Patents

Literature

2937 results about "Magnesium ion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium ions have important biological roles. Magnesium is an essential element in biological systems. Magnesium occurs typically as the Mg 2+ ion. It is an essential mineral nutrient for life and is present in every cell type in every organism.

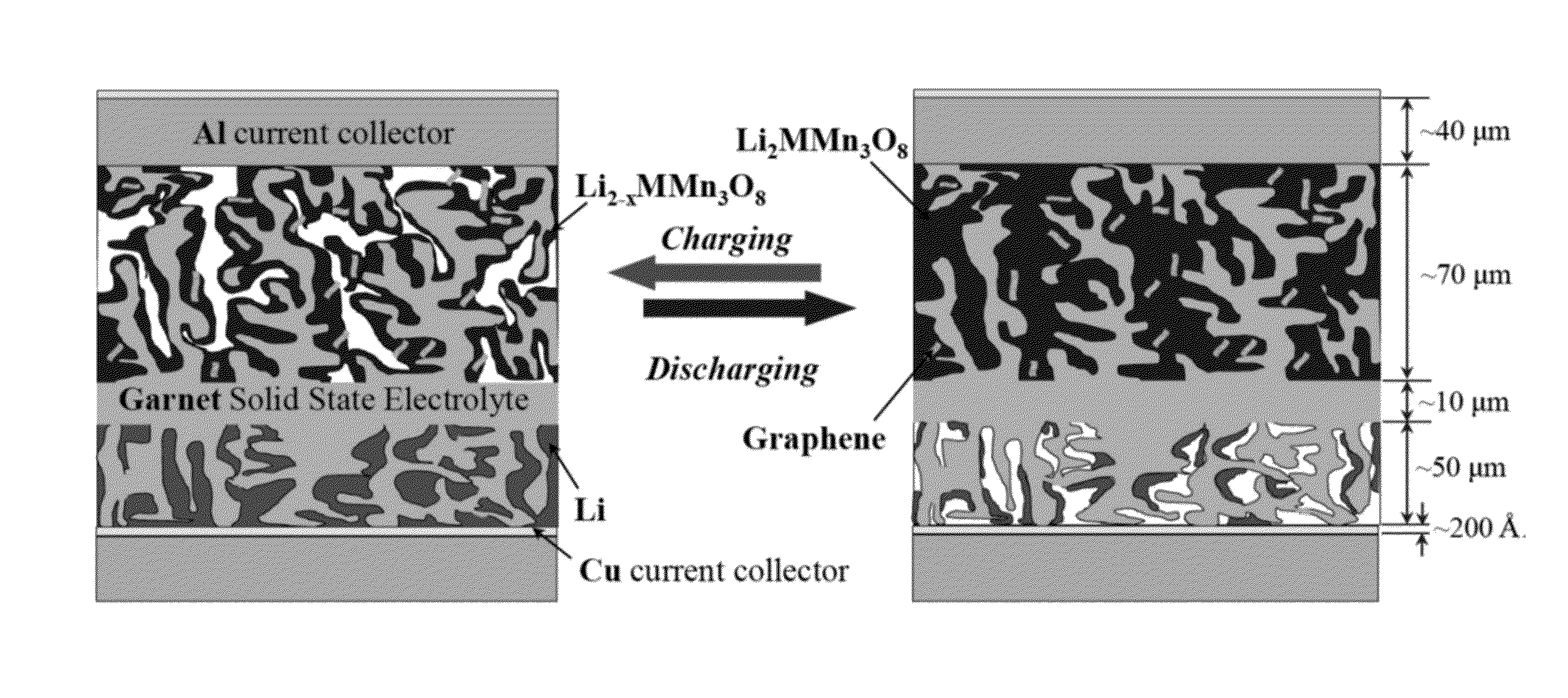

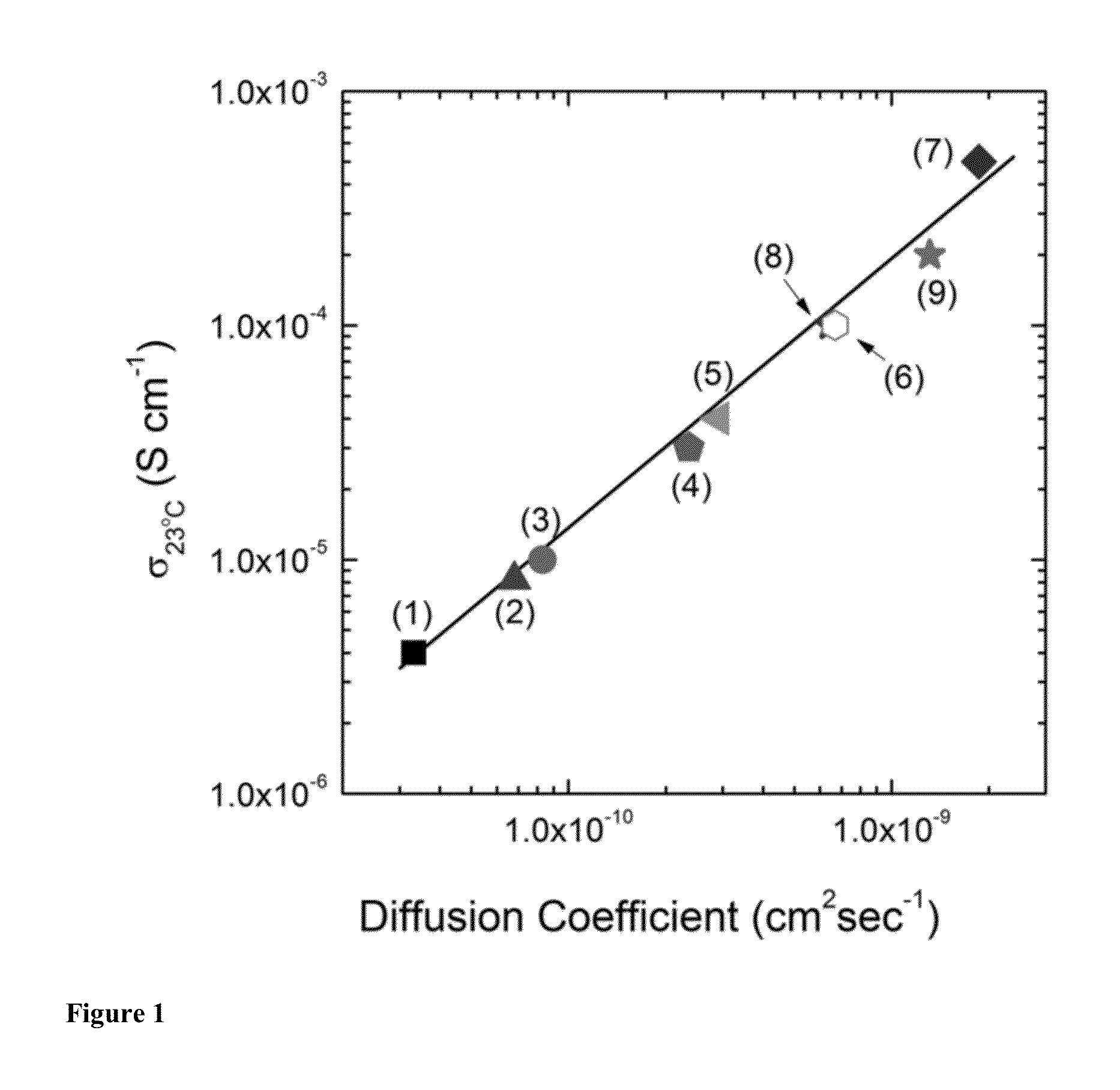

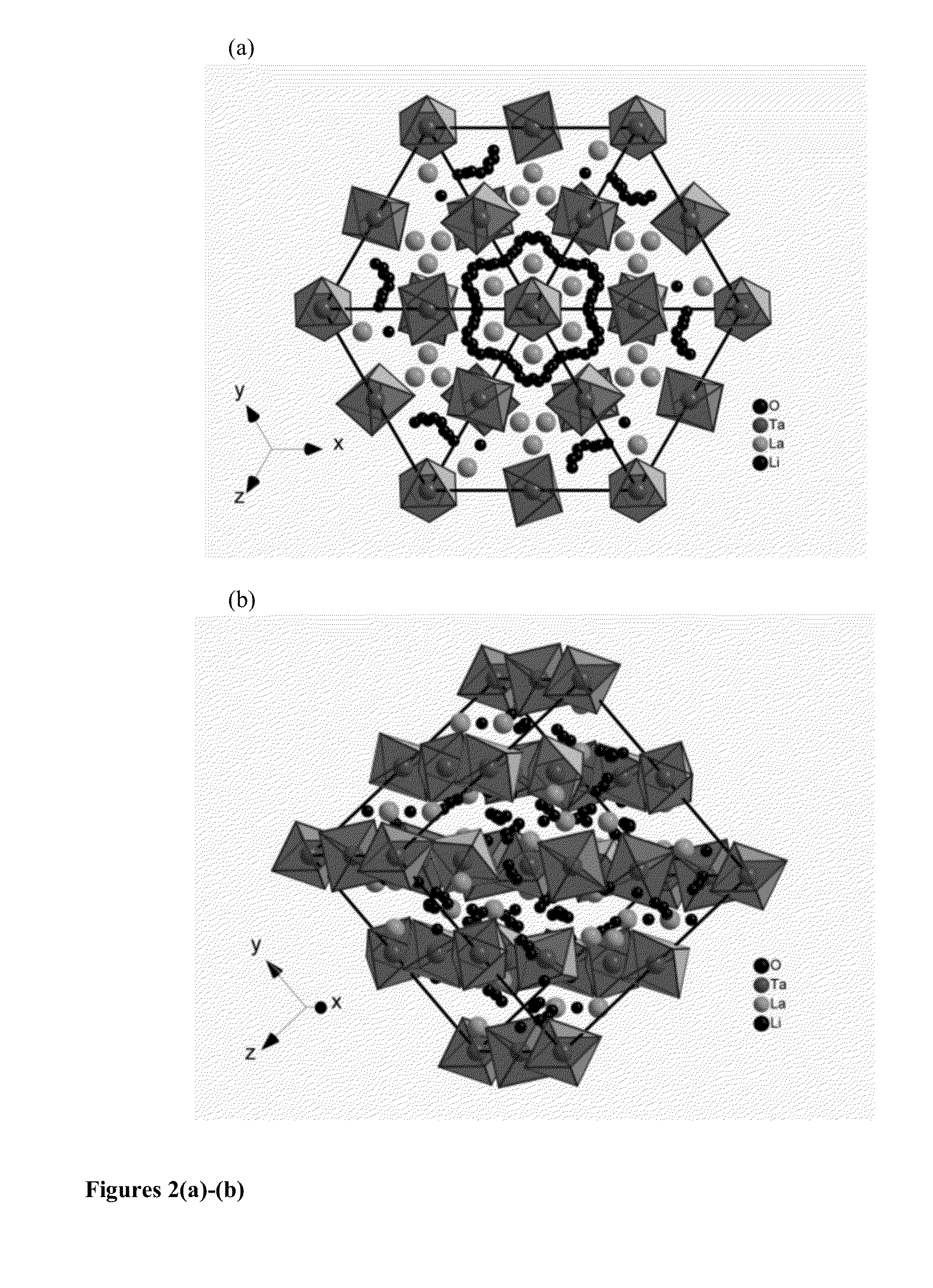

Ion conducting batteries with solid state electrolyte materials

ActiveUS20140287305A1Final product manufactureActive material electrodesSolid state electrolytePorous layer

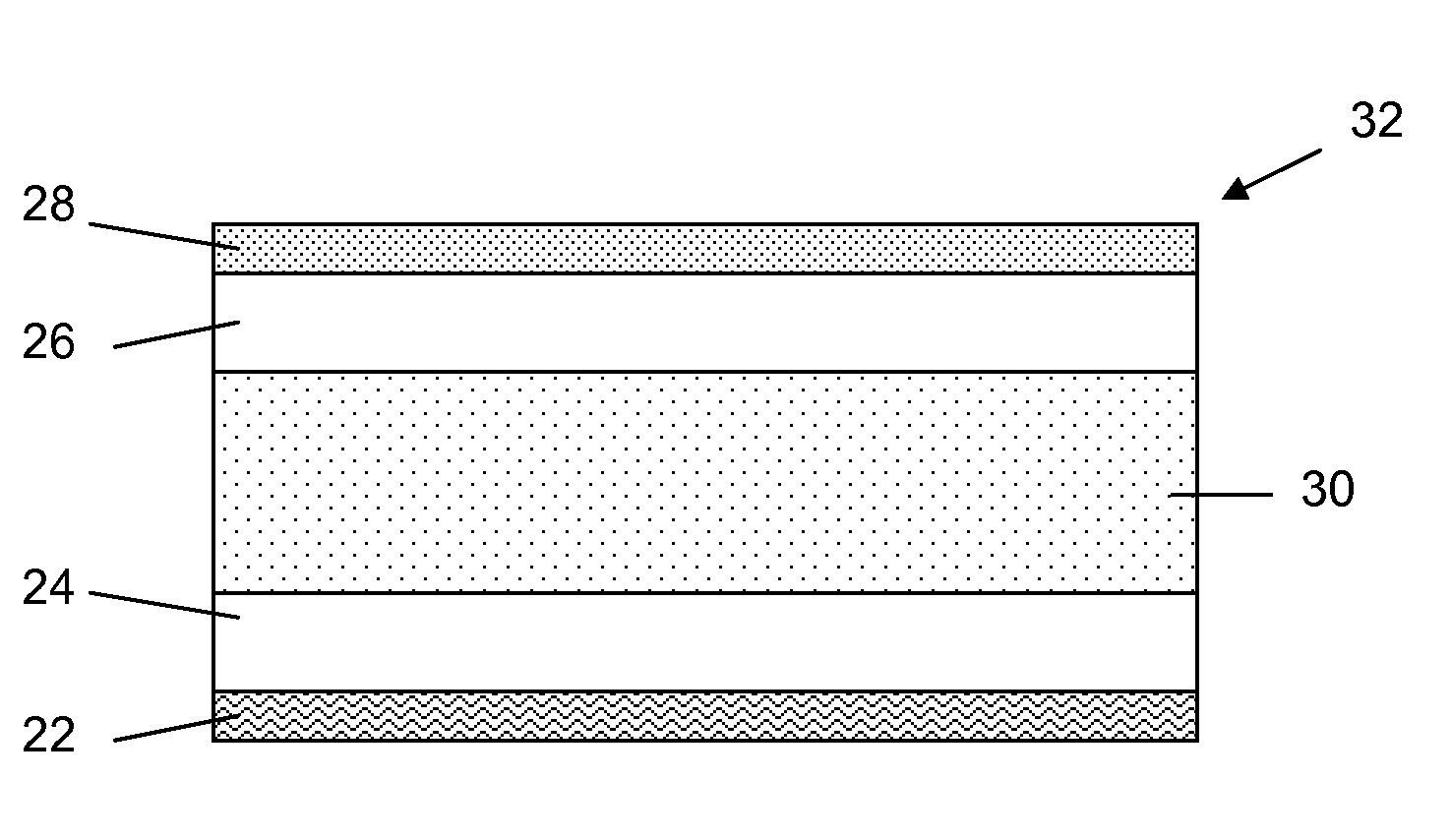

Solid-state, ion-conducting batteries with an ion-conducting, solid-state electrolyte. The solid-state electrolyte has at least one porous region (e.g., porous layer) and a dense region (e.g., dense layer). The batteries are, for example, lithium-ion, sodium-ion, or magnesium-ion conducting solid-state batteries. The ion-conducting, solid-state electrolyte is, for example, a lithium-garnet material.

Owner:UNIV OF MARYLAND

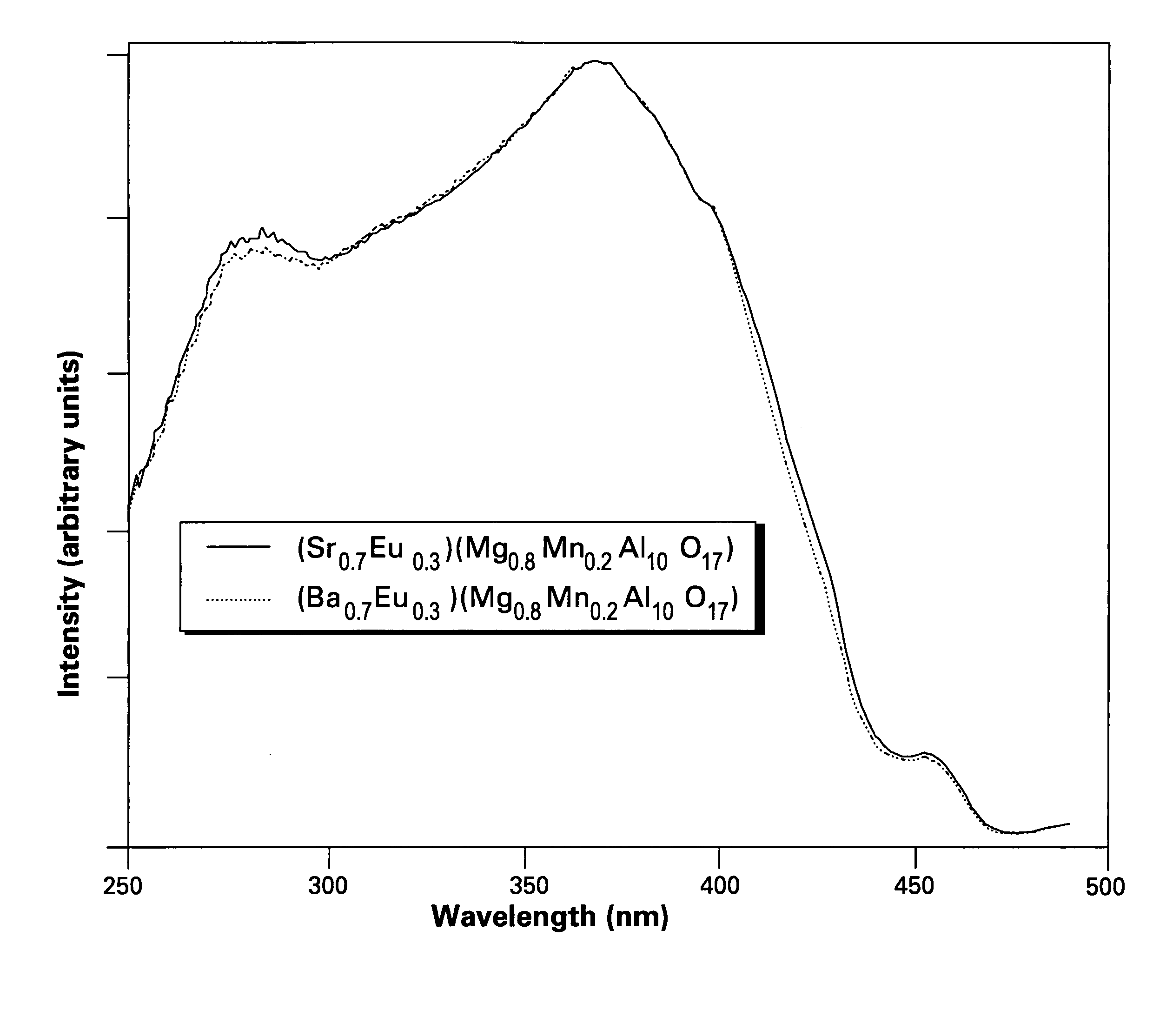

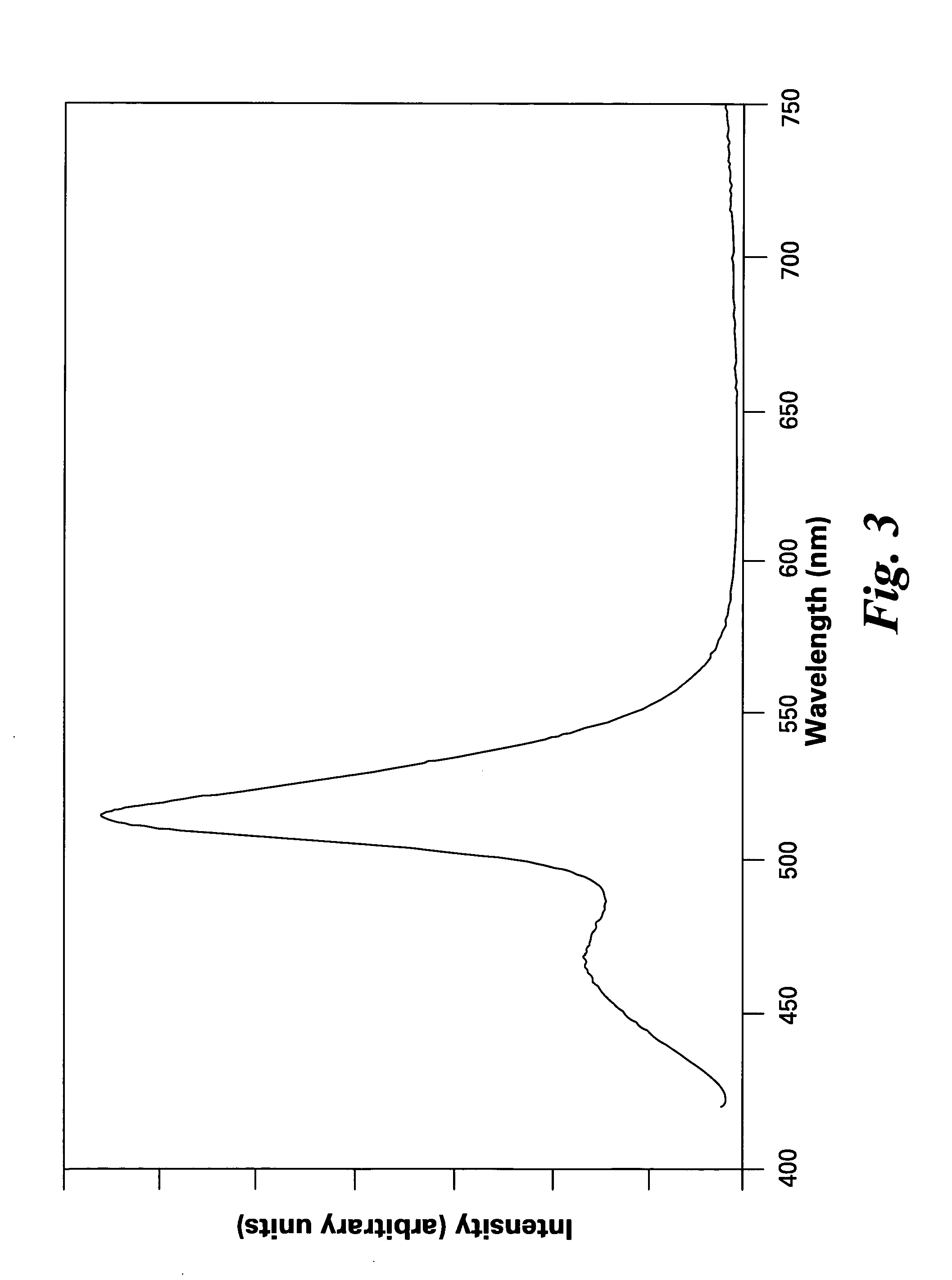

Phosphors containing oxides of alkaline-earth and group-IIIB metals and white-light sources incorporating same

