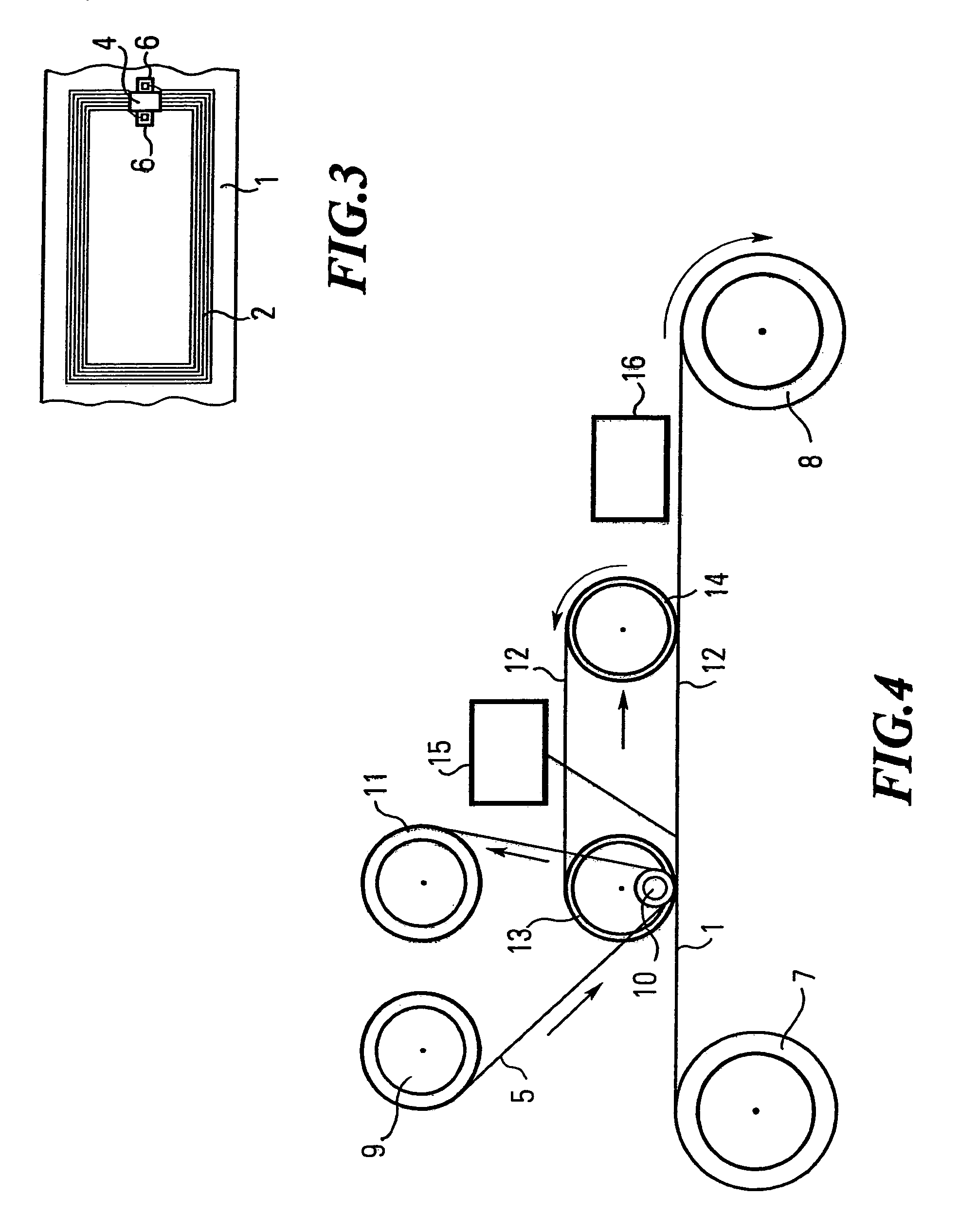

Styrene-isobutylene copolymers and medical devices containing the same

ActiveUS20100076538A1Improve equipment reliabilityReduce degradationInternal electrodesExternal electrodesElectricityEngineering

In accordance with various aspects of the invention, copolymers comprising styrene and isobutylene monomers are used in the construction of implantable and insertable medical devices for electrical stimulation, including, for example, electronic signal generating components and electrical leads for such devices.

Owner:CARDIAC PACEMAKERS INC

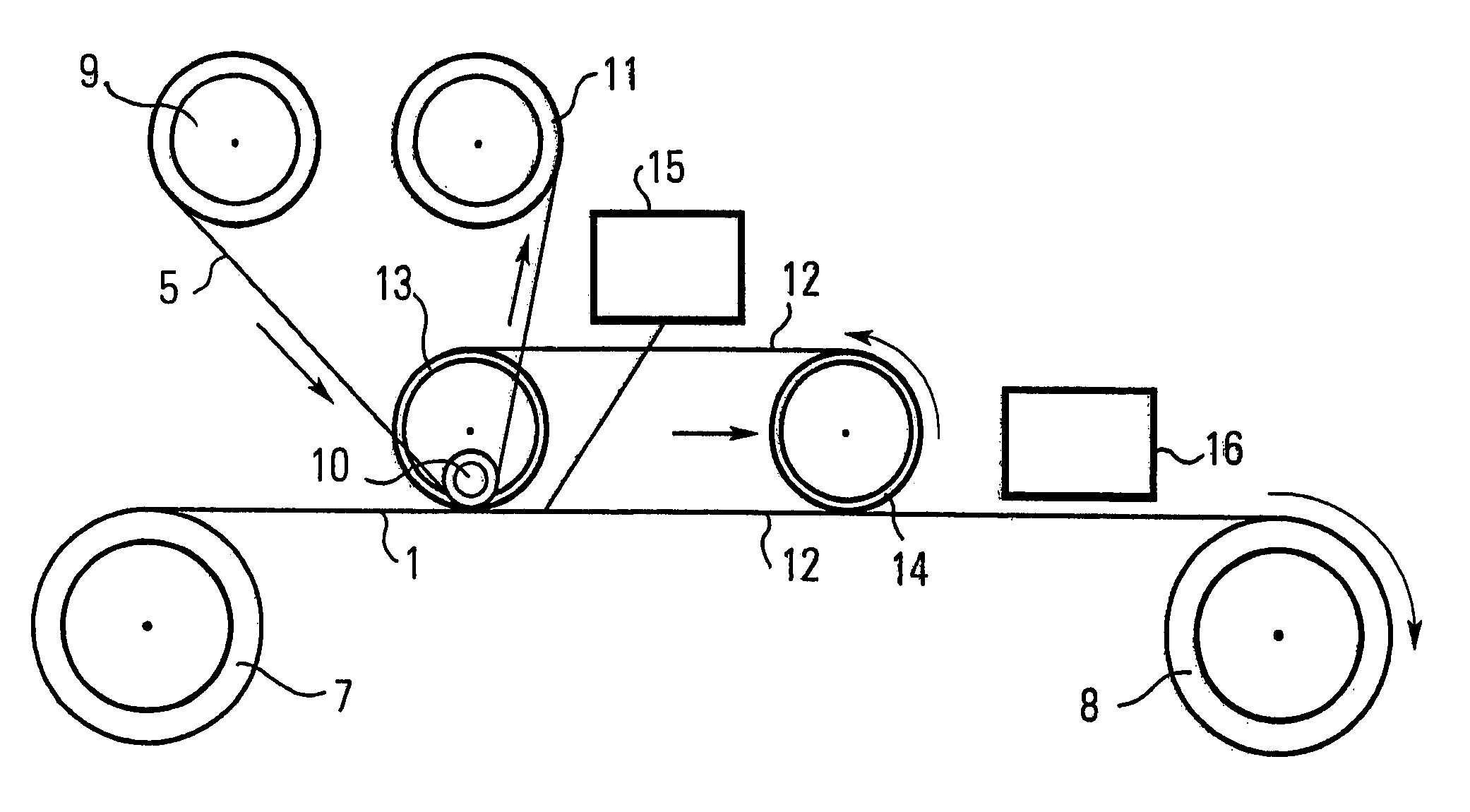

Method for connecting microchips to an antenna arranged on a support strip for producing a transponder

InactiveUS6972394B2Easy to makeEasy to implementDecorative surface effectsSoldering apparatusComputer moduleBonding process

The invention relates to a method of connecting micro-chip modules to antennas arranged on a first carrier tape for the manufacture of transponders. The method is characterised in that the micro-chips are packaged in a preceding bonding process to form a chip module with electrical terminals and are applied to a second carrier tape. The two carrier tapes are wound off a reel and brought one above the other, whereby the chip modules are removed from the second carrier tape and placed at a predetermined point on the first carrier tape. This method facilitates a continuous manufacturing process which is particularly economical and particularly fast.

