Glass substrate for display device and method for manufacturing same

A technology for glass substrates and displays, applied in the field of glass substrates for oxide semiconductor thin film transistors) displays, glass substrates for displays and its manufacture, glass substrates for flat panel displays, low temperature polysilicon thin film transistors) glass substrates for displays, and can solve problems , heat shrinkage reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

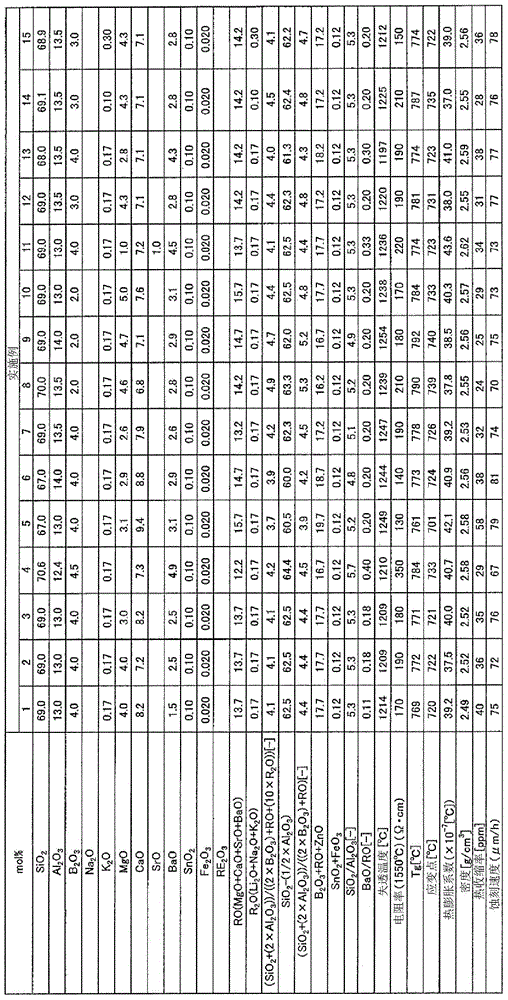

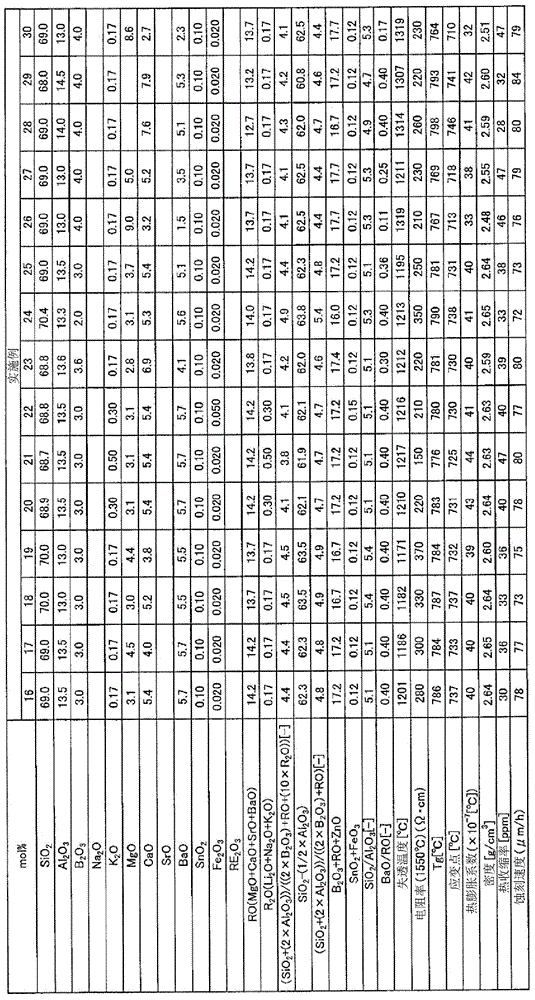

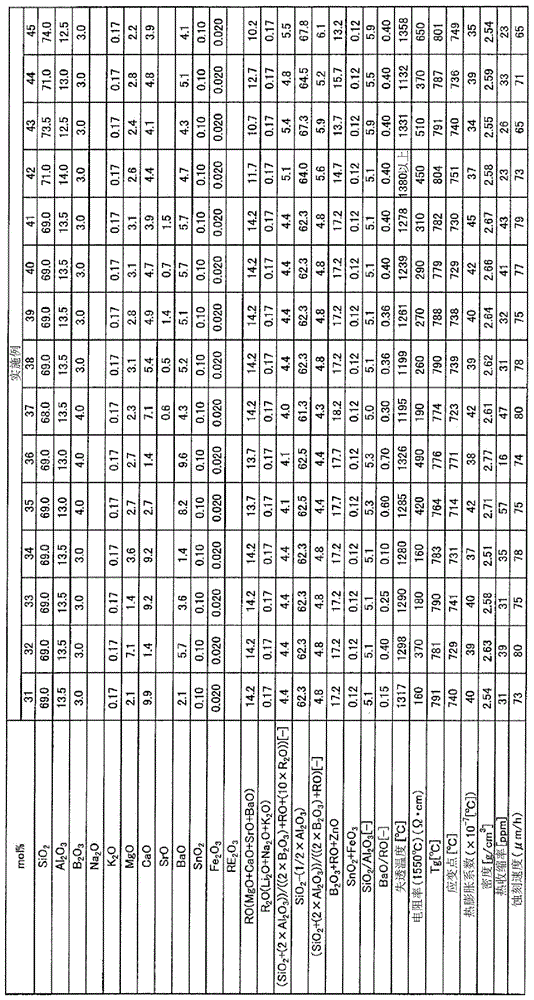

[0352] Hereinafter, this embodiment will be described in more detail based on examples. However, this embodiment is not limited to the Examples. In the following examples and comparative examples, the physical properties described below were measured.

[0353] (strain point)

[0354] The measurement was performed using a beam bending measuring device (manufactured by Tokyo Industrial Co., Ltd.), and the strain point was obtained by calculation in accordance with the beam bending method (ASTMC-598).

[0355] (devitrification temperature)

[0356] The glass was pulverized, and the glass pellets passed through the 2380 μm sieve and remained on the 1000 μm sieve were added to the platinum boat. This platinum boat was held in an electric furnace having a temperature gradient of 1050 to 1380° C. for 5 hours, then taken out from the furnace, and devitrification generated inside the glass was observed with a 50-power optical microscope. The highest temperature at which devitrifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Strain point | aaaaa | aaaaa |

| Strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com