Patents

Literature

90results about How to "Promotes crystal growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

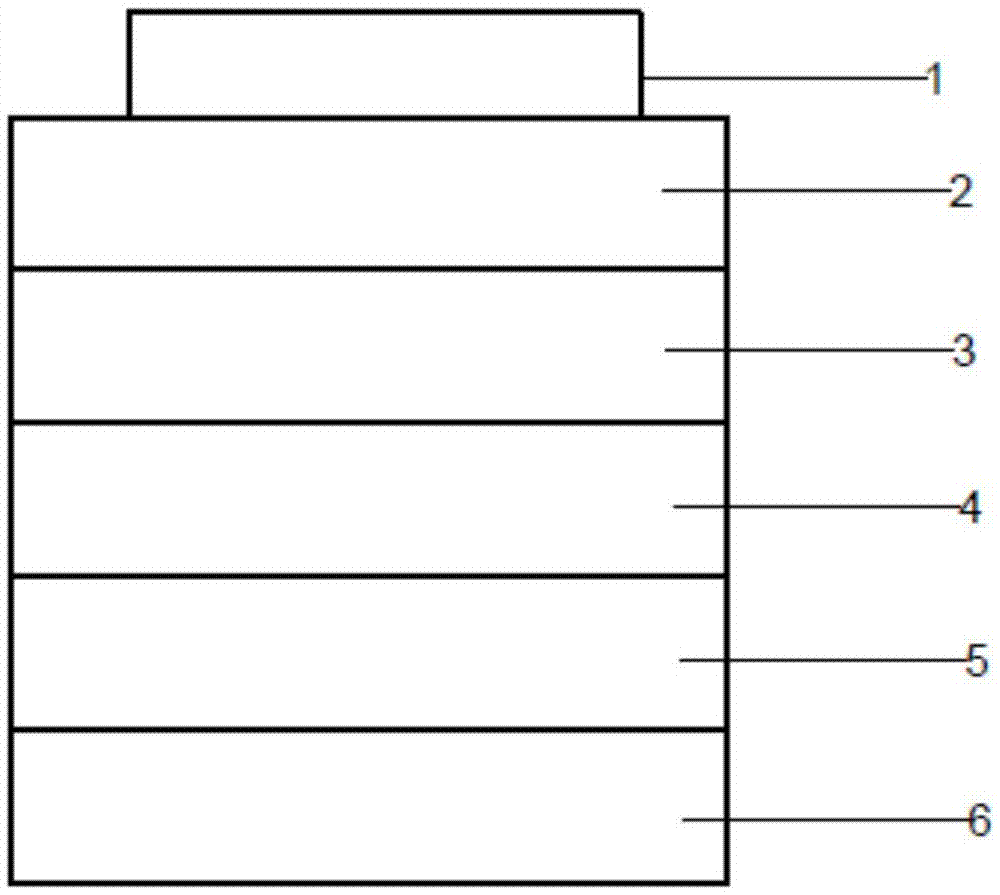

Perpendicular magnetic recording medium with improved magnetic anisotropy field

InactiveUS20100035085A1High HcExcellent crystallographic C axis orientationMagnetic materials for record carriersRecord information storageMagnetic anisotropyAlloy

A perpendicular magnetic recording medium comprising a substrate, a soft underlayer, a seed layer, a non-magnetic FCC NiW alloy underlayer, a non-magnetic HCP underlayer, and a magnetic layer. We have discovered that the combination of a seed layer comprising Ta and a NiW alloy underlayer uniquely improves media recording performance and thermal stability by achieving excellent coercivity of the thin bottom magnetic recording layer and narrow C axis orientation distribution.

Owner:WD MEDIA

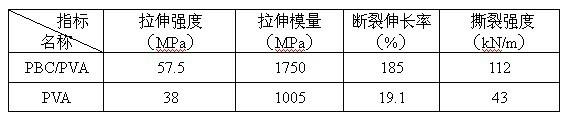

Biodegradable polycarbonate butylene terephthalate composite material and preparation method of biodegradable polycarbonate butylene terephthalate composite material

The invention relates to a biodegradable polycarbonate butylene terephthalate composite material and a preparation method of the biodegradable polycarbonate butylene terephthalate composite material. The biodegradable polycarbonate butylene terephthalate composite material is characterized in that the material comprises the following components in part by weight: 30 to 70 parts of aliphatic polycarbonate butylene terephthalate, 10 to 40 parts of other biodegradable materials, 1.0 to 10 parts of filler, 0.5 to 1.5 parts of rare earth composite nucleating agent, 0.5 to 1.5 parts of dispersant, 4.0 to 15 parts of plasticizer, 1.5 to 4 parts of heat resistance stabilizer, 0.05 to 1.5 parts of antioxidant, 0.5 to 1.0 part of lubricant, 0.1 to 1.0 part of anti-block agent and 0.05 to 0.5 part of biodegradation accelerator. The composite material has high melt strength, good film forming ability, high tensile strength, high tearing strength and good light-conversion effect.

Owner:JIANGSU XINGYE PLASTIC +1

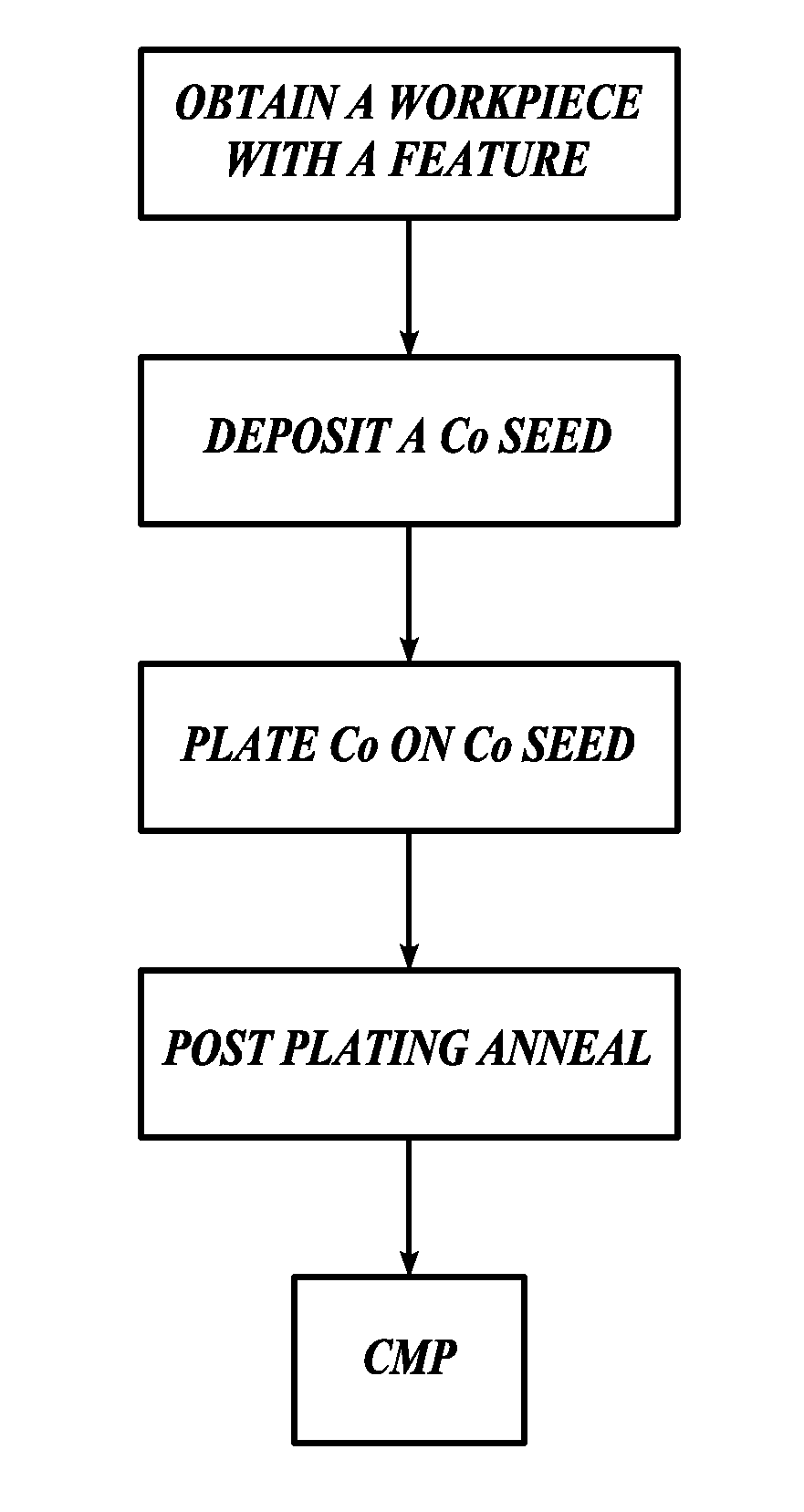

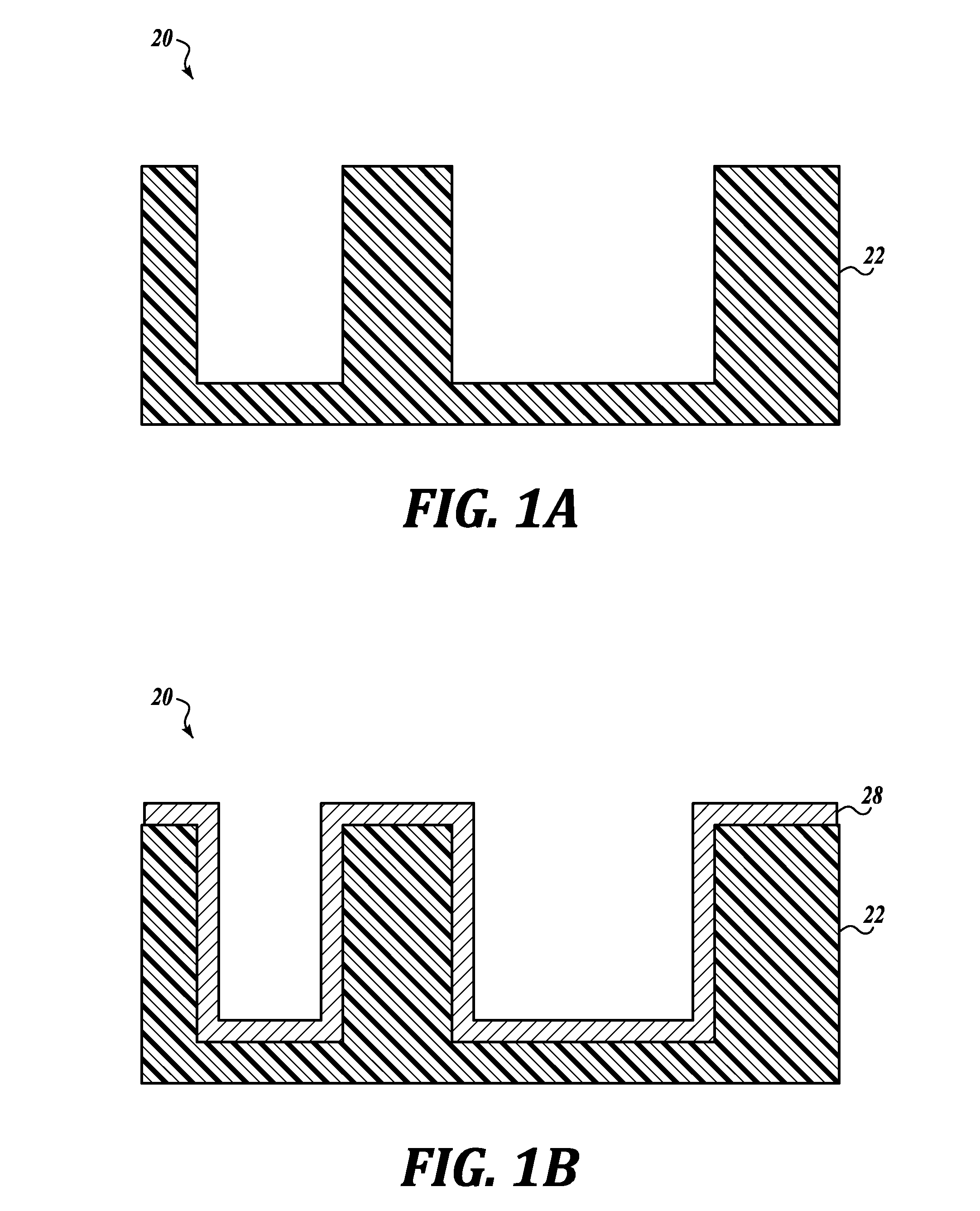

Methods for forming cobalt interconnects

InactiveUS20160309596A1Reduces overburdenLow resistivitySemiconductor/solid-state device detailsSolid-state devicesCobaltElectroplating

A method for depositing metal in a feature on a workpiece includes forming a seed layer in a feature on a workpiece, wherein the seed layer includes a metal selected from the group consisting of cobalt and nickel; electrochemically depositing a first metallization layer on the seed layer, wherein electrochemically depositing the metallization layer includes using a plating electrolyte having a plating metal ion and a pH in the range of 6 to 13; and heat treating the workpiece after deposition of the first metallization layer.

Owner:APPLIED MATERIALS INC

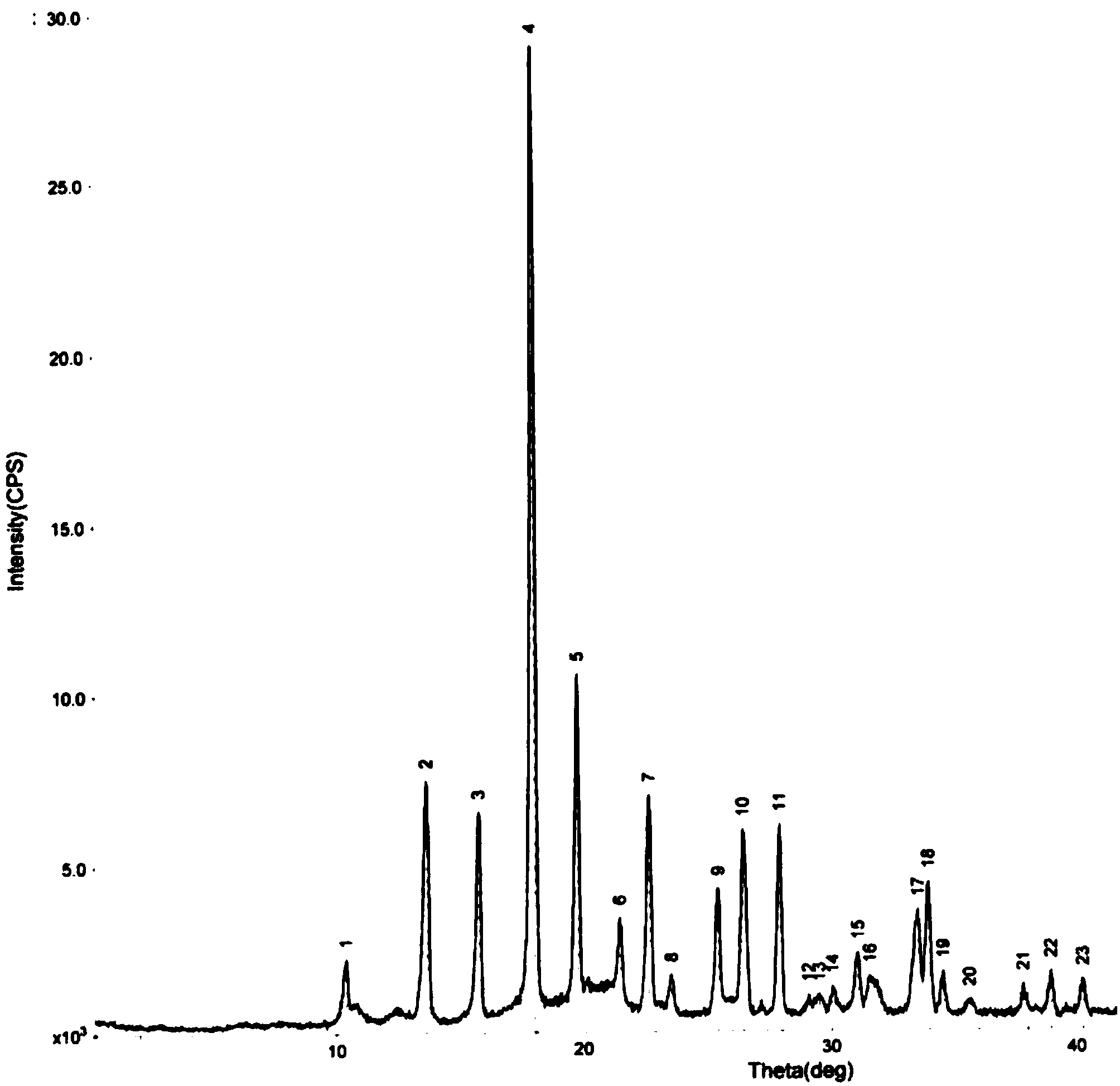

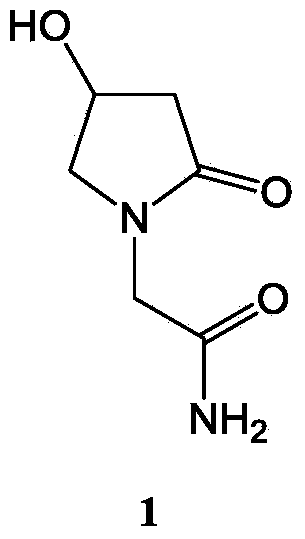

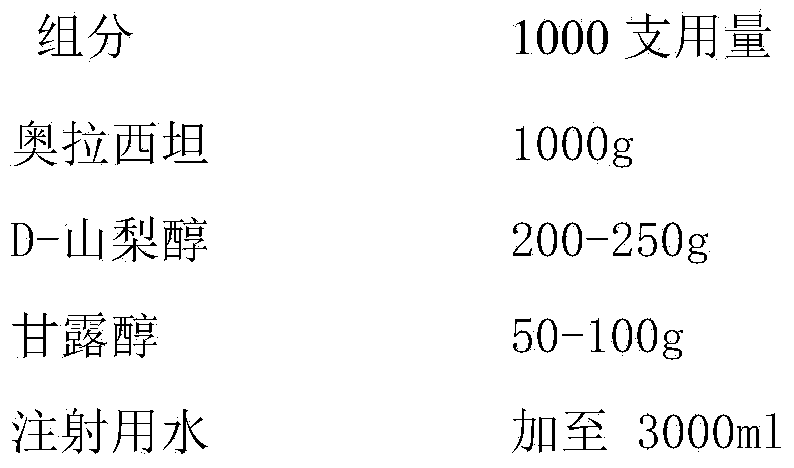

Oxiracetam freeze-drying preparation for injection and preparation method thereof

ActiveCN103446067AStable in natureLong validity periodOrganic active ingredientsPowder deliveryFreeze-dryingImpurity

The invention relates to an oxiracetam freeze-drying preparation for injection and a preparation method thereof, belonging to the technical field of medicines. The freeze-drying preparation is a crystal form compound formed by oxiracetam, D-sorbitol and mannitol in a weight ratio of 1: (0.2-0.25): (0.05-0.1). The oxiracetam freeze-drying preparation has the beneficial effects that the production cycle is shortened by about 20 hours, the rate of finished products is increased by above 99%, the phenomena such as the upward shifting and the eruption of the product are avoided, medicine molecules are constrained in crystal lattices, the water content is extremely low and can be controlled below 0.1%, the preparation is difficult to degrade and has relatively good stability, the period of validity is up to 36 months, the impurity content is greatly reduced, the single maximum impurity is less than 0.1%, and the total impurities are less than 0.5%; no organic solvents are involved in the production process, the energy consumption and the cost are substantially reduced, and the technology has environmentally-friendly effect and is suitable for large-scale industrialization production. Compared with the prior art, the oxiracetam freeze-drying preparation provided by the invention has obviously improved curative effect and is suitable for clinical application.

