Patents

Literature

106 results about "Spinel ferrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

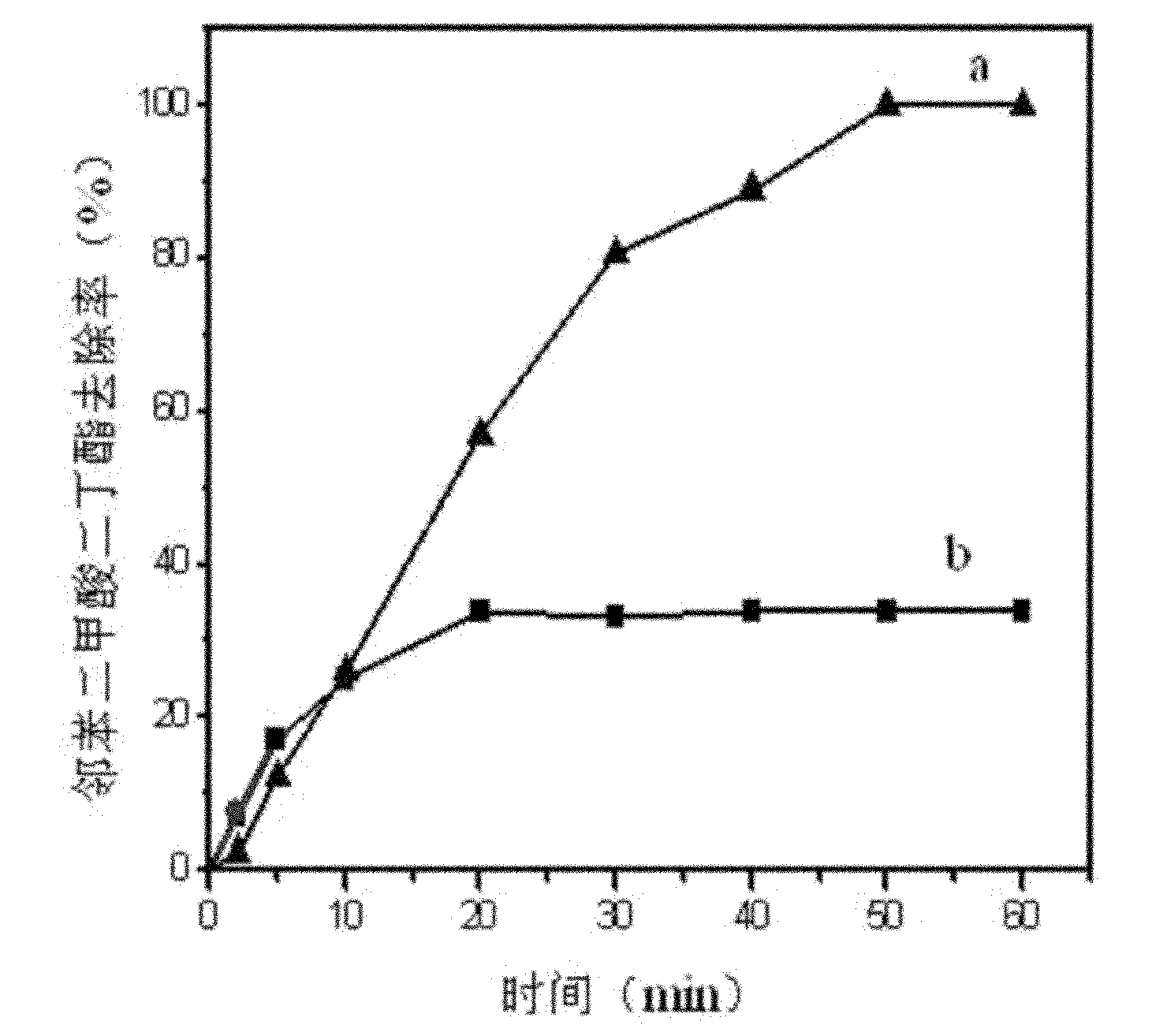

Application of spinel ferrite catalyst and method for urging persulfate to generate free radicals to catalytically degrade organic matters

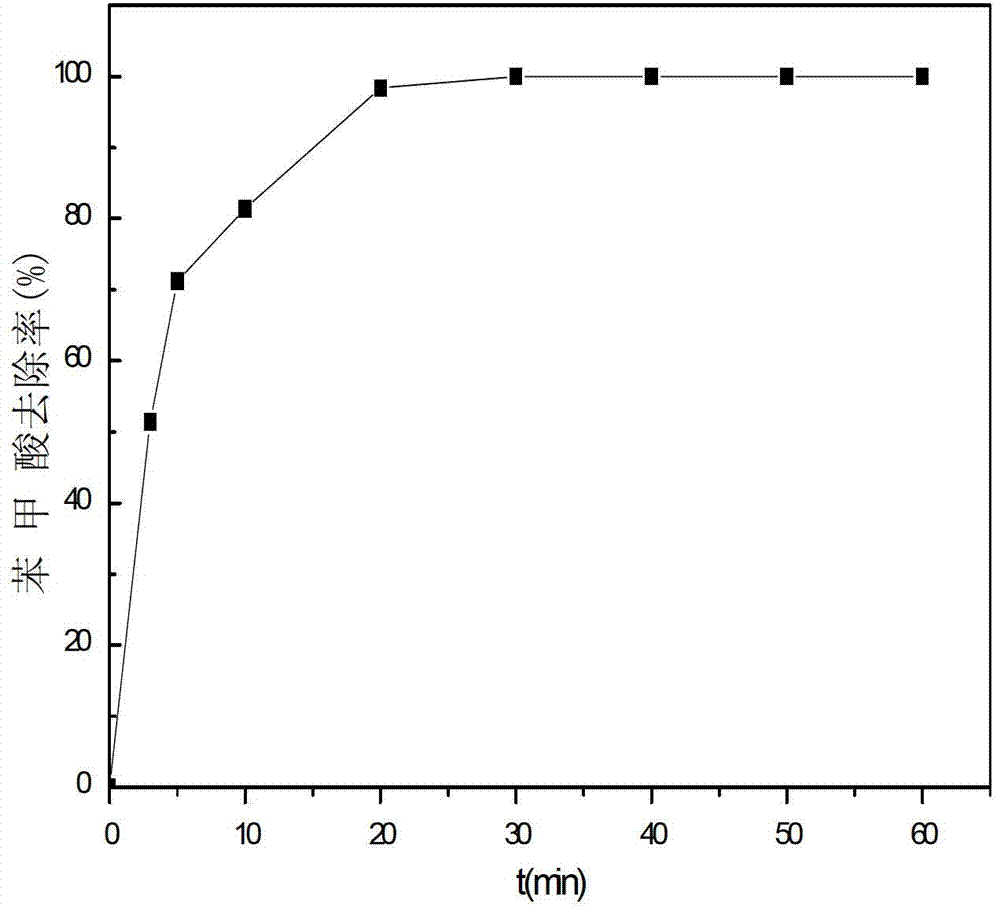

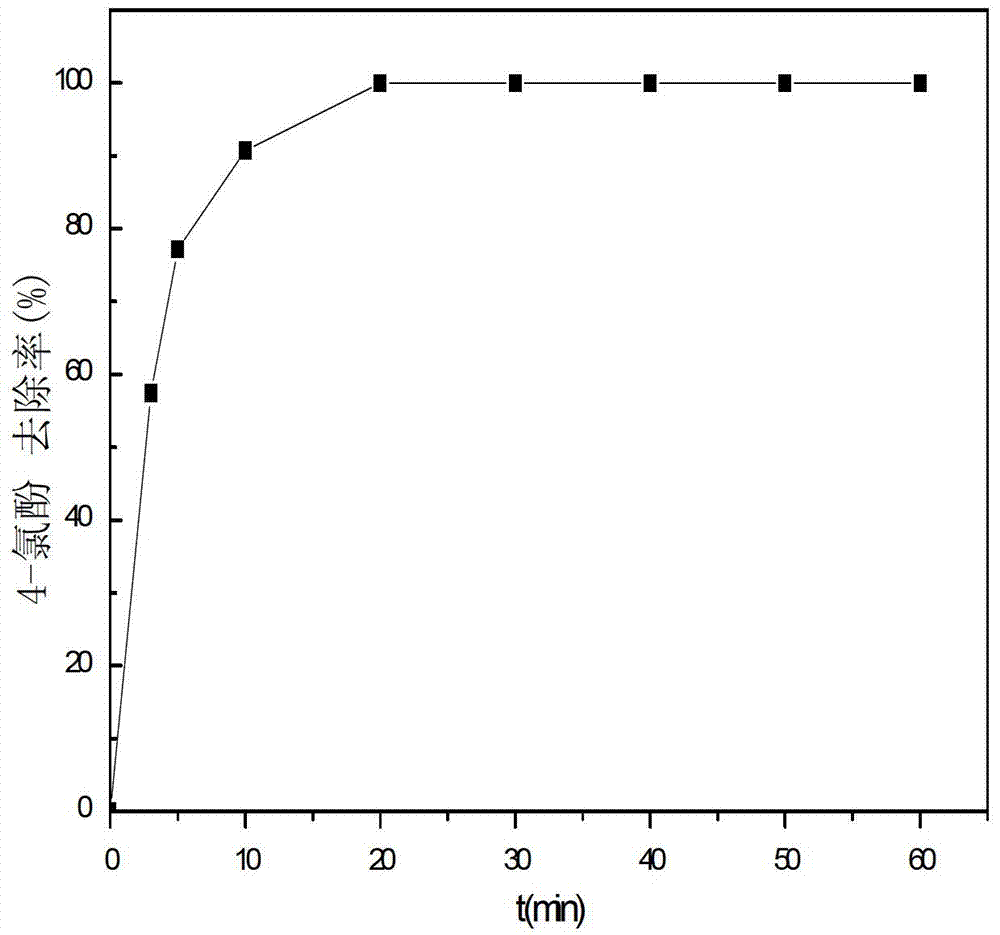

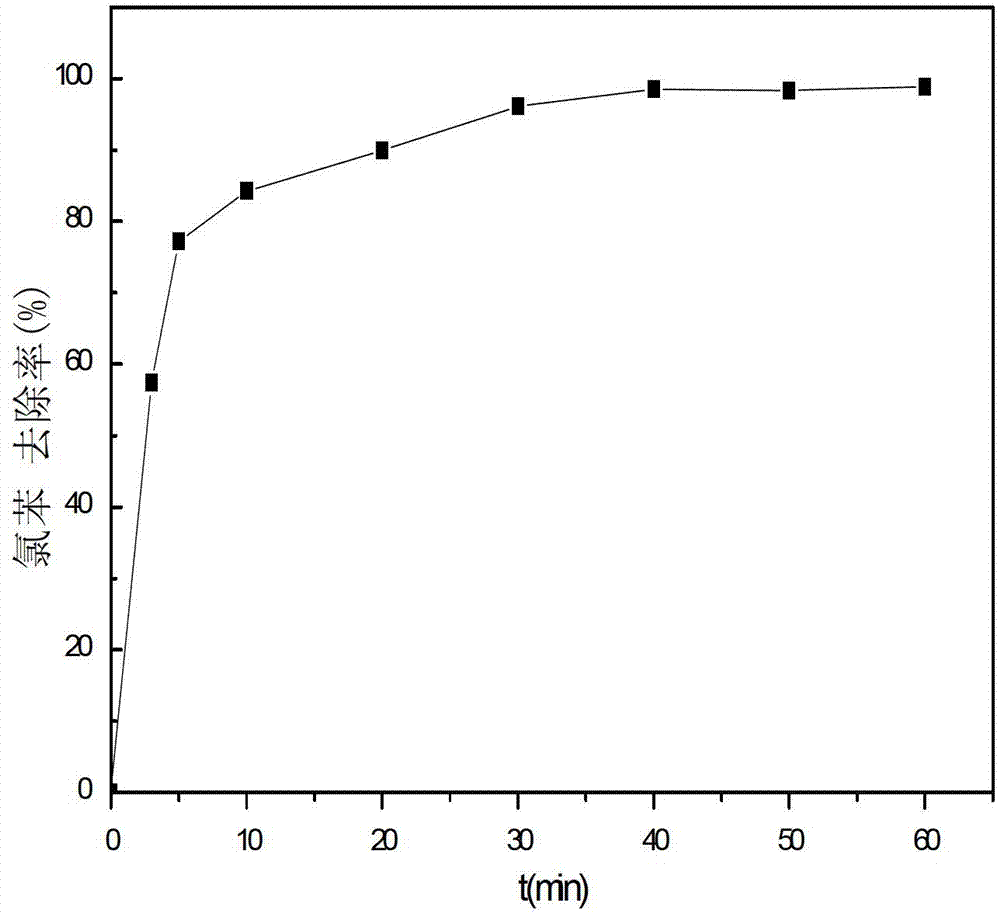

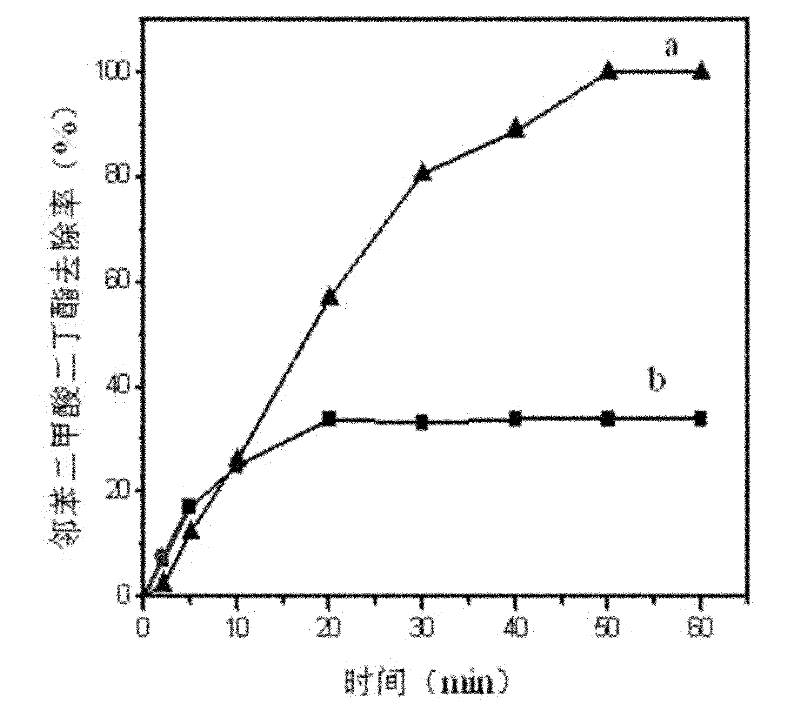

InactiveCN103030208AStable structureHigh mechanical strengthSolid waste disposalWater contaminantsPersulfateSulfate

Application of spinel ferrite catalyst and a method for urging persulfate to generate free radicals to catalytically degrade organic matters relate to application of spinel ferrite catalyst and a method for degrading organic matters. The invention aims to solve the problems of high probabilities of oxygenolysis and breakage, low strength, impurity dissolution, low catalytic efficiency and difficulty in recovering in the existing catalyst as catalyst generated by sulfate free radicals and complex reaction system, rigor reaction conditions and higher cost in the existing activating technology. The spinel ferrite catalyst, as catalyst for urging the generation of persulfate free radicals, for urging persulfate or mono-persulfate to generate free radicals is applied; and the method comprises the following steps: the spinel ferrite catalyst is adopted as catalyst for urging the generation of persulfate free radicals to urge persulfate or mono-persulfate to generate free radicals; and then sulfuric acid free radicals are used for degrading the organic matters. The application and the method are mainly applied in catalytic degradation of the organic matters.

Owner:HARBIN INST OF TECH

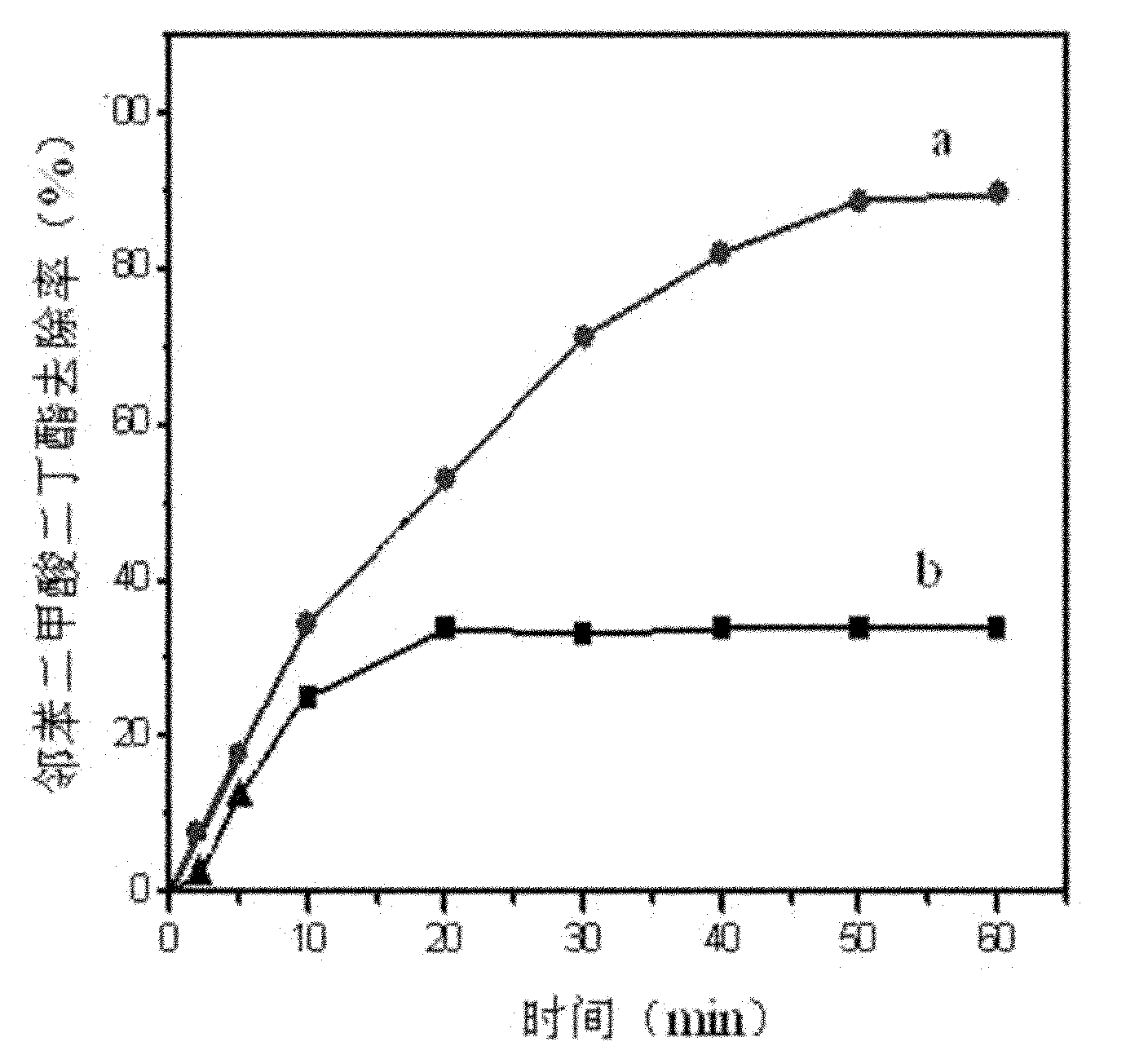

Catalyst for oxidation and decomposition of organic pollutants in water with ozone and method thereof for catalyzing sewage treatment with ozone

InactiveCN102151567AStable structureHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationDecompositionSewage

The invention discloses a catalyst for oxidation and decomposition of organic pollutants in water with ozone and a method thereof for catalyzing sewage treatment with ozone, and relates to a catalyst for decomposing the organic pollutants in water and the method thereof for sewage treatment. By adopting the catalyst, the problems that the traditional solid catalyst for catalyzing the decomposition of organic pollutants in the water with ozone is easy to be oxidized and decomposed by ozone, easy to break, can dissolve out impurities, has low strength and low catalytic efficiency and is difficult to recover can be solved. The catalyst for oxidation and decomposition of the organic pollutants in the water with ozone refers to spinel ferrite or a composite of spinel ferrite; and the method of the catalyst for catalyzing the sewage treatment with ozone comprises the following steps of: adjusting pH and temperature of sewage, then introducing ozone, further adding the catalyst and treating for 1 minute-120 minutes, then using a magnetic field to recover the catalyst, and finally absorbing tail gas of the ozone. The catalyst can improve the removal rate of organic matters to 90%-100%, and can be used for sewage treatment or deep treatment of drinking water.

Owner:HARBIN INST OF TECH

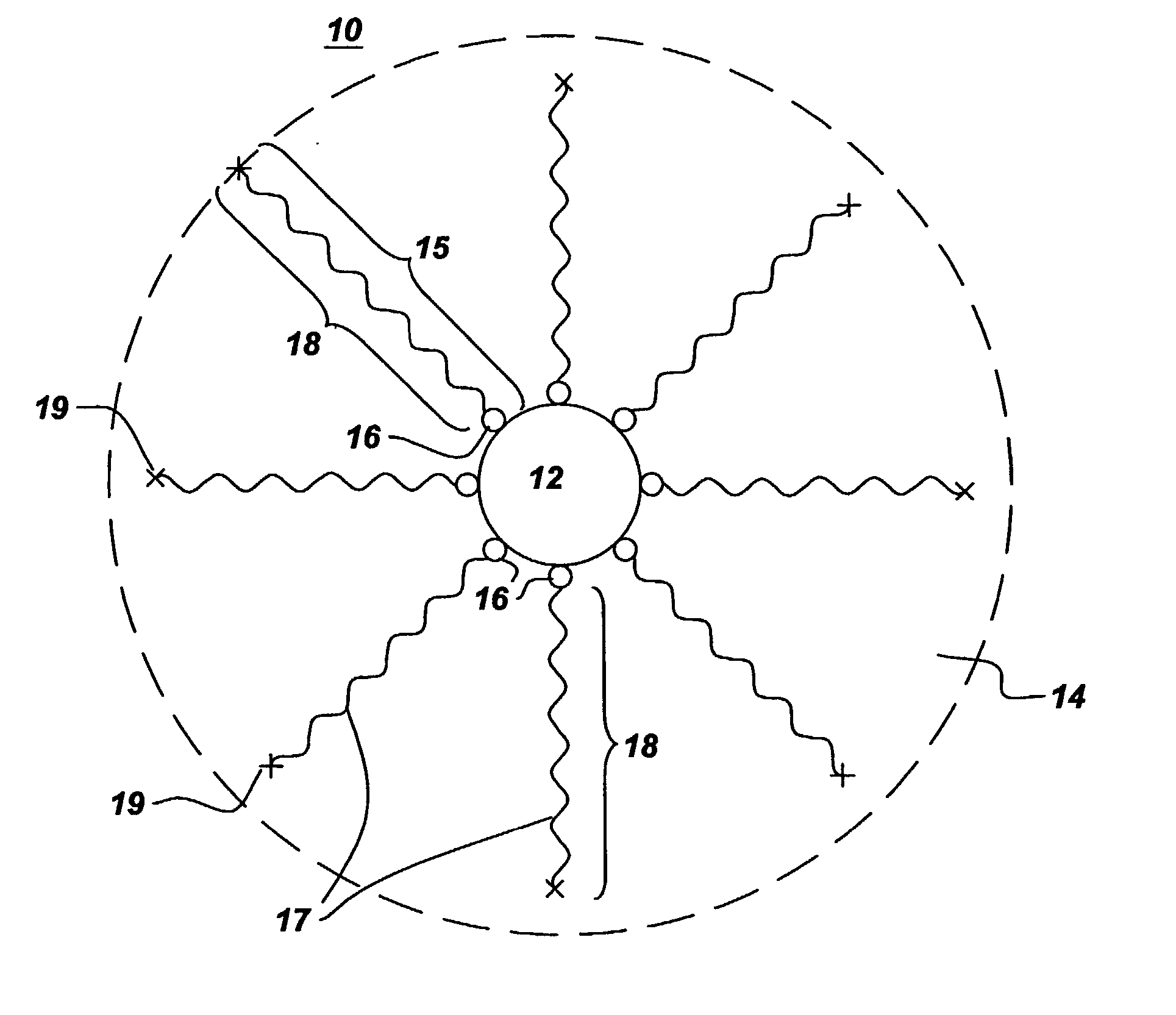

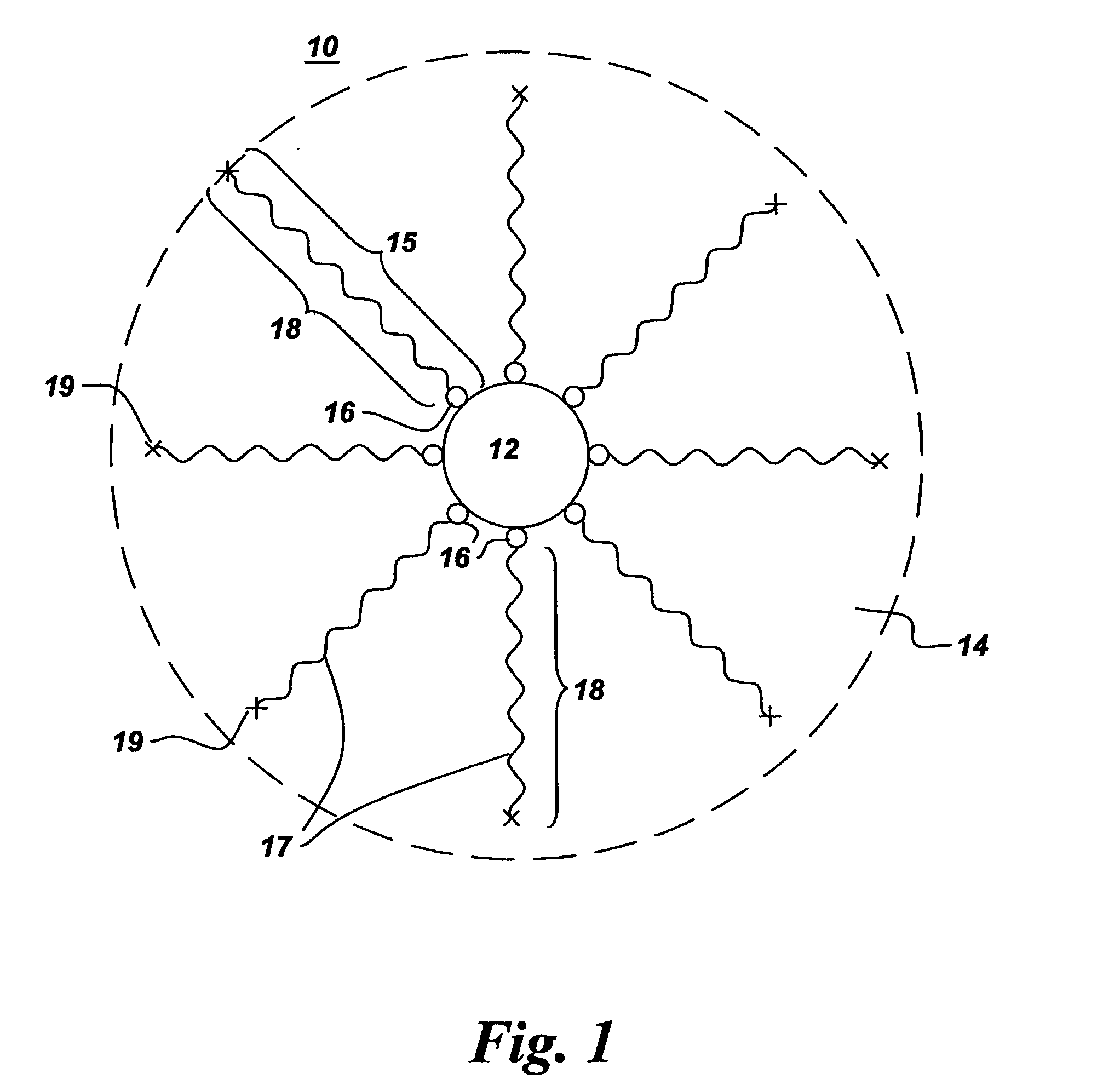

Nanoparticle having an inorganic core

A nanoparticle comprising an inorganic core and a polymerizable outer coating. The inorganic core comprises a substantially crystalline inorganic material such as a superparamagnetic material. In one embodiment, the inorganic core comprises a single crystal mixed spinel ferrite comprising iron in a first oxidation state and at least one metal in a second oxidation state, wherein the second oxidation state is different from the first oxidation state.

