Perovskite thin-film solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low photoelectric conversion efficiency and poor repeatability of devices, achieve good solubility and controllability, promote crystal growth, Effects that improve performance and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

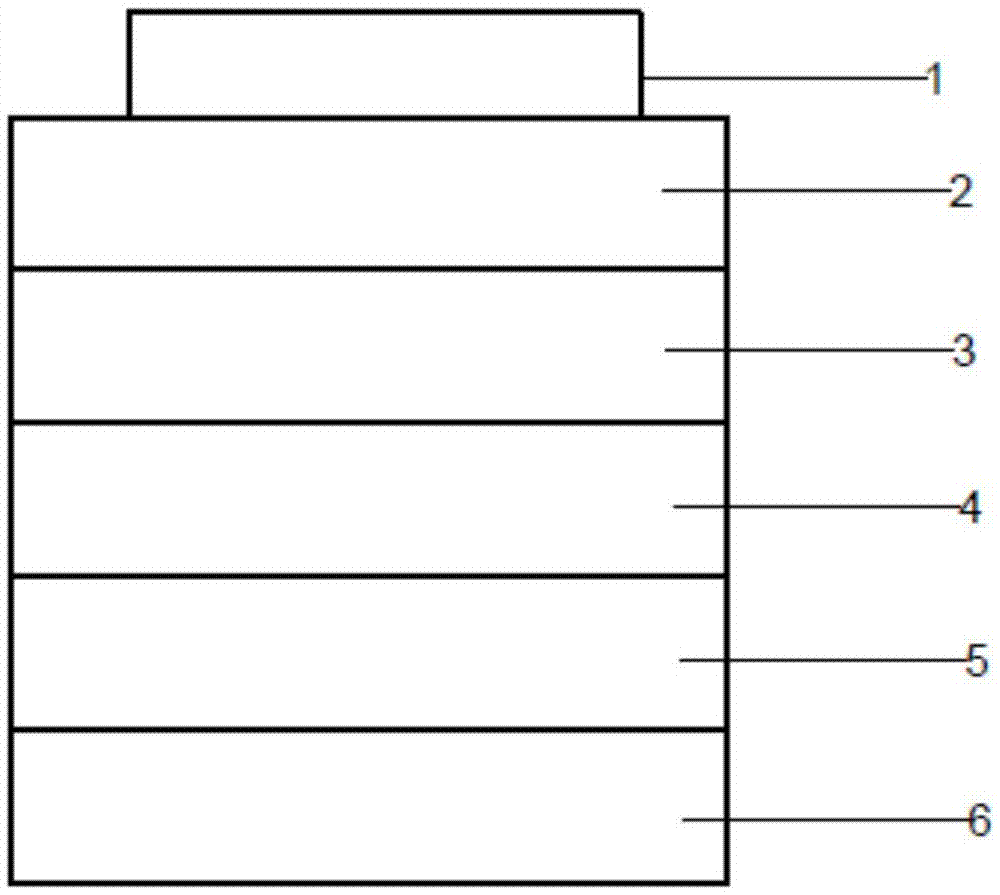

[0064] Further, the preparation method may further include: first preparing and forming a hole transport layer on the anode, and then preparing and forming a perovskite light-absorbing layer on the hole transport layer.

[0065] Further, the preparation method may further include: first forming an electron transport layer on the perovskite light-absorbing layer, and then disposing the cathode on the electron transport layer.

[0066] Further, the preparation method may further include: depositing an electrode interface modification material on the anode by printing or coating to form the electrode interface modification layer.

[0067] In some embodiments, the preparation method includes: dissolving the electrode interface modification material in a solvent to form an electrode interface modification material solution, and then printing or coating the electrode interface modification material solution on the anode to form The electrode interface modification layer.

[0068] M...

