Patents

Literature

103results about How to "Increase in coercivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

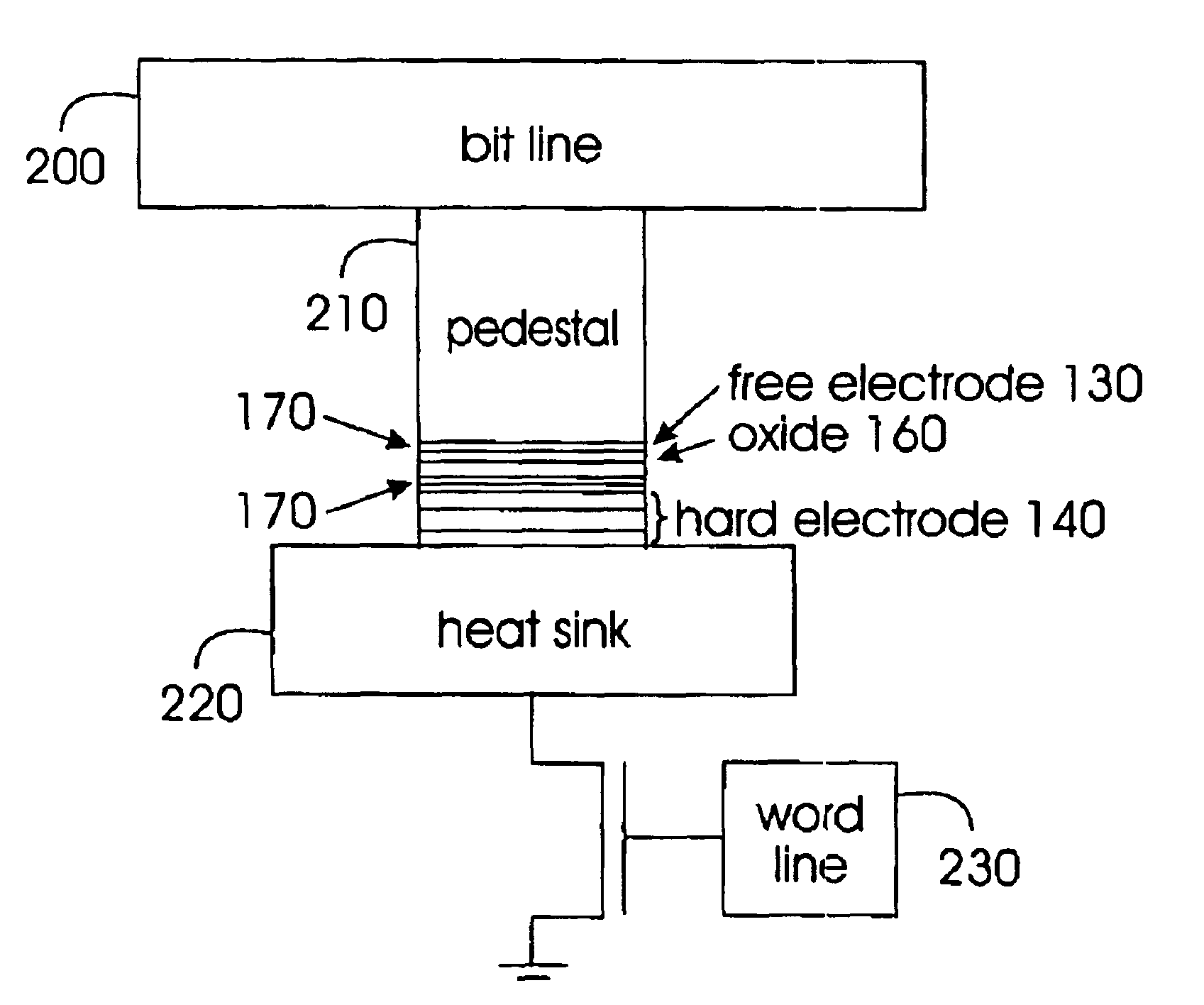

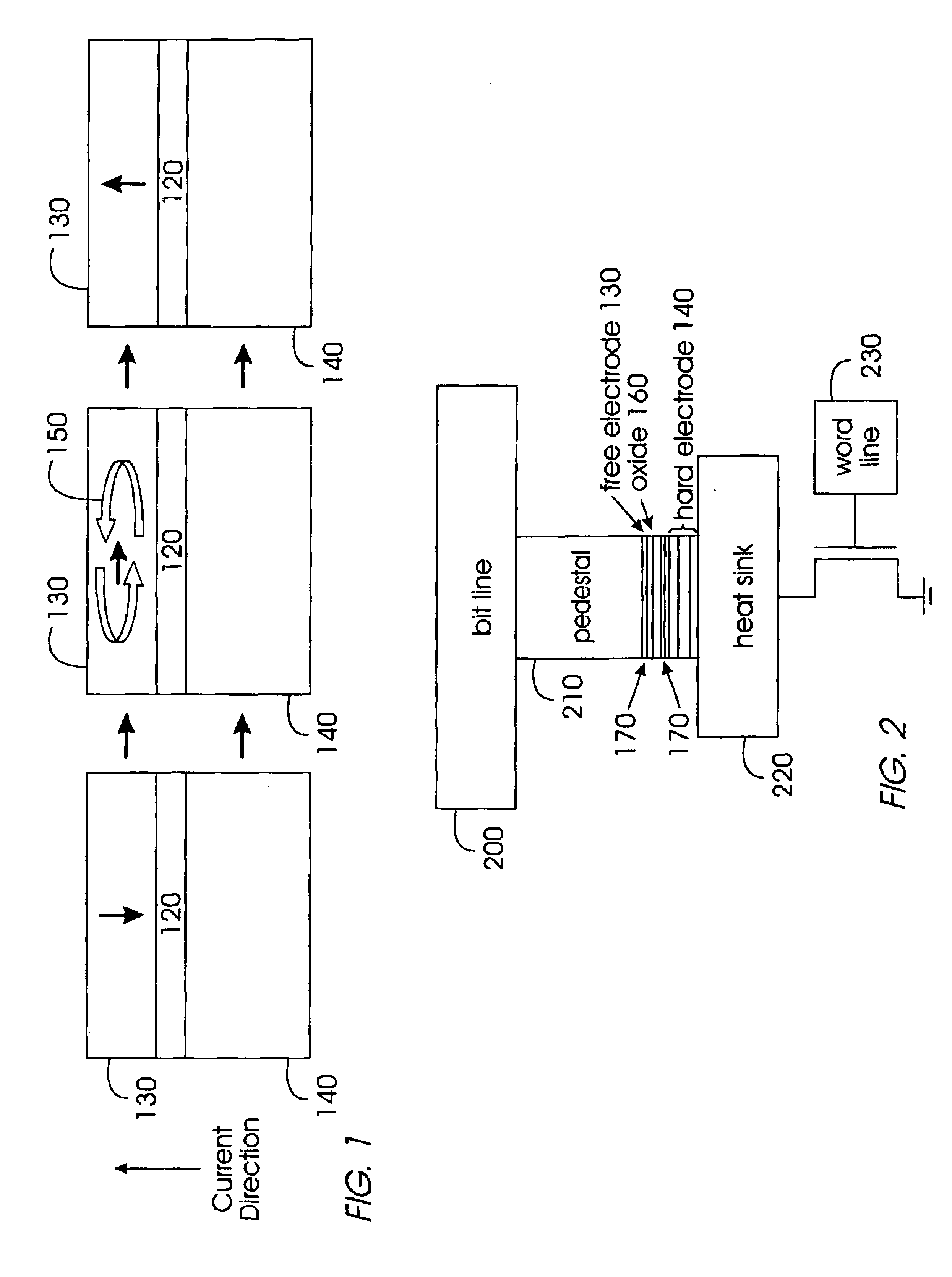

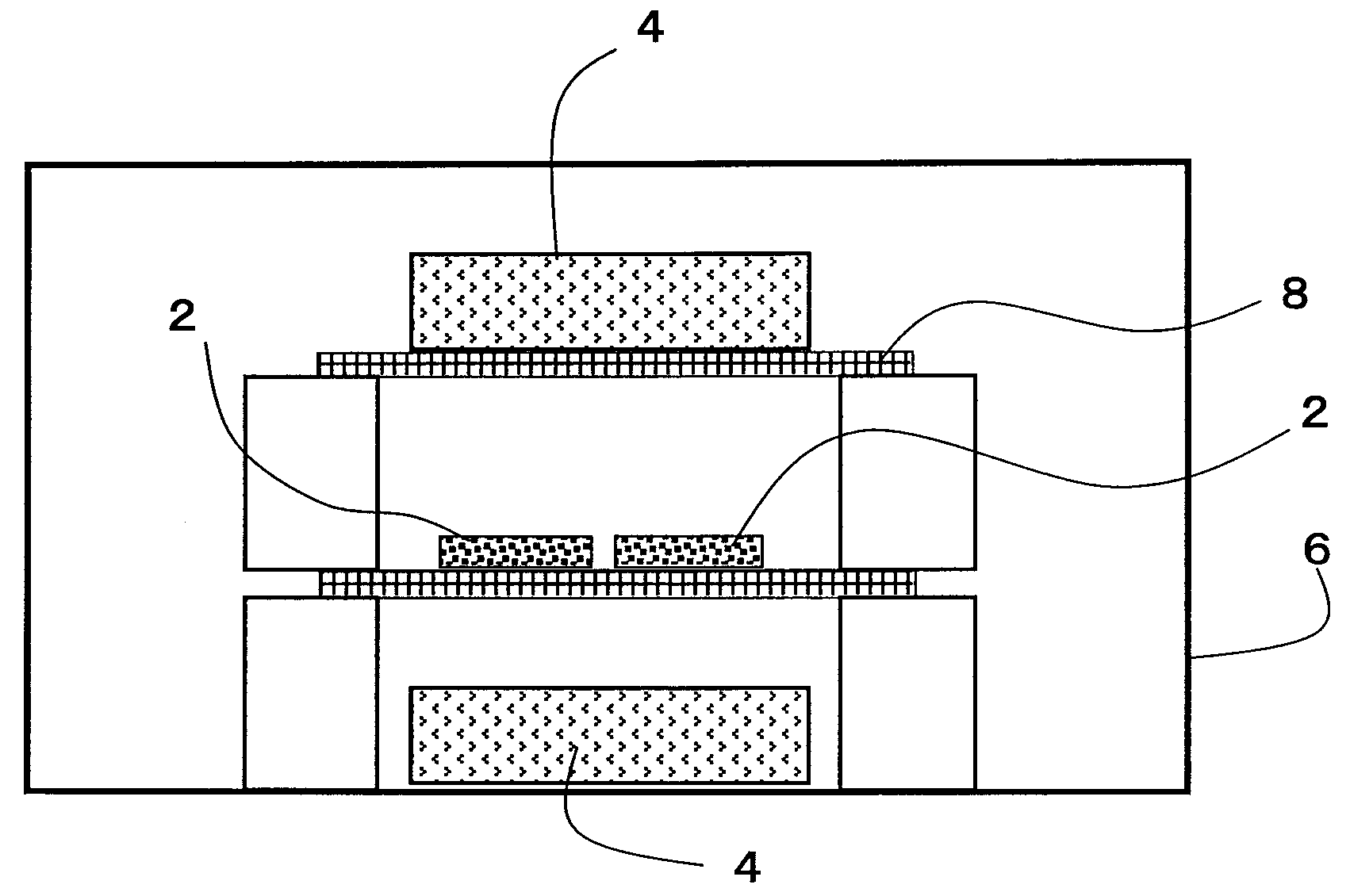

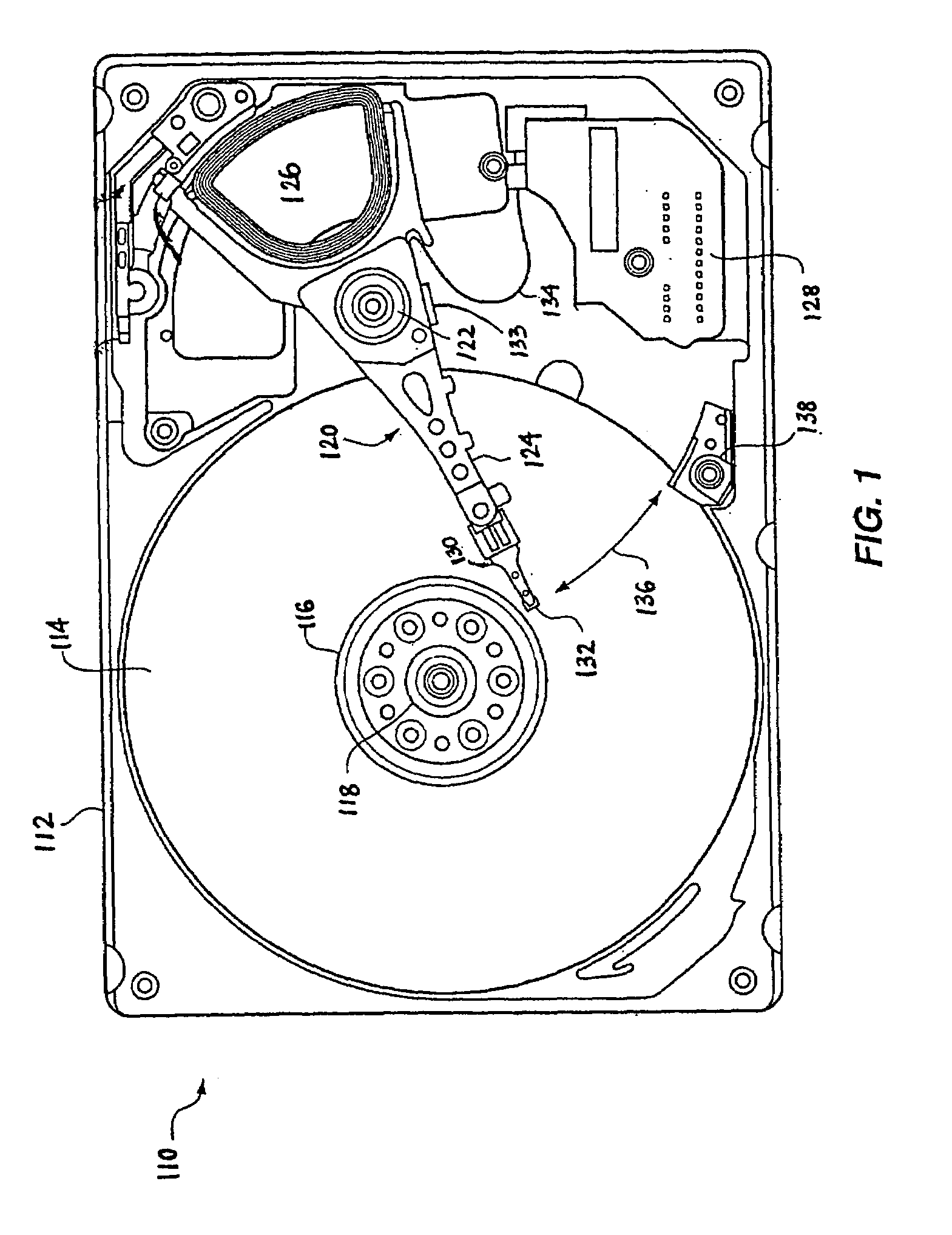

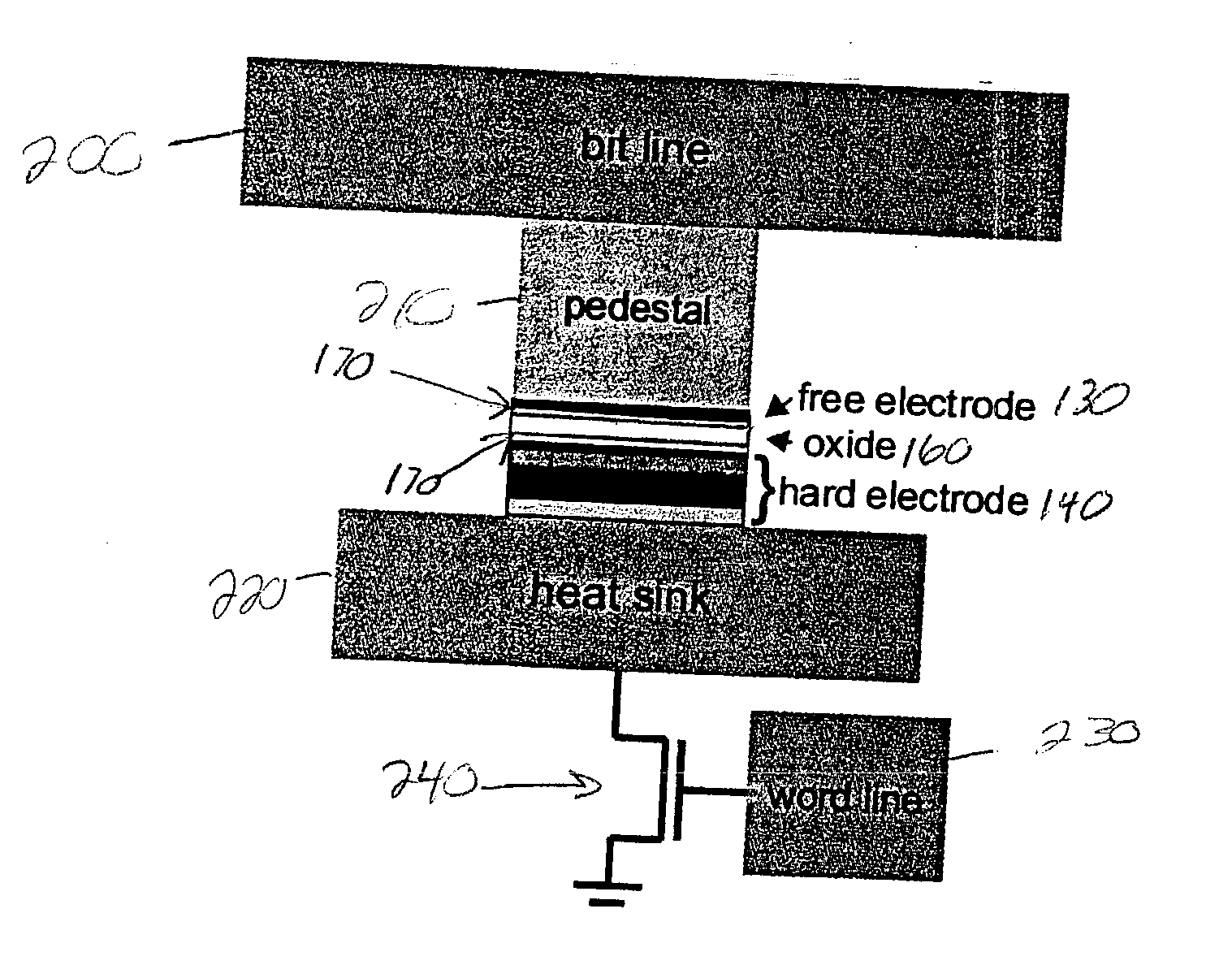

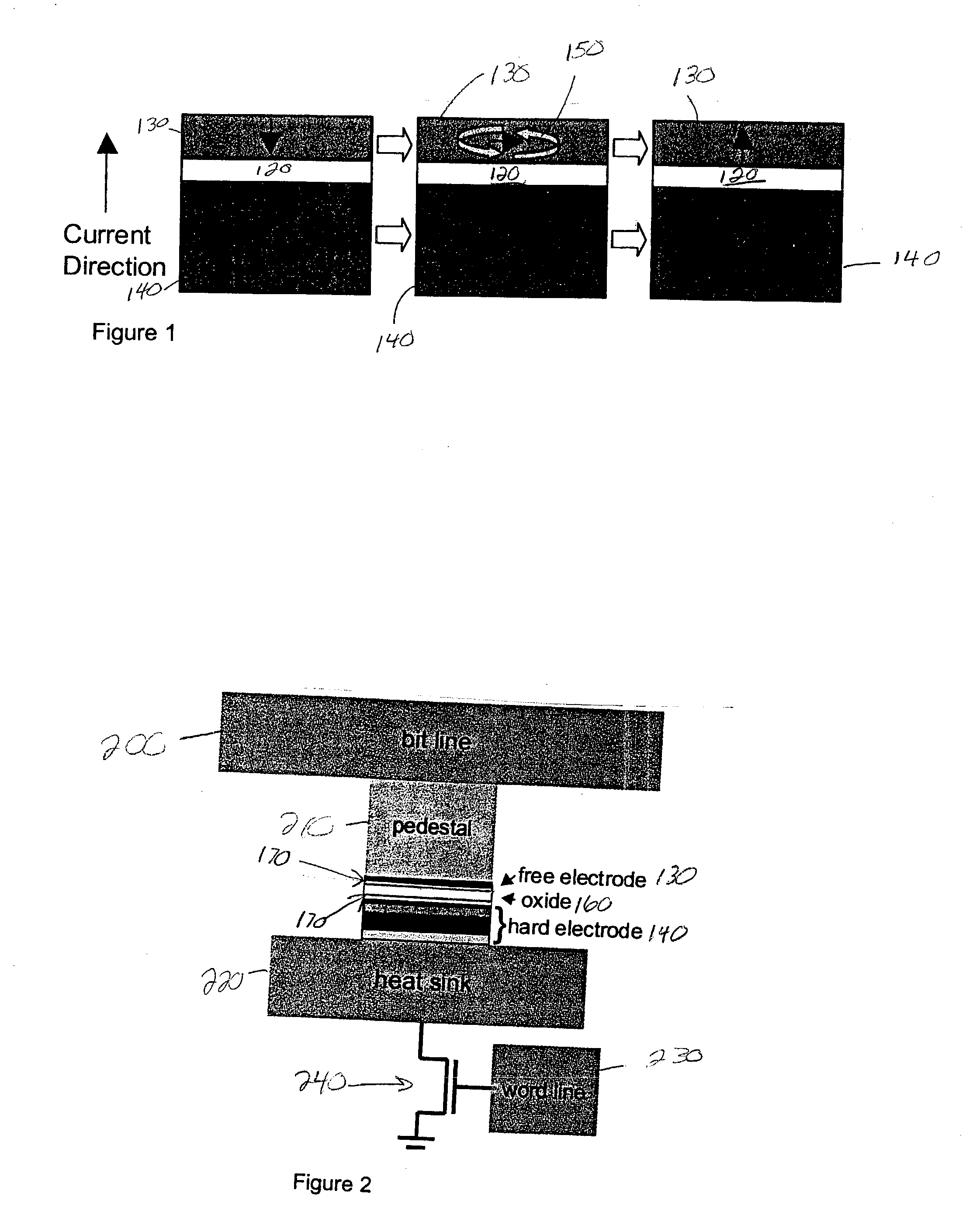

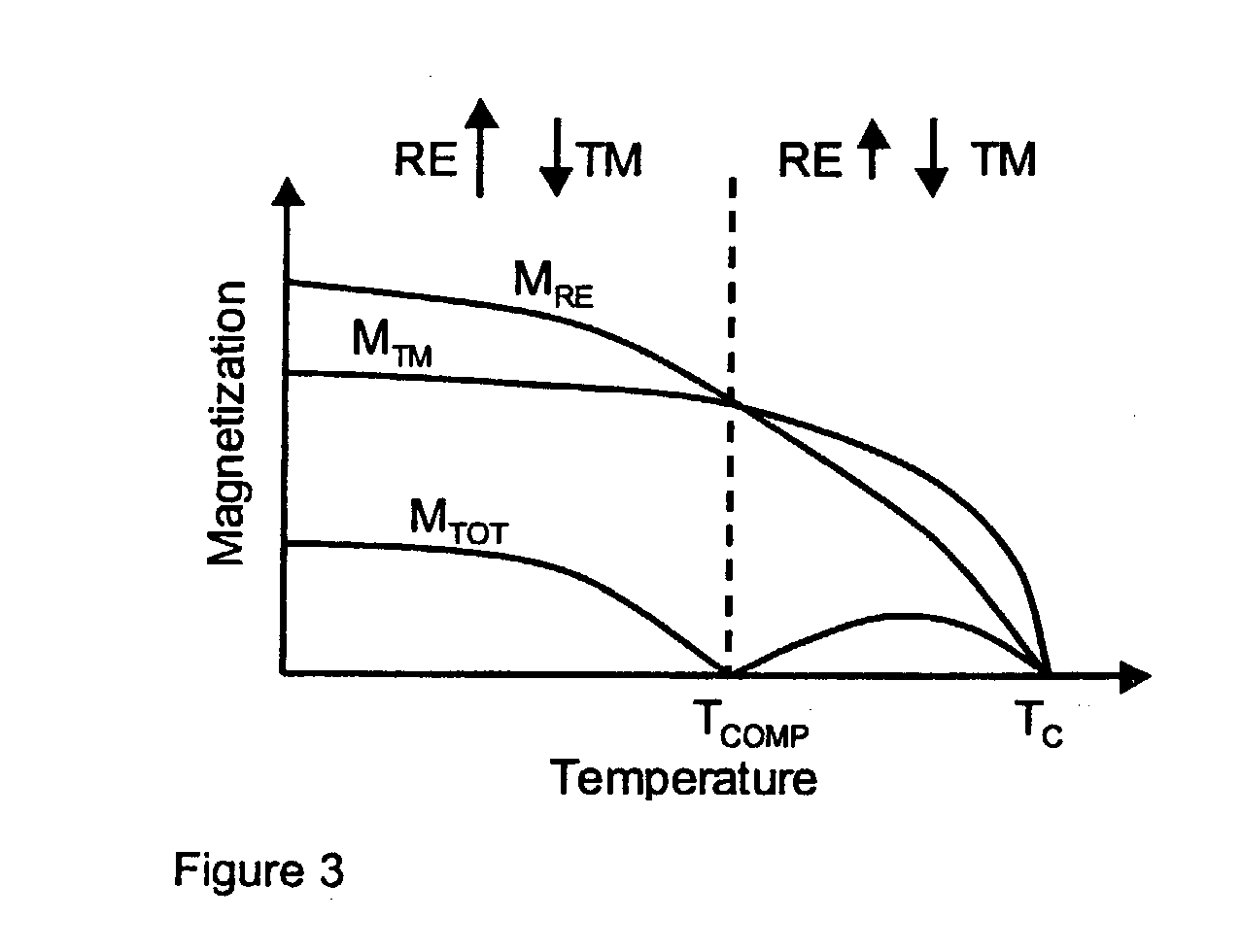

Thermally-assisted magnetic writing using an oxide layer and current-induced heating

InactiveUS6771534B2Increase in sizeIncrease in coercivityNanostructure applicationNanomagnetismElectrical resistance and conductanceElectrical conductor

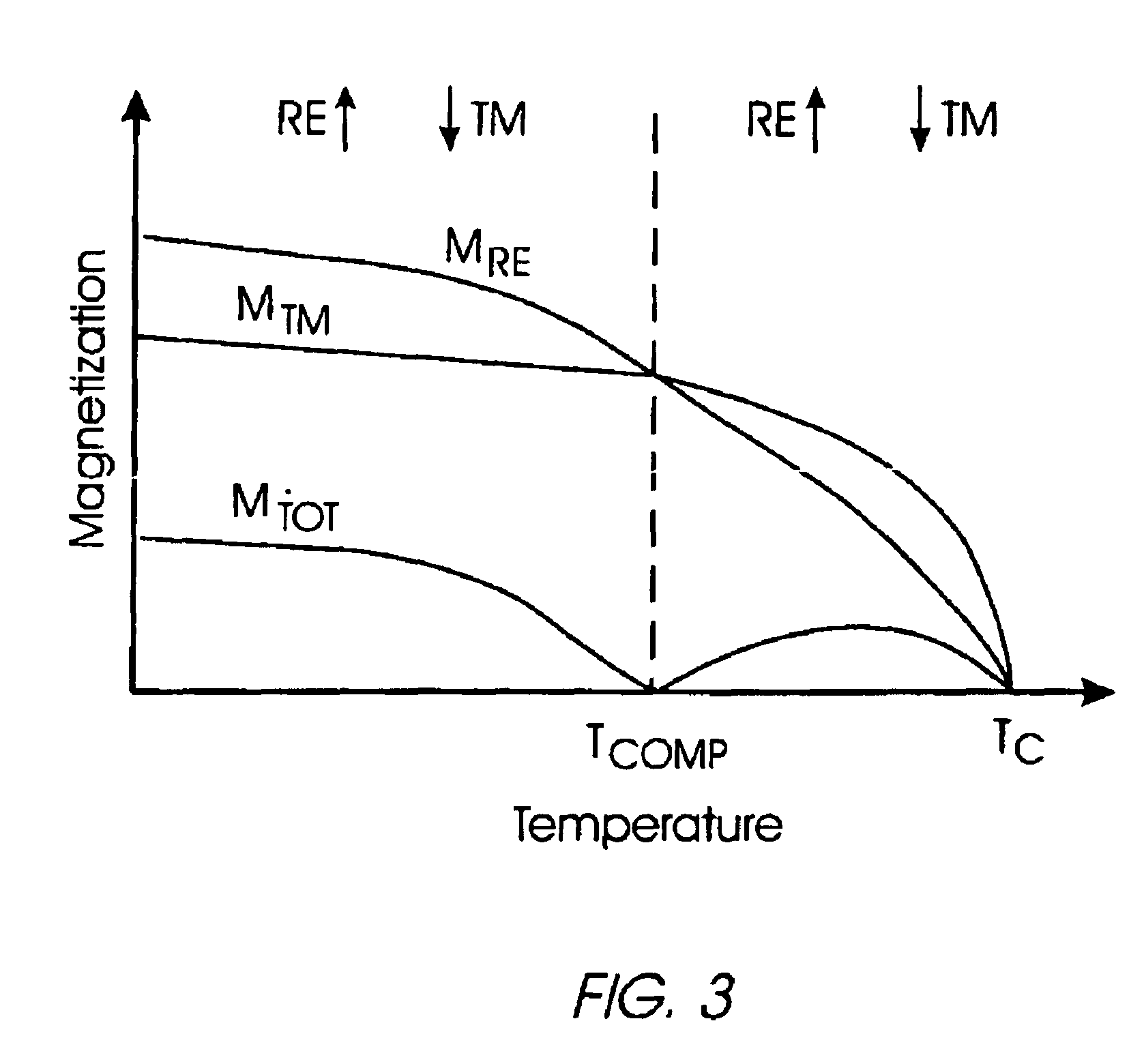

A method and structure for a non-volatile magnetic random access memory (MRAM) device that has a stable magnetic electrode, an oxide layer adjacent the stable magnetic electrode, and a free magnetic electrode. The oxide layer is between the stable magnetic electrode and the free magnetic electrode. In the invention, a conductor is connected to a stable magnetic electrode. The oxide layer has a resistance at levels to allow sufficient power dissipation to lower the anisotropy of the free magnetic electrode through current induced heating. Current-induced heating is used in combination with spin-transfer torque or a magnetic field to switch the free magnetic electrode.

Owner:GLOBALFOUNDRIES U S INC

Perpendicular magnetic recording medium with improved magnetic anisotropy field

InactiveUS20100035085A1High HcExcellent crystallographic C axis orientationMagnetic materials for record carriersRecord information storageMagnetic anisotropyAlloy

A perpendicular magnetic recording medium comprising a substrate, a soft underlayer, a seed layer, a non-magnetic FCC NiW alloy underlayer, a non-magnetic HCP underlayer, and a magnetic layer. We have discovered that the combination of a seed layer comprising Ta and a NiW alloy underlayer uniquely improves media recording performance and thermal stability by achieving excellent coercivity of the thin bottom magnetic recording layer and narrow C axis orientation distribution.

