Patents

Literature

277results about How to "Avoid blackening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

solid state imaging device

InactiveCN102300058AAvoid blackeningBlackening phenomenon correctionTelevision system detailsColor television detailsOutput compareEngineering

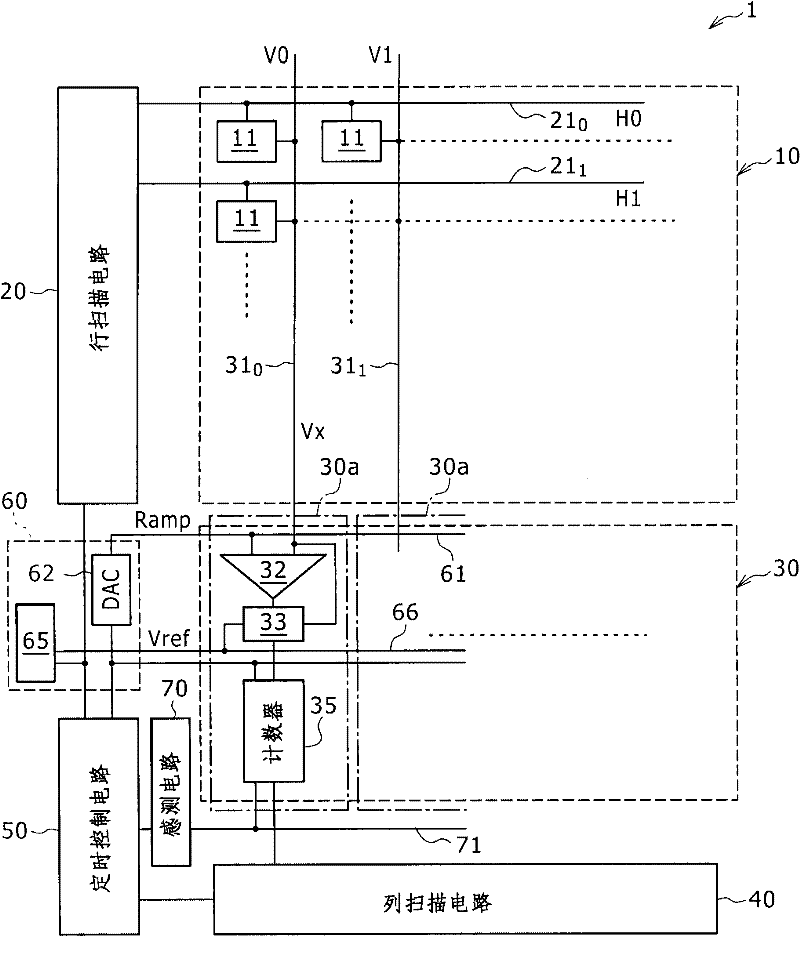

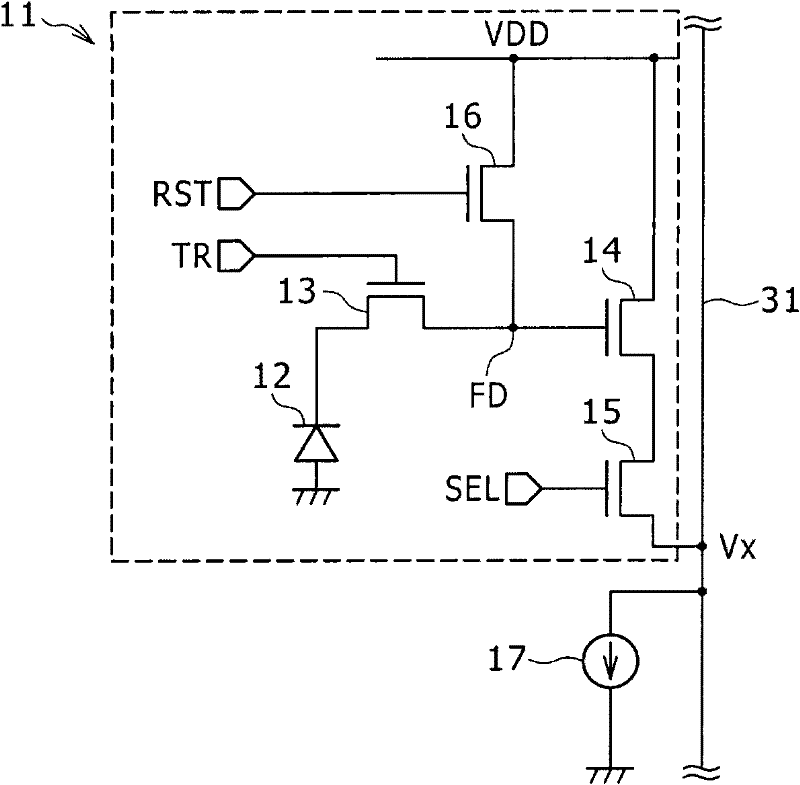

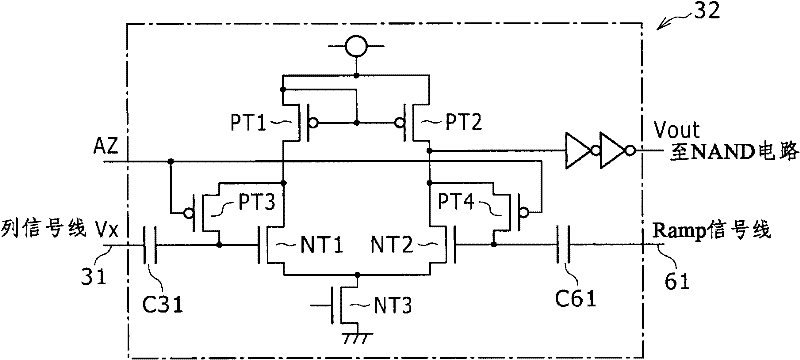

The present invention provides a solid-state imaging device including: a comparison section that compares a pixel signal from a pixel with a ramp signal and outputs a comparison signal; a measurement section that starts counting in synchronization with the ramp signal, and is supplied to Counting is continued until the signal of the measuring section is reversed to measure the comparison time; the comparator output control section, which is located between the output of the comparing section and the input of the measuring section, if when counting is started, the pixel signal value exceeds The predetermined value determined by the phenomenon, then when the comparison signal is supplied to the measurement part to invert the comparison signal, the comparator output control part stops counting, however, if the pixel signal value does not exceed the predetermined value, it will The non-inverted signal is supplied to the measurement part to continue counting during the measurement period. This solid-state imaging device can correct the blackening phenomenon with a small-scale circuit configuration.

Owner:SONY CORP

Transparent protective coat for concrete

The invention belongs to the technical field of anticorrosive materials and discloses a transparent protective coat for concrete. According to a three-layer matched scheme of a combined action principle of physical shielding and chemical sealing, the transparent protective coat for concrete comprises a base coat, a floating coat and a topcoat, wherein the base coat is alkyl alkoxy silane, the floating coat is a cationic acrylic polymer emulsion film-forming system; the topcoat is a water-based fluorocarbon resin and polyurethane associative thickener system with pH value of 8-9; the content of the water-based fluorocarbon resin is not less than 20%; the minimum film-forming temperature is not less than 27 DEG C. The transparent protective coat for the concrete has high permeability and excellent sealing property for the concrete, is simple and convenient to construct, transparent in coating and excellent in stain resistance, avoids water dampness and discoloration of the concrete, inhibits nonuniform absorption of the concrete, effectively prevents the concrete surface from blackening, keeps the natural surface effect of the concrete, and is suitable for the protection and application field of various reinforced concrete structures.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Method for producing organic solderability preservative on surface of circuit board

InactiveCN104918417AModerate roughnessUniform colorNon-metallic protective coating applicationOrganic filmEtching

The invention belongs to the circuit board production technical field and relates to a method for producing an organic solderability preservative on the surface of a circuit board. According to the method of the invention, sand blasting and board grinding procedures are omitted in a pretreatment process, and technological parameters of pickling and micro-etching are adjusted, and therefore, the problem of the smash of fine sands onto a board surface and the problem of high roughness and unevenness of a copper surface when a grinding brush is adopted to perform board grinding can be solved, and the roughness of the copper surface of the circuit board can be moderate and uniform, and the thickness of a formed organic film can be basically consistent with the thickness of etched copper; the circuit board is arranged in an antioxidant cylinder before the production of the organic film, a cylinder dragging plate is adopted to perform cylinder dragging processing at first, so that impurities in an antioxidant solution can be removed, and production parameters can be stabilized, and the concentration of Cu<2+> in the solution is controlled below 15ppm, and therefore, the organic film can be effectively prevented from blackening or color difference of the organic film can be effectively prevented, and yield can be improved; technological methods and parameters in various links are modified, and optimal parameter combinations can be explored, and therefore, the color of the organic film formed on the copper surface can be uniform.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

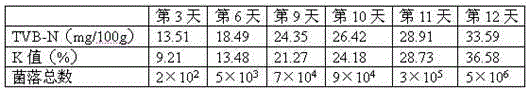

Shrimp fresh-keeping agent and shrimp fresh-keeping method

InactiveCN101991177AKeep umamiMaintain qualityClimate change adaptationFood preservationAcetic acidPhytic acid

The invention discloses a shrimp fresh-keeping agent and a shrimp fresh-keeping method. The shrimp fresh-keeping agent comprises chitosan, phytic acid, ethylenediamine tetracetic acid nucleotide and 4-hexylresorcinol, and can effectively inhibit the occurrence of melanism in the shrimp refrigeration process. The shrimp fresh-keeping method comprises the following steps of: selecting and cleaning raw material shrimps; soaking the shrimps with the fresh-keeping agent; then, draining water; packing the shrimps by adopting a modified atmosphere package manner; and finally, storing the shrimps under the ice temperature condition. The method effectively prevents the melanism of the fresh shrimps, can prolong the fresh-keeping period of the shrimps, can reduce the loss of the nutrient content and ensure the quality of the shrimps.