Owner:CSPC OUYI PHARM CO LTD

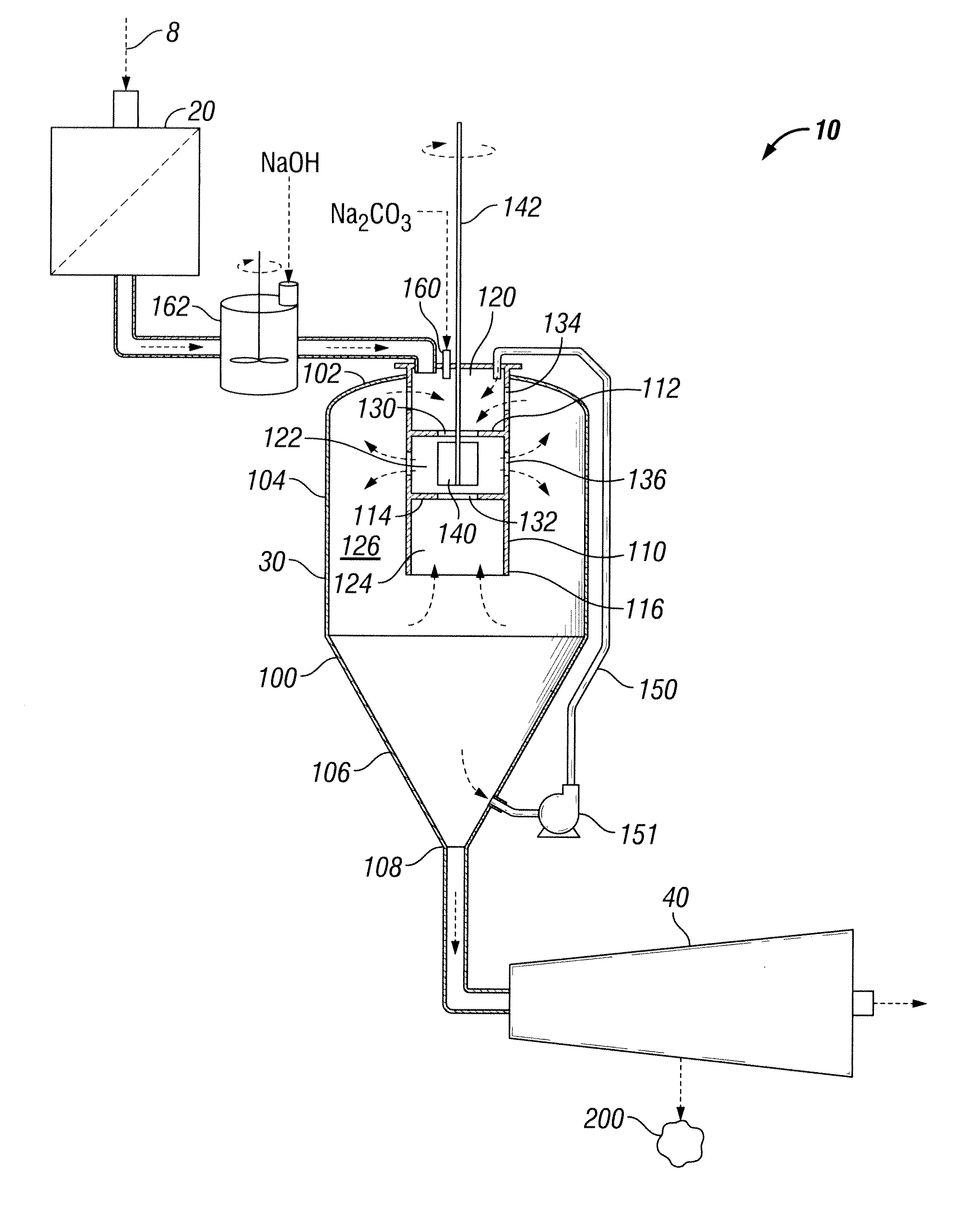

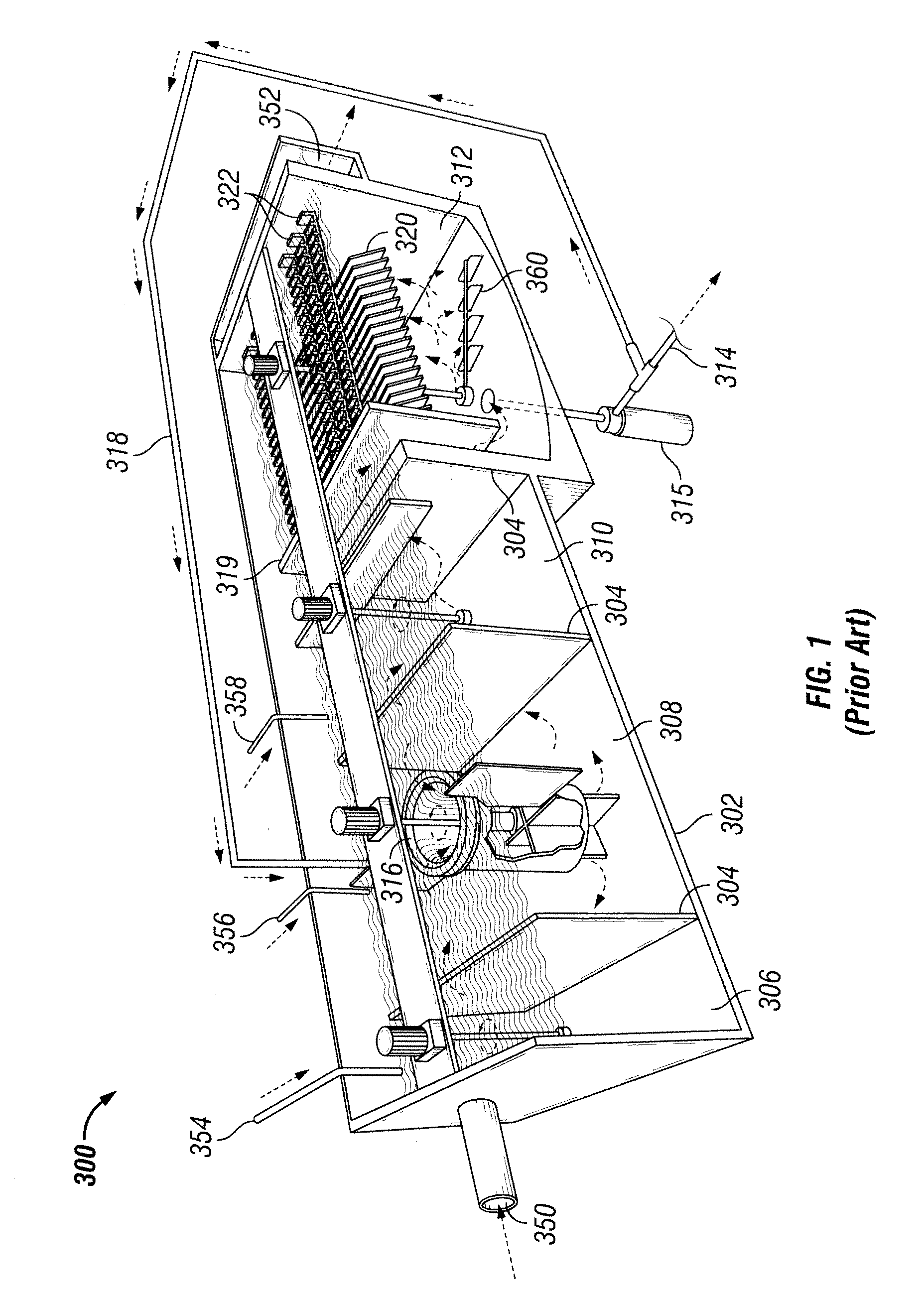

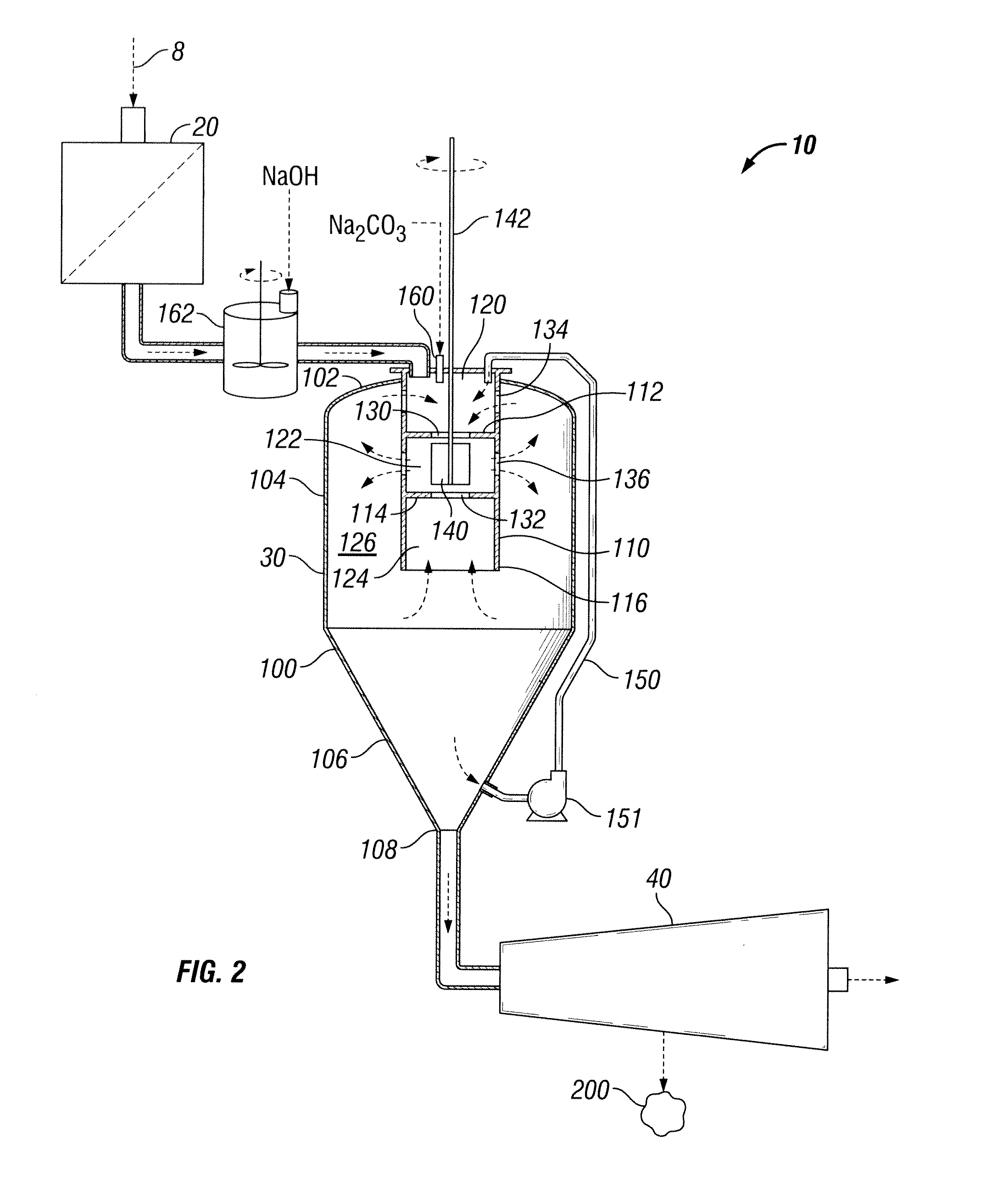

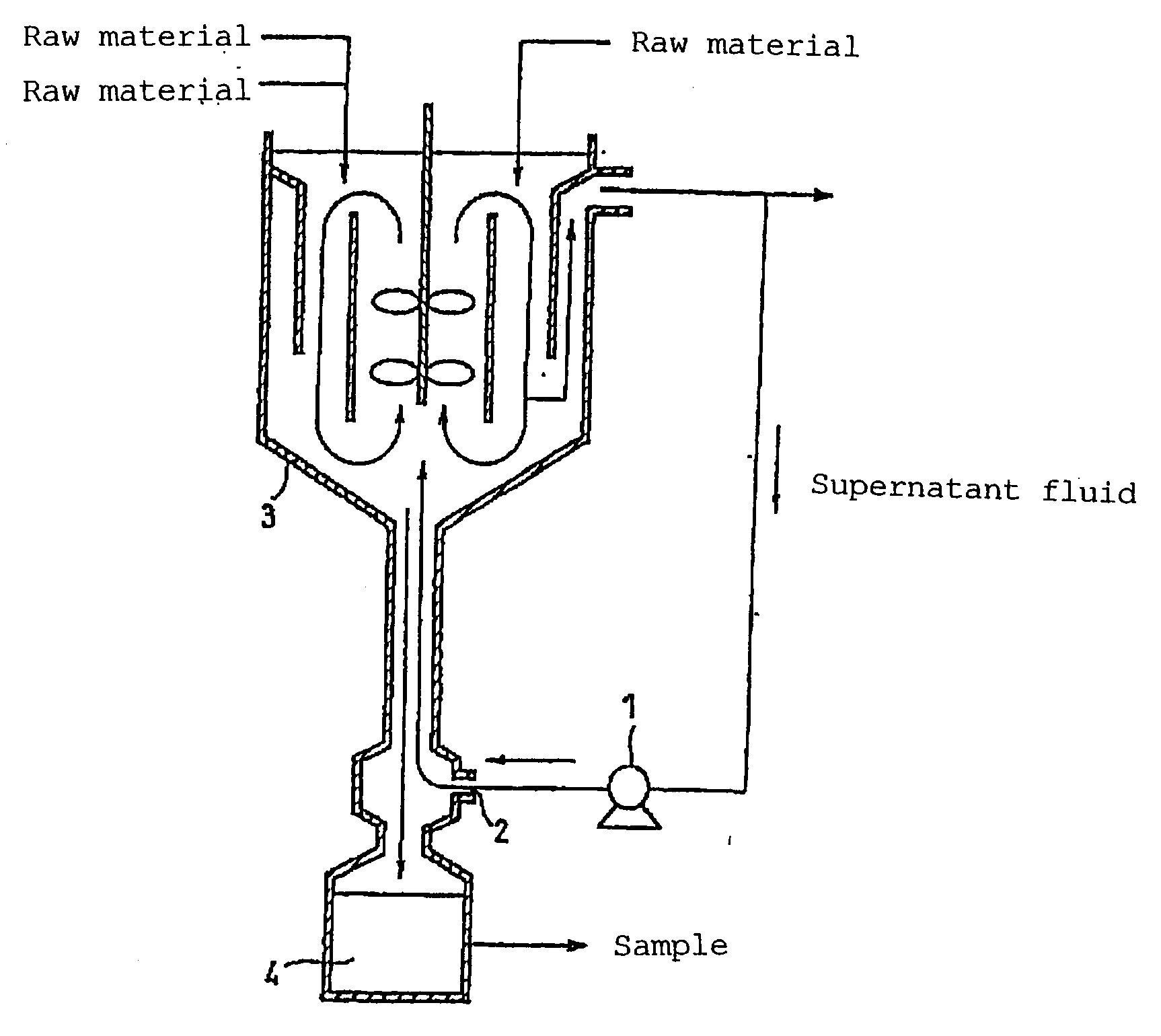

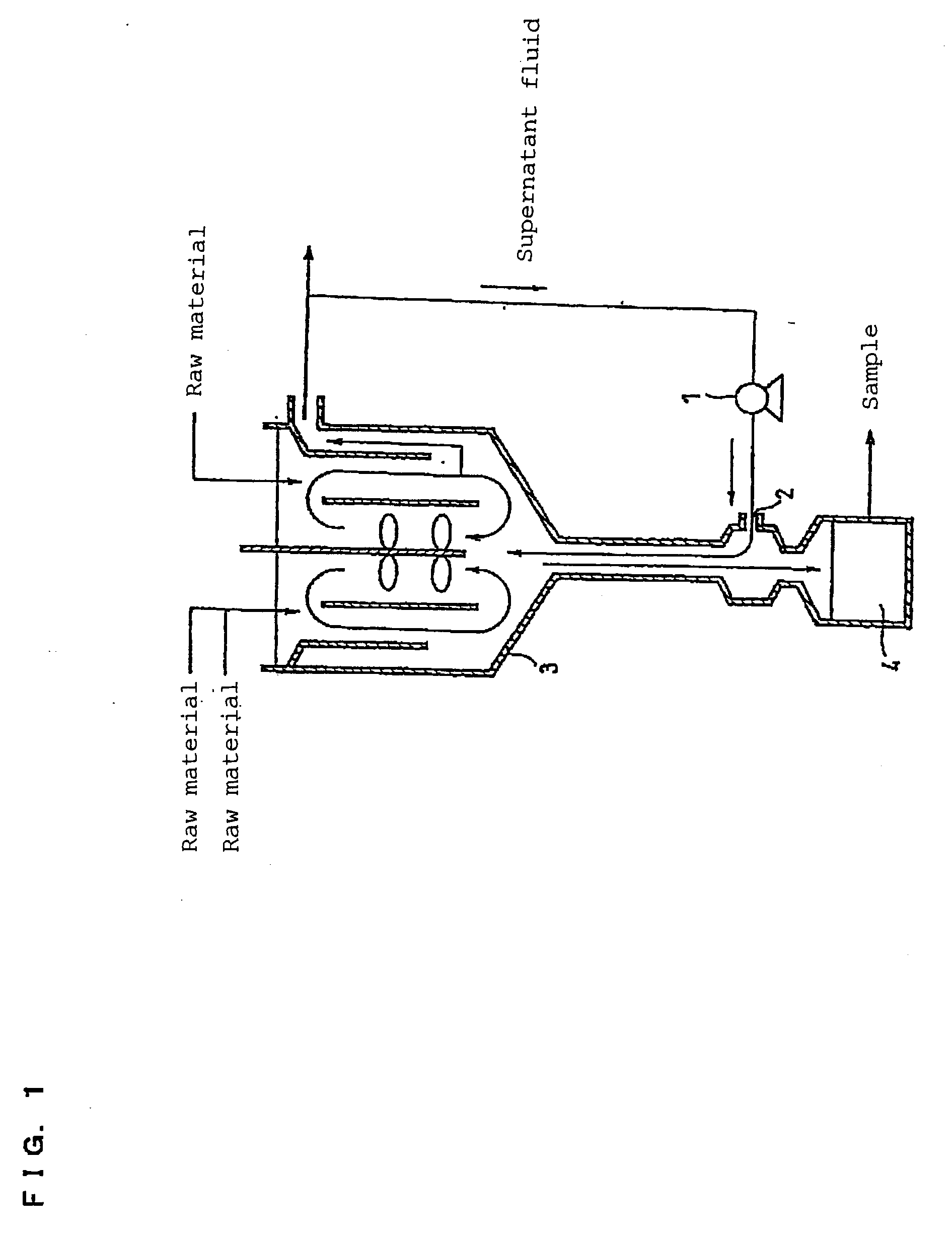

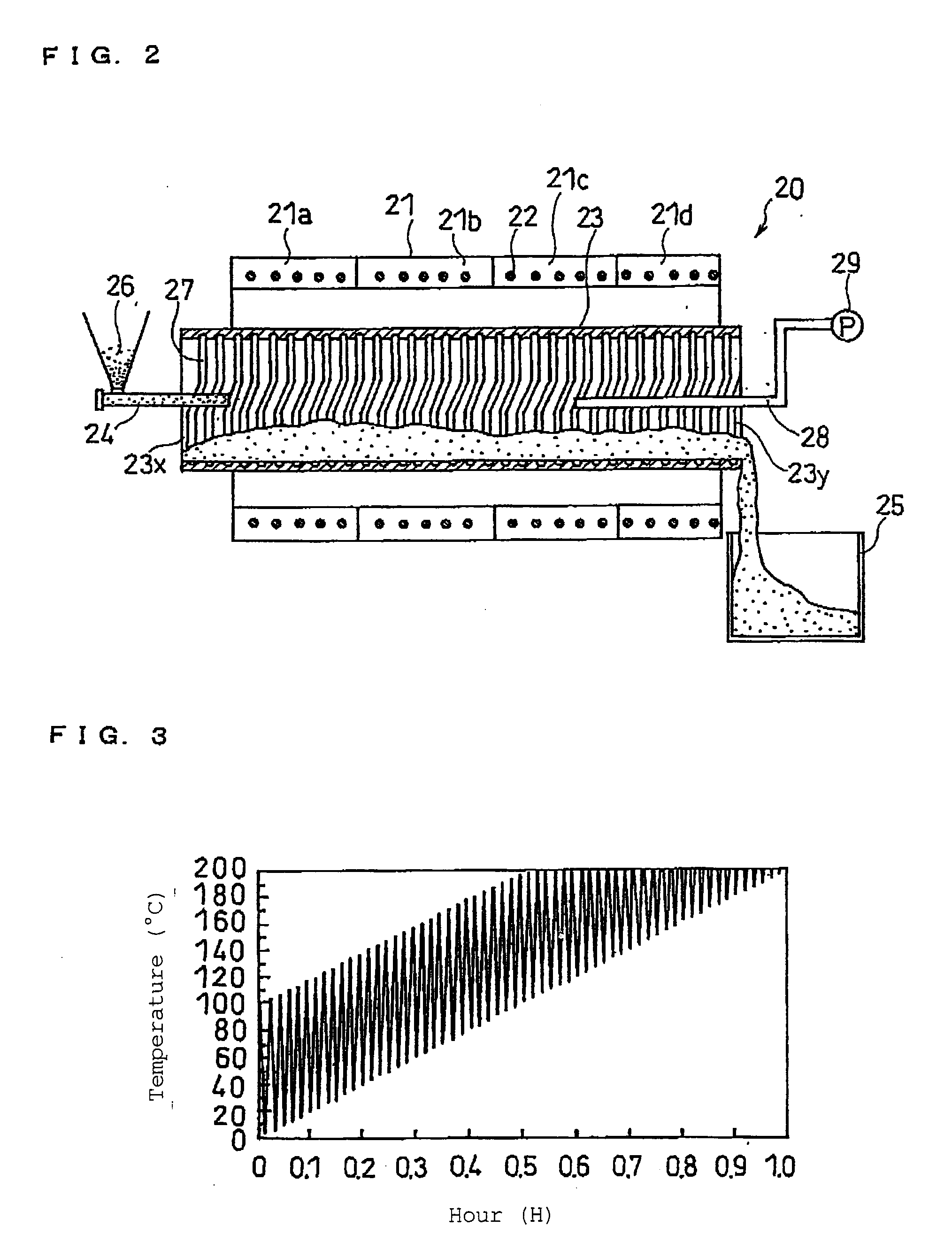

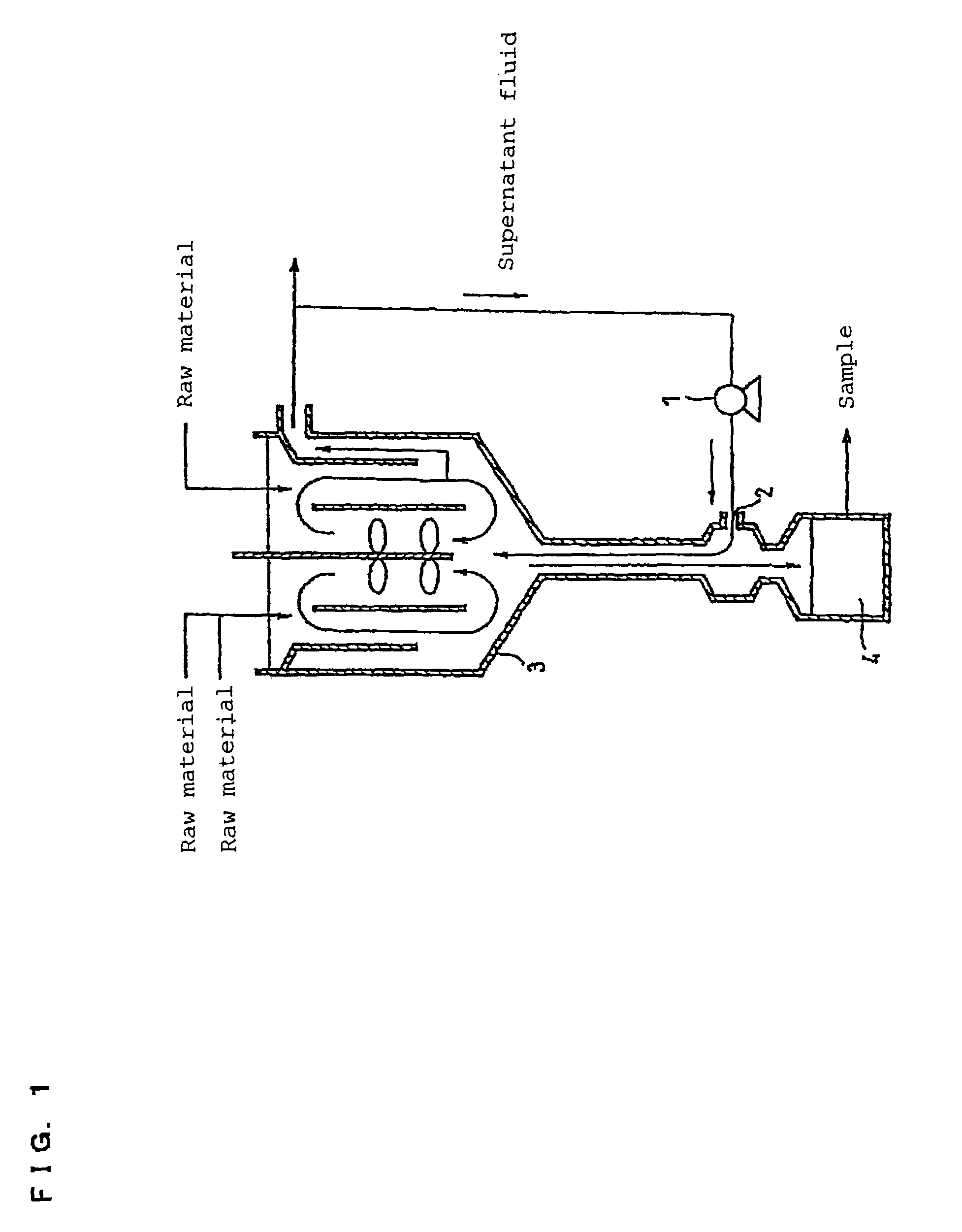

Method and apparatus for treating well flow-back and produced water or other wastewater

InactiveUS20120199524A1Promotes crystal growthPromote growthFlow mixersTransportation and packagingFlocculationTotal dissolved solids

A polymer-free method and self-draining self-cleaning apparatus for treatment of water with high total dissolved solids including optional pretreatment, precipitation / flocculation, and separation. The pH is raised by addition of caustic soda and / or soda ash. In a vertical clarifier silo, the feed is gently mixed to cause dissolved solids to precipitate and agglomerate to form suspended flocculates. The clarifier includes an internal mixer surrounded by a cylindrical tube diffuser. Rotation of the mixer provides gentle dual circulation patterns within the clarifier that allow for flocculates of a predetermined size to settle from suspension. The clarifier may also include one or more vertical recirculation lines to recirculate some of the heavier flocculates at the bottom of the vessel into the mixer chamber to enhance precipitation via the seeding effect. The suspended flocculates are stripped from the feed water in a centrifugal separator. The clarifier silo may be trailer mounted for rapid deployment.

Owner:TERVITA

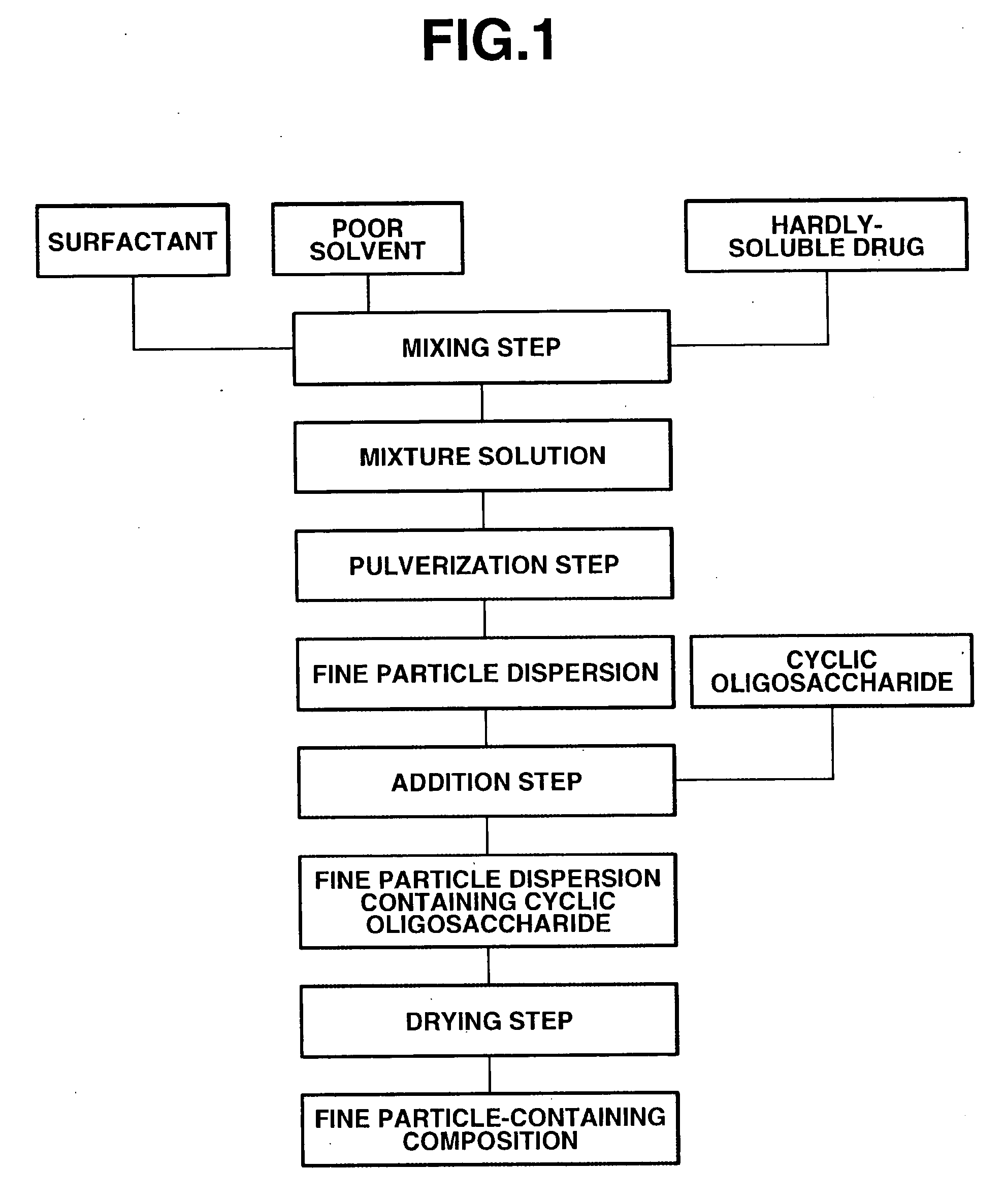

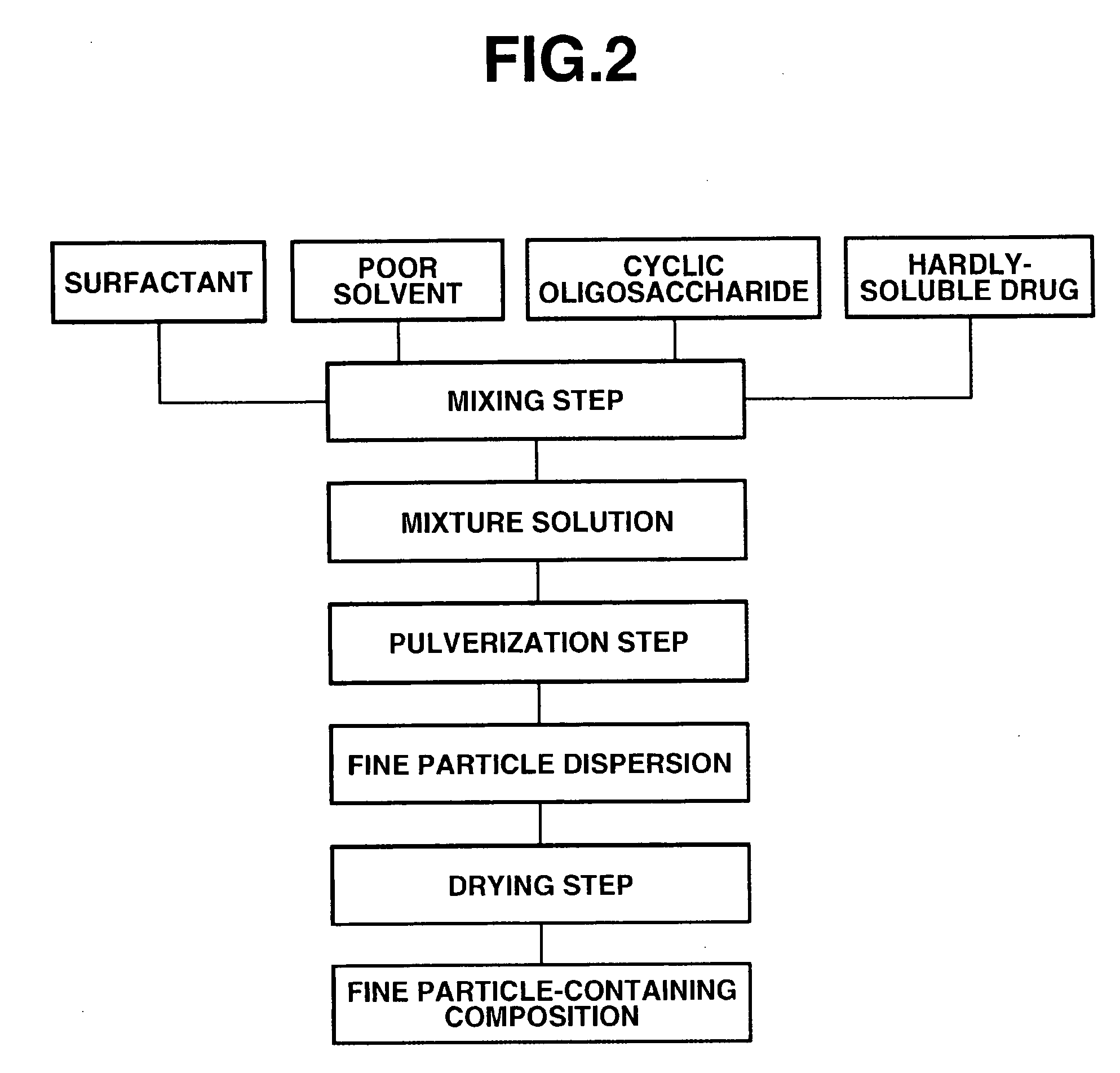

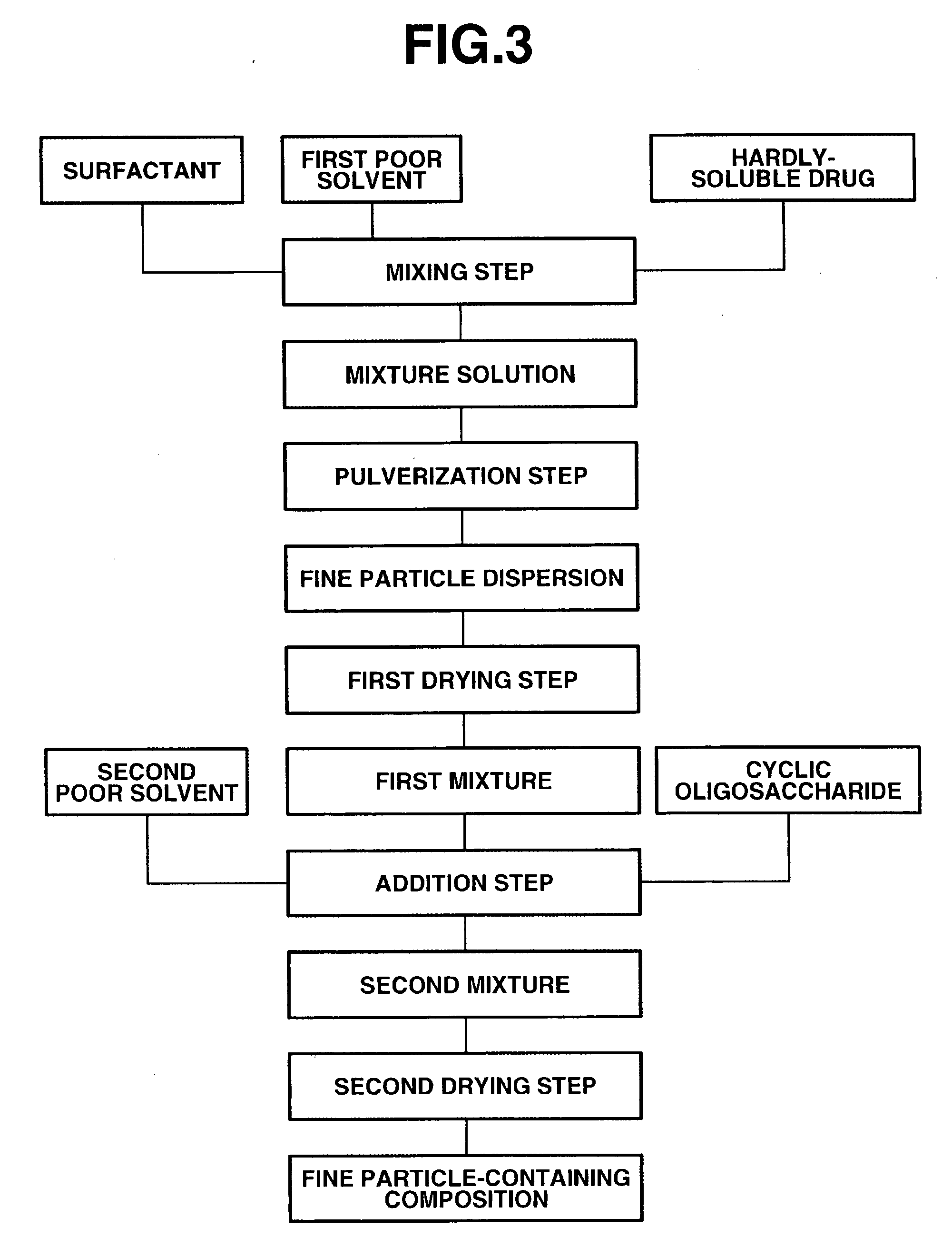

Fine Particle-Containing Composition and Manufacturing Method Therefor

The present invention provides a composition containing fine particles of a hardly-soluble drug which is stable and is not affected by storage environment conditions, as well as a manufacturing method therefor. The present invention provides a fine particle-containing composition containing fine particles of the hardly-soluble drug, a surfactant and a cyclic oligosaccharide, wherein an average particle size of the fine particles is at least 50 nm but not more than 1000 nm. The present invention also provides a method for manufacturing a fine particle-containing composition, comprising (I) a mixing step in which the hardly-soluble drug, the surfactant and a poor solvent are mixed to obtain a liquid mixture, (II) a pulverization step in which the liquid mixture is pulverized with a wet disperser to obtain a dispersion of fine particles, (III) an addition step in which the cyclic oligosaccharide is added to the dispersion of fine particles, and (IV) a drying step in which the dispersion of fine particles containing the cyclic oligosaccharide is dried.

