Patents

Literature

1649 results about "Persulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A persulfate (sometimes known as peroxysulfate or peroxodisulfate) is a compound containing the anions SO²⁻₅ or S₂O²⁻₈. The anion SO²⁻₅ contains one peroxide group per sulfur center, whereas in S₂O²⁻₈, the peroxide group bridges the sulfur atoms. In both cases, sulfur adopts the normal tetrahedral geometry typical for the S(VI) oxidation state. These salts are strong oxidizers.

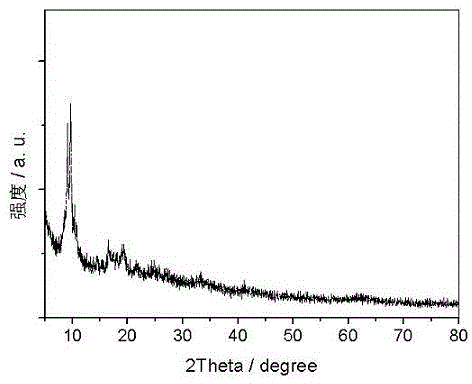

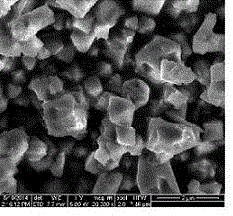

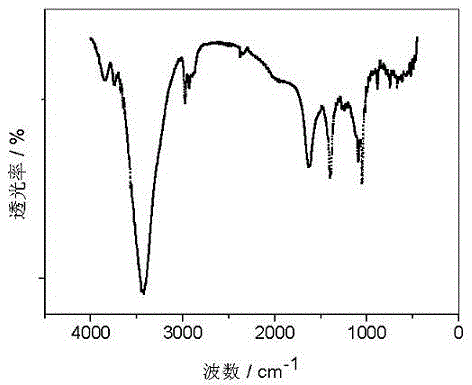

Application of spinel ferrite catalyst and method for urging persulfate to generate free radicals to catalytically degrade organic matters

InactiveCN103030208AStable structureHigh mechanical strengthSolid waste disposalWater contaminantsPersulfateSulfate

Application of spinel ferrite catalyst and a method for urging persulfate to generate free radicals to catalytically degrade organic matters relate to application of spinel ferrite catalyst and a method for degrading organic matters. The invention aims to solve the problems of high probabilities of oxygenolysis and breakage, low strength, impurity dissolution, low catalytic efficiency and difficulty in recovering in the existing catalyst as catalyst generated by sulfate free radicals and complex reaction system, rigor reaction conditions and higher cost in the existing activating technology. The spinel ferrite catalyst, as catalyst for urging the generation of persulfate free radicals, for urging persulfate or mono-persulfate to generate free radicals is applied; and the method comprises the following steps: the spinel ferrite catalyst is adopted as catalyst for urging the generation of persulfate free radicals to urge persulfate or mono-persulfate to generate free radicals; and then sulfuric acid free radicals are used for degrading the organic matters. The application and the method are mainly applied in catalytic degradation of the organic matters.

