Patents

Literature

1046 results about "Hard water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard water is water that has high mineral content (in contrast with "soft water"). Hard water is formed when water percolates through deposits of limestone, chalk or gypsum which are largely made up of calcium and magnesium carbonates, bicarbonates and sulfates.

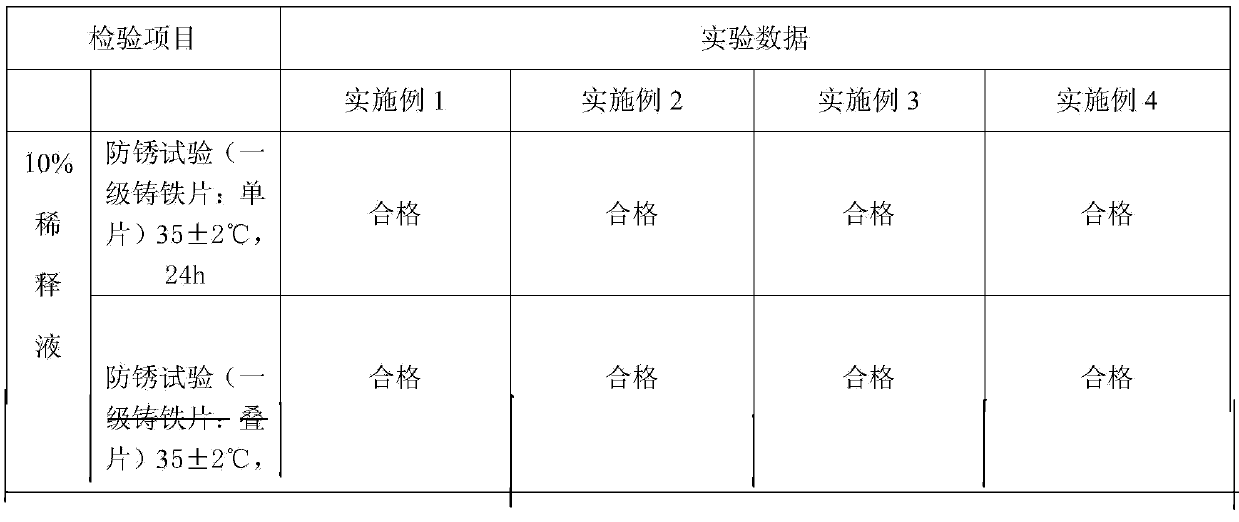

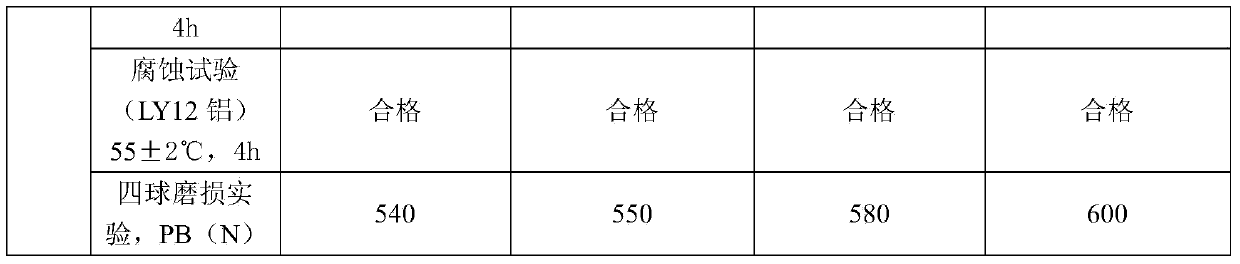

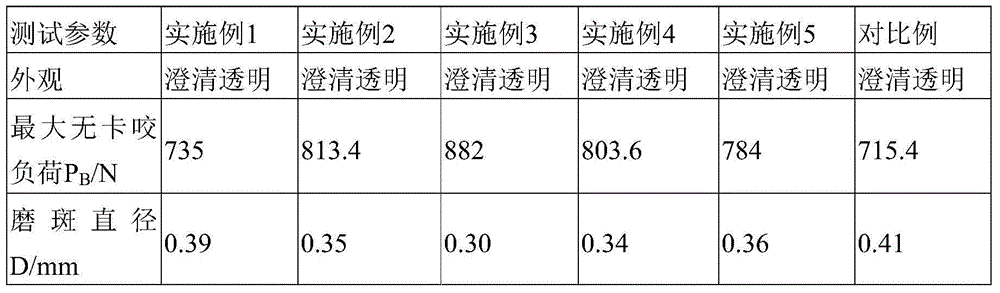

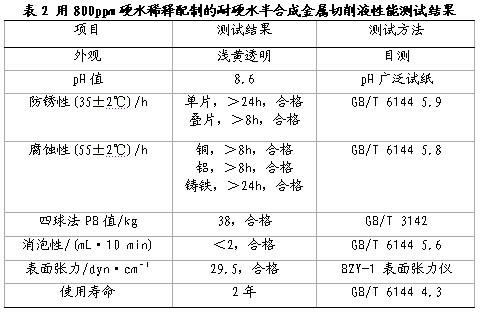

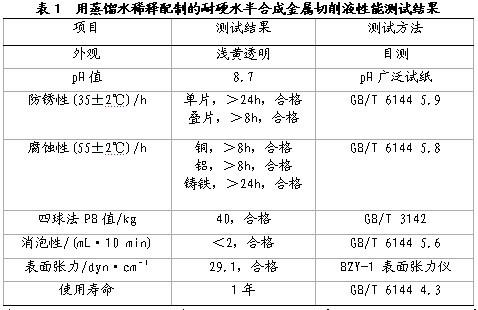

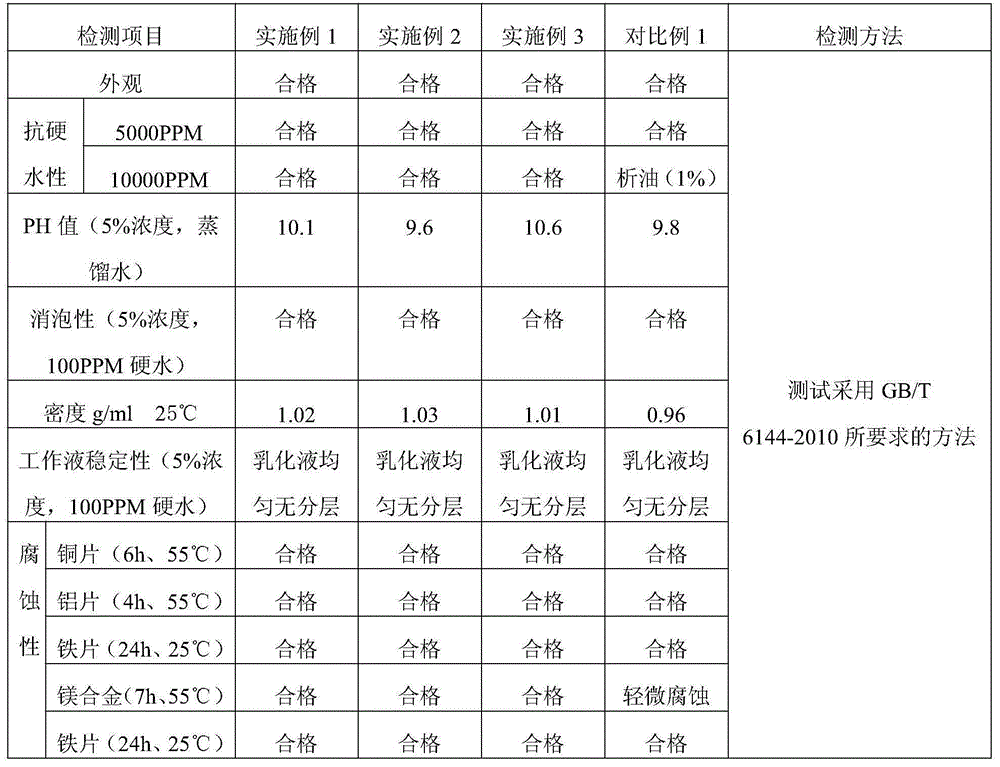

Boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof

The invention discloses a boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof. The microemulsified cutting fluid is prepared from the following raw materials in percentage by mass: 30-60% of base oil, 1-5% of rust inhibitor, 0-5% of extreme pressure agent, 1.5-8% of bactericide, 3-15% of mixed base, 0-5% of coupling agent, 1-8% of anti-hard water agent, 1.2-5% of corrosion inhibitor, 5-20% of lubricant, 3-15% of anionic surfactant, 3-20% of emulsifier and the balance of water. The microemulsified cutting fluid disclosed by the invention has excellent lubricating properties, and can simultaneously satisfy multiple processing modes, including fraising, boring, tapping, threading, high-speed milling, hole drilling and the like. The microemulsified cutting fluid is especially suitable for processing electronic aluminum alloys. In addition, the microemulsified cutting fluid has the advantages of excellent defoaming property, excellent wettability, high raw liquor stability, high emulsifying stability, high biological stability, longer service life, lower consumption and lower cost.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