Owner:EISIA R&D MANAGEMENT CO LTD

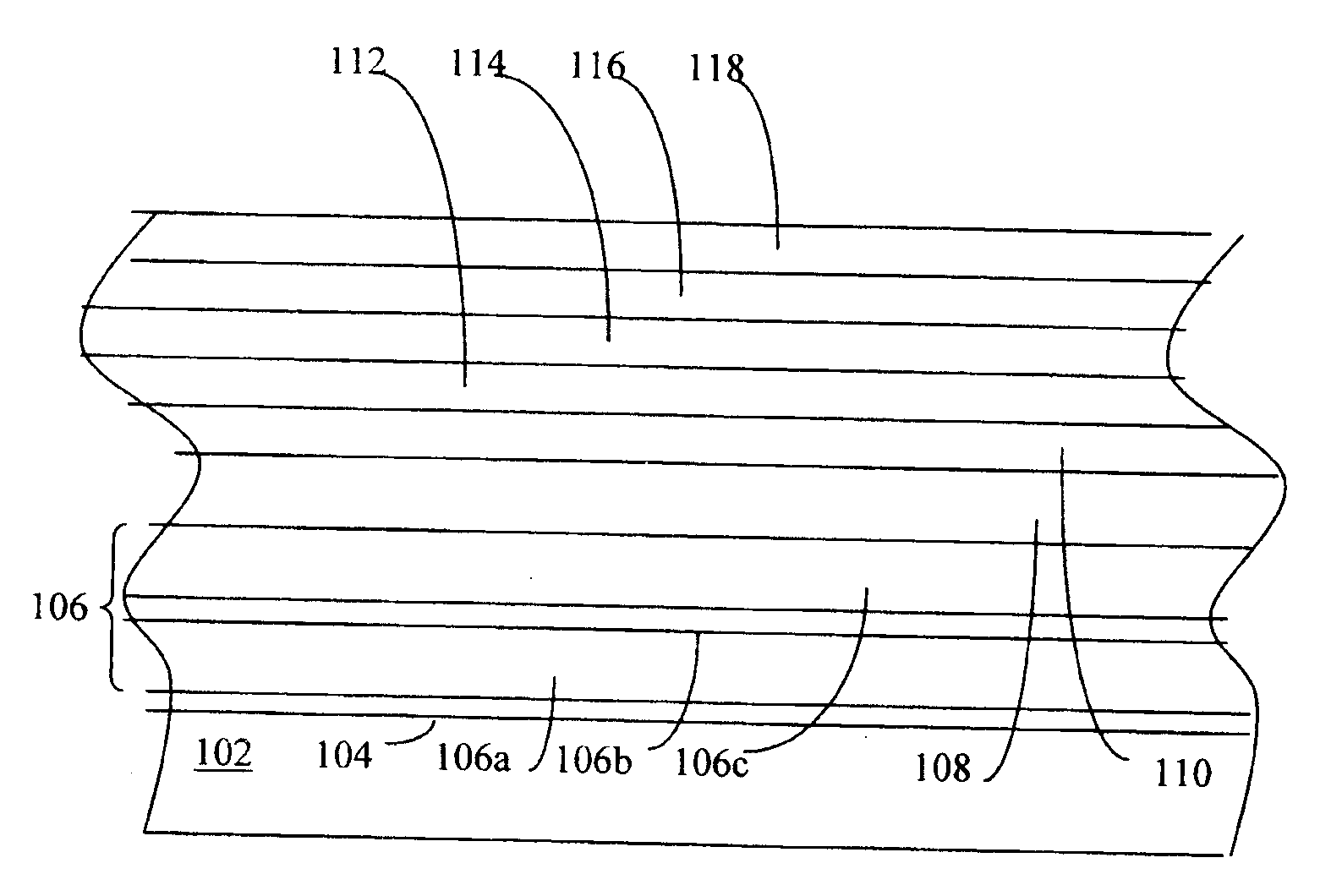

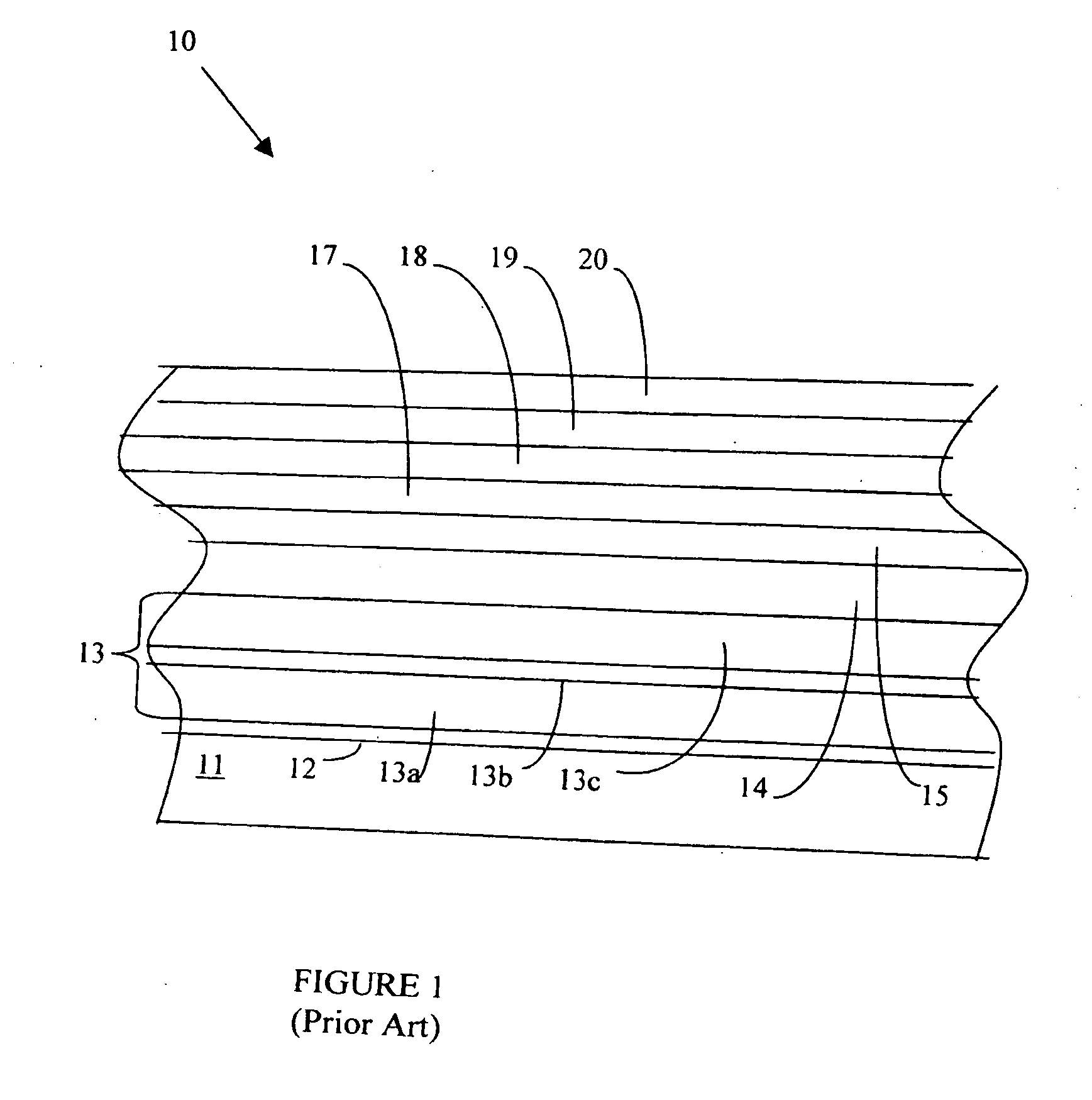

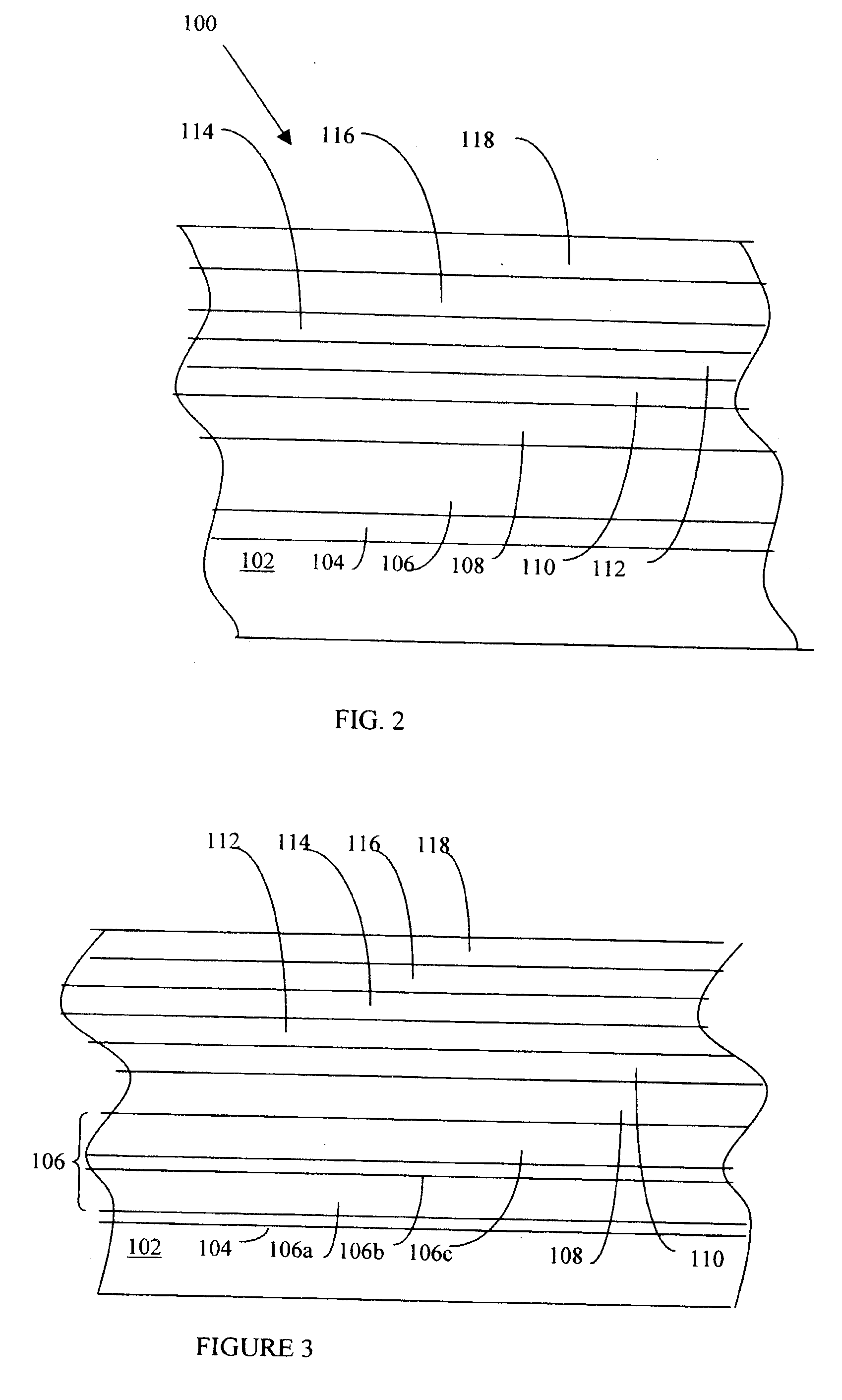

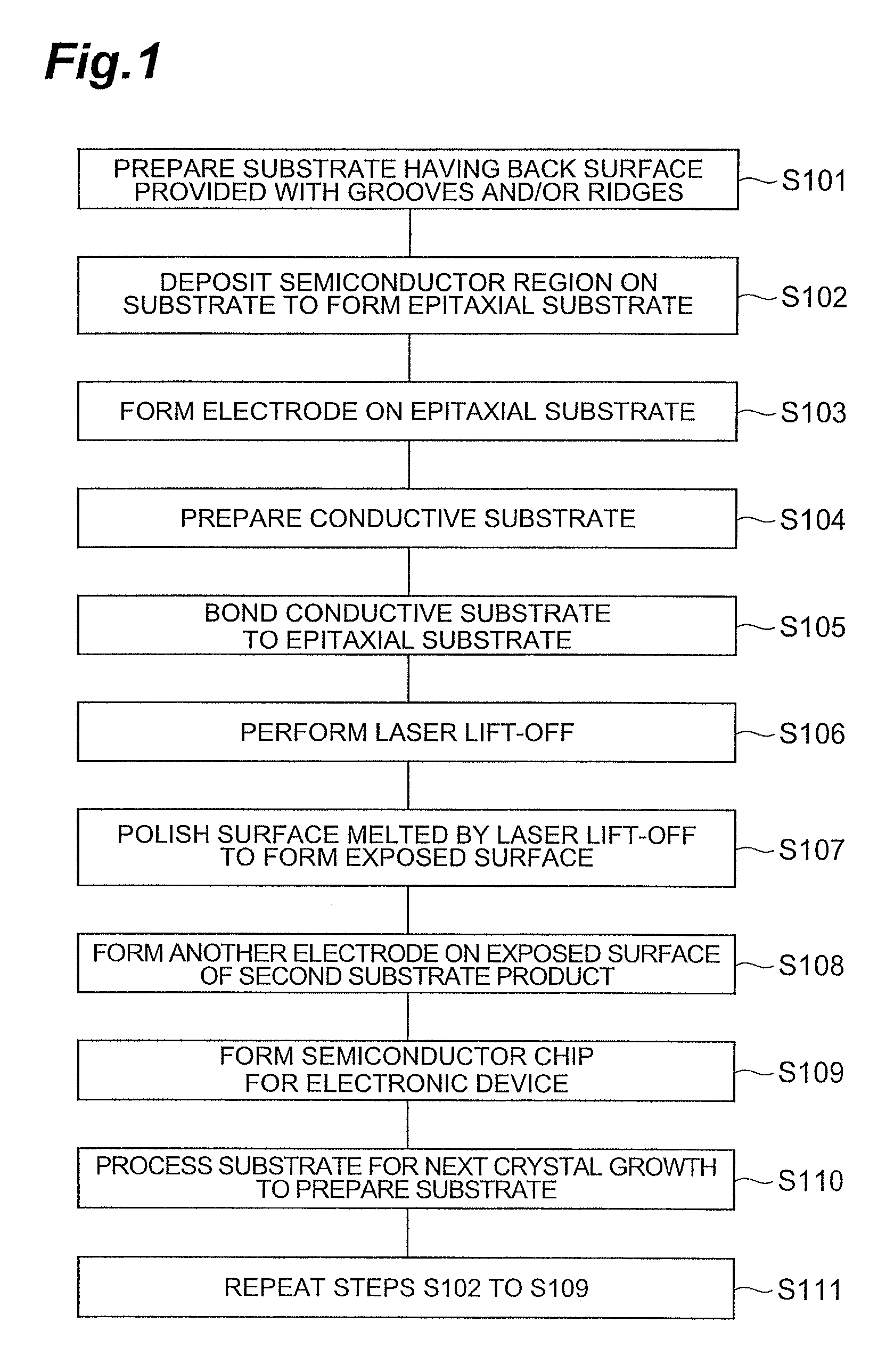

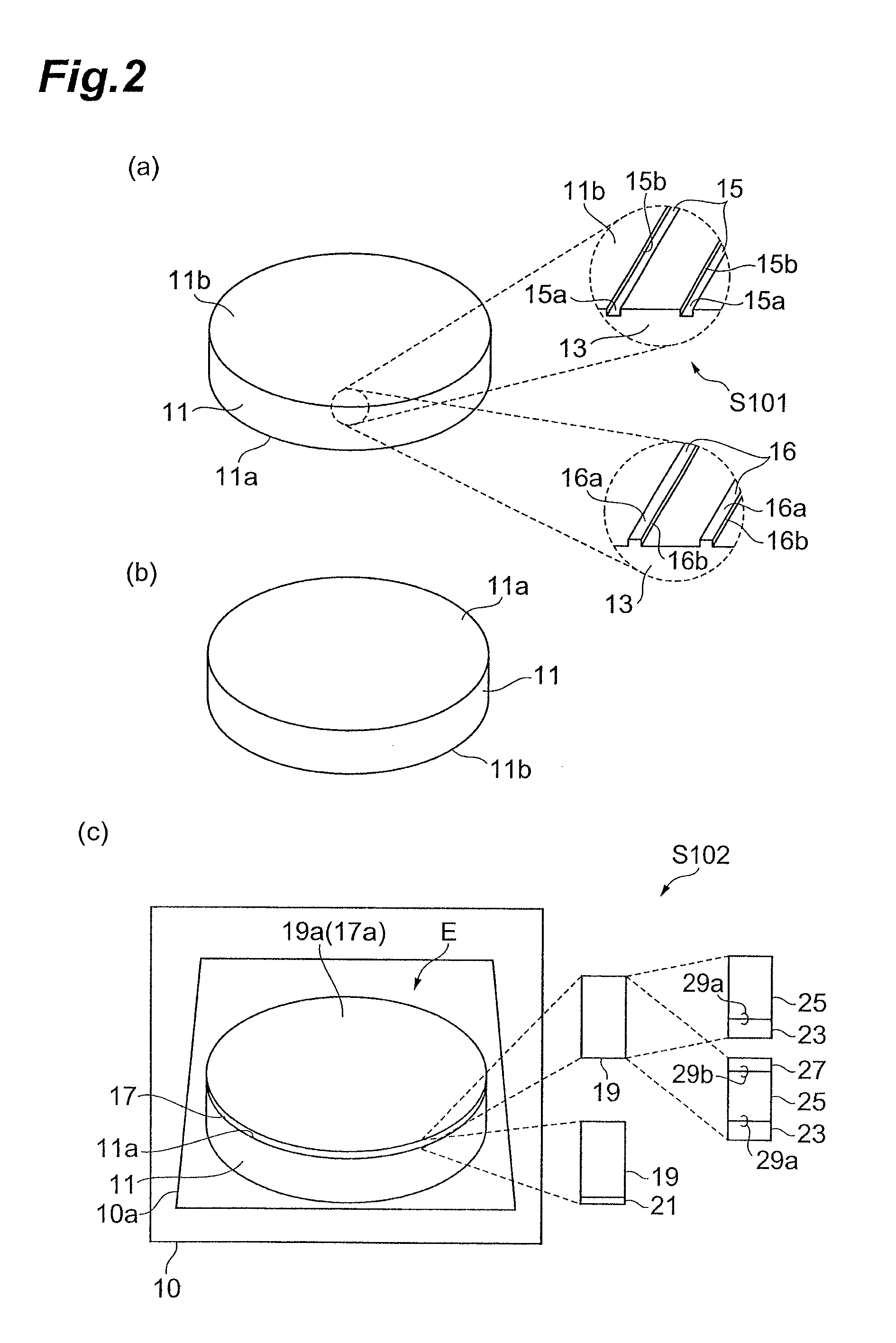

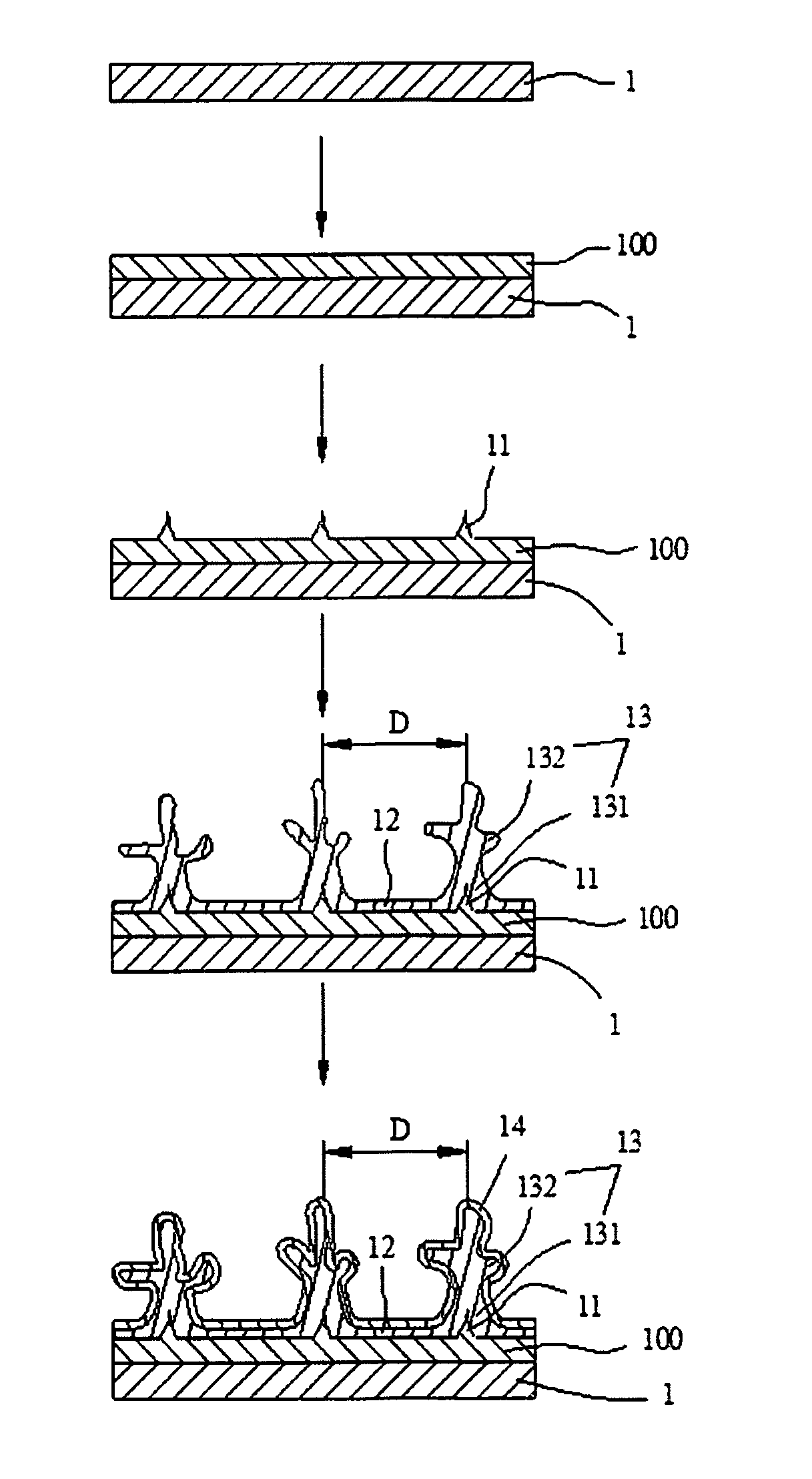

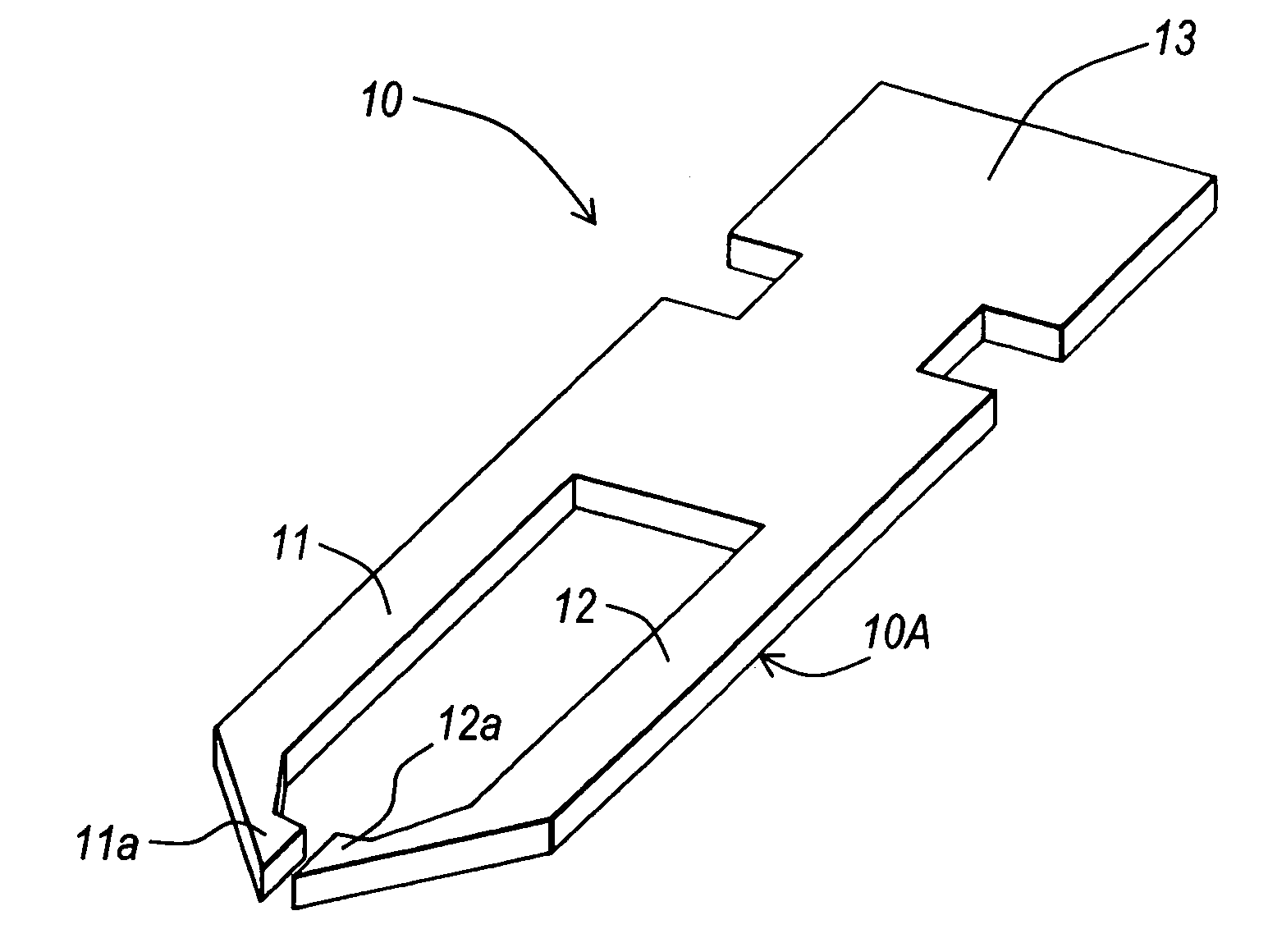

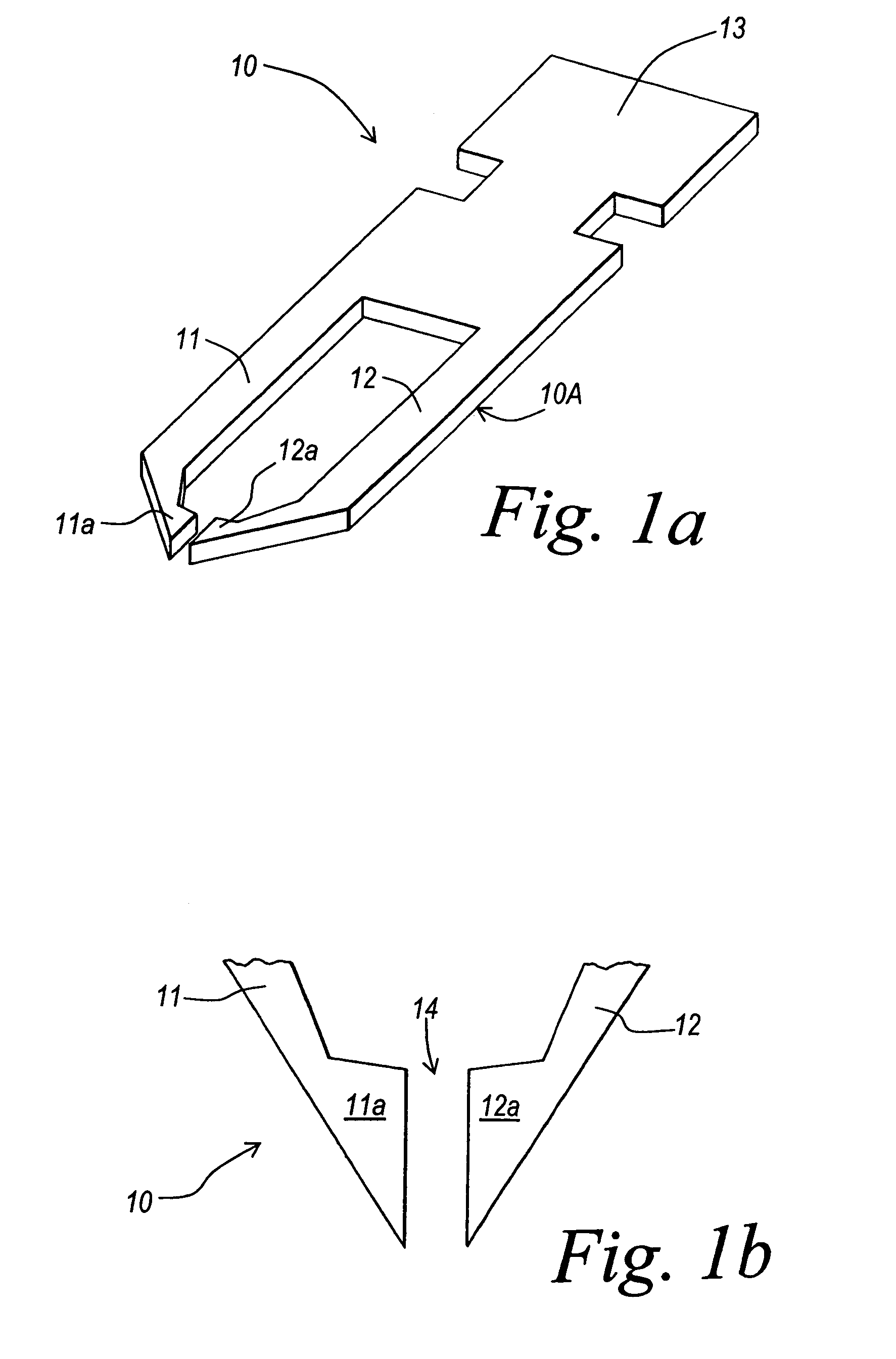

Method for fabricating gallium nitride based semiconductor electronic device

InactiveUS7998836B1Preventing reduction in adhesivenessPromotes crystal growthSemiconductor/solid-state device manufacturingDiodeLaser lightGallium nitride

A method of fabricating a gallium nitride-based semiconductor electronic device is provided, the method preventing a reduction in adhesiveness between a gallium nitride-based semiconductor layer and a conductive substrate. A substrate 11 is prepared. The substrate 11 has a first surface 11a and a second surface 11b, the first surface 11a allowing a gallium nitride-based semiconductor to be deposited thereon. The substrate 11 includes a support 13 of a material different from the gallium nitride-based semiconductor. The support is exposed on the second surface 11b of the substrate 11. An array of grooves 15 is provided in the second surface 11b. A semiconductor region including at least one gallium nitride-based semiconductor layer is deposited on the first surface 11a of the substrate 11, and thereby an epitaxial substrate E is fabricated. A conductive substrate 33 is bonded to the epitaxial substrate E such that the semiconductor region 17 is provided between the first surface 11a of the substrate 11 and the conductive substrate E. Subsequently, the second surface 11b is irradiated with laser light for laser lift-off.

Owner:SUMITOMO ELECTRIC IND LTD

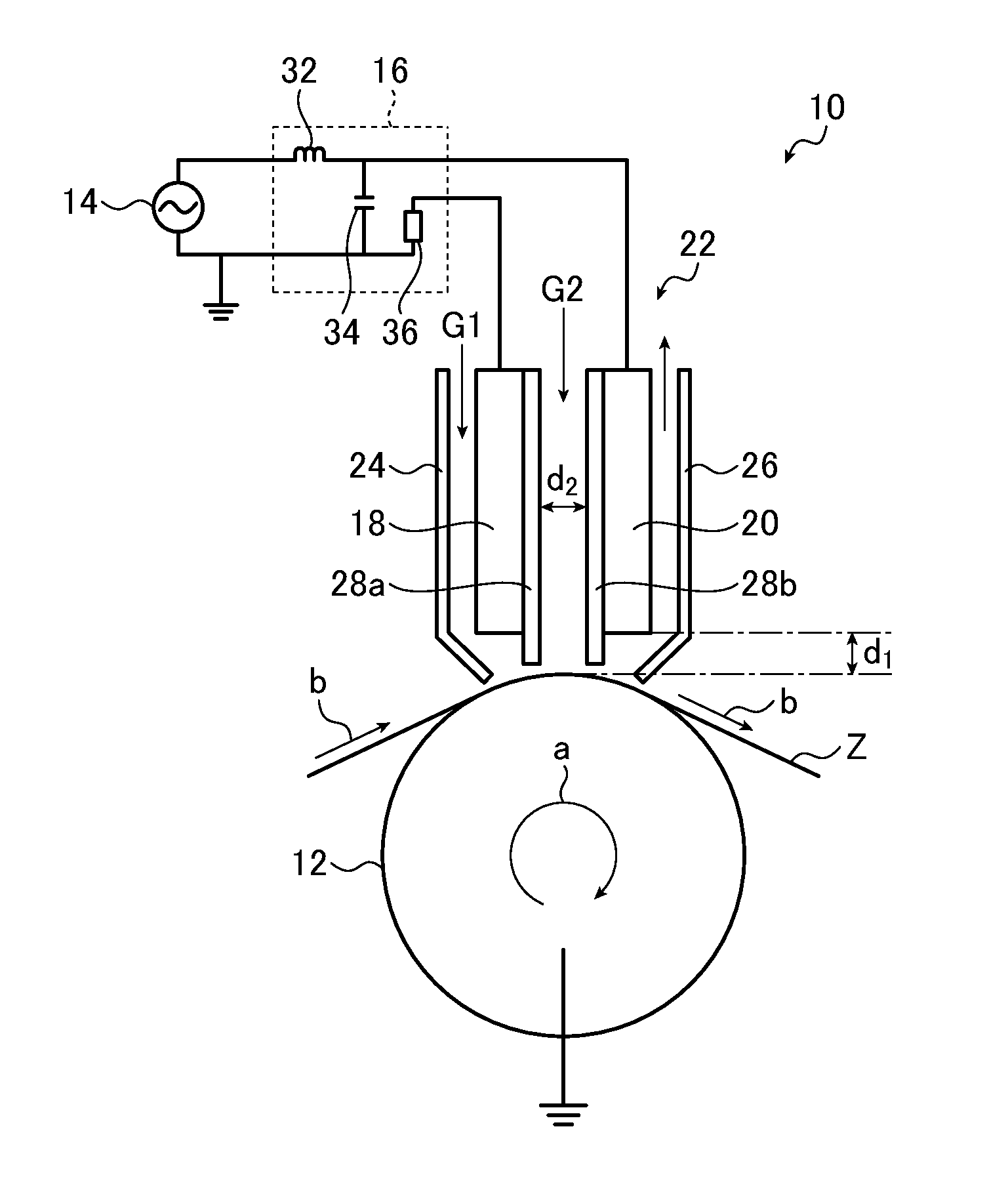

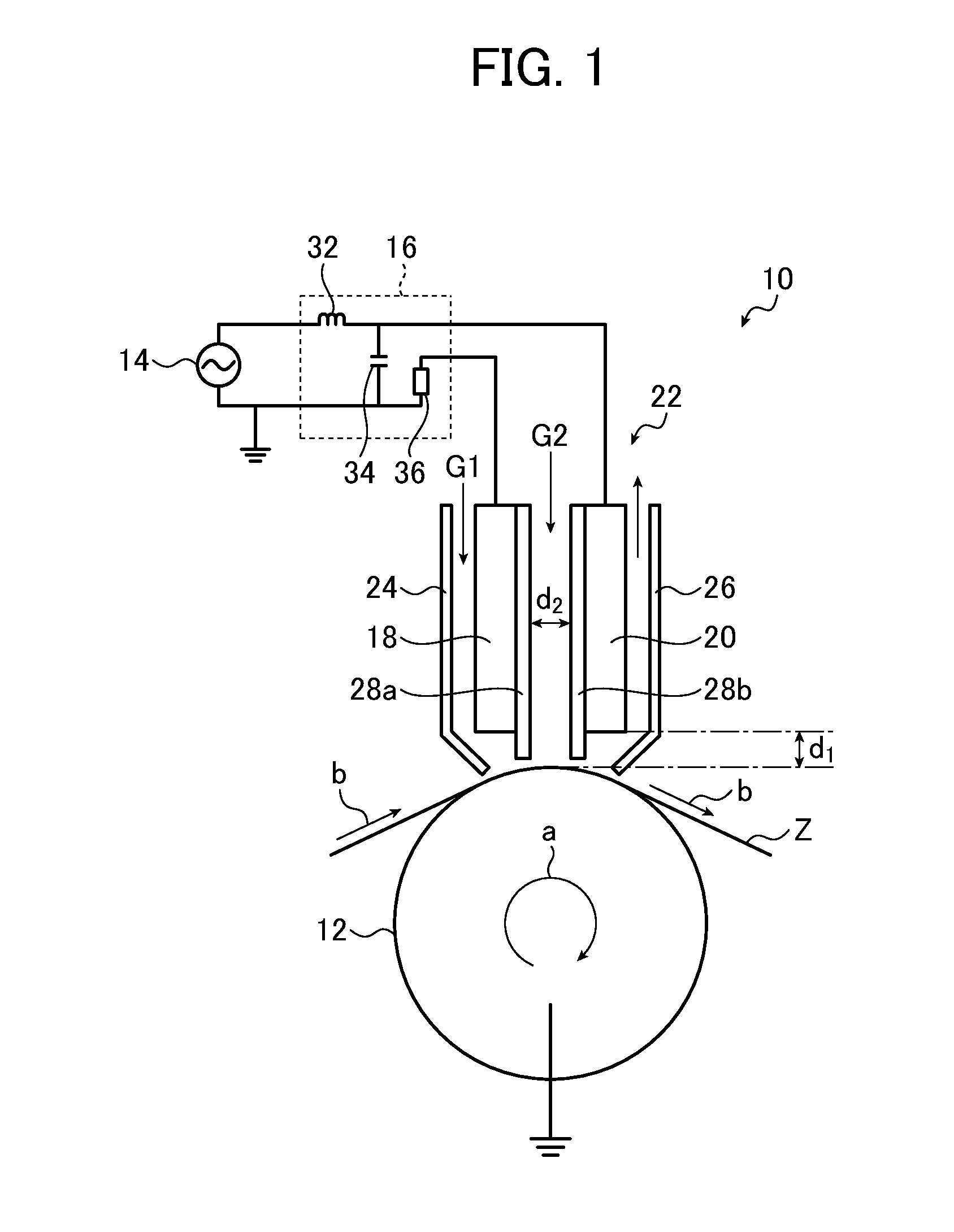

Method of manufacturing transparent conductive film

InactiveUS20110244140A1Increase valueHigh confinement effectOxide conductorsSpecial surfacesPulse controlTransparent conducting film

An atmospheric-pressure plasma-enhanced MOCVD (metal organic chemical vapor deposition) uses a power circuit for supplying power for plasma generation, including a pulse control circuit provided inside in order to form a transparent conductive film on the surface of the substrate, the transparent conductive film having a low resistivity, excellent optical characteristics and a good texture formed on the surface using dielectric barrier discharge.

Owner:FUJIFILM CORP

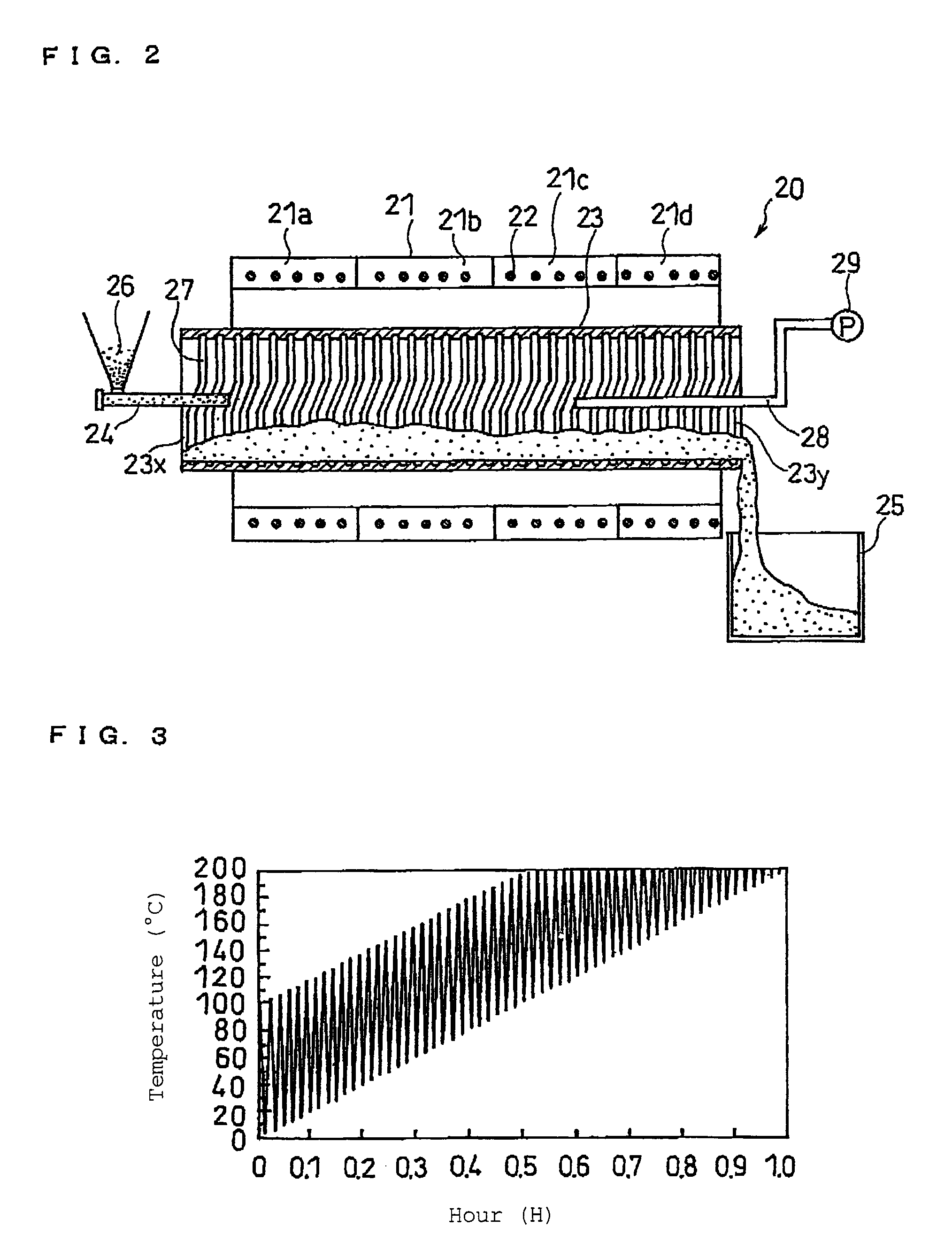

Method for producing lithum-containing transition metal oxide

ActiveUS20090194734A1Reduce decreaseIncrease contentElectrode manufacturing processesNon-aqueous electrolyte accumulatorsLithium carbonatePhysical chemistry

A method for producing a lithium-containing transition metal oxide represented by the general formula: Li[Lix(NiaM1−a)1−x]O2 where M is metal other than Li and Ni, 0≦x, and 0<a. The method includes: (i) mixing a transition metal compound containing Ni and M in a molar ratio of a:(1−a) with lithium carbonate in a predetermined ratio; (ii) causing the temperature of the mixture to reach a predetermined temperature range while repeatedly raising and lowering the temperature thereof; and (iii) thereafter reacting the transition metal compound with the lithium carbonate in the predetermined temperature range.

Owner:PANASONIC CORP

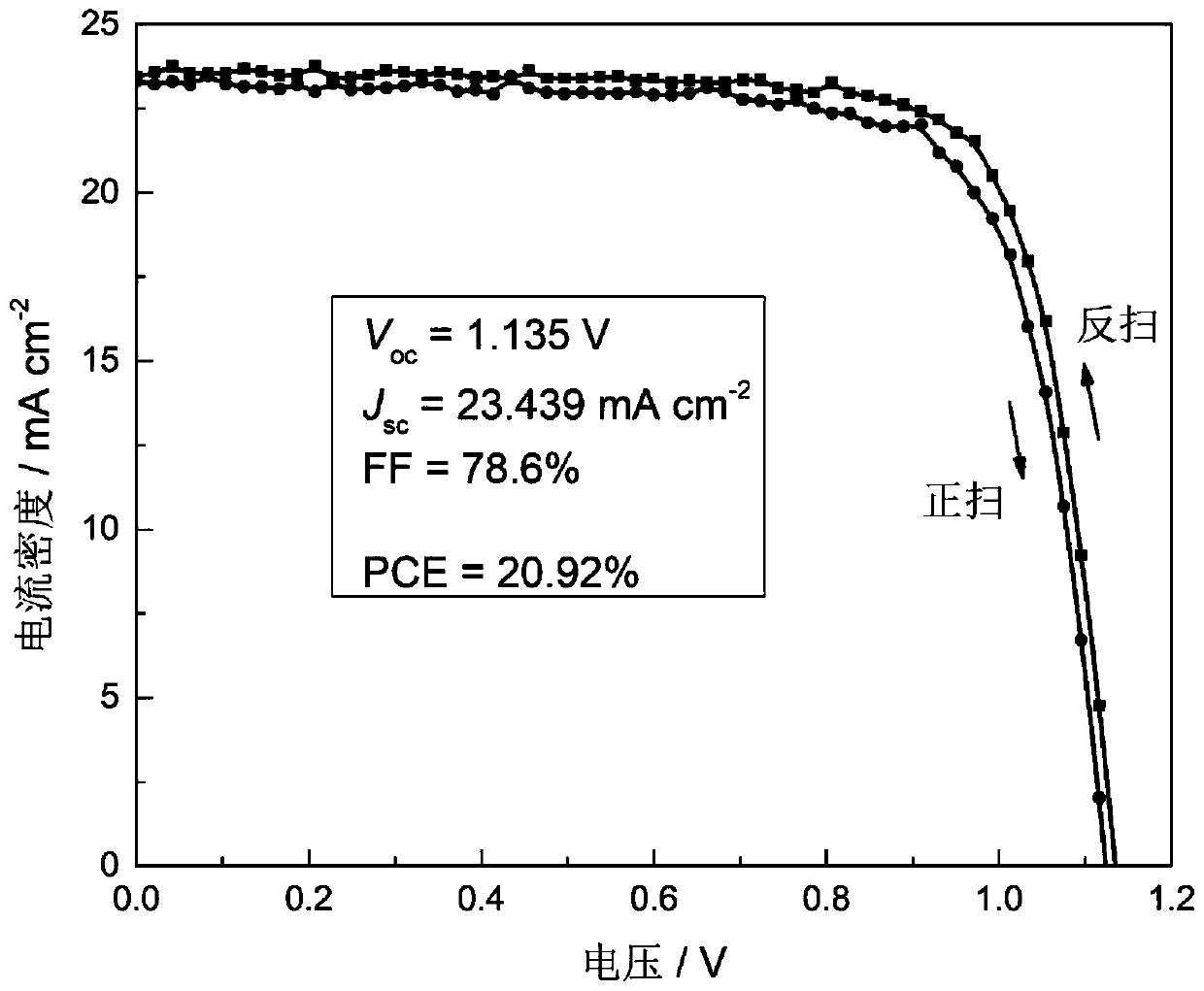

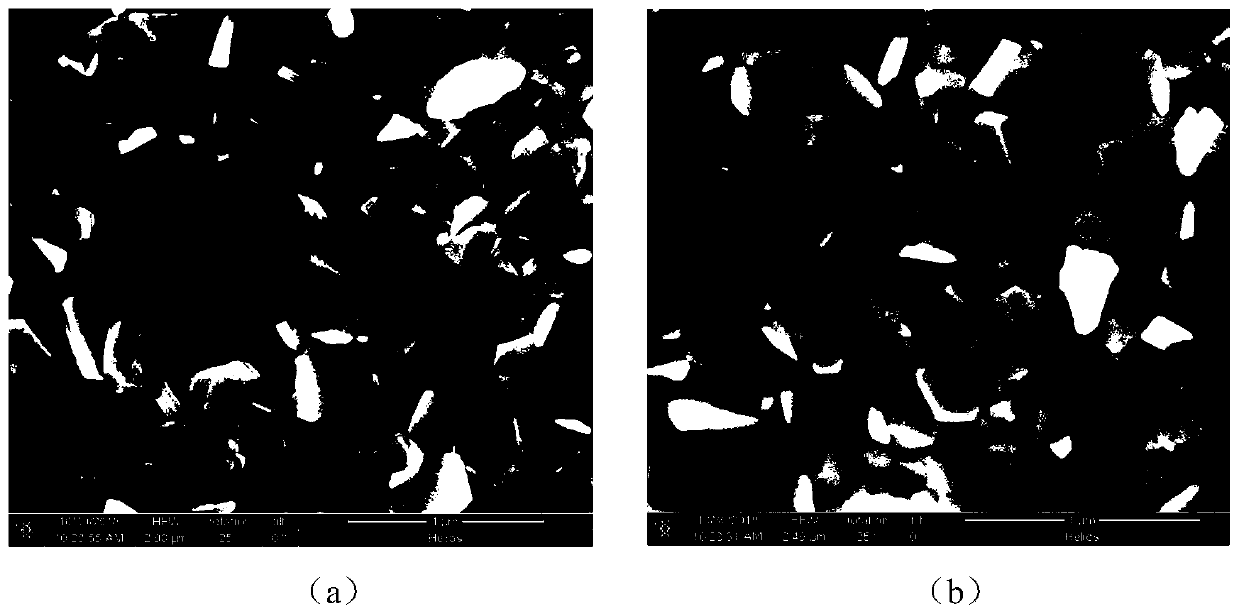

Perovskite thin-film solar cell and preparation method thereof

InactiveCN107104189AReduce crystallization defectsPromotes crystal growthSolid-state devicesSemiconductor/solid-state device manufacturingIonElectrode interface

The invention discloses a perovskite thin-film solar cell, which comprises a cathode, a perovskite light absorption layer and an anode. An electrode interface modification layer is formed between the anode and the perovskite light absorption layer. The electrode interface modification layer comprises atoms and / or ions capable of reacting with the perovskite light absorption layer so as to promote the crystallinity of perovskite crystals. Meanwhile, the electrode interface modification layer is used for improving the surface roughness and the morphology of the anode. The invention also discloses a preparation method of the perovskite thin-film solar cell. The electrode interface modification layer is arranged in the structure of the perovskite thin-film solar cell, so that the performance and the reproducibility of a device are effectively improved. Meanwhile, the preparation process is simple and controllable, and raw materials are cheap and easy to obtain. Therefore, the preparation method is suitable for the preparation of large-area flexible perovskite solar devices.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

