Patents

Literature

243results about "Liquid application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

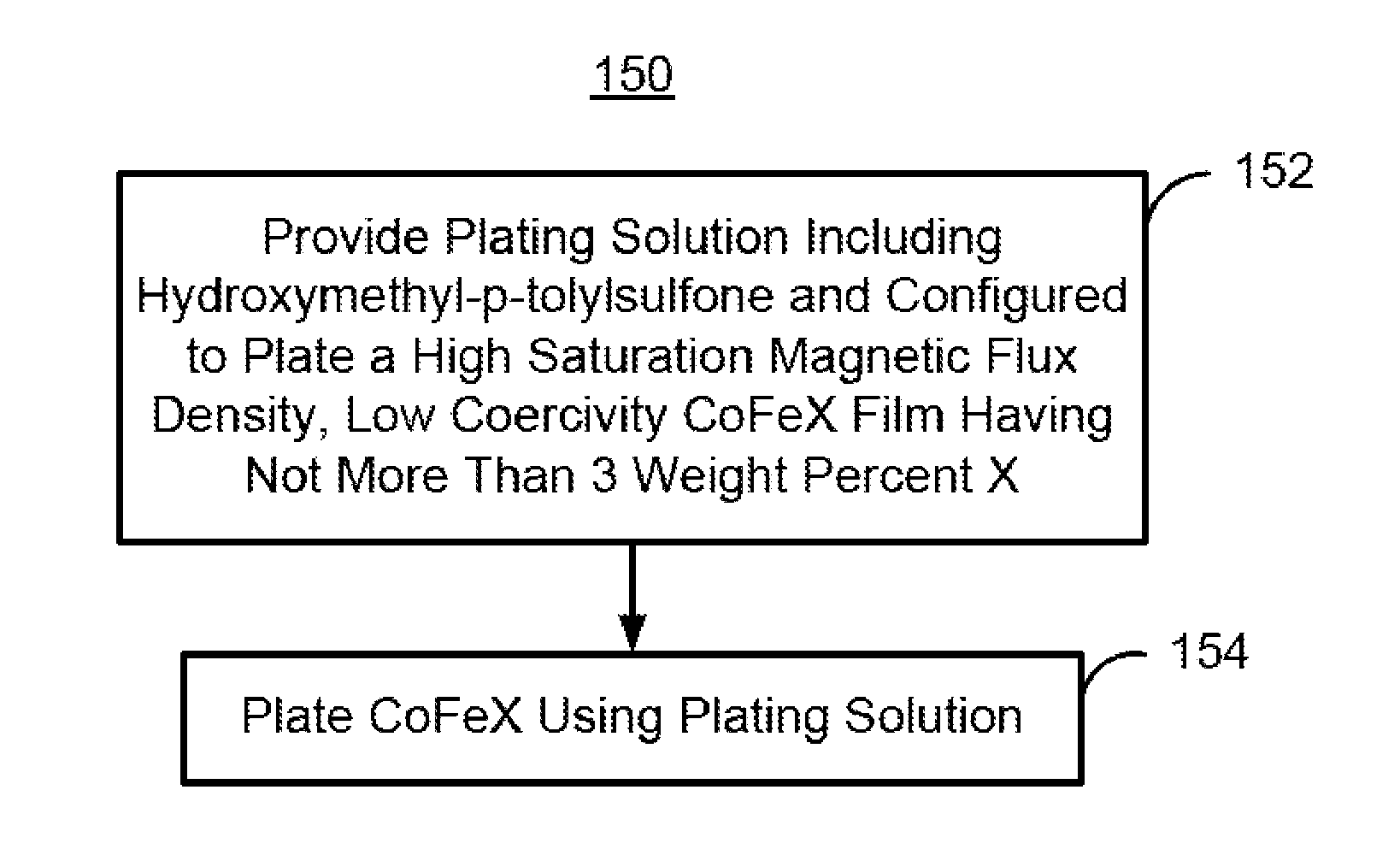

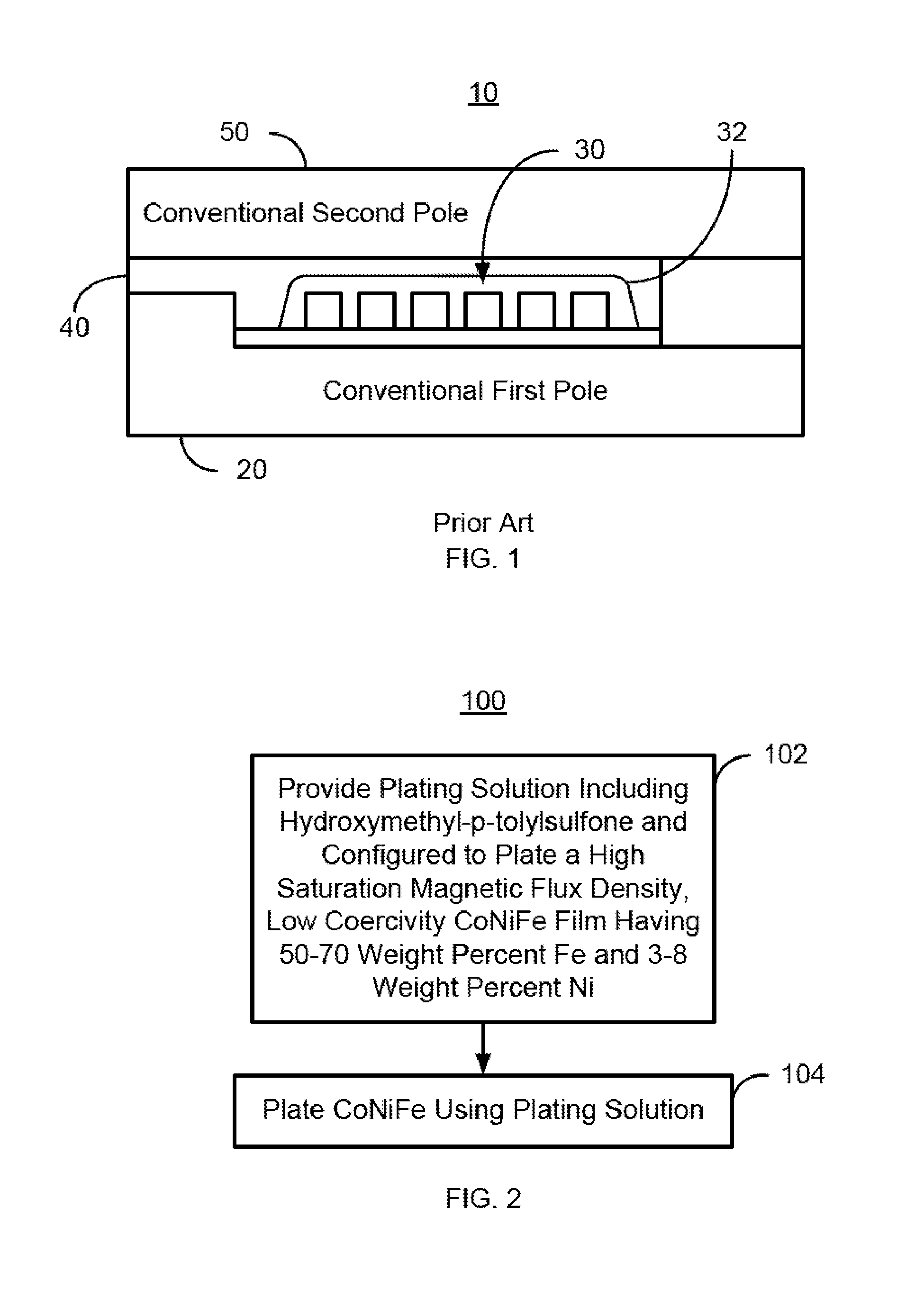

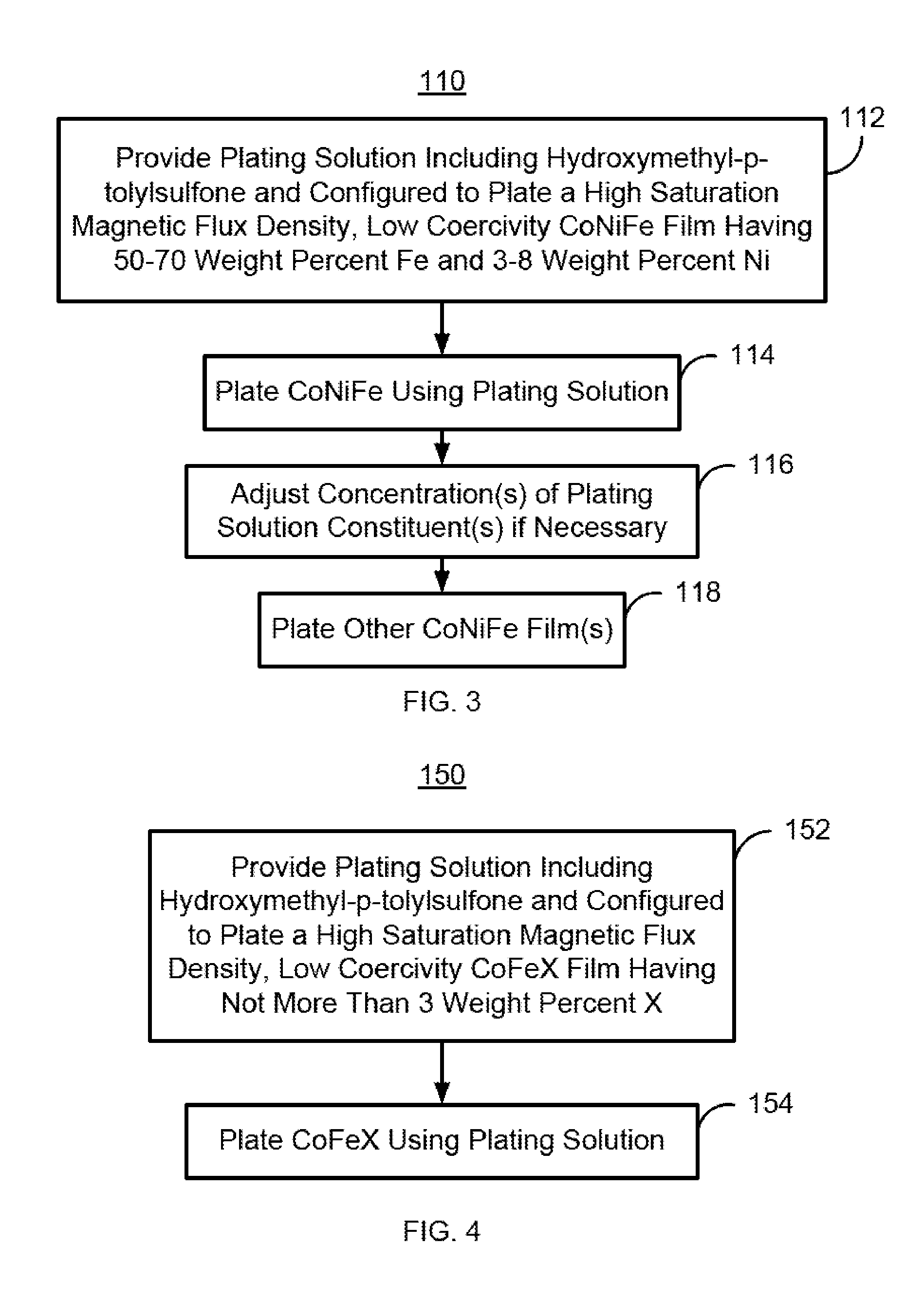

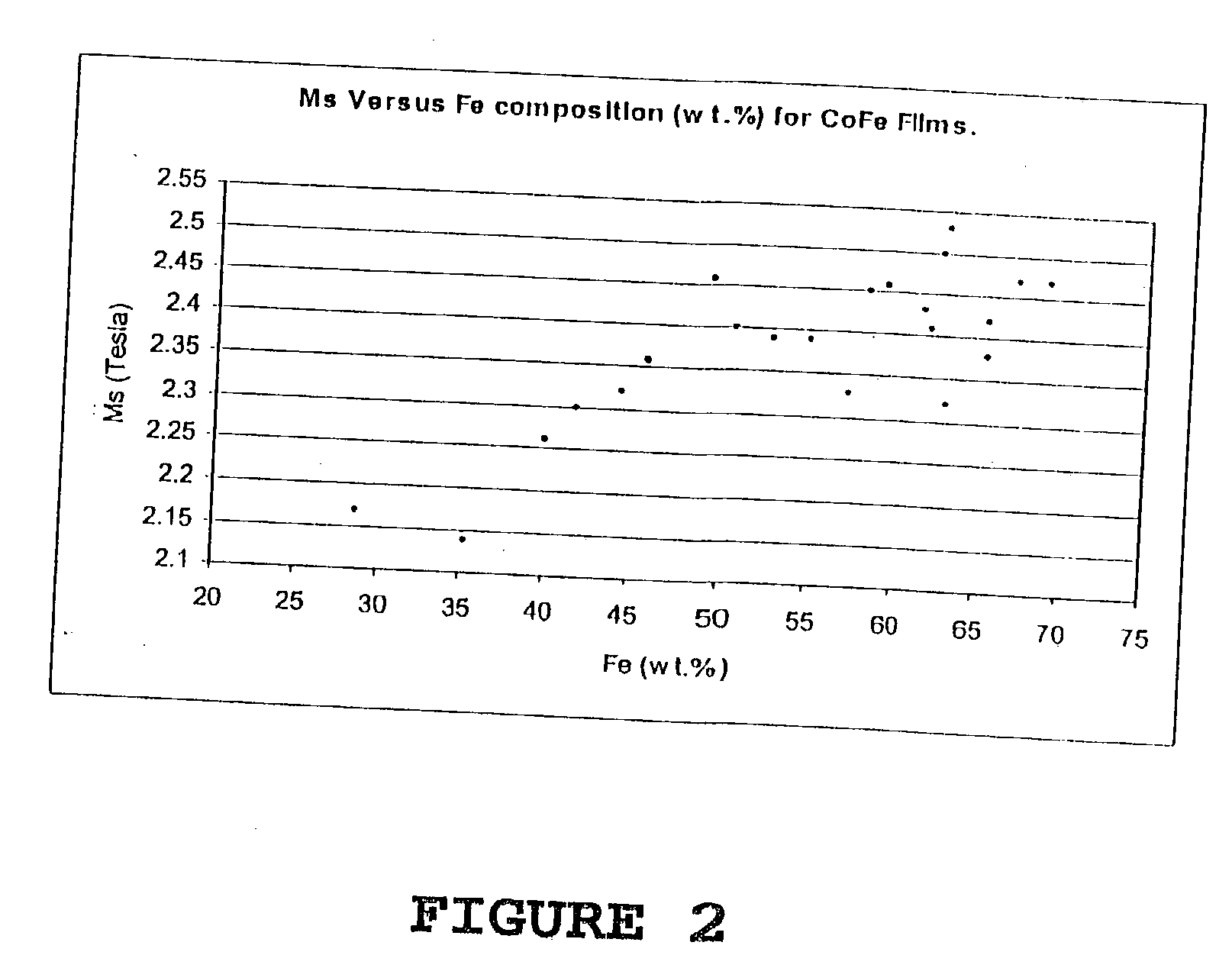

Method and system for providing high magnetic flux saturation CoFe films

InactiveUS8670211B1High magnetic flux densityLiquid applicationRecord information storageRecording headMagnetic flux

A method and system plates CoFeX, where X is an insertion metal. The method and system include providing a plating solution including hydroxymethyl-p-tolylsulfone (HPT). The plating solution being configured to provide a CoFeX film having a high saturation magnetic flux density of greater than 2.3 Tesla and not more than 3 weight percent of X. The method and system also include plating the CoFeX film on a substrate in the plating solution. In some aspects, the plated CoFeX film may be used in structures such as main poles of a magnetic recording head.

Owner:WESTERN DIGITAL TECH INC

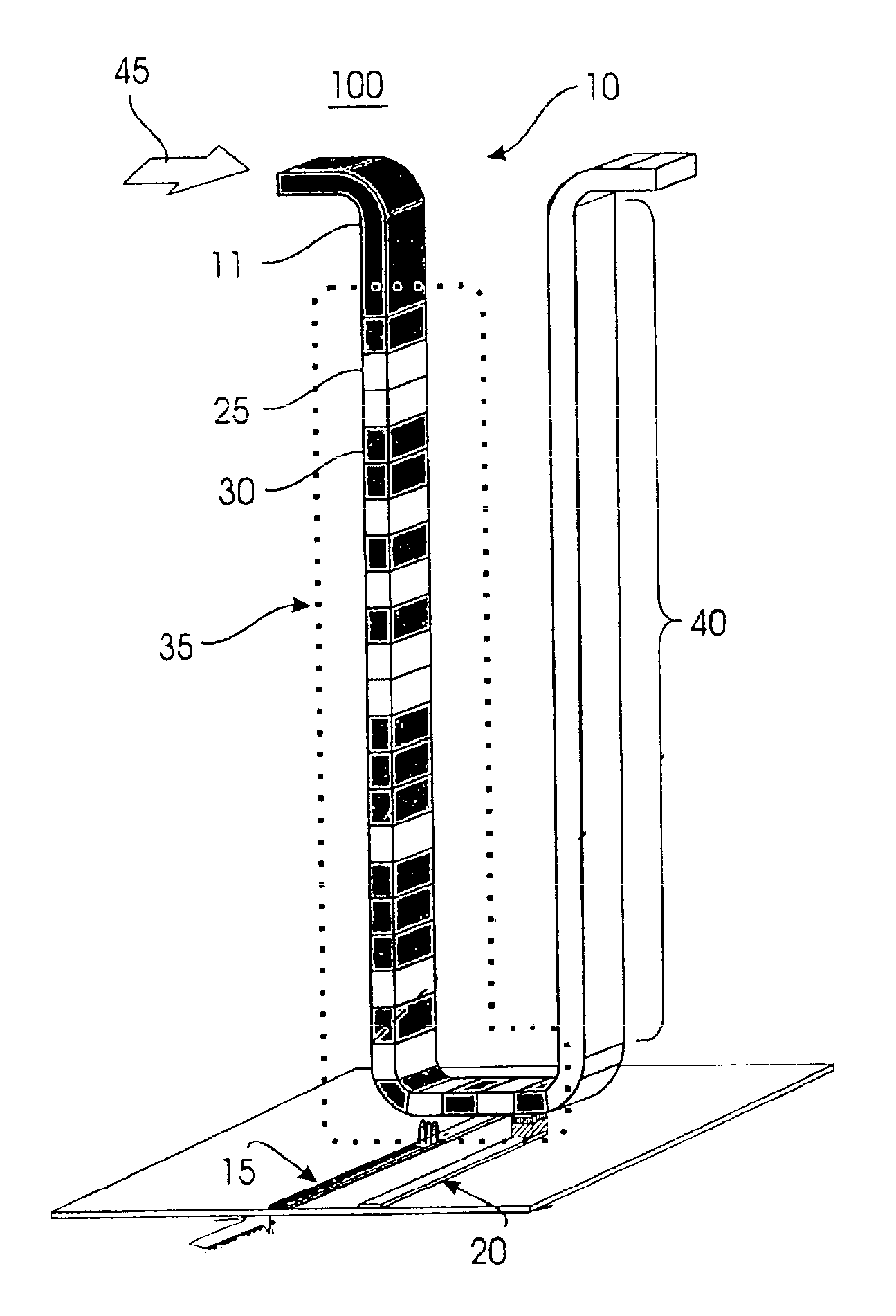

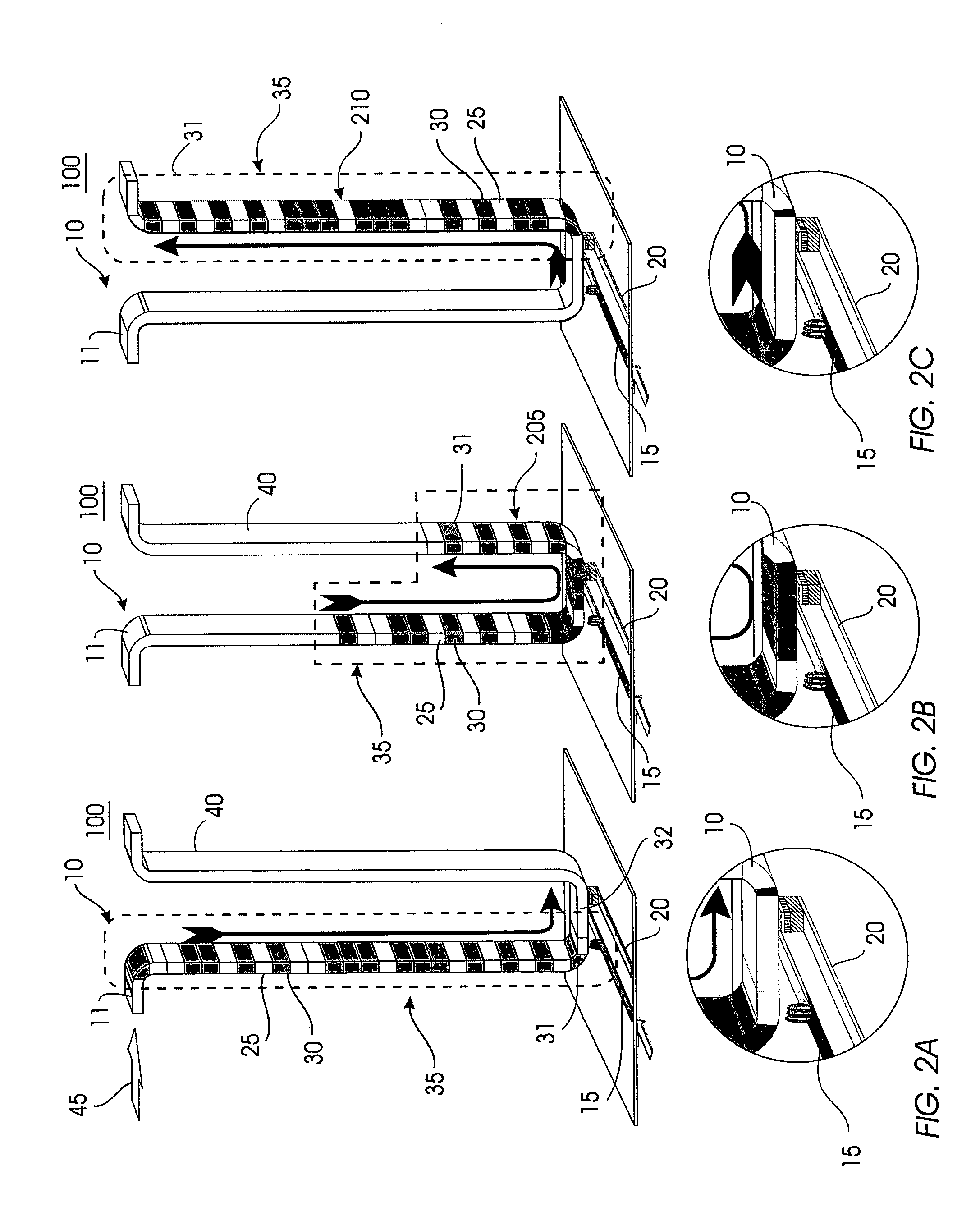

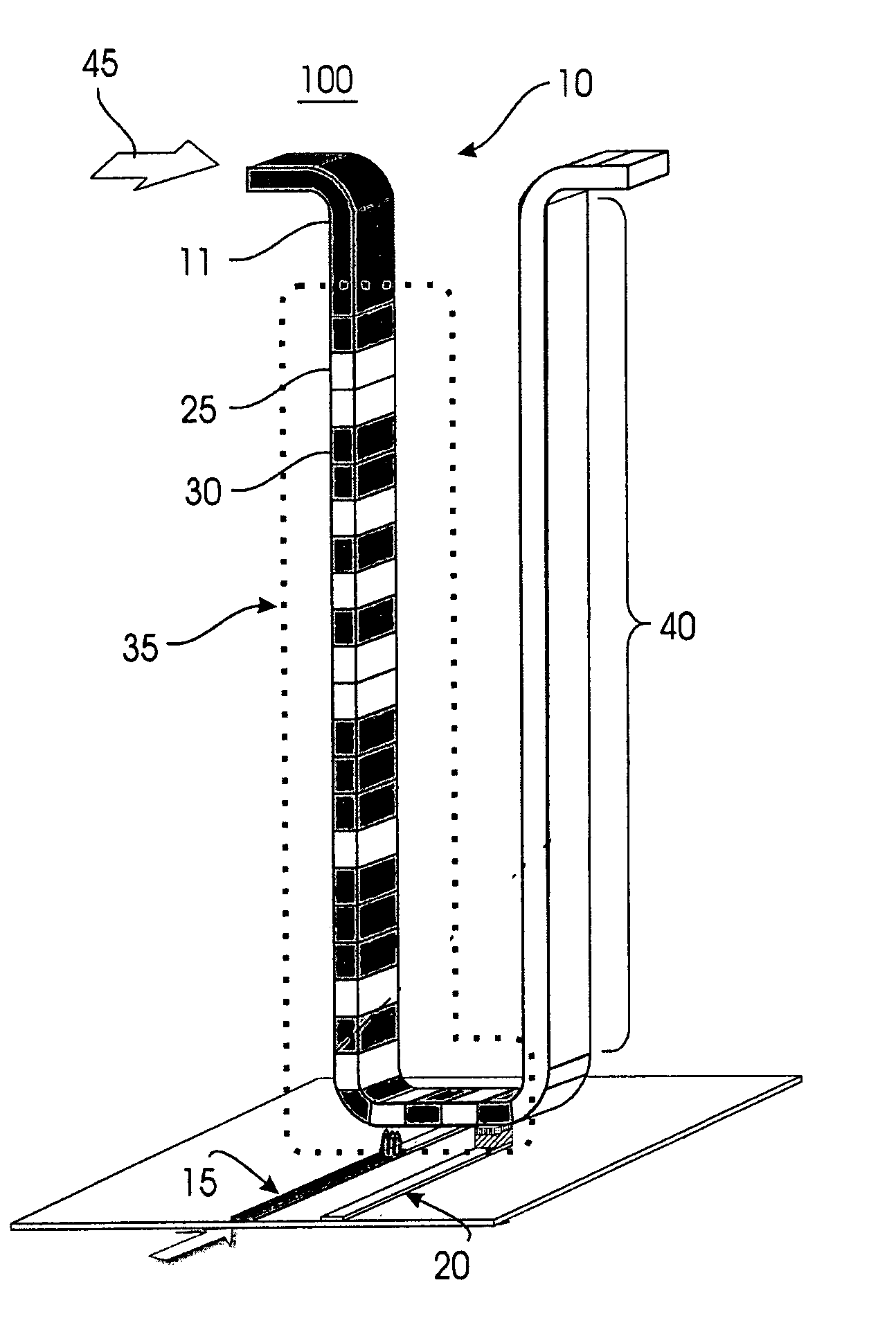

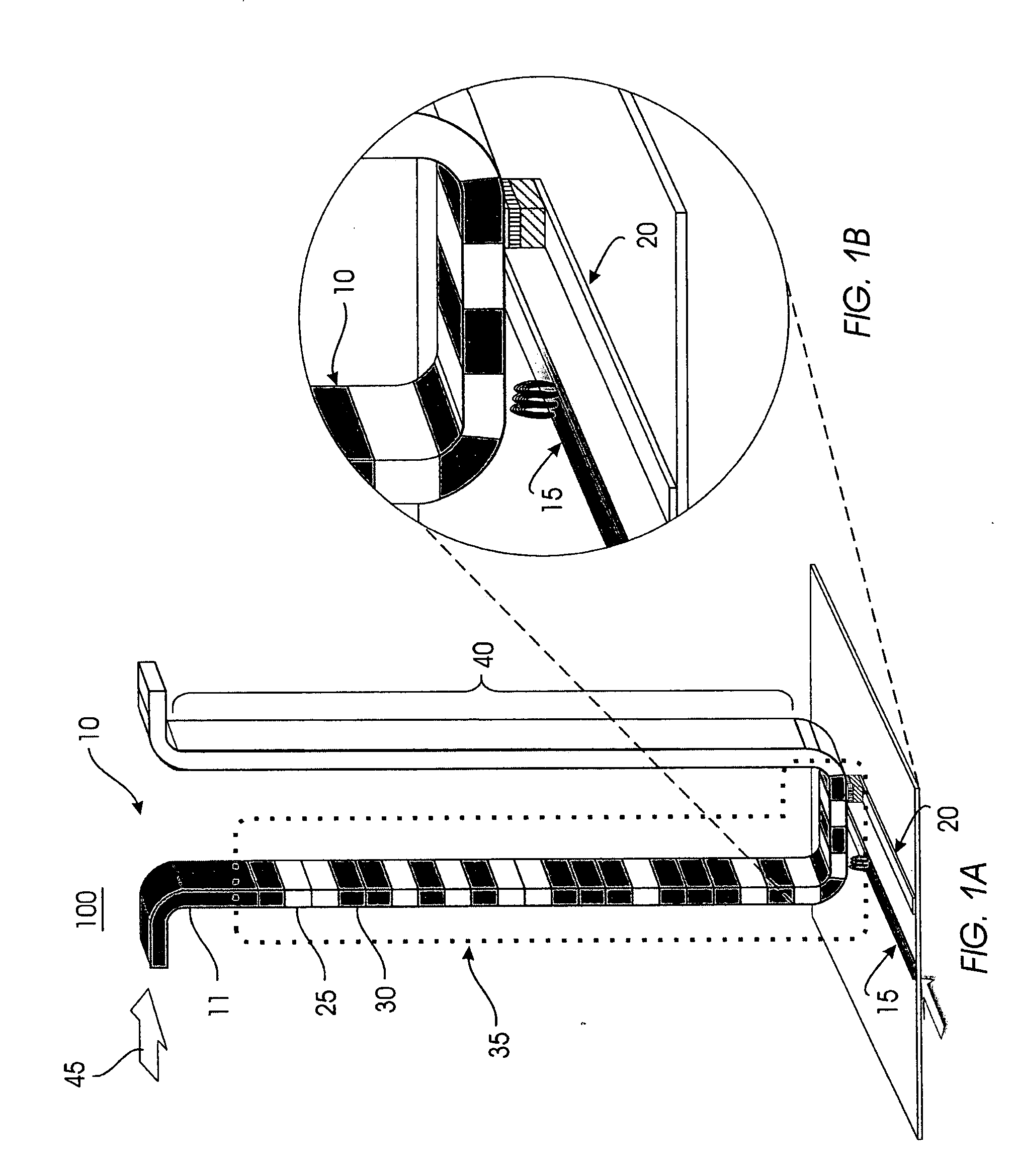

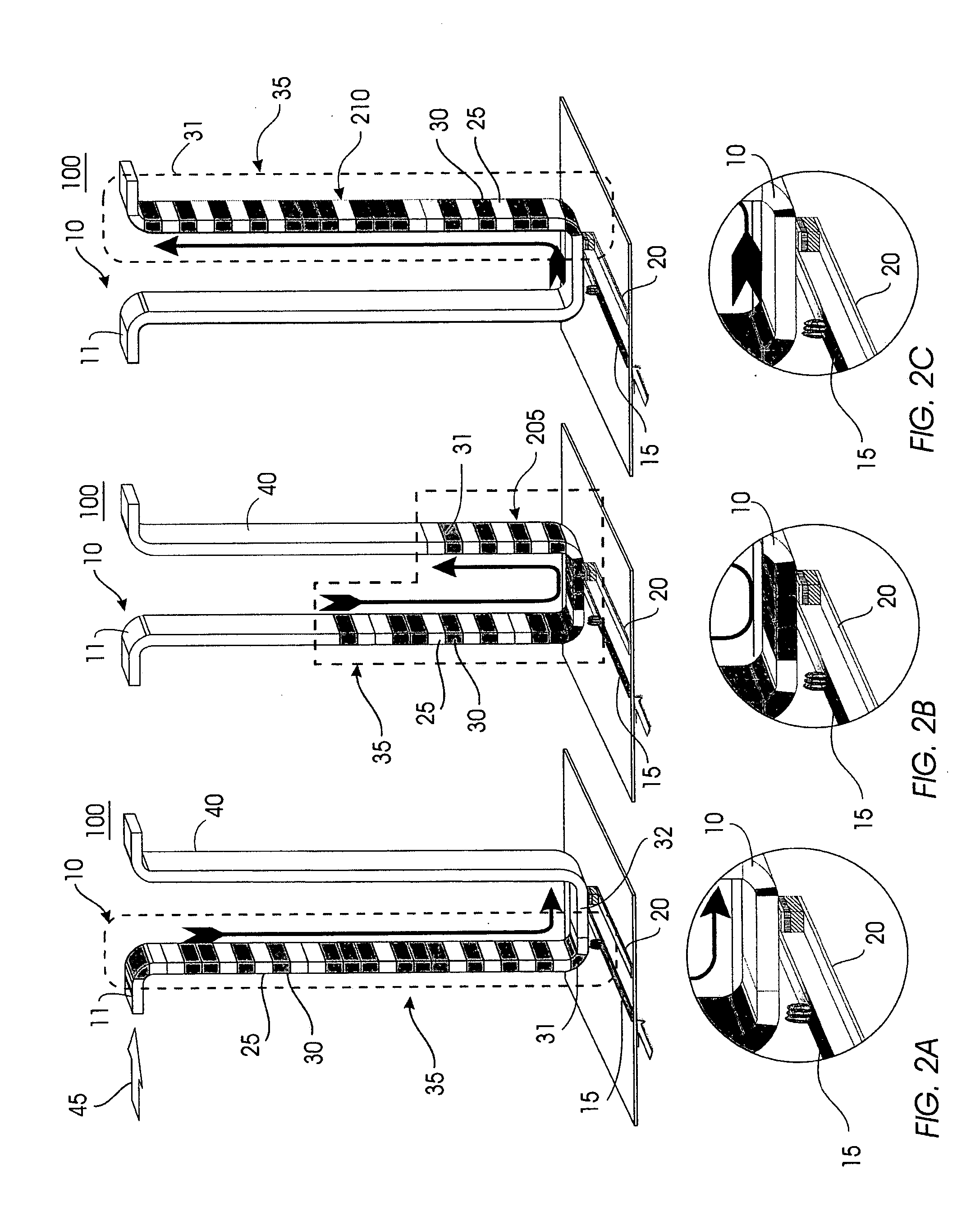

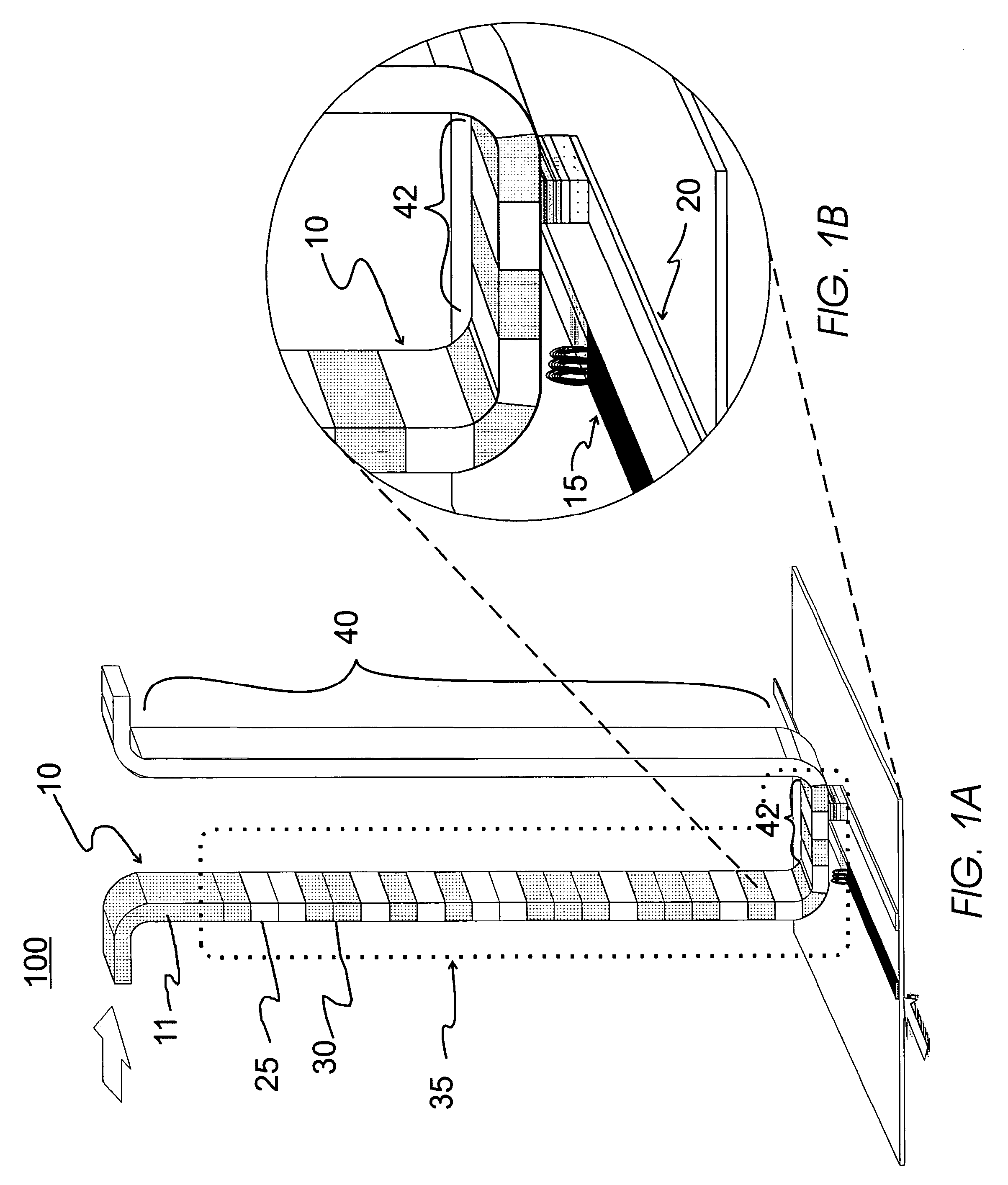

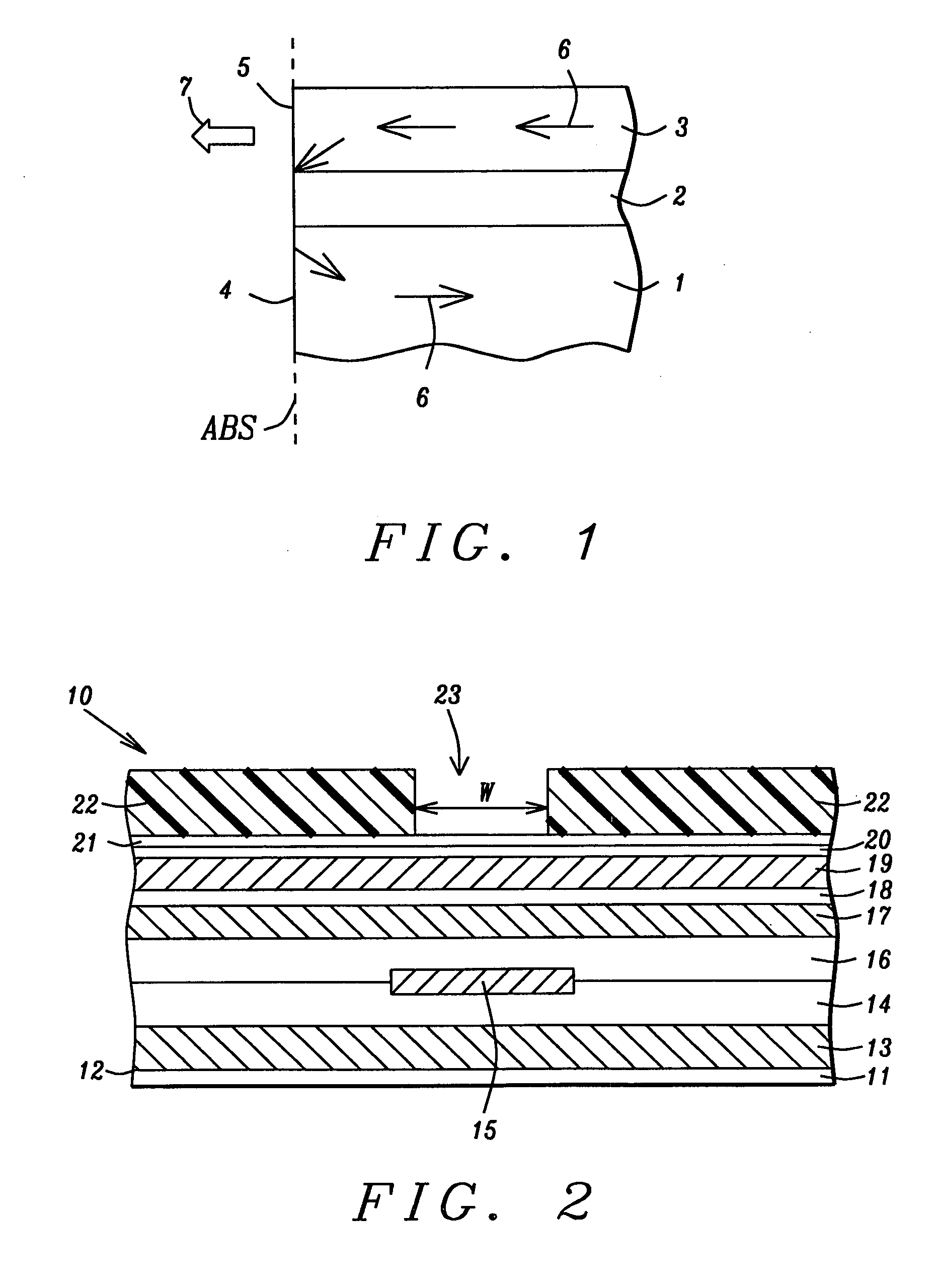

System and method for writing to a magnetic shift register

InactiveUS6898132B2Variable capacityHigh cost of readingLiquid applicationDigital storageShift registerMolecular physics

A writing device can change the direction of the magnetic moment in a magnetic shift register, thus writing information to the domains or bits in the magnetic shift register. Associated with each domain wall are large magnetic fringing fields. The domain wall concentrates the change in magnetism from one direction to another in a very small space. Depending on the nature of the domain wall, very large dipolar fringing fields can emanate from the domain wall. This characteristic of magnetic domains is used to write to the magnetic shift register. When the domain wall is moved close to another magnetic material, the large fields of the domain wall change the direction of the magnetic moment in the magnetic material, effectively “writing” to the magnetic material.