Owner:FUJIAN XINHUADONG FOODS

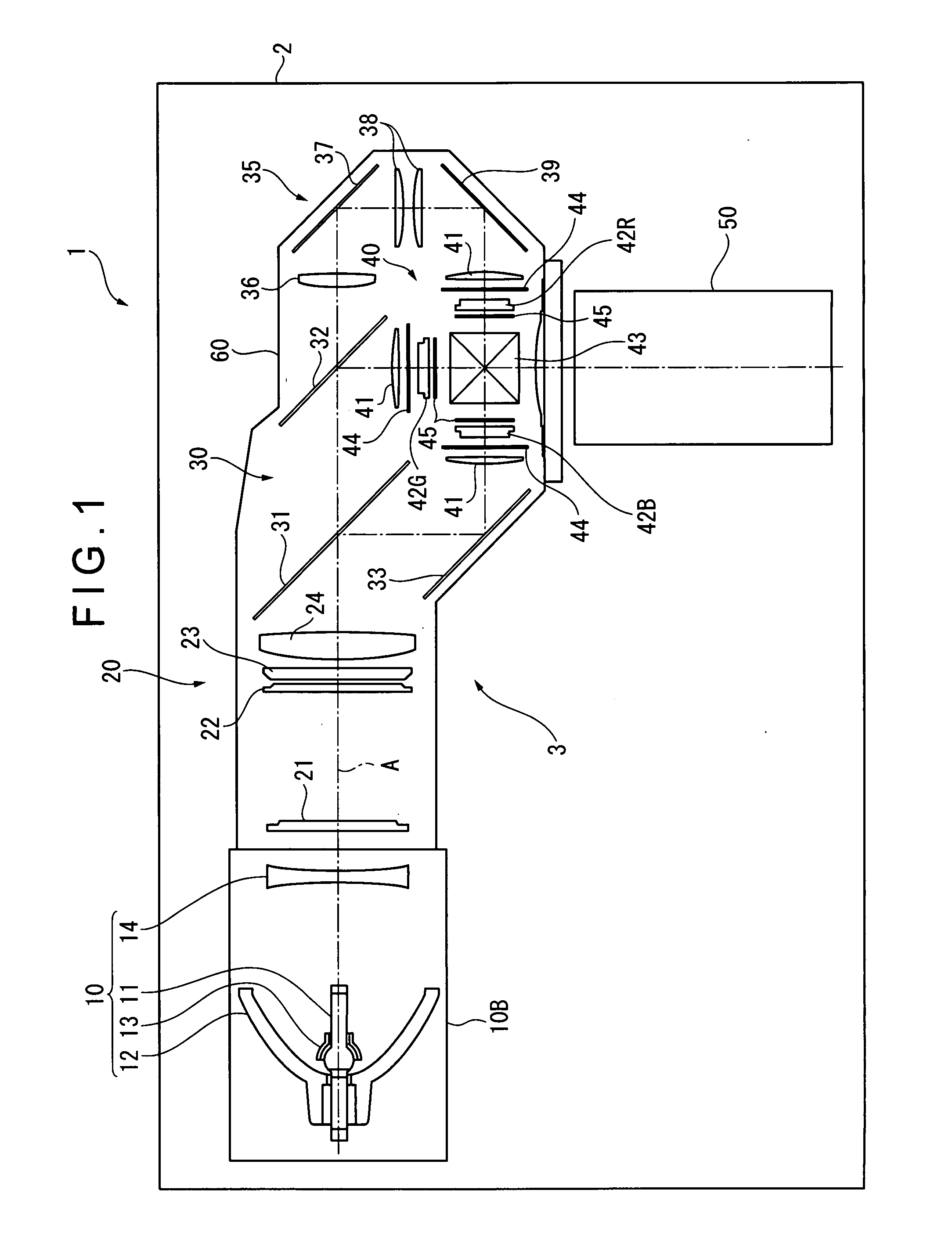

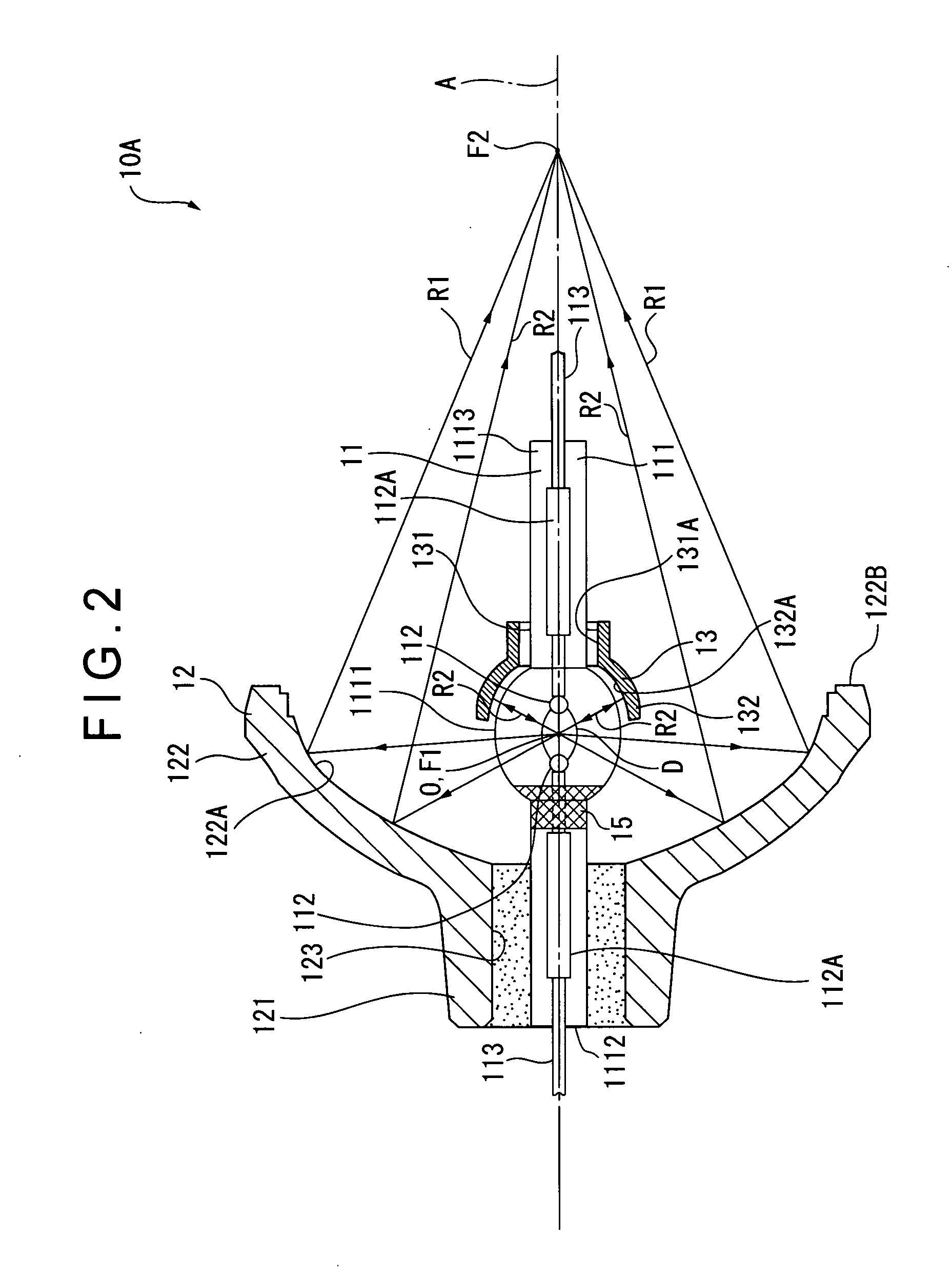

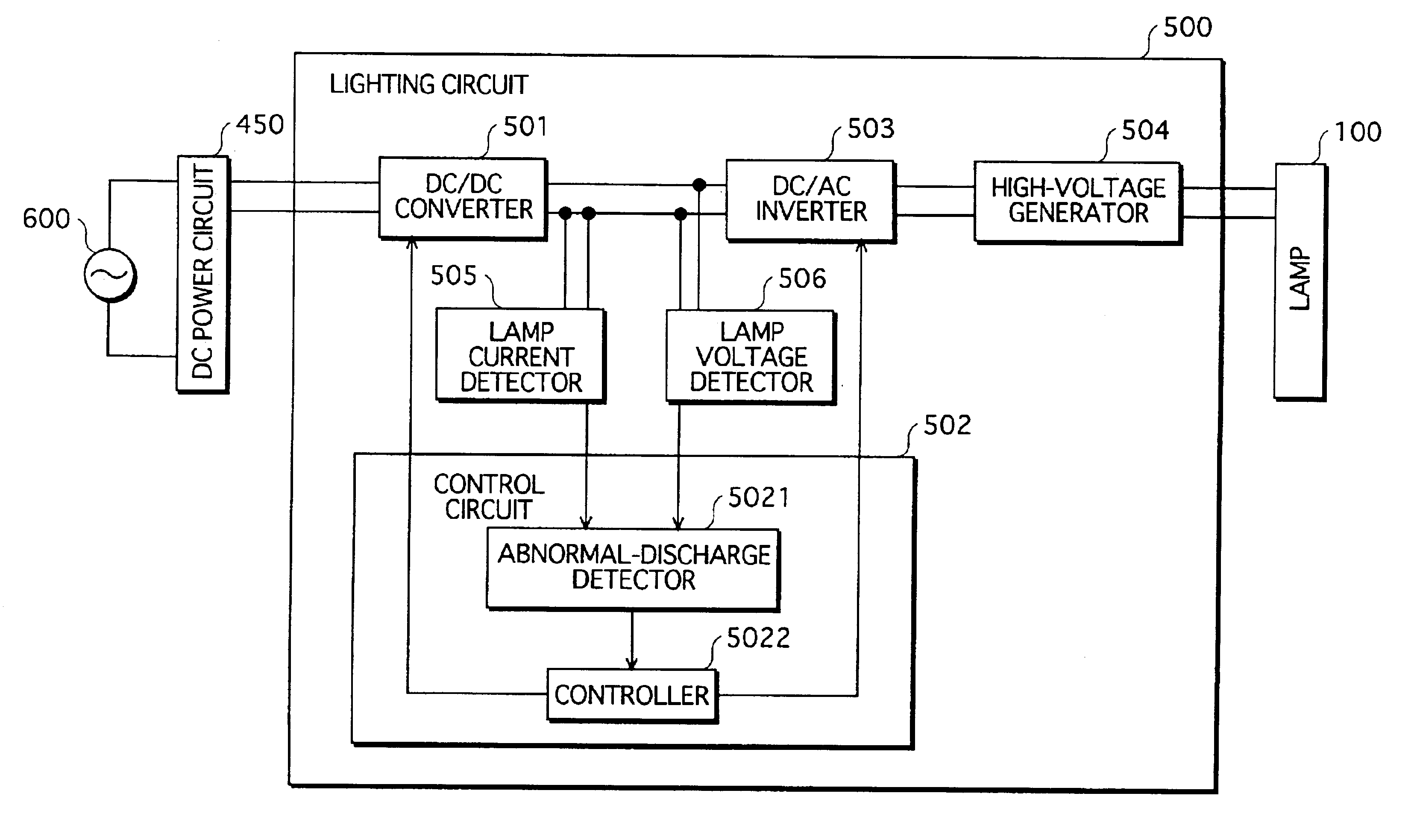

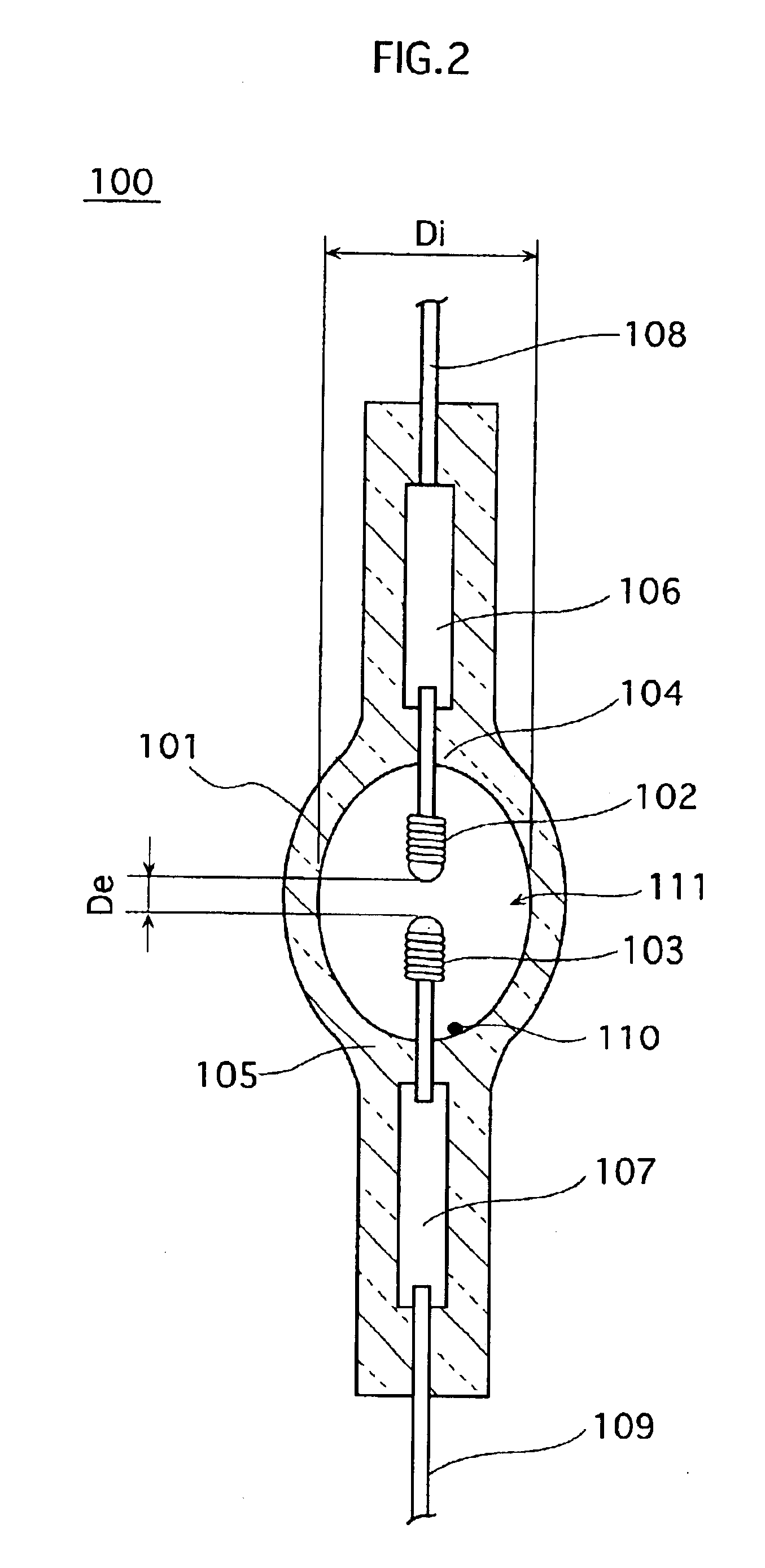

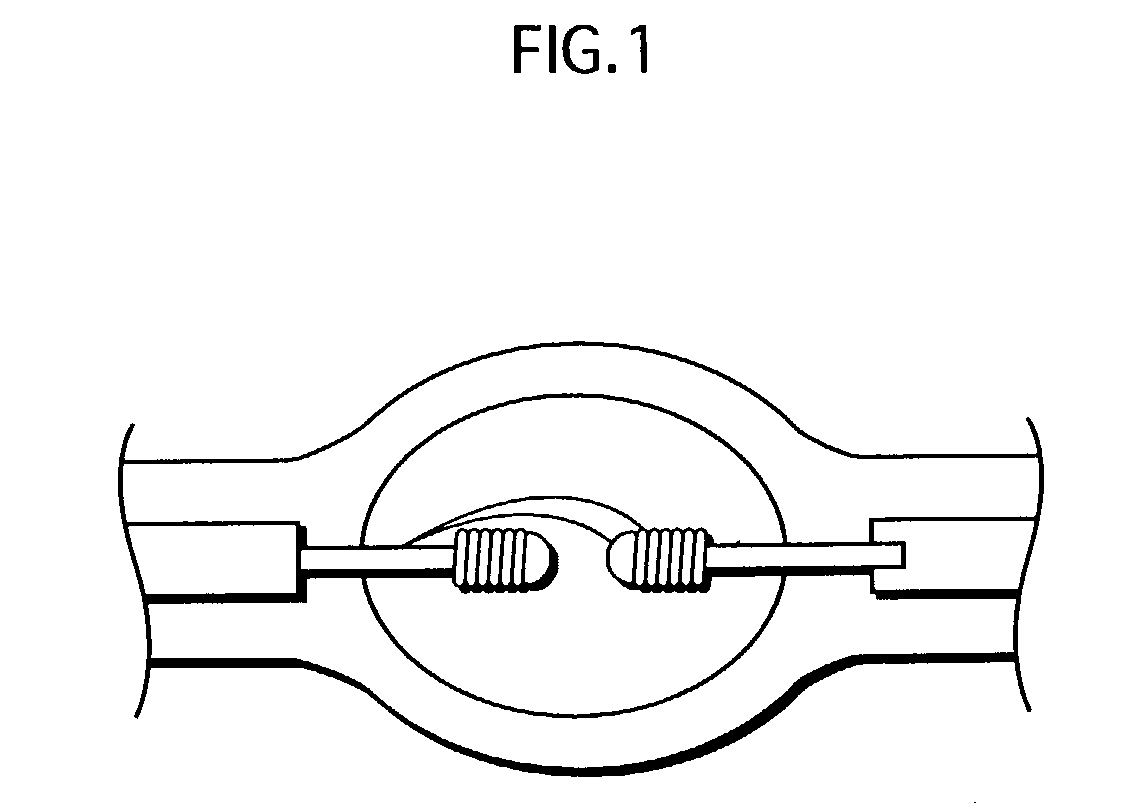

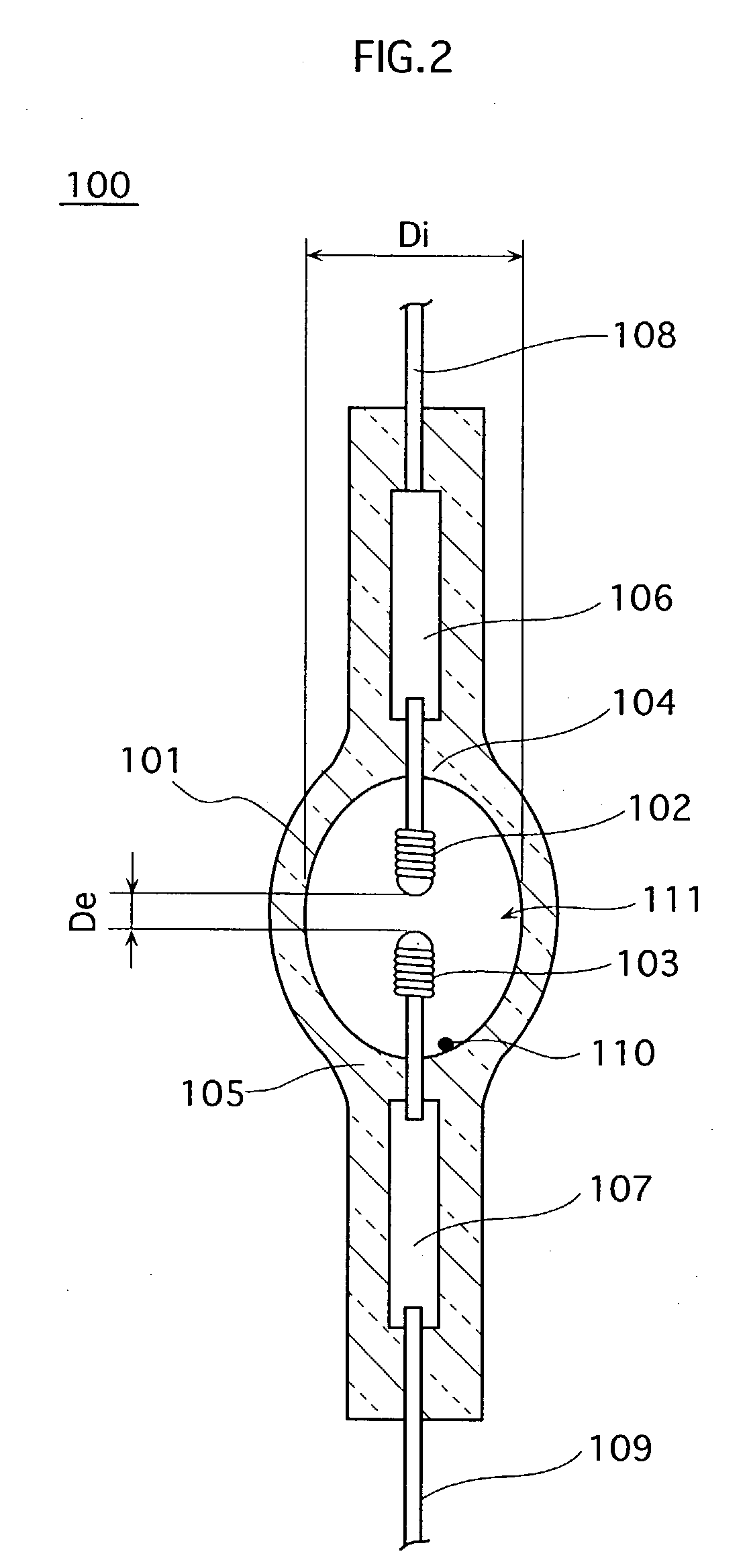

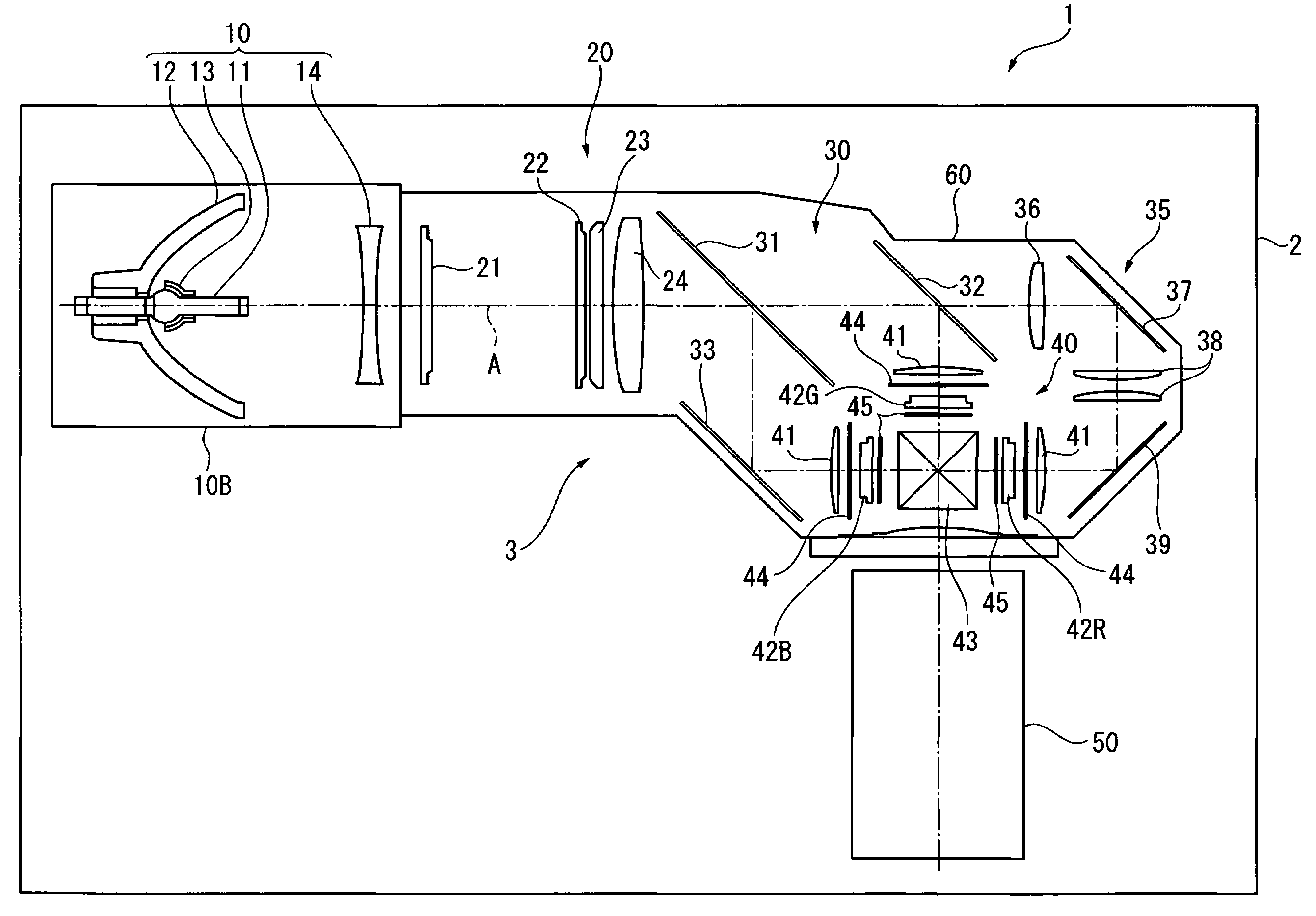

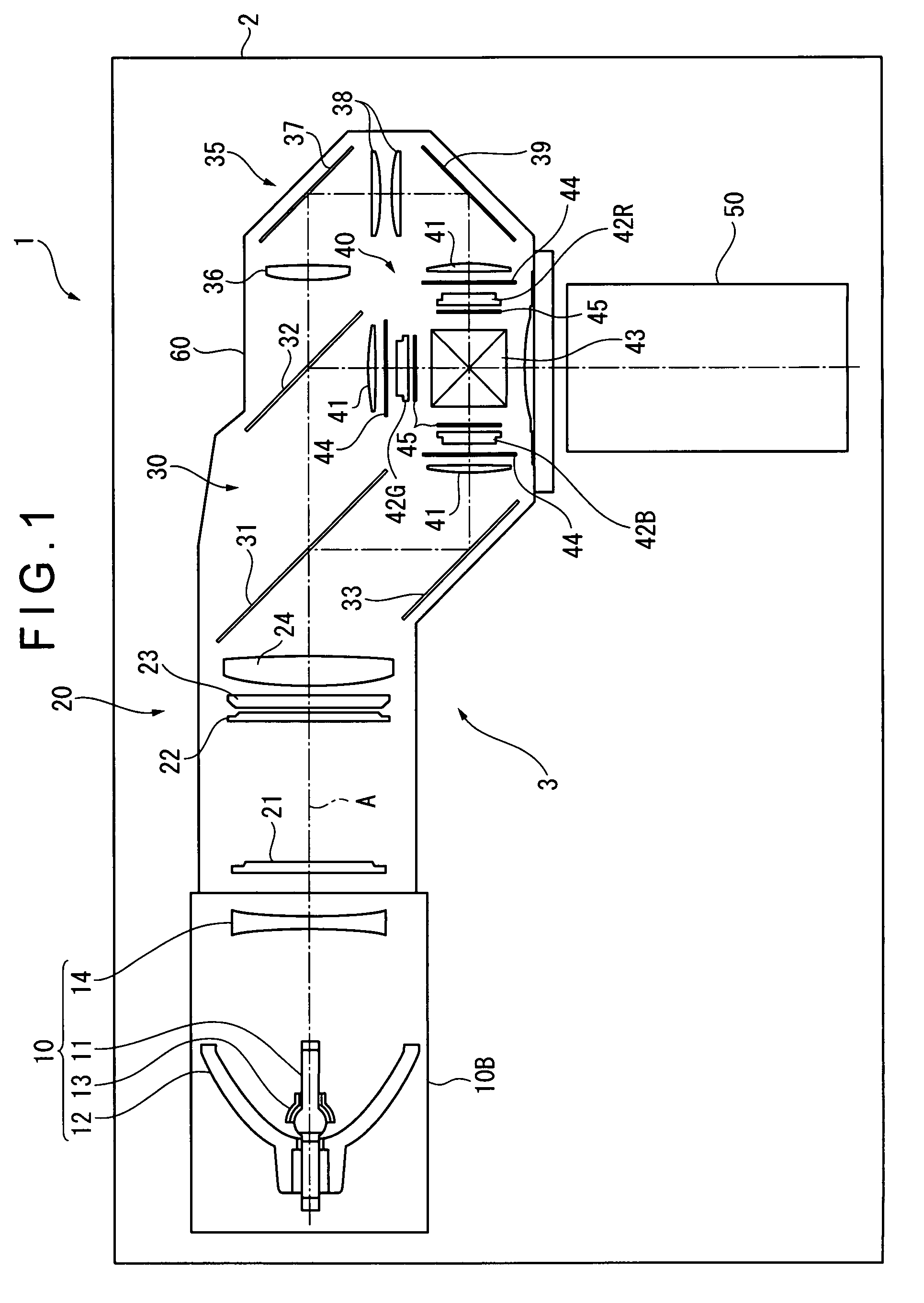

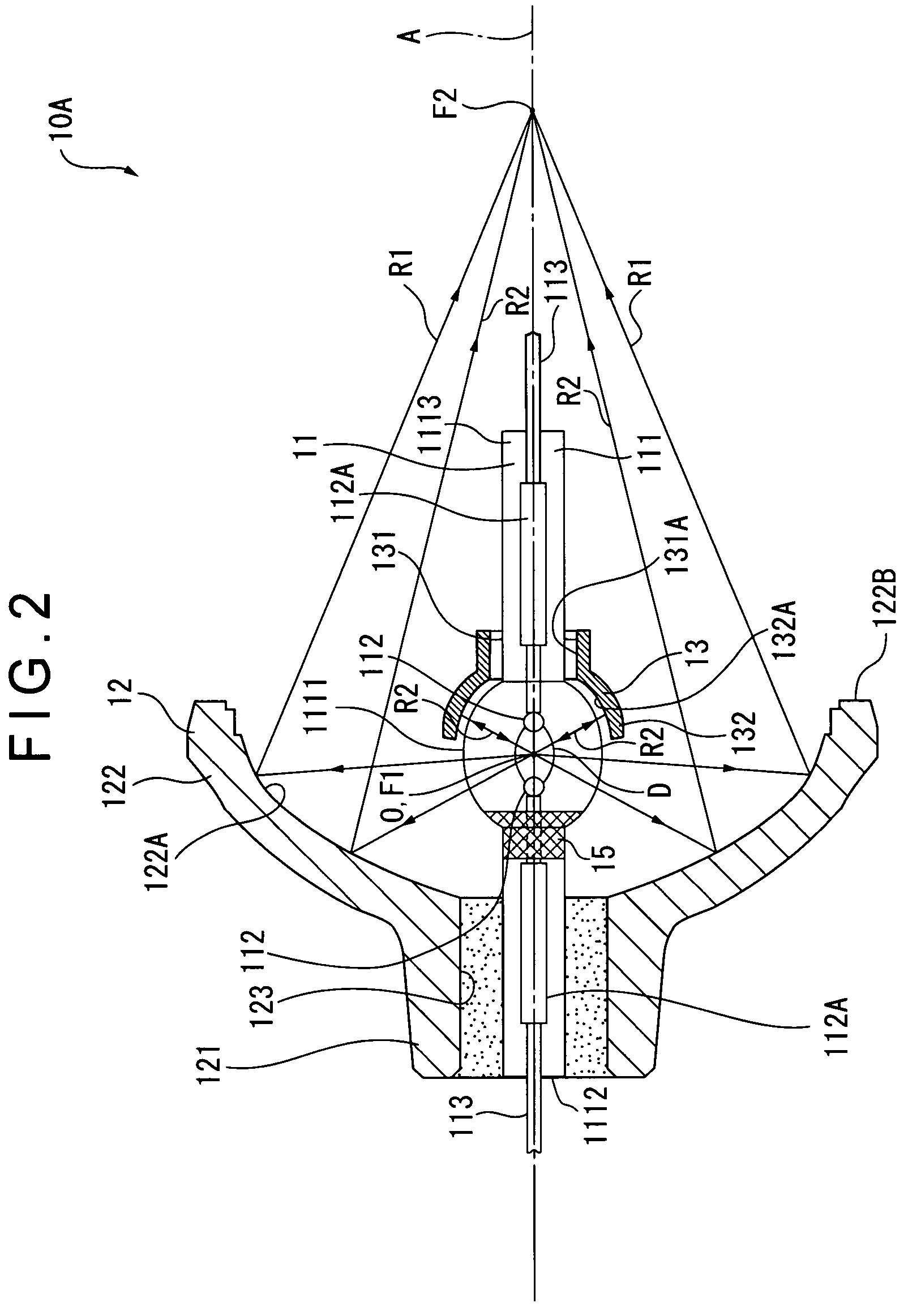

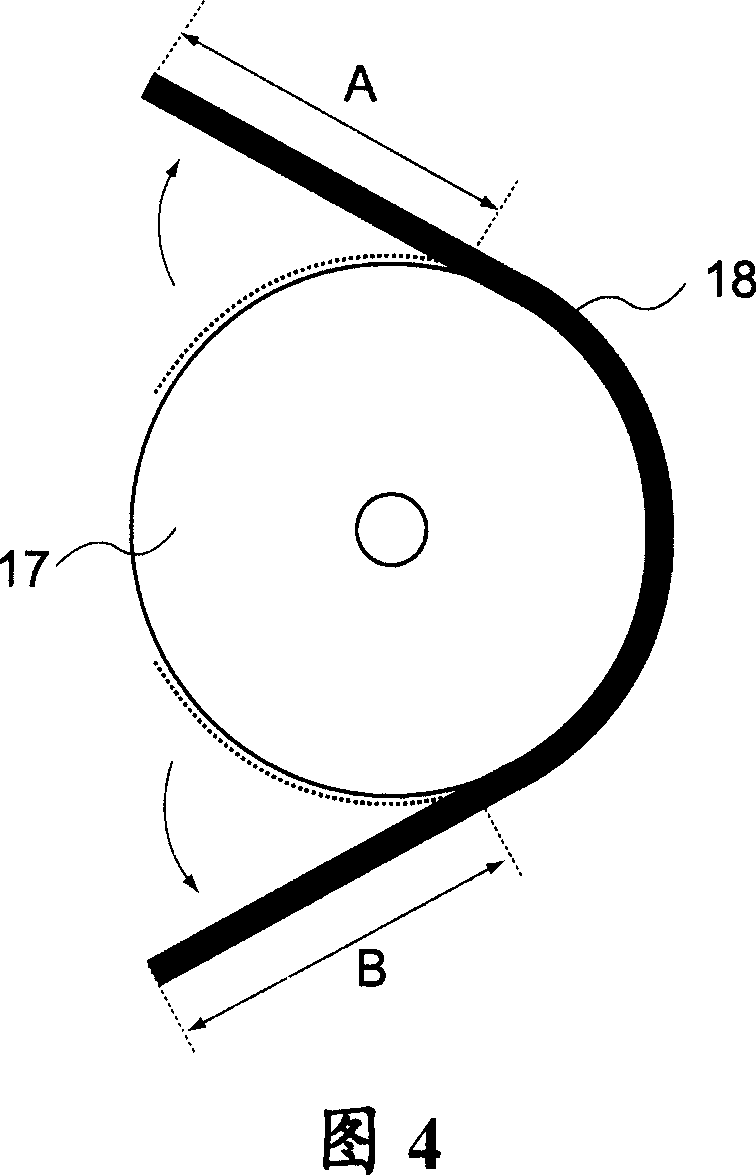

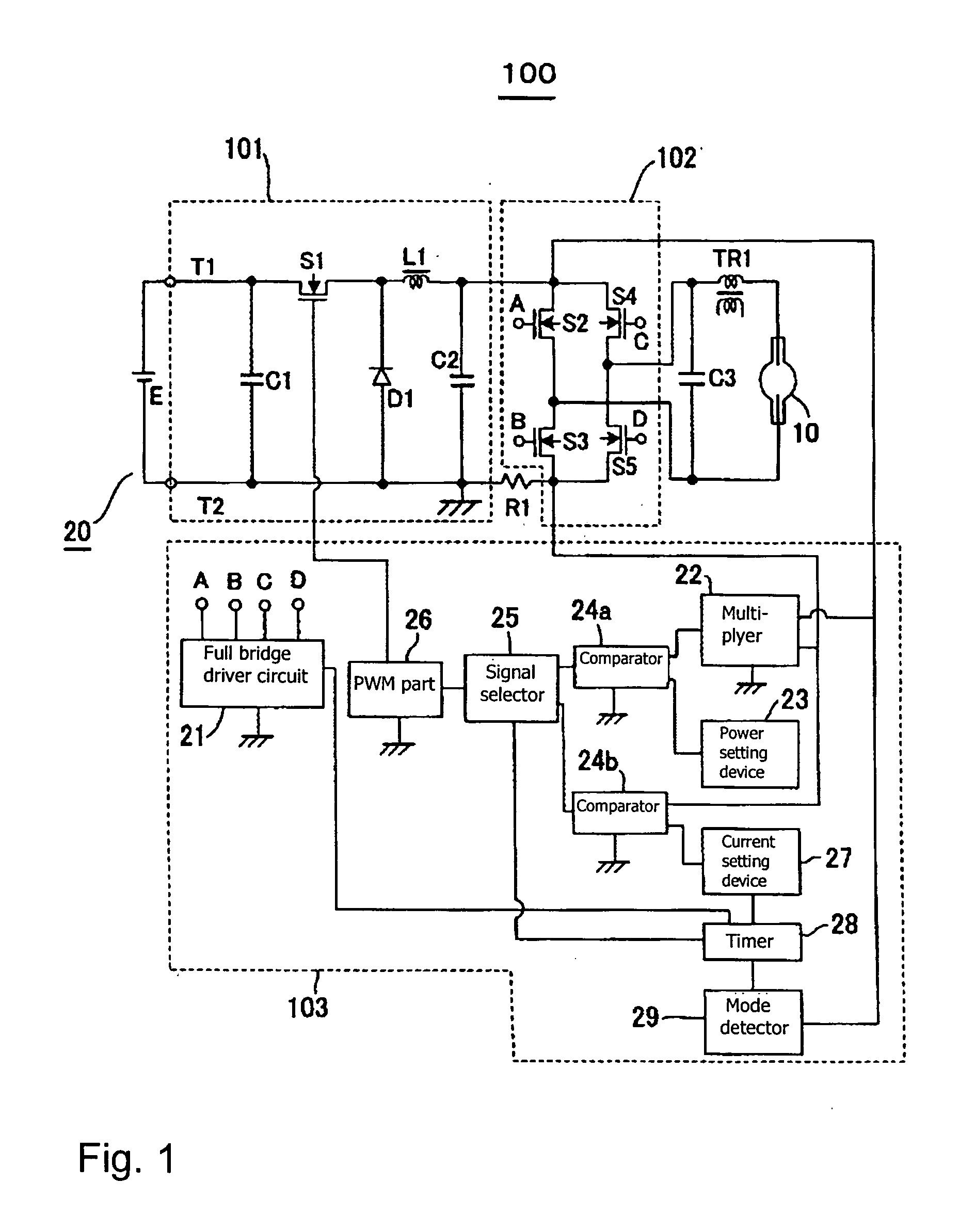

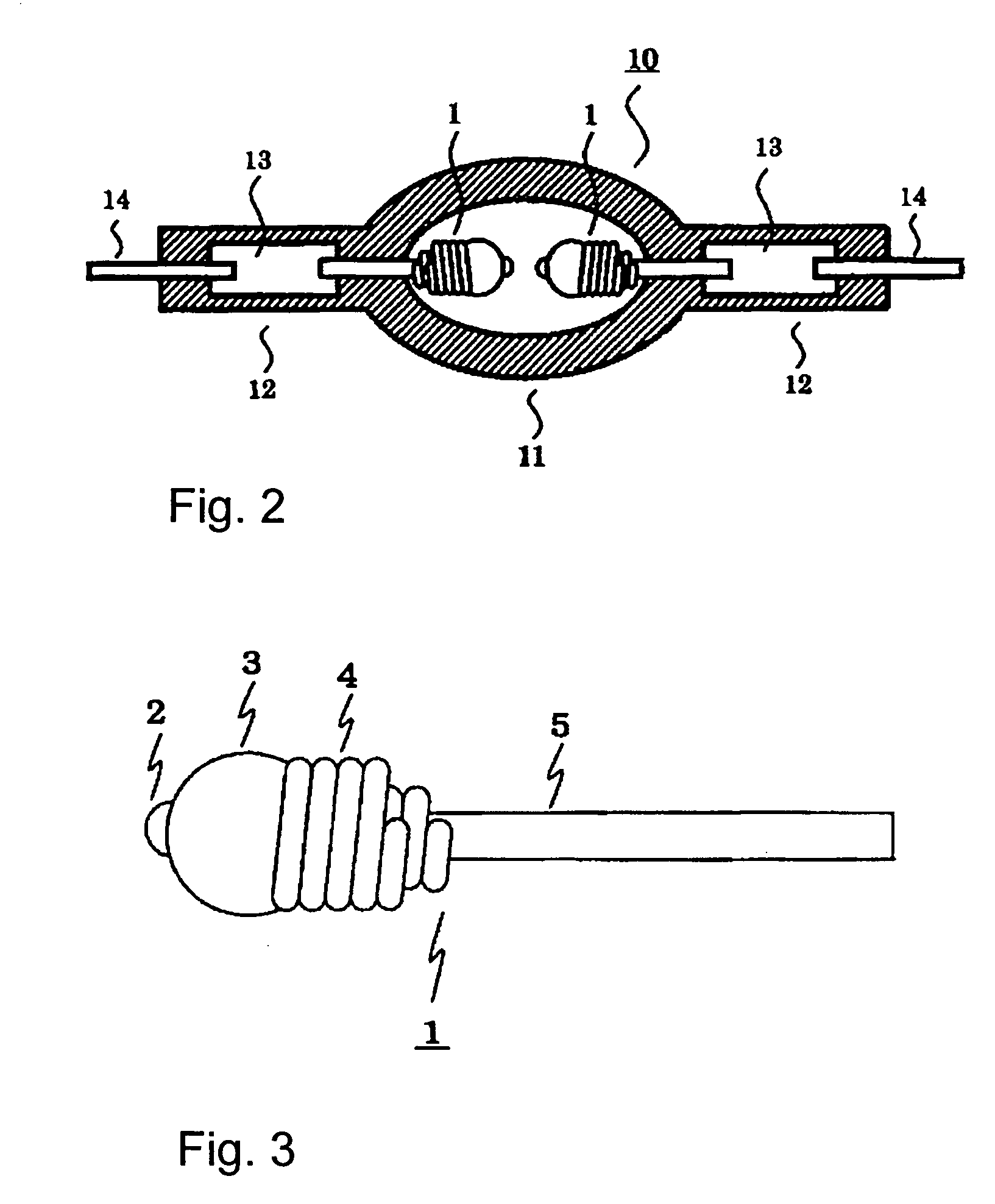

Light source device and projector

InactiveUS20070189016A1Prolong lifeReducing bias of temperature distributionTelevision system detailsPoint-like light sourceLight beamOptoelectronics

A light source device includes: a light source lamp having a light-emitting tube with a discharge space and a pair of electrodes disposed in the discharge space of the light-emitting tube; a reflector extending in a substantially concave shape in section, the reflector reflecting a light beam irradiated from the light source lamp; and a sub-reflection mirror having a reflection surface that is disposed to face a reflection surface of the reflector, the sub-reflection mirror reflecting a part of the light beam irradiated from the light source lamp toward the discharge space. The light-emitting tube has a light-emitting section having the discharge space therein and sealing sections provided on both sides of the light-emitting section. The sub-reflection mirror is formed in a shape of a bowl that covers the light-emitting section of the light-emitting tube, the sub-reflection mirror having an opening for mounting the sub-reflection mirror to the light-emitting tube by allowing one of the sealing sections of the light-emitting tube to be inserted thereinto. A heat insulating member is provided to at least a part of the light-emitting section and the other one of the sealing sections of the light-emitting tube.