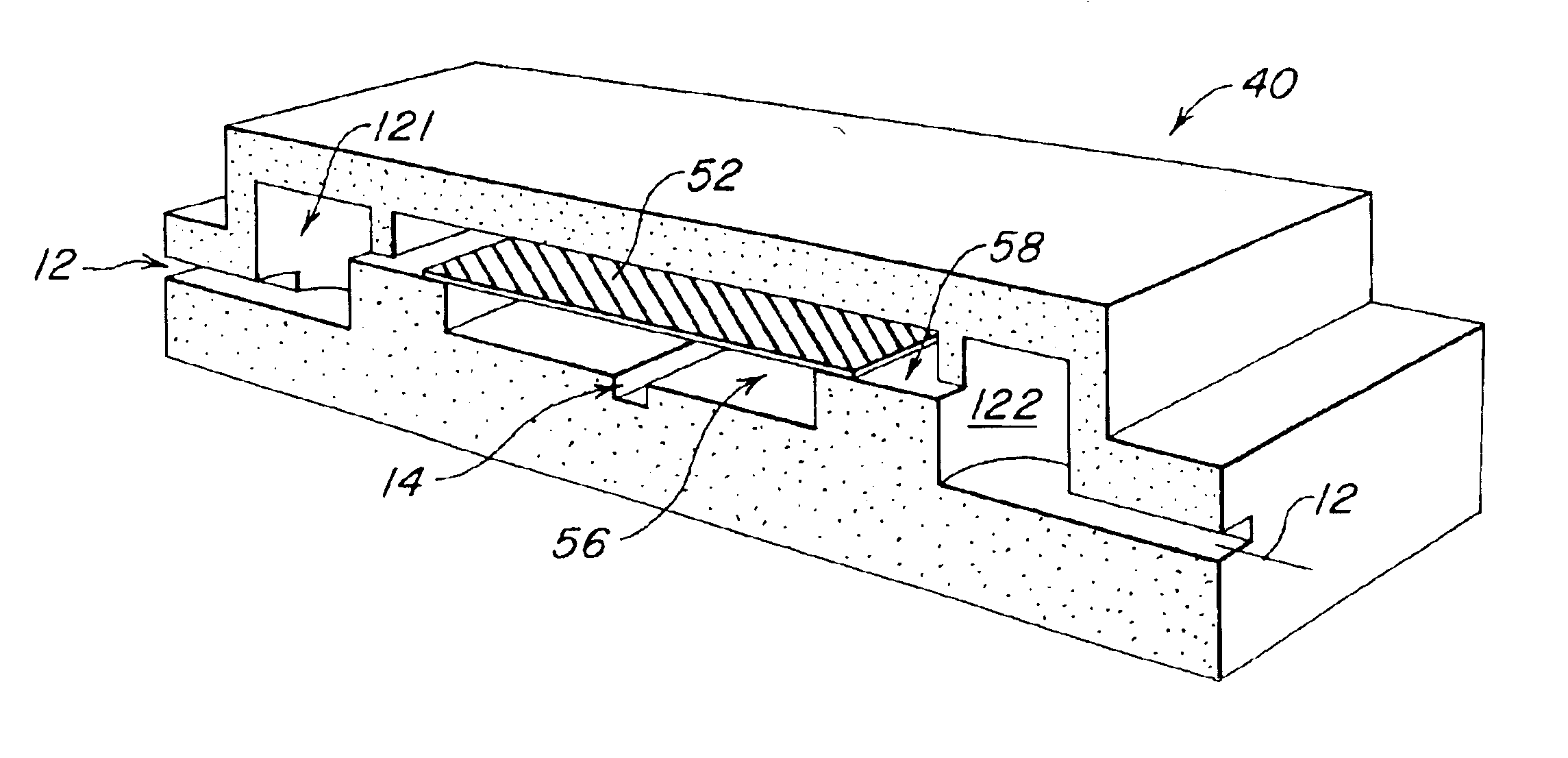

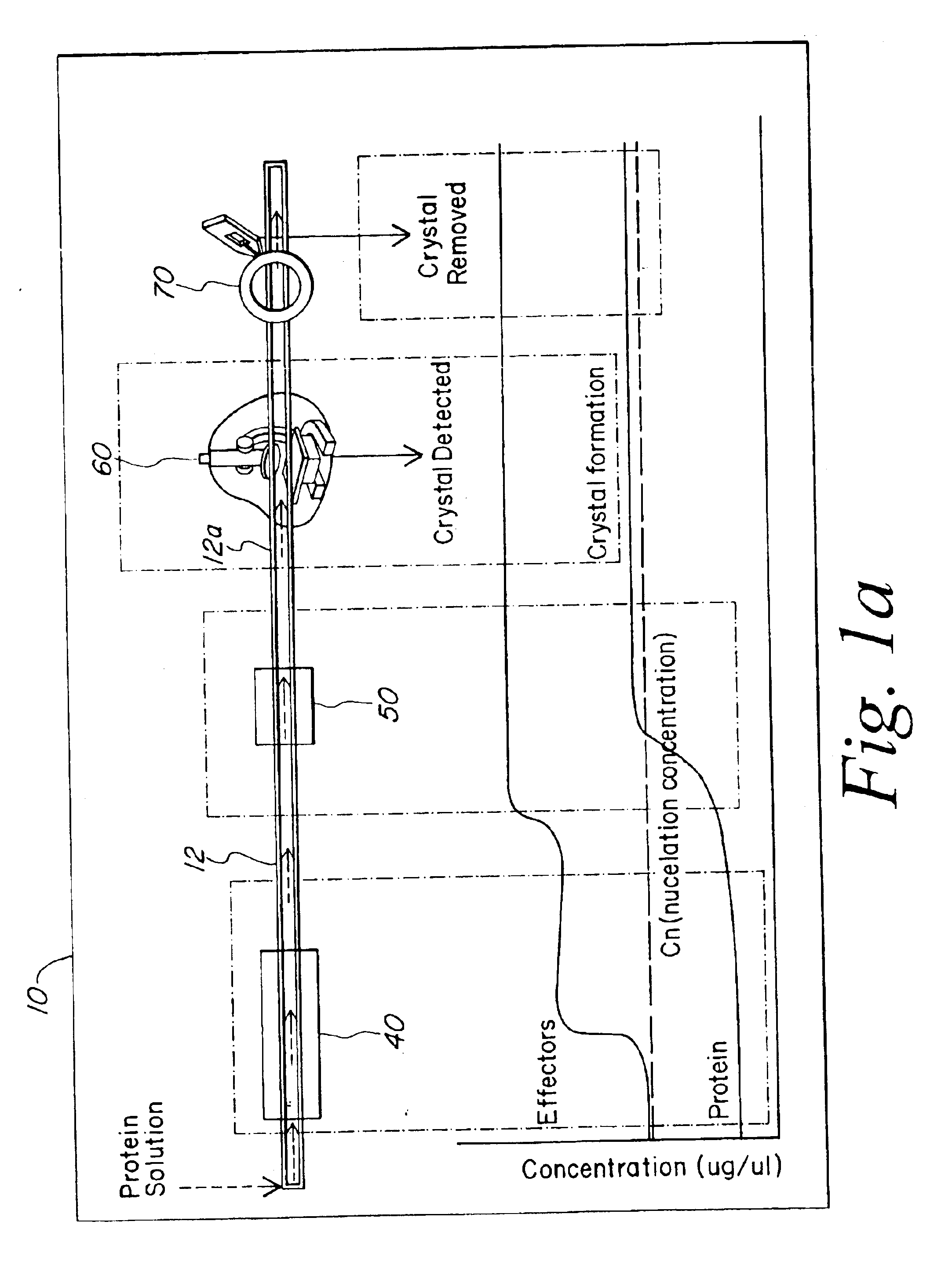

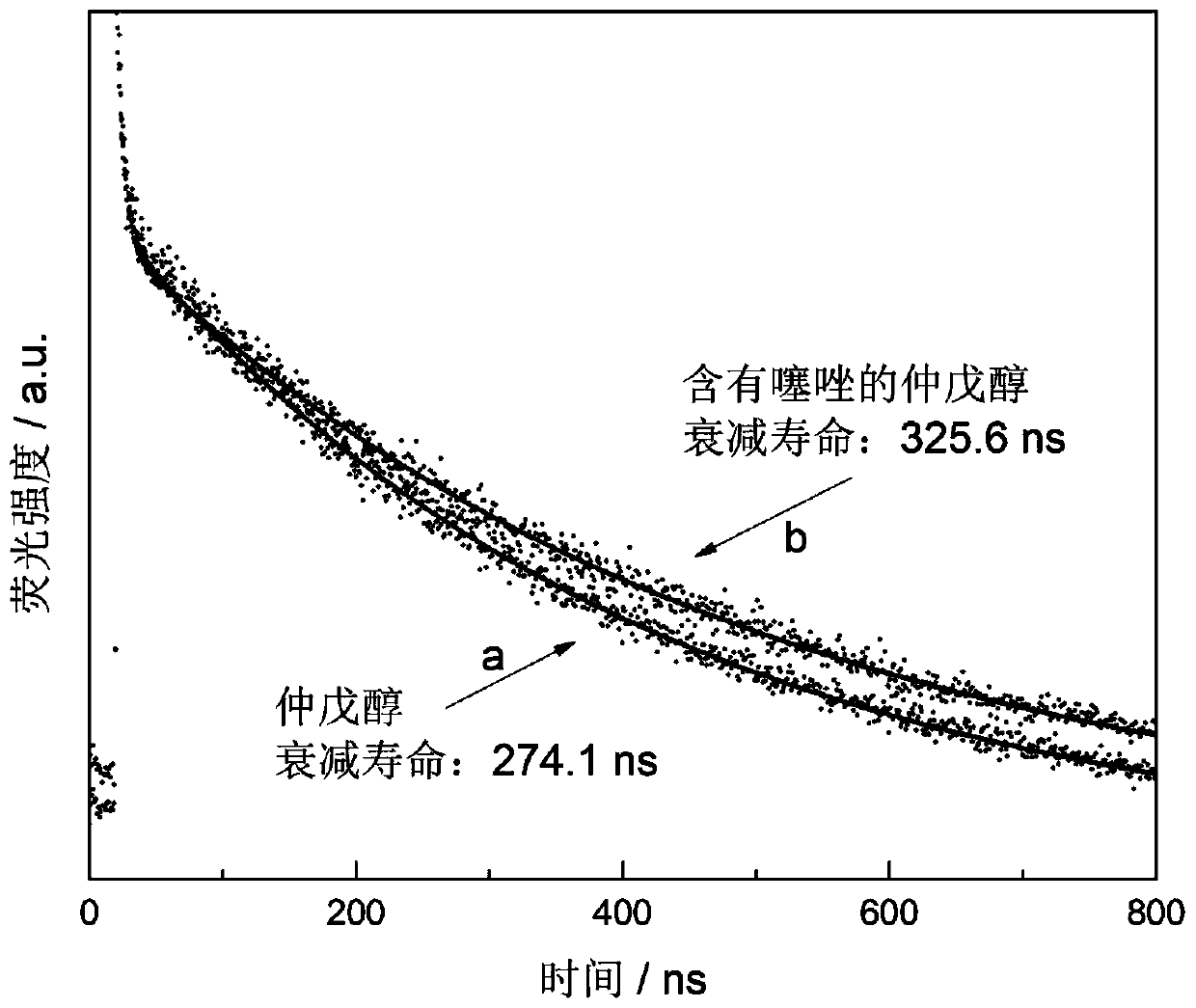

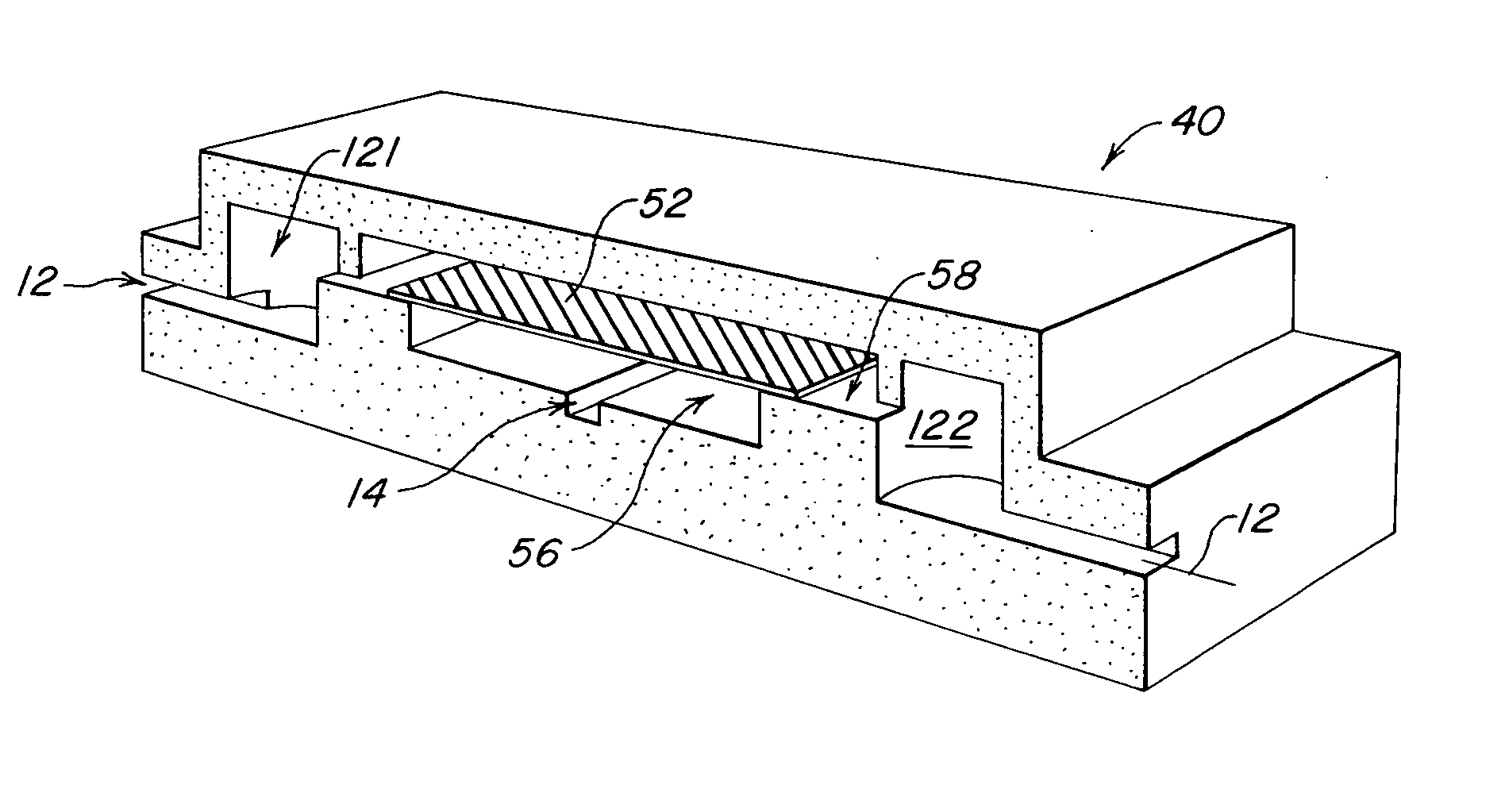

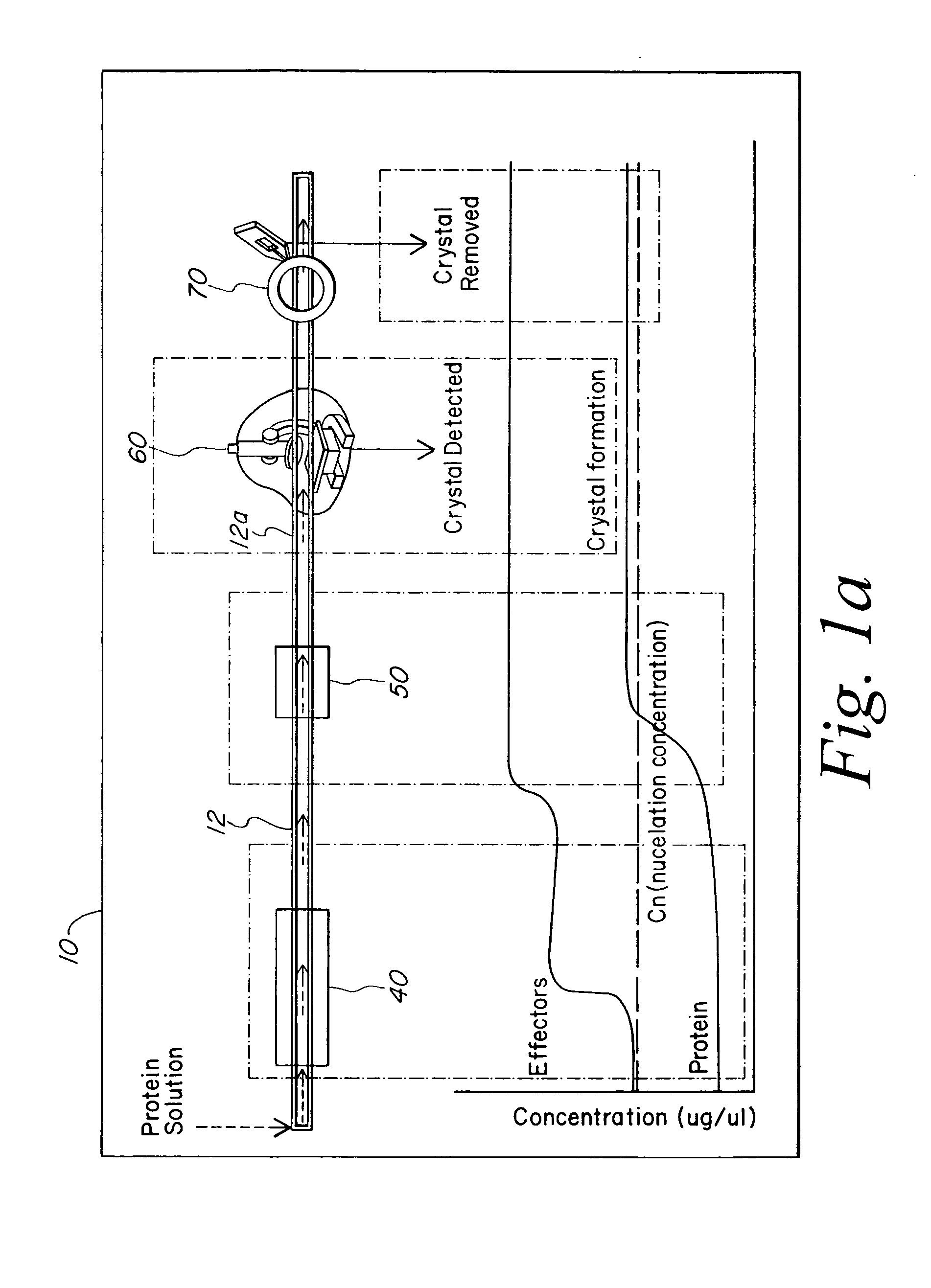

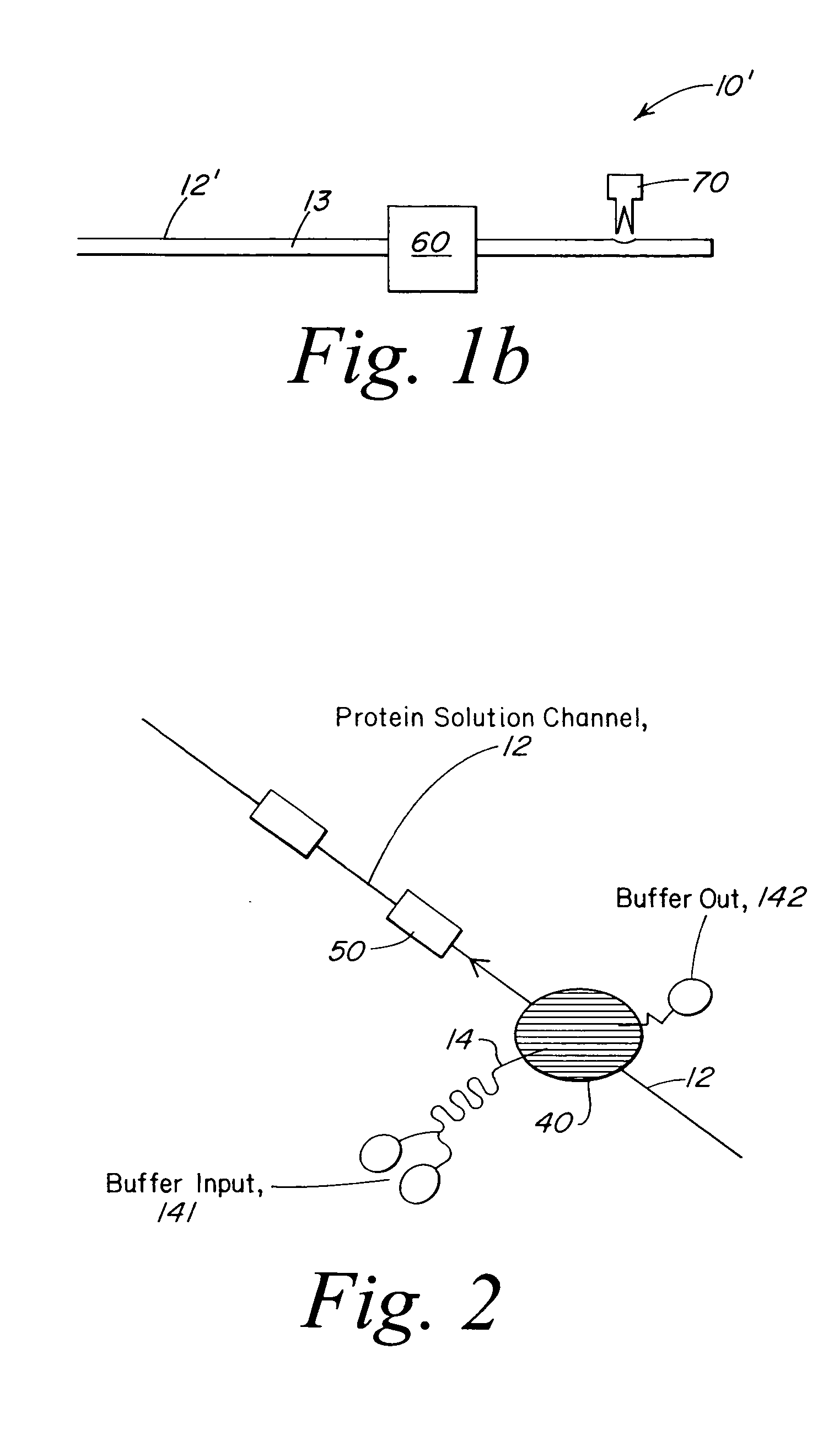

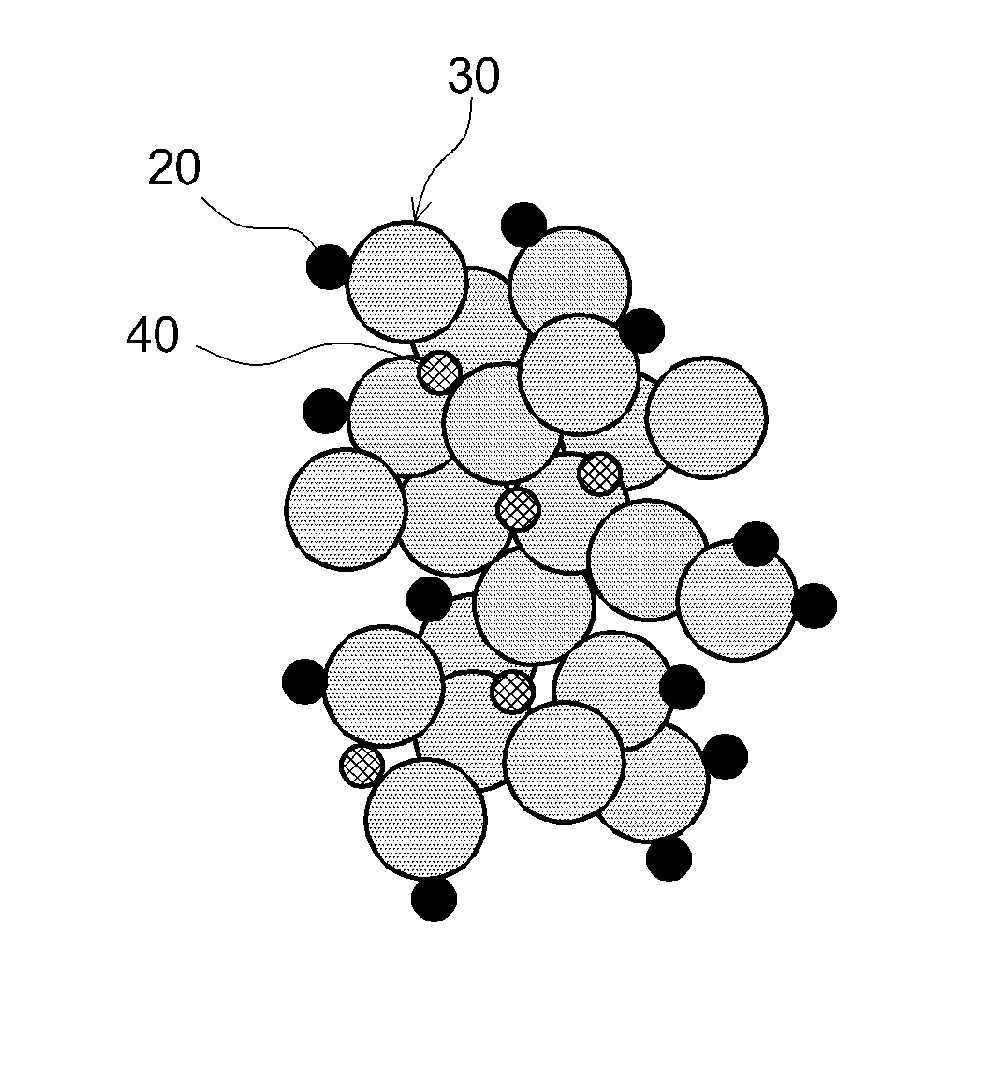

Microfluidic chip for biomolecule crystallization

InactiveUS6849459B2Promotes crystal growthPolycrystalline material growthFrom normal temperature solutionsMicrofluidic chipSolvent

A system for crystallizing a protein and other biomolecules comprises a flow channel for conveying a solution containing the biomolecule to be crystallized and one or more substations related to the crystallization process formed along the flow channel. The system operates by flowing a biomolecule solution through a the flow channel, then performing dialysis on a micro-scale to set crystallization conditions. After dialysis, the concentration of the biomolecule solution is changed by removing water or solvent from the biomolecule solution to promote formation of crystals in a segment of the flow channel. Formed crystals may be observed and harvested from the flow channel.

