Rare earth sintered magnet and process for producing the same

A technology of sintered magnets and manufacturing methods, applied in the direction of inductance/transformer/magnet manufacturing, permanent magnets, magnetic materials, etc., can solve the problem of small coercive force improvement effect, and achieve the effect of increasing coercive force and suppressing the reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Using the strip casting method, from Nd 12.5 Fe 78.5 co 1 B 8 Composed alloy ingots are produced to produce alloy flakes with a thickness of 0.2 to 0.3 mm. Next, the flakes are filled in a container, hydrogen gas of 500 kPa is stored at room temperature, and then released to obtain an amorphous powder with a size of about 0.15 to 0.2 mm, which is then pulverized by a jet mill to produce a powder of about 3 μm. micro powder.

[0081] After adding and mixing 0.05% by mass of zinc stearate to the micropowder, it was press-molded in a magnetic field, packed into a vacuum furnace, and sintered at 1080° C. for 1 hour to obtain a cubic magnet block material of 10 mm square.

[0082] Next, this cubic magnet block material was cut with a grinding wheel to produce a Nd—Fe—B based rare earth magnet having a length of 10 mm, a width of 10 mm, and a thickness of 5 mm. The product in this state was used as it is as a comparative sample (1). Thickness is 5mm, volume is 500mm 3 ...

Embodiment 2

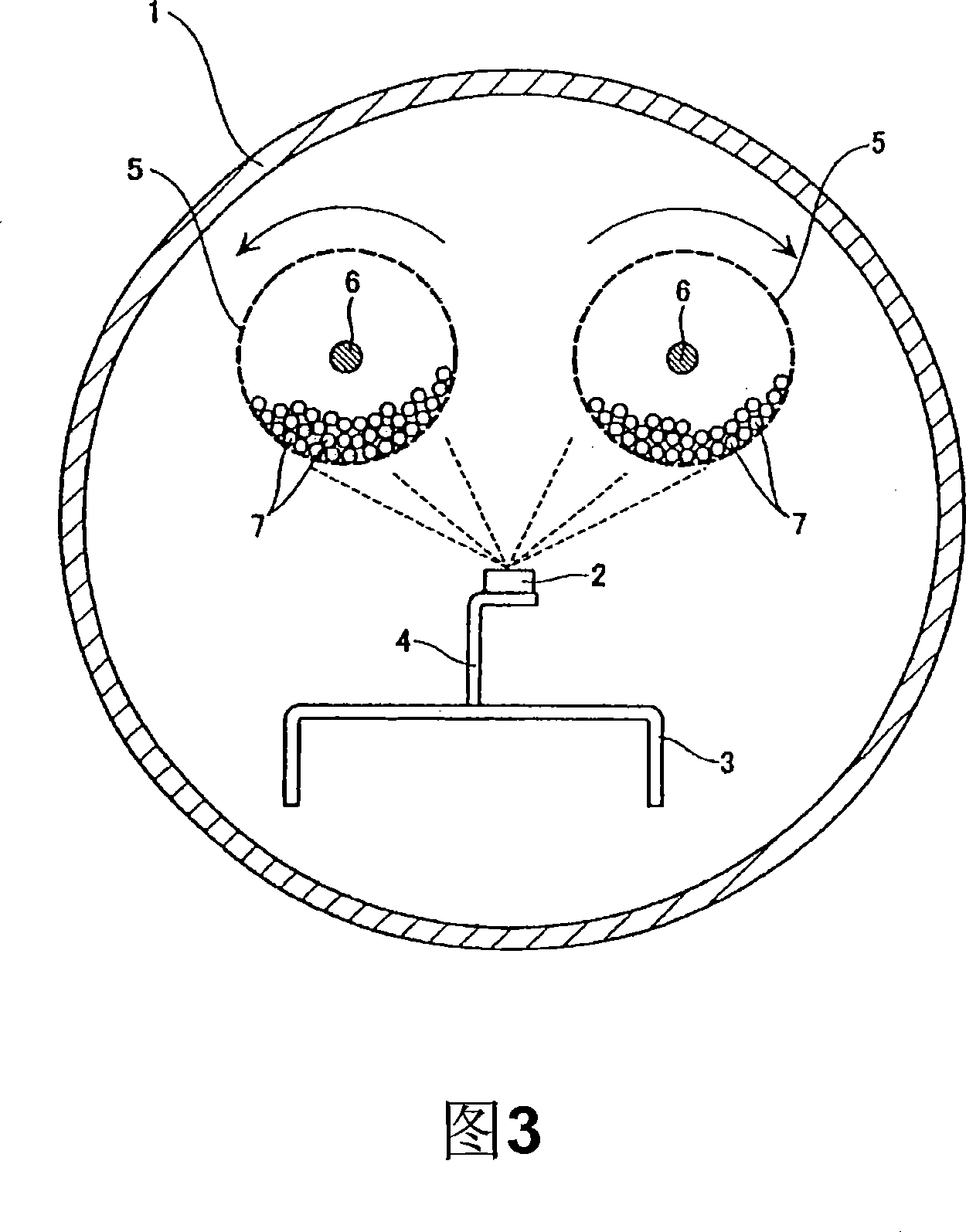

[0091] A Nd-Fe-B rare earth magnet with a length of 10 mm, a width of 10 mm, and a thickness of 4 mm was fabricated by cutting, and then formed on the surface of the Nd-Fe-B rare earth magnet using the vapor deposition device shown in Figure 3. RHM alloy film. A Tb-30% by mass Cu alloy (terbium-copper alloy) was used as the molten vapor-deposited product.

[0092] The actual film-forming operation by vapor deposition is performed in the following steps. After placing the three cut Nd-Fe-B rare earth magnets of a predetermined shape in the vacuum chamber of the vapor deposition device, heating and melting the TbCu alloy (terbium copper alloy) to evaporate it, and In the same manner as in Example 1, a 2 μm TbCu alloy (terbium copper alloy) film was formed on the surface of the Nd—Fe—B based rare earth magnet.

[0093] The magnetic properties of each sample were measured with a BH tracer after applying pulse magnetization of 3 MA / m. The demagnetization curves of Example 2 and ...

Embodiment 3

[0097] A Nd-Fe-B rare earth magnet with a length of 10 mm, a width of 10 mm, and a thickness of 6 mm was produced by cutting, and then, using the vapor deposition device shown in Figure 3, the Nd-Fe-B rare earth magnet was formed on the surface. RHM alloy layer. As the molten evaporated material, a Dy-20% by mass Fe alloy (dysprosium-iron alloy) was used.

[0098] The actual film-forming operation by vapor deposition is performed in the following steps. After placing the above-mentioned Nd-Fe-B rare earth magnets of three predetermined shapes in the vacuum chamber of the vapor deposition device, heating and melting the DyFe alloy (dysprosium-iron alloy) to evaporate it, in addition, In the same manner as in Example 1, a DyFe alloy (dysprosium-iron alloy) film of 2 μm was formed on the surface of the Nd—Fe—B based rare earth magnet.

[0099] The magnetic properties of each sample were measured with a BH tracer after applying pulse magnetization of 3 MA / m. The demagnetization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com