InactiveUS7077978B2Discharge tube luminescnet screensCathode ray tubes/electron beam tubesAlkaline earth metalManganese

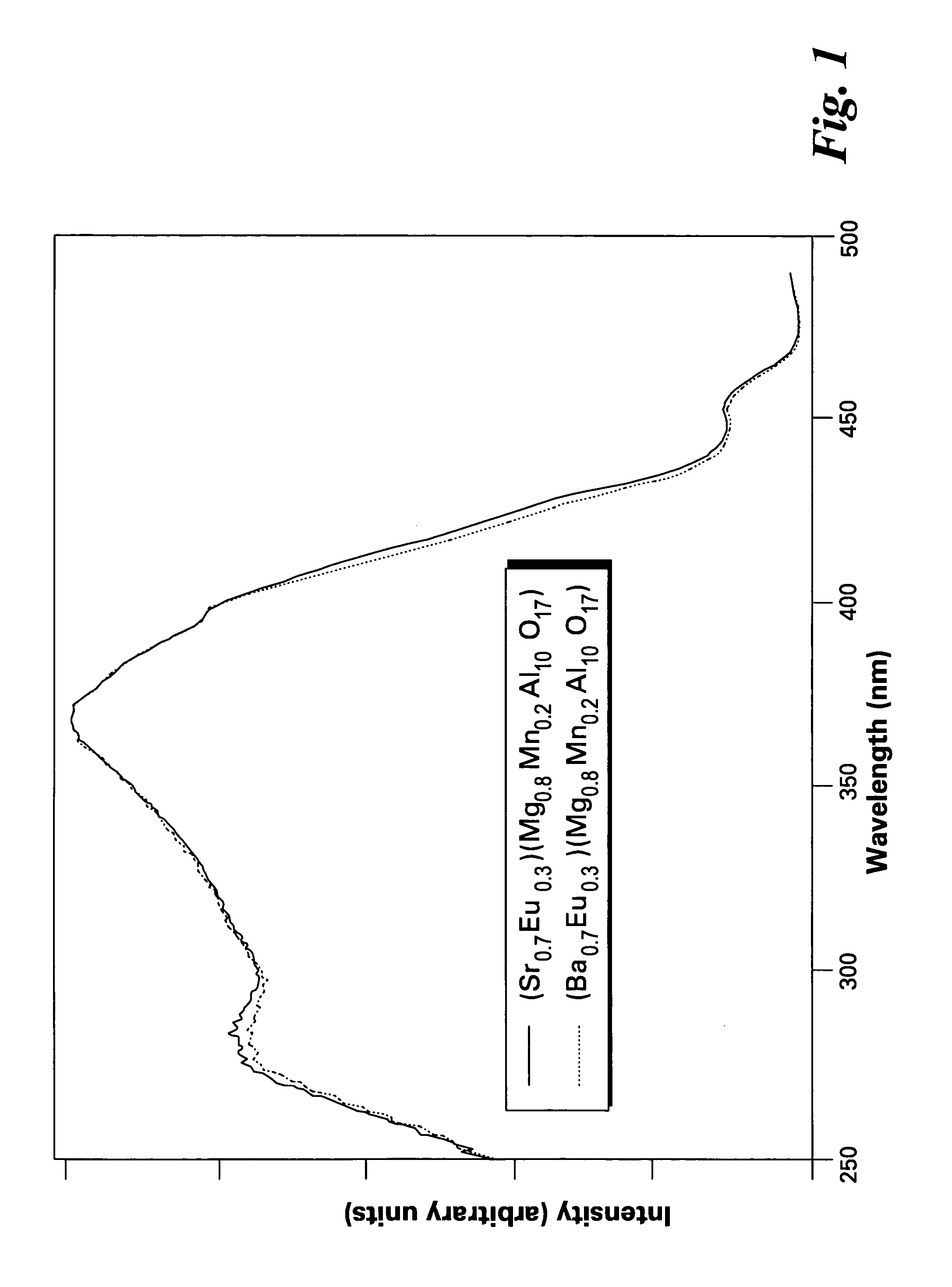

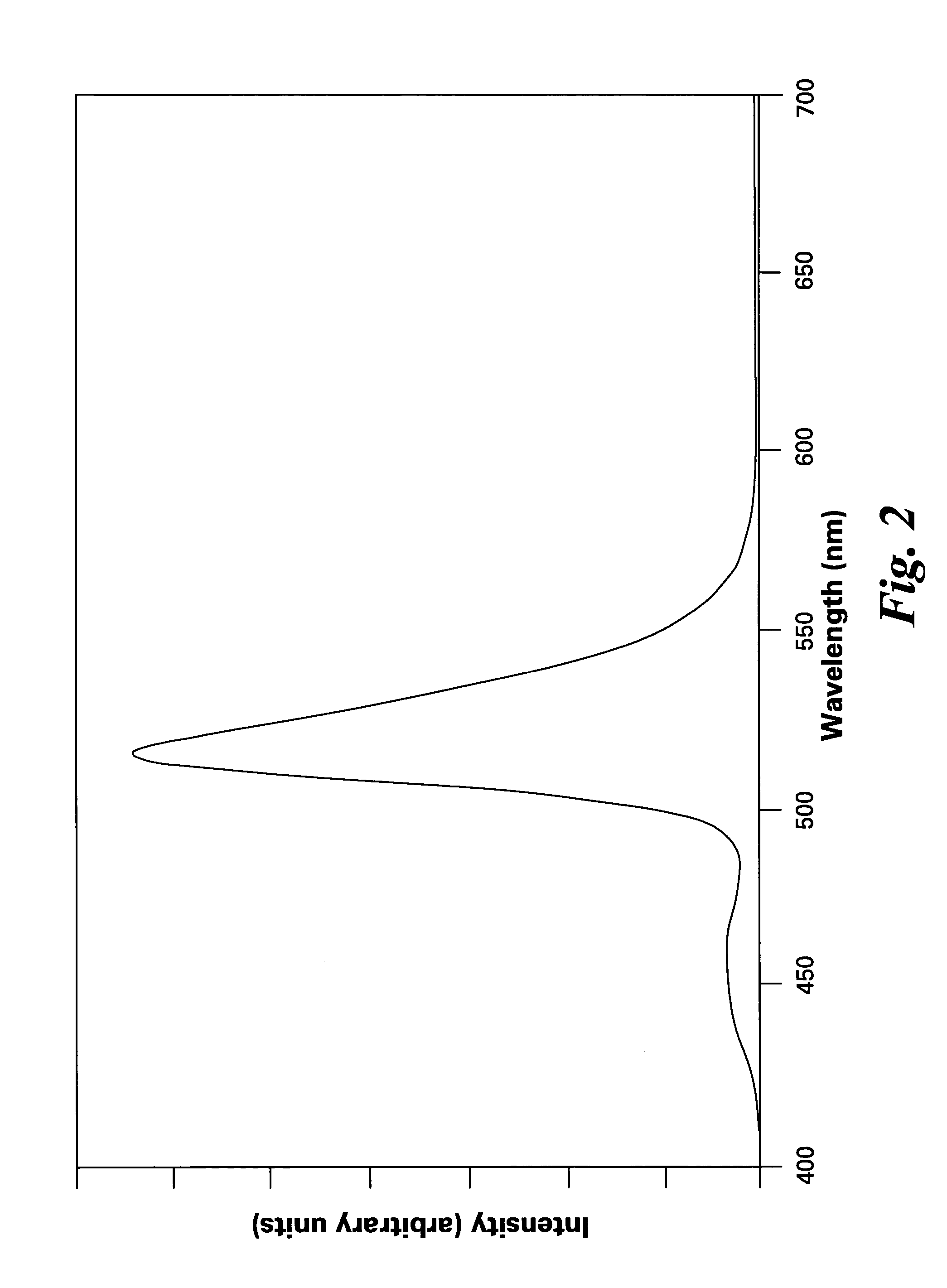

A phosphor comprises a material having a formula of AMgD10O17:Eu2+,Mn2+, wherein A is at least an alkaline-earth metal selected from the group consisting of Ba, Sr, Ca, and combinations thereof; and D is at least a metal selected from the group consisting of Al, Ga, In, and combinations thereof; wherein Eu2+ ions are present in an amount from about 10 to about 50 atom percent of a combined quantity of A ions and europium ions, and Mn2+ ions are present in an amount from about 5 to about 30 atom percent of a combined quantity of magnesium ions and manganese ions. The phosphor is used alone or in conjunction with other phosphors to convert UV / blue radiation emitted by a source, such as an LED or a gas discharge device, to visible light.

Owner:GENERAL ELECTRIC CO

Rechargeable magnesium ion cell components and assembly

InactiveUS20110159381A1Cost-effective fabricationHigh voltageSilver accumulatorsElectrode carriers/collectorsEngineeringMagnesium ion

A magnesium battery electrode assembly is described, including a current collector comprising a carbonaceous material and an electrode layer comprising an electrode active material disposed on the current collector.

Owner:PELLION TECH

Rechargeable magnesium battery

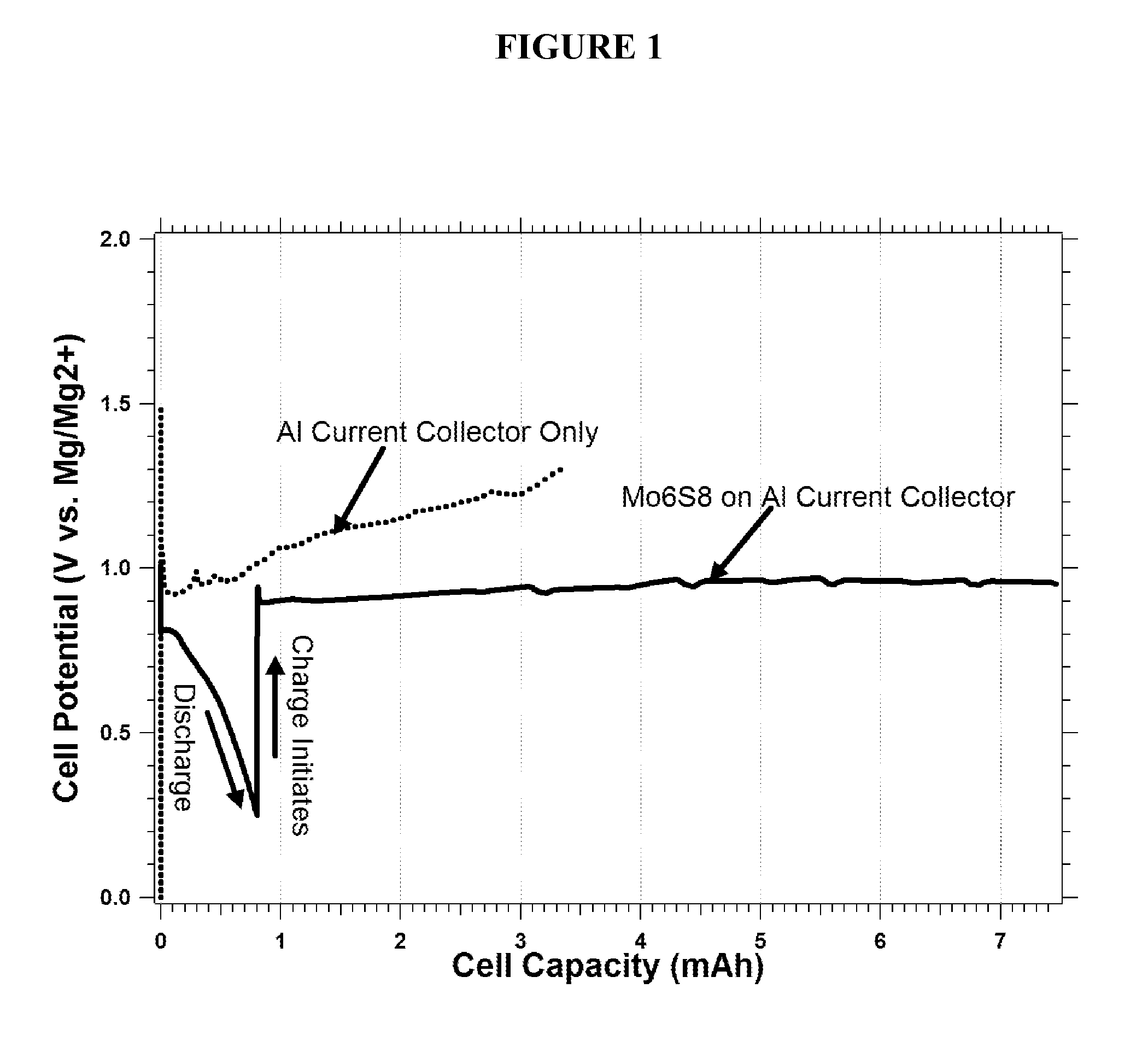

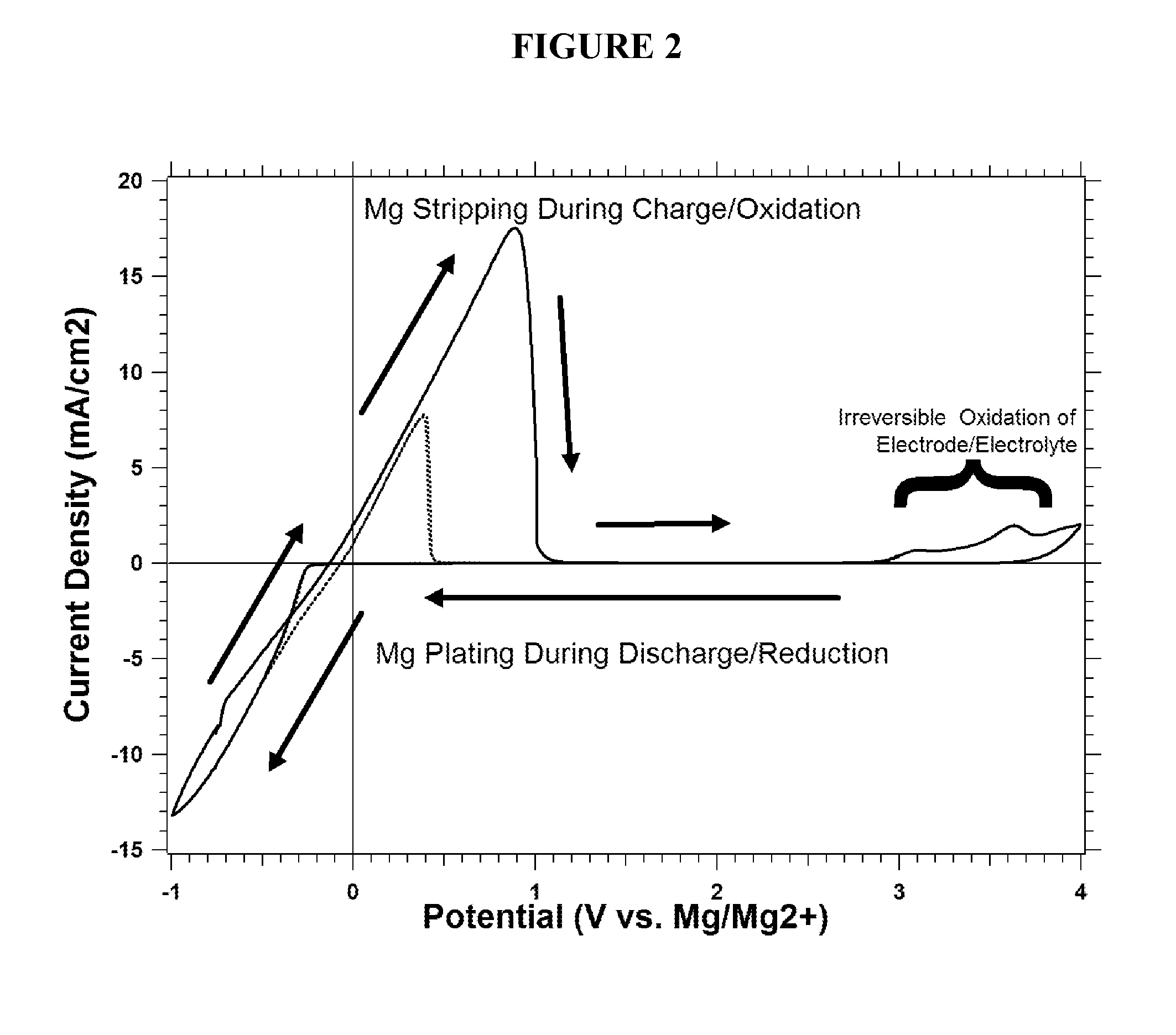

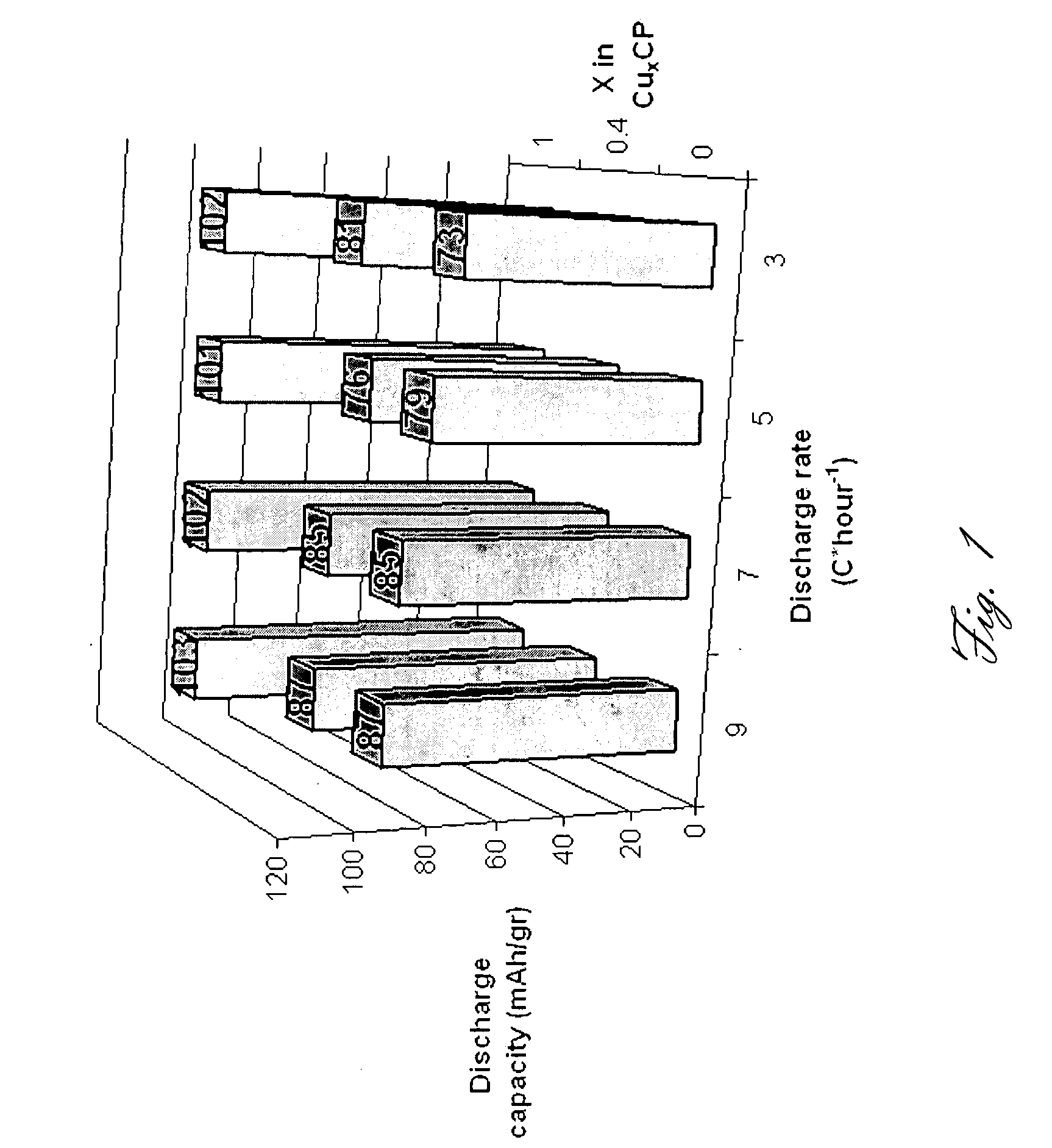

ActiveUS20080182176A1Improved kineticsImprove conductivityMaterial nanotechnologyPhosphorus sulfur/selenium/tellurium compoundsElectrochemical windowCopper

This invention generally relates to electrochemical cells utilizing magnesium anodes, new solutions and intercalation cathodes. The present invention is a new rechargeable magnesium battery based on magnesium metal as an anode material, a modified Chevrel phase as an intercalation cathode for magnesium ions and new electrolyte solution from which magnesium can be deposited reversibly, which have a very wide electrochemical window. The Chevrel phase compound is represented by the formula Mo6S8-YSeY in which y is higher than 0 and lower than 2 or by the formula MXMo6S8 in which M is selected from the group comprising of copper (Cu), nickel (Ni), silver (Ag) and / or any other transition metal; further wherein x is higher than 0 and lower than 2.