Owner:CYTONOMEST

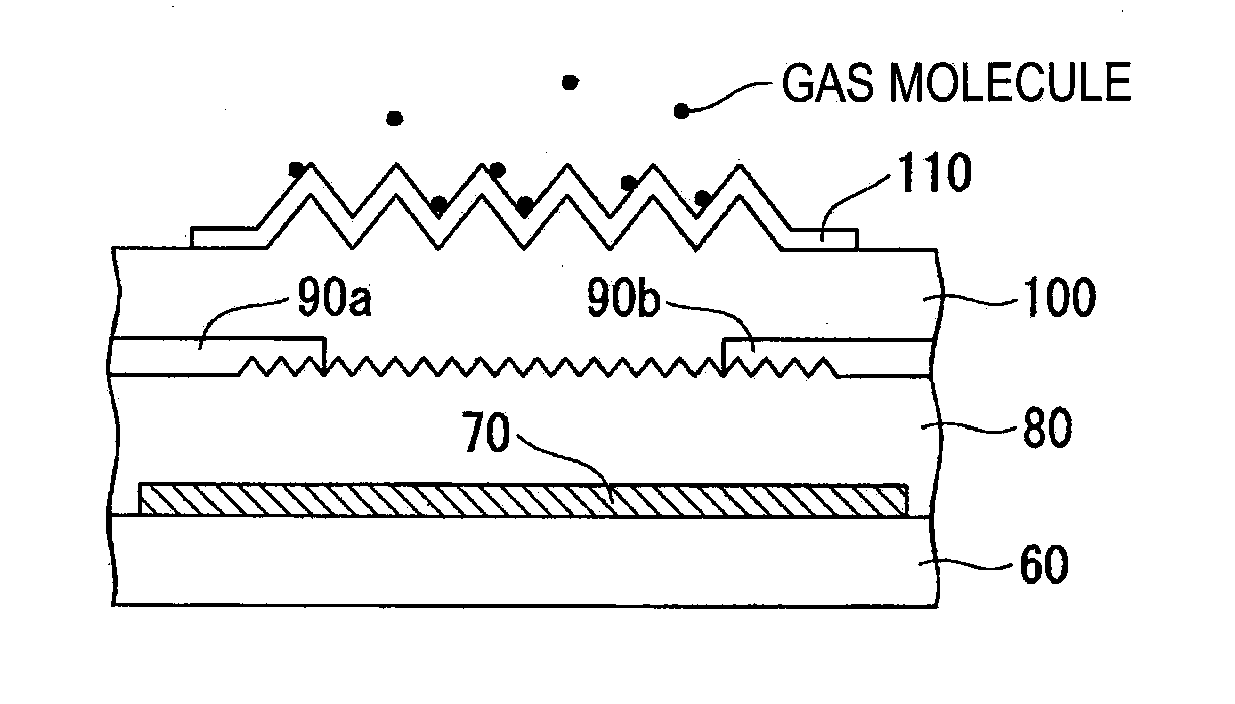

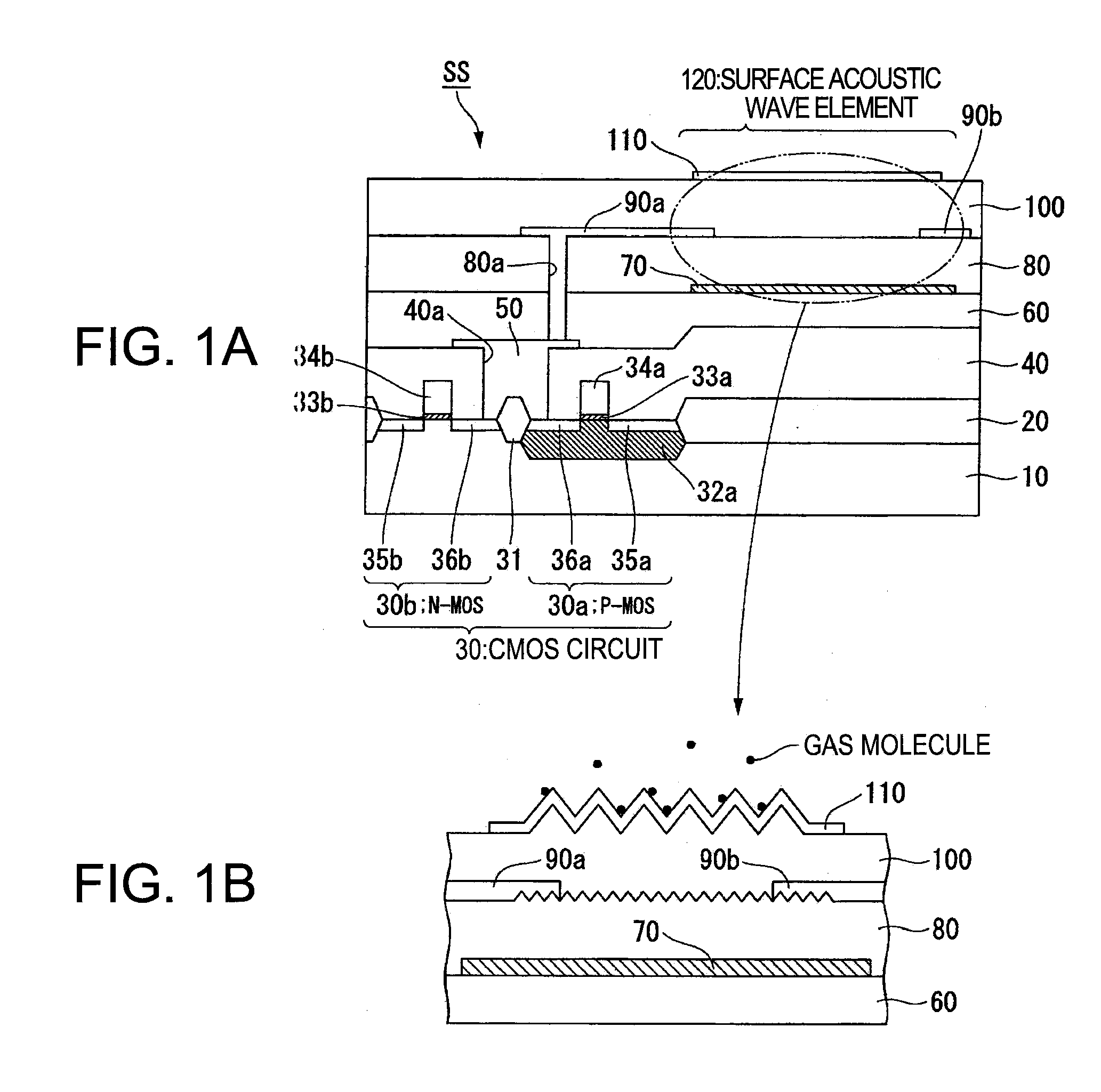

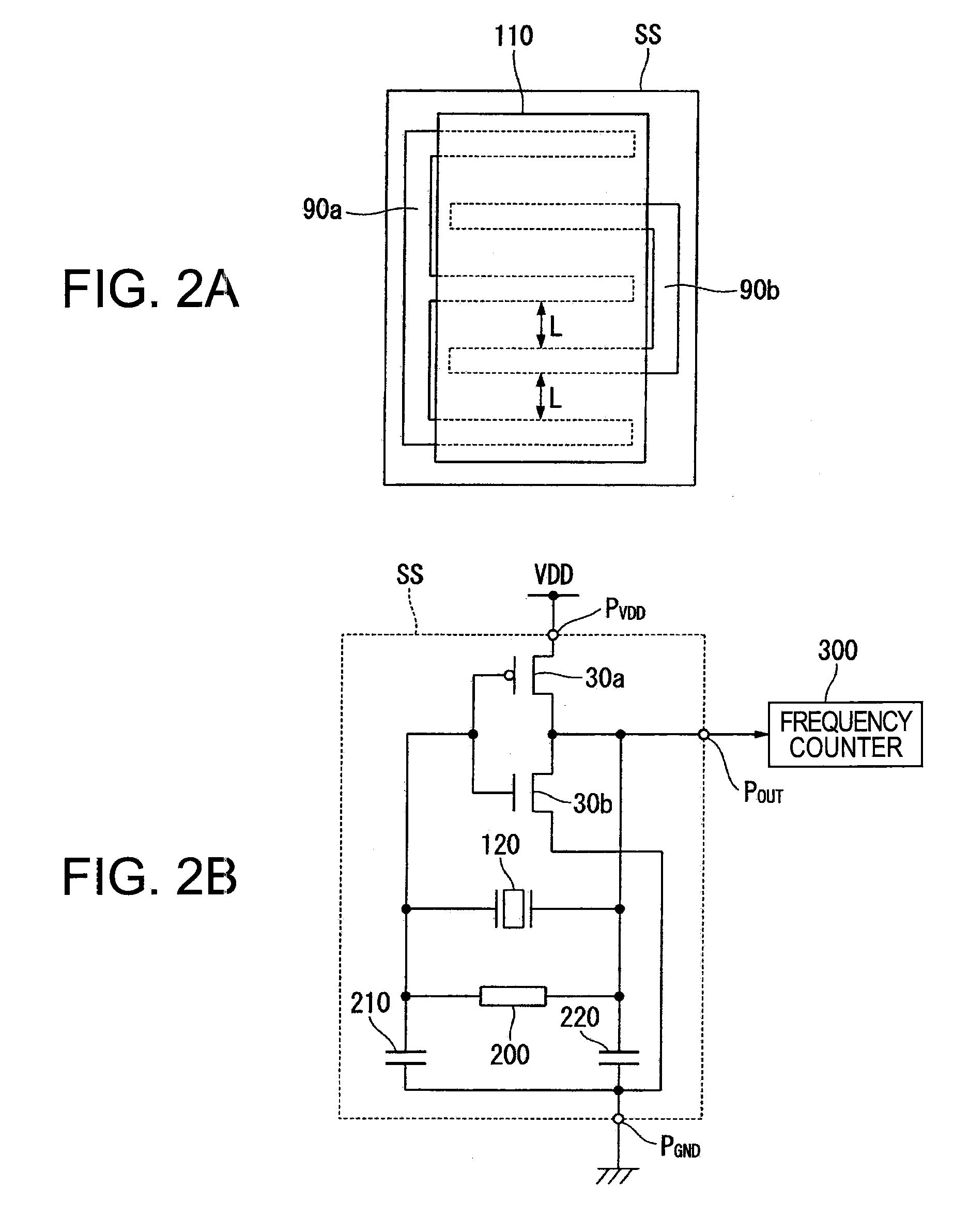

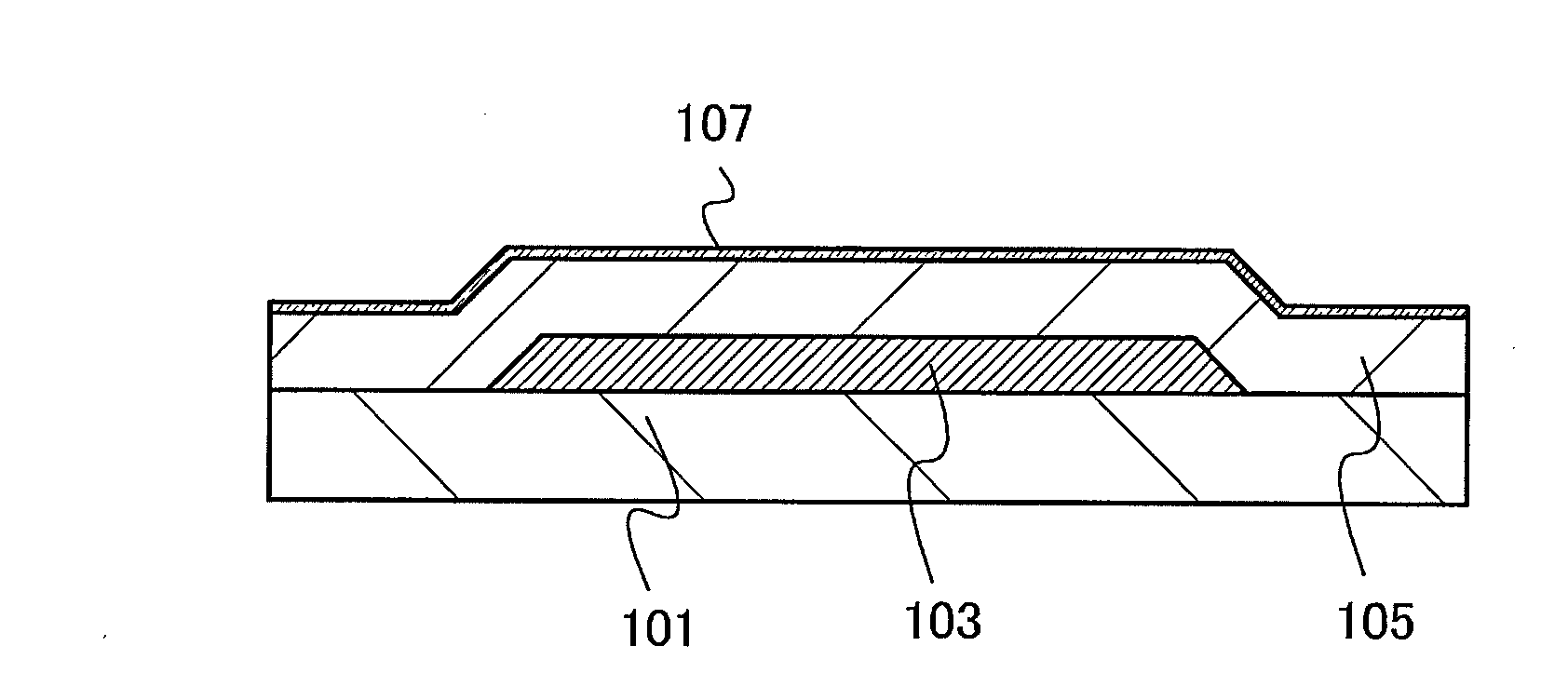

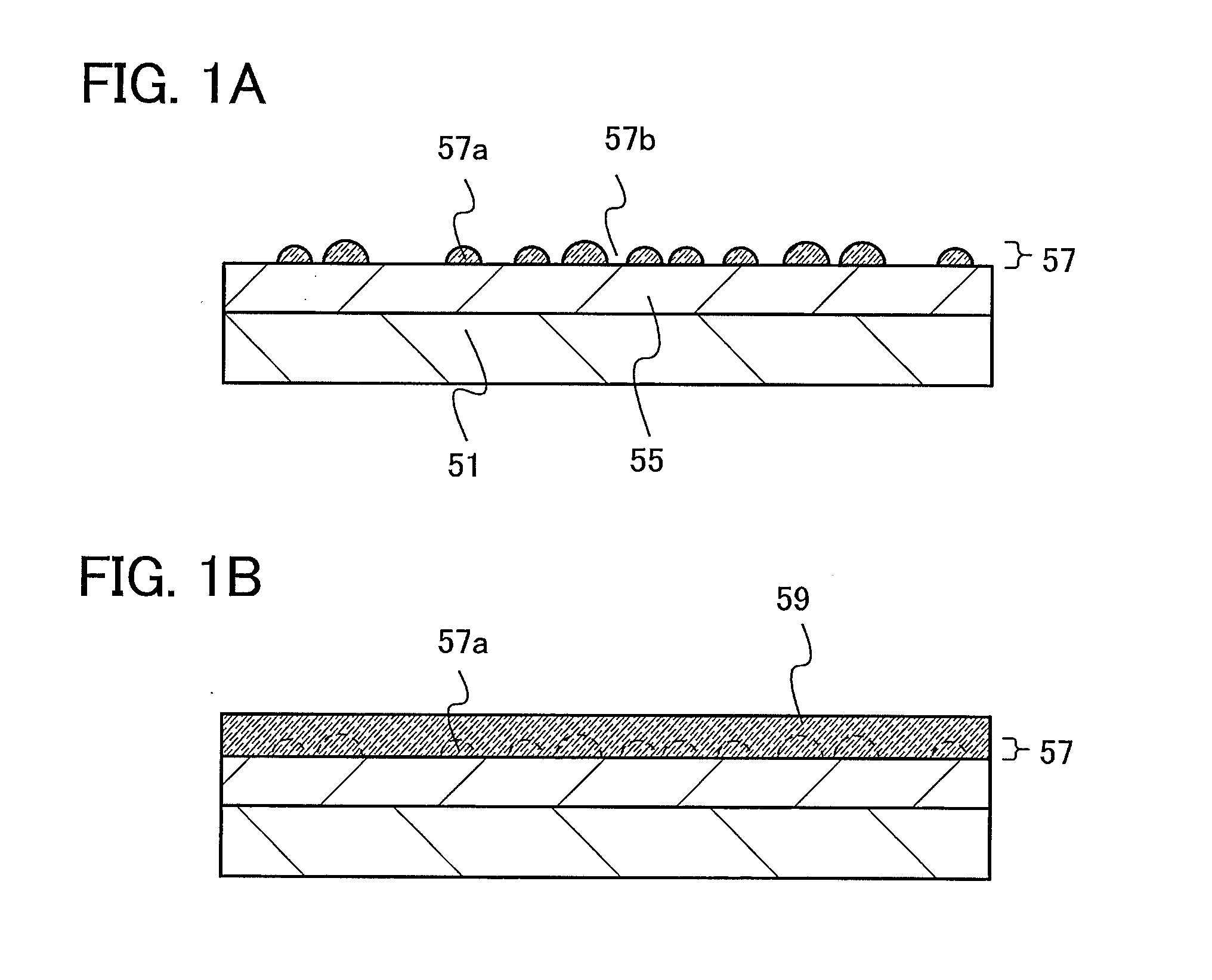

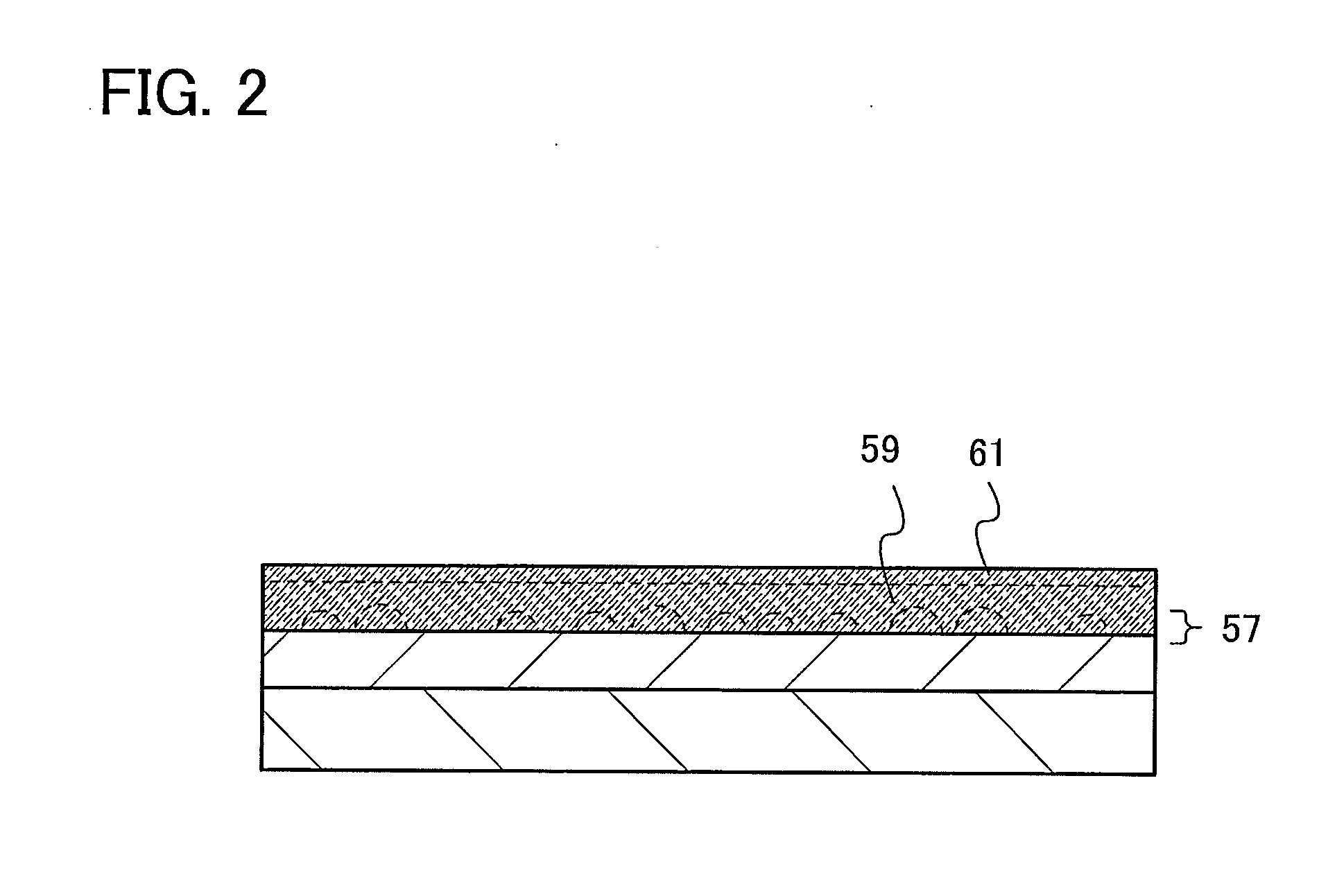

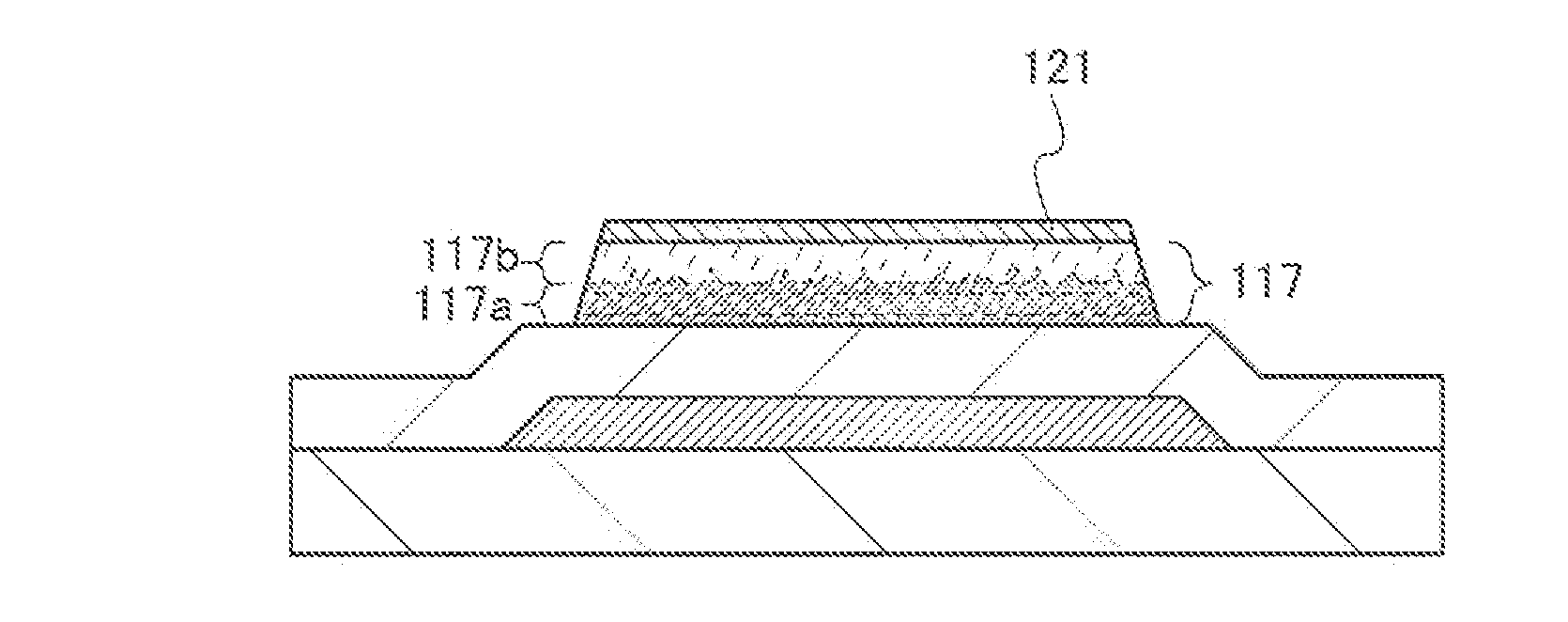

Semiconductor sensor and method for manufactruing the same

ActiveUS20090184381A1High sensitivityLow pricePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMolecular adsorptionAcoustic wave

A semiconductor sensor includes: a semiconductor substrate; a plurality of piezoelectric thin films layered on the semiconductor substrate, the plurality of piezoelectric thin films including at least a pair of the piezoelectric thin films layered above and below; a pair of electrodes that are formed at an interface of at least the pair of the piezoelectric thin films layered above and below and excite surface acoustic waves; a thin film directly under a lowest-layer piezoelectric film of the piezoelectric thin films; a metal thin film that is formed at an interface of the lowest-layer piezoelectric thin film and the thin film, and facilitate a growth of a ridge-and-valley portion on a surface of an uppermost-layer piezoelectric thin film of the piezoelectric thin films; and a sensitive film for molecular adsorption formed on at least the ridge-and-valley portion on the uppermost-layer piezoelectric thin film.

Owner:SEIKO EPSON CORP

Perovskite film preparation method based on anti-solution bath, and solar cell

ActiveCN109904318AAchieve crystallization controlRealize shape controlFinal product manufactureSolid-state devicesPerovskite solar cellAnti solvent

The invention discloses a perovskite film preparation method based on an anti-solution bath, and a solar cell. A proper solute is added into an anti-solvent to prepare anti-solutions with different functions; crystallization control and morphology regulation of a perovskite film are realized; and meanwhile, an interface between the perovskite film and a carrier transmission layer is passivated, sothat the surface defect state and the interface recombination are reduced, the carrier concentration and the extraction efficiency at the interface are improved, and the carrier transmission is better facilitated. The perovskite solar cell prepared with the anti-solution bath method has relatively high photoelectric conversion efficiency and high stability. The preparation method is simple and convenient, relatively short in production period and high in controllability and repeatability, and has a wide application prospect in the production and preparation of large-area and large-scale perovskite solar cells.

Owner:PEKING UNIV

Microfluidic chip or biomolecule crystallization

InactiveUS20050112774A1Promotes crystal growthPolycrystalline material growthAnalysis using chemical indicatorsSolventDialysis

A system for crystallizing a protein and other biomolecules comprises a flow channel for conveying a solution containing the biomolecule to be crystallized and one or more substations related to the crystallization process formed along the flow channel. The system operates by flowing a biomolecule solution through a the flow channel, then performing dialysis on a micro-scale to set crystallization conditions. After dialysis, the concentration of the biomolecule solution is changed by removing water or solvent from the biomolecule solution to promote formation of crystals in a segment of the flow channel. Formed crystals may be observed and harvested from the flow channel.

Owner:GILBERT JOHN +1

Method for producing lithium-containing transition metal oxide

ActiveUS7939202B2Increase contentPromotes crystal growthElectrode manufacturing processesNon-aqueous electrolyte accumulatorsLithium carbonatePhysical chemistry

A method for producing a lithium-containing transition metal oxide represented by the general formula: Li[Lix(NiaM1−a)1−x]O2 where M is metal other than Li and Ni, 0≦x, and 0<a. The method includes: (i) mixing a transition metal compound containing Ni and M in a molar ratio of a:(1−a) with lithium carbonate in a predetermined ratio; (ii) causing the temperature of the mixture to reach a predetermined temperature range while repeatedly raising and lowering the temperature thereof; and (iii) thereafter reacting the transition metal compound with the lithium carbonate in the predetermined temperature range.

Owner:PANASONIC CORP

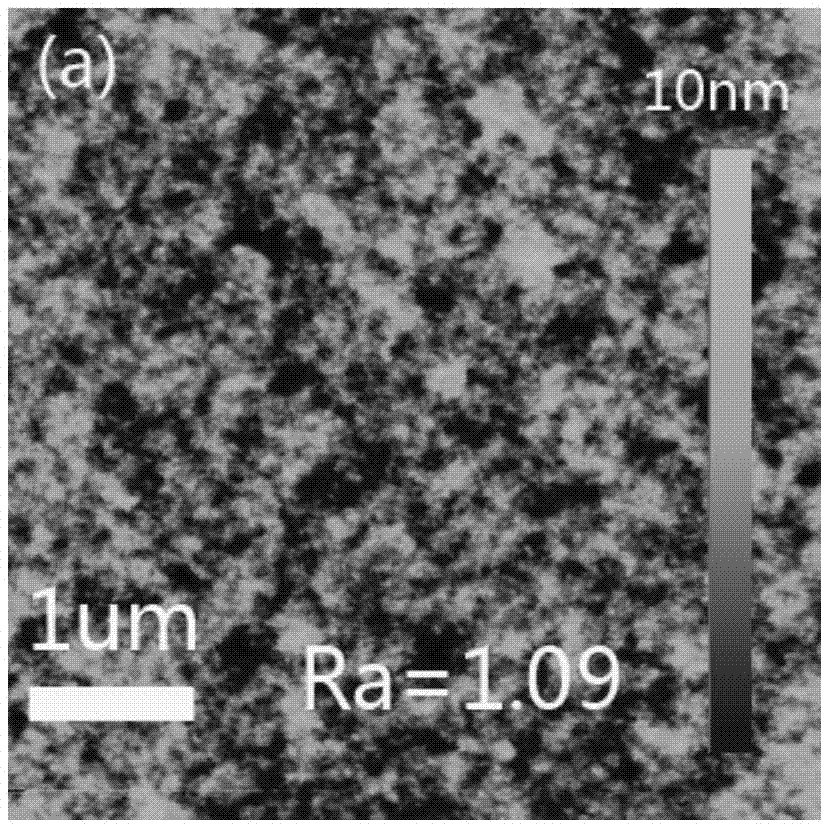

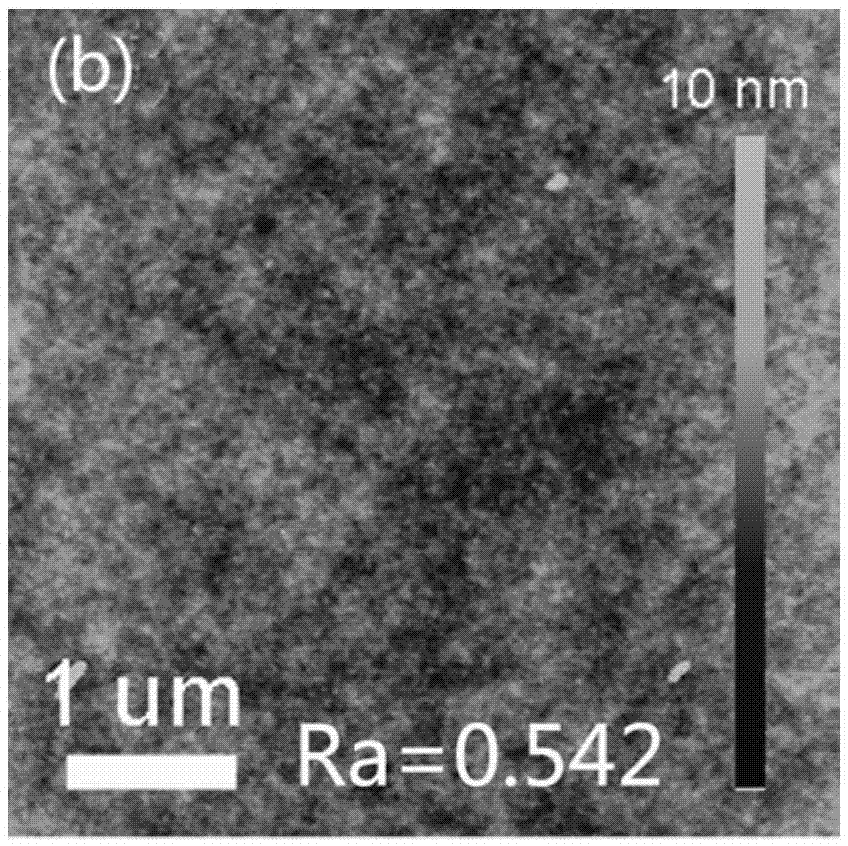

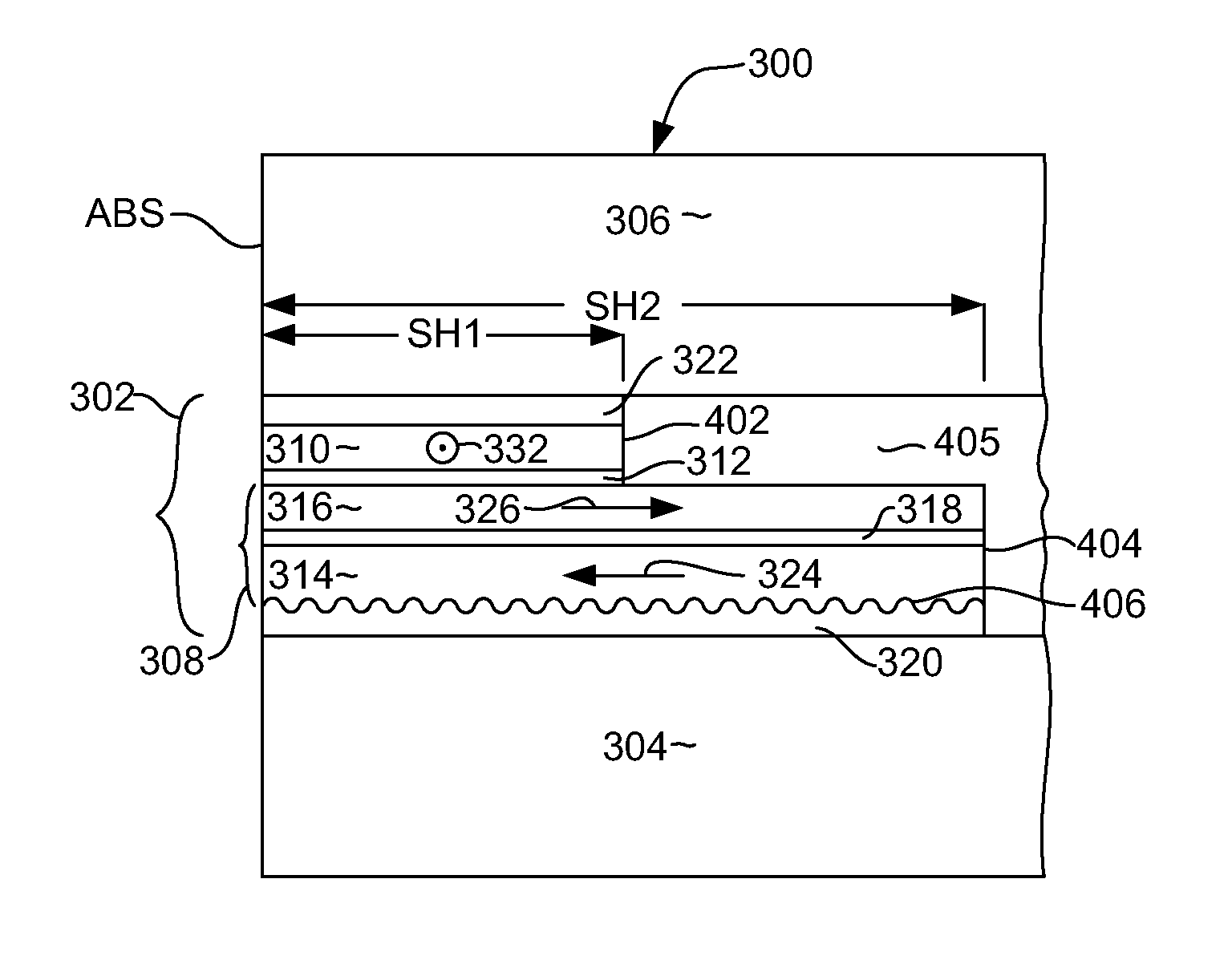

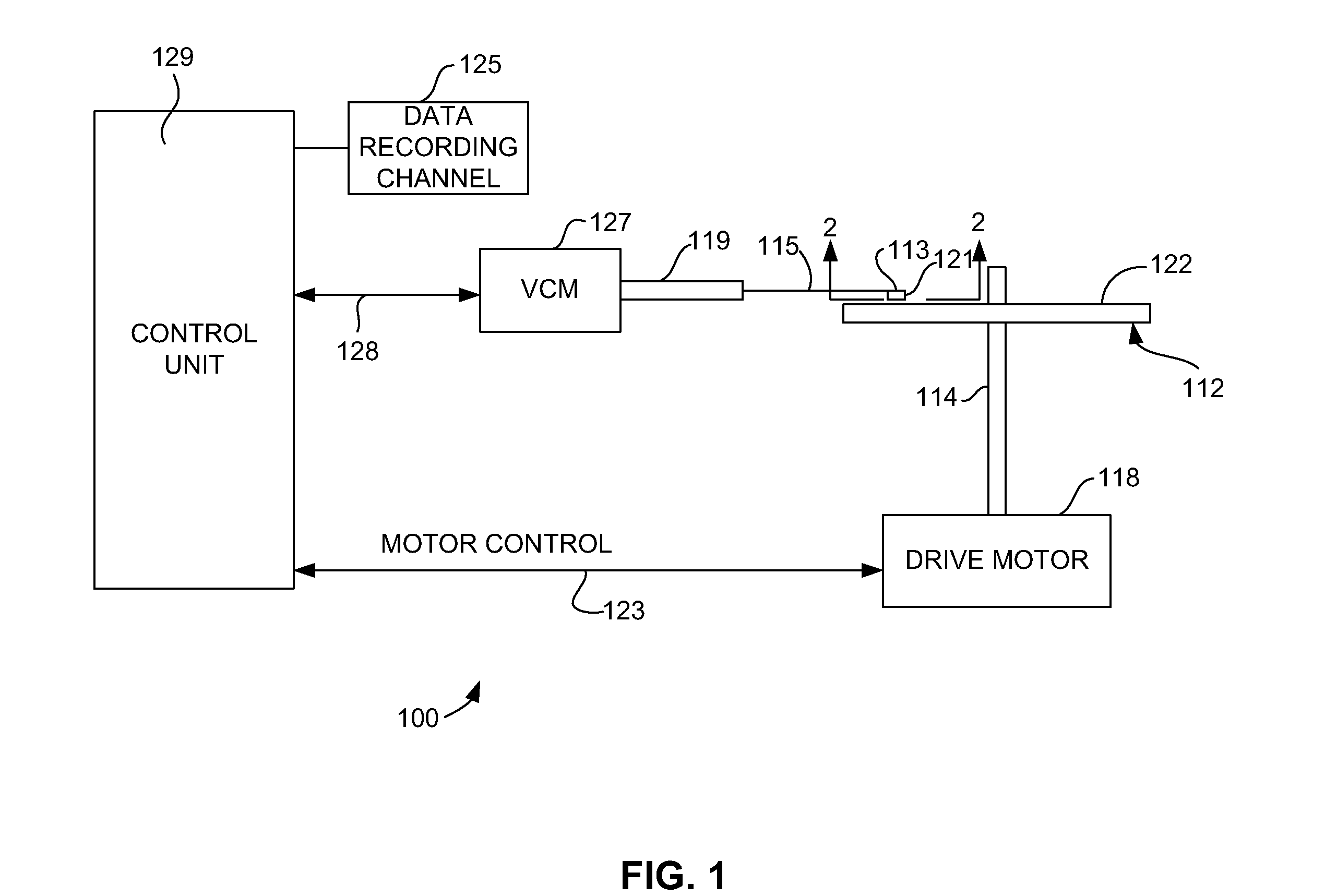

Magnetoresistive sensor having reduced read gap and strong pinned layer stability

InactiveUS20140133052A1High aspect ratioReduce degradationDecorative surface effectsRecord information storageMagnetic anisotropyOptoelectronics

A magnetic read head having a reduced read gap and a stable magnetic pinned layer structure. The sensor includes a seed layer that has a surface formed with an anisotropic texture. A magnetic pinned layer formed over the seed layer has a body centered cubic structure which causes the pinned layer structure to have a magnetic anisotropy with an easy axis oriented perpendicular to the air bearing surface when deposited over the textured seed layer. A magnetic free layer structure formed over the pinned layer structure and over a non-magnetic barrier layer has a face centered cubic structure which causes the magnetic free layer to have a magnetic anisotropy with an easy axis oriented parallel with the air bearing surface.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

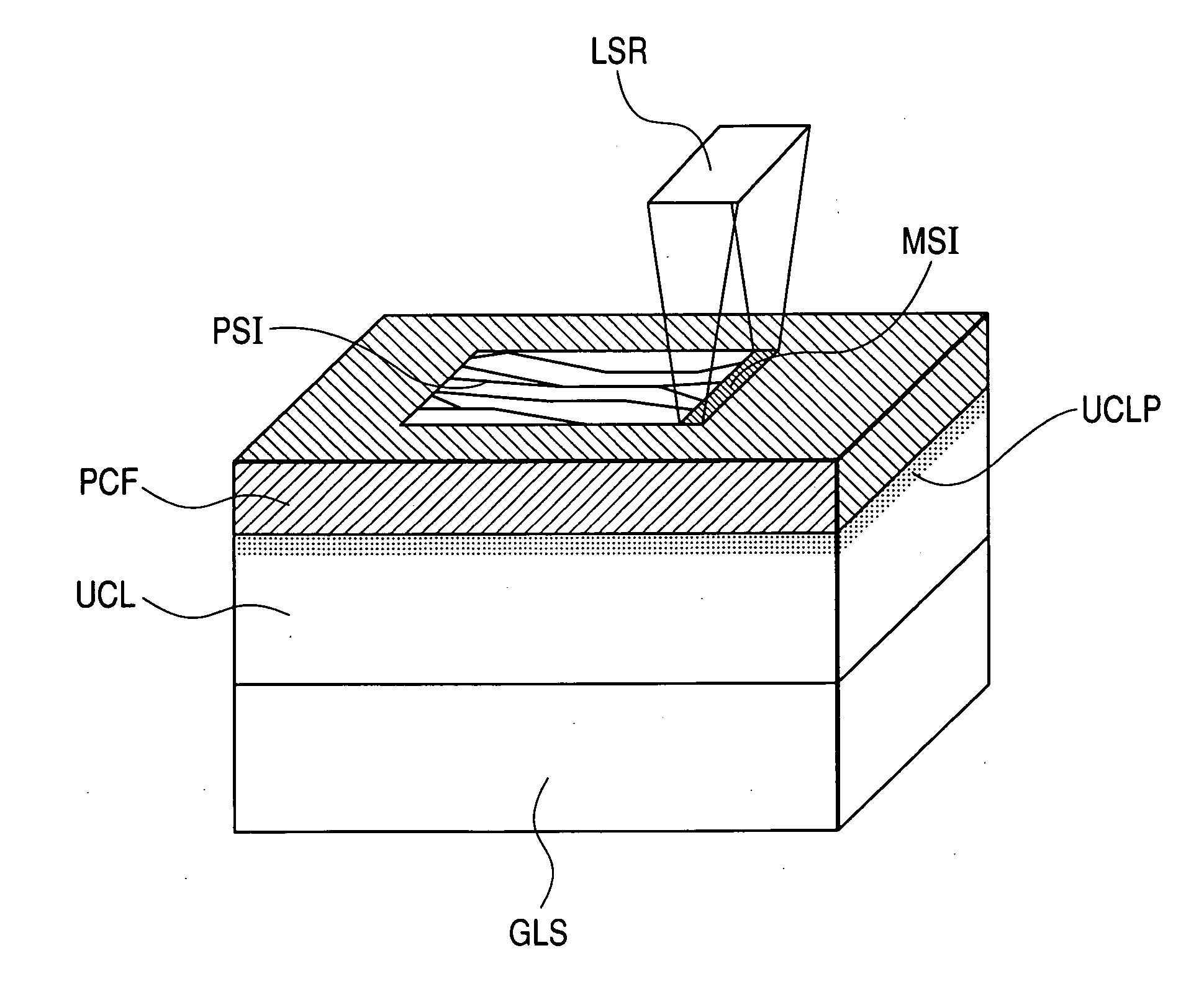

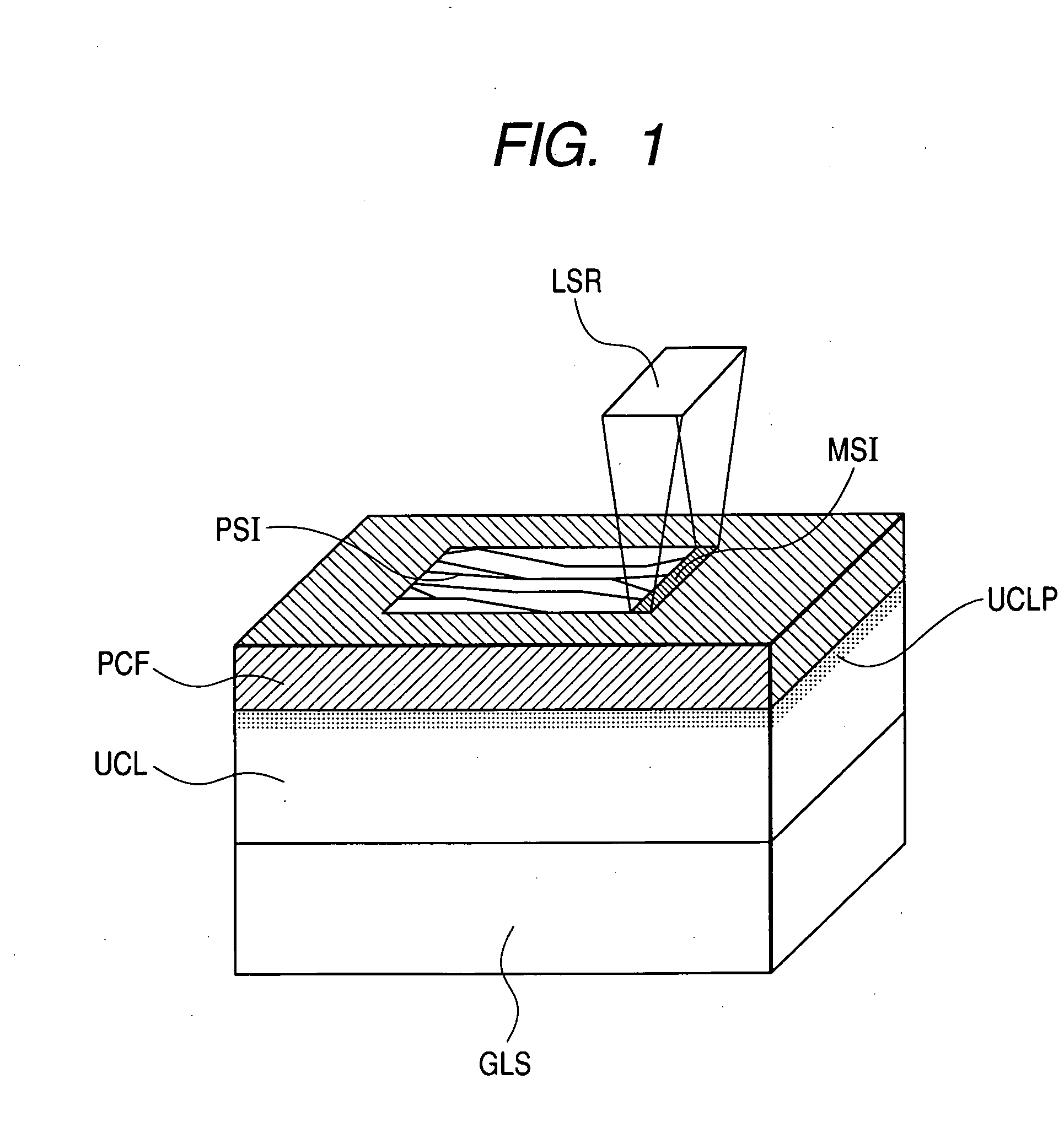

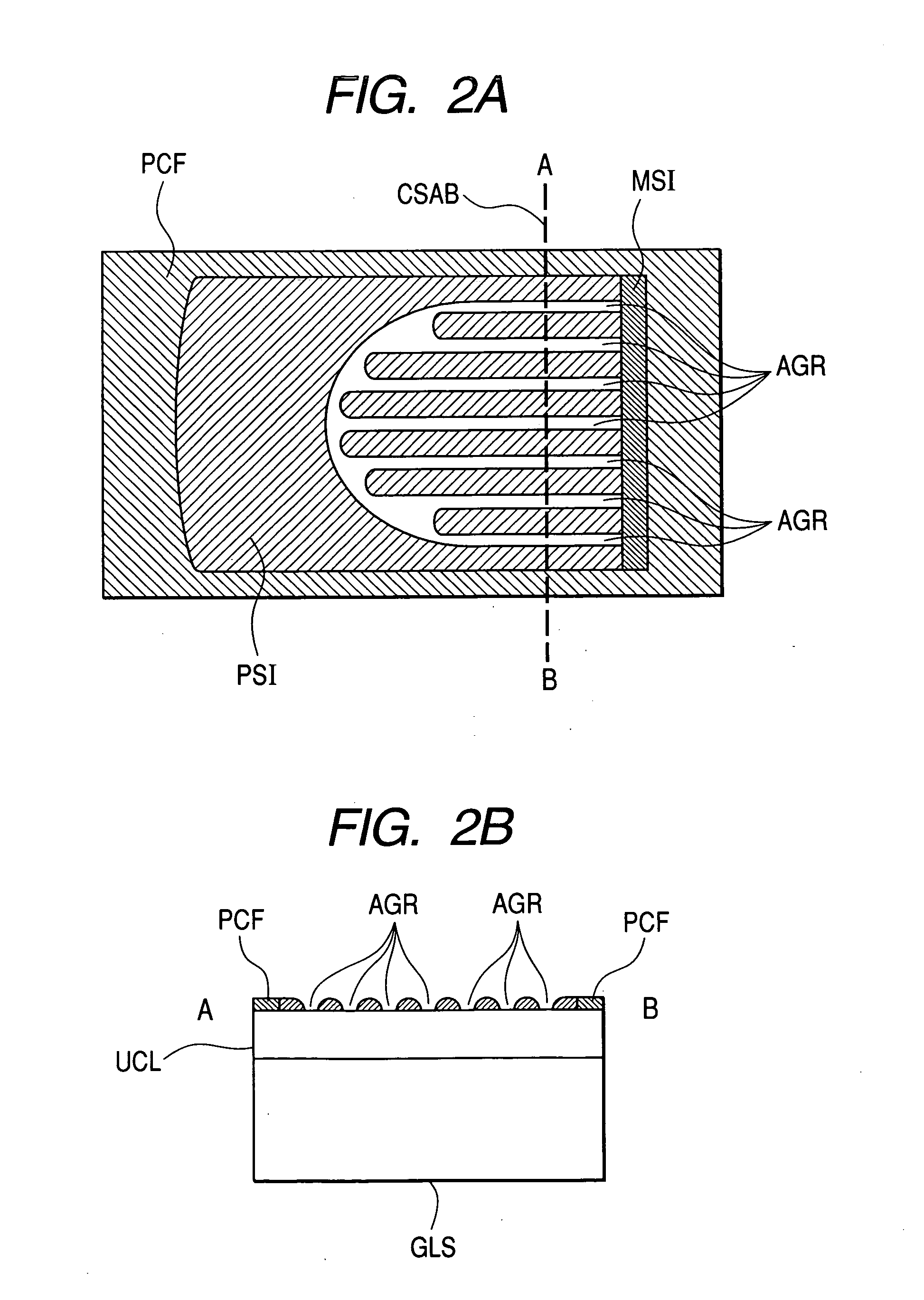

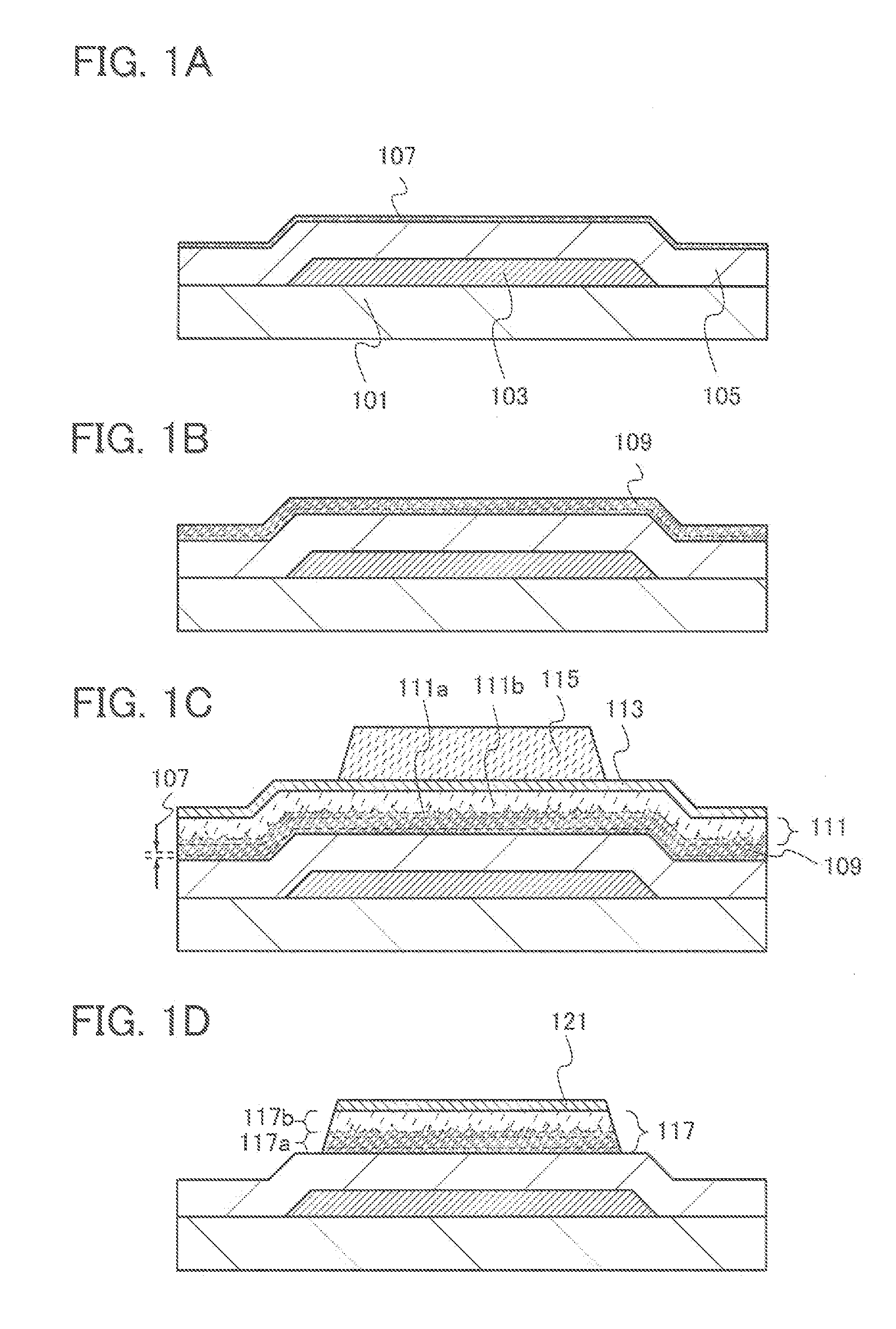

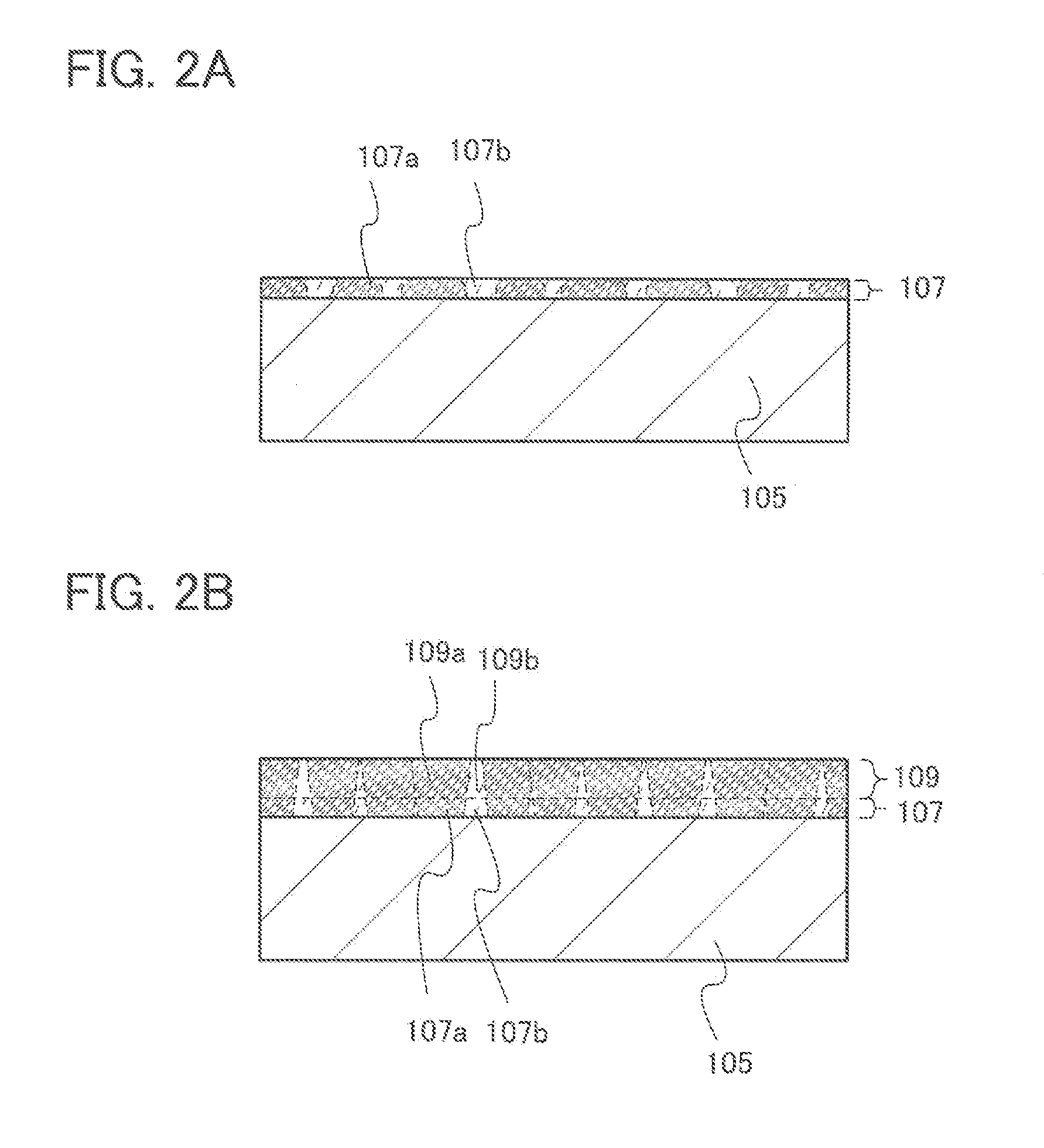

Thin film semiconductor circuit, manufacturing method thereof, and image display apparatus utilizing the same thin film semiconductor circuit

InactiveUS20060001051A1High manufacturing yieldQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingRe crystallizationPolycrystalline silicon

Agglomeration of a polycrystalline silicon film is eliminated at the time of obtaining a high quality polycrystalline silicon film by forming a silicon layer on an insulating film substrate and conducting long-term melting and re-crystallization. For this purpose, a layer or a plurality of layers of an underlayer UCL are provided on an insulating substrate GLS, the area near the surface in contact with a precursory silicon film PCF provided on this underlayer UCL is formed as an insulating film UCLP showing a film composition to improve the wettability of the melted silicon layer, and thereafter a high quality polycrystalline silicon film PSI is formed through elimination of agglomeration by melting of the precursory silicon film PCF using a laser beam LSR.

