Patents

Literature

1258 results about "Composite cathode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

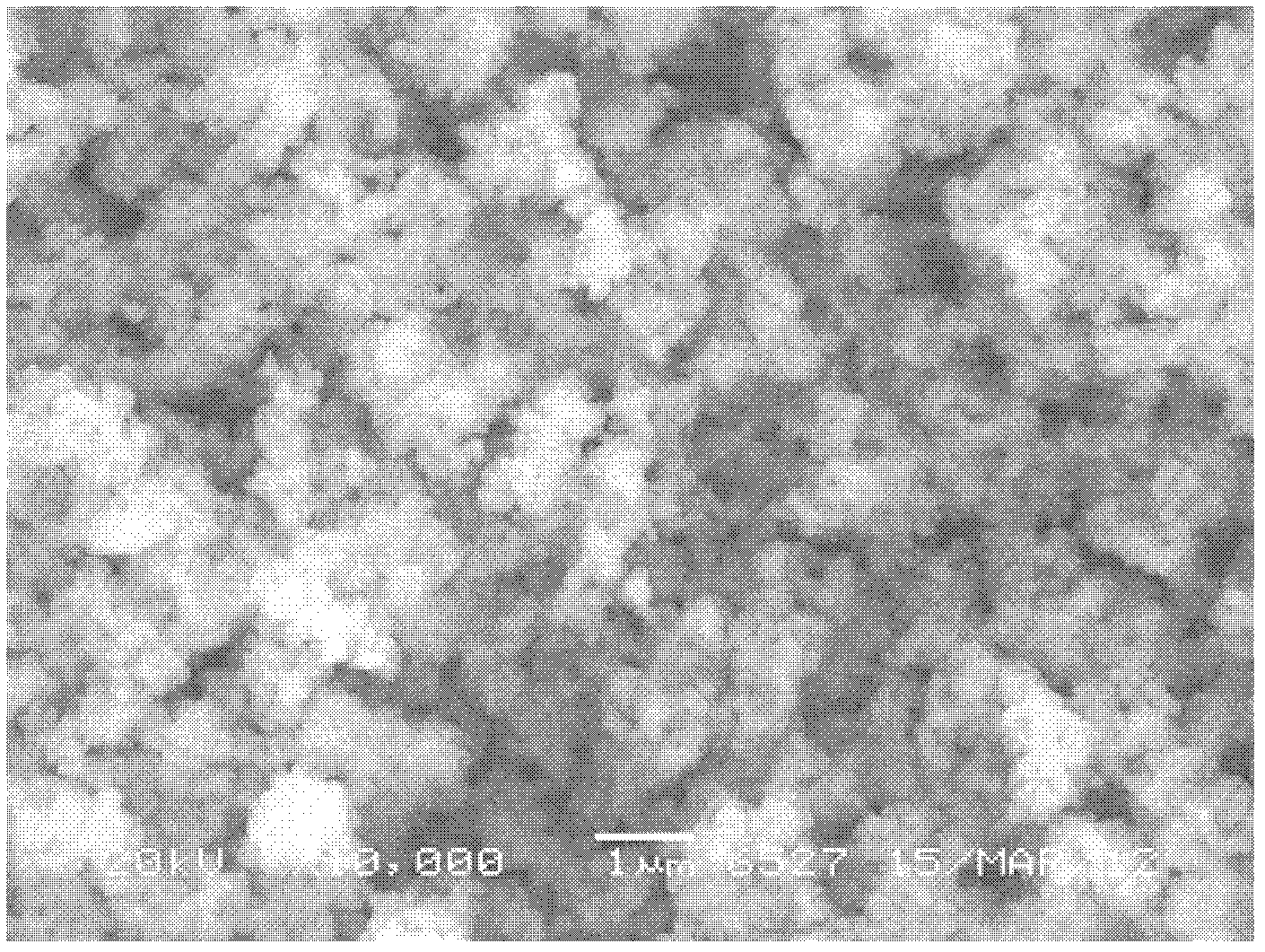

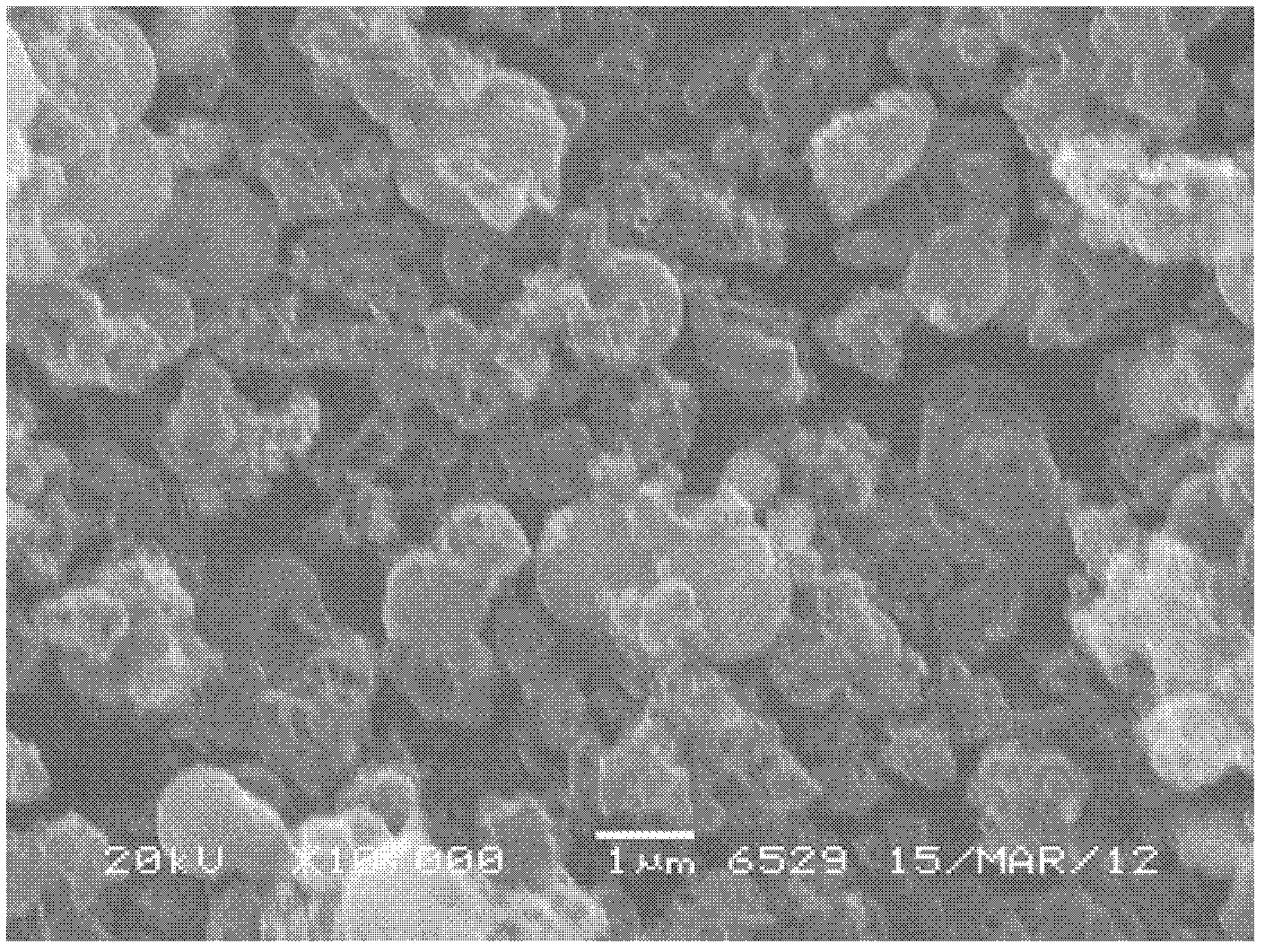

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

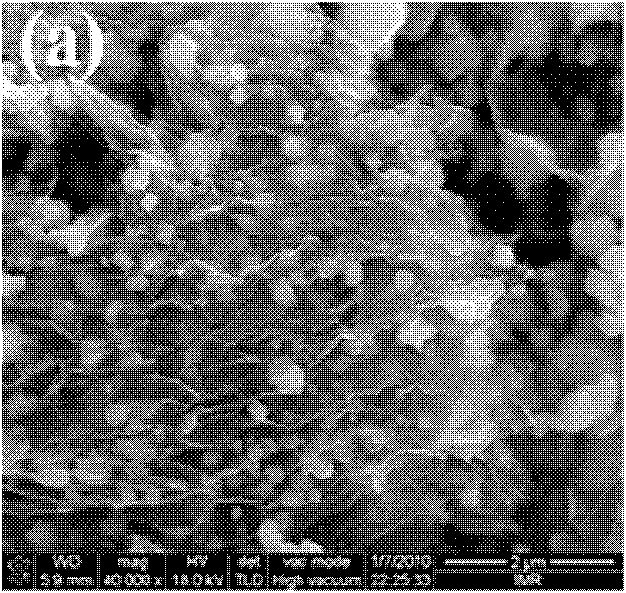

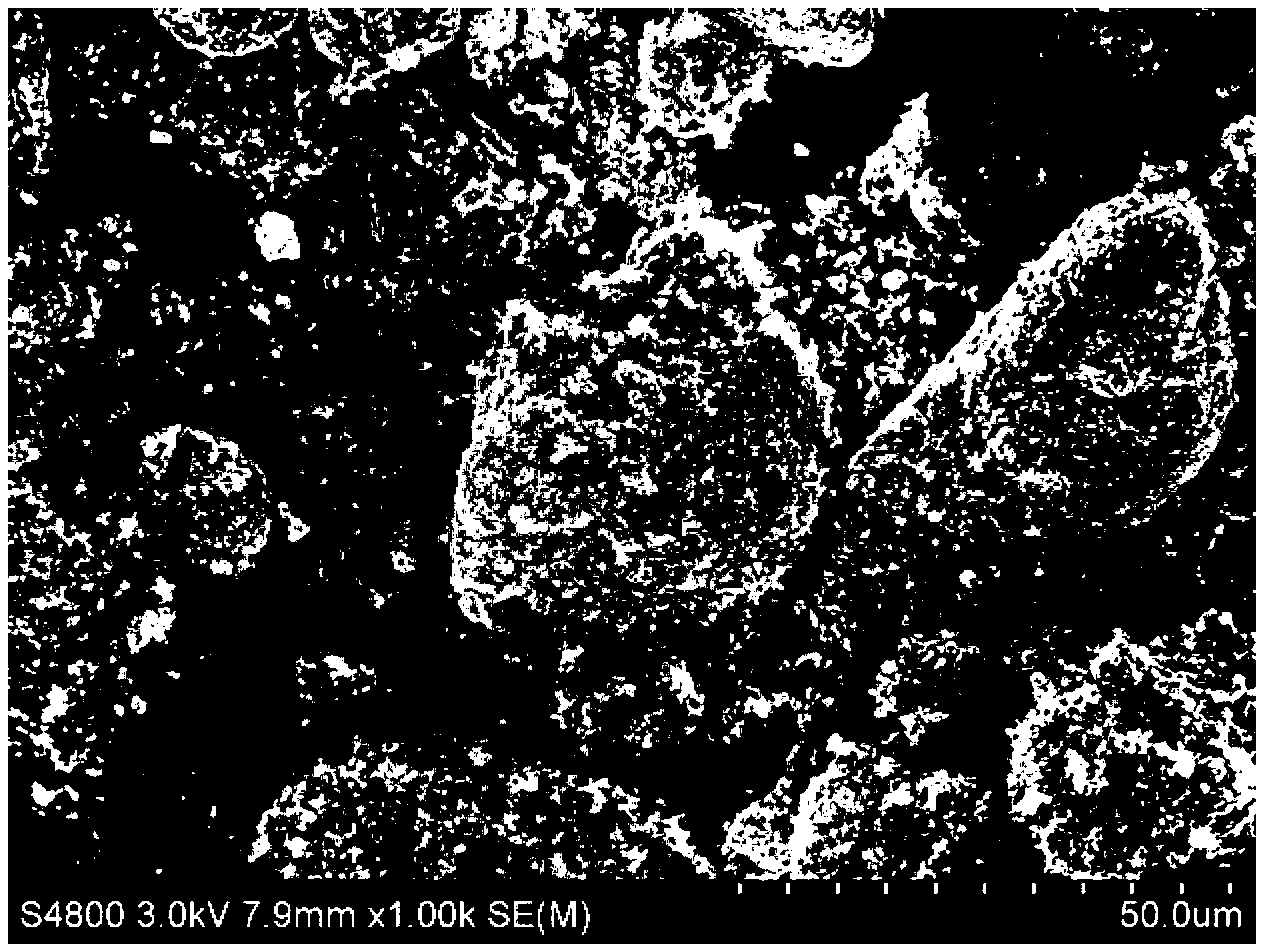

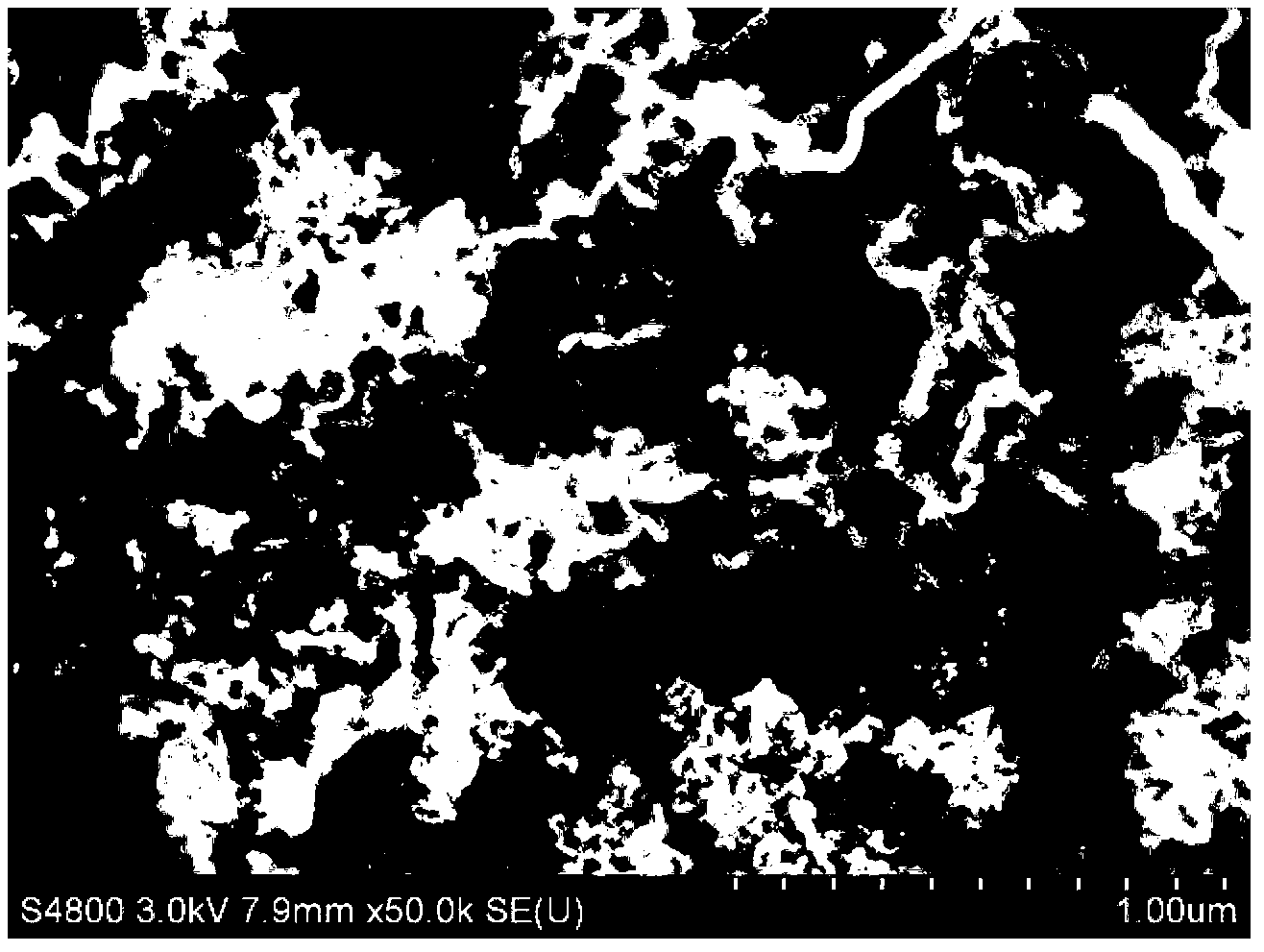

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Novel composite cathodes, electrochemical cells comprising novel composite cathodes, and processes for fabricating same

The present invention pertains to composite cathodes suitable for use in an electrochemical cell, said cathodes comprising: (a) an electroactive sulfur-containing cathode material, wherein said electroactive sulfur-containing cathode material, in its oxidized state, comprises a polysulfide moiety of the formula —Sm—, wherein m is an integer equal to or greater than 3; and, (b) an electroactive transition metal chalcogenide composition, which encapsulates said electroactive sulfur-containing cathode material, and which retards the transport of anionic reduction products of said electroactive sulfur-containing cathode material, said electroactive transition metal chalcogenide composition comprising an electroactive transition metal chalcogenide having the formula MjYk(OR)l wherein: M is a transition metal; Y is the same or different at each occurrence and is oxygen, sulfur, or selenium; R is an organic group and is the same or different at each occurrence; j is an integer ranging from 1 to 12; k is a number ranging from 0 to 72; and l is a number ranging from 0 to 72; with the proviso that k and l cannot both be 0. The present invention also pertains to methods of making such composite cathodes, cells comprising such composite cathodes, and methods of making such cells.