Owner:BAR ILAN UNIV

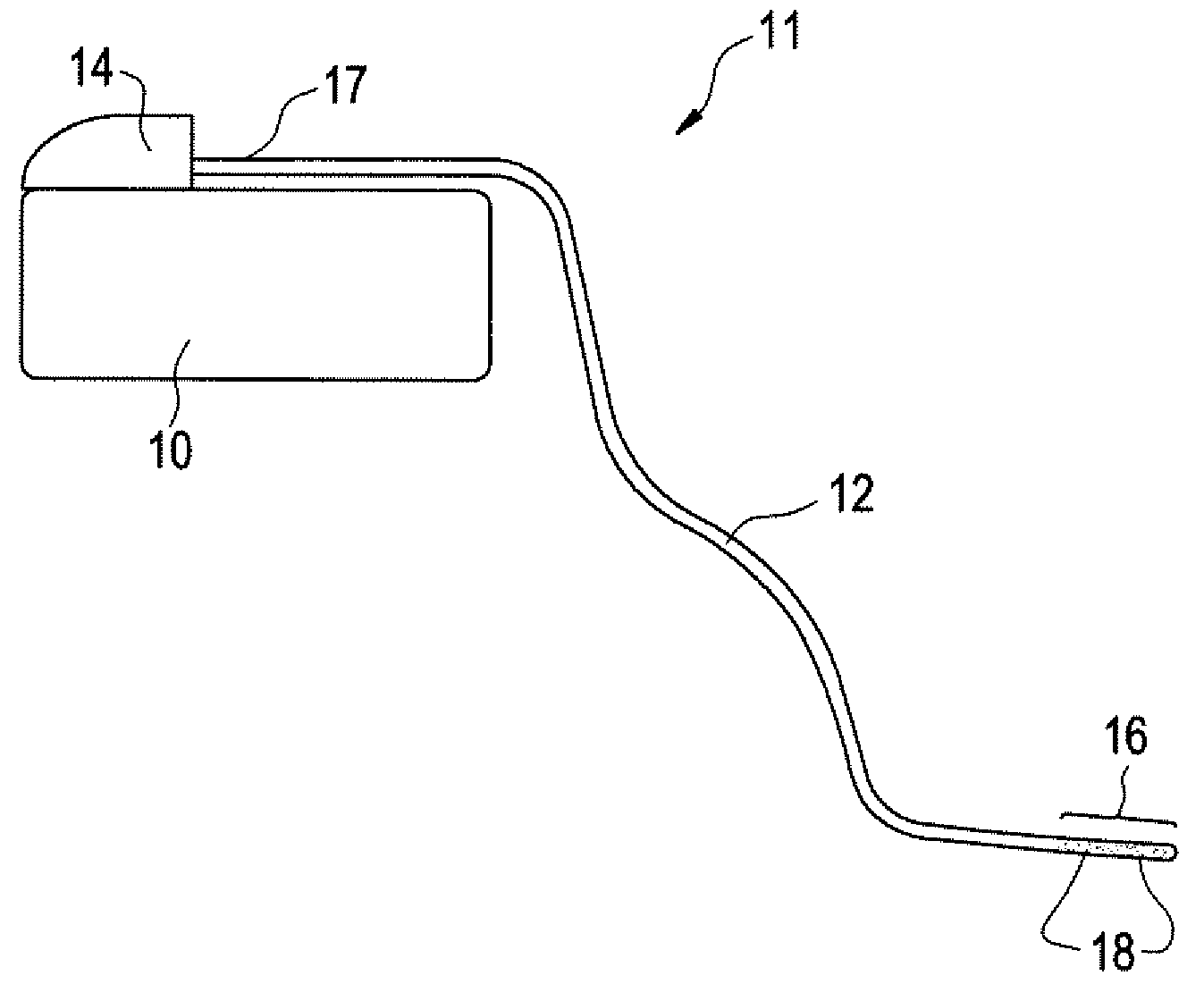

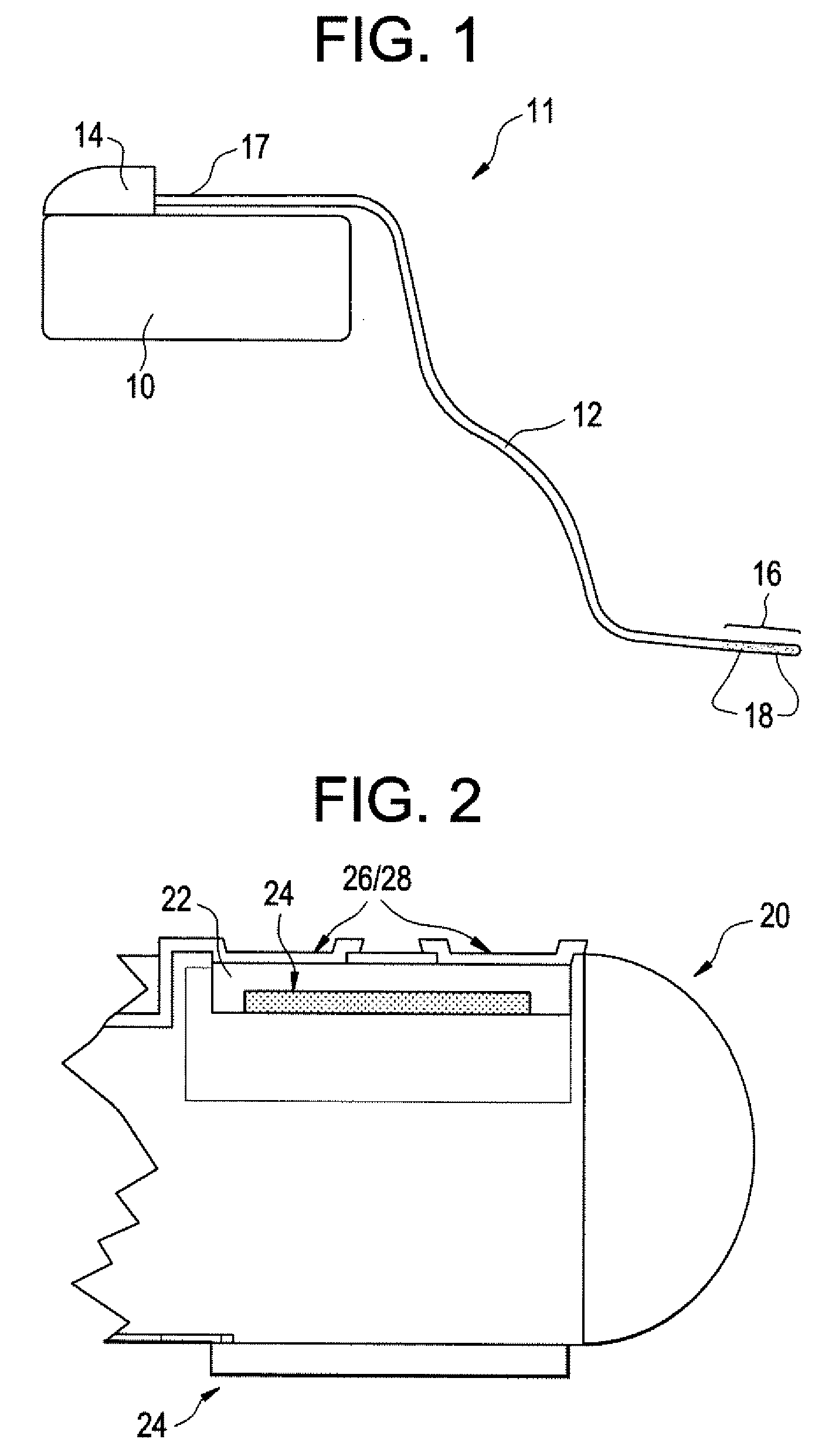

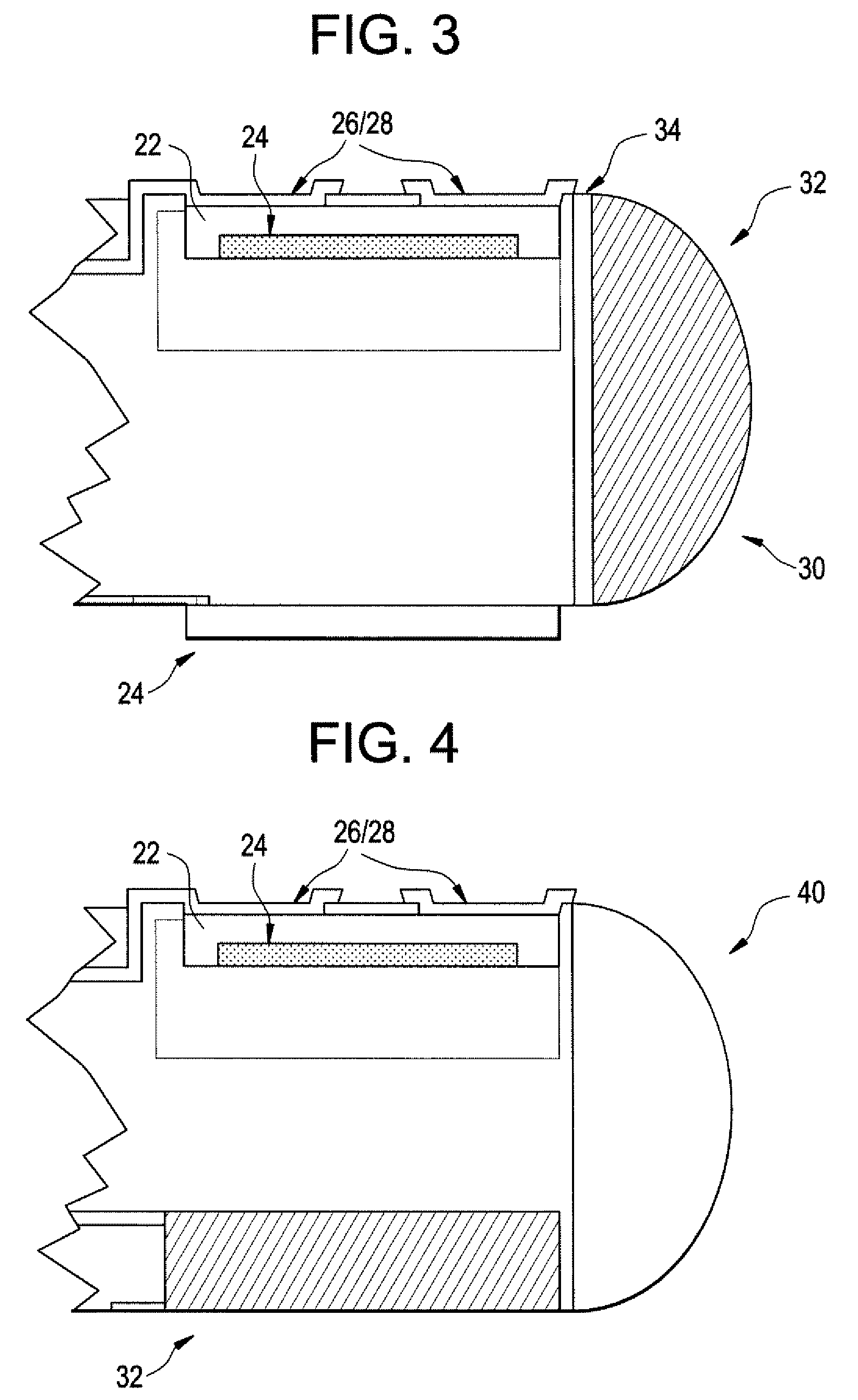

Cardiac Biosensor Devices and Methods

Implantable medical devices for cardiac care are provided that include a housing having a power source and control electronics; at least one lead extending from the housing and having one or more discrete reservoirs therein, each reservoir having an opening to an outer surface of the lead; one or more sensors, which monitor or detects an analyte, biomarker, or physical parameter that is associated with cardiac health, located in the reservoirs and in operable communication with said control electronics; and at least one selectively disintegratable reservoir cap sealing each of the reservoir openings, wherein the reservoir cap is operably connected to the power source and control electronics to disintegrate the reservoir cap and expose the sensors in vivo. The sensor may detect an analyte or biomarker selected from potassium ion, sodium ion, lithium ion, magnesium ion, ammonium ion, ionized calcium, lactate, oxygen, carbon dioxide, and creatinine, urea, BUN, and bilirubin.

Owner:MICROCHIPS INC

Technology for recovering water resources and salt from coking wastewater in coal chemical industry

ActiveCN105502782ANo secondary hazardous waste generatedLow running costMultistage water/sewage treatmentAlkali metal chloridesChemical treatmentAdvanced oxidation process

A technology for recovering water resources and salt from coking wastewater in the coal chemical industry comprises the following steps: the wastewater is subjected to defluorination chemical treatment and subjected to sodium carbonate softening and precipitating treatment simultaneously, an advanced oxidation process is used for TOC (total organic carbon) degradation, a multi-medium and activated carbon filter is used for filtering separation, ultrafiltration is performed, nanofiltration membrane separation is performed, calcium and magnesium ions are separated, the calcium and magnesium ions in water produced through nanofiltration are lower than 2 mg / L, CaF2 crystallization scaling is hard to form, and nanofiltration passing liquid and nanofiltration strong brine are obtained; the nanofiltration passing liquid and the nanofiltration strong brine are treated respectively. Fluoride ions, hardness and organic carbon in the wastewater are removed, separation of multivalent salt and monovalent salt as well as concentration and evaporative crystallization of the salt is realized, more than 98% of the water resources is recovered, more than 95% of the salt resources are recovered, secondary hazardous waste is not produced, the system operation cost is reduced, and the problem about resource recovery and the environmental problem are solved finally.

Owner:湖南湘牛环保实业有限公司

High temperature reverse transcription using mutant DNA polymerases

InactiveUS20020012970A1Improve efficiencyImprove fidelityMicrobiological testing/measurementTransferasesBiologyDNA

Owner:ROCHE MOLECULAR SYST INC

Processes for water treatment

InactiveUS7077963B2Low costEconomical and efficientWaste water treatment from quariesSolid waste disposalSufficient timeMagnesium ion

The invention provides compositions comprising bauxite refinery residues that have been reacted with sufficient calcium and magnesium ions that they have a reaction pH of less than 10.5, and one or more water treating additives. The invention also provides processes for treatment of water containing dissolved inorganic substances involving stepwise treatment of the water in which the reacted bauxite refinery residues are added after the addition of a pH-raising additive. The invention also provides processes for treatment of water containing dissolved inorganic substances in which the reacted bauxite refinery residues are added stepwise, with one or more water treating additives also being added in at least one of the steps. The invention also provides a process for the neutralisation of bauxite refinery residue by reacting it with a base amount and a treating amount of calcium ions and a base amount and a treating amount of magnesium ions for a time sufficient to produce an at least partially-neutralized residue exhibiting a reaction pH of less than 10.5.

Owner:NAUVEAU TECH INVESTMENTS

Electrolyte purgative

ActiveUS20050271749A1Reduce the amount requiredIncreased tonicityOrganic active ingredientsBiocideMagnesium saltPotassium

The invention relates to compositions for use in purgatives, to purgatives comprising such compositions, and to methods for inducing purgation of the colon. The composition may comprise at least one water-soluble sodium salt; at least one water-soluble minimally degradable sugar in an amount, by weight, of from about 1 to about 3 times the weight of sodium ions in said composition; at least one water-soluble potassium salt in an amount, by weight, of from about 0.05 to about 1 time the weight of said sodium salt in said composition; and at least one water-soluble magnesium salt, wherein the weight of magnesium ions in said composition is from 0.1 to about 10 times the weight of sodium ions in said composition.