Owner:HITACHI DISPLAYS

Tartrate removing method from red wine by continuous deepfreeze

The invention relates to a tartrate removing method from red wine by continuous deepfreeze which comprises, cooling the wine to -4 to -5 deg. C, mixing with measuring crystal method phase at the entrance of the cooling apparatus, thermal insulation 10 hours, equivalent temperature phenindamine tartrate separation, diatomaceous earth filtration and heat exchanging with the wine liquid, and exporting.

Owner:SINO FRENCH JOINT VENTURE DYNASTY WINERY

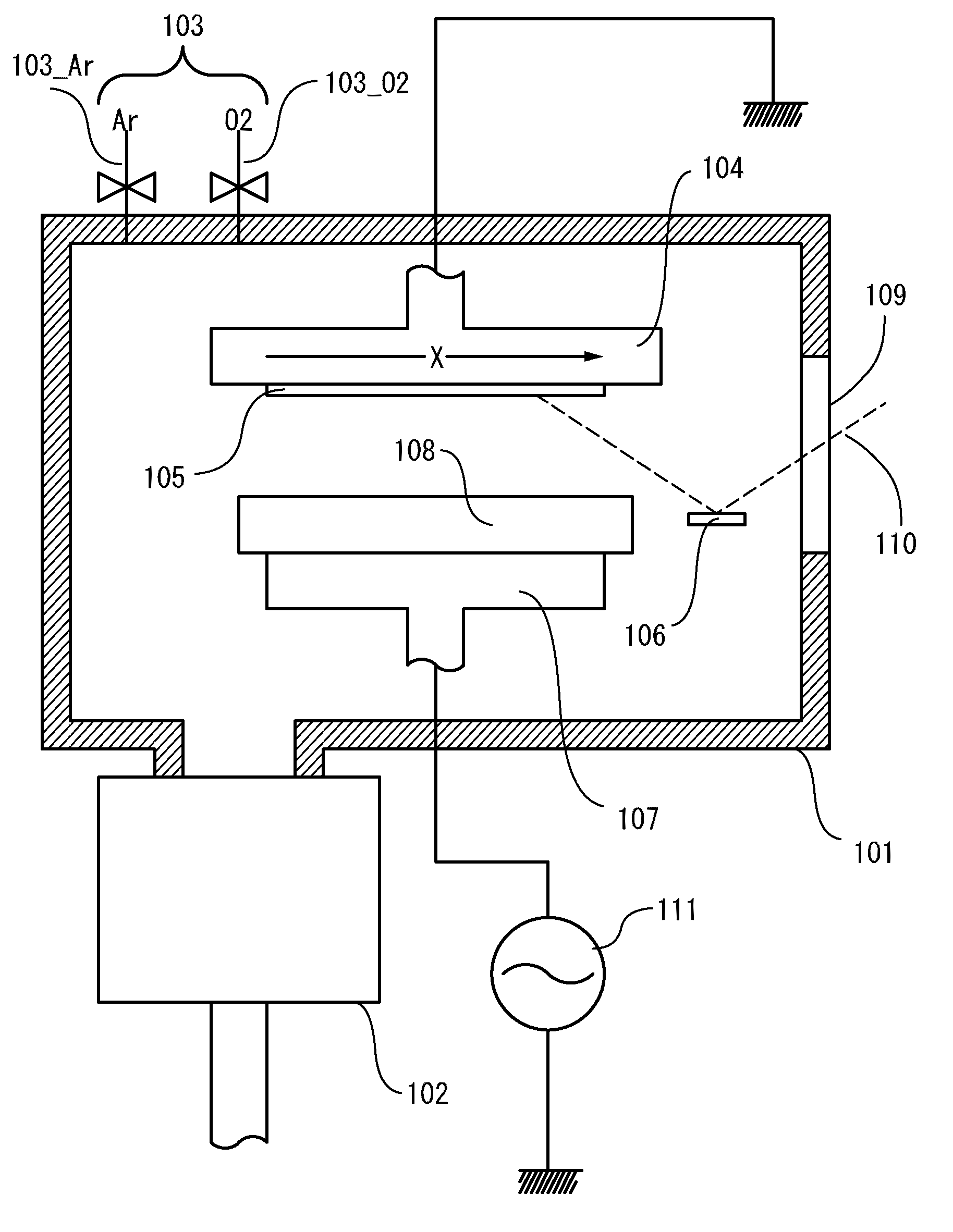

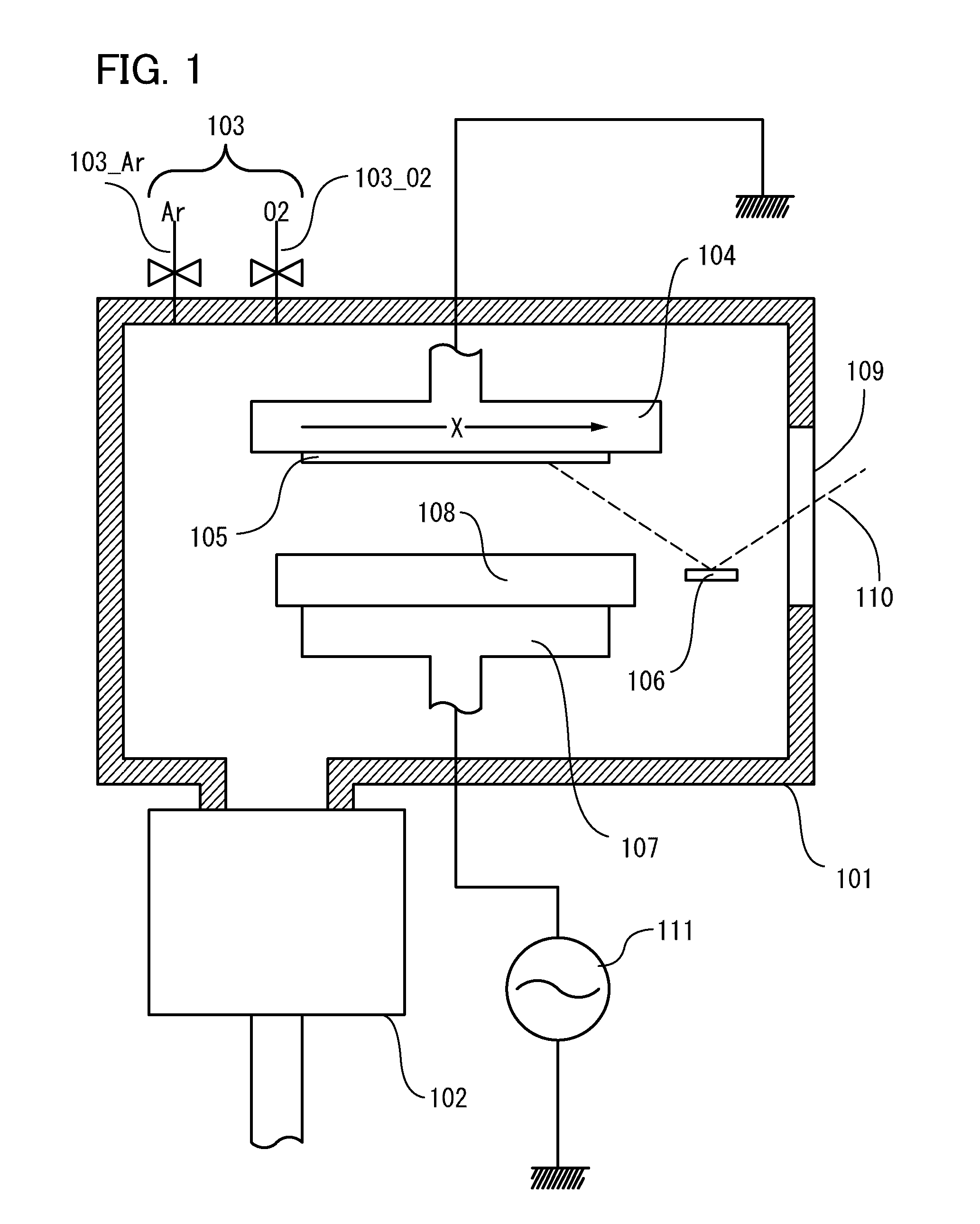

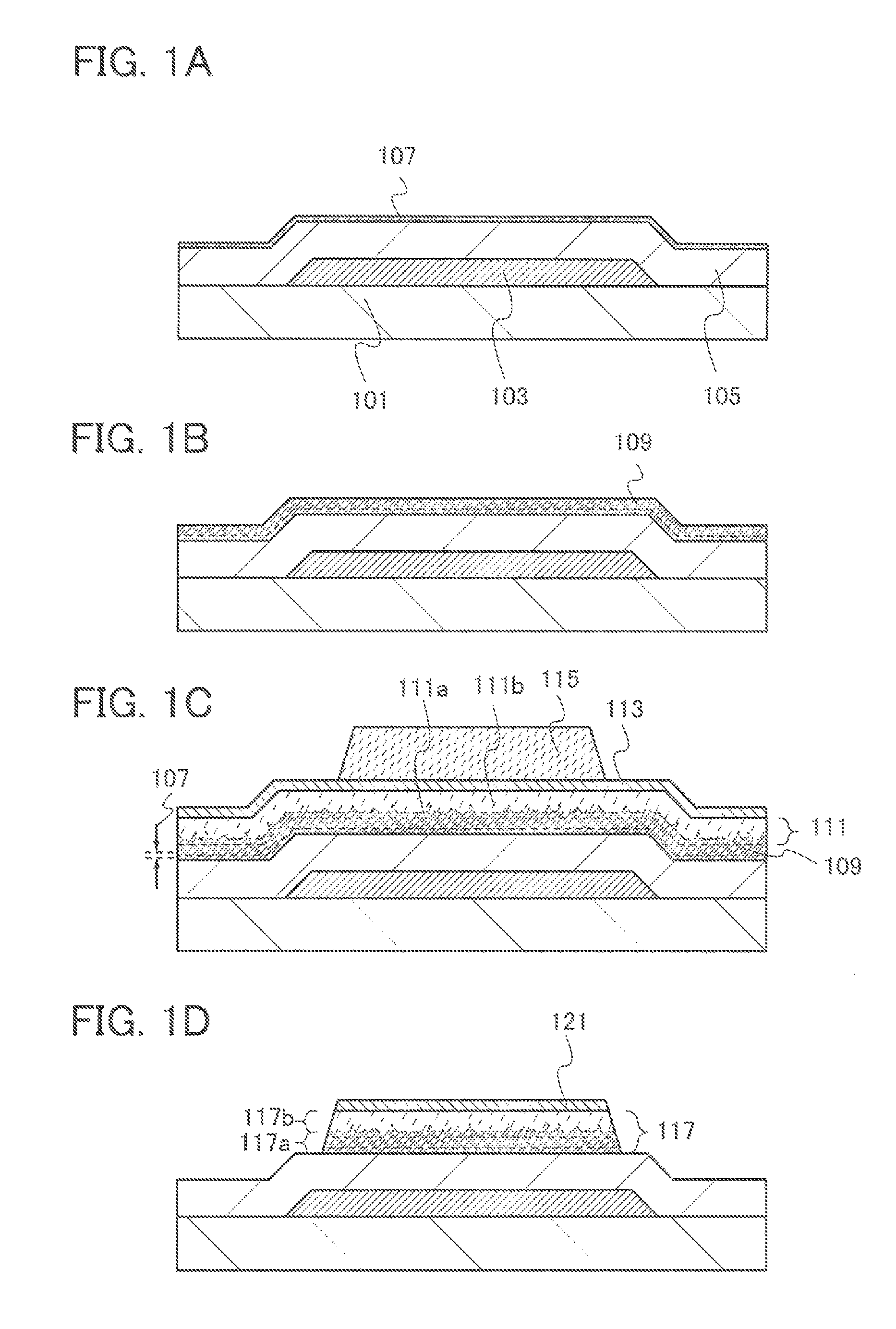

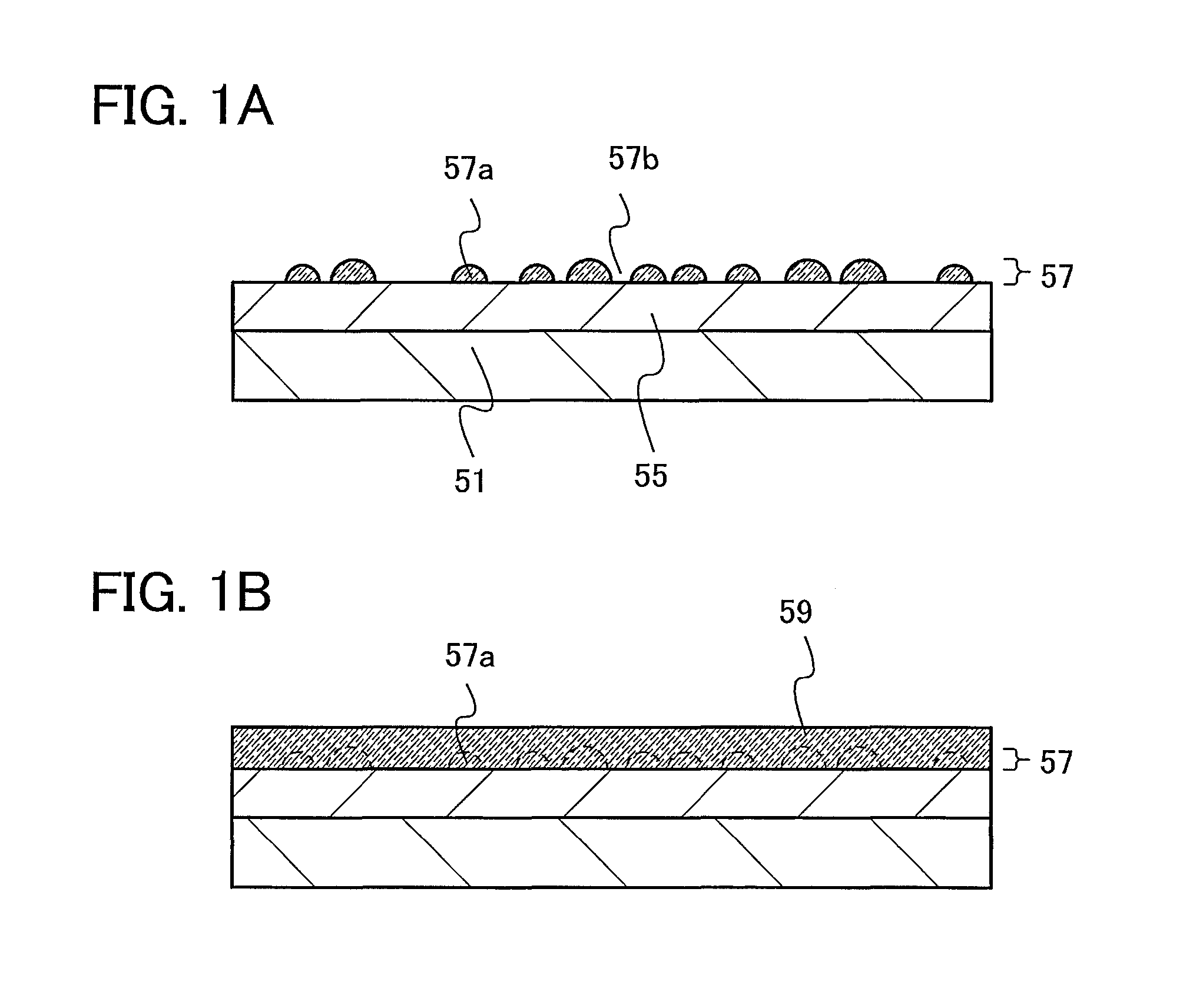

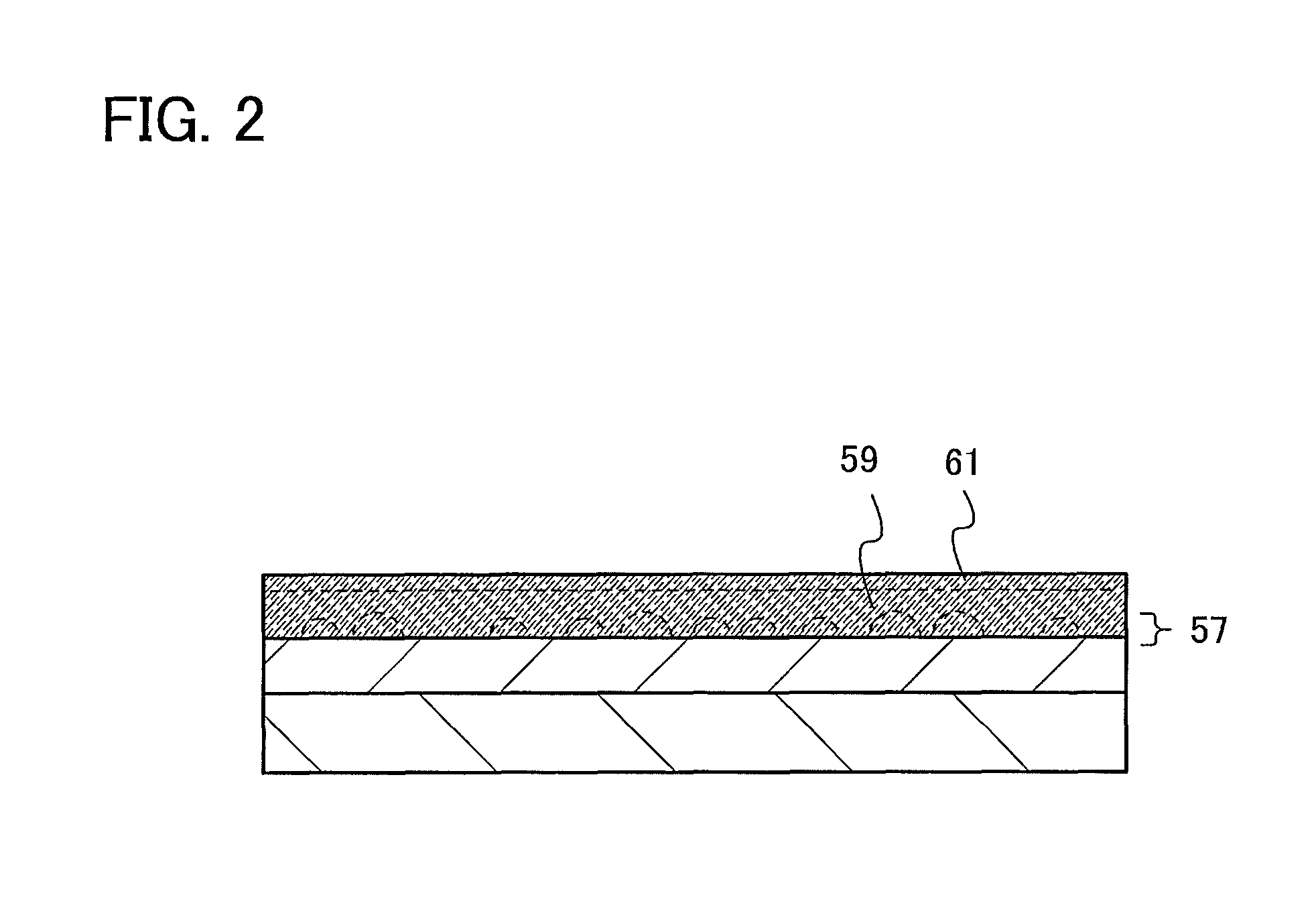

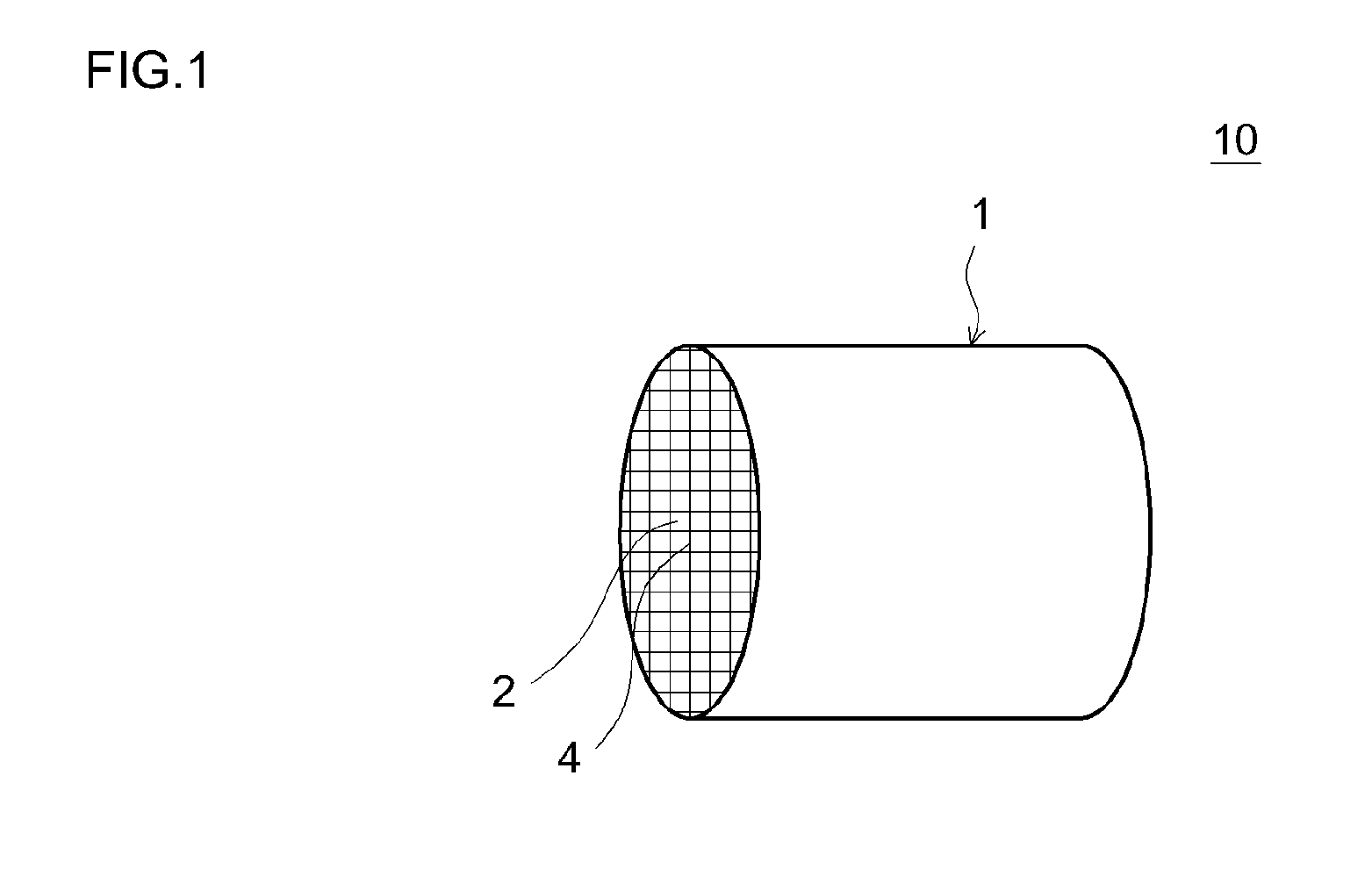

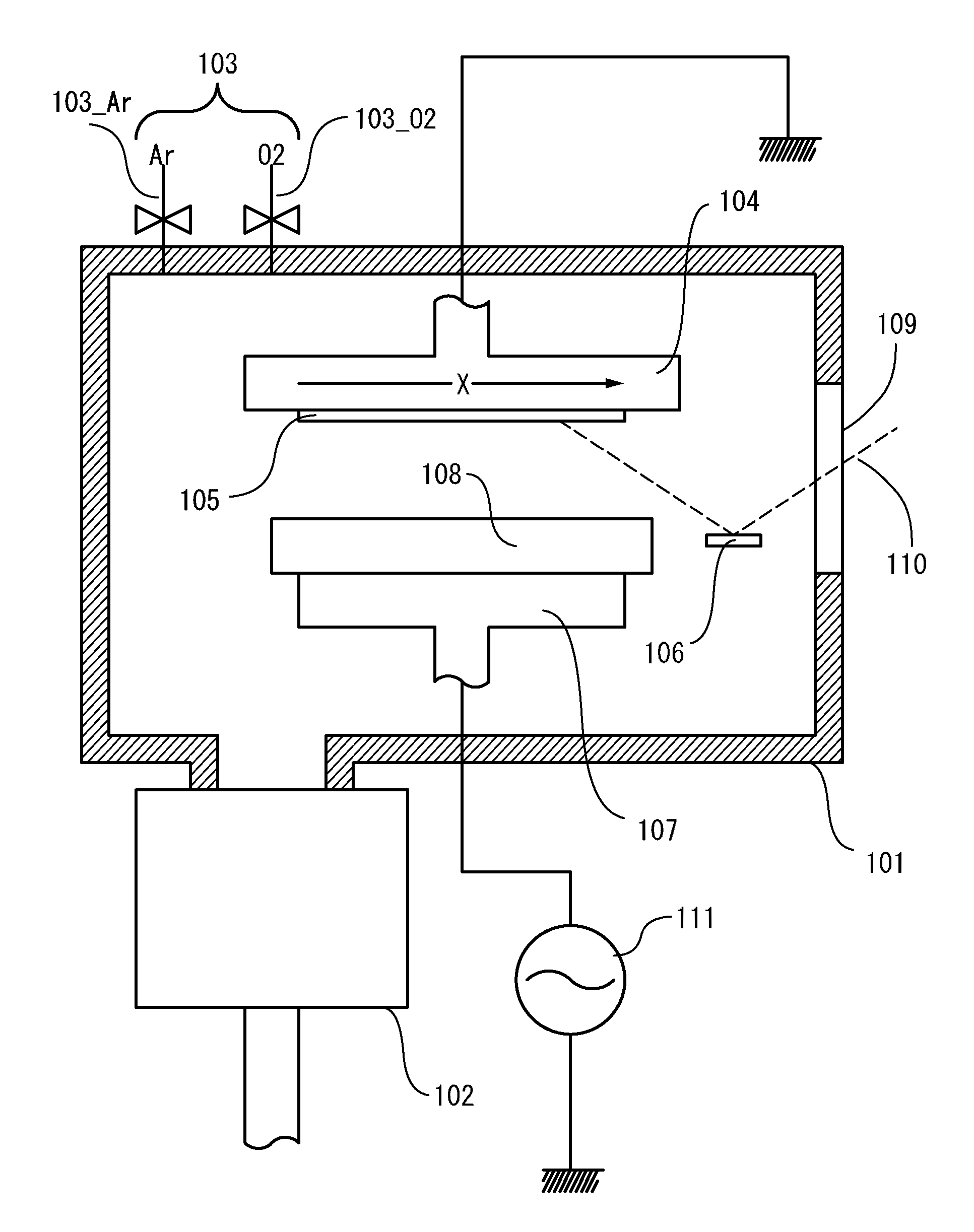

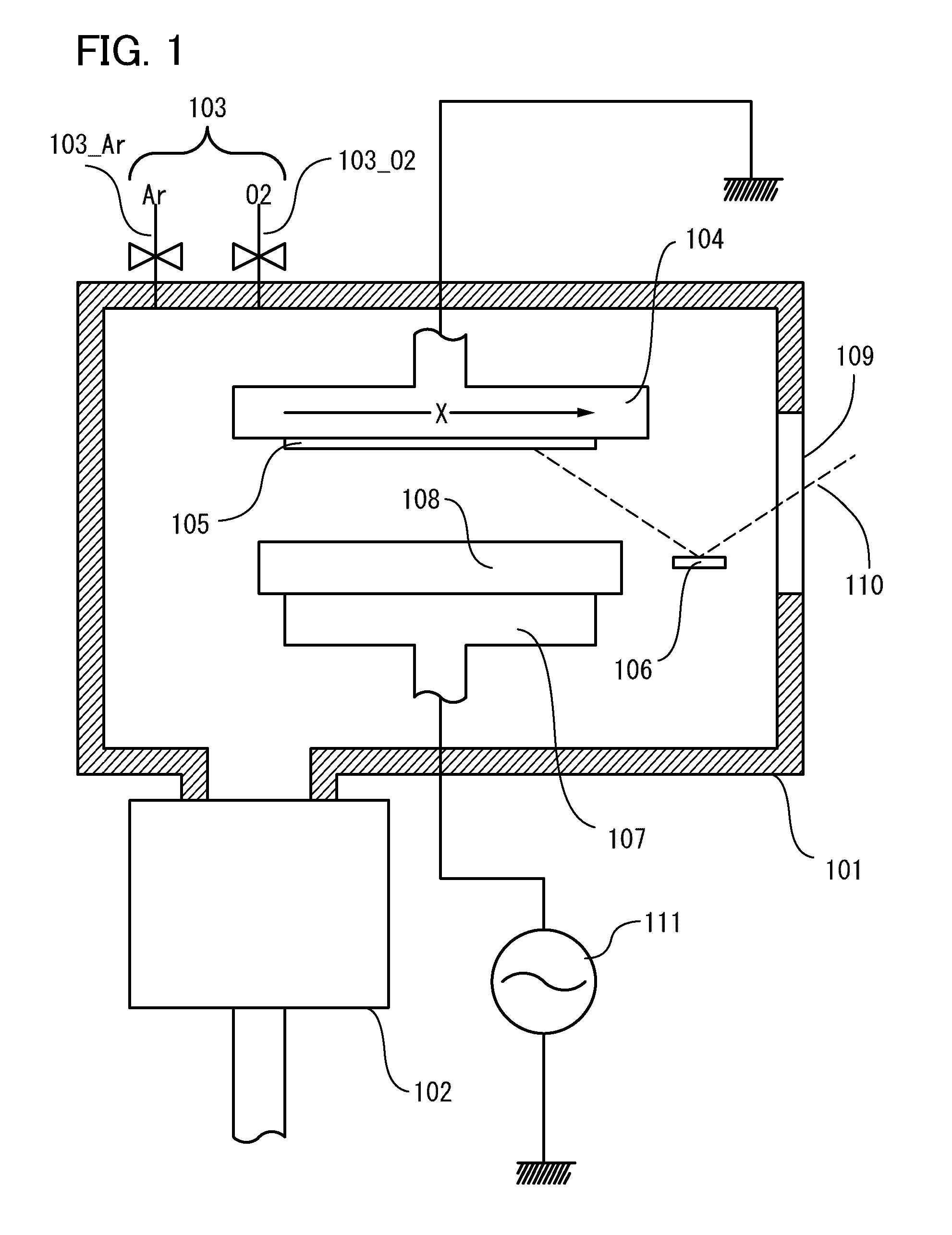

Microcrystalline silicon film, manufacturing method thereof, semiconductor device, and manufacturing method thereof

InactiveUS20130056742A1High crystallinityExcellent electrical propertiesTransistorSemiconductor/solid-state device manufacturingHydrogenMicrocrystalline silicon

A manufacturing method of a microcrystalline silicon film includes the steps of forming a first microcrystalline silicon film over an insulating film by a plasma CVD method under a first condition; and forming a second microcrystalline silicon film over the first microcrystalline silicon film under a second condition. As a source gas supplied to a treatment chamber, a deposition gas containing silicon and a gas containing hydrogen are used. In the first condition, a flow rate of hydrogen is set at a flow rate 50 to 1000 times inclusive that of the deposition gas, and the pressure inside the treatment chamber is set 67 to 1333 Pa inclusive. In the second condition, a flow rate of hydrogen is set at a flow rate 100 to 2000 times inclusive that of the deposition gas, and the pressure inside the treatment chamber is set 1333 to 13332 Pa inclusive.

