Patents

Literature

3607 results about "Continuous rolling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

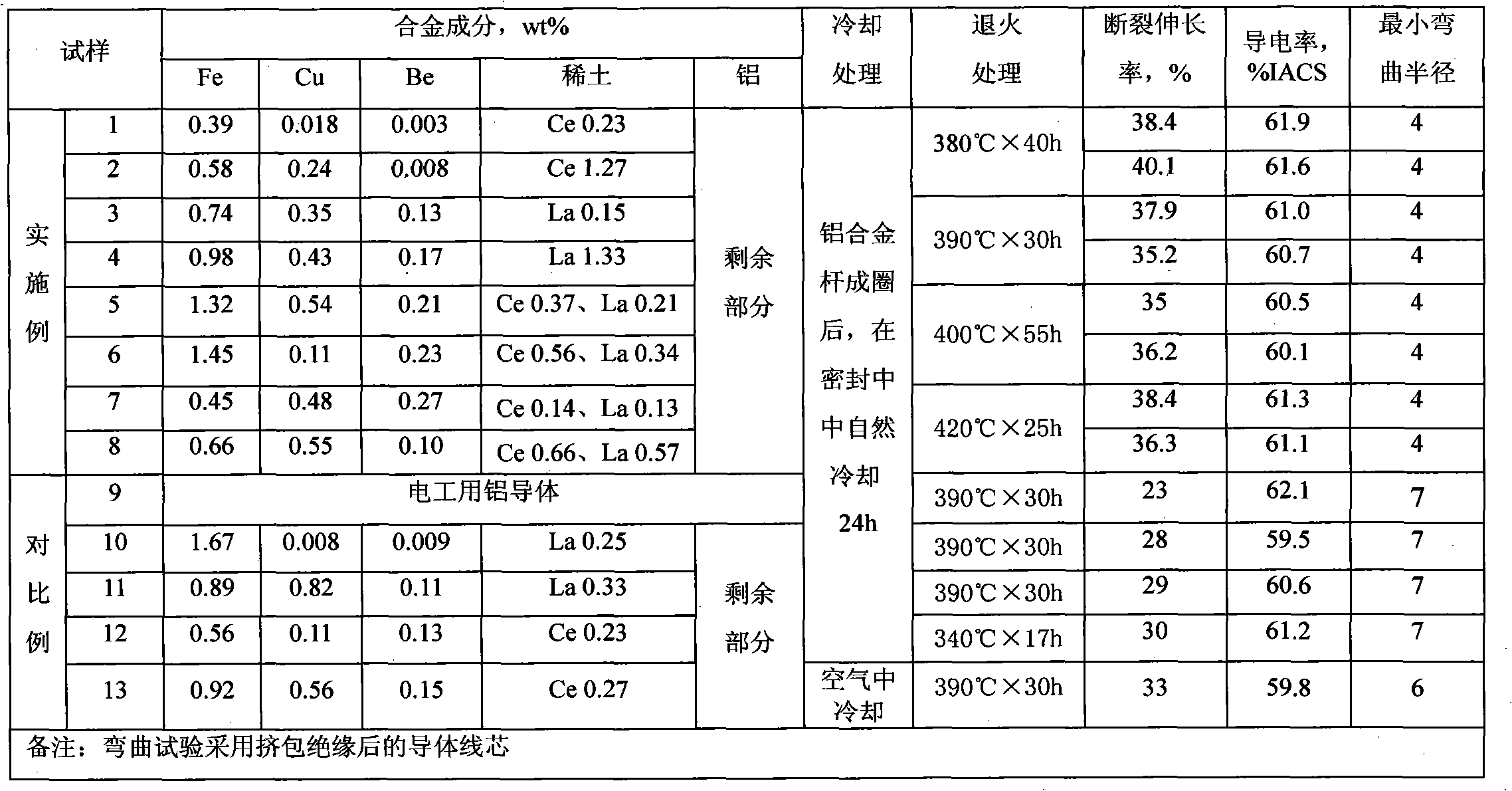

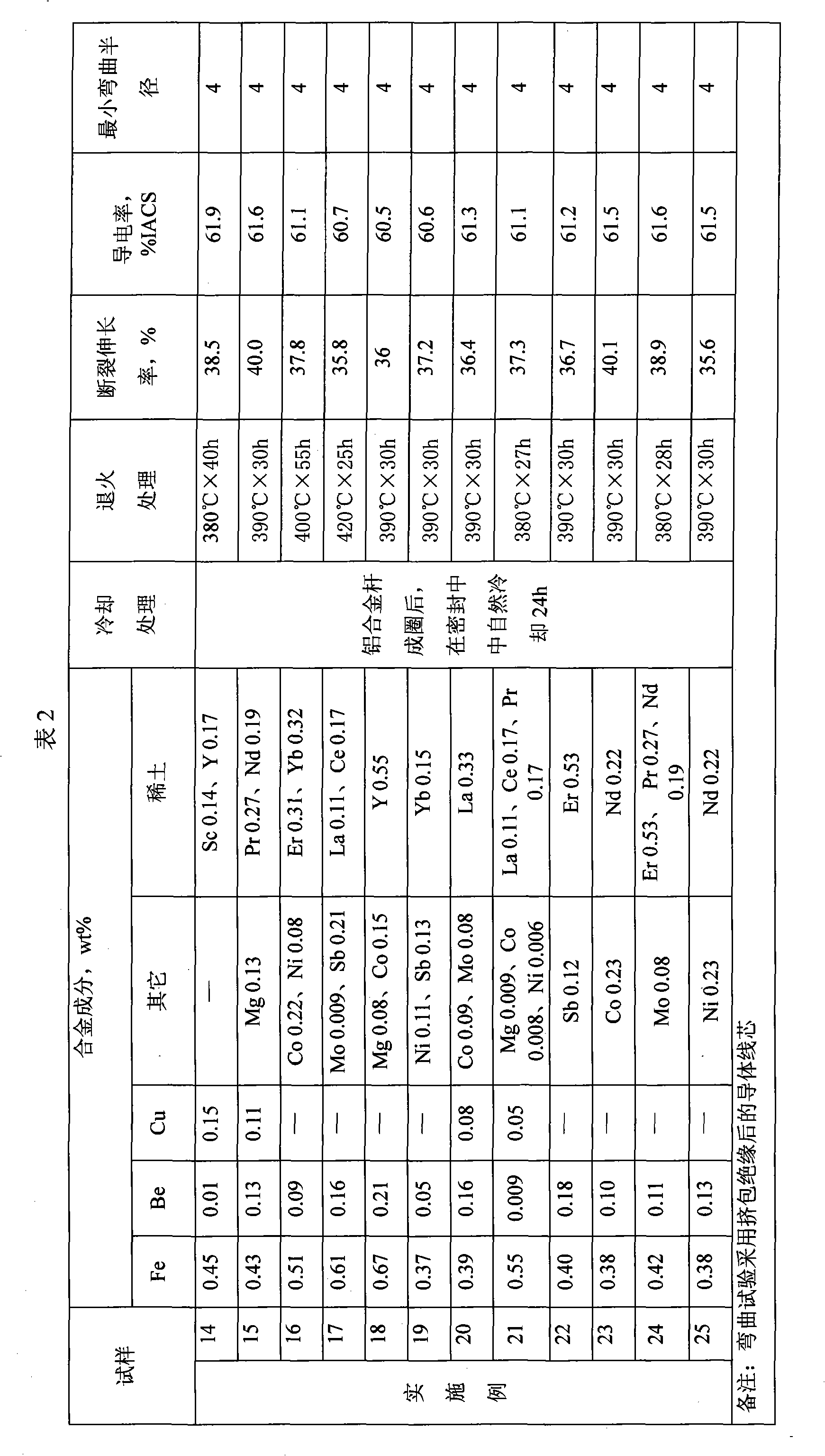

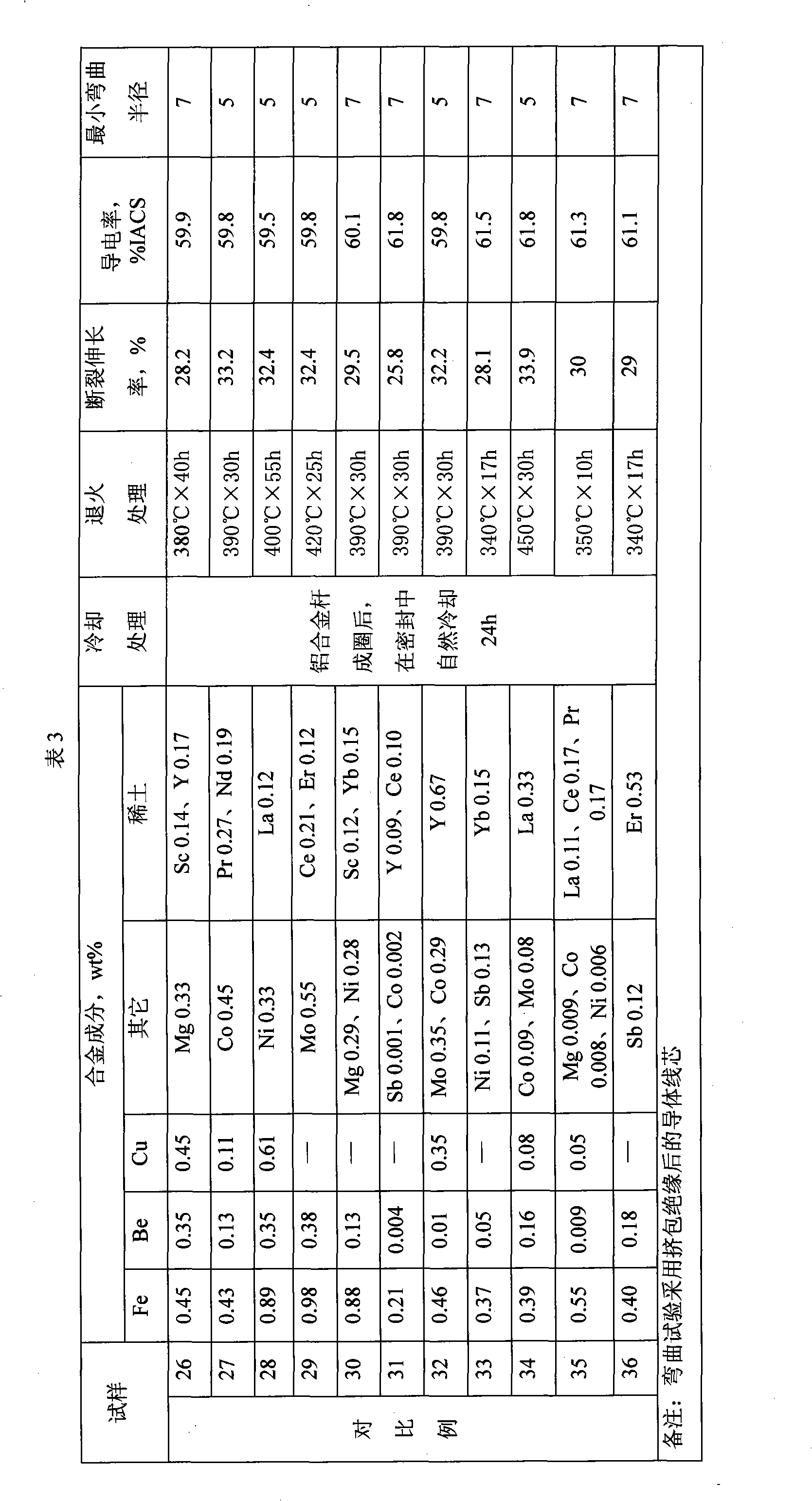

Super-soft aluminum alloy conductor and preparation method thereof

The invention provides a super-soft aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises the following materials in percentage by weight: 0.3 to 1.5 percent of Fe, 0.001 to 0.3 percent of Be, 0.005 to 0.6 percent of Cu, 0.1 to 1.5 percent of rare earth, less than or equal to 0.08 percent of Si, less than or equal to 0.15 percent of total inevitable impurities, and the balance of aluminum. The aluminum alloy is drawn into an aluminum alloy wire by melting, continuous casting and continuous rolling, and the aluminum alloy wire is put into an annealing furnace and annealed for 20 to 40 hours at the temperature of between 380 and 420 DEG C to form the aluminum alloy conductor, wherein the annealing is performed in a sealed heat insulation device under the protection of nitrogen. The aluminum alloy has extremely good toughness and elongation performance, the coefficient of elongation reaches or exceeds 35 percent and even can reach 40 percent, and the electric conductivity can reach 60 percent IACS.

Owner:ANHUI JOY SENSE CABLE

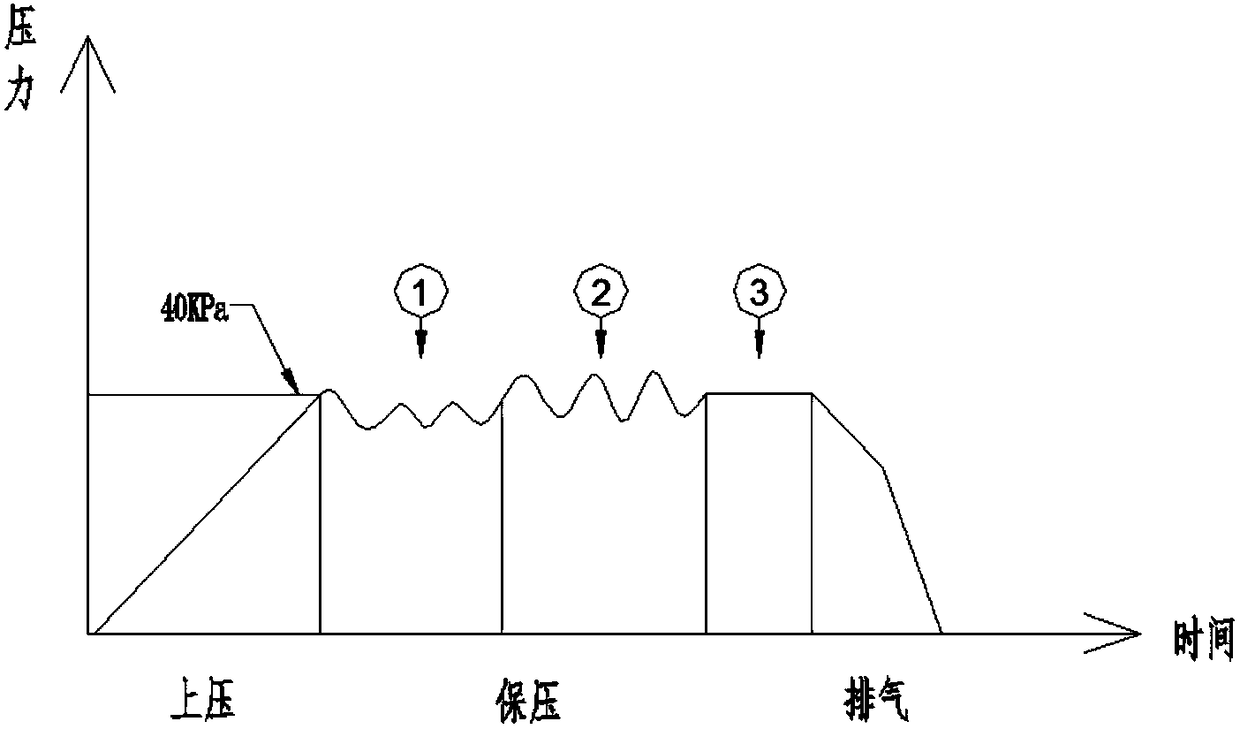

Electric pressure cooker and congee cooking method

The invention provides a congee cooking method, and is applied to an electric pressure cooker. After being heated, the electric pressure cooker internally reaches a preset pressure and then enters a pressure maintaining stage, the pressure maintaining stage comprises a first stage and a second stage, wherein in the first stage, low-power heating is carried out to exhaust outward continuously and inflate the electric pressure cooker simultaneously; in the second stage, low-power heating is carried out continuously, and periodic exhaust is carried out simultaneously. The congee cooking method has the advantages that congee is prevented from overflowing the pot through inflation during congee cooking, continuous heating, continuous boiling and continuous exhaust are achieved in the pressure maintaining stage, so that rice grains keep continuous rolling, and the taste of congee is improved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Method for controlling hot continuous rolling finish rolling process

InactiveCN102941232AHigh precisionAccurately predict the service lifeRoll mill control devicesMetal rolling arrangementsAutomatic controlControl system

The invention provides a method for controlling a hot continuous rolling finish rolling process, which belongs to the technical field of automatic steel rolling control. The method is that after the parallel data interface (PDI) data is obtained, according to the technological requirements which are established in a rolling plan, the thickness of a hot continuous rolling finish rolling target outlet and the target temperature of the finish rolling outlet are determined; the practical temperature of a hot continuous rolling finish rolling inlet is obtained; the load distribution of a rack is determined; rolling parameters including the roller linear velocity, inlet temperature, rolling force, roller gap position and motor power parameter of various racks are calculated; the rolling parameters are subjected to limit checking and are judged whether to meet the operation conditions of equipment or not, if yes, the rolling parameters are sent to a control system in a command mode, and the hot continuous rolling finish rolling process is controlled; and if not, calculation is carried out again. Through calculating the rolling force, the prediction precision and the thickness precision are improved, the service cycle of a roller is accurately predicted, based on a roller thermal expansion model, the rolling process has different rolling intervals, and good thickness controlling precision is obtained.

