Patents

Literature

102results about How to "Inhibit devitrification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

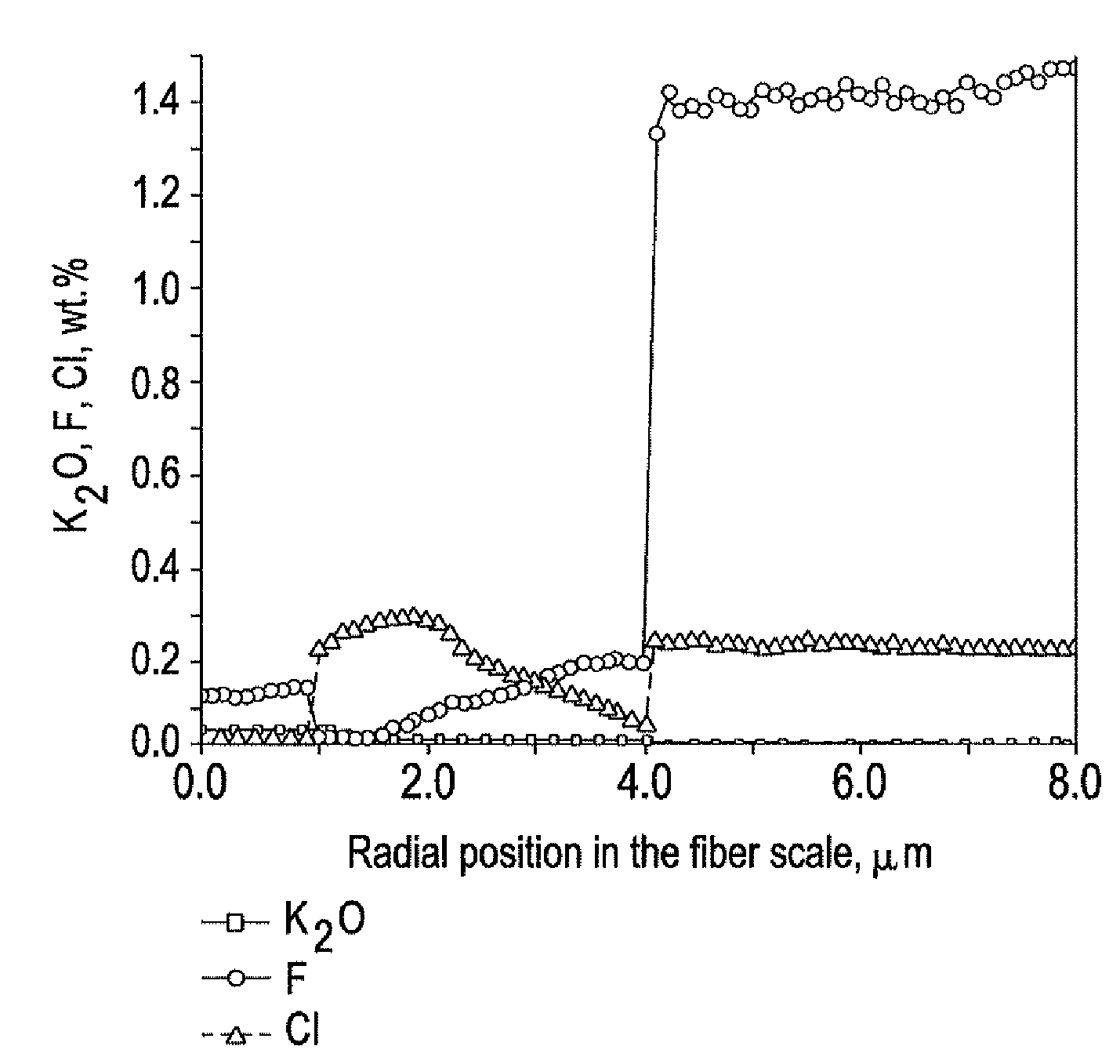

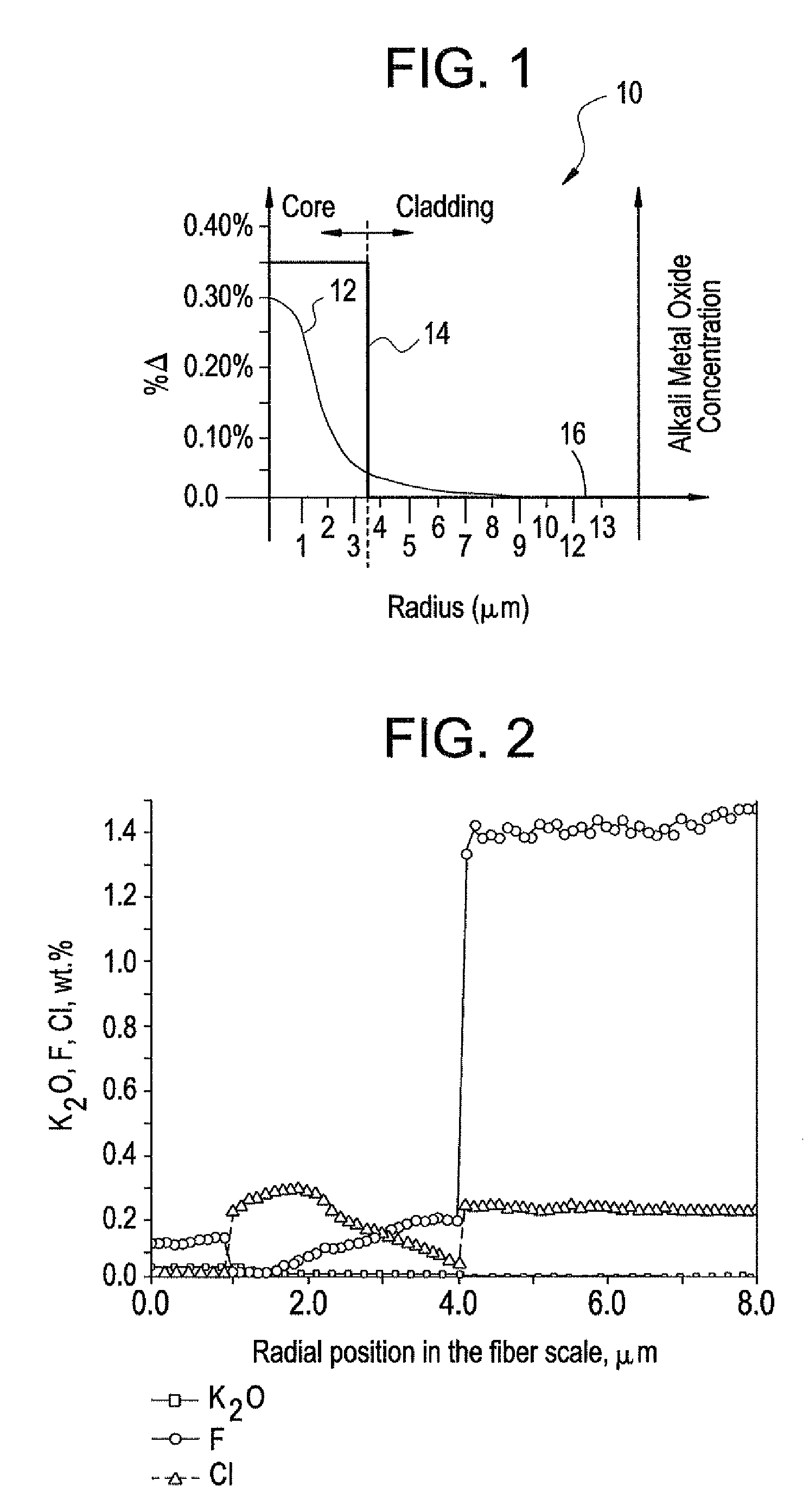

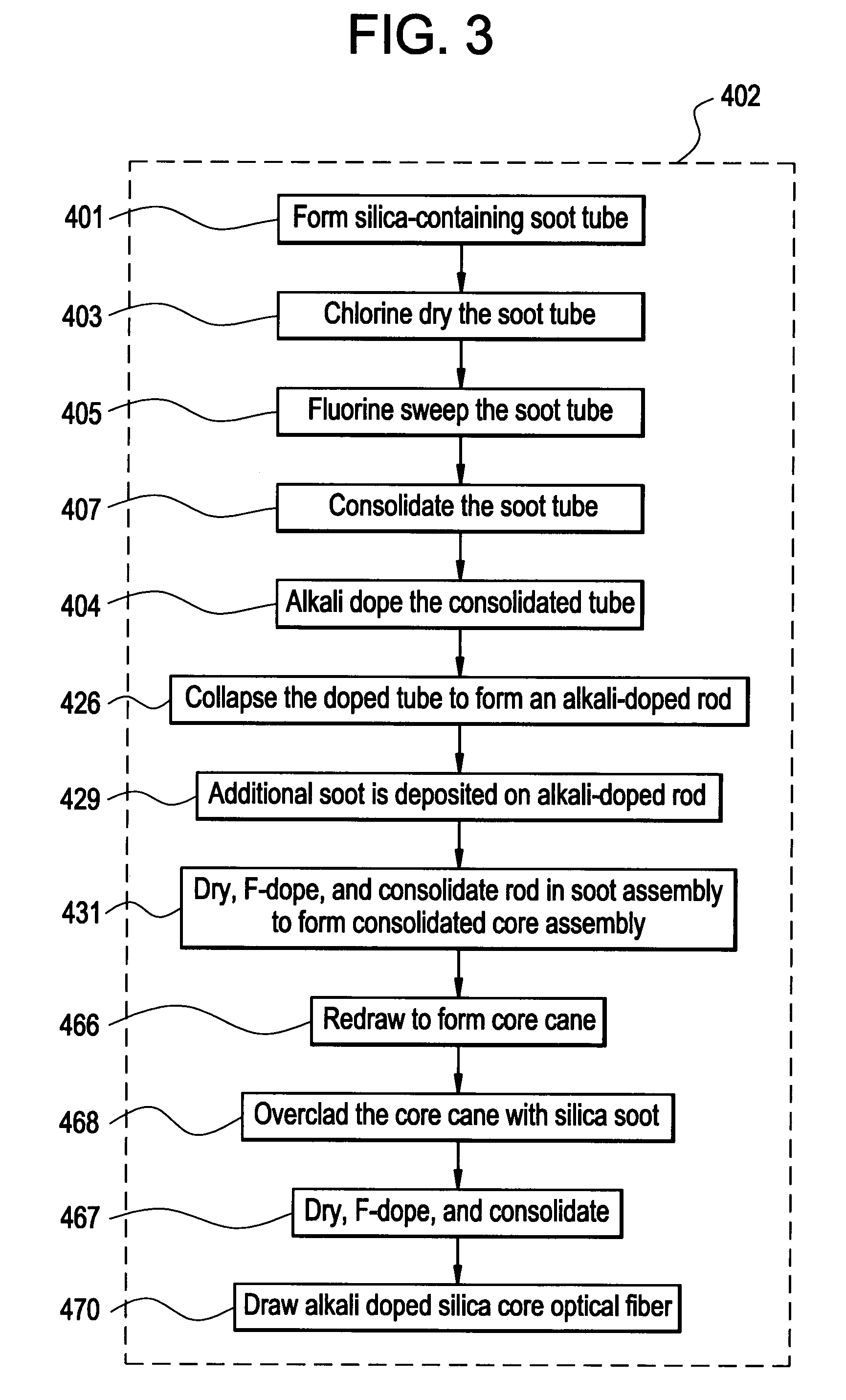

Optical fiber containing alkali metal oxide

ActiveUS20070297735A1Reduce lossReduce concentrationGlass making apparatusOptical fibre with multilayer core/claddingDopantAlkali metal oxide

