Patents

Literature

293results about "Rare end control device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling planeness of cold-rolling strip steel

ActiveCN101618402ARealize coordinated controlAccurate detectionRare end control deviceTemperature control deviceAutomatic controlEngineering

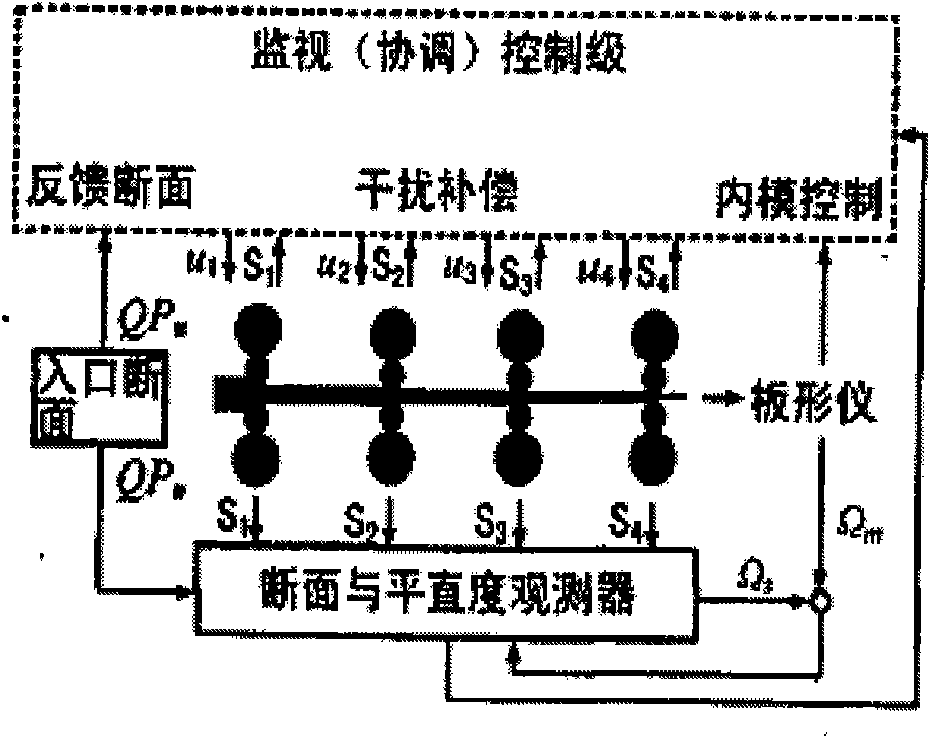

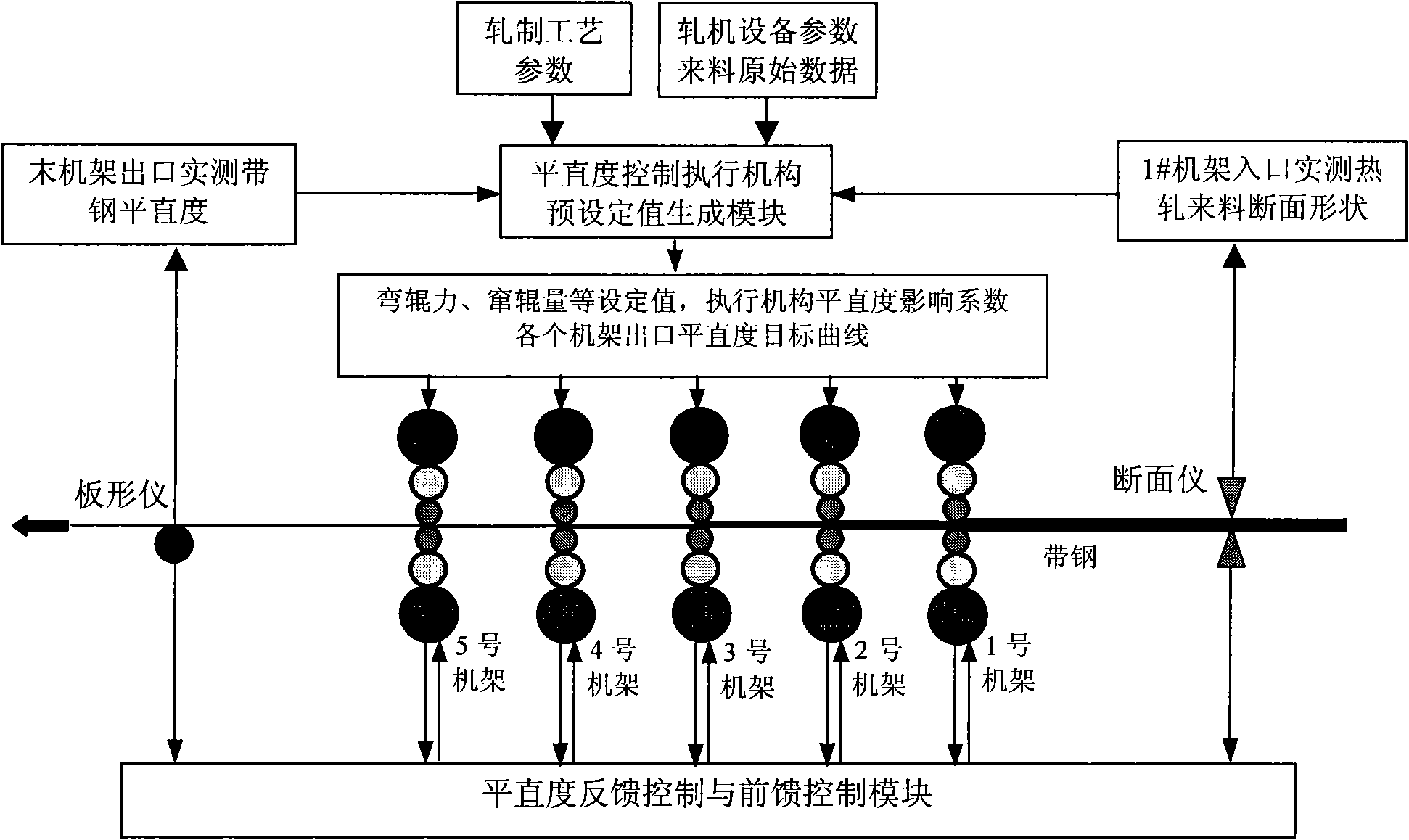

The invention discloses a method for controlling the planeness of cold-rolling strip steel, which comprises the following steps of: carrying out planeness feed-forward control, planeness feedback control and coordination control between both; detecting the cross-section shape and the planeness of a hot rolling incoming material, and actually-measured rolling technological parameters of each frame in real time based on a profiler configured on a No. 1 frame inlet, wherein the parameters comprise rolling force actually-measured values and plate shape adjusting mechanism actually-measured values, and carrying out the feed-forward control on the planeness of each frame outlet; and actually measuring the planeness of the cold-rolling strip steel based on a plate shape roller configured on an outlet of a cold rolling mill, and intensively carrying out the feedback control on the planeness of a final frame outlet. The method can eliminate the influences of the cross-section shape and the planeness of the hot rolling incoming material and fluctuations of the rolling technological parameters on the planeness of the final frame outlet to improve the planeness quality of the cold-rolling strip steel on the one hand, and can automatically control the planeness of each frame outlet, reduce incidence of abnormal conditions, such as fracture surfaces, deviation and the like, and improve the stability in the production process of tandem cold strip rolling on the other hand.

Owner:BAOSHAN IRON & STEEL CO LTD

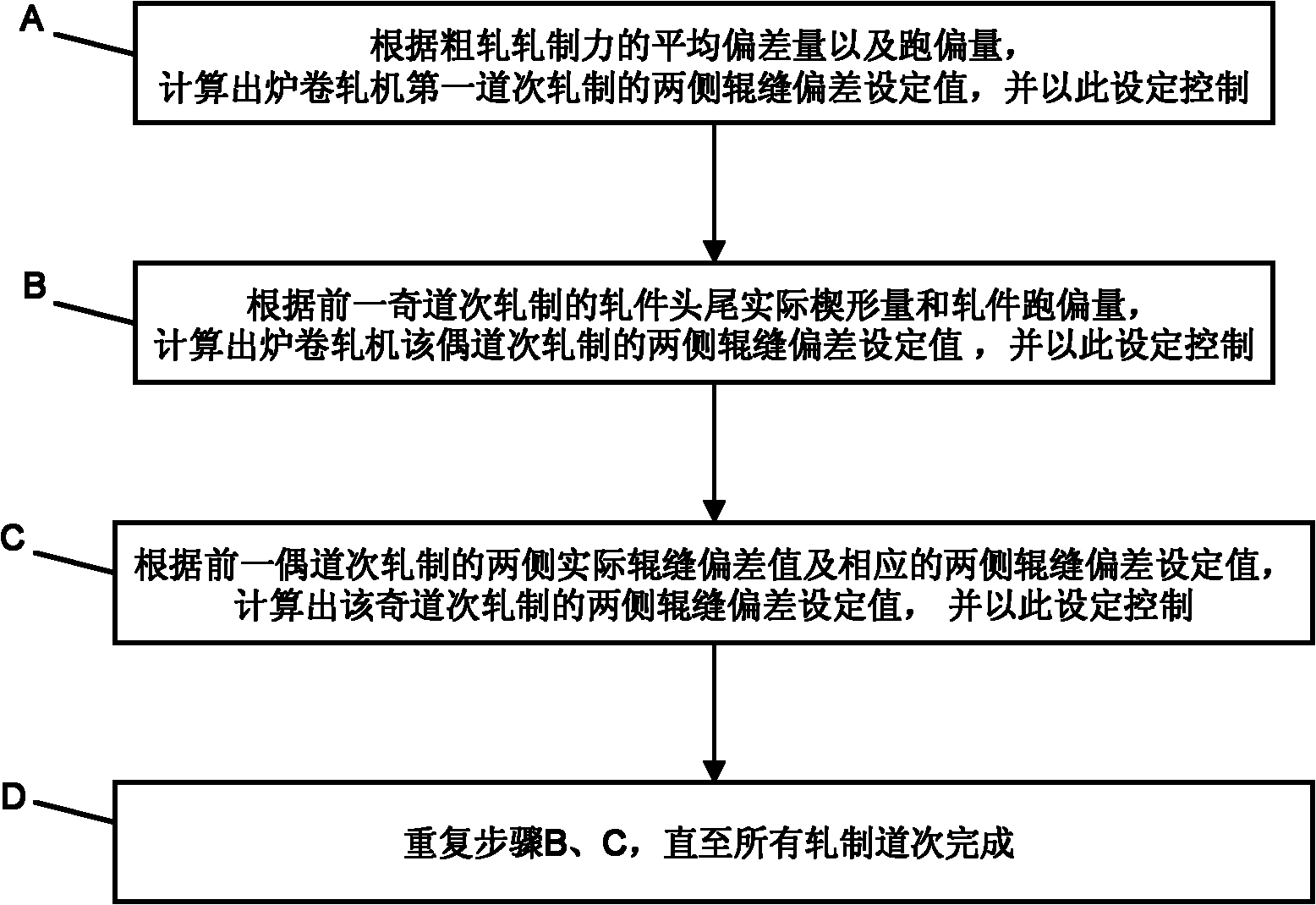

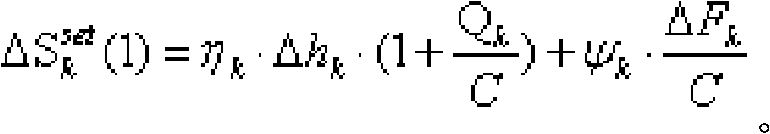

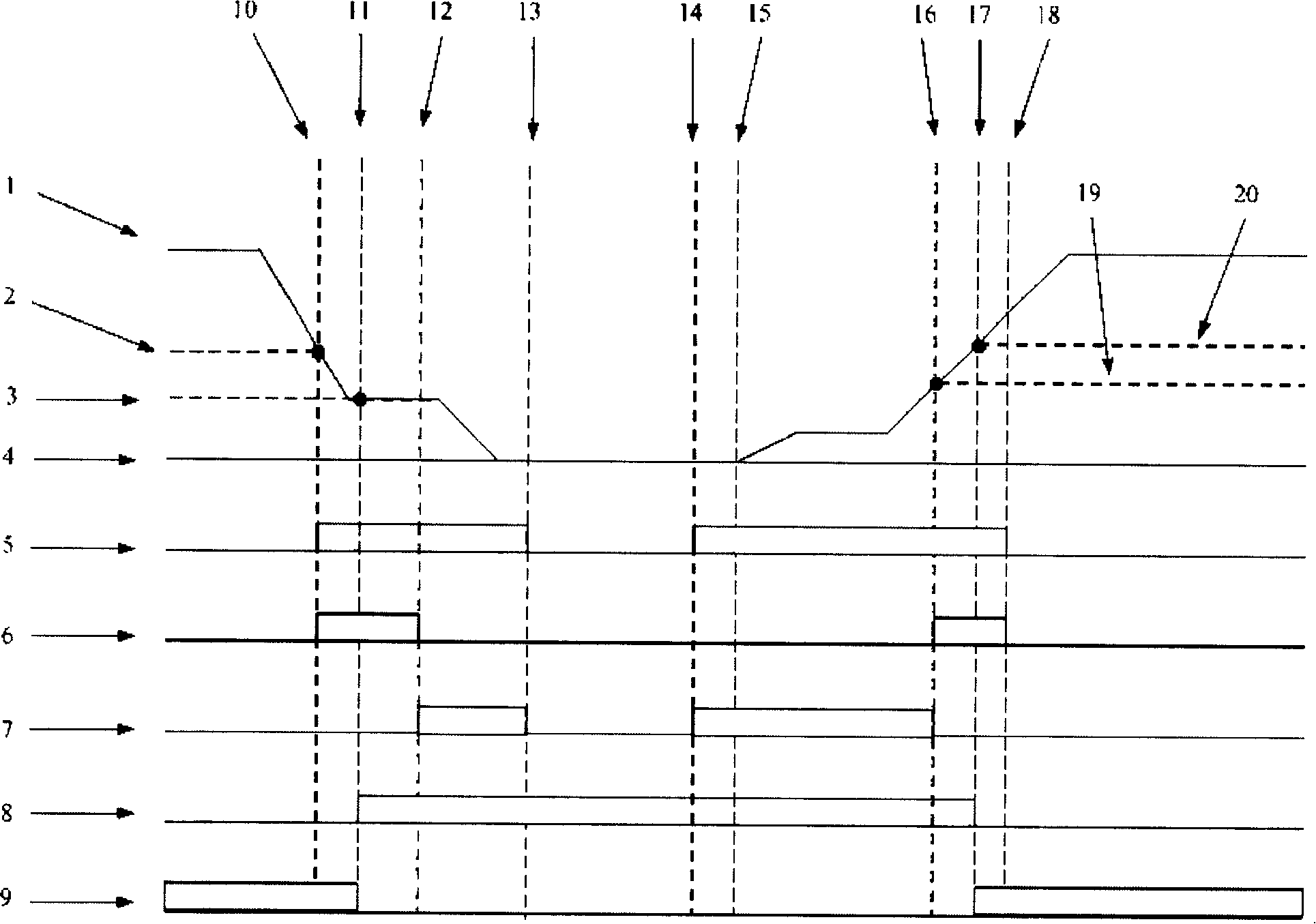

Steckel mill rolled piece head-and-tail deviation control method

InactiveCN102641903AImprove rolling stabilityPrevent set controlRare end control deviceRoll force/gap control deviceStrip millStrip steel

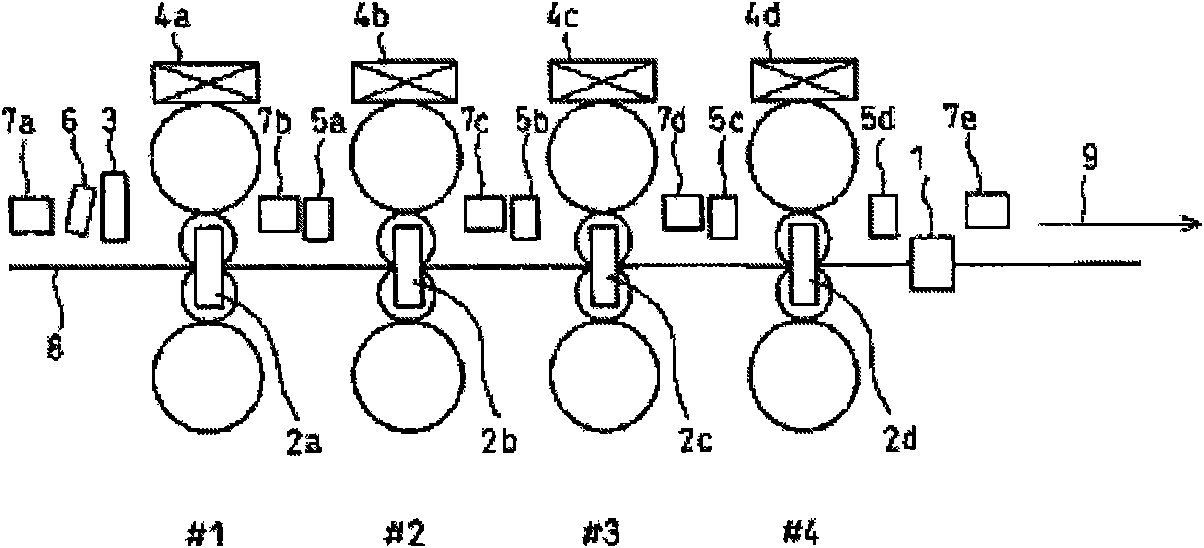

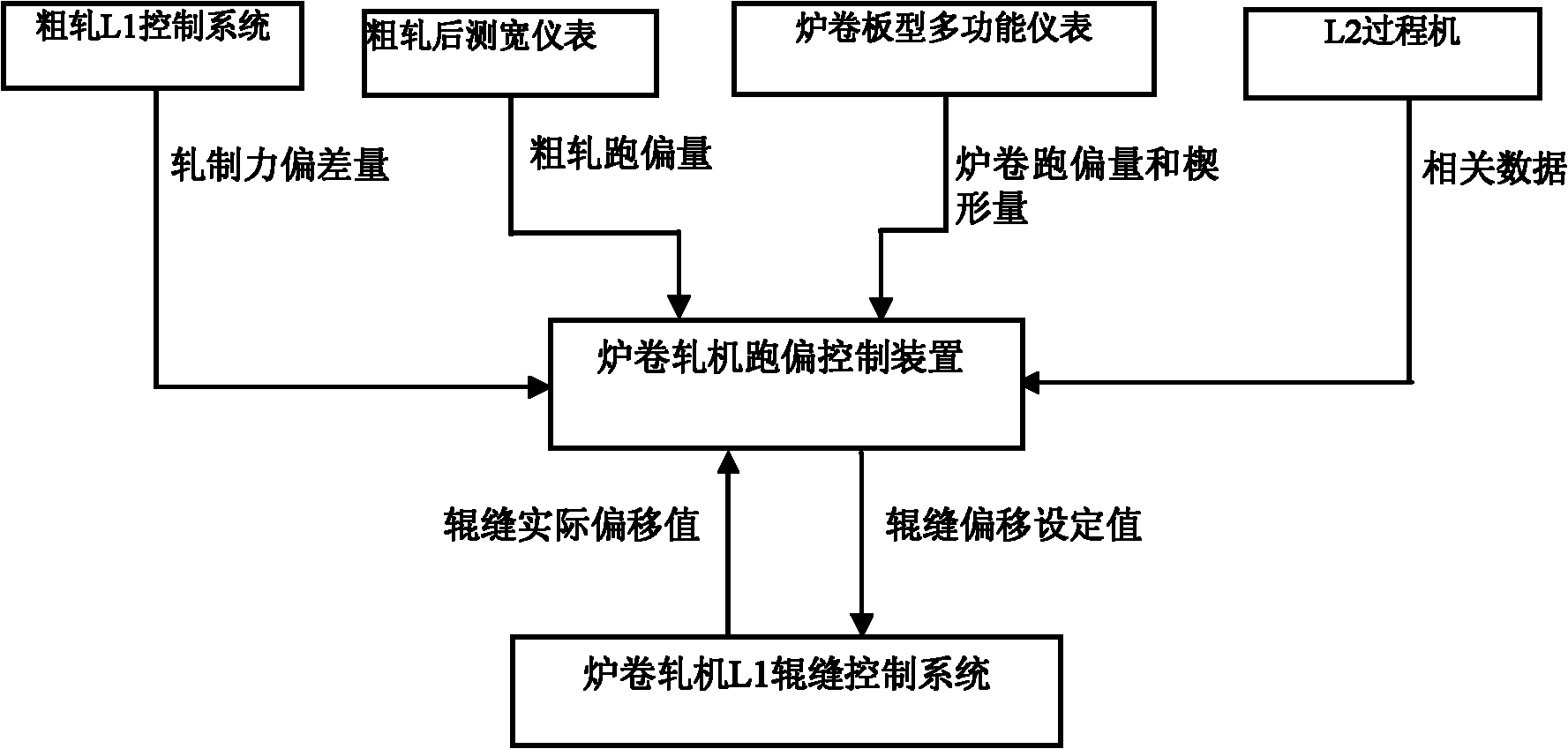

The invention discloses a steckel mill rolled piece head-and-tail deviation control method which comprises the following steps that: based on existing equipment configuration, different modes are distinguished by integrating the rolling information of a steckel mill according to the rolled piece deviation and rough rolling force in the final step of rough rolling, then the deviation controlled by roll gaps on both sides of the steckel mill is determined, and roll gap setting control for preventing deviation is carried out. Through the method, the hand-and-tail deviation of strip steel can be reduced, shut-down accidents caused by the deviation of strip steel can be prevented, and the rolling stability of the steckel mill can be improved.