Owner:SEIKO EPSON CORP

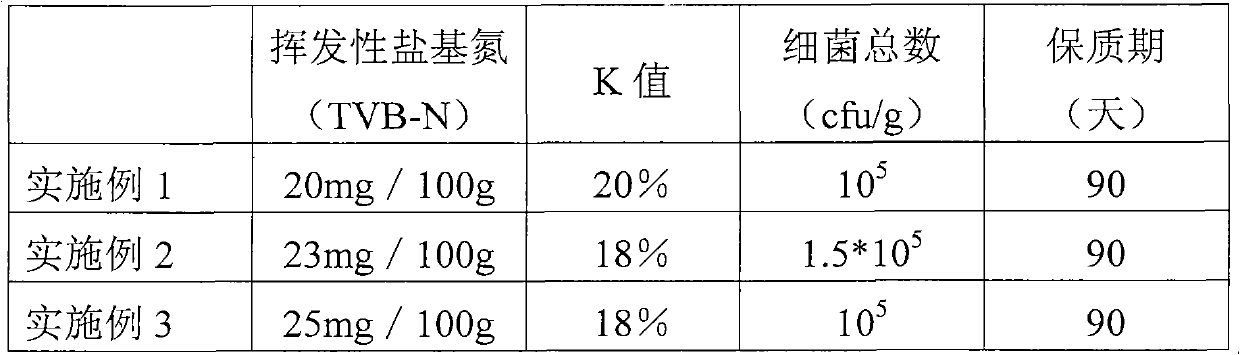

Refreshing agent and method for inhibiting blackening of prawns

The invention provides a refreshing agent and method for inhibiting blackening of prawns. The refreshing agent comprises ergothioneine, kelp polyphenols, laminarin, and glacial acetic acid. The refreshing method comprises the following steps: extracting kelp polyphenols and laminarin; then adding ergothioneine, the extracted kelp polyphenols and the extracted laminarin to deionized water; uniformly agitating; and then adding glacial acetic acid to obtain the refreshing agent, wherein the prepared refreshing agent comprises 0.2 to 0.9% of ergothioneine in mass percent concentration, 0.3 to 0.9% of kelp polyphenols in mass percent concentration, 0.3 to 1% of laminarin in mass percent concentration, and 0.6 to 1% of glacial acetic acid in mass percent concentration. The refreshing agent is used for refreshing prawns. The refreshing method has the advantages of being few in steps and convenient in operation; the refreshing agent can remain the original color and luster of the prawns, shows a good blackening inhibiting effect and great antibacterial effect, keeps the prawns fresh, and also can prolong the shelf life of prawn products.

Owner:BOHAI UNIV

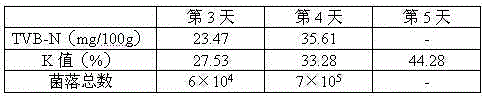

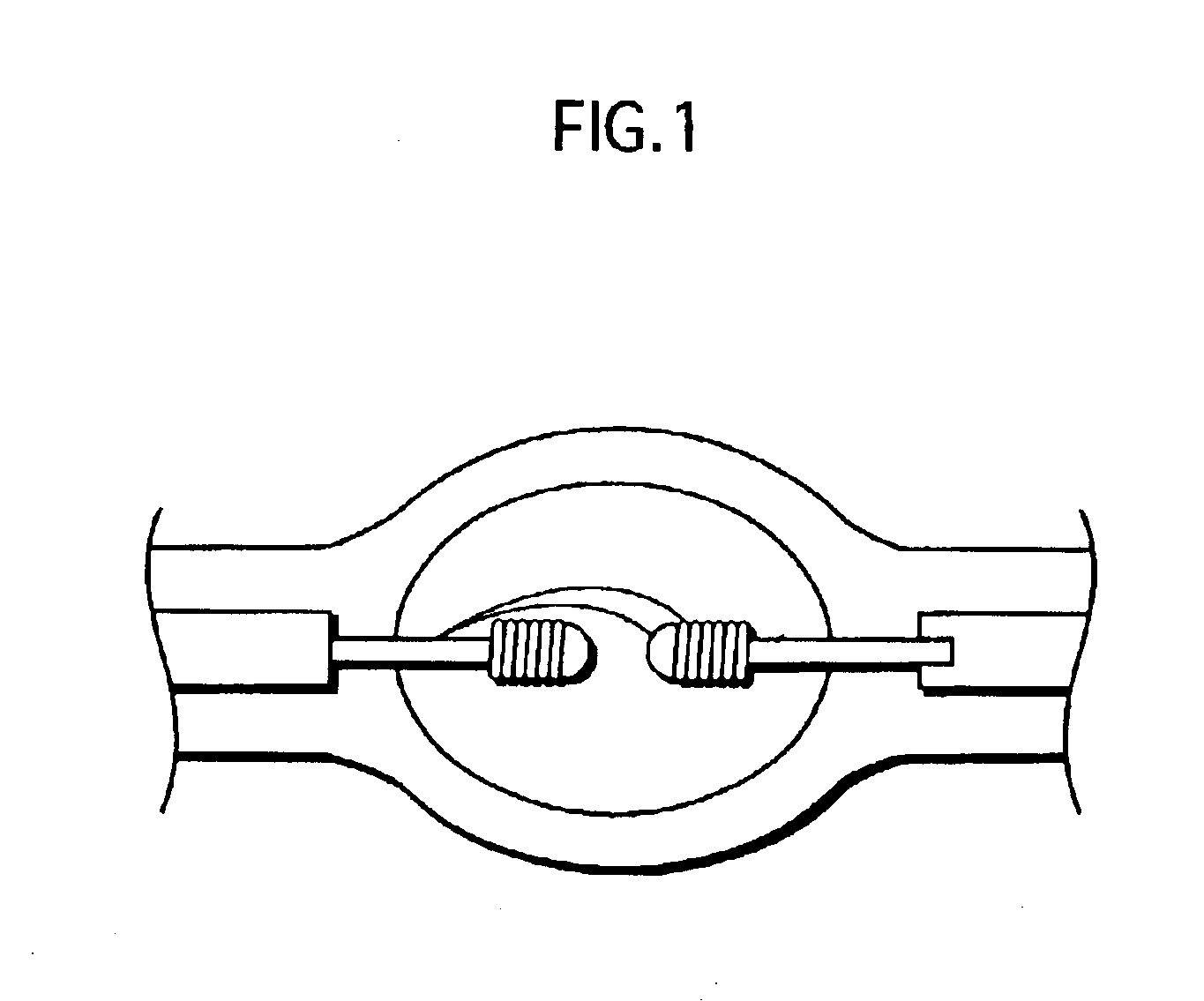

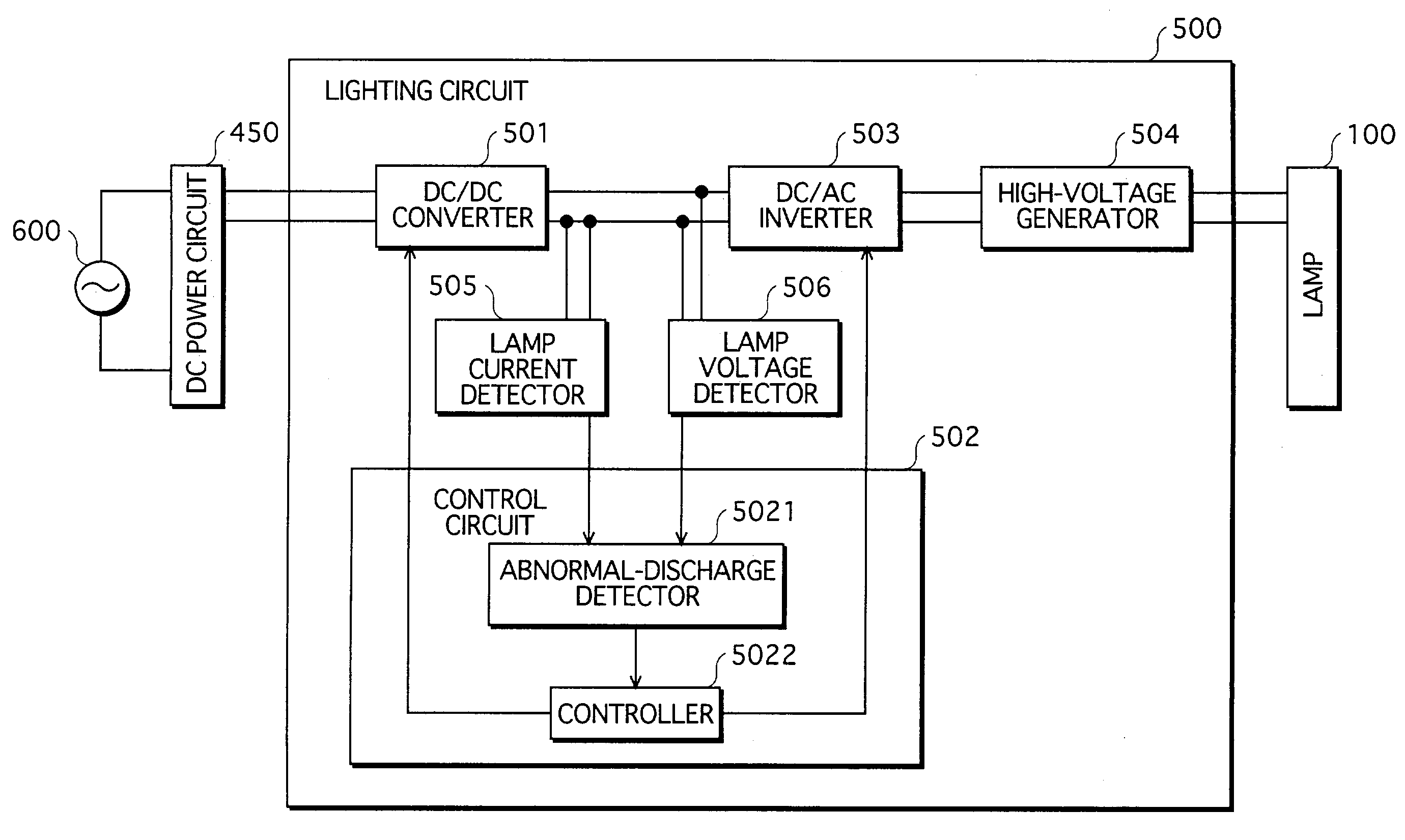

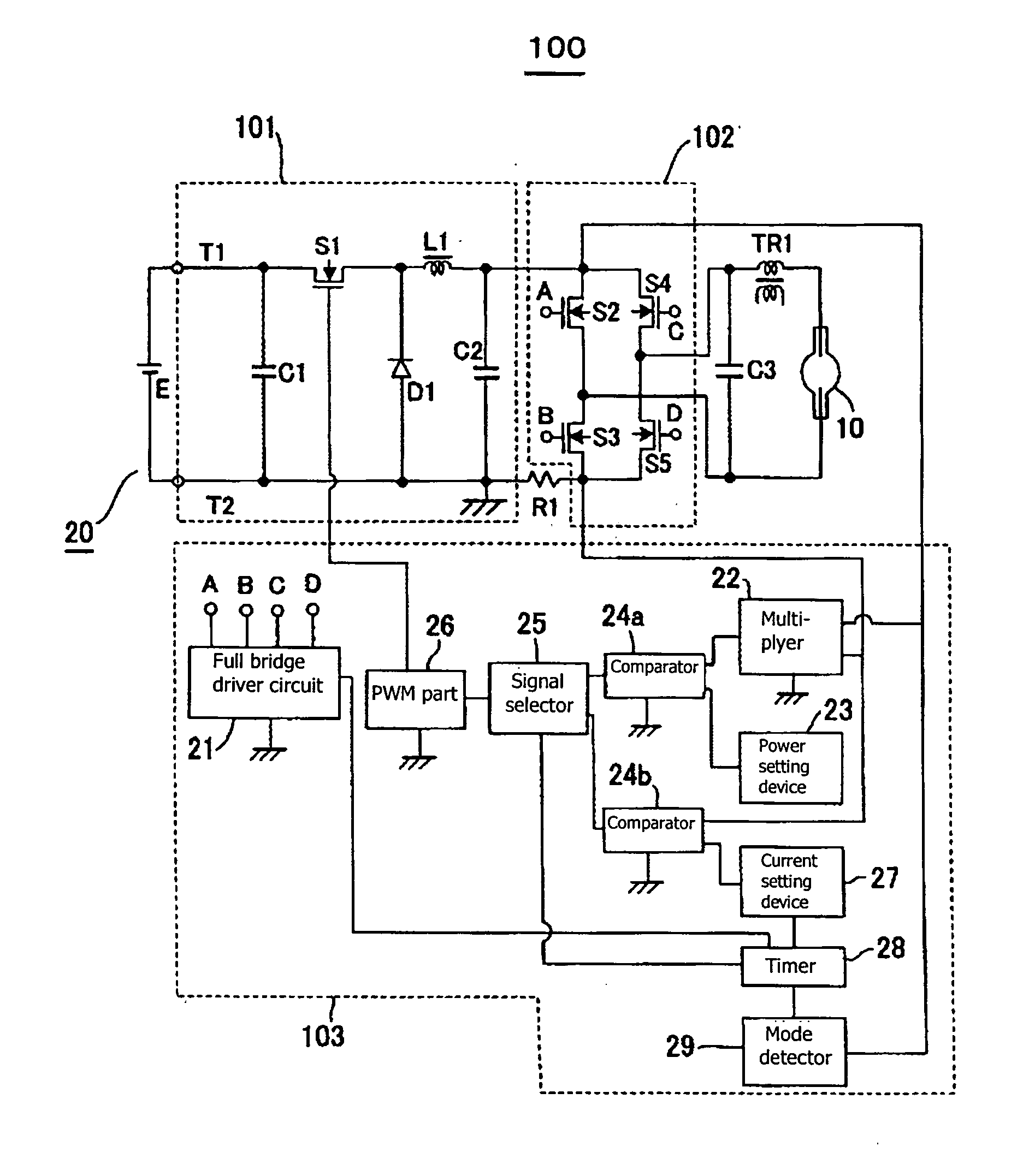

Lighting method and apparatus for high-pressure discharge lamp, and high-pressure discharge lamp apparatus

InactiveUS6794832B2Avoid blackeningTotal current dropElectric light circuit arrangementGas discharge lamp usageEffect lightEngineering

Disclosed are a lighting method for a high-pressure discharge lamp, a lighting apparatus for a high-pressure discharge lamp, and a high-pressure discharge lamp apparatus each suppresses abnormal blackening of a discharge tube that may occur at an initial stage of operation from a discharge start. According to the lighting method of the present invention, the lamp current is reduced upon detection, by an abnormal discharge detector 5021, of an abnormal discharge that is produced between a tip of one electrode and a root of the other electrode.

Owner:PANASONIC CORP

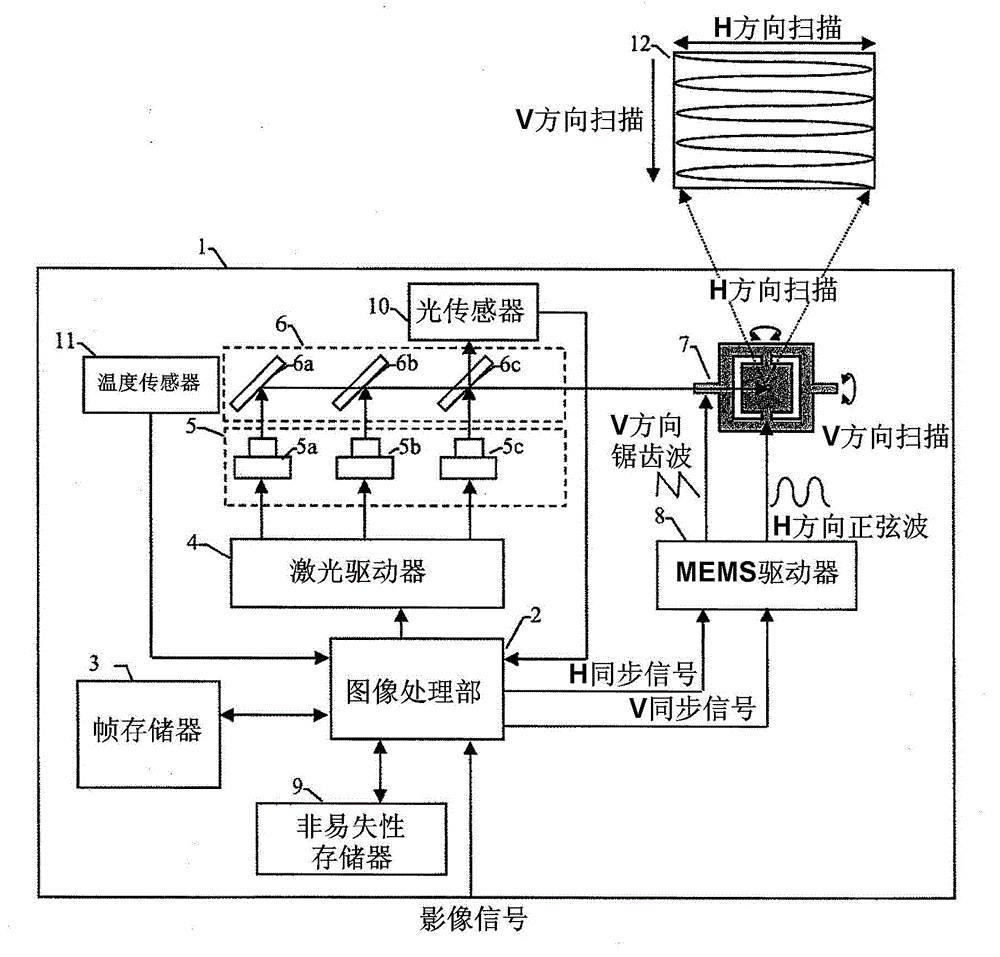

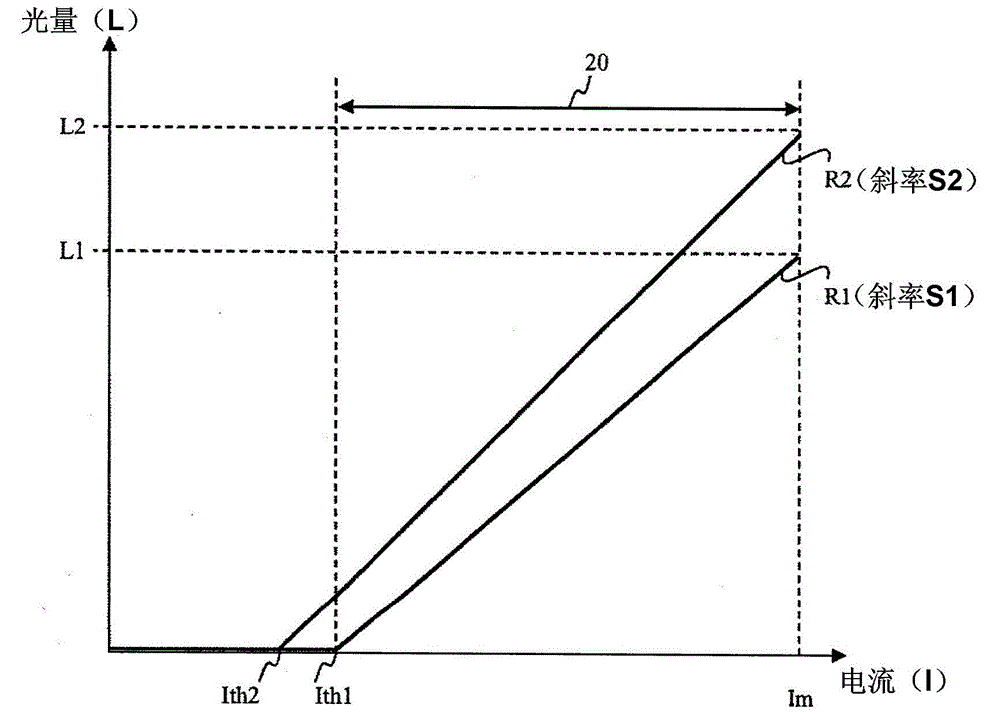

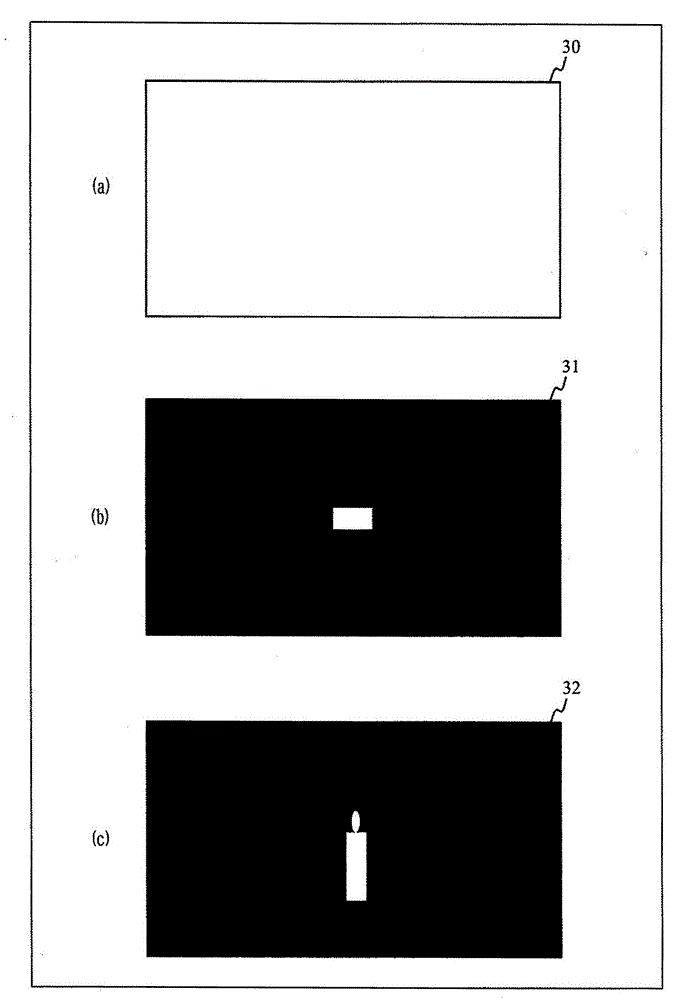

Laser projection display device and laser drive control method

ActiveCN104038747AAvoid blackeningQuality improvementPicture reproducers using projection devicesCathode-ray tube indicatorsDisplay deviceLaser scanning

A laser projection display device includes: a laser light source drive unit; an attribute amount detection unit for detecting the attribute amount of a picture signal; a light sensor for measuring the light amounts of the laser light sources; and a temperature sensor for measuring the temperatures of the laser light sources. The laser projection display device is configured so that the current vs. light amount output characteristics of the laser light sources with a threshold current and current gain as a parameter are corrected in accordance with the load amount of the picture signal per frame if the change of the attribute amount exceeds a predefined amount; the light sources are driven at a predefined timing of the vertical blanking interval; controls the threshold currents and current gains in accordance with the light amounts; and the threshold currents and current gains are corrected on the basis of the measured temperatures.

Owner:HITACHI-LG DATA STORAGE

Method for using alga polyphenol to prevent blackening of seawater shrimps

The invention relates to a method for using alga polyphenol to prevent blackening of seawater shrimps, and the method comprises steps of: 1, selecting fresh algae, washing and draining the algae, and smashing the algae to slurry by a tissue homogenizer for standby; 2, using ethanol with concentration of 80-90% to blend the slurry and the ethanol uniformly to prepare a material liquid, according to the ratio of the slurry to the ethanol being 1g / mL: 6-8g / mL, processing the material liquid in a supersonic wave processor for 2-5 minutes, and then low-fire processing for 2-5 minutes in a microwave oven; 3, putting the microwave processed material liquid into a water-bath shaker at a temperature of 55 DEG C-65 DEG C, carrying out light-free extraction for 0.5-2 hours at a rotating speed of 80-120 r / min, carrying out pumping filtration process, and the alga polyphenol solution containing the alga polyphenol is obtained; 4, immersing the seawater shrimps by using the alga polyphenol solution with concentration of 180-220 ug / mL for 5-15 min, air drying, dishing up, and wrapping the shrimps with a PE preservative film and refrigerating the shrimps at 3+ / - 1 DEG C. The method of the invention has the advantages of simple operation, low cost, and good effect for preventing blackening, can be widely used for preventing the blackening of seawater shell-fish products, can prolong shelf life of the products, promote goods value, simultaneously improve added value of the algae, and has important meanings for increasing economic benefit and promoting fishery synergy.