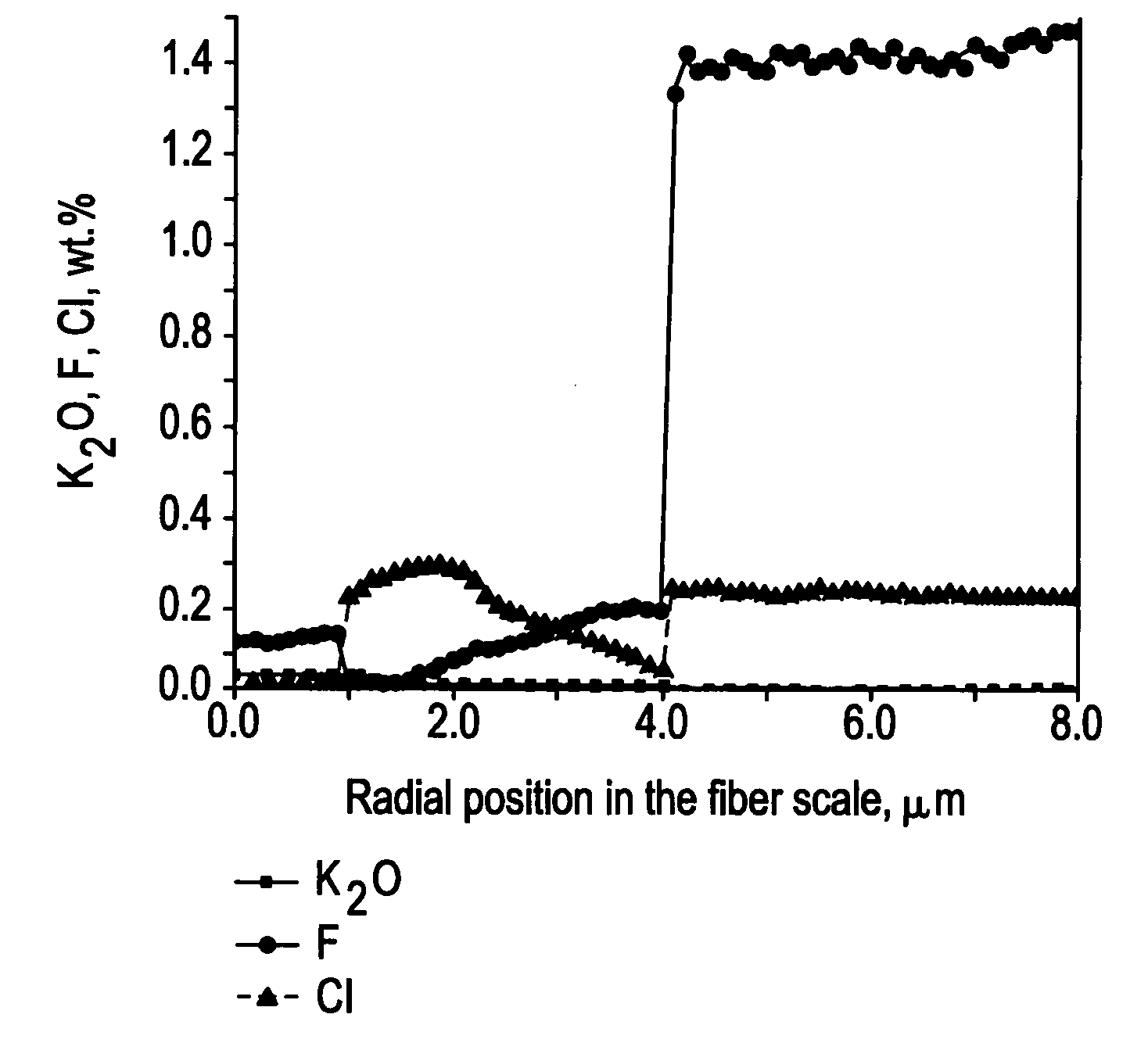

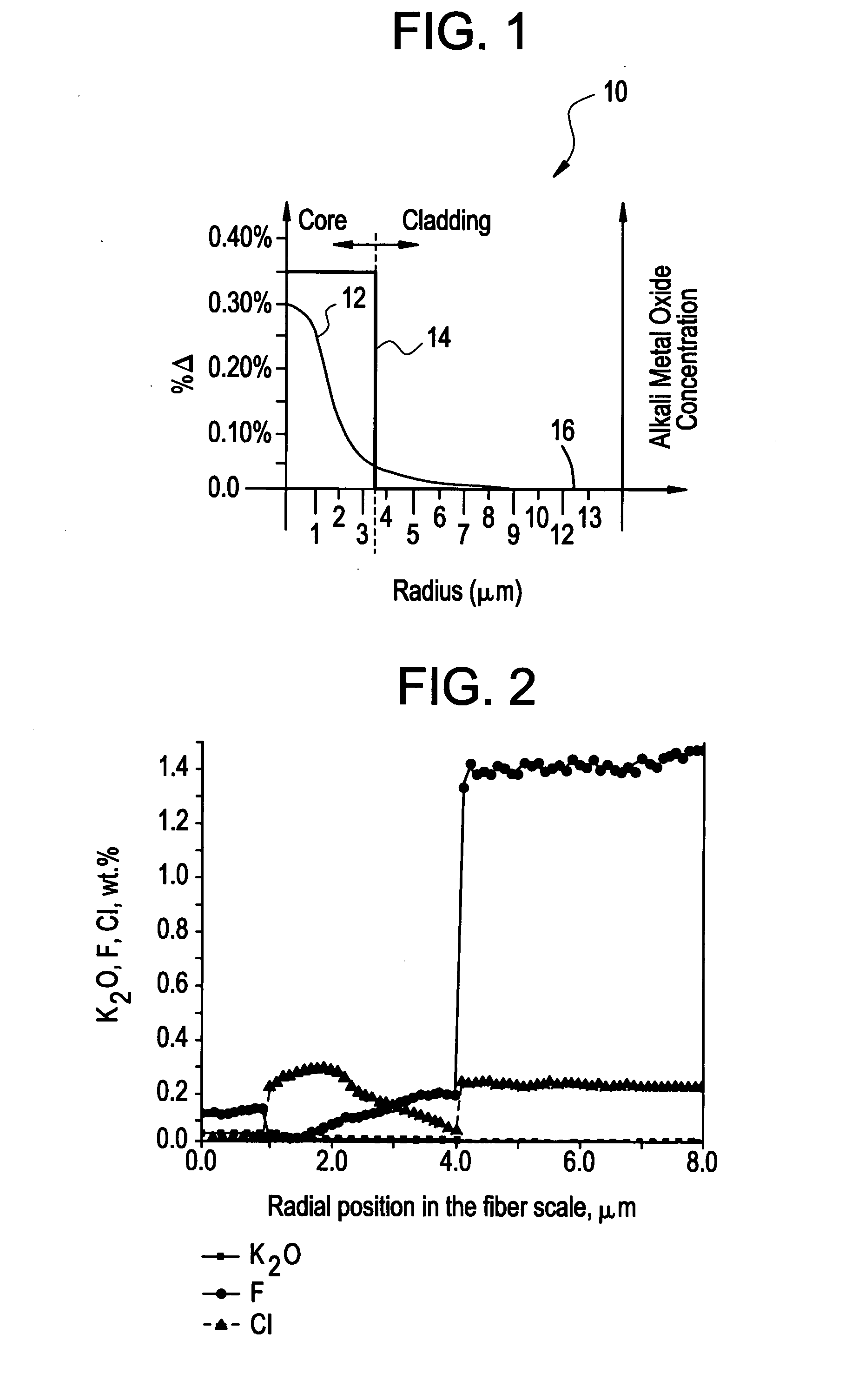

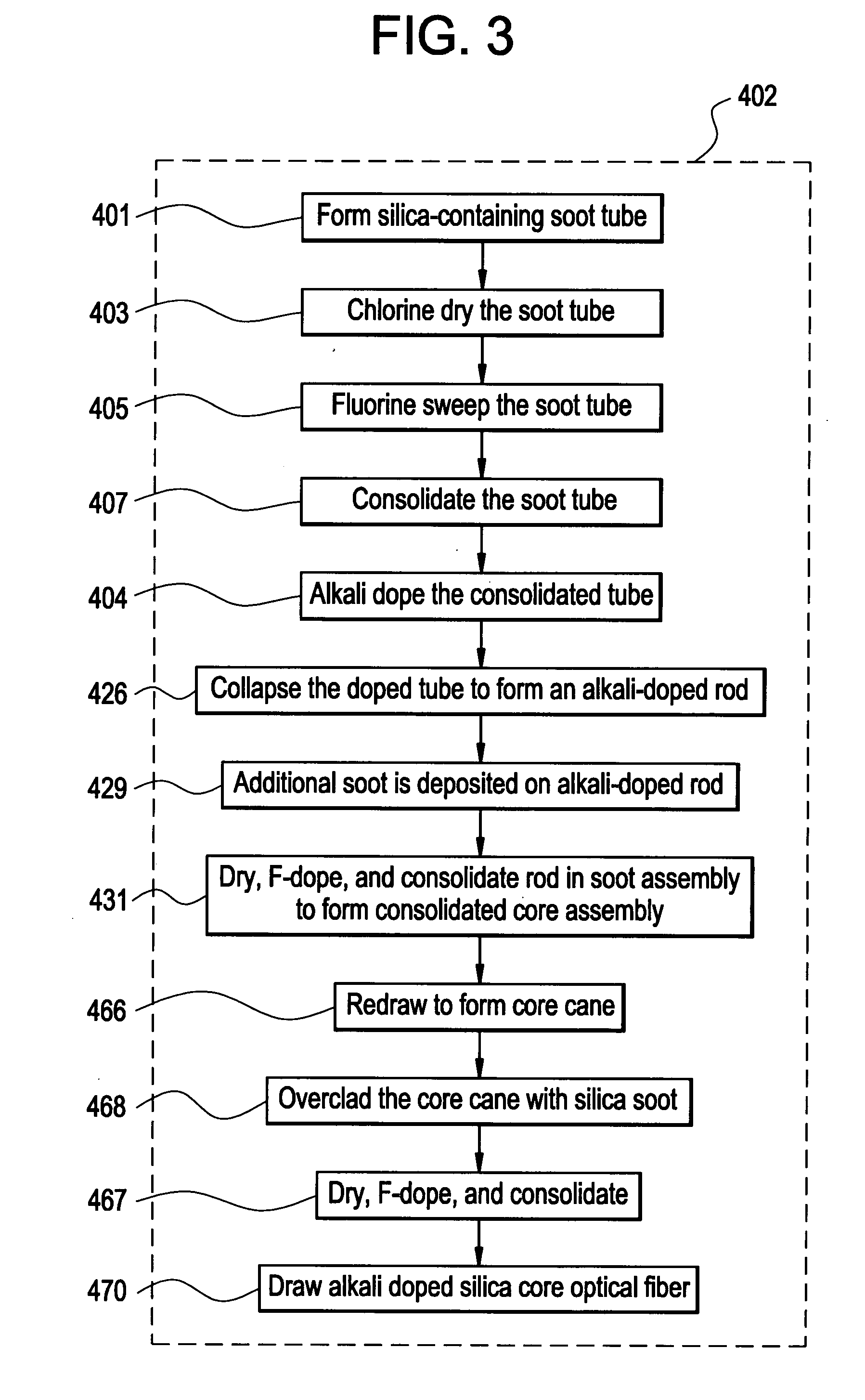

Disclosed is an optical fiber having a silica-based core comprising an alkali metal oxide selected from the group consisting of K2O, Na2O, LiO2, Rb2O, Cs2O and mixtures thereof in an average concentration in said core between about 50 and 500 ppm by weight, said core further comprising chlorine and fluorine, wherein the average concentration of fluorine in said core is greater than the average concentration of alkali metal oxide in said core and the average concentration of chlorine in said core is greater than the average concentration of alkali metal oxide in said core; and a silica-based cladding surrounding and directly adjacent the core. By appropriately selecting the concentration of alkali metal oxide dopant in the core and the cladding, a low loss optical fiber may be obtained.

Owner:CORNING INC

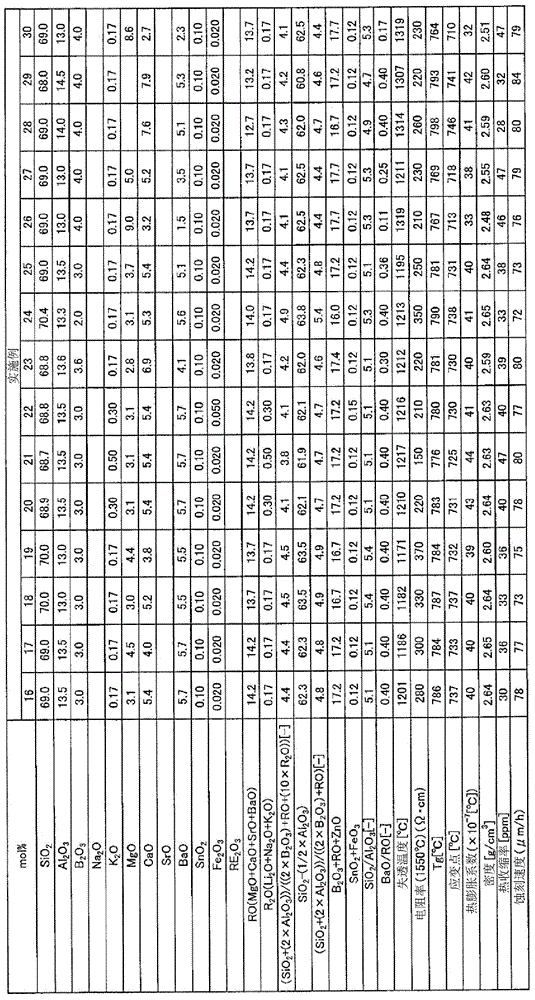

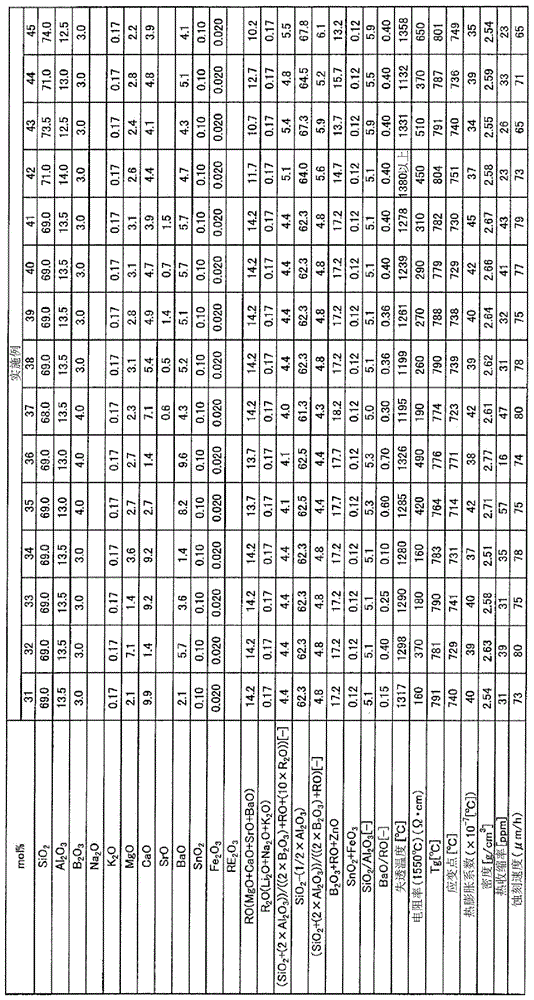

Glass substrate for display device and method for manufacturing same

ActiveCN103910487AInhibit or avoid melt lossInhibit devitrificationGlass productionDevitrificationMelting tank

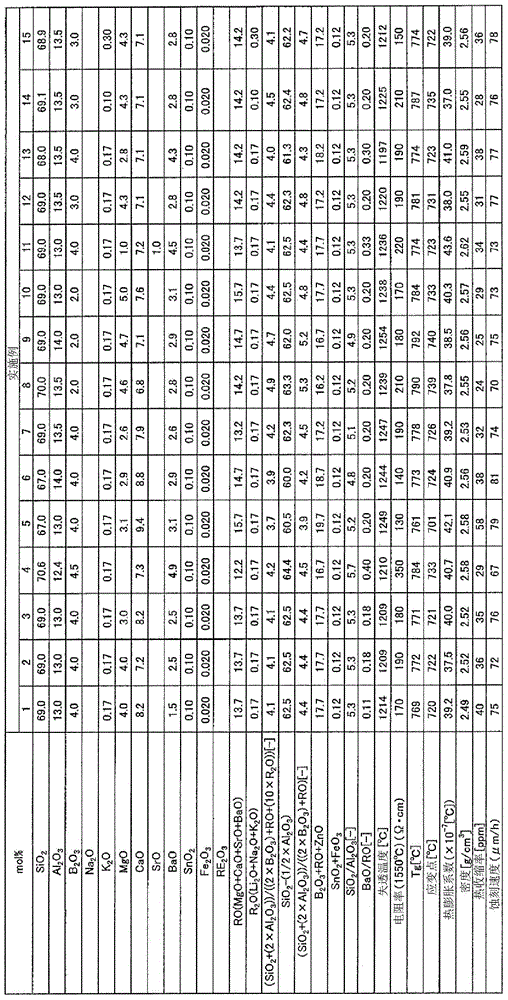

The invention relates to a glass substrate for display device and a method for manufacturing same and provides a glass substrate which is high in strain point and capable of preventing a melting tank from melting loss, a glass substrate which is high in strain point and capable of suppressing devitrification, a glass substrate which is high in strain point and etching speed, and a method for manufacturing the glass substrate. The glass substrate contains Sio2 and Al2O3, 0-8% of B2O3, 0.01-0.8 % of R2O, and 0.05-1 of BaO / RO in mol%, and the strain point is over 670 DEG C. The glass substrate may contain Sio2, Al2O3 and MgO, 0.1-0.9 of MgO / (RO+ZnO), the strain point is over 700 DEG C, and the contraction rate is 5ppm-75ppm. The glass substrate may contain Sio2, Al2O3 and BaO, 0-7% of B2O3, 1-15% of BaO, and less than 6.0 of Sio2 / Al2O3, and the strain point is over 700 DEG C. RO represents (MgO+CaO+SrO+BaO), and R2O represents (Li2O+Na2O+K2O).

Owner:AVANSTRATE INC

Optical fiber containing alkali metal oxide

ActiveUS7536076B2Reduce lossReduce concentrationGlass making apparatusOptical fibre with multilayer core/claddingDopantAlkali metal oxide

Disclosed is an optical fiber having a silica-based core comprising an alkali metal oxide selected from the group consisting of K2O, Na2O, LiO2, Rb2O, Cs2O and mixtures thereof in an average concentration in said core between about 50 and 500 ppm by weight, said core further comprising chlorine and fluorine, wherein the average concentration of fluorine in said core is greater than the average concentration of alkali metal oxide in said core and the average concentration of chlorine in said core is greater than the average concentration of alkali metal oxide in said core; and a silica-based cladding surrounding and directly adjacent the core. By appropriately selecting the concentration of alkali metal oxide dopant in the core and the cladding, a low loss optical fiber may be obtained.