Owner:GENERAL ELECTRIC CO

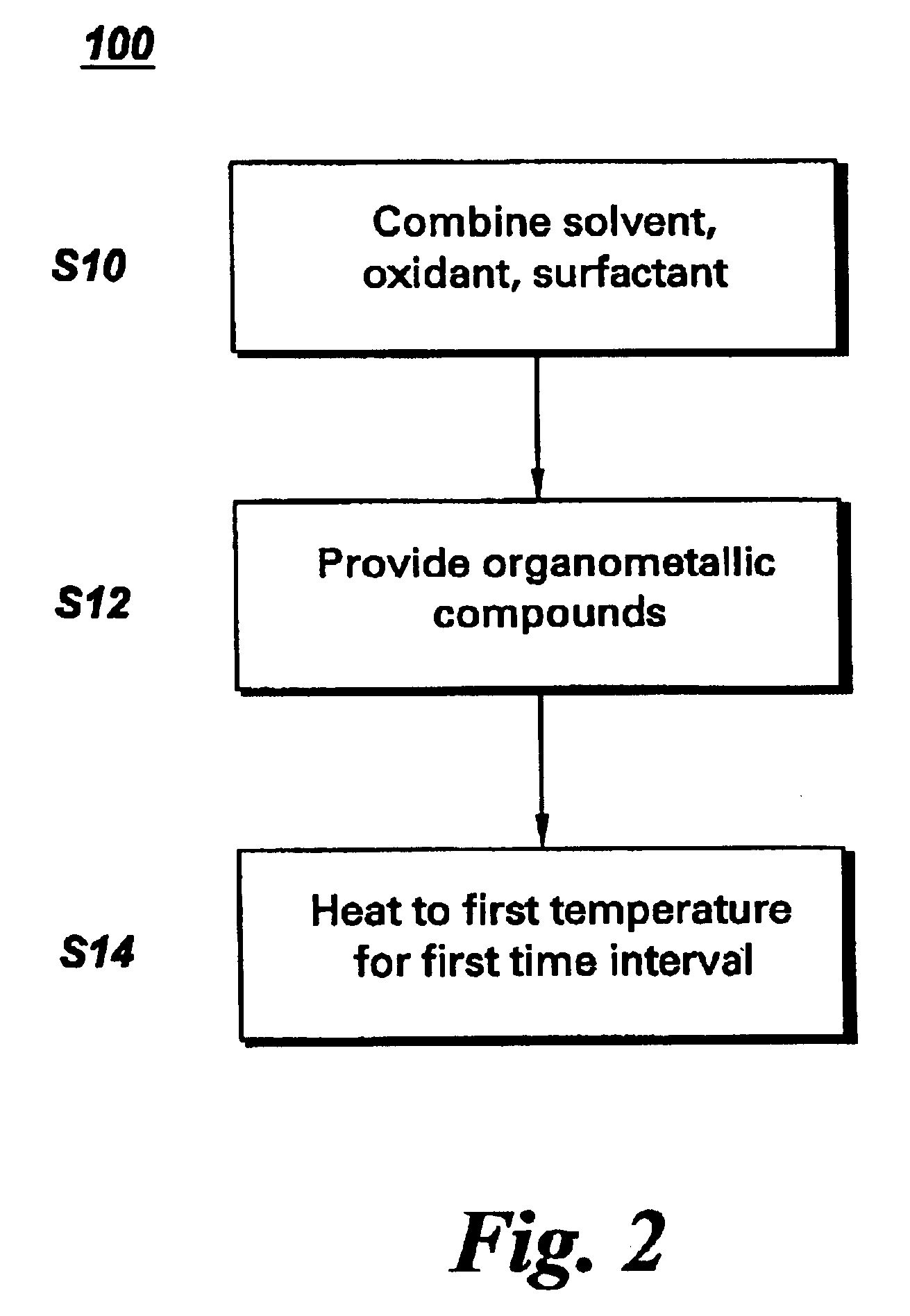

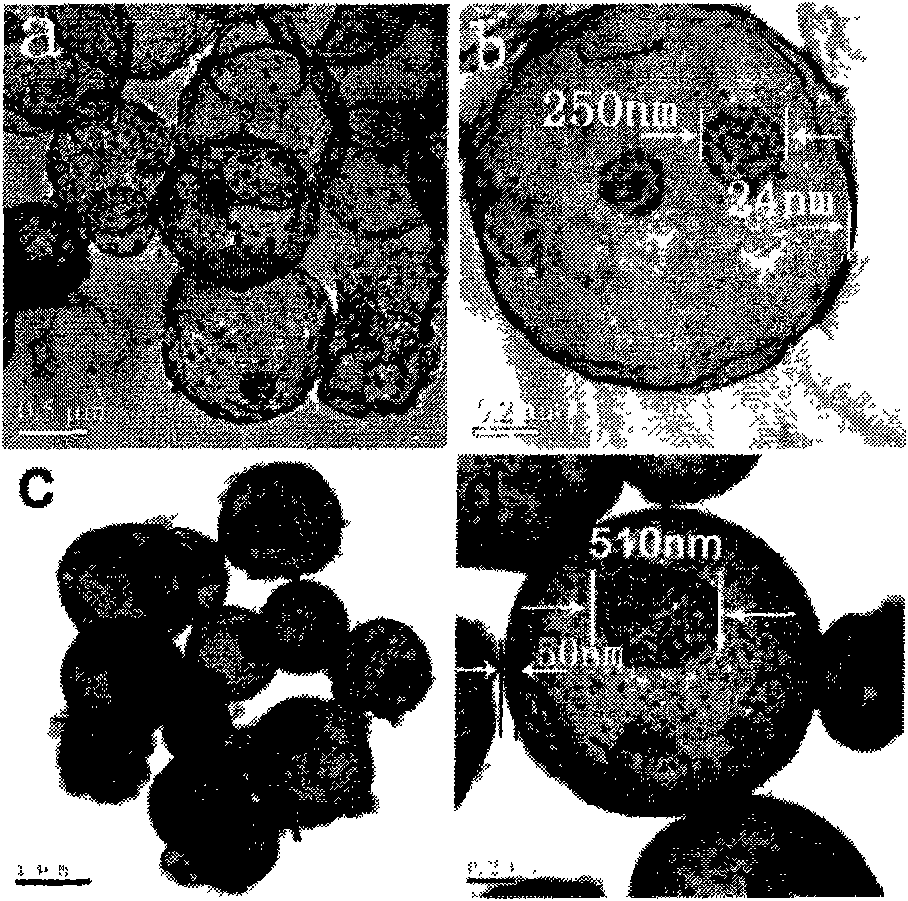

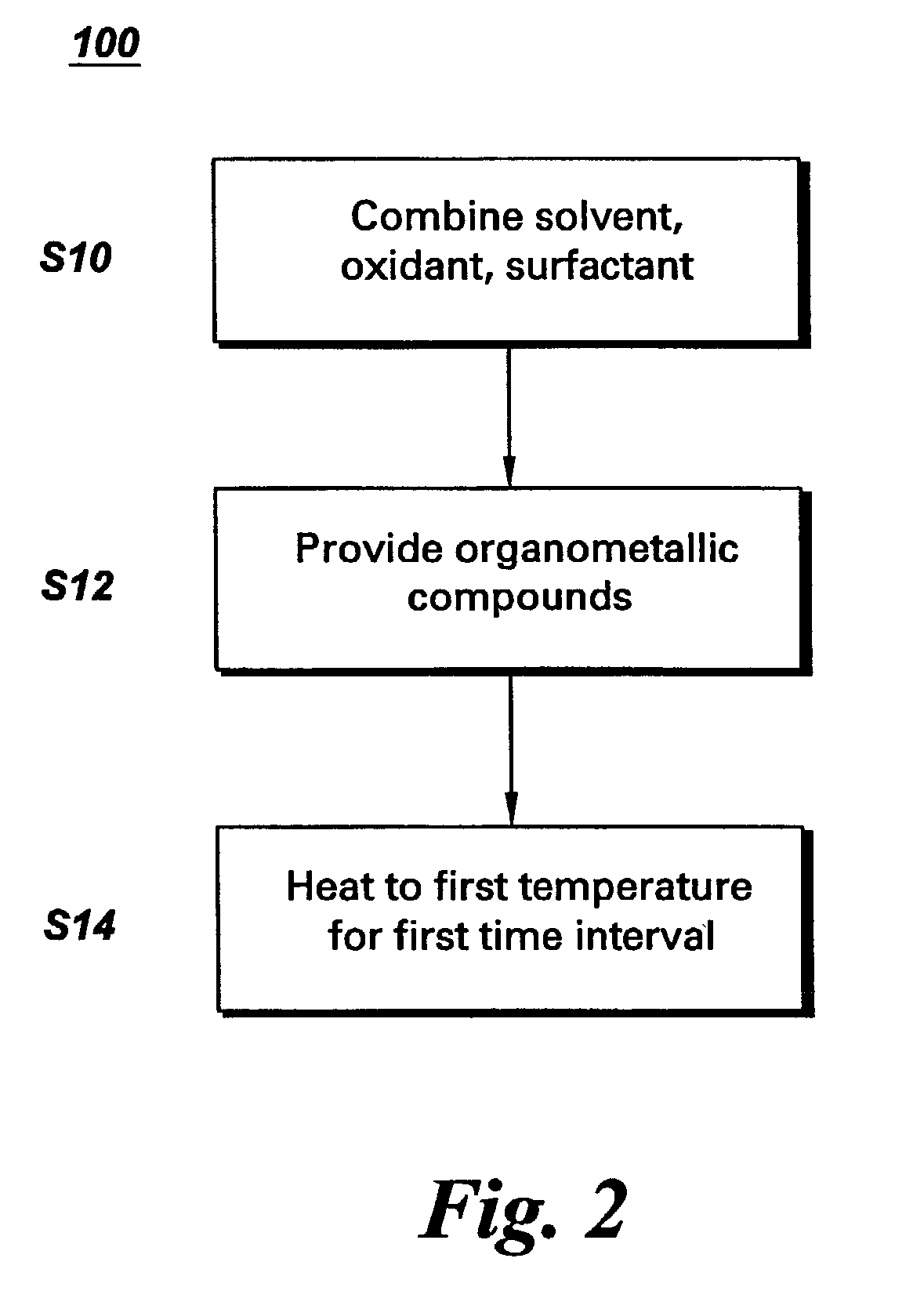

Method for preparing magnetic spinel ferrite hollow ball in one-step method

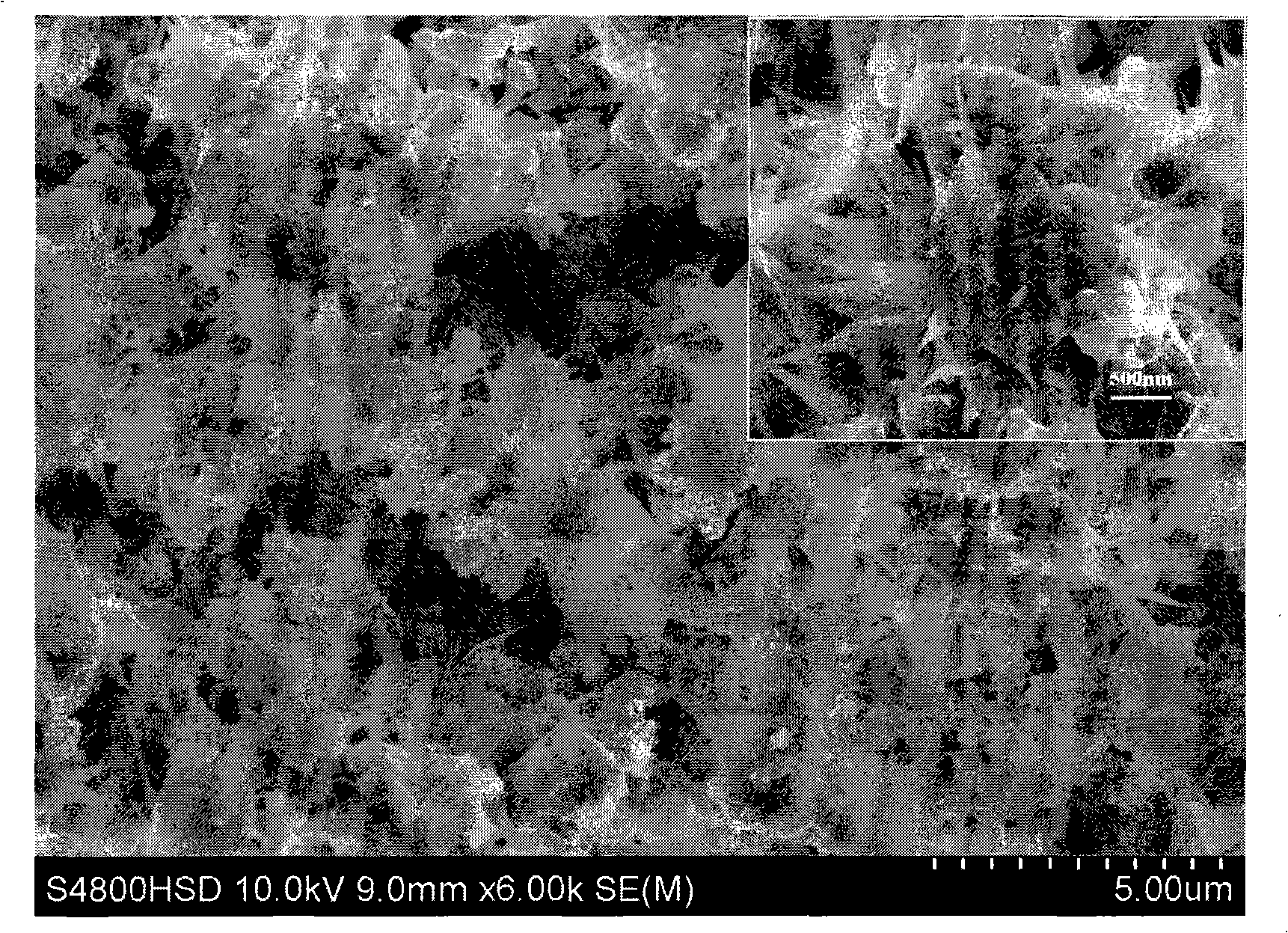

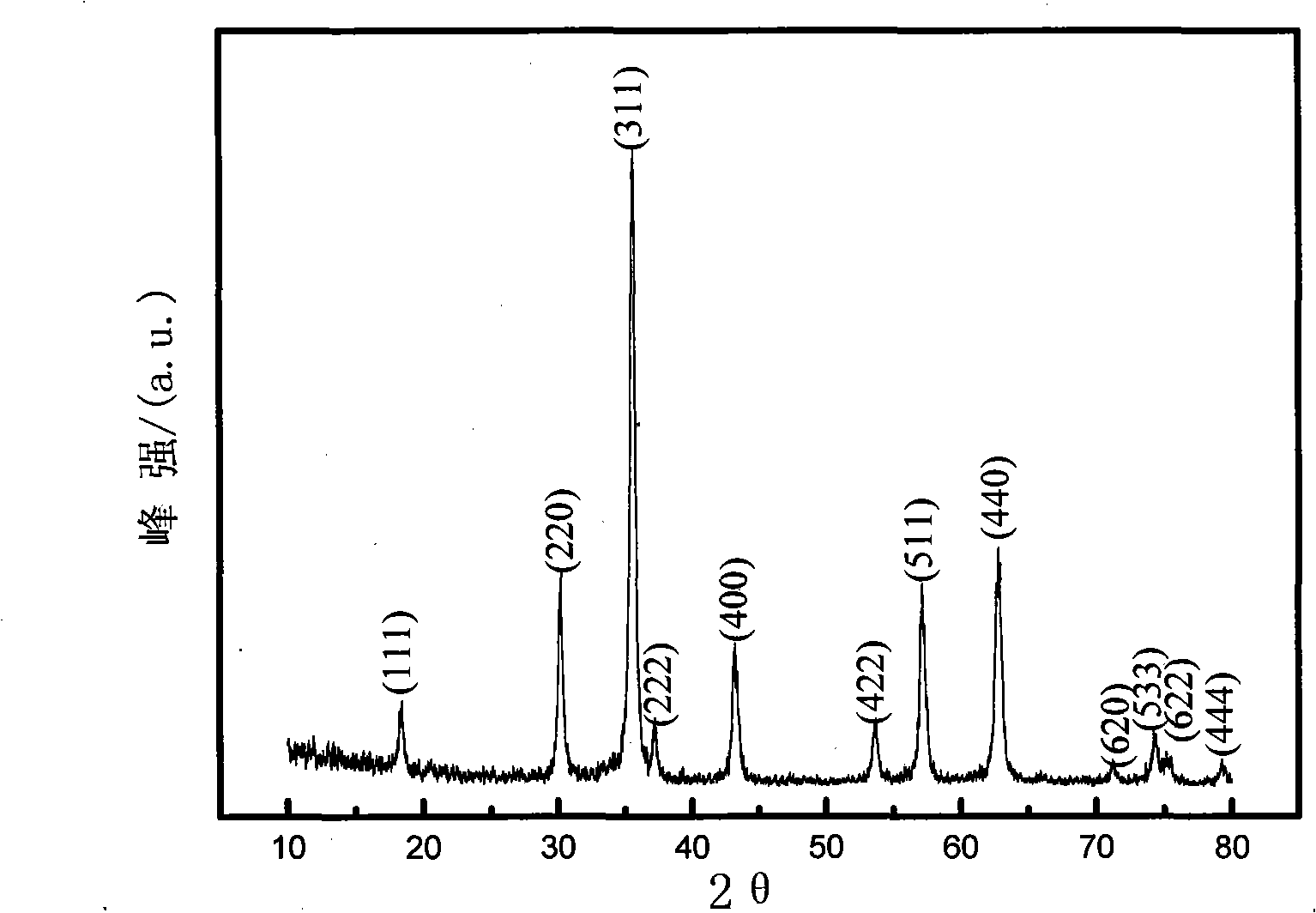

InactiveCN101693616AEasy to operateThe reaction steps are simpleNanostructure manufactureInorganic material magnetismSolventHigh pressure

The invention relates to a method for preparing magnetic spinel ferrite hollow ball in one-step method, which belongs to the technical field of magnetic nano material preparation technology. The preparation method comprises the following steps: utilizing polyatomic alcohol as dissolvent, dissolving tervalence malysite and other divalent inorganic metal salt into polyatomic alcohol, adding right amount of weak base and surface activator, evenly stirring to form brown and transparent mixed solution, placing the solution into a high-pressure stainless steel autoclave which utilizes polytetrafluoroethylene as inside lining, filling volume is 50%-80%, and the solution is sealed in the high-pressure stainless steel autoclave, products are separated by magnets when the solution is reacted 12-24 hours under 160-250 DEG C, the products are washed by water and alcohol, and are dried, thereby getting magnetic spinel ferrite MFe2O4 (M=Co, Ni, Mn, Zn) hollow balls. The method has simple operation, can self-assemble to form a hollow ball structure without templates, does not need subsequent treatment (removal of templates), and is suitable for industrial production of bigger yield, and the products which are got have single material phase and stable property.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

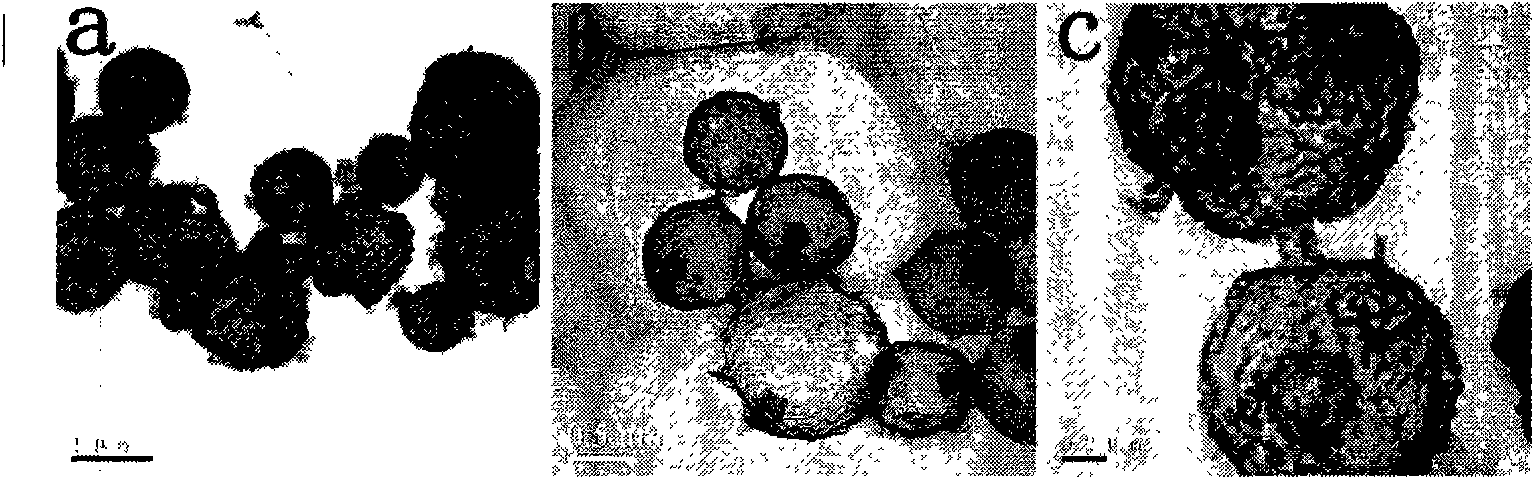

Core-shell structure magnetic microsphere aluminum oxide and method for preparing the same

InactiveCN101112687AHigh sphericityMeet the use requirementsCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsMicrosphereProtection layer

The invention provides a core-shell structure magnetic micro-spherical alumina MeFe2O4-SiO2-Al2O3 and the preparation method. According to the positioning effect of the LDHs laminated metal element, the invention firstly prepares the Me-Fe2+-Fe3+-LDHs laminated precursor by introducing the Me2+, Fe2+ and Fe3+ into the hydrotalcite laminate, and the spinel ferrite MeFe2O4 is formed by high-temperature roasting; the Na2SiO3.9H2O or silicon ester hydrolysis is adopted to coat a SiO2 protection layer on the surface of the MeFe2O4, the organic alcohol aluminum hydrolysis method is adopted to coat the alumina layer for a plurality of times, and finally the magnetic micro-spherical alumina MeFe2O4-SiO2-Al2O3 is obtained. The method saves the forming process of the traditional preparation method, and adjusts the magnetic structure and pore structure of the samples by changing the thickness of the SiO2 protection layer and the adding quantity of the magnetic object MeFe2O4 for meeting the application requirement of the magnetic stable bed process.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of spinel ferrite hollow sphere with core-shell structure

ActiveCN101774646ANo pollution in the processAvoid difficult surface modificationIron compoundsHigh concentrationCore shell

The invention relates to a preparation method of a spinel ferrite hollow sphere with a core-shell structure. Carbon spheres are used as templates. The method comprises the following steps of: firstly, using a hydrothermal method to manufacture the carbon sphere templates at 80-210 DEG C; then, dispersing the carbon spheres in a high-concentration metal salt solution to absorb metal ions; and finally, carrying out thermal treatment on the metal ions with carbon spheres in the air so as to remove the carbon spheres to obtain the spinel ferrite hollow sphere with the core-shell structure. Because the method omits the steps of layer-by-layer coating and multi-time modification, the method has short technical process and convenient operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Spinel type ferrite magnetic hollow microsphere and preparation thereof

The invention relates to a magnetic hollow microsphere of spinel ferrite and a preparation method thereof and pertains to the technical field of magnetic materials with intercalation structure. The general chemical formula of the magnetic hollow microsphere of spinel ferrite is M<2+>Fe<3+>2O4. The method comprises the following steps: firstly, on the surface of sulfonated polystyrene microspheres, metal-salt ions with different charges are absorbed; then, by adopting coprecipitation, hydrotalcite generates in situ on the surface of the sulfonated polystyrene microspheres; and then, by means of a program of increasing temperature and roasting, the magnetic hollow microspheres of spinel ferrite can be obtained. The process can adjust and control the generation of the hydrotalcite on the surface of the sulfonated polystyrene microspheres by regulating synthetic conditions and crystallization temperature, and regulate magnetic property of the spinel ferrite by adjusting and regulating the composition of LDHs laminates. The magnetic hollow microsphere of spinel ferrite of the invention has special technique conditions, simple operation and mild synthetic conditions, and owing to the unique structure and properties, the hollow microsphere can be widely applied in such respects as drug carriers, nanoreactors, filtration, separation, magnetic filling materials and magnetic photon crystals, etc.