Owner:SION POWER CORP

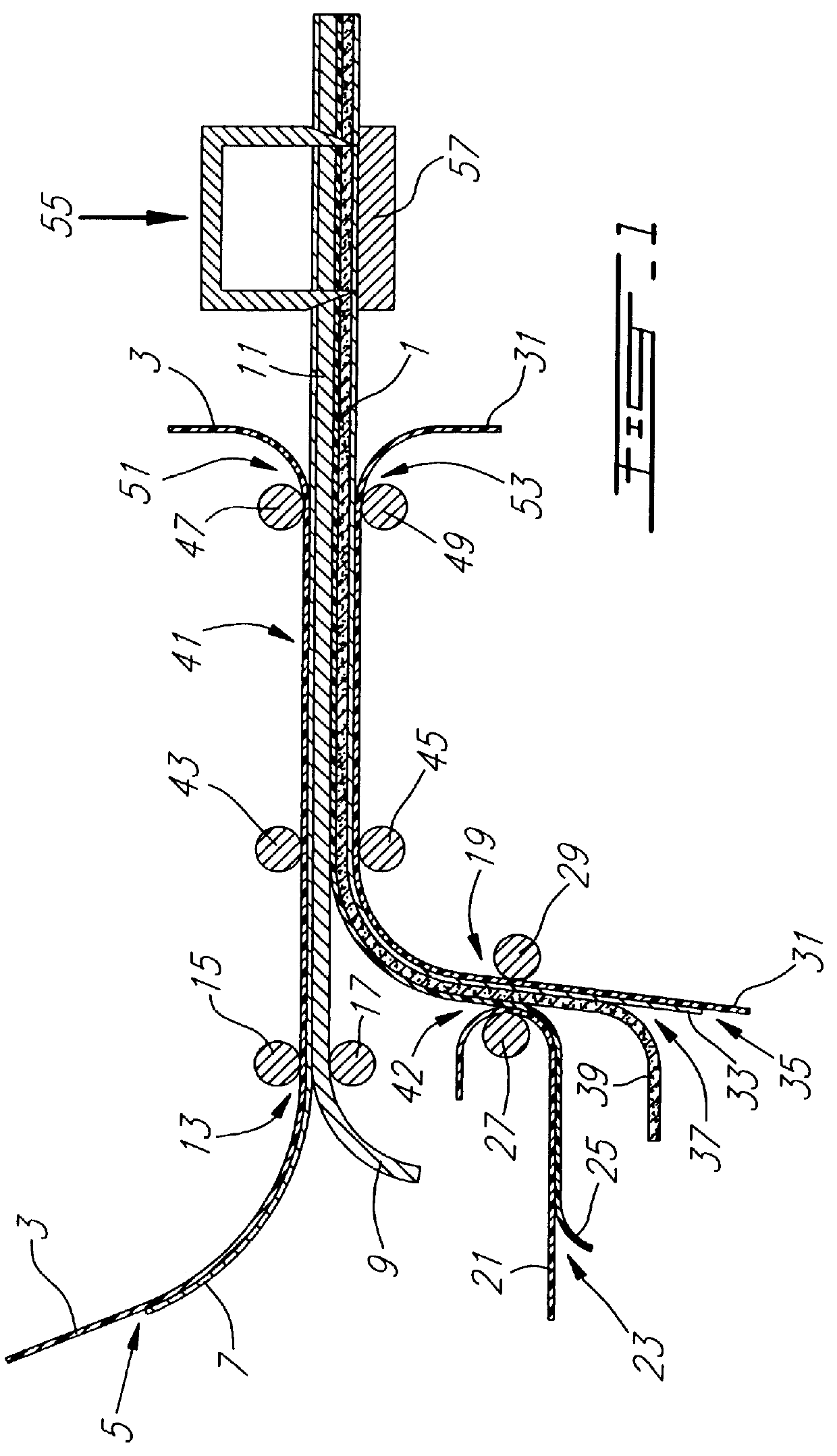

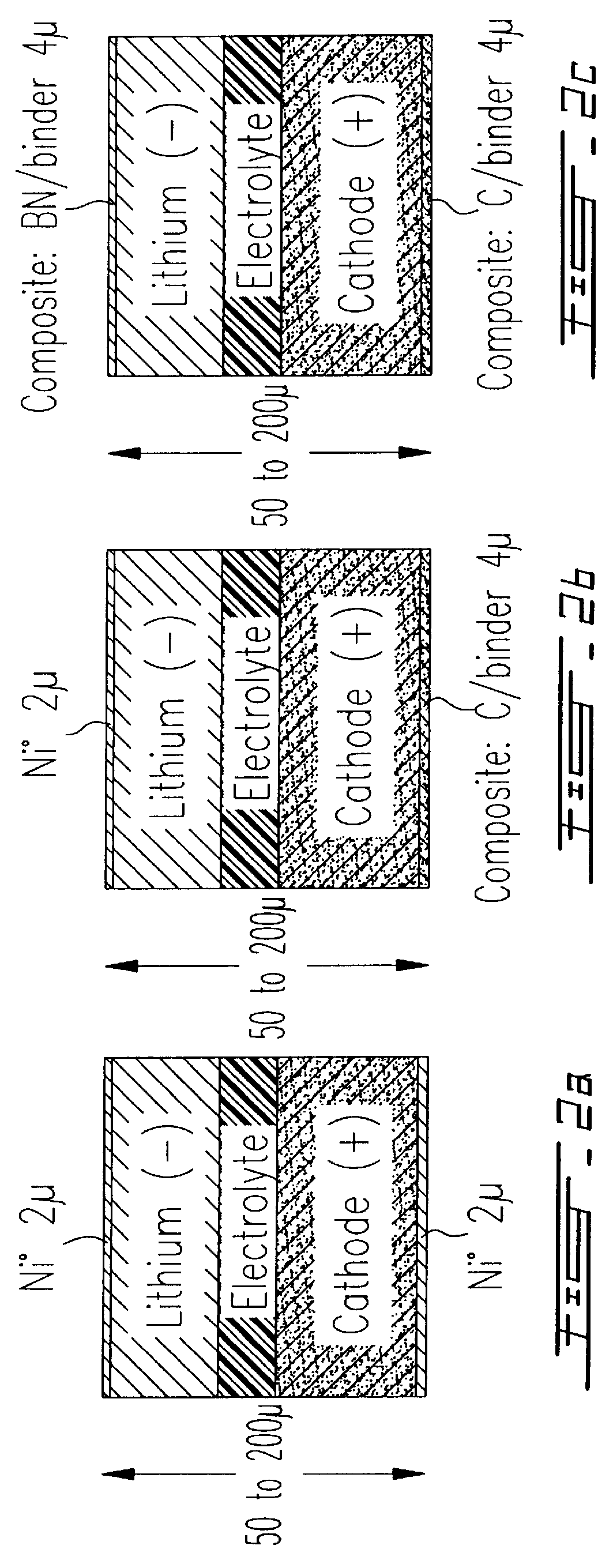

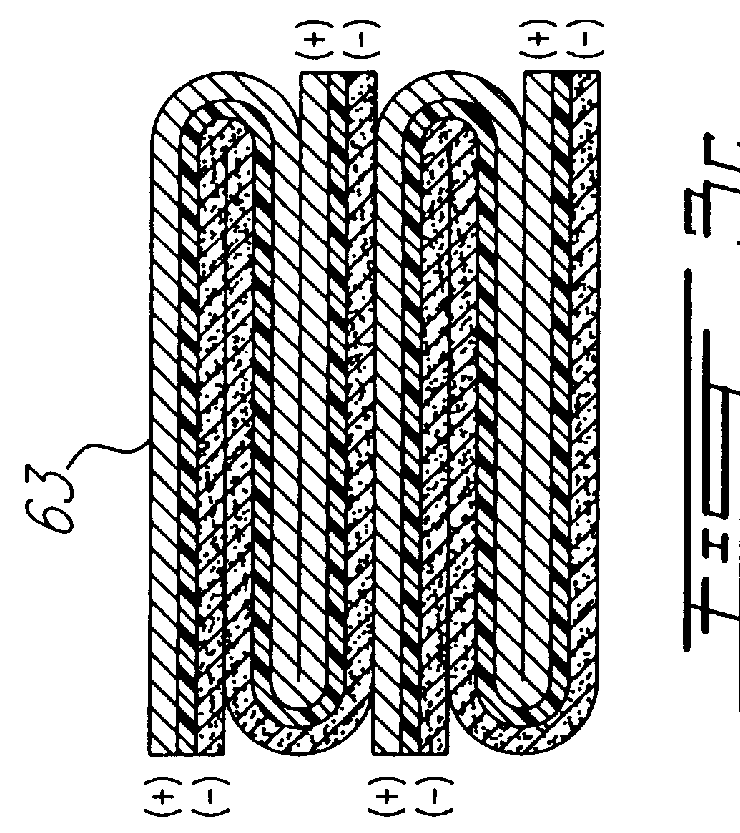

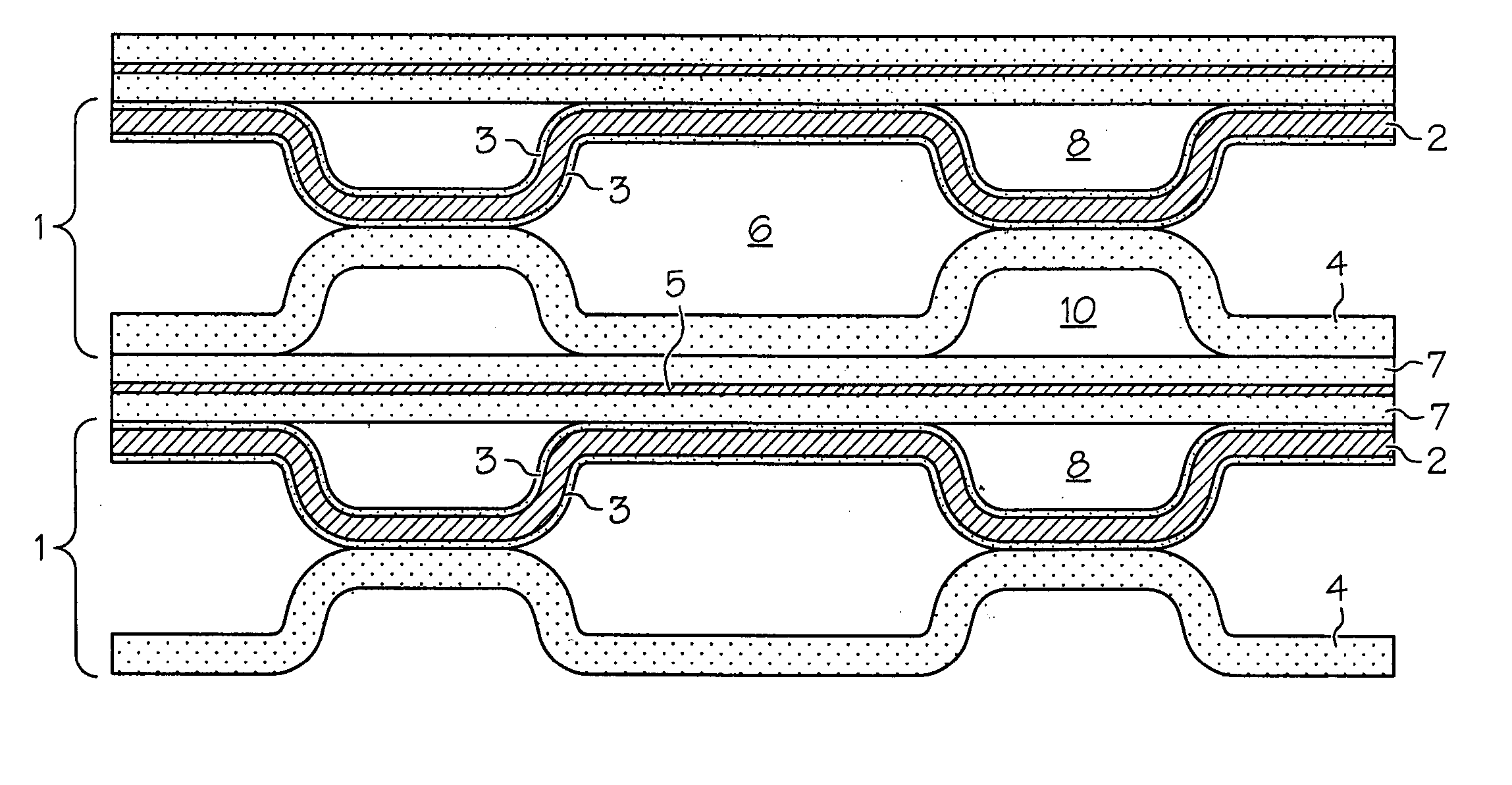

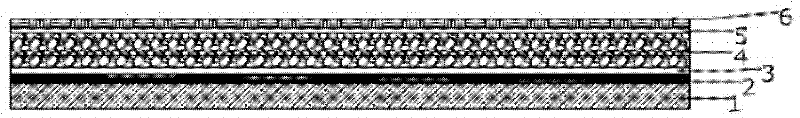

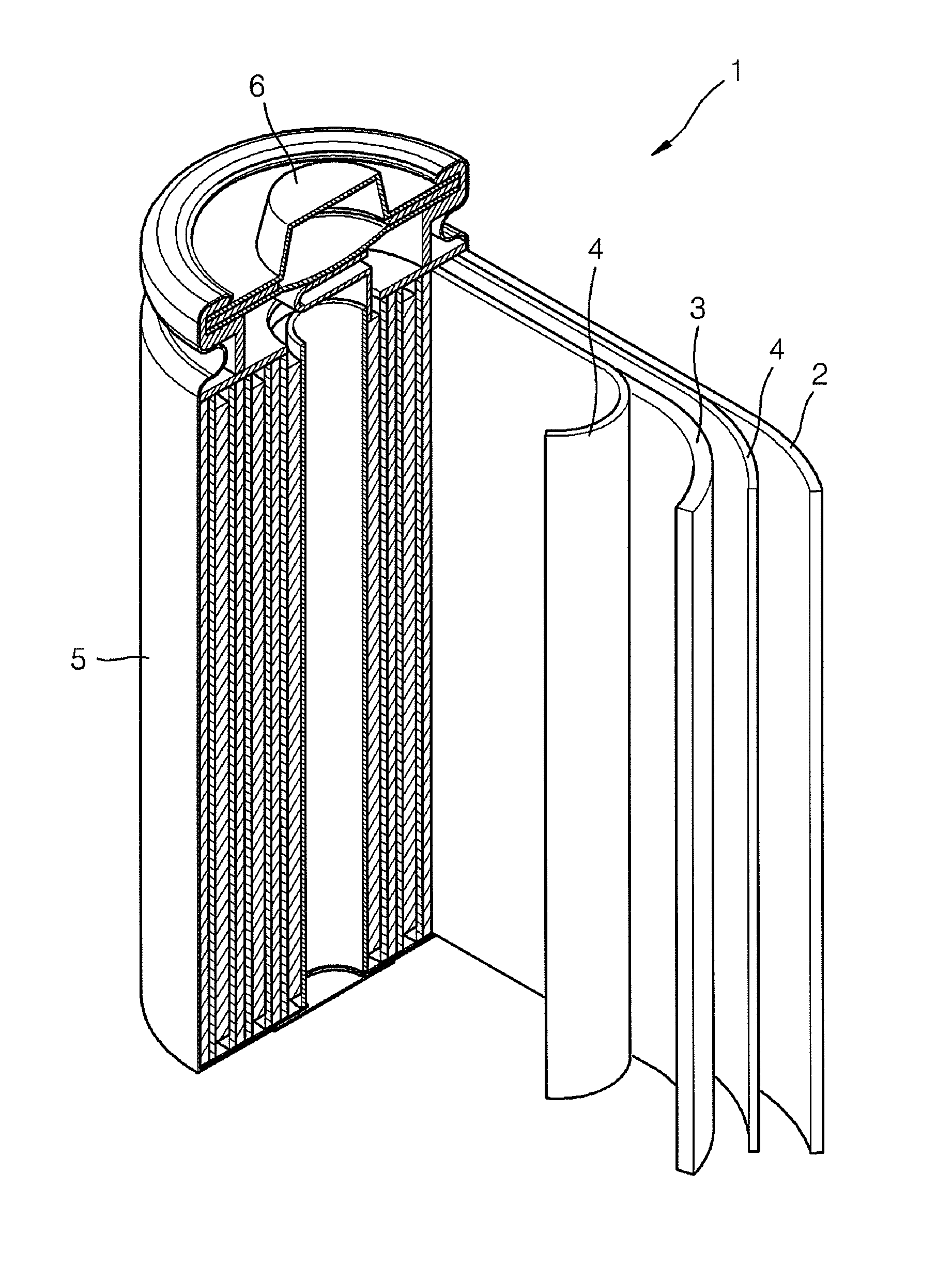

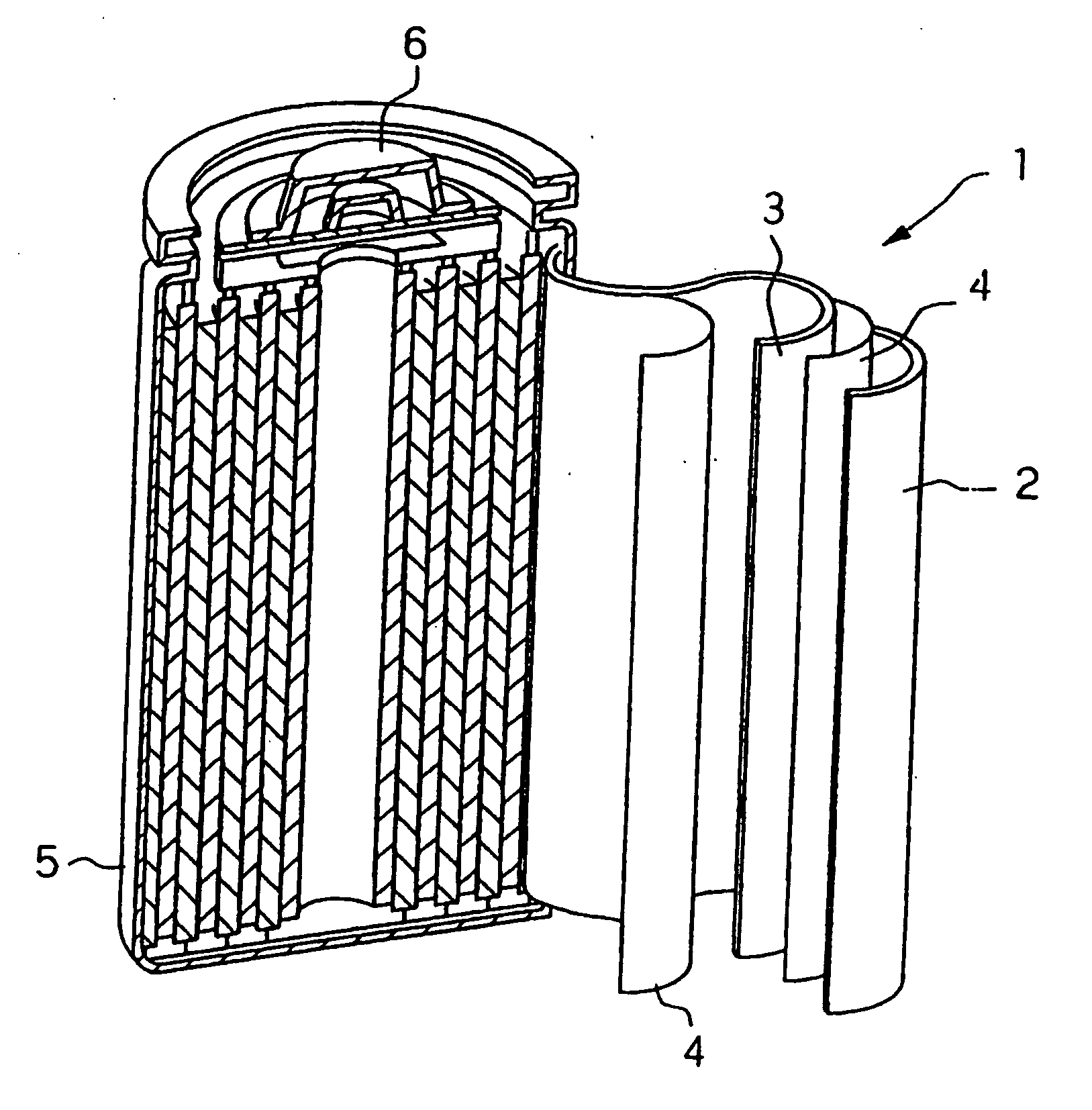

Ultra thin solid state lithium batteries and process of preparing same

InactiveUS6030421ASimple manufacturing processEasy to operateElectrode manufacturing processesFinal product manufactureMetallic lithiumConductive materials

There is provided a mother-battery containing at least the following films: an anode of metallic lithium or sodium, a polymer electrolyte which is conductive towards the alkaline ions of the anode and also acts as a separator between the electrodes, and a composite cathode consisting of a compound which is reducible to lithium or sodium, an additive of electronic conduction and a polymer electrolyte binder. The mother battery also includes an electronically conductive thin coating on the external face of the anode and, possibly of the cathode, in which the conductive material is chemically inert towards the electrode material and which also serves to establish permanent electrical contacts on the external faces. The laminated mother-battery of larger surface area and at least partially charged is thereafter subjected to a sharp mechanical cutting out to give thin polymer electrolyte batteries with lithium or sodium anode. The thus cut out batteries preserve substantially their voltage after mechanical cutting out which is recovered by a mechanism of self-healing.

Owner:BATHIUM CANADA

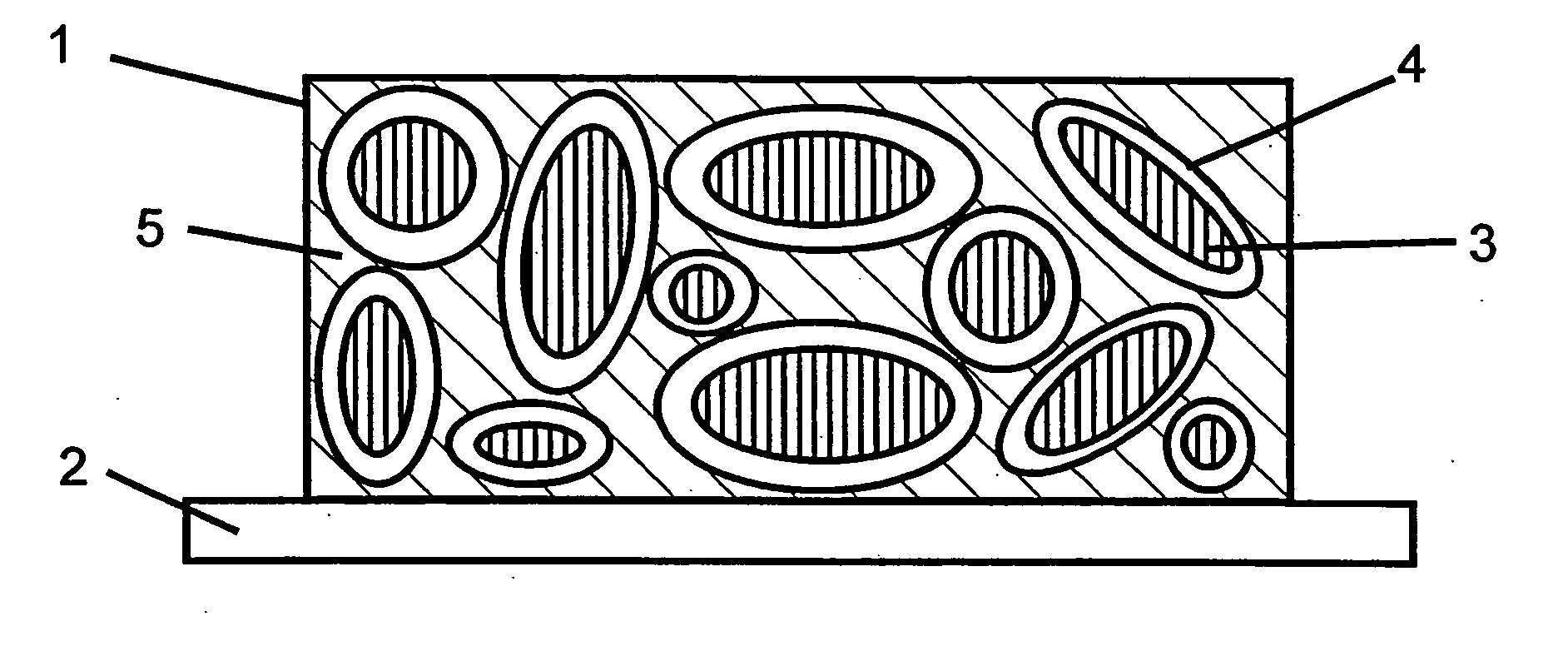

Cathode active material, method of preparing the same, and cathode and lithium battery containing the material

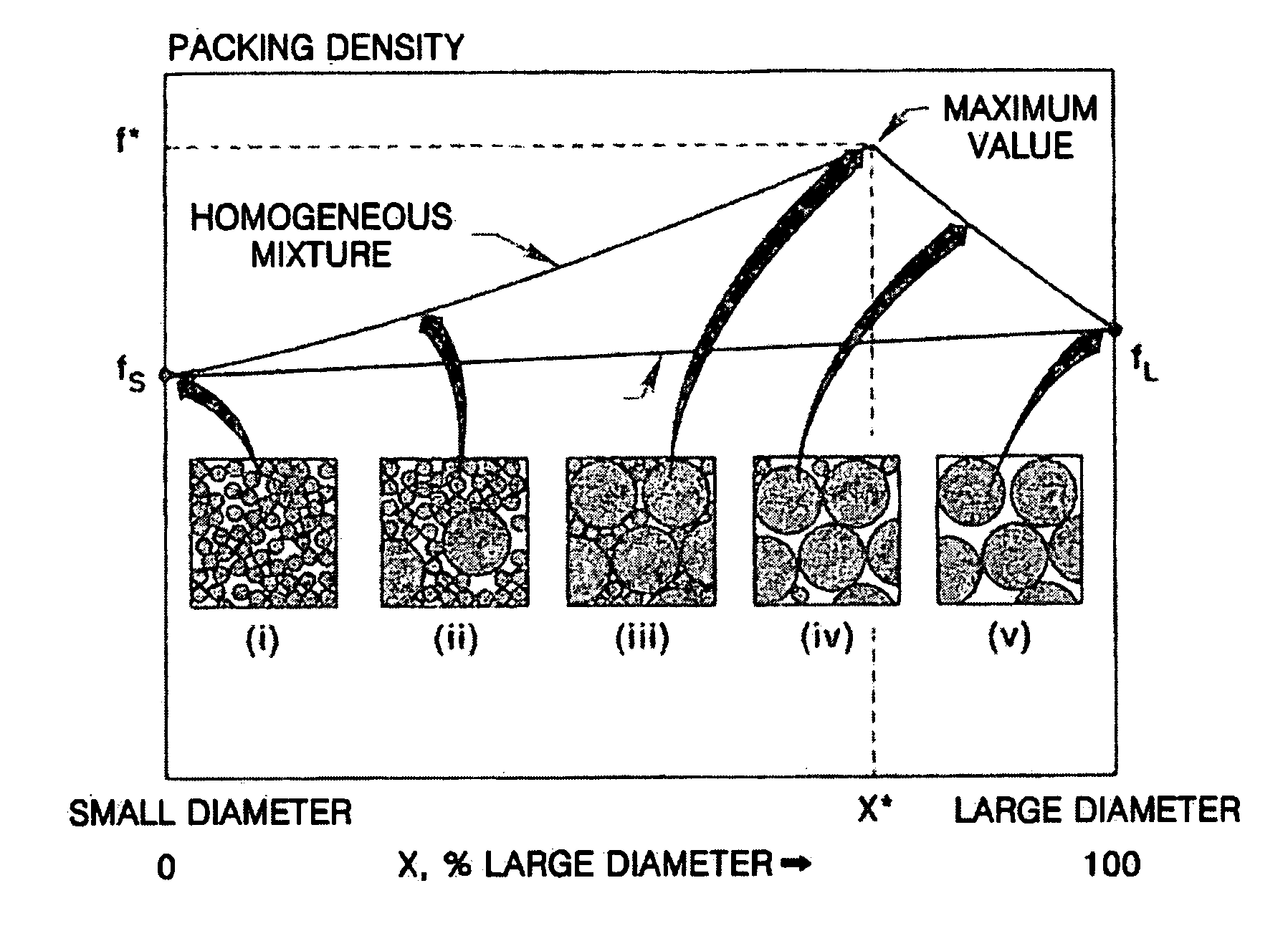

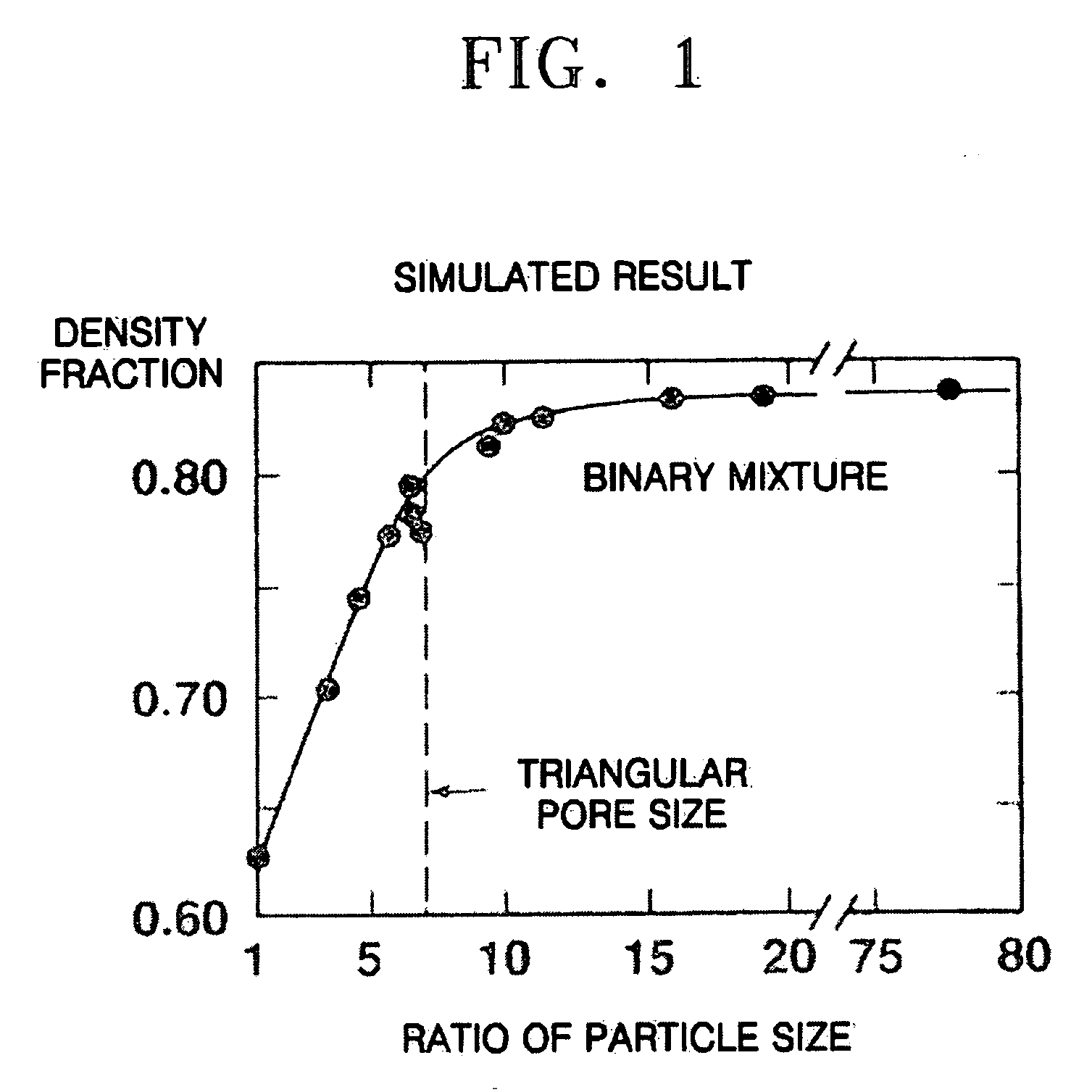

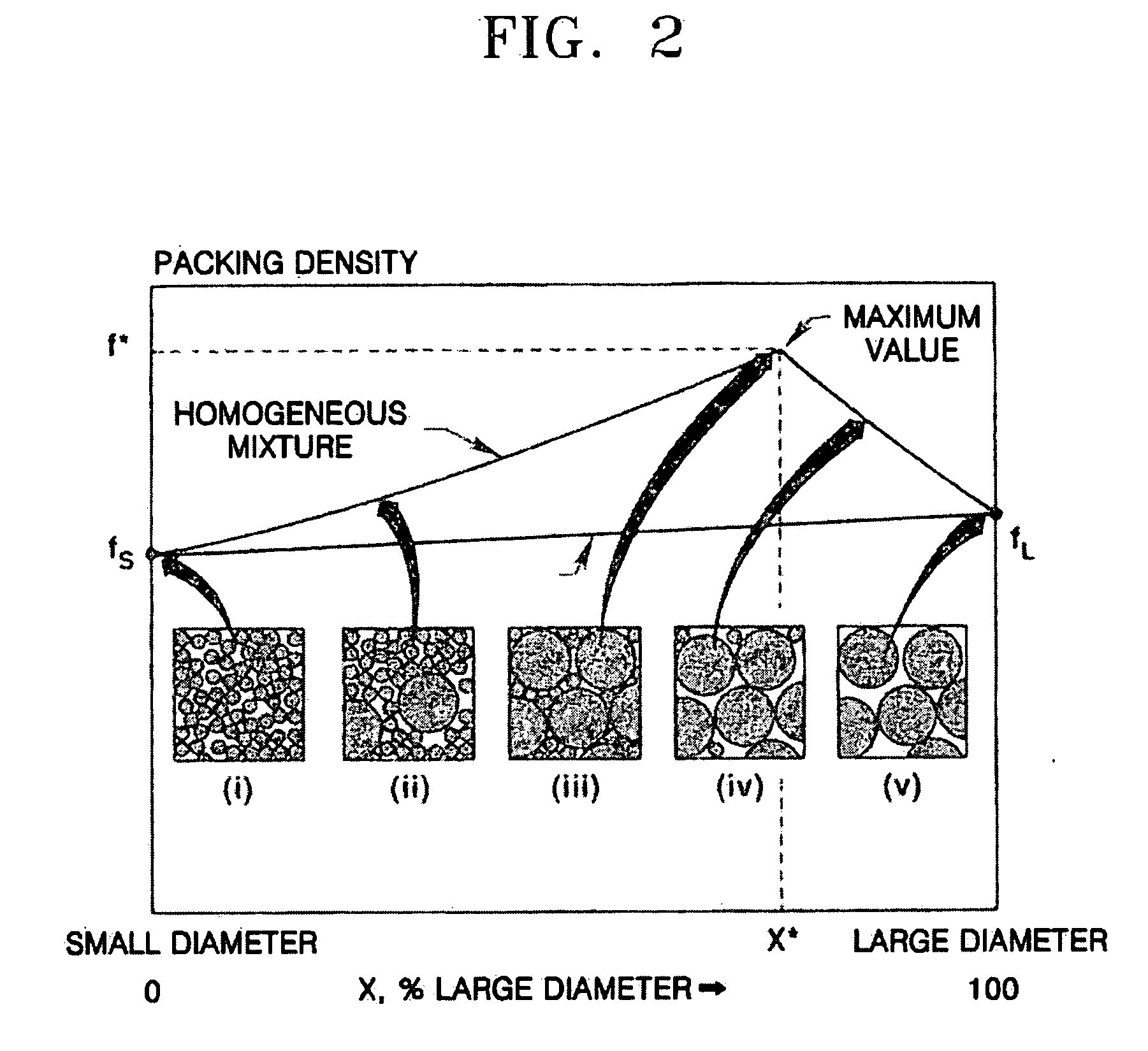

ActiveUS20060257745A1Improve high voltage stabilityImprove thermal stabilityWalking sticksElectrode rolling/calenderingComposite cathodeHigh rate

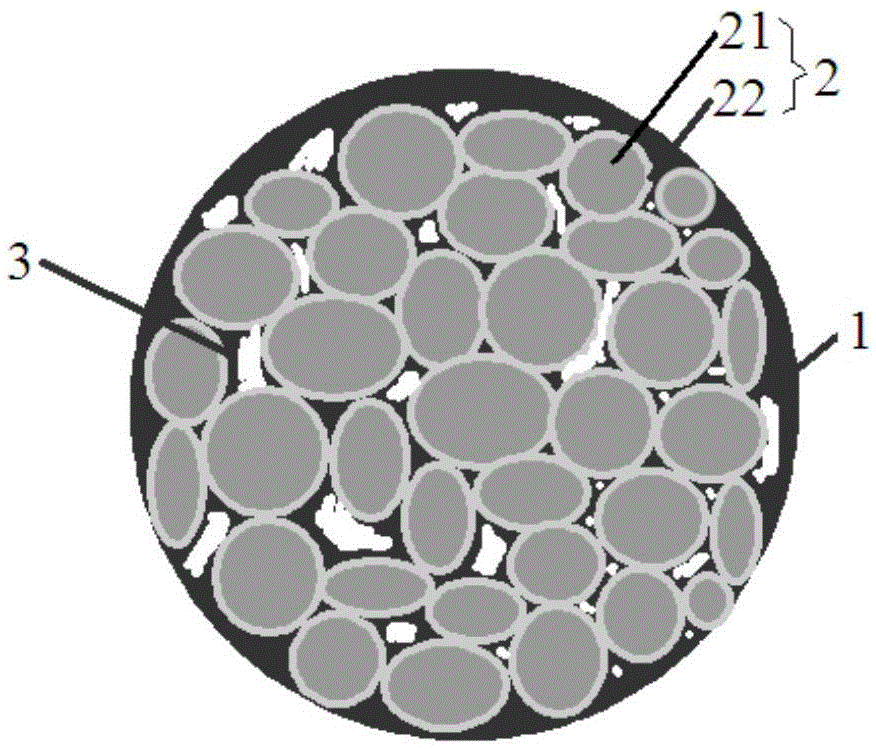

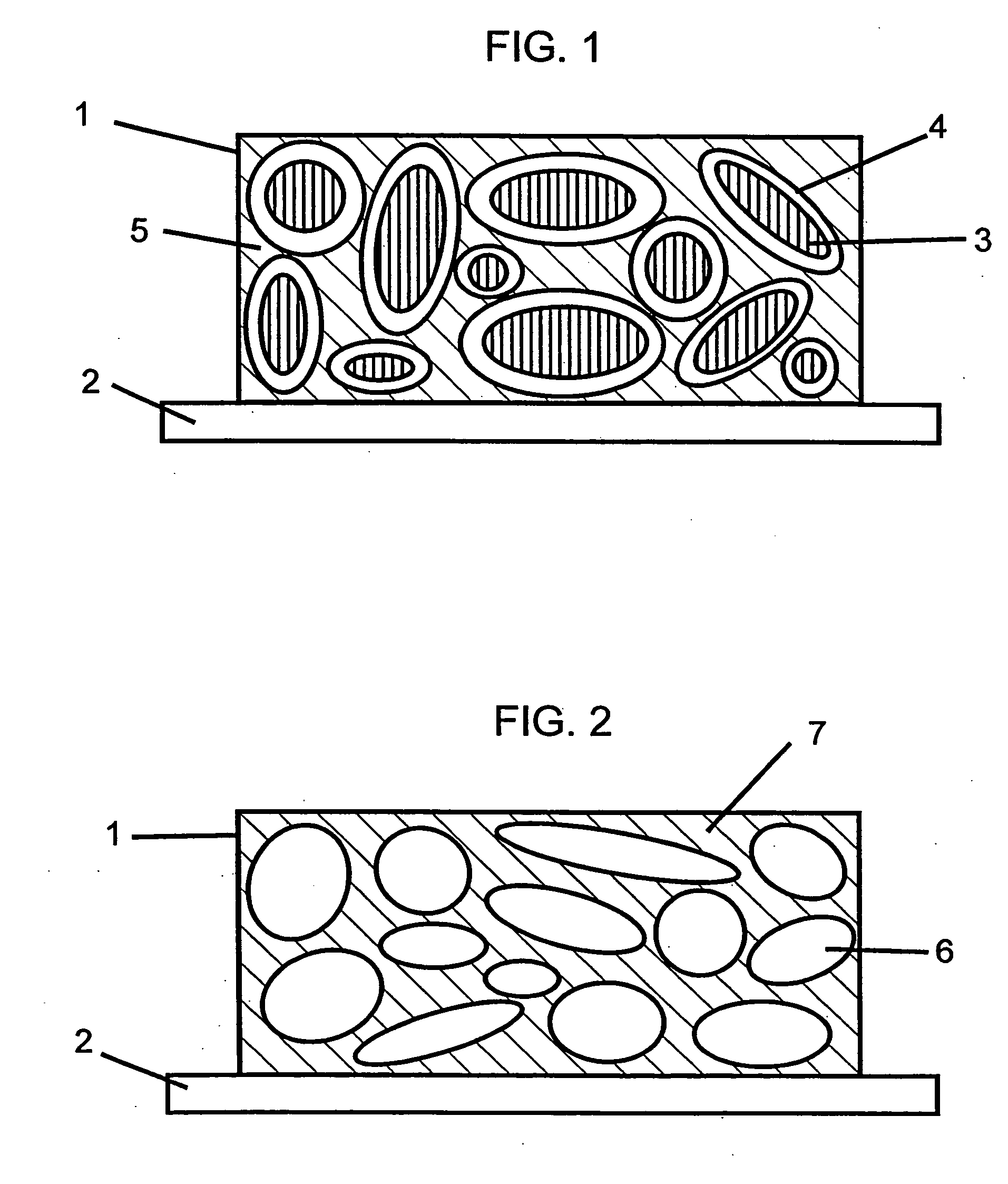

Composite cathode active materials having a large diameter active material and a small diameter active material are provided. The ratio of the average particle diameter of the large diameter active material to the average particle diameter of the small diameter active material ranges from about 6:1 to about 100:1. Mixing the large and small diameter active materials in a proper weight ratio improves packing density Additionally, including highly stable materials and highly conductive materials in the composite cathode active materials improves volume density, discharge capacity and high rate discharge capacity.