Owner:NORTHEASTERN UNIV

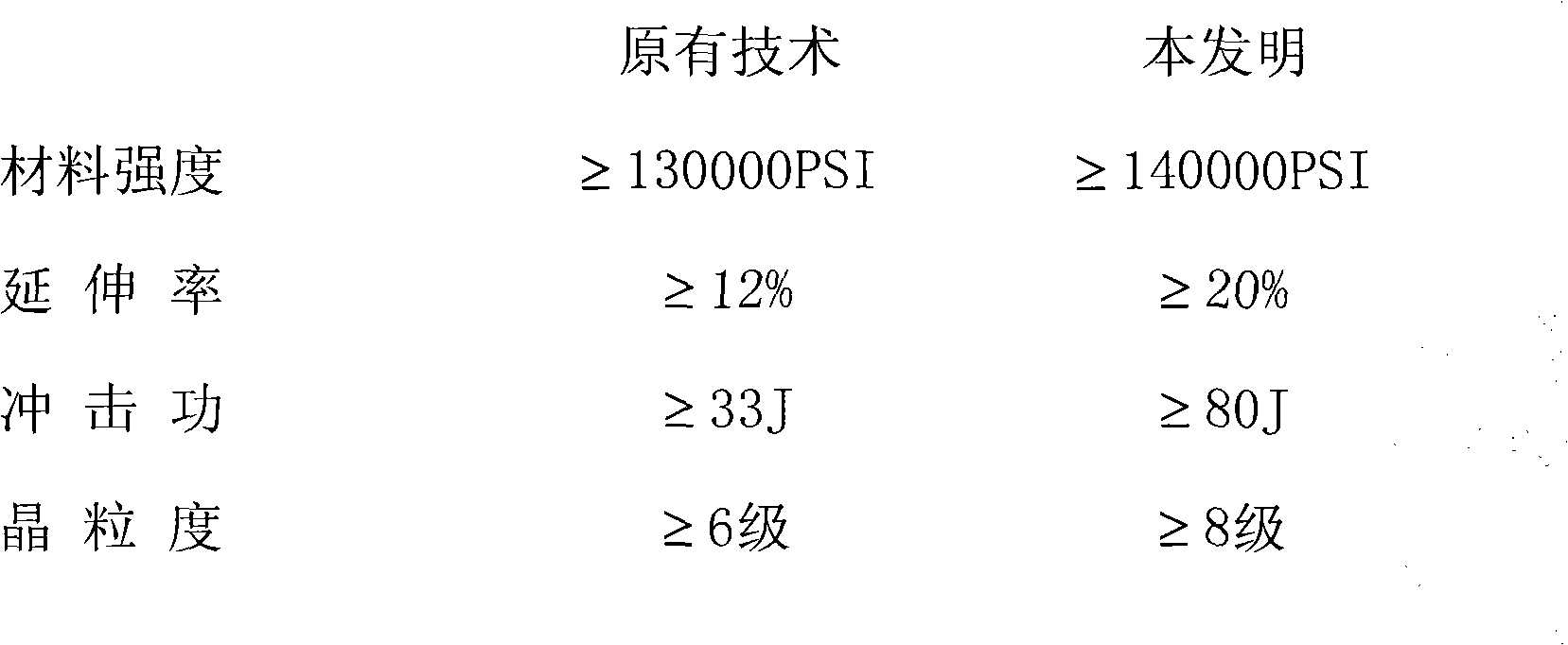

Rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and production method thereof

InactiveCN102251180ALow elemental contentReduce residual stressDrilling rodsProcess efficiency improvementRare earthFlame cutting

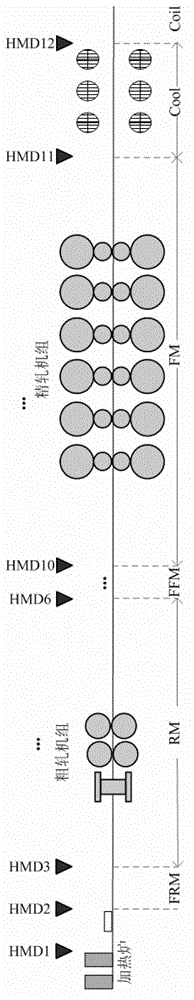

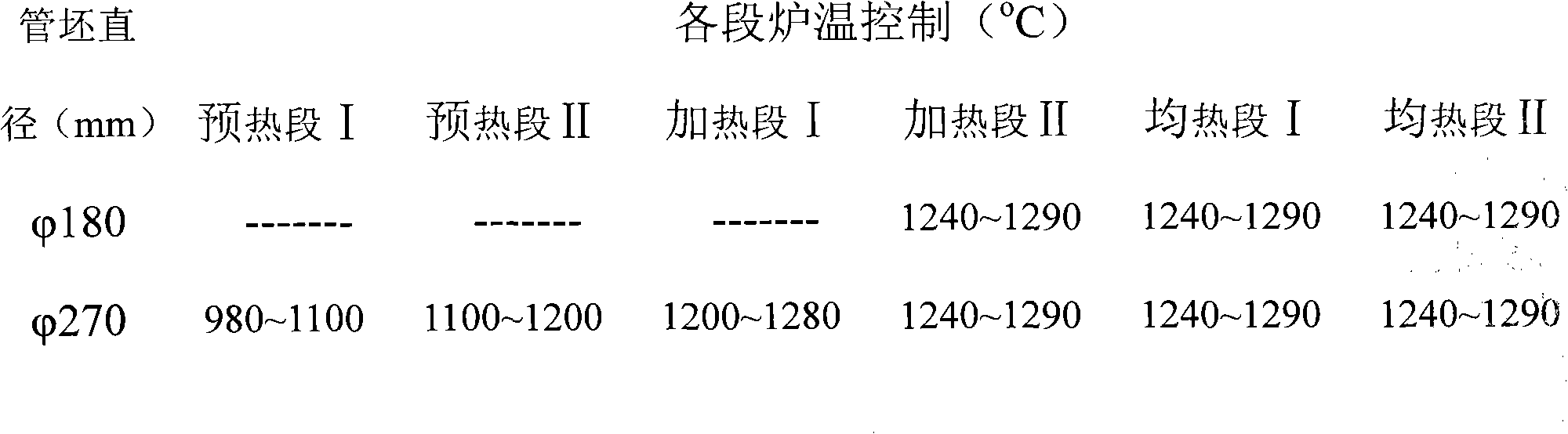

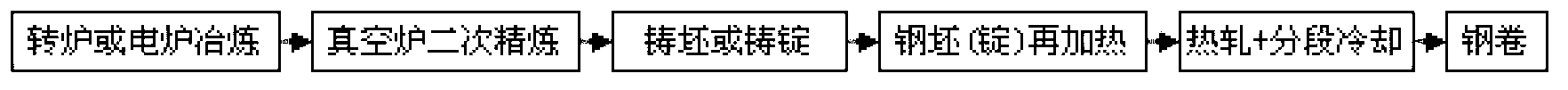

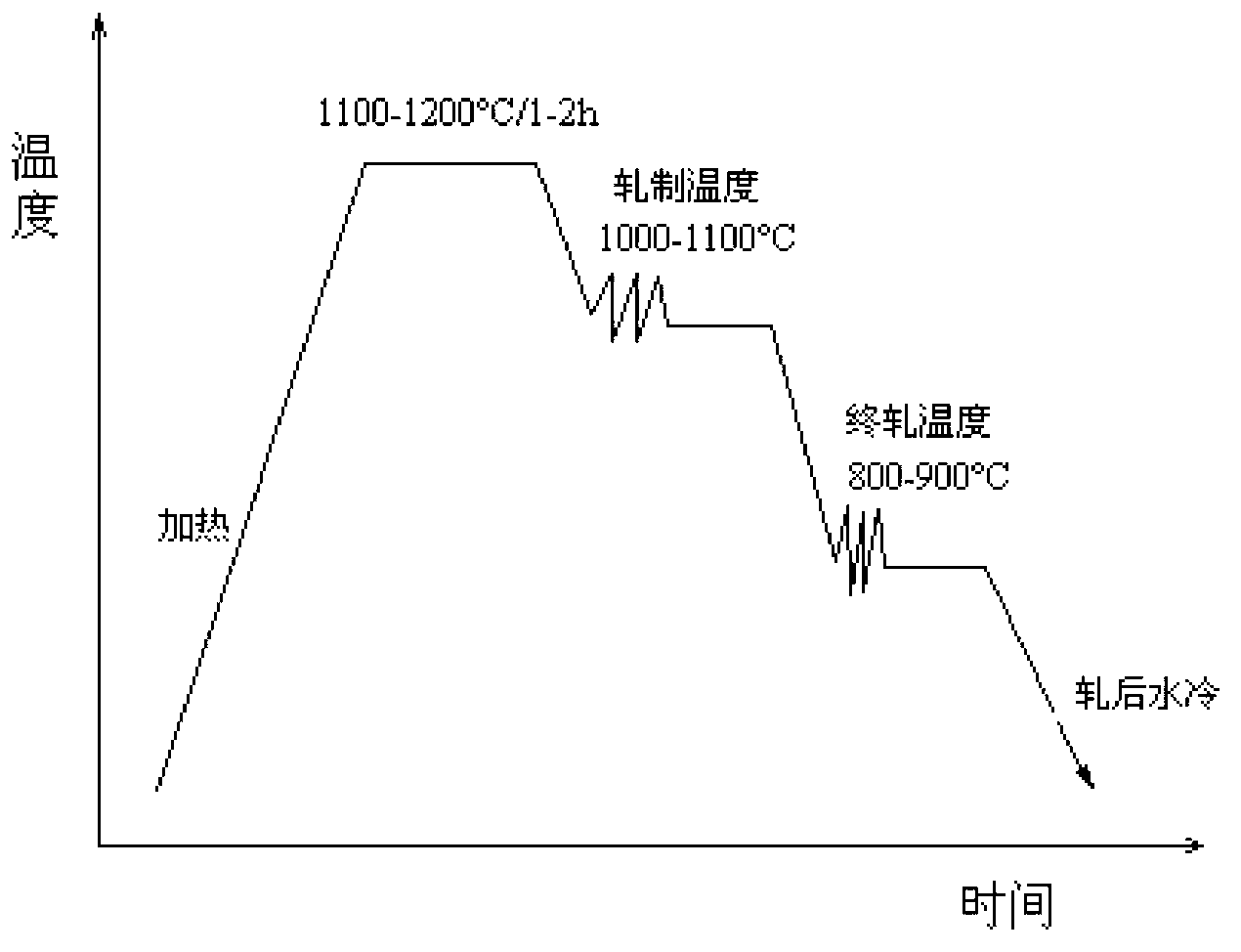

A rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and a production method thereof belong to the technical fields of ferrous metal smelting and metal press working. The petroleum casing comprises the following raw materials by weight percent: 90% of blast furnace molten iron and 10% of high quality steel scrap. The casing blank comprises the following chemical components by weight percent: 0.18-0.35% of C, 0.10-0.35% of Si, 0.55-1.10% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 0.60-1.10% of Cr, 0.15-0.50% of Mo, 0.01-0.03% of Al, 0.0005-0.0100% of RE ( RE is the mixed rare earth metals of Ce and La and the weight percents of Ce and La are 67% and 33% respectively), less than 0.10% of Cu, less than 0.10% of Ni and the balance of Fe and trace elements. The process flow of the production method is as follows: pretreating molten iron, smelting in a top-bottom blowing converter, refining in a ladle furnace (LF), performing VD vacuum treatment, performing continuous casting of round billets, performing flame cutting, heating the casing blanks, boring, performing continuous rolling, performing sizing and diameter reducing, cooling, performing saw cutting, performing heat treatment, straightening, performing flaw inspection and lathing screw threads. The mechanical properties of the petroleum casing are as follows: the strength is no less than 140000PSI, the residual stress is no more than 80MPa, the impact power is no less than 80J and the grain size is no less than the grade 8. The product is characterized in that the residual stress is low, the content of harmful elements is low, the impact toughness is high, the grains are small, and the product resists extrusion and is difficult to damage.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

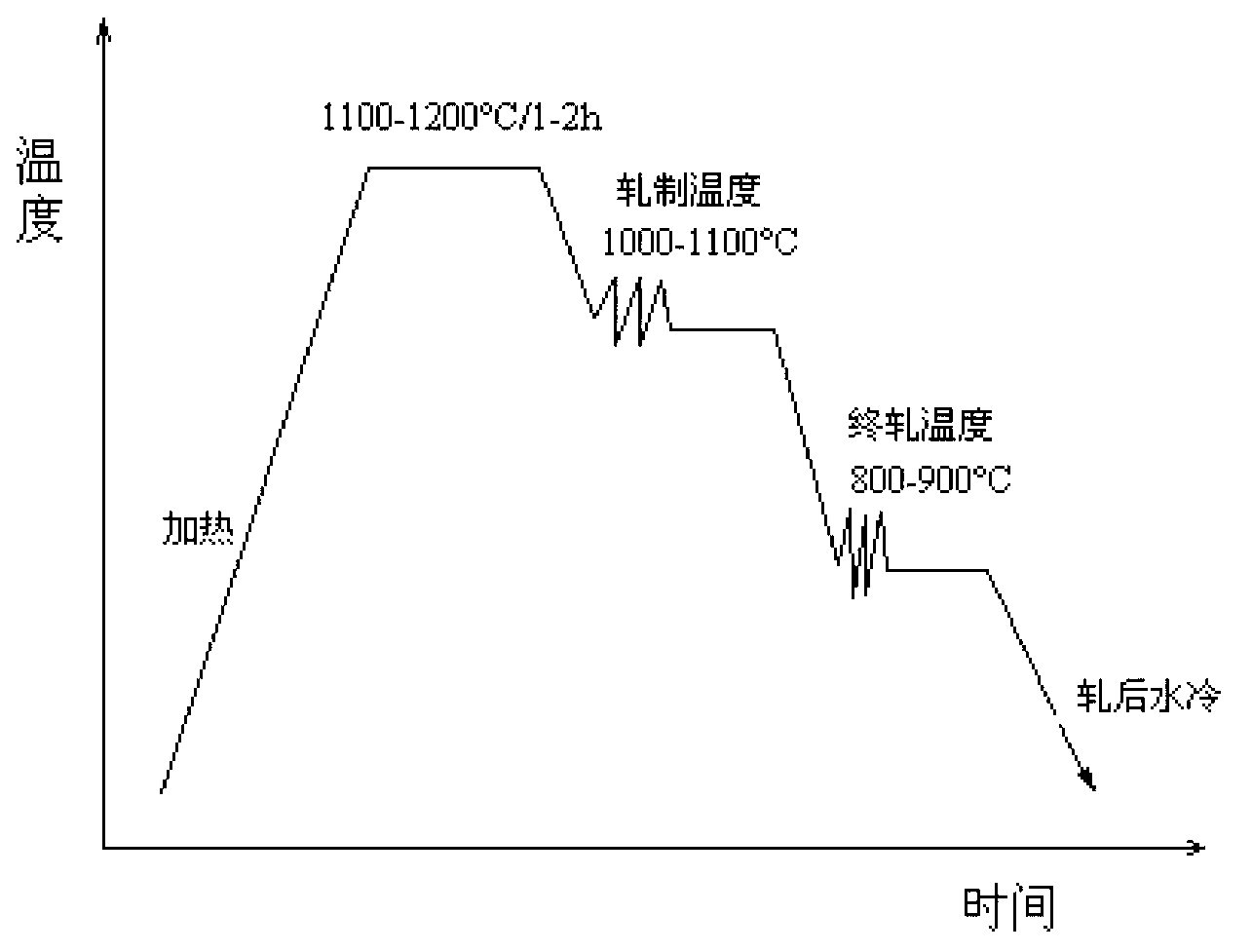

700MPa high strength hot rolling Q&P steel and manufacturing method thereof

ActiveCN103215516AHigh strengthPrevent precipitationFurnace typesHeat treatment furnacesAustenite grainChemical composition

The invention relates to 700MPa high strength hot rolling Q&P steel and a manufacturing method thereof. The steel has the following chemical components in percentage by weight: 0.15-0.40% of C, 1.0-2.0% of Si, 1.5-3.0% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.3-1.0% of Al, less than or equal to 0.0065% of N, 0.005-0.015% of Ti and the balance of Fe. The yield strength is greater than or equal to 70MPa, the strength of extension is greater than or equal to 1300MPa, and the ductility is greater than 10%. According to the invention, through a reasonable compound design, based on common C-Mn steel components, austenite crystal is refined by micro Ti treatment by improving the content of Si to inhibit separation of cementite, so that the austenite transformation kinetics in the air cooling process is accelerated by improving the content of Al. Meanwhile, a hot continuous rolling process is matched with a sectional cooling process, so that proeutectoid ferrite+martensite+retained austenite tissues are obtained. The cost of the alloy is greatly lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

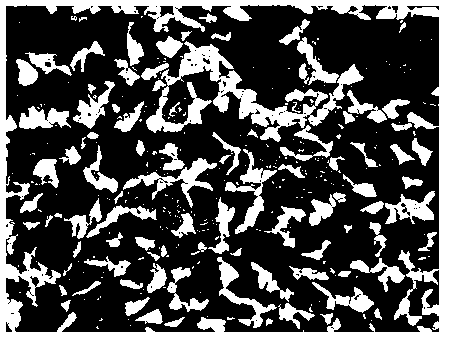

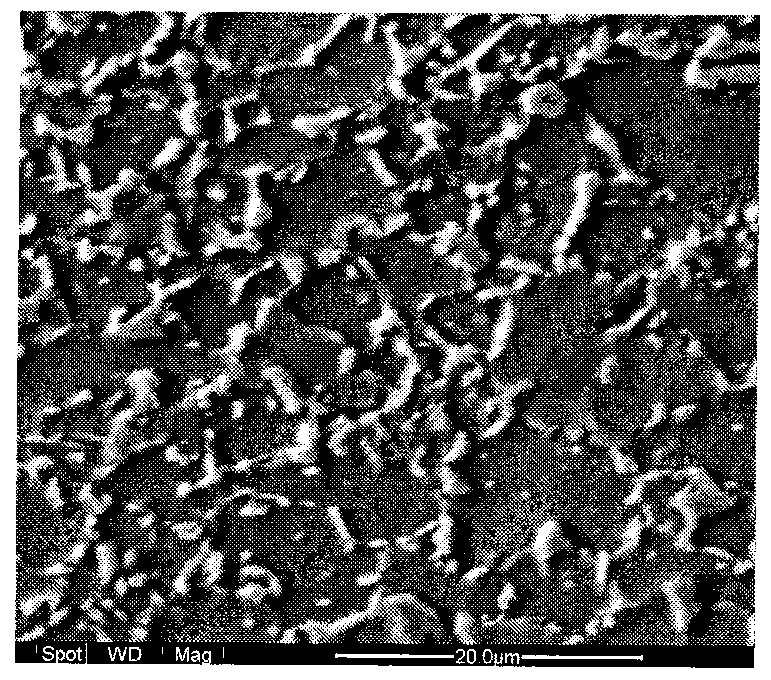

Preparation method of ultra-fine grain high-entropy alloy

The invention belongs to the technical field of metal materials and machining and relates to a preparation method of an ultra-fine grain high-entropy alloy. Firstly, smelting is conducted, an FeCoCrNiMn series high-entropy alloy is compounded to be an intermediate alloy composed of pure metal with the purity being higher than 99.5% or alloy elements, a vacuum furnace is adopted for smelting, and the furnace casting temperature is 1550-1600 DEG C; then after cast ingots are subjected to homogenization heat treatment at the temperature of 1000-1350 DEG C, strong deformation asynchronous and synchronous mixed cold rolling treatment is conducted, continuous rolling is conducted through single-pass large percent reduction, the total rolling quantity is no smaller than 85%, and alloy structure nanocrystallization is achieved; and the rolled alloy is subjected to annealing treatment under the temperature of 450-800 DEG C, and the high-entropy alloy of an ultra-fine grain structure is obtained. Compared with the prior art, the preparation method is simple in technique, easy to achieve on a plate rolling production line, high in production efficiency and low in cost; and the size of the prepared ultra-fine grain high-entropy alloy is large, the comprehensive mechanical performance is excellent, and the preparation method can be applied to the fields of engineering machinery, aeronauticsand astronautics, military industry, electronics, instruments and the like.

Owner:SHANGHAI JIAO TONG UNIV

Process for manufacturing low-silicon low-carbon deep punching/drawing steel

ActiveCN101343677ARelaxation of sulfur content requirementsReduce manufacturing costManufacturing convertersProcess efficiency improvementExtensibilitySlag

The invention discloses a production method of low-silicon and low-carbon deep punching / drawing steel, bottom-blowing argon is performed in the whole process of converter smelting, and a single slag / double slag technique is adopted to pour out the dephosphorized slag, high-basicity slag is produced in later period, the dualistic basicity of final slag R is more than 3.5, the terminal temperature of molten steel is 1620 DEG C to 1650 DEG C, and tapping ( P ) is less than 0.012 percent. The molten steel is refined by adopting low-silicon and low-carbon high-basicity reductive slag in a LF furnace refining station, thus to manufacture reductive slag for desulphurisation, and the ( Al ) in the molten steel is less than 0.005 percent. The molten steel refined by the LF furnace is vacuum-treated by a RH vacuum furnace, the carbon and the silicon in the molten steel is circularly removed, the molten steel is continuously casted into a casting blank through a CSP sheet bar conticaster, the casting blank is sent into CSP sheet bar heat continuous rolling mill and rolled into a coiled sheet after being heated in a roller hearth soaking furnace, a hot rolled coiled sheet is coldrolled into cold rolled coiled sheet through a cold tandem mill or a single mill after being acidwashed, and leveled through a leveling machine after being annealed by a cover furnace, and a leveling divided coil is stretched and divided. The production method has the advantages that the production cost of the working procedure is saved, the consumption of the refractory consumption of the converter is reduced, the equipment investment is saved, the process of the production technique is steady and smooth, the n value of the cold rolled plate is bigger than 0.23, the r value thereof is bigger than 2.1, and the deep punching performance and the extensibility are good.

Owner:湖南华菱涟钢特种新材料有限公司 +1

Lubricating material for cold rolling and its preparation method and use

ActiveCN103589491ASolving Stress Corrosion ProblemsHarm reductionLubricant compositionEmulsionChlorinated paraffins

The invention belongs to the technical field of lubricating materials and discloses a lubricating material for cold rolling and its preparation method and use. The lubricating material for cold rolling comprises, by mass, 20-60% of base oil, 0.3-1% of an anti-oxidant, 20-60% of a lubricant, 3-10% of an extreme pressure agent, 0-5% of an antirust agent, 1-3% of a purification dispersant, 3-9% of an emulsifier, and 2-6% of an anionic surfactant. The lubricating material is especially suitable for a four-roller four continuous rolling unit having the size of 650mm and high lubricity requirements, does not contain chlorinated paraffin, prevents stress corrosion on a cold-rolled finished product, and has excellent lubricity. Compared with the common emulsion on the current market, the lubricating material reduces a rolling force by 7-10%, prolongs a roller service life by 10-15%, reduces comprehensive energy consumption by 10-15% and effectively prolongs a rolling mill bearing service life.