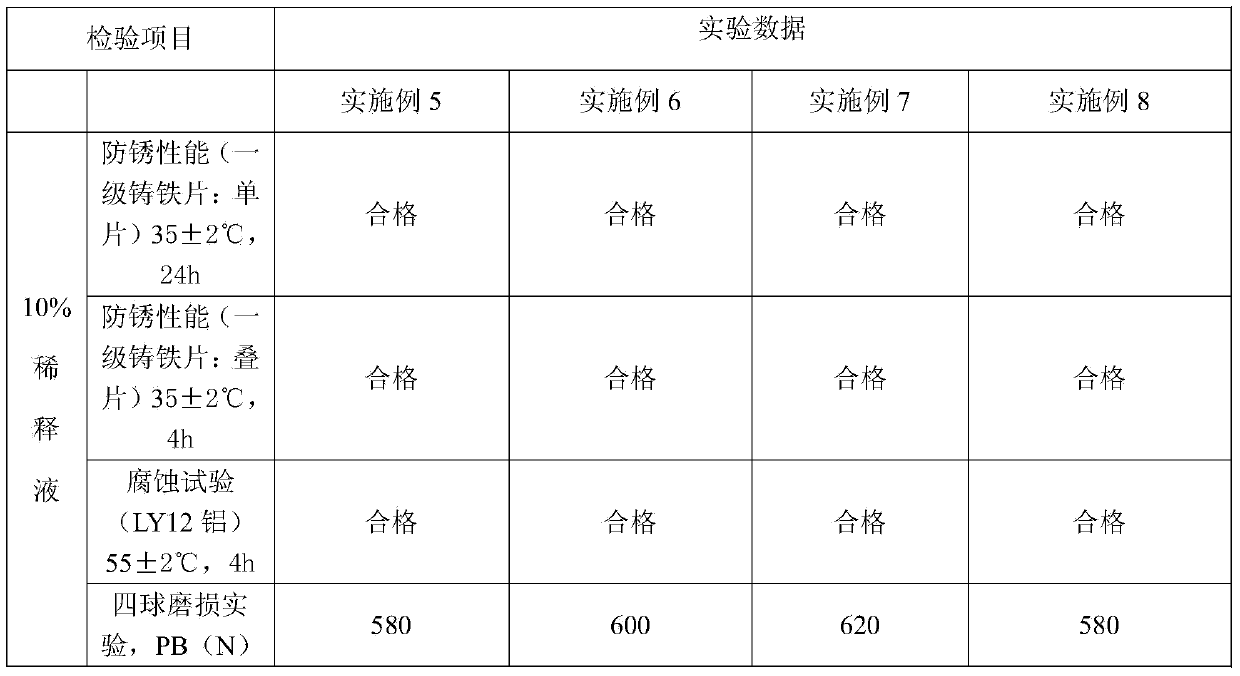

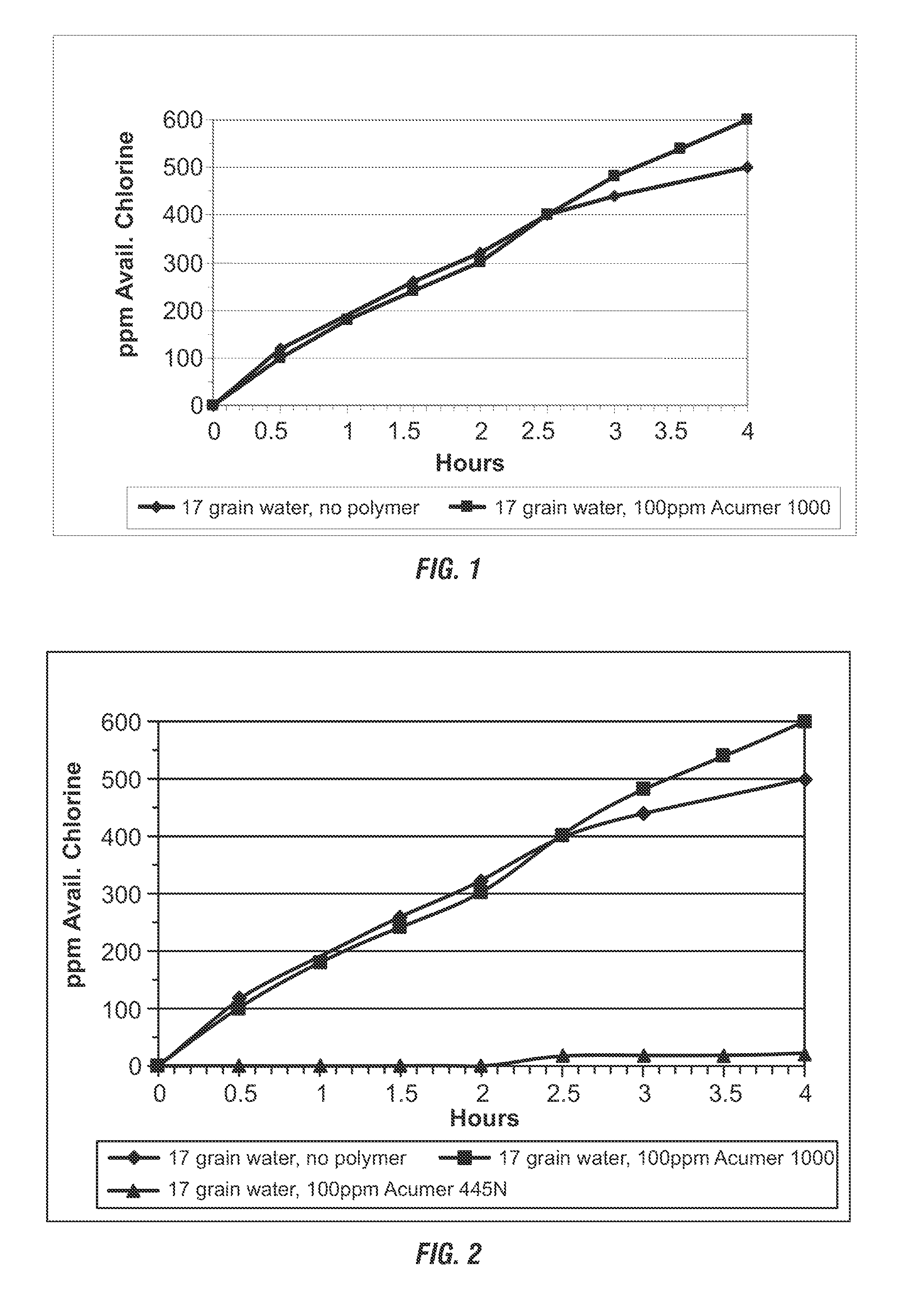

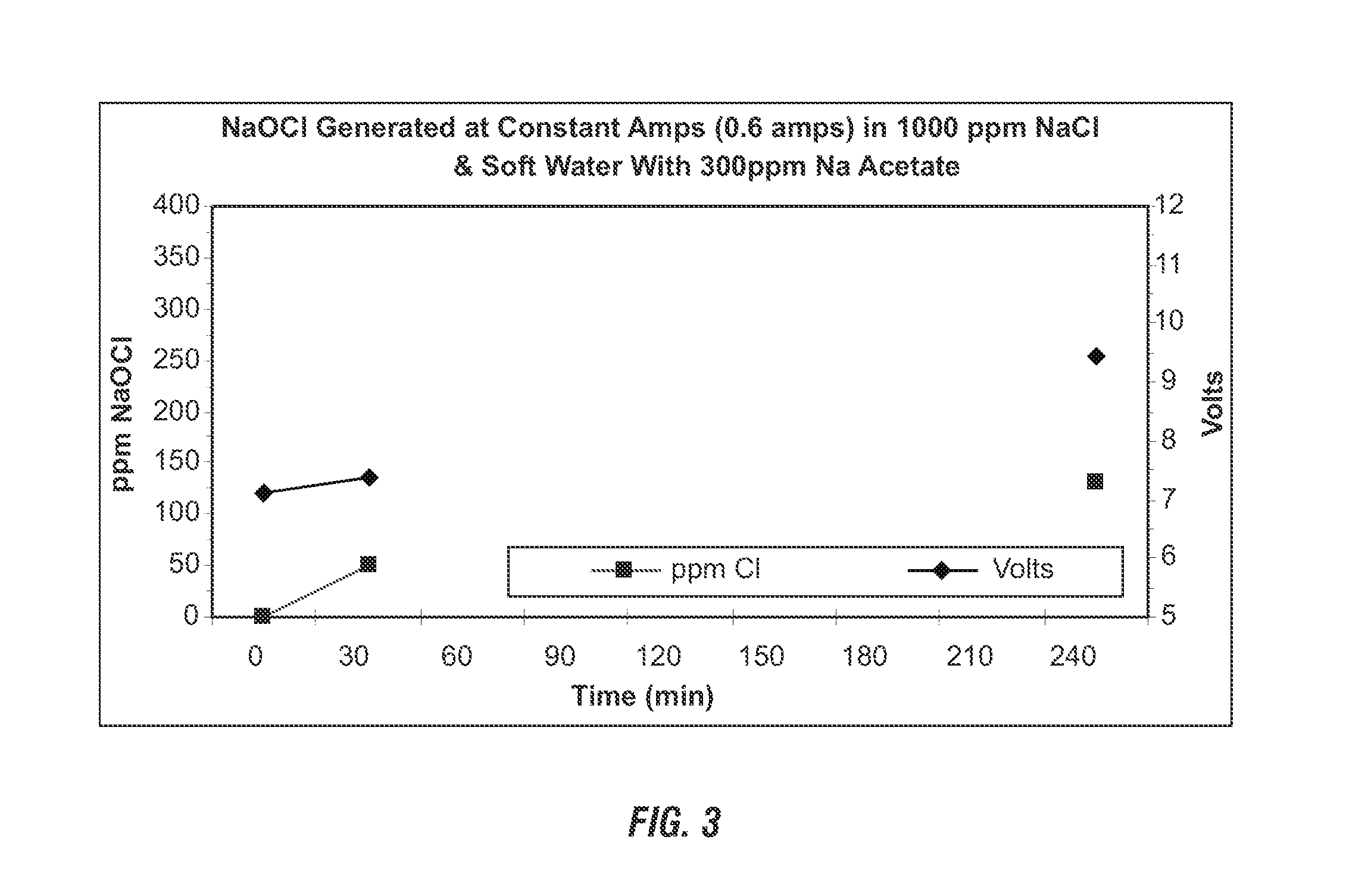

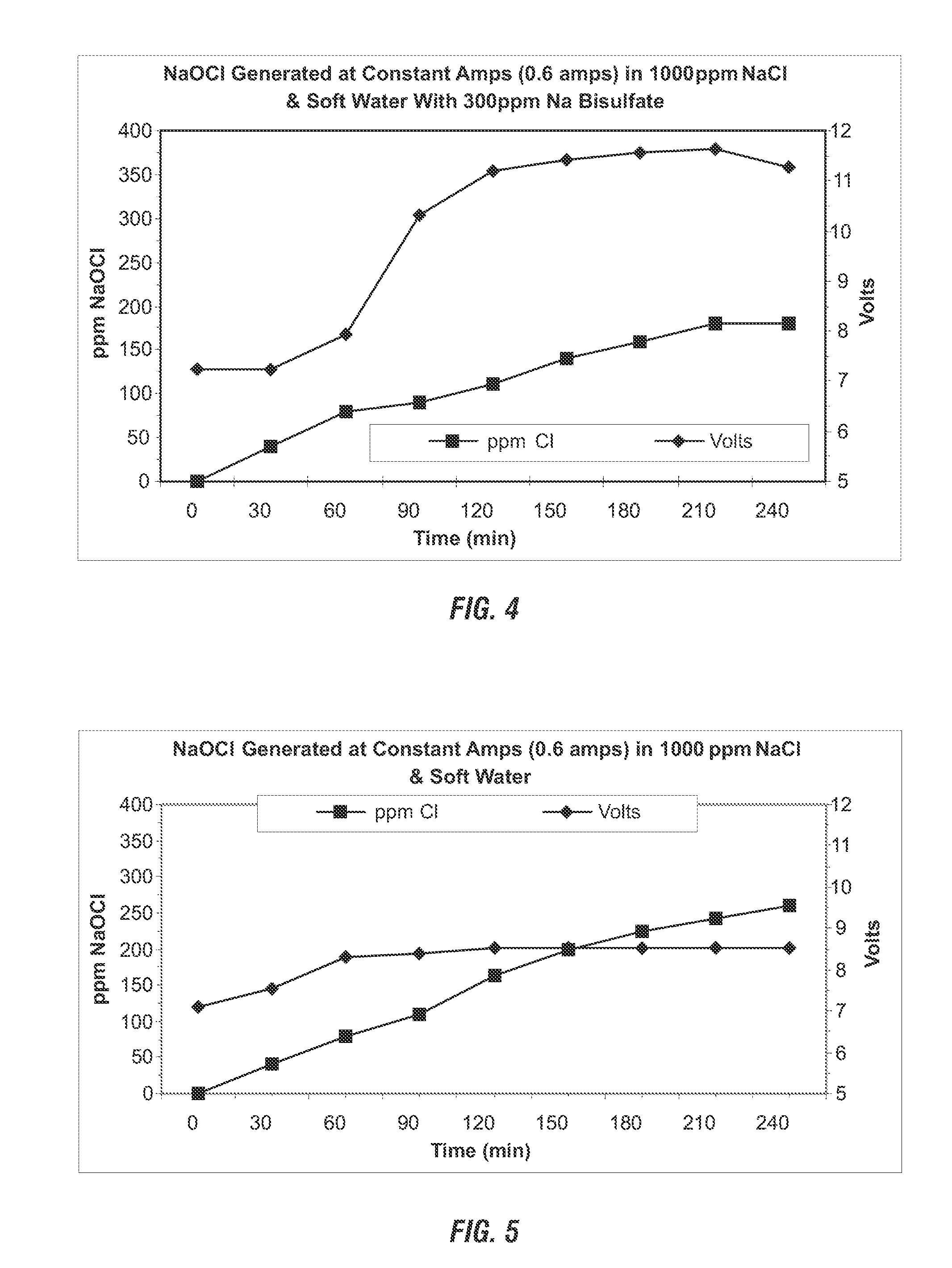

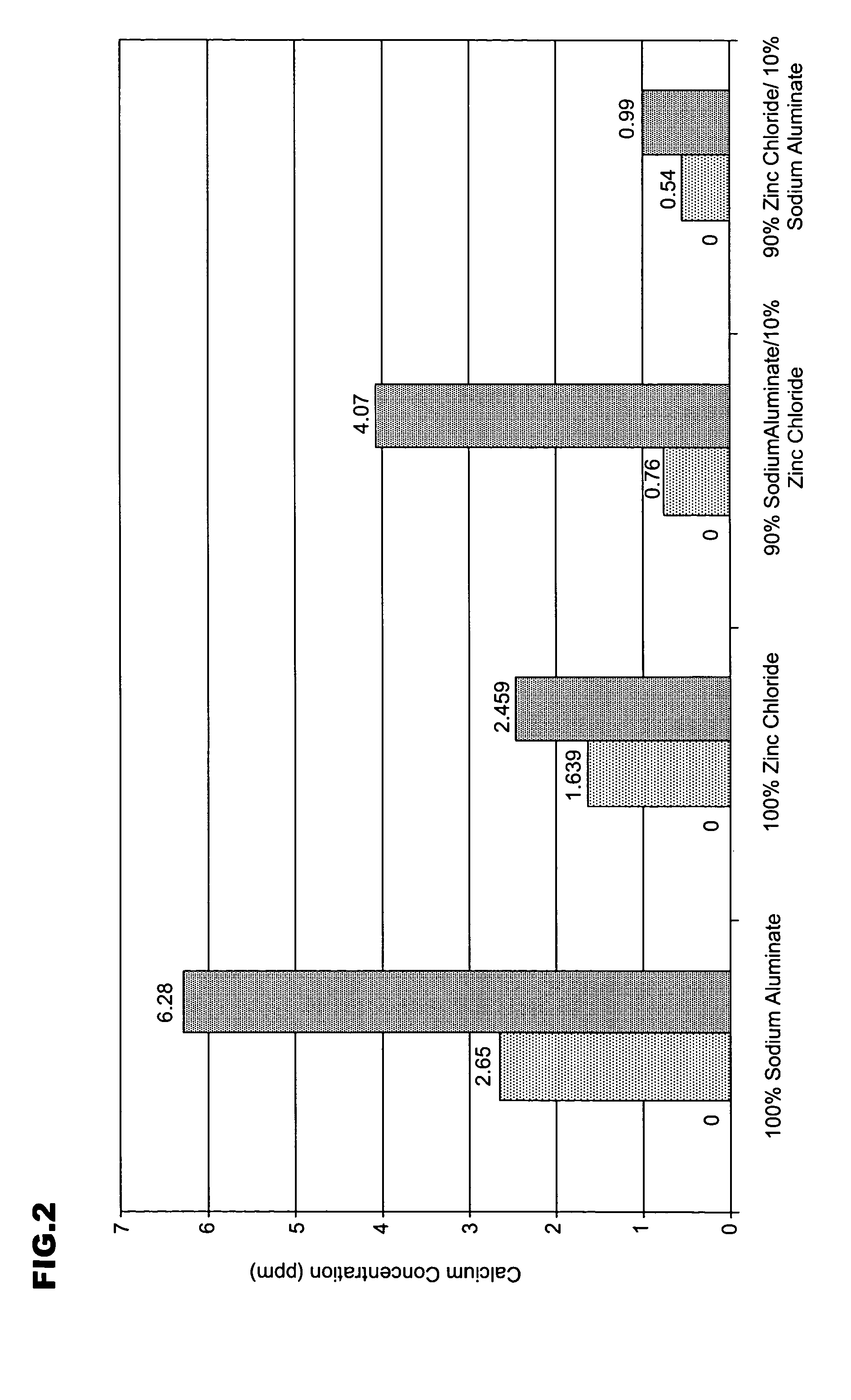

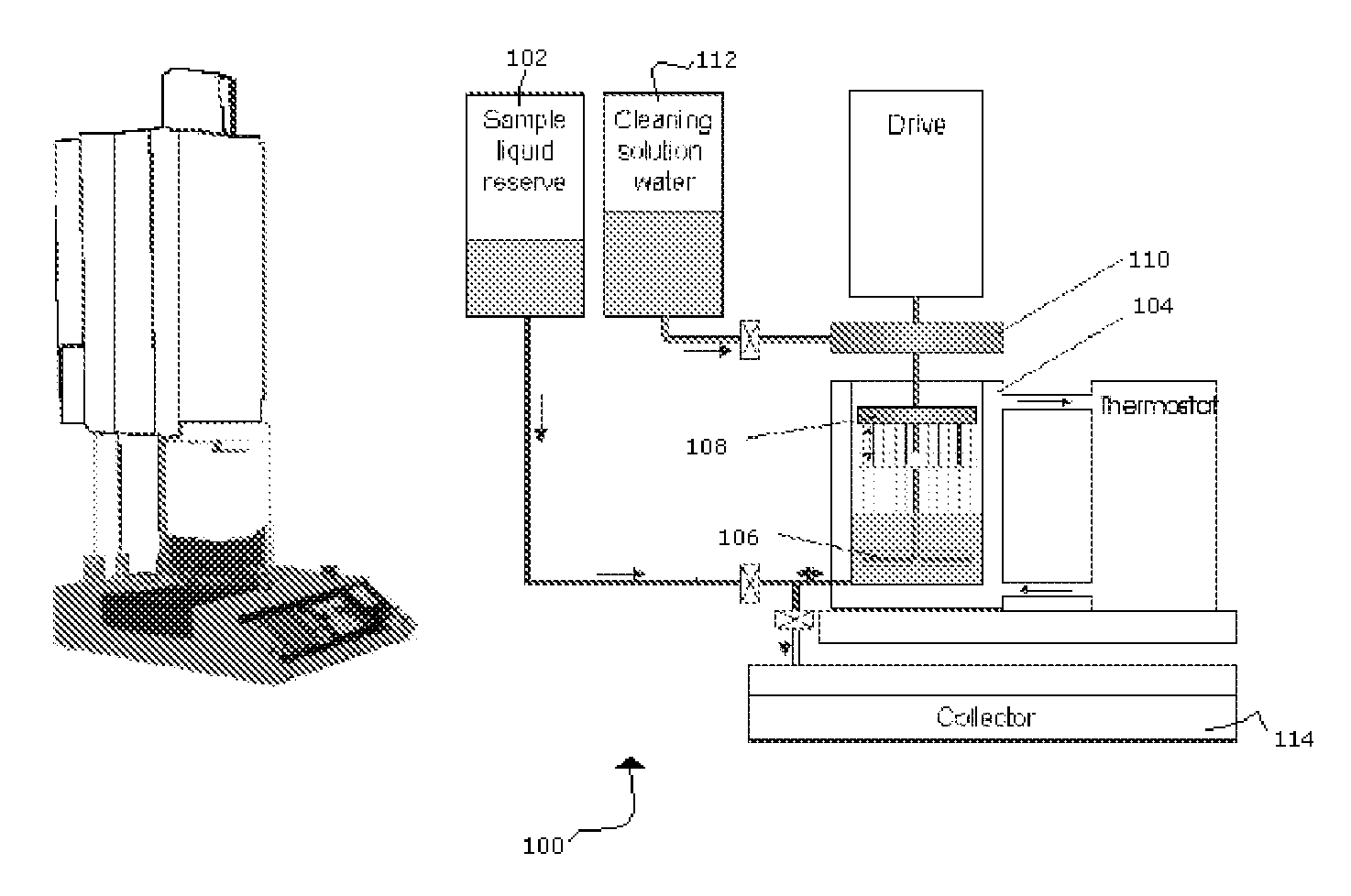

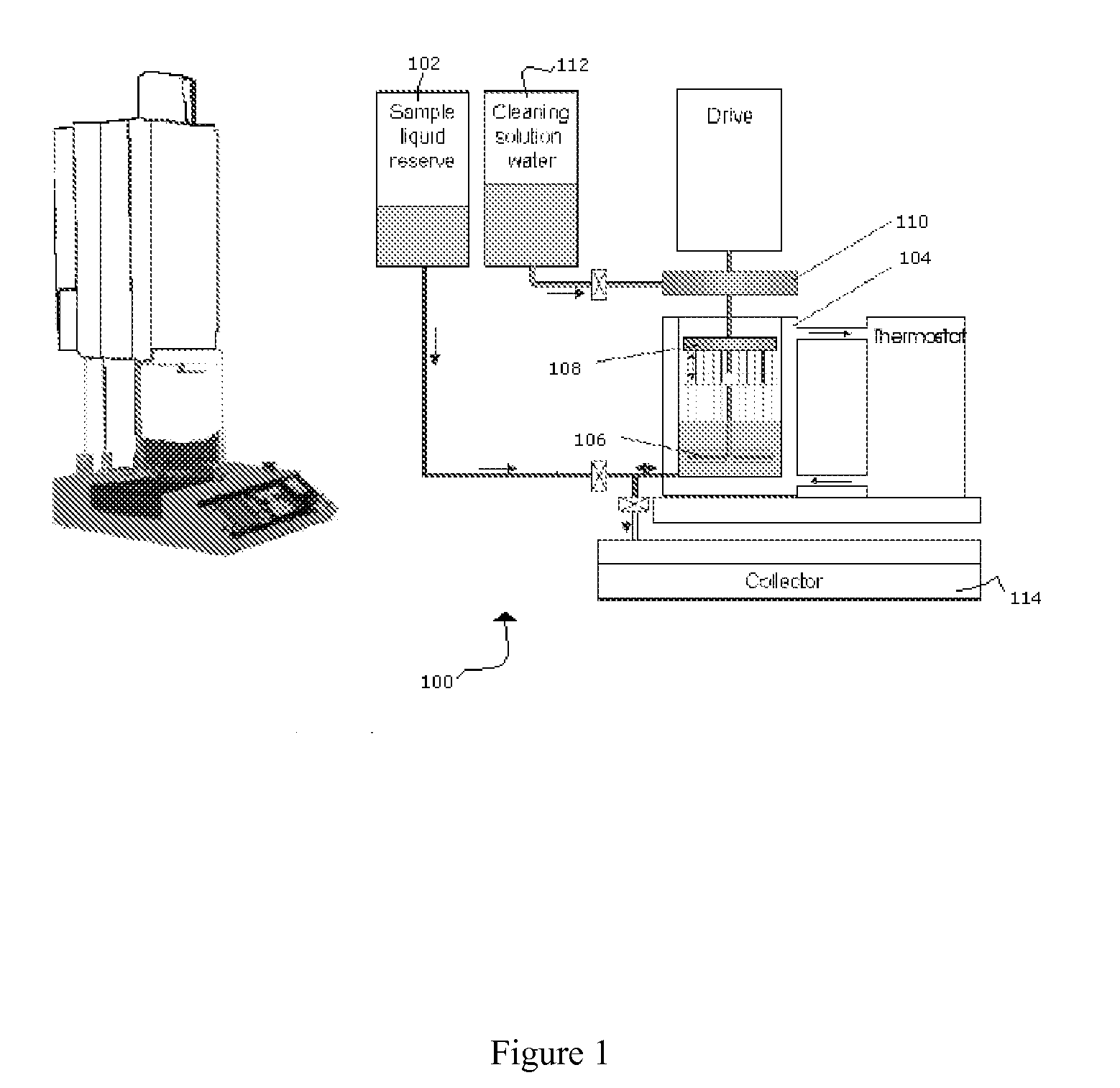

Control of hard water scaling in electrochemical cells

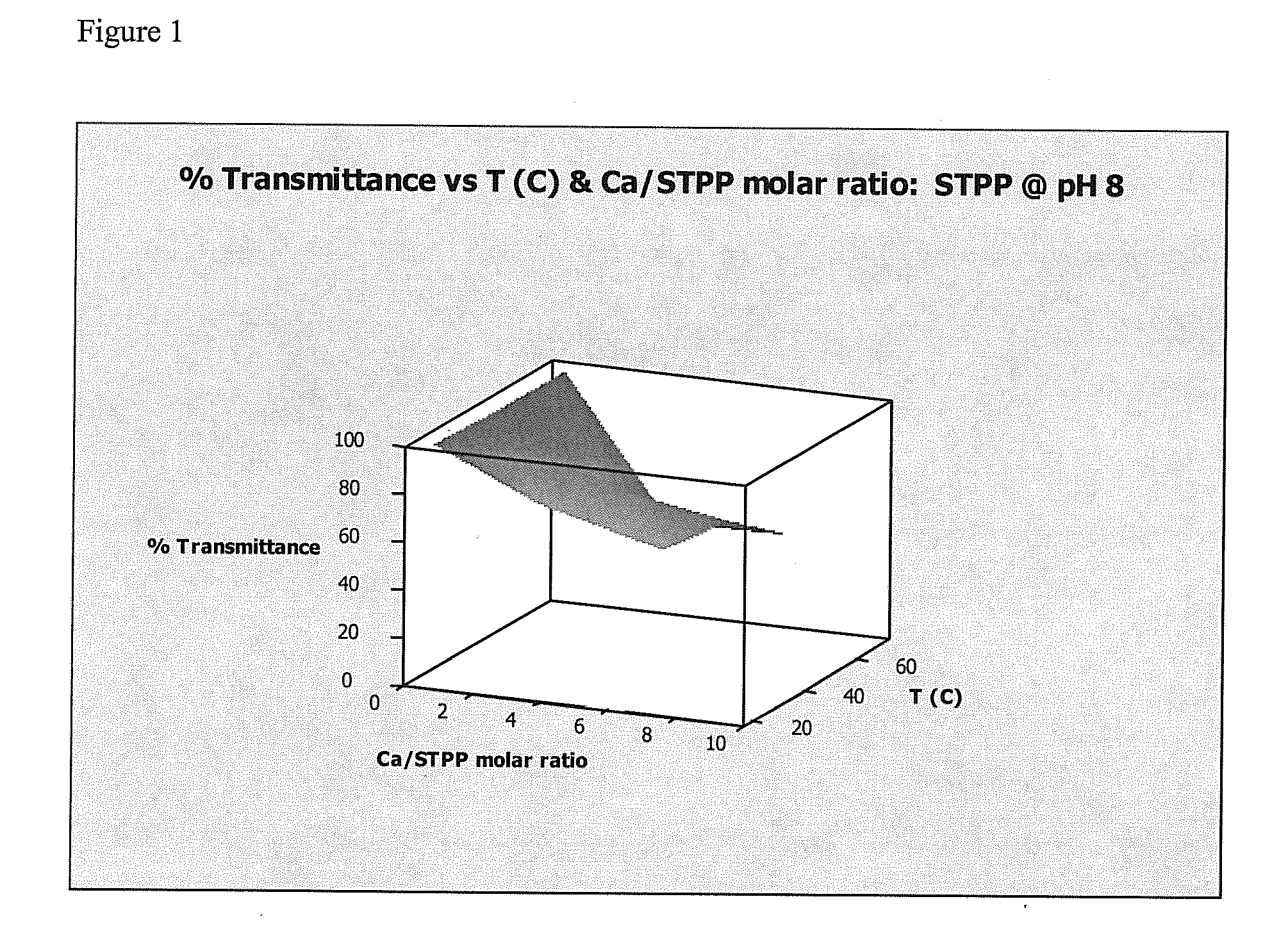

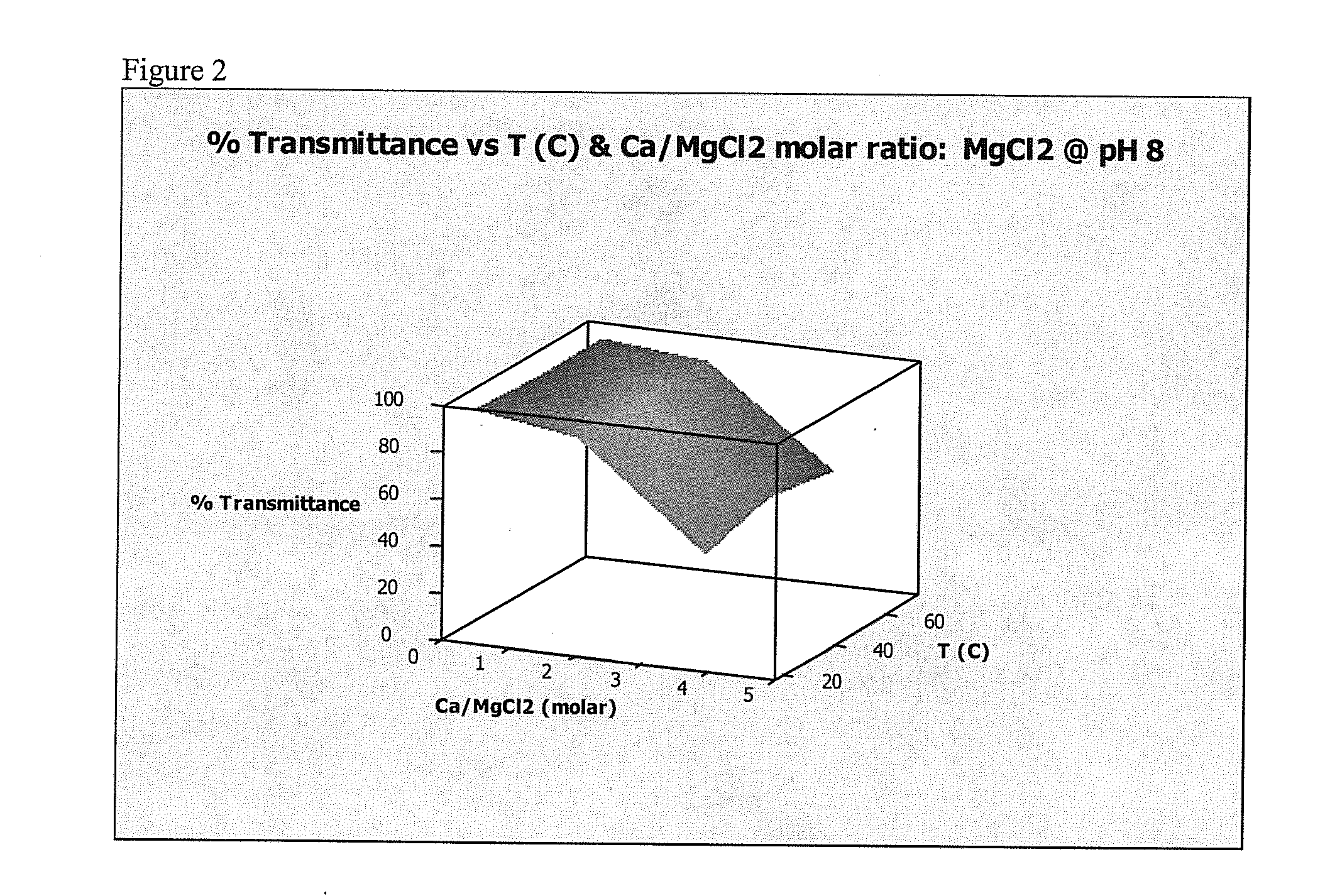

InactiveUS20110168567A1Easy to cleanEffectively sanitizesElectrolysis componentsScale removal and water softeningHypochloriteHard water