Owner:GLOBALFOUNDRIES US INC

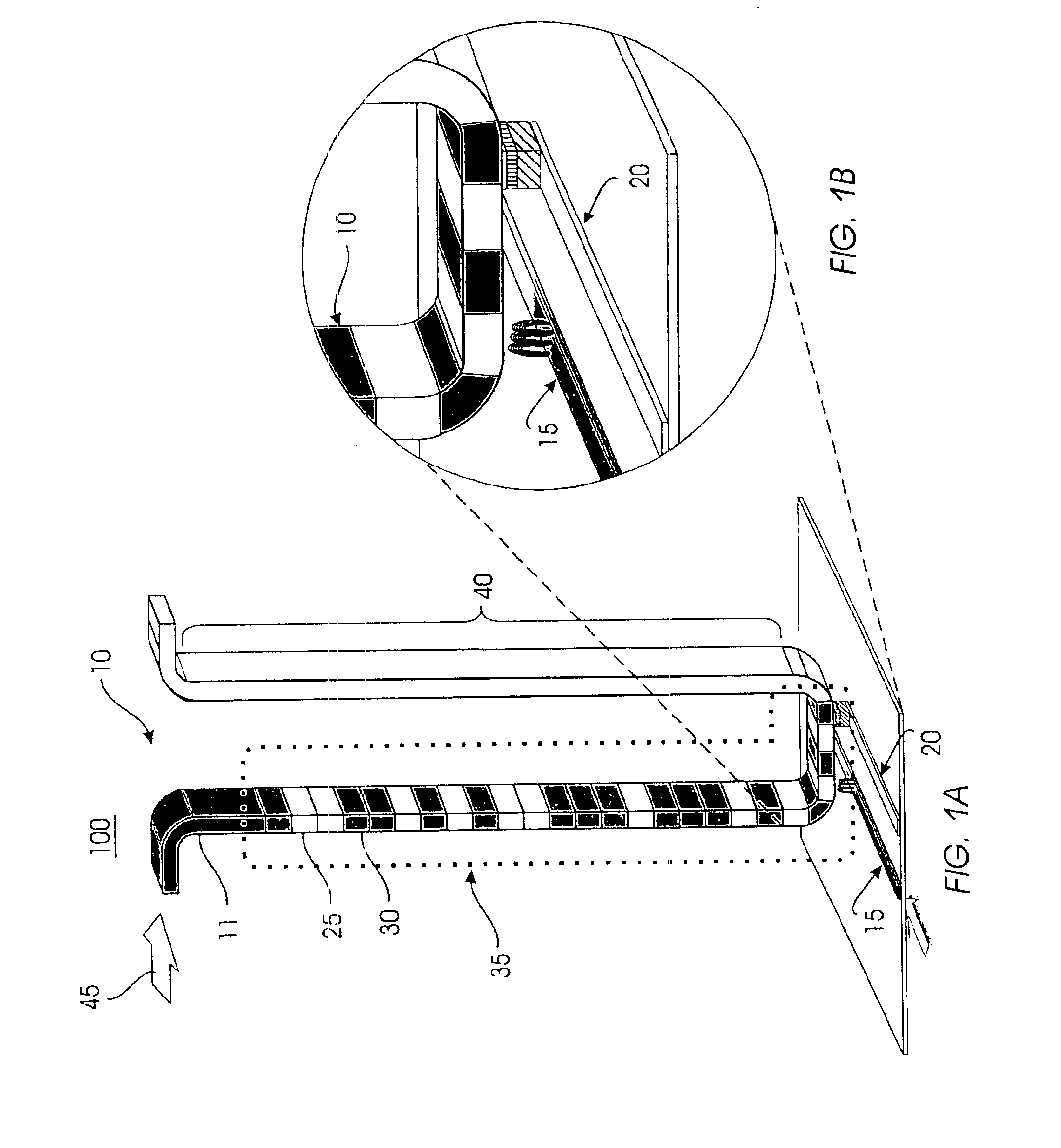

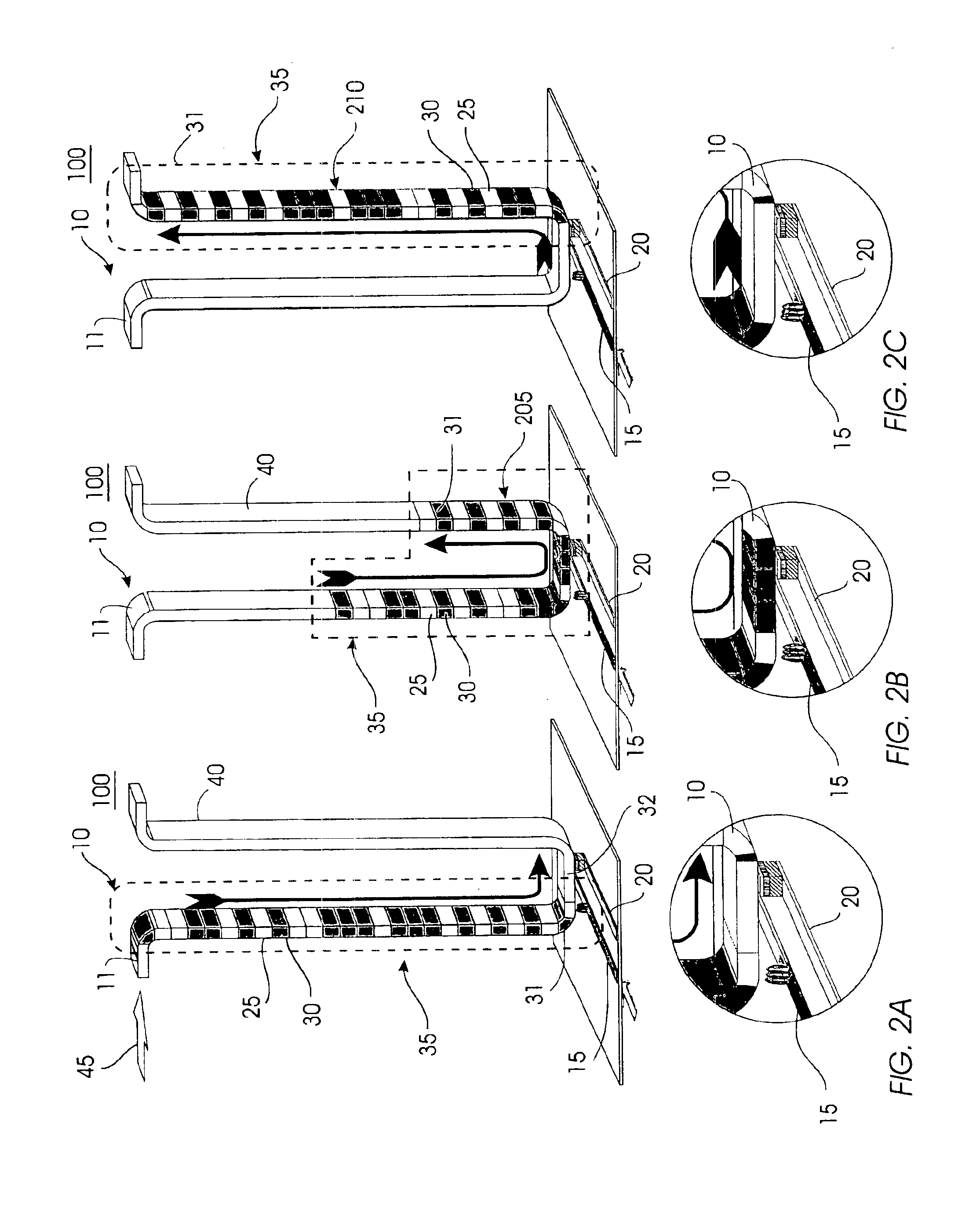

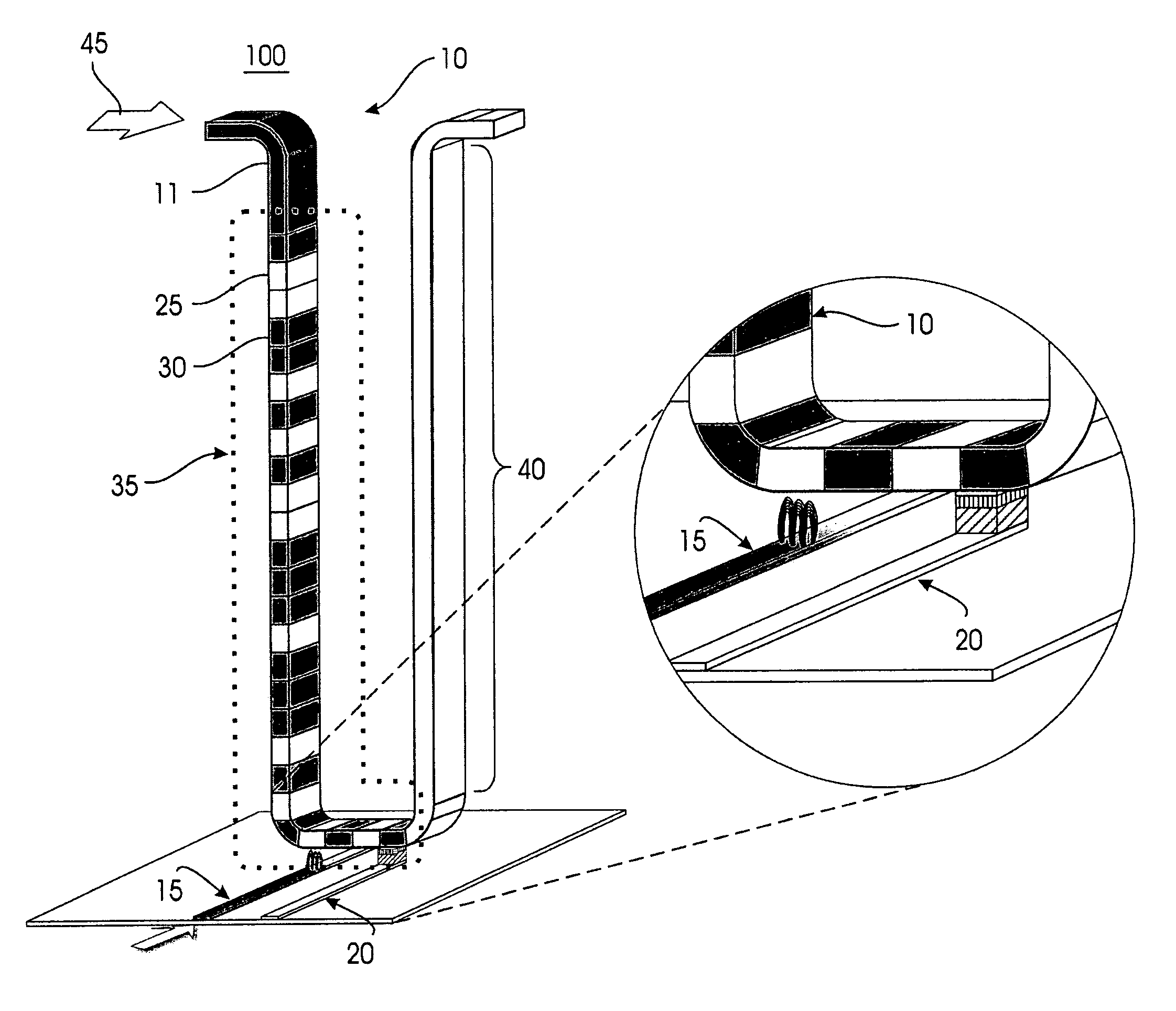

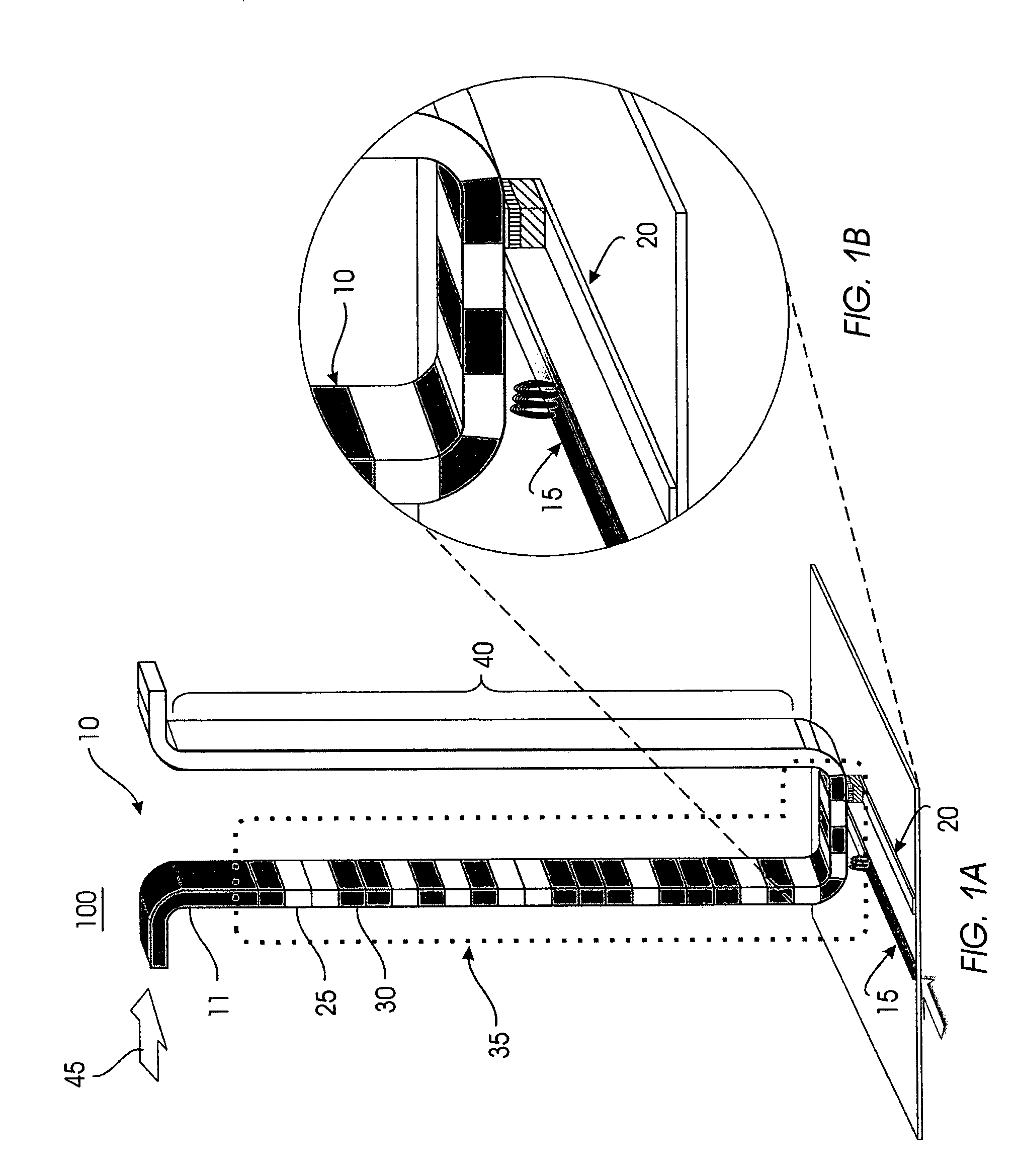

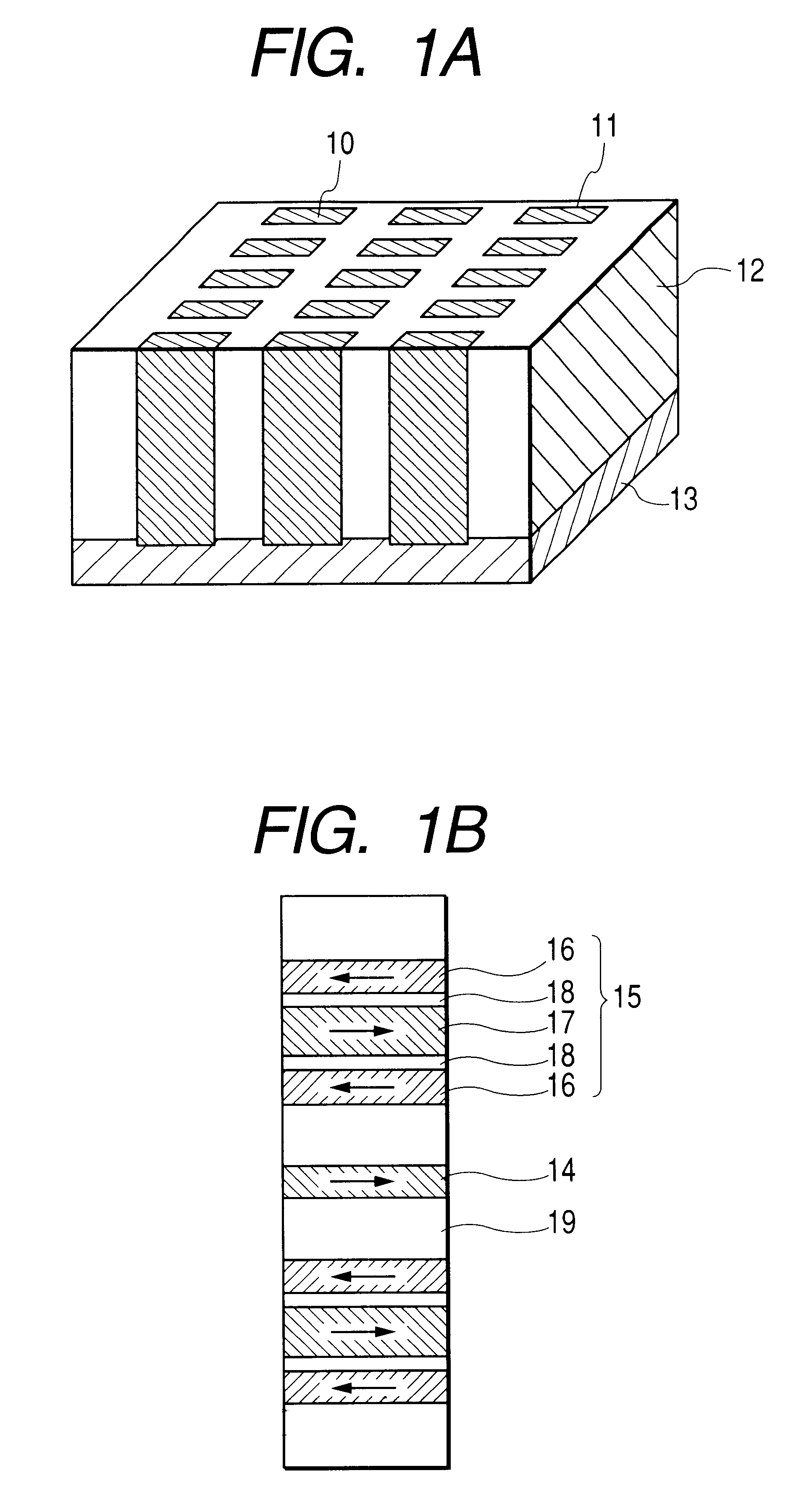

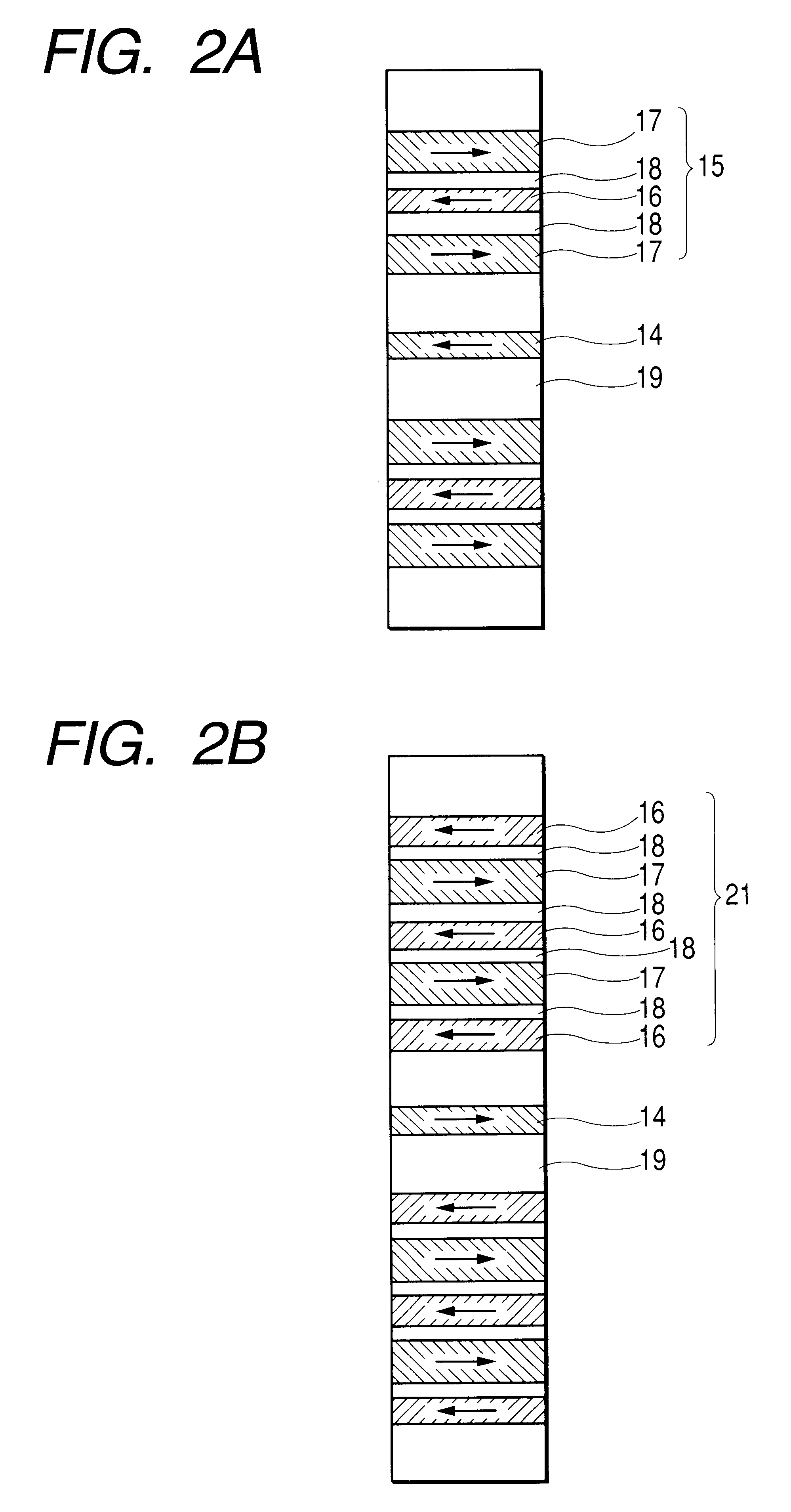

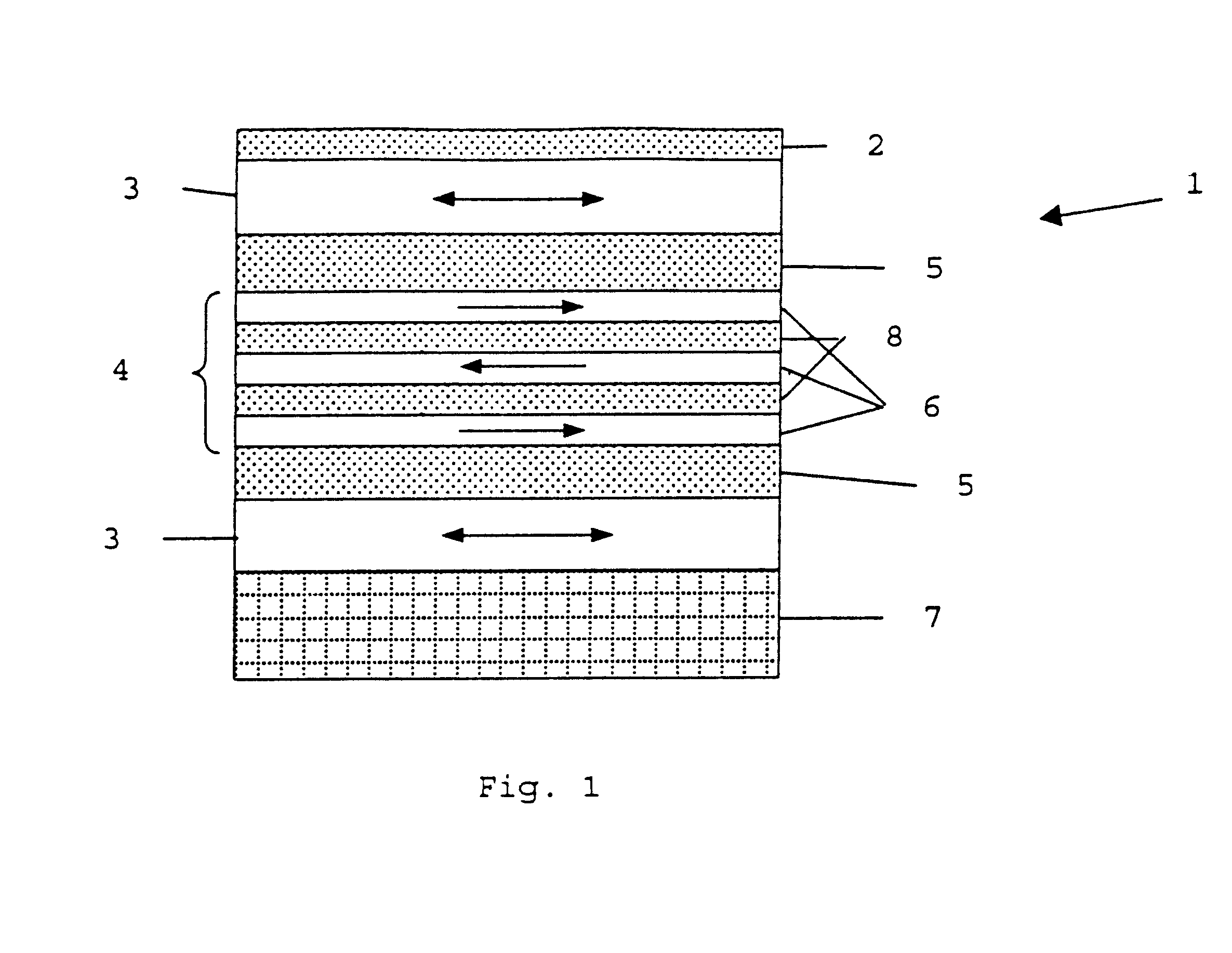

Magnetic shift register with shiftable magnetic domains between two regions, and method of using the same

InactiveUS7031178B2Highly localized and large magnetic fieldsComparable in costLiquid applicationDigital storageShift registerProcessor register

A magnetic shift register uses the inherent, natural properties of domain walls in magnetic materials to store data. The shift register uses spin electronics without changing the physical nature of its constituent materials. The shift register comprises a fine track or strip of magnetic materials. Information is stored as domain walls in the track. An electric current is applied to the track to move the magnetic moments along the track past a reading or writing device. In a magnetic material with domain walls, a current passed across the domain wall moves the domain wall in the direction of the current flow. As the current passes through a domain, it becomes “spin polarized”. When this spin polarized current passes through the next domain and across a domain wall, it develops a circle of spin torque. This spin torque moves the domain wall.

Owner:GLOBALFOUNDRIES U S INC

Magnetic shift register with shiftable magnetic domains between two regions, and method of using the same

InactiveUS20050094427A1Comparable in costIncrease memory capacityLiquid applicationDigital storageShift registerSpins

A magnetic shift register uses the inherent, natural properties of domain walls in magnetic materials to store data. The shift register uses spin electronics without changing the physical nature of its constituent materials. The shift register comprises a fine track or strip of magnetic materials. Information is stored as domain walls in the track. An electric current is applied to the track to move the magnetic moments along the track past a reading or writing device. In a magnetic material with domain walls, a current passed across the domain wall moves the domain wall in the direction of the current flow. As the current passes through a domain, it becomes “spin polarized”. When this spin polarized current passes through the next domain and across a domain wall, it develops a circle of spin torque. This spin torque moves the domain wall.

Owner:GLOBALFOUNDRIES US INC

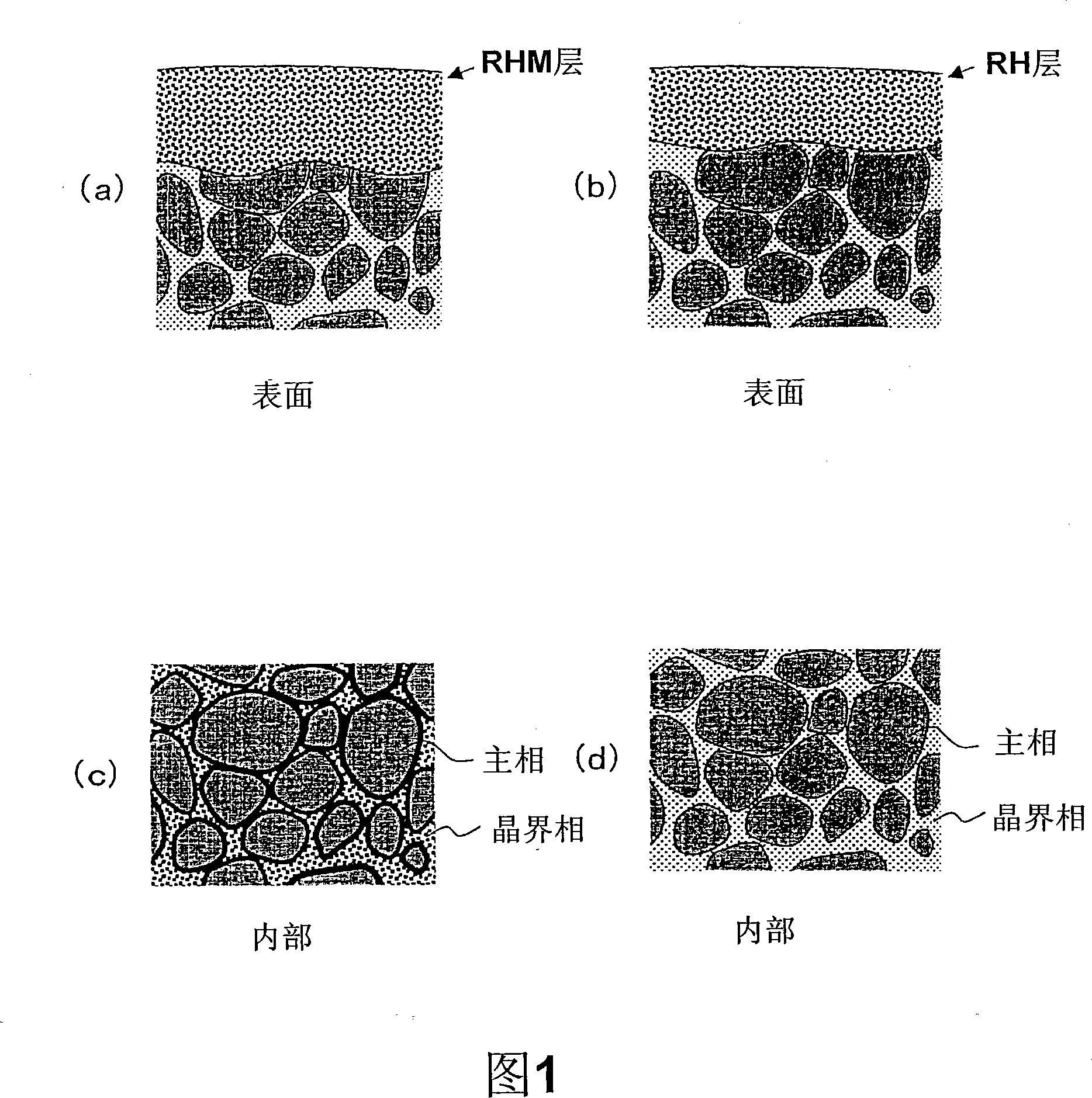

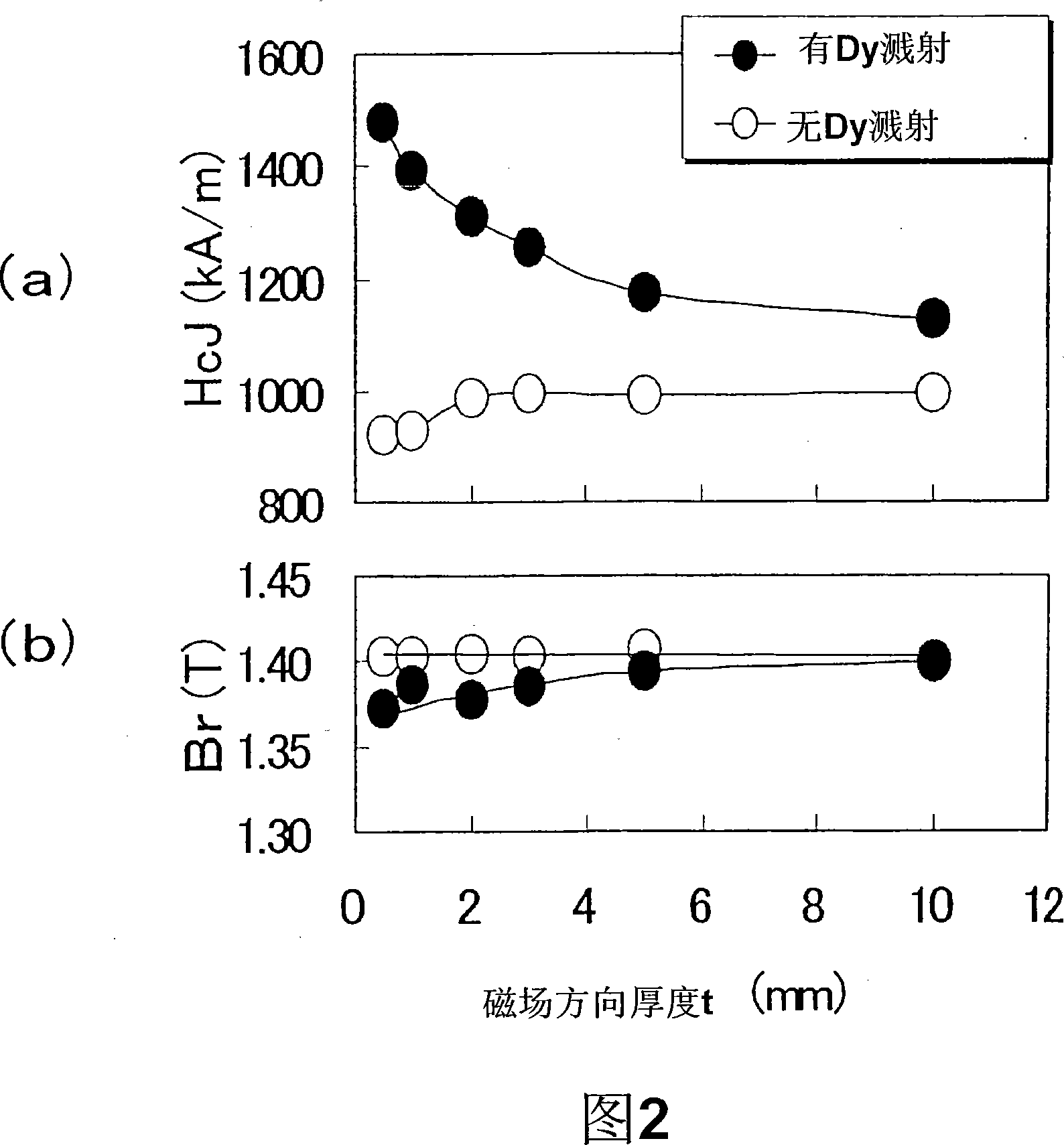

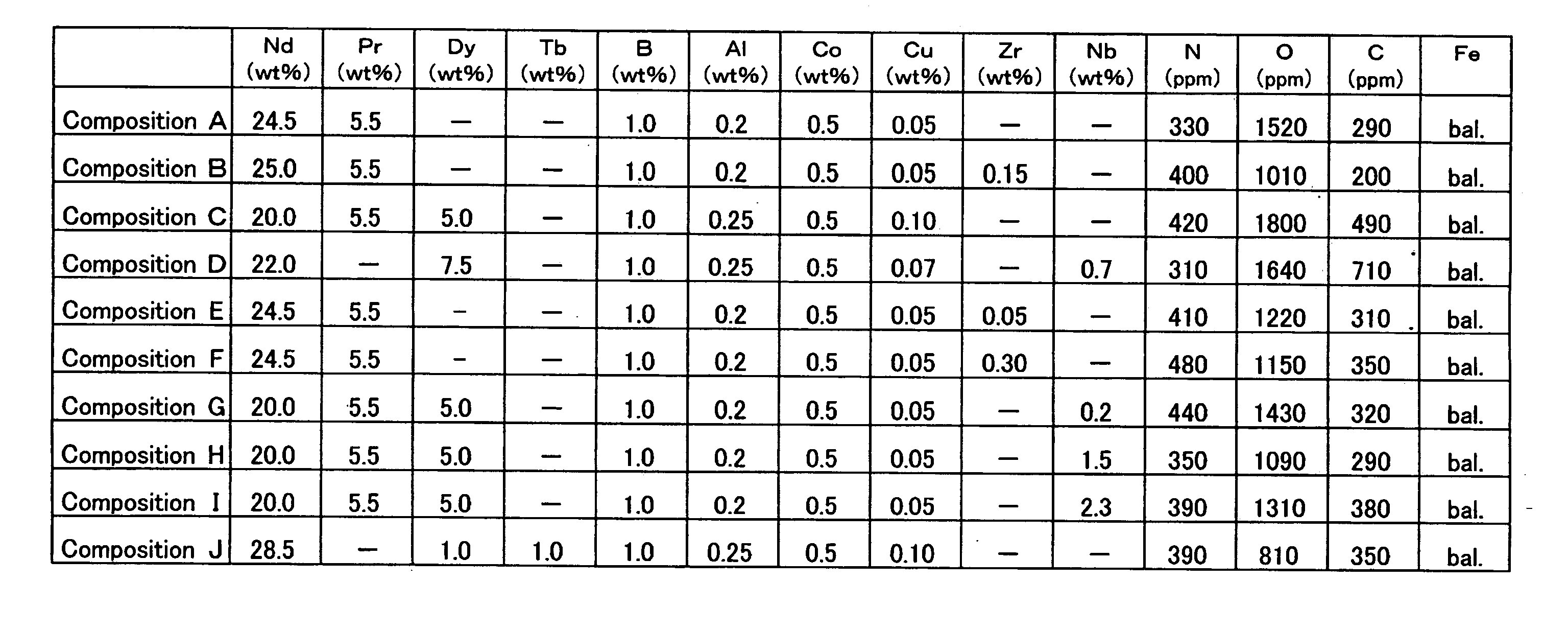

Rare earth sintered magnet and process for producing the same

ActiveCN101006534APhenomena that promote grain boundary diffusionEfficient replacementLiquid applicationPermanent magnetsRare-earth elementSintered magnets

