Patents

Literature

1041results about How to "Efficient replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

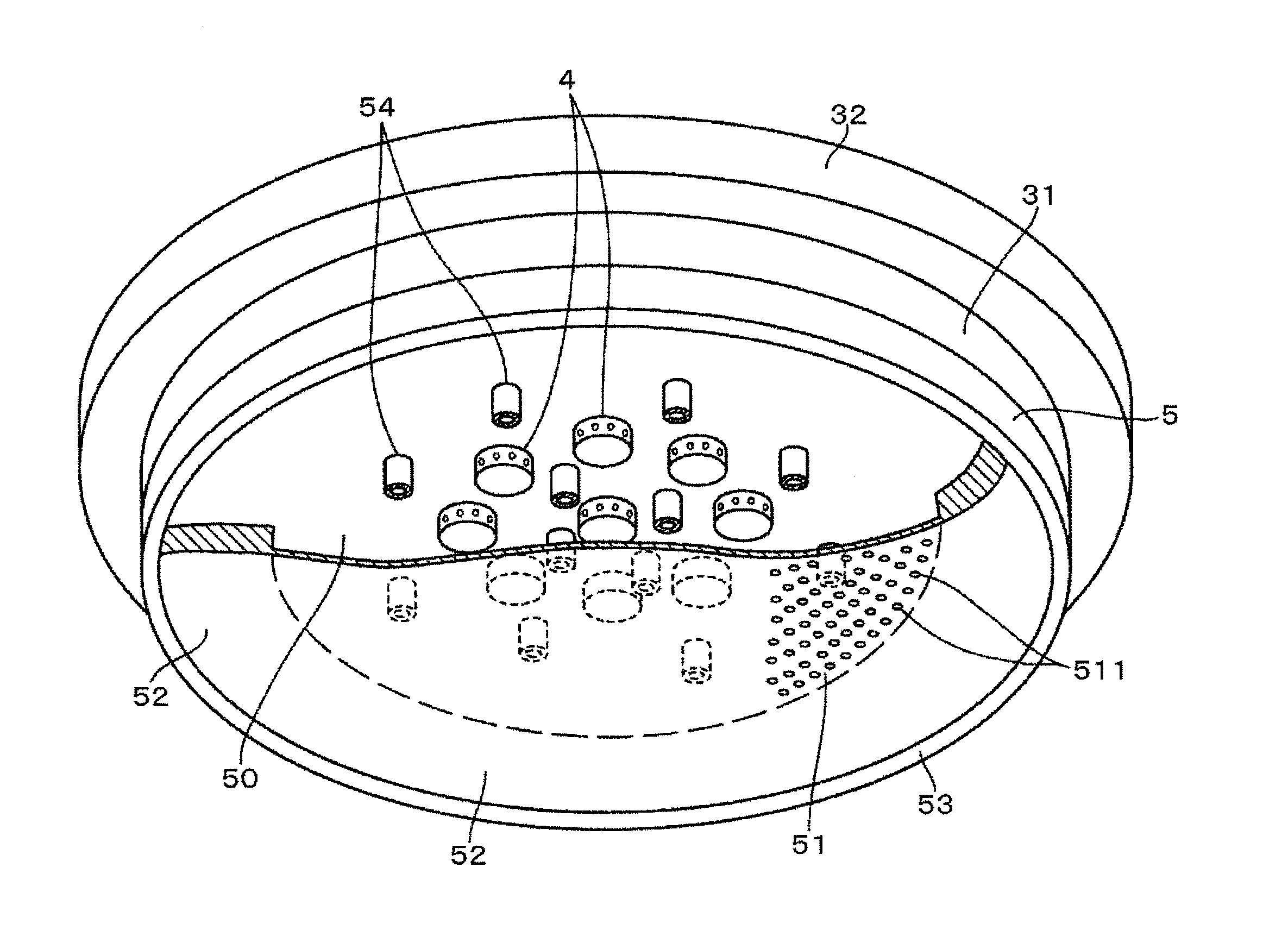

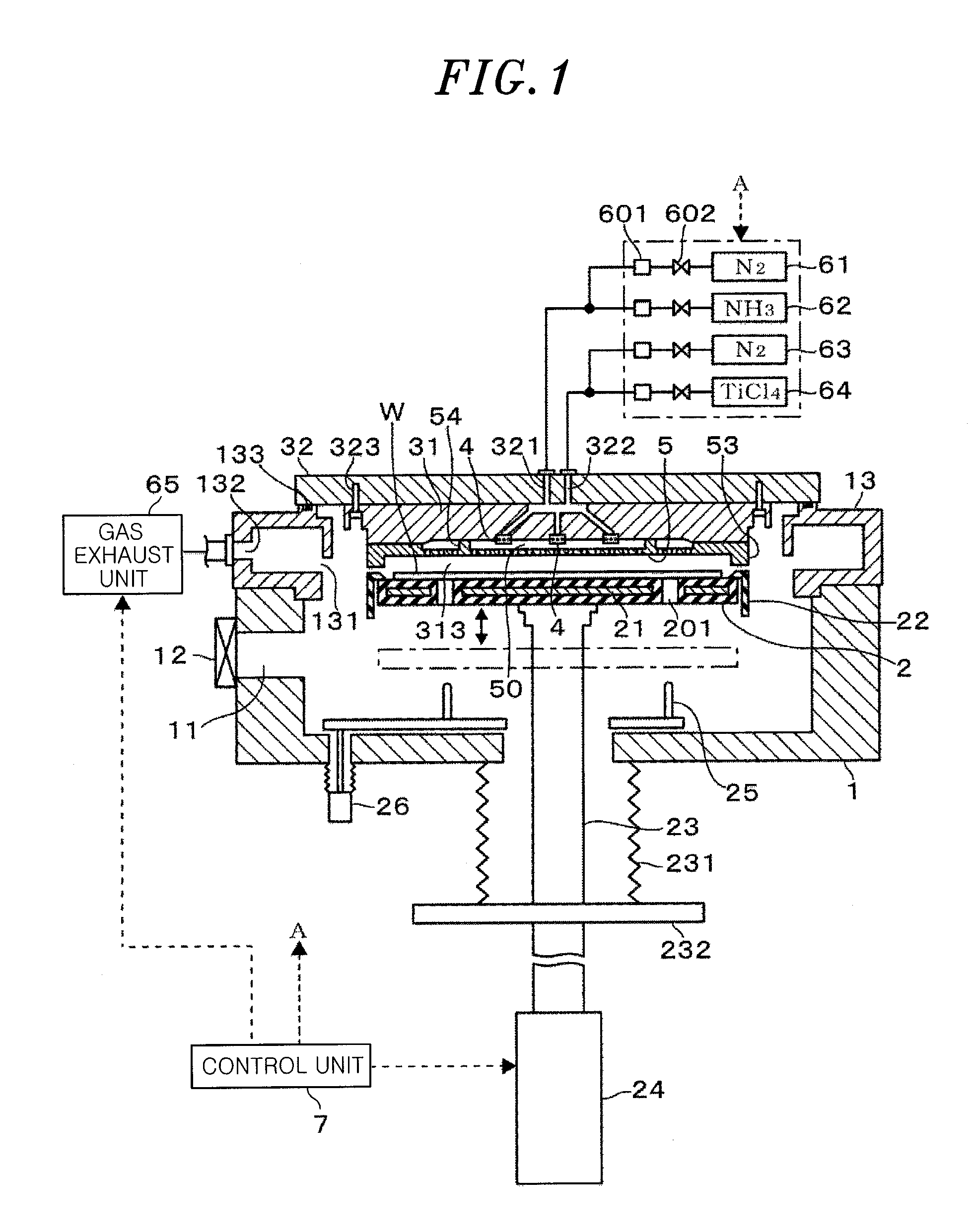

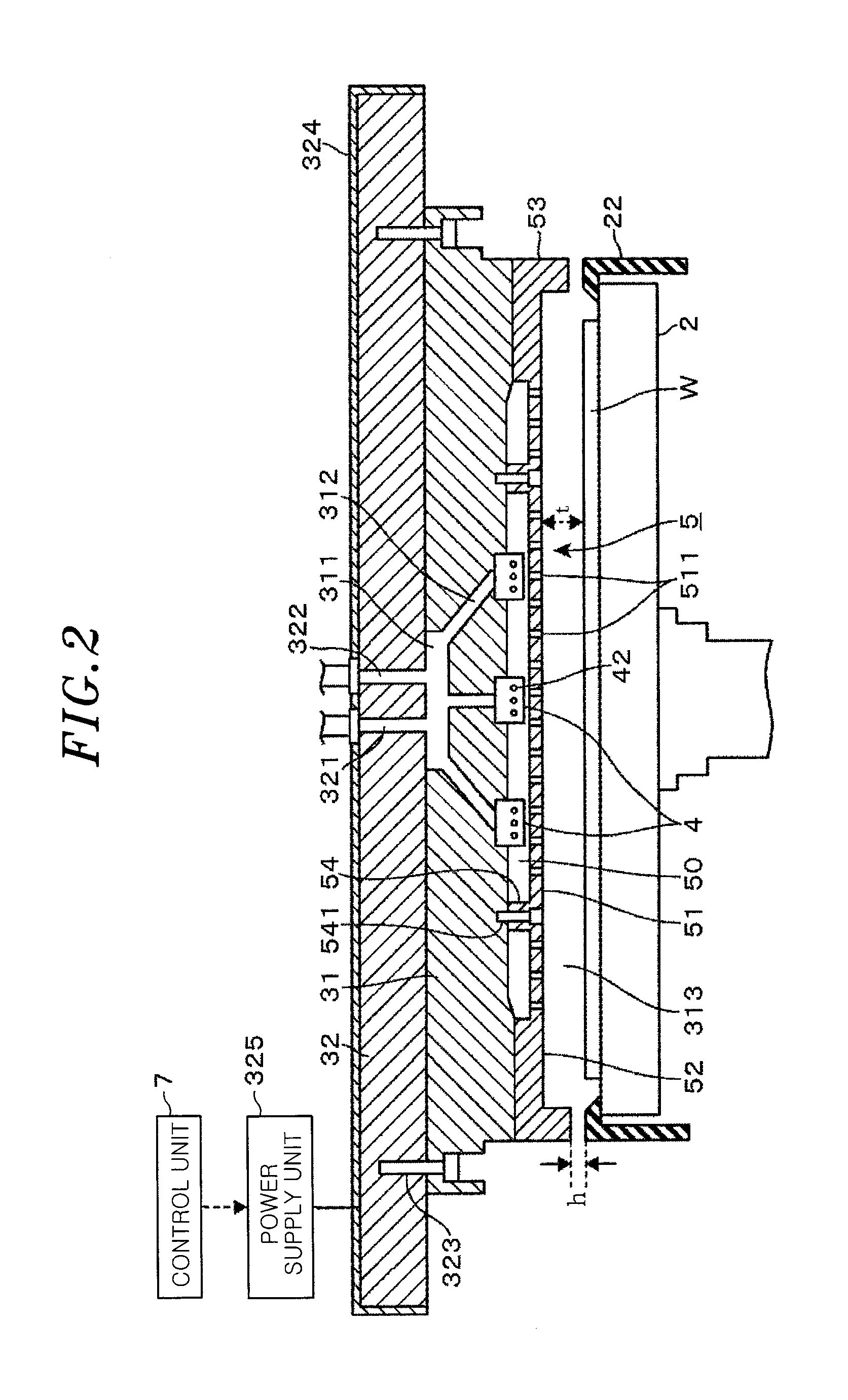

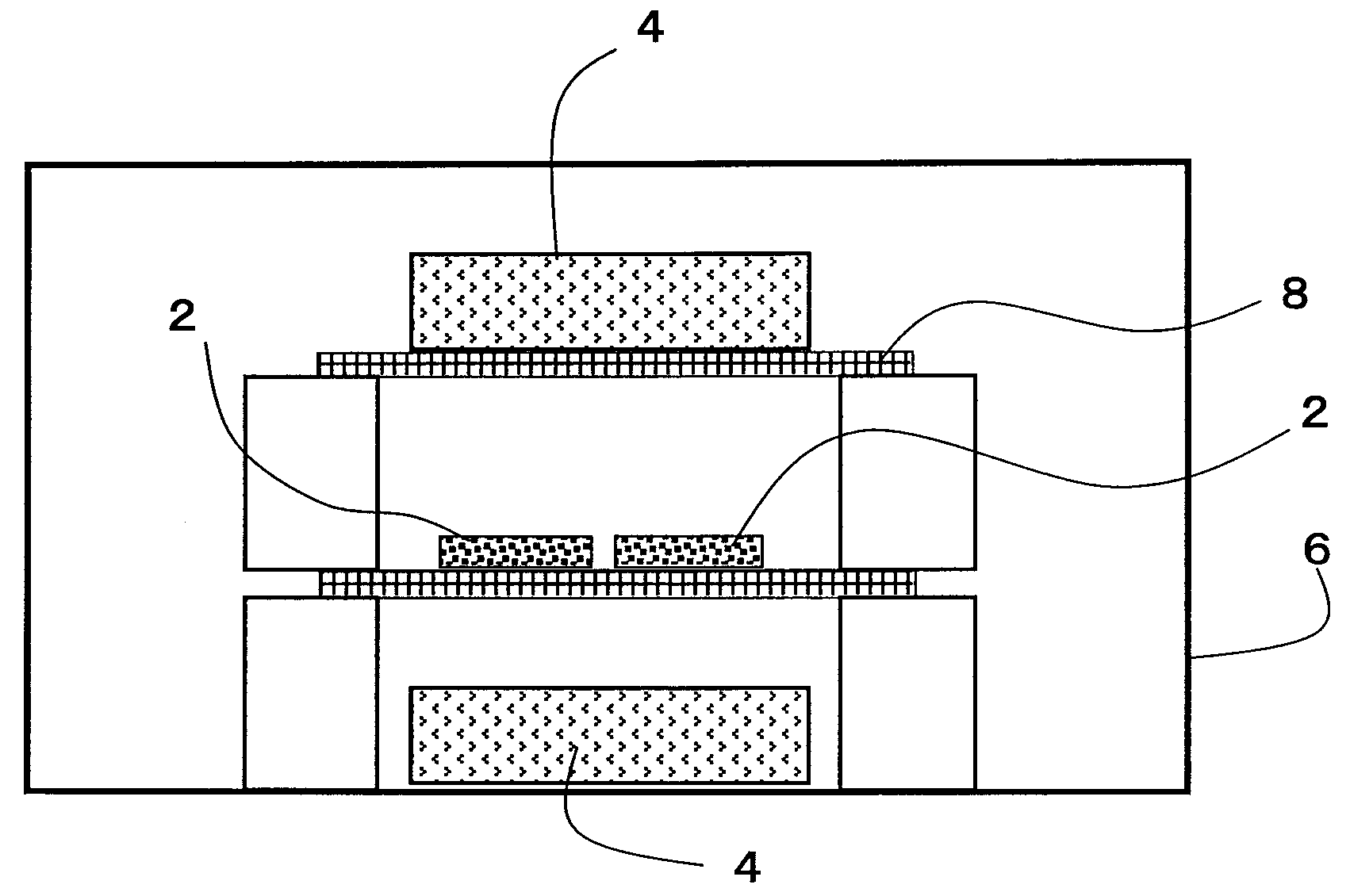

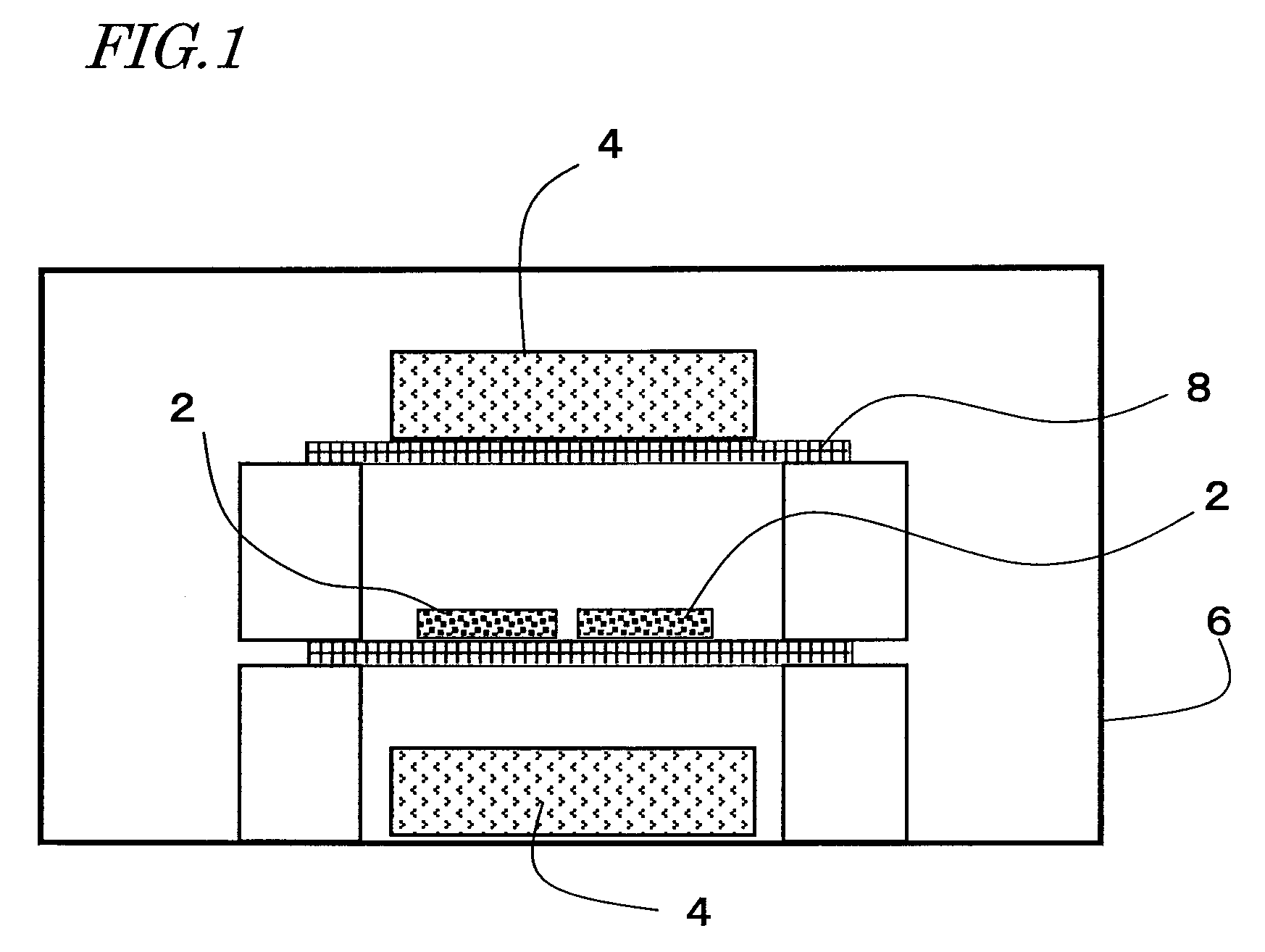

Film forming apparatus

ActiveUS20150267298A1High in-plane uniformityEfficient replacementChemical vapor deposition coatingGas supplyForming processes

A film forming apparatus for performing a film forming process by sequentially supplying a plurality of reactant gases to a substrate and supplying a replacement gas includes a mounting table configured to mount thereon a substrate, and a shower head having a flat surface facing the mounting table and a plurality of gas supply opening. An annular protrusion is provided at the shower head to form a gap between the annular protrusion and a top surface of the mounting table. A plurality of gas supply units is provided at a ceiling portion at an upper side of the shower head. Each gas supply unit has gas discharge openings formed along a circumferential direction. The diffusion space is disposed such that an outer periphery of the diffusion space is located at an inner side of an outer periphery of the substrate mounted on the mounting table in a plan view.

Owner:TOKYO ELECTRON LTD

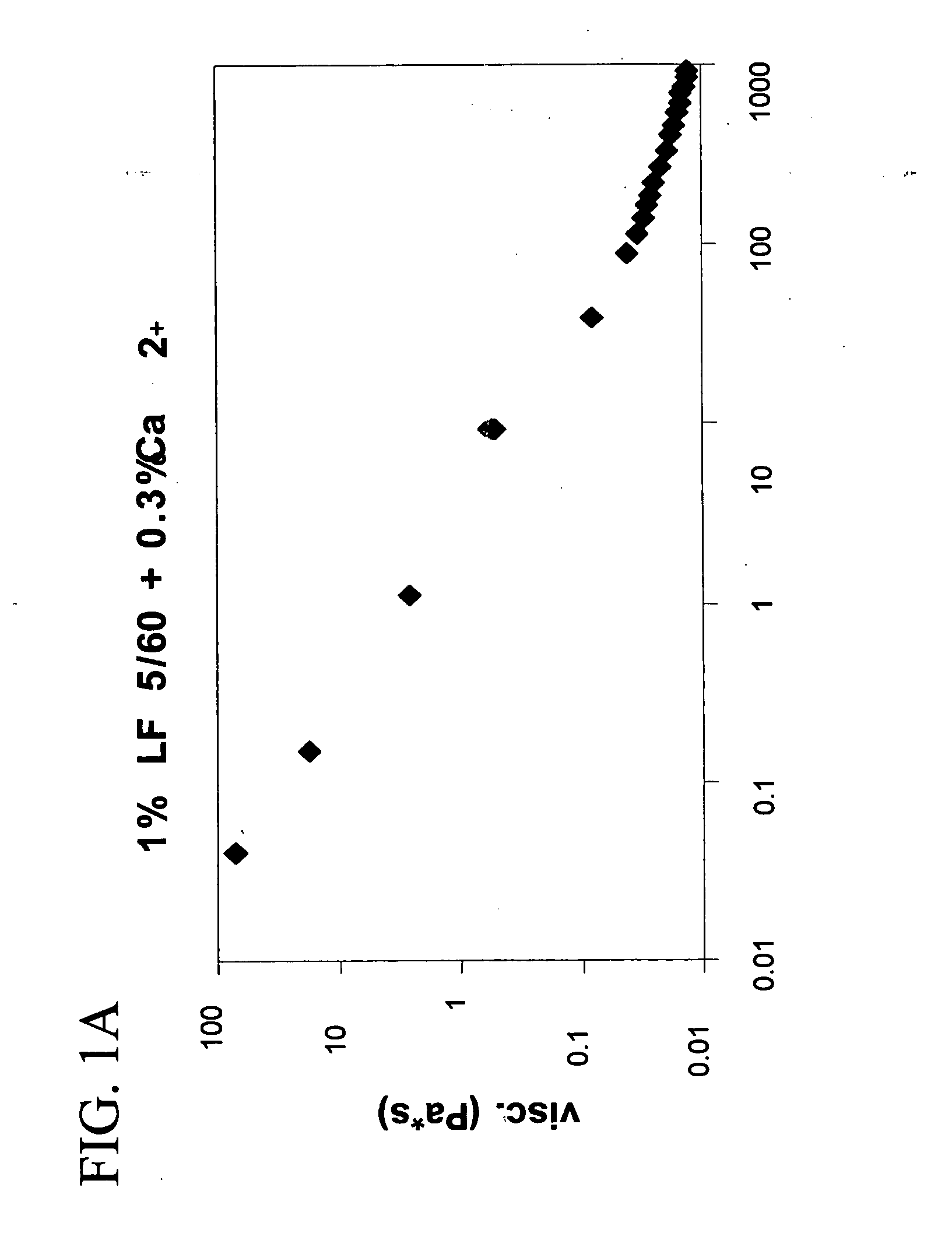

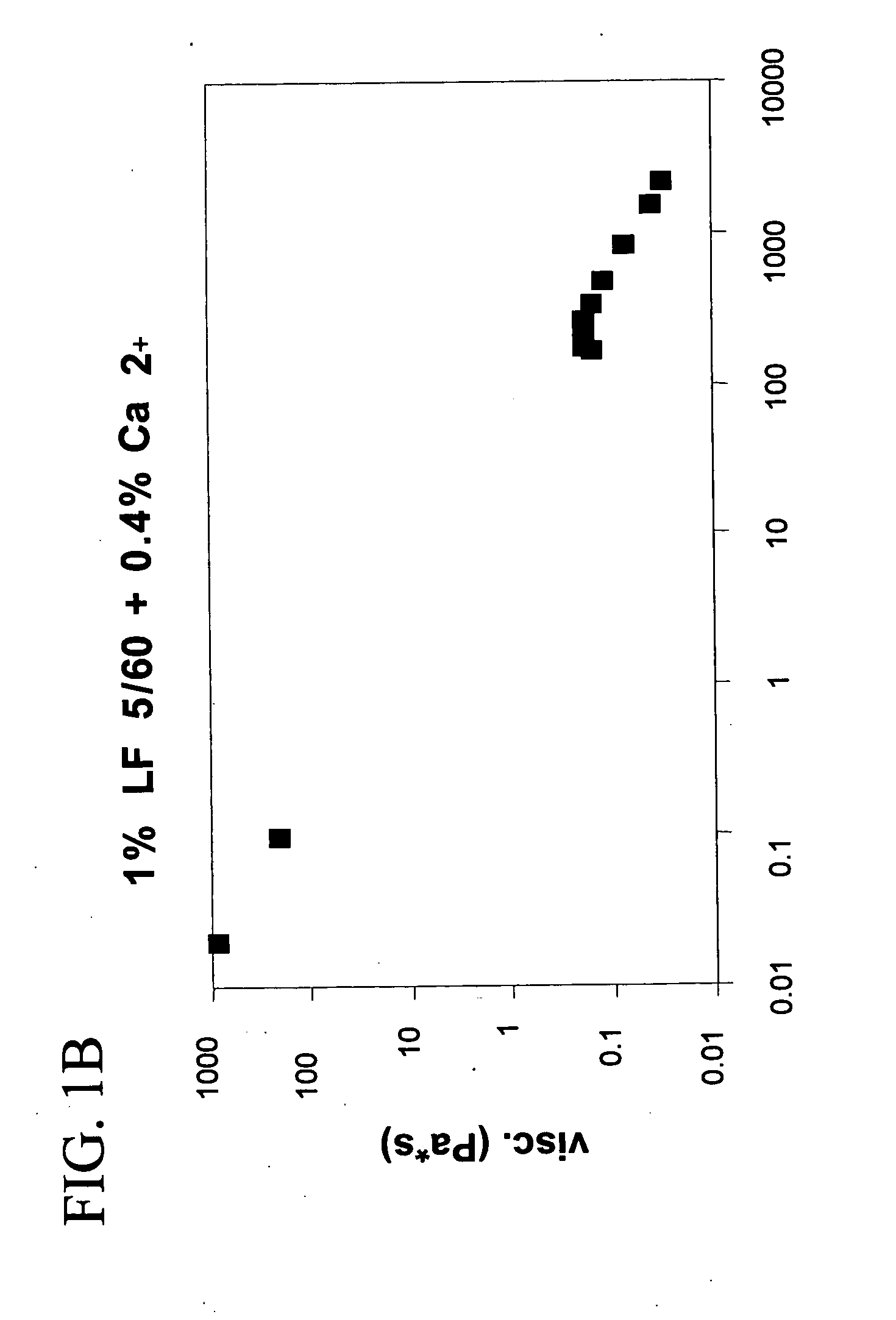

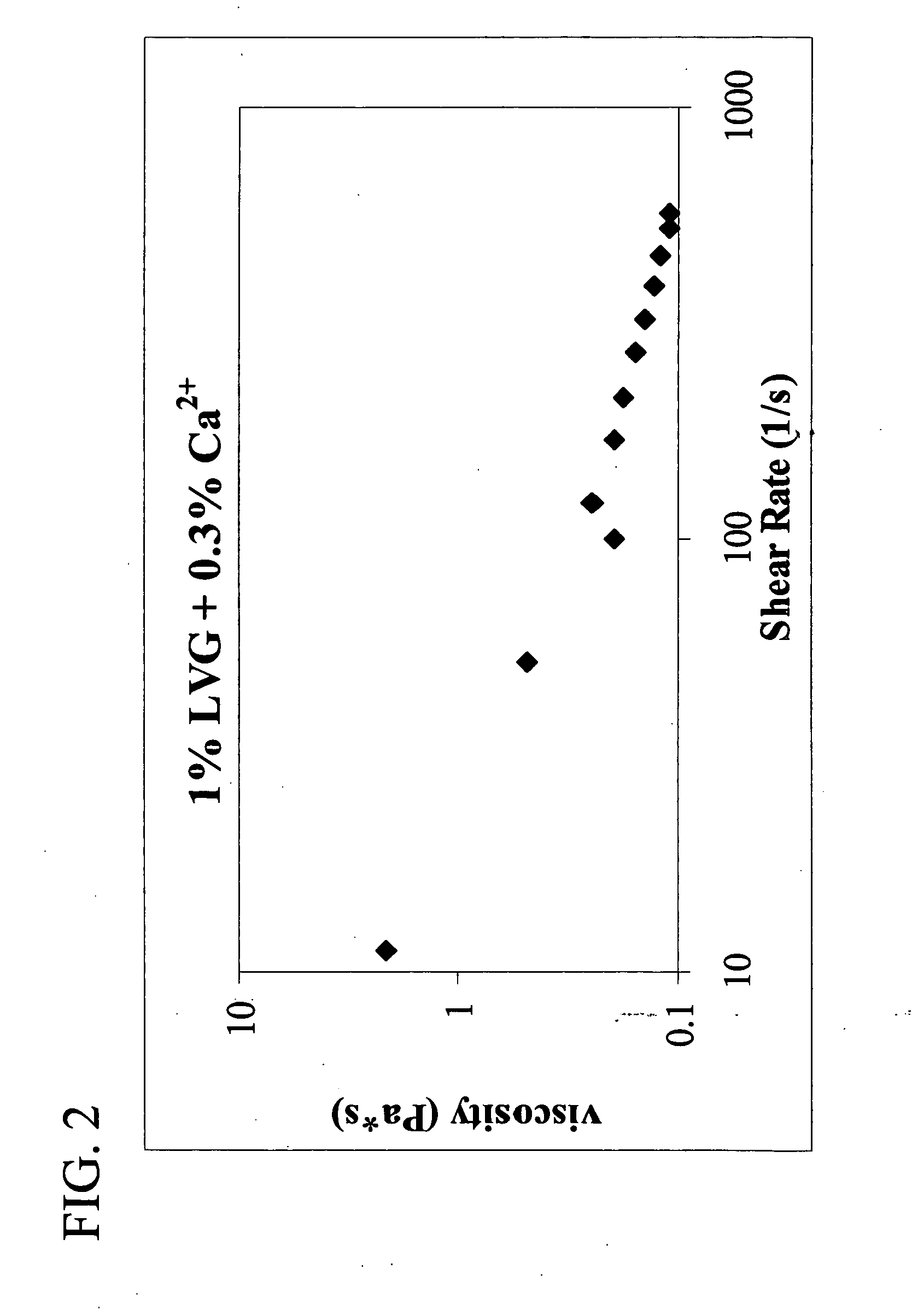

Injectable cross-linked polymeric preparations and uses thereof

InactiveUS20050003010A1Promote regenerationFunction increaseOrganic active ingredientsPowder deliveryCross-linkDamages tissue

A composition for promoting repair of damaged tissues, being a cross-linked alginate solution, which can be maintained in liquid form indefinitely (under constant conditions) and only gels in vivo. This cross-linked alginate solution is an ideal material to be used for tissue repair. Injection of said material into cardiac tissue post-myocardial infarct induced tissue regeneration. The invention provides such injectable solution, as well as compositions and method of preparation thereof. The invention also provides various methods and uses of the cross-linked alginate solution, for cardiac tissue regeneration, induction of neo-vascularization, enhancing SDF-1 expression and guiding stem cell chemotaxis, among others. A kit for tissue repair is also provided.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

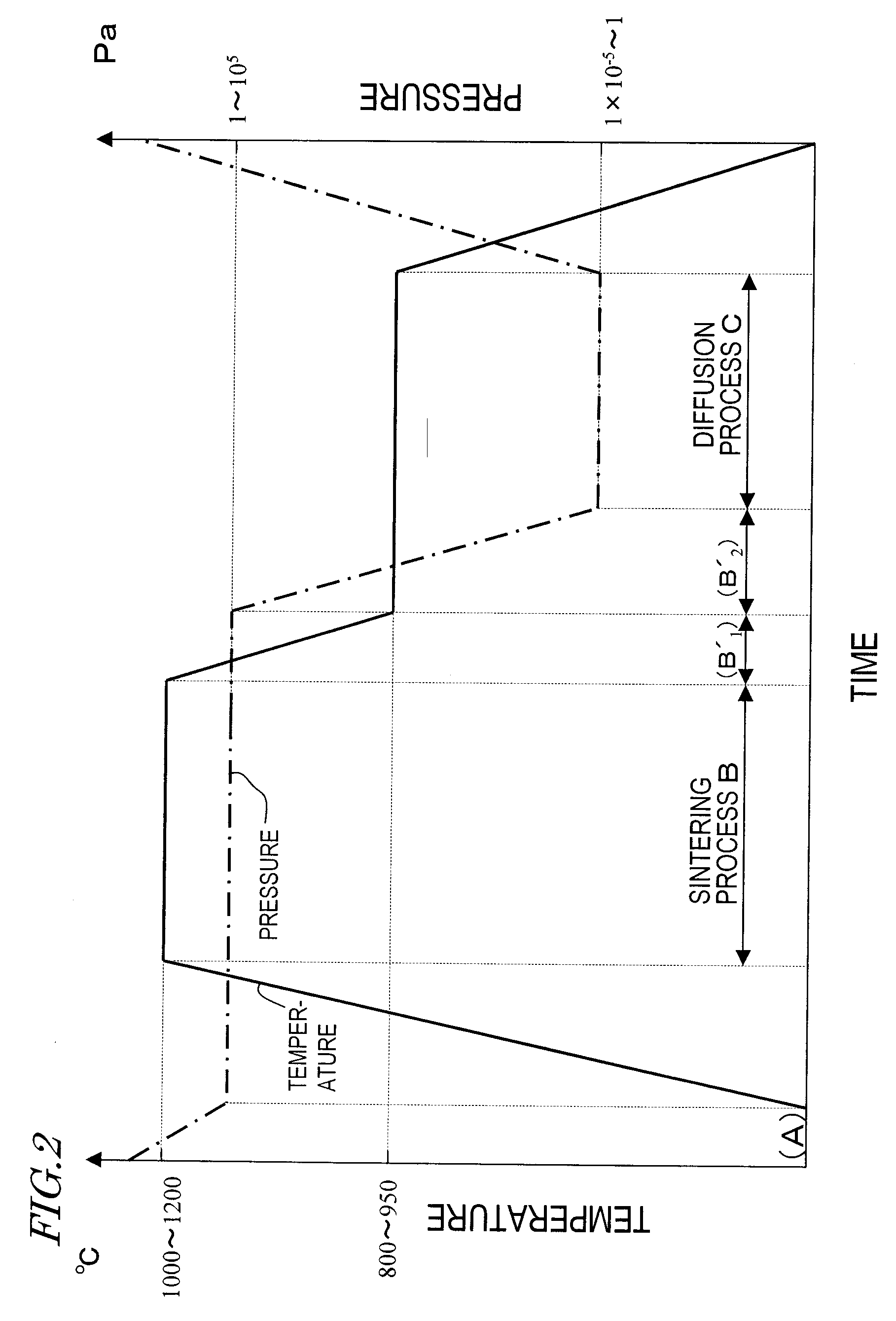

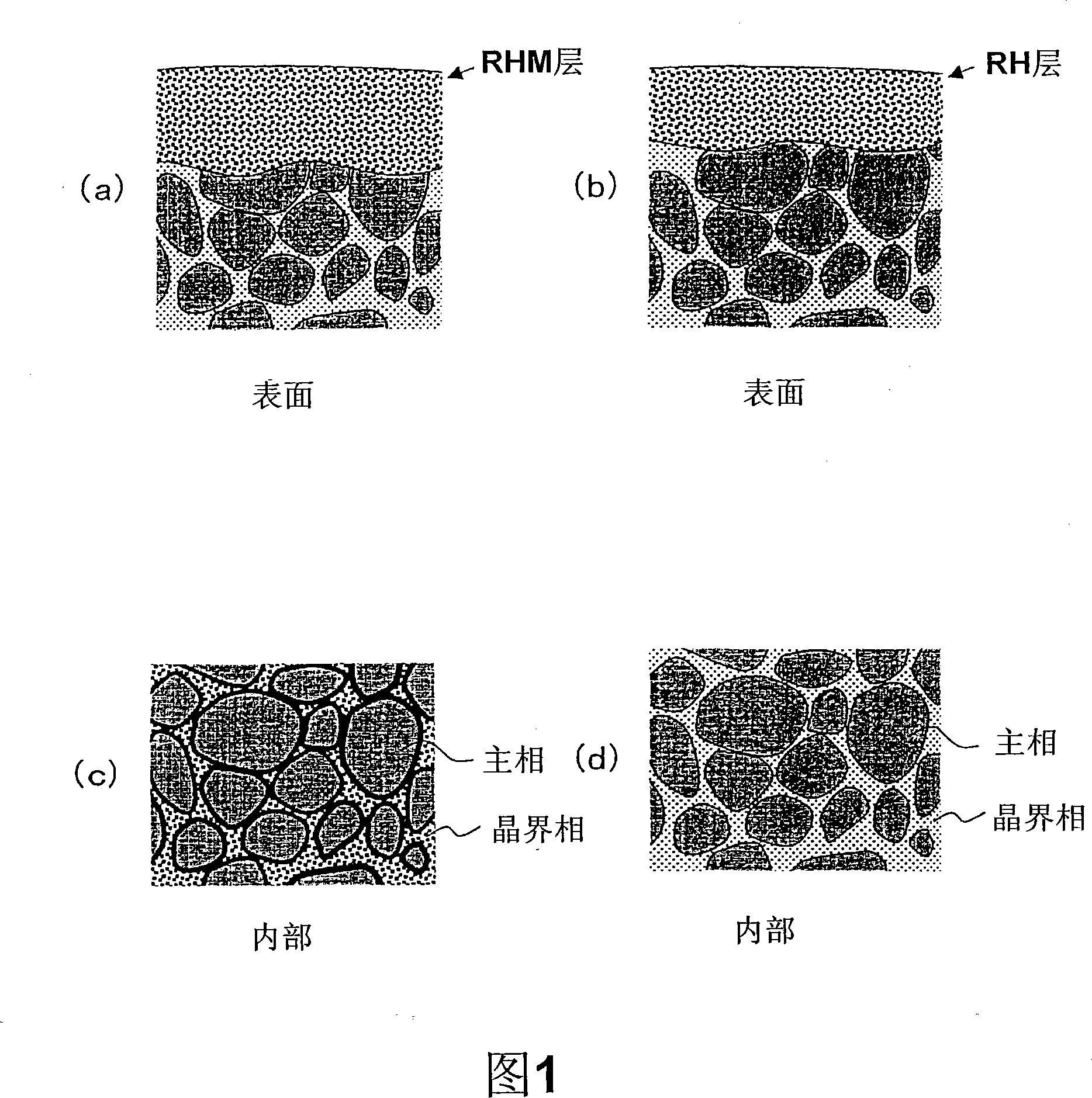

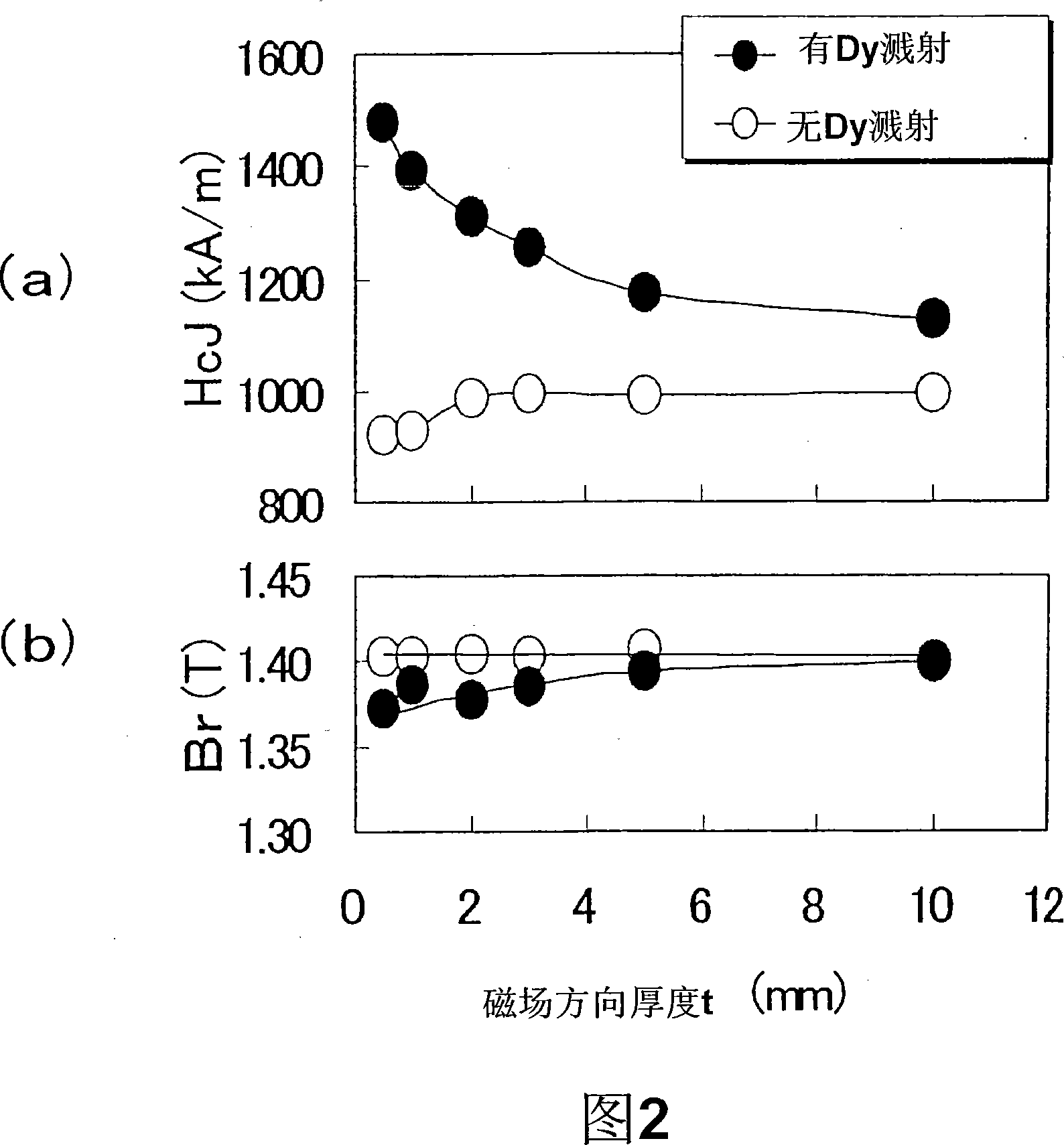

R-Fe-B Rare Earth Sintered Magnet and Method for Producing Same

ActiveUS20080286595A1Decrease in remanence Br minimizedCoercivity HcJ can be increasedInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementMetallurgy

In a method for producing an R—Fe—B based rare-earth sintered magnet according to the present invention, first, provided is an R—Fe—B based rare-earth sintered magnet body including, as a main phase, crystal grains of an R2Fe14B type compound that includes a light rare-earth element RL, which is at least one of Nd and Pr, as a major rare-earth element R. Thereafter, the sintered magnet body is heated while a heavy rare-earth element RH, which is at least one element selected from the group consisting of Dy, Ho and Tb, is supplied to the surface of the sintered magnet body, thereby diffusing the heavy rare-earth element RH into the rare-earth sintered magnet body.