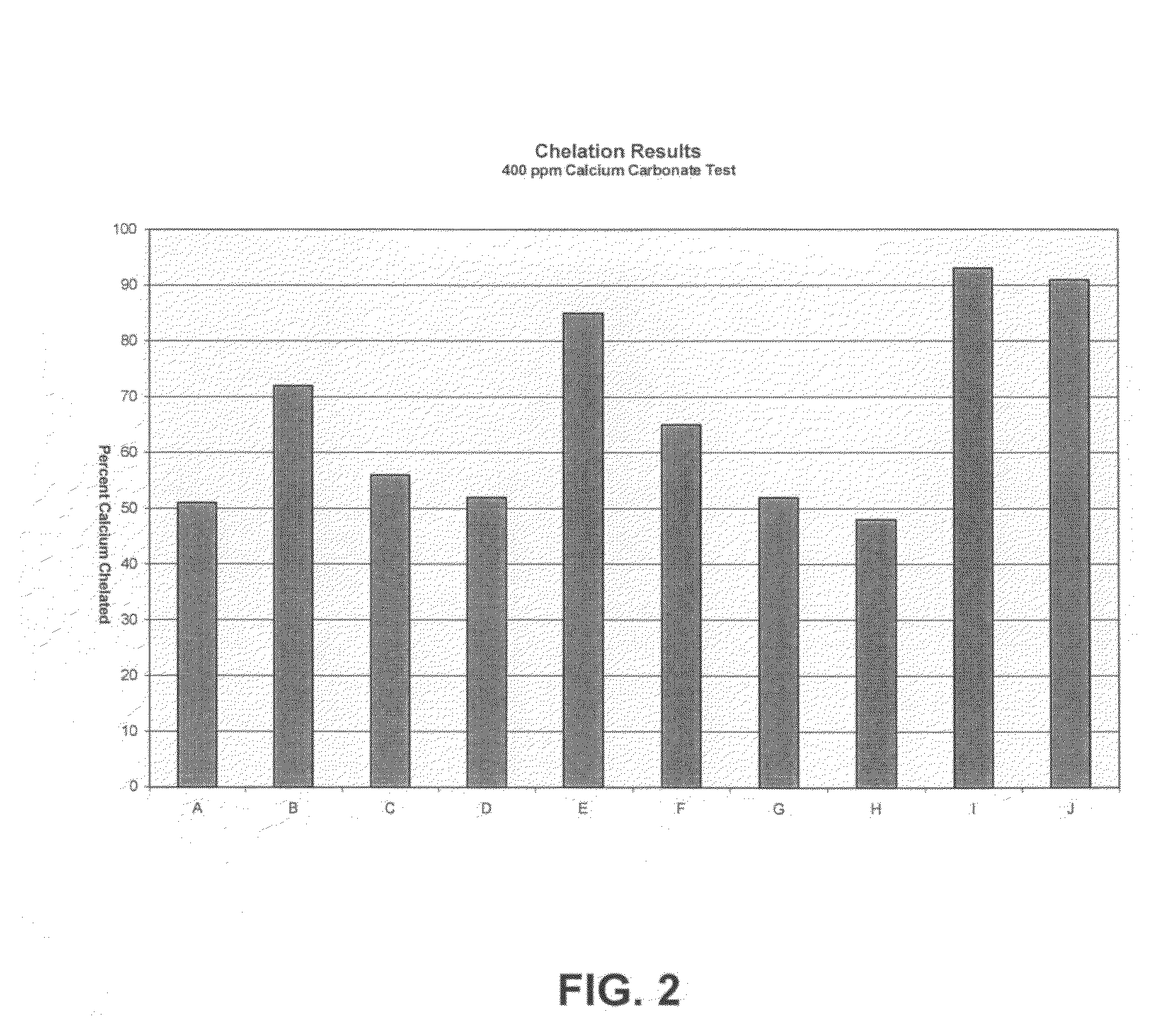

A threshold agent composition and methods of using the same to produce hypochlorite and other effluent streams from an electrochemical cell without the detrimental effects of hard water scaling are disclosed. The invention further discloses use of chemistries to prevent hard water scale formation in various electrochemical cells to enhance cell longevity without decreasing chlorine, hypochlorite or other effluent production.