Owner:GUANGZHOU MECHANICAL ENG RES INST

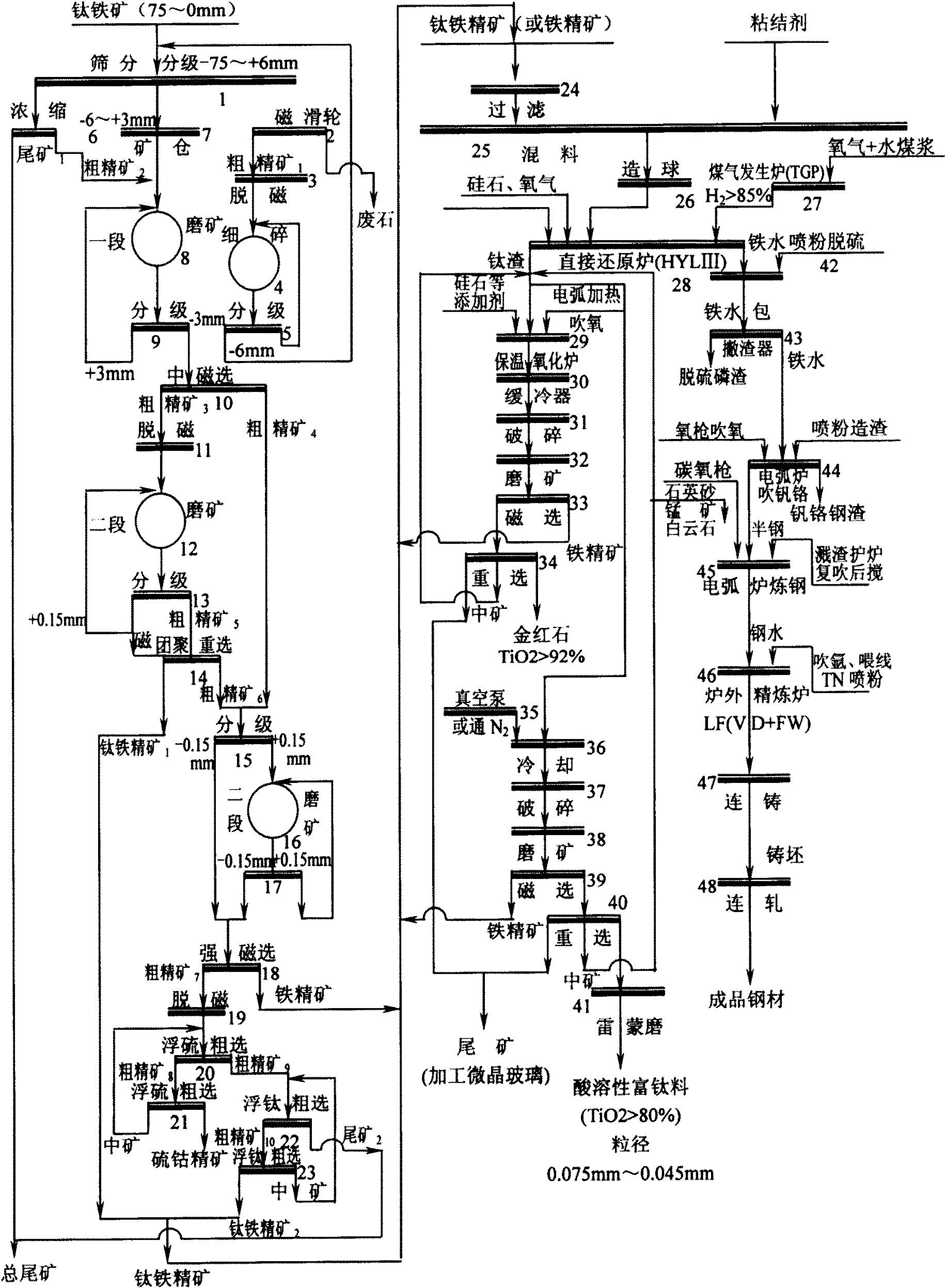

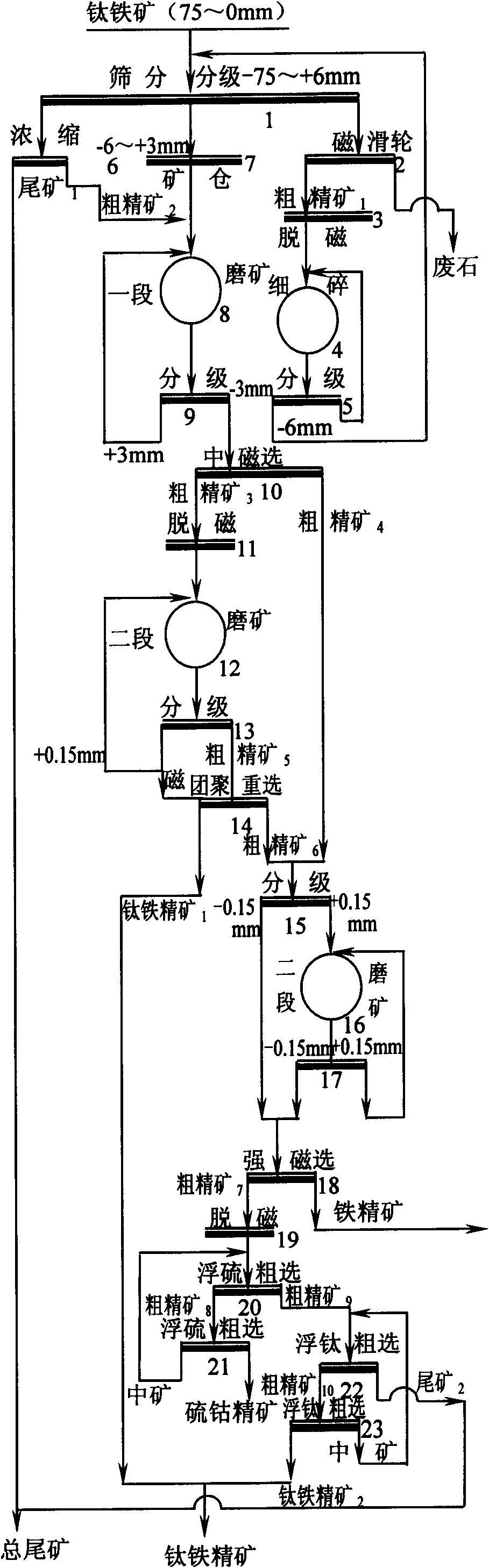

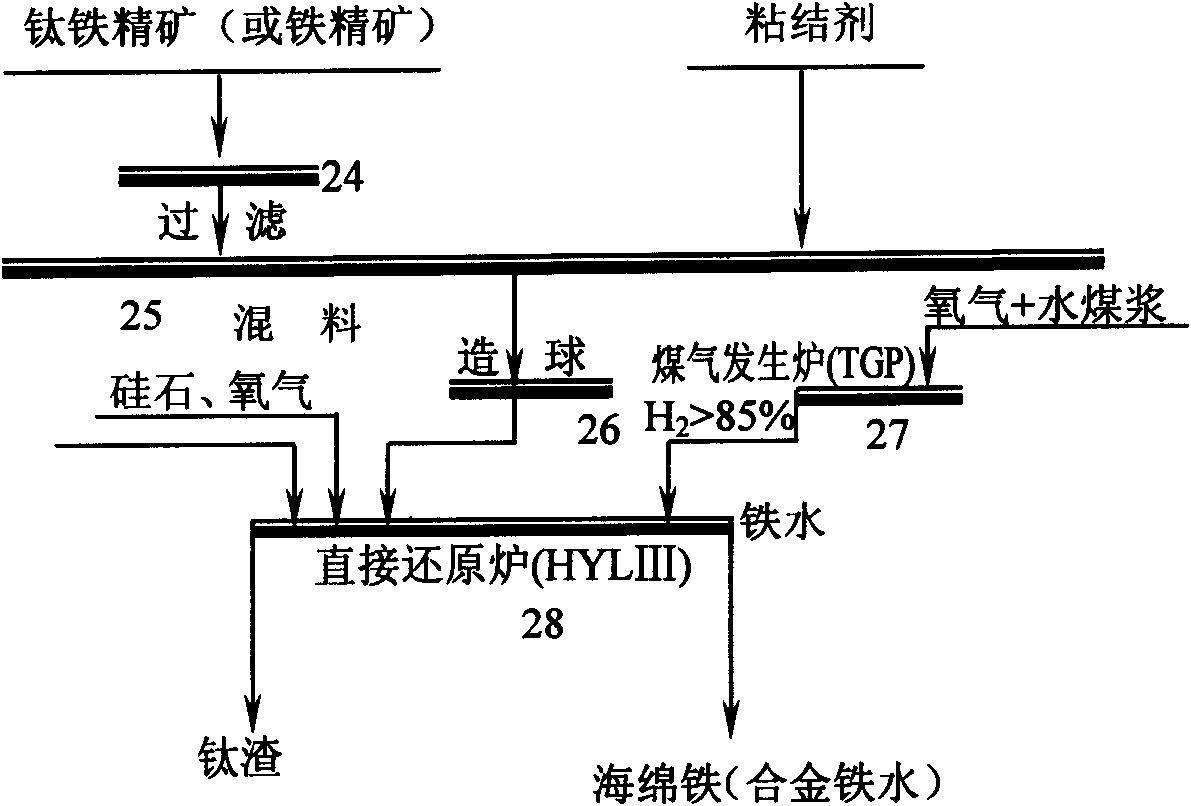

Method for producing titanium and steel products by utilizing titanium and iron ores

InactiveCN101613825AIncrease profitHigh recovery rateProcess efficiency improvementElectric furnaceRutileContinuous rolling

The invention discloses a method for producing titanium and steel products by utilizing titanium and iron ores, which belongs to the field of technical innovation of mining, dressing and smelting full process flow of the titanium and iron ores. Ordinary blast furnaces are not suitable for the smelting of high-titanium and medium-titanium schreyerite; and schreyerite mining, dressing and smelting enterprises in Panxi region extract rich parts and discard poor parts, and discard weathered ore of submarginal ore which accounts for over 95 percent of that of raw ore and is taken as mining mullock. The method comprises the following step: directly reducing titaniferous iron concentrate dressed from the mining mullock (TiO2 is over 5 percent, and TFe is over 13 percent) of the schreyerite, electric furnace melt producing titanium slag and molten water with electric furnace melt components, and producing a titanium-rich material and rutile with the titanium slag through mineral dressing by a fire method; producing alloy molten iron with the molten iron through electric smelting and vanadium-chrome steel slag blowing; and producing various alloy steel products the alloy molten iron in a continuous casting and continuous rolling mode through the electric smelting. The recovery rates of titanium, iron and vanadium are improved to 80 percent from 3.86 percent, improved to 70 percent from 34.5 percent and improved to 70 percent from 20.90 percent respectively.

Owner:PANZHIHUA JINTAI HI TECH

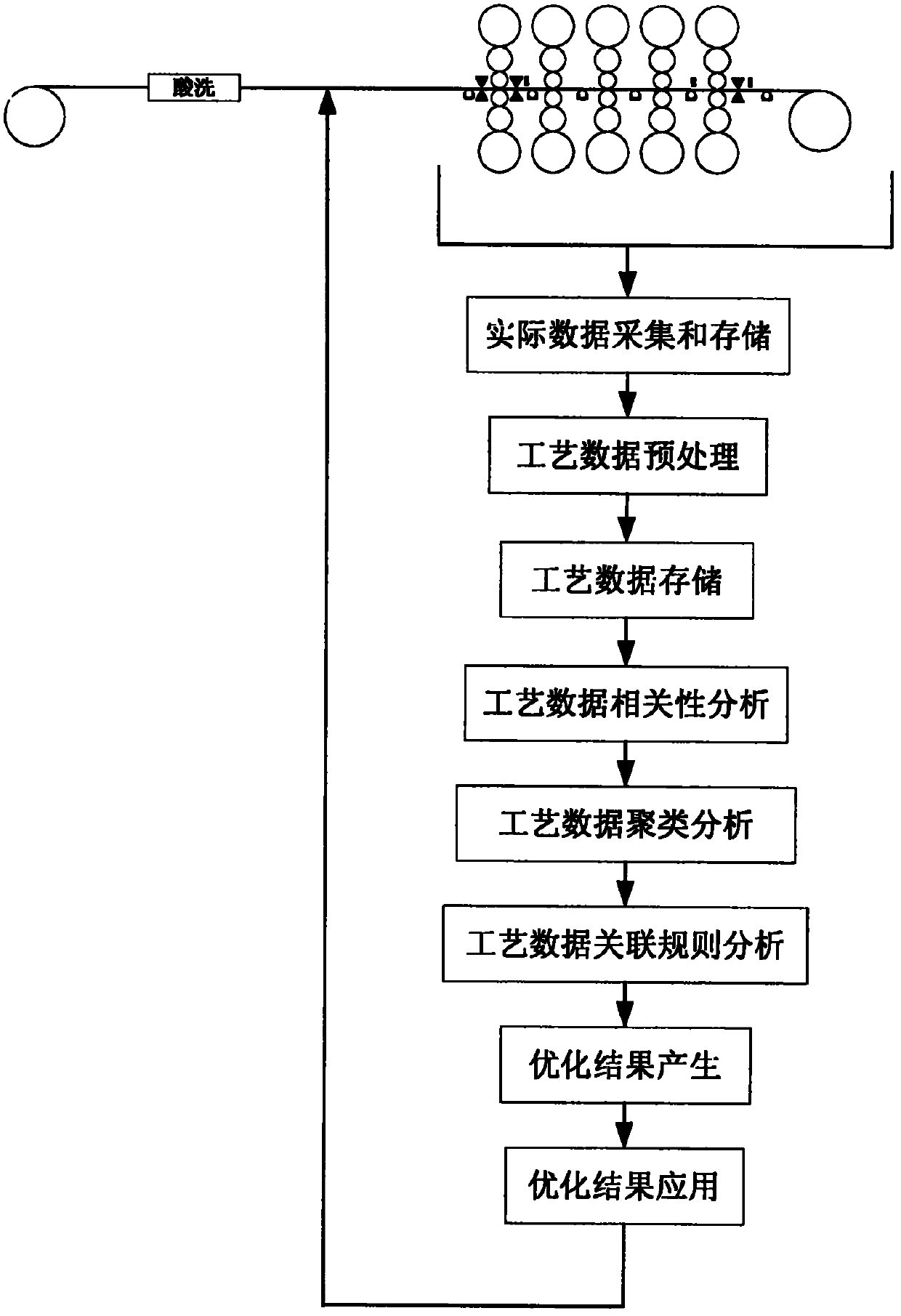

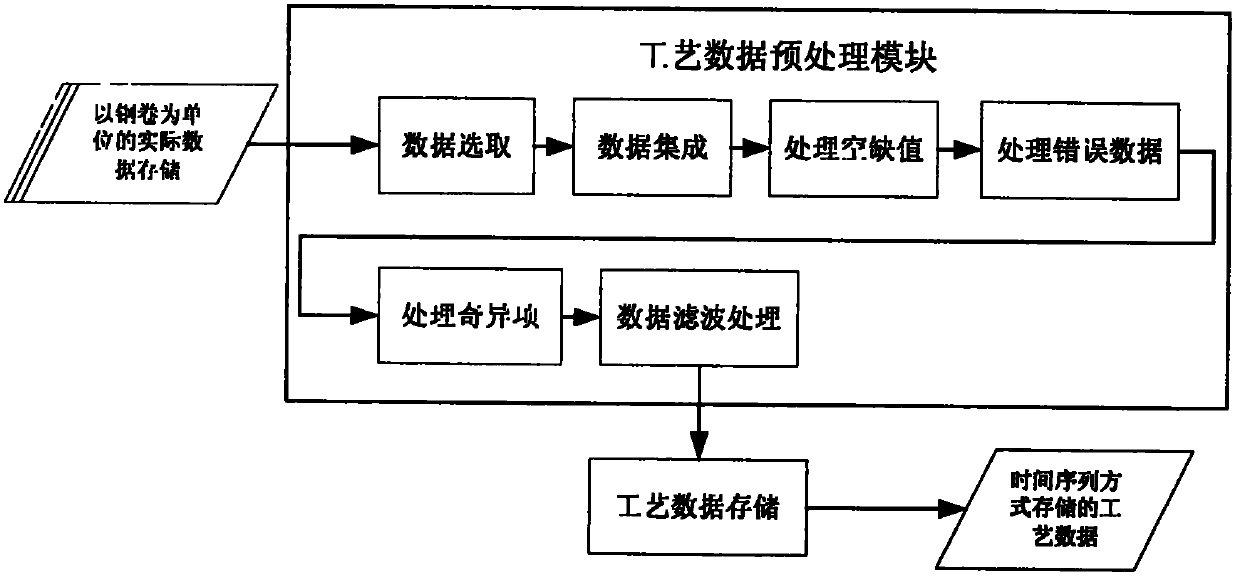

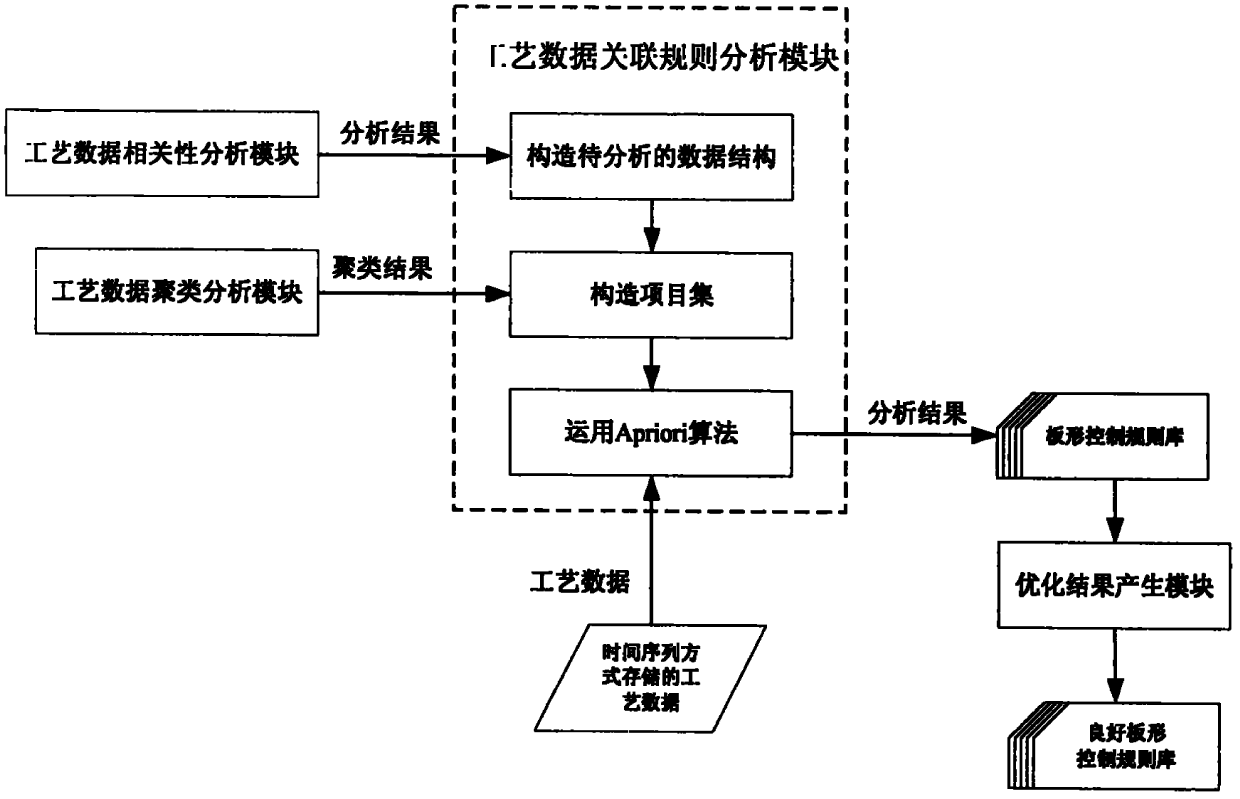

Data mining-based plate shape control key process parameter optimization system

ActiveCN102069094AImprove pass rateImprove the rate of successProfile control deviceAutomatic controlData acquisition