Owner:WD MEDIA

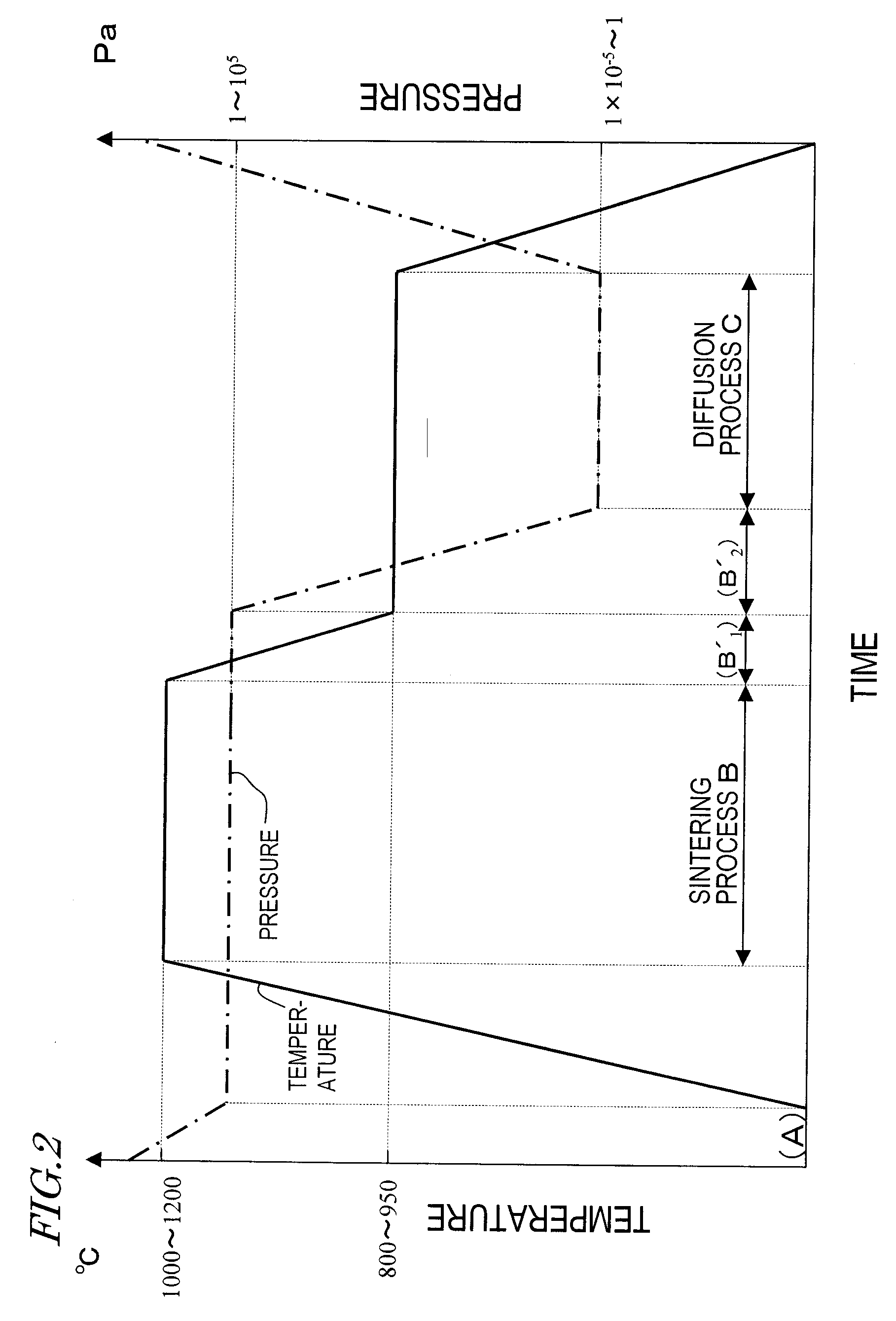

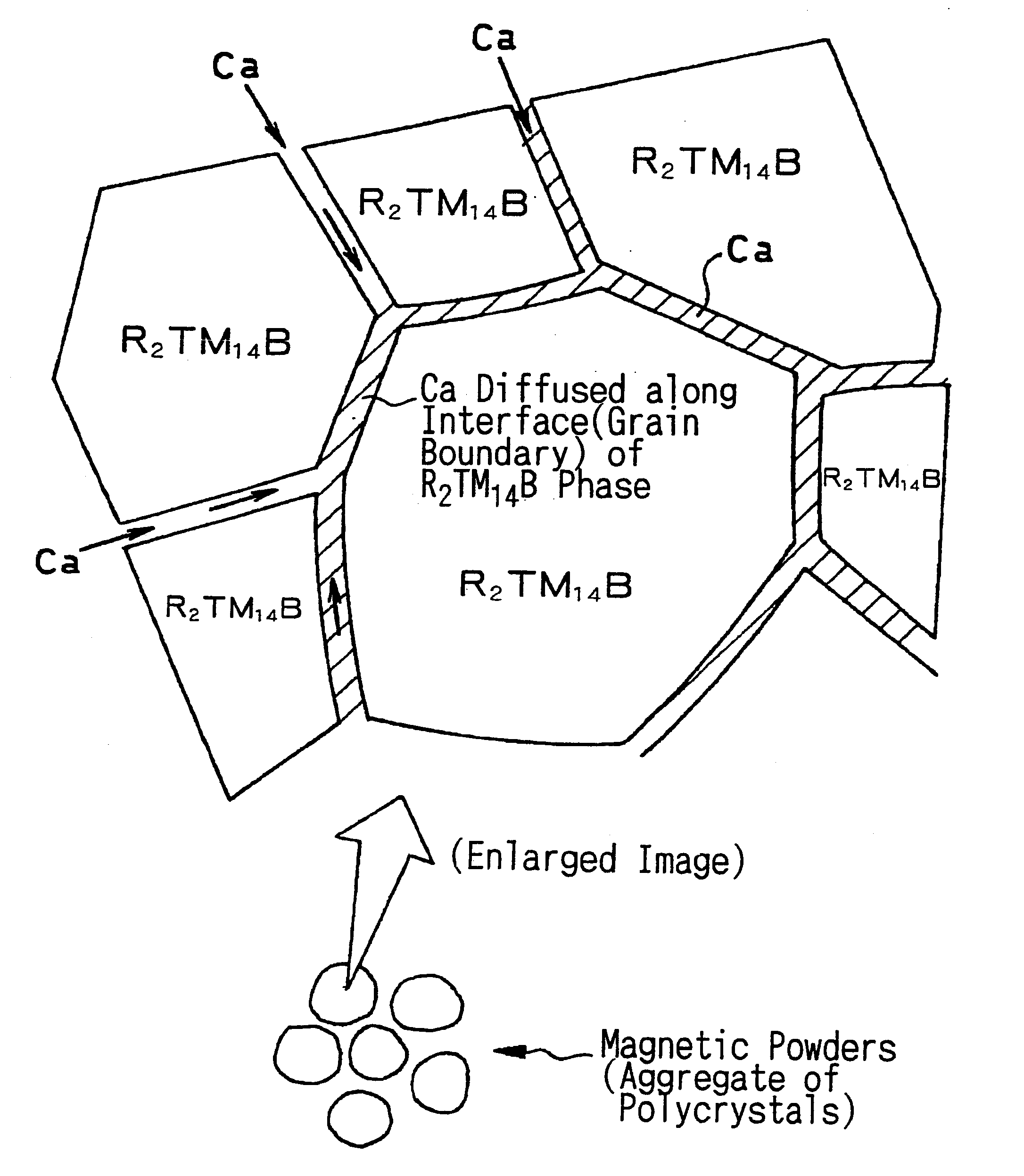

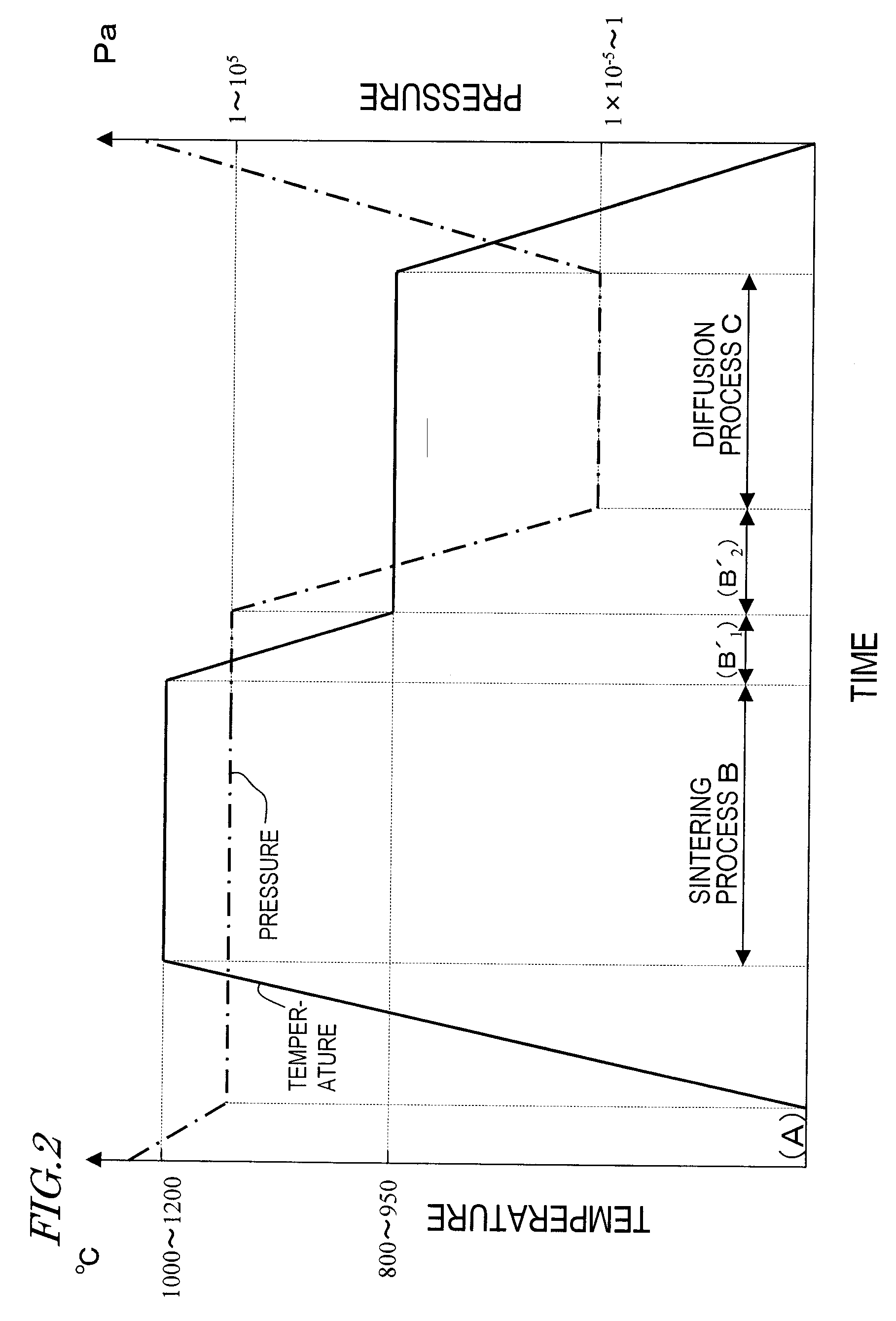

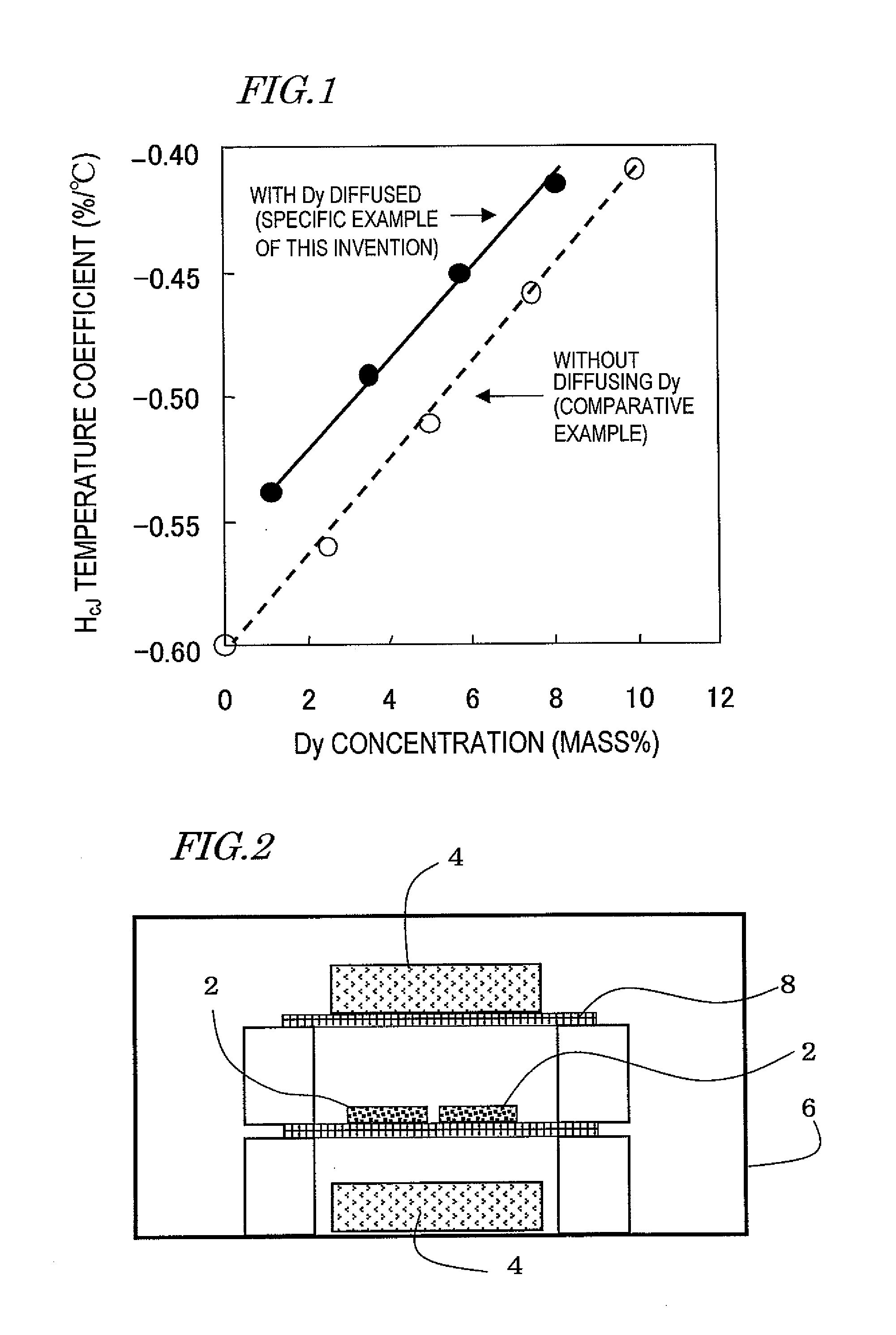

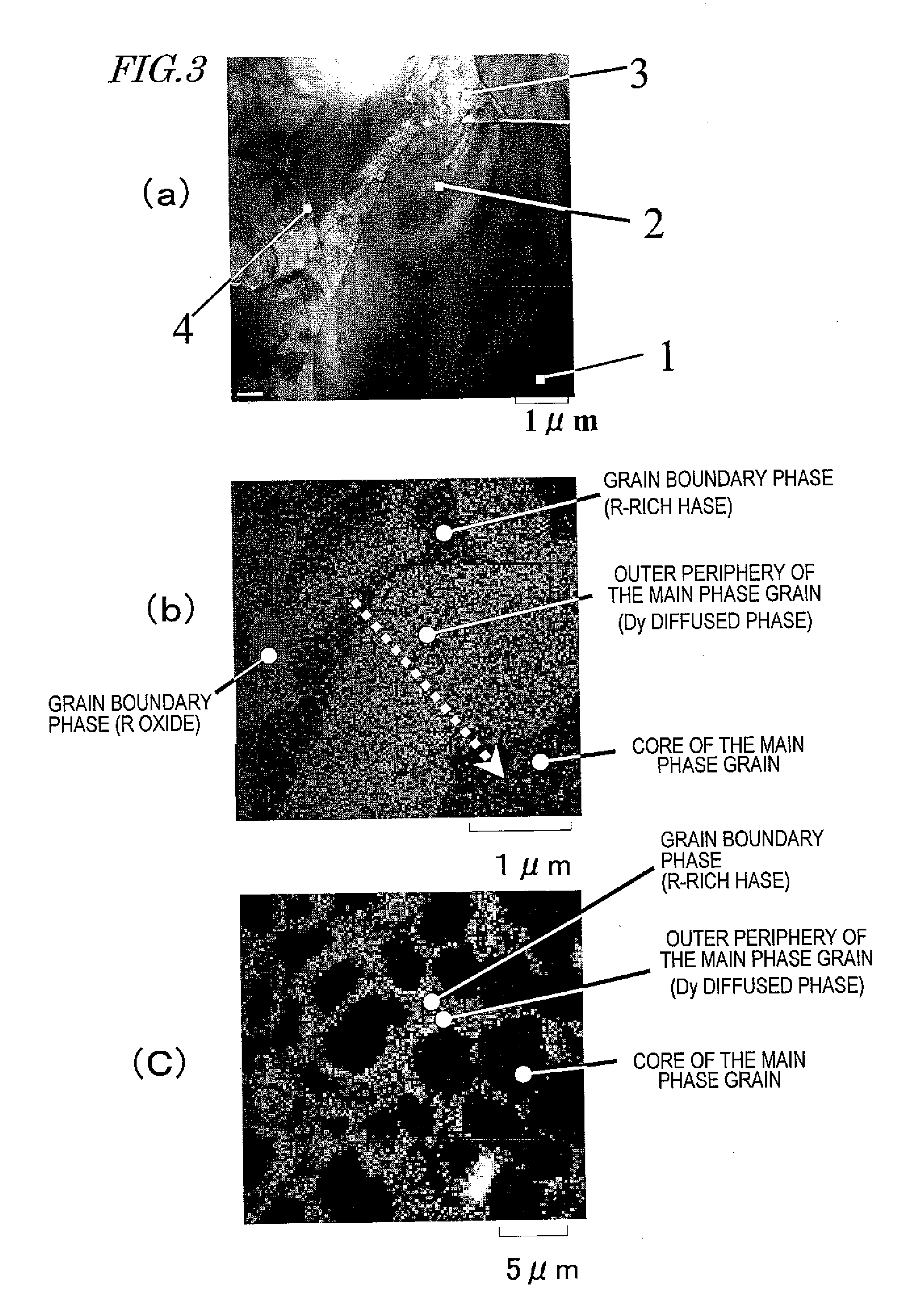

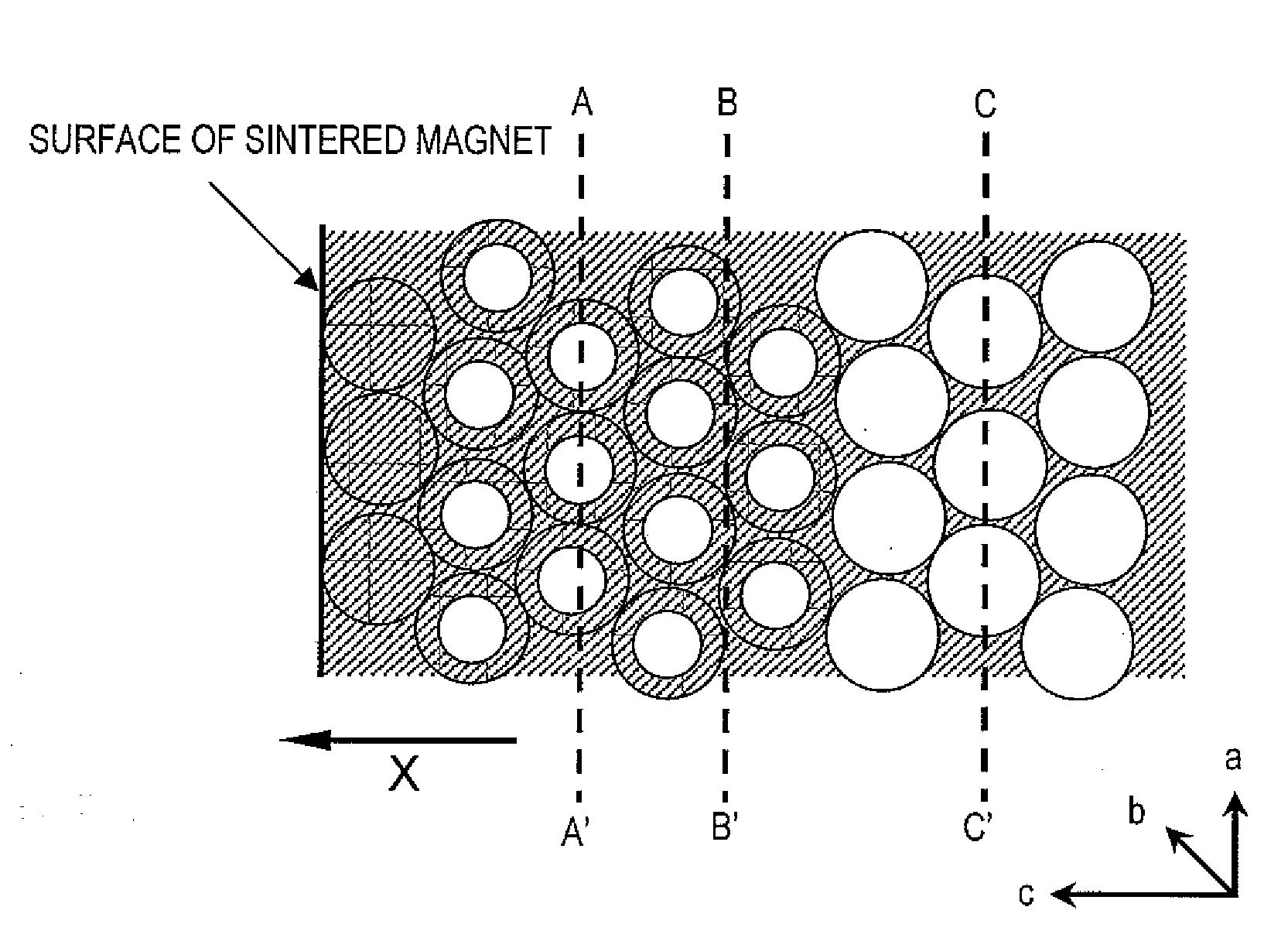

R-Fe-B Rare Earth Sintered Magnet and Method for Producing Same

ActiveUS20080286595A1Decrease in remanence Br minimizedCoercivity HcJ can be increasedInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementMetallurgy

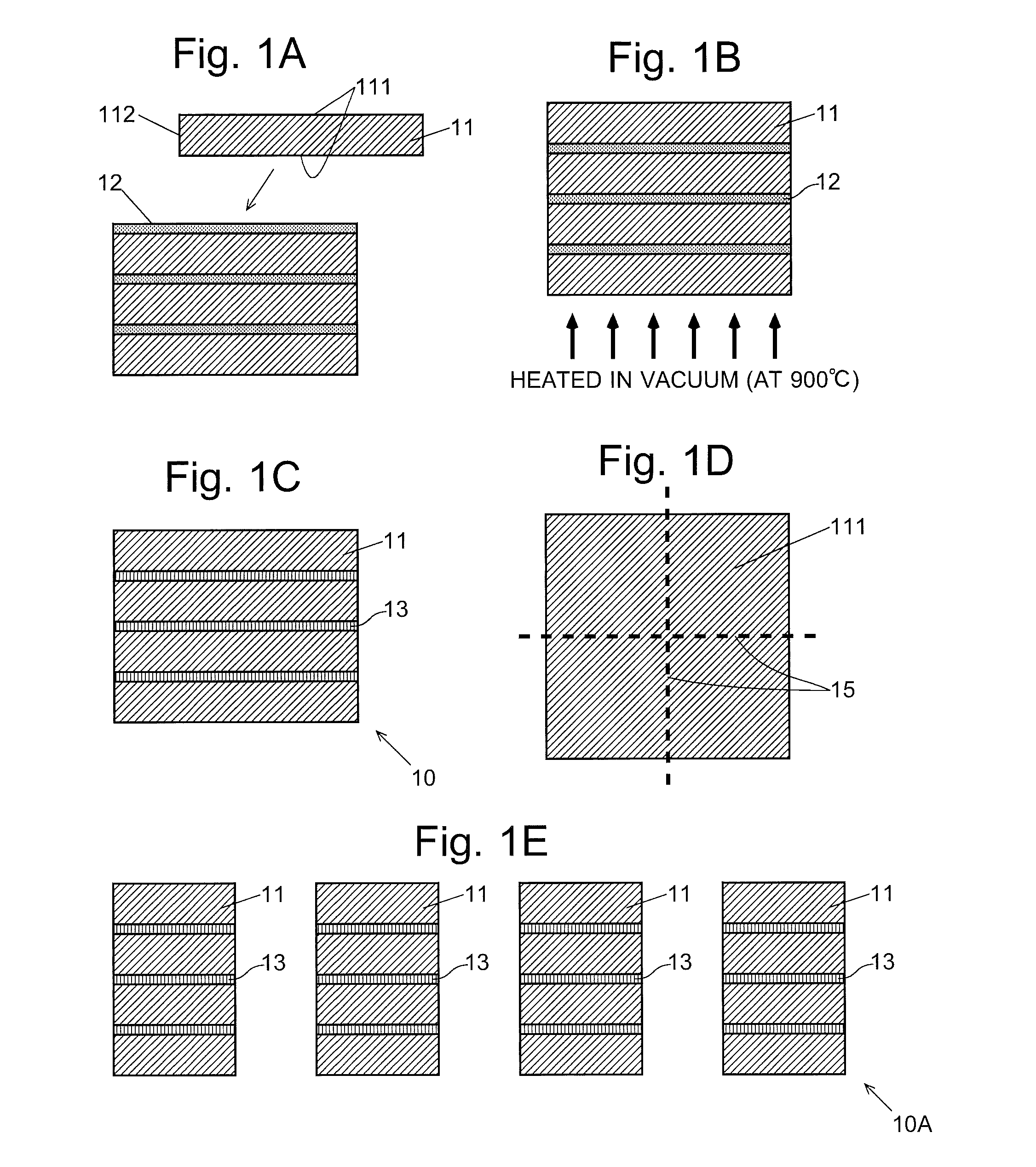

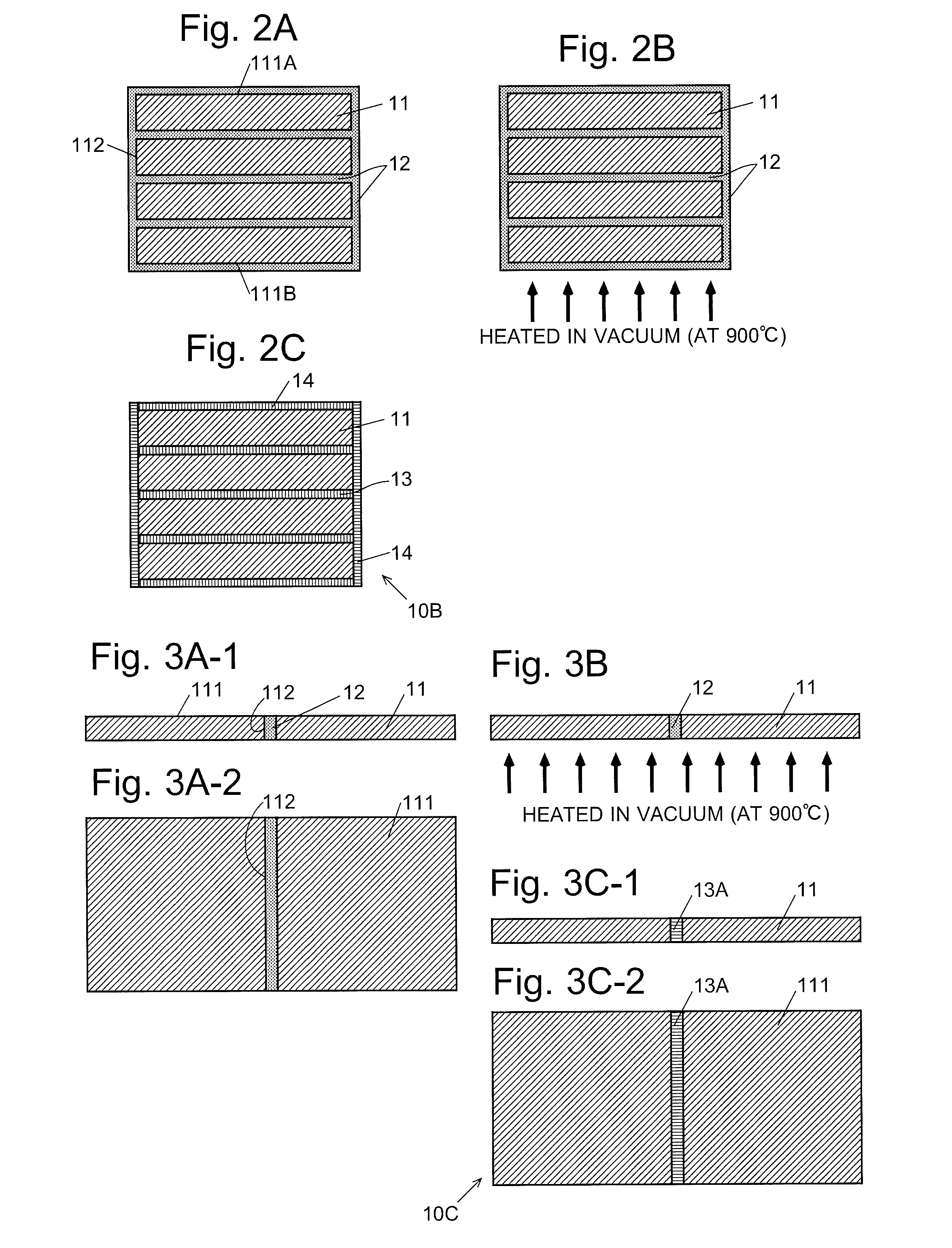

In a method for producing an R—Fe—B based rare-earth sintered magnet according to the present invention, first, provided is an R—Fe—B based rare-earth sintered magnet body including, as a main phase, crystal grains of an R2Fe14B type compound that includes a light rare-earth element RL, which is at least one of Nd and Pr, as a major rare-earth element R. Thereafter, the sintered magnet body is heated while a heavy rare-earth element RH, which is at least one element selected from the group consisting of Dy, Ho and Tb, is supplied to the surface of the sintered magnet body, thereby diffusing the heavy rare-earth element RH into the rare-earth sintered magnet body.

Owner:HITACHI METALS LTD

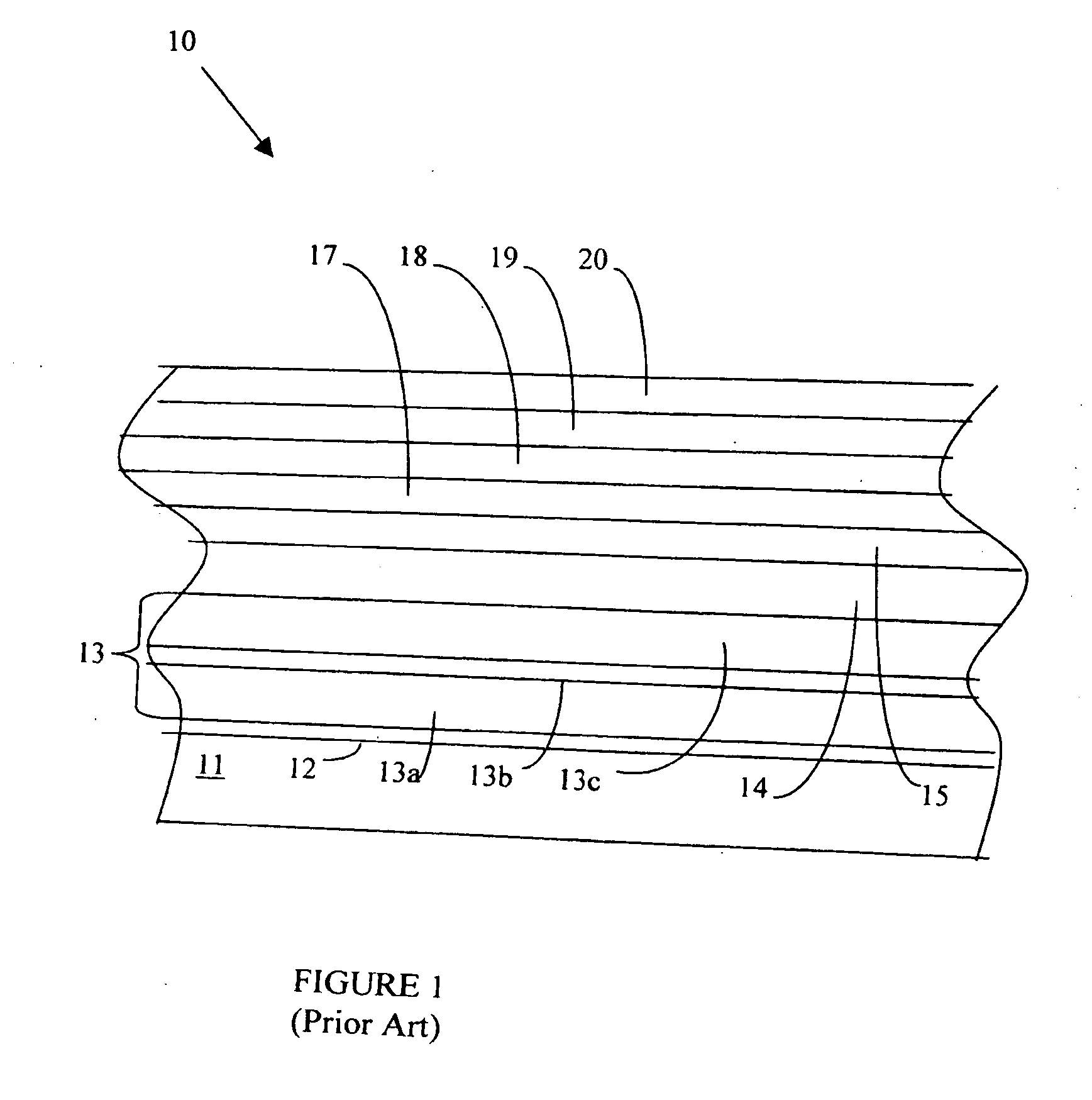

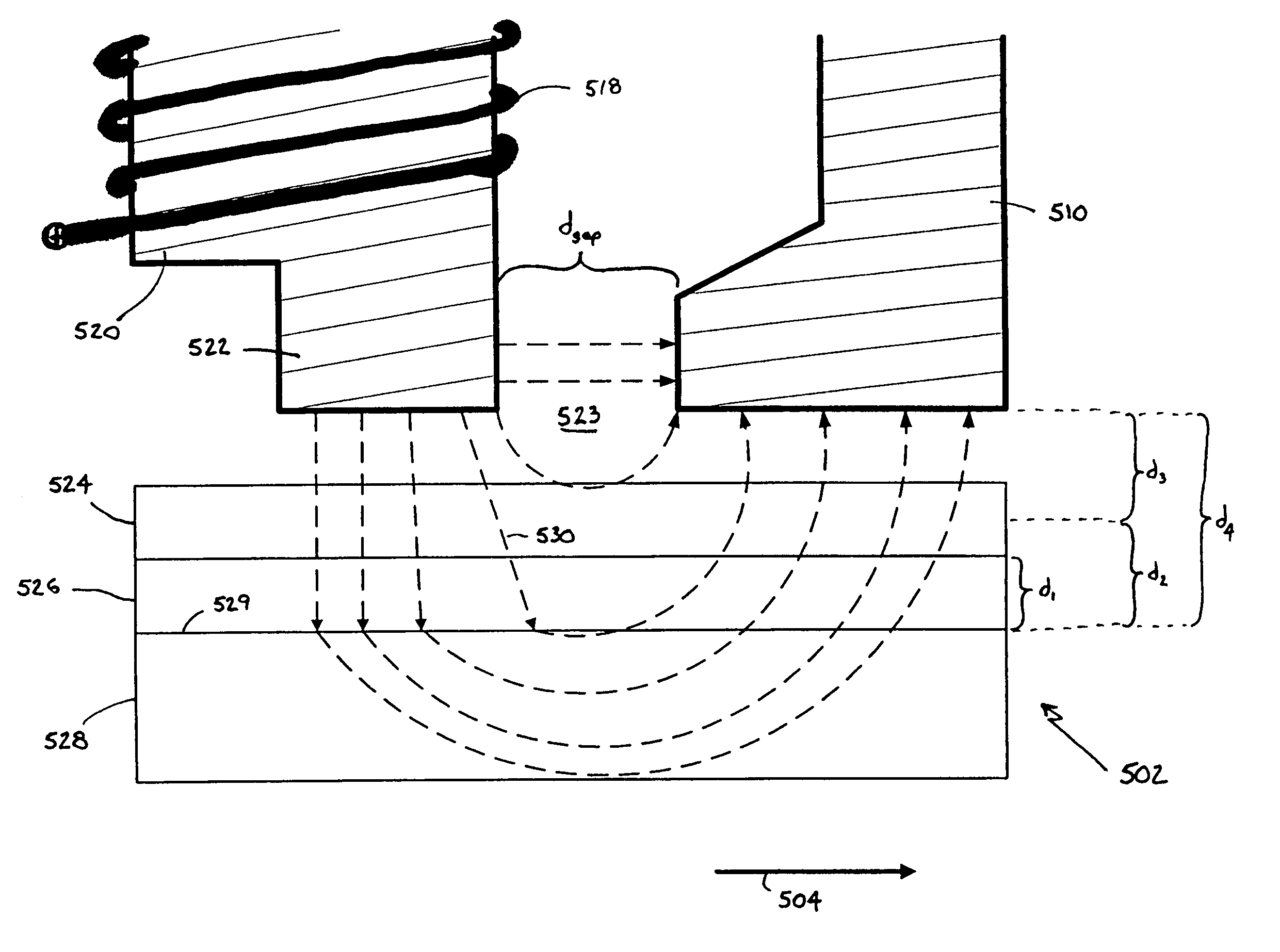

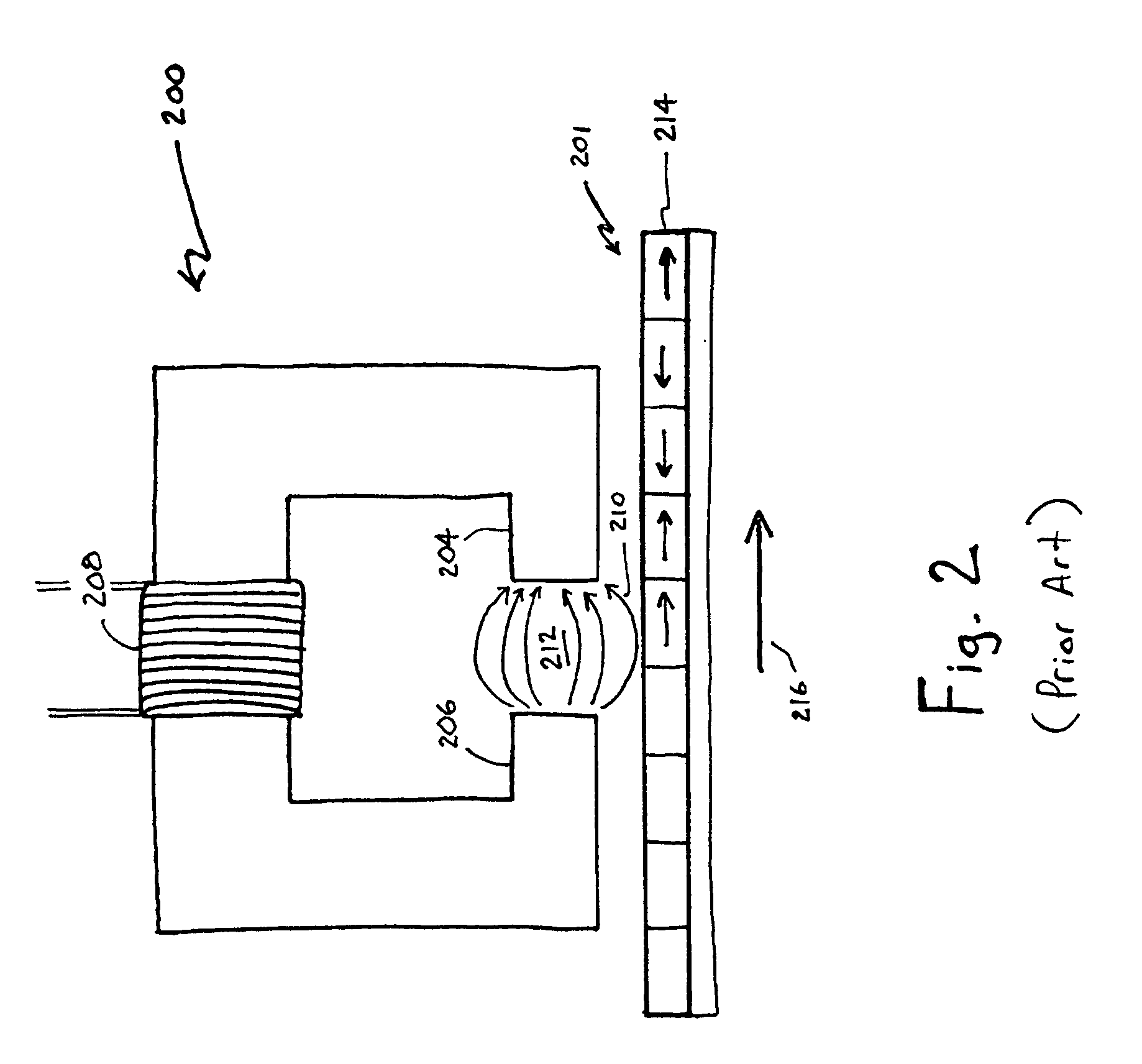

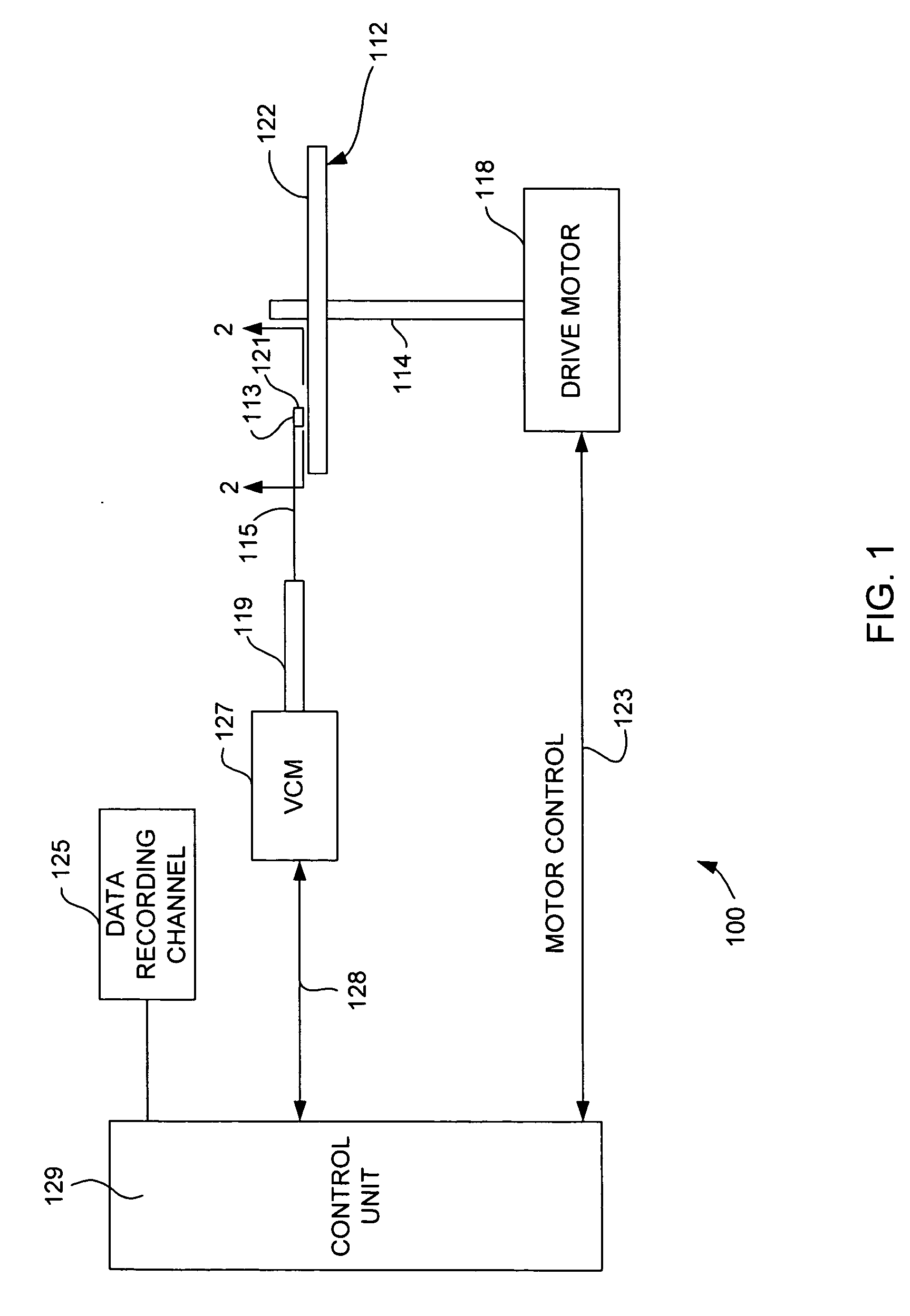

Longitudinal media with soft underlayer and perpendicular write head

InactiveUS7149045B1High write field gradientReduce width of transitionRecord information storageDigital recordingEngineeringRecording layer

A magnetic recording device including a longitudinal magnetic recording medium. The longitudinal magnetic recording medium includes a magnetically soft underlayer disposed under a longitudinal recording layer. A perpendicular write head is utilized to write data to the longitudinal magnetic recording medium wherein the longitudinal recording layer is disposed within an effective write gap formed by the perpendicular write head and the underlayer. The longitudinal component of the perpendicular write head is sufficient to switch the magnetic grains in the recording layer in the presence of the perpendicular field. The magnetic recording medium can have a high areal density and improved magnetic properties.

