Dynamic roll gap compensation method during cold continuous rolling flying gauge control

A technology of dynamically changing specifications and compensation methods, applied in the direction of rolling force/roll gap control, etc., can solve the problems of low thickness control accuracy and out-of-tolerance thickness of head and tail, so as to reduce head thickness deviation and improve setting accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

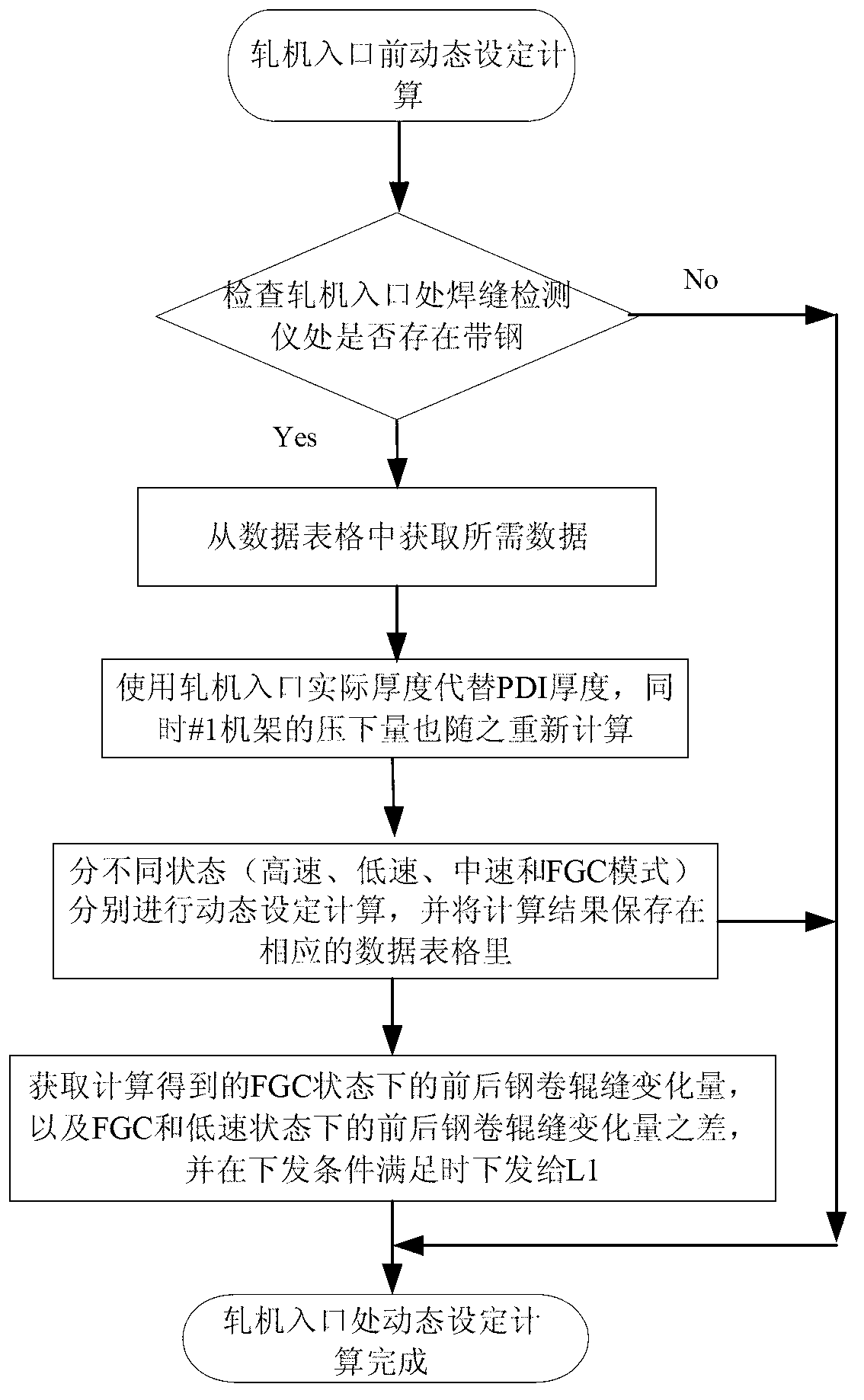

