Flexible assembly welding robot workstation

A welding robot and robot technology, applied in welding accessories, manipulators, manufacturing tools, etc., can solve the problems of many times of transfer and clamping, large deviation of group position, poor welding quality, etc., so as to reduce the number of workpiece clamping and transfer, High integration, improving the effect of group pair accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

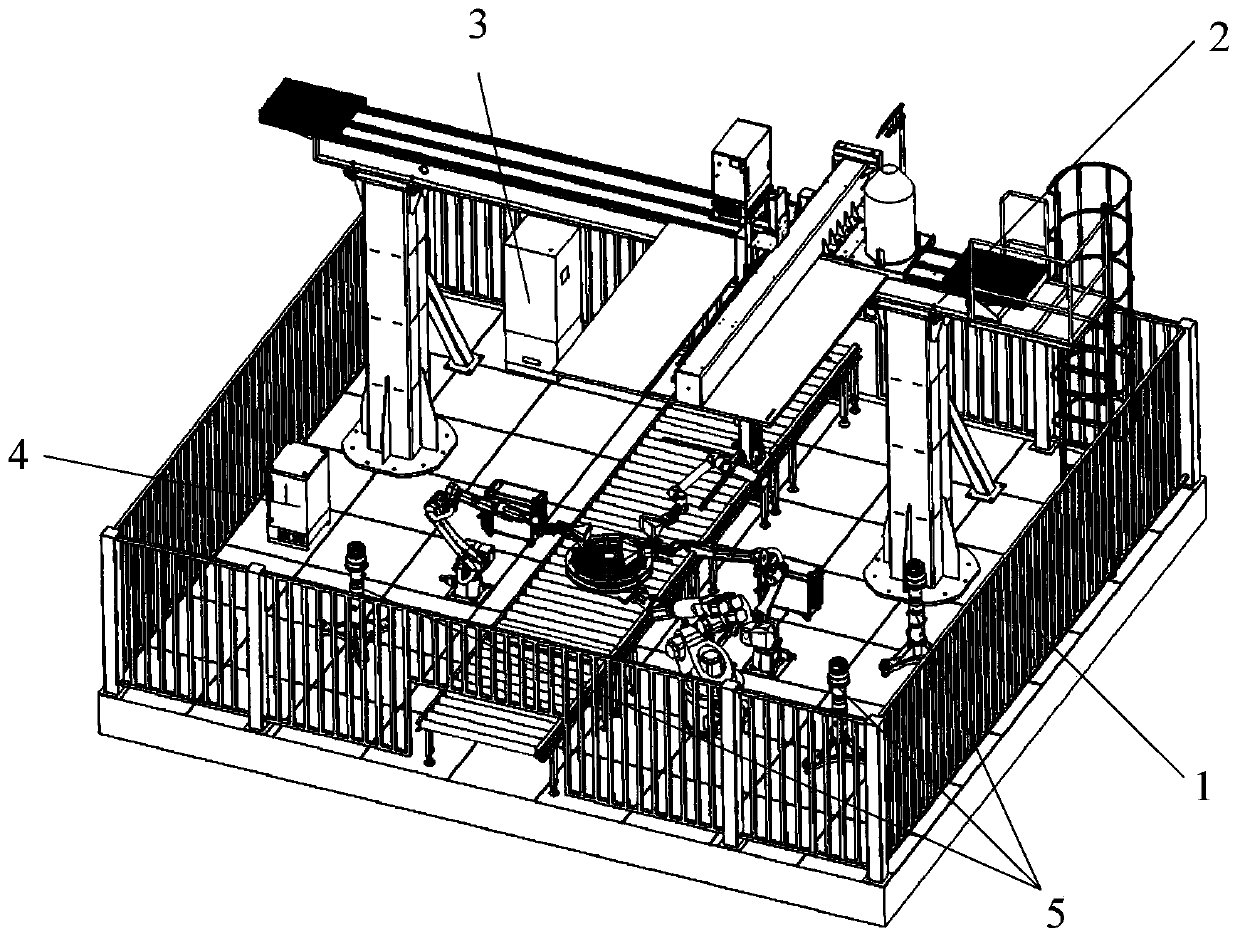

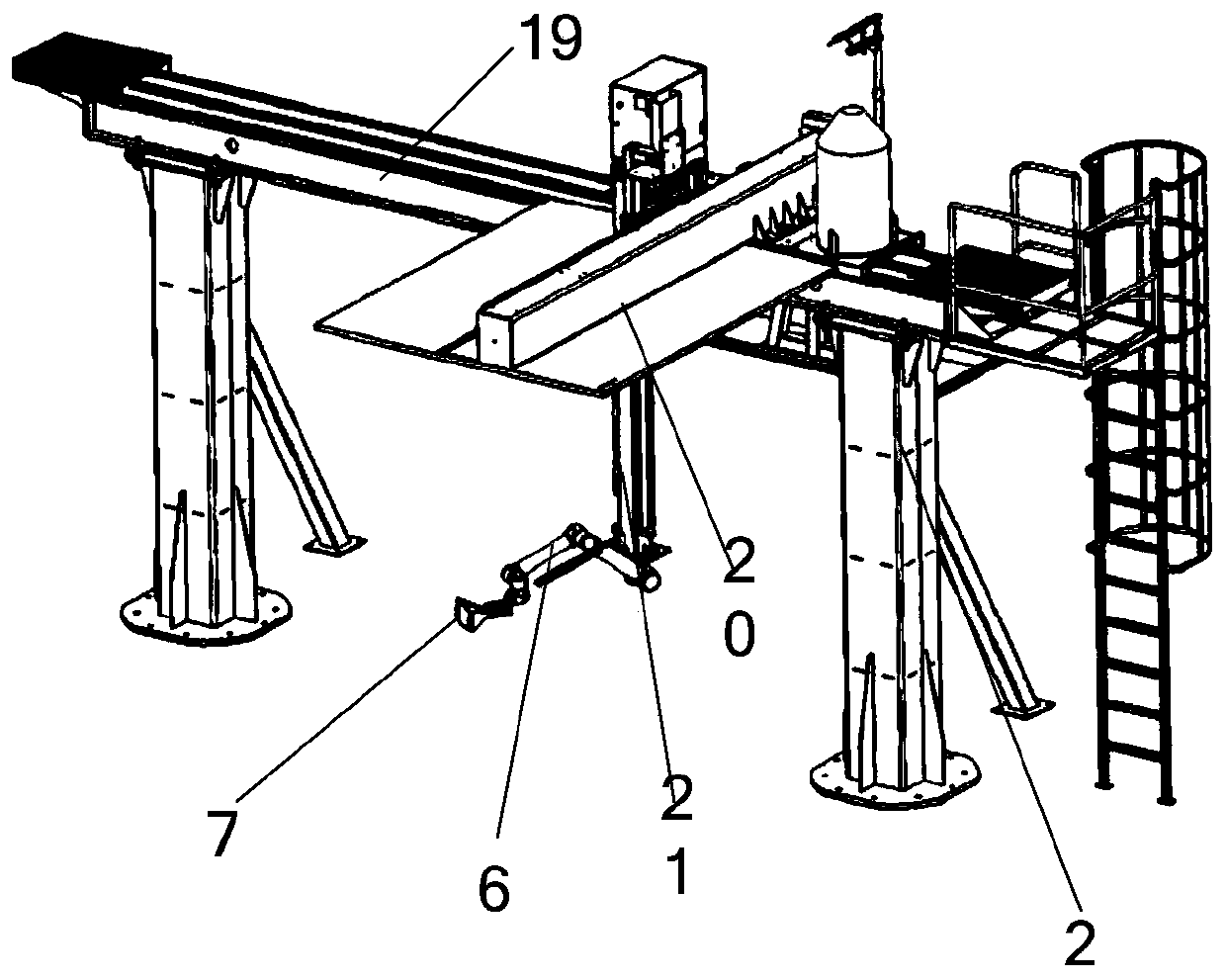

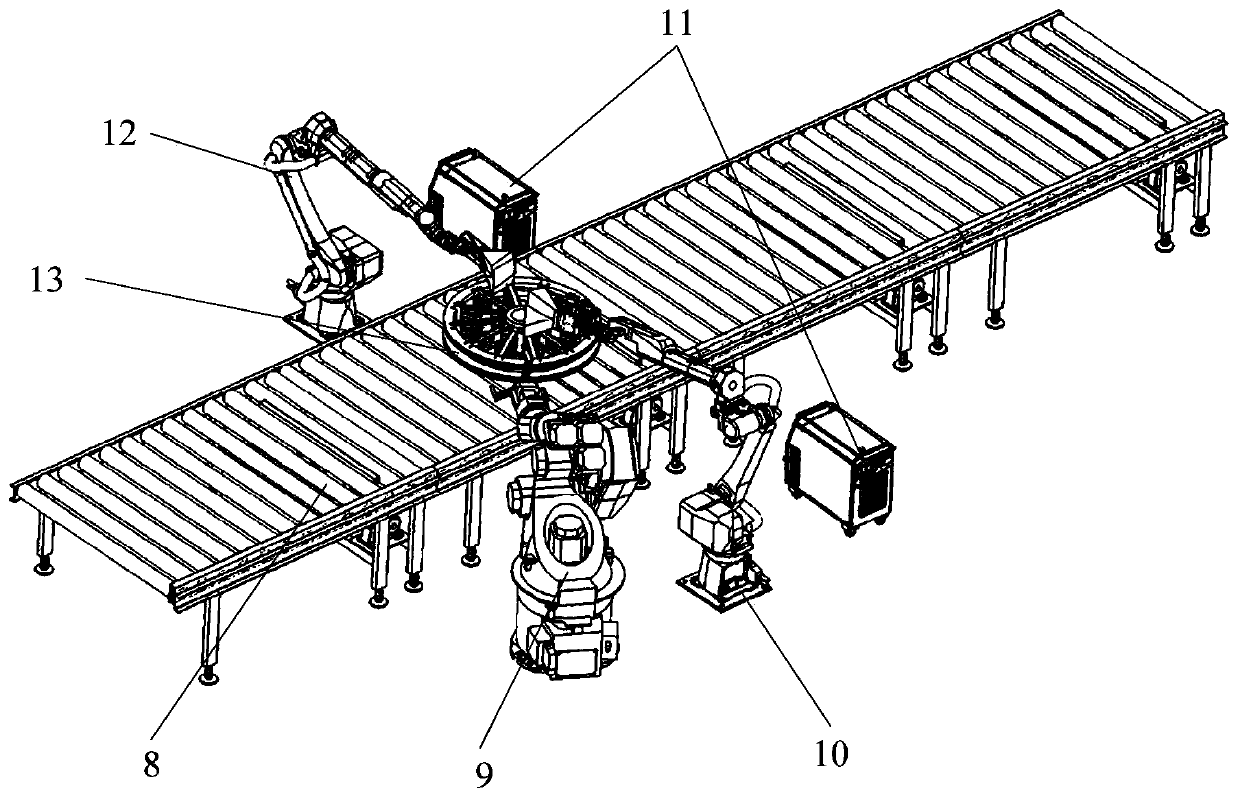

[0042] like figure 1 , figure 2 As shown, a flexible butt welding robot workstation of the present invention includes: a global vision unit, a flexible welding robot group, a gantry truss detection unit, and a master control unit. in:

[0043] The global vision unit includes three sets of global vision devices 5, which are respectively fixed at specific positions on both sides of the conveying platform. The image information of the workpiece is dynamically recognized through multiple sets of visual components, and then the positioning of different workpieces at different positions is realized through the calculation of the industrial computer.

[0044] The flexible welding robot group ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com