Embodiment 1

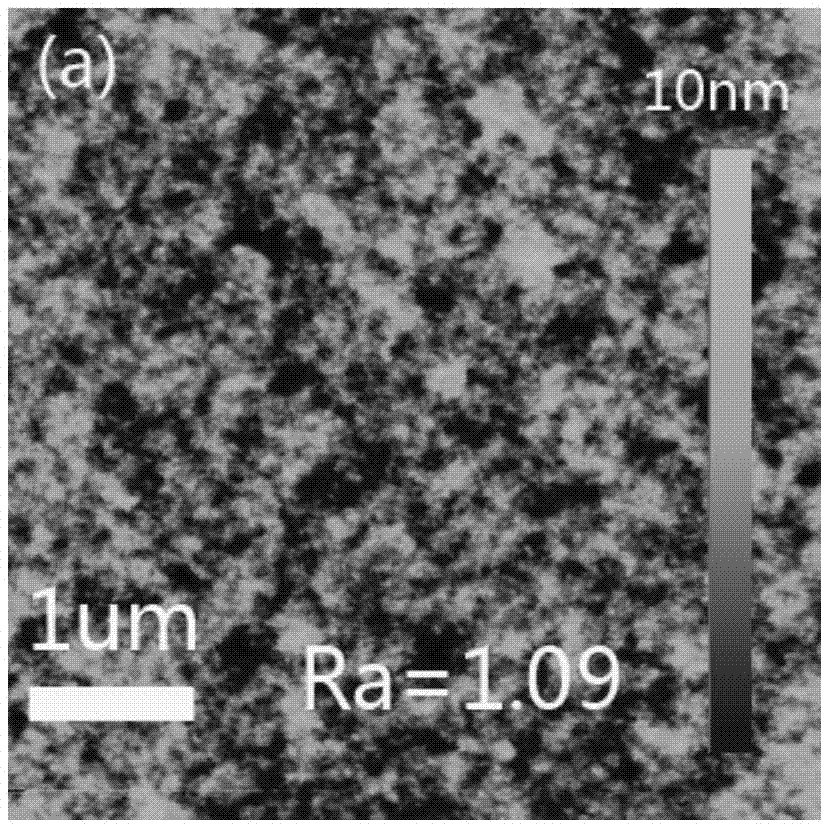

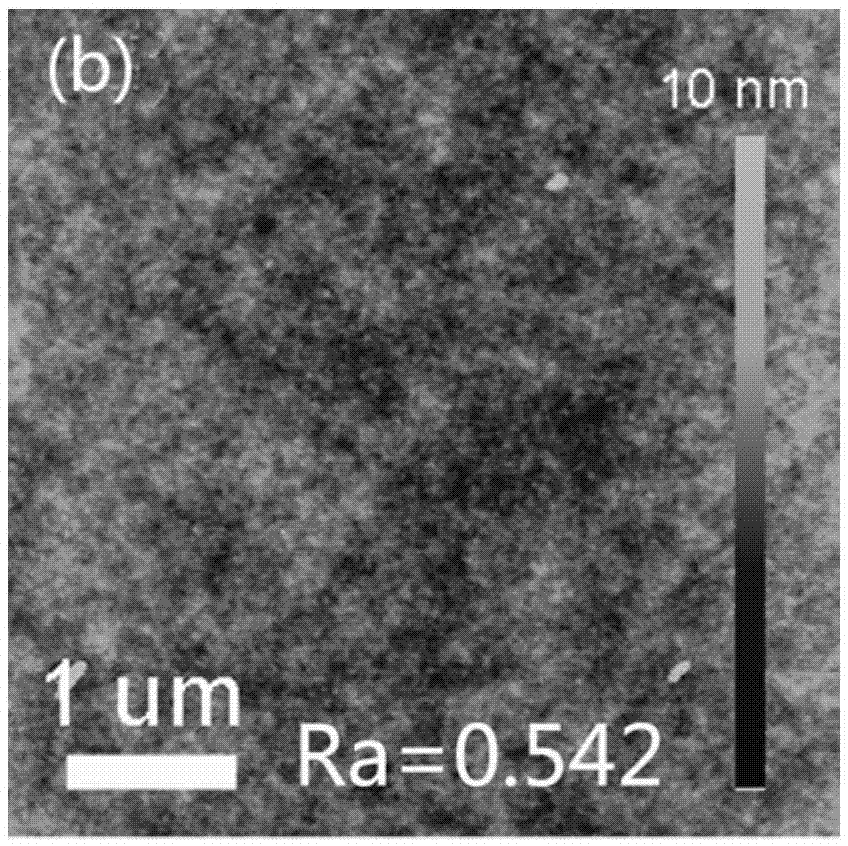

[0091] Embodiment 1: This example selects a single specific material, does not limit the selection of other materials, but only illustrates its invention. First, the ITO glass substrate was cleaned with acetone, ethanol, and isopropanol by ultrasonic for 30 minutes, then the substrate was blown dry with nitrogen gas, and then treated with ultraviolet light for 30 minutes. Spin-coat the hole transport layer PEDOT:PSS (4083) on the dried glass substrate after UV treatment, the rotation speed is 3500 rpm, and rotate for 60 seconds to obtain a layer of uniform PEDOT:PSS film. The surface morphology is shown in AFM Figure 2a . Subsequently, the PEDOT:PSS film was fired in air at 125° C. for 10 minutes, and then cooled to room temperature to form a hole transport layer. Use 1wt% PSS polymer aqueous solution to spin-coat on the hole transport layer at a rotation speed of 2000 rpm for 60 seconds, and place it in a glove box after 5 minutes at 140°C to form an electrode interface mod...

Embodiment 2

[0095] Embodiment 2: This example selects a single specific material, does not limit the selection of other materials, but only illustrates its invention. First, the ITO glass substrate was cleaned with acetone, ethanol, and isopropanol by ultrasonic for 30 minutes, then the substrate was blown dry with nitrogen gas, and then treated with ultraviolet light for 30 minutes. Referring to the manner of Example 1, a hole transport layer was formed. Then use 1wt% PSS-Na polymer salt solution to spin-coat on the hole transport layer, the rotation speed is 2000 rpm, the time is 60 seconds, and put it in the glove box after 5 minutes at 140 ° C to form an electrode interface modification layer . Then the perovskite precursor solution CH 3 NH 3 PB 3 Spin coating on the electrode interface modification layer for 60 seconds, and then anneal the formed precursor film at 95° C. for 70 minutes to obtain a perovskite light-absorbing layer. Then spin-coat the PCBM (10mg / ML) solution on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com