Owner:CORNING INC

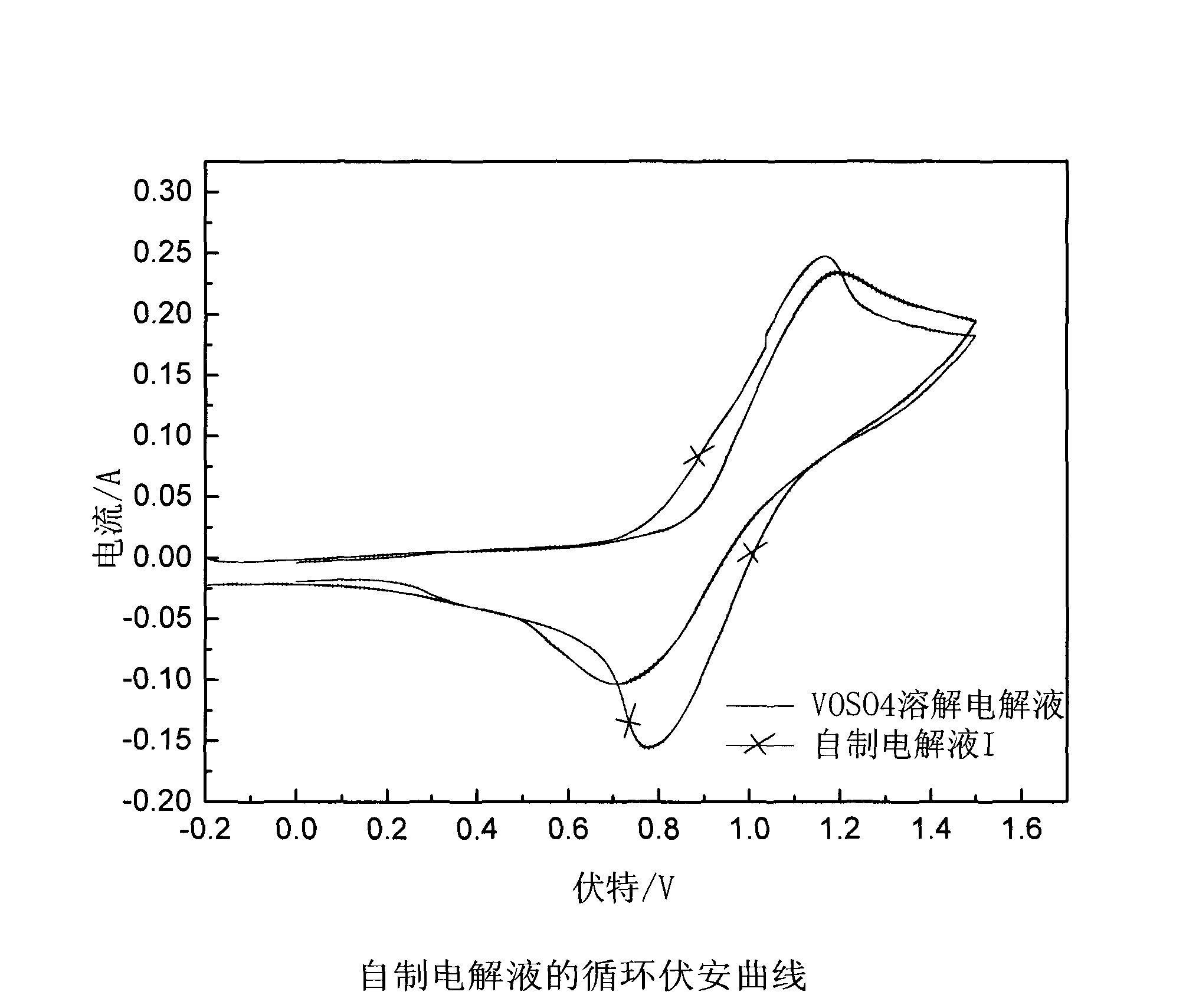

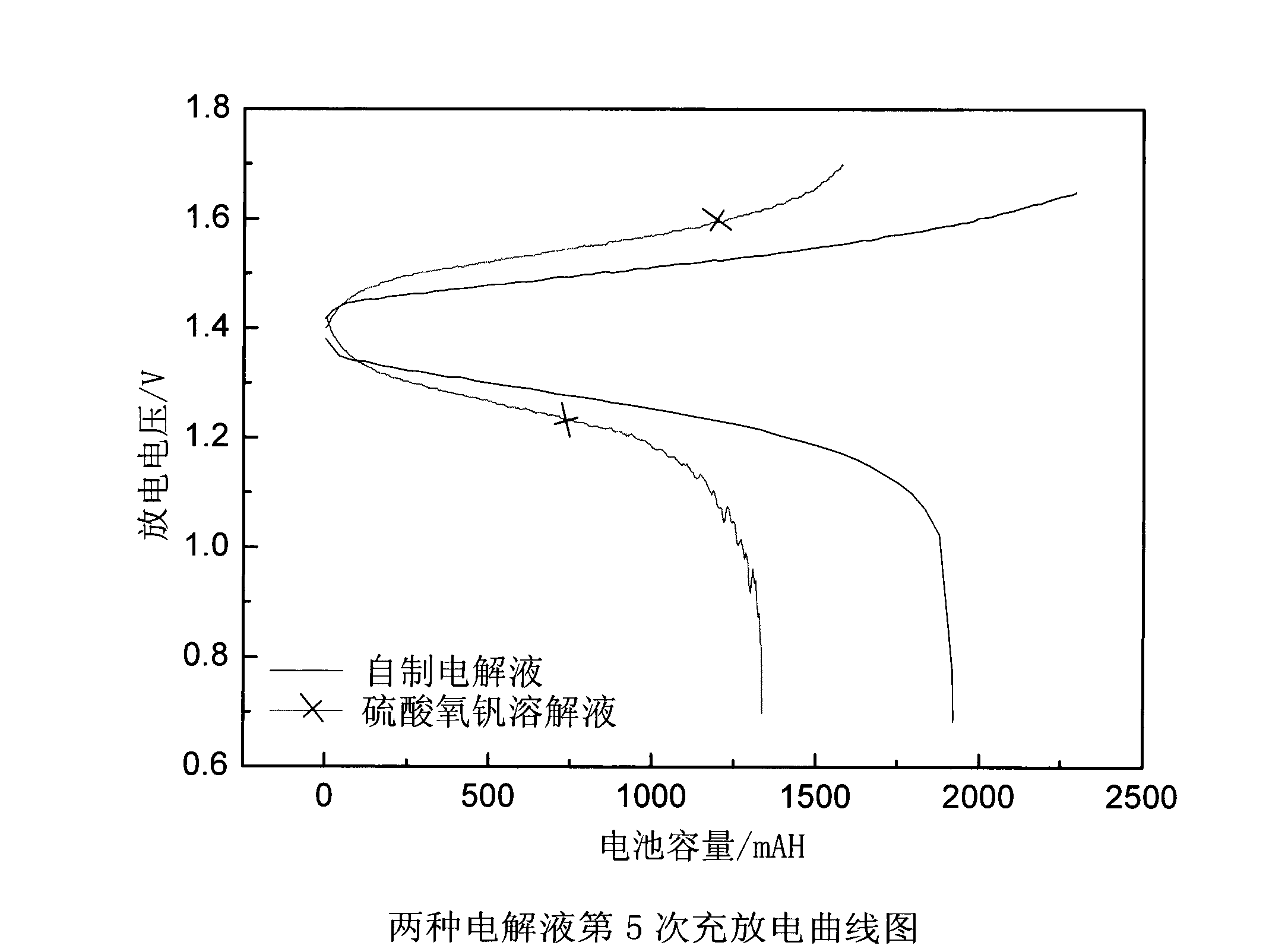

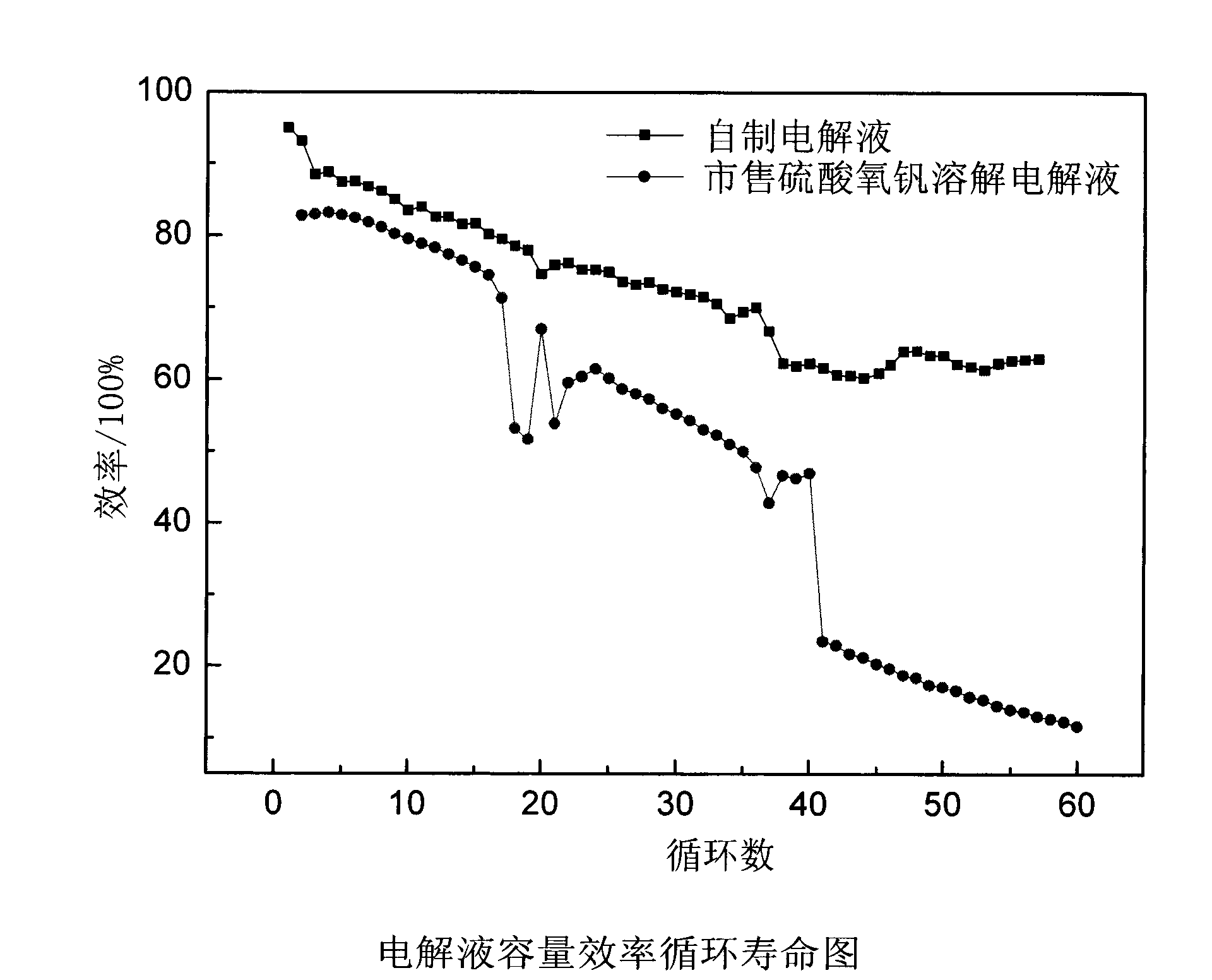

Method for preparing electrolyte for vanadium cell

InactiveCN101651221AImprove solubilityImprove production efficiencyFinal product manufactureRegenerative fuel cellsPhysical chemistryHydroquinone Compound

The invention provides a method for preparing an electrolyte for a vanadium cell, which comprises the following steps: A, dissolving vanadic oxide or vanadous oxide into a sulphuric acid solution; B,adding a reducer selected from one or more compounds of ascorbic acid, ascorbase, ascorbic acid derivative, ascorbate, tea polyphenol, pyrocatechol, hydroxyphenol, hydroquinone and the like. The highconcentration electrolyte for the vanadium cell can be directly prepared from vanadium oxides by the method.

Owner:BIG PAWER ELECTRICAL TECH XIANGYANG +1

Glass composition and glass fiber

InactiveUS20060165968A1Good acid and alkali resistanceGood bondSynthetic resin layered productsYarnTitanium dioxideMaterials science

The glass fiber of the present invention is formed of the glass composition including 50 to 60% SiO2, 0.1 to 10% Al2O3, 20 to 45% MgO+CaO+SrO+BaO, 0.5 to 20% TiO2, 0.1 to 10% ZrO2, and 0 to 2% Li2O+Na2O+K20 in terms of mol %, in which a BaO / CaO mol ratio is from 0.3 to 1.6.

Owner:NIPPON ELECTRIC GLASS CO LTD

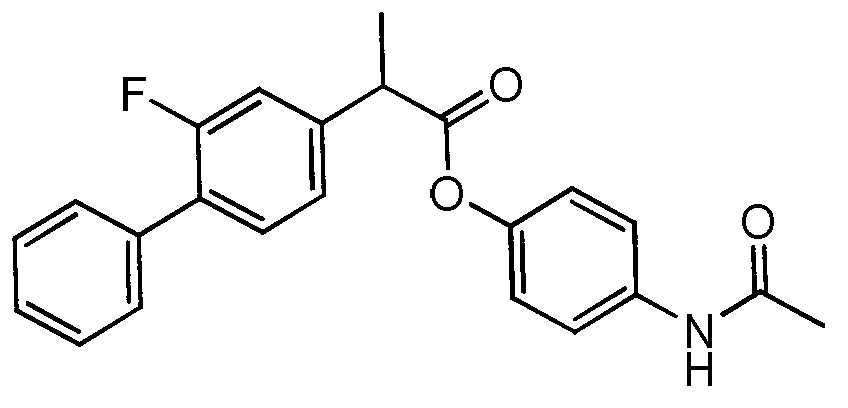

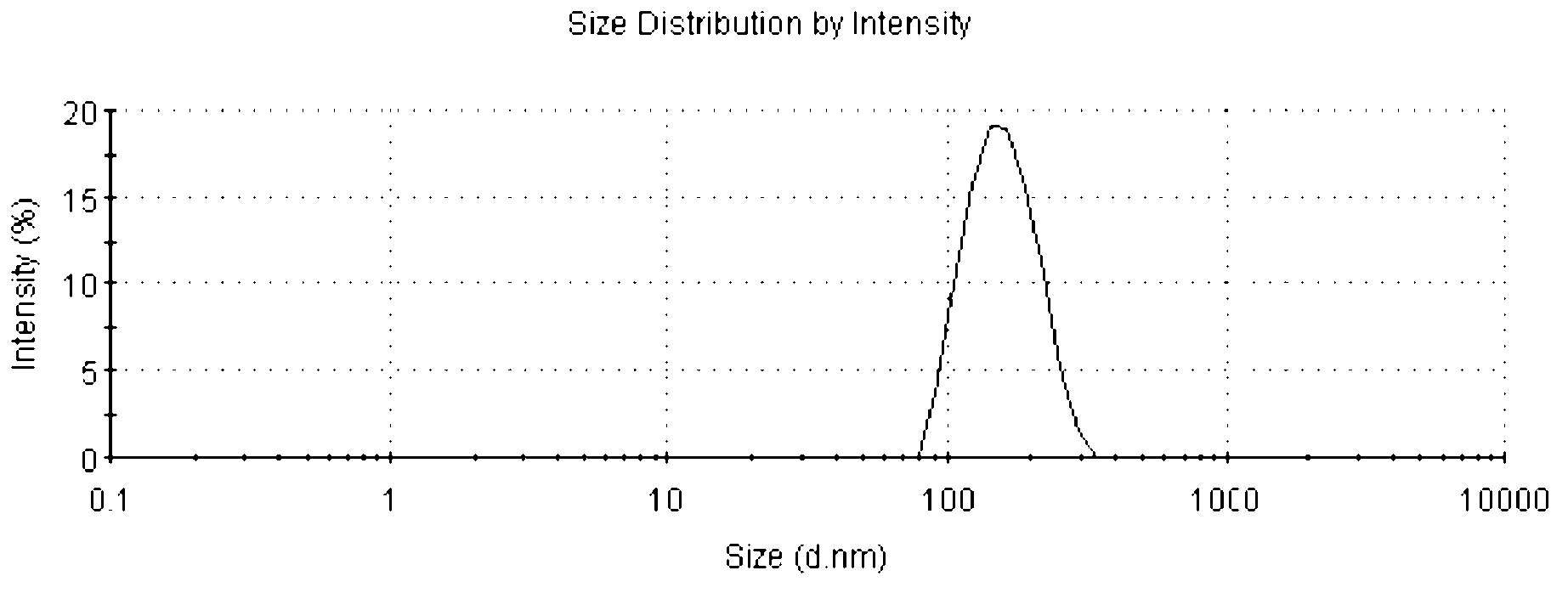

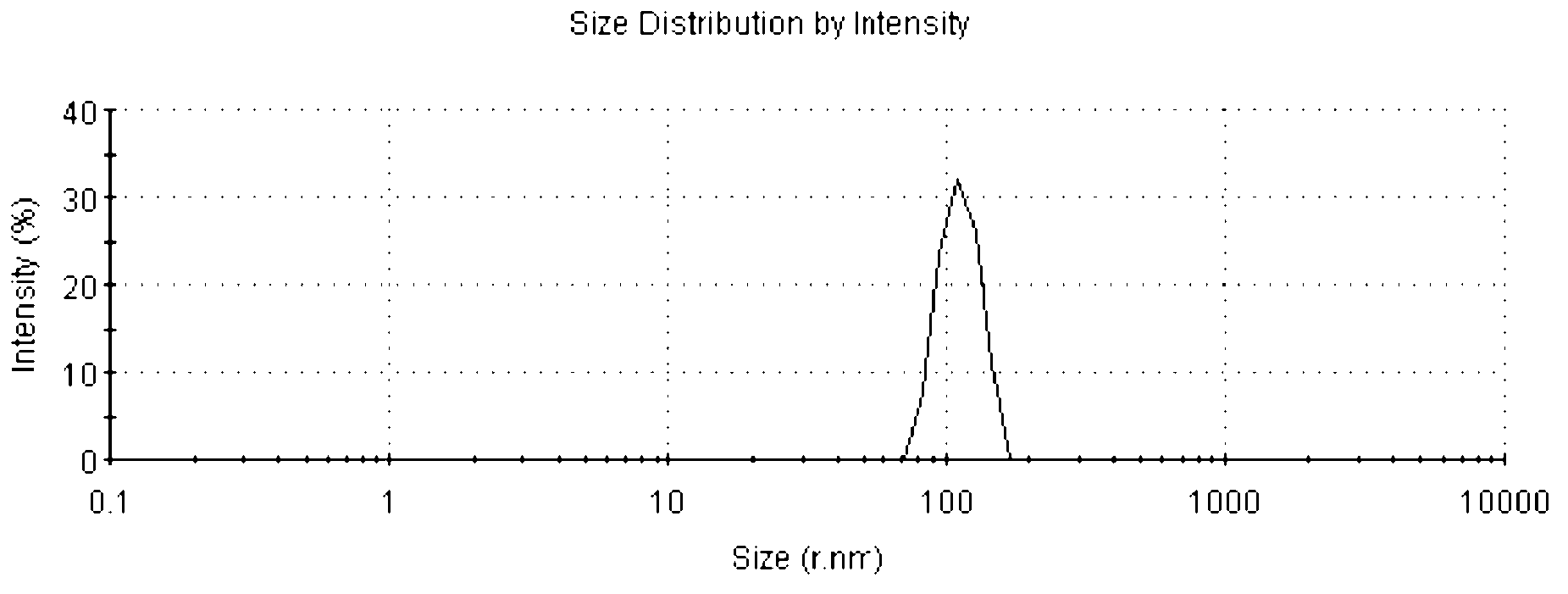

Flurbiprofen acetaminophen resin lipid microsphere injection, freeze-drying lipid microsphere injection and preparation methods

ActiveCN103054800AImprove solubilityImprove physical stabilityPowder deliveryOrganic active ingredientsSolubilityTreatment effect

The invention relates to a flurbiprofen acetaminophen resin lipid microsphere injection, a freeze-drying lipid microsphere injection and a preparation method. Through a reasonable composition proportion and a preparation process with controllable parameters, good stability and strong operability, the flurbiprofen acetaminophen resin which is an indissolvable drug is wrapped in an oil phase and an interfacial film of a lipid microsphere, so that not only is the solubility of the drug remarkably strengthened, but also precipitation and oxidation do not occur easily, the physical and chemical stabilities of the drug are greatly improved, the devitrification phenomenon is avoided in the use and storage processes, a slow release effect is exerted and the action time of the drug in the blood plasma is prolonged, meanwhile, as the lipid microsphere targets to an inflammation part, the toxicity and the vessel stimulation during injection are remarkably reduced, the clinical application of the injections is safer, the treatment effect is more remarkable, and the injections and the methods are suitable for industrialized production and clinical application.

Owner:WUXI ERYUN TECH CO LTD

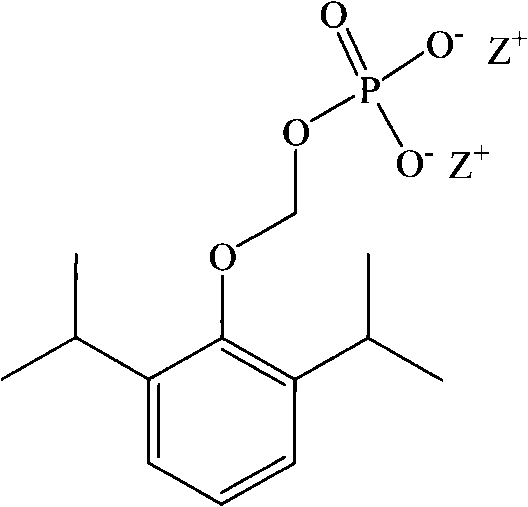

New precursor medicinal preparation

ActiveCN101716149AInhibit devitrificationPrevent precipitationPowder deliveryNervous disorderSolubilityFreeze-drying

The invention discloses a freeze-drying preparation of a water-solubility propofol precursor compound and a preparation method thereof. The freeze-drying preparation of the propofol precursor compound, prepared in the method of the invention, has the advantages of favorable water solubility, stability and safety.