Owner:HITACHI METALS LTD

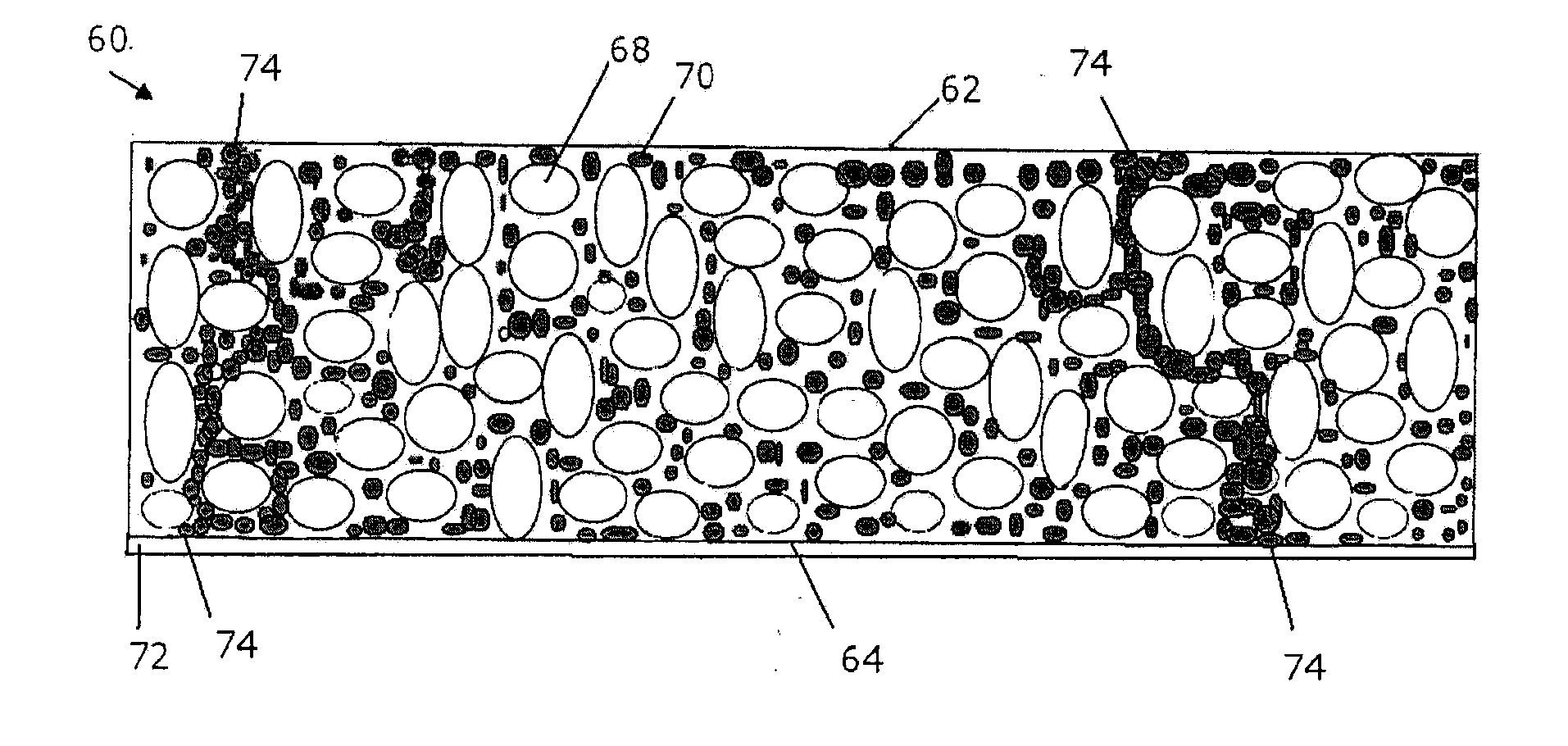

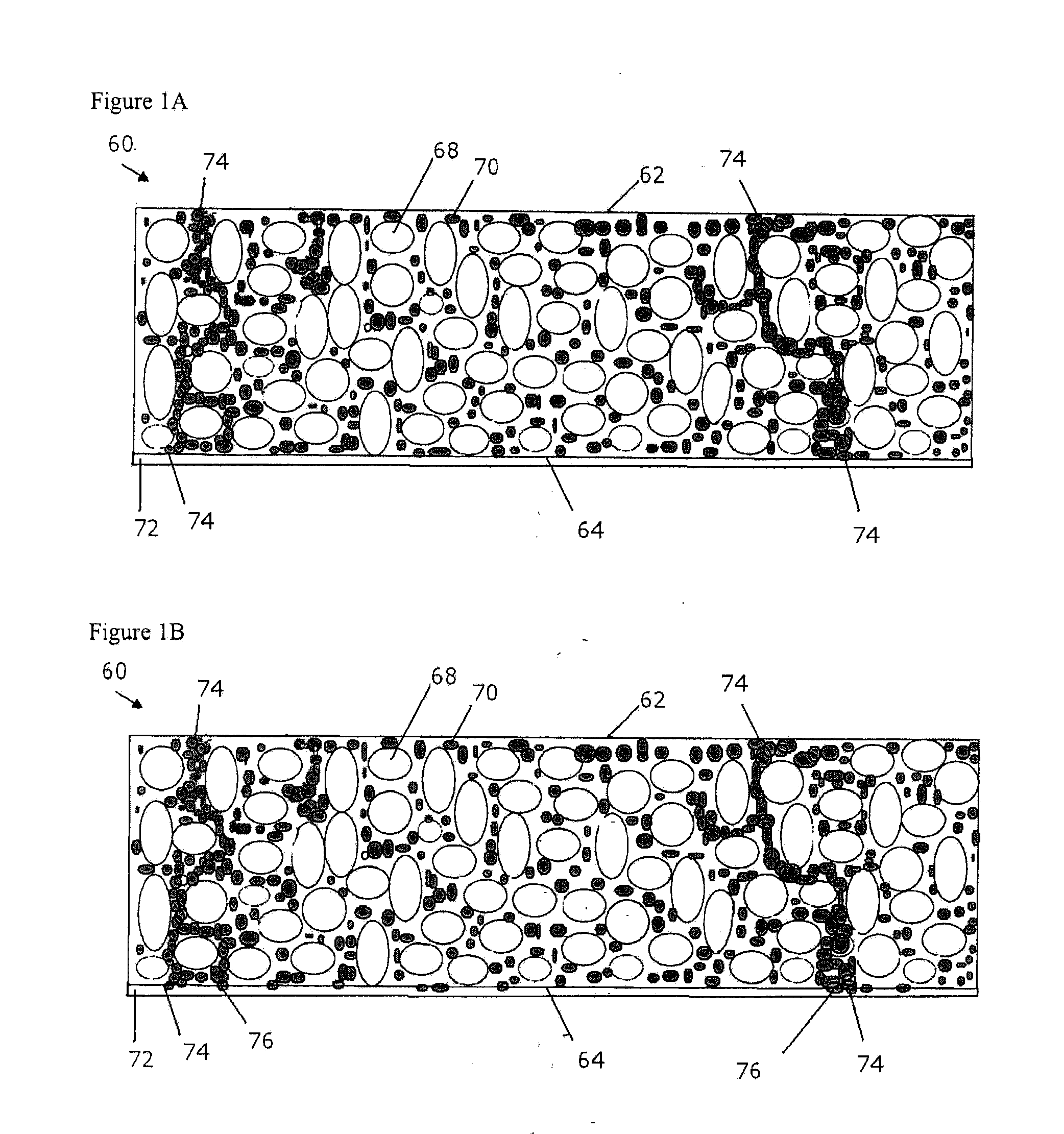

Conductive polymer foams, method of manufacture, and uses thereof

A polymer foam layer is disclosed, comprising a polymer foam and a plurality of electrically conductive particles dispersed within the polymer foam, polymer foam layer having an unabraded first surface and an opposite, second surface, wherein the electrically conductive particles essentially continuously span the polymer foam layer, and a portion of the electrically conductive particles are exposed at the first surface of the layer and another portion of the electrically conductive particles are exposed at the second surface. The foams are useful as gaskets for electromagnetic shielding, grounding pads, battery contact conductive spring elements, and the like.

Owner:ROGERS CORP

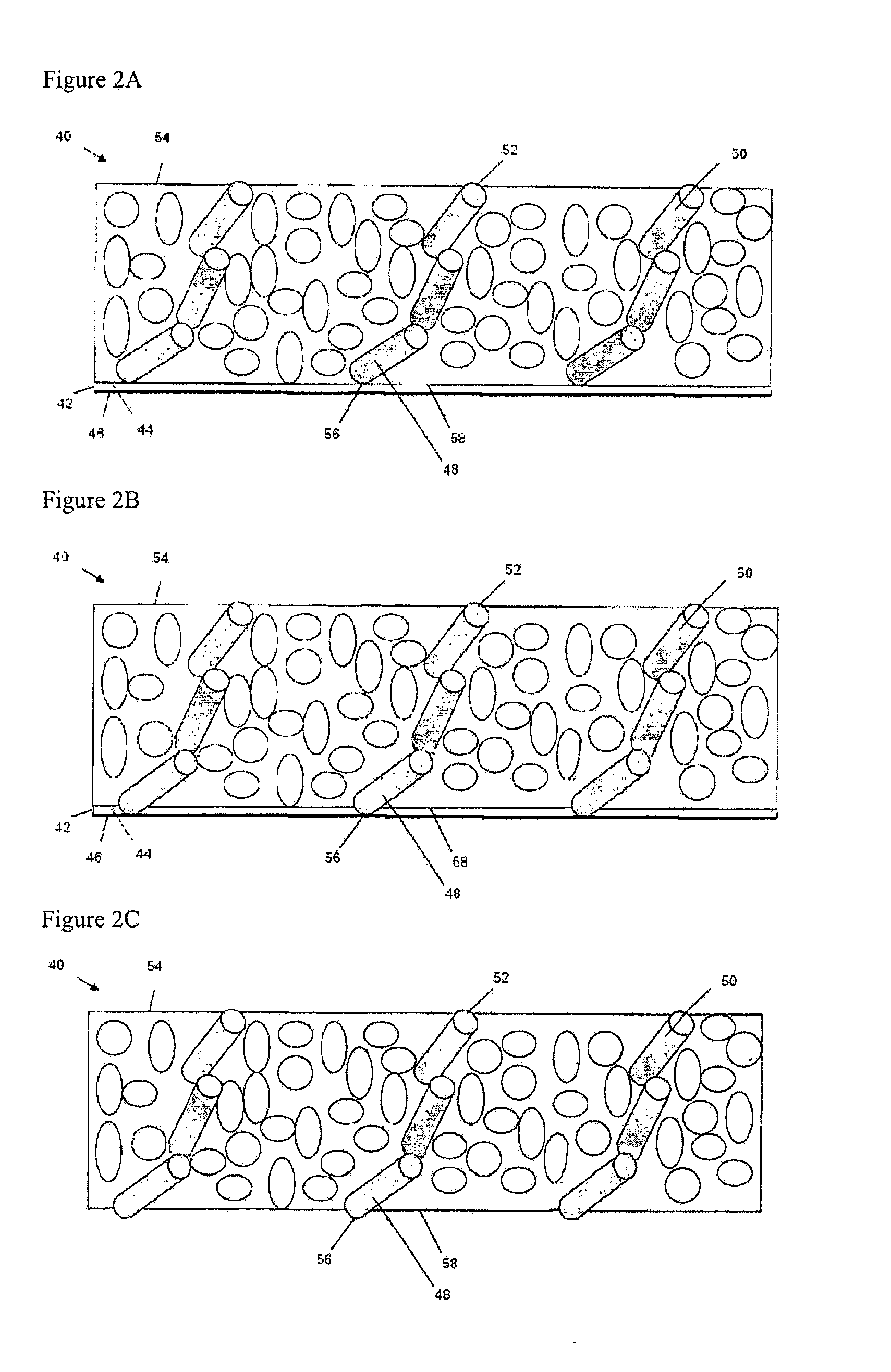

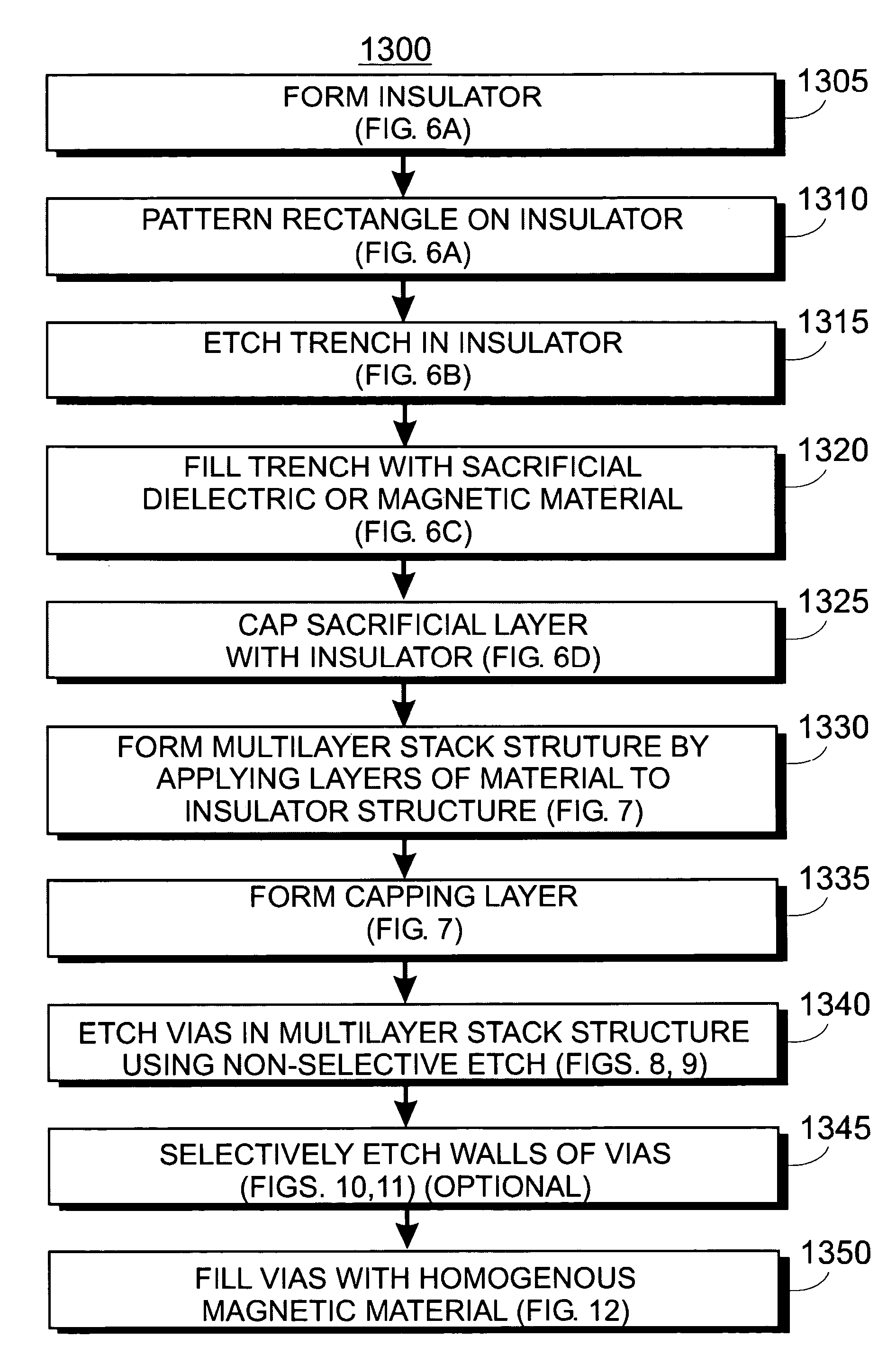

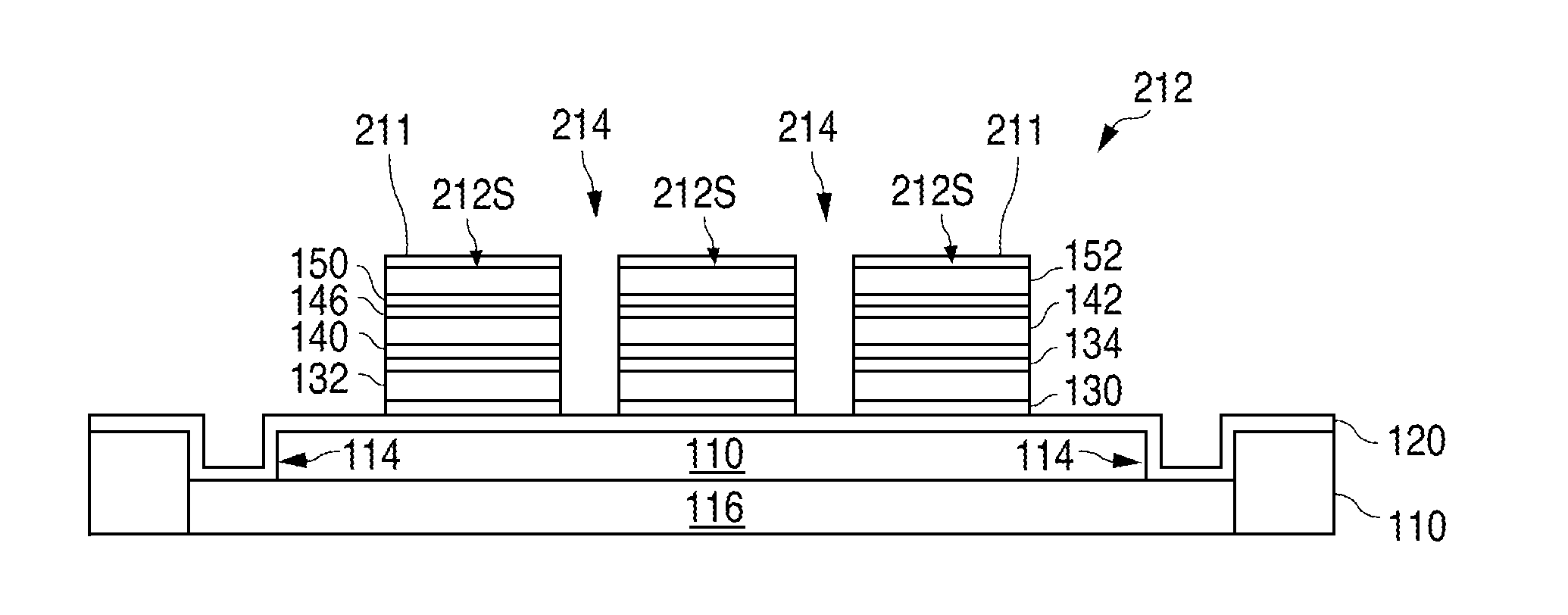

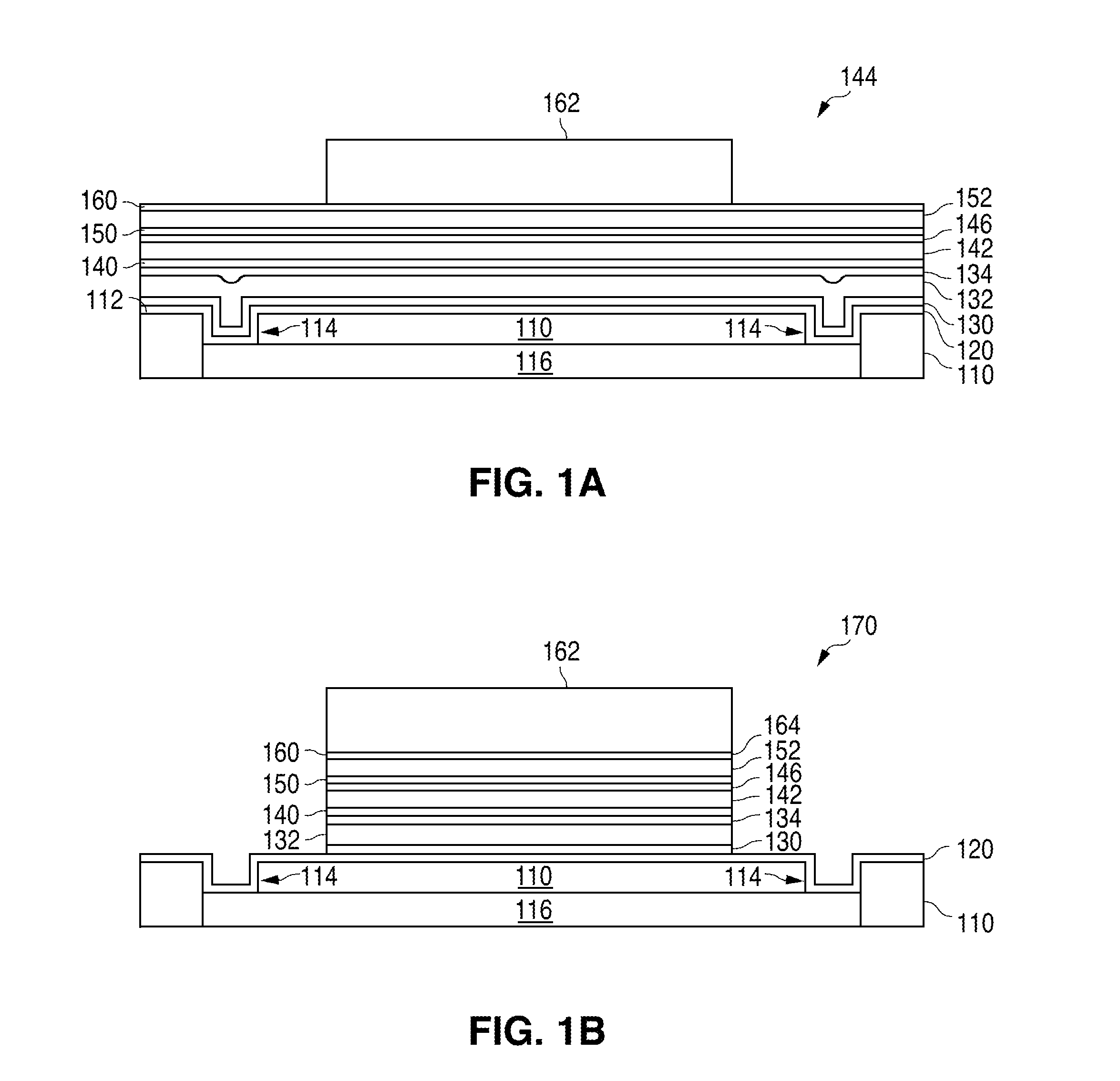

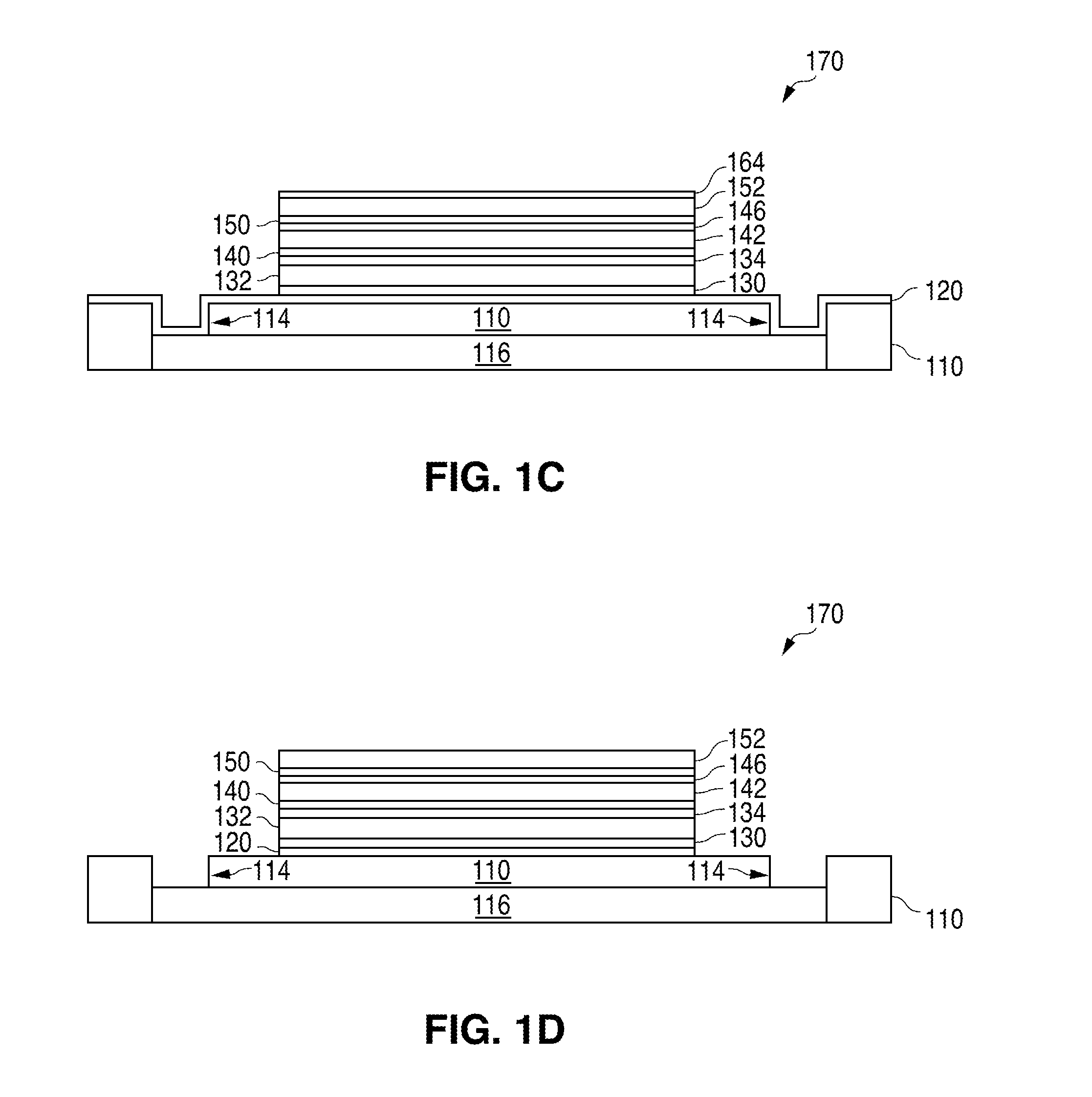

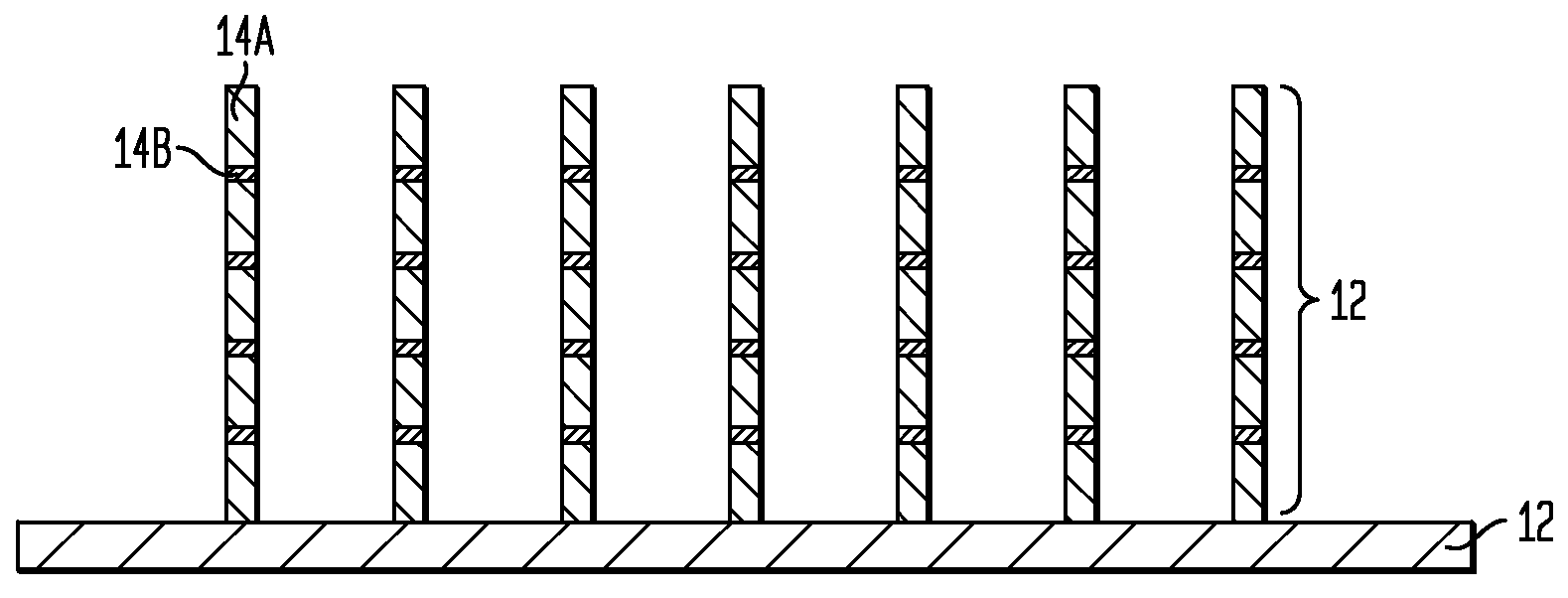

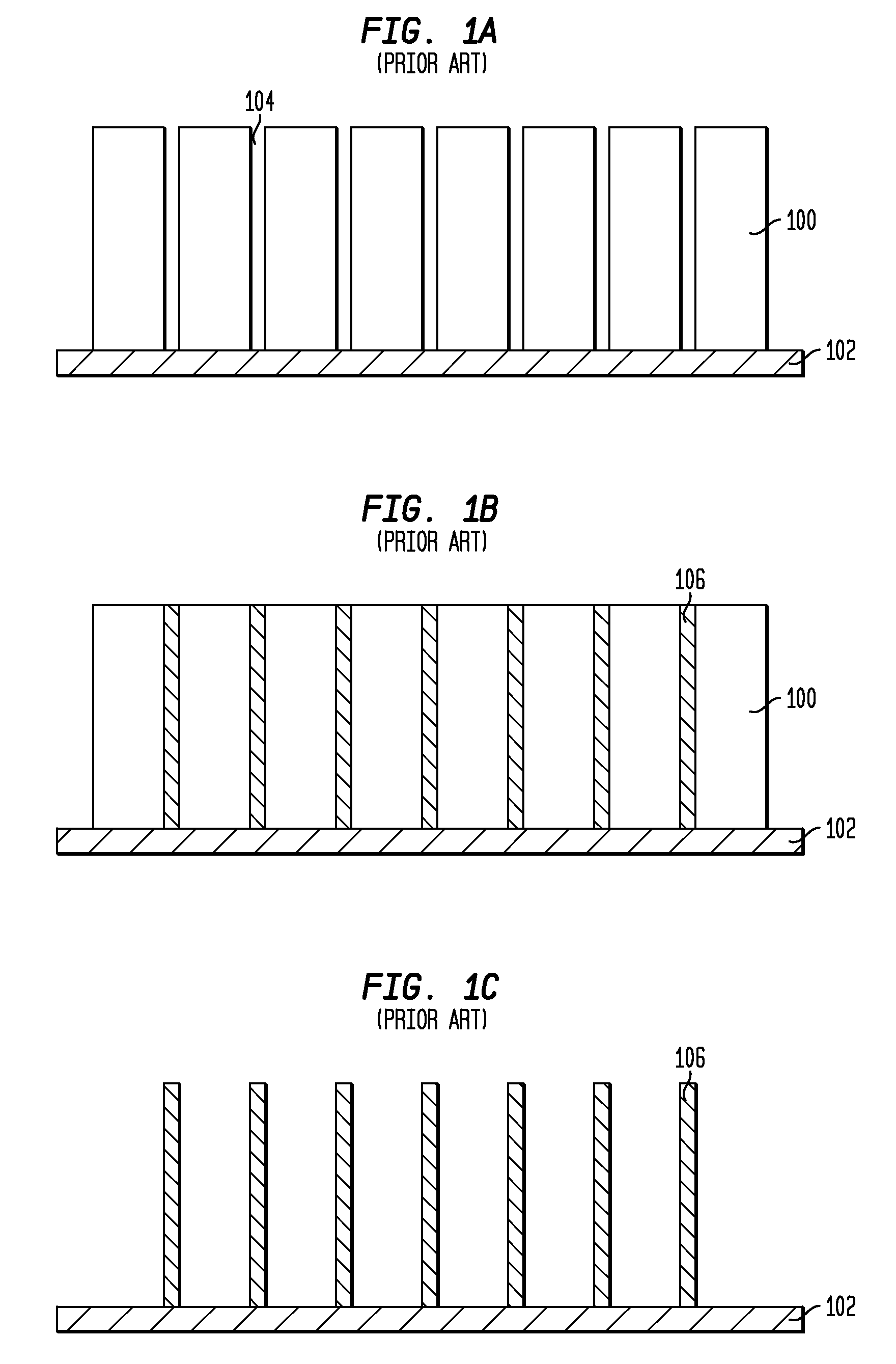

Method of fabricating a shiftable magnetic shift register

A magnetic data track used in a magnetic shift register memory system may be fabricated by forming a multilayered stack of alternating dielectric and / or silicon layers. Vias of approximately 10 microns tall with a cross-section on the order of 100 nm×100 nm are etched in this multilayered stack of alternating layers. Vias may be etched form smooth or notched walls. Vias are filled by electroplating layers of alternating types of ferromagnetic or ferrimagnetic metals. The alternating ferromagnetic or ferrimagnetic layers are comprised of magnetic materials with different magnetization or magnetic exchange or magnetic anisotropies. These different magnetic characteristics allow the pinning of magnetic domain walls at the boundaries between these layers. Alternatively, vias are filled with a homogeneous ferromagnetic material. Magnetic domain walls are formed by the discontinuity in the ferromagnetic or ferromagnetic material that occurs at the notches or at the protuberances along the via walls.

