Patents

Literature

54results about How to "Reduce crystallization defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single crystal CVD synthetic diamond material

ActiveUS20140335339A1Improve optical qualityReduce concentrationPolycrystalline material growthSynthetic resin layered productsPhotoluminescenceSingle crystal

A single crystal CVD synthetic diamond material comprising: a total as-grown nitrogen concentration equal to or greater than 5 ppm, and a uniform distribution of defects, wherein said uniform distribution of defects is defined by one or more of the following characteristics: (i) the total nitrogen concentration, when mapped by secondary ion mass spectrometry (SIMS) over an area equal to or greater than 50×50 μm using an analysis area of 10 μm or less, possesses a point-to-point variation of less than 30% of an average total nitrogen concentration value, or when mapped by SIMS over an area equal to or greater than 200×200 μm using an analysis area of 60 μm or less, possesses a point-to-point variation of less than 30% of an average total nitrogen concentration value; (ii) an as-grown nitrogen-vacancy defect (NV) concentration equal to or greater than 50 ppb as measured using 77K UV-visible absorption measurements, wherein the nitrogen-vacancy defects are uniformly distributed through the synthetic single crystal CVD diamond material such that, when excited using a 514 nm laser excitation source of spot size equal to or less than 10 μm at room temperature using a 50 mW 46 continuous wave laser, and mapped over an area equal to or greater than 50×50 μm with a data interval less than 10 μm there is a low point-to-point variation wherein the intensity area ratio of nitrogen vacancy photoluminescence peaks between regions of high photoluminescent intensity and regions of low photolominescent intensity is <2× for either the 575 nm photoluminescent peak (NV0) or the 637 nm photoluminescent peak (NV); (iii) a variation in Raman intensity such that, when excited using a 514 nm laser excitation source (resulting in a Raman peak at 552.4 nm) of spot size equal to or less than 10 μm at room temperature using a 50 mW continuous wave laser, and mapped over an area equal to or greater than 50×50 μm with a data interval less than 10 μm, there is a low point-to-point variation wherein the ratio of Raman peak areas between regions of low Raman intensity and high Raman intensity is <1.25×; (iv) an as-grown nitrogen-vacancy defect (NV) concentration equal to or greater than 50 ppb as measured using 77K UV-visible absorption measurements, wherein, when excited using a 514 nm excitation source of spot size equal to or less than 10 μm at 77K using a 50 mW continuous wave laser, gives an intensity at 575 nm corresponding to NV0 greater than 120 times a Raman intensity at 552.4 nm, and / or an intensity at 637 nm corresponding to NV− greater than 200 times the Raman intensity at 552.4 nm; (v) a single substitutional nitrogen defect (Ns) concentration equal to or greater than 5 ppm, wherein the single substitutional nitrogen defects are uniformly distributed through the synthetic single crystal CVD diamond material such that by using a 1344 cm−1 infrared absorption feature and sampling an area greater than an area of 0.5 mm2, the variation is lower than 80%, as deduced by dividing the standard deviation by the mean value; (vi) a variation in red luminescence intensity, as defined by a standard deviation divided by a mean value, is less than 15%; (vii) a mean standard deviation in neutral single substitutional nitrogen concentration of less than 80%; and (viii) a colour intensity as measured using a histogram from a microscopy image with a mean gray value of greater than 50, wherein the colour intensity is uniform through the single crystal CVD synthetic diamond material such that the variation in gray colour, as characterised by the gray value standard deviation divided by the gray value mean, is less than 40%.

Owner:ELEMENT SIX LTD

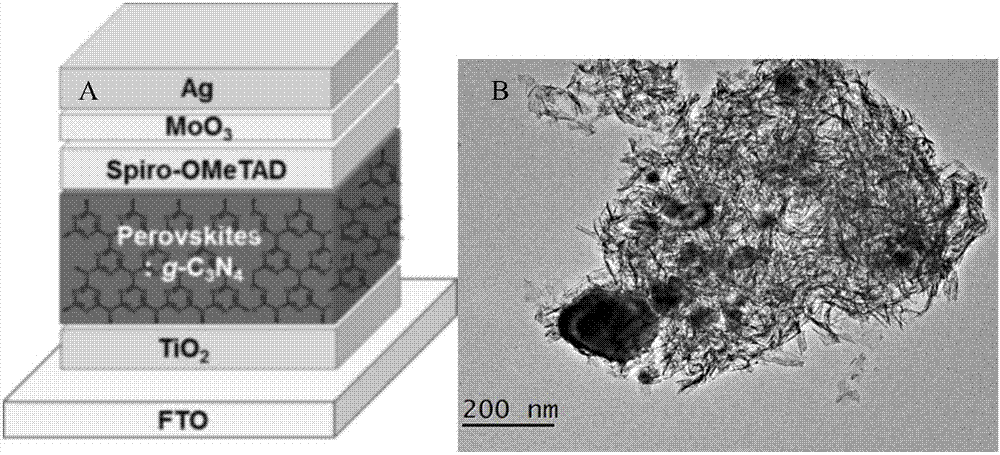

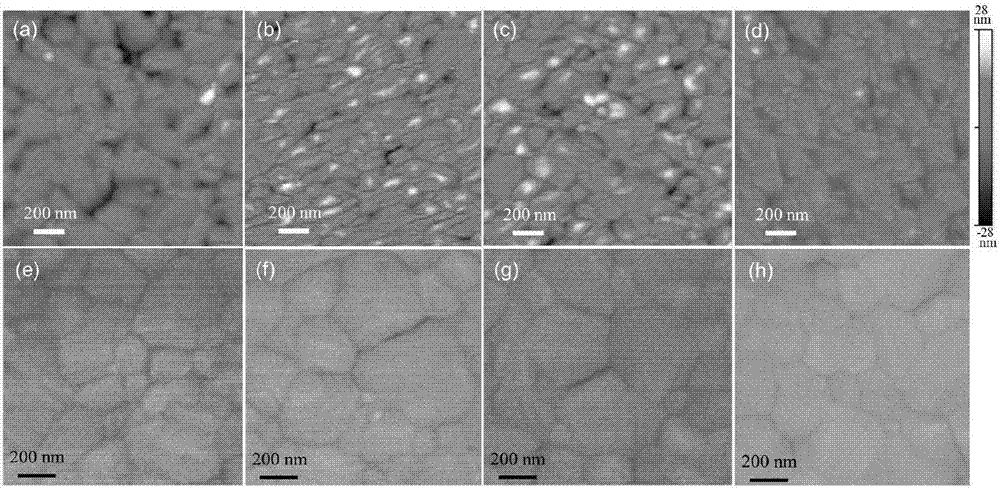

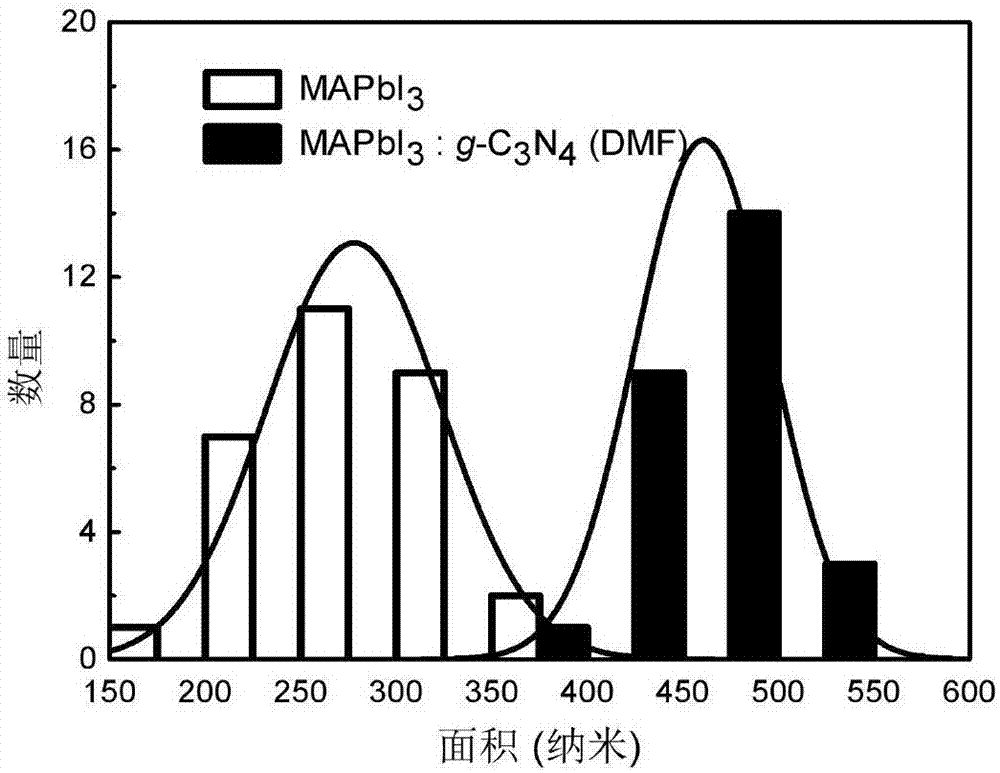

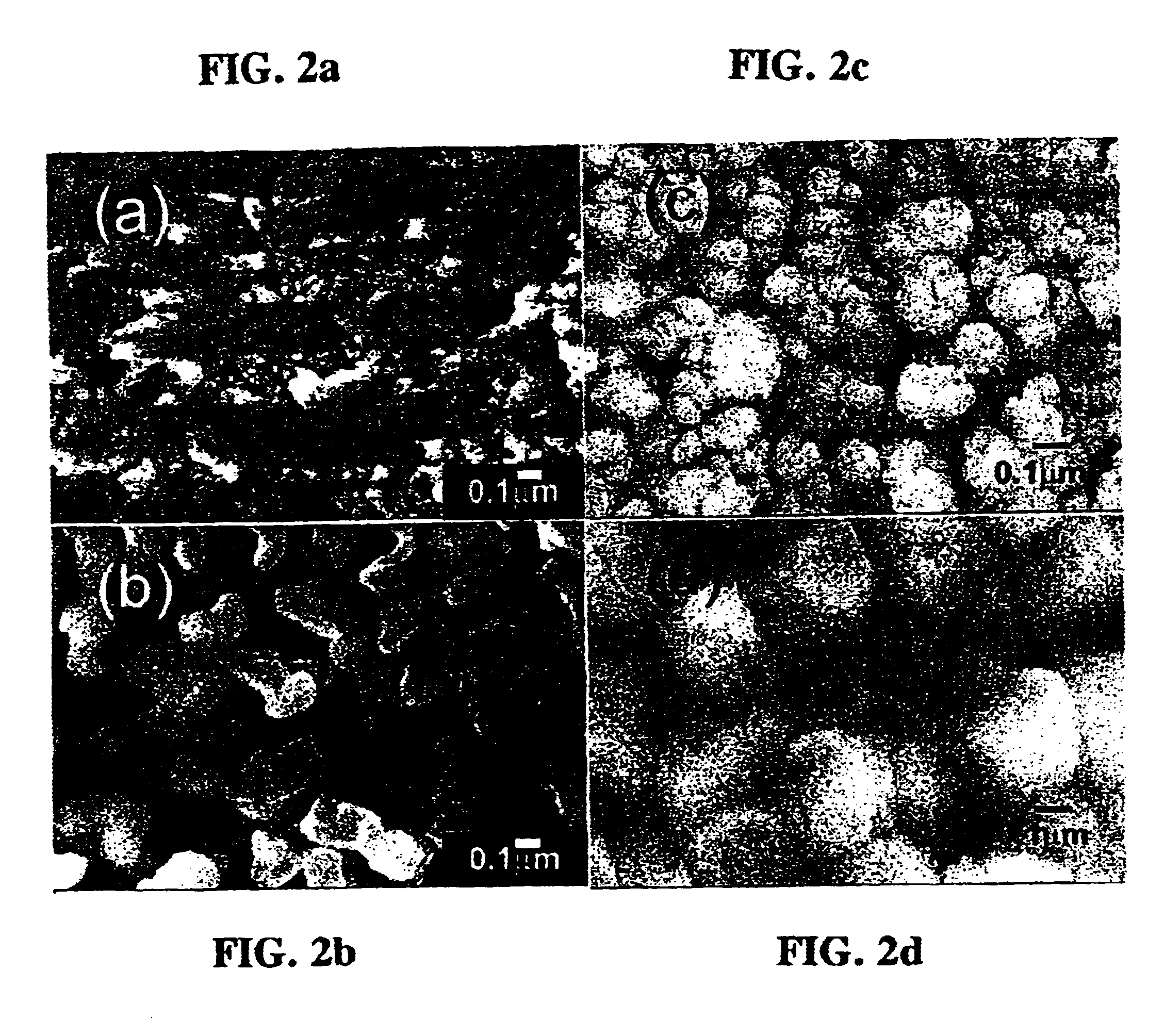

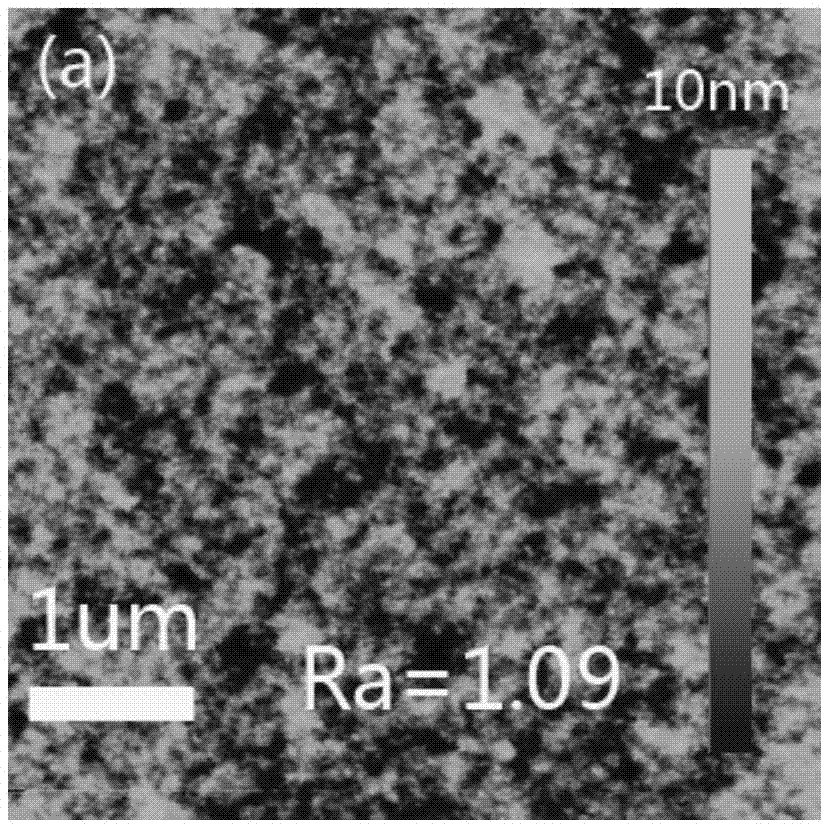

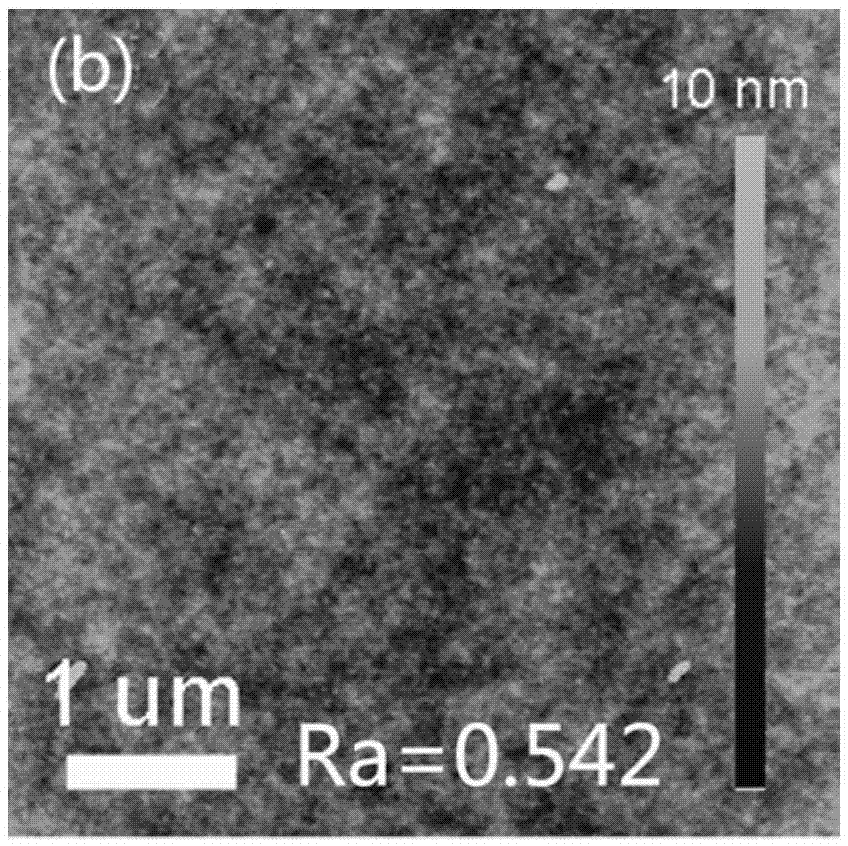

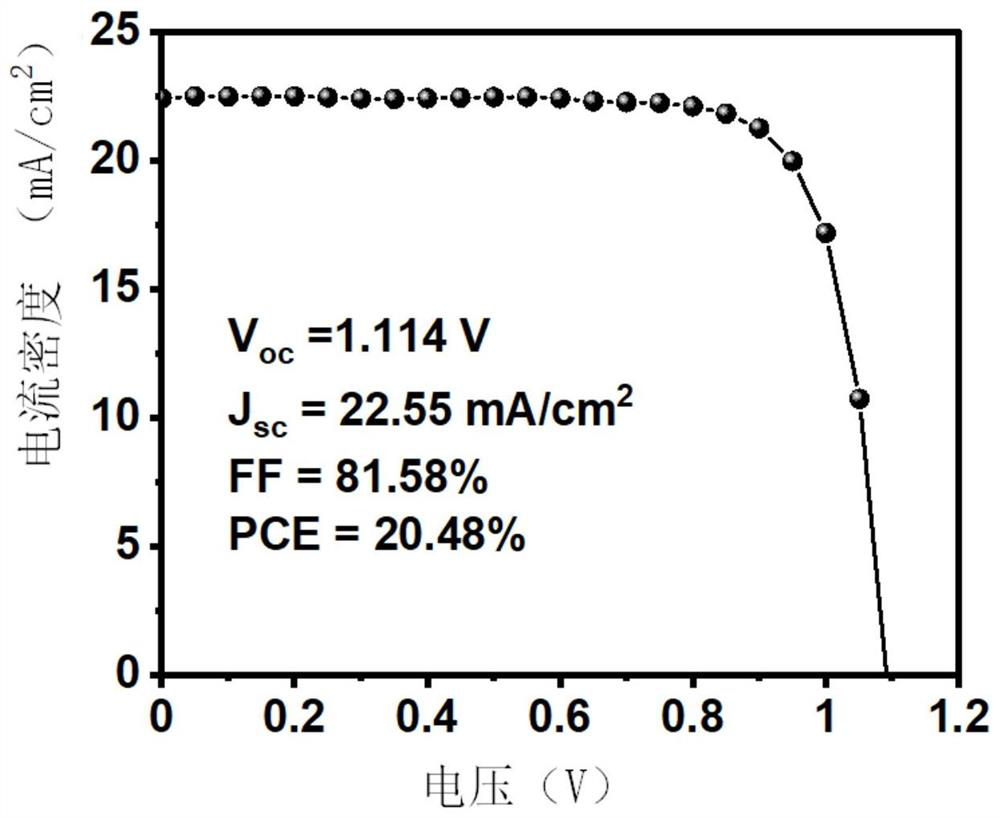

Method for preparing perovskite solar cell on basis of two-dimensional material graphene-phase carbon nitride

ActiveCN107887511AImprove crystallizationStable manufacturingSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSolvent

The invention provides a method for preparing a perovskite solar cell on the basis of a two-dimensional material graphene-phase carbon nitride. The graphene-phase carbon nitride is doped into a perovskite precursor solution to prepare the perovskite solar cell. The method has the following advantages that (1) the raw material required for synthesis of the material is low in cost, and the product is small in toxicity; (2) solvent volatilization during the annealing process is effectively slowed down, so that a perovskite thin film crystal is more uniform and compact; (3) the grain crystal sizeof a perovskite layer is increased, a crystal boundary easy to combine with charge is effectively reduced, and the filling factor of a device is improved; (4) a surface of the perovskite thin film ispassivated, and the hysteresis phenomenon of the device is effectively improved; and (5) the conductivity of the surface of the perovskite thin film is improved, the contact resistance of the interface is reduced, and the short-circuit current of the device is increased. The preparation process is simple and convenient and is low in preparation difficulty; by doping of the graphene-phase carbon nitride, the smoothness and the uniformity of the perovskite thin film can be effectively improved; and by a series of gradient doping, the device performance is remarkably changed.