Owner:YICHANG HUMANWELL PHARMA

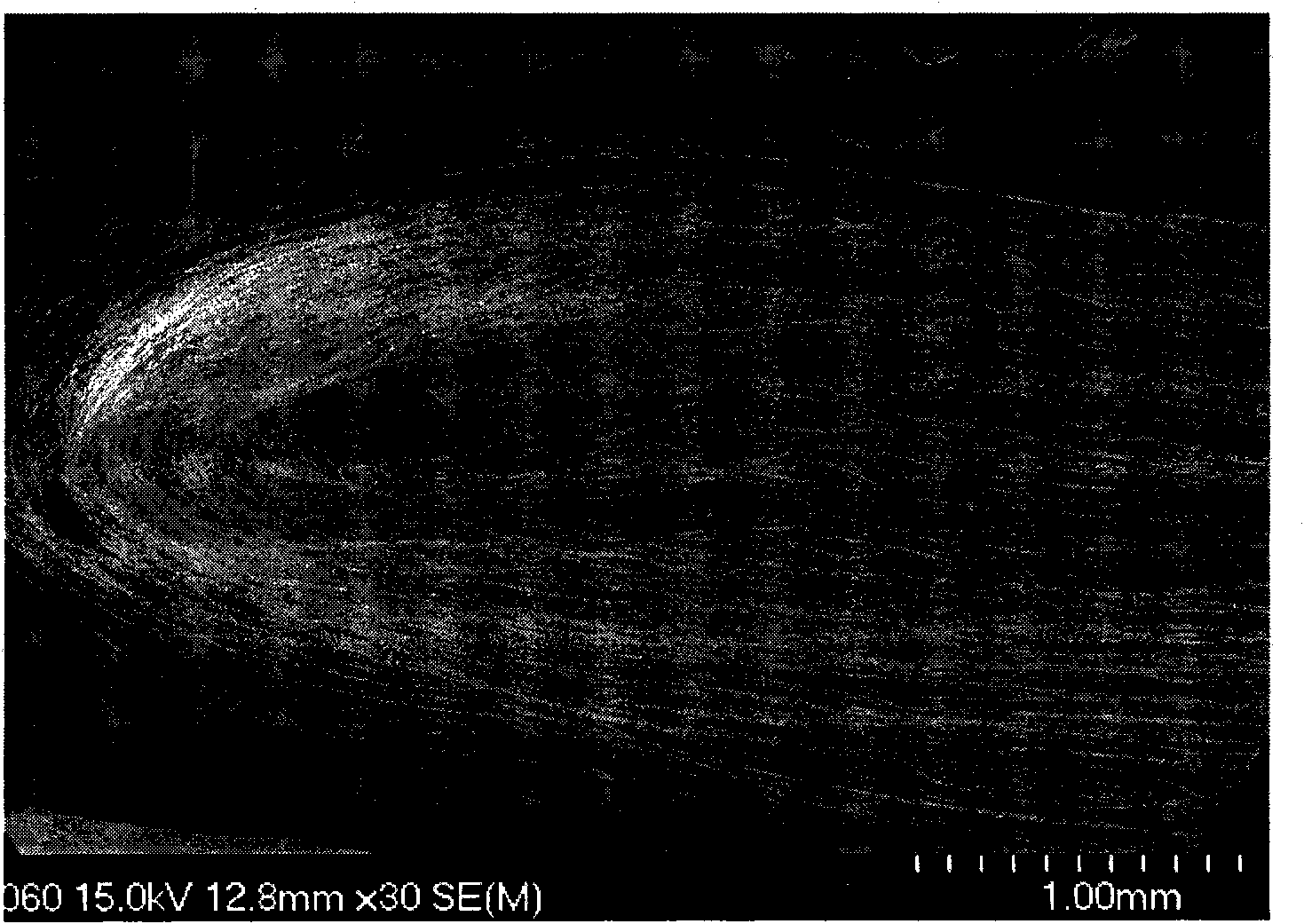

Glass fiber

InactiveUS7629279B2Good acid and alkali resistanceInhibit devitrificationSynthetic resin layered productsYarnGlass fiberMaterials science

Owner:NIPPON ELECTRIC GLASS CO LTD

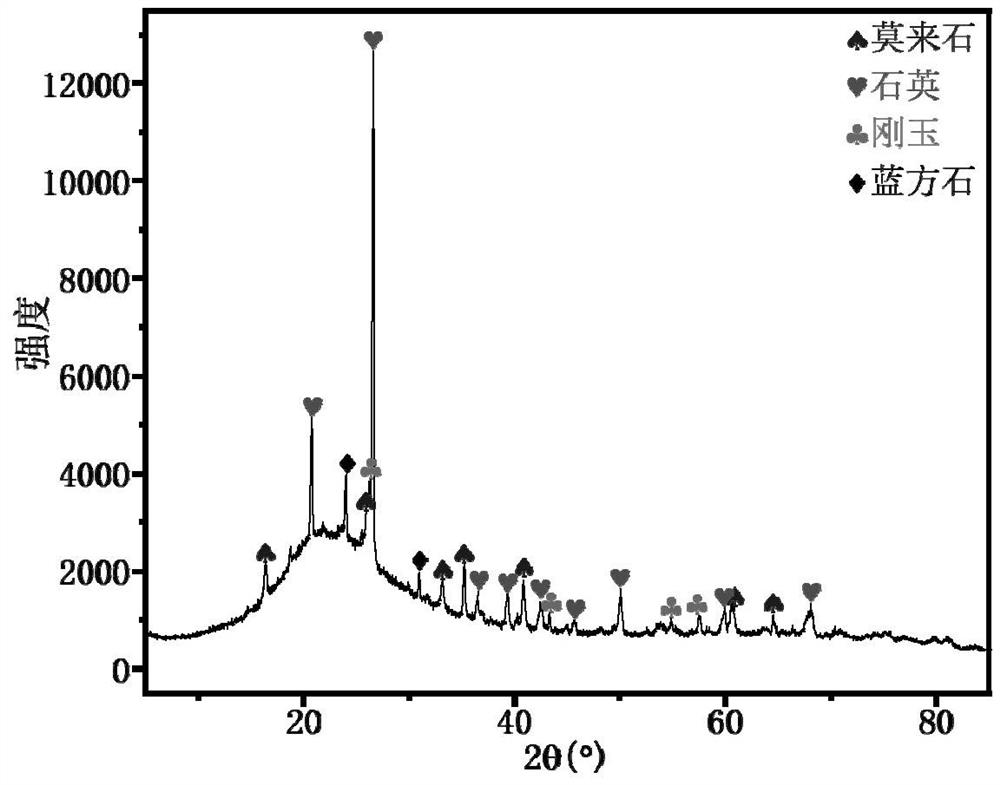

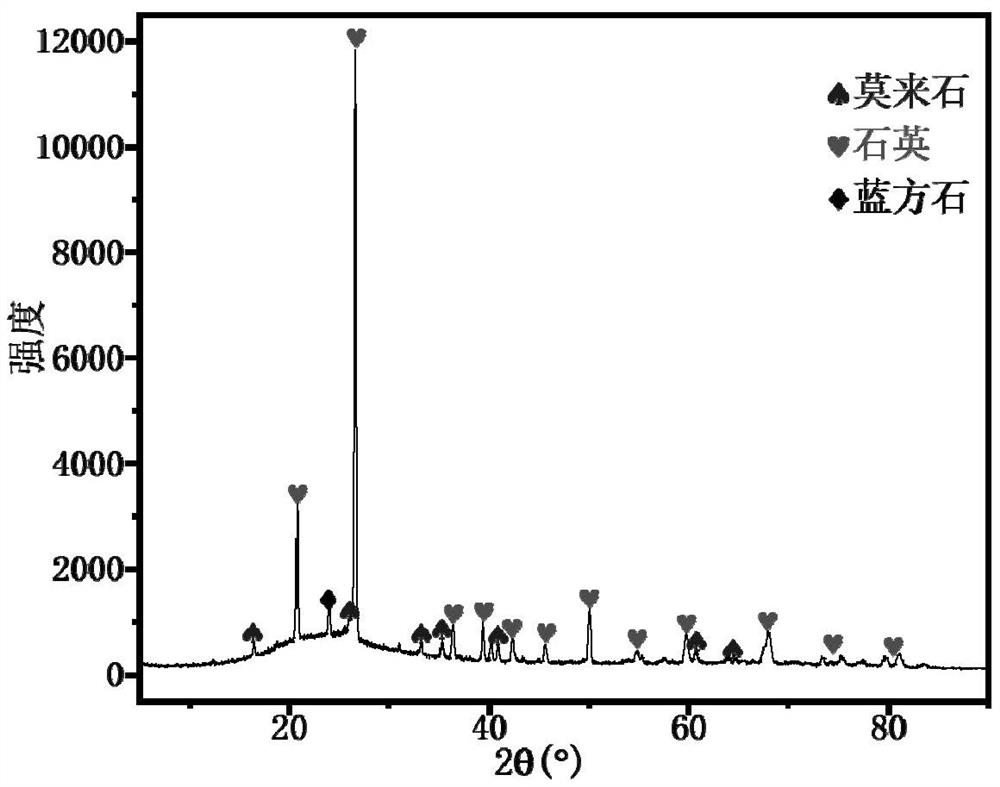

Mutton fat jade ceramic tile and preparation method thereof

ActiveCN111995382AGood light transmissionHigh light transmittanceCeramic materials productionKaolin clayPotassium feldspar

The invention discloses a mutton fat jade ceramic tile and a preparation method thereof. The preparation method comprises the following steps that a mutton fat jade green body is prepared, and mineralcompositions of the mutton fat jade green body comprise, by mass, 42.0%-50.0% of light-transmitting potassium feldspar, 37.0%-43.0% of acicular light-transmitting kaolin and 7.0%-21.0% of fused quartz sand; a design pattern is printed on the mutton fat jade green body in an ink-jet mode; and a mutton fat jade protective glaze is applied to the mutton fat jade green body subjected to ink-jet printing of the designed pattern, and firing is conducted to obtain the mutton fat jade ceramic tile. The mineral composition of the mutton fat jade protective glaze includes the following components in percentage by mass: 35.0 to 45.0 percent of light-transmitting potassium feldspar, 20.0 to 30.0 percent of acicular light-transmitting kaolin, 12.0 to 18.0 percent of fused quartz, 4.0 to 6.0 percent ofcorundum, 6.0 to 8.0 percent of barium carbonate and 1.0 to 3.0 percent of zinc oxide.

Owner:MONALISA GRP CO LTD

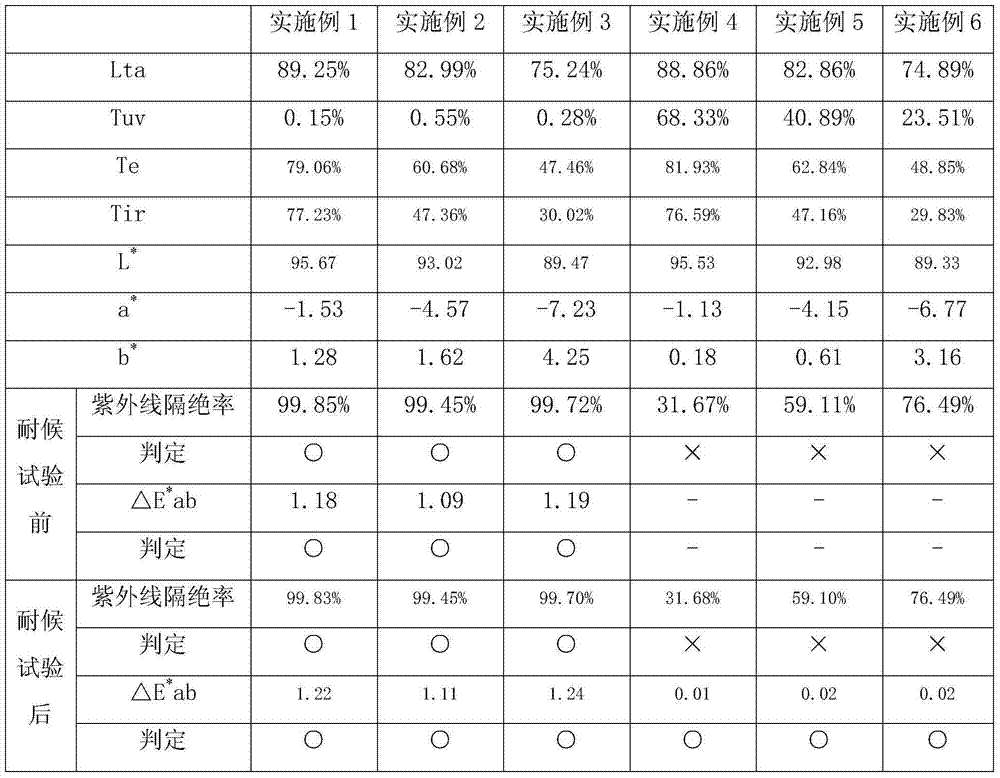

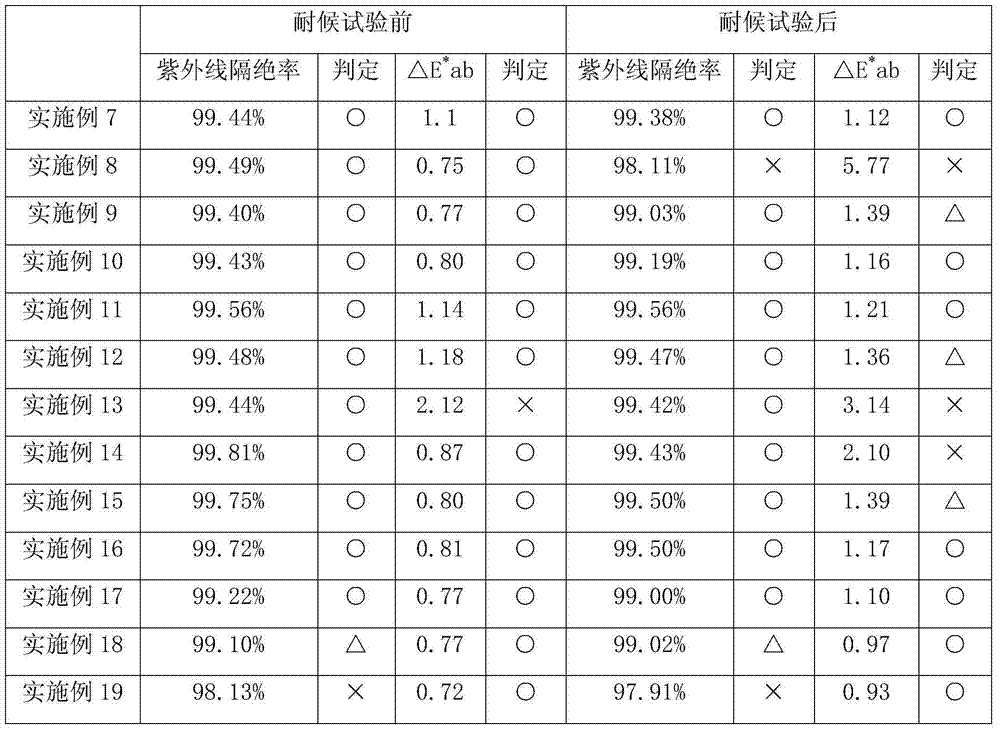

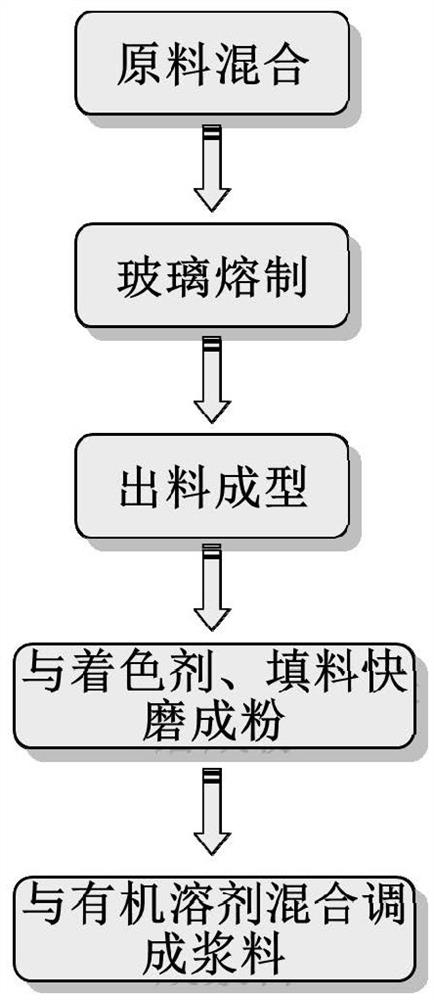

Coating liquid for forming ultraviolet absorbing coatings and ultraviolet absorbing glass

ActiveCN103613280APrevent discolorationInhibit devitrificationSynthetic resin layered productsRadiation-absorbing paintsDevitrificationWeather resistance

The invention relates to the technical field of ultraviolet absorbing coatings, particularly provides coating liquid for forming ultraviolet absorbing coatings on the surfaces of objects, such as glass and the like, and ultraviolet absorbing glass with the ultraviolet absorbing coatings formed by the coating liquid and further provides a method for preparing the ultraviolet absorbing glass. According to the coating liquid for forming the ultraviolet absorbing coating, the ultraviolet absorbing glass and the method for forming the ultraviolet absorbing glass, through storing and releasing ultraviolet excited electrons in an ultraviolet absorbent, the gradually accumulated excited electrons of the ultraviolet absorbent during ultraviolet ray absorption are reduced, then, the ultraviolet absorbent and a silica matrix are protected, the ultraviolet absorbing glass is prevented from discoloration or devitrification, the weather resistance of the ultraviolet absorbing coatings is guaranteed, and the color consistency of the ultraviolet absorbing glass is guaranteed.