Owner:HARBIN INST OF TECH

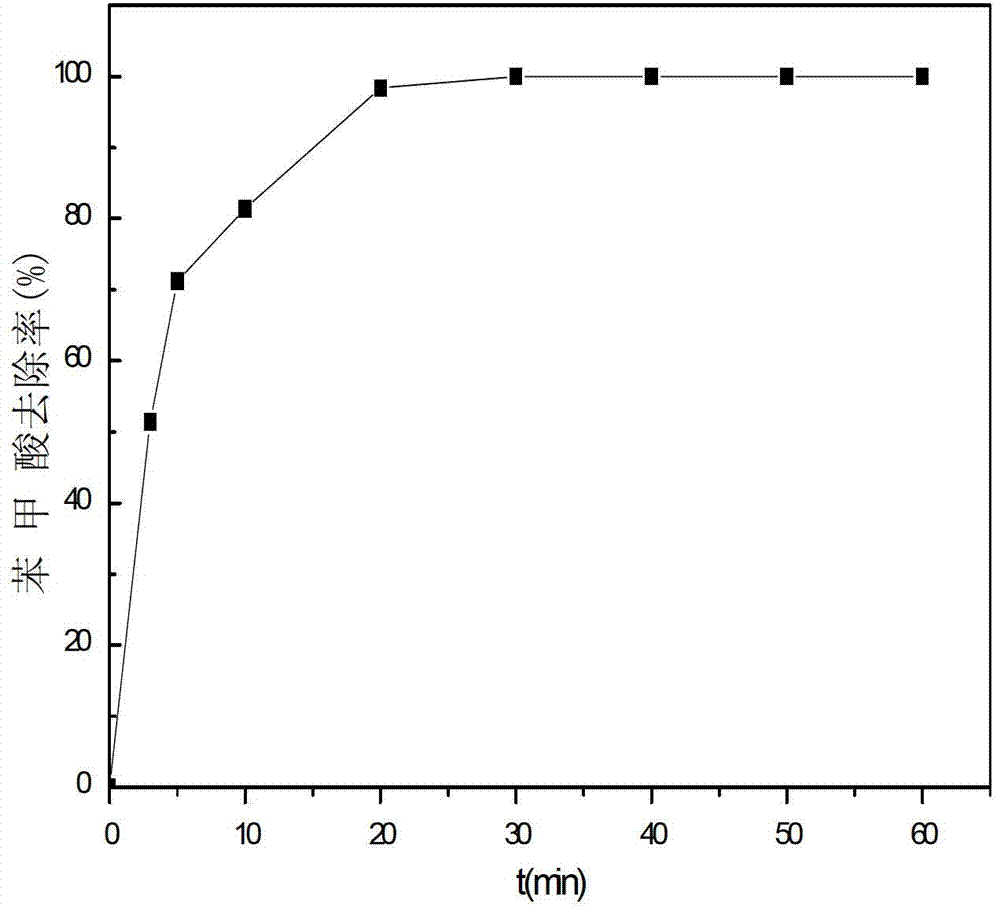

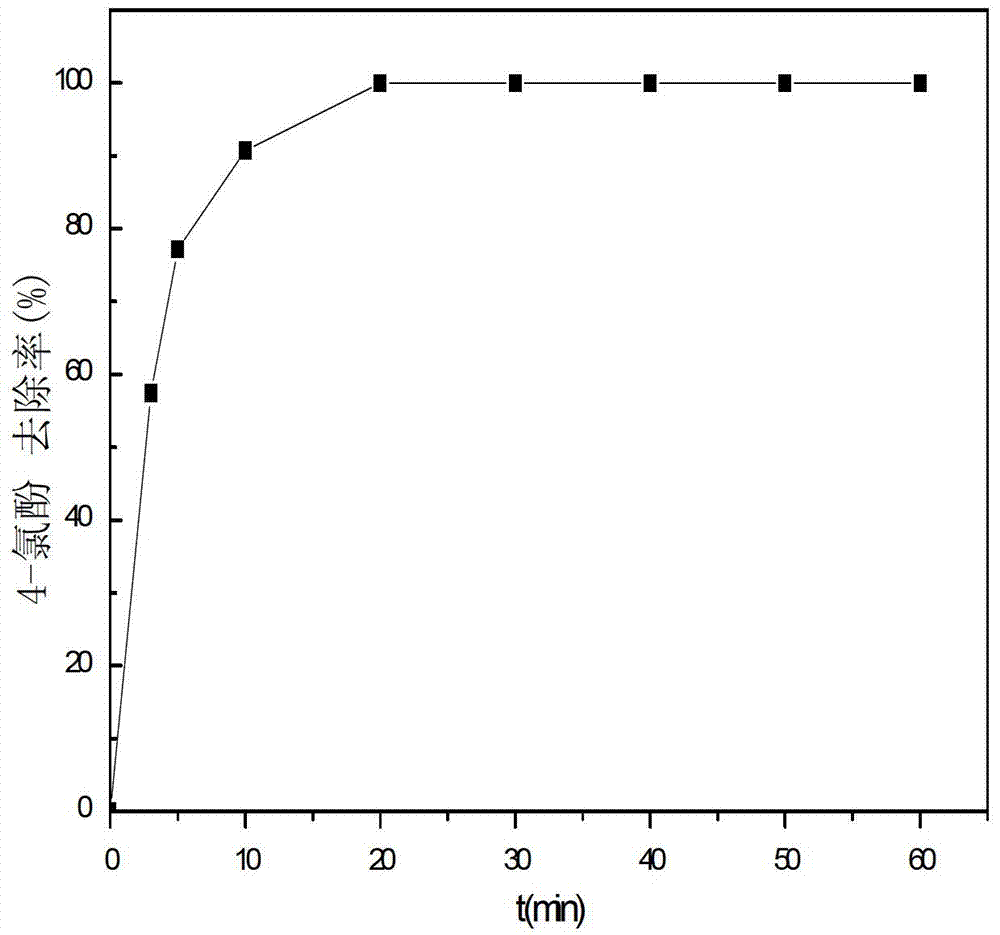

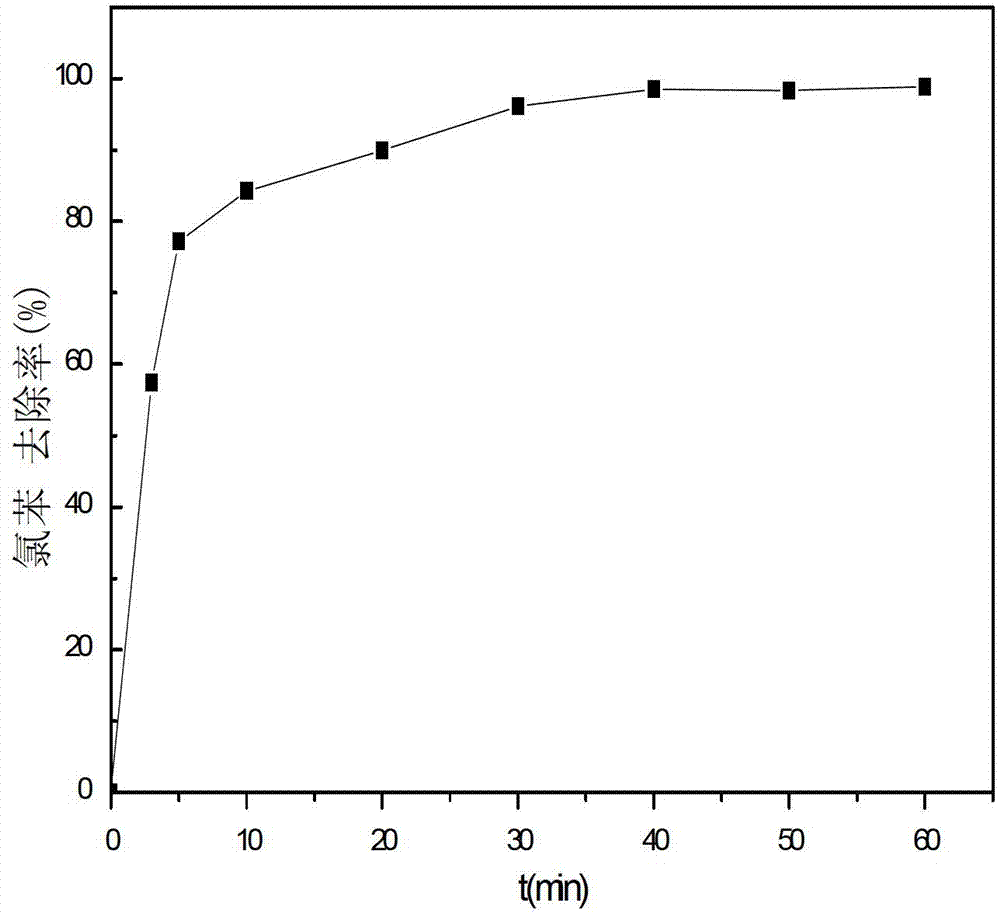

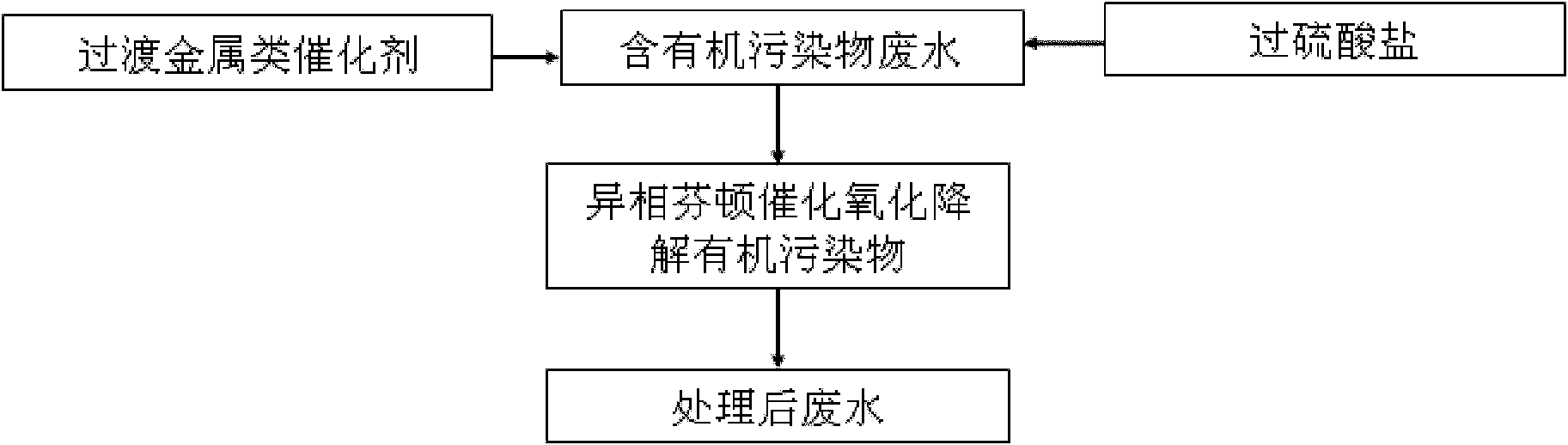

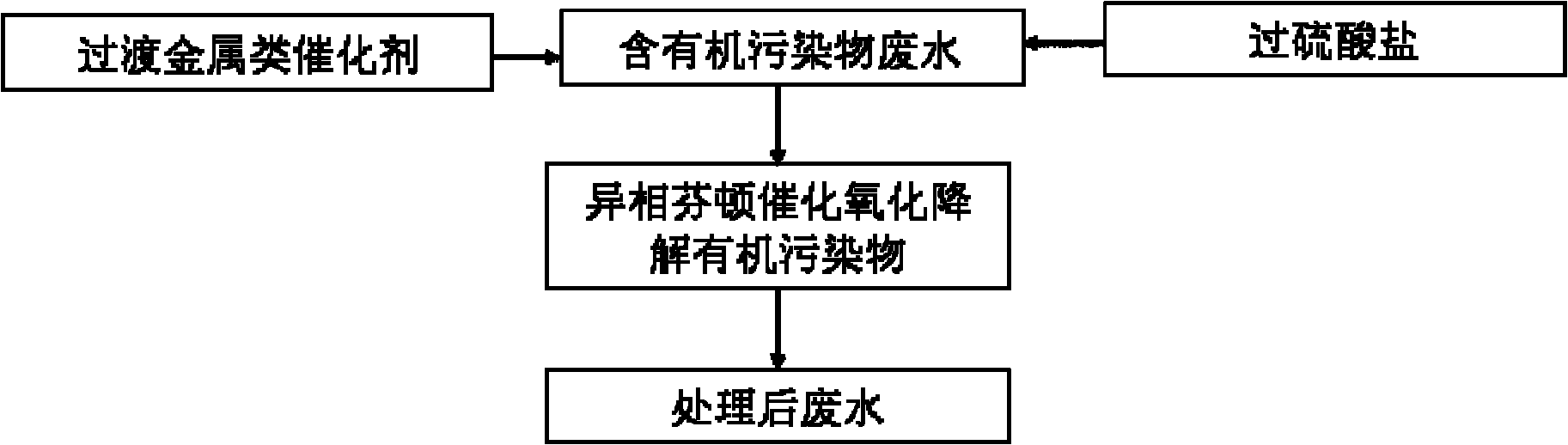

Processing method of heterocatalysis persulfate Fenton oxidation water

InactiveCN102020350ALong-lasting and efficient purificationImprove durabilityWater/sewage treatment by oxidationPersulfateFenton reagent

The invention proposes a processing technology of heterocatalysis persulfate Fenton oxidation water. In the method, transitional metal, transitional metallic oxide and a transitional metal / transitional metallic oxide composite material are used as out-phase Fenton reagents; and persulfate is catalyzed and decomposed to generate hydroxyl radical free radical, thus oxidizing to remove the organic matters in the waste water. Compared with the water treatment technique of homogeneous phase persulfate, the out-phase transitional metal and the transition metal oxide catalyst can slowly release transitional metal icons, thus ensuring that the organic matters in the water are purified lastingly and efficiently by the processing method of the heterocatalysis persulfate Fenton oxidation water. The processing technology of heterocatalysis persulfate Fenton catalyzed oxidation water built by the invention is suitable for processing various organic wastewater, has the advantages of good durability, high efficiency, environmentally friendliness, and no secondary pollution, is easy to operate, conforms to the requirements of actual water treatment units, and has great application potential in the field of environmental pollution regulation.

Owner:HUAZHONG NORMAL UNIV

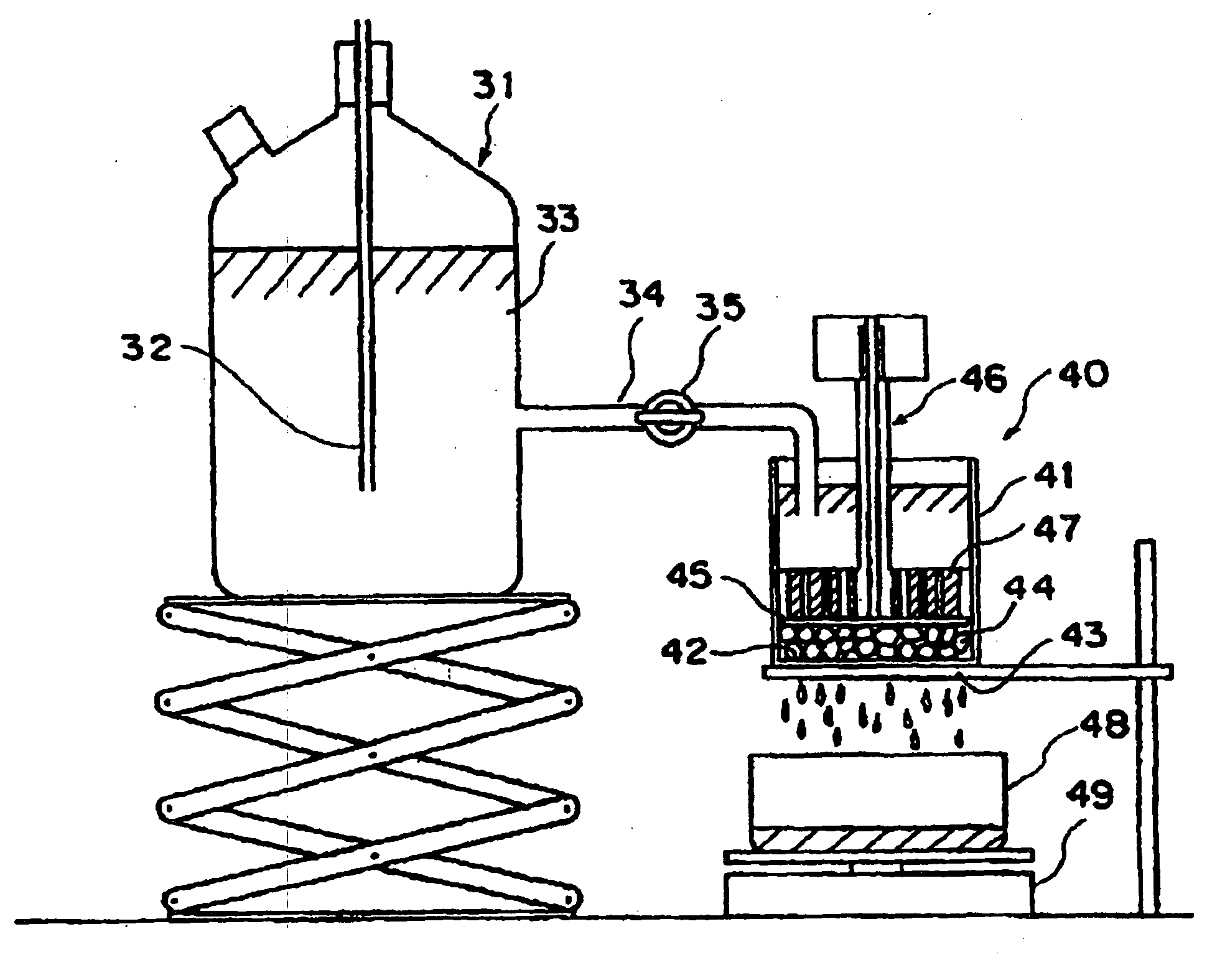

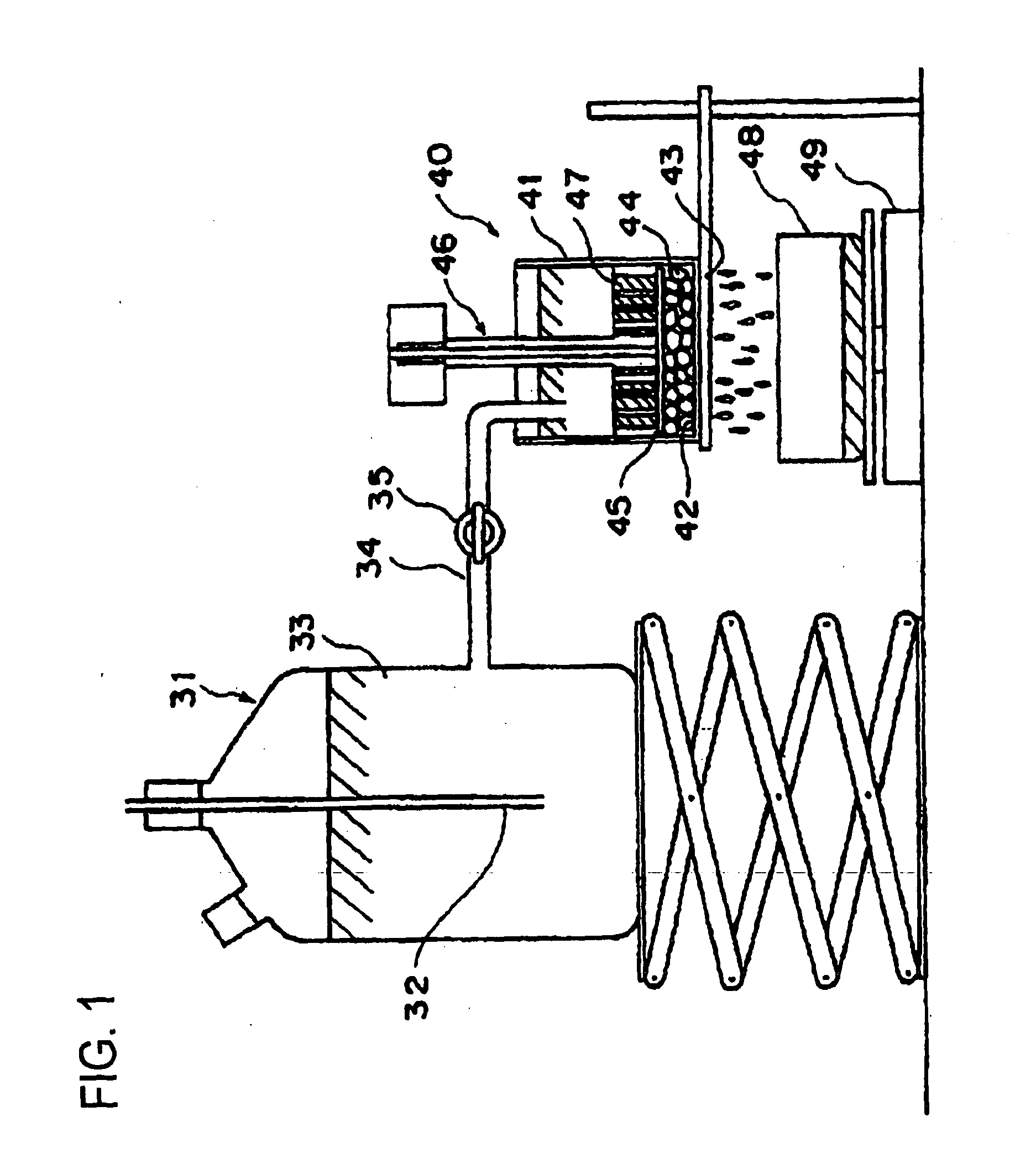

Method for surface-treatment of water absorbent resin

InactiveUS20090239966A1Improve production efficiencyEffecting introduction of a surface crosslink simplyPhotomechanical apparatusOptical articlesSaline waterAbsorption ratio

This invention is to provide a method for surface-treatment of a water absorbent resin excelling in water absorption properties. This invention relates to a method for the surface-treatment of a water absorbent resin, which comprises: a) mixing 100 parts by weight of a water absorbent resin, 0.01-20 parts by weight of at least one radical polymerization initiator selected from the group-consisting of persulfates, hydrogen peroxide, and azo compounds, and a radically polymerizing compound and b) irradiating the resultant mixture with active energy rays. The treatment particularly exalts the absorption ratio against pressure and the saline flow conductivity.

Owner:NIPPON SHOKUBAI CO LTD

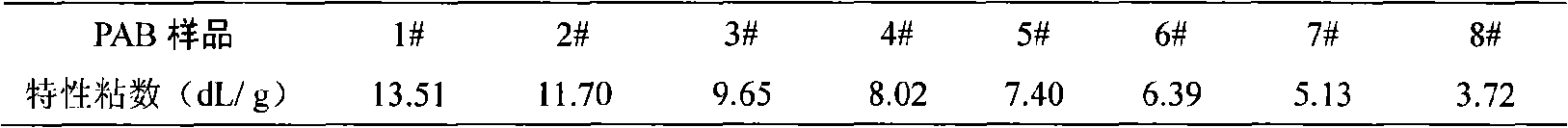

Acrylic amide modified graft copolymer, preparation method and application thereof

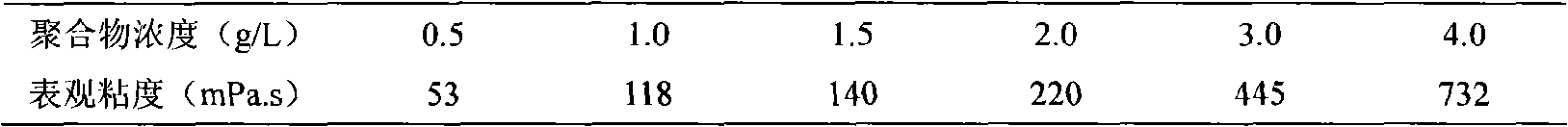

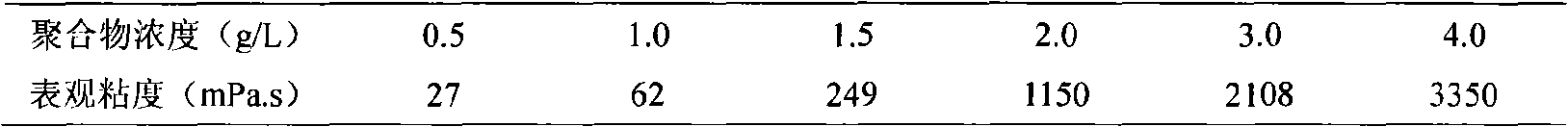

The invention discloses an acrylamide modified graft copolymer and a preparation method and usage thereof. The invention is characterized in that 20 parts of acrylamide, 1-20 anionic monomer and / or cationic monomer, 0.1-15 macromonomer, 0.05-10 ionic lyophobic monomer and 50-1000 deionized water are added into a three-necked reaction bottle, the pH value is adjusted to be 3-9, N2 is introduced for 30min, then 0.002-0.5 part of initiator persulfate is added at 30-75 DEG C, the reaction lasts 8-36h, then copolymer PAB is obtained, and finally water is used for dilution to obtain strong PAB solution. During polymerization, no surfactant is used, and the macromonomer with a long chain and the ionic lyophobic monomer with intermolecular association function are introduced into the copolymer PAB, so the capabilities of cooperative tackification and salt-resistance between the rigid conformation of a molecular chain and the intermolecular association can be played optimally, the PAB exhibits unique solution property and has higher colloidal viscosity in high saline solution than in fresh water, and the PAB obtains the capabilities of tackification, salt resistance, low surface tension and strong molecular association and can be used for the oil-displacing acrylamide modified graft copolymer. The copolymer is prepared into water solution with mass concentration of 0.2-3.0g / L and surfactant concentration of 0.01-2 mmol / L, then the water solution is added into a mixing vessel by a stirring device, and then a polymer oil-displacing agent with tackification, salt resistance and cutting resistance is obtained. The PAB has the functions of both a tackifier and a macromolecule surfactant. The copolymer PAB is prepared into water solution which has mass concentration of 0.05-7%, so the macromolecule surfactant with excellent surface activeness can be obtained and then applicable to an emulsifier, an emulsion splitter, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