Owner:MAXTOR

Thermally-assisted magnetic writing using an oxide layer and current-induced heating

InactiveUS20040095801A1Increase in sizeIncrease in coercivityNanostructure applicationNanomagnetismStatic random-access memoryElectrical conductor

A method and structure for a non-volatile magnetic random access memory (MRAM) device that has a stable magnetic electrode, an oxide layer adjacent the stable magnetic electrode, and a free magnetic electrode. The oxide layer is between the stable magnetic electrode and the free magnetic electrode. In the invention, a conductor is connected to a stable magnetic electrode. The oxide layer has a resistance at levels to allow sufficient power dissipation to lower the anisotropy of the free magnetic electrode through current induced heating. Current-induced heating is used in combination with spin-transfer torque or a magnetic field to switch the free magnetic electrode.

Owner:GLOBALFOUNDRIES US INC

R-t-b-type sintered magnet and method for production thereof

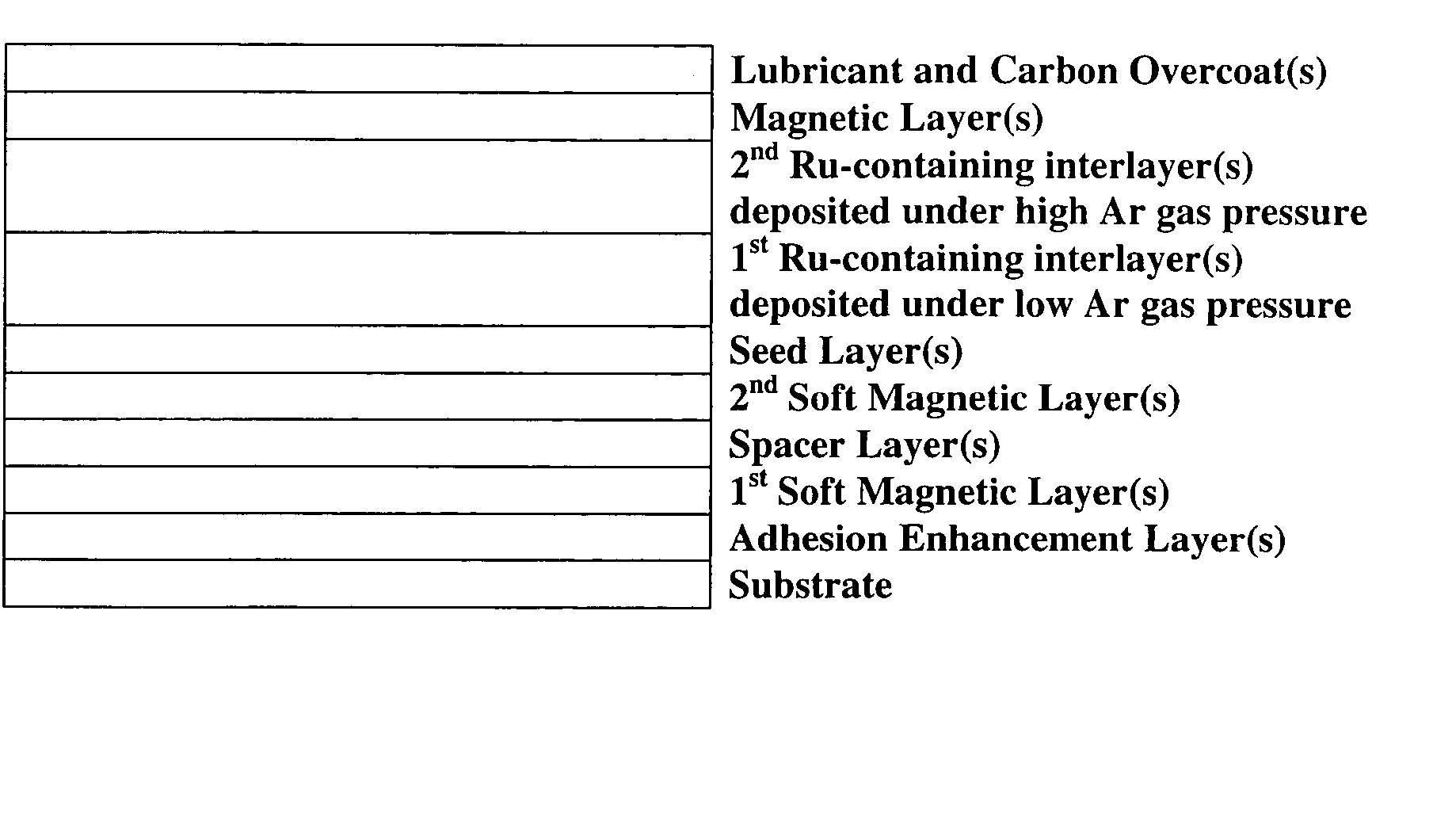

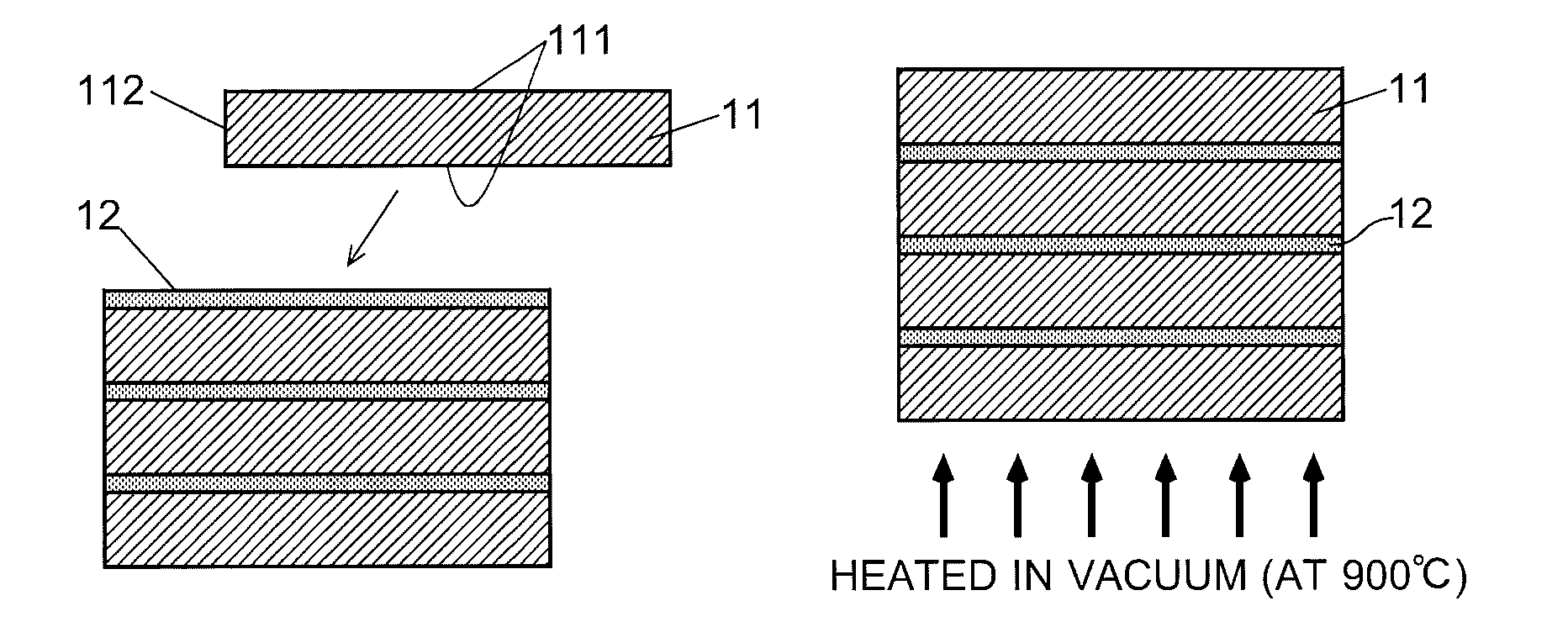

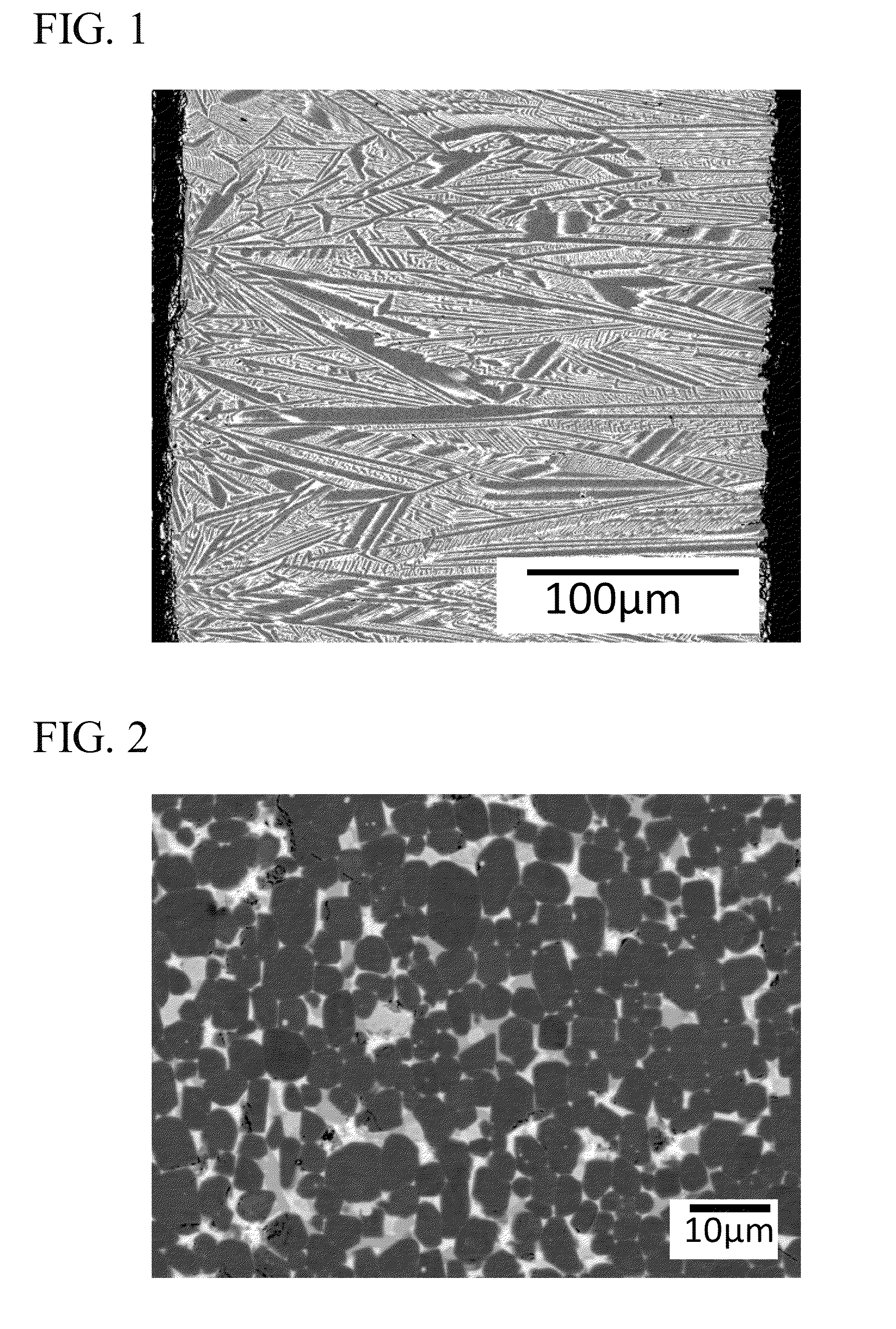

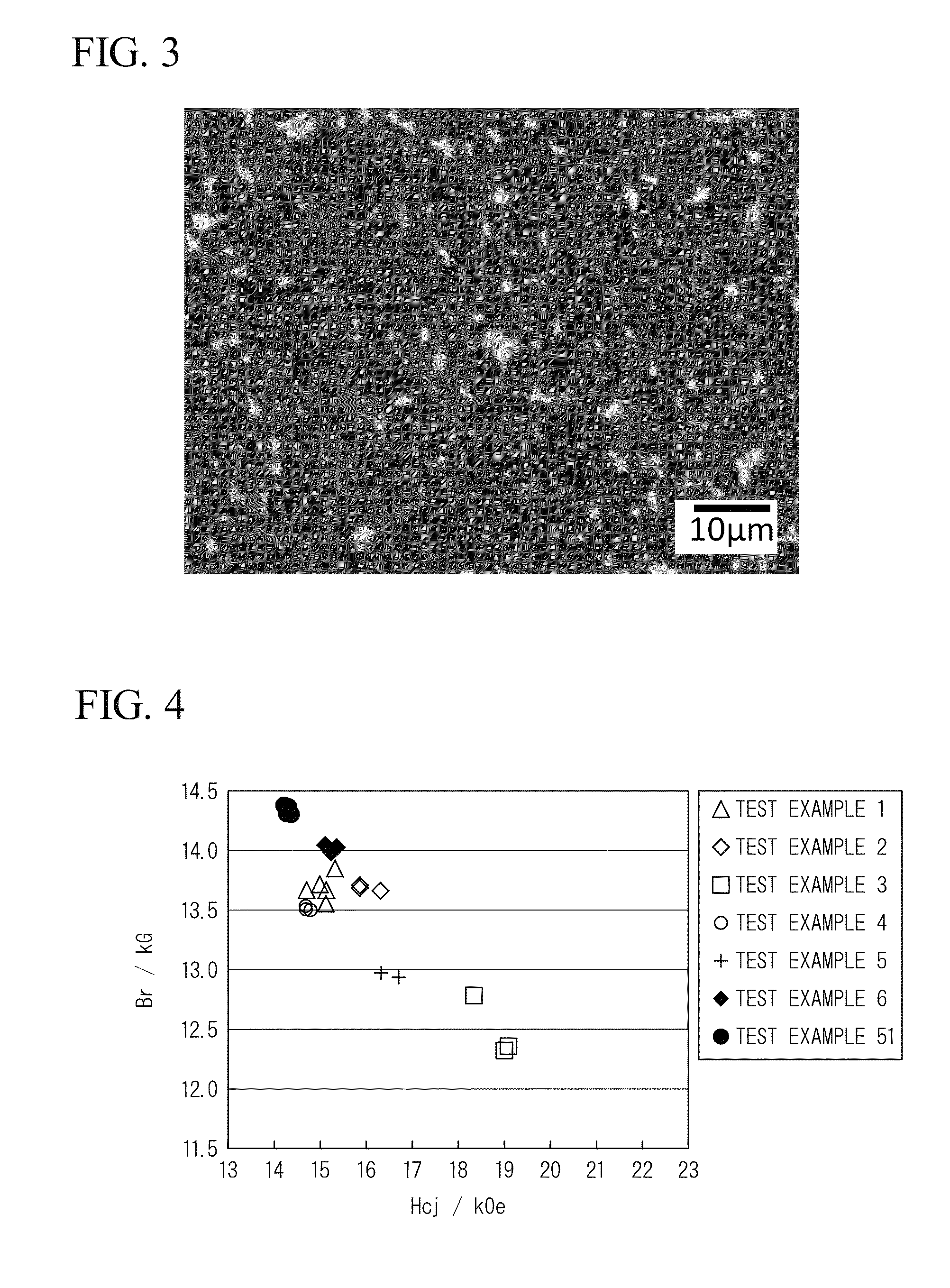

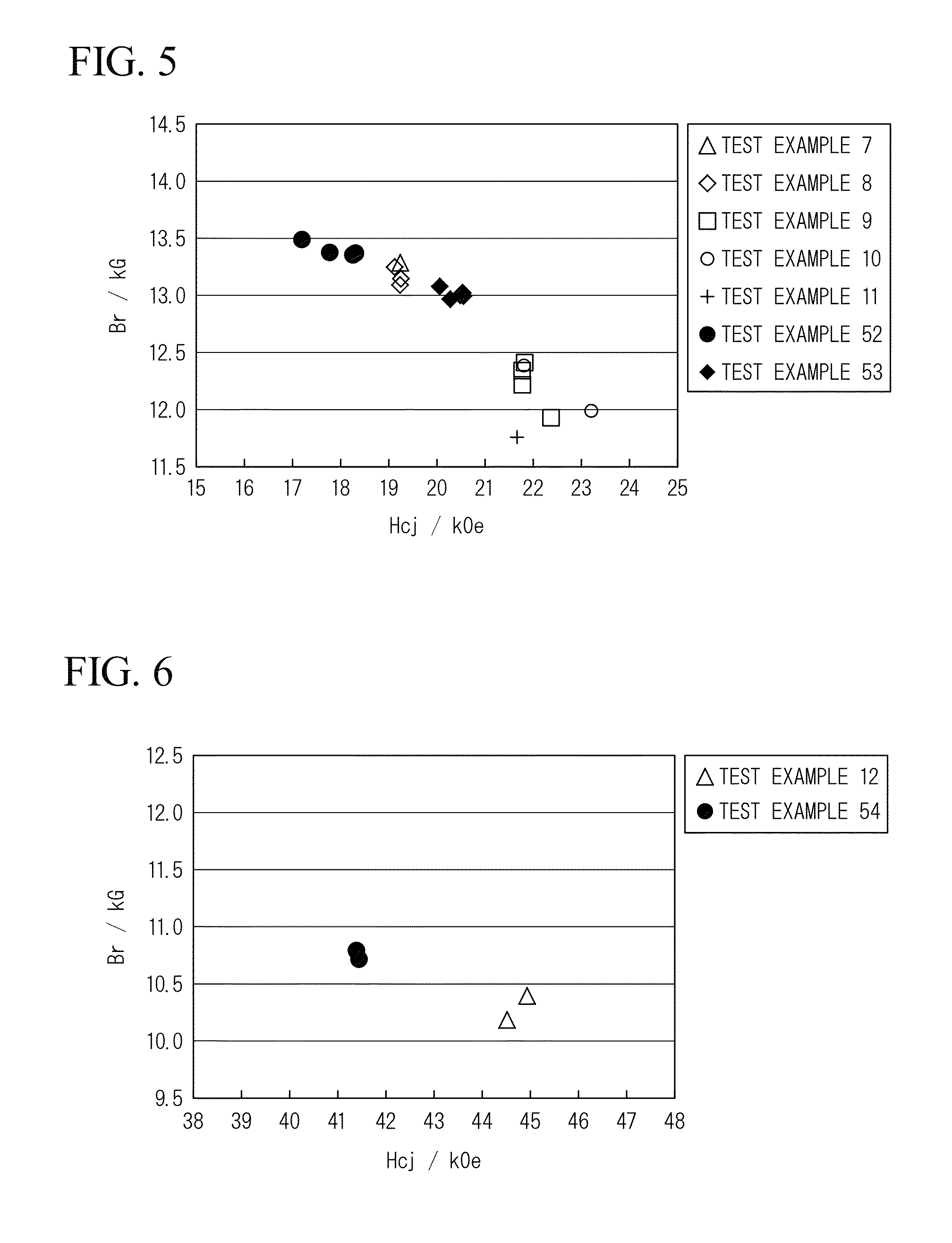

ActiveUS20110025440A1Increase in coercivityImprove remanencePermanent magnetsInductances/transformers/magnets manufactureSintered magnetsOxygen content

An R-T-B based sintered magnet according to the present invention has a composition including: 27.3 mass % to 29.5 mass % of R; 0.92 mass % to 1 mass % of B; 0.05 mass % to 0.3 mass % of Cu; 0.02 mass % to 0.5 mass % of M; and T as the balance, and has an oxygen content of 0.02 mass % to 0.2 mass %. The main phase of the sintered magnet is an R2T14B type compound. The crystal grain size of the main phase is represented by an equivalent circle diameter of 8 μm or less. And crystal grains with equivalent circle diameters of 4 μm or less account for at least 80% of the overall area of the main phase.