Owner:ECOLAB USA INC

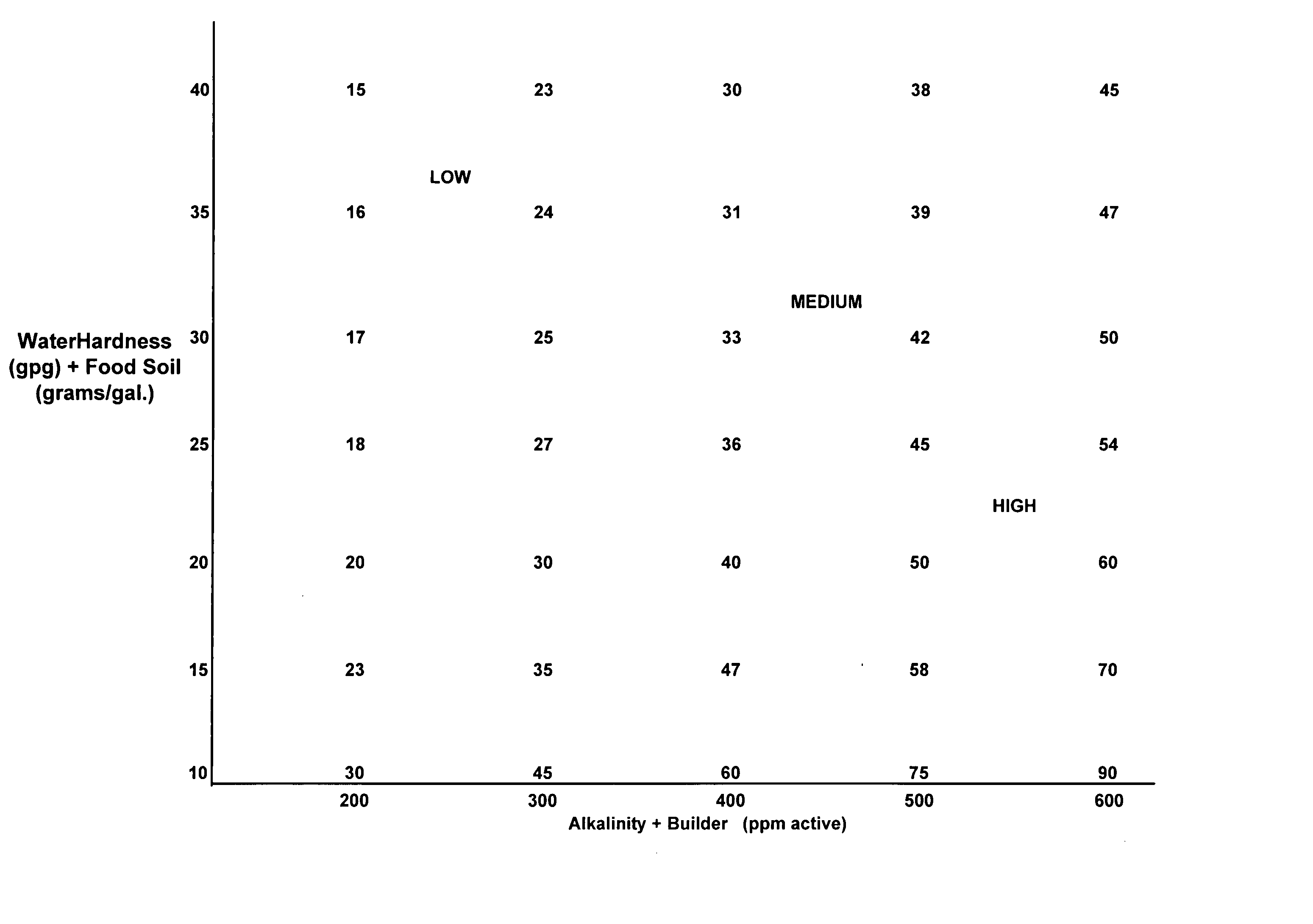

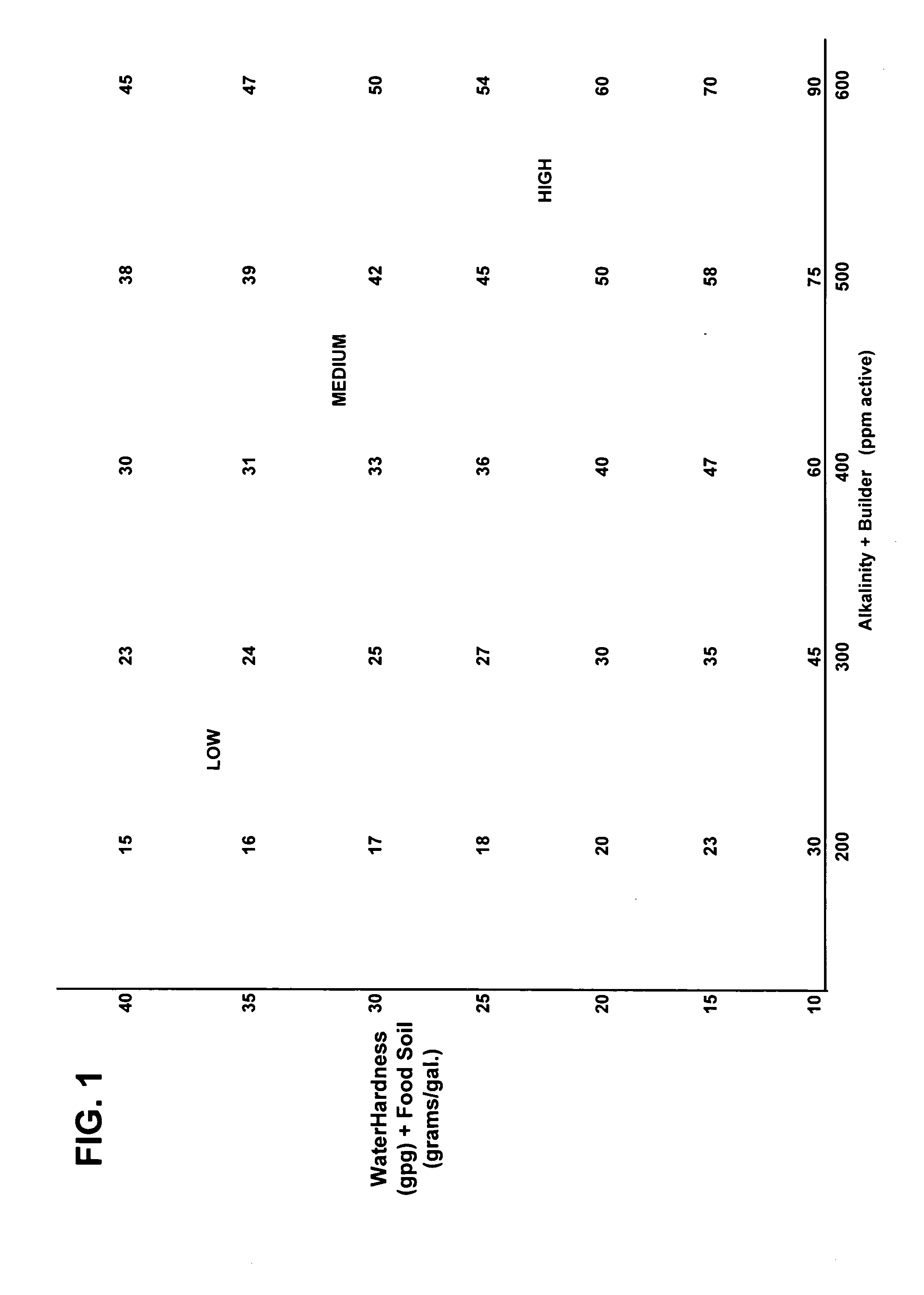

Warewashing composition for use in automatic dishwashing machines, and methods for manufacturing and using

InactiveUS20050020464A1Reduce corrosionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAluminum IonHard water

A warewashing detergent composition is provided according to the invention. The warewashing detergent composition includes a cleaning agent, an alkaline source, and a corrosion inhibitor. The cleaning agent comprises a detersive amount of a surfactant. The alkaline source is provided in an amount effective to provide a use composition having a pH of at least about 8. The corrosion inhibitor includes a source of aluminum ion and a source of zinc ion. The relative amounts of the source of zinc ion and the source of aluminum ion can be controlled to reduce visible filming when the warewashing detergent composition is used in the presence of hard water. Methods for using and manufacturing a warewashing detergent composition are provided.

Owner:ECOLAB USA INC

Water-based cutting fluid used for processing neodymium-iron-boron material slices and application method thereof

ActiveCN102311860AGuaranteed lubrication effectGuaranteed anti-rust performanceLubricant compositionSolubilityWater based

The invention discloses a water-based cutting fluid used for processing neodymium-iron-boron material slices and an application method thereof. The cutting fluid comprises the following components in parts by weight: organic amine, organic acid, water-soluble phosphate, polyether, antirust corrosion inhibitor, dispersing agent and surfactant, antiseptic bactericide, anti-hard-water agent, defoaming agent, auxiliary agent and water, wherein environmentally-friendly lubricating agent, extreme-pressure agent and antirust agent are reasonably matched in the cutting fluid disclosed by the invention, thus the lubricating property, extreme pressure property and antirust property of the cutting fluid are guaranteed; organic base, organic acid and special auxiliary agent are reasonably matched, thus the corrosion dissolution phenomenon of the cutting fluid to adhesive is greatly weakened; the dispersing agent and the surfactant are used for reducing surface tension of solution, thus permeability and settlement performance of the cutting fluid are enhanced; pH value of a final product is 7.5-8.5; and solubility of the cutting fluid to adhesive used for binding neodymium-iron-boron material in a processing cycle is extremely low, and the condition that product processing accuracy error is large or a tool is damaged as the adhesive is dissolved by the cutting fluid can not be caused.

Owner:AMER TECH CO LTD

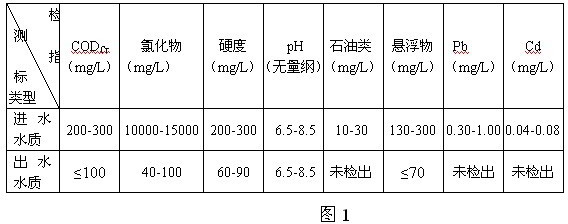

Anti-magnesium hard water anti-magnesium corrosion environmentally-friendly water soluble cutting solution

ActiveCN101560433APrevent corrosion and discolorationExcellent anti-magnesium hard water performanceLubricant compositionDisinfectantDefoaming Agents

The invention discloses an anti-magnesium hard water anti-magnesium corrosion environmentally-friendly water soluble cutting solution, which is composed of organic acid, organic amine, corrosion inhibitor, base oil, synthetic ester, surfactant, water and other additives. The invention employs particular surfactant to improve the anti-magnesium hard water performance of the product, employs special compound corrosion inhibitor to enhance the anticorrosion performance of the product, and compounds a plurality of rust inhibitors, lubricants, disinfectants and defoaming agents, the product has excellent anti-magnesium hard water performance, anti-magnesium corrosion performance and operating safety performance, and can heighten the service performance and processing performance of the product greatly. Meanwhile, the product, which is good for environmental protection, is an environmentally-friendly magnesium alloy cutting solution with excellent performances.