Owner:FUYAO GLASS IND GROUP CO LTD

Glass powder suitable for OLED packaging as well as preparation method and application thereof

ActiveCN113121117ALower glass turning pointLow softening pointSolid-state devicesSemiconductor/solid-state device manufacturingMetallurgyMaterials science

The invention discloses glass powder suitable for OLED packaging as well as a preparation method and application thereof. A basic glass powder material in the non-devitrification low-melting-point glass powder comprises the following components in percentage by weight: 50 to 90 percent of Bi2O3, 5 to 25 percent of B2O3, 3 to 20 percent of ZnO, and less than 10 percent of at least one additive selected from MgO, SiO2, Al2O3, Na2O, K2O, Li2O, SrO, BaO, CaO, Nd2O3, Sm2O3 and Sb2O3.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A fully-glazed frit and a preparing method thereof

Owner:江西宏瑞新材料有限公司

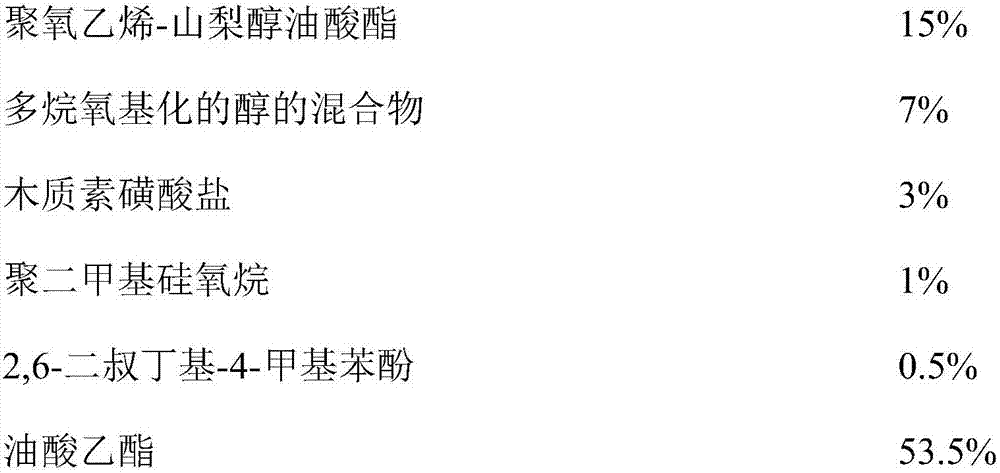

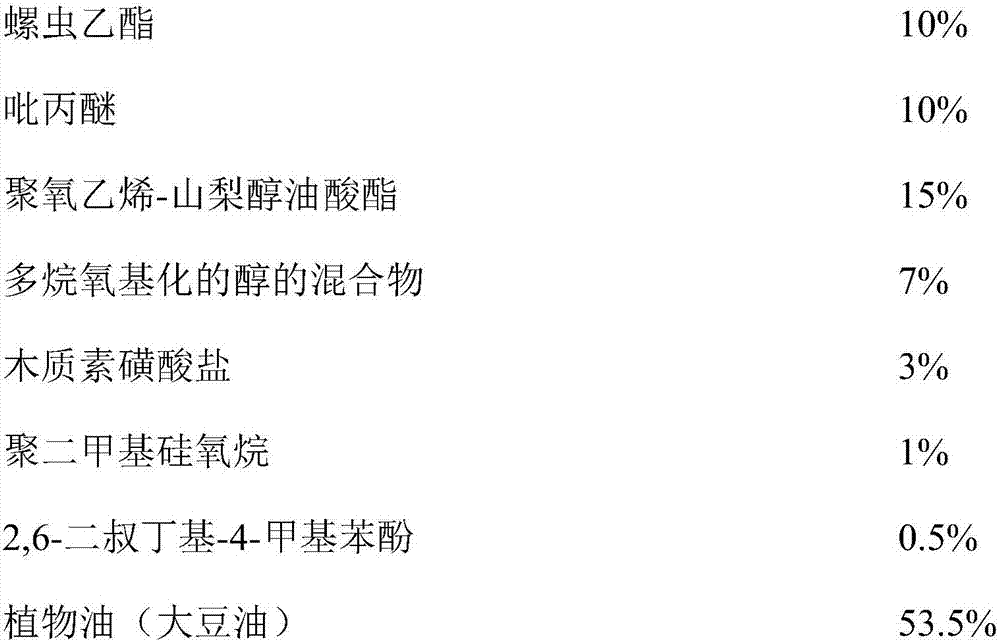

Oil-based concentrated solution, preparation method and application thereof

PendingCN107439569AControl particle size growth issuesSmall particle sizeBiocideAnimal repellantsAntioxidantSpirotetramat

The invention discloses an oil-based concentrated solution, a preparation method and application thereof. The oil-based concentrated solution comprises the following components: (a) at least one active spirotetramat matter which is solid under room temperature, (b) at least one active pyriproxyfen matter which is solid under room temperature, (c) at least one aliphatic ester with the formula R1-COO-R2 and / or R1-COO-R2-OOC-R1, (d) at least one nonionic surfactant and / or at least one anionic surfactant and (e) one or at least two additives randomly selected from an emulgator, a de-foaming agent, a preservative, an antioxidant, a colorant or inertial filling material, wherein pyriproxyfen is dissolved in the component c under molecular state and spirotetramat is suspended in the component c under particle state. The oil-based concentrated solution prepared according to the invention is capable of effectively controlling the problem of grain size increasing of spirotetramat in a storage process, promoting the preparation stability, enhancing the compounding effect and enhancing the bioavailability.

Owner:JIANGSU ROTAM CHEM

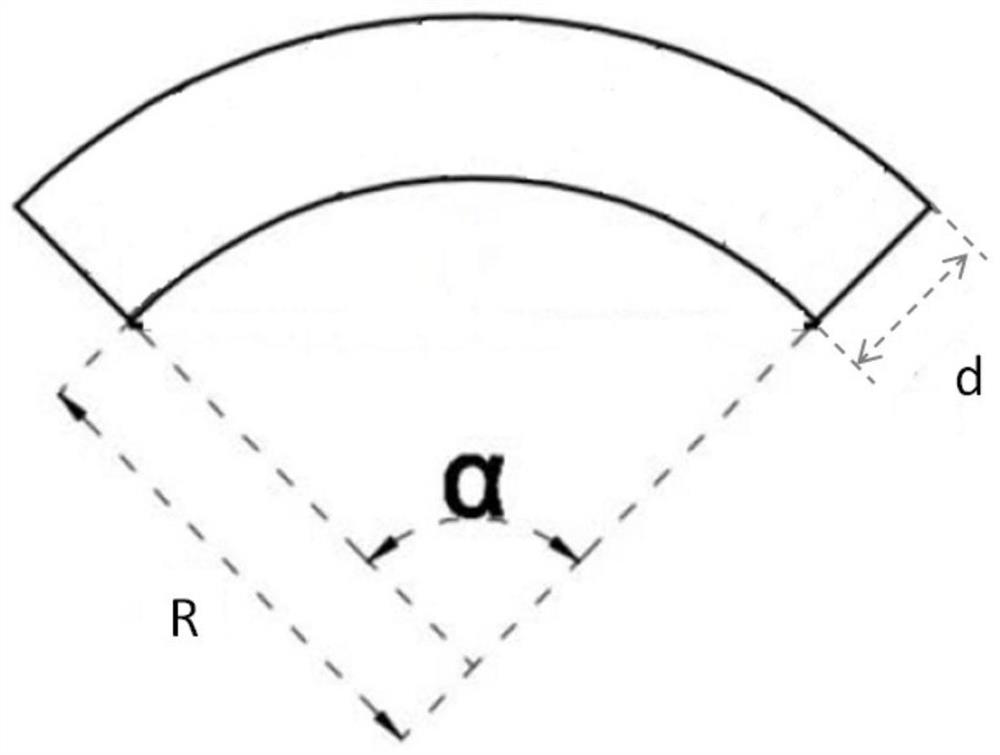

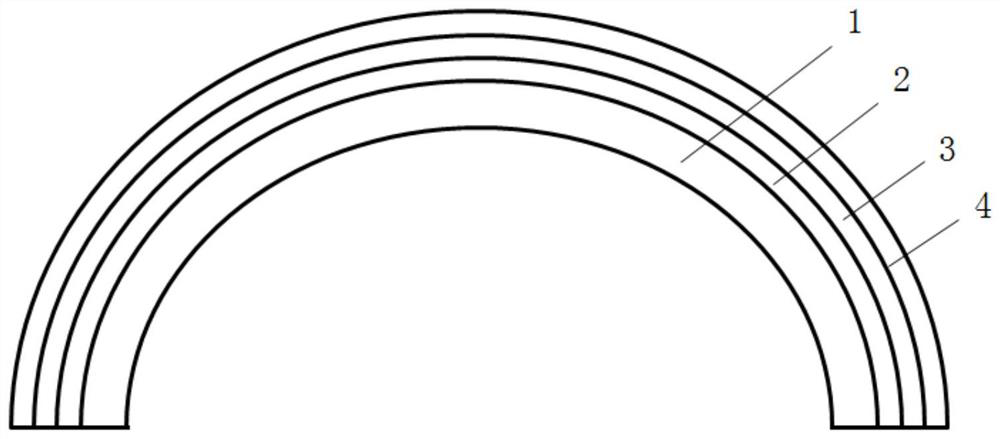

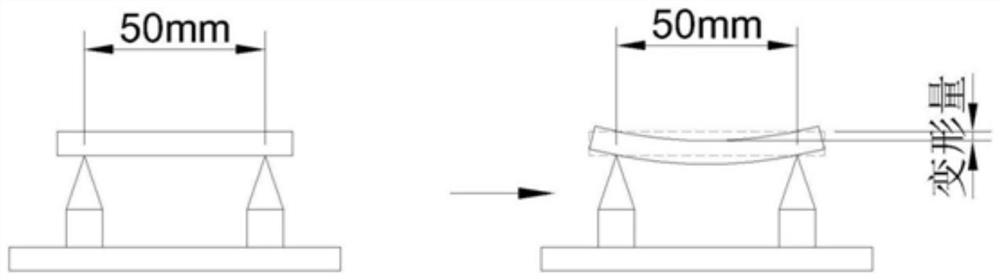

High-curvature wide-color-gamut ceramic curved surface rock plate and preparation method and application thereof

ActiveCN113979738AGuaranteed basic performanceReduce contentCovering/liningsSolid waste managementCelluloseGlaze

The invention discloses a high-bending-degree wide-color-gamut ceramic curved surface rock plate and a preparation method and application thereof. The thickness of the curved surface rock plate is 3-6 mm, the curvature radius is larger than or equal to 100 mm, and the arc center angle is 0-180 DEG C. The curved surface rock plate comprises a glaze layer, and the glaze layer comprises a ground glaze layer and a cover glaze layer arranged on the upper portion of the ground glaze layer. The ground glaze layer is prepared from the following raw materials in parts by weight: 81-90 parts of EN-1 frit, 8-12 parts of kaolin, 2-7 parts of quartz, 0.3-0.5 part of sodium tripolyphosphate and 0.15-0.22 part of sodium carboxymethyl cellulose; the cover glaze layer is prepared from the following raw materials in parts by weight: 30-45 parts of 7 # transparent frit, 8 parts of kaolin, 0-7 parts of quartz, 0-40 parts of albite, 0-15 parts of potassium feldspar, 0-5 parts of dolomite, 0-5 parts of calcite, 0-6 parts of barium carbonate, 0.3-0.5 part of sodium tripolyphosphate and 0.15-0.22 part of sodium carboxymethyl cellulose. According to the ground glaze formula adopted by the curved surface rock plate, after hot bending and re-burning, glaze cracks of the bottom surface glaze are not generated, the phenomena of matt recrystallization and glaze layer devitrification are avoided, and the color gamut range is widened.

Owner:广东东唯新材料有限公司 +4

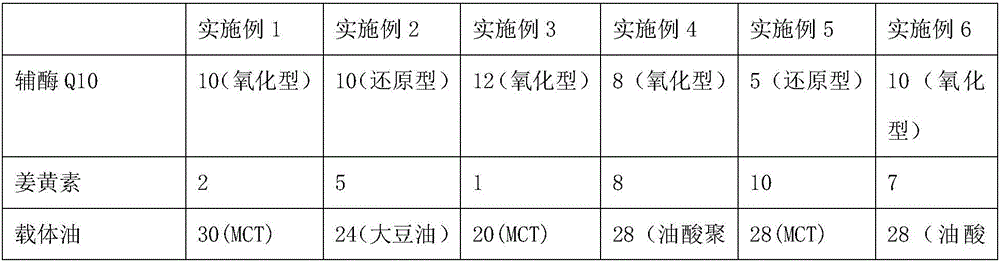

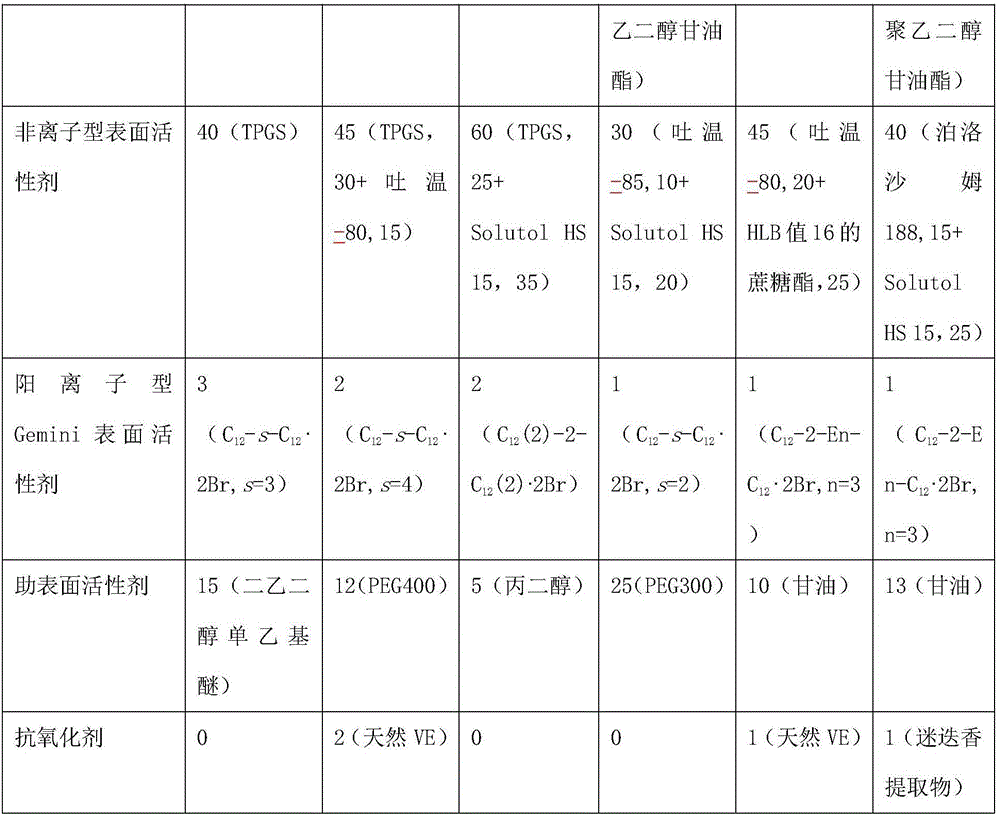

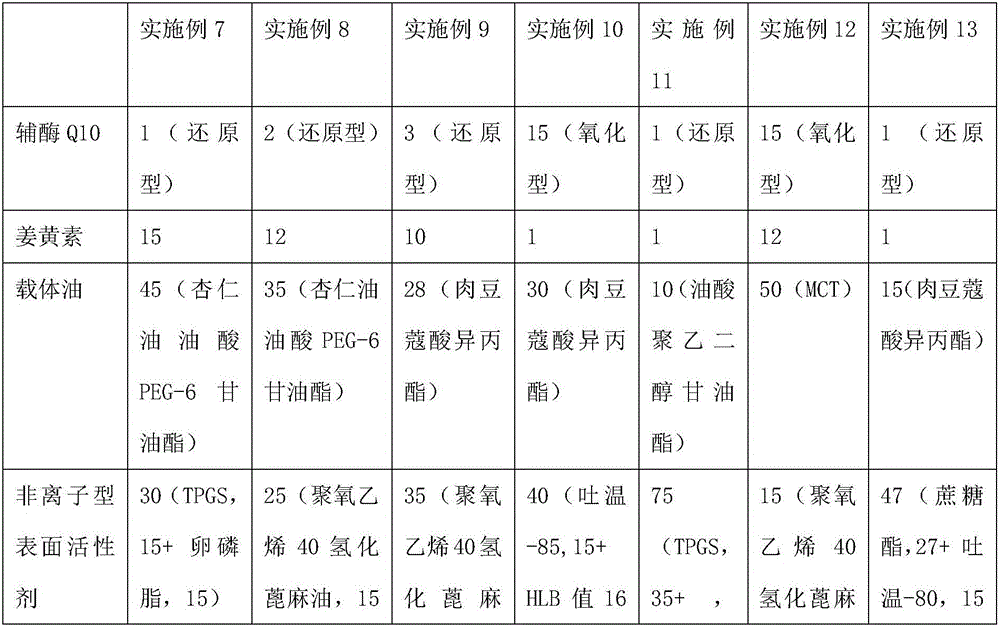

Self-microemulsion nutrient composition containing coenzyme Q10 and preparation method and application

ActiveCN106619588AEasy to addInhibit devitrificationNervous disorderKetone active ingredientsEnvironmental resistanceAntioxidant

The invention discloses a self-microemulsion nutrient composition containing coenzyme Q10 and a preparation method and application. The self-microemulsion nutrient composition comprises the following components in parts by weight: 1-15 parts of coenzyme Q10, 1-15 parts of curcumin, 10-50 parts of carrier oil, 15-75 parts of a nonionic surfactant, 1-5 parts of a cationic gemini surfactant, 5-30 parts of a cosurfactant and 0-2 parts of an antioxidant, wherein the components are prepared into a uniform, stable, clear and transparent solution. The self-microemulsion nutrient composition has good stability, crystallization of coenzyme Q10 is remarkably inhibited, and the product shelf life is prolonged. In the application process, the composition can be simply and conveniently added into systems of water-phase food, medicines and the like according to demand amounts, and is safe and effective. Meanwhile, the whole preparation process is green, environmental-friendly, low in energy consumption and easy in industrial production.