Owner:SAMSUNG SDI CO LTD

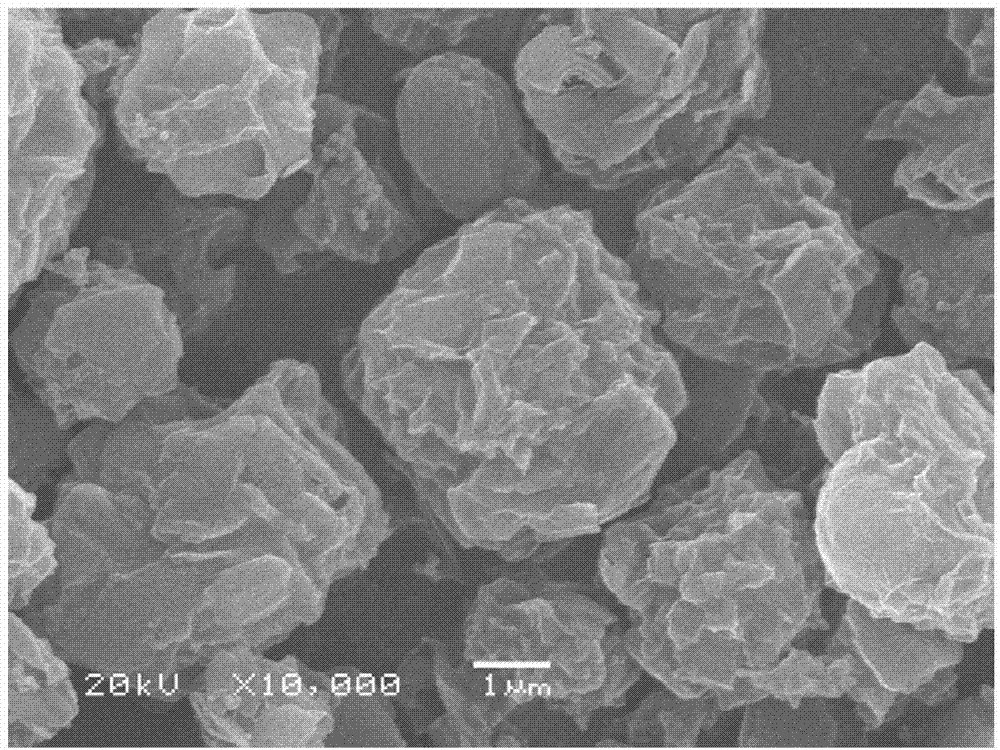

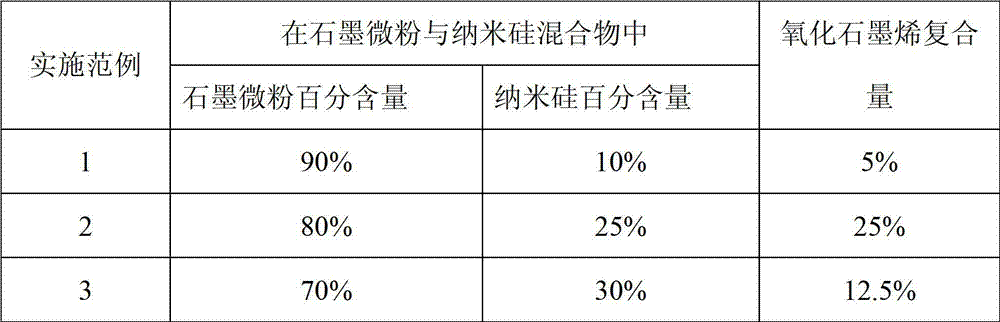

Preparation method of silicon and carbon-coated graphene composite cathode material

ActiveCN103050666ARealize in situ restorationThe preparation process is simple, convenient and practicalMaterial nanotechnologyCell electrodesCarbon coatedStructural stability

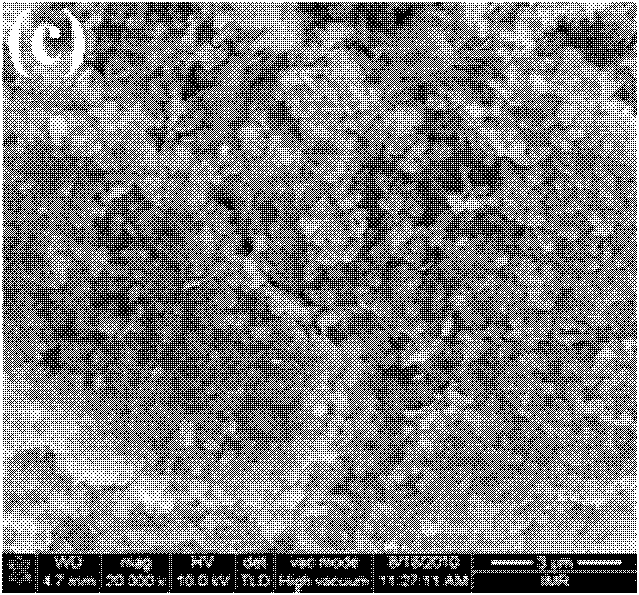

The invention discloses a preparation method of a silicon and carbon-coated graphene composite cathode material. The technical problem to be solved is to enhance the electronic conductivity of the silicon-based cathode material, buffer the volume effect produced in the process of deintercalation of the lithium in the silicon-based cathode material and enhance the structure stability in the circulation process of the material at the same time. The material is prepared by using a spray drying-thermally decomposing treatment process in the invention. The preparation method comprises the following steps of: evenly dispersing nano silicon and graphite micro powder in a dispersion solution of oxidized graphene, carrying out thermal treatment under an inert protection atmosphere after spray drying, subsequently cooling along a furnace to obtain the silicon and carbon-coated graphene composite cathode material. The extra binder does not need to add in the process of manufacturing balls in the invention and the outer oxidized graphene is thermally reduced in situ to graphene in the thermal treatment process of the composite precursor, so that the process is simple and easy to operate; and the practical degree is high. The prepared composite material has the advantages of great reversible capacity, designable capacity, good cycling performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

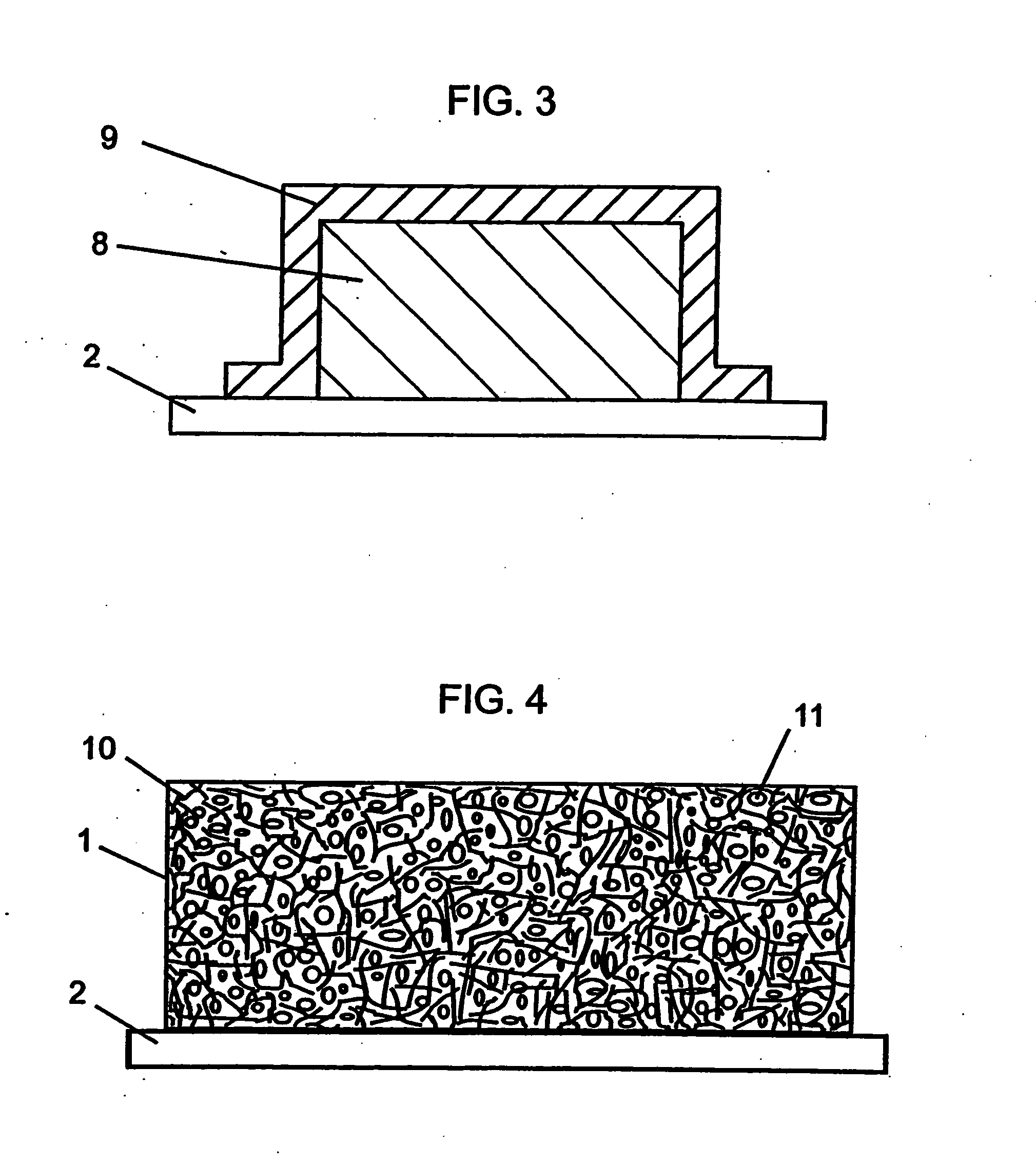

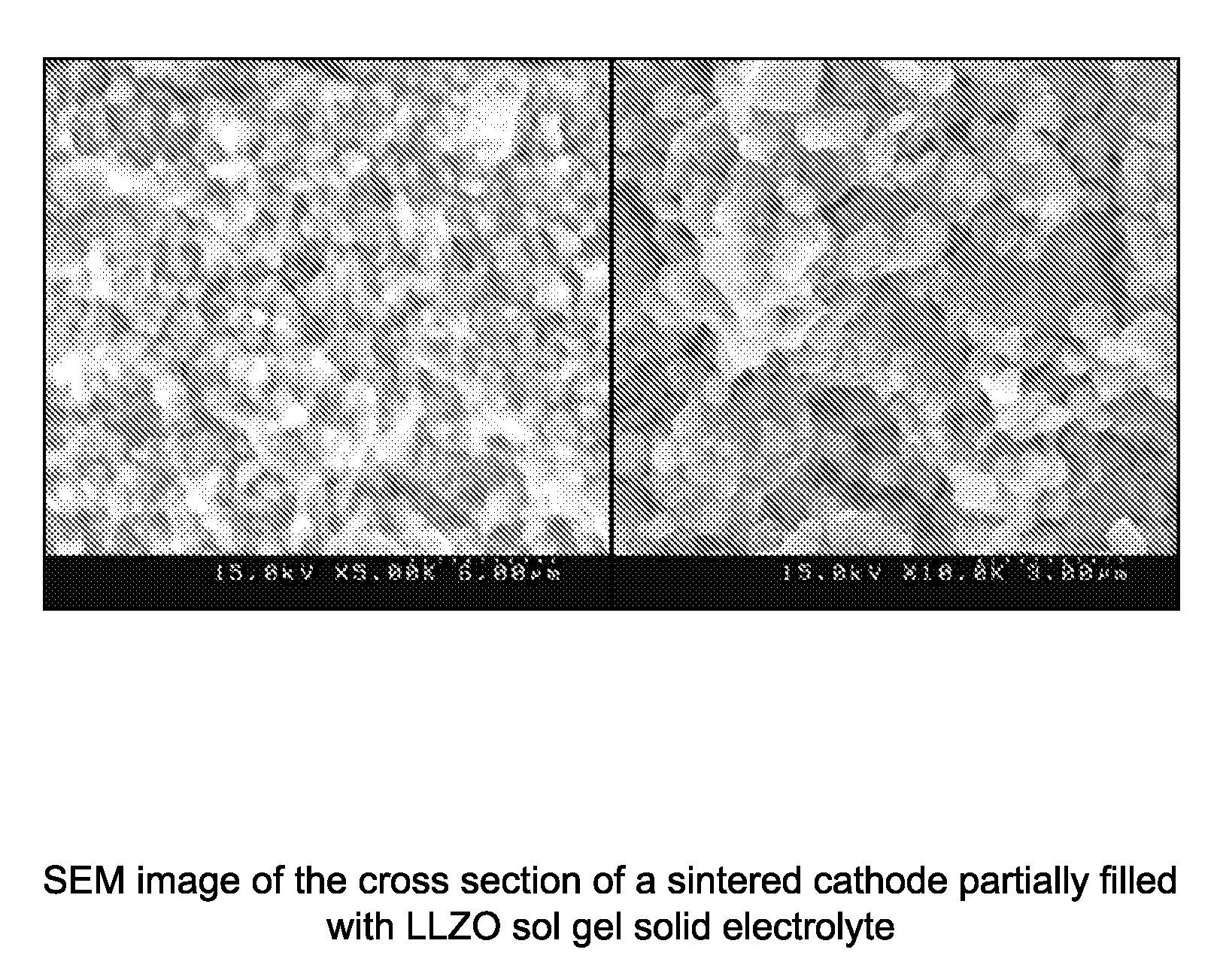

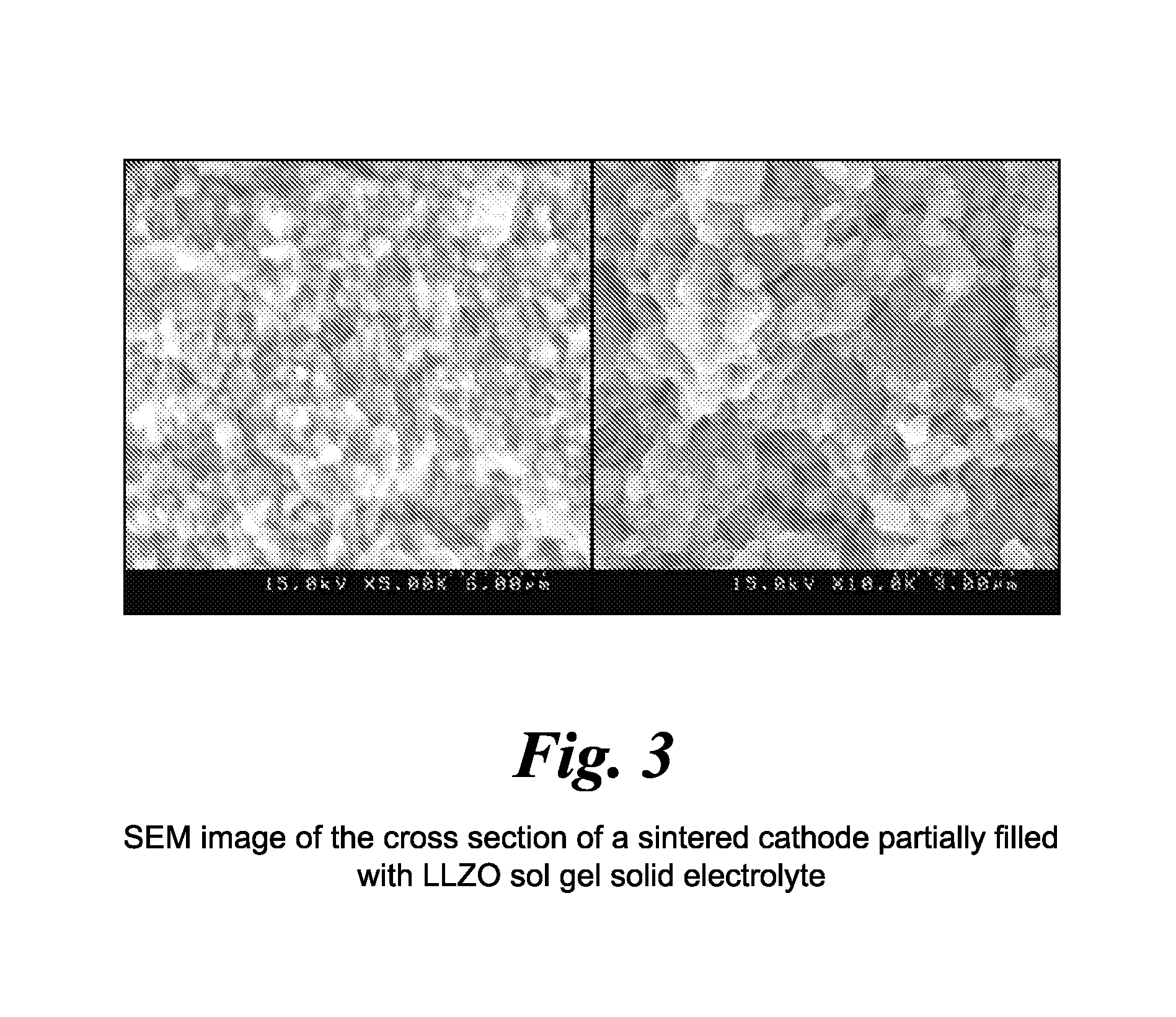

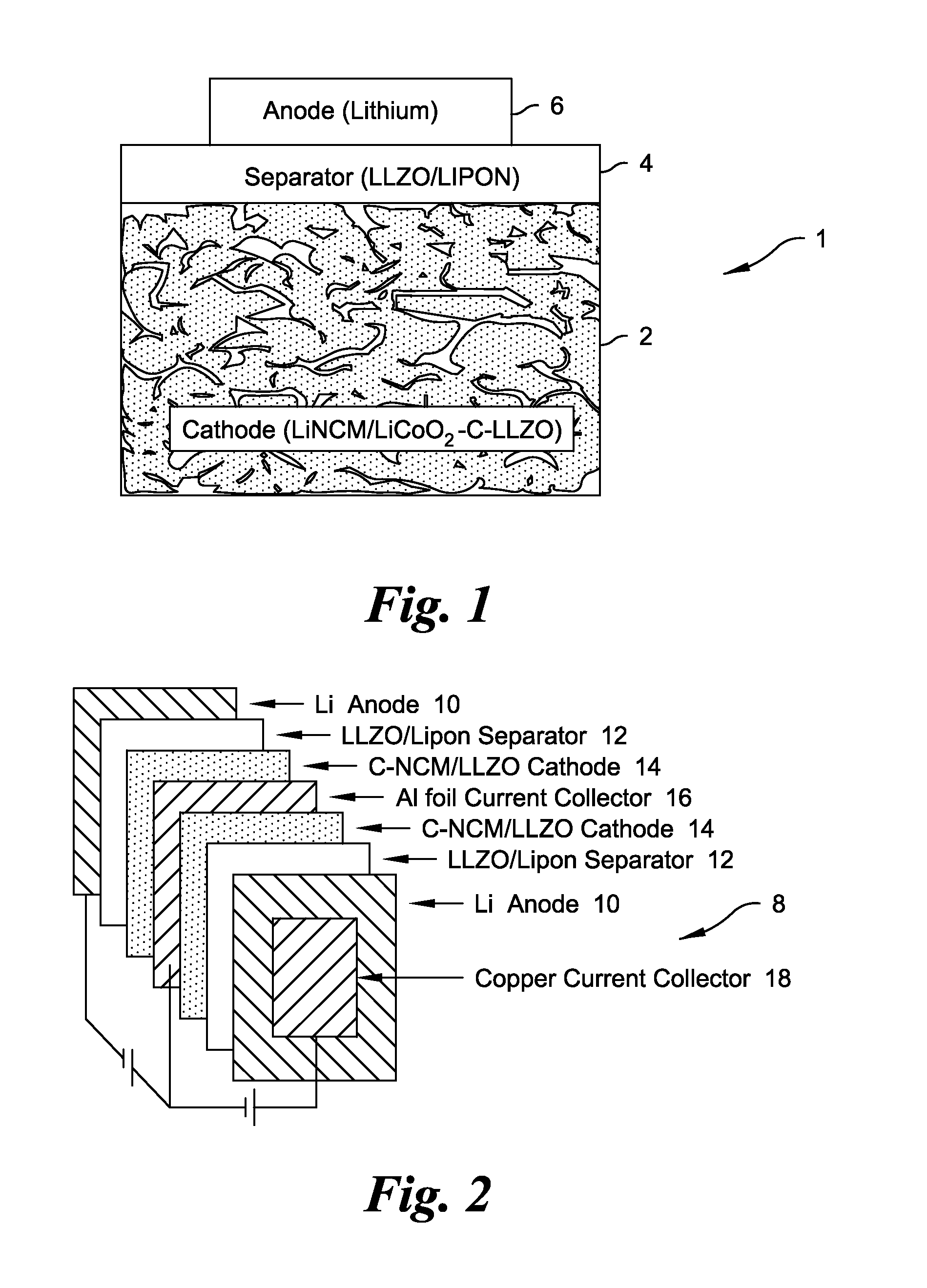

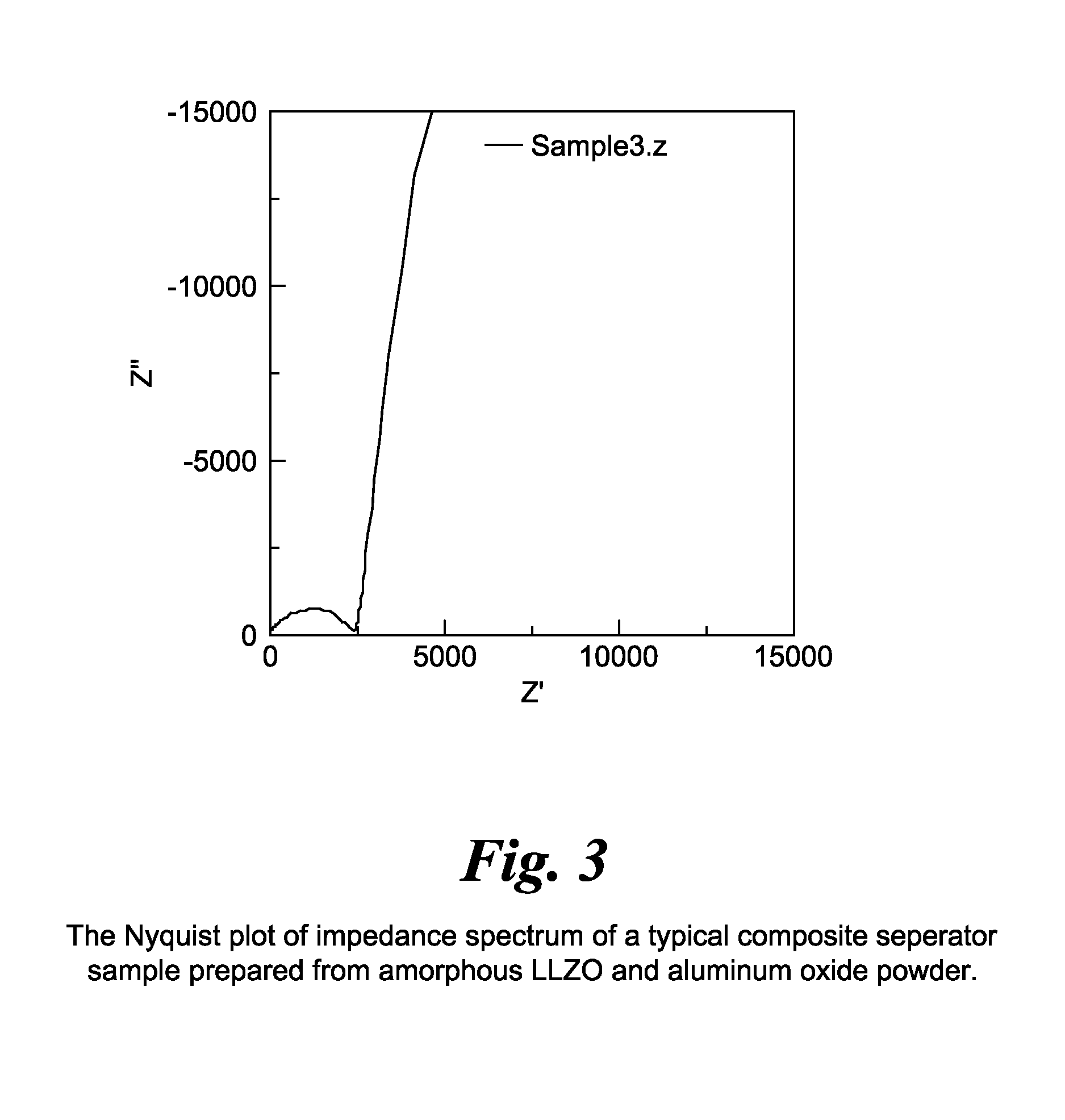

Impregnated sintered solid state composite electrode, solid state battery, and methods of preparation

InactiveUS20150056520A1Electrode thermal treatmentSolid electrolyte cellsComposite cathodeComposite electrode

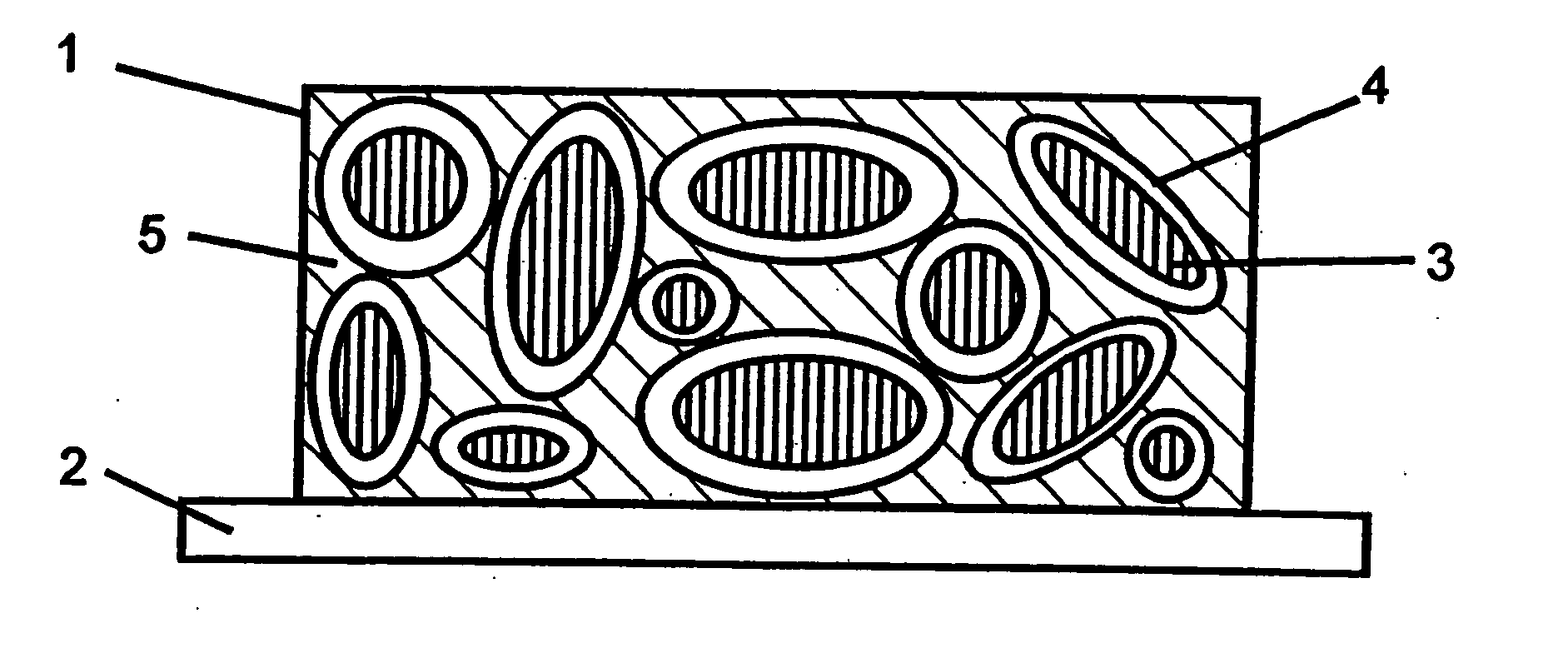

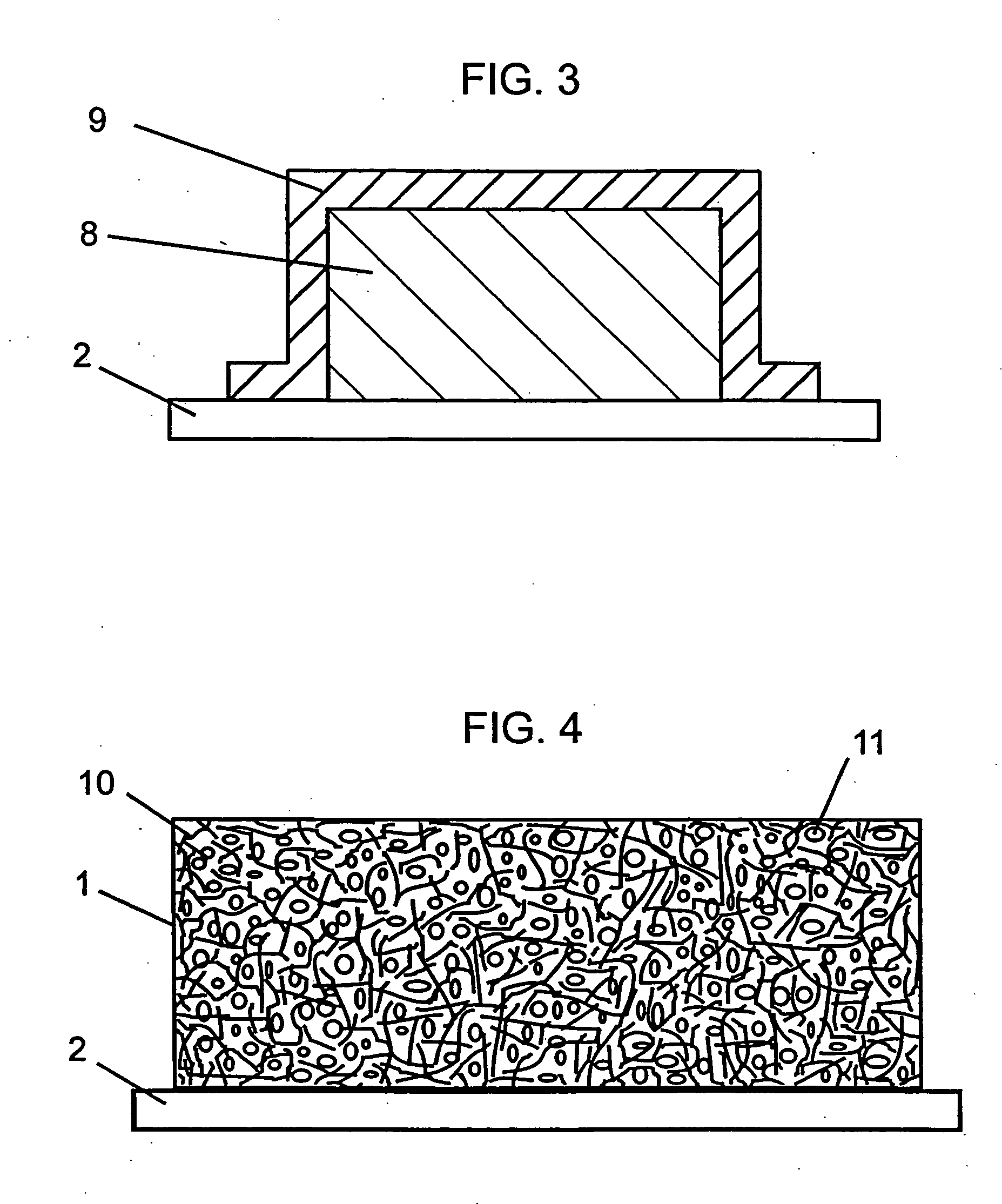

An impregnated solid state composite cathode is provided. The cathode contains a sintered porous active material, in which pores of the porous material are impregnated with an inorganic ionically conductive amorphous solid electrolyte. A method for producing the impregnated solid state composite cathode involves forming a pellet containing an active intercalation cathode material; sintering the pellet to form a sintered porous cathode pellet; impregnating pores of the sintered porous cathode pellet with a liquid precursor of an inorganic amorphous ionically conductive solid electrolyte; and curing the impregnated pellet to yield the composite cathode.