Owner:BEIJING UNIV OF CHEM TECH

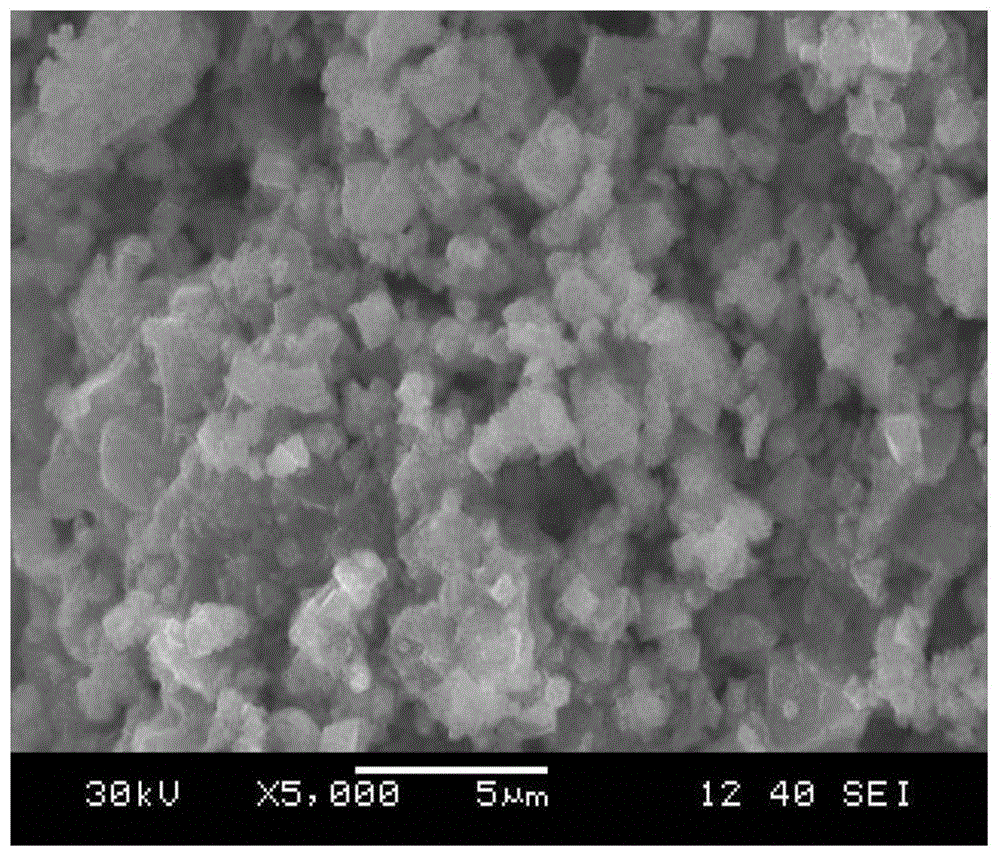

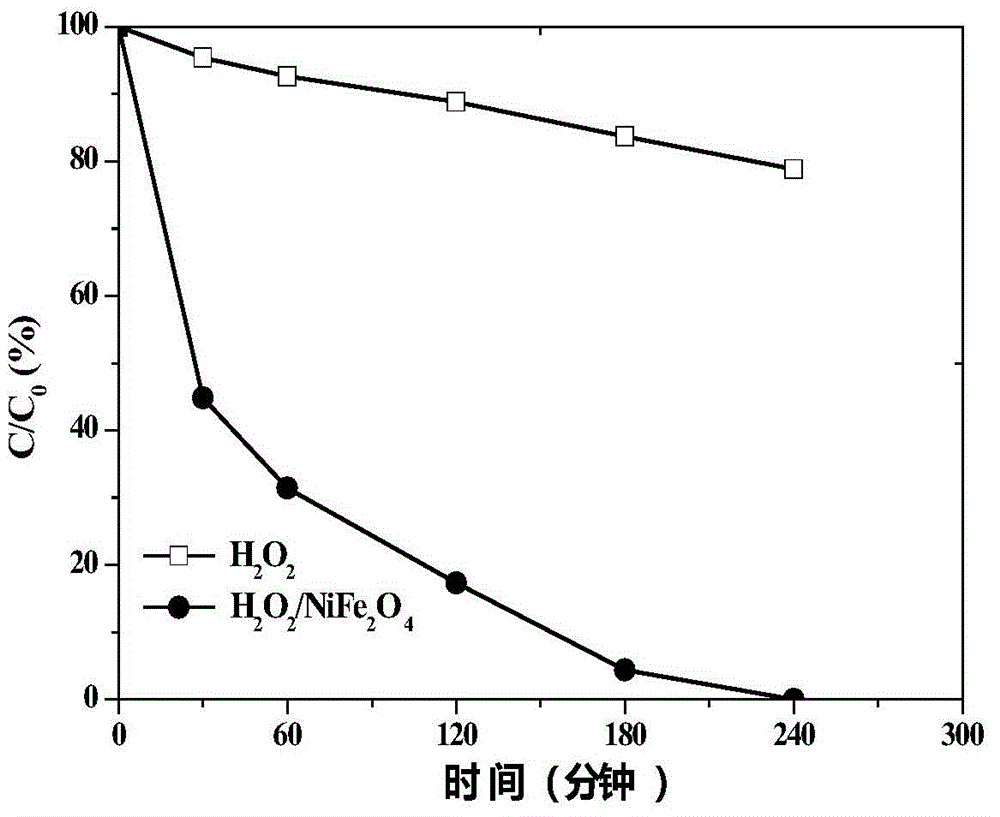

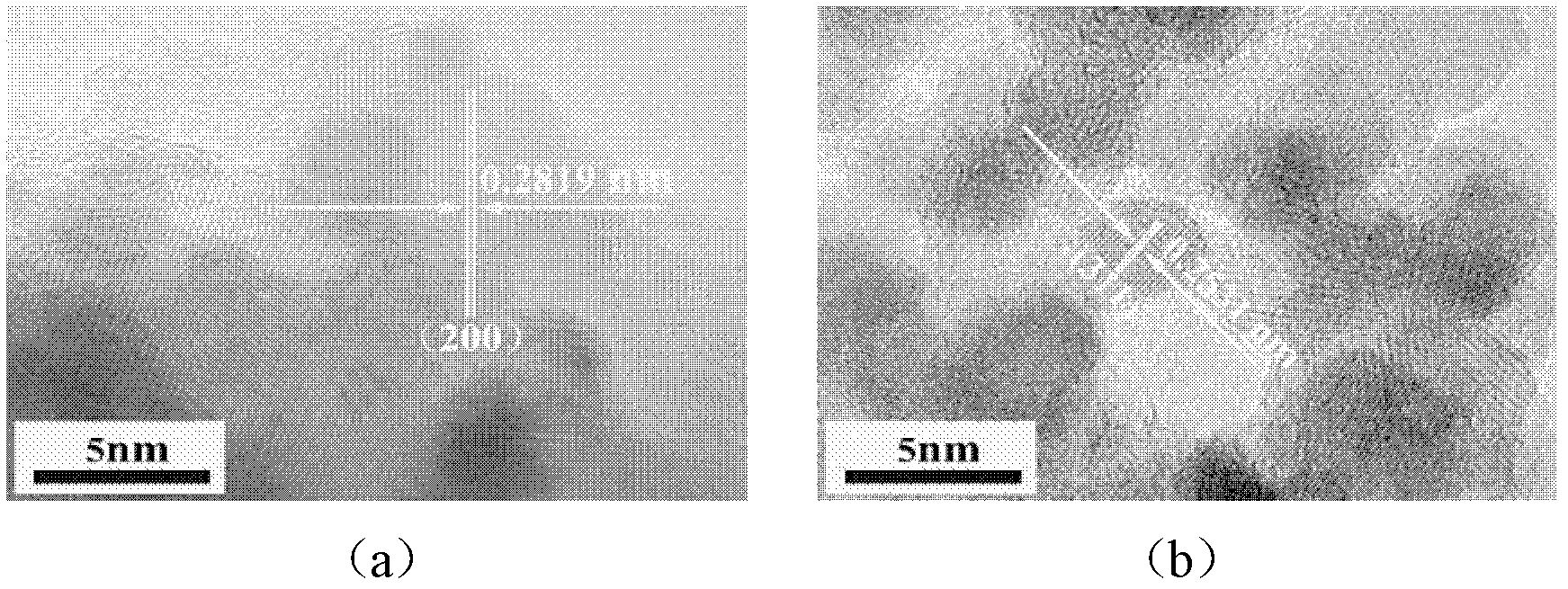

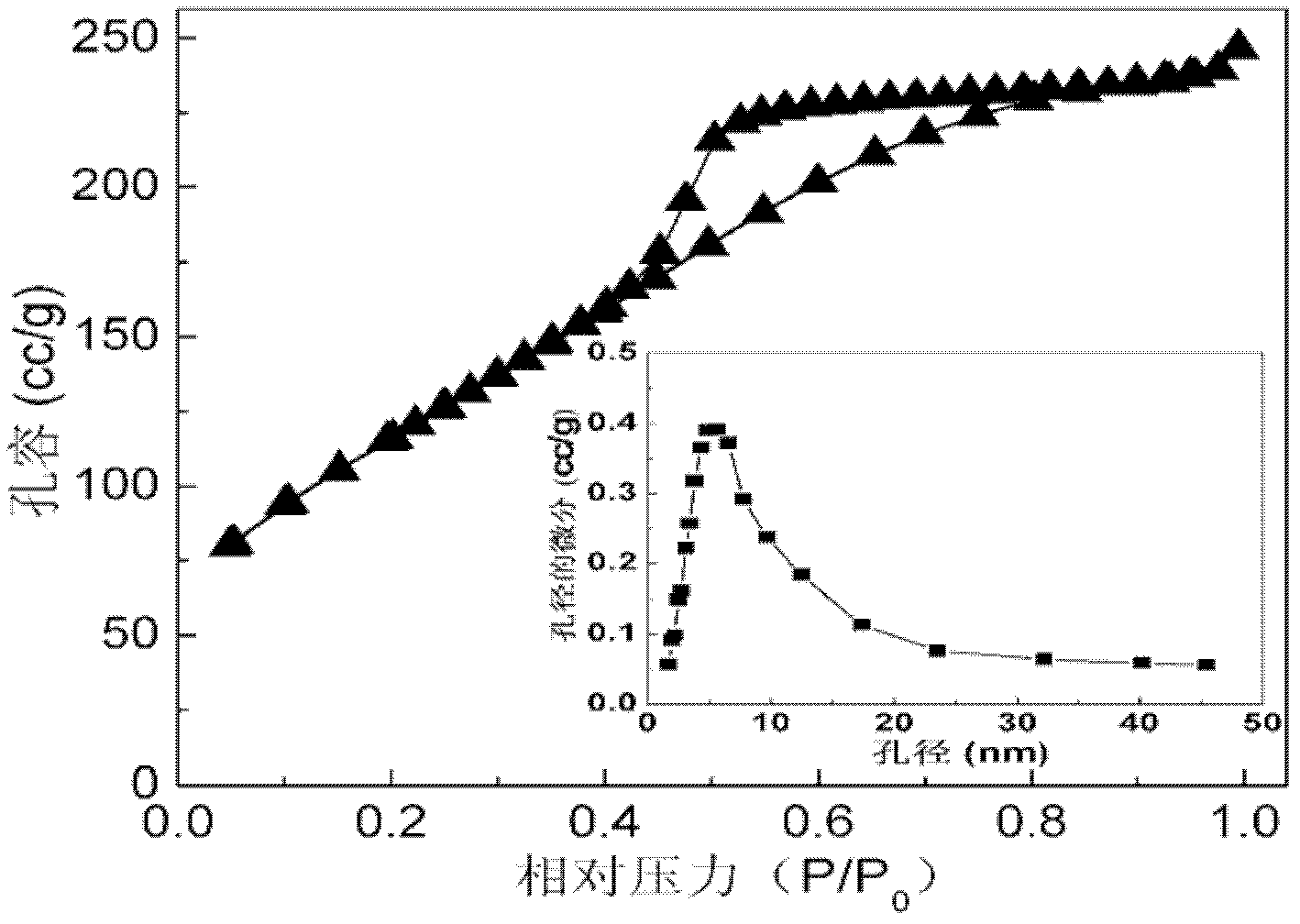

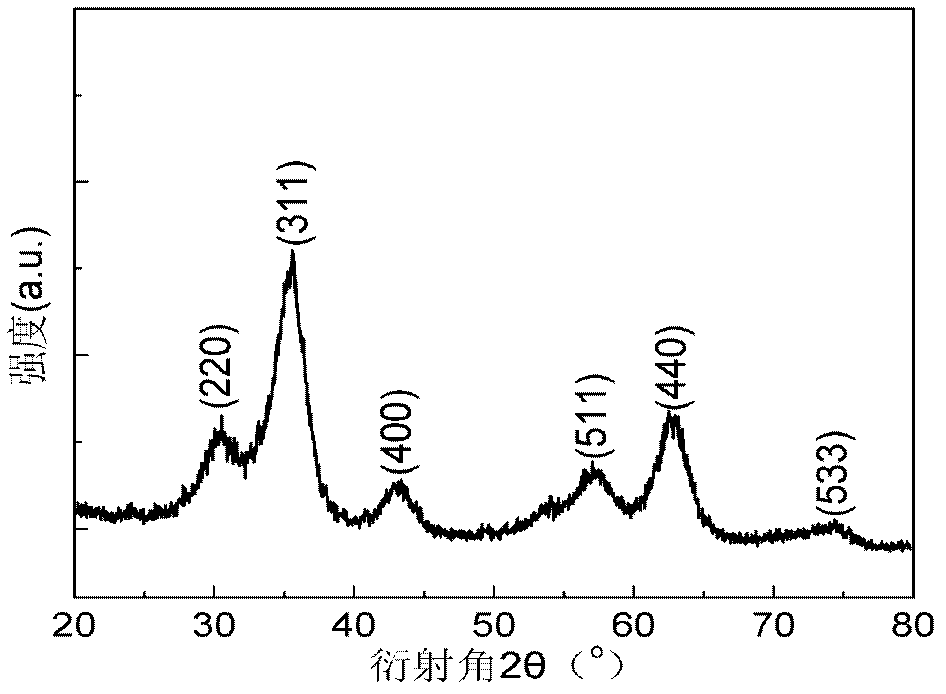

Magnetic fenton catalyst spinel ferrite employing fenton iron sludge as iron source and application of magnetic fenton catalyst spinel ferrite

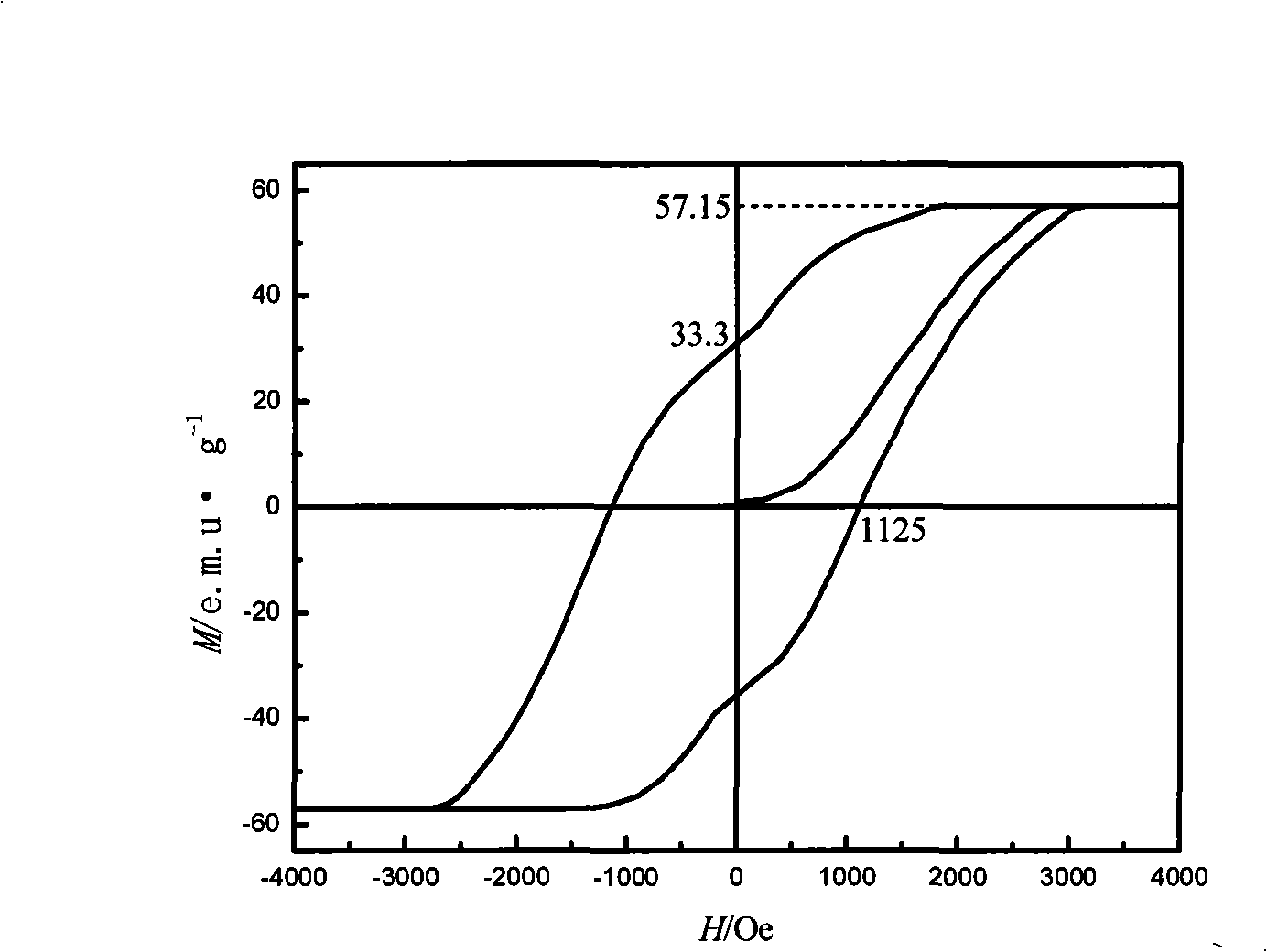

ActiveCN104437502AReduce processing costsAchieve recyclingWater contaminantsIron compoundsDispersitySludge

The invention discloses a magnetic fenton catalyst spinel ferrite employing fenton iron sludge as an iron source and an application of the magnetic fenton catalyst spinel ferrite. According to the preparation process, the magnetic fenton catalyst spinel ferrite is prepared from iron sludge generated in the fenton process, and nitrate of divalent metals (such as nickel, manganese, zinc, barium and cobalt) as raw materials by adopting a coprecipitation method; and the spinel ferrite instead of Fe<2+> is adopted as a fenton catalyst, and thus a novel fenton oxidation water treatment method is provided. The obtained spinel ferrite magnetic material is small in dimension and good in dispersity in an aqueous solution system, and can be effectively separated and recycled by virtue of an external magnetic field. In addition, the novel fenton catalyst is synthesized by adopting the iron sludge generated by fenton as the iron source; recycling of hazardous solid waste fenton iron sludge is achieved; the subsequent treatment cost of the fenton iron sludge is reduced; and the magnetic fenton catalyst spinel ferrite has a wide application prospect in application of water treatment.

Owner:NANJING UNIV OF SCI & TECH

High-efficiency superparamagnetic ferrite nano arsenic adsorbent and preparation process thereof

InactiveCN102527319ALarge specific surface areaLow costOther chemical processesAlkali metal oxides/hydroxidesSorbentSuperparamagnetism

The invention belongs to the field of nano adsorption materials and in particular relates to a high-efficiency superparamagnetic ferrite nano arsenic adsorbent and a preparation process thereof. The prepared nano ferrite can well remove harmful ions (such as arsenic) from water and has strong magnetic recovery capacity, so that the problems of excessive harmful ions in the water and incapability of recovery of the adsorbent at present are solved. The adsorbent consists of superparamagnetic spinel ferrite phase nanoparticles and is nanopowder with the grain size of 3 to 8 nm, wherein the specific surface area is 100 to 500 m<2> / g. According to the process, pure crystallized nano ferrite powder is prepared by using anhydrous metal chloride, absolute ethanol and sodium hydroxide as reaction precursors and performing solvent thermal reaction. The prepared superparamagnetic ferrite nanoparticles are high in purity, small in grain size, high in specific surface area and high in hydrophilicity and more new selectable materials are provided for reducing the harmful ion (such as arsenic) content of water.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

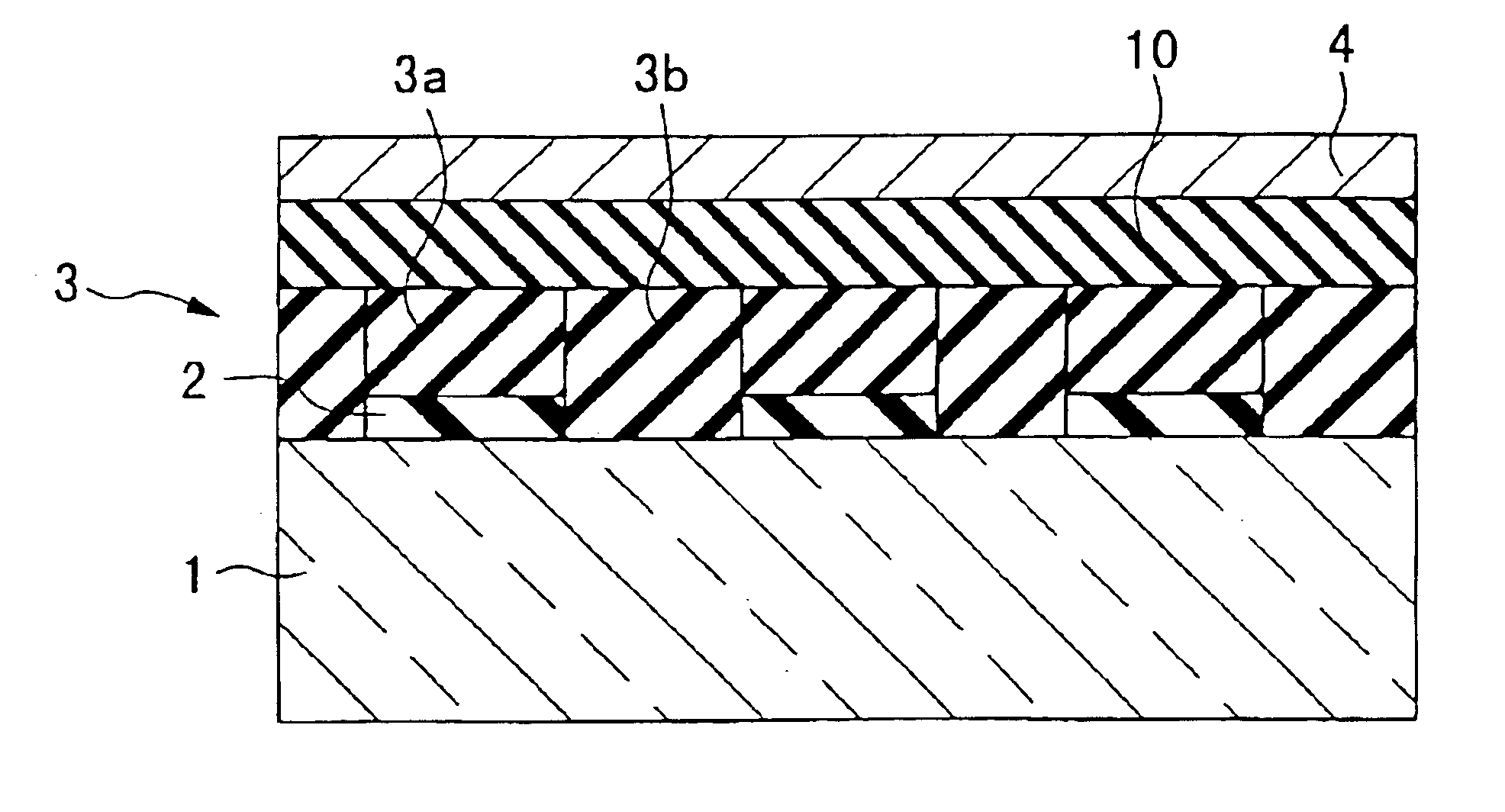

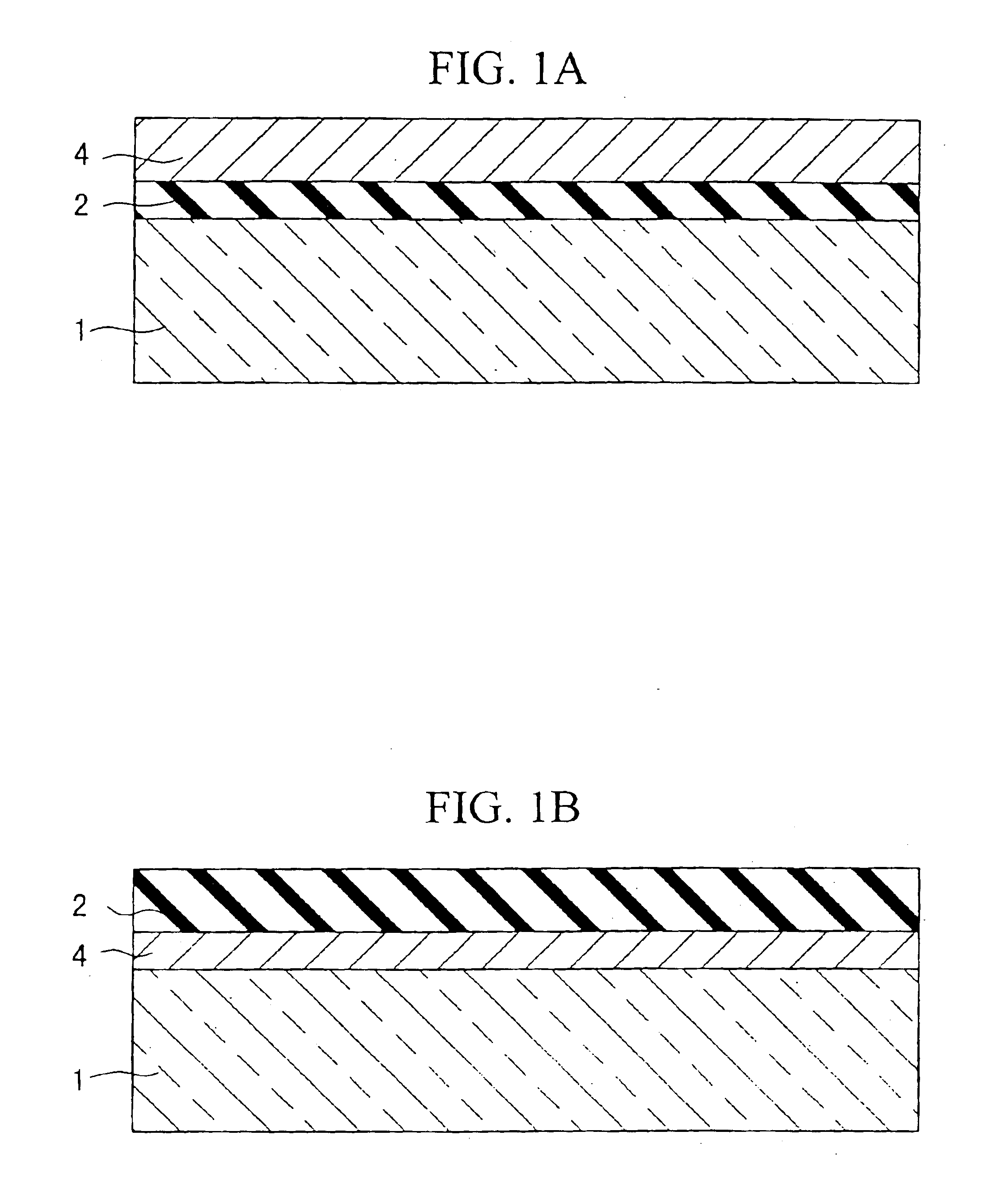

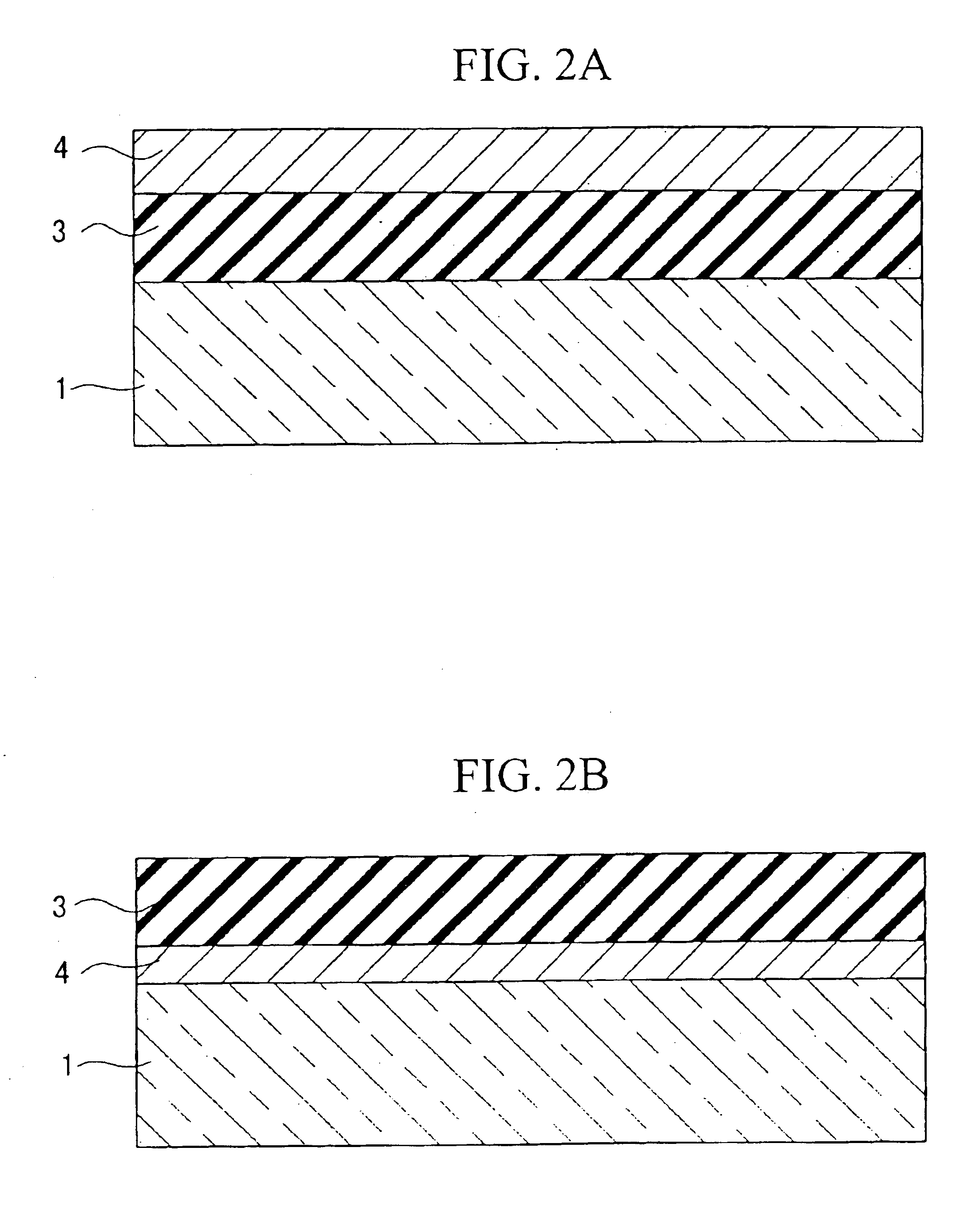

Opto-magnetic recording medium with a garnet ferrite recording layer, and opto-magnetic information recording/reproducing device

InactiveUS6759137B1Raise the ratioReduce the required powerRecord information storageMagnetic materialsFerrite layerRecording layer

This invention relates to magneto-optical recording media such as magneto-optical disks and cards, manufacturing methods of the medium and a magneto-optical recording and playback device to record and play back data using the magneto-optical recording media. The magneto-optical recording medium of the present invention has a recording layer and a reflective layer on a substrate, and the recording layer has a layered structure in which at least one spinel ferrite (or rutile-type oxide or hematite) layer and at least one garnet ferrite layer are piled together. It is preferable that the layered structure is formed on tracks where data are recorded. The manufacturing method of the present invention comprises the steps of heat treatment in the range of 500-700° C., preferably 600-630° C., after the formation of the recording layer. In the magneto-optical recording and playback device to record and play back data of the present invention, the wavelength of light for recording data is different from that for reading data, which is preferable for a magneto-optical recording medium comprising a garnet ferrite layer.

Owner:CENT NAT DE LA RECHERCHE SCI +1

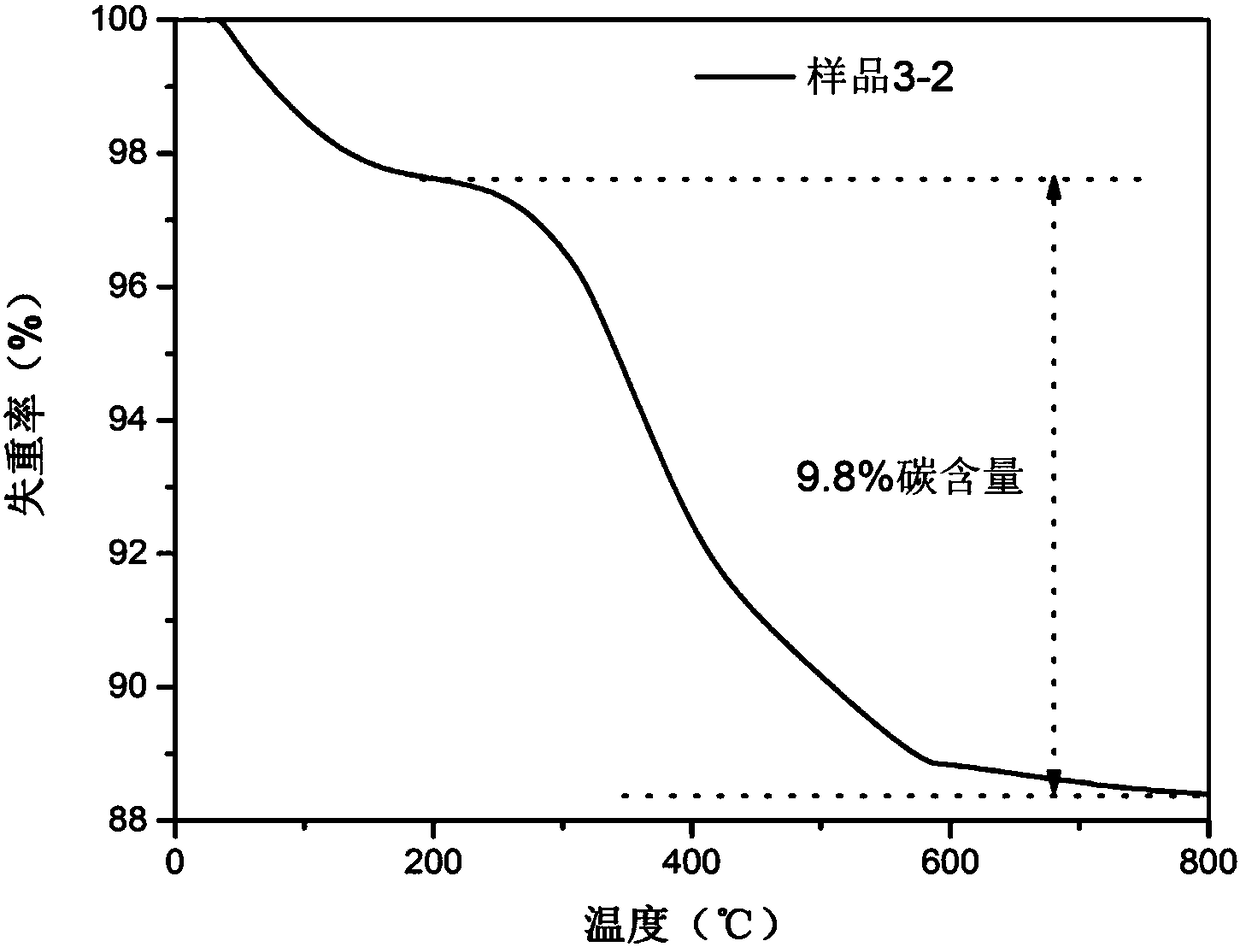

Preparation method and application of general magnetic adsorbent

ActiveCN108393073AReduce crystallizationReduce hydrolysisOther chemical processesWater contaminantsSorbentSewage treatment

The invention relates to a preparation method and an application of a universal magnetic adsorbent, belongs to the field of preparation of magnetic porous nanocomposite materials, and concretely relates to a carbon and magnetic spinel ferrite MFe2O4 hybrid nanocomposite MFe2O4 / C synthesized by adopting a solvothermal method, and its application as a dye sewage treatment adsorbent after being calcined. The adsorbent has a good adsorption performance on a cationic dye and an anionic dye in a wide solution pH range of (3.0-11.0), can be quickly separated from an aqueous solution under the actionof an external magnetic field, and is convenient, fast, economical and efficient.

