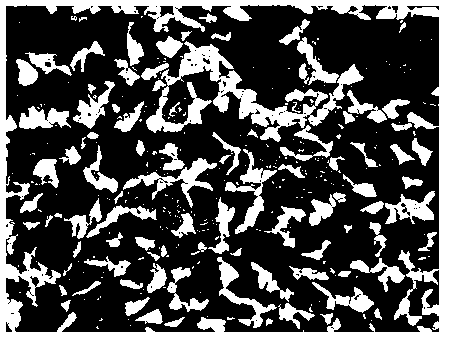

Low-yield-ratio high-strength hot-rolled Q&P steel and manufacturing method thereof

A technology with low yield ratio and manufacturing method, applied in the field of wear-resistant steel, can solve problems such as low strength and difficult realization of ferrite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

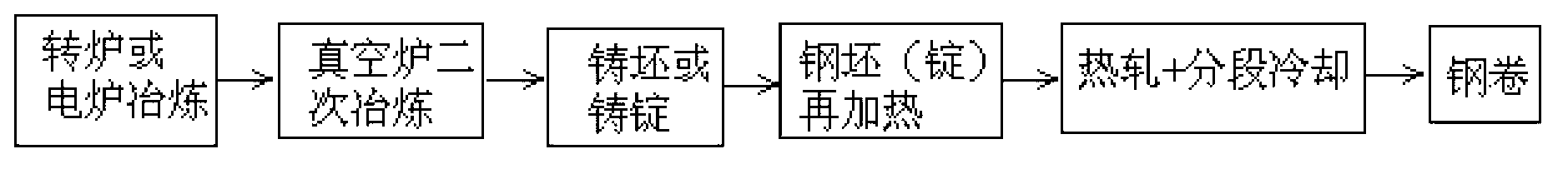

[0051] The manufacture of the low yield ratio high-strength hot-rolled Q&P steel of embodiment 1-9 specifically comprises the steps:

[0052] 1) Smelting, secondary refining, casting:

[0053] According to the chemical composition of each steel in Table 1, adopt converter or electric furnace smelting, vacuum furnace secondary refining, and casting to form billets or ingots; the thickness of billets is 120mm;

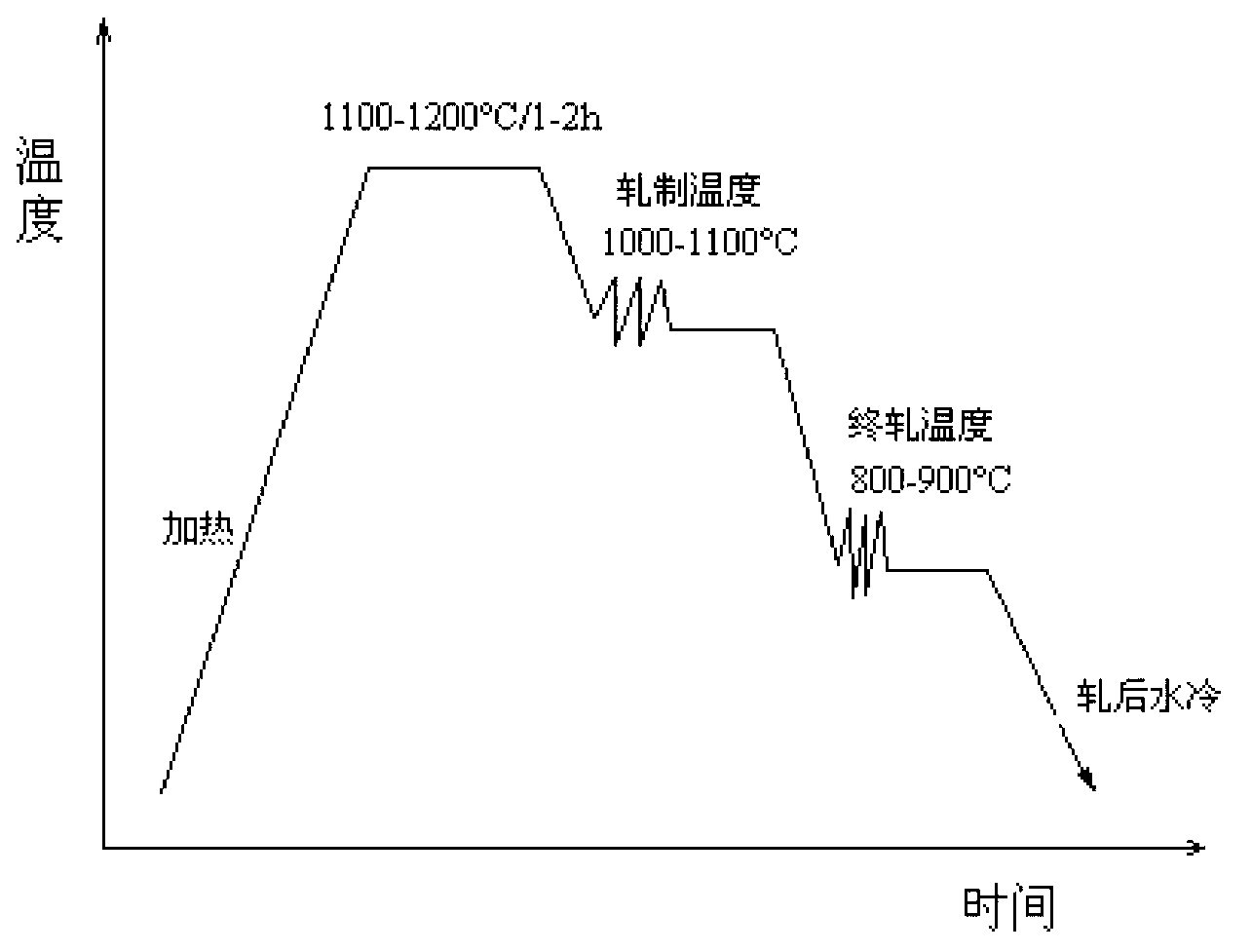

[0054] 2) Heating and hot rolling:

[0055] Heating the slab or ingot obtained in step 1) to 1100-1200°C and holding it for 1-2 hours, the starting temperature of rolling is 1000-1100°C, 5-7 passes of hot rolling and the cumulative deformation under high pressure is ≥50% , and then when the temperature of the intermediate billet drops to 900-950°C, rolling is carried out for 3-5 passes and the cumulative deformation is ≥70%; the hot-rolling process is as follows figure 2 Shown; The specific heating and hot rolling process parameters of each embodiment are as shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com