Patents

Literature

75results about How to "Reduce the number of transshipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

On-line quenching and plate shape controlling technology for 12MnNiVR steel plate

ActiveCN103555914AImprove cooling efficiencyReduce the number of transshipmentsRare end control deviceWork treatment devicesWater flowEconomic benefits

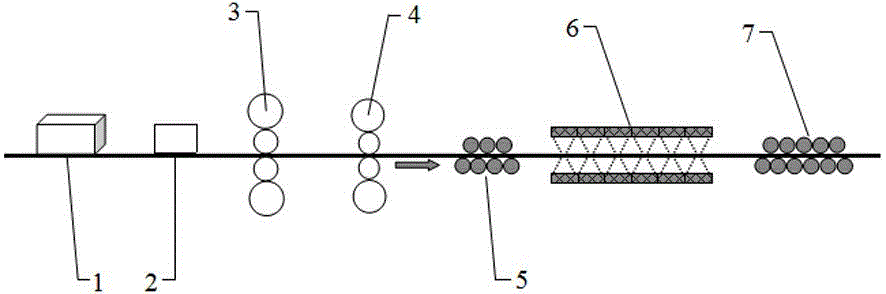

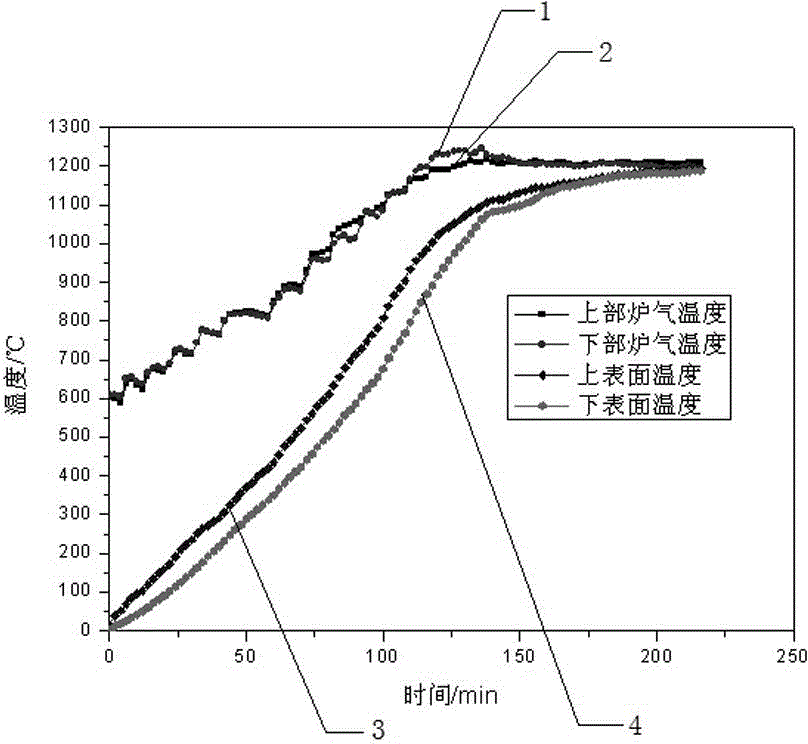

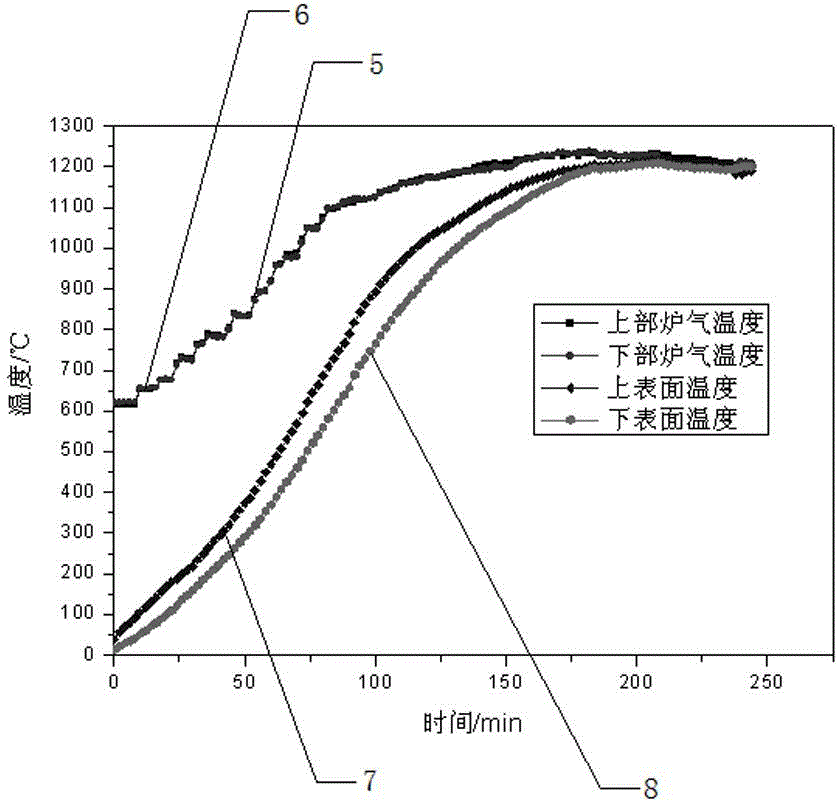

The invention discloses on-line quenching and plate shape controlling technology for a 12 MnNiVR steel plate, comprising: a blank material cold installation step, a de-scaling step, a rough rolling step, a finish rolling step, a pre-straightening step and an on-line quenching step; wherein in the on-line quenching step, the steel plate enters a ultrafast cooling system with 18 groups of cooling headers, the ultrafast cooling system sets a water flow amount based on the steel plate target thickness, sets an area roller-way speed being 0.7-1.2m / s, sets a roller-way acceleration being 0.003-0.01m / s2, controls a cooling start temperature being 790-740 DEG C, and controlling a cooling final temperature being 180-270 DEG C, and the steel plate departs from the ultrafast cooling system when a cooling final temperature is 180-270 DEG C. The technology provided by the invention raises cooling uniformity, cooling efficiency and once plate shape qualified rate of an on-line quenched steel plate, simplifies a thermal refining technology flow of 12MnNiVR, and finally raises economic benefit of enterprises.

Owner:NANJING IRON & STEEL CO LTD

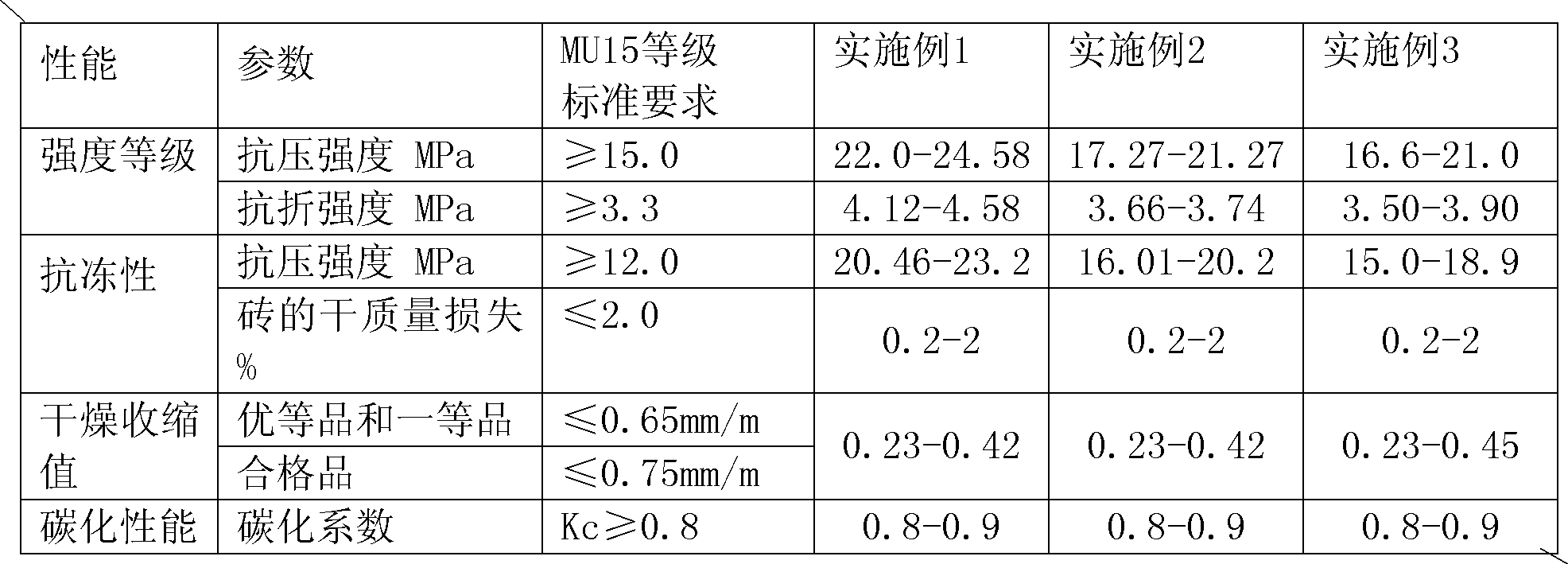

High-strength non-evaporating brick and preparation method thereof

InactiveCN101654941ASolve the problemSolve transportation difficultiesCeramic shaping apparatusBuilding componentsFrostBrick

The invention discloses a high-strength non-evaporating brick and a preparation method thereof, belonging to the technical field of building materials. The non-evaporating brick comprises the following components in percentage by weight: 30-45 unground grain slag, 30-45 heavy slag, 10-20 fly ash, 2-5 industrial by-product gypsum, 1-5 activity excitant and 5-14 water. The preparation method of thehigh-strength non-evaporating brick is simple, has low production cost and produces non-evaporating bricks with strong frost-resistant performance, low drying shrinkage value and high strength over MU15.