Owner:JOHNSON IP HLDG LLC

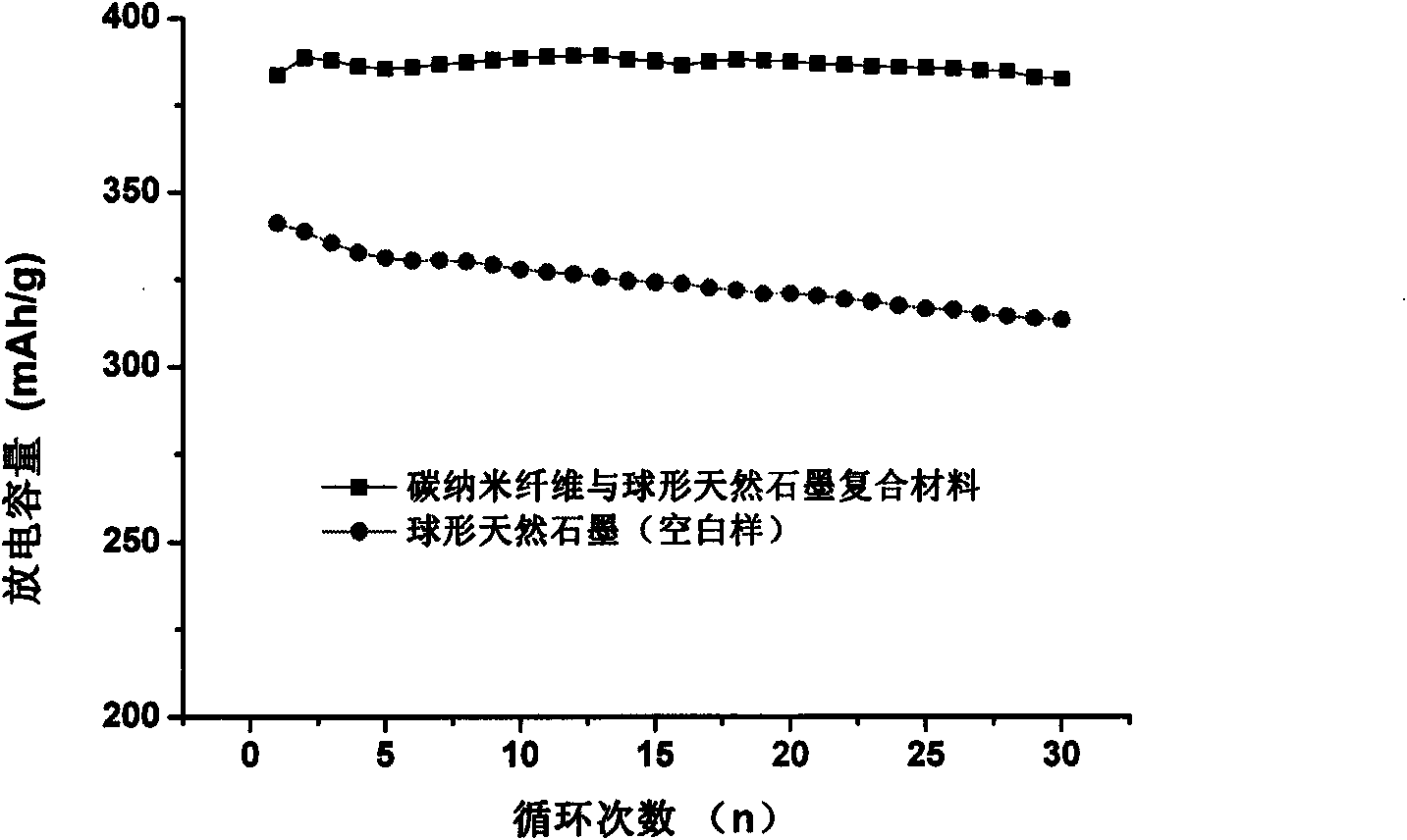

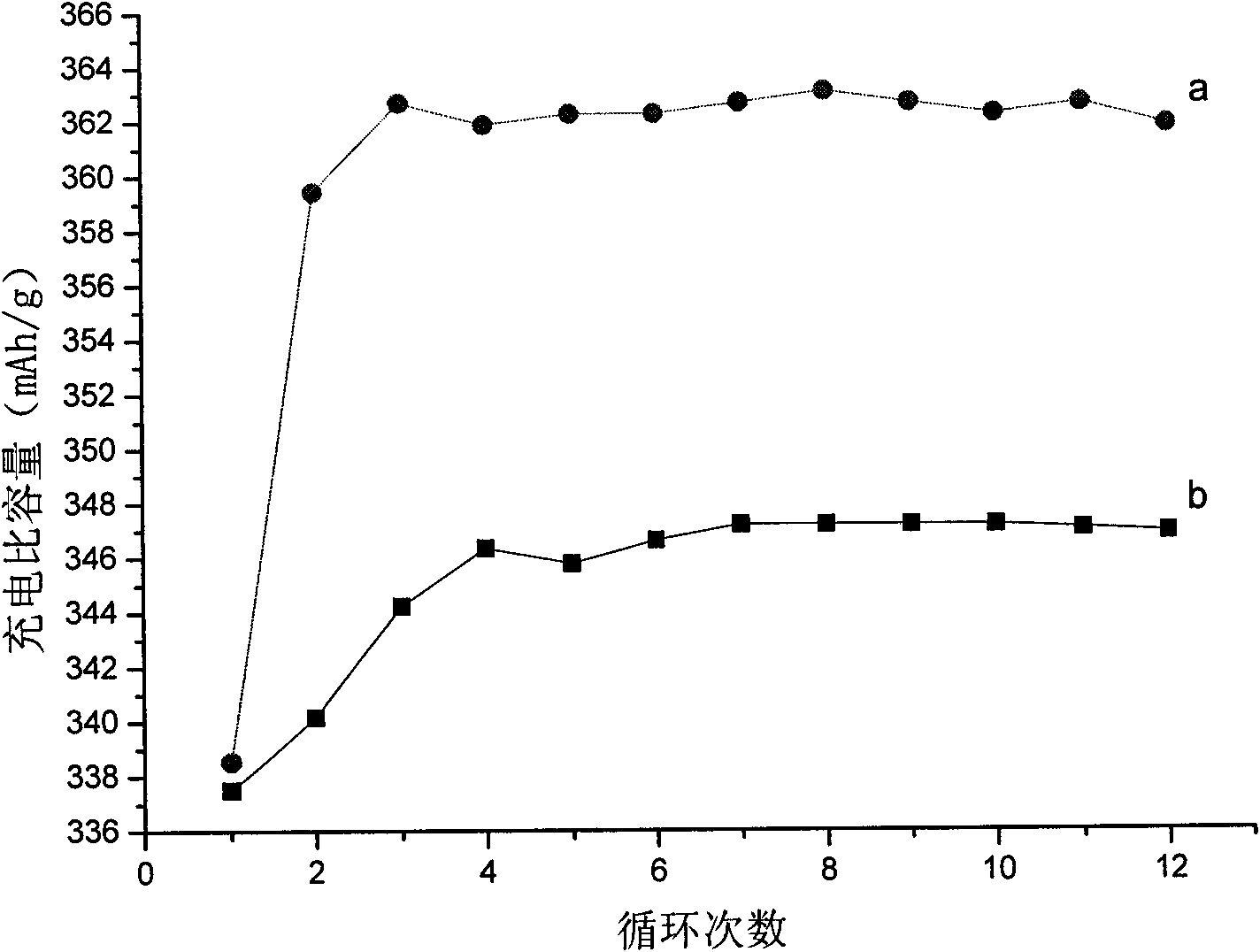

Lithium ion battery composite cathode material and preparation method

InactiveCN101604743APromote circulationImprove cycle performanceElectrode manufacturing processesActive material electrodesFuranEpoxy

The invention relates to a lithium ion battery composite cathode material and a preparation method. The cathode material comprises a hard carbon precursor material containing hetero atoms, and natural spherical graphite, wherein the hard carbon precursor material selects one or more than two of phenolic resin, polyfurfural, furan resin, polyvinyl alcohol, epoxide resin or polyacrylonitrile as raw materials, and accounts for 5 to 45 percent of the natural spherical graphite by mass; modifier of the hetero atoms is boron-containing modifier including boric acid and diboron trioxide, phosphor-containing modifier including phosphoric acid and phosphorus pentoxide, and nitrogen-containing modifier HNO3; and one of the modifiers accounts for 5 to 35 percent of the hard carbon precursor by mass. An analog battery formed by the cathode material which is prepared by the method has the capacity over 350 mAH / g and first coulomb efficiency up to 95.8 percent, and has good circulation performance. The preparation method has the advantages of low cost and simple process.

Owner:珠海华丽新能源科技有限公司

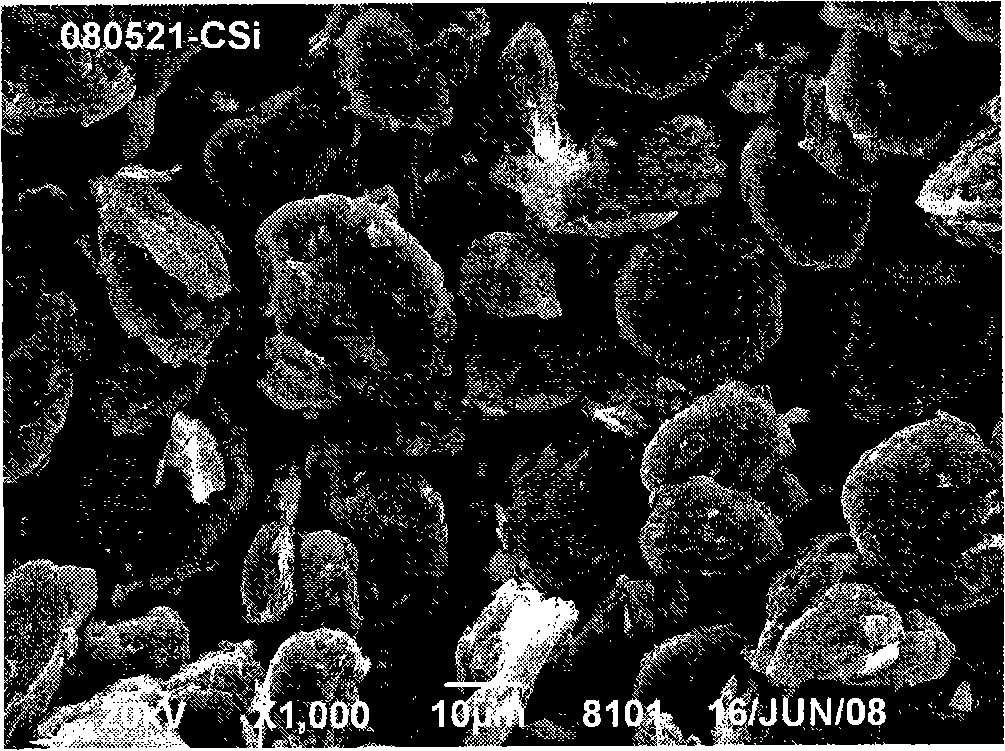

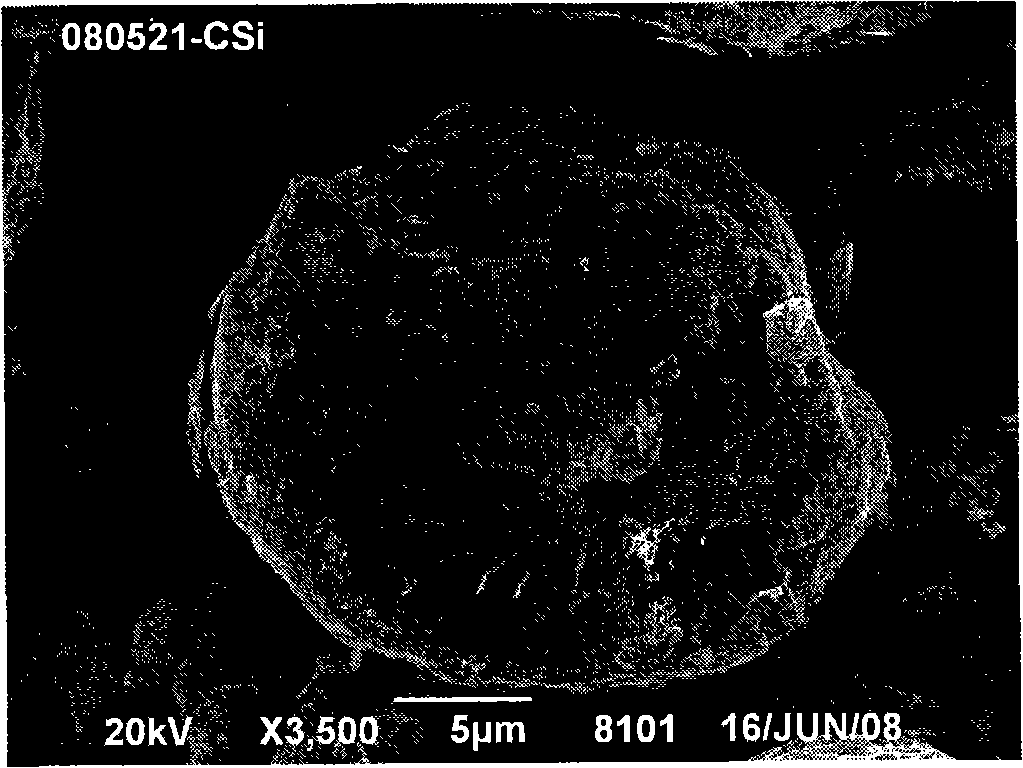

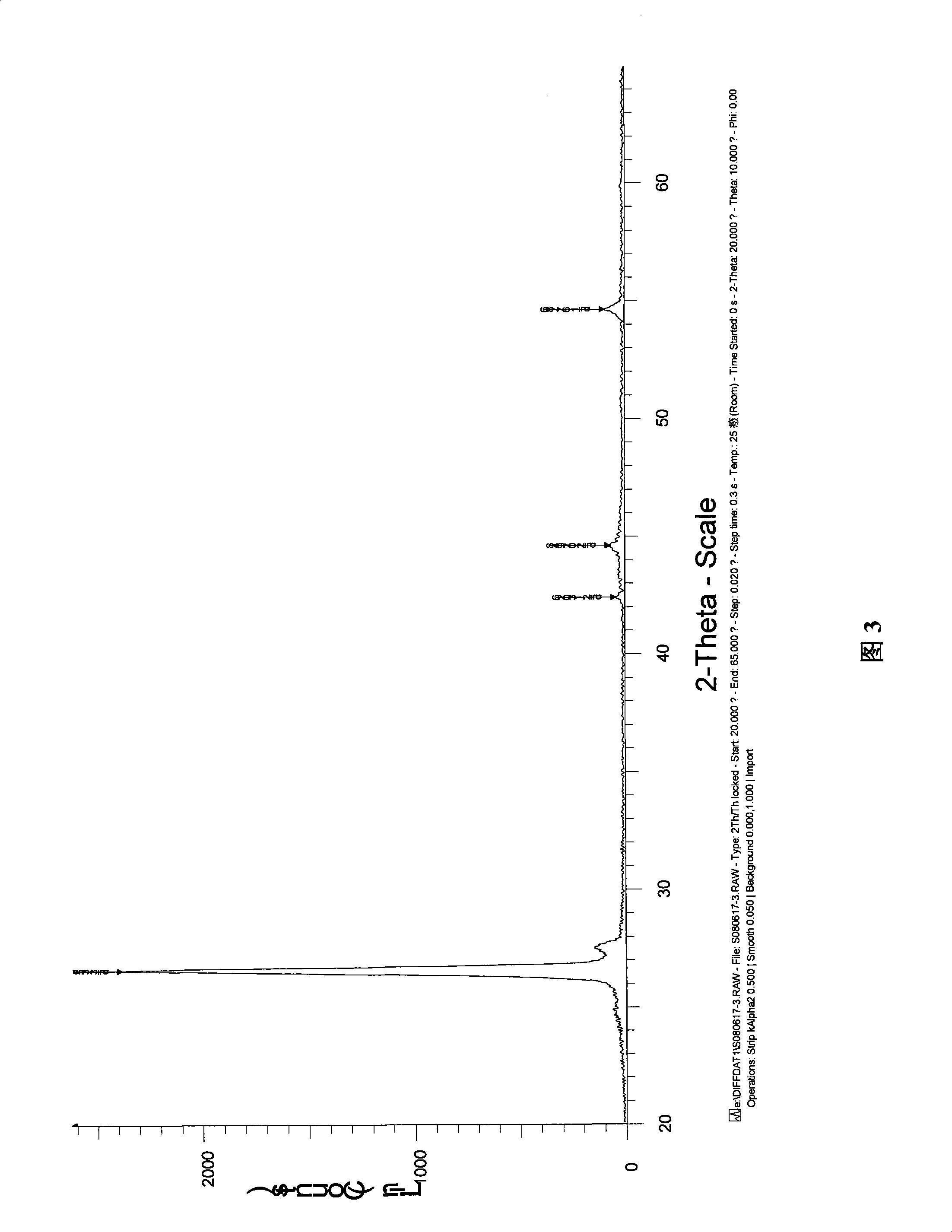

Silicon-carbon composite cathode material of lithium ion battery and preparation thereof

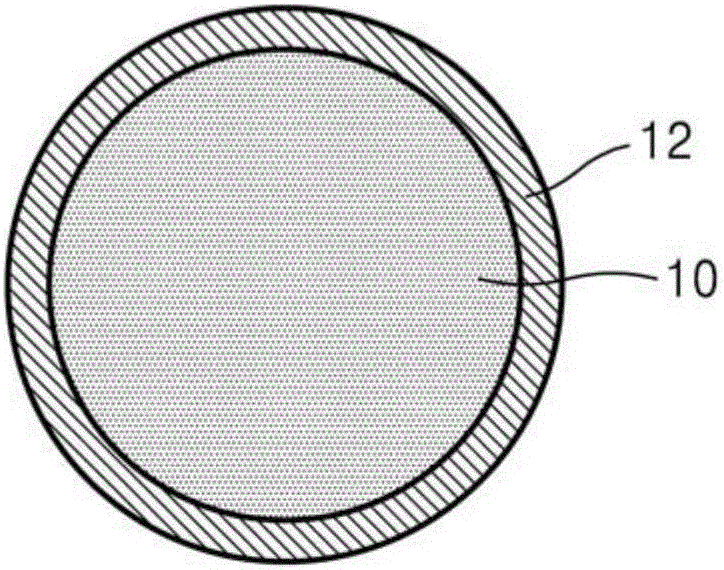

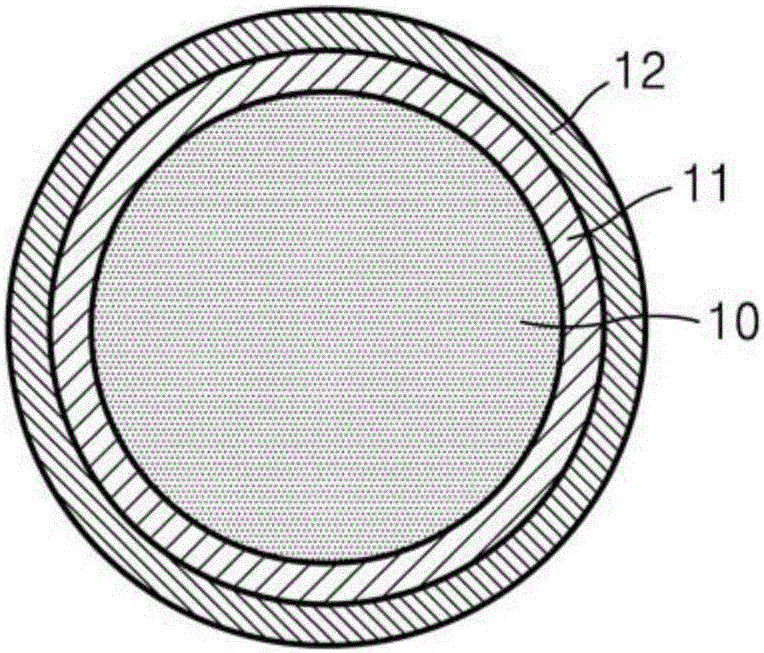

InactiveCN101339987AImprove battery energy densityImprove cycle performanceElectrode manufacturing processesChemical/physical/physico-chemical processesCarbon compositesCarbonization

The invention provides a silicon-carbon composite cathode material for preparing a lithium-ion battery at the room temperature and a preparation method thereof. The composite cathode material is a material with a nuclear shell structure and comprises the following proportional elements: 0.01-10% of simple substance silicon and 90-99.9% of carbon. With regard to the preparation method, silicon powder and graphite are mixed for ball grinding and then added with bitumen or polymer cladding material for ball grinding again, after the treatment of carbonization, the mixture is crushed and sieved to obtain the material containing 0.01-10wt% of silicon and 10-99.9% of carbon. The capacity of the material is more than 350mAh / g, the cycle efficiency of the material is larger than 90% for the first time, and keeps larger than 80% after 200 cycles, and the material has good charging and discharging property.

Owner:湖南海容新材料有限责任公司

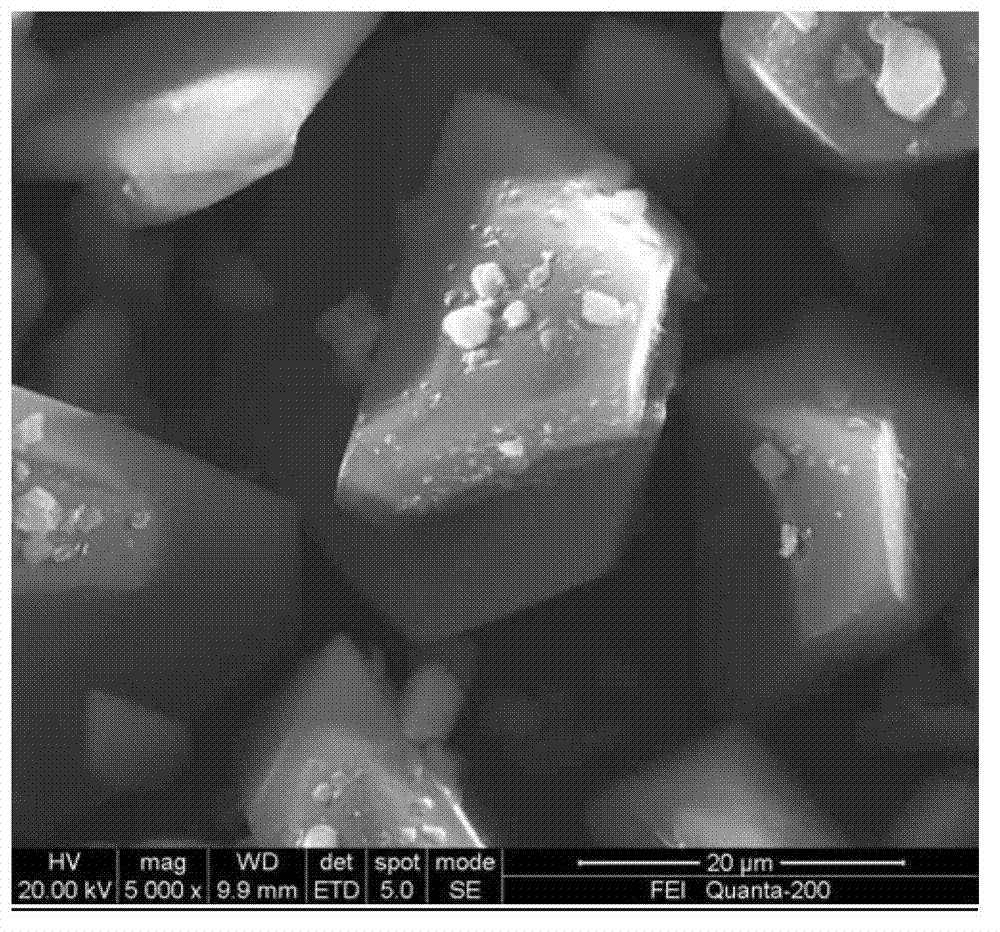

Spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with core-shell structure and preparation method thereof

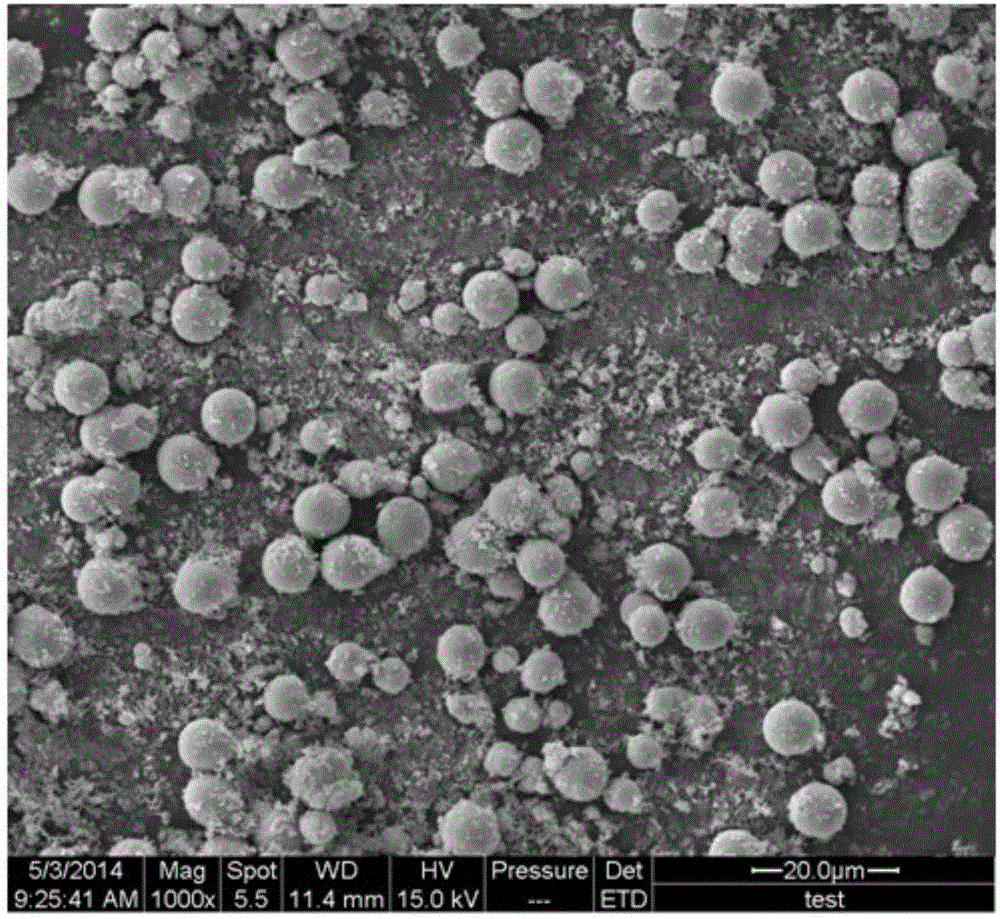

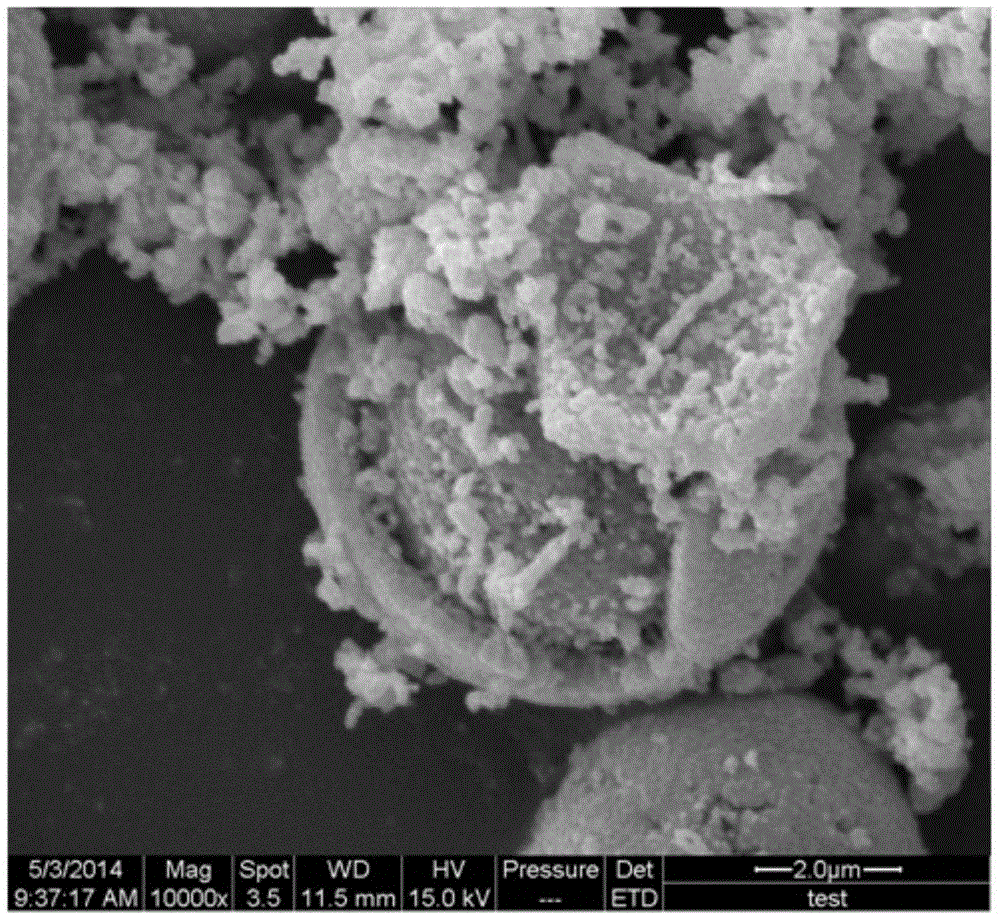

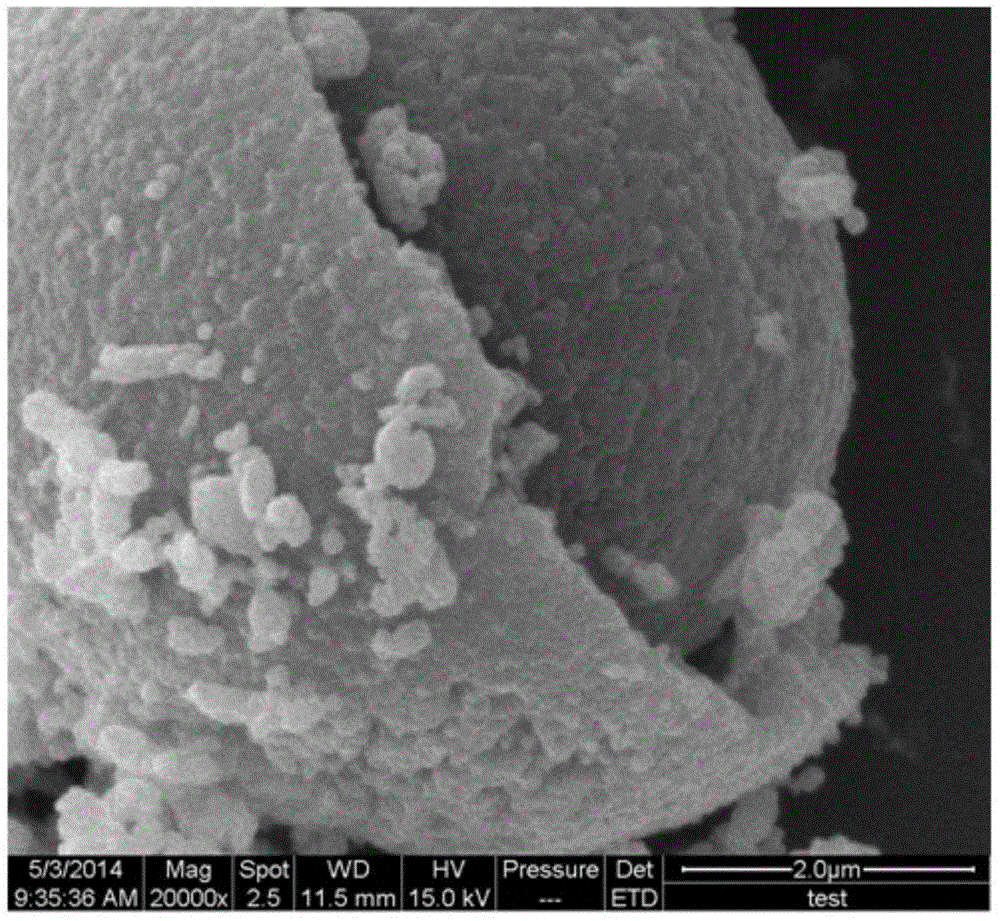

ActiveCN104157831APromote circulationRaise the ratioCell electrodesSecondary cellsComposite cathodeMaterial synthesis

The invention relates to a spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with a core-shell structure and a preparation method thereof, which belongs to the technical field of material synthesis. The prepared lithium ion composite cathode material takes a layered lithium-rich manganese-based Li[Lia(NixCoyMnz)]O2 as a core material, takes spinel nickel manganese acid lithium LiNi0.5Mn1.5O4 as a shell material; a coprecipitation method is employed to obtain a core-shell precursor, the core-shell precursor and the lithium source are uniformly mixed and calcined to obtain the spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with the core-shell structure. According to the invention, the layered lithium-rich manganese-based is taken as the core material, and the spinel nickel manganese acid lithium is taken as the shell material; under the prerequisite that material gram capacity is kept, material structural stability is increased, material cycle, multiplying power and safety performances are improved, function composite and complementation of the core material and the shell layer material can be realized, and the problem that high capacity and high security can not be achieved simultaneously is solved. The composite cathode material has the advantages of simple process and obviously increased performance.