Owner:HITACHI METALS LTD

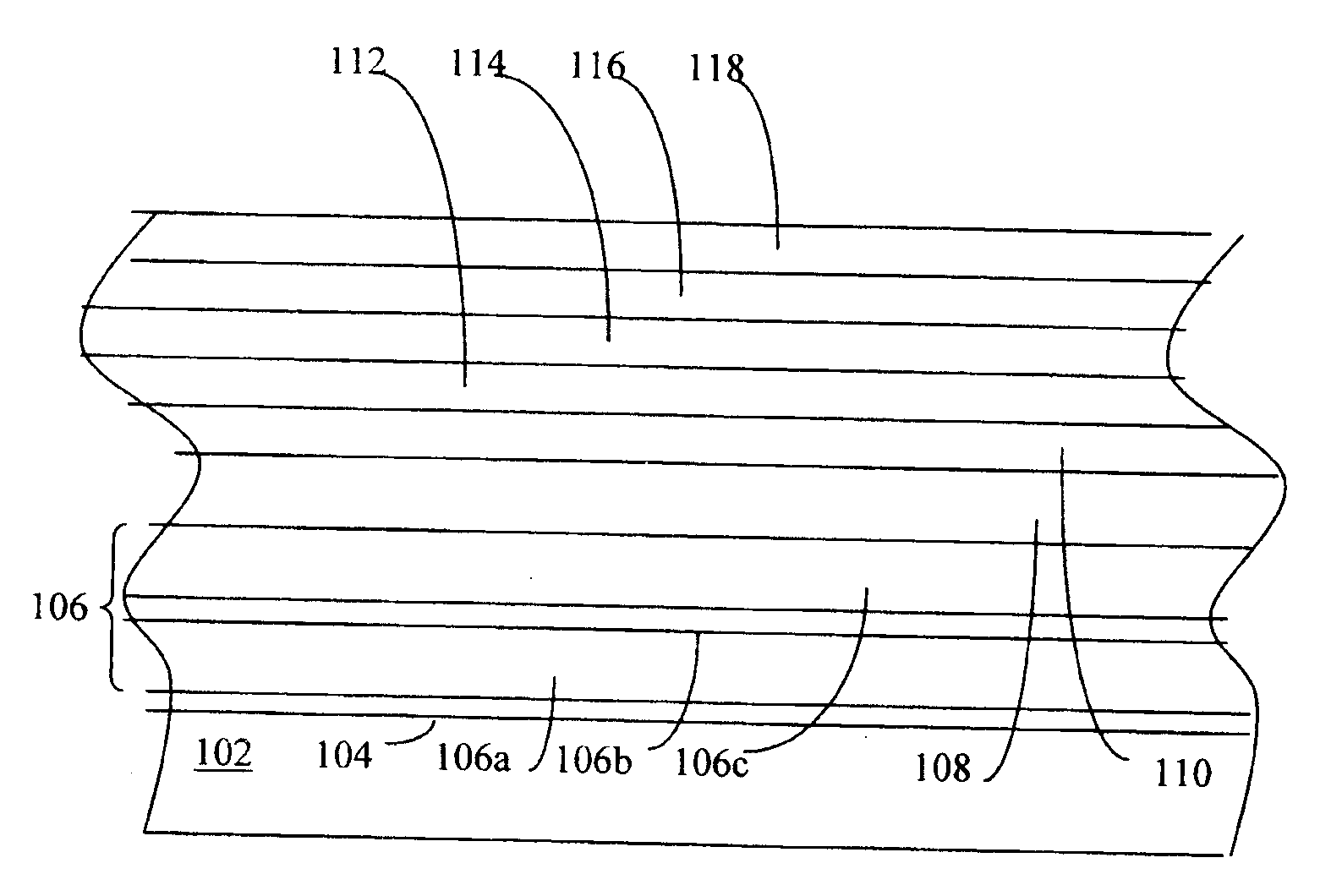

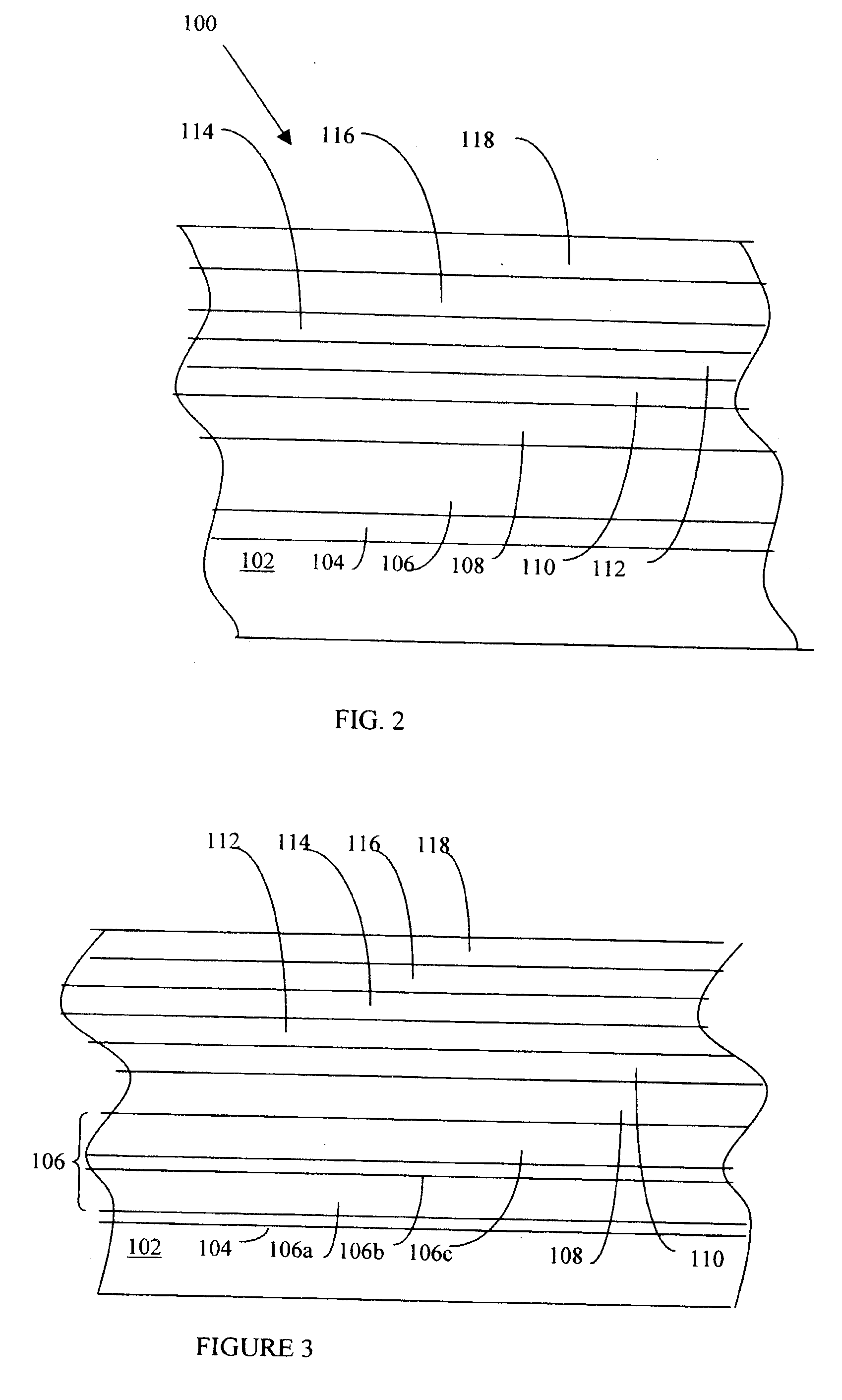

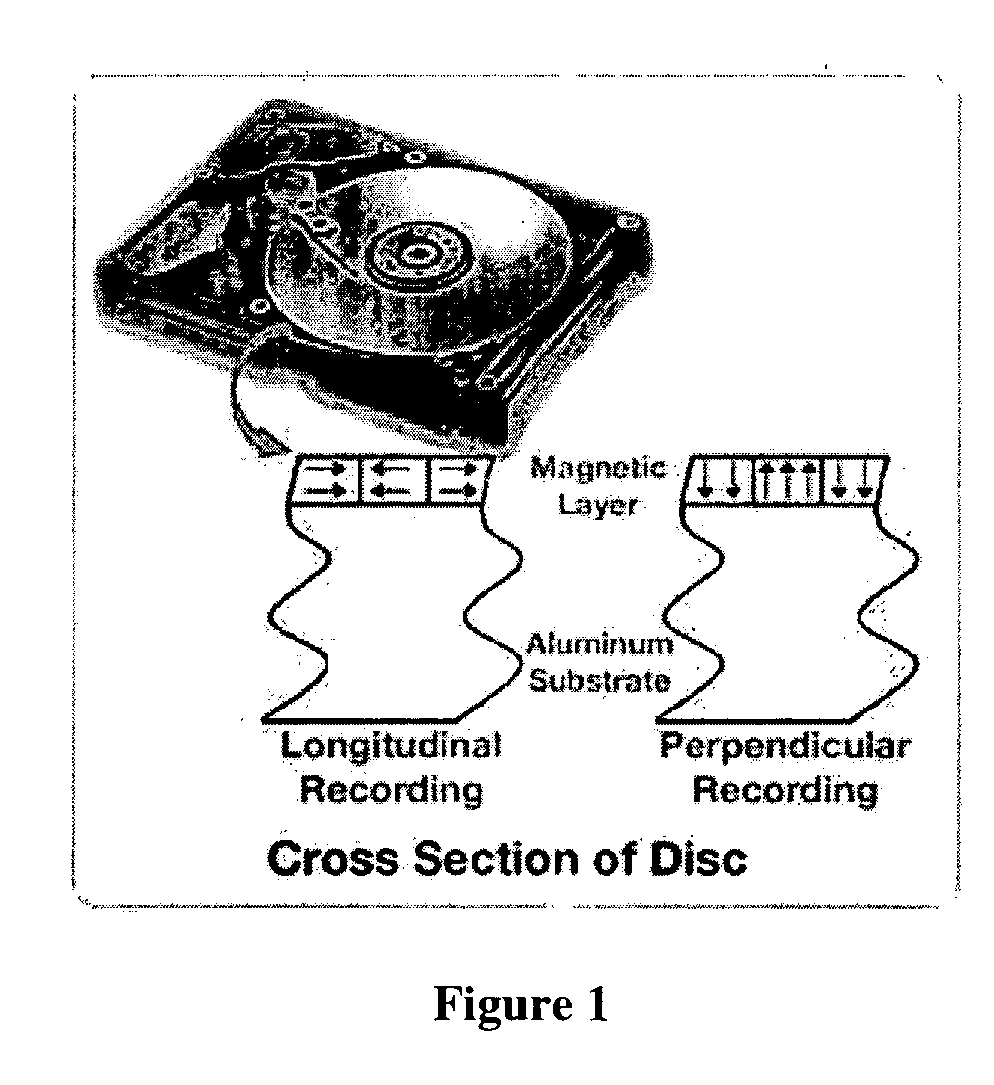

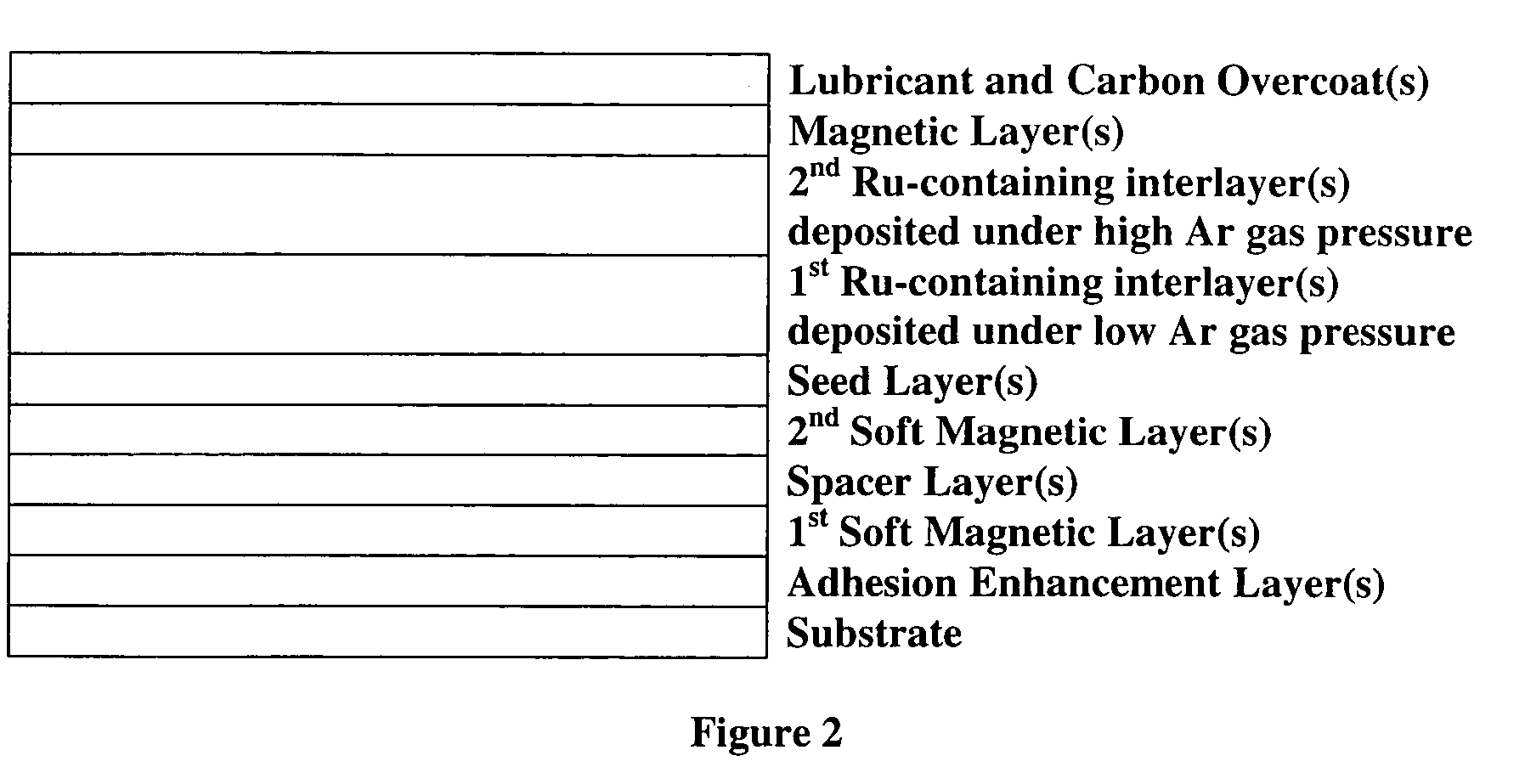

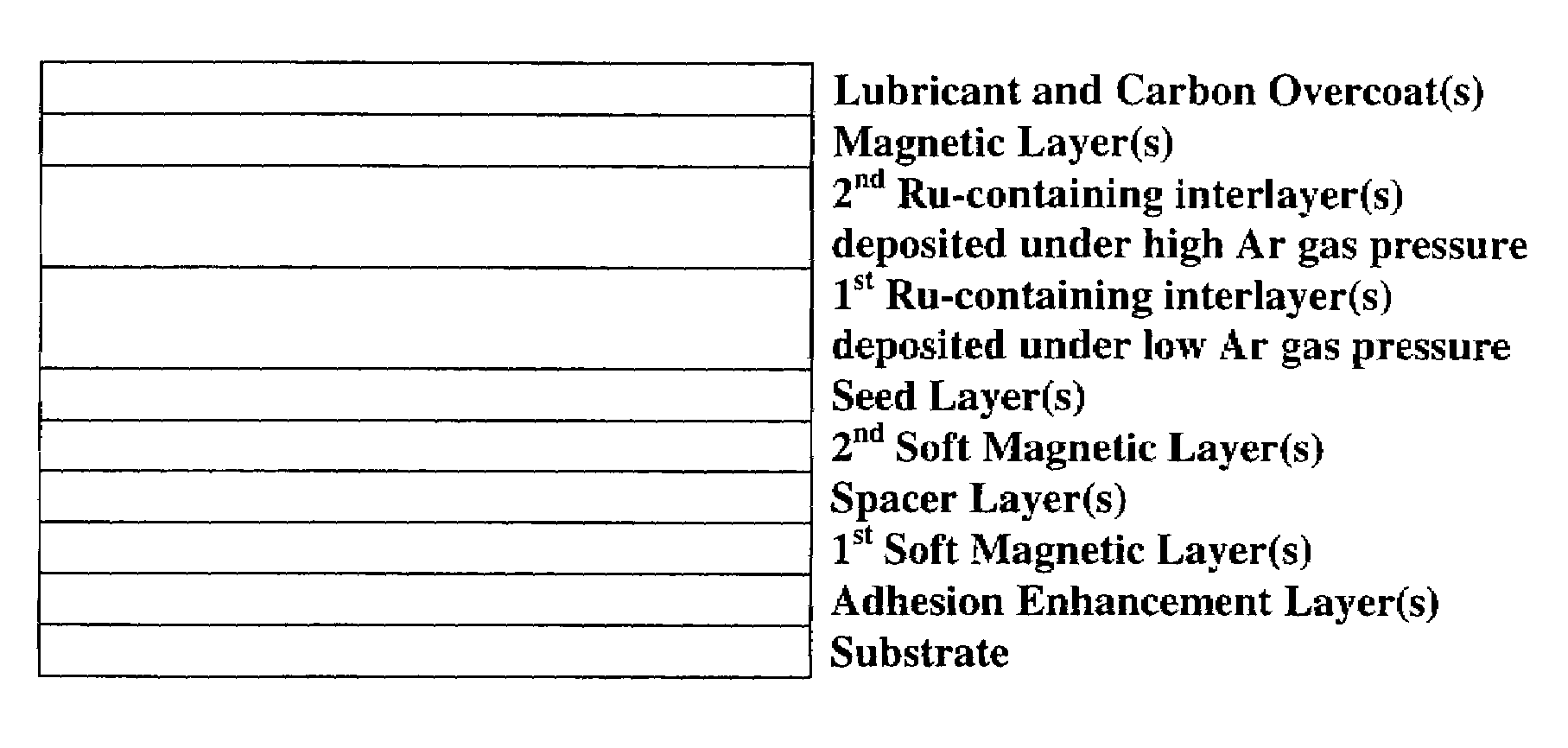

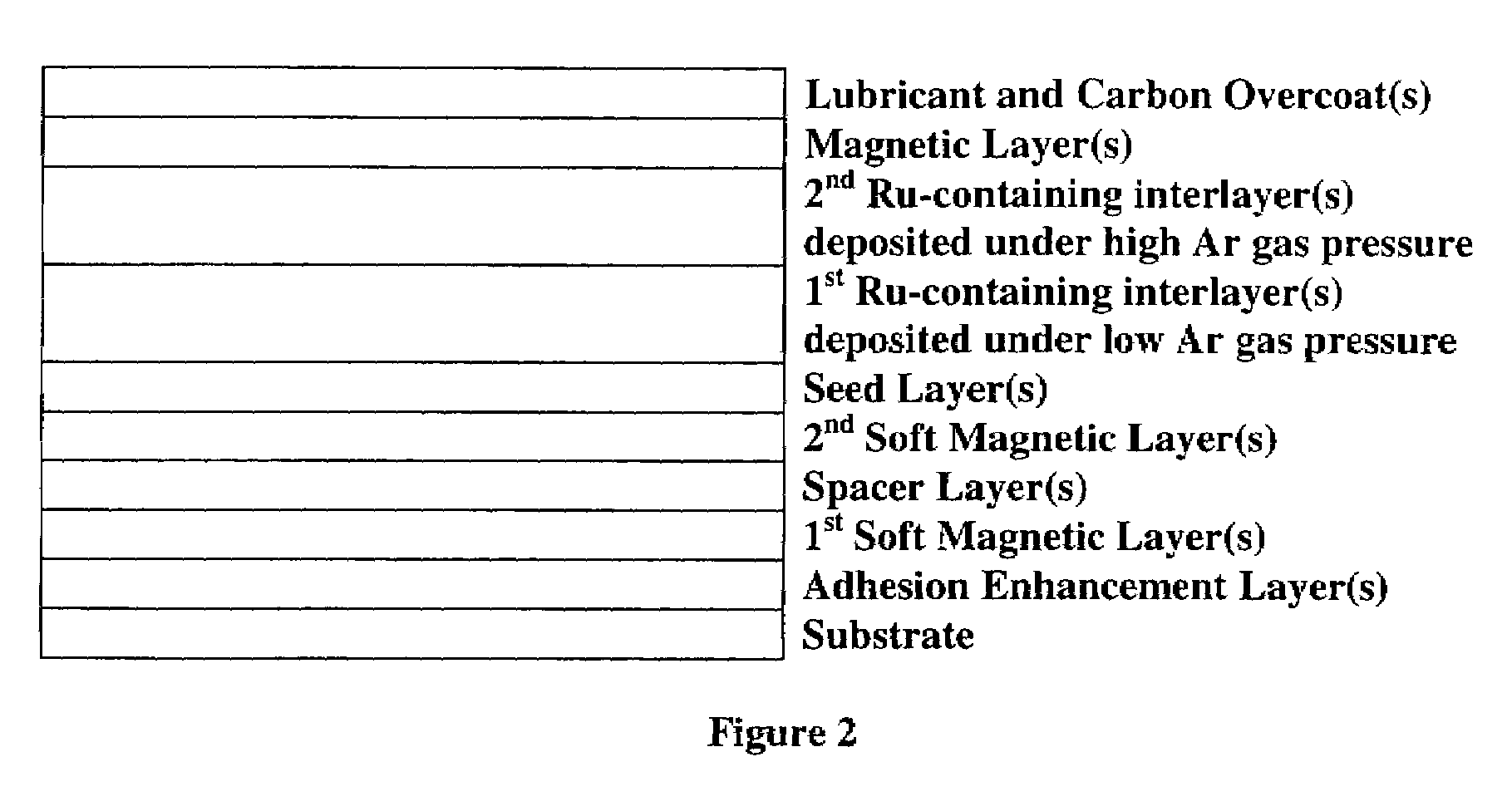

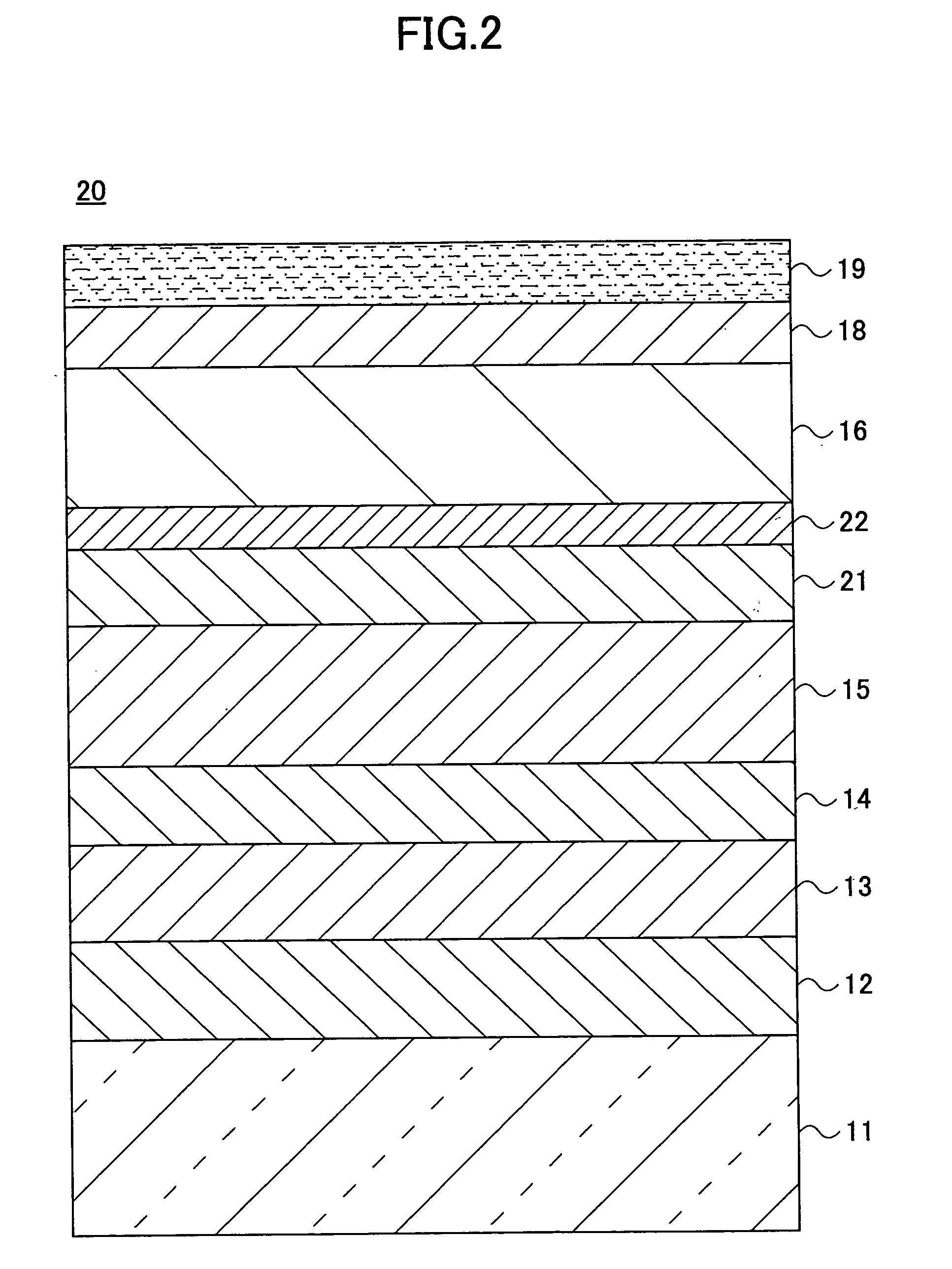

Inter layers for perpendicular recording media

InactiveUS20050202286A1Enhances coercivityImprove performanceProtective coatings for layersBase layers for recording layersInter layerRuthenium

A magnetic recording medium, the order of layers in which is the substrate, the soft underlayer, the seedlayer, the 1st RuCrx-containing interlayer, the 2nd RuCrx-containing interlayer and the magnetic recording layer with preferably a oxides or nitrides-containing magnetic layer comprising grains, is disclosed. High-chromium ruthenium-chromium alloy used as inter layers significantly enhances coercivity and SMNR preferably due to the improved lattice match between RuCr inter layers and CoPt-based magnetic recording layers, and the surface energy of RuCr layers contributes to the performance improvement with the high-chromium addition into Ru inter layers.

Owner:SEAGATE TECH LLC

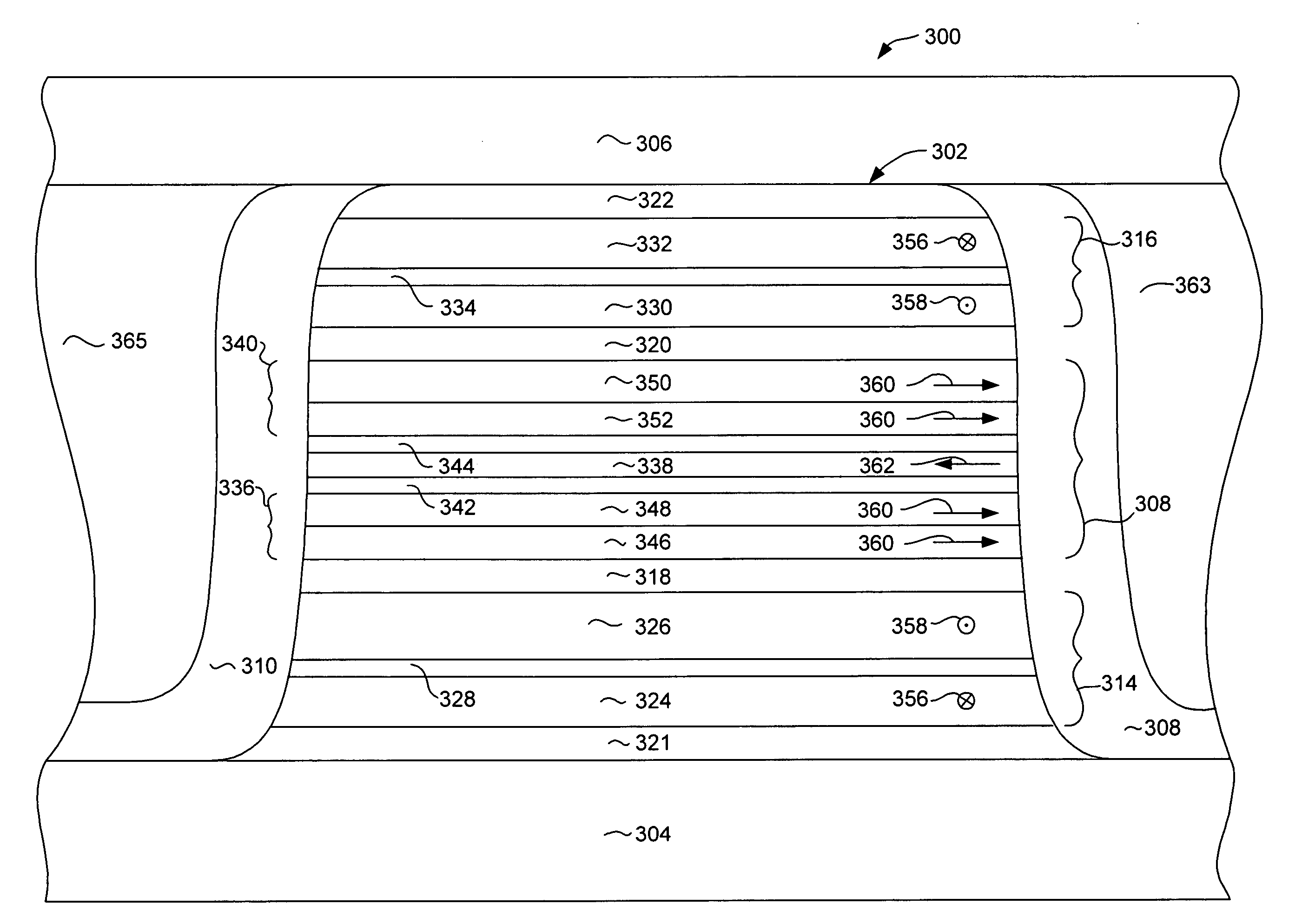

Trilayer SAF with current confining layer

InactiveUS20060023376A1Electrical resistance is minimizedReduce the impactRecord information storageManufacture of flux-sensitive headsPartial oxidationInter layer

A current perpendicular to plane (CPP) GMR sensor having first and second outer pinned layers and a trilayer free layer therebetween. The free layer includes first and second outer magnetic layers, and a partially oxidized magnetic layer disposed there between. The middle partially oxidized layer is antiparallel coupled with the outer magnetic layers of the free layer by first and second coupling alyers which prevent oxygen migration from the central layer into the outer magnetic layers of the free layer. The partial oxidation of the middle layer provides a limited amount of electrical resistance at a desired location within the free layer to increase GMR.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

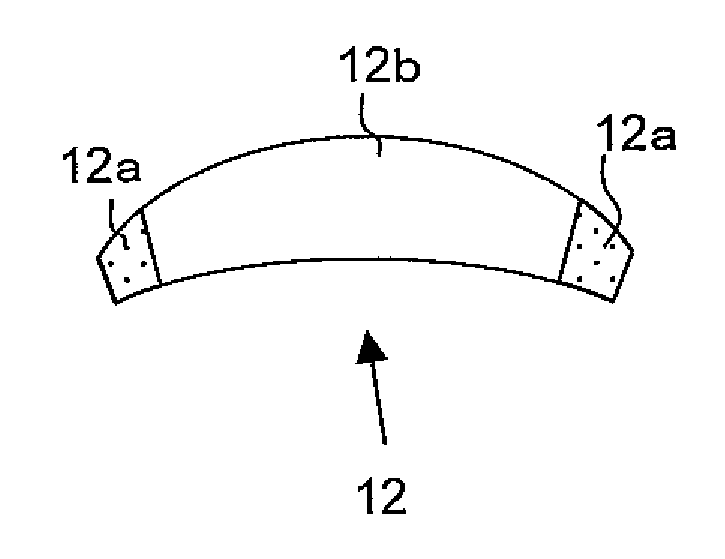

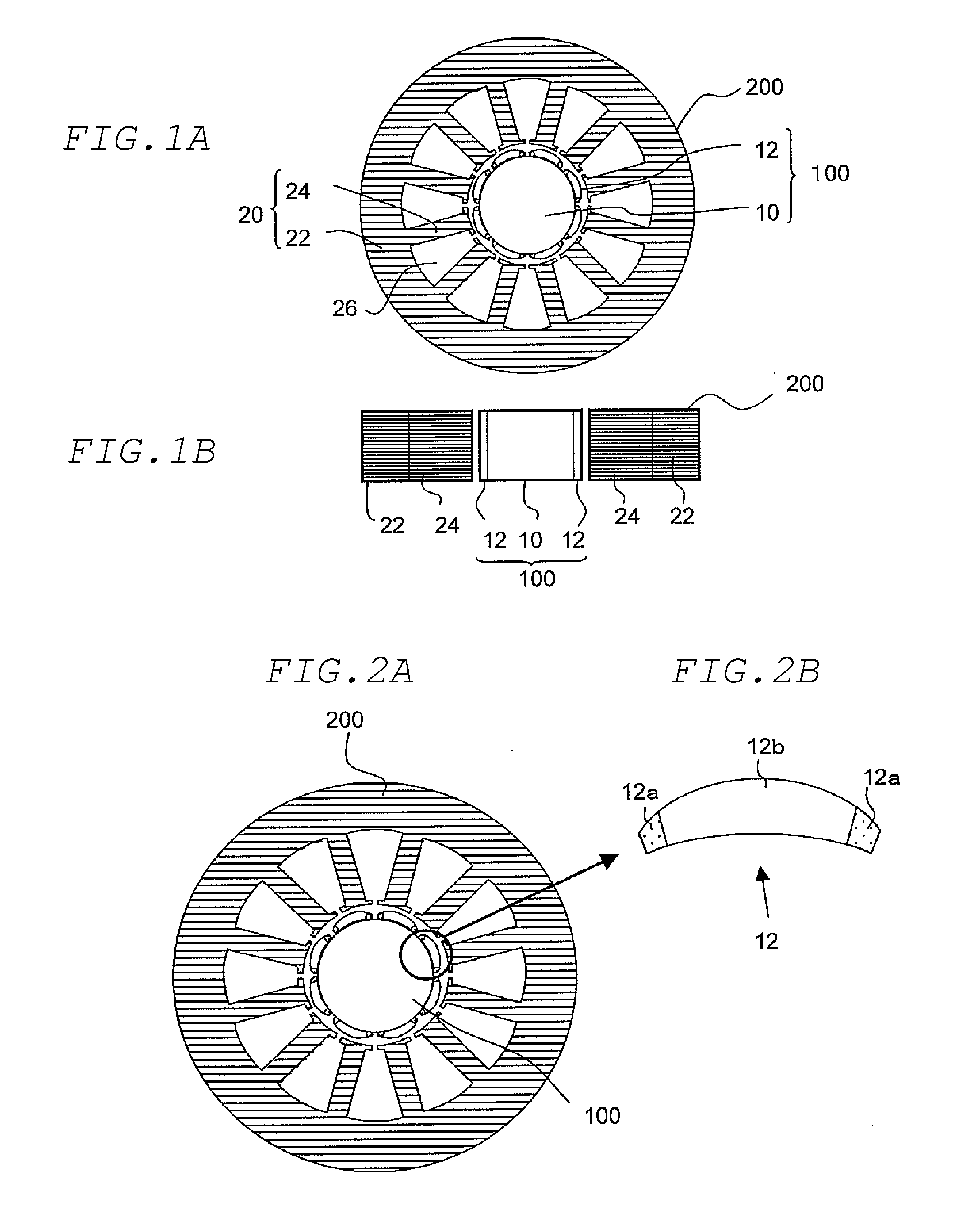

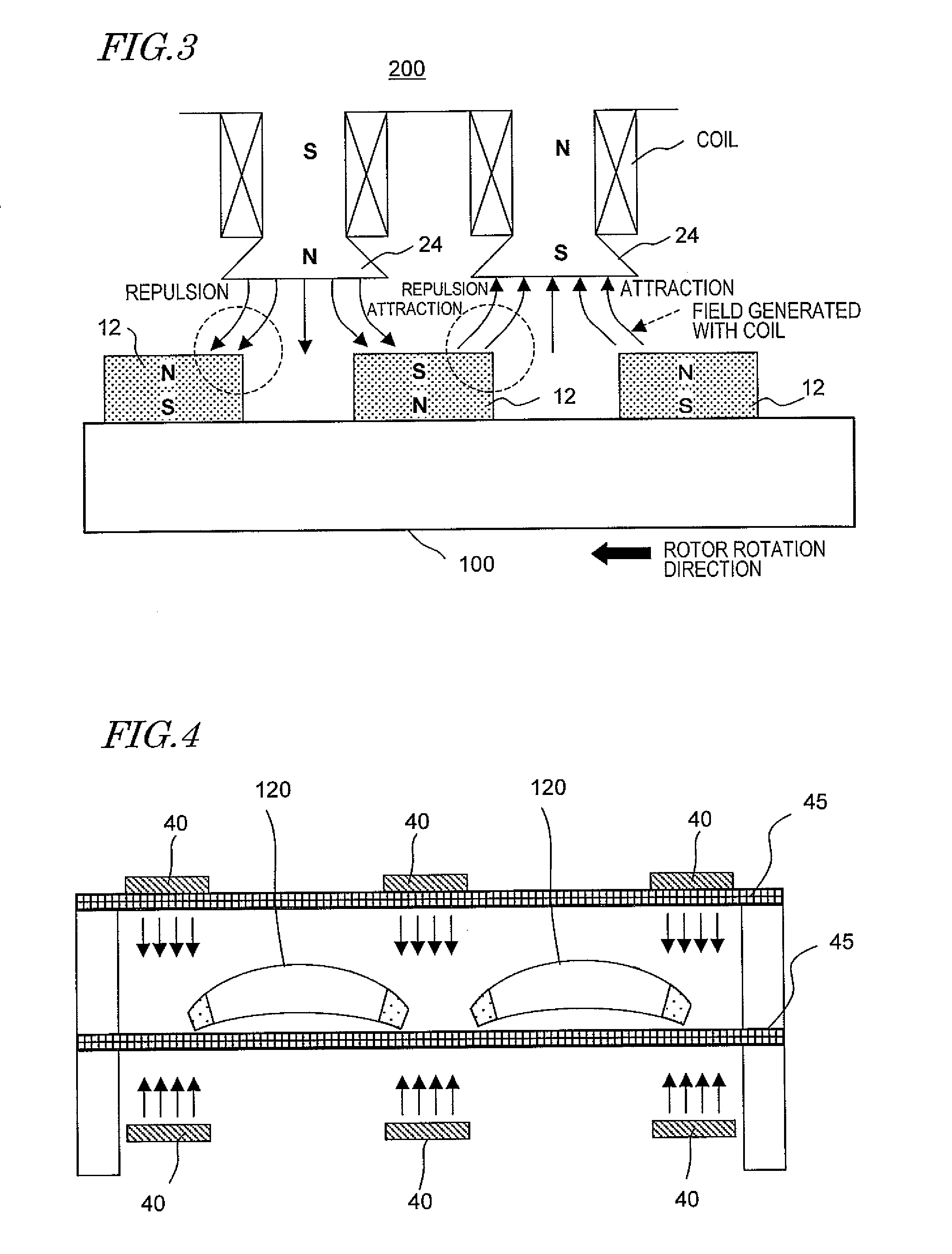

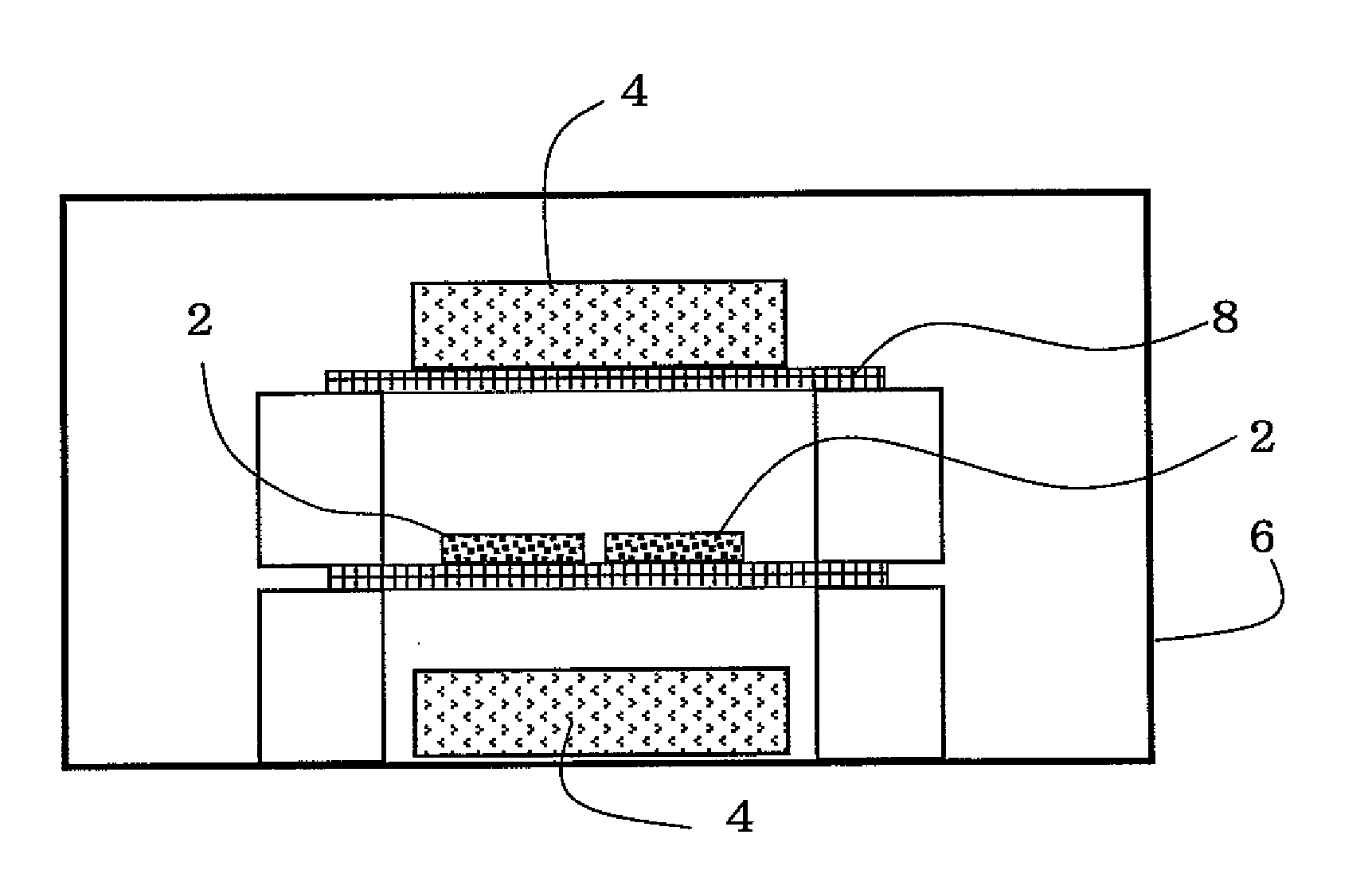

Permanent magnet motor and method for manufacturing same

ActiveUS20100109468A1Reduce noiseReduce occurrenceSynchronous machine detailsInductances/transformers/magnets manufactureHigh concentrationRare-earth element

A permanent magnet motor includes: a rotor and a stator; and a plurality of permanent magnets placed on either the rotor or the stator. Each permanent magnet is an R—Fe—B based rare-earth sintered magnet including a light rare-earth element RL (at least one of Nd and Pr) as a major rare-earth element R, and partially includes a high coercivity portion in which a heavy rare-earth element RH (at least one element selected from the group consisting of Dy, Ho and Tb) is diffused in a relatively higher concentration than in the other portion.

Owner:HITACHI METALS LTD

Permanent magnets and R-TM-B based permanent magnets

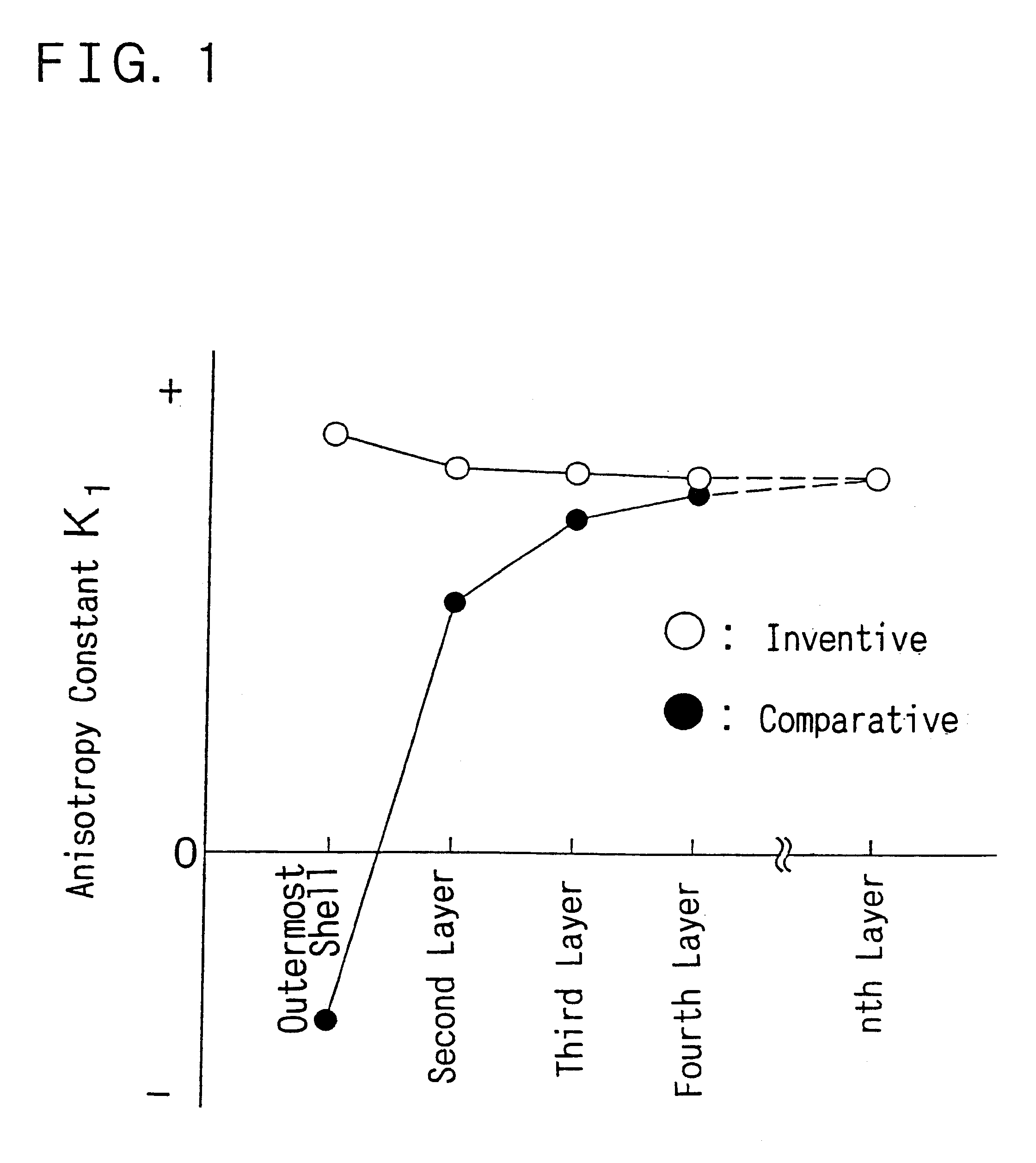

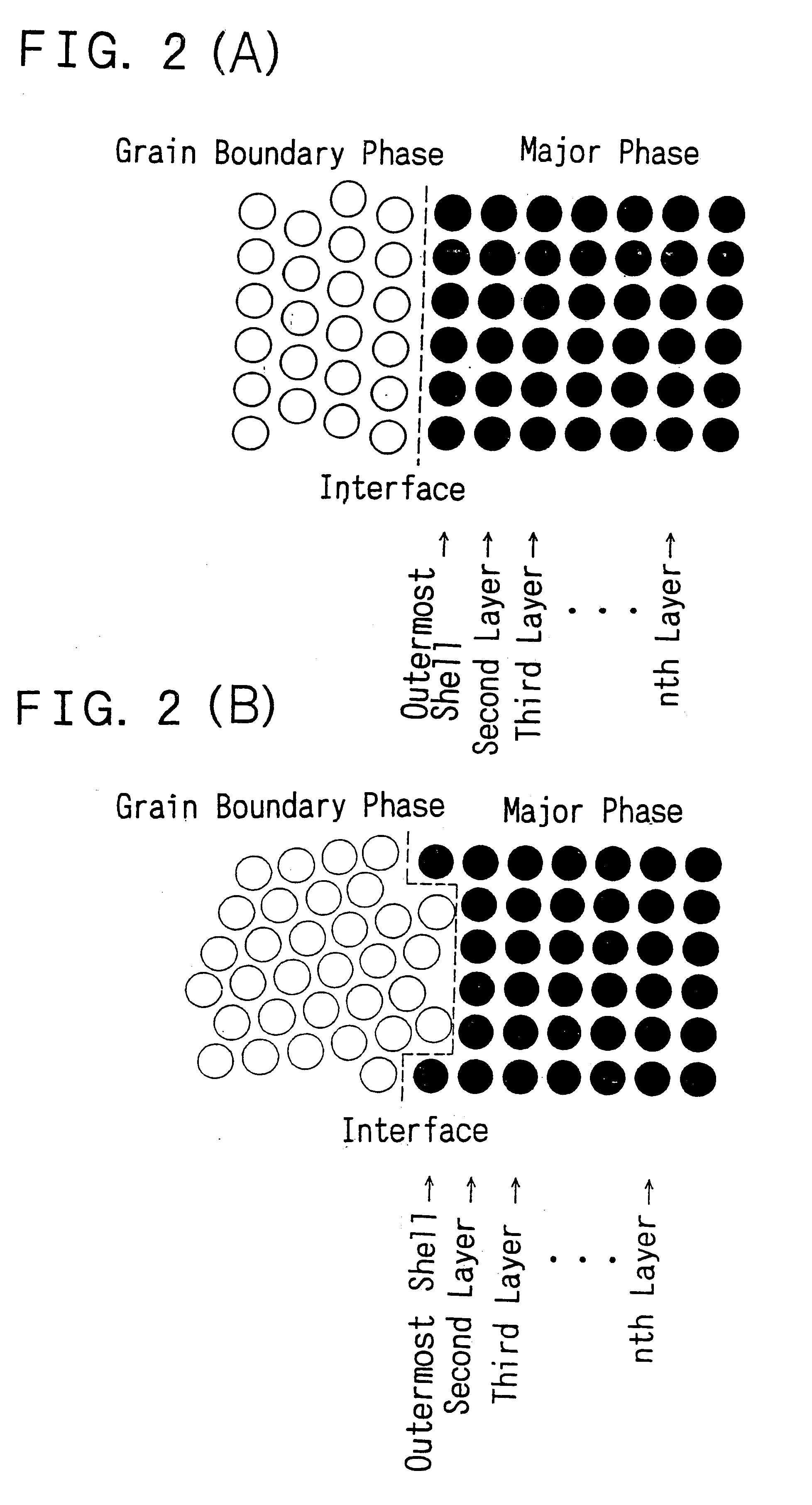

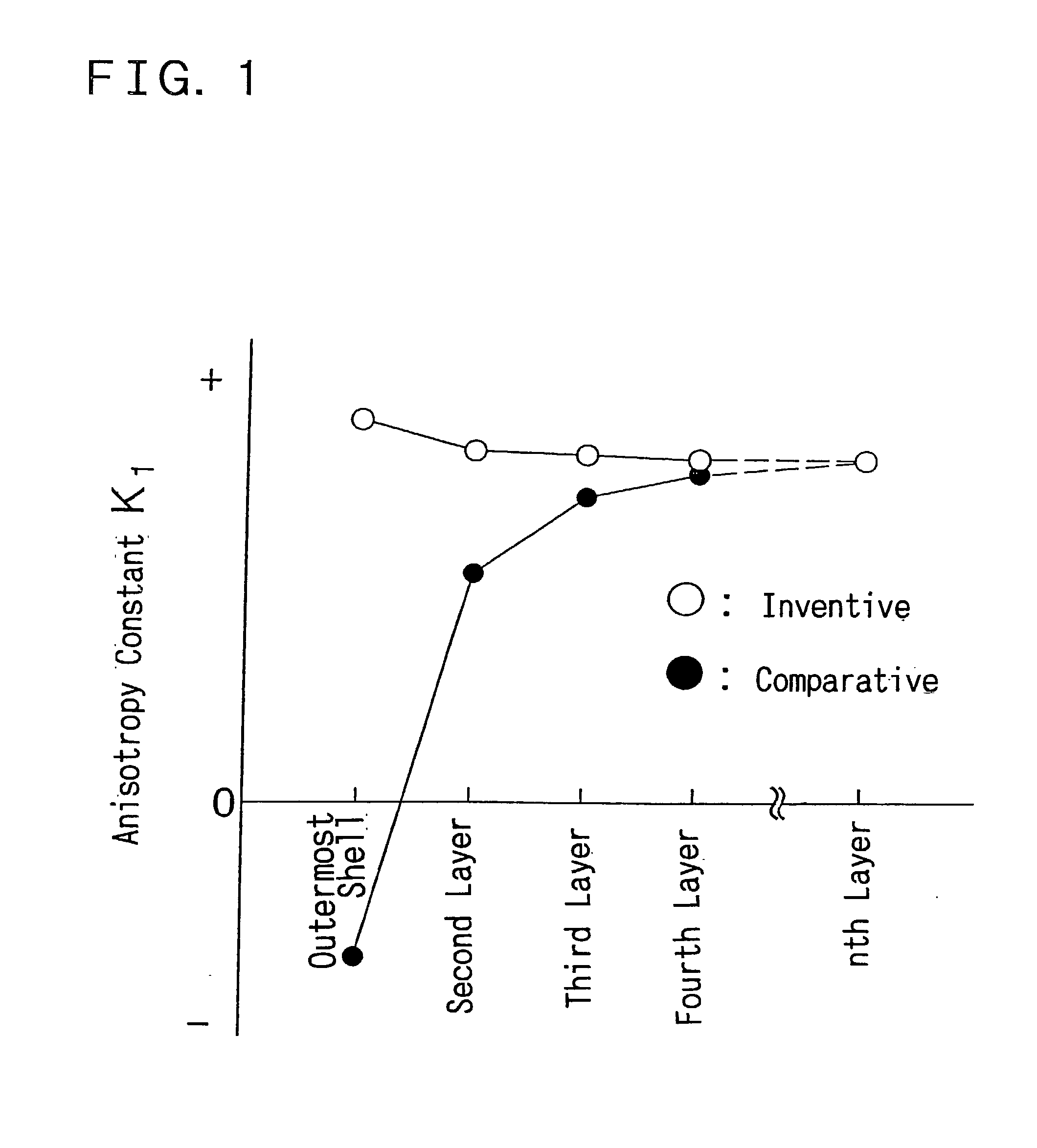

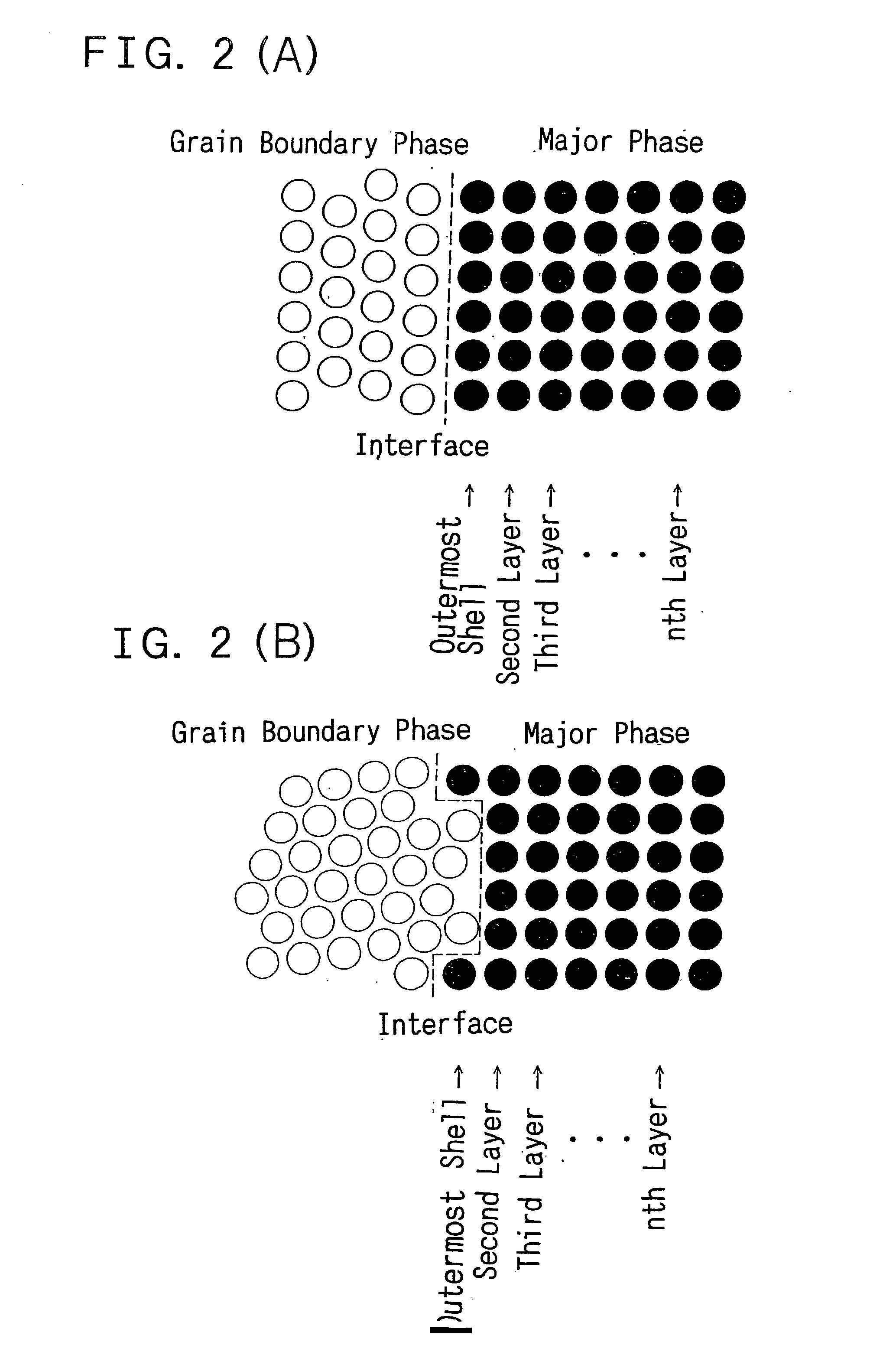

InactiveUS6511552B1Improve magnetic propertiesSure easyInductances/transformers/magnets manufactureMagnetic materialsNucleationMagnetocrystalline anisotropy