The invention relates to a data mining-based plate shape control key process parameter optimization system, and belongs to the technical field of automatic control of cold continuous rolling plate shape. The data mining method is adopted for acquiring key process parameter optimization settings which can meet the good cold continuous rolling plate shape. The system is characterized by comprising the following functional modules: an actual data acquisition and storage module, a process data pre-processing module, a process data storage module, a process data correlation analysis module, a process data clustering analysis module, a process data association rule analysis module, an optimization result generating module and an optimization result application module. The system has the advantage that the good plate shape can be obtained by applying the plate shape control system. The method avoids endless theoretical research on plate shape control and fully utilizes actual plate shape control process data containing successful operation experience of field operators, and the plate shape process parameter settings which can obtain the good plate shape are acquired by data mining, so the plate shape qualification rate and the finished product rate of cold continuous rolled strip steel are improved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

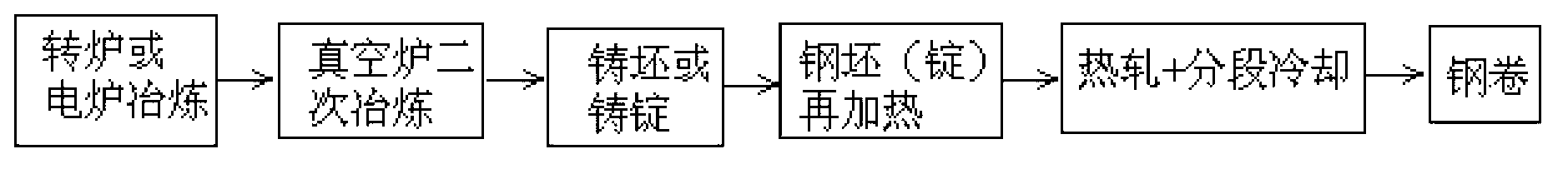

Method of sheet billet continuously casting and rolling to produce thin strip steel coil

ActiveCN101108394AShort production processSave construction investmentMetal rolling arrangementsProduction lineStrip mill

A method of using thin plate adobe continuous casting and rolling to producing thin band steel coil is provided, which belongs to rolling metal at once after continuous casting, in particular relating to thin standard band steel production method. The invention is characterized in that: a conticaster, a swing shear, a roller-hearth type heating furnace, a scale breaker, a vertical miller, 7 mill groups, laminar flow cooling device and reeling machine are connected to a CSP produce line, the produce line adopts reasonable temperature system, rolling equipment, rolling way and combining with cooling after rolling, the molten steel after continuous casting is a casting adobe of 50 to 70mm thick and 900 to 1300 wide, after cutting, heating, scale breaking, proceed continuous rolling to form a thin band of 1.2 to 1.5mm thick and 900 to 1300 wide, then after cooling to reel steel coil. The production flow is short, the equipment is few, the investment is less and the running expense is low; The technics and equipment is reasonable and high efficient, double locomotive and double flow casting, heating by two furnaces, seven rolling machines roll continuously, the production is smooth and saves energy with high production efficiency; the product performance is even and stable, the board shape is regular with high accuracy and good surface quality.

Owner:MAANSHAN IRON & STEEL CO LTD

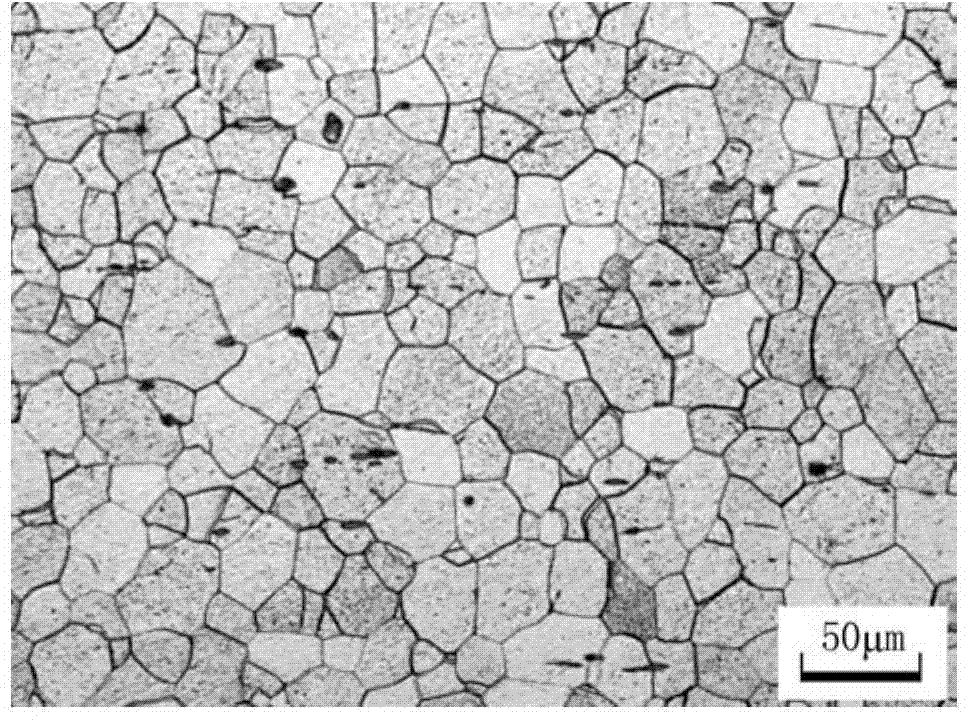

Rolling production method capable of reducing hardness of 42CrMo

ActiveCN106216391AMeet the national standardMeet user needsTemperature control deviceWork treatment devicesAutomatic controlContinuous rolling

The invention belongs to the field of production machining of special steel of the metallurgical industry, and relates to a rolling production method capable of reducing hardness of 42CrMo. A 42CrMo casting blank serves as a raw material, and the method sequentially comprises following working procedures of heating, descaling, a rough rolling, cooling after rough rolling, continuous rolling, through water cooling, bar reducing sizing mill finish rolling, cooling bed cooling and finally obtaining a finished product bar; by the adoption of the technology, the site operation is simple, online automatic control is easily achieved, and operation labor intensity of a worker is reduced; through the online controlled rolling controlled cold technology, straightness of the 42CrMo steel grade is greatly improved; the subsequent heat treatment technology (annealing technology) is reduced, production cost is saved, the production period is shortened, and the steel market competitiveness is improved; the hardness value range of the obtained 42CrMo steel ranges from 220 HBW to 260 HBW; a metallographic structure comprises ferrite and pearlite; the banded structure is smaller than or equal to 2 levels; the grain size is larger than or equal to 8 levels; and the mechanical property can meet the national standard and user needs.

Owner:DAYE SPECIAL STEEL CO LTD

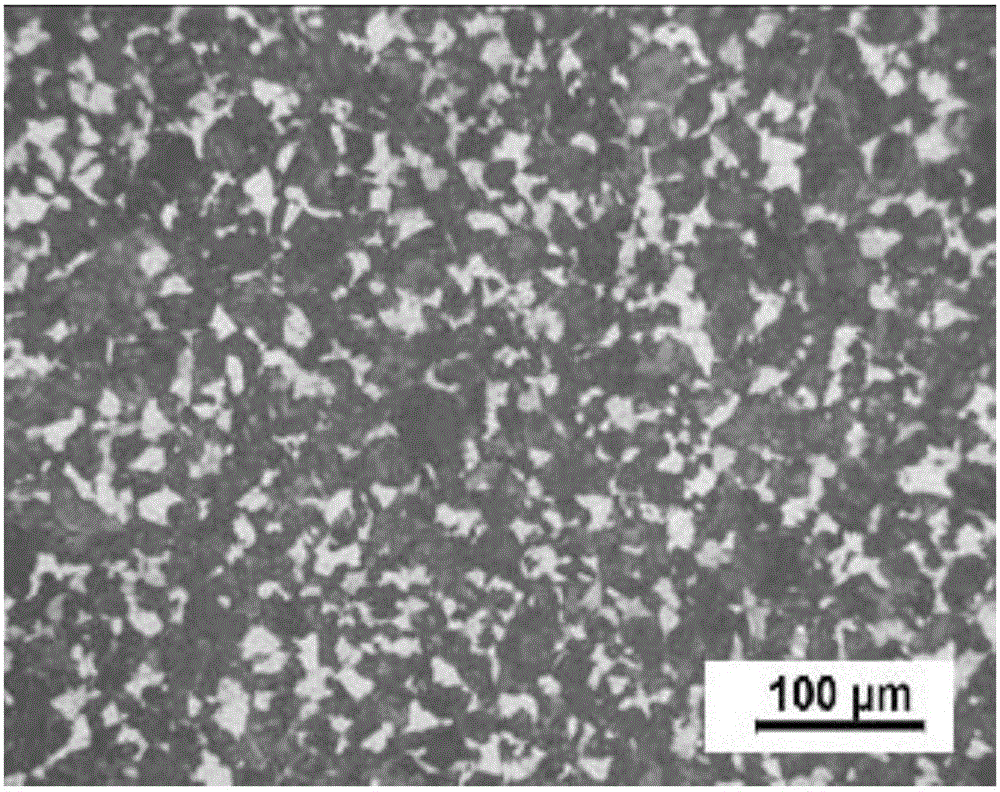

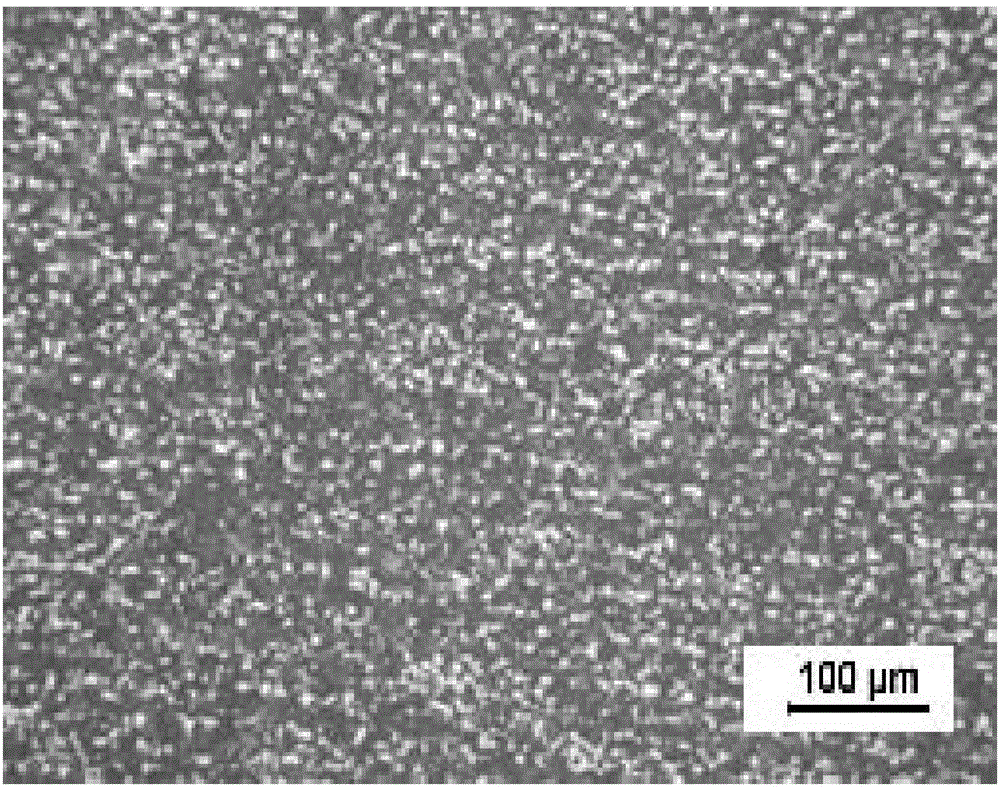

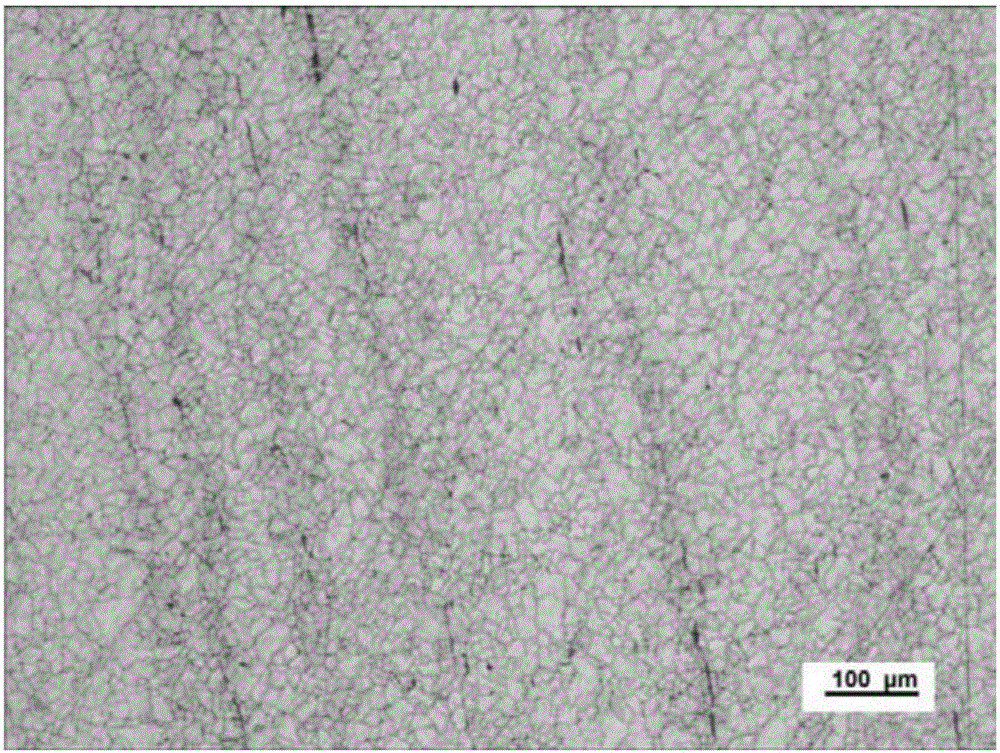

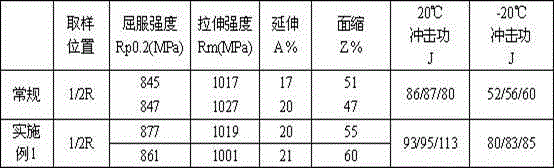

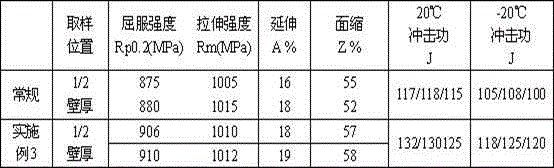

High-toughness medium-carbon quenched and tempered round steel of grade 120 KSI and manufacturing method thereof

The invention discloses high-toughness medium-carbon quenched and tempered round steel of the grade 120 KSI. The high-toughness medium-carbon quenched and tempered round steel of the grade 120 KSI comprises, by mass, 0.35%-0.50% of C, 0.15%-0.40% of Si, 0.60%-1.30% of Mn, equal to or less than 0.015% of P, equal to or less than 0.040% of S, 0.75%-1.30% of Cr, 0.15%-0.35% of Mo, equal to or less than 0.25% of Ni, equal to or less than 0.25% of Cu, 0.015%-0.040% of Alt, equal to or less than 0.10% of V, equal to or less than 0.10% of Nb, equal to or less than 0.05% of Ti, equal to or less than 0.008% of N, equal to or less than 0.0010% of B and the balance Fe and unavoidable impurity elements, wherein the content of V, the content of Nb and the content of Ti are not equal to or less than 0.010% at the same time. The round steel with the maximum specification reaching 260 mm is manufactured through Kanbara reactor (KR) pretreatment, basic oxygen furnace (BOF) smelting, ladle furnace (LF) refining, Ruhrstahl Heraeus (RH) vacuum degassing, continuous casting, heating, continuous rolling, and hardening and tempering, so that the requirements for high specifications and toughness are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Method for producing ferritic stainless steel bands with roughened surfaces through cold continuous rolling

ActiveCN103372567AExtended rolling kilometersImprove surface qualityWork treatment devicesMetal rolling arrangementsHydrofluoric acidReduction rate

A method for producing ferritic stainless steel bands with roughened surfaces through cold continuous rolling comprises that (1), a five-rack serial type cold continuous rolling is performed, a five-rack serial type cold continuous rolling unit is adopted, the diameter of a working roll of each rolling mill is 300-500mm, and endless rolling is performed; the roughness degrees of the rolls of the first rack to the fourth rack are in a range of 0.5-1.0mum and decrease sequentially; the working roll of the fifth rack is subjected to roughening and chromium plating treatment; an emulsion lubrication rolling mode is adopted, the temperature of an emulsion is 50-60DEG C, the emulsion is sprayed to roll gaps for cooling and lubricating, the temperature of cold-rolled band steel is controlled below 150DEG C; the accumulated reduction rate of the first rack to the fourth rack is larger than 60%, the reduction rate of the fifth rack is in a range of 4-10%, and the roughness of the cold-rolled band steel is controlled in a range of 0.5-1.0mum; (2), the cold-rolled band steel is subjected to annealing acid picking treatment, heating and annealing are performed in a continuous horizontal gas furnace, the annealing temperature is in a range of 800-1000DEG C, and recrystallization of the band steel is finished; finished surfaces are obtained finally through electrolytic picking by Na2SO4 and H2SO4 solutions and soaking picking by a nitric acid and hydrofluoric acid mixed acid solution sequentially after annealing.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Parameter setting method of hot continuous rolling thin slab coiling device and coiling method of hot continuous rolling thin slab

The invention relates to a parameter setting method of a hot continuous rolling thin slab coiling device and a coiling method of a hot continuous rolling thin slab. The parameters to be set are as follows: an advance speed set value of each set of roller beds = a finish rolling final rack speed set value * (a total roller bed advance rate + advance rate of each set); a lagging speed set value of each set of roller beds = the finish rolling final rack speed set value * a roller bed lagging rate; the side guide plate pressure coefficient is 0.8 + / - 0.15; the side guide plate additional value is from +5 to +10 mm; and the pinch roll is set, and the pinch roll of the coiling device is standardized to ensure the regular standardization, the pinch roll advance rate, pinch roll lagging rate, pinch roll pressure coefficient, upper pinch roll diameter of the coiling device and lower pinch roll diameter of the coiling device. The coiling method is implemented by controlling the coiling device with a computer according to the setting parameters. By using the parameter setting method of the hot continuous rolling thin slab coiling device and the coiling method of the hot continuous rolling thin slab, the surface quality is improved and the rejection rate is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