Owner:武汉钢铁有限公司

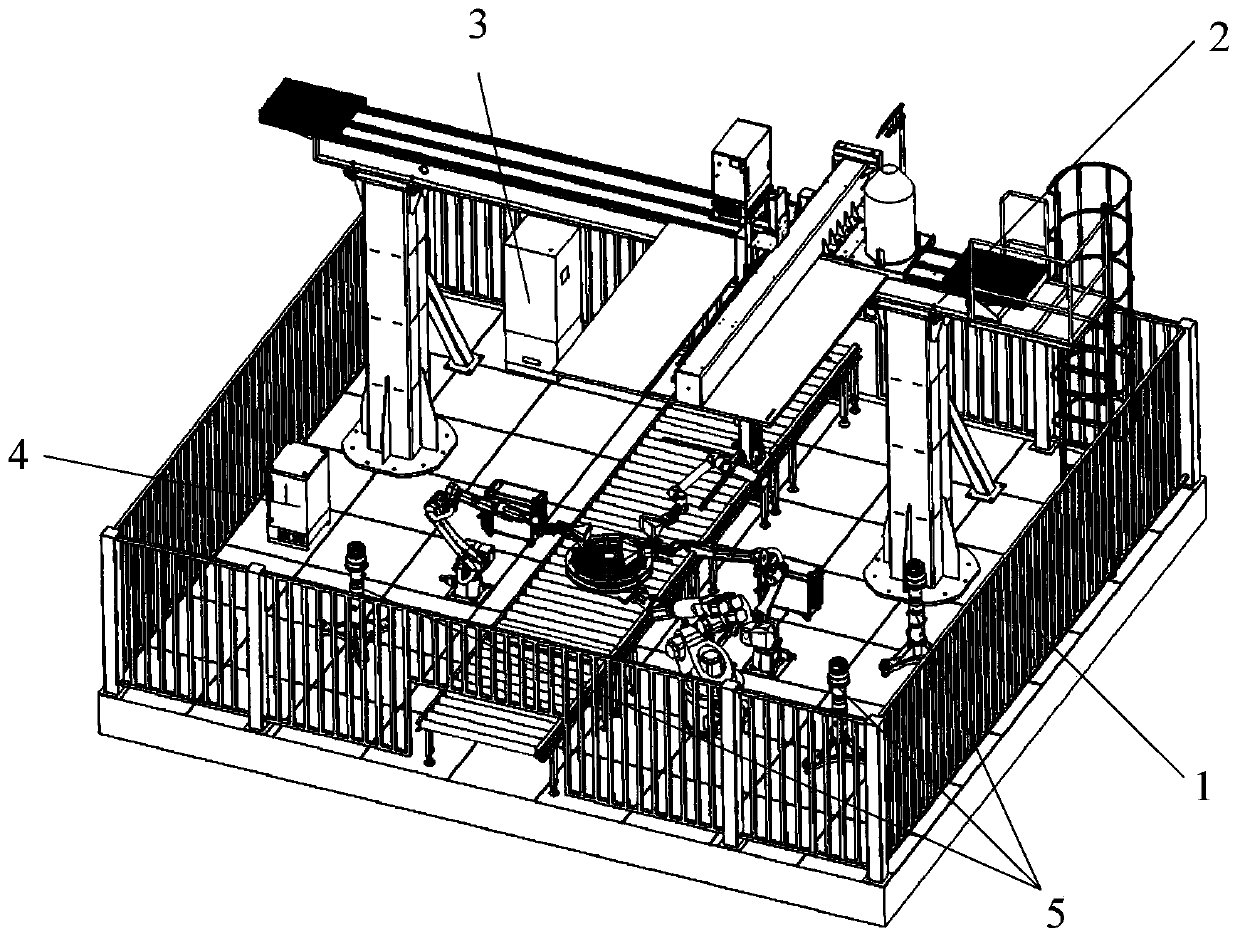

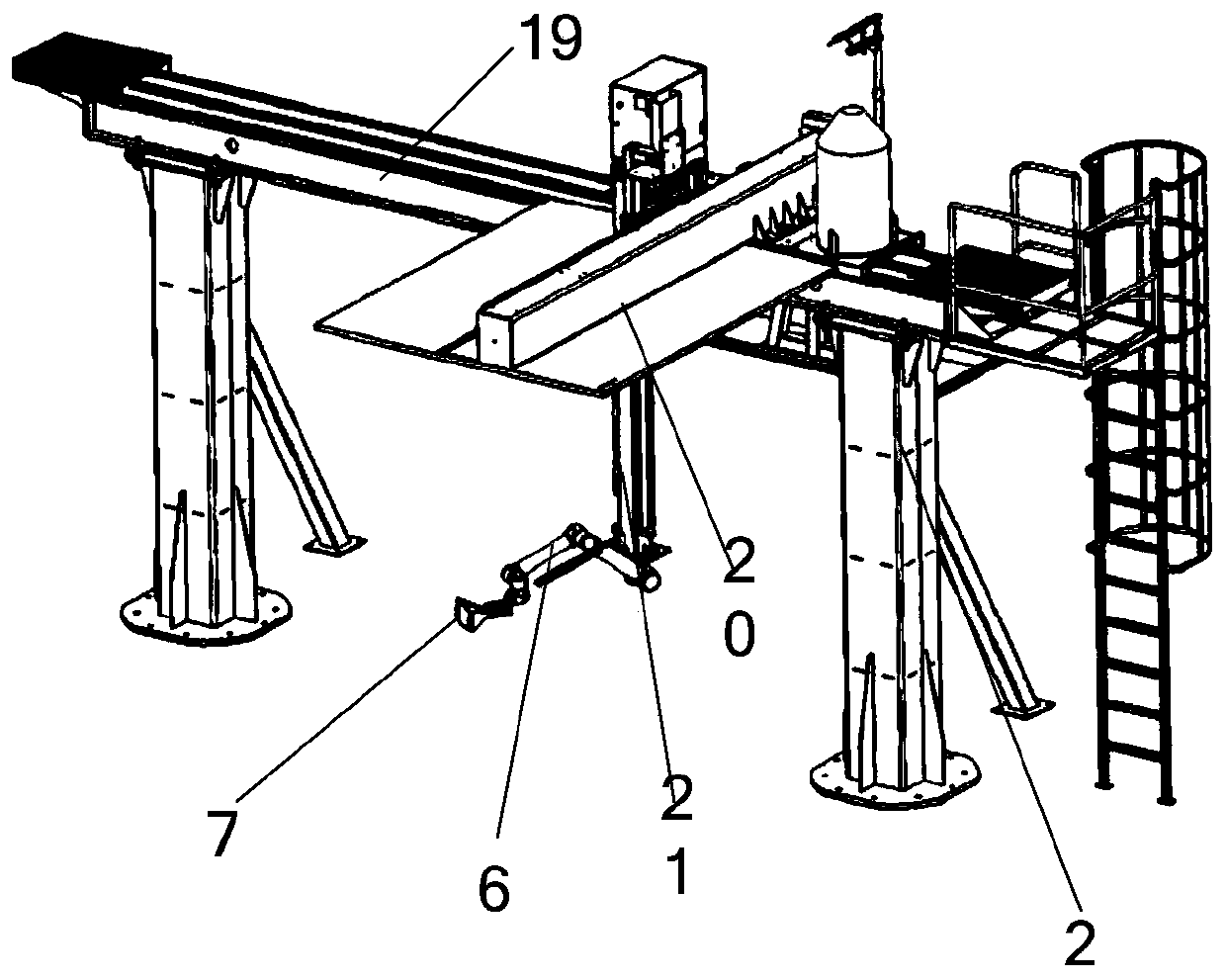

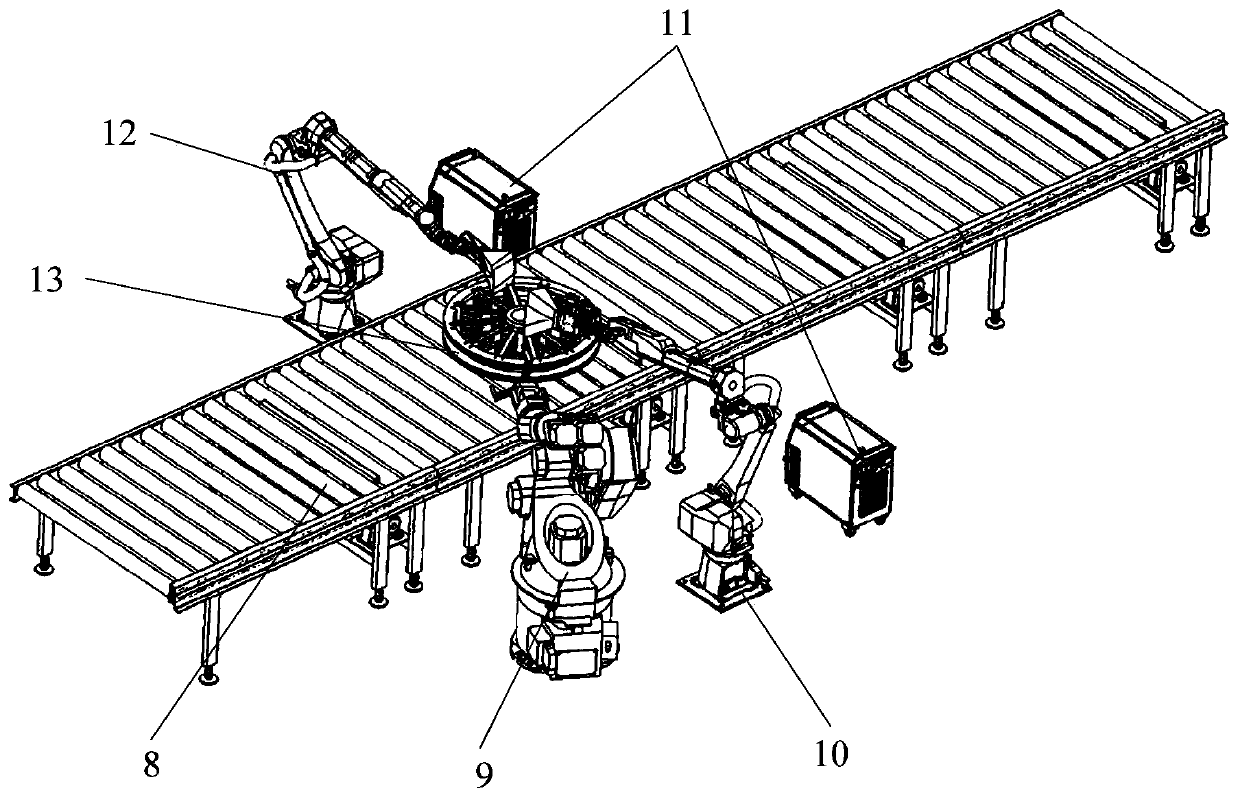

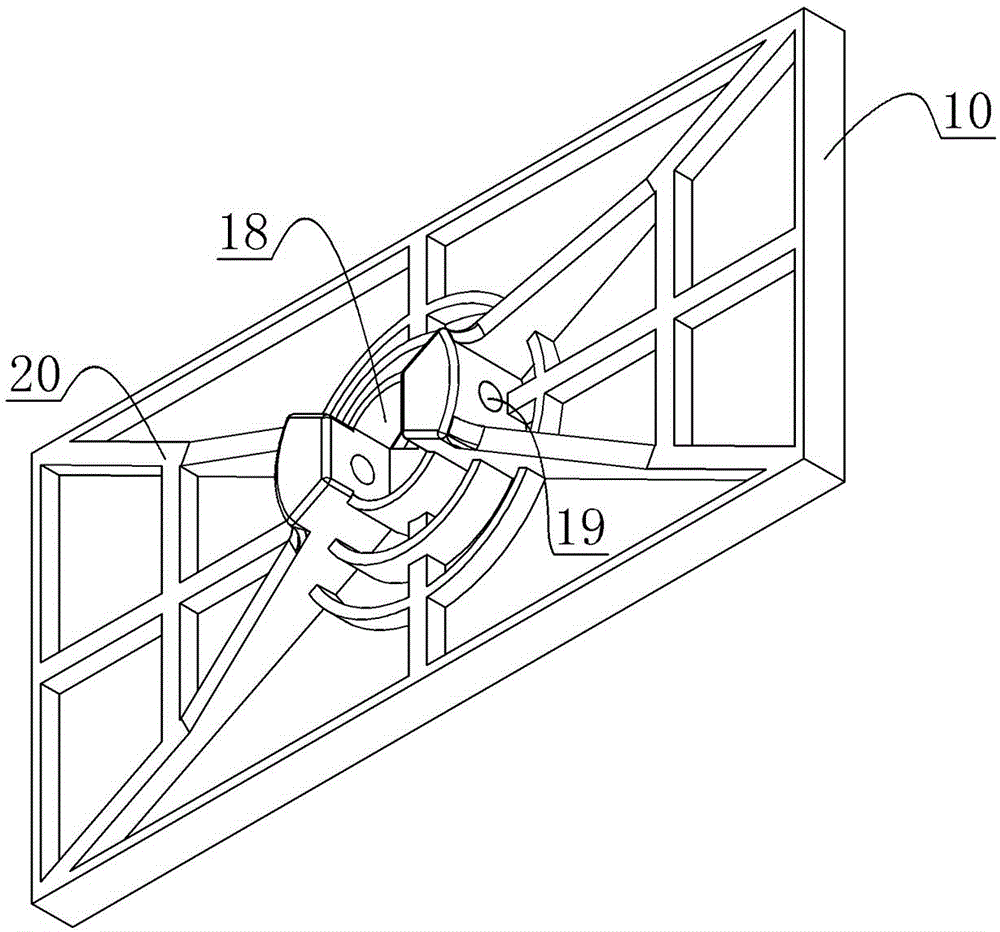

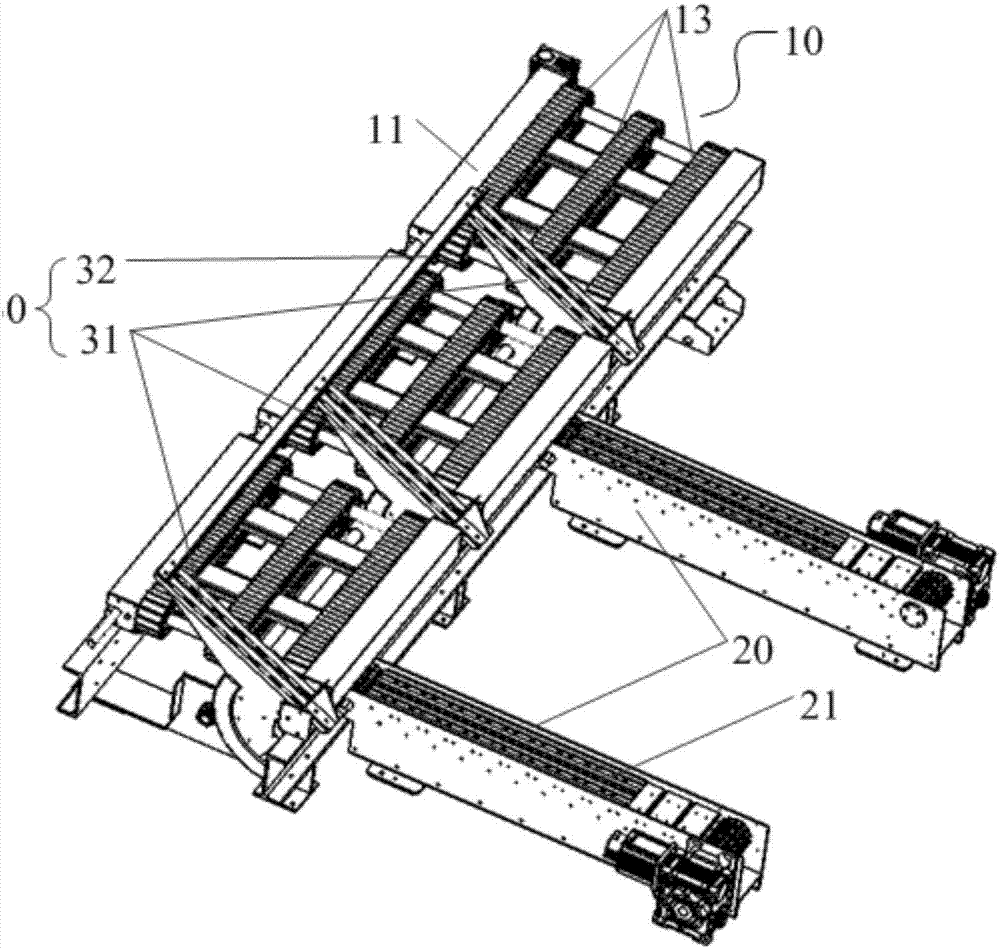

Flexible assembly welding robot workstation

ActiveCN110524582AImprove flexibilityHighly integratedProgramme-controlled manipulatorTotal factory controlEngineeringSpot welding

The invention discloses a flexible assembly welding robot workstation that comprises a global vision unit, a flexible welding robot group, a gantry truss detection unit, a master control unit and a conveying platform; the flexible welding robot group is arranged on the two sides of the conveying platform, welding workpieces are arranged on the conveying platform, the global vision unit is arrangedon the periphery of the flexible welding robot group, the gantry truss detection unit is arranged above the conveying platform, and the flexible welding robot group is controlled by the master control unit to conduct welding according to obtained image information. The high integration degree, high flexibility and high efficiency of the welding robot are achieved, the problems that manual assembly spot welding position deviation is large, and workpiece consistency is poor are solved, and the workpiece clamping and transferring frequency is effectively reduced. Multi-position assembly spot welding of workpieces is achieved, seamless connection of welding procedures is achieved, and the assembly precision, the welding consistency and the welding quality are improved.

Owner:XIAN ZHONGKE PHOTOELECTRIC PRECISION ENG CO LTD

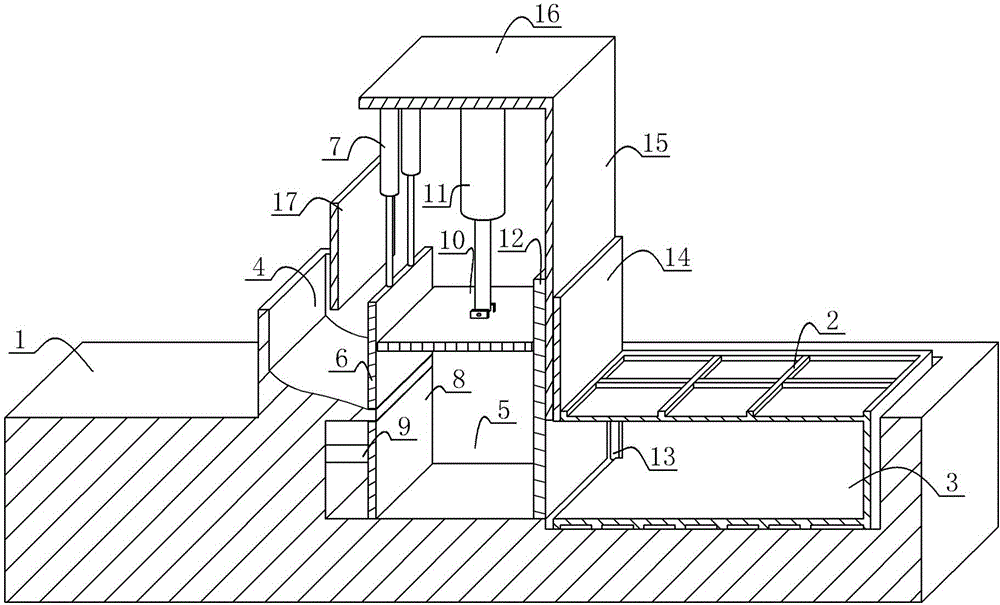

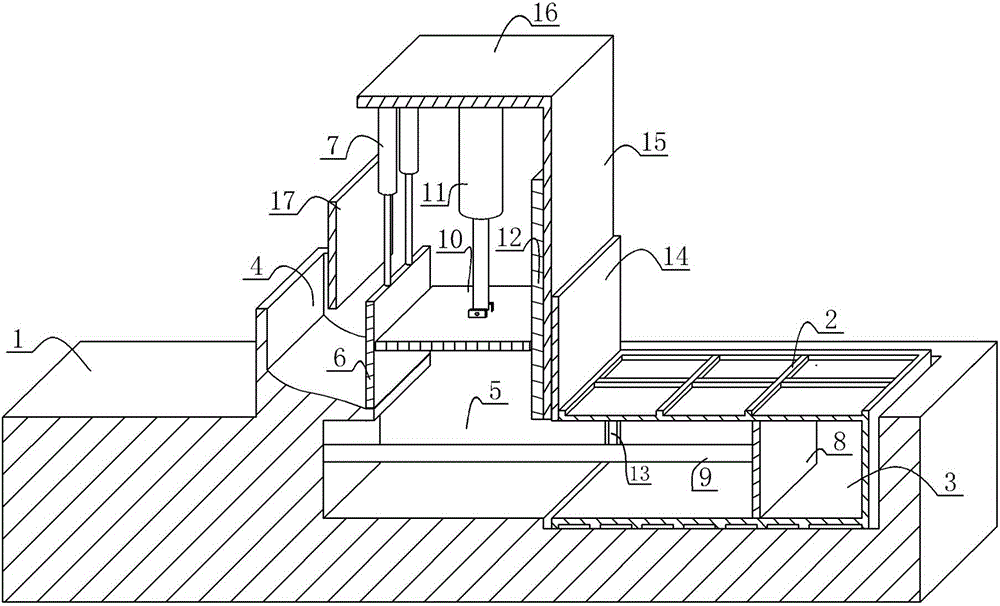

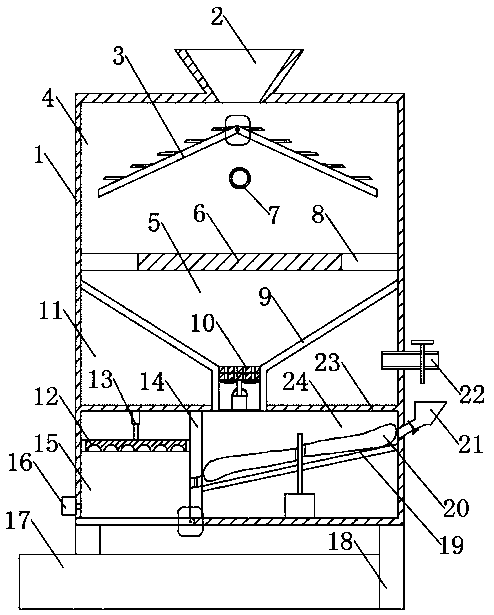

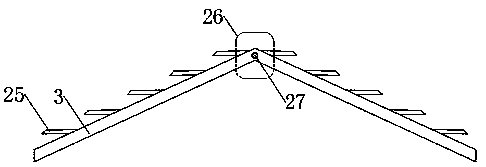

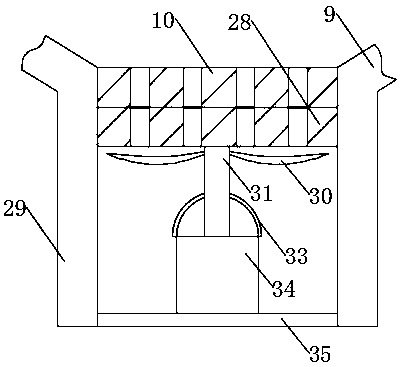

Garbage transfer station with automatic compression function

InactiveCN104386399ASmall footprintLarge storage capacityRefuse receptaclesRefuse transferringHydraulic cylinderPollution

The invention provides a garbage transfer station with an automatic compression function. The garbage transfer station comprises a garbage can, a garbage pouring groove, a horizontal push plate and a compression plate, wherein a compression cavity is arranged under one side of the garbage pouring groove, the compression plate is arranged right above the compression cavity, the compression plate is connected with a compression hydraulic cylinder used for driving the compression plate to compress garbage in the compression cavity, the horizontal push plate is connected with a push-in hydraulic cylinder, and when the compression cavity and a garbage storage cavity are in communication positions, the horizontal push plate can push the compressed garbage into the garbage storage cavity under the drive of the push-in hydraulic cavity. The garbage transfer station provided by the invention has the advantages that the whole garbage compression and push-in process is automatically completed under the control effect of a hydraulic system, and the garbage is subjected to compression processing, so the storage quantity of the garbage can is increased in comparison with that of uncompressed garbage. The number of transfer times of the garbage transfer station is reduced, the garbage transportation cost is reduced, the problems of secondary pollution, low capacity rate and the like are effectively solved, and important popularization and application values are realized.

Owner:SHANDONG UNIV OF SCI & TECH +2

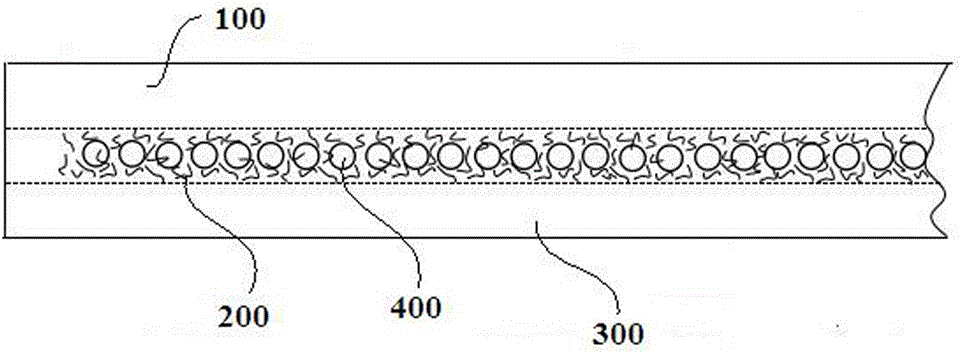

Magnetic conveying belt and magnetic linear driving device

ActiveCN106185171AOptimized formulaIncrease attractivenessNatural rubber adhesivesConveyorsMagnetic tension forceMagnetic line

The invention discloses a magnetic conveying belt and a magnetic linear driving device. The magnetic conveying belt comprises an upper covering layer, an adhesive layer and a lower covering layer which are sequentially connected from top to bottom, wherein steel wire rope cores are distributed in the adhesive layer; and the adhesive layer is made of magnetic rubber. The magnetic line driving device comprises the magnetic conveying belt used for conveying materials; a linear driving device which is used for providing power-assisted driving for the magnetic conveying belt and comprises a support, a driving roller, an auxiliary roller and a power conveying belt; and magnetic attraction force devices which are located below the power conveying belt and provide magnetic attraction force to attract the magnetic conveying belt to be tightly attached to the power conveying belt.

Owner:QINGDAO HUAXIA RUBBER IND

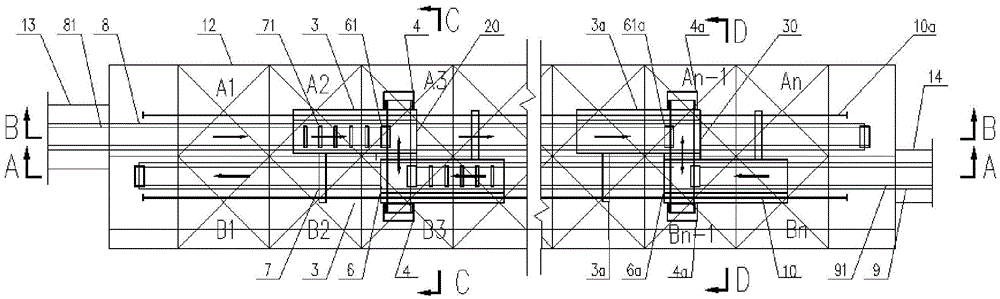

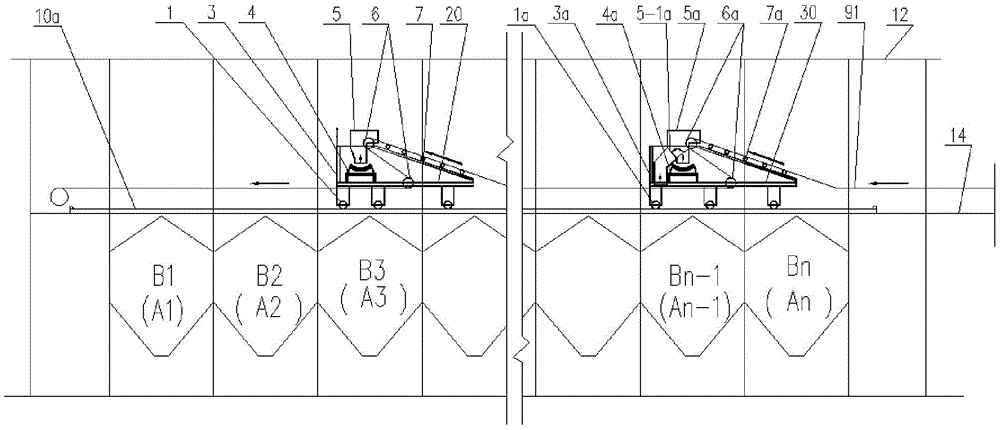

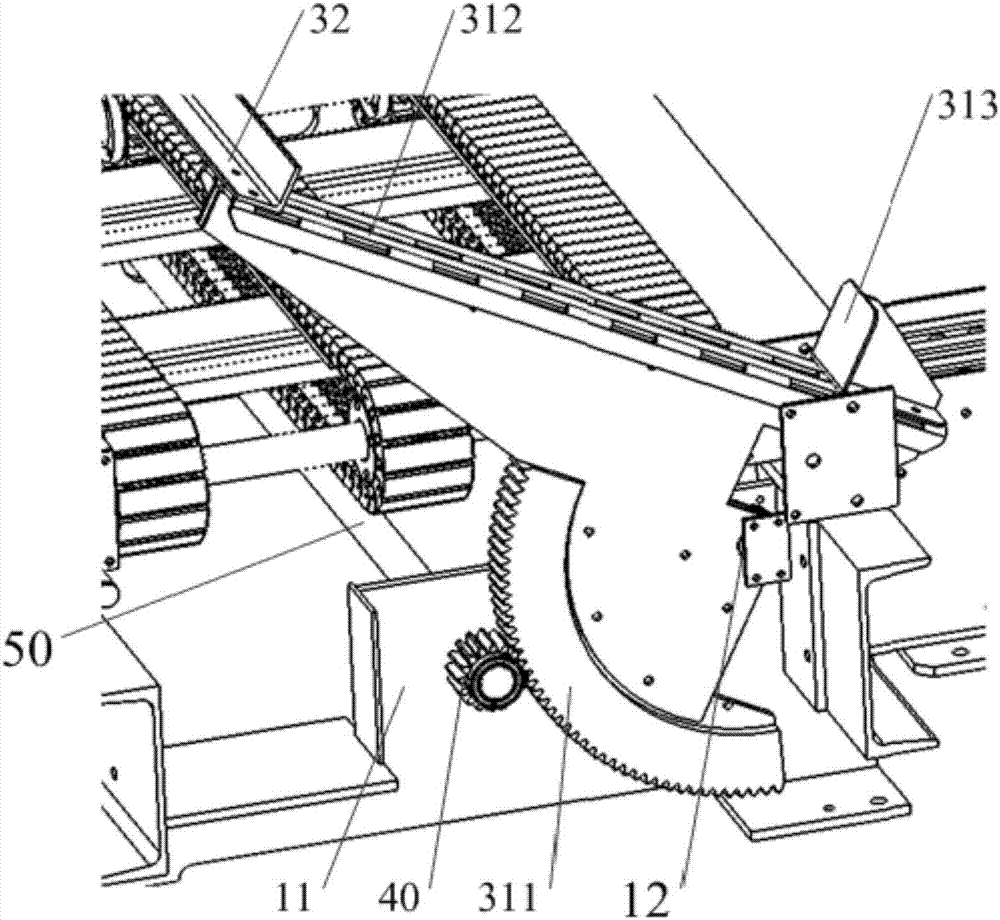

Unloading system of two-way feeding ore bin

The invention discloses an unloading system of a two-way feeding ore bin and aims to solve the problem that in the prior art, a two-way feeding ore bin is loose in structure. The unloading system of the two-way feeding ore bin comprises a belt type conveyor and two material distributing and unloading carts matched with the belt type conveyors; each material distributing and unloading cart comprises a cart frame and a material distributing device and a material unloading device which are opposite in direction; each material distributing device comprises a material distributing hopper, and each material distributing funnel comprises two unloading outlets and a material distributing plate arranged at the intersecting position of the two unloading outlets; each unloading device comprises an unloading funnel, the material distributing funnels are flush with the material unloading funnels, and a reversible belt type conveyor is arranged below the material distributing funnels and the material unloading funnels; the belt conveyor is matched with one material distributing device and one material unloading device, and the material distributing devices are arranged in front of the material unloading devices. The unloading system is compact in structure, good in production interchangeability, high in production safety, less in one-time investment and low in operation and maintenance cost.