Owner:SUZHOU UNIV

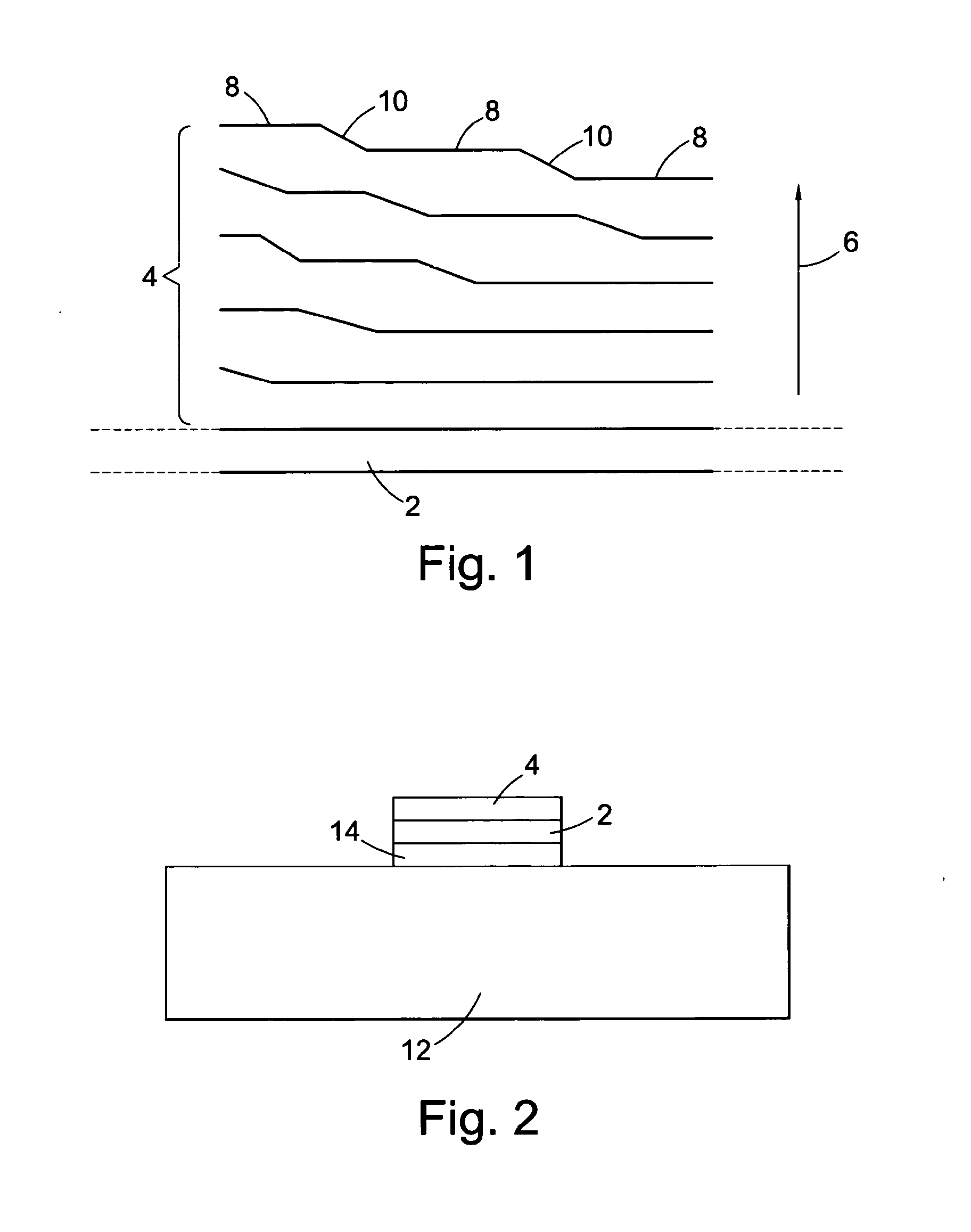

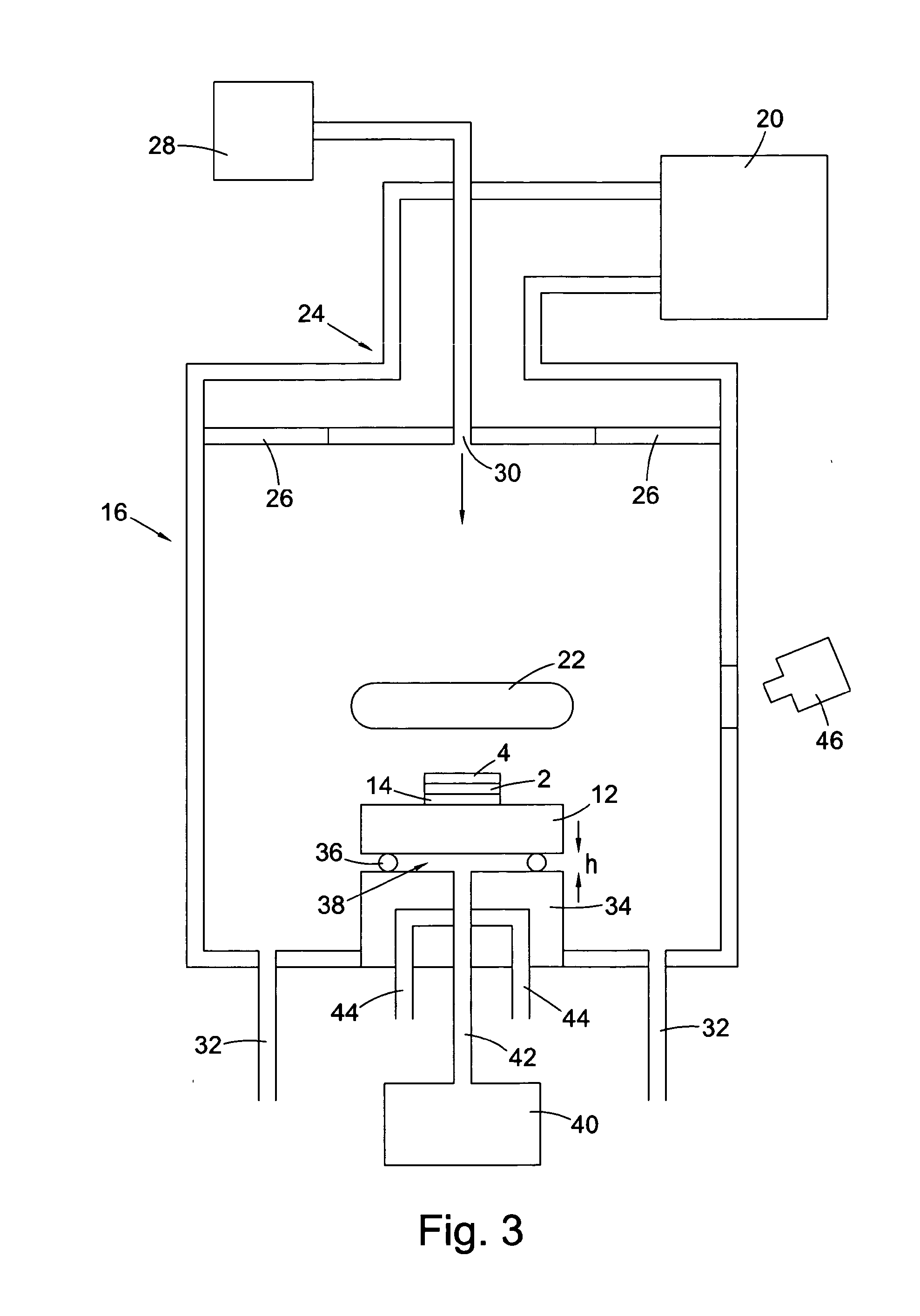

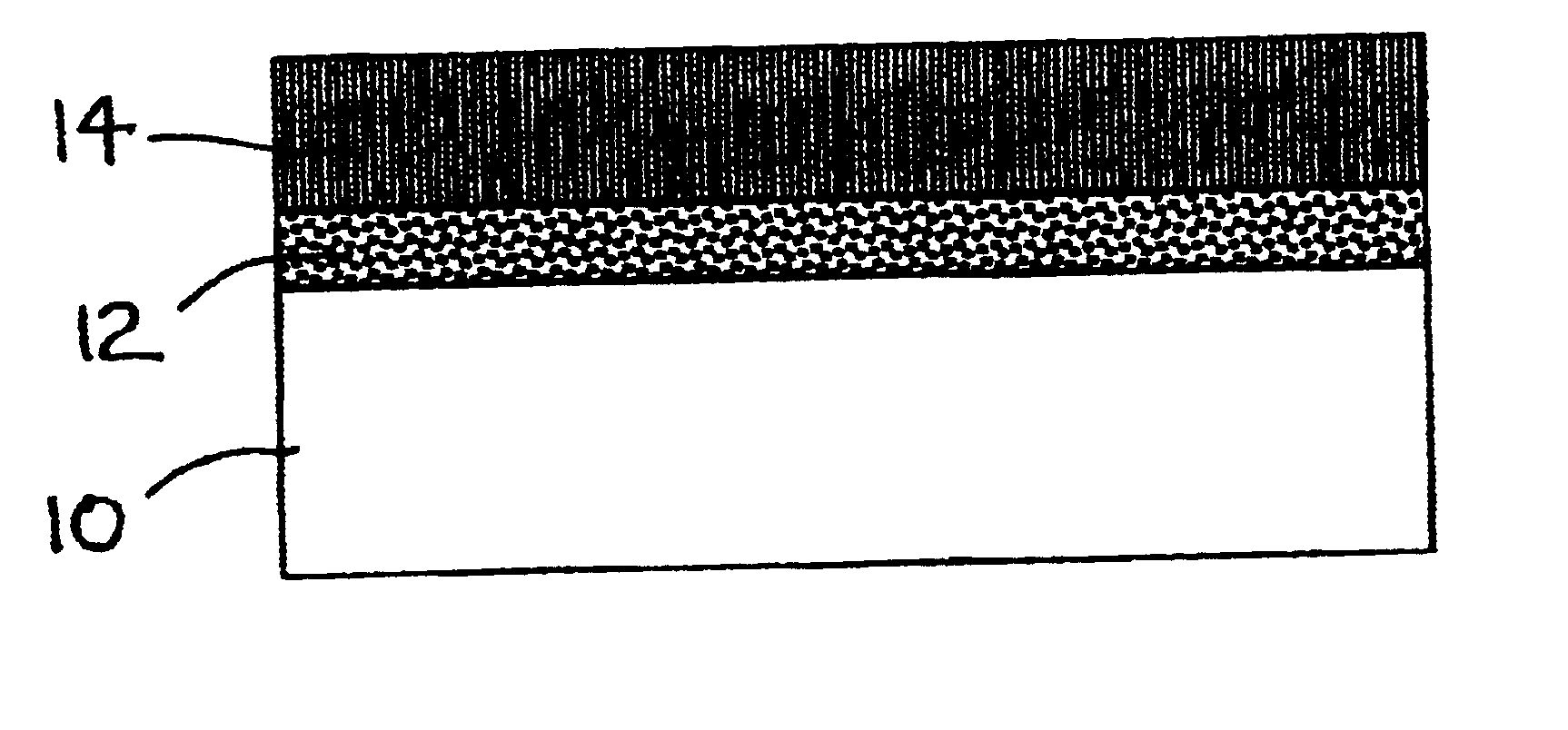

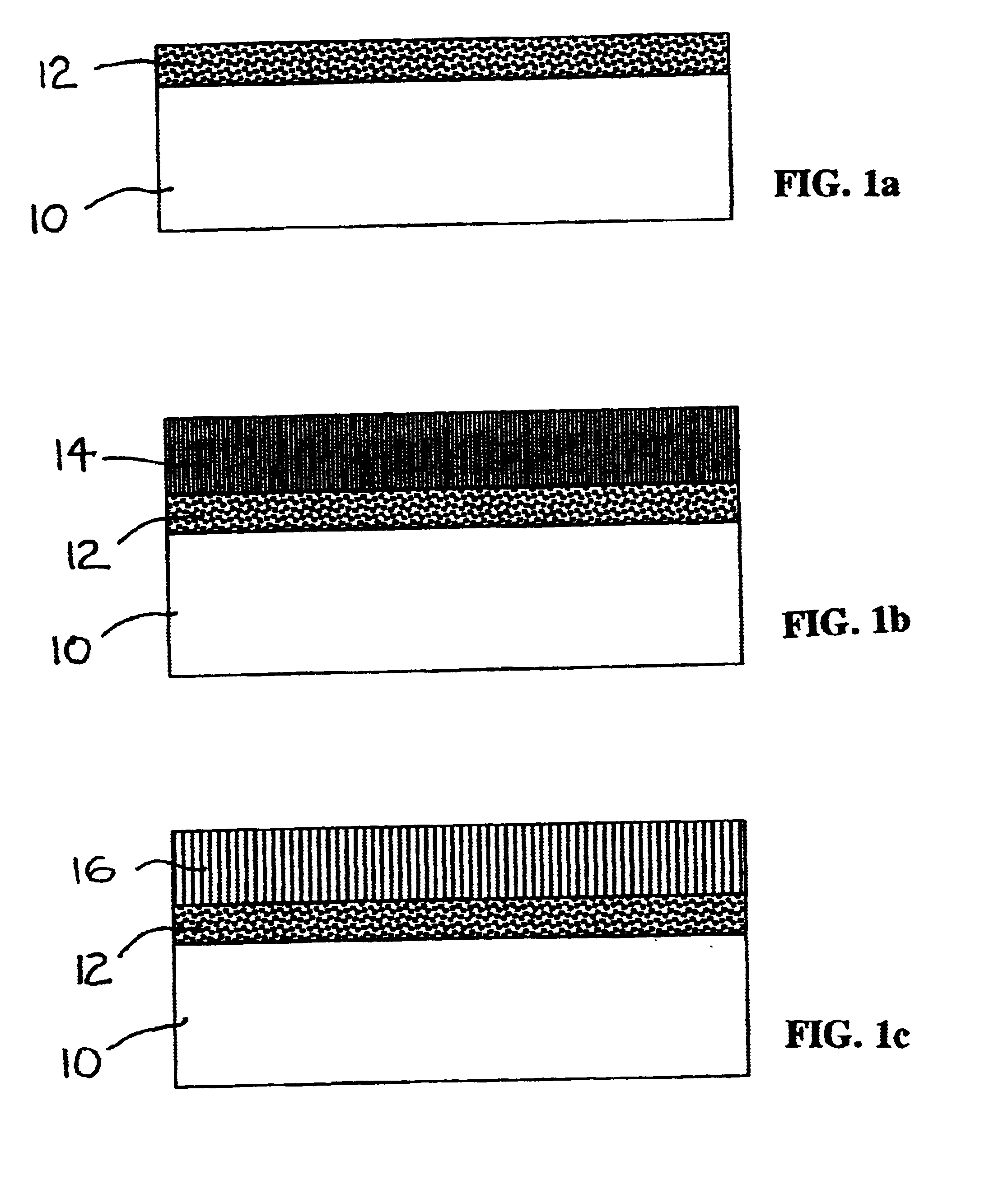

Strain-relieved tunable dielectric thin films

InactiveUS6617062B2Relieves film strainStrain-relieved and defect-reduced tunableVacuum evaporation coatingSputtering coatingBarium strontium titanateDielectric loss

Tunable dielectric thin films are provided which possess low dielectric losses at microwave frequencies relative to conventional dielectric thin films. The thin films include a low dielectric loss substrate, a buffer layer, and a crystalline dielectric film. Barium strontium titanate may be used as the buffer layer and the crystalline dielectric film. The buffer layer provides strain relief during annealing operations.

Owner:NXP USA INC

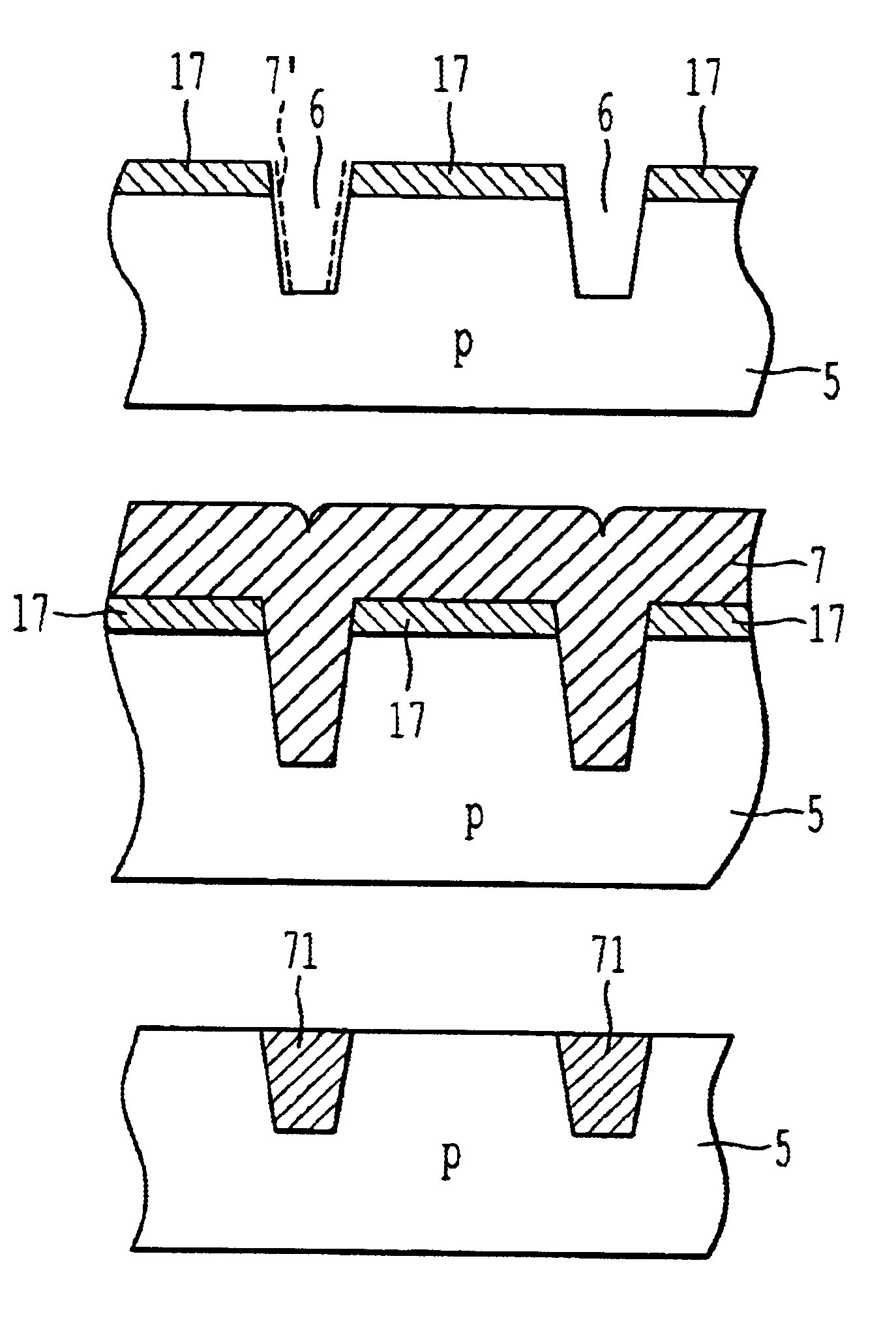

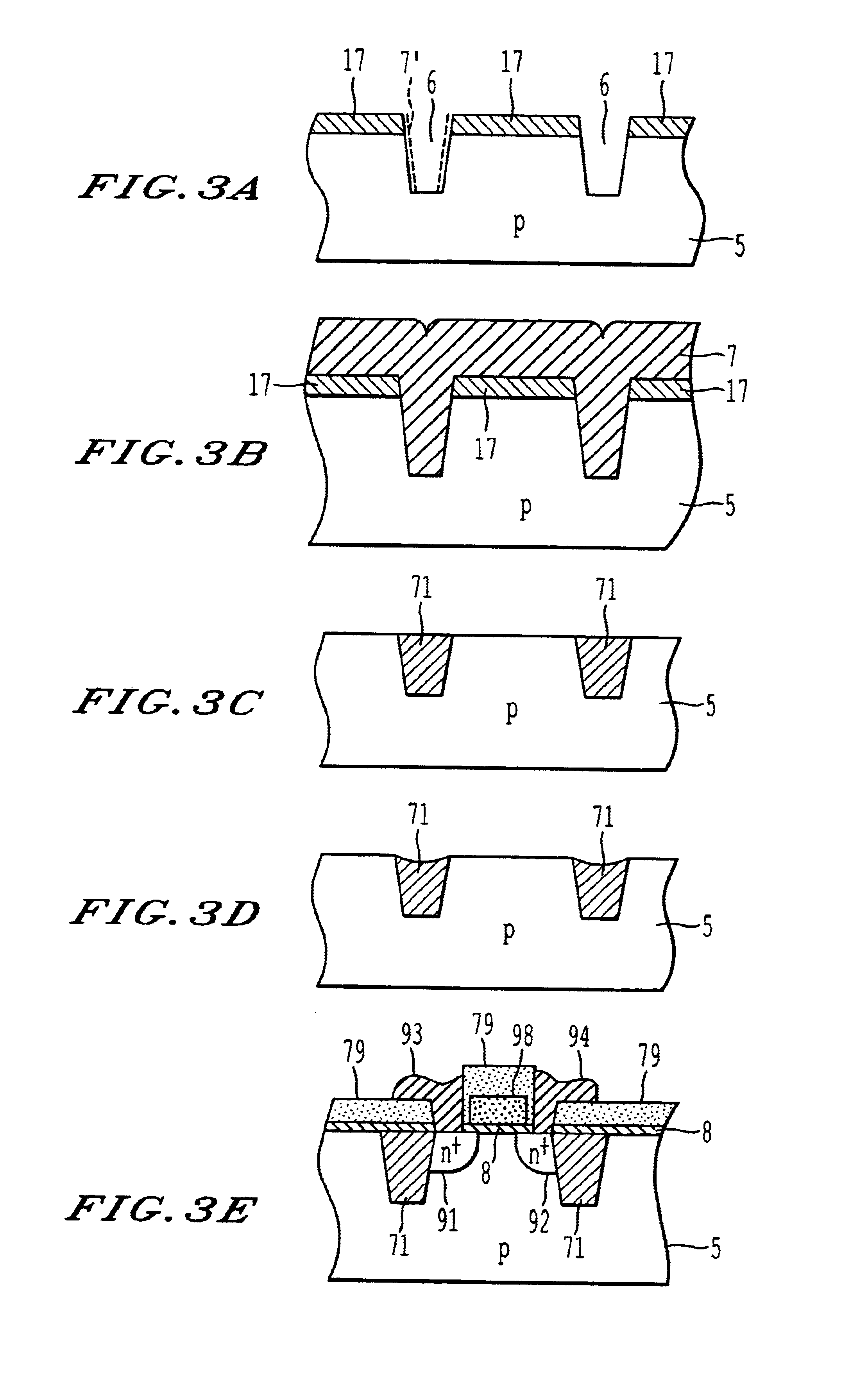

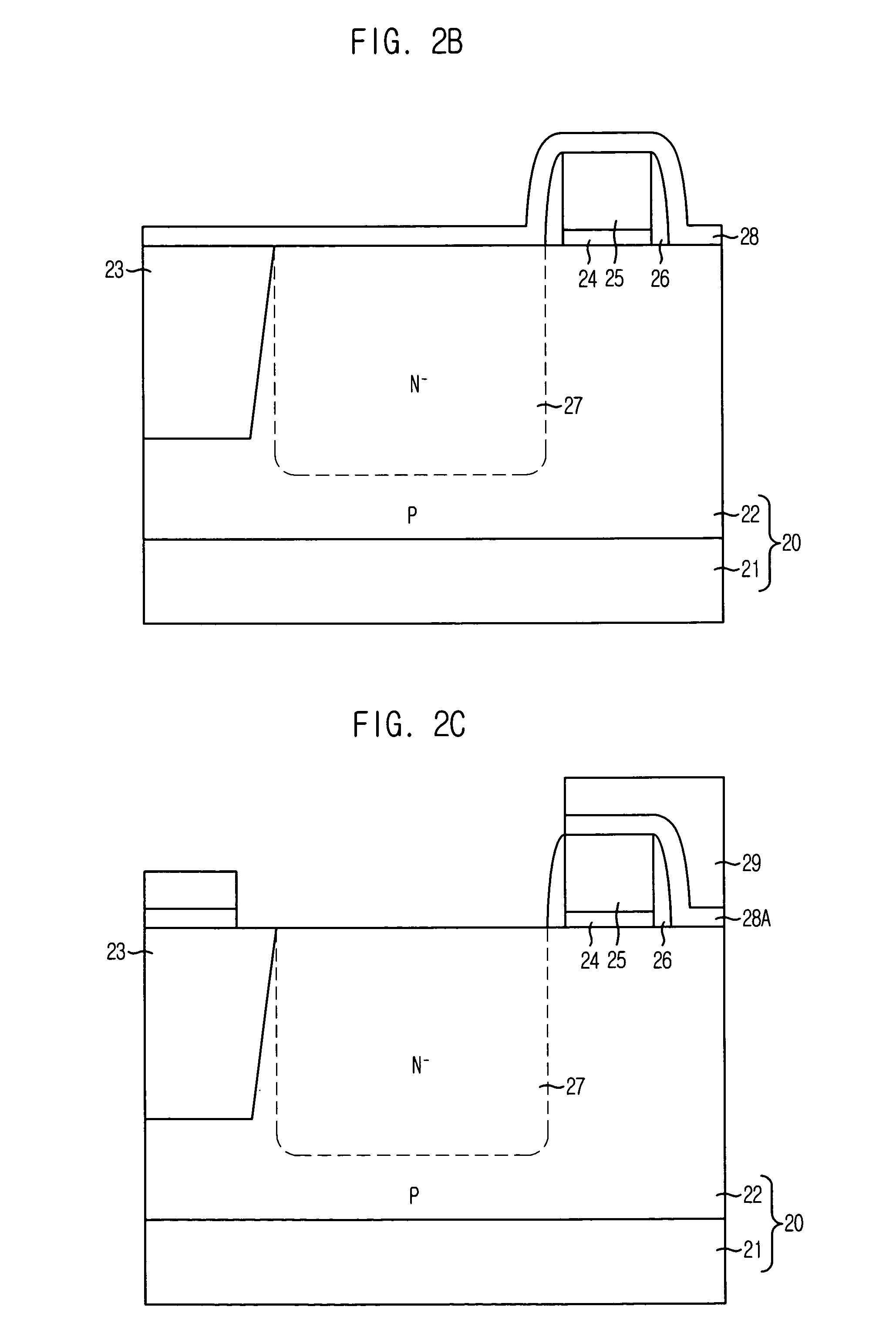

Method of manufacturing a substrate having shallow trench isolation

InactiveUS6919260B1Reduced areaHighly integratedSemiconductor/solid-state device manufacturingEngineeringDislocation

A semiconductor substrate having a shallow trench isolation (STI) structure and a method of manufacturing the same are provided, i.e., an isolation substrate in which grooves are selectively formed at predetermined locations of the semiconductor substrate and oxide films using organic silicon source as material are buried in the grooves as buried oxide films. The present invention is characterized in that the buried oxide films are annealed at a predetermined temperature within the range of 1100 to 1350° C. before or after planarization of the semiconductor substrate such that ring structures of more than 5-fold ring and ring structures of less than 4-fold ring are formed at predetermined rates in the buried oxide films. The above annealing allows stress of the oxide film buried in the grooves to be relaxed. Hence, the generation of dislocation is suppressed.

Owner:KK TOSHIBA

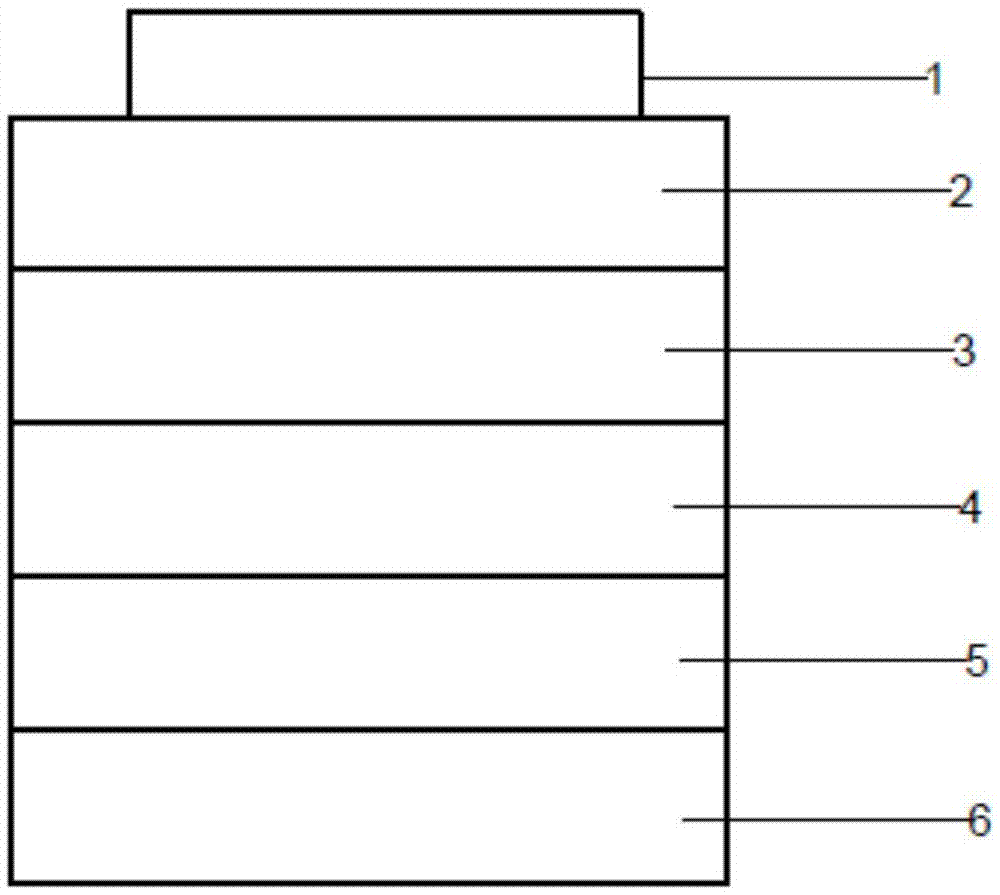

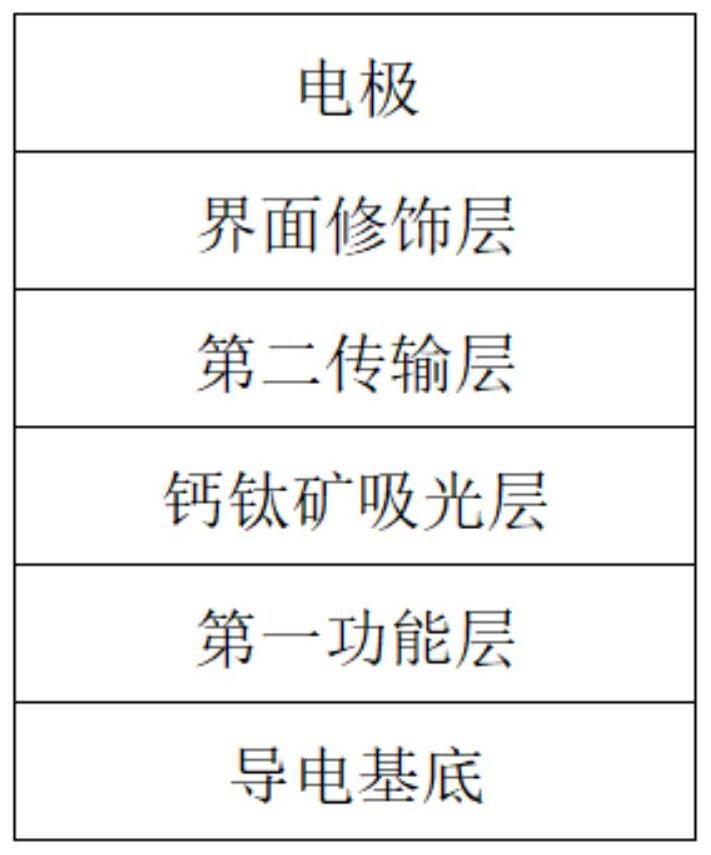

Perovskite thin-film solar cell and preparation method thereof

InactiveCN107104189AReduce crystallization defectsPromotes crystal growthSolid-state devicesSemiconductor/solid-state device manufacturingIonElectrode interface

The invention discloses a perovskite thin-film solar cell, which comprises a cathode, a perovskite light absorption layer and an anode. An electrode interface modification layer is formed between the anode and the perovskite light absorption layer. The electrode interface modification layer comprises atoms and / or ions capable of reacting with the perovskite light absorption layer so as to promote the crystallinity of perovskite crystals. Meanwhile, the electrode interface modification layer is used for improving the surface roughness and the morphology of the anode. The invention also discloses a preparation method of the perovskite thin-film solar cell. The electrode interface modification layer is arranged in the structure of the perovskite thin-film solar cell, so that the performance and the reproducibility of a device are effectively improved. Meanwhile, the preparation process is simple and controllable, and raw materials are cheap and easy to obtain. Therefore, the preparation method is suitable for the preparation of large-area flexible perovskite solar devices.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Cubic boron nitride, catalyst for synthesizing cubic boron nitride, and process for producing cubic boron nitride

ActiveCN1744943AHigh strengthReduce or suppress deterioration componentsNitrogen compoundsOther chemical processesProduction rateAdditive ingredient

Cubic boron nitride (CBN) is produced with a CBN synthesis catalyst which comprises a CBN synthesis catalyst ingredient and an organic substance with which the surface of the catalyst ingredient has been coated. The amount of the organic substance is preferably 0.01 to 50 parts by weight per 100 parts by weight of the CBN synthesis catalyst ingredient. The organic substance preferably is stearic acid and / or lauric acid. By the use of such CBN synthesis catalyst, CBN which has a sharp shape with a well developed (111) plane and which is reduced in catalyst ingredient inclusion therein can be produced at a high conversion (in high yield) through simple steps and operations with satisfactory productivity.