Owner:ZHEJIANG MARINE DEV RES INST

Method for storing white shrimps by using film coating preservative in combination with ice-temperature technique

InactiveCN101731723AGood film formingAvoid blackeningClimate change adaptationFood preservation4-HexylresorcinolFilm coating

The invention discloses a method for storing white shrimps by using a film coating preservative in combination with an ice-temperature technique. The process flow of the invention comprises the following steps: 1, shocking and inactivating the white shrimps by crushed ice, cleaning the white shrimps by clean water, draining the white shrimps, and then coating the film coating preservative on the white shrimps; and 2, storing the white shrimps at the ice temperature which is between 2.2 DEG C below zero and 0 DEG C. The preservative consists of 4-hexylresorcinol, citric acid, ascorbic acid, chitosan, glacial acetic acid and water, wherein the mass of the 4-hexylresorcinol, citric acid, ascorbic acid and chitosan account for 0.005 to 0.015 percent, 1.0 to 2.0 percent, 0.5 to 2.5 percent and 0.8 to 1.5 percent of the mass of the preservative respectively, the glacial acetic acid accounts for 0.8 to 1.2 percent of the volume of the preservative, and the balance is water. By the combination of the film coating preservative and ice-temperature technique, the shelf life of the white shrimps is prolonged by 1 to 2 times compared with that of the white shrimps frozen at a temperature of 4 DEG C.

Owner:SHANGHAI OCEAN UNIV

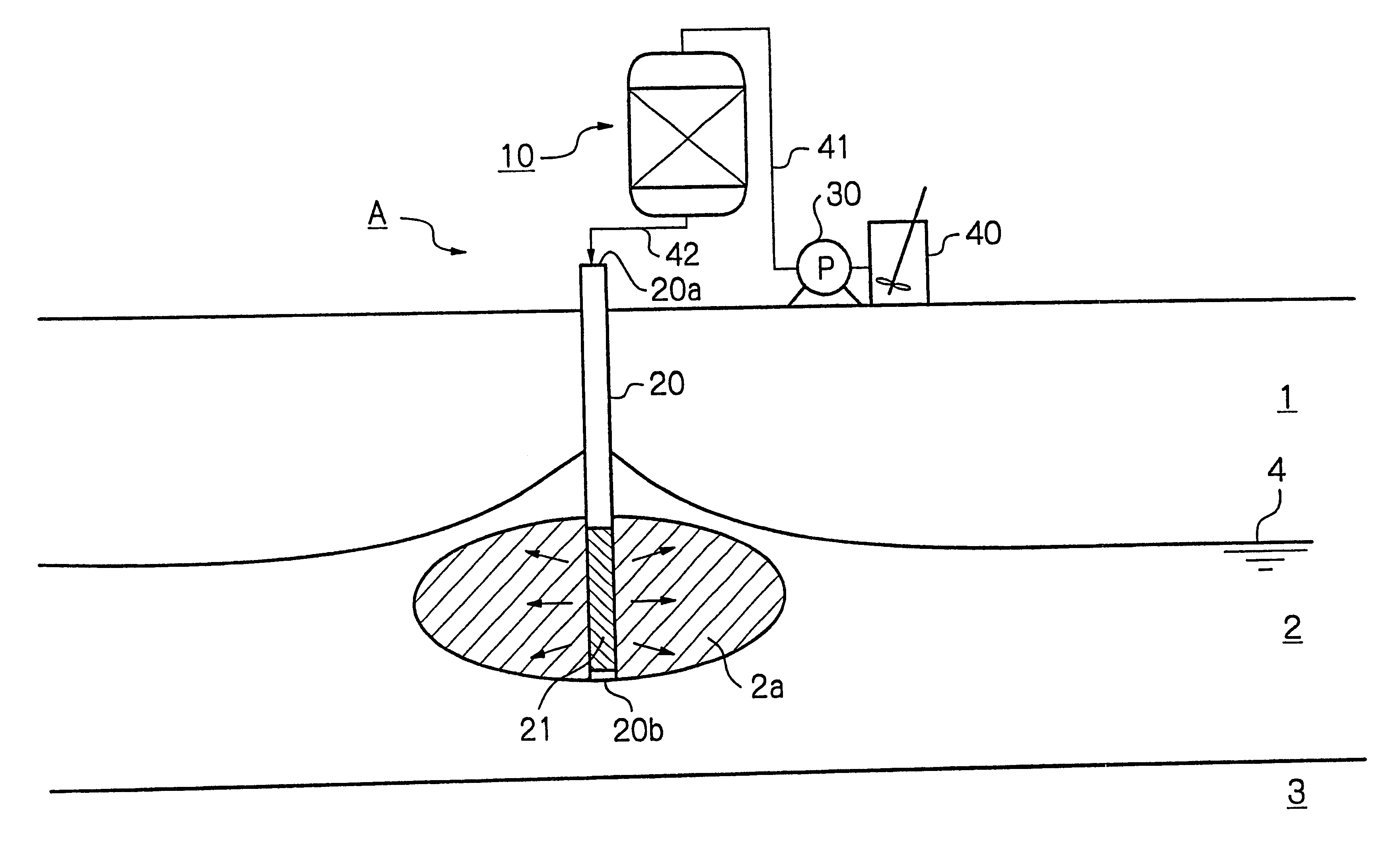

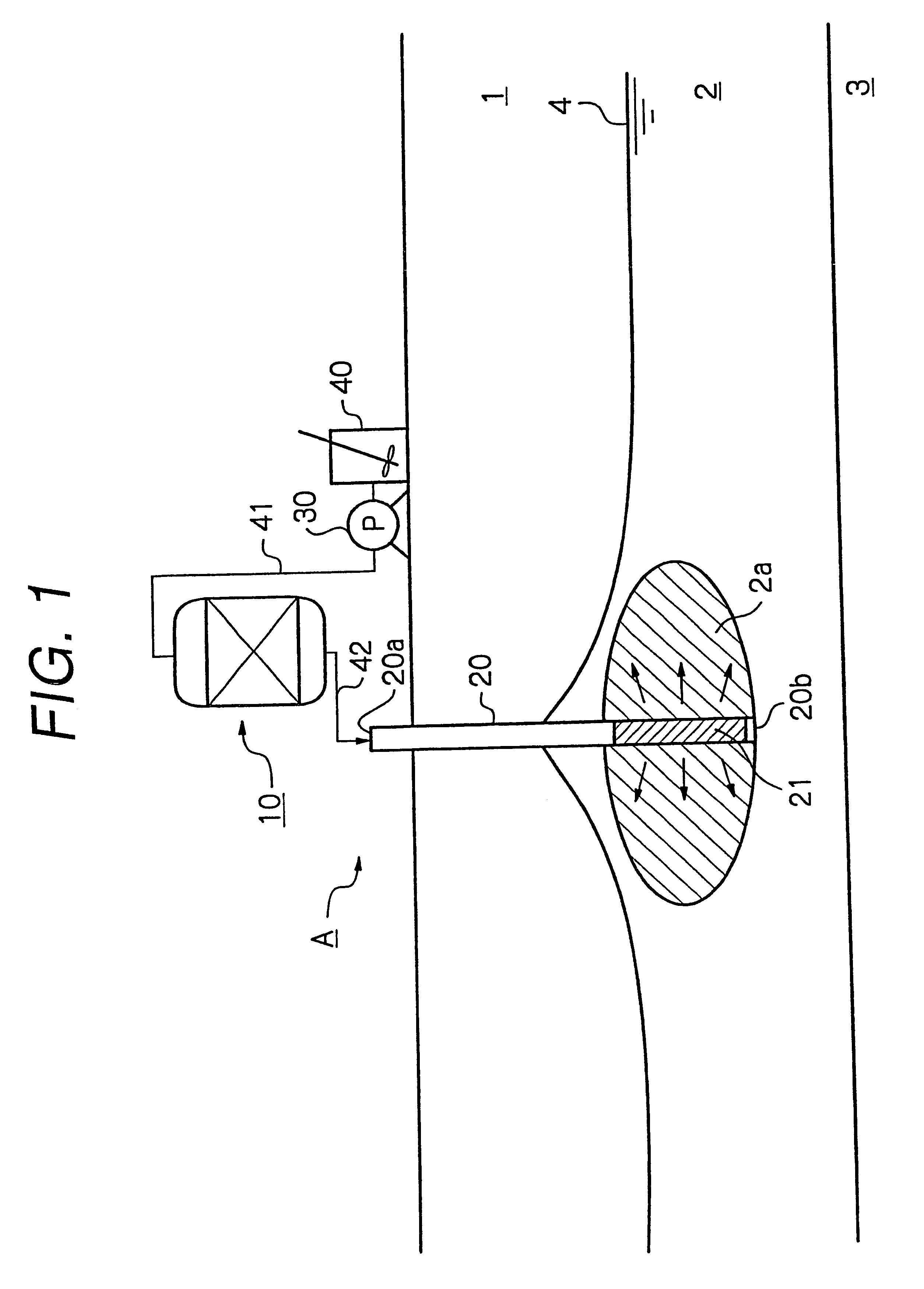

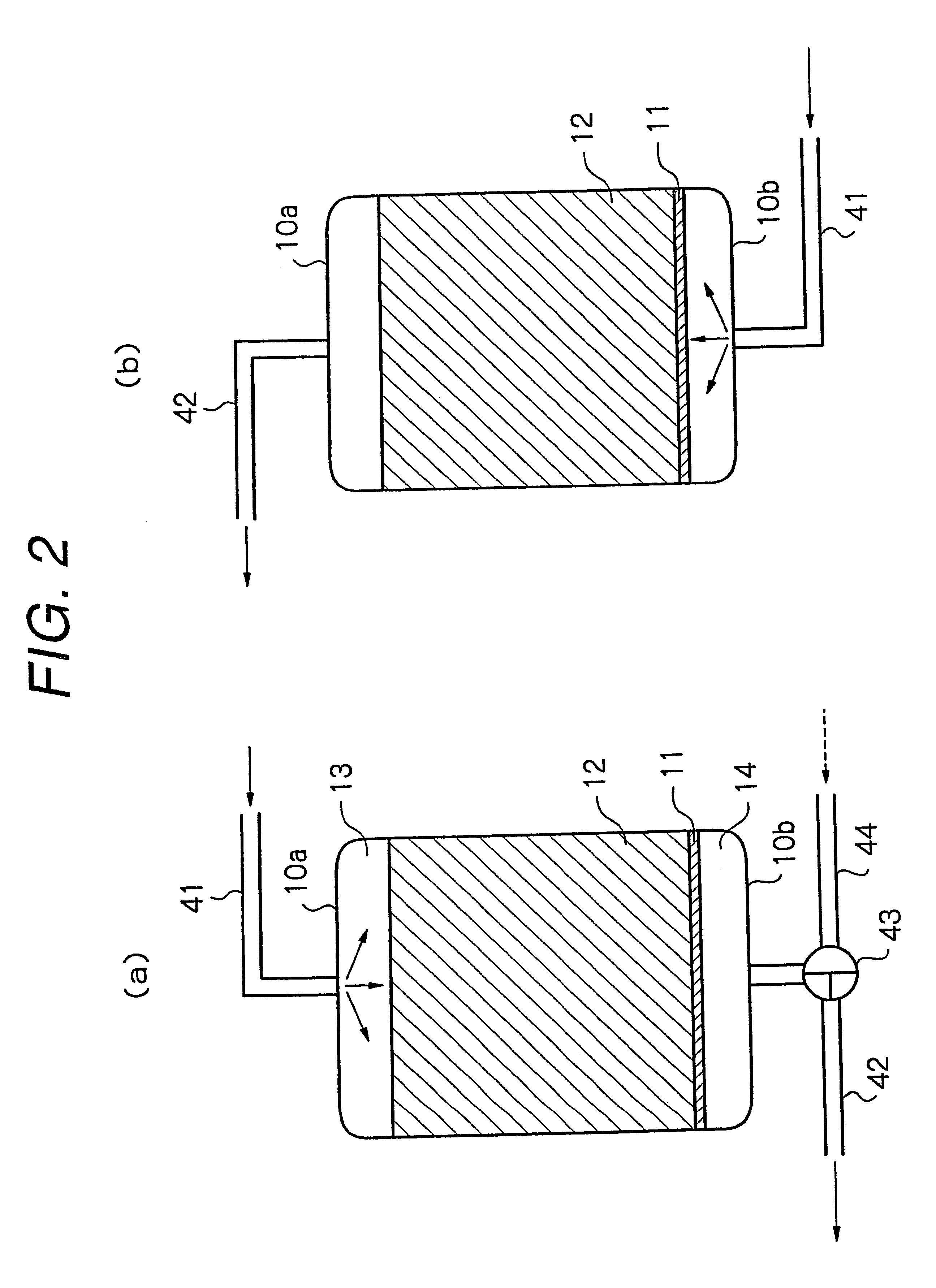

Method and apparatus for purifying polluted substances containing halogenated organic compound

InactiveUS6679992B1Reduced state of solutionHigh activityWater cleaningWater treatment compoundsNutrient solutionAnaerobic microorganisms

A nutrient solution is reduced with a reducing agent, and introduced into a contaminated object. Alternatively, groundwater reduced with a reducing agent is introduced into the contaminated object. Groundwater is contacted with the reducing agent while being circulated between an aquifer and a housing. A nutrient source for heterotrophic anaerobic microorganism may also be introduced into the contaminated object. The contaminated object contaminated with halogenated organic compounds can be purified efficiently and easily.

Owner:EBARA CORP

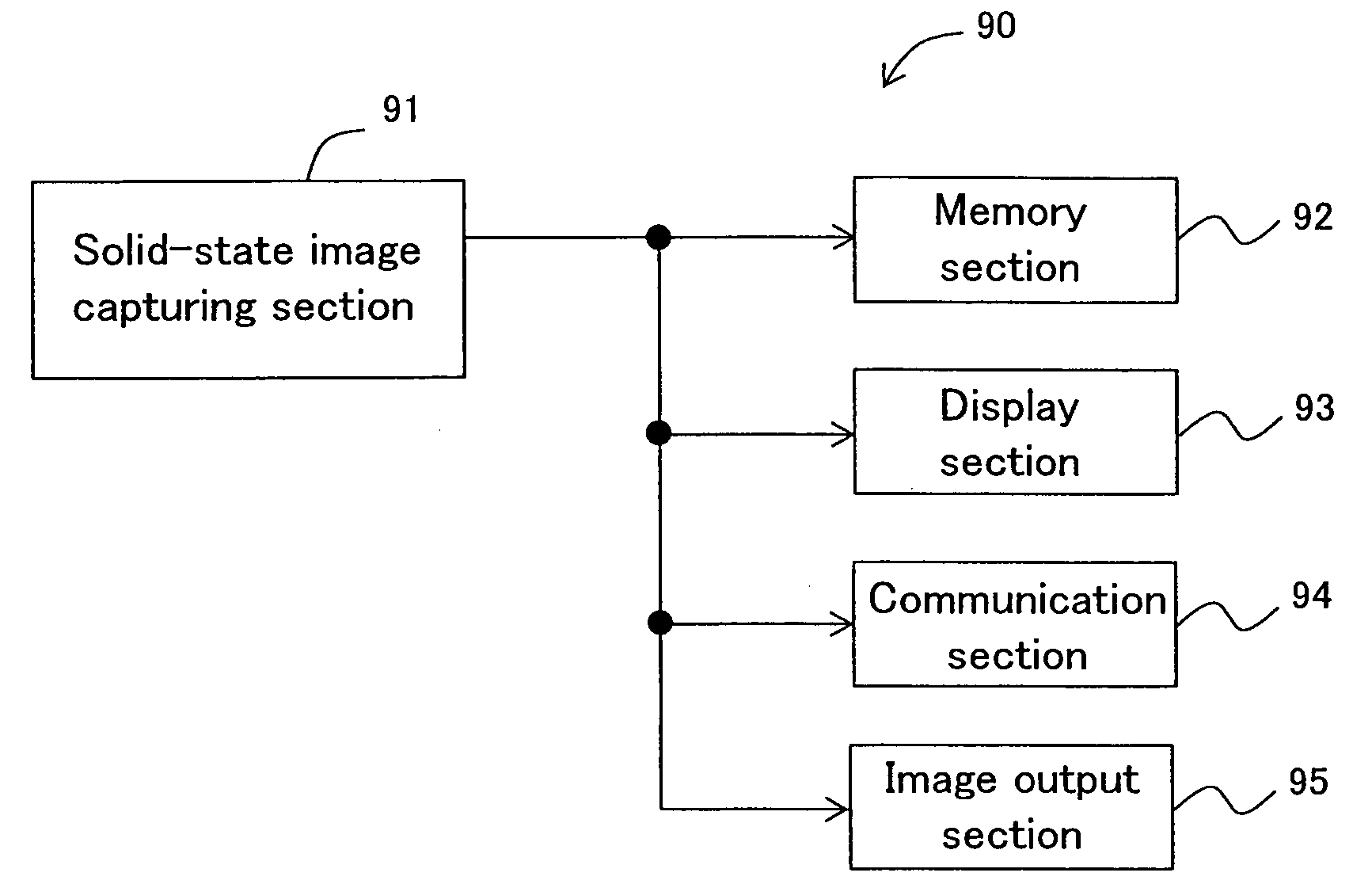

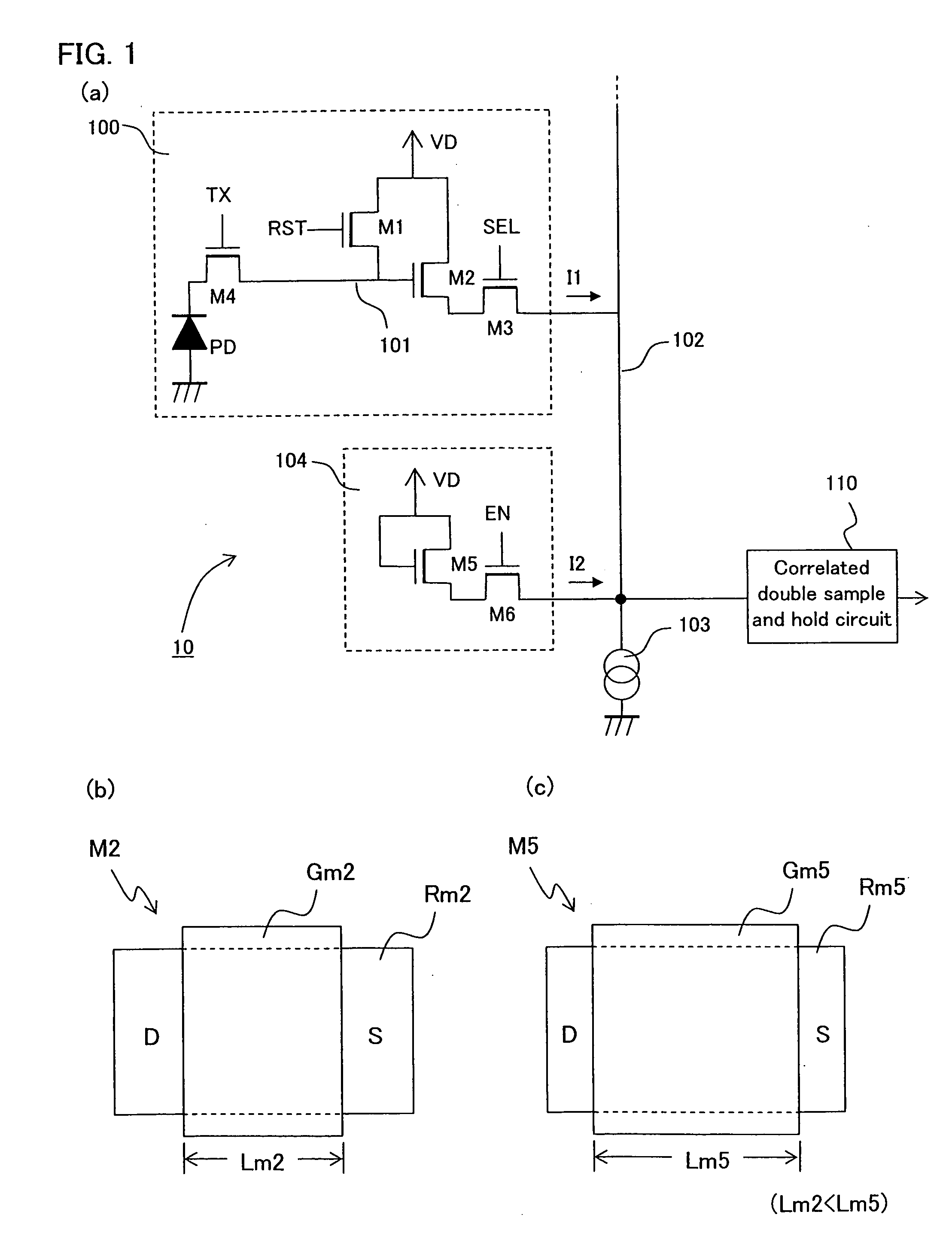

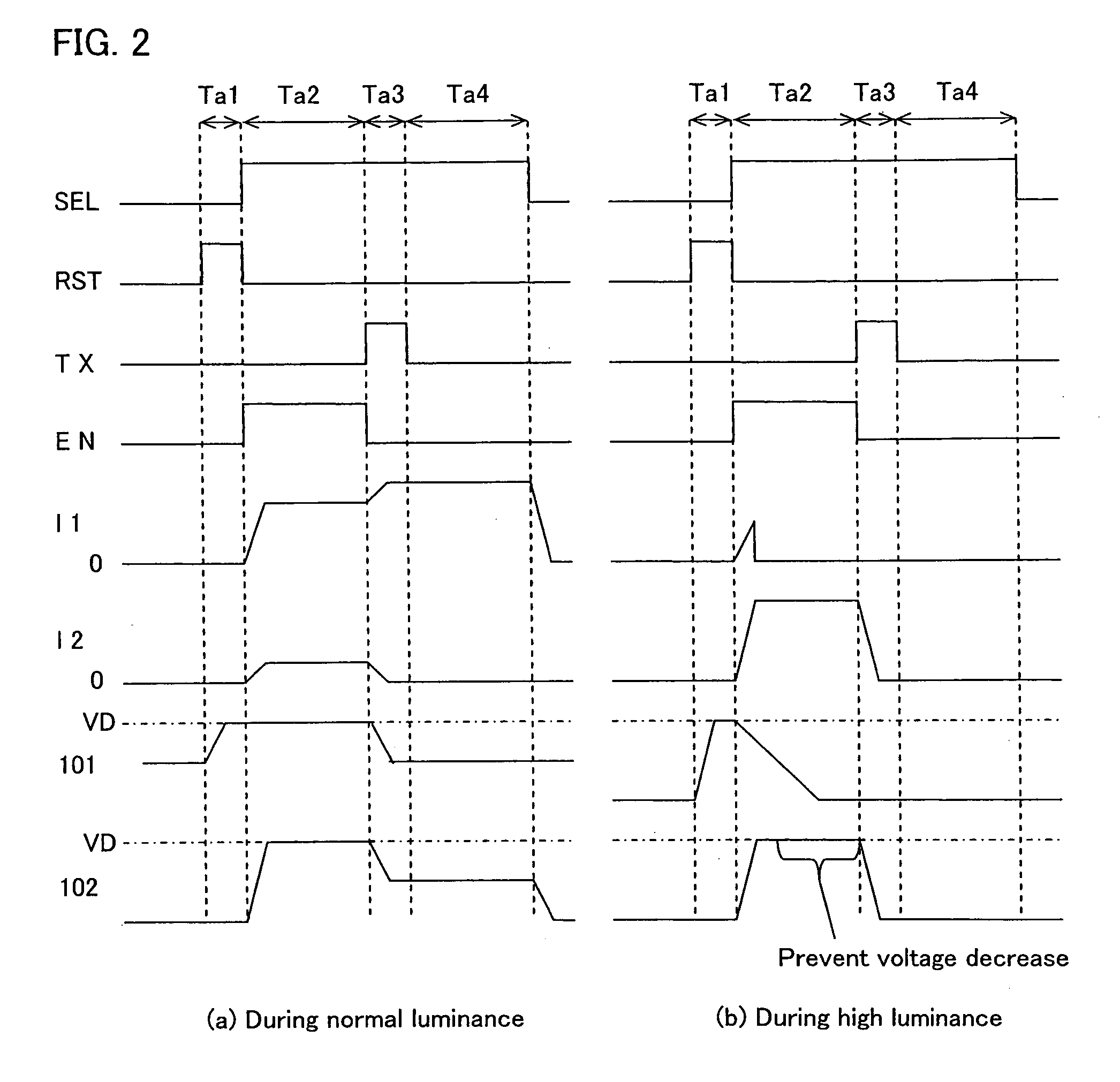

Image sensor and an electronic information device

ActiveUS20080284891A1Avoid blackeningIncrease in dispersionTelevision system detailsTelevision system scanning detailsPhotoelectric conversionVoltage reference

An image sensor is disclosed. The image sensor includes a plurality of pixels arranged in a matrix which detects a pixel signal of each pixel based on a voltage difference between a reset voltage which is a reference voltage of each pixel and a signal voltage generated by a photoelectric conversion at each pixel, and includes a plurality of read lines located for each pixel column, wherein the reset voltage and the signal voltage are read from the pixel of the corresponding pixel column; and a reset current supply section provided for each read line, wherein at the same time a first reset current is supplied from a pixel to the read line when reading the reset voltage from the pixel, the section supplies a second reset current to the read line such that a sum of the first reset current and the second reset current is constant.

Owner:SHARP KK

Processing method capable of preventing abalone soup cans from blackening

ActiveCN102150894APrevent oxidative browningEffective complexationFood preparationEngineeringProcess engineering

The invention discloses a processing method capable of preventing abalone soup cans from blackening. The method comprises the following steps: timely performing anti-blackening color protection process treatment for three times during fishing of abalone, workshop pretreatment and pre-boiling and soup-loading process, and then performing sterilization and storage. Through the three times of timely continuous anti-oxidation and anti-blackening color protection treatment with seamless oxygen contact, the original color, luster and quality of products can be effectively kept.