Owner:BAOSHAN IRON & STEEL CO LTD

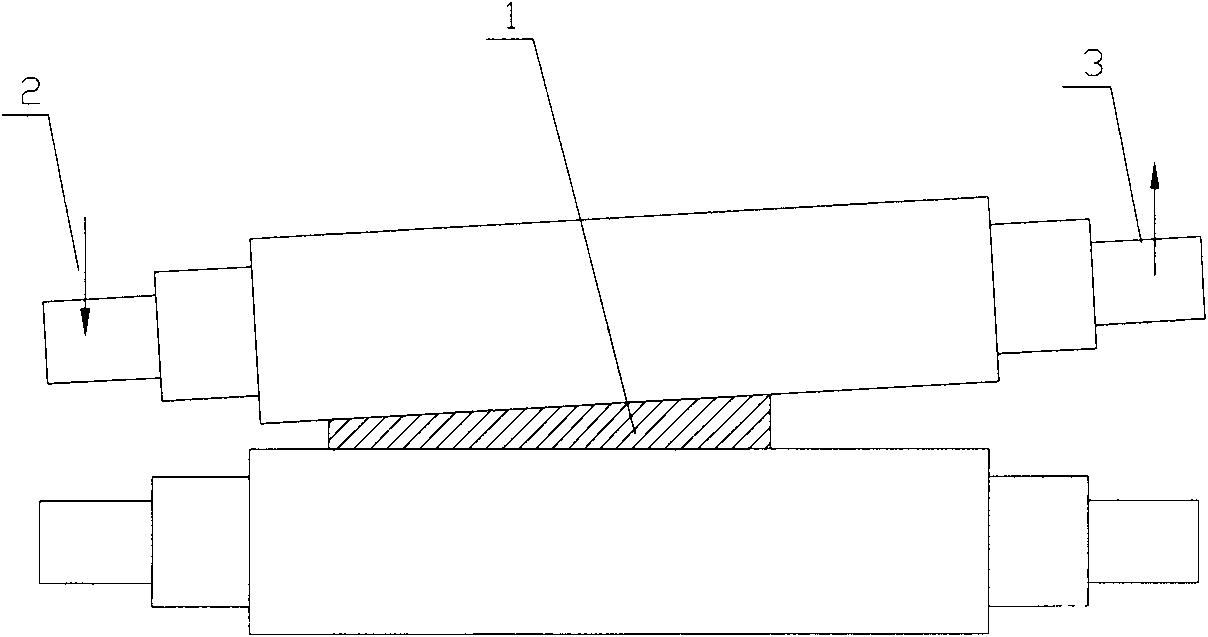

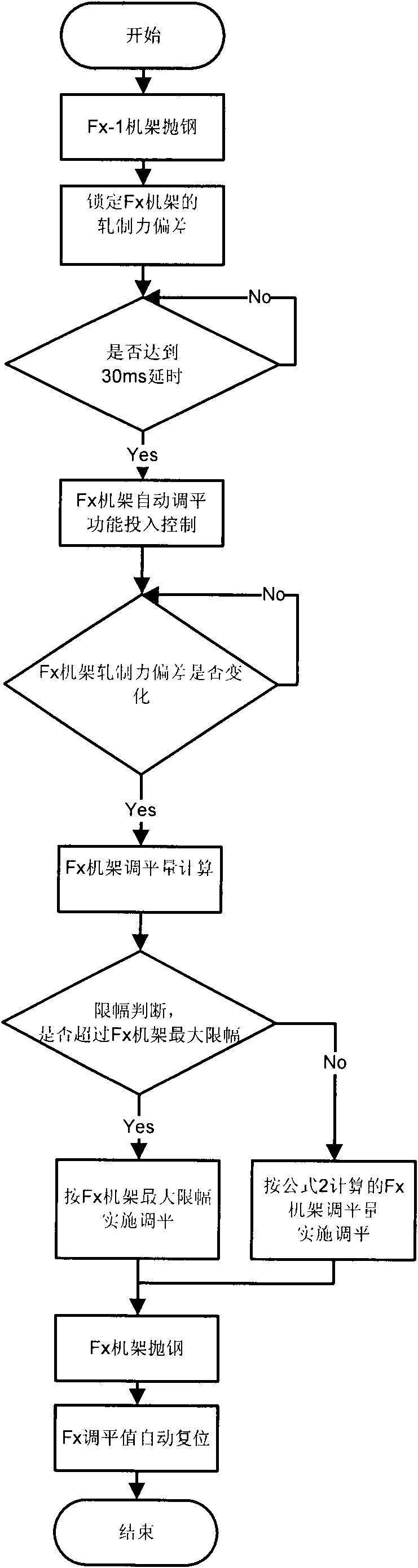

Steel strip tail deviation control method

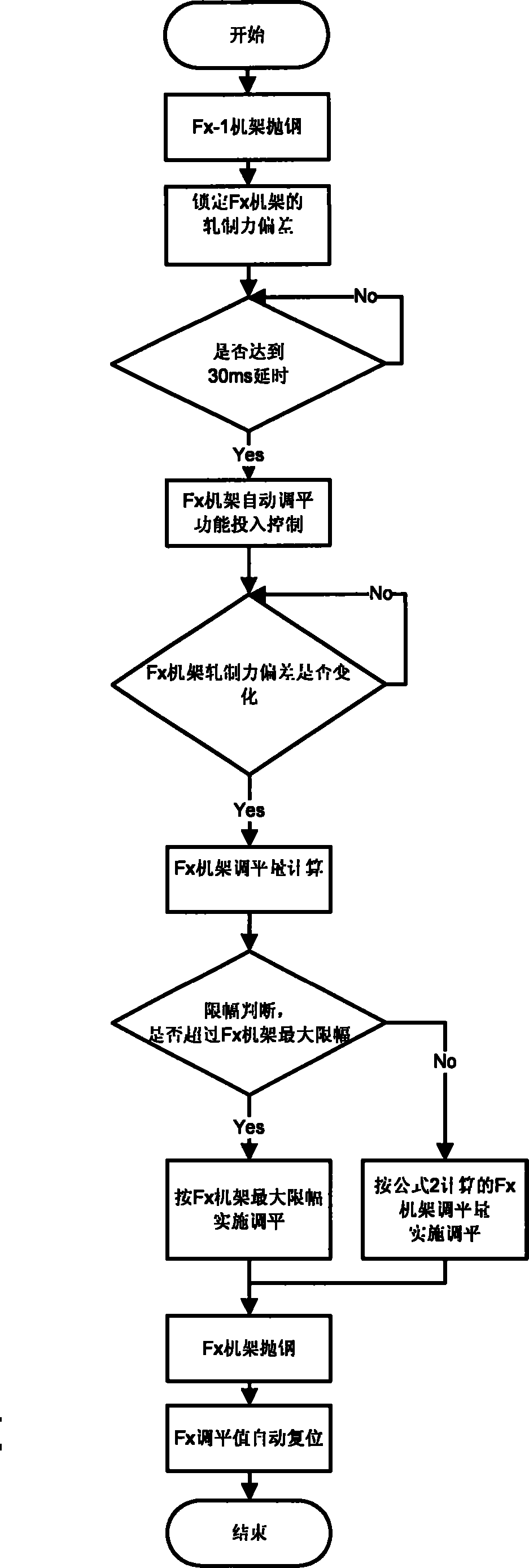

The invention discloses a steel strip tail deviation control method, which includes: locking the rolling force deviation of an Fx rolling mill and setting the same as the automatic leveling target for the next roll after steel blasting of an Fx-1 or Fx-2 rolling mill; judging whether the deviation of rolling force of two sides of the Fx rolling milling within the nth sampling cycle by an automatic leveling system of the Fx rolling mill varies or not, and determining that the steel strip deviates if the rolling force deviation varies; computing the leveling amount of the nth sampling cycle by the automatic leveling system for the Fx rolling mill and judging whether the leveling amount exceeds the maximum limit value of the Fx rolling mill or not; raising or pressing transmission side roll gap according to the maximum limit value of the Fx rolling mill if the leveling amount exceeds the maximum limit value; and raising or pressing the transmission side roll gap according to the leveling amount if the leveling amount does not exceed the maximum limit value.

Owner:BAOSHAN IRON & STEEL CO LTD

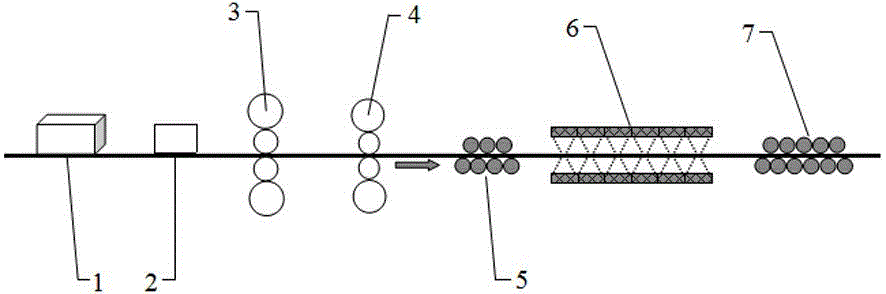

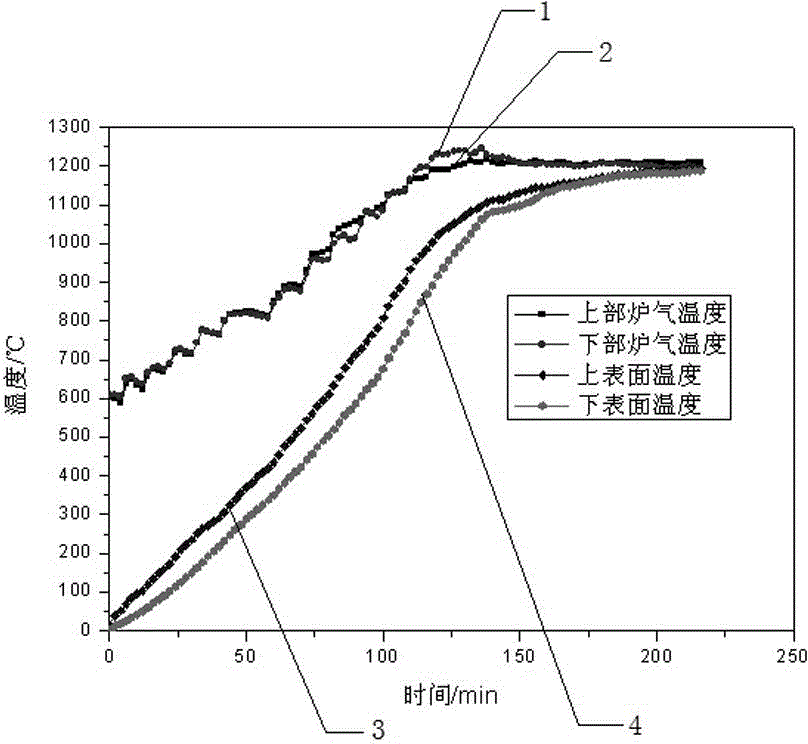

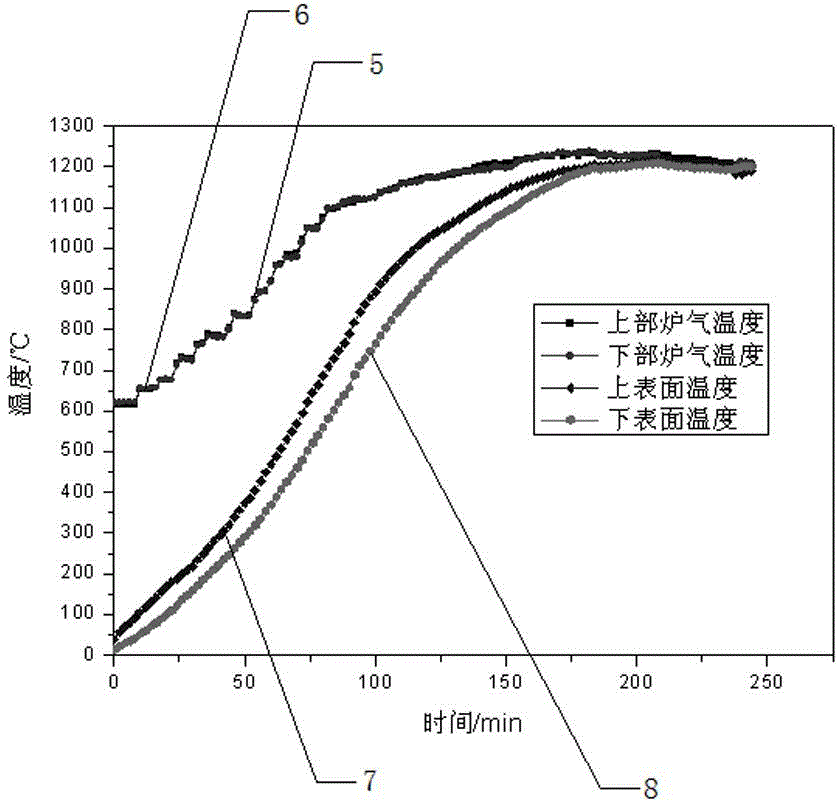

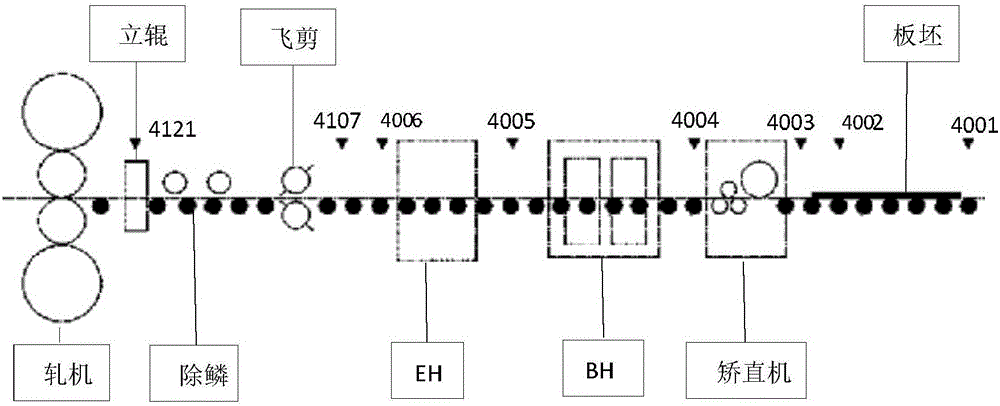

On-line quenching and plate shape controlling technology for 12MnNiVR steel plate

ActiveCN103555914AImprove cooling efficiencyReduce the number of transshipmentsRare end control deviceWork treatment devicesWater flowEconomic benefits

The invention discloses on-line quenching and plate shape controlling technology for a 12 MnNiVR steel plate, comprising: a blank material cold installation step, a de-scaling step, a rough rolling step, a finish rolling step, a pre-straightening step and an on-line quenching step; wherein in the on-line quenching step, the steel plate enters a ultrafast cooling system with 18 groups of cooling headers, the ultrafast cooling system sets a water flow amount based on the steel plate target thickness, sets an area roller-way speed being 0.7-1.2m / s, sets a roller-way acceleration being 0.003-0.01m / s2, controls a cooling start temperature being 790-740 DEG C, and controlling a cooling final temperature being 180-270 DEG C, and the steel plate departs from the ultrafast cooling system when a cooling final temperature is 180-270 DEG C. The technology provided by the invention raises cooling uniformity, cooling efficiency and once plate shape qualified rate of an on-line quenched steel plate, simplifies a thermal refining technology flow of 12MnNiVR, and finally raises economic benefit of enterprises.

Owner:NANJING IRON & STEEL CO LTD

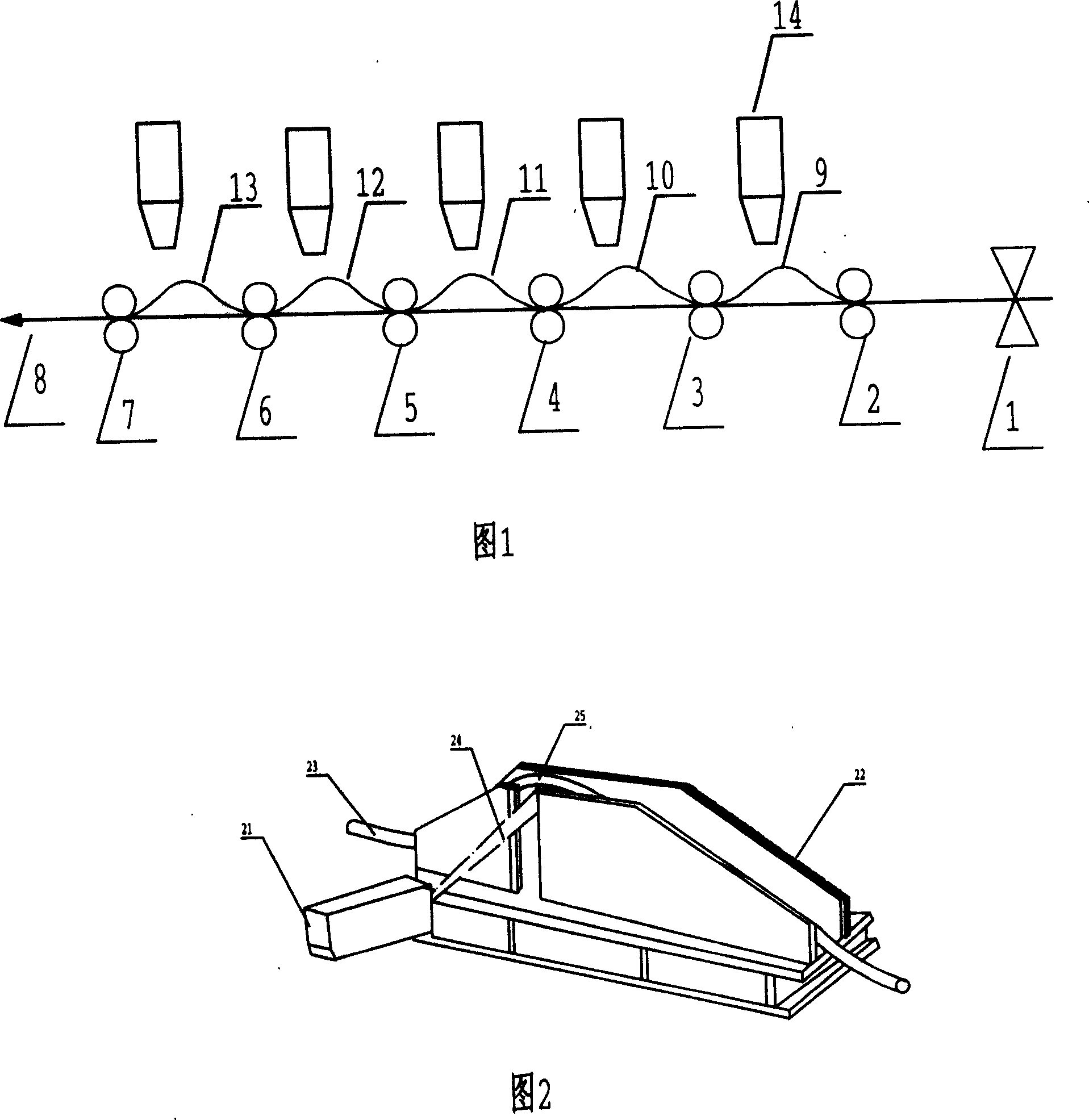

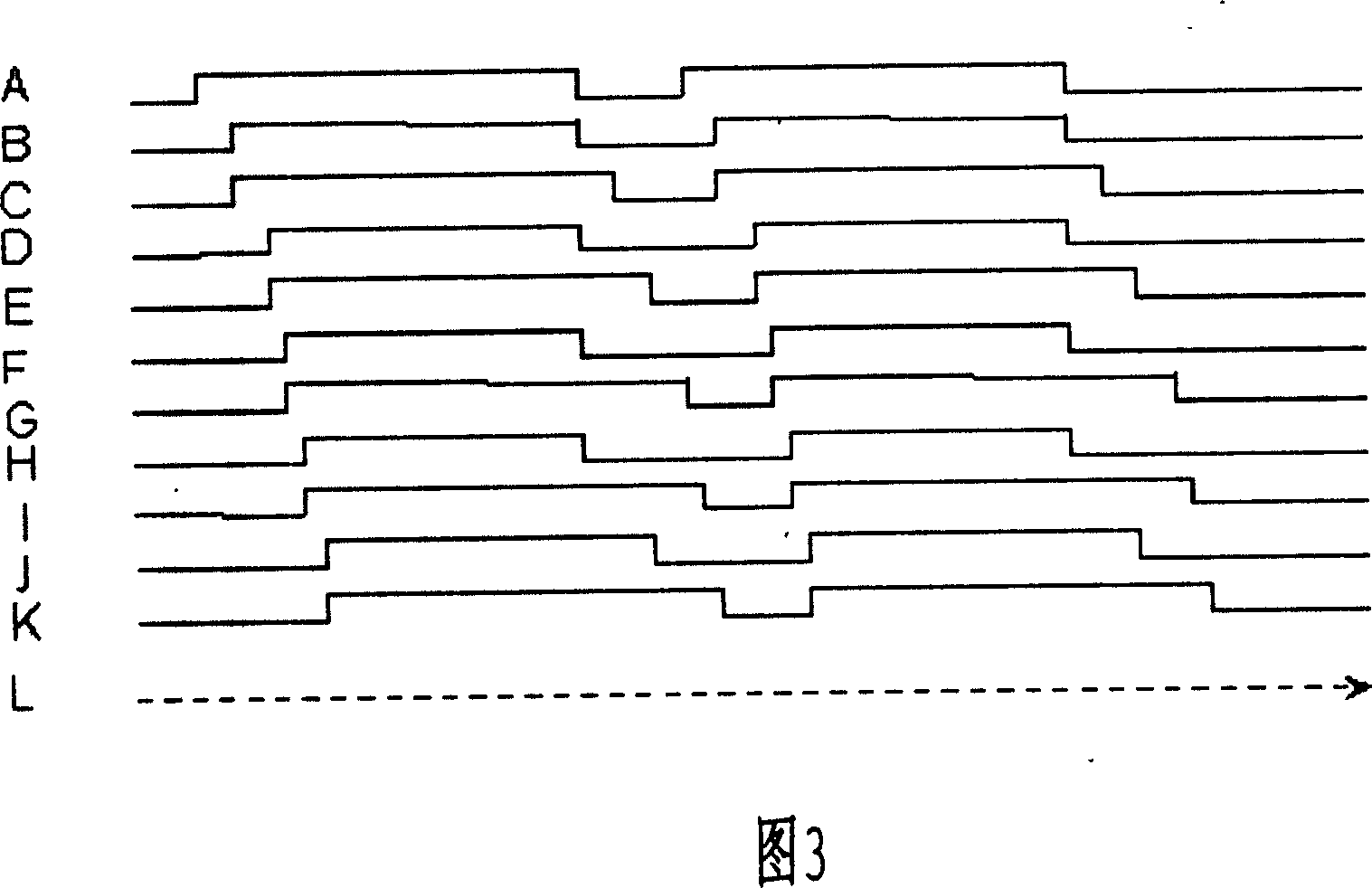

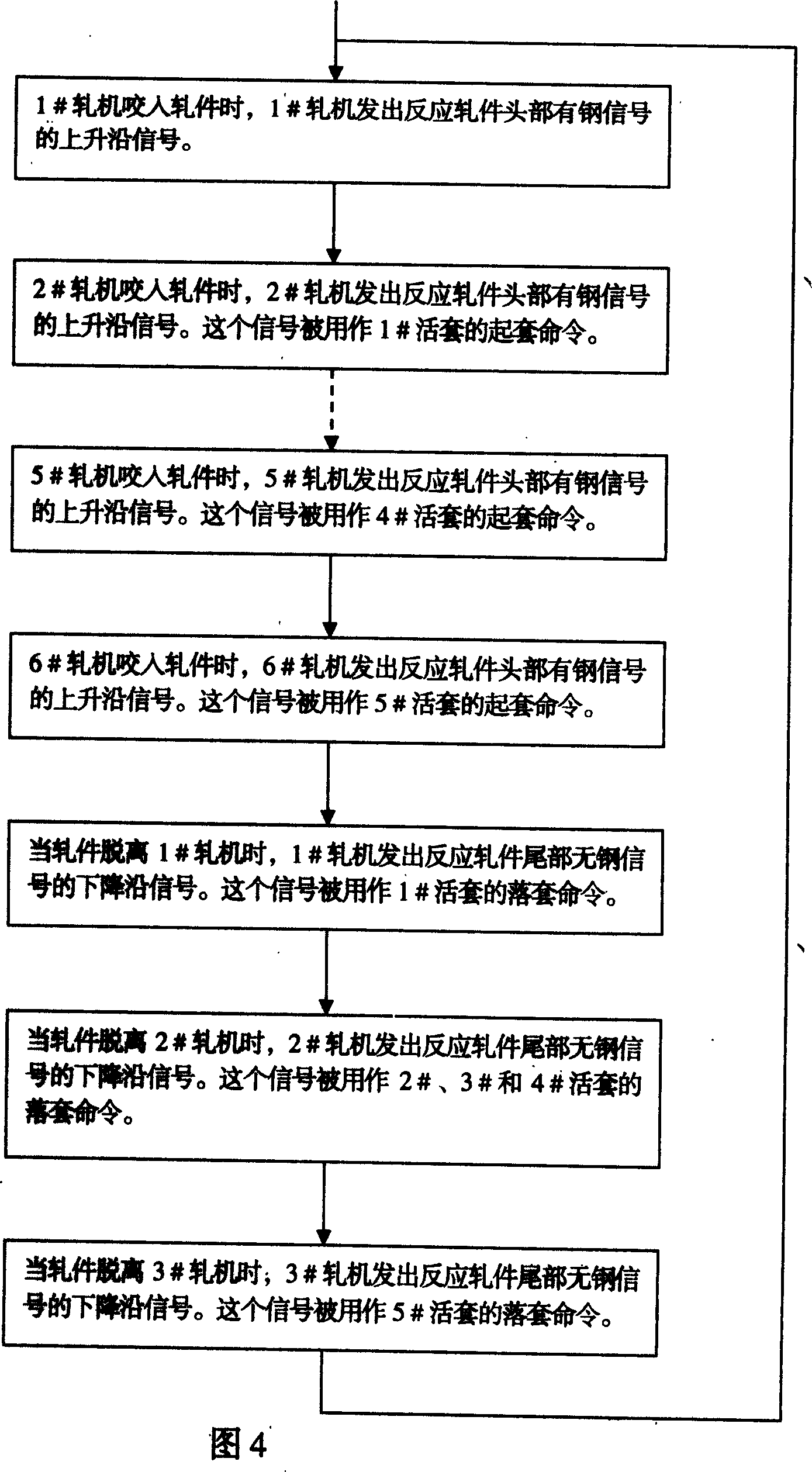

Method for solving difficulty of looping tail at steel rolling production-line

InactiveCN101003064ASolve the tail flick problemReduce steel pile accidentsRare end control deviceFlexible work arrangmentsProduction lineControl signal

A method for preventing the loops from not containing the steel tail features that the load head signal of down stream rolling mill is used as the loop lifting command, the load tail signal of upstream rolling mill is used as the loop lowering command, and the load signal of the first rolling mill is directly used as the control signal of the loop lifters for the next three rolling mills.