Owner:QIDONG YUSHIRO CHEMICAL INDUSTRY CO LTD +1

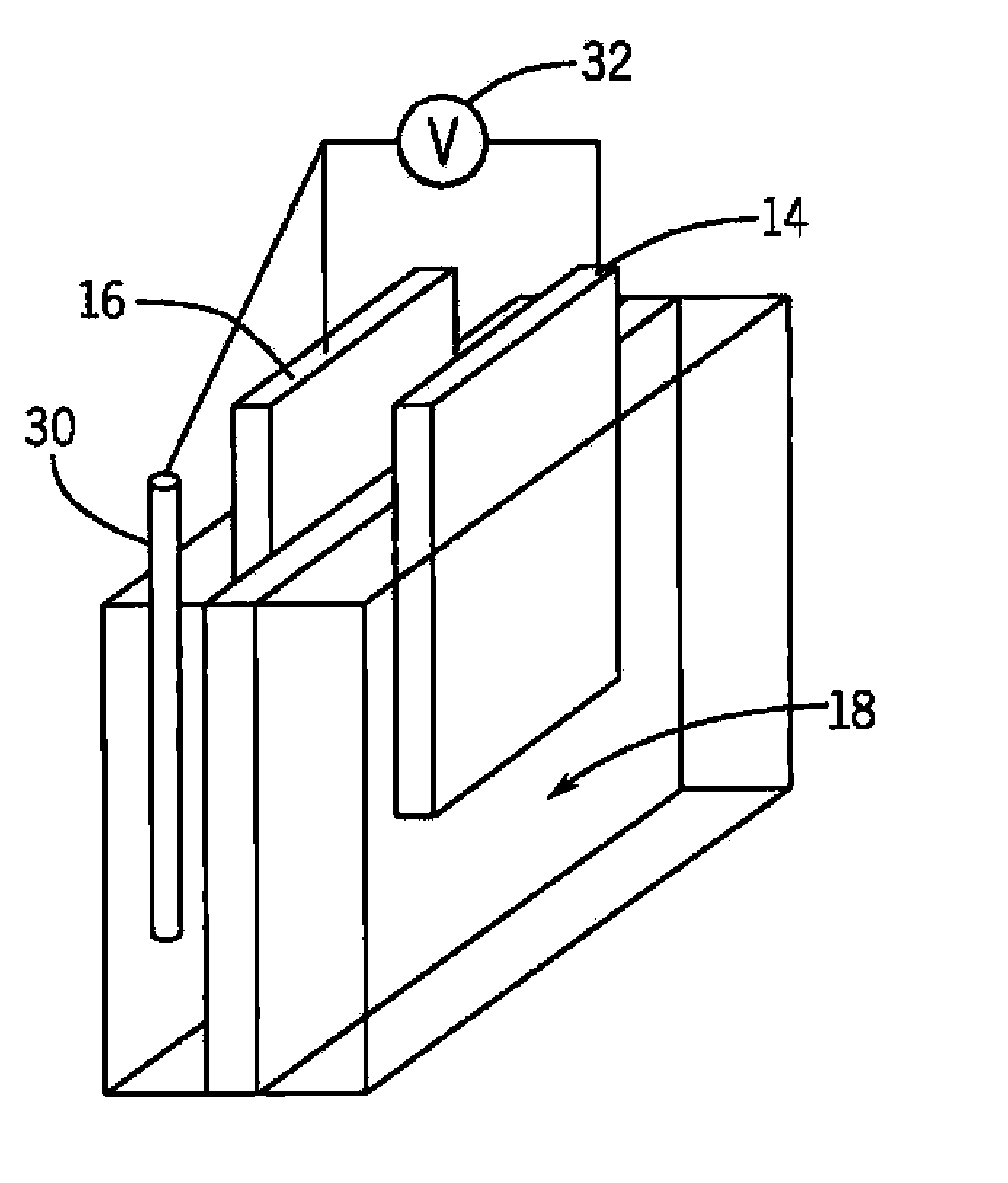

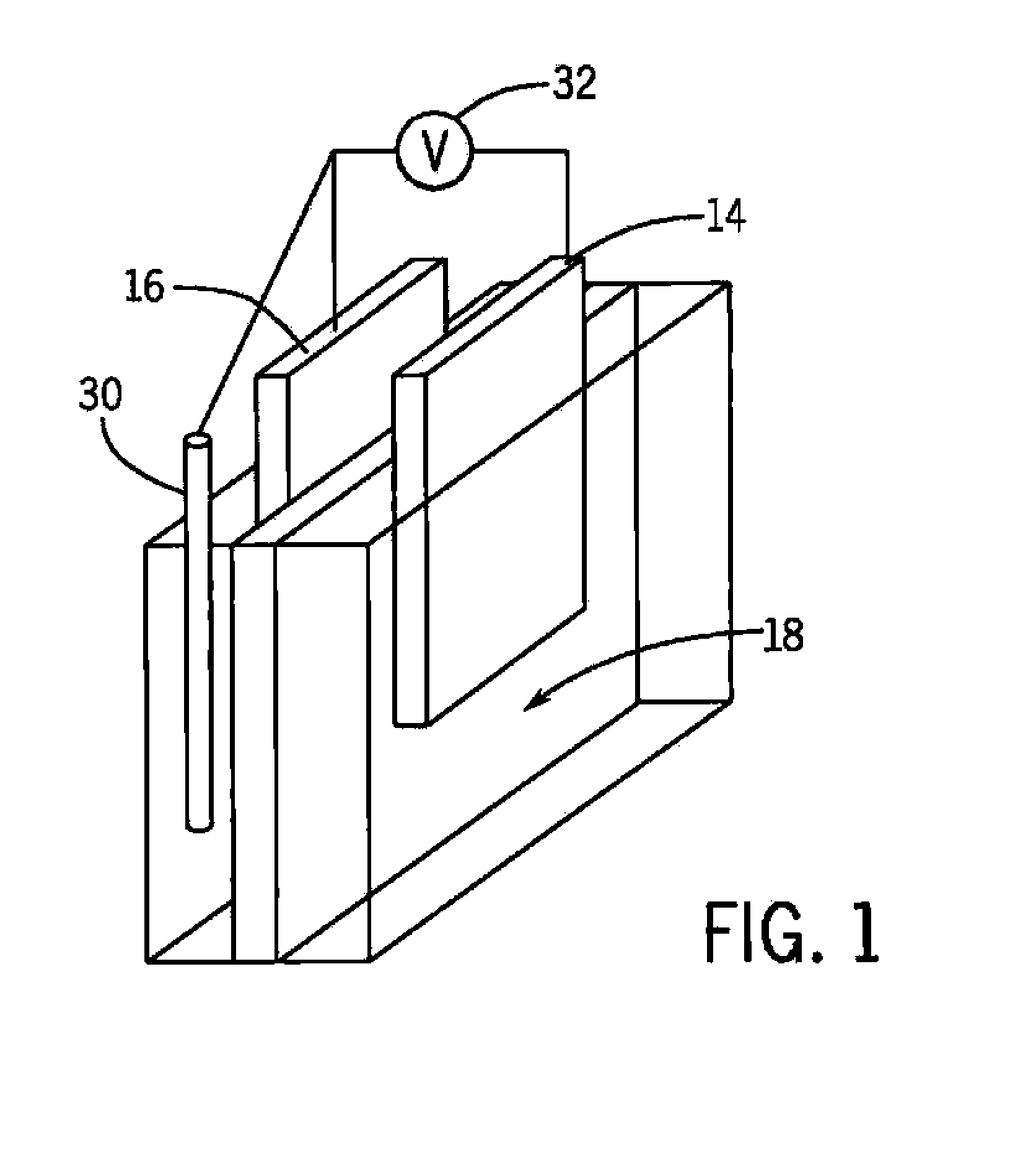

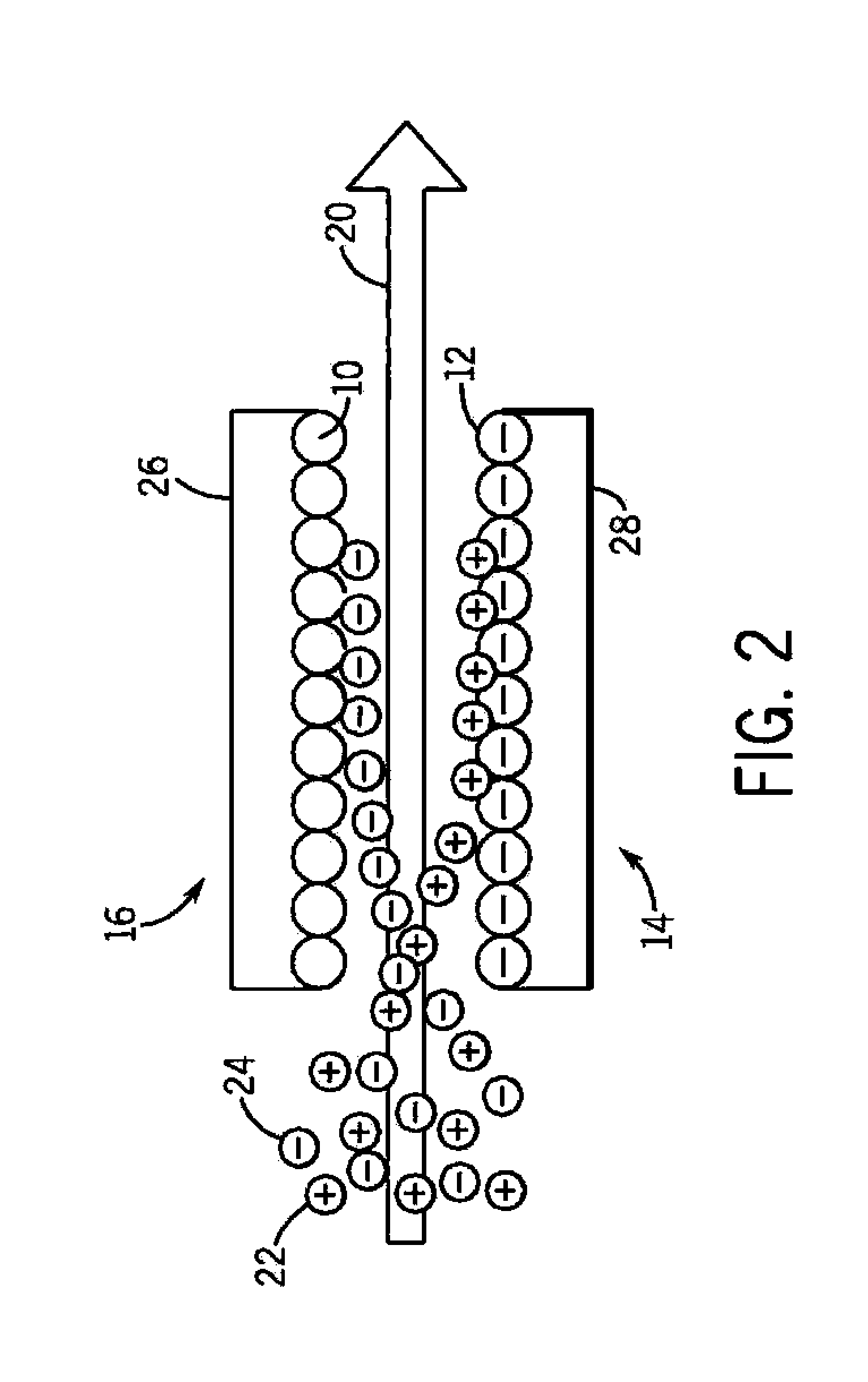

Nanoporous Insulating oxide Deionization Device Having Electrolyte Membrane, and Method of Manufacture and Use Thereof

ActiveUS20080121531A1Avoid shortingCellsPolycrystalline material growthZeta potentialAlkaline earth metal

A nanoporous insulating oxide deionization device, method of manufacture and method of use thereof for deionizing a water supply (such as a hard water supply), for desalinating a salt water supply, and for treating a bacteria-containing water supply. The device contains two composite electrodes each constructed from a conductive backing electrode and a composite oxide layer being an insulating oxide or a non-insulating oxide and an intermediate porous layer. The composite layer being substantially free of mixed oxidation states and nanoporous and having a median pore diameter of 0.5-500 nanometers and average surface area of 300-600 m2 / g. The composite layer made from a stable sol-gel suspension containing particles of the insulating oxide, the median primary particle diameter being 1-50 nanometers. The difference in zeta potential, at a pH in the range of 6-9, being sufficient to suitably remove alkaline and alkaline earth cations (such as Ca2+ and Na1+), various organic and other inorganic cations and organic and inorganic anions from water, preferably household hard water. One composite layer being constructed from a mixture of Al2O3, MgAl2O4 and / or Mg-doped. Al2O3 particles, and the other composite layer being constructed from SiO2 or TiO2.

Owner:WISCONSIN ALUMNI RES FOUND

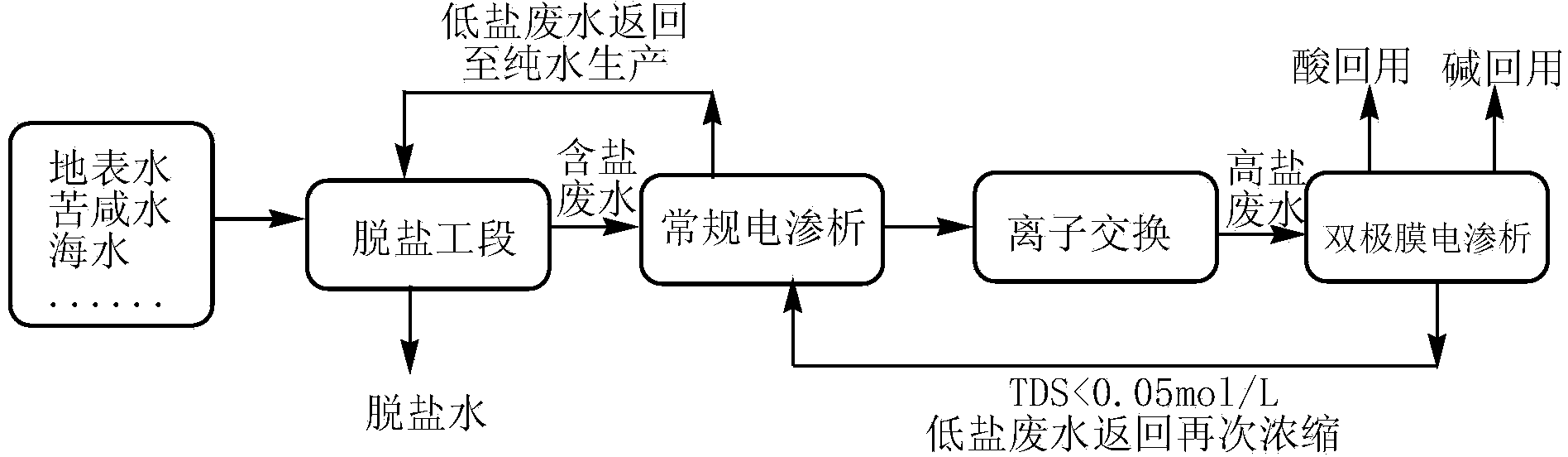

Recycling treatment method for salt-containing wastewater

ActiveCN103508521AHigh recovery rateSimple and efficient preprocessingGeneral water supply conservationDispersed particle separationSaline waterDesalination

The invention relates to a recycling treatment method for salt-containing wastewater. The recycling treatment method is characterized by comprising the following steps: (1) carrying out desalting, concentrating and initial hard water removal on the salt-containing wastewater through a general electrodialyzer at first, returning obtained low-salt wastewater to a desalting process for preparing pure water, and carrying out deep hard water removal on high-salt wastewater through ion exchange; (2) pumping the preprocessed high-salt wastewater into a bipolar membrane electrodialyzer for recycling treatment, dissociating sodium chloride and water for greatly reducing the content of salt in the wastewater, and obtaining hydrochloric acid and sodium hydroxide at the same time; returning the obtained low-salt wastewater to a water concentration chamber of the general electrodialyzer for concentrating again. According to the recycling treatment method, the environmental pollution caused by direct discharge of the high-salt wastewater is avoided, wastes (salt) are turned into wealth (acid and alkali), the water recovery rate of a salt water removal process is increased, the integral water preparation cost is remarkably reduced, and good economic and social benefits are achieved.

Owner:OCEAN UNIV OF CHINA +1

Water-based fully-synthetic ferrous metal processing liquid with high-hard-water-rust resistance

PendingCN108277077ANo pollution in the processOvercome the disadvantage of poor antirust performance in high hard waterLubricant compositionWater basedHard water

The invention provides a water-based fully-synthetic ferrous metal processing liquid with high-hard-water-rust resistance, wherein the water-based fully-synthetic ferrous metal processing liquid comprises, by weight, 5-25 parts of a composite rust inhibitor, 5-30 parts of a lubricant, 5-30 parts of a pH value stabilizer, 1-9 parts of a coupling agent, 0.1-2 parts of an antifoaming agent, 1-4 partsof a sterilization agent, and 20-50 parts of water. According to the preset invention, the ferrous metal processing liquid has advantages of no environment pollution, excellent rust resistance, excellent cooling performance, excellent hard-water resistance and high biological stability, and can overcome the disadvantage of poor high-hard-water-rust resistance of the traditional water-based fully-synthetic ferrous metal processing liquid.

Owner:超滑科技(佛山)有限责任公司

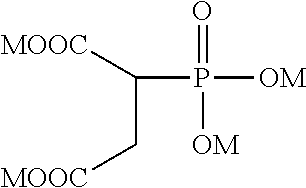

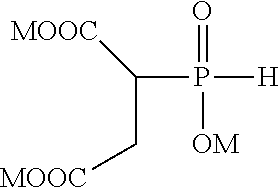

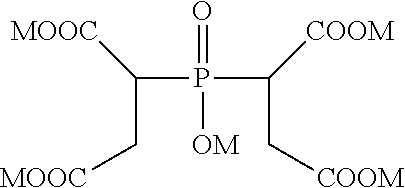

Detergent composition comprising phosphinosuccinic acid adducts and methods of use

ActiveUS8871699B2Improve aestheticsPrevent scalingInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsHard waterAdduct

Detergent compositions effective for controlling hard water scale accumulation are disclosed. Detergent compositions employing phosphinosuccinic acid and mono-, bis- and oligomeric phosphinosuccinic acid (PSO) derivatives with alkali metal carbonate and / or alkali metal hydroxide reduce had water scale accumulation on treated surfaces at alkaline conditions between about pH of 9 and 12.5. Methods employing the detergent compositions and preventing hard water scale accumulation are also provided.

Owner:ECOLAB USA INC

Water soluble magnesium compounds as cleaning agents and methods of using them

InactiveUS20080274928A1Reduce and prevent formationImprove solubilityInorganic/elemental detergent compounding agentsSpecific water treatment objectivesMagnesium saltWater insoluble

The present invention relates to compositions and methods employing a water soluble magnesium compound. In certain embodiments, the composition includes water and water soluble magnesium compound, but lacks other materials commonly used in cleaning compositions. The methods and compositions can provide magnesium ion at predefined ratios to calcium ion in water, such as magnesium ion in a molar amount equal to or in excess over a molar amount of calcium ion. A water soluble magnesium salt including an anion of a water soluble calcium salt is more effective than a magnesium salt with an anion of a water insoluble calcium salt. These compositions can be used for reducing lime scale or precipitate formation from hard water, removing soap scum, or the like.

Owner:ECOLAB USA INC

Water-Repellent Structure and Method for Making the Same

InactiveUS20070148407A1Reduce thicknessHigh transparencyRecord information storageMagnetic recordingRough surfaceHard water

A water-repellent structure and a method for fabricating the same are provided. The method adopts an atmospheric pressure plasma deposition (APPD) technique to form a hardened coating having a rough surface on a substrate, and form a water-repellent coating on the rough surface. Because the water-repellent structure includes the hardened coating and the water-repellent coating, hardness, abrasion-resistance, transparency and hydrophobicity of the water-repellent structure are improved. The hard water-repellent structure protects the substrate from friction. Moreover, because the present invention adopts the APPD technique to form the water-repellent structure, the cost of production is reduced dramatically. Thus, the present invention can solve drawbacks of prior art.

Owner:IND TECH RES INST

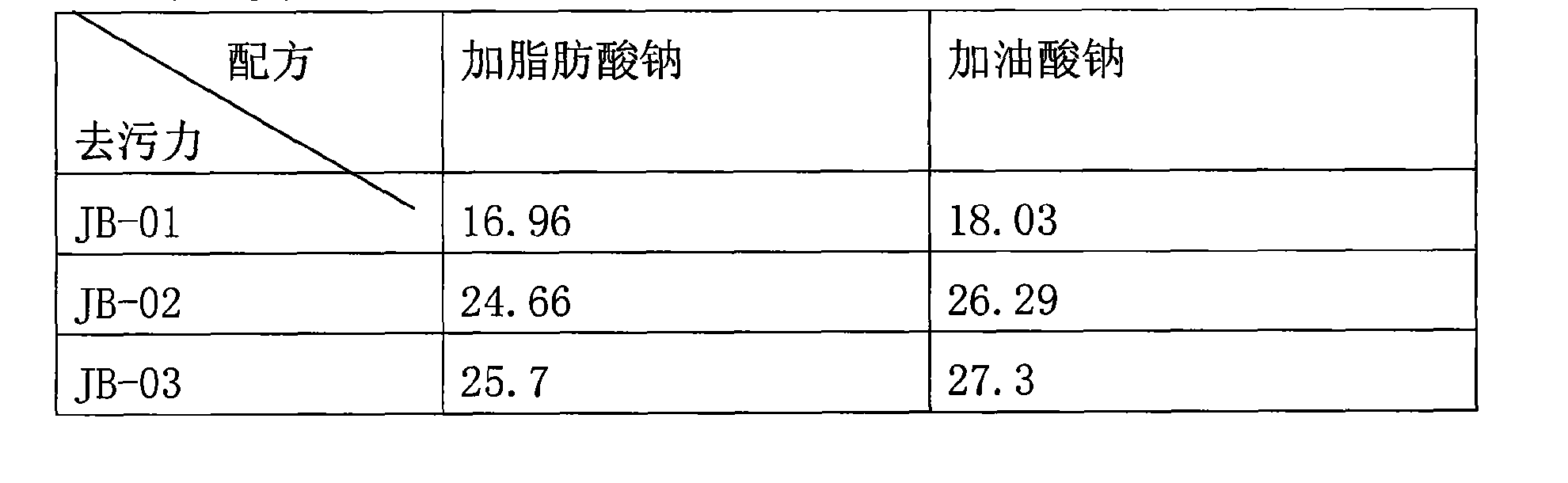

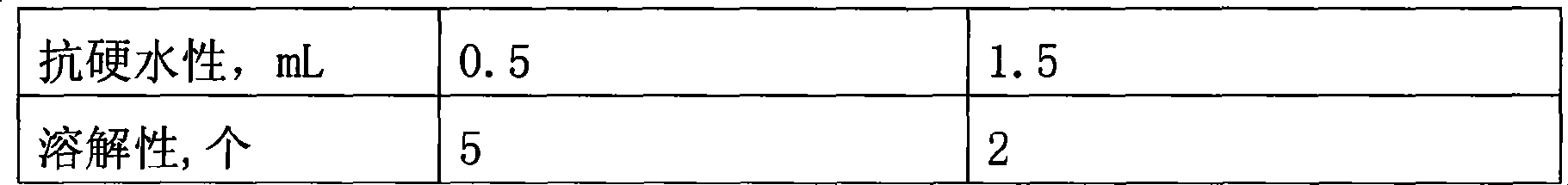

Neat soap washing powder and preparing technique thereof

InactiveCN101368147AImprove decontamination abilityNo stimulationSoap detergent compositionsSolubilitySodium stearate

The invention relates to a household chemicals manufacturing technique, in particular to a genuine soap washing-powder manufacturing technique, which solves the problems of no hard water tolerance, low solubility and weak detergency caused by sodium stearate added into the powder in the genuine soap washing-powder of the prior art. The weight percentages of integrants comprised in the genuine soap washing-powder are 5-30 portions of surface active agent, 2-40 portions of eunatrol, 20-70 portions of washing auxiliary detergent, 0.1-10 portions of auxiliary material and 5-50 portions of sodium sulfate used as plugging compound. Different manufacturing techniques are applied for adding the oleic acid or eunatrol into the washing-powder. The invention has the advantages of strong detergency, no skin irritation, no environment pollution, simple application, easy manufacturing, environment protection, high efficiency and low production cost.

