Carbon nano tube-containing sulfur-based composite cathode material and preparation method thereof

A composite positive electrode material and nanotube technology, which is applied in the field of sulfur-based composite positive electrode material and its preparation, can solve the problems of poor power characteristics and low electronic conductivity of lithium secondary batteries, achieve good cycle stability, simple synthesis method, Effect of Improving Power Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

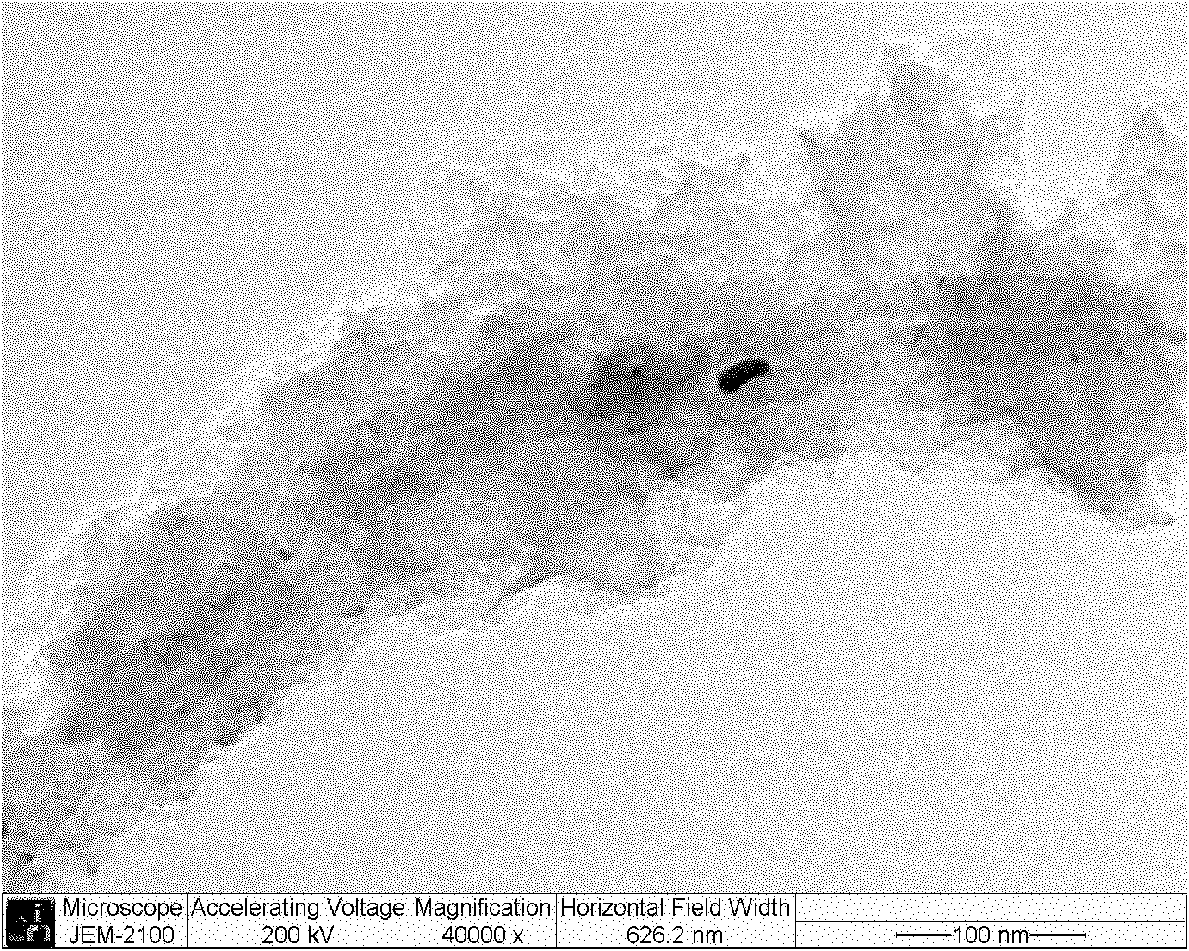

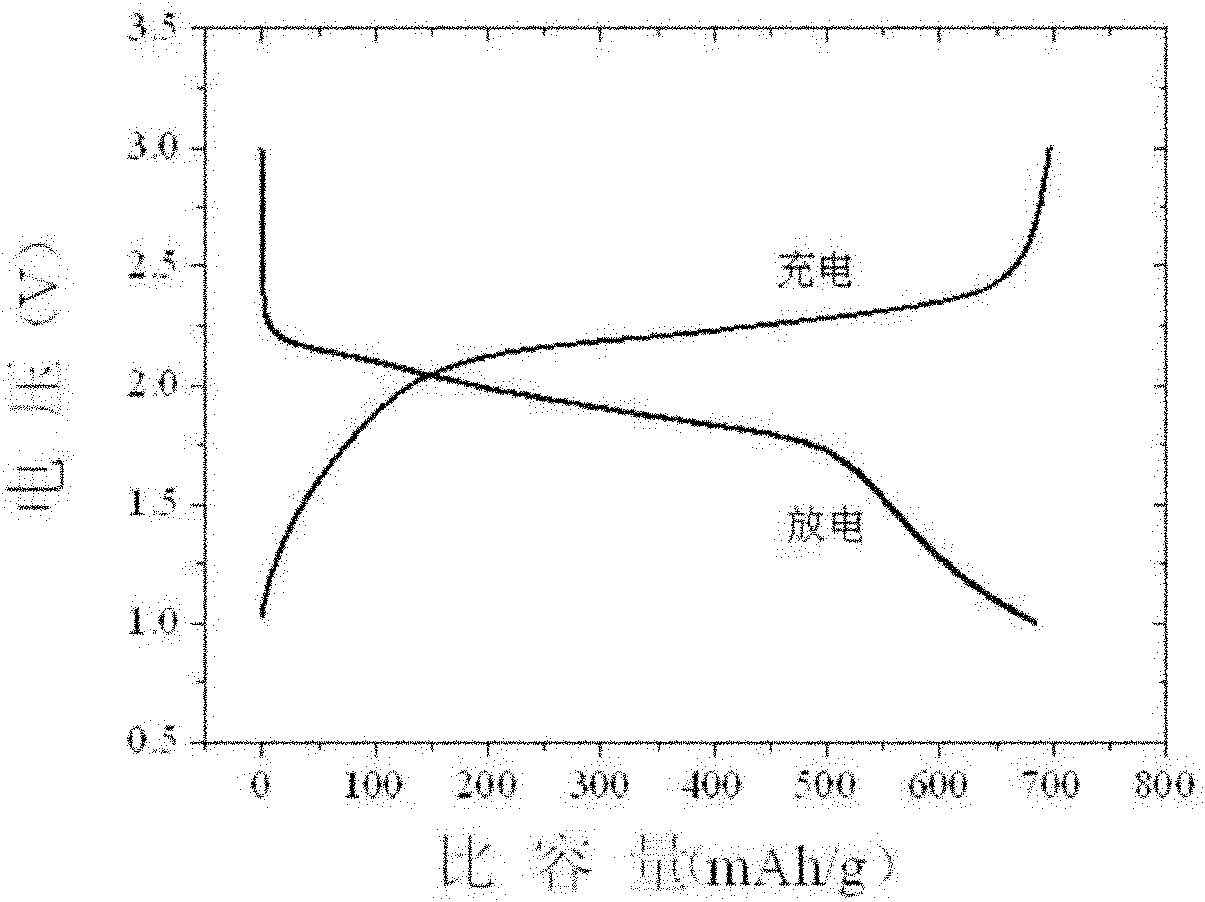

[0025] Disperse 0.7g of multi-walled carbon nanotubes in 100g of dimethyl sulfoxide and water in a mixed solvent with a mass ratio of 1:1, then add 20g of acrylonitrile, 0.3g of initiator ammonium persulfate, and continue stirring under nitrogen protection The temperature was raised to 50° C., kept for 3 hours, washed and filtered to obtain polyacrylonitrile coated on the surface of carbon nanotubes. figure 1 It is a TEM photo of polyacrylonitrile coated on the surface of multi-walled carbon nanotubes. It can be seen that acrylonitrile is more uniformly coated on the surface of multi-walled carbon nanotubes by in-situ polymers, with a thickness