Owner:MUEHLBAUEHR AG

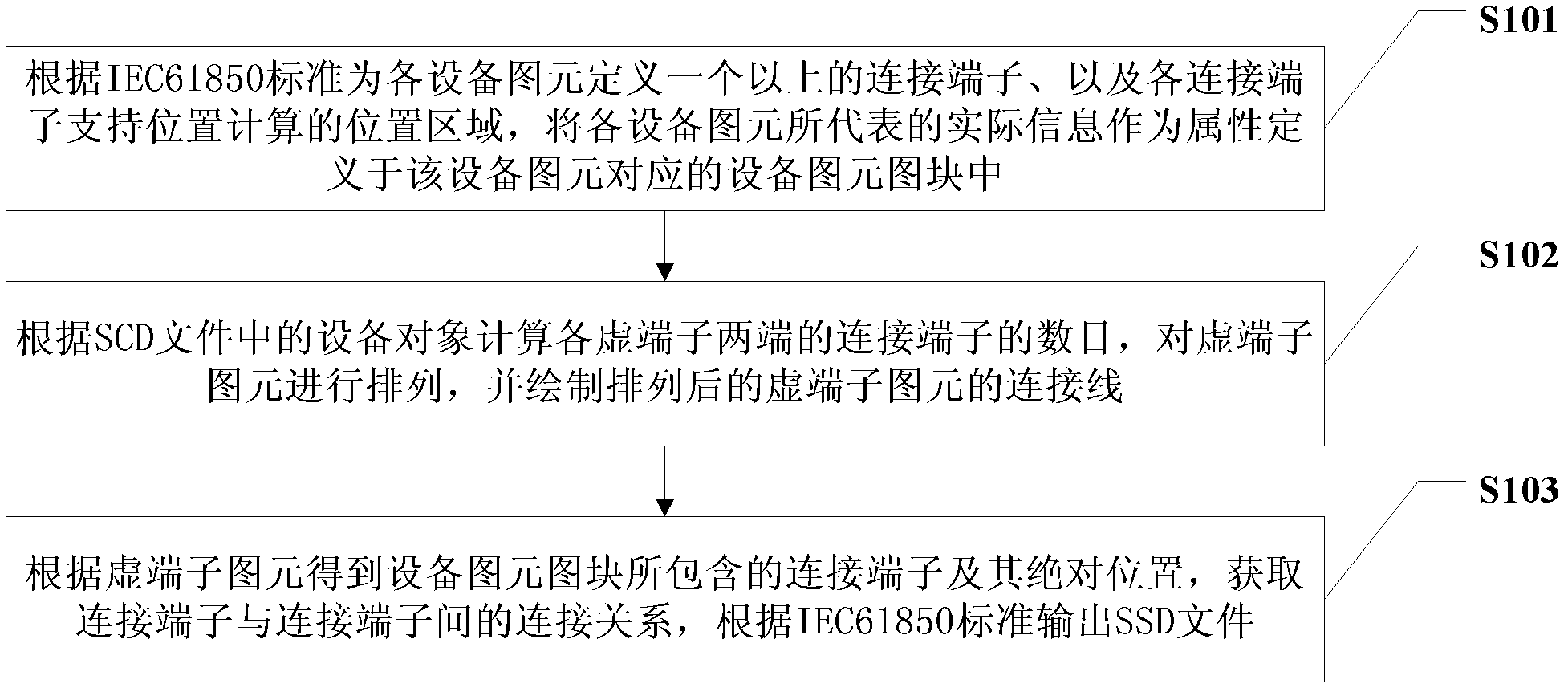

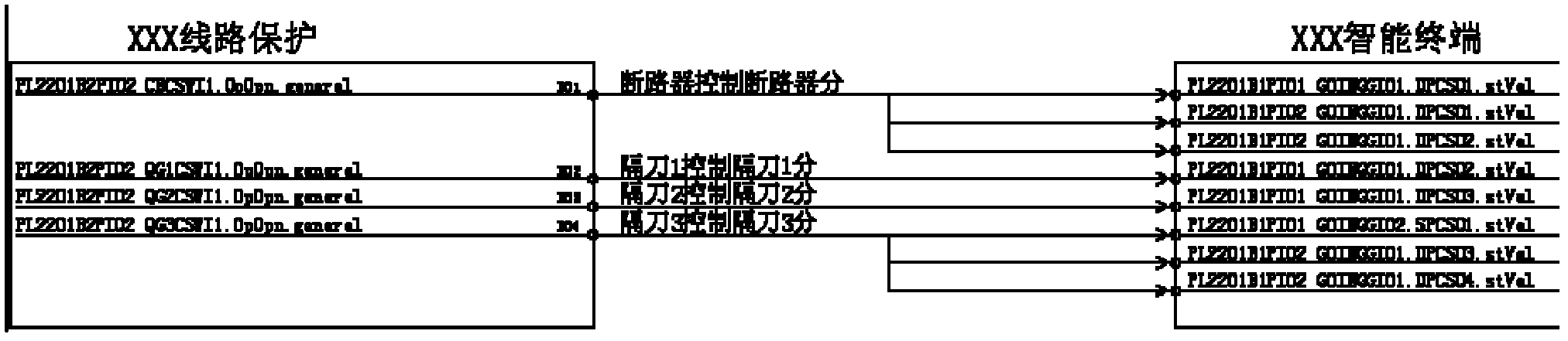

IEC61850-based CAD electric power graphic generation analysis method

ActiveCN102360398AAvoid mistakesImprove production speed and levelSpecial data processing applicationsVirtual terminalAnalysis method

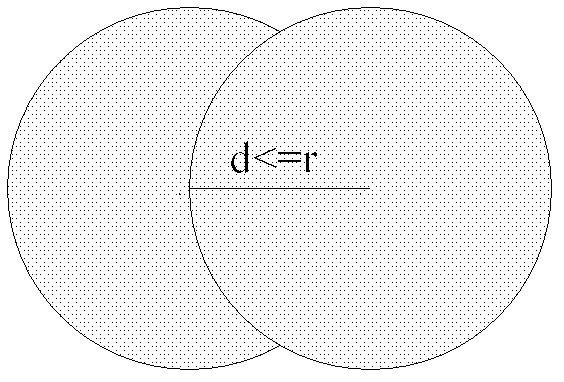

The invention discloses an IEC61850-based CAD electric power graphic generation analysis method, which comprises the steps of: defining more than one connecting terminal graphic block for equipment primitives and position regions calculated via supporting positions of connecting terminal graphic blocks according to an IEC61850 standard, and defining the actual information represented by the equipment primitives in the graphic blocks subordinative to the equipment primitives as an attribute; calculating the number of connecting terminals on the two ends of virtual terminals in a selected SCD file, calculating the spatial dimensions of the equipment primitives, arranging the primitives of the virtual terminals, and drawing connecting lines of the arranged primitives of the virtual terminals; acquiring terminals included by the primitives and absolute positions of the terminals according to the primitives of the virtual terminals, acquiring the connecting relation of the terminals, and outputting an SSD file according to the IEC61850 standard. The invention has the advantages of avoiding an error due to manual primitive connection, improving the making speed and level of intelligent transformer substation SCD and enhancing the design efficiency of a CAD electric power graphic.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

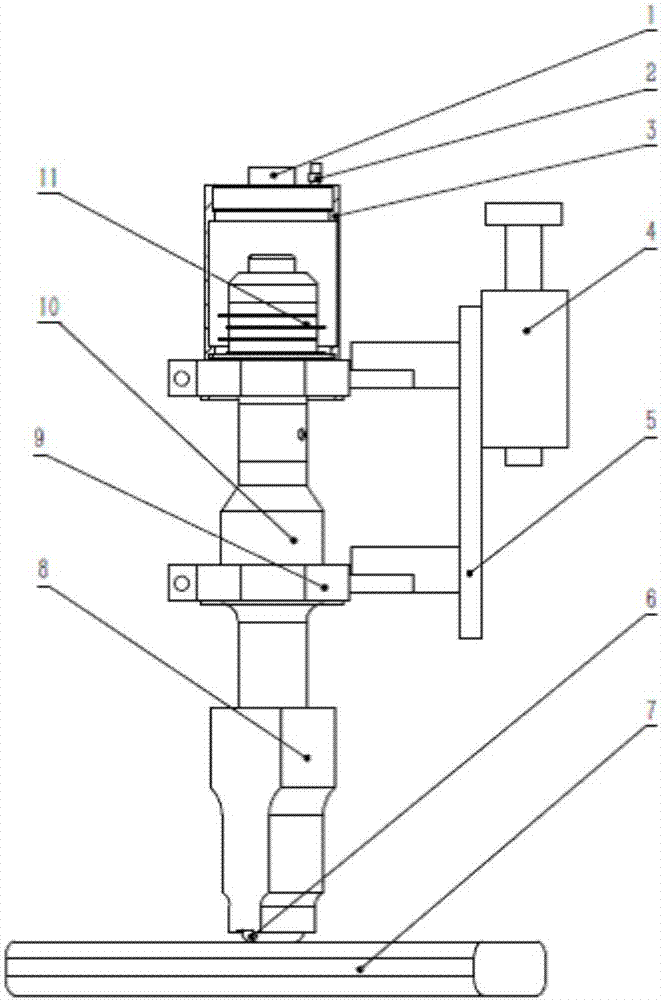

Ultrasonic and micro-forging composite device for improving microstructure and performance of additively manufactured metal and additive manufacturing method

ActiveCN107470628AImprove efficiencyHigh speedAdditive manufacturing apparatusIncreasing energy efficiencyComposite effectManufacturing technology

The invention provides an ultrasonic and micro-forging composite device for improving the microstructure and performance of additively manufactured metal and an additive manufacturing method. The ultrasonic and micro-forging composite device comprises an energy converter, a pneumatic slider, a pneumatic slider connection frame, an amplitude transformer, a tool head and a roller. The energy converter is arranged in an energy converter shell, the energy converter shell is provided with an inserting piece and a pipeline connector, the amplitude transformer is connected to the lower end of the energy converter, the tool head is connected below the energy converter, the roller is located between the tool head and a workpiece, and the pneumatic slider is connected with the energy converter shell and the amplitude transformer through the pneumatic slider connection frame. By means of the ultrasonic and micro-forging composite device, the advantages that ultrasonic impact frequency is high and deformation generated by mechanical rolling is large are combined, the composite effect of ultrasonic impact and continuous rolling micro-forging can be achieved, and the purpose of improving the microstructure of the additively manufactured metal and the mechanical performance of parts is achieved. Through organic combination of the ultrasonic and micro-forging composite device and the additive manufacturing method with an existing additive manufacturing technology, the technical bottleneck that structure control is easy while performance control is difficult in existing metal additive manufacturing is solved, and innovation and development of metal rapid forming and manufacturing technologies are induced.

Owner:HARBIN ENG UNIV +1

Pharmaceutical composition as solid dosage form and method for manufacturing thereof

ActiveUS7094545B2Improve manufacturing speedIncrease speed and capacityOrganic active ingredientsPeptide/protein ingredientsSolid Dose FormBULK ACTIVE INGREDIENT

The present invention relates to a novel pharmaceutical composition as a solid dosage form comprising desmopressin as a therapeutically active ingredient, and to a method for manufacturing thereof. The invention relates to a pharmaceutical composition as a solid dosage form comprising desmopressin, or a pharmaceutically acceptable salt thereof, as a therapeutically active ingredient together with a pharmaceutically acceptable excipient, diluent or carrier, or mixture thereof, wherein at least one of said excipient, diluent and carrier is a substance selected from a monosaccharide, disaccharide, oligosaccharide and a polysaccharide, wherein the said substance has an average particle size in the range of from 60 to 1,000 μm. A method according to the present invention provides an improved production of solid dosage forms of desmopressin.

Owner:FERRING BV

Method for making ceramic work piece and cermet work piece

InactiveUS20060119017A1Accelerate manufacturing speedLow manufacturing costCeramic shaping apparatusClaywaresCermetAqueous sodium hydroxide

Method for making ceramic work piece or cermet work piece is realized by utilizing a multi-layer processing method. Several kinds of materials are mixed to form slurry. Then the slurry is formed into a thin green layer, which will be dried by infrared light, so that the thin green layer will be hardened. Next, the thin green layer exposed under a high-energy beam is sintered to bond together locally due to heat effect at different temperature levels, respectively. After multiple repetitions of this procedure a three-dimensional ceramic part or cermet part can be fabricated layer upon layer. The green portion, which is not scanned by the high-energy beam, can be removed with suitable methods, such as submerged in water or sodium hydroxide water solution, due to disparate characteristics of scanned and unscanned portions. A ceramic part or a cermet part can be rapidly produced in this way.

Owner:NAT TAIPEI UNIV OF TECH

Reactive additive manufacturing

ActiveUS20160271878A1High quality partHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceReaction product

An additive manufacturing method may involve: Providing a first and a second material, the second material capable of reacting with the first material to form a reaction product; forming at least the first material into a first layer; subjecting at least a portion of the first layer to energy in the presence of the second material, the energy being sufficient to initiate a reaction between at least the first and second materials to form a portion of the article, the portion of the article comprising the reaction product; forming a second layer of at least the first material on the first layer; and subjecting at least a portion of the second layer to energy in the presence of the second material, the energy being sufficient to initiate a reaction between the first and second materials to form an additional portion of the article.

Owner:ELEMENTUM 3D INC

Polysulfonamide nanofiltration or reverse-osmosis composite membrane, and preparation method thereof

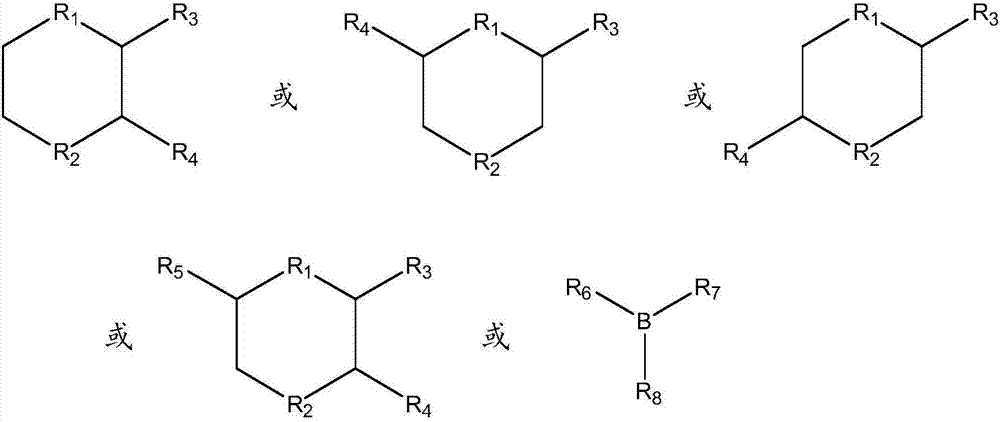

InactiveCN107126850AHigh desalination rateImprove desalination propertiesMembranesGeneral water supply conservationSulfonyl chlorideReverse osmosis

The invention discloses a polysulfonamide nanofiltration or reverse-osmosis composite membrane, and a preparation method thereof. the preparation method for the polysulfonamide nanofiltration or reverse-osmosis composite membrane comprises the following steps: pretreatment of a porous supporting membrane; alternate layer-upon-layer assembling of a sulfonyl chloride organic-phase solution and a polyamine water-phase solution on the surface of the porous supporting membrane via reaction; heat treatment; etc.; wherein heat treatment can be carried out during or after layer-upon-layer assembling. Nanoparticles, a surfactant, a catalytic acid absorbent or catalyst, a pore forming agent and other additives are added into the sulfonyl chloride organic-phase solution and the polyamine water-phase solution. The polysulfonamide nanofiltration or reverse-osmosis composite membrane prepared by using the method has improved desalination performance and acid resistance, smoother surface and lower roughness compared with composite membranes prepared through traditional interfacial polymerization, and has good application prospects in the fields of nanofiltration and reverse osmosis.