Owner:DALIAN UNIV OF TECH

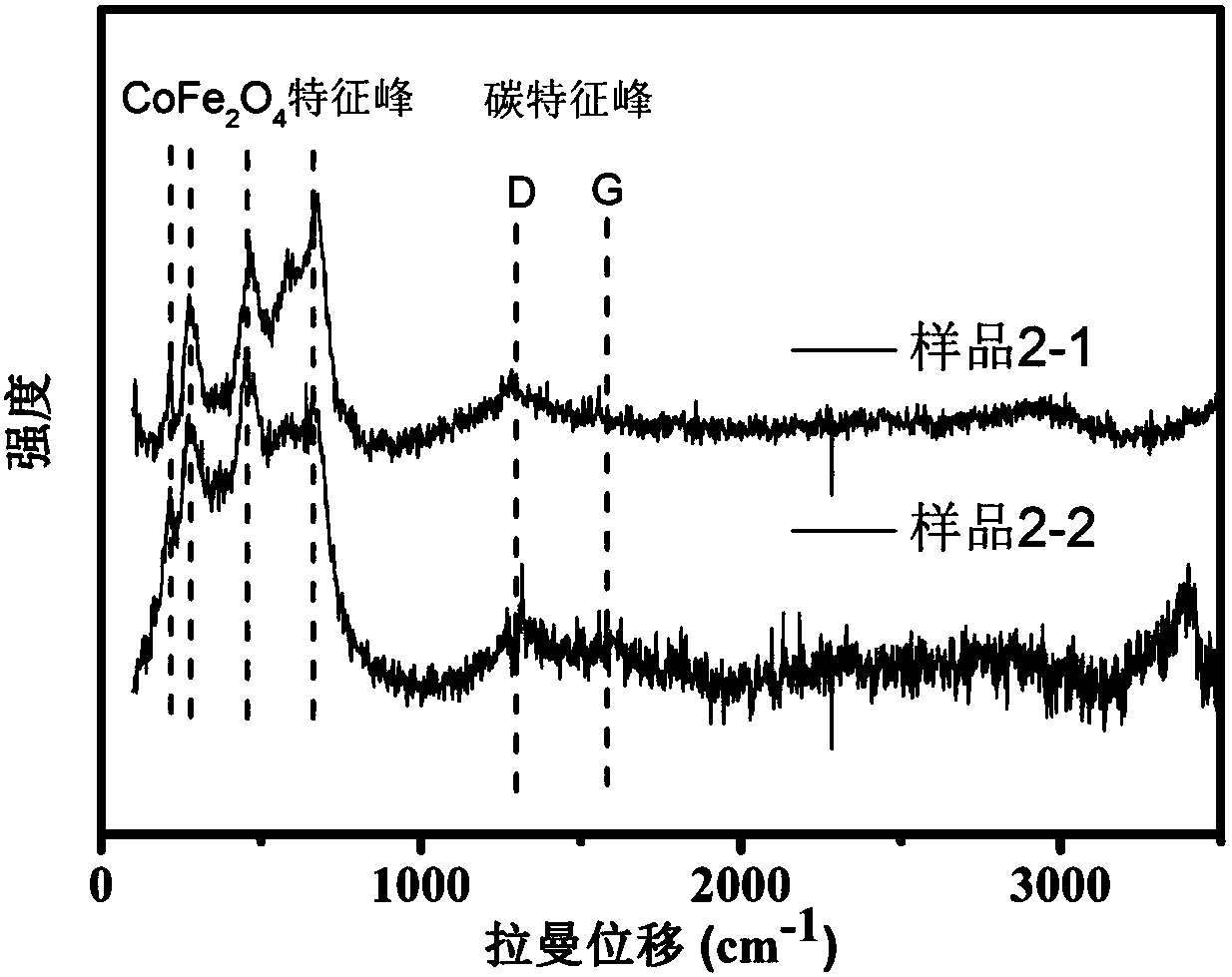

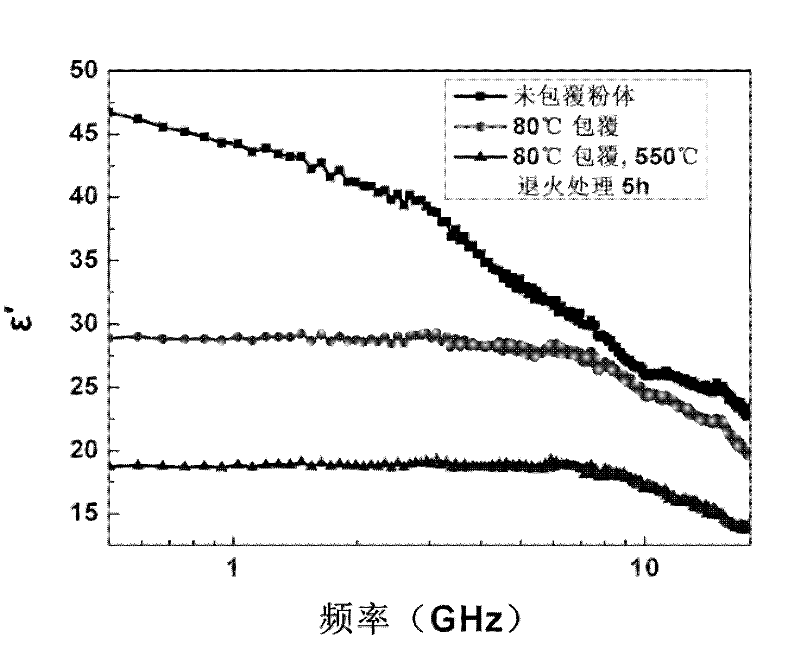

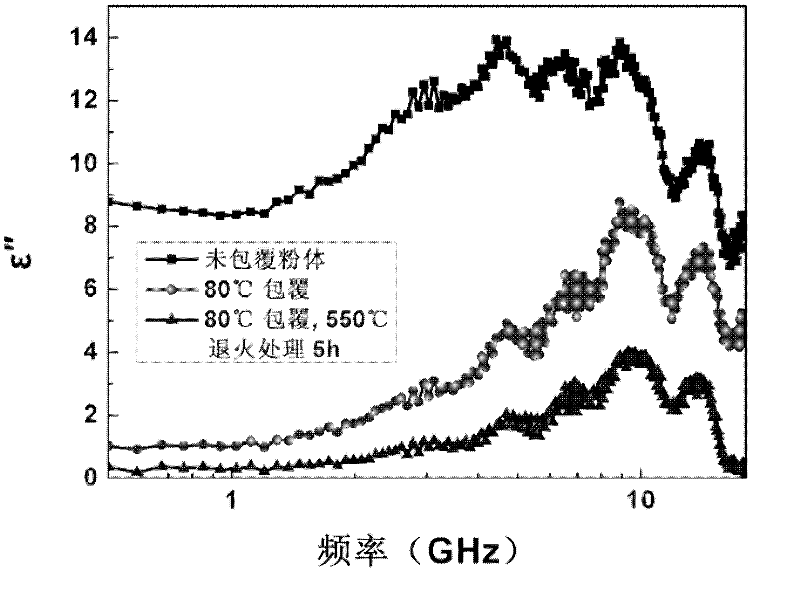

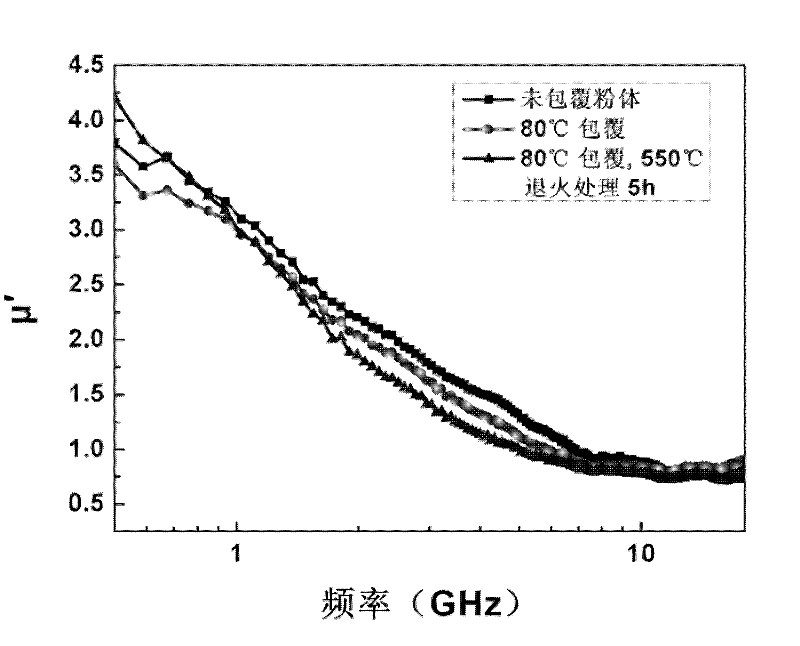

Method for improving electromagnetic wave absorption performance of Fe-Si-Al powder

InactiveCN102528022AImprove microwave permeabilityLow dielectric constantInorganic material magnetismAl powderWater baths

A method for improving electromagnetic wave absorption performance of Fe-Si-Al powder relates to the technology of electromagnetic wave absorption and comprises the following steps: 1) performing ball mill flattening treatment on Fe-Si-Al soft magnetic alloy powder; 2) fast and mechanically stirring the powder obtained through the step 1) and scattering the powder into water and leading in air from the bottom of a container; 3) respectively preparing mixed salt solution with the corresponding molar ratio according to spinel ferrites to be wrapped, and preparing strong alkali solution according to the corresponding molar ratio; 4) stirring the scattered solution obtained by the step 2) under water bath heating at the temperature of 25-80 DEG C; 5) adding the salt solution and the strong alkali solution which are prepared through the step 3) into treated solution treated by the step 4); and 6) finishing reaction, cleaning the powder, drying and annealing. The method for improving the electromagnetic wave absorption performance of the Fe-Si-Al powder greatly reduces dielectric constant and simultaneously improves the microwave magnetic conductance of the powder.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

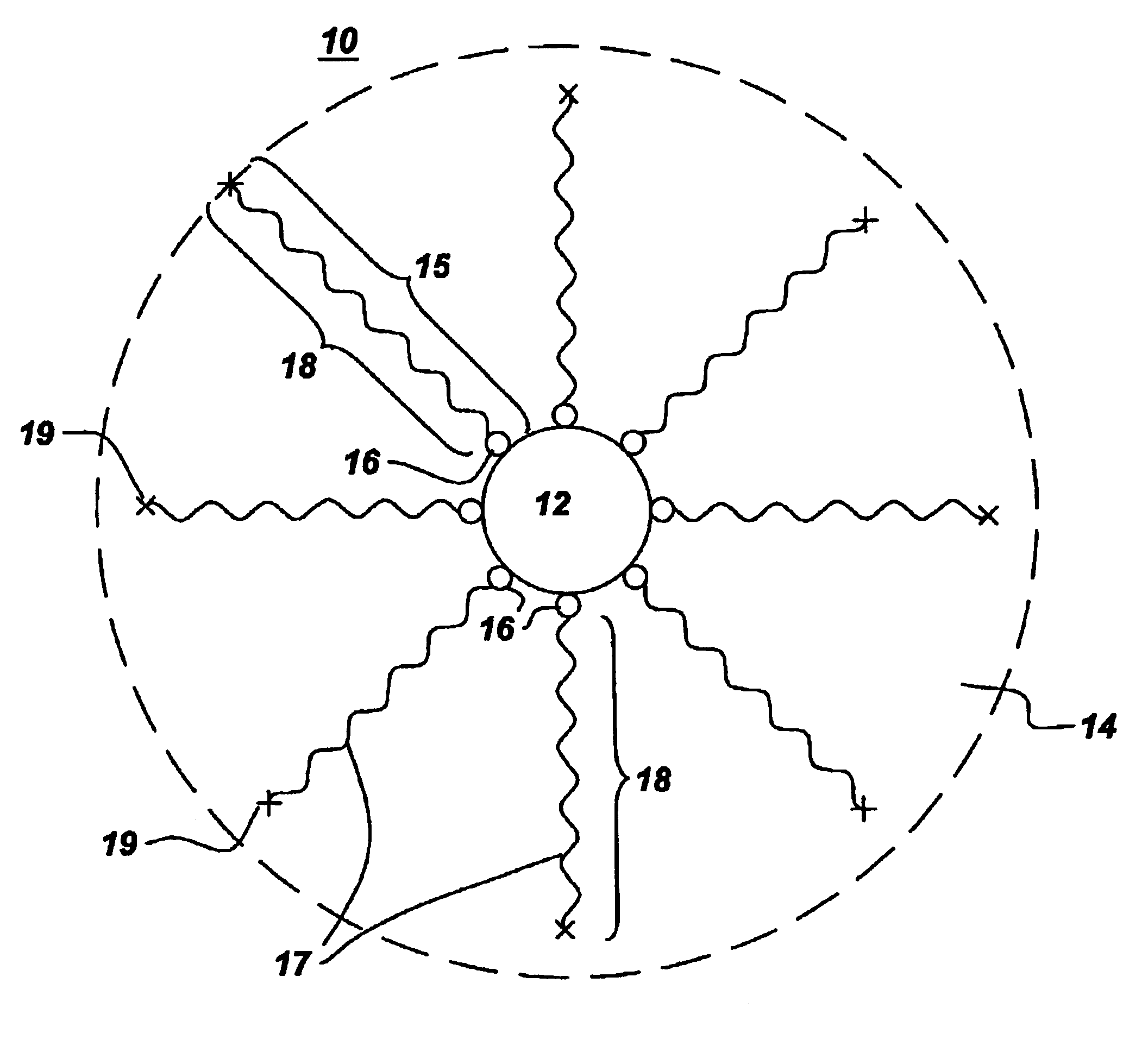

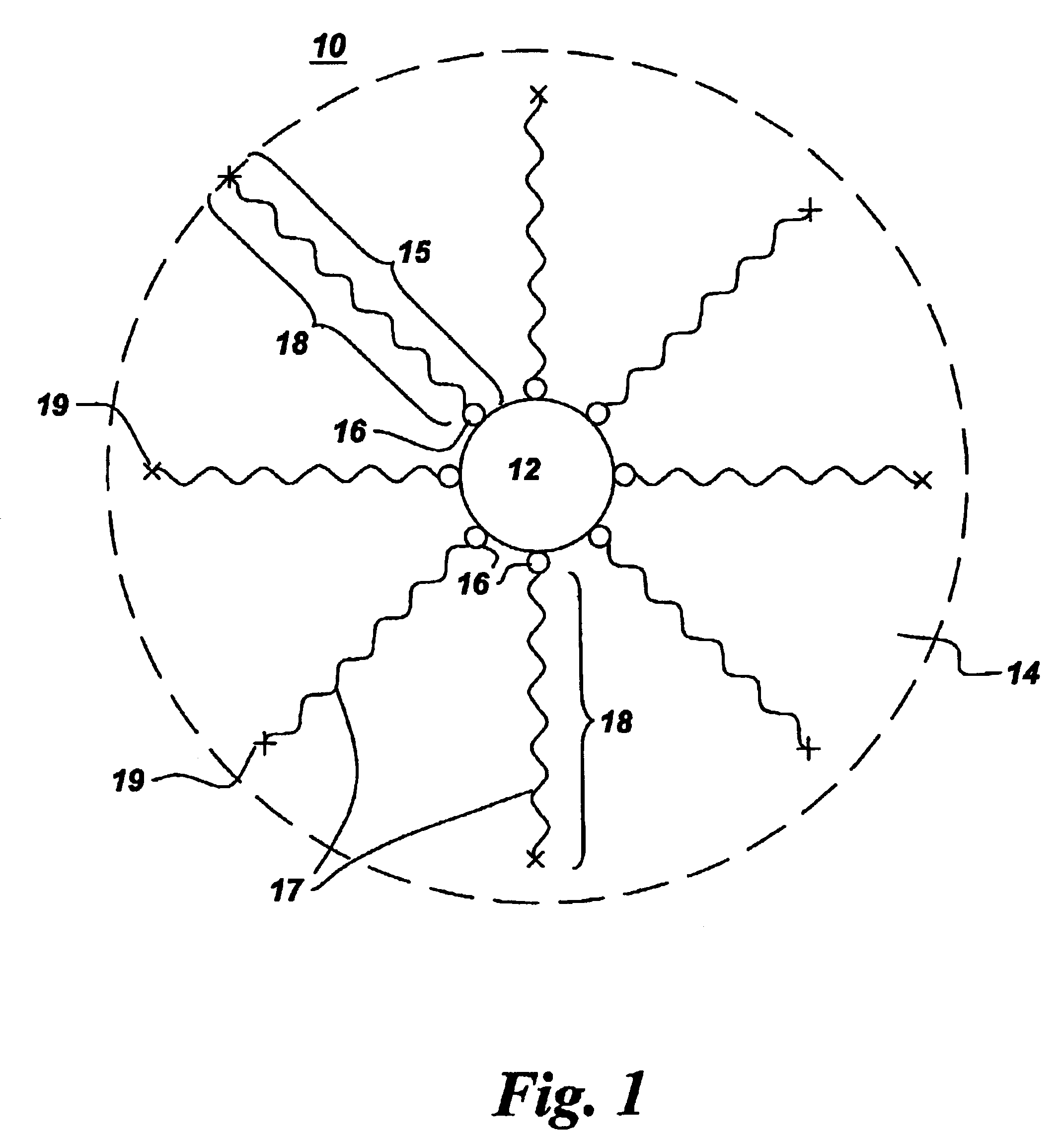

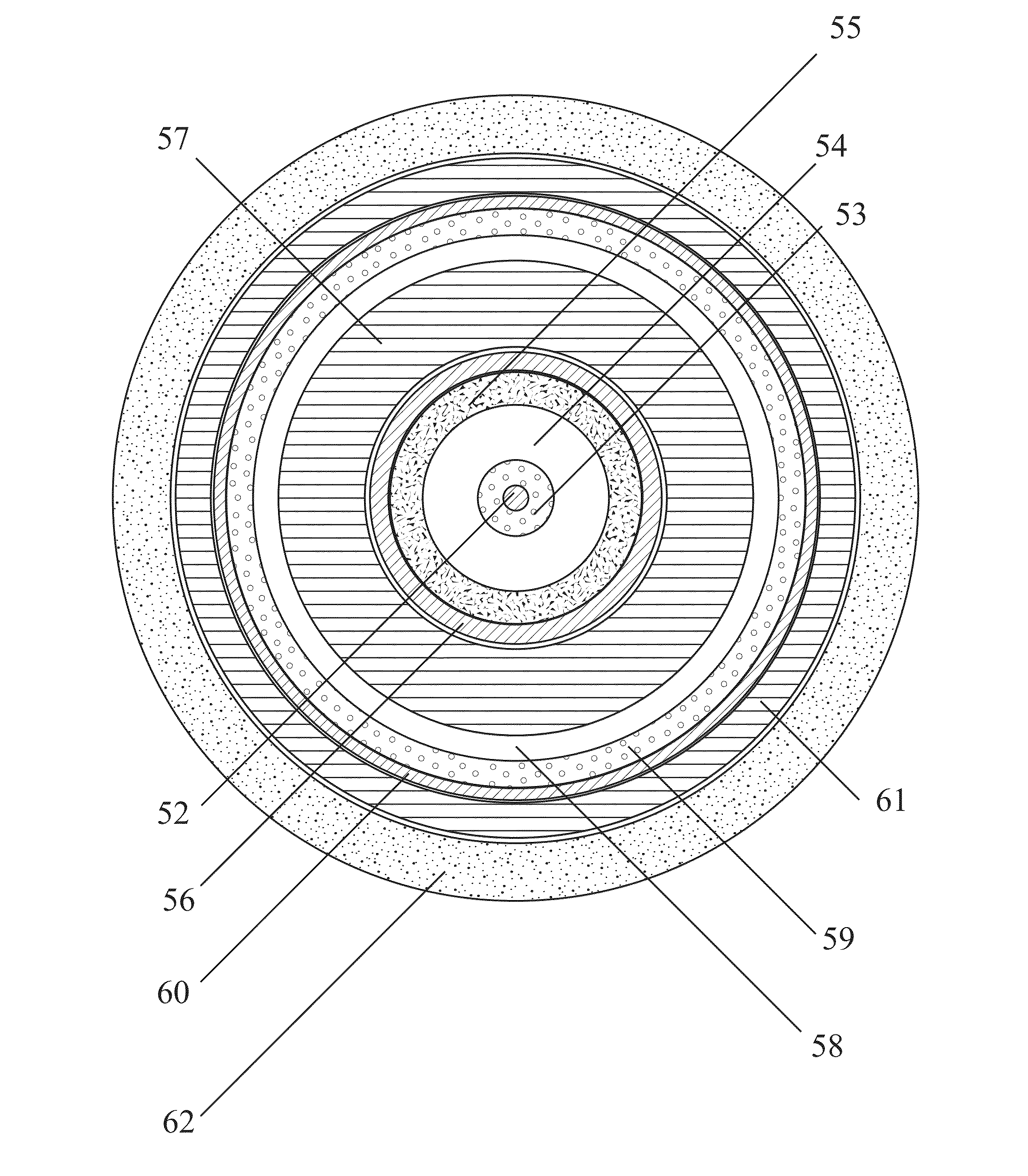

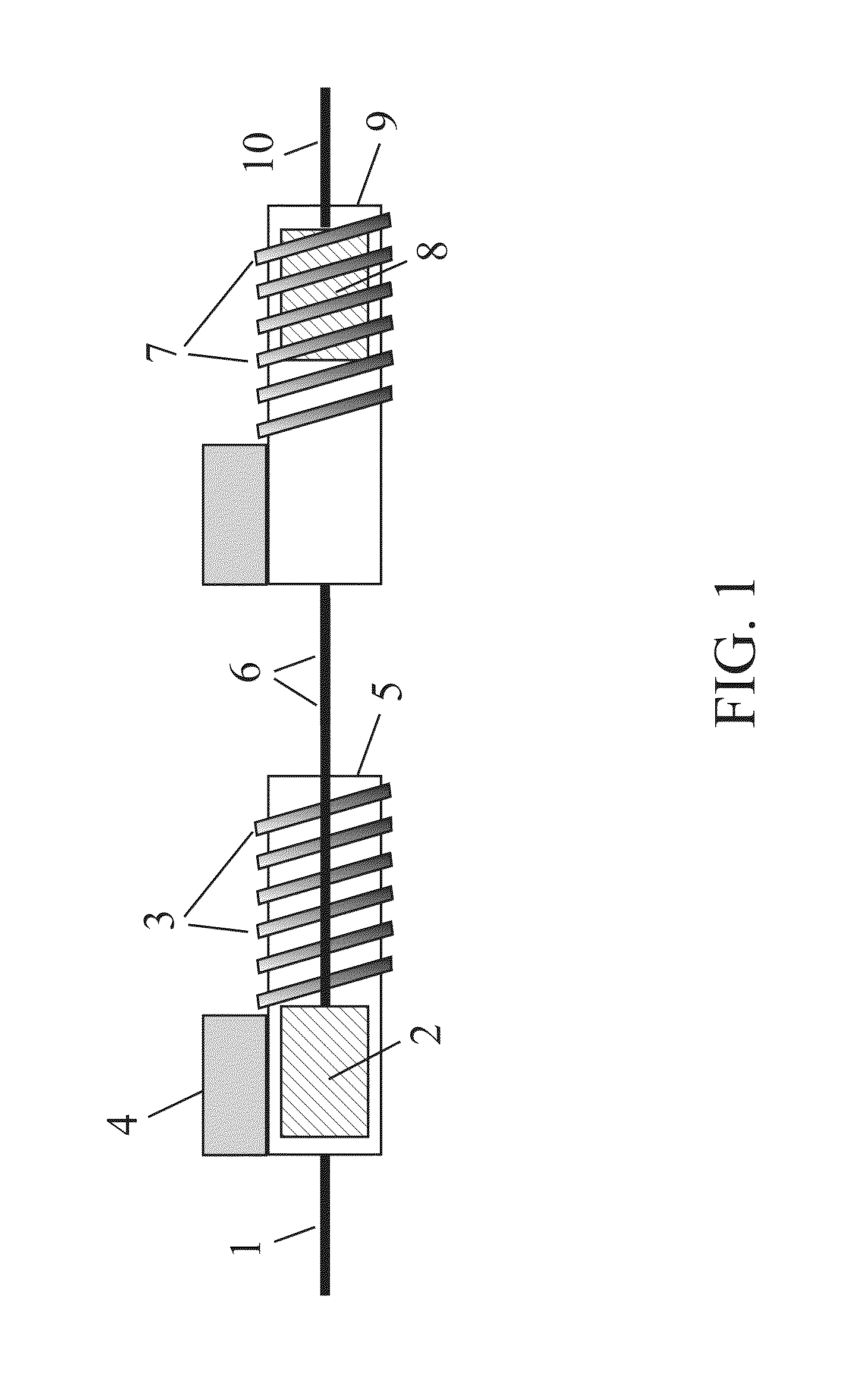

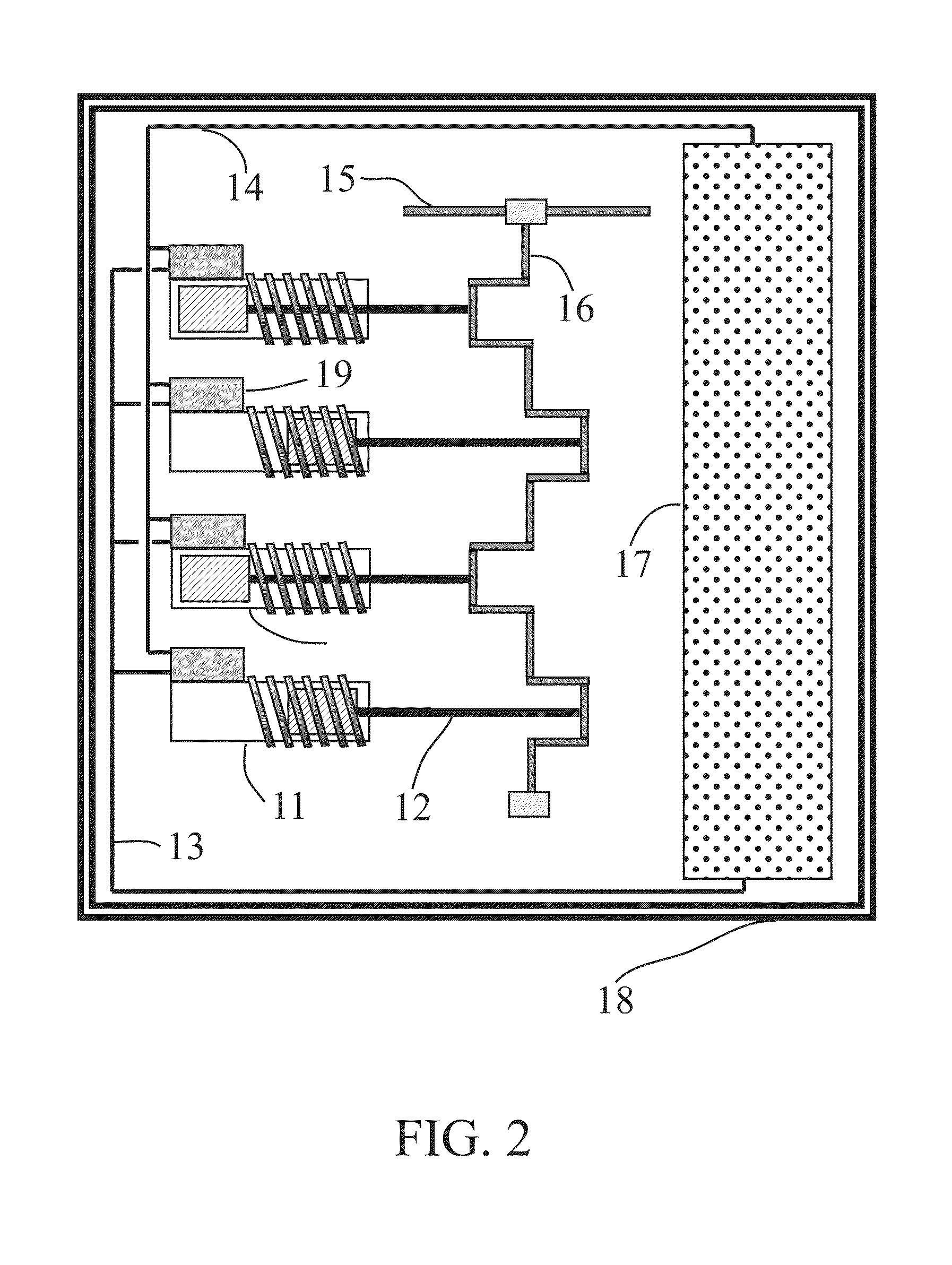

Positron Systems for Energy Storage, Production and Generation

InactiveUS20160086680A1Sufficient effectWeaken energyConversion outside reactor/acceleratorsNuclear energy generationPositron emittersFerrofluid

A positron based system is disclosed which extracts electric power from matter-antimatter annihilation reactions between electrons and positrons. In one embodiment, for storage and distribution of electric power, a solar array provides power to a cyclotron that produces the positron emitter 52Manganese. The positron emitting 52Mn is incorporated into spinel ferrite nanoparticles capable of suspension in an electrolyte fluid. This liquid pourable energy source is deployed to operate an internal annihilation engine, and to support a system for production of further positrons by a chain reaction pair production method. The various embodiments of this fundamental and new energy system also includes a photonic energy based mechanical piston system containing ferrofluids, an annihilator electrical circuit component and the use of positrons to produce an electron depleted material to generate a static positive electric field device for battery recharging, vehicle levitation, water desalination by deionization and ion plasma rocket engine drive.