Owner:SHOWA DENKO KK

Regenerated environmental-friendly yarn label strap and manufacturing method thereof

ActiveCN103572468AIncrease tightnessGood orientationHeating/cooling textile fabricsWoven fabricsYarnGram

The invention relates to a label strap and a manufacturing method of the label strap, in particular to a regenerated environmental-friendly yarn label strap and a manufacturing method of the regenerated environmental-friendly label strap. The thickness of the label strap is 0.11-0.15mm, the hardness is 2.8-3.7, and the gram weight is 120-180g / m<2>; base cloth is made of PET material, the specification of yarns for manufacturing the base cloth is 50-150D, the warp density is 90-130 roots / cm, and the weft density is 36-45 roots / cm. The manufacturing method includes the step of beaming, slashing and weaving, the step of pretreatment for dyeing and finishing; the step of dyeing, the step of sizing in a continuous and segmented mode, the step of calendering for the first time at the temperature of 150-170 DEG C, pressure of 5-15MPa and speed of 5-15m / min, the step of calendering for the second time at the temperature of 190-210 DEG C, pressure of 10-15MPa and speed of 10-16m / min and the step of slitting. The manufactured regenerated environmentally-friendly yarn label strap functionally defined to be suitable for a double-faced TTR hot transfer printing mode, the color fastness to soaping meets the GB / T3921 textile color fastness test standard, environmental requirements meet the OEKO-TEX primary standard, and the label strap is suitable for dry ink printing and wet ink printing modes.

Owner:HUZHOU SINY LABEL MATERIAL

Fixed color label cloth

InactiveCN103991259ANot easy to fadeEnsure color fixationFibre treatmentSynthetic resin layered productsYarnColour fastness

The invention discloses a fixed color label cloth. The fixed color label cloth is characterized by comprising basic layer cloth and a coating layer arranged on the basic layer cloth, wherein the thickness of the basic layer cloth is 0.110mm-0.130mm, the hardness is 2.6-3.5, the gram weight is 128g / m<2>-188g / m<2>, and the thickness of the coating layer s 0.120mm-0.150mm; the specification of yarns for manufacturing the basic layer cloth is 100-150D, the warp density is 95 / cm-130 / cm, and the weft density is 33 / cm-42 / cm. The fixed color label cloth provided by the invention has the advantages that the fixed color label cloth can be subjected to special treatment after dyeing, the colour fastness, flatness and uniformity are improved, and the fixed color label cloth is realized.

Owner:湖州市菱湖振民丝带厂

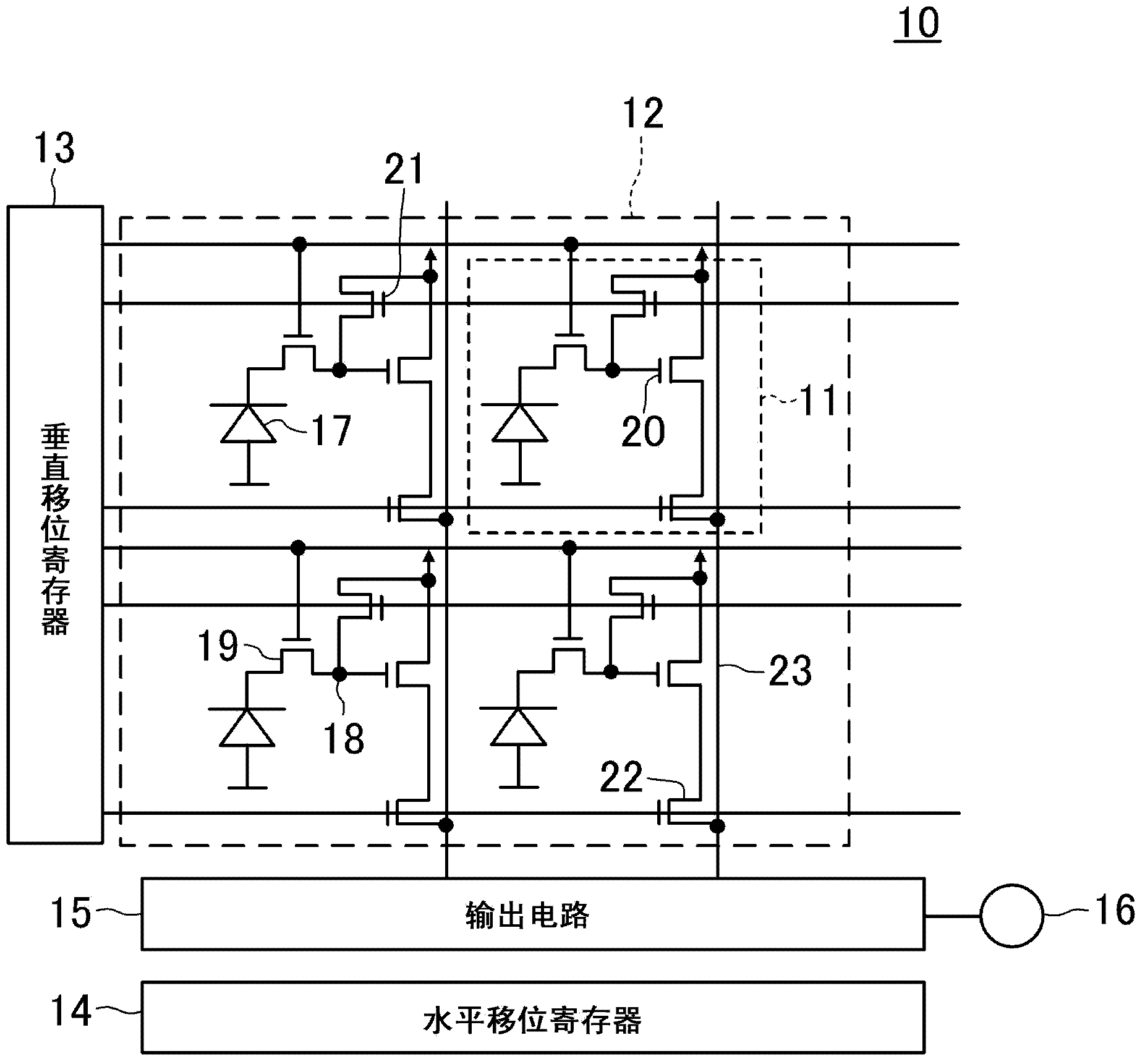

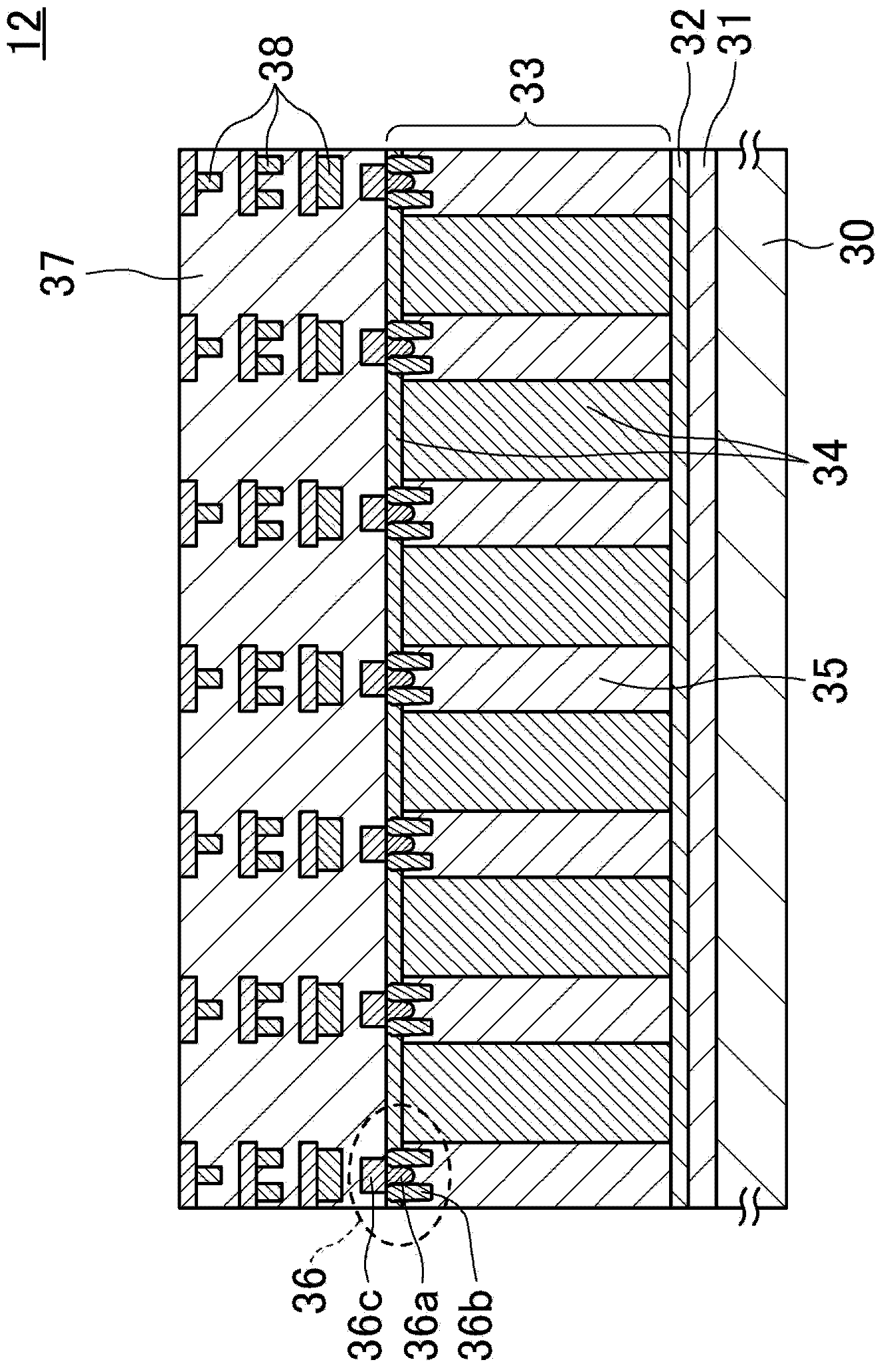

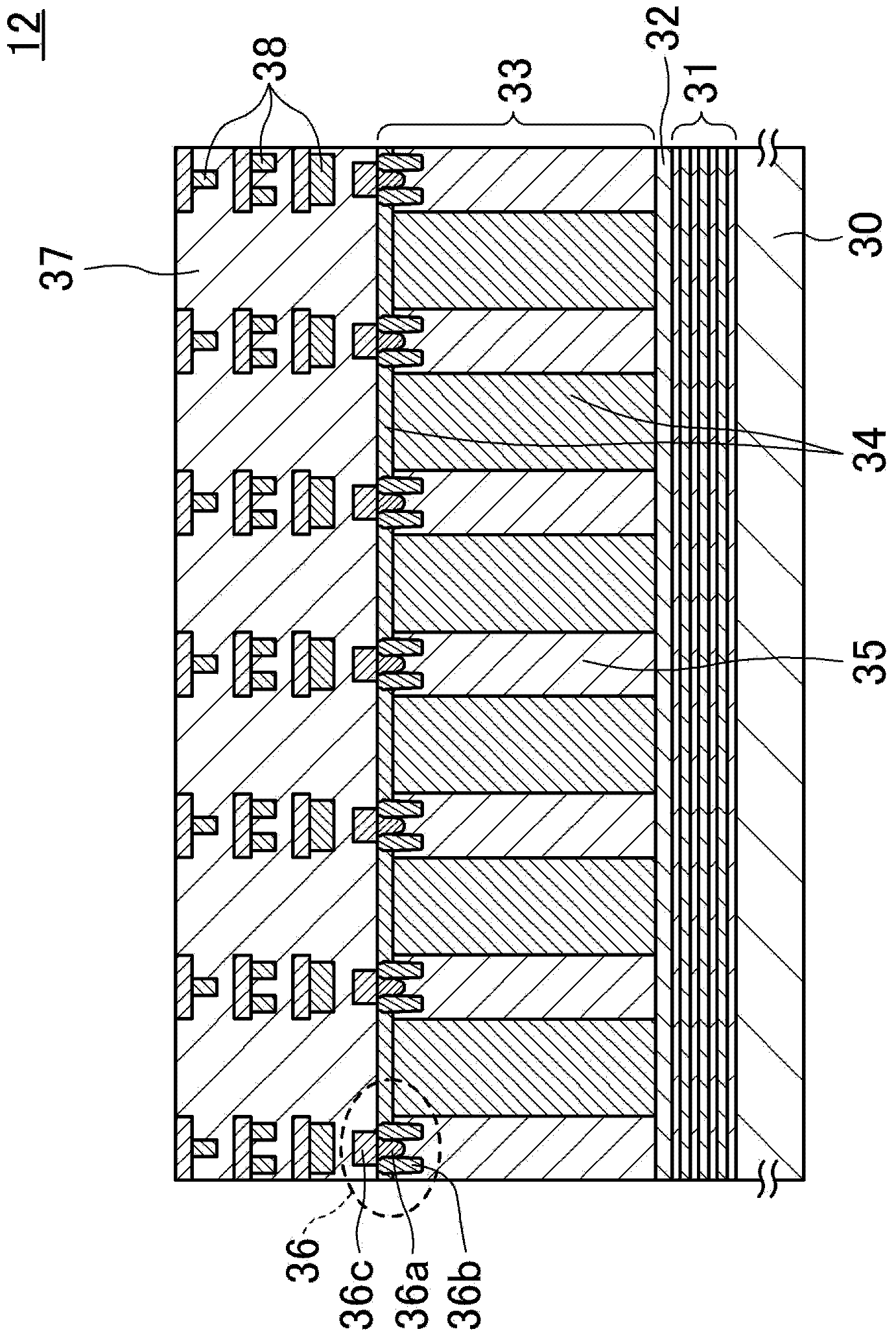

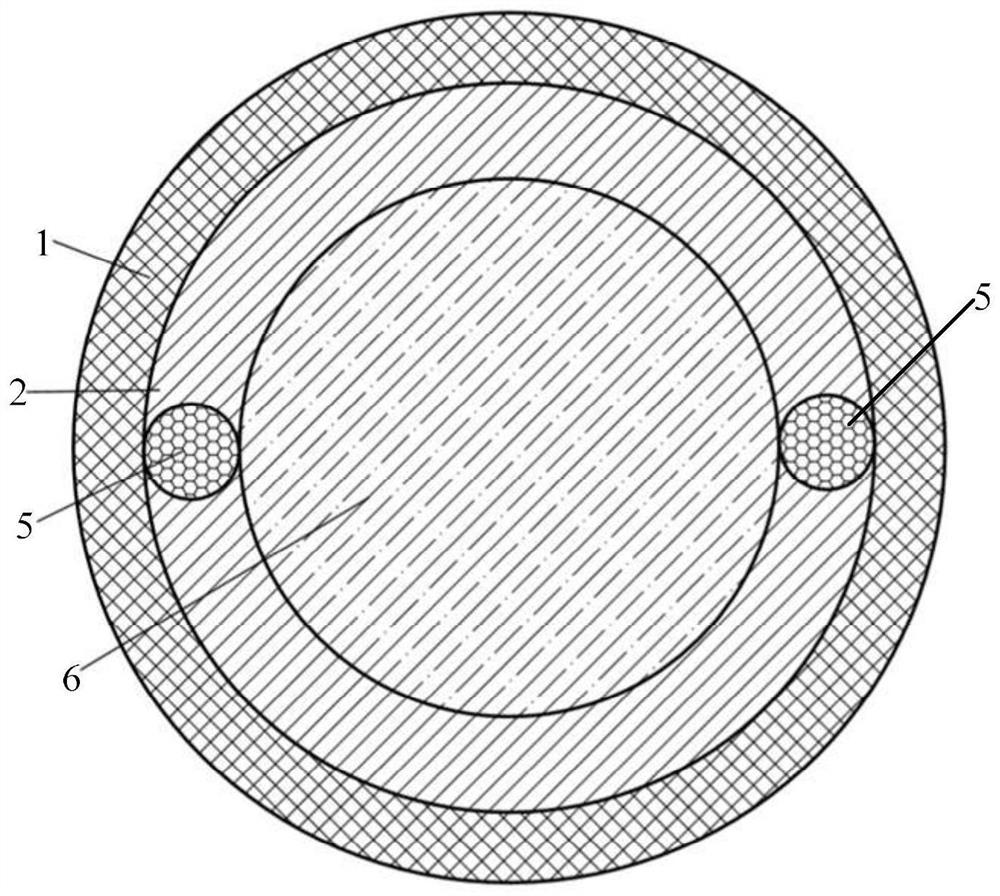

Solid-state imaging device and manufacturing method therefor

ActiveCN103493202AHigh sensitivityReduce crystallization defectsSolid-state devicesRadiation controlled devicesRefractive indexPhotoelectric conversion

A solid-state imaging device comprises a substrate (30), an insulating layer (31) formed on top of the substrate (30), a semiconducting layer (32) formed on top of the insulating layer (31), and a silicon layer (33) formed on top of the semiconducting layer (32). The silicon layer (33) has a plurality of pixel units each including a photoelectric conversion unit (34) converting light to a signal charge and a circuit reading the signal charge, and the refractive index of the insulating layer (31) is lower than the refractive index of the semiconducting layer (32).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