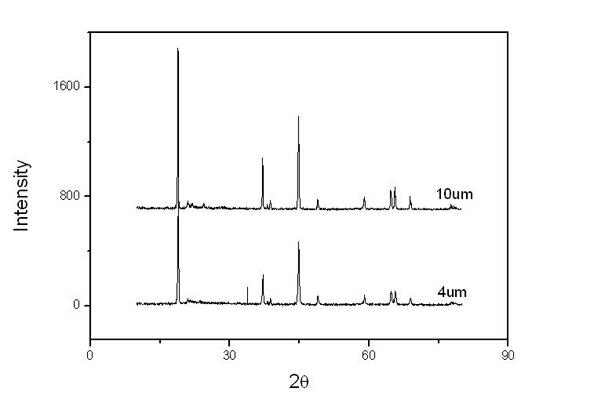

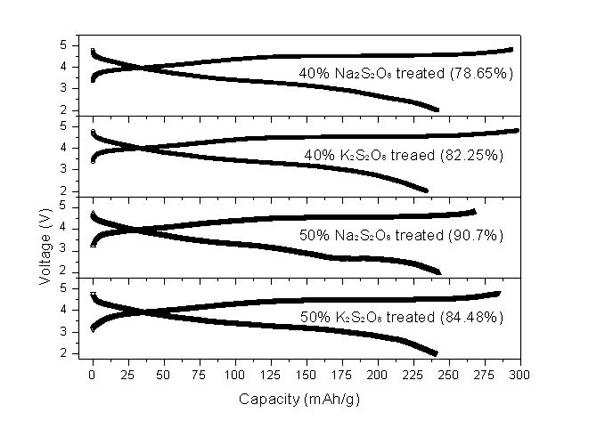

Synthesis and surface modification method of lithium excessive laminar oxide anode material

The invention relates to a synthesis and surface modification method of a lithium rich anode material Li1+xM1-xO2 (M is one or more of Ni, Co and Mn, and X is more than or equal to 0 and less than or equal to 1 / 3) for a lithium ion battery. The method comprises the following steps of: synthesizing a precursor by using a carbonate precipitation method, mixing the precursor and a lithium salt, and calcining for 2 to 20 hours at the temperature of between 800 and 1,100 EG C to obtain a lithium rich material, wherein the prepared lithium rich material has controllable particle size and higher reversible capacity; and dissolving persulfate or sulfate in an amount which is 5 to 80 mass percent of the lithium rich material into deionized water, adding the lithium rich material, stirring for 2 to 100 hours at the temperature of between 25 and 80 DEG C, heating the materials to the temperature of between 100 and 500 DEG C in a muffle furnace, calcining the materials for 2 to 20 hours, fully filtering the obtained materials, and washing off impurities to obtain the surface modified anode material Li1+x-yM1-xO2. The synthesized lithium rich material has controllable particle size; the first charge / discharge efficiency of the lithium rich material and the discharge specific capacity and the cyclical stability under high magnification can be improved; and the method is simple, low in cost, convenient for operation and suitable for industrialized production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Method for combined remediation of organic matter polluted soil

InactiveCN105834207AImprove degradation efficiencyIncrease transfer rateContaminated soil reclamationSulfateSoil organic matter

The invention relates to a method for combined restoration of organic-contaminated soil, comprising the following steps: (1) adding an aqueous solution of a surfactant to the organic-contaminated soil for solubilization treatment; (2) adding persulfate and an activator, Reaction, after the reaction is completed, separate and dry to obtain the repaired organic matter-contaminated soil. Compared with the prior art, the invention has the advantages of high removal rate of adsorbed organic pollutants, low cost, simple and easy method, and environmental friendliness.

Owner:SHANGHAI RES INST OF CHEM IND

Method for selectively recycling lithium from lithium iron phosphate waste

ActiveCN106910959AEfficient leachingLow costWaste accumulators reclaimingProcess efficiency improvementHypochloriteSelective leaching

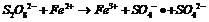

The invention discloses a method for selectively recycling lithium from lithium iron phosphate waste through a direct oxidization method. The method is characterized by comprising the steps that the lithium iron phosphate waste is added into a water solution, meanwhile, an oxidizing agent is added, stirring is carried out, lithium iron phosphate and the oxidizing agent react to generate iron phosphate, lithium ions enter the solution, and therefore a pure lithium-containing solution and iron phosphate solids are obtained. The adopted oxidizing agent comprises one or a mixture of persulfate, ozone, oxygen, pypocholoride and hydrogen peroxide. The molar weight of the oxidizing agent is 0.6-20 times that of lithium iron phosphate. The lithium-containing solution can be directly used for preparing a high-purity lithium product. According to the method, efficient and selective leaching of lithium can be achieved simply by adding a certain amount of oxidizing agent, and the method is mild in reaction condition, short in process and simple in equipment.

Owner:GUANGDONG GUANGHUA SCI TECH

Method for preparing high-density spherical lithium iron phosphate and lithium iron manganese phosphate

InactiveCN1632970AWide variety of sourcesImprove conductivityElectrode manufacturing processesLithium compoundsFerrous ammonium phosphatePersulfate

This invention discloses a high-density ball ferric phosphate lithium and manganous phosphate iron lithium process method used in lithium ion battery positive electrode material in energy material process technique field. The process method comprises the following steps: to use ferric persulfate, phosphor or complex builder or manganese sulfate to process the mixture liquid; to react with the hartshorn solution to generate ball ferrous phosphate ammonium or manganese phosphate ferrous front driver; to mix it with lithium carbonate with mole proportion of one to one after washing and drying; under protection of nitrogen gas and after 600 to 900 degrees for 8 to 48 hours to get the ferric phosphate lithium or manganese phosphate ferrous.

Owner:TSINGHUA UNIV

Filter cake removal fluid and method

InactiveUS6886635B2Control the pace of the reactionCleaning apparatusLiquid/gas jet drillingPersulfatePolysaccharide

A method for removing filter cake from a subterranean borehole comprising drilling the borehole with a drilling fluid that includes additives to form a filter cake having an oxidation-degradable component, preferably a polysaccharide. The filter cake is contacted with a clear brine containing a mixture of a persulfate salt in a variable density brine to degrade the polymers within the filter cake. The persulfate mixture breaks down the filter cake in well bores having temperatures ranging from about 65° F. to 165° F. Concentration of the persulfate sets the pace of the reaction.

Owner:TETRA TECH INC

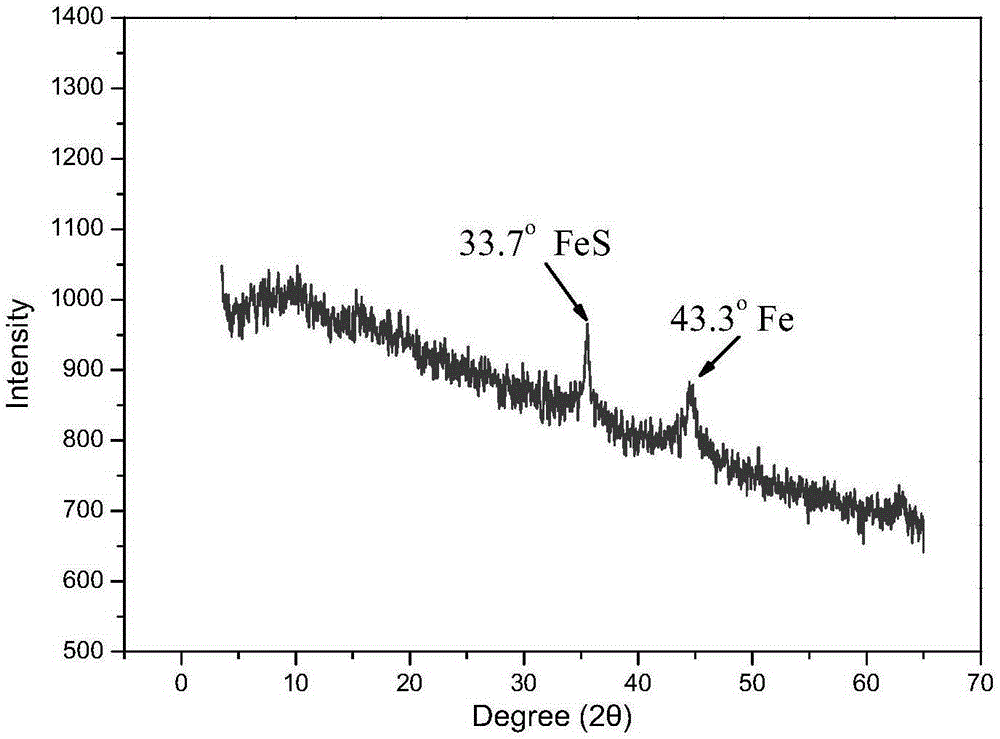

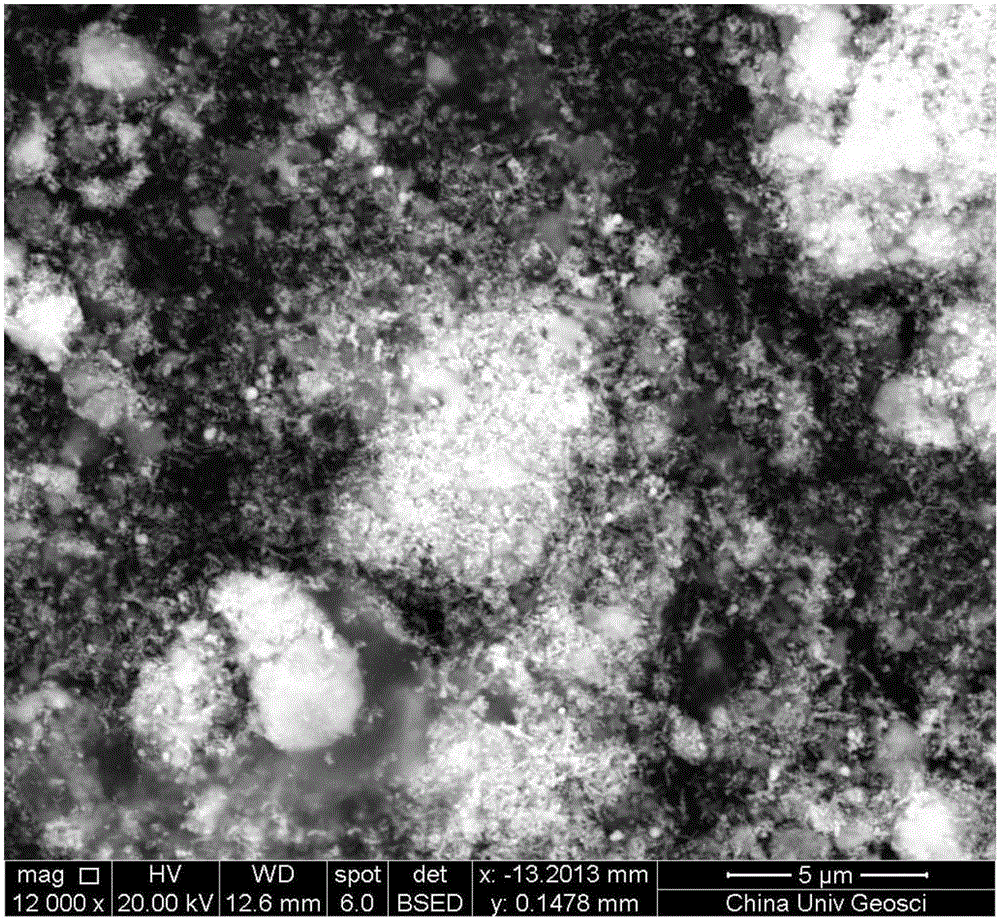

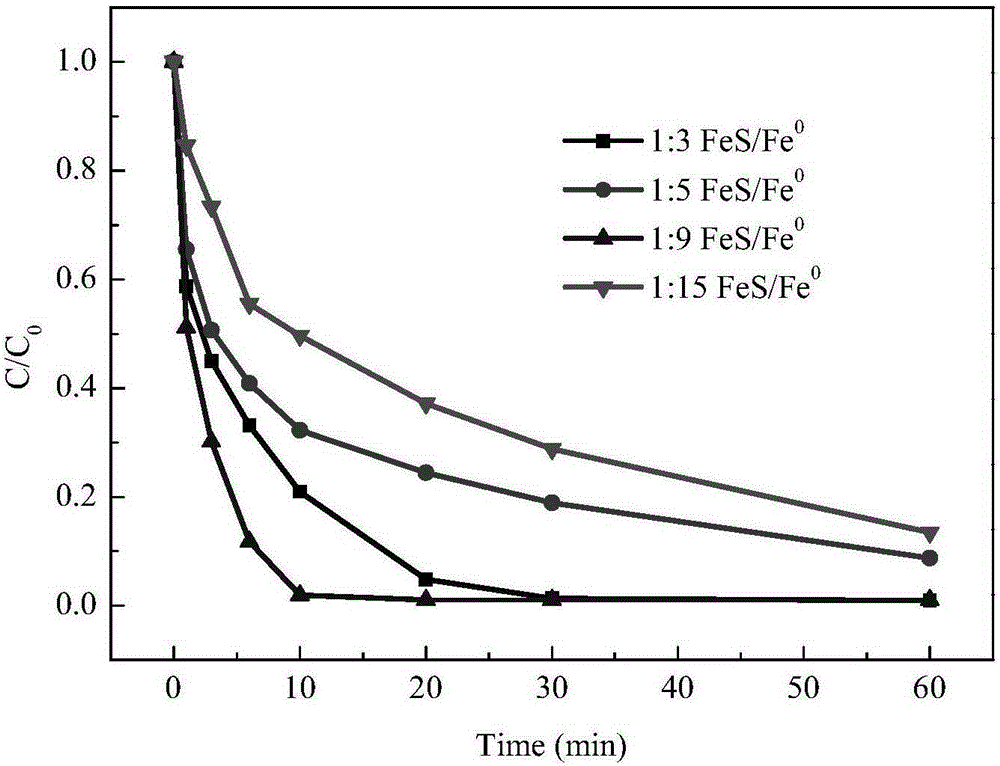

FeS and Fe0 composite and preparation method and application thereof

InactiveCN105174414AEfficient degradationHigh reactivityIron sulfidesWater/sewage treatment by reductionWastewaterSurface water