Owner:HUATIAN ENG & TECH CORP MCC

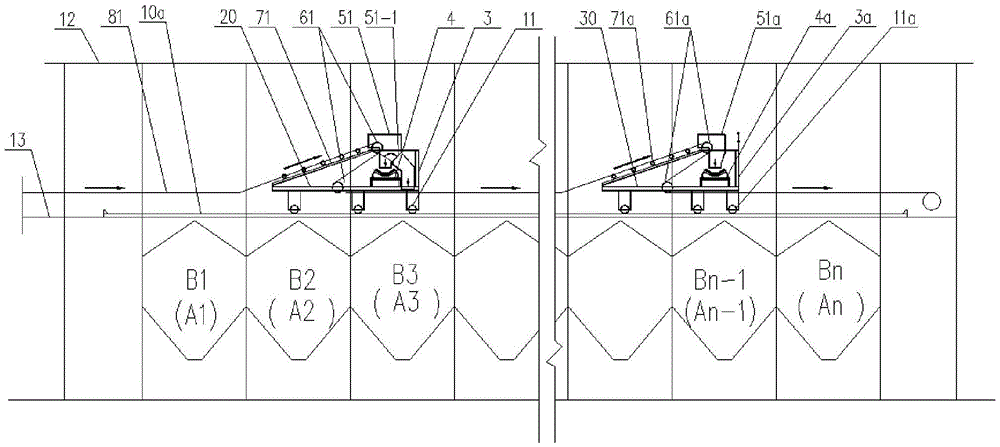

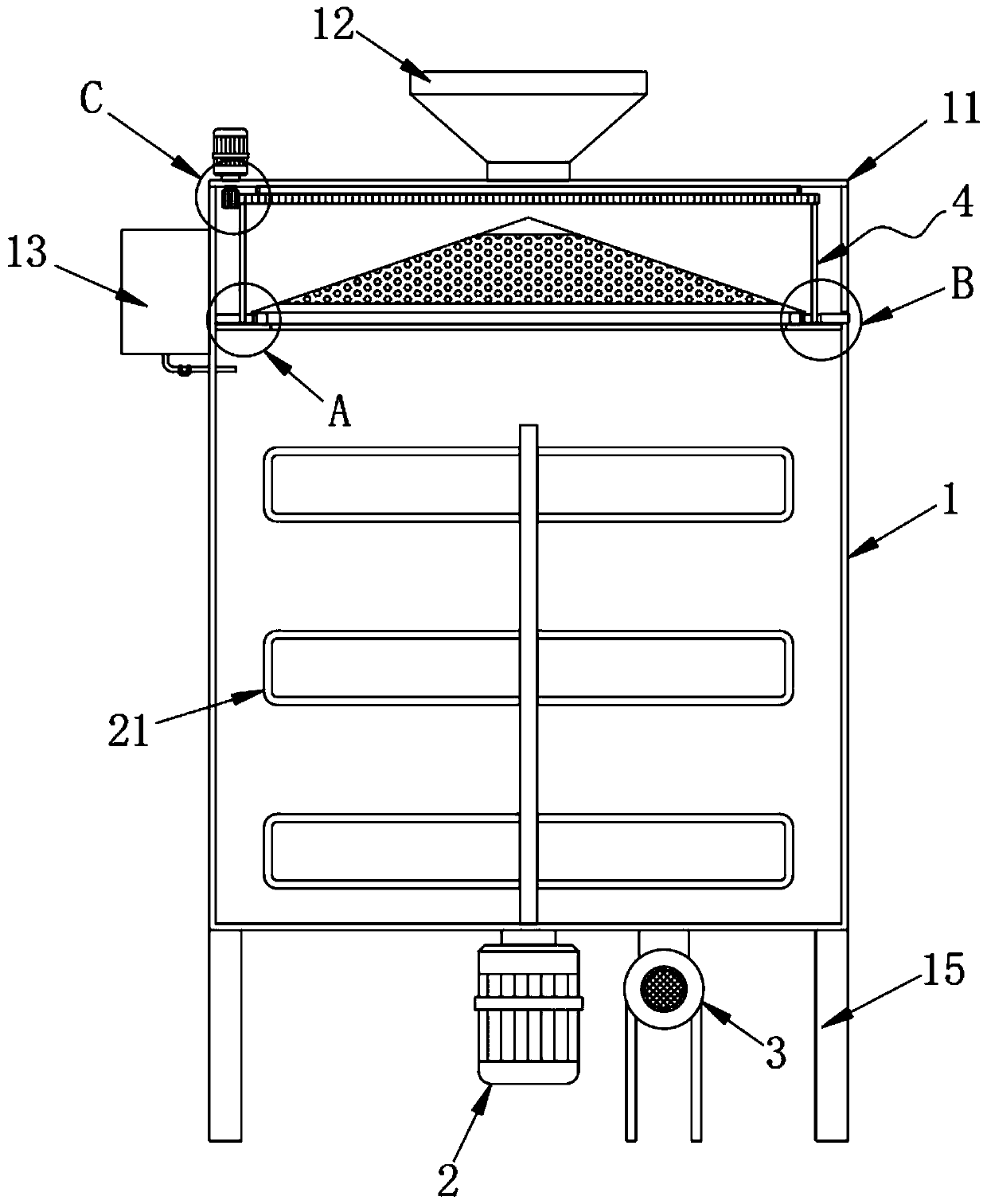

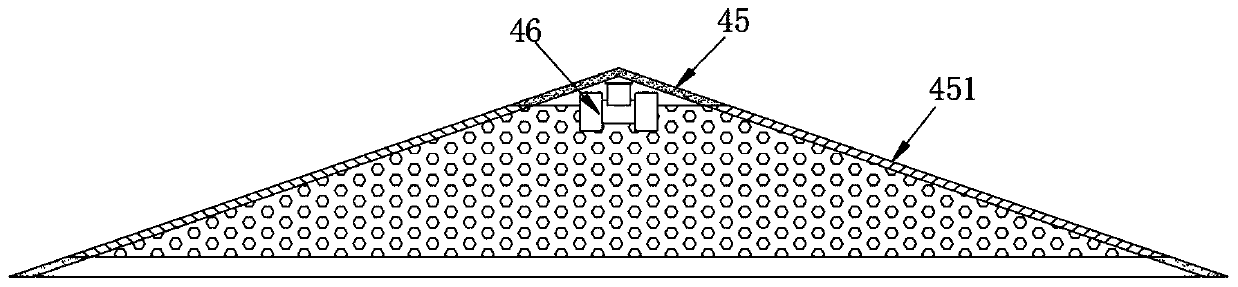

Green-ball concentrated screening equipment and process thereof

The invention belongs to the technical field of iron ore concentrate agglomeration and particularly relates to green-ball concentrated screening equipment and a process thereof. The green-ball concentrated screening equipment comprises a green-ball material collected belt conveyor, a swing belt conveyor, a large ball roller-type screening machine, a large ball chute, a large ball material received belt conveyor, a green-ball crusher, a bulk material collected belt conveyor, an undersize ball wide belt conveyor, a roller-type cloth screening machine, an undersize small ball chute, a small ball belt conveyor and an oversize ball slide carriage. The process comprises the following procedures of: (1) adding green-balls to the green-ball material collected belt conveyor, adding obtained materials to the swing belt conveyor, adding obtained materials to the large ball roller-type screening machine, adding obtained materials to the large ball material received belt conveyor, adding obtained materials to the roller-type cloth screening machine, and adding obtained materials to a chain grating machine; (2) adding obtained materials to the large ball roller-type screening machine, adding obtained materials to the undersize ball wide belt conveyor, adding obtained materials to the green-ball crusher, adding obtained materials to the bulk material collected belt conveyor, and adding obtained materials to a pelletizing chamber; (3) adding obtained materials to the roller-type cloth screening machine, adding obtained materials to the small ball belt conveyor, adding obtained materials to the bulk material collected belt conveyor, and adding obtained materials to the pelletizing chamber. The invention has the advantages of reasonable design, small investment, high finished product ratio, low process energy consumption, low repair rate and high economic benefit.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

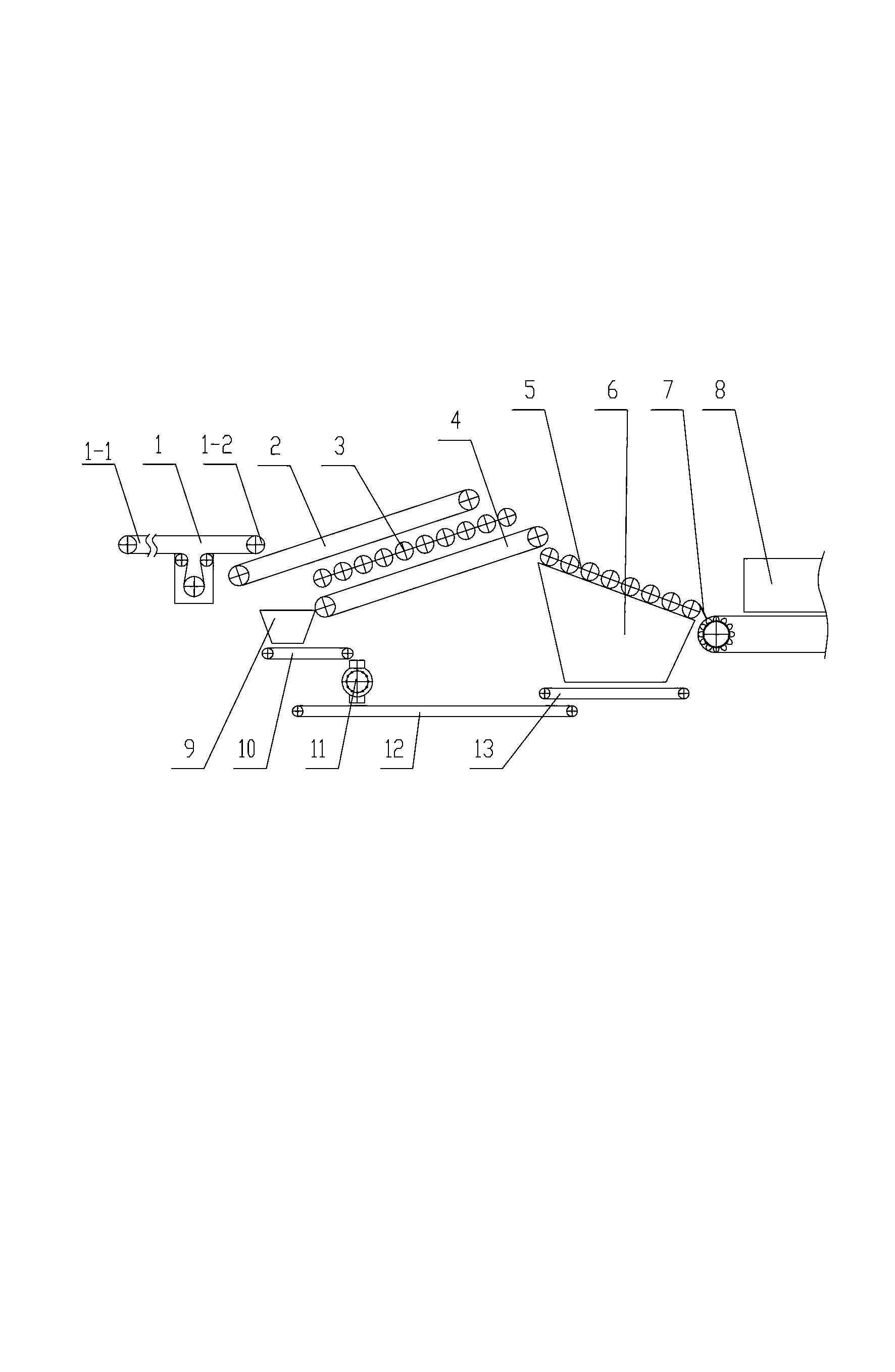

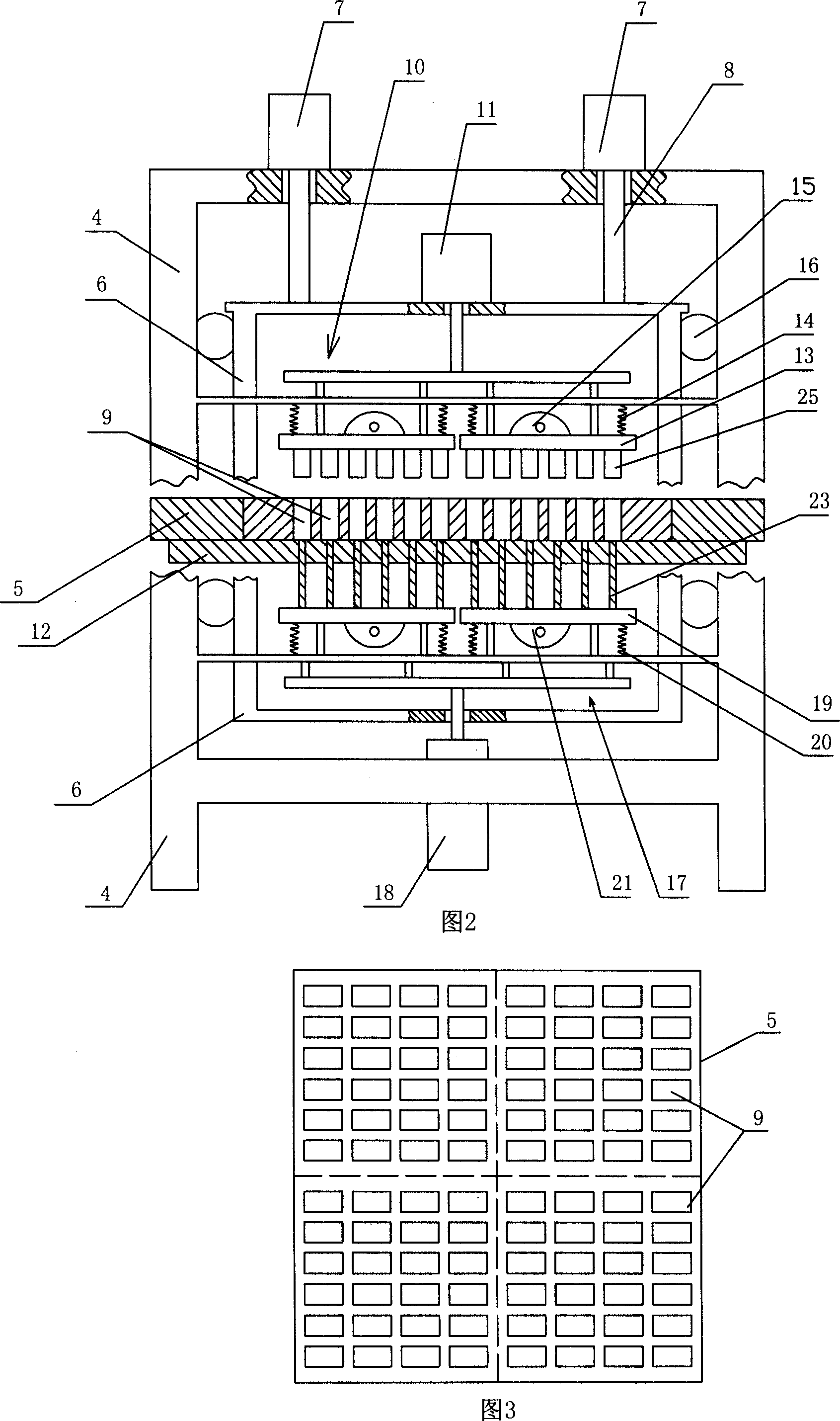

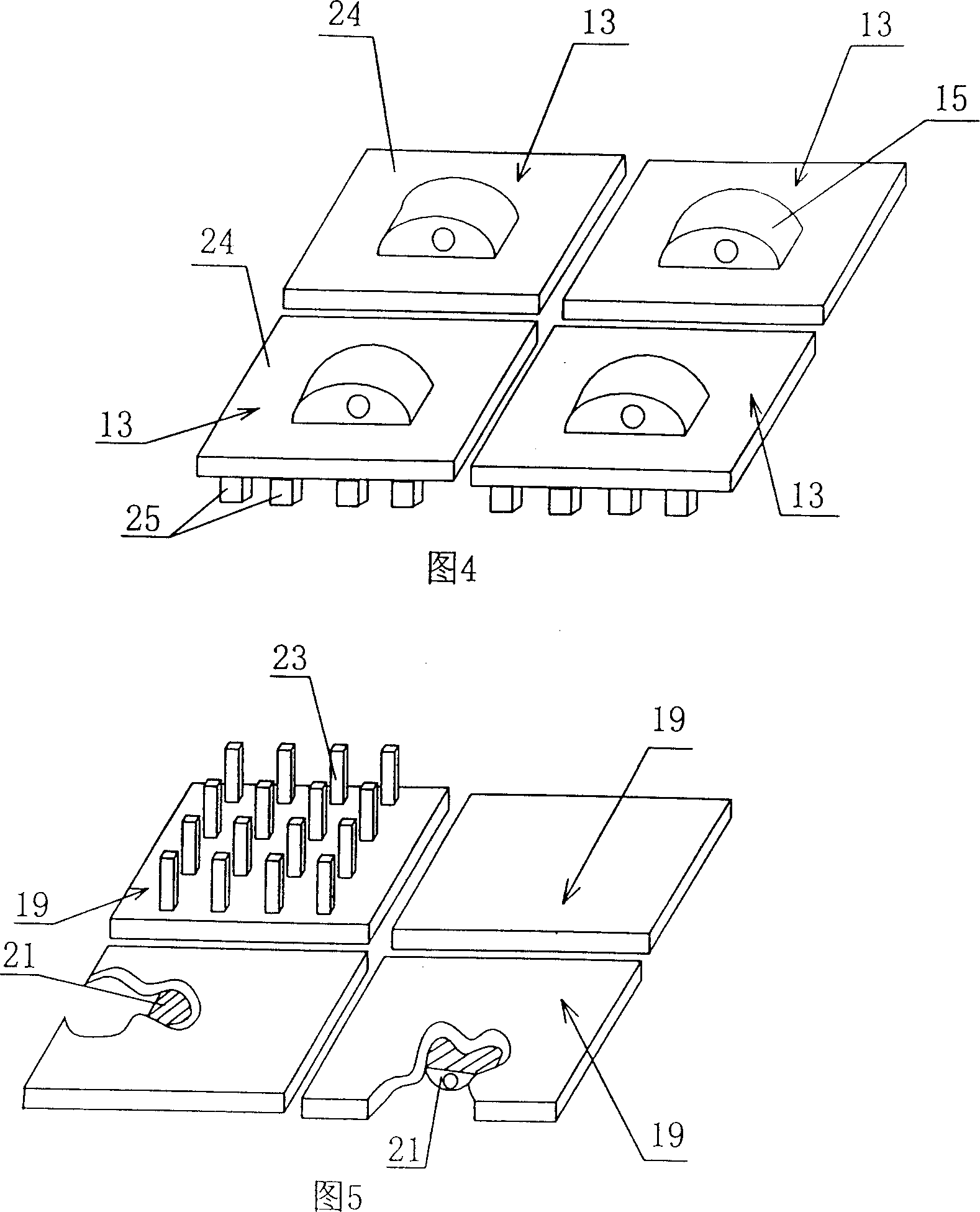

Concrete building block continuous producing technology

InactiveCN101143463ASave production landReduce the number of transshipmentsCeramic shaping plantsMolding machineUltimate tensile strength

A continuous production technology for a concrete block comprises a quantitative hopper feed into a die box of a concrete block molding machine. The adoption of a vibration extrusion molding leads to a direct palletizing and a transshipment strength for the molded block. The direct palletizing is done after block-molding and mold-stripping. The palletized block is transshipped into the hardening process. A top product is produced out after the hardening process. The technology saves a plurality of wooden carriers and carrier storage racks as well as storage space, saves the production site, reduces the number of transit and lowers transit cost. The heat of hydration in the hardening process of the concrete block is fully utilized. When the blocking process is done at a lowered temperature, the hardening time is shortened more than one and a half times than that at a natural temperature environment. The invention greatly saves production cost and improves production efficiency.