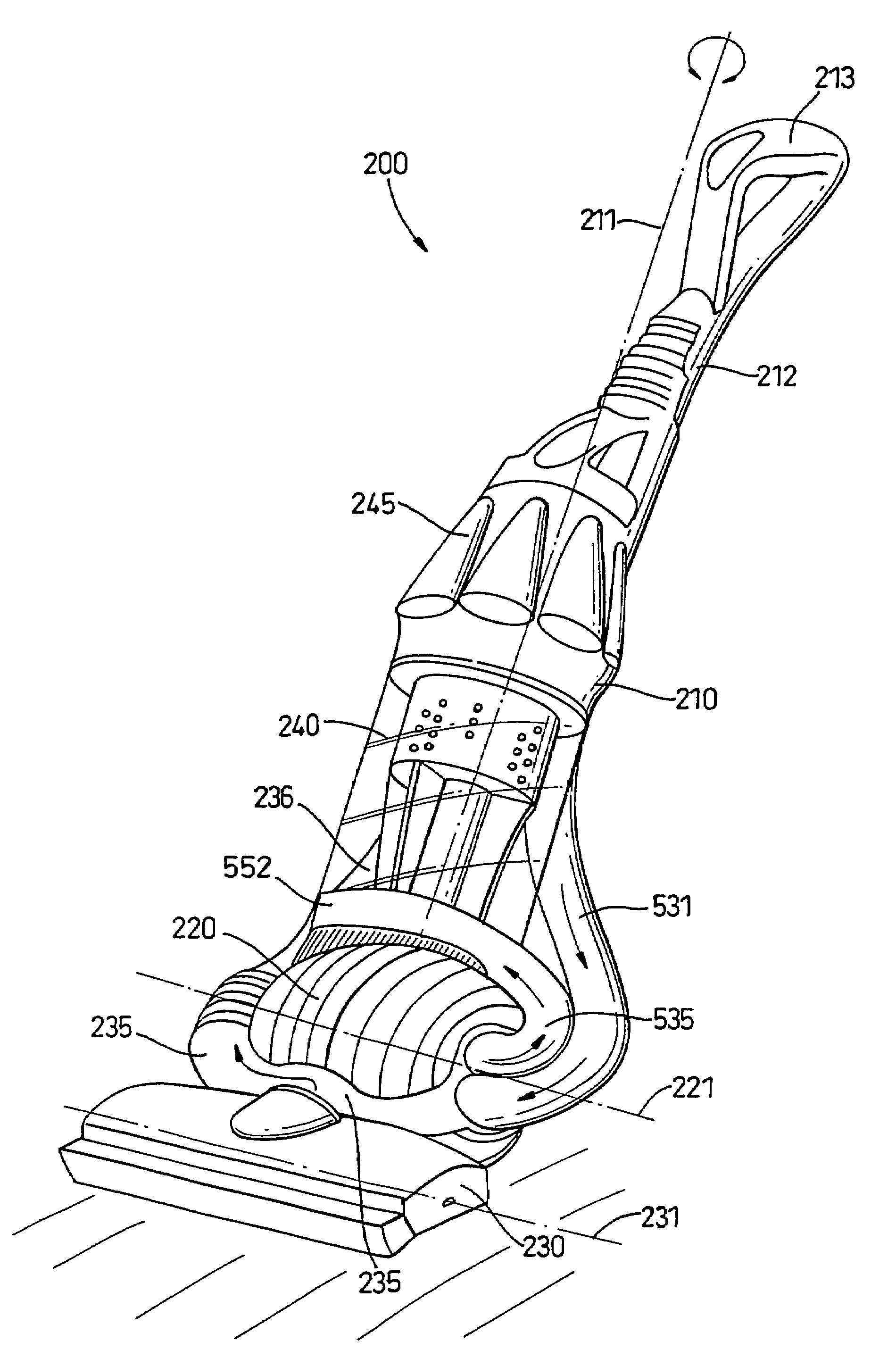

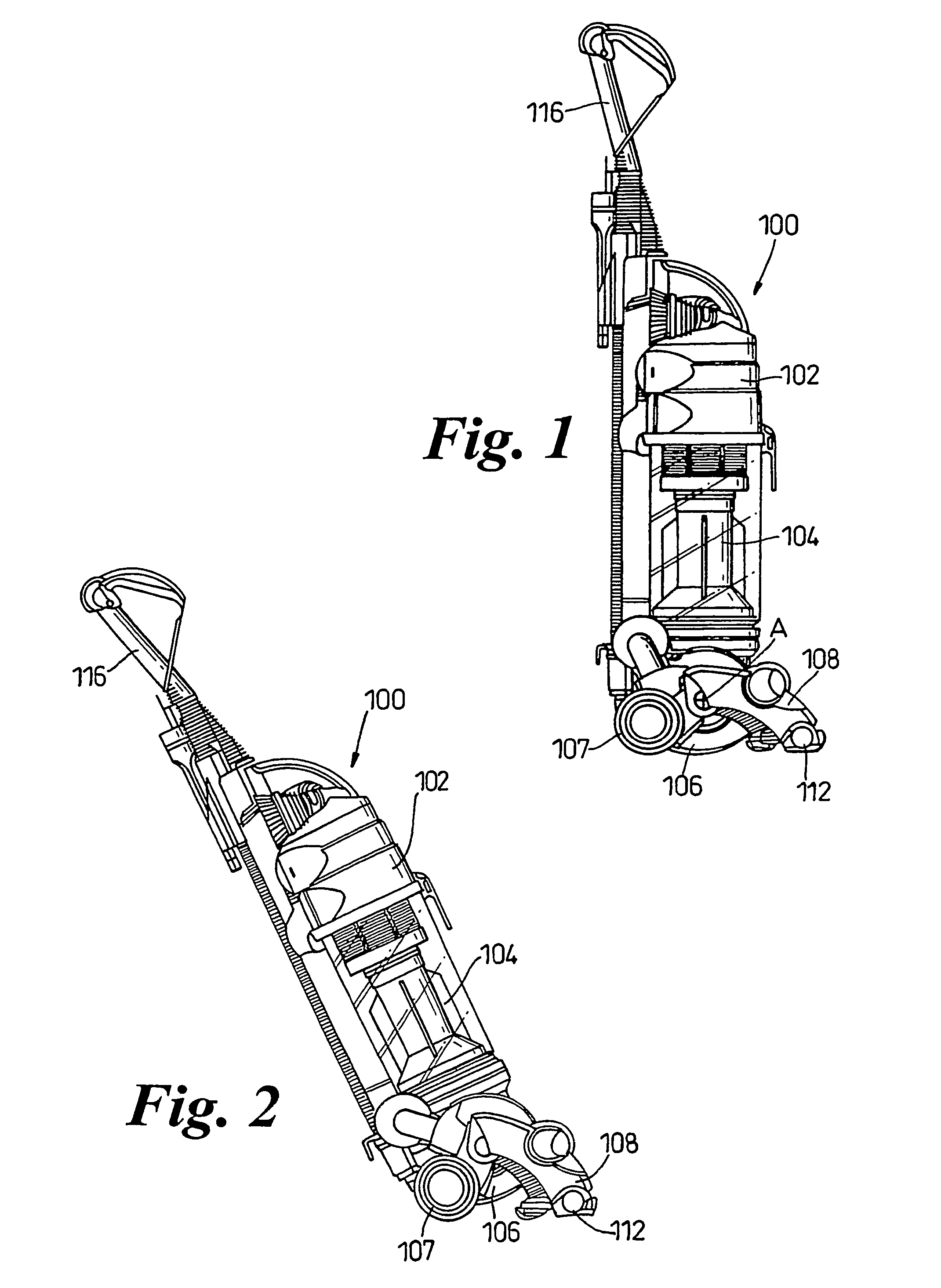

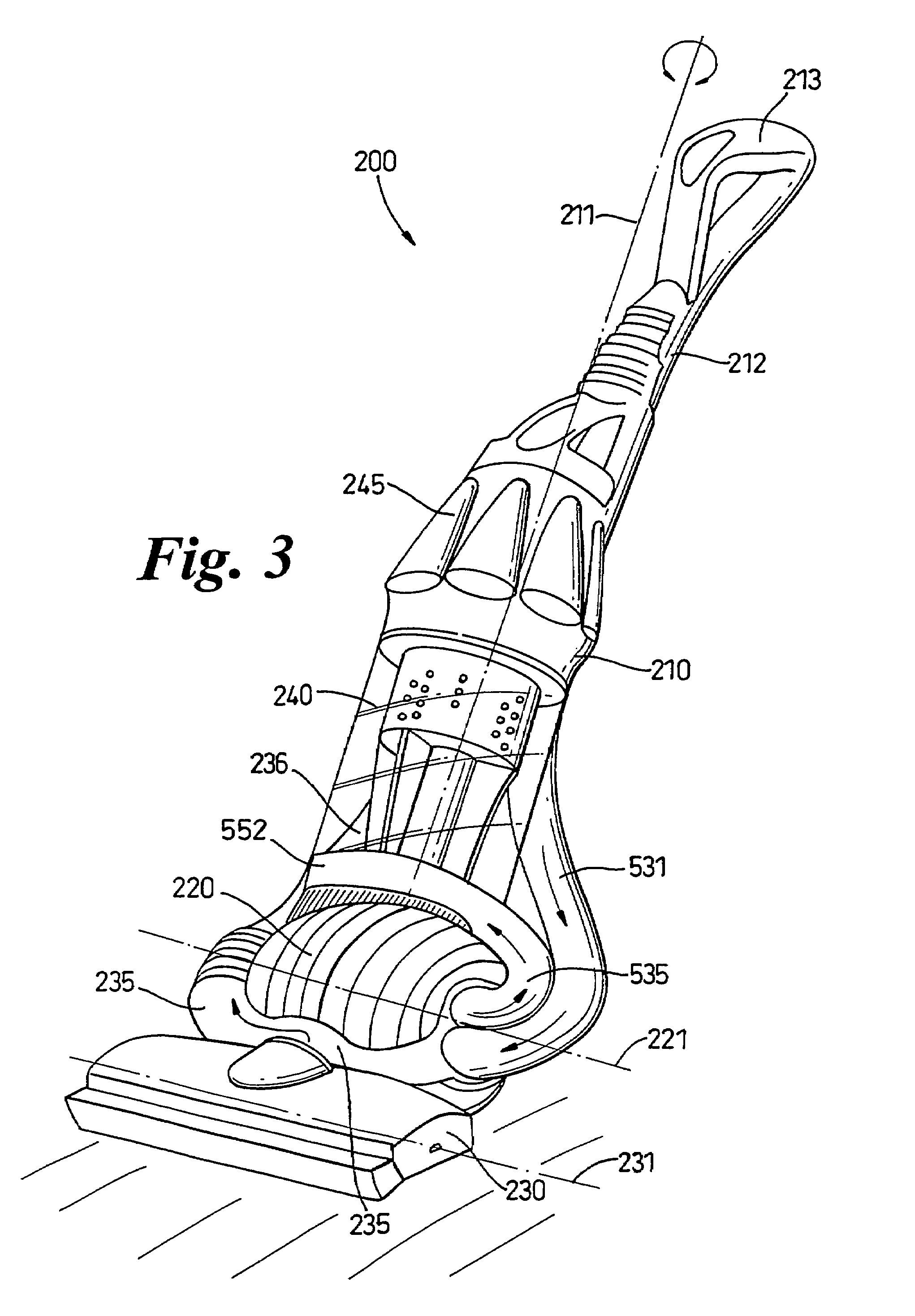

Surface treating appliance

ActiveUS7581284B2Improve mobilitySmooth transitionCleaning filter meansSuction filtersEngineeringContinuous rolling

Owner:DYSON TECH LTD

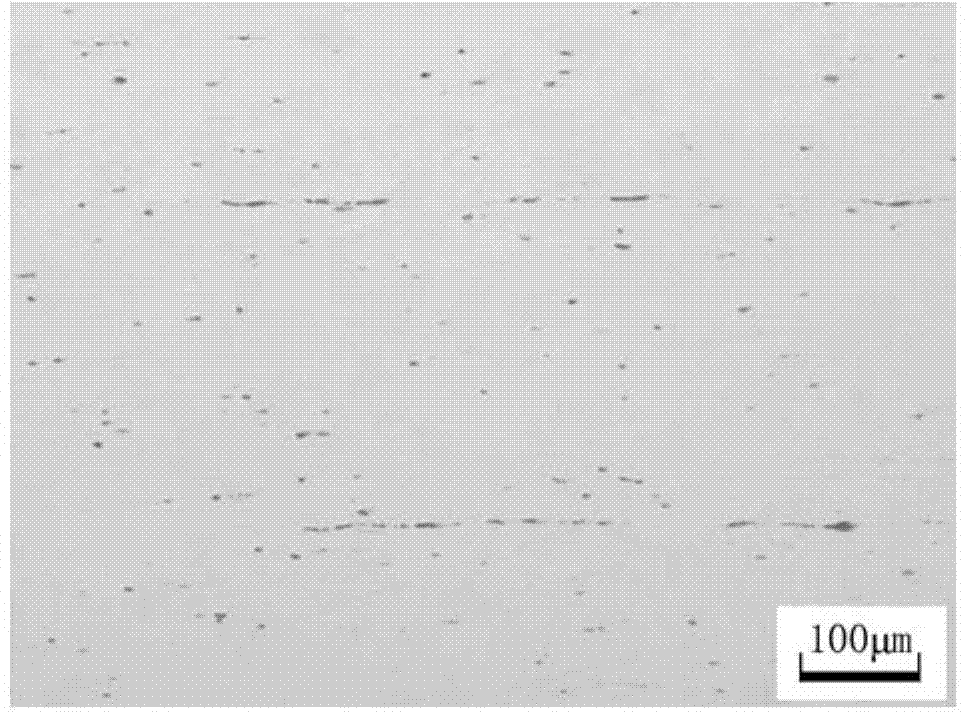

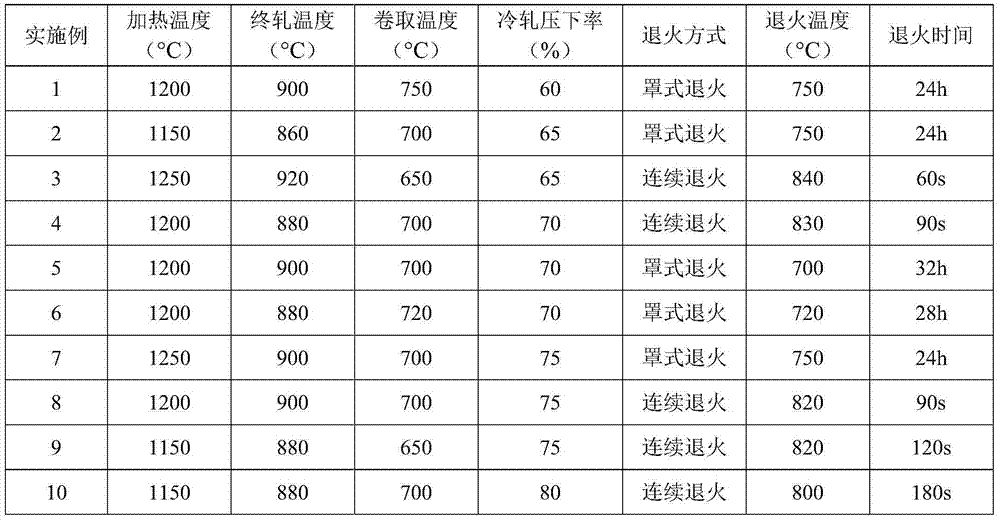

Enamel steel with scaling resistance and manufacturing method thereof

InactiveCN103484757ASimple chemical compositionReduce smelting costTemperature control deviceReduction rateAcid washing

The invention discloses enamel steel with scaling resistance. The enamel steel is prepared from the following components in percentage by weight: 0.0020-0.0050% of C, 0.30-0.50% of Mn, 0.0050-0.0100% of Si, 0.010-0.015% of P, 0.011-0.020% of S, 0-0.010% of Als, 0.011-0.020% of O and the balance of Fe and other inevitable impurities. A manufacturing method sequentially comprises the following steps: pretreatment of molten iron, smelting by a converter, refining, continuous casting, hot continuous rolling, acid washing, cold continuous rolling, annealing and finishing, wherein the heating temperature for hot continuous rolling is 1150-1250 DEG C, the finish rolling temperature is 860-920 DEG C, the winding temperature is 650-750 DEG C, and the cold rolling reduction rate of cold continuous rolling is 60-80%. The enamel steel disclosed by the invention has no scaling phenomenon and low production difficulty, and is suitable for being applied to the technical field of iron and steel smelting.