Owner:SEMICON ENERGY LAB CO LTD +1

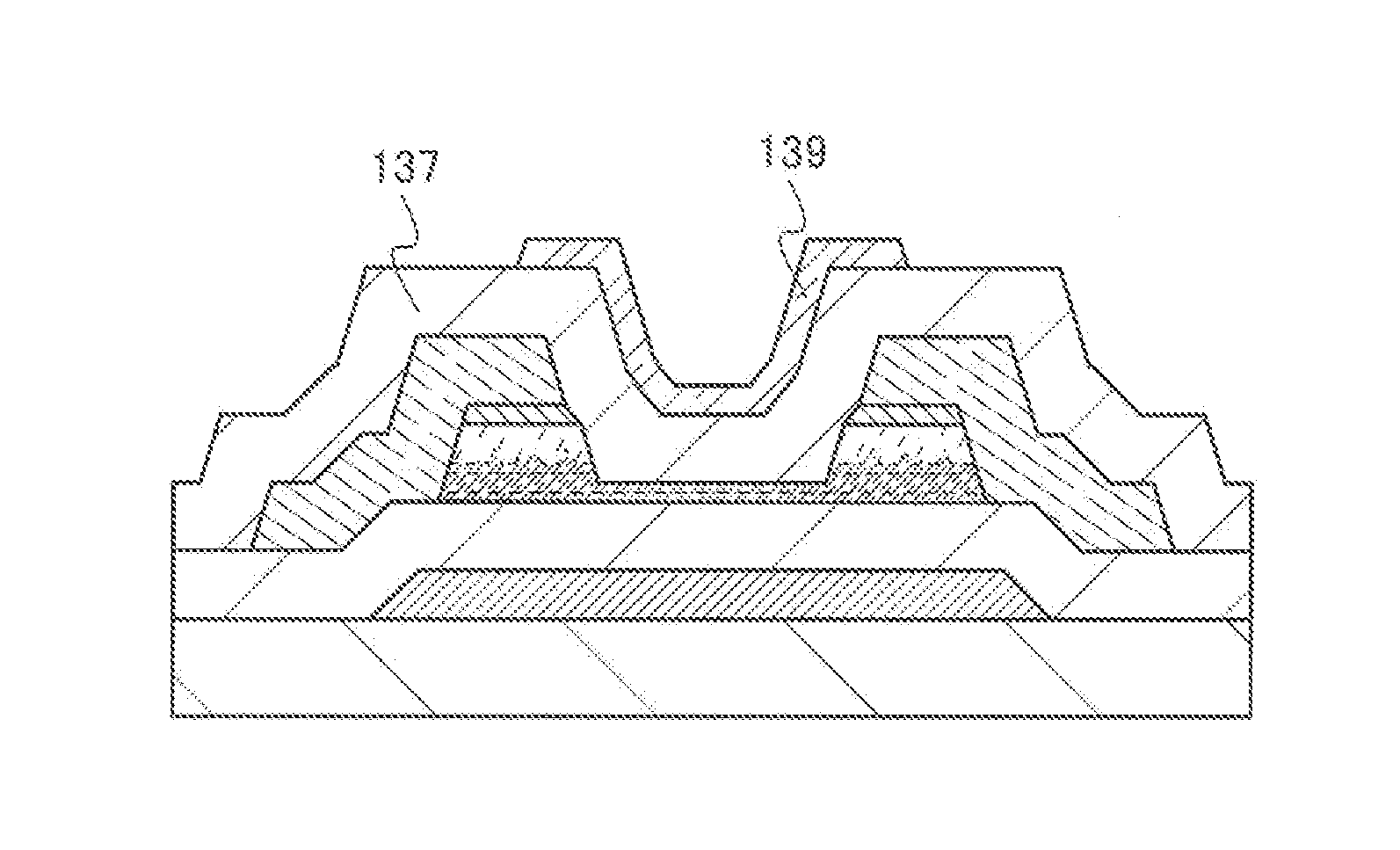

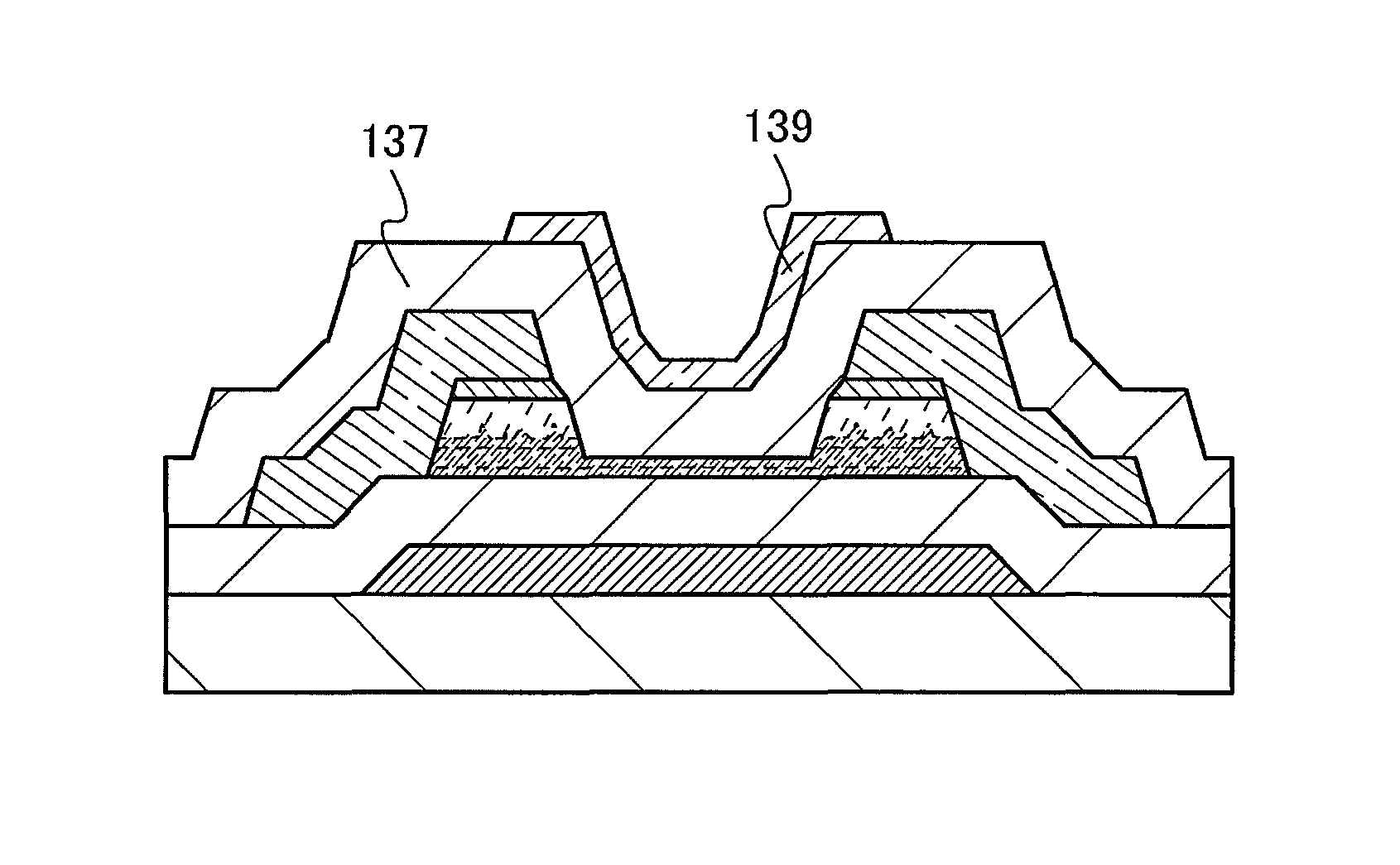

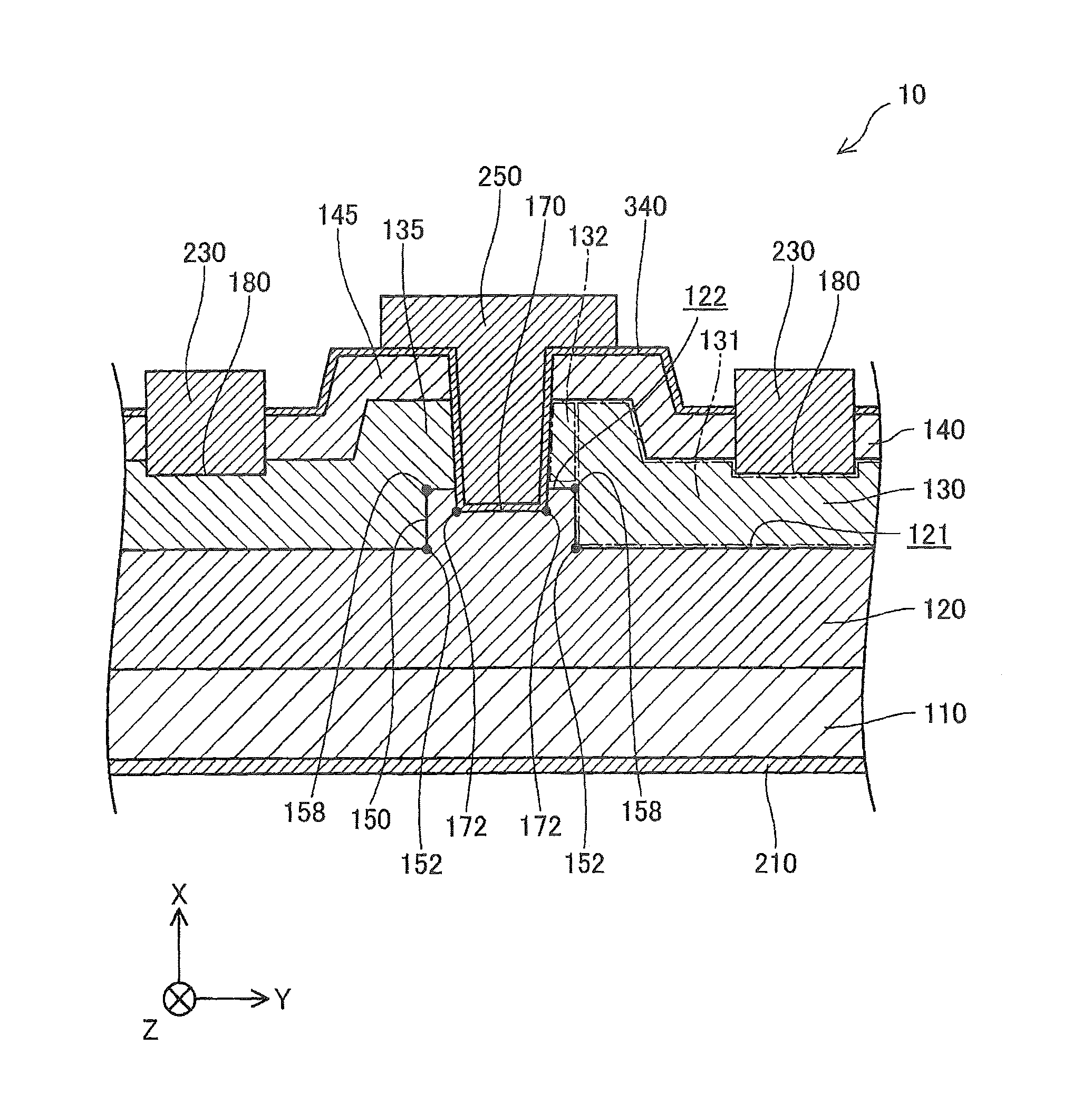

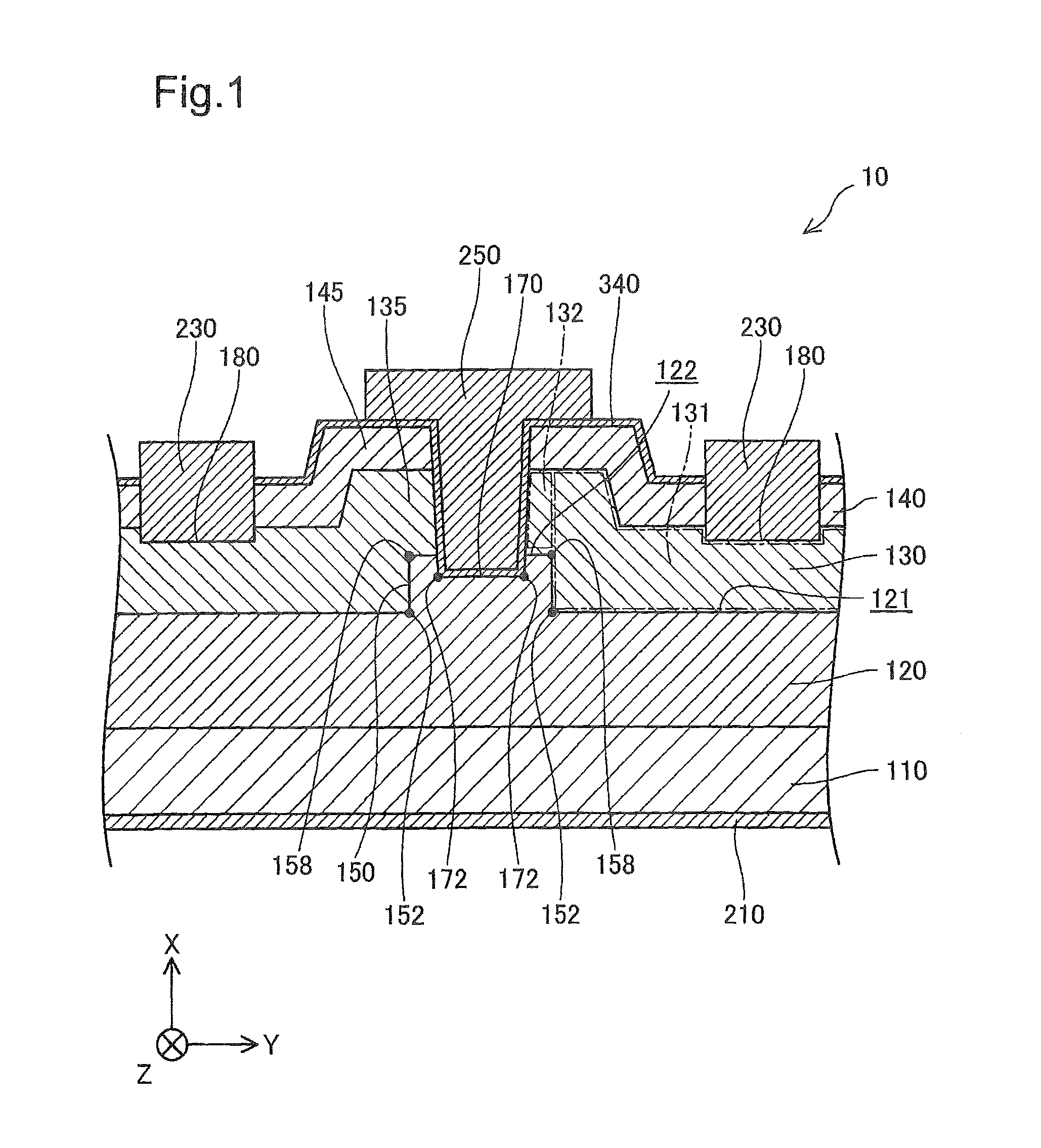

Thin film transistor and manufacturing method thereof

InactiveUS20110204364A1High currentLower average currentTransistorSemiconductor/solid-state device manufacturingProduction rateOxide thin-film transistor

A method for manufacturing a thin film transistor having high electric characteristics with high productivity. In the method for forming a channel region of a dual-gate thin film transistor including a first gate electrode and a second gate electrode which faces the first gate electrode with the channel region provided therebetween, a first microcrystalline semiconductor film is formed under a first condition for forming a microcrystalline semiconductor film in which a space between crystal grains is filled with an amorphous semiconductor, and a second microcrystalline semiconductor film is formed over the first microcrystalline semiconductor film under a second condition for promoting crystal growth.

Owner:SEMICON ENERGY LAB CO LTD

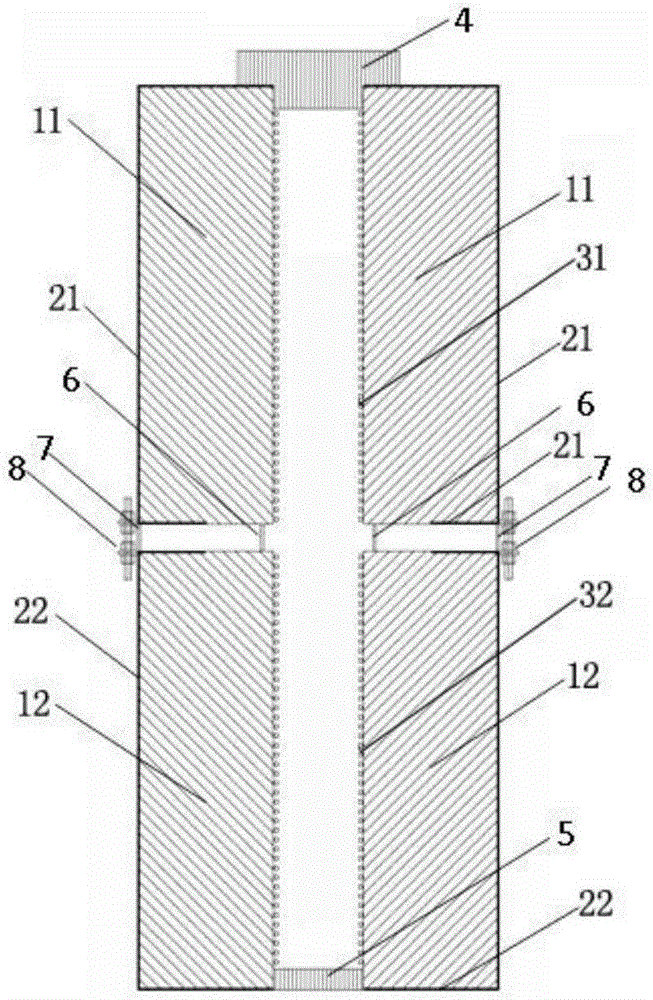

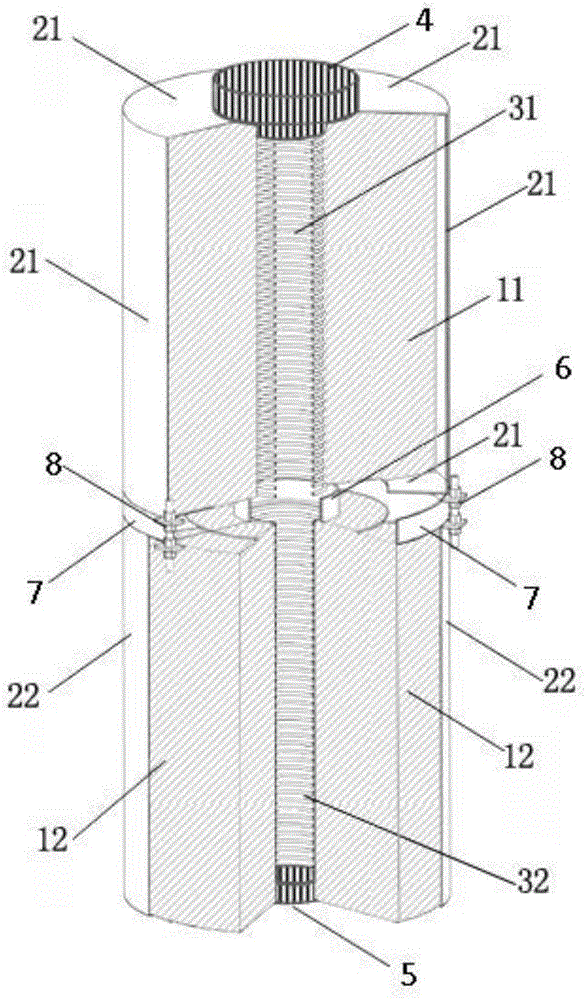

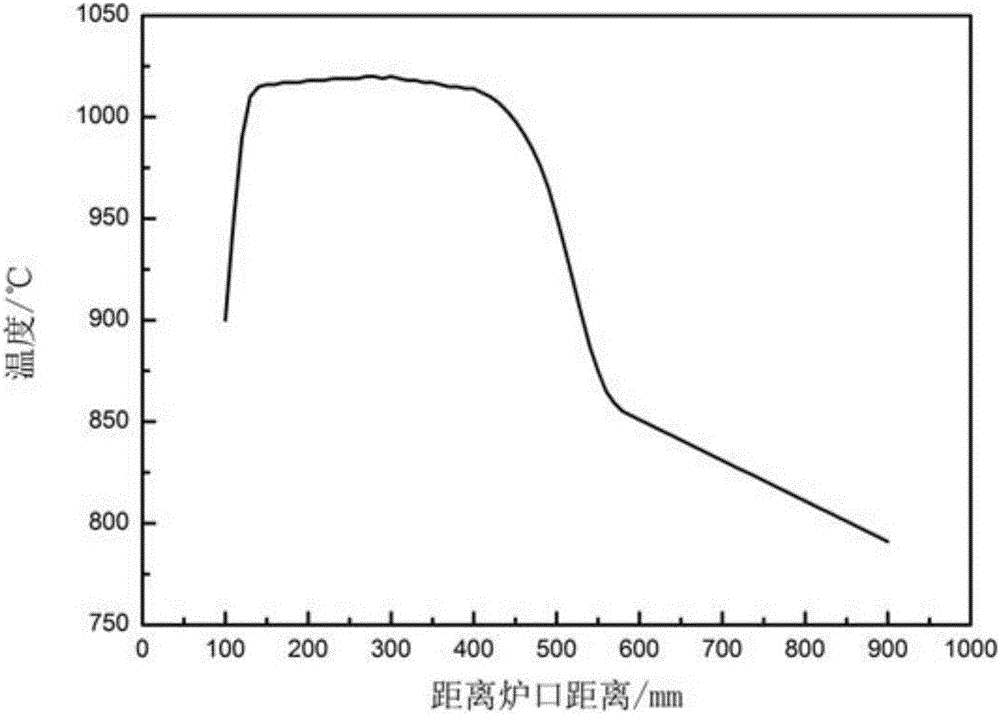

High-gradient visual tubular single crystal growth furnace

ActiveCN105951169AAdd dimensionAvoid the phenomenon of radial temperature field asymmetryFrom frozen solutionsResistance wireSingle crystal growth

The invention discloses a high-gradient visual tubular single crystal growth furnace. The furnace comprises an upper furnace body, a lower furnace body and a middle observation area. The upper furnace body is sequentially provided with an upper furnace shell, upper heat-preserving cotton and an upper heating resistance wire from outside to inside, the lower furnace body is sequentially provided with a lower furnace shell, lower heat-preserving cotton and a lower heating resistance wire from outside to inside, an upper furnace opening plug is arranged on the top of the upper furnace body, and a lower furnace opening plug is arranged at the bottom of the lower furnace body; the middle observation area between the upper furnace body and the lower furnace body is sequentially provided with gold-plated quartz inner tubes and non-gold-plated quartz outer tubes from inside to outside, and gaps are formed between the gold-plated quartz inner tubes and non-gold-plated quartz outer tubes; the circle centers of the upper furnace shell, the lower upper furnace shell, the upper heat-preserving cotton, the lower heat-preserving cotton, the upper heating resistance wire, the lower heating resistance wire, the gold-plated quartz inner tubes and non-gold-plated quartz outer tubes are coaxial. The high-gradient visual tubular single crystal growth furnace avoids the phenomenon that a radial temperature field is not symmetrical due to single-window observation, observation is easy, manufacturing cost is low, and industrial popularization is easy.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

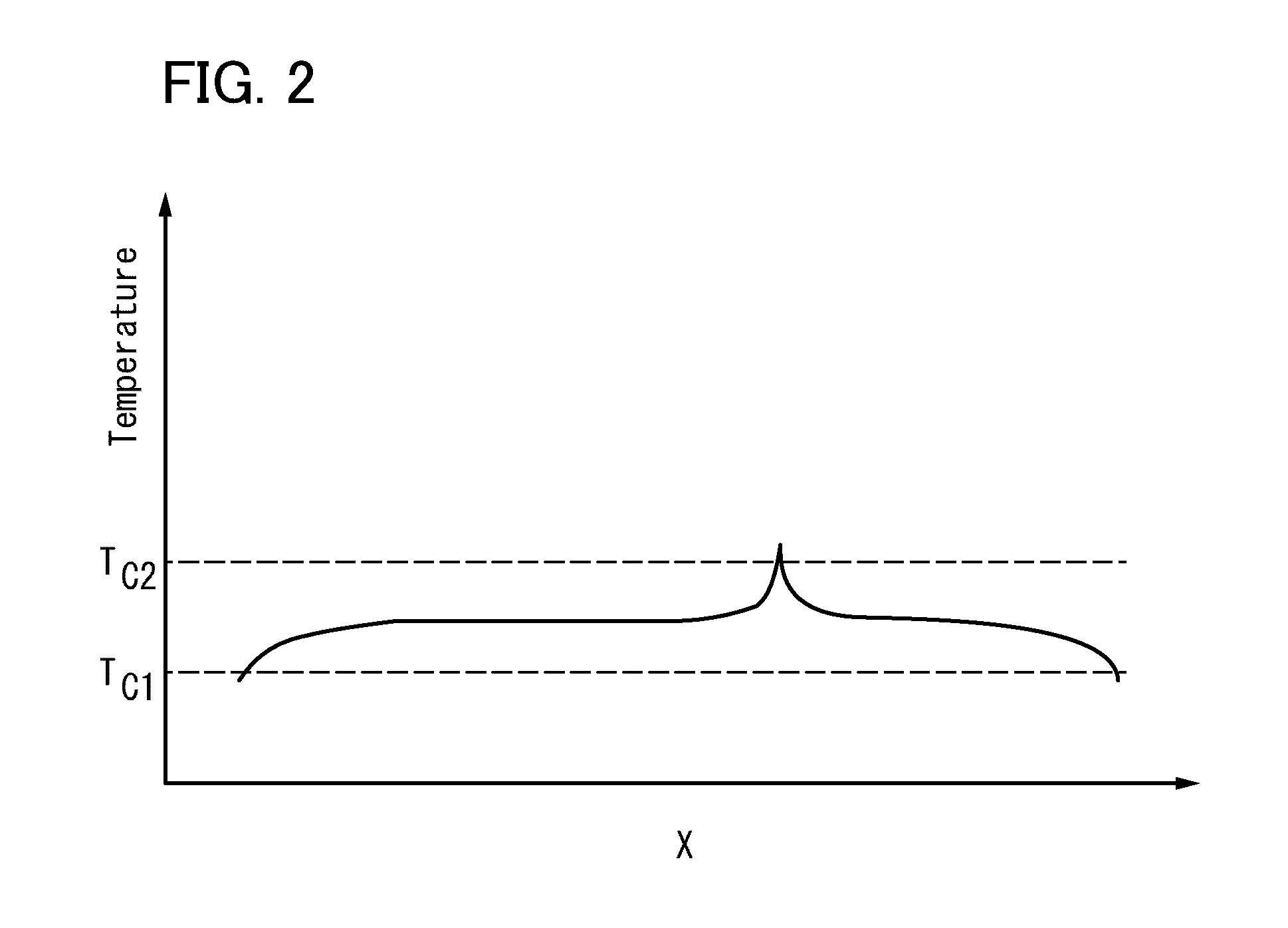

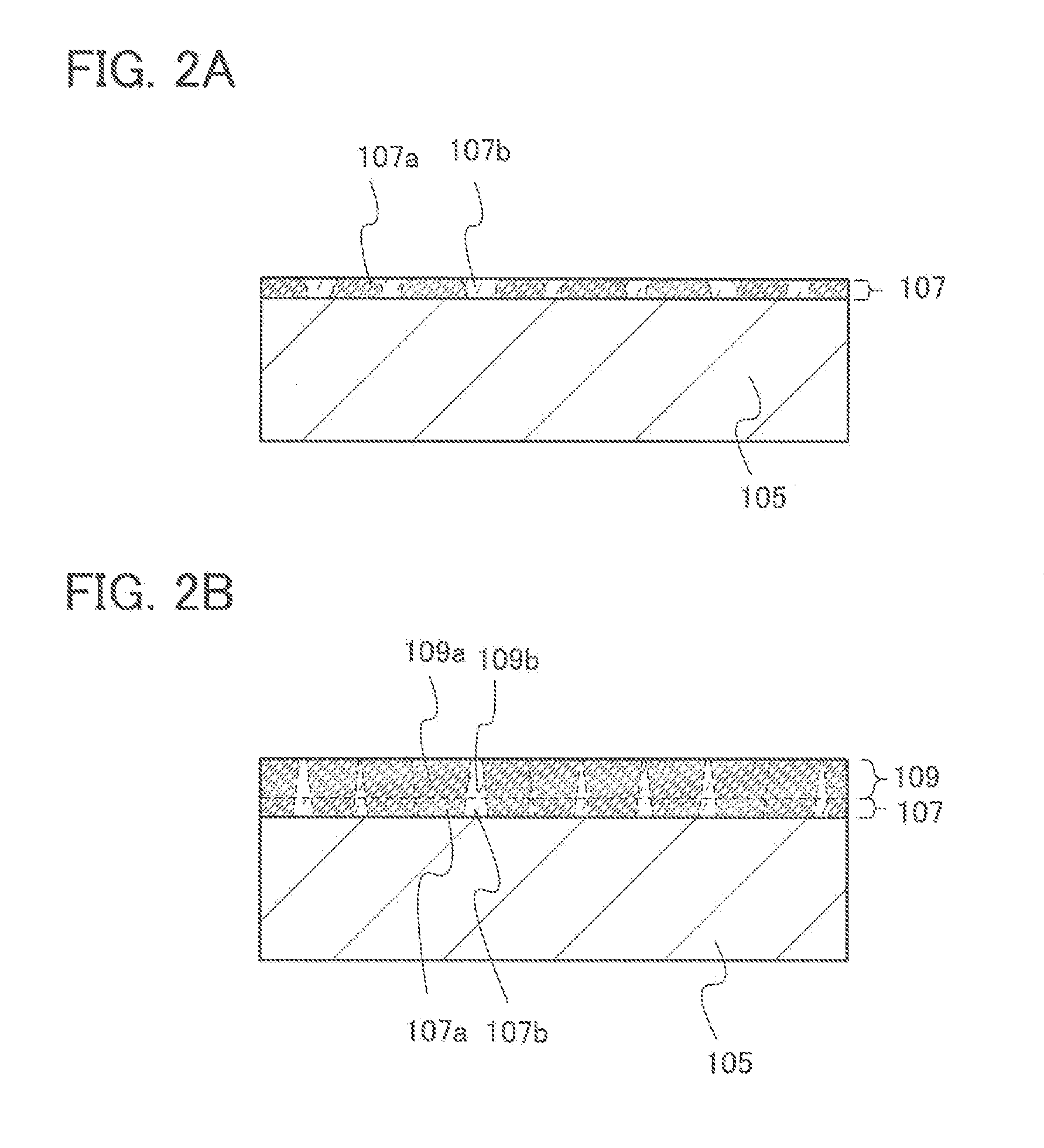

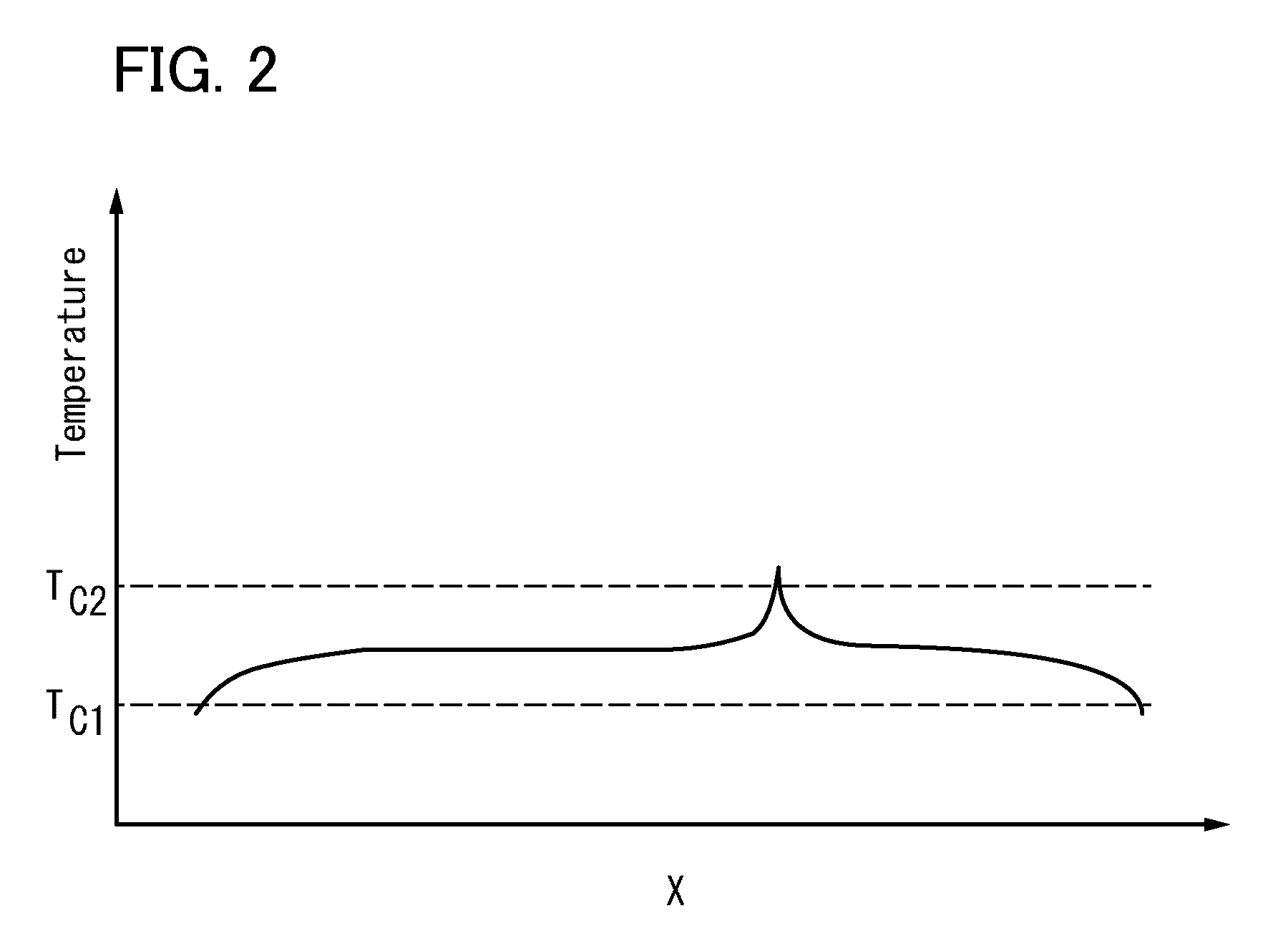

Method of forming crystalline oxide semiconductor film

ActiveUS20120060750A1Improve featuresImprove reliabilityPolycrystalline material growthVacuum evaporation coatingCrystalline oxideCrystallinity

An oxide semiconductor film with excellent crystallinity is formed. At the time when an oxide semiconductor film is formed, as a substrate is heated to a temperature of higher than or equal to a first temperature and lower than a second temperature, a part of the substrate having a typical length of 1 nm to 1 μm is heated to a temperature higher than or equal to the second temperature. Here, the first temperature means a temperature at which crystallization occurs with some stimulation, and the second temperature means a temperature at which crystallization occurs spontaneously without any stimulation. Further, the typical length is defined as the square root of a value obtained in such a manner that the area of the part is divided by the circular constant.

Owner:SEMICON ENERGY LAB CO LTD

Thin film transistor and manufacturing method thereof

InactiveUS8383434B2Improve electrical characteristicsImprove featuresSemiconductor/solid-state device manufacturingSemiconductor devicesProduction rateEngineering

A method for manufacturing a thin film transistor having high electric characteristics with high productivity. In the method for forming a channel region of a dual-gate thin film transistor including a first gate electrode and a second gate electrode which faces the first gate electrode with the channel region provided therebetween, a first microcrystalline semiconductor film is formed under a first condition for forming a microcrystalline semiconductor film in which a space between crystal grains is filled with an amorphous semiconductor, and a second microcrystalline semiconductor film is formed over the first microcrystalline semiconductor film under a second condition for promoting crystal growth.

Owner:SEMICON ENERGY LAB CO LTD

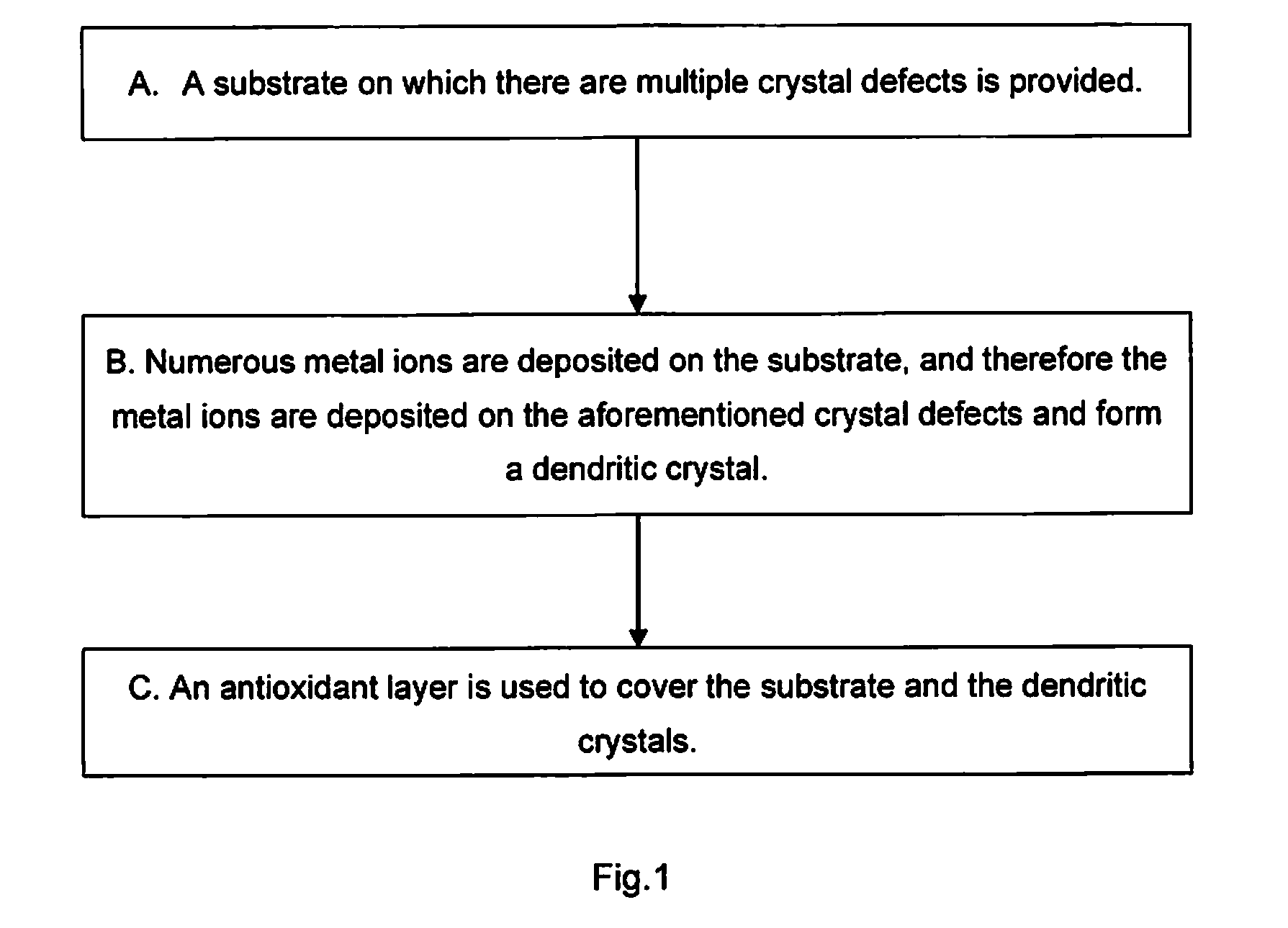

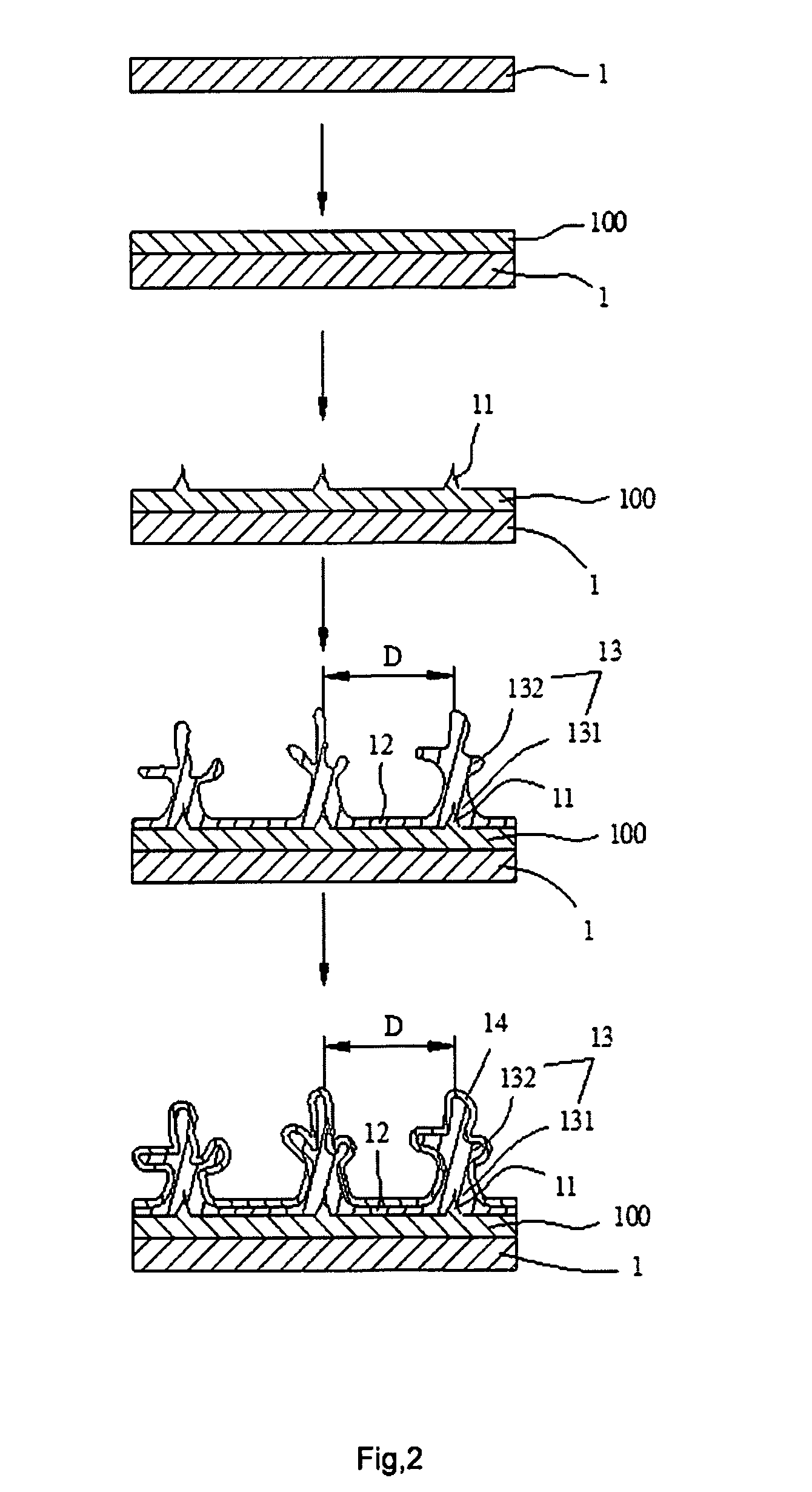

Heat transfer component with dendritic crystal structures and purpose and method of use for such a component

InactiveUS20150327404A1Improve cooling efficiencyPractical value can be improvedSemiconductor/solid-state device detailsSolid-state devicesMain branchCrystal structure

A heat transfer component with dendritic crystal structures and a purpose and method of use for such a component; this component is used to resolve the deficiency concerning conventional heat transfer components possessing inadequate surface areas for heat dissipation. Dendritic crystal structure is comprising: a substrate and multiple dendritic crystals. The substrate contains multiple preset crystal defects in which all the dendritic crystals deposit and congregate, and a space is located between each dendritic crystal for thermal convection. Regarding the method of use, the substrate is connected to a heat source, which then induces directional heat transfer from the substrate and the metal layer to the main branch and at least one sub-branch of the dendritic crystal, or the dendritic crystal is placed on a heat source, which induces heat transfer from the crystal to the substrate.