Owner:GLOBALFOUNDRIES US INC

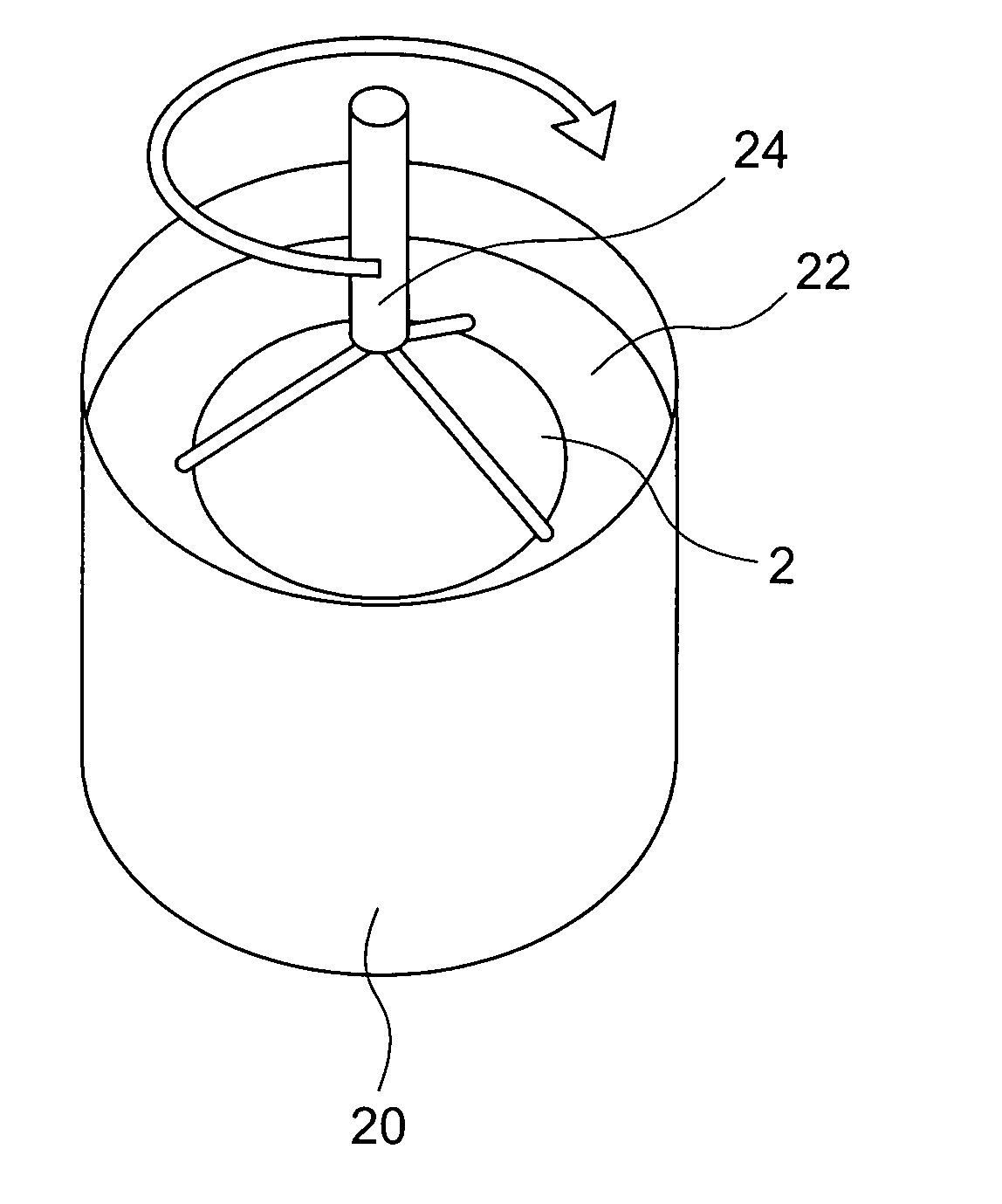

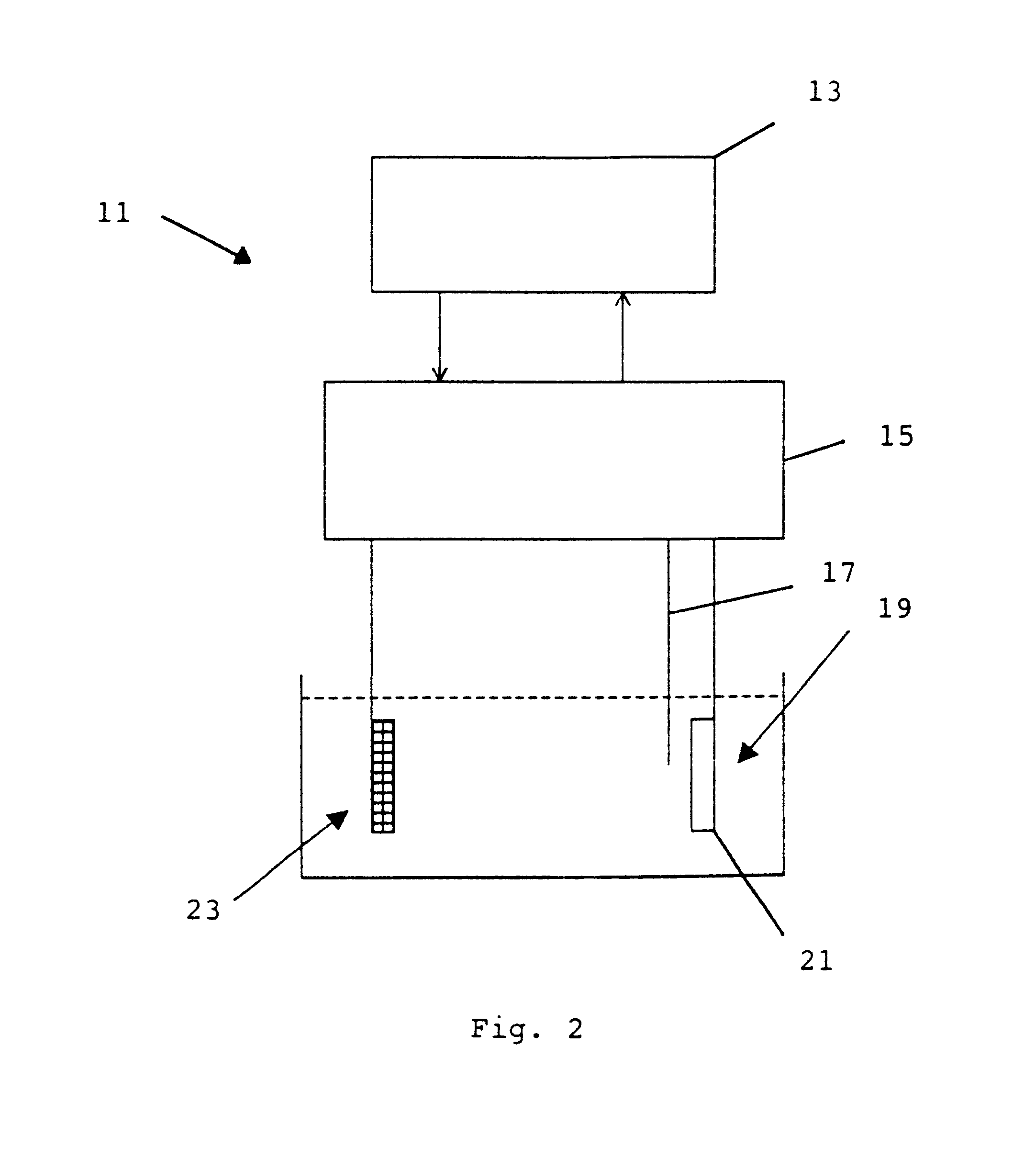

Apparatus and method for highly controlled electrodeposition

An apparatus and method for highly controlled electrodeposition, particularly useful for electroplating submicron structures. Enhanced control of the process provides for a more uniform deposit thickness over the entire substrate, and permits reliable plating of submicron features. The apparatus includes a pressurized electrochemical cell to improve plating efficiency and reduce defects, vertical laminar flow of the electrolyte solution to remove surface gases from the vertically arranged substrate, a rotating wafer chuck to eliminate edge plating effects, and a variable aperture to control the current distribution and ensure deposit uniformity across the entire substrate. Also a dynamic profile anode whose shape can be varied to optimize the current distribution to the substrate. The anode is advantageously able to use metallic ion sources and may be placed close to the cathode thus minimizing contamination of the substrate.

Owner:COOK BIOTECH +1

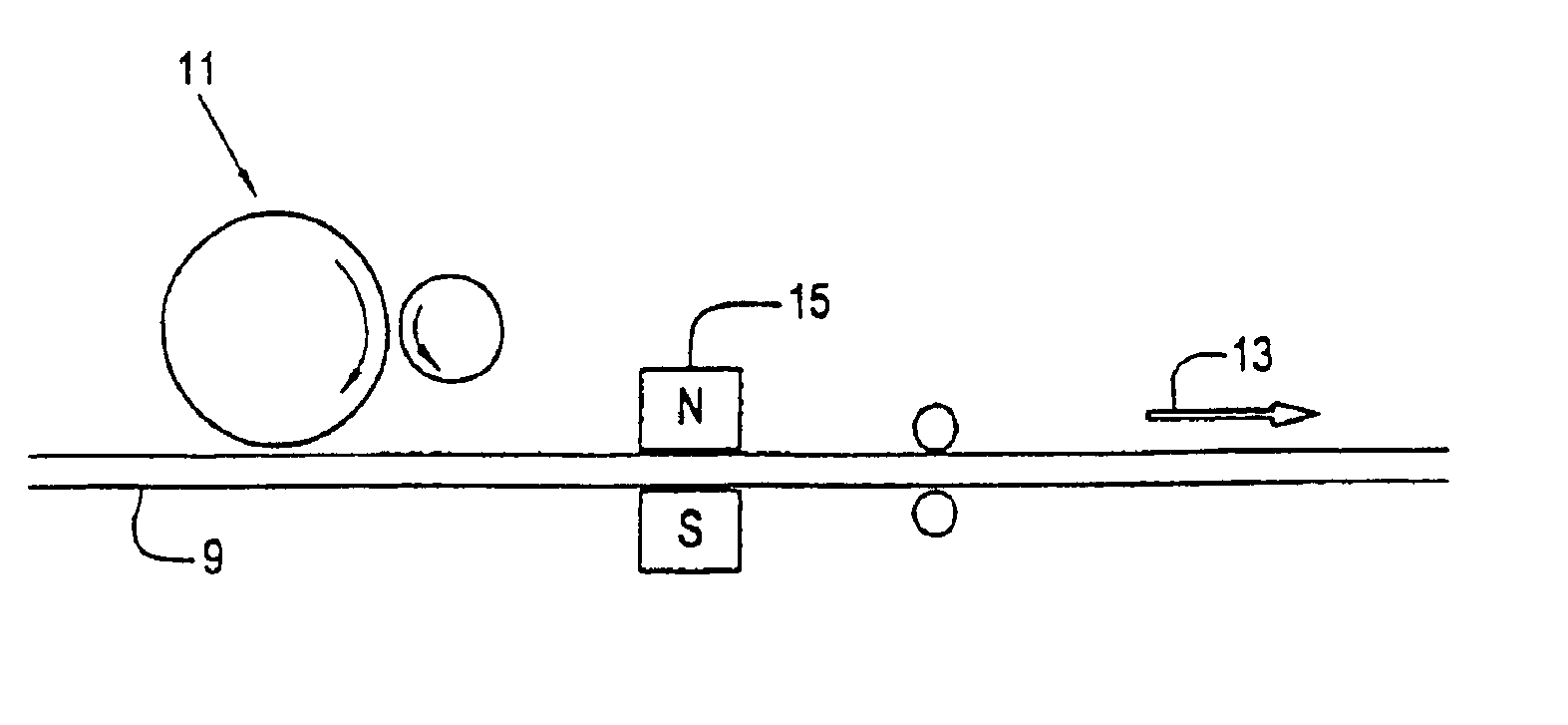

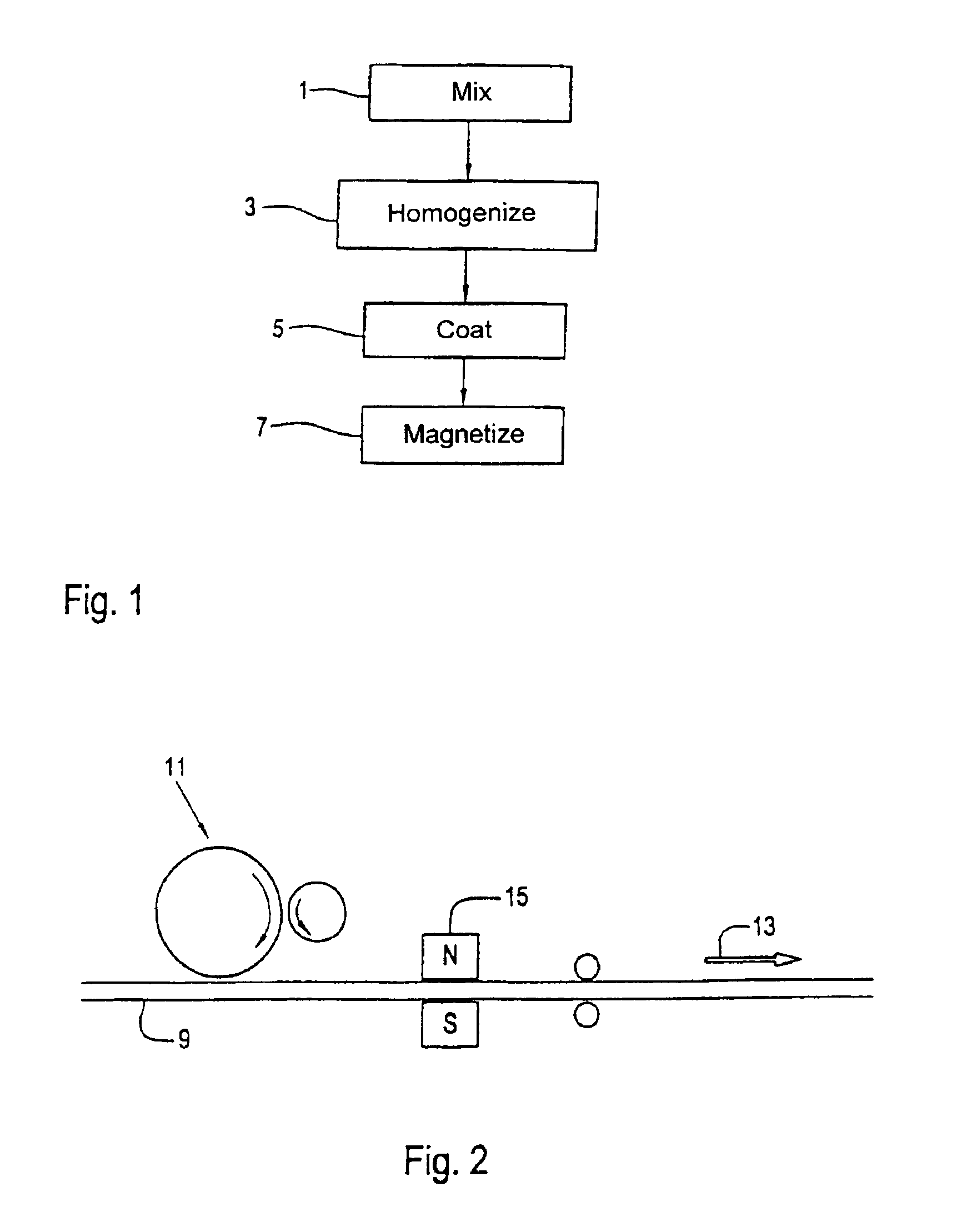

Apparatus and method for making a magnetic coated medium, and a coated medium therefrom

InactiveUS6881450B1Limited penetrationLow costMagnetic paintsLiquid applicationPlastic filmHot-melt adhesive

The invention is directed to a method of magnetically linking a ferromagnetic object to a partially magnetized coating material made by applying a coating to a surface of a continuously-moving medium including the steps of providing a coating material by mixing a binder material suitable for being spread substantially and regularly over the surface and a ferromagnetic component, the binder material being a hot melt adhesive; providing a continuously-moving medium having a top surface to be substantially coated, the surface capable of receiving a substantially and regularly spread coating material; passing the coating material and continuously-moving medium between rollers to form a substantially constant thickness of the coating material substantially covering the top surface and allowing the coating material to set to form the coated medium as a magnetizable component, wherein the medium that is coated is one of a paper, a card, wallpaper, a flexible plastic sheet, a rigid plastic sheet, and walls; partially magnetizing the coating material during continuous movement of the medium to create a magnetized area and an unmagnetized area; and magnetically and temporarily linking a ferromagnetic object to the magnetized area so that the coated medium and ferromagnetic object are held together by magnetic attraction.

Owner:TEXIER CLAUDE

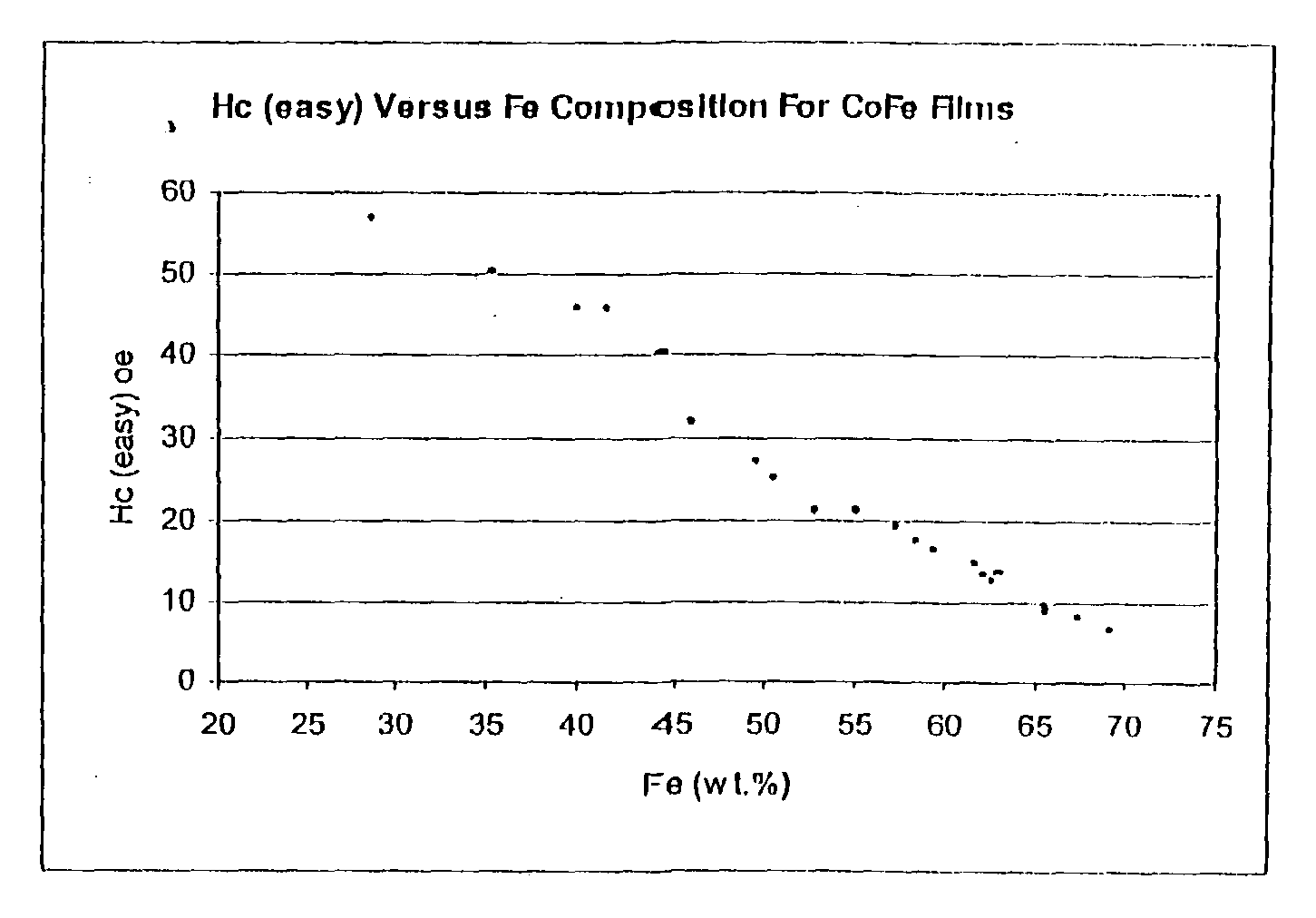

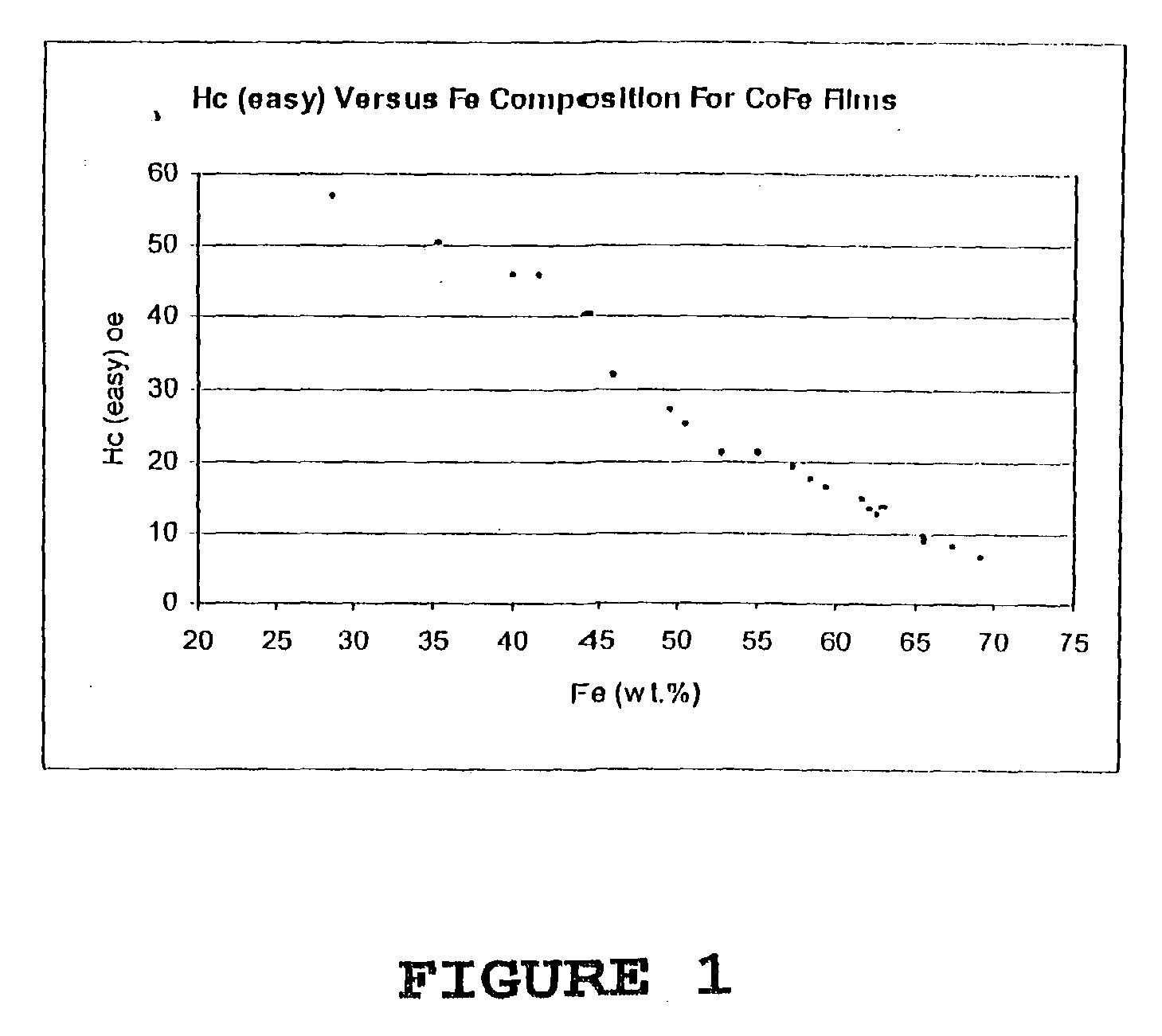

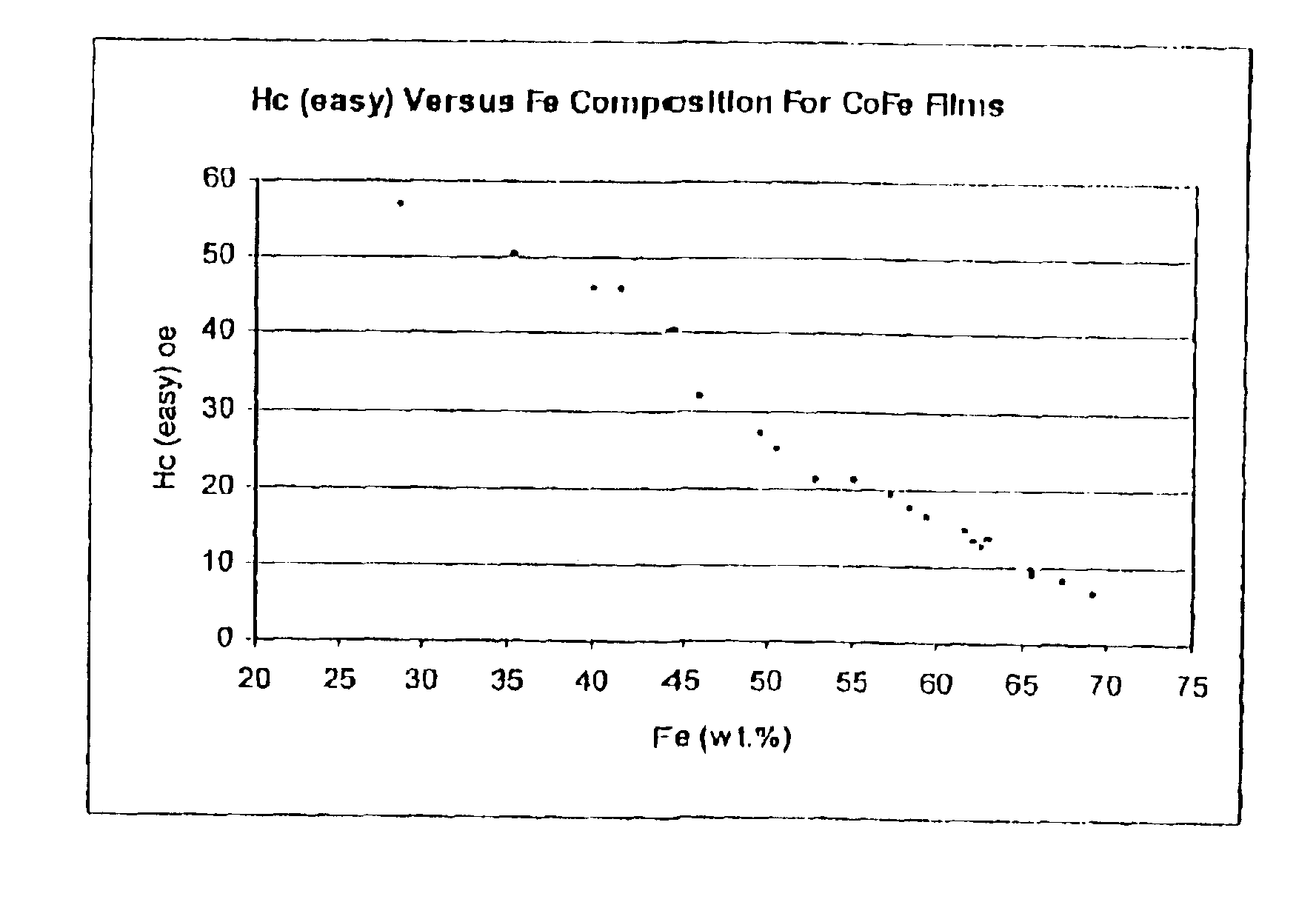

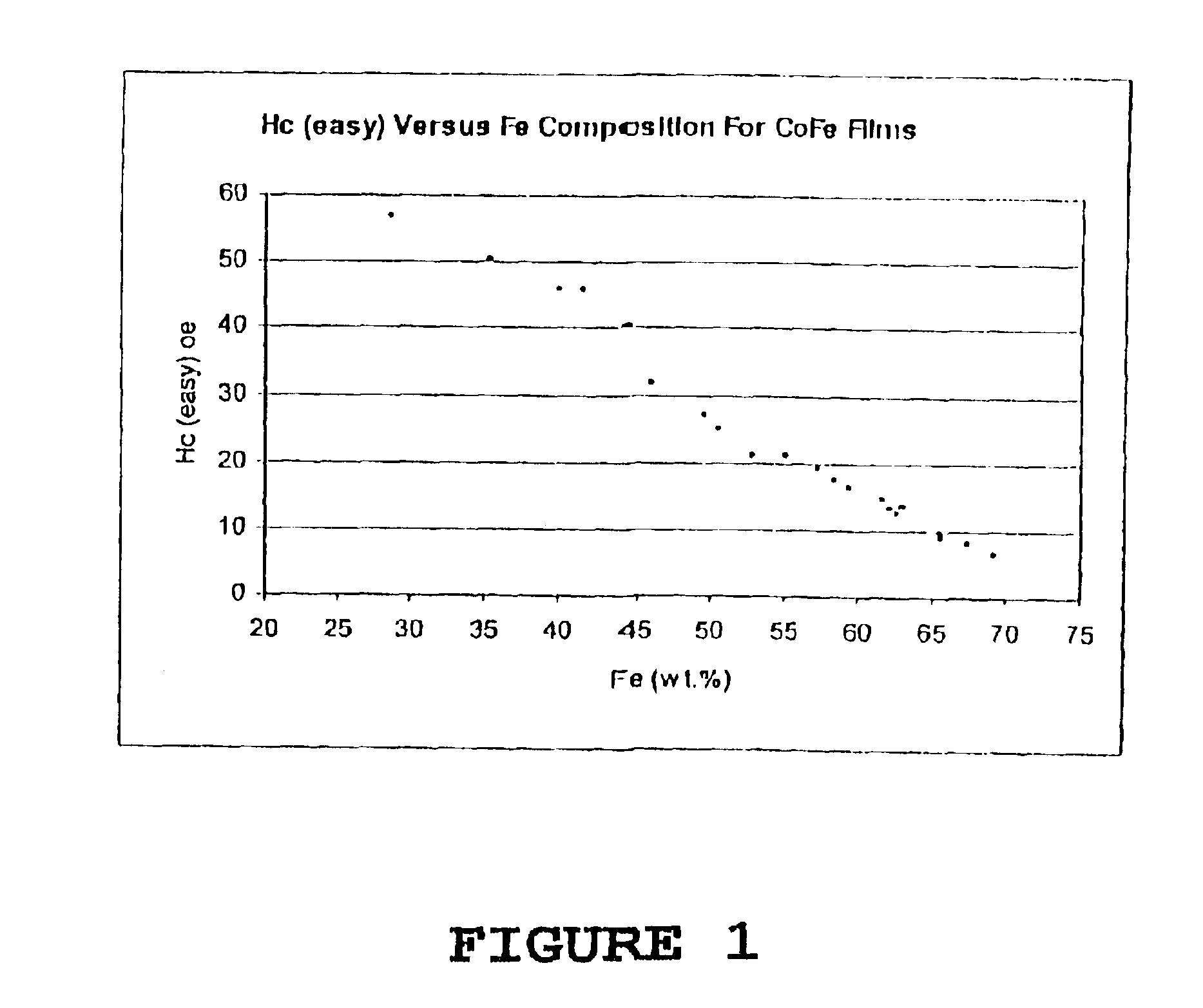

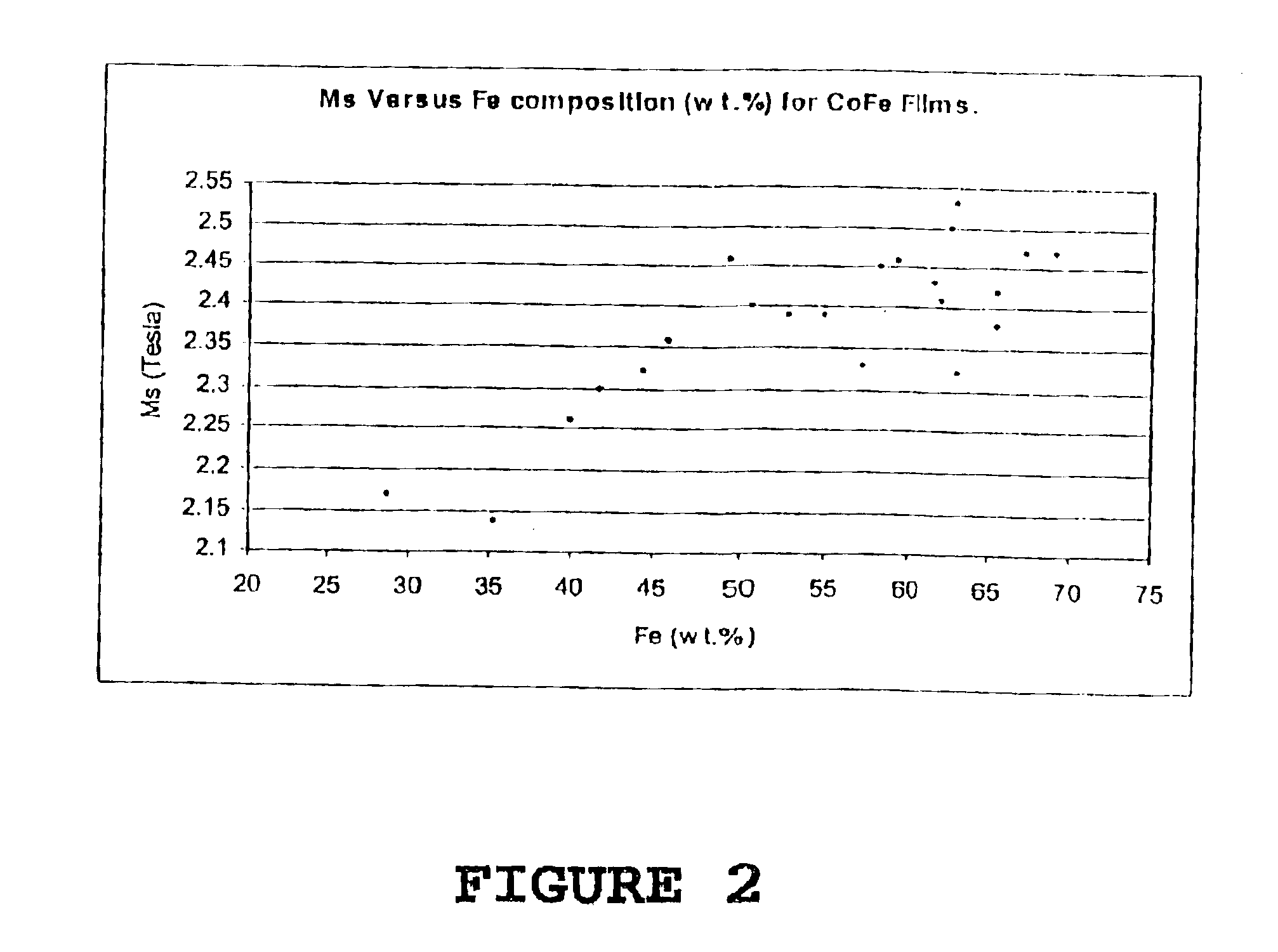

CoFe alloy film and process of making same

A cobalt-iron alloy film having saturation magnetization of at least about 2.30 Telsa. The film alloy includes about 55 wt % to about 75 wt. % iron and the remainder cobalt. The film is made by a process in which the film is electrodeposited from an aqueous medium which includes one or more ferrous salts, one or more cobaltous salts, a buffer having a pKa of about 6 to about 8, at least one carboxylic acid having a pKa of between about 3.5 and about 5.5, an aromatic sulfinic acid or its salt and optionally, a halide salt and / or a surfactant. The alloy film is useful as a write head in magnetic recording.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