Owner:HITACHI METALS LTD

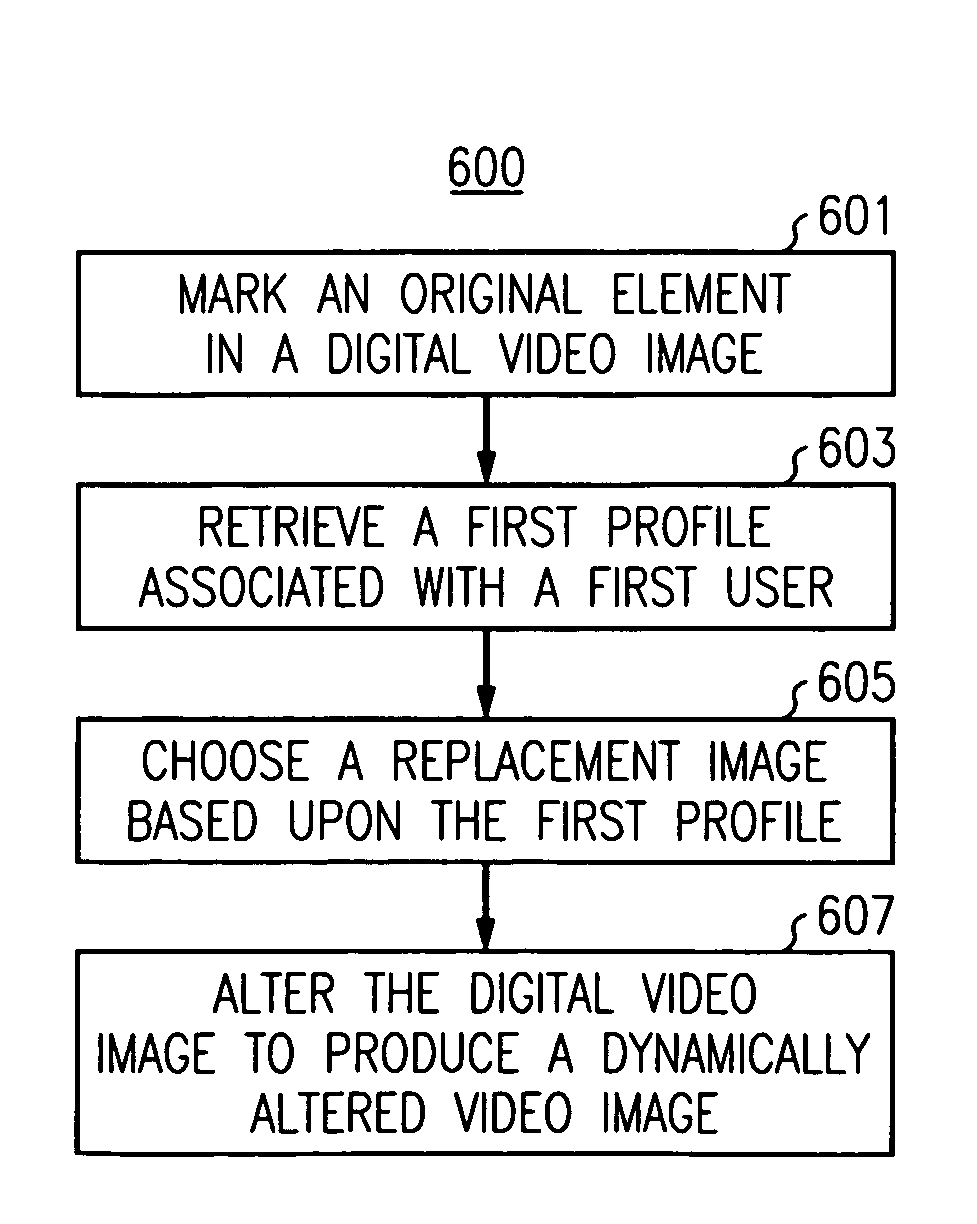

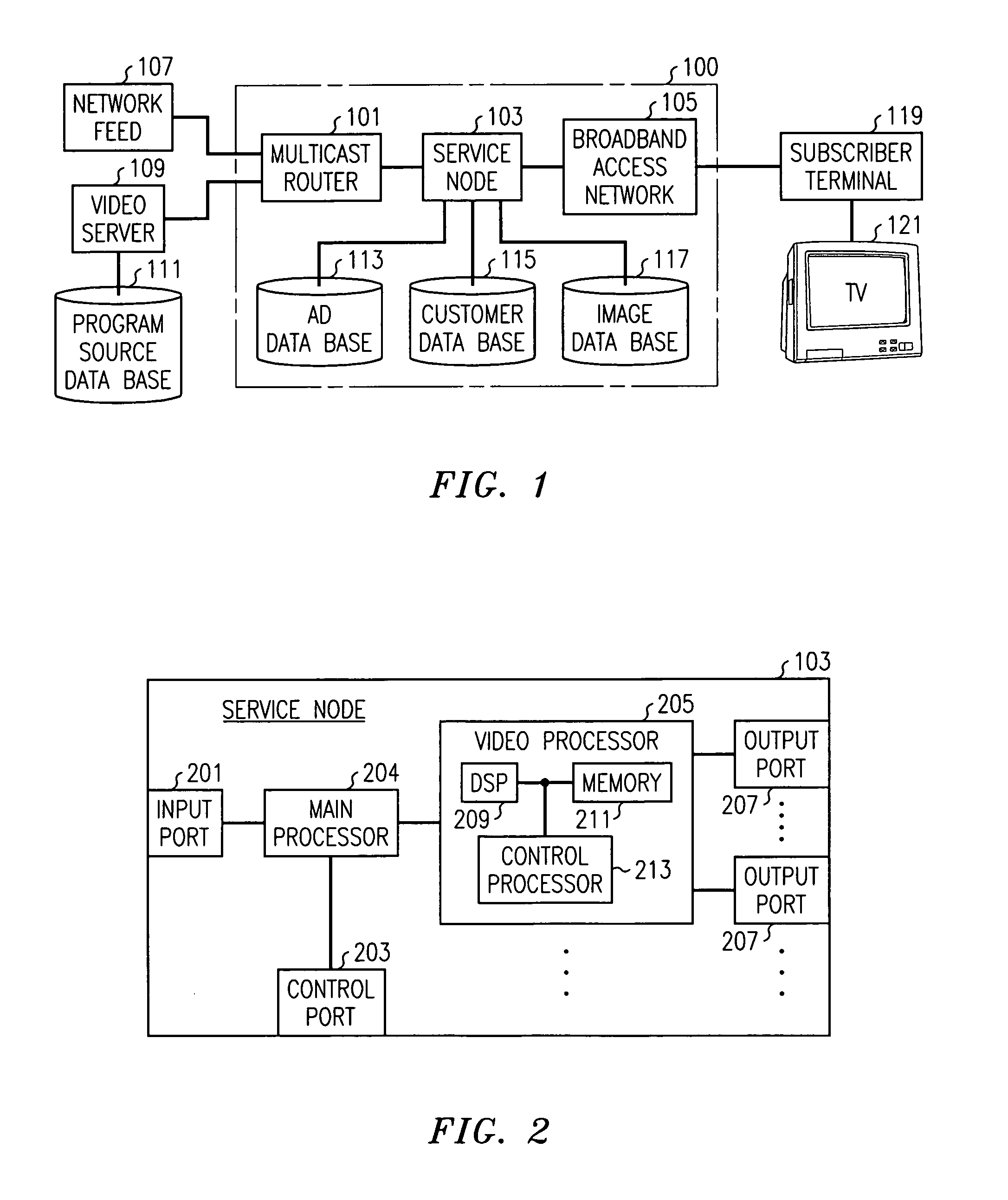

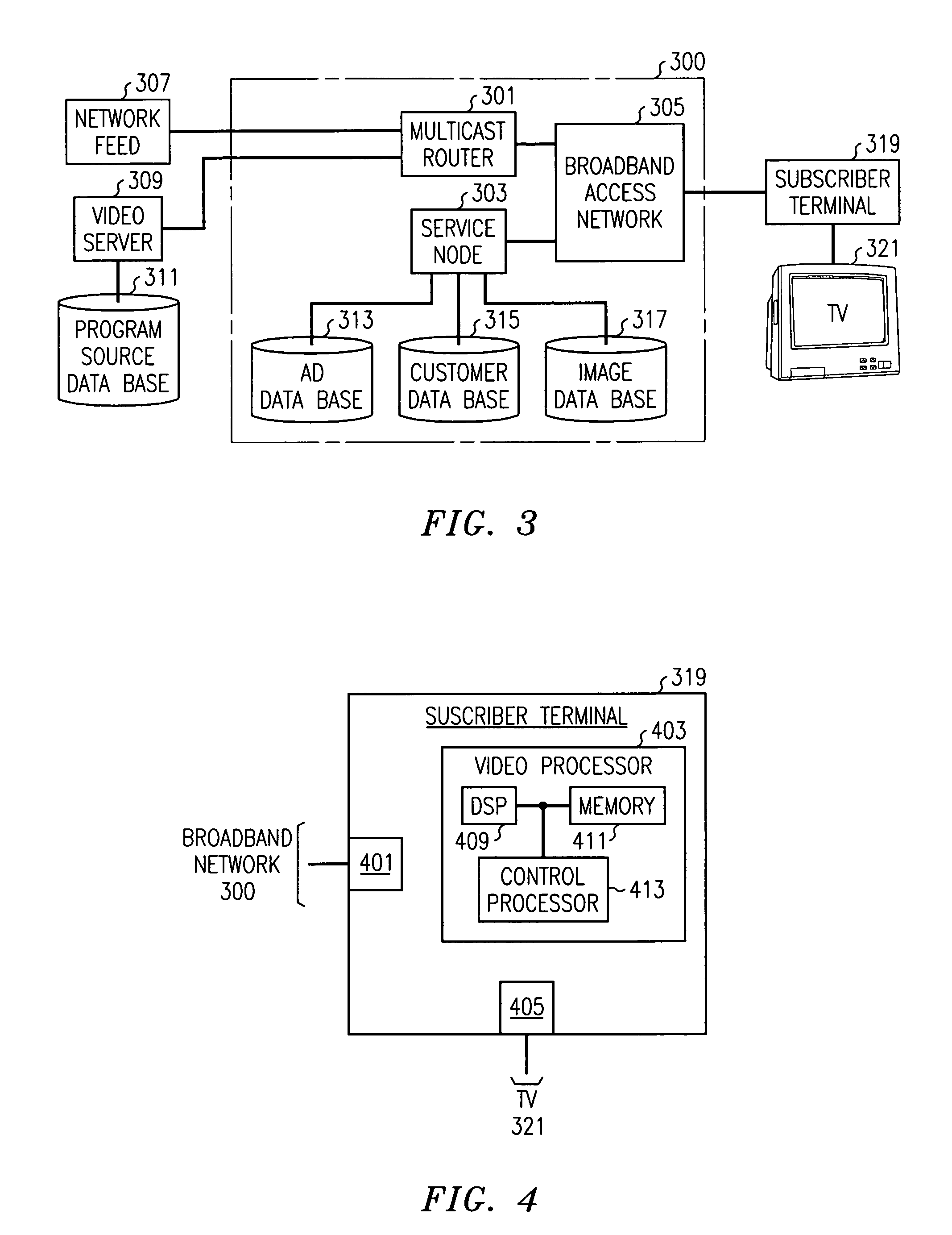

Method and apparatus for dynamically altering digital video images

InactiveUS7334249B1Reduce decreaseEfficient replacementBroadcast with distributionAnalogue secracy/subscription systemsDigital videoVideo processing

Owner:LUCENT TECH INC

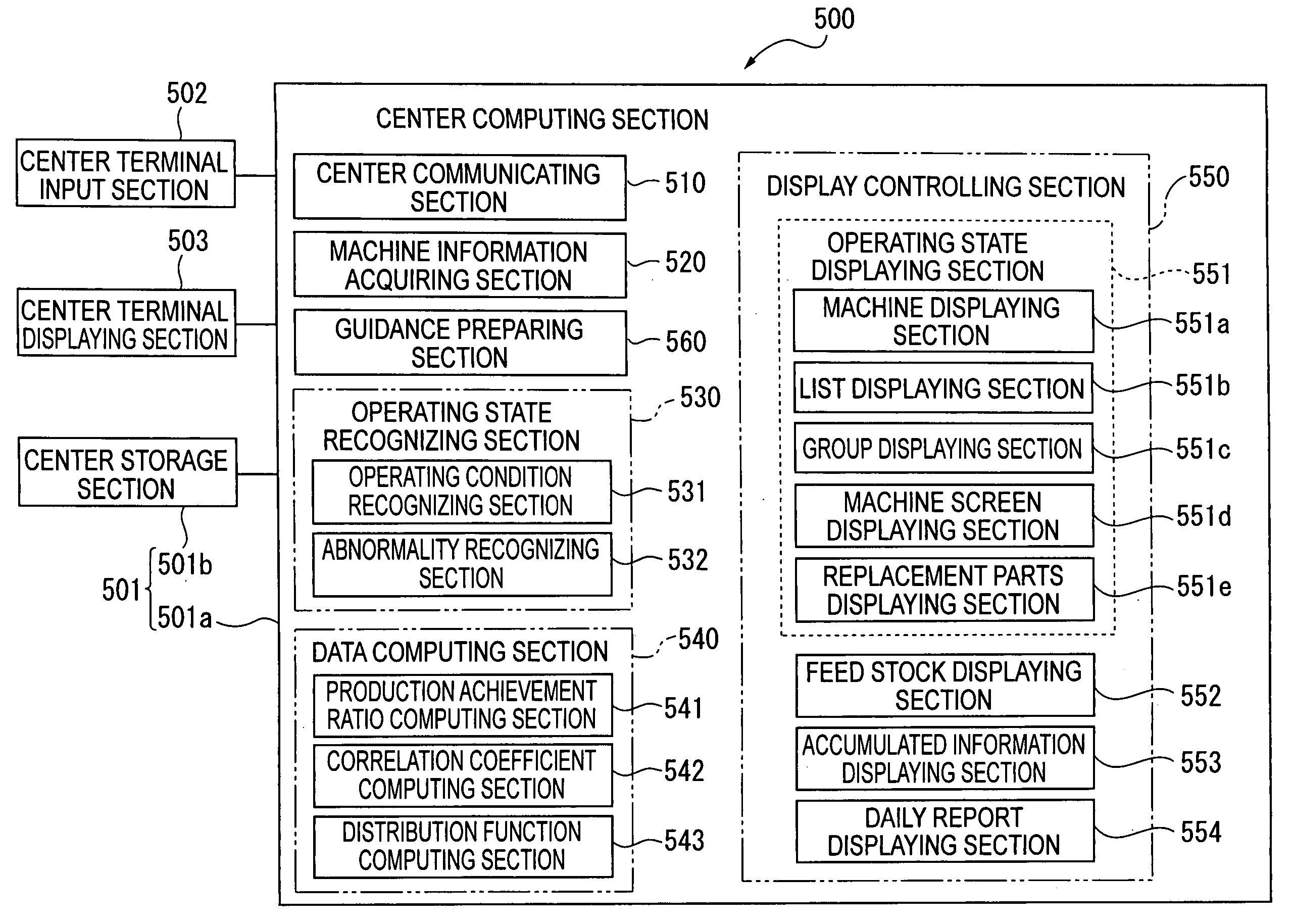

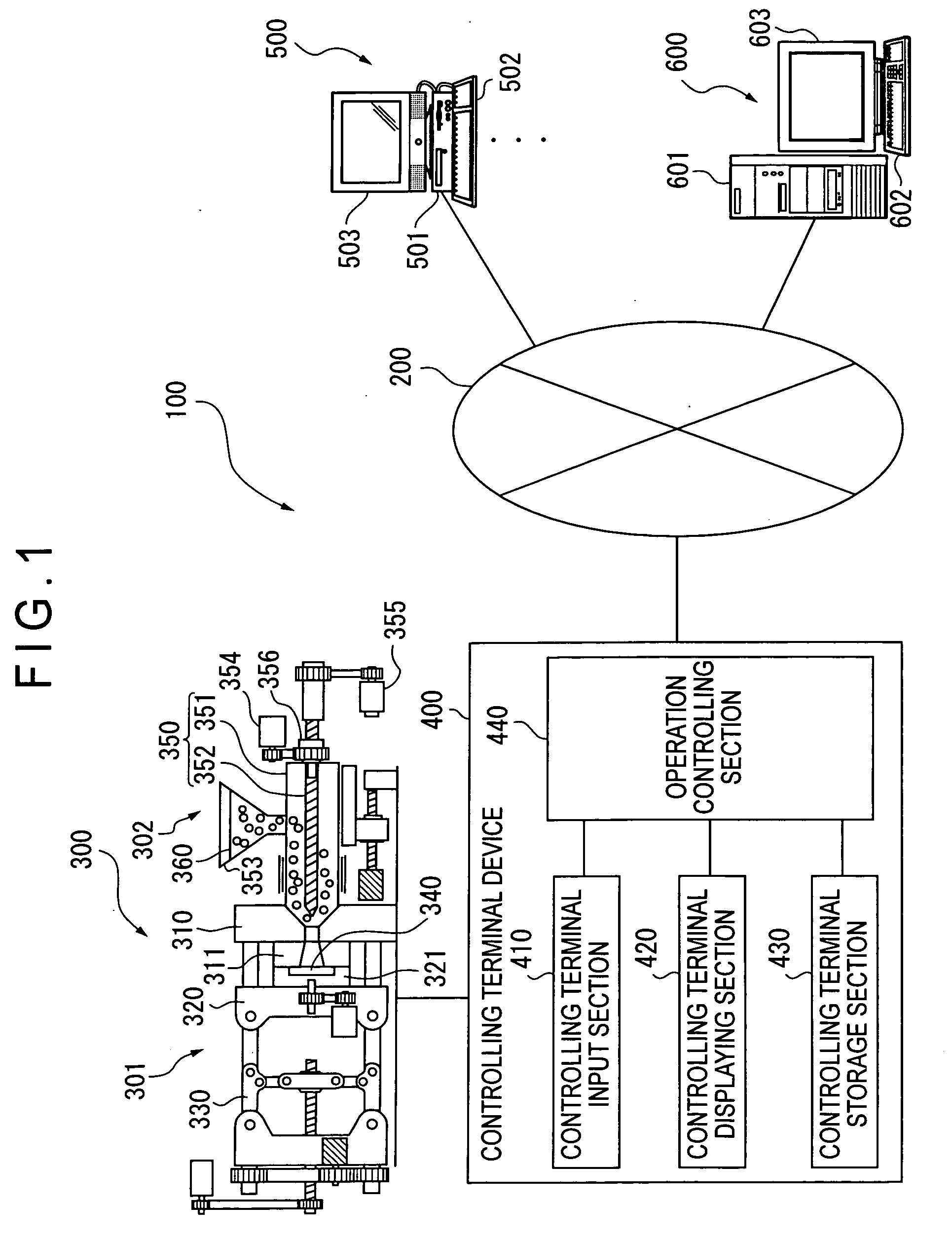

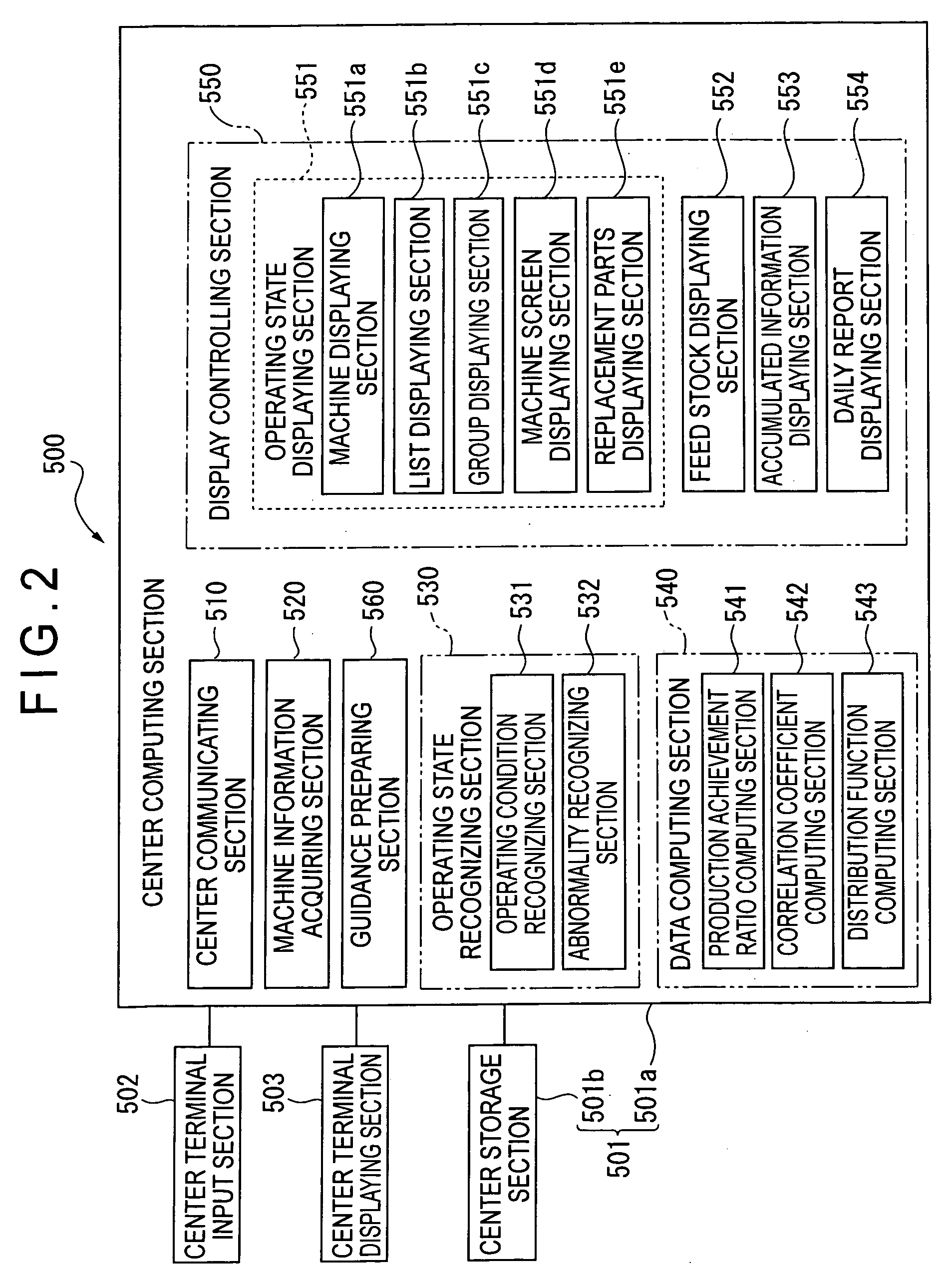

Management supporting apparatus, management supporting system, management supporting method, management supporting program, and a recording medium with the program recorded therein

ActiveUS20040148136A1Efficient replacementEasy to manageProgramme controlComputer controlSupporting systemManagement support systems

Operation state information for each cycle of manufacturing operations of each of injection molding machines 300 is acquired by a center management terminal device 400 via a network from a plurality of controlling terminal device 400 for controlling the injection molding machines 300. Cumulative utilization of replacement parts of each injection molding machine 300 put into practical operation is recognized by the operating condition recognizing section of the center management terminal device 400 based on the parts state information for the replacement parts of each injection molding machine 300 included in the operating state information. Based on the cumulative utilization, availability of the parts is recognized with reference to lifetime information concerning lifetime of the parts previously stored in the center storage section, and situation of the availability is displayed with a different display format on the center terminal displaying section 503.