The invention belongs to the field of chemical materials, and particularly relates to a FeS and Fe0 composite and a preparation method and application thereof. The FeS and Fe0 composite is formed by compositing nano FeS and nano Fe0, the surface of the nano Fe0 is coated with the nano FeS, and the molar ratio of the nano FeS to the nano Fe0 is 2:1 to 15:1. According to the FeS and Fe0 composite and the preparation method and application thereof, the preparation process is simple, convenient, environmentally friendly and feasible, the prepared FeS and Fe0 composite is high in reaction activity, capable of efficiently and rapidly reducing and adsorbing heavy metal ions in waste water within a wider temperature range, a pH value range and a dissolved oxygen content range and further capable of rapidly and efficiently activating hydrogen peroxide and persulfate to make a system generate hydroxyl free radicals and sulfate free radicals to degrade and mineralize organic pollutants, and therefore the FeS and Fe0 composite can be widely applied to degradation of the organic pollutants in surface water and underground water.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

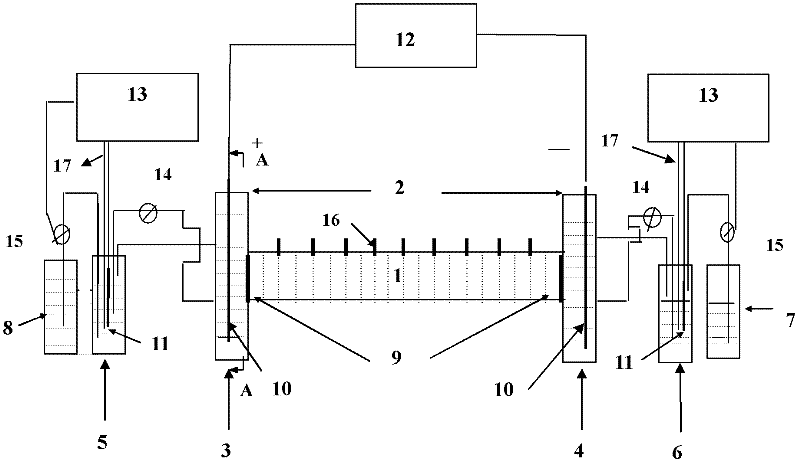

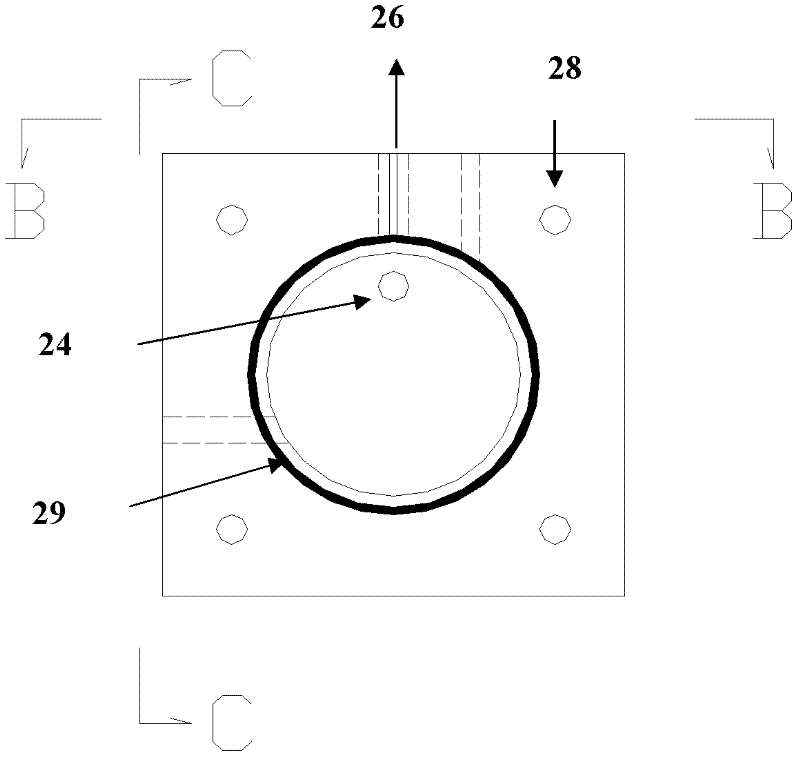

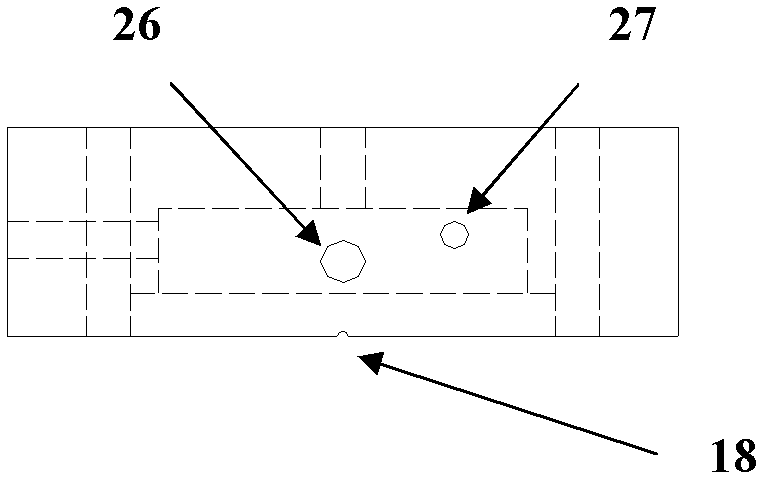

Electric complex-strengthening repairing method and device of heavy metal-organic co-contaminated soil

InactiveCN102513348APromote migrationImprove removal efficiencyContaminated soil reclamationHypochloritePersulfate

The invention provides an electric complex-strengthening repairing method and device of heavy metal-organic co-contaminated soil. The method provided by the invention comprises the following steps of: filling contaminated soil into an electric repairing device, and then adding an oxidant into a cathode electrolyte and an anode electrolyte or directly spraying the oxidant on the contaminated soil, wherein the oxidant comprises hydrogen peroxide, pypocholoride and persulfate; applying a direct-current electric field on a cathode and an anode, wherein the strength of the electric field is 0.5-2 V / cm; and controlling the pH values of the cathode electrolyte and the anode electrolyte to be 3-11. By selecting the suitable for oxidant and controlling the pH value of the electrolyte, the migration of the heavy metal can be effectively increased and the removing efficiency is improved; and meanwhile, the oxidant is used for effectively degrading organic pollutants when the pollutants are migrated, thereby relieving the post-treatment and simultaneously removing the heavy metal and the organic pollutants.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Method for remedying organic compound pollution in soil and/or water

ActiveCN103752601AReduce consumptionWater contaminantsContaminated soil reclamationHydrogenPersulfate

The invention discloses a method for remedying the organic compound pollution in soil and / or water. The method comprises the following steps: adding persulfates into the soil which is dispersed in the water and subjected to the organic compound pollution, or adding the persulfates into the water subjected to the organic compound pollution; adjusting the pH (Potential of Hydrogen) value to 3-12; adding hydrogen peroxide; and finally adding an activating agent, wherein the activating agent is a chelate chelated by metal salts and a chelate agent; the metal salt is selected from one or any combination of two of Fe salts or Mn salts. In the condition that the same amount of the organic compound is oxidized, the method provided by the invention can be used for greatly saving the consumption of hyperoxides.

Owner:BEIJING GEOENVIRON ENG & TECH

Synthesizing microcapsules of storing energy through phase change by using method of emulsion polymerization

A process for synthesizing the phase-change energy-accumulating microcapsules by emulsion polymerizing method features that the liposoluble organic phase-change material, vinyl or bivinyl monomers, water, non-ionic or anionic surfactant and the persulfate, percarbonate, perborate, hydrogen peroxide, or their redox pair take part is core-shell polymerizing reaction in emulsion to obtain said microcapsules.

Owner:DONGHUA UNIV

Transformation liquid for preparation of corrosion-resistant oxidation film on aluminium alloy surface and method of use thereof

InactiveCN101139708AImprove corrosion resistanceGood adhesionMetallic material coating processesHigh resistancePersulfate

The invention discloses a transforming solution for preparing anti-corrosion compound oxidation film on an aluminum alloy surface and a using method for the oxidation film. The invention is characterized in that, the transforming solution is a film-forming promoter containing rare-earth salt (nitrate or sulfate and compound salt of cerium, praseodymium, and neodymium), such compound oxidant as radical of permanganate, nitrate and perchlorate, etc., film-forming promoter of vanadium salt and strontium salt, etc.; the transforming solution contains no sexavalent chromium, is environmental friendly; the reaction speed is improved by the compound oxidant and the film-forming promoter, no heating is needed for the chemical transforming, the treating time is 1-5 min. The invention can rapidly prepare under room temperature compound oxidation film comprising compound rare-earth oxide, alumina and manganese oxide with good resistance to corrosion on aluminum alloy surface. The treating solution from the invention is of rapid film-forming speed, simple process, even film layer, high resistance to corrosion, and low environmental pollution, etc.

Owner:陈东初 +2

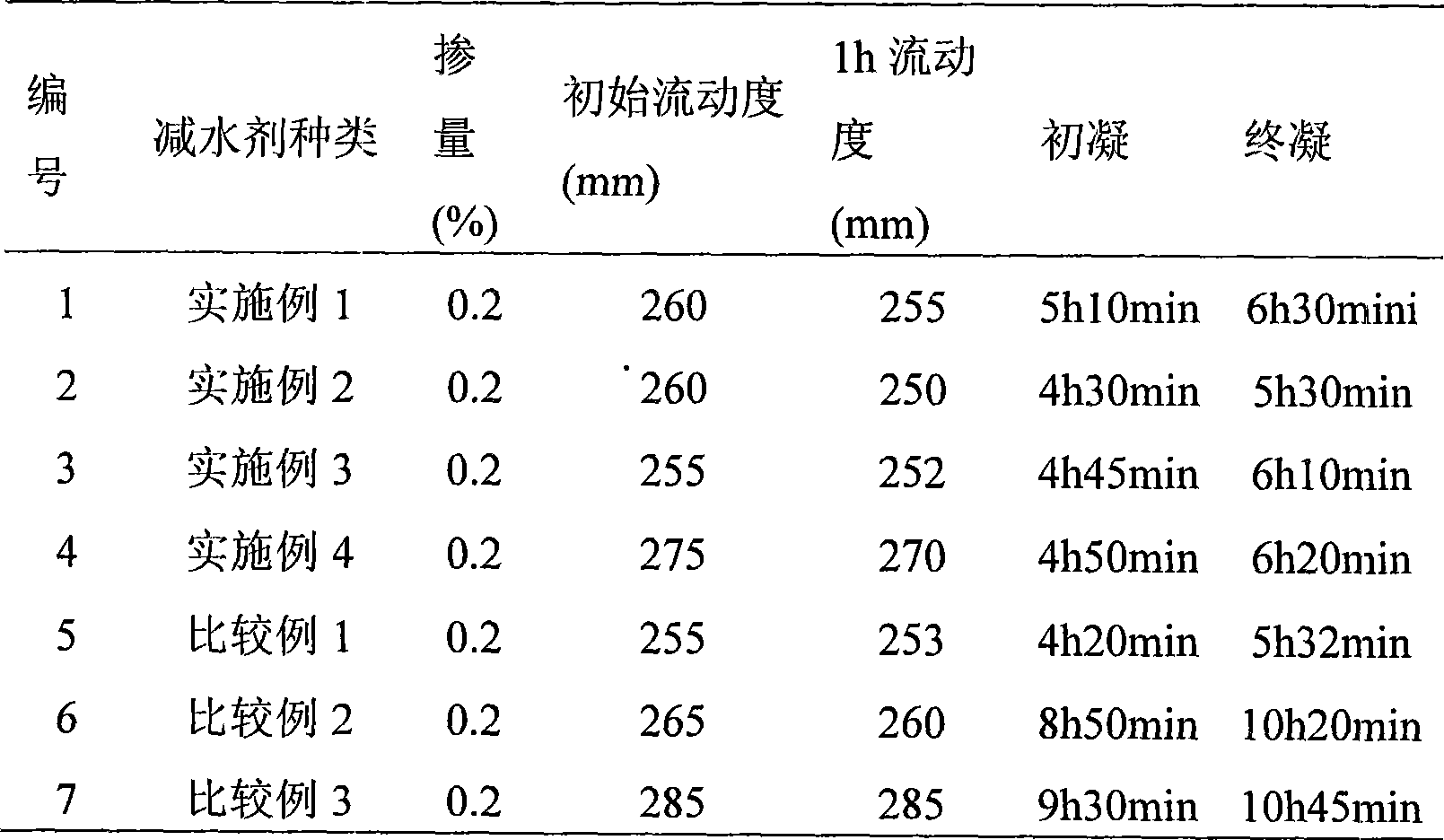

Method for preparing sustained-release polycarboxylic water reducer

The invention discloses a method for preparing a sustained-release polycarboxylic water reducer and belongs to the field of water reducers. The water reducer is prepared by the following steps: adding a macromonomer of a polyoxyethylene ether or ester containing an unsaturated double bond, an unsaturated sulfonic acid or a salt monomer a thereof, a mono-olefin carboxylic acid derivative b, a diolefin carboxylic acid derivative c and water to a reaction kettle; reacting at the temperature of between 60 and 85 DEG C for 1.0 to 6.0 hours under the action of persulfate of an initiator; and reducing the temperature to 40-55 DEG C, and neutralizing the mixture to a pH between 6 and 8 by using alkaline solution. The method for preparing the sustained-release polycarboxylic water reducer introduces the mono-olefin carboxylic acid derivative b and the diolefin carboxylic acid derivative c into a main chain of polycarboxylic acid, so that the prepared polycarboxylic water reducer has sustained-release effect on the fluidity of concrete. Therefore, the loss and evaporation of water content of concrete caused by long-time transportation and high temperature are effectively prevented, a bleeding phenomenon resulted from over-large slump of early strength concrete is avoided, and the problem of over-quick loss of the slump in the engineering is solved. The he sustained-release polycarboxylic water reducer can be applied to delivering and pumping construction of the concrete in high-temperature season.