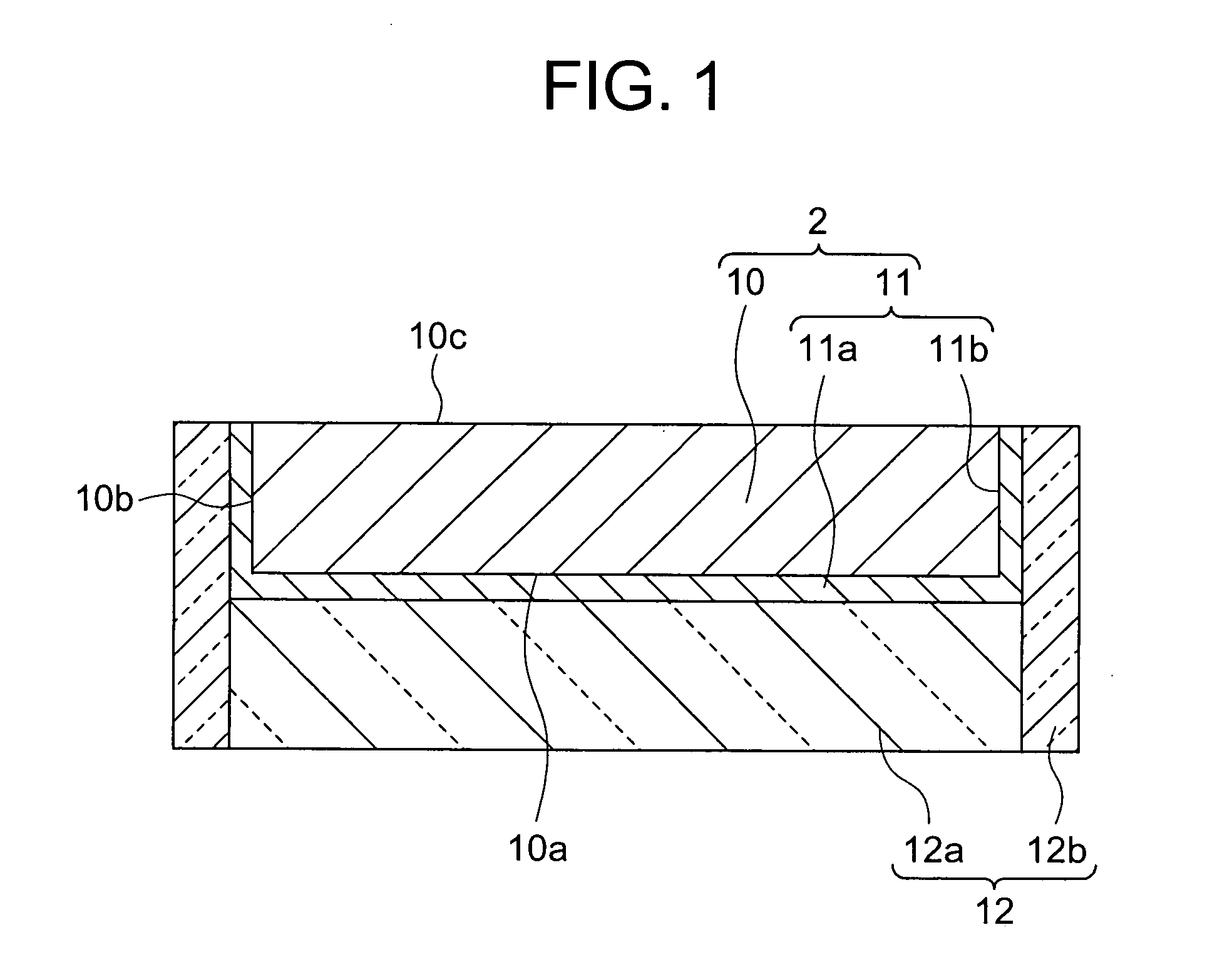

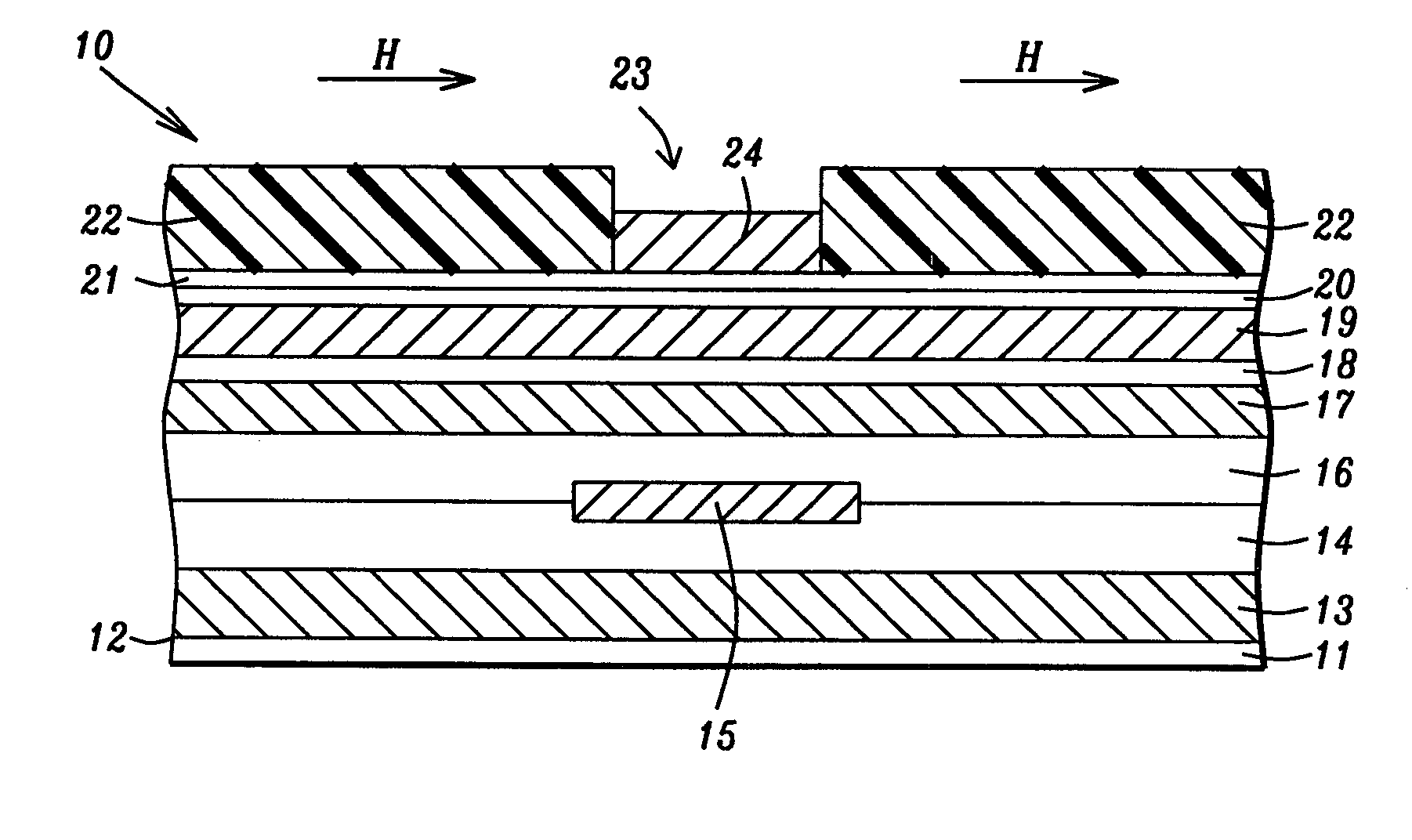

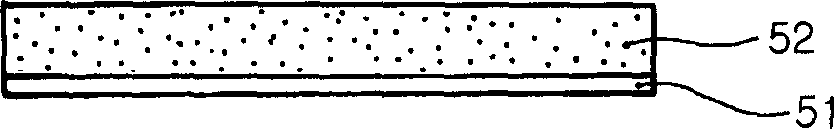

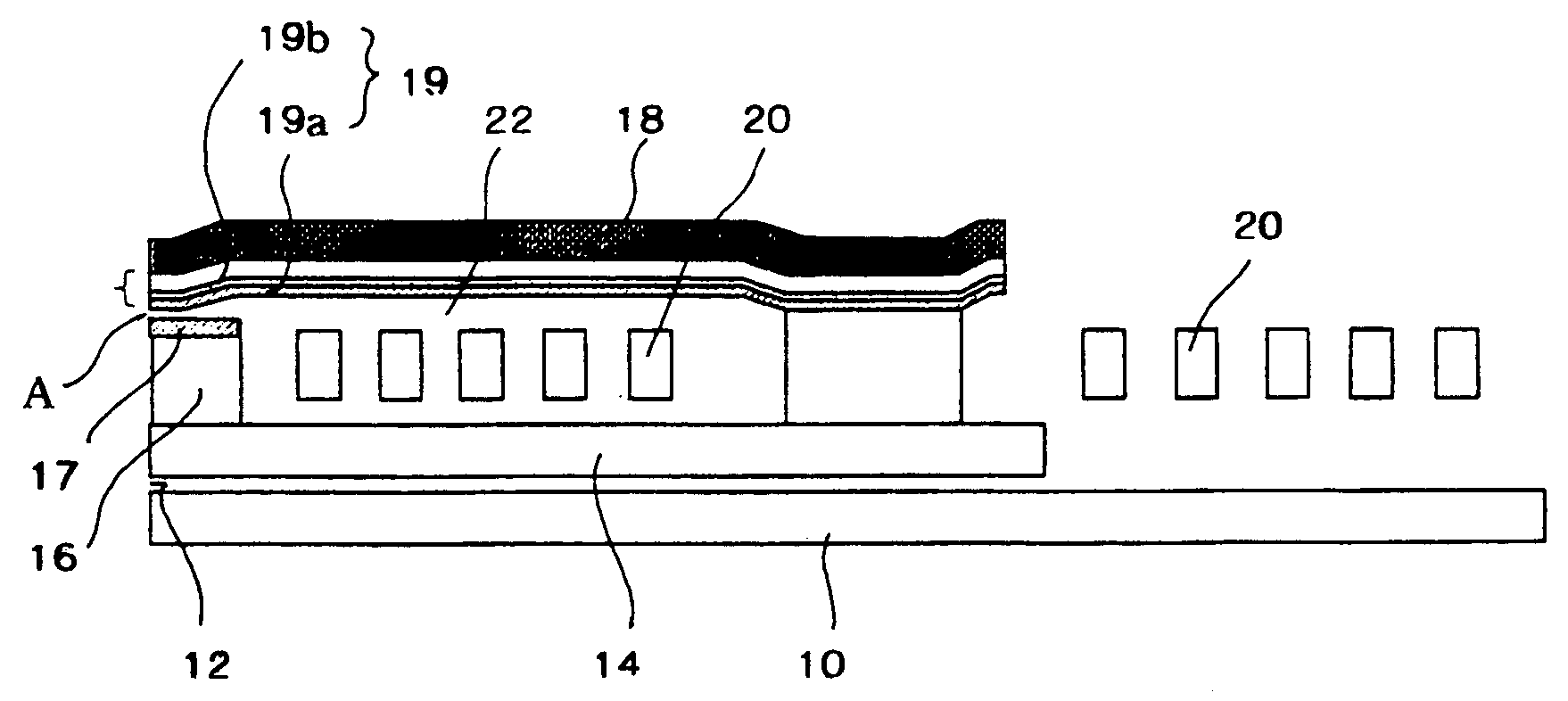

Magnetic garnet single crystal film formation substrate, optical element and production method of the same

InactiveUS20060112873A1Quality improvementImprove production yieldPolycrystalline material growthLiquid-phase epitaxial-layer growthOptical isolatorOptoelectronics

A magnetic garnet single crystal film formation substrate 2 for growing a thick magnetic garnet single crystal film, wherein crystal defects, warps, cracks and flaking, etc. are not caused, by liquid phase epitaxial growth is provided. The substrate 2 comprises a base substrate 10 composed of a garnet-based single crystal being unstable with a flux used for the liquid phase epitaxial growth; a buffer layer 11a composed of a garnet-based single crystal thin film formed on a crystal growing surface 10a of said base substrate 10 and being stable with said flux; and a protective layer 11b formed at least on side surfaces 10b of said base substrate 10 crossing with said crystal growing surface of said base substrate 10 and being stable with said flux. By using the substrate, a high quality magnetic garnet single crystal film can be produced. The magnetic garnet single crystal film is used as an optical element, such as a Faraday element, used for an optical isolator, optical circulator and magneto-optical sensor, etc.

Owner:TDK CORPARATION

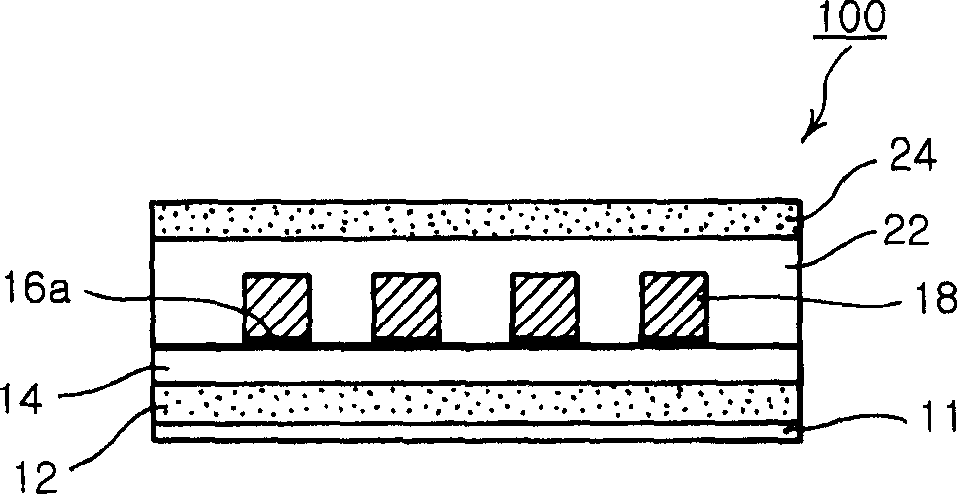

Method of Forming a Laminated Magnetic Core with Sputter Deposited and Electroplated Layers

A laminated magnetic core, which has a number of magnetic layers and a number of insulation layers which are arranged so that an insulation layer lies between each vertically adjacent pair of magnetic layers, is formed in a method that forms the magnetic layers with an electroplating process, and the insulation layers with a sputter depositing process.

Owner:TEXAS INSTR INC

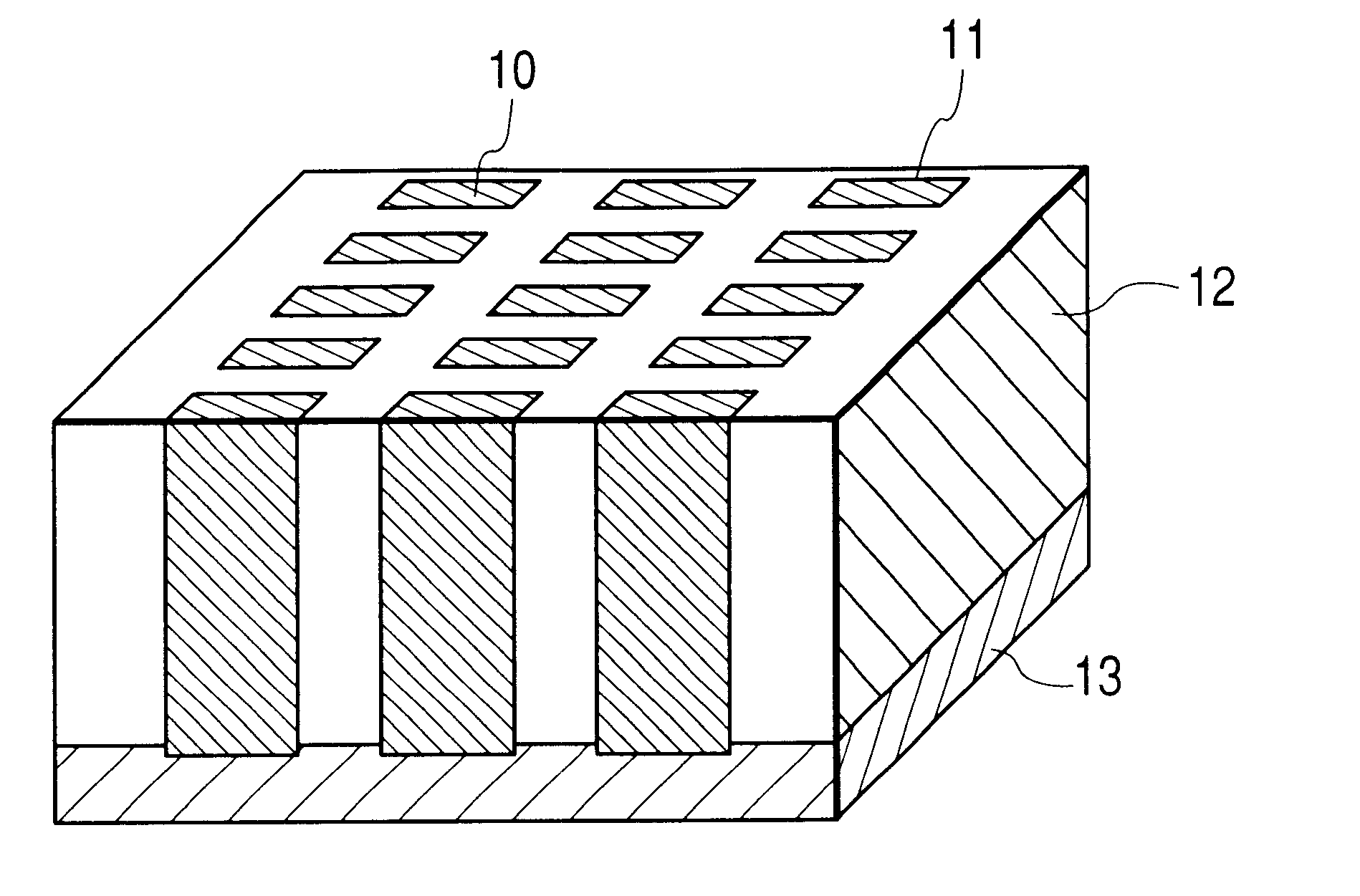

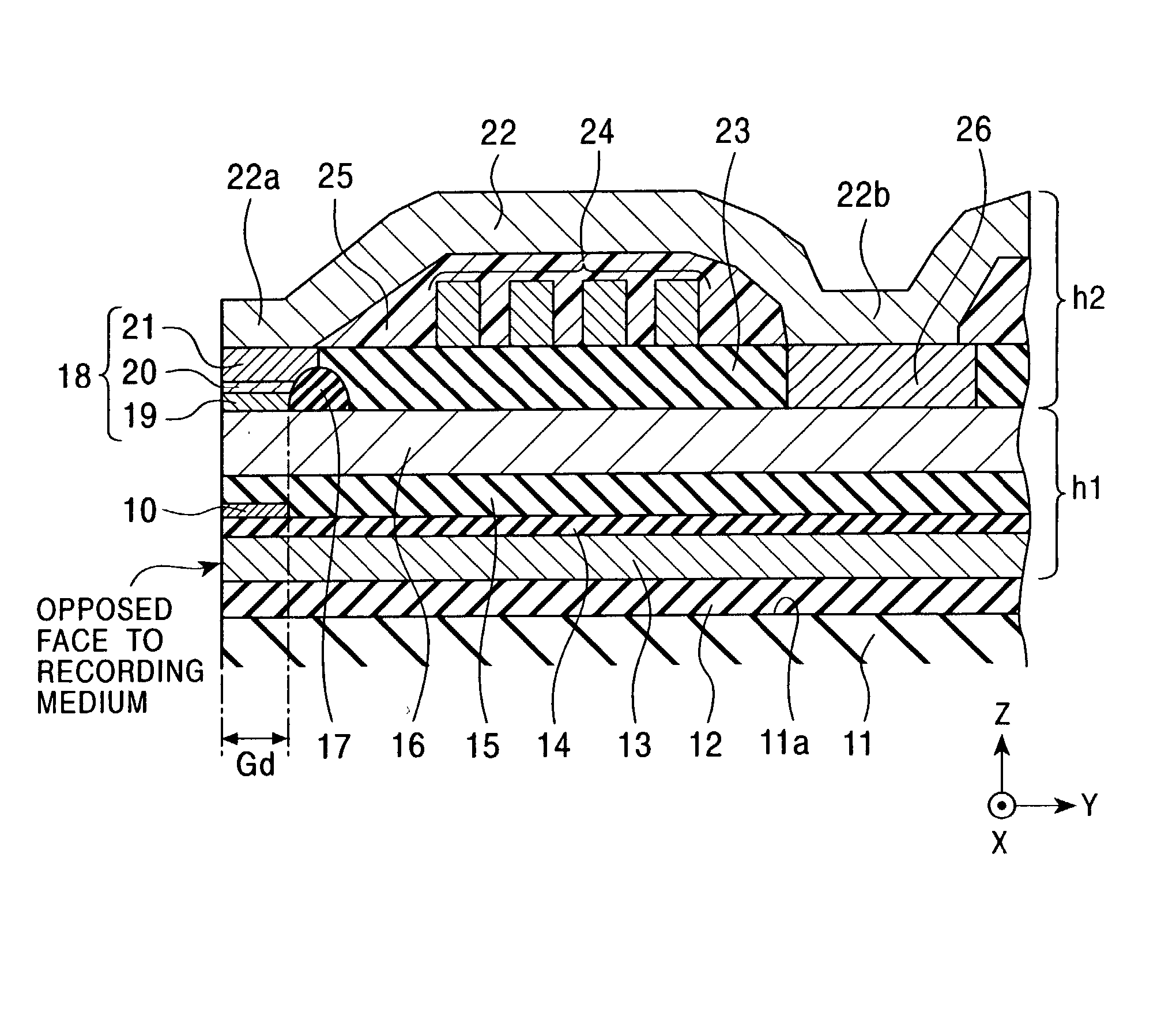

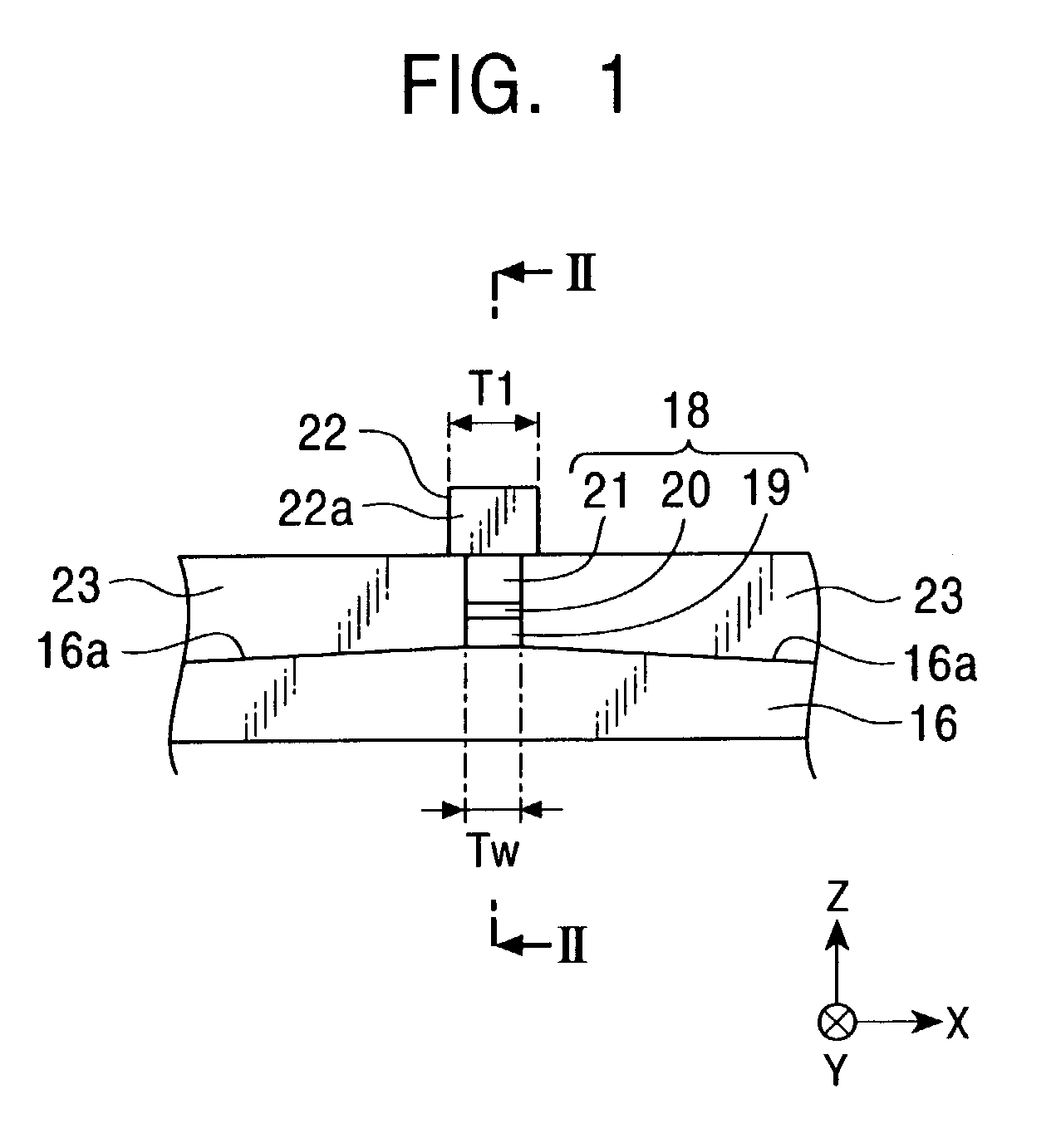

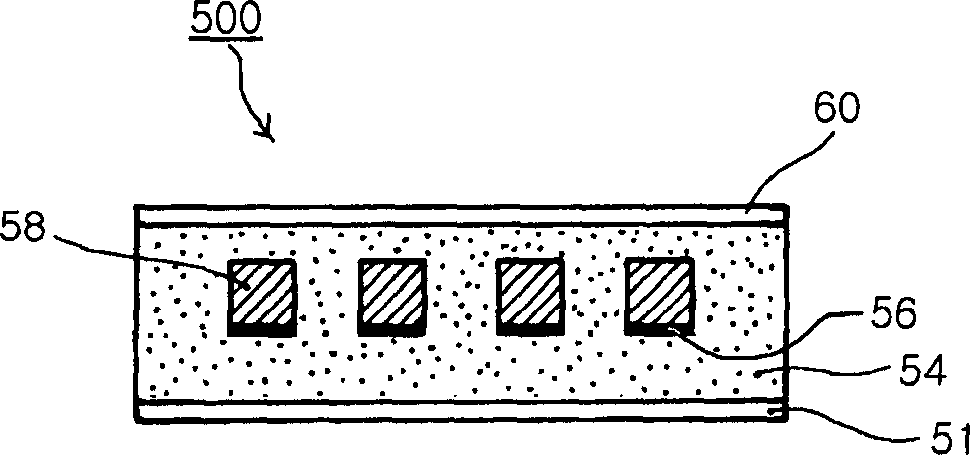

Magnetic device and solid-state magnetic memory

A magnetic device which has a layer having pores on a substrate and is to be used by applying electric current in the direction of depth of the pores includes a laminated structure in which a first ferromagnetic layer, a second ferromagnetic layer having a smaller coercive force than the first ferromagnetic layer and a non-magnetic layer are laminated within a part or all of the pores, wherein a hard layer having the first ferromagnetic layer, and a free ferromagnetic layer including the second ferromagnetic layer are laminated through the non-magnetic layer, and the hard layer further has a laminated structure in which a plurality of first ferromagnetic layers form antiferromagnetic coupling through the non-magnetic layer. A solid-state magnetic memory has the magnetic device.