Owner:TOSHIBA MASCH CO LTD

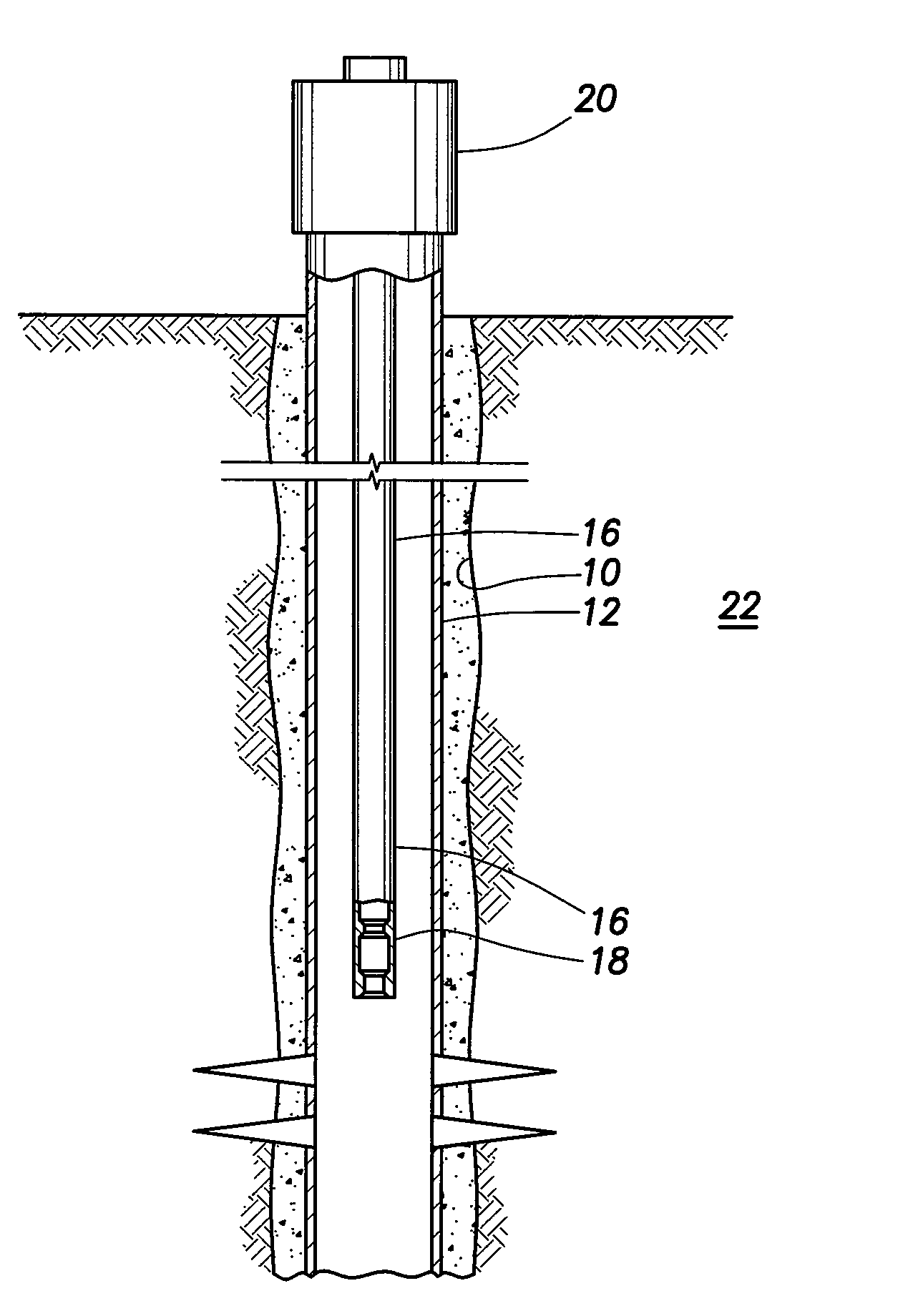

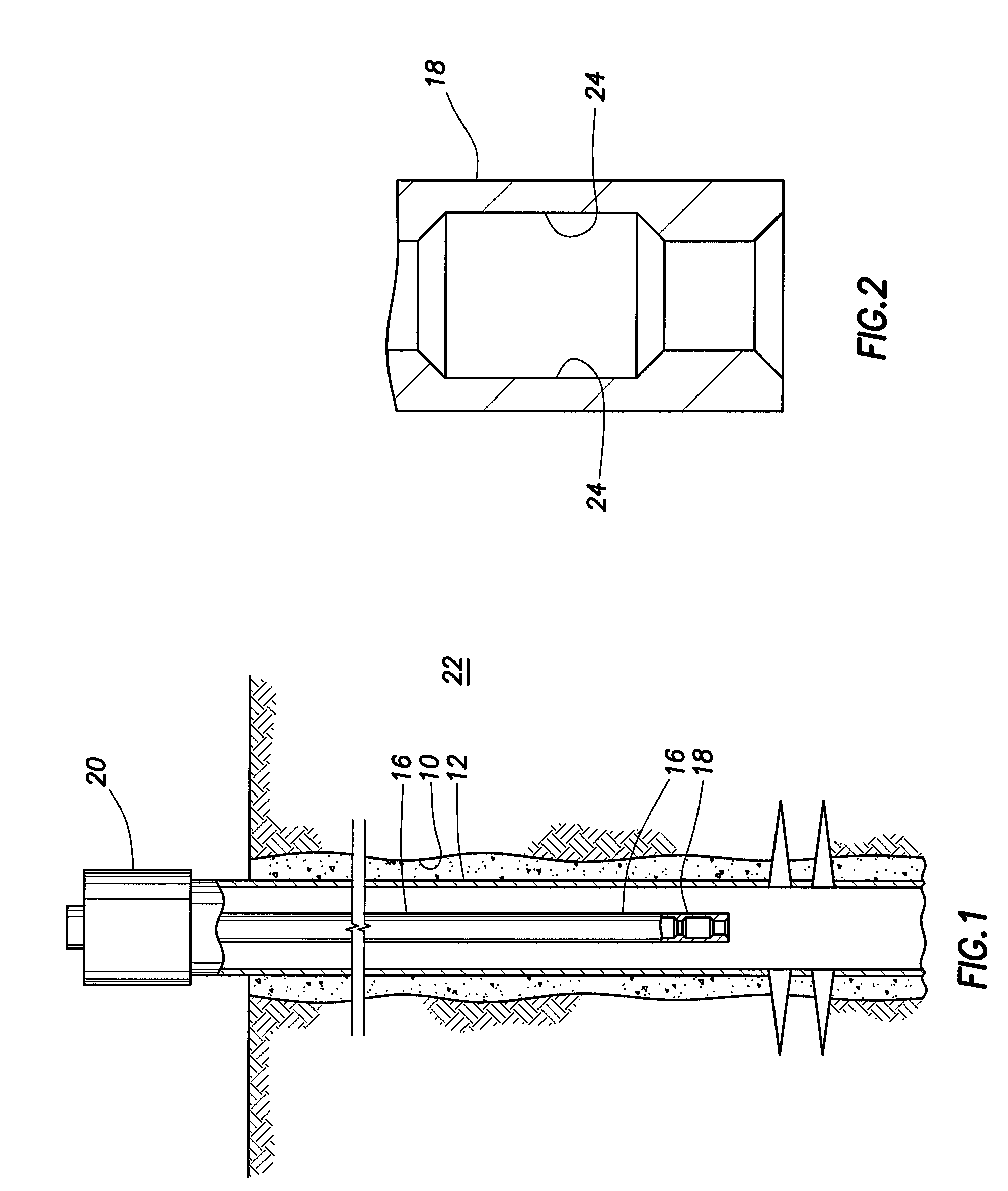

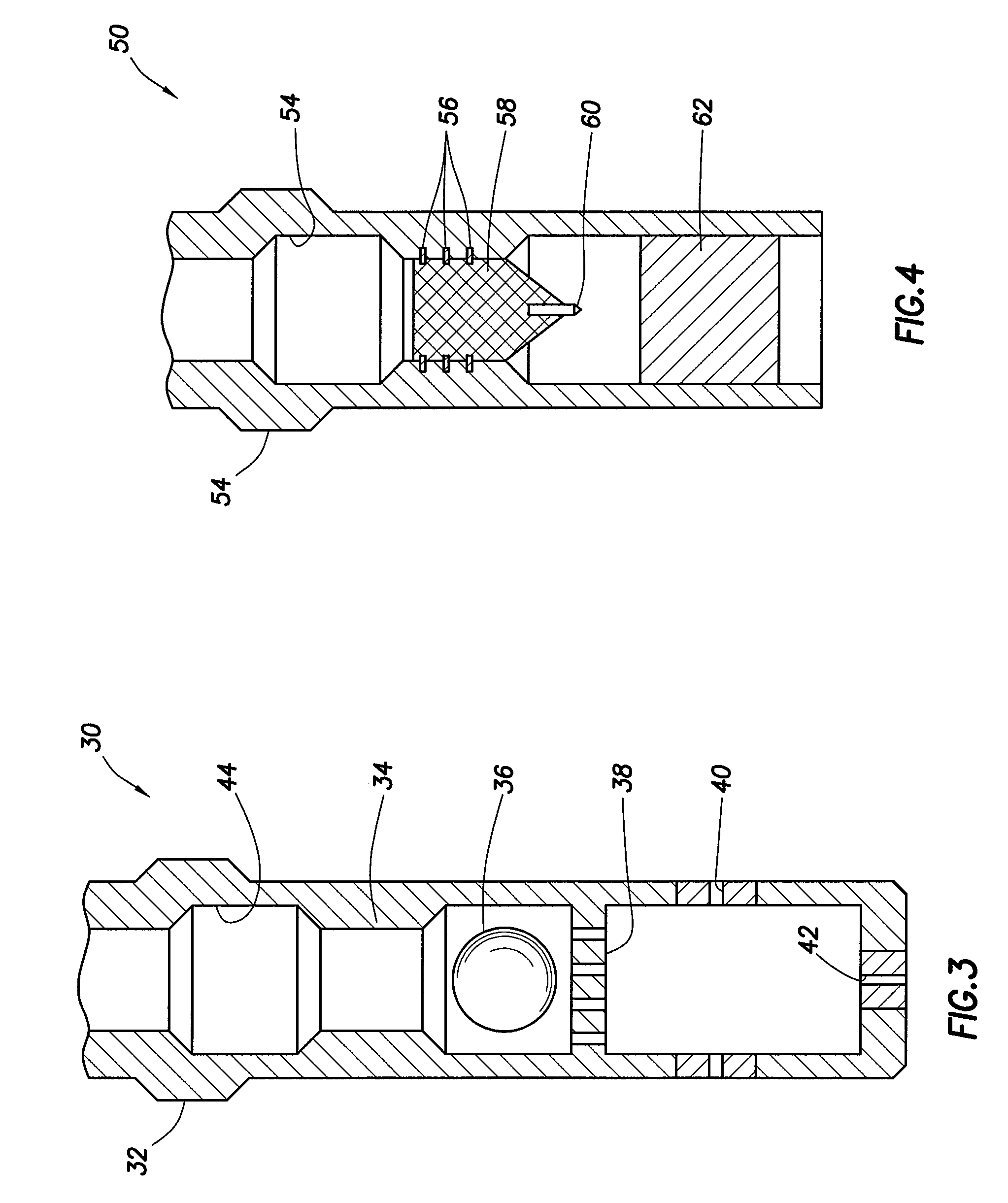

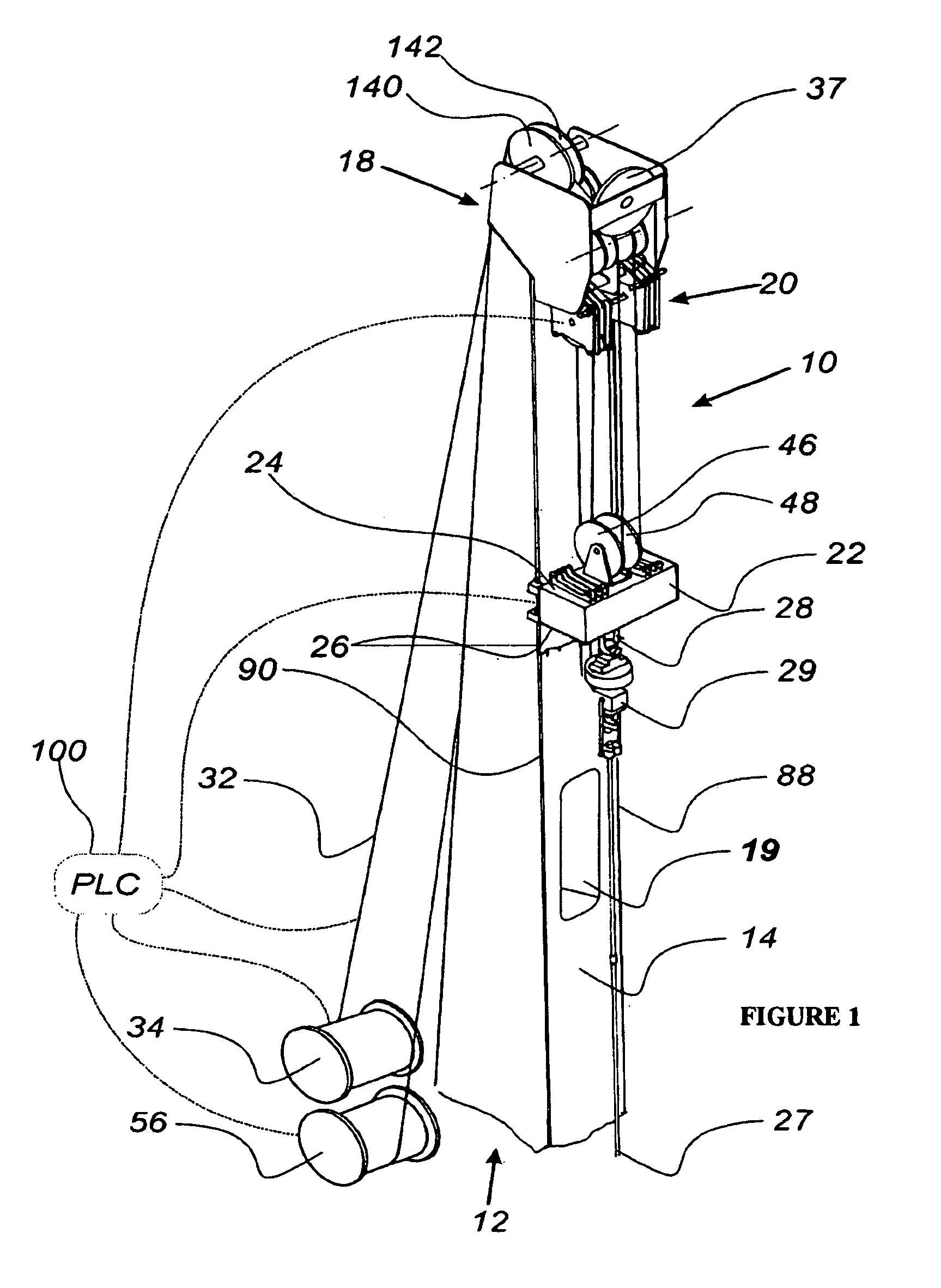

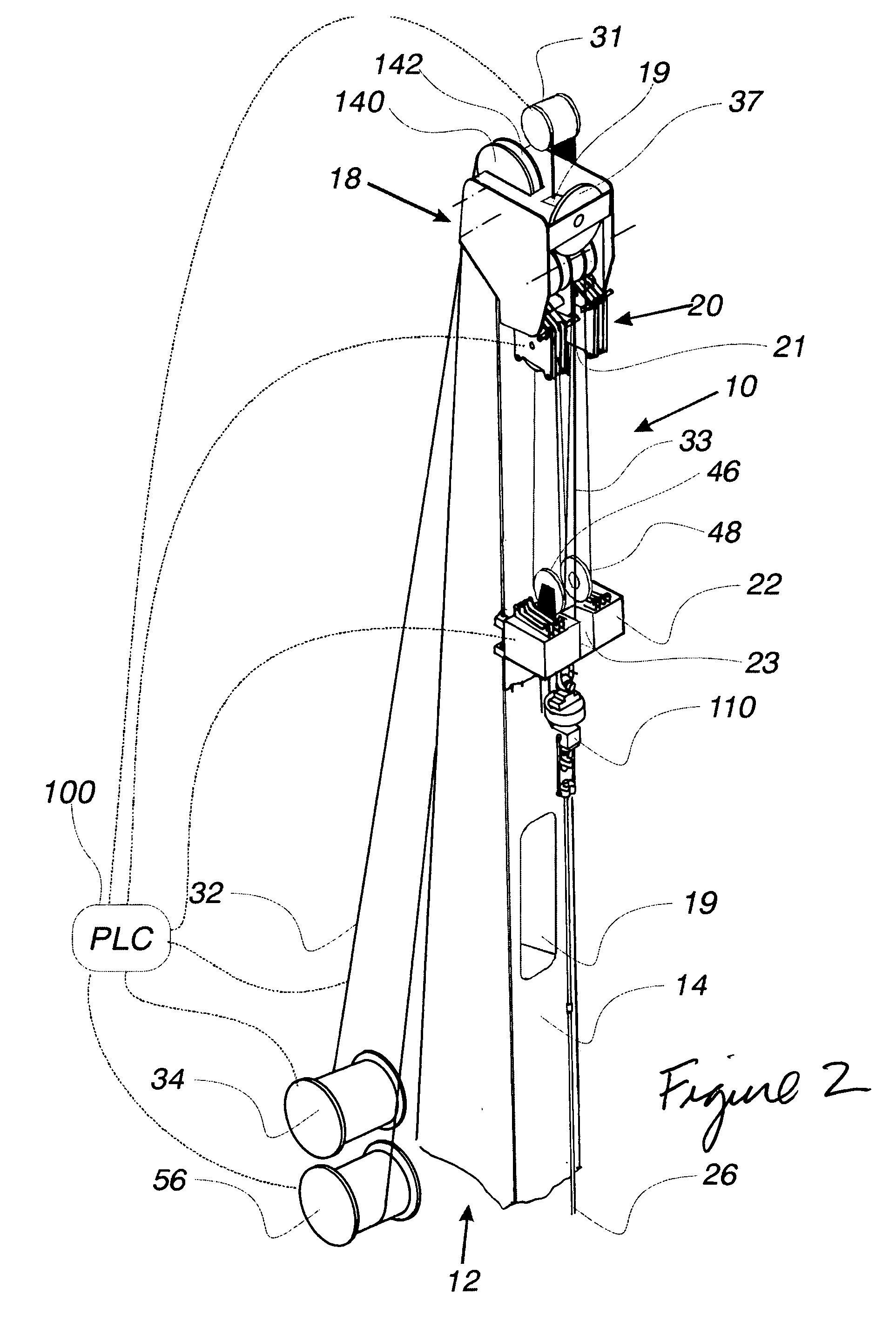

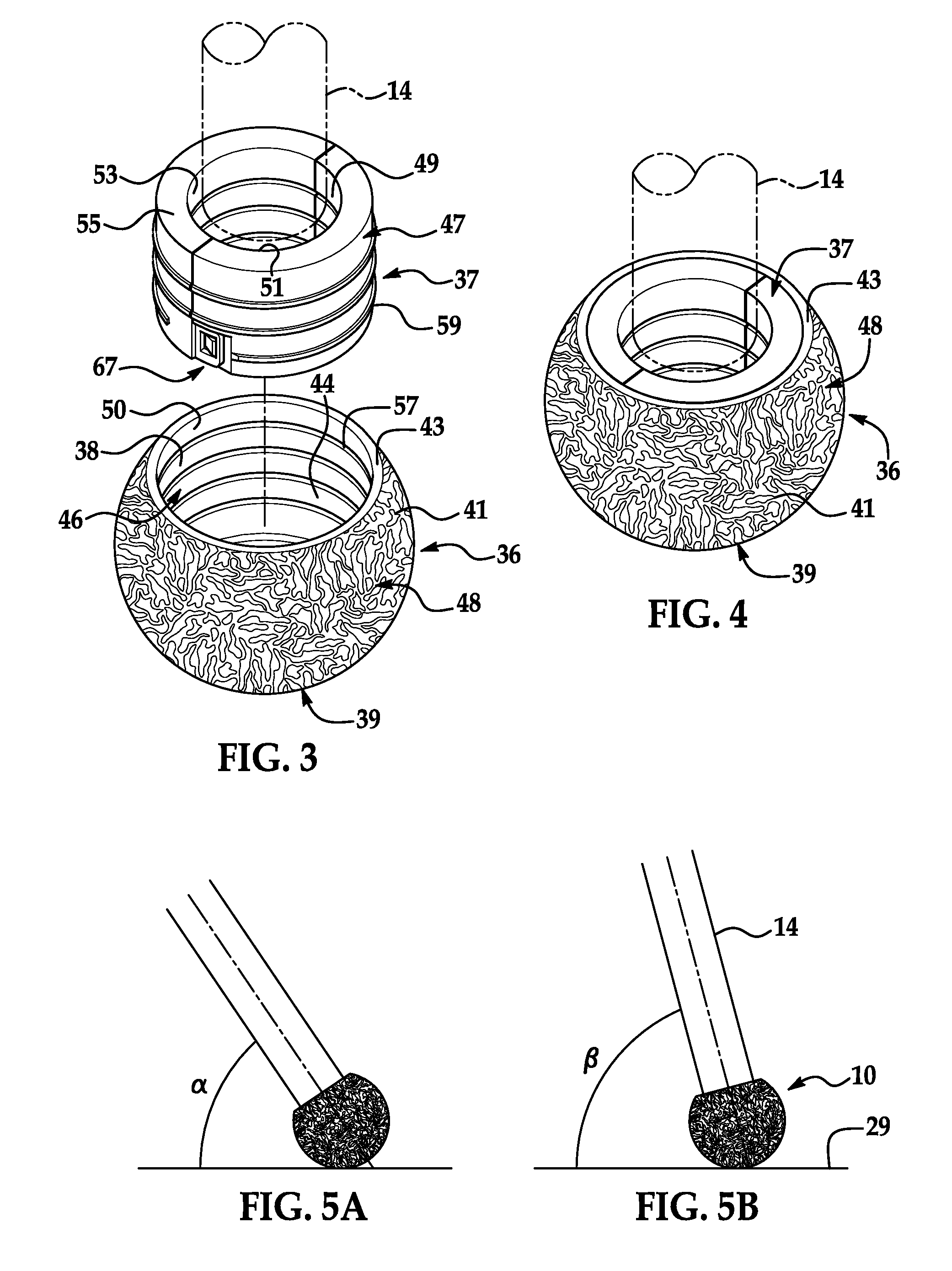

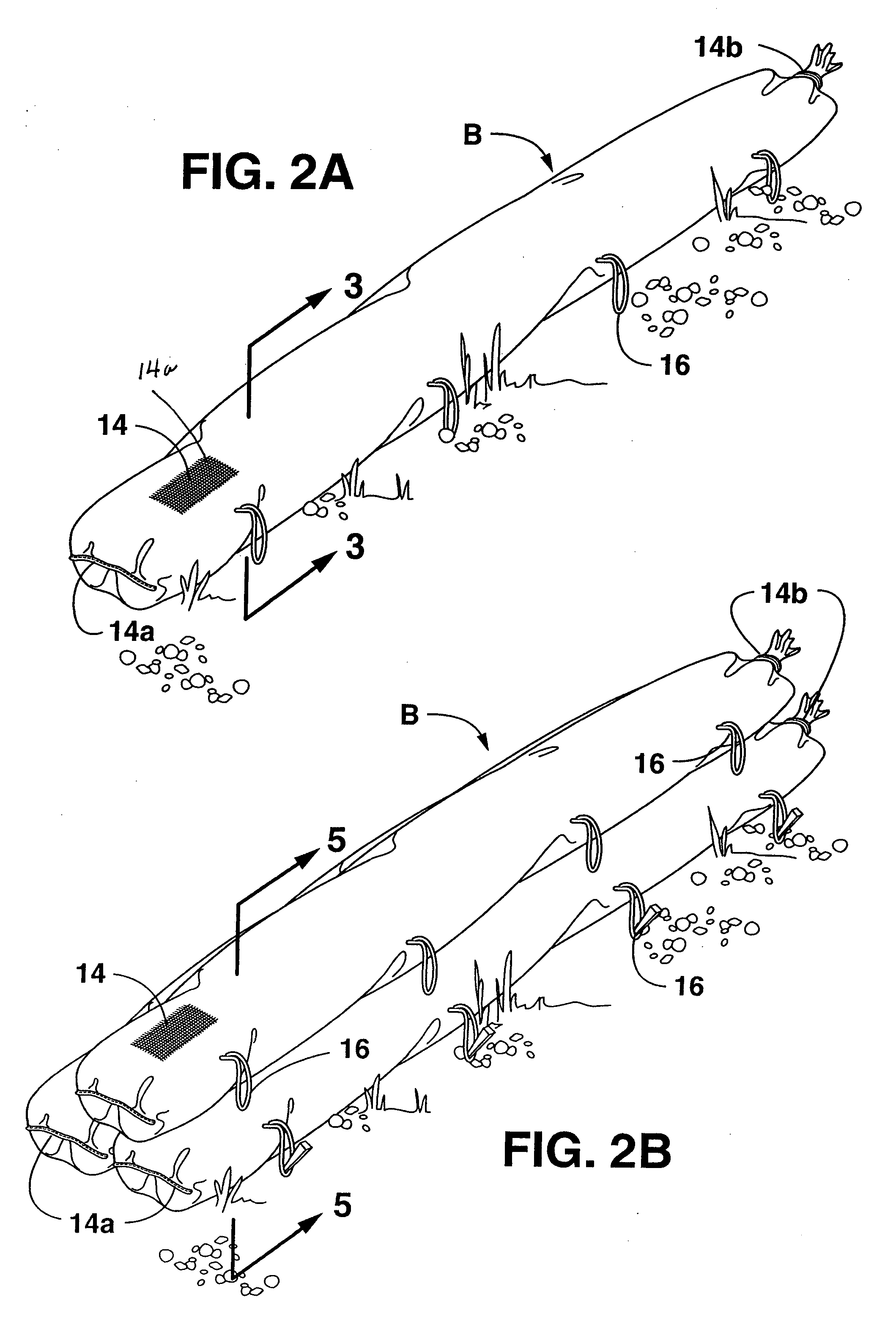

Method and Apparatus for Multi-Zone Stimulation

InactiveUS20100200230A1Prevent migrationTool be lowFluid removalSealing/packingEnvironmental geologyMaterial Perforation

Methods of treating a well bore in a single trip are provided. A tubing string may be inserted into a subterranean formation having a well bore, where the tubing string has a locking device on an end. A workover tool may be positioned in a first zone of the subterranean formation, where the workover tool engages the locking device. One or more perforations may be created or enhanced in a first zone of a subterranean formation using the workover tool, and the tubing string may be positioned in a second zone of the subterranean formation. A fracturing fluid may be introduced into the first zone of the subterranean formation at a rate and pressure sufficient to create or enhance one or more fractures in the subterranean formation. The first zone of the subterranean formation may be isolated from the second zone of the subterranean formation and one or more perforations in the second zone of the subterranean formation may be created or enhanced using the workover tool.

Owner:HALLIBURTON ENERGY SERVICES INC

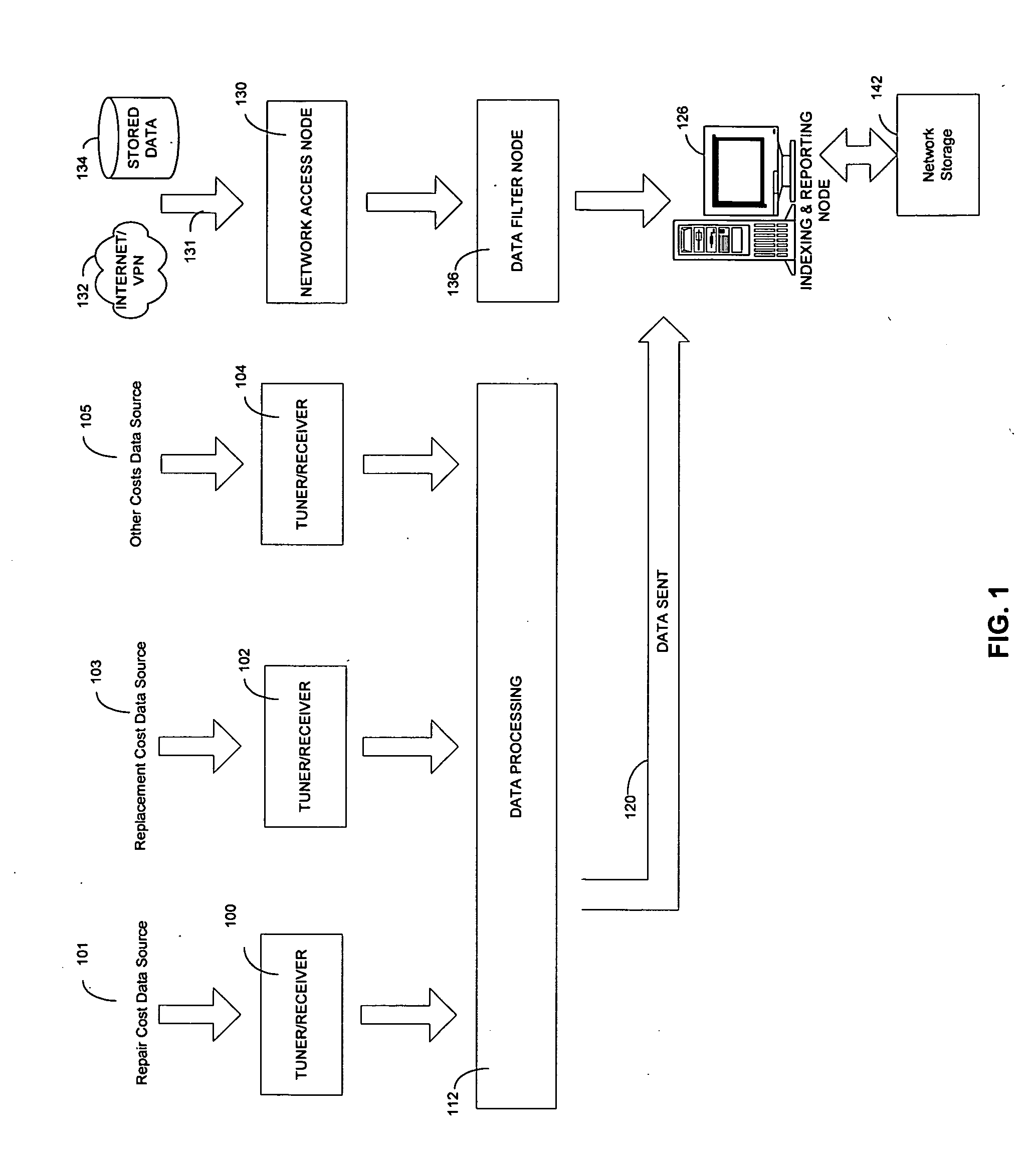

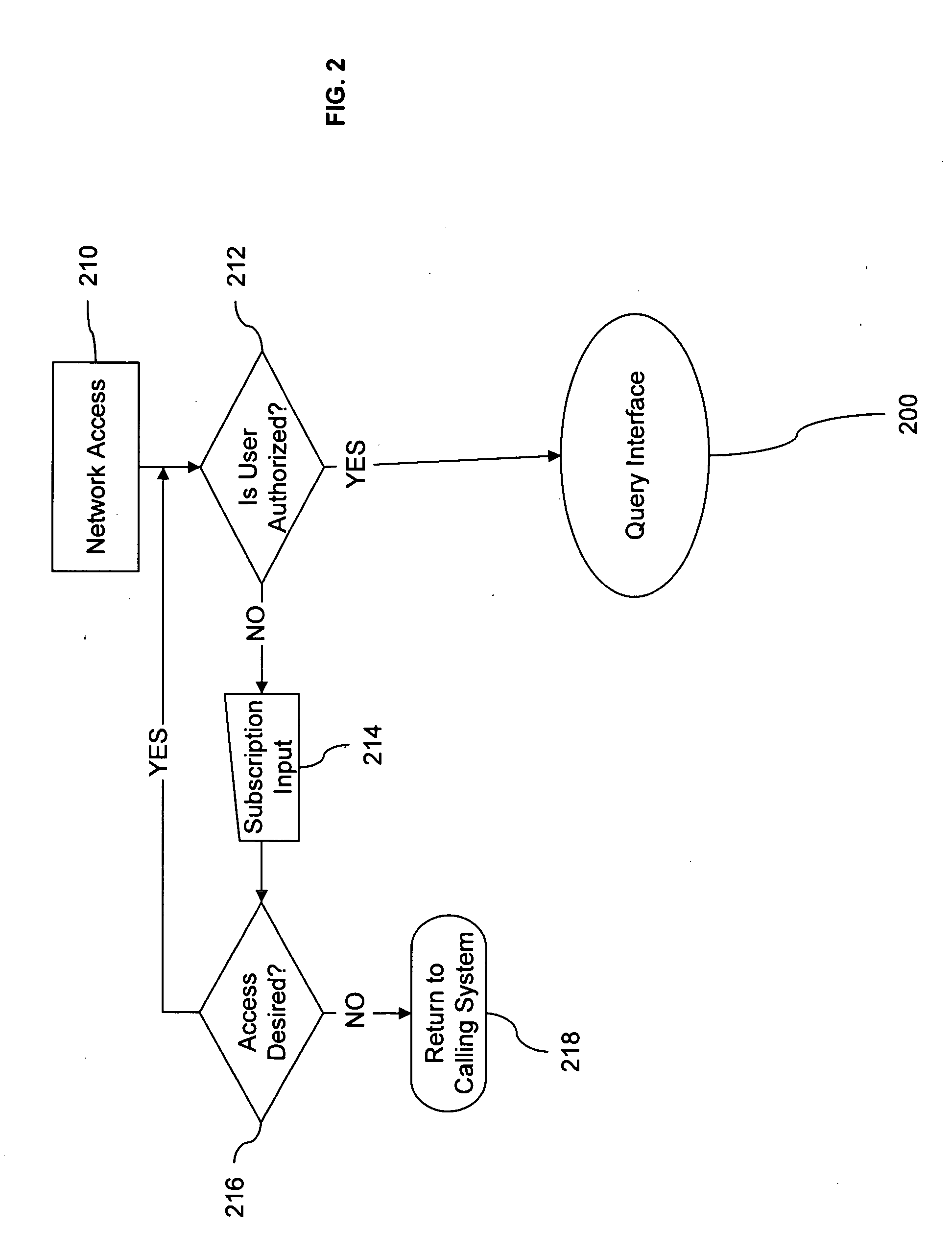

System and method for salvage calculation, fraud prevention and insurance adjustment

InactiveUS20080097796A1Improved claim file documentationReduce frequency and likelihoodFinanceTime informationComputer science

Disclosed is a novel system and method that provides real time information to an insurance adjuster. The system obtains information related to an insured item which has an outstanding claim. Information includes the cost to repair a specific item, the salvage value of the item, and the cost to replace the item. The system then compares the information related to the insured item from an economic perspective to determine whether it should be repaired or replaced. Since the system is objective, it reduces the reliance on subjective human factors such as collusion and lack of expertise. As a result, the system reduces the number of fraudulent and inaccurate transactions related to the specific item.

Owner:HARTFORD FIRE INSURANCE

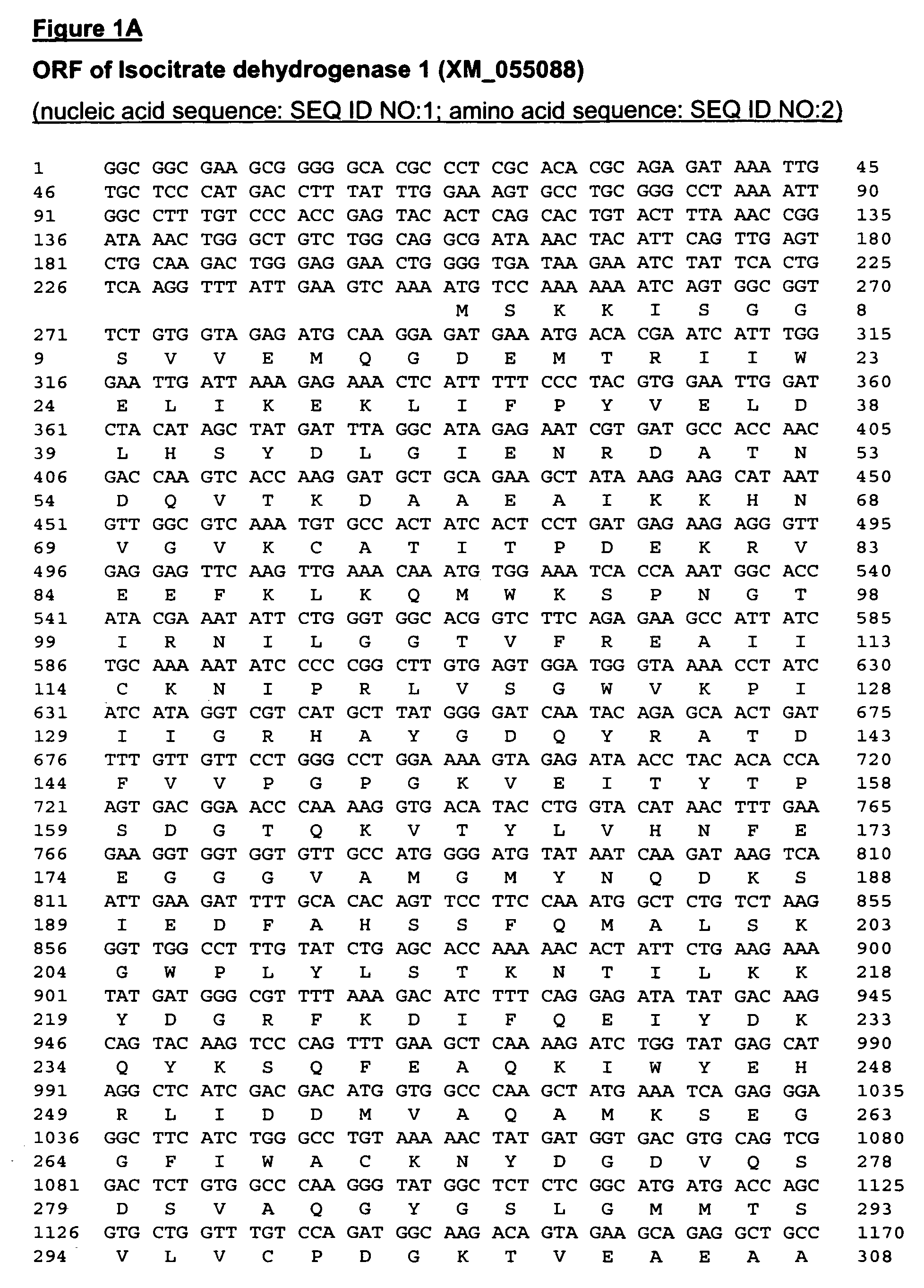

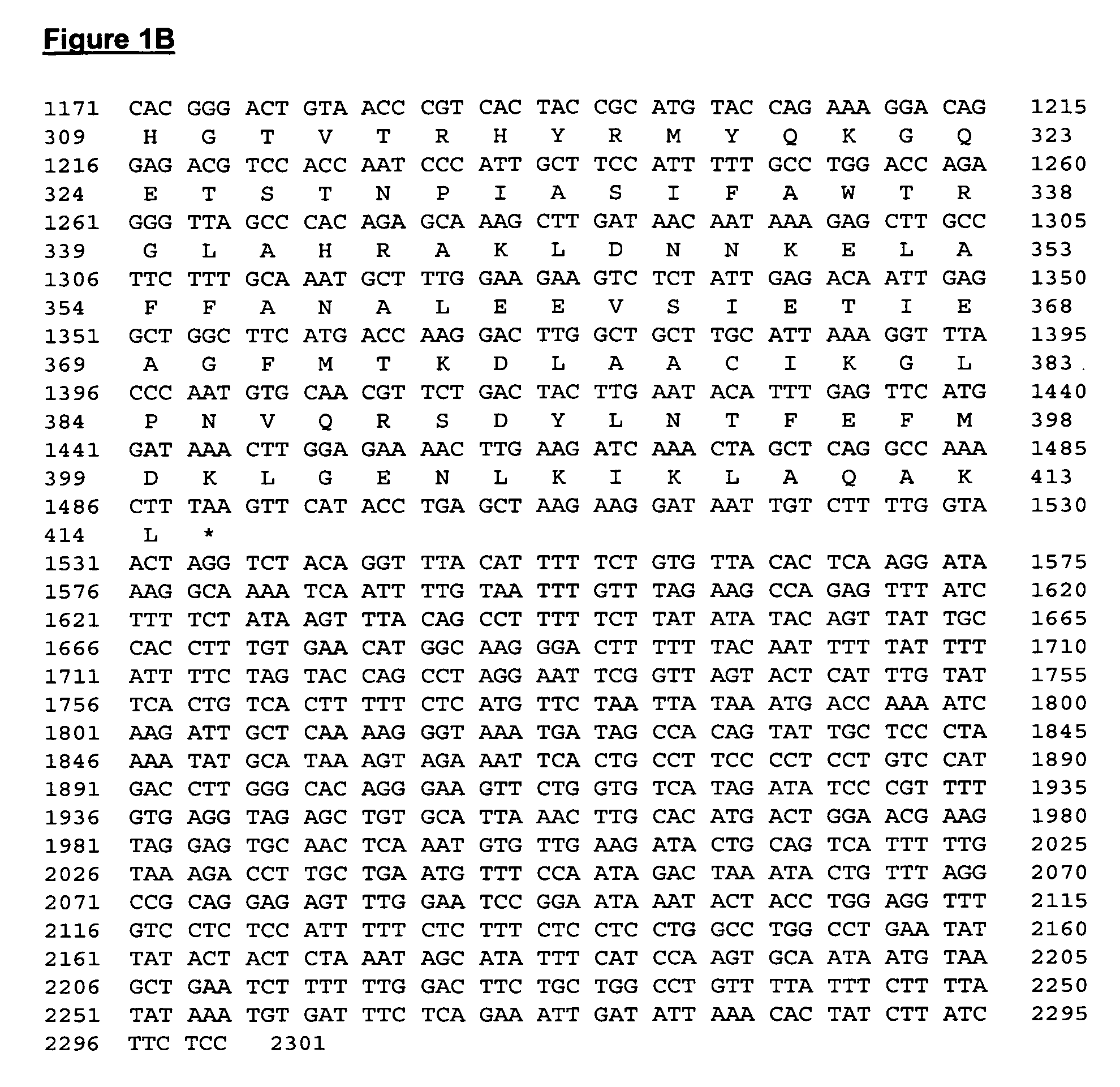

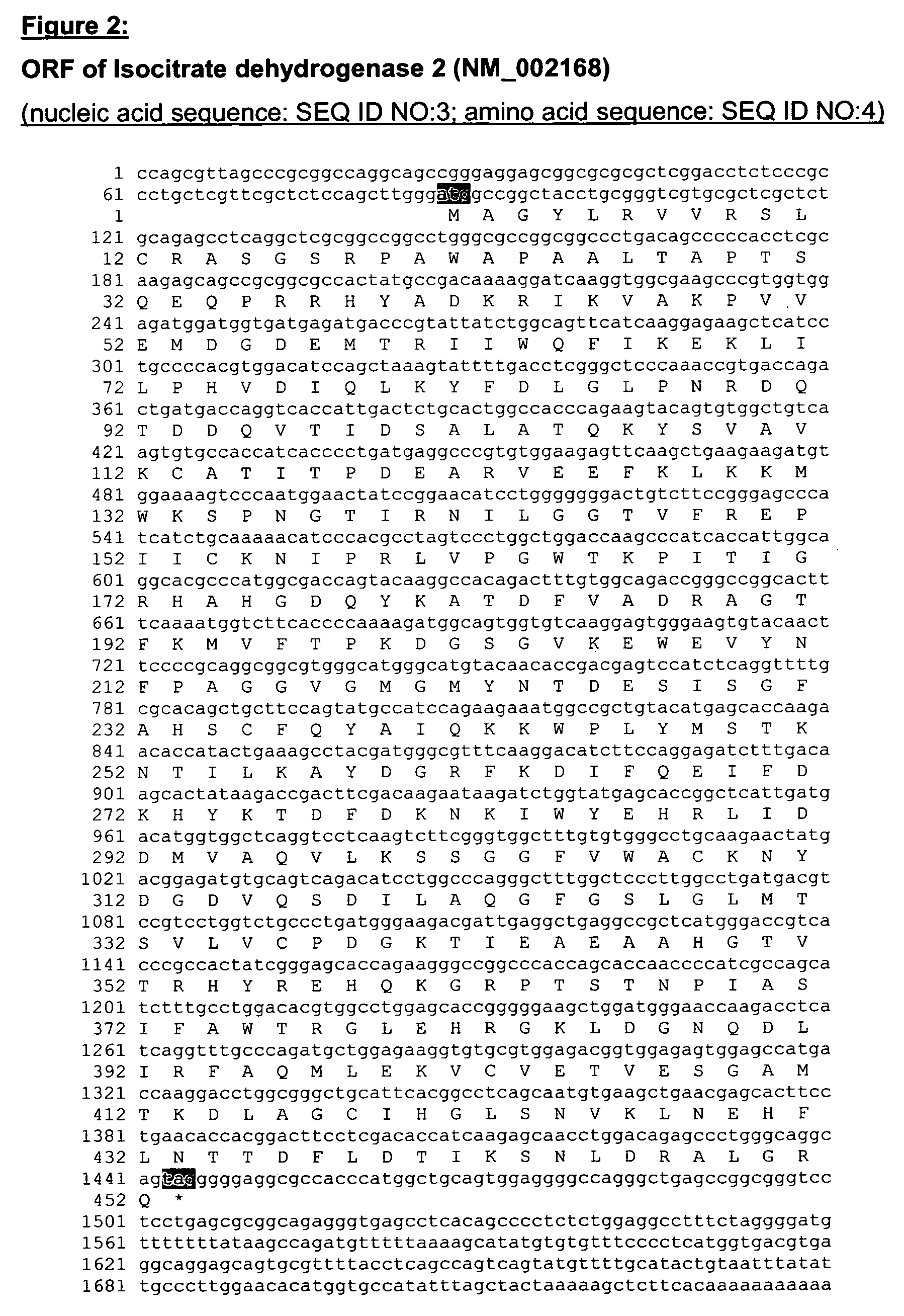

Isociatrate dehydrogenase and uses therof

InactiveUS20080300208A1Positive viabilityPromote cell deathOrganic active ingredientsSugar derivativesDiseaseApoptosis