Owner:WUHAN IRON & STEEL (GROUP) CORP

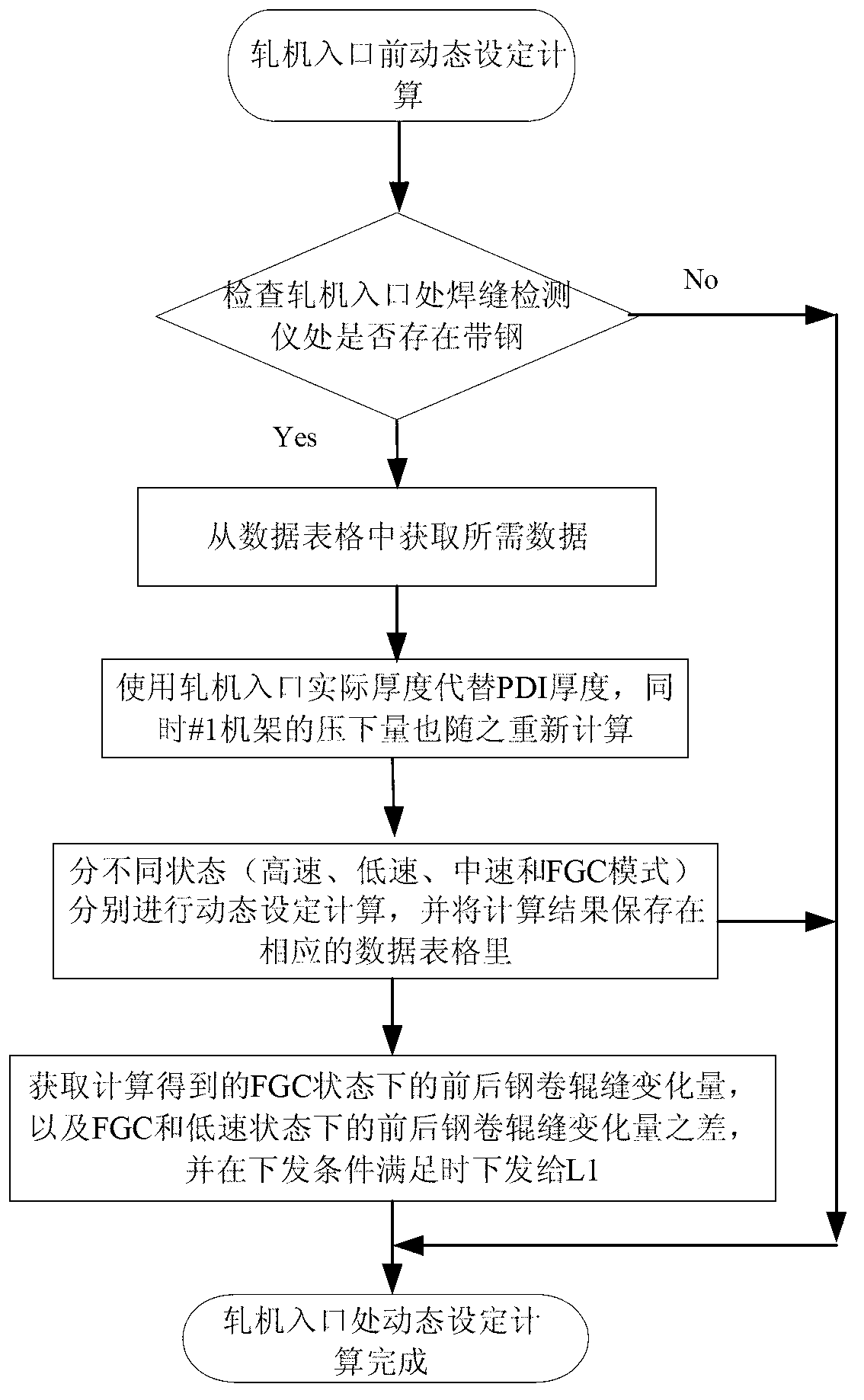

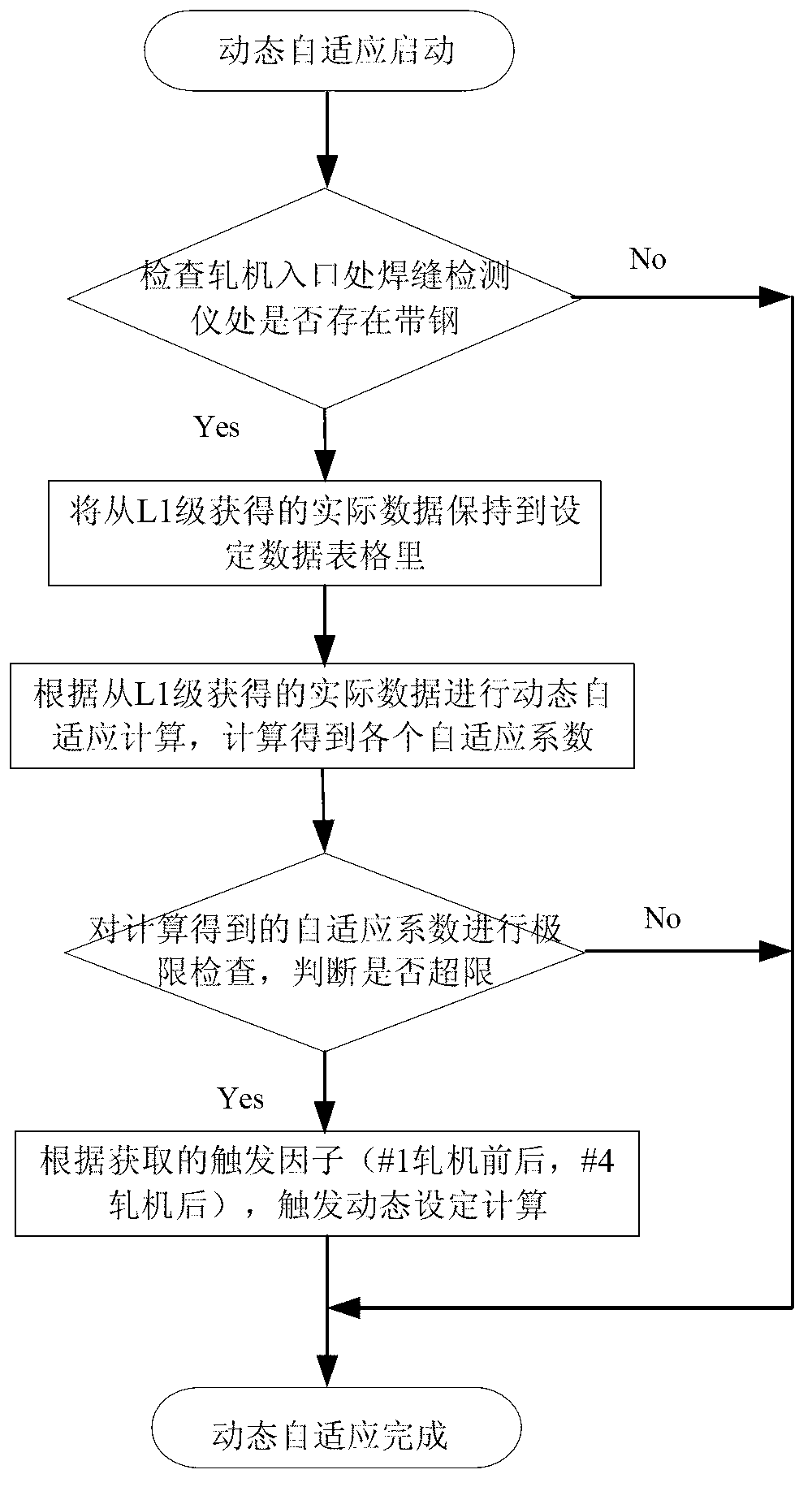

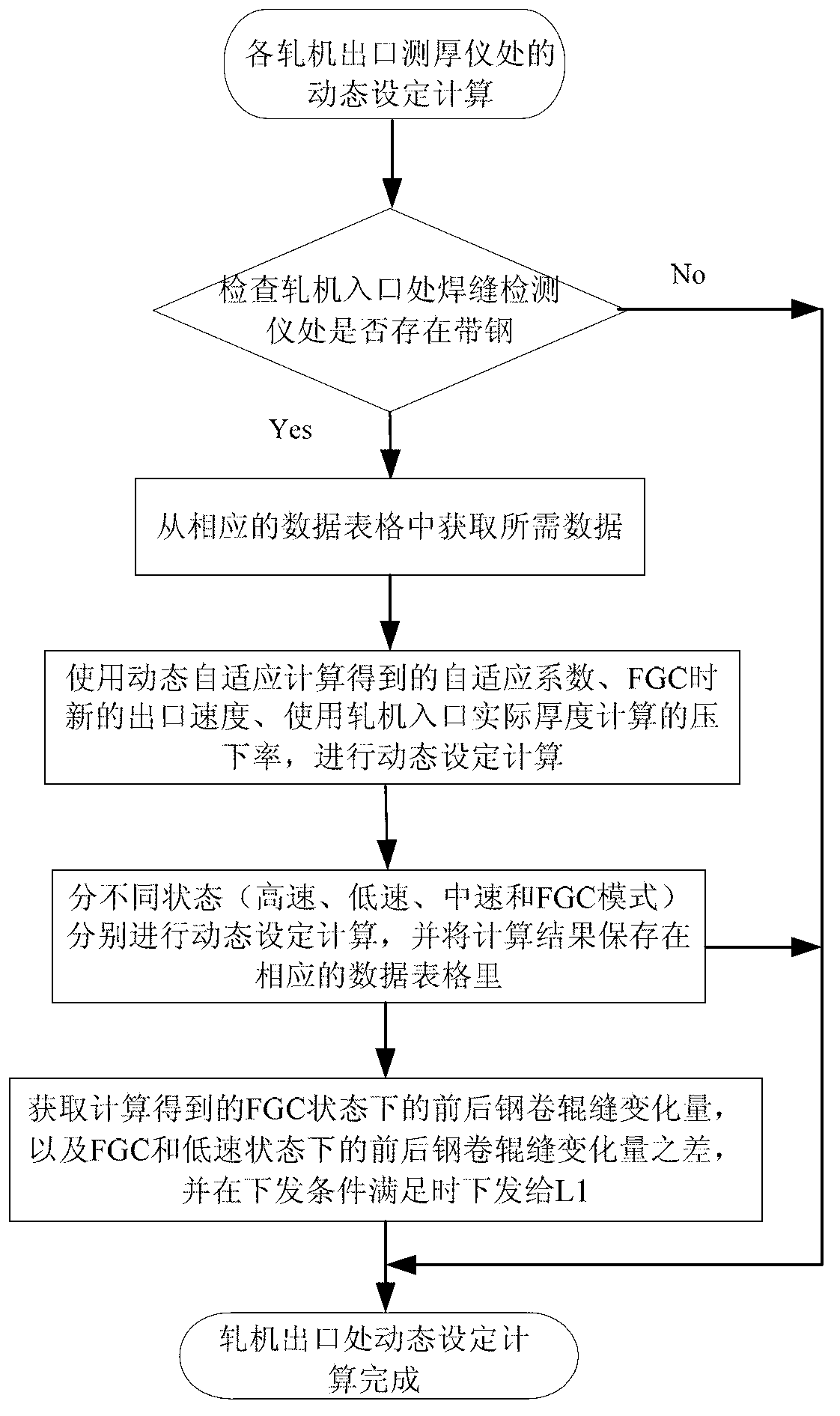

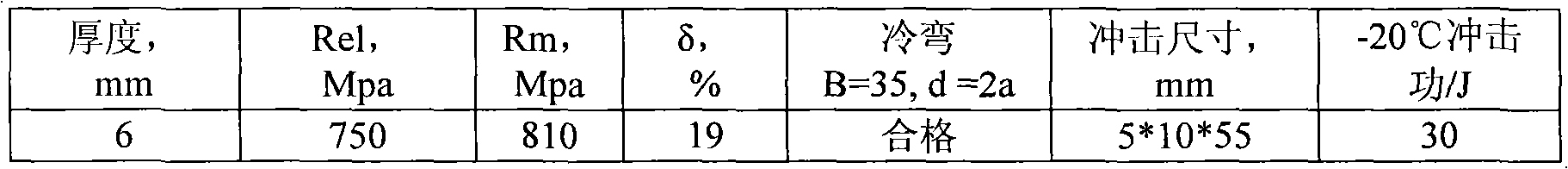

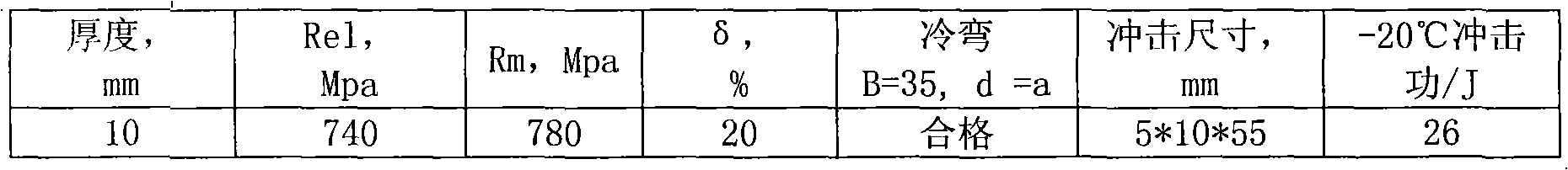

Dynamic roll gap compensation method during cold continuous rolling flying gauge control

ActiveCN103286142AImprove setting accuracyReduce head thickness deviationRoll force/gap control deviceAutomatic controlModel system

The invention discloses a dynamic roll gap compensation method during cold continuous rolling flying gauge control and belongs to the technical field of automatic control of cold continuous rolling. The method includes a part of roll gap compensation for a welding gap position at the position of a rolling mill inlet front thickness gauge and a part of roll gap compensation for the welding gap position at the positions of all rolling mill outlet thickness gauges. A roll gap adjustment value is determined by a model system of a process computer to a great degree due to the fact that a large part of AGC functions are not introduced during flying gauge control. Therefore, computational accuracy of the model system can directly affect thickness control accuracy during flying gauge control. A practical inlet thickness acquired by using a practical thickness gauge at the position of the rolling mill inlet front thickness gauge is adopted to replace a raw material thickness to improve initial data accuracy for setting a model, and a set value of a roll gap during FGC is corrected according to calculated deviation between a front steel coil roll gap and a back steel coil roll gap so as to improve setting accuracy of the roll gap. More accurate roll force is acquired in the method of dynamic self-adapting at the positions of all the rolling mill outlet thickness gauges, setting accuracy of the roll gap is improved, and then the roll gap value can be compensated during flying gauge control.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH +2

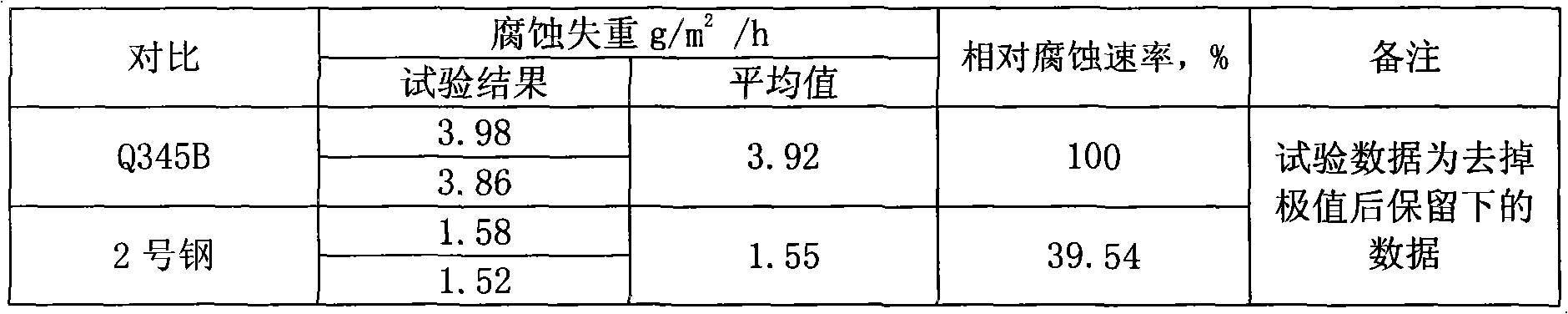

Low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa and manufacturing method thereof

InactiveCN101921965AAdd corrosion resistant elementsLow costUltimate tensile strengthContinuous rolling

The invention provides low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa for containers and a manufacturing method thereof. Based on the carbon manganese structural steel composition, the reinforcement effect is enhanced by adding a proper amount of micro-alloy elements such as Nb, Ti, Cu, Cr, Ni and the like, adopting a controlled rolling and controlled cooling technique, taking production characteristics of a normal hot continuous rolling machine into consideration and using a high-Ti component design. Meanwhile, Si content is reduced and high cold forming performance is ensured. The weathering steel for the containers comprises the following components in percentage by weight: 0.05 to 0.10 percent of C, less than or equal to 0.15 percent of Si, 1.5 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.01 percent of S, 0.3 to 0.8 percent o Cr, 0.2 to 0.4 percent of Cu, 0.15 to 0.4 percent of Ni, 0.09 to 0.15 percent of Ti, 0.02 to 0.08 percent of Nb, less than or equal to 0.005 percent of N, less than or equal to 0.002 percent of O and the balance of Fe and inevitable impurities. The yield strength is over 700MPa, the tensile strength is over 800MPa and the elongation is over 18 percent.

Owner:SHANDONG IRON & STEEL CO LTD

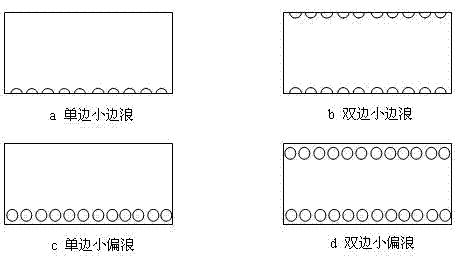

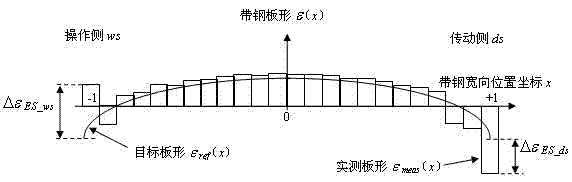

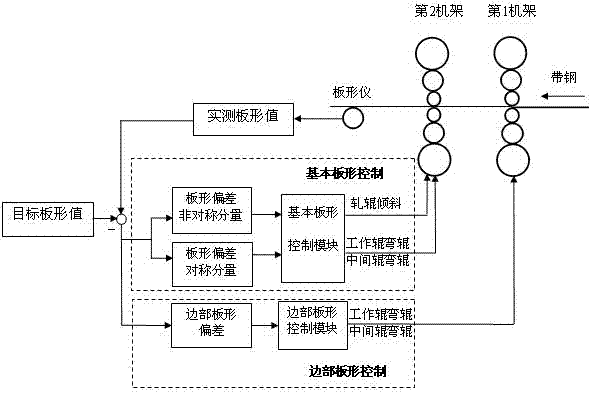

Control method of edge portion strip shape of cold rolling strip steel

The invention relates to a rolling method of cold rolling strip steel, in particular to a control method of edge portion strip shape of thin strip steel rolled by a cold continuous rolling mill or a two-stand temper mill. In a strip shape feedback control system centered on a last stand and on the basis of fundamental strip shape control function of major control for conventional edge waves and center waves, the method identifies the state of the edge portion strip shape of the strip steel based on the difference between the actual measured strip shape of strip steel edge portion together with the adjacent areas at the exit of last stand and an objective strip shape, and adjusts the corresponding strip shape executive mechanisms of the last stand and the rest stands according to the state of the edge portion strip shape to realize effective control for the edge portion strip shape of the strip steel, such as small edge waves and small side waves, thereby further improving the quality of the strip steel after cold rolling or temper rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

Weather-resistant hot rolled narrow steel strip and method for manufacturing same

InactiveCN101135030AReduce controlLow costRoll mill control devicesMetal rolling arrangementsChemical compositionContinuous rolling

The present invention relates to one kind of weather resistant hot roller narrow steel strip for welded structure and its production process. The steel strip has the chemical composition comprising C 0.07-0.12 wt%, Si 0.25-0.50 wt%, Mn 0.30-0.50 wt%, P 0.07-0.15 wt%, S less than 0.035 wt%, Cu 0.25-0.40 wt%, Cr 0.30-1.2 wt%, Ni 0.10-0.50 wt%, and Fe and inevitable impurity for the rest. It is produced through smelting in a top blown converter, LF refining, continuously casting steel strip billet and hot rolling in a continuous rolling mill train. It has high purity, excellent corrosion resistance, excellent welding performance and homogeneous mechanical performance. It may be applied in making square welded tube or other accessories for container.

Owner:LAIWU IRON & STEEL GRP

Diphasic steel plate by continuous casting and rolling middle bar strip and manufacturing method thereof

ActiveCN101130847ASimple chemical compositionHigh tensile strengthMetal rolling arrangementsChemical compositionSheet steel

The present invention provides a dual phase steel sheet made up by using medium-thin sheet billet through a certain continuous-casting and continuous-rolling process. The component composition of said steel sheet includes (by wt%) 0.04%-0.11% of C, 0.02%-1.5% of Si, 0.6%-2.50% of Mn, 0.02%-2.0% of Cr, also can contain Mo or Ti, the rest is Fe and unavoidable impurity. The microscopic structure of said steel sheet includes: matrix phase is ferrite and second phase mainly is martensite. Besides, said invention also provides the concrete operation steps of its production method.