Owner:山西焦煤运城盐化集团有限责任公司

Metal cutting fluid containing graphene dispersion solution and preparation method thereof

The invention relates to a metal cutting fluid containing a graphene dispersion solution and a preparation method thereof. The metal cutting fluid is composed of the following raw materials: 0.2-2.0% of lubricating additive, 5-7% of rust inhibitor, 0.2-0.5% of corrosion inhibitor, 0.05-0.15% of hard water resisting agent, 15-20% of lubricant and the balance of water. The lubricating additive is the graphene dispersion solution. The metal cutting fluid has favorable lubricating property and antirust property; by using the water base as the carrier, the metal cutting fluid is free of base oil; and the production process has the advantages of low energy consumption and low production cost, and is simple to operate.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

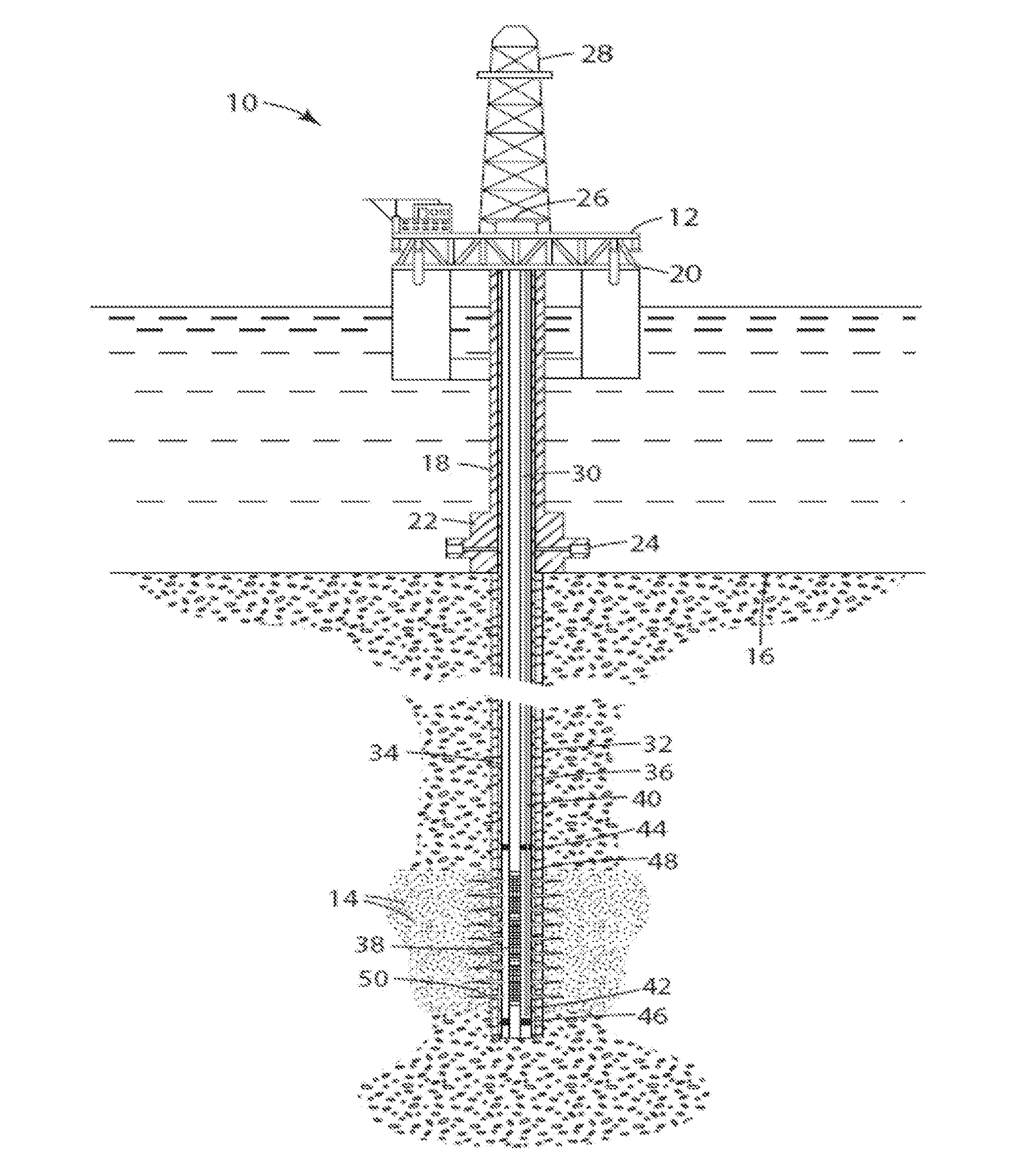

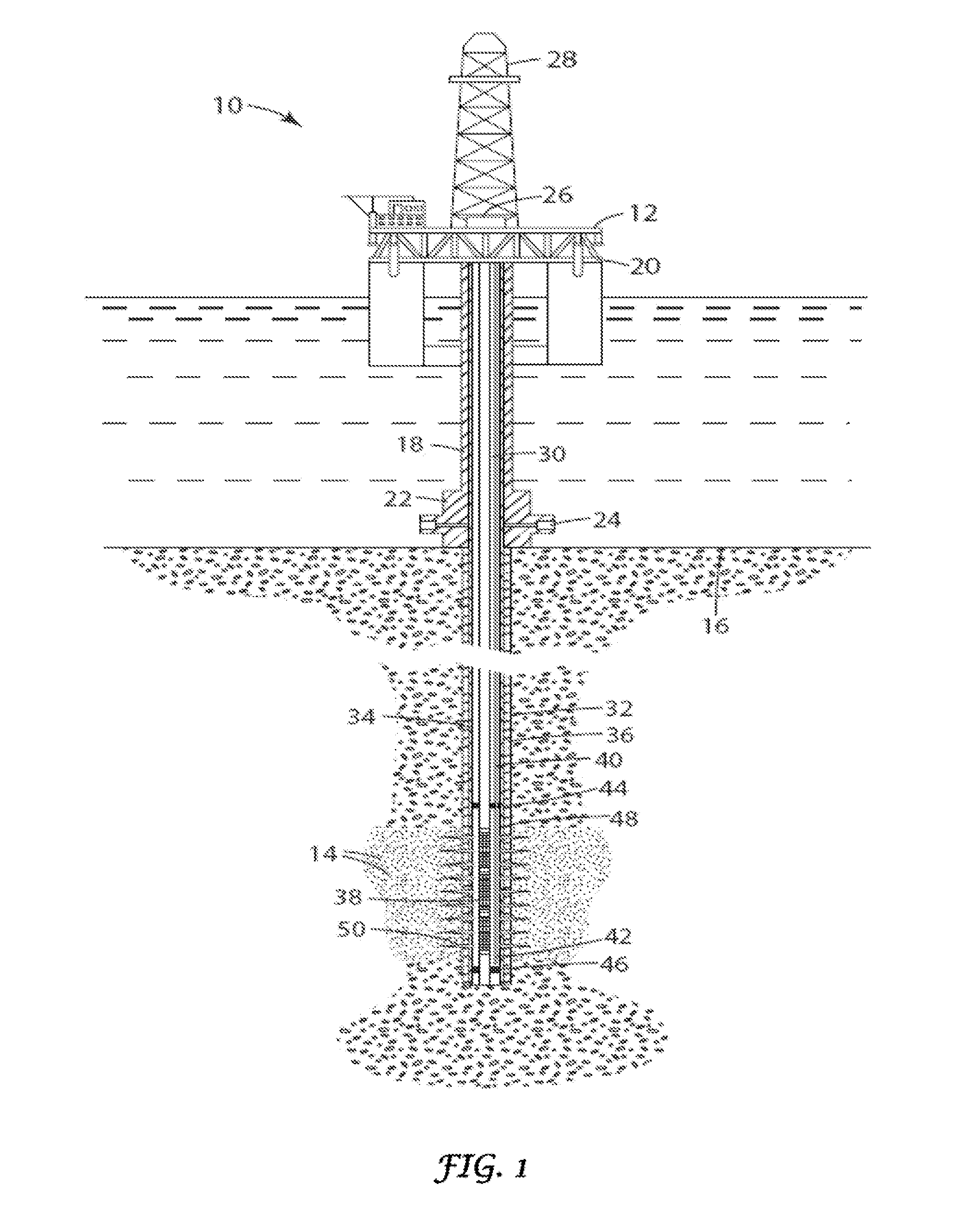

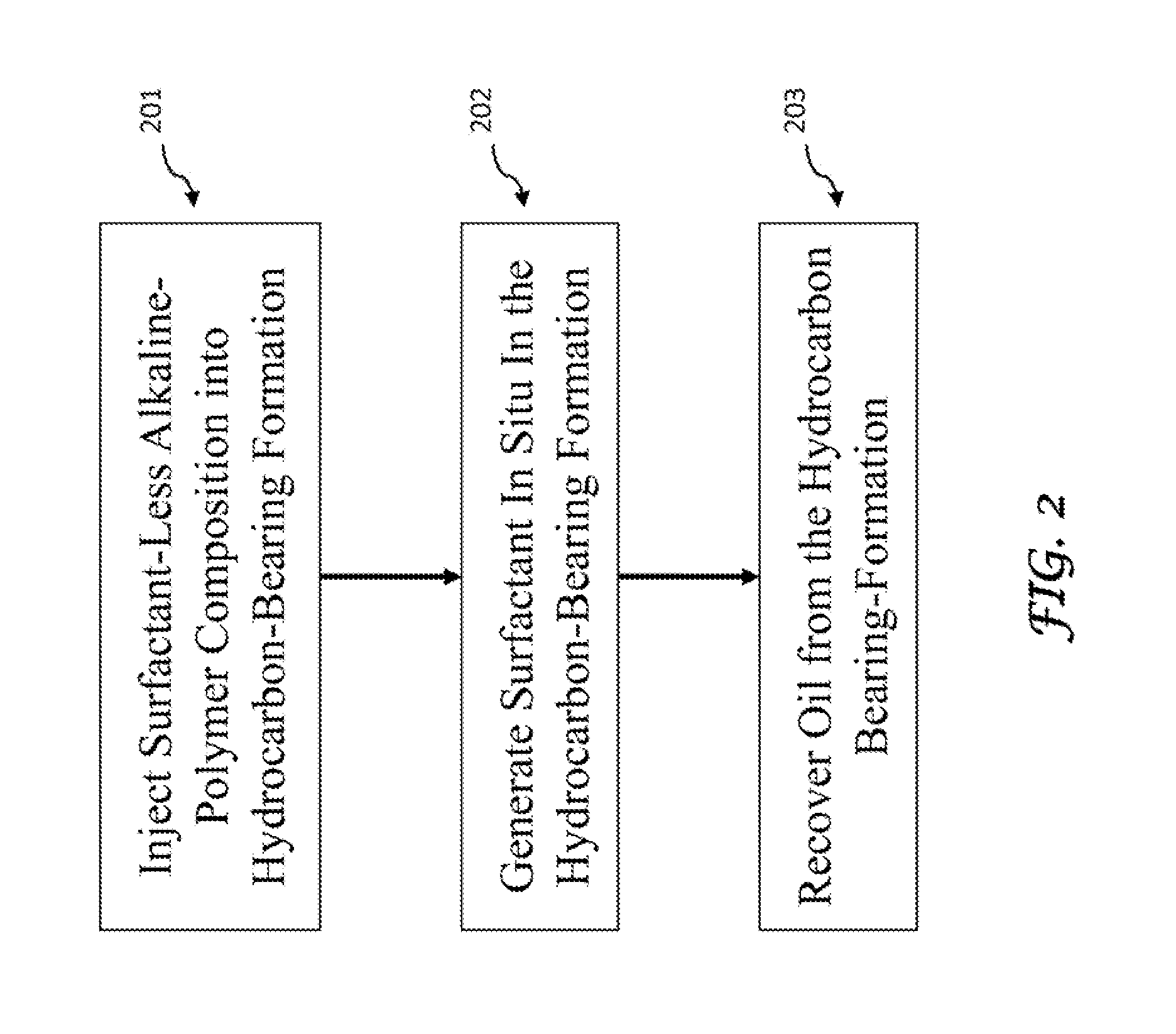

Surfactant-Less Alkaline-Polymer Formulations for Recovering Reactive Crude Oil

Compositions and methods for oil recovery using a surfactant-less alkaline-polymer system in hard water or hard brine is described in the instant invention. The formulation further includes a chelating agent, an alkaline agent (which can be the same as the chelating agent), and a co-solvent. The formulations as disclosed herein are capable of forming a surfactant in-situ resulting in Winsor Type III micro-emulsions of low interfacial tension.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Biodegradable concentrated neutral detergent composition

ActiveUS20120021963A1Improve stabilityExtended shelf lifeOrganic detergent compounding agentsSurface-active detergent compositionsHydrotropeHard water

A biodegradable concentrated neutral detergent composition comprises various chelate compounds, various corrosion inhibitors, an alkaline compound, at least one sequestrant, various surfactants and hydrotropes, and water. The detergent can be highly concentrated, has a good long term shelf life, and when diluted is very effective in cleaning metals such as surgical instruments and prevents corrosion resistance of the metal even in a hard water environment.

Owner:AMERICAN STERILIZER CO

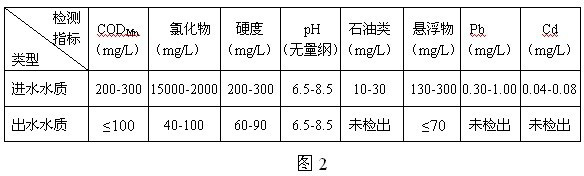

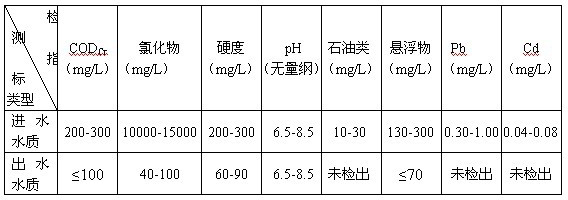

Semi-synthesis cutting fluid for magnesium alloy, preparation method and application method

ActiveCN102732363AFire Hazard PreventionAvoid difficult issuesLubricant compositionWater solubleHard water

The invention discloses a semisynthesis cutting fluid for magnesium alloy. According to the invention, the hidden danger of fire hazard in the process of magnesium alloy processing is totally avoided by using an environment-friendly water-soluble system; excellent reasonable proportioning of additives and combined application of corrosion inhibitors effectively prevent the surface of processed magnesium alloy from corrosion and blackening; designing of a low foam type formula enables generation of foam in the cutting fluid for the magnesium alloy to be totally inhibited; application of a delicate low-foam surfactant enables the problem of difficult cleaning of workpiece surface due to excessive oil stains to be overcome; application of an additive with resistance to hard water enables hard water-resistance of the fluid to be effectively improved, the fluid has hard water-resistance of 15000 ppm, allowing the service life of the fluid to be prolonged, all the indexes of the fluid reach or exceed relevant indexes in GB6144-2010, anti-rust performance lasts for more than 72 h per sheet, and the life cycle of the fluid is more than 8 months, 3 to 6 times the life cycle of magnesium alloy cutting fluid on the market; and reasonable design of an environment-friendly formula enables the problems of difficulty in treating waste liquid and the like to be effectively overcome.

Owner:AMER TECH CO LTD

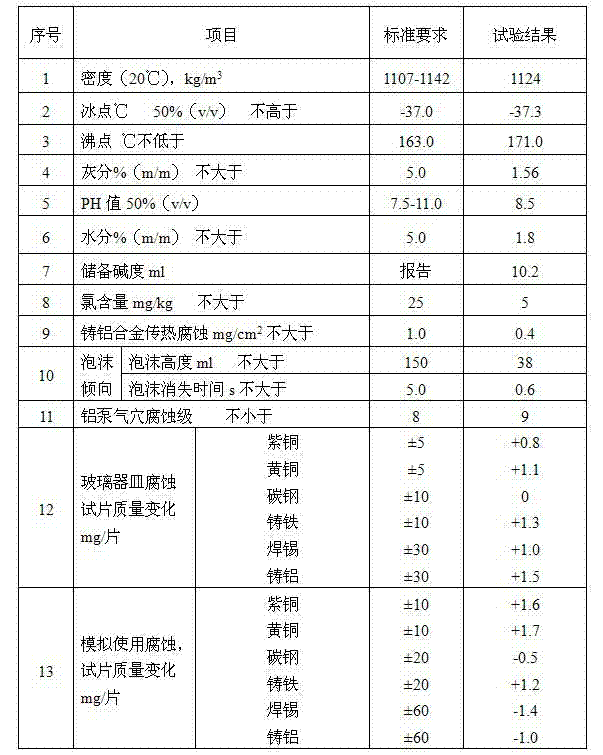

Engine coolant

ActiveCN101629070APrevent precipitationGuaranteed anti-corrosion performanceHeat-exchange elementsSodium nitrateDefoaming Agents

The invention relates to an engine coolant, which comprises the following compositions in portion by weight: 100 portions of glycol, 60 to 160 portions of deionized water, 1.0 to 1.6 portion of sodium benzoate, 1.0 to 1.4 portion of sodium tetraborate, 0.1 to 0.5 portion of sodium nitrate, 0.5 to 0.9 portion of phthalic acid, 0.3 to 0.6 portion of sodium silicate, 0.03 to 0.06 portion of silicate stabilizer, 0.3 to 0.4 portion of sodium hydroxide, 0.1 to 0.3 portion of pyrrodiazole, 0.01 to 0.06 portion of defoaming agent and 0.005 to 0.02 portion of coloring agent; the engine coolant is characterized in that: the coolant does not contain molybdate, amine, nitrite, phosphate and other substances which are harmful to the environment and human body and has excellent anticorrosive and protective function on red copper, brass, steel, cast iron, soldering tin, cast aluminum and other metals of a cooling system and magnesium alloy adopted in an engine; and the coolant has strong anti-hard water capacity and low cost, meets the requirement of SH / T0521-1999 standard and is applicable to industrialized production.