Permanent magnets in which the ferromagnetic phase is matched with the grain boundary phase, and permanent magnets in which magnetocrystalline anisotropy in the vicinity of the outermost shell of the major phase is equivalent in intensity to that in the inside to suppress nucleation of the inverse magnetic domain. Guideline for designing permanent magnets having high magnetic performance is provided.

Owner:HITACHI METALS LTD

R—Fe—B rare earth sintered magnet and method for producing same

ActiveUS8206516B2Increase in coercivityDecreasing remanenceInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementMetallurgy

In a method for producing an R—Fe—B based rare-earth sintered magnet according to the present invention, first, provided is an R—Fe—B based rare-earth sintered magnet body including, as a main phase, crystal grains of an R2Fe14B type compound that includes a light rare-earth element RL, which is at least one of Nd and Pr, as a major rare-earth element R. Thereafter, the sintered magnet body is heated while a heavy rare-earth element RH, which is at least one element selected from the group consisting of Dy, Ho and Tb, is supplied to the surface of the sintered magnet body, thereby diffusing the heavy rare-earth element RH into the rare-earth sintered magnet body.

Owner:HITACHI METALS LTD

Inter layers for perpendicular recording media

InactiveUS7235314B2Increase in coercivityImprove performanceProtective coatings for layersBase layers for recording layersInter layerRuthenium

Owner:SEAGATE TECH LLC

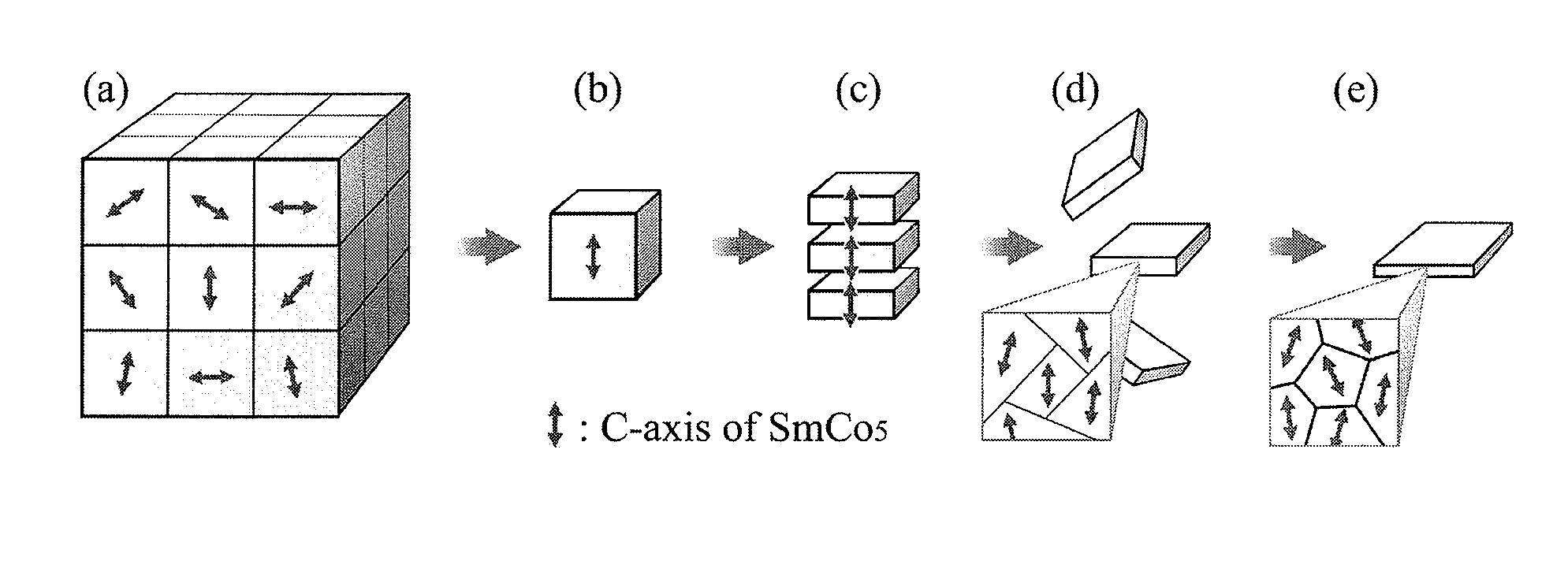

Magnetic nanoflakes

InactiveUS20120021219A1Increase in coercivityHigh energyMaterial nanotechnologyNanomagnetismMagnetic anisotropyHigh energy

Magnetic nanoflakes fabricated by surfactant assisted, wet, high energy ball milling of bulk precursors, with or without preceding dry, high energy ball milling, wherein certain nanoflakes indicate hard magnetic properties, crystallographic texture and magnetic anisotropy.

Owner:ELECTRON ENERGY CORP

Permanent magnets and R-TM-B based permanent magnets

InactiveUS20030136469A1Increase in coercivityInorganic material magnetismInductances/transformers/magnets manufactureNucleationMagnetocrystalline anisotropy

Permanent magnets in which the ferromagnetic phase is matched with the grain boundary phase, and permanent magnets in which magnetocrystalline anisotropy in the vicinity of the outermost shell of the major phase is equivalent in intensity to that in the inside to suppress nucleation of the reverse magnetic domain, more specifically having a magnetocrystalline anisotropy not less than one-half the magnetocrystalline anisotropy of the interiors of the ferromagnetic grains, are disclosed.

Owner:HITACHI METALS LTD

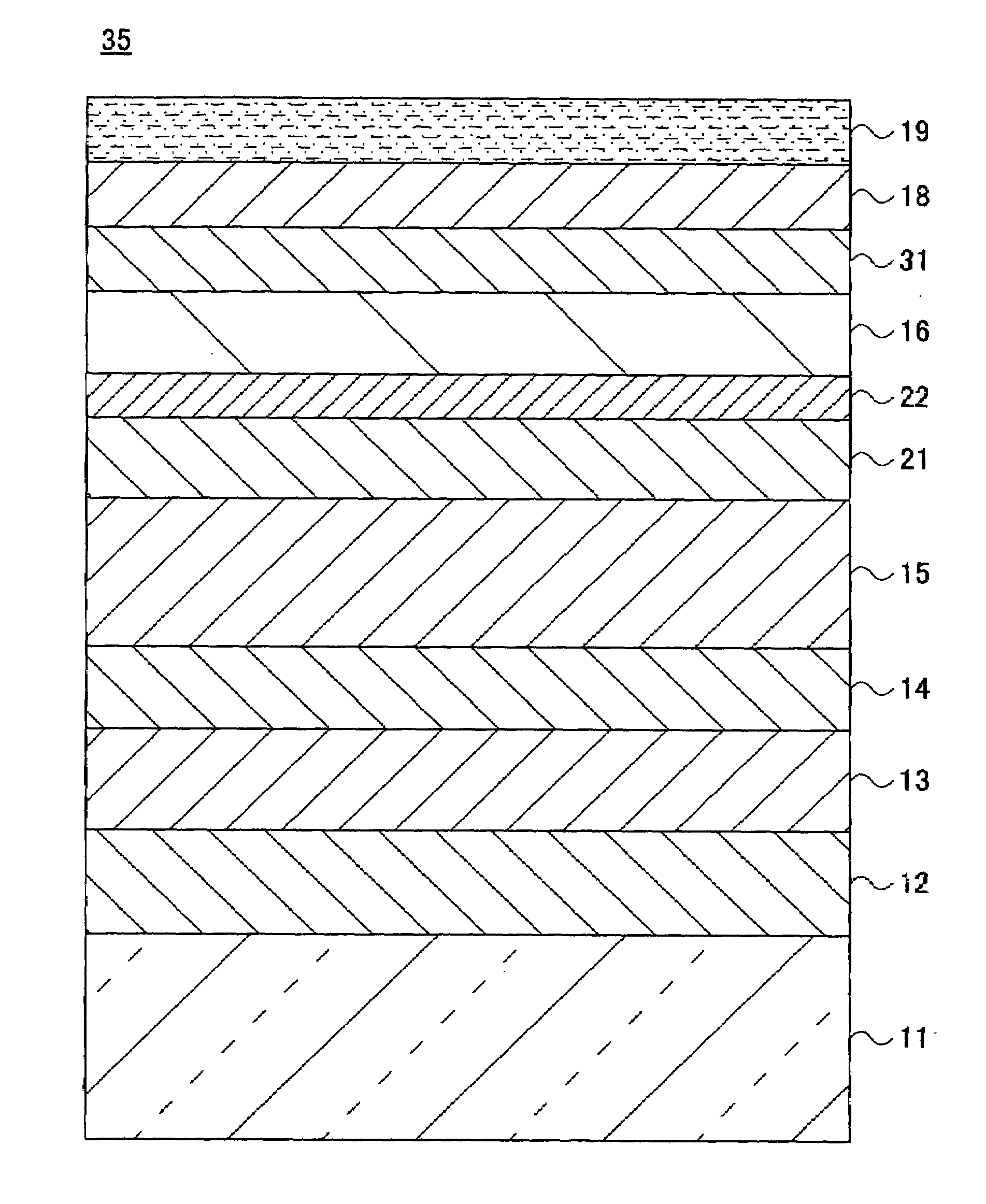

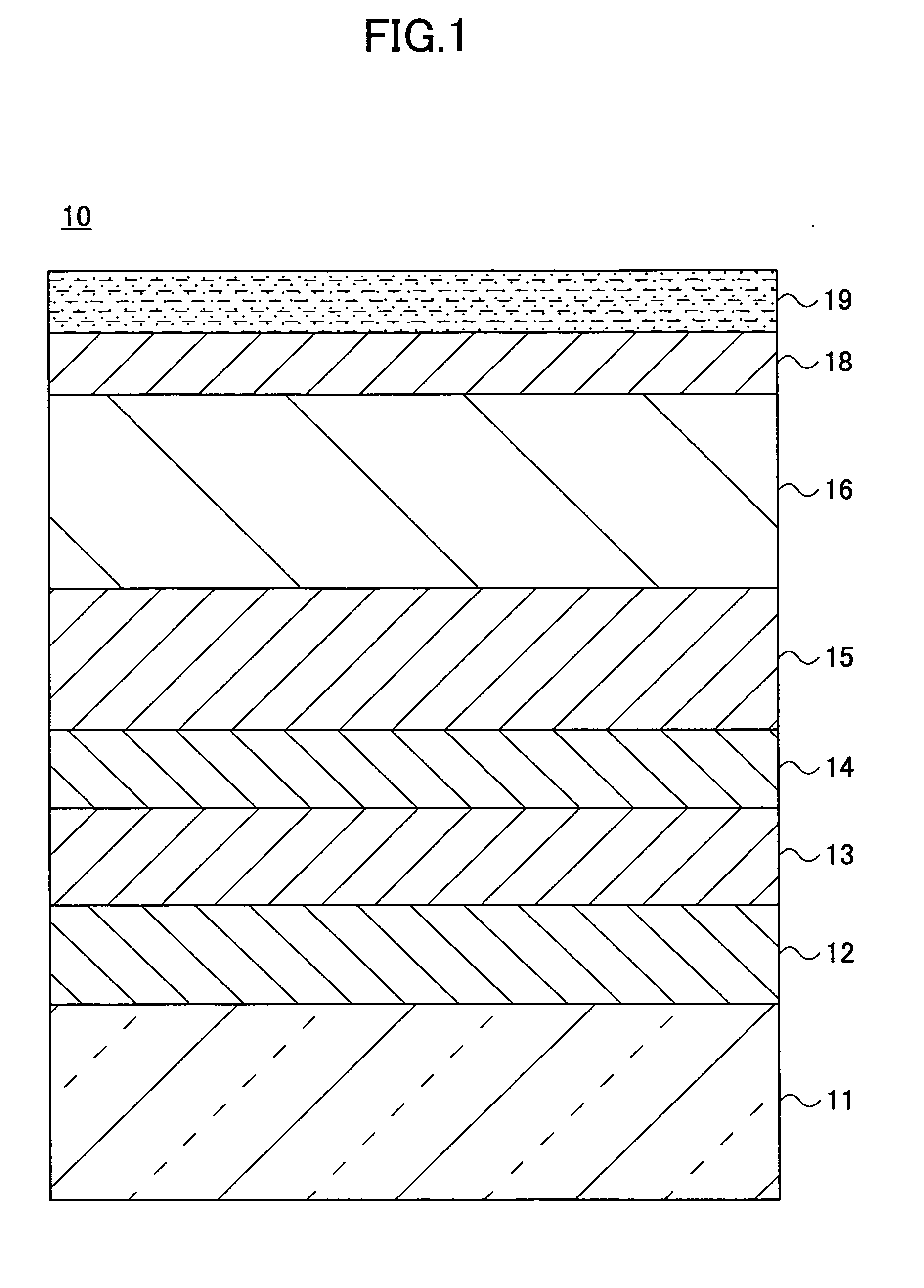

Magnetic recording medium, method of producing same, and magnetic storage apparatus

InactiveUS20070218316A1Improve recording densityImprove signal-to-noise ratioDifferent record carrier formsVacuum evaporation coatingMagnetic storageCrystal structure

A magnetic recording medium according to one aspect of the present invention includes a substrate; an underlayer positioned on the substrate and made of a material having a body-centered-cubic crystalline structure or a B2 crystalline structure; a first intermediate layer positioned on the underlayer and having a hexagonal closest packing crystalline structure, and being made of Co or a Co alloy; a second intermediate layer positioned on the first intermediate layer and having a hexagonal closest packing crystalline structure, and being made of a material selected from the group consisting of Ru, Ti, Re, Zr, Hf, and a Ru alloy; and a magnetic layer positioned on the second intermediate layer and including multiple magnetic grains each having a hexagonal closest packing crystalline structure and an axis of easy magnetization oriented in a direction substantially parallel to a surface of the substrate, wherein the magnetic grains are isolated from each other.

Owner:SHOWA DENKO KK

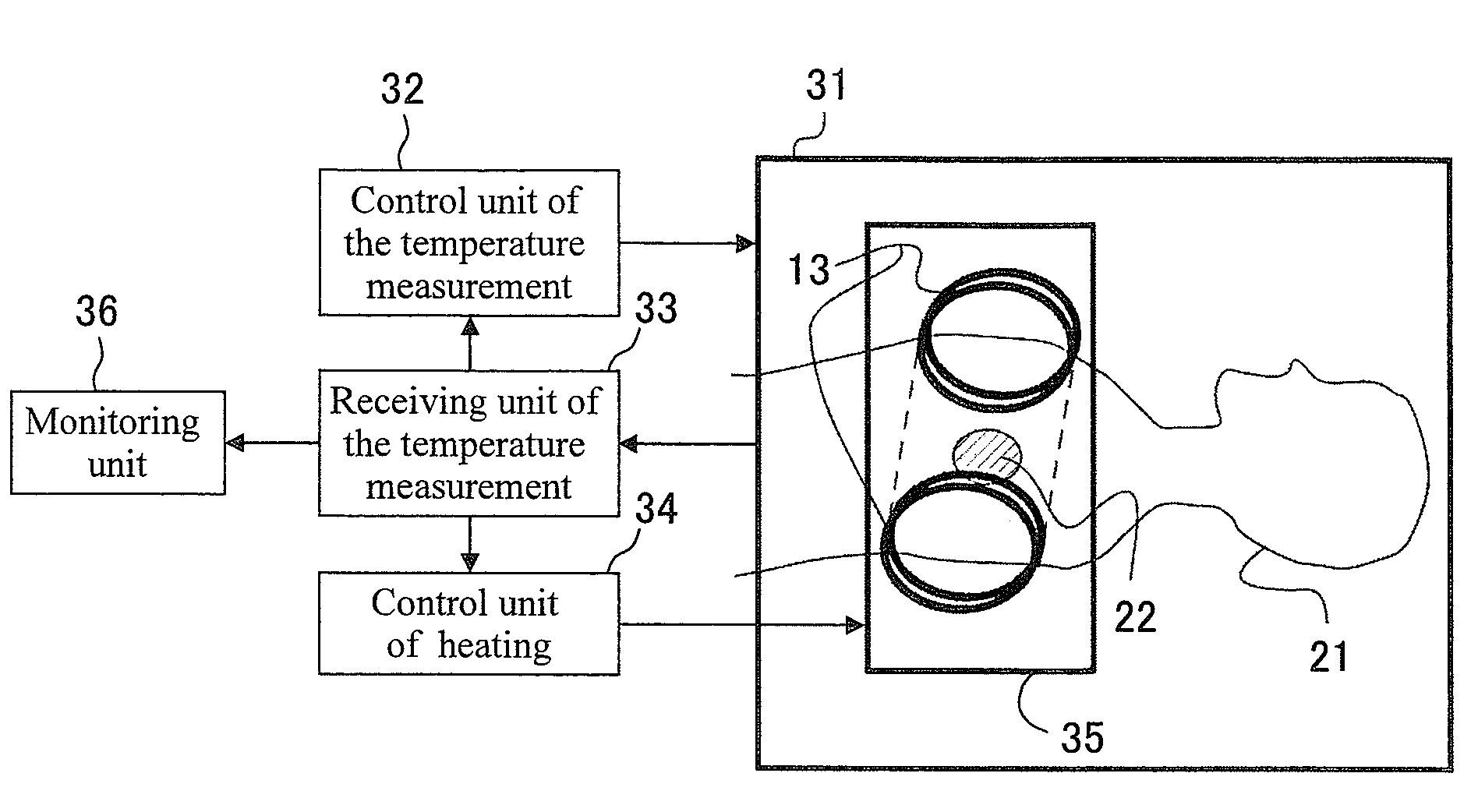

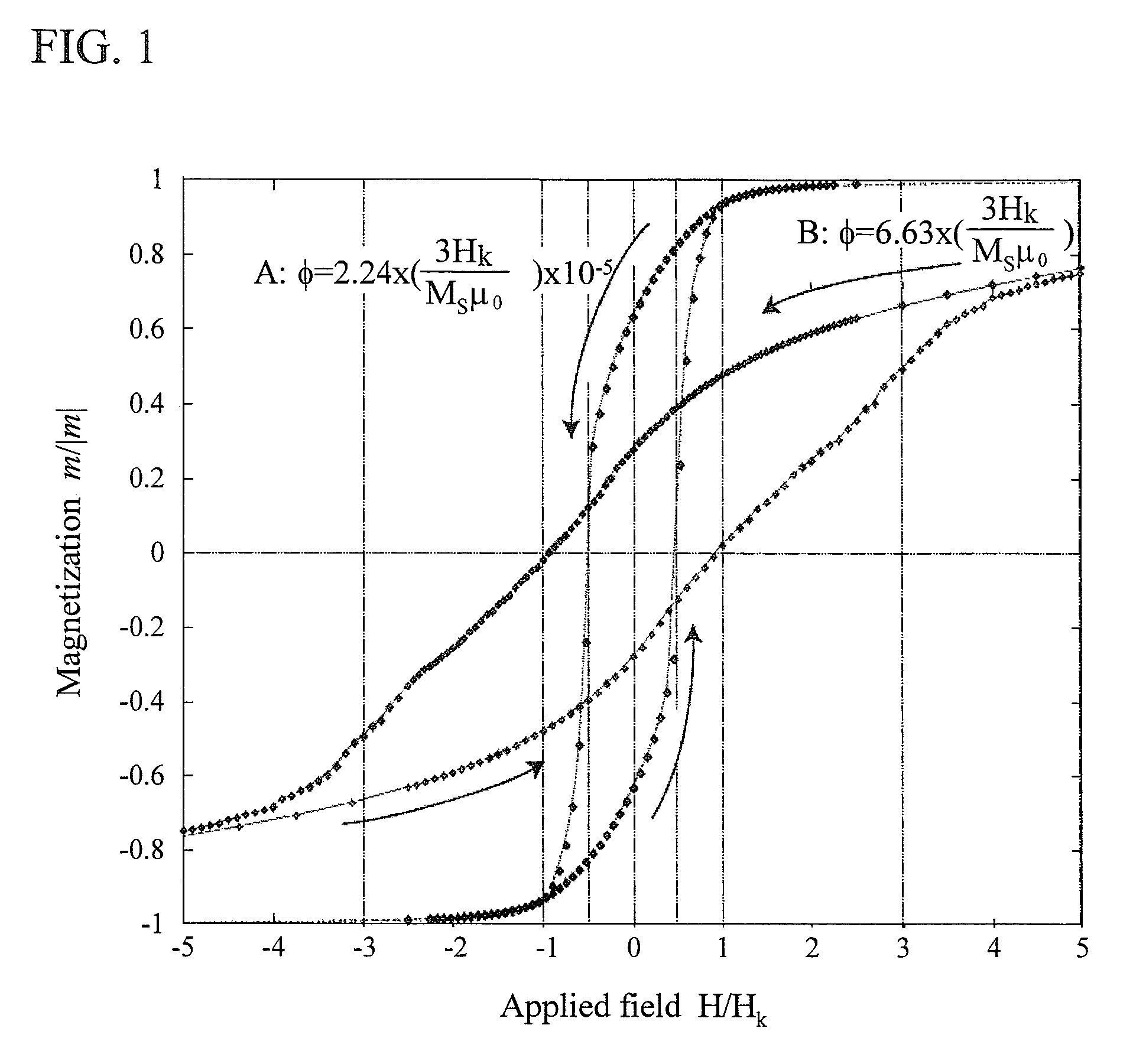

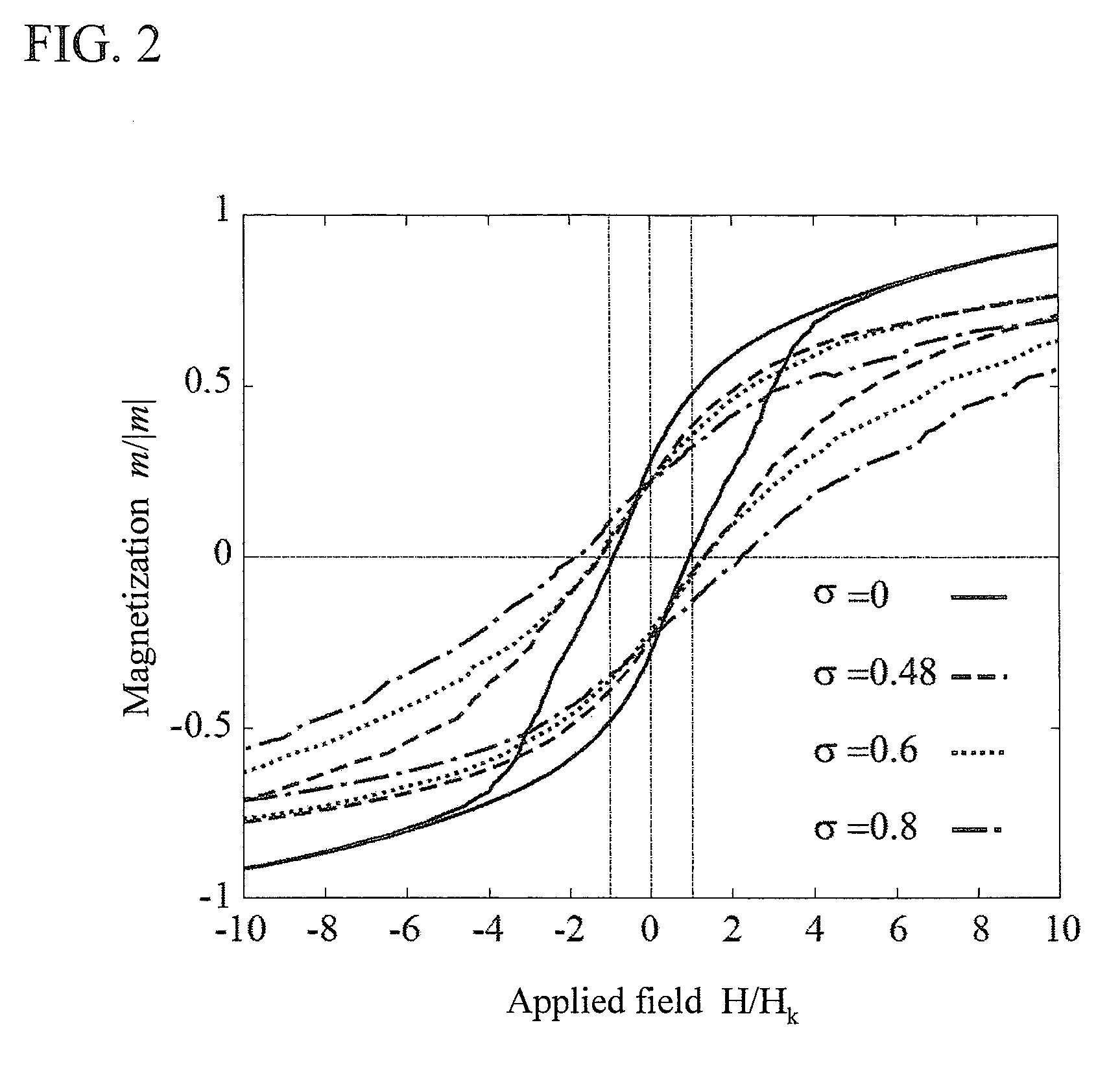

Drug Carrier Containing Magnetic Fine Particles and System Using the Same

InactiveUS20090054722A1Quick effectRapidly of efficacyPowder deliveryElectrotherapyHysteresisElectricity

The present invention provides drug carriers having high heating efficiency by high-frequency dielectric heating in a state of being selectively accumulated in a target site. The drug carriers each consist of a drug, magnetic fine particles, and a shell containing the drug and the magnetic fine particles. The shell has an outer diameter in a range from 10 nm to 200 nm. The magnetic fine particles having an average particle diameter of d has a standard deviation σ of particle diameter distribution satisfying 0.8d>σ>0.4d. The magnetic fine particles contained in the individual drug carriers generate hysteresis heat due to high-frequency dielectric heating by irradiation of a high-frequency magnetic field.

Owner:HITACHI LTD

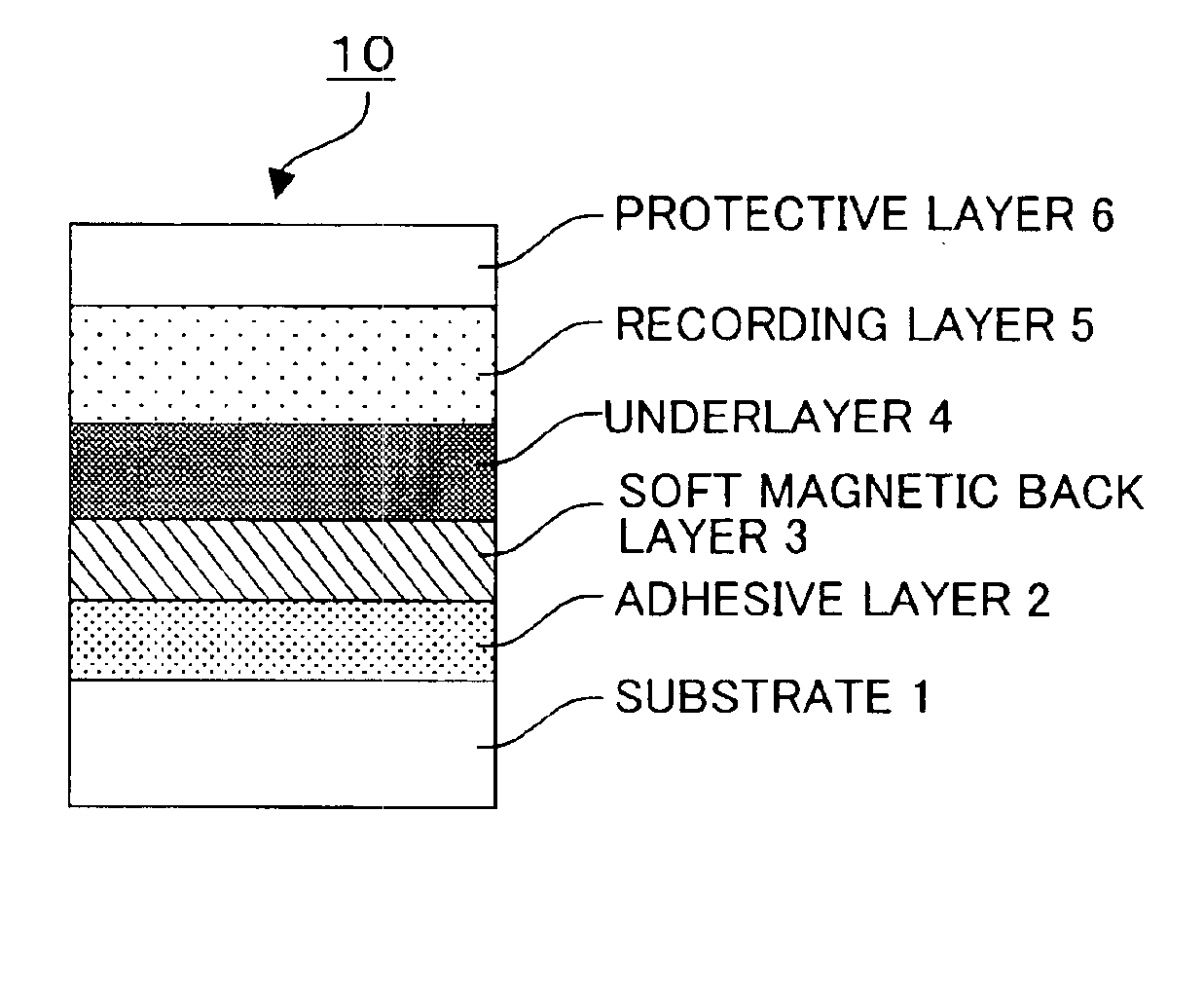

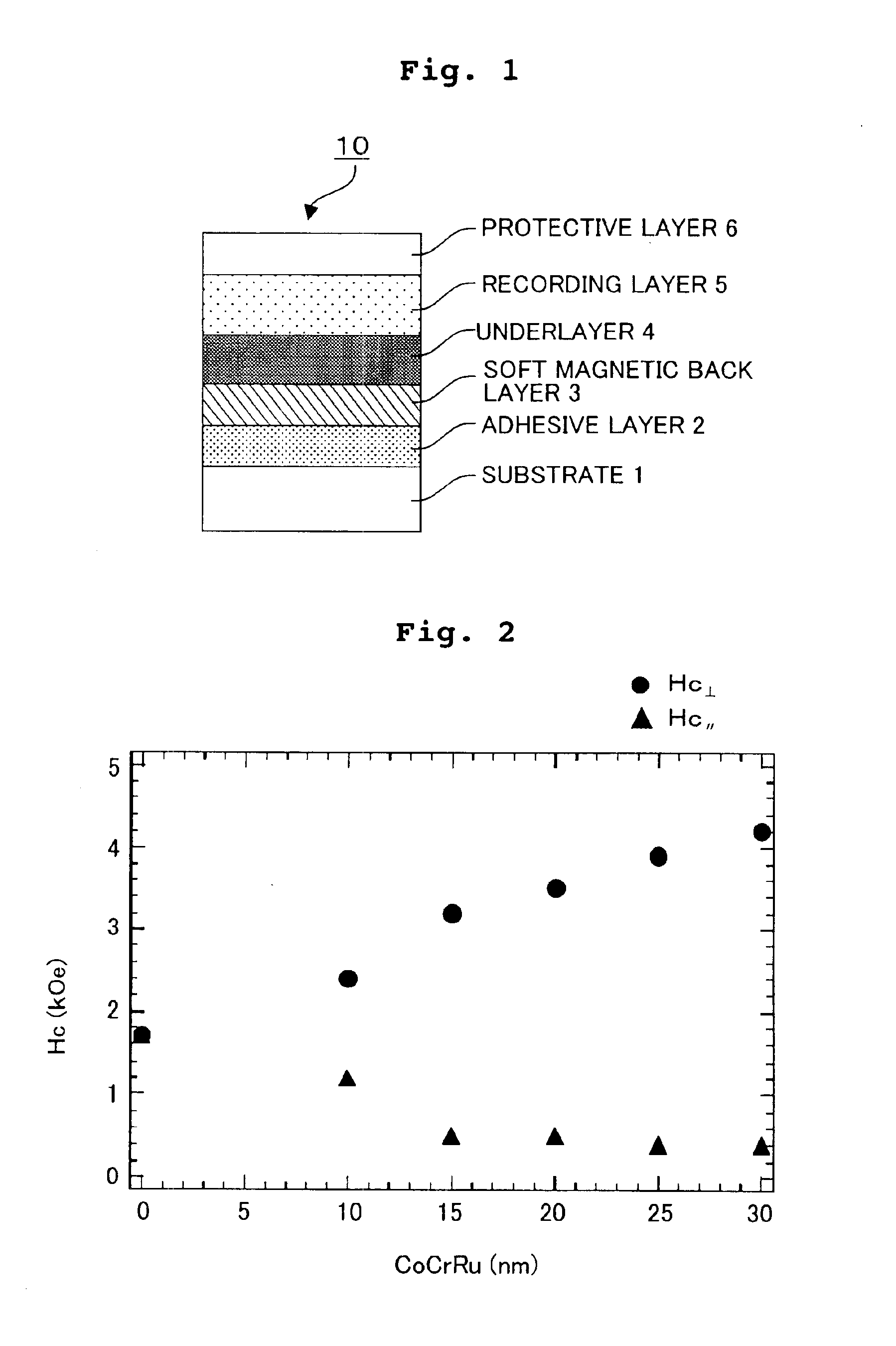

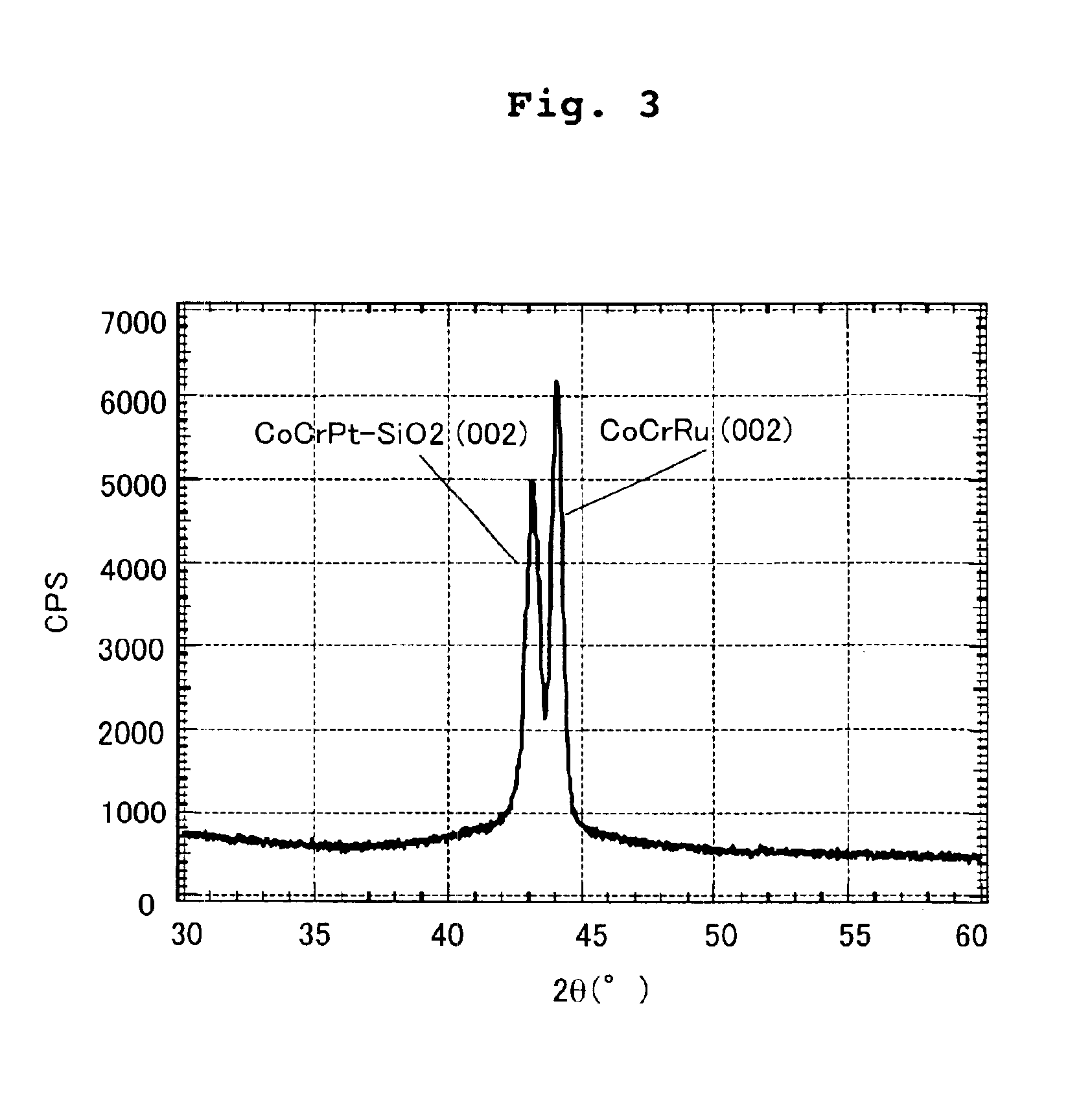

Magnetic recording medium and magnetic recording apparatus

InactiveUS6866948B2Improve coercive forceReduce noiseBase layers for recording layersRecord information storageOptoelectronicsAlloy