Owner:QUARK FARMACUITIKALS INC

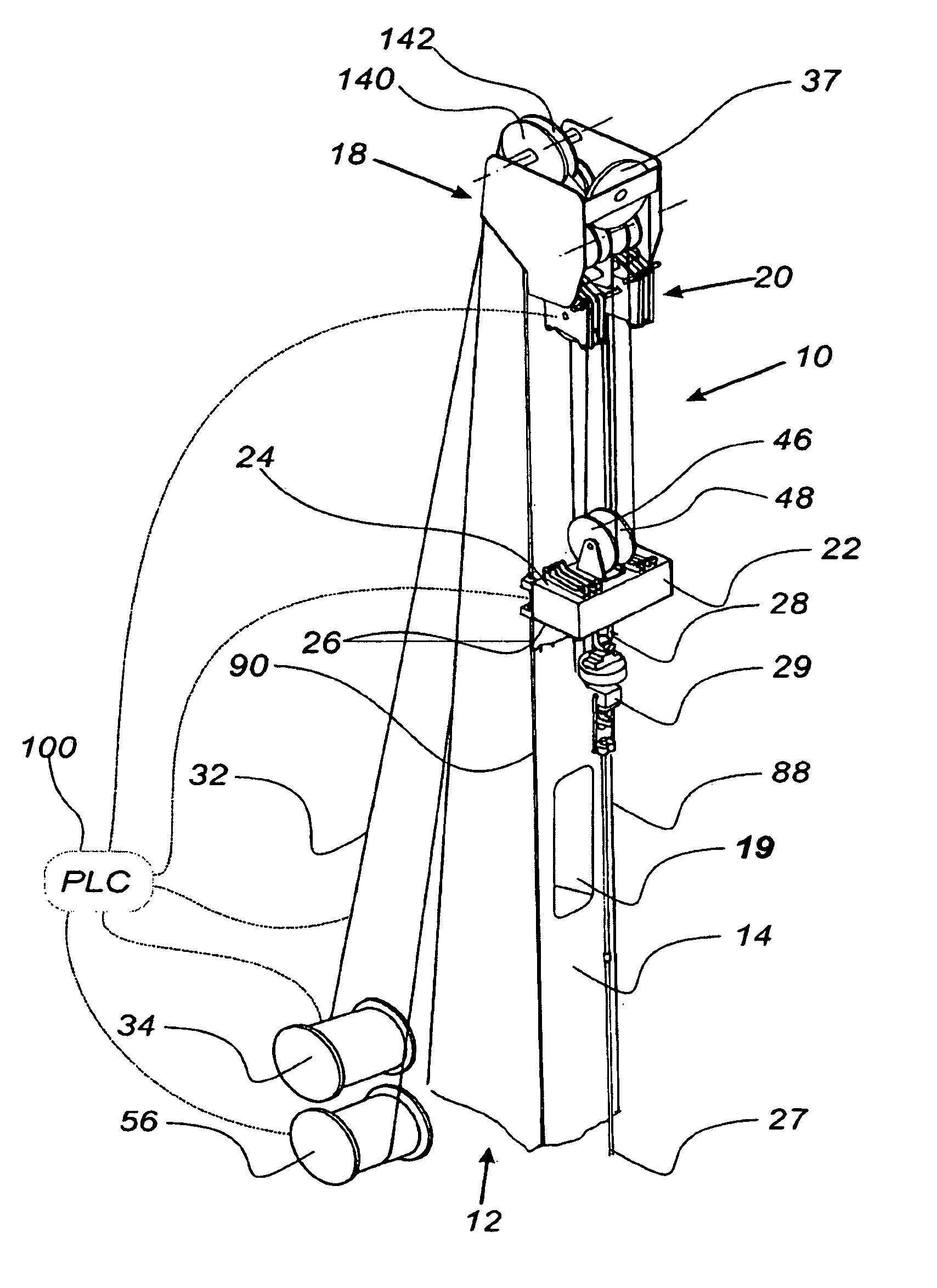

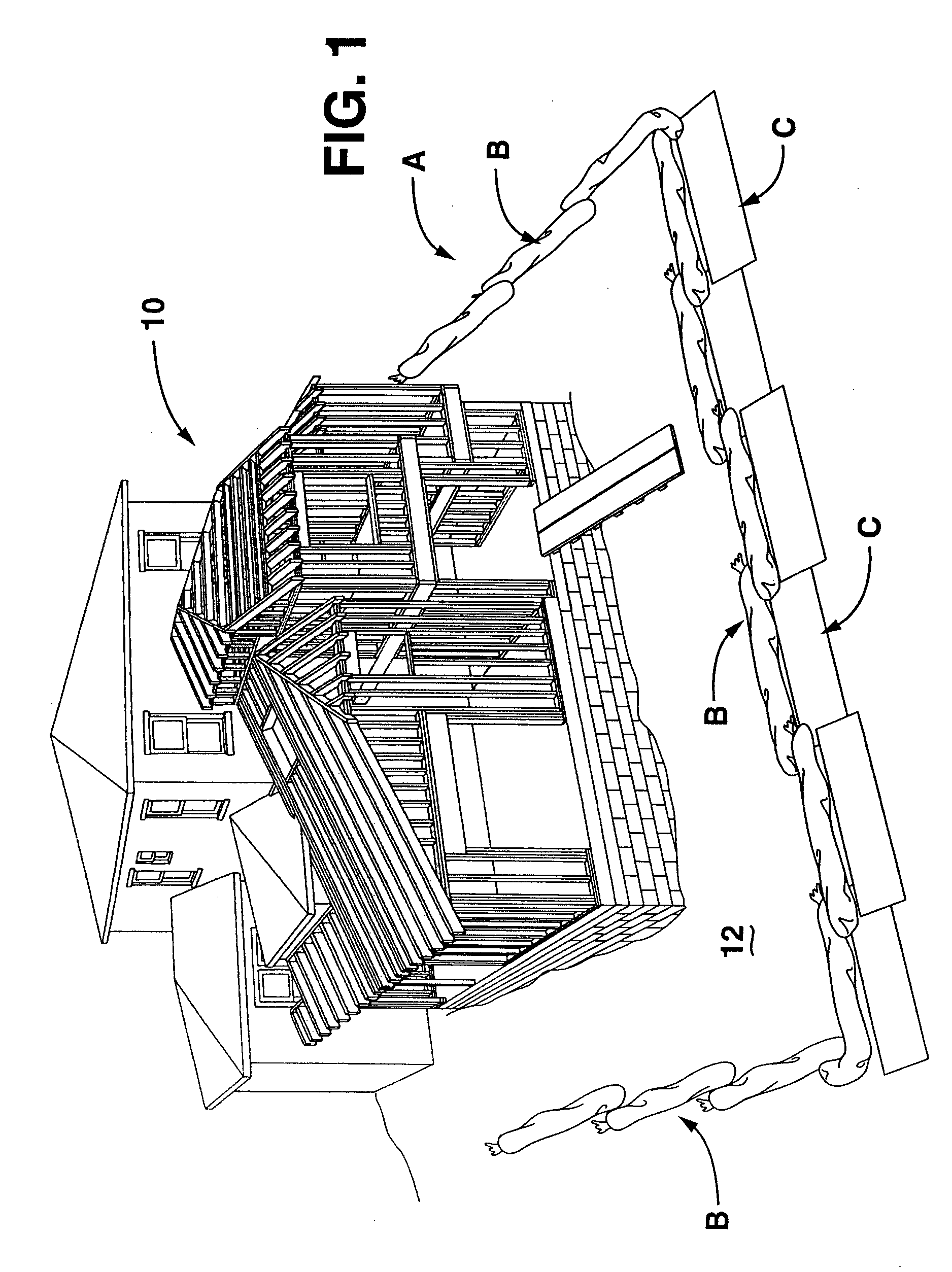

Hoist system

The invention is a hoist system for use on a drilling rig made of a tubular mast with a front, back, and top side, a splittable block connected to the mast top side, a trolley with a trolley top and bottom side, wherein the trolley's top side is connected to the splittable block and wherein the trolley is removably secured on the mast's front side, a gripper connected to the trolley bottom side for gripping a load, a hoist cable passing through the splittable block and connected on one end to a hoist cable winch, and a hoist cable winch adapted to pull the hoist cable over the mast top side and through the splittable block to move the trolley relative to the tubular mast and lift the load.

Owner:ITREC BV

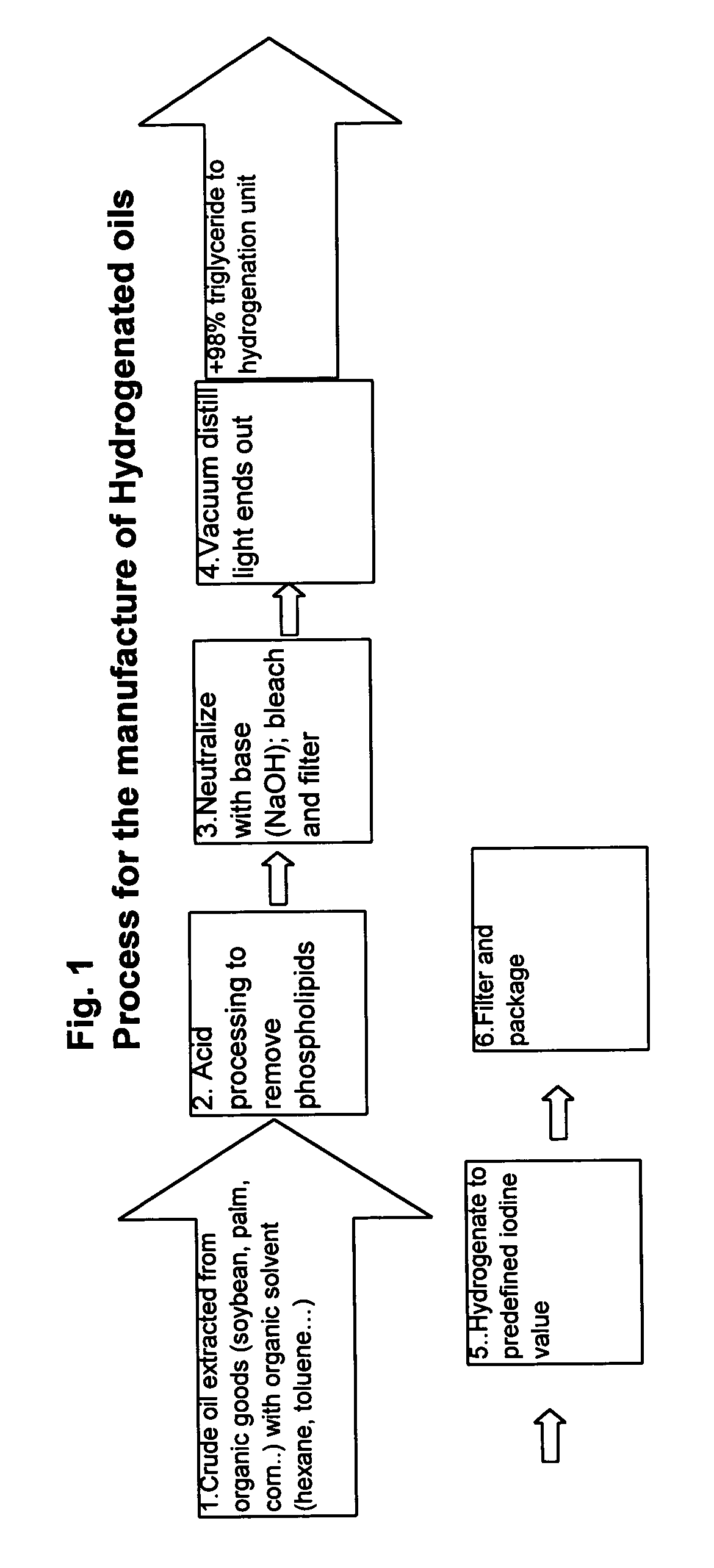

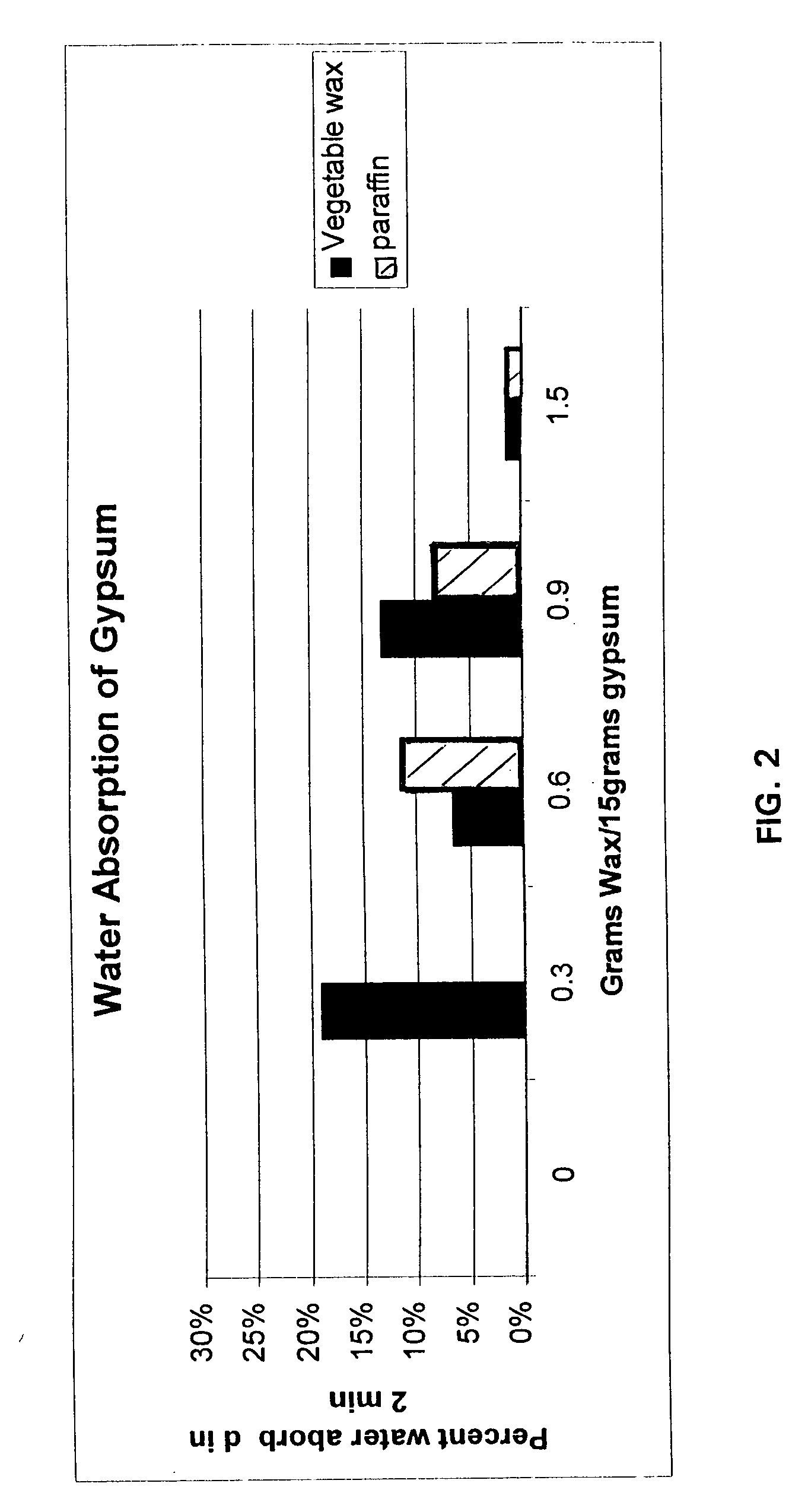

Additive to render gypsum board moisture resistant

InactiveUS20060196391A1Improve waterproof and moisture-proof performanceMore water resistantBuilding componentsCoatingsStearic acidMoisture barrier

Waxes prepared from hydrogenated plant oils, such as palm and soybean, are used to render gypsum board resistant to water. Unlike petroleum-derived waxes used for the same purpose, vegetable derived waxes are renewable and readily converted into forms such as emulsions or powder that facilitate incorporation into gypsum board manufacturing. Such water resistant materials are characterized by enhanced moisture barrier properties. The compositions have a low iodine value (between 2-5), and melting points between approximately 120-185 degrees F. (Mettler Drop Point). The wax comprises a triglyceride whose fatty acids are predominantly stearic acid (C18). The composition is used as an additive in the manufacture of water resistant gypsum board.

Owner:HRD CORP

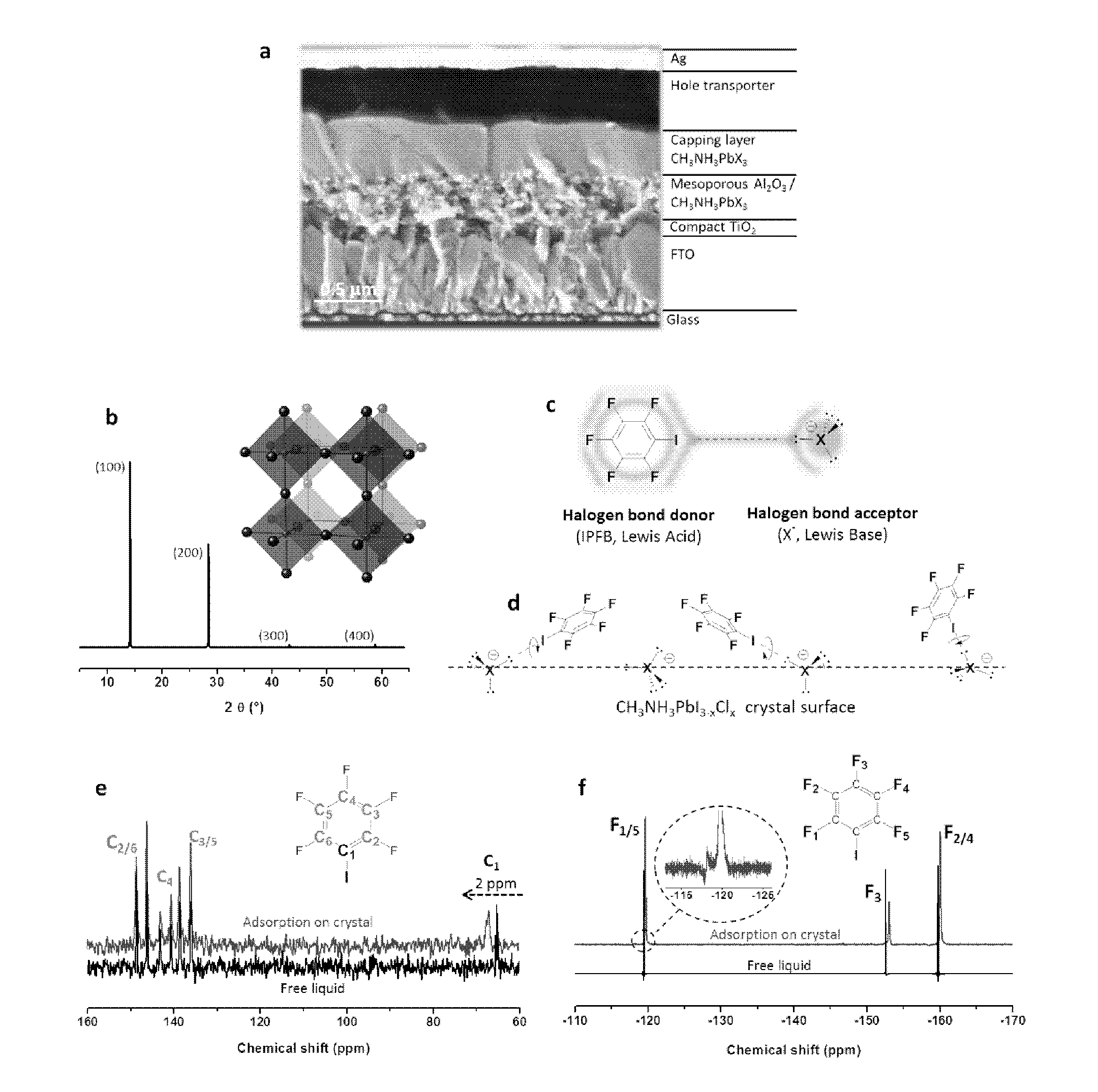

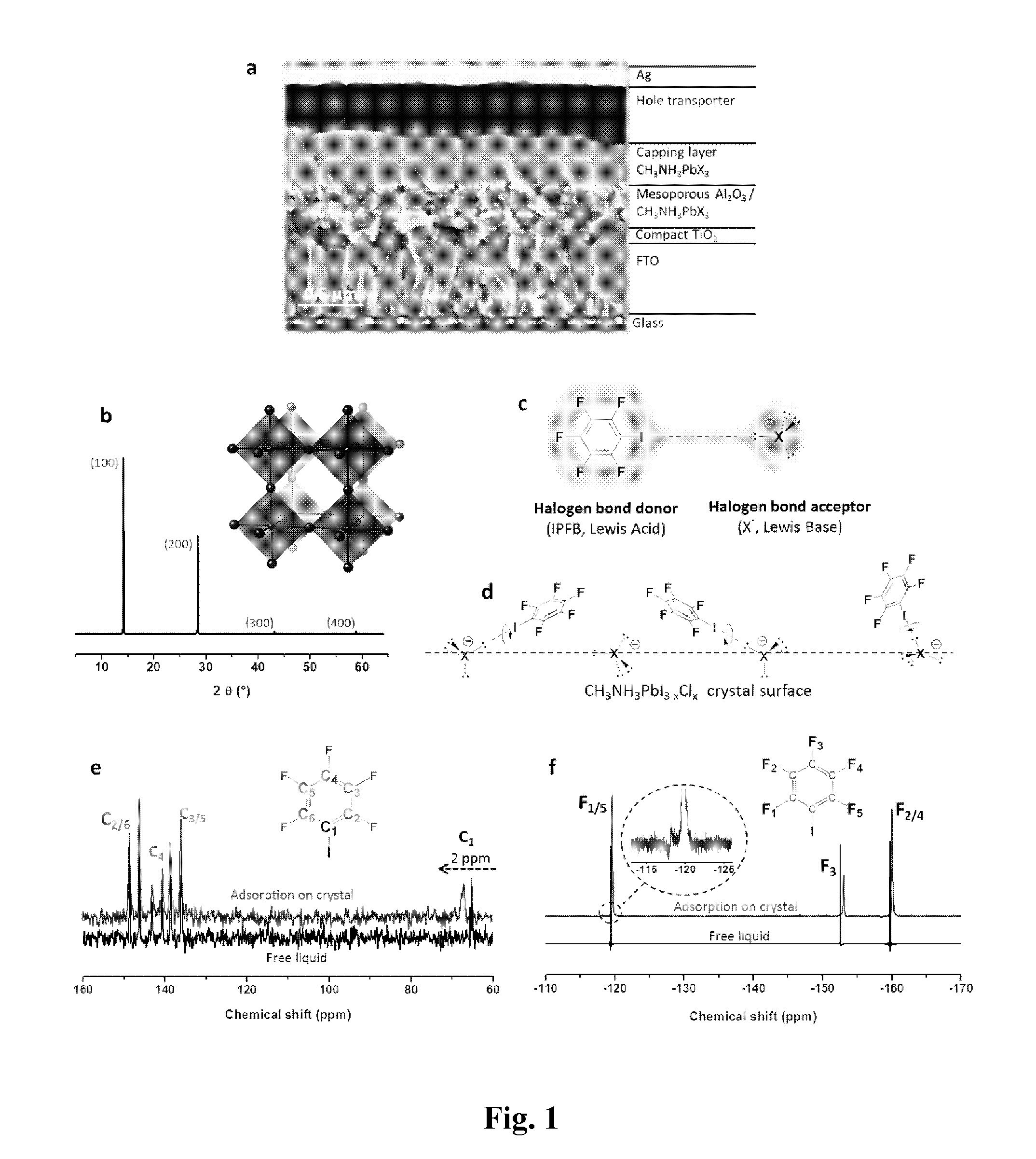

Photovoltaic device comprising a metal halide perovskite and a passivating agent

ActiveUS20160380125A1Enhanced photoluminescenceReduce defect densityFinal product manufactureSolid-state devicesSimple Organic CompoundsMetal halides

The present invention relates to devices comprising metal halide perovskites and organic passivating agents. In particular, the invention relates to photovoltaic and optoelectronic devices comprising passivated metal halide perovskites. The device according to the invention comprises: (a) a metal halide perovskite; and (b) a passivating agent which is an organic compound; wherein molecules of the passivating agent are chemically bonded to anions or cations in the metal halide perovskite. The invention also provides a process for producing a photovoltaic device, which photovoltaic device comprises: (a) a metal halide perovskite; and (b) a passivating agent which is an organic compound; wherein molecules of the passivating agent are chemically bonded to anions or cations in the metal halide perovskite, wherein the process comprises treating a metal halide perovskite with a passivating agent, which passivating agent is an organic compound and is suitable for chemically bonding to anions or cations in the metal halide perovskite.

Owner:OXFORD UNIV INNOVATION LTD

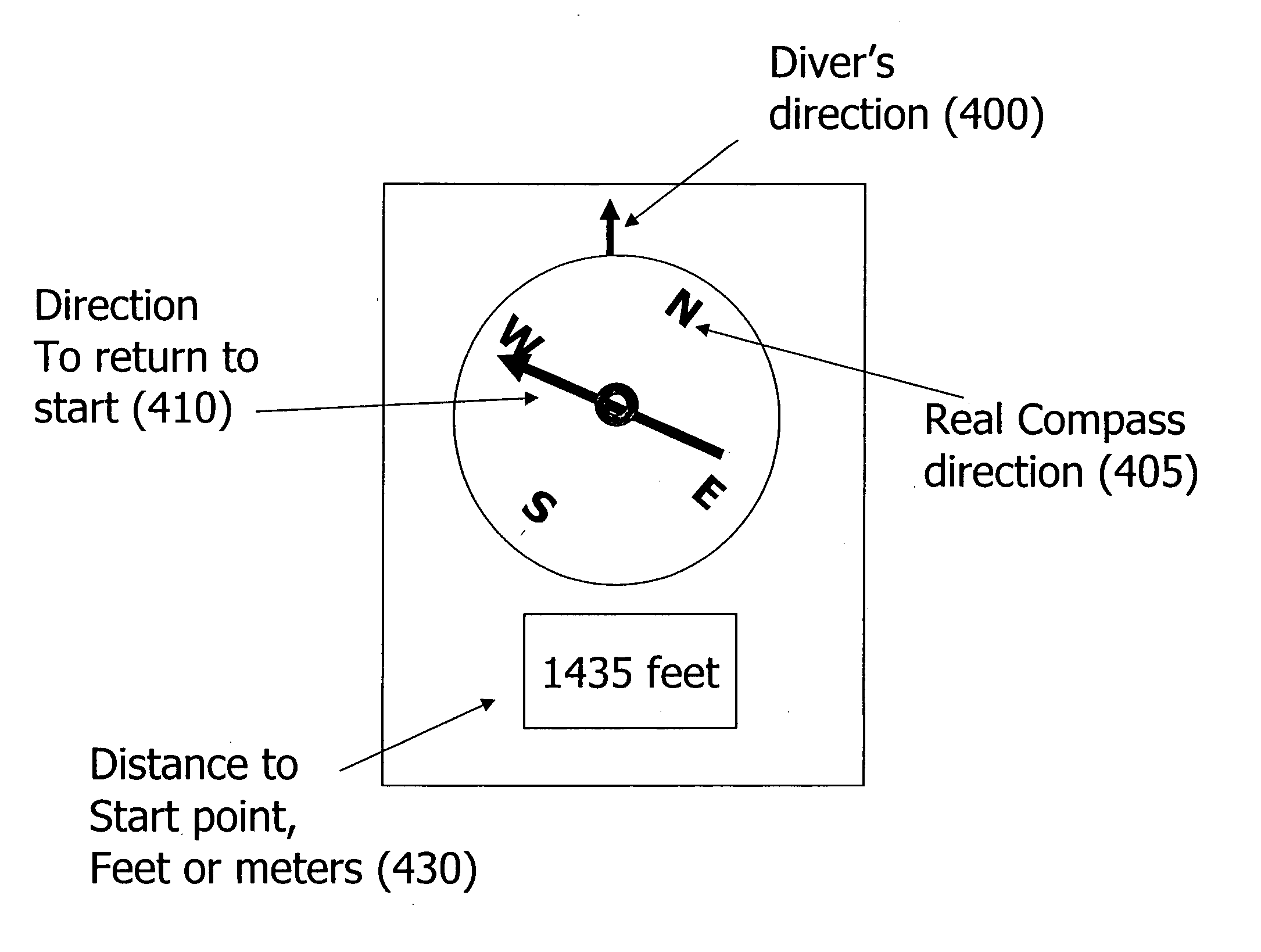

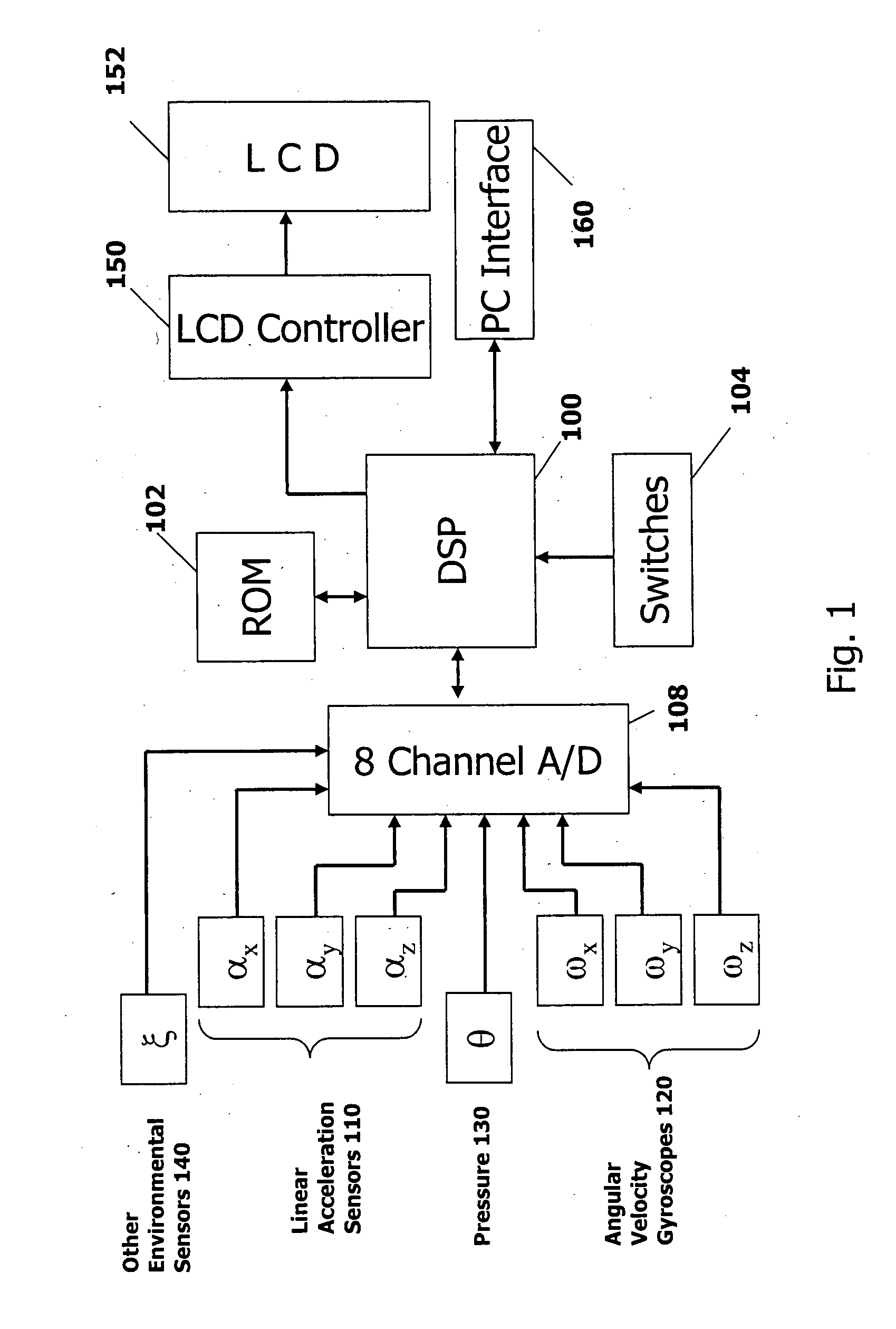

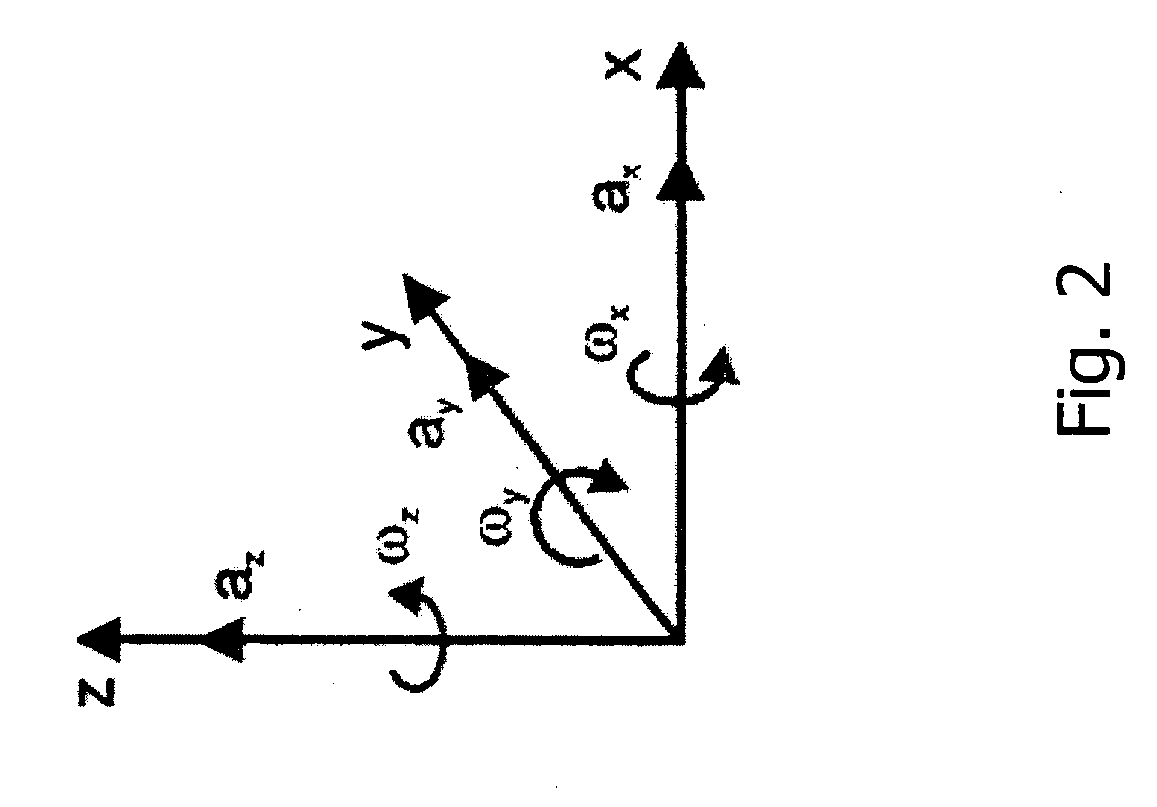

Independent personal underwater navigation system for scuba divers

InactiveUS20070006472A1Enhance enjoymentAdd funNavigation instrumentsCompassesAngular velocityInertial navigation system

An underwater personal Inertial Navigation System (INS) that uses linear acceleration and angular velocity sensors to fix the position of a diver in relation to a reference point. The sensor inputs are corrected by other sensors such as pressure or magnetic sensors.