Owner:PETROCHINA CO LTD

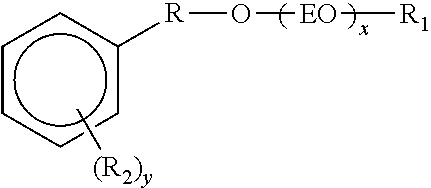

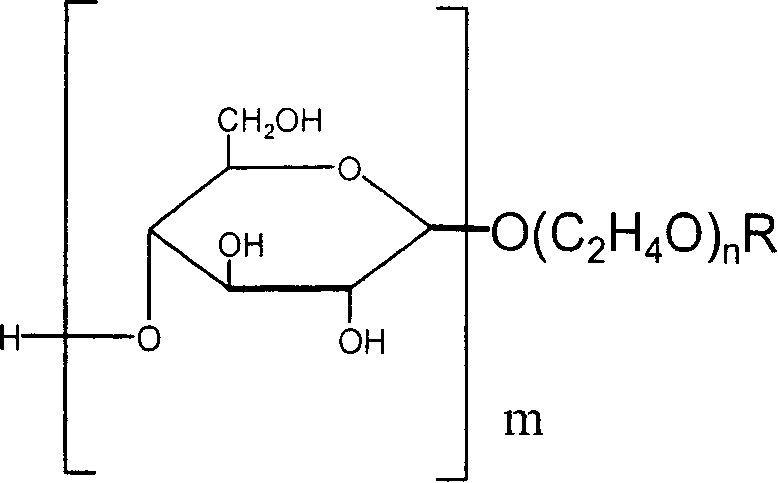

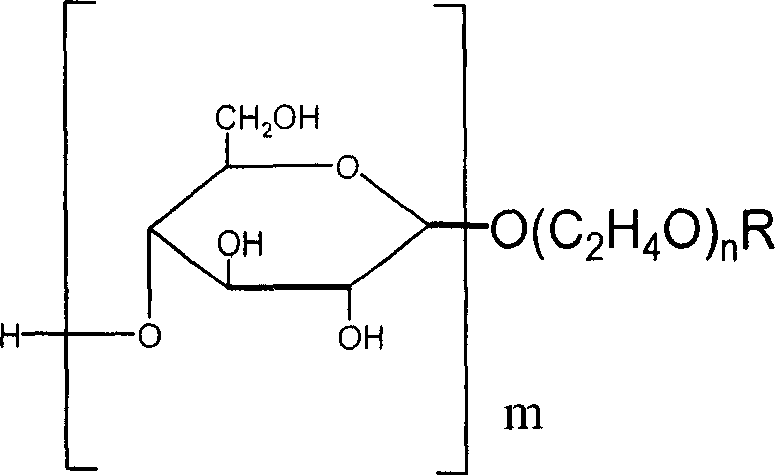

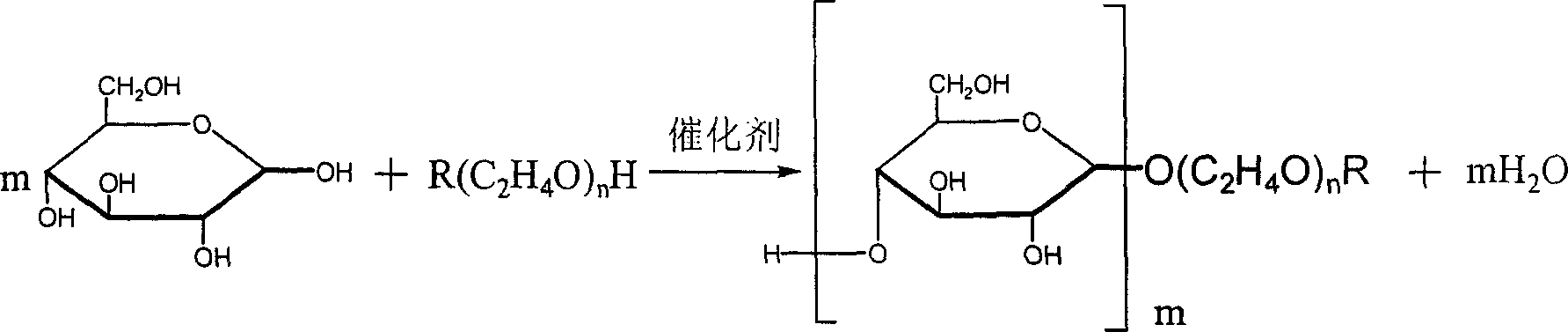

Surface active agent alcohol ether glucoside and its preparation method

InactiveCN1651129AGood water solubilityImprove hard water resistanceTransportation and packagingMixingSolubilityAlcohol

An alcohol-ether-glucoside as surfactant is prepared through acetalization reaction between emtrol polyoxyvinylether and glucose. Its advantages are high water solubility, surface activity, and resistance to hard water and alkali, and easy biodegradation.

Owner:CHINA RES INST OF DAILY CHEM IND

Hard water-resistant semi-synthetic metal cutting fluid and preparation method thereof

InactiveCN102492533AImprove emulsion stabilityExtended service lifeLubricant compositionWater softeningActive agent

Owner:马思特(上海)化学有限公司

Biodegradable scale control composition for use in highly concentrated alkaline hard surface detergents

ActiveUS7902137B2Safe handlingImprove securityMechanical apparatusOrganic detergent compounding agentsPotable waterHard water

Owner:AMERICAN STERILIZER CO

Electro-adsorption demineralization water purifier

InactiveCN101412550AReduce turbidityReduced salt removal capacityDispersed particle separationAutomatic controlDesorption