Owner:王海清

PCB inner layer circuit making device and making method

InactiveCN108337825AShorten production timeReduce waiting timePrinted circuit aspectsMultilayer circuit manufactureCooking & bakingBatch processing

The invention discloses a PCB inner layer circuit making device comprising a first feeding temporary storage frame, an inner layer pre-processing grinding plate roughening line, a second feeding temporary storage frame, an inner layer printing ink coating and baking line, a third feeding temporary storage frame, a reading mechanism, an exposure mechanism, a fourth feeding temporary storage frame,a developing, etching and unwinding line and an optical detecting mechanism, which are arranged in sequence, wherein each feeding temporary storage frame is connected with a mechanical arm for grabbing material, and the devices are sequentially connected by a conveyor belt along a material processing sequence. The device improves the processing efficiency and prevents the problem of scratching andscrapping the surface of the board by manual material handling, thereby improving the product yield and reducing the production cost. The invention further discloses a PCB inner layer circuit makingmethod for reducing the manual operation steps and the production time, eliminating the manual loading and unloading, and reducing the handling operations, thereby saving manpower, reducing the laborcosts, and being suitable for industrial batch processing of PCBs.

Owner:江西景旺精密电路有限公司

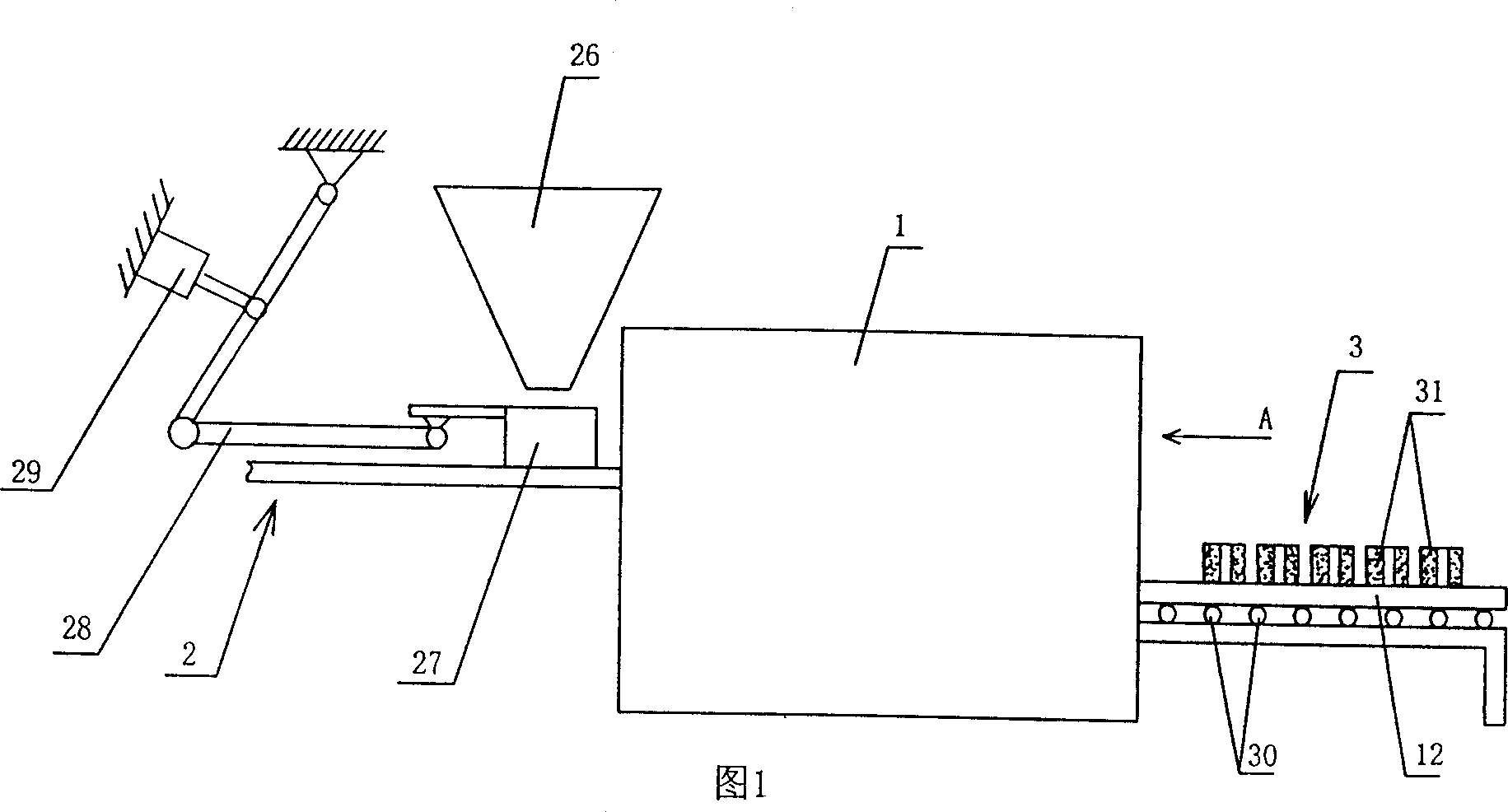

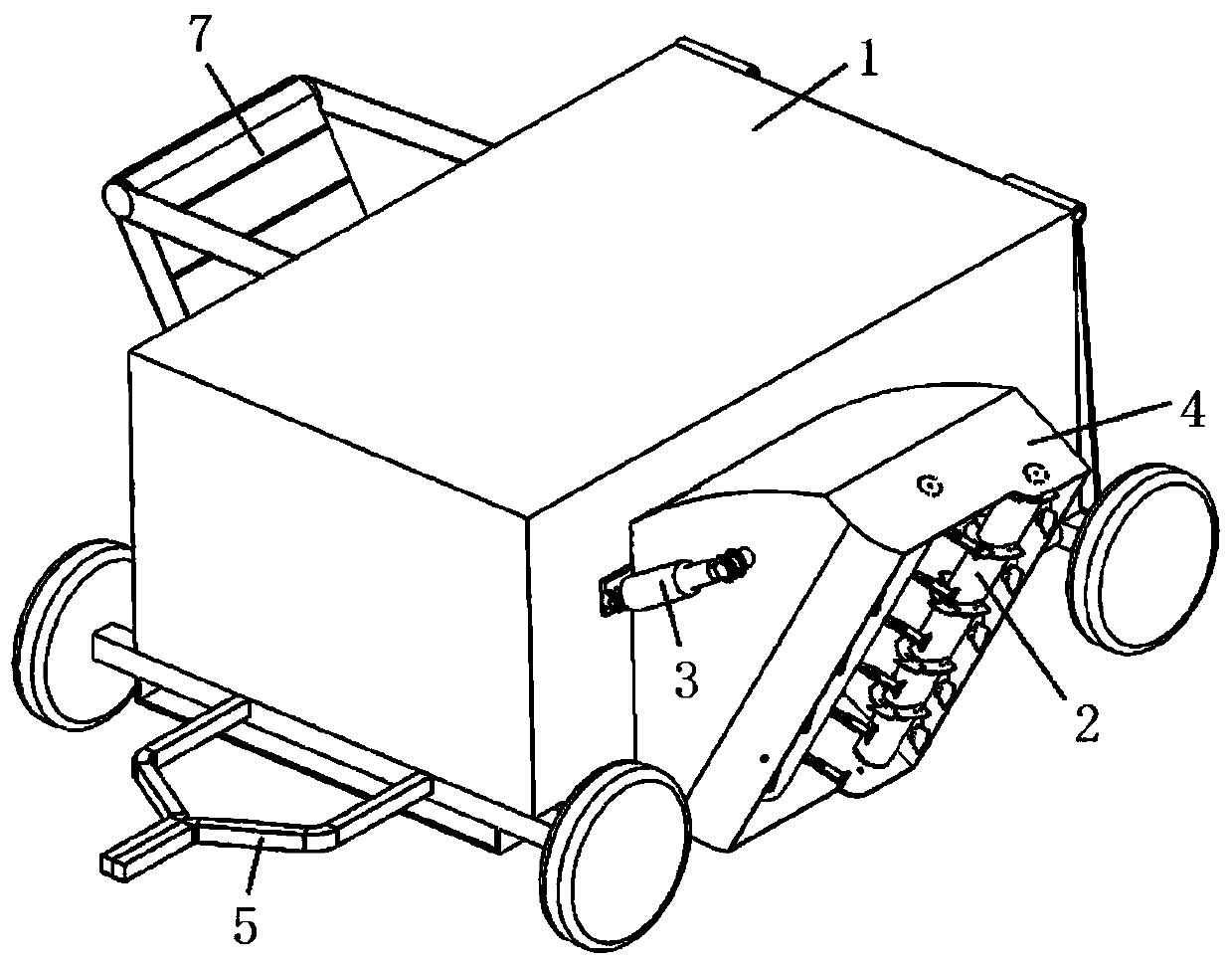

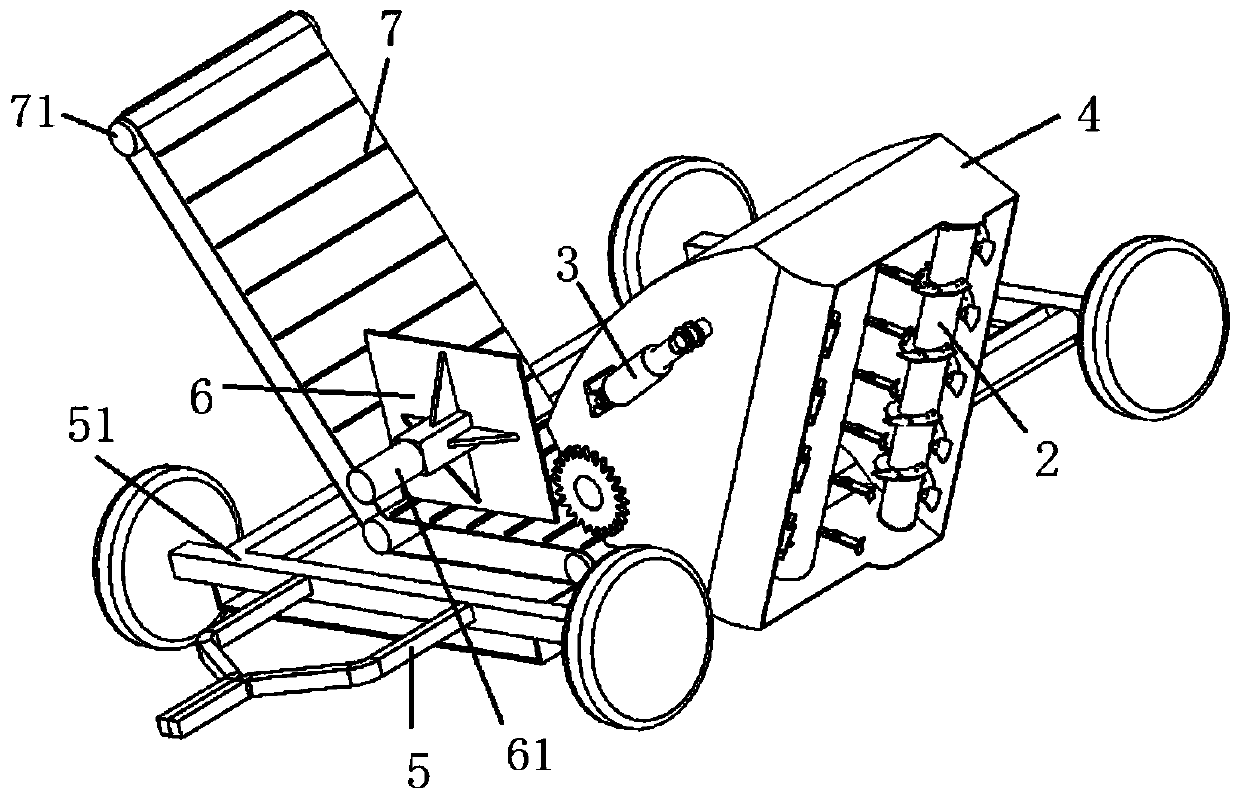

High-grasping-vine vegetable waste collecting and transferring machine and operating method thereof

The invention discloses a high-grasping-vine vegetable waste collecting and transferring machine and an operating method thereof. The high-grasping-vine vegetable waste collecting and transferring machine comprises a rack, a feeding assembly, a smashing assembly and a conveying assembly, wherein a machine cover is arranged on the upper part of the rack; the feeding assembly is arranged on one sideof the machine cover; a feeding roller and a crushing roller are contained in the feeding assembly; the feeding roller rotates to wind a material; the crushing roller rotates to break the material adhered onto the feeding roller in stages; a discharge hole in the bottom part of the feeding assembly is located in the machine cover; the smashing assembly is arranged in the machine cover and realizes secondary smashing of the material; a conveying belt in the conveying assembly is located at the rear end of a smashing cutter; and the other end of the conveying belt outwards stretches out of themachine cover. According to the high-grasping-vine vegetable waste collecting and transferring machine and the operating method thereof provided by the invention, the feeding roller winds the material, the crushing roller crushes the material, the smashing cutter smashes the material for the second time, and the smashed material is conveyed to a destination through a transport cart or a transfer machine, so that a vegetable waste can be quickly away from a field. The high-grasping-vine vegetable waste collecting and transferring machine provided by the invention is capable of effectively collecting grasping-vine vegetable wastes and high in efficiency.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