Owner:HEBEI IRON AND STEEL

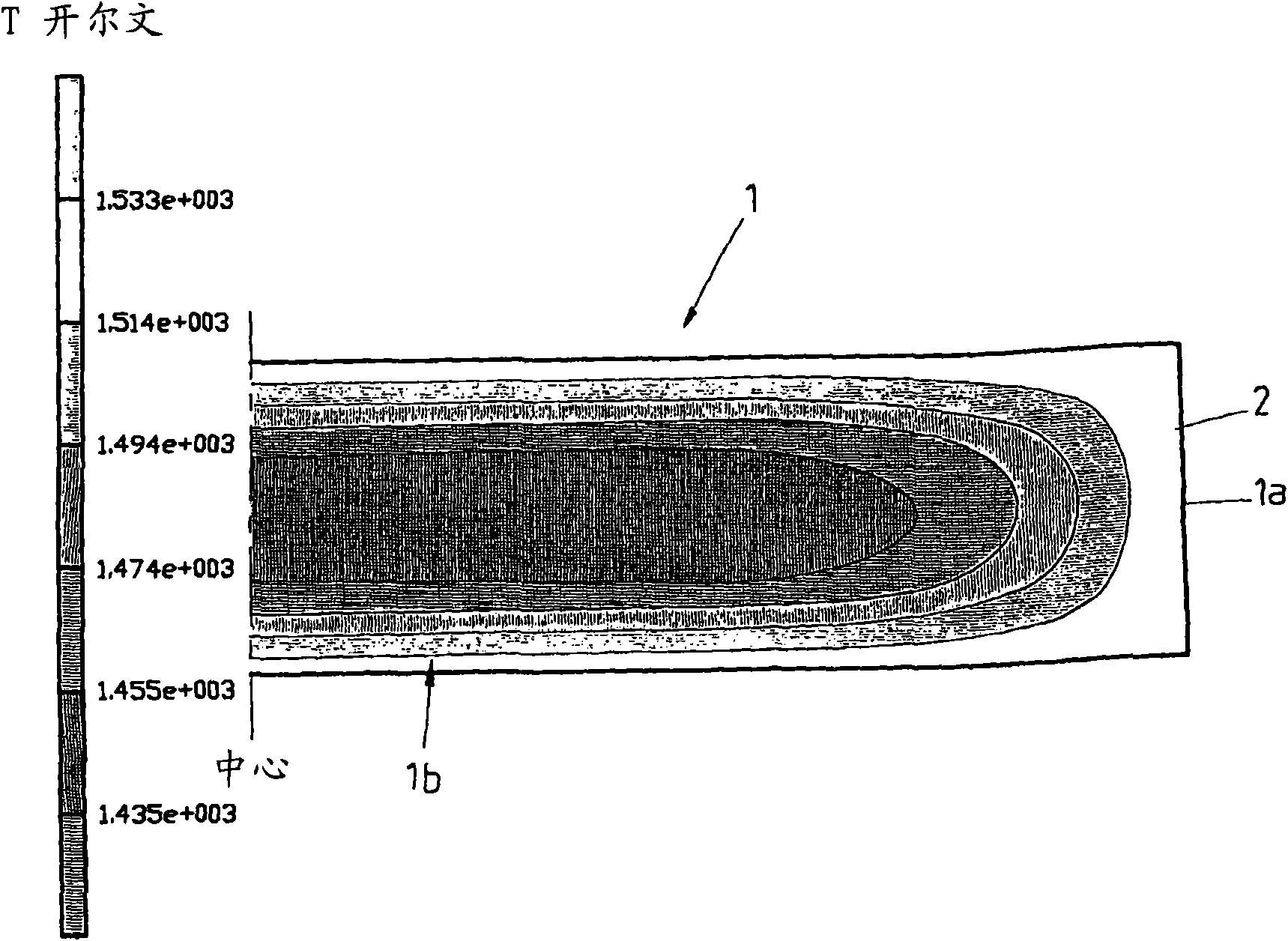

Device for influencing the temperature distribution over a width

InactiveCN101678419ARare end control deviceTemperature control deviceStrip steelIncrease temperature

The invention relates to a device (10) for influencing the temperature distribution over the width of a rolled material and / or a strip (11) or a slab, particularly in a hot strip mill, wherein at least one cooling device is provided and has nozzles (14) for applying a cooling means, wherein the nozzles (14) are arranged in such a manner or are controlled such that a cooling means is applied particularly to positions at which an increased temperature is detected. Furthermore, the invention relates to a device (10) for influencing the strip surface evenness by strip cooling, wherein according tothe surface evenness of the strip (11), the cooling device is controlled in such a manner that the uneven areas are reduced or removed. In addition, with this invention the strip contour can be influenced in a specific manner, wherein the strip (11) or the slab is cooled over the width thereof in such a manner that the strip contour better approximates a desired target contour.

Owner:SMS GRP GMBH

Method for making easy-to-pickle steel plate

InactiveCN102671992AIncreasing the thicknessImprove lateral uniformityRare end control deviceWork treatment devicesSheet steelStrip steel

The invention provides a method for making an easy-to-pickle steel plate and belongs to the technical field of metallurgy. The method comprises the following steps of: smelting molten steel, and making a plate blank by continuous casting; descaling by using high pressure water, performing rough rolling on the descaled plate blank, performing finish rolling, cooling to the temperature of 500 to 550 DEG C, cooling at the speed of 5 to 10 DEG C per minute to obtain the steel which is easy to pickle and in a hot rolling state and of which the content of FeO is over 25 percent; performing finish rolling, cooling to the temperature of 650 to 700 DEG C at the speed of 1 to 5 DEG C per minute to obtain the steel which is easy to pickle and in a cold rolling state and has a uniform structure and of which the content of iron oxide scale FeO is less than 10 percent. By adopting the method, the thickness of the iron oxide scale is reduced by 20 to 30 percent compared with the conventional process, the pickling speed of the strip steel is increased from 150 to 160 m per minute to 180 to 200 m per minute compared with the conventional process, not only the pickling quality of the steel plate is guaranteed, but also the pickling efficiency is effectively improved.

Owner:NORTHEASTERN UNIV +1

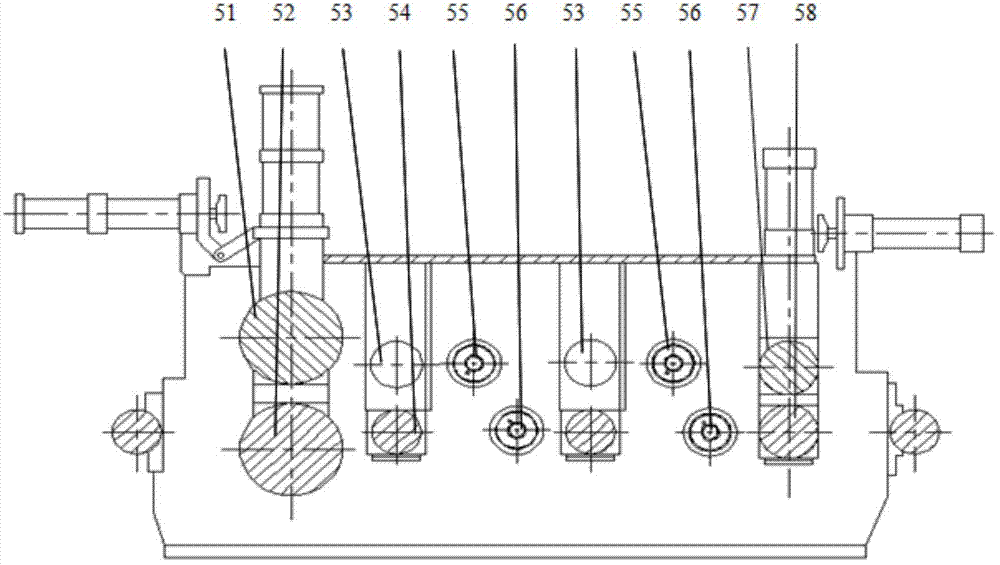

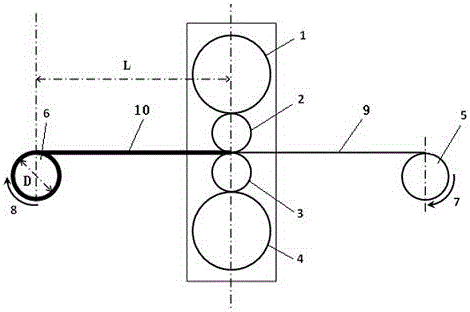

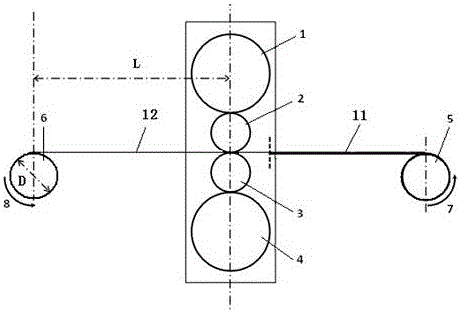

Pinch roll unit

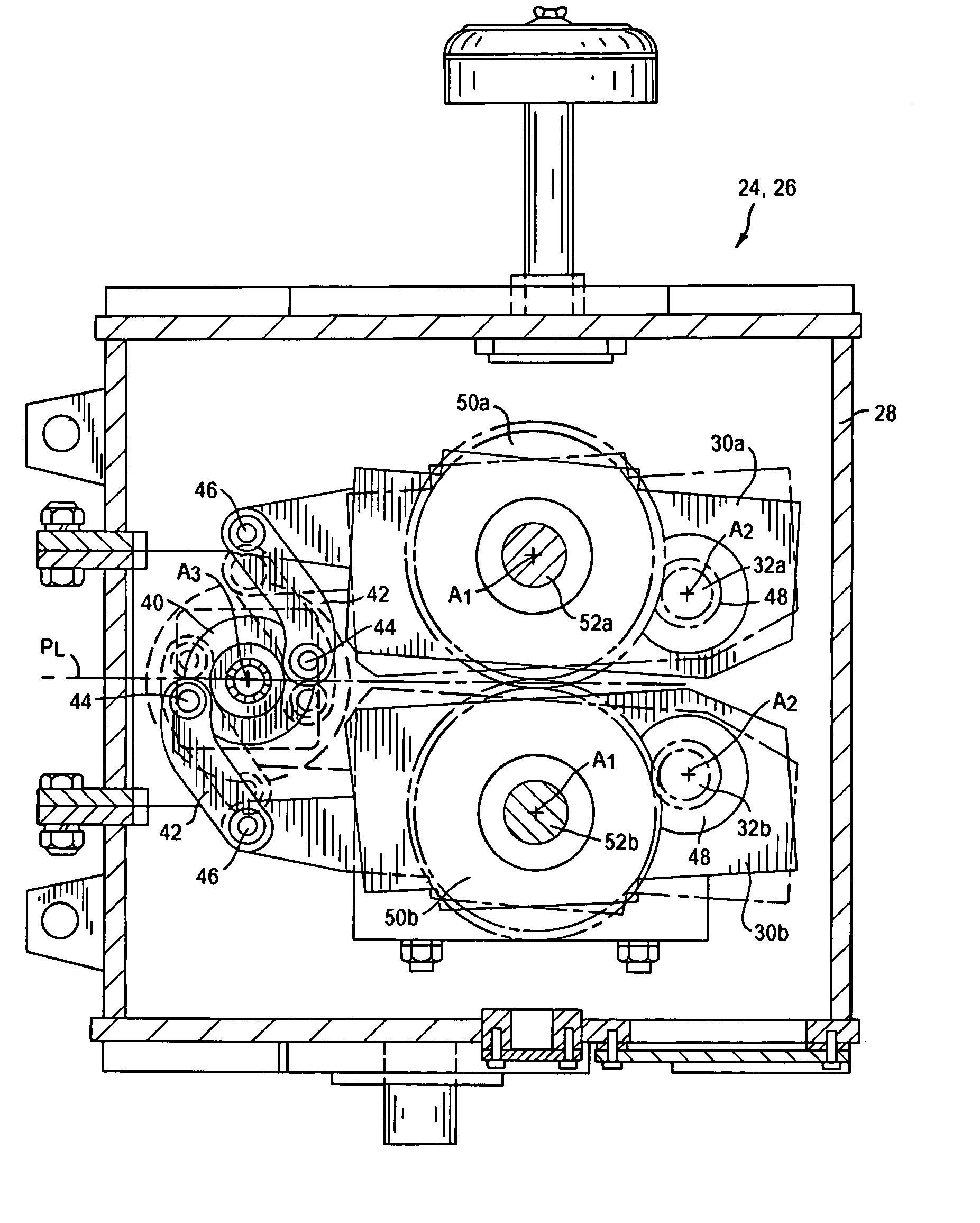

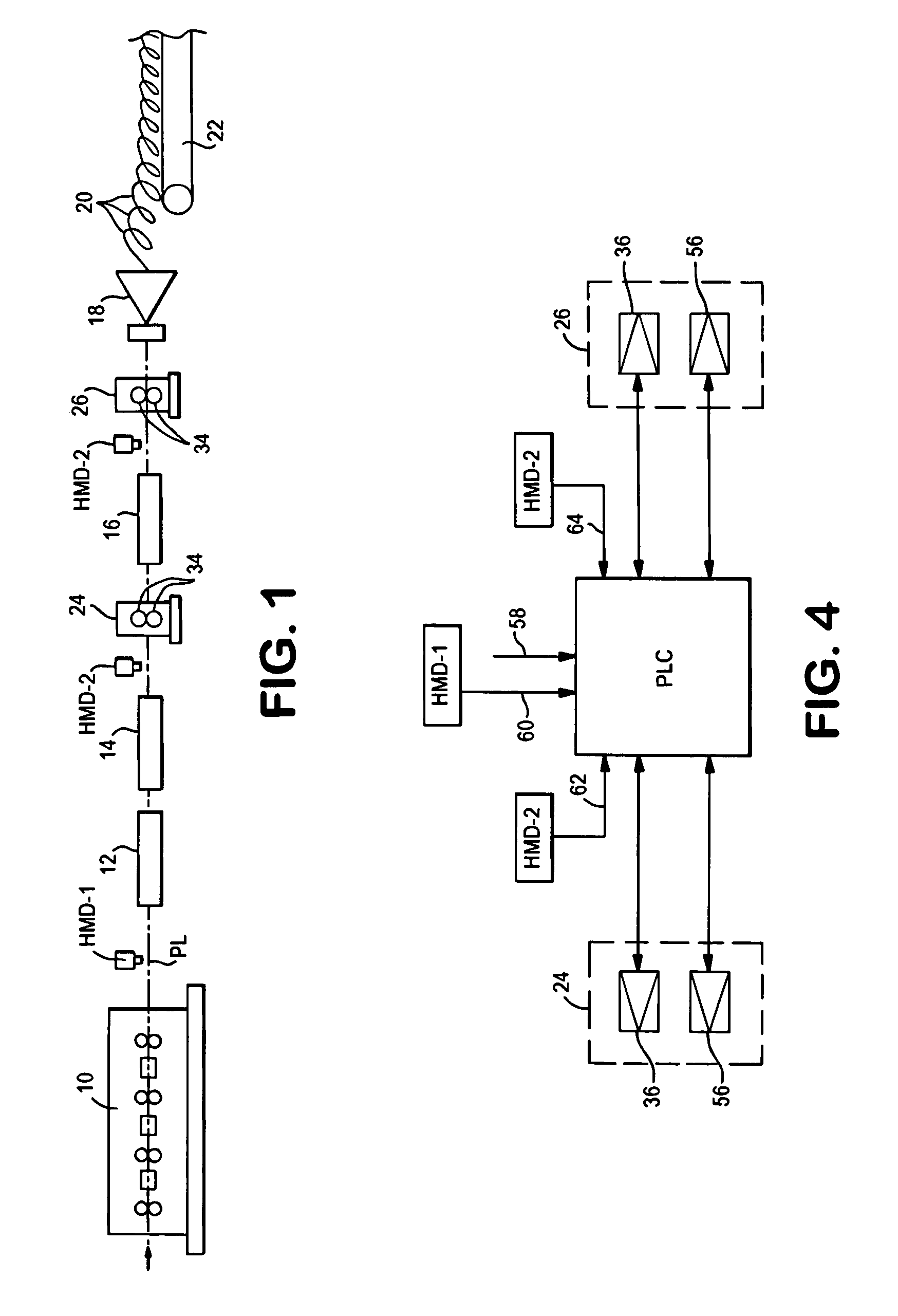

A pinch roll unit for either propelling or retarding a product moving along the pass line of a rolling mill comprises a pair of levers mounted for rotation about parallel first axes. Roll shafts are carried by the levers with each roll shaft being journalled for rotation about a second axis parallel to the first axis of its respective lever. Pinch rolls are carried by the roll shafts and are positioned to define a gap therebetween for receiving the product. An electrically powered first motor operates via a linkage to rotate the levers about the first axes and to move the pinch rolls between open positions spaced from the product, and closed positions contacting and gripping the product therebetween. An electrically powered second motor rotatably drives the pinch rolls.

Owner:PRIMETALS TECH USA

Method for controlling head and tail shapes of hot-rolled strip steel

ActiveCN102989787APrevent shape deterioration etc.Improve shape qualityRare end control deviceStructural engineeringStrip steel