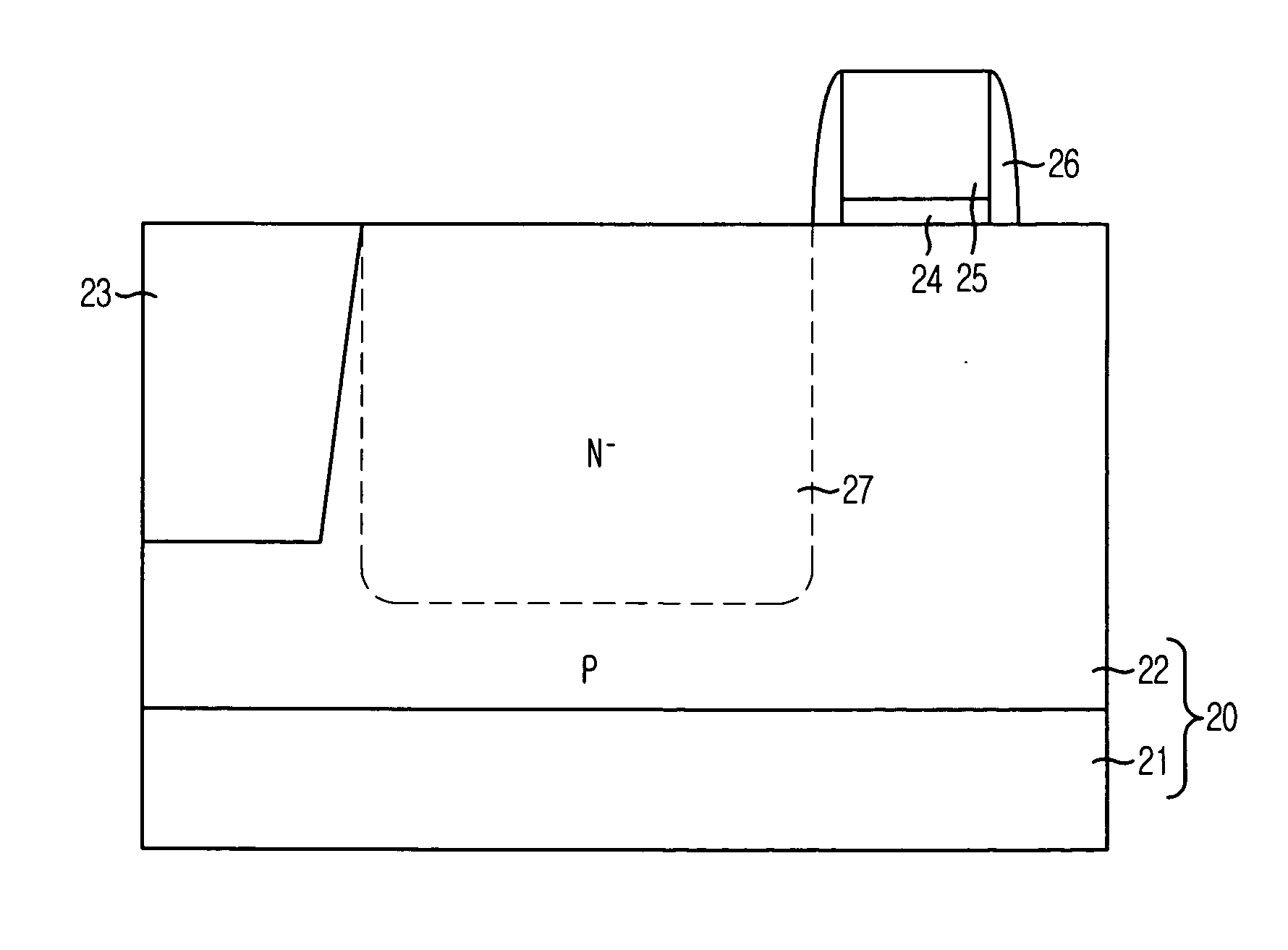

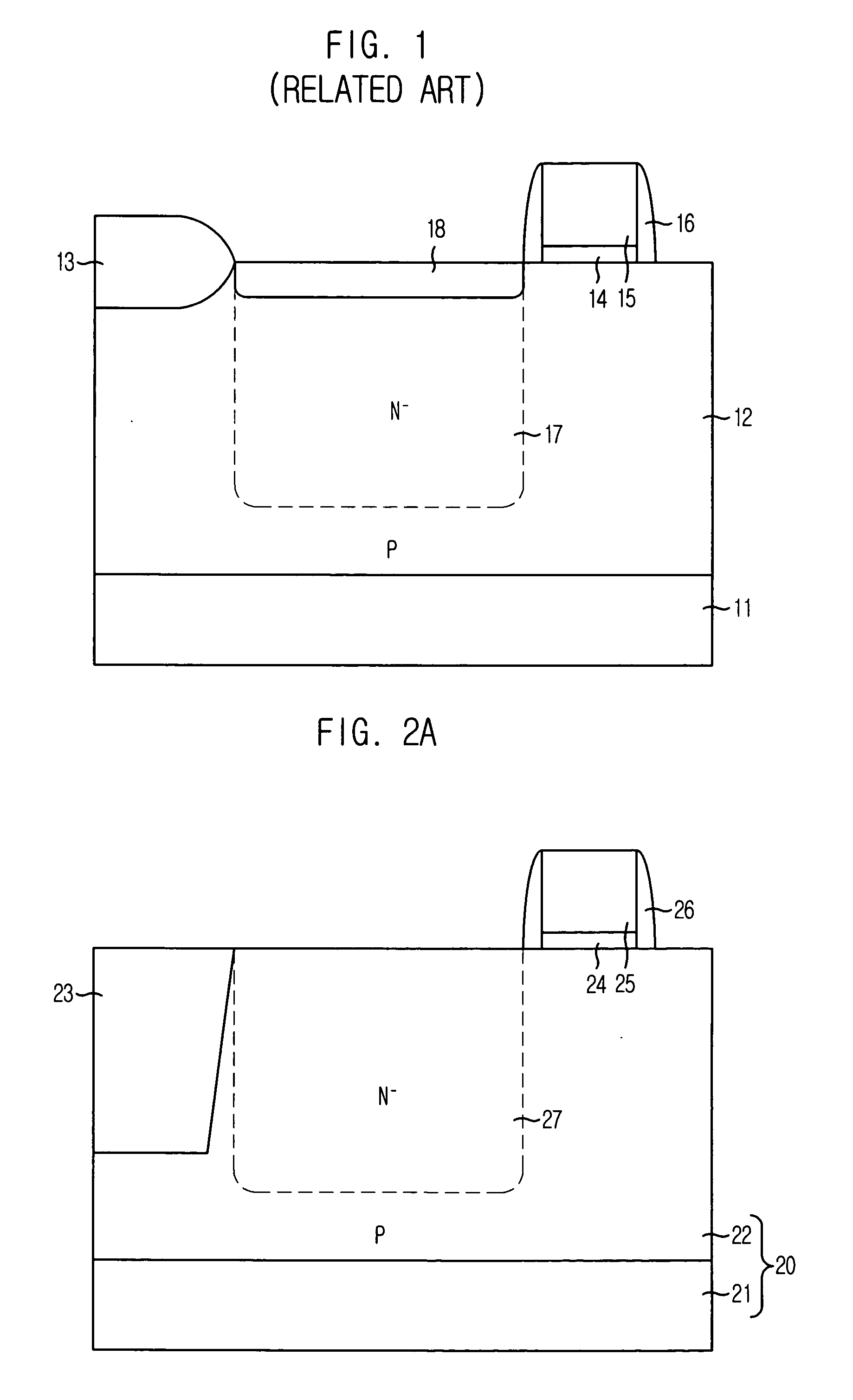

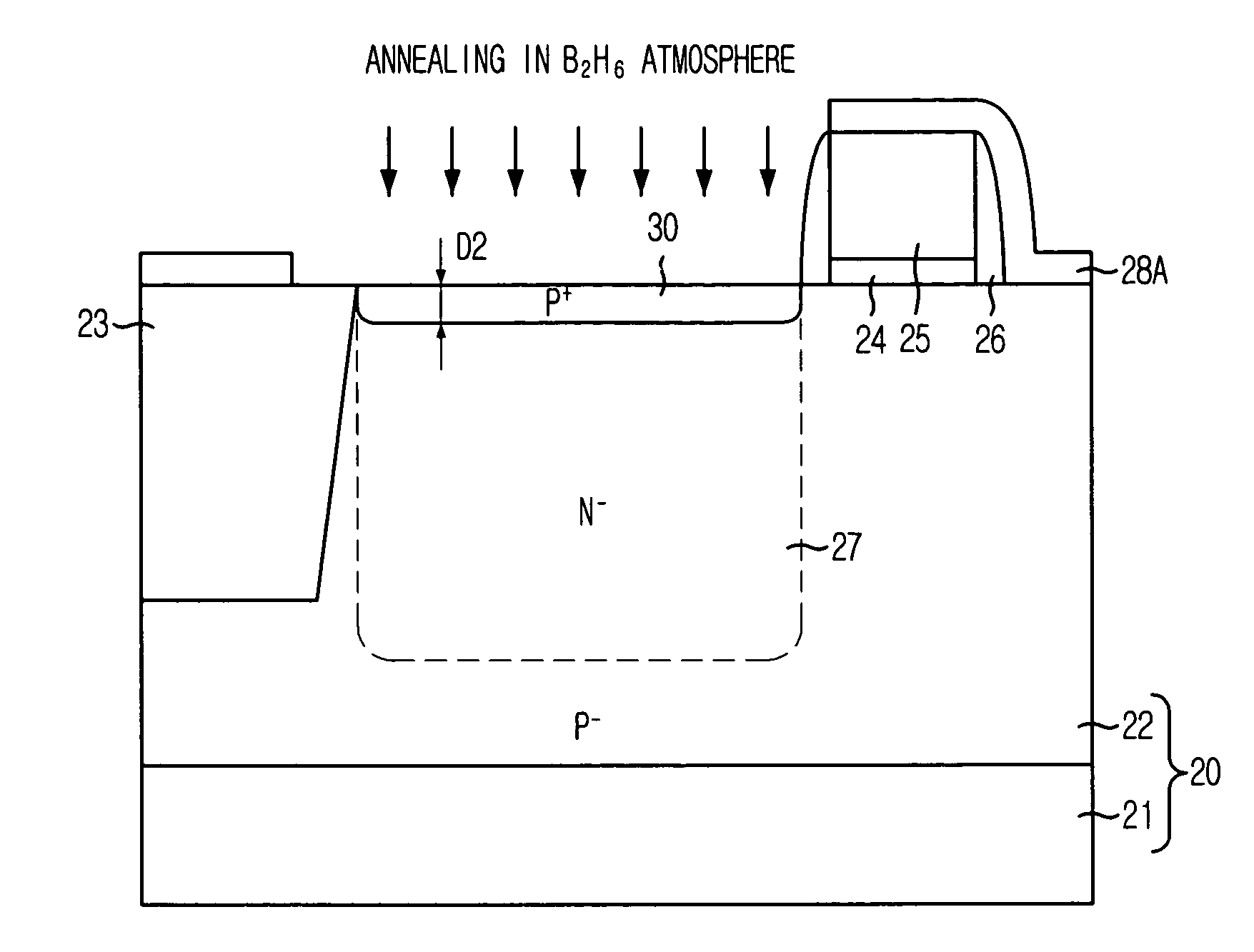

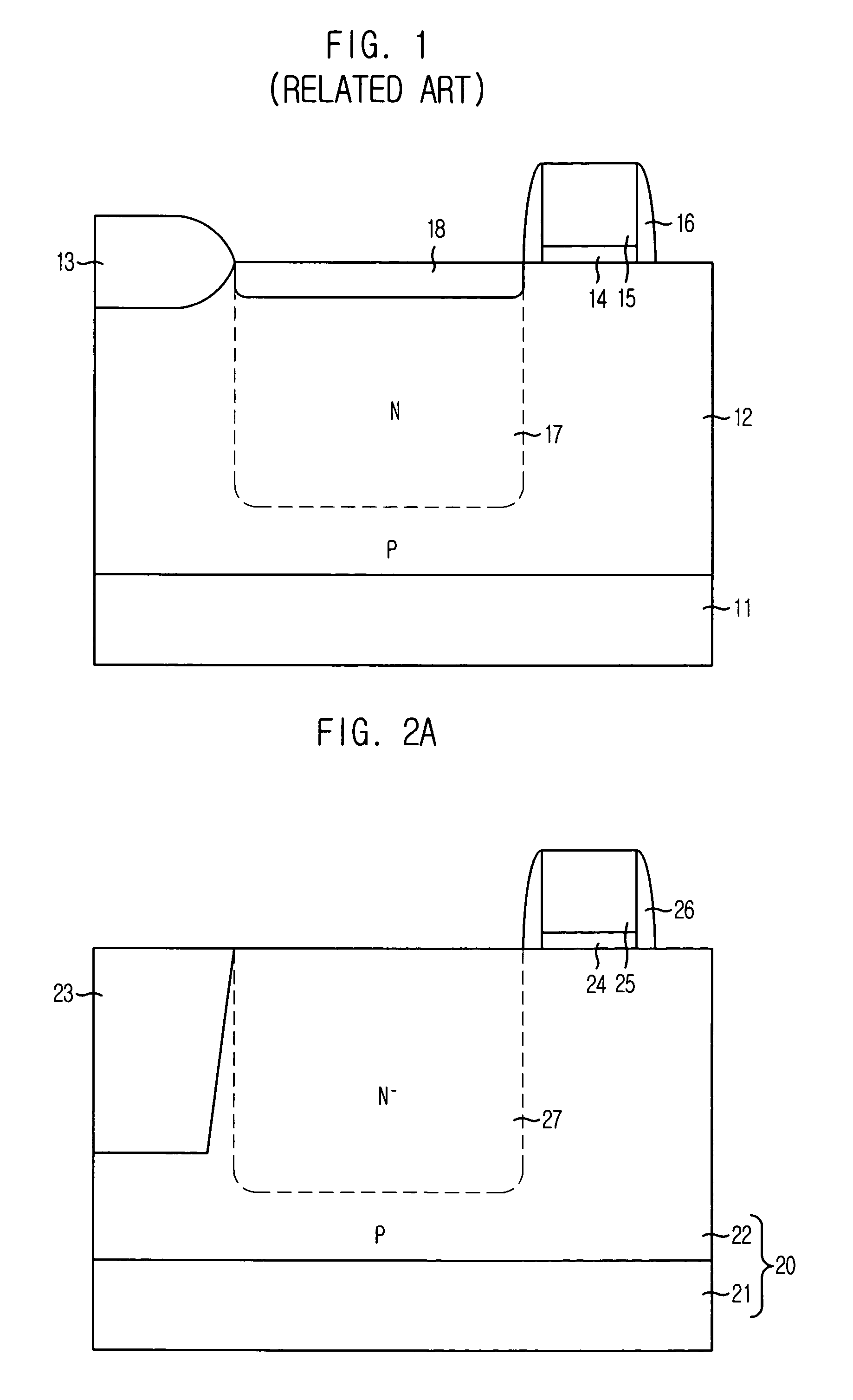

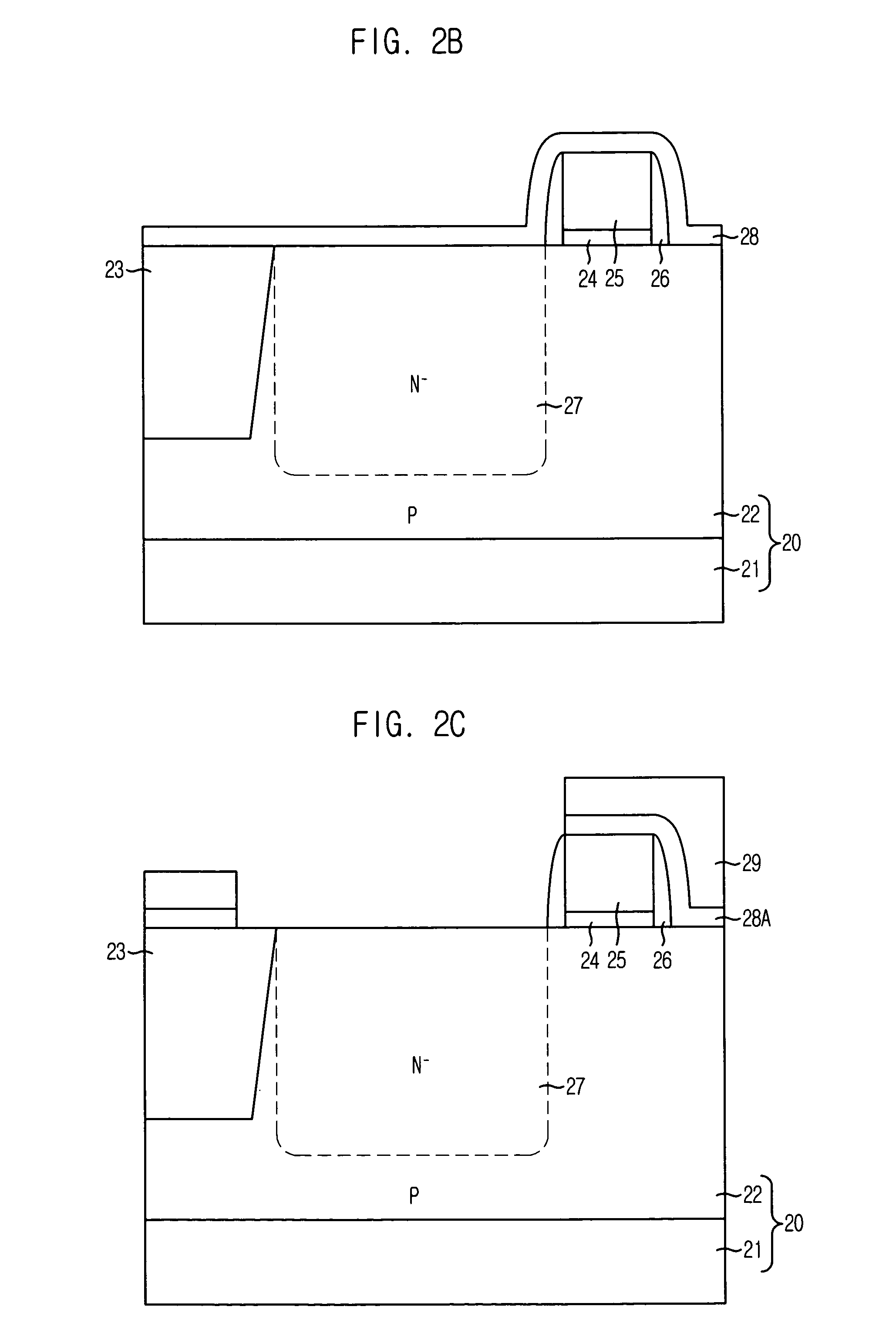

Method for fabricating CMOS image sensor

ActiveUS20070004120A1Convenient lightingSmall thicknessSolid-state devicesSemiconductor/solid-state device manufacturingCMOSPhotodiode

A method for fabricating a complementary metal-oxide semiconductor (CMOS) image sensor includes performing an ion implantation process onto a photodiode region in a first conductivity type semiconductor layer to form a second conductivity type first impurity region, and performing an annealing process in a gas atmosphere including first conductivity type impurity atoms to form a first conductivity type second impurity region underneath a surface of the first conductivity type semiconductor layer in the second conductivity type first impurity region, wherein the first conductivity type second impurity region is doped with the diffused first conductivity impurity atoms.

Owner:INTELLECTUAL VENTURES II

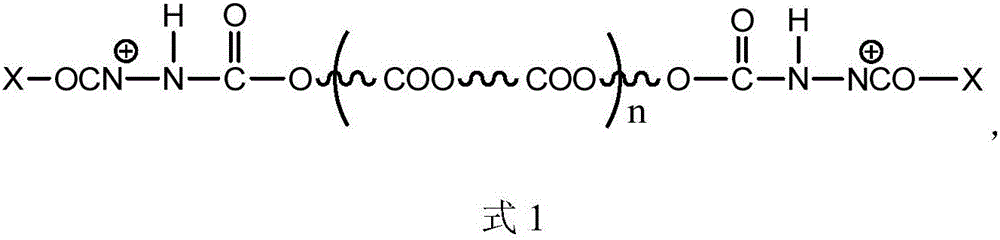

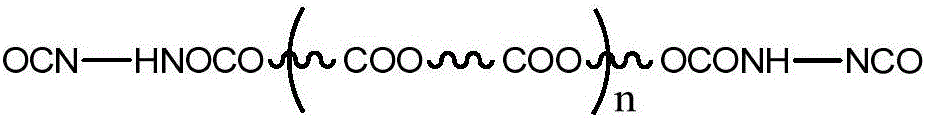

Crystallization accelerating agent for crystallization/semi-crystallization polyurethane and preparing method and application thereof

ActiveCN105778032AFast crystallizationHigh hardnessPolyureas/polyurethane adhesivesPolyesterAging resistance

The invention discloses a crystallization accelerating agent for crystallization / semi-crystallization polyurethane and a preparing method and application thereof.In the prior art, control over the crystallization morphology and the crystallization speed of the crystallization / semi-crystallization-type polyurethane does not exist, and the advantage of a crystallization / semi-crystallization polymer can not be most effectively developed.According to the crystallization accelerating agent, polyester diol serves as a structural body, and closed isocyanate serves as a potential reactive functional group.The crystallization accelerating agent is applied to the crystallization / semi-crystallization polyurethane, the crystallization speed can be increased, and the crystallization morphology can be improved; in the use process or the heat existing process, the potential closed isocyanate functional group can be further reacted with polyurethane resin or an active group on a contact base material, and hardness, strength and aging resistance are improved.

Owner:传化智联股份有限公司 +2

Method for manufacturing semiconductor device

InactiveCN102668037AFully activatedNo meltingSemiconductor/solid-state device manufacturingSemiconductor devicesIrradiationSemiconductor

Disclosed is a method for manufacturing a semiconductor device, wherein a semiconductor Si substrate, which is thinned down to 300 [mu]m or less, is heated such that the temperature at a position deeper than 1 [mu]m from the back surface of the semiconductor Si substrate is within a temperature range of 950-1412 DEG C (inclusive) without melting Si during a laser annealing process. Specifically disclosed is a method for manufacturing a semiconductor device, wherein a semiconductor region is formed by introducing an impurity from the front surface of a semiconductor substrate, the substrate is fixed to a supporting substrate using an electrostatic chuck, and then the impurity is activated by heating the front surface of the substrate by irradiation of a laser having a long wavelength of 3 [mu]m or more, while heating the entire substrate at 250 DEG C or more.

Owner:HITACHI LTD

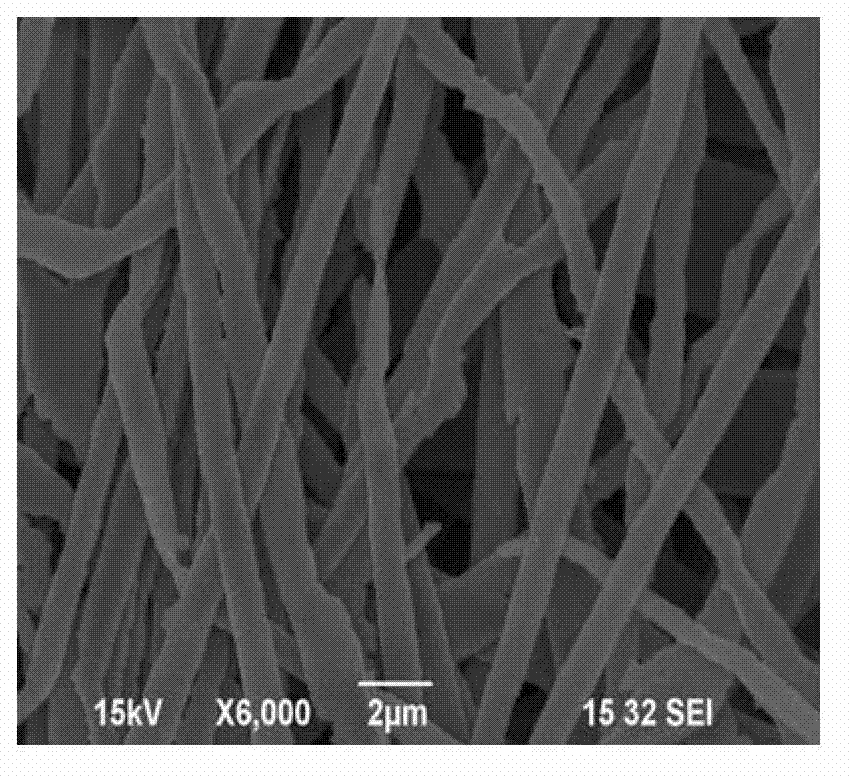

Method for preparing nano-structure single crystal silver

InactiveCN102776565AStable growth environmentSimplify the experimental stepsPolycrystalline material growthFrom normal temperature solutionsNano structuringSynthesis methods

The invention relates to a method for preparing nano-structure single crystal silver. The method comprises the following steps of: reducing high-conductivity forming porous activated carbon containing chloride ion, putting the activated carbon into a silver-containing precursor solution, growing nano-structure single crystal silver on the surface of the activated carbon, providing a crystal nucleus and slow and stable crystal growth environment required by growth of single crystal silver through the silver-containing precursor and proper chlorine content, and obtaining nano silver single crystal with multiple features by controlling the concentration of the solution containing the silver-containing precursor and the growth time. The method belongs to a green synthesis method, pollution is avoided, any additive is not required, and the nano-structure single crystal silver is grown on the surface of the forming porous activated carbon at room temperature; the nano-structure single crystal silver is high in productivity, high in purity and easily separated from the forming porous activated carbon, the silver is naturally stripped after growth, and the activated carbon is ultrasonically treated by absolute ethyl alcohol or alkaline liquor and can be regenerated; and the obtained single crystal silver has the characteristics of high mechanical strength, high conductivity and low crystal defect.

Owner:SHANGHAI JIAO TONG UNIV +1

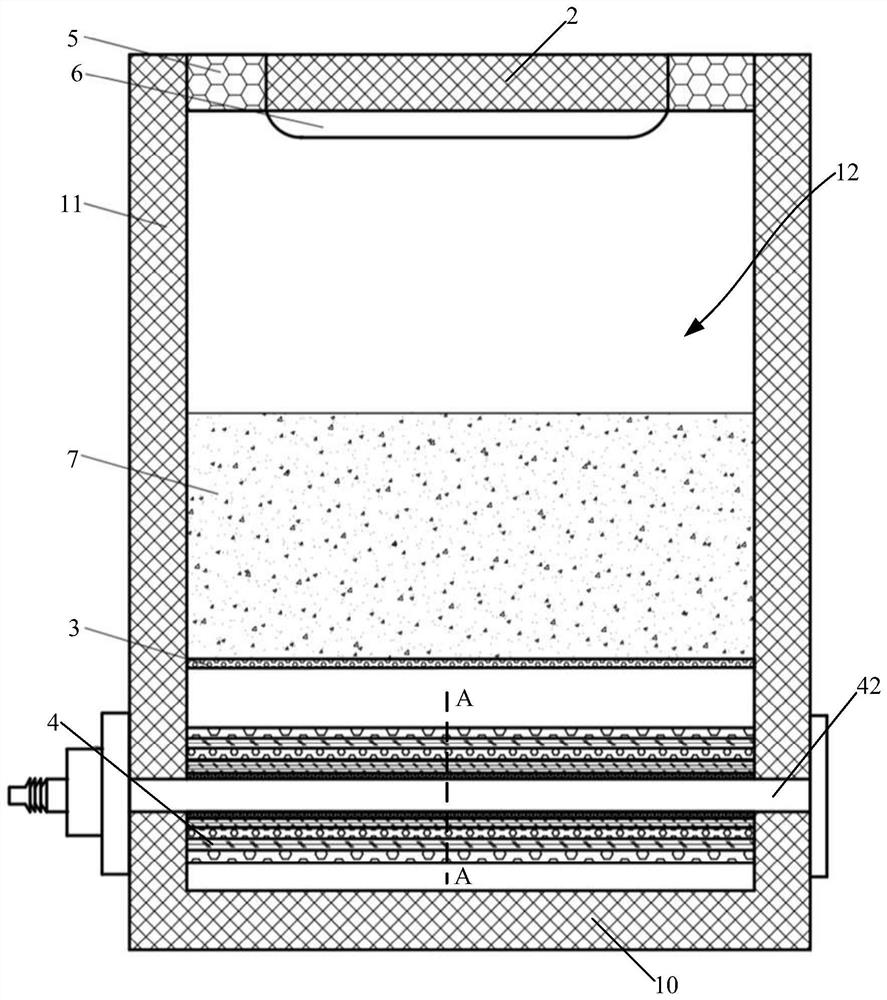

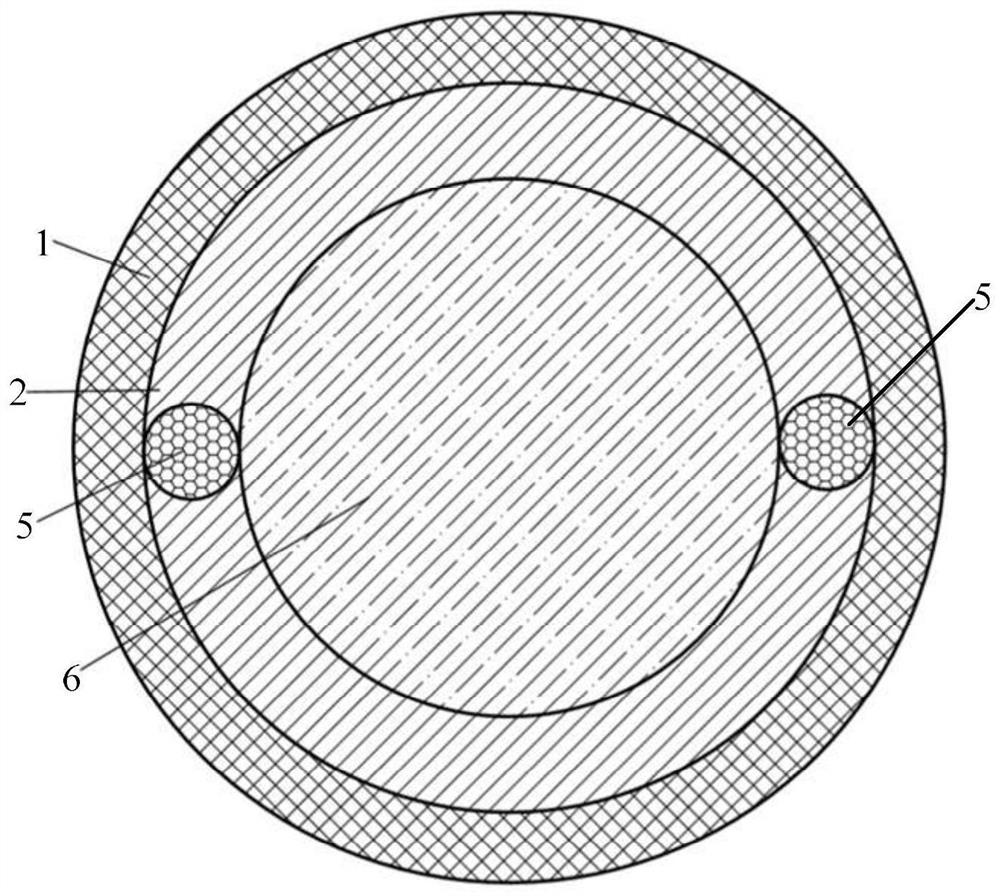

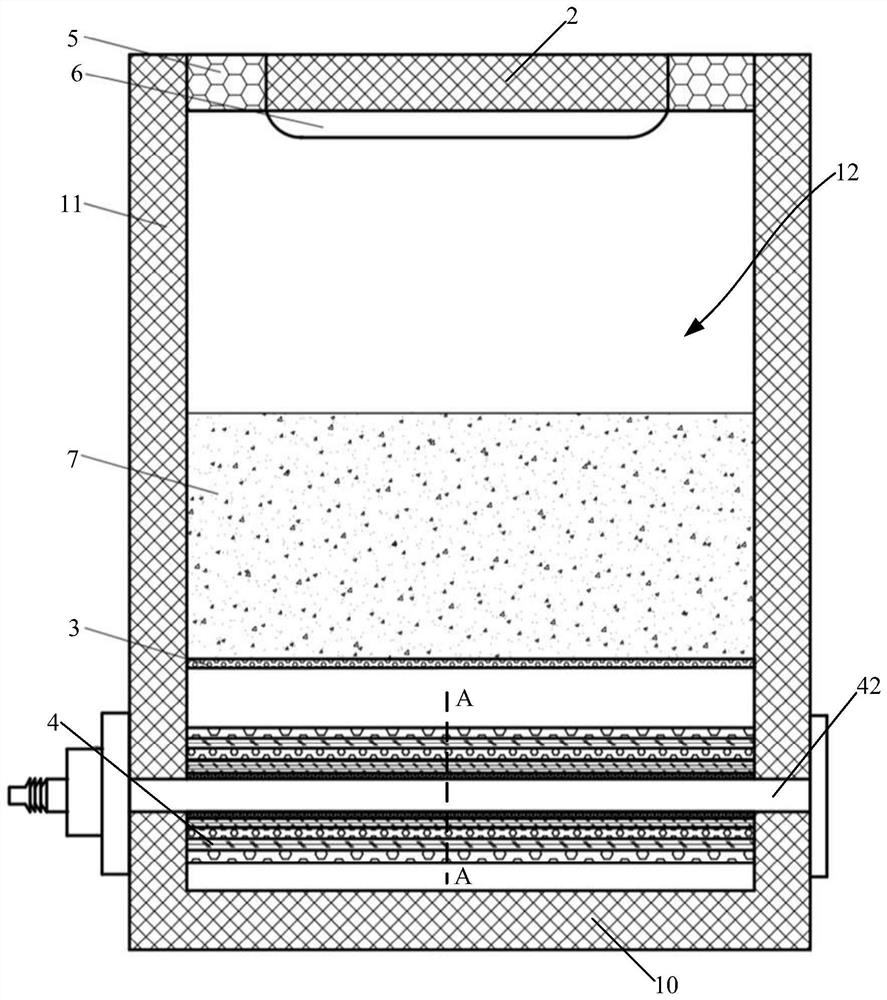

Growth method for growing silicon carbide crystals by PVT method

ActiveCN112144110AAvoid crystalline defectsReduce carbon wrap defectsPolycrystalline material growthFrom condensed vaporsCarbide siliconSeed crystal

The invention provides a growth method for growing silicon carbide crystals by a PVT method. The method comprises the following steps: providing a crucible; placing a silicon carbide raw material anda seed crystal in the crucible; putting the crucible into a growth chamber, vacuumizing, introducing protective gas, and setting the temperature of the chamber; raising the temperature to a first preset temperature, introducing chlorine-containing gas through a gas dispersing device in the crucible, raising the temperature to a second preset temperature, and stopping introducing the chlorine-containing gas or continuously introducing the chlorine-containing gas for a first preset time; raising the temperature to a third preset temperature, and annealing to obtain the silicon carbide crystal after the silicon carbide crystal starts to grow for a second preset time. According to the growth method, the release rate and uniformity of the chlorine-containing gas can be effectively controlled, and the crystallization defect caused by condensation of gas-phase silicon on the surface of the crystal is avoided; by controlling the introduction time and flow of the chlorine-containing gas, the crystallization defect can be further avoided; due to the arrangement of the porous graphite block, introduced excessive chlorine-containing gas and carbon particles suspended in a growth atmosphere canbe dissipated, and the defects of carbon inclusions in crystals are reduced.