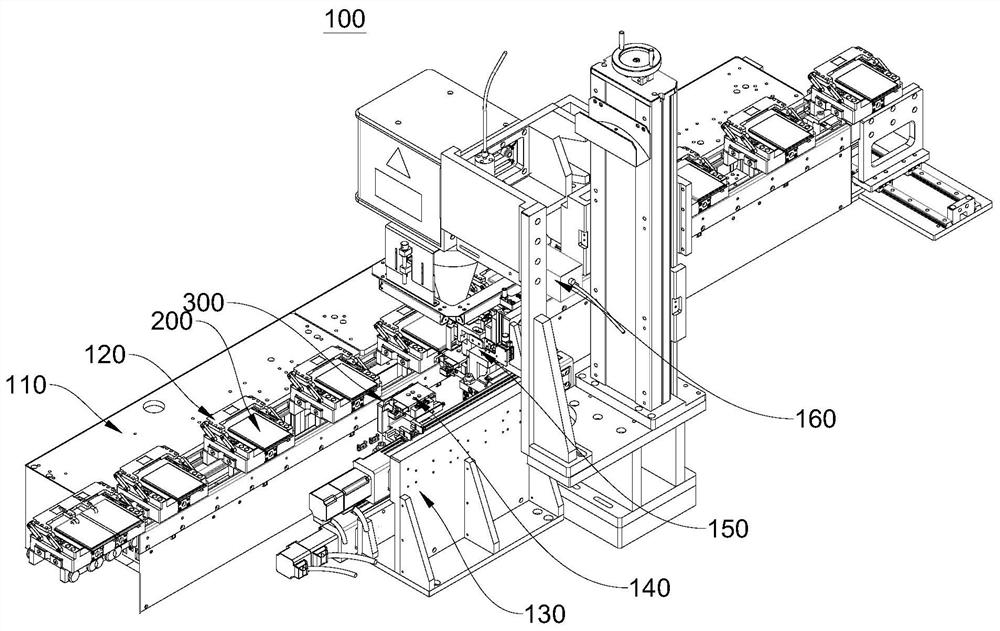

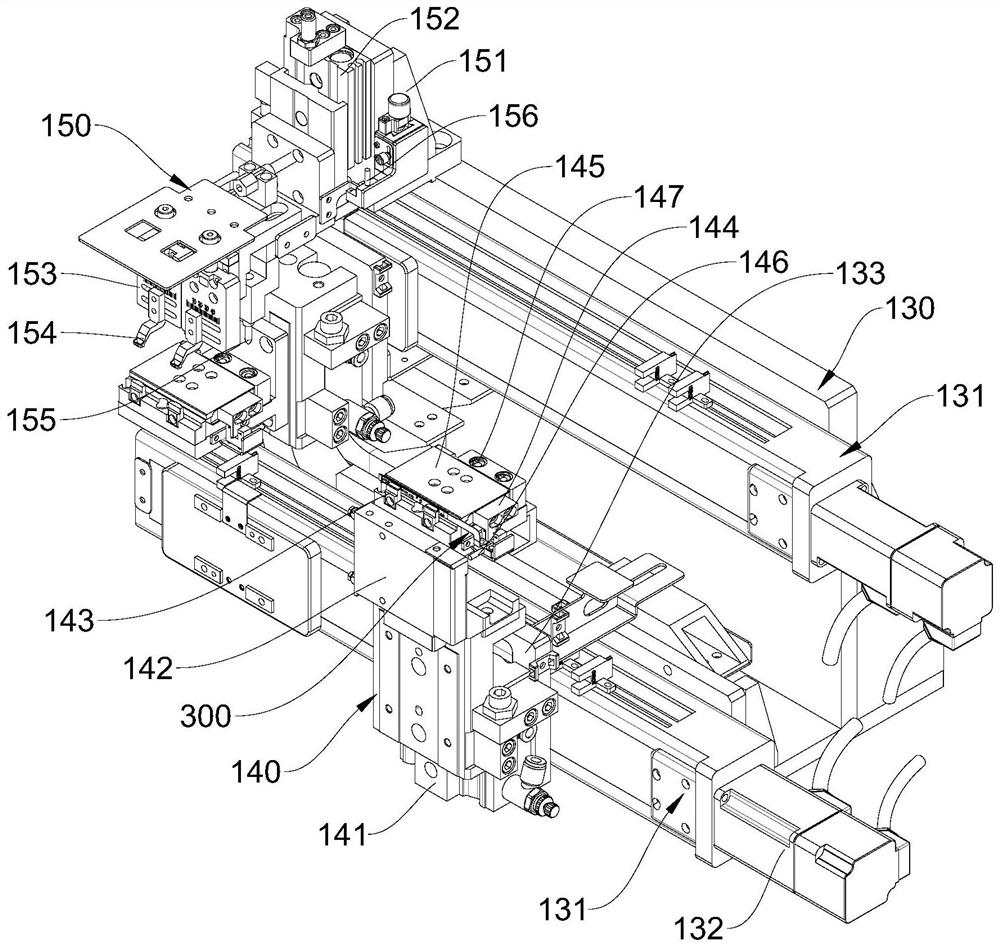

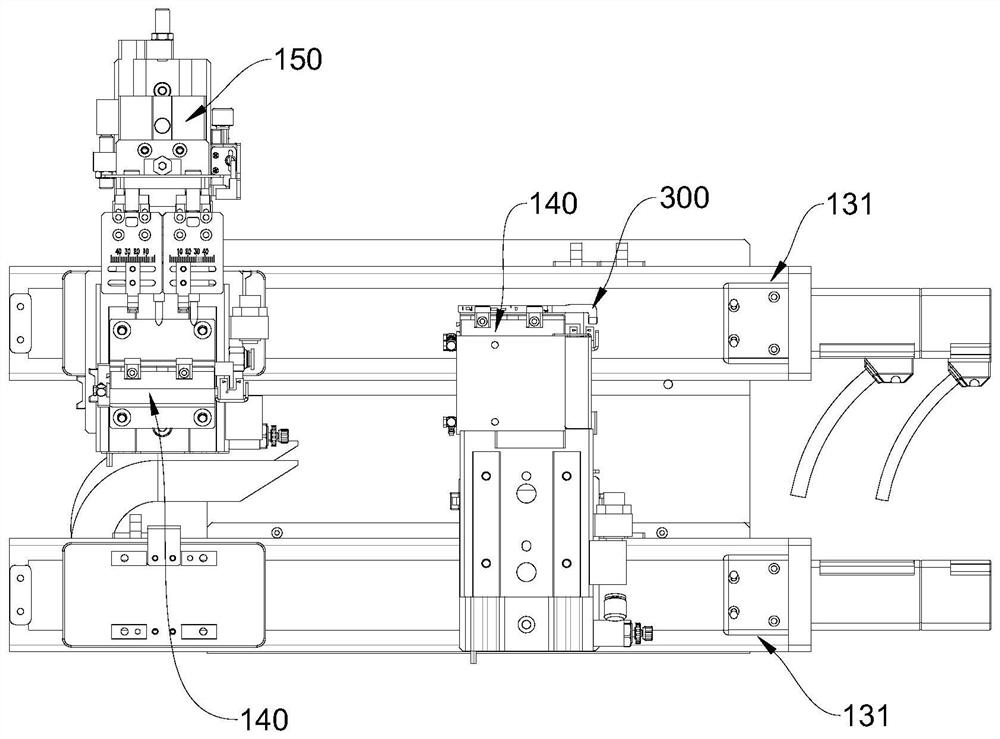

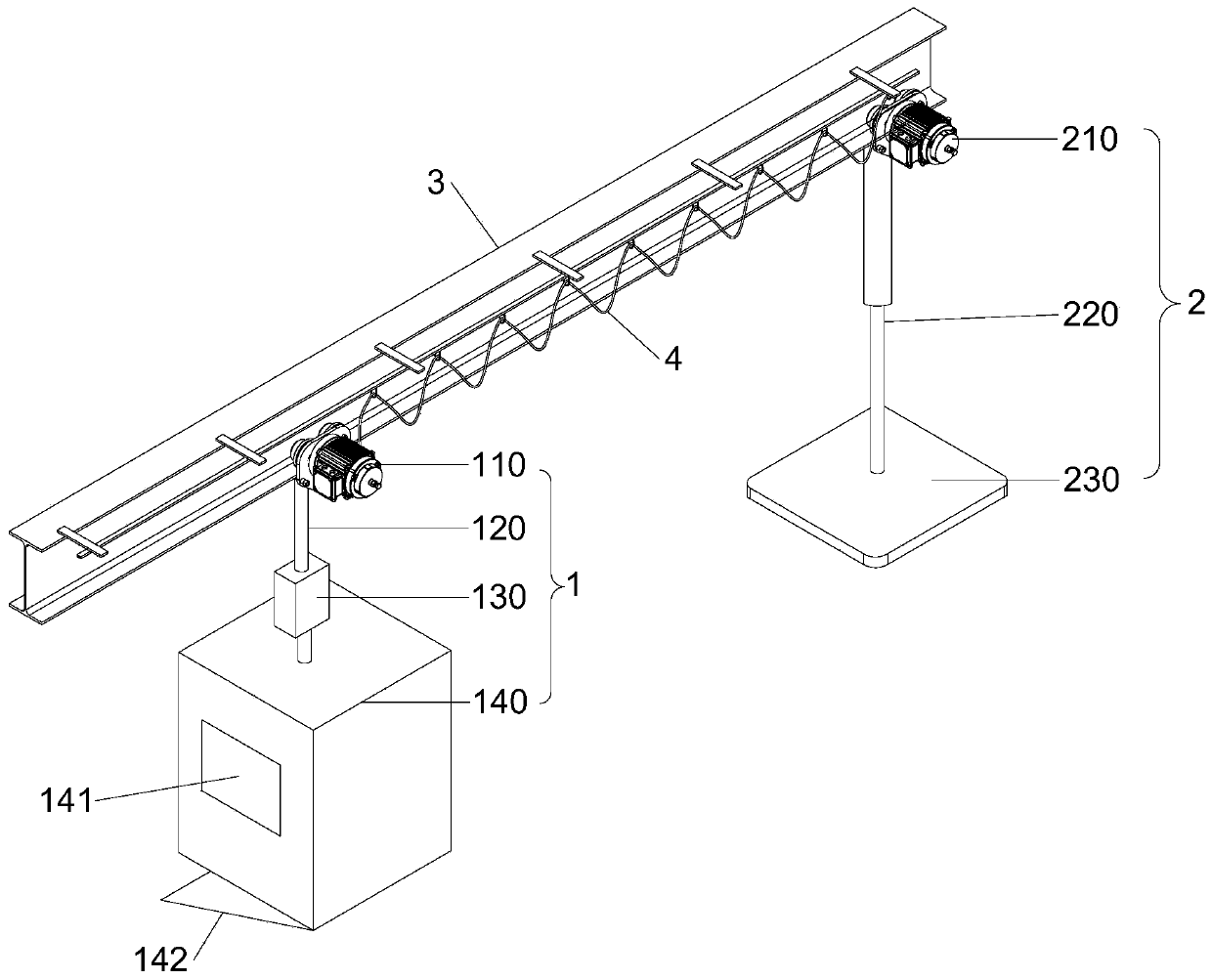

Online welding mechanism and online welding production line

ActiveCN111822804ALow costReduce risk of damageMetal working apparatusSoldering auxillary devicesProduction lineProcess engineering

The embodiment of the invention provides an online welding mechanism and an online welding production line, and relates to the technical field of battery production. The online welding mechanism comprises a first conveying mechanism, a carrier, a second conveying mechanism, a clamping mechanism and a welding mechanism, wherein the carrier is used for bearing a battery cell, the carrier is movablyinstalled on the first conveying mechanism, the clamping mechanism is used for clamping a PCM plate, the clamping mechanism is movably installed on the second conveying mechanism, and when the batterycell carried by the carrier is in butt joint with the PCM plate carried by the clamping mechanism and synchronously moves to the welding position of the welding mechanism, the welding mechanism is used for welding a tab of the battery cell with a nickel sheet of the PCM plate. Therefore, the online welding mechanism and the online welding production line do not need to adopt a CCD positioning system to position the battery cell and do not need a high-precision index plate system, so that the cost is greatly reduced, the times of mechanically carrying the battery cell are reduced, the risk that the battery cell is damaged is greatly reduced, and the productivity efficiency is greatly improved.

Owner:速博达(深圳)自动化有限公司

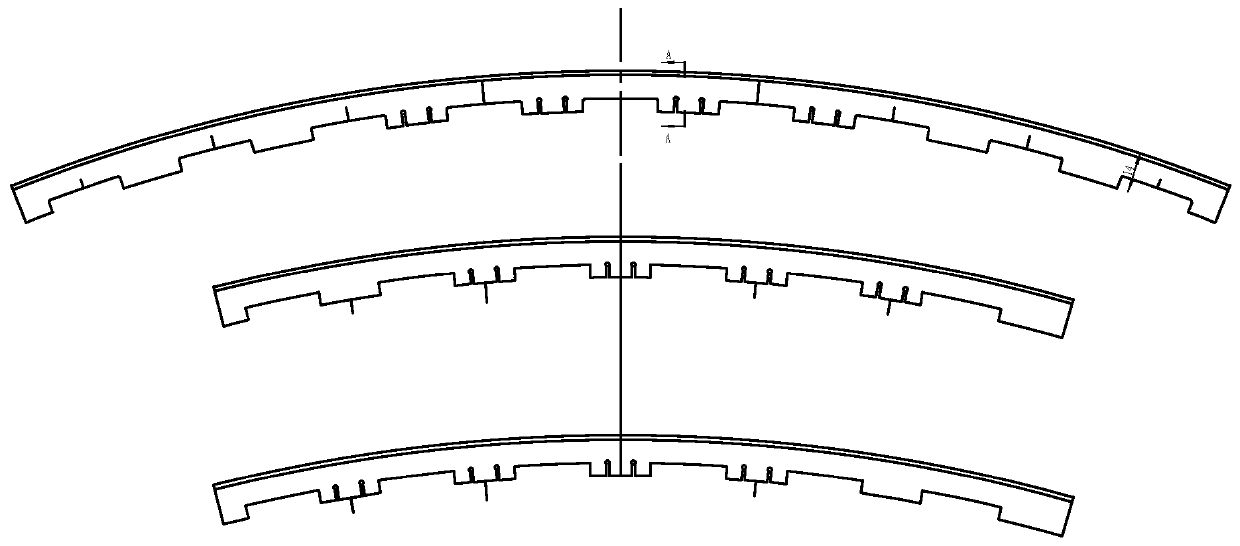

Device used for unloading and stacking gypsum light hollow partition boards

PendingCN106946026AReduce laborReduce the number of transshipmentsConveyorsStacking articlesStructural engineeringHollow core

The invention discloses a device used for unloading and stacking gypsum light hollow partition boards. The device comprises a transport unit, a turnover mechanism and a plurality of conveyors, wherein the conveyors are perpendicularly fixedly arranged at one side of the transport unit; and the turnover mechanism is rotatably connected with one side, with the conveyors, of the transport unit. According to the device disclosed by the invention, produced gypsum light hollow partition boards are transported to the upper side of the turnover mechanism through the transport unit, and are turned over onto the conveyors through the turnover mechanism; then, the conveyors drive the gypsum light hollow partition boards to operate by certain distance to leave an empty position for one gypsum light hollow partition board; when a certain number of gypsum light hollow partition boards are accumulated on the conveyors, transfer tools such as a forklift are used by a worker to transfer the gypsum light hollow partition boards to an air-curing site to cure in air, so that amount of labor of the worker is reduced, using frequency of carrying tools is omitted, and the whole production line is more intelligent.

Owner:四川美霖科技有限责任公司

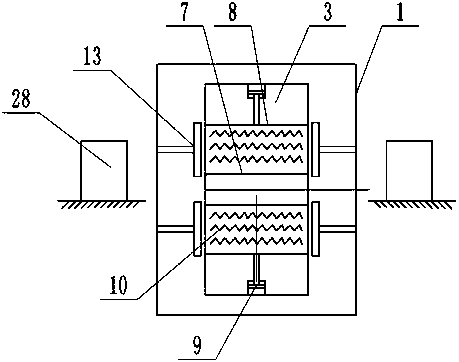

Sand turning device for casting piece processing

ActiveCN110756725AReduce the number of transshipmentsImprove space utilizationMould handling/dressing devicesElectric machineProcess engineering

The invention belongs to the technical field of casting, and particularly relates to a sand turning device for casting part processing. The sand turning device comprises a stirring barrel and a stirring motor fixed at the bottom end of the stirring barrel, wherein the stirring motor is electrically connected with an external power supply, the output end of the stirring motor is fixedly connected with a stirring paddle, the stirring paddle is positioned inside the stirring barrel, a discharging mechanism is further mounted at the bottom end of the stirring barrel, and a screening mechanism is further installed at the top end of the inner portion of the stirring barrel. According to the sand turning device, the required fine sand is firstly put through a feeding hopper and screened through ascreening mechanism, and the fine sand falls into the stirring barrel for stirring and mixing. While the fine sand is stirred and mixed, the fine sand can be screened and filtered, impurities in thefine sand are removed, the fine sand does not need to be screened and filtered separately, the transferring times of the fine sand is reduced, the production efficiency is improved, the labor intensity of personnel is relieved, the occupied area of the equipment can be reduced at the same time, and the space utilization rate in the factory is improved.

Owner:合肥达力机械制造有限公司

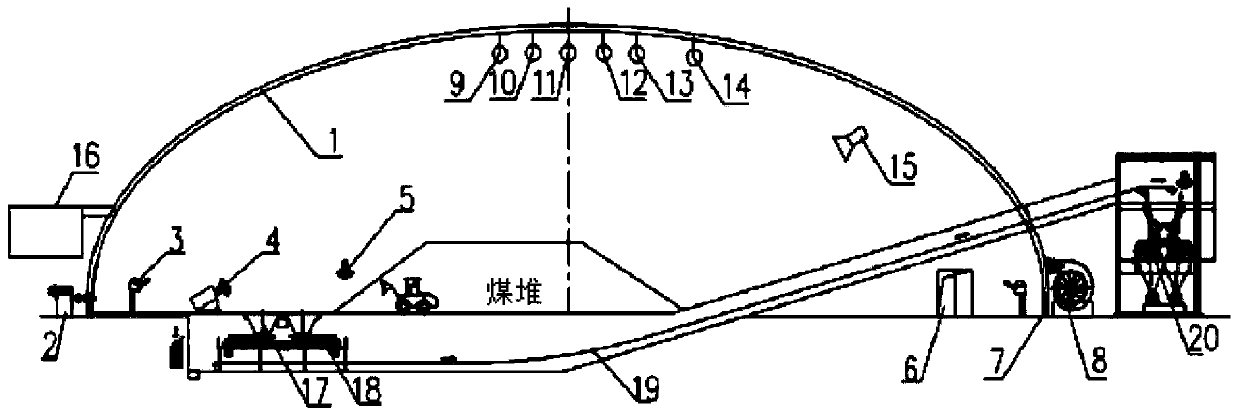

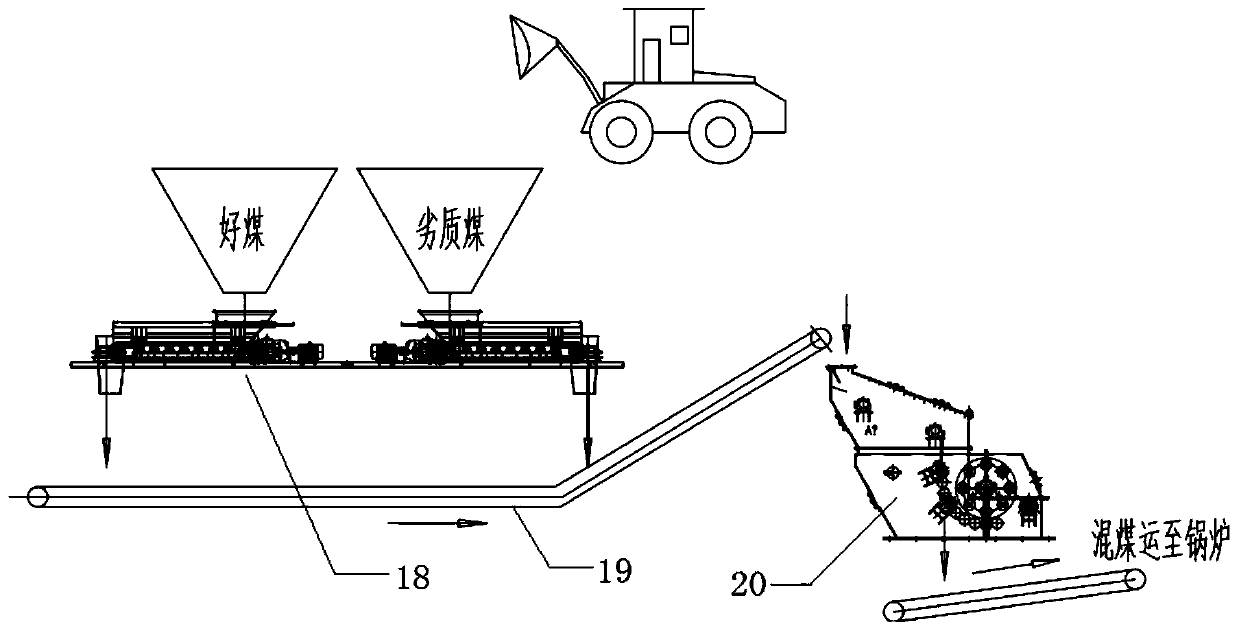

Coal blending weighing screening and breaking system in gas film coal storage yard

PendingCN111468265AMeet the qualified coal burning requirementsReduce maintenanceGas treatmentUsing liquid separation agentAutomatic controlThermodynamics

The invention discloses a coal blending weighing screening breaking system in a gas film coal storage yard. The system comprises a gas film yard system surrounding the coal storage yard and a coal blending weighing screening and breaking system body mounted in the gas film yard system, the coal blending weighing screening breaking system body comprises two weighing coal feeders and a screening andbreaking integrated machine, the weighing coal feeders and the screening and breaking integrated machine are connected through a belt transport machine, a coal blocking wall, a gas film, a monitoringunit, an air blowing system, an atomizing dust suppression device and an automatic control system are mounted in the gas film yard system, coal blending is achieved in the gas film yard system, mixedcoal is subjected to screening and breaking integration, dust and equipment investment are reduced, compositions and mounting positions of the monitoring unit, the air blowing system and the atomizing dust suppression device are optimized in the gas film yard system, coal yard full-closed environment-friendly technical needs can be met, dust conditions in the coal yard can be subjected to real-time and automatic monitoring, and the coal dust zero emissions can be achieved.

Owner:CHINA CHENGDA ENG

Machining method for valve

ActiveCN105563039AReduce the number of clampingReduce the number of transshipmentsEngineeringRejection rate

The invention relates to a machining method for a valve and belongs to the technical field of machining of valves, aiming at solving the technical problems of conventional machining methods of valves that a valve workpiece needs to be clamped for multiple times in machining, positioning error is large, dimension precision cannot reach design requirements and valve sealing precision is poor. The machining method comprises the following steps: carrying out rough machining on one end of a casting; carrying out finish machining on one end of a valve casting; arranging a cold welding machine rotating electrode on a lathe saddle, wherein a lathe revolving platform rotates according to technical clamping speed, carrying out surfacing on a sealing end face of the valve casting according to the technical clamping feed rate by taking a core wire as a lathe tool by using the cold welding machine rotating electrode to reach a surfacing thickness required by technical clamping; arranging a miniature rotary grinding head on the lathe saddle, and grinding and polishing the sealing end face of the valve casting by using the miniature rotary grinding head so as to reach technical clamping requirements; and turning over the casting to complete machining of the other end. The machining method has the advantages of being high in machining precision, small in errors, less in workpiece transfer times, low in machining cost and low in rejection rate.

Owner:阳泉市煜昌机械制造有限公司

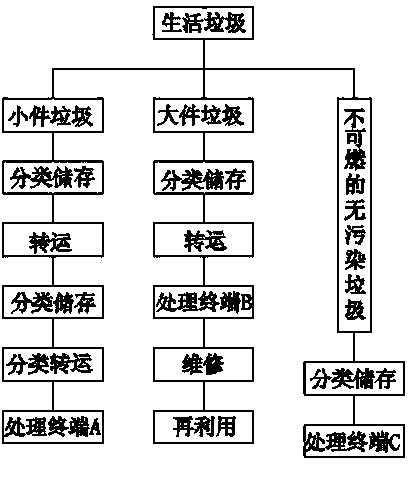

Environment-friendly separate garbage collection, transferring and processing method

InactiveCN103567215AEasy to handleImprove processing efficiencySolid waste disposalFurniture waste recoveryPaper millPollution

The invention provides an environment-friendly separate garbage collection, transferring and processing method. The method comprises the following steps: determining and sorting processing ways, and transferring and processing garbage in different processing ways, and the method is characterized by comprising the following specific steps: dividing the garbage into small garbage, large garbage and incombustible non-pollution garbage; processing the small garbage, namely separately putting, separately storing in a transfer station and separately transferring to all processing terminals; processing the large garbage, namely separately storing, separately transferring to all processing terminals and reusing after processing; and processing the incombustible non-pollution garbage, namely storing and transferring to all processing terminals. The processing terminals include paper mills, plastic prilling factories, glass treatment plants, metal smelting factories, waste incineration power plants, electronic product recovery factories, furniture recycle maintenance factories and the like. The method provided by the invention has the beneficial effects that the recovery rate is high, healthy and environment-friendly effects can be achieved, and the landfill and waste incineration can be reduced.