Owner:FILLER AARON GERSHON

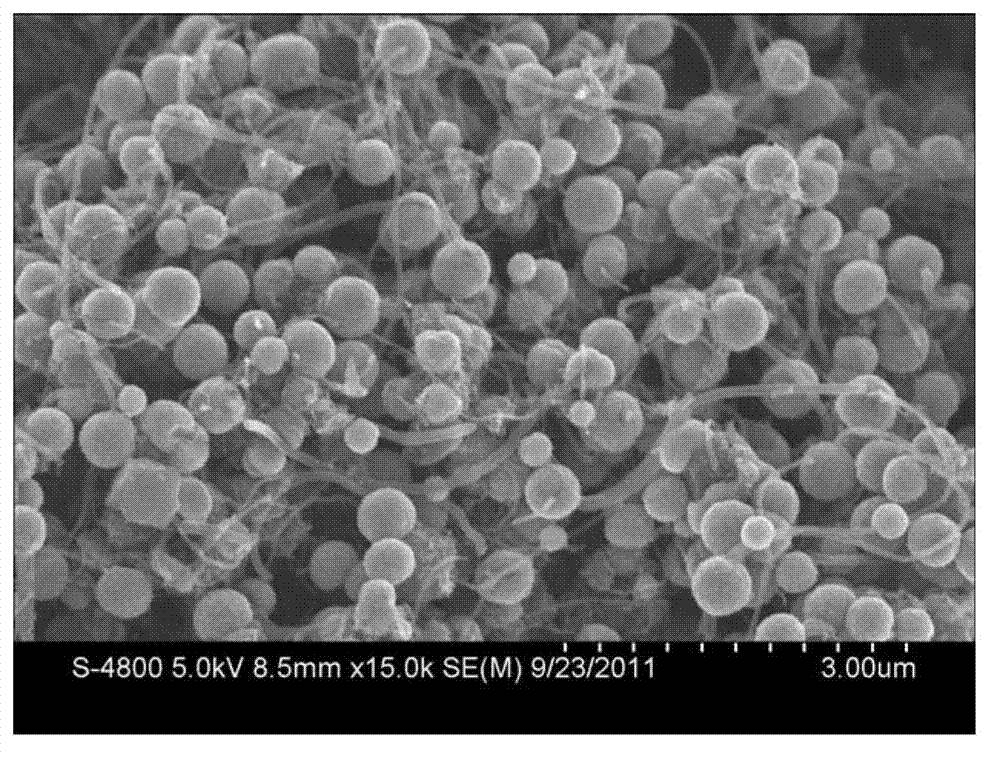

Spinel ferrite/CNx nanocomposite and preparation method thereof

InactiveCN102963938AImproving Impedance MatchingImprove absorbing performanceMaterial nanotechnologyCarbon nanotubesNitrogen gasNanometre

The invention provides a spinel ferrite / CNx nanocomposite and a preparation method thereof. According to the spinel ferrite / CNx nanocomposite prepared by the method provided by the invention, spinel ferrite nanoparticles are uniformly distributed on the surface of a nitrogen-doped carbon nanotube in a united-bead manner and are homogeneous in size and regular in crystal form, the cost of required raw materials is low, during preparation, the carbon nanotube has no need of early-stage functional treatment and nitrogen protection, and the spinel ferrite / CNx nanocomposite can be obtained at lower temperature (200-250 DEG C); and the preparation method is simple in process and can achieve large-scale preparation, thereby being applicable to scale production.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

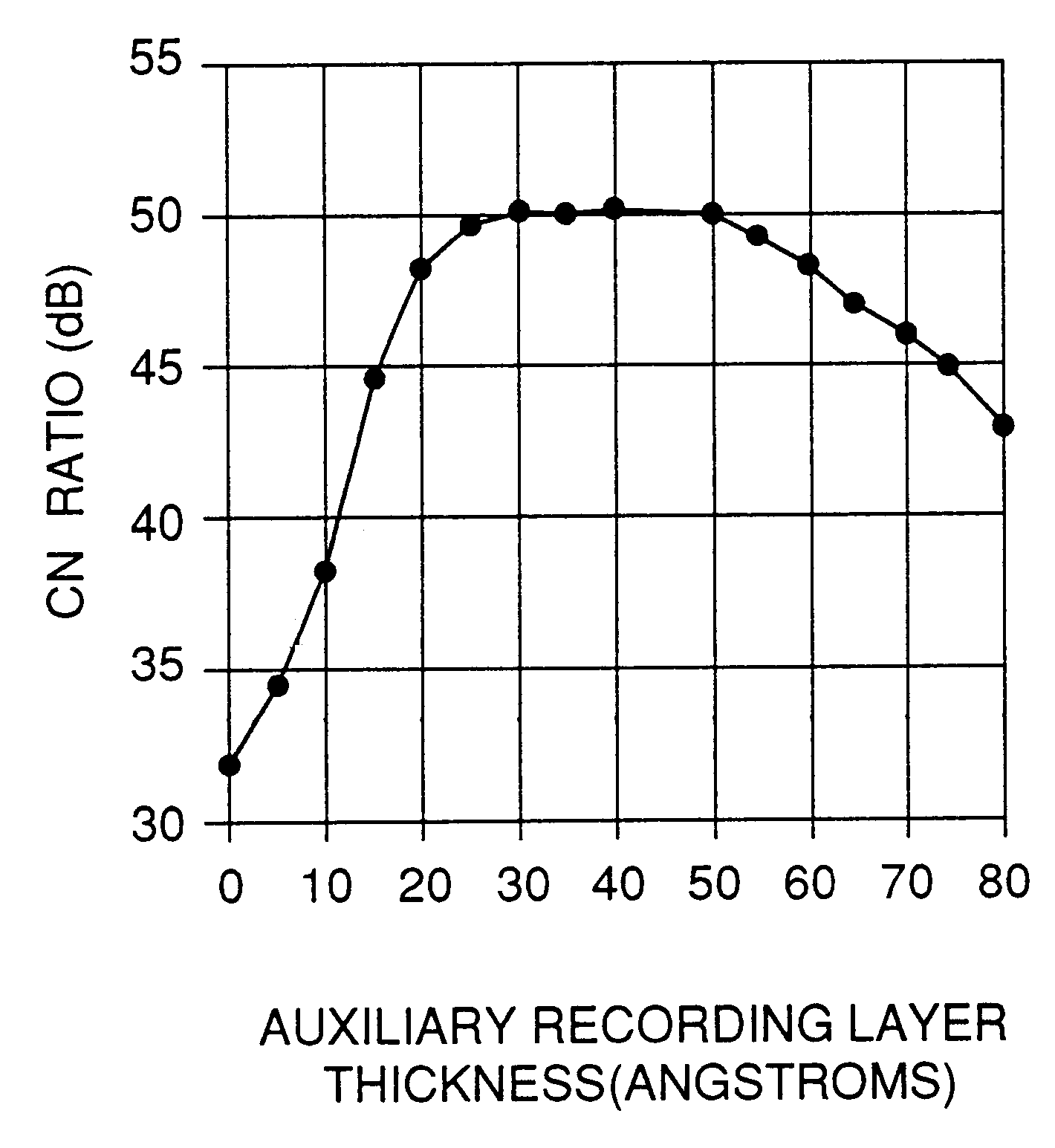

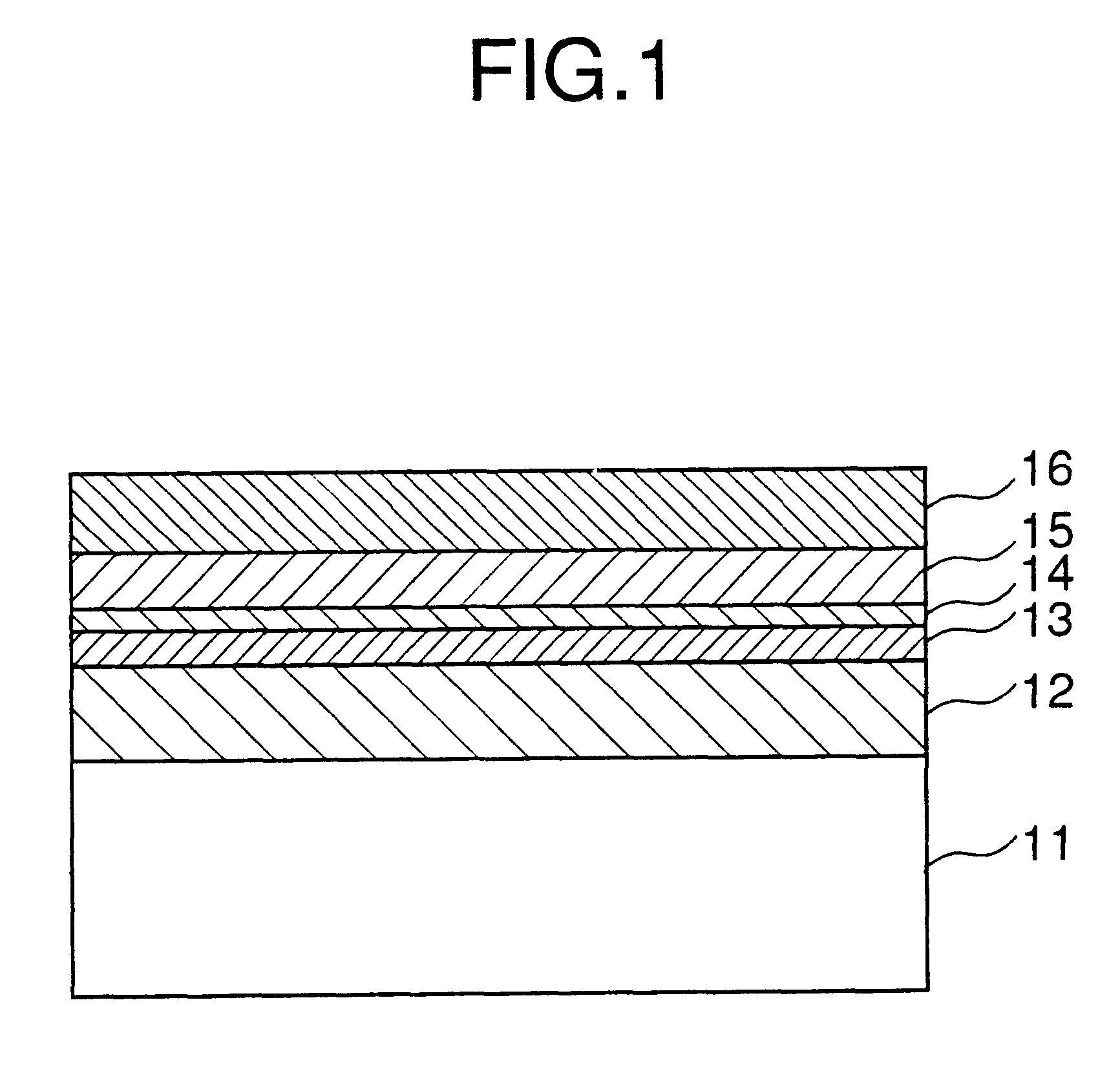

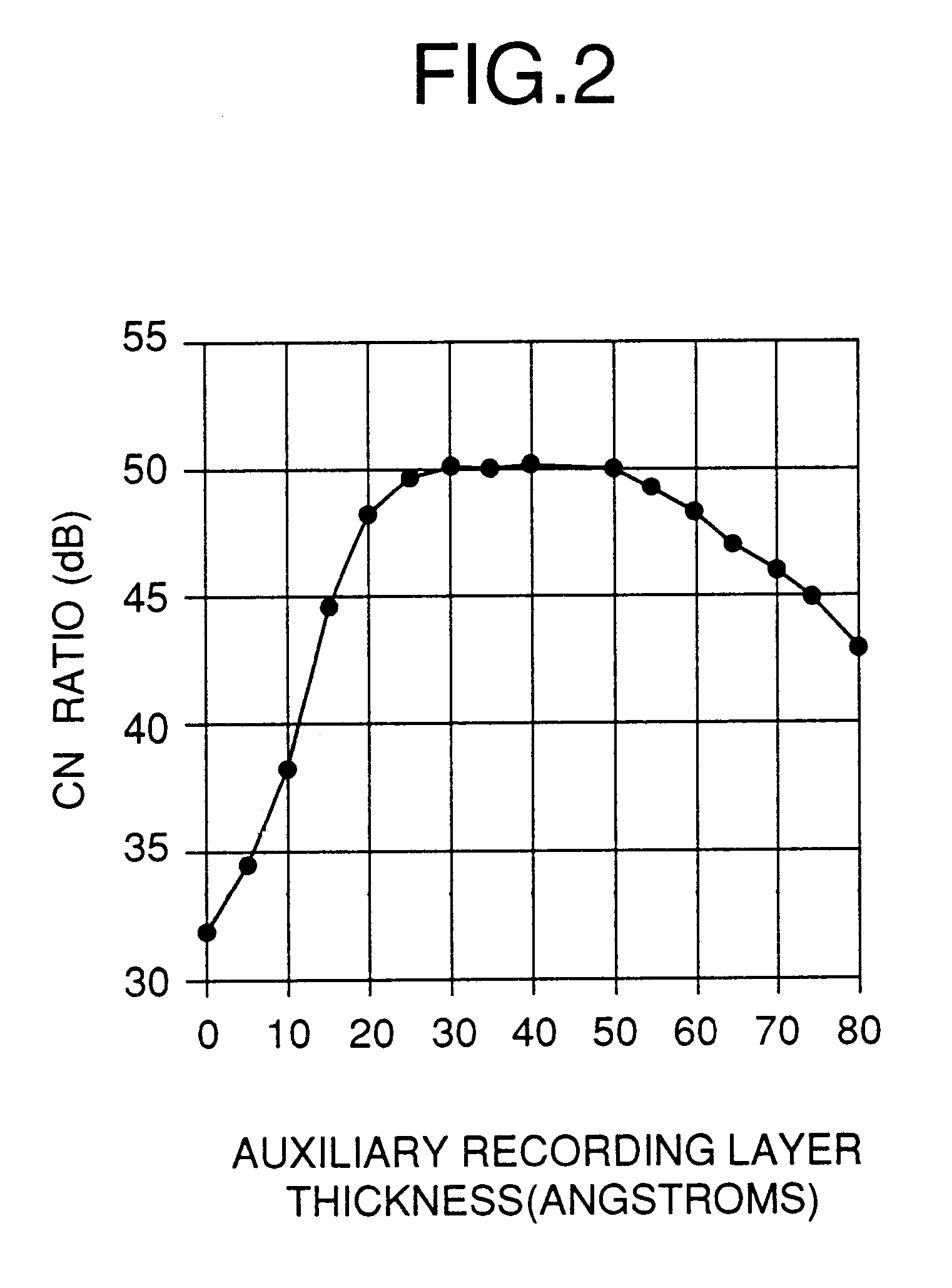

Magneto-optical recording medium

InactiveUS6436524B1Ensure correct executionExcellent magnetic propertiesSilicaRecord information storageRare earthMagnetization

When recording using magnetic field modulation recording, the magneto-optical recording medium which is disclosed is capable of satisfactory recording with a low magnetic field. This recording medium is a layered superposition of a recording layer 13 and an auxiliary recording layer 14 having a film thickness of less than or equal to 100 angstroms. The recording layer 13 is a film having an easy perpendicular axis of magnetization whose value of magnetization at room temperature is at least 150 emu / cc, and for example a heavy rare earth-transition metal alloy, a magnetic multilayer film which employs a precious metal, an oxide like a garnet or Spinel ferrite, or some other magnetic alloy may be used. The auxiliary recording layer 14 is typically a heavy rare earth-transition metal alloy, and has a Curie temperature higher (desirably at least 30K higher) than that of the recording layer 13. It is desirable to further provide a stabilizing layer superimposed upon the recording layer 13 which has a lower Curie temperature and also a higher coercive field at room temperature than the recording layer recording layer 13. If HREx(Fe1-yCoy)1-x is used for the recording layer recording layer 13 (here HRE is a heavy rare earth metal), it is desirable that 0.08<=x<=0.20 and also 0.0<=y<=0.3.

Owner:SEIKO EPSON CORP

Rare-earth doped spinel ferrite/aluminum-doped zinc oxide composite fiber and preparation method thereof

InactiveCN101545159AHigh purityOptimizing Control ParametersInorganic material artificial filamentsFiberAluminum doped zinc oxide

The invention discloses a rare-earth doped spinel ferrite / aluminum-doped zinc oxide composite fiber and a preparation method thereof. The composite fiber is in a sandwich structure by coating an interlayer outside a core which is a rare-earth doped spinel ferrite fiber and has the diameter of 5 microns to 20 microns, and the interlayer is an aluminum-doped zinc oxide coating with the thickness of 50nm to 100nm. The method used for preparing target products has the advantages of high preparation purity, controllable process parameters and microstructures, simple technology, convenient operation, and the like and has important practical meanings on the premise that practical performance is not reduced, such as lower cost, little pollution, and the like. The composite fiber has favorable mechanical and optical performance, is a novel structure-function integrated material, is suitable for multiband absorption, function enhancement, and the like and satisfies the equipment requirements, such as thinness, lightness, width and strength.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of tourmalinite fuel oil activator

ActiveCN103980964AStrong NMR propertiesImprove conductivityLiquid carbonaceous fuelsWater useCombustion

The invention discloses a preparation method of a tourmalinite fuel oil activator. The tourmalinite fuel oil activator comprises tourmalinite nano-powder as a main functional component. The preparation method comprises the following steps of compounding the tourmalinite nano-powder and spinel ferrite, mixing the compound and an additive according to a mass ratio of the tourmalinite nano-powder, the spinel ferrite to the additive of 87-93: 5-9: 2-4, carrying out sintering to obtain a solid mixture, and adding water and a surfactant into the mixture, wherein the amount of the used mixture is 1-5% the total amount of the solid-liquid mixture, a water use ratio is in a range of 5-98% and a surfactant use ratio is in a range of 2-30%. The tourmalinite fuel oil activator obtained by the preparation method can improve fuel oil quality, promote full combustion of fuel oil, improve combustion efficiency, save fuel oil, improve fuel oil atomization quality, and realize full combustion of fuel oil thereby reducing discharge of harmful gas so that energy saving and emission reduction are realized.

Owner:丘寿勇 +1

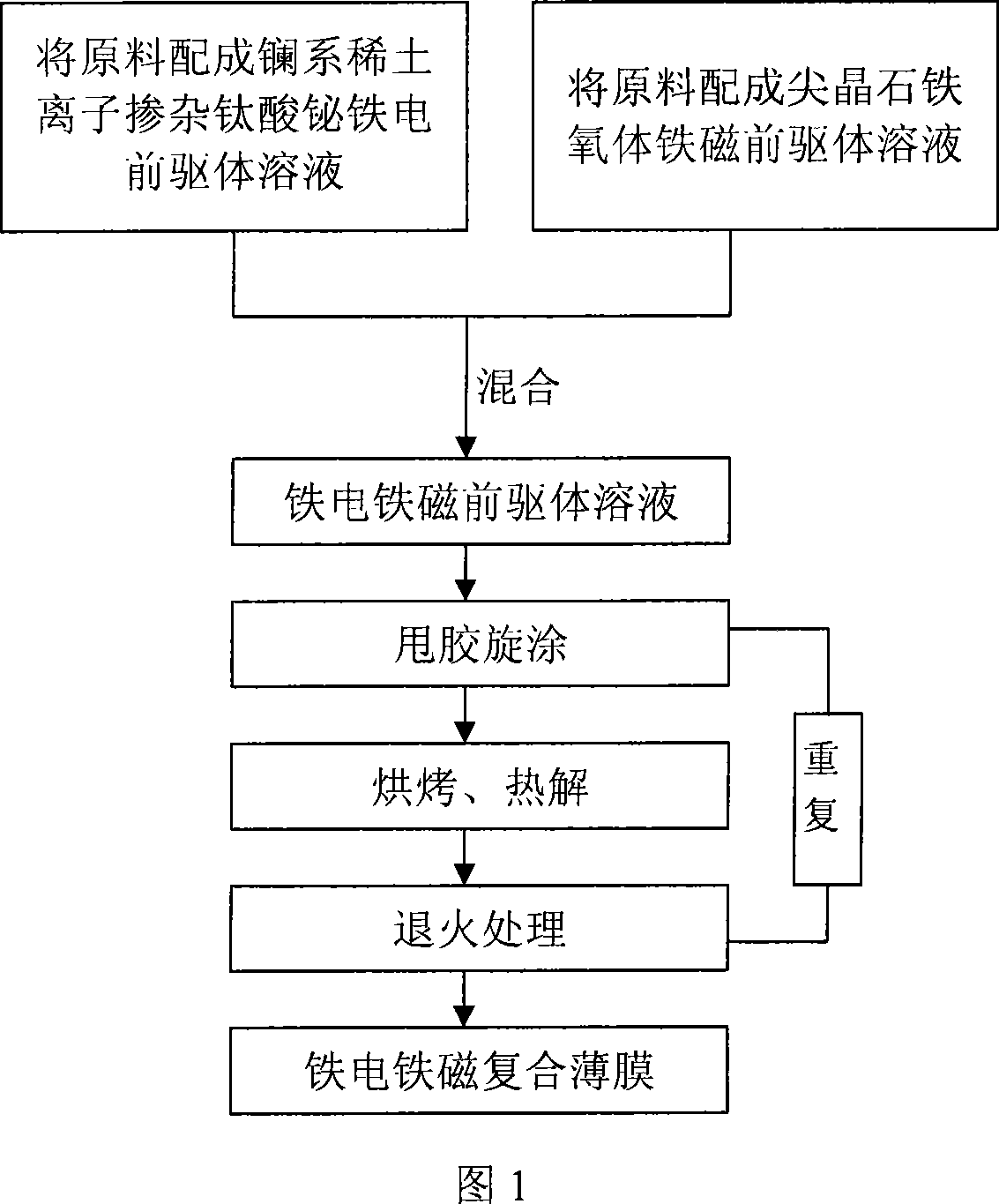

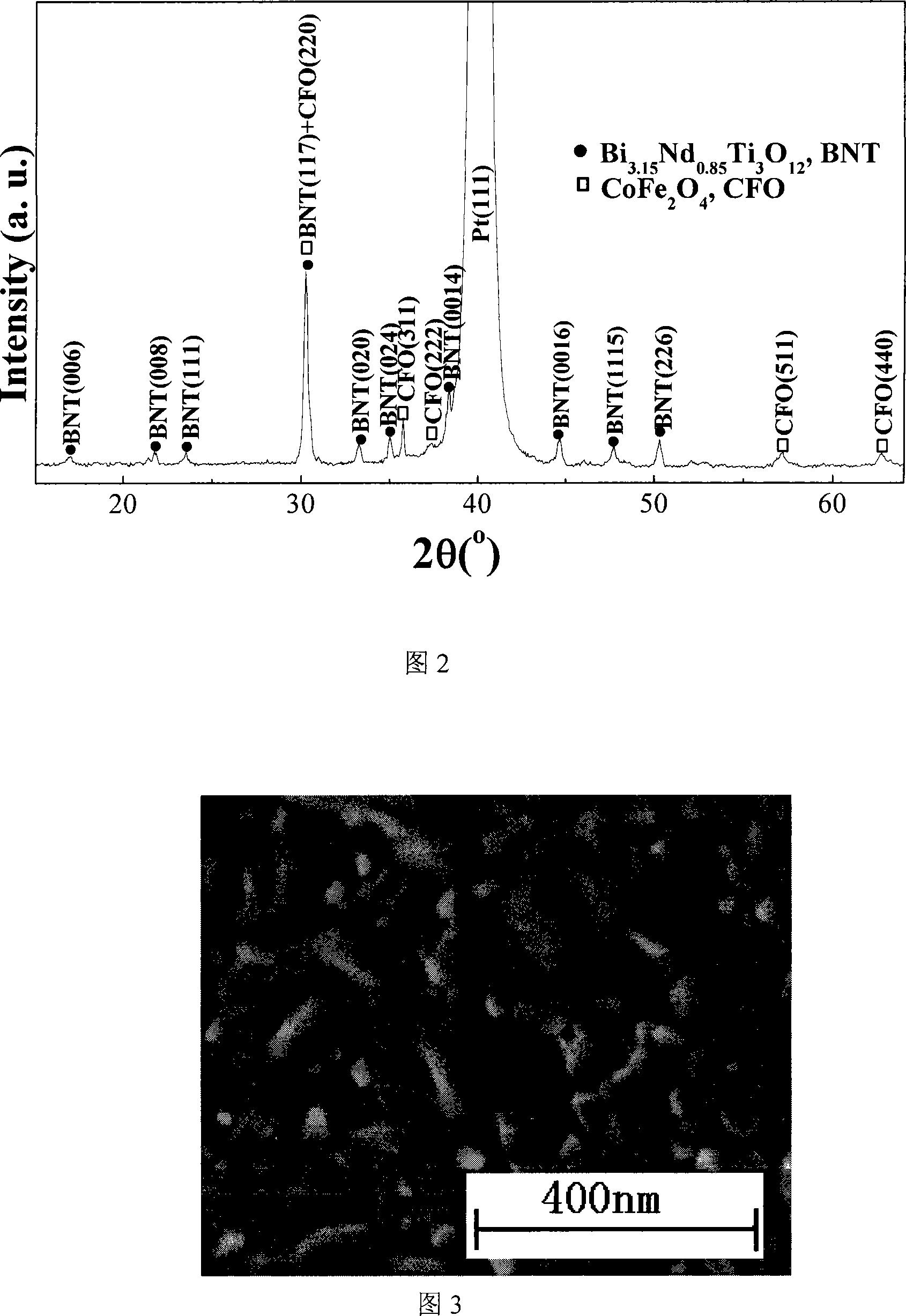

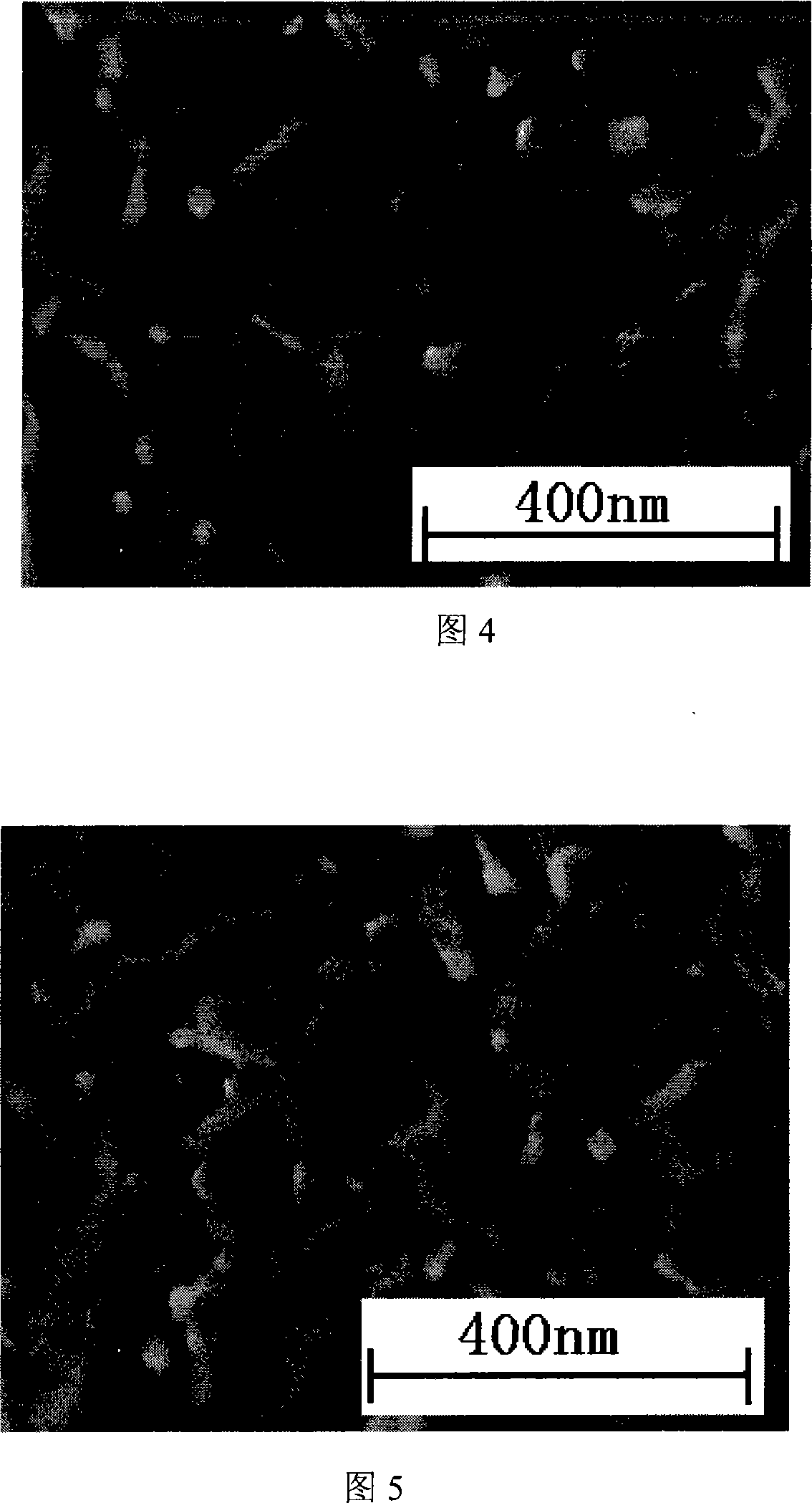

La rear earth ion doped-bismuth titanate spinel ferrite ferroelectric ferromagnetic composite film and its preparation method

InactiveCN101090024AChange the magnetoelectric propertiesComposite uniformMagnetic film to substrate applicationMagnetic layersComposite filmRare earth ions

This invention relates to a lead-free ferrite ferromagnetic compound film of bismuth titanate / spinel ferrite doped with lanthanide series rare earth ions and its preparation method, first of all which prepares lanthanide series of rare earth ionic doped bismuth titanate ferroelectric solution and places it for 3-7days, then prepares a spinel ferrite ferromagnetic solution and takes acetylacetone as the stabilizer to mix the bismuth titanate ferroelectric solution with the ferrite ferromagnetic solution to get a uniform mixed solution of them then to filter and coat it on the substrate uniformly by a glue-throwing and spin coating technology to get a wet film to be baked, pyrogenated and annealed to get a ferroelectric and ferromagnetic compound film of single layer multi-crystal lanthanide series rare earth ionic doped bismuth titanate / spinel ferrite and then repeats the above mentioned steps to get the film with necessary thickness. Said compound film does not contain lead.