Owner:中电化合物半导体有限公司

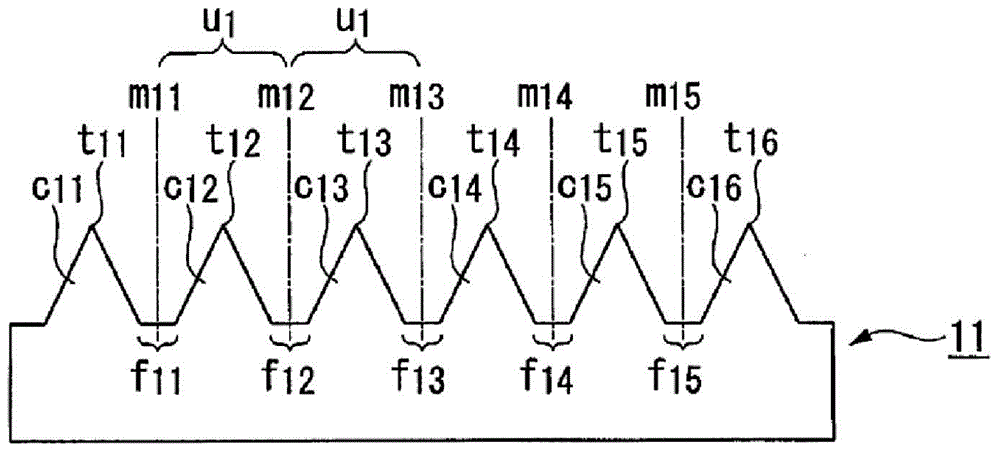

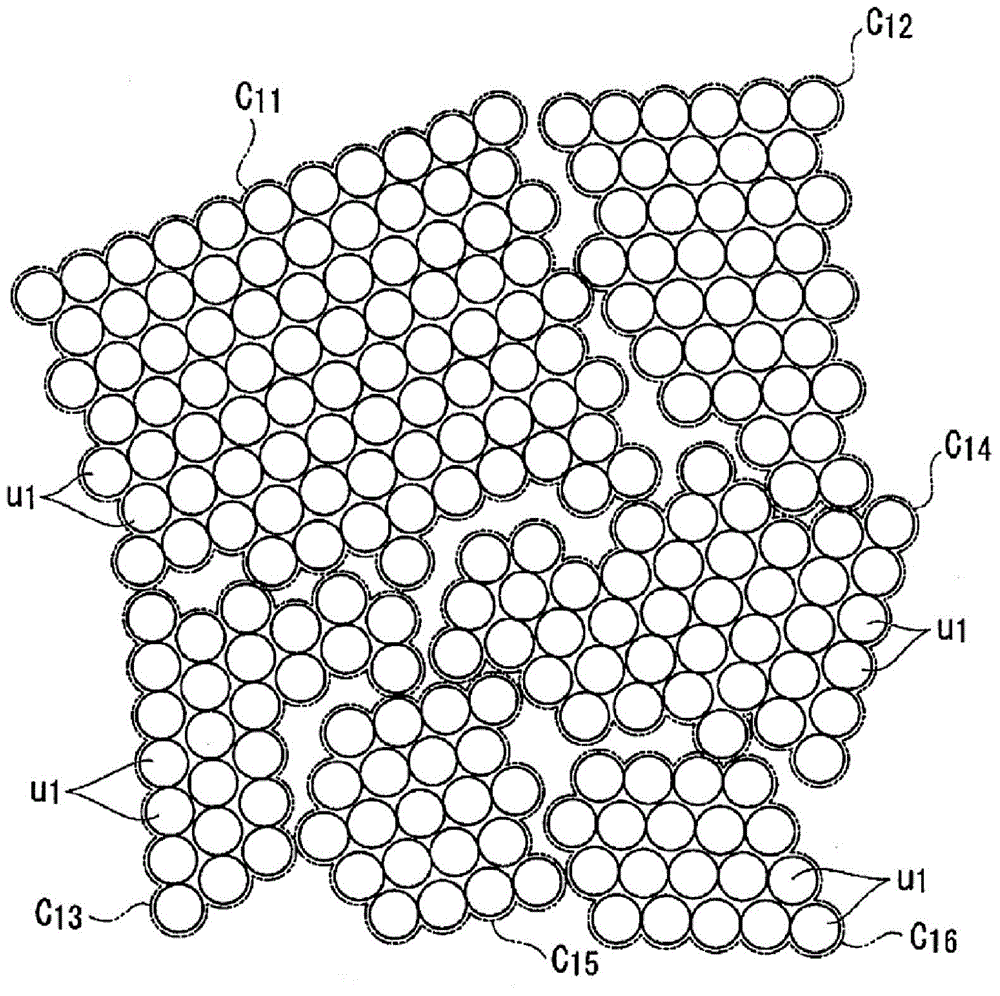

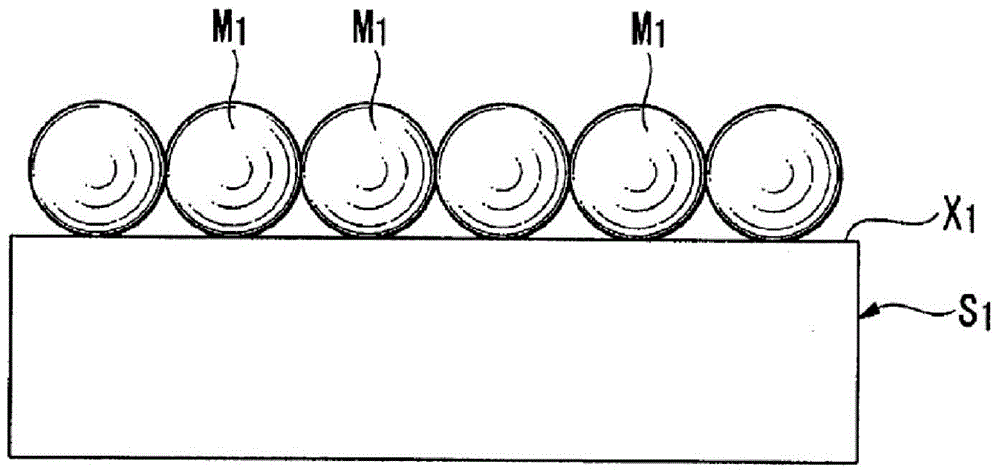

Substrate for semiconductor light emitting elements, semiconductor light emitting element, method for producing substrate for semiconductor light emitting elements, and method for manufacturing semiconductor light emitting element

ActiveCN104584243ASufficient light extraction efficiencyPrevent color shiftSemiconductor/solid-state device manufacturingSemiconductor devicesProject structureSemiconductor

This method for manufacturing a semiconductor light emitting element comprises: a particle arranging step wherein a plurality of particles (M) are arranged in a single layer on a substrate (S); a particle etching step wherein spaces are formed among the particles (M) by dry etching the arranged plurality of particles (M) under such conditions that the particles (M) are etched but the substrate (S) is not substantially etched; and a substrate etching step wherein the substrate (S) is dry etched using the plurality of particles (M1) after the particle etching step as an etching mask, thereby forming a recessed and projected structure on one surface (X) of the substrate (S).

Owner:OJI HLDG CORP

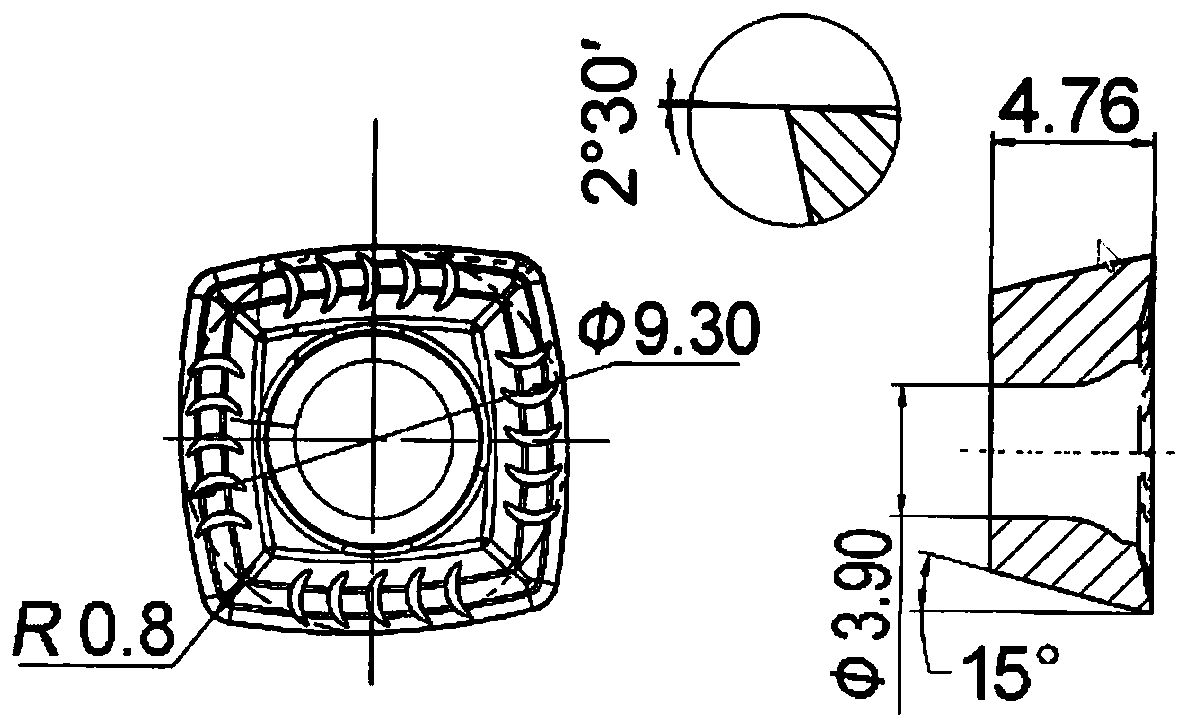

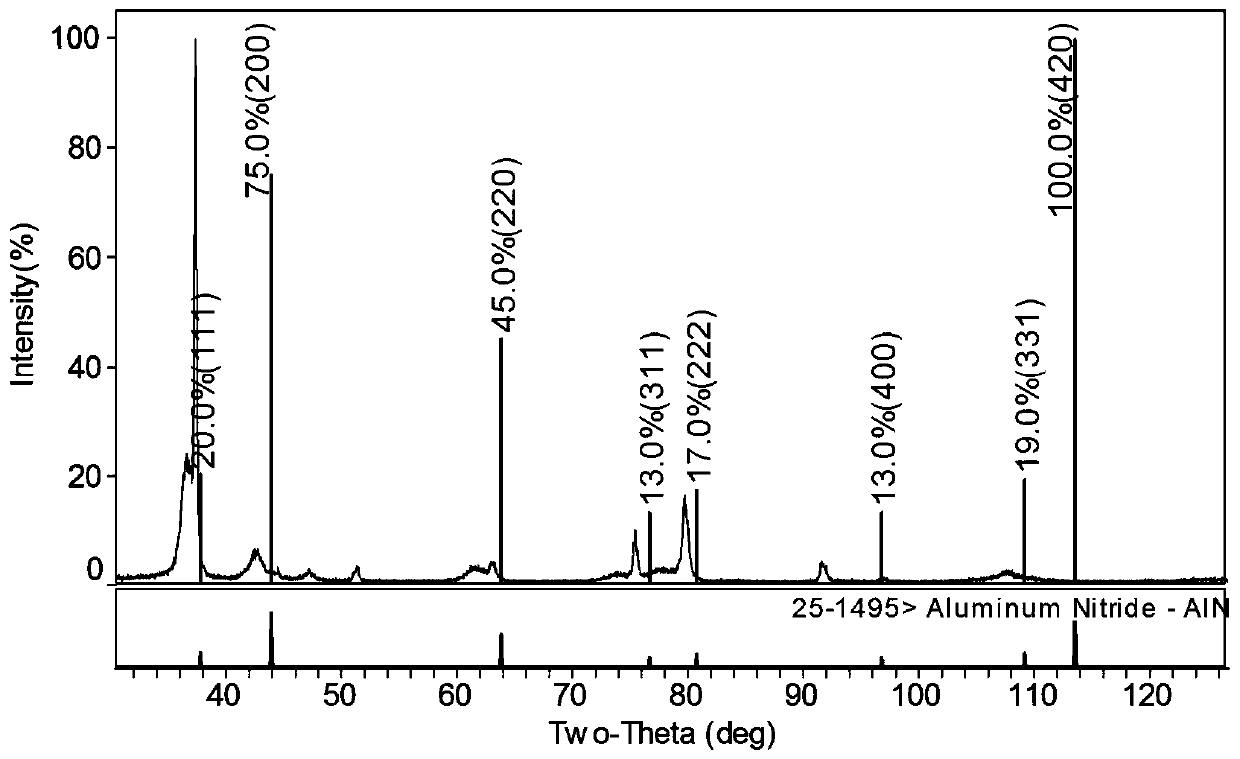

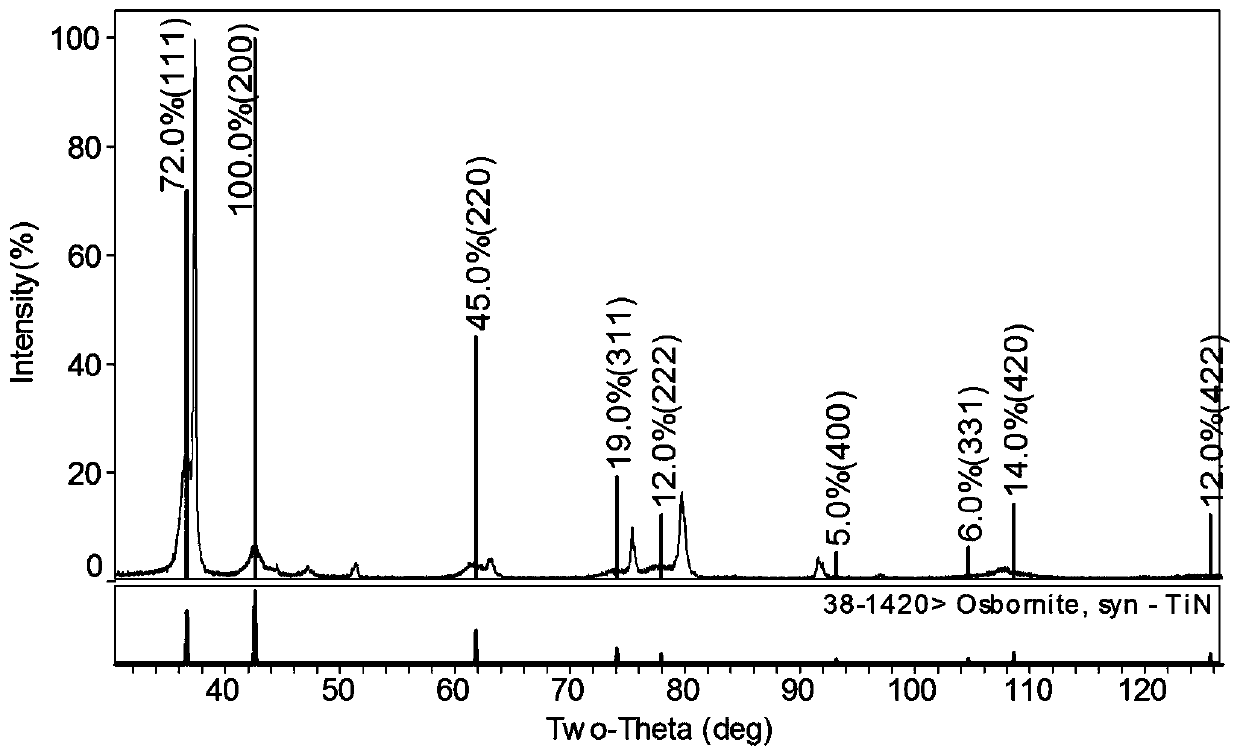

PVD coating with strong (111) texture and preparation method thereof

ActiveCN110284038AExtended service lifeAchieve carbon and oxygen balanceVacuum evaporation coatingSputtering coatingCrystal structureAlloy

The invention relates to a PVD coating with a strong (111) texture and a preparation method thereof. The crystal structure of the single or complex phase of the PVD coating is consistent with or similar to at least one of fcc-TiN or fcc-AlN, and the (111) crystal surface texture coefficient of the coating is larger than 2.5. According to the preparation method, a WC-based hard alloy or a TiCN-based metal ceramic hard material is adopted as a matrix, the target regulation on the surface structure of the coating is realized by carrying out secondary sintering regulation on the matrix of the hard material before coating; and the surface structure of the matrix is changed, so that the nucleation and growth conditions of the PVD coating are changed, the effect that the strong (111) texture is formed is achieved, the service life of a coating cutter is remarkably prolonged, and the requirements for high performance and high service life on the PVD coating cutter of high-efficiency machining of a difficult-to-machine material are met.

Owner:CENT SOUTH UNIV

Formula of environment-friendly thin film transistor liquid-crystal display (TFT-LCD) substrate glass

ActiveCN102584007AIncrease contentReduce crystallization defectsLiquid-crystal displayThin-film-transistor liquid-crystal display

Provided is a formula of environment-friendly thin film transistor liquid-crystal display (TFT-LCD) substrate glass. The formula is designed to be environment-friendly and more perfect in performance, an object glass substrate with no surface defects including bulbs is formed even if no As2O3 or Sb2O3 serving as clarifying agents is used, and the object glass substrate contains no As2O3 or Sb2O3 and their compounds. Components in raw materials of the glass substrate include by weight percentage: 56-64% of SiO2, 7-11% of B2O3, 14-18% of Al2O3, 3-8% of CaO, 0.5-8% of SrO, 0.1-10% of BaO, 0-2.0% of ZnO and 0.1-1.0% of SnO.

Owner:SHIJIAZHUANG XUXIN OPTOELECTRONIC TECH CO LTD

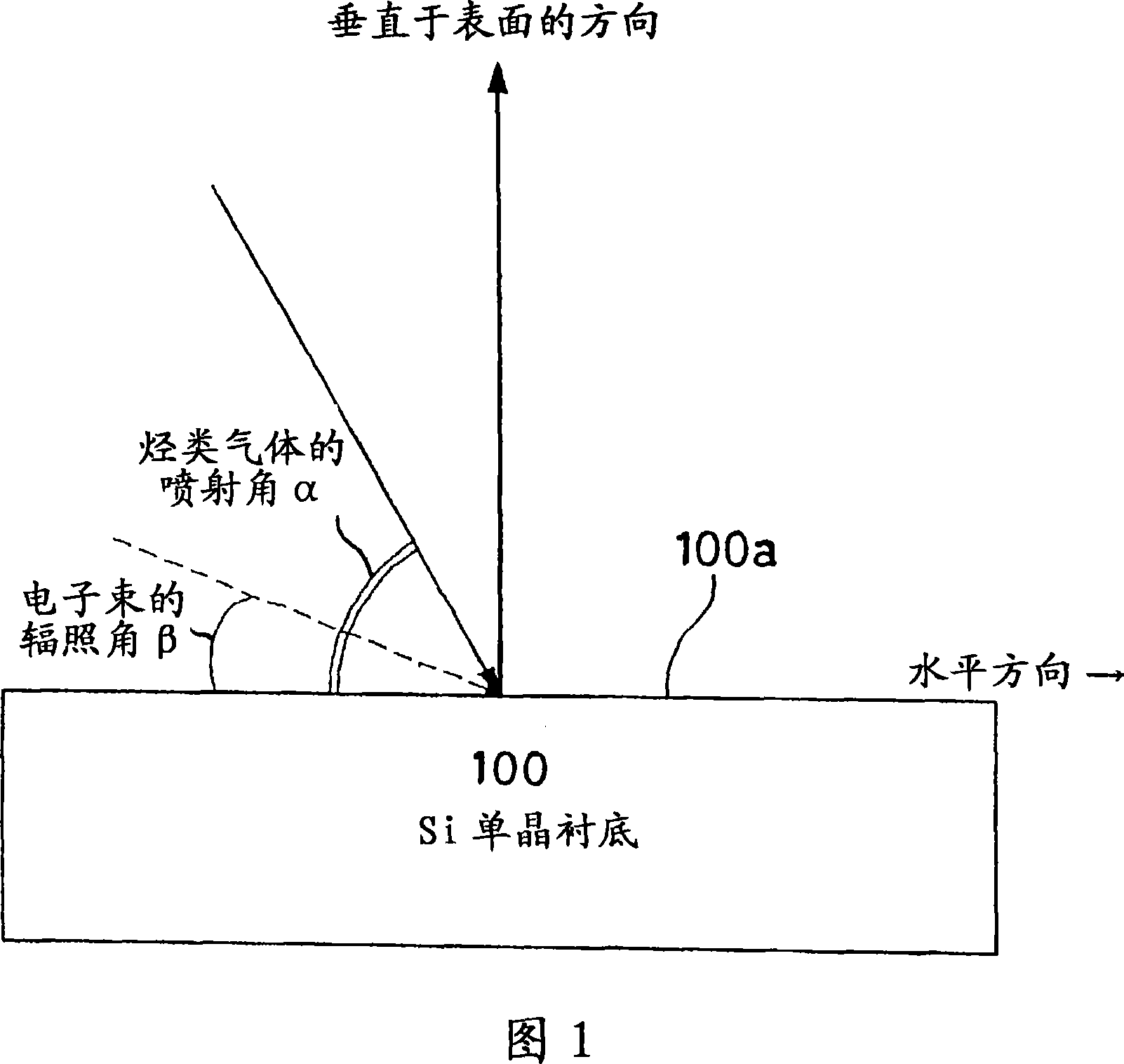

Method for production of silicon carbide layer, gallium nitride semiconductor device and silicon substrate

InactiveCN101203940AAvoid decompositionAvoid Facilitating DecompositionSemiconductor/solid-state device manufacturingPolycrystalline material growthCubic silicon carbideGallium nitride

A method for producing a silicon carbide layer on a surface of a silicon substrate includes the step of irradiating the surface of the silicon substrate heated in a high vacuum at a temperature in a range of from 500 DEG C to 1050 DEG C with a hydrocarbon-based gas as well as an electron beam to form a cubic silicon carbide layer on the silicon substrate surface.

Owner:SHOWA DENKO KK

Perovskite light absorption layer and preparation method thereof, and solar cell and preparation method thereof

PendingCN114784196AImprove compactnessRefine the grain sizeSolid-state devicesSemiconductor/solid-state device manufacturingElectrical batteryPhysical chemistry

The invention provides a perovskite light absorption layer and a preparation method thereof, and a solar cell and a preparation method thereof. The perovskite light absorption layer comprises a perovskite substrate and amine salt. The amine salt is used for doping and repairing the perovskite matrix through steam deposition. According to the perovskite light absorption layer provided by the invention, the gas-solid reaction is generated between the amine salt steam and the formed perovskite substrate, the perovskite substrate is repaired, the amine salt in a steam form not only can quickly generate a gas-solid substitution reaction on the surface of the perovskite, but also can gradually permeate into a perovskite body phase, so that the gas-solid substitution reaction can be quickly performed on the surface of the perovskite; according to the perovskite light absorption layer and the preparation method thereof, the defect of element vacancy easily formed in perovskite is overcome, the defect of a perovskite matrix is reduced, the prepared perovskite light absorption layer is good in compactness and large in grain size, the quality and the working stability of the perovskite light absorption layer are remarkably improved, and the reproducibility is good.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