Owner:赣州科隆百亚新材料有限公司

Conductive polymer and method for producing the same, conductive polymer dispersion, and solid electrolytic capacitor and method for producing the same

InactiveUS20110233450A1Improve conductivityLow ESRHybrid capacitor electrolytesSolid electrolytic capacitorsPolymer sciencePersulfate

The present exemplary embodiment provides a conductive polymer having high conductivity and a method for producing the same, and a conductive polymer dispersion, and further provides a solid electrolytic capacitor having low ESR and a method for producing the same. A conductive polymer is produced by a method including the steps of dissolving a sulfonic acid group-containing resin having a weight average molecular weight of 2,000 or more and 50,000 or less and a compound represented by the following formula (1) in a solvent; mixing at least one monomer selected from pyrrole, thiophene, and derivatives thereof in an obtained solution; subjecting the monomer to chemical oxidative polymerization, using a persulfate, to obtain a conductive polymer; and washing the conductive polymer to remove the compound represented by the formula (1) contained in the conductive polymer.CnHn+2(OH)n (1)wherein n represents an integer of 3 to 6.

Owner:TOKIN CORP

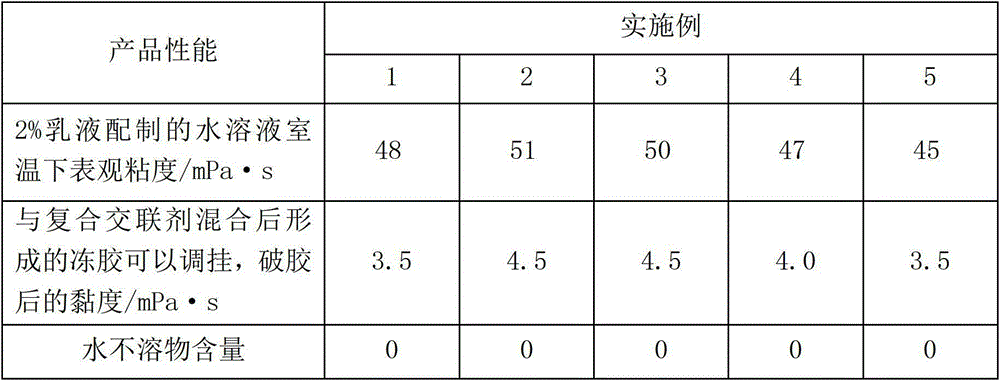

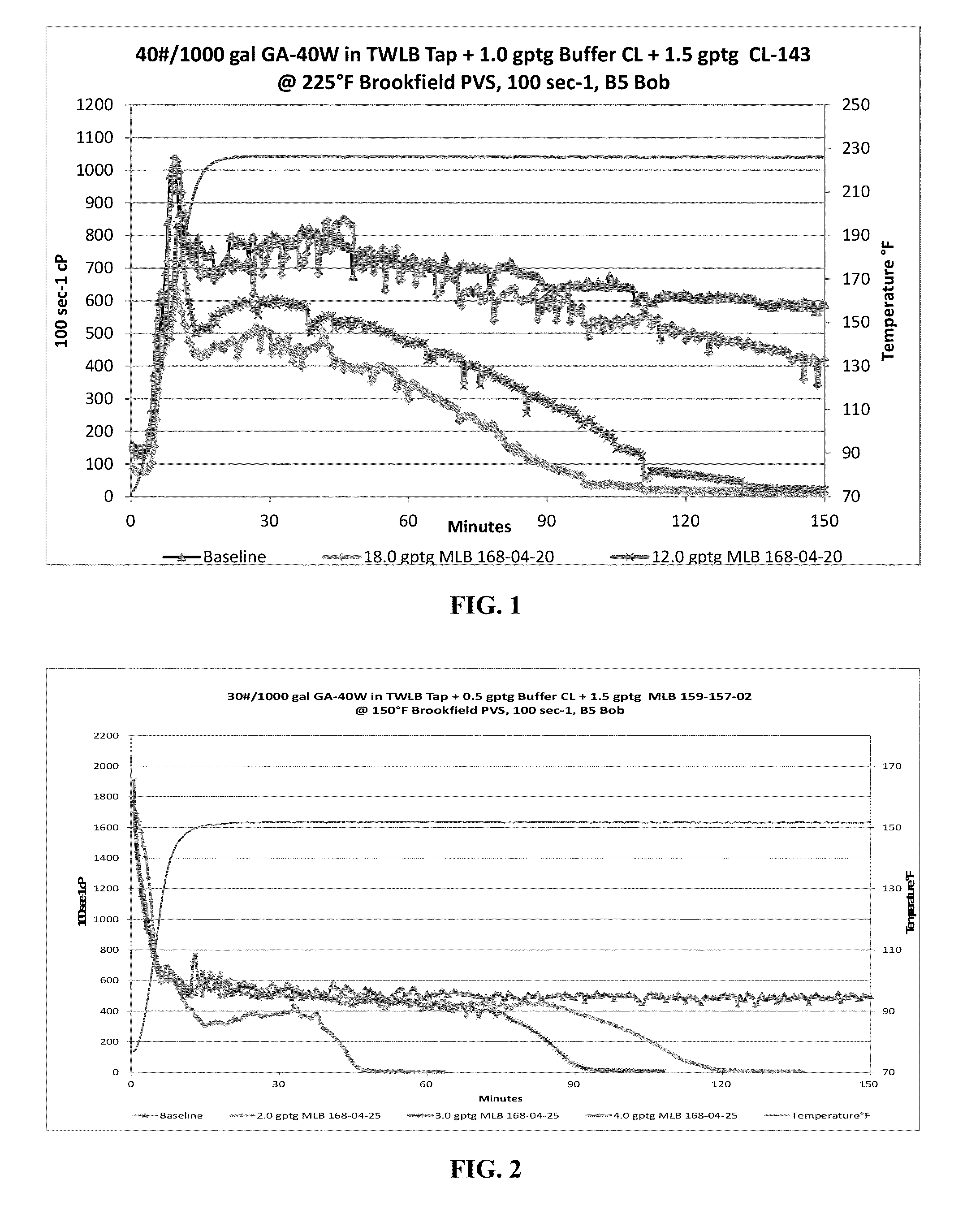

Inverse emulsion polymer thickener for fracturing fluid and preparation method thereof

ActiveCN103146372AAvoid harmMeet the fracturing constructionDrilling compositionPolymer sciencePersulfate

The invention relates to an inverse emulsion polymer thickener for a fracturing fluid and a preparation method thereof. The thickener is polymerized by water, 2-acrylamidyl-2-methyl sodium proparesulfonic acid liquid with mass fraction of 50%, alkyl acrylamide, acrylamide, a cationic monomer, N, N-methylene bisacrylamide, a tween-80 emulsifier, ethylene diamine tetraacetic acid disodium salt, 30% sodium hydroxide, white oil, acrylic ester, a span-80 emulsifier, sulfite, a peroxysulphate initiator, a water-soluble azo initiator and OP-15. According to the invention, raw materials are industrial products, and purification is not needed before reaction; polymerization is initiated by initiators by adding a complexing agent, and the preparation process is simple; the thickener provided by the invention is fast in dispersing, easy to prepare, free from pollution and harm, small in use level and good in stability, in particular resists high temperature of 220 DEG C, and is suitable for fracturing a high-temperature stratum; and the thickener is higher in shear resistance, can meet the fracturing construction of high flow, has high sand carrying performance, and is free from residue and is not harmful to the reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oxidative breakers in a silicone based suspension

An oxidative breaker system for use in reducing the viscosity of a guar-based suspension includes a silicone oil carrier fluid, an oxidizer and a suspension aid. The suspension aid is preferably fumed silica. The oxidizer may be selected from the group consisting of alkali metal peroxide, transition metal peroxide, persulfate, bromide and bromate. In highly preferred embodiments, the oxidizer is magnesium peroxide or calcium peroxide. Also disclosed is a method for breaking a guar-based suspension with the inventive oxidative breaker system.

Owner:PNC BANK NAT ASSOC

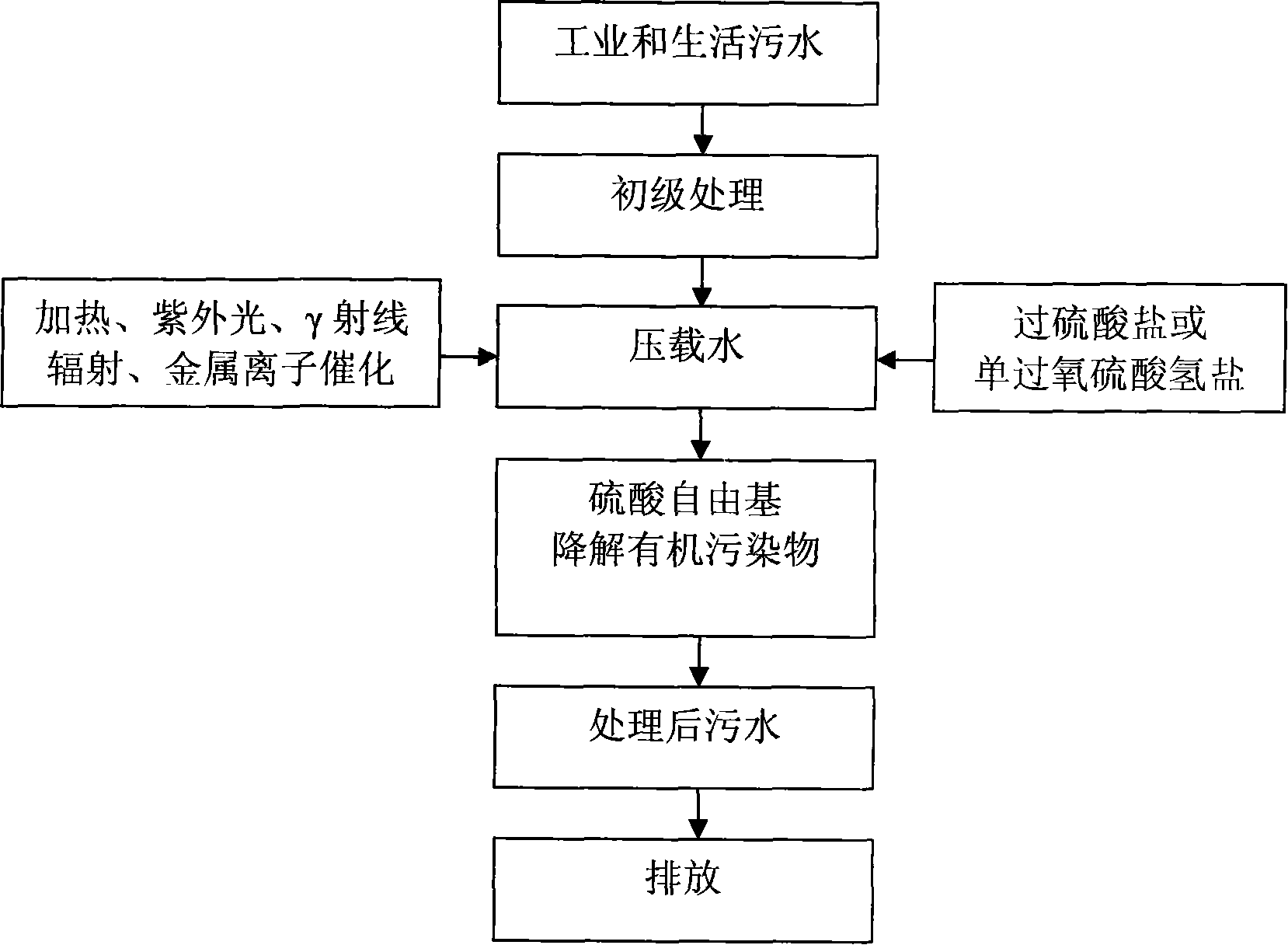

Method for processing sulphuric acid free radical oxidized water

InactiveCN101172691ANo secondary pollutionImprove processing efficiencyWater/sewage treatment by irradiationWater/sewage treatment by oxidationDecompositionFenton reagent