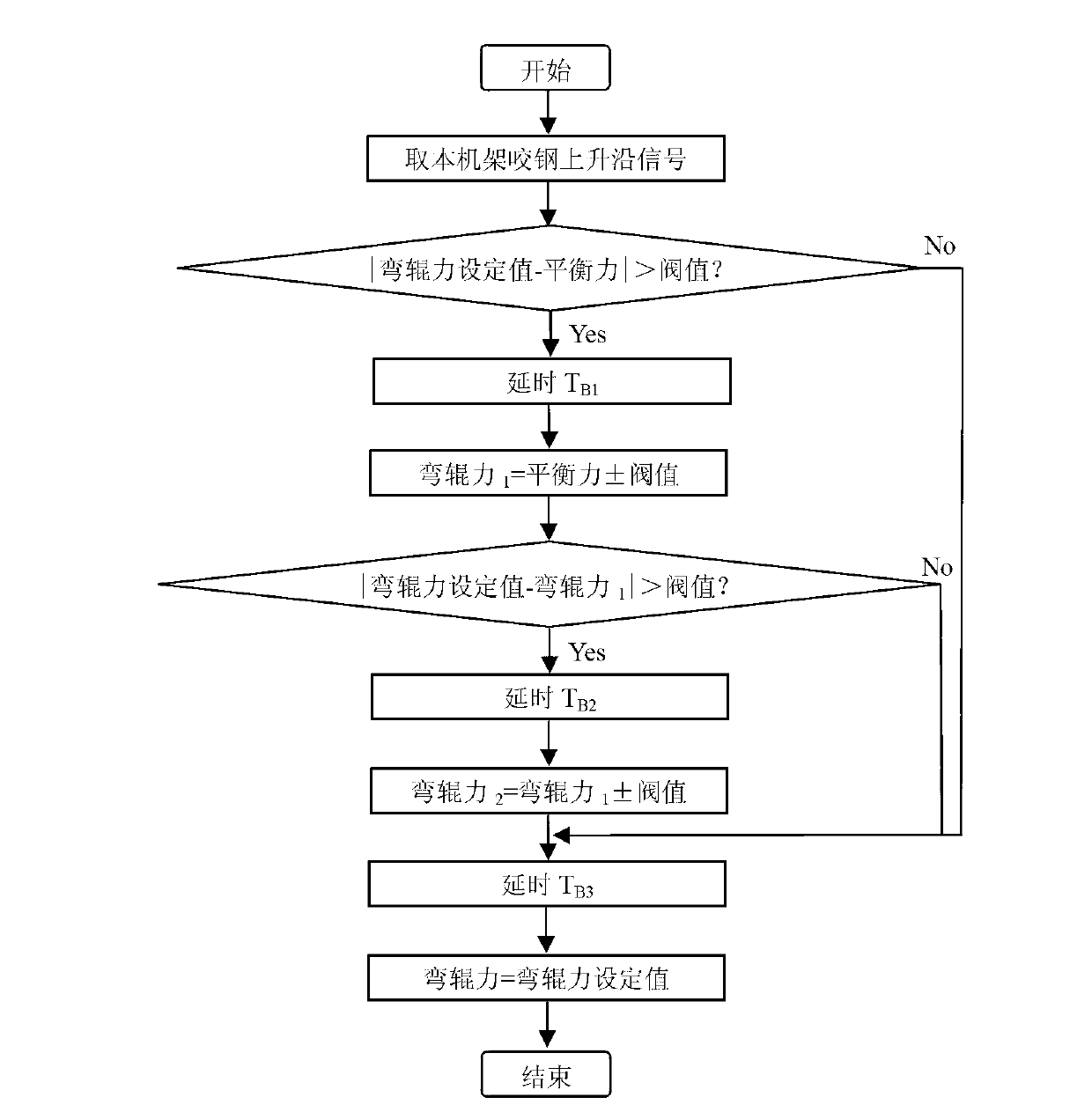

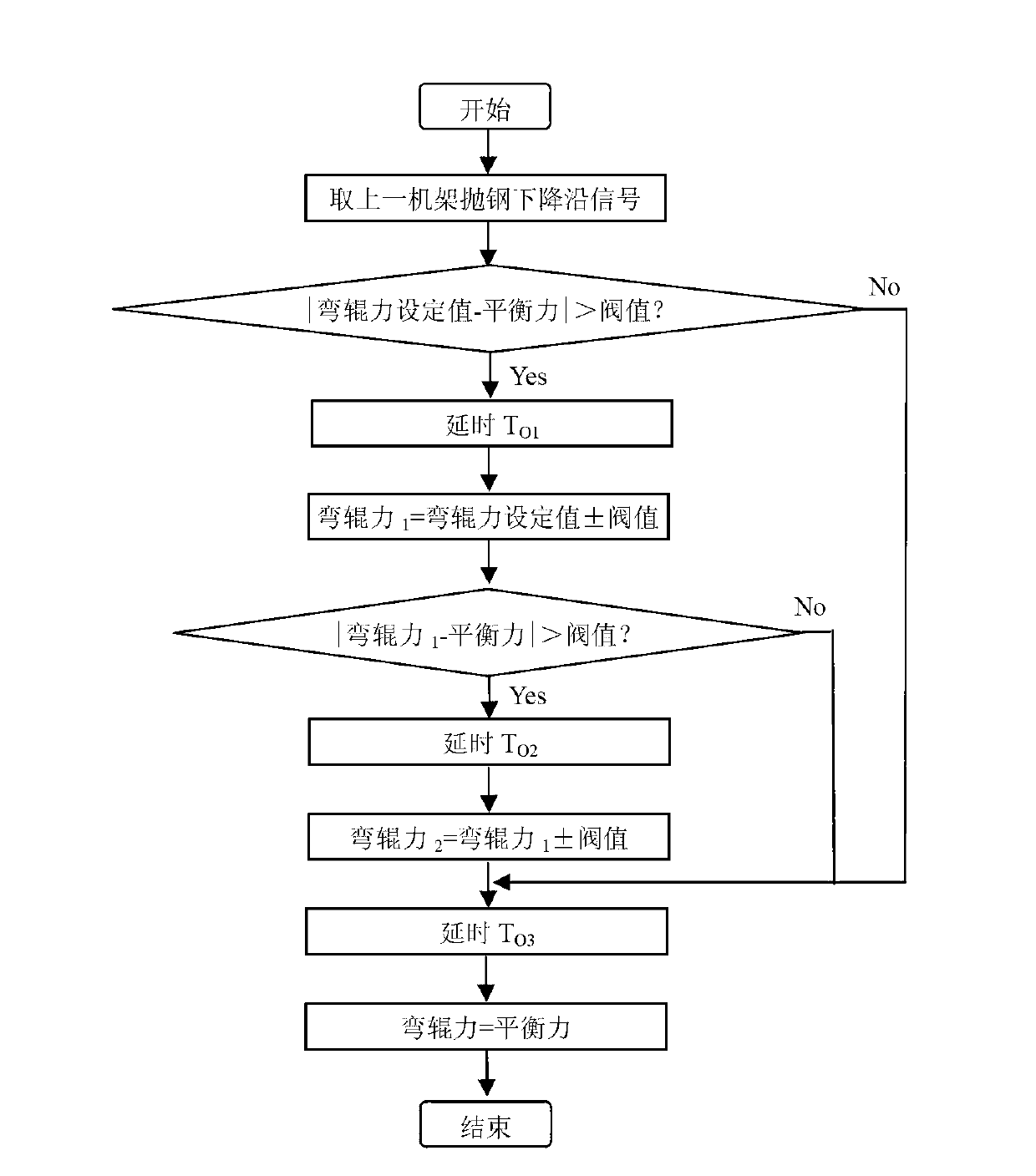

The invention provides a method for controlling the head and tail shapes of hot-rolled strip steel. For the control on the head shape of strip steel, the smooth switching between the balancing and roll bending of a rack is controlled through a steel biting rising edge signal of the rack; and for the control on the tail shape of the strip steel, the smooth switching between the roll bending and balancing of a follow-up rack is controlled through a steel throwing falling edge signal of an upstream rack. According to the invention, through the reasonable design on a hydraulic balancing and roll bending control scheme of a working roll of a rear finishing mill, phenomena such as the head and tail shapes of strip steel are deteriorated due to the instantaneous switching between balancing and roll bending, and the like can be effectively prevented, thereby improving the quality of head and tail shapes of the strip steel, avoiding the occurrence of creasing and strip breakage accidents, and reducing the production cost.

Owner:ANGANG STEEL CO LTD

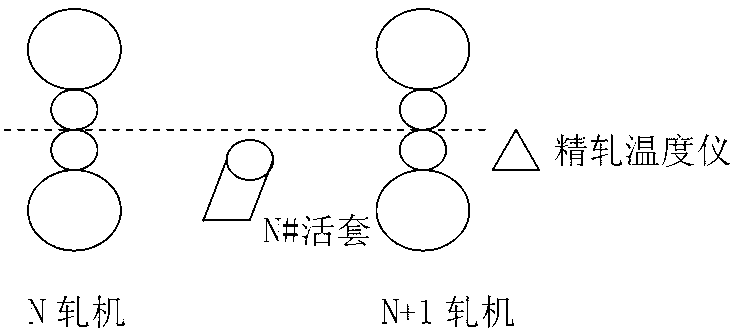

Hot continuous rolling stainless steel strip steel tail portion loop control method

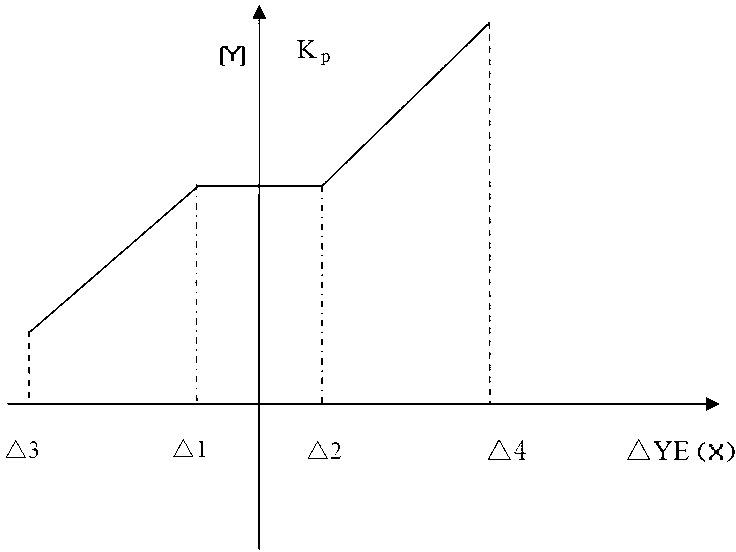

The invention belongs to the field of hot rolling strip steel, and particularly relates to a hot continuous rolling stainless steel strip steel tail portion loop control method. Step 1, a broken line is designed, a rectangular plane coordinate system is built, a force moment deviation value of a trip steel tail portion loop, namely, the difference between the given moment and the actual moment, serves as the X axis of the rectangular plane coordinate system, and a loop moment control coefficient value serves as the Y axis of the rectangular plane coordinate system, and the broken line is a three-section linear equation; step2, the algorithm of a strip steel tail portion loop moment controller is that Yn=Yn-1 +Kpn*{[1+TA / TN]*deltaYEn-deltaYEn-1}; step 3, if being within the range between delta1 and delta2, the moment deviation value of the trip steel tail portion loop is calculated according to the step 1, and if being beyond the range between the delta1 and the delta2, the moment deviation value of the trip steel tail portion loop is calculated according to the broken line, maximum amplitude limiting and minimum amplitude limiting are also adopted, the maximum amplitude limiting value is 8*10<-6>, and the minimum amplitude limiting value is 1*10<-6>; step 4, the loop is controlled by a hydraulic loop servo valve according to the result, calculated through the step 3, of the loop moment control coefficient.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

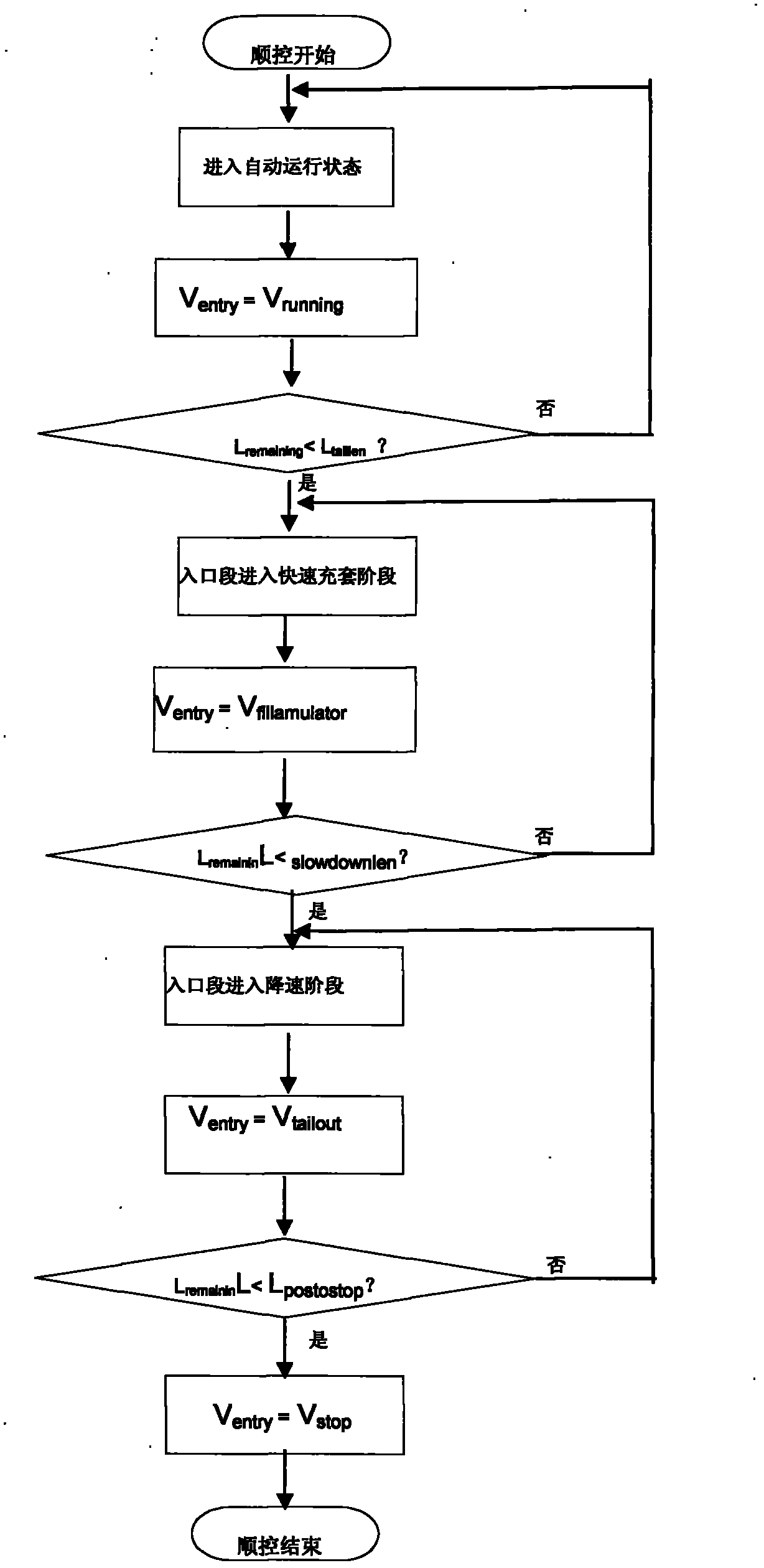

Method for solving problem of loop charging and drifting of production line of pickling-rolling coupled machine

ActiveCN101934293AGuaranteed to proceed normallyUse adequate and accurateRare end control deviceFlexible work arrangmentsLiquid coreProduction line

The invention relates to a sector segment actuating mechanism taking pressure as a control target, belonging to the technical field of continuous casting equipment in a metallurgy industry. The sector segment actuating mechanism comprises a displacement sensor, a hydraulic cylinder, a pressure sensor, an electric control system, a hydraulic system and a sector segment, wherein the hydraulic cylinder of the sector segment is provided with the displacement sensor and the pressure sensor which are matched with the hydraulic cylinder; the signal output ends of the displacement sensor and the pressure sensor are connected with the electric control system; the output of the electric control system is connected with the hydraulic system; and the hydraulic system is connected with the hydraulic cylinder of the sector segment. The sector segment can reflect the stress of a casting blank in real time by taking the pressure as the control target, solve the problems of errors caused by sensor drifting and initial roll gap setting, prevent the casting blank from internally cracking and the sector segment from being damaged due to overload because of superabundant shrinkage mass and also ensure good casting blank quality through the force analysis of the casting blank. Besides, the method can also be used for judging the position of a liquid core of the casting blank and providing accurate feedback data for the application of a dynamic soft reduction technology.

Owner:HEBEI IRON AND STEEL

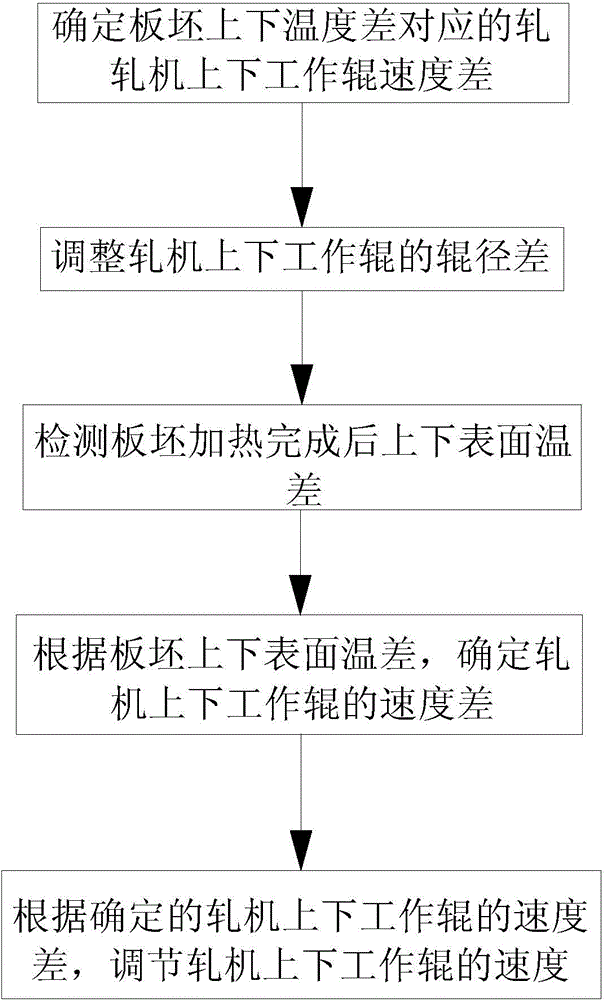

Method for controlling rough rolling squat in continuous hot rolling strip

ActiveCN104624665AIncrease productivityReduce manufacturing costRare end control deviceStrip millStrip steel

The invention discloses a method for controlling a rough rolling squat in a continuous hot rolling strip. By means of the method, the production efficiency is improved, and the squat in a rolling plate is avoided. According to the method, when plate billets are rolled continuously, a speed difference delta V between an upper working roll and a lower working roll of a rolling mill is determined during rolling process of a roughing mill corresponding to an upper-lower temperature difference delta T of the different plate billets when the plate billets are discharged out of a furnace at a heating stage; then according to the speed difference delta V between the upper working roll and the lower working roll of the rolling mill during a practical production process, revolving speeds of the upper working roll and the lower working roll of the rolling mill are set; so that the squat does not occur on the plate billets during the rolling process; it is not necessary to stop the rolling mill to conduct adjustment and heating treatment on the upper surfaces and the lower surfaces of the plate billets; by the adoption of the method for controlling the rough rolling squat in the continuous hot rolling strip, the product quality is improved, the production efficiency is improved, and the manufacturing cost is lowered.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

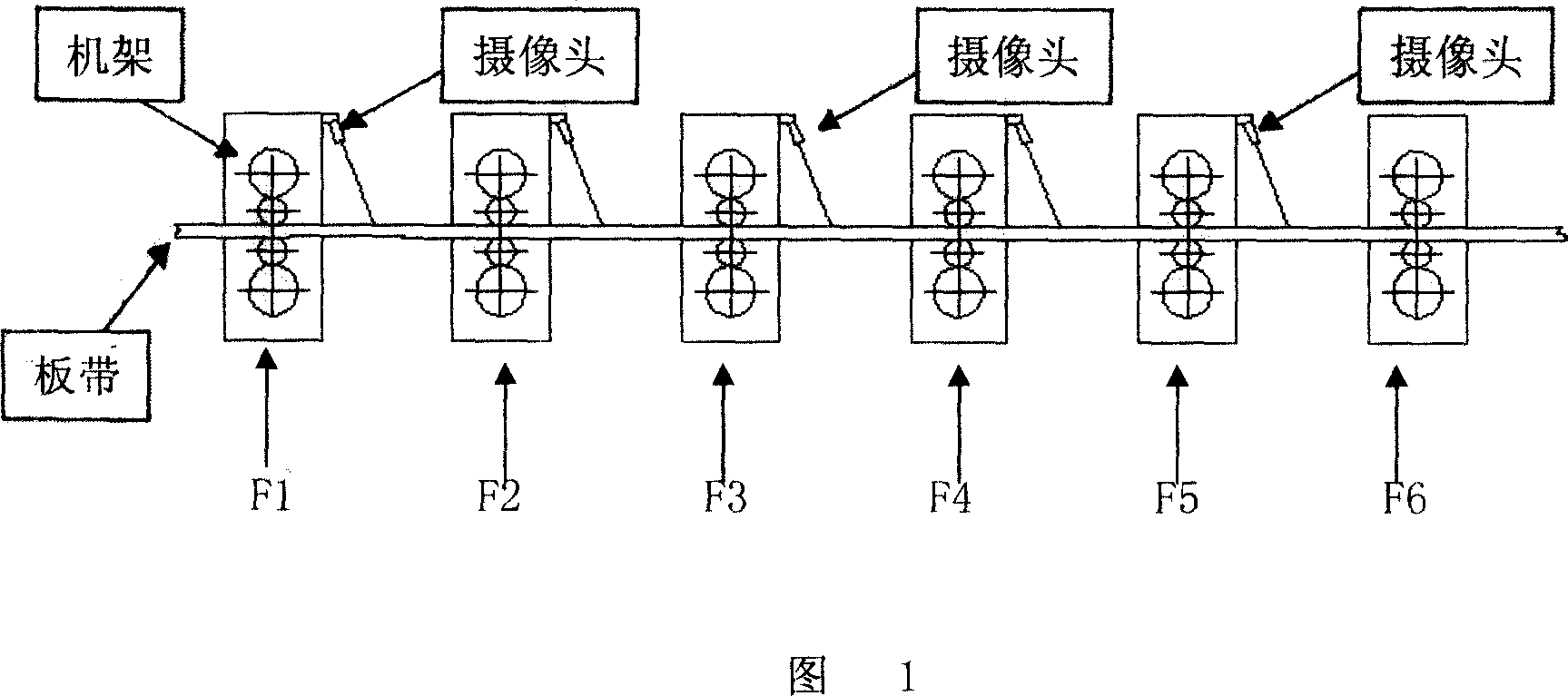

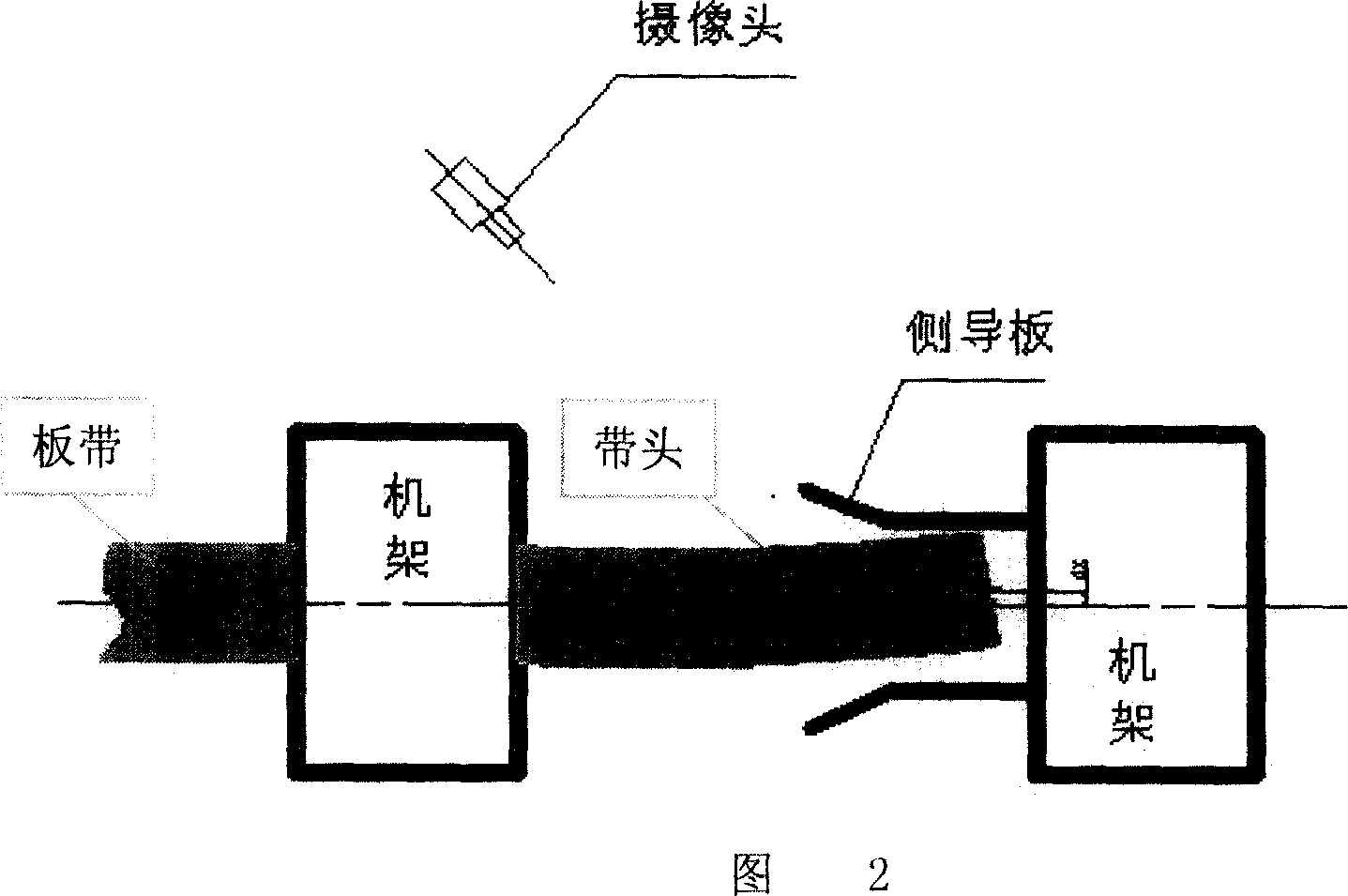

Rolling process of hot rolled steel sheet

InactiveCN1974040AServe as a modelRare end control deviceGuiding/positioning/aligning arrangementsSheet steelDisplay device