Owner:福州日兴水产食品有限公司

Lighting method and apparatus for high-pressure discharge lamp, and high-pressure discharge lamp apparatus

InactiveUS20030201735A1Avoid blackeningTotal current dropElectric light circuit arrangementHigh-pressure discharge lampsEffect lightEngineering

Disclosed are a lighting method for a high-pressure discharge lamp, a lighting apparatus for a high-pressure discharge lamp, and a high-pressure discharge lamp apparatus each suppresses abnormal blackening of a discharge tube that may occur at an initial stage of operation from a discharge start. According to the lighting method of the present invention, the lamp current is reduced upon detection, by an abnormal discharge detector 5021, of an abnormal discharge that is produced between a tip of one electrode and a root of the other electrode.

Owner:PANASONIC CORP

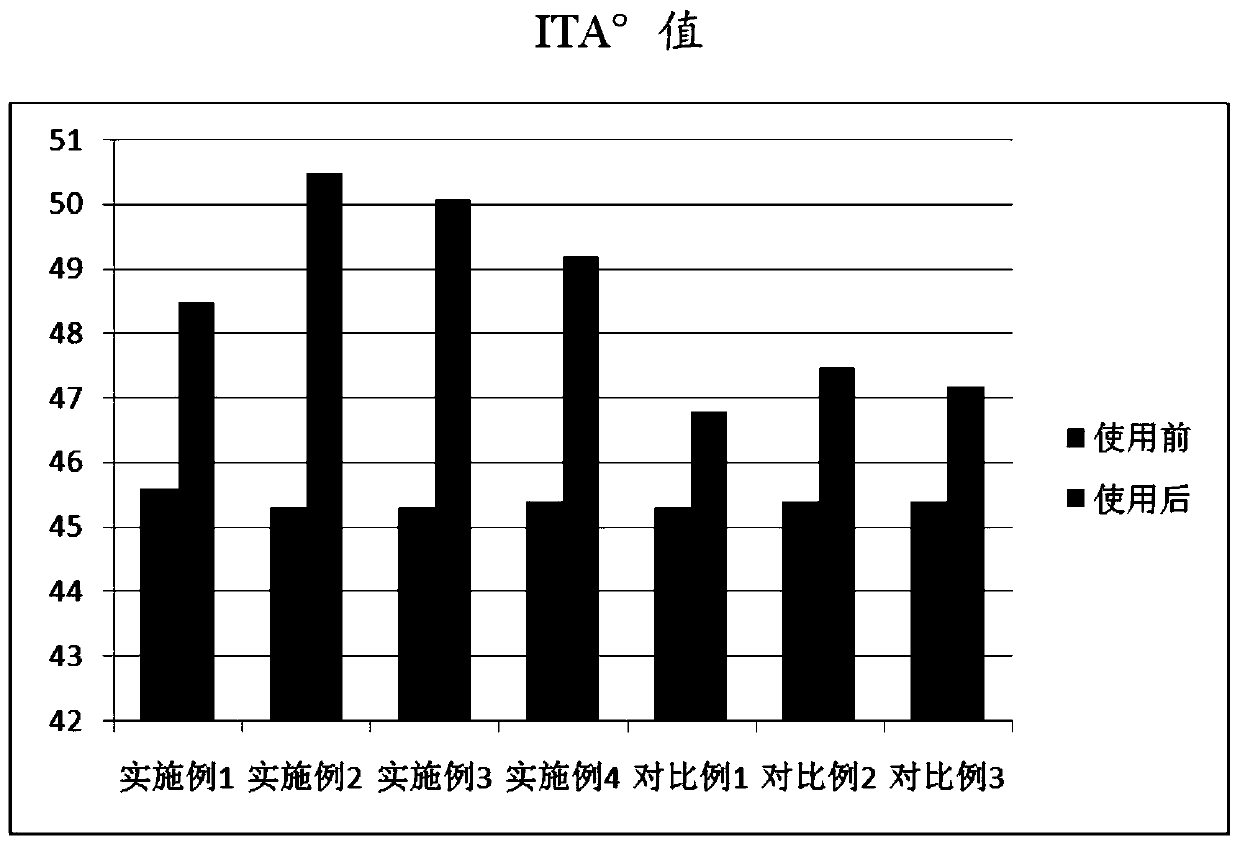

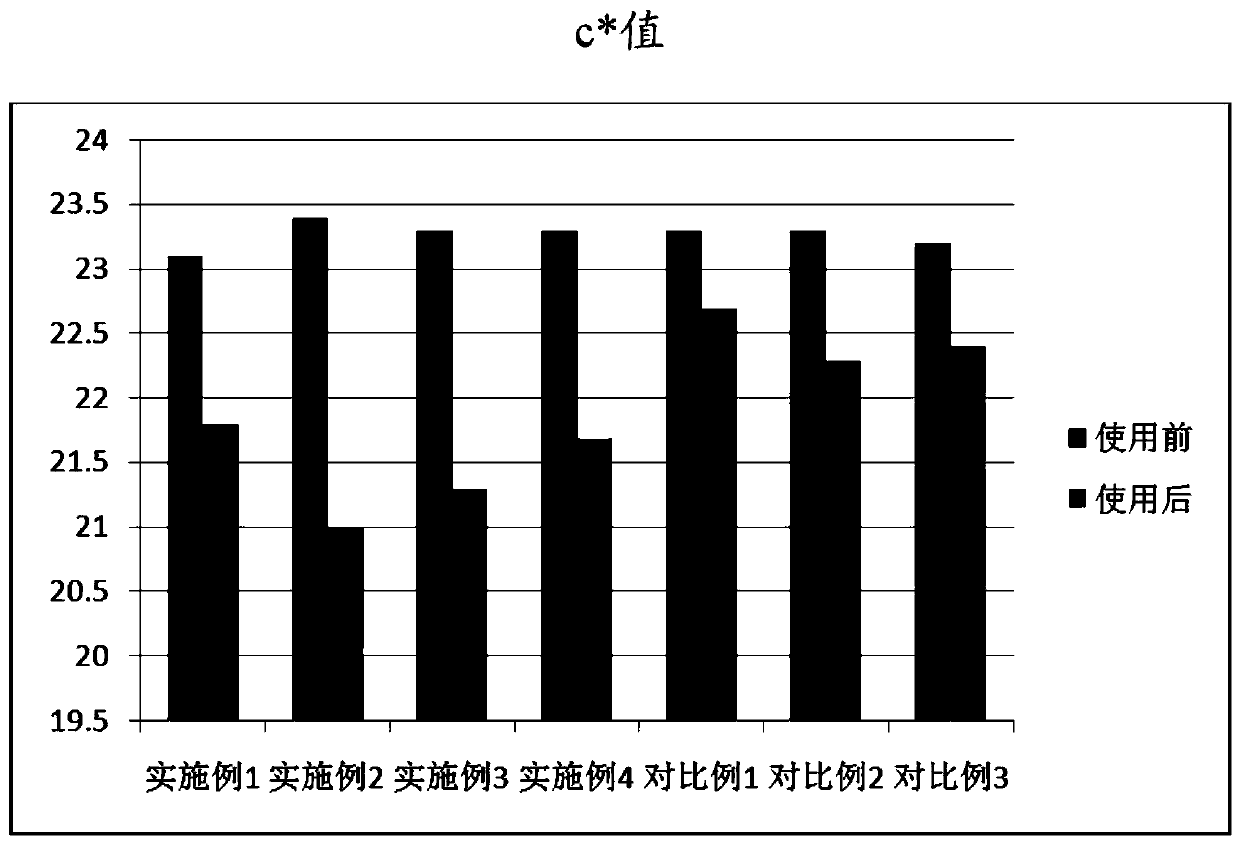

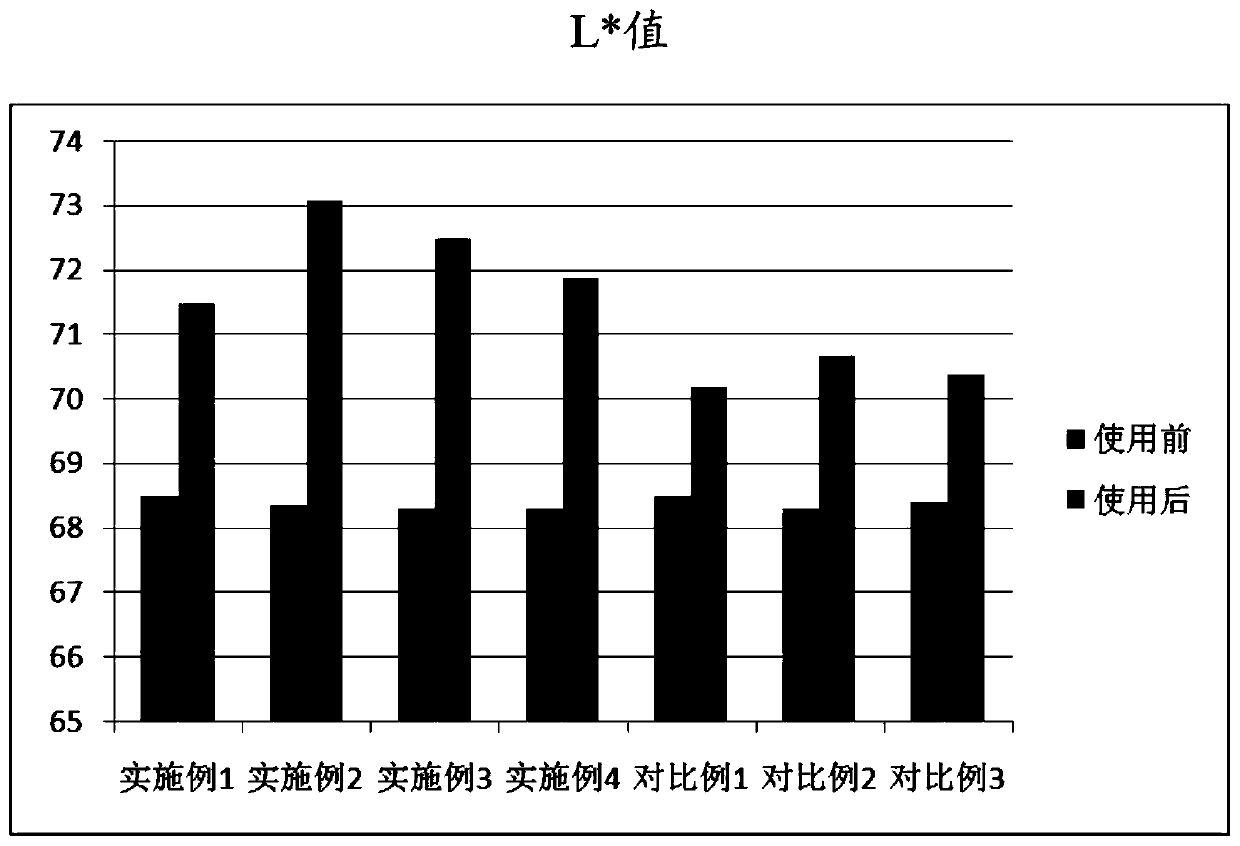

Whitening skin care product and preparation method thereof

ActiveCN111407680AInhibit transferAvoid blackeningCosmetic preparationsToilet preparationsNicotinamideSkin tone

The invention discloses a whitening skin care product. The whitening skin care product contains the following whitening ingredients: nicotinamide, acetyl chitin, 3-O-ethyl-ascorbic acid, hydroxydecylubiquinone, 4-(alpha-methylbenzyl)resorcinol and resveratrol, and the whitening ingredients can be combined to play the whitening effect from multiple paths, wherein hydroxydecyl ubiquinone and acetylchitin can resist ROS produced by external stimuli (such as: UV irradiation, lack of sleep, environmental pollution, and the like); 3-O-ethyl-ascorbic acid and 4-(alpha-methylbenzyl)resorcinol can inhibit enzymes required for producing melanin; 3-O-ethyl-ascorbic acid also can inhibit polymerization of melanin into large melanin polymers, and thereby evens skin tone; nicotinamide can inhibit thetransfer of melanin from melanocytes to keratinocytes to prevent skin from developing and blackening, and makes melanin be digested and swallowed in the melanocytes; and resveratrol can reduce melaninthat has been formed to lighten spots. Combining with a formula design of the invention, the whitening essence of the whitening skin care product can effectively whiten skin, lighten spots and even skin tone.

Owner:泉后(广州)生物科技研究院有限公司

Fresh shrimp preservative, and preparation method and usage method thereof

ActiveCN103689752AAvoid blackeningTotal number of delaysMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsShrimpPreservative

The invention belongs to the field of processing aquatic products, and particularly relates to a fresh shrimp preservative, and a preparation method and a usage method thereof. The fresh shrimp preservative comprises the following compositions in percentage by weight: 1.5-2.1% of chitosan, 5-6% of phytic acid, 0.8-1.2% of citric acid, 15-18% of minced raw garlic, 8-10% of edible vinegar, and the balance being yellow rice wine. Proved by repeated experiments, the fresh shrimp preservative is relatively good in anti-microbial preservation effect as compositions are organically combined, the melanism occurrence of shrimps in the refrigeration process can be effectively inhibited, the increase of total bacteria number and volatile basic nitrogen can be effectively postponed, and the preservation period can be prolonged.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

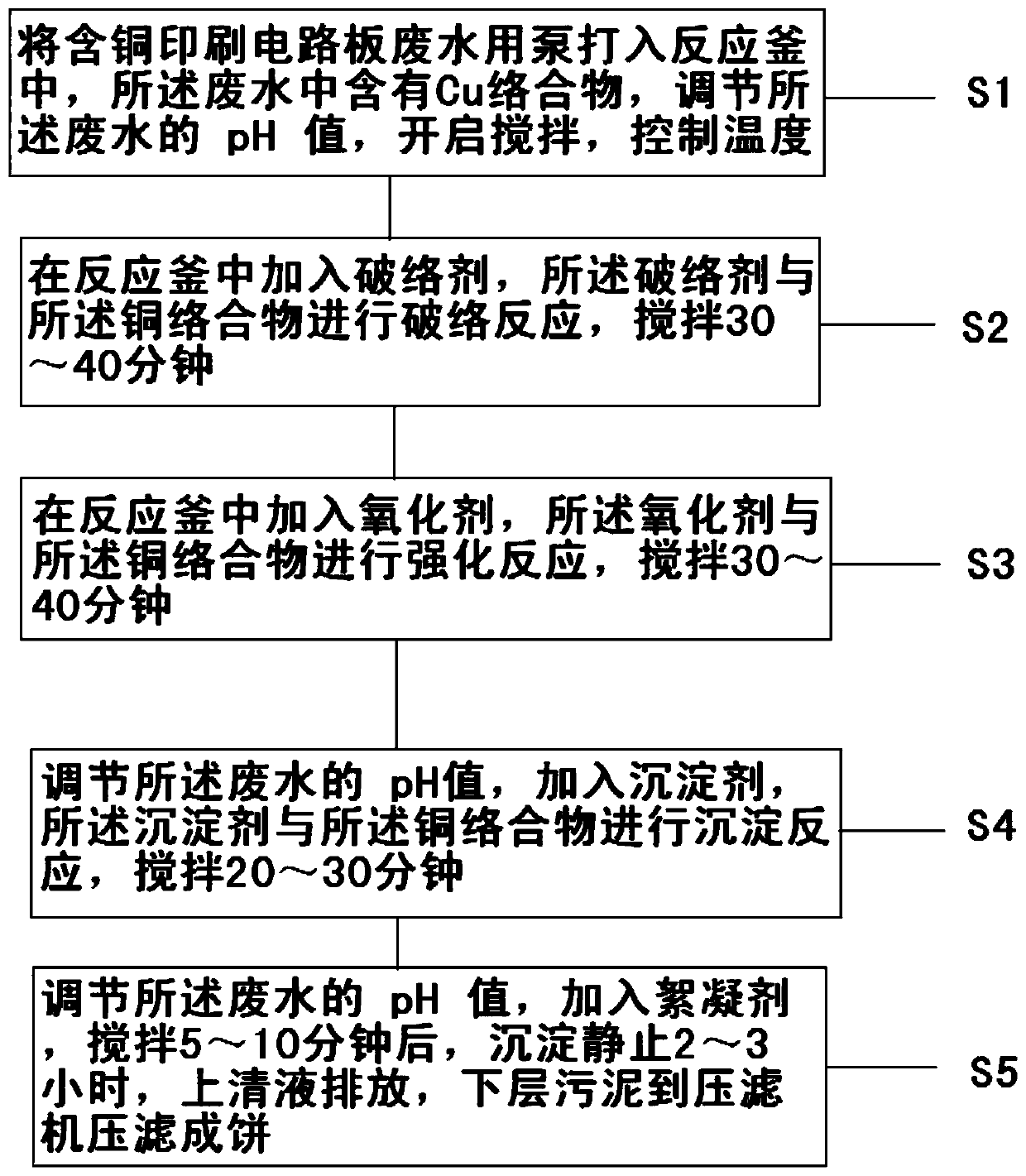

Copper-containing printed circuit board wastewater treatment method

InactiveCN110683676AOvercome yellowing of water qualityOvercome the shortcomings of poor precipitation effectSludge treatmentWater contaminantsPulp and paper industryPrinted circuit board

The invention discloses a copper-containing printed circuit board wastewater treatment method which specifically comprises the following steps: step 1, pumping copper-containing printed circuit boardwastewater, which contains copper complex, into a reaction kettle by using a pump, and adjusting the pH value of the wastewater, step 2, adding a complex breaking agent into the reaction kettle, carrying out complex breaking reaction on the complex breaking agent and the wastewater copper complex, and stirring for 30-40 minutes; step 3, adding an oxidizing agent into the reaction kettle, carryingout enhanced reaction on the oxidizing agent and the wastewater copper complex, and stirring for 30-40 minutes; 4, adjusting the pH value of the wastewater, adding a precipitant, carrying out precipitation reaction on the precipitant and the wastewater copper complex, and stirring for 20-30 minutes; and step 5, regulating the pH value of the wastewater, adding a flocculating agent, stirring for 5-10 minutes, precipitating and standing for 2-3 hours. The invention solves the problems of high cost and poor precipitation effect in the existing wastewater treatment method.

Owner:JINDUICHENG MOLYBDENUM CO LTD

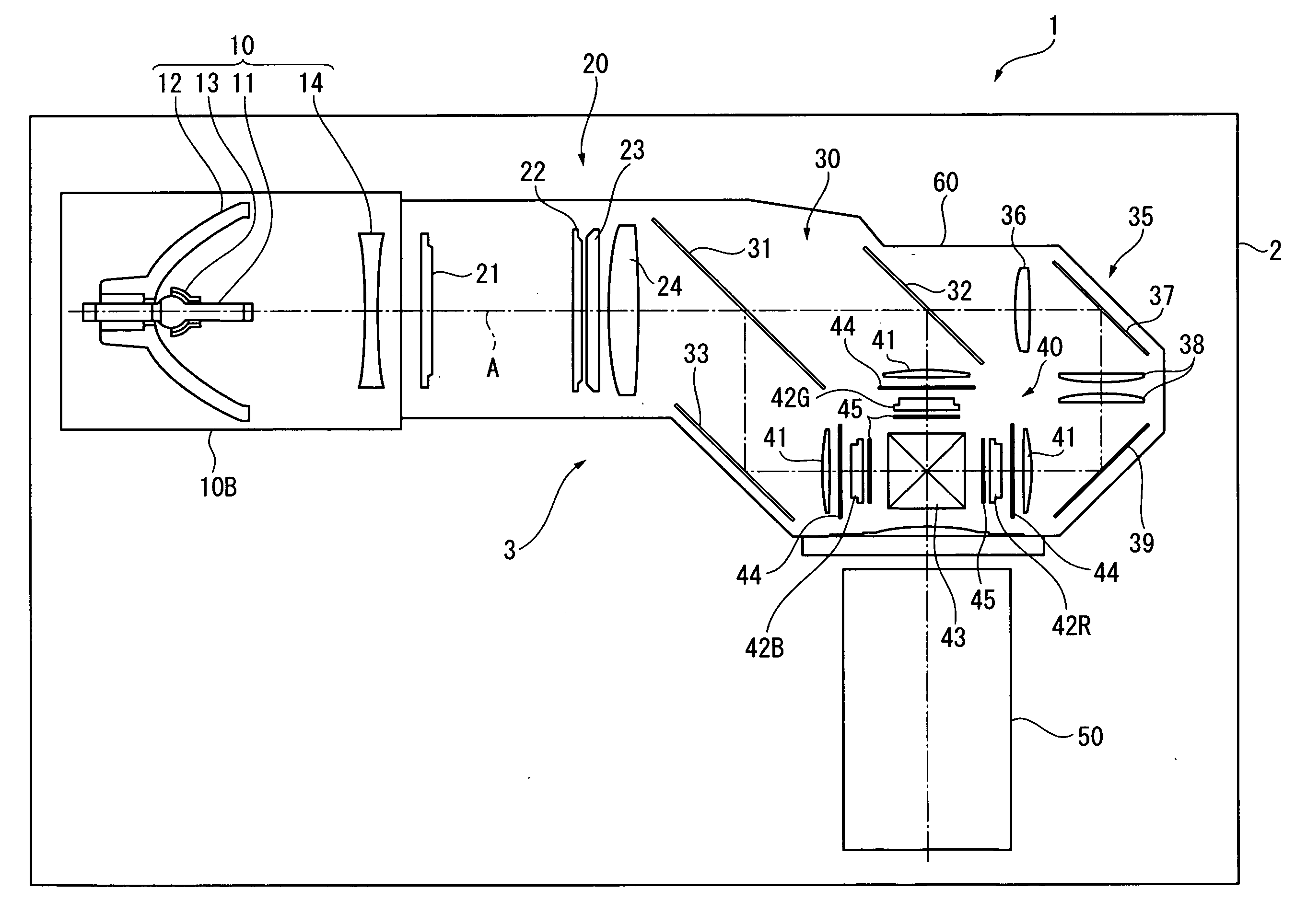

Light source device and projector

InactiveUS7549771B2Prolong lifeReducing bias of temperature distributionTelevision system detailsPoint-like light sourceLight beamOptoelectronics

A light source device includes: a light source lamp having a light-emitting tube with a discharge space and a pair of electrodes disposed in the discharge space of the light-emitting tube; a reflector extending in a substantially concave shape in section, the reflector reflecting a light beam irradiated from the light source lamp; and a sub-reflection mirror having a reflection surface that is disposed to face a reflection surface of the reflector, the sub-reflection mirror reflecting a part of the light beam irradiated from the light source lamp toward the discharge space. The light-emitting tube has a light-emitting section having the discharge space therein and sealing sections provided on both sides of the light-emitting section. The sub-reflection mirror is formed in a shape of a bowl that covers the light-emitting section of the light-emitting tube, the sub-reflection mirror having an opening for mounting the sub-reflection mirror to the light-emitting tube by allowing one of the sealing sections of the light-emitting tube to be inserted thereinto. A heat insulating member is provided to at least a part of the light-emitting section and the other one of the sealing sections of the light-emitting tube.

Owner:SEIKO EPSON CORP

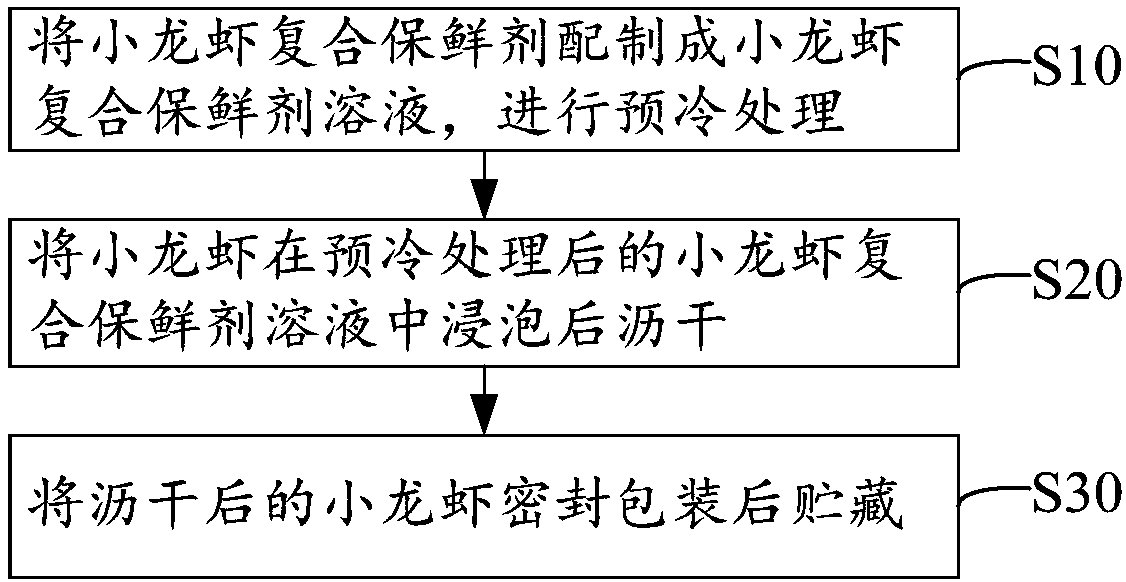

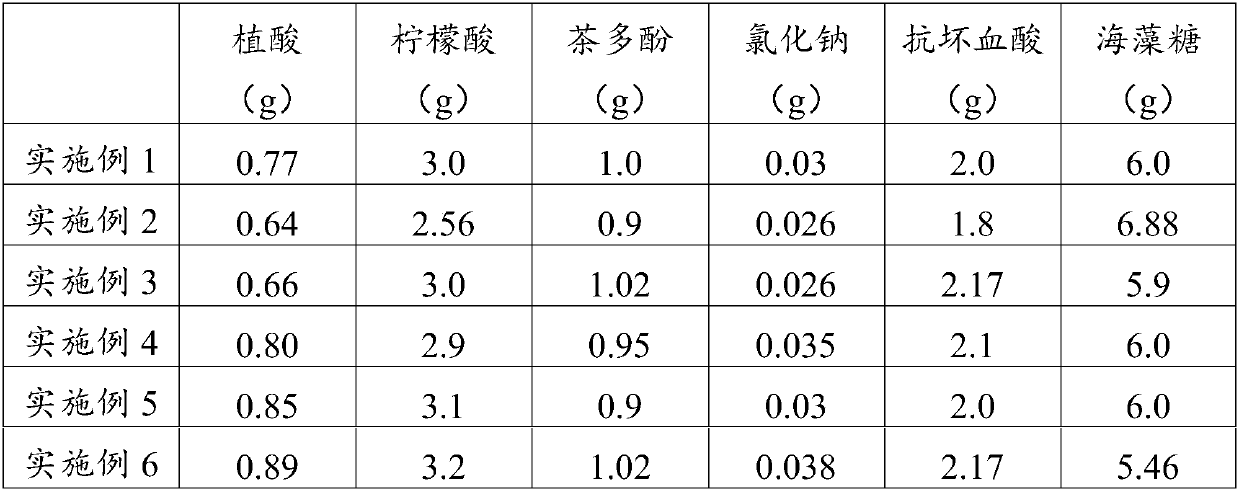

Crawfish compound fresh-keeping agent and crawfish fresh-keeping treatment method

ActiveCN107624859AGrowth inhibitionSuppresses volatile base nitrogenMeat/fish preservationChemistryTrehalose

The invention discloses a crawfish compound fresh-keeping agent and a crayfish fresh-keeping treatment method. The crawfish compound fresh-keeping agent comprises the following components in percentage by mass: 5-7% of phytic acid, 20-25% of citric acid, 7-8% of ascorbic acid, 0.2-0.3% of tea polyphenols, 14-17% of sodium chloride and 42.7-53.8% of trehalose. Through the synergistic action of thecomponents including the phytic acid, the citric acid, the ascorbic acid, the tea polyphenols, the sodium chloride and the trehalose, the growth of microorganisms and the increase of total volatile basic nitrogen are effectively inhibited so as to not only inhibit the blackening of crawfishes in a storage process, but also keep the freshness of the crawfishes and prolong the shelf life of the crawfishes.