Owner:RITE PREP PTY LTD AS TRUSTEE FOR THE RITE PREP UNIT TRUST

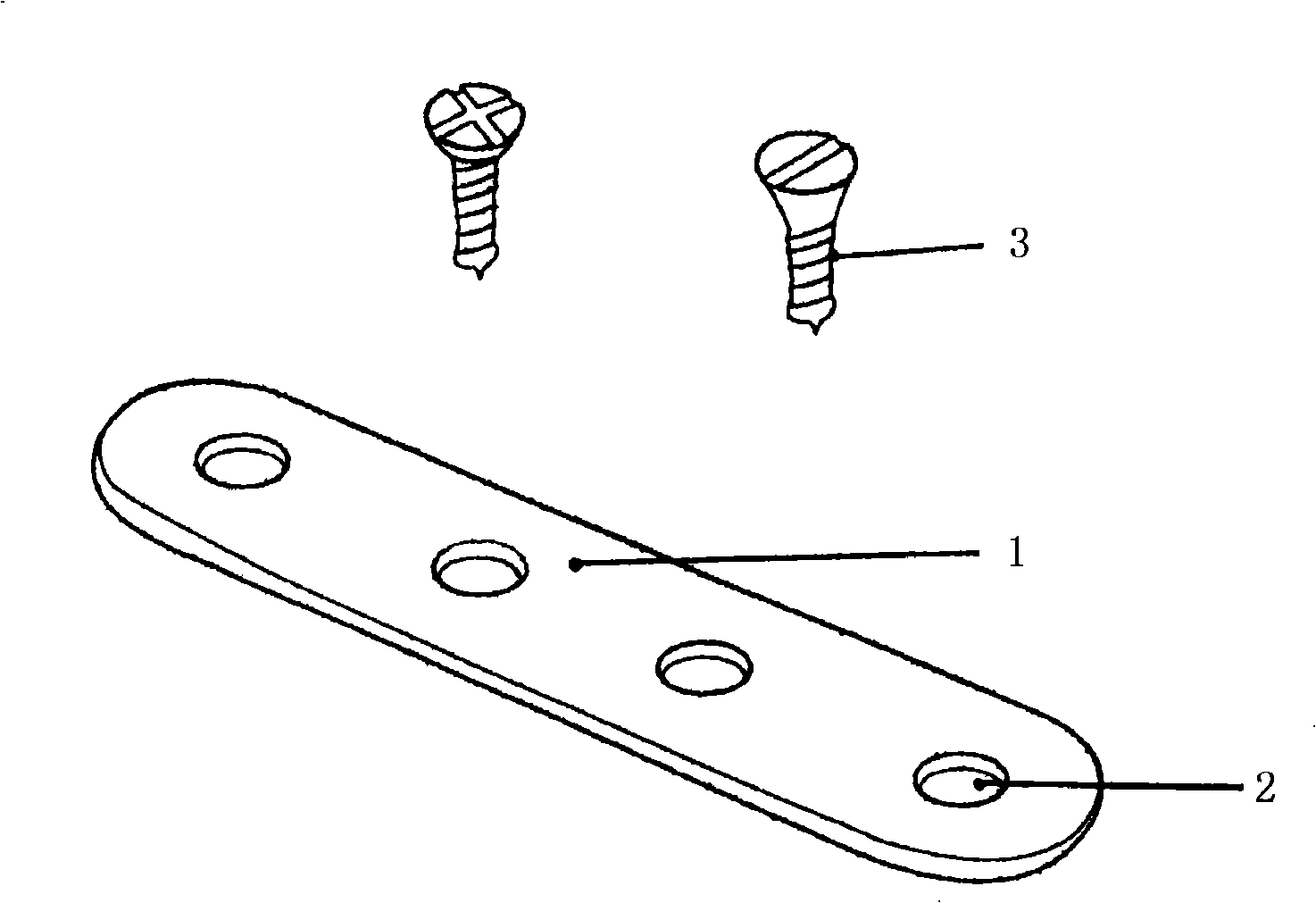

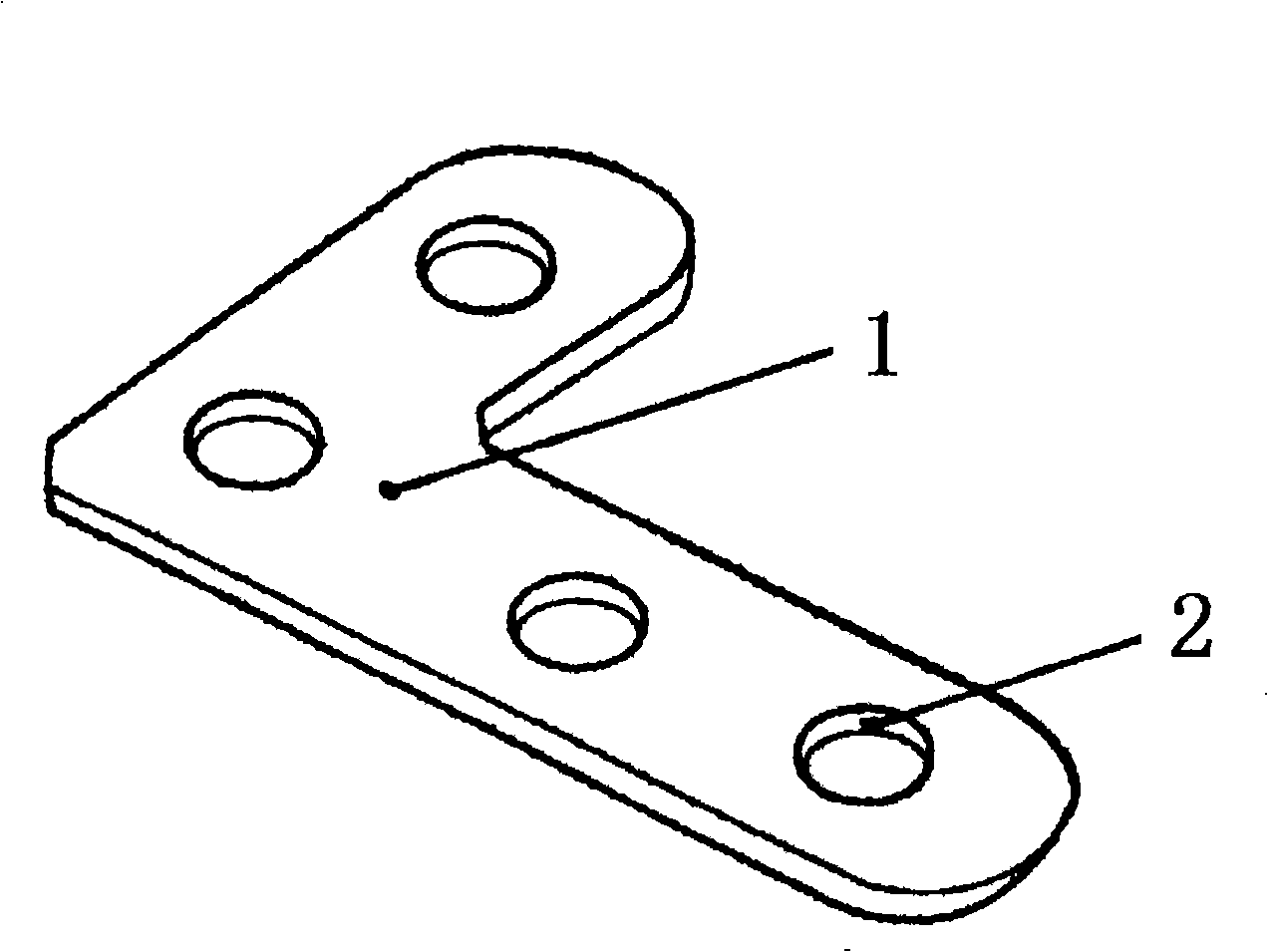

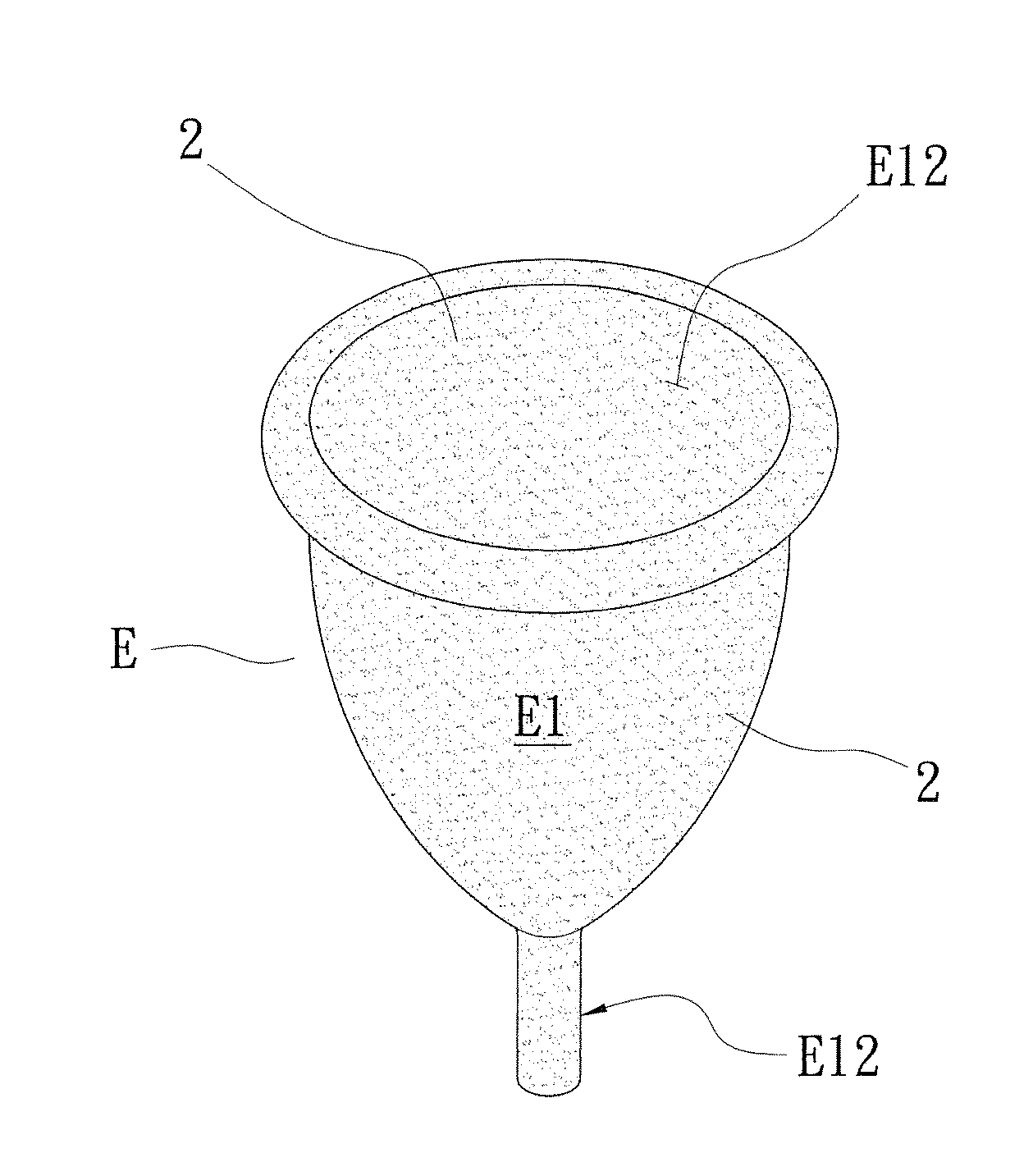

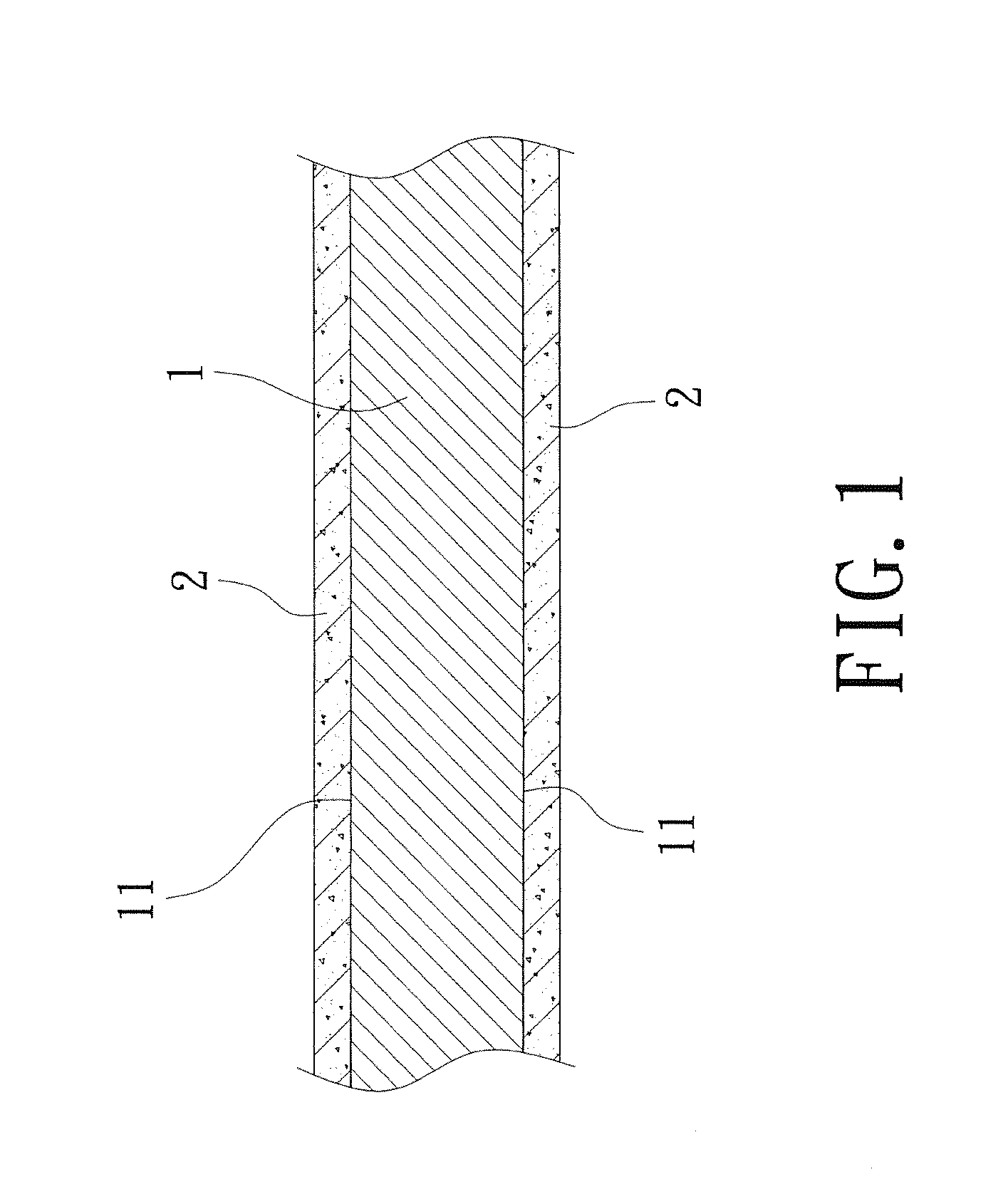

Biological and adsorbable bone internal fixation implantation instrument

InactiveCN101283922APromote healingUniform corrosion degradationInternal osteosythesisProsthesisInternal bone fixationReconstructive surgery

The invention relates to a bone implanting and internal fixation appliance with bioactivity and absorbability, which belongs to the field of bio-medical appliances, particularly to the field of medical appliances used for bone wound surgery, reparative and reconstructive surgery and plastic and cosmetic surgery. The appliance includes bone nails and a bone plate made of magnesium and the alloy thereof with bioactivity and absorbability. The bone implanting and internal fixation appliance is a bone internal fixation device, which comprises a blade plate and matched screws, intramedullary nails, a fracture and dislocation fixing device of vertebral column, bone nails or screws having individual fixation effect, wherein the bone internal fixation device is made of magnesium and the alloy thereof with bioactivity and absorbability. The bone internal fixation device can solve the problem in bioactivity of prior bone internal fixation device and promote healing the tissue where the device in implanted. The device also includes a protection layer prepared on the surface of the internal fixation device for controlling the degradation rate of magnesium alloy and the dissolution rate of magnesium ions, thus controlling the bioactivity and the absorption speed of the magnesium alloy device in an organism.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

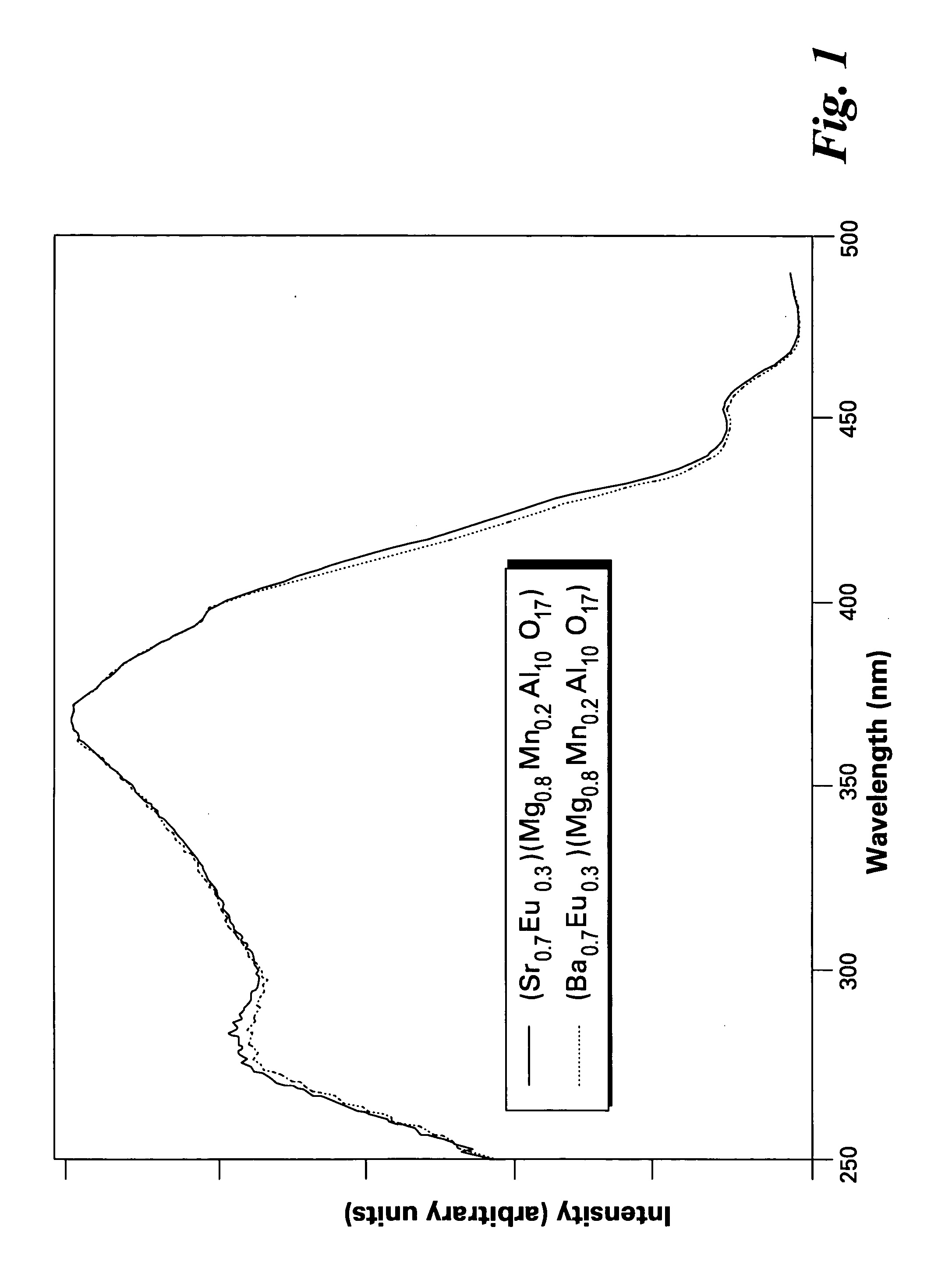

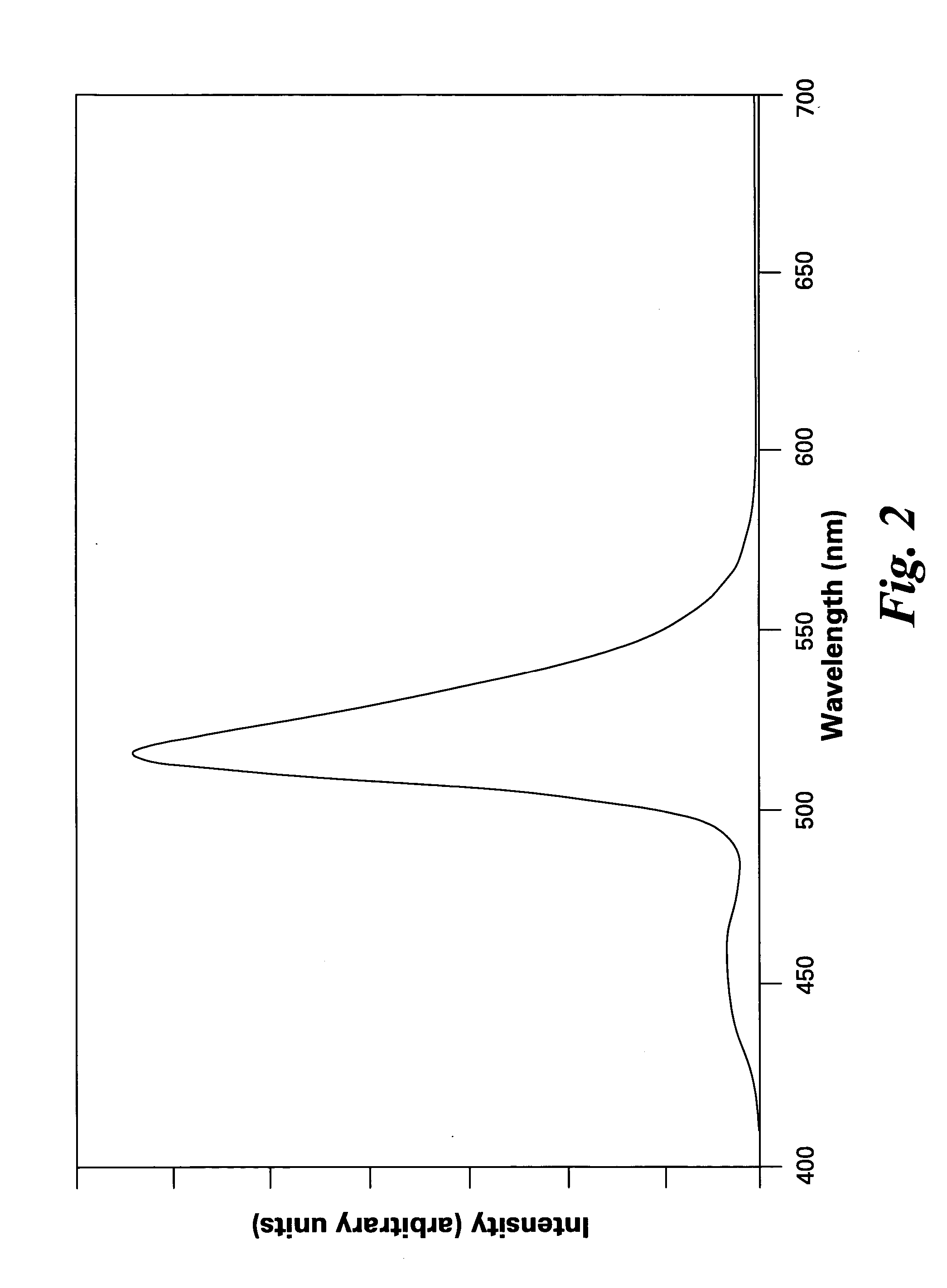

Phosphors containing oxides of alkaline-earth and group-IIIB metals and white-light sources incorporating same

InactiveUS20050253114A1Discharge tube luminescnet screensCathode ray tubes/electron beam tubesAlkaline earth metalManganese

A phosphor comprises a material having a formula of AMgD10O17:Eu2+,Mn2+, wherein A is at least an alkaline-earth metal selected from the group consisting of Ba, Sr, Ca, and combinations thereof; and D is at least a metal selected from the group consisting of Al, Ga, In, and combinations thereof; wherein Eu2+ ions are present in an amount from about 10 to about 50 atom percent of a combined quantity of A ions and europium ions, and Mn2+ ions are present in an amount from about 5 to about 30 atom percent of a combined quantity of magnesium ions and manganese ions. The phosphor is used alone or in conjunction with other phosphors to convert UV / blue radiation emitted by a source, such as an LED or a gas discharge device, to visible light.