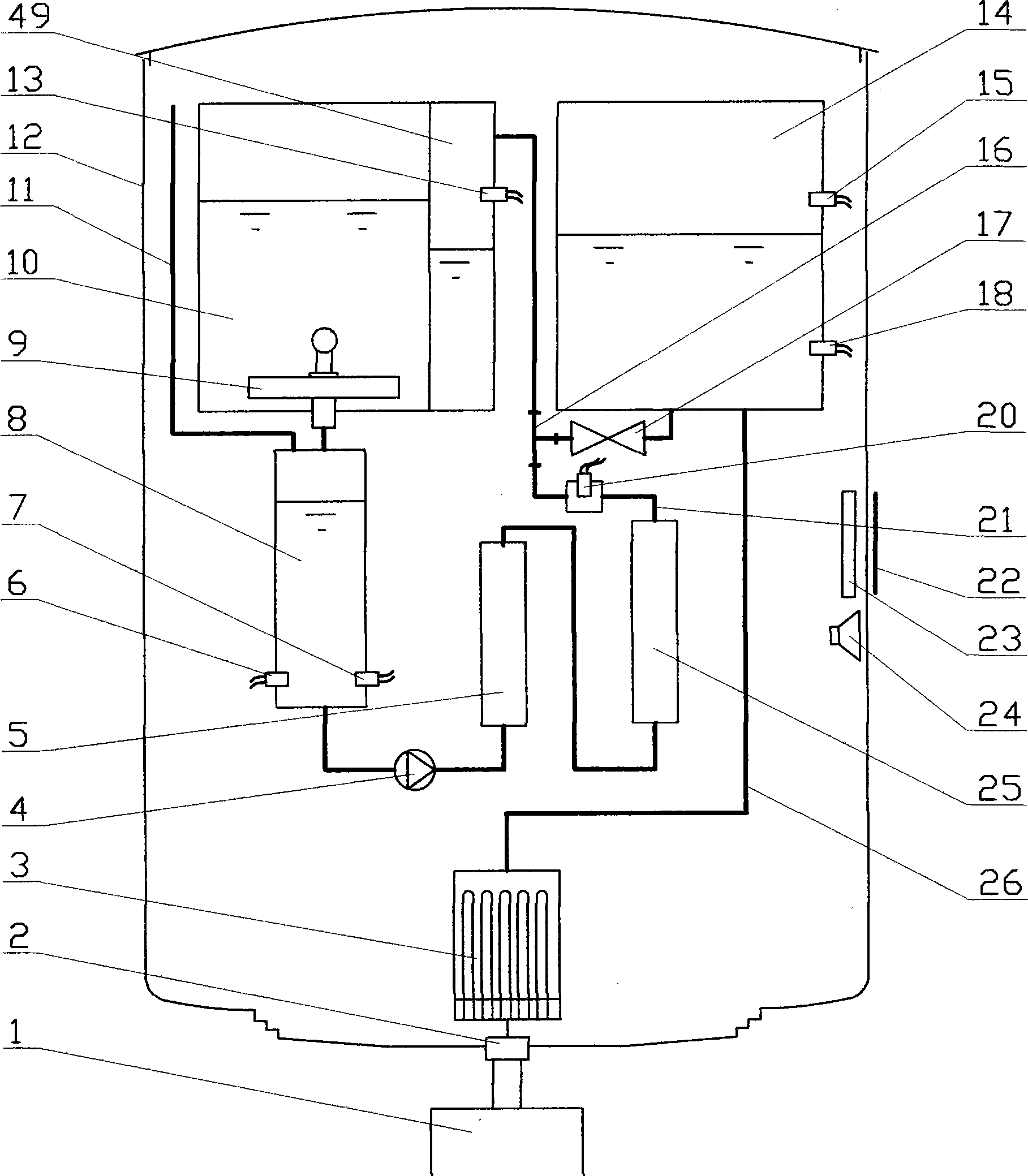

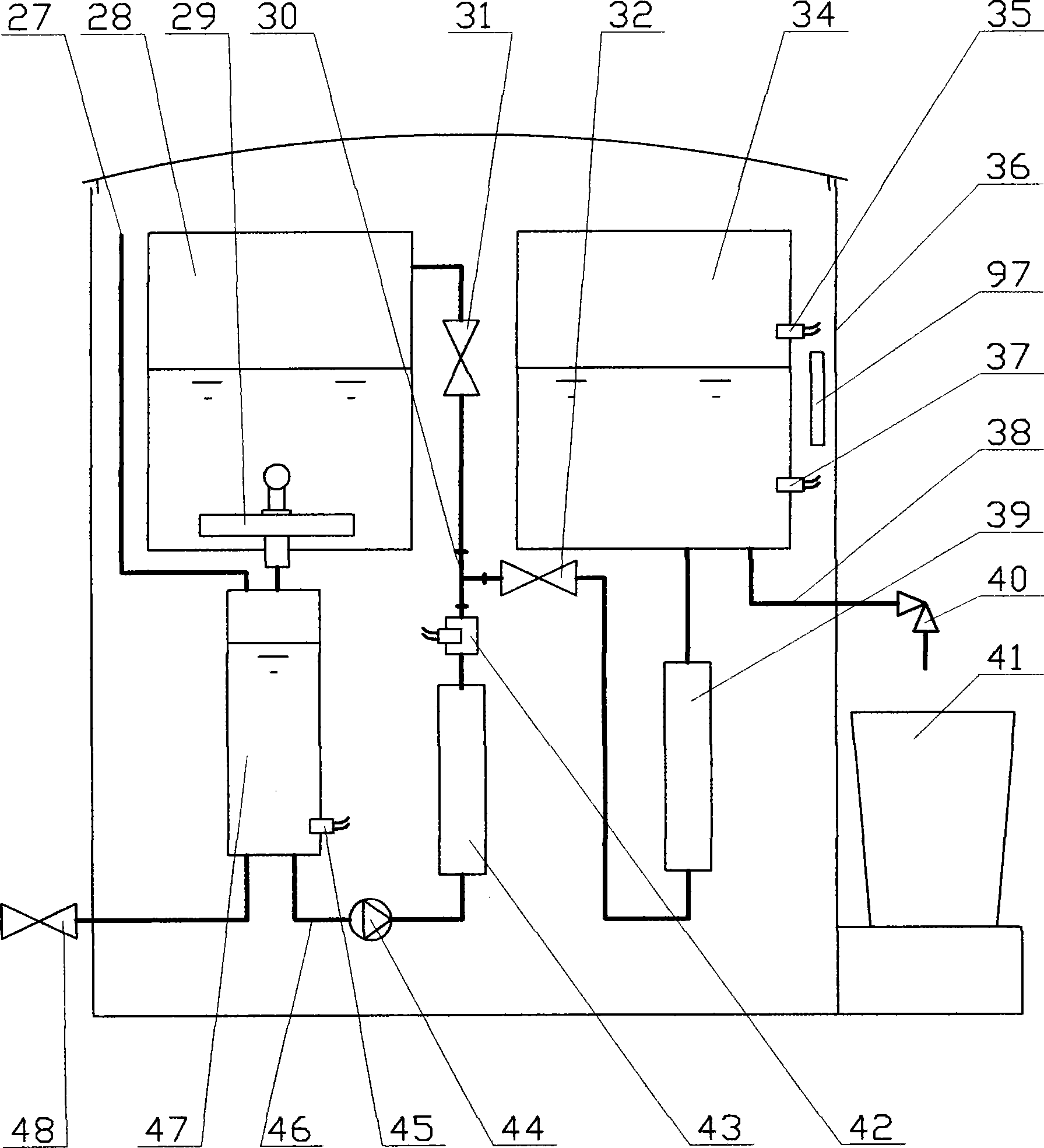

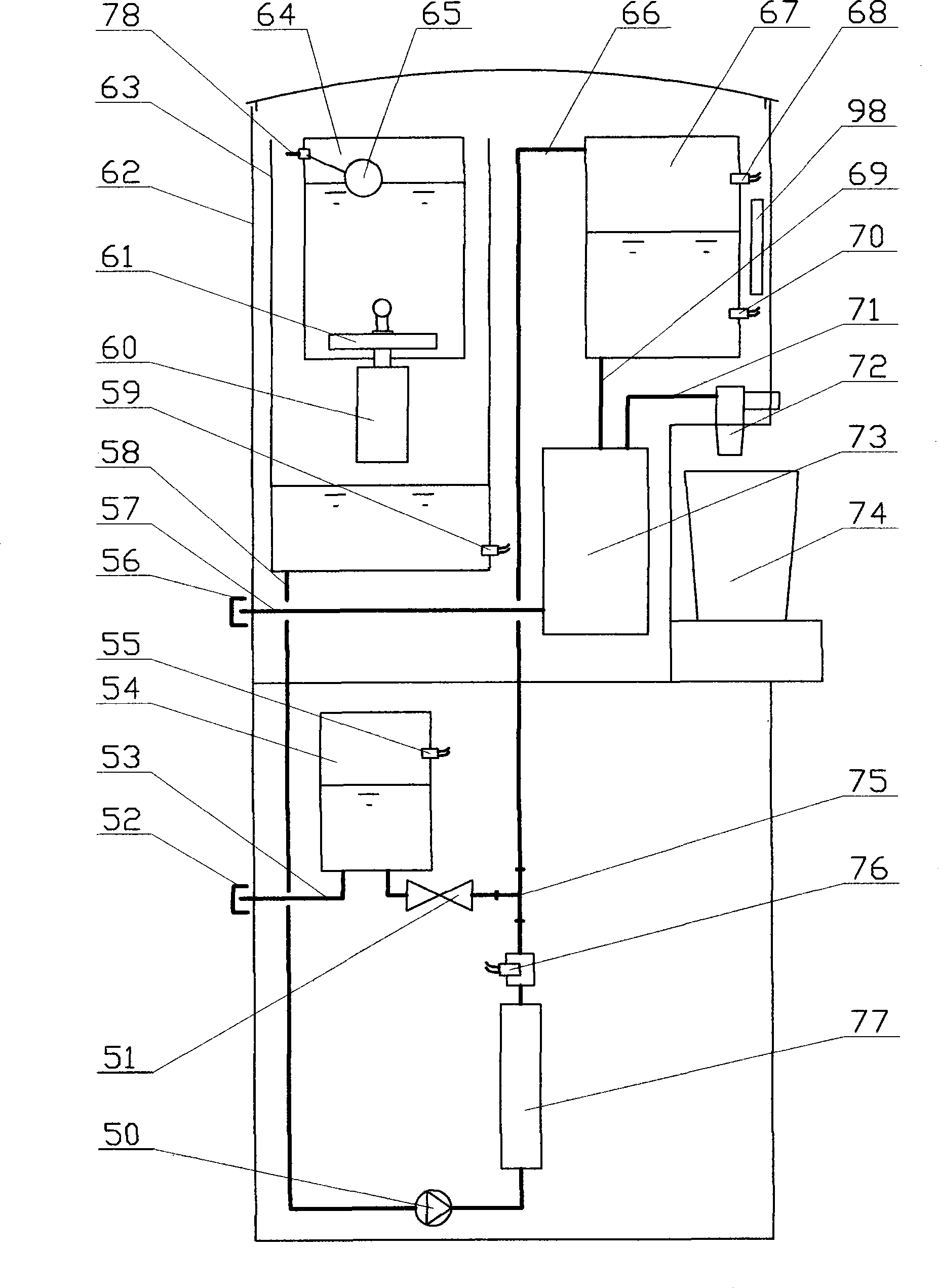

The invention discloses an electro-absorptive desalination water purifier, which comprises a high-precision pretreatment filter element, an electro-absorptive filter element, an electrical control circuit board, and a water quality probe capable of detecting the content of salinity in water. After suspended substances and particulate matters in raw water are removed through the high-precision pretreatment filter element, then the salinity in the water is removed through the electro-absorptive filter element, the water quality probe is arranged in a water outlet pipeline of the electro-absorptive filter element; the water outlet pipeline is divided into two paths behind the water quality probe; and one path is a fresh water pipeline communicated with a water purification tank, while the other path is a sewage pipeline which is communicated with a sewage tank or is emptied. The water purifier has the advantages that the water purifier can realize the automatic control to the water quality of water outlet by controlling the electric conductivity of the water outlet; hardness components are contained in the salinity, so the desalination water purifier is also a water softener and is particularly suitable for hard water areas in the north of China; after the electro-absorptive filter element has saturated absorption, the electro-absorptive filter element can obtain the regeneration through the desorption, has small discharge capacity during the regeneration, and saves water resources; and concentrated water drained during the regeneration does not contain acid and alkali liquid, and does not pollute the environment.

Owner:黄樟焱

Water-base cleaning agent composition capable of quickly removing carbon deposit and heavy oil

InactiveCN101445939AEasy to cleanSolve problems that cannot be dissolved and are difficult to removeWater basedFuel oil

This invention claims a water-base cleaning agent composition capable of quickly removing carbon deposit and heavy oil, which can greatly improving performances of removing each heavy oil stain, cleaning dirt, resisting hard water and corrosion inhibition, especially the strongest performance of removing the carbon deposit at the metallic surface, solving the problems the current technology cannot remove each carbon deposit attached to the metal surface and the impurity cannot dissolve. This invention is realized by using following technical scheme: mixing 1% to 5% of synergistic agent, 0% to 10% of sodium hydroxide, 15% to 18% of activating agent, 0 to 5% of energizer, 4% to 8% of inhibiter, 0.5 to 1.5% of stabilizing agent, 0 to 5% of additive with water to prepare the water-base cleaning agent composition. This invention is suitable for cleaning components in the processing processes of each metal, alloy and non-metal in the machine manufacture and maintenance process, and cleaning the carbon deposit and the heavy oil stain. This invention is a non-ODS environmentally friendly water-base cleaning agent.

Owner:PLA NO 5719 FACTORY

Hard water foaming agents and methods for gypsum board production

Compositions and methods for reducing the impact of hard water on gypsum board foaming are provided. The compositions include adding a foam to water and a calcined slurry. The foam includes water, dispersed air and a surfactant. Surfactants for use include a hydrophobic portion having an alkyl chain length distribution of about 20% to about 60% C8 chains; about 20% to about 60% C10 chains; about 14% to about 36% C12 chains and about 2% to about 20% C14 chains and also having a hydrophilic portion having about 0.2 to 3.0 ethoxy groups.

Owner:UNITED STATES GYPSUM CO

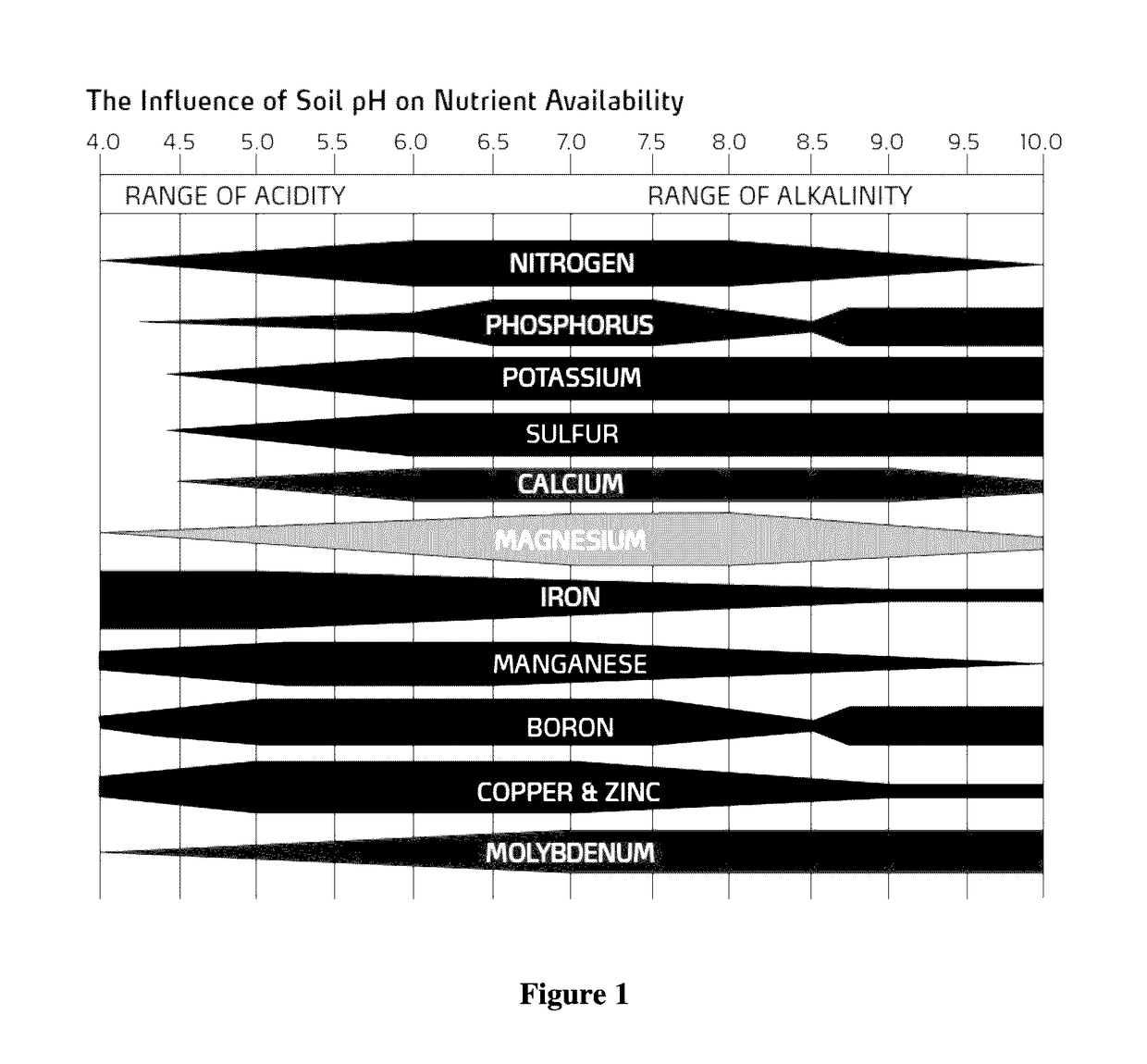

Multifunctional Organic Agricultural Fertilizer Composition and Process for Preparation Thereof

ActiveUS20170166488A1Reduce volatilityInhibit complexation/tieOrganic phosphatic fertilisersAgriculture gas emission reductionAdjuvantStimulant

The invention disclosed herein is a multifunctional agricultural organic bio-complexed composition comprising essential and non-essential nutritional elements; useful as a fertilizer, nutrient, bio-stimulant, complexing agent, pH controller, pH indicator, pH corrector, hard water salts in-activator, surface tension reducer, Spreader, penetrator, adjuvant, alkaline hard water ill effects mitigator, water conditioner and drip system irrigation cleaner. The invention also disclosed herein a process for preparation thereof.

Owner:CHAUDHRY SUUNIL SUDHAKAR

Ion-sensitive hard water dispersible polymers and applications therefor

InactiveUS6855790B2Difficulty in dispersibilityIncrease contentAnionic surface-active compoundsDetergent materialsFiberWater dispersible

The present invention is directed to ion-sensitive, hard water dispersible polymers. The present invention is also directed to a method of making ion-sensitive, hard water dispersible polymers and their applicability as binder compositions. The present invention is further directed to fiber-containing fabrics and webs comprising ion-sensitive, hard water dispersible binder compositions and their applicability in water dispersible personal care products.

Owner:KIMBERLY-CLARK WORLDWIDE INC

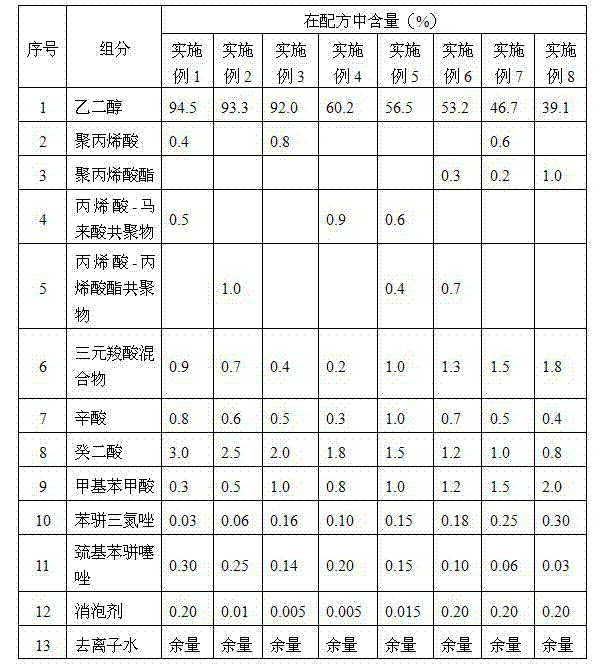

Full-organic hard water stable engine cooling liquid and making method thereof

ActiveCN103666404AImproves hard water stabilityHard water stabilityHeat-exchange elementsCarboxylic acidHard water

The invention relates to full-organic hard water stable engine cooling liquid which is characterized by being prepared by stirring and mixing the following components: 30-96 percent of ethylene glycol, 0.1-10.0 percent of organic carboxylic acid, 0.01-0.5 percent of an azole corrosion inhibitor, 0.05-1.0 percent of a hard water stabilizing agent, 0.001-0.2 percent of a defoaming agent and the balance of deionized water. The sum of the mass percentages of all the components is 100. According to the full-organic hard water stable engine cooling liquid, the hard water stability of the cooling liquid is obviously improved and effectively kept within 14d under the temperature of 90+ / -2 DEG C.

Owner:北京蓝星清洗有限公司

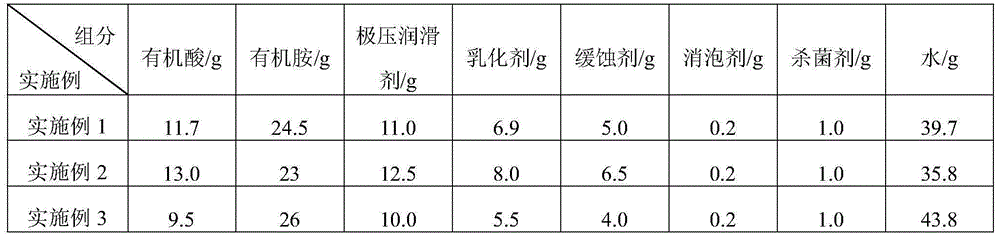

Environment-friendly water-soluble cutting fluid for magnesium alloy cutting

InactiveCN105038942AExtended service lifeImprove wear resistanceLubricant compositionOrganic acidHydrogen

The invention relates to an environment-friendly water-soluble cutting fluid for magnesium alloy cutting, which comprises the following components in parts by weight: 5-20 parts of organic acid, 15-30 parts of organic amine, 5-16 parts of lubricant, 3-11 parts of emulsifier, 1-6 parts of corrosion inhibitor, 0.1-0.5 part of defoaming agent, 0.1-3.5 parts of bactericide and 15-70 parts of water. The magnesium alloy cutting fluid has the advantages of favorable abrasion resistance, favorable hard water resistance, favorable rust and corrosion resistance, and is capable of effectively protecting the cutter and prolonging the service life of the cutter. The water-soluble cutting fluid can quickly take away the heat generated in the machining process, lower the temperature of the machined surface and effectively avoid the defect of high flammability of the magnesium chips due to high temperature. The aluminum-magnesium alloy cutting fluid provided by the embodiment of the invention does not release hydrogen when being used for magnesium alloy cutting, thereby ensuring the safe proceeding of the production process.

Owner:深圳市奥科宝特种油剂有限公司

Green microemulsion metal cutting fluid and its preparation method

ActiveCN102719306AEffective protectionImprove machining accuracyLubricant compositionOil phaseAnti oxidant

The invention discloses a green microemulsion metal cutting fluid and is characterized in that its formula comprises mixed base oil, synthetic ester, an oiliness agent, an extreme pressure antiwear additive, a clean dispersant agent, an antirust anticorrosion additive, an anti-oxidant, an oil mist inhibitor, a bactericide, an antifoaming agent, an anionic surfactant, a nonionic surfactant and a cosurfactant. A preparation method of the green microemulsion metal cutting fluid comprises the following steps of: firstly preparing an oil phase, heating the base oil to 50-60 DEG C, successively adding the oiliness agent, synthetic ester, the extreme pressure antiwear additive, the clean dispersant agent and the antirust anticorrosion additive, uniformly stirring and mixing to prepare an oil phase system; then preparing a water phase, successively adding the bactericide and the antifoaming agent into water, uniformly stirring and mixing to prepare a water phase system; finally emulsifying the systems, and slowly adding the water phase into the oil phase system to form the green microemulsion metal cutting fluid. The green microemulsion metal cutting fluid provided by the invention has advantages of excellent extreme pressure wear resistance, resistance to hard water, long using period and the like.

Owner:上海福岛新材料科技有限公司

Treating method for desalting high-salt-content waste water in oil and gas field

InactiveCN102603092AMeet emission requirementsEfficient removalGeneral water supply conservationMultistage water/sewage treatmentSolubilityFiltration membrane

The invention relates to a treating method for desalting high-salt-content waste water in an oil and gas field during exploration and transmission of oil and natural gas. The method comprises the following steps of: a, adding a hard water softener and a flocculant to waste water, wherein based on each stere of waste water, the addition amounts of the components are as follows: 0.5-0.9kg of hydroxide, 0.5-0.9kg of carbonate and 1.5-3.0kg of the flocculant; b, filtering the waste water by utilizing an ultra-filtration membrane, and filtering by sequentially utilizing a quartz sand filter and a fine filter; and c, carrying out a reverse osmosis desalination treatment on filtered water. According to the treating method for desalting the high-salt-content waste water in the oil and gas field, disclosed by the invention, through various forms and multi-level treatments, organic matters and soluble salt-type matters in water bodies of the oil and gas filed are effectively removed, and thus the chloride concentration of the high-salt-content waste water of the oil and gas field is less than 250mg / L, and other indexes of the high-salt-content waste water can meet first-level standard requirements of the Sewage Comprehensive Drainage Standard (GB8978-1996).

Owner:SICHUAN RENZHI PETROCHEMICAL TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com