A magnetic recording medium based on the perpendicular recording system, which has high coercivity and low medium noise, is provided by using an underlayer which has a thin film thickness and which makes it possible to improve the orientation of a recording layer. The magnetic recording medium based on the perpendicular recording system has the recording layer which is formed of a CoPtCr alloy magnetic film containing oxygen. The magnetic recording medium has such a structure that an adhesive layer 2, a soft magnetic back layer 3, the underlayer 4, the recording layer 5, and a protective layer 6 are successively stacked on a substrate 1. A CoCrRu film, which has a film thickness of 5 nm to 20 nm, is used as the underlayer for the recording layer formed of the CoPtCr alloy magnetic film containing oxygen. Thus, it is possible to improve the crystalline orientation of the recording layer with the underlayer having the thin film thickness.

Owner:HITACHT MAXELL LTD

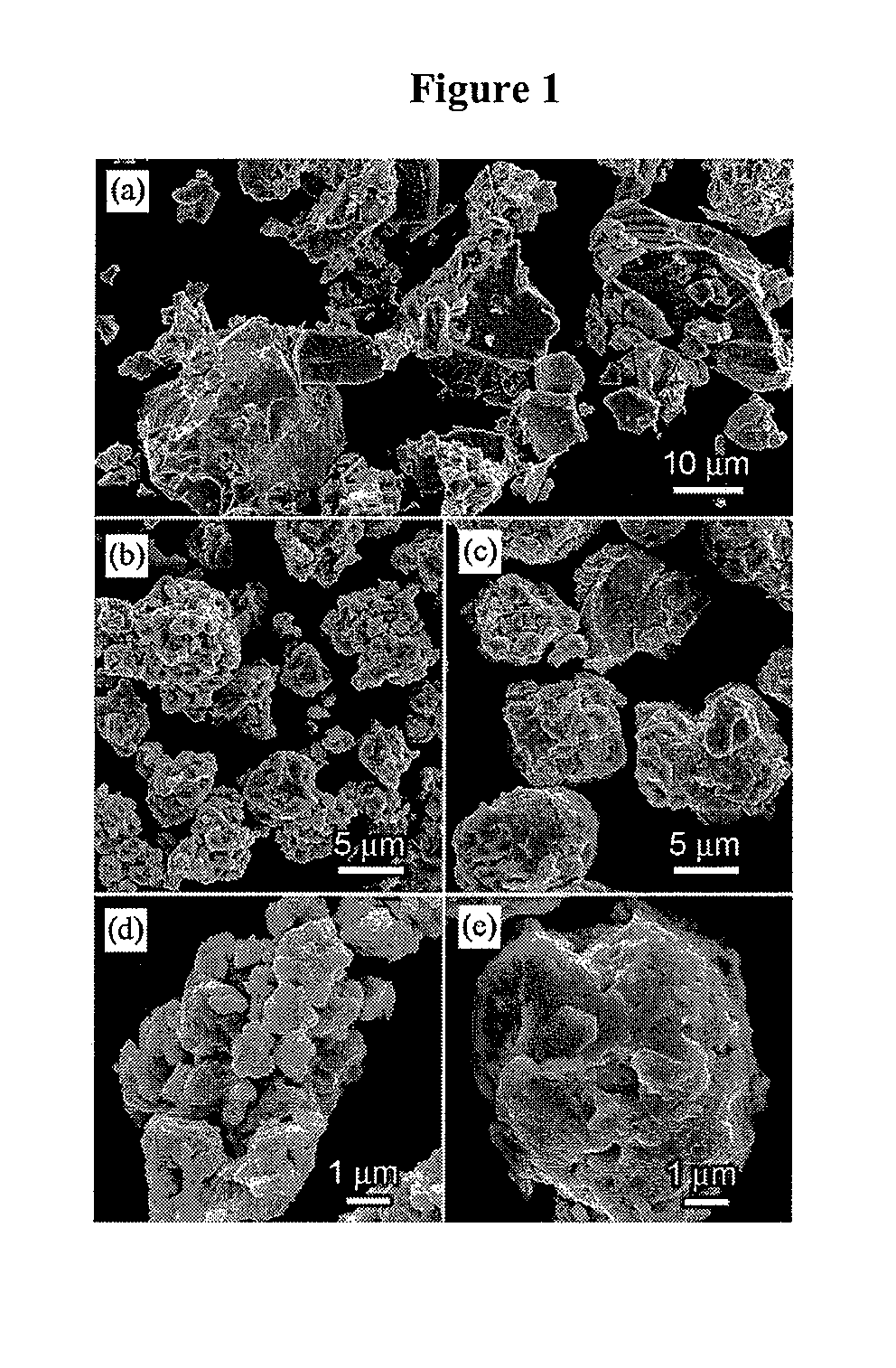

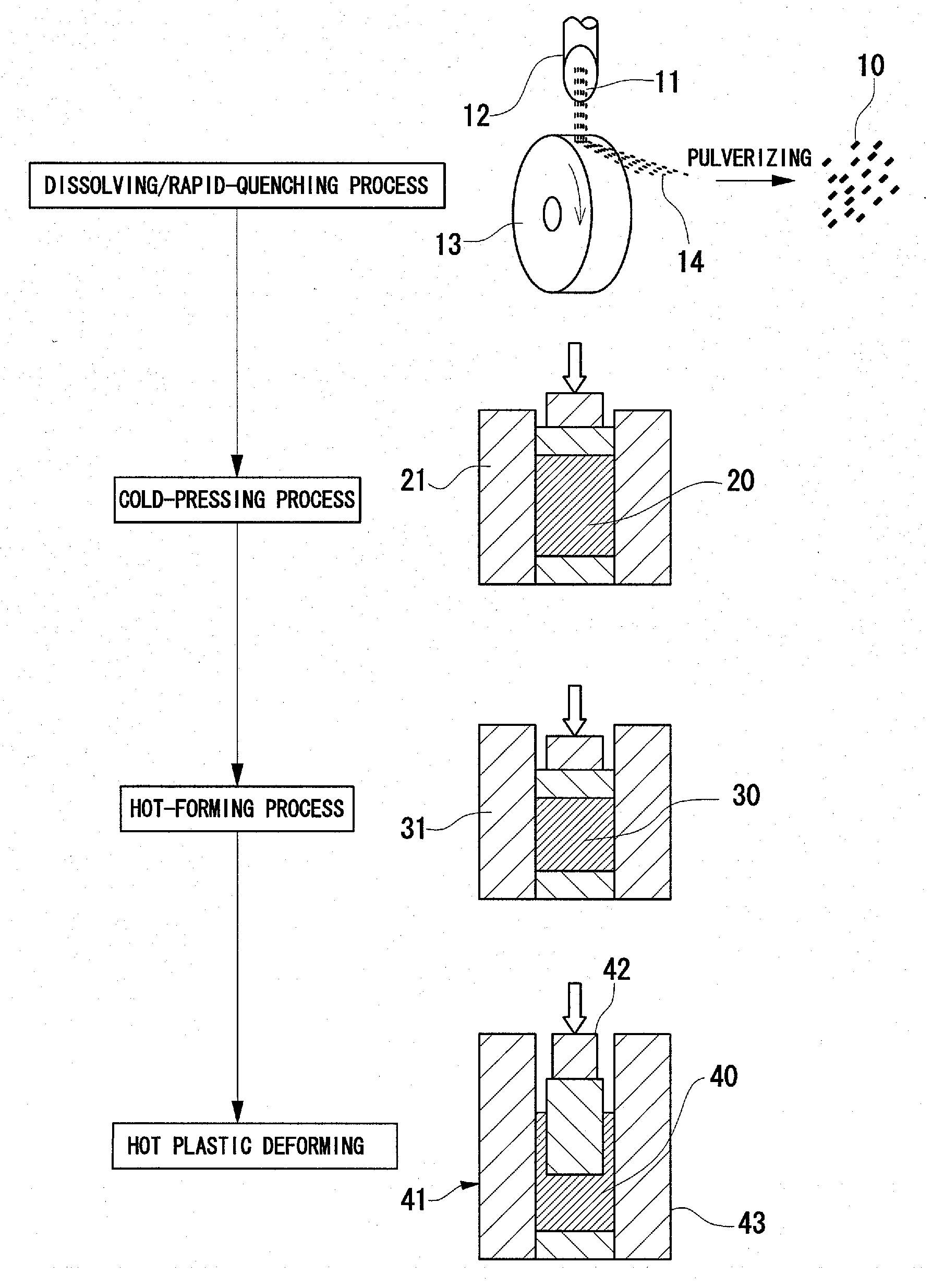

Material for Anisotropic Magnet and Method of Manufacturing the same

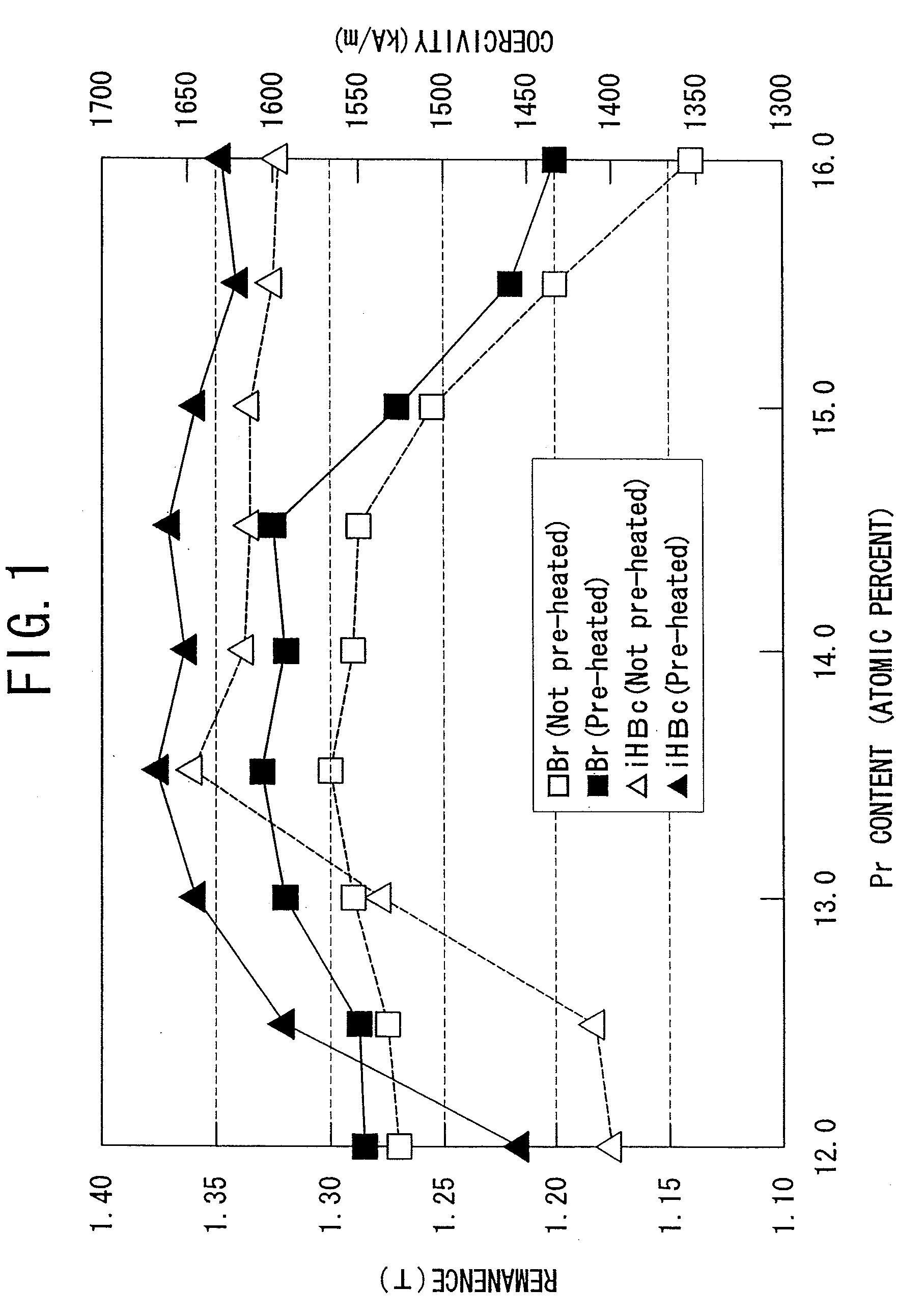

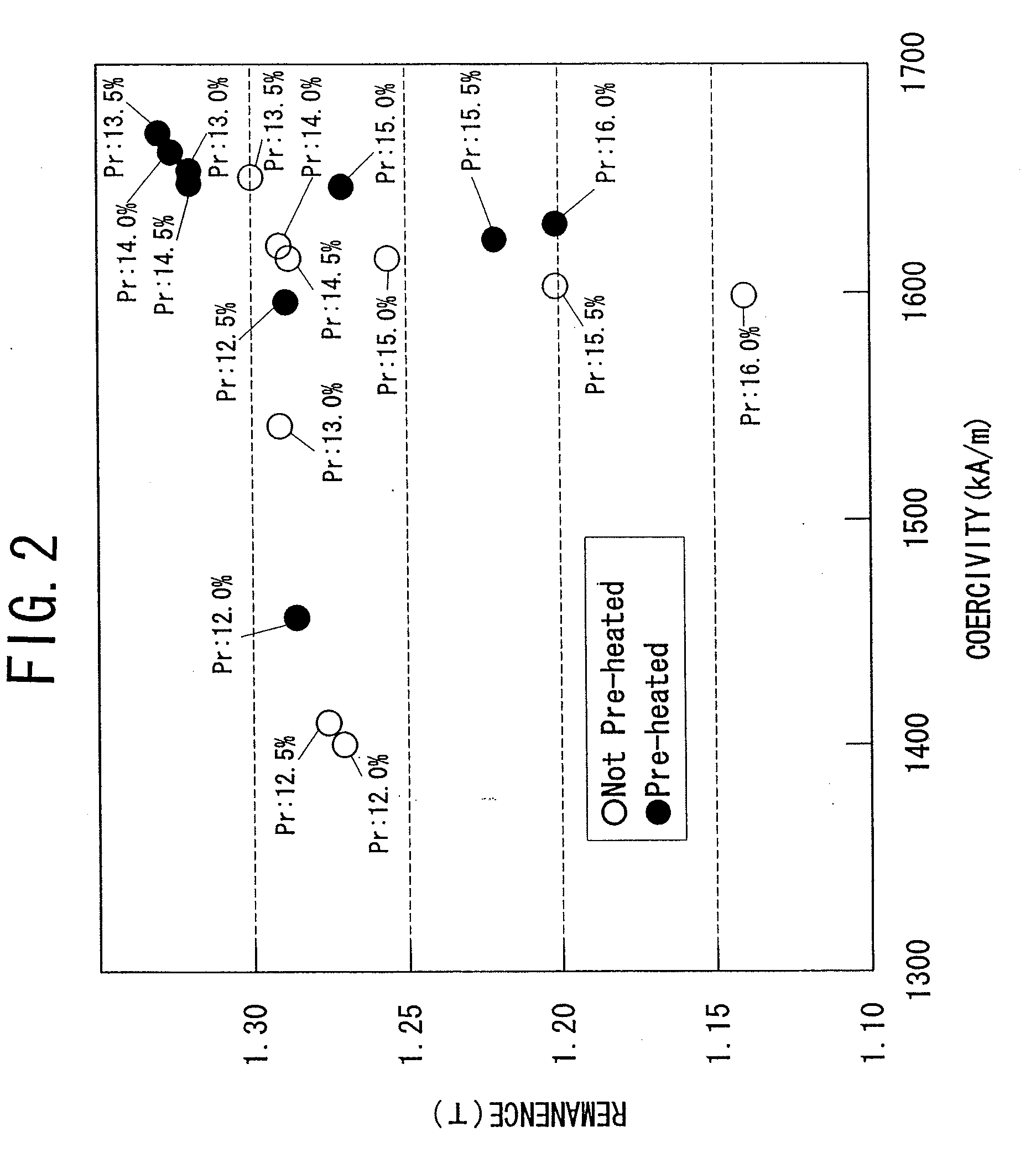

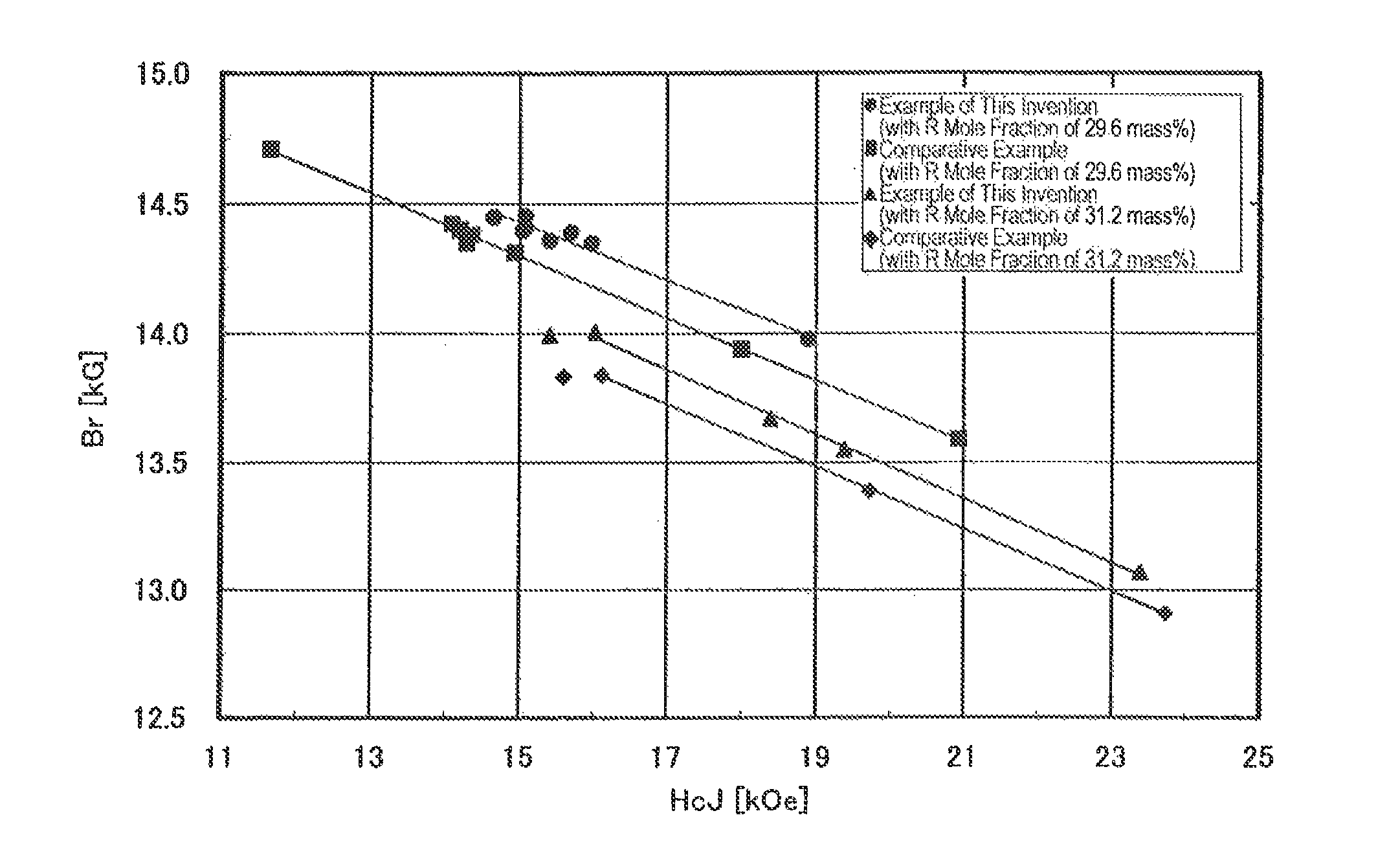

ActiveUS20100172783A1Increase in coercivityDecreasing remanenceTransportation and packagingMetal-working apparatusRemanenceMetallurgy

A material for anisotropic magnet, comprising,(1) a Pr-T-B—Ga-based composition containing Pr: 12.5 to 15.0 atomic percent, B: 4.5 to 6.5 atomic percent, Ga: 0.1 to 0.7 atomic percent, and the balance of T and inevitable impurities, wherein T is Fe or obtained by substituting Co for a portion of the Fe; and having,(2) a degree of magnetic alignment of 0.92 or more, wherein the degree of magnetic alignment is defined by remanence (Br) / saturation magnetization (Js); and(3) a crystal grain diameter of 1 μm or less.

Owner:DAIDO STEEL CO LTD

Method for preparing r-fe-b based sintered magnet

ActiveUS20140352847A1Easy to operateLow production costInorganic material magnetismEncapsulation/impregnationRare-earth elementMetallurgy

A method for preparing an R—Fe—B based sintered magnet, including: preparing a R1—Fe—B-M sintered magnet having a thickness of between 1 and 10 mm; spraying a layer of Tb or Dy having a thickness of between 10 and 200 μm on each surface of the sintered magnet in a sealed box under an Ar atmosphere by hot spraying method; and transferring the sintered magnet coated with the layer of Tb or Dy to a vacuum sintering furnace, heating the sintered magnet at the temperature of between 750 and 1000° C. in a vacuum condition or under the Ar atmosphere, and allowing heavy rare earth element Tb or Dy to enter an inner part of the sintered magnet via grain boundary diffusion.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

R-Fe-B RARE EARTH SINTERED MAGNET

ActiveUS20110012699A1Increase in coercivityCoercivity HcJ be increasePermanent magnetsInorganic material magnetismRare-earth elementCrystallite

Owner:HITACHI METALS LTD

R-Fe-B ANISOTROPIC SINTERED MAGNET

ActiveUS20110205006A1Remanence Br decreasedCoercivity HcJ can be increasedPermanent magnetsInorganic material magnetismRare-earth elementX-ray

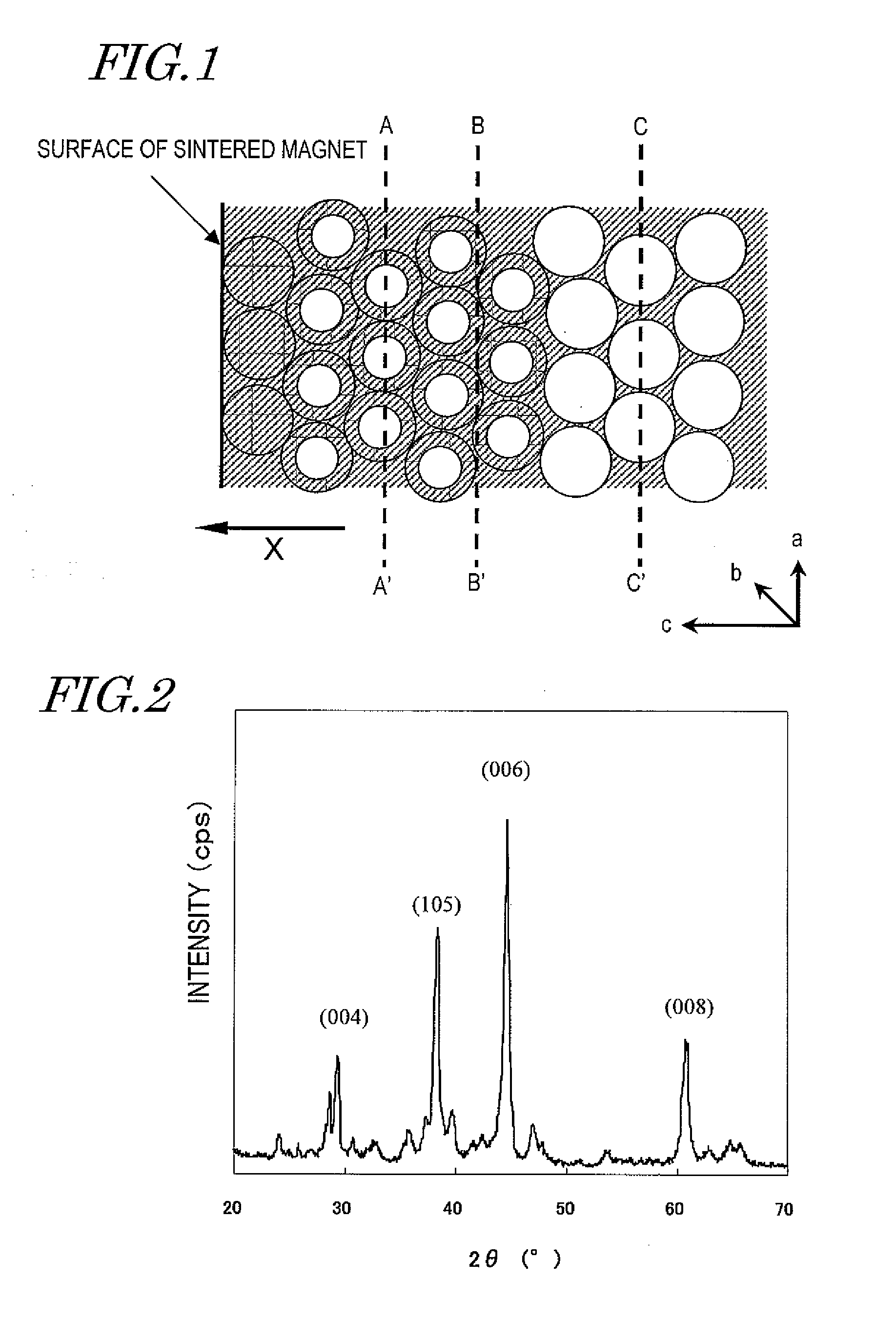

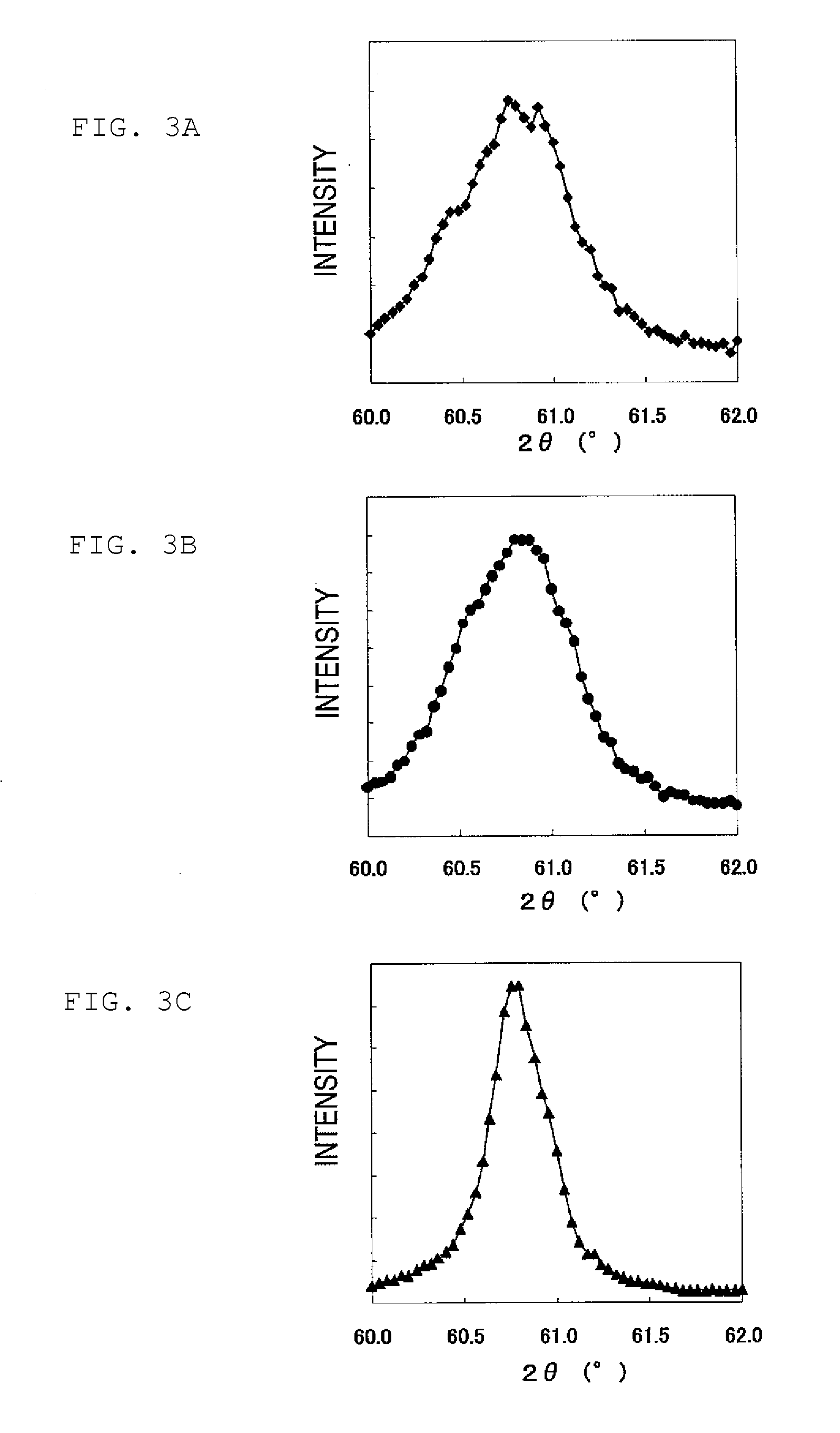

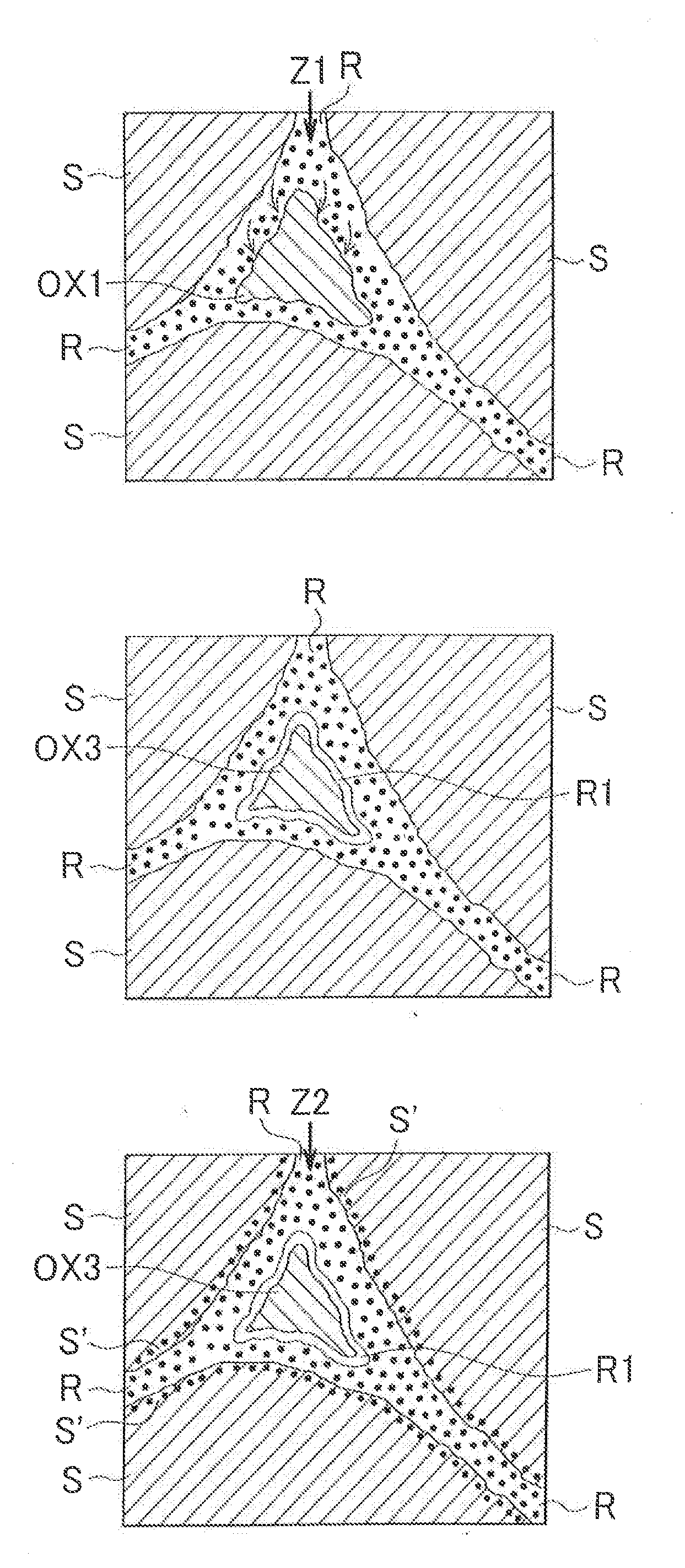

An R—Fe—B based anisotropic sintered magnet according to the present invention has, as a main phase, an R2Fe14B type compound that includes a light rare-earth element RL (which is at least one of Nd and Pr) as a major rare-earth element R, and also has a heavy rare-earth element RH (which is at least one element selected from the group consisting of Dy and Tb). In the crystal lattice of the main phase, the c-axis is oriented in a predetermined direction. The magnet includes a portion in which at least two peaks of diffraction are observed within a 2θ range of 60.5 degrees to 61.5 degrees when an X-ray diffraction measurement is carried out using a CuK α ray on a plane that is located at a depth of 500 μm or less under a pole face of the magnet and that is parallel to the pole face.