Owner:XIANGTAN UNIV

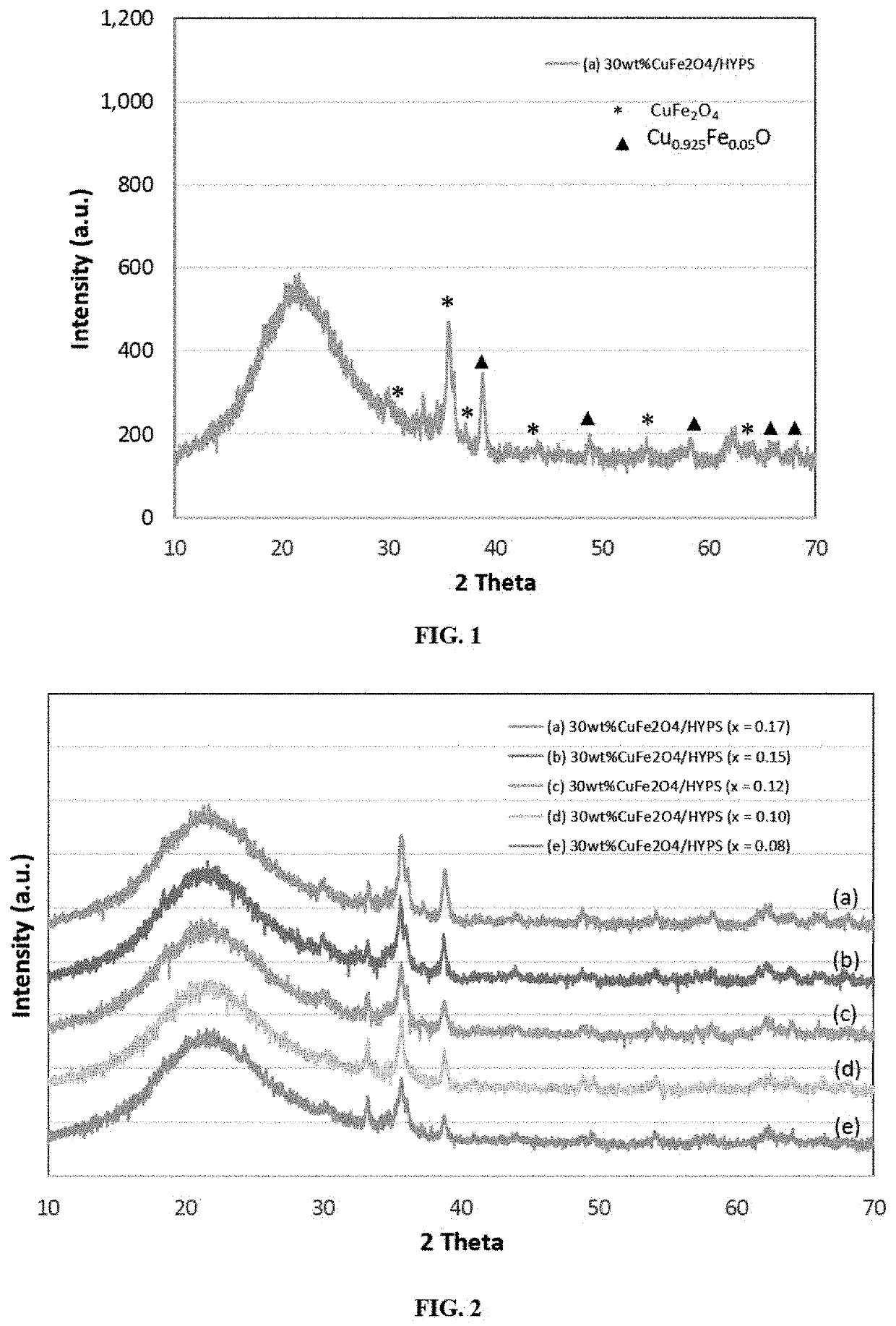

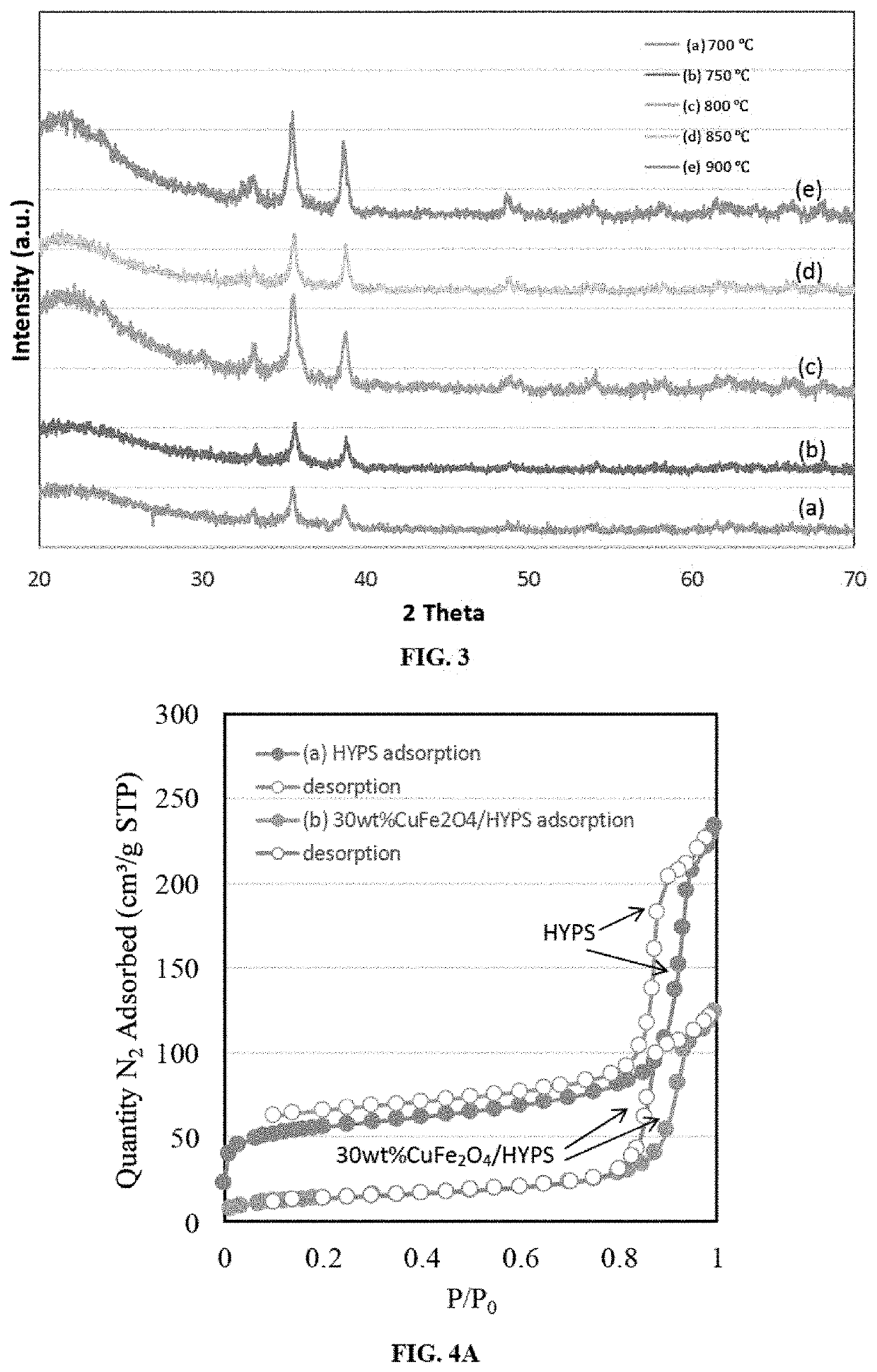

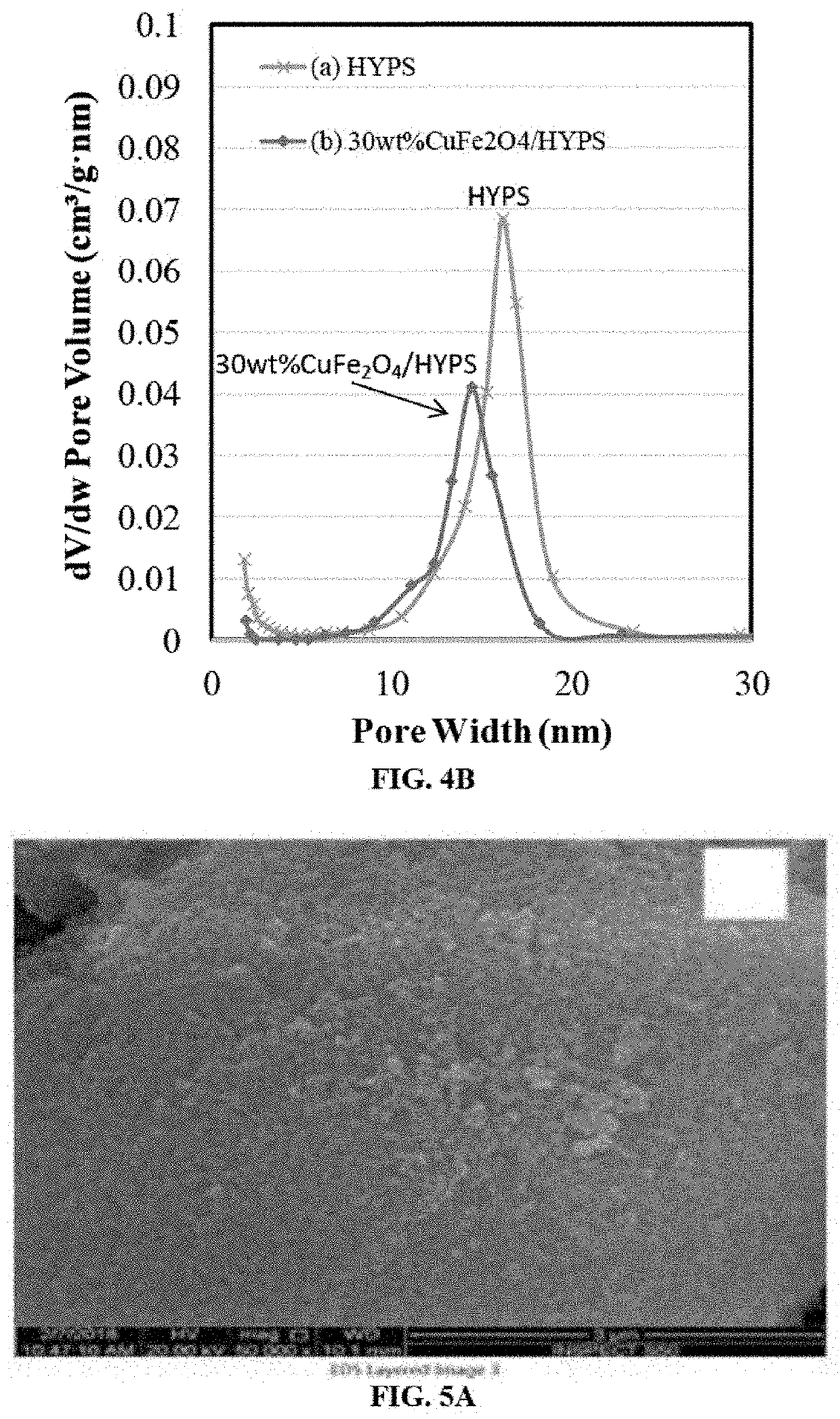

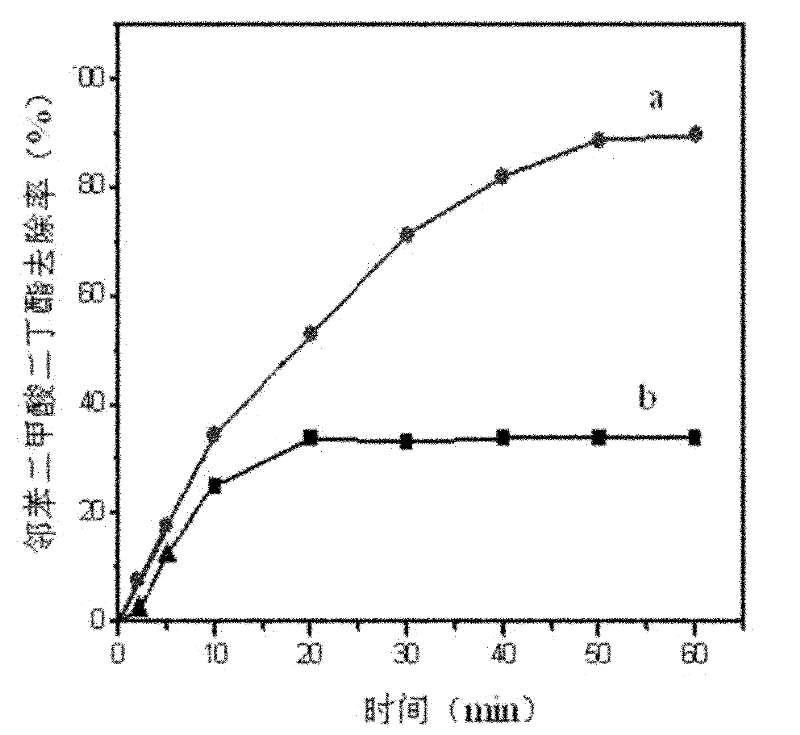

Spinel ferrite impregnated mesoporous silica containing a platinum complex

ActiveUS20200338122A1Inorganic active ingredientsInorganic non-active ingredientsPlatinum complexPhysical chemistry

A nanotherapeutic having platinum complexes encapsulated by a nanoformulation containing at least one spinel ferrite of formula CuFe2O4, NiFe2O4, CoFe2O4, and MnFe2O4 deposited on mesoporous silica. A method of preparing the nanotherapeutic that involves mixing a metal(II) salt and a Fe(III) salt with the mesoporous silica nanoparticles to form a powdery mixture, calcining the powdery mixture to form the nanoformulation, and mixing the nanoformulation with the platinum complex. A method for treating cancer with the nanotherapeutic.

Owner:IMAM ABDULRAHRNAN BIN FAISAL UNIVERSITY

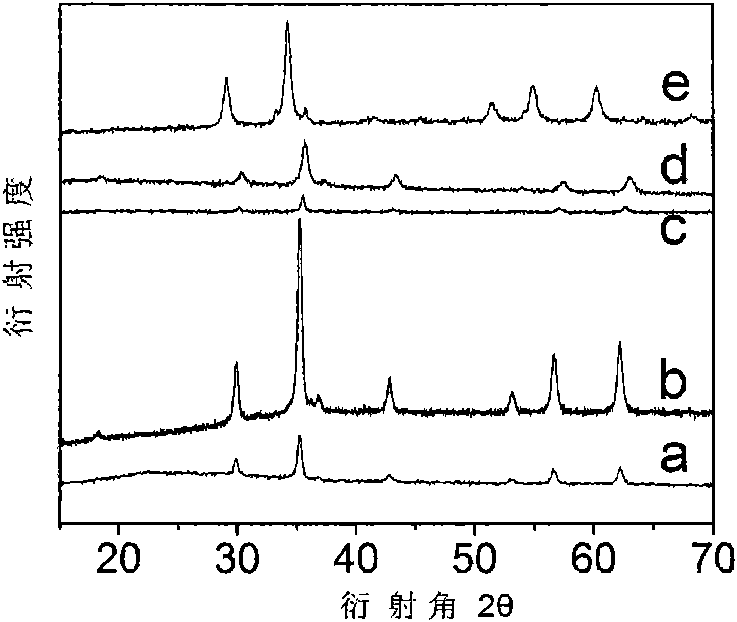

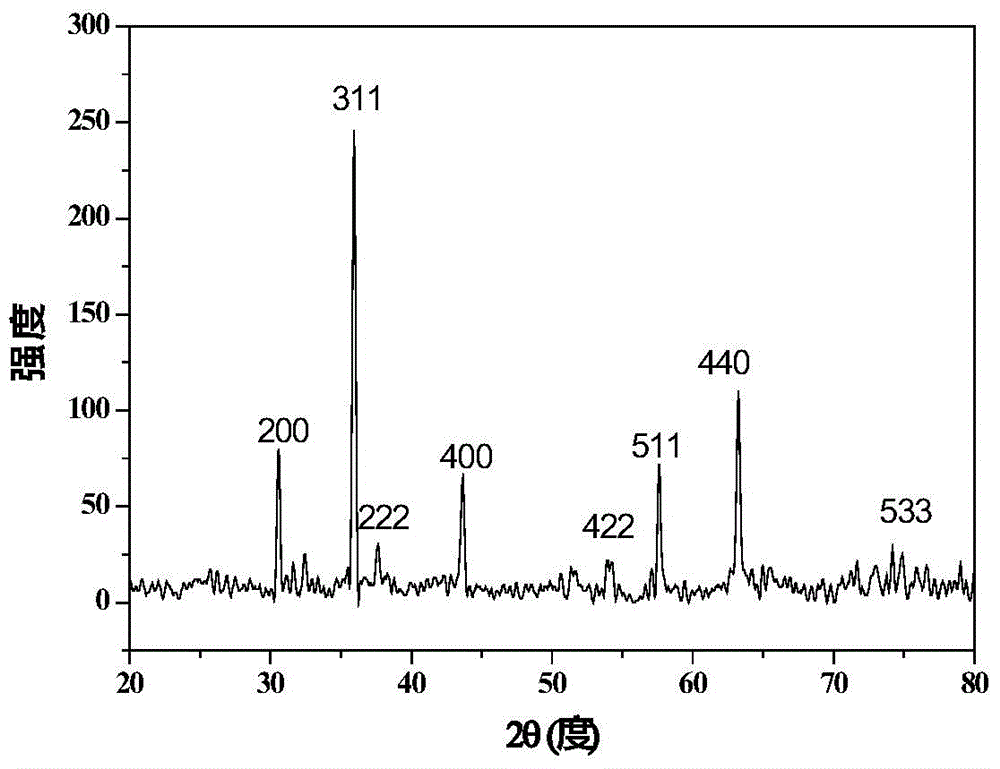

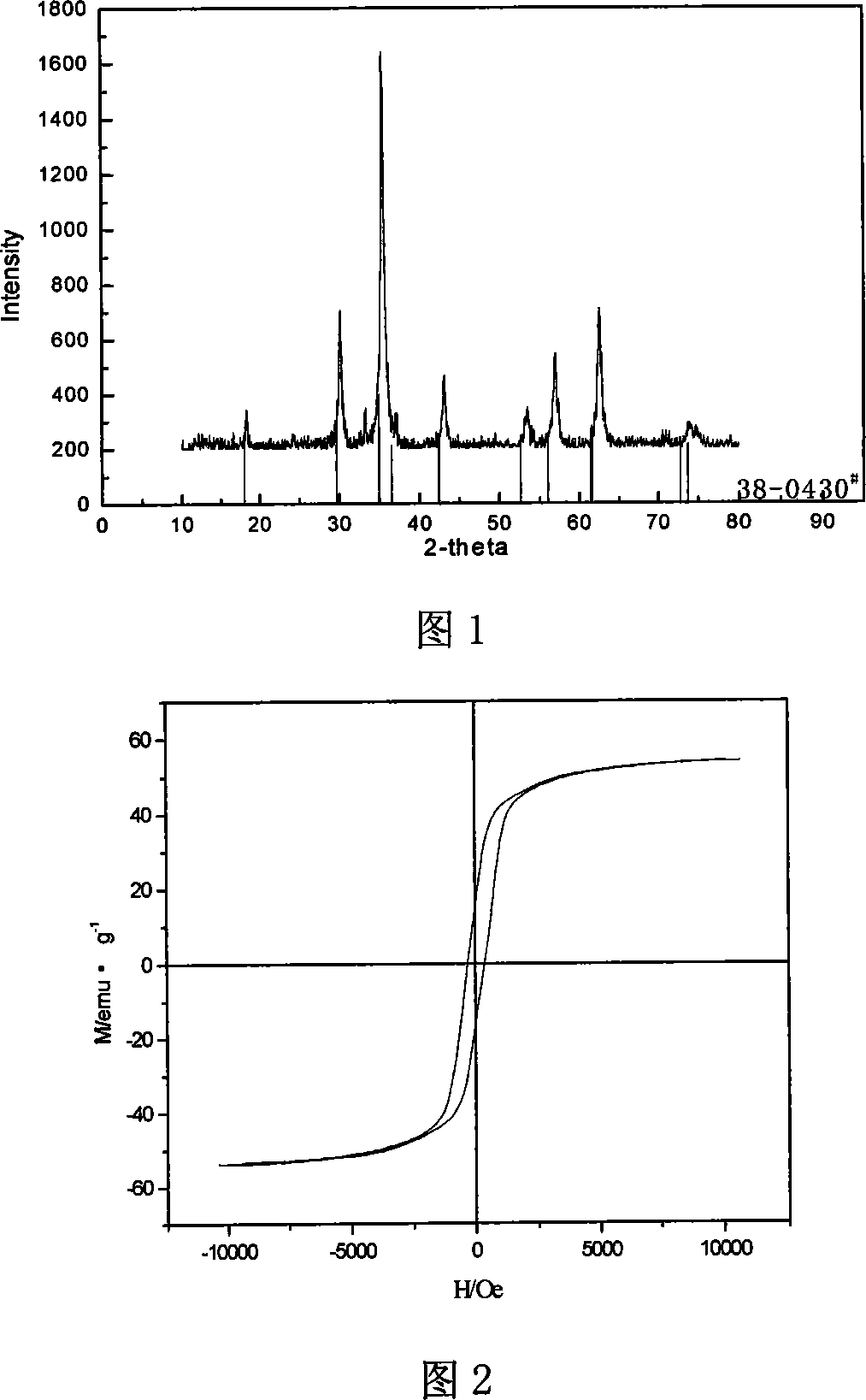

Method for preparing nano spinel ferrite with equal grain size

InactiveCN101157549AParticle size controlSmall particle sizeReaction temperaturePolytetrafluoroethylene

The invention relates to a preparation method of particle size homogeneous nanometer spinel ferrite, which belongs to the art of the metal oxides preparation. Metallic ion is first deoxidized into highly scattered nanometer metallics in a colloid mill, and then the blended solution containing the nanometer metallics is transferred into a Teflon gallbladder for water hot crystallization under high-pressured reaction so as to form the spinel ferrite particle with a diameter of 5 to 200 nanometers. The invention has the advantages that the high-speed shearing action of the colloid mill ensures that the deoxidized metallics are highly dispersed, thereby enabling the particle size homogeneous nanometer spinel ferrite. The reaction is carried in the solution, and the diameter of the nanometer particle can be controlled through adjusting the reactant density, the reaction temperature and the reaction time; since no need for high-temperature roasting process in the reaction, the operation becomes quite easy. Moreover, the invention has low cost and low energy consumption, thereby being favorable for industrialized application.

Owner:BEIJING UNIV OF CHEM TECH

Catalyst for oxidation and decomposition of organic pollutants in water with ozone and method thereof for catalyzing sewage treatment with ozone

InactiveCN102151567BStable structureHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationDecompositionSewage

The invention discloses a catalyst for oxidation and decomposition of organic pollutants in water with ozone and a method thereof for catalyzing sewage treatment with ozone, and relates to a catalyst for decomposing the organic pollutants in water and the method thereof for sewage treatment. By adopting the catalyst, the problems that the traditional solid catalyst for catalyzing the decomposition of organic pollutants in the water with ozone is easy to be oxidized and decomposed by ozone, easy to break, can dissolve out impurities, has low strength and low catalytic efficiency and is difficult to recover can be solved. The catalyst for oxidation and decomposition of the organic pollutants in the water with ozone refers to spinel ferrite or a composite of spinel ferrite; and the method ofthe catalyst for catalyzing the sewage treatment with ozone comprises the following steps of: adjusting pH and temperature of sewage, then introducing ozone, further adding the catalyst and treating for 1 minute-120 minutes, then using a magnetic field to recover the catalyst, and finally absorbing tail gas of the ozone. The catalyst can improve the removal rate of organic matters to 90%-100%, and can be used for sewage treatment or deep treatment of drinking water.

Owner:HARBIN INST OF TECH

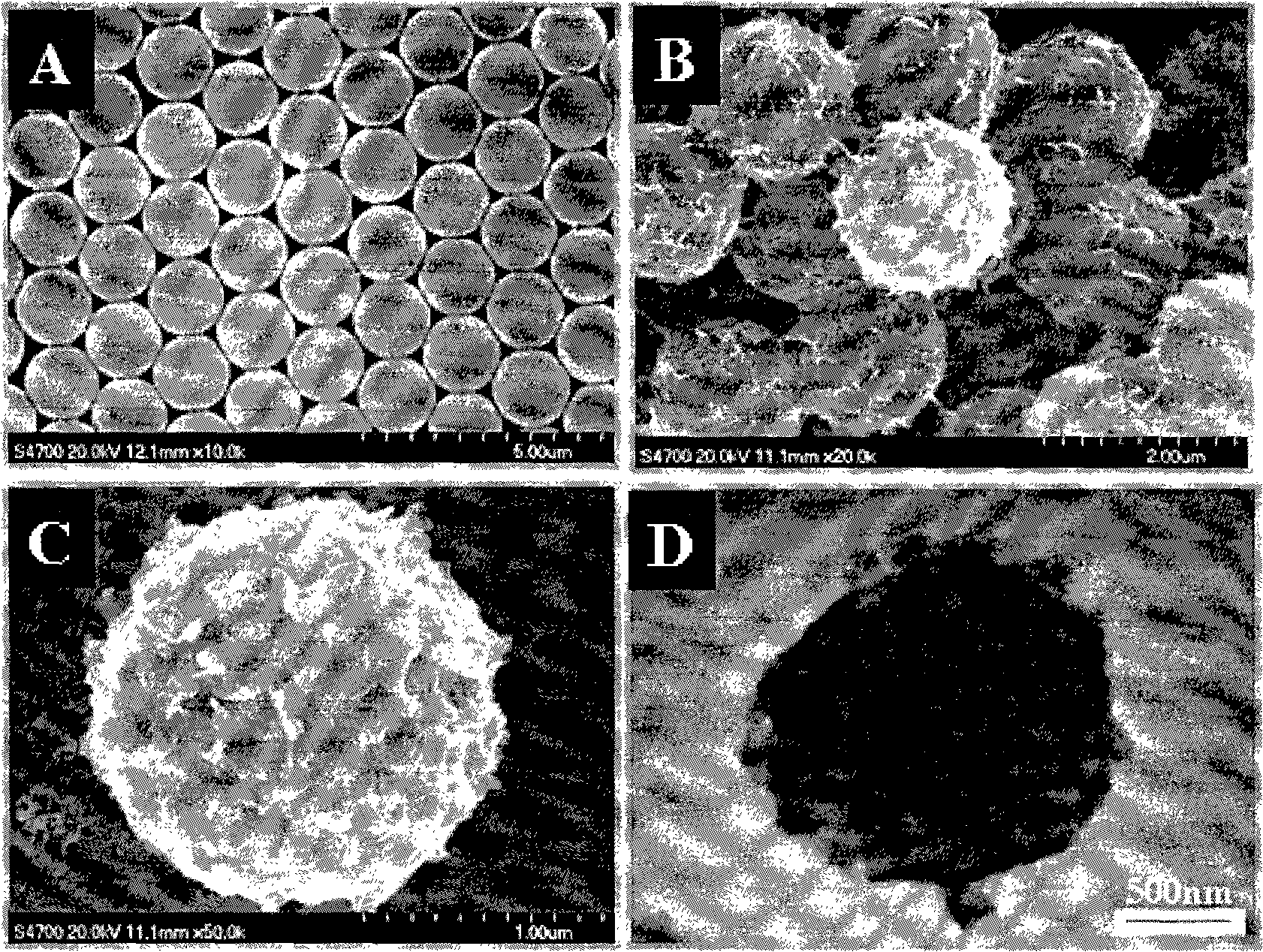

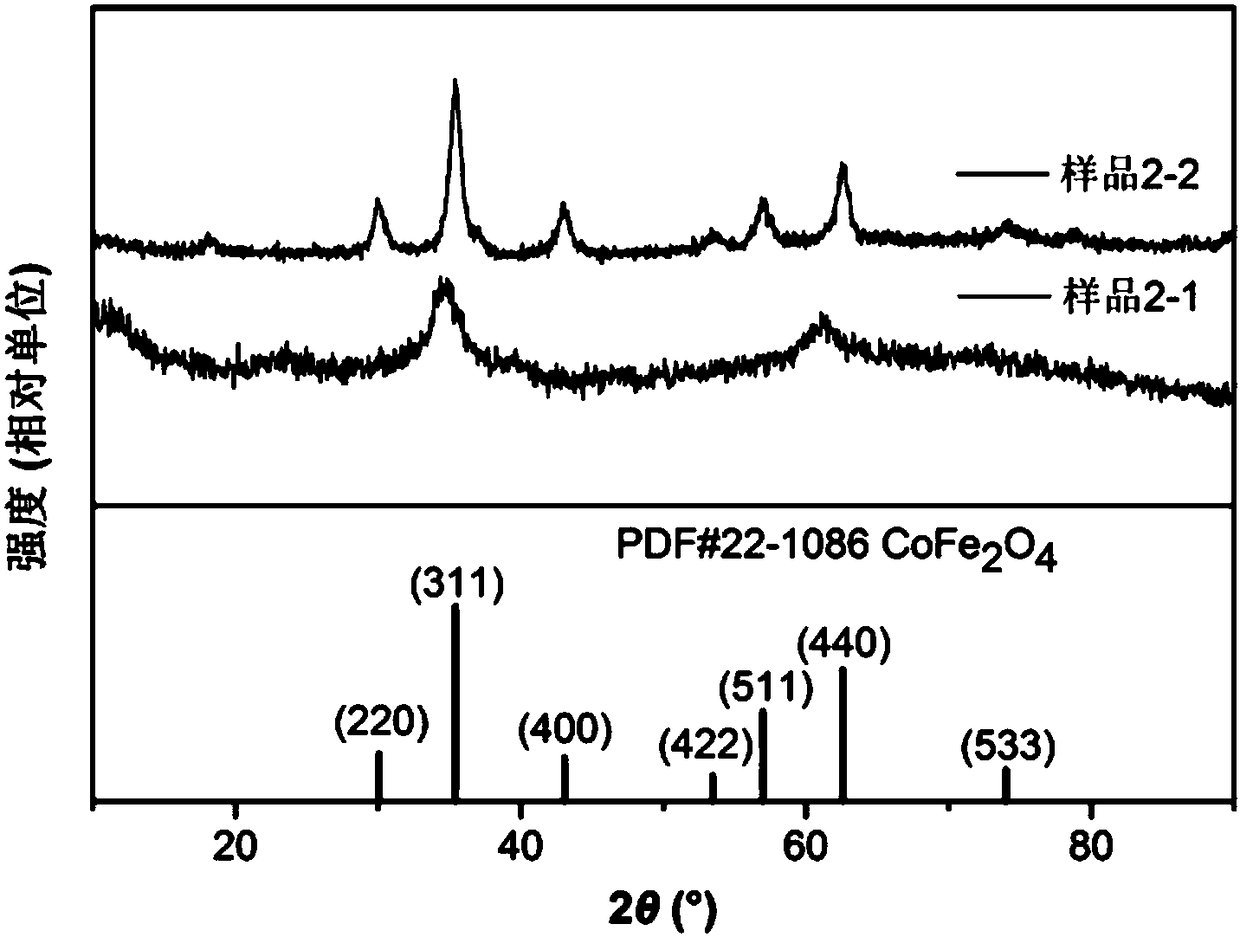

Method for preparing flower-shaped spinelle cobalt ferrite powder

The invention provides a preparation method for floriated spinelle cobalt ferrite powder. The method procedure is that: a certain quantity of saturated oxalic acid solution is measured; corresponding quantities of cabaltous nitrate and ferric nitrate are weighted according to a ratio of preparing 0.002mol of ferrite by per 100ml of the saturated oxalic acid solution, wherein, the theoretical stoichiometric proportion of the ferrite is 1:2, and the cabaltous nitrate and the ferric nitrate are added into the oxalic acid solution; 0.2 to 0.5g PEG of surface active agent is added and stirred for 0.5 to 1.0 hour to prepare well-proportioned mixture solution; NaOH is used for regulating the PH value to be 12 and the well-proportioned mixture solution is stirred with magnetic force at room temperature for 0.5 to 1.0 hour until the sample generates a lot of precipitates; heating and stirring are carried out for 2 to 3 hours in a water-bath with the temperature of 75 DEG C to 85 DEG C to get a precursor; the precursor is washed sequentially by alcohol and distilled water for a plurality of times; the precursor is dried at the temperature of 80 DEG C; the dried precursor is ground into refined powder; and the refined power is roasted for 6 hours at the temperature of 800 DEG C. The floriated ferrite prepared by the invention has the advantages of high purity quotient, simple technique, being easy to control the pattern and low cost. Compared with a traditional coprecipitation method, a small quantity of the surface active agent is added to assist the formation of the floriated spinelle cobalt ferrite before regulating the PH value.

