Dielectric-varied capacitive flexible three-dimensional force tactile sensor

A tactile sensor and three-dimensional force technology, which is applied in the field of sensing, can solve the problems of complex preparation process, limited application occasions, and difficult arraying of three-dimensional force sensors, and achieve the effects of improving surface adaptability, easy arraying, and easy deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

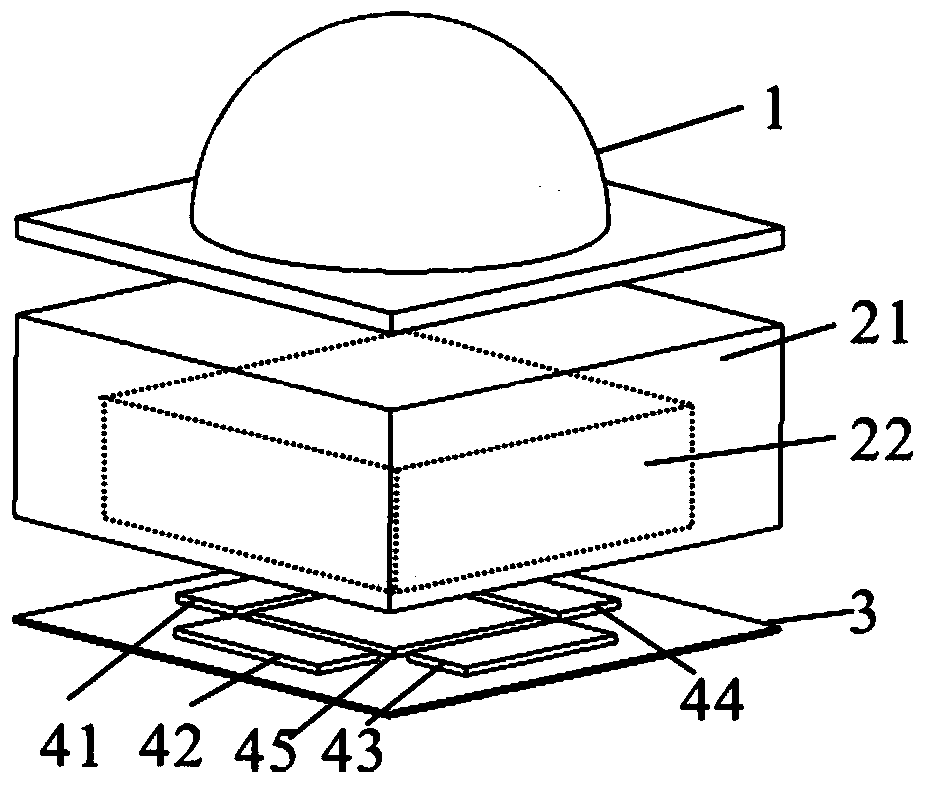

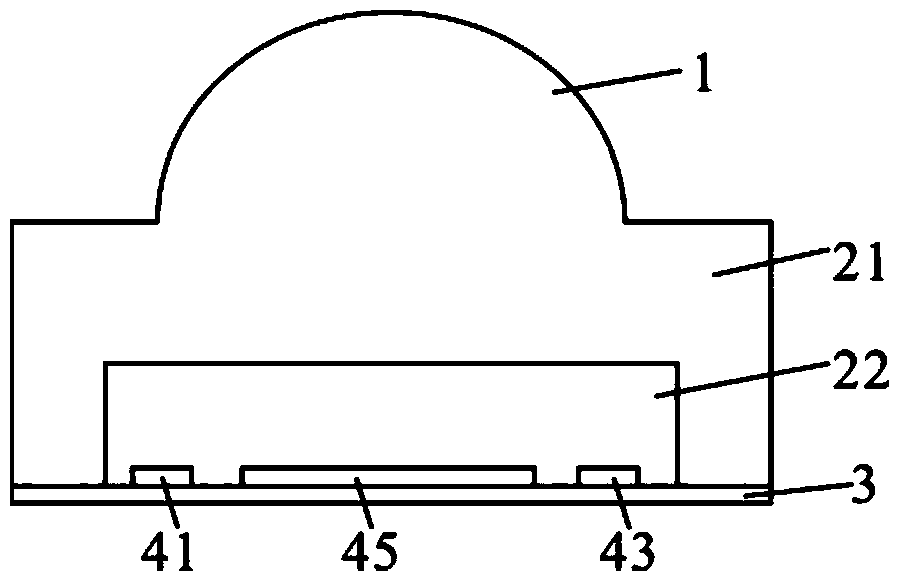

[0024] Such as figure 1 and figure 2 As shown, the variable medium capacitive flexible three-dimensional force tactile sensor of this embodiment includes a PDMS hemispherical contact 1 , a composite multi-media layer and a flexible printed circuit board 3 made of polyimide.