Owner:SCUBA NAV

Rare earth sintered magnet and process for producing the same

ActiveCN101006534APhenomena that promote grain boundary diffusionEfficient replacementLiquid applicationPermanent magnetsRare-earth elementSintered magnets

Owner:HITACHI METALS LTD

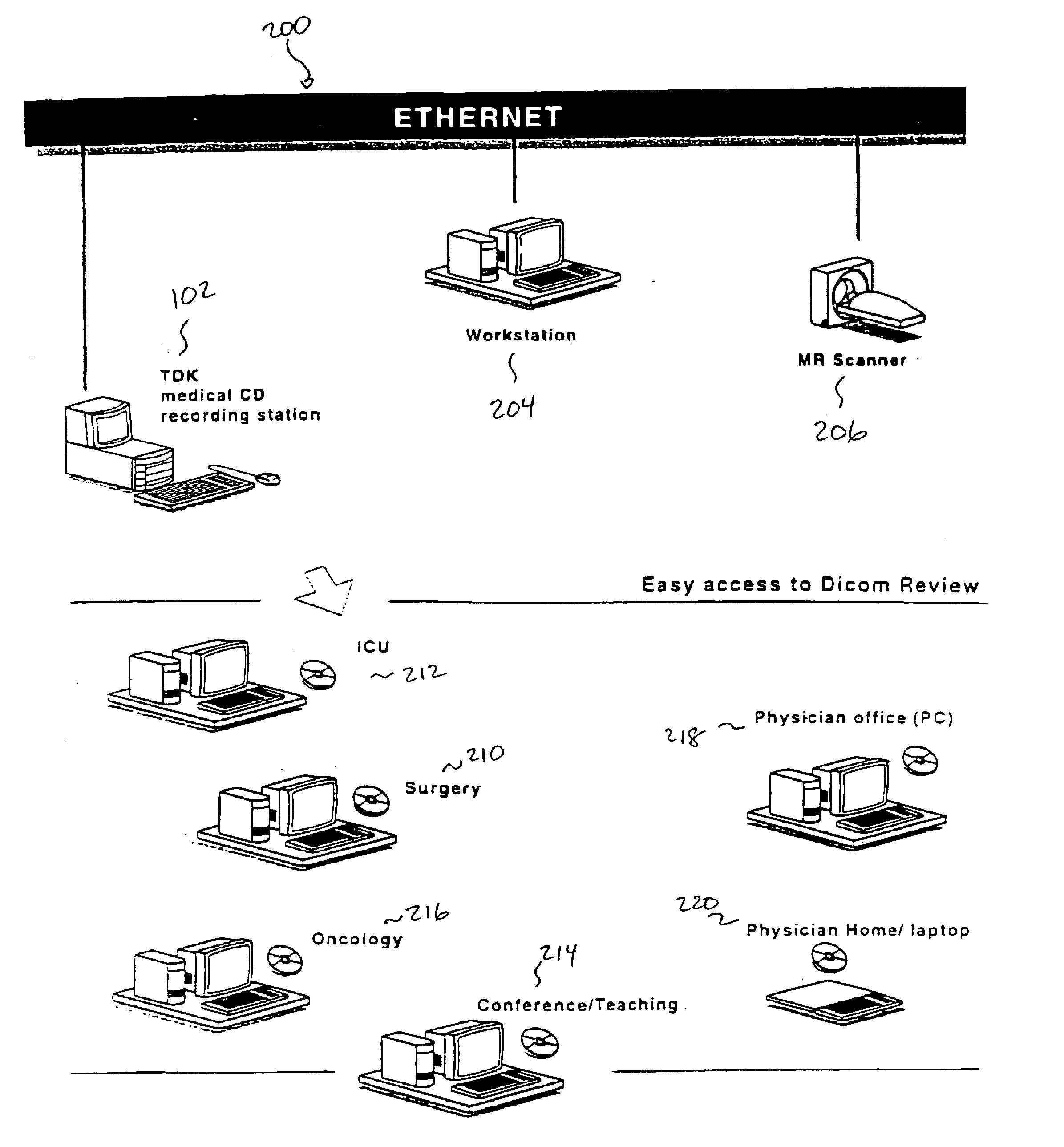

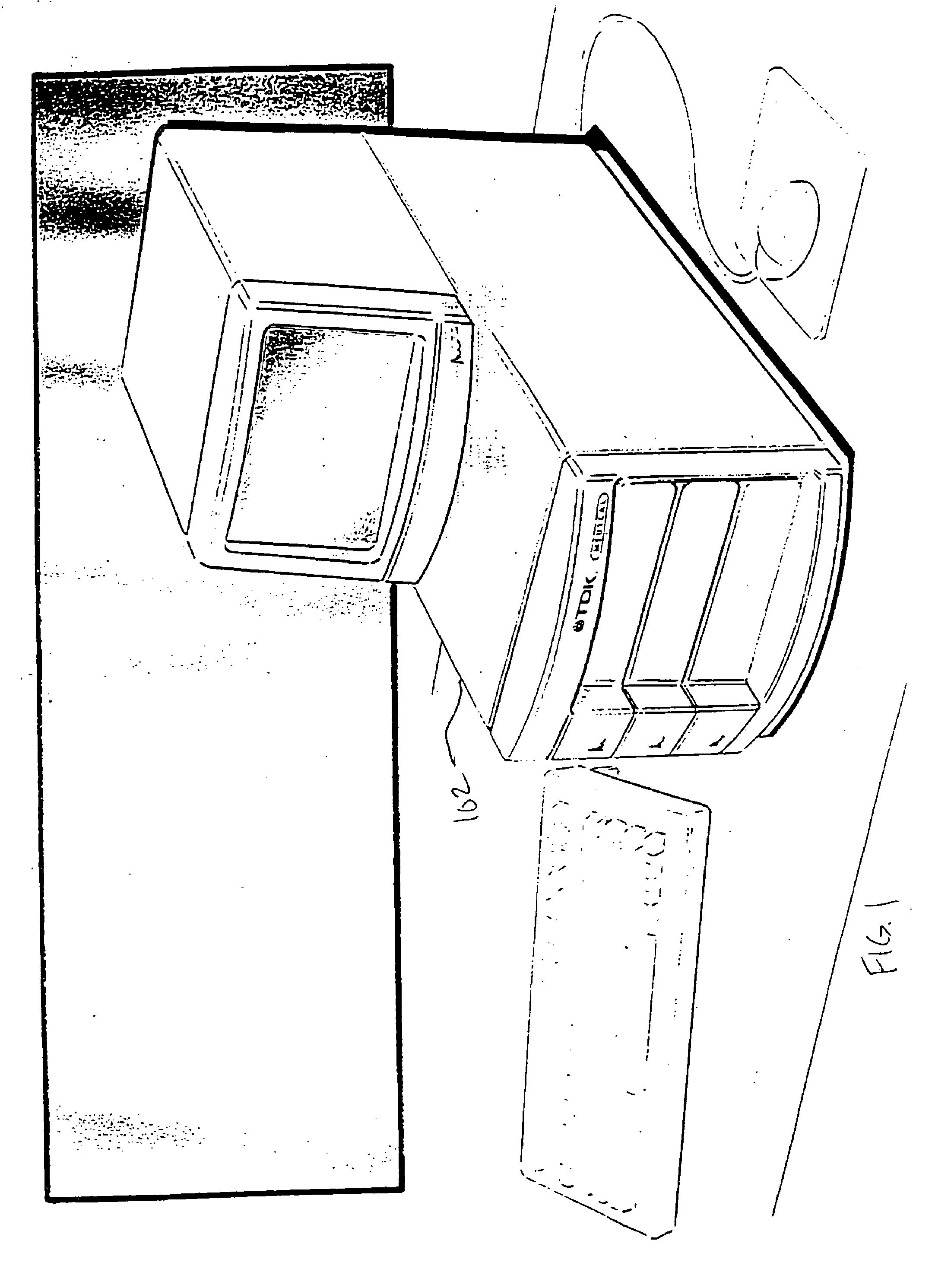

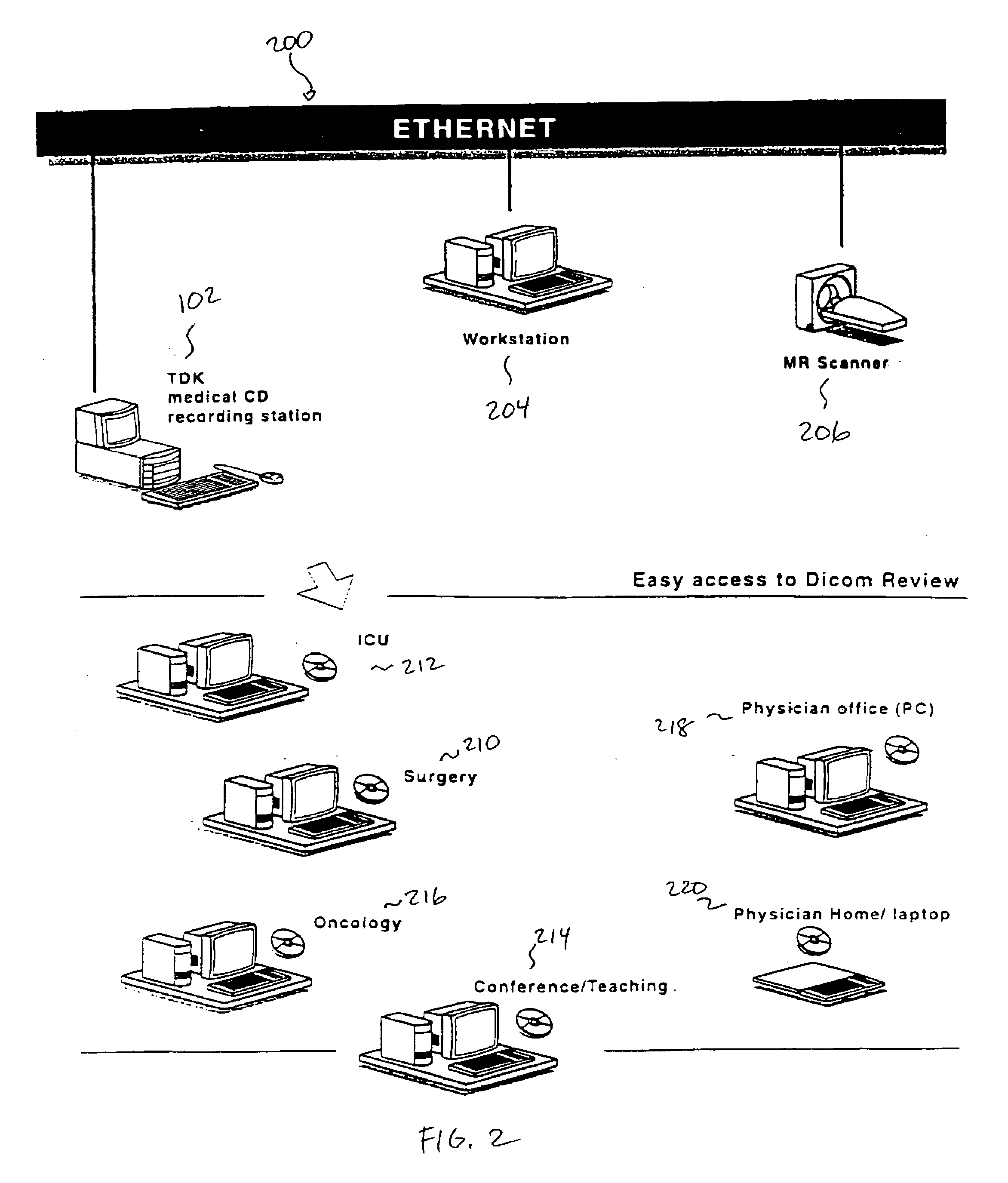

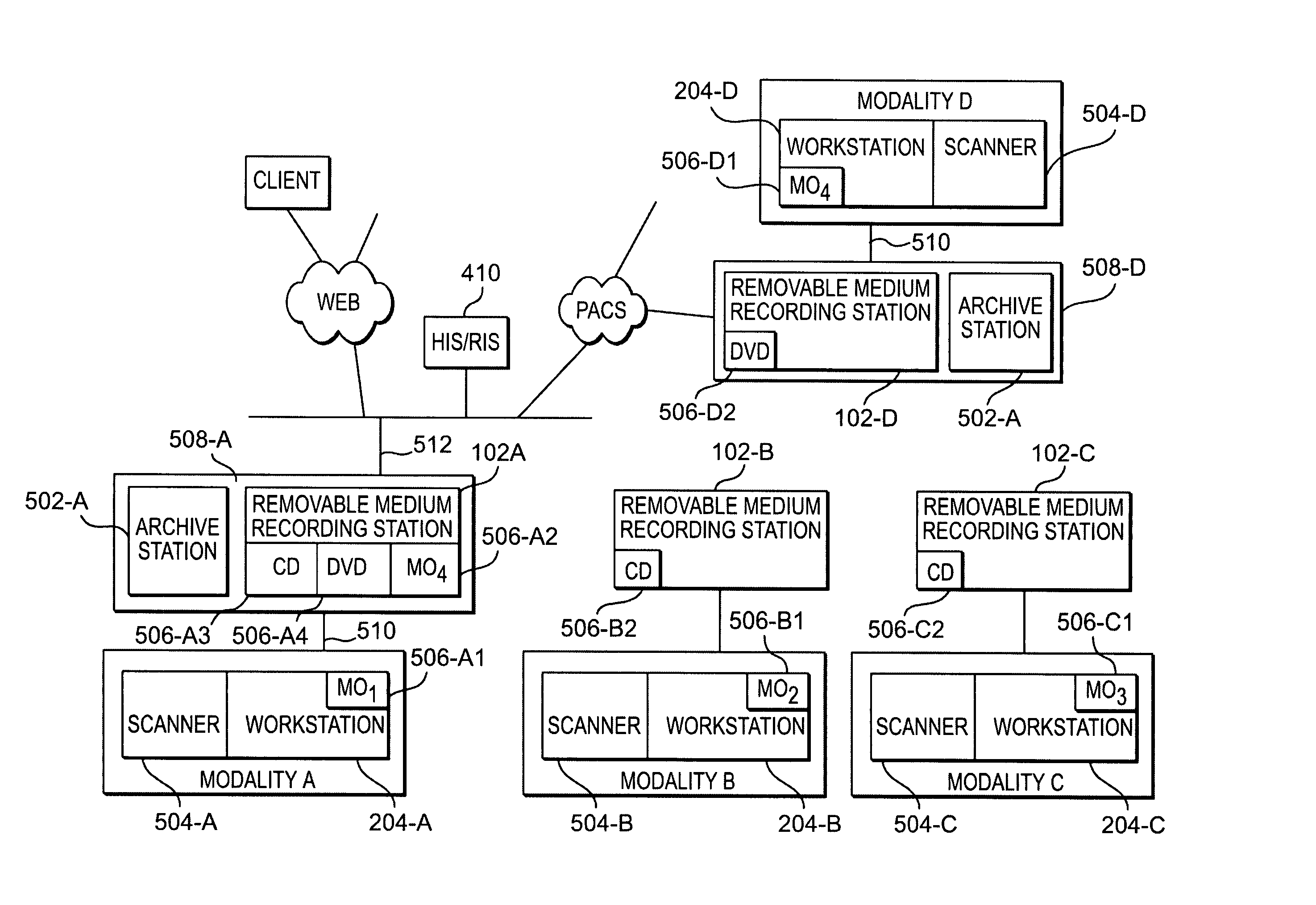

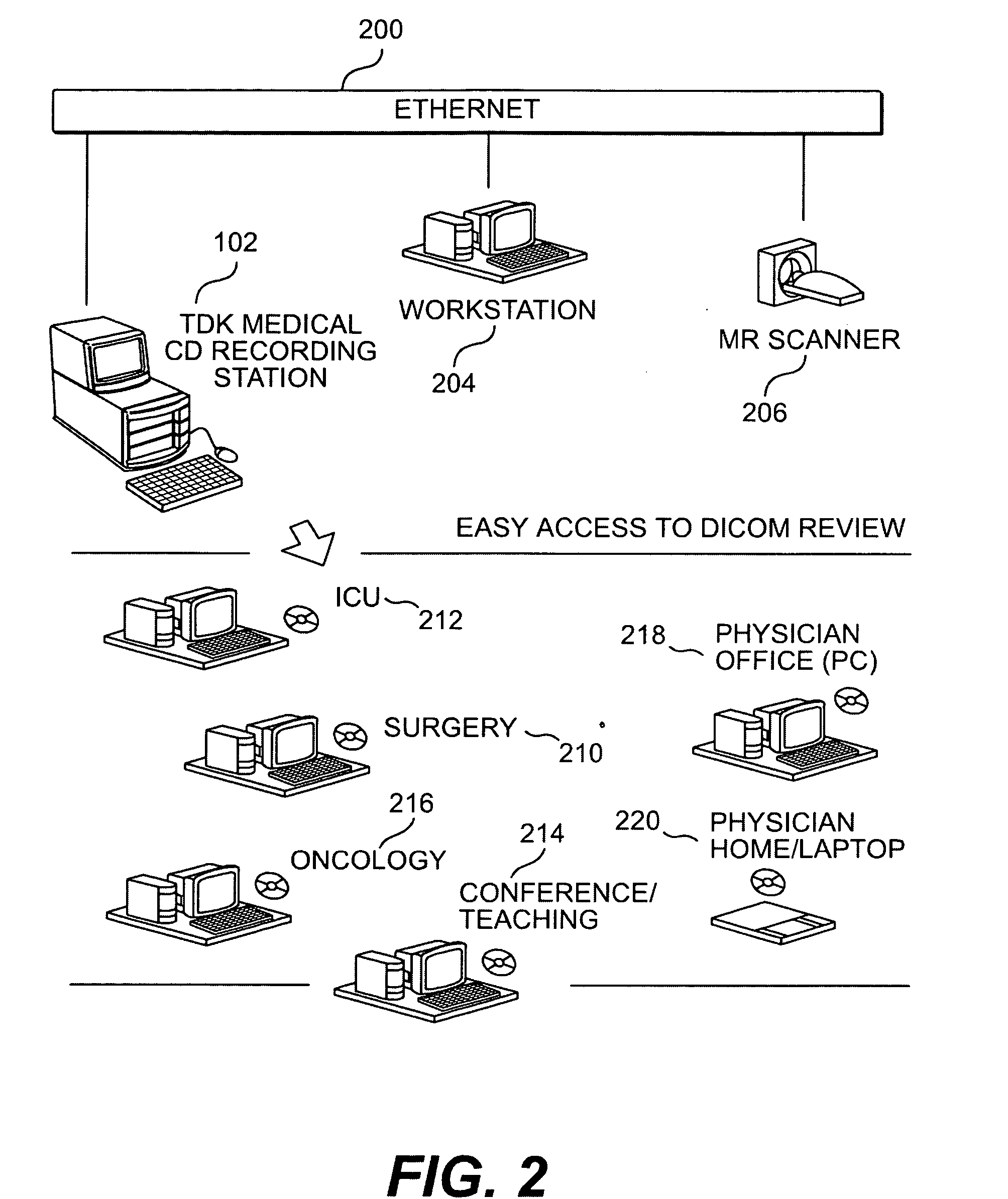

Removable media recording station for the medical industry

InactiveUS6954802B2Easy accessImprove distributionData processing applicationsCharacter and pattern recognitionIt investmentRemovable media

A removable medium recording station records medical image data in a format and removable medium that are widely accepted. The removable medium recording station can be used to effectively replace an installed storage device on an existing stand-alone medical image workstation. Storage onto removable media is transformed into an outboard operation. This transformation enables a hospital to migrate existing medical imaging systems to new formats and media without sacrificing a large portion of their initial investment. Additionally, the removable medium recording station can be attached as a peripheral on an existing medical modality network. In this capacity, the removable medium recording station enables an operator on the medical modality network to store medical images in a selected format and on a selected type of removable medium regardless of the proprietary format used by the enterprise level archive server. The removable medium recording station enables a hospital to add new functionality without sacrificing their investment in their enterprise solution.

Owner:TDK US CORP

System and method for salvage calculation, fraud prevention and insurance adjustment

InactiveUS8229767B2Reduce frequency and likelihoodEfficient repairFinanceTime informationComputer science

Disclosed is a novel system and method that provides real time information to an insurance adjuster. The system obtains information related to an insured item which has an outstanding claim. Information includes the cost to repair a specific item, the salvage value of the item, and the cost to replace the item. The system then compares the information related to the insured item from an economic perspective to determine whether it should be repaired or replaced. Since the system is objective, it reduces the reliance on subjective human factors such as collusion and lack of expertise. As a result, the system reduces the number of fraudulent and inaccurate transactions related to the specific item.

Owner:HARTFORD FIRE INSURANCE

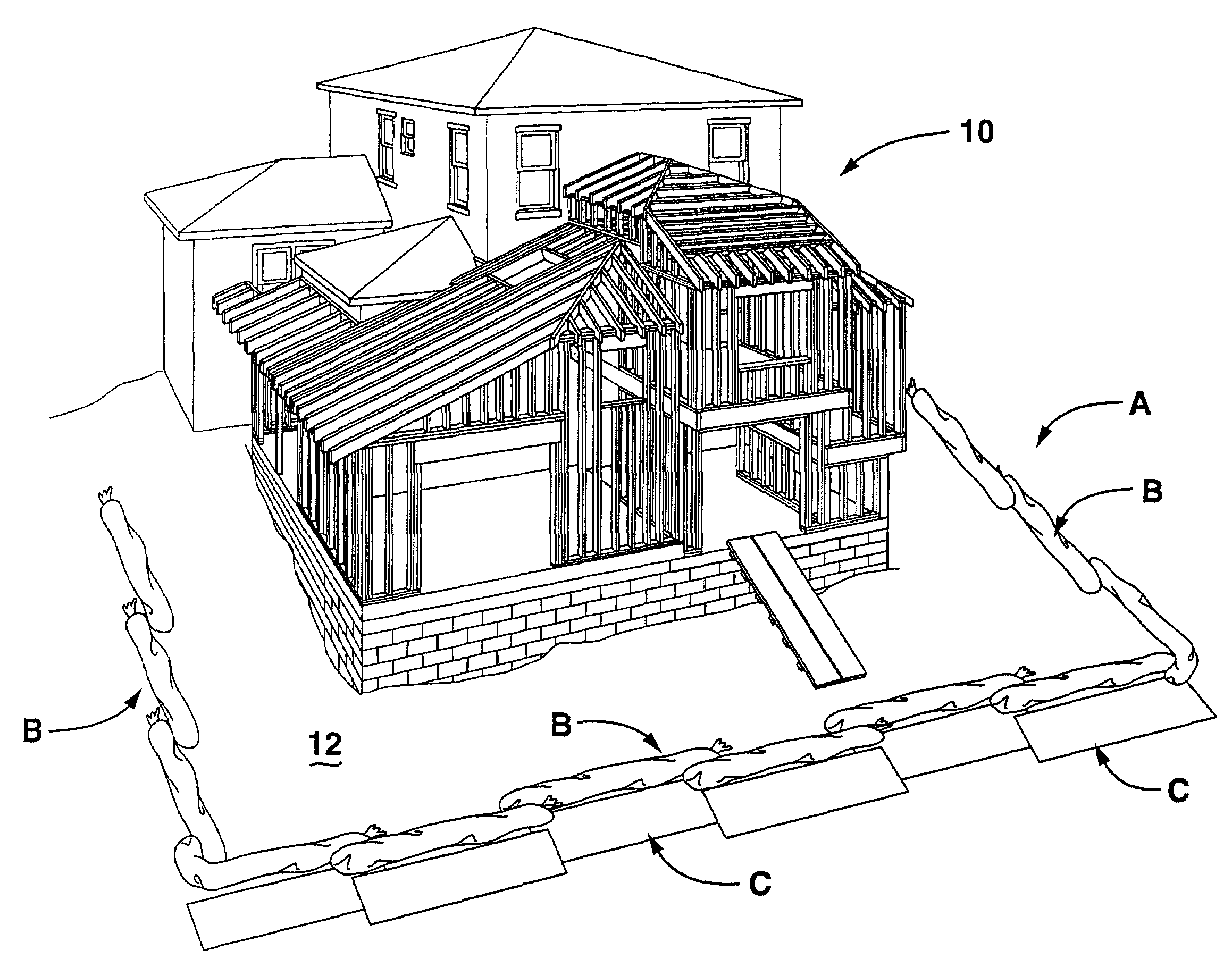

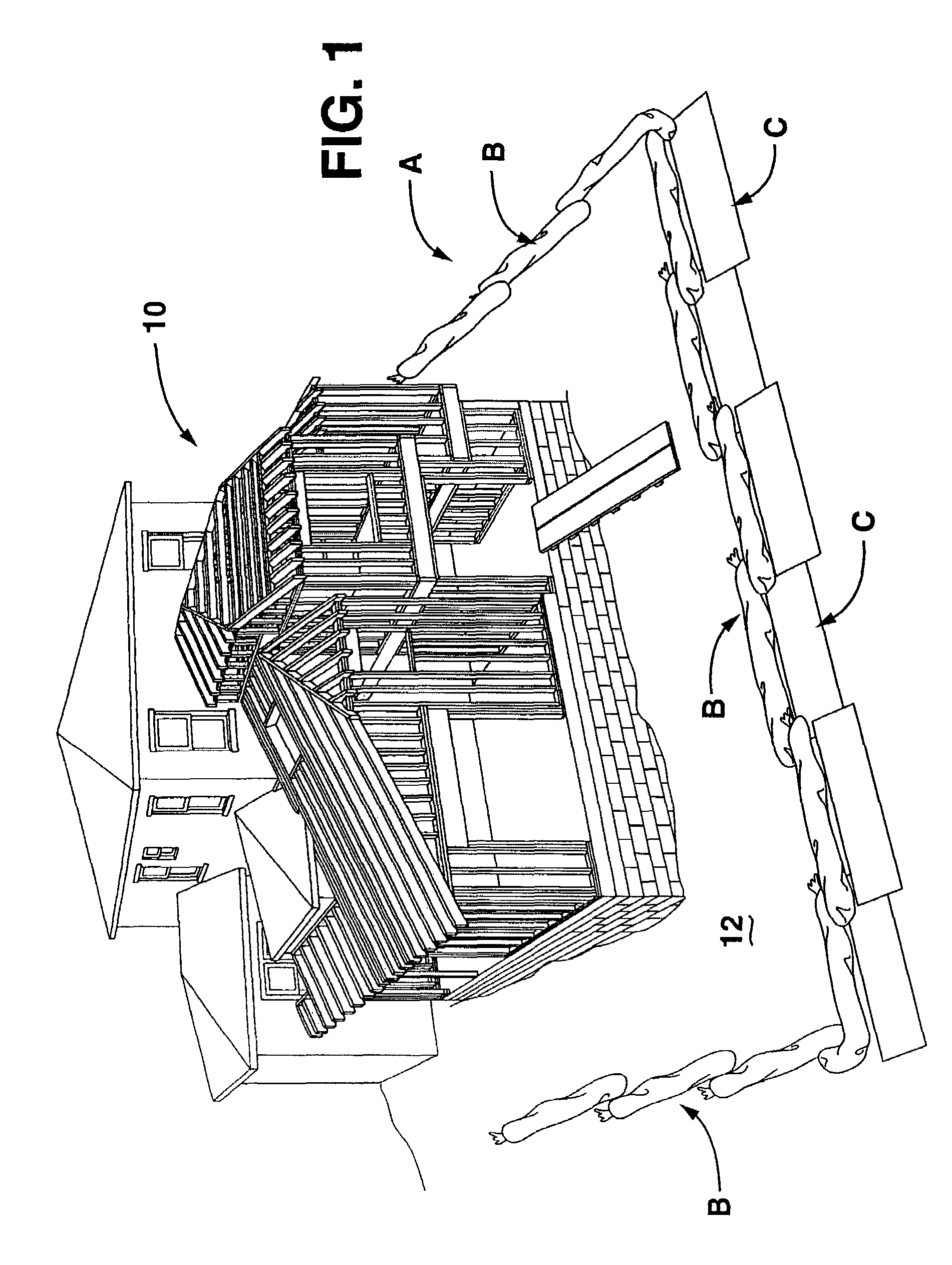

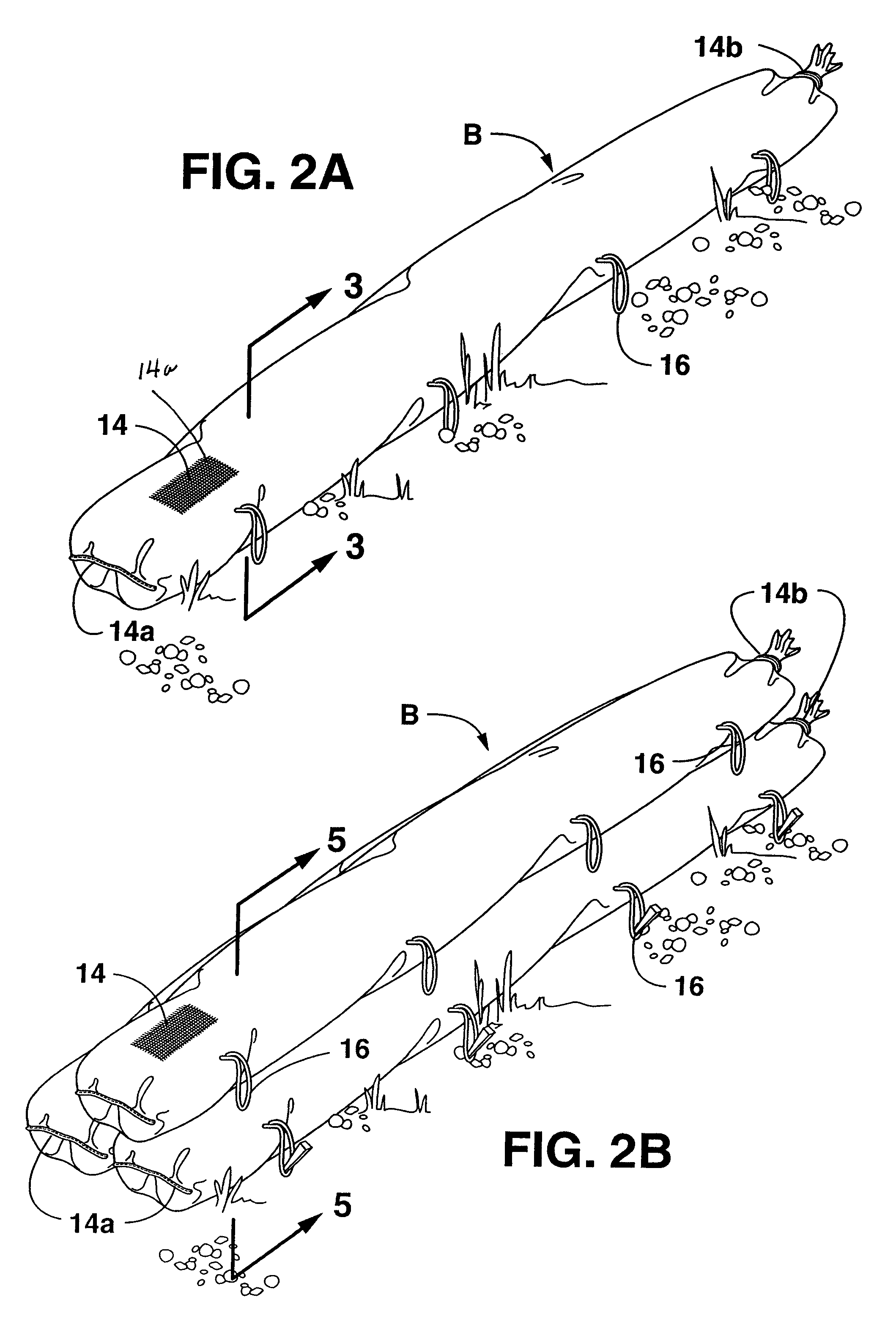

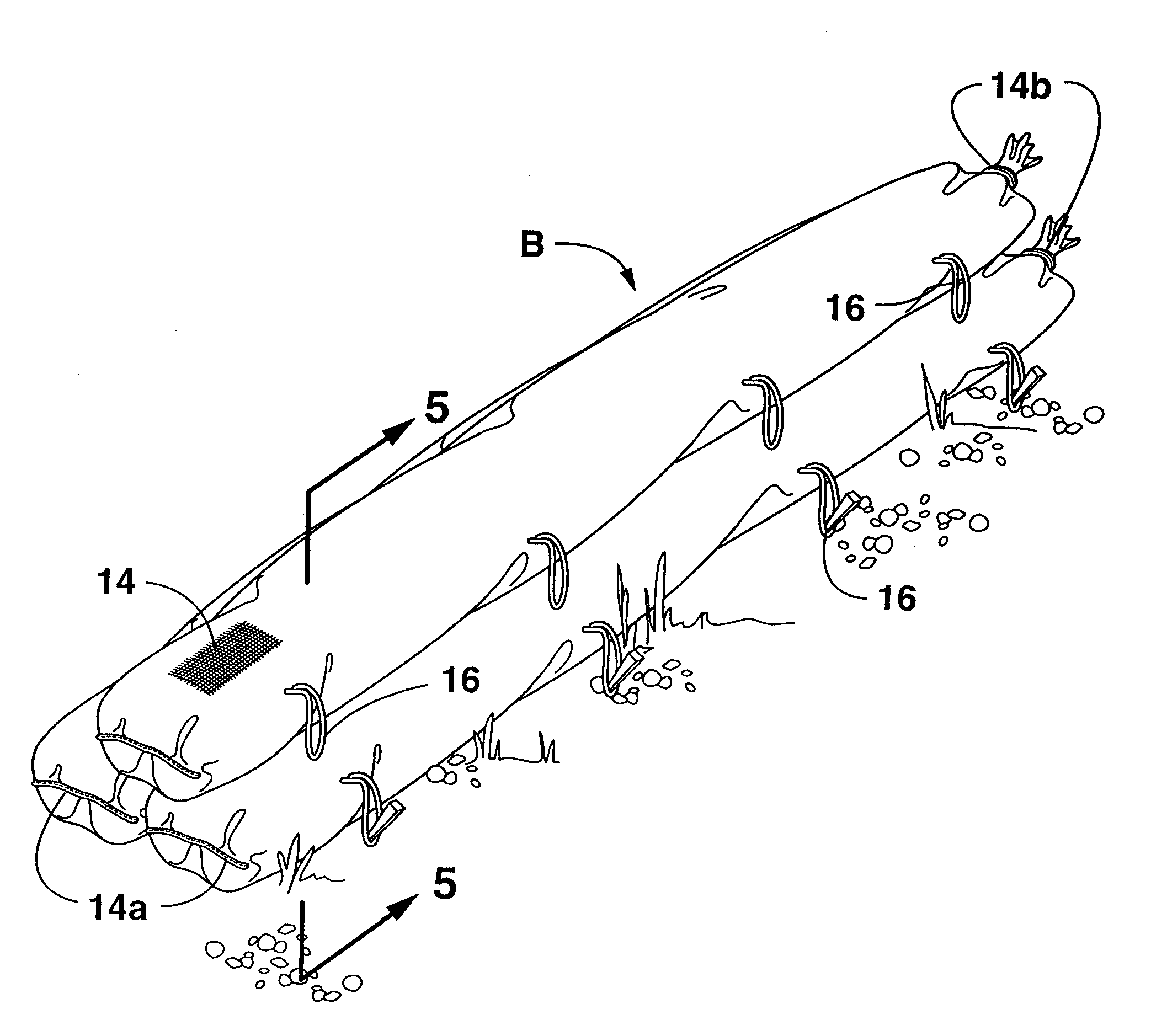

Water filtration and erosion control system

ActiveUS7449105B2Useful in erosion controlErosion minimizationLoose filtering material filtersCartridge filtersPondingControl system

An erosion control system and method wherein a fabric filter bag is embedded with and / or filled with a flocculating polymer and is positioned on a sloping soil surface to dam and pond water flowing thereacross for settling of the particles in the water, and as the ponding water seeps into the bag the colloidal particles will be filtered or agglomerated for settling. The water then passes through and out of the bag and is further subjected to agglomeration and filtering by a skirt of filter material also impregnated with flocculating polymer, said skirt being anchored to the bag or stacked to maintain the position adjacent and downslope from the bag.

Owner:DENNY HASTINGS FLP 14

Medical archive library and method

InactiveUS20050240445A1Easy accessImprove distributionData processing applicationsComputerised tomographsData selectionRemovable media

A low-cost scaleable turnkey system and method for archiving medical image data. The archive system and method permits the selective storing of medical data (including image data) received from a medical modality (e.g., CT, MRI, etc.) onto a removable medium (e.g., DVD or Blu-ray), which may subsequently be placed via robotics in a magazine within the system housing. In addition to directing the archiving of the medical data as described, software components of the archive system permit a specific medium in a magazine to be addressed, retrieved, and read as needed.

Owner:TDK US CORP

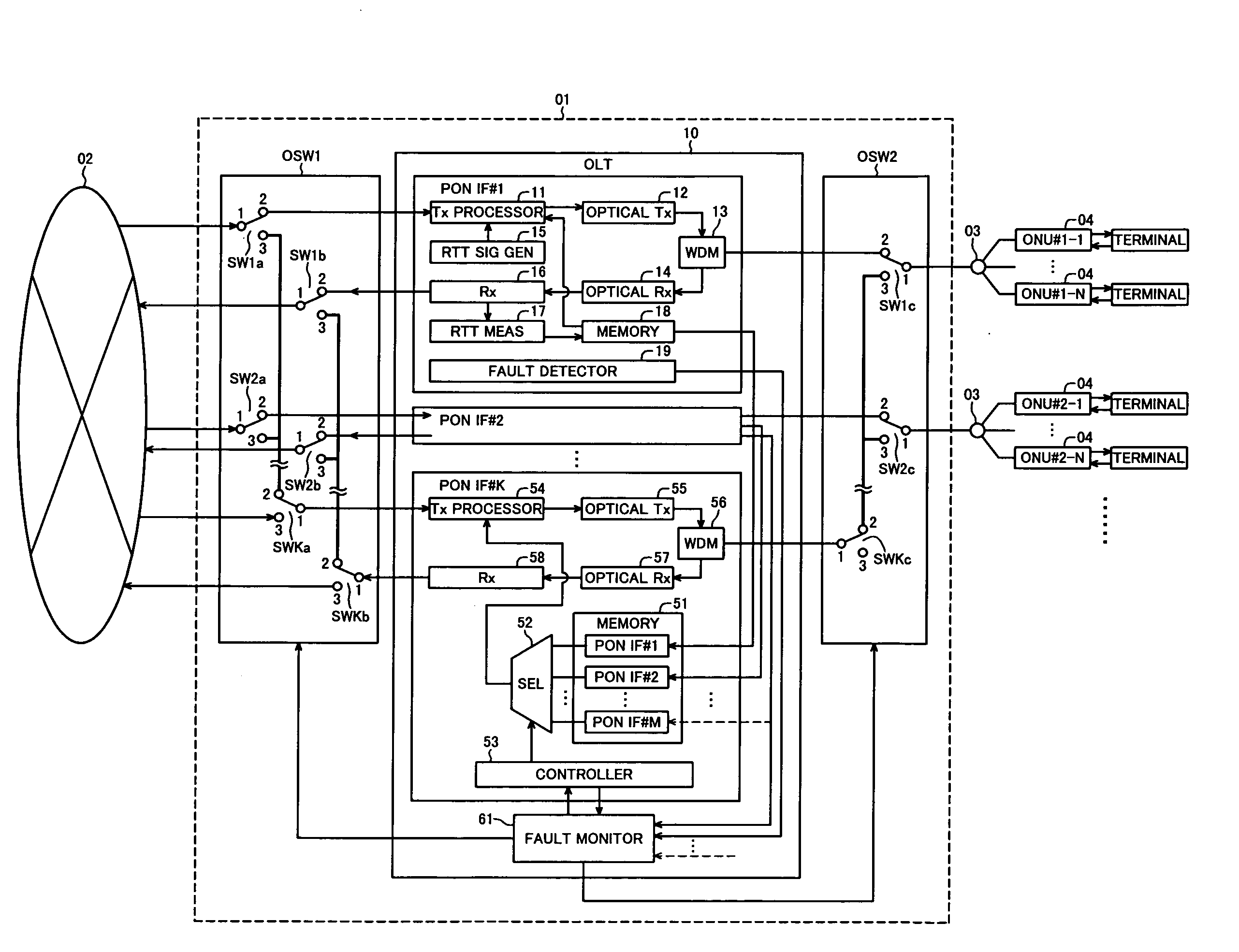

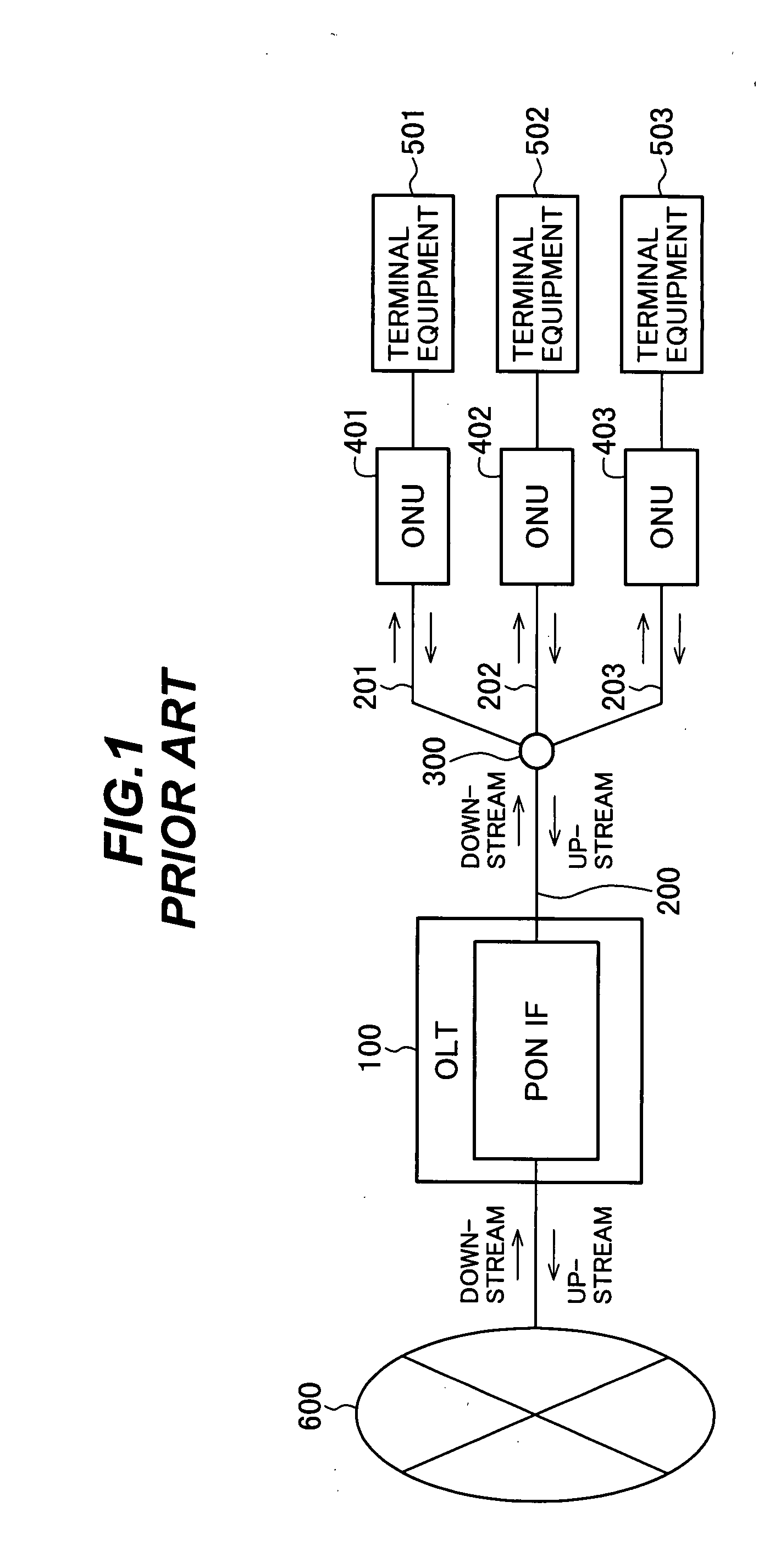

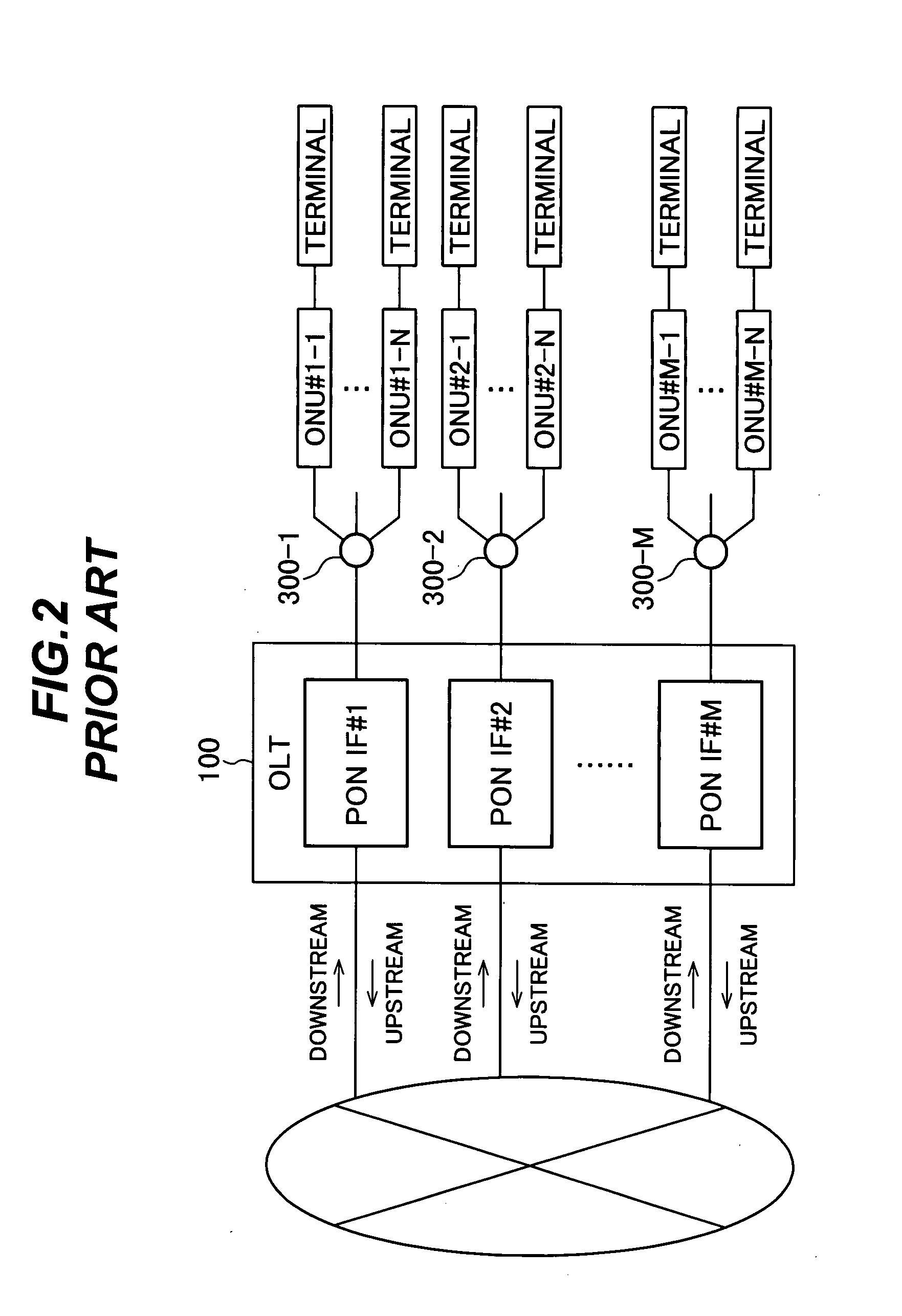

Optical communition system with N + 1 redundancy

ActiveUS20080037981A1Efficient replacementMultiplex system selection arrangementsLaser detailsCommunications systemOptical communication

An optical communication system has two or more active interfaces, each controlling the transmission and reception of optical signals between a communication network and one or more subscriber terminals according to control information pertaining to the individual subscriber terminals. The control information used by all the active interfaces is stored in a memory. The optical communication system also has a standby interface that is functionally equivalent to the active interfaces, and an optical switching apparatus that switches data transmission paths among the network, the active and standby interfaces, and the subscriber terminals. If a fault is detected in an active interface, the standby interface extracts the control information of the faulty interface from the memory, and the optical switching apparatus switches the data transmission paths so that the standby interface replaces the faulty interface.