Owner:HARBIN ENG UNIV

Nanoparticle having an inorganic core

A nanoparticle comprising an inorganic core and a polymerizable outer coating. The inorganic core comprises a substantially crystalline inorganic material such as a superparamagnetic material. In one embodiment, the inorganic core comprises a single crystal mixed spinel ferrite comprising iron in a first oxidation state and at least one metal in a second oxidation state, wherein the second oxidation state is different from the first oxidation state.

Owner:GENERAL ELECTRIC CO

Method for preparing spinel ferrite powder

This invention relates to a method for preparing spinel-type ferrite powder. The procedures are: (1) weighing, according chemometrics ratio of the components, the raw materials: Zn(NO3)2, Fe(NO3)3, Mn(NO3)2 and rare-earth metals nitrates, mixing them evenly to produce metals nitrates solution; (2), mixing egg-white and distilled water with ratio of 3:2, under room temperature agitating to produce egg-white water solution, (3), adding said nitrates solution into egg-white solution slowly and agitating, (4), strong agitation for 1.5-2.5hrs, until the solution is changed from thick paste into yellow brown emulsion, (5), putting the same in a water-bath under temperature of 80+-5deg.C, for heating 8-12hrs, to obtain pre-product, (6), milling the same, and then being sintered under temperature 450-700deg.C for 3-7hrs, (7), it is then quickly cooled in ice-water, (8), drying the same under 100deg.C to obtain the final product. This invention has advantages: simple operation, low cost, mild condition, low toxity and low corrosion.

Owner:HARBIN ENG UNIV

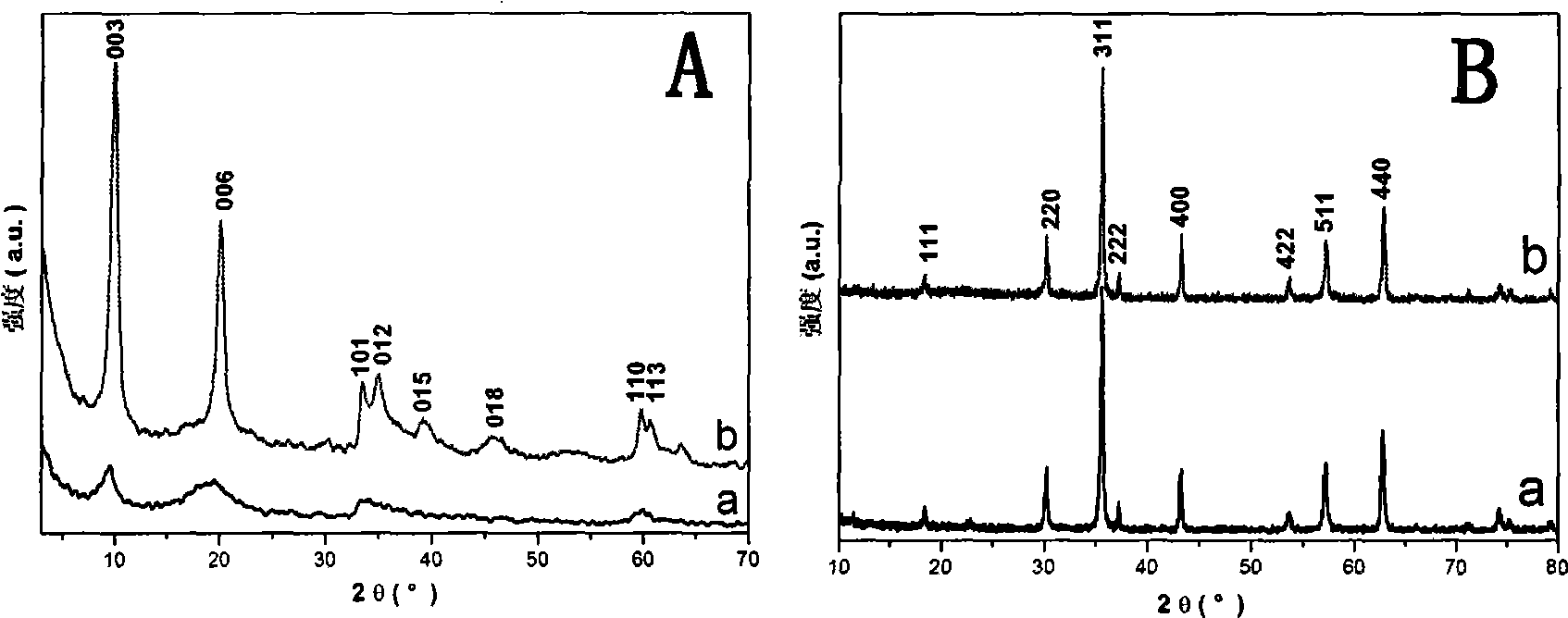

Method for preparing spinel type ferrite under mild condition

This invention relates to method for preparing spinel-type ferrite at mild condition. Fist, LDH micro-crystal is synthesized by using single-dropping method, then proceeded is crystal-type transmission under 80-100deg.C, after that proceeded are: washing, negative filtration, drying to obtain single crystalline-phase spinel-type ferrite. This invention method has advantages of: no need of pre-product of hydrotalcite with better crystallization degree, no need of high temperature sintering, the reaction needs only ambient pressure and temperature lower than 100deg.C. The invention has advantages of: simple operation, simple equipment, safety, low consumption, less pollution.

Owner:BEIJING UNIV OF CHEM TECH

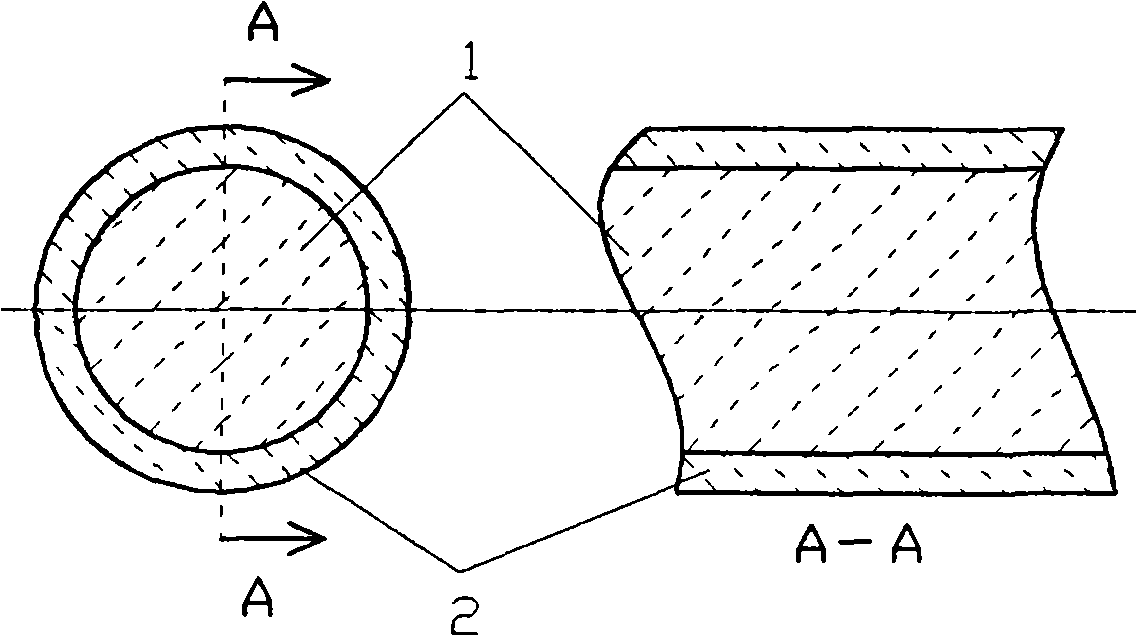

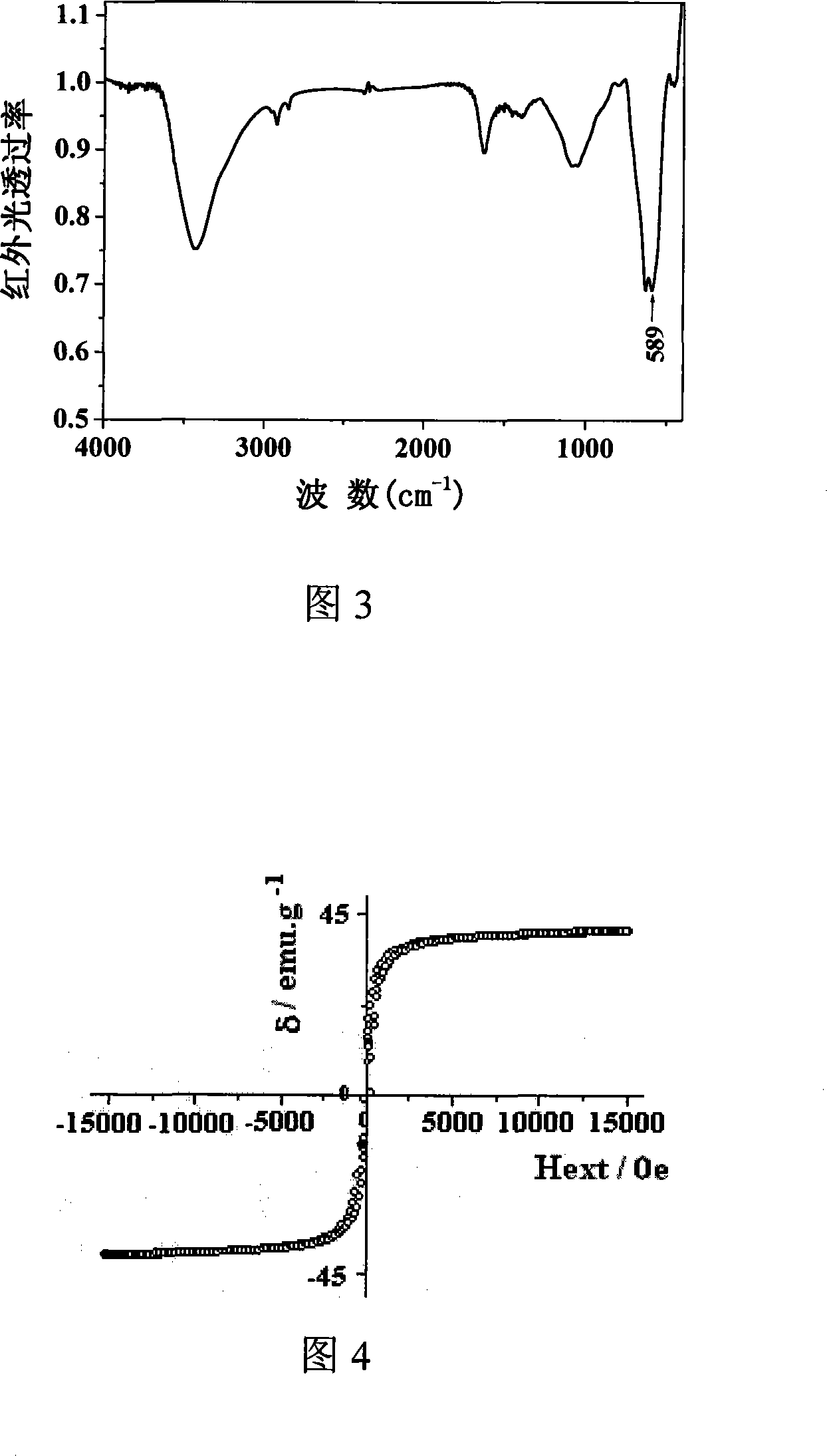

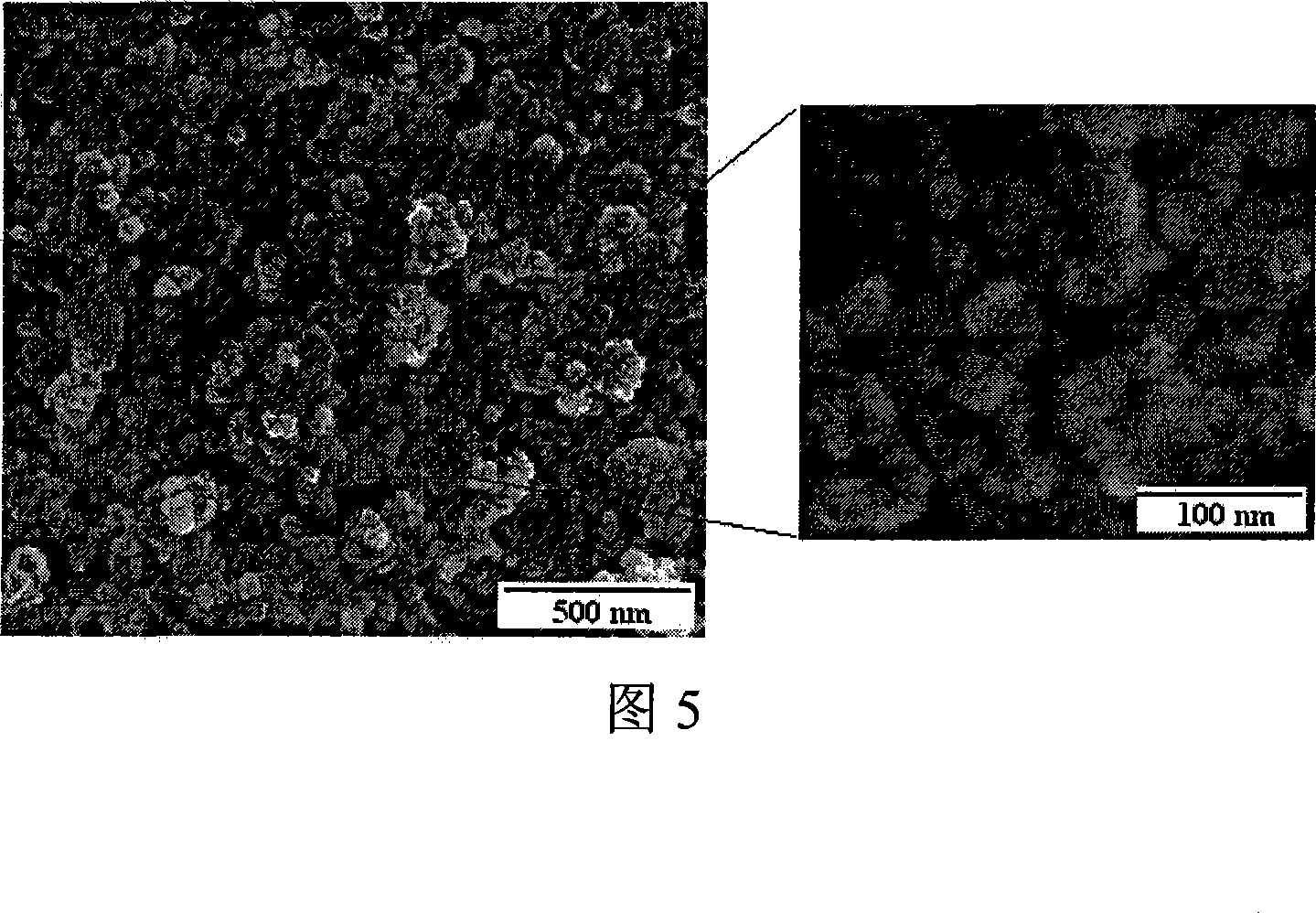

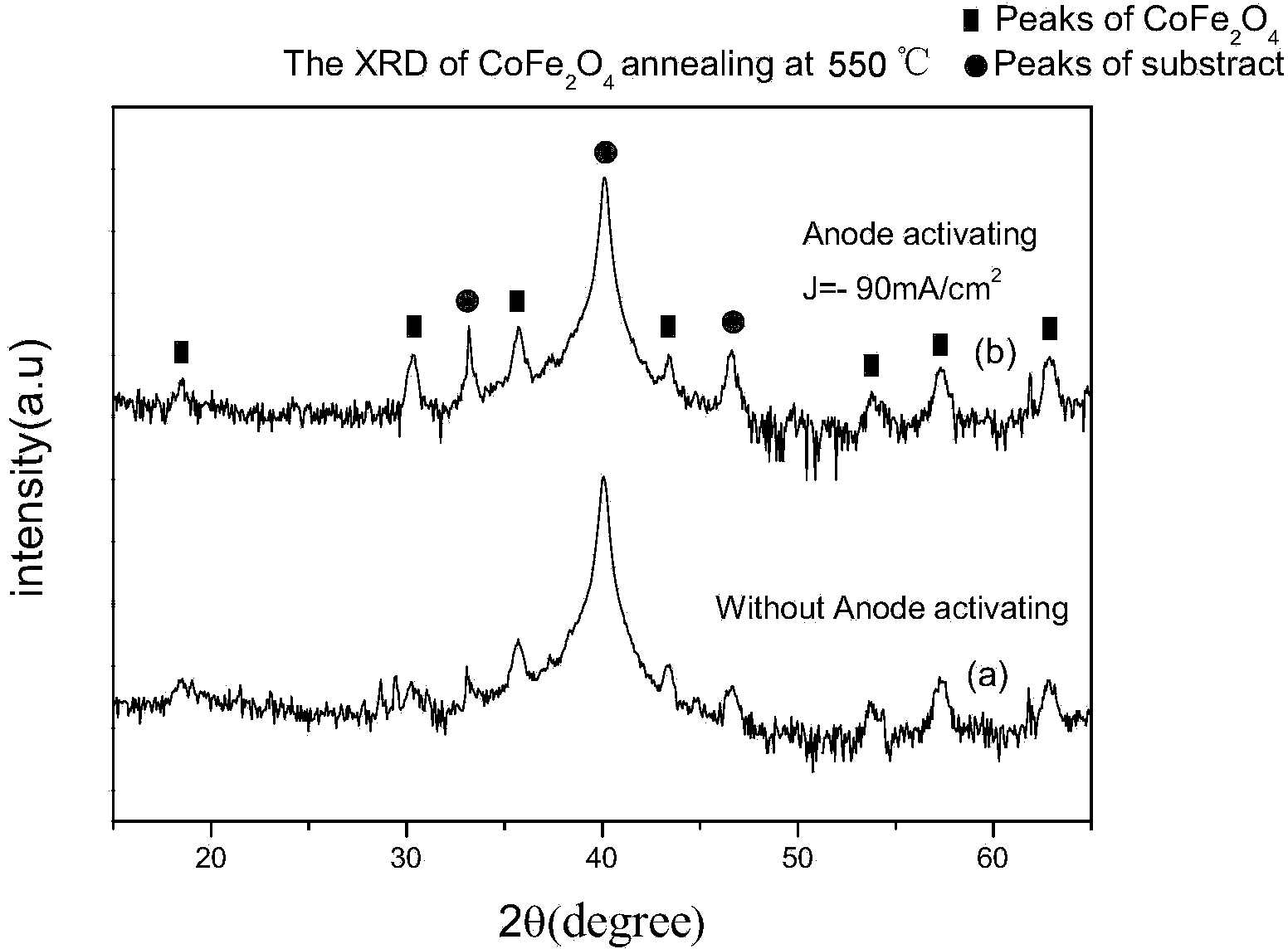

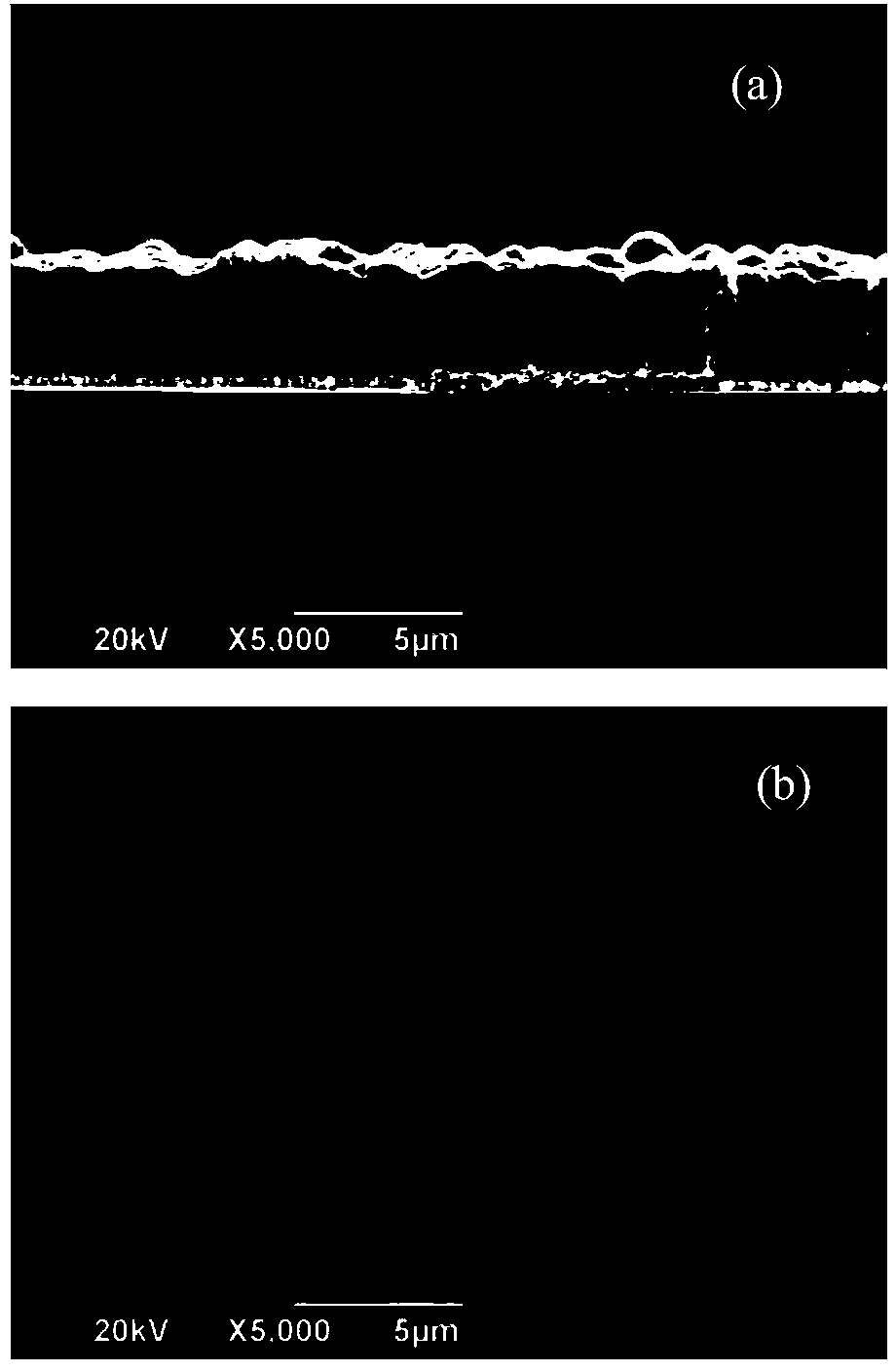

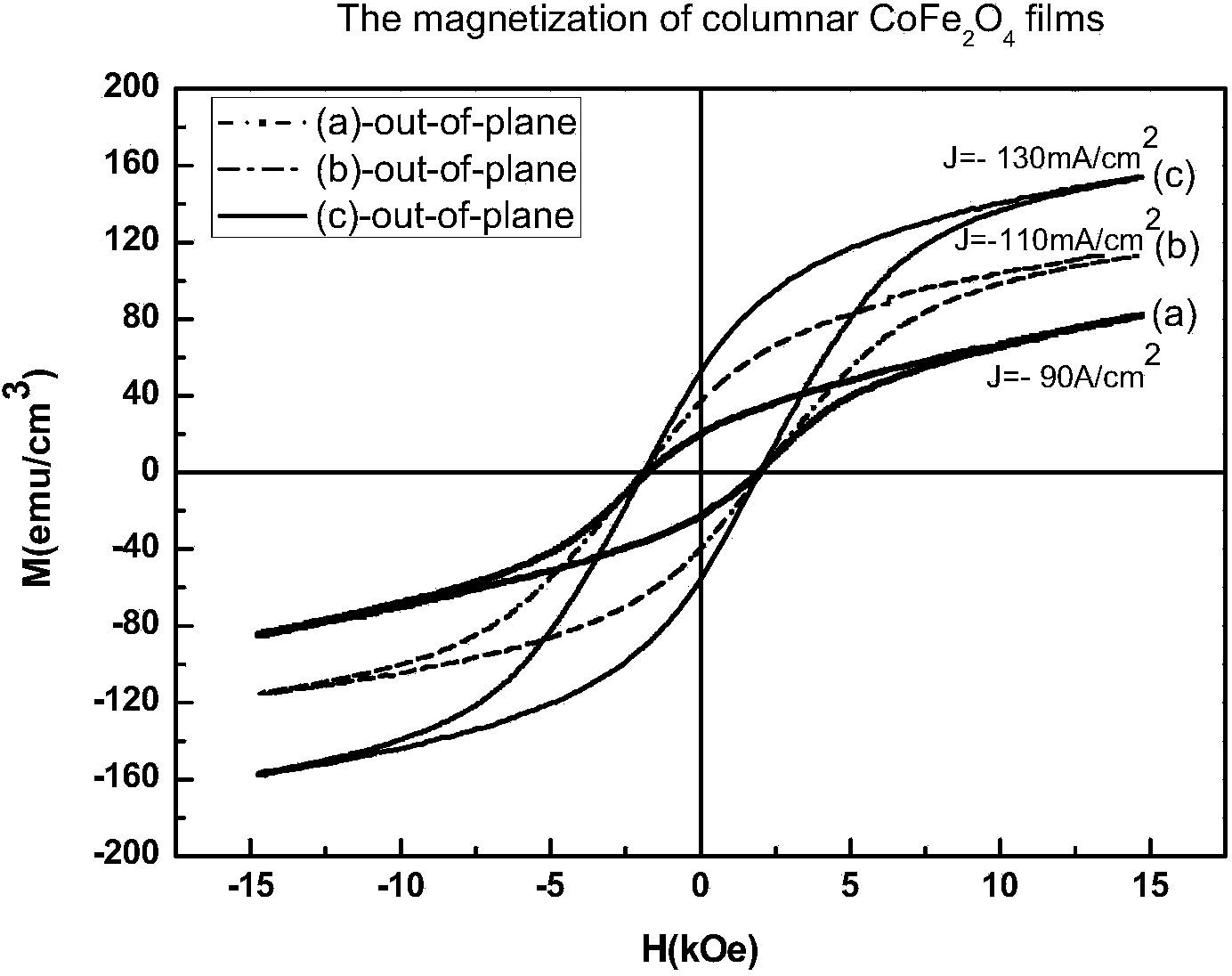

Method for preparing spinel ferrite film

The invention provides a method for preparing a spinel ferrite and belongs to the technical field of films. The method comprises the following steps: preparing an alloy film by adopting an electrochemical deposition method, carrying out anode activation on the alloy film in an alkaline solution by adopting a galvanostatic method; and finally sintering to obtain the spinel ferrite film. The spinel ferrite film prepared by adopting the method requires short sintering time, oxygen is not needed in sintering, the film is of a cylindrical structure, has high saturated magnetic strength in the direction vertical to the film, and has a better magnetic performance.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