Owner:DALIAN MARITIME UNIVERSITY

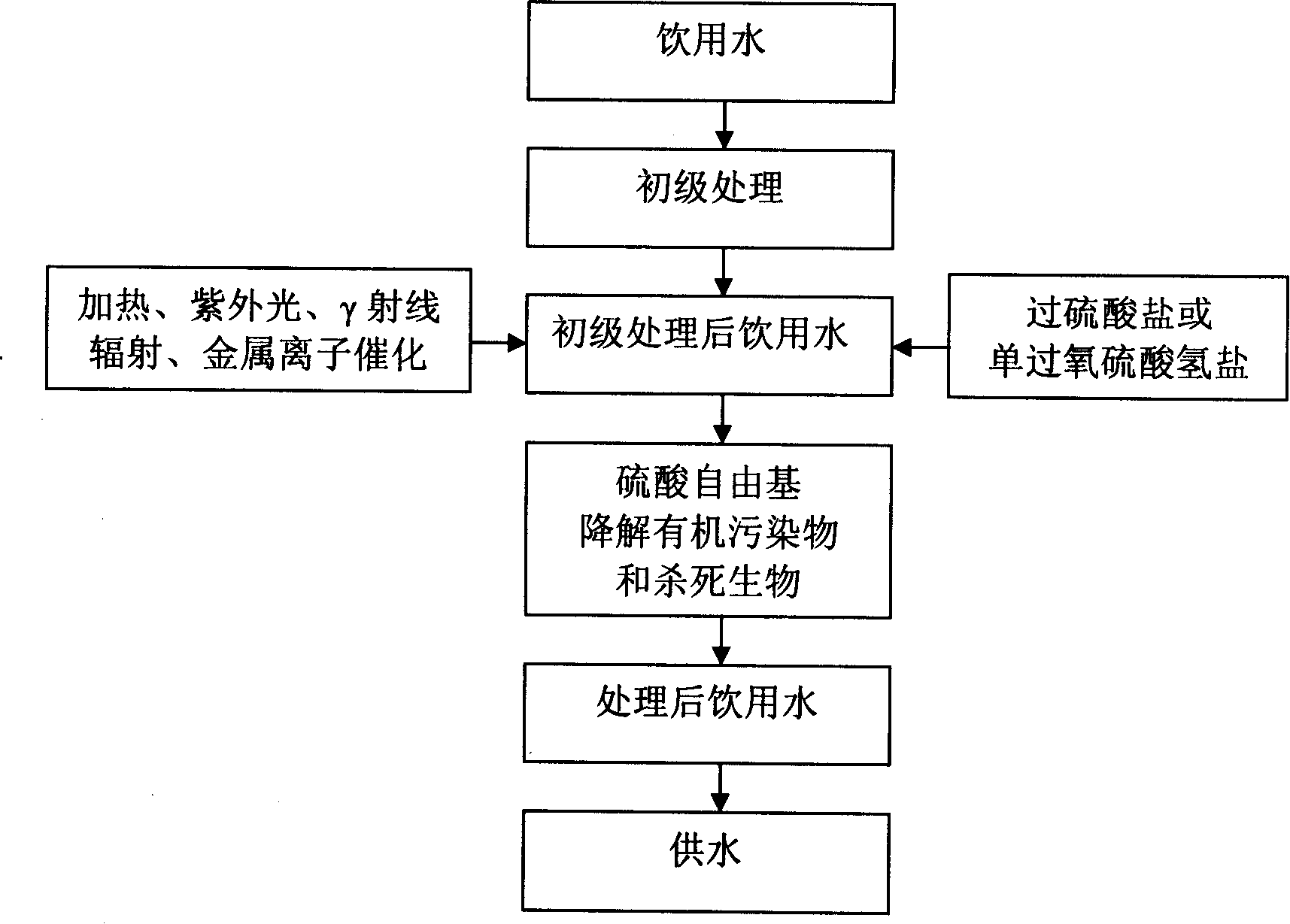

Method for treating ship ballast by high-level oxidation technology based on sulphuric acid free radical

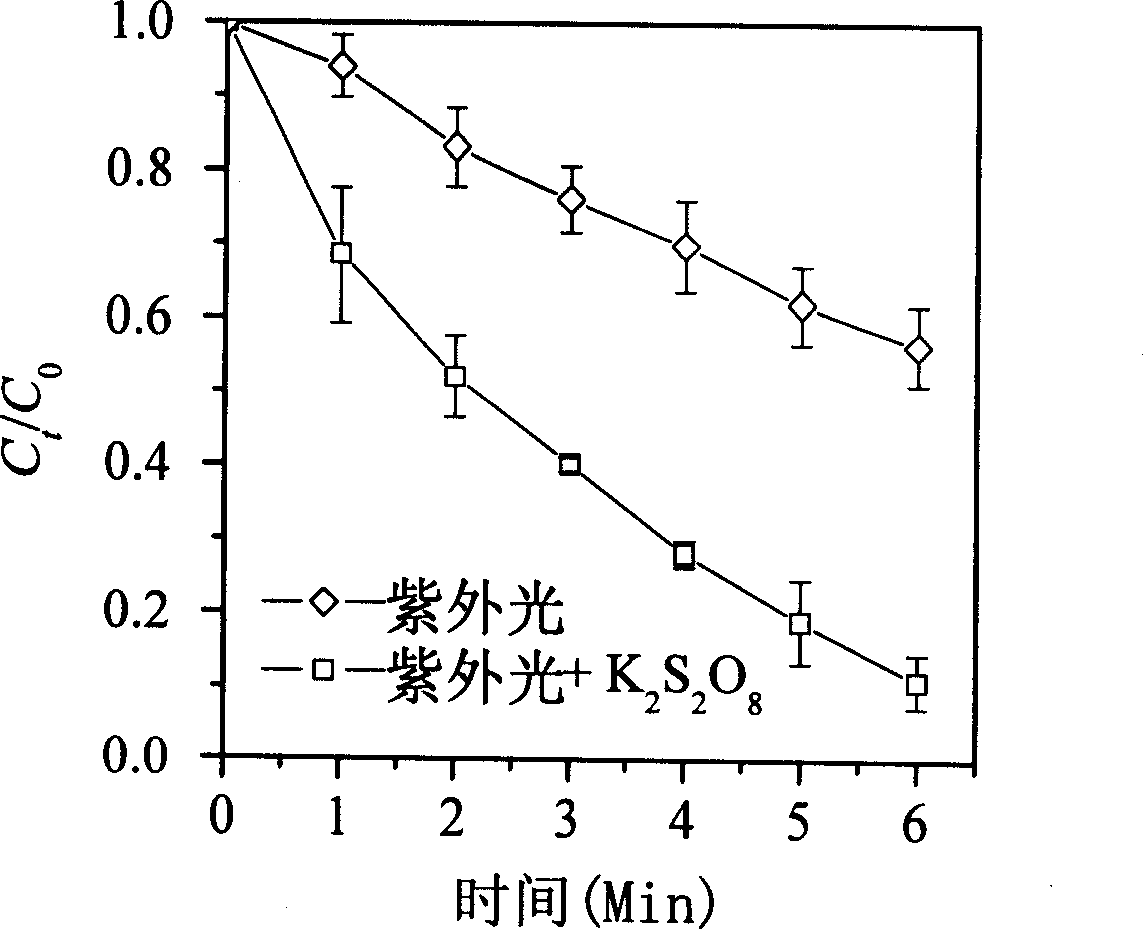

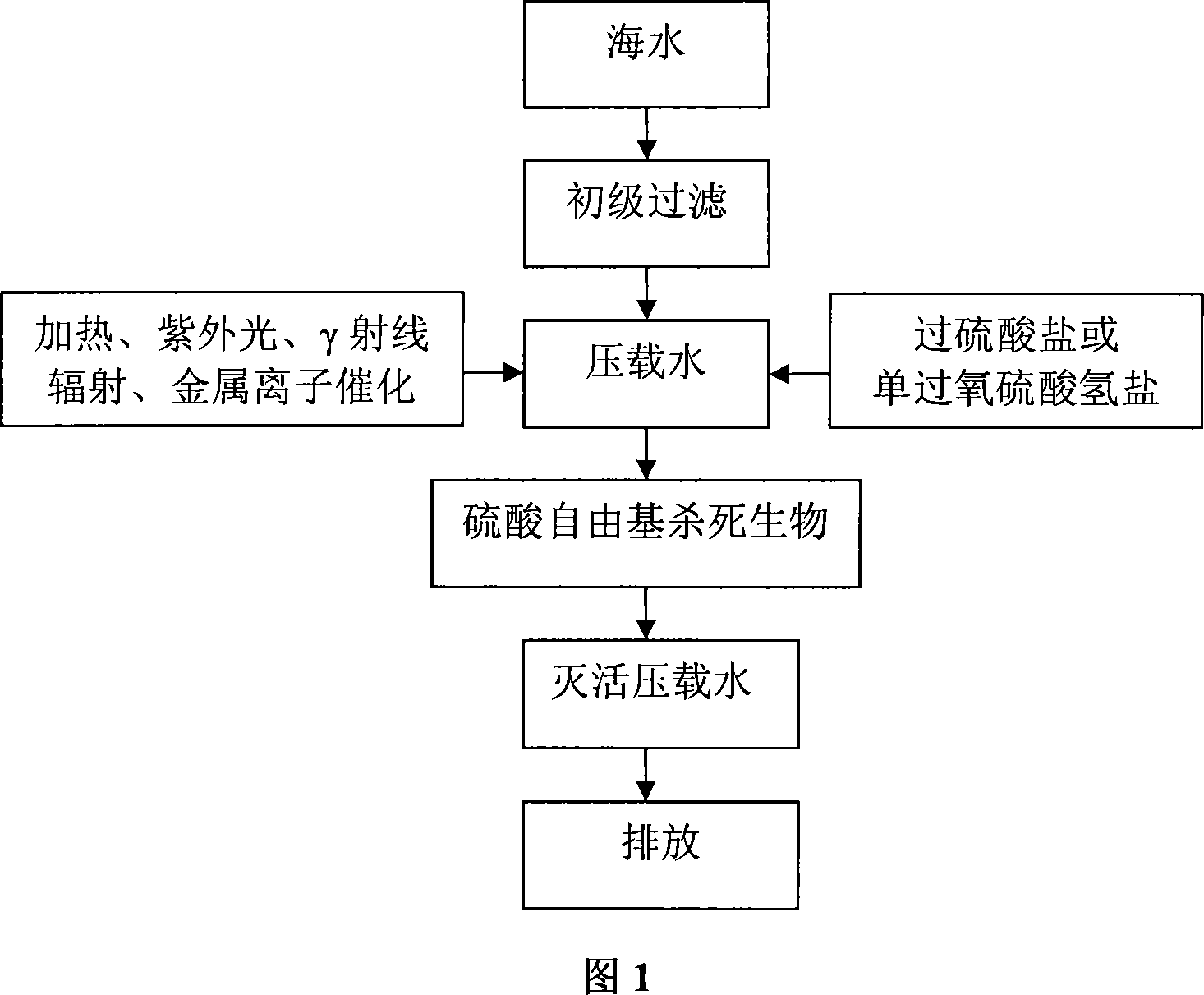

InactiveCN101045573ANo secondary pollutionReduce energy consumptionWater/sewage treatment by irradiationSeawater treatmentHydrogenPersulfate

A process for treating the water-ballast of ship by high-grade oxidizing technique based on free radicals of sulfuric acid in order to kill the microbes in it includes such steps as filtering, adding persulfate or hydrogen monoperoxysulfate salt, generating the free radicals of sulfuric acid by thermo-decompsoing, ultraviolet decomposing, gamma-ray radiation, or metallic ion' s catalytic decomposing, and reaction between said free radicals and water-ballast.

Owner:DALIAN MARITIME UNIVERSITY

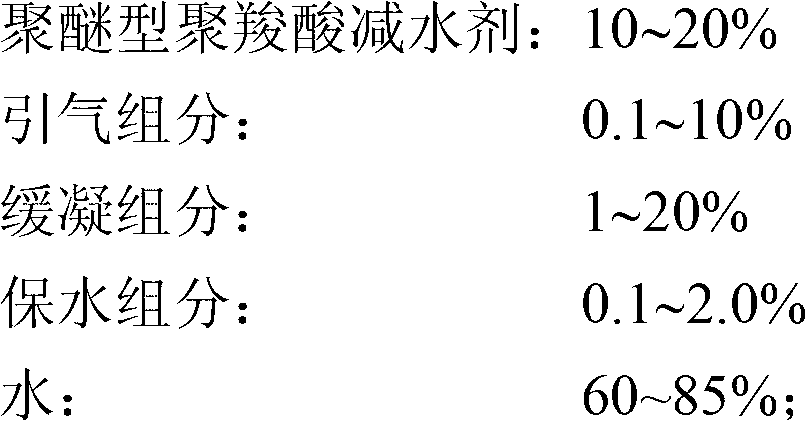

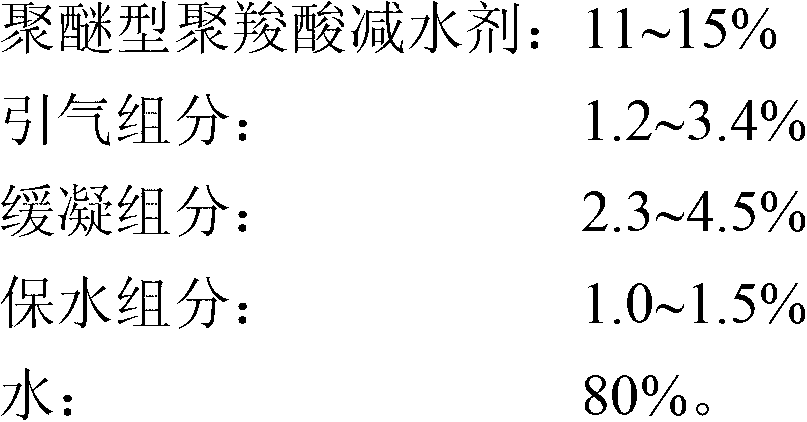

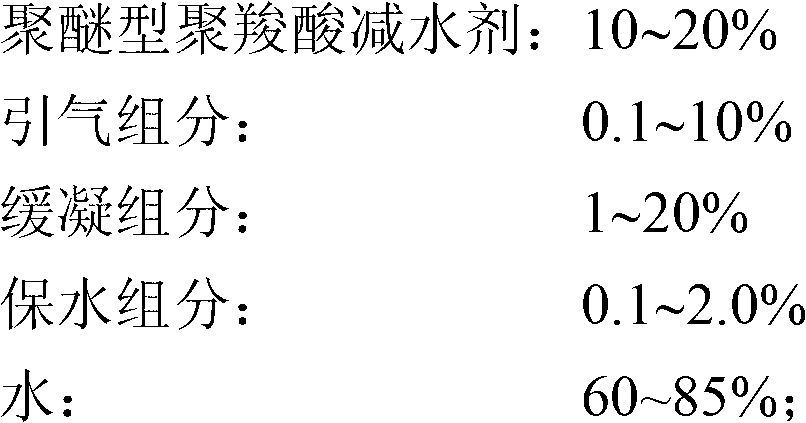

Water-based mortar modifier, its preparation method and application

The invention discloses a water-based mortar modifier, its preparation method and application. The modifier comprises the following preparation raw materials by mass: 10-20% of polyether polycarboxylic acid water reducing agent, 0.1-10% of air entraining components, 1-20% of coagulation retarding components, 0.1-2% of water retention components and 60-85% of water. The polyether polycarboxylic acid water reducing agent is prepared by the method of: dissolving an enol polyether macromonomer, acrylic acid, and maleic anhydride in water, conducting heating to raise the temperature to 60-70DEG C, then adding a persulfate water solution dropwisely, carrying out heat preservation under 60-65DEG C for 2-4h, then performing cooling to a temperature of 45DEG C, and adjusting the pH value of the system to 7-8, thus obtaining the polyether polycarboxylic acid water reducing agent. The modifier provided in the invention can form a protective film on a cement particle surface, and at the same time can produce uniform and tiny bubbles, as well as reduce the friction between the particles in the system, thus effectively improving the workability and plasticity of the mortar system. Furthermore, the mortar modifier provided in the invention is a water-based multifunctional building mortar modifier, and is convenient to use. Doping of the modifier can significantly improve the workability and vicidity of mortar, and can maintain the properties effectively for 8-16 hours.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