The present invention discloses the rolling process of hot rolled steel sheet. In the operation of the rolling process, video cameras are installed in the frame and display terminal is set in the rolling operation desk. During rolling, deviation trend of the rolled band is obtained through observing the positions of the band head, middle and tail in the frame and deviation rectifying operation is performed according to the deviation trend of the rolled band. The method can decrease the thickness of rolled band and raise the quality of the rolled product.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

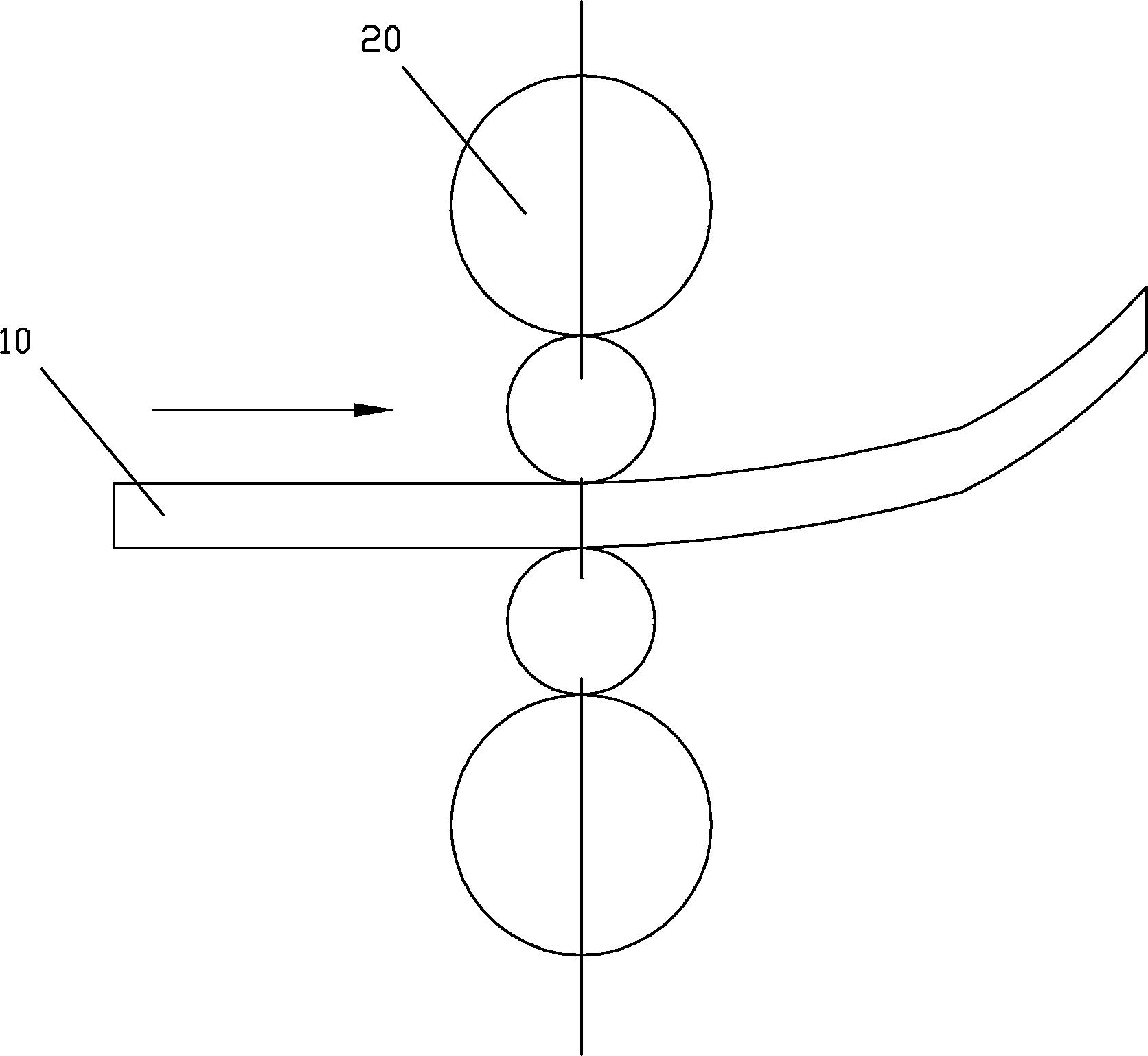

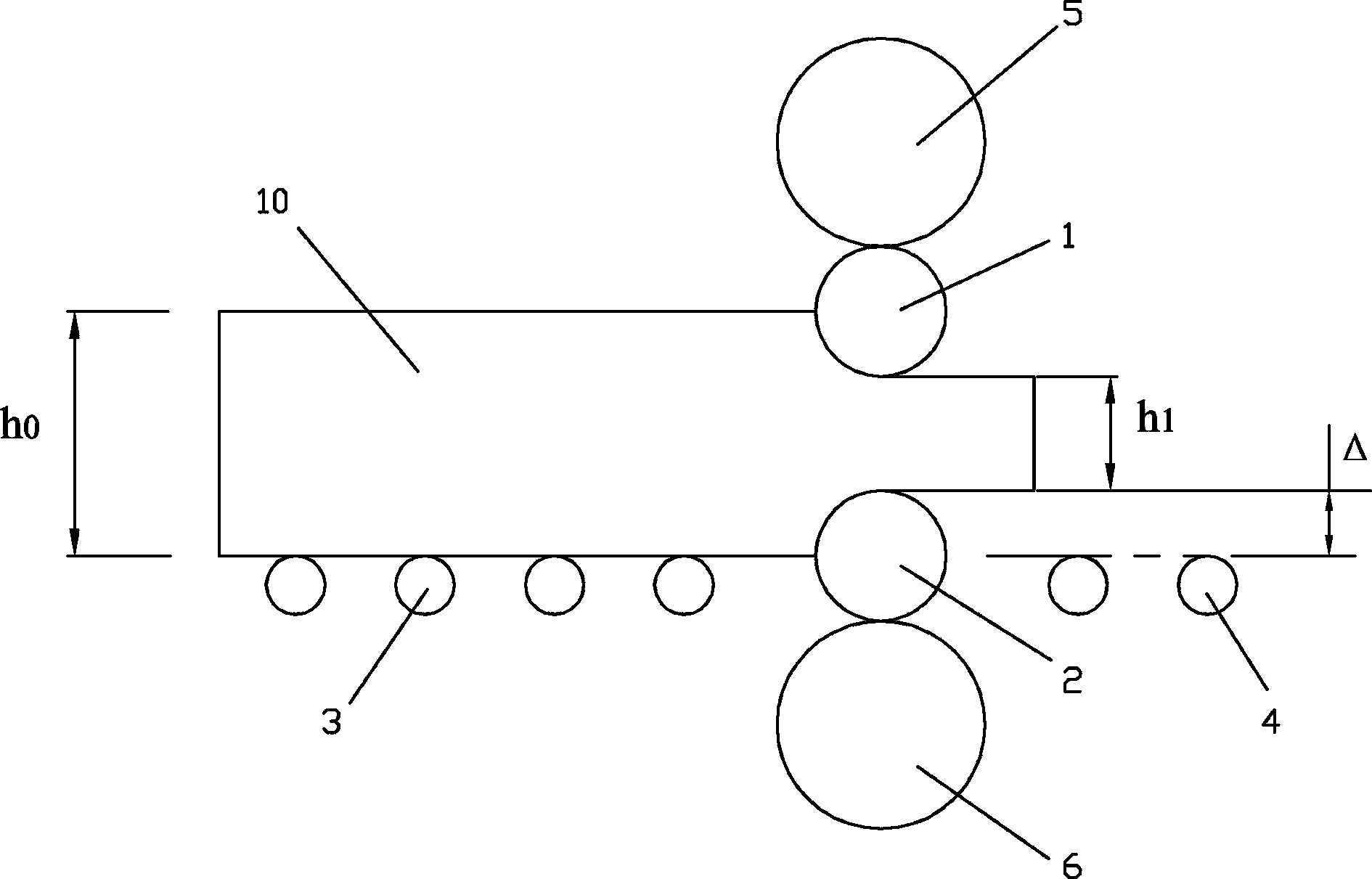

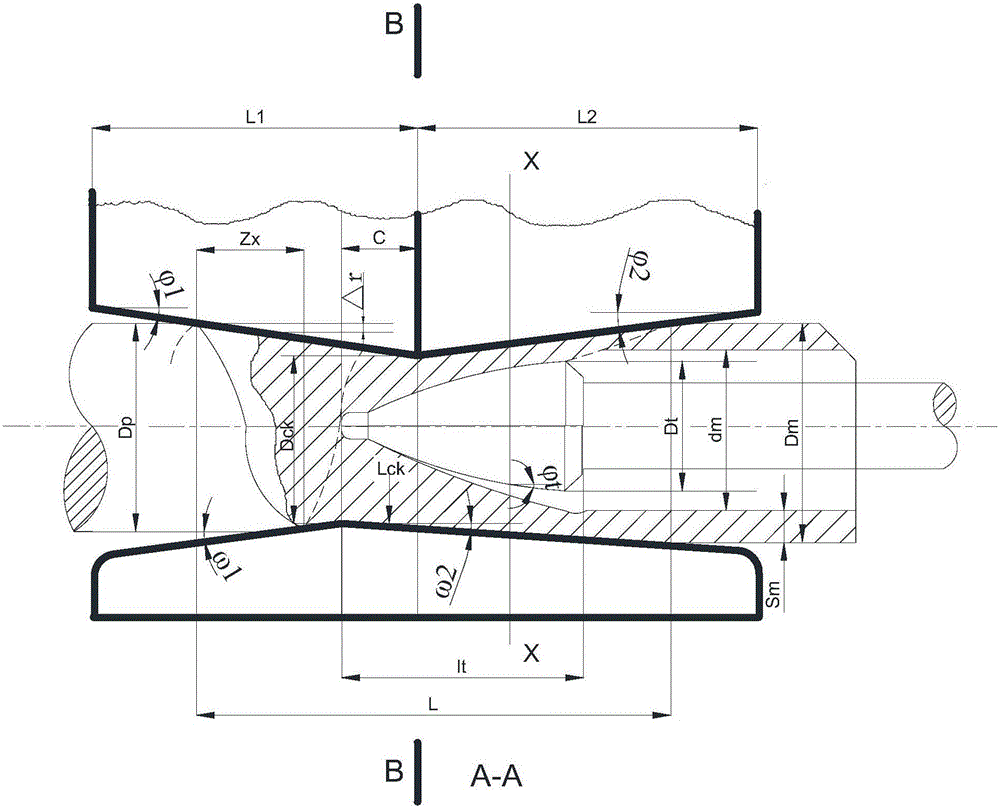

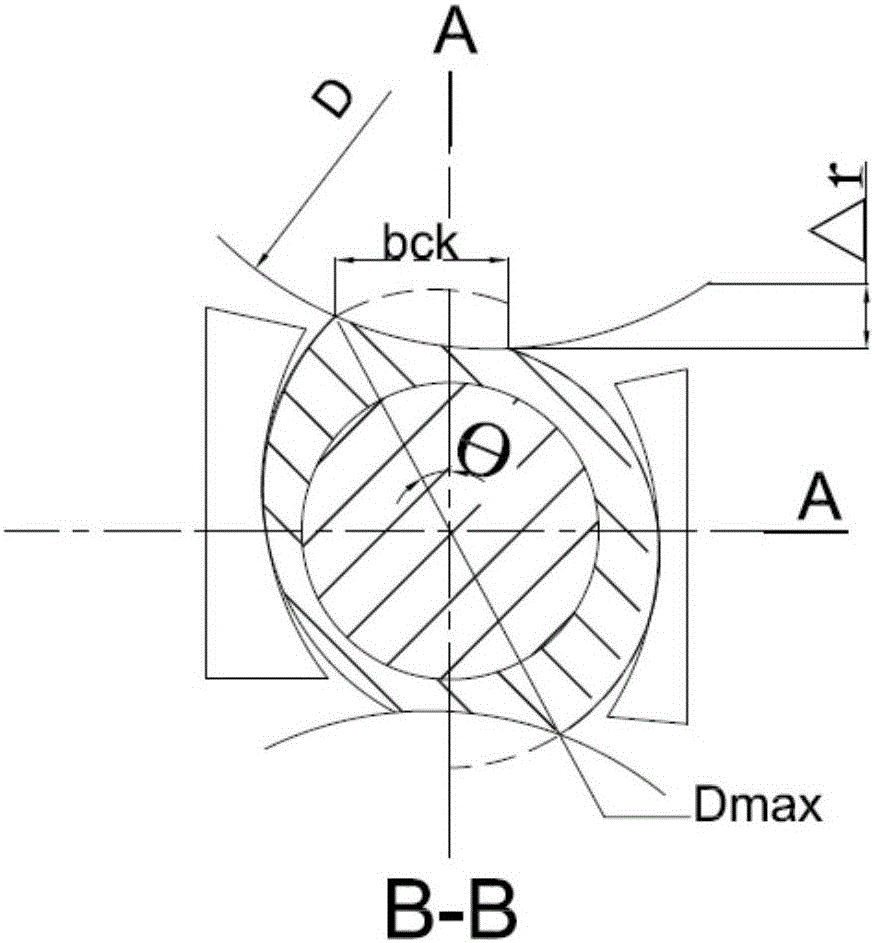

Head warping control method for rough rolling in production of hot-rolled steel strips

Disclosed is a head warping control method for rough rolling in production of hot-rolled steel strips. Firstly, a lower-rollers electric pressing-up mechanism is adopted, and a rolling line height Delta, namely the height difference between the upper roller face of a lower operating roller of a roller mill and the upper roller faces of the roller beds of the inlet and outlet, is set as (img file = 'DDA00002978950300011.TIF' wi = '318' he = '112' / ) in millimeters; h0 and h1 represent the rolled member inlet and the outlet thicknesses respectively in millimeters, and the delta is a rolling line height additional value and ranges from 2 to 10mm; meanwhile, the speed difference between an upper operating roller and the lower operating roller is adjusted, the roller mill speed increment is acquired as (img file = 'DDA00002978950300012.TIF' wi = '462' he = '172' / ), d omega is a rotating speed increment in rad / s, and the DW is the diameter of rollers in millimeters. The method has the advantages that the problem of head warping for rough rolling during hot rolling production is optimized, damage to production equipment by head warping is reduced, and production stability is improved.

Owner:BAOSTEEL STAINLESS STEEL +1

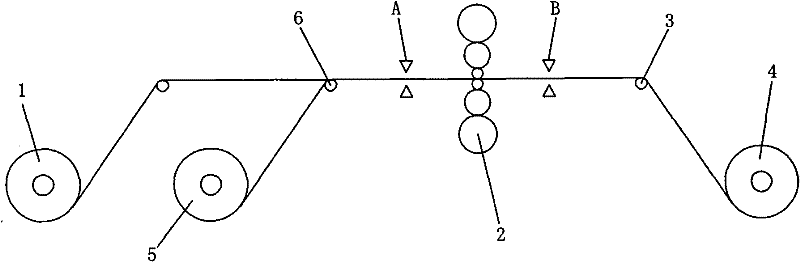

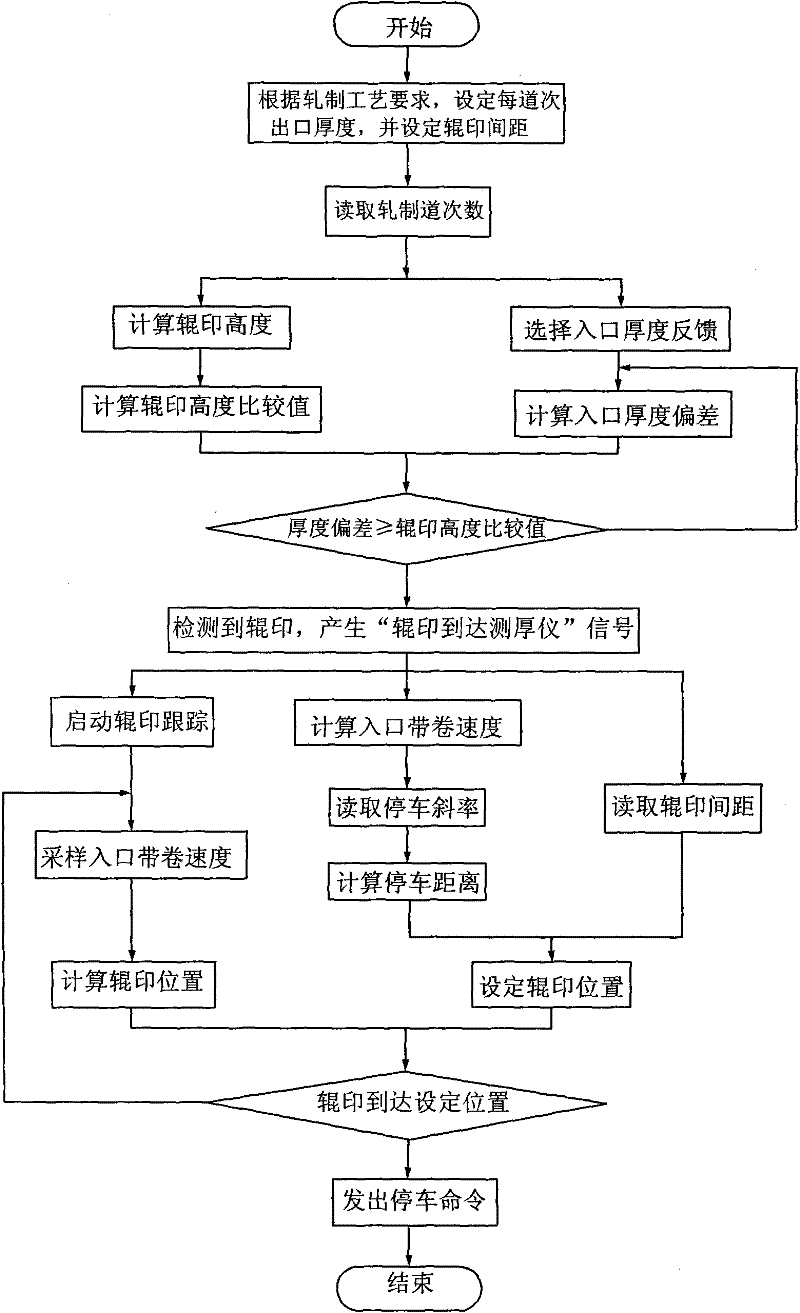

Control method for stopping reversible cold-rolling mill

InactiveCN102205348APrecise length controlHigh yieldRare end control deviceMetal rolling arrangementsControl systemRolling mill

The invention relates to a control method for stopping a reversible cold-rolling mill and belongs to the technical field of automation control for rolling. The method comprises the following steps: setting a strip coil outlet thickness and a rolling mark distance for each-pass rolling; by starting from the second-pass rolling, calculating a rolling mark height and a comparison value of the rolling mark height for each-pass rolling; by starting from the second-pass rolling, reading the strip coil outlet thickness and an actual value of the strip coil outlet thickness for each-pass rolling by arolling control system, and after comparing, acquiring a strip coil outlet thickness deviation for each-pass rolling; after comparing the strip coil outlet thickness deviation and the comparison value of the rolling mark height, calculating an actual displacement of the rolling mark at real time or starting the parking timing by the rolling control system; calculating a rolling mark parking displacement or a parking delay at real time by the rolling control system; and when the actual displacement of the rolling mark is equal to the rolling mark parking displacement or the parking timing reaches the parking delay, controlling the rolling mill to park at each pass by the rolling control system. The method can be used for precisely positioning the strip tail position of each pass rolling strip coil of the reversible cold-rolling mill, so as to increase the yield of strip coil rolling.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

On-line computation method of hot continuous rolling rough rolling short stroke curve parameters

ActiveCN103128107AImprove adaptabilityHigh precisionRare end control deviceNeuron networkAutomatic control

The invention discloses an on-line computation method of hot continuous rolling rough rolling short stroke curve parameters and belongs to the technical field of hot rolled strip automatic control. According to the on-line computation method of the hot continuous rolling rough rolling short stroke curve parameters, a multi-step broken-line mode is adopted, neuron network is adopted to forecast width deviation which is generated when a rolled piece is through current pass forward direction rolling and next pass reversed direction rolling (if a current pass is not the last pass) under the condition that the head and the end of the rolled piece are not under short stroke control, wherein head and end parameters of the rolled piece are exchanged in the pass capable of reverse rolling, then short stroke curve parameters of a vertical roll rolling pass is confirmed according to deviation of the entrance width of the head and the end of the rolled piece and the forecast rolled width deviation. The on-line computation method of the hot continuous rolling rough rolling short stroke curve parameters is good in adaptability, high in accuracy, convenient to debug and maintain and beneficial for improving a yield rate of hot continuous rolling.