Owner:美盐集(应城)日化有限公司

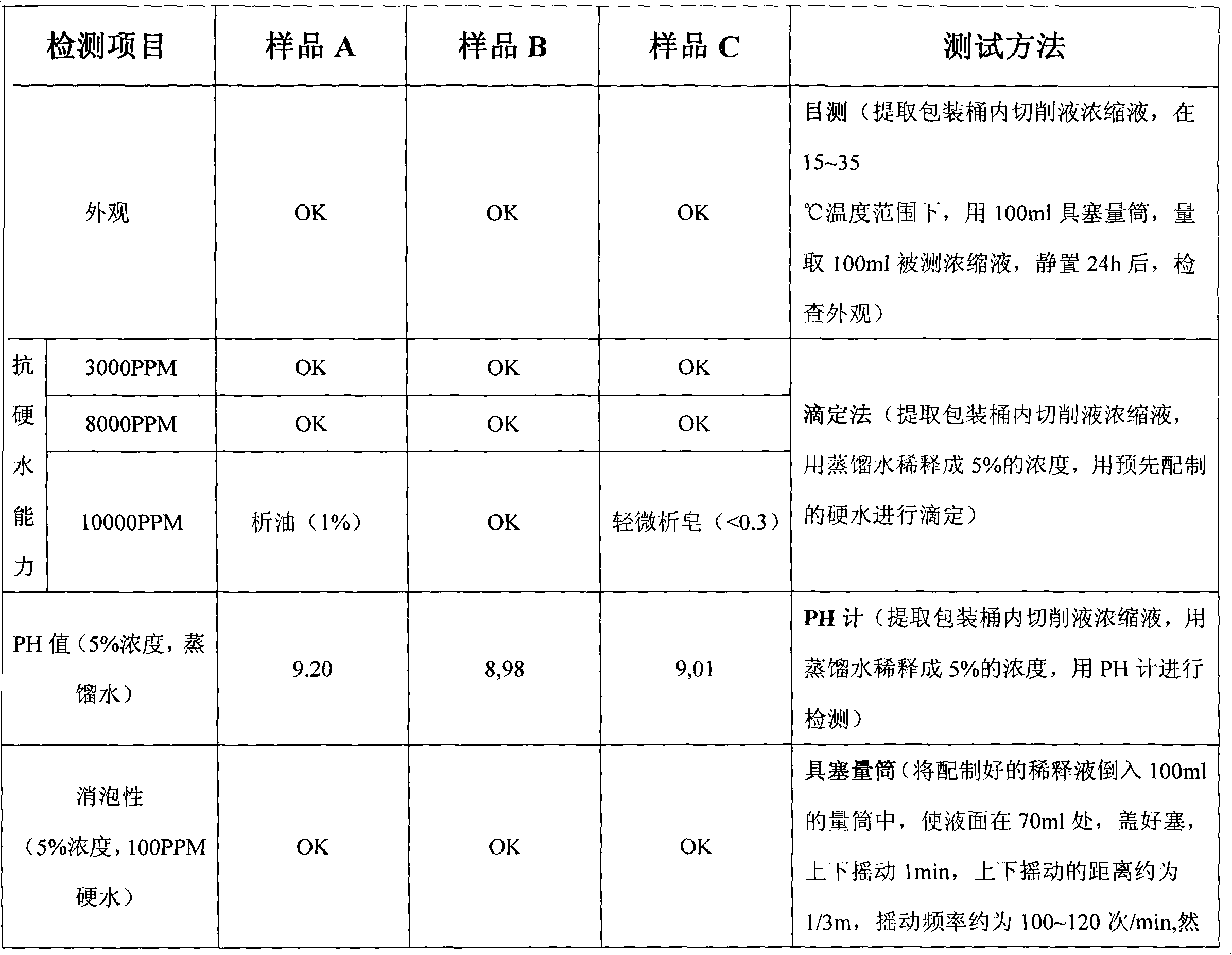

Magnesium alloy cutting fluid and preparation method thereof

InactiveCN101886021AExtended service lifePrevent precipitationLubricant compositionPhosphateDisinfectant

The invention discloses magnesium alloy cutting fluid, which comprises the following raw materials in percentage by mass: 20 to 30 percent of water, 3.0 to 5.0 percent of EDTA4 sodium, 3.0 to 7.0 percent of isopropanolamine, 30 to 50 percent of naphthenic base oil, 5.0 to 7.0 percent of T702, 4.0 to 8.0 percent of phosphate ester, 3.0 to 6.0 percent of AEO-9, 2.0 to 5.0 percent of disinfectant and 4.0 to 8.0 percent of span 80. Specific bacterial inhibitors and mold inhibitors are added into the magnesium alloy cutting fluid respectively, so that the magnesium alloy cutting fluid avoids corrosion of magnesium alloy materials, can control bacterial reproduction effectively, and extend the service life of the cutting fluid greatly by synergizing with an extraordinary hard water resistance capability.

Owner:范成立

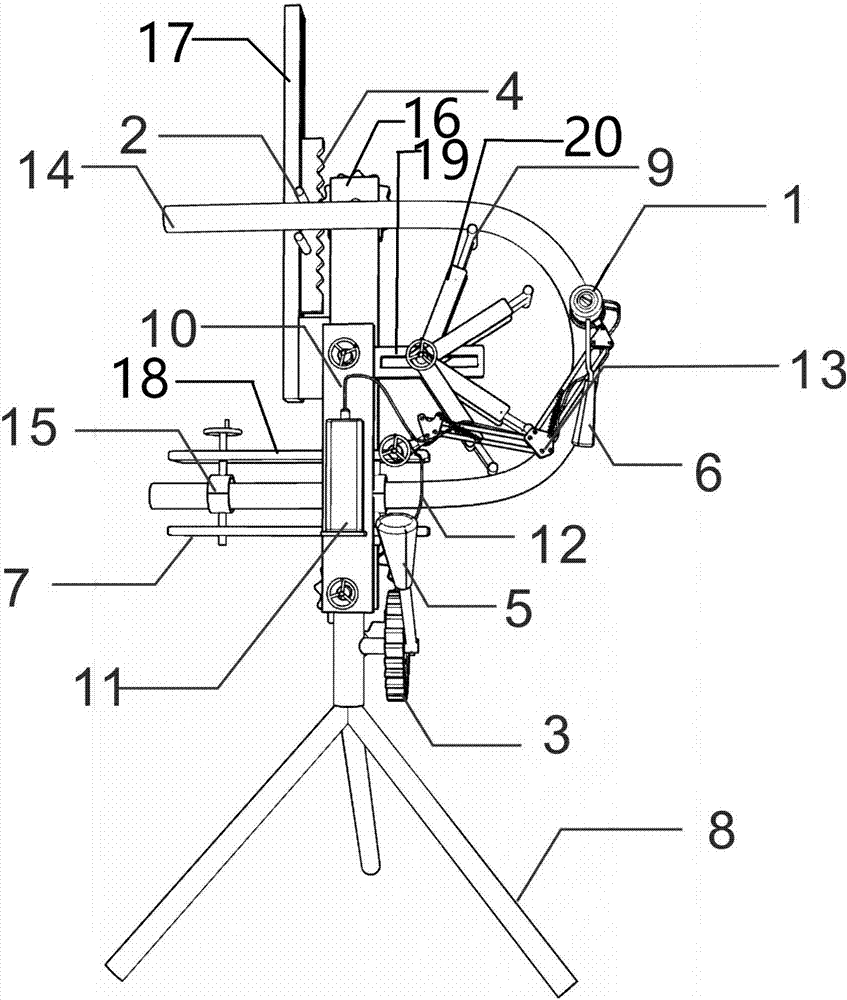

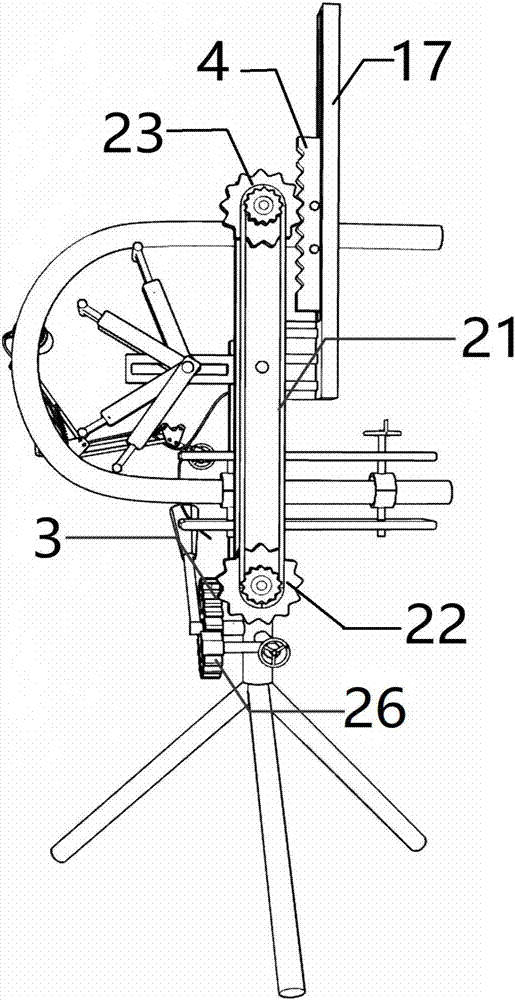

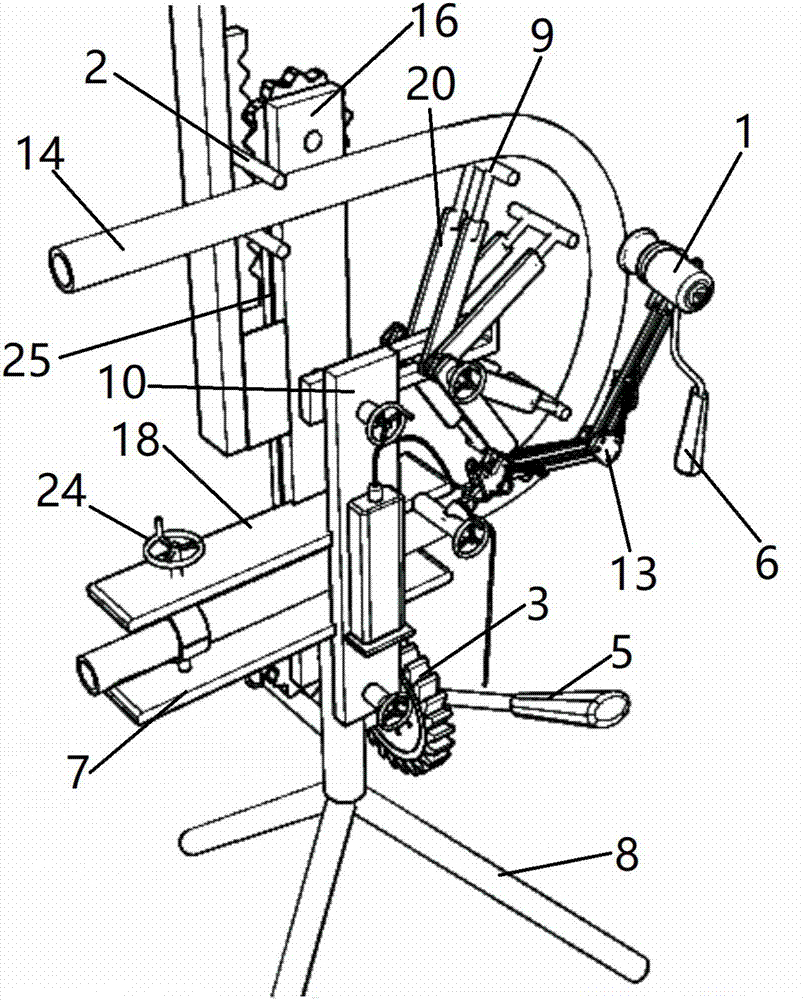

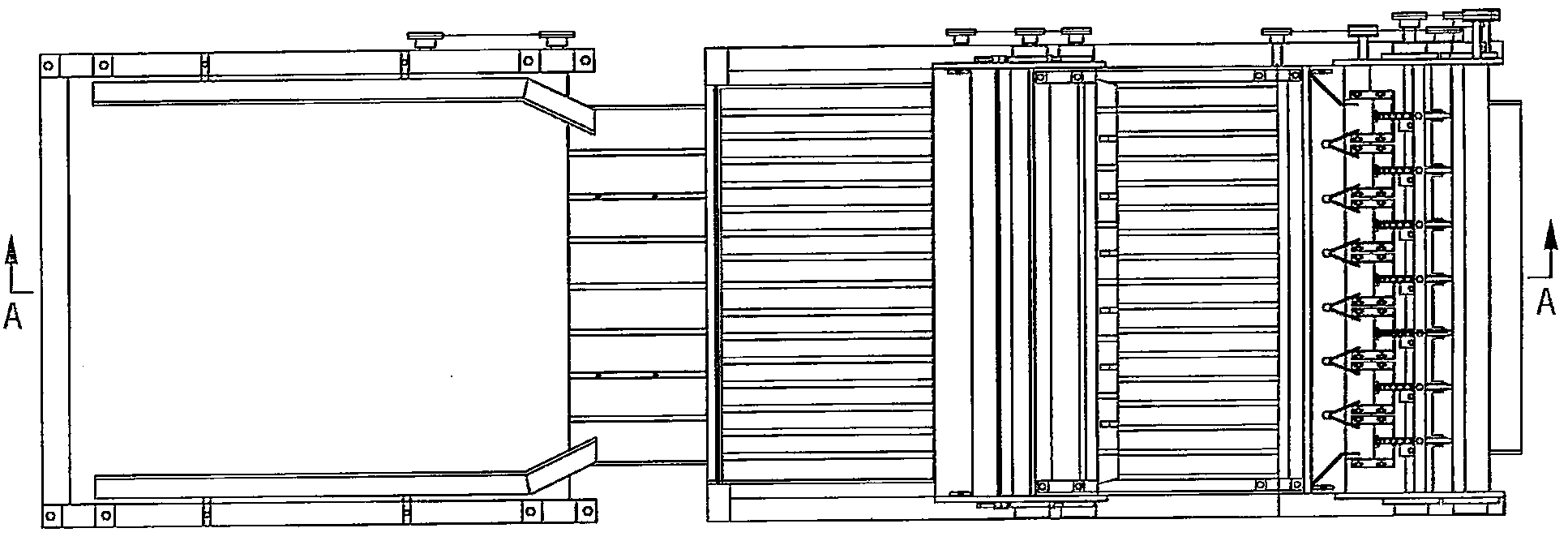

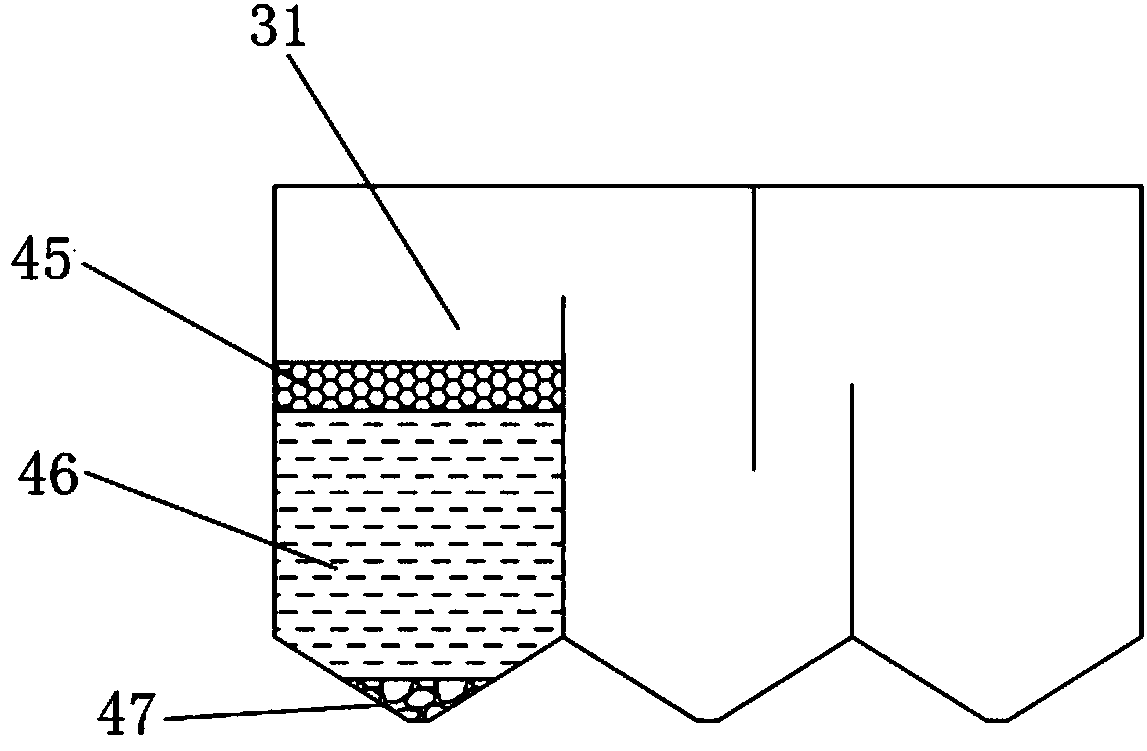

Auxiliary-heat bamboo bending device

ActiveCN107097315AContinuous and stable deformation forceContinuous and stable outputWood treatment detailsReed/straw treatmentEngineering