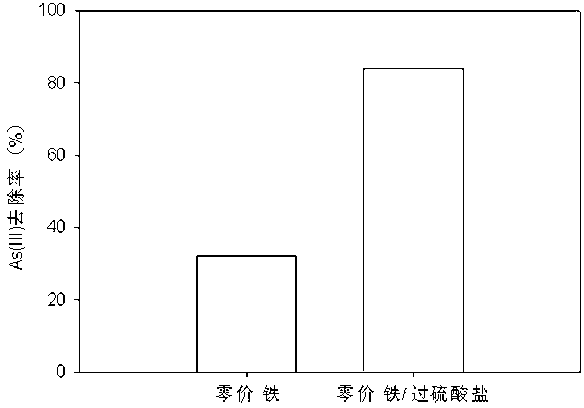

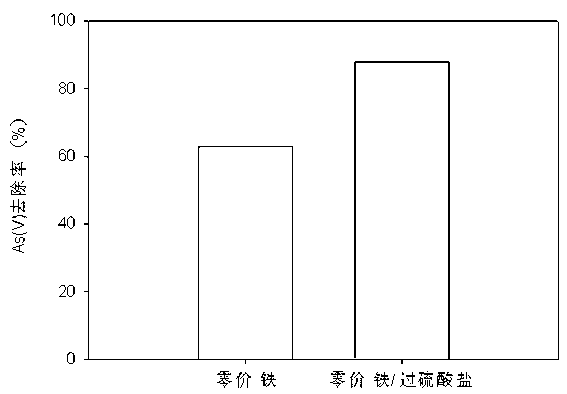

Water treatment method for removing arsenic by strengthening zero-valent iron

ActiveCN103342410AEasy to operateEasy to useWater/sewage treatment by oxidationWater treatment systemPersulfate

The invention relates to a technology for removing and controlling arsenic which has very high toxicity in water, and discloses a water treatment method for removing arsenic by strengthening zero-valent iron, which can be used for groundwater repair, drinking water treatment, industrial arsenic-containing wastewater treatment, sewage deep treatment and integrated small-scale water treatment systems. The water treatment method specifically comprises the following steps of: adding persulfate and zero-valent iron into water containing arsenic, wherein the persulfate is added in a molar ratio of the persulfate to arsenic of (5:1)-(100:1), and the molar ratio of the zero-valent iron to the persulfate in the water is (1:1)-(10:1); and when the mixed solution is fully mixed, filtering or depositing to finish the removal of arsenic. The water treatment method is very simple to operate, easy to popularize and apply and safe to use, and can be used for ensuring the water quality safety.

Owner:SUN YAT SEN UNIV

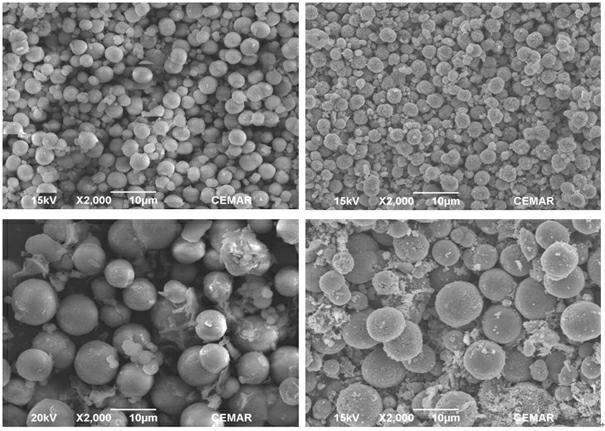

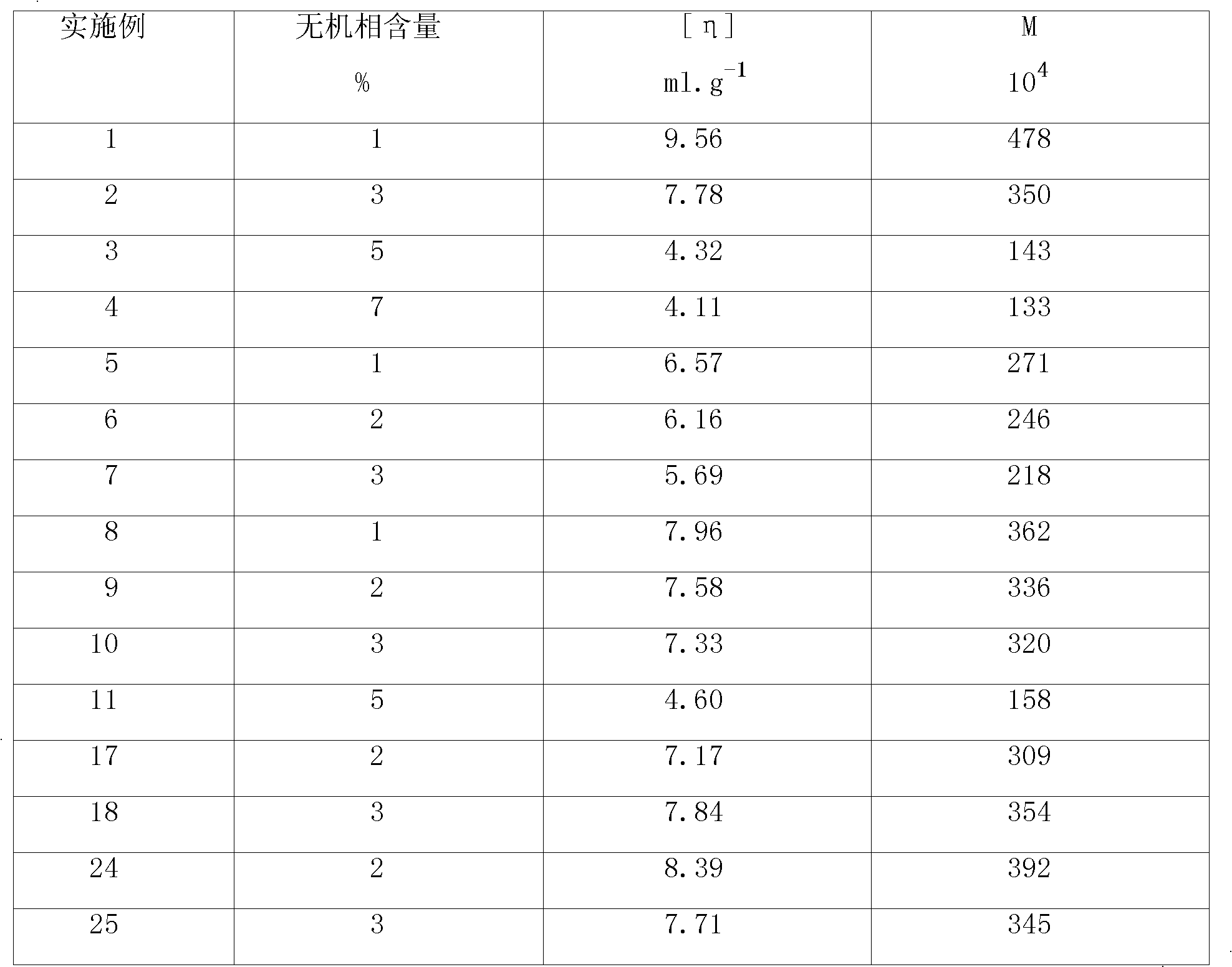

Polyacrylamide inorganic nano composite drilling fluid aid and preparation method thereof

The invention discloses a polyacrylamide inorganic nano composite material prepared by adopting a polymerization composite method of polyacrylamide and nano inorganic phase and a drilling fluid aid. The inorganic material is nano dispersed suspension formed by co-precipitation hydrothermal reaction and surface treatment reaction of laminated silicate, nitrate or the both. The suspension is mixed with acrylamide aqueous solution, cosolvent and complexing agent; and the mixture is polymerized under the initiation of persulfate and sulfite to form the polyacrylamide nano composite material with proper molecular weight, good water solubility and good tackifying effect, wherein the dimension of the inorganic phase is 30 to 70 nanometers. The drilling fluid prepared from the composite material has remarkable viscosity increment, good rheological property and filtration control, temperature and salt resistance and protection property on a reservoir layer, and improves the yield and recovery rate.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