Owner:UNIV OF SCI & TECH BEIJING

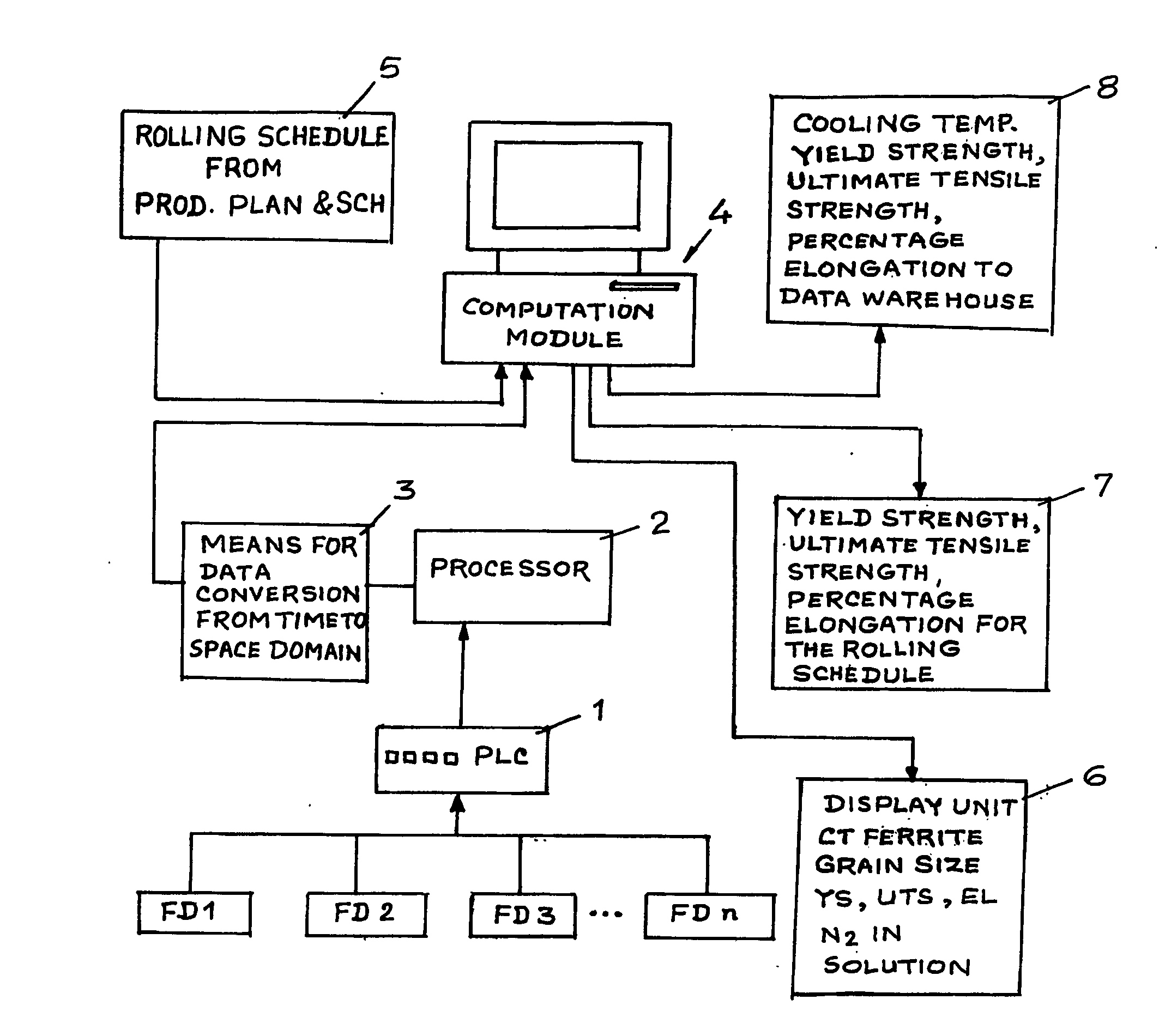

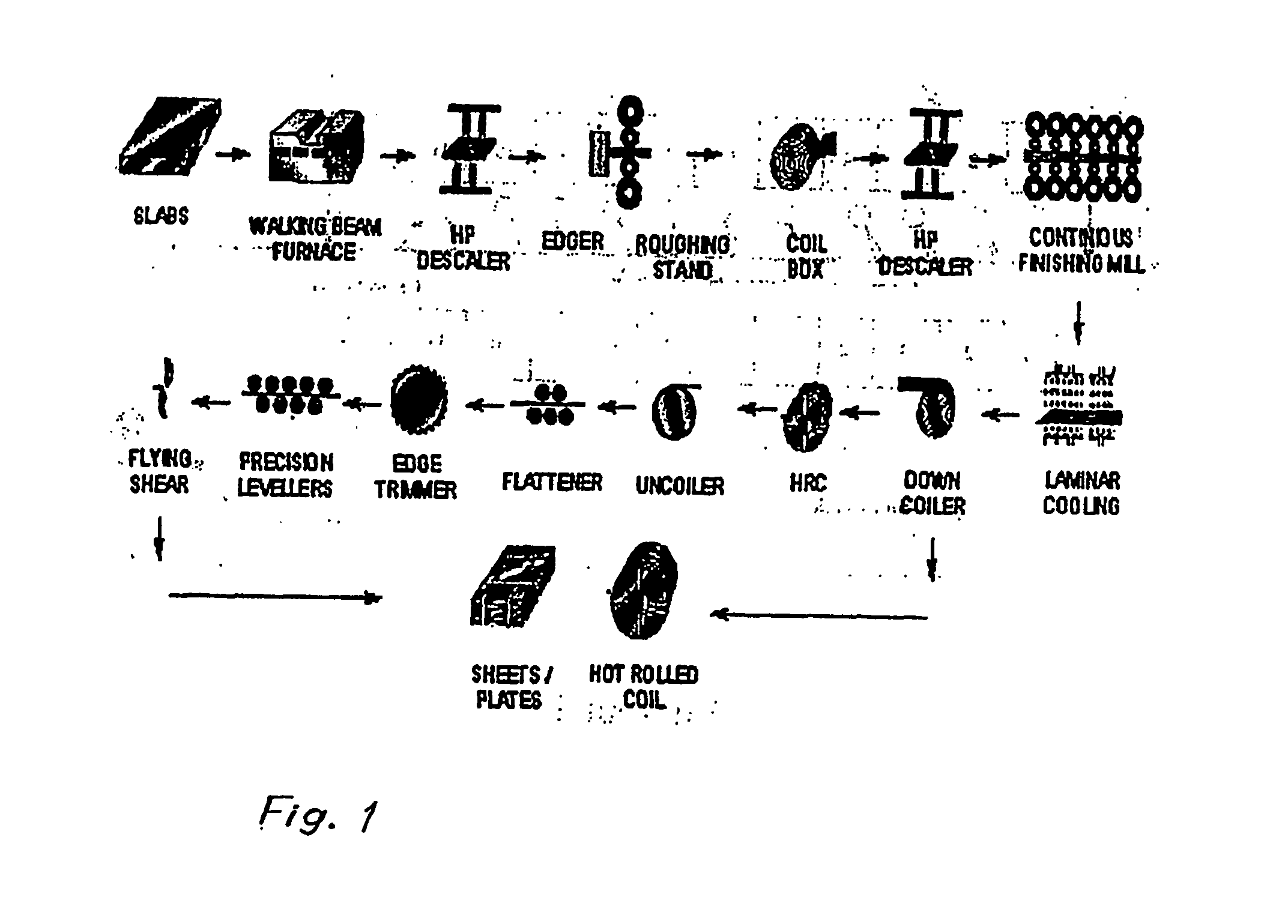

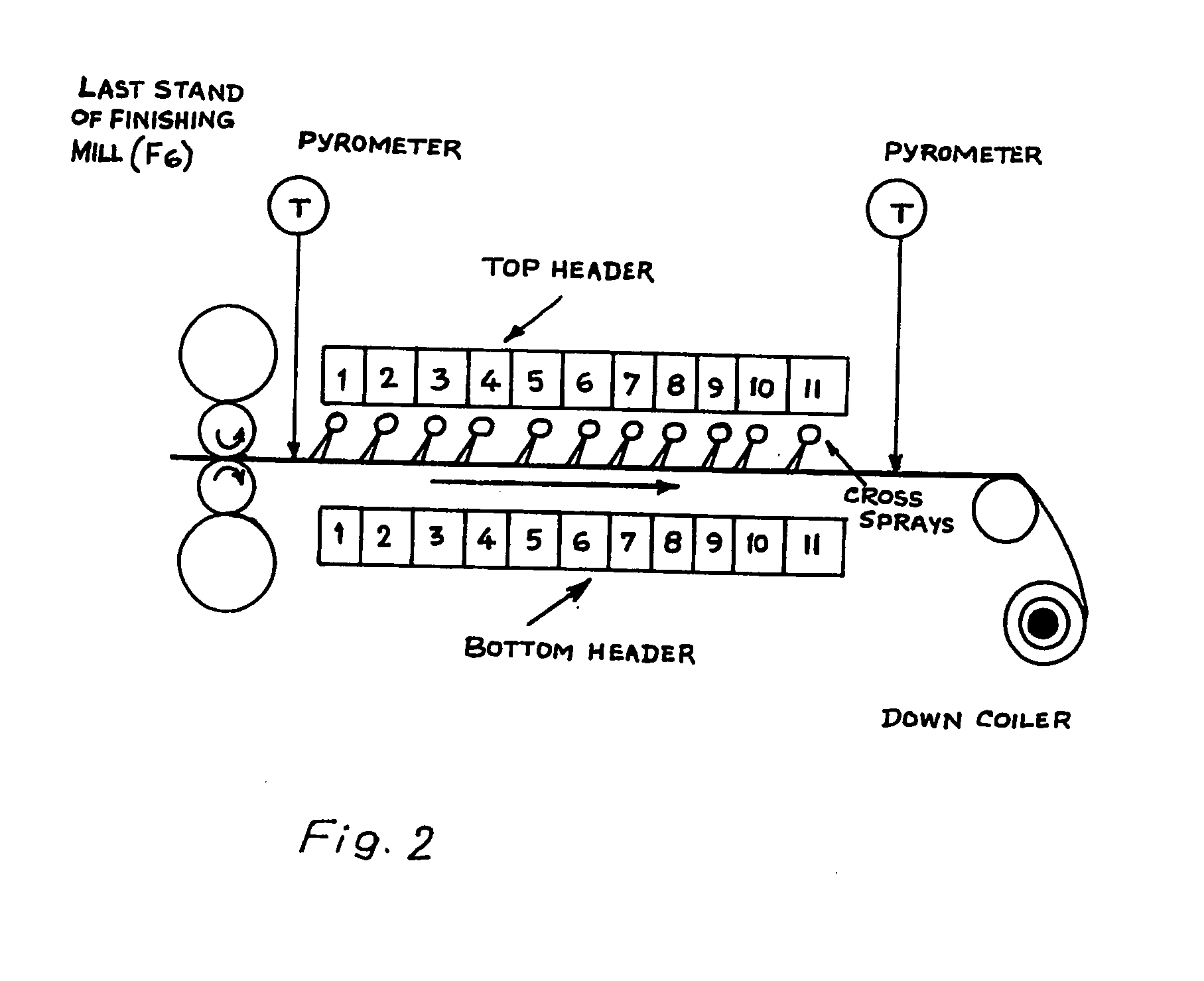

System and method for online property prediction for hot rlled coil in a hot strip mill

ActiveUS20070106400A1Quality improvementRequired propertyRare end control deviceRoll force/gap control deviceTime domainData warehouse

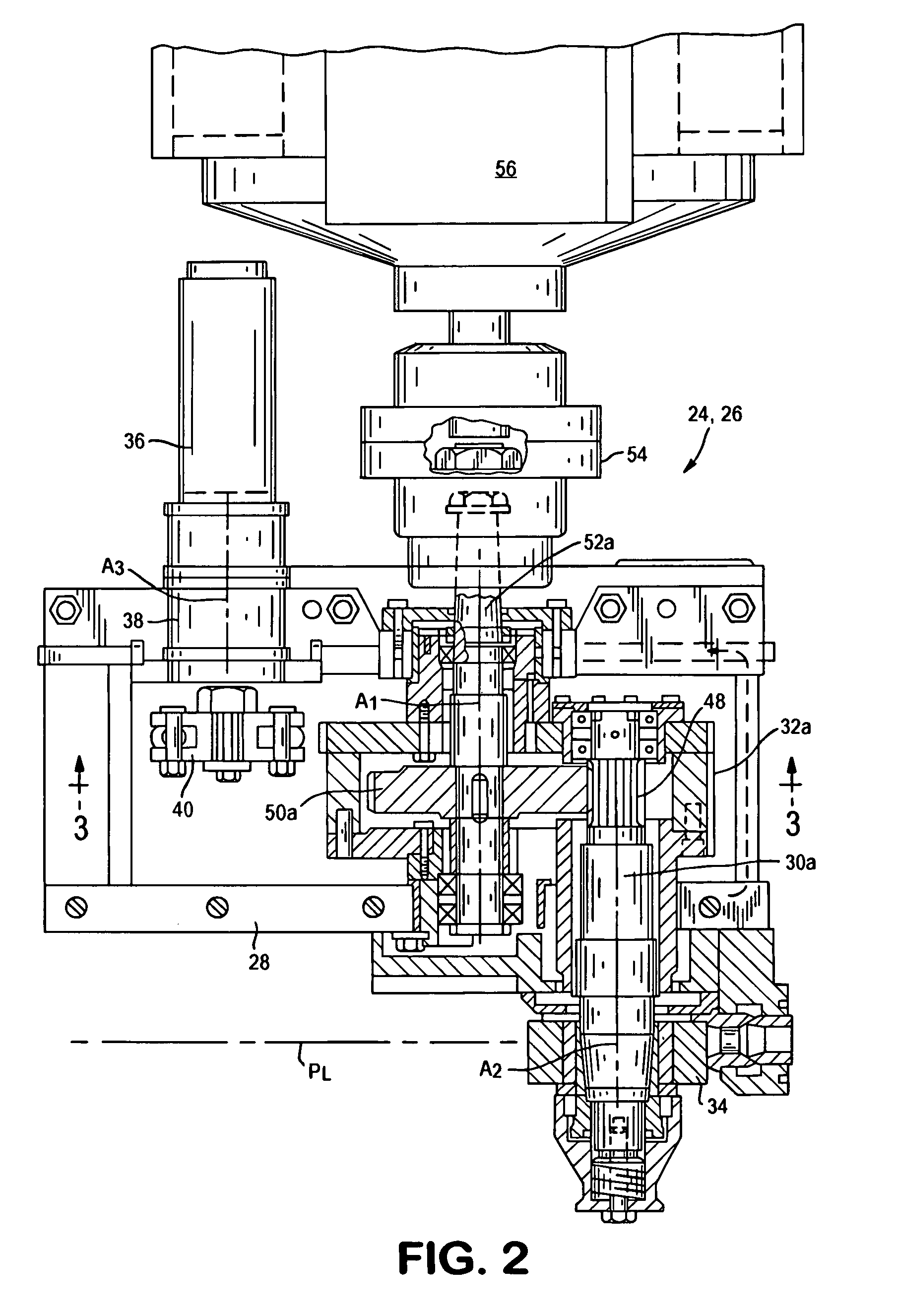

A system for on-line property prediction for hot rolled coils in a hot strip mill of a steel plant, including a unit for capturing the chemistry from the steel making stage and providing the data on rolling schedule. Field devices are provided at the instrumentation level for measuring process parameters during hot rolling. A programmable logic controller is used for acquiring data of measured parameters from the field devices and feeding the data to a processor. Means is provided for conversion of the measured data from time domain to space domain using segment tracking. A computation module processes the converted space domain data for predicting mechanical properties along the length and through the thickness of the strip being rolled. A display unit displays the predicted properties. The data obtained can be stored in a data warehouse for future use. A unit provided in the system can collect the predicted properties and feed the same to the scheduling unit.

Owner:TATA STEEL

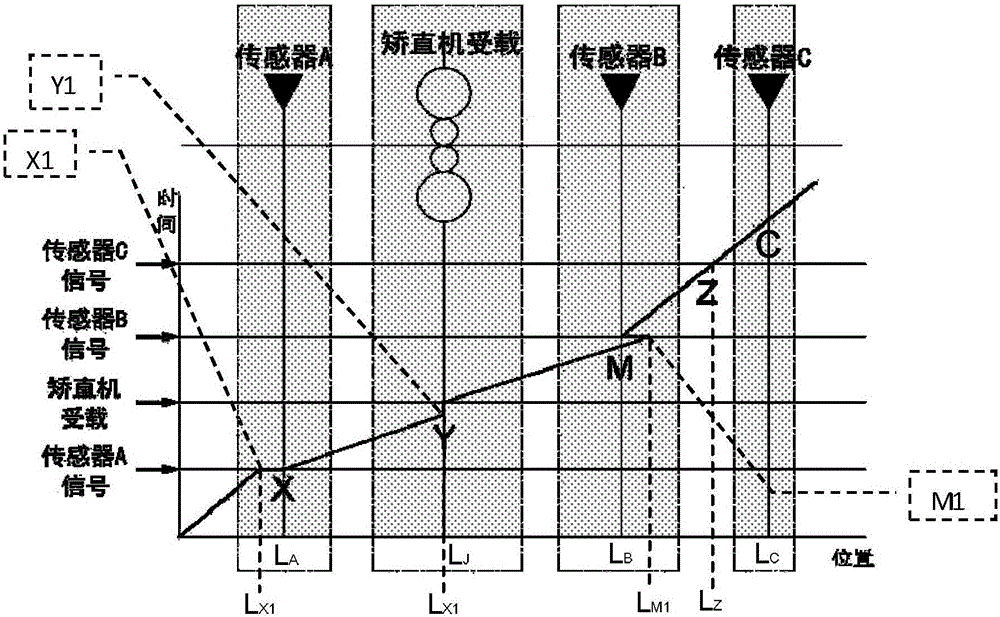

Automatic head and tail residue monitoring method of hot rolling strip steel

ActiveCN104772345AReduce labor intensityImprove reliabilityRare end control deviceStrip steelEngineering

The invention discloses an automatic head and tail residue monitoring method of a hot rolling strip steel. The method comprises the following steps: S11, a function of measuring the roll gaps and the rotating speeds of an inlet pinch roll and an outlet pinch roll of a dephosphorization box in real time is started; S12, whether the roll gap and the rotating speed of the inlet pinch roll meet a first warning condition is judged, if so, a step S14 is executed, and if not, a step S13 is executed; S13, whether the roll gap and the rotating speed of the outlet pinch roll meet a second warning condition is judged, if so, a step S14 is executed, and if not, a step S12 is executed; and S14, warning information is output, and steel feeding is stopped. The method has the advantages that while the labor intensity of an operation worker is reduced, the monitoring reliability is improved, the risk of producing steel scrap is reduced, the accident extensification is prevented, and the stability of hot rolling strip steel production is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

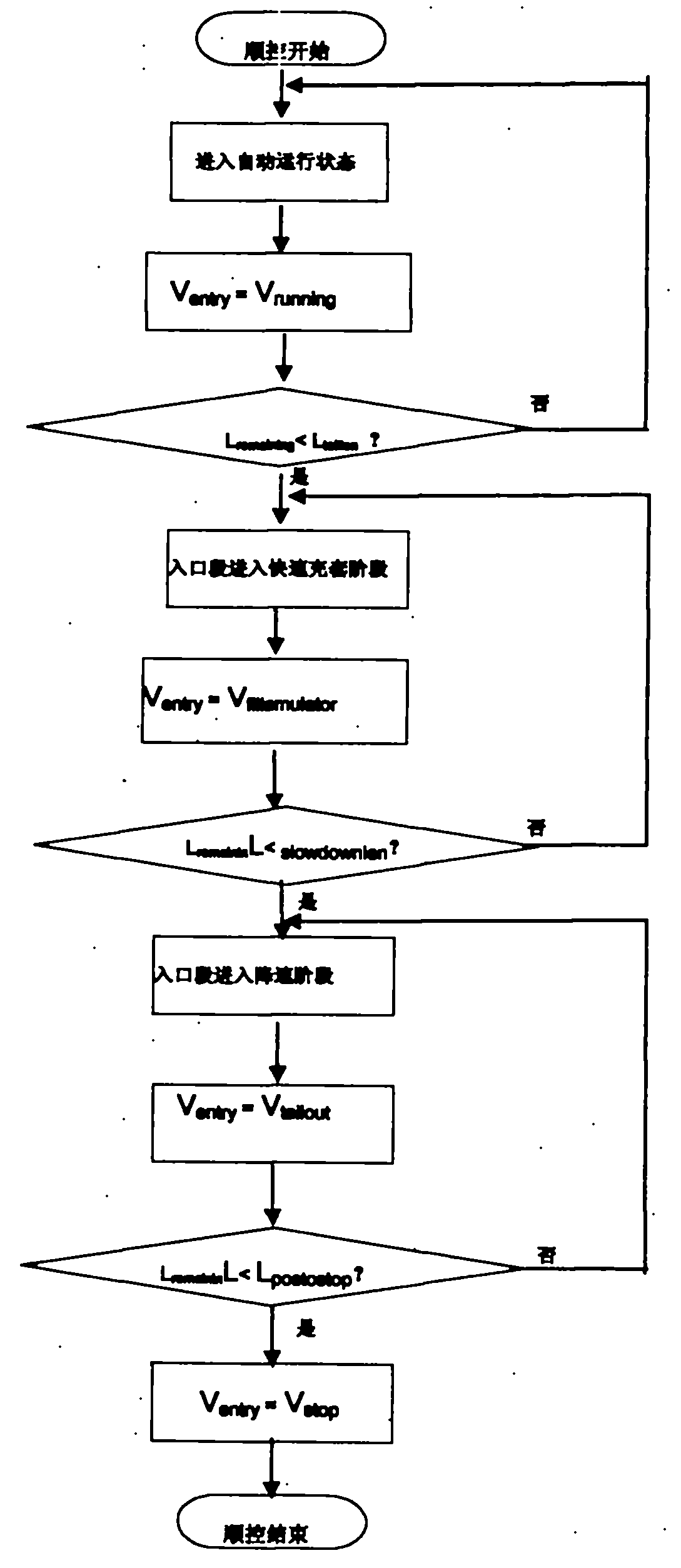

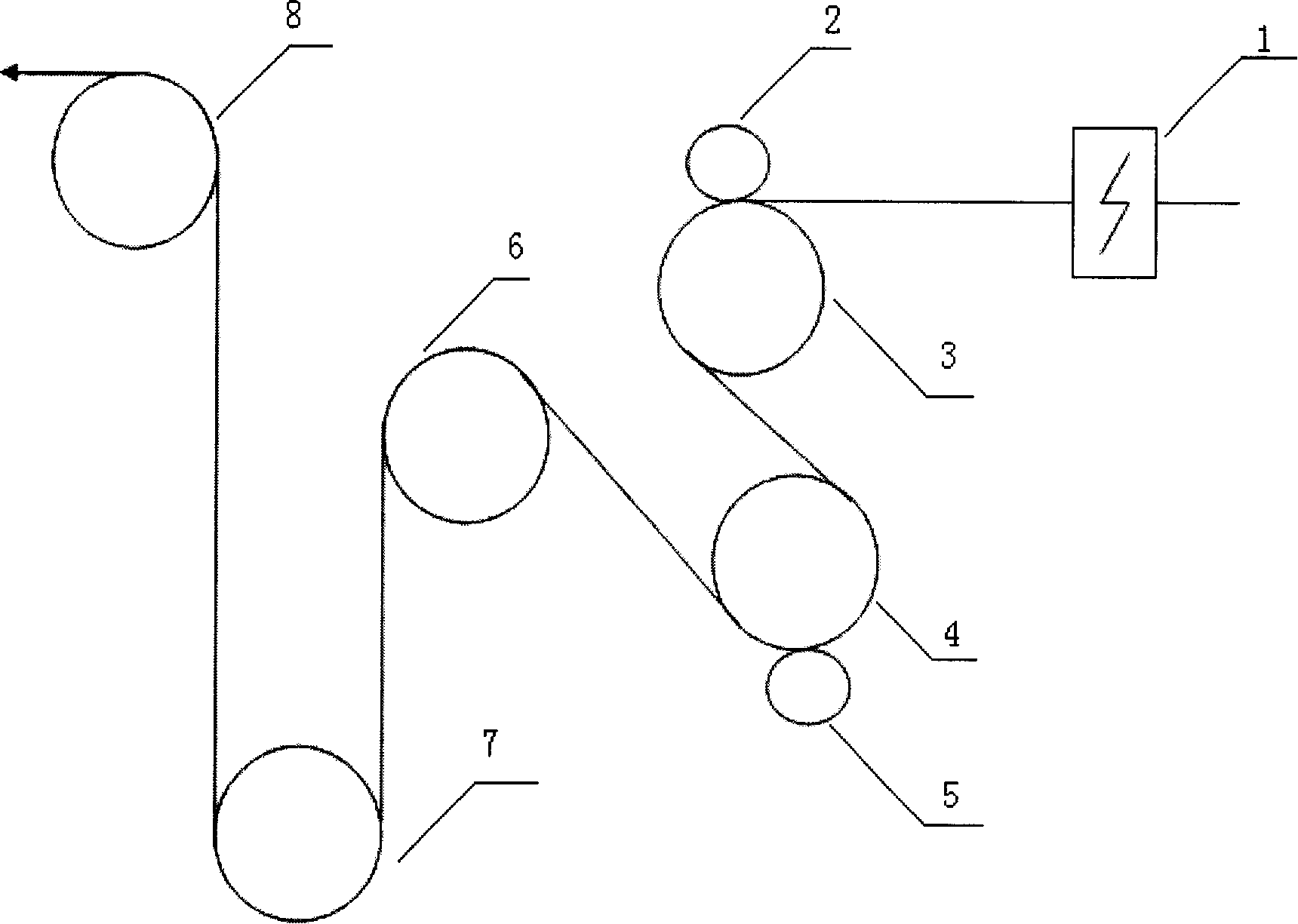

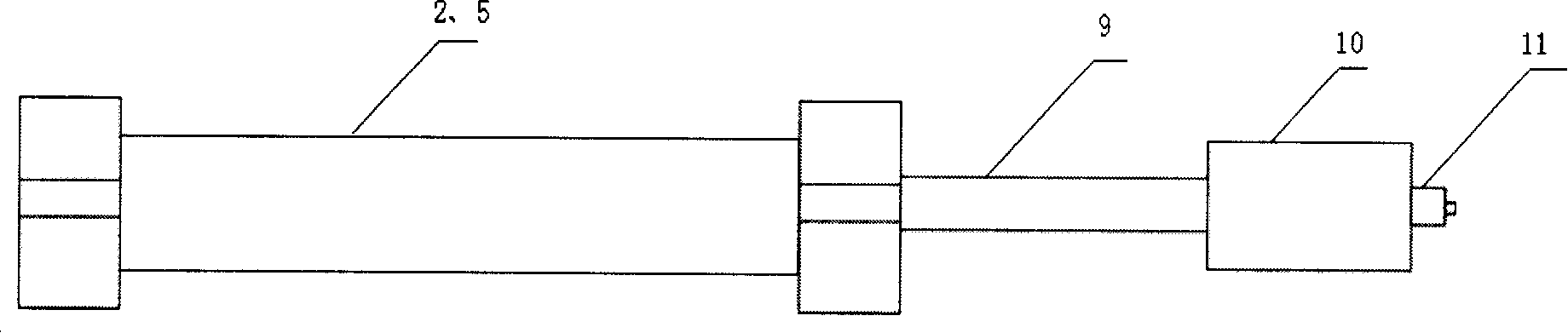

Precise strip steel tail positioning control method for strip steel coiler

The invention is suitable for the technical field of strip steel coiler control, and provides a precise strip steel tail positioning control method for a strip steel coiler. The precise strip steel tail positioning control method comprises the following steps: obtaining a first signal sent by a synchronous grating, wherein the first signal is sent when the synchronous grating detects the tail of strip steel; after confirming that the first signal is that the tail of the strip steel reaches the detected area of the synchronous grating, obtaining recorded revolutions per minute RN, which is updated in real time, of the coiler from an initial state to a current state, and calculating a real-time value of a coiling diameter; calculating length SN from the tail of the strip steel to the coiler in real time according to the real-time value of the coiling diameter and the revolutions per minute RN; and while determining that the length SN reaches speed reduction length Sde used for speed reduction, starting a reduction process. According to the embodiment of the invention, the strip steel rail is precisely positioned, the speed reduction process is started at a proper moment, and a smooth speed set value is designed, so that the speed reduction process is very stable, and good control effect can be obtained.