Owner:ANGANG STEEL CO LTD

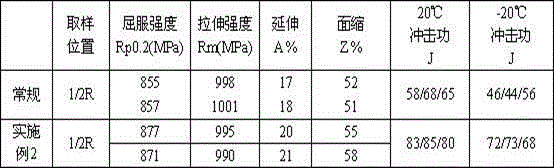

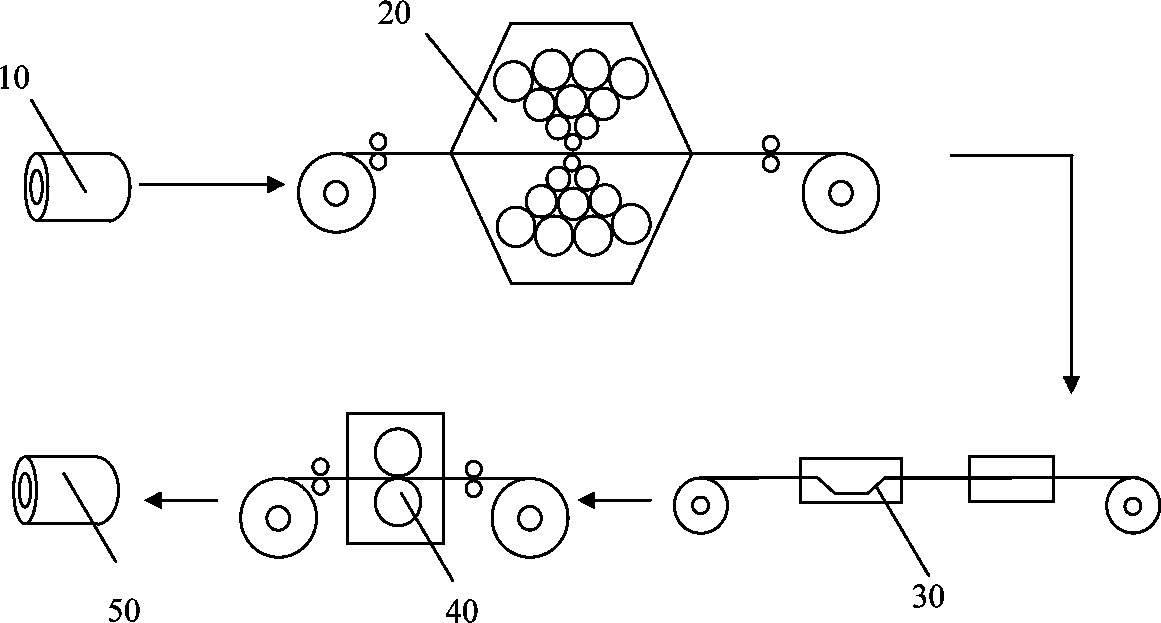

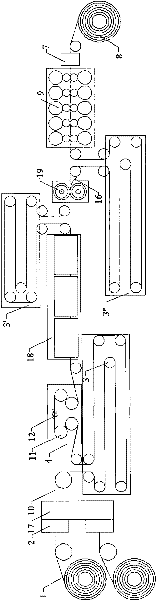

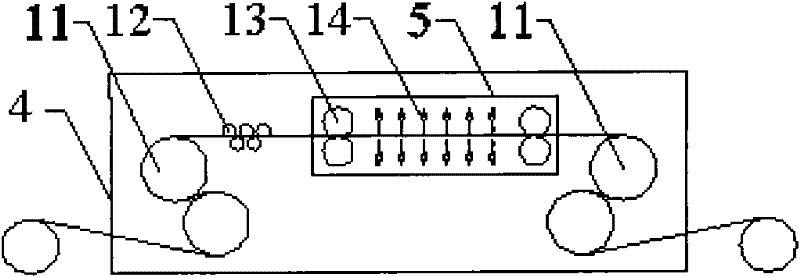

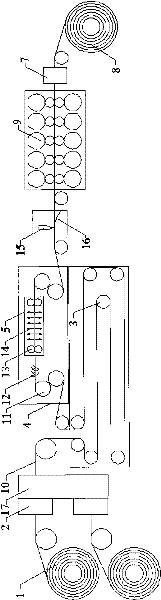

Cold metal plate strip cold continuous rolling production line and production method

InactiveCN102172835AImprove the effect of energy saving and emission reductionIncrease flexibilityWork treatment devicesOther manufacturing equipments/toolsProduction lineEngineering

The invention relates to a cold metal plate strip cold continuous rolling production line, which comprises at least uncoiling machine (1), a plate strip head and tail cutting machine (2), welding equipment (17), a stretching and straightening device (4), at least one jet flow descaling unit (5), tension rolls (11), a trimming device (15), randomly selected cold continuous rolling machine set (9), flying shears (7), a coiling machine (8), and a movable sleeve device, wherein the stretching and straightening device (4) comprises at least two tension roll groups (11) and a bending roll group (12); the tension roll groups (11) are arranged in front and at back of the jet flow descaling unit (5) respectively; and the movable sleeve device is only welded between the welding equipment and the stretching and straightening device (4). When the continuous type metal plate strip cold continuous rolling production line and a high-pressure jet flow descaling mode are improved, the productivity of the cold continuous rolling line is improved obviously, the environmental-protection control index of the cold rolling process segment is obviously improved, and the floor area and maintenance cost of the production line are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-yield-ratio high-strength hot-rolled Q&P steel and manufacturing method thereof

The invention relates to low-yield-ratio high-strength hot-rolled Q&P steel and a manufacturing method thereof. The steel comprises the chemical components of 0.20-0.40% of C, 1.0-2.0% of Si, 1.5-3.0% of Mn, no more than 0.015% of P, no more than 0.005% of S, 0.02-0.08% of Al, no more than 0.006% of N, 0.005-0.015% of Ti, and balance of Fe and unavoidable impurities. According to the invention, through low-cost component design, on a basis of common C-Mn steel, Si content is increased such that cementite precipitation is inhibited, and austenite grains are micronized through micro-Ti treatment. Also, with a combination of hot continuous rolling process and sectioned cooling process, a structure comprising proeutectoid ferrite, martensite, and residual austenite is obtained. The yield strength is lower than 700MPa, a tensile strength is higher than 1000MPa, a yield ratio is 0.50-0.60, and alloy cost is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing low carbon bainite high-strength steel based on sheet bar continuous casting and rolling process flow

ActiveCN101254527ASimple metallurgical compositionImprove toughnessProcess efficiency improvementMetal rolling arrangementsThin slabLaminar cooling

The invention discloses a method for producing high-strength low-carbon bainite steel based on thin slab continuous casting and rolling process. The method includes the following steps: melting by using a rotary furnace or an electric furnace, refining molten steel in an LF furnace after the component analysis, performing the composition adjustment, continuously casting thin slabs, directly heating the thin slabs at the temperature of 950-1100 DEG C in a roller-hearth heating (soaking) furnace at a temperature not less than 1150 DEG C, controlling the tapping temperature of heated thin slabs in a range from 1050 DEG C to1160 DEG C, rolling by using a continuous rolling mill to produce plates, finishing at a temperature of 840-860 DEG C, performing laminar cooling, and coiling with a down coiler at a temperature of 550-600 DEG C to produce the steel coil. The method can produce non-tempered high-strength steel based on thin slab continuous casting and rolling process, and has the advantages of simple metallurgical composition of steel, low cost of alloying production, and stability in high toughness and good forming and welding properties of the steel coil.

Owner:湖南华菱涟源钢铁有限公司 +1

Method for manufacturing cold rolling non oriented electrical steel through continuous casting and tandem rolling sheet bar

InactiveCN1796015AAvoid the problem of fine dispersed precipitationEasy to grow grainsOther manufacturing equipments/toolsMetal rolling arrangementsElectrical steelMolten steel

The method for producing cold-rolled non-oriented electrical steel by using sheet bar and adopting continuous casting and continuous rolling process includes the following steps: a). utilizing the following components: C is less than or equal to 0.005%, Si is less than or equal to 3.5%, Mn is less than or equal to 1.5%, Al is less than or equal to 1.5%, P is less than or equal to 0.2%, S is less than or equal to 0.010%, N is less than or equal to 0.005%, O is less than or equal to 0.02% and the rest is iron and smelting; b). continuous casting, continuously casting molten steel to obtain sheet bar; c). heating, the temperature of sheet bar before which is fed into the furnace is 700-900deg.C, retaining said temperature for 30s-5min; heating sheet bar in ferrite phase area and heating temperature is less than or equal to 1120deg.C; d). hot-rolling, rolling in ferrite phase area, final rolling temperature is 800deg.C-950deg.C; e). coiling, coiling temperature is 500deg.C-900deg.C; and f). normalizing treatment or non-annealing treatment, acid-pickling, first cold-rolling or secondary cold-rolling with intermediate annealing to target thickness, then making final annealing so as to obtain the invented product.

Owner:BAOSHAN IRON & STEEL CO LTD

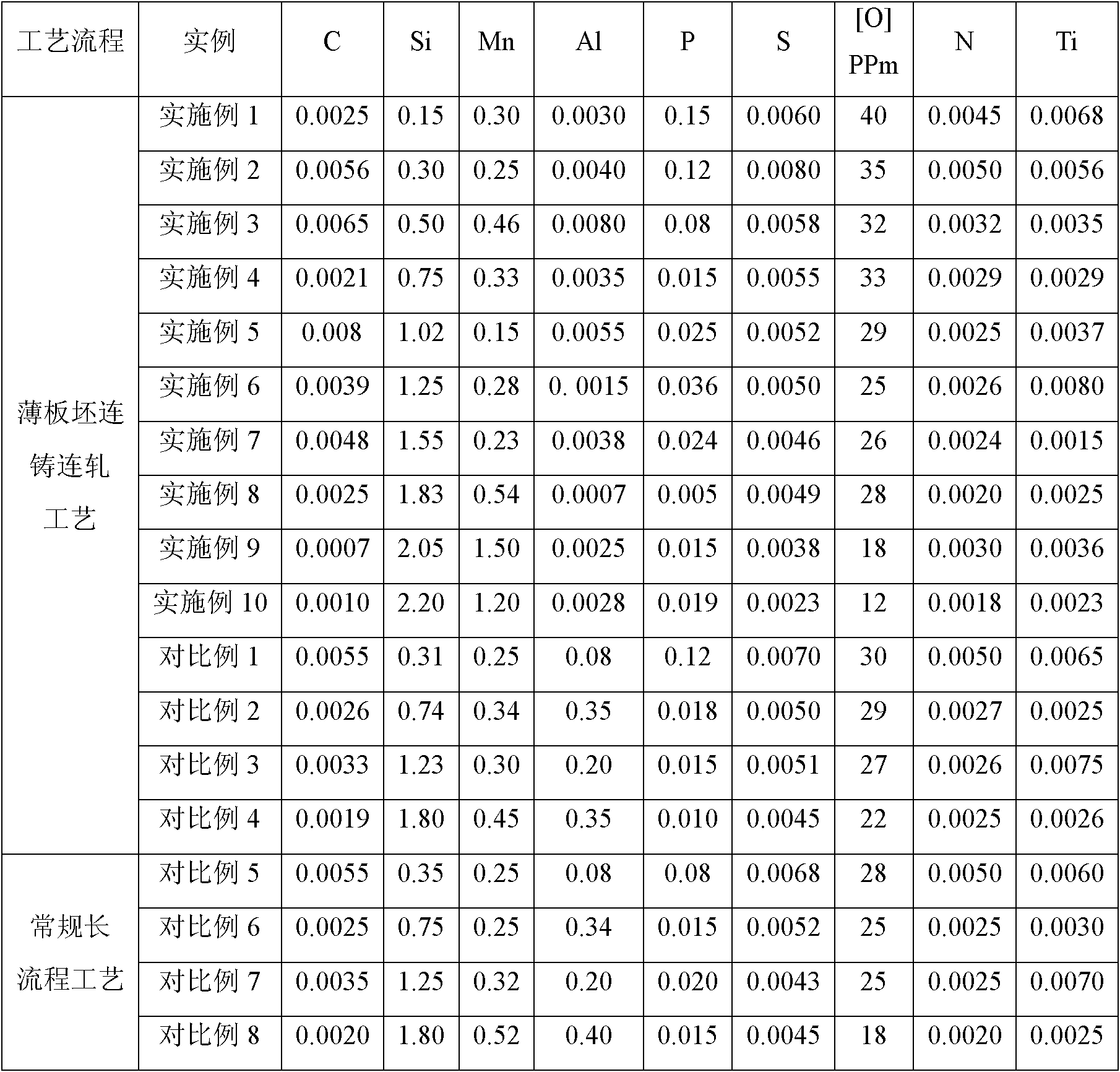

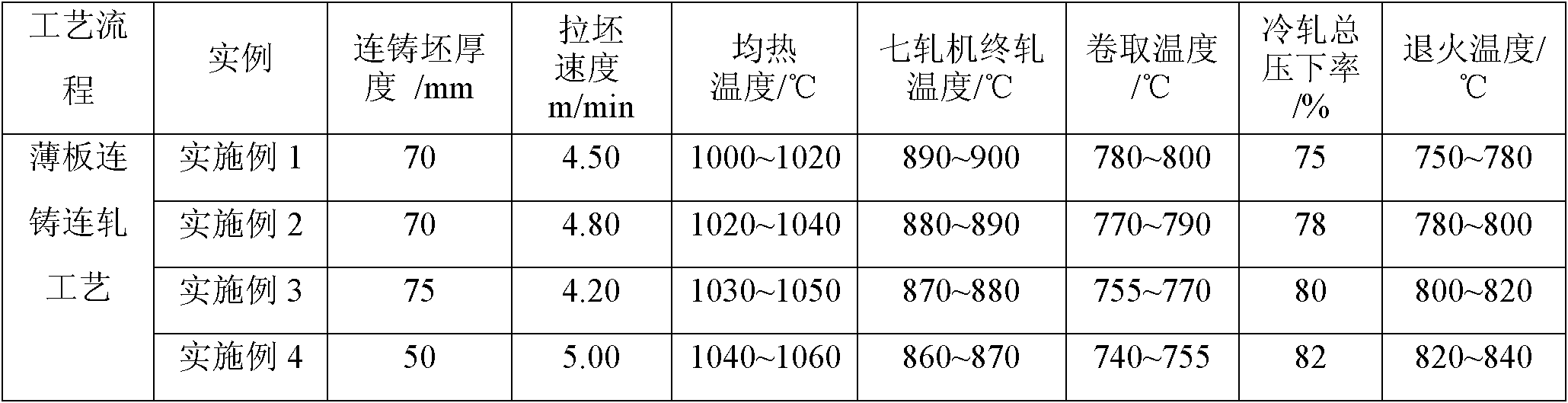

Non-oriented electrical steel for thin slab continuous casting-continuous rolling production and method thereof

InactiveCN102134675AReduce SiReduce Mn contentMetal rolling arrangementsTunnel kilnChemical composition

The invention relates to non-oriented electrical steel and a production method thereof. The non-oriented electrical steel comprises the following chemical compositions in percentage by weight: less than or equal to 0.008 percent of C, 0.15 to 2.2 percent of Si, less than or equal to 0.008 percent of Al, 0.15 to 1.5 percent of Mn, 0.004 to 0.15 percent of P, less than or equal to 0.008 percent of S, less than or equal to 40PPm of [O], less than or equal to 0.005 percent of N, less than or equal to 0.008 percent of Ti, and the balance of iron and inevitable impurities. The production method comprises the following steps of: smelting by using a converter and performing vacuum treatment; continuously casting into slabs with the thickness of 50-90 millimeters; soaking in a tunnel kiln; continuously rolling by using seven mills; coiling; performing pickling; performing cold rolling; performing recrystallization annealing; and obtaining the steel for later use. The alloy is reasonable in design and is not needed to be subjected to calcium treatment; the procedures are simple; the cost is reduced; the defect of low casting property in thin slab continuous casting-continuous rolling production can be effectively overcome; the advantages on cost and magnetic property of the non-oriented electrical steel in the thin slab continuous casting-continuous rolling production are fully shown, and the market competitiveness of the product is greatly improved.

Owner:武汉钢铁有限公司

Fine crystal strengthen carbon constructional steel and manufacture process for hot-rolling thin slab thereof

InactiveCN101153367AHigh strengthHigh elongationShaping toolsHeat treatment process controlChemical compositionThin slab

The invention relates to a manufacture process of carbon steel and carbon steel hot rolling plate, in particular to a manufacture process of fine grain reinforcement carbon structural steel and hot rolling sheet plate of the steel. The invention mainly solves the technical problem that hot rolling plate of higher strength can not be produced on common completely continuous hot continuous rolling mill by use of common carbon structural steel at present. The fine grain reinforcement carbon structural steel adopts the following chemical composition (weight percent): 0.14 percent to 0.20 percent of C, 0.10 percent to 0.40 percent of Si, 0.65 percent to 0.90 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S and the rest, Fe. The manufacture process of the hot rolling sheet plate is as follows: a continuous casting slab which meets the requirements of compositions is heated to 1,210 DEG C to 1,250 DEG C; a rough rolling stage comprises five-pass tandem rolling and the end temperature of the rough rolling stage is between 1,050 DEG C and 1,060 DEG C; in addition, the thickness of an intermediate slab ranges from 35 mm to 45 mm. When rough rolling is finished, the intermediate slab is curled through a hot coil box and then is unfolded for finish rolling; a finish rolling stage comprises six-pass tandem rolling with the start rolling temperature ranging between 920 DEG C and 940 DEG C and the end temperature ranging between 820 DEG C and 860 DEG C; after finish rolling, the thickness of a steel plate is between 2 mm to 8 mm; in addition, a laminar flow cooling stage adopts forepart intensive cooling with the coiling temperature ranging from 520 DEG C to 620 DEG C.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