Owner:杨华

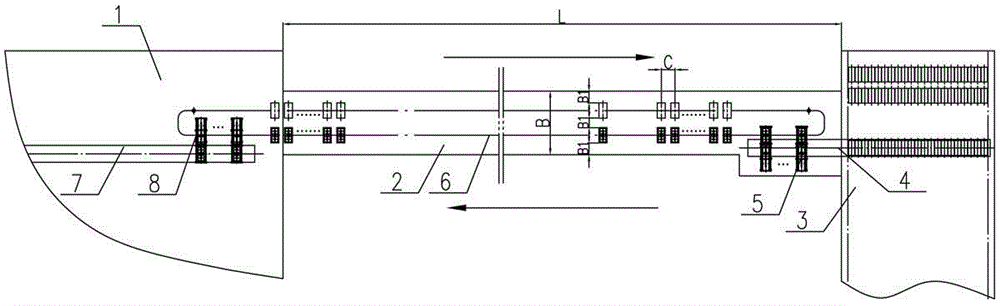

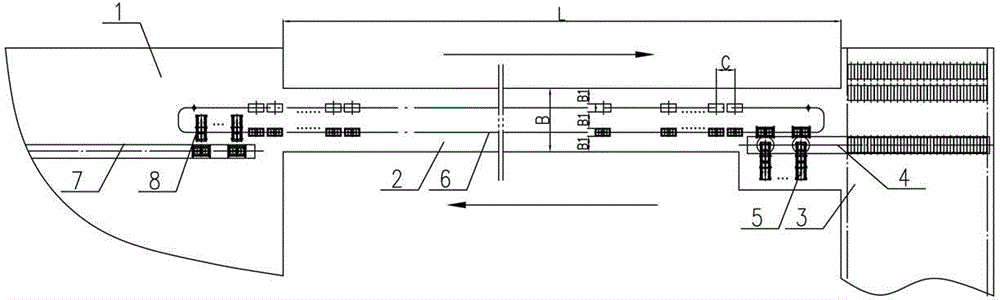

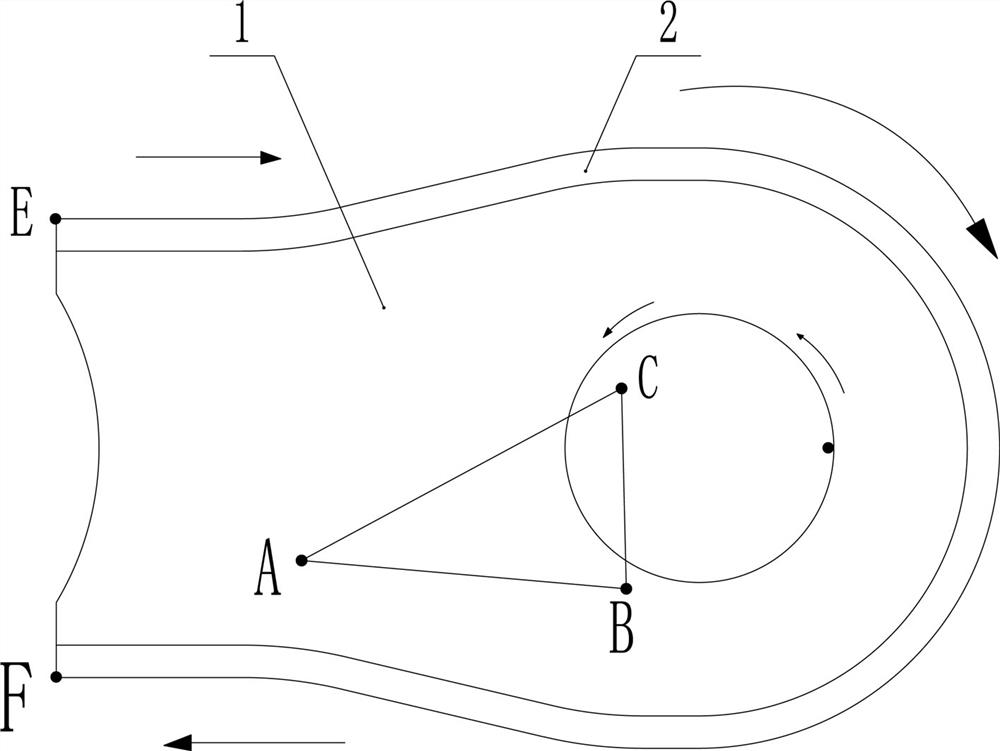

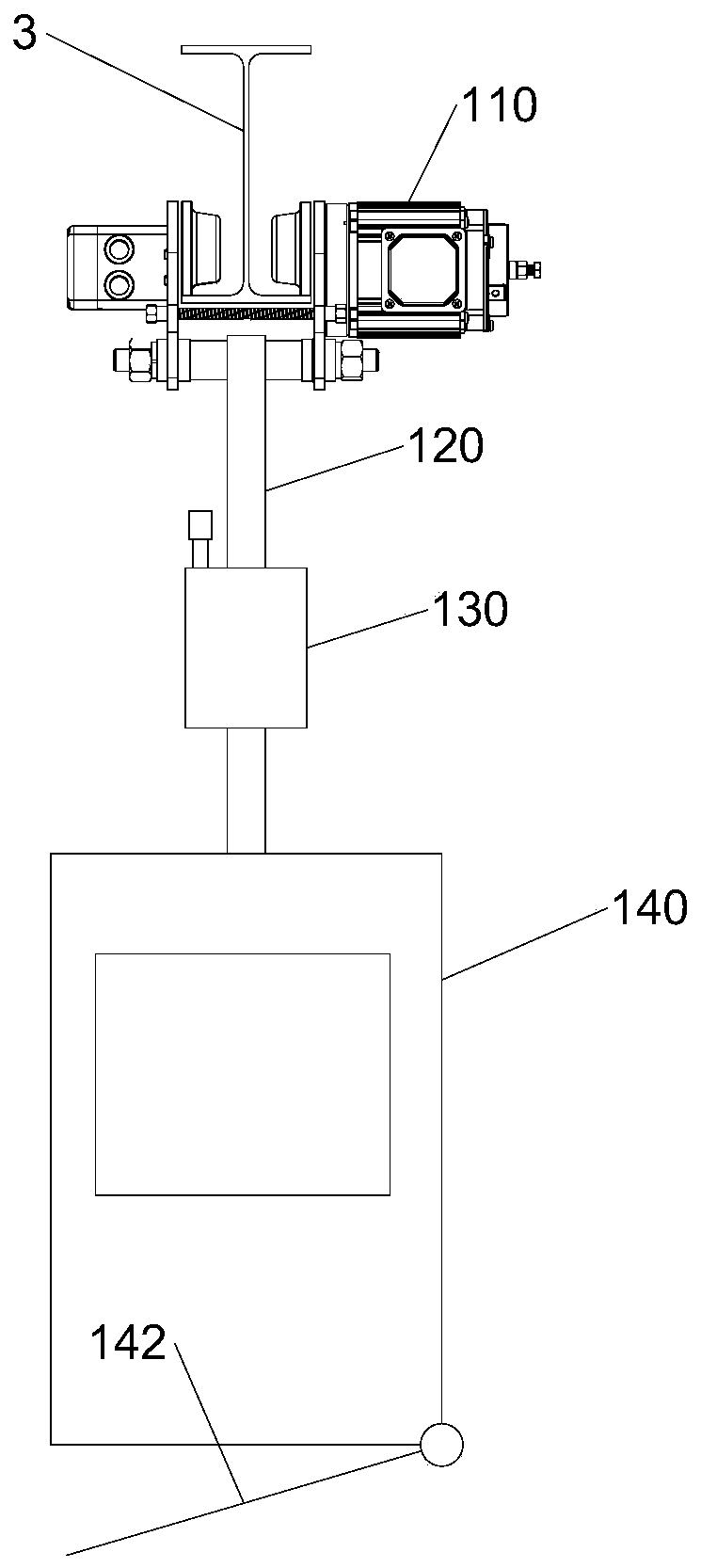

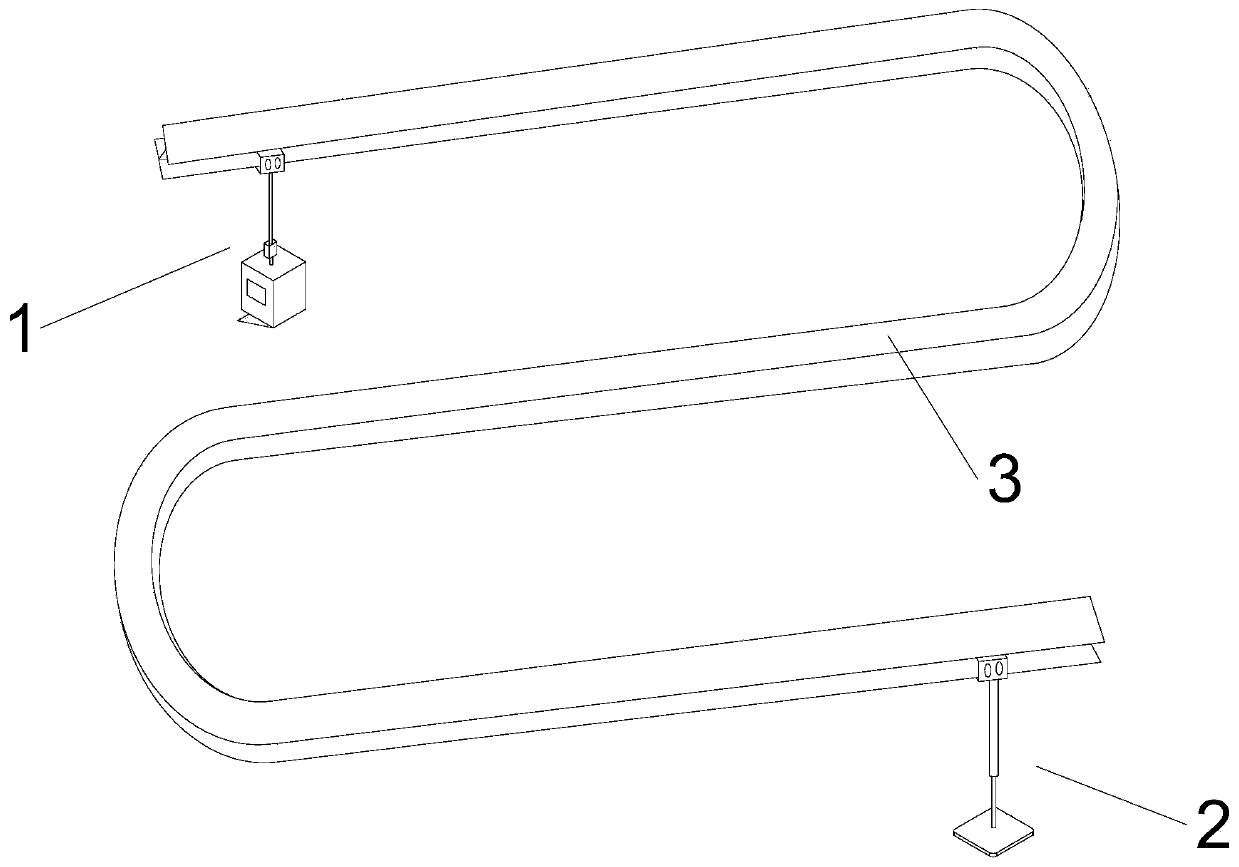

An anode carbon block suspended chain conveying system

InactiveCN106315169AImprove automationImprove mechanical propertiesConveyor partsMechanical conveyorsEconomic benefitsChain conveyor

The invention relates to an anode carbon block conveying system and in particular provides an anode carbon block suspended chain conveying system between an anode carbon block warehouse and an anode assembly workshop of an electrolytic aluminum enterprise. A carbon block conveying gallery is arranged between an anode assembly workshop and an anode carbon block warehouse; an assembly workshop carbon block conveyor and a carbon push-out device are arranged in the anode assembly workshop; a carbon block warehouse carbon block conveyor and a carbon block push-in device are arranged in the anode carbon block warehouse; a suspension type suspended chain conveyor is arranged in the carbon block conveying gallery; lifting tools are arranged under the suspension type suspended chain conveyor. The system can reduce the manpower quotas of enterprises, increase the labor productivity of the enterprises, reduce the engineering construction and production operating costs, reduce the electrolytic aluminum production cost and bring certain economic benefits for the enterprises.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

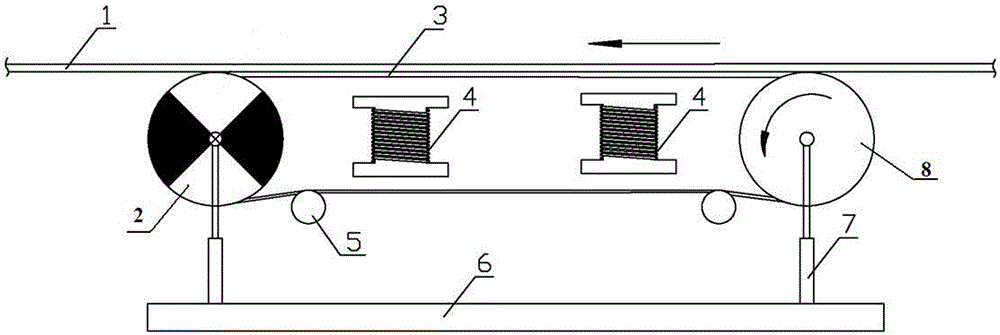

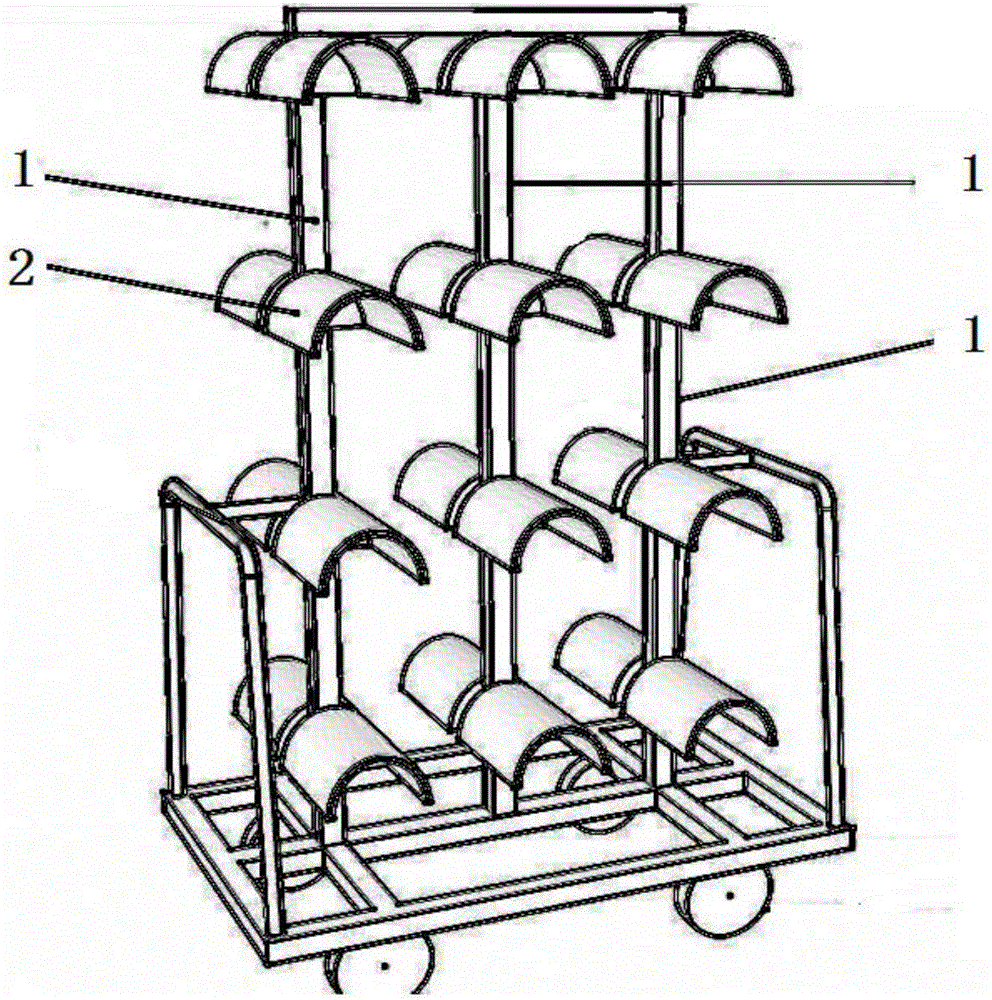

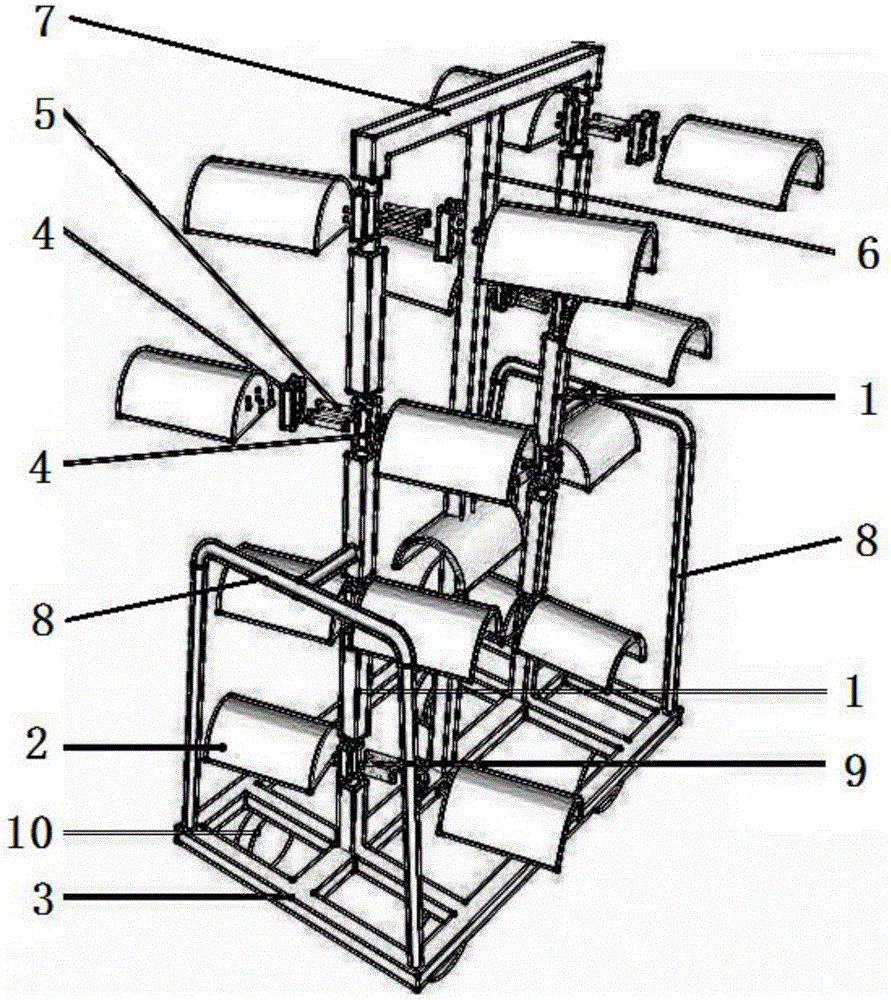

Yarn retreating equipment and yarn retreating method using yarn retreating equipment

The invention discloses yarn retreating equipment which comprises a yarn transporting vehicle and a yarn retreating device. The yarn transporting vehicle comprises a base, at least one stand column and multiple yarn tiles. The stand columns are fixed to the base. The yarn tiles are fixed to the stand columns through bearings. The yarn retreating device comprises a support, yarn guide covers and a yarn guide pipe. A yarn inlet is formed in each yarn guide cover. One end of the yarn guide pipe transversely penetrates the yarn inlet. The invention further discloses a yarn retreating method using the above yarn retreating device. The yarn retreating method includes the steps that multiple original spinning cakes are arranged on the yarn tiles in a sleeving manner correspondingly; the yarn transporting vehicle is moved to make the original spinning cakes correspond to the yarn guide covers, retreated thread strands are limited in the yarn guide covers, and then the thread strands penetrate out of the yarn guide pipe; and when yarn retreating is finished on one original spinning cake on one yarn tile, the yarn tile is rotated, and another original spinning cake is subjected to yarn retreating. The whole yarn transporting vehicle does not need to be rotated by rotating the yarn tiles, the original spinning cakes on different sides can be subjected to yarn retreating, in addition, the retreated thread strands can be limited in the yarn guide covers, and the space, occupied by the treated yarn strands, of a production workshop is reduced.

Owner:CHONGQING POLYCOMP INT

Red mud solid waste comprehensive treatment reduction duplex furnace and process

ActiveCN110607437AReasonable structureFunctionalRotary drum furnacesRecycling and recovery technologiesRed mudSlag

The invention discloses a red mud solid waste comprehensive treatment reduction duplex furnace. The reduction duplex furnace comprises a rotary kiln and a melting furnace; and the rotary kiln and themelting furnace mutually communicate to form the reduction duplex furnace. The invention further discloses a process of the red mud solid waste comprehensive treatment reduction duplex furnace; and the process comprises the steps of: (1) preparation of red mud composite materials; (2) drying of the red mud composite materials; (3) calcining of the red mud composite materials; (4) crushing and mixing; (5) pellet pressing; (6) vacuum heat reduction; (7) smelting by the melting furnace; (8) preparation of raw materials; and (9) furnace slag treatment. The rotary kiln integrates drying, calcining,crushing, mixing and pellet pressing, improves the reliability of red mud comprehensive treatment, and reduces the transfer times and corresponding treatment cost; and a drying plate is reasonable instructural design and convenient for quick drying and leakage, and only needs drying by 10-20 minutes to greatly improve the drying efficiency.