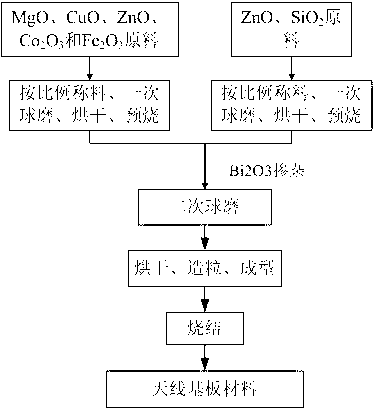

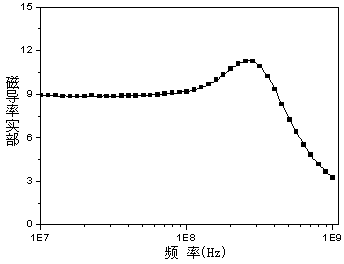

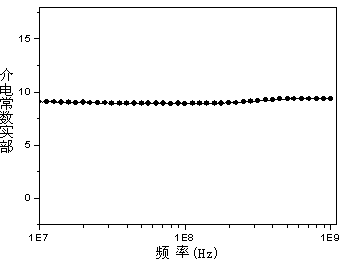

Antenna substrate material using spinel ferrite as matrix and preparation method thereof

The invention discloses an antenna substrate material using spinel ferrite as a matrix and a preparation method thereof. The antenna substrate material is a composite ceramic material comprising two phases, wherein the main crystal phase is spinel ferrite, and the auxiliary phase is zinc silicate; and the mass percentage of the main crystal phase to the auxiliary phase is 94:6-96:4. The antenna substrate material disclosed by the invention can obviously reduce the dimension and volume of the low-frequency (10-200MHz) microstrip antenna, and ensure the characteristic impedance of the antenna substrate material to be equal or approximate to the characteristic impedance of vacuum, thereby obviously enhancing the radiant efficiency of the antenna.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

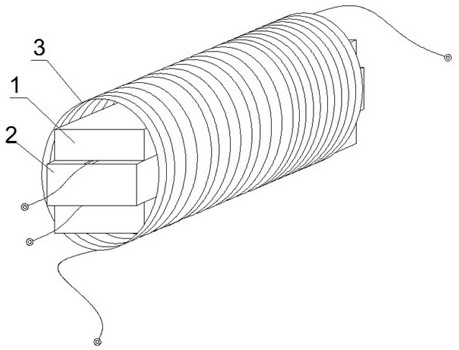

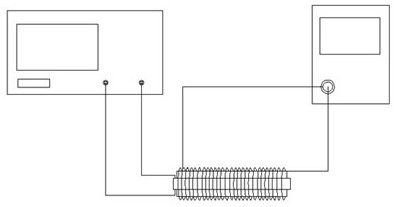

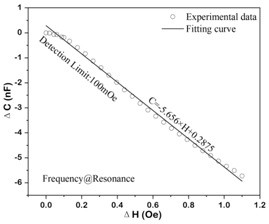

Magnetic field detection method based on magnetic dielectric effect, test device and working method thereof

PendingCN112327225AImplement the conversion functionReduce volumeMagnetic field measurement using galvano-magnetic devicesCapacitanceExternal bias

The invention provides a magnetic field detection method based on magnetic dielectric effect, a test device and a working method thereof. The test device comprises a magnetoelectric composite detection structure, the magnetoelectric composite detection structure is formed by laminating spinel ferrite and piezoelectric ceramic, and a to-be-detected alternating magnetic field is captured by a ferrite material and then generates mechanical strain with the same frequency as excitation. And then the mechanical strain is transmitted to a piezoelectric ceramic material through interlayer coupling andfinally output in a capacitance signal mode, detection of an alternating-current magnetic field is achieved, and an impedance analyzer is used for scanning a capacitance spectrum of a magnetoelectriccomposite detection structure to complete measurement of typical sensing parameters such as sensitivity and resolution of a magnetic sensing device. Compared with a traditional electromagnetic sensorinduction detection mode, the method gets rid of the limitation of an external bias magnetic field, improves the detection sensitivity, is not liable to be interfered by an external power frequency signal, the signal-to-noise ratio is higher, and the overall device is more compact.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

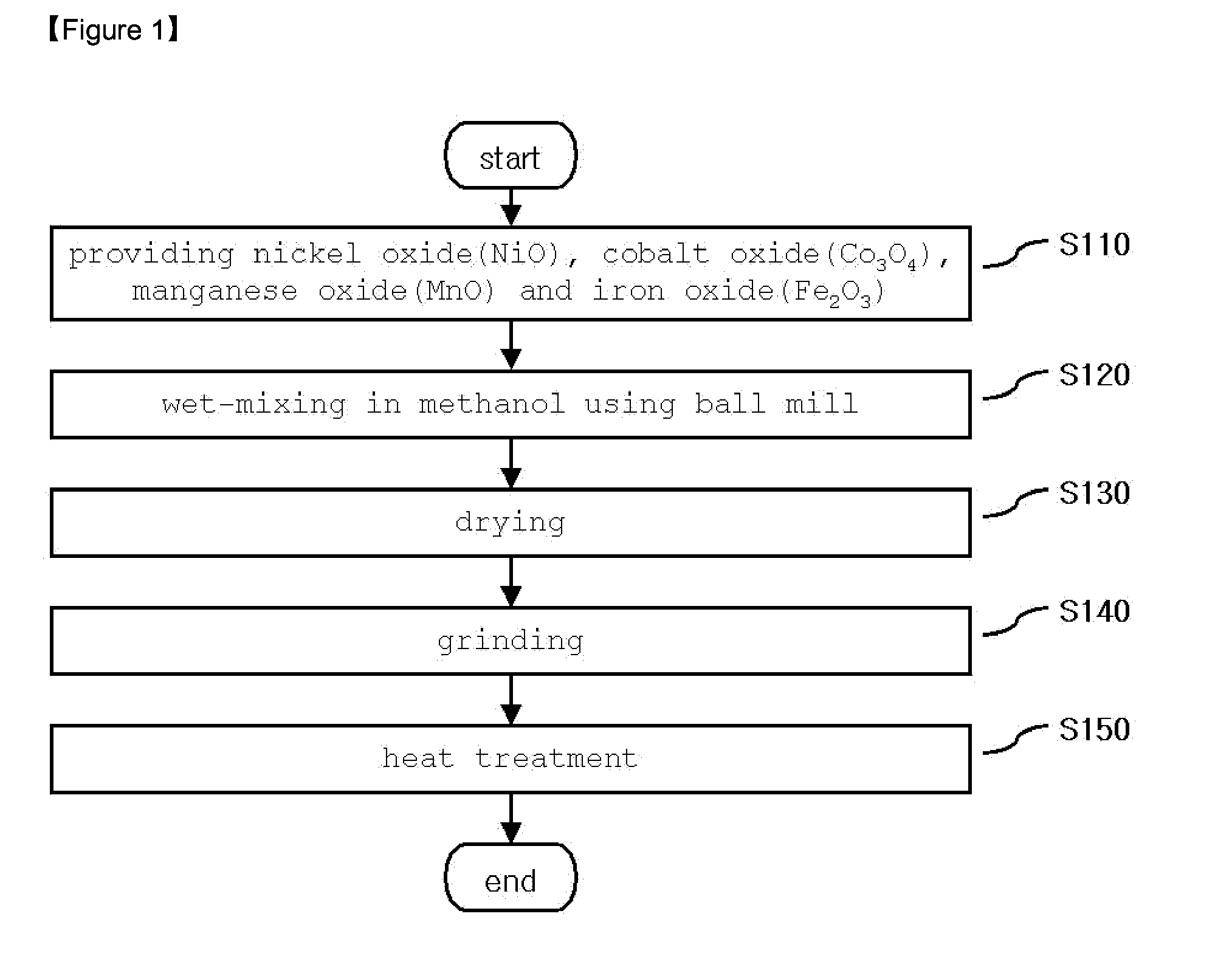

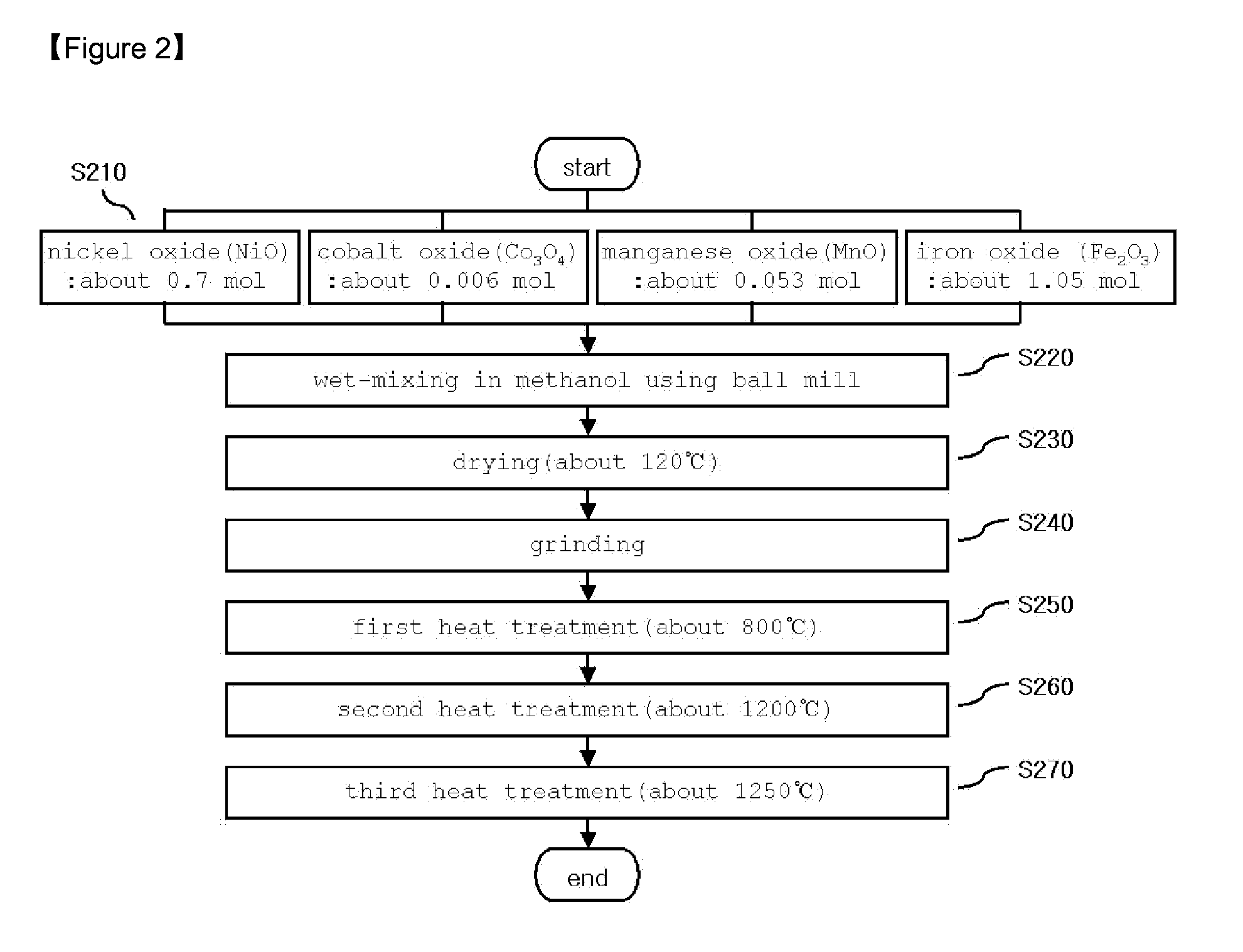

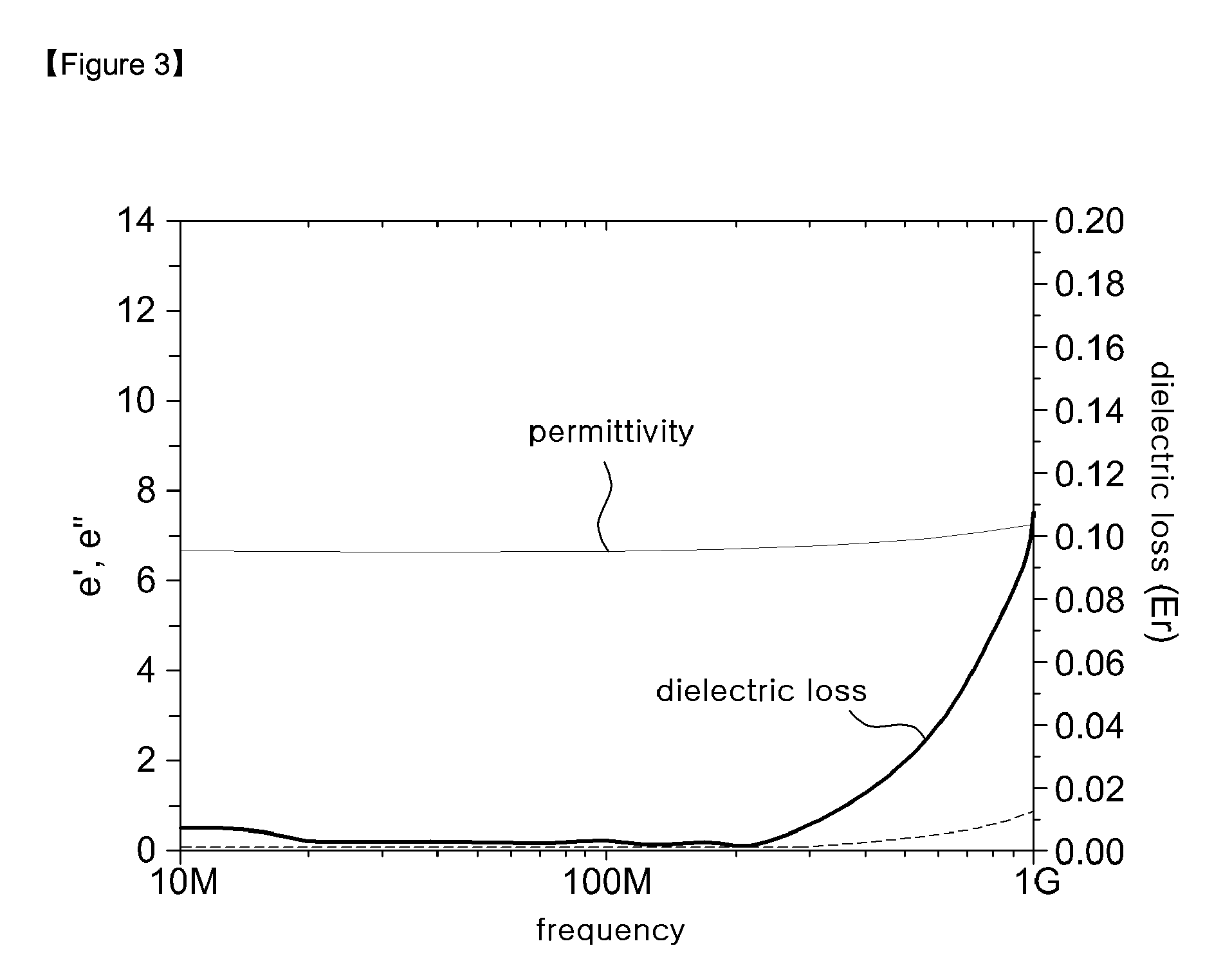

Method for producing nickel-manganese-cobalt spinel ferrite having low permeability loss and nickel-manganese-cobalt spinel ferrite produced thereby

InactiveUS20110147643A1Reduce penetrationLow dielectric lossFerroso-ferric oxidesMagnetic materialsManganese oxideMaterials science

Disclosed herein is a method for producing a spinel ferrite which has a low permeability loss and a low dielectric loss so that the spinel ferrite can be widely used as a material for high-frequency (MHz) electronic components, and a spinel ferrite produced thereby. The method for producing the spinel ferrite comprises the steps of: providing nickel oxide, cobalt oxide, manganese oxide and iron oxide; wet-mixing the nickel oxide, the cobalt oxide, the manganese oxide and the iron oxide in methanol to obtain a mixture; collecting powder from the mixture and drying the collected powder; grinding the dried powder; and heat-treating the dried powder, thereby producing a nickel-manganese-cobalt spinel ferrite having a low permeability loss and a low dielectric loss. The nickel-manganese-cobalt spinel ferrite can be widely as a material for RF electronic components, and when it is applied to an antenna, it can reduce the length of the antenna and improve the bandwidth, efficiency and performance of the antenna.

Owner:EMW CO LTD

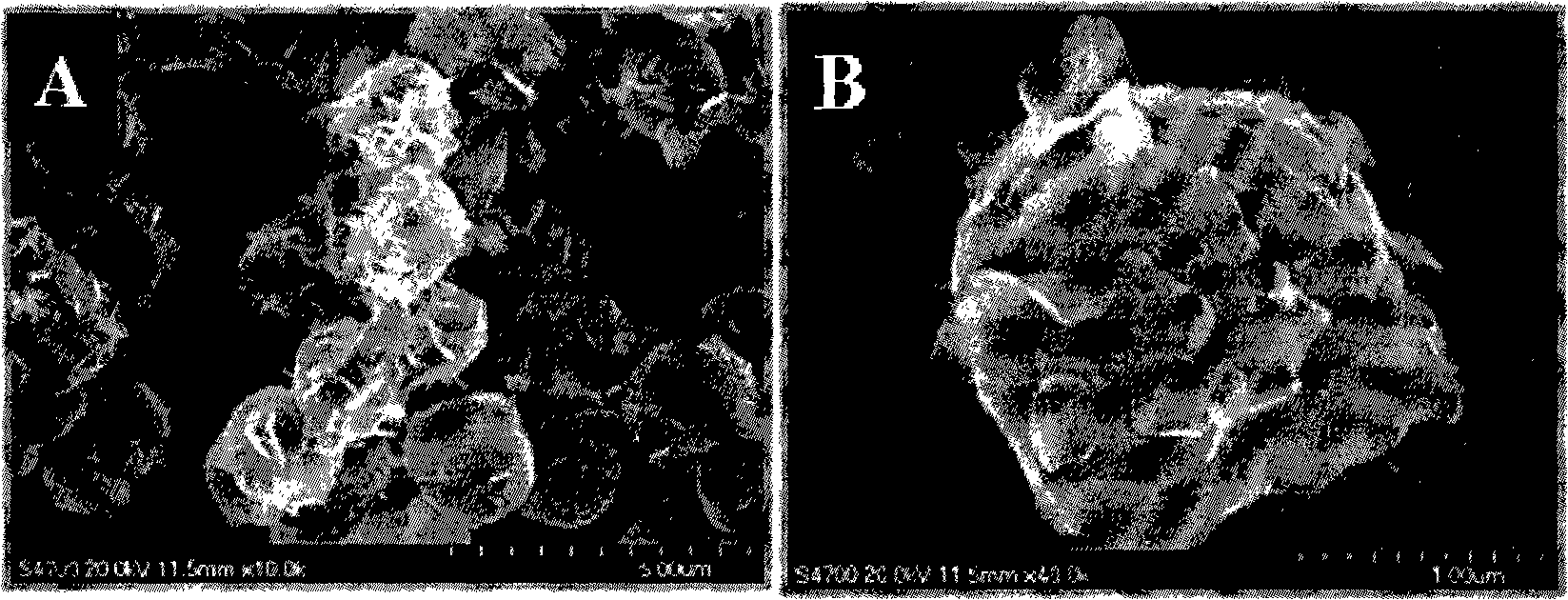

Method for preparation of magnetic spinel ferrites from layered double hydroxide precursors

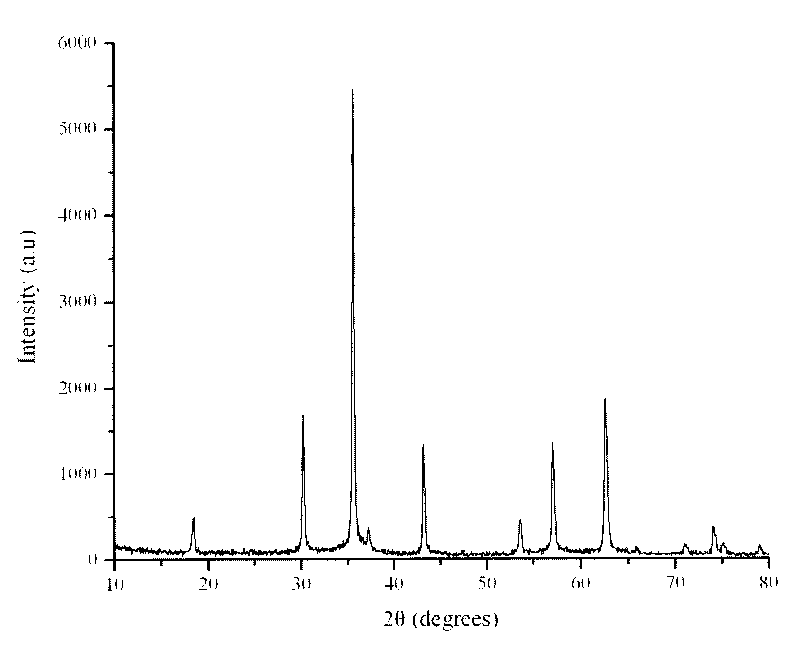

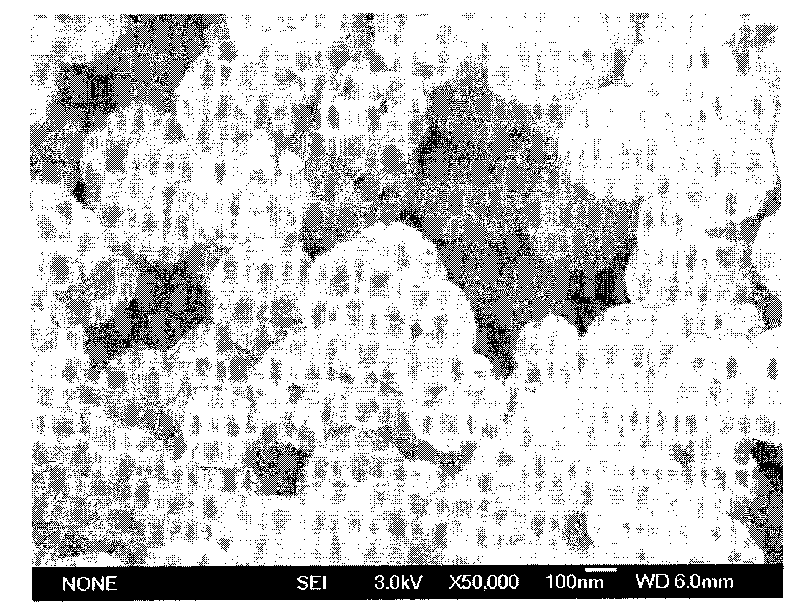

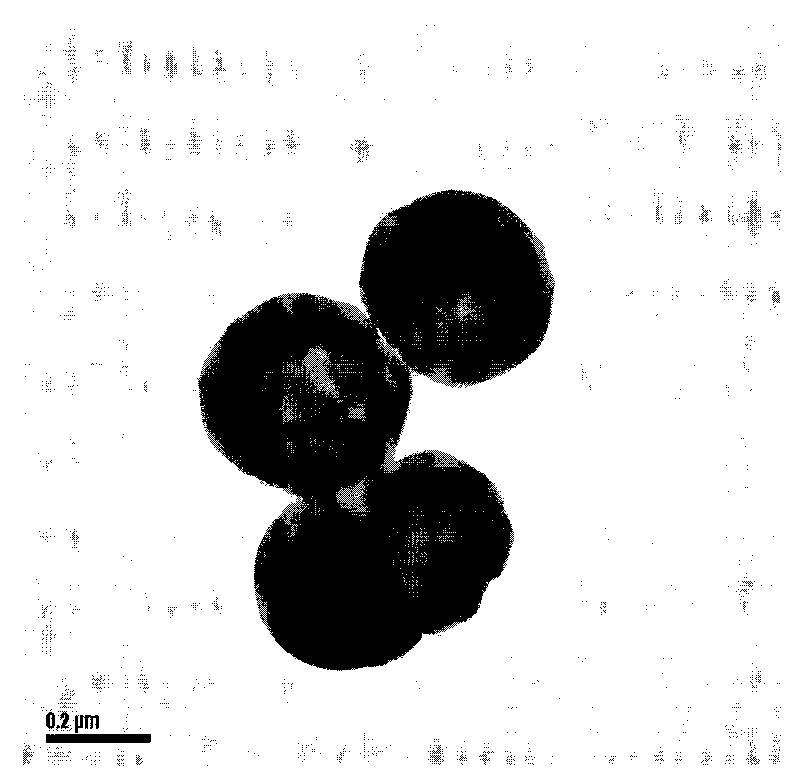

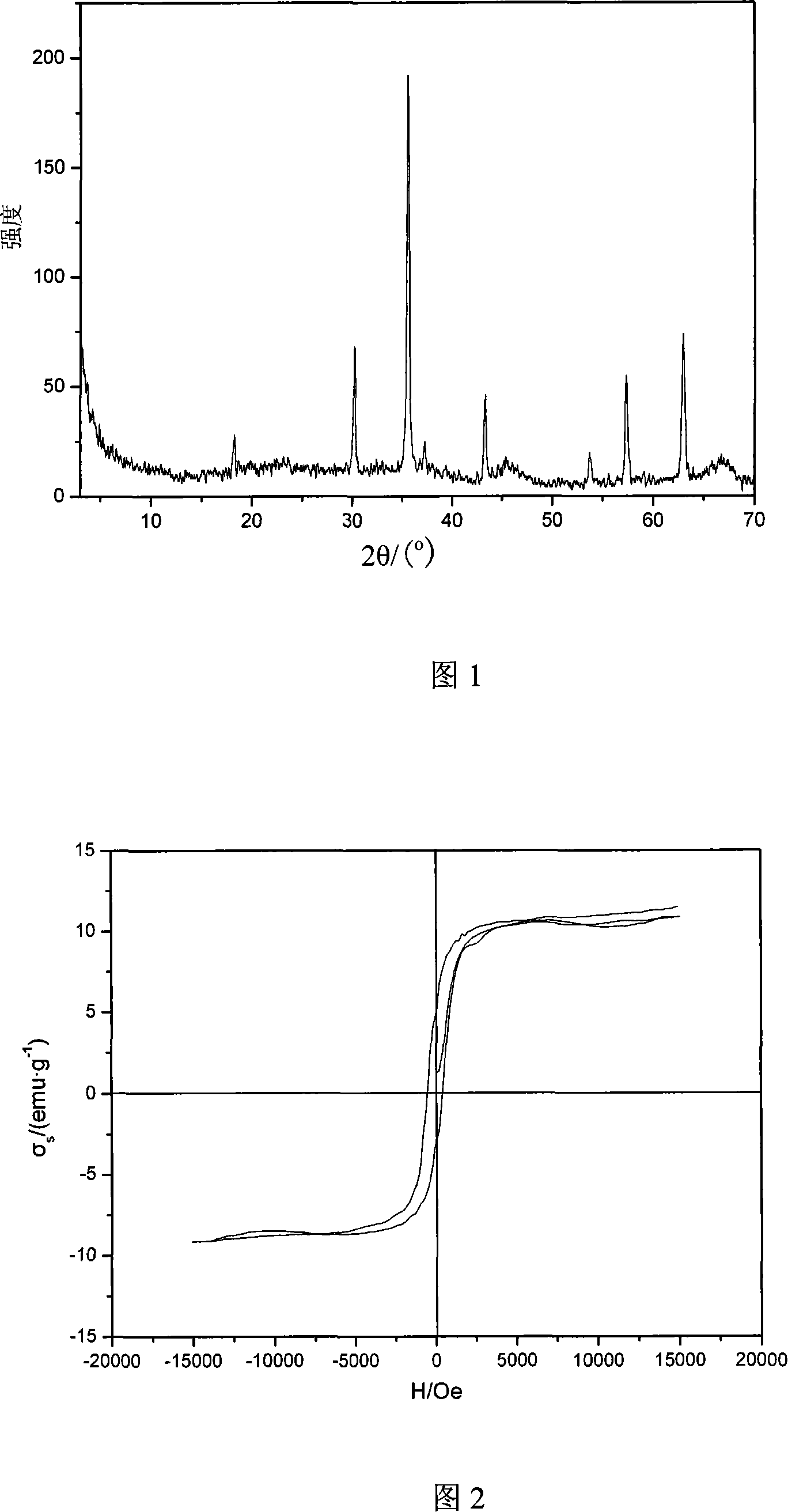

InactiveUS20050129609A1High activityLow mixture uniformityLiquid applicationFerroso-ferric oxidesDispersityMagnetization

The invention describes a method of preparing magnetic ferrites from layered precursors in which Fe2+ is first introduced into the layers of layered double hydroxides (LDHs) in order to prepare Me-Fe2+—Fe3+ LDHs, and then by utilizing the easily oxidized nature of Fe2+, binary or multi-component ferrite materials containing Fe3+ in a single crystalline phase can be prepared. Values of the saturation magnetization of ferrites prepared by the method are significantly increased compared with ferrites prepared by traditional methods. Because the metal elements in the layered precursor have the characteristics of a high degree of dispersion, high activity and small particle size (average particle size 40-200 nm), no milling is required before calcination, thus simplifying the production process, shortening the production period, reducing capital investment in equipment and economizing on energy costs. In addition, the method does not corrode production equipment and does not pollute the environment.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com