Owner:WISDRI ENG & RES INC LTD

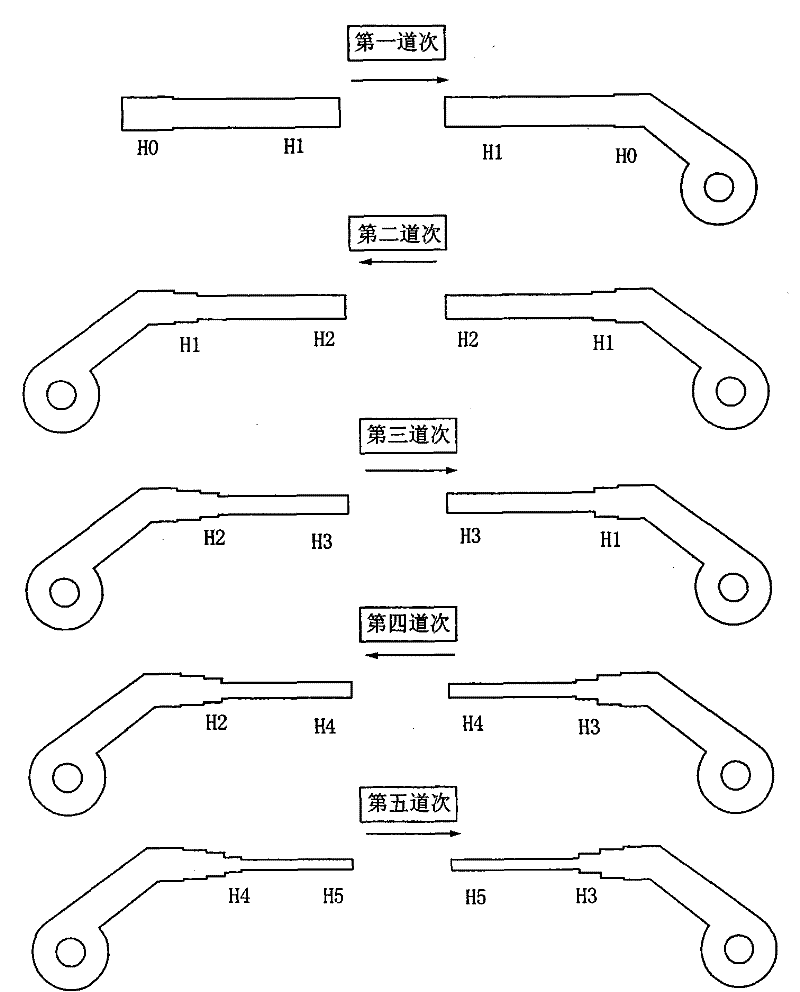

Method for improving yield of reciprocating rolled plate

InactiveCN105710128AHigh yieldSolve long-standing problemsRare end control deviceMetal rolling arrangementsWinding machineEconomic benefits

The invention belongs to the technical field of plate cold rolling methods, and relates to a method for improving the yield of a reciprocating rolled plate. The method is used for improving the yield of cold-rolled plates and strips obtained in a reciprocating rolling manner. According to the technical scheme, a steel strip head guide strip is welded to the head of a steel strip to be rolled, and a steel strip tail guide strip is welded to the tail of the steel strip to be rolled; and in the reciprocating rolling process, the steel strip head guide strip and the steel strip tail guide strip are wound around a winding machine mandrel of a winding machine, winding of the steel strip to be rolled is replaced for obtaining tension, and therefore the parts, unable to be rolled, of the head and the tail of the steel strip to be rolled are greatly reduced, the yield is remarkably improved, and according to statistics, the steel strip rolling yield of a single-rack reciprocating rolling unit can be improved to 96.7% from 88%. The method is an innovation in the steel strip cold rolling methods; and by means of the measures of simply welding the steel strip guide strips, the problems which are not solved by the reciprocating rolling unit for a long time are solved, the rolling yield of the steel strip of the reciprocating rolling unit is greatly improved, the economic benefits of enterprises are remarkably improved, and the method is worthy of use and popularization in the industry.

Owner:TANGSHAN IRON & STEEL GROUP

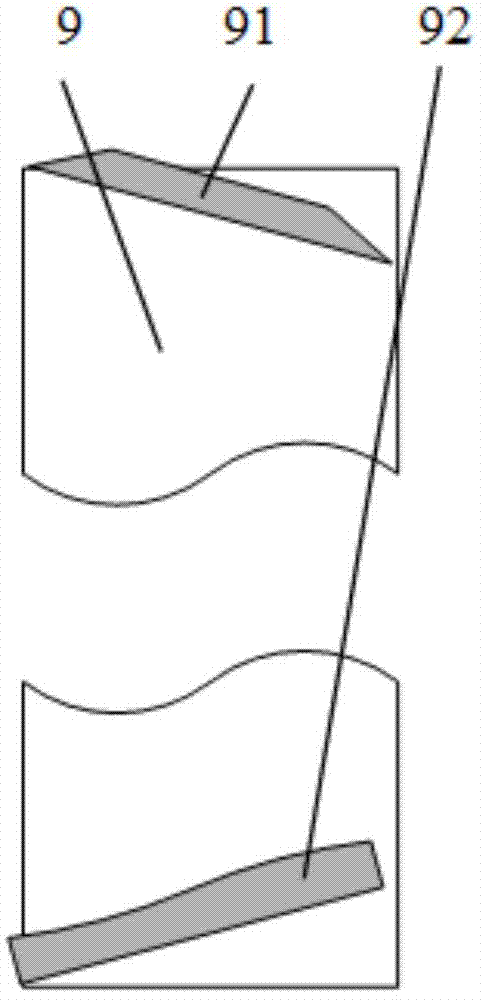

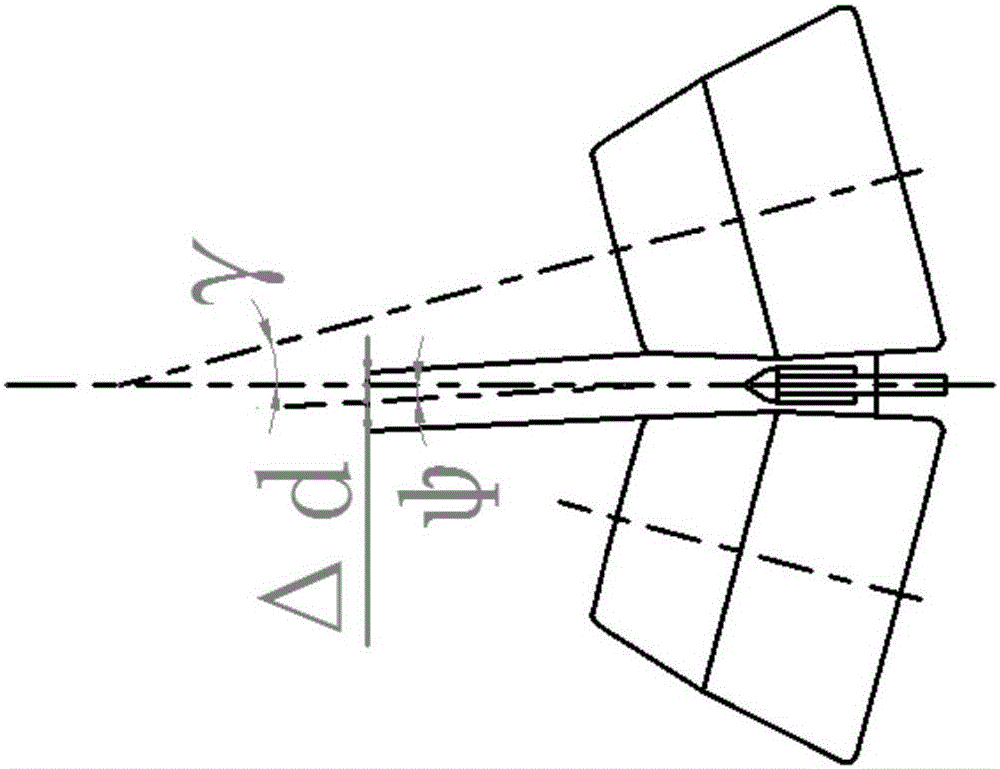

Method for controlling tail wiggling quantity of inclined rolling perforator

InactiveCN105689409AQuality improvementAvoid safety accidentsRare end control deviceMetal rolling arrangementsEngineeringMechanical engineering

The invention discloses a method for controlling a tail wiggling quantity of an inclined rolling perforator. The method comprises the steps of: 1) measuring parameters of the inclined rolling perforator and a blank; 2) judging the deviation of the blank in the rolling process; 3) calculating a deviation quantity delta d of the tail part of the blank in one place in the rolling process; 4) correcting the tail wiggling quantity of the blank to obtain a corrected tail wiggling quantity dx; and 5) controlling of the tail wiggling quantity of the blank: control devices for preventing the blank from swinging are mounted on the left and right sides of the blank in an inlet of the inclined rolling perforator far from the center line dx of the blank. Aiming at the tail wigging problem of the pipe blank caused by a complex deformation area with an asymmetric shape in a traditional inclined rolling perforating process, the method obtains the tail wigging quantity of the pipe blank through theoretical analysis; and according to the magnitude of the wigging quantity, multiple control devices are mounted in the inlet of the inclined rolling perforator to achieve the purpose of controlling the tail wiggling of the pipe blank, so that the quality of perforated pipe is improved, and the generation of unnecessary accidents in actual production is prevented.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

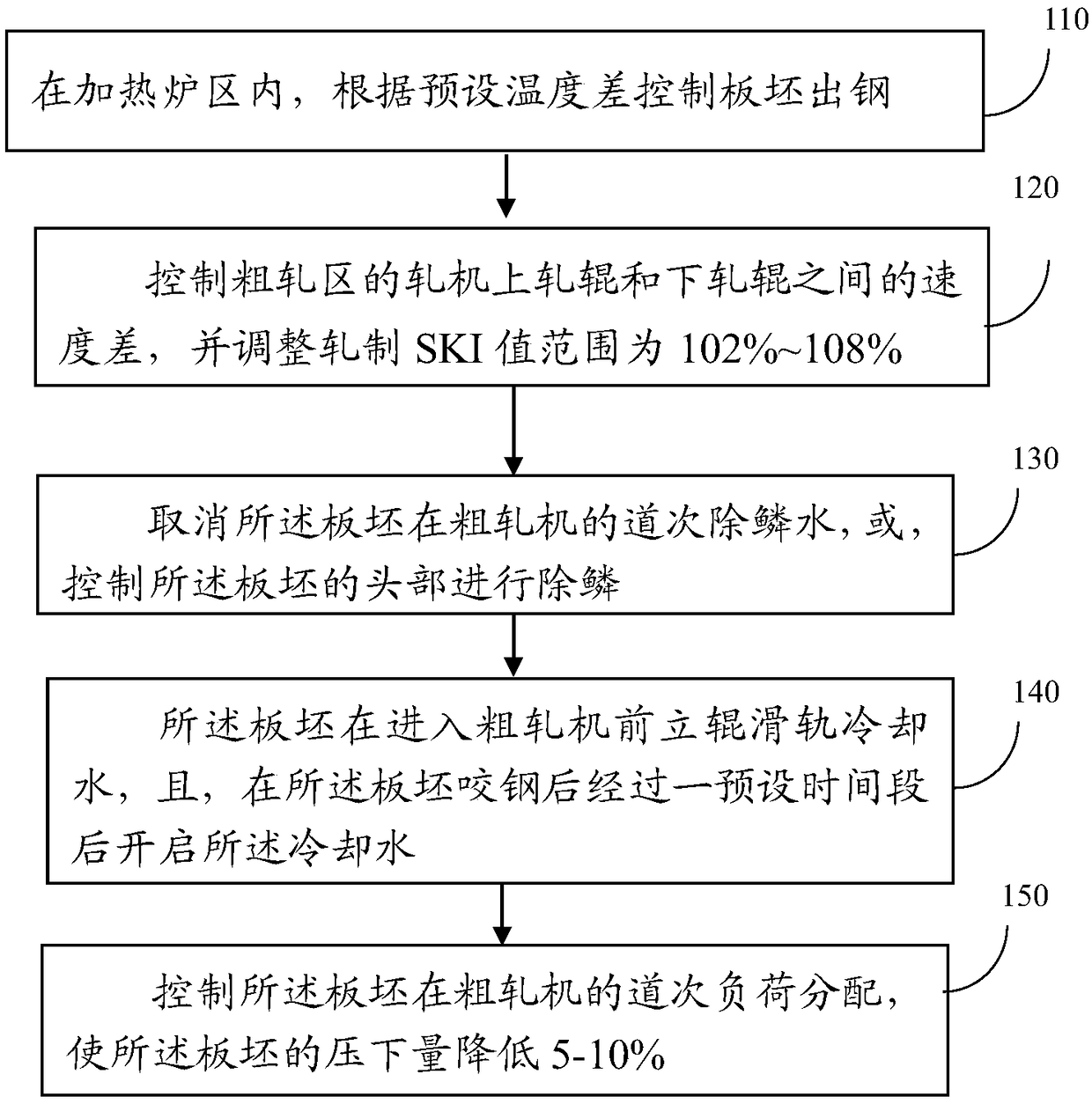

Control method for head warpage of plate blank

InactiveCN108838216ASmall amount of depressionAlleviate the problem of warped headRare end control deviceProduction lineTemperature difference

The invention discloses a control method for head warpage of a plate blank, and belongs to the technical field of steel rolling. The method comprises the following steps of controlling outlet steel ofthe plate blank according to a preset temperature difference in a heating furnace area; controlling the speed difference between an upper roller and a lower roller of a rolling machine in a rough rolling area, and regulating the SKI value range of rolling to be 102 to 108 percent; removing pass descaling water of the plate blank in a rough rolling machine, or, controlling the head of the plate blank to perform descaling; turning off cooling water of a vertical roller sliding rail before the plate blank enters the rough rolling machine, and, turning on the cooling water after a preset time after the steel of the plate blank is bitten; and controlling pass load distribution of the plate blank in the rough rolling machine so that the rolling reduction of the plate blank is reduced by 5 to 10percent. Through the method, the technical problem that a head warpage phenomenon can often be caused in the rough rolling area of a production line in the prior art is solved; and the technical effects of shortening accident time and non-scheduled shutdown time, relieving the head warpage problem of the plate blank, greatly reducing head warpage accidents, and improving the operation rate of a production line are achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

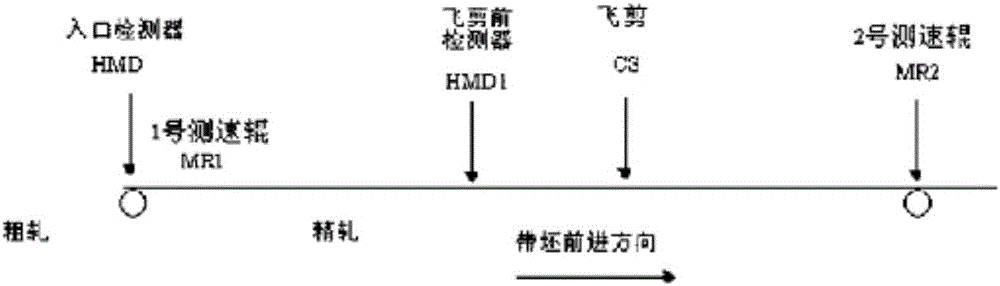

Hot-rolled flying shear head and tail initial shearing position dynamic control method

ActiveCN107433287ARealize dynamic controlAccuracy requirements metRare end control deviceMetal rolling arrangementsProduction lineSite location

The invention relates to control over a steel billet flying shear of a hot rolling machine, in particular to an initial shearing position dynamic control method applicable to a hot rolling machine flying shear. The method comprises the following steps of determining a position tracking detection range; determining dynamic detection points; calculating the distance from each dynamic detection point to a flying shear start point; determining the width of a tracking travel window; determining the practical running position of a strip steel; determining the calculated shearing length of the strip steel; comparing the calculated shearing length of the strip steel with a strip steel shearing length set value; and starting the flying shear to shear the strip steel. The detection areas of the head and tail positions of the strip steel are controlled through a finish rolling inlet of a hot continuous rolling production line; through combination with arrangement of the strip steel head and tail position tracking travel window and correction of the basic displacement of the strip steel, position tracking integrated initial points are switched dynamically, and dynamic control over strip steel initial shearing position control points is realized. Position tracking data are more aligned with the requirement for the practical site location precision.