Owner:青岛致用新材料科技有限公司

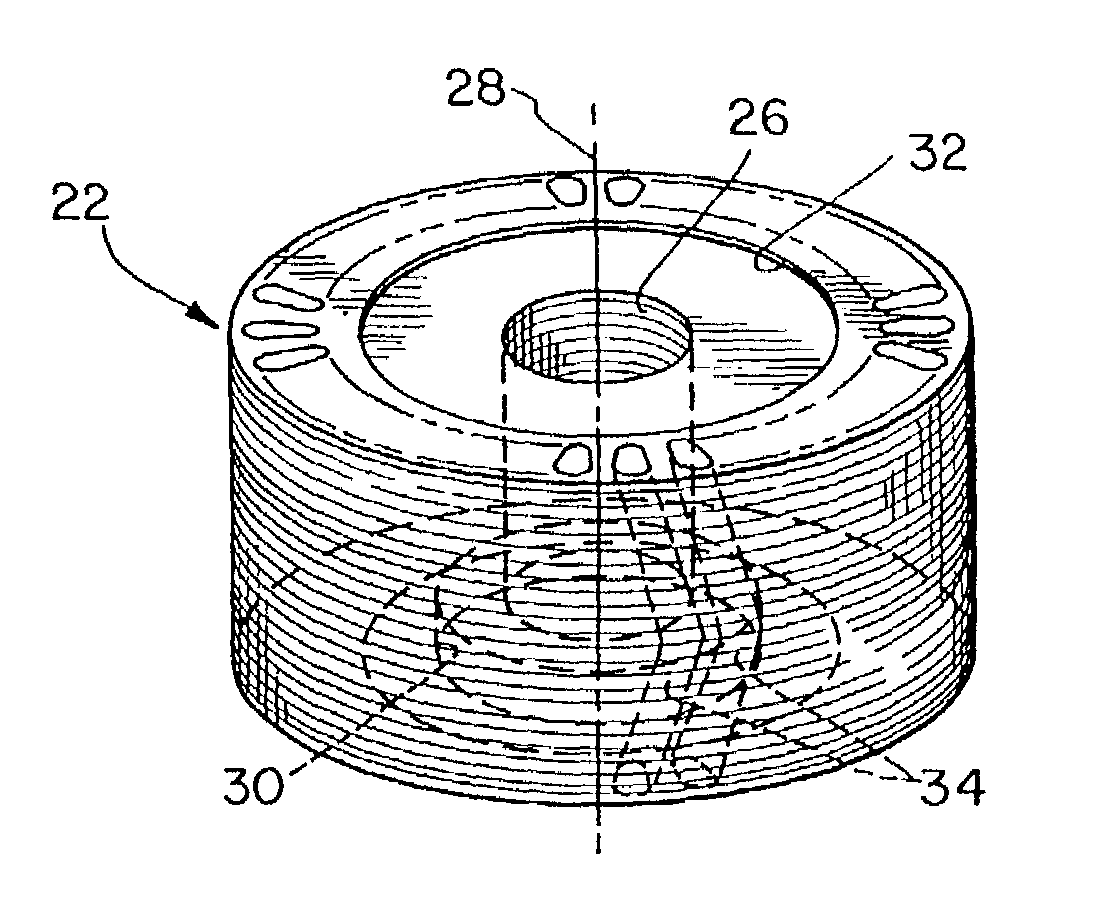

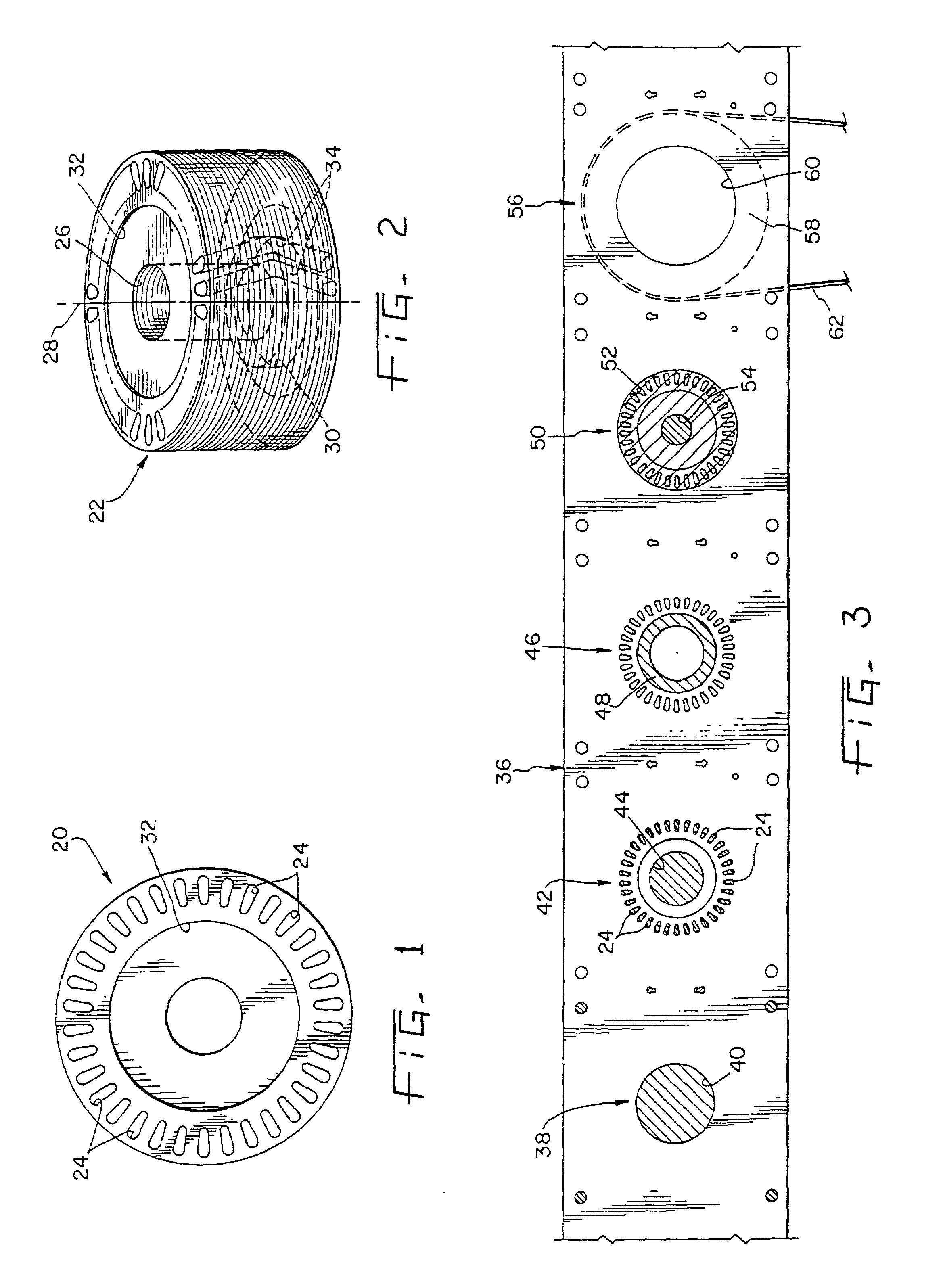

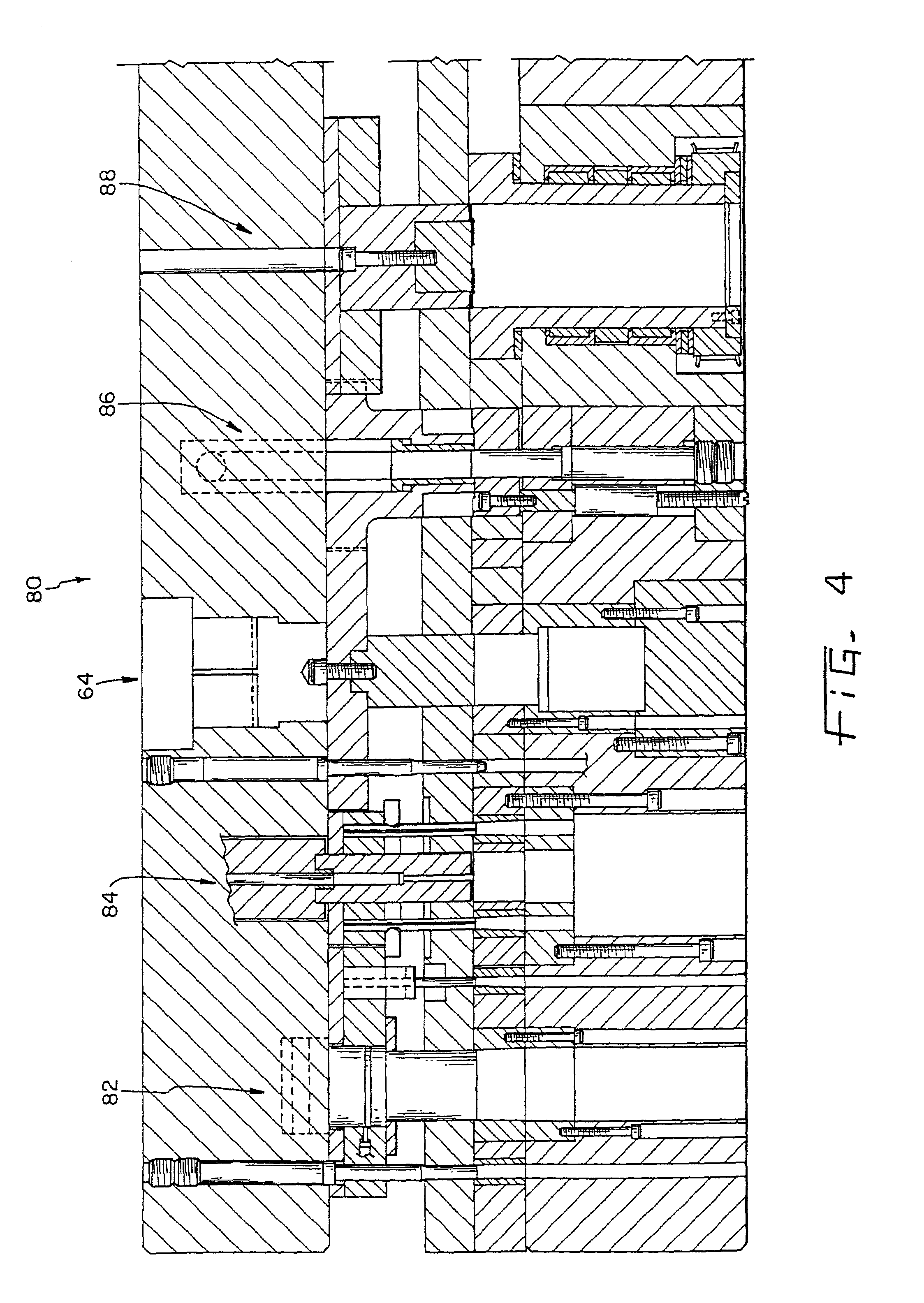

Lamination stack with center interlock

InactiveUS6984913B2Quick laminationFirmly connectedManufacturing stator/rotor bodiesMagnetic circuit shape/form/constructionEngineering

Owner:L H CARBIDE

Apparatus for manufacturing stacked type electronic part

InactiveUS6958095B2Improve productivityDecrease productivityLiquid surface applicatorsPrinted electric component incorporationElectrical conductorMechanical engineering

An object of the present invention is to provide an apparatus for manufacturing a stacked type electronic part which can manufacture a stacked type electronic part dried at low temperature for a product by increasing a manufacturing speed. A base plate is placed in a predetermined linear section path to be moved back and forth and be moved vertically. Above the section path are juxtaposed one or more insulator layer forming means discharging an insulating resin paste, conductor layer forming means jetting a conductor paste by an ink jet system and drying means drying the pastes. A thin film layer having a predetermined conductor pattern placed on an insulator layer while the base plate is moved back and forth one or more times. Those steps are repeated to form a stacked type electronic part.