Owner:OKI ELECTRIC IND CO LTD

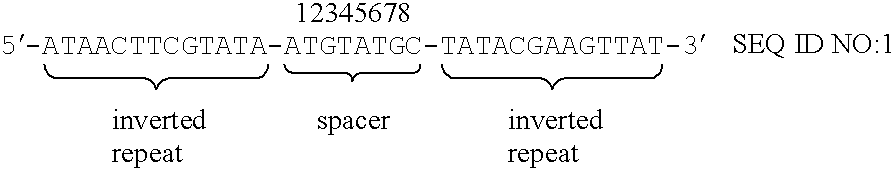

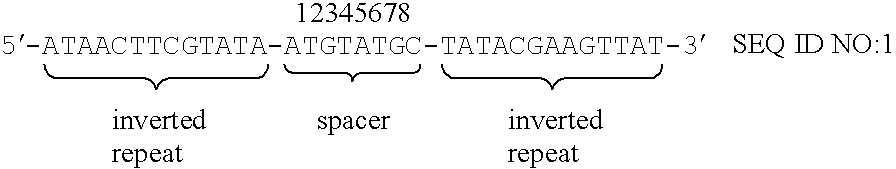

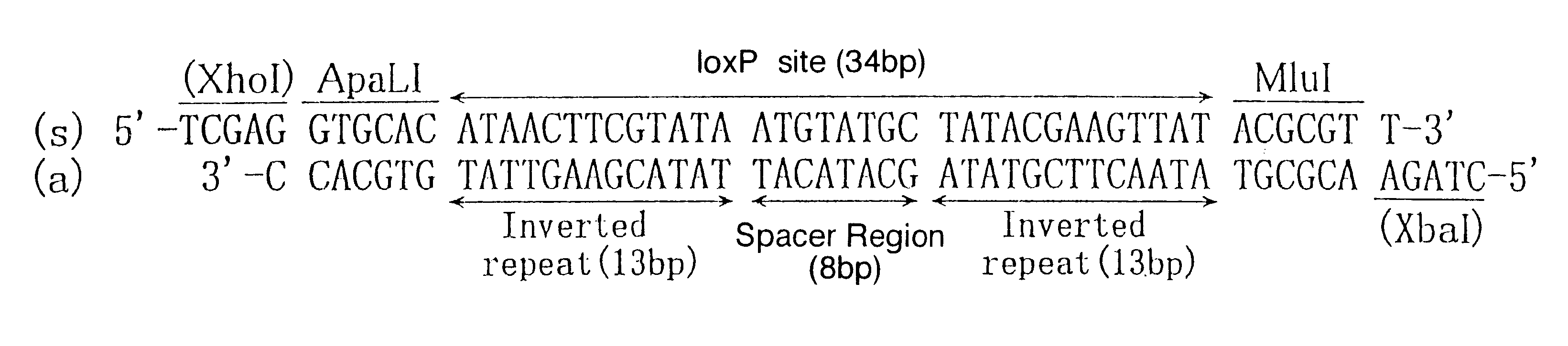

Mutant loxP site and applications thereof

InactiveUS6465254B1Improve efficiencyEfficient replacementBiocideGenetic material ingredientsEscherichia coliNucleotide

Highly efficient gene integration or gene replacement in the higher eucaryote including animal cells can be performed by using mutant loxP site having the following properties (a)-(c) in the present invention.(a) a nucleotide sequence wherein, in a wild-type loxP site of the following formula (SEQ ID NO: 1) derived from E. coli P1 phage, at least one of the bases consisting of second (T), third (G), fourth (T) and fifth (A) bases, and at least one of the bases consisting of sixth (T) and seventh (G) bases within the 8 bases in the central part of the sequence (spacer region) are substituted by different base, and regions except for the spacer region are optionally substituted by any base:(b) a specific recombination between said mutant loxP and the wild-type loxP site can not occur even in the presence of recombinase Cre; and(c) a specific recombination between the mutant loxP sites having identical nucleotide sequences can occur in the presence of recombinase Cre.

Owner:SUMITOMO DAINIPPON PHARMA CO LTD

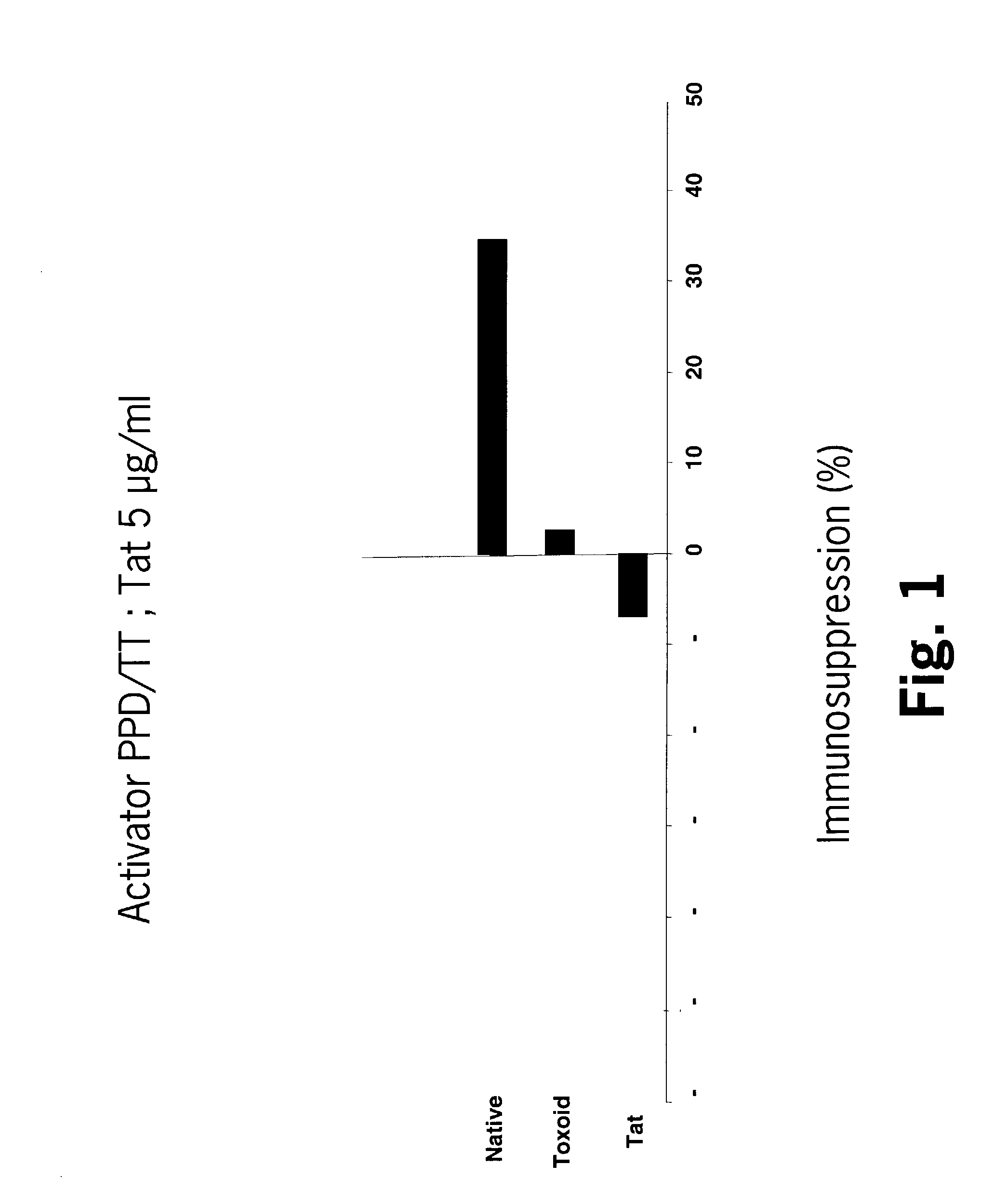

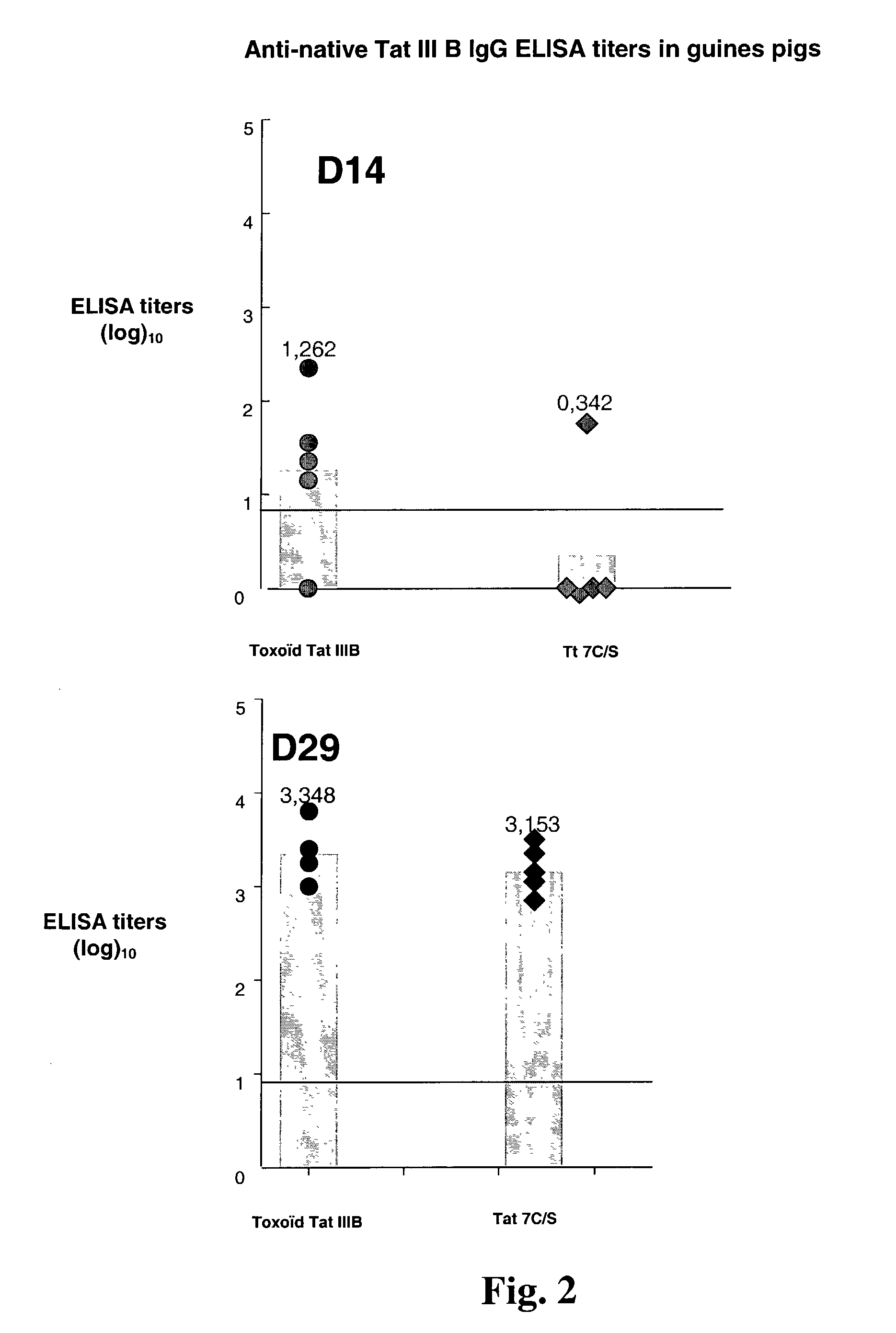

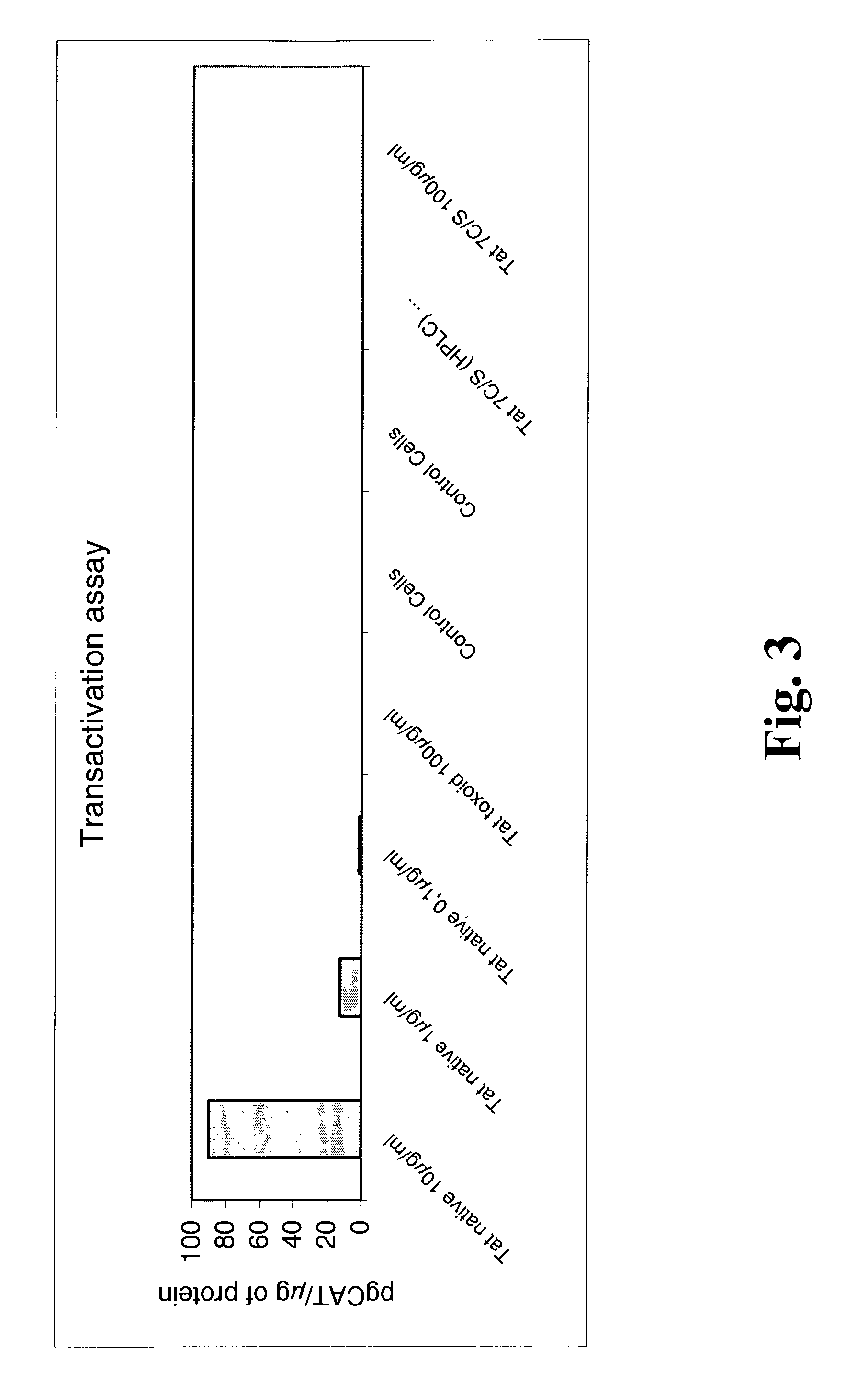

Mutated HIV Tat

The present invention provides a Tat protein wherein all the cysteine residues of the cysteine-rich domain have been replaced with another amino acid, preferably with serine, nucleic acids encoding it, and methods of using it to elicit a humoral and cellular immune responses in a mammal. The Tat protein of the invention is therefore useful, inter alia, for prophylactic and / or therapeutic anti-HIV use as well as raising anti-native Tat antibodies in mammals.

Owner:AVENTIS PASTUER LTD

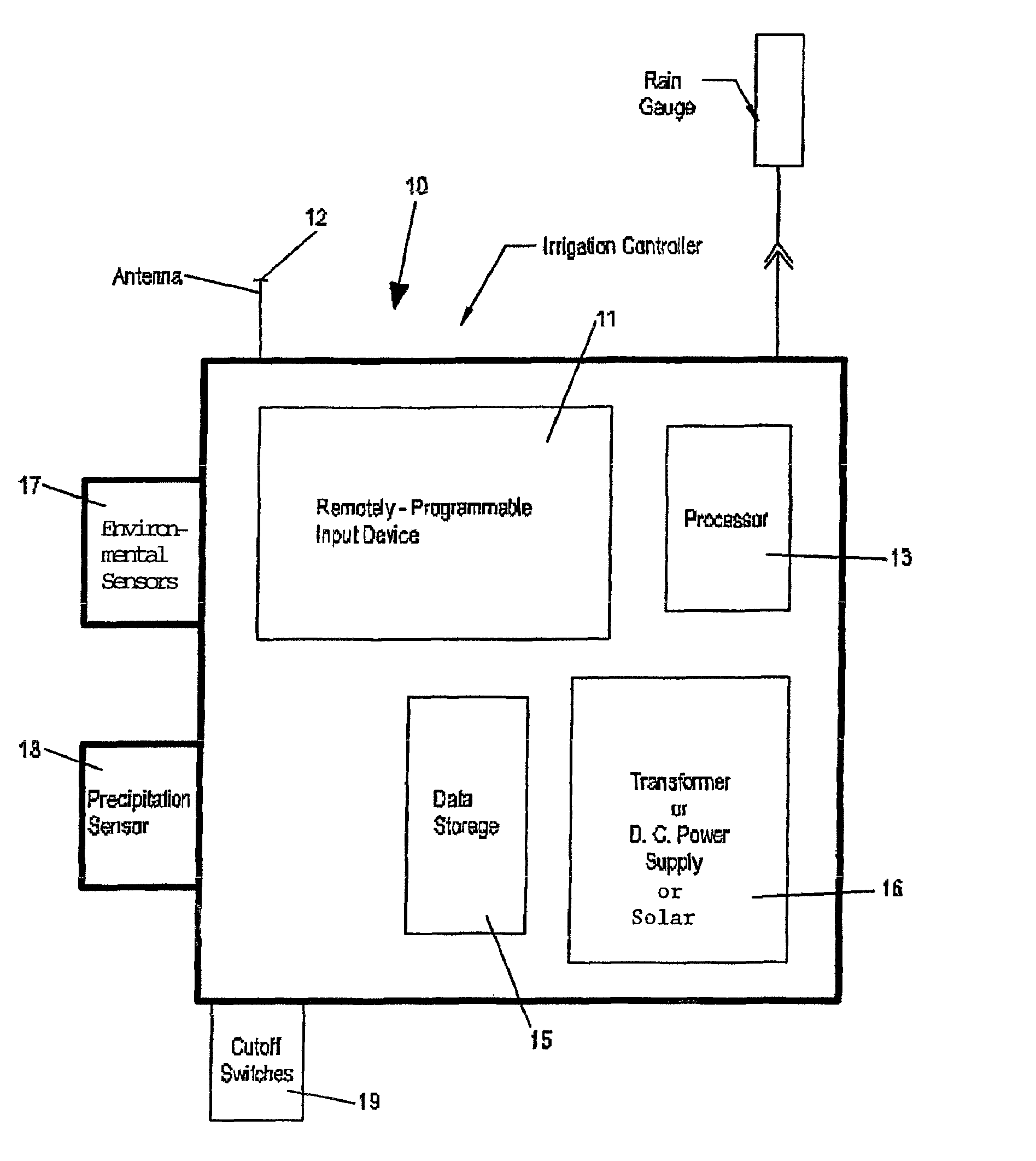

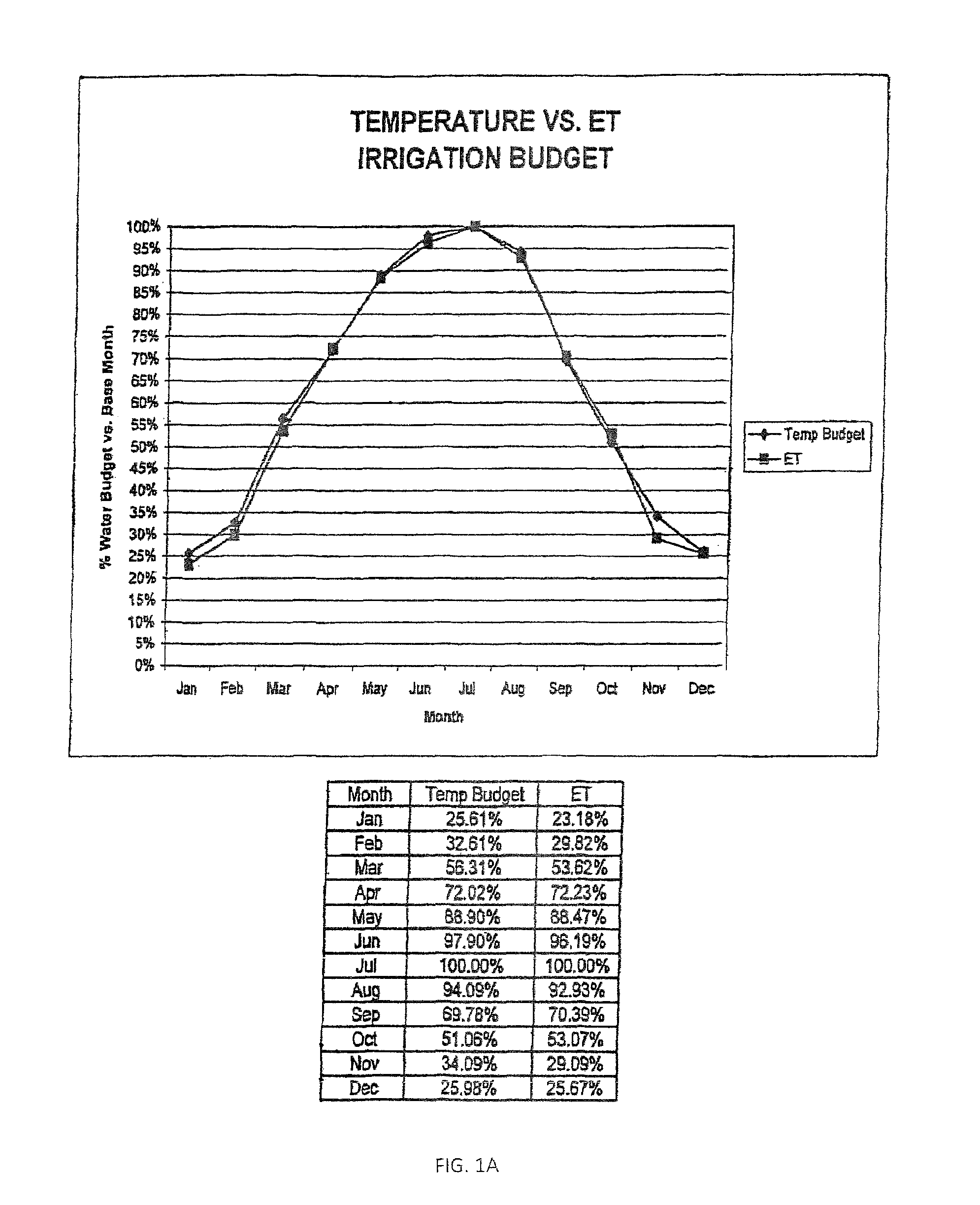

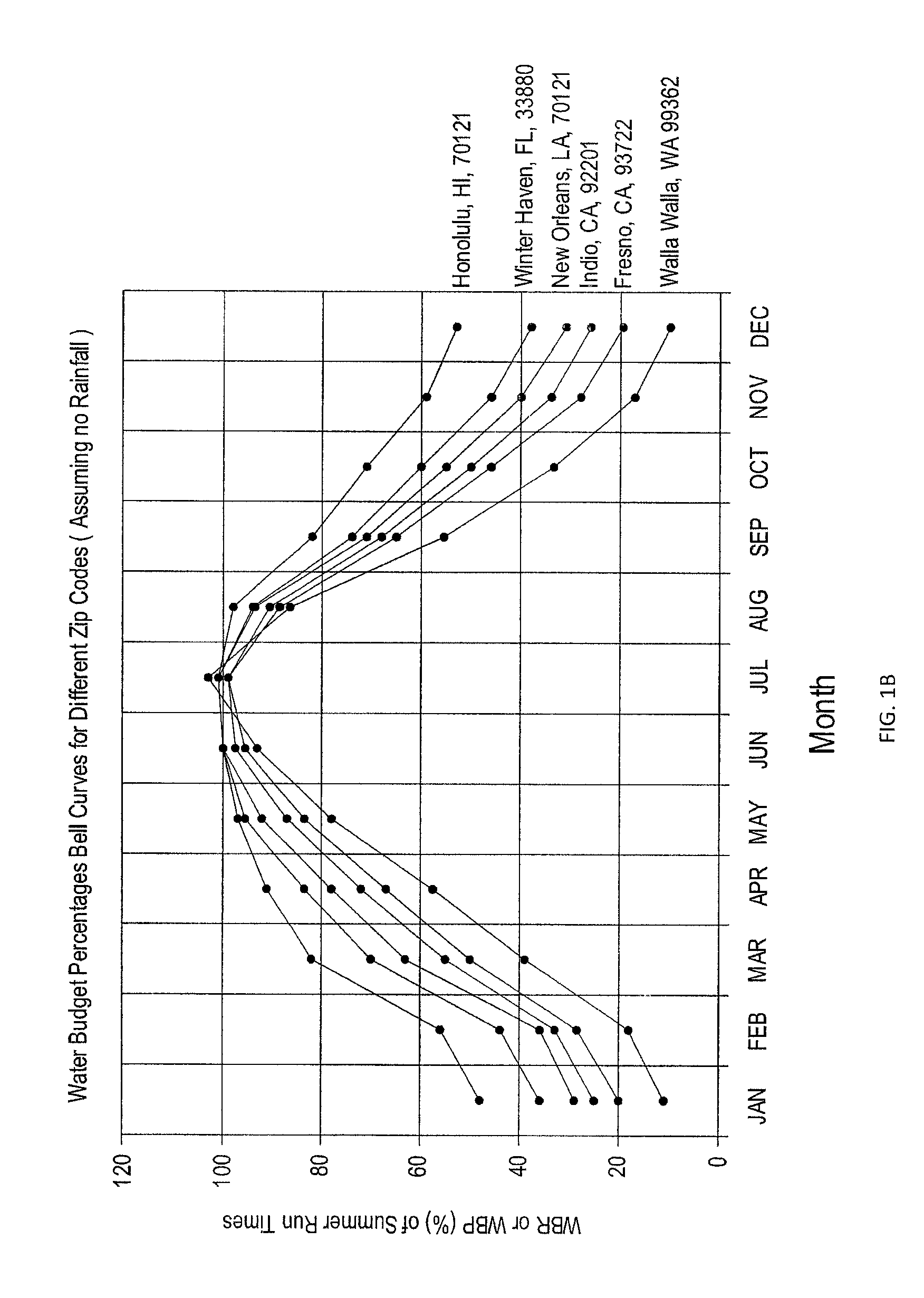

Landscape irrigation management with automated water budget and seasonal adjust, and automated implementation of watering restrictions

ActiveUS8538592B2Easy to implementEfficient replacementProgramme controlFinanceEngineeringRunning time

Embodiments of the present invention provide methods and apparatus for water conservation with landscape irrigation controllers, plug-in and add-on devices, and centralized systems. In embodiments of the invention, a water budget percentage is determined by comparing current local geo-environmental data with stored local geo-environmental data, and the preliminary irrigation schedule or station run times are automatically modified based upon that water budget percentage. Embodiments of the present invention also provide for automation of mandated landscape watering restrictions alone, or in various combinations with water budgeting methods and apparatus.

Owner:HUNTER INDUSTRIES

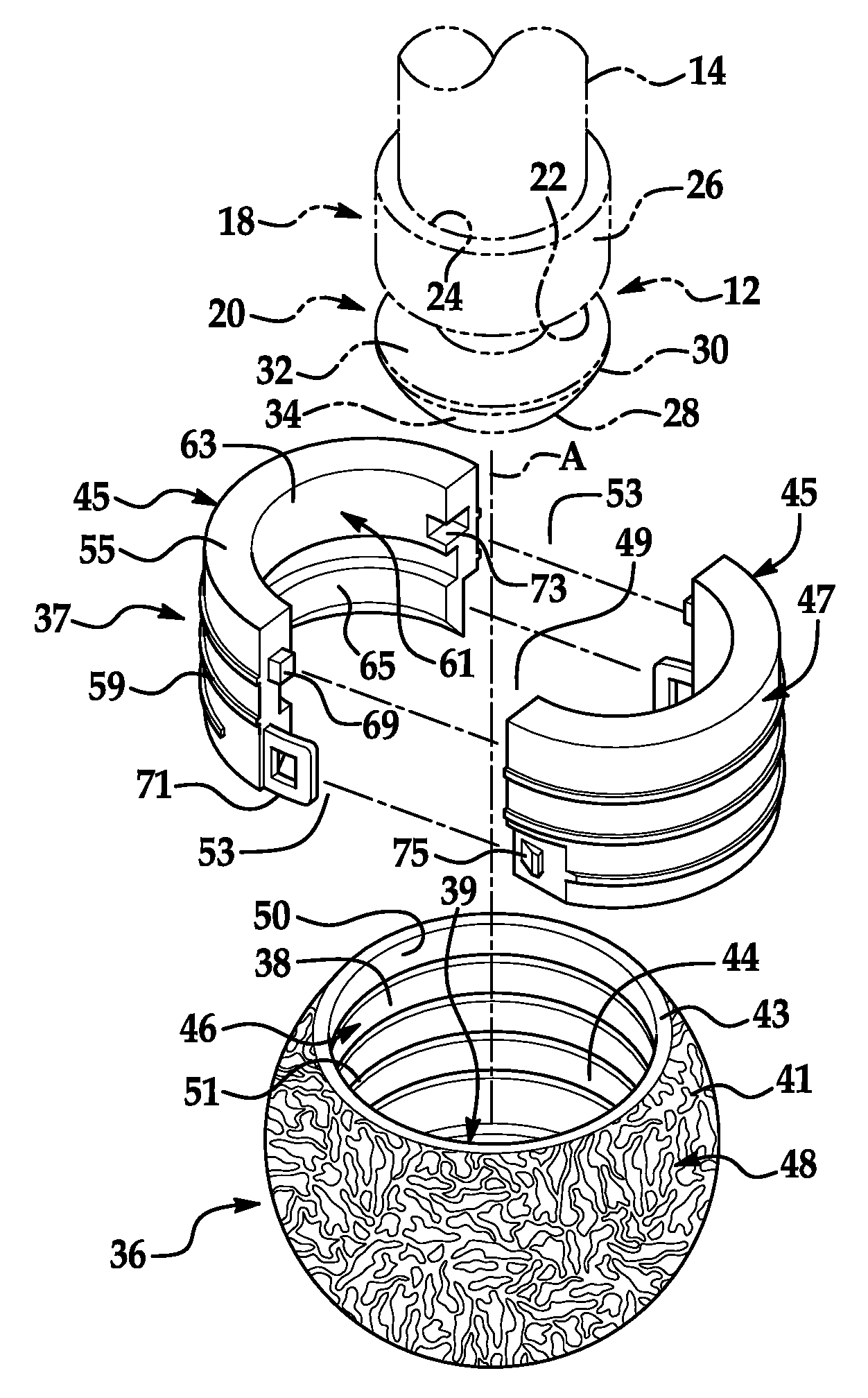

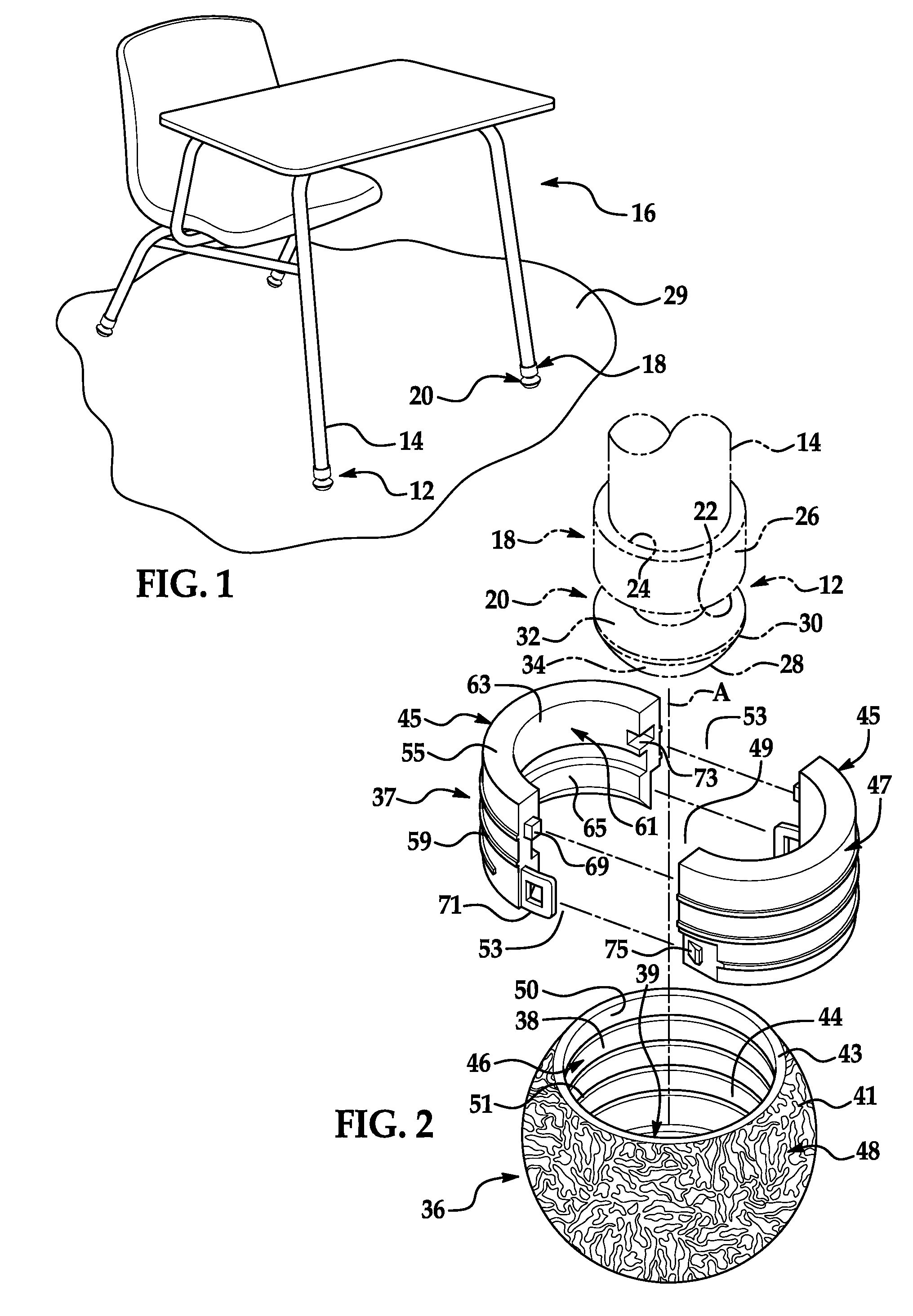

Furniture-glide assembly

ActiveUS20080244870A1Easy and fast cleaningEasy and faster to and keep sanitaryCastorsMulti-purpose toolsEngineeringMechanical engineering

A glide assembly is adapted to be mounted about an existing foot attached to the free end of a leg of a piece of furniture that is adapted to be supported upon a surface. The glide assembly includes a body defining an exterior surface and a bore extending partially through the body to define a hollow interior, an interior surface, a top, open end of the body, and a bottom, closed end of the body disposed opposite the open end. An insert assembly is mountable about the foot and adapted to be received through the open end and fixedly secured within the hollow interior of the body so as to mount the body about the foot. A cap is designed to be replaceably attached to the closed end of the body and adapted to engage the surface upon which the leg is supported.