Owner:南京时拓能源科技有限公司

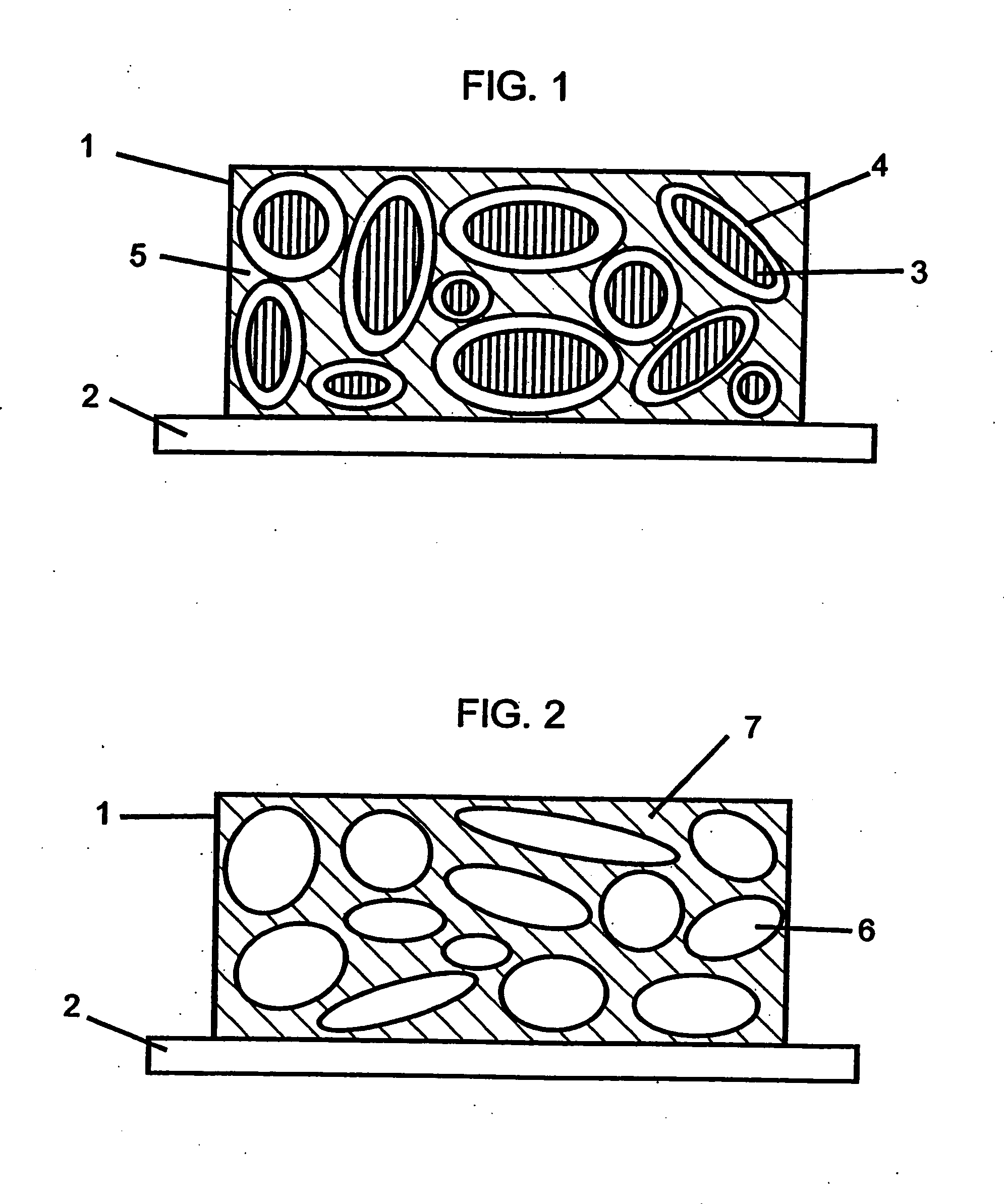

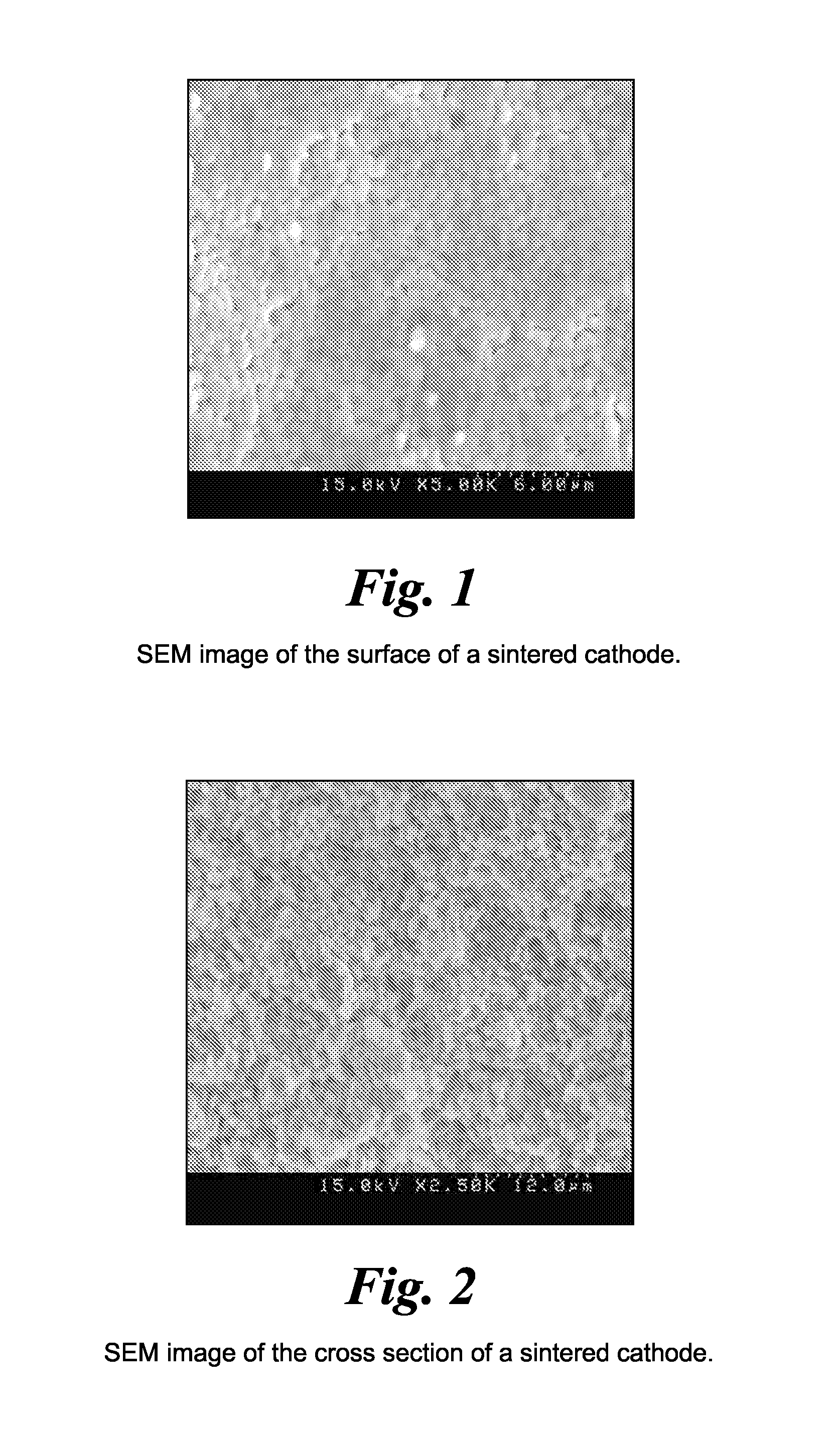

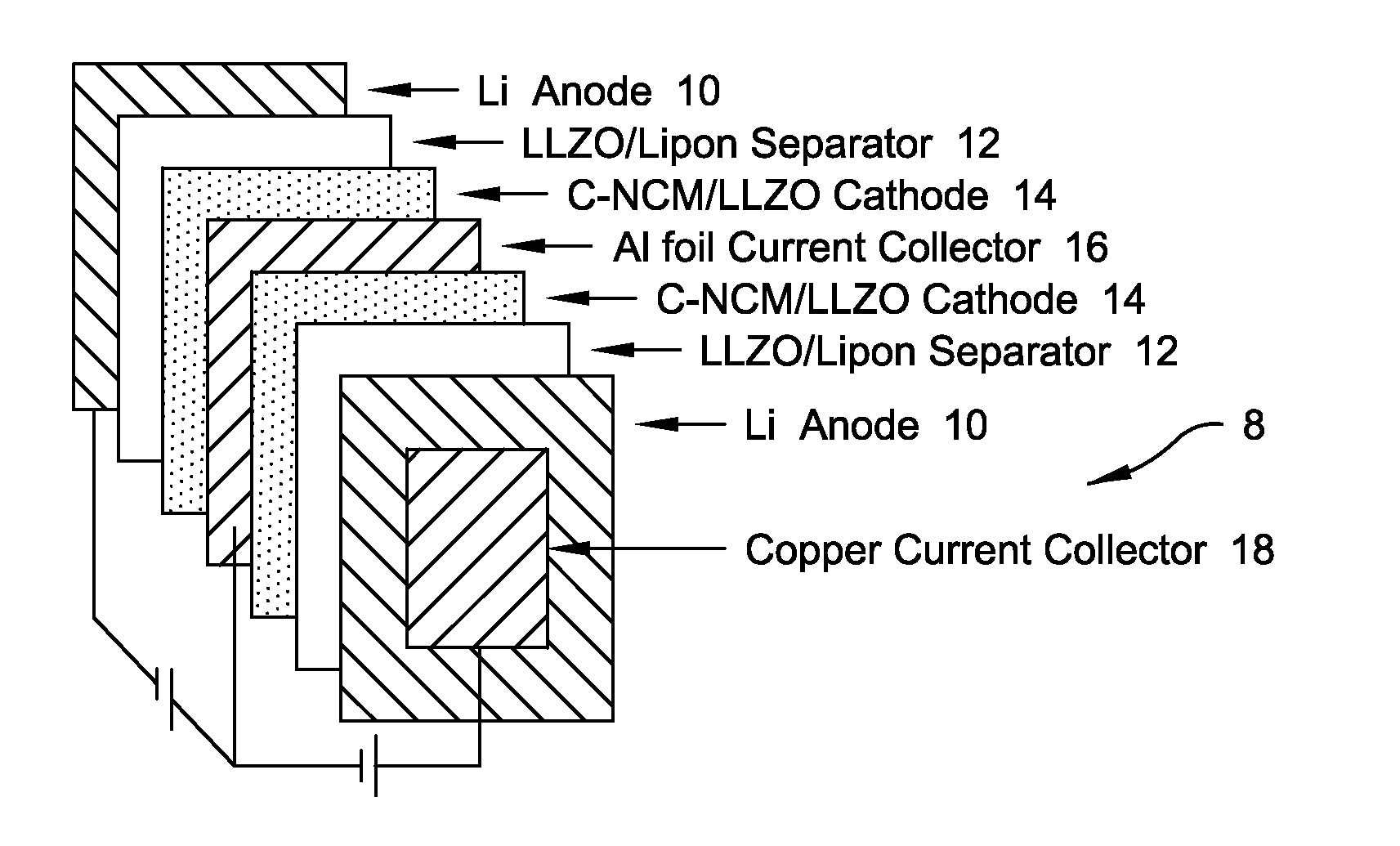

High capacity solid state composite cathode, solid state composite separator, solid-state rechargeable lithium battery and methods of making same

ActiveUS20150333307A1Large capacityLow costElectrode rolling/calenderingElectrode thermal treatmentComposite cathodeLanthanum

A high capacity solid state composite cathode contains an active cathode material dispersed in an amorphous inorganic ionically conductive metal oxide, such as lithium lanthanum zirconium oxide and / or lithium carbon lanthanum zirconium oxide. A solid state composite separator contains an electronically insulating inorganic powder dispersed in an amorphous, inorganic, ionically conductive metal oxide. Methods for preparing the composite cathode and composite separator are provided.

Owner:JOHNSON IP HLDG LLC

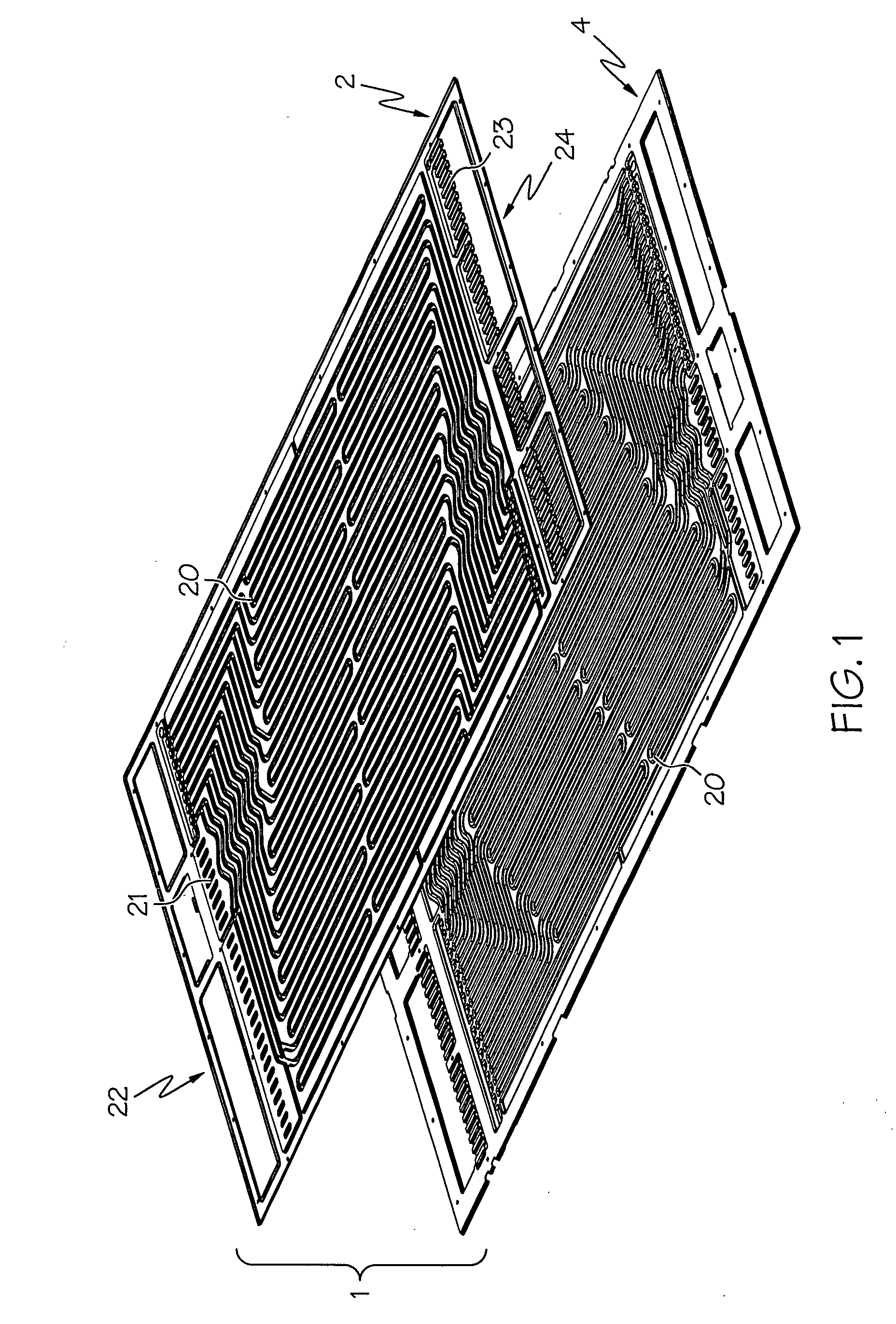

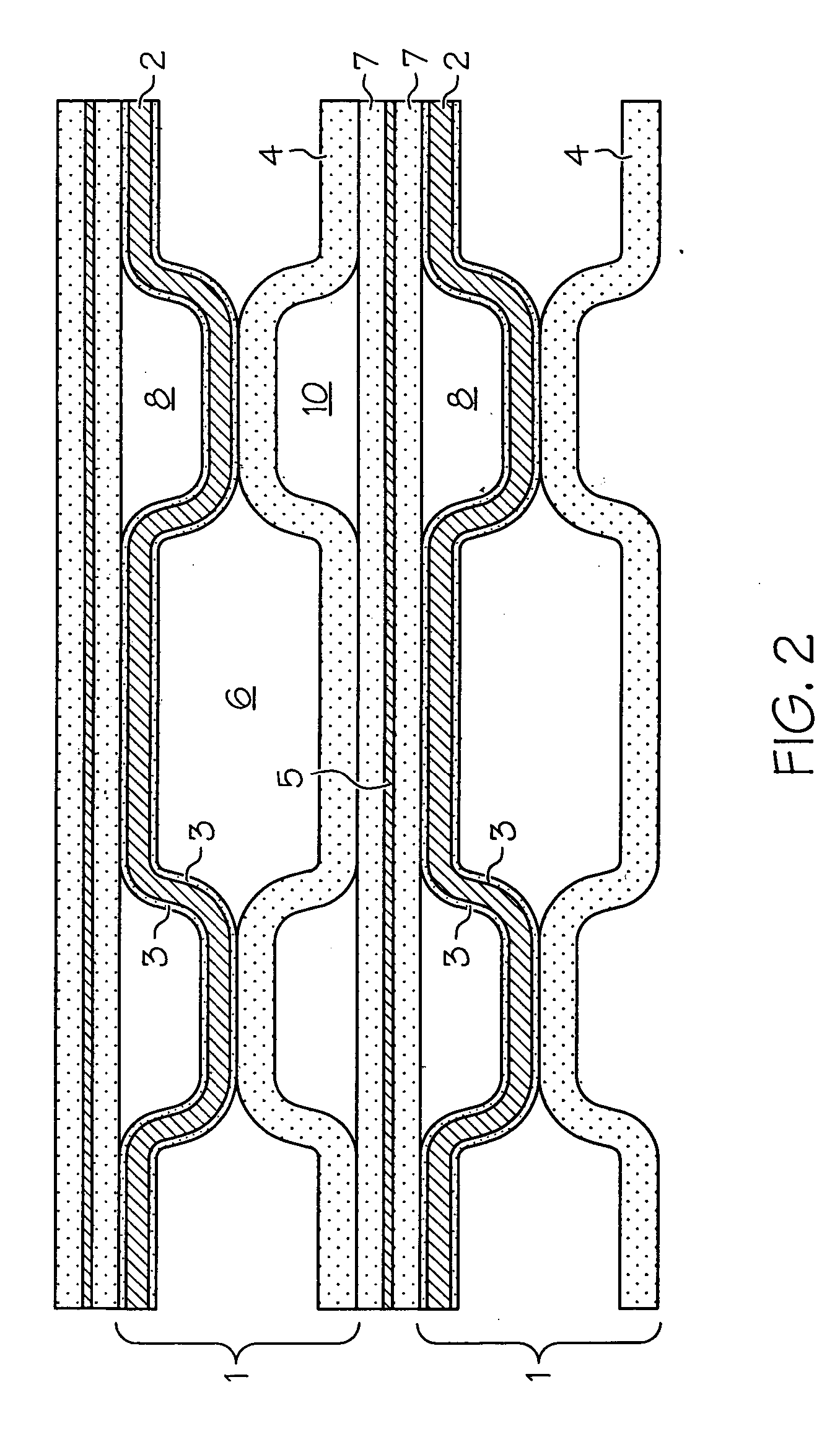

Hybrid bipolar plate assembly and devices incorporating same

InactiveUS20050244700A1Enhances performance and efficiency and durabilityEliminates hydrogen permeationElectrode carriers/collectorsCell component detailsFuel cellsComposite cathode

A hybrid bipolar plate assembly comprises a metallic anode plate, a polymeric composite cathode plate, and a metal layer positioned between the metallic anode plate and the composite cathode plate. The metallic anode and composite cathode plates can further comprise an adhesive sealant applied around the outer perimeter to prevent leaking of coolant. The assembly can be incorporated into a device comprising a fuel cell. Further, the device can define structure defining a vehicle powered by the fuel cell.

Owner:GM GLOBAL TECH OPERATIONS LLC

Silicon-carbon composite cathode material with three-dimensional preformed hole structure and preparation method thereof

ActiveCN102623680ALow tap densityReduce volume specific capacityCell electrodesCarbon compositesCarbonization

The invention discloses a silicon-carbon composite cathode material with a three-dimensional preformed hole structure and a preparation method thereof. According to the composite cathode material, a carbon material having high electric conductivity and a stable structure is used as a matrix for dispersedly containing high-volume silicon particles, and proper three-dimensional expansion spaces are reserved around one or several silicon particles. The preparation method comprises the following steps of: carrying out surface modification on the silicon particles; coating the silicon particles by silicon dioxide; coating the silicon dioxide / silicon composite particles by carbon source precursors; carrying out high-temperature carbonization treatment; and removing a silicon dioxide template, and the like. When the composite material prepared by the preparation method is used for a lithium ion battery, the reversible specific capacity is high, and the cycle performance is excellent. The silicon-carbon composite cathode material has the advantages of simple preparation process and wide raw material resource and is suitable for industrial production.

Owner:湖南宸宇富基新能源科技有限公司

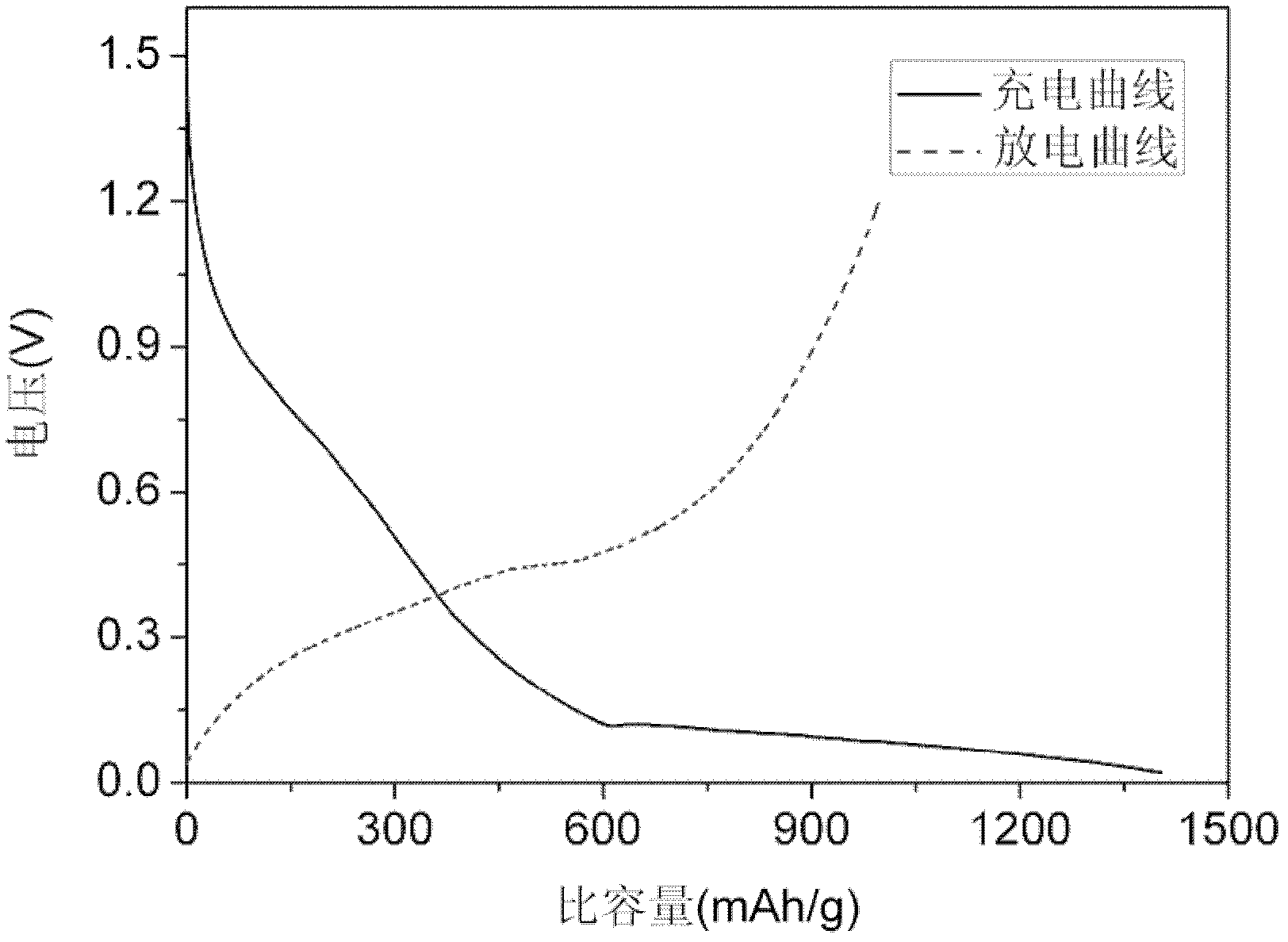

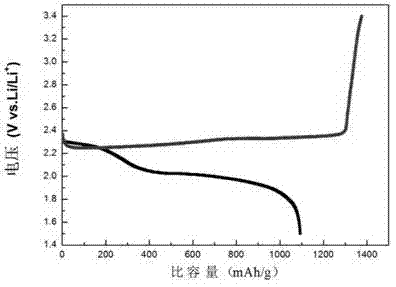

Carbon nano tube-containing sulfur-based composite cathode material and preparation method thereof

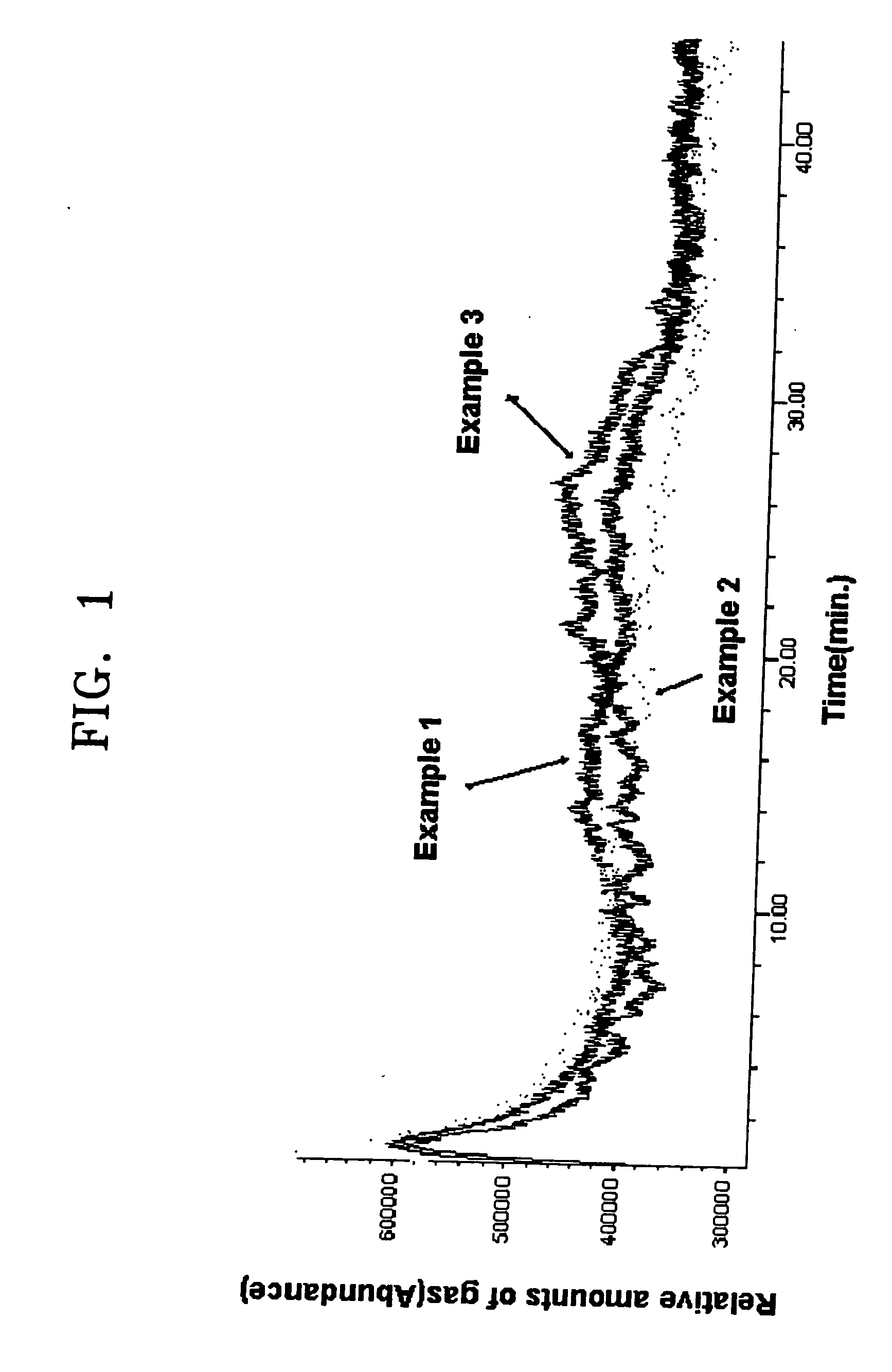

ActiveCN101891930AIncrease contentImprove power characteristicsNon-aqueous electrolyte accumulator electrodesIn situ polymerizationAcrylonitrile

The invention discloses a carbon nano tube-containing sulfur-based composite cathode material and a preparation method thereof. The sulfur-based composite cathode material is a ternary composite material AxByCz, wherein A is a dehydrocyclization product of an acrylonitrile-itaconic acid copolymer; B is elemental sulfur; C is a carbon nano tube; x is more than or equal to 30 weight percent and less than or equal to 60 weight percent; y is more than or equal to 30 weight percent and less than or equal to 60 weight percent; and z is more than or equal to 1 weight percent and less than or equal to 20 weight percent. The preparation method comprises the following steps of: in-situ polymerizing an acrylonitrile-itaconic acid monomer on the surface of the multi-wall carbon nano tube, and performing thermal treatment on both of the acrylonitrile-itaconic acid copolymer and the elemental sulfur, so that the sulfur is uniformly dispersed in a substrate formed by the dehydrocyclization of the acrylonitrile-itaconic acid copolymer. The carbon nano tube-containing sulfur-based composite cathode material and a lithium cathode form a secondary lithium-sulfur battery which is charged and discharged at the room temperature. The carbon nano tube-containing sulfur-based composite cathode material has the reversible specific capacity of 697 mAh / g and high cyclical stability.