Owner:UHT CORP

Manufacturing method of semiconductor device including etching step

InactiveUS20110034031A1Etching speed is fastShorten production timeDecorative surface effectsSemiconductor/solid-state device manufacturingLaser beamsSemiconductor

A manufacturing method of a semiconductor device includes: irradiating a laser beam on a single crystal silicon substrate, and scanning the laser beam on the substrate so that a portion of the substrate is poly crystallized, wherein at least a part of a poly crystallized portion of the substrate is exposed on a surface of the substrate; and etching the poly crystallized portion of the substrate with an etchant. In this case, a process time is improved.

Owner:DENSO CORP

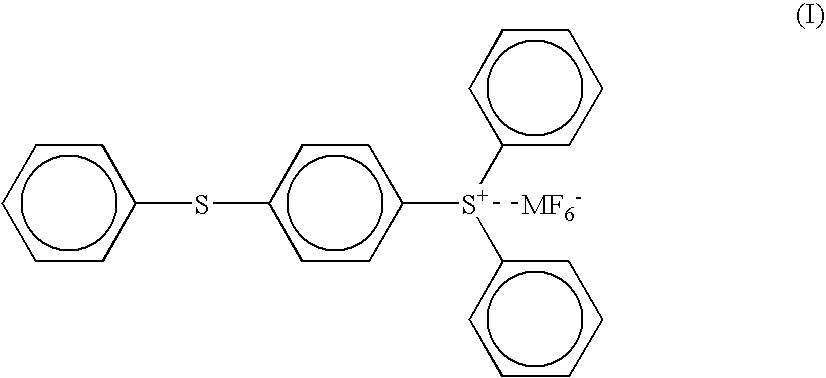

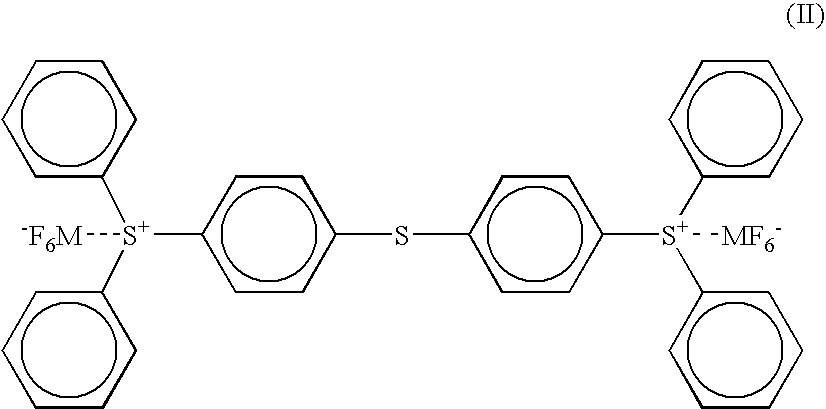

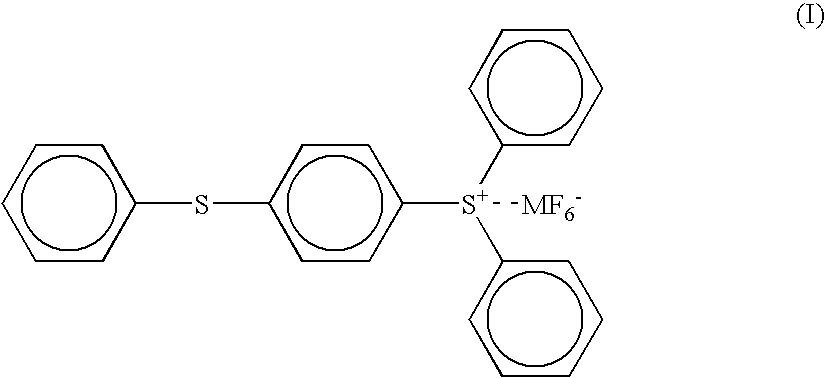

Actinic radiation-curable stereolithographic resin composition having improved stability

ActiveUS20070060682A1Good aging stabilityGood storage stabilityAdditive manufacturing apparatusPhotosensitive materialsCationic polymerizationOrganic compound

It is intended to provide the following resin composition for stereolithography which is superior in storage stability and aging stability during operation, shows no increase in viscosity upon prolonged storage, has a high light-curing sensitivity and, therefore, makes it possible to produce, upon photo irradiation, an object by stereolithography, which is superior in dimensional accuracy, fabricating accuracy, water resistance, moisture resistance and mechanical properties at a high fabricating speed and a high productivity. A resin composition for stereolithography which is an actinic radiation-curable resin composition containing a cationic-polymerizable organic compound, a radical-polymerizable organic compound, a photo cationic polymerization inhibitor and a photo radical polymerization inhibitor, in which the photo cationic polymerization inhibitor contains a compound represented by the following formula (I) and having a purity of 80% or higher: wherein M represents an antimony atom or a phosphorus atom; and the broken line between S+ and MF6− represents an ionic bond.

Owner:CMET +1

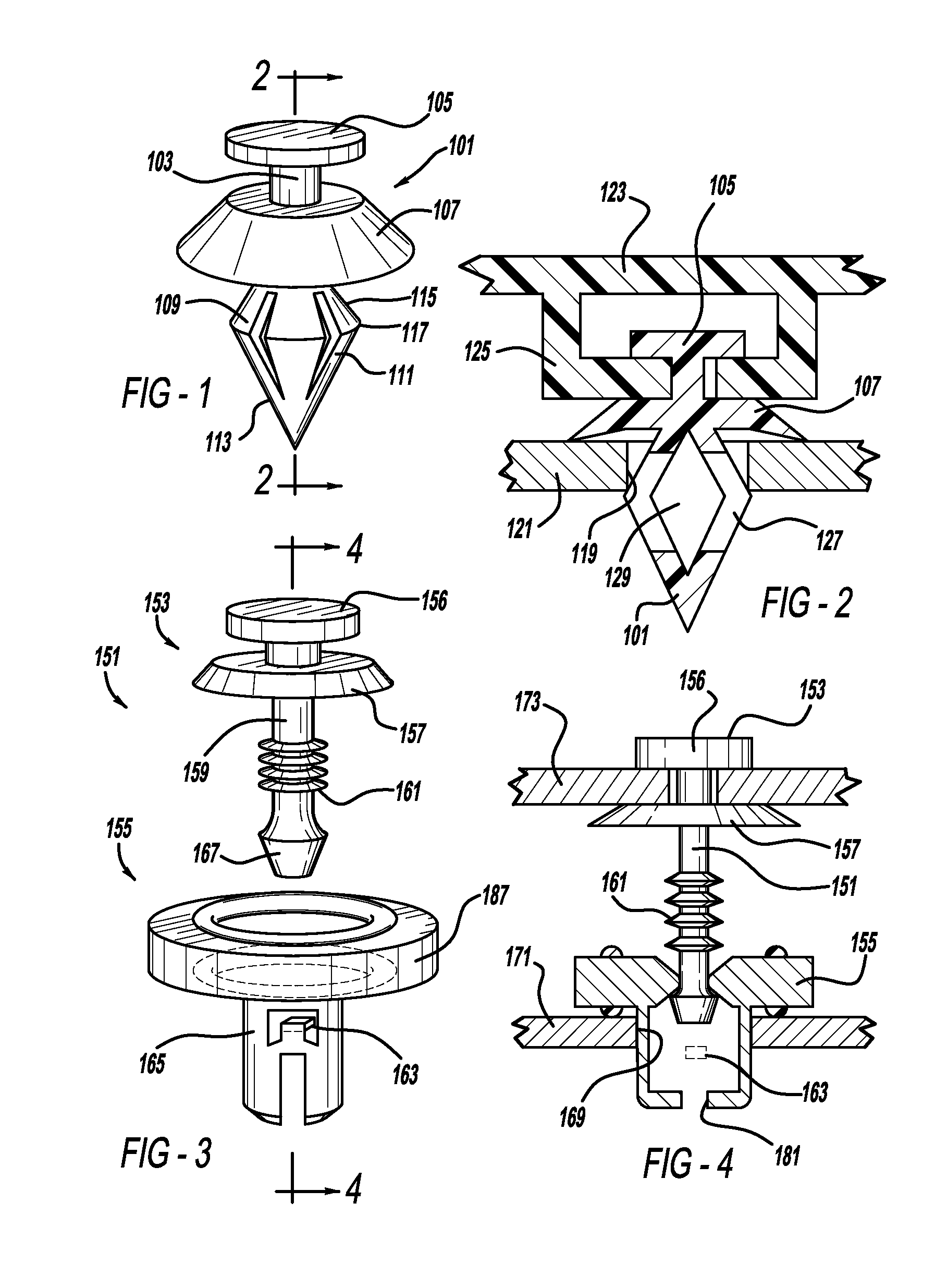

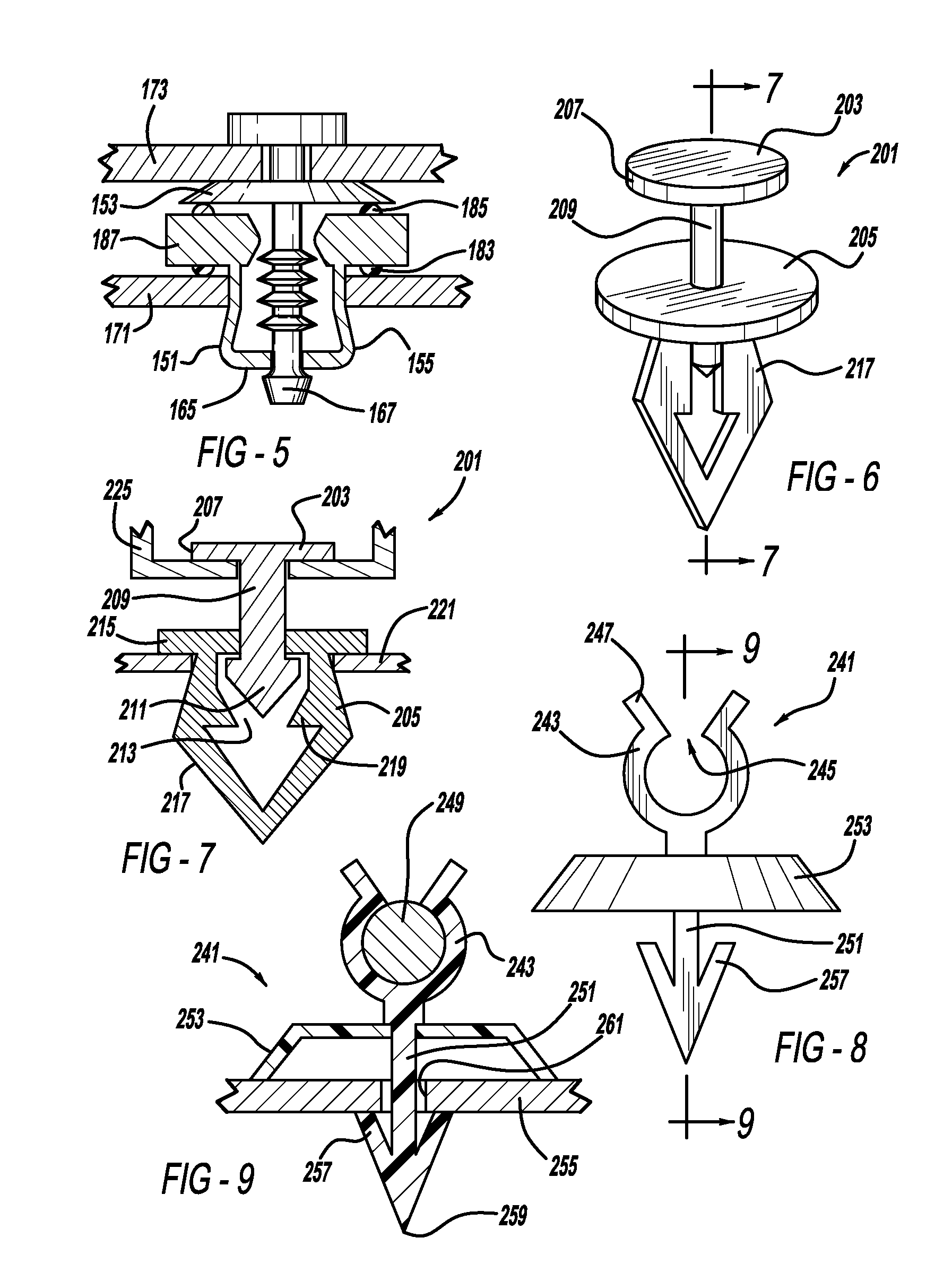

Composite structure

InactiveUS20120045613A1Improve joint strengthSimple profileLamination ancillary operationsLaminationFiberEngineering