Owner:HIWATT PROD

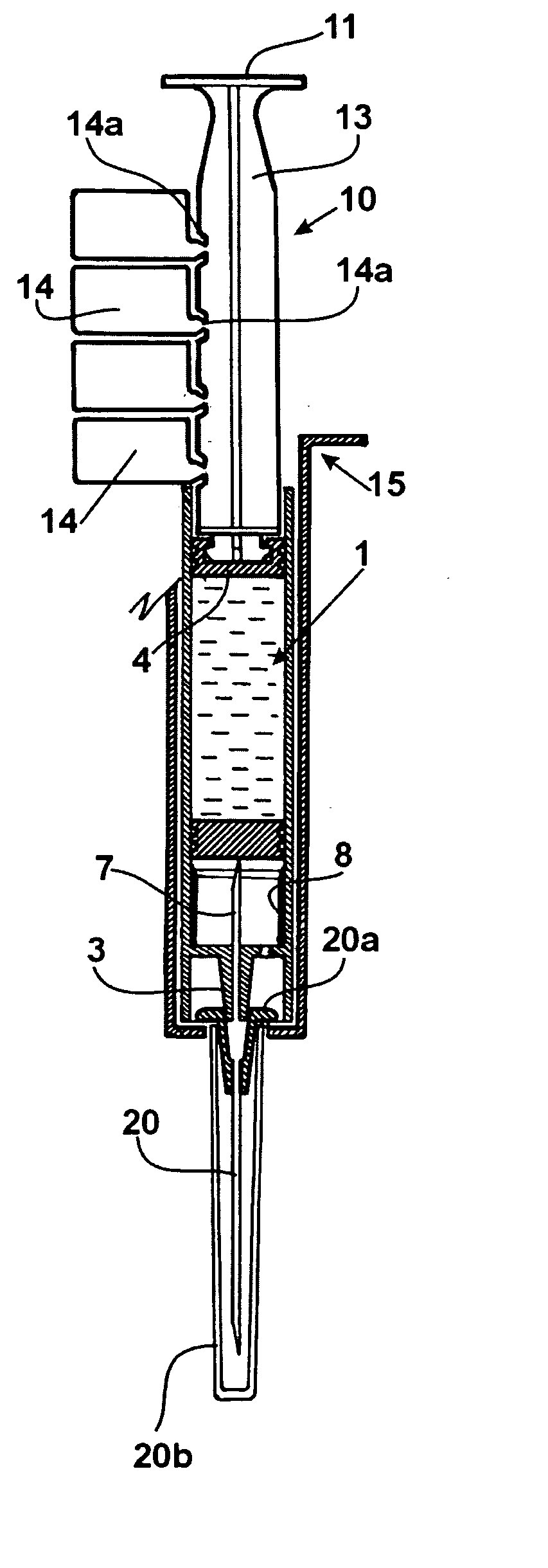

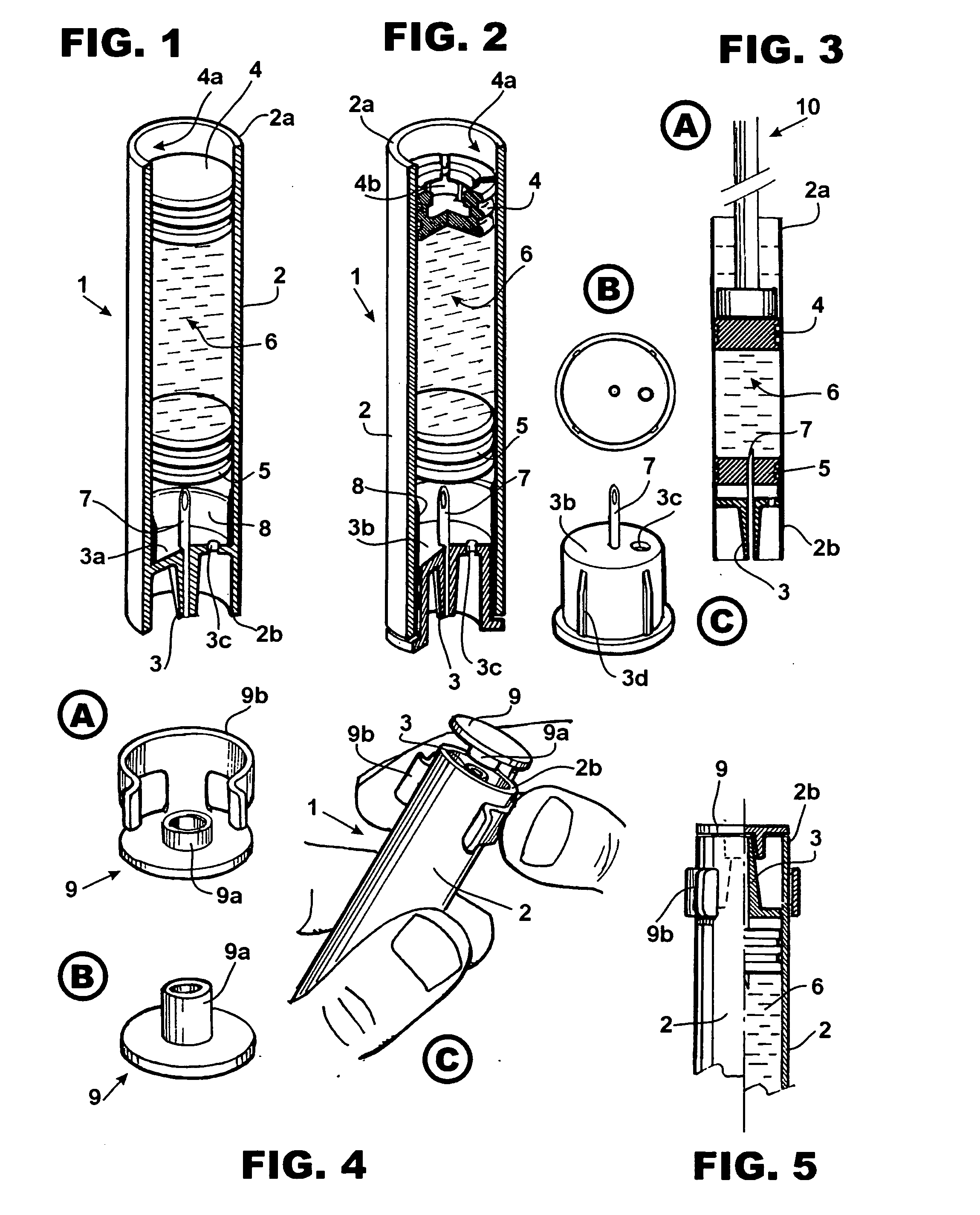

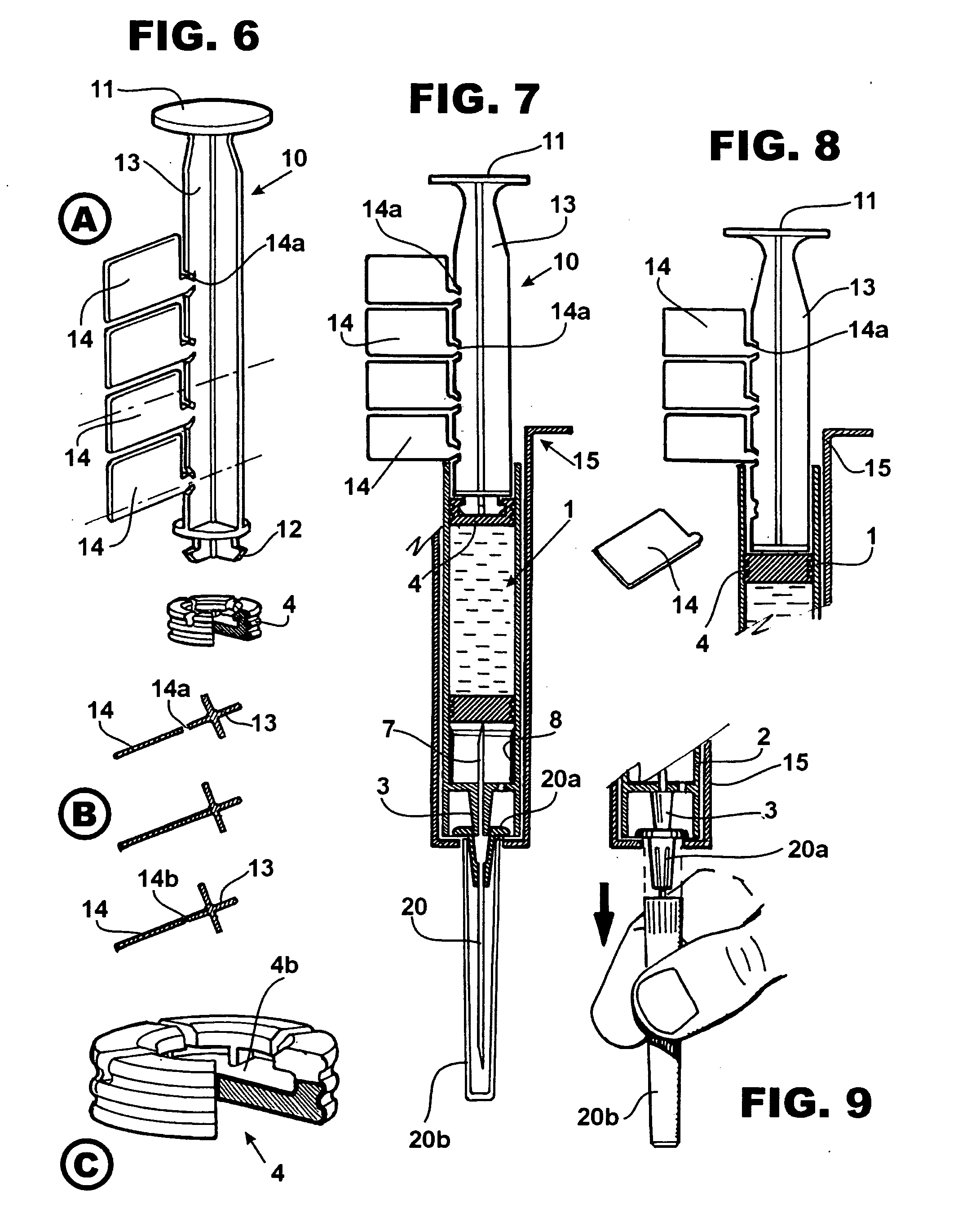

Unit to administer injectable medication manually or automatically

InactiveUS20050137532A1Avoid possibilityEfficient replacementAmpoule syringesIntravenous devicesDispensing medicationsRisk stroke

This injecting unit (1) comprises a tubular body (2) with a receptacle (6) containing a solution; this receptacle (6) is delimited by an impelling plunger (4) and a drillable bottom (5); the drillable bottom (5) faces a perforating means (7) communicated with an injection nozzle (3); the impelling plunger (4) can be connected to automatic or manual action rods (10). Therefore, the injecting unit (1) may be used both in machines and devices [dispensers, fractionators, mixers, dosing apparatus] and manually. The rod (10) may include stroke stops (14) which allow dispensing medication in doses.

Owner:ROLLA JOSE SANTIAGO

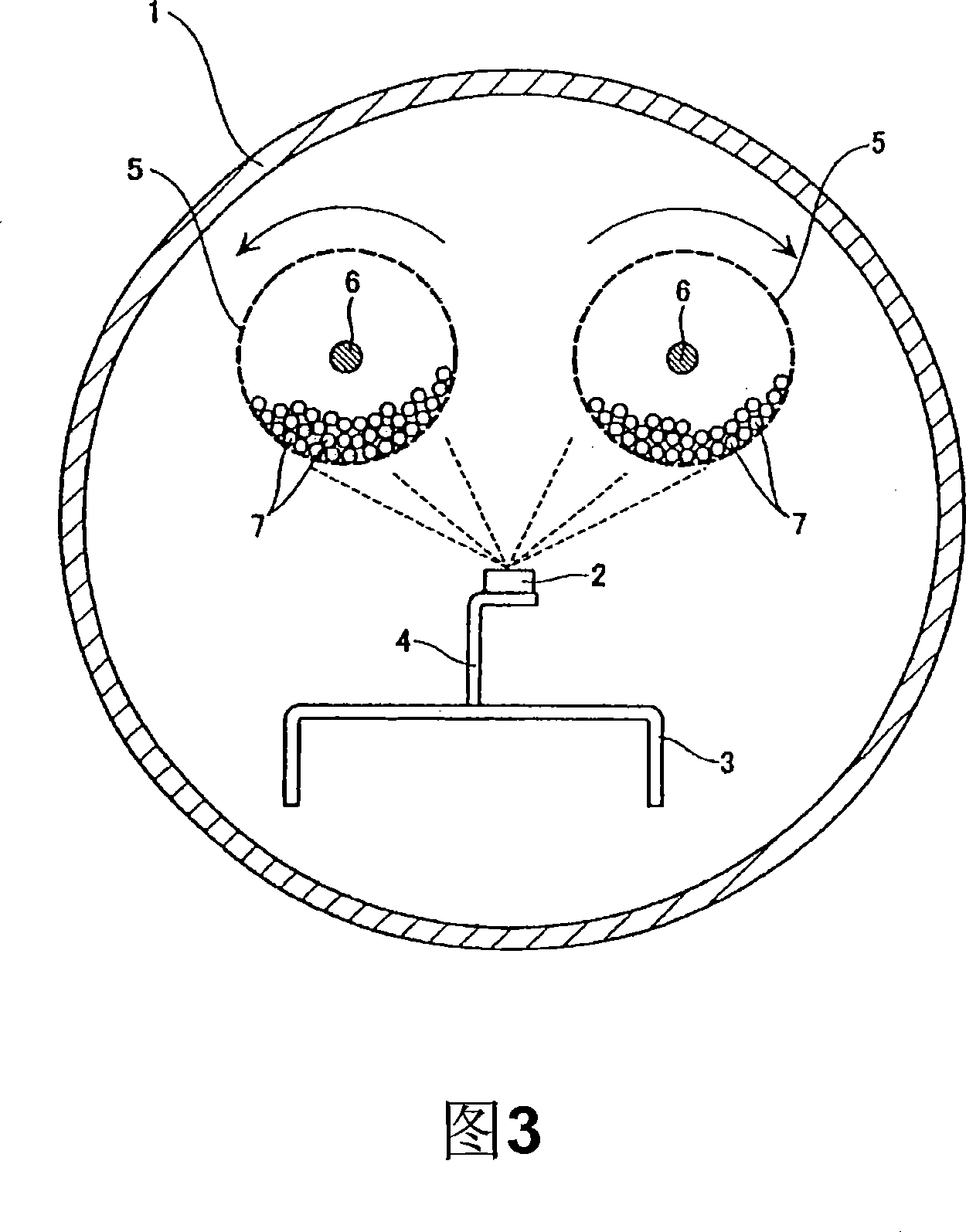

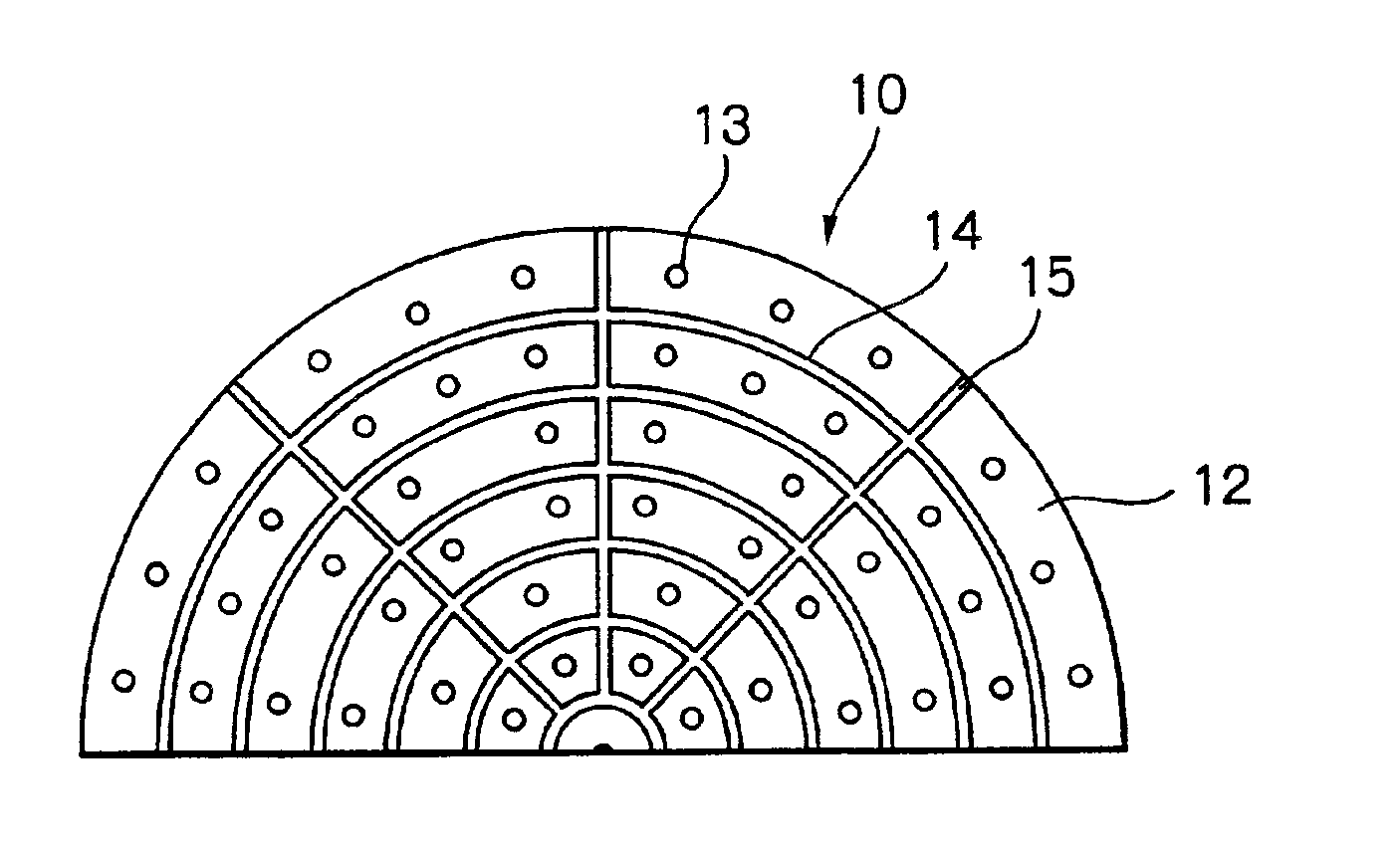

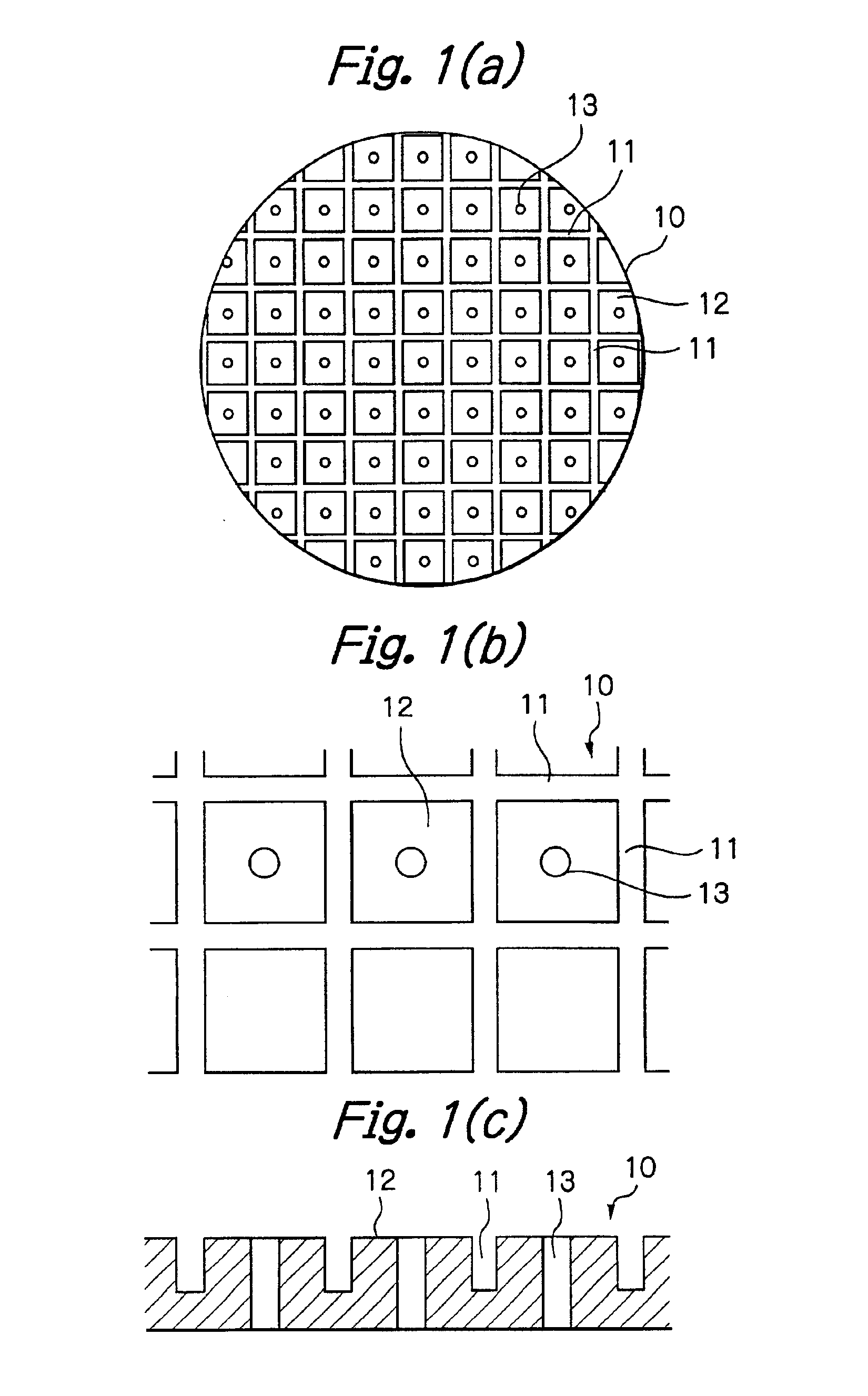

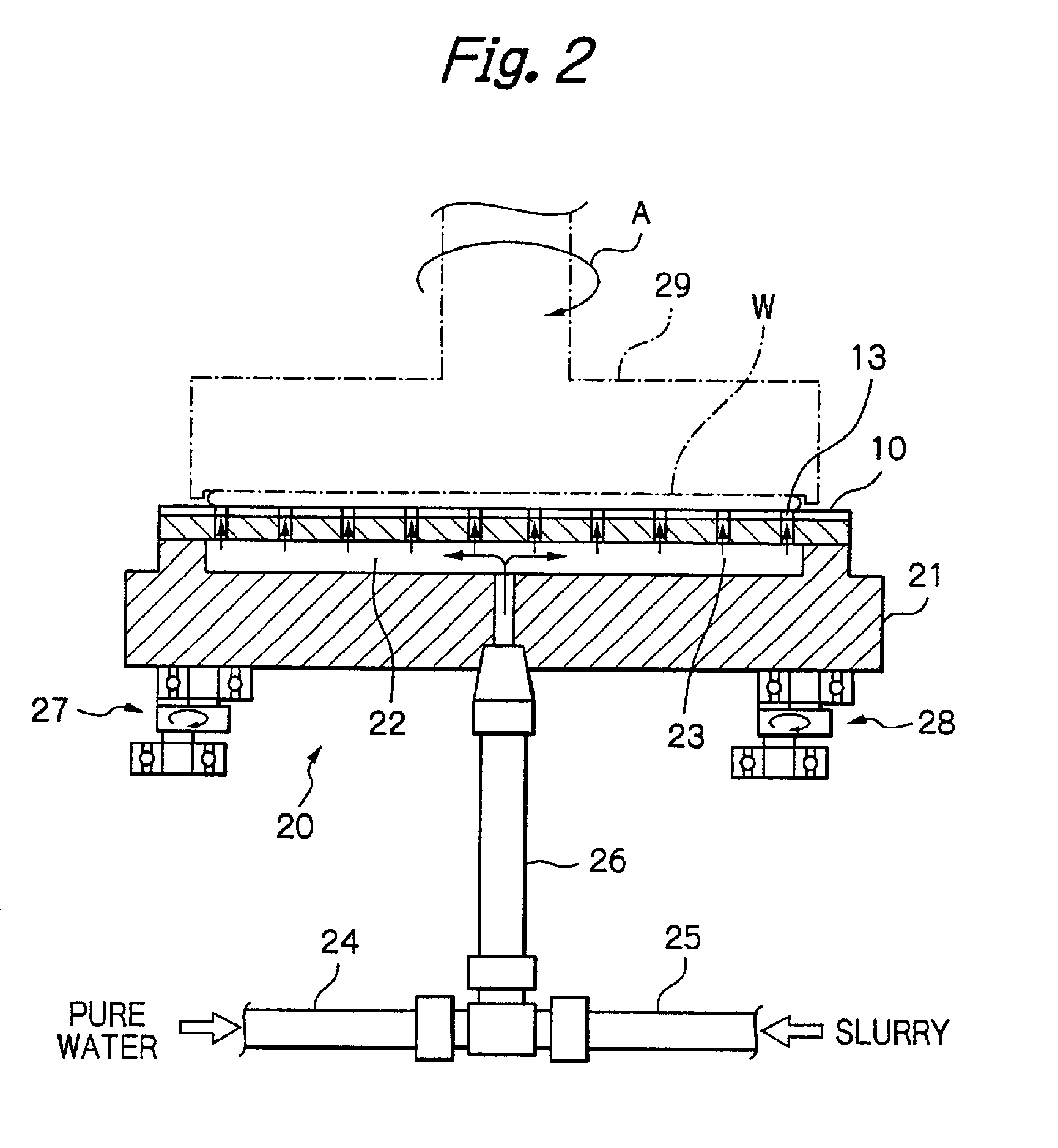

Polishing apparatus

ActiveUS7140955B2Efficient replacementAvoid mixingEdge grinding machinesPolishing machinesEngineeringDirect communication

A polishing apparatus includes a plurality of polishing fluid supply openings terminating in a polishing surface of a polishing table, and a plurality of grooves which are formed in the polishing surface and arranged so as not to be in direct communication with the polishing fluid supply openings. The polishing apparatus further includes a polishing fluid supply system for supplying a polishing fluid to a surface of a substrate through the openings. The grooves may extend at right angles relative to one another so as to define a plurality of lands therebetween, and the polishing fluid supply openings are formed through the lands.

Owner:EBARA CORP

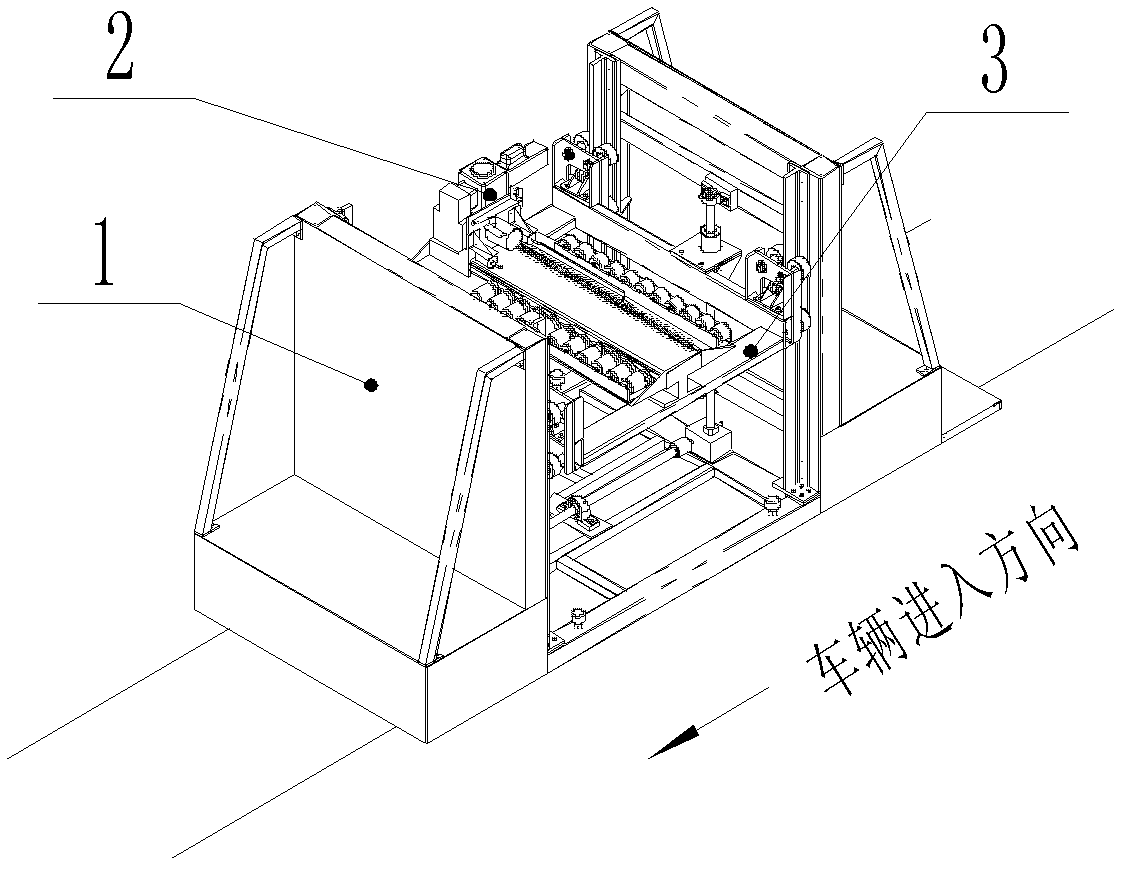

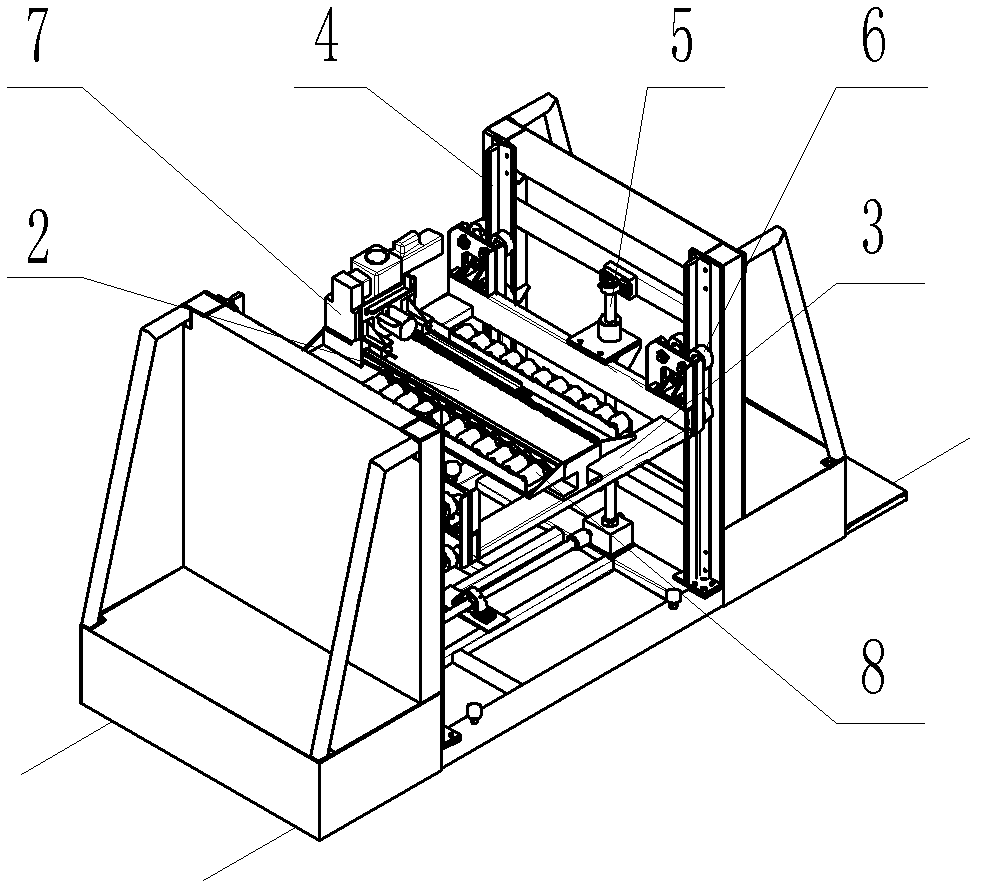

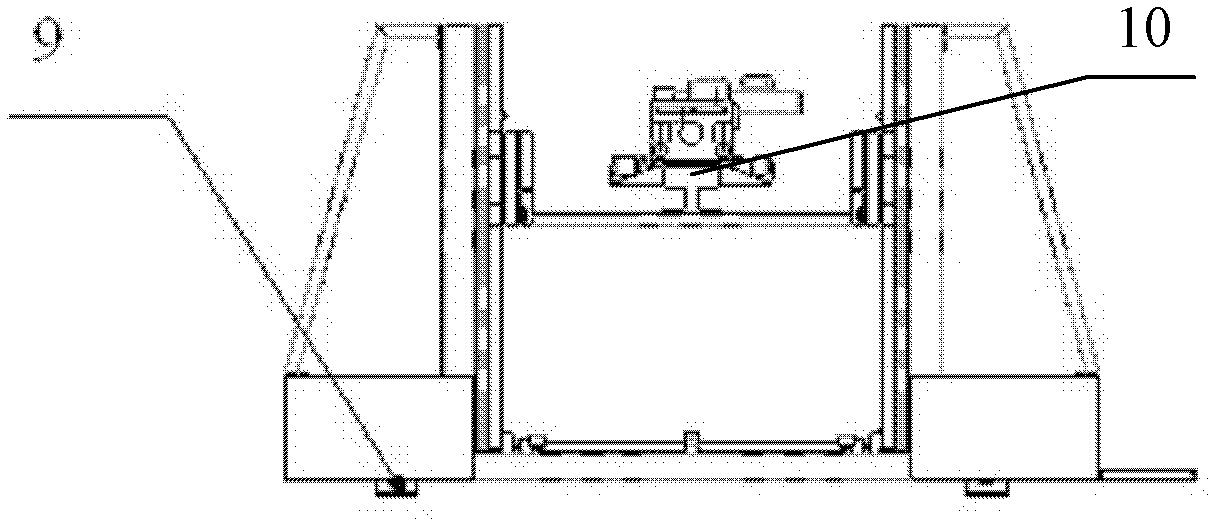

Replacing device for battery boxes of electric vehicle

ActiveCN102556009ALow manufacturing costSmall device sizeElectric propulsion mountingElectric/fluid circuitChanging equipmentElectric vehicle

The invention provides a replacing device for battery boxes of an electric vehicle, which is used for taking down one undercharged battery box from the vehicle, conveying the undercharged battery box to a battery transfer rack or conveying one fully-charged battery box on the battery transfer rack, and mounting the fully-charged battery box on the vehicle. The battery boxes don't need to rotate when being replaced by the device, so that replacing time is saved, and the problem that a large rotating space is needed for replacing the battery boxes is solved. The device comprises a translational device, a mechanical arm and a lifting device, the mechanical arm has a bidirectional moving function, namely, the mechanical arm is capable of extending along the vehicle direction and extending along a battery rack, and two rows of rollers are arranged on the mechanical arm so as to be convenient for drawing off the battery boxes. The device has the advantages that the device consisting of various conventional products is lower in manufacture cost, small in size, flexible in action and fine in universality, the required moving passage width is obviously decreased, and occupied area for replacing is saved.

Owner:BEIJING STATE GRID PURUI EXTRA HIGH VOLTAGE POWER TRANSMISSION TECH CO LTD +1

Water filtration and erosion control system and method

ActiveUS20080019780A1Useful in erosion controlErosion minimizationBarrages/weirsLoose filtering material filtersPondingControl system

An erosion control system and method wherein a fabric filter bag is embedded with and / or filled with a flocculating polymer and is positioned on a sloping soil surface to dam and pond water flowing thereacross for settling of the particles in the water, and as the ponding water seeps into the bag the colloidal particles will be filtered or agglomerated for settling. The water then passes through and out of the bag and is further subjected to agglomeration and filtering by a skirt of filter material also impregnated with flocculating polymer, said skirt being anchored to the bag or stacked to maintain the position adjacent and downslope from the bag.