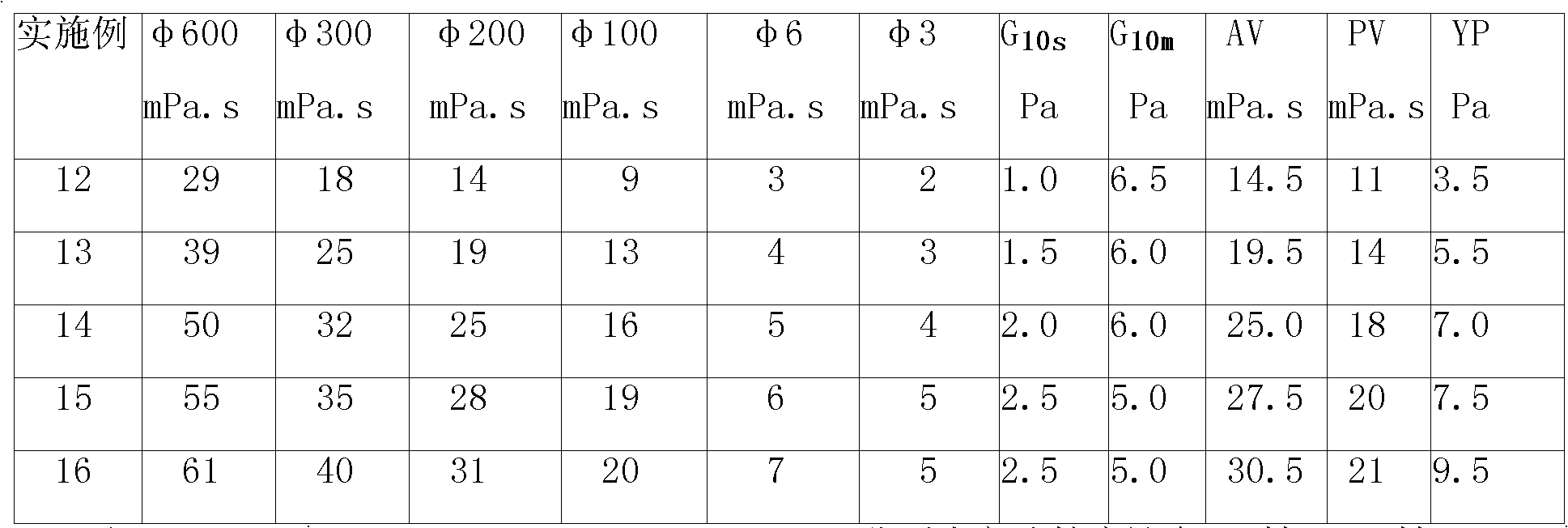

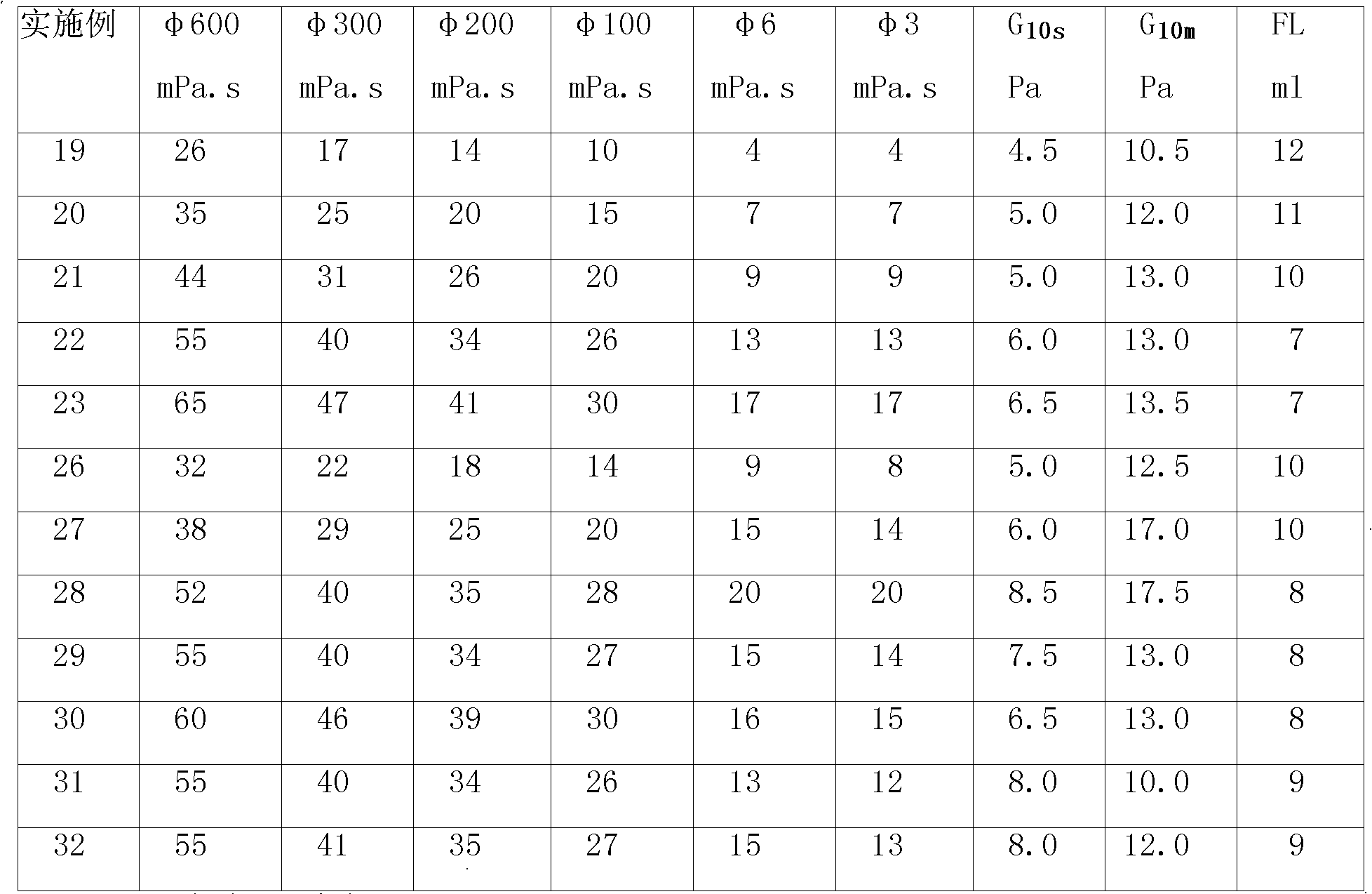

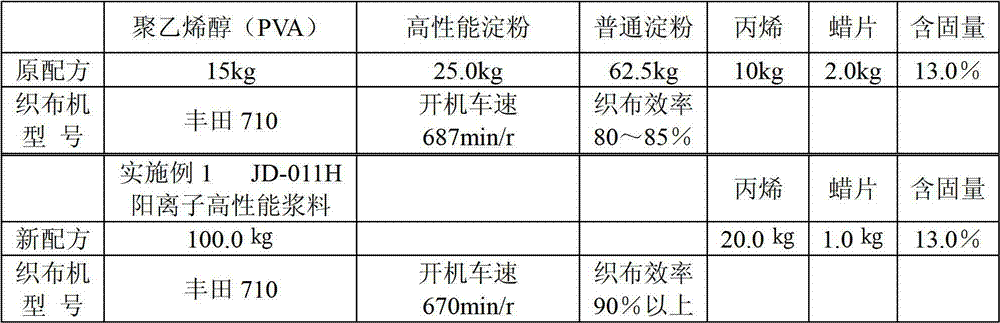

Cation high performance slurry

The invention discloses cation high performance slurry. The slurry is formed by commixture reaction of raw materials including corn starch, sodium hydroxide, trimethylamine hydrochloride and persulfate with the following quality content: 80-95% of the corn starch, 1-10% of the sodium hydroxide, 1-15% of the trimethylamine hydrochloride, and 0.1-15% of persulfate. The cation high performance slurry has the advantages of strong adhesive force, good film formation property, tenacious chorion and good elasticity, the flexibility (anti-fatigue property) is improved by 3-4 times compared with common modified starch slurry, the cation high performance slurry has good wear-resisting property and ageing resistance, and a serous fluid has good liquidity and stable viscosity under an I normal temperature condition; and the slurry contains no polyvinyl alcohol, when a spinning purified cotton yarn is subjected to a sizing process, a variety with 60 yarns with common compactness can be processed without polyvinyl alcohol, when sash cotton or purified cotton yarn with more than 60 yarns is subjected to sizing process, little polyvinyl alcohol or no polyvinyl alcohol is used, desizing is easy, waste water of serous fluid is easy to process, pollution of the waste water to the environment is small, and zero-pollution discharge in the production process is realized.

Owner:YIXING JUNDA SLURRY TECH

Method for treating organic waste water by using electrochemistry under assistance of persulfate

InactiveCN102249378AReduce dosageLess side effectsWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationElectrochemical responseSulfate radicals

The invention relates to a method for treating organic waste water by using electrochemistry under the assistance of persulfate. The method comprises the following steps of: putting sulfate, a divalent or tervalent ferric salt and organic waste water into an electrochemical reactor consisting of a DSA (Dimensional Stable Anode) and an anti-corrosive cathode; adjusting the pH value of a reaction liquid to 3-9; stirring; and switching on a power supply for reacting. The method is characterized in that: special requirement on the ferric salt is not made, the ferric salt can be divalent or tervalent, generated free sulfate radicals can be used for effectively treating organic pollutants in water; meanwhile, in the electrochemical reactor, reutilization of divalent ferric ions can be realized under the reducing action of the cathode, so that the adding amount of the ferric salt is reduced, side reactions between an excessive amount of ferric salt and free sulfate radicals are reduced, ineffective consumption of free sulfate radicals is avoided, and the generation of iron sludge is reduced simultaneously.

Owner:WUHAN UNIV

Method of treating organic wastewater based on Fenton-like reaction of iron-based organic-framework material

InactiveCN104310565AIncrease the areaLarge apertureWater treatment compoundsWater contaminantsSulfate radicalsPtru catalyst

The invention discloses a method of treating organic wastewater based on Fenton-like reaction of an iron-based organic-framework material. The method comprises the following steps: by taking the iron-based organic-framework material as a catalyst and taking persulfate or hydrogen persulfate as an oxidant, degrading organic pollutants by virtue of sulfate radicals formed in a reaction process. The iron-based organic-framework material has a relatively great specific surface area and a relatively great bore diameter, is regular in metal ion spatial arrangement, uniform in distribution, high in active point location density, high in catalytic activity, environmentally friendly, easy to recycle and capable of being recycled. And moreover, the method is simple in equipment, convenient to operate, capable of efficiently degrading organic pollutants in water within a relatively wide pH value range, and very great in application prospect.

Owner:UNIV OF JINAN

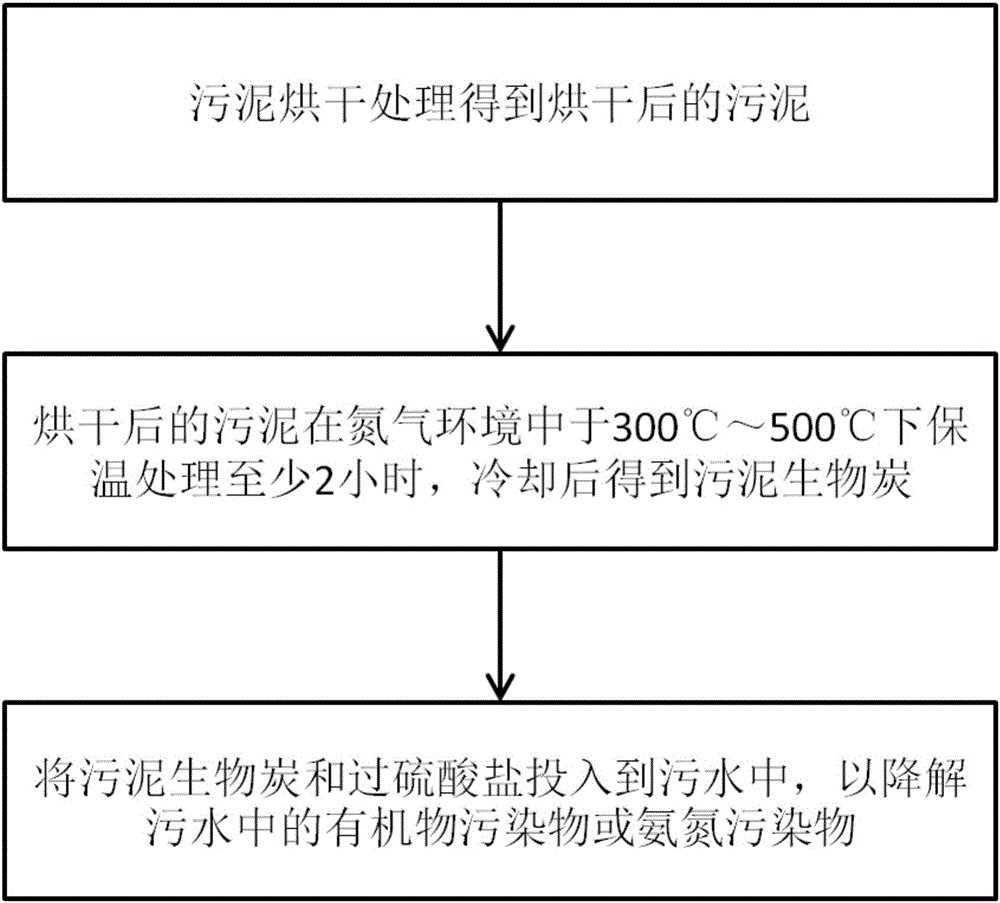

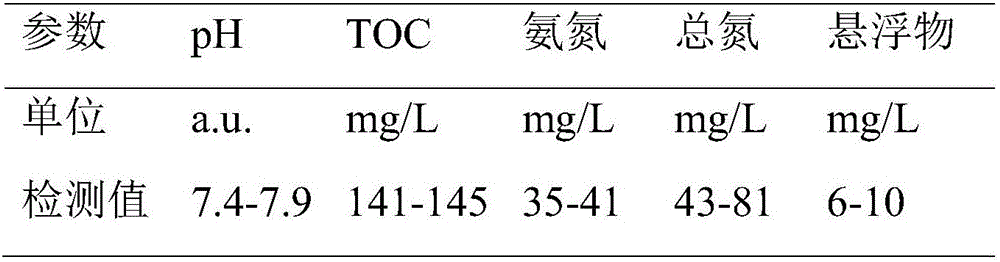

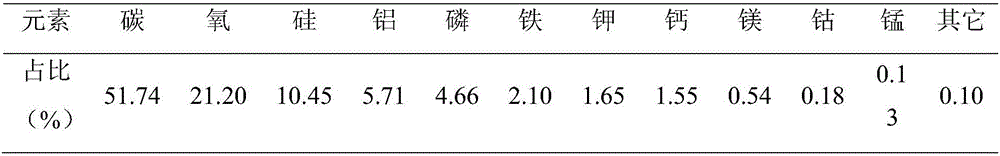

Method for degrading organic substances or ammonia nitrogen by catalyzing persulfate through sludge biochar

ActiveCN106045002AEfficient degradationEasy to prepareWater/sewage treatment by oxidationPersulfateSludge

The invention discloses a method for degrading organic substances or ammonia nitrogen by catalyzing persulfate through sludge biochar. The method includes the following steps that firstly, sludge is dried to obtain dried sludge, then the dried sludge is subjected to pyrolysis treatment for at least 2 h in the ammonia environment at 300-500 DEG C, and then sludge biochar is obtained after cooling; secondly, the sludge biochar and persulfate are put into sewage to degrade the organic substances or ammonia nitrogen in the sewage. By improving key preparation conditions of sludge biochar and increasing the application ratio of the sludge biochar and persulfate, under the catalytic function of the sludge biochar, persulfate can efficiently degrade the organic substances and ammonia nitrogen in sewage on the basis of catalysis and oxidization of sulfate free radicals, the problem of organic pollutant and the ammonia nitrogen pollution problem in sewage are effectively solved, and the degradation effect is good.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing carboxylic styrene butadiene latex for carpet back coating

The invention discloses a preparation method of a back lining material used as the back lining of carpets, more particularly relates to a preparation method of the carpets and carboxylic styrene butadiene latex. Butadiene and cinnamene are taken as main monomers, then functional monomers and auxiliary monomers are added, anion emulsifier and non-ionic emulsifier are used complexly, pyrolysis type persulfates of potassium peroxydisulfate water solution or ammonium persulfate water solution, etc. are used as activator, n-dodecylmercaptan is used as molecular weight regulator, a batch feeding or dropwise feeding way is adopted, and vacuum flashing desaeration is used for composing the environment protection carboxylic styrene butadiene latex used as the backing lining of carpets. The carboxylic styrene butadiene latex prepared by the method has good elasticity and enduring performance, high adhesion strength and low volatility harmful substances after being used in woven carpets and tufted carpets, thereby being a green environment protection product upon meeting the requirements of environment protection.

Owner:溧阳巨神科技材料有限公司

Process for preparing nano silicon dioxide-acrylate composite emulsion

The preparation process of nanometer composite silica-acrylate emulsion includes the following steps: mixing small molecular alcohol, silane as coupling agent, deionized water and acid solution through stirring; adding the hydrolyzed product of nanometer silica and silane as coupling agent into benzene derivative solvent under the protection of inert gas via stirring; centrifugal separation, flushing with alcohol or acetone and vacuum drying to obtain modified nanometer silica; dispersing acrylate monomer into fine emulsion; mixing the modified silica, anionic or non-ionic emulsifier, stabilizer and water, emulsifying and adding soluble persulfate or liposoluble peroxide; and adding the fine emulsion into the mixed solution to obtain the nanometer composite silica-acrylate emulsion. The present invention has less environmental pollution and is suitable for industrial application.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Preparation of polycarboxylic acid water reducing agent for prefabricated part

The invention discloses a preparation method for a polyocarboxy acid water reducing agent for precast units, which belongs to the field of water reducing agent. Under the action of a persulphate initiator, methoxypolyethylene glycol acrylate, acrylic acid, unsaturated sulfonic acid or a salt monomer b thereof, unsaturated amide or a salt monomer c thereof are copolymerized in an aqueous solution; a terminator is used to process the rest initiator of the reaction at a later polymerization stage; and finally alkaline solution is used for neutralization and the water reducing agent is obtained. The methoxypolyethylene glycol with high polymerization degree is introduced as a grafting side chain, thereby making the prepared water reducing agent effectively shorten the concrete coagulation time without reducing the concrete initial fluidity and improving the concrete compression strength. The early strength type polyocarboxy acid high performance water reducing agent can be widely applied to the construction of various concrete projects with a low temperature or early strength requirements, in particular to the low energy consumption production process of precast concrete units. The water reducing agent has wide generalization space.

Owner:HUIZHOU JIANKE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com