Owner:BAOSHAN IRON & STEEL CO LTD

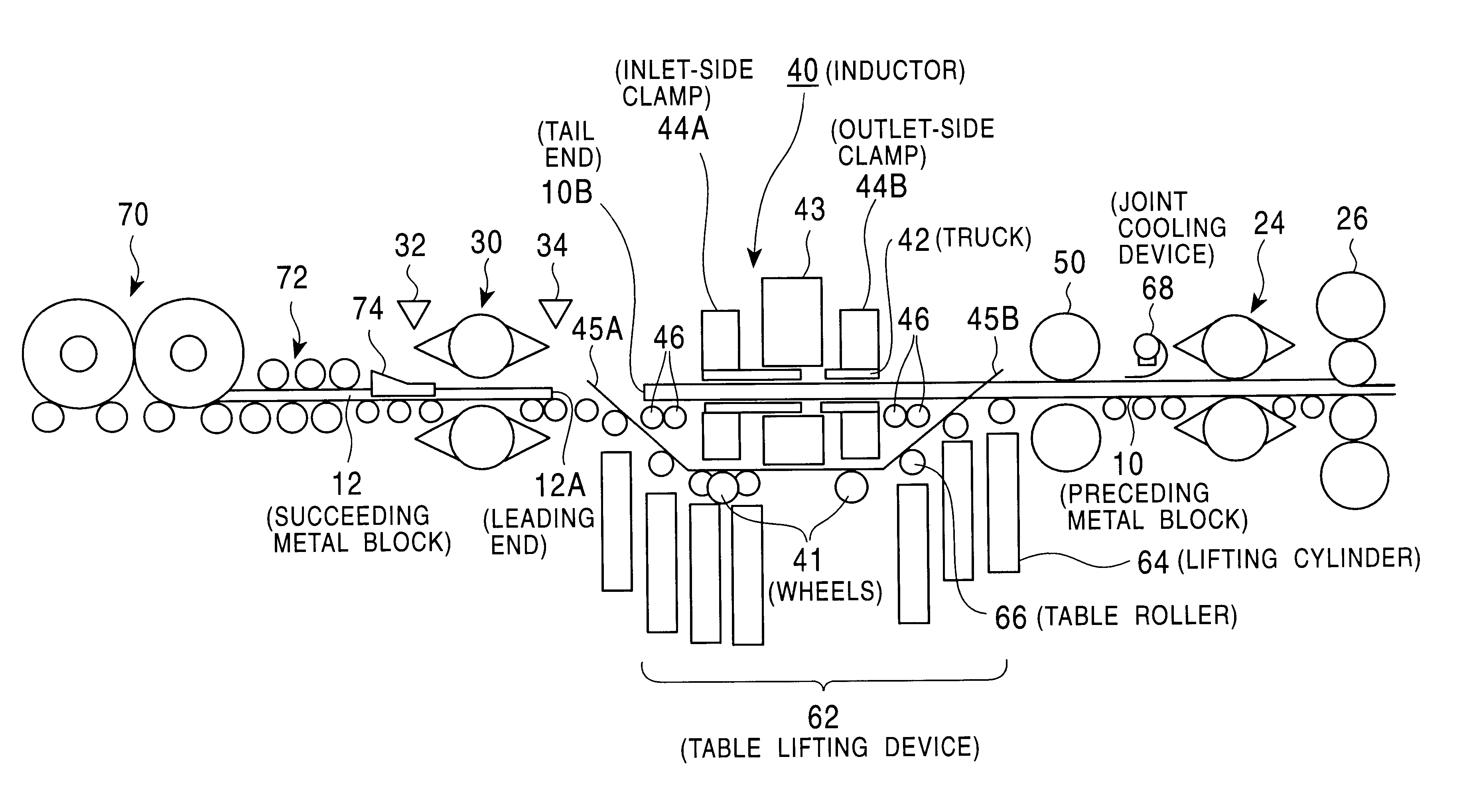

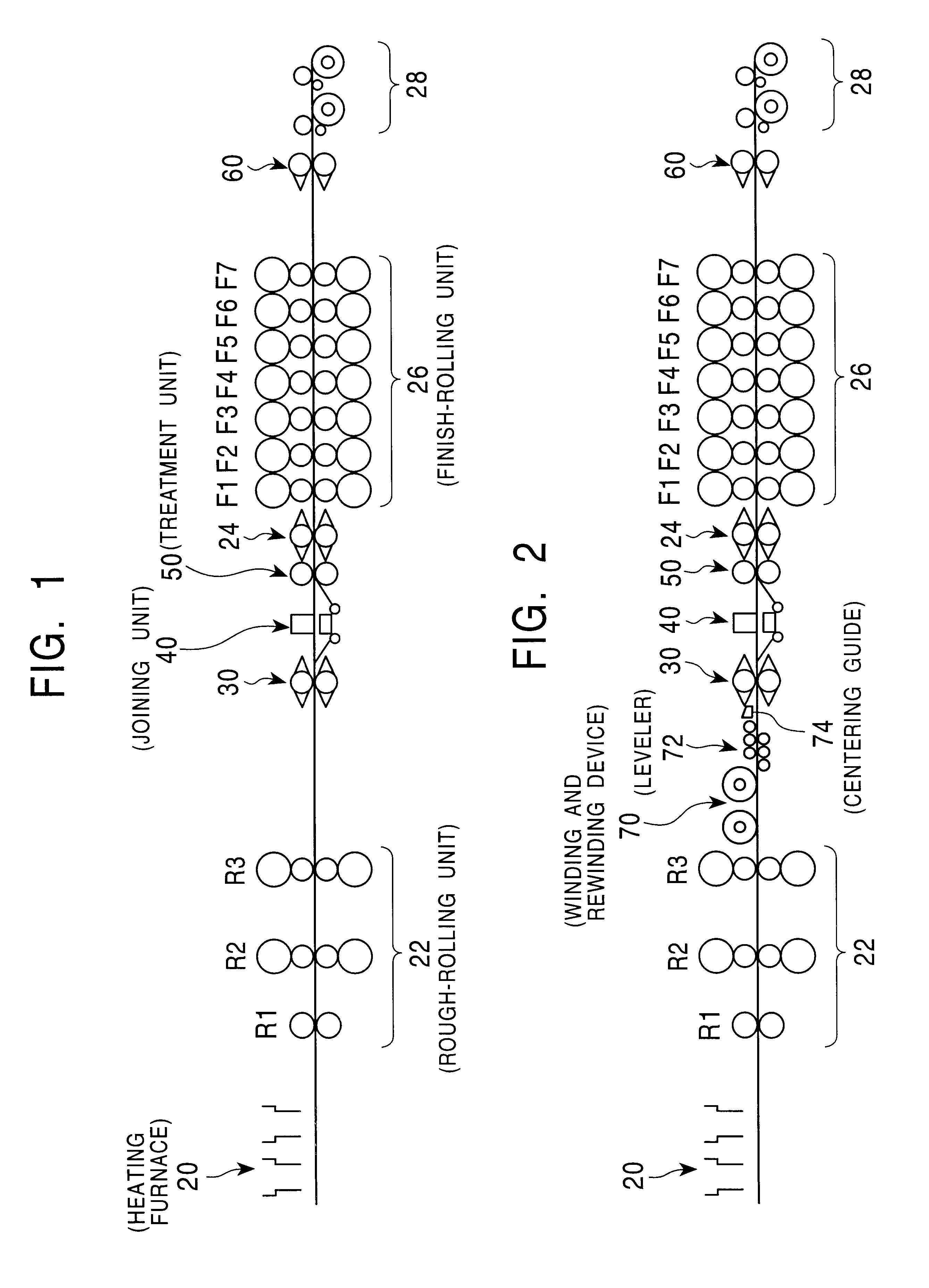

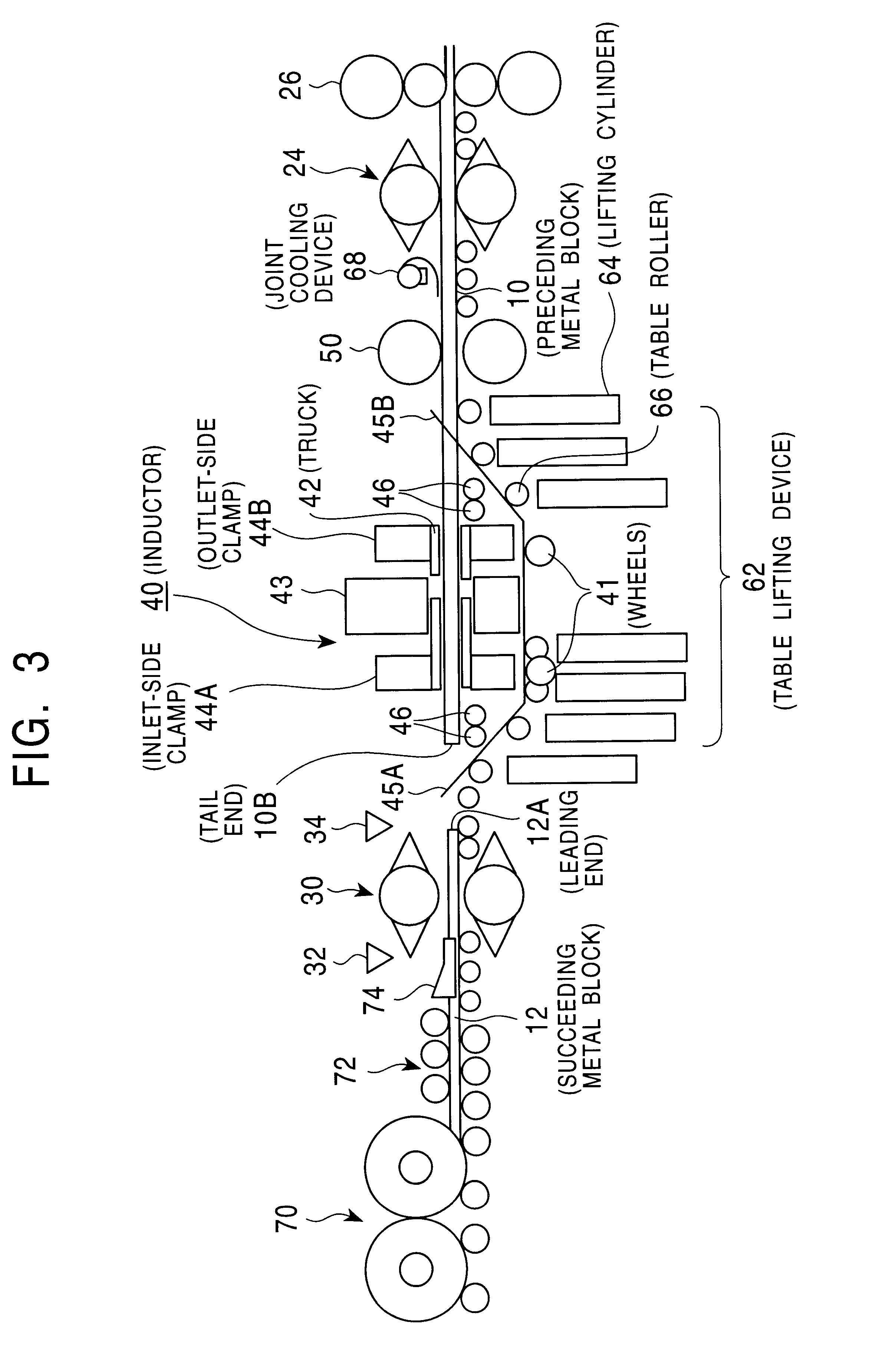

Method of hot-rolling metal pieces

InactiveUS6449996B1Reduce speedTroublesome operations for changing the settings are eliminatedRare end control deviceWork treatment devicesMaterials scienceMetal

The present invention eliminates the need to stop the operation of a line even when trouble arises before, during, or after an operation of joining metal blocks in hot rolling. According to a specific solving means of the present invention, when a succeeding metal block is to be subjected to hot finish rolling in succession to a preceding metal block after the leading end of the succeeding metal block is joined to a tail end 10B of the preceding metal block on the inlet side of a finish rolling mill 26, it is determined before and after joining whether or not endless rolling is impossible. When it is impossible, joining is aborted, and the succeeding metal block 12 is temporarily stopped, is fed again after the tail end 10B of the preceding metal block moves out of the finish rolling mill 26, and is finish-rolled under the conditions set for batch rolling. When joining was not performed successfully, a joint 11 is cut between a joining unit and the finish rolling mill 26, and the rolled material is bitten by the finish rolling mill set for batch rolling.

Owner:KAWASAKI STEEL CORP

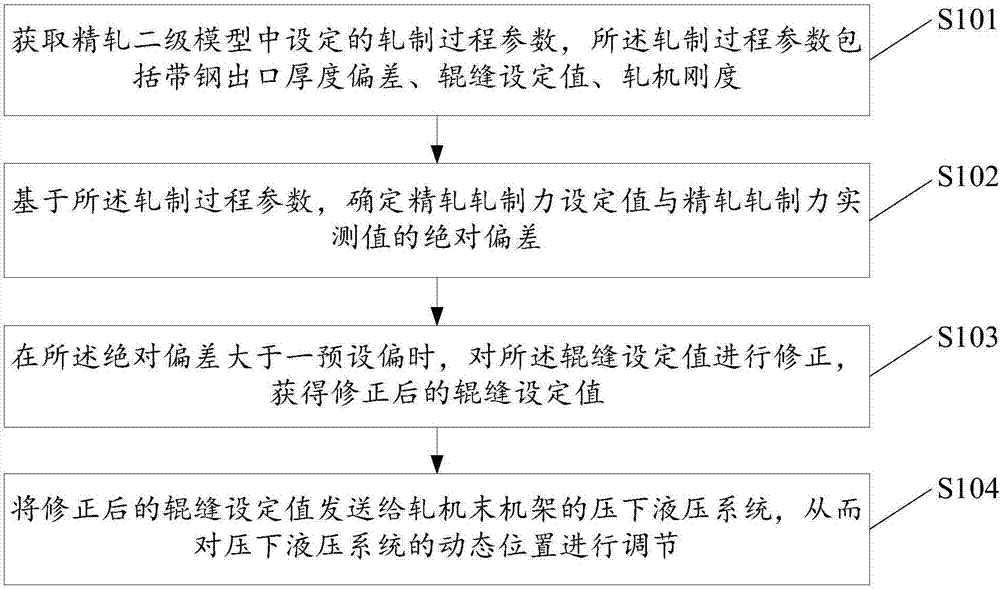

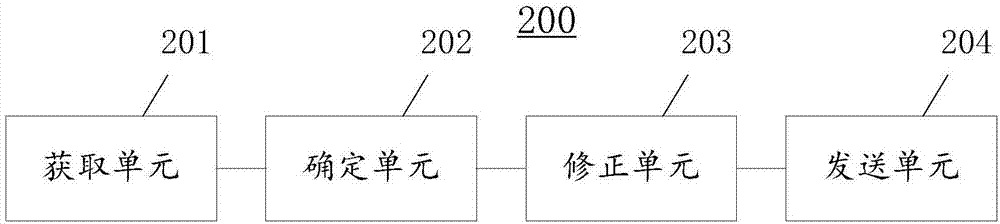

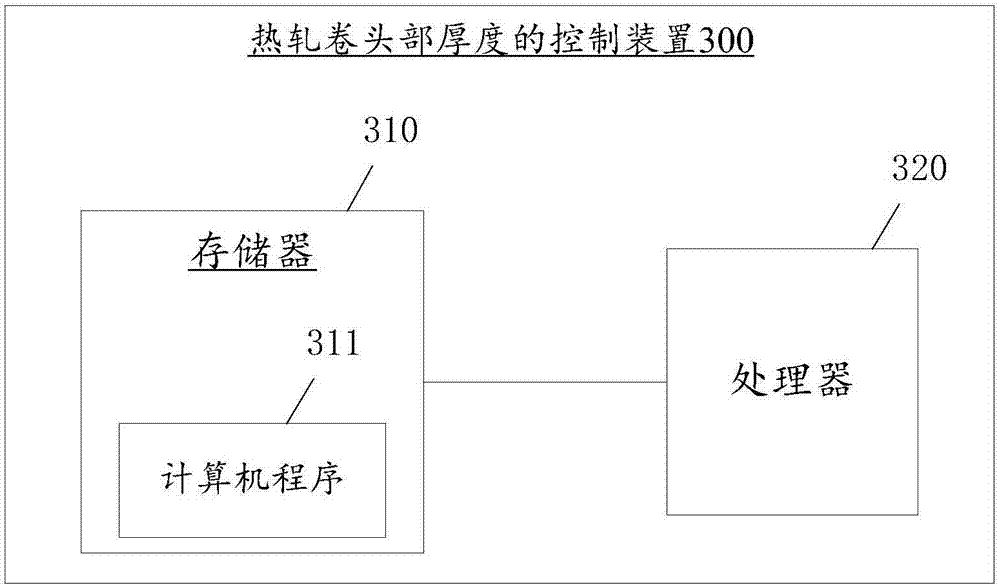

Control method and device for thickness of hot-rolled head portion

ActiveCN107363105ASolve the technical problem of unsatisfactory thickness control effectHigh control precisionRare end control deviceRoll force/gap control deviceProduction lineControl system

The invention discloses a control method for the thickness of a hot-rolled head portion. The control method is applied to a finish rolling control system of a hot rolling production line, and comprises the following steps: obtaining rolling process parameters in a finish rolling two-level model, wherein the rolling process parameters comprises a deviation of a band steel outlet thickness, a roller clearance set value and the rigidity of a rolling mill; based on the rolling process parameters, determining an absolute deviation of a set value of finish rolling force and an actually measured value of the finish rolling force; when the absolute deviation is greater than a preset deviation, correcting the roller clearance set value, and obtaining a corrected roller clearance set value; and sending the corrected roller clearance set value to a pressing hydraulic system at the tail rack of the rolling mill to adjust a dynamic position of the pressing hydraulic system. The control method achieves the technical effects of improving the control precision of the thickness of the head portion of band steel and improving the plate shape quality of the head portion of the band steel at a finish rolling outlet. Meanwhile, the invention further discloses a control device for the thickness of the hot-rolled head portion.

Owner:SHOUGANG CORPORATION

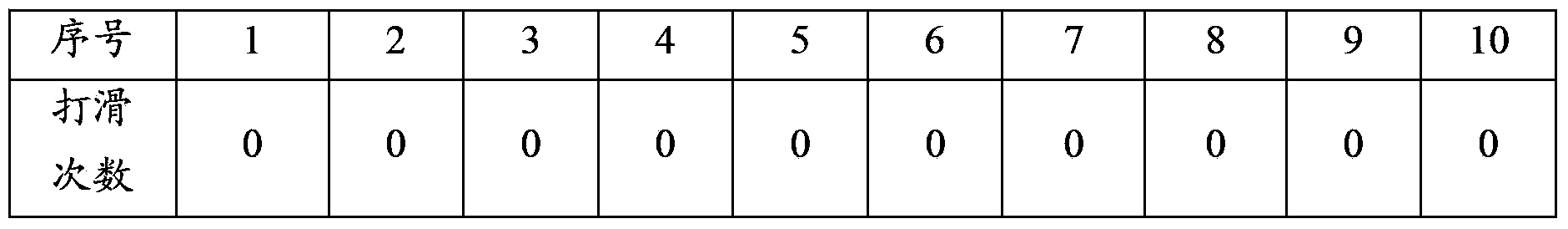

Continuous rolling mill entrance region tight rolls system and control method thereof

ActiveCN101229566APrevent slidingReduce scratchesRare end control deviceTensioning/braking arrangementsControl systemEngineering

The invention discloses a tension roll group system at entrance of a continuous rolling mill and a control method thereof. The tension roll group system consist of a tension roll, a press roll and an auto control system used for controlling the tension roll group system at the entrance of the continuous rolling mill. The press roll is connected with a power device. The invention changes the press roll of the tension roll into belt drive control and controls the tension roll system through the control method which is to adjust speed and torque of the press roll according to the speed, loop tension and the working status of the equipment at the entrance of a continuous rolling mill, prevent strip from sliding at the tension roll group and protect the surface quality of the strip and the surface of the tension roll, thereby reducing scratching of the strip tail.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for controlling upwarp end at the time of wide and thick steel plate rolling

InactiveCN103394525AAvoid head tiltGuaranteed final straightnessRare end control deviceUltimate tensile strengthMechanical property

The invention relates to a method for controlling an upwarp end at the time of wide and thick steel plate rolling, in particular to a method for controlling the upwarp end when a steel plate which has yield strength greater than 500 Mpa and thickness greater than 49 mm is rolled, and belongs to the field of steel rolling. According to the method, the steel plate is rolled in a controlled mode; in a second stage of precision rolling, the holding thickness is 1.5 to 3 times that of a finished steel plate; the precision rolling process is conducted for 3-5 times; before the precision rolling process is conducted for the last time, the steel plate is manually swung on a roller bed for holding for 10-35 seconds; then, the precision rolling process is conducted for the last time. By the adoption of the method, the upwarp end which appears when the steel plate which has the yield strength greater than 500 Mpa and the thickness greater than 49 mm is rolled can be eliminated, the effect that the final flatness of the steel plate meets operating requirements is ensured, the adoption of the method does not affect the mechanical property of the steel plate either, and no safety accident of equipment occurs.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

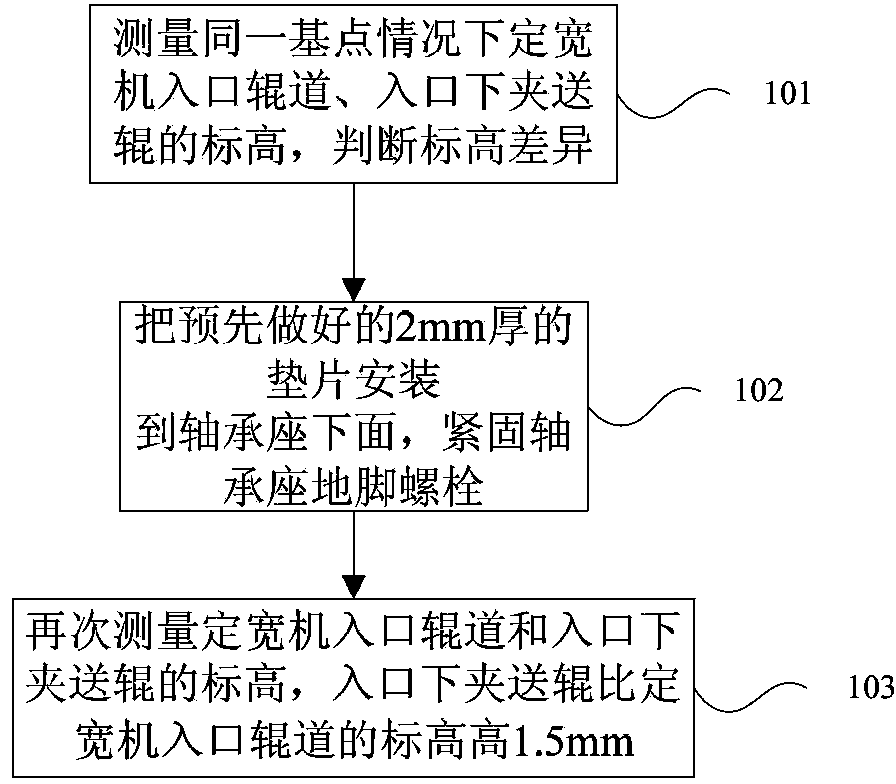

Method for preventing slab from sliding at inlet of fixed width machine

ActiveCN103433294APrevent slippingRaise the elevationRare end control deviceMetal rolling arrangementsEngineeringFixed width

The invention provides a method for preventing a slab from sliding at the inlet of a fixed width machine and relates to the technical field of hot rolling. The method comprises the steps of measuring the elevation values of an inlet roll way and an inlet lower pinch roll of the fixed width machine under the condition of the same base point to obtain an elevation difference; when the elevation value of the inlet lower pinch roll is smaller than that of the inlet roll way of the fixed width machine, selecting and mounting a gasket with the preset thickness under a bearing block of the inlet lower pinch roll according to the elevation difference, and re-measuring the elevation value; when the difference between the elevation values is smaller than the target preset elevation value, reselecting the gasket with the different preset thickness. The elevation value of the inlet lower pinch roll is improved, so after a kowtow slab enters the inlet lower pinch roll of the fixed width machine, even if the kowtow position is lapped on an inlet lower guide roll of the fixed width machine and a rear slab is raised, the inlet lower pinch roll of the fixed width machine can be kept contacted with the slab, so the kowtow slab can be effectively prevented from skidding at the inlet lower pinch roll of the fixed width machine.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

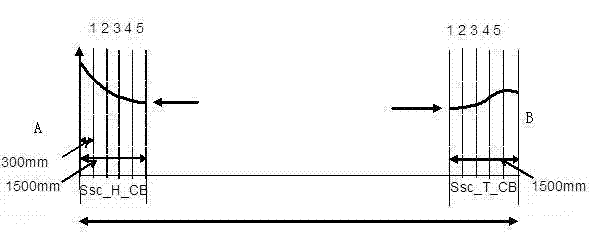

Method for controlling strip steel head and tail widths through coil box production process

InactiveCN103042043AHigh control precisionImprove hit rateRare end control deviceMetal rolling stand detailsProduction lineControl system

Disclosed is a method for controlling strip steel head and tail widths through a coil box production process. The method is characterized in that six parameters of the steel type, the width, the side pressure amount, the hot rolling thickness and the coiling box utilization mode are set in a width control system of a coil box in a 2250mm hot rolling production line; head and tail short stroke width control is performed on account of the six parameters, that is, vertical roll opening degree adjusting is performed once at an interval of 300mm in a 1.5m length range of the head and tail of a strip steel entering an edging mill; and the hot rolling thickness is set to be in a range of a first grade and a third grade, that is, the thickness of the first grade is smaller than 2.9mm, the thickness of the second grade is larger than or equal to 2.9mm and smaller than 12.5mm, and the thickness of the third grade is smaller than or equal to 2.9mm. According to the method, the dimension control accuracy of the head and the tail of the 2250mm hot rolling production line are improved greatly, the hit rate in a range of 0mm to 12mm is improved to 94.7% from 90%, the width abnormal product rate is reduced to 0.5% from 1.86%, and the width and quality of products are improved greatly.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for eliminating head indentation of hot-rolled strip steel

The invention discloses a method for eliminating head indentation of hot-rolled strip steel, and belongs to the control technology of a metallurgical hot-rolled strip steel coiling machine. The method is characterized in that head tracking computation is carried out in a primary computer; load correction is carried out for the first time after the head of the strip steel reaches a pinch roll, and load correction is carried out for the second time after the head of the strip steel reaches a wrapper roll; setting according to steel grade and specification is carried out in a secondary computer which is used for sending a hardness group code and a thickness code to the primary computer before the coiling machine establishes tracking; and the primary computer is used for automatically regulating a tripping-off value of the wrapper roll according to different hardness and different thicknesses and carrying out preset control on pressure of the wrapper roll. The method can be used for almost eliminating head indentation defects of the strip steel, so that good benefits are obtained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com