Owner:CANON KK

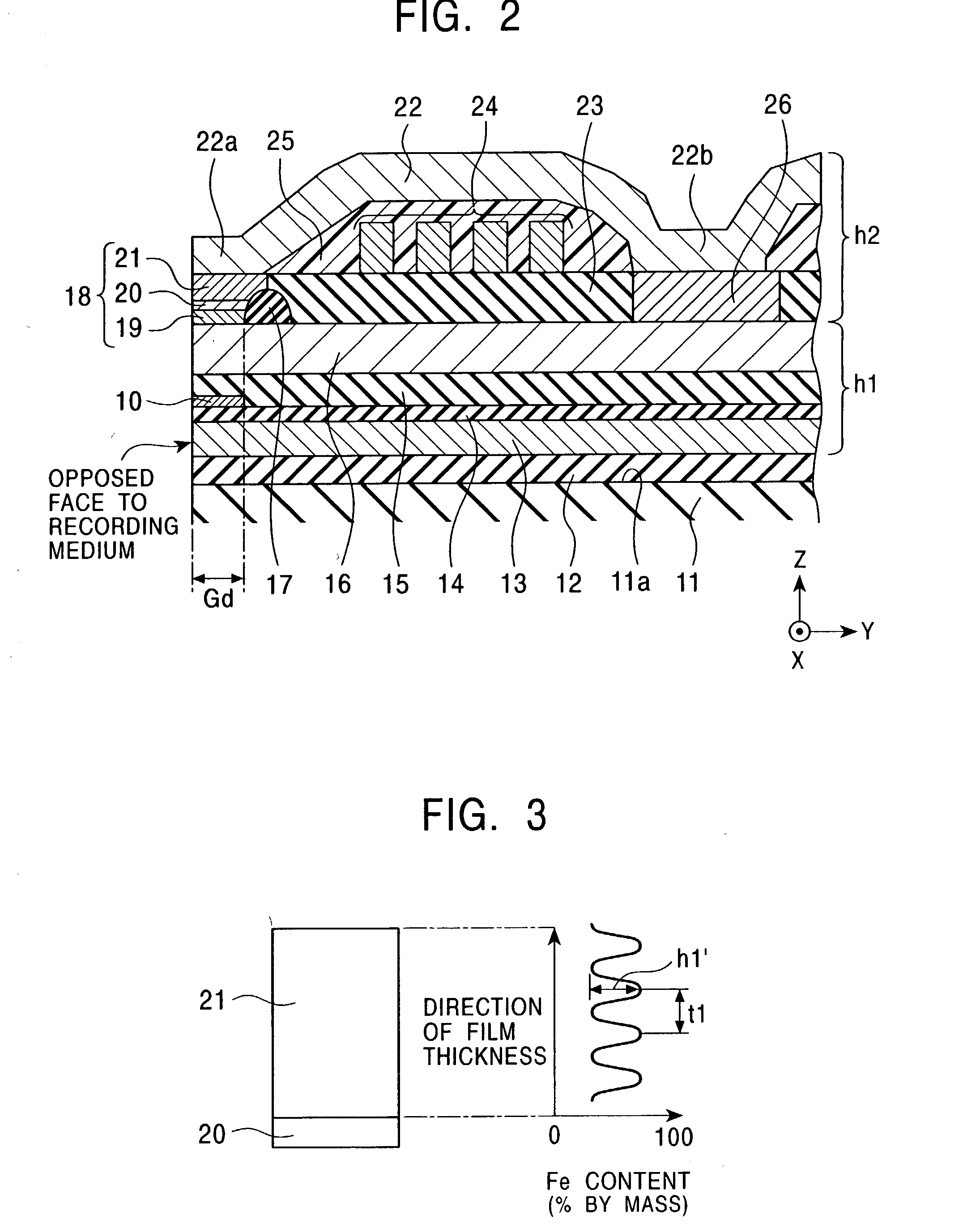

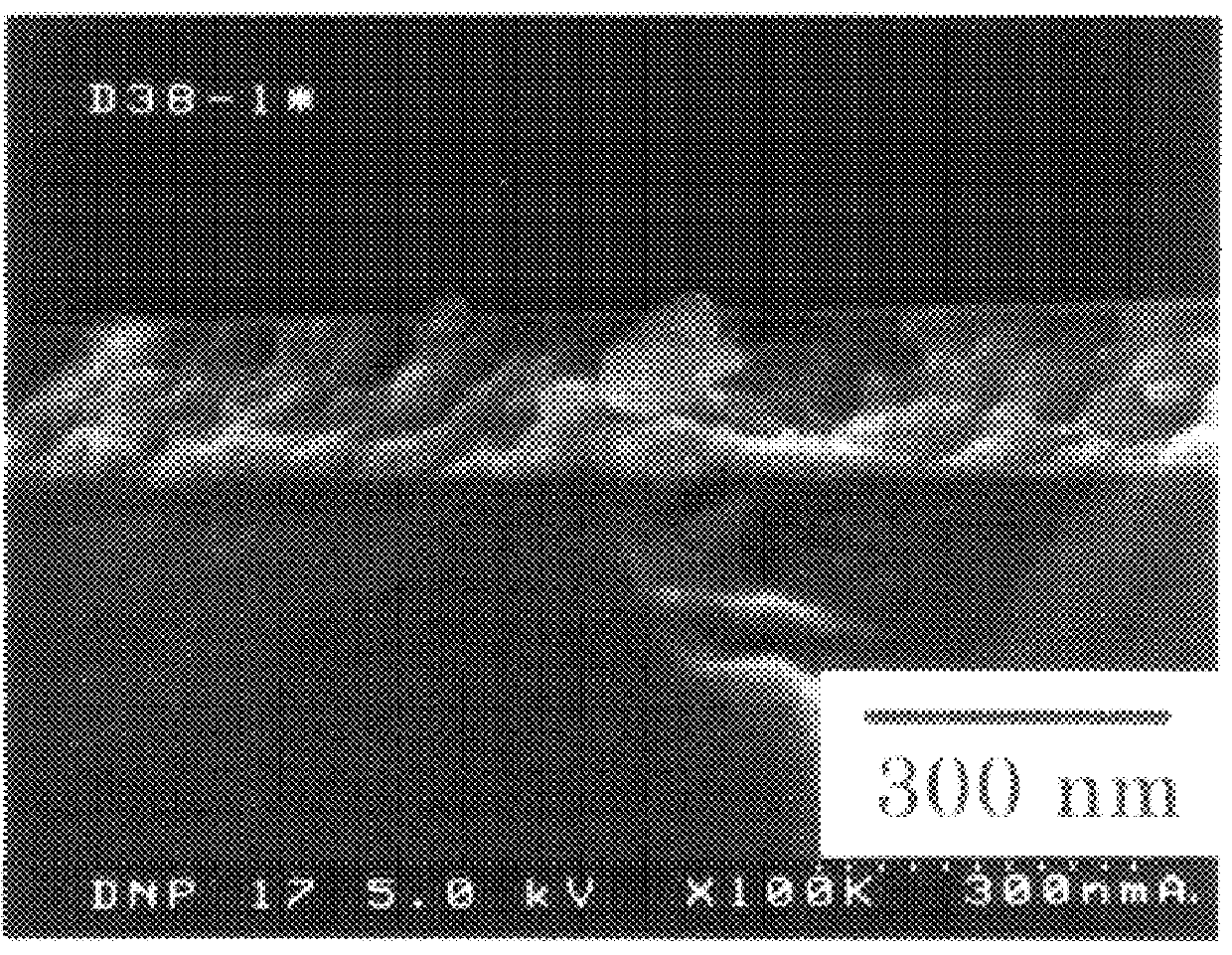

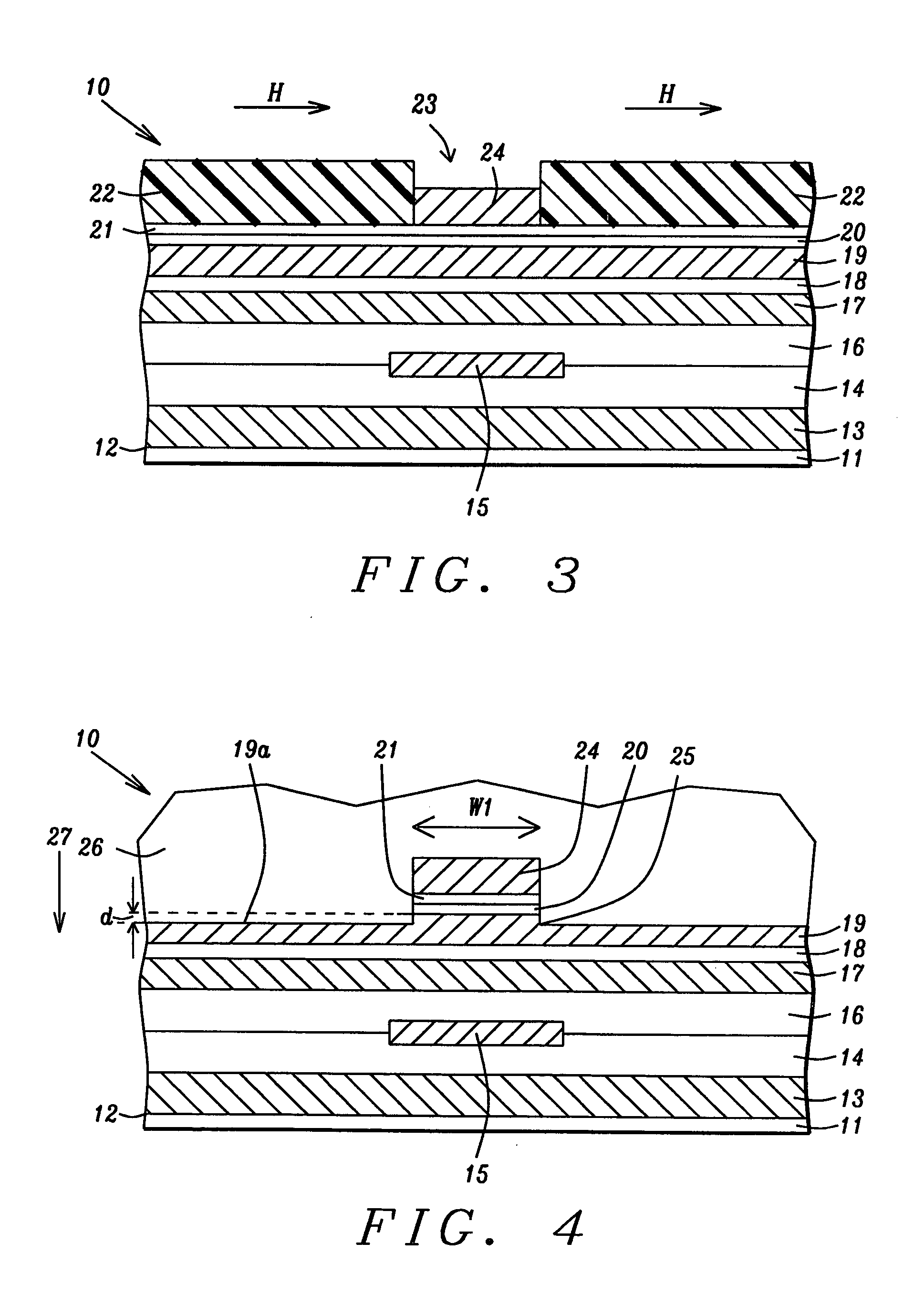

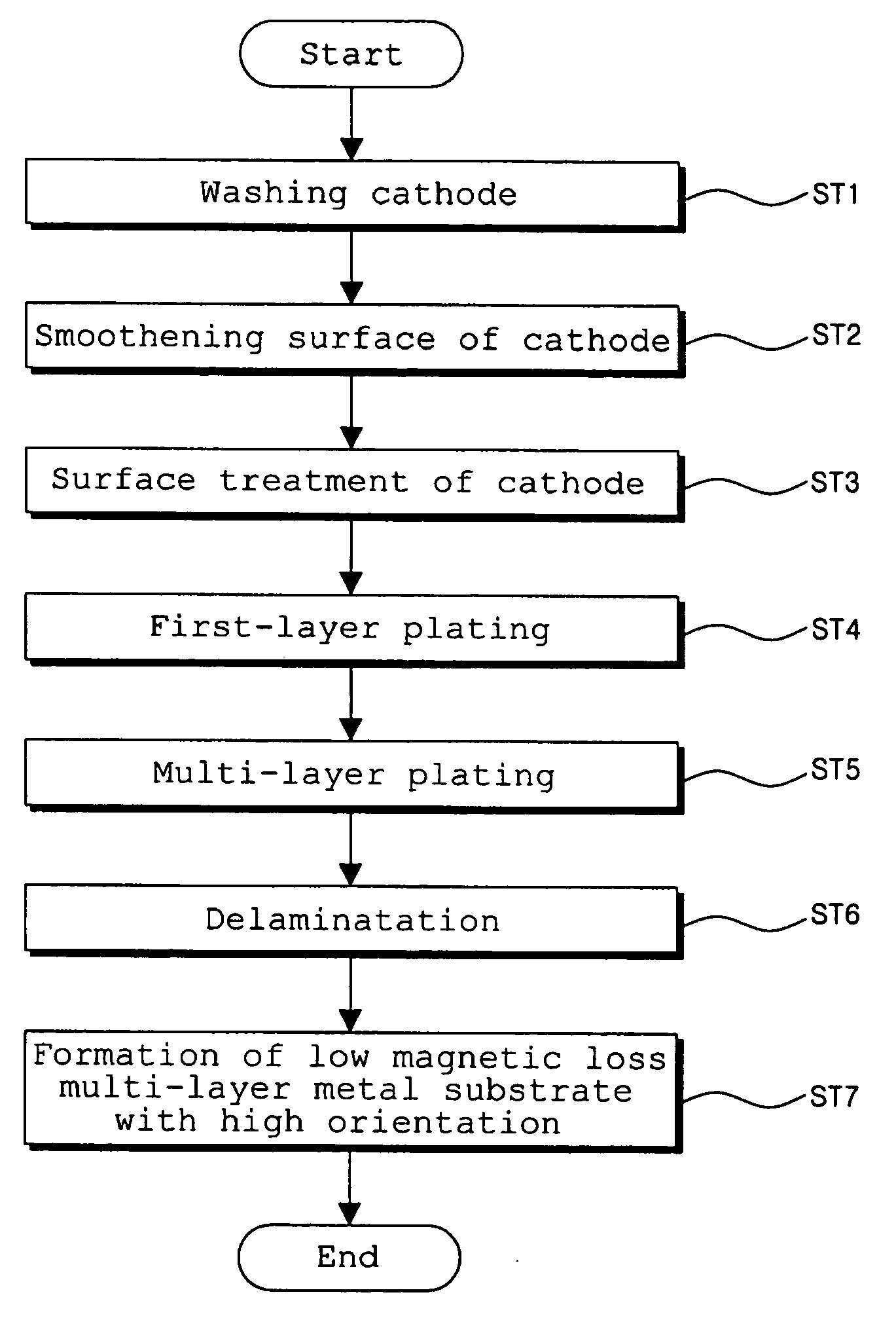

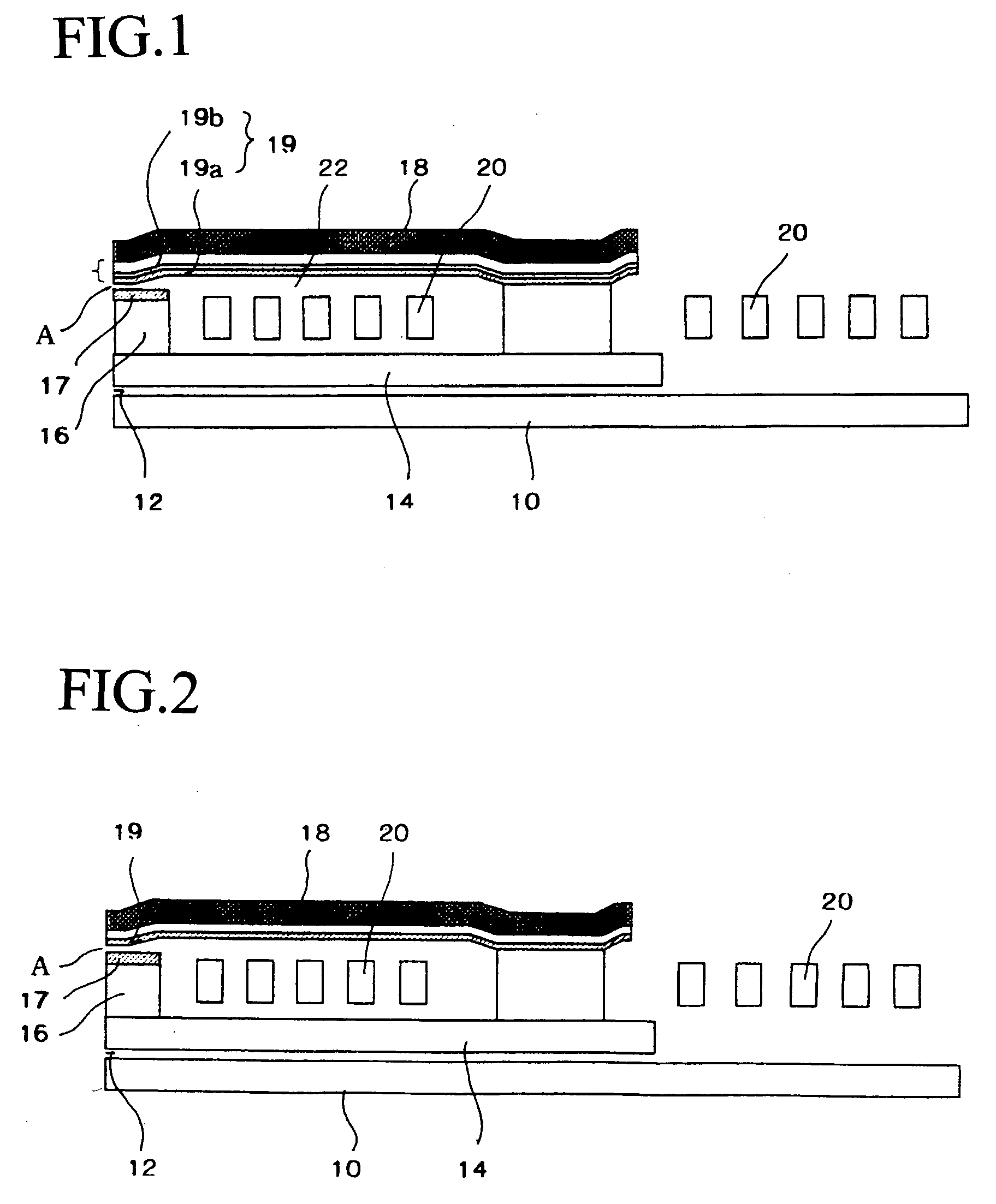

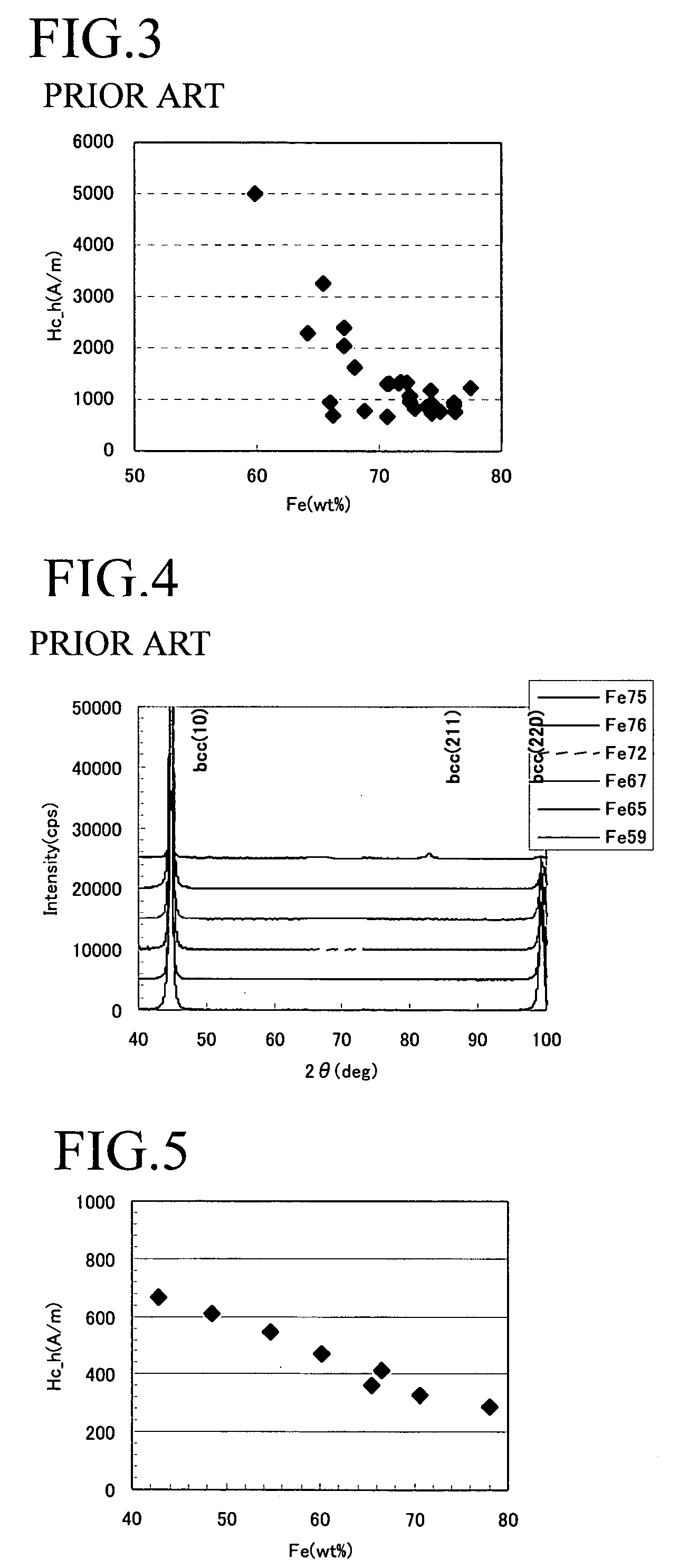

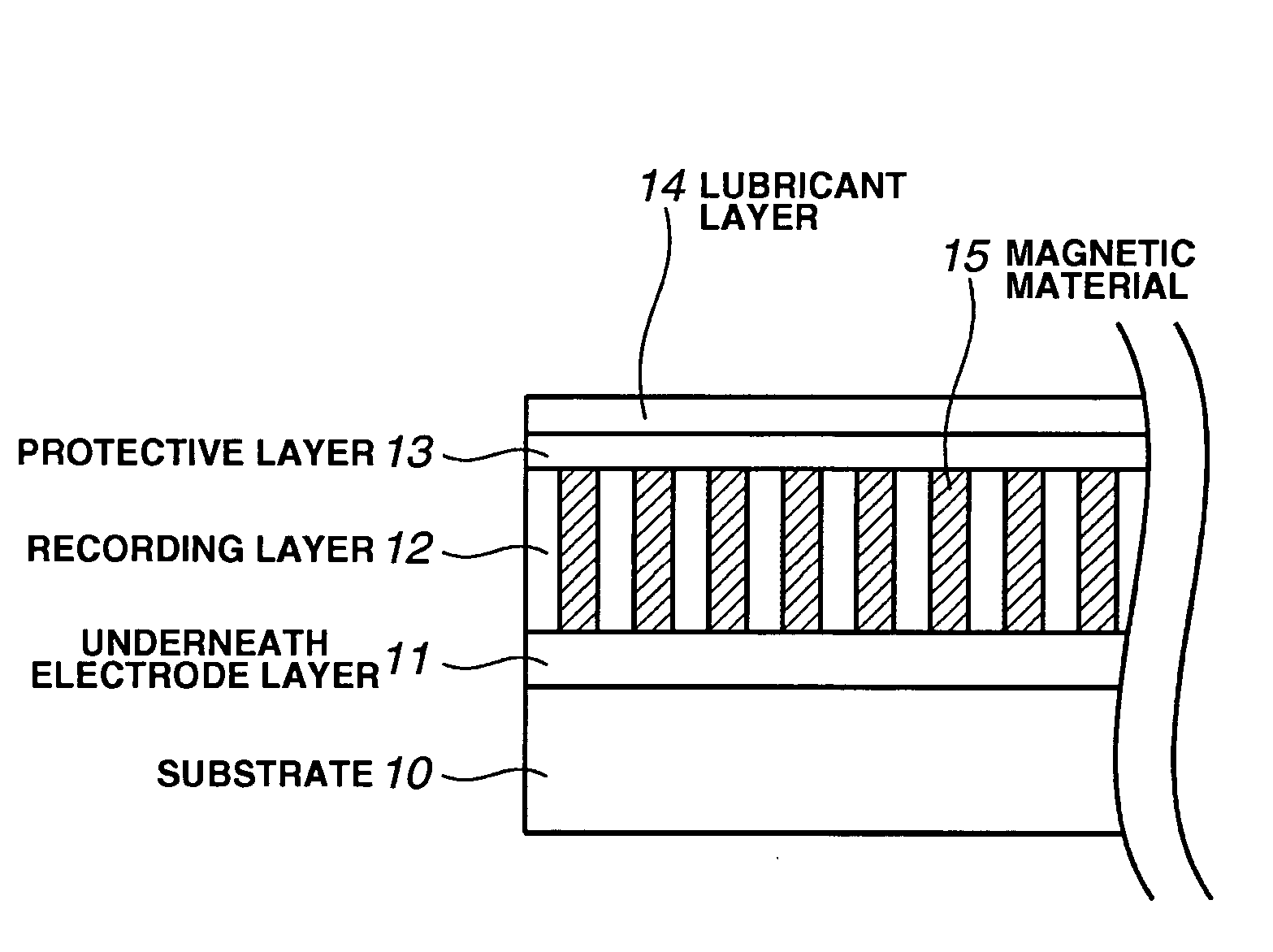

Soft magnetic film and thin film magnetic head using soft magnetic film, process for manufacturing soft magnetic film and process for manufacturing thin film magnetic head

ActiveUS20030048582A1Low coercivityHigh magnetic flux densityNanomagnetismMagnetic measurementsChemical compositionHigh density

The upper magnetic pole layer and / or lower magnetic pole layer comprises a soft magnetic film having a variable region in which the chemical composition of Fe changes in the direction of thickness in at least a part thereof, and the difference of the proportions of Fe between the regions most abundant in Fe and most deficient in Fe is 4% by mass or more in the variable region. The structure of the soft magnetic film permits the saturation magnetic flux density Bs to be improved while decreasing the coercive force Hc by forming fine crystal grains, thereby enabling a thin film magnetic head excellent in high density recording to be manufactured.

Owner:TDK CORPARATION

Metal complex solution, photosensitive metal complex solution, and method for forming metallic oxide films

InactiveUS6387012B1Reduce resolutionLower resistanceRadiation applicationsLiquid applicationOrganic acidOrganic solvent

A metal complex solution comprising an organic solvent, and a complex composed of an organic acid salt of at least one metal and an organic amine or organic ketone compound, dissolved in the organic solvent; a photosensitive metal complex solution comprising the metal complex solution, and a photosensitive resin added to the solution; and a method for forming metallic oxide films, using these solutions.

Owner:DAI NIPPON PRINTING CO LTD

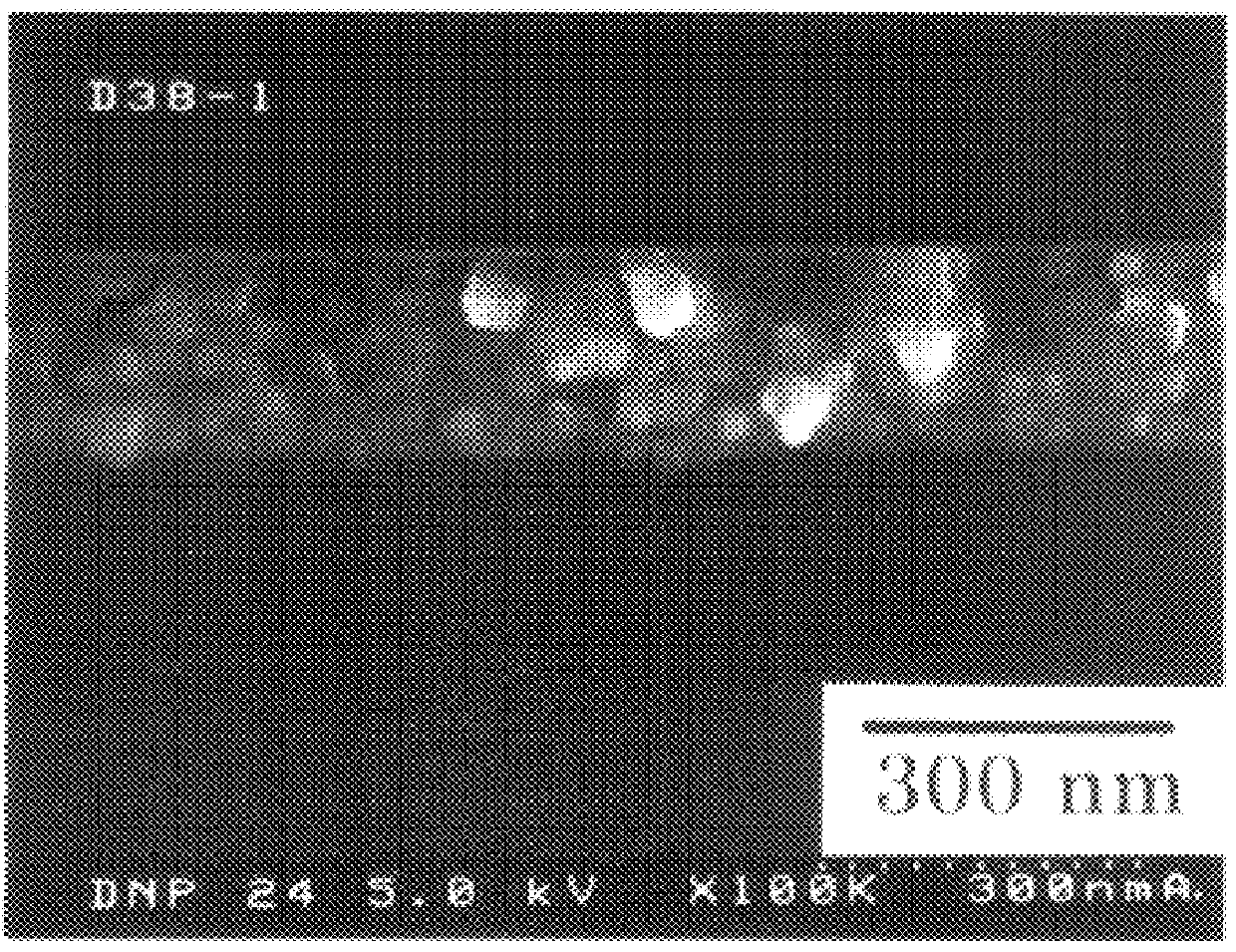

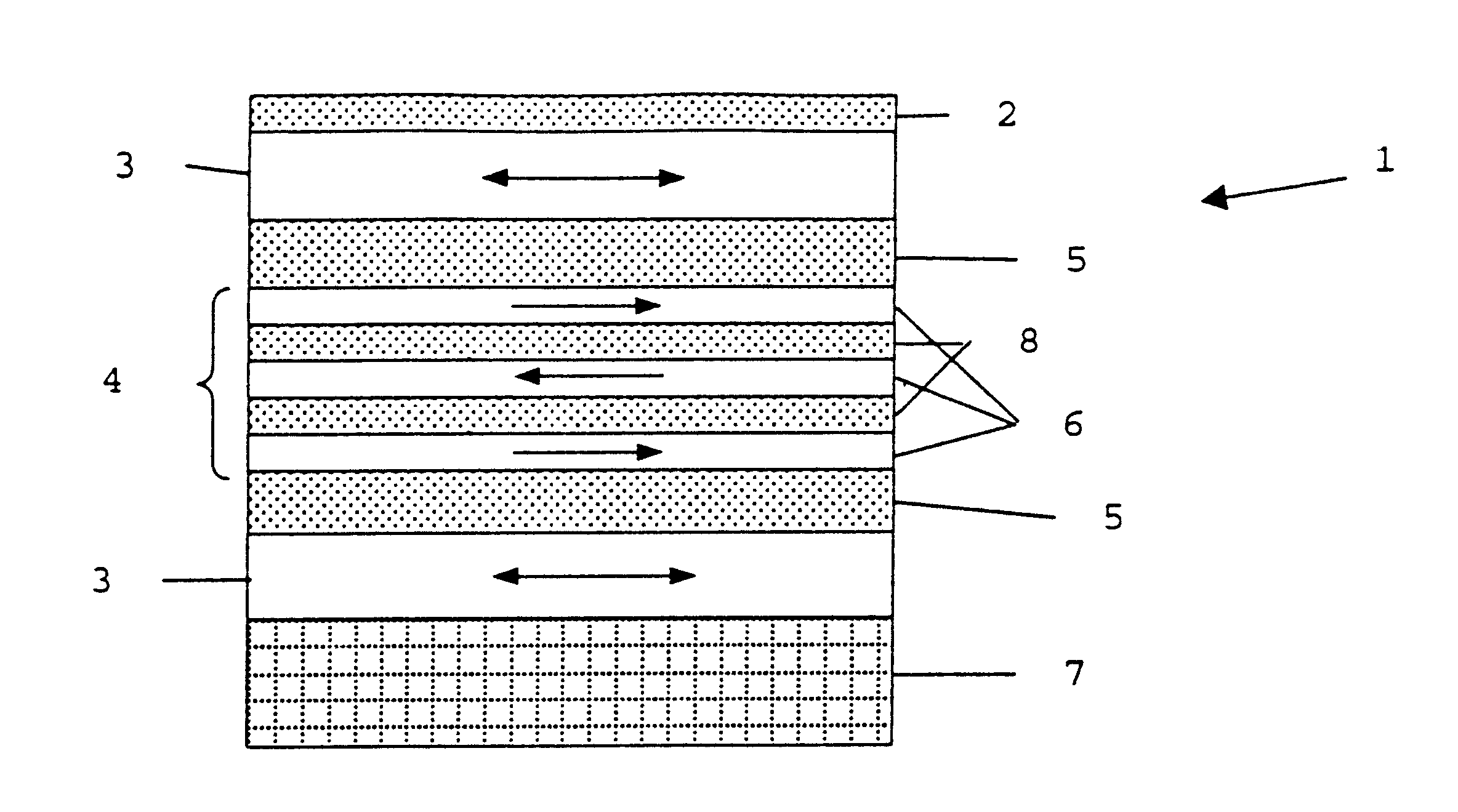

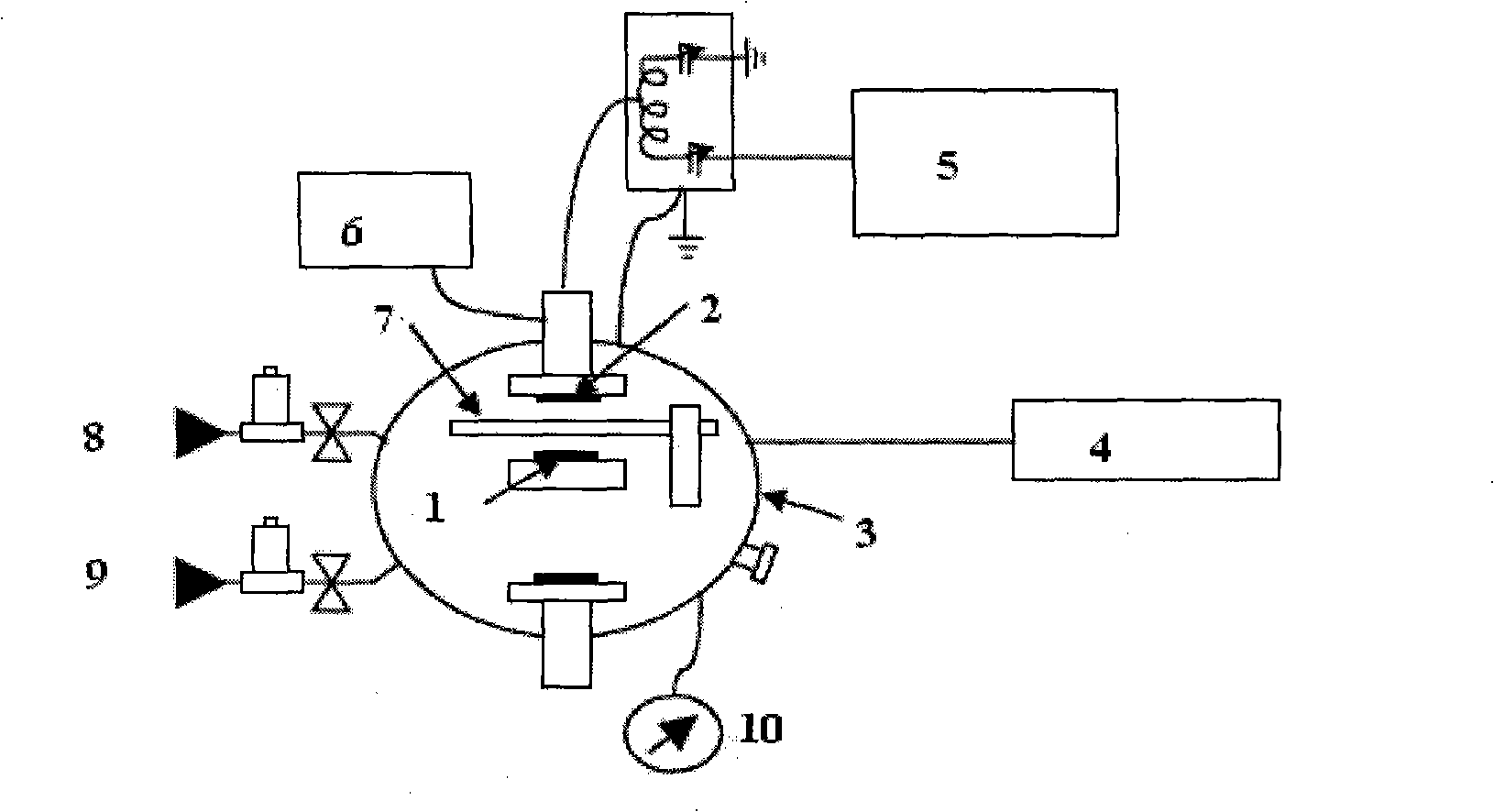

Formation of nanostructures comprising compositionally modulated ferromagnetic layers by pulsed ecd

The present invention is related to a method for forming a structure that contains alternating first and second ferromagnetic layers of different material compositions. A substrate containing a supporting matrix with at least one open pore and a conductive base layer is first formed. Electroplating of the substrate is then carried out in an electroplating solution that contains at least one ferromagnetic metal element and one or more additional, different metal elements. A pulsed current with alternating high and low potentials is applied to the conductive base layer of the substrate structure to thereby form alternating ferromagnetic layers of different material compositions in the open pore of the supporting matrix.

Owner:GLOBALFOUNDRIES US INC

CoFe alloy film and process of making same

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

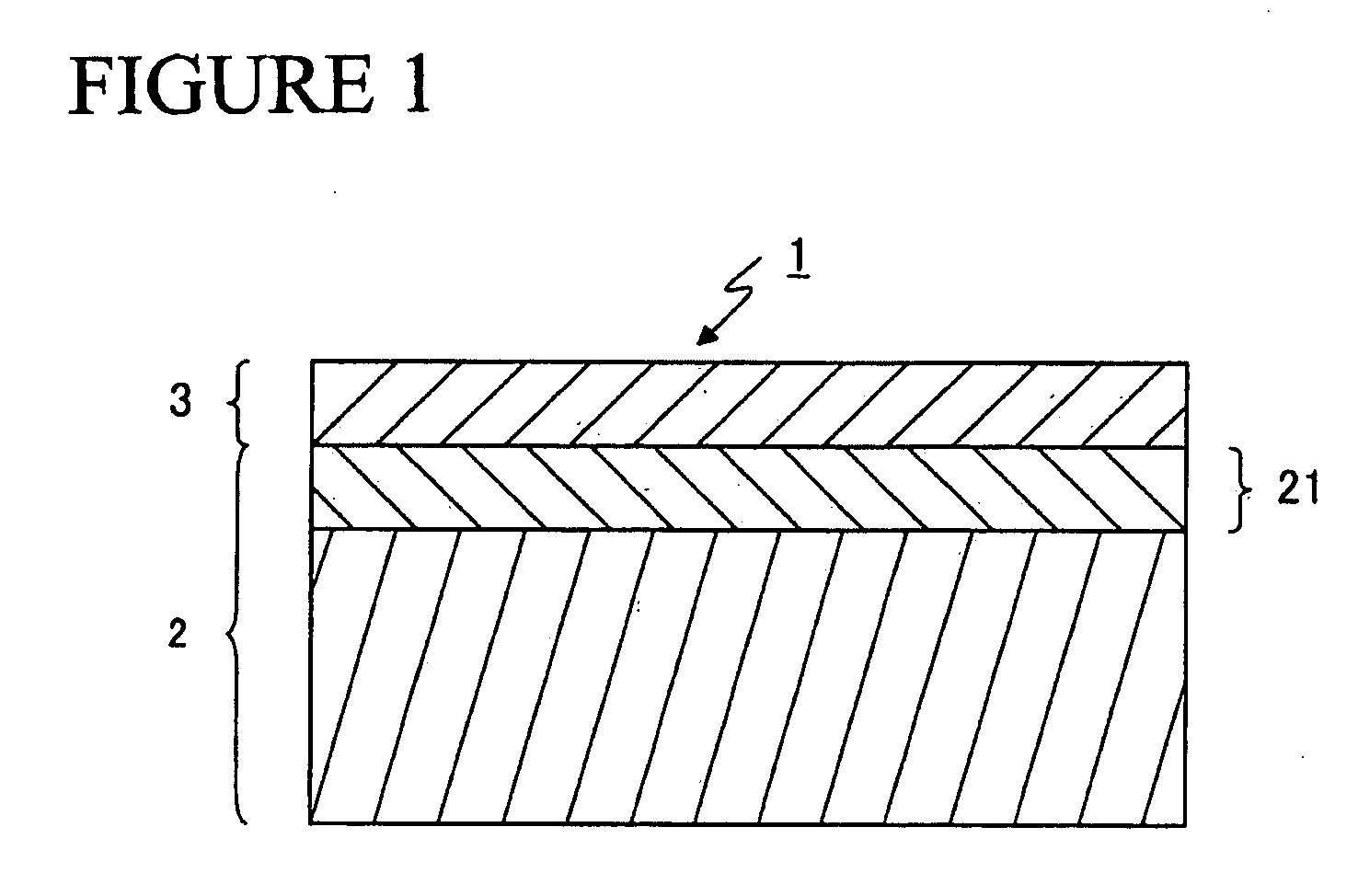

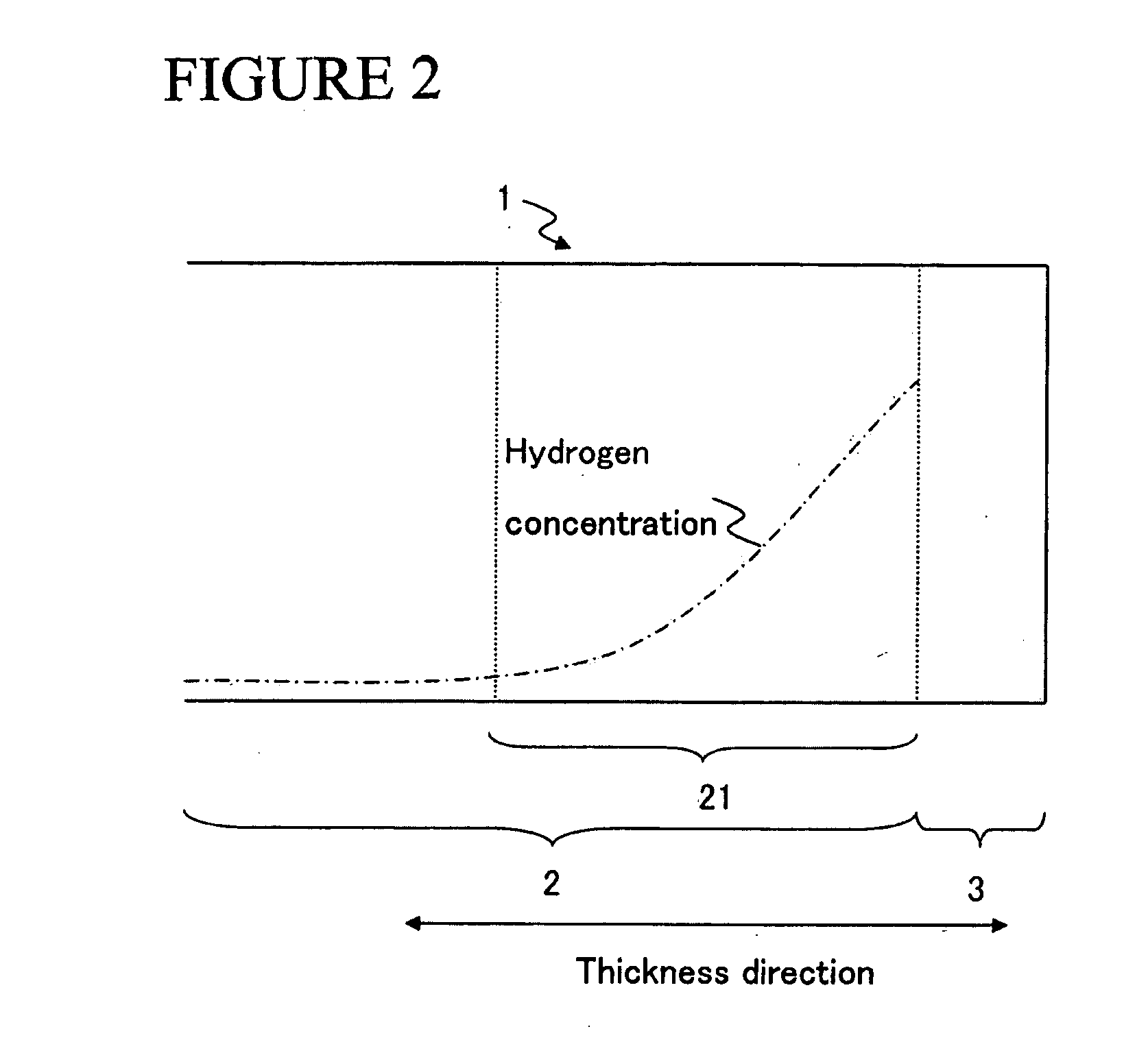

R-t-b system permanent magnet

ActiveUS20070102069A1Improve corrosion resistanceCollapse of partLiquid applicationMagnetic materialsRare-earth elementHydrogen concentration

An R-T-B system permanent magnet 1 comprises a magnet body 2 comprising a sintered body comprising at least a main phase comprising R2T14B grains (wherein R represents one or more rare earth elements, and T represents one or more transition metal elements including Fe or Fe and Co essentially) and a grain boundary phase containing R in a larger amount than the main phase, the magnet body 2 having a 300 μm or less thick (not inclusive of zero thick) hydrogen-rich layer 21 having a hydrogen concentration of 300 ppm or more formed in the surface layer portion, and an overcoat 3 covering the surface of the magnet body 2 can improve the corrosion resistance of the R-T-B system permanent magnet 1 with an overcoat 3 formed thereon without degrading the magnetic properties thereof. The present invention can be applied to formation of the overcoat 3 by electrolytic plating, can fully ensure the corrosion resistance as a primary target of the overcoat 3 formation without substantially degrading the production efficiency, and can provide the R-T-B system permanent magnet 1 with a high dimensional precision by suppressing the partial collapse (detachment of grains) of the surface thereof.

Owner:TDK CORPARATION

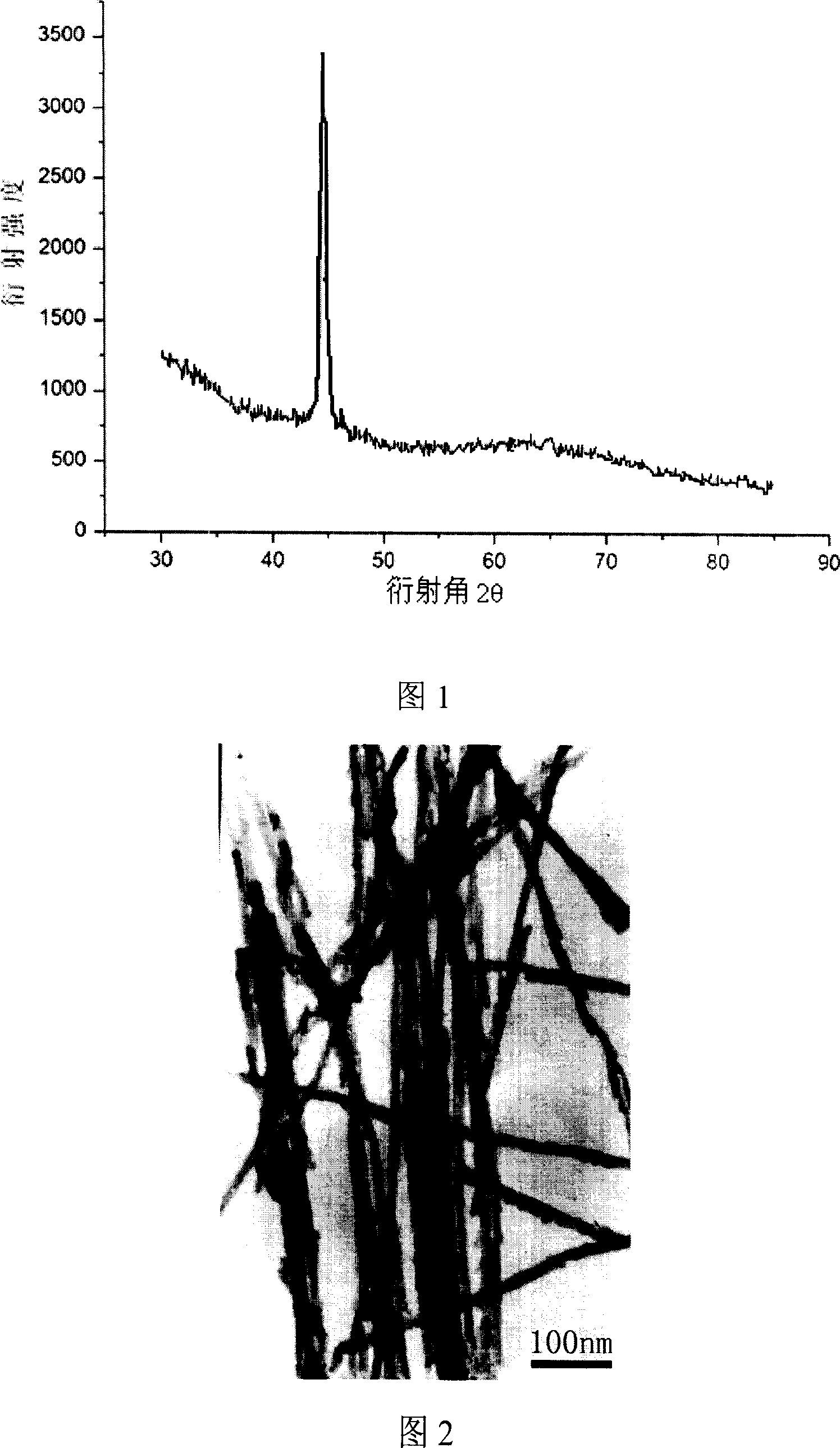

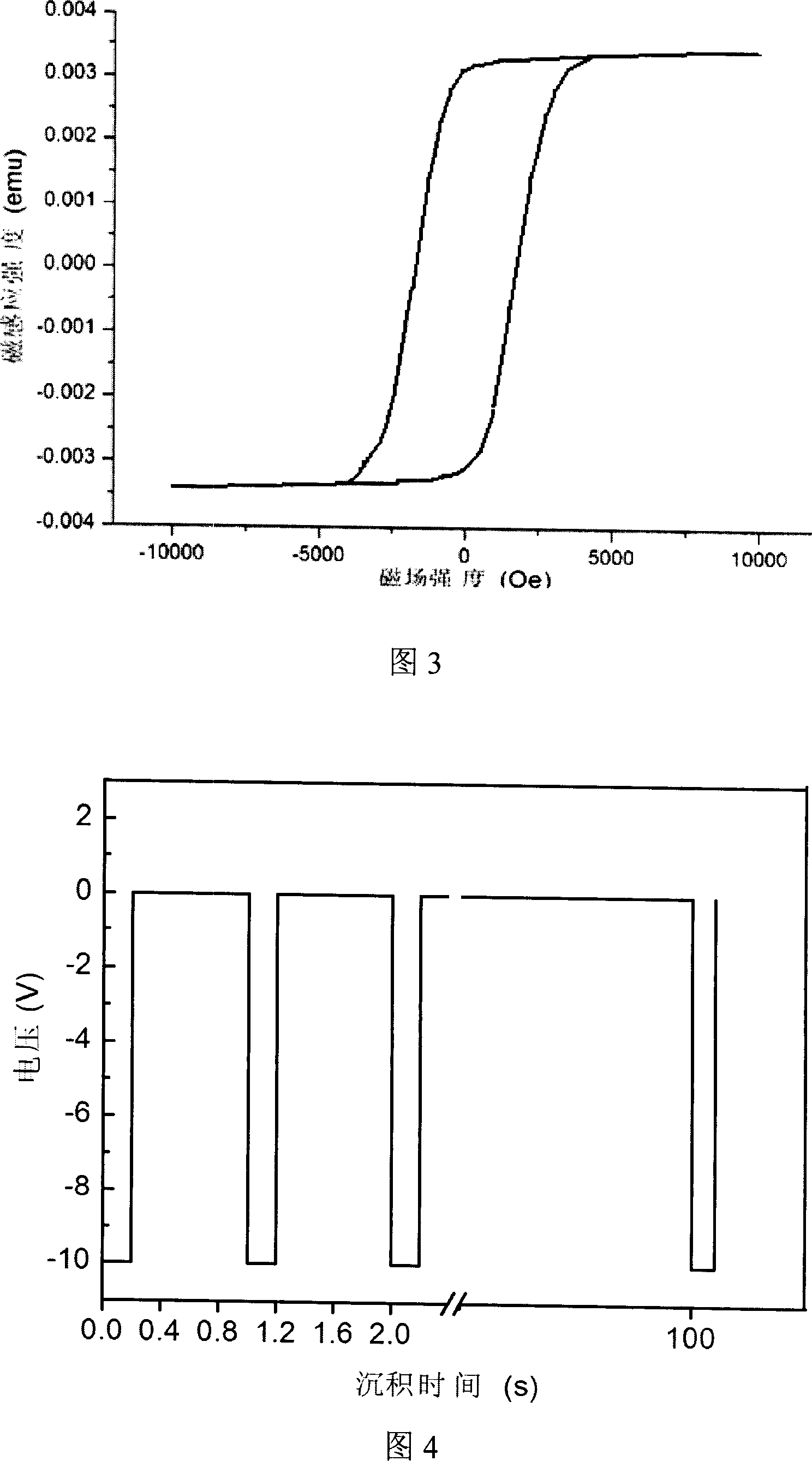

Method of preparing high square ratio magnetic one-dimensional nano line array

InactiveCN101016650AImprove coercive forceTaking into account controllabilityPolycrystalline material growthLiquid applicationRemanenceLine array

The invention discloses a preparing method of high square ratio magnetic one-dimensional nanometer line array, which comprises the following steps: adopting source voltage of impulsion; proceeding electrical plating deposition for porous aluminum oxide mold with time at 5-50 h; getting the product; setting square ratio (remanence ratio) bigger than 90% and coercitive force at 500-2000Oe. This invention possesses simple operating course, which can increase the square ratio (remanence ratio) and coercitive force and controllability of nanometer line array growth.