A structure comprising a cured composite part formed from a series of plies of fibre-reinforced composite material; a doubler plate attached to the composite part by an array of pointed prongs which partially penetrate the composite part; and a hole passing through the doubler plate and the composite part. An interface plate carries the array of prongs on a first side and is attached to the doubler plate on a second side.

Owner:AIRBUS OPERATIONS LTD

Pharmaceutical composition as solid dosage form and method for manufacturing thereof

InactiveUS20060252696A1Improve manufacturing speedIncrease speed and capacityBiocideOrganic active ingredientsSolid Dose FormBULK ACTIVE INGREDIENT

The present invention relates to a novel pharmaceutical composition as a solid dosage form comprising desmopressin as a therapeutically active ingredient, and to a method for manufacturing thereof. The invention relates to a pharmaceutical composition as a solid dosage form comprising desmopressin, or a pharmaceutically acceptable salt thereof, as a therapeutically active ingredient together with a pharmaceutically acceptable excipient, diluent or carrier, or mixture thereof, wherein at least one of said excipient, diluent and carrier is a substance selected from a monosaccharide, disaccharide, oligosaccharide and a polysaccharide, wherein the said substance has an average particle size in the range of from 60 to 1,000 μm. A method according to the present invention provides an improved production of solid dosage forms of desmopressin.

Owner:FERRING BV

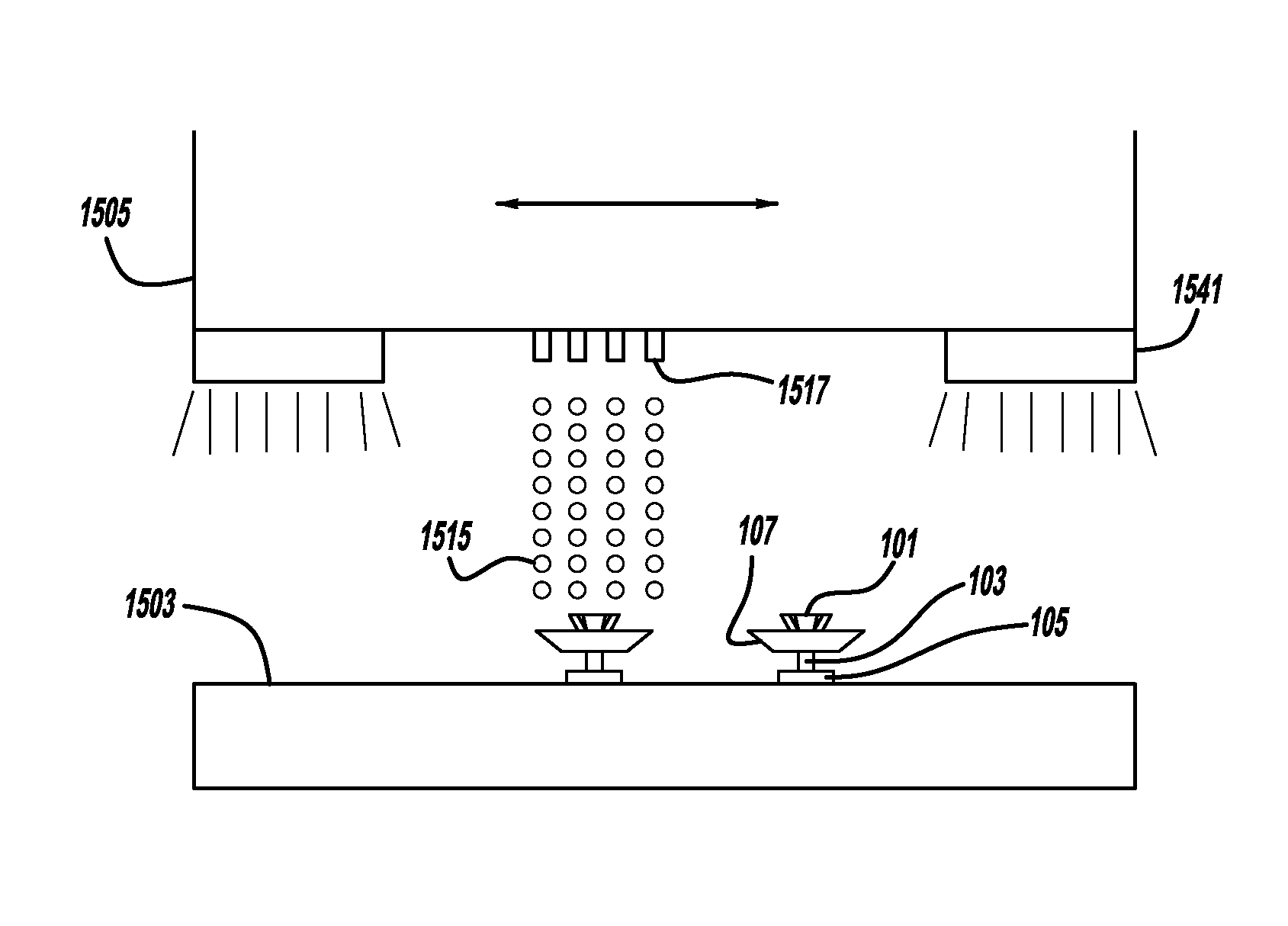

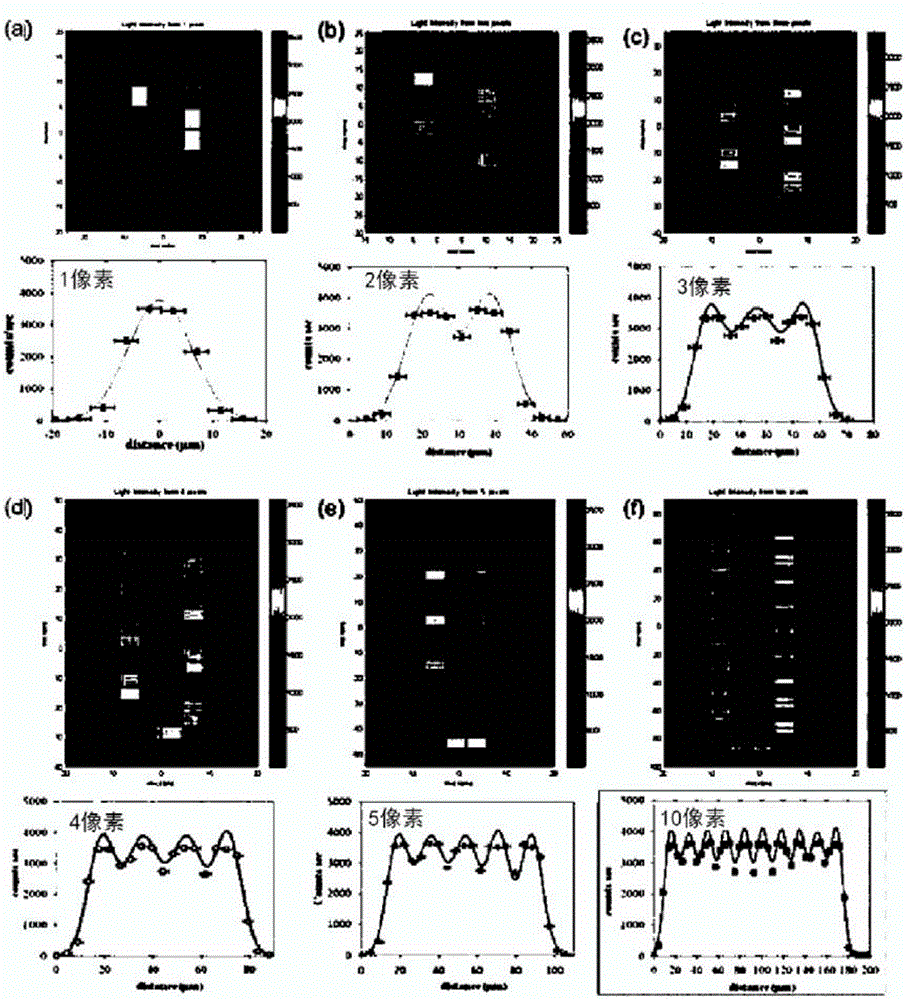

Systems and methods for fabricating three-dimensional objects

ActiveCN105163922AHigh resolutionImprove manufacturing speedAdditive manufacturing apparatus3D object support structuresControl systemLight beam

Systems and methods for fabricating three-dimensional objects are disclosed. The system includes an optical imaging system providing a light source; a photosensitive medium adapted to change states upon exposure to a portion of the light source from the optical imaging system; a control system for controlling movement of the optical imaging system, wherein the optical imaging system moves continuously above the photosensitive medium. The method includes moving a maskless optical imaging system providing the light beam in a continuous sequence; presenting the light beam on a portion of the photosensitive medium; lowering a plate upon which the photosensitive medium resides; and applying a new layer of the photosensitive medium.