Owner:HITACHI METALS LTD

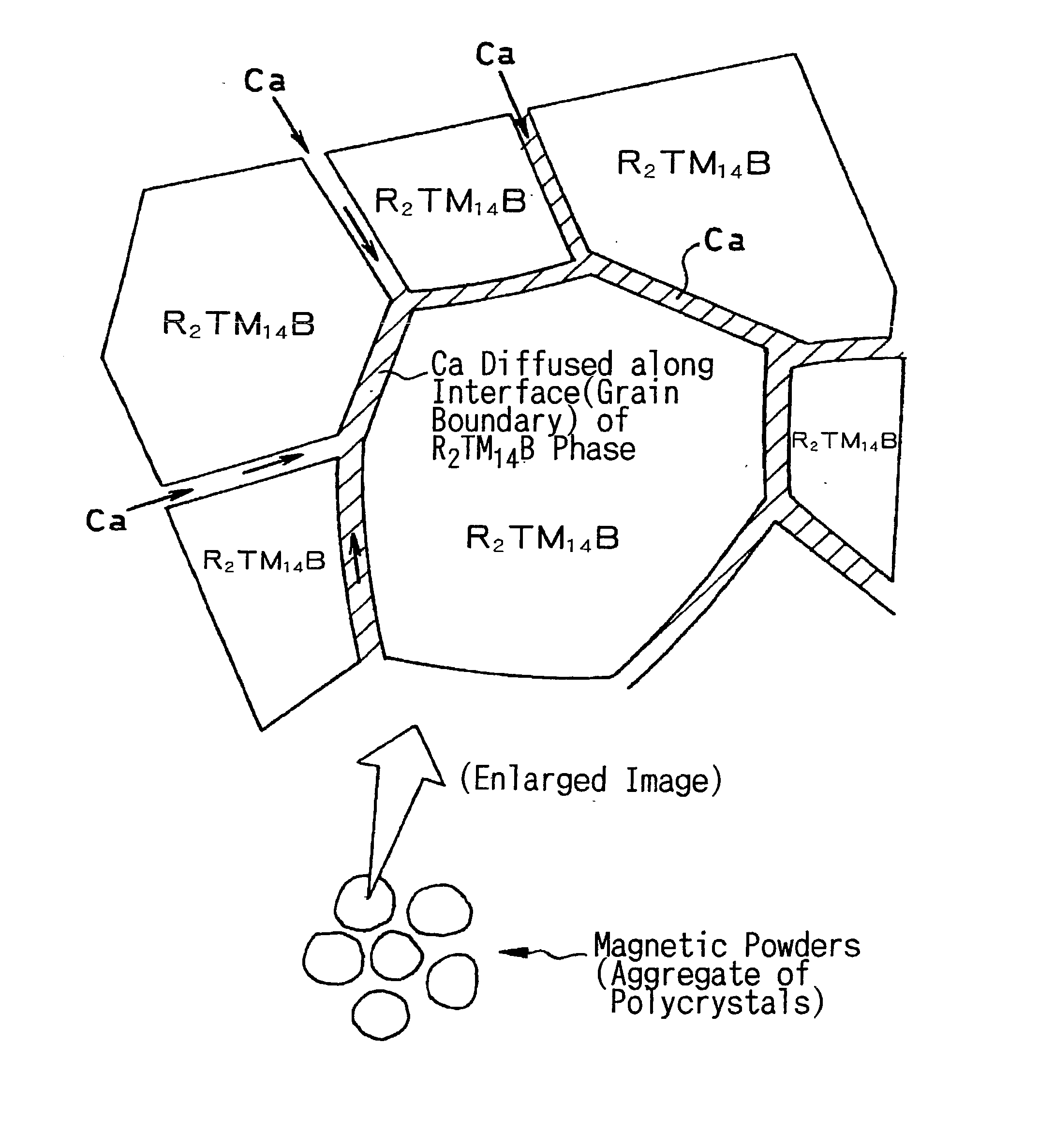

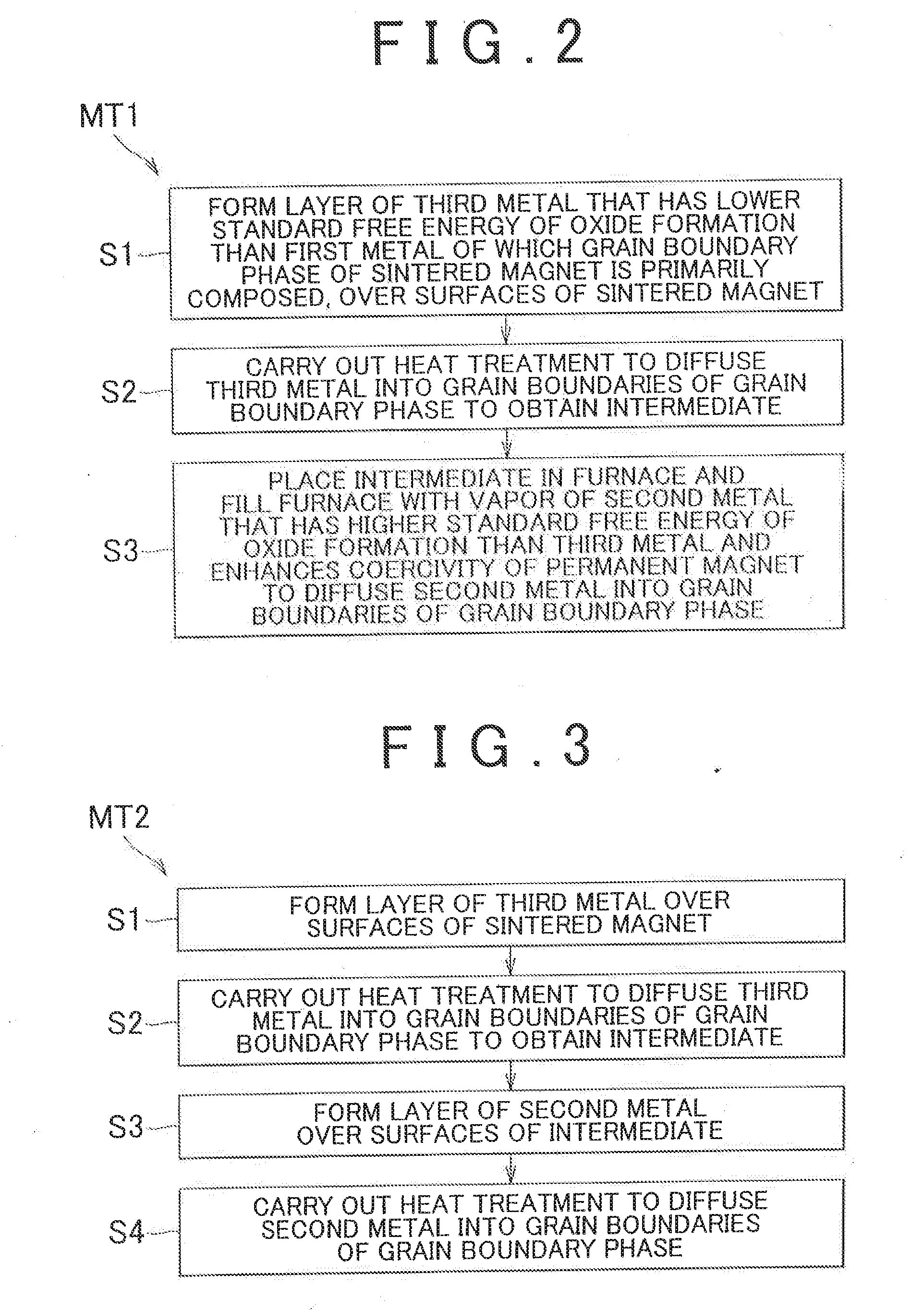

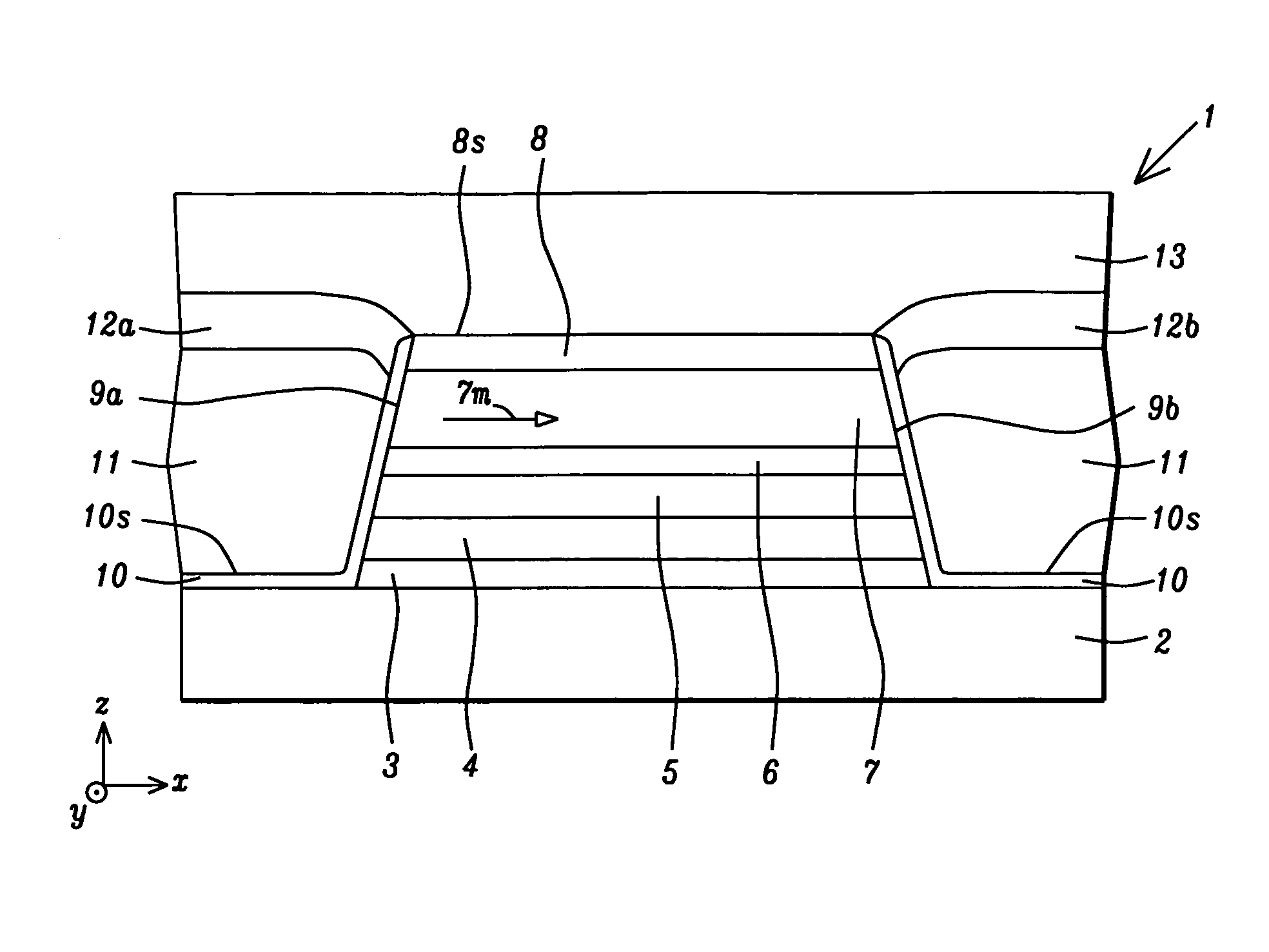

Permanent magnet and method of producing permanent magnet

ActiveUS20130135069A1Increase output powerLow production costVacuum evaporation coatingSputtering coatingFree energiesGrain structure

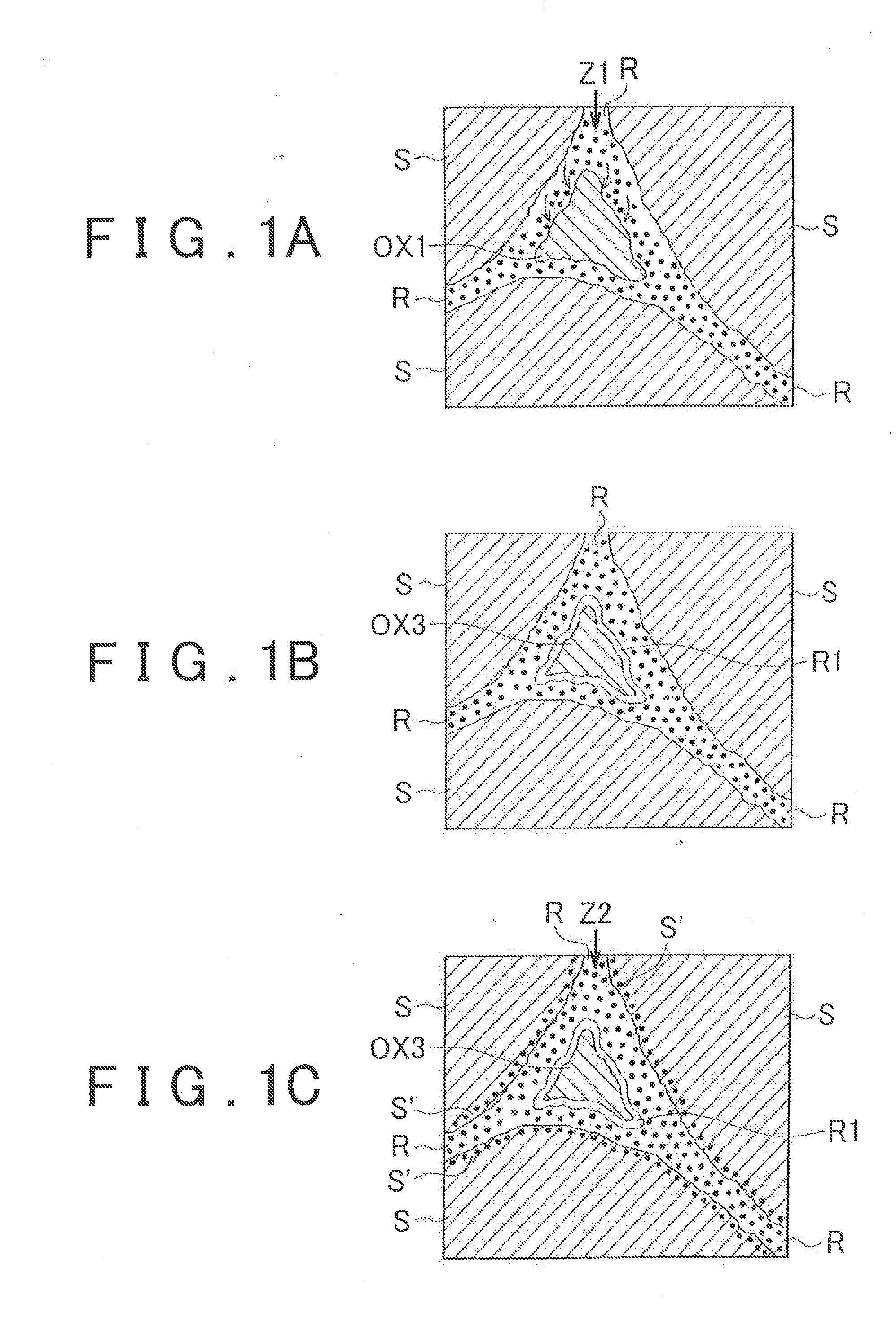

A permanent magnet has a grain structure that includes a main phase and a grain boundary phase that is primarily composed of a first metal. A second metal that enhances the coercivity of the permanent magnet and a third metal that has a lower standard free energy of oxide formation than the first metal and the second metal are diffused in the permanent magnet, and the third metal is present in the form of an oxide in the grain boundary phase.

Owner:TOYOTA JIDOSHA KK

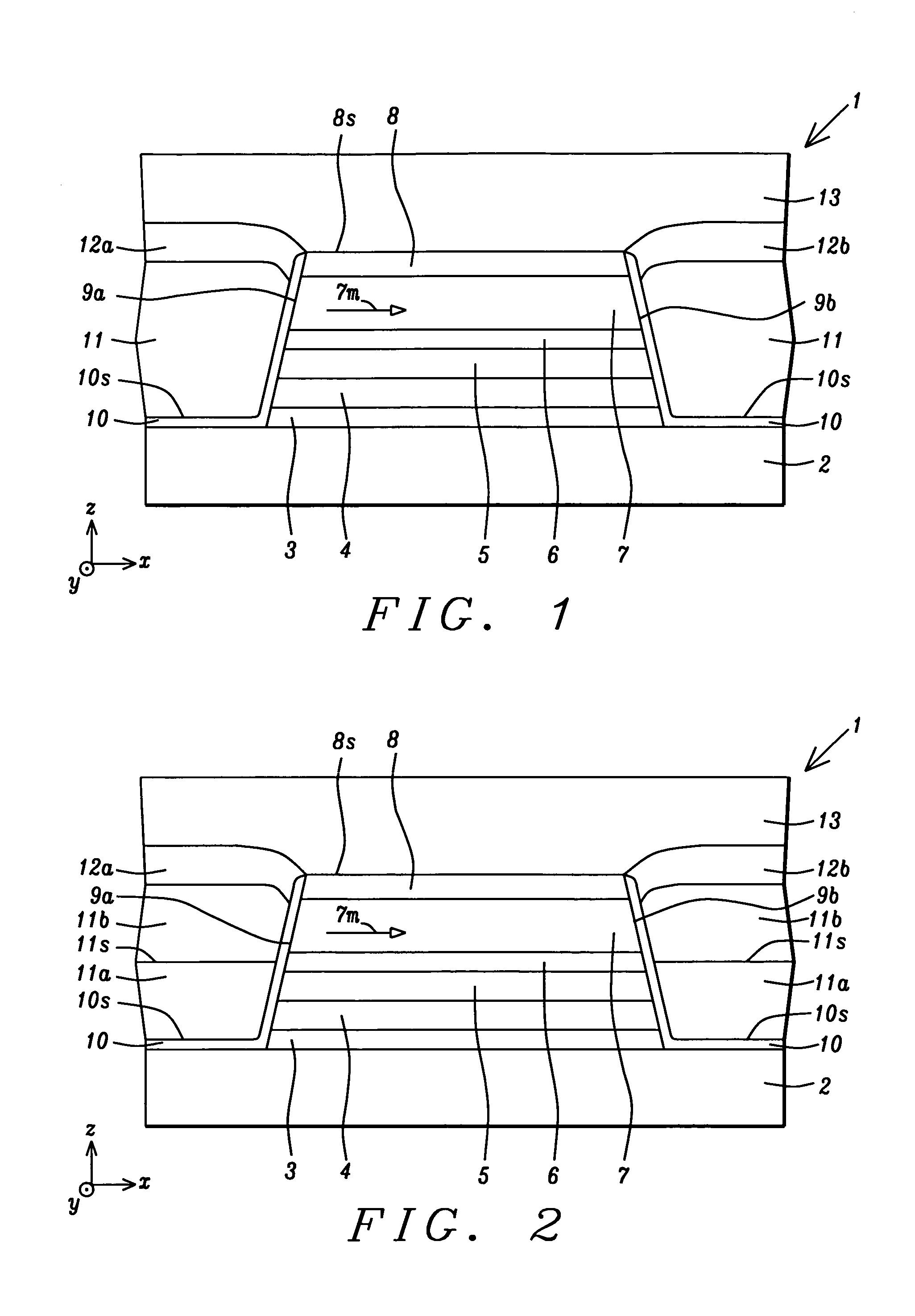

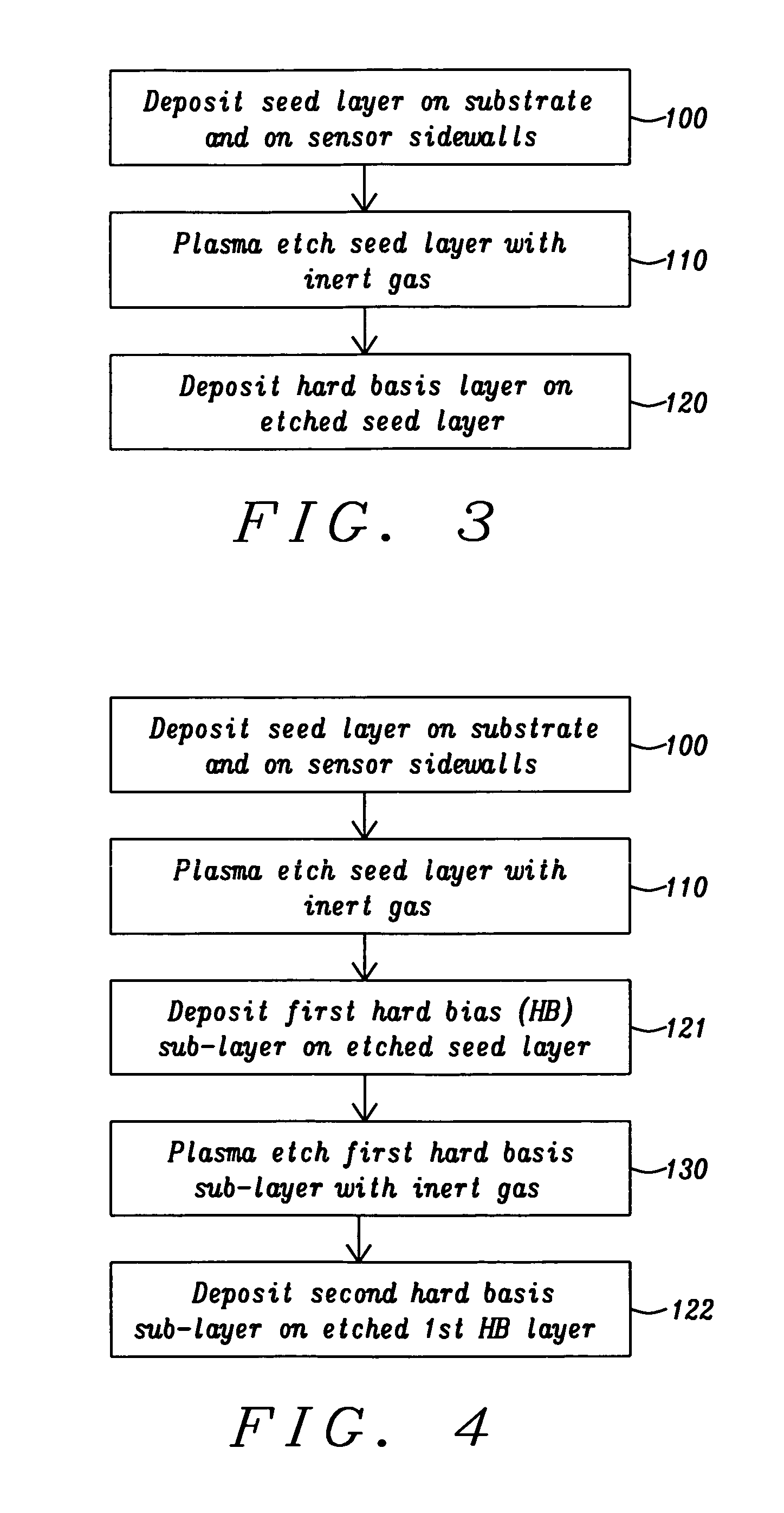

Method for fabricating a high coercivity hard bias structure for magnetoresistive sensor

ActiveUS20100276272A1High recording densityGreat coercivityMagnetic measurementsVacuum evaporation coatingCrystalliteHigh concentration

A hard bias (HB) structure for longitudinally biasing a free layer in a MR sensor is disclosed that includes a mildly etched seed layer and a hard bias (HB) layer on the etched seed layer. The HB layer may contain one or more HB sub-layers stacked on a lower sub-layer which contacts the etched seed layer. Each HB sub-layer is mildly etched before depositing another HB sub-layer thereon. The etch may be performed in an IBD chamber and creates a higher concentration of nucleation sites on the etched surface thereby promoting a smaller HB average grain size than would be realized with no etch treatments. A smaller HB average grain size is responsible for increasing Hcr in a CoPt HB layer to as high as 2500 to 3000 Oe. Higher Hcr is achieved without changing the seed layer or HB material and without changing the thickness of the aforementioned layers.

Owner:HEADWAY TECH INC

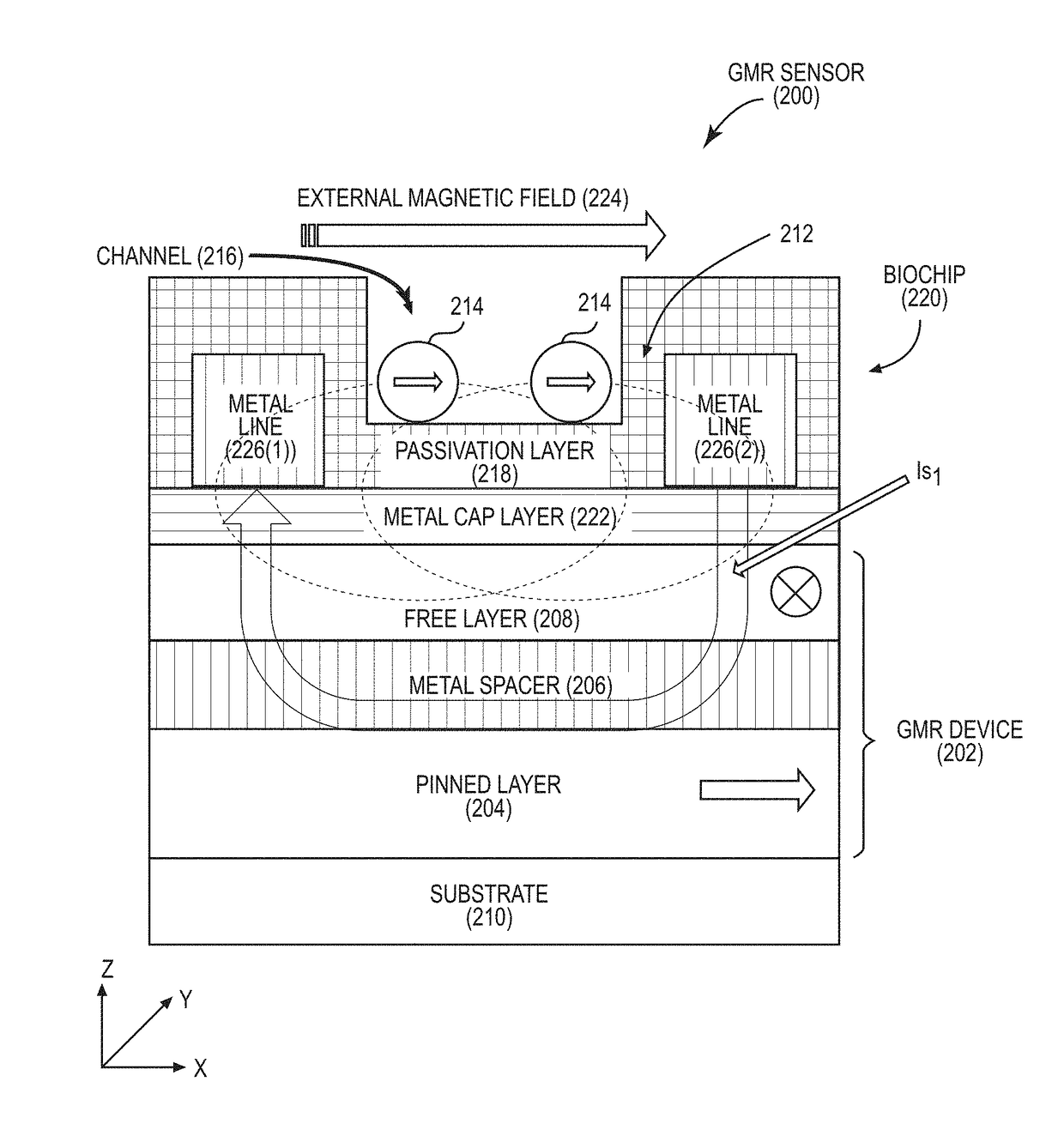

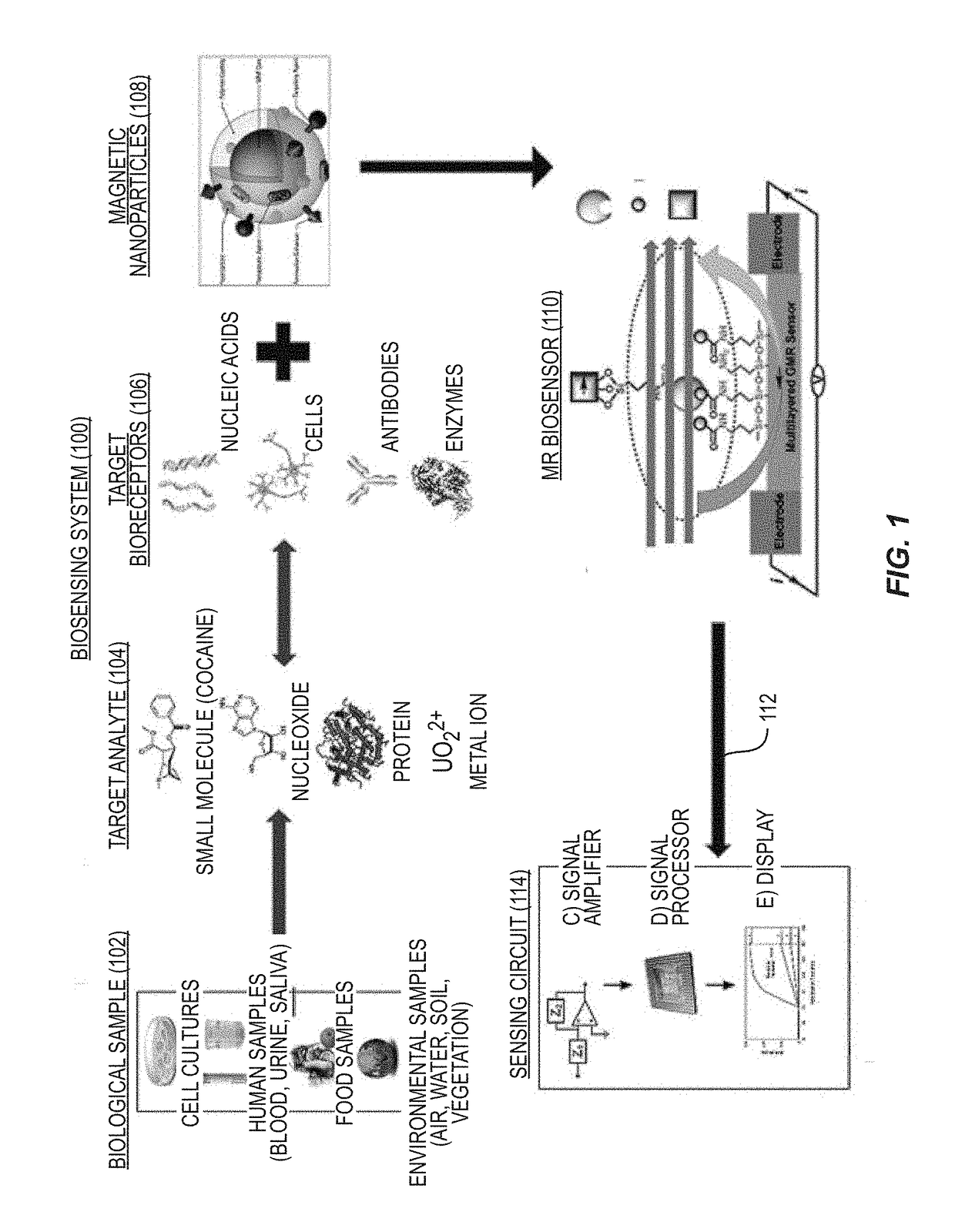

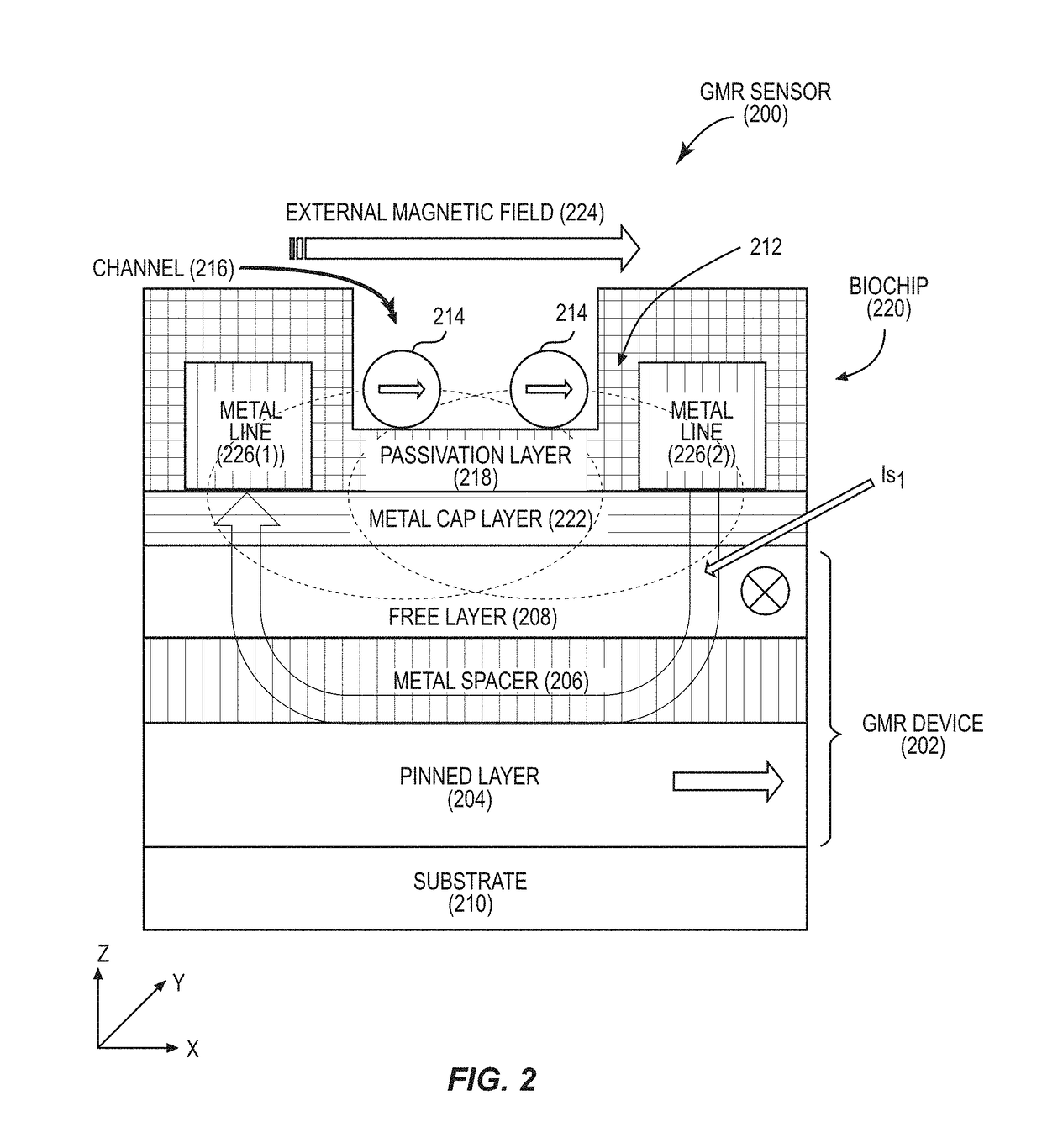

Tunnel magneto-resistive (TMR) sensors employing tmr devices with different magnetic field sensitivities for increased detection sensitivity

ActiveUS20180284200A1Easy to changeReduce magnetization angleMagnetic-field-controlled resistorsSolid-state devicesElectrical resistance and conductanceMagnetic anisotropy

Tunnel magneto-resistive (TMR) sensors employing TMR devices with different magnetic field sensitivities for increased detection sensitivity are disclosed. For example, a TMR sensor may be used as a biosensor to detect the presence of biological materials. In aspects disclosed herein, free layers of at least two TMR devices in a TMR sensor are fabricated to exhibit different magnetic properties from each other (e.g., MR ratio, magnetic anisotropy, coercivity) so that each TMR device will exhibit a different change in resistance to a given magnetic stray field for increased magnetic field detection sensitivity. For example, the TMR devices may be fabricated to exhibit different magnetic properties such that one TMR device exhibits a greater change in resistance in the presence of a smaller magnetic stray field, and another TMR device exhibits a greater change in resistance in the presence of a larger magnetic stray field.