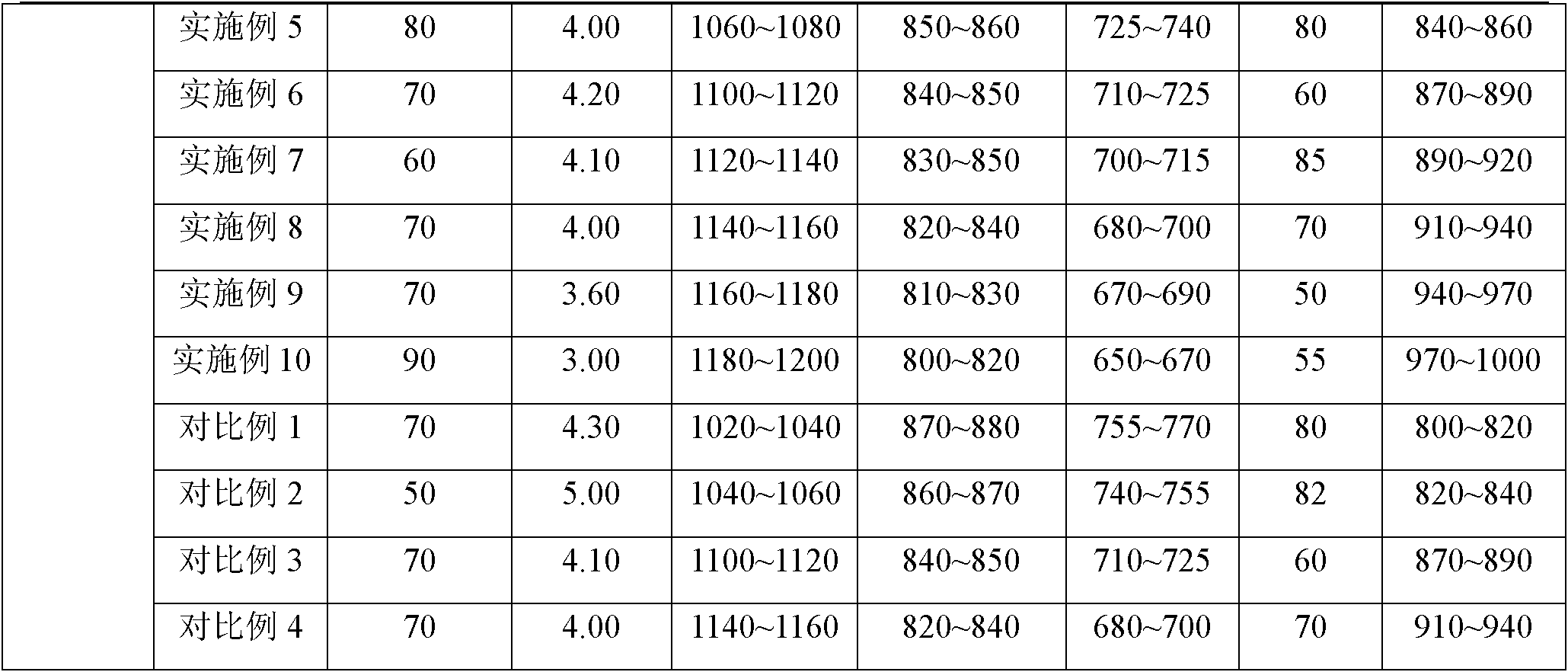

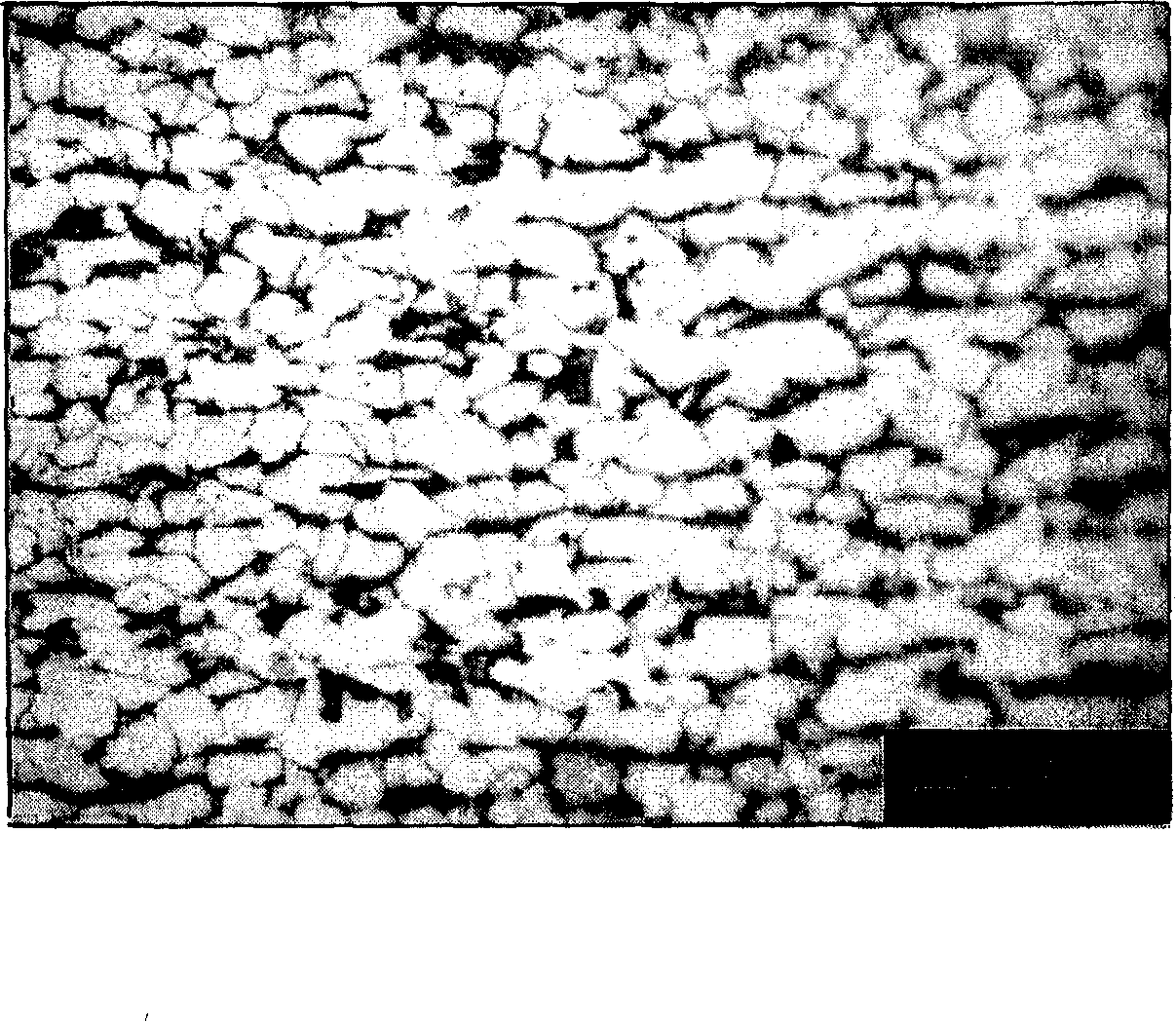

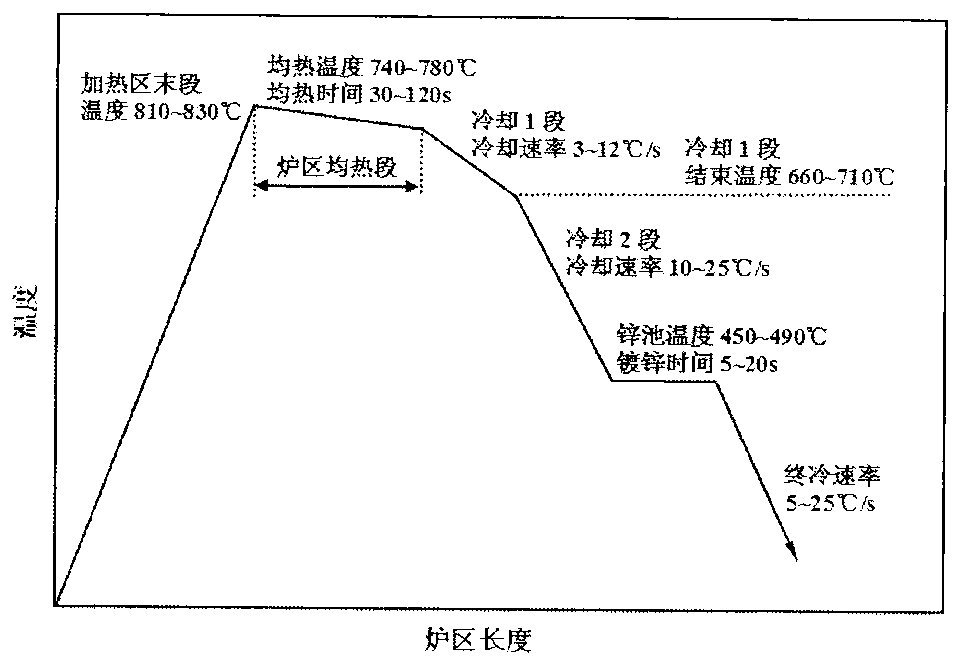

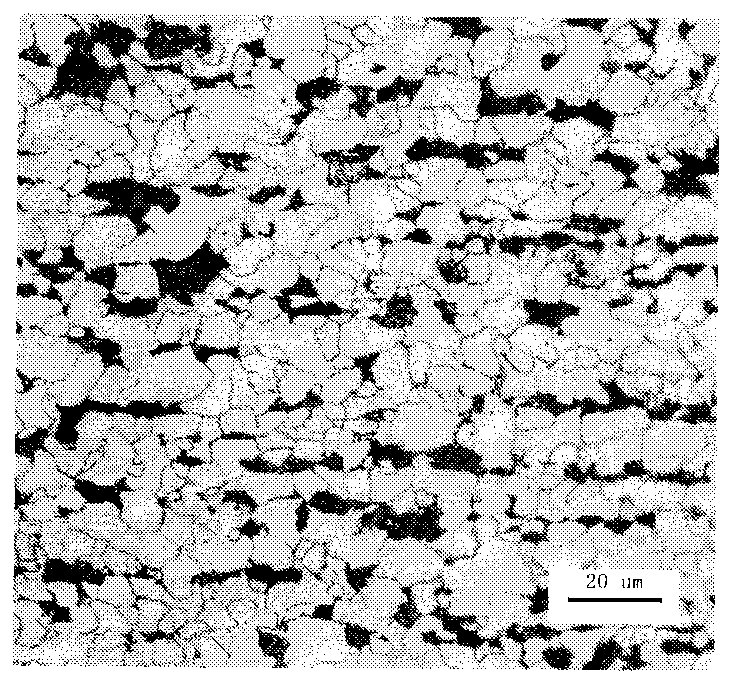

High-strength cold-rolled hot-galvanized dual-phase steel plate and manufacture method thereof

ActiveCN102719751AAdd lessReduce compositionTemperature control deviceContinuous annealingUltimate tensile strength

The invention discloses a high-strength cold-rolled hot-galvanized dual-phase steel plate, characterized in that components, in mass percentage, are: 0.03% to 0.15% of C, less than or equal to 0.15% of Si, 1.00% to 1.75% of Mn, less than or equal to 0.015% of P, less than or equal to 0.012% of S, 0.02% to 0.15% of Al, 0.35% to 0.75% of Cr, 0.02% to 0.15% of Cu, 0.010% to 0.035% of Ti, less than or equal to 0.005% of N, in addition meeting the requirement that the total percentage of Mn, 1.29Cr and 0.46Cu is not less than 1.5% and not more than 2.5%, and the balance being Fe and inevitable impurities. The manufacture method comprises converter smelting, secondary refining, continuous casting, hot continuous rolling, cold acid continuous rolling, annealing galvanizing and hot dipping, wherein a galvanized substrate with a reasonable organization and composition and an excellent plate shape is obtained through controlled rolling and controlled cooling while rolling; and through employing a micro-slowly cooling way for heating from an end segment to an isothermal segment and a secondary fast cooling way for a fast cooling segment during continuous annealing galvanizing, the cold-rolled hot-galvanized dual-phase steel plate is obtained, wherein the steel plate is advantageous by having a tensile strength between 490 to 700 MPa, well-matched strength and ductility, an excellent coating performance, and a thickness between 0.5 to 2.5 mm, and can be used as an automobile cover component, an inner plate, a structural component, etc.

Owner:ANGANG STEEL CO LTD

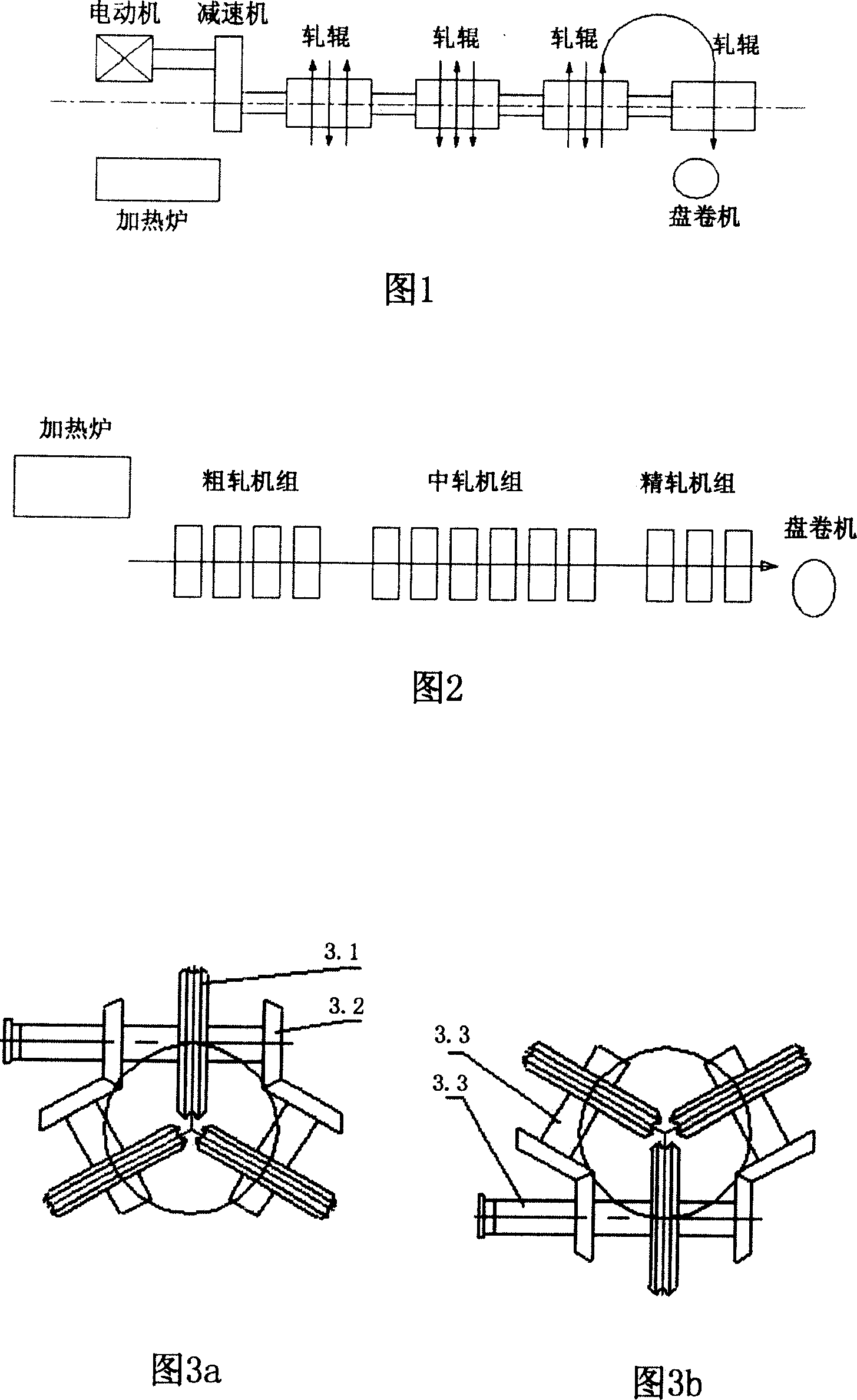

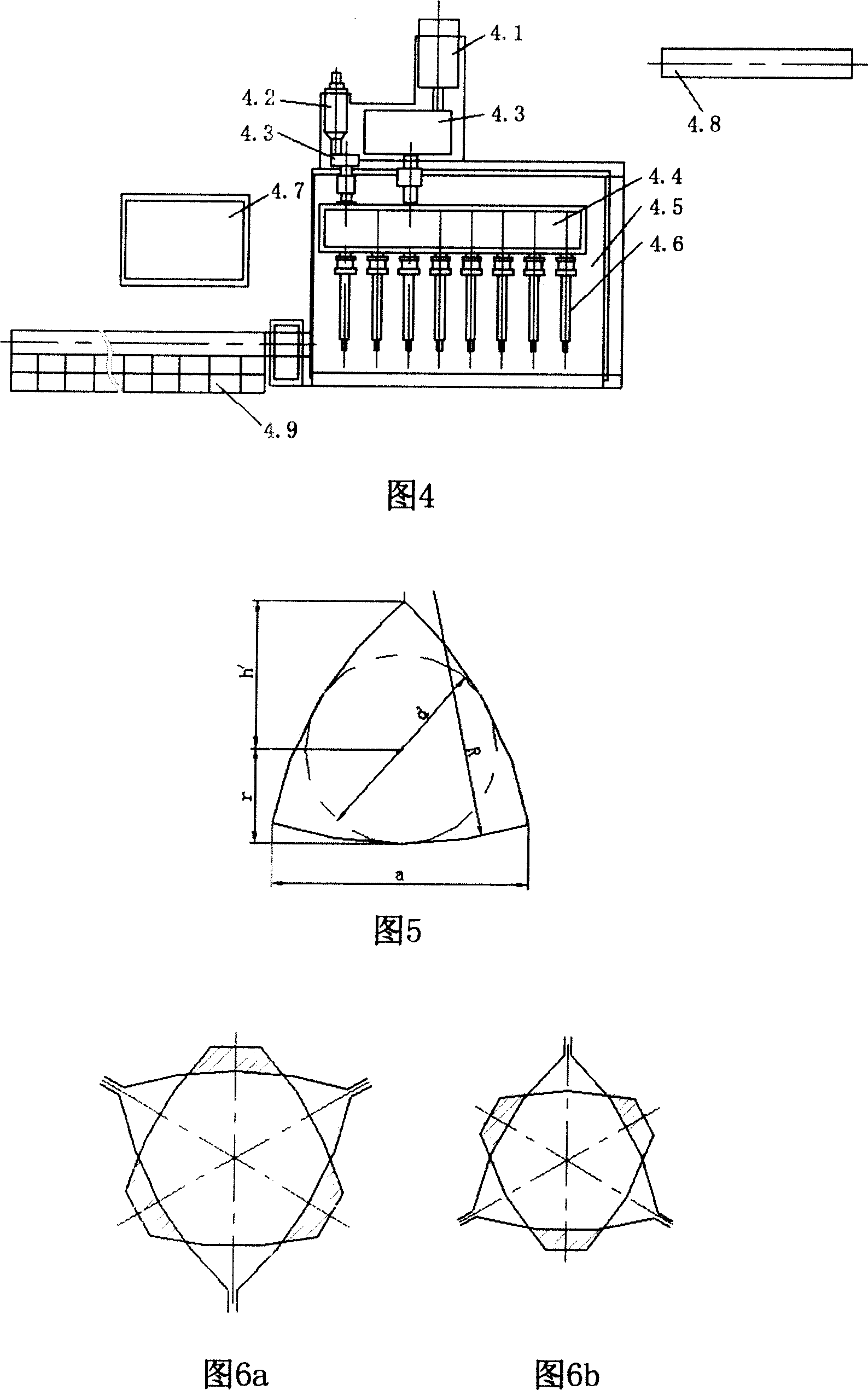

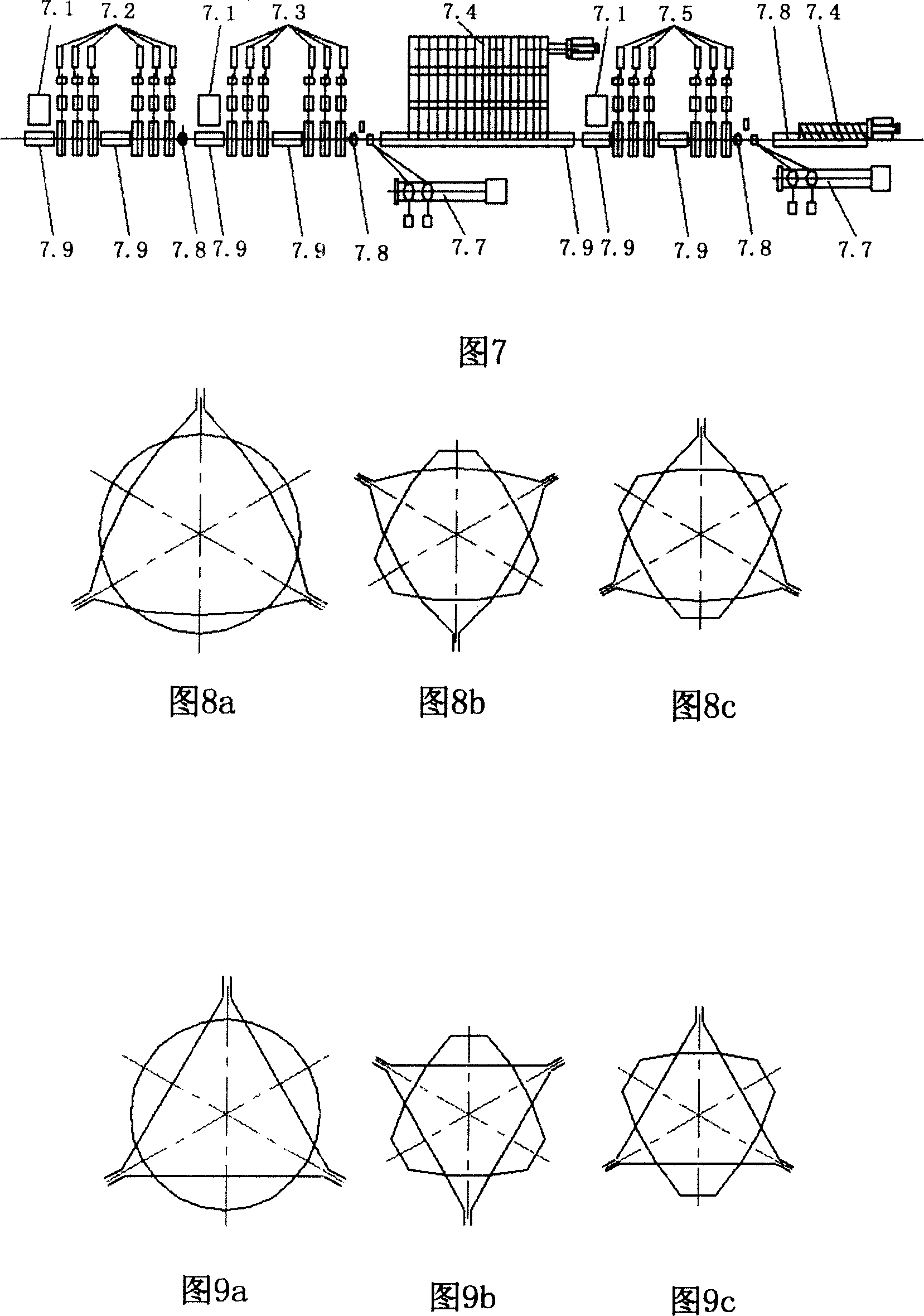

Method for rolling titanium and titanium alloy bar wire bar with three-roller type Y continuous rolling mill

InactiveCN101152653AImprove surface qualityFew beginningsTemperature control deviceMetal rolling stand detailsLow noiseWire rod

The invention provides a method for rolling of titanium and titanium alloy bar and wire rod with three-roller Y continuous rolling mill. The technical proposal of the invention is as follows that the three-roller Y continuous rolling mill group is used for 6 to 18 pass continuous rolling of heated titanium and titanium alloy bar billet of phi50mm to form bar billet of 30 to 8mm (or hexagonal and triangular structure of 24 to 8mm) or rolling wire billet of phi20 to 8mm. by adopting the method, bar billet of phi50mm can be rolled into bar billet of phi30 to 8mm (or triangular and hexagonal structure) or rolling wire billet of phi20 to 8mm after heated for one time. Compared with the prior methods of multiple fire time casting, swaging, two-roller transverse-arrangement non-continuous rolling and two-roller longitudinal-arrangement continuous rolling, all of which are used for production of titanium and titanium alloy bar or rolling wire billet, the invention not only has the advantages of high efficiency, energy saving, low noise, small occupying and high precision of the size as well as good organization perforation of titanium and titanium alloy bar and wire rod, but also can produce triangular or hexagonal section and other allotype section.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com