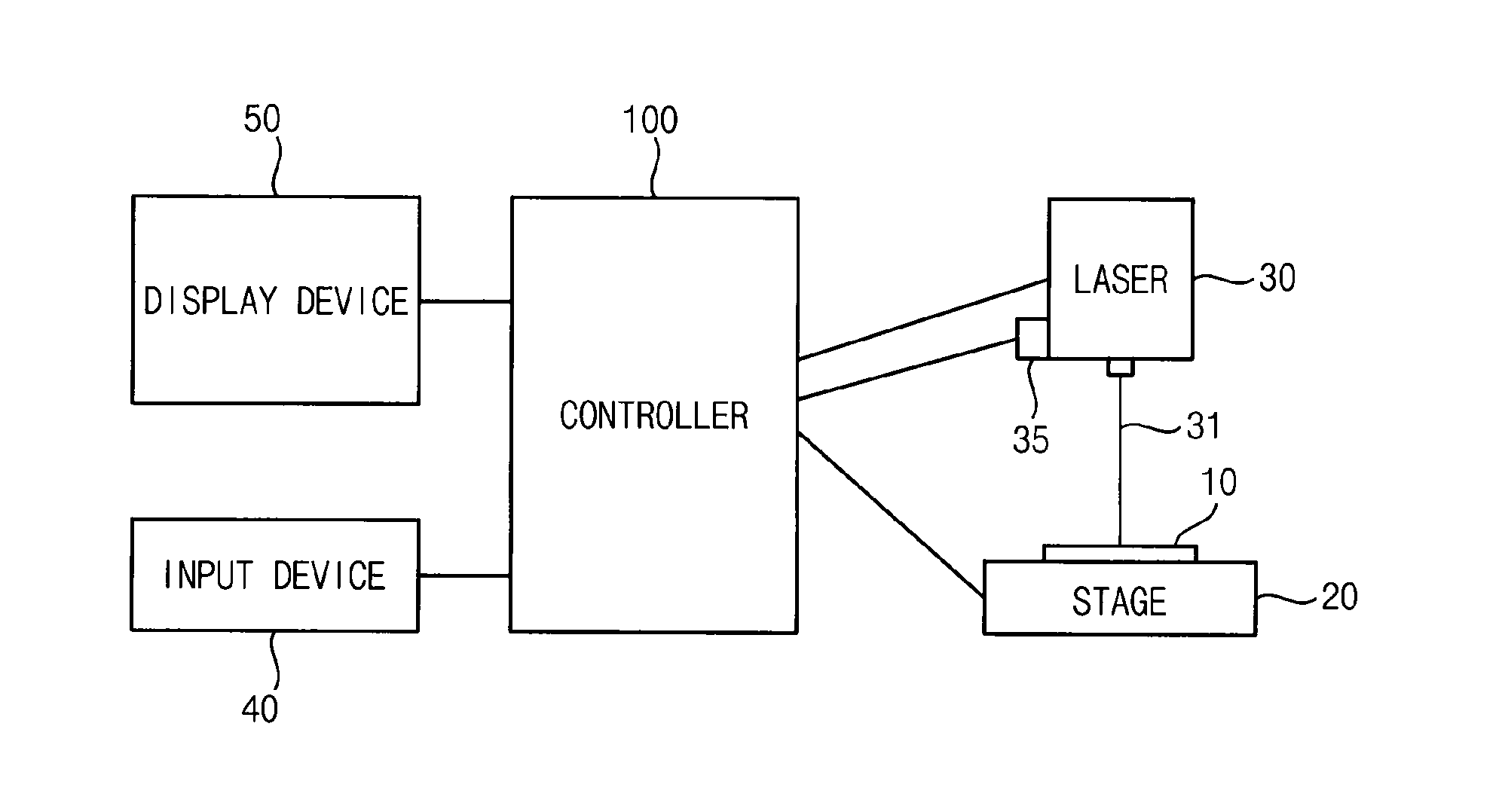

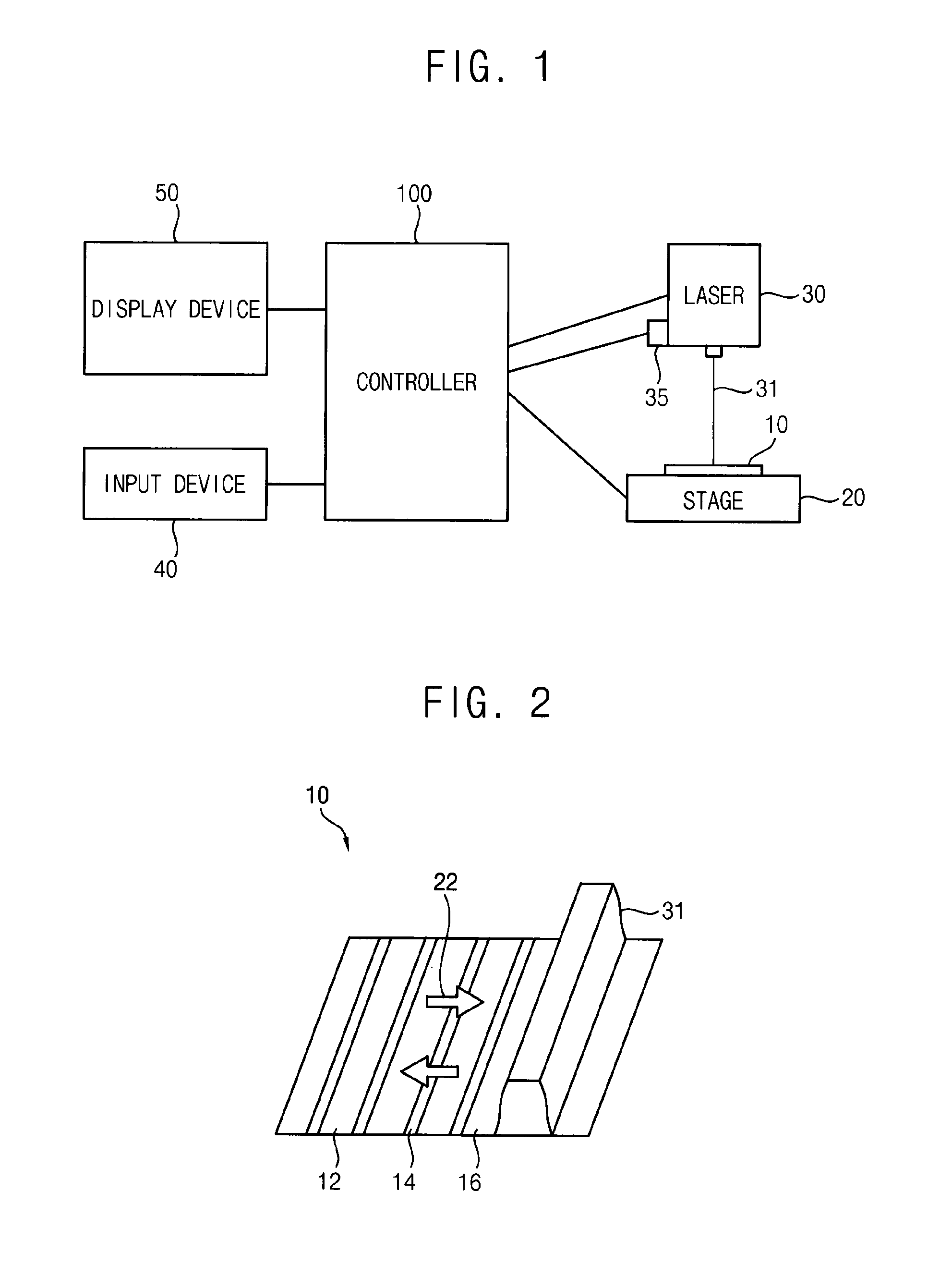

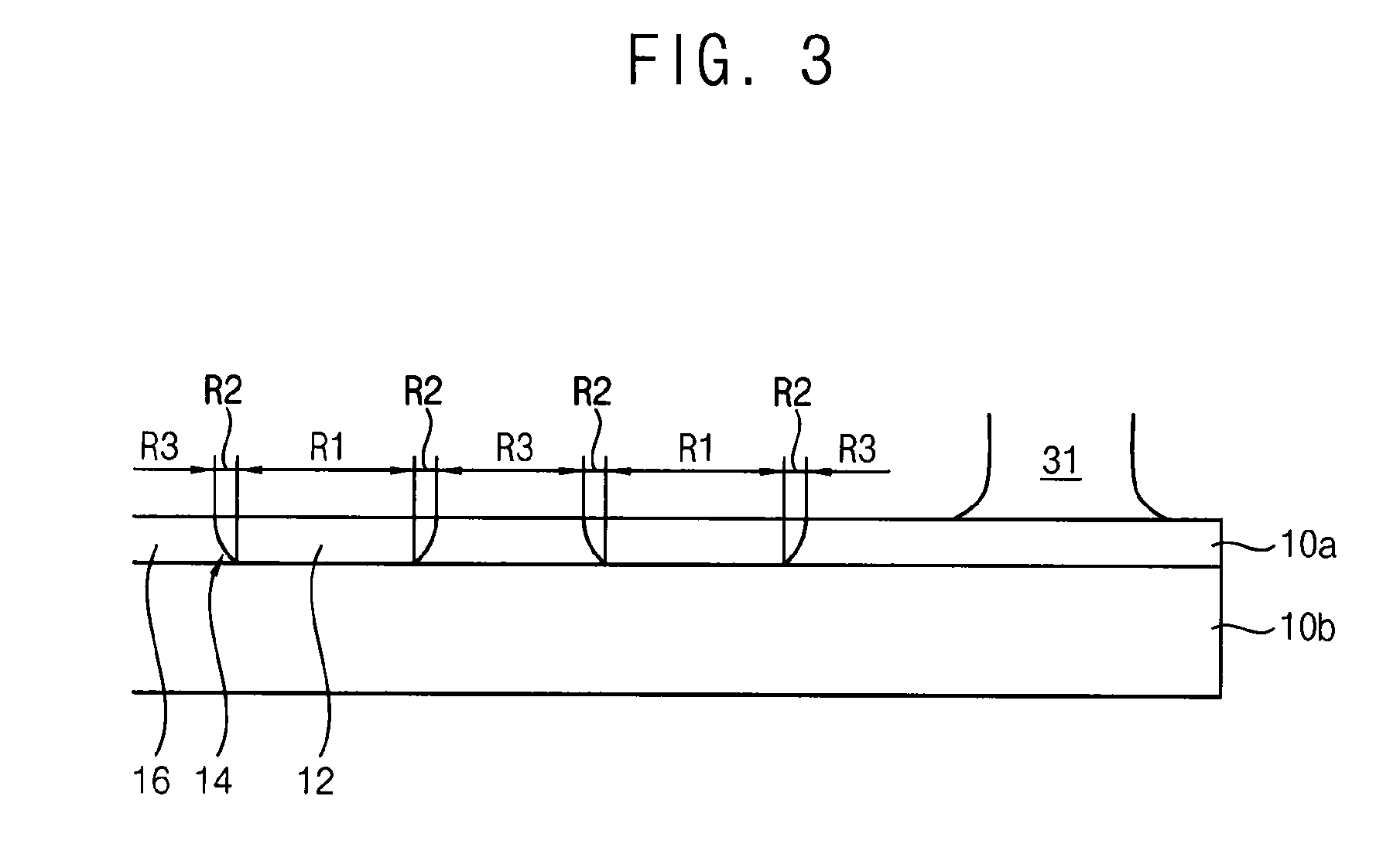

Laser apparatus and method of irradiating laser beam using the same

InactiveUS20140360987A1Reduce defectsImprove response speedLaser detailsAfter-treatment detailsIrradiation laserOptoelectronics

A laser apparatus includes: a laser which selectively irradiates a laser beam to a portion of a target based on a laser driving voltage, where an intensity of the laser beam is substantially stabilized within about 10 nanoseconds; a stage which controls a relative location between the target and the laser based on a stage driving voltage; and a controller which applies the stage driving voltage to the stage, and applies the laser driving voltage to the laser