Owner:DDM SYST

Acceleration of stereolithography

ActiveUS9975295B2Improve manufacturing speedLow viscosityManufacturing platforms/substrates3D object support structuresTinStereolithography

Owner:CARBON INC

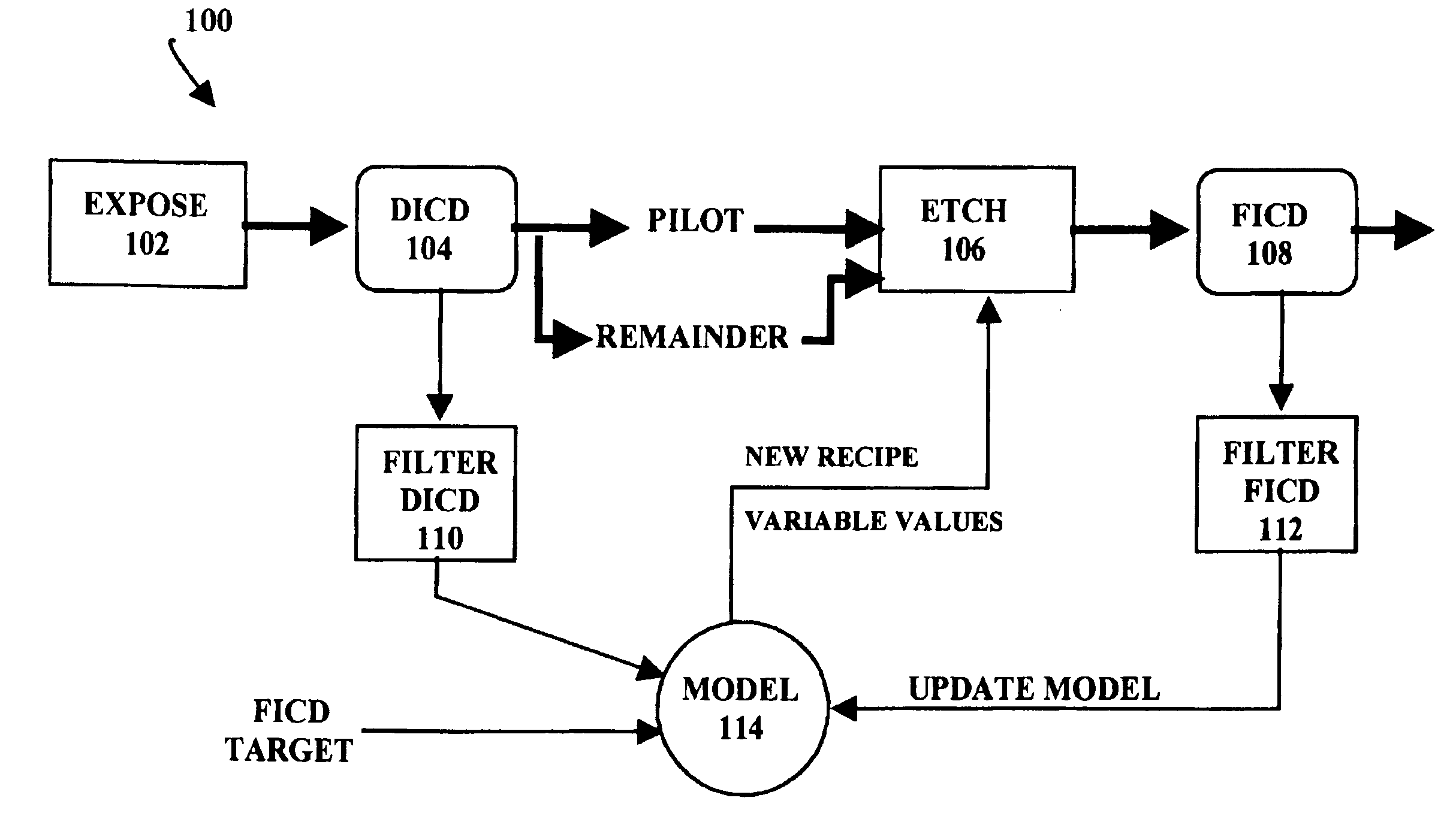

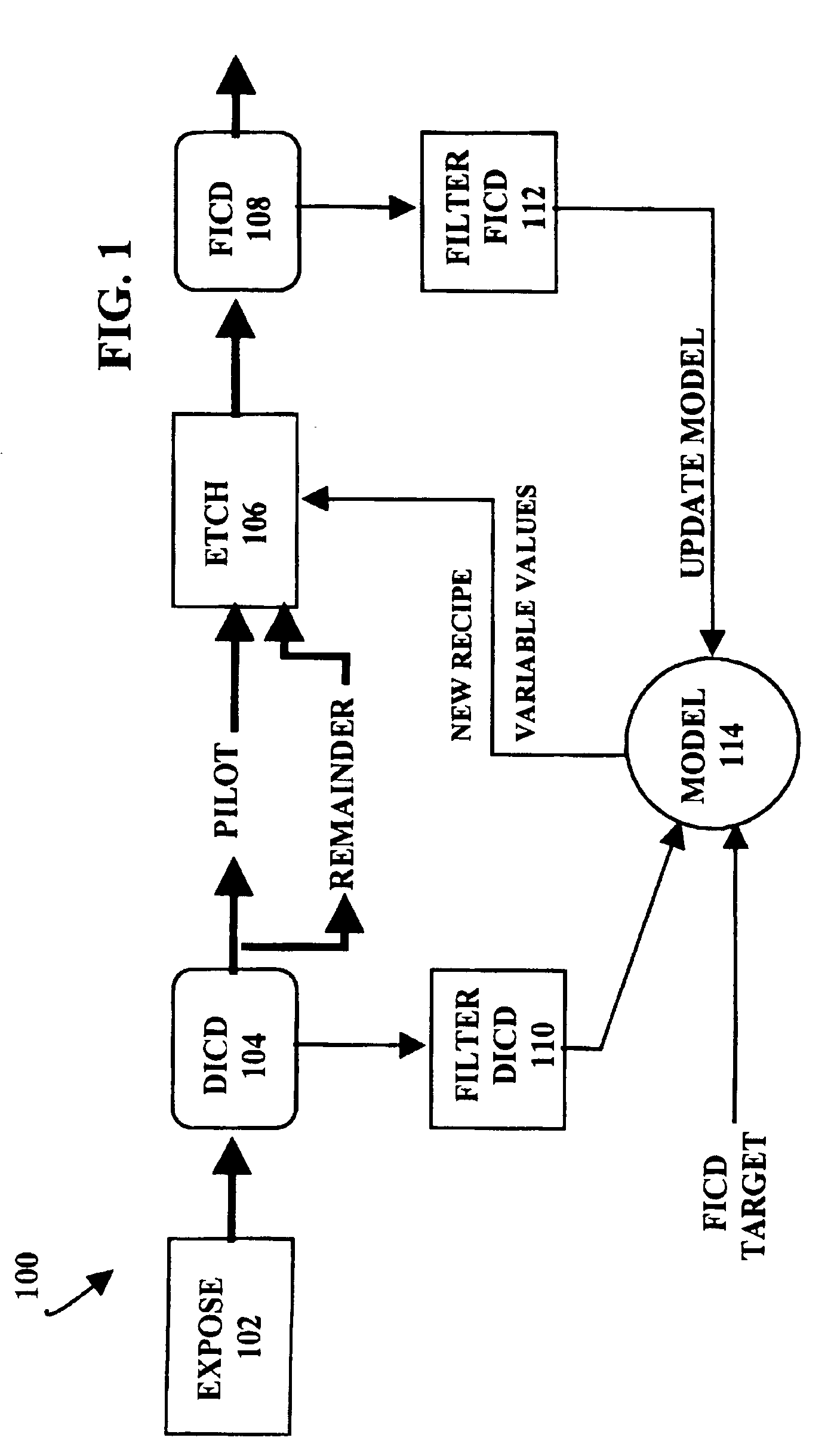

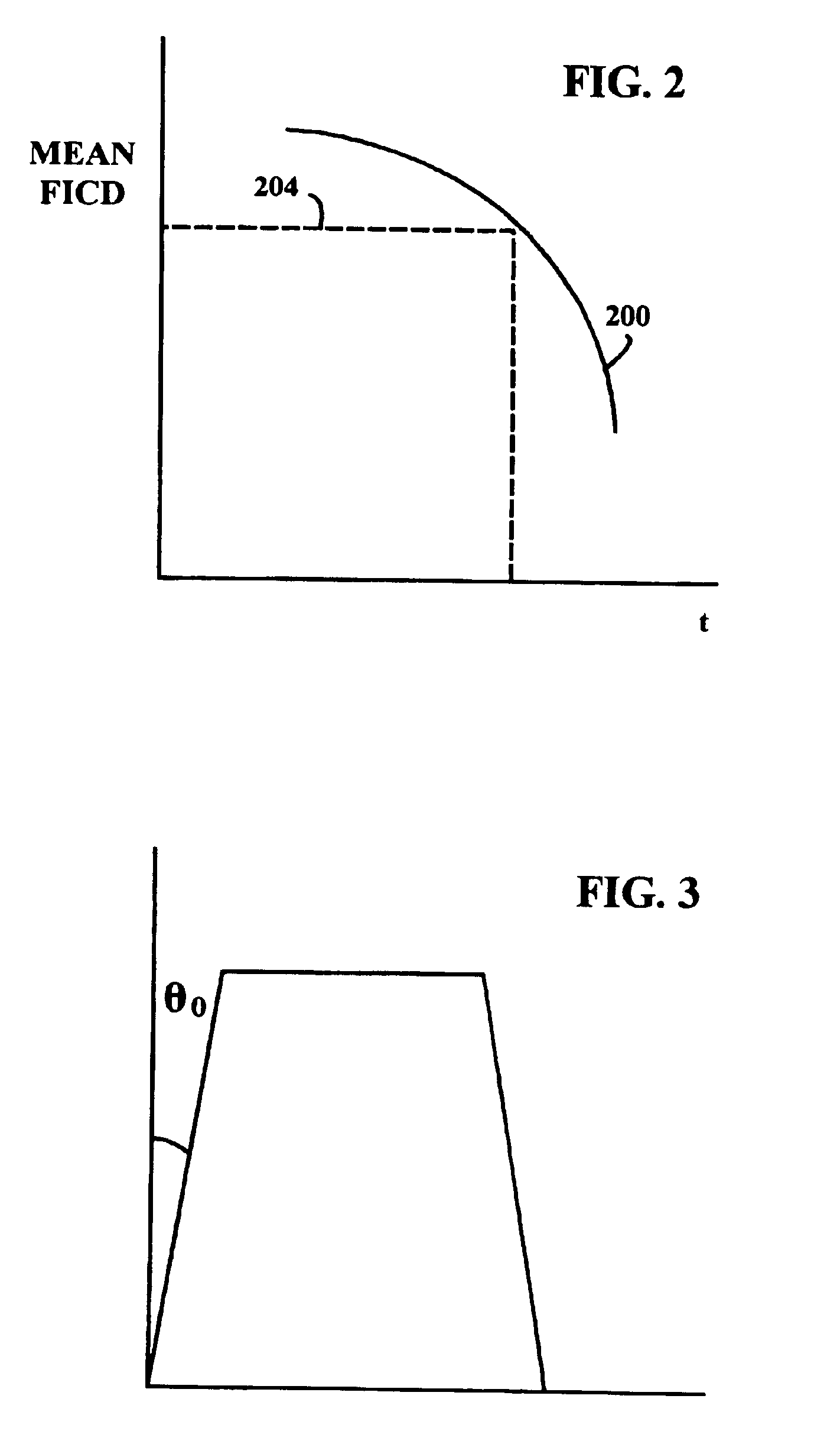

Run to run control process for controlling critical dimensions

InactiveUSRE39518E1Improve manufacturabilityEasy to controlSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingResistControl system

It has been discovered that all causes of critical dimension variation, both known and unknown, are compensated by adjusting the time of photoresist etch. Accordingly, a control method employs a control system using photoresist etch time as a manipulated variable in either a feedforward or a feedback control configuration to control critical dimension variation during semiconductor fabrication. By controlling critical dimensions through the adjustment of photoresist etch time, many advantages are achieved including a reduced lot-to-lot variation, an increased yield, and increased speed of the fabricated circuits. In one embodiment these advantages are achieved for polysilicon gate critical dimension control in microprocessor circuits. Polysilicon gate linewidth variability is reduced using a control method using either feedforward and feedback or feedback alone. In some embodiments, feedback control is implemented for controlling critical dimensions using photoresist each time as a manipulated variable. In an alternative embodiment, critical dimensions are controlled using RF power as a manipulated variable. A run-to-run control technique is used to drive the critical dimensions of integrated circuits to a set specification. In a run-to-run control technique a wafer test or measurement is made and a process control recipe is adjusted based on the result of the test or measurement on a run-by-run basis. The run-to-run control technique is applied to drive the critical dimensions of a polysilicon gate structure to a target specification. The run-to-run control technique is applied to drive the critical dimensions in an integrated circuit to a defined specification using photoresist etch time as a manipulated variable.