Owner:GUANGDONG UNIV OF TECH

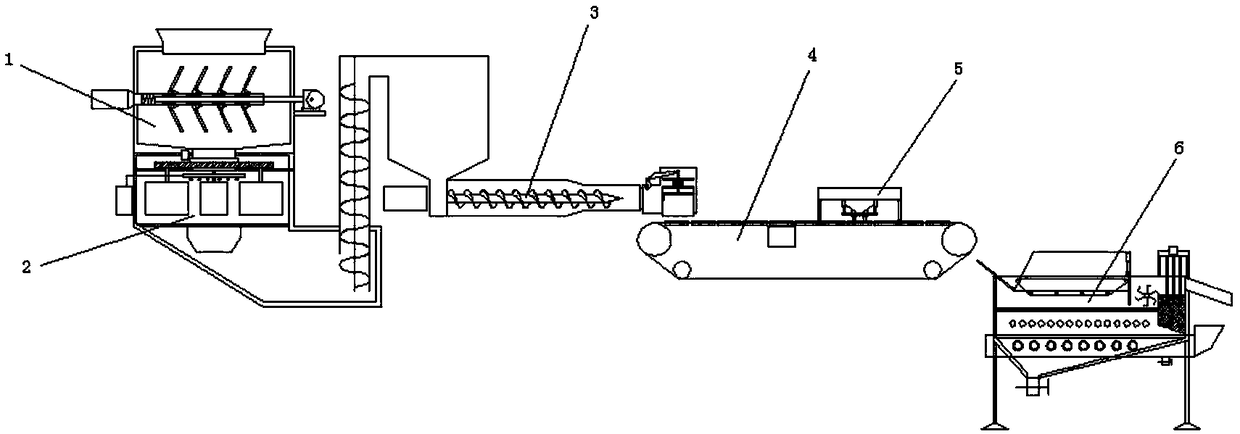

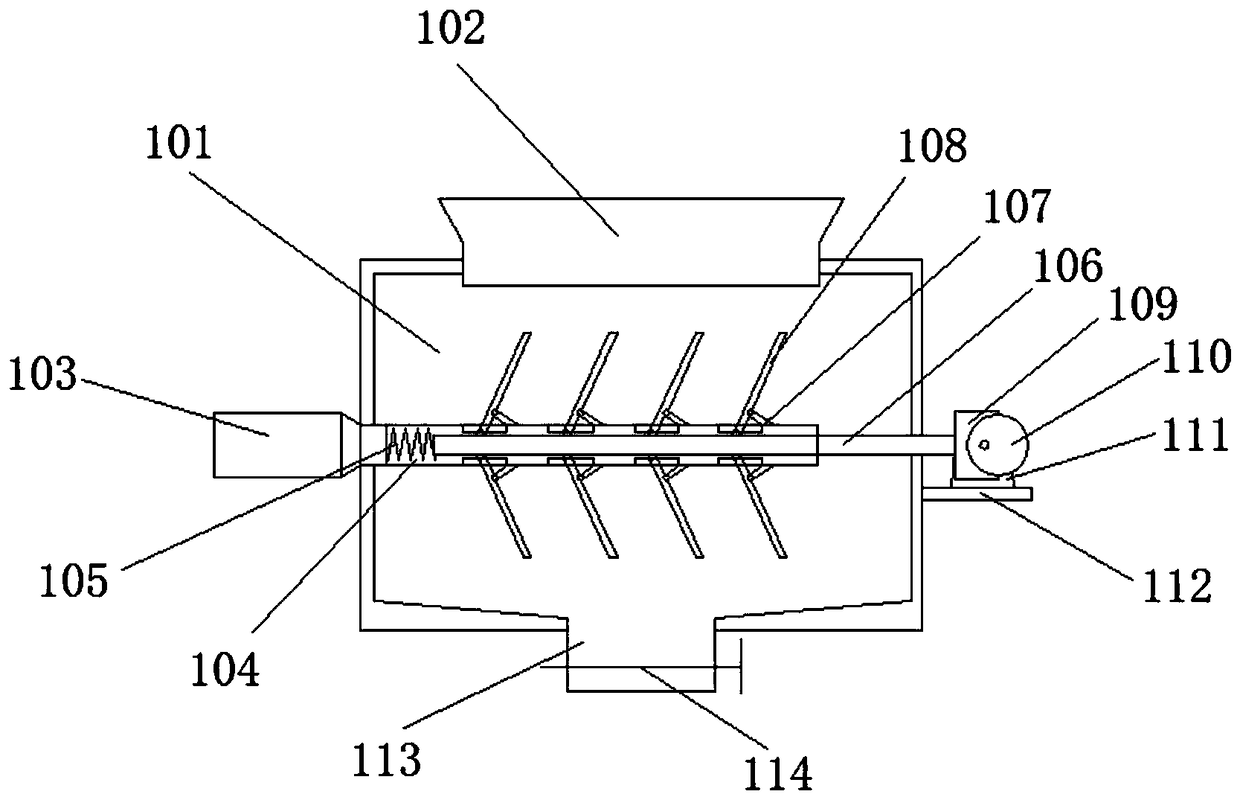

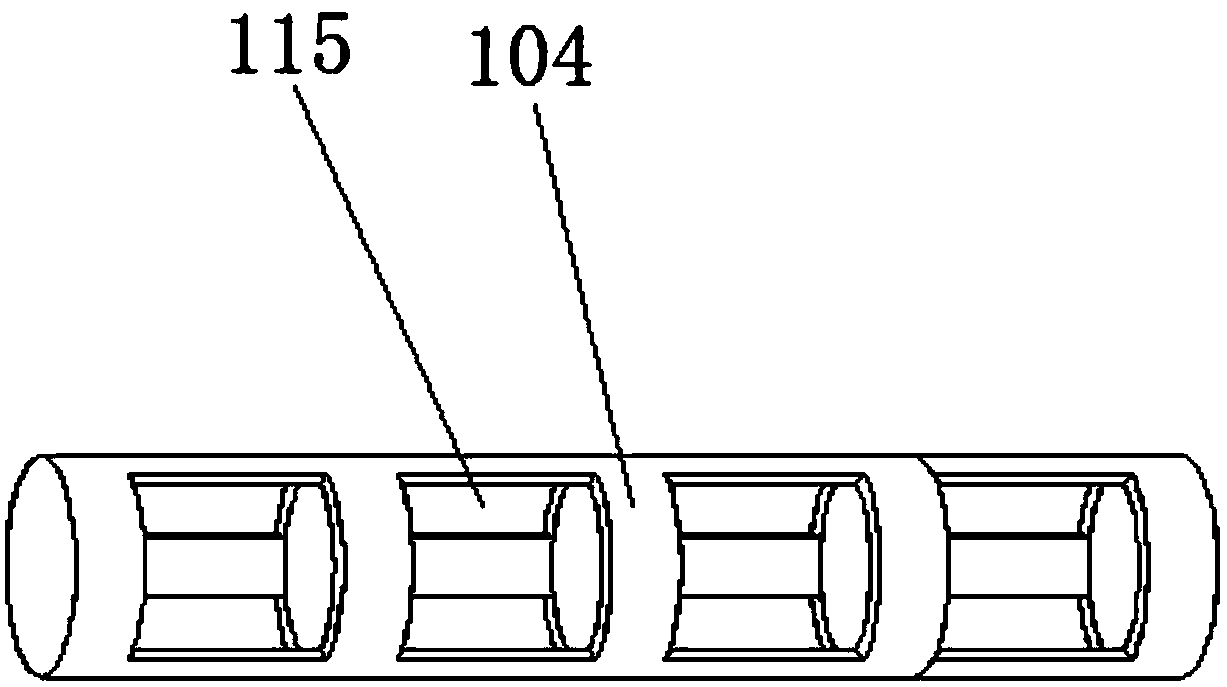

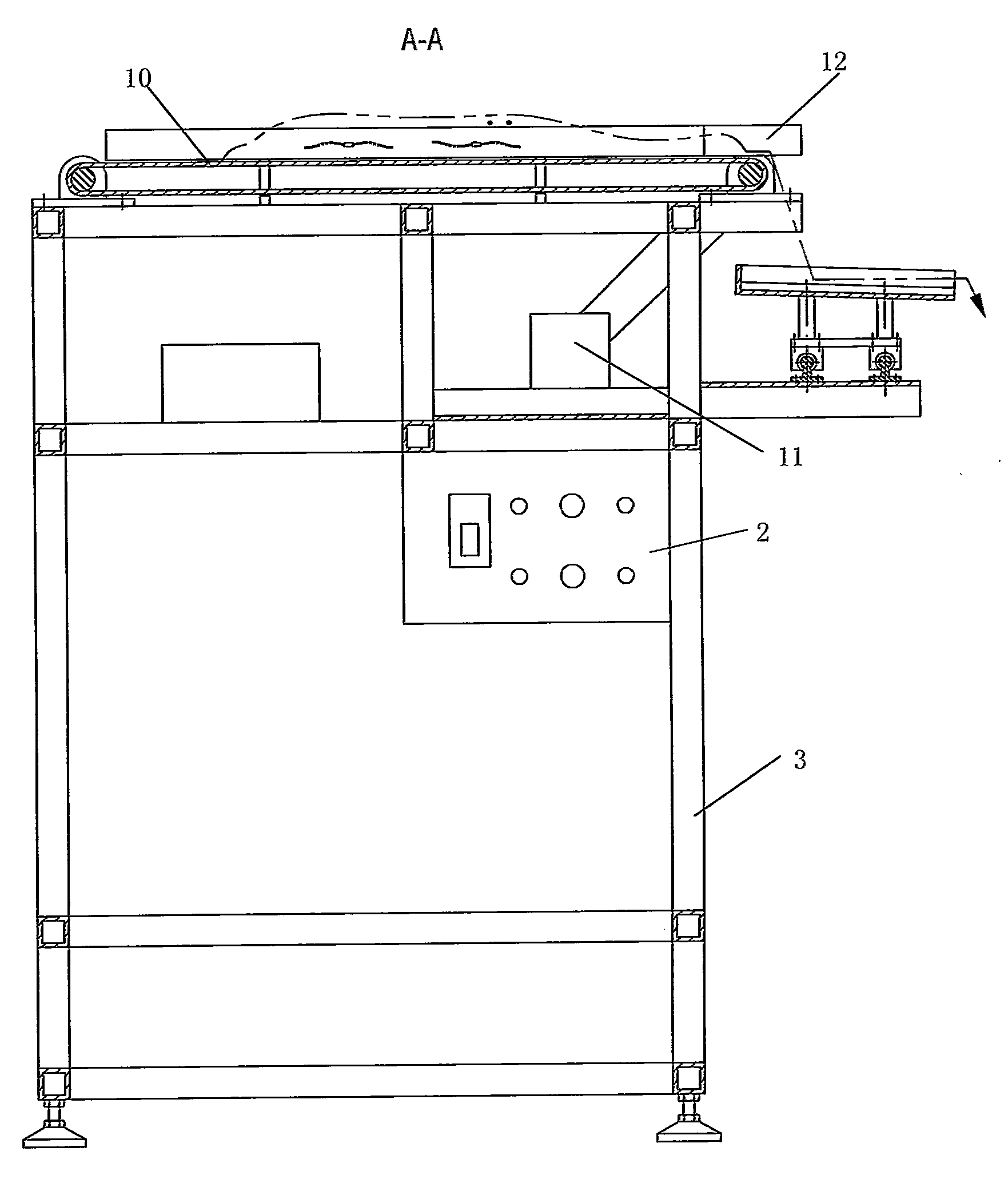

Flour mixing device of deep-fried dough stick machine

ActiveCN109006896AWell mixedImprove the mixing effectMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsDeep fryingAgricultural engineering

The invention discloses a flour mixing device of a deep-fried dough stick machine, and relates to the field of food processing. The flour mixing device includes a mixing mechanism, a dough kneading mechanism is arranged at the bottom of the mixing mechanism, a leavening cabin is connected to the right side of the dough kneading mechanism through a lifting machine, an extrusion machine is fixed tothe bottom of the leavening cabin, a discharging mechanism is arranged at the right end of the extrusion machine, a conveying machine is arranged below the discharging mechanism, a composite shaping mechanism is arranged at the middle of the conveying machine, a stretching detachment mechanism is arranged on the right portion of the conveying machine, and a deep-frying device is arranged at the bottom of the right end of the conveying machine. By adopting the flour mixing device of the deep-fried dough stick machine, a manual deep-fried dough stick making process can be stimulated, after wateris automatically added into flour and is mixed with the flour to make dough, the dough is kneaded, leavened, pressed, shaped and then stretched, finally, the dough is deeply fried, manual labor is greatly reduced, the mouthfeel of deep-fried dough sticks is ensured, the deep-fried dough sticks are efficiently and rapidly made, and the flour mixing device is suitable for being used in breakfast stores.

Owner:张乐

Method for producing resin composition containing natural material filler, and resin composition produced by the method

In a method for producing a natural material filler-containing resin composition by kneading a resin and a natural material filler, the kneading is carried out in the presence of a boron compound. The natural material filler may be treated with the boron compound preliminarily before the kneading. The natural material filler-containing resin composition that makes it possible to avoid blackening even if the kneading is carried out at a high temperature provides, when being molded, resin products that exhibit excellent natural-material-like texture.

Owner:PALM

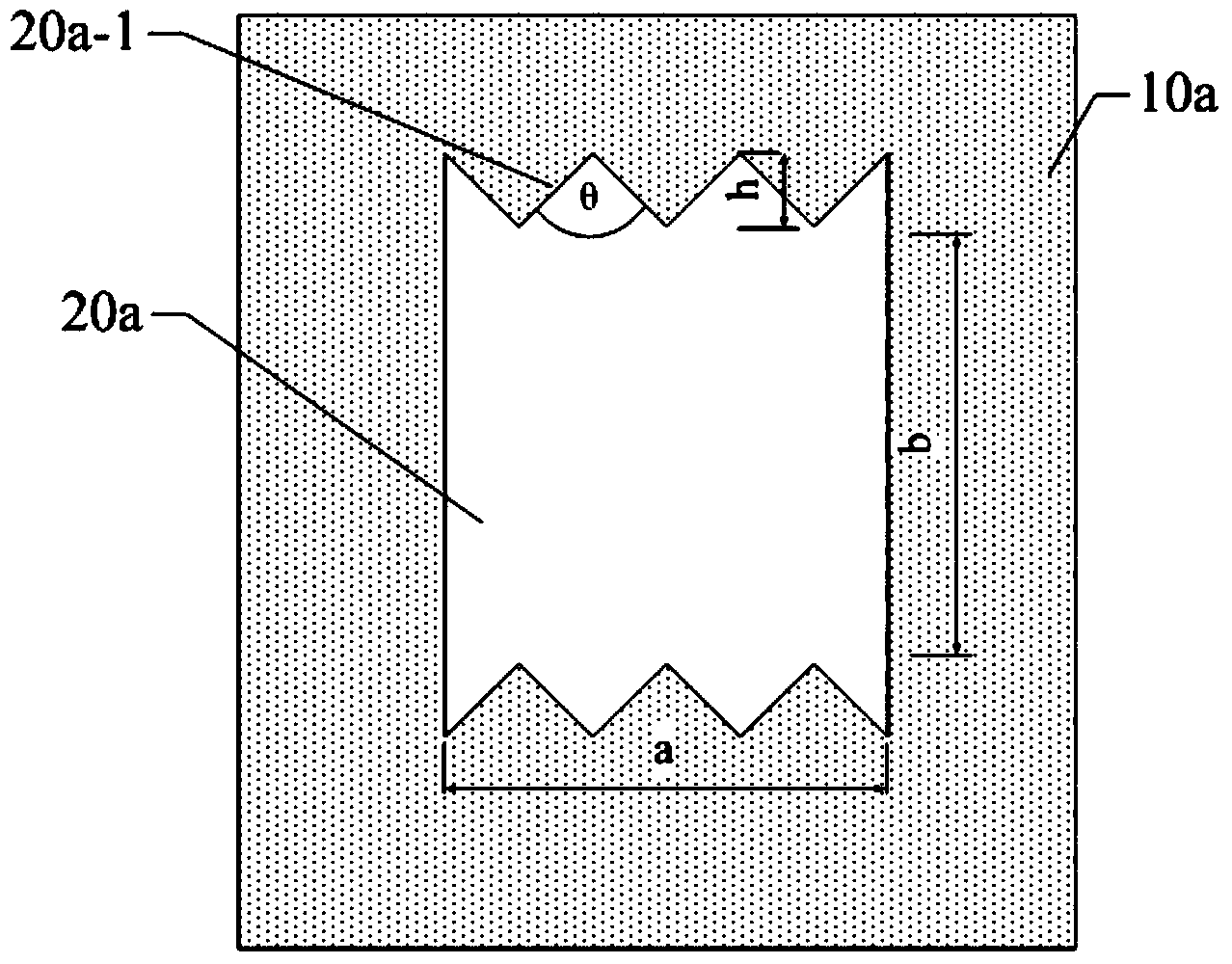

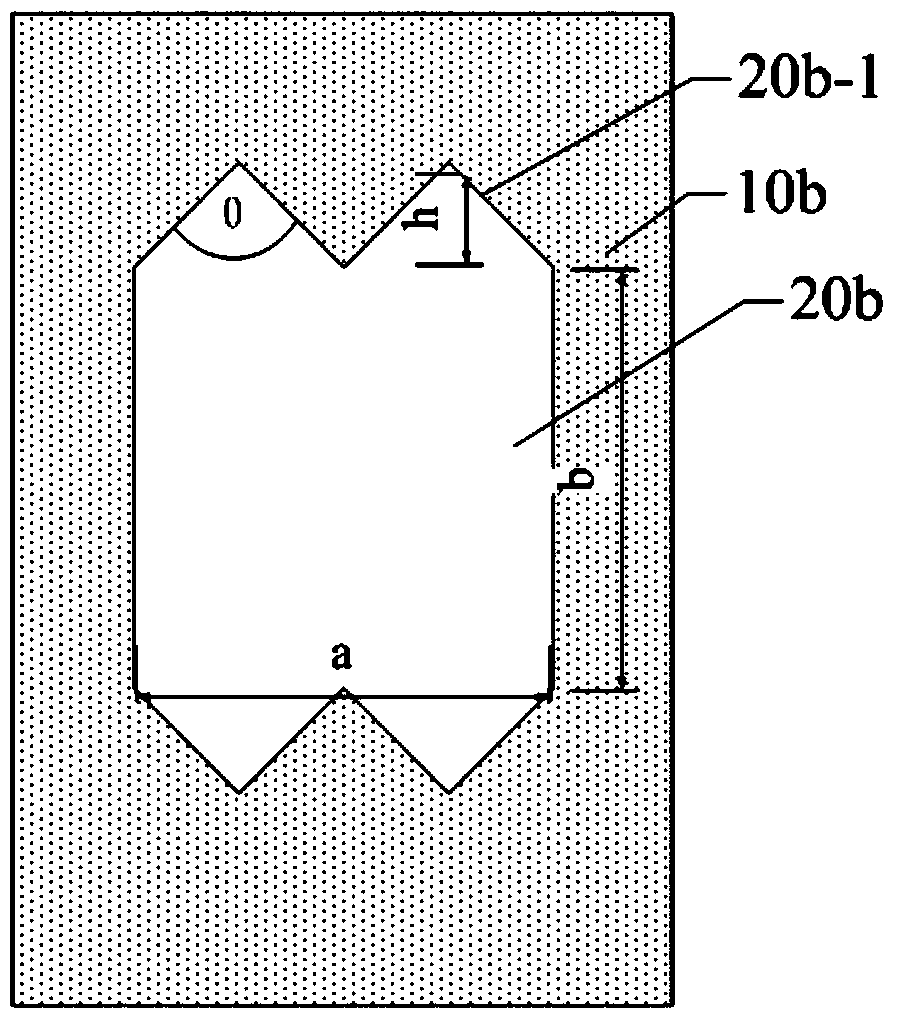

Mask plate and through hole forming method

InactiveCN103760748ASmall sizeIncrease exposurePhotomechanical exposure apparatusMicrolithography exposure apparatusImage resolutionEngineering

The invention relates to the technical field of display, and discloses a mask plate and a through hole forming method. A light-transmitting pattern is formed on the mask plate, and the edge of the light-transmitting pattern is curved. The mask plate is applicable to all positive photoresist materials and positive photosensitive resin materials which are required to be exposed and developed; the edge of the light-transmitting pattern of the mask plate is curved, so that the exposure amount of the overall pattern can be increased; the size of the curved edge is far less than the resolution of an exposure machine, so that only a small amount of photoresist or positive photosensitive resin on the curved edge is exposed, and most part of the photoresist or the positive photosensitive resin are remained; therefore, the overall size of a through hole is small and does not exceed 4 mu m, and the requirement for fine cabling under a high resolution is met.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

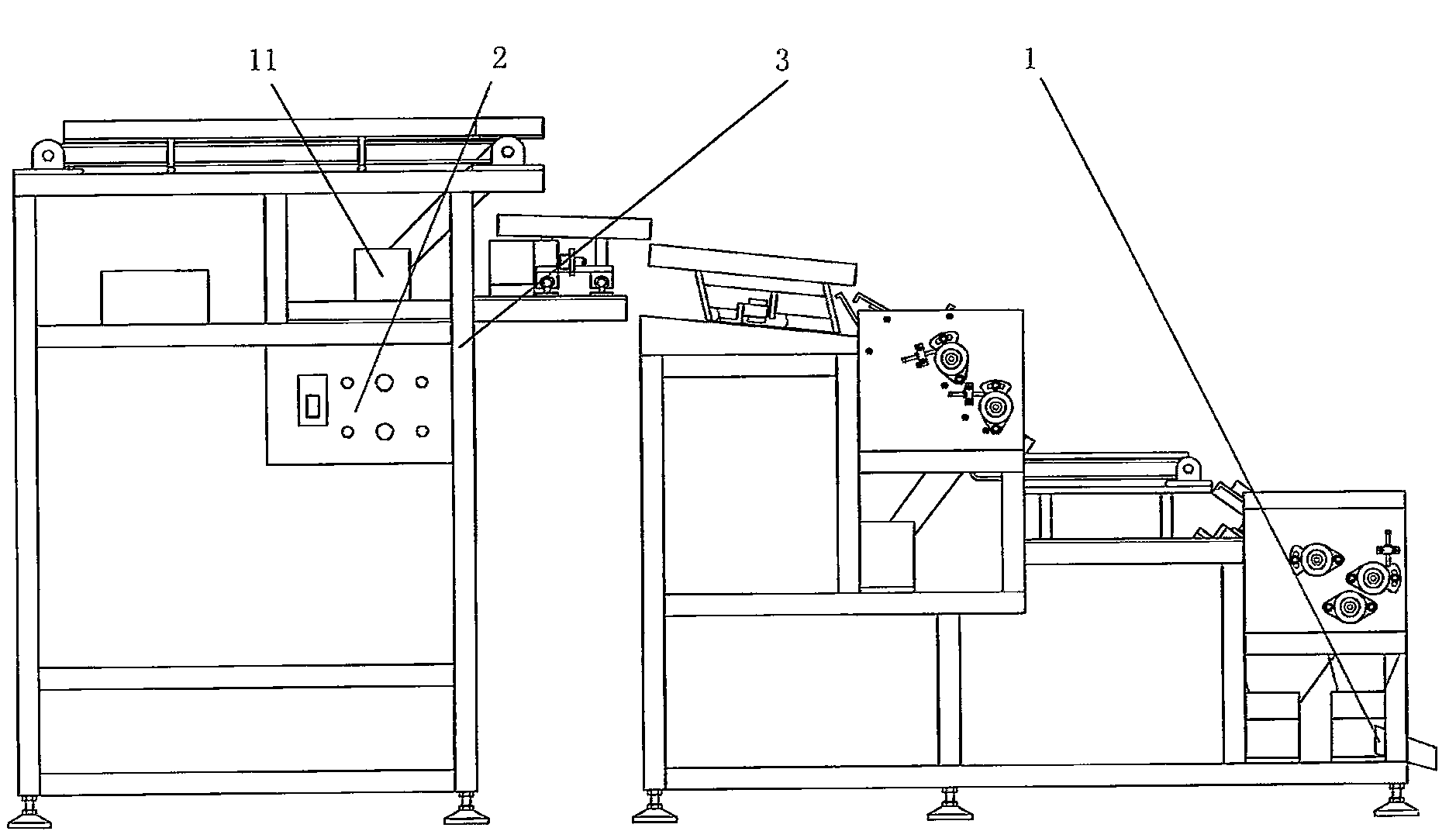

Diode lead-out line straightening machine

InactiveCN103071738AIncrease productivityAvoid blackeningSemiconductor/solid-state device manufacturingControl systemMechanical engineering

The invention discloses a diode lead-out line straightening machine, which comprises a primary straightening device, a transmission conveying device, an oscillation orientation precise straightening device, a finished product gathering hopper, a control system, a stander and a supply device enabling the diodes to be sequentially arranged at intervals. The supply device, the primary straightening device, the transmission conveying device and the oscillation orientation precise straightening device are sequentially connected with one another, the oscillation orientation precise straightening device comprises a first straightening roll, a second straightening roll, a material uniformly-distributing mechanism, a reversing device enabling the orientation of lead-out liens of the diodes to be in consistency, a second drive mechanism for driving the first straightening roll to rotate and supplying power to the material uniformly-distributing mechanism and a third drive mechanism for driving the second straightening roll to rotate, the first straightening roll and the second straightening roll make relative differential movement, and a precise straightening passage with an adjustable gap and capable of dropping the diodes processed by the material uniformly-distributing mechanism is arranged between the first straightening roll and the second straightening roll. Through twice screening, the twisting, broken pin and reject phenomenon of the diodes in the straightening process can be avoided, and the phenomenon that the diode misses the straightening also can be avoided.

Owner:张成骏

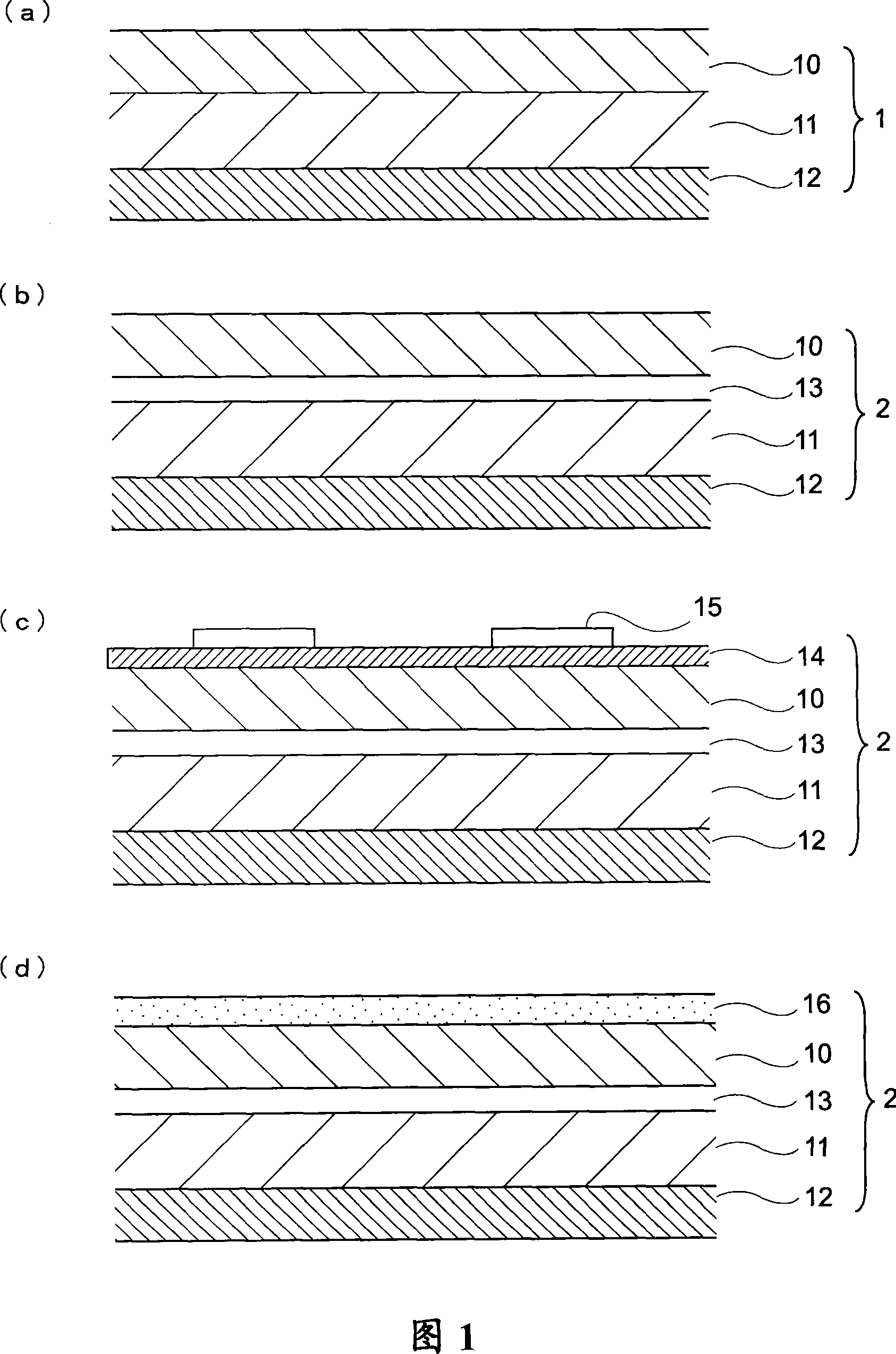

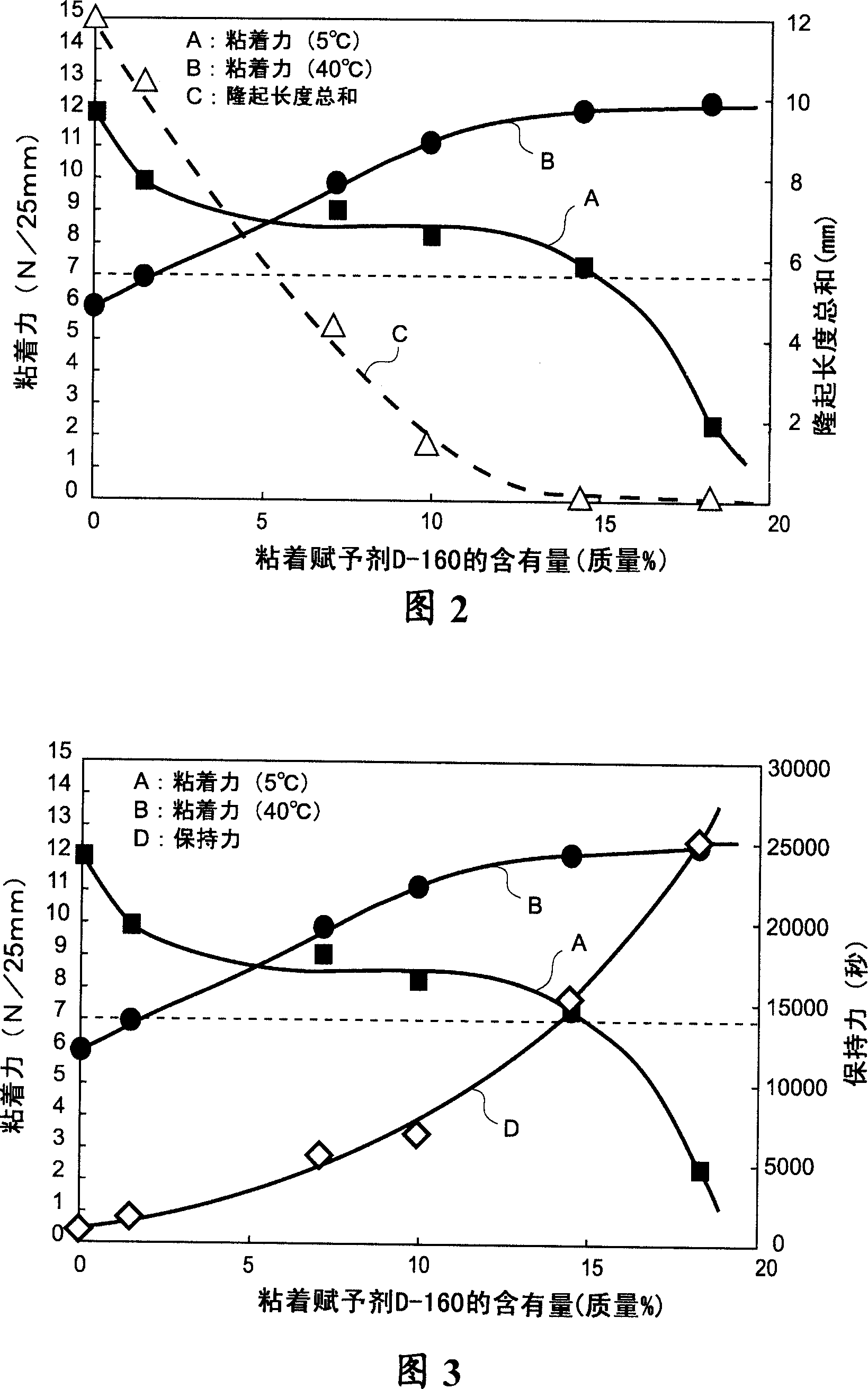

Adhesive sheet for tire

ActiveCN1989215AEasy to adjust adhesionEasy to adjust cohesionStampsFilm/foil adhesivesPressure sensitiveChemistry

A pressure-sensitive adhesive sheet for a tire which has a base material and a pressure-sensitive adhesive layer, wherein said pressure-sensitive adhesive layer comprises a hot-melt type adhesive composition and further satisfies the following pressure-sensitive adhesion characteristics (A) and (B): (A) it exhibits a value of 7 N / 25 mm or more in terms of the pressure-sensitive adhesion strength to a SBR plate at 5 DEG C, and (B) it exhibits a value of 7 N / 25 mm or more in terms of the pressure-sensitive adhesion strength to a SBR plate at 40 DEG C. The above pressure-sensitive adhesive sheet exhibits a high pressure-sensitive adhesion strength to a tire in a wide range of temperature region and has a good pressure-sensitive adhesion strength also to a studless tire.

