Magnesium alloy cutting fluid and preparation method thereof

A technology of cutting fluid and magnesium alloy, which is applied in the direction of lubricating composition and petroleum industry, can solve the problems of increased water hardness, reduced anti-rust performance of cutting fluid, and corrosion of machine tools, so as to enhance the ability to resist hard water, control bacterial reproduction, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

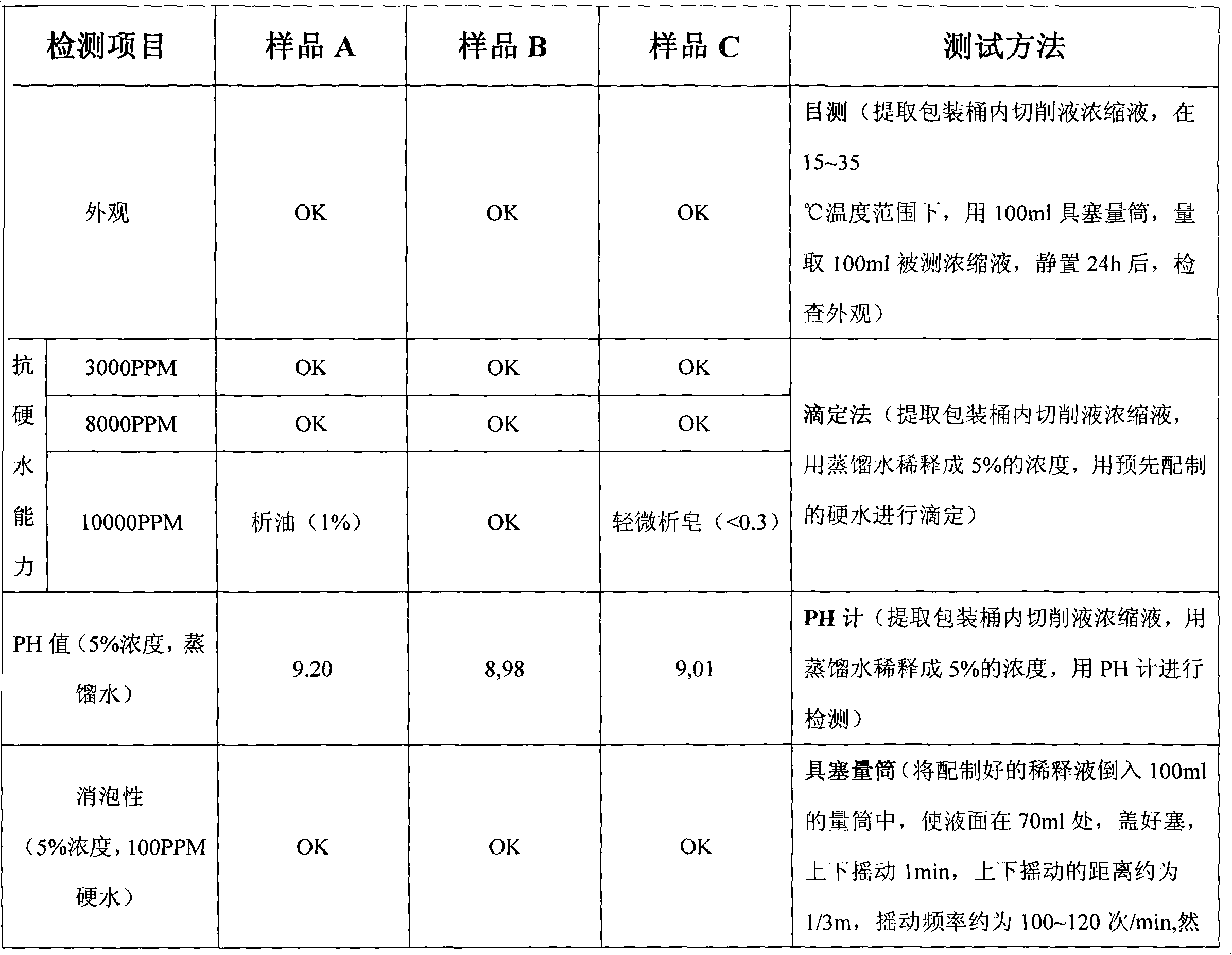

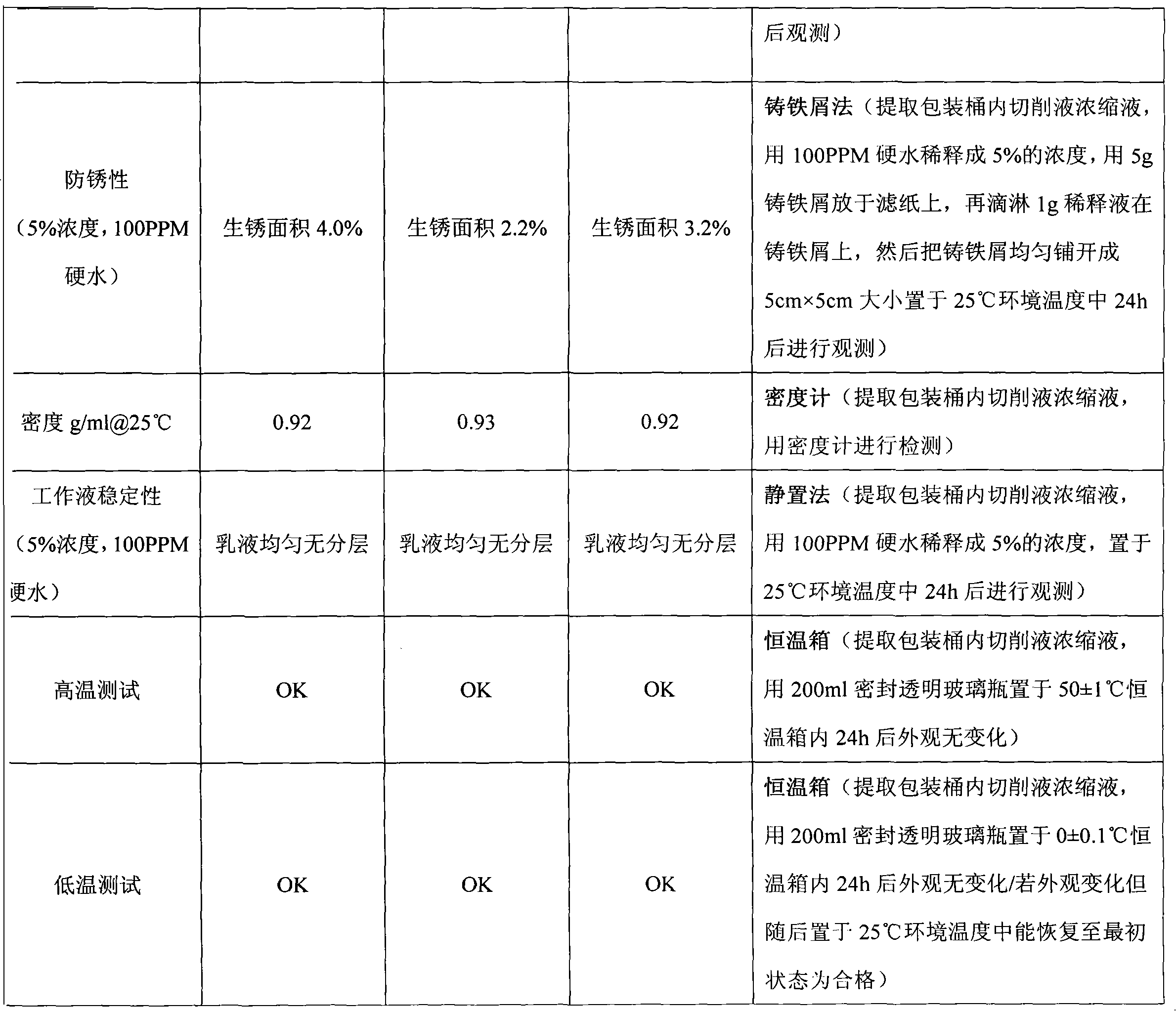

[0025] When preparing cutting fluid, the mass percentage of raw materials used is: water 23%, EDTA4 sodium 4.0%, isopropanolamine 5%, naphthenic base oil 40%, T702 6.0%, phosphate ester 6.0%, AEO-9 4.5% , Fungicide 3.5%, Span 80 8%. The cutting fluid sample A was formulated according to the above ratio, and the sample quality test was carried out.

Embodiment 2

[0027] When preparing cutting fluid, the mass percentages of raw materials used are: water 20%, EDTA4 sodium 4.0%, isopropanolamine 5%, naphthenic base oil 45%, T702 6.0%, phosphate ester 6.0%, AEO-9 4.5% , Fungicide 3.5%, Span 80 6%. According to the above proportions, the cutting fluid sample B was prepared, and the sample quality test was carried out.

Embodiment 3

[0029] When preparing cutting fluid, the mass percentages of raw materials used are: water 28%, EDTA4 sodium 4.0%, isopropanolamine 5%, naphthenic base oil 35%, T702 6.0%, phosphate ester 6.0%, AEO-9 4.5% , Fungicide 3.5%, Span 80 8%. According to the above ratio, the cutting fluid sample C was prepared, and the sample quality test was carried out.