Owner:FAR EAST UNIVERSITY

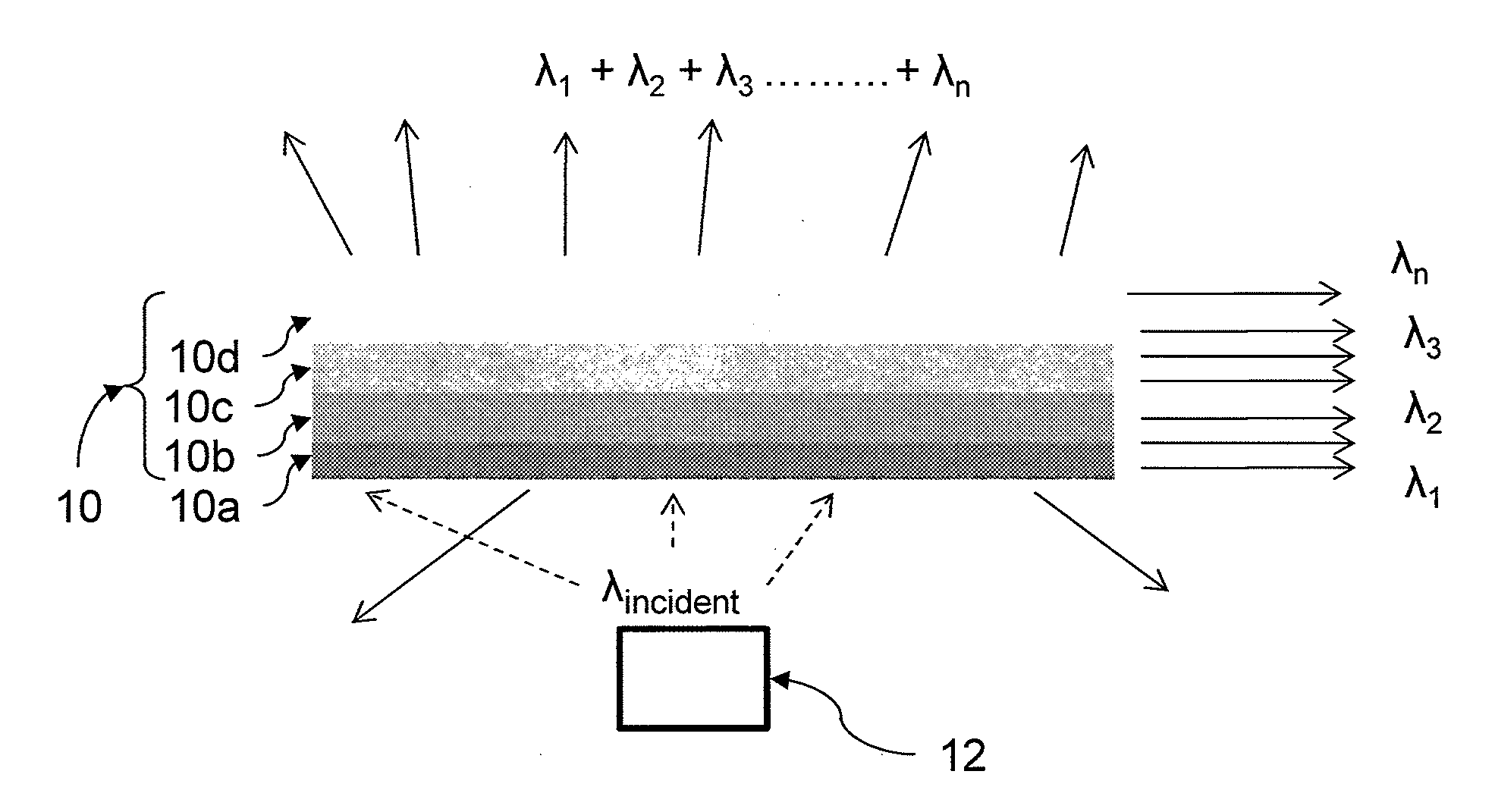

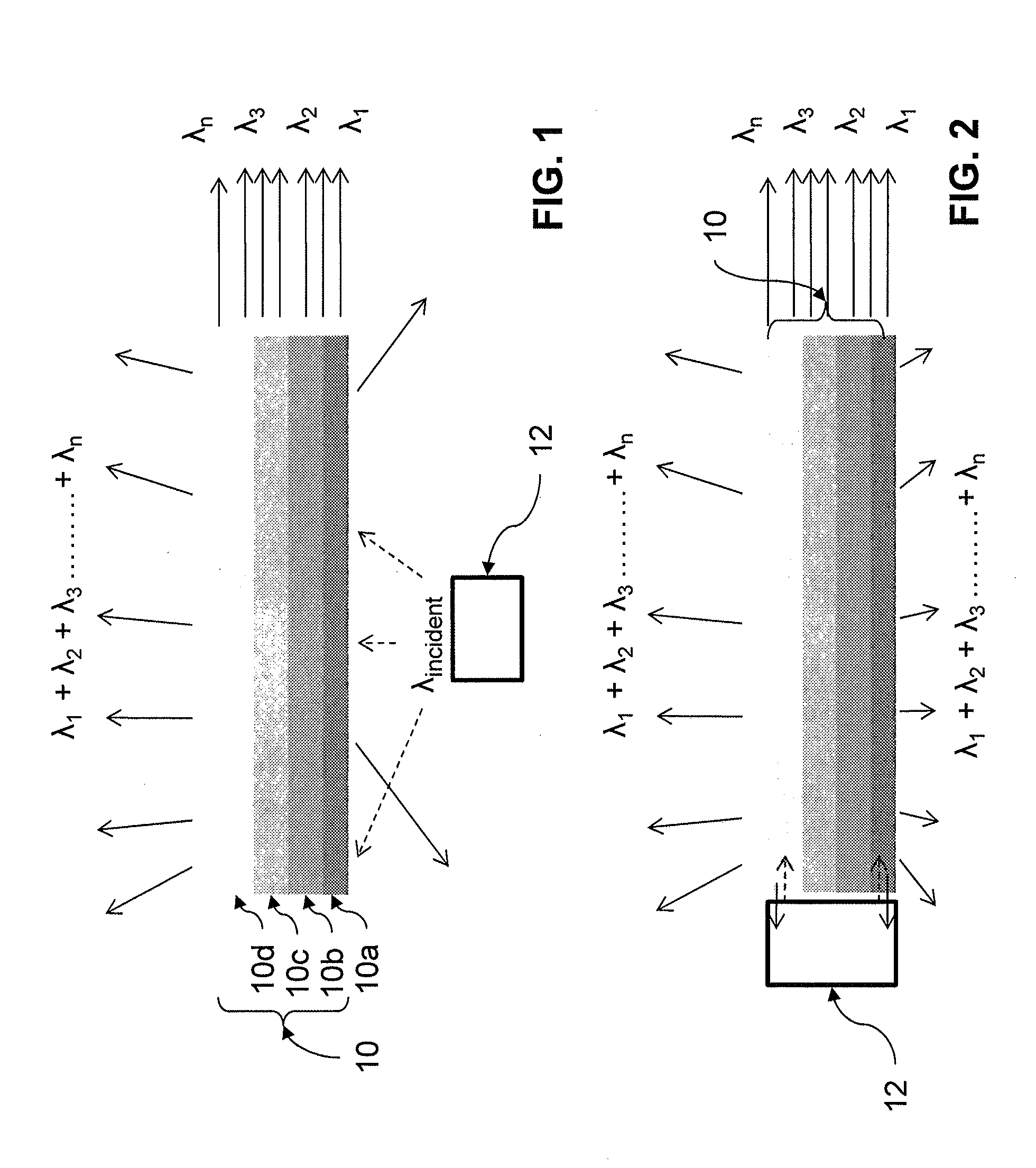

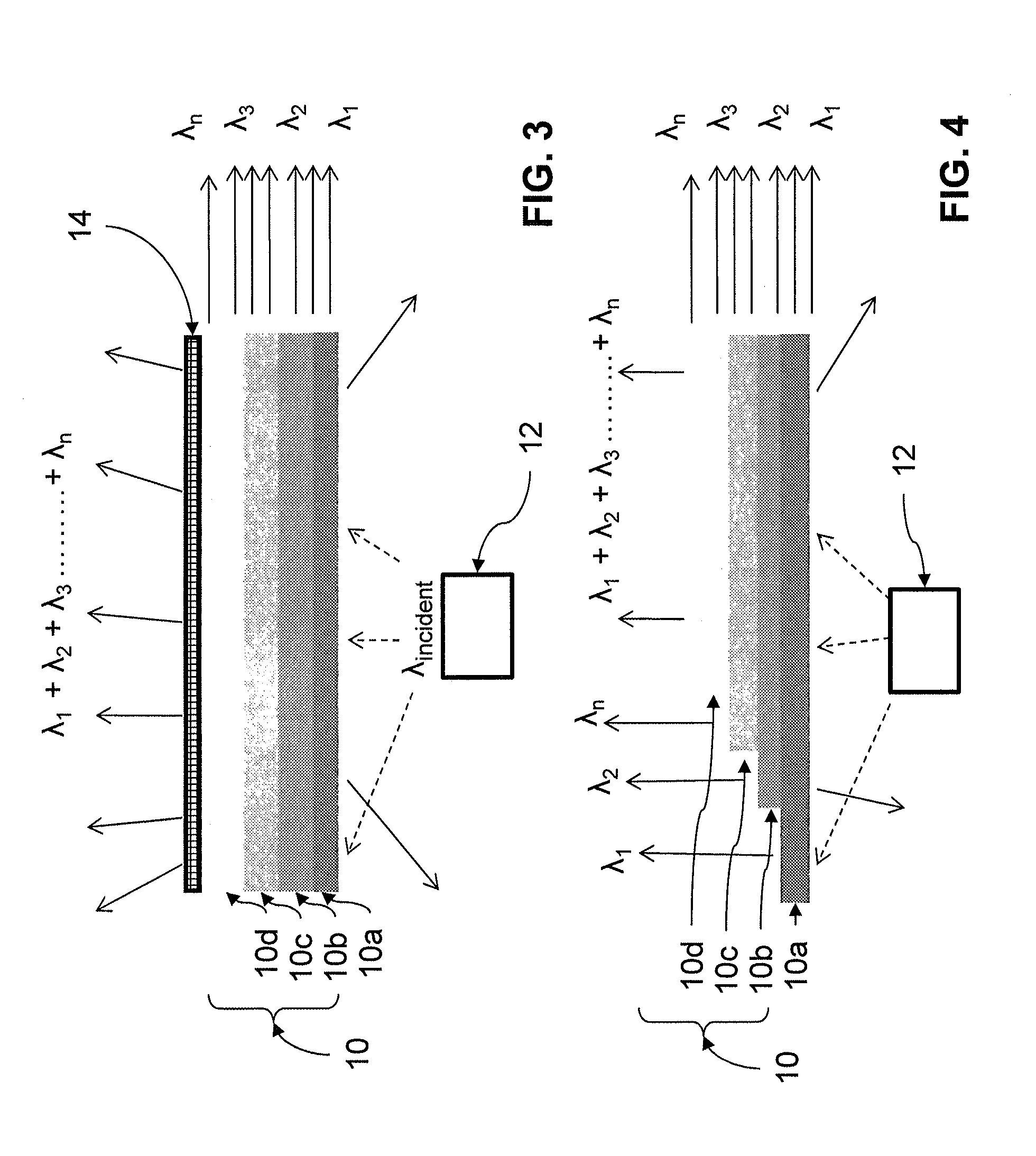

Full spectrum solid state white light source, method for manufacturing and applications

ActiveUS20130113011A1Enhance directional light outputImprove aestheticsMaterial nanotechnologyPolycrystalline material growthSecondary emissionLighting system

A method of manufacturing a down-conversion substrate for use in a light system includes forming a first crystallography layer including one or more phosphor materials and, optionally, applying at least one activator to the crystallography layer, heating the crystallography layer at high temperature to promote crystal growth in the crystallography layer, and drawing out the crystallography layer and allowing the crystallography layer to cool to form the down-conversion substrate. A light system includes an excitation source for emitting short wavelength primary emissions; and a down-conversion substrate disposed in the path of at least some of the primary emissions from the excitation source to convert at least a portion of the primary emissions into longer-wavelength secondary emissions, wherein the substrate includes one or more crystallography layers, wherein each crystallography layer includes one or more phosphor materials, and optionally at least one activator. Down-converted secondary light may be produced by the system.

Owner:RENESSELAER POLYTECHNIC INST

Microcrystalline silicon film, manufacturing method thereof, semiconductor device, and manufacturing method thereof

InactiveUS8884297B2High crystallinityExcellent electrical propertiesTransistorSemiconductor/solid-state device manufacturingHydrogenProduct gas

A manufacturing method of a microcrystalline silicon film includes the steps of forming a first microcrystalline silicon film over an insulating film by a plasma CVD method under a first condition; and forming a second microcrystalline silicon film over the first microcrystalline silicon film under a second condition. As a source gas supplied to a treatment chamber, a deposition gas containing silicon and a gas containing hydrogen are used. In the first condition, a flow rate of hydrogen is set at a flow rate 50 to 1000 times inclusive that of the deposition gas, and the pressure inside the treatment chamber is set 67 to 1333 Pa inclusive. In the second condition, a flow rate of hydrogen is set at a flow rate 100 to 2000 times inclusive that of the deposition gas, and the pressure inside the treatment chamber is set 1333 to 13332 Pa inclusive.

Owner:SEMICON ENERGY LAB CO LTD +1

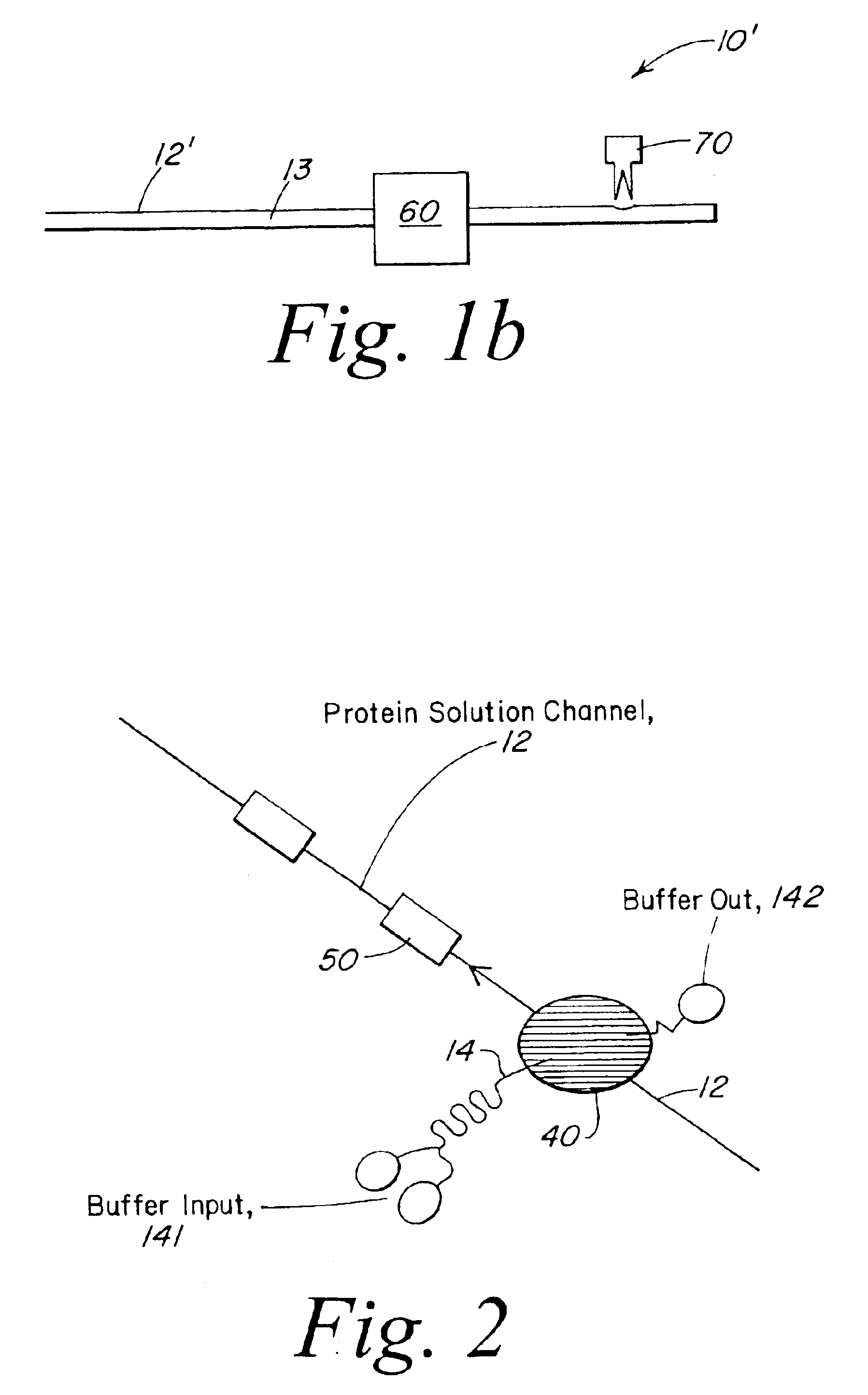

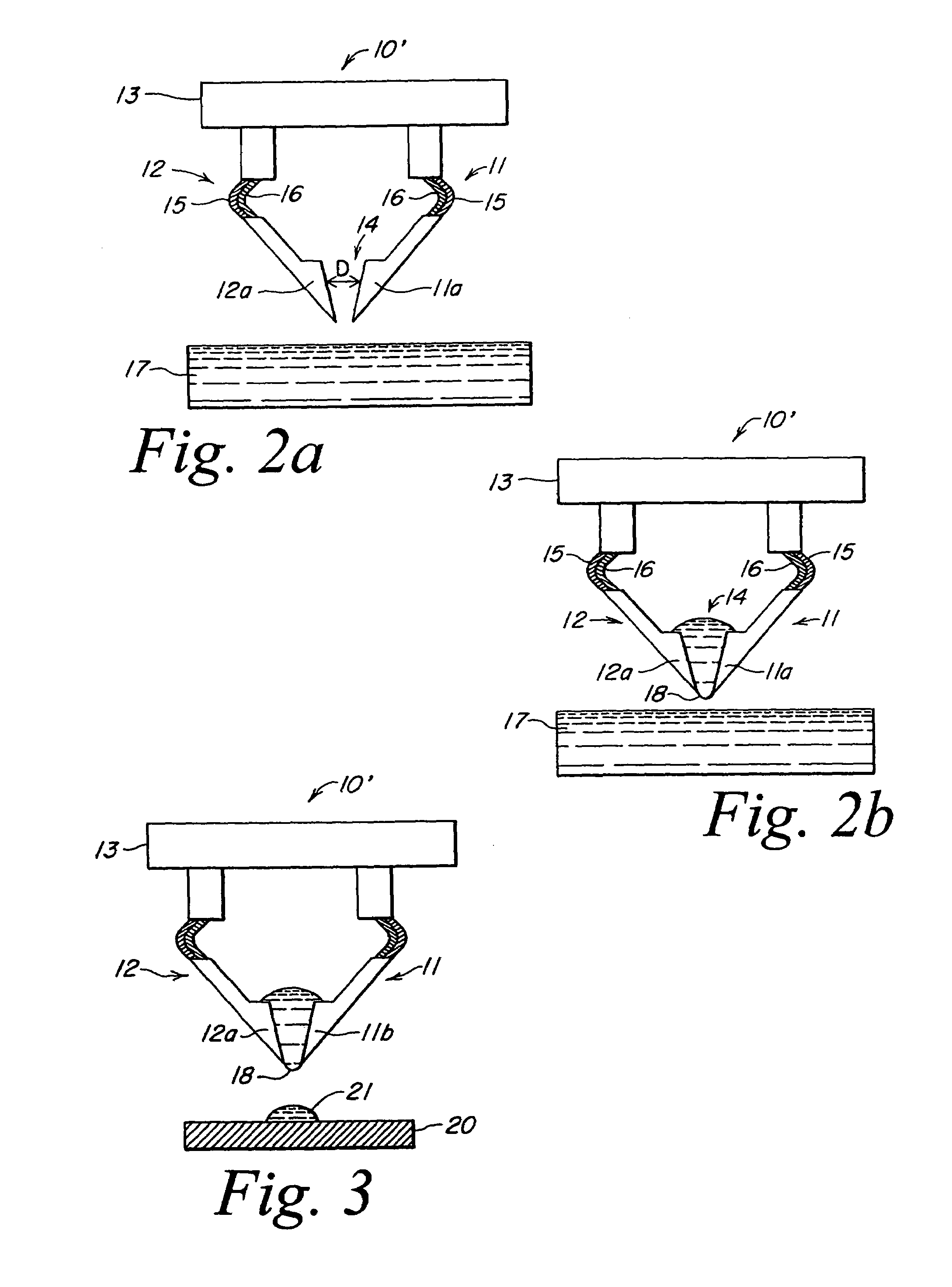

Microfabricated two-pin system for biomolecule crystallization

InactiveUS7153699B2Promotes crystal growthQuality improvementChemical library matterPeptide librariesTranspirationEngineering

A two-pin liquid handling system for crystallizing biomolecules comprises a pair of interacting pins for holding a droplet of liquid therebetween. Each pin includes a tip spaced predetermined distance from the other pin to define a sample acquisition region. The two-pin liquid handling system includes a temperature and humidity control element for controlling the temperature of the sample acquisition region to cause transpiration of water to and from a droplet of biomolecule solution to promote crystallization of the biomolecule.

Owner:CYTONOMEST

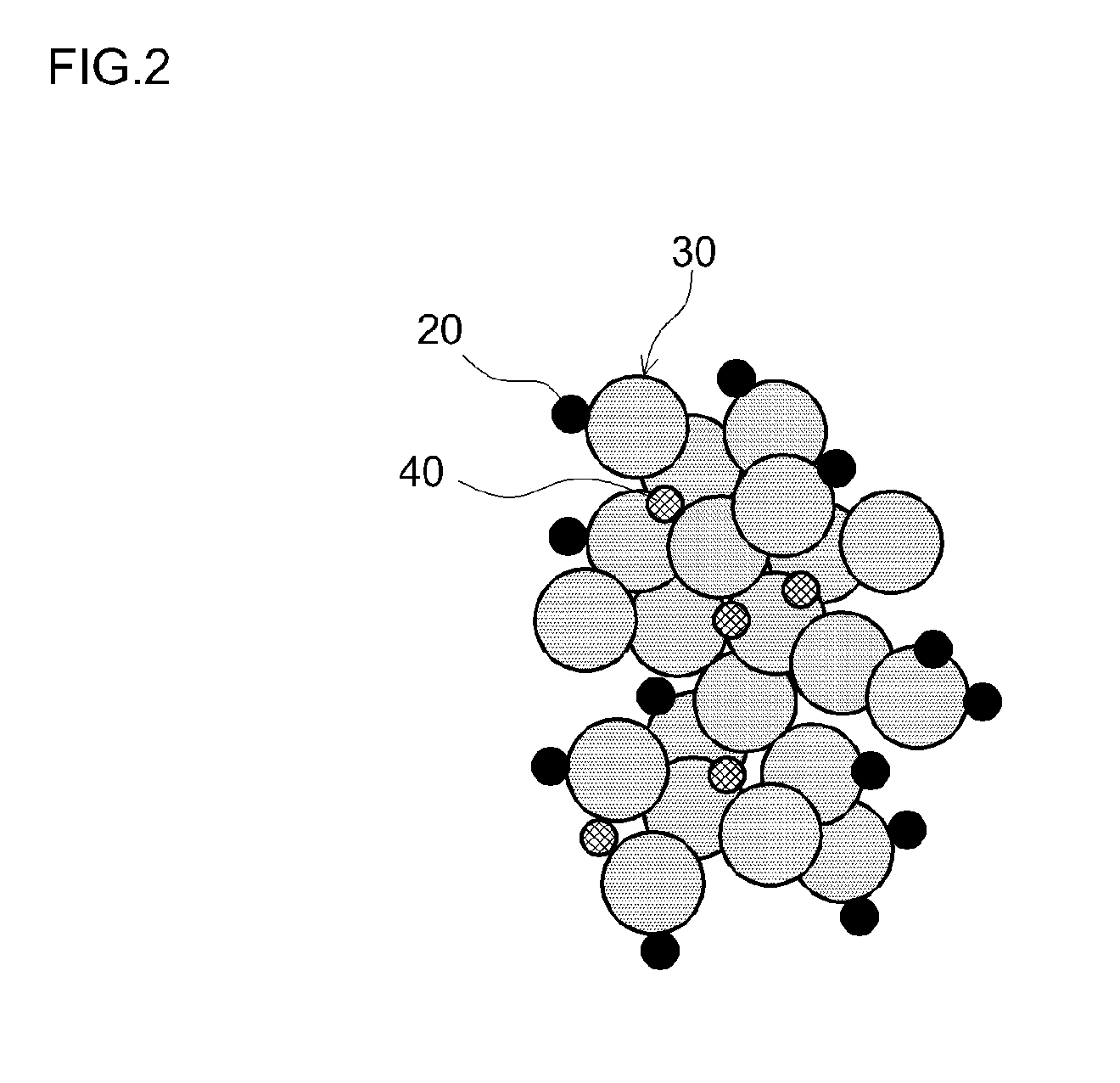

Exhaust gas purifying catalyst

ActiveUS20160288052A1Low heat resistanceImprove heat resistanceInternal combustion piston enginesHeterogenous catalyst chemical elementsCeriumMicroparticle

The exhaust gas-purifying catalyst of the invention includes a noble metal, and crystallites that form CZ composite metal particles which serve as a carrier supporting the noble metal and contain at least zirconium (Zr) and cerium (Ce). The CZ composite oxide particles (crystallites) further contain crystal growth-suppressing fine particles which are fine metal particles comprising primarily a metallic element M that melts at 1,500° C. or above and which suppress crystal growth by the CZ composite oxide particles. The content of the metallic element M included in the CZ composite oxide particles, expressed in terms of the oxide thereof, is 0.5 mol % or less of the total oxide.

Owner:CATALER CORP

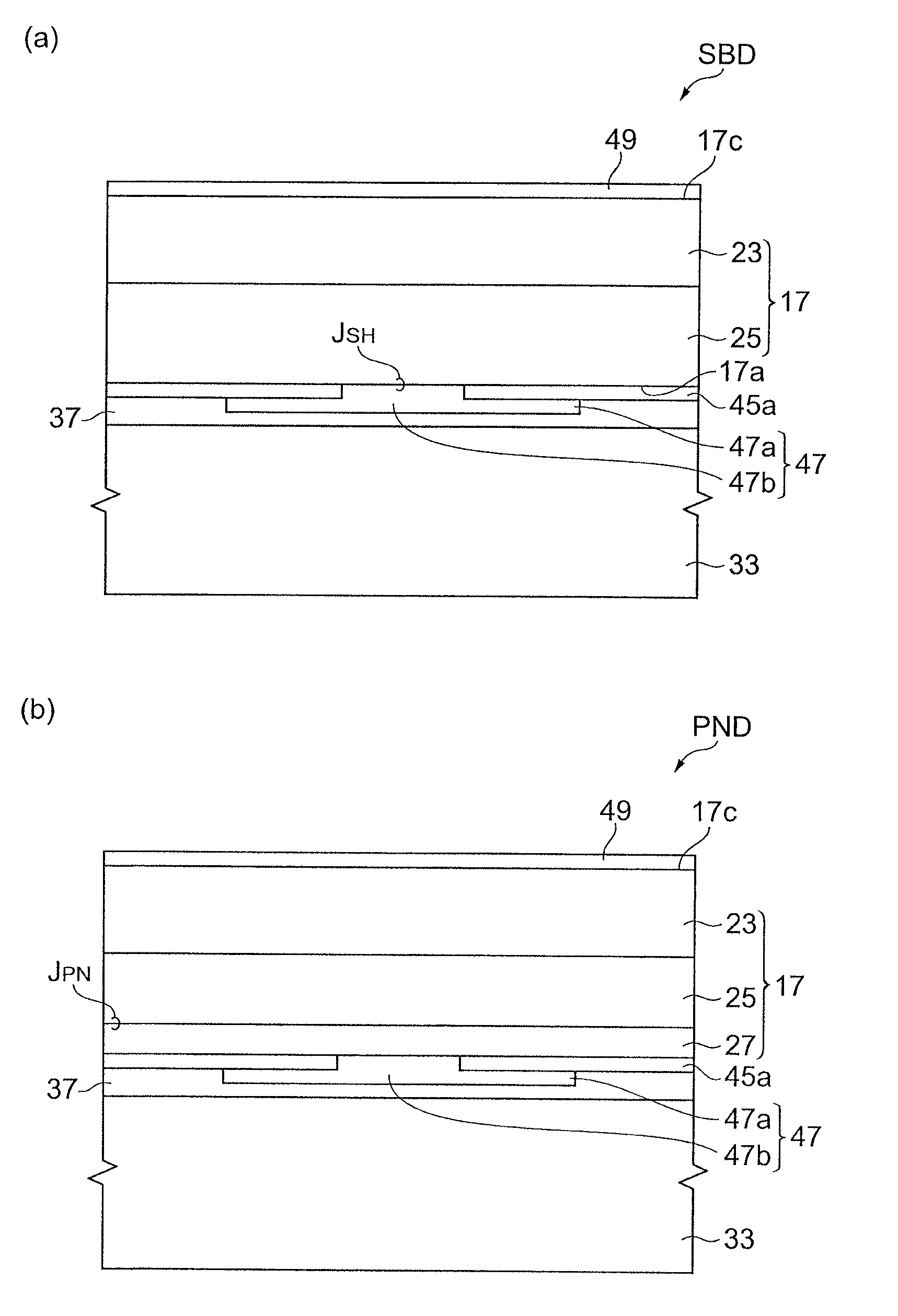

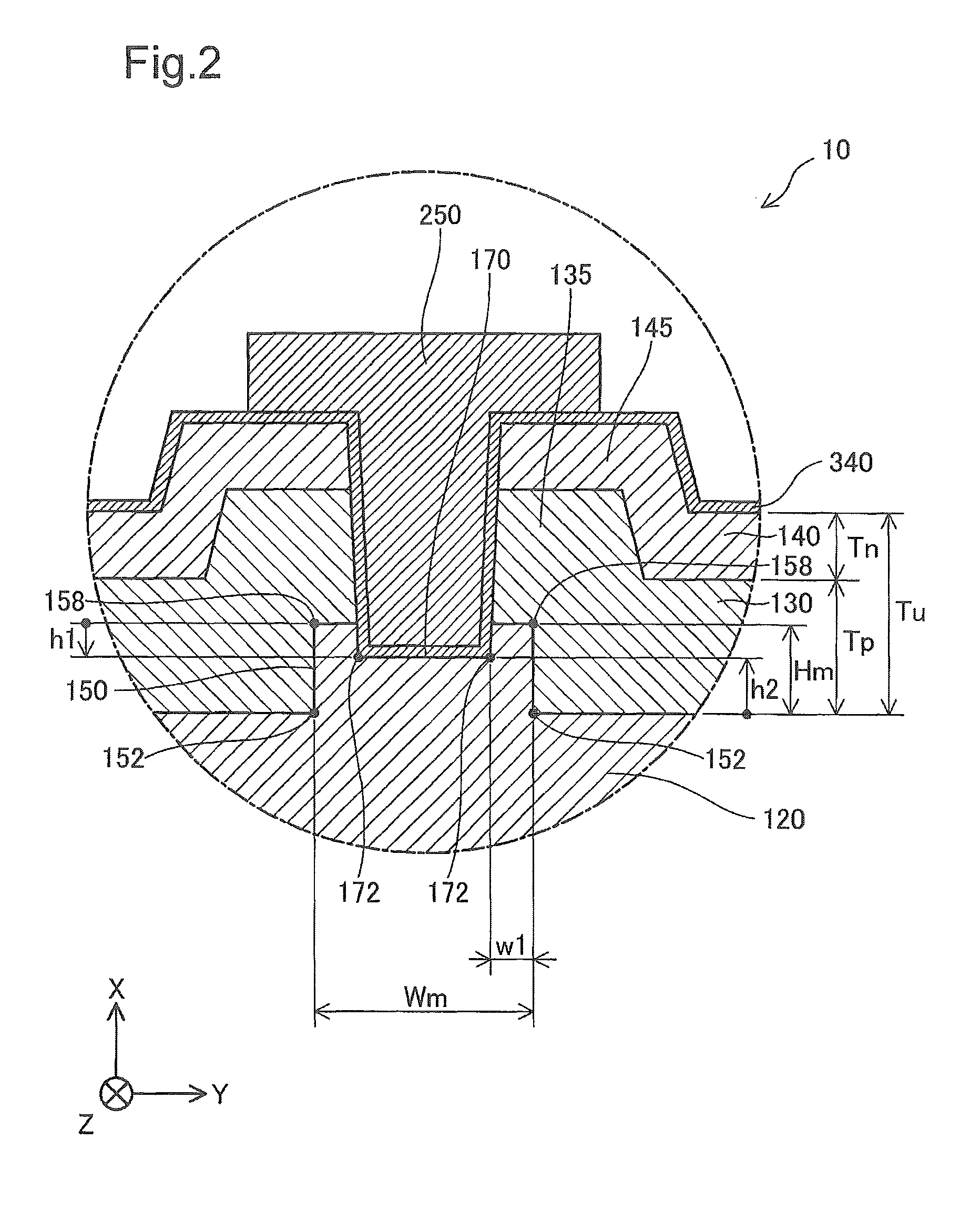

Semiconductor device including first interface and second interface as an upper surface of a convex protruded from first interface and manufacturing device thereof

ActiveUS9349856B2Improve electrical performanceEasy to manufactureSemiconductor devicesEngineeringSemiconductor

A semiconductor device includes a first n-type semiconductor layer, a p-type semiconductor layer, a second n-type semiconductor layer and a trench. The first n-type semiconductor layer includes a first interface and a second interface. The second interface forms an upper surface of a convex protruded from the first interface. The p-type semiconductor layer is stacked on the first n-type semiconductor layer and includes a first region stacked on the first interface and a second region stacked on the second interface. The first region is uniformly continuous with the second region. The second n-type semiconductor layer is stacked on the p-type semiconductor layer. The trench is depressed from the second n-type semiconductor layer through the p-type semiconductor layer into the convex of the first n-type semiconductor layer.

Owner:TOYODA GOSEI CO LTD

Method of forming crystalline oxide semiconductor film

ActiveUS9546416B2Microscopic oxygen vacancies can be reducedPromotes crystal growthPolycrystalline material growthVacuum evaporation coatingCrystalline oxideCrystallinity

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com