Owner:GENERAL ELECTRIC CO

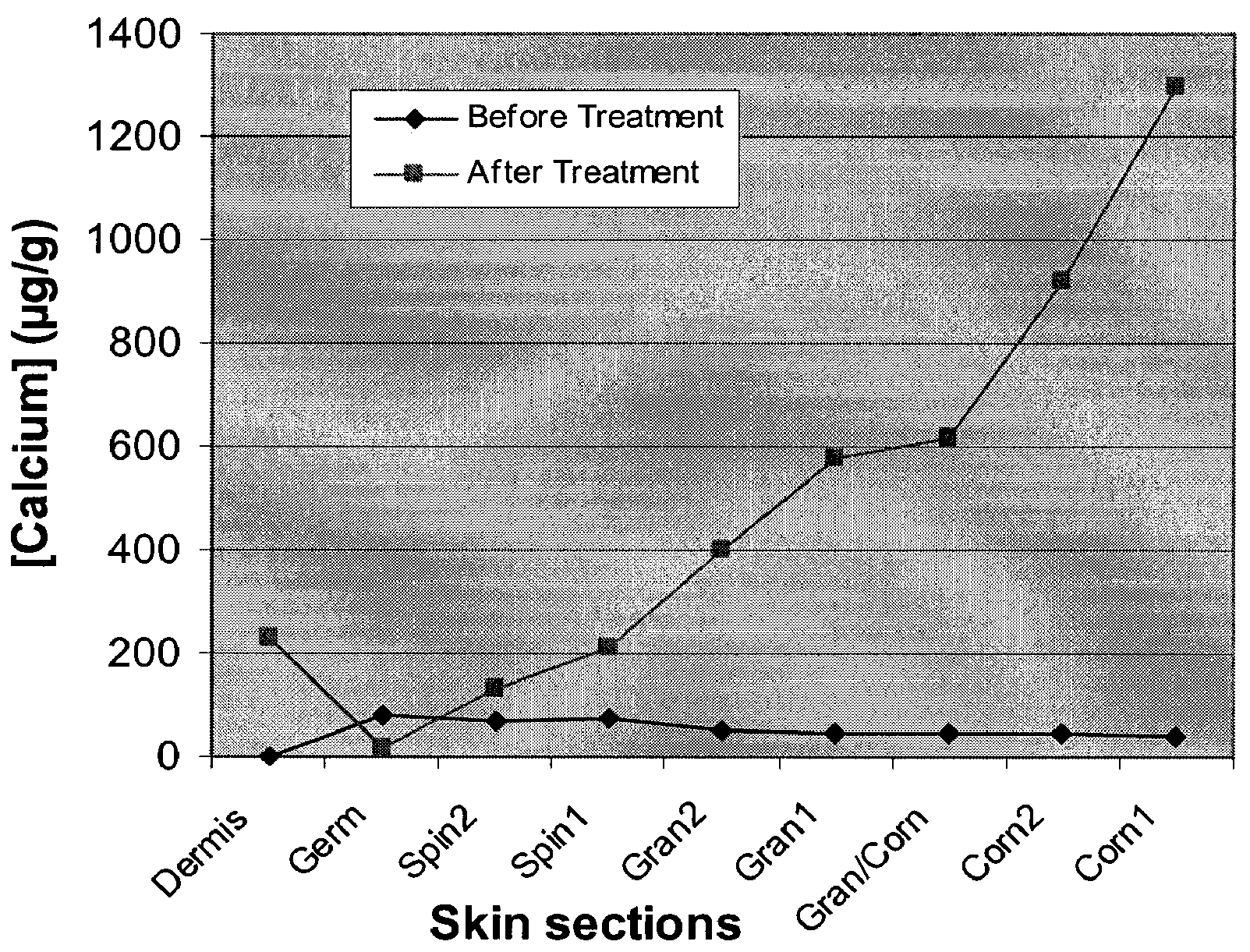

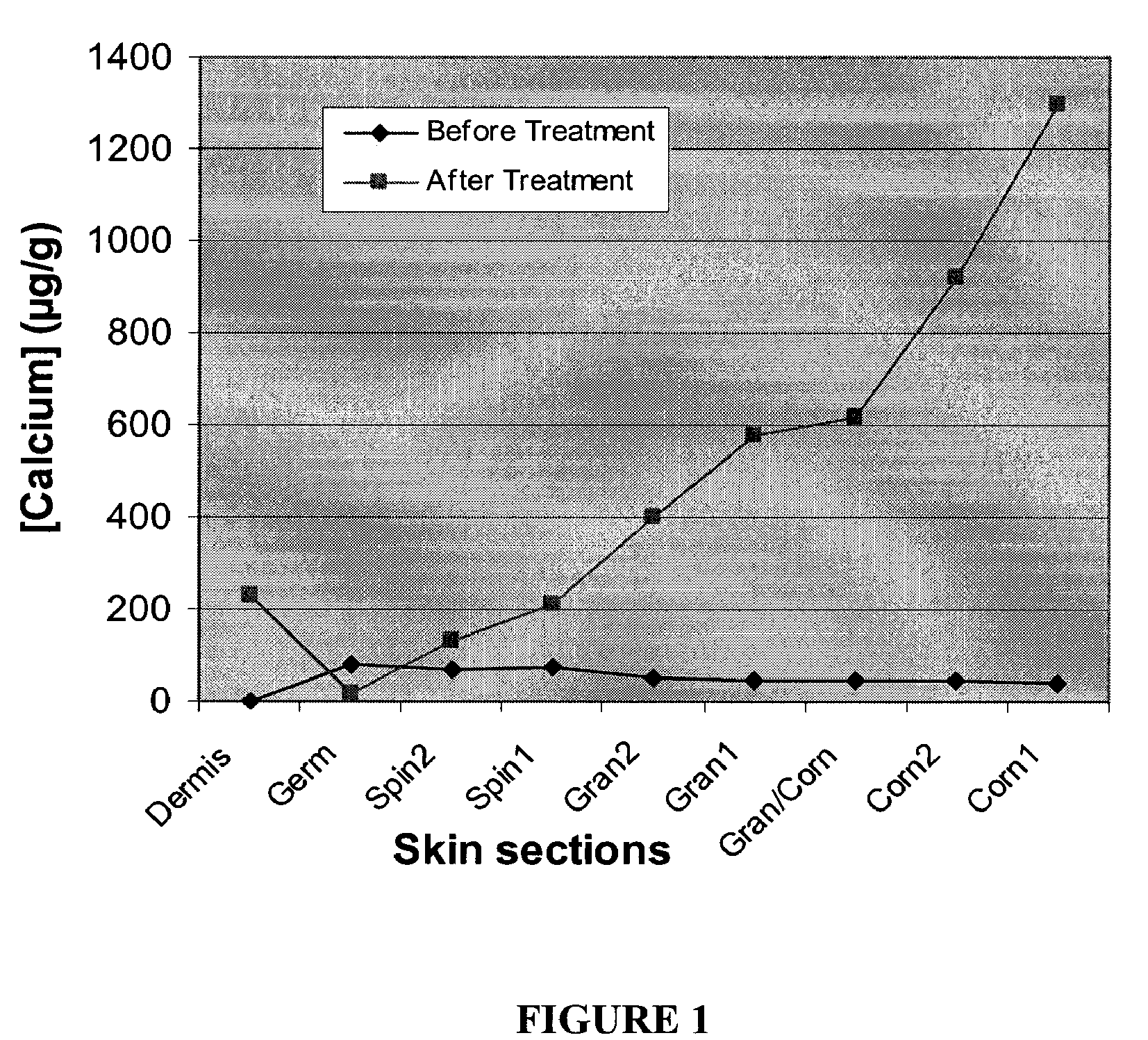

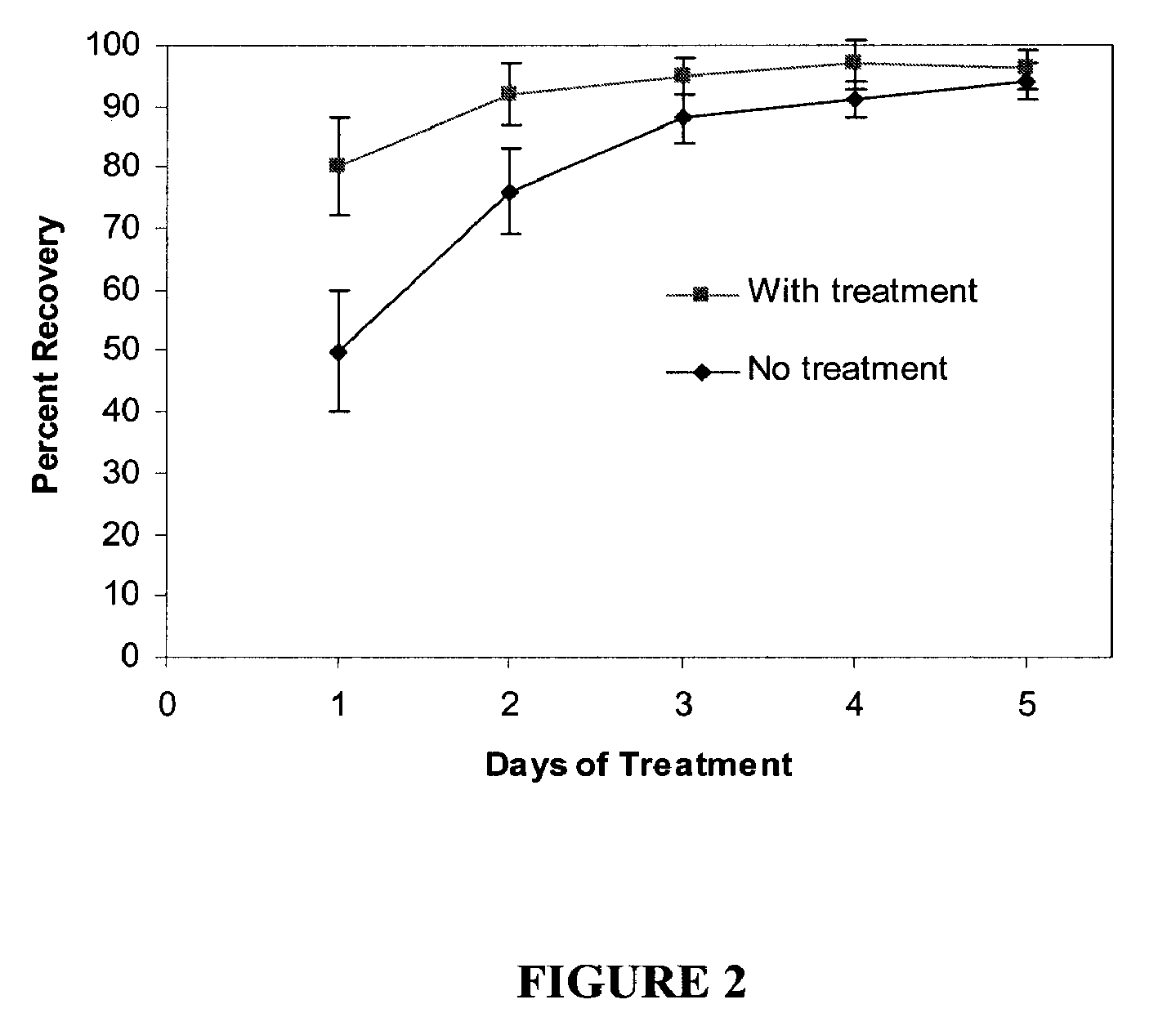

Cosmetic and cosmeceutical compositions for restoration of skin barrier function

Compositions, kits and methods are provided for restoring skin barrier function to skin exposed to environmental elements and / or in a pathological condition. In general, divalent cations such as calcium ions and / or magnesium ions are included in a physiologically acceptable medium. In some embodiments, divalent cations are balanced with monovalent cations such as sodium and potassium ions at appropriate ratios in order to maintain the homeostasis of skin barrier. The compositions, kits and methods can be used as cosmetics, cosmeceuticals or pharmaceuticals for improving skin condition, and preventing or treating dermatological diseases and skin disorders.

