Preparation method of high power capacity lithium ion battery cathode material

A technology for lithium-ion batteries and negative electrode materials, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of limited improvement and material cycle performance that cannot meet the needs, achieve high specific capacity, easy industrial production, and preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

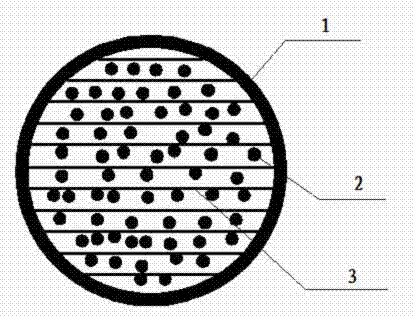

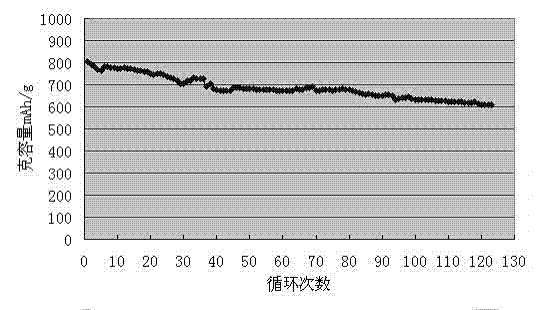

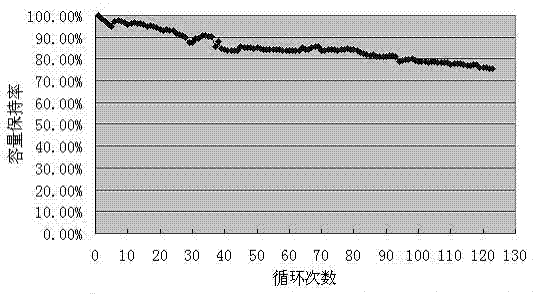

[0023] Weigh a certain amount of natural spherical graphite, according to the ratio of graphite:concentrated sulfuric acid:potassium permanganate=1:2.5:0.05 (mass ratio), first add concentrated sulfuric acid and stir until uniform, then slowly add potassium permanganate, Continue to stir for 30 minutes after the addition, then wash with water until neutral, then dry, expand in a muffle furnace at a temperature of 900°C for 25 seconds to obtain micro-expanded graphite, and mix micro-expanded graphite and silicon powder in a mass ratio of 1:0.15 Mix, then ultrasonically disperse until uniform, then suction filter, dry, then mix and coat the obtained powder with 13% asphalt, heat to 1000°C under nitrogen protection, keep it warm for 3 hours, then cool to room temperature, and finally get this product Invented silicon-carbon composite anode materials, such as figure 1 As shown, nano-silicon 2 is distributed between graphitic carbon layers 3 , and the silicon-carbon composite negat...

Embodiment 2

[0026] Prepare micro-expanded graphite as described in Example 1, mix micro-expanded graphite and silicon powder at a mass ratio of 1:0.2 and ultrasonically disperse until uniform, then suction filter and dry, and then mix the obtained powder with 15% asphalt coating, heating to 1100° C. under the protection of nitrogen, keeping the temperature for 3 hours, and then cooling to room temperature to finally obtain the silicon-carbon composite negative electrode material of the present invention.

[0027] The test conditions of the electrode material are as described in Example 1, charging and discharging at a current density of 50 mA / g. The first discharge point capacity of the electrode material is 990mAh / g, and the capacity after 100 cycles is still 772mAh / g, with a retention rate of 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com