between 10-100nm. Mix elemental sulfur with polyacrylonitrile coated on the surface of carbon nanotubes at a mass ratio of 16:1, heat to 400°C under nitrogen protection and keep it warm for 1 hour to obtain a sulfur-based composite positive electrode material containing carbon nanotubes. Wherein the content of carbon nanotubes is 10wt%,...

Embodiment 2

[0027] Disperse 0.5g of multi-walled carbon nanotubes in 100g of dimethyl sulfoxide and water in a mixed solvent with a mass ratio of 1:1, then add 20g of acrylonitrile, 1g of itaconic acid, and 0.5g of initiator azobisisobutyrocyanide , under the protection of nitrogen, the temperature was increased to 65° C. under continuous stirring, kept for 2 hours, washed and filtered to obtain an acrylonitrile-itaconic acid copolymer coated on the surface of carbon nanotubes, wherein the content of itaconic acid was 4 wt%. Mix elemental sulfur with acrylonitrile-itaconic acid copolymer coated on the surface of carbon nanotubes in a mass ratio of 8:1, heat to 300°C under nitrogen protection and keep it warm for 4 hours to obtain a sulfur compound containing carbon nanotubes. matrix composite cathode material, wherein the content of carbon nanotubes is 6wt%, and the content of elemental sulfur is 42wt%.