Owner:GENEPHARM

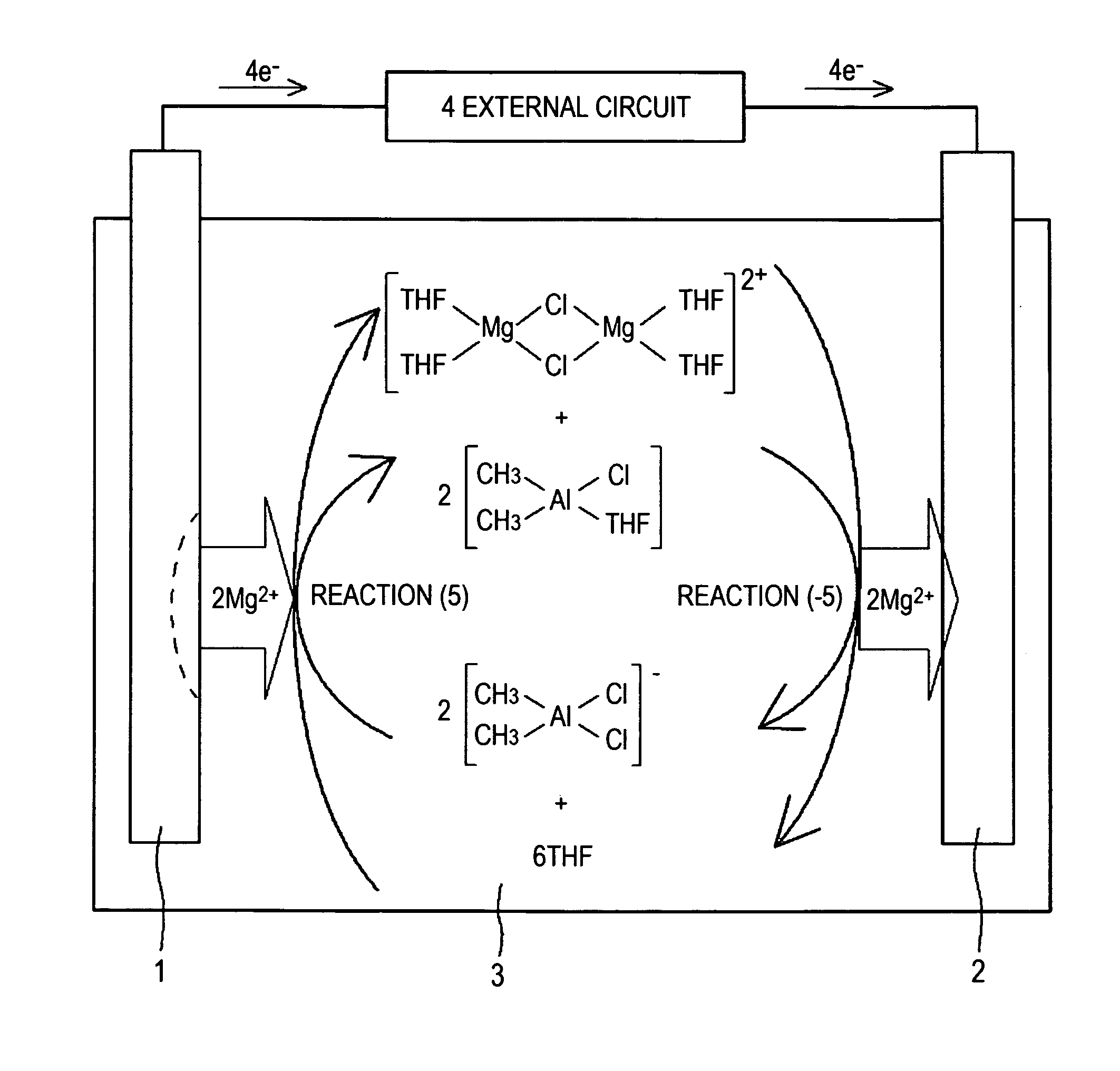

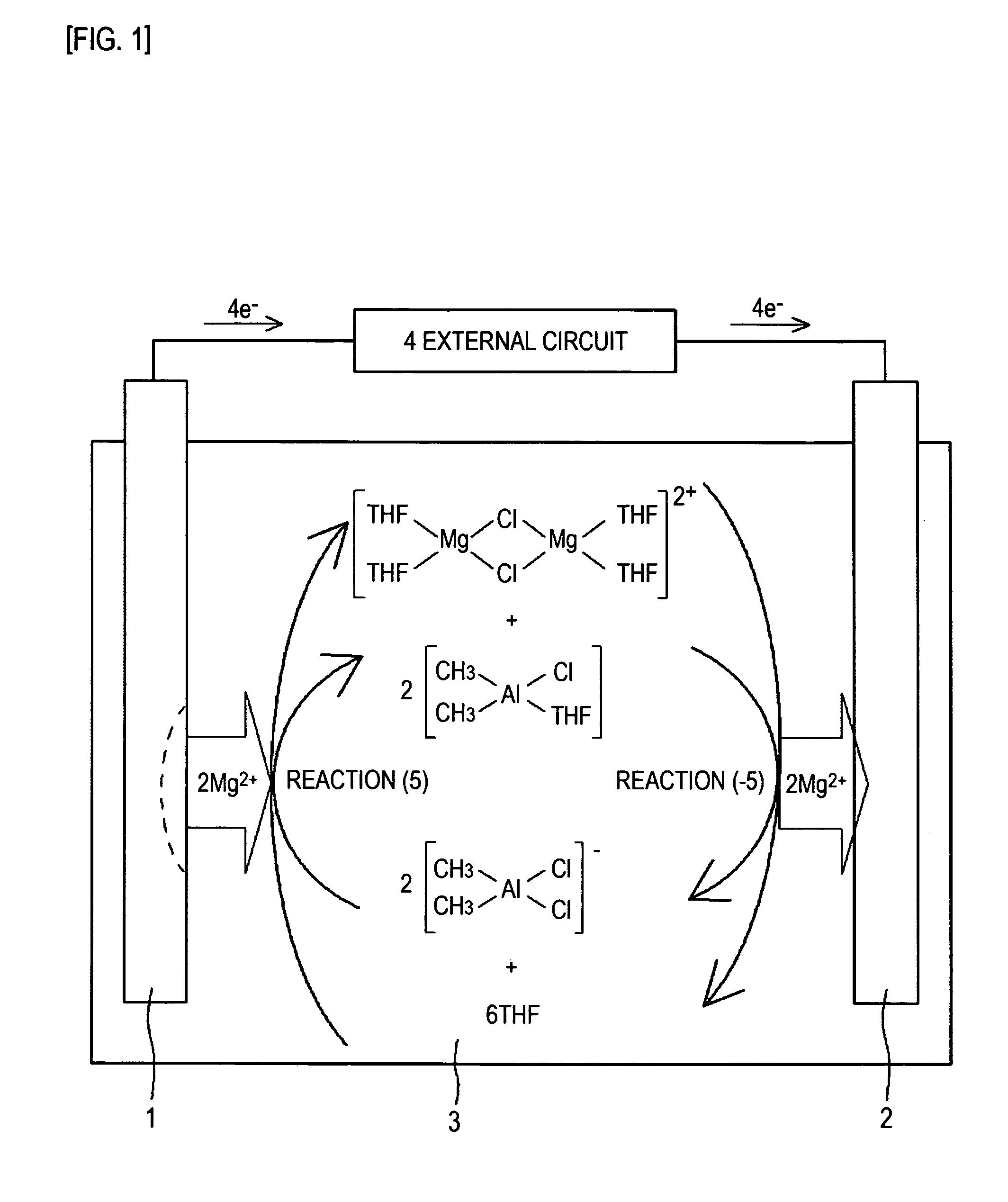

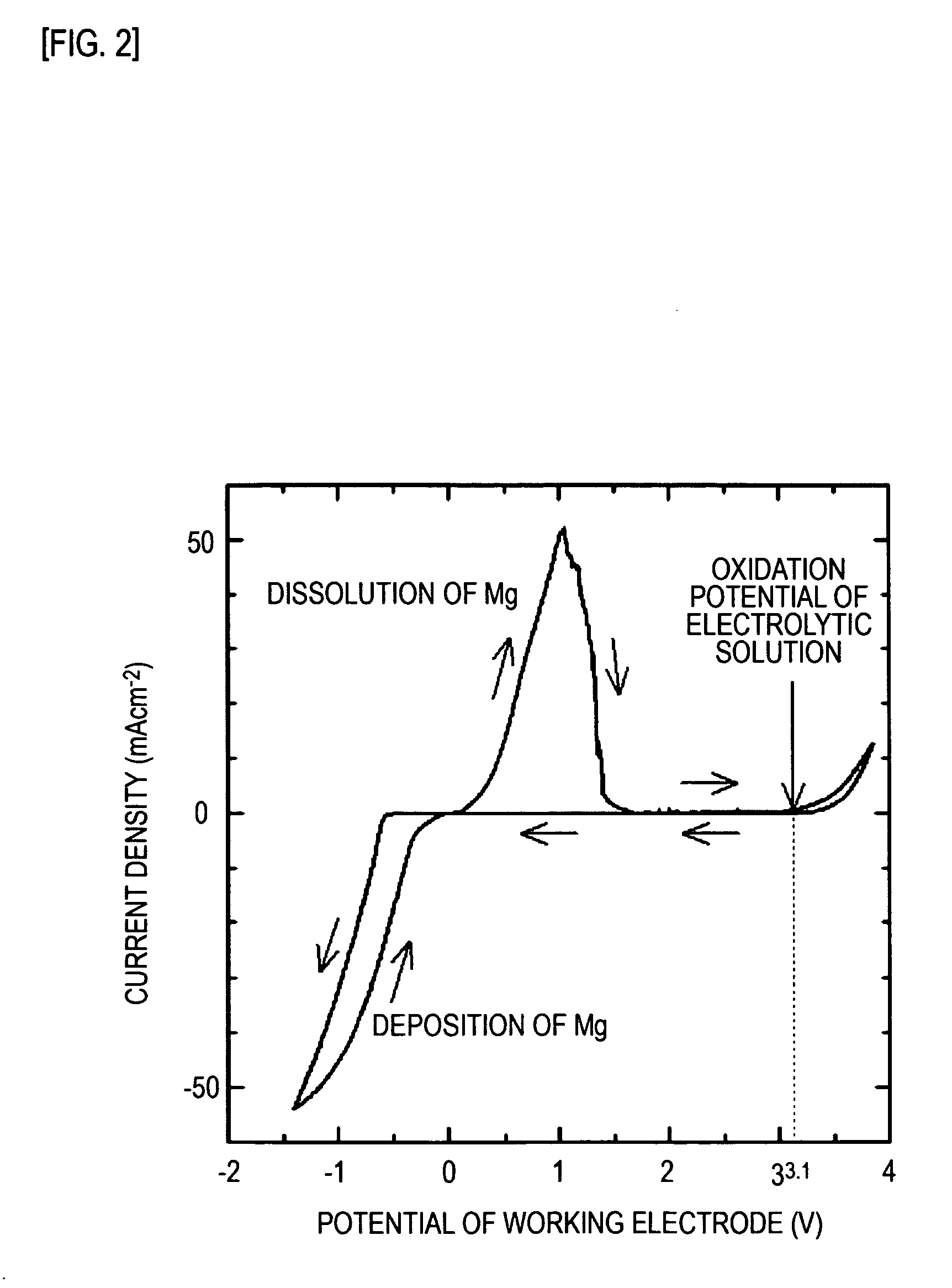

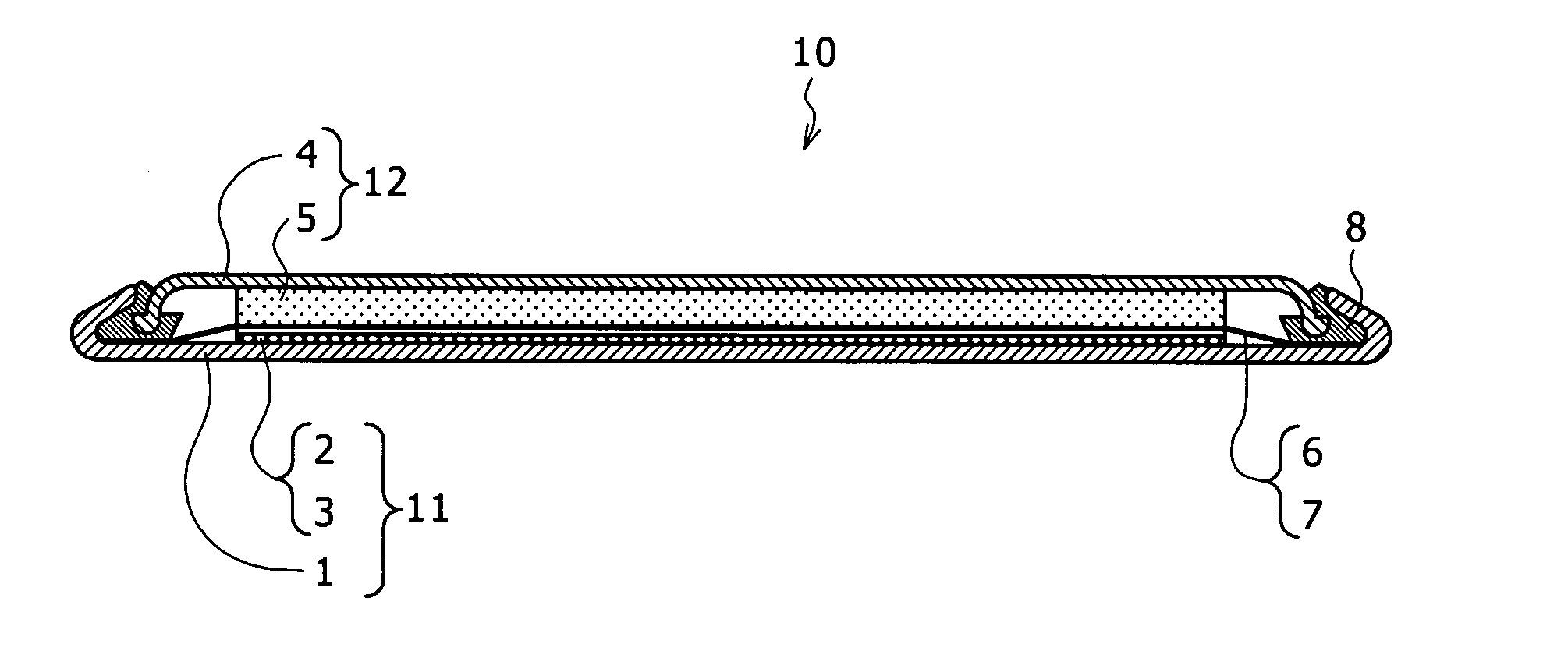

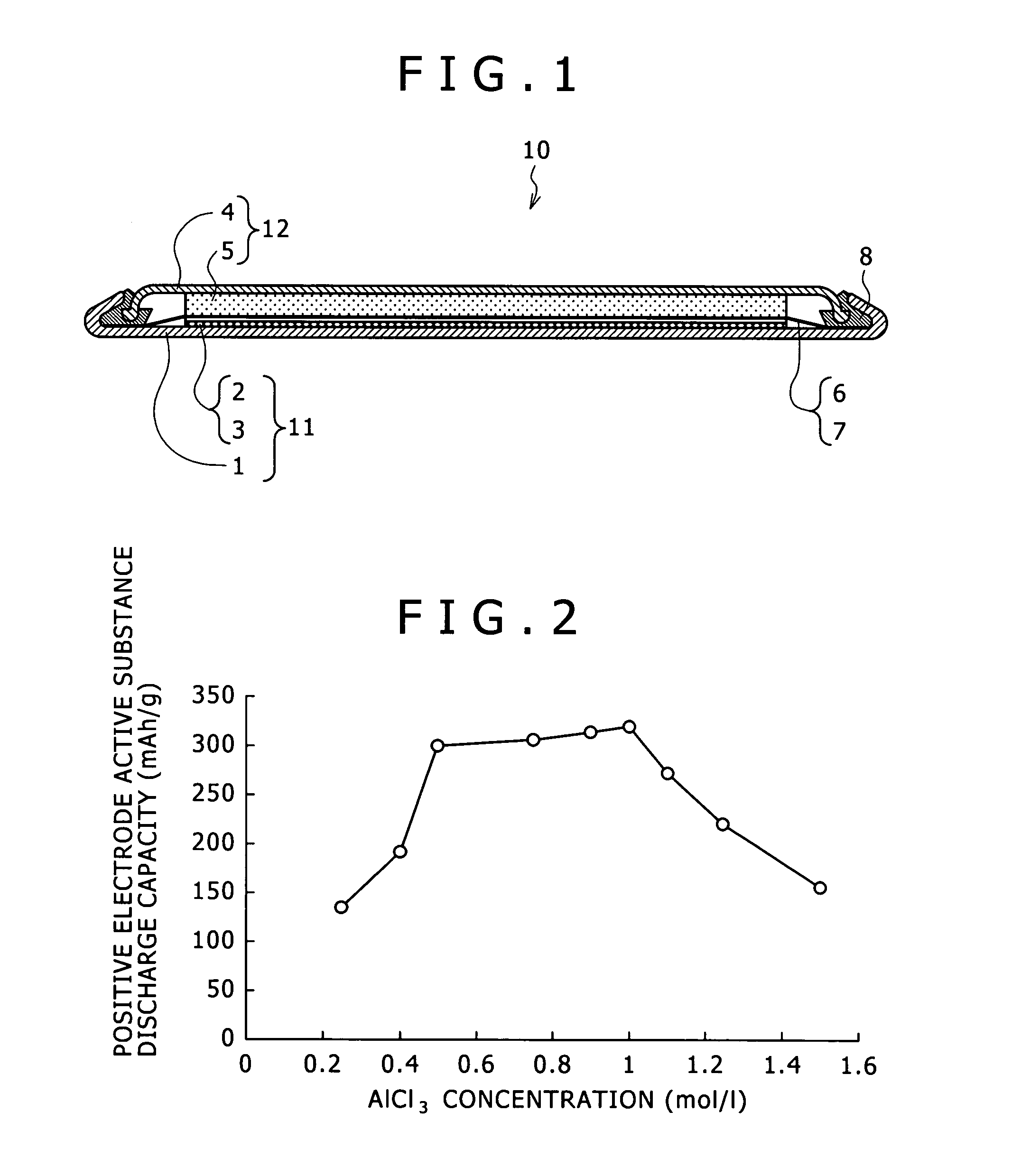

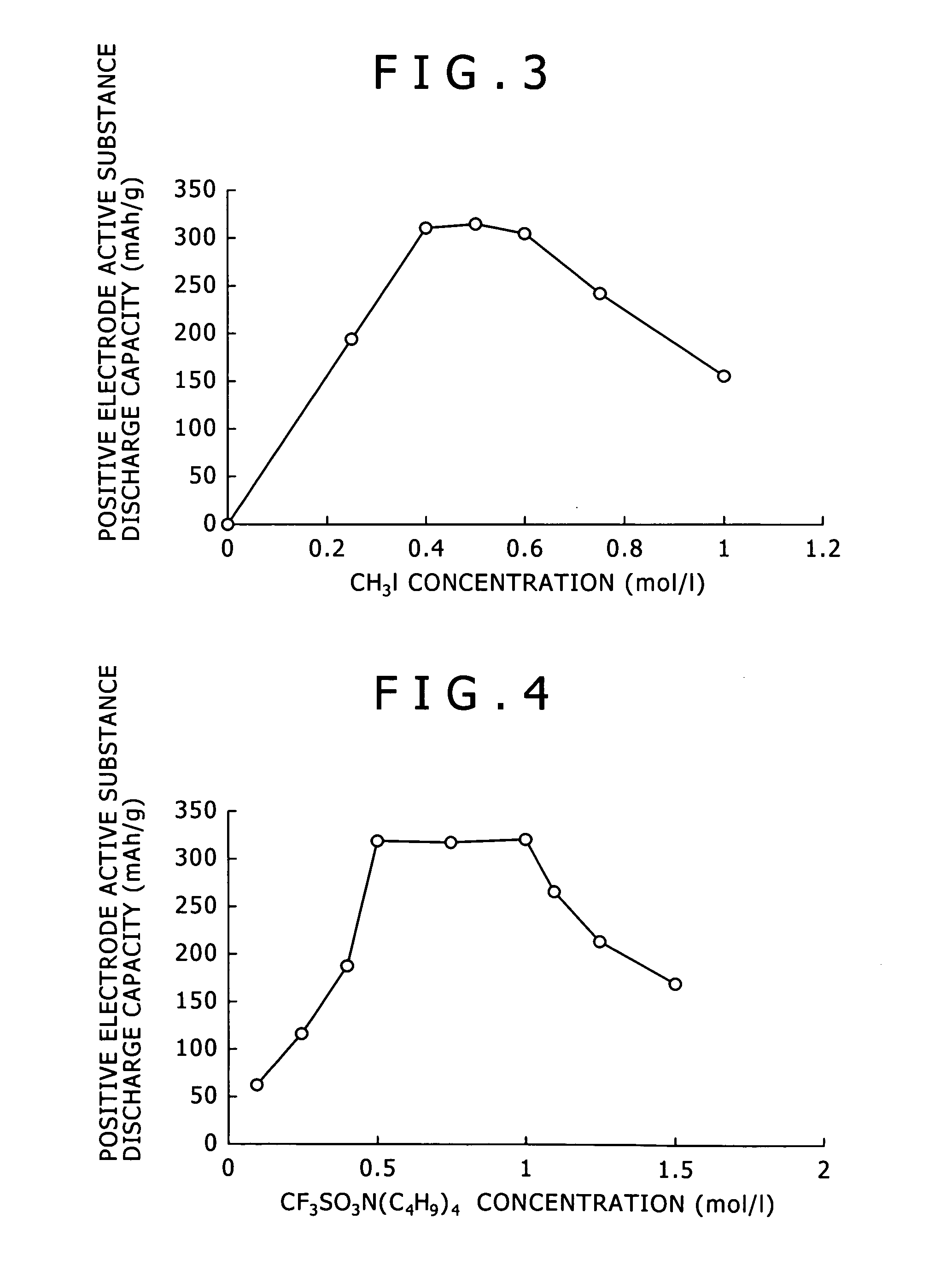

Magnesium ion-containing nonaqueous electrolytic solution and method for manufacturing the same, and electrochemical device

ActiveUS20100136438A1Easy to makeRaw material is easyAlkaline accumulatorsCell electrodesDimethylaluminum chlorideAlloy

Owner:MURATA MFG CO LTD

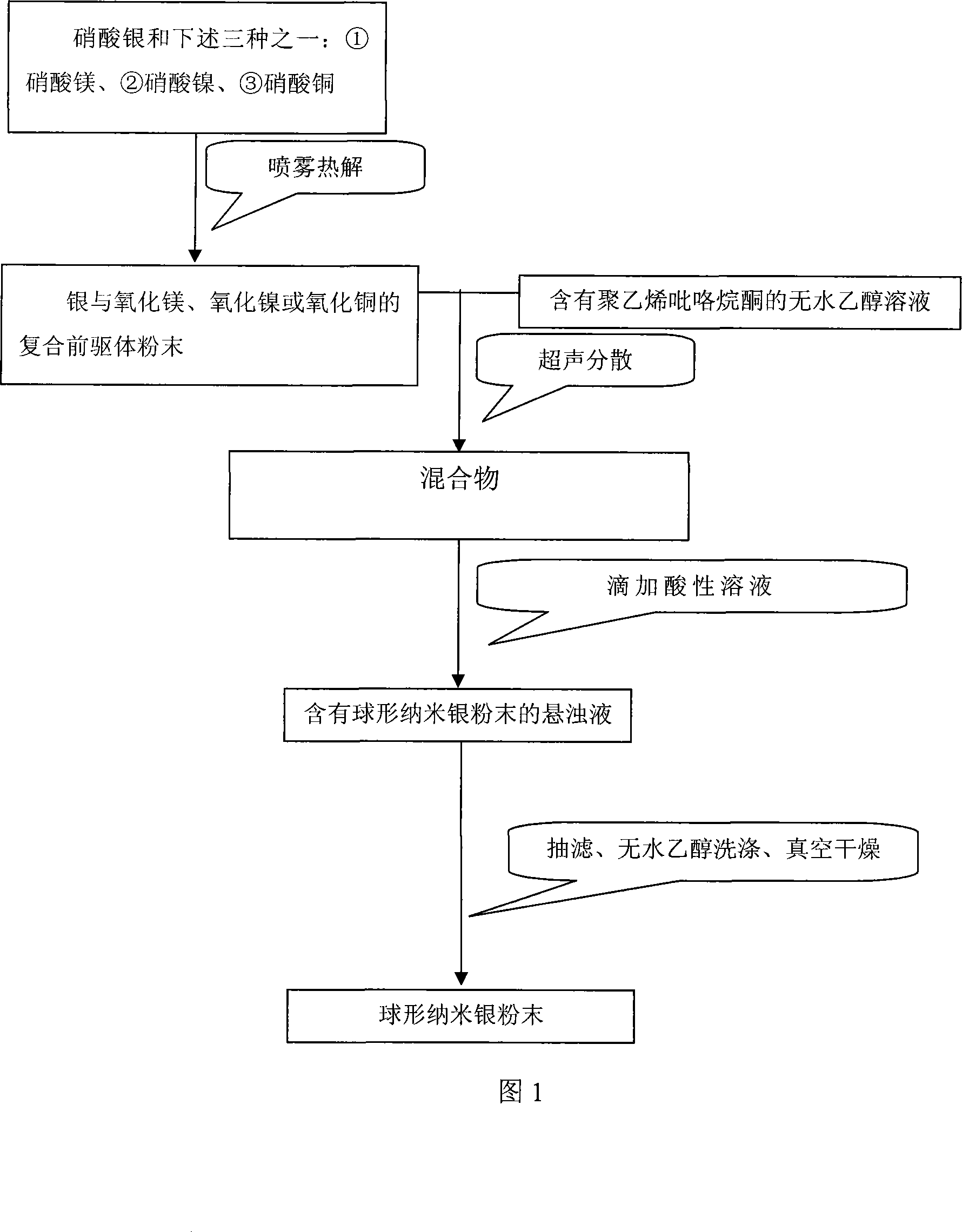

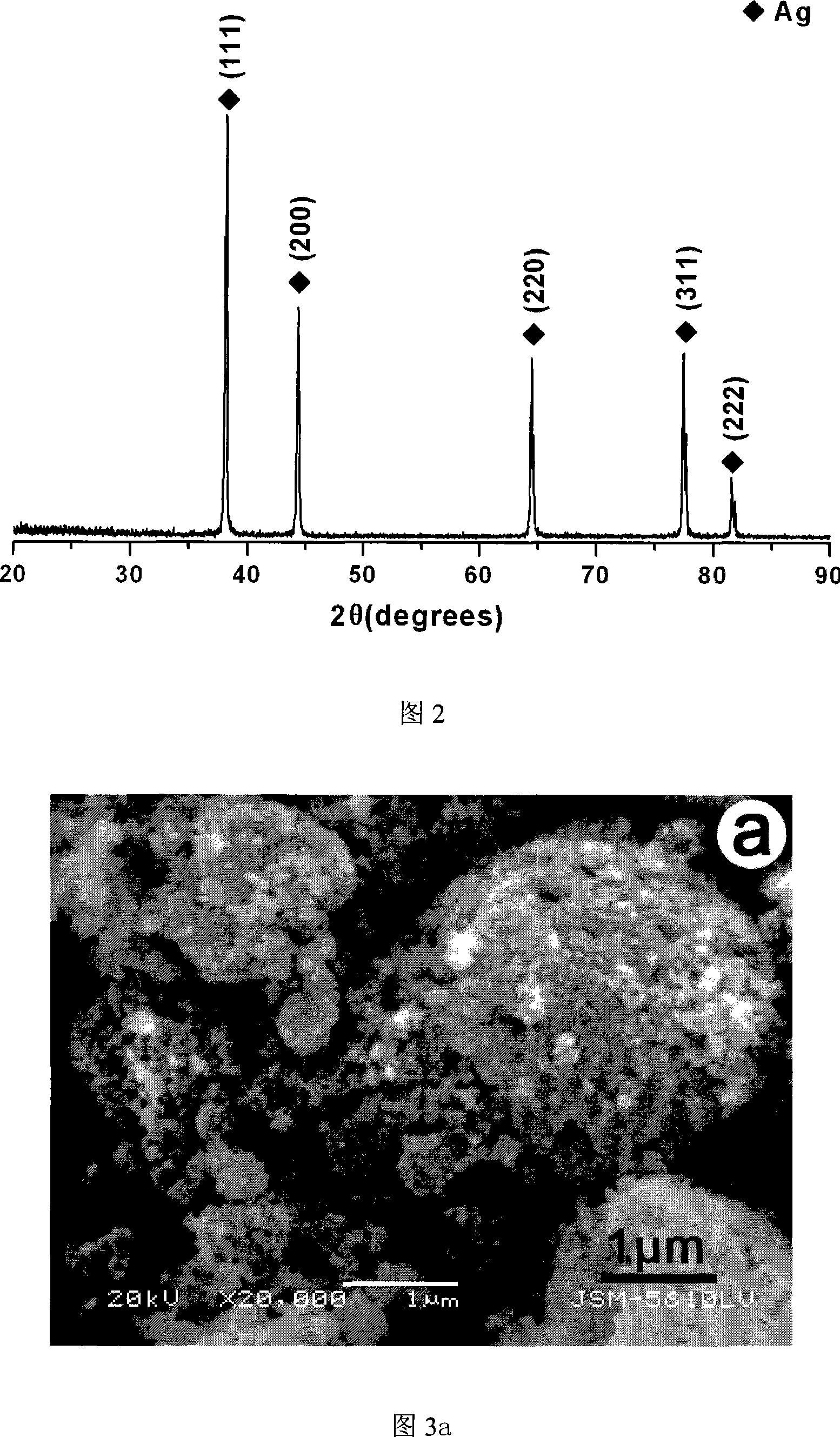

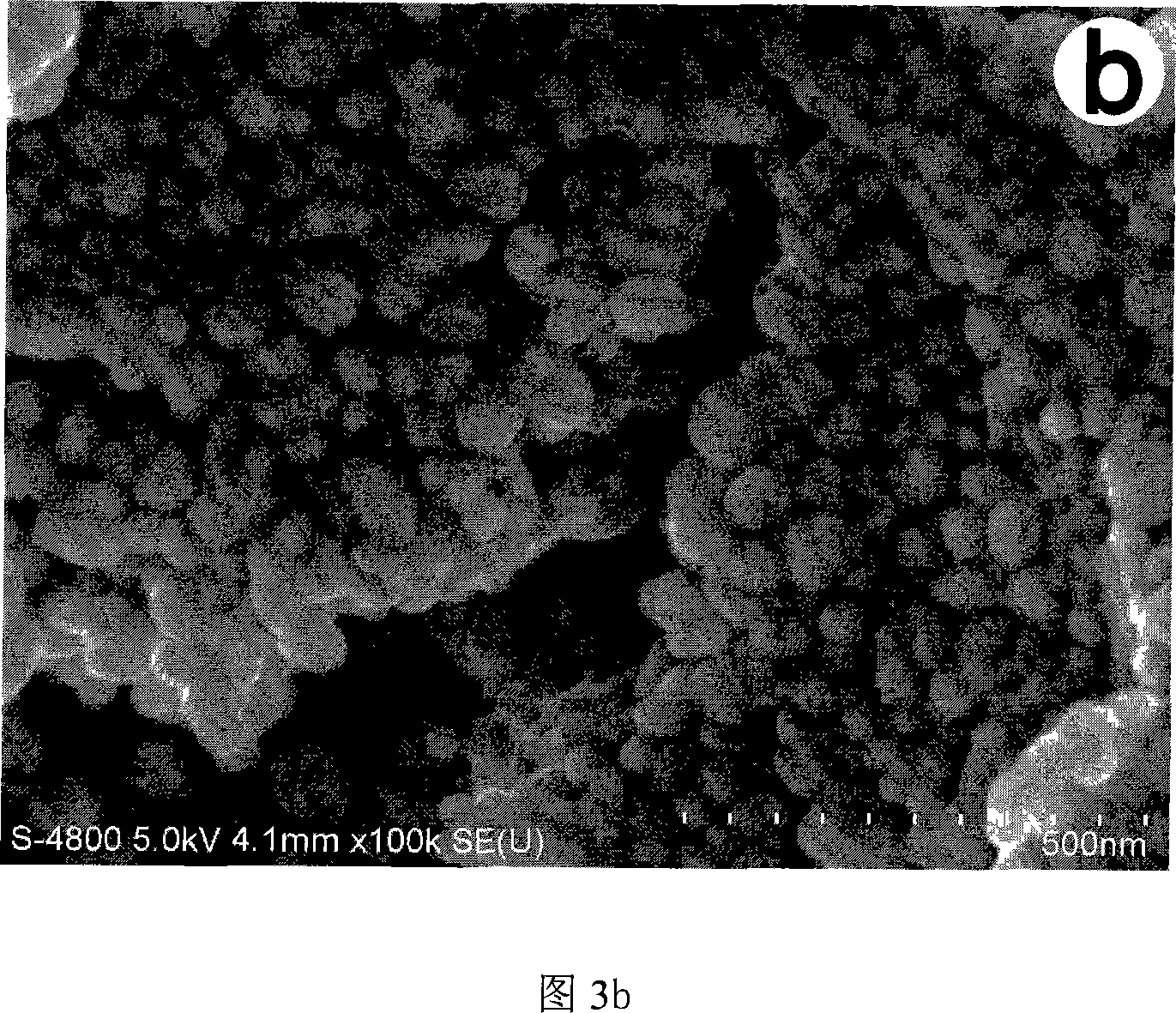

Method for preparing spherical nano silver powder

The invention relates to a method for preparing a spherical nanometer sliver powder. A method for preparing a spherical nanometer sliver powder is characterized in that the invention includes the following steps: 1) spraying and pyrolyzing: a, dissolving silver nitrate with one of the three: {1}magnesium nitrate, {2}nickel nitrate, {3}copper nitrate into water to prepare into a water liquor with a consistency of 10 to 40wt percent; the mol ratio of magnesium ion, nickel ion or copper ion in the liquor is 0.05 to 1 :4; then spraying for pyrogenation; b, under the existence of a dispersant and protecting agent, adding into a non-water ethanol to disperse to acquire a mixture; 2) preparing the spherical nanometer sliver powder: a, dripping acid liquor into the mixture and adjusting a PH value between 3 to 5 to acquire a suspension containing the spherical nanometer sliver powder; b, pumping filtration, washing and drying to acquire the spherical nanometer sliver powder. The preparing method is simple and easy to be controlled, has no pollution and low cost, is suitable for industrialization scale production. The prepared spherical nanometer sliver powder belongs to the nanometer grade and the powder has uniform distribution of the grain diameter, regular shape and high yield.

Owner:WUHAN UNIV OF TECH

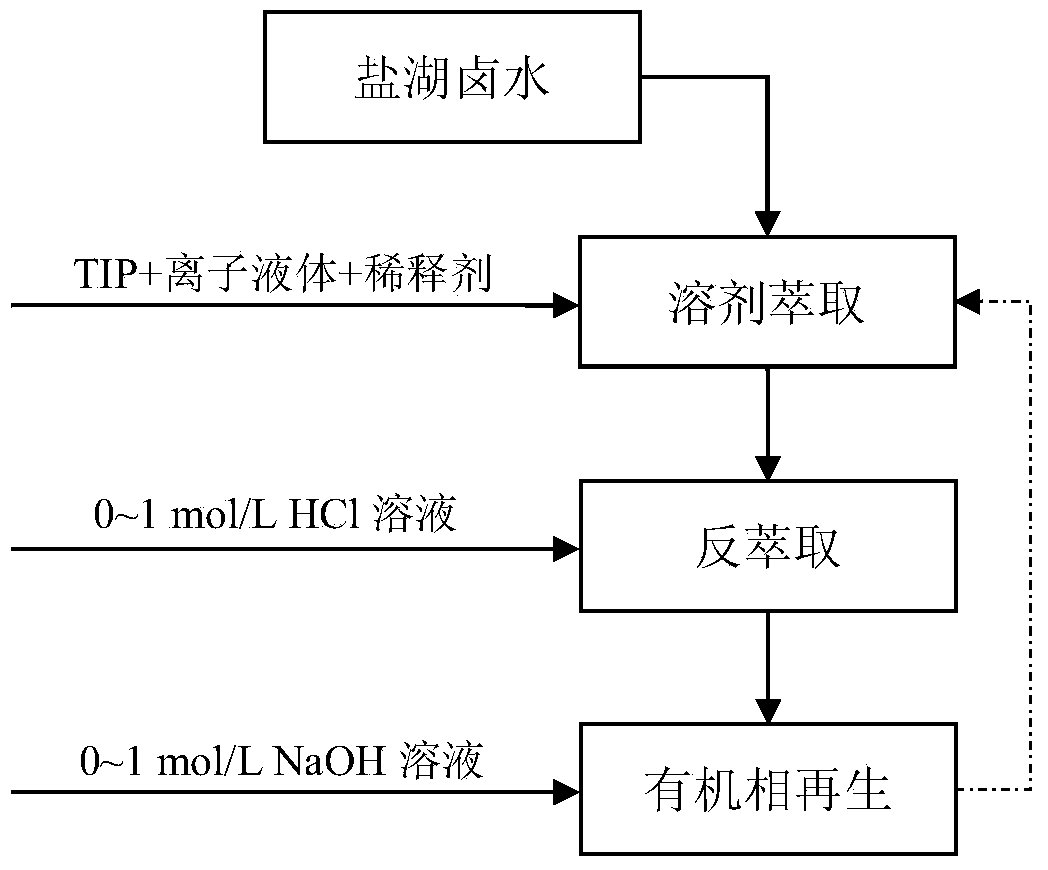

Method for efficiently extracting lithium from salt lake brine

ActiveCN103710549AAvoid interferenceHigh separation factorProcess efficiency improvementSeparation factorIonic liquid

The invention relates to a method for efficiently extracting lithium from salt lake brine. The method comprises the following steps: (1) forming an extraction organic phase by an extraction agent, a co-extraction agent and a diluent, and then mixing the extraction organic phase with salt lake brine according to the volume ratio of (3-4):2 for three-stage extraction with single extraction time being 2-10 minutes to obtain an organic phase; and (2) mixing the organic phase obtained in step (1) with a reverse extraction acid solution (0-1 mol / L) for three-stage reverse extraction with single reverse extraction time being 2-10 minutes, and collecting an aqueous phase which is an aqueous solution containing lithium ions. The co-extraction agent of an extraction system of the method is hydrophobic ionic liquid, compared with conventional synergist ferric trichloride, the interference caused by iron ions is avoided, the reverse extraction acidity is greatly reduced, more importantly the lithium-magnesium separation factor is significantly improved, and the elution step of magnesium ions is reduced; in addition, the method provided by the invention is easy in process, easy to control, high in operation reliability, and good in recyclability of the organic phase, and greatly reduces the production cost for extracting the lithium from the salt lake brine.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

High temperature reverse transcription using mutant DNA polymerases

InactiveUS7179590B2Improve efficiencyImprove fidelitySugar derivativesMicrobiological testing/measurementBiologyDNA

Owner:ROCHE MOLECULAR SYST INC

Method for producing high-purity lithium carbonate by using lithium concentrate

ActiveCN103318925AReduce consumptionGuaranteed RecoveryLithium compoundsLithium sulphatePhysical chemistry