Owner:LONE STAR SILICON INNOVATIONS LLC

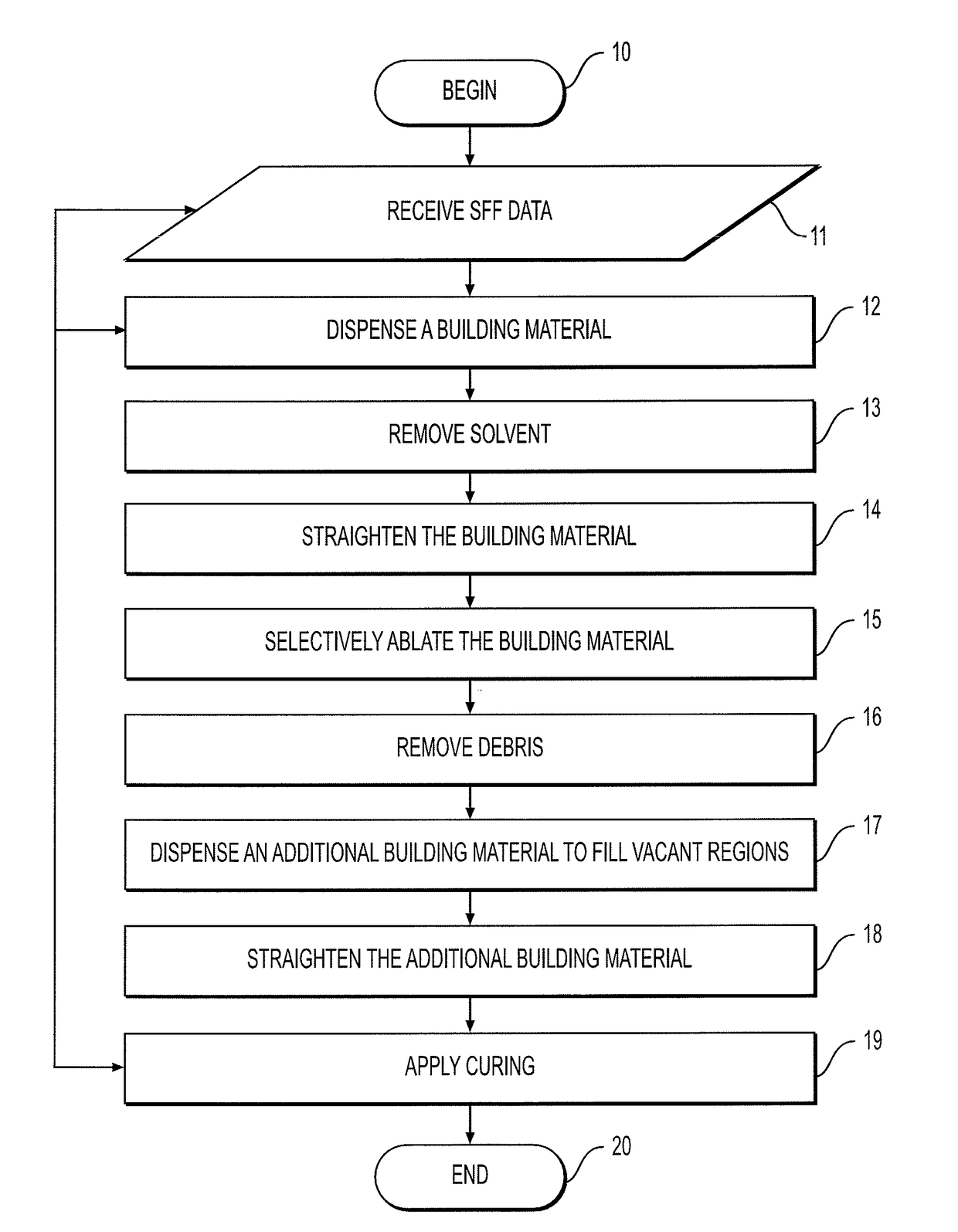

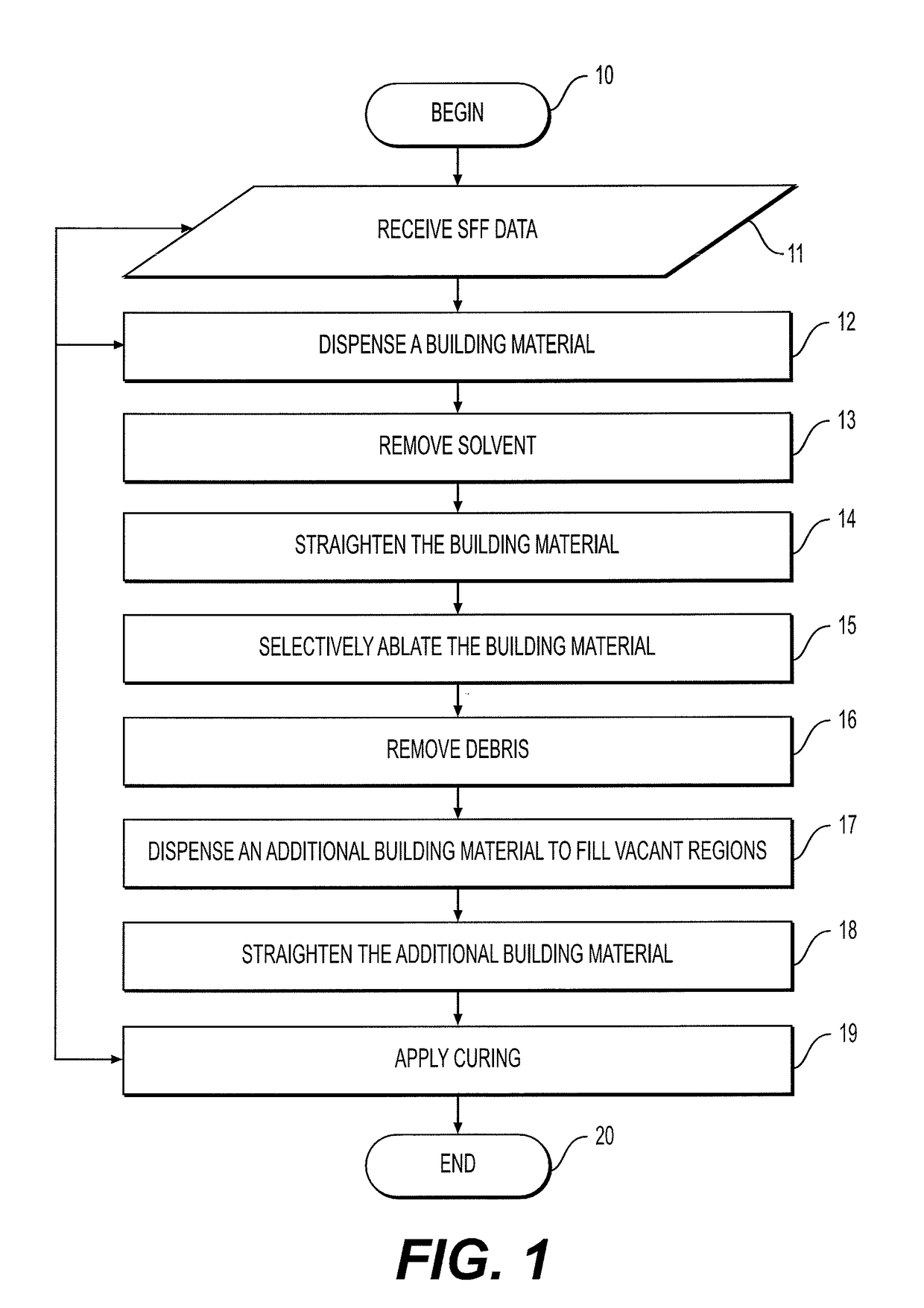

Method and system for additive-ablative fabrication

ActiveUS20180071989A1Reduce resolutionHigh resolutionProgramme controlIncreasing energy efficiencyFree formThree dimensional shape

A method of solid free form fabrication (SFF) is disclosed. The method comprises: receiving SFF data collectively pertaining to a three-dimensional shape of the object and comprising a plurality of slice data each defining a layer of the object. The method also comprises, for each of at least a few of the layers, dispensing a building material on a receiving medium, straightening the building material, and selectively ablating the building material according to respective slice data.

Owner:IO TECH GRP LTD

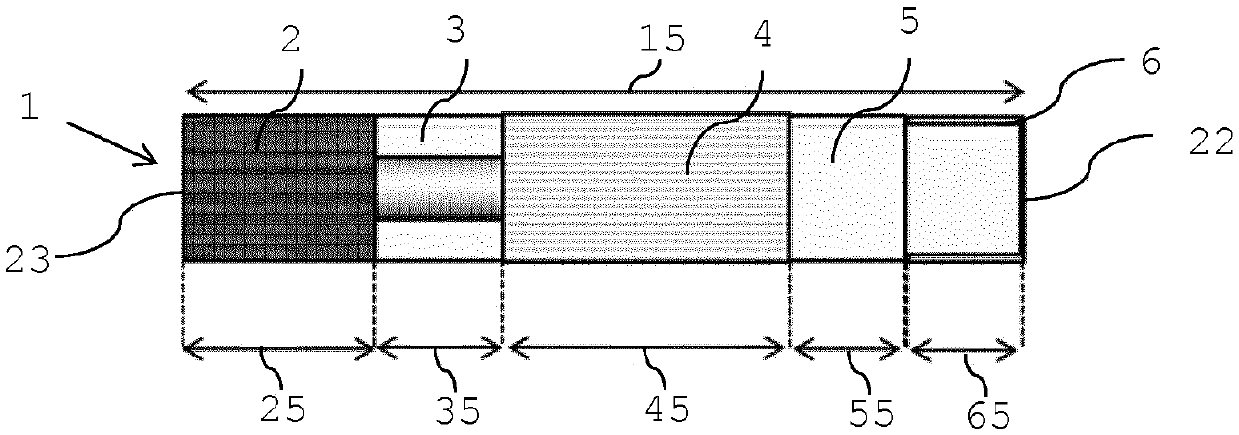

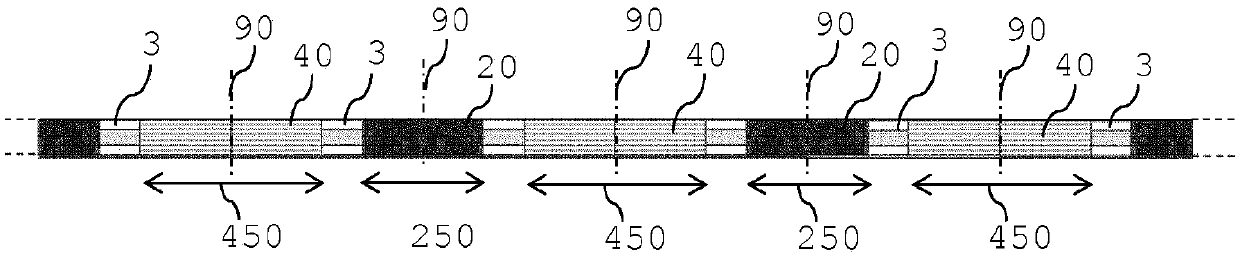

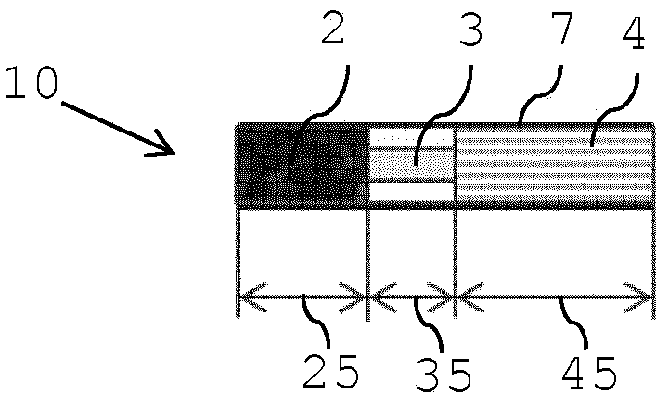

Aerosol-generating article and method for manufacturing aerosol-generating articles

PendingCN107690288ASimplify the manufacturing processImprove manufacturing speedCigar manufactureCigarette manufactureEngineeringMechanical engineering

The aerosol-generating article (1) comprises a tobacco element and a mouthpiece element. The tobacco element comprises an aerosol-forming substrate (2), a support element (3) arranged downstream of the aerosol-forming substrate (2) and an aerosol-cooling element (4) arranged downstream of the support element. The mouthpiece element comprises a filter segment (5) and a hollow tube (6). The aerosol-cooling element (4) has a length of at most 15 millimeter. A length of the mouthpiece element is adapted according to the length of the aerosol-cooling element (4) such that a total length of the aerosol-generating article (1) is kept at a predefined total length. The invention also relates to a method for manufacturing aerosol-generating articles.