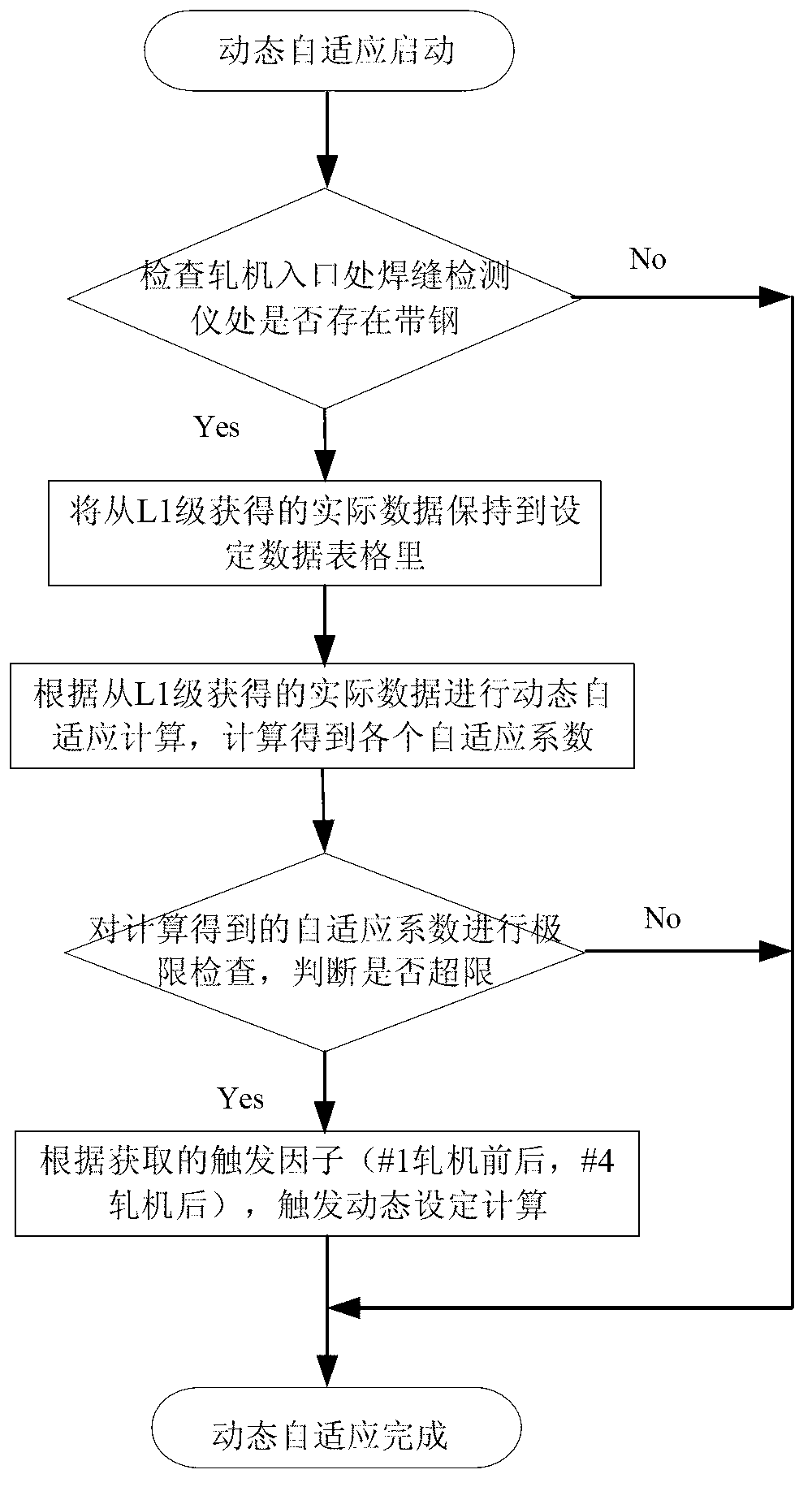

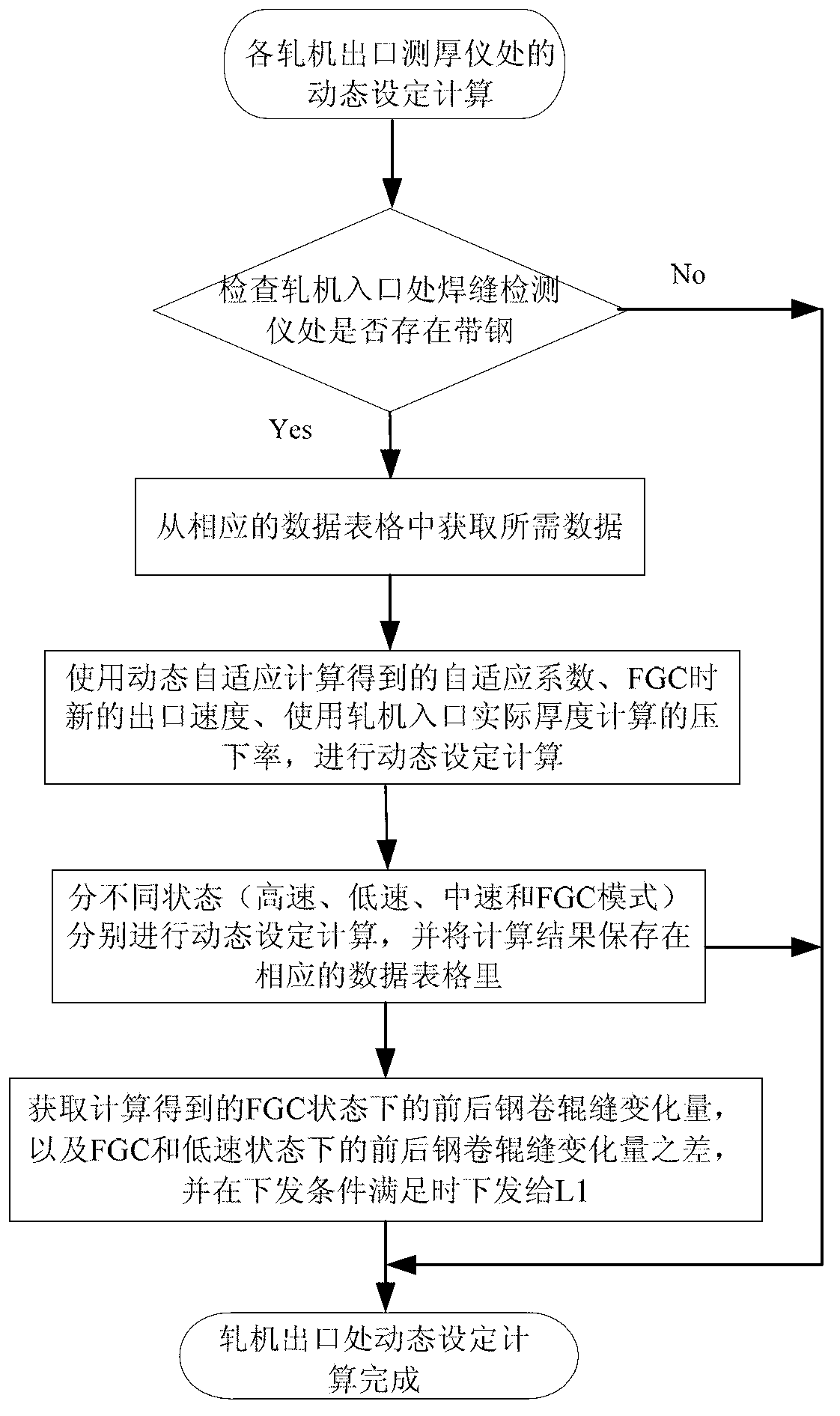

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] The dynamic roll gap compensation method is related to whether there are thickness gauges installed before and after the rolling mill of the cold rolling production line. Only when the weld meets the thickness gauge can dynamic compensation calculation be performed. This inventive method is applied to a cold-rolled silicon steel production line. The factory uses five-stand six-roll rolling, and a total of 4 thickness gauges are installed. Two thickness gauges are installed before and after #1 rolling mill, and #5 rolling mill is installed before and after. 2 thickness gauges.

[0024] Therefore, the dynamic roll gap compensation method is calculated at the entrance of #1 rolling mill, and at the exit of #1 rolling mill, #4 rolling mill exit and #5 rolling mill exit. The dynamic compensation calculation at the mill entry gauge is not th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com