Owner:SHANGHAI JIAO TONG UNIV

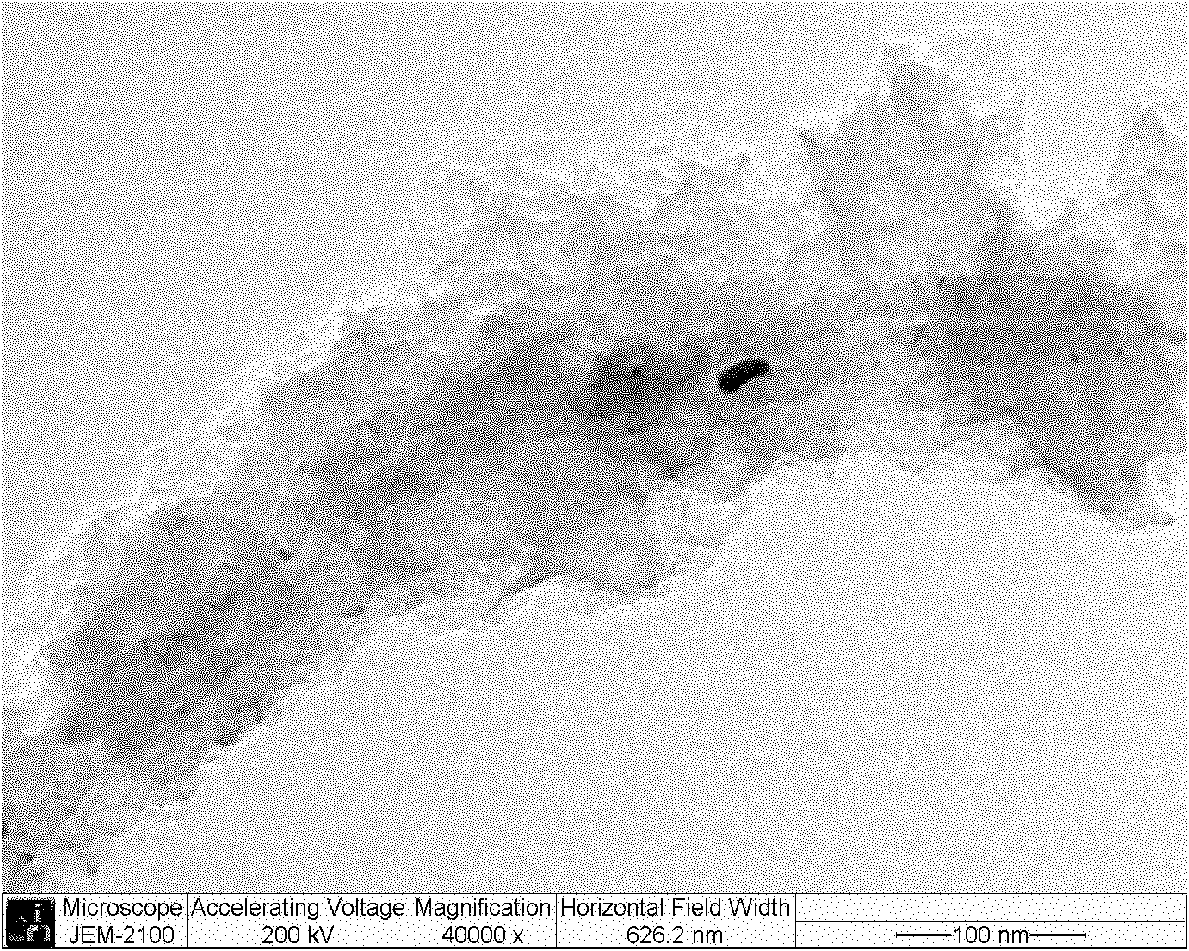

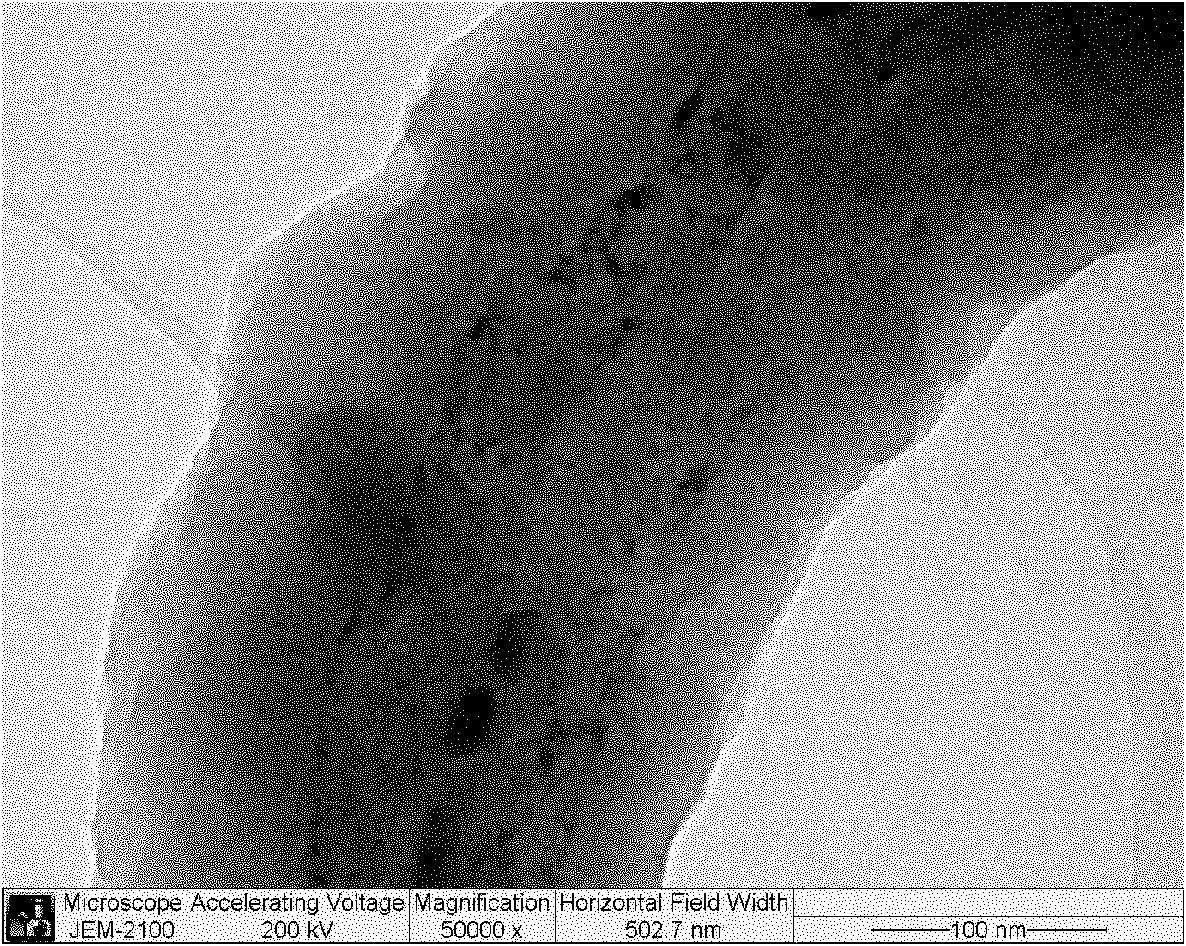

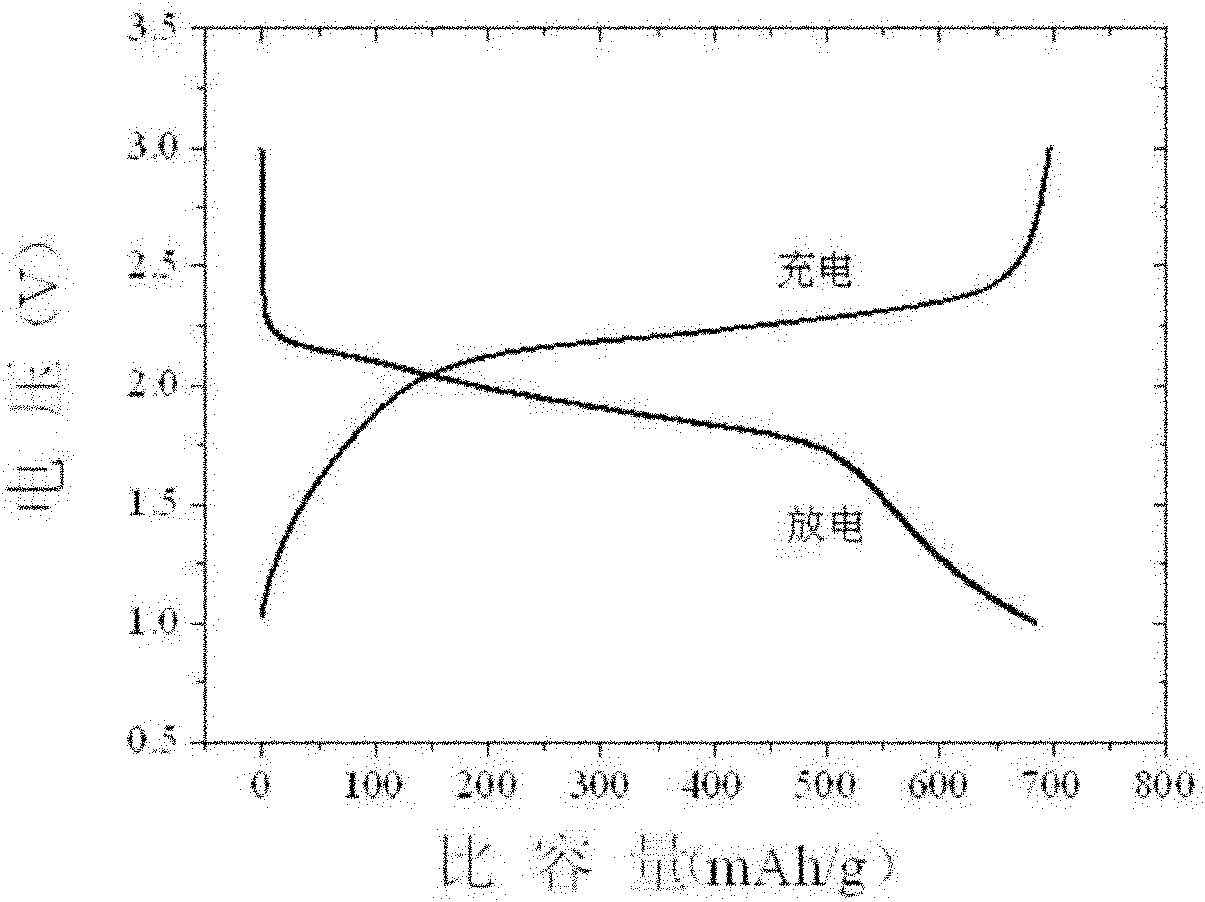

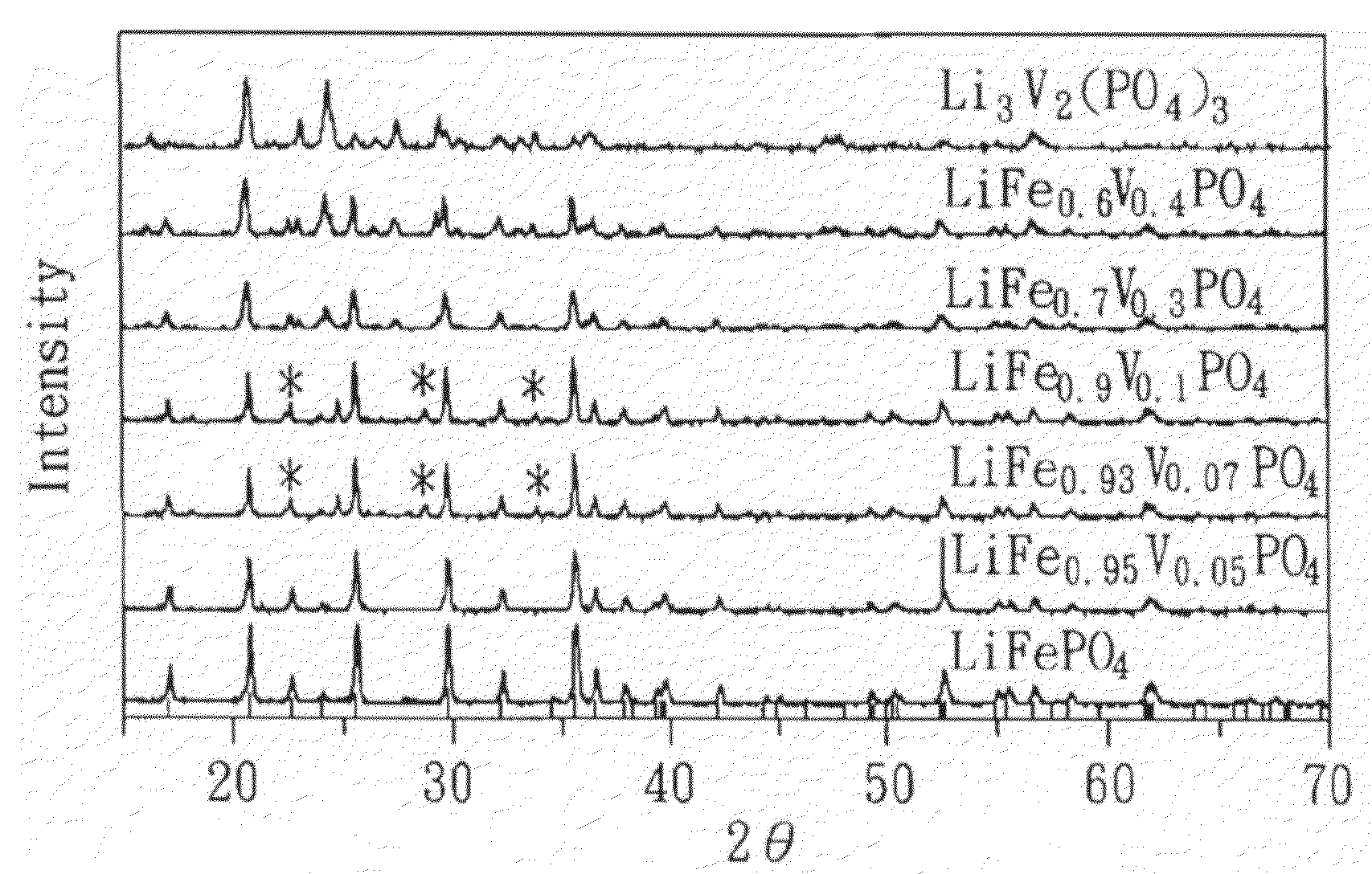

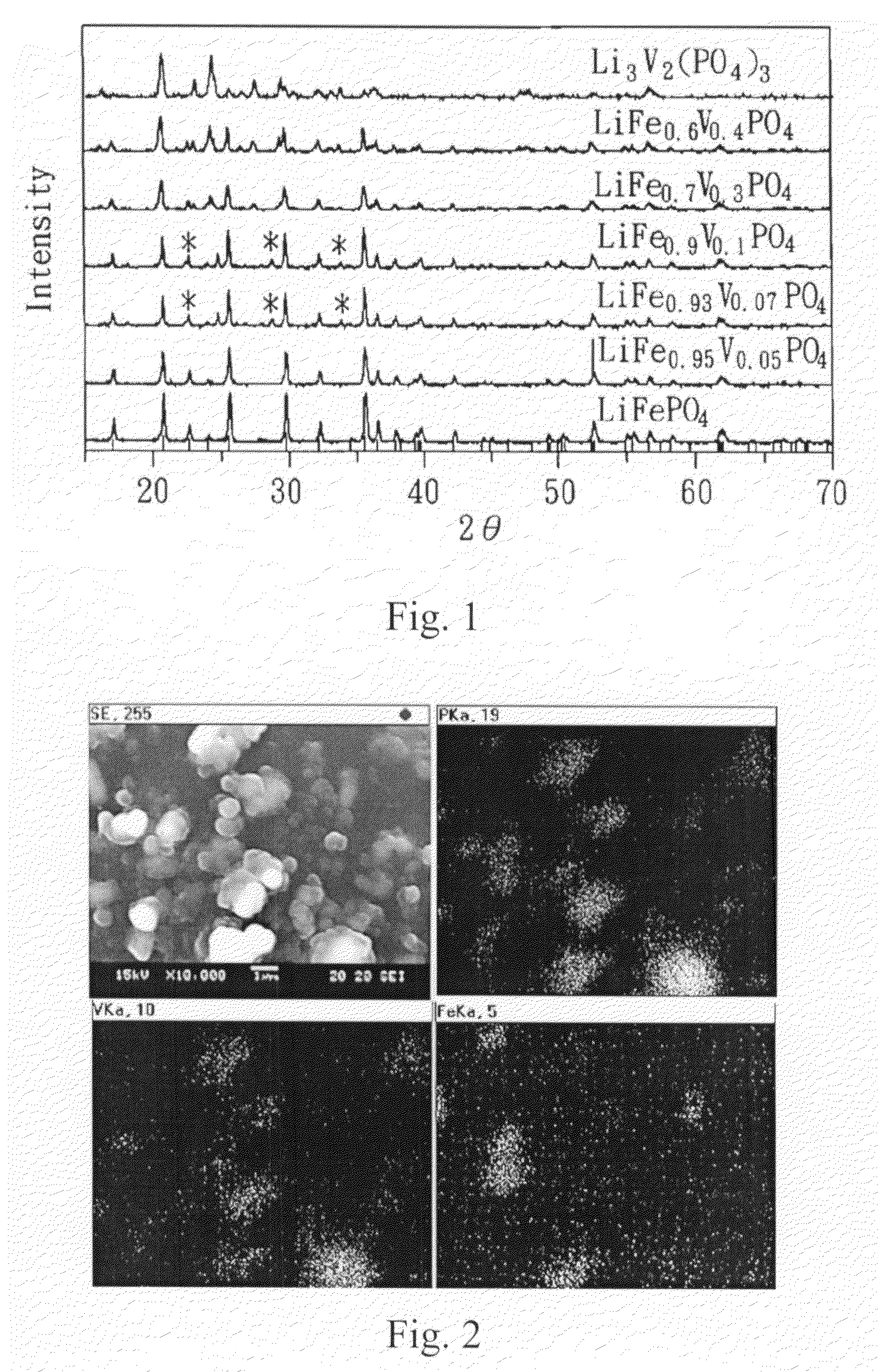

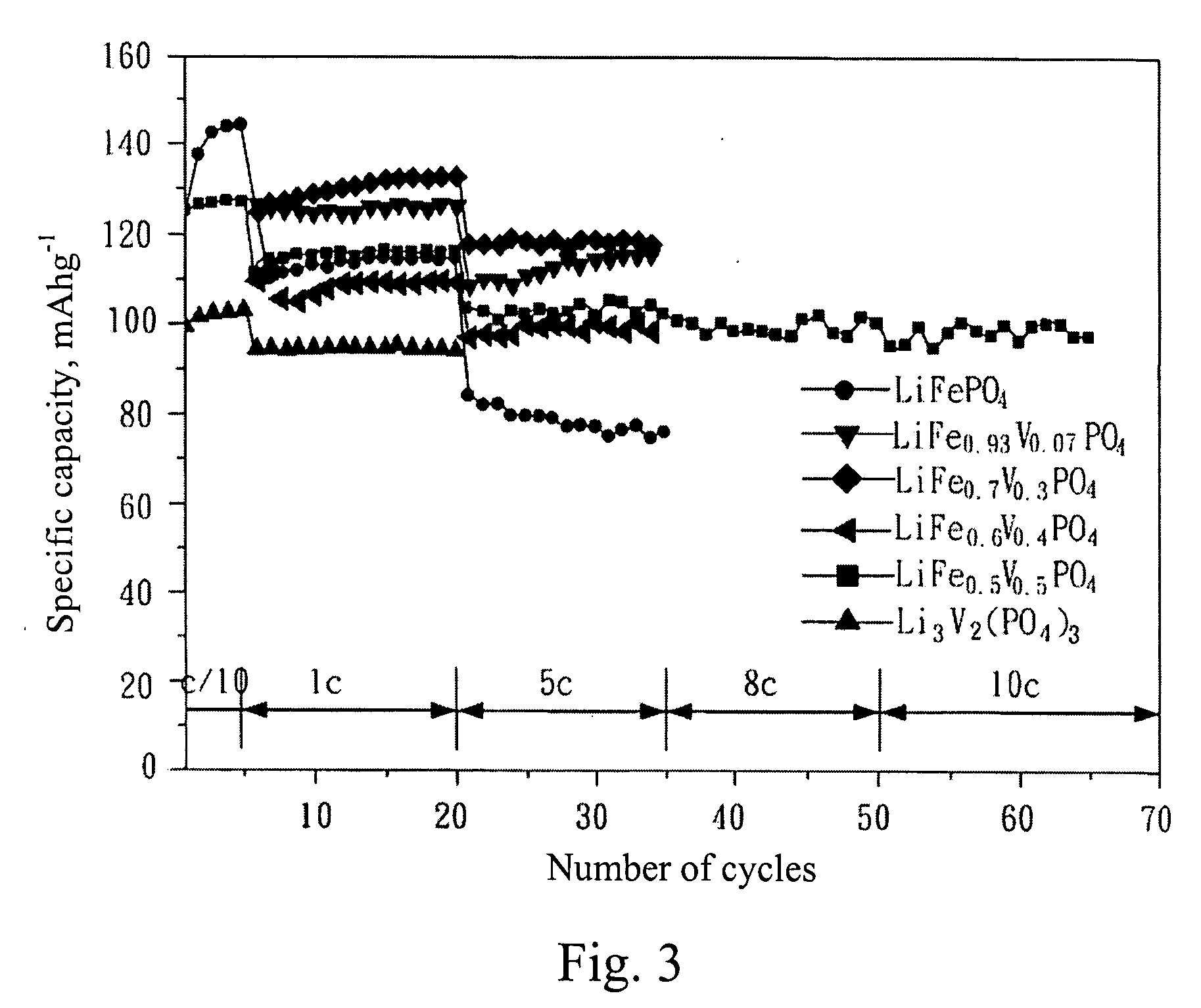

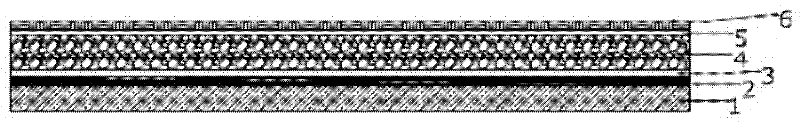

Preparation and application of LiFePO4/Li3V2 (PO4)3 composite cathode materials for lithium ion batteries

InactiveUS20080008938A1Improve conductivityCathode material of highElectrode manufacturing processesDuplicating/marking methodsComposite cathodeIron powder

A method of preparing LiFePO4 / Li3V2(PO4)3 composite cathode materials and their applications as cathode materials for lithium ion batteries are disclosed. The preparation method includes the following steps: (A) providing a mixture of iron powder, lithium salt, vanadium salt, and a phosphate salt whereafter these compounds are dissolved into a mixed acid solution; (B) drying the solution in order to obtain precursor powders; and (C) heating the precursor powders at a temperature ranging between 400 and 1000° C. to form LiFe1-y′Vy′PO4 / Li3V2-y″Fey″(PO4)3 composite powders. Alternatively, prepare the composite cathode by preparing olivine LiFe1-y′Vy′PO4 and monoclinic Li3V2-y′Fey″(PO4)3 powders as in previous procedures followed by mixing adequately. The low cost of iron powder thus facilitates to prepared composite cathode materials exhibiting higher electrical conductivity and superior cycling performance at high C rates than those of olivine LiFe1-y′Vy′PO4 and monoclinic Li3V2-y″Fey″(PO4)3. The invention will help the development of the lithium ion batteries and related industries.

Owner:TATUNG COMPANY

High-capacity metal lithium powder composite cathode and preparation method thereof, and multi-layer composite electrode

InactiveCN102201565AHigher quality than capacityQuality improvementNon-aqueous electrolyte accumulator electrodesAdhesiveTin

The invention discloses a high-capacity metal lithium powder composite cathode and a preparation method thereof and a multi-layer composite electrode. The high-capacity metal lithium powder composite cathode comprises the following components in part by weight: 1 to 80 parts of metal lithium powder, 10 to 90 parts of cathode powder, 1 to 10 parts of conductive agent, 1 to 4.5 parts of adhesive and 0 to 0.5 part of surfactant. By compounding the metal lithium powder with materials such as graphite, soft carbon, hard carbon, tin and oxides thereof, silicon and oxides thereof and the like, mass ratio capacity and volume ratio capacity of a cathode material are improved, using amount of active substances is reduced, and the battery specific capacity is improved; the specific capacity of the cathode can be adjusted by adjusting the rate of metal lithium to the graphite; short circuit in a battery caused by piercing of a diaphragm through metal dendritic crystal growth can be effectively prevented through the separation of an insulating protective layer, so that the safety performance of the battery is improved; and the metal lithium powder is counteracted with irreversible capacity loss of the cathode, and primary Kulun efficiencies of the graphite, the hard carbon, the soft carbon, the tin, the silicon and other cathode materials are improved.

Owner:EC POWER LLC

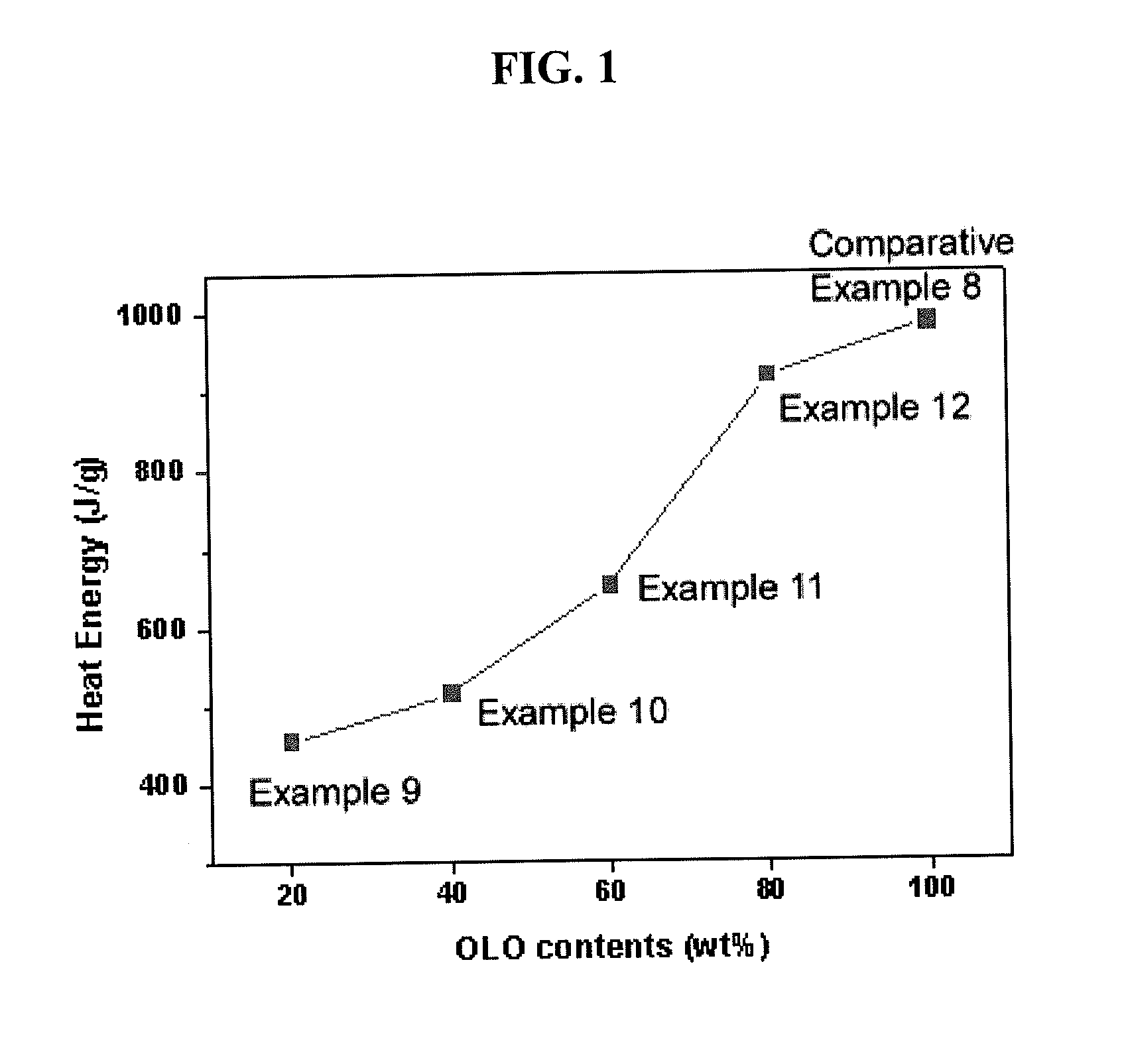

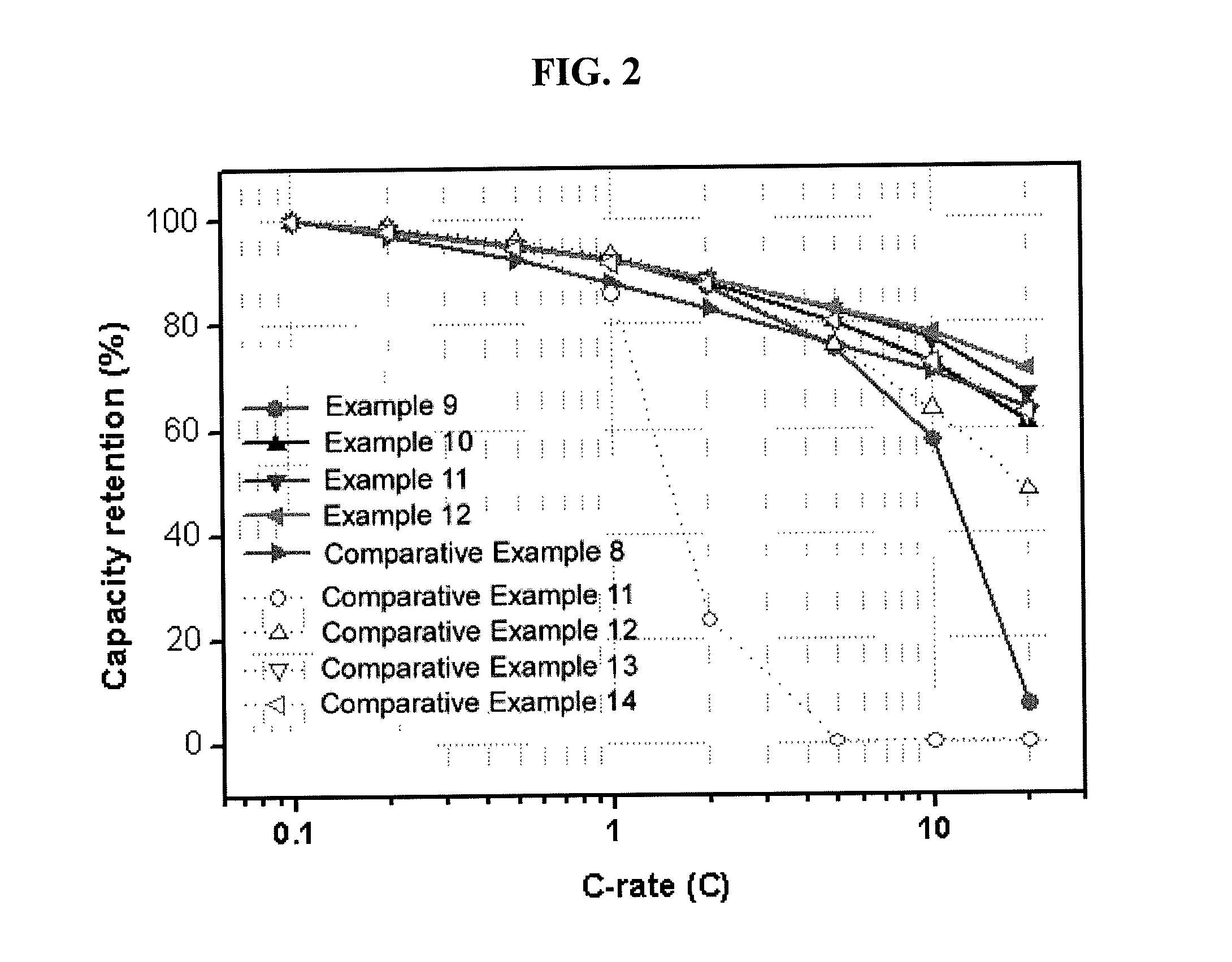

Anode active material with whole particle concentration gradient for lithium secondary battery, method for preparing same, and lithium secondary battery having same