The invention relates to a method for producing high-purity lithium carbonate by using lithium concentrate. The method is characterized by comprising the following steps of: preparing an acid clinker, preparing a mixing size, preparing a lithium sulfate leaching solution, preparing a lithium sulfate purification liquid, preparing a lithium sulfate finishing solution, preparing a sodium carbonate solution, performing primary lithium deposition reaction, preparing a sodium separating mother liquor, preparing excellent lithium carbonate in a sweating manner, and preparing 99.99% of high-purity lithium carbonate. By adopting the method, the principle of removing calcium and magnesium ions is ingeniously utilized in preparation of common lithium carbonate; a fussy procedure of removing calcium and magnesium by ion exchange resin is avoided when the common lithium carbonate is purified to prepare the high-purity lithium carbonate; a method of recycling after separating out sodium sulfate in a freezing manner is adopted to process the primary lithium settling mother liquor; the high-purity lithium carbonate mother liquor in precipitation of the high-purity lithium carbonate is used as an optimal lithium carbonate washing liquor for primary lithium sedimentation after being recycled for a plurality of times. Thus, the method has the characteristics of simple process, high production efficiency, high recovery rate and low production cost.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

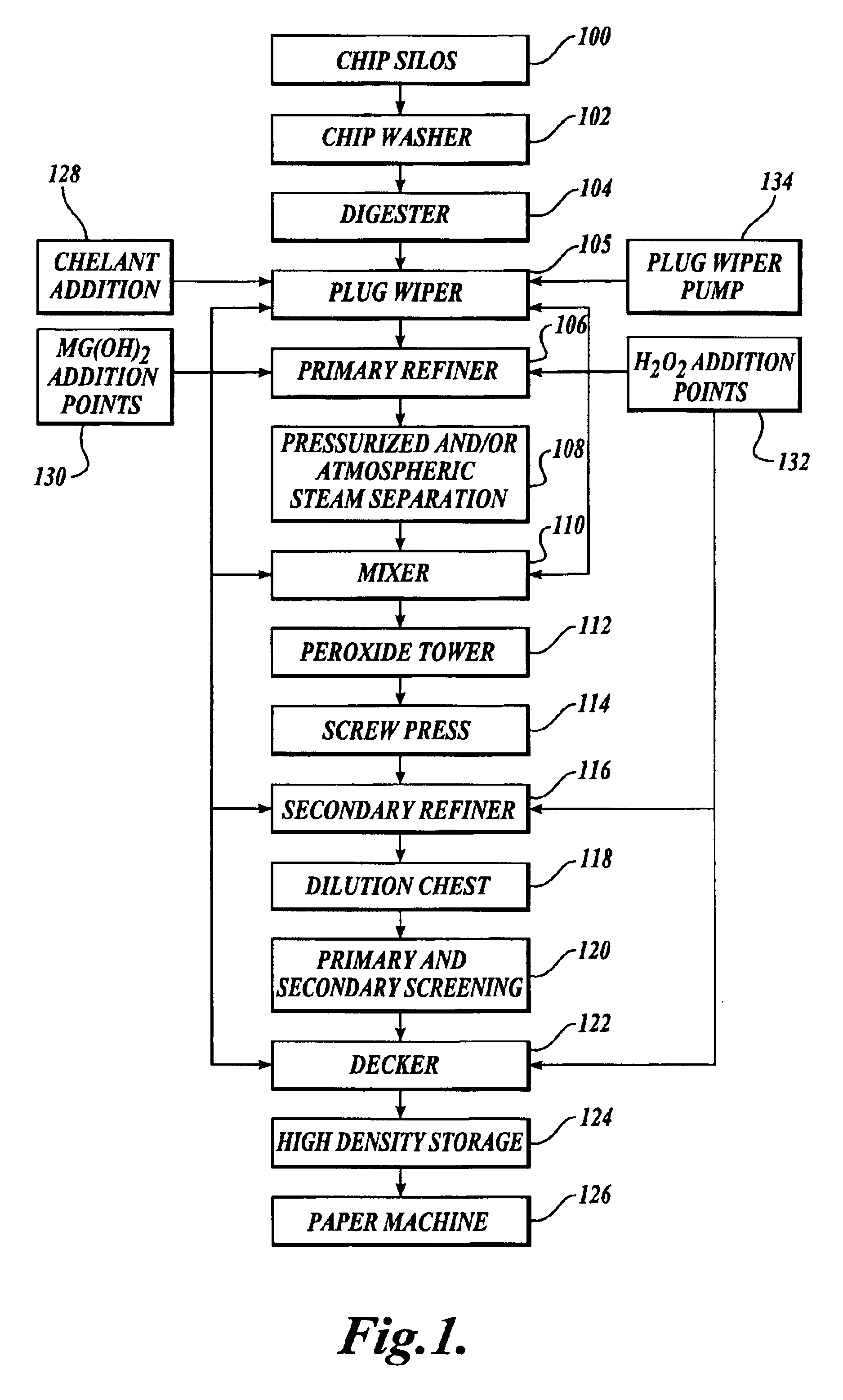

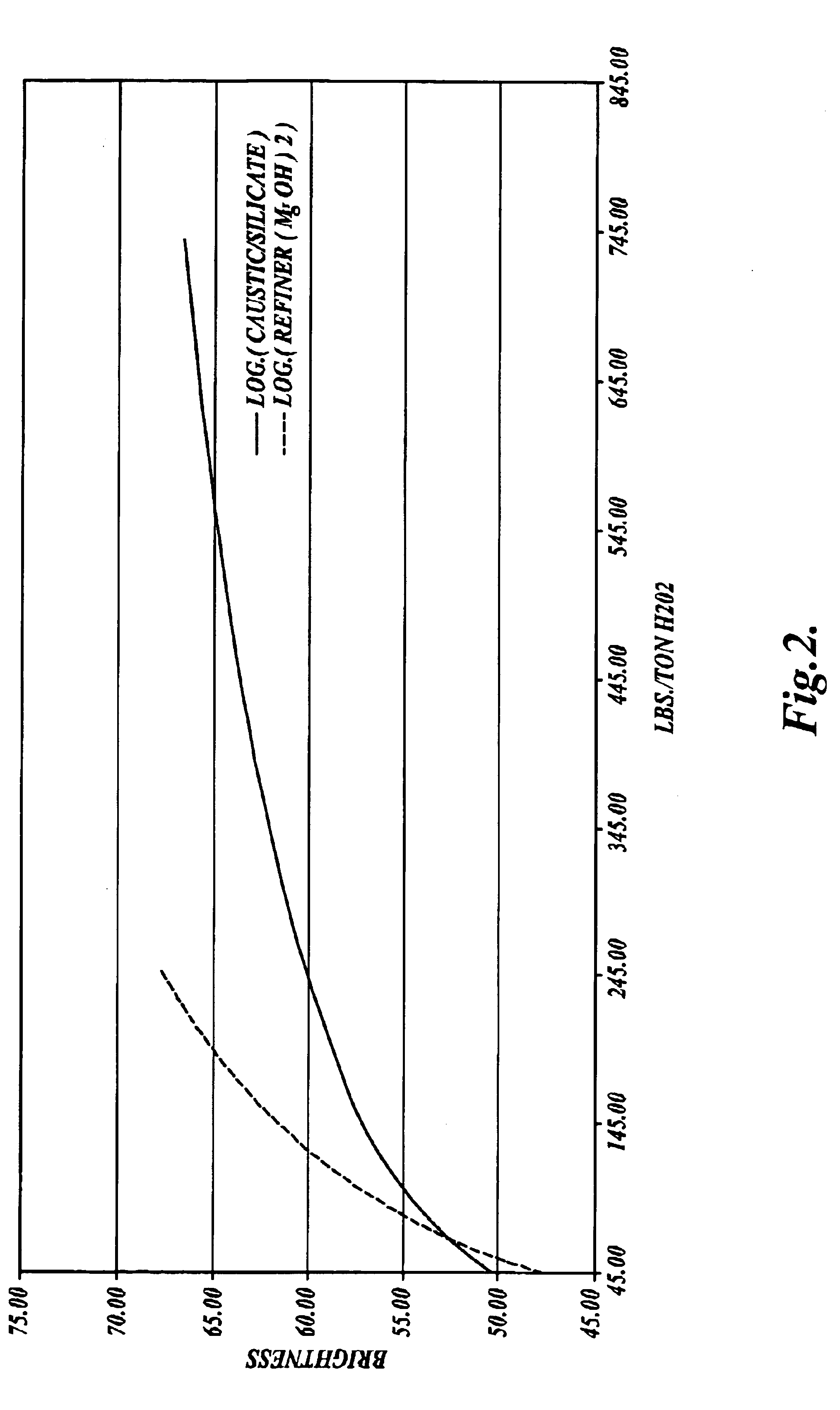

Refiner bleaching with magnesium oxide and hydrogen peroxide

InactiveUS6881299B2Eliminate useHigh retention rateFats/resins/pitch/waxes removal in pulpPulp de-wateringParticulatesMagnesium ion

Methods of bleaching mechanical pulp under alkaline conditions with hydrogen peroxide. The methods include introducing a source of magnesium ions and hydroxyl ions to a refiner. The wood particulates are refined into a pulp in the presence of the magnesium ions and hydroxyl ions, and optionally perhydroxyl ions to simultaneously refine and bleach the pulp in a refiner.

Owner:NORTH PACIFIC PAPER

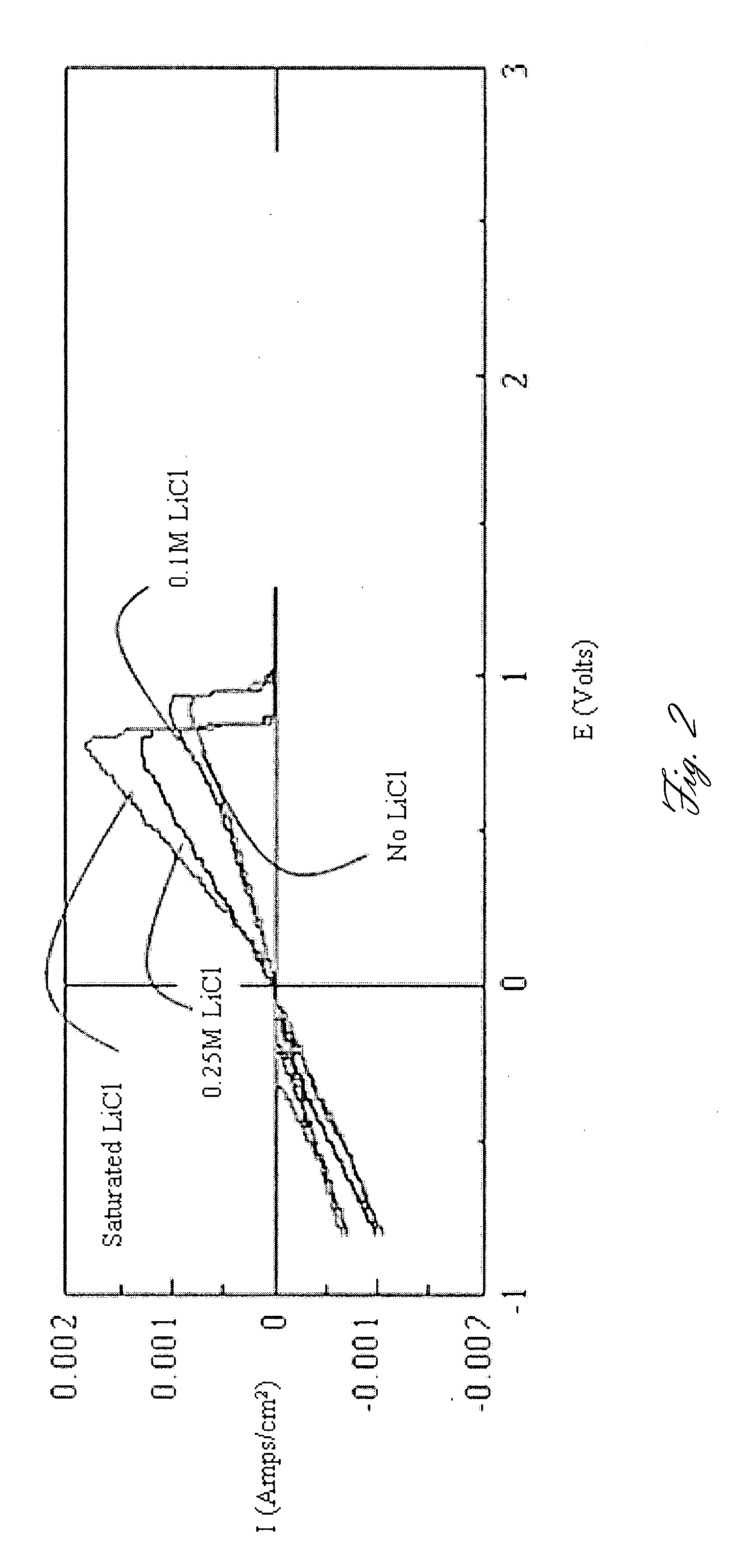

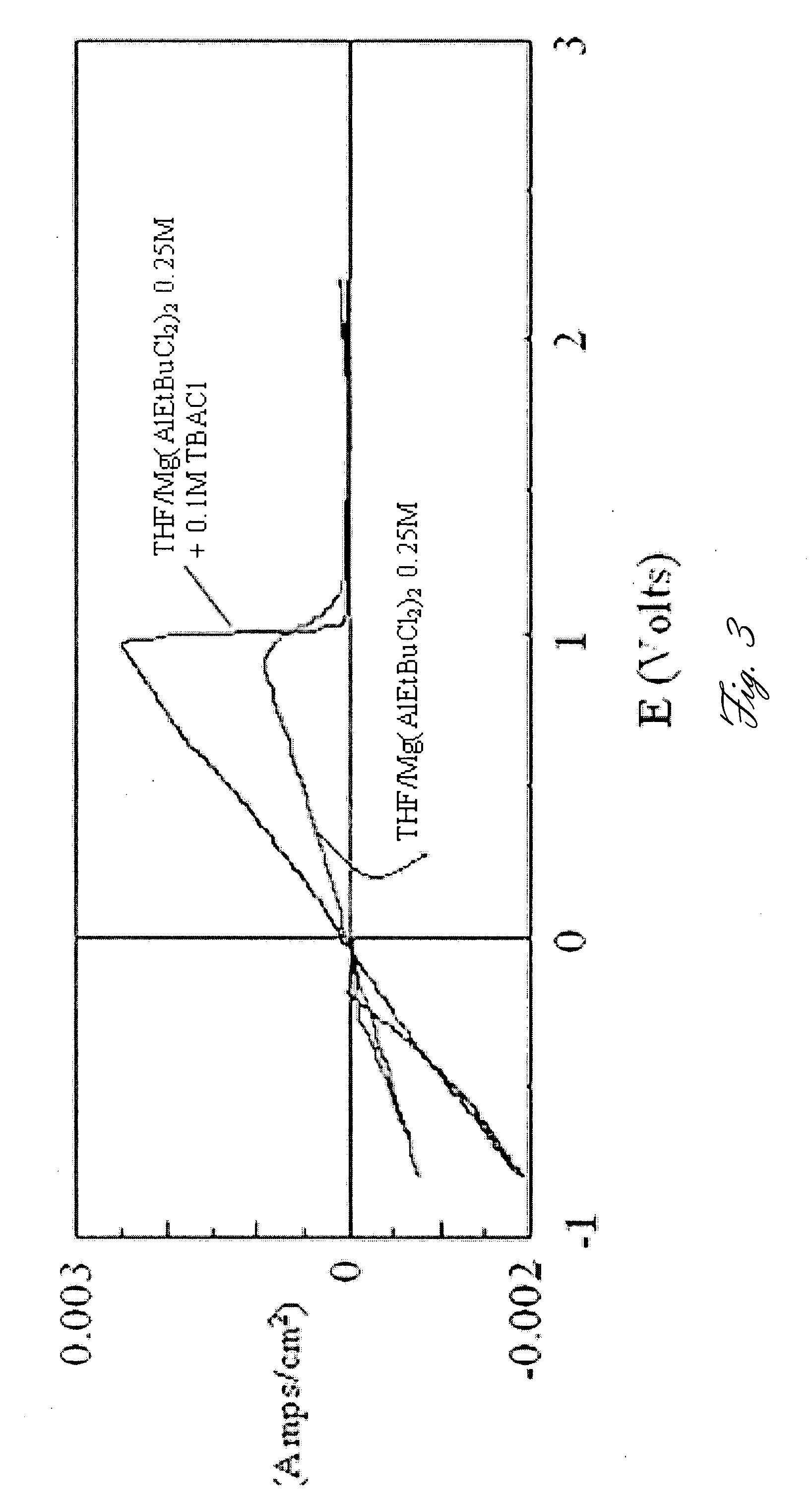

Magnesium ion-containing non-aqueous electrolyte and a production process thereof, as well as electrochemical device

ActiveUS20090068568A1Effective resourcesEfficient use ofCell electrodesOrganic electrolyte cellsAluminum IonPhosphate ion

A magnesium ion containing non-aqueous electrolyte in which magnesium ions and aluminum ions are dissolved in an organic etheric solvent, and which is formed by: adding metal magnesium, a halogenated hydrocarbon RX, an aluminum halide AlY3, and a quaternary ammonium salt R1R2R3R4N+Z− to an organic etheric solvent; and applying a heating treatment while stirring them (in the general formula RX representing the halogenated hydrocarbon, R is an alkyl group or an aryl group, X is chlorine, bromine, or iodine, in the general formula AlY3 representing the aluminum halide, Y is chlorine, bromine, or iodine, in the general formula R1R2R3R4N+Z− representing the quaternary ammonium salt, R1, R2, R3, and R4 represent each an alkyl group or an aryl group, and Z− represents chloride ion, bromide ion, iodide ion, acetate ion, perchlorate ion, tetrafluoro borate ion, hexafluoro phosphate ion, hexafluoro arsenate ion, perfluoroalkyl sulfonate ion, or perfluoroalkyl sulfonylimide ion.

Owner:MURATA MFG CO LTD

Composition for metal surface treatment and surface treated metallic material

InactiveUS6514357B1Improve corrosion resistanceLow costSolid state diffusion coatingAnti-corrosive paintsAluminum IonSheet steel

A composition for metal surface treatment which comprises an aluminum ion, a magnesium ion, a manganese ion, a water-soluble organic resin, an acid and water; and a surface treated metal material which has been treated with the composition. The resultant surface treated metal material is free from the danger of water contamination owing to chromium, since the composition is free of chromium, and also is excellent in both electrical conductivity and corrosion resistance. Accordingly, the metal material can be used in a wide variety of applications in place of a conventional chromate-treated steel sheet and the like.

Owner:50 DAI NIPPON TORYO

Water soluble magnesium compounds as cleaning agents and methods of using them

InactiveUS20080274928A1Reduce and prevent formationImprove solubilityInorganic/elemental detergent compounding agentsSpecific water treatment objectivesMagnesium saltWater insoluble