Owner:PHILIP MORRIS PROD SA

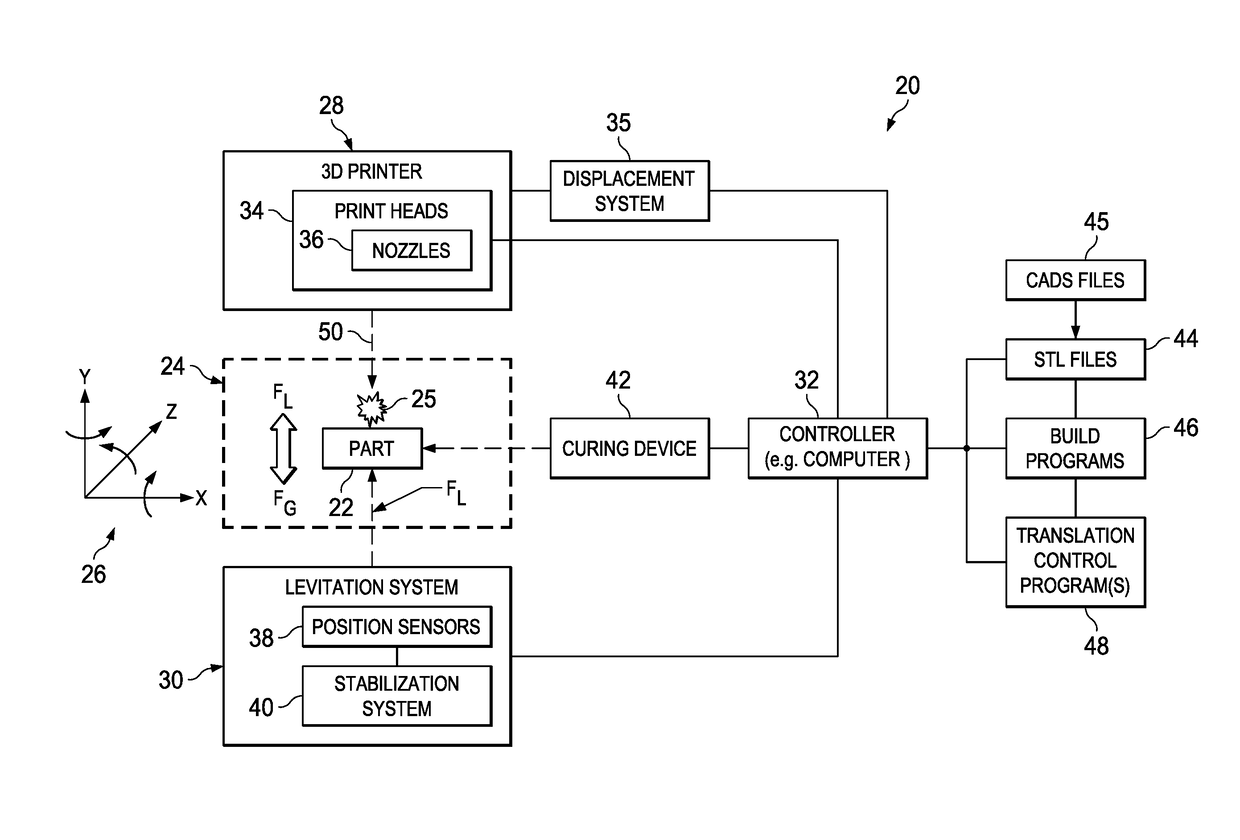

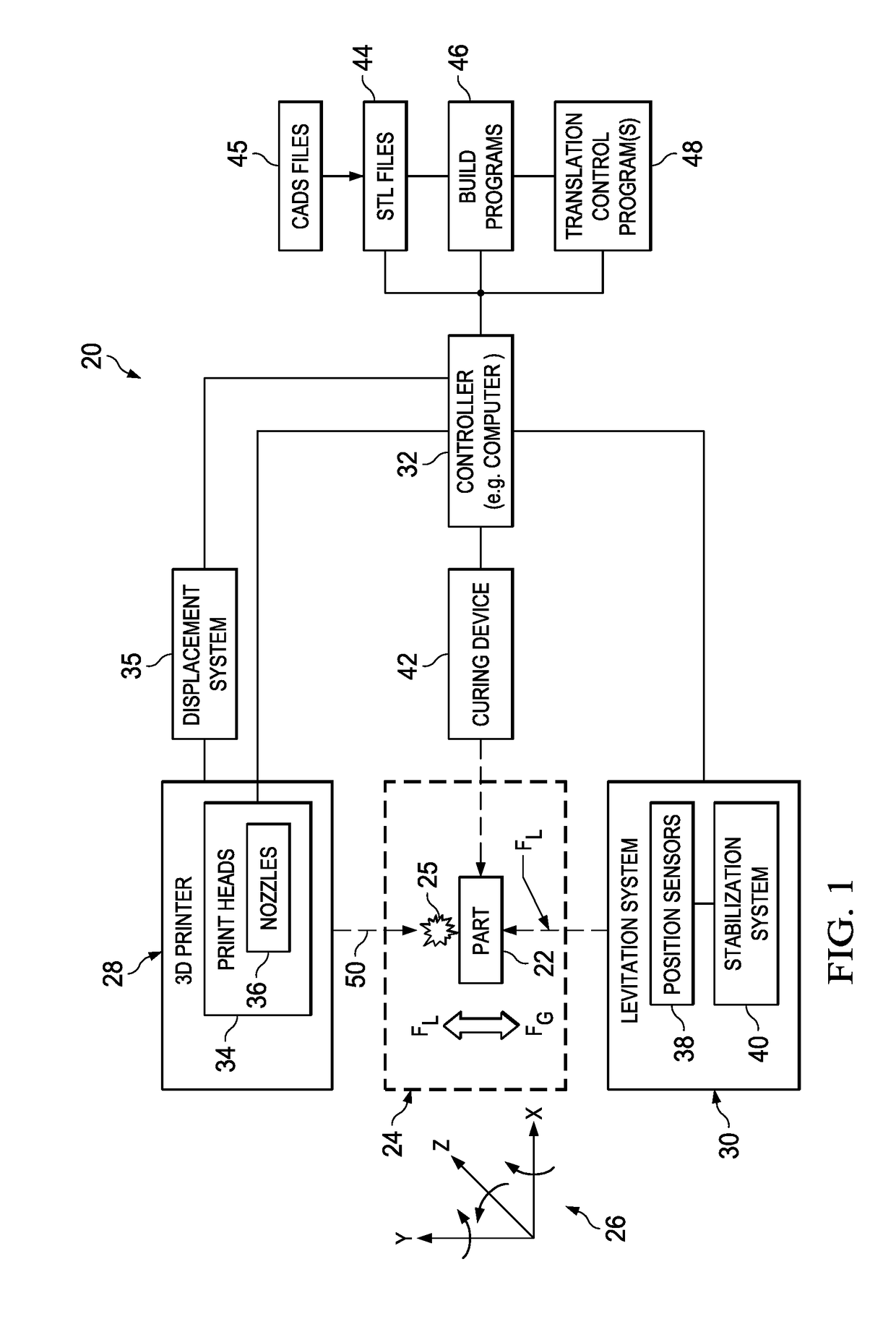

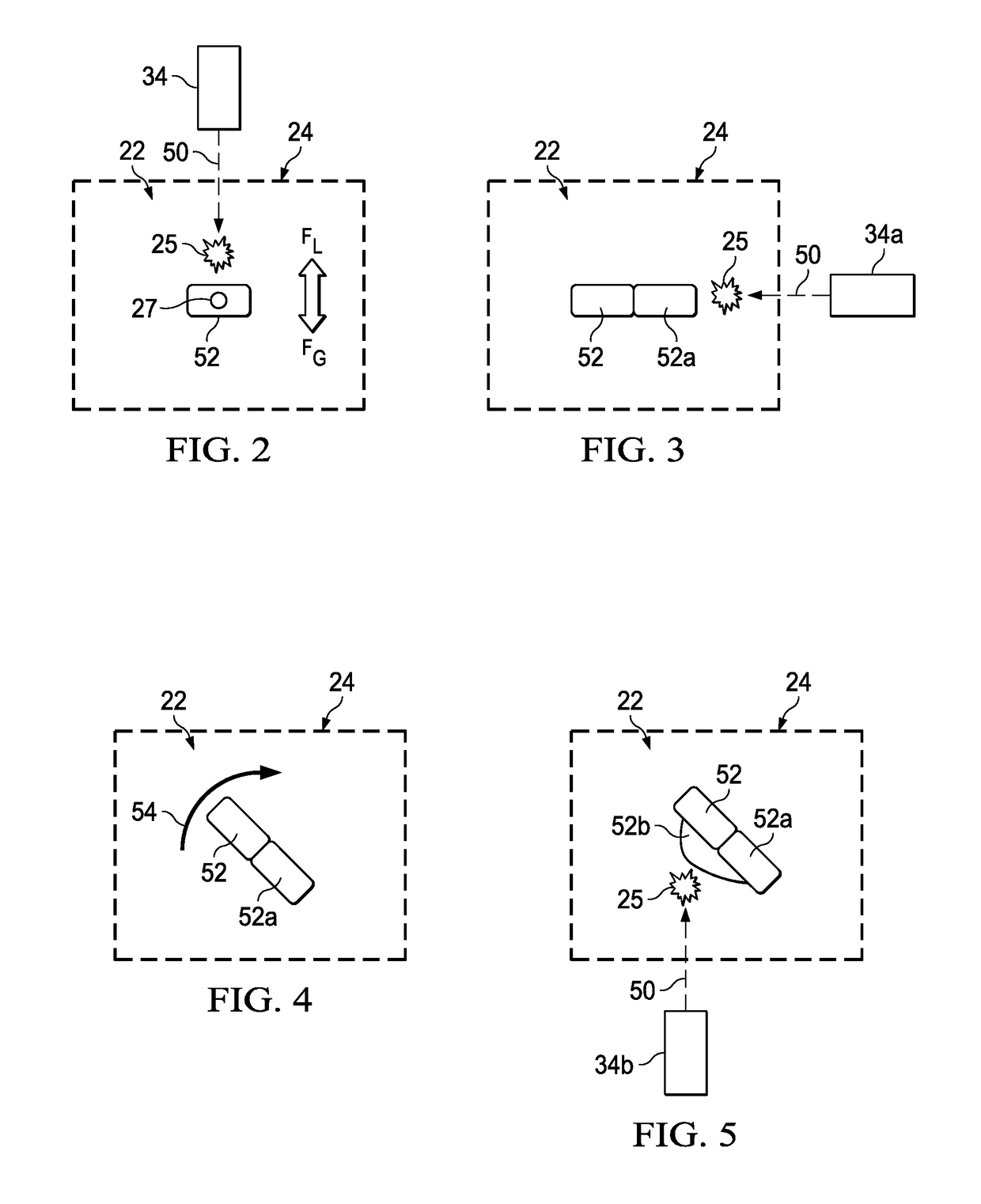

Free-Form Spatial 3-D Printing Using Part Levitation

ActiveUS20180009158A1Improve manufacturing speedAdditive manufacturing apparatus3D object support structuresSpatial OrientationsLevitation

A part is fabricated by an additive manufacturing process while levitating in space. Constituent features of the part are formed by 3-D printing. A part levitation system allows the spatial orientation of the part to be manipulated relative to one or more print heads.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com