Owner:EAST CHINA UNIV OF SCI & TECH

Spin-valve structure and method for making spin-valve structures

InactiveUS6721141B1Enhanced signalHigh sensitivityNanostructure applicationNanomagnetismSpin valveNuclear magnetic resonance

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

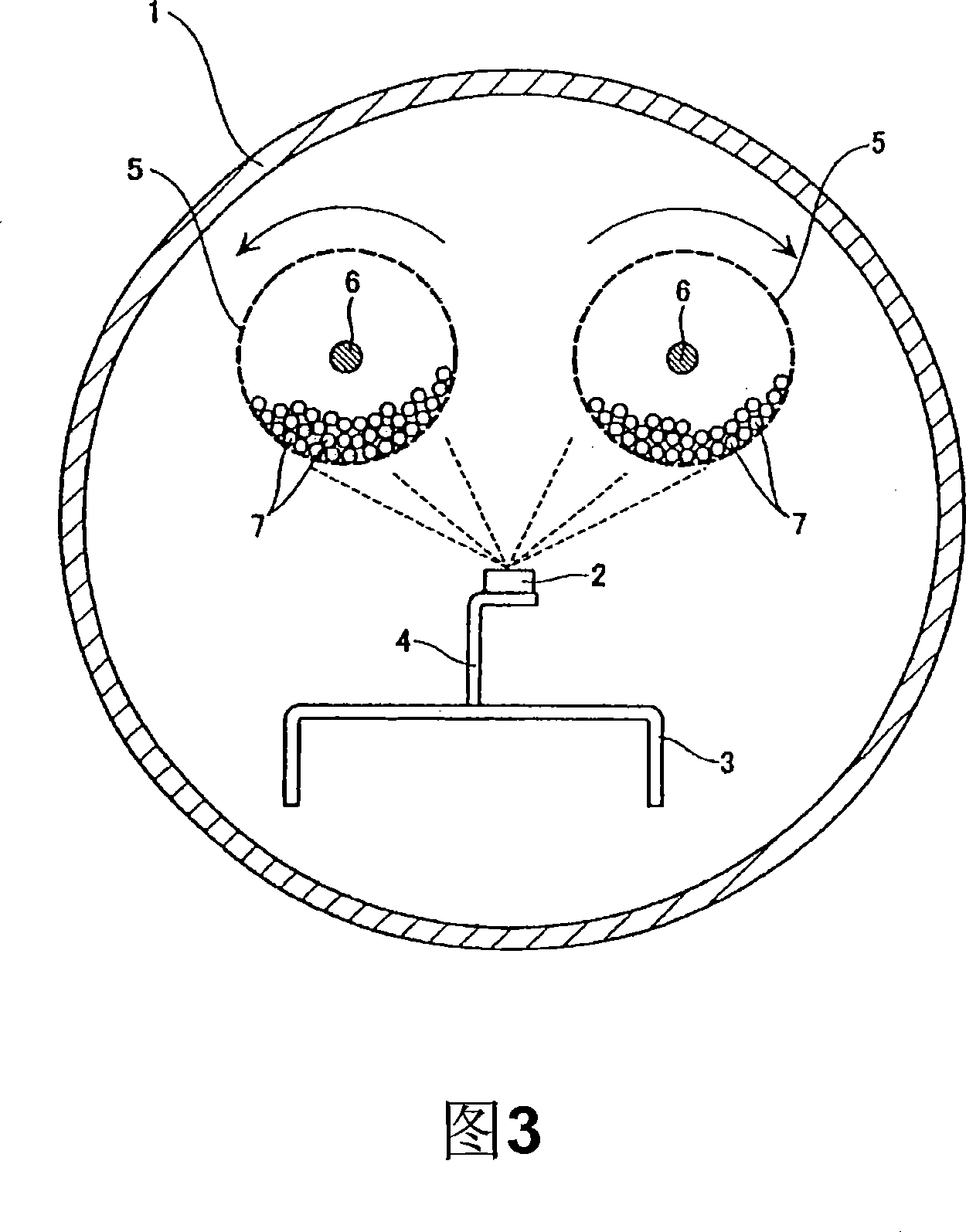

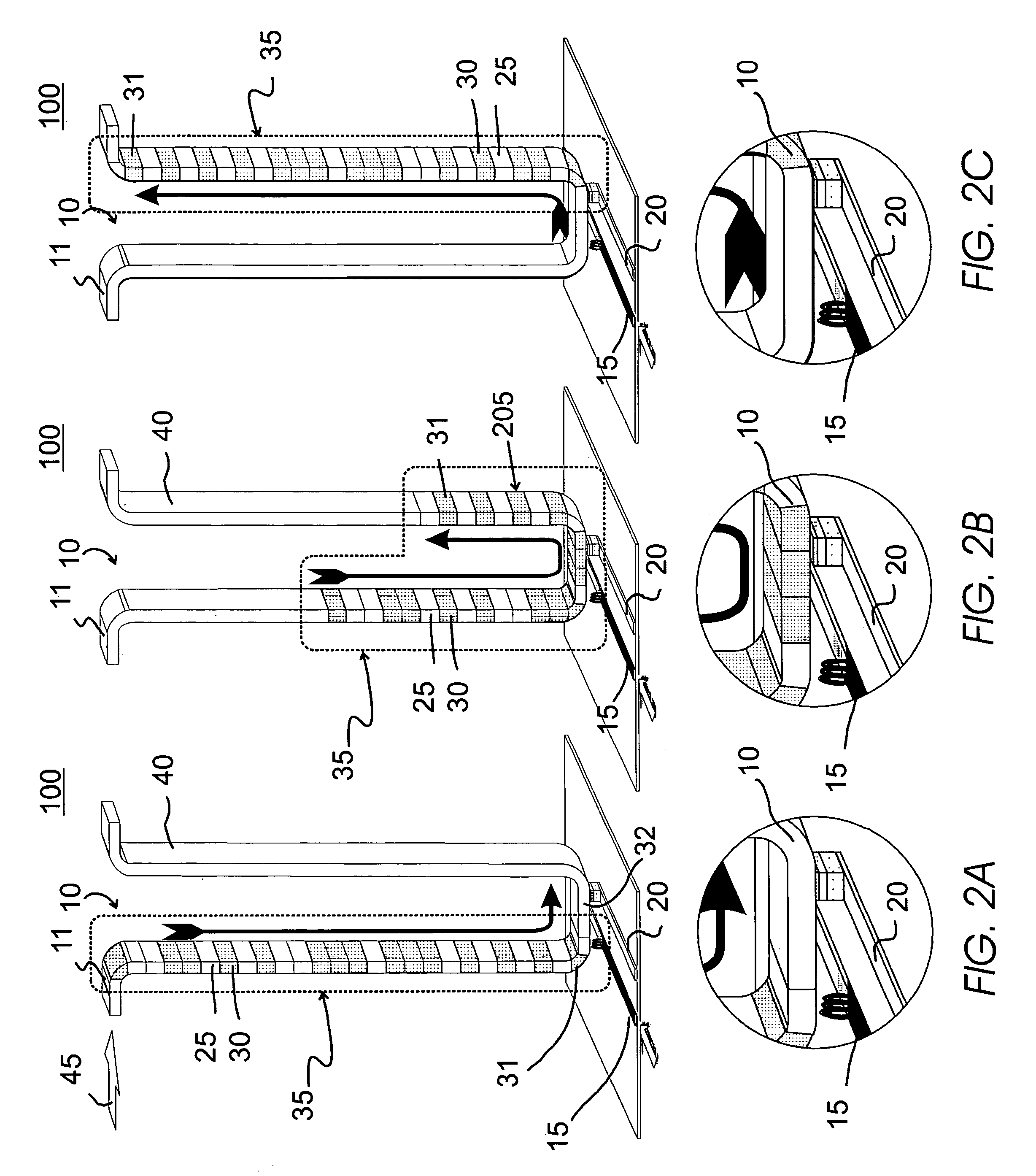

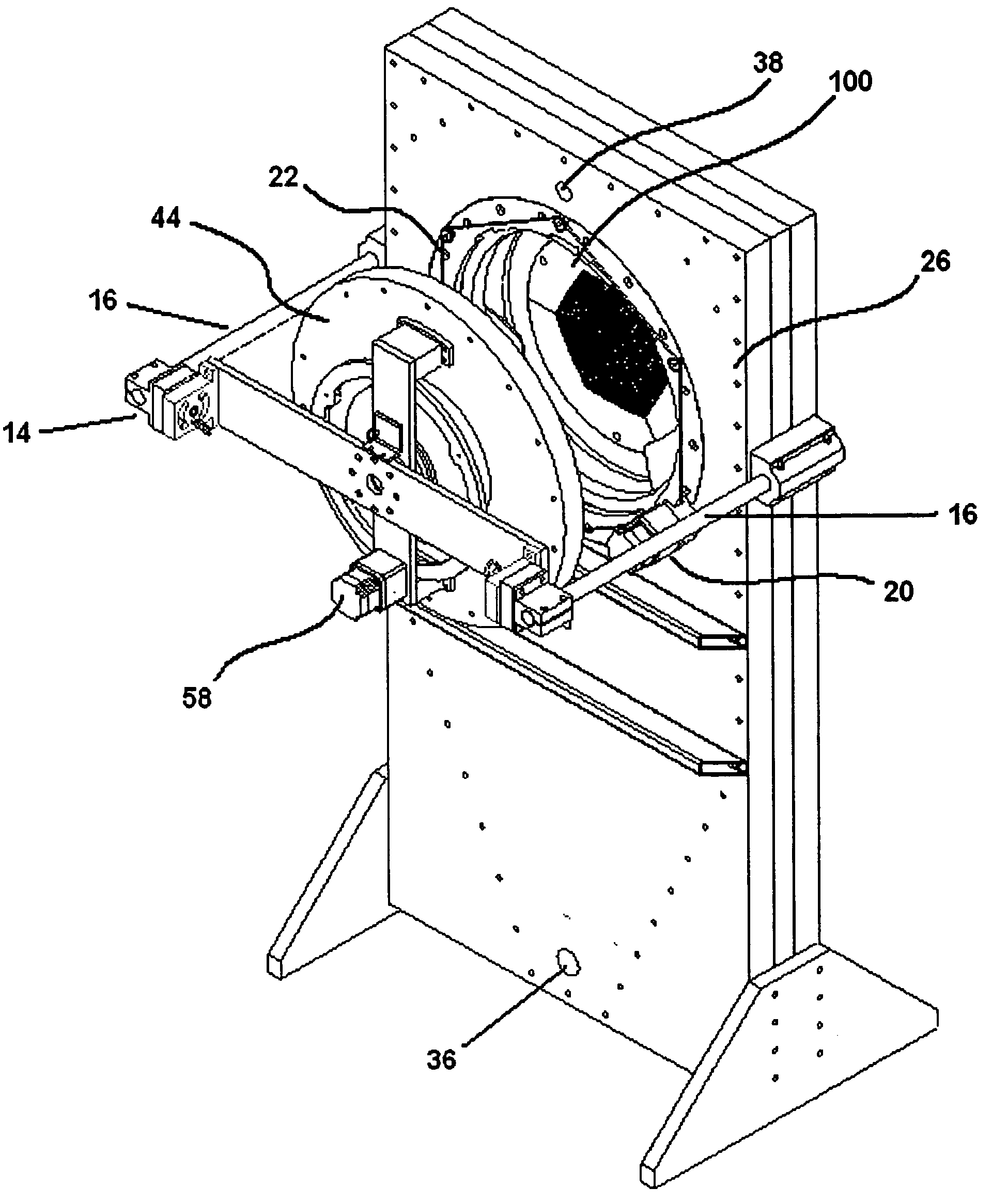

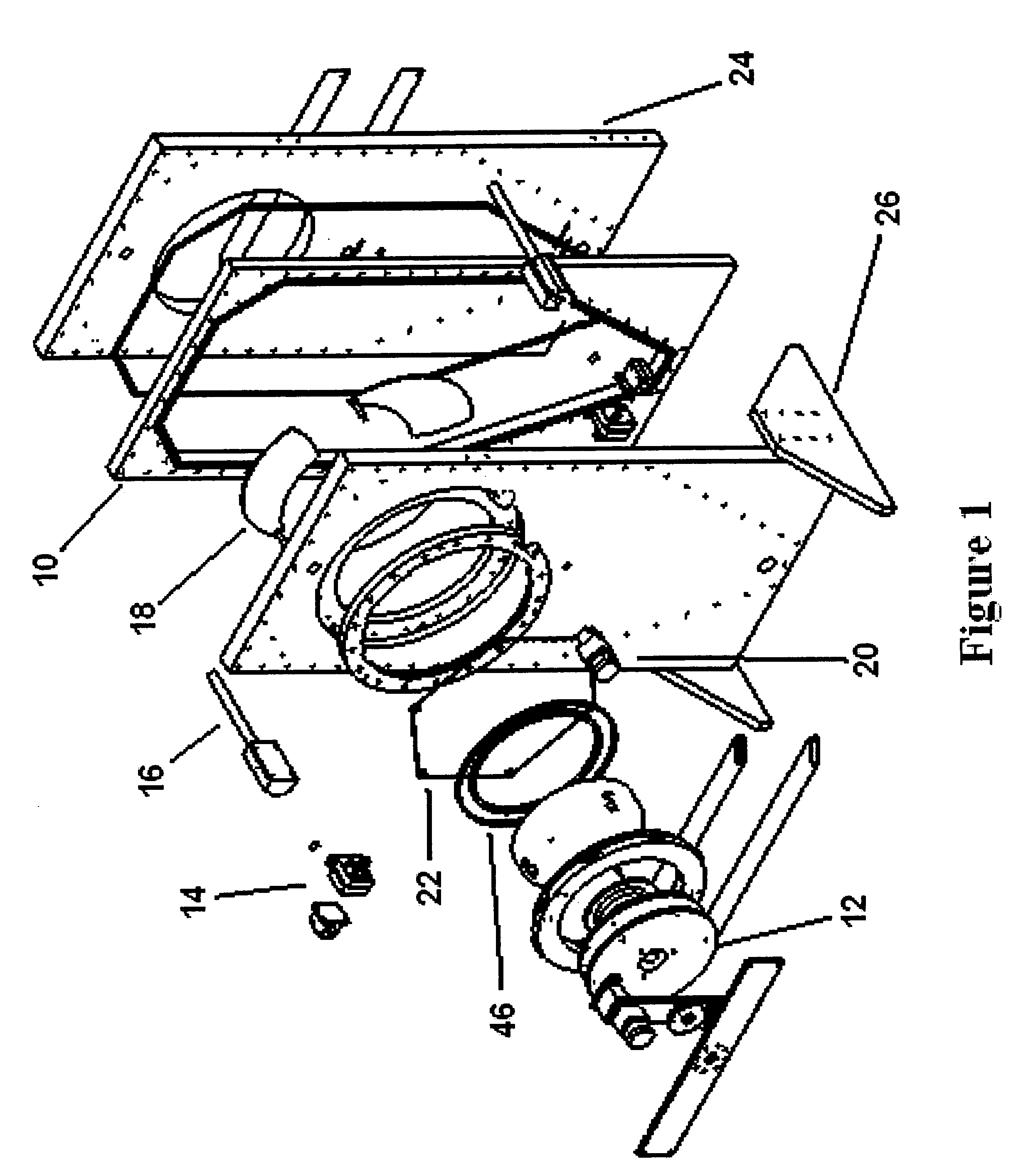

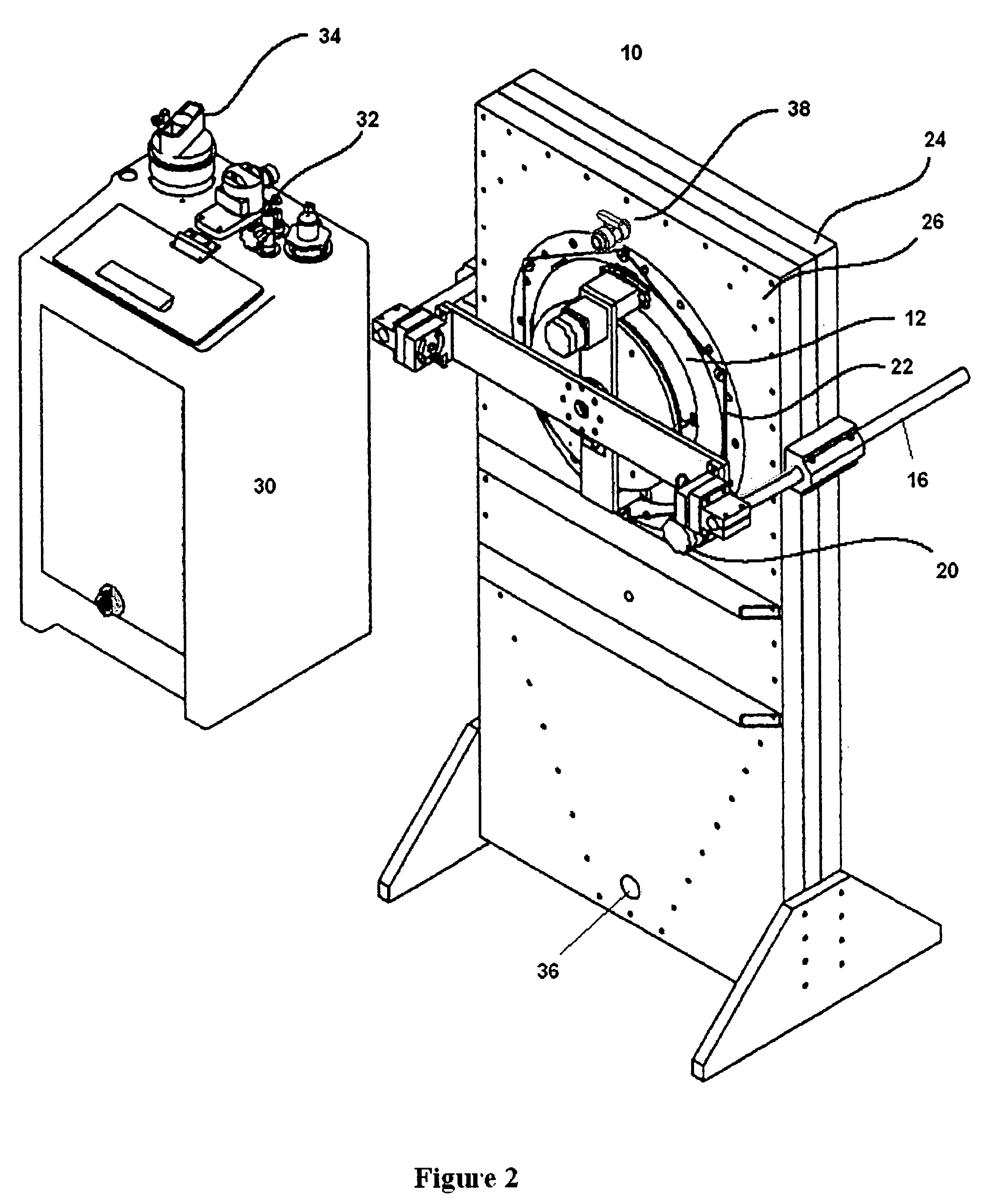

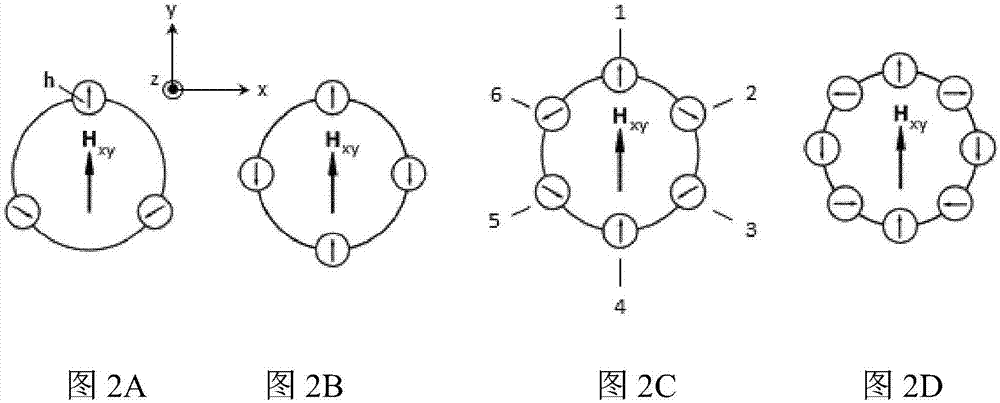

Devices and methods for orienting platelet-shaped magnetic or magnetizable pigment particles

The present invention relates to the field of devices and processes for producing optical effect layers (OEL) comprising magnetically bi-axially oriented platelet-shaped magnetic or magnetizable pigment particles, in particular for producing said OELs as anti-counterfeit means on security documents or security articles or for decorative purposes. The process described herein comprises the step of a) applying on a substrate surface a radiation curable coating composition comprising platelet-shaped magnetic or magnetizable pigment particles, b) exposing the radiation curable coating composition to a dynamic magnetic field of a magnetic assembly comprising a Halbach cylinder assembly, and c) at least partially curing the radiation curable coating composition of step b) so as to fix the platelet-shaped magnetic or magnetizable pigment particles in their adopted positions and orientations, said step c) being carried out partially simultaneously or simultaneously with step b).

Owner:SICPA HLDG SA

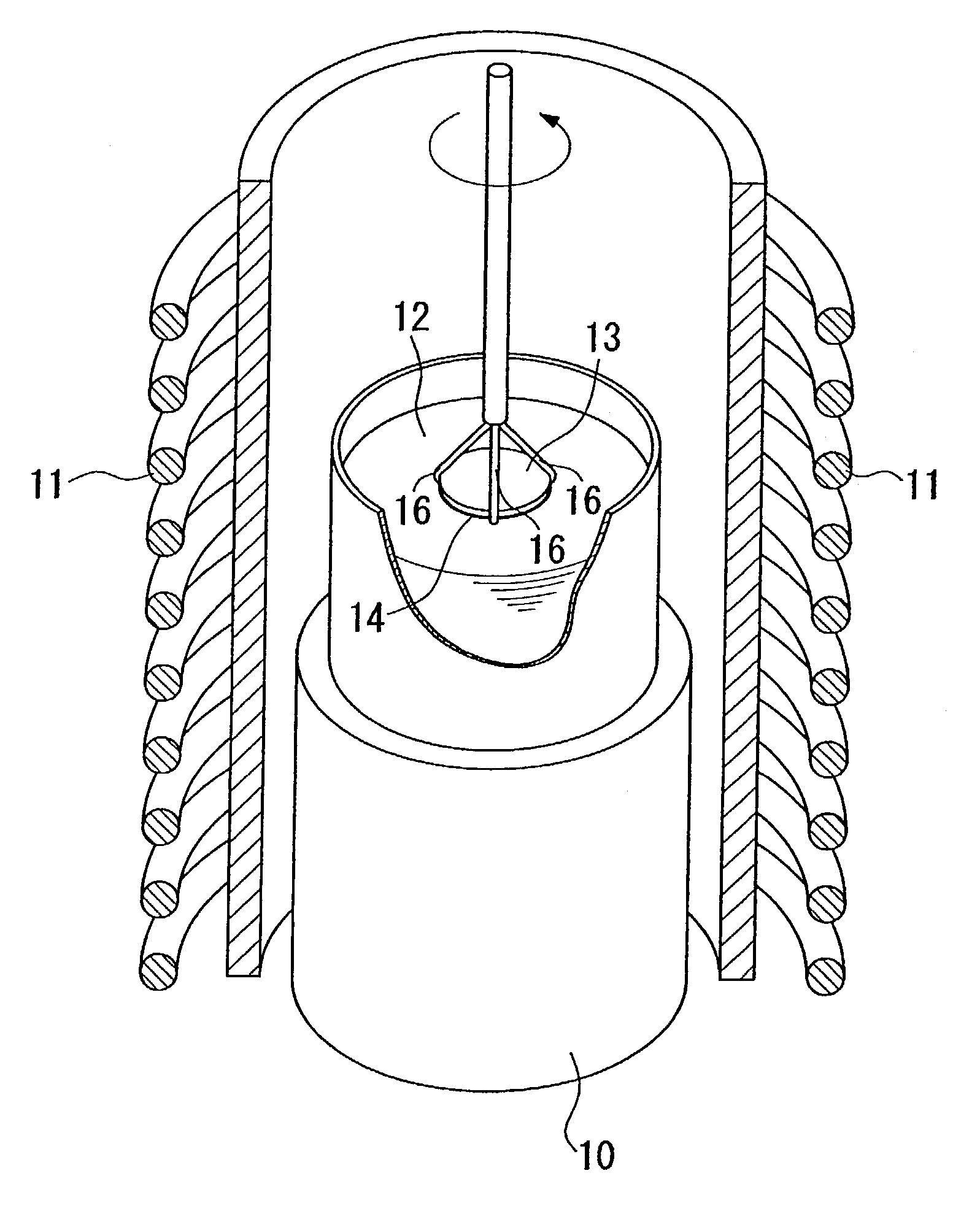

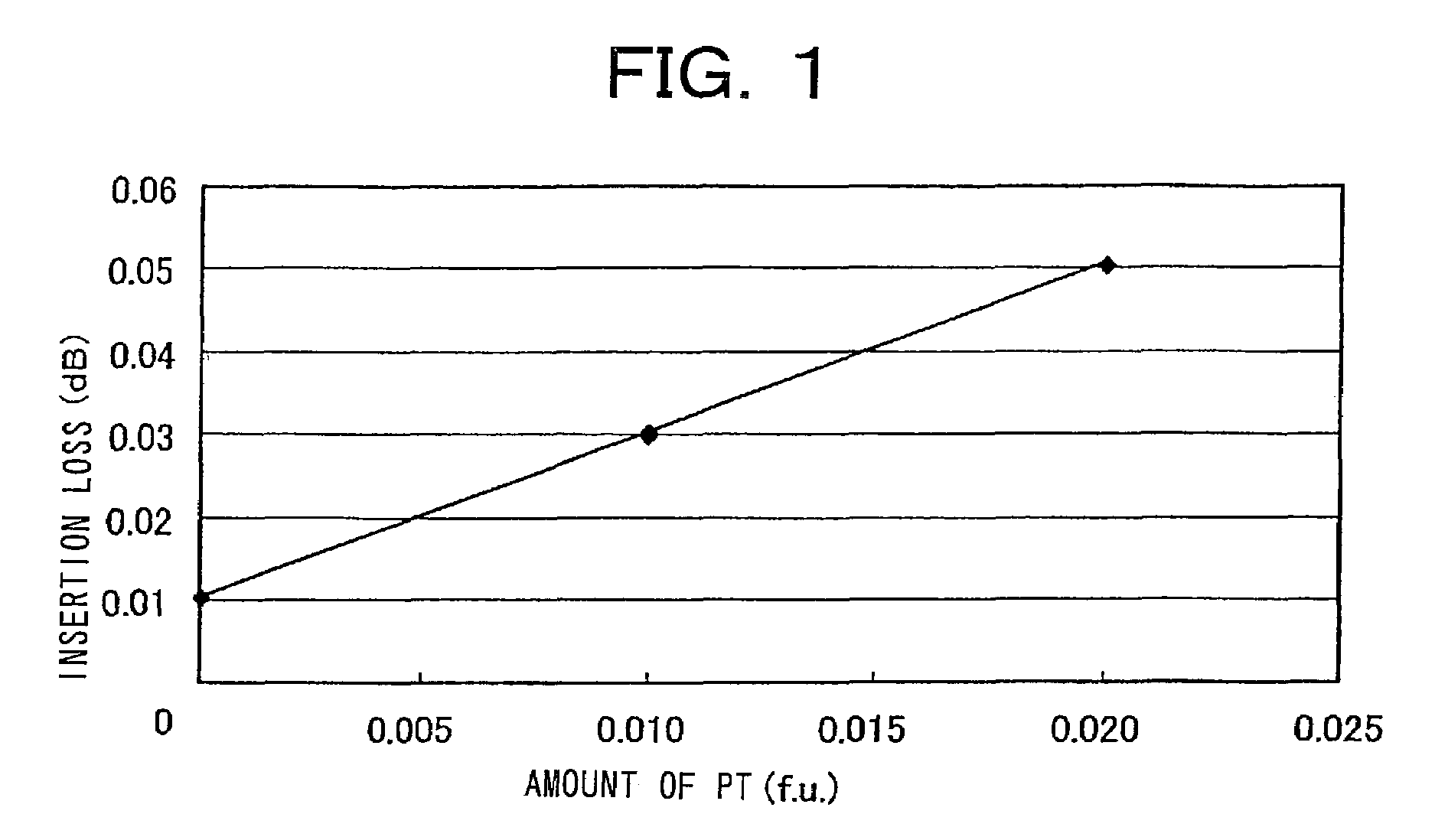

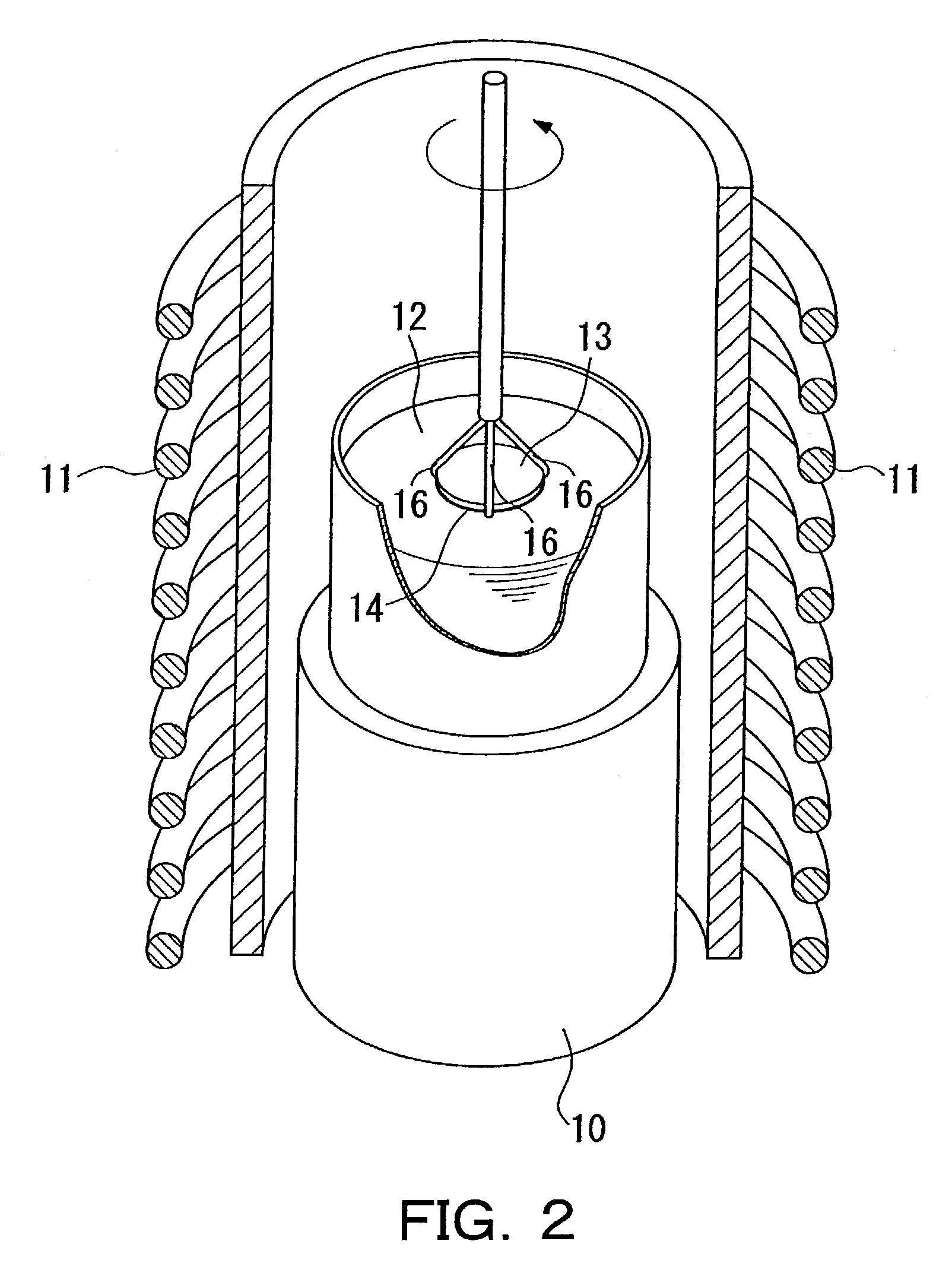

Magnetic garnet material, faraday rotator, optical device, bismuth-substituted rare earth-iron-garnet single-crystal film and method for producing the same and crucible for producing the same

ActiveUS7133189B2Excellent magnetic propertiesReduced insertion lossPolycrystalline material growthLiquid-phase epitaxial-layer growthCrucibleRare earth

Proposed is a technique of producing a magnetic garnet material of which the light absorption characteristics worsen little even though it is produced through LPE. The crucible for LPE is formed of a material containing Au. The amount of Au to be taken in single crystal formed in an Au crucible is smaller than that of Pt to be taken therein formed in a Pt crucible. As compared with Pt, the influence of Au on magnetic garnet film that increases the insertion loss in the film is small.

Owner:TDK CORPARATION

Electrodeposition of FeCoNiV films with high resistivity and high saturation magnetization

ActiveUS20050271904A1Easy to implementLiquid applicationVacuum evaporation coatingMagnetizationHigh resistivity

A magnetic layer that may serve as a top pole layer and bottom pole layer in a magnetic write head is disclosed. The magnetic layer has a composition represented by FewCoxNiyVz in which w, x, y, and z are the atomic % of Fe, Co, Ni, and V, respectively, and where w is between about 60 and 85, x is between about 10 and 30, y is between 0 and about 20, z is between about 0.1 and 3, and wherein w+x+y+z=100. An electroplating process having a plating current density of 3 to 30 mA / cm2 is used to deposit the magnetic layer and involves an electrolyte solution with a small amount of VOSO4 which is the V source. The resulting magnetic layer has a magnetic saturation flux density Bs greater than 1.9 Telsa and a resistivity ρ higher than 70 μohms-cm.