Owner:刘森林

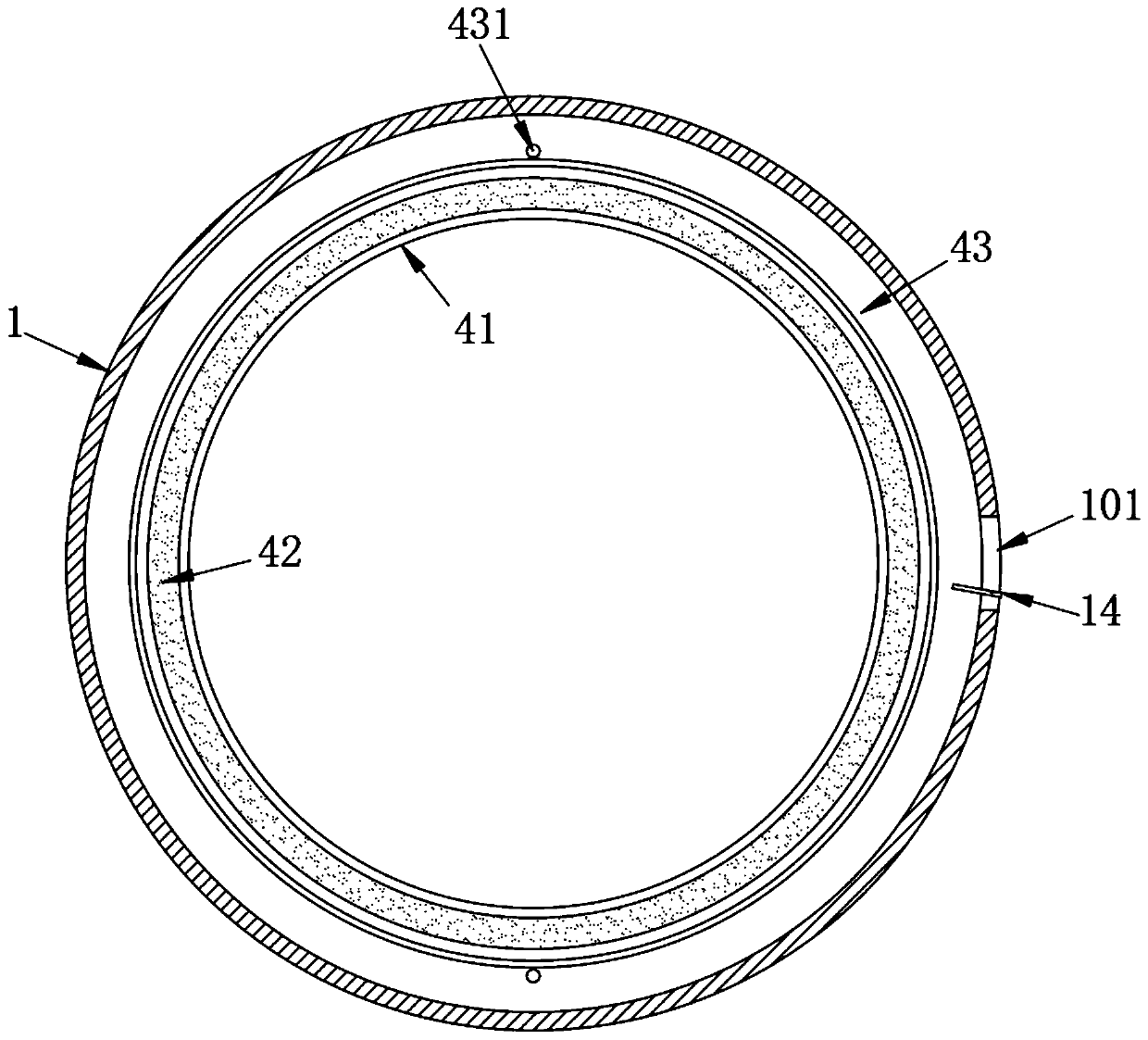

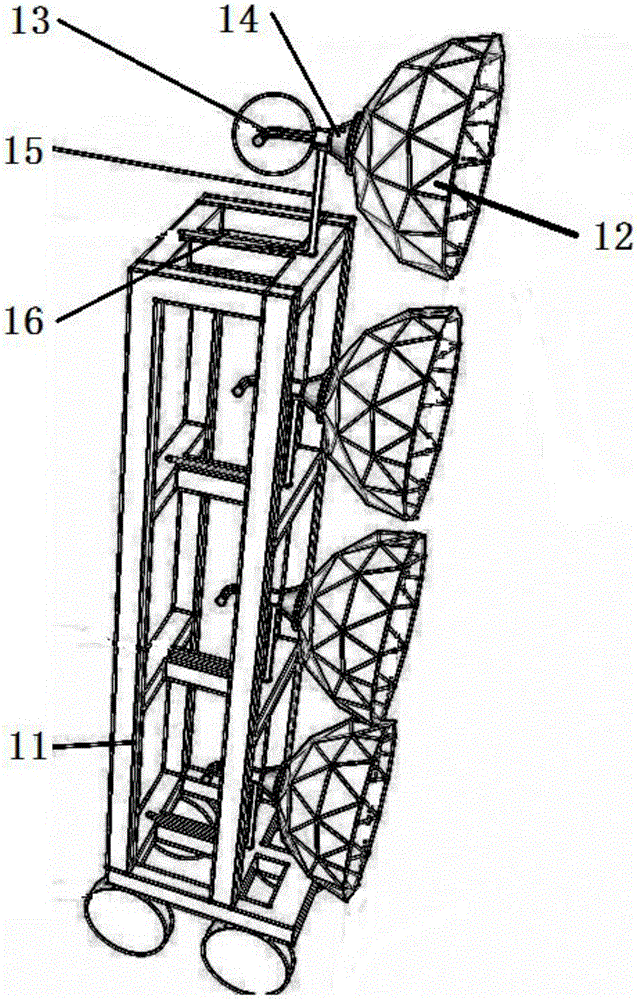

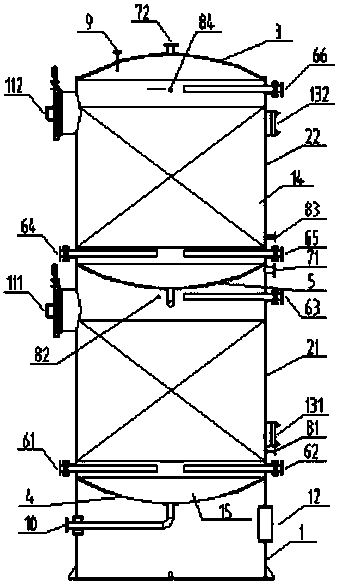

Adsorption tower group for extracting lithium from salt lake brine

ActiveCN109052435AReduce the number of transshipmentsReduce volumeSpecific water treatment objectivesLithium compoundsSorbentDesorption

The invention discloses an adsorption tower group for extracting lithium from salt lake brine. The adsorption tower group comprises a base, wherein an inspection hole and an emptying opening are respectively formed in the side wall of the base; two or more adsorption towers which are longitudinally connected in series are arranged at the top of the base; each adsorption tower comprises an adsorption tower body; an upper head is arranged at the top of the uppermost adsorption tower body; a lower head is arranged at the lower part of the adsorption tower body connected with the base; a separation head is arranged between two adsorption tower bodies which are connected in series; a vent nozzle is formed in the upper part of a liquid outlet in the side wall of the upper part of the adsorptiontower body; a man hole is further formed in the upper part of the side wall of each adsorption tower body; a vent nozzle is formed in the top of the upper head of each adsorption tower; the tower is filled with an adsorbent. The adsorption tower group has the advantages that adsorption, washing and desorption operations can be accomplished in one tower, the transportation frequency of a pump can be reduced, the operation energy consumption is low, the dosage of the adsorbent is small, and occupied space and civil engineering equipment investment are reduced.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

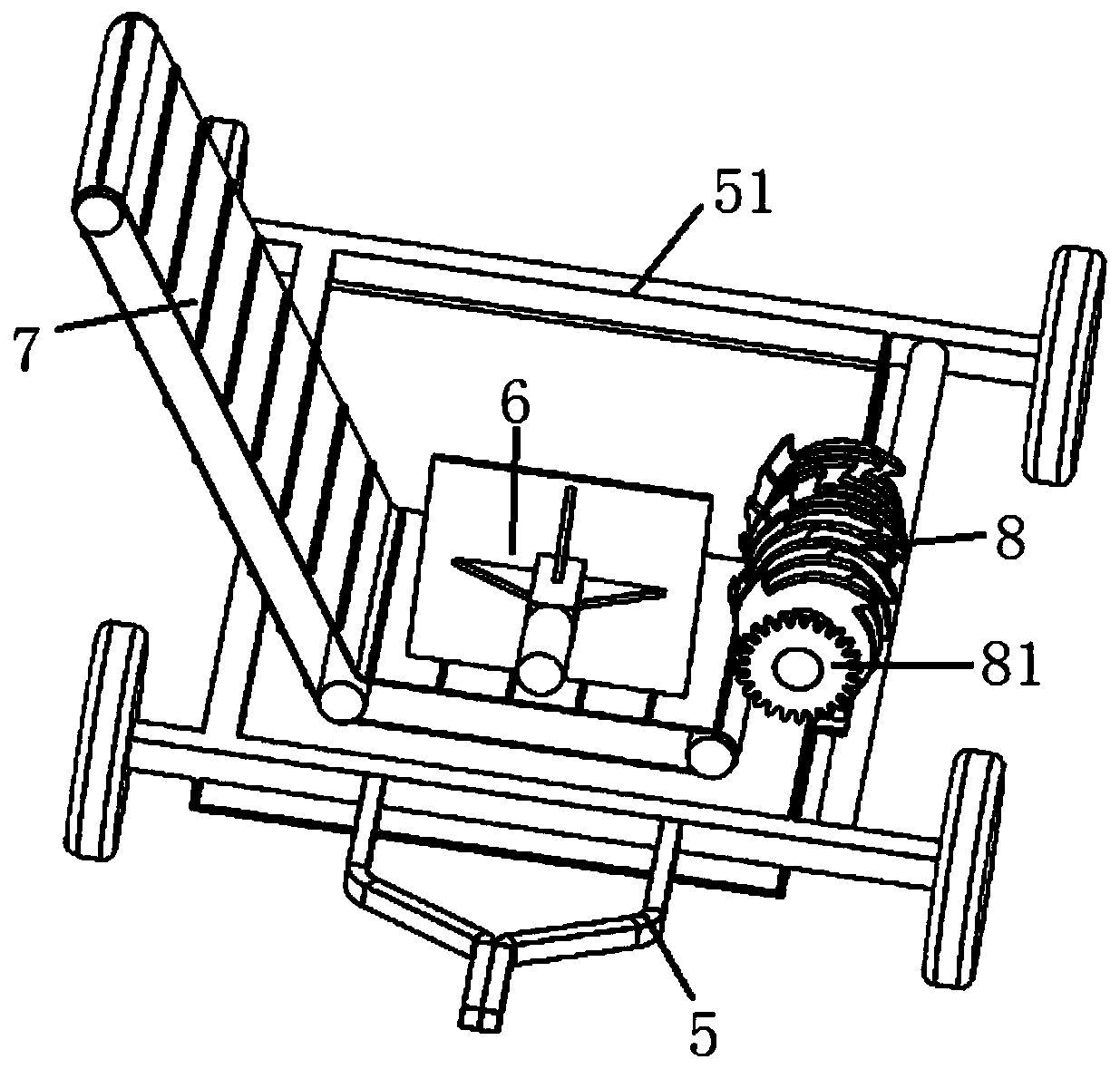

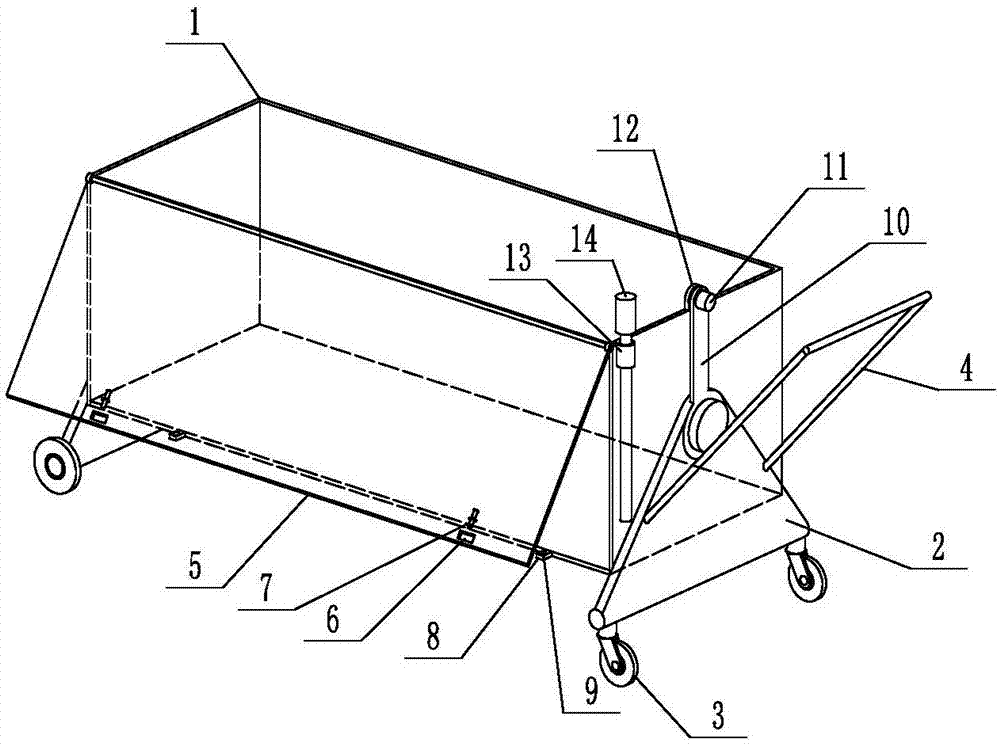

Chicken manure transfer trolley

InactiveCN107264592ALabor-saving operationReduce the number of transshipmentsHand carts with multiple axesVehicle frameEngineering

The invention discloses a chicken manure transfer vehicle, which comprises a compartment, and is characterized in that two ends of the compartment are connected with a vehicle frame through bearings, wheels are arranged at the lower end of the vehicle frame, and a handle is fixedly connected with the right end of the vehicle frame. The side wall of the compartment is provided with a side door, the upper end of which is connected to the upper end of the compartment through a rotating shaft, a fixing hole is provided at the lower end of the door, and a fixing pin I is provided at the upper end of the fixing hole, and a fixing pin I is provided at the bottom end of the compartment. The fixed block is equipped with a pin hole I matched with the fixed pin I. The upper end of the frame is fixedly connected with a fixed rod. The upper end of the fixed rod is provided with a fixed pin II. The fixed pin II Cooperate with the pin hole II arranged at the upper end of the carriage, and the right end of the carriage is connected to the control rod through the fixing seat. The beneficial effect of the invention is that there are many feces in a container, the dumping is convenient, and the working efficiency is improved.

Owner:诸城康诚农牧发展有限公司

High-strength non-evaporating brick and preparation method thereof

InactiveCN101654941BSolve transportation difficultiesProtect environmentCeramic shaping apparatusBuilding componentsBrickFrost

Owner:武汉钢铁有限公司

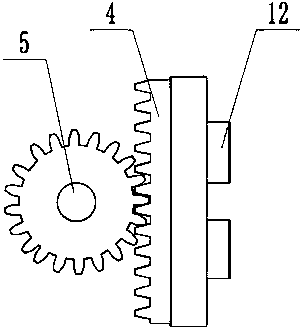

Door panel production line

ActiveCN106827080BAvoid damageImprove anti-corrosion and insect-proof performanceFeeding devicesWood treatment detailsProduction lineHydraulic cylinder

The invention discloses a door sheet production line. The door sheet production line comprises a frame; guide rails are arranged on two sides of the frame, and are slidingly connected with conveying plates; racks positioned on the same sides of the guide rails are arranged at the middle parts of the conveying plates, and are connected with gears matched with the racks; electromagnets positioned on the same sides of the guide rails are arranged on the conveying plates; the conveying plates are provided with fixed baffle plates and slide baffle plates; limiting devices are arranged on one sides, far from the fixed baffle plates, of the slide baffle plates; drying devices positioned between the slide baffle plates and the fixed baffle plates are arranged in the conveying plates; first hydraulic cylinders positioned between the fixed baffle plates and the slide baffle plates are arranged above the conveying plates, and are connected with pressing plates produced by metal; and cutting devices are arranged on two sides of the conveying plates. The production line is adopted to cut door sheets in the door sheet conveying process, and at the same time, the drying is performed, so that the door sheet transfer times are reduced, the labor intensity is largely reduced, and the door sheet machining efficiency is improved.

Owner:重庆市佳禾家具制造有限公司

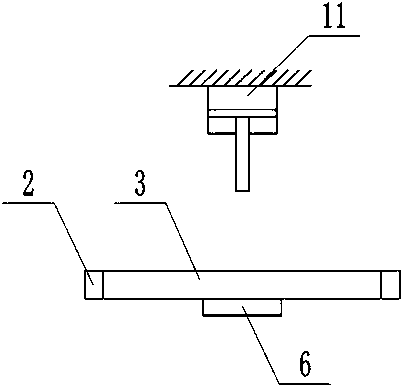

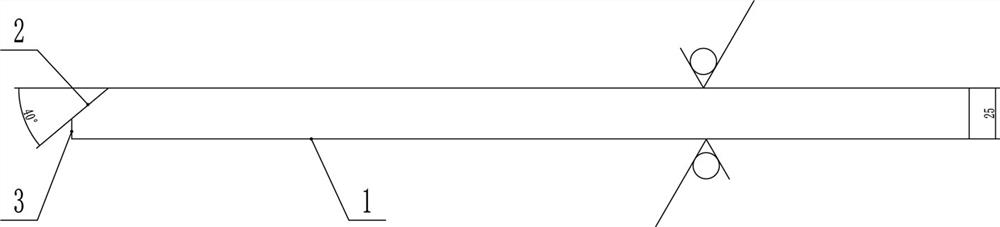

Fan-shaped section machining process

The invention provides a fan-shaped section machining process, and relates to the field of a machining process. In order to solve the problems of an existing process that machining is performed in different work procedures, the machining work procedures are complicated; the transfer is complicated; the machining efficiency is low; meanwhile, during the notch machining, the standards are not unified; and the notch position movement often occurs, and the product quality is influenced. The process comprises the following steps of 1, performing blanking shape pressing; 2, drawing bent plane linesand inner hole circular arc lines, drawing two end surface lines of arc sections, and drawing a plurality of notch lines, each hole line and narrow groove lines; 3, precisely milling bent planes; 4, precisely cutting inner hole circular arcs and two end surfaces of the arc sections, precisely cutting a plurality of notches, precisely cutting each hole, and precisely cutting a plurality of narrow grooves; and 5, precisely grinding planes. The fan-shaped section machining process is applicable to the machining of fan-shaped sections.

Owner:HARBIN TURBINE

Valve body machining method

The invention discloses a valve body machining method. The valve body machining method comprises the following steps that firstly, a valve body blank is inspected, specifically, all final inspection is conducted on the blank before a machining stage, and shape misalignment, rough surfaces and unevenness which are generated due to the reason of casting and casting interior material loose defects are not allowed; secondly, the valve body blank is clamped on a valve body fixture; thirdly, the common center position of all machining portions of the valve body blank is selected, specifically, the cross center point of the X direction, the Y direction and the Z direction, namely, the center position of the valve body blank is selected; fourthly, one end of the valve body blank is finish-machinedtill the size required by the technological process is achieved; and fifthly, a micro rotating grinding head is installed on a lathe tool rest, and the sealing end face of a valve body casting is ground and polished through the micro rotating grinding head till the technological requirement is met. The valve body machining method has the advantages that the machining precision is high, small errors are generated, the working efficiency is high, the workpiece clamping frequency is low, the workpiece transferring frequency is low, the machining cost is low, and the rejection rate is low.

Owner:嘉兴市劼力机械科技有限公司

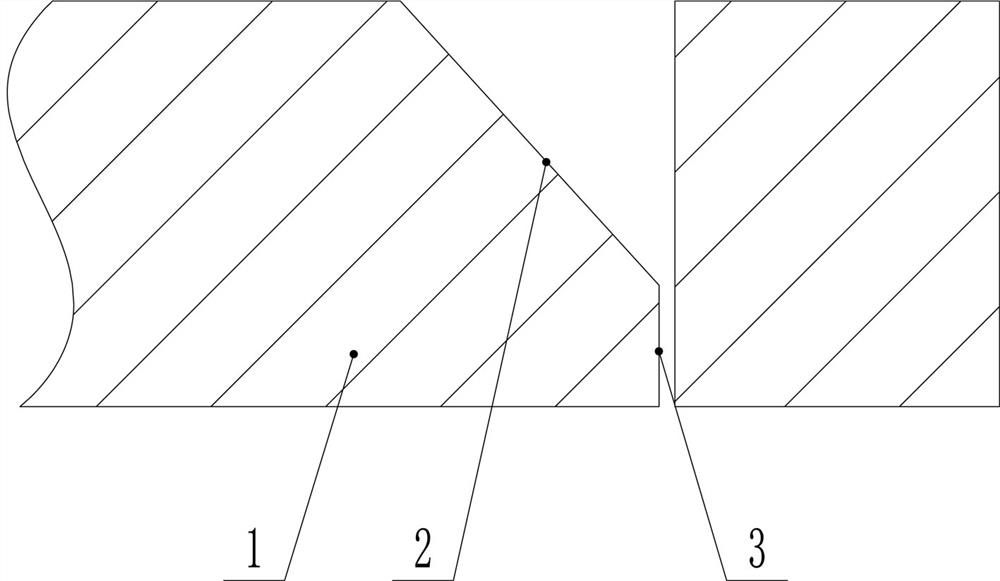

Machining method for Y-shaped groove part of hydraulic support structural part

ActiveCN112620903AHigh precisionReduced processing performancePlasma welding apparatusStructural engineeringMachine

The invention provides a machining method for a Y-shaped groove part of a hydraulic support structural part. The machining method comprises the following steps that a, a steel plate to be cut is horizontally placed on a workbench of a rotary plasma cutting machine; b, space coordinates of three points, not located on the same straight line, of the top face of the steel plate are collected; c, an included angle beta between the steel plate and the horizontal plane is calculated according to the space coordinates of the three points; and d, the angle of a target Y-shaped groove is set to be alpha, the angle of a cutting gun of the rotary plasma cutting machine is adjusted to coincide with the inclination direction of the Y-shaped groove, and cutting is conducted from one end of the edge of the to-be-cut Y-shaped groove of the target part to the other end of the edge of the Y-shaped groove. The machining method for the Y-shaped groove part of the hydraulic support structural part has the advantages of being few in machining process, high in machining efficiency, high in slope precision and good in product quality.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

Hanging podded moving weighing releasing method

PendingCN111332662AReduce manufacturing costReduce areaConveyorsRefuse transferringControl engineeringMechanical engineering

The invention discloses a hanging podded moving weighing releasing method, and relates to the technical field of garbage releasing devices. The hanging podded moving weighing releasing method comprises the steps that a guide rail is installed at the upper end of the interior of a garbage chamber, a moving releasing device and a moving compression device are correspondingly hoisted at two ends of the guide rail, and a plurality of garbage cans are arranged below the guide rail; a user directly releases garbage into a pod body of the moving releasing device, a first moving sport vehicle drives the moving releasing device to move on the guide rail, and the garbage in the pod body is transferred into the garbage cans; then a second moving sport vehicle drives the moving compression device to move on the guide rail and move into the full garbage cans, and the garbage in the garbage cans is compressed; and an alarm cannot be triggered when one of the garbage cans is full, the alarm is triggered to designated personnel when the garbage cans with a set number in advance are full, and the garbage cans in the garbage chamber are cleaned at a time by manual operation.