Owner:XIAMEN KINGDOMWAY BIOTECH CO LTD +1

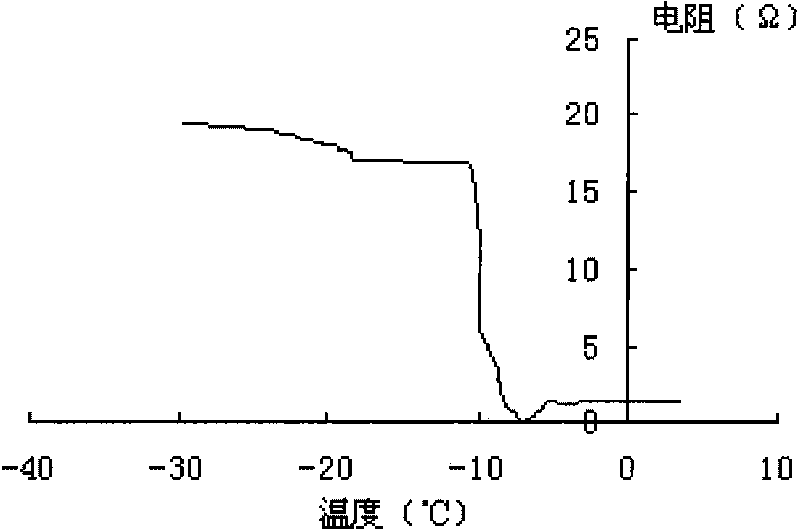

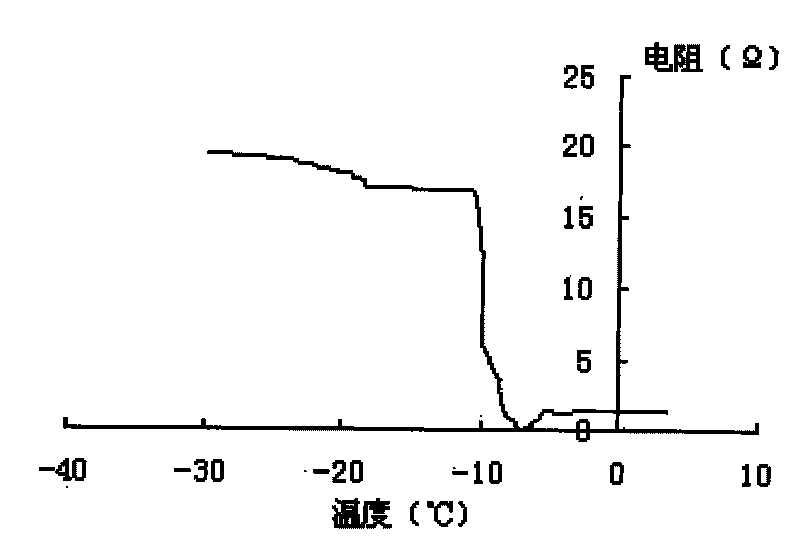

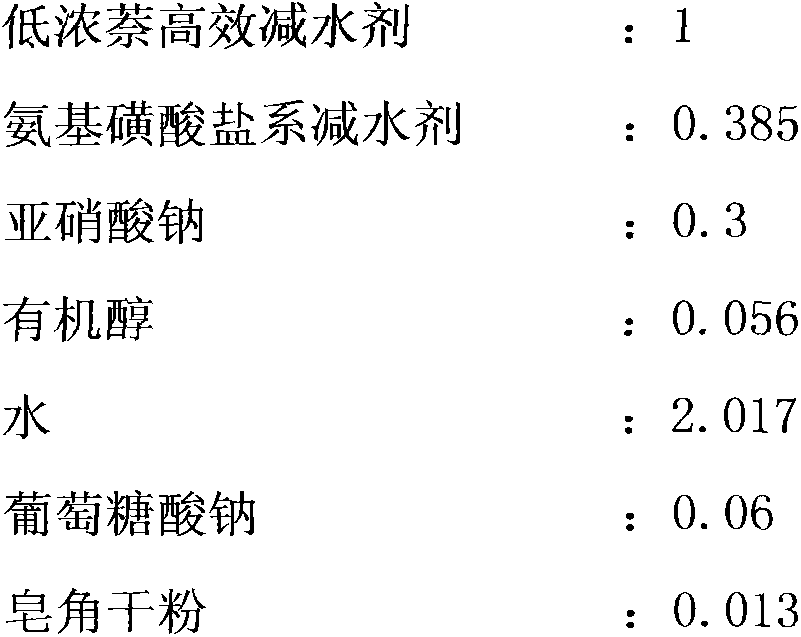

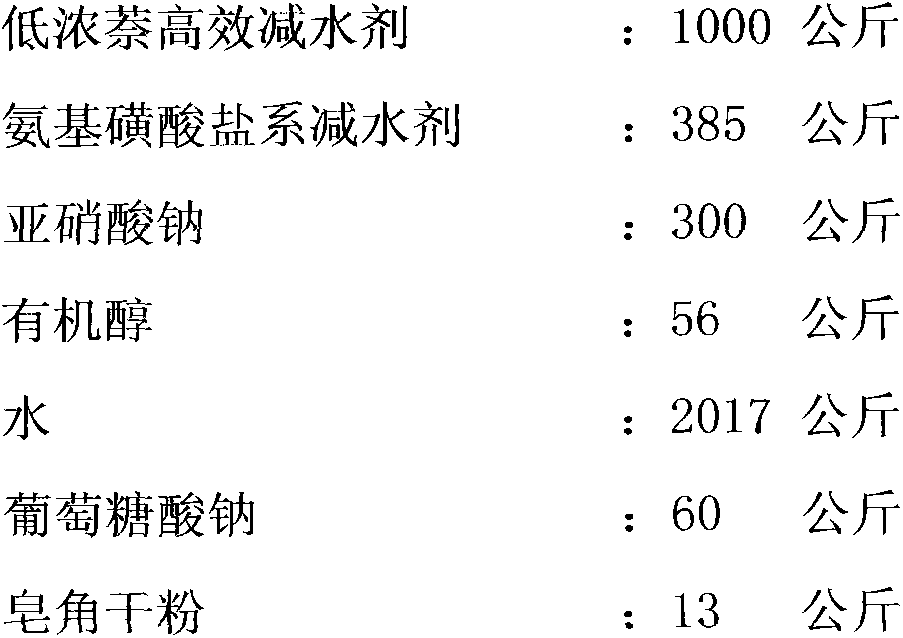

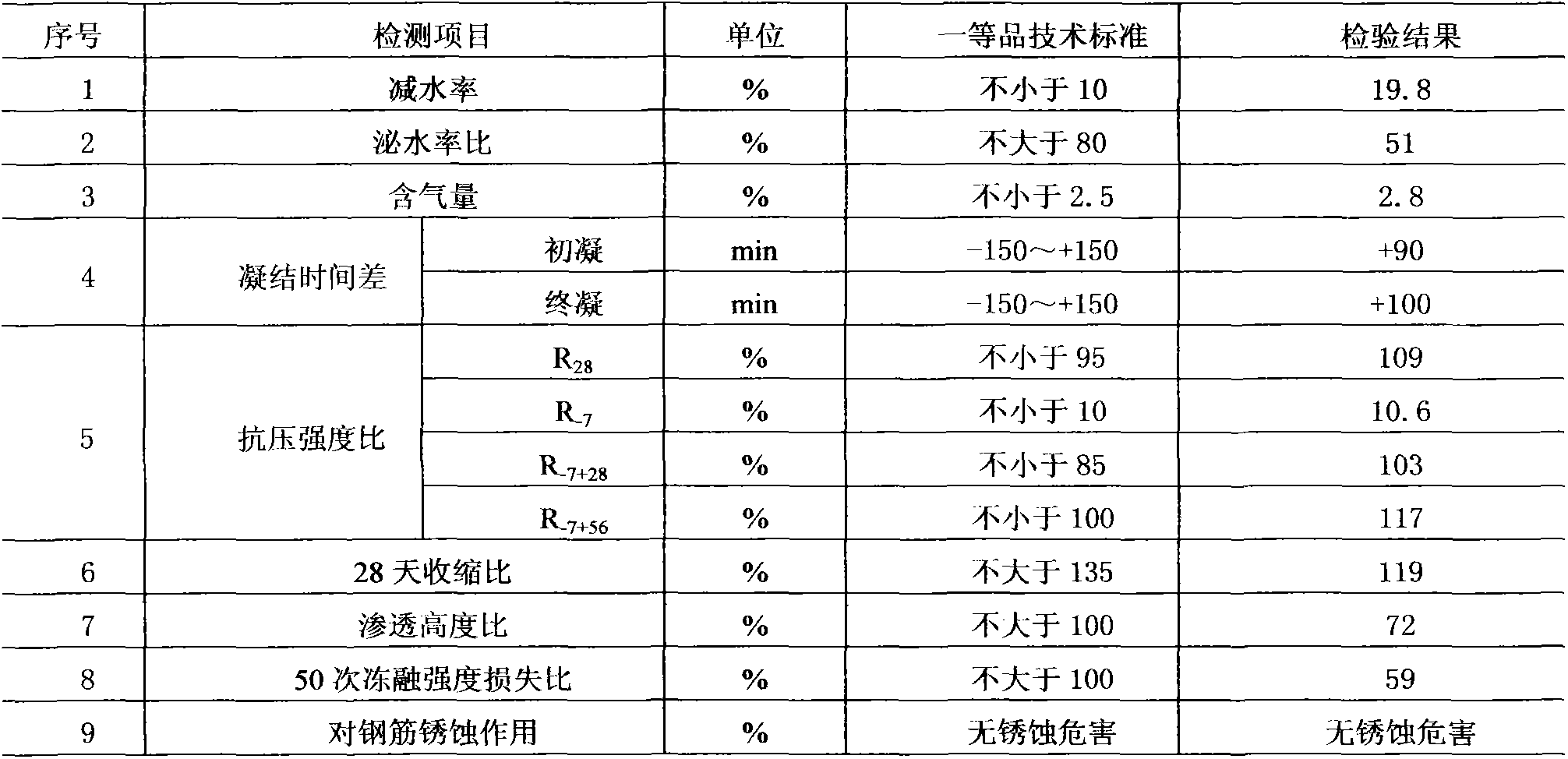

Concrete composite liquid anti-freezing pumping agent

The invention provides a concrete composite liquid anti-freezing pumping agent and belongs to the technical field of the concrete pumping agent. The pumping agent is composed of the following components: a low-concentration naphthalene efficient water reducer, a sulfamate water reducer, sodium nitrite, an organic alcohol, water, sodium gluconate and dry Chinese honeylocust fruit powder, in a weight ratio of 1: 0.385: 0.3: 0.056: 2.017: 0.06: 0.013. The concrete composite liquid anti-freezing pumping agent provided by the invention has the advantages that all the components have synergistic effect to inhibit crystallization of an early strength component at a minus temperature, well control the slump of the concrete and keep development of the early strength of the concrete, and simultaneously, bubbles are introduced into the concrete and neat paste to improve the workability (peaceability) of the concrete and the cement neat paste, and therefore, the adaptability of the liquid anti-freezing pumping agent can be improved and the anti-freezing durability of the concrete can be greatly improved; besides, the anti-freezing pumping agent is free of chlorine, low in alkali, and in the form of a liquid, and thereby more convenient for storage, transportation and use.

Owner:韩越

High-refractive index and low-dispersion heavy lanthanum flint optical glass

The invention relates to a high-refractive index and low-dispersion heavy lanthanum flint optical glass which is prepared from the following components in percentage by mass of oxides: 9.25-13.37 percent of B2O3, 5.48-7.34 percent of SiO2, 43.60-51.63 percent of La2O3, 3.53-9.12 percent of Y2O3, 4.18-10.23 percent of Gd2O3, 3.47-6.52 percent of Nb2O5, 3.47-6.62 percent of ZrO2, 0.81-1.50 percent of WO3, 3.96-6.95 percent of TiO2, 3.28-6.79 percent of ZnO and 0.61-1.52 percent of Al2O3; and in the composition, the following conditions are also met: B / Si is larger than 1.33 and smaller than 2.54 (by mass percentage), a sum of the mass percentages of La2O3, Y2O3 and Gd2O3 is 58.61-60.32 percent, and a sum of the mass percentages of WO3 and TiO2 is 4.85-8.34 percent. The optical glass does not contain Ta2O3 with high cost to facilitate reduction of the cost of the glass, does not contain alkali metals, alkaline-earth metals and toxic components including Pb, As and Cd either, has the refractive index nd being 1.883-1.915 and an abbe number vd being 35.65-38.32, is excellent in crystallization resistance and is suitable for batch production.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Optical glass

An optical glass having a refractive index (nd) within a range from 141 to 1.47 and an Abbe number (νd) within a range from 90 to 100 comprises in mass % on element basis: P 0.1-5.0%Al 1.0-20.0%F30.0-60.0% andO 1.0-20.0%and comprises, as an essential component, one or more elements selected from the group consisting of Ca, Sr and Ba. In this optical glass, the ratio (Si+B+P+Al) / F is within a range from 0.15 to 0.40.

Owner:OHARA

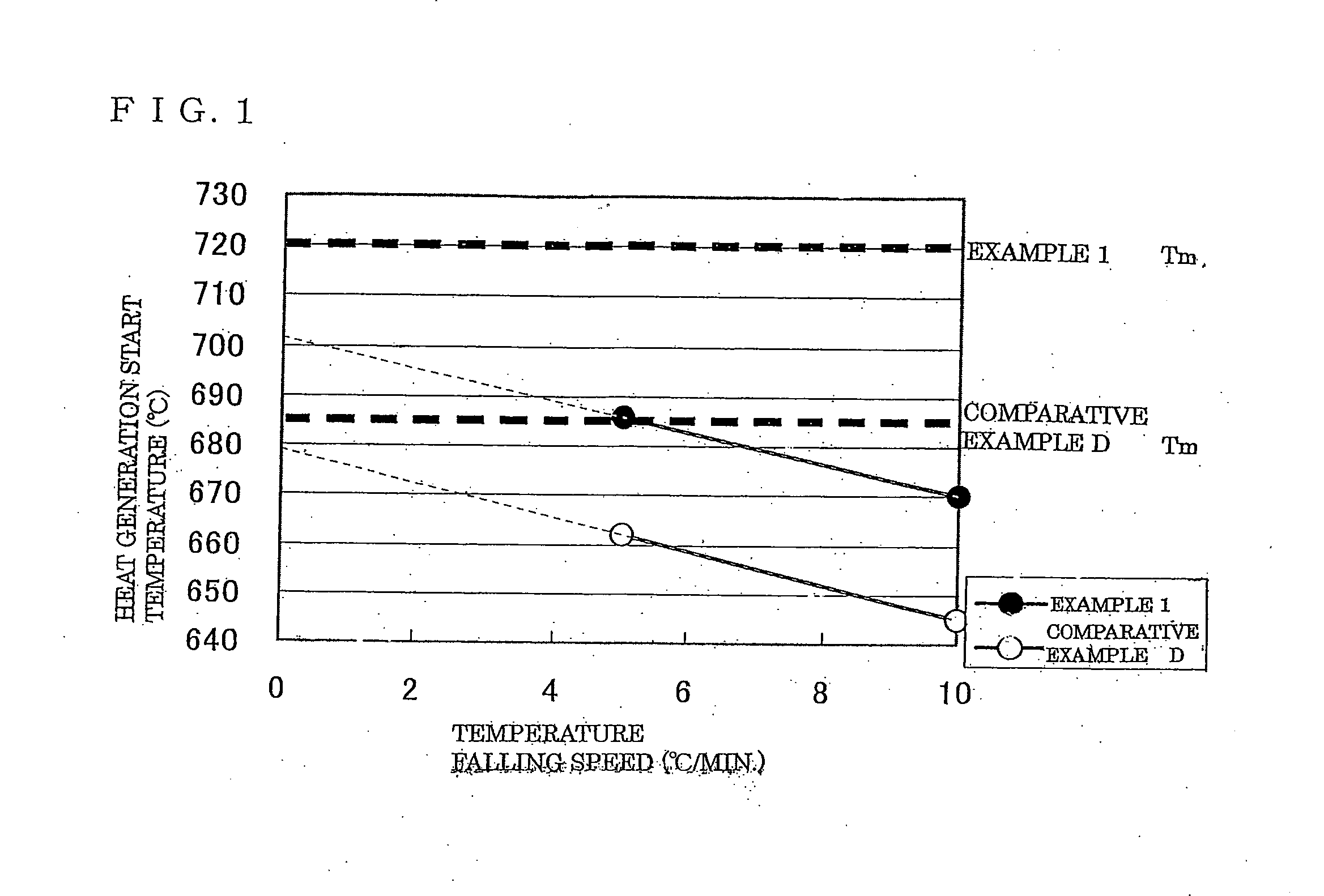

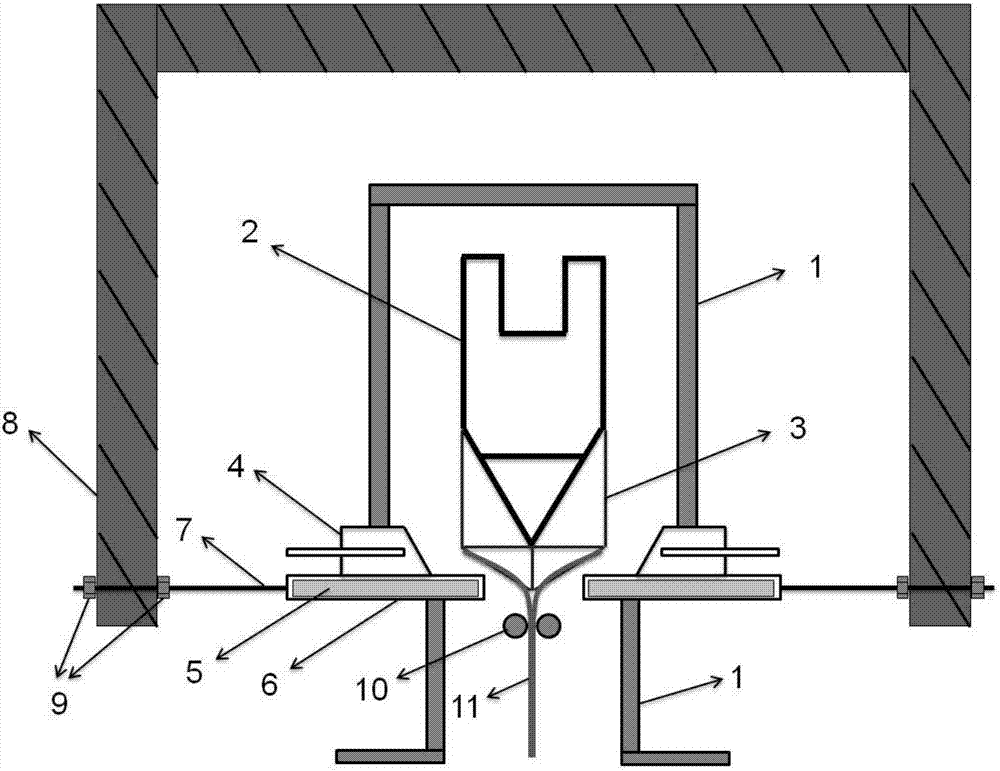

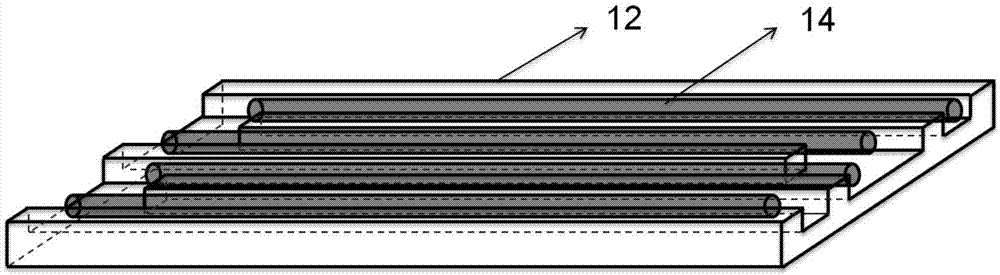

Heating device of drainage plate in muffle furnace and control method of heating device