Owner:DENNY HASTINGS FLP 14

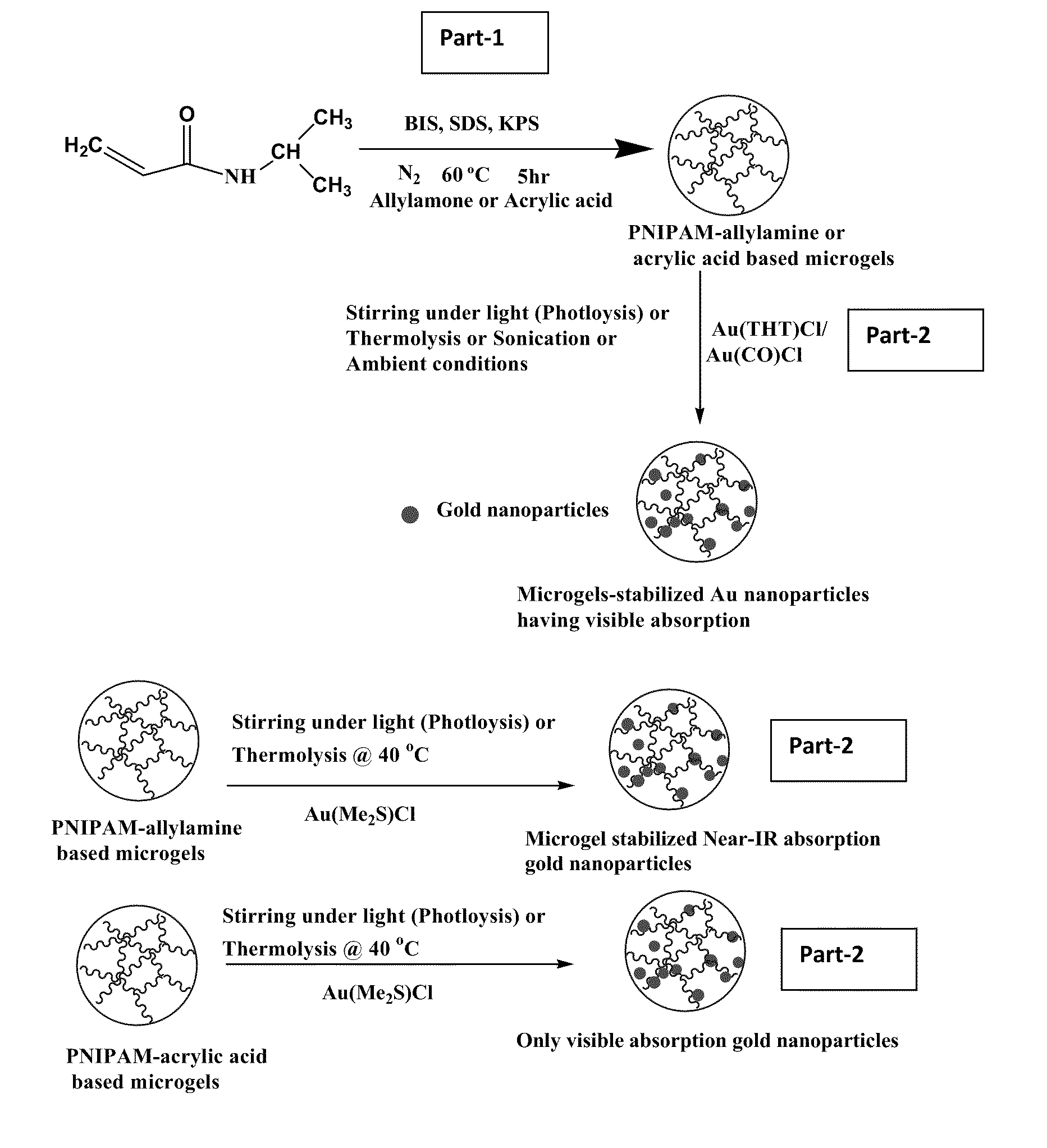

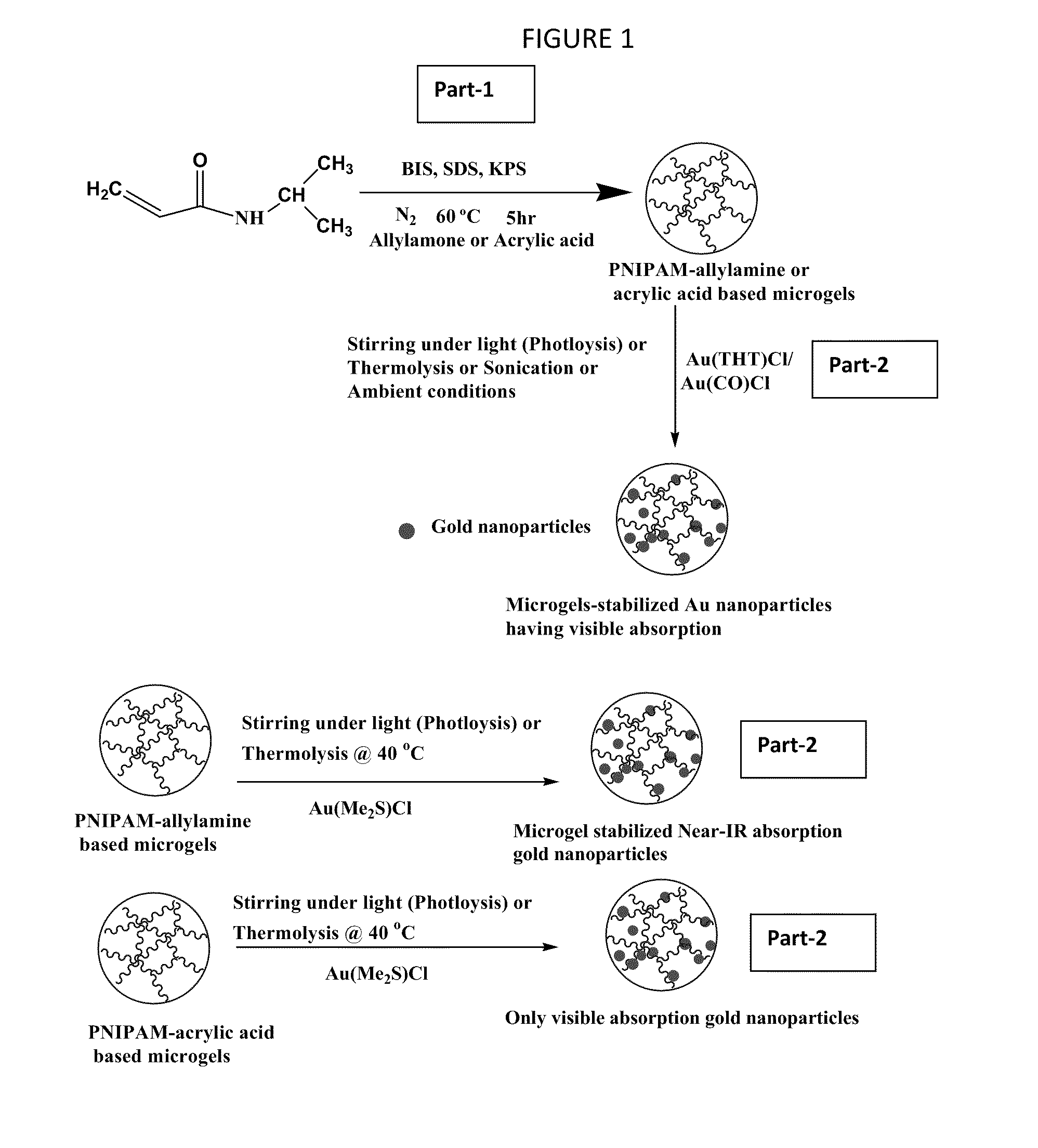

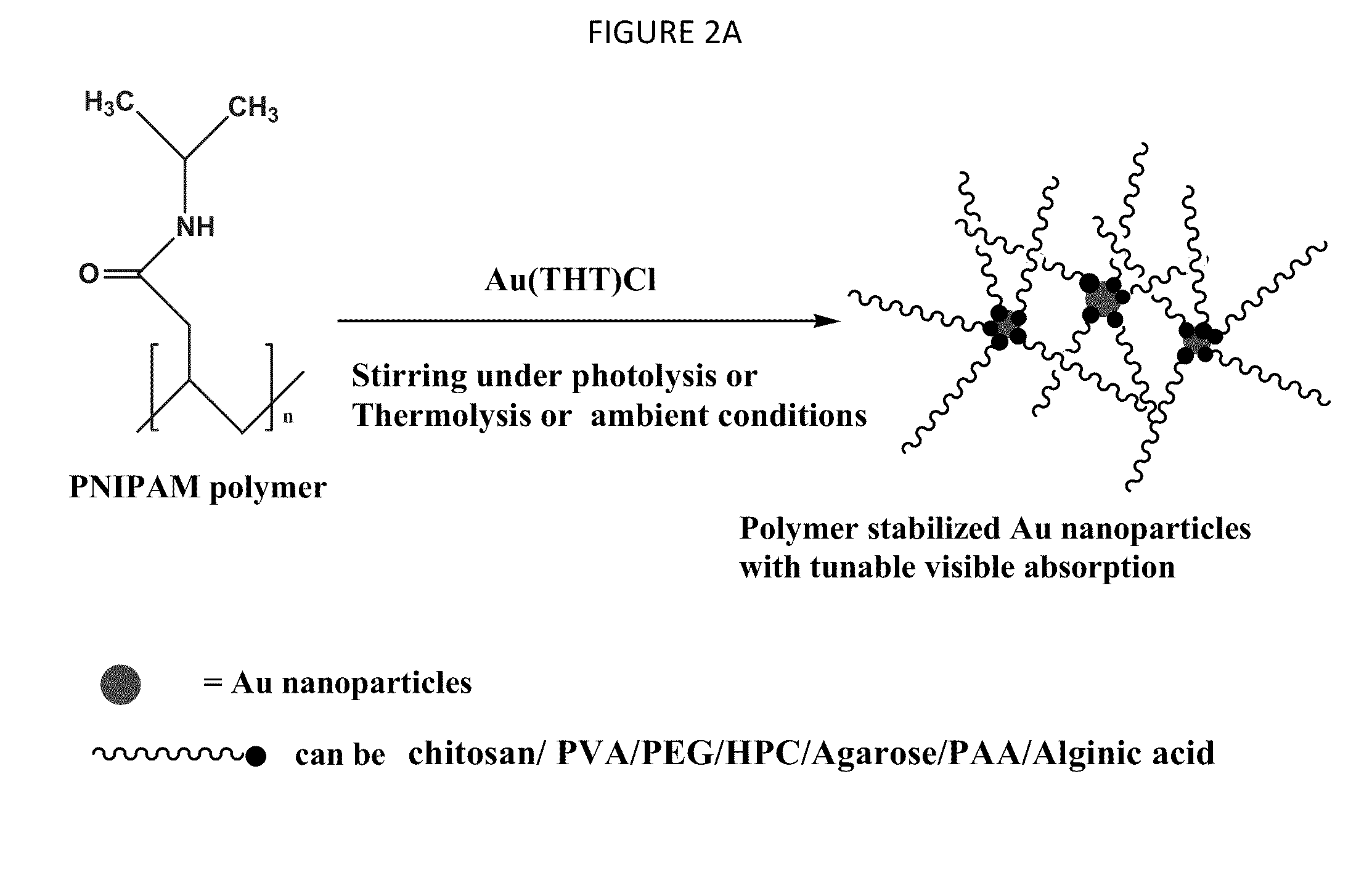

Gold, silver, and copper nanoparticles stabilized in biocompatible aqueous media

InactiveUS20100172997A1Enhance all biological applicationLess chemicalsMaterial nanotechnologyPowder deliveryParticle compositionCopper nanoparticle

The present invention includes metal nanoparticles composition and methods of making and using the same by converting a metal (I) to a metal (0) and forming one or more metal nanoparticles from the metal (0). The one or more metal nanoparticles are stabilized with one or more biocompatible stabilizers to prevent agglomeration and make them amenable for biomedical applications.

Owner:UNIVERSITY OF NORTH TEXAS

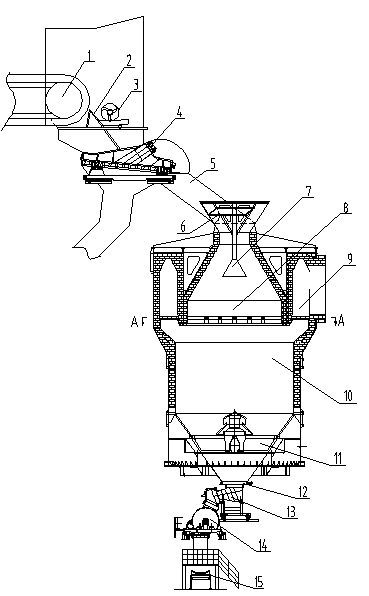

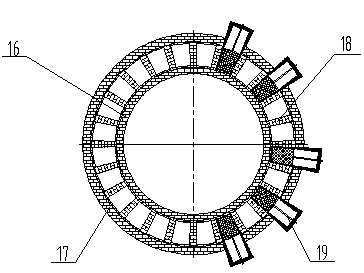

Sintering furnace type cooling device

ActiveCN103234359AReduce height differenceImprove qualityHandling discharged materialThermal energyFlue gas

A sintering furnace type cooling device relates to the technology field of sintering cooling devices. An outlet of a sintering machine is provided with a single roll crusher; an outlet of the single roll crusher is provided with a hot sinter screen; the hot sinter screen is connected with an inlet of a chute; an outlet of the chute is connected with a furnace opening of a cooling furnace; a distributing device is arranged inside the furnace opening of the cooling furnace; a ventilation device is arranged at the bottom of the cooling furnace; a discharging device is connected under the ventilation device; a belt conveyer is arranged under the discharging device; the cooling furnace comprises a pre-store area which is arranged on the upper portion, a cooling area which is arranged on the lower portion and an annular flue area which is arranged on the periphery of the pre-store area; radial supporting columns which are integrally and radially distributed are arranged at the bottom of the annular flue area; a high-temperature flue gas adjustment plate is coated on two adjacent radial supporting columns; and the high-temperature flue gas adjustment plate is capable of sliding along a diametrical direction of the annular flue. The sintering furnace type cooling device has the advantages of effectively overcoming the defects that an existing sintering cooling system is serious in air infiltration and low in waste heat utilization rate, achieving efficient heat replacement, improving the temperature of the flue gas and reducing energy consumption in cooling.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

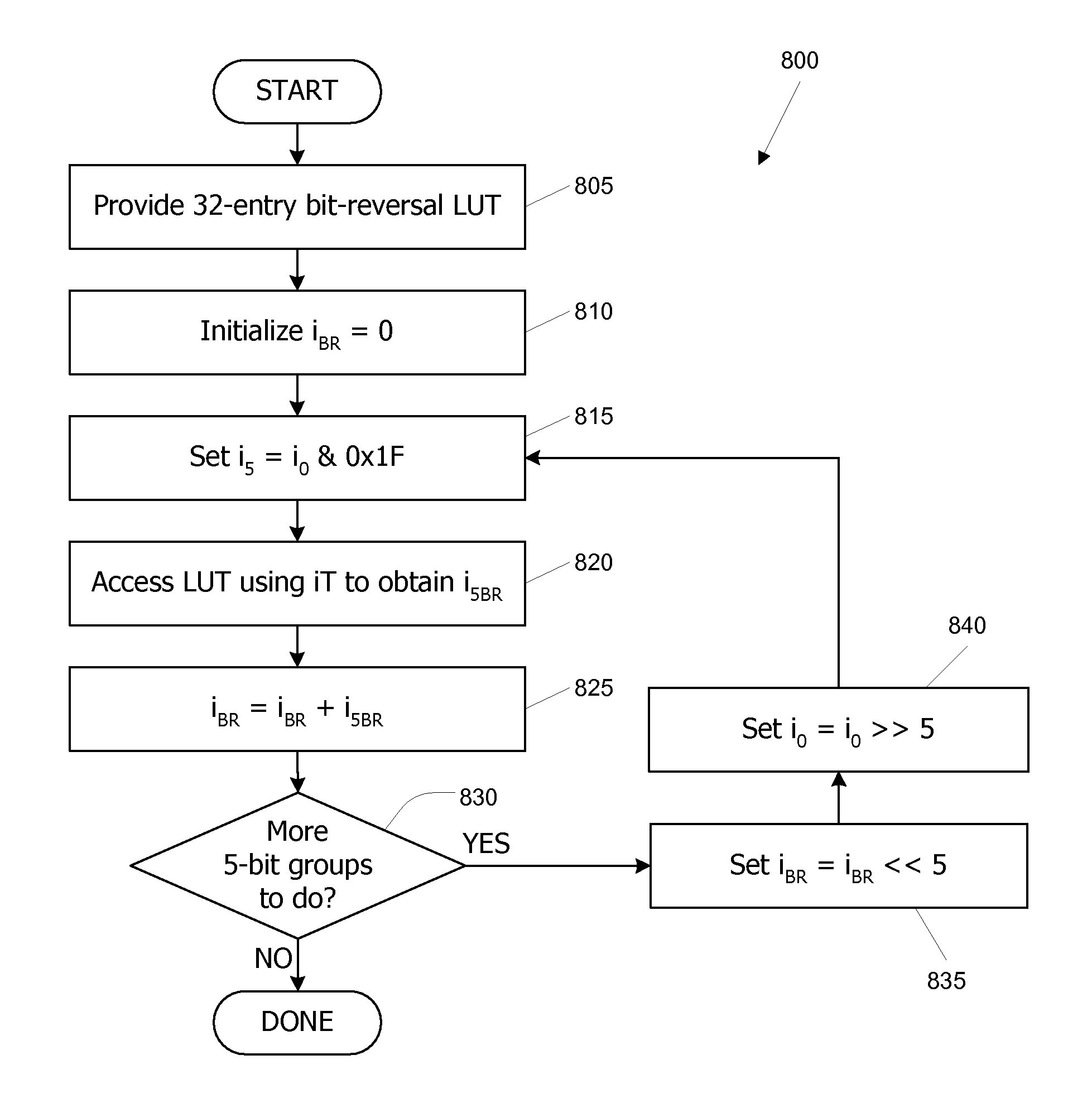

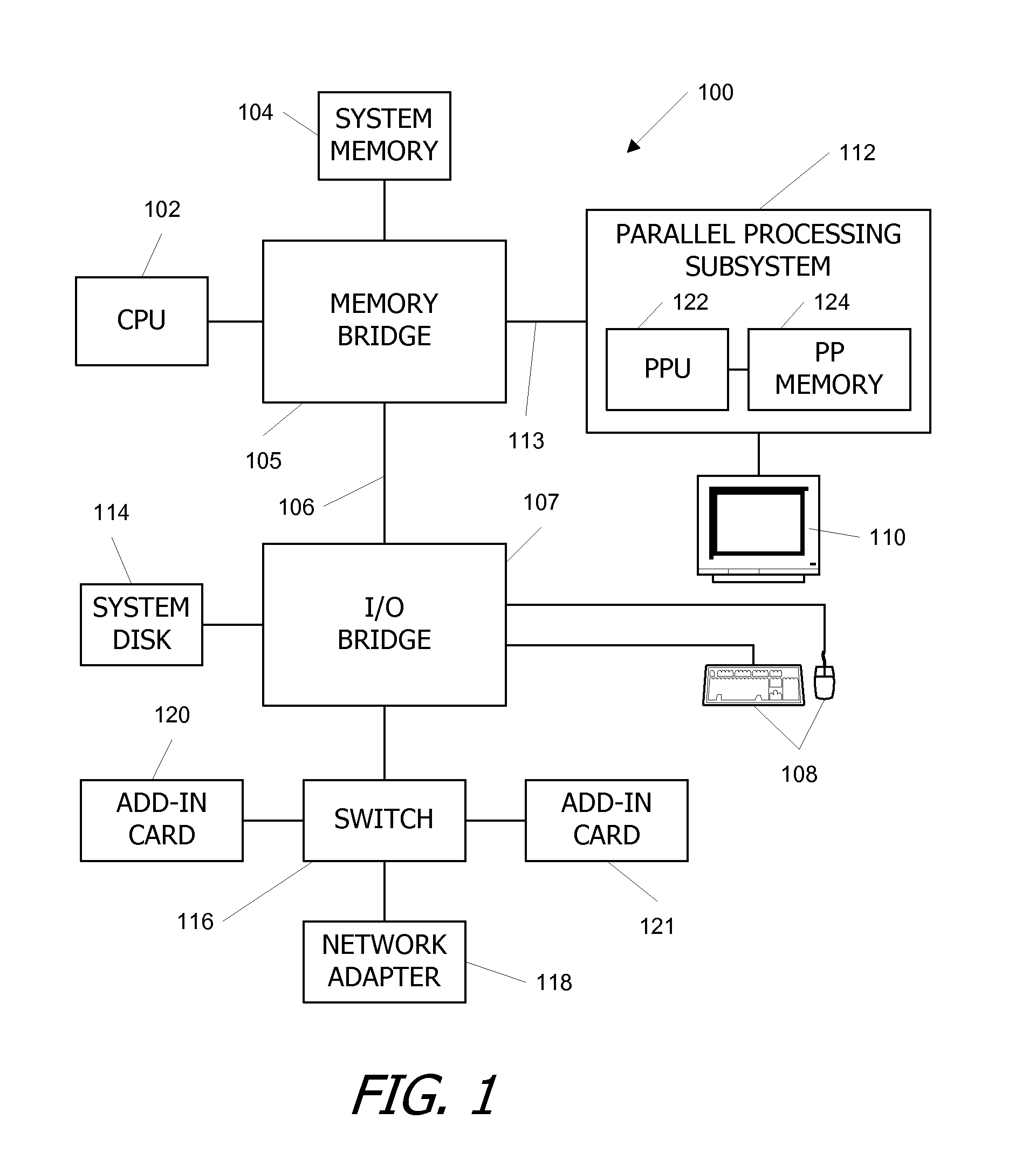

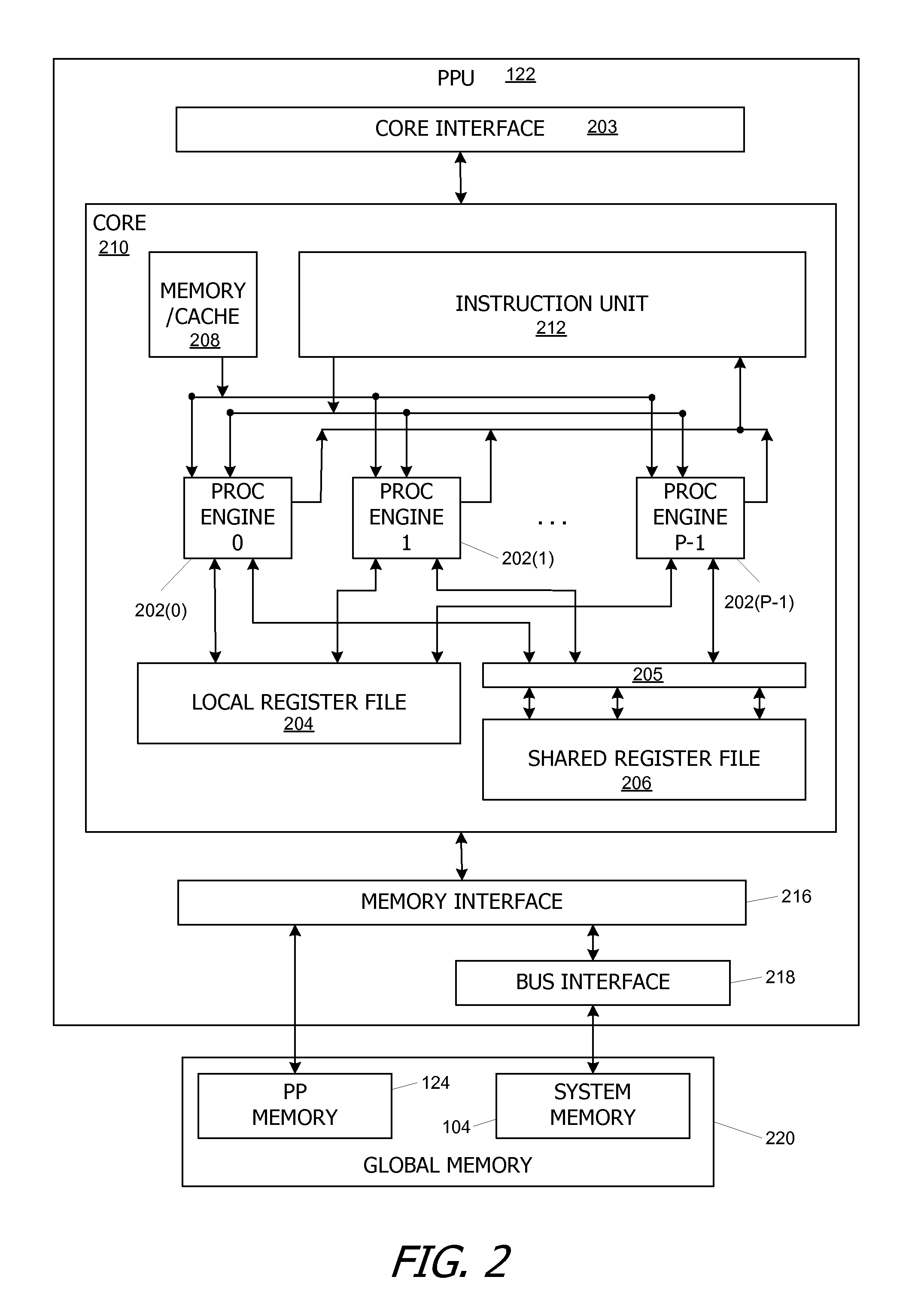

Bit reversal methods for a parallel processor

ActiveUS7640284B1Efficient replacementDigital computer detailsHandling data according to predetermined rulesData setMemory bank

Parallelism in a processor is exploited to permute a data set based on bit reversal of indices associated with data points in the data set. Permuted data can be stored in a memory having entries arranged in banks, where entries in different banks can be accessed in parallel. A destination location in the memory for a particular data point from the data set is determined based on the bit-reversed index associated with that data point. The bit-reversed index can be further modified so that at least some of the destination locations determined by different parallel processes are in different banks, allowing multiple points of the bit-reversed data set to be written in parallel.

Owner:NVIDIA CORP

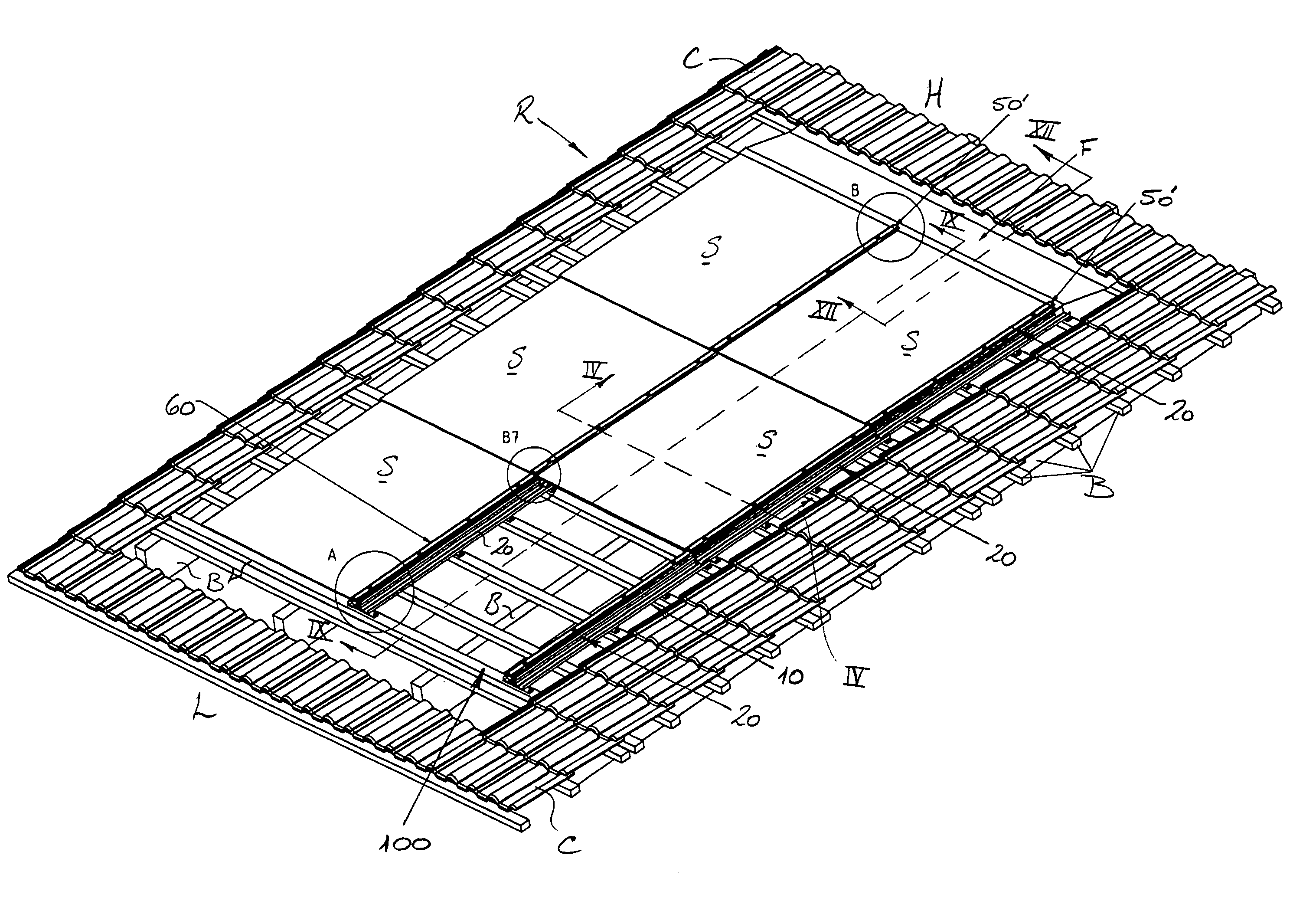

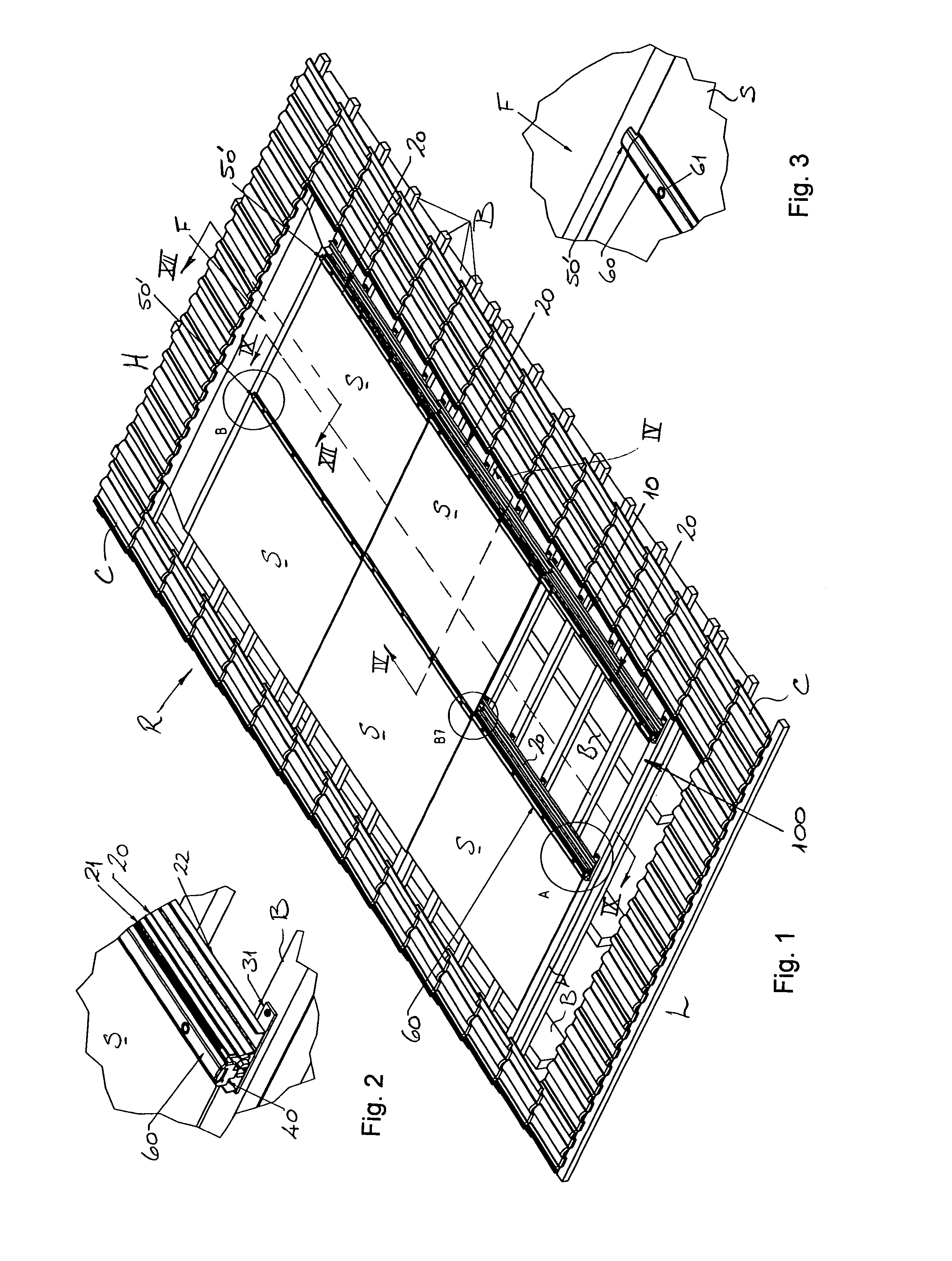

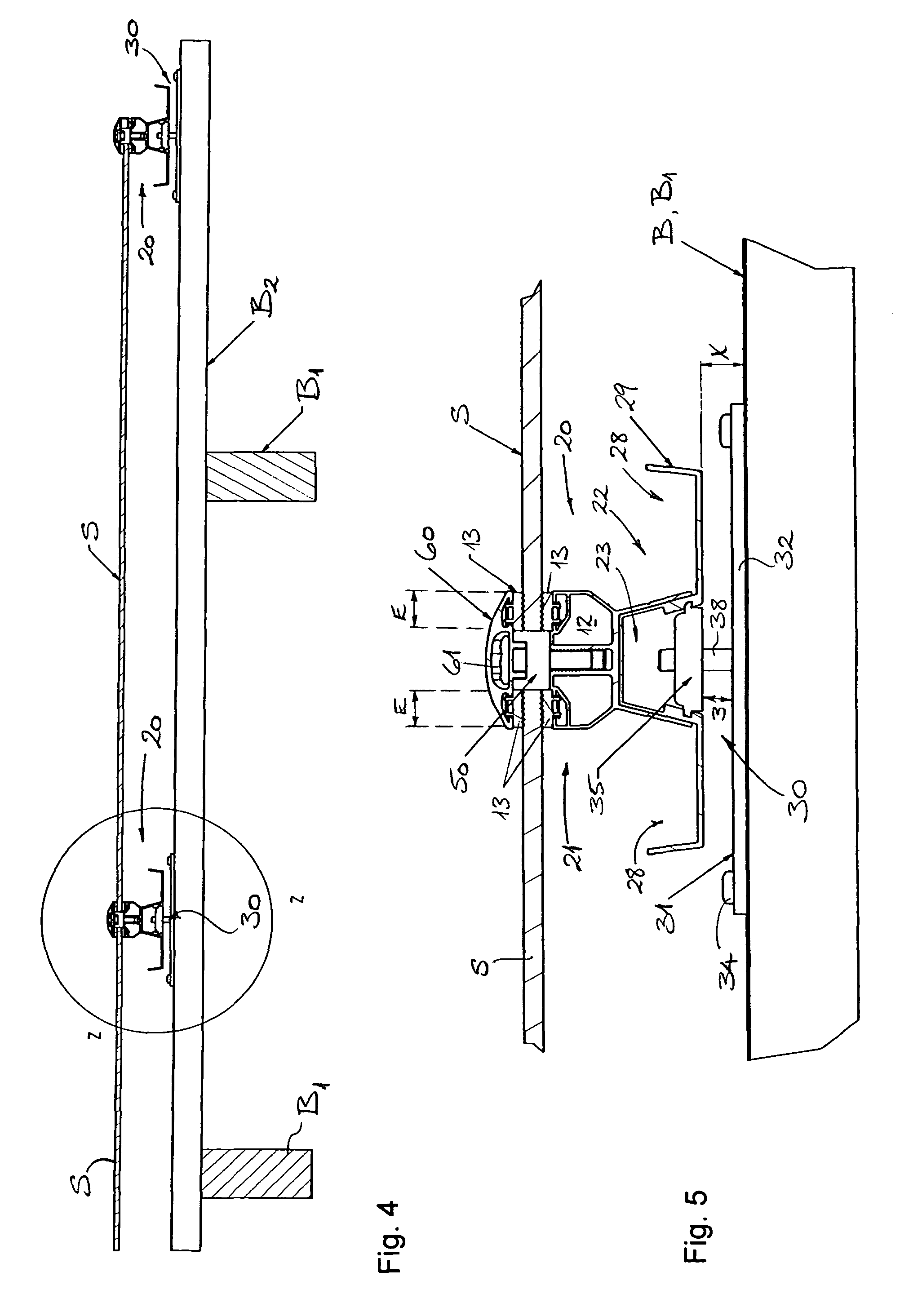

Mounting system for solar panels, and mounting rail and anchoring device therefor

InactiveUS20120325761A1Readily adaptEasy to adaptSolar heating energySolar heat devicesEdge regionEngineering

In one broad aspect, the present invention provides a mounting system (100) for mounting one or more solar panels (S), comprising: a plurality of elongate mounting members (20) adapted to be arranged and secured spaced apart and substantially parallel to one another; and a plurality of anchoring devices (30) for securing each of the mounting members (20) to a support structure, such as a roof structure. Each of the mounting members (20) is adapted to receive and support an edge region (E) of a solar panel (S), such that each solar panel (S) extends between at least two mounting members (20). Furthermore, each anchoring device (30) comprises a footing (31) to be rigidly fastened to the support structure, and a coupling member (35) for connection with a respective one of the mounting members (20). A spacing between the coupling member (35) and the footing (31) is selectively variable by a user to adjust and / or set an elevation (X) of the respective mounting member (20) relative to the support structure. In a related aspect, the invention provides a mounting rail (20) for the mounting system (100). In another related aspect, the invention also provides an anchoring device (30) for the mounting system (100).

Owner:RENUSOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com