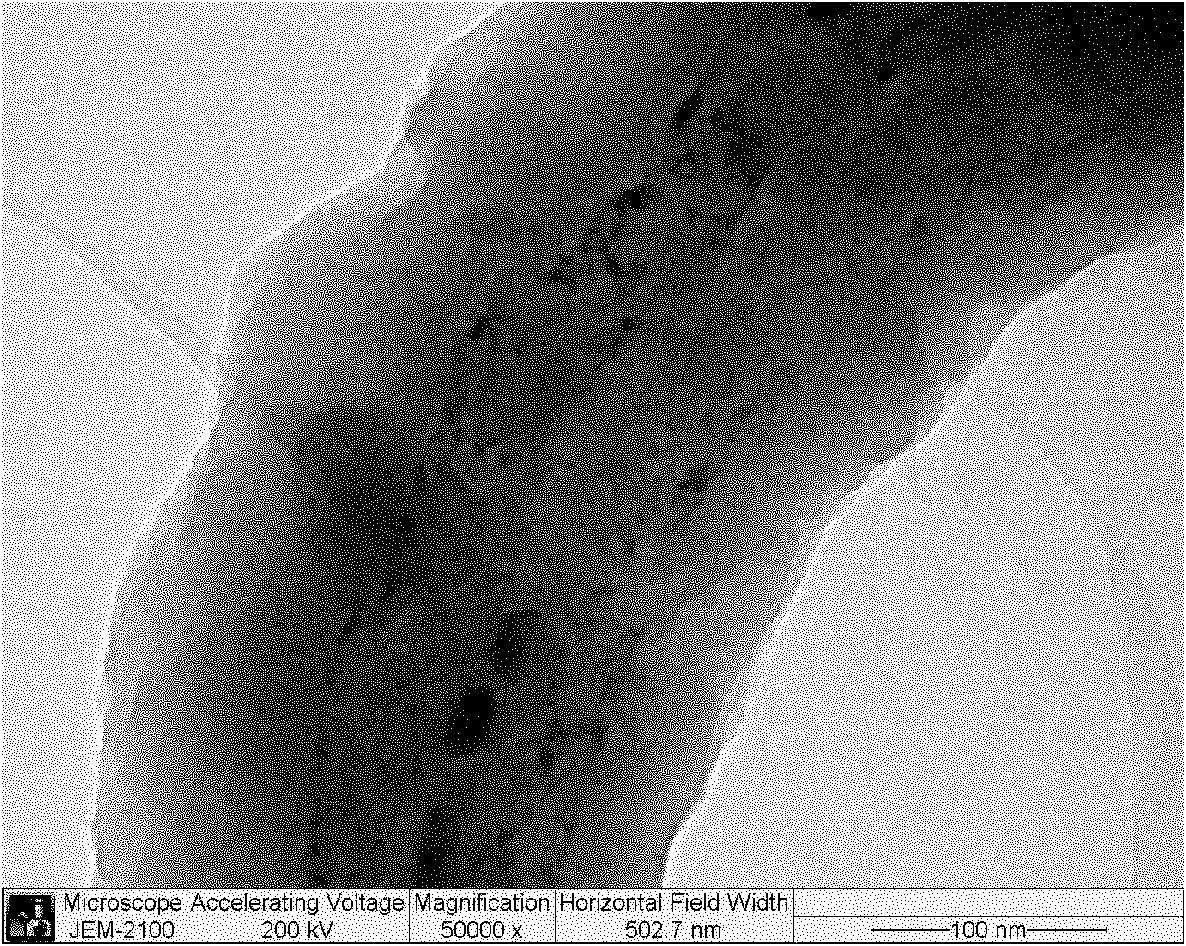

[0028] figure 2It is a TEM photo of a sulfur-based composite positive electrode ma...

Embodiment 3

[0030] 0.3g multi-walled carbon nanotubes are dispersed in 100g dimethyl sulfoxide and the mixed solvent that water mass ratio is 1: 1, then add 25g acrylonitrile, 5g ammonium itaconate, 0.4g initiator ammonium chlorate, in Under the protection of nitrogen, the temperature was raised to 80° C. under continuous stirring, and kept for 8 hours, washed and filtered to obtain an acrylonitrile-ammonium itaconate copolymer coated on the surface of carbon nanotubes, wherein the content of ammonium itaconate was 10 wt%. Mix elemental sulfur with acrylonitrile-ammonium itaconate copolymer coated on the surface of carbon nanotubes in a mass ratio of 4:1, heat to 350°C under the protection of argon and keep it warm for 2 hours to obtain a carbon nanotube-containing The sulfur-based composite cathode material, wherein the content of carbon nanotubes is 3wt%, and the content of elemental sulfur is 50wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com