ActiveCN107445458AIncrease temperatureImprove stabilityGlass forming apparatusEngineeringMuffle furnace

The invention discloses a heating device of a drainage plate in a muffle furnace and a control method of the heating device. The device comprises a soaking cover, a drainage plate and two heaters which are arranged in the muffle furnace as well as a horizontal adjusting mechanism arranged on the muffle furnace, wherein the drainage plate is arranged in the soaking cover; the two heaters are positioned at a junction of the muffle furnace and a moulding area and are arranged on the side wall of the soaking cover respectively and are in sealing contact with the side wall of the soaking cover; the two heaters are symmetrically arranged on the two sides of the drainage plate; the horizontal adjusting mechanism is used for adjusting the horizontal inserting depths of the heaters. An aim of increasing temperature of the drainage plate is achieved by designing and producing an inserting type heater to replace an original upper plywood mechanism in the moulding area and adjusting the inserting depth and power (or current) of the heater, thus the crystallization of molten glass on the drainage plate is inhibited, the stability and consistency of the moulding quality of a glass substrate are further improved, and the service life of the muffle furnace is prolonged to a great degree.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

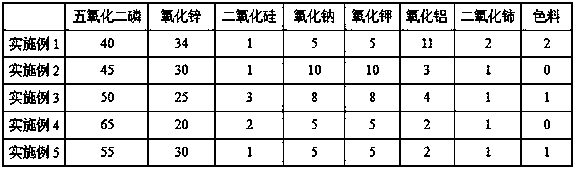

Soft lead-free low-temperature sealing glass and preparation method thereof

The invention discloses soft lead-free low-temperature sealing glass and a preparation method thereof. The soft lead-free low-temperature sealing glass is prepared from the following components by weight percent: 40-65% of phosphorus pentoxide, 0.1-5% of silica, 20-40% zinc oxide, 3-13% of sodium oxide, 3-13% of potassium oxide, 1-15% of alumina, 1-5% of cerium dioxide and 0-3% of a coloring material (such as chromium oxide and iron oxide), wherein the sum of the weight percentages of all the components is 100%, and the mass ratio of the sodium oxide to the potassium oxide is equal to 1 to 1.The low-temperature sealing glass prepared by the method is soft glass with a thermal expansion coefficient with a range of (12-16)*10<-6> / DEG C, and the sealing temperature of the low-temperature sealing glass is only 450-550 DEG C, so that the low-temperature sealing glass is suitable for aluminum alloy sealing requiring a very low operating temperature. The soft lead-free low-temperature sealing glass is soft and high in wettability, and has the thermal expansion coefficient between kovar alloy and aluminum alloy, thus being well matched with the sealing between the kovar alloy and the aluminum alloy.

Owner:FUZHOU RUIKE BULANG MEDICAL TECH CO LTD

Method for increasing yield of SiC nano fiber by applying boric acid

The invention provides a method for increasing the yield of an SiC nano fiber by applying boric acid and relates to an application method of the boric acid, solving the problems that the existing SiC nano fiber preparation method has the defect of low yield, and the boric acid is not applied to the production field of the SiC nano fiber. The method for increasing the yield of the SiC nano fiber by applying the boric acid is carried out according to the following steps that: 1, sucrose and silicasol are mixed, then boric acid is added into the mixed liquid, the mixed liquid is dried, and xerogel is obtained; 2, the xerogel obtained in the step 1 is put in a tubular furnace, nitrogen gas is introduced into the tubular furnace, the temperature of the tubular furnace is raised and kept, and gel powder is obtained; and 3, ball milling is carried out for 3 hours, absolute ethyl alcohol is added, an atmosphere sintering furnace is adopted, and the furnace is cooled to room temperature to obtain an SiC nano floss layer in the shape of wool felt. The invention applies the boric acid in the production of the nano fiber, the yield of the SiC nano fiber is increased by more than 10 times after the boric acid is applied, and the fiber length reaches 5 to 6cm.

Owner:HARBIN INST OF TECH

High temperature structured ceramic material SiBONC and preparation method

The material related by this invention is amorphous and crystallite ceramics composed of Si, B, O, N, C is mole ratio (1-6):1:(2-8):(1-2):(0.2-0.5). The prepn. steps are: a. silicon tetrachloride and benzaldehyde are mixed and illuminated by ultraviolet lamp to react to generate silica compound; b. alkylamine is put into the silicon compound to generate organic polymer Si-O-N, C. boron compound is put into into the organic polymer Si-O-N to generate organic polymer Si-B-O-N-C; d. organic polymer Si-B-O-N-C is splited to Si-B-O-N-C powder in pipe-type air protecting furnace; e. the prepared Si-B-O-N-C powder is fired to produce compacted ceramics Si-B-O-N-C by vacuum air heat pressing.

Owner:HARBIN INST OF TECH

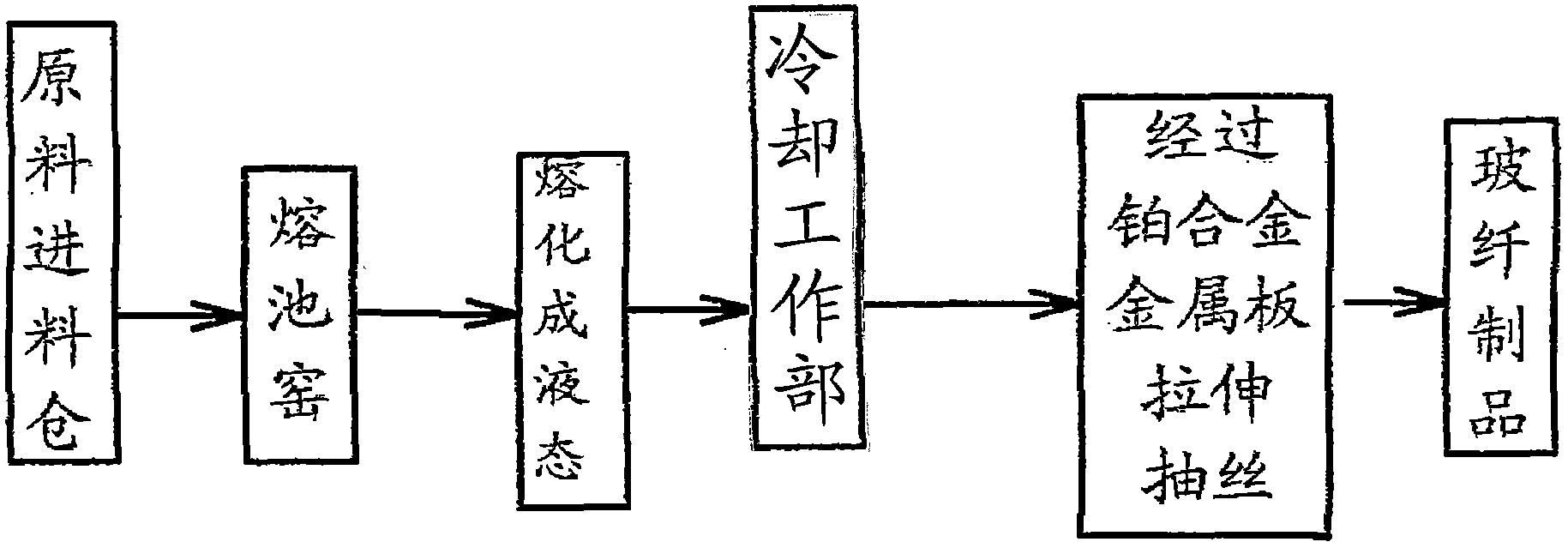

Alkali-free glass fiber having improved property, and preparation method thereof

InactiveCN106946464AImprove performanceIncrease elasticityGlass furnace apparatusGlass productionGlass fiberEnvironmental resistance

The present invention relates to an alkali-free glass fiber having improved property, and a preparation method thereof, wherein the chemical components of the alkali-free glass fiber comprise, by weight, 56-57.5% of SiO2, 3-4.5% of B2O3, 13.5-15% of Al2O3, 19-20.5% of CaO, 2.8-3.5% of MgO, 0.8-1.1% of R2O=K2O+Na2O, 0.2-0.6% of TiO2, and the balance of Fe2O3+ZnO+ZrO2+Cr2O3, and raw material preparation, melting, drawing, spooling, glue immersing, drying and detection are performed to obtain the alkali-free glass fiber. According to the present invention, by adjusting the component ratio of the formula, the pollution caused by boron volatilization is reduced, the environmental protection is easily achieved, the resources are saved, and the powder production cost is substantially reduced; and through the synergistic effect of various components and the strict control of the component content, the prepared alkali-free glass fiber has excellent performance.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

Glass fiber, preparation method thereof and glass fiber composite material

InactiveCN103232165ALow viscosity temperatureLow crystallization temperature propertiesGlass making apparatusSilicon oxideCerium oxide

The invention discloses a glass fiber, a preparation method thereof and a glass fiber composite material. The nominal diameter of the glass fiber ranges from 3 micro to 15 micro and the deviation value of the diameter of the glass fiber is within + / -15% of the nominal diameter. According to the weight percent, in the glass fiber, the alumina content is 20-33%, the silicon oxide content is 4.11-5.48 times of calcium oxide and the calcium oxide content is 0.9-2.1 times of magnesium oxide. Under the condition of high alumina content (20-33% or 23-33% or 25-33%), the glass fiber can generate a new product property with the function of dispersion of aluminum, silicon, calcium and magnesium, so that the problem in the prior art that the dissolving and the quality of air bubbles cannot be controlled resulting from high glass viscosity as a result of high aluminum content is solved; energy and consumption are greatly reduced; the carbon emission is lowered; the devitrification temperature is low, so that mass production can be carried out; and besides, pollutant discharge of toxic boron gas is not generated in the production process.

Owner:杨德宁

Process for preparing high temperature texture ceramic material SiBONC

The present invention relates to preparation process of ceramic material. The preparation process of high temperature structural ceramic material SiBONC includes the following steps: A. mixing silicon tetrachloride and benzaldehyde and irradiating the mixture with ultraviolet lamp for reaction to obtain Si-O polymer; B. adding alkyl amine into the silica polymer to obtain organic Si-O-N polymer; C. adding boride into the organic Si-O-N polymer to obtain organic Si-B-O-N-C polymer; D. cracking organic Si-B-O-N-C polymer in tubular protecting atmosphere furnace to obtain Si-B-O-N-C powder; E. sintering the Si-B-O-N-C powder in vacuum / atmospheric pressure to obtain compact Si-B-O-N-C ceramic. The Si-B-O-N-C ceramic has simple preparation process, and low cost.

Owner:HARBIN INST OF TECH

Porous foam glass ceramic brick and production method thereof

InactiveCN109081596AReduce manufacturing costLower oxygen levelsGlass shaping apparatusFoaming agentBrick

The invention discloses a porous foam glass ceramic brick and a production method thereof. The porous foam glass ceramic brick is made from, by weight, 40-60 parts of fly ash, 10-30 parts of red mud,5-10 parts of glass waste, 5-10 parts of feldspar, 10-15 parts of a foaming agent, and 3-5 parts of a fluxing agent. The above materials are subjected to ball milling, the milled materials are screened to 200 mesh and are mixed well; the mixture is subjected to heap roasting and cutting to obtain the porous foam glass ceramic brick. The fly ash, red mud, glass waste are used as main materials to produce the porous foam glass ceramic brick; the production method is simple and low in cost; industrial wastes can be greatly consumed and turned into wealth, resources are saved, and the environmentis protected.

Owner:XIANNING NANBO PHOTOELECTRIC GLASS CO LTD

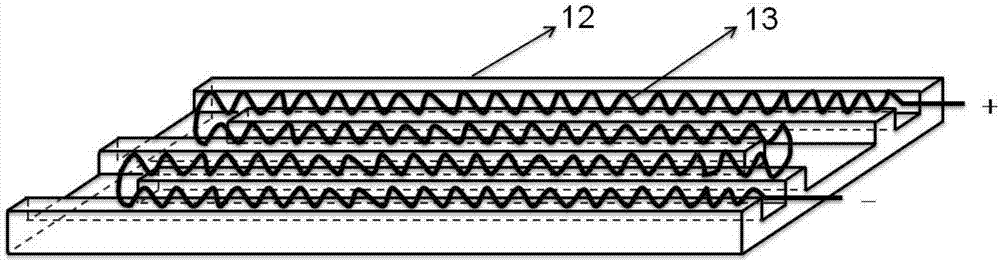

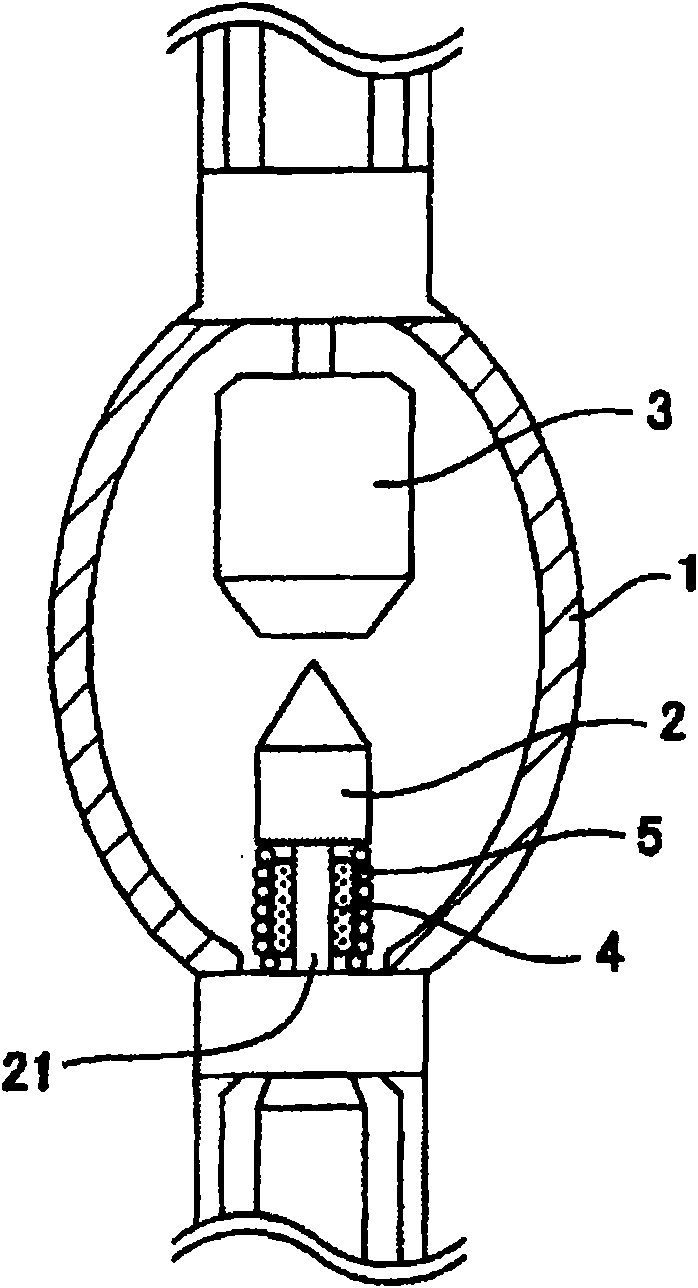

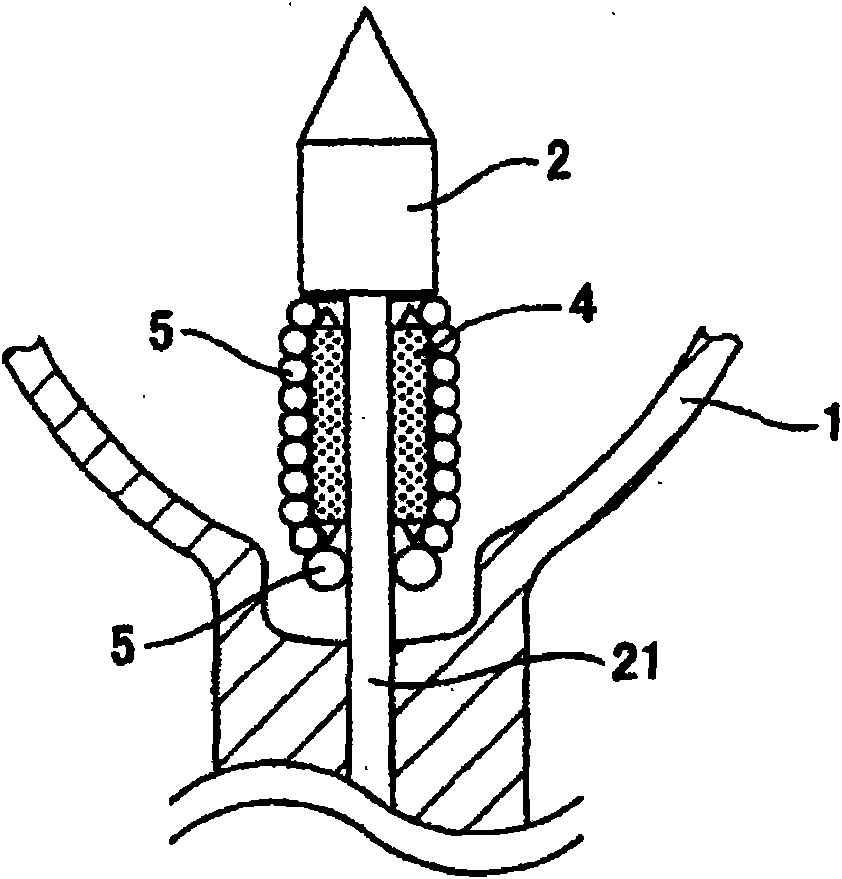

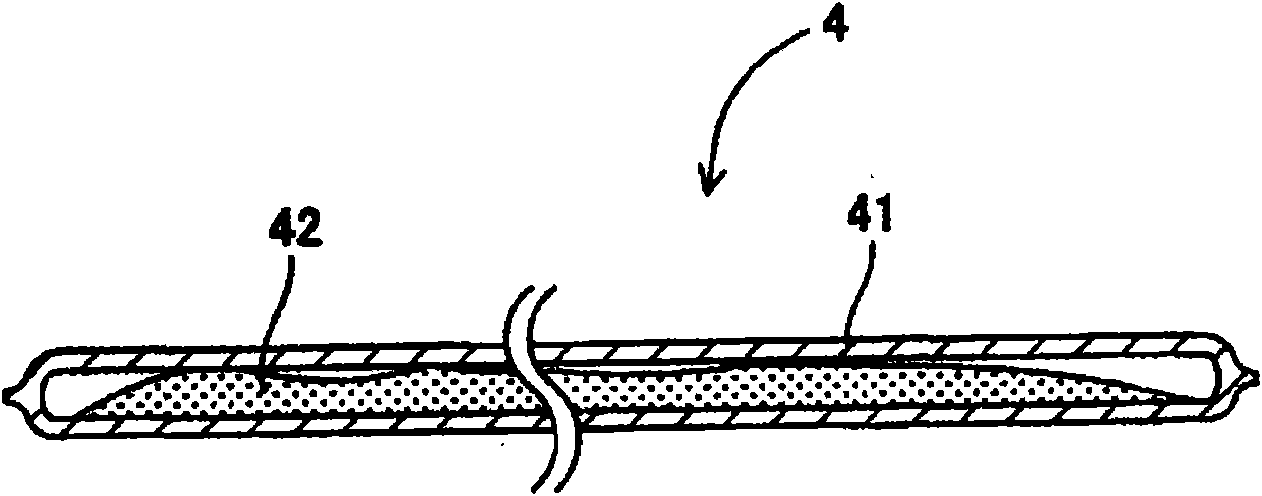

Short-arc mercury lamp

ActiveCN101593663AInhibit devitrificationAvoid blackeningPhotomechanical apparatusHigh-pressure discharge lampsKryptonNoble gas