Owner:河南寻宝环保科技有限公司

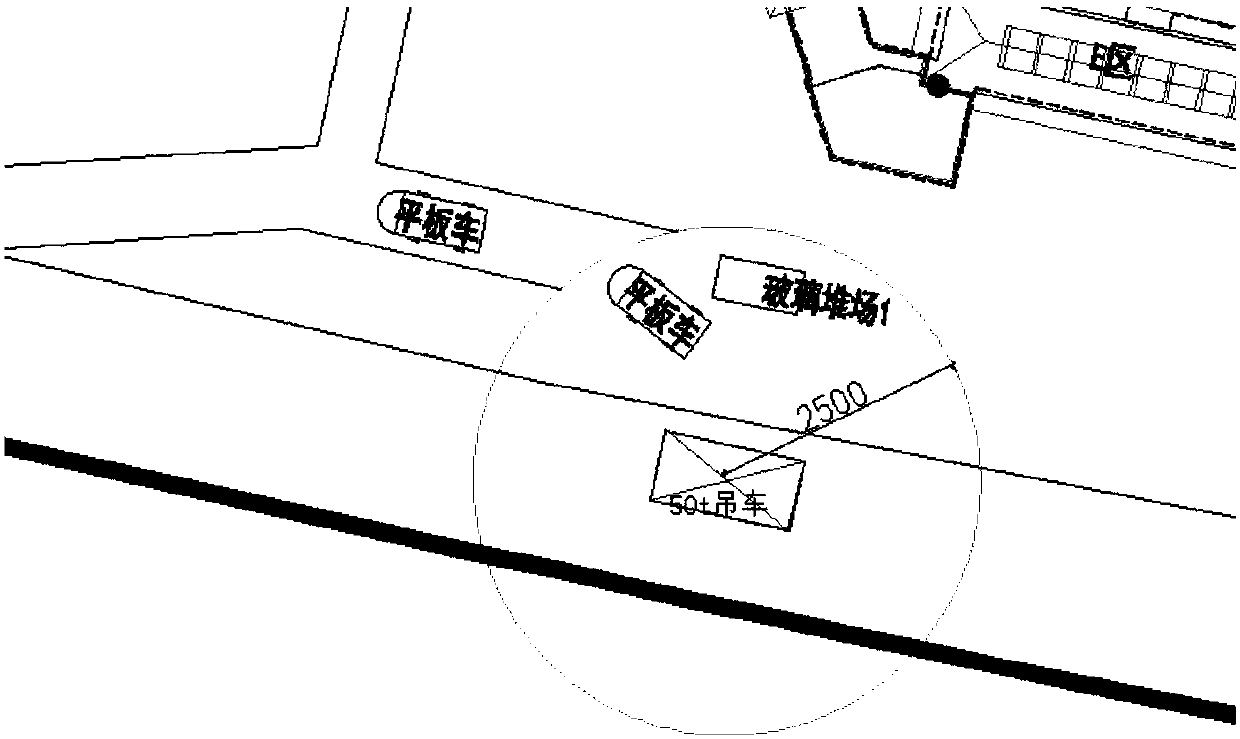

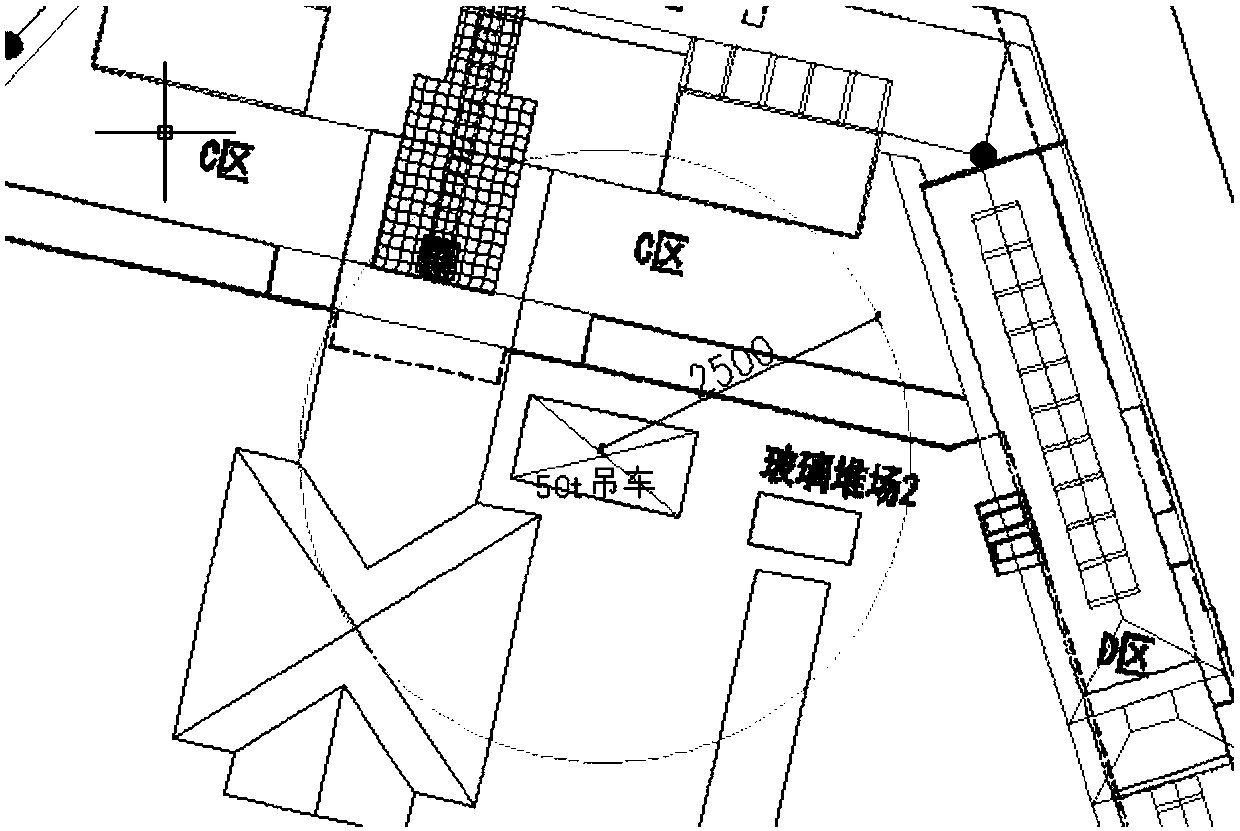

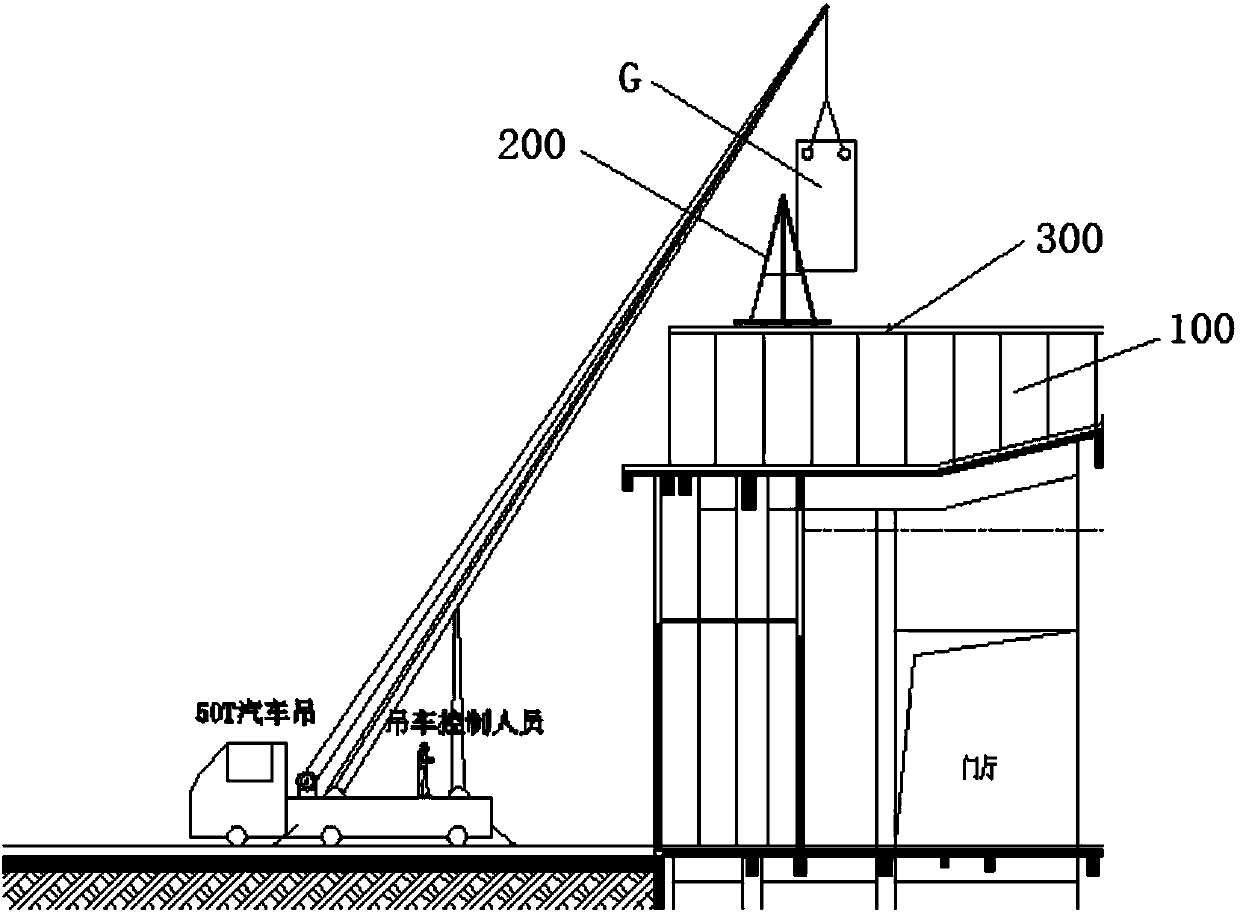

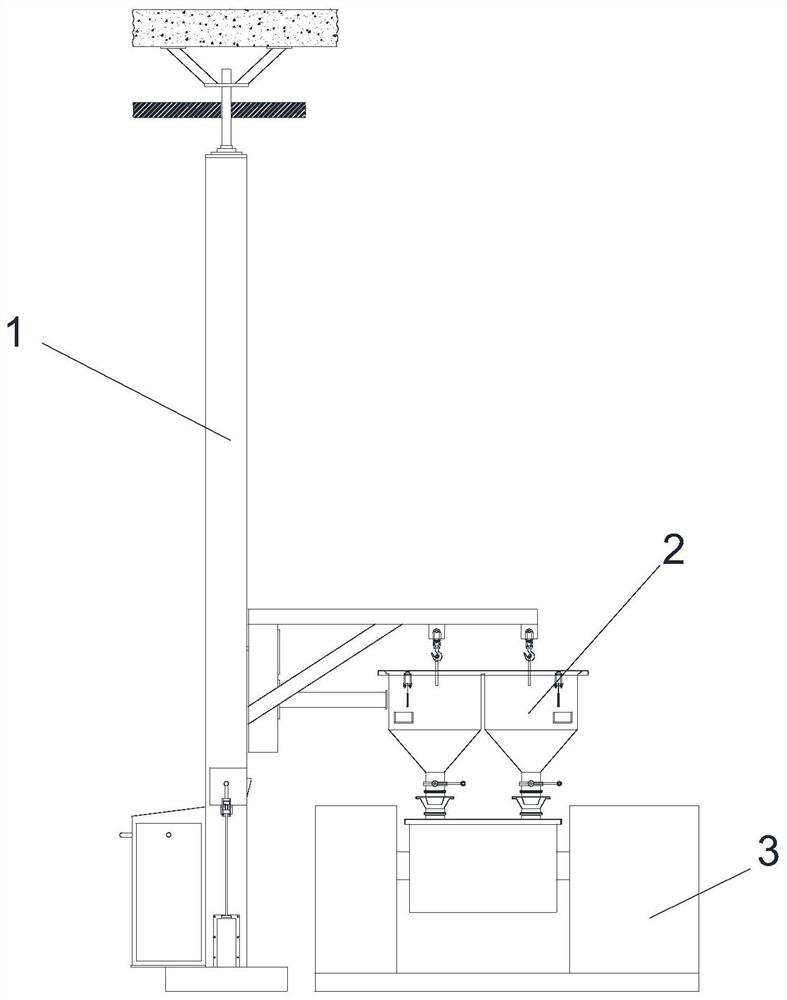

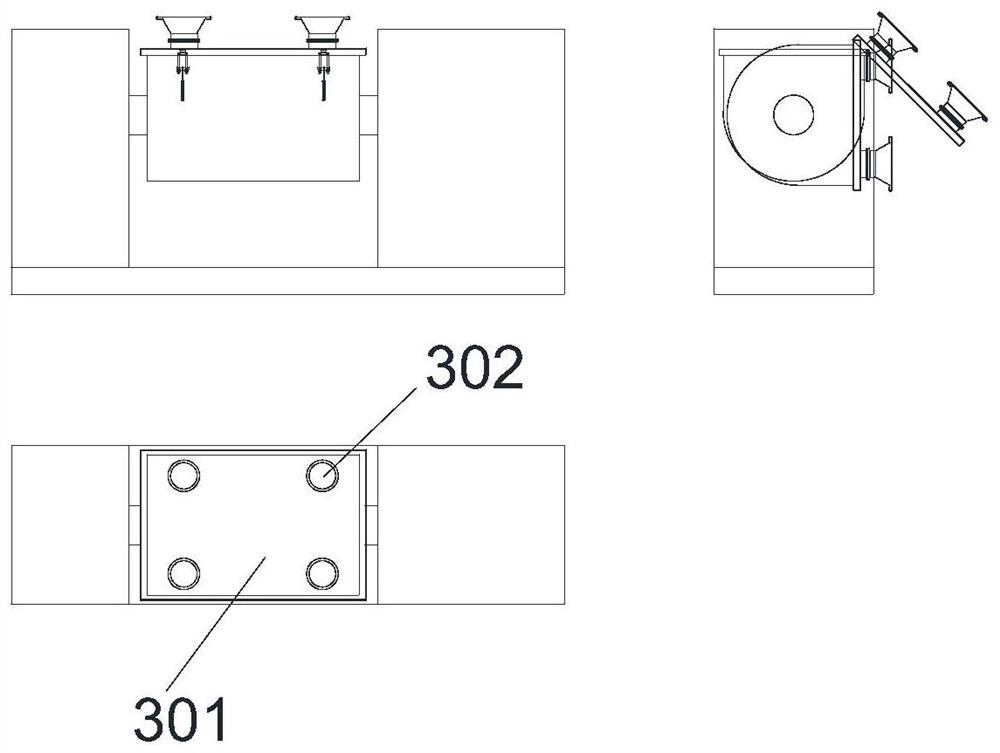

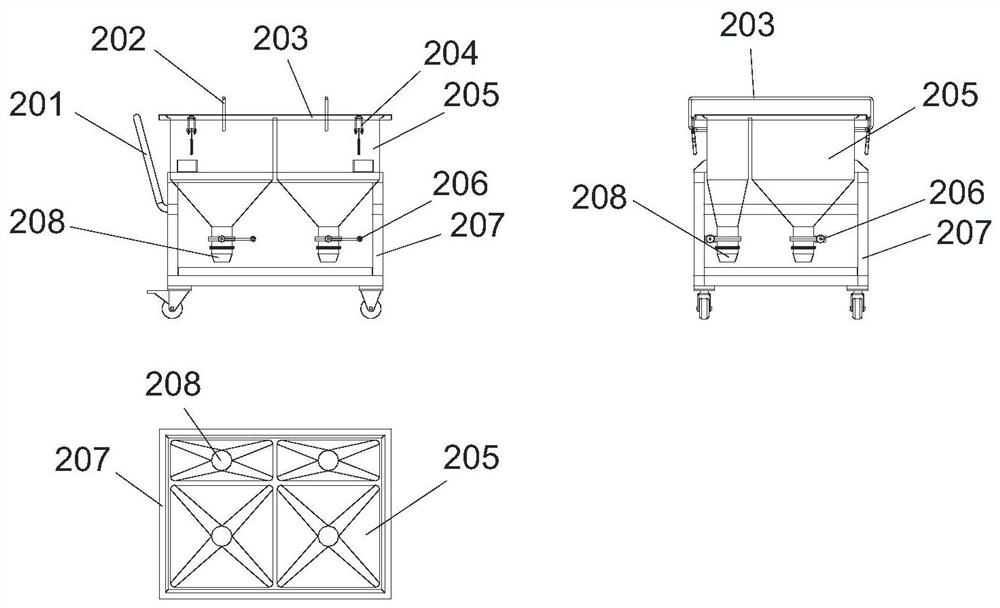

Installation construction method for extra-large glass of sloping roof

InactiveCN107558672AReduce the number of transshipmentsReduce breakage rateRoof toolsBuilding construction

Owner:中建八局装饰工程有限公司

Glass deep processing production line connecting method

PendingCN113618536ASolve the contradiction of different glass orderSolve pain points and difficultiesEdge grinding machinesGrinding feedersArchitectural glassProduction line

The invention relates to the technical field of glass machinery, in particular to a glass deep processing production line connecting method for building glass. The glass deep processing production line connection method comprises the following steps that after a cutting and sheet breaking process, order information of size information and number information of broken glass is sent to an upper computer to form size information for comparison; glass size information of the edging and cleaning procedure is obtained in the edging and cleaning procedure, and the obtained glass size information of the edging and cleaning procedure is compared with the corresponding size information on the upper computer, and in combination with the number information, sheet discharging sequence information is obtained; and the sheet discharging sequence information is output. An operator does not need to consider or less considers how to arrange sheets, so that the labor intensity of the operator can be reduced.

Owner:佛山市汉腾自动化有限公司

Closed production system of traditional Chinese medicine solid preparation

PendingCN112704643AReduce generationReduced risk of cross-contaminationSievingDrying solid materials with heatProcess engineeringGranulation

The invention relates to the field of production of traditional Chinese medicine solid preparations, in particular to a closed production system of a traditional Chinese medicine solid preparation. The closed production system comprises the following five processes: tank mixing, oscillating granulation, boiling drying, screening and blending; in the five processes, the functions in all the steps are achieved through a feeding lifting device, a tank mixer, paste and powder barrels, an oscillating granulator, a customized stock bin, a wet particle barrel, boiling dryers, a straightening granulator, a screening machine, a vacuum feeder, a mixing turnover hopper and a column type hopper mixer; containers in the five procedures can guarantee the sealing performance when being butted with other devices through closed connection and transport, so that the dust production problem in the turnover process is effectively reduced, occupational hazards and the pollution risk are reduced, and meanwhile, the labor intensity of a worker is reduced, and the production efficiency is improved.

Owner:SICHUAN YIBIN WULIANGYE GROUP YIBIN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com