Owner:SAMSUNG DISPLAY CO LTD

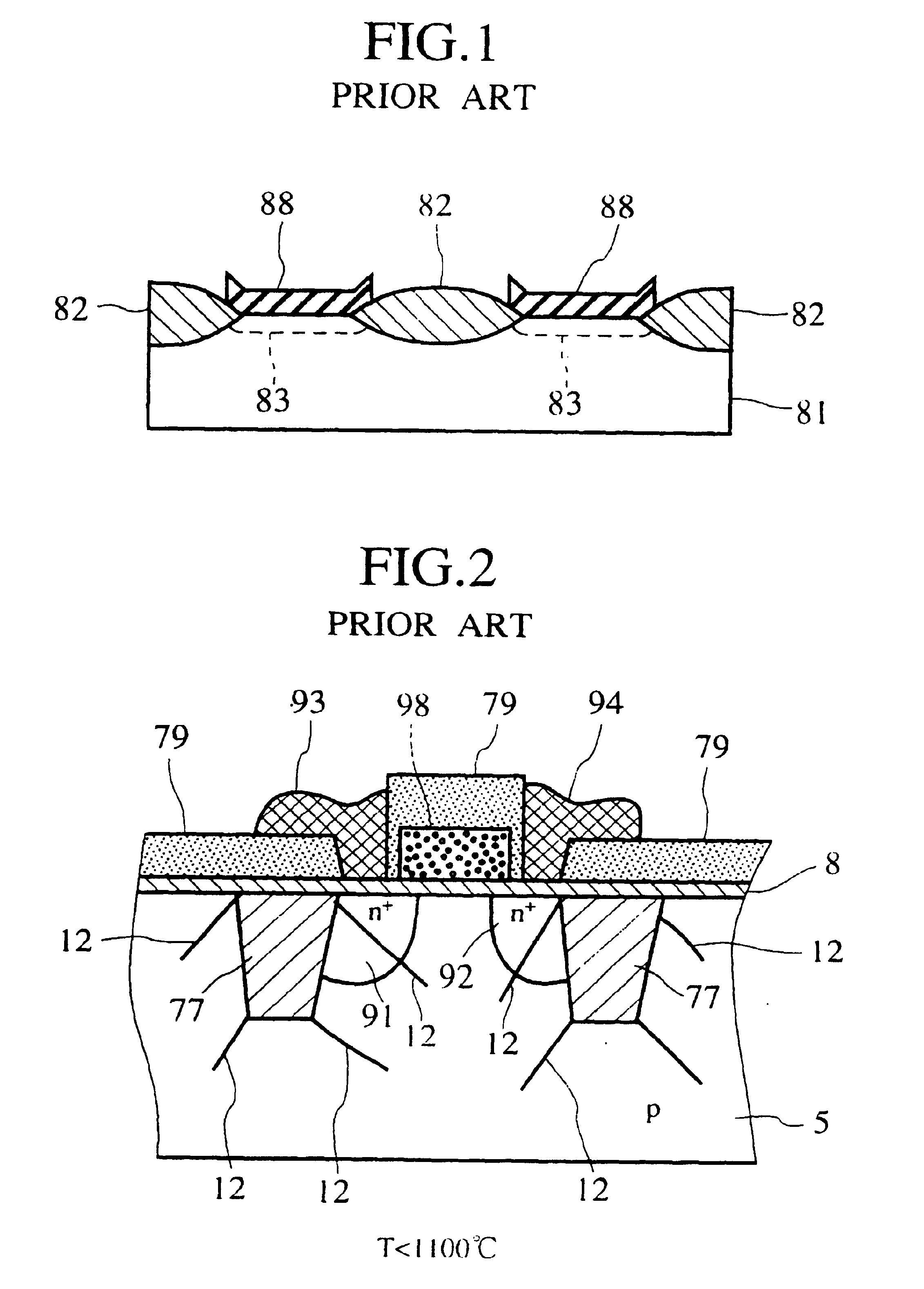

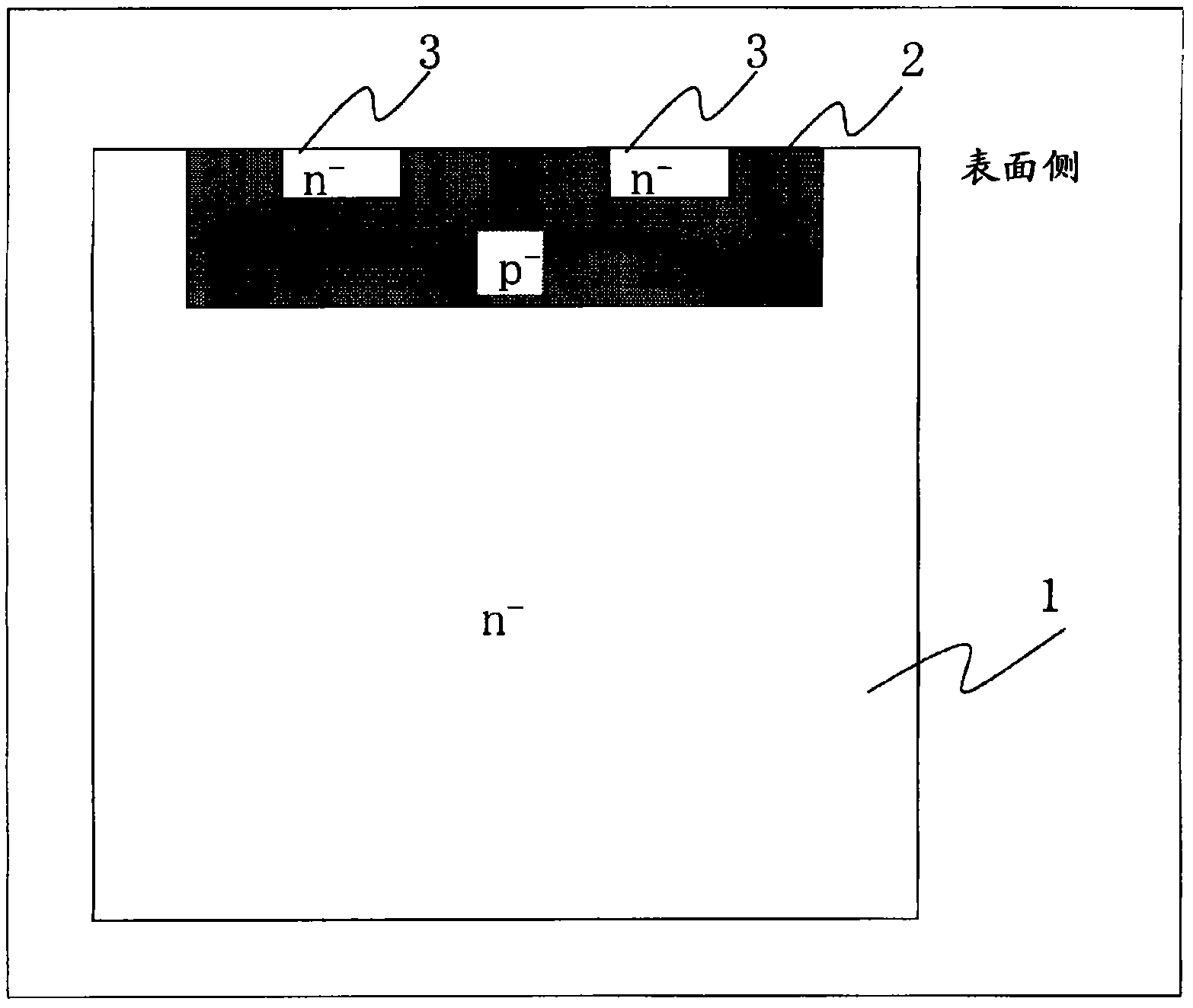

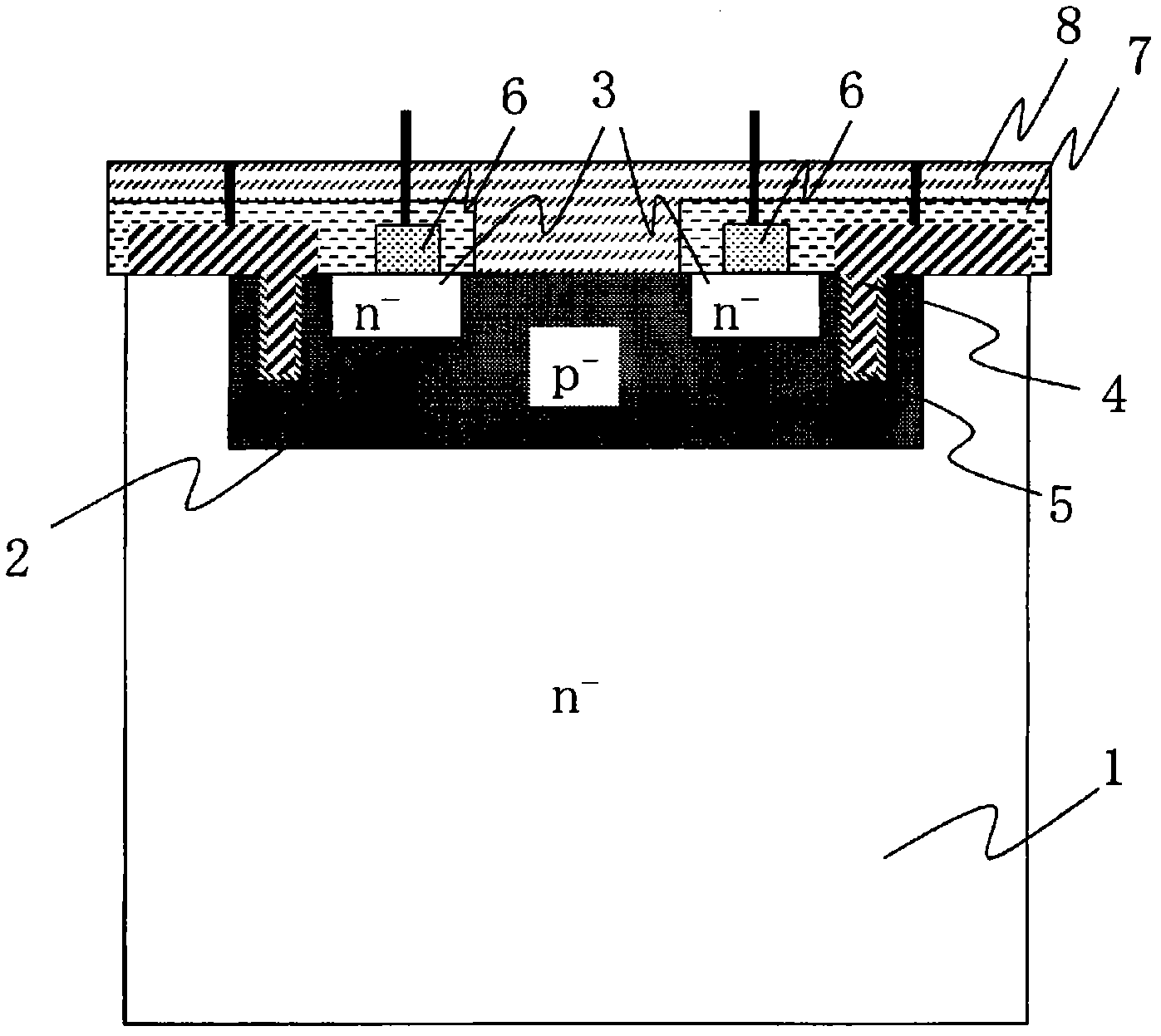

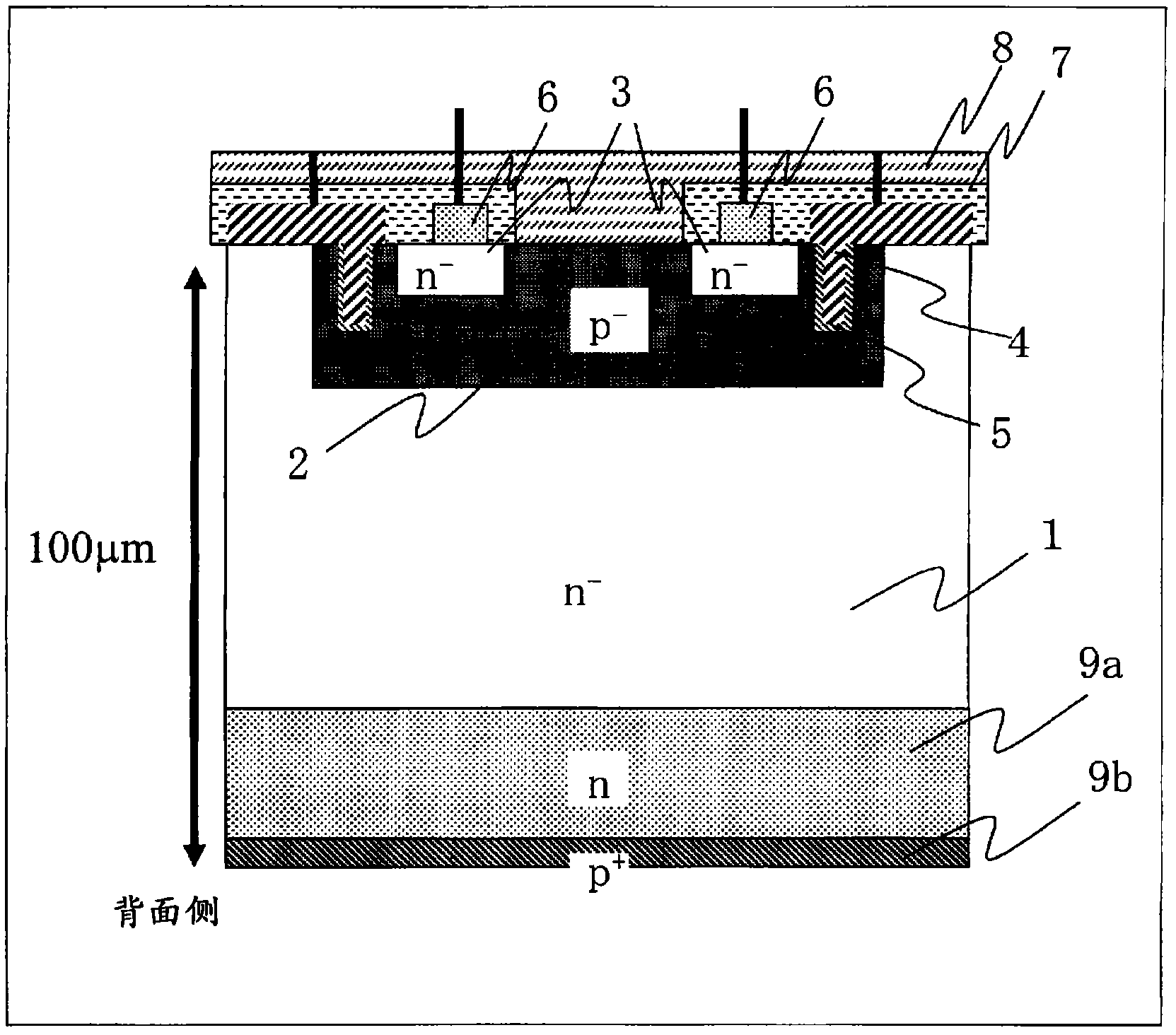

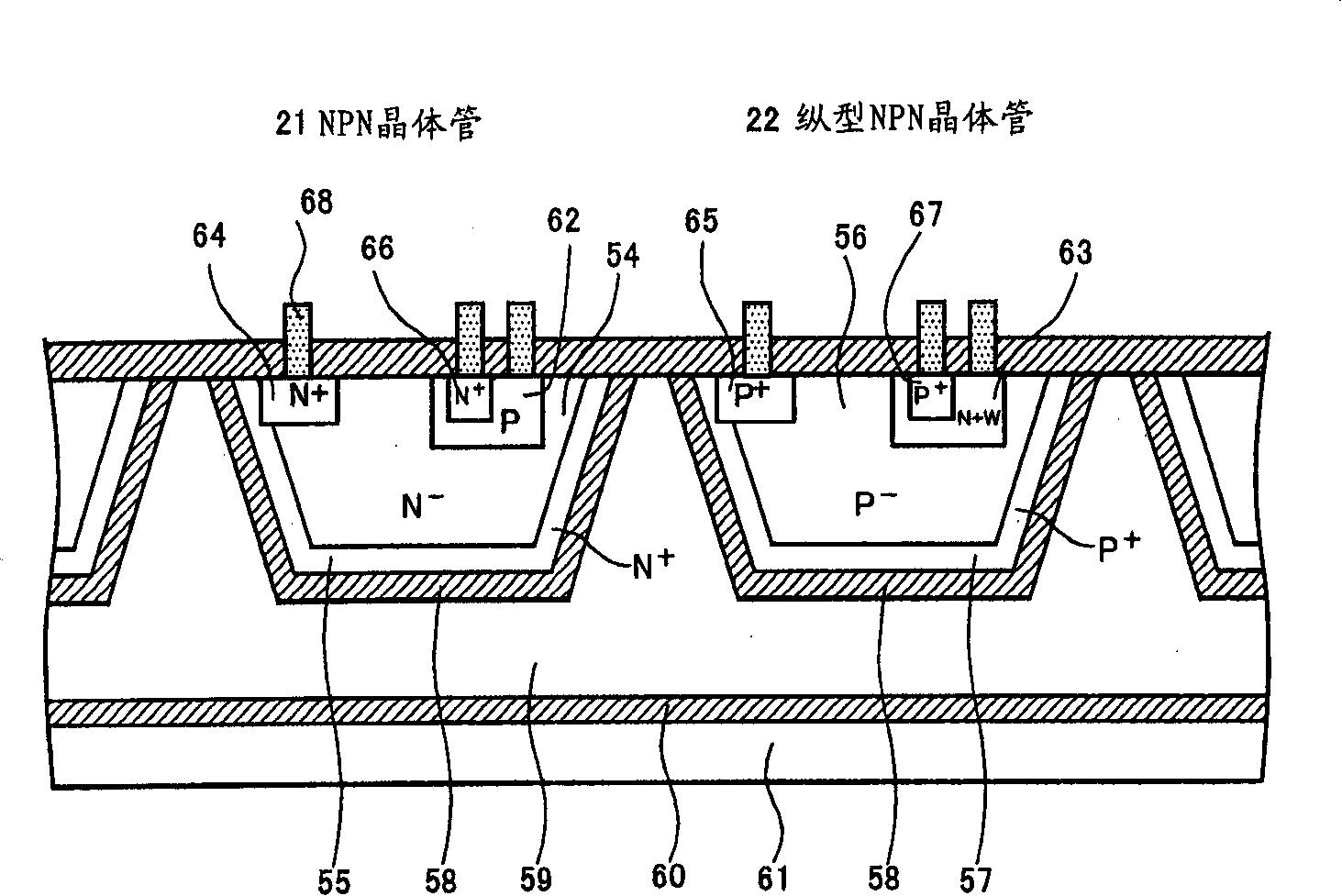

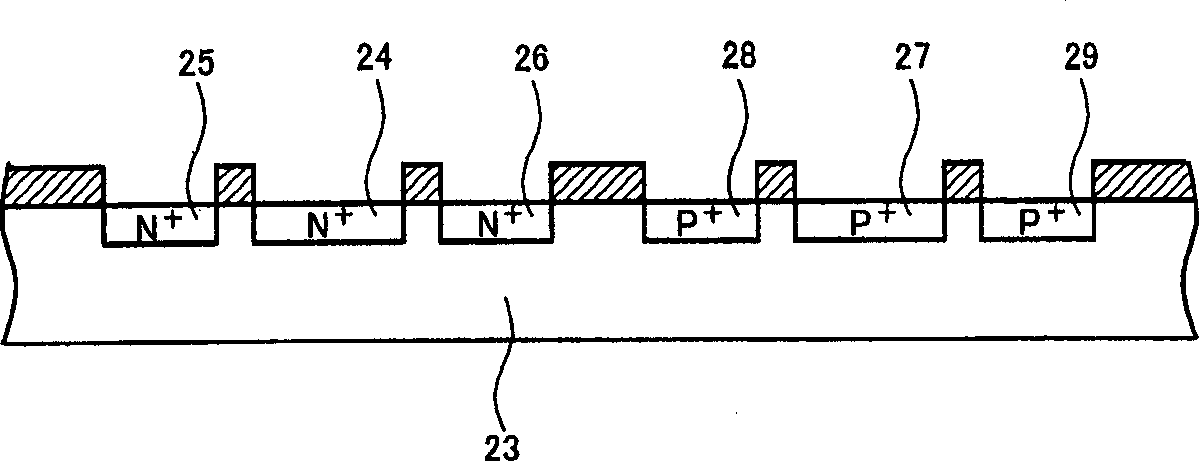

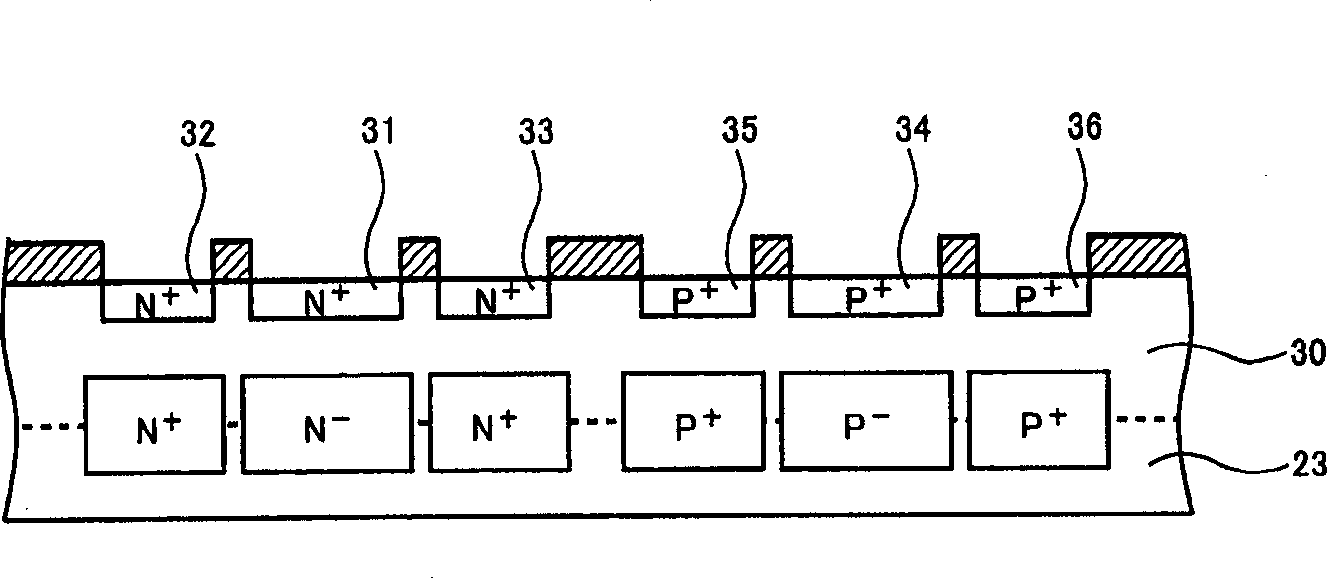

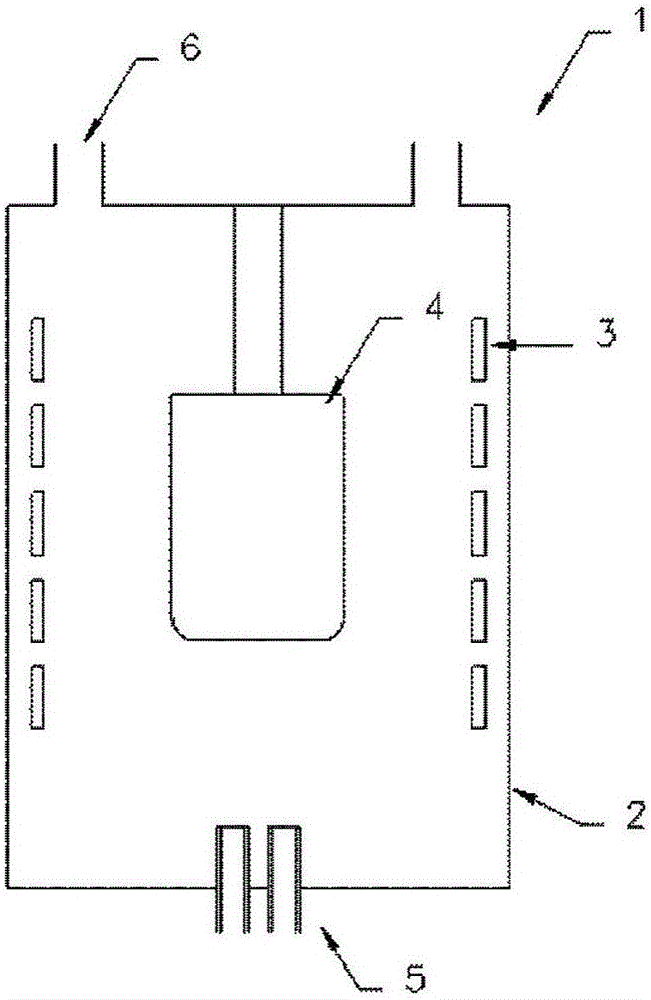

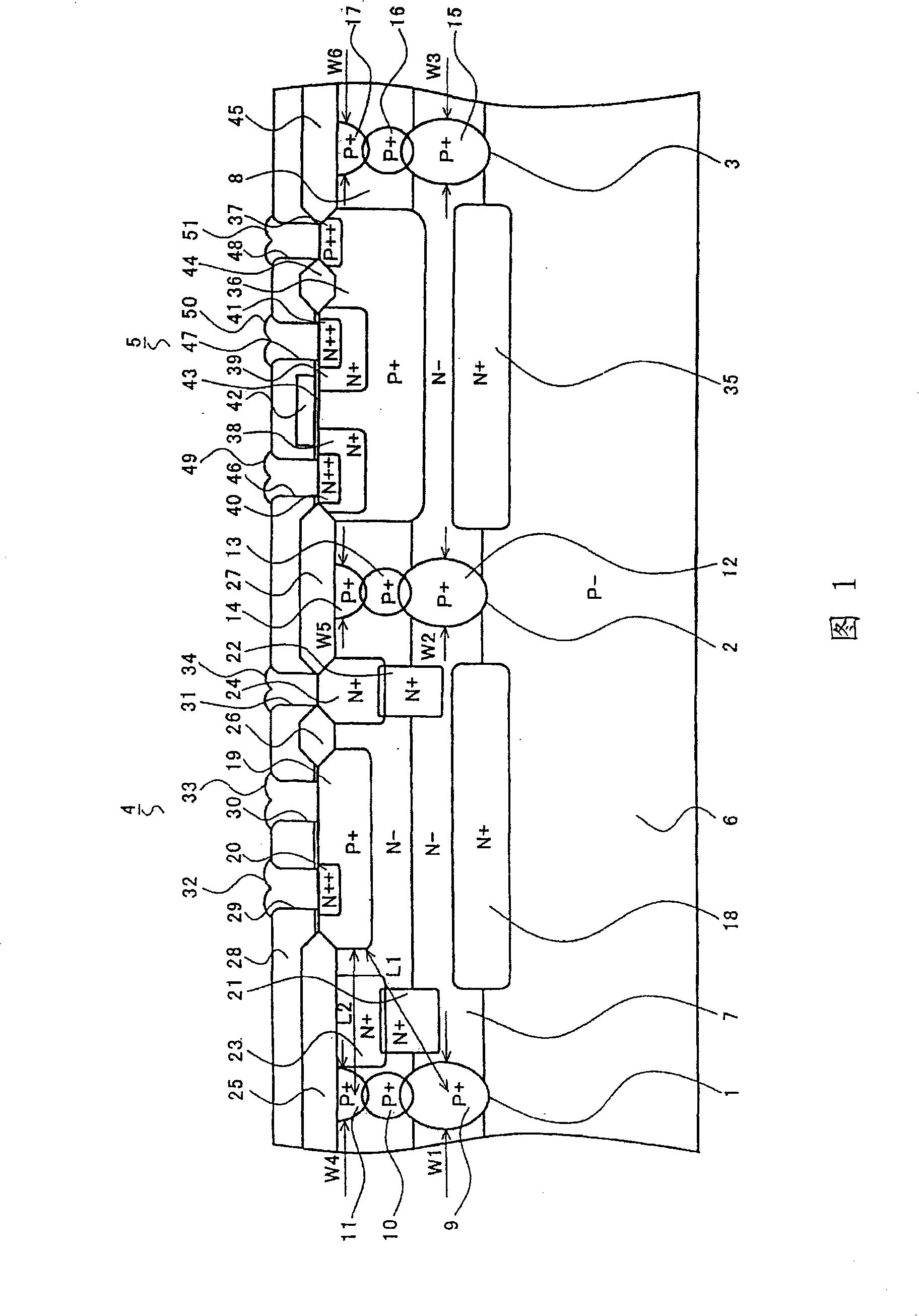

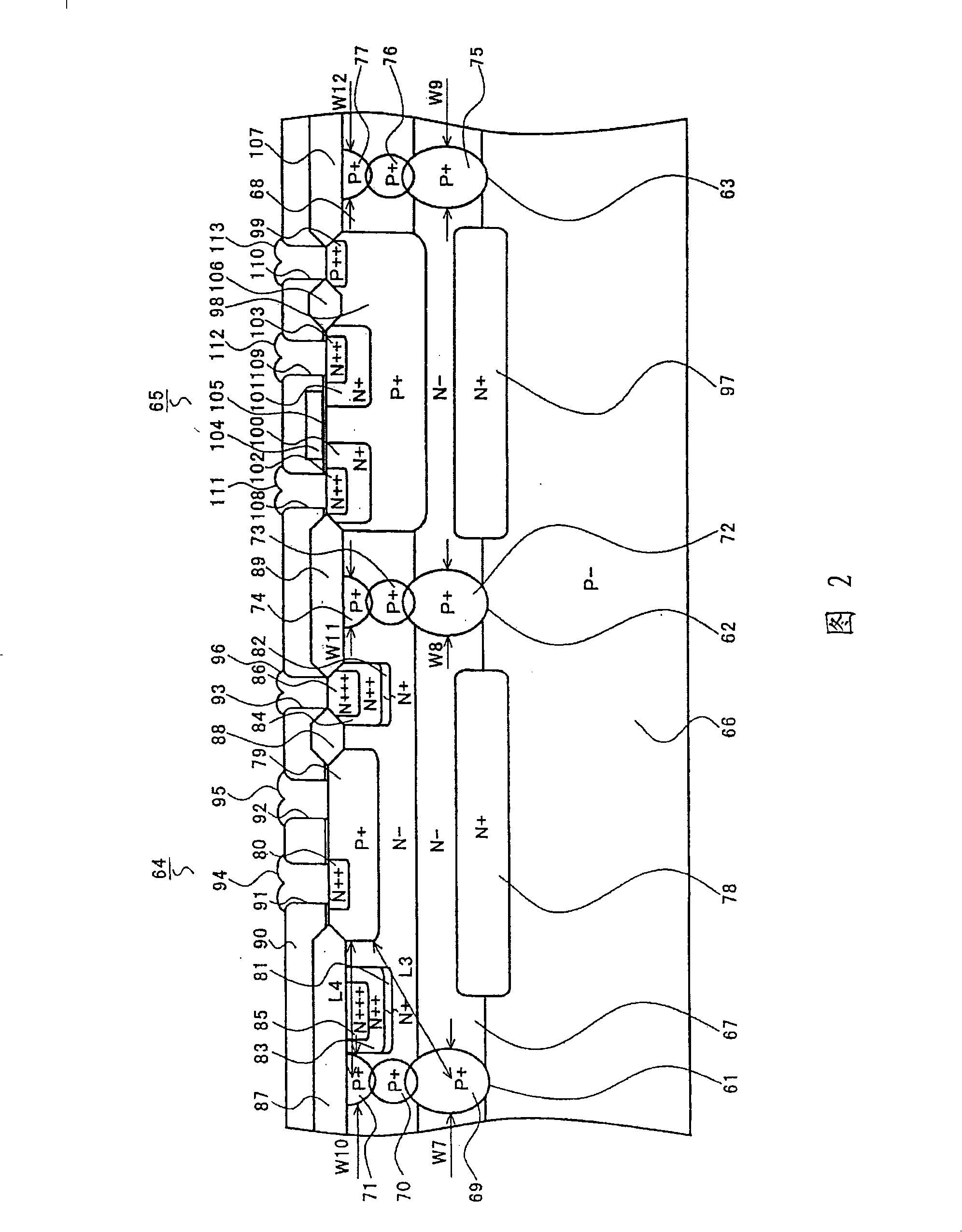

Method for manufacturing semiconductor integrated circuit device

The invention provides a production method for semiconductor integrated circuit device for improving the breakdown voltage of transistors in the dielectric separated complementary bipolar transistor of an NPN transistor and a longitudinal PNP transistor. In the production method for semiconductor integrated circuit device, when forming the collector area and collector extraction area of the semiconductor integrated circuit device, by laminating four epitaxial layers, the buried layer of the collector area and the buried layer of the collector extraction area are simultaneously formed for each epitaxial layer. Then, the respective buried layers are diffused, linked and etched to a V groove die. Thus, the collector area and collector extraction area made into thick films are simultaneously formed and breakdown voltage is improved.

Owner:SANYO ELECTRIC CO LTD

Method for fabricating CMOS image sensor

ActiveUS7537971B2Convenient lightingSmall thicknessSolid-state devicesSemiconductor/solid-state device manufacturingCMOSPhotodiode

A method for fabricating a complementary metal-oxide semiconductor (CMOS) image sensor includes performing an ion implantation process onto a photodiode region in a first conductivity type semiconductor layer to form a second conductivity type first impurity region, and performing an annealing process in a gas atmosphere including first conductivity type impurity atoms to form a first conductivity type second impurity region underneath a surface of the first conductivity type semiconductor layer in the second conductivity type first impurity region, wherein the first conductivity type second impurity region is doped with the diffused first conductivity impurity atoms.

Owner:INTELLECTUAL VENTURES II

A pyrolysis boron nitride container and a method of manufacturing the same

ActiveCN106245000AEasy to remove the filmAvoid crackingChemical vapor deposition coatingThermal chemical vapor depositionSingle crystal

A pyrolysis boron nitride container and a method of manufacturing the same are provided. The container is not liable to be demoulded or stripped, or the like and is suitable for culturing single crystals, and therefore the container and the method are provided. The method is a method for manufacturing the pyrolysis boron nitride container, and includes steps of preparing pyrolysis boron nitride into a film on a carbon-made container mould material through a thermal chemical vapor deposition process, removing the formed film from the container mould material to obtains a moulded part having a shape of the container, treating the moulded part having the shape of the container through oxidation to remove carbon derived from the container mould material and attached to the surface, and subjecting the moulded part having the shape of the container to thinning treatment from the side in contact with the mould material to form a container.

Owner:SHIN ETSU CHEM IND CO LTD

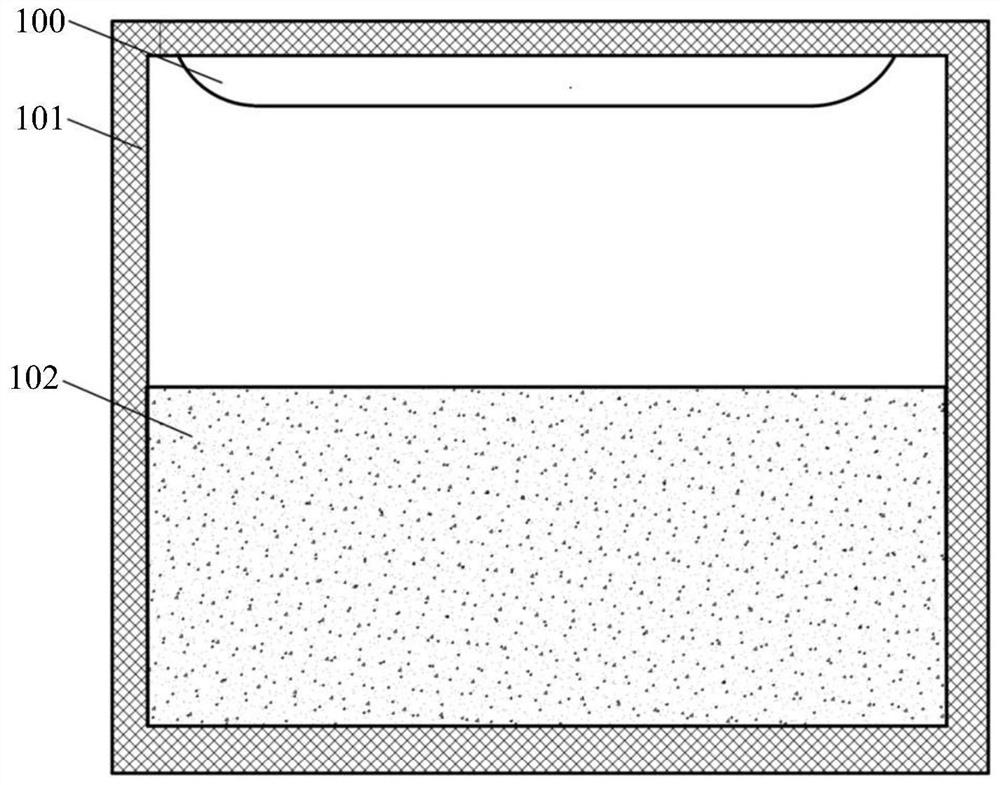

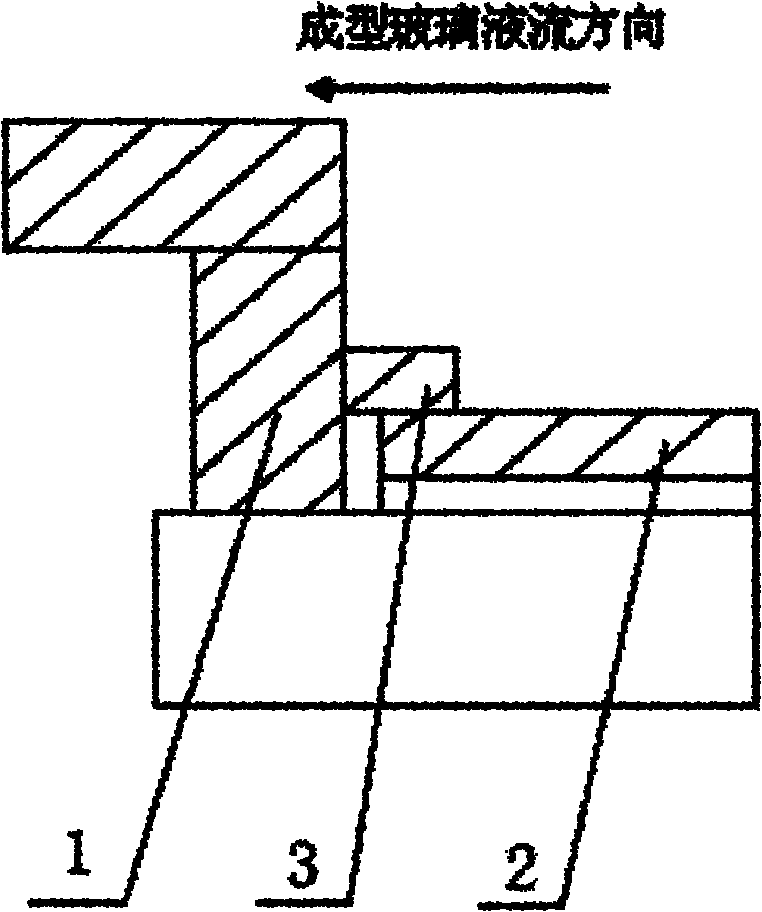

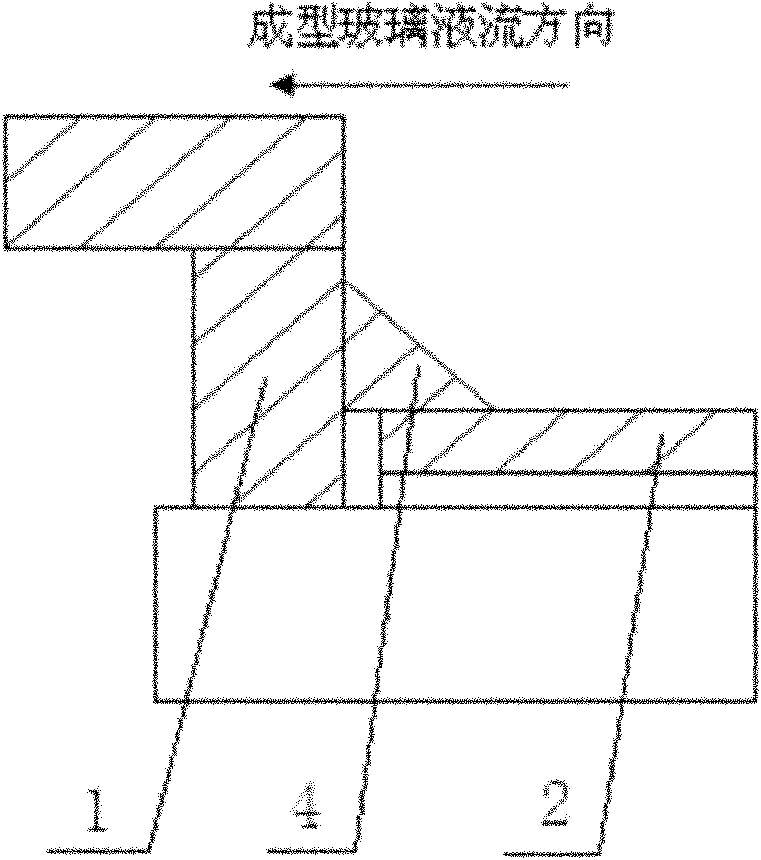

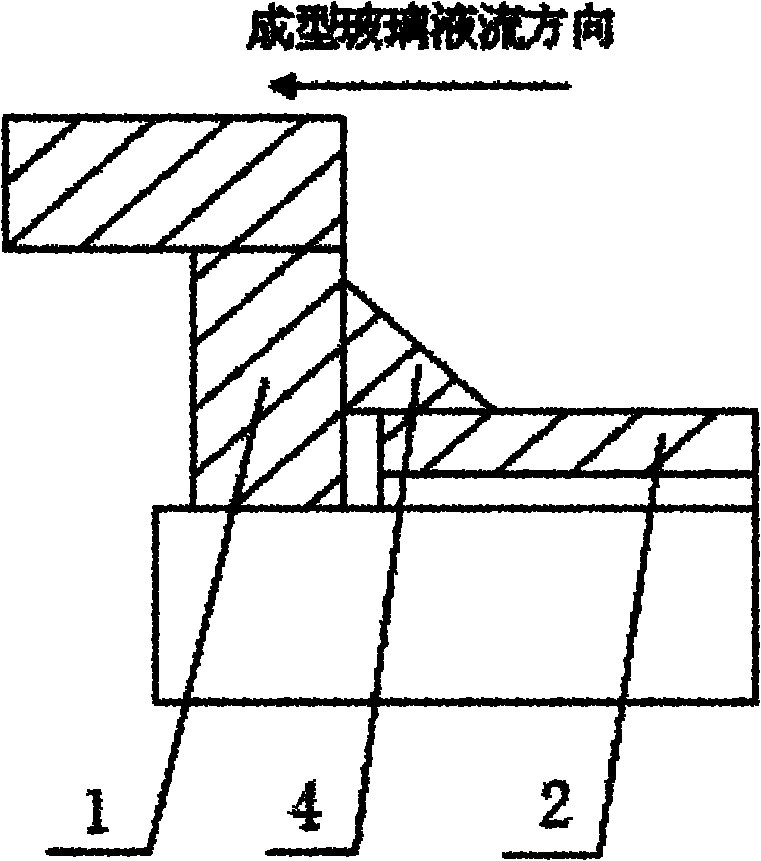

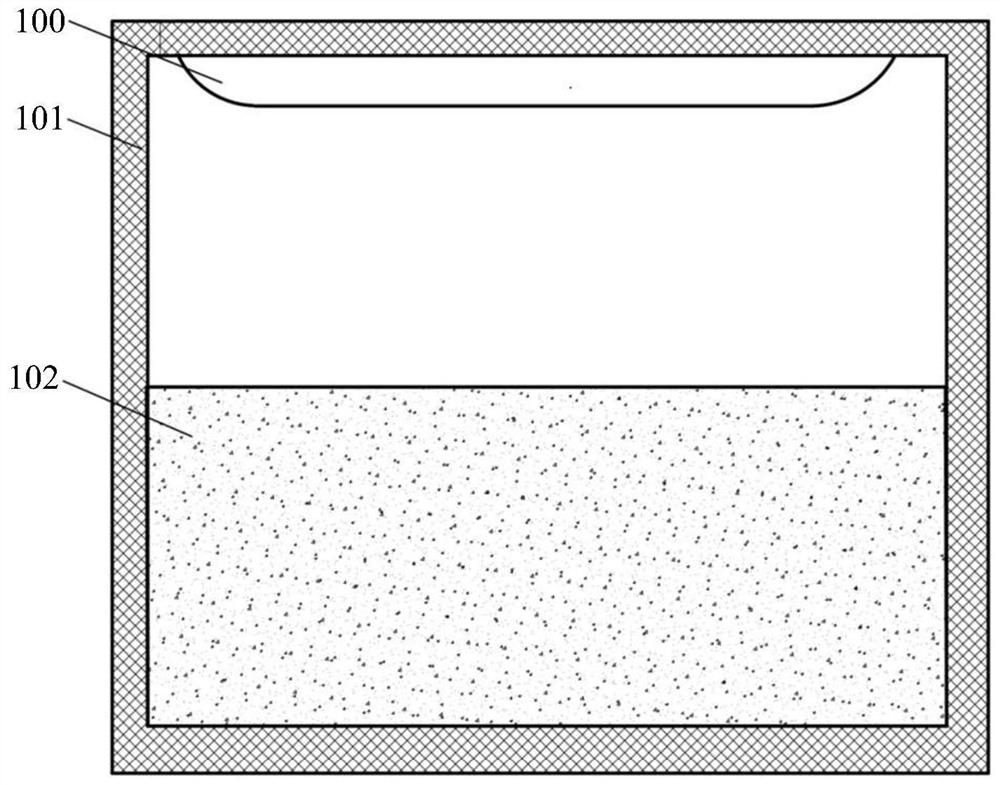

Molten bath of glass kiln

InactiveCN102140006AInhibit devitrificationReduce crystallization defectsGlass furnace apparatusGlass productionMelting tankDevitrification

The invention discloses a molten bath of a glass kiln, which comprises a bath wall and a bath bottom; a right-angle corner is formed between the bath wall and the bath bottom; a right angled triangle brick is arranged at the right-angle corner; two right-angle sides of the right angled triangle brick are respectively clung to the bath wall and the bath bottom; and both ends of an inclined edge are respectively and closely contacted with the bath bottom and the bath wall. The molten bath has the advantages of effectively changing glass liquid flow and reducing the retention time of glass liquid at the corner so as to lead glass liquid not to have the time element of devitrification, thereby avoiding the occurrence of glass devitrification phenomenon, substantially reducing the defect of glass devitrification, improving product quality and increasing finished product ratio.