The invention provides a short-arc mercury lamp that absorbs impure gas like oxygen gas and hydrogen gas exist in a luminous tube by a getter effectively so as to emit UV with wavelength 300-350nm favorably. In the short-arc mercury lamp provided in the invention, the luminous tube (1) made of silex glass is sealed with noble gas and quick silver, and is provided with a pair of electrodes (3,3), characterized in that: in an air-tight container (4) made of tantalum or niobium, any one of yttrium, ziroconium and vanadium (42) is sealed together with noble gas; the container (4) is mounted on anelectrode (2). Besides, the characteristics is that the noble gas sealed in the container (4) comprises at least one of argon, krypton and xenon, and pressure P (Pa) sealed in under room temperature is that p bigger than or equal to 70 (Pa).

Owner:USHIO DENKI KK

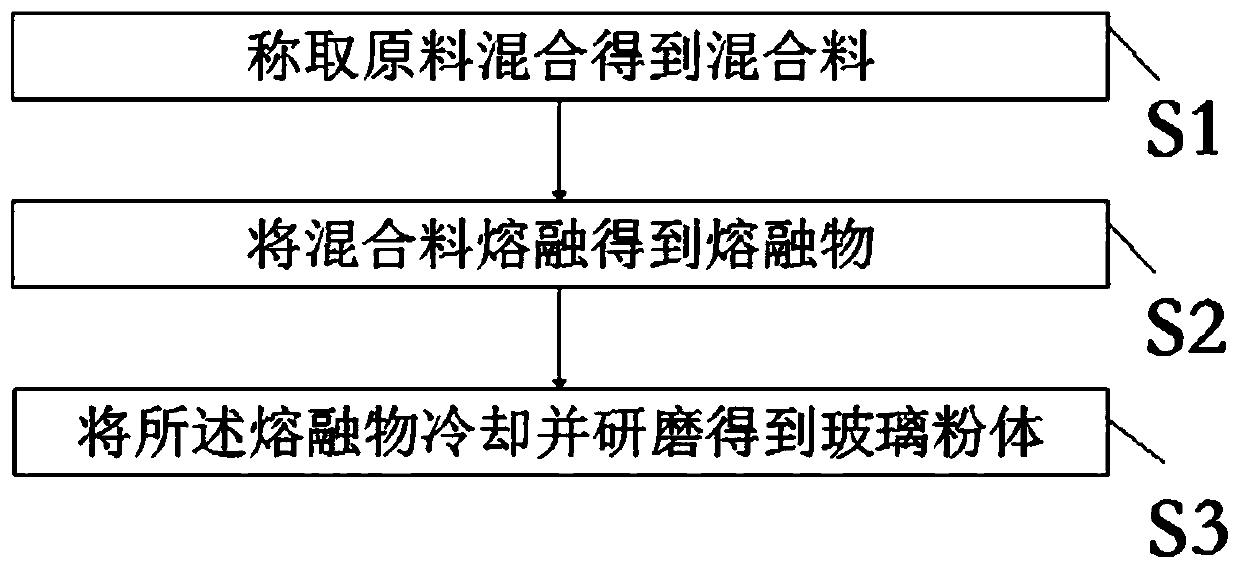

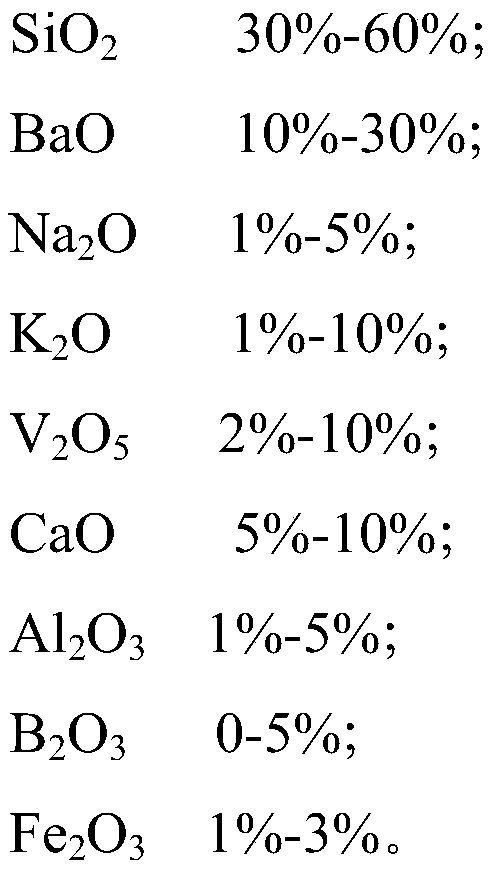

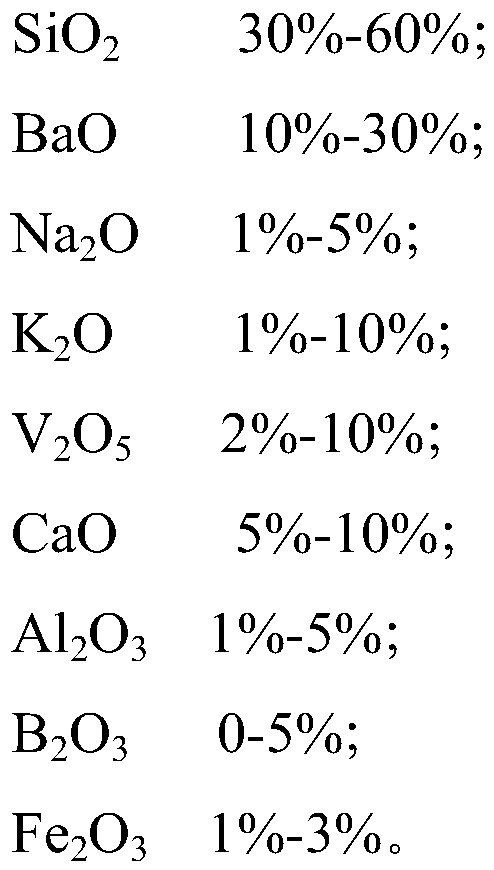

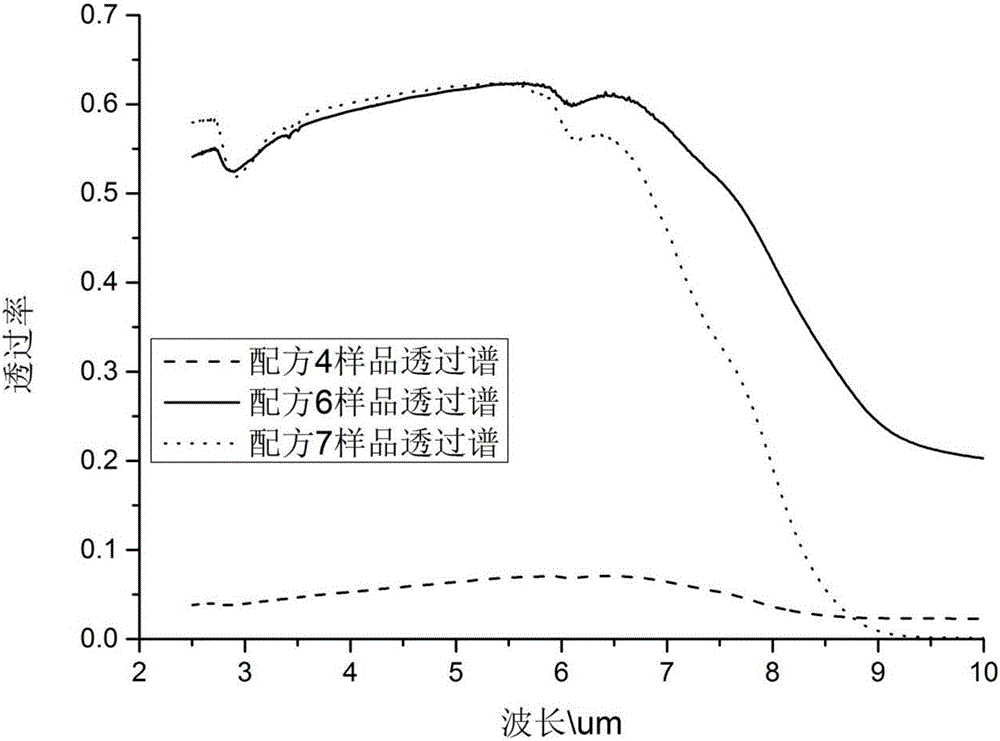

Preparation method of glass powder, and glass powder

The embodiment of the invention provides a preparation method of glass powder, and the glass powder. The preparation method comprises the following steps: weighing raw materials, and mixing to obtaina mixture; melting the mixture to obtain a melt; and cooling and grinding the melt to obtain glass powder, wherein the raw materials comprise 30%-60% of SiO2, 10%-30% of BaO, 1%-5% of Na2O, 1%-10% ofK2O, 2%-10% of V2O5, 5%-10% of CaO, 1%-5% of Al2O3, 0-5% of B2O3 and 1%-3% of Fe2O3. The glass powder prepared through the method is high in TK-100 temperature, good in insulating property, capable ofmeeting the requirement for high-pressure resistance, good in water-resistant chemical stability and good in weather resistance, and can meet the performance requirement for glass and metal sealing materials with the requirement for high reliability, such as air conditioners, refrigerator compressor binding post products and the like.

Owner:BEIJNG ASAHI ELECTRONICS MATERIAL CO LTD

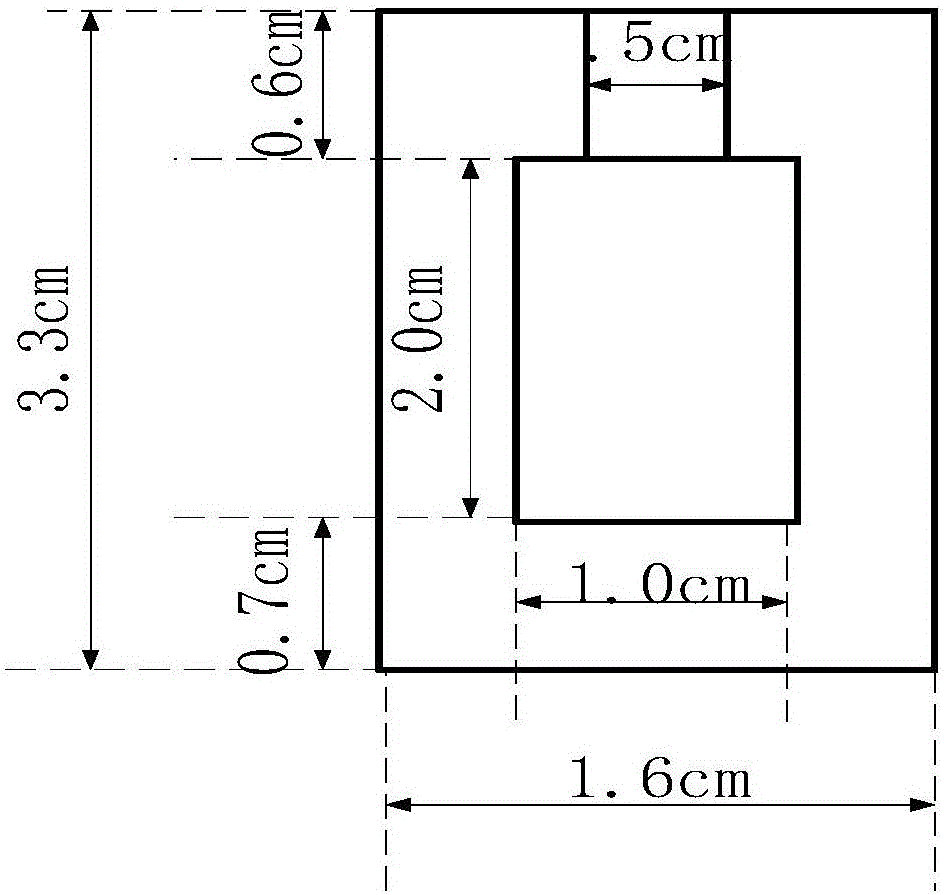

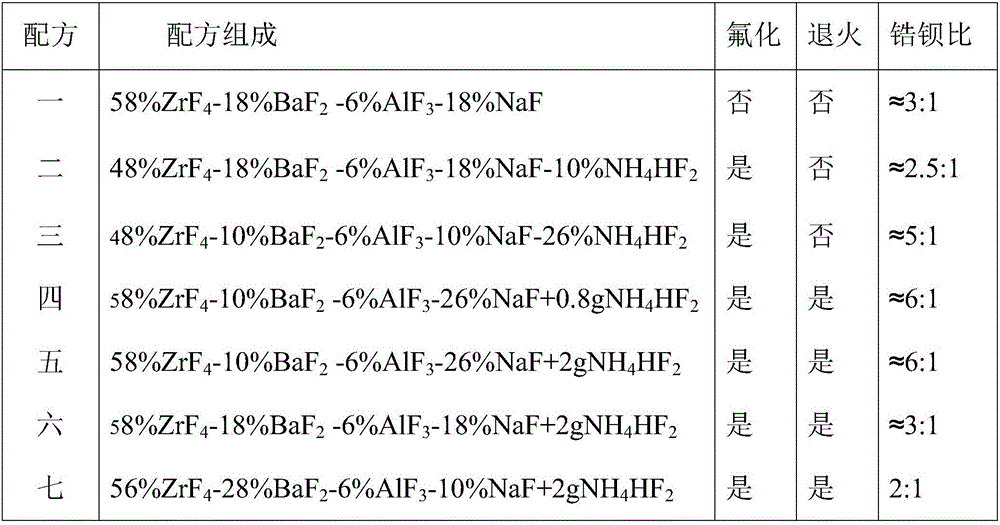

Low-cost ZBAN quaternary system fluoride optical glass and preparation method thereof

The invention discloses low-cost ZBAN quaternary system fluoride optical glass and a preparation method thereof. The glass provided by the invention is prepared from quaternary fluoride systems ZrF4, BaF2, AlF3 and NaF; good ventilation characteristics are realized in near-infrared to medium infrared waveband; the fluoride glass transmission rate at the 4 to 6 mum waveband can reach 60 percent. The invention also provides the preparation method of the glass. The preparation method mainly comprises modified melting, shaping and annealing processes. The glass and the preparation method are based on simple preparation conditions; the drying and oxygen-free environment in the raw material melting process is ingeniously realized through methods of low-temperature fluorination and the like; the experiment cost is reduced; the requirements on experiment requirements is reduced; the process is simple; the material cost is low; the optical glass cost is greatly reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Special anti-blocking agent for ammonium sulfate as well as preparation method and application thereof

ActiveCN108264412ALow costEasy to useAmmonium salt fertilisersLayered/coated fertilisersWater solubleFilm-forming agent

The invention provides a special anti-blocking agent for ammonium sulfate as well as a preparation method and application thereof. The anti-blocking agent is a water-soluble liquid anti-blocking agent, and is concretely prepared from 20 to 50 percent of water, 10 to 30 percent of volatile solvents, 20 to 40 percent of film-forming agents, at most 10 percent of habit modifiers, at most 10 percent of surfactants, at most 10 percent of crystal control agents and at most 3 percent of antifoaming agents. The special anti-blocking agent effectively overcomes the use defect of the oil and tablet anti-blocking agent; the anti-blocking effect is improved; meanwhile, the surface whitening, powdering and mildewing phenomenon of ammonium sulfate fertilizers can be effectively reduced; the preparationprocess is simple; the efficiency is high; the use is convenient; the special anti-blocking agent is suitable for industrialized preparation and is favorable for popularization and application.

Owner:北京尧之龙科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com