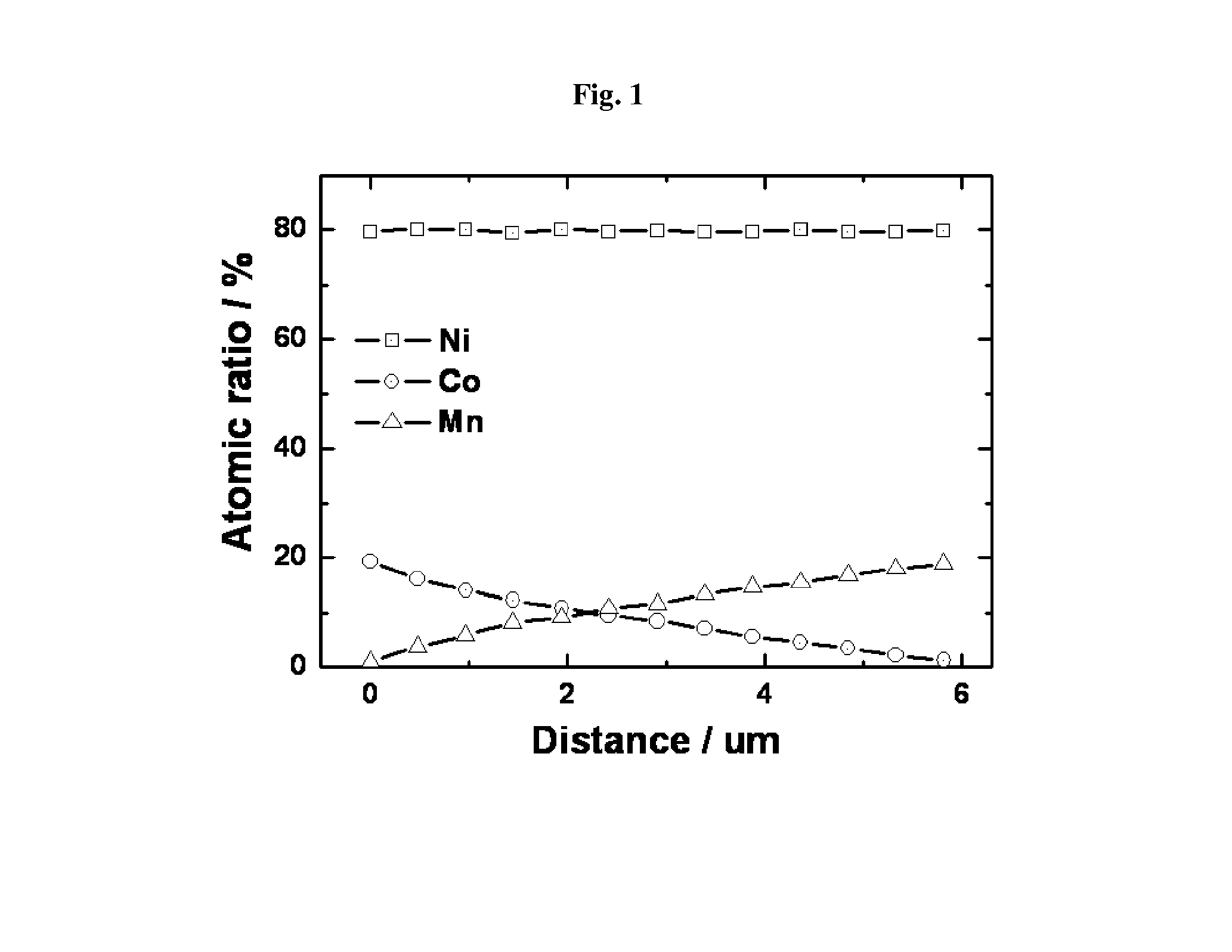

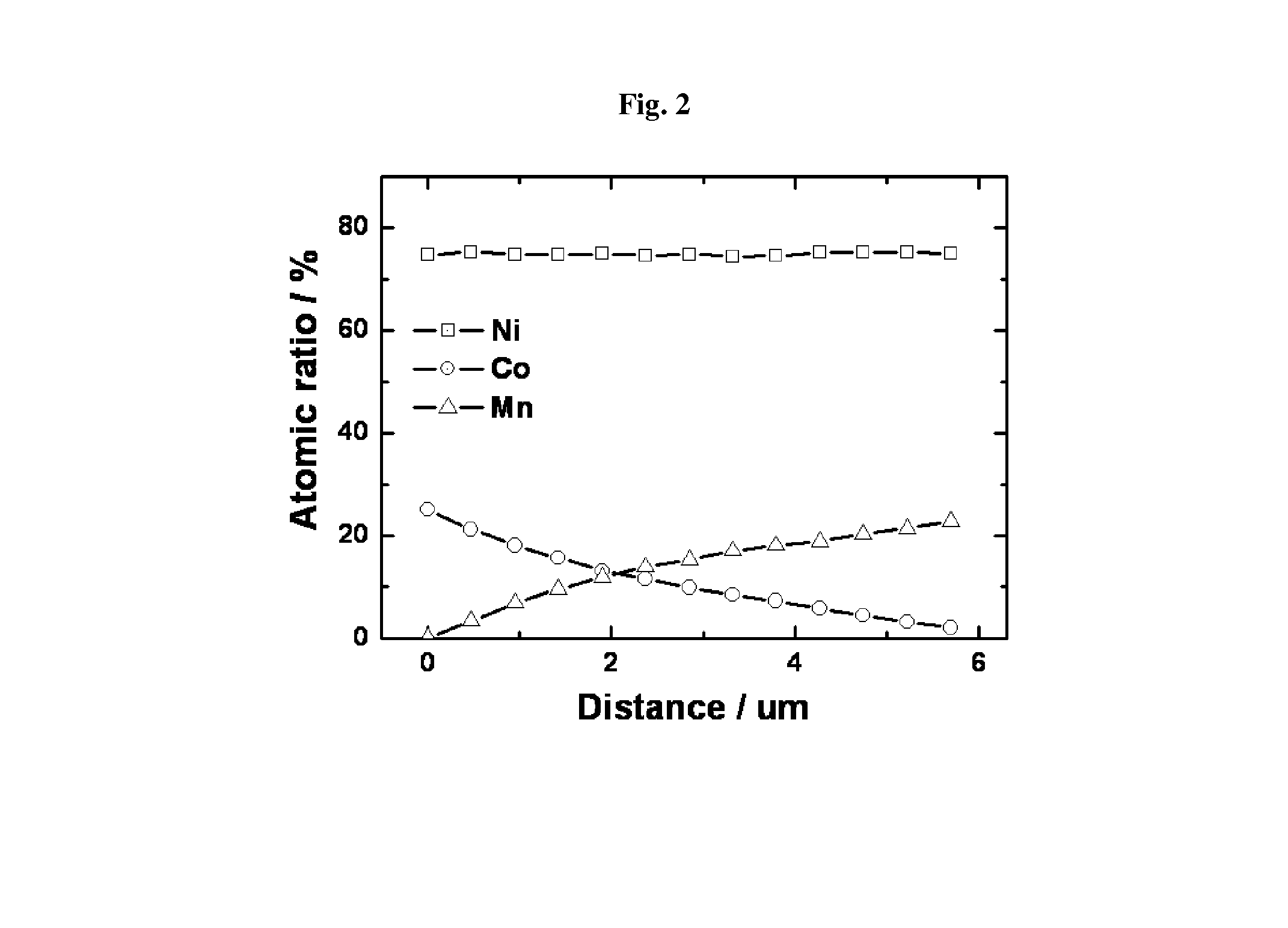

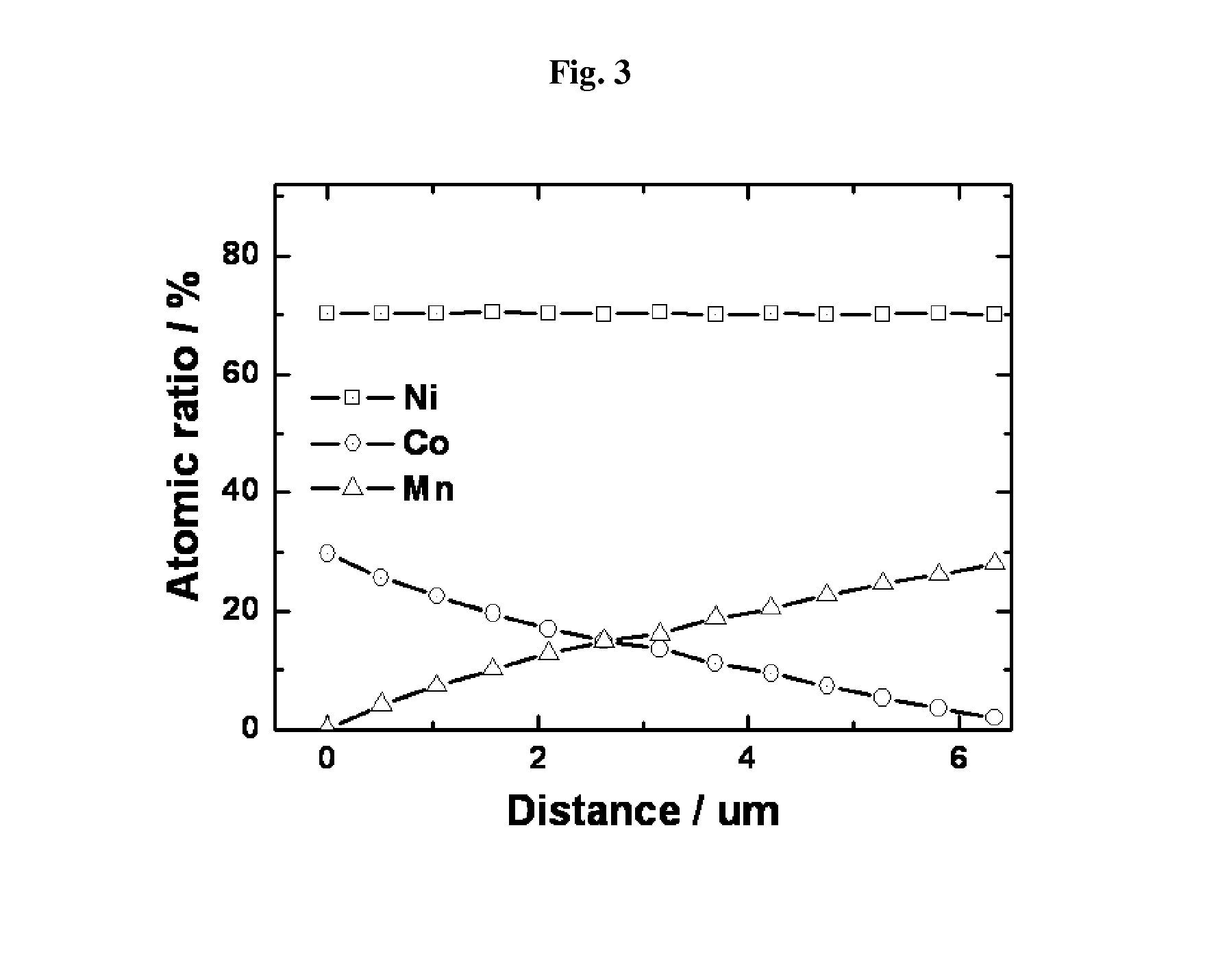

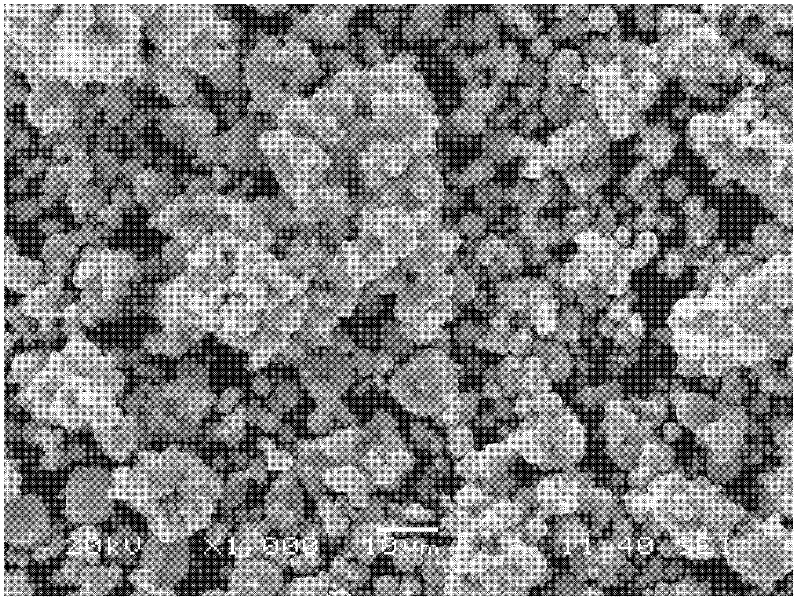

ActiveUS20140027670A1Improve thermal stabilityExcellent capacity characteristicsFinal product manufacturePositive electrodesComposite cathodeCrystal structure

The present invention relates to a cathode active material with whole particle concentration gradient for a lithium secondary battery, a method for preparing same, and a lithium secondary battery having same, and more specifically, to a composite cathode active material, a method for manufacturing same, and a lithium secondary battery having same, the composite cathode active material having excellent lifetime characteristics and charge / discharge characteristics through the stabilization of crystal structure as the concentration of a metal comprising the cathode active material shows concentration gradient in the whole particle, and having thermostability even in high temperatures.

Owner:LG CHEM LTD

Lithium ion battery phosphatic composite cathode material and preparation method thereof

ActiveCN102244263AEasy to processImprove electrochemical performanceCell electrodesMicro structurePhosphoric acid

The invention discloses a lithium ion battery phosphatic composite cathode material and a preparation method thereof. The composite material is a multinuclear core shell structure composed of a plurality of cores and a housing layer, the cores are lithium iron phosphate particles wrapped by lithium vanadium phosphate and the housing layer is amorphous carbon. Preparation of the lithium iron phosphate particles wrapped by lithium vanadium phosphate comprises the following steps: preparing precursor sol with a sol gel method, adding lithium iron phosphate powder to disperse uniformly, carrying out spray drying on the above mixture, calcining the above resultant in inert gas, and followed by cooling and grinding to obtain the lithium iron phosphate particles wrapped by lithium vanadium phosphate. Preparation of the composite cathode material comprises the following steps: dissolving a carbon source compound into deionized water, adding core materials, dispersing the above resultant uniformly, carrying out second spray drying, calcining the above resultant in inert gas, and followed by cooling to obtain the composite cathode material. The composite material prepared in the invention has good electronic conduction performance, good ionic conduction performance and excellent electrochemistry performance. Because of existence of lithium vanadium phosphate, energetic density of a material is raised. Because of the multinuclear core shell structure like nano / micro structures, the composite material has good processing performance, and tap density of the material is greatly raised.

Owner:CENT SOUTH UNIV

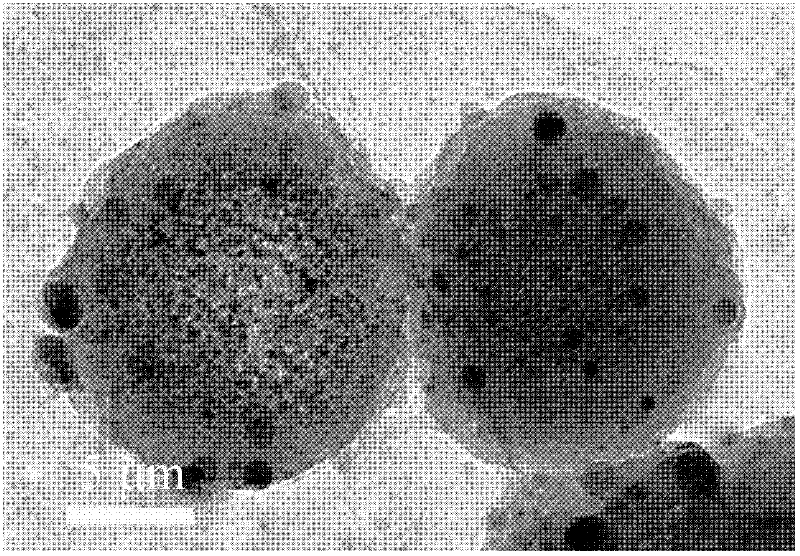

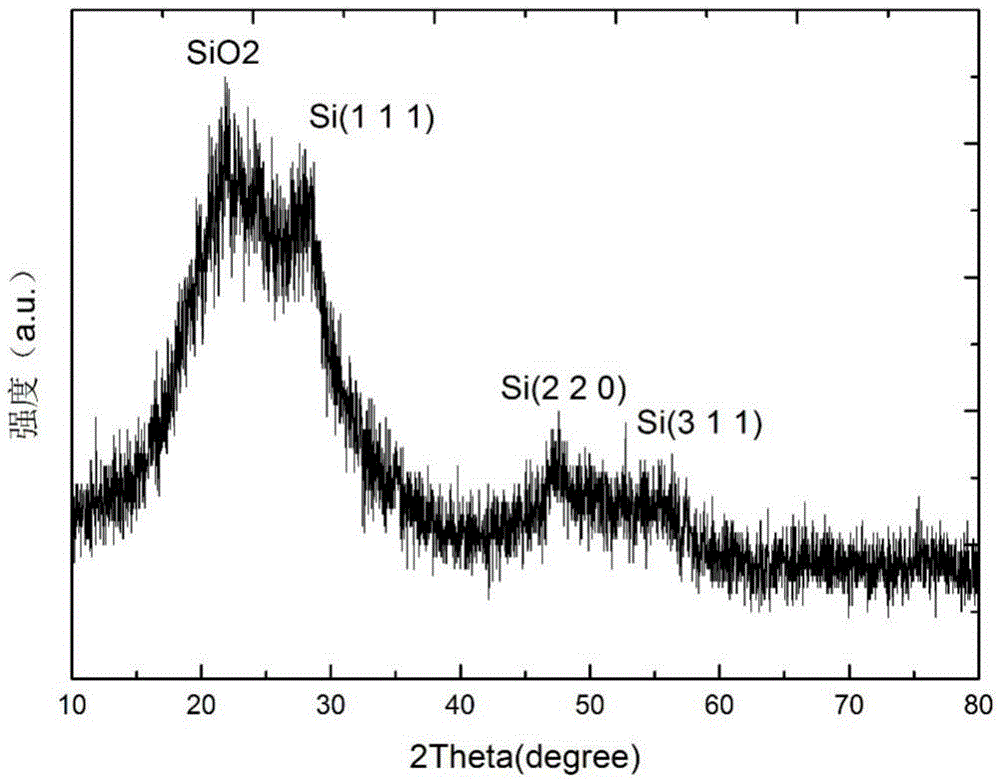

SiO<x>/C composite cathode material, method for preparing same and application of SiO<x>/C composite cathode material

ActiveCN105655564AImprove conductivityIncrease capacityCell electrodesSecondary cellsCarbon compositesCarbon layer

The invention provides an SiO<x> / C composite cathode material, a method for preparing the same and application of the SiO<x> / C composite cathode material. The SiO<x> / C composite cathode material is of a core-shell structure. A shell layer of the SiO<x> / C composite cathode material is a carbon layer, a core of the SiO<x> / C composite cathode material comprises a plurality of silicon carbon composite material particles, the silicon carbon composite material particles include SiO<x> particles and amorphous conductive carbon layers, the amorphous conductive carbon layers cover the surfaces of the SiO<x> particles, and free spaces are reserved between the silicon carbon composite material particles. The SiO<x> / C composite cathode material, the method and the application have the advantages that the SiO<x> / C composite cathode material is excellent in conductivity, firm in structure and stable in capacity, the coulomb efficiency and the cycle performance can be greatly improved, technological conditions for the method are controllable, the SiO<x> / C composite cathode material prepared by the aid of the method is stable in performance and high in production efficiency, and the production cost can be reduced.

Owner:王凤鸣

Composite cathode active material for lithium battery, cathode for lithium battery including the same, and lithium battery including the cathode

A composite cathode active material for a lithium battery including: a lithium composite oxide; and a coating layer including a metal oxide and a lithium fluoride, (LiF) wherein the coating layer is disposed on at least a portion of a surface of the lithium composite oxide.

Owner:SAMSUNG ELECTRONICS CO LTD +1

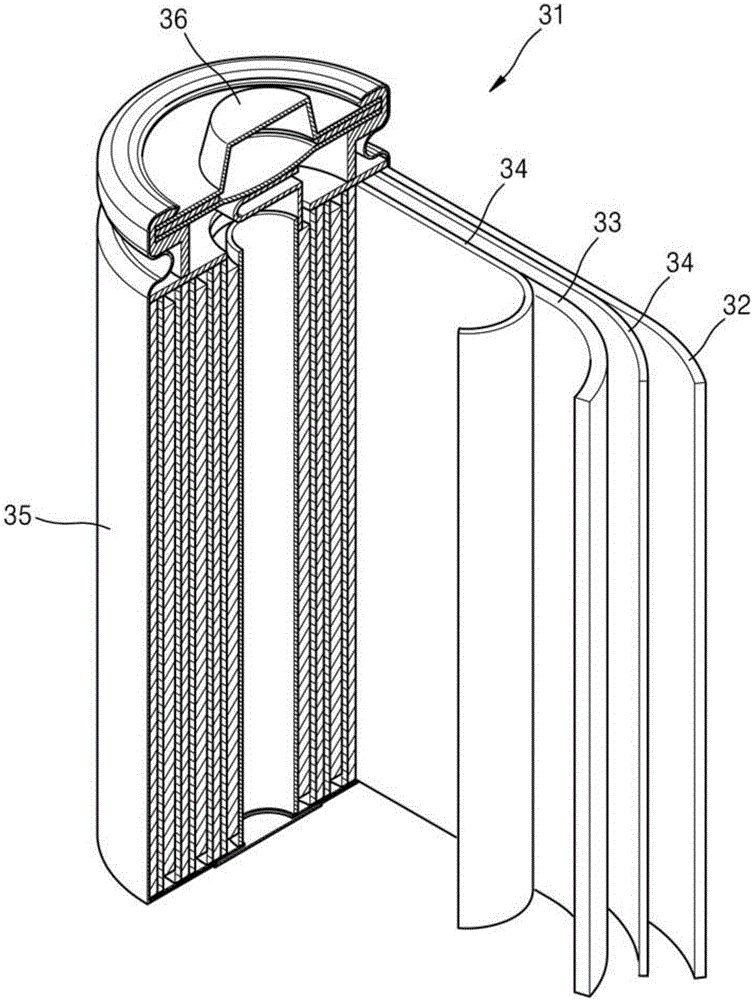

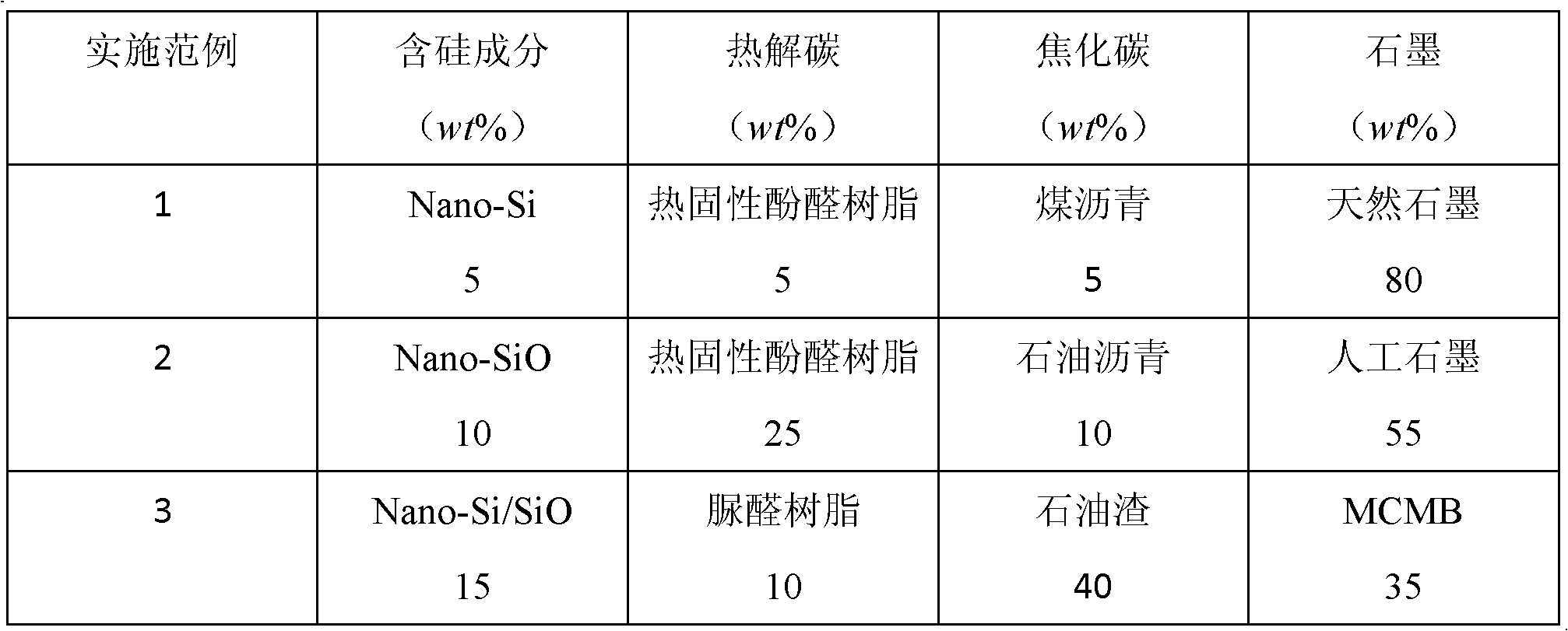

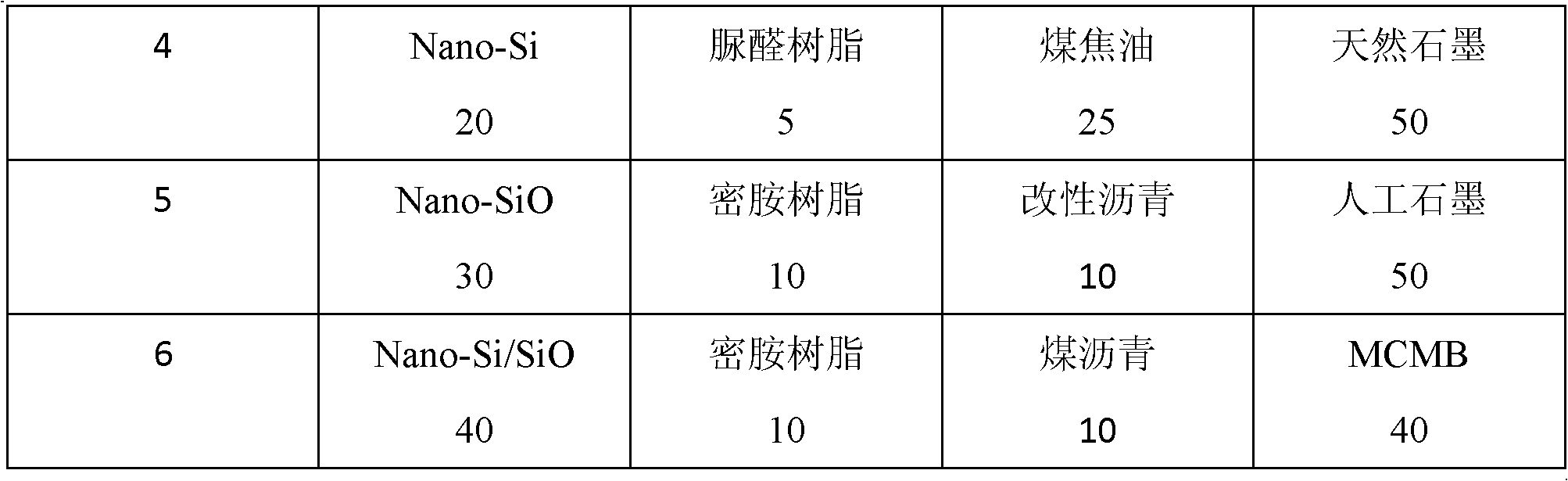

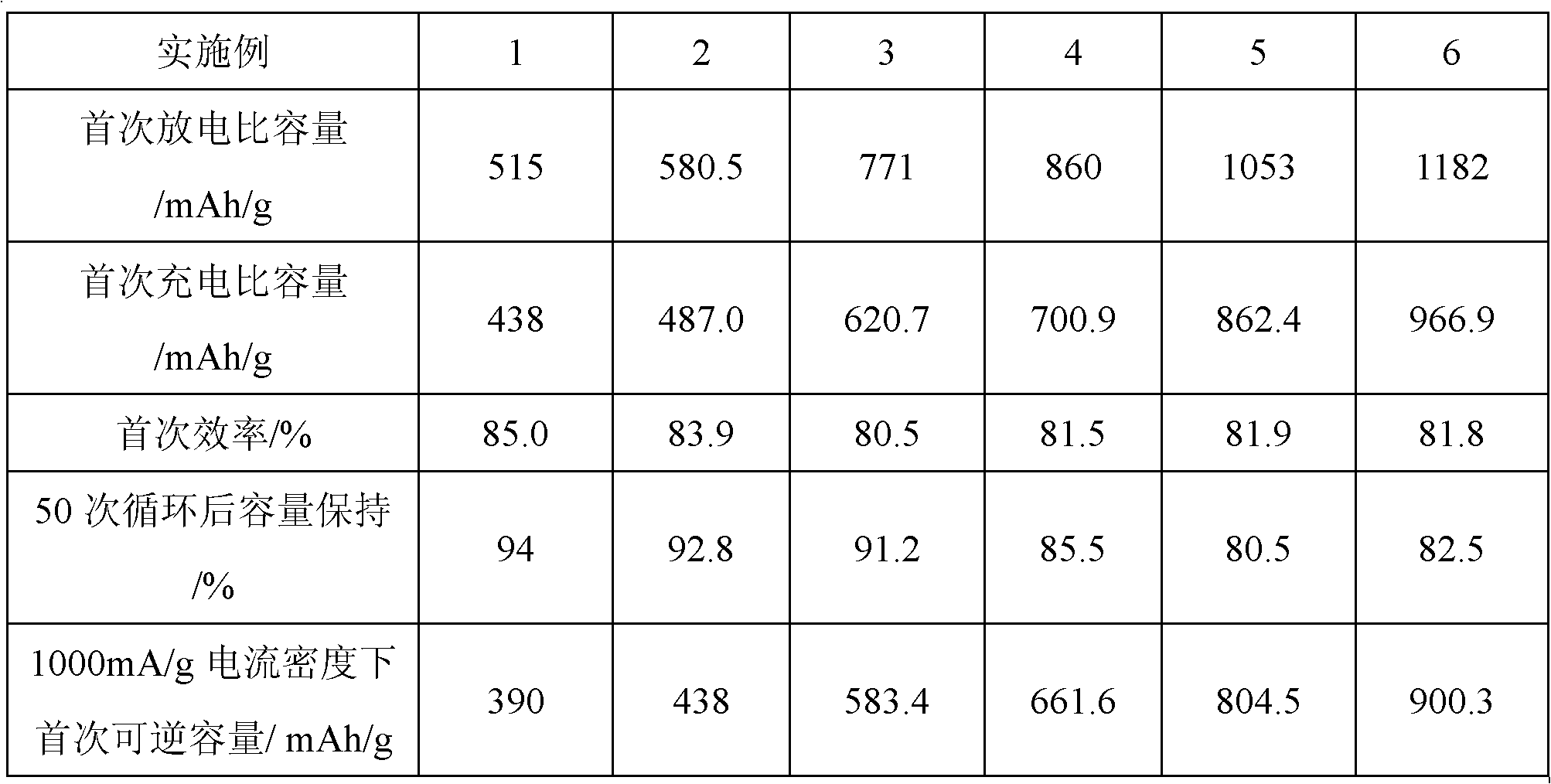

Preparation method for composite cathode material of lithium ion battery

The invention discloses a preparation method for a composite cathode material of a lithium ion battery by means of spray drying pyrolysis treatment. The preparation method includes the steps: dissolving a first type of binder organic carbon source into solvent of a proper quantity, adding a silicon source, a second type of binder and a dispersing agent, dispersing uniformly, adding graphite, dispersing for a certain time, subjecting uniformly dispersed suspension to spray drying, and using the first type of binder organic carbon source to bond the silicon source, the graphite and the second type of binder particles into spherical or spherical-like forms to obtain a composite precursor; and transferring the precursor into a shielding atmosphere for sintering, heating the second type of binder to a certain temperature to be melted into a liquid crystal state, bonding the particle silicon source and the graphite into cores, subjecting the organic carbon source to pyrolysis at the high temperature to form a coating, and furnace cooling to obtain the carbon-silicon composite cathode material of the lithium ion battery. The preparation method is simple, easy in implementation and high in practicality. The carbon-silicon composite prepared by the method has the advantages of high reversible capacity, designable capacity, high circulating performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

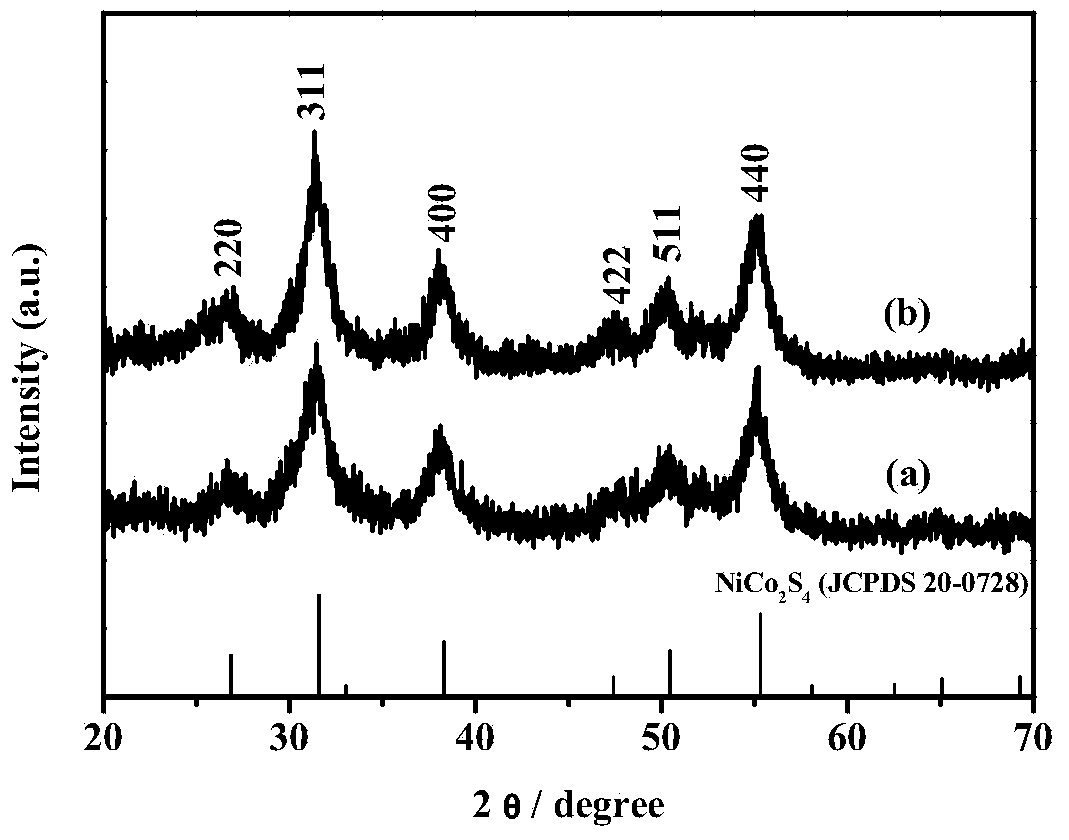

Water-system asymmetric super-capacitor based on NiCo2S4 and NiCo2S4 composite material

ActiveCN104299797AIncrease energy densityImprove cycle stabilityHybrid capacitor electrodesDouble layer capacitorsComposite cathodeInternal resistance

The invention relates to a water-system asymmetric super-capacitor based on NiCo2S4 and a NiCo2S4 composite material, and belongs to the technical field of chemical power supplies. The super-capacitor comprises the following materials: (1) NiCo2S4 and the NiCo2S4 composite cathode material (including AC / NiCo2S4, CQDs / NiCo2S4, GNP / NiCo2S4, CNTs / NiCo2S4 and CF / NiCo2S4) which serve as an anode, (2) a carbon-based anode material (including AC, CQDs, GNP, CNTs and CF) which serves as an cathode, (3) a KOH solution which serves as an electrolytic solution, (4) a diaphragm, (5) an anode gasket, (6) a cathode gasket, and (7) a housing. The prepared asymmetric super-capacitor has the voltage window of 1.5 V and is high in energy density, excellent in cyclic stability, low in internal resistance, easy to prepare, safe to use, low in cost, environment-friendly and suitable for commercialized production.