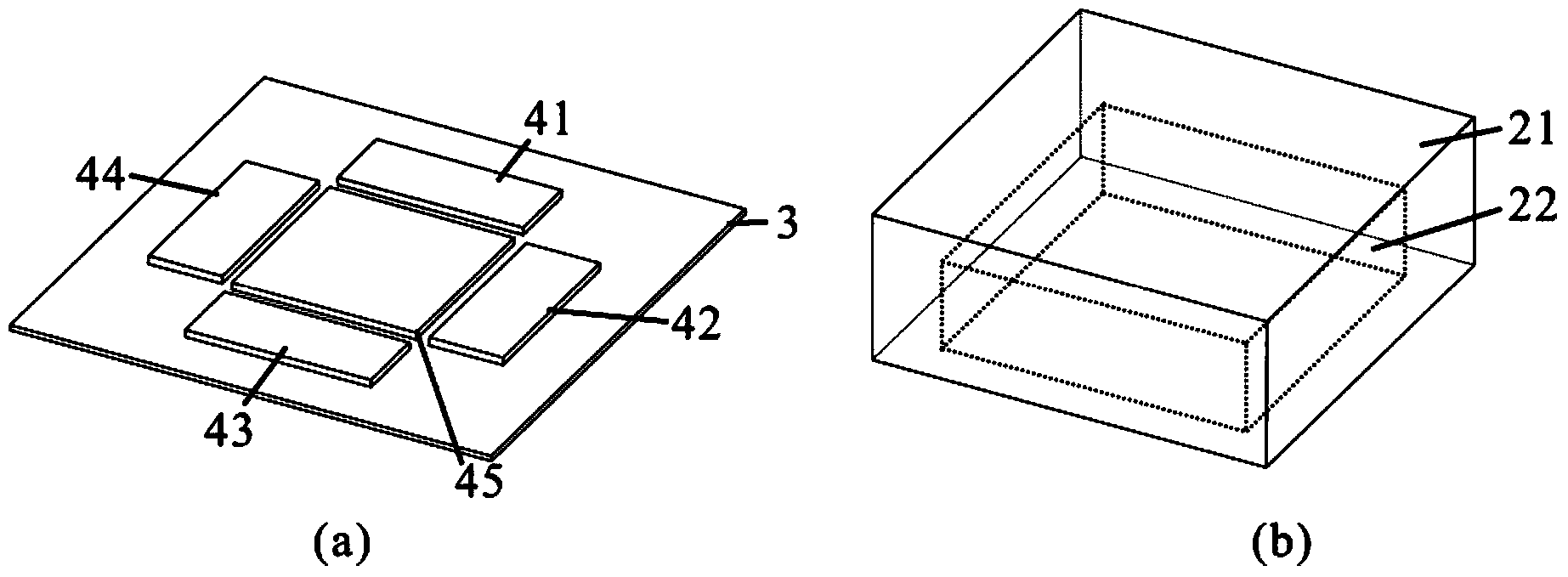

[0025] Such as image 3 As shown in a, on the printed circuit board 3, a square common electrode 45 and four identical rectangular sensing electrodes (the first sensing electrode 41; the second sensing electrode 42) located at the periphery of each side of the common electrode are printed on the printed circuit board 3 by a square common electrode 45. ; The third sensing electrode 43; the fourth sensing electrode 44); The sensing electrodes are symmetrical in pairs with the center of the common electrode as the symmetrical point. The length of the long side of each sensing electrode is equal to the side length of the common electrode, and the long side of each sensing electrode is parallel to the side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com