Owner:QUALCOMM INC

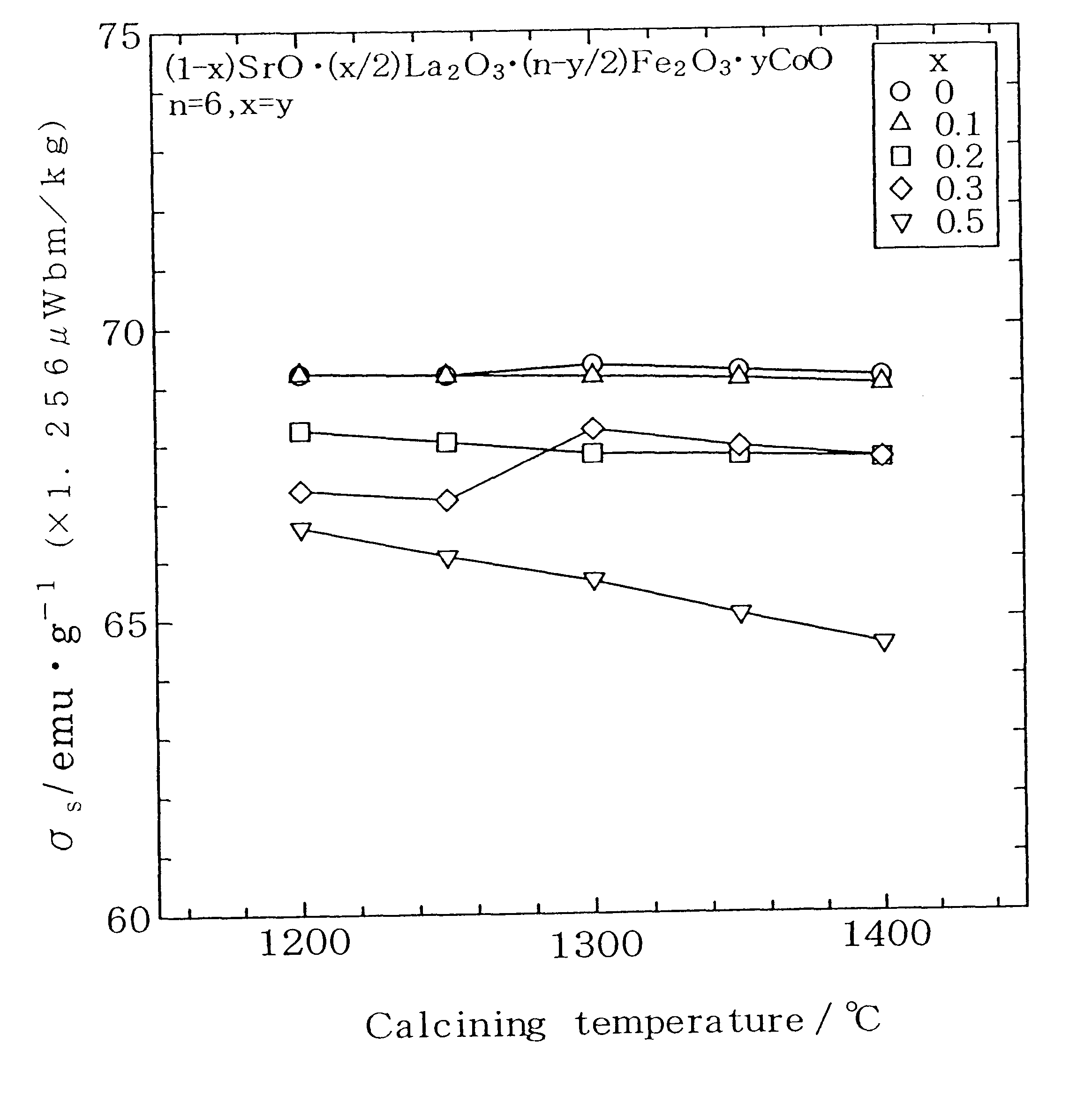

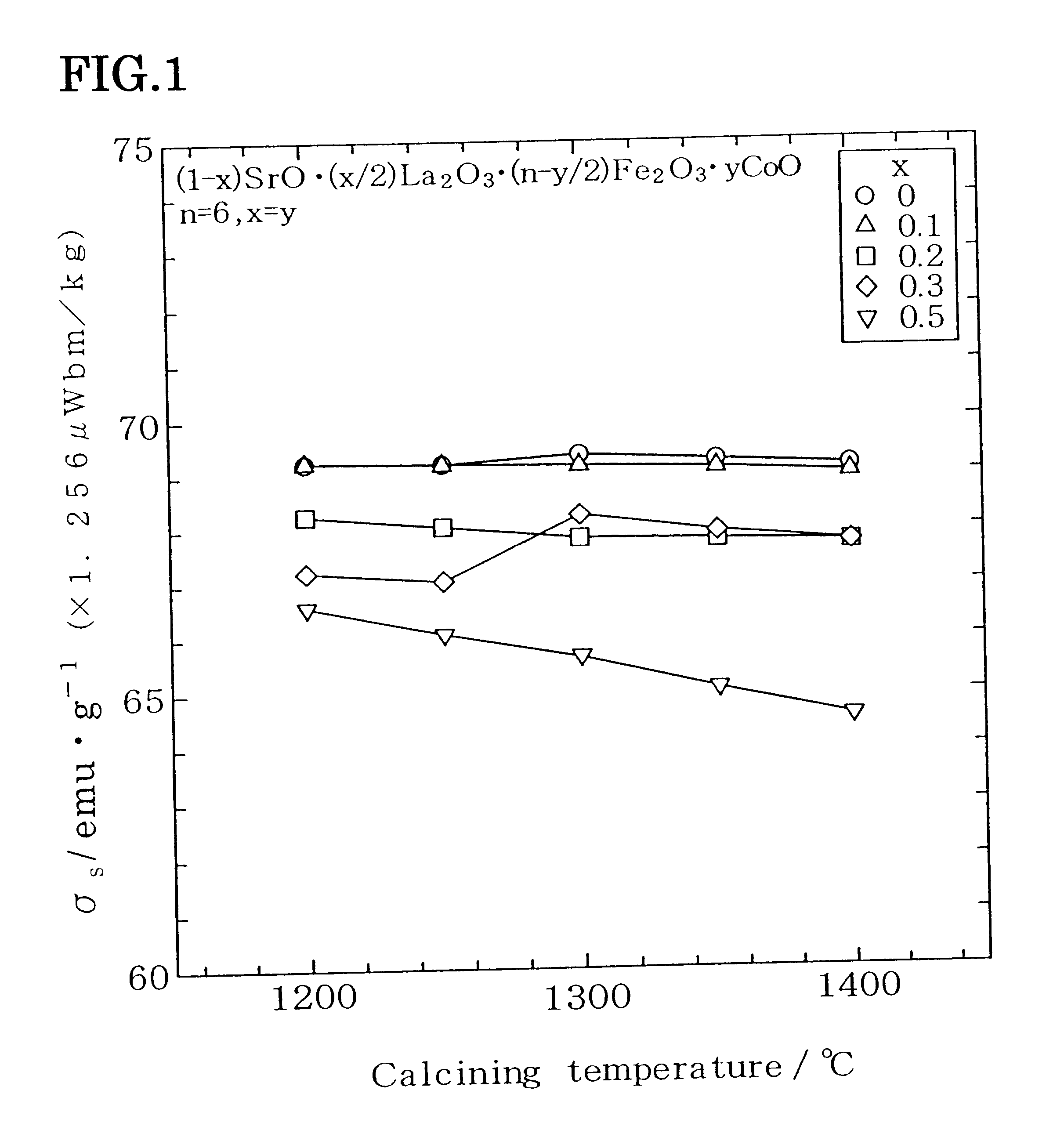

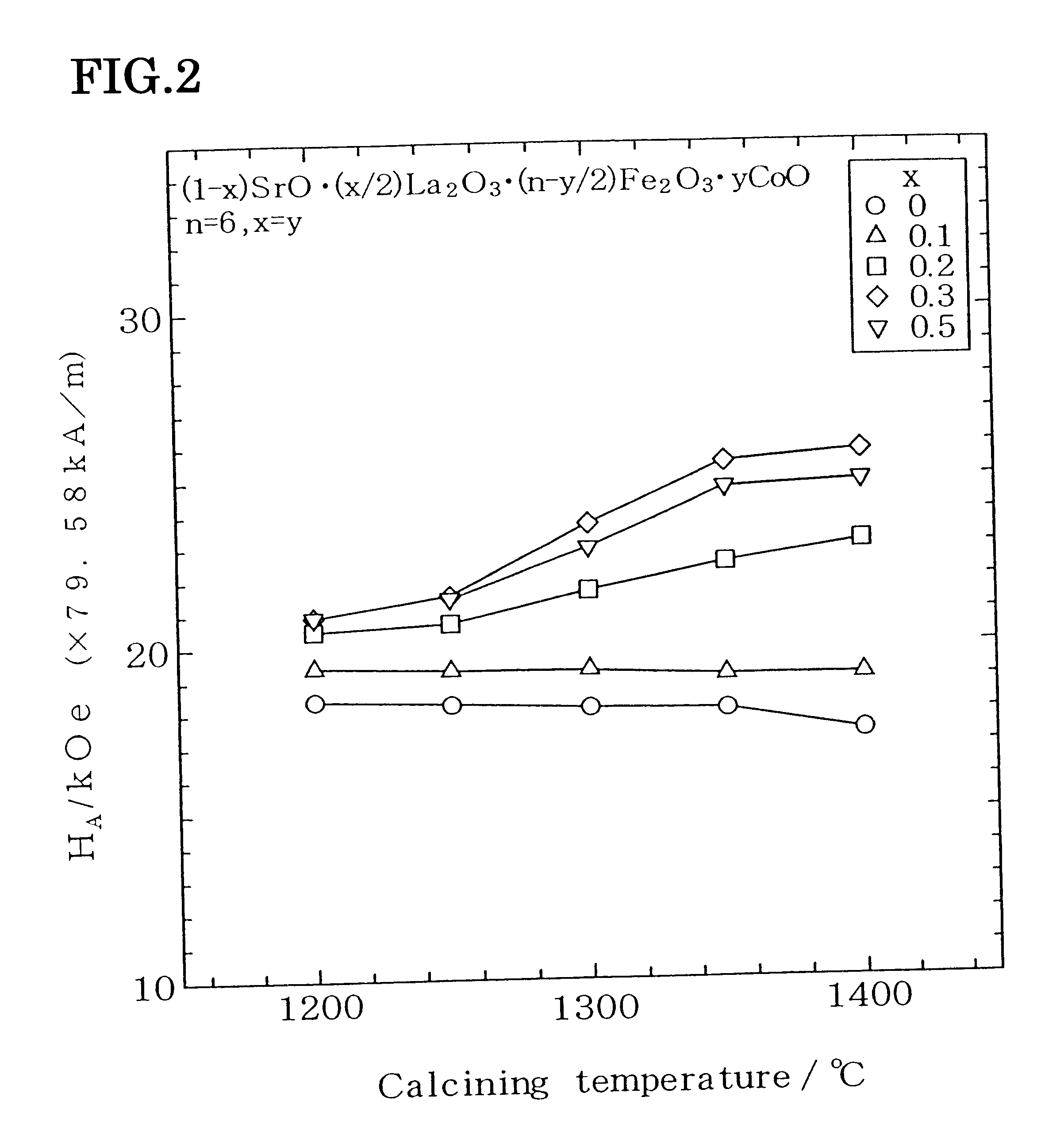

Ferrite magnet powder and magnet using said magnet powder, and method for preparing them

InactiveUS6419847B1Decrease in saturation magnetizationIncrease in coercivityInorganic material magnetismFerroso-ferric oxidesMagnetizationCalcination

An La-Co ferrite magnet powder, in which Sr and Fe are replaced with La and Co, respectively, is made by carrying out a calcination process at a temperature higher than 1300° C. and equal to or lower than 1450° C. Fe has a magnetic moment oriented upwardly with respect to a crystal c-axis at a number of sites thereof, and also has an opposite magnetic moment oriented downwardly with respect to the crystal c-axis at another number of sites thereof. And Fe is replaced with Co at the greater number of sites thereof. As a result, high coercivity is attained. In this manner, coercivity can be increased while suppressing decrease in saturation magnetization sigmas.

Owner:SUMITOMO SPECIAL METAL CO LTD

Method for producing r-t-b system sintered magnet

InactiveUS20180025819A1Increase in coercivityImprove coercive forceTransportation and packagingMetal-working apparatusSintered magnetsMaterials science

A step of providing an R1-T1-X (where R1 is mainly Nd; T1 is mainly Fe; and X is mainly B) based sintered alloy compact mainly characterized by a molar ratio of [T1] / [X] being 13.0 or more; a step or providing an R2-Ga—Cu (where R2 is mainly Pr and / or Nd and accounts for not less than 65 mol % and not more than 95 mol %; and [Cu] / ([Ga]+[Cu]) is not less than 0.1 and not more than 0.9 by mole ratio) based alloy; and a step of, while allowing at least a portion of a surface of the R1-T1-X based sintered alloy compact to be in contact with at least a portion of the R2-Ga—Cu based alloy, performing a heat treatment at a temperature which is not less than 450° C. and not more than 600° C.

Owner:HITACHI METALS LTD

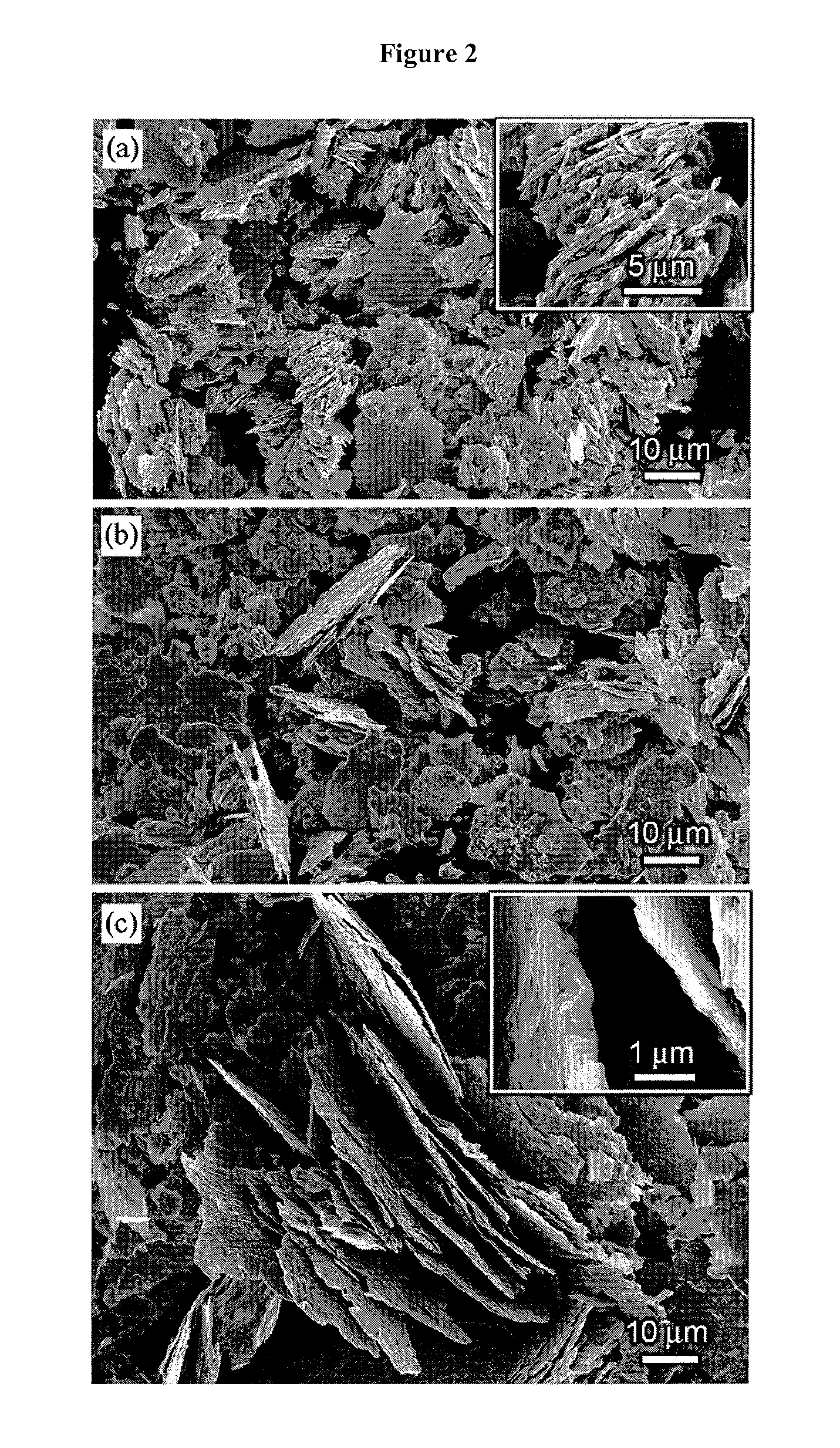

RFeB-BASED SINTERED MAGNET PRODUCTION METHOD AND RFeB-BASED SINTERED MAGNETS

InactiveUS20160297028A1Large amount of thicknessIncrease in coercivityTransportation and packagingPermanent magnetsRare-earth elementSintered magnets

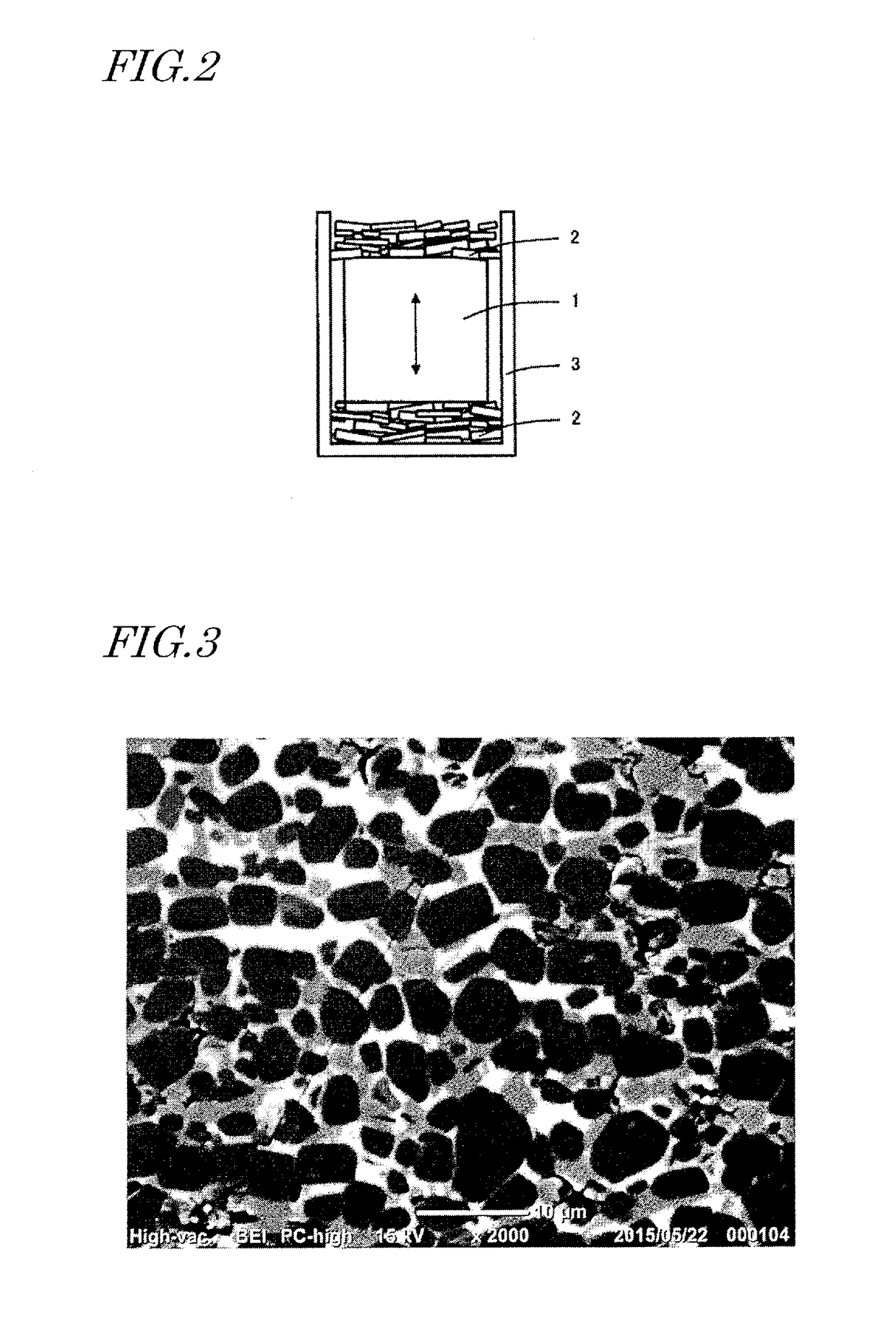

A method for producing RFeB system sintered magnet composed of at least two unit sintered magnets bonded to each other at flat bonding surfaces, each unit sintered magnet composed of crystal grains whose main phase is made of R2Fe14B containing, as a main rare-earth element R, light rare-earth element RL wherein at least one element selected from the group of Nd and Pr. Paste prepared by mixing organic matter and metallic powder containing at least one element selected from heavy rare-earth elements RH of Dy, Ho and Tb is sandwiched between neighboring unit sintered magnets, and a grain boundary diffusion treatment is performed. Coercivity is improved by this grain boundary diffusion treatment. Since an oxide or similar compound of RH and / or RL is formed at boundary of unit sintered magnets, the influence of eddy current during a period of use is suppressed, and unit sintered magnets are strongly bonded together.

Owner:INTER METALLICS KK +1

R-t-b rare earth sintered magnet and method of manufacturing the same

ActiveUS20140314612A1Excellent coercivityIncrease in coercivityInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementSintered magnets

Owner:TDK CORPARATION

Method for producing R-T-B sintered magnet

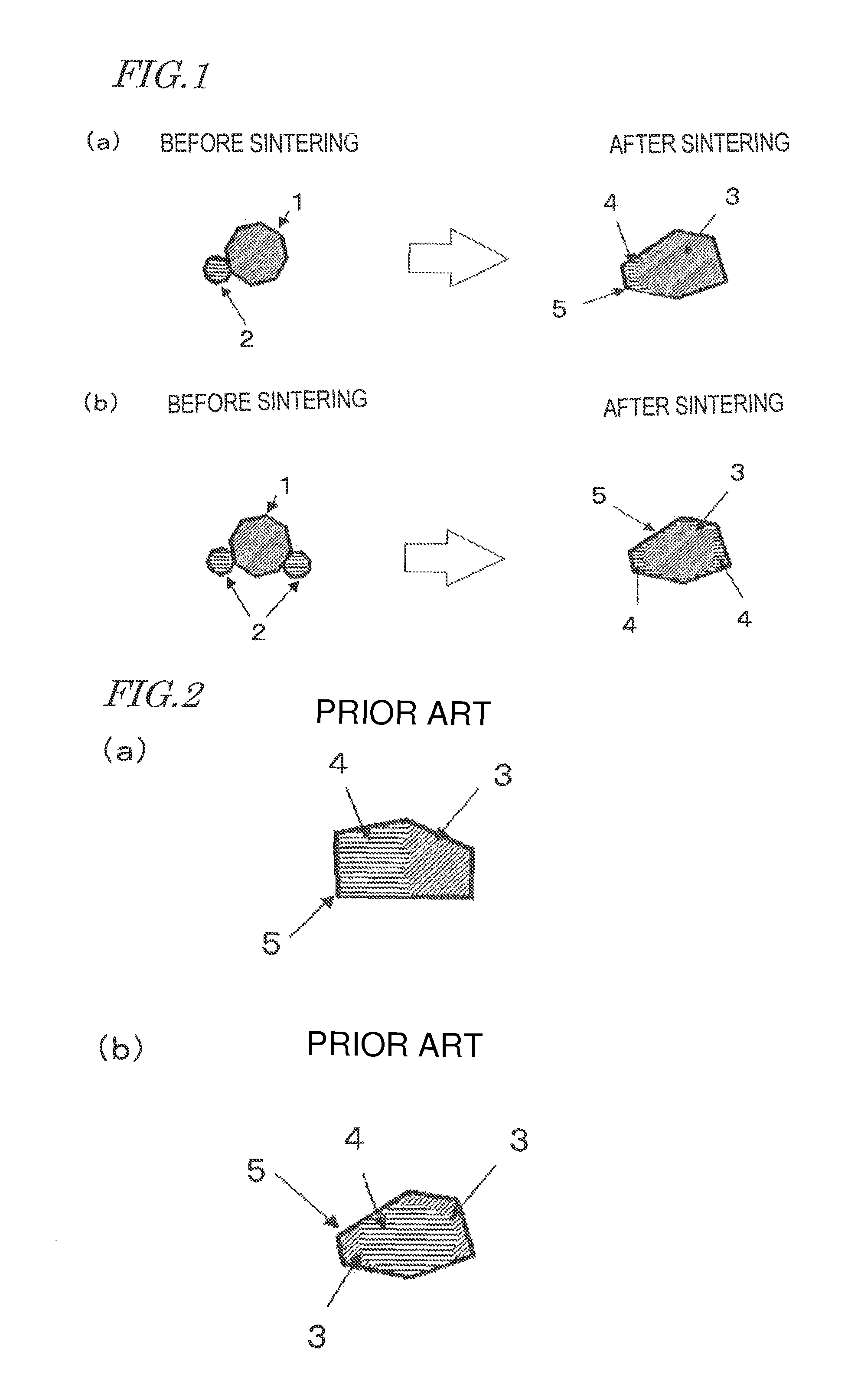

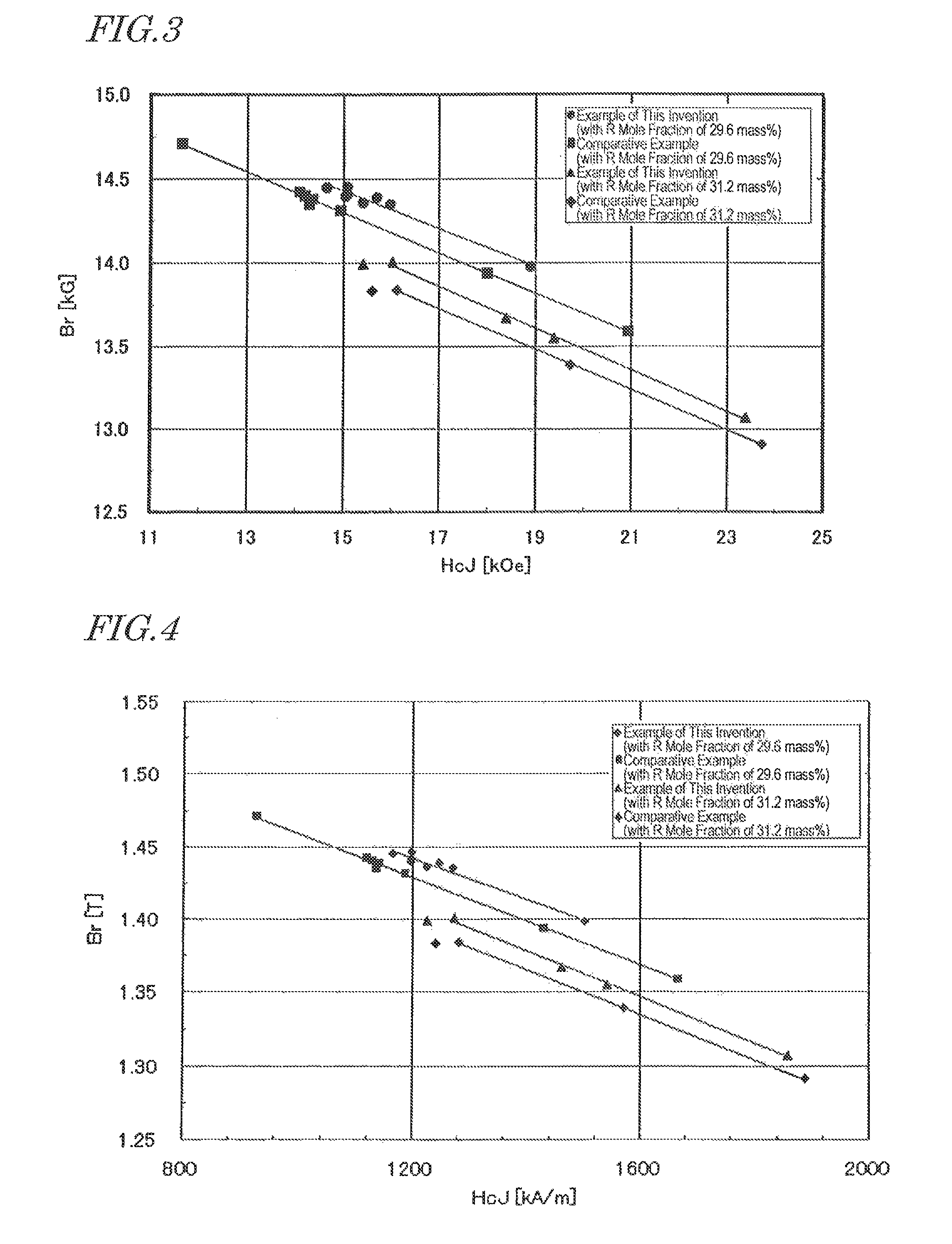

ActiveUS8287661B2Decreasing remanenceIncrease in coercivityTransportation and packagingMetal-working apparatusRare-earth elementSintered magnets

A method for producing a sintered R-T-B based magnet includes the steps of: providing R-T-B based alloy powders A and B so that the R-T-B based alloy powder B has a particle size D50 that is smaller by at least 1.0 μm than that of the R-T-B based alloy powder A and that there is a difference ΔRH of at least 4 mass % between the higher content of a heavy rare-earth element RH in the R-T-B based alloy powder B and the lower content of the heavy rare-earth element RH in the R-T-B based alloy powder A; mixing these two R-T-B based alloy powders A and B together; compacting the mixed R-T-B based alloy powder to obtain a compact with a predetermined shape; and sintering the compact.

Owner:HITACHI METALS LTD

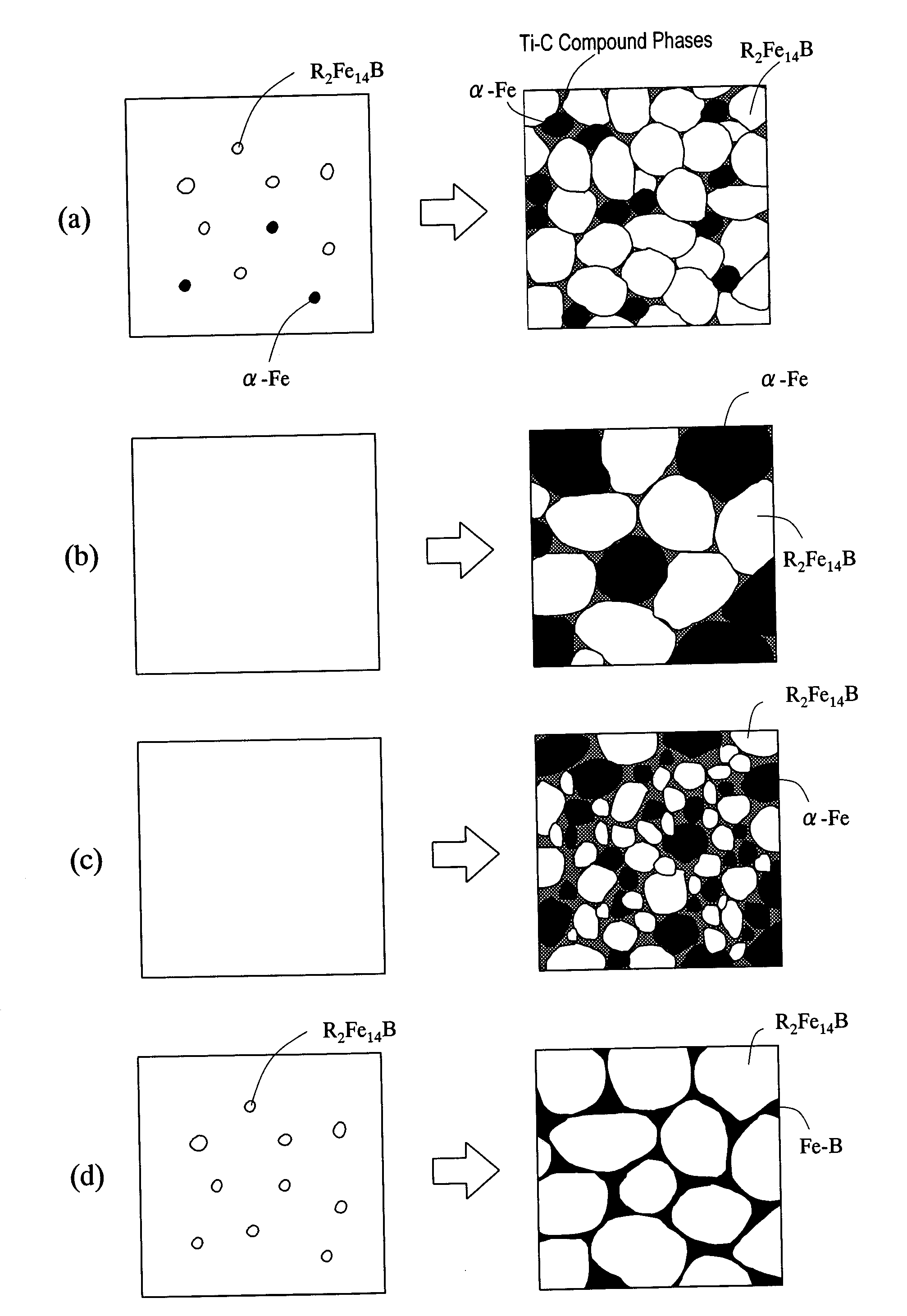

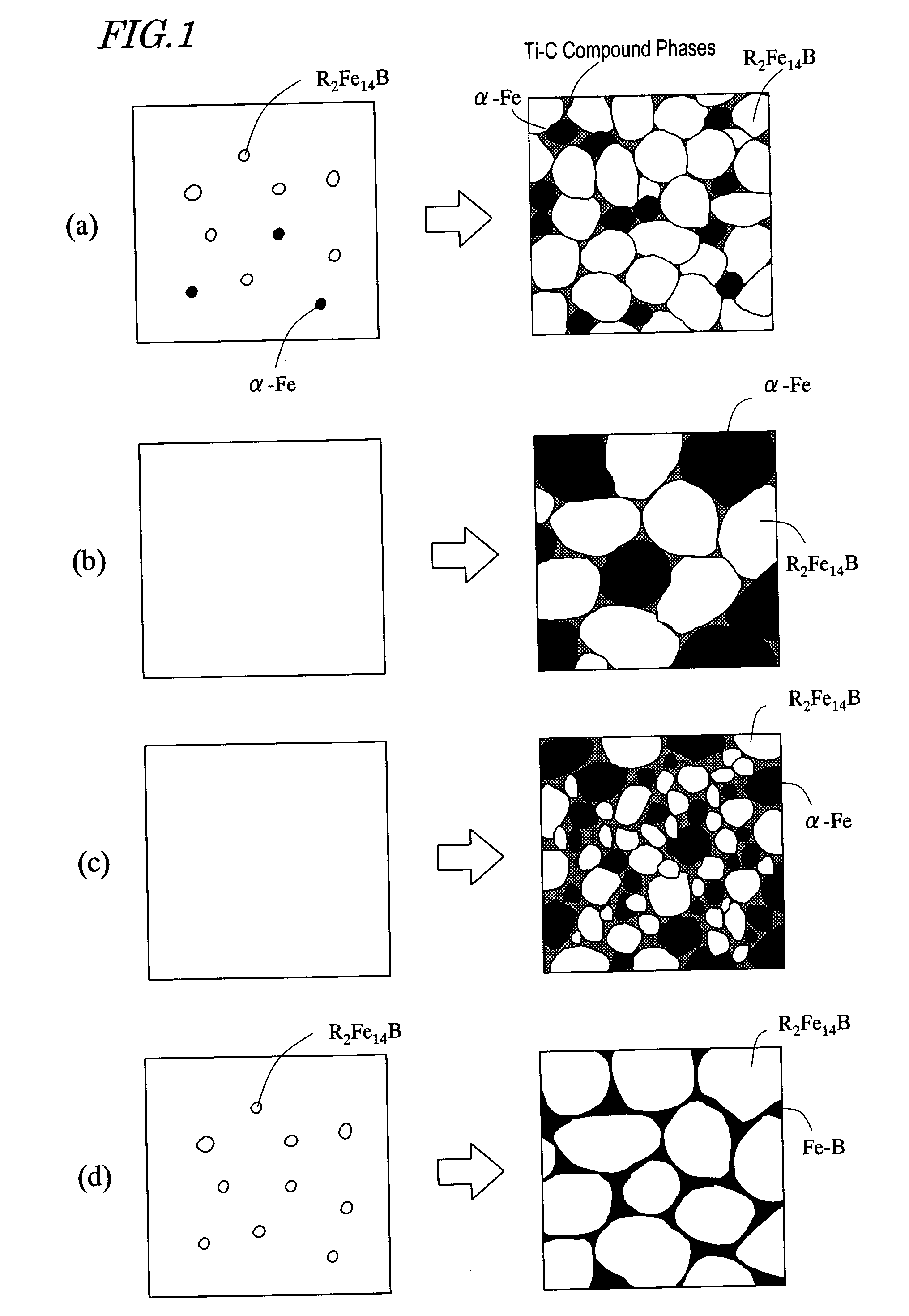

Iron-based rare-earth-containing nanocomposite magnet and process for producing the same

InactiveUS20090129966A1Improve coercive forceHigh remanence BrNanomagnetismTransportation and packagingRare-earth elementGrain boundary

An iron-based rare-earth nanocomposite magnet according to the present invention includes an Nd2Fe14B phase and an α-Fe phase and has a composition represented by the compositional formula: T100-x-y-z-n(B1-qCq)xRyTizMn, where T is at least one transition metal element selected from the group consisting of Fe, Co and Ni and always including Fe, R is at least one rare-earth element including substantially no La or Ce, and M is at least one metal element selected from the group consisting of Al, Si, V, Cr, Mn, Cu, Zn, Ga, Zr, Nb, Mo, Ag, Hf, Ta, W, Pt, Au and Pb, and the mole fractions x, y, z, n and q satisfy the inequalities of: 4 at %≦x≦10 at %, 6 at %≦y≦10 at %, 0.05 at %≦z≦5 at %, 0 at %≦n≦10 at %, and 0.05≦q≦0.5, respectively. The magnet includes 5 vol % to 60 vol % of α-Fe phase with an average crystal grain size of 1 nm to 50 nm and 40 vol % to 90 vol % of Nd2Fe14B phase with an average crystal grain size of 5 nm to 100 nm. A non-magnetic phase including at least Ti and C (carbon) is present on the grain boundary between the α-Fe and Nd2Fe12B phases.

Owner:HITACHI METALS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com