Owner:CENT SOUTH UNIV

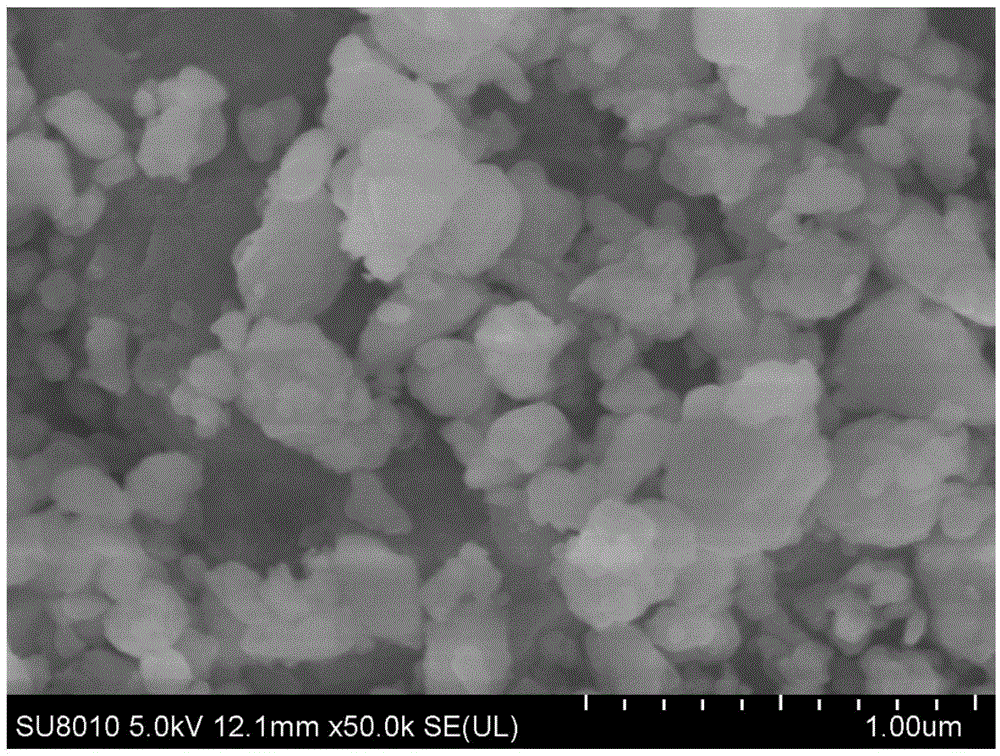

Nitrogen-doped carbon-clad manganese oxide lithium ion battery composite cathode material, and preparation method and application of composite cathode material

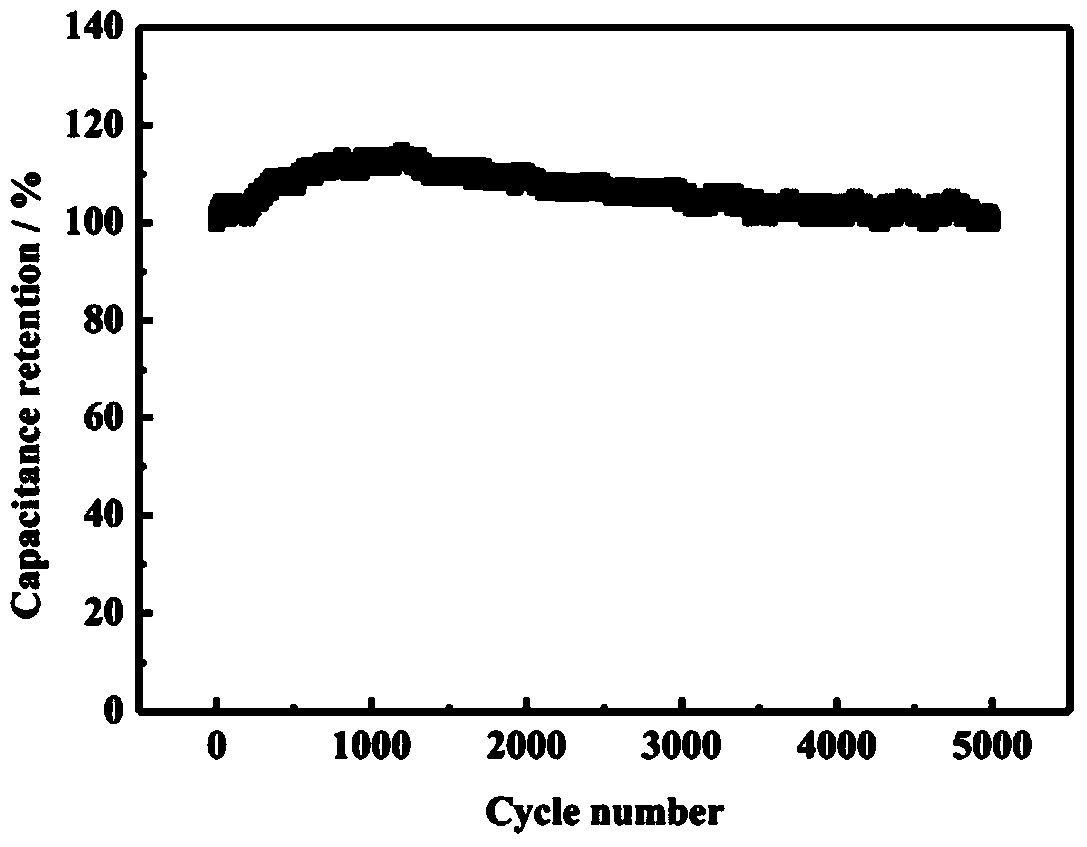

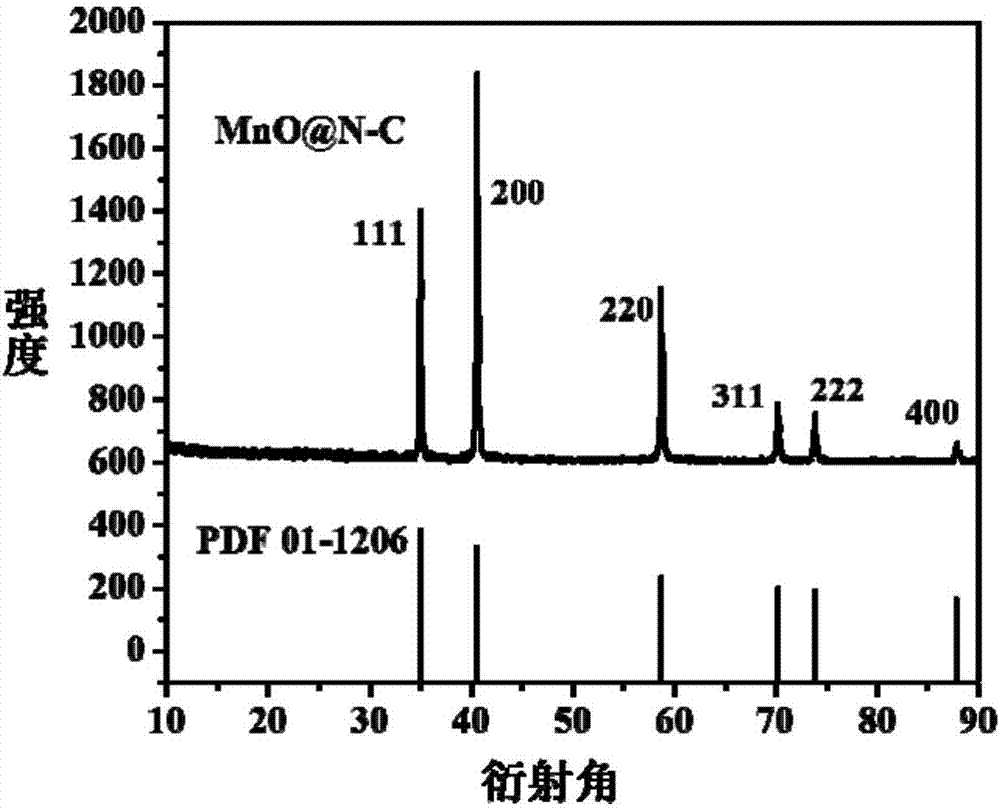

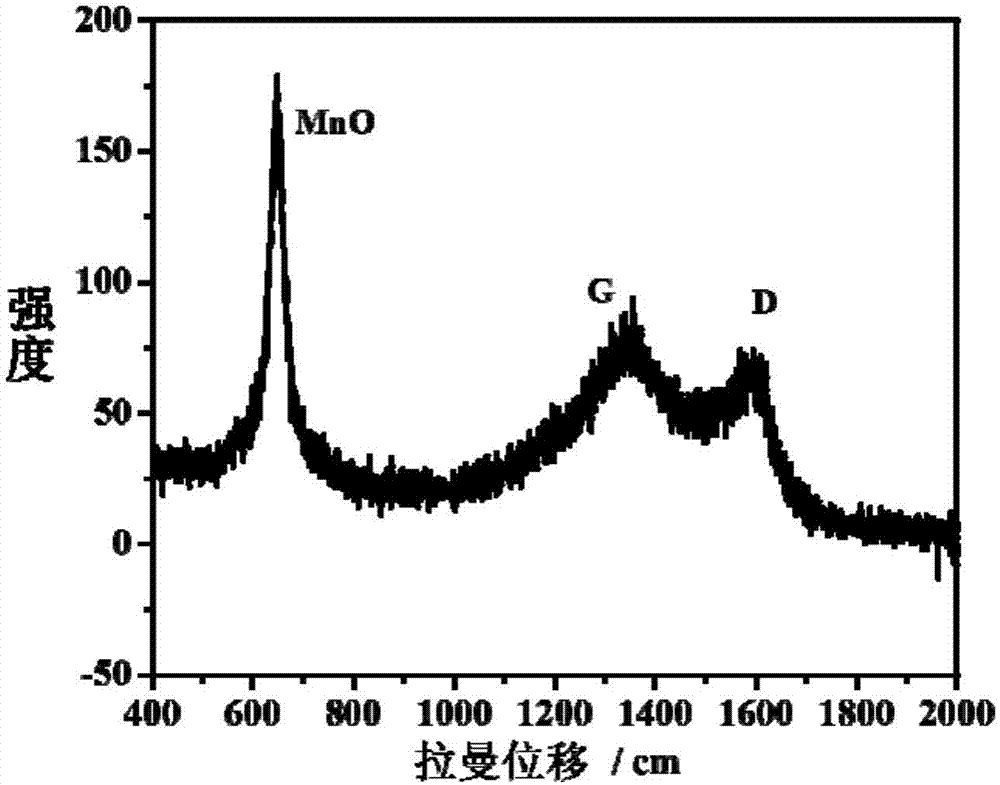

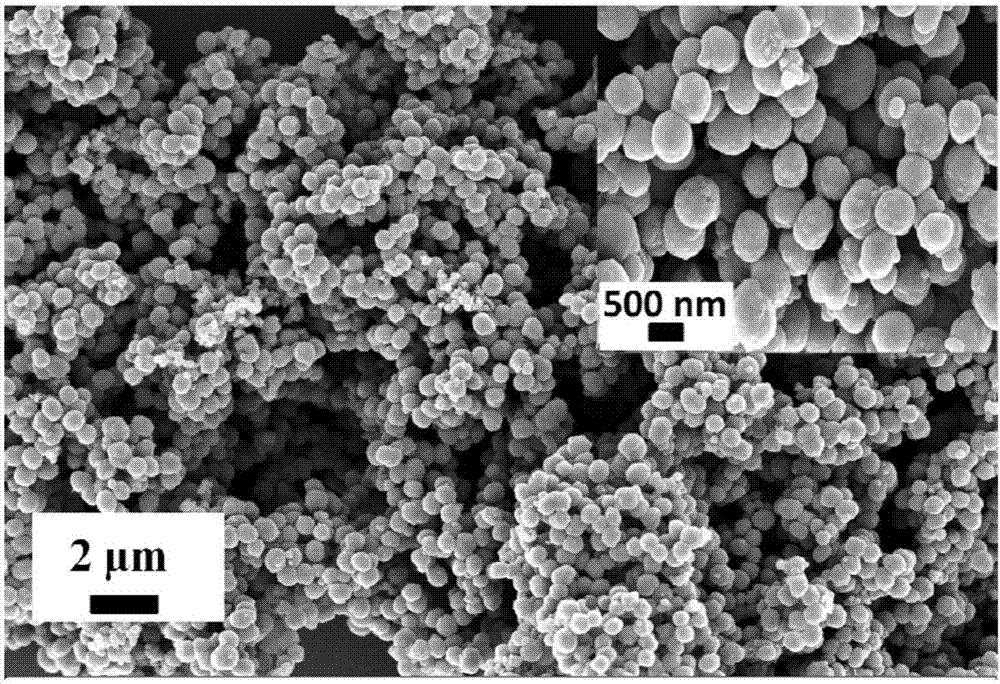

ActiveCN107369825AImprove electrochemical performanceLow costSecondary cellsNegative electrodesCarbon layerCarbonization

The invention discloses a nitrogen-doped carbon-clad manganese oxide lithium ion battery composite cathode material, and a preparation method and an application of the composite cathode material. The composite material is composited by nanoscale manganese oxide and dopamine, wherein manganese oxide is spherical. The method comprises the steps of mixing a prepared spherical manganese oxide nano particle and dopamine hydrochloride, performing filtering, washing and drying to obtain a manganese oxide and polydopamine composite, and then converting a polymerization layer into a nitrogen-doped carbon layer by high-temperature carbonization. The prepared nitrogen-doped carbon-clad manganese oxide (MnO@NC) lithium ion battery composite cathode material is stable in structure and good in conductivity, and has excellent rate capability and cycling stability as a lithium ion battery cathode material; and polymerization of the dopamine is only completed at a room temperature and under a slightly alkaline condition, so that the composite cathode material is low in cost, low in energy consumption, convenient to control and environment-friendly, is suitable for a practical application of a lithium ion battery, and can realize industrial mass production.

Owner:SOUTH CHINA UNIV OF TECH

Composite cathode active material, and cathode and lithium battery including the material

A composite cathode active material including an overlithiated metal oxide having a layered structure, a material having an olivine structure, and one or more of: an inorganic material, and nitrogen atoms doped in the material having an olivine structure. The inorganic material includes a nitride or carbide of a non-transition metal. The composite cathode active material may be included in a cathode, and the cathode may be included in a lithium battery.

Owner:SAMSUNG SDI CO LTD

Novel composite cathodes, eletrochemical cells comprising novel composite cathodes, and processes for fabricating same

InactiveUS20050196672A1Ease of transportationNanotechFinal product manufactureComposite cathodeOrganic group

The present invention pertains to composite cathodes suitable for use in an electrochemical cell, said cathodes comprising: (a) an electroactive sulfur-containing cathode material, wherein said electroactive sulfur-containing cathode material, in its oxidized state, comprises a polysulfide moiety of the formula —Sm—, wherein m is an integer equal to or greater than 3; and, (b) an electroactive transition metal chalcogenide composition, which encapsulates said electroactive sulfur-containing cathode material, and which retards the transport of anionic reduction products of said electroactive sulfur-containing cathode material, said electroactive transition metal chalcogenide composition comprising an electroactive transition metal chalcogenide having the formula Mj Yk (OR)l wherein: M is a transition metal; Y is the same or different at each occurrence and is oxygen, sulfur, or selenium; R is an organic group and is the same or different at each occurrence; j is an integer ranging from 1 to 12; k is a number ranging from 0 to 72; and l is a number ranging from 0 to 72; with the proviso that k and l cannot both be 0. The present invention also pertains to methods of making such composite cathodes, cells comprising such composite cathodes, and methods of making such cells.

Owner:SION POWER CORP

Composite cathode material of lithium ion battery and preparation method thereof

ActiveCN101540390ASolving Dispersion ProblemsChange the combinationElectrode manufacturing processesActive material electrodesFiberGas phase

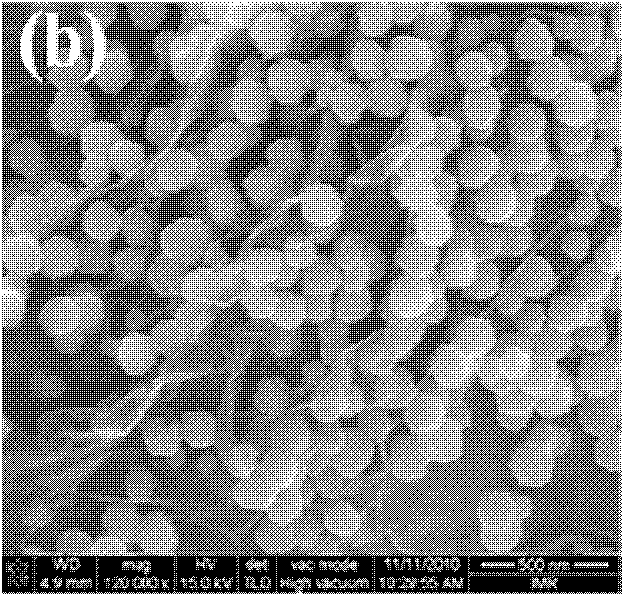

The invention discloses a composite cathode material of a lithium ion battery and a preparation method thereof, and pertains to the technical field of nano-materials and chemical power source. The material is a composite of cathode material and a carbon nanotube or carbon nanofiber; the method of the invention comprises the step of adopting a chemical vapor deposition process for the in-situ growth of the carbon nanotube or the carbon nanofiber on the surface of the cathode material; the invention has simple process, energy conservation and consumption reduction and low production cost; and the composite cathode material is prepared by the steps that the carbon nanotube or the carbon nanofiber are directly erected on the surface of the cathode material to form a sea urchin type structure, and the carbon nanotube or the carbon nanofiber has good distribution uniformity, concentration degree and crystallinity on the surface of the cathode material; and the invention is characterized by high conductivity, high capacity, capability of rapid charge and discharge and the like in performance. The materials prepared by adopting the method of the invention can be widely applied in the new energy devices including lithium ion batteries, supercapacitors and the like, and can also be applied to catalyst carrier, absorbing materials, conductive materials and heat conducting materials and the like.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD

Lithium-sulfur battery cathode material and preparation method thereof

ActiveCN102780001AInhibition of dissolutionImprove cycle performanceCell electrodesMetal-organic frameworkDissolution

The invention discloses a lithium-sulfur battery cathode material and a preparation method thereof. The cathode material is formed by in-situ compositing of a mesoporous metal-organic framework and elemental sulfur. The mesoporous metal-organic frame is of a laminated pore structure consisting of a macro pore, a meso pore and a micro pore, wherein the pores are communicated with one another. The structure can adsorb more elemental sulfur and can simultaneously inhibit the dissolution of sulfur elementary substance and multi-sulfur compounds in electrolyte, so that the cycle performance of a lithium-sulfur battery is improved and high utilization rate of an active substance of the cathode material is kept. A sulfur and metal-organic framework material composite cathode material is prepared by a two-step process of low-temperature liquid phase composition and sulfur extraction, a composite material precursor with homogeneously dispersed high load sulfur content can be obtained through in-situ compositing at a low temperature with a liquid-phase preparation method, redundant sulfur on the surface of the precursor and in pore passages is extracted by an organic solvent, the aperture of the composite material can be further effectively adjusted and controlled, selective distribution of sulfur is realized, and the composite material with excellent electrochemical performance is obtained. By adopting the preparation method, the distribution of the sulfur in the composite material can be effectively improved, and the electrochemical performance of the composite material is optimized. Meanwhile, the preparation method is simple and is easy to perform industrially, and mass production is facilitated.

Owner:CENT SOUTH UNIV +1

Silicon monoxide composite cathode material for lithium ion battery, and preparation method thereof

The invention discloses a silicon monoxide composite cathode material for a lithium ion battery, and a preparation method of the silicon monoxide composite cathode material, aiming at improving the cycle performance. The composite cathode material comprises the components by mass percent: 10-30% of composite particle material and 70-90% of natural graphite or artificial graphite, wherein the composite particle material is silicon monoxide covered by a carbon nano tube and an amorphous carbon coating layer. The method comprises the following steps of: forming the carbon nano tube and the amorphous carbon coating layer on the surface of silicon monoxide to obtain composite particles, and mixing the composite particles with the graphite. Compared with the prior art, the preparation method enables cracking carbon to be covered on the surfaces of silicon monoxide particles, so that the volume effect of the silicon monoxide particles can be effectively inhibited in the charge-discharge process of a battery, the cycle performance is good, the specific capacity is more than 500mAh / g, and the capacity retention ratio is more than 85% after the circulation is carried out for 100 times; and the preparation method is simple in preparation technology, low in raw material cost and suitable for the cathode material for the high-capacity lithium ion battery.

Owner:BTR NEW MATERIAL GRP CO LTD

Cathode active material, method of preparing the same, and cathode and lithium battery applying the material

ActiveUS20060204850A1Prevent gelationElectrode manufacturing processesFinal product manufactureHigh rateSlurry

Composite cathode active materials comprising a composite oxide and an acid treated with an organic solvent are provided. The composite cathode active materials are prepared by treating mixtures of nickel-based composite oxides and organic acids with organic solvents. The active materials suppress gelation of the electrode slurries for a long period of time, even when the active materials are mixed with fluorine-based polymers, by decreasing the basicity of the slurries and the amount of lithium present on the surfaces of the active materials. As a result, electrode slurries having high stability can be prepared. Cathodes and lithium batteries comprising the slurries have excellent charge-discharge characteristics, including high capacity and excellent high rate discharge characteristics.

Owner:SAMSUNG SDI CO LTD

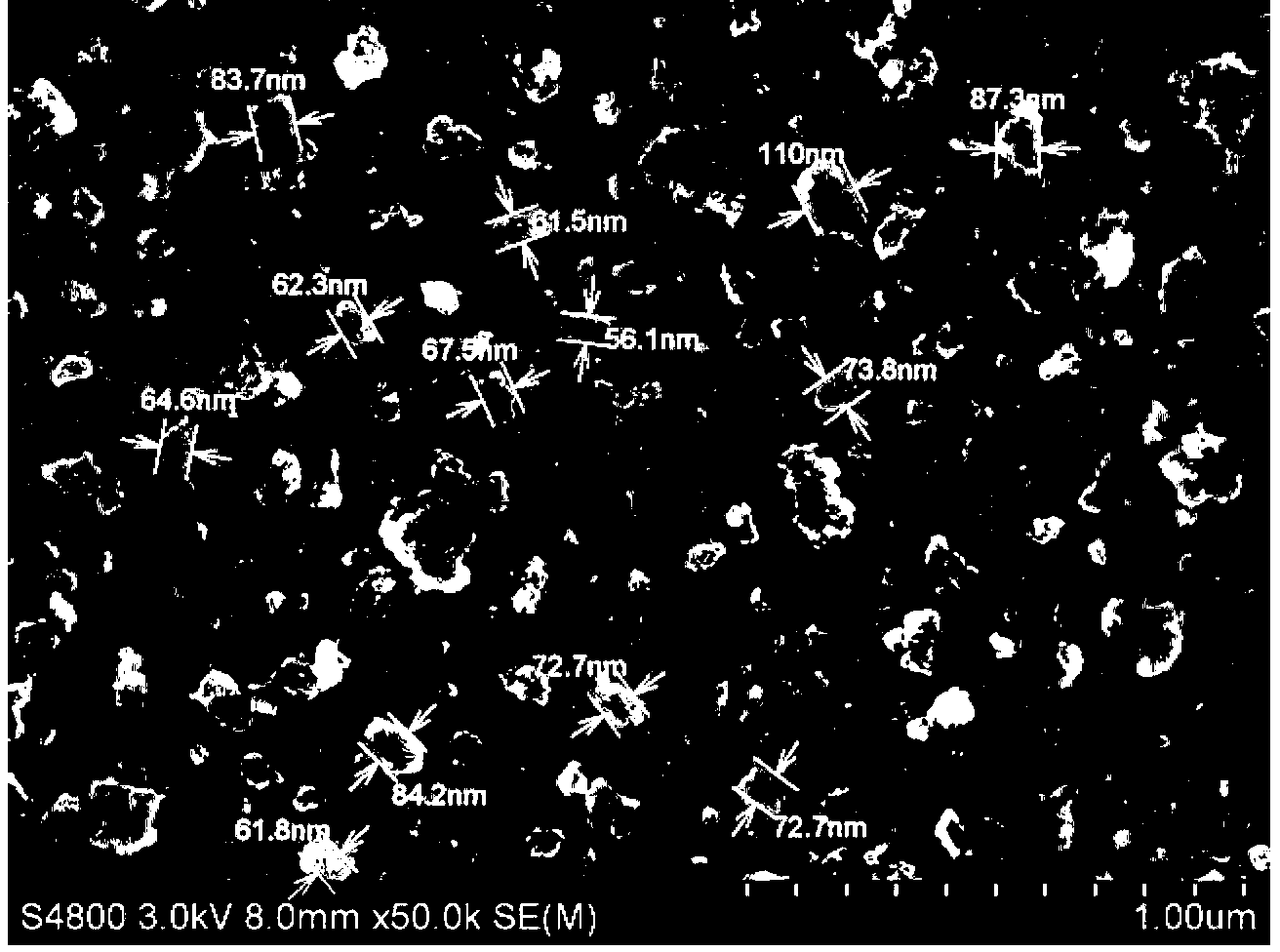

Nano-Si or nano-Sn containing composite cathode material for lithium ion battery and preparation method thereof

The invention belongs to the technical field of nano-materials and chemical power sources and particularly provides a nano-Si or nano-Sn containing composite cathode material for a lithium ion battery and a preparation method thereof. The composite cathode material of the invention comprises the following components: cathode active substances, nano-Si or nano-Sn, and macromolecule polymers. The method taking the above components as raw materials comprises the following steps: firstly, preparing mixed solution; then, removing organic solvent; further coating the mixed solution with the macromolecule polymers; then, removing organic solvent; and finally, carrying out carbonization treatment to obtain the finished product. The invention has the advantages of fewer components, low cost, simple process and low energy consumption; and the composite cathode material prepared by the method of the invention has a core-shell structure and has the characteristics of high capacity, high stability and high capability of rapidly charging and discharging. Therefore, the composite cathode material of the invention is widely applicable to lithium ion batteries, super-capacitors and other components based on new energy resources and particularly applicable to lithium ion batteries for electric vehicles.

Owner:重庆锦添翼新能源科技有限公司 +1

LiNiCoAlO2 composite cathode material and preparation method thereof, and lithium ion battery

InactiveCN103715423AReduce lithium impurity contentEasy to processAluminium compoundsCell electrodesOrganic acidComposite cathode

The invention relates to a LiNiCoAlO2 composite cathode material and a preparation method thereof, and a lithium ion battery. The composite cathode material is of a core-shell structure, wherein a core is LiNi1-x-yCoxAlyO2 subjected to washing treatment by using a mixed solution of alcohol and organic acids, x is greater than 0 and less than or equal to 0.2, and y is greater than 0 and less than or equal to 0.1; and a shell is a metal oxide layer. According to the invention, the composite cathode material is prepared by using a process combining an operation of washing a base material by using a mixed solution of alcohol and organic acids and an operation of carrying out spray drying on a material wrapped on the shell layer. The composite cathode material disclosed by the invention is low in lithium impurity content and high in high-temperature cycling and high-temperature storage performances.

Owner:BTR NEW MATERIAL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com