[0030] The sample that above-mentioned three embodiments obtain is detected:

[0031]

[0032]

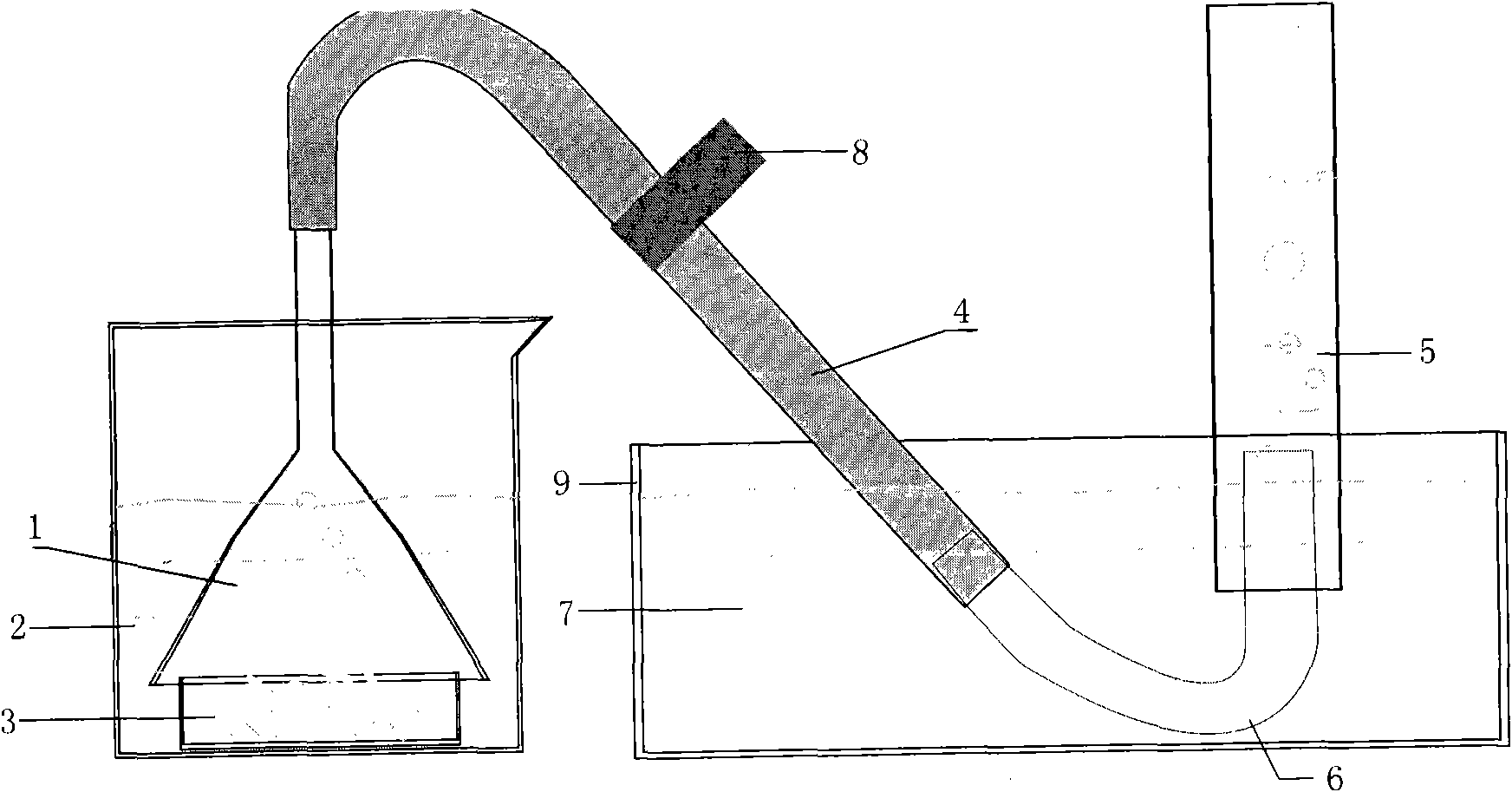

[0033] Combined with the accompanying drawings, when conducting experiments on magnesium alloy cutting fluid, the operation steps are as follows:

[0034] The first step is to fill the graduated test tube 5 with water, block the mouth of the test tube with your index finger and place it upside down in the sink 9 filled with water 7;

[0035] In the second step, connect the hose 4 and the elbow 6 and sink them into the water tank, make the interior full of water and clamp the hose with the clamp 8, and then insert one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com