Owner:HEADWAY TECH INC

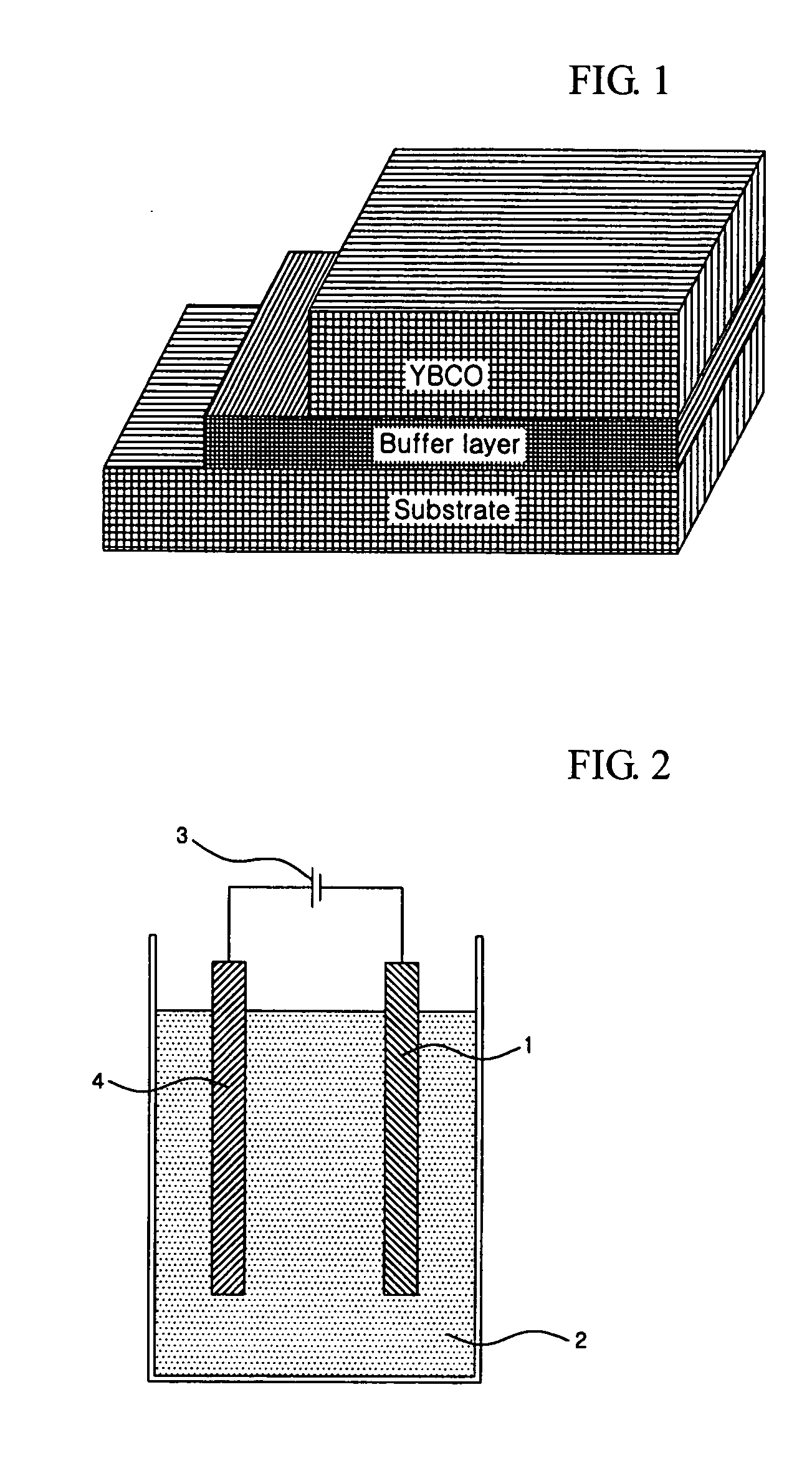

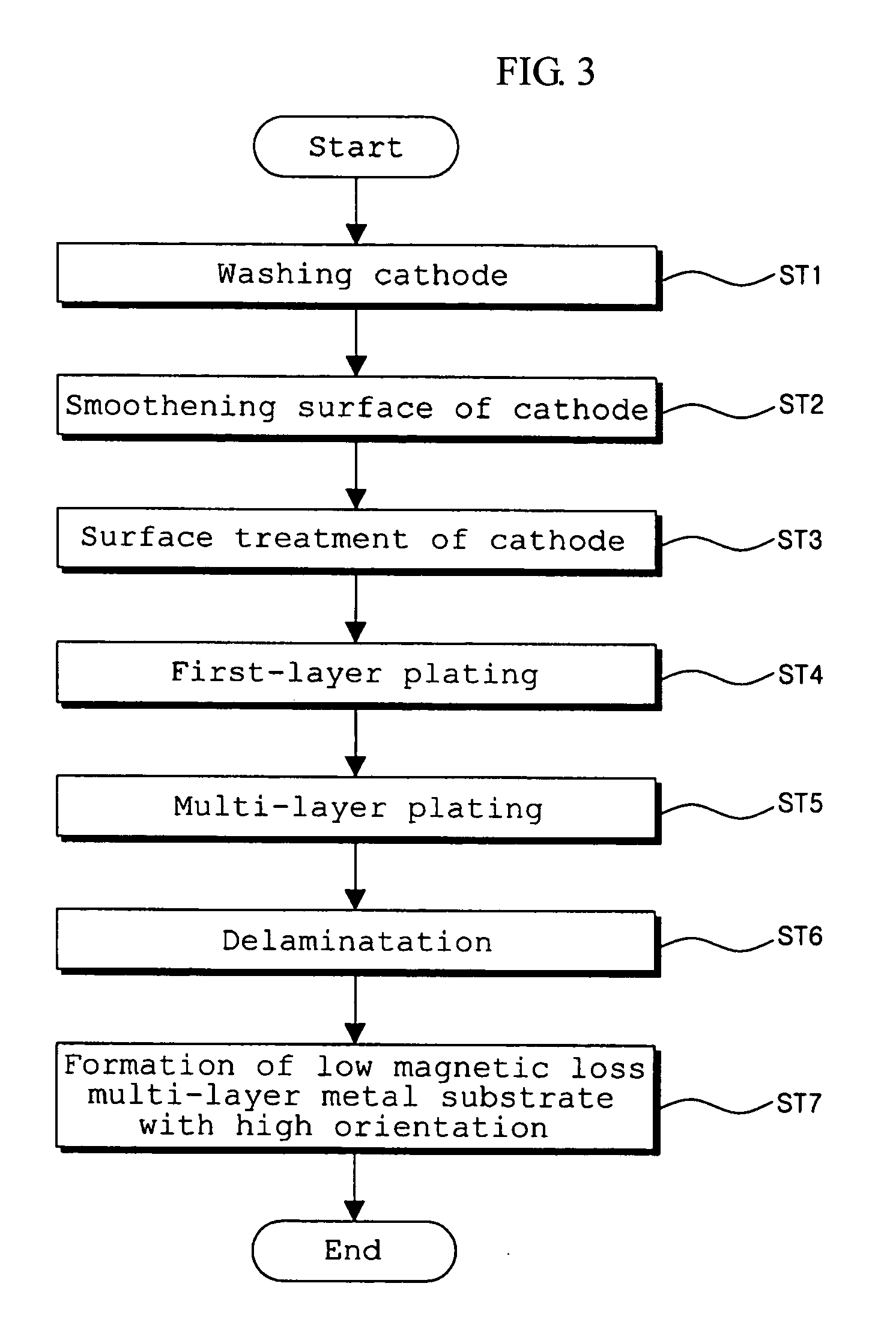

Low magnetic loss metal tape with biaxial texture and manufacturing method thereof

InactiveUS20060159949A1Low magnetic lossImprove biaxial textureLiquid applicationMagnetic layersWater bathsSingle crystal

The present invention is provided to manufacture a low magnetic loss metal tape with biaxial texture and a manufacturing method thereof. The low magnetic loss metal tape has a non-magnetic metal layer deposited on a nickel layer in the form of stack. The low magnetic loss metal tape with biaxial texture is manufactured by the following steps. A biaxially textured nickel layer is formed on a surface of cathode rotating in an electroplating bath including a cathode with single crystalline structure or similary high orientation, and an anode made of high purity nickel. The nickel layer formed on the cathode is then washed in a water bath. Subsequently, a non-magnetic metal layer is formed on the washed nickel layer rotating in a plating bath with a non-magnetic metal solution. The metal tape is finally manufactured by delaminating and winding the nickel / non-magnetic metal layers.

Owner:KOREA INST OF MASCH & MATERIALS

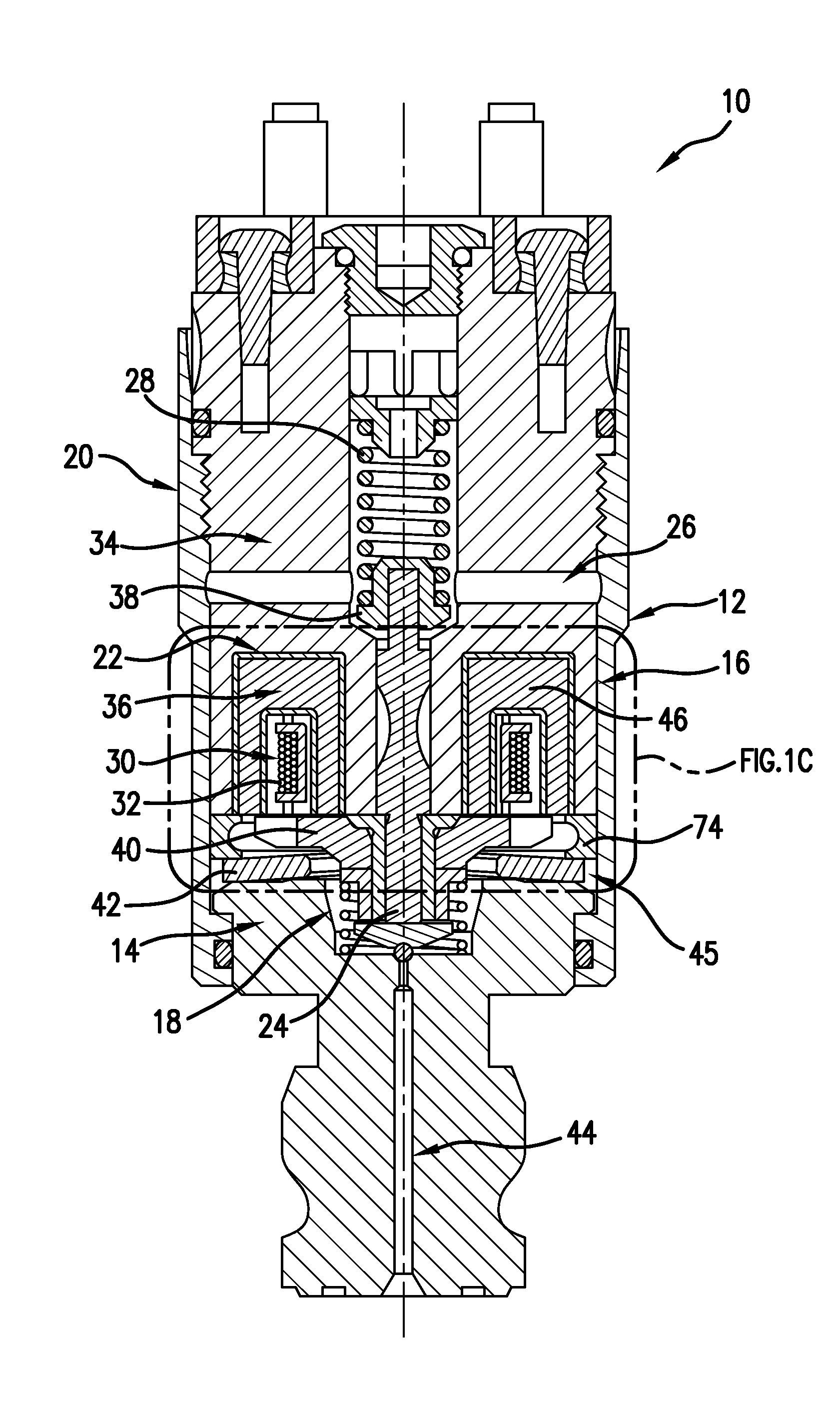

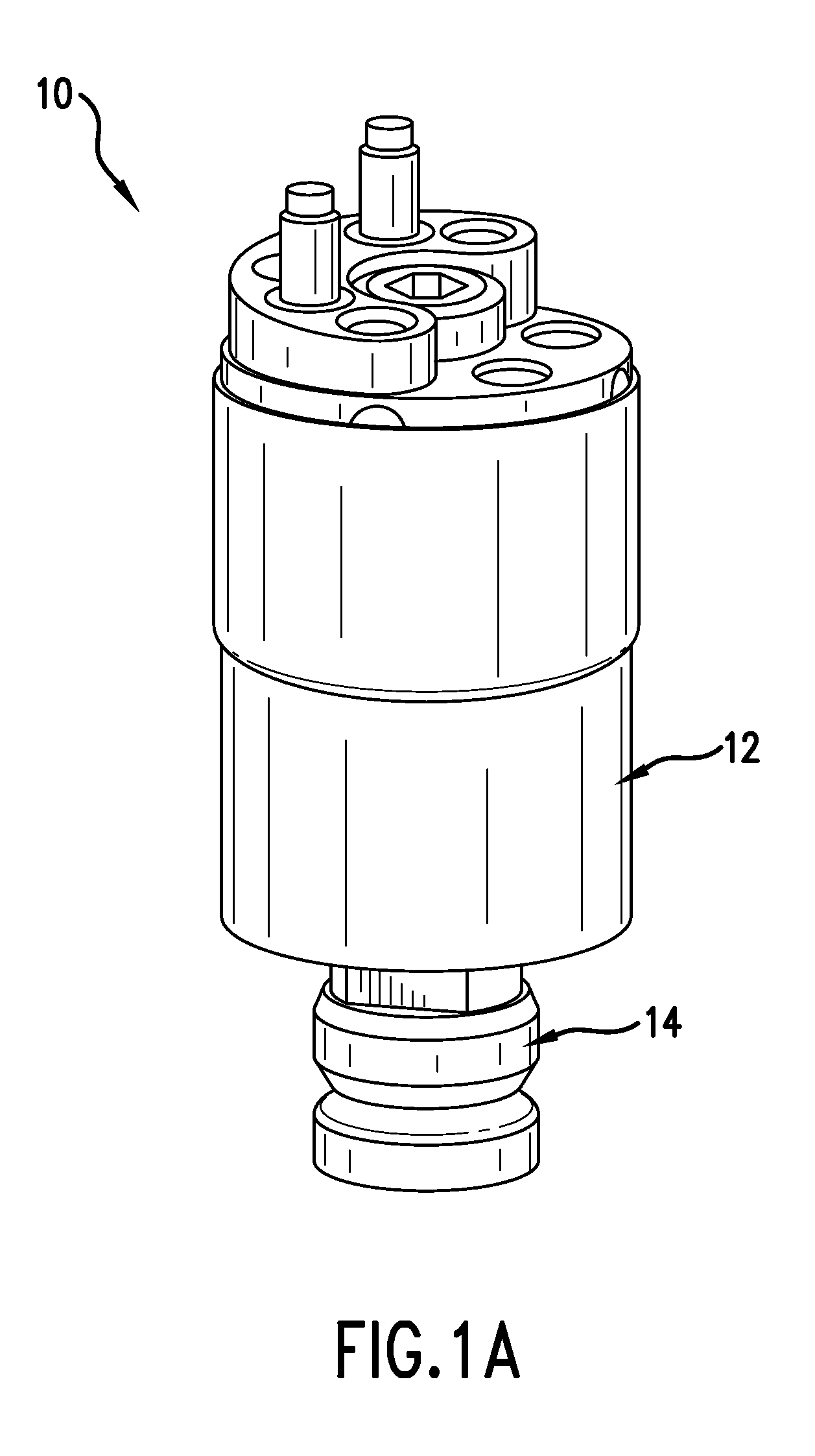

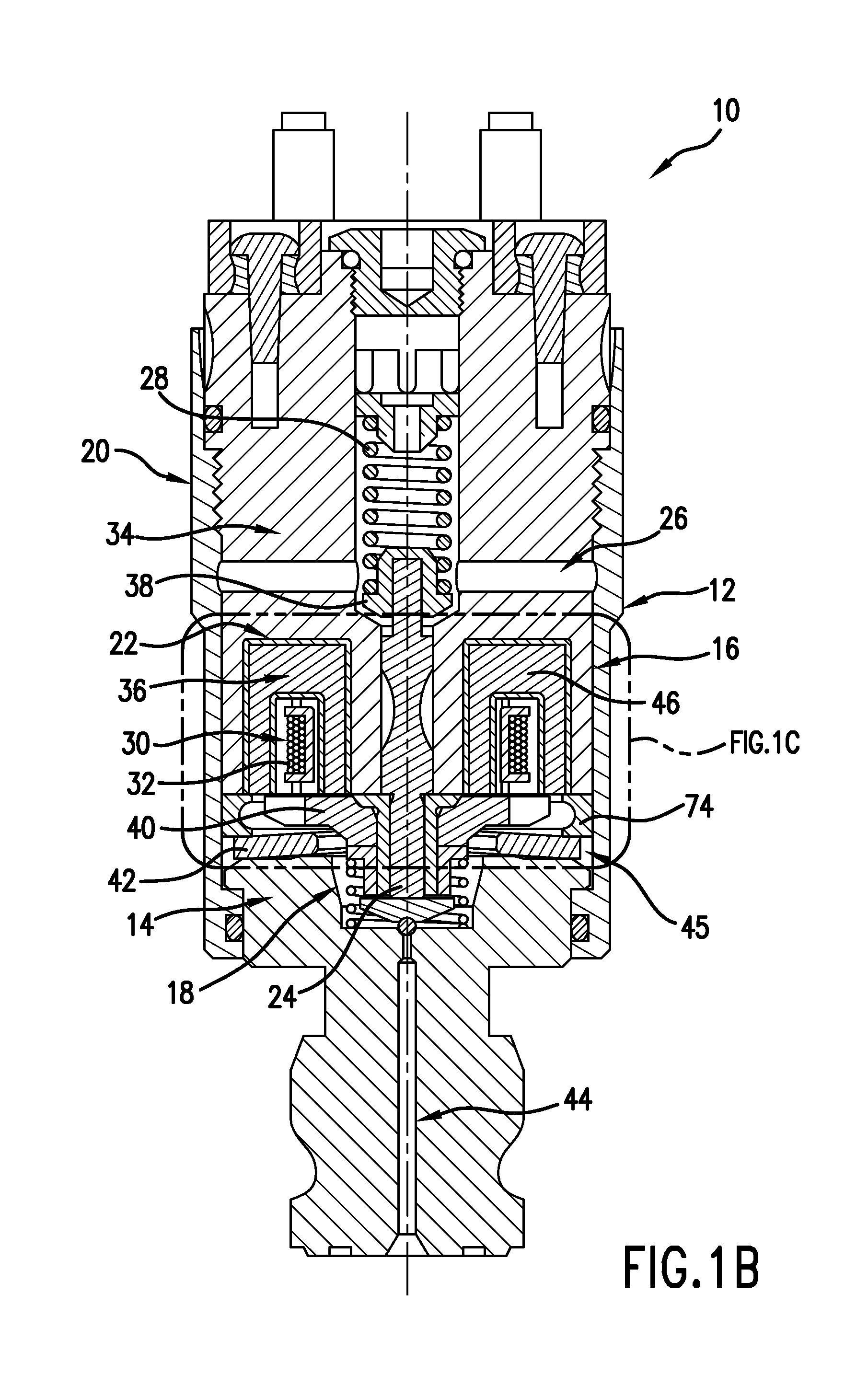

Solenoid actuated flow control valve including stator core plated with non-ferrous material

InactiveUS20090267008A1Improve reliabilityHigh strengthOperating means/releasing devices for valvesLiquid applicationSolenoid valveEngineering

An electromagnetic valve includes an extra-high pressure injection system control valve having soft metal powder particles in a magnetic stator core. Electroless nickel plating is applied to the stator core to provide an intermediate surface to absorb grinding wheel stress as a working face is exposed during manufacturing, as well as an external compression layer or casing to hold or encapsulate the powder particles in place and together during assembly and use.

Owner:CUMMINS INTPROP INC

Planar magnetic inductor and method for manufacturing the same

InactiveCN1801412AImprove the inductanceImprove high frequency characteristicsLiquid applicationPrinted circuit manufactureInductorInductance

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

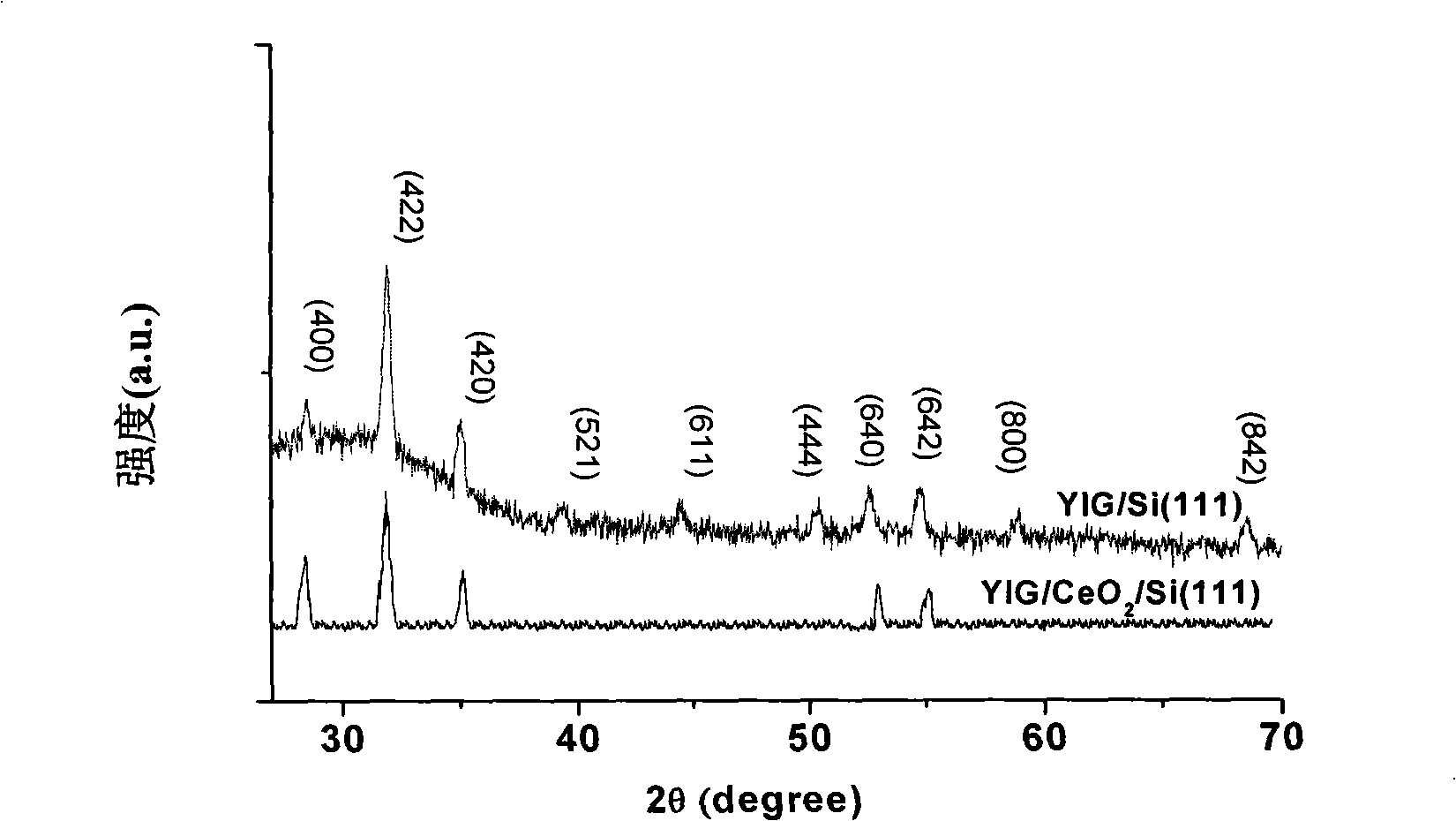

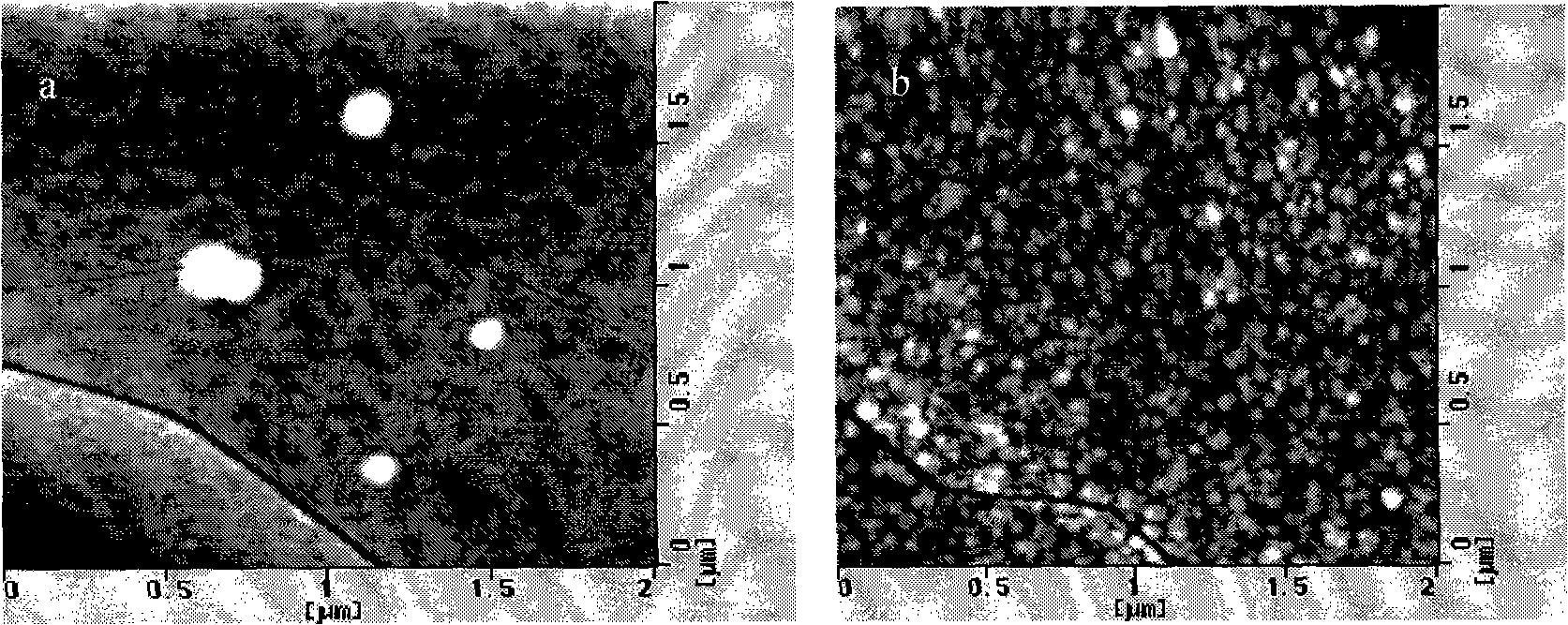

Yttrium-iron-garnet film structure and preparation method

InactiveCN101311374AFine surfaceReduce surface roughnessPolycrystalline material growthLiquid applicationFilm materialFilm structure

The invention relates to an yttrium iron garnet film structure which belongs to the field of electronic material, in particularly to a method for preparing radio frequency magnetron sputtering of yttrium iron garnet film materials. The film structure consists of a Si substrate and an yttrium iron garnet film layer, wherein a CeO2 transient layer is also arranged between the Si substrate and the yttrium iron garnet film layer. The yttrium iron garnet film structure has the advantages that: surface of the film is improved greatly, surface roughness is reduced obviously, saturation magnetization and remnant magnetization of the film is improved, and coercive force is reduced.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

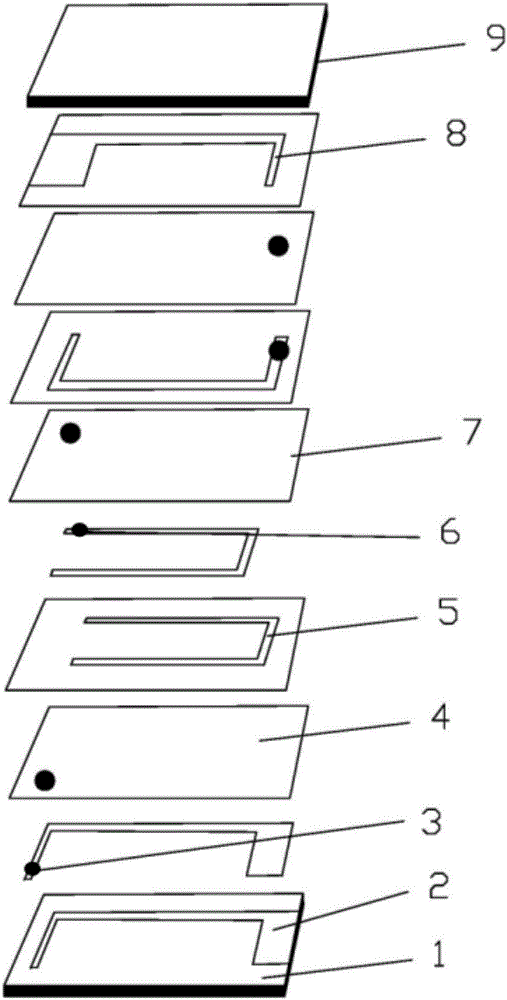

Preparation method of laminated magnetic bead

ActiveCN106653356AReduced magnet shrinkageMagnet shrinkage shortenedLiquid applicationCoils manufactureScreen printingMagnetic bead

The invention relates to the field of electronic components, in particular to a preparation method of a laminated magnetic bead. A dry casting process is adopted for producing an upper substrate and a lower substrate of the laminated magnetic bead; a wet casting process is adopted for producing an internal dielectric film, and an internal coil of the laminated magnetic bead is manufactured by combining a screen printing process; and an isostatic pressing method is adopted by subsequent procedures, thereby ensuring the consistency of magnet shrinkage rates of a dry method and a wet method. The problems of a long production cycle and low efficiency are solved; and meanwhile, the quality problem of a laminated magnetic bead stress jumper is also solved. According to the preparation method, the magnet shrinkage rate of the magnetic bead is reduced, the production efficiency is improved and the production cycle of the magnetic bead is shortened to within 12 days from 15 days.

Owner:GUANGDONG FENGHUA BANGKE ELECTRONIC CO LTD

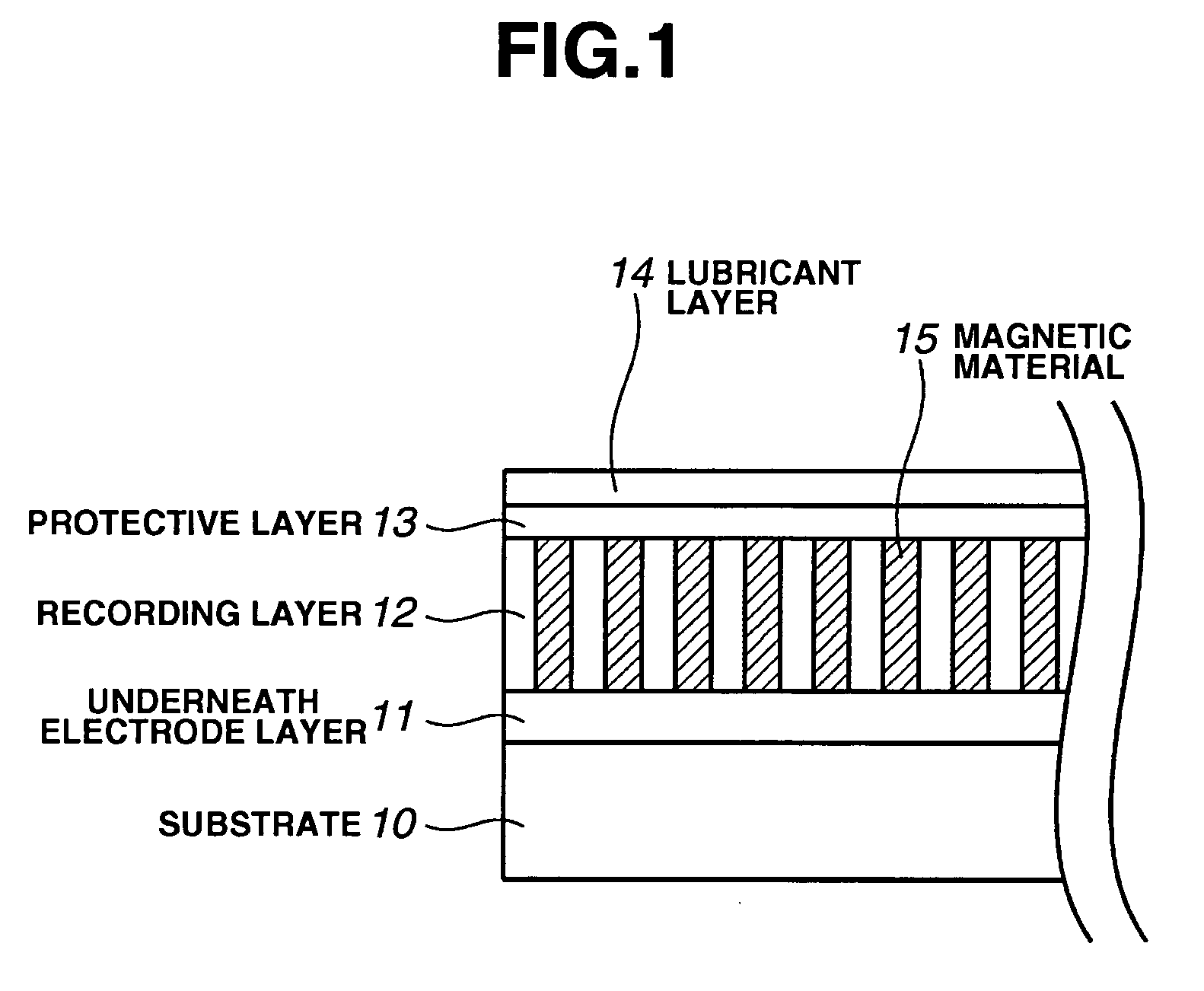

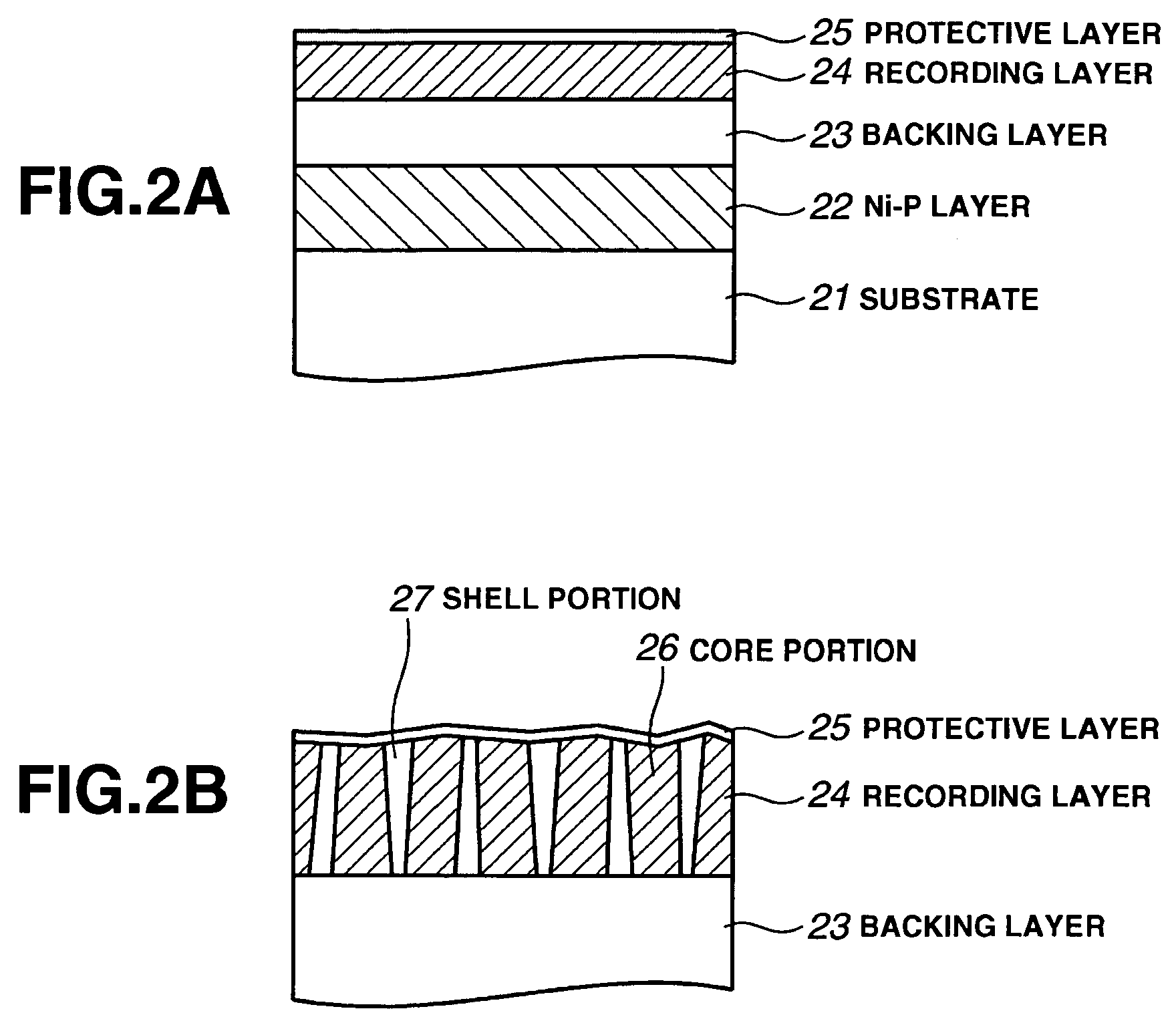

Magnetic thin film and method of manufacturing the same

InactiveUS20050053802A1High saturated magnetic flux densityGood soft magnetismManufacture head surfaceLiquid applicationMagnetic characteristicMaterials science

The magnetic thin film has high saturation magnetic flux density and superior soft magnetic characteristics. The magnetic thin film of the present invention comprises: a base layer being made of FeCo / NiFe; and a plated layer being formed on the base layer, the plated layer being made of FeCo.

Owner:FUJITSU LTD

Cobalt-platinum or iron-plantinum magnetic material containing 1% to 40% Cu, Ni or B

InactiveUS7286324B2Reduce the temperatureLiquid applicationMagnetic layer production by platingMagnetic anisotropyElectroplating

A CoPt- or FePt-alloy magnetic material in which a temperature to transform into an L10-ordered alloy is reduced and magnetic anisotropy energy is controlled, and a method for manufacturing the magnetic material are provided. In a CoPt- or FePt-alloy magnetic material obtained according to plating, at least one element of Cu, Ni and B is contained with an atomic percent equal to or more than 1% and equal to or less than 40%. A method for manufacturing a magnetic material includes a step of depositing a magnetic material in which at least one element of Cu, Ni and B is contained in a CoPt- or FePt-alloy magnetic material with an atomic percent equal to or more than 1% and equal to or less than 40%, from a plating solution, and a step of transforming the deposited magnetic material into an L10-ordered alloy according to annealing at a temperature equal to or lower than 500° C.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com