Owner:HUAERRUN GLASS IND

A kind of antistatic polypropylene foam sheet

Owner:JIN BAOLI TECH SUZHOU

A formula of environment-friendly tft-lcd substrate glass

Provided is a formula of environment-friendly thin film transistor liquid-crystal display (TFT-LCD) substrate glass. The formula is designed to be environment-friendly and more perfect in performance, an object glass substrate with no surface defects including bulbs is formed even if no As2O3 or Sb2O3 serving as clarifying agents is used, and the object glass substrate contains no As2O3 or Sb2O3 and their compounds. Components in raw materials of the glass substrate include by weight percentage: 56-64% of SiO2, 7-11% of B2O3, 14-18% of Al2O3, 3-8% of CaO, 0.5-8% of SrO, 0.1-10% of BaO, 0-2.0% of ZnO and 0.1-1.0% of SnO.

Owner:SHIJIAZHUANG XUXIN OPTOELECTRONIC TECH CO LTD

Growth method of silicon carbide crystal grown by pvt method

ActiveCN112144110BQuality improvementControlled release ratePolycrystalline material growthFrom condensed vaporsCarbide siliconCrucible

The invention provides a method for growing silicon carbide crystals by a PVT method, the method comprising: providing a crucible; placing a silicon carbide raw material and a seed crystal in the crucible; putting the crucible into a growth chamber and vacuuming it, and then introducing a protective gas , set the temperature of the chamber; when the temperature rises to the first preset temperature, the chlorine-containing gas is introduced through the degassing device in the crucible, the temperature rises to the second preset temperature, and the feeding is stopped or continued for the first preset time Chlorine-containing gas; the temperature rises to a third preset temperature, and after the silicon carbide crystals start to grow for a second preset time, silicon carbide crystals are obtained by annealing. This growth method can effectively control the release rate and uniformity of chlorine-containing gas, and avoid crystallization defects caused by the condensation of gas-phase silicon on the crystal surface; by controlling the time and flow rate of chlorine-containing gas, crystallization defects can be further avoided; the placement of porous graphite blocks It can make the excess chlorine-containing gas introduced and the carbon particles suspended in the growth atmosphere escape, and reduce the carbon inclusion defects in the crystal.

Owner:CEC COMPOUND SEMICON CO LTD

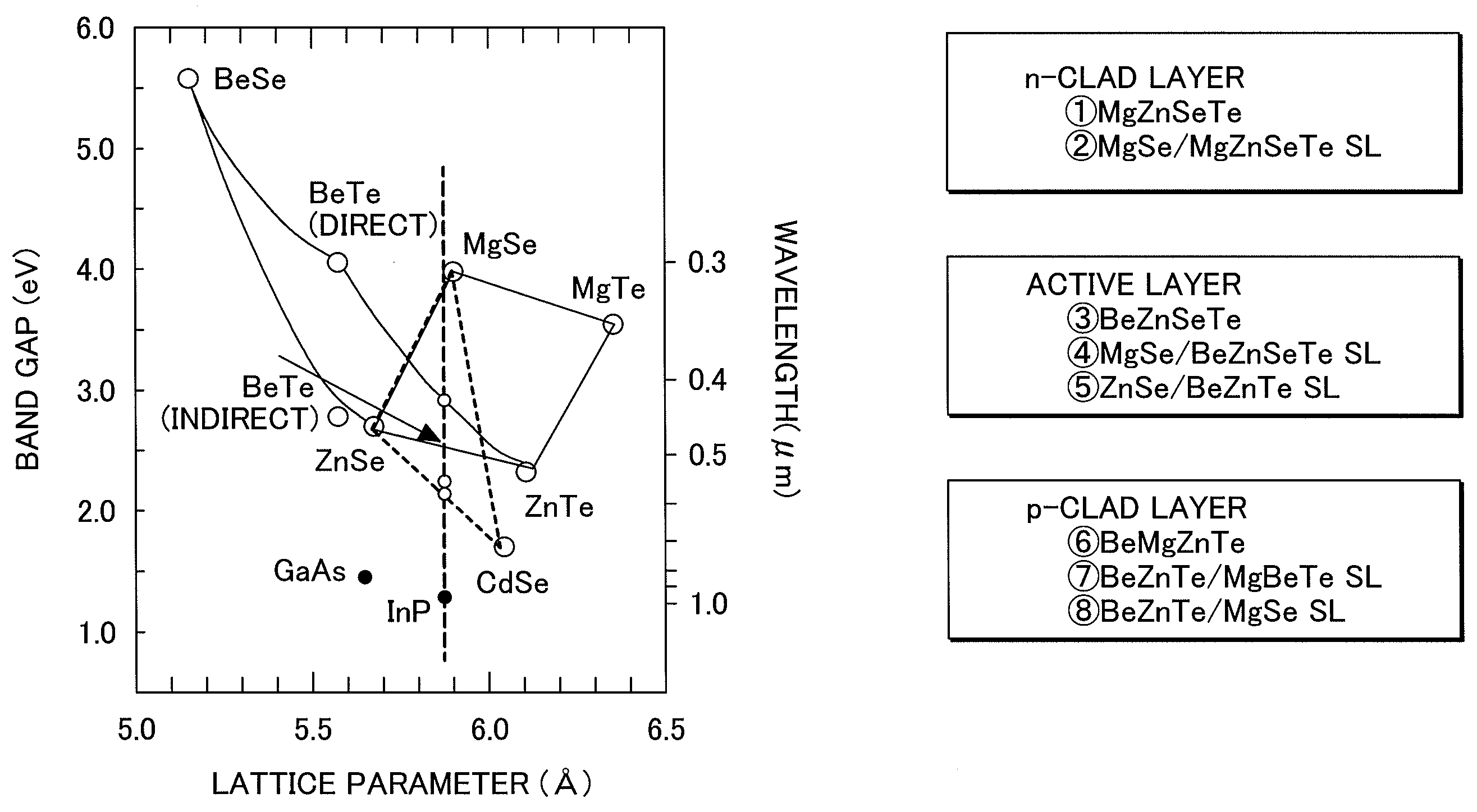

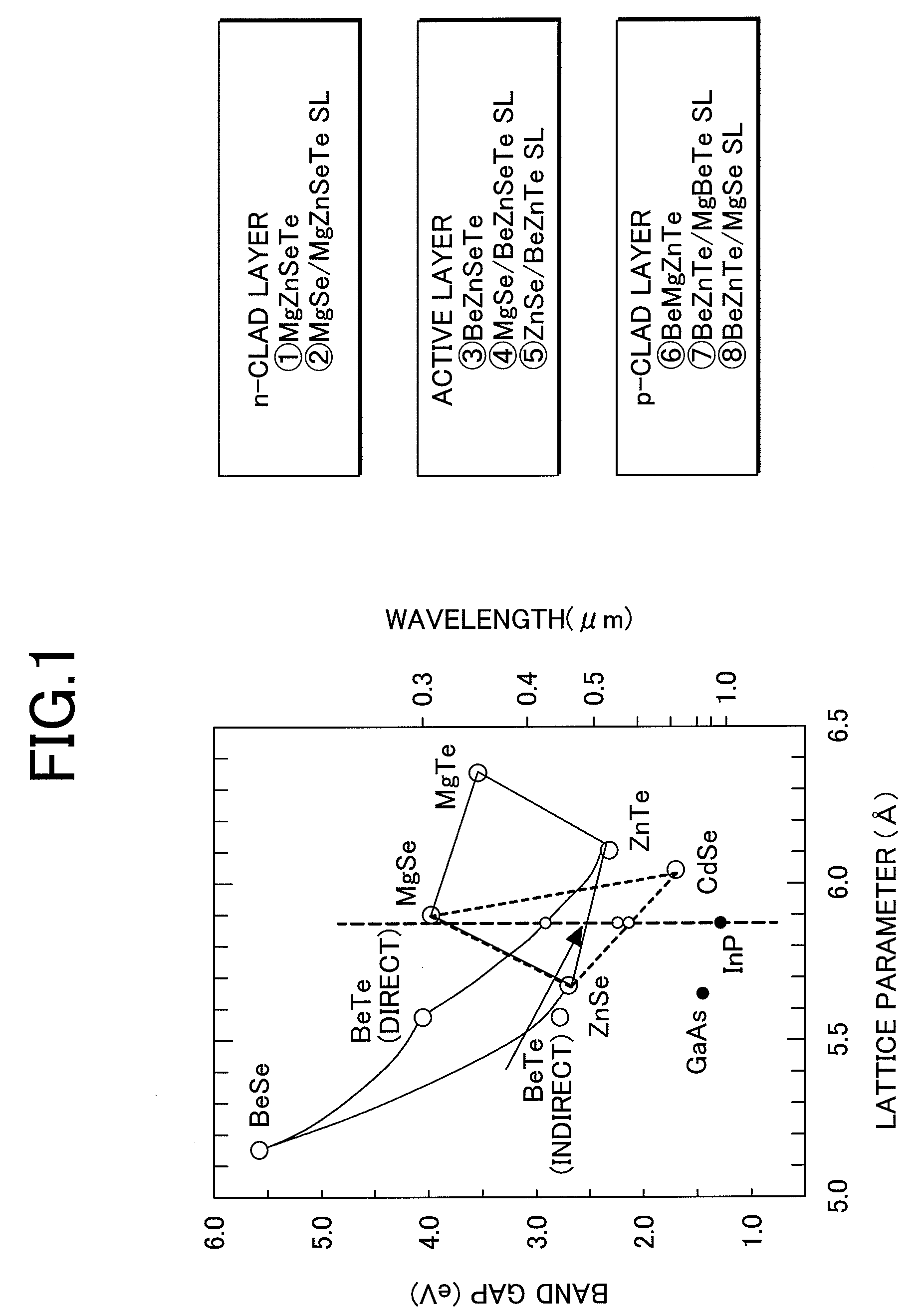

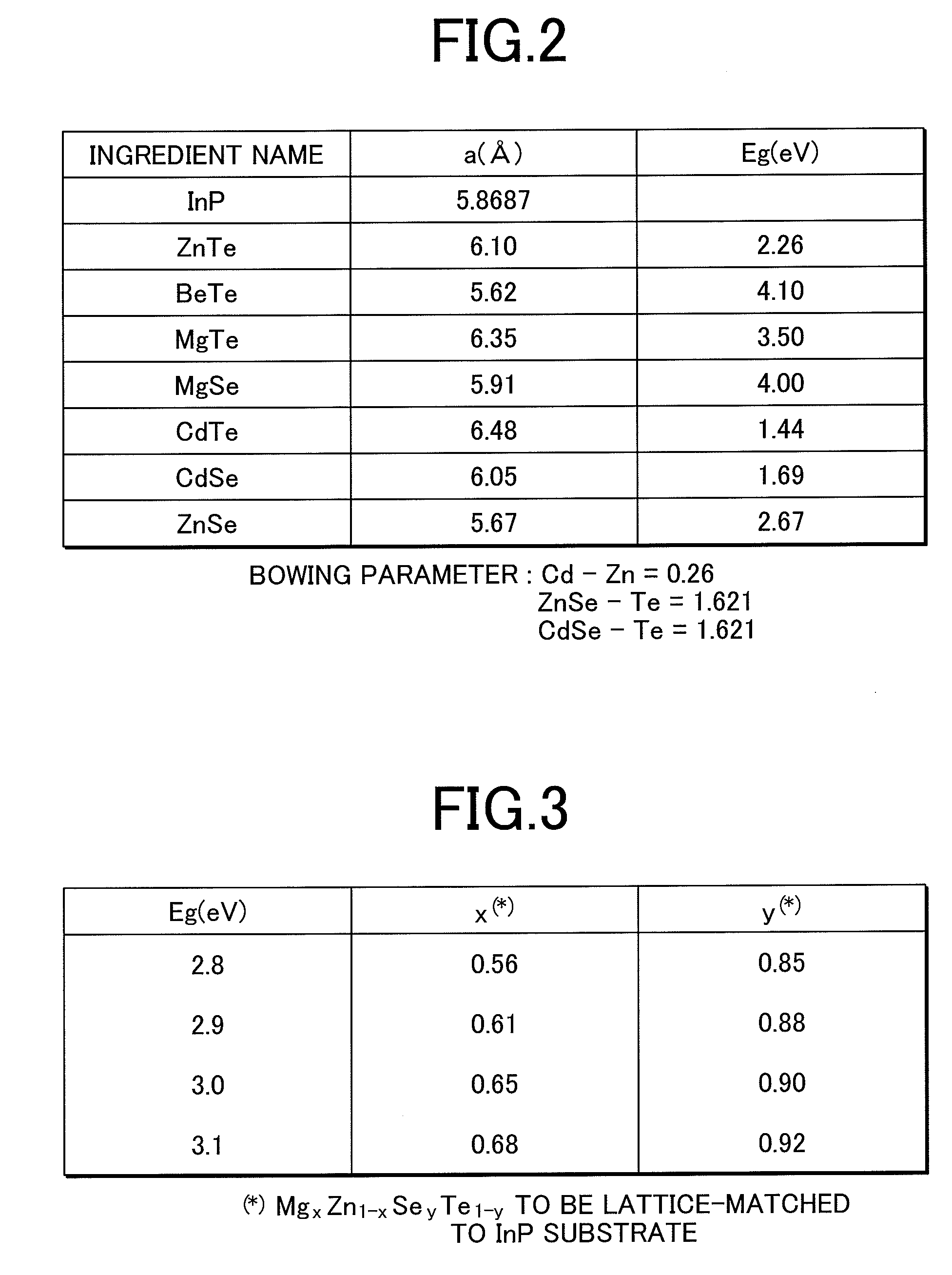

El semiconductor device

InactiveUS20090059985A1Easy to manufactureImprove luminous performanceLaser detailsLaser active region structureHigh energyConduction band

An n-type cladding layer structure which has good luminescence properties without the use of substances corresponding to RoHS Directive and a high Cl-doping efficiency, i.e. which facilitates the manufacture of a semiconductor optical element and device with low crystal defects and high reliability, and an active layer and a p-type cladding layer therefor are provided. The n-type layer being lattice matched to an InP substrate and containing Group II-VI compound as a main ingredient is a Group II-VI compound semiconductor, in which the Group II elements consist of Mg, Zn, and Be and the Group VI elements consist of Se and Te. The n-type layer of the present invention is characterized by a large energy gap, high energy of the bottom of a conduction band that is effective for suppress the Type II luminescence, high carrier concentration, and low crystal defects attributed to a good quality crystallinity.

Owner:HITACHI LTD +2

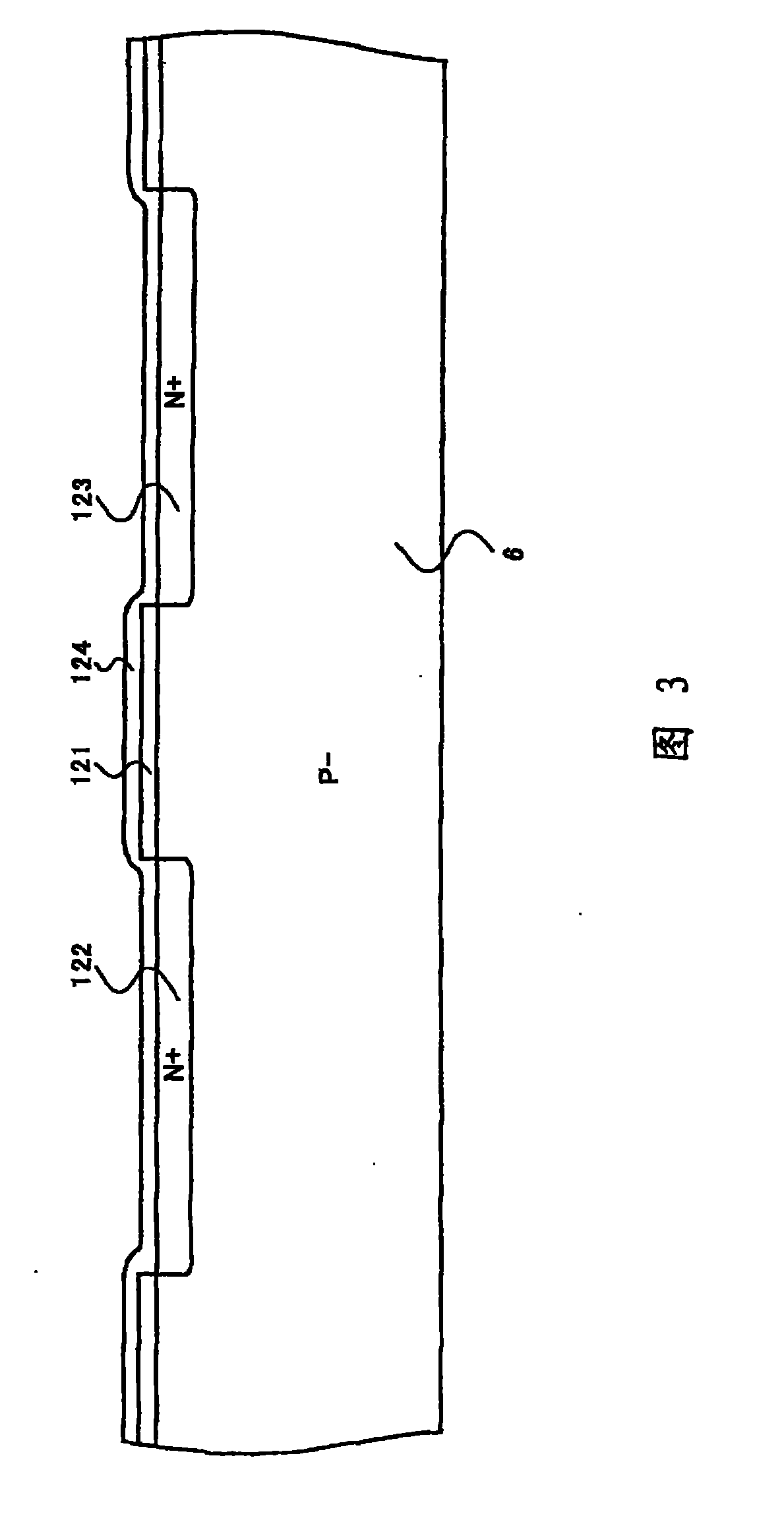

Semiconductor device and manufacturing method thereof

InactiveCN101304029BDiffusion width narrowedNarrowing formation areaSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLateral diffusion

Owner:SANYO ELECTRIC CO LTD +1

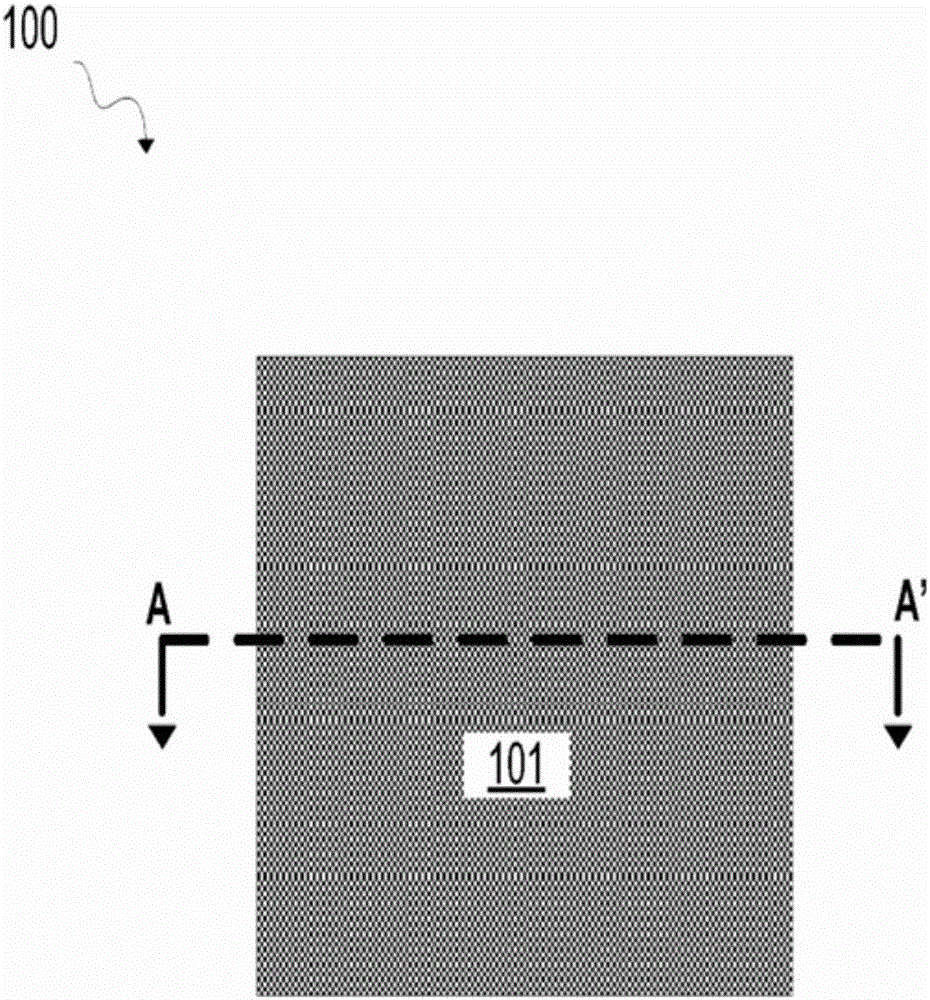

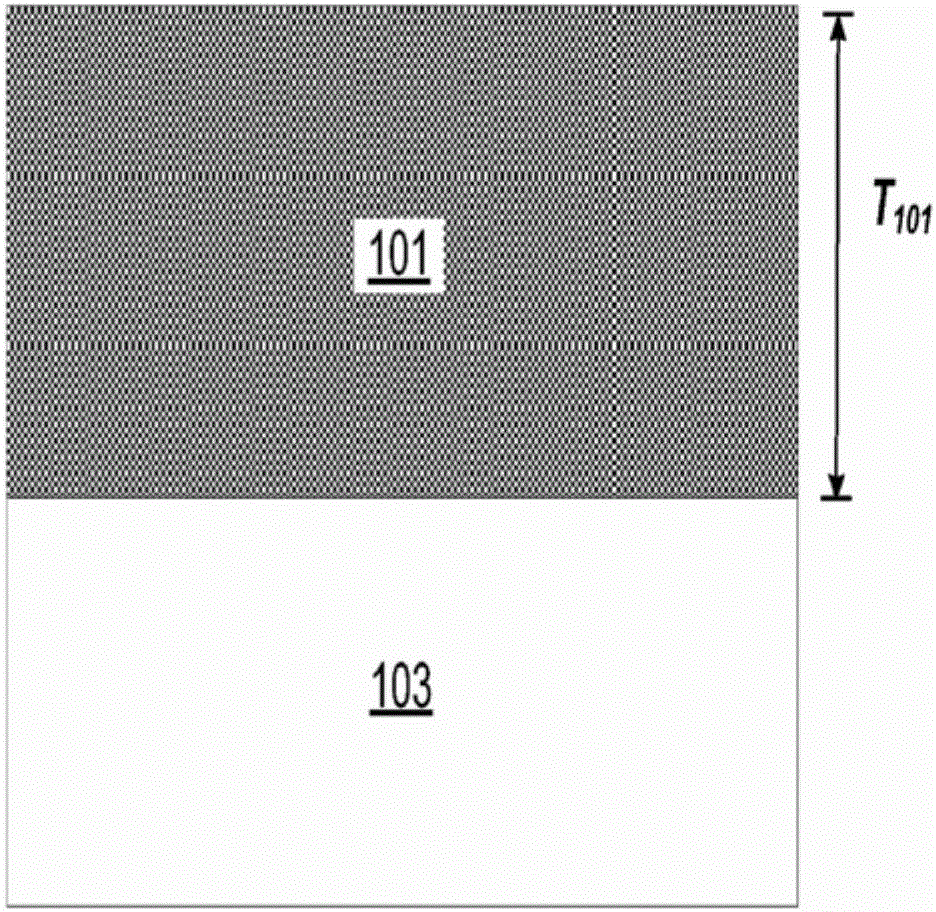

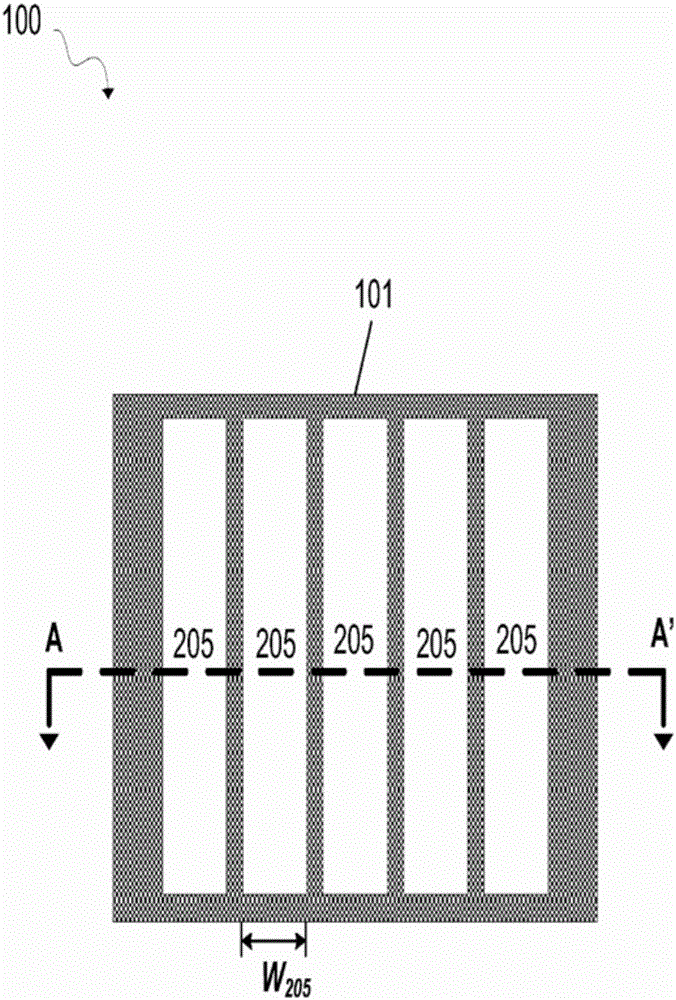

Defect reduction with rotated double aspect ratio trapping

ActiveCN106057638AReduce crystallization defectsSemiconductor/solid-state device manufacturingSemiconductor devicesAspect ratioLattice mismatch

A structure and method for fabricating a heteroepitaxially grown lattice-mismatched semiconductor layer with a lower defect density is disclosed. A first semiconductor layer is epitaxially grown on an upper surface of a lattice mismatched crystalline substrate in a lower trench using a first ART deposition process. The structure is then rotated 90 degrees along a horizontal plane and a second semiconductor layer is epitaxially grown on an upper surface of the first semiconductor layer in an upper trench using a second ART deposition process. This results in an upper portion of the second semiconductor layer being substantially free of epitaxy defects.

Owner:GLOBALFOUNDRIES U S INC MALTA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com