Owner:LINTEC CORP

Device for operation of a discharge lamp of the short arc type

InactiveUS20060108949A1Easy to useSmall time intervalElectric light circuit arrangementHigh-pressure discharge lampsFeeding durationAlternating current

A device for operating a discharge lamp of the short arc type having a feed device which supplies a direct current to the discharge lamp when operation starts and an alternating current afterwards, in which the feed device supplies a direct current which is smaller than the rated current to the discharge lamp at the start of operation, and a direct current which is at least as large as the rated current, afterwards. A control which ascertains whether the discharge lamp at the start of operation is in a hot or cold start operating state, and which establishes one of the following parameters based on whether the hot or cold operating state ascertained to exist: the value of the direct current which is at least as great as the rated current; the feed duration of the direct current which is at least as great as the rated current.

Owner:USHIO DENKI KK

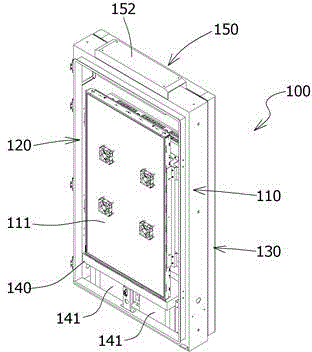

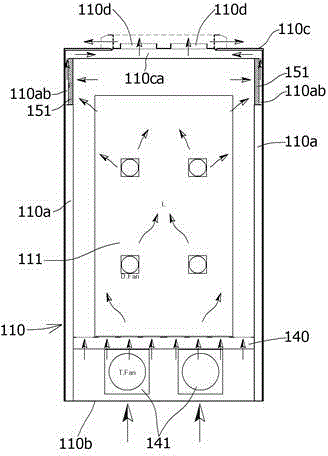

Outdoor advertisement display device installation frame for the bus shelter

InactiveCN104424865AImprove cooling effectPrevent blackeningMachine supportsCooling/ventilation/heating modificationsDisplay deviceEngineering

The invention relates to an outdoor advertisement display device installation frame for the bus shelter. The installation frame comprises a case frame used for containing and installing a display device for bus shelter advertising. The case frame comprises a main frame with a space formed therein. The space can accommodate and install an LCD plate for advertisement displaying and a controller for controlling the LCD plate. The case frame also comprises a switching door frame arranged in front of the main frame and used for opening and closing, and a rear fixing frame arranged behind the main frame and used for fixing the controller. The lower end of the main frame is provided with an air inlet pipeline used for making outside air supplied to the lower side of the LCD plate through a turbo fan. The upper end of the main frame is provided with a cover body frame composed of a filter used for purifying and discharging outside air passing through the LCD plate and an air discharge pipeline discharging air and preventing inflows of rainwater. Blackening phenomena of the LCD plate can be prevented by effectively cooling heat generated on the front and the back of the LCD plate. Durability is thus improved.

Owner:铺莱默斯株式会社

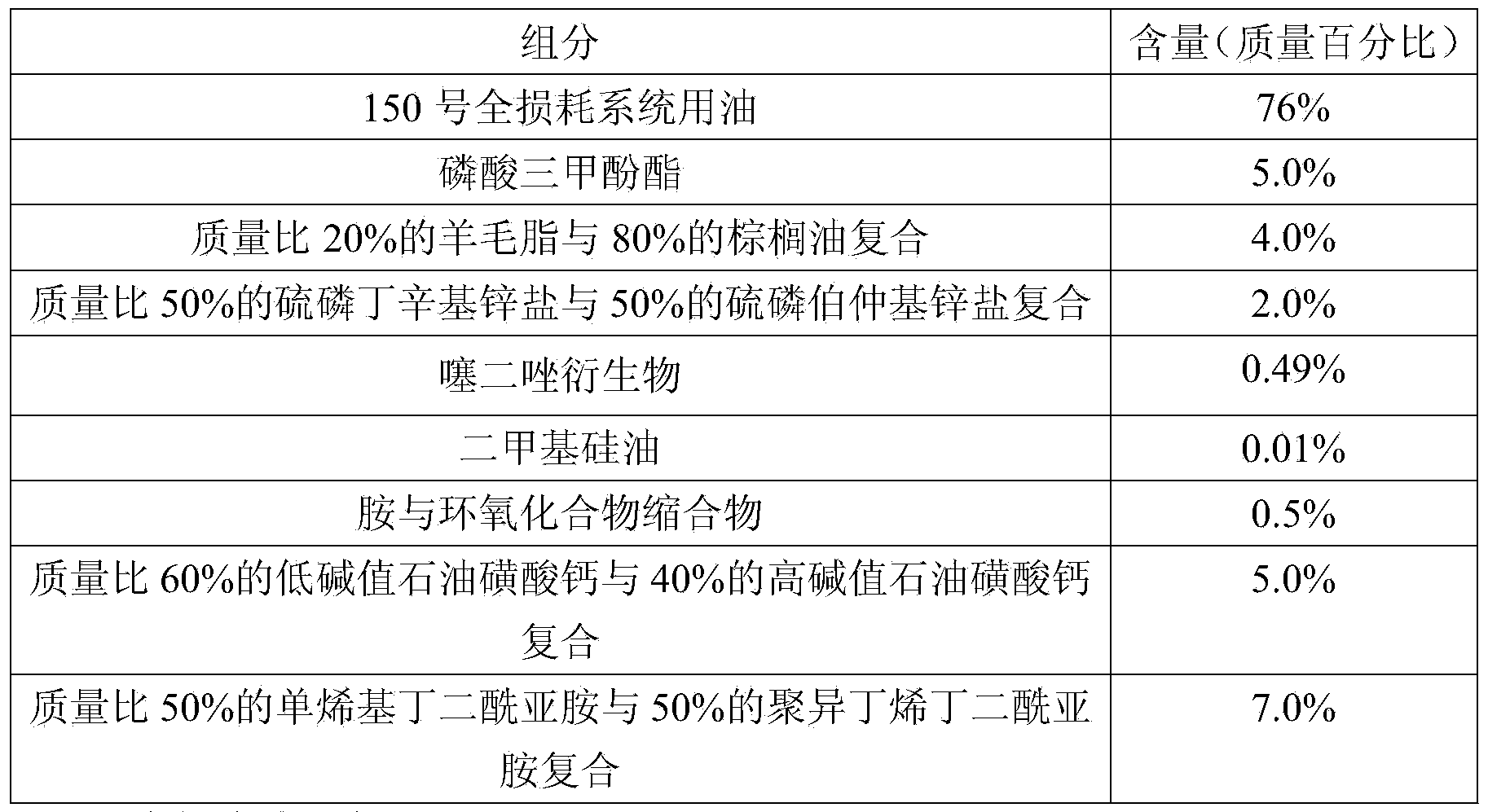

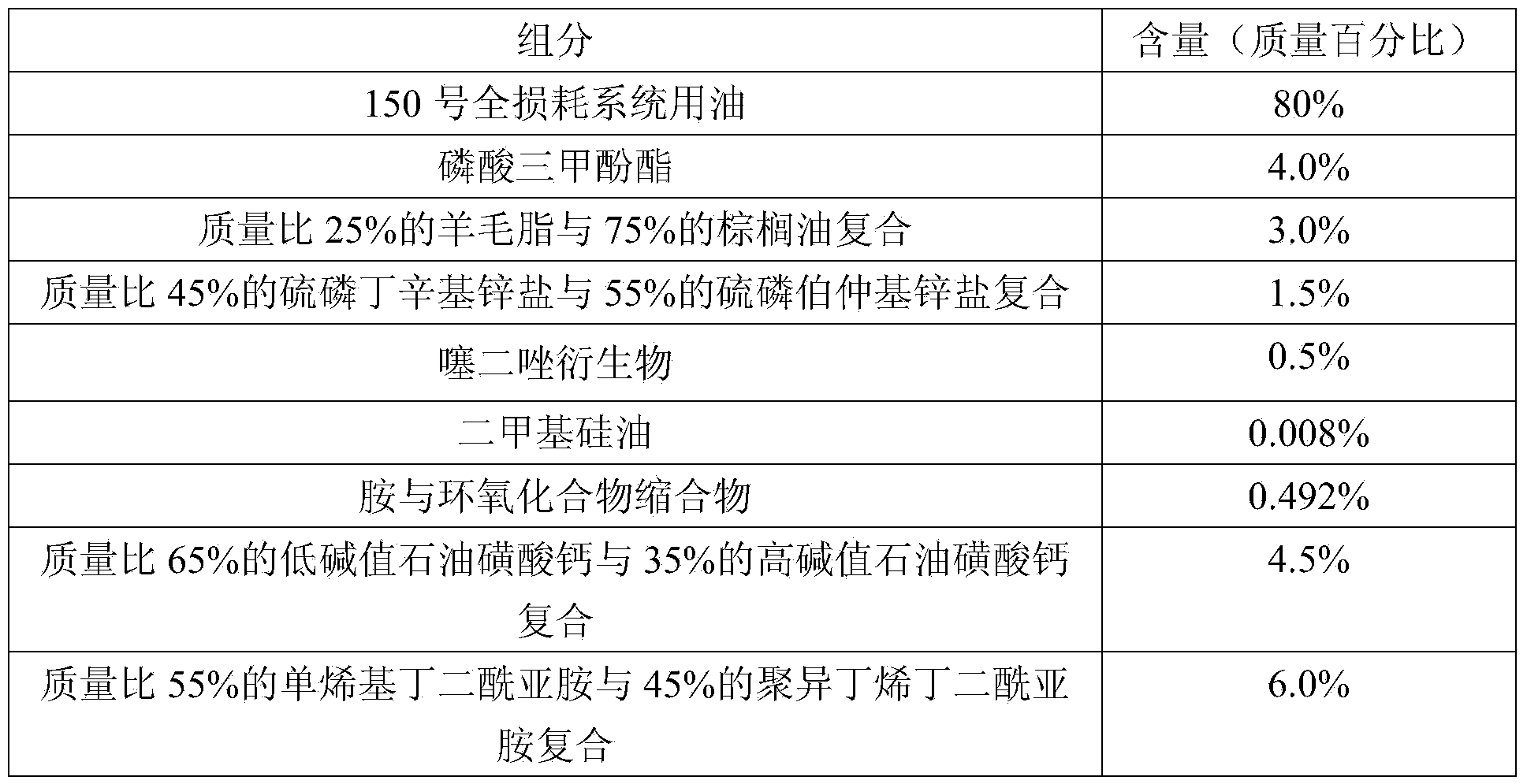

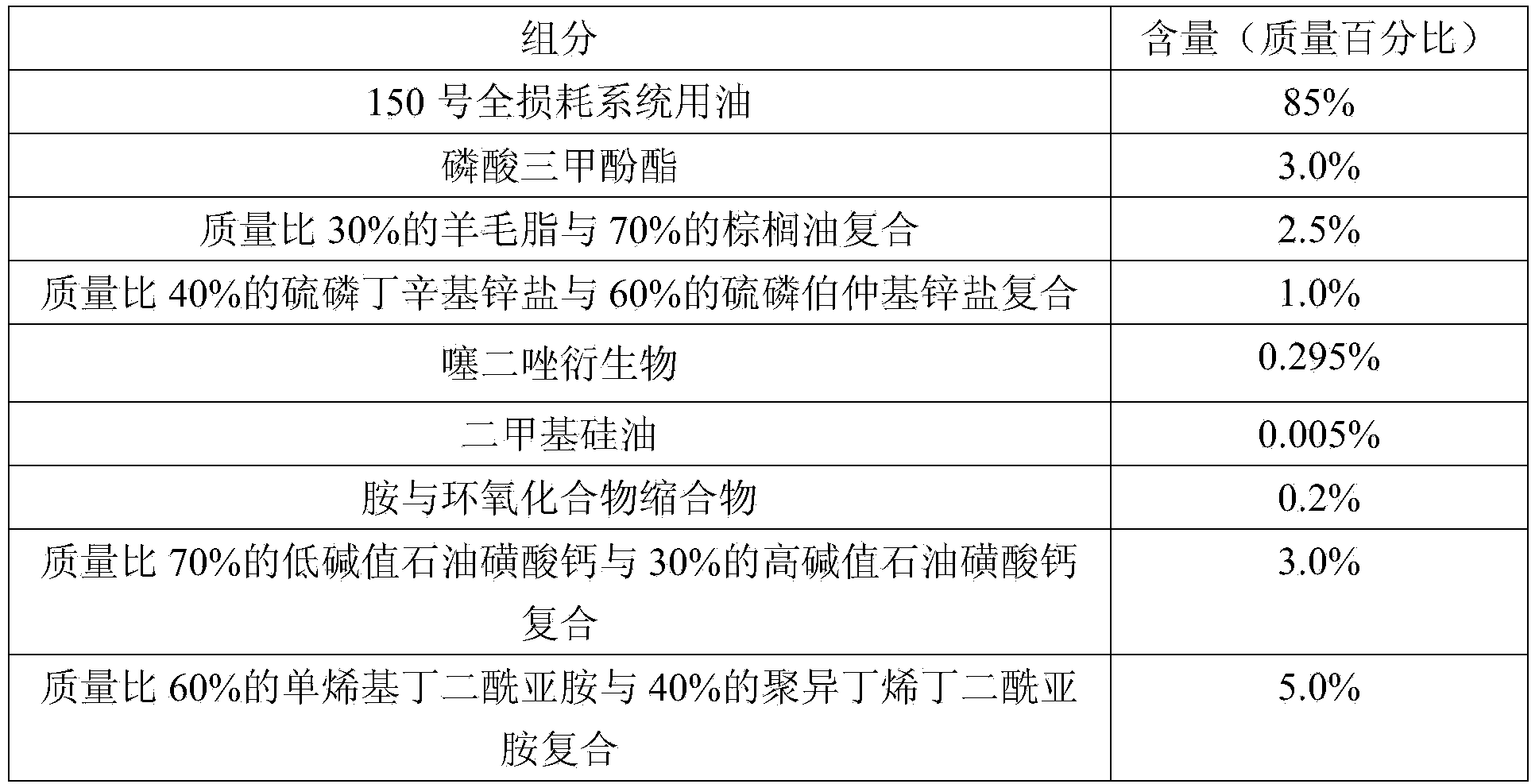

Hot rolling lubricant for titanium and titanium alloy strips

The invention relates to a hot rolling lubricant for titanium and titanium alloy strips. The lubricant uses #150 total loss oil for a system as basic oil, and is matched with a plurality of composite additives. The lubricant comprises an antiwear agent, an oiliness agent, an antioxidant preservative, an antioxygen, an anti-foaming agent, a demulsifying compound, a clearing agent, a dispersant and the like. The lubricant has cooling, lubricating and cleaning properties, and can be used for reducing the extent of the roller adhered to titanium and reducing damage caused by adhesion on the surfaces of the plate and strip, and avoiding a possible melanism phenomenon of the lubricant.

Owner:GUANGXI UNIV

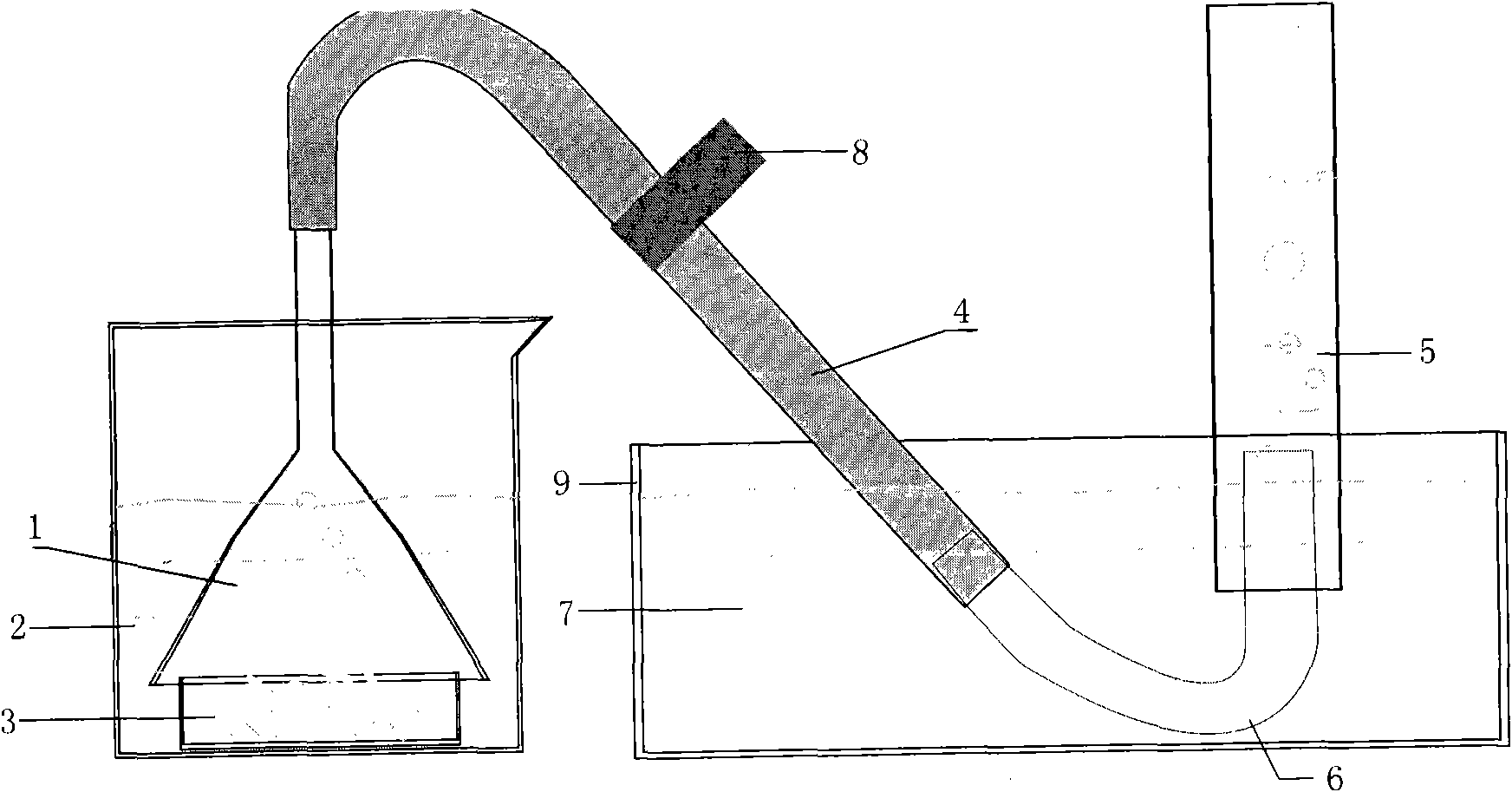

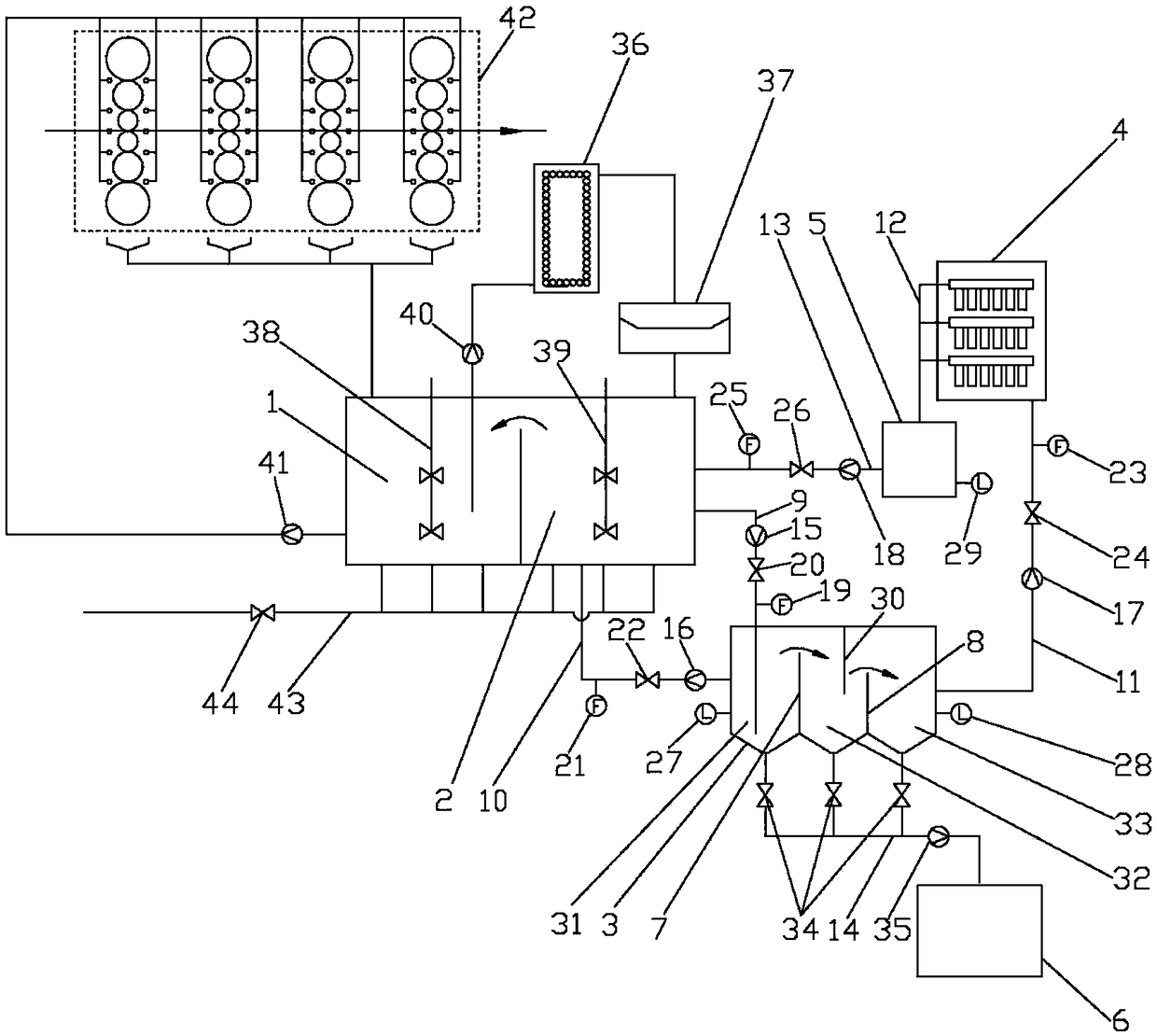

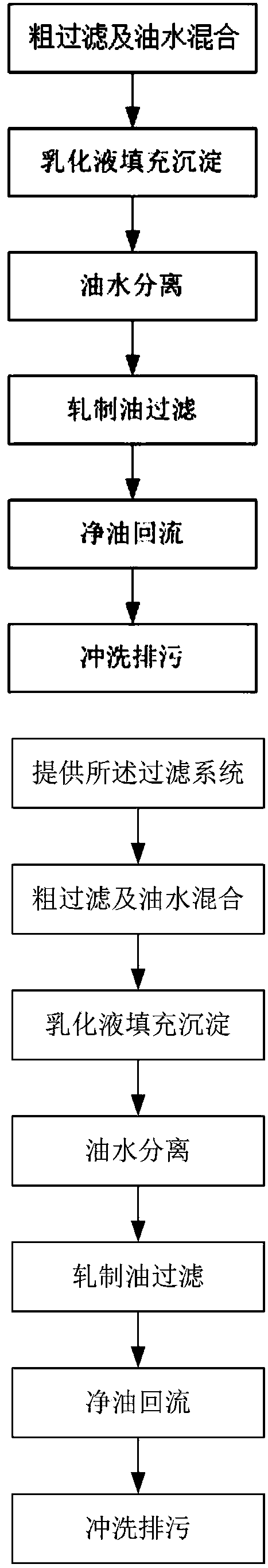

Emulsion filtration system and method for cold continuous rolling of stainless steel

ActiveCN108187402AImprove filtration efficiencyImprove filtering effectFiltration circuitsEmulsionFiltration

The invention discloses an emulsion filtration system for cold continuous rolling of stainless steel. The emulsion filtration system comprises a contaminated emulsion tank, a filtering device, a purified emulsion tank, a standing tank, a rolling oil filter, a purified oil tank and a sewage discharge tank, wherein the bottom part of the contaminated emulsion tank and the bottom part of the purifiedemulsion tank respectively communicate with a compressed air pipeline in a workshop; the purified emulsion tank and the standing tank are in communication; the standing tank and the rolling oil filter are in communication; the rolling oil filter and the purified oil tank are in communication; the purified oil tank and the purified emulsion tank are in communication; the bottom part of the standing tank communicates with the sewage discharge tank; and the interior of the standing tank is provided with a first overflow plate and a second overflow plate. The invention also provides an emulsion filtration method for cold continuous rolling of stainless steel. The invention has the following beneficial effects: the emulsion filtration system and method provided by the invention realize sedimentation of large-sized particles and oil-water separation of an emulsion through arrangement of the standing tank, can filter rolling oil rich in small-sized particular impurities by utilizing the rolling oil filter, can remove 90% or more particular impurities, and have high filtering efficiency and good filtering effect.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com