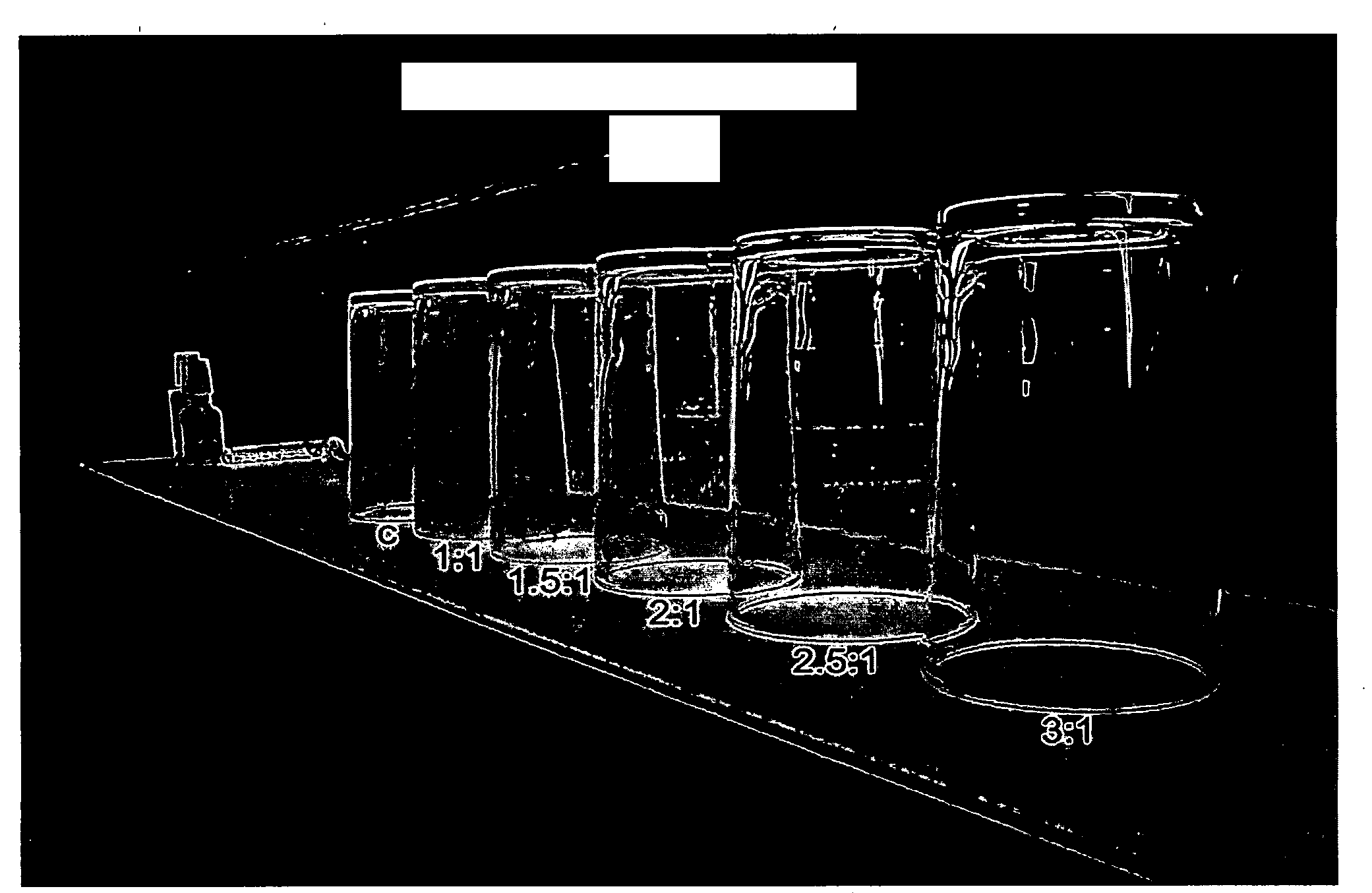

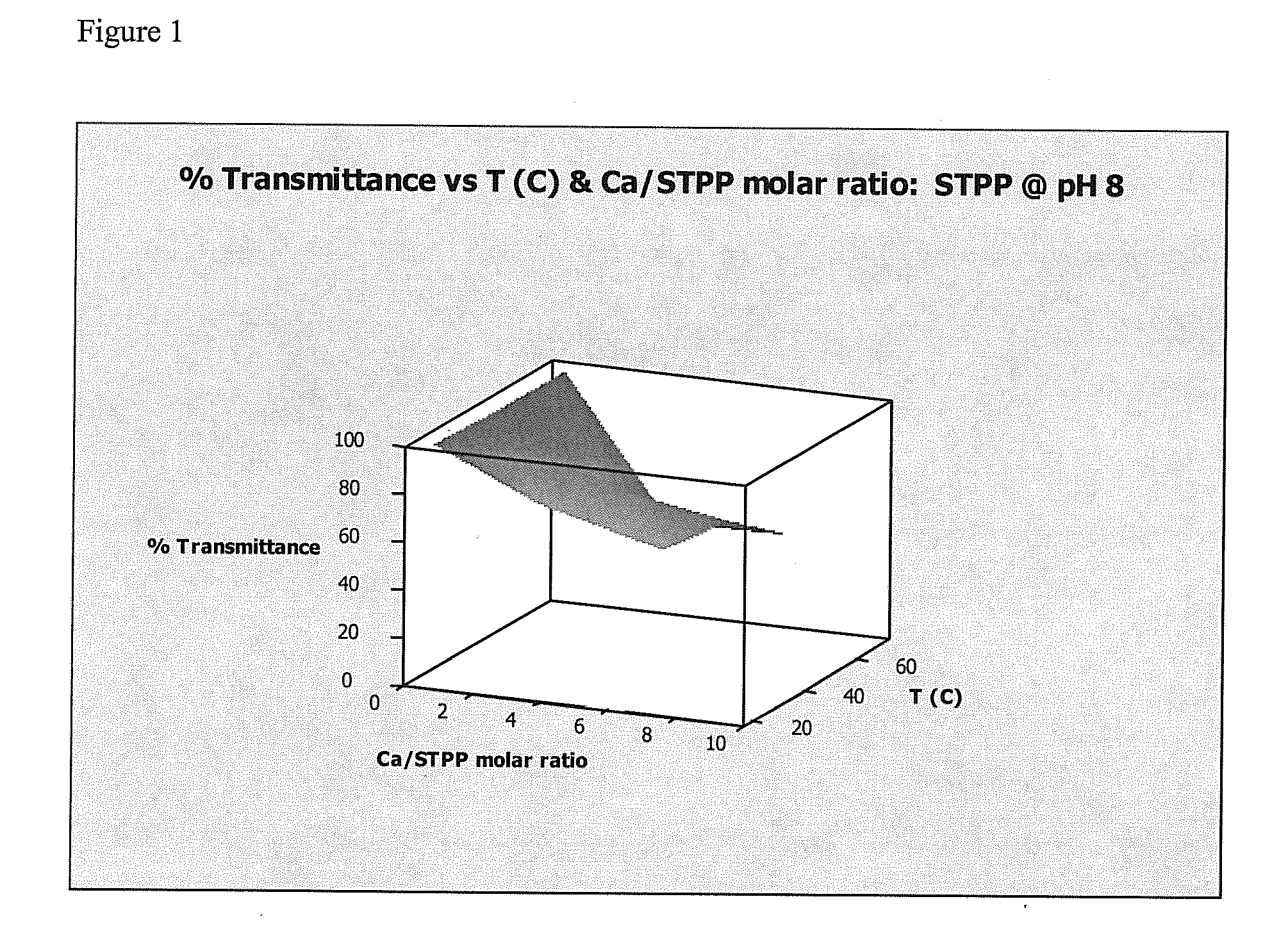

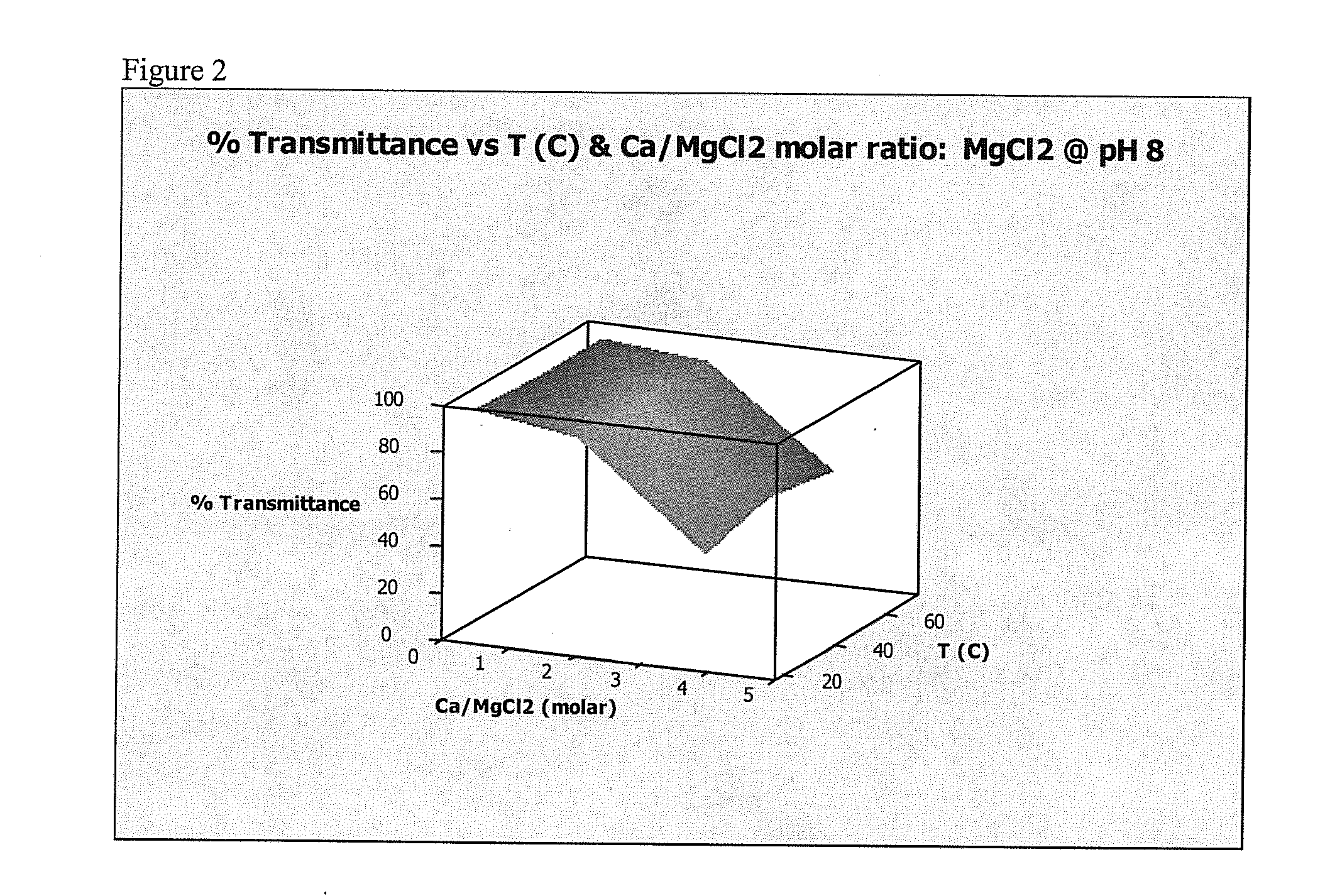

The present invention relates to compositions and methods employing a water soluble magnesium compound. In certain embodiments, the composition includes water and water soluble magnesium compound, but lacks other materials commonly used in cleaning compositions. The methods and compositions can provide magnesium ion at predefined ratios to calcium ion in water, such as magnesium ion in a molar amount equal to or in excess over a molar amount of calcium ion. A water soluble magnesium salt including an anion of a water soluble calcium salt is more effective than a magnesium salt with an anion of a water insoluble calcium salt. These compositions can be used for reducing lime scale or precipitate formation from hard water, removing soap scum, or the like.

Owner:ECOLAB USA INC

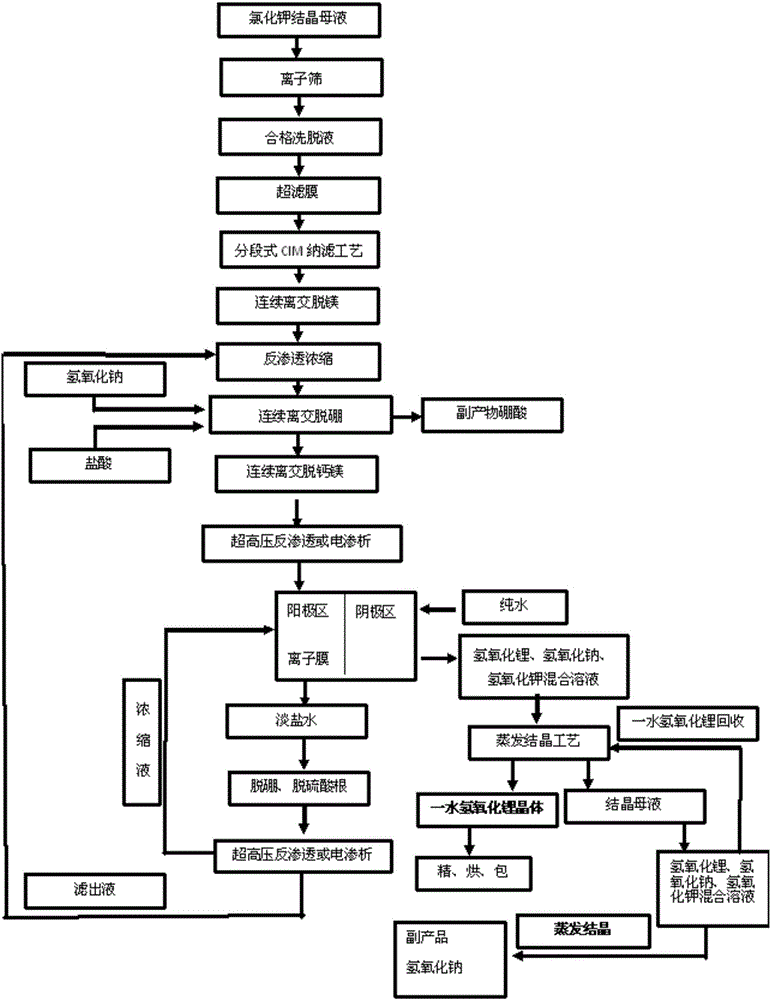

Production method of high-purity lithium hydroxide

ActiveCN106011917AHigh yieldReduce consumptionCellsBoron-oxygen compoundsLithium hydroxideUltrafiltration

The present invention relates to a production method of high-purity lithium hydroxide. A crystallization mother liquor waste water is obtained after production of potassium chloride by using a salt lake bittern as the raw material, a magnesium-lithium ratio of the crystallization mother liquor waste water is 200-500:1, an eligible eluant is obtained through ion sieve adsorption and elution of the crystallization mother liquor waste water, and after treatment of the eluant through the ultrafiltration membrane technology, the sectional type nanofiltration technology, the external regeneration continuous hybridization technology and the reverse osmosis technology, a reverse osmosis concentrated solution is obtained. In the reverse osmosis concentrated solution, the content of magnesium ions is <=300 ppm, the content of lithium ions is 4-6 g / L, the content of sodium ions is 3-5 g / L, the content of calcium ions is <=5 ppm, the content of sulfate ions is 1-30 ppm and the content of boron is <=400 ppm. According to the production method provided by the present invention, the reverse osmosis concentrated solution is used as the raw material, the process comprises ultrahigh pressure reverse osmosis continuous hybridization for boron-removing, continuous hybridization for sulfate radical removing, ion-exchange membrane electrolysis, and crystallizing evaporation, and by using the hybridization boron-removing technology, the ion-exchange membrane electrolysis technology and the crystallizing evaporation technology, the high-purity lithium hydroxide is obtained, with the byproducts being the boric acid and sodium hydroxide. The process is continuous, controllable, high in extraction rate, low in production cost and easy to industrialize.

Owner:启迪清源(上海)新材料科技有限公司

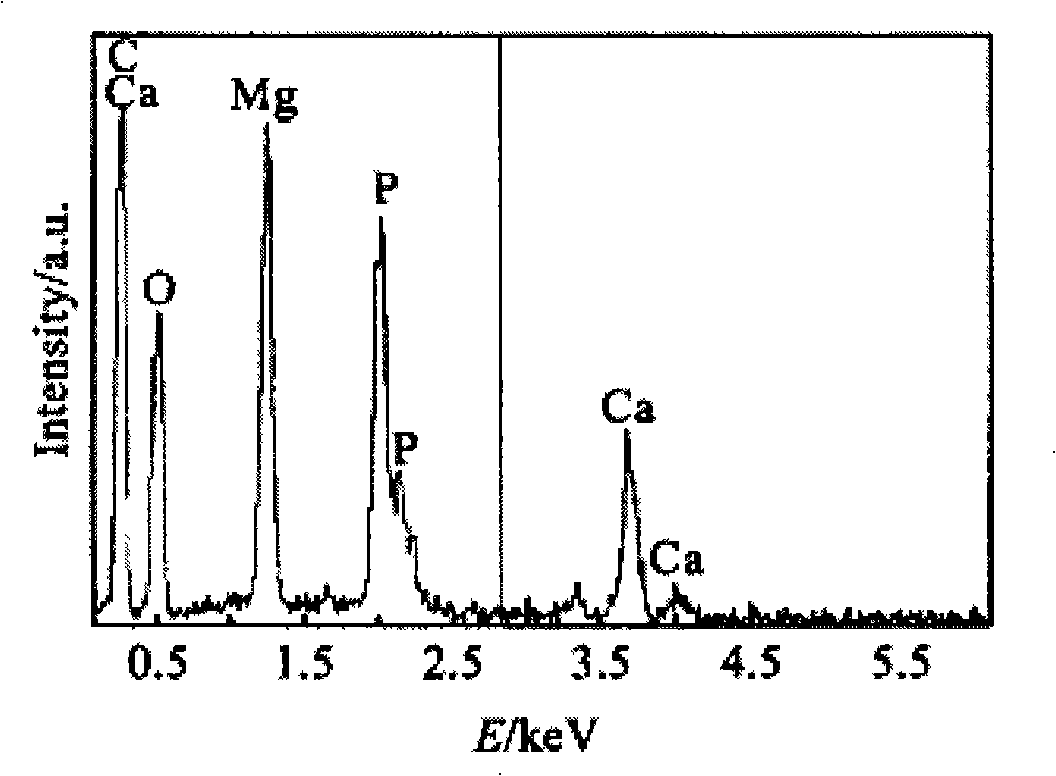

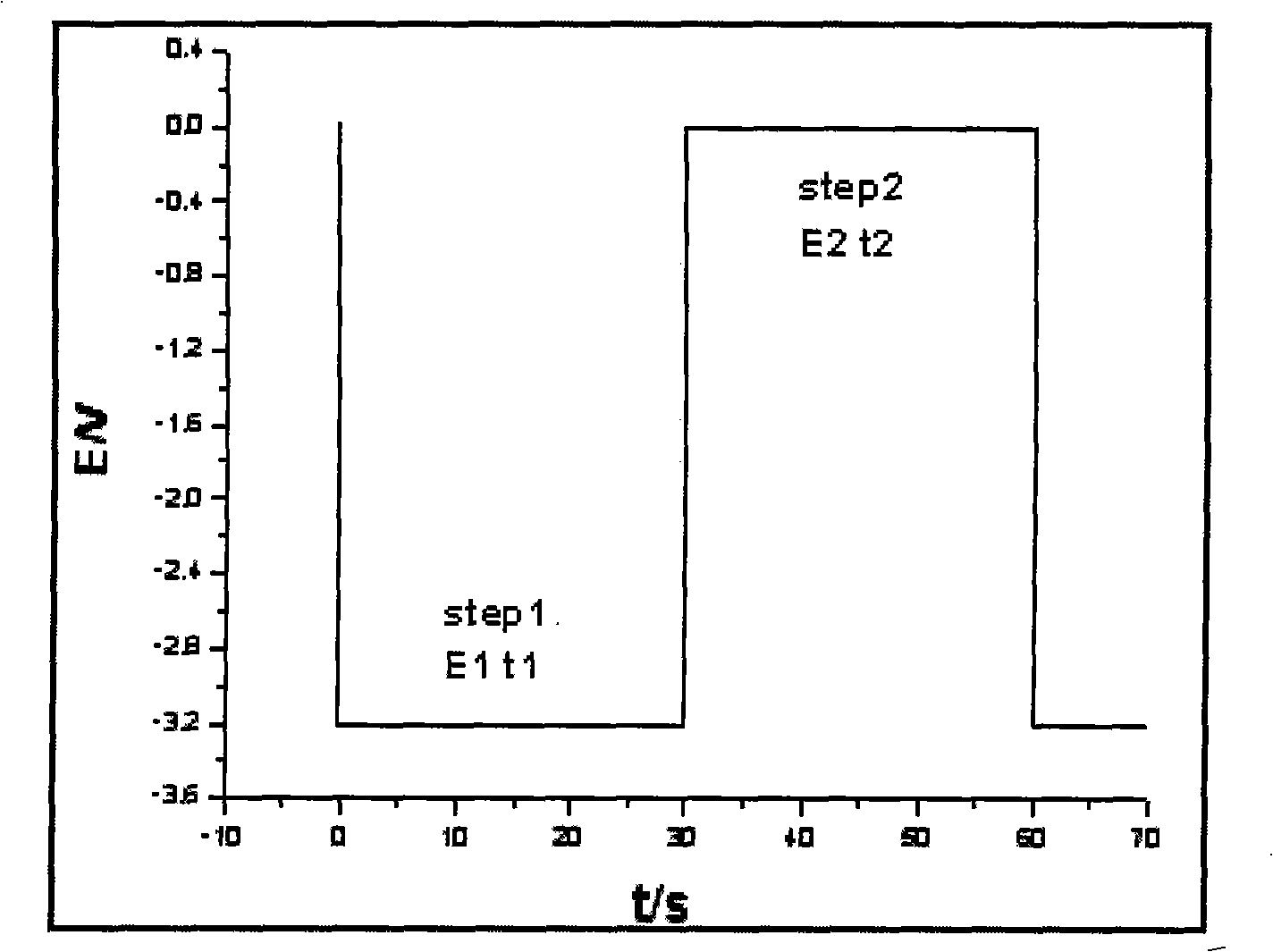

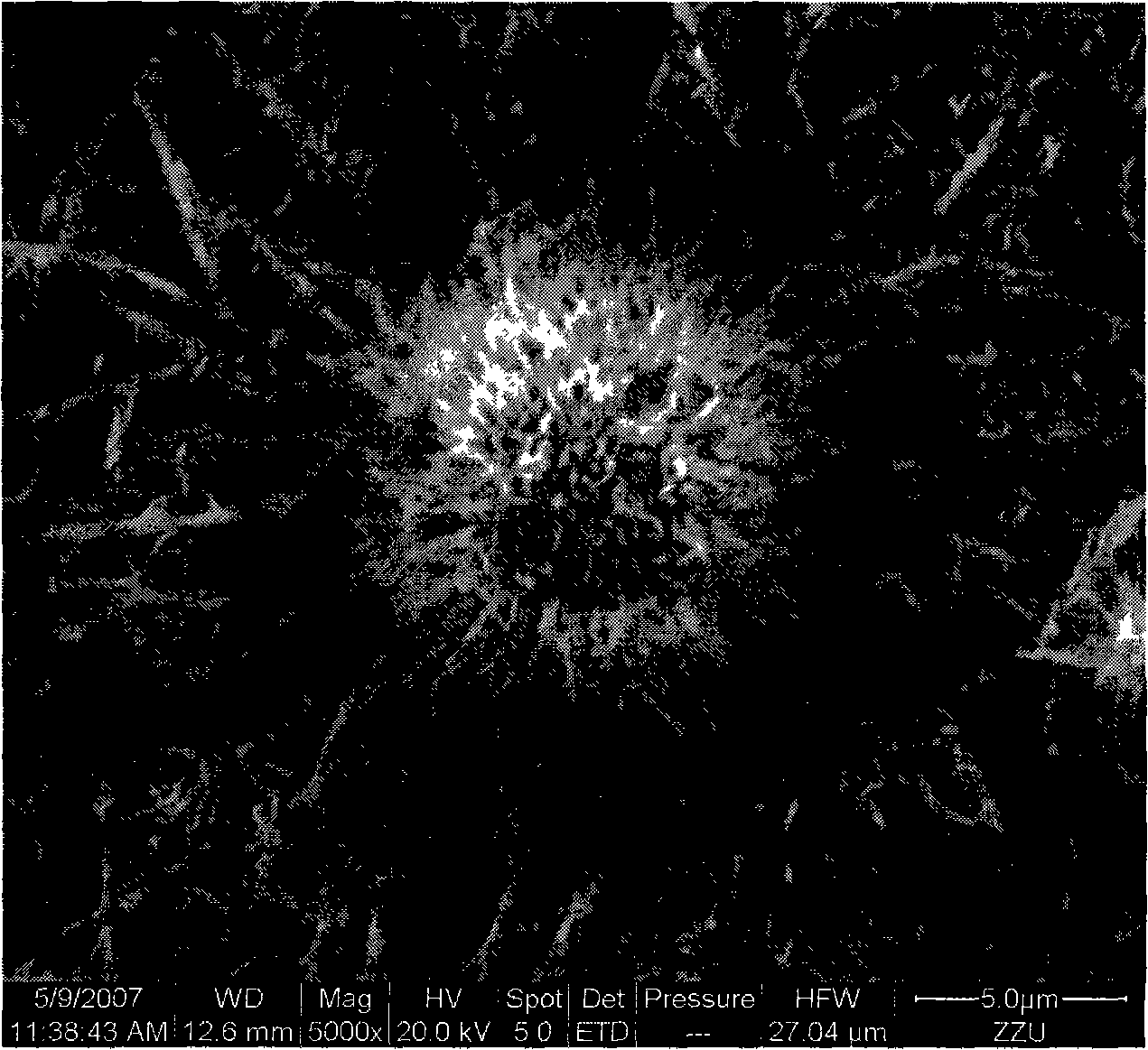

Preparation of nano-HAP coating/magnesium alloy composite biological material

InactiveCN101302638AHigh bonding strengthImprove biological activityElectrolytic inorganic material coatingProsthesisMagnesium phosphateBiocompatibility Testing

The invention provides a method for making a nano HAP coating / magnesium alloy composite biomaterial. The method is as follows: the method takes a magnesium alloy as a cathode and graphite as an anode; the magnesium alloy and the graphite are placed in electrolyte containing NH4H2PO4, NaHO3 and Ca(OH3)2.4H2O so as to carry out stepped electrodeposition at a temperature of between 60 and 95 DEG C and a voltage of between minus 5 V to minus 1 V and 0 V, thereby effectively improving the interface bonding between a coating and a matrix and reducing hydrogen evolution during electrodeposition; meanwhile, the increase of magnesium ions at an interface can realize in-situ doping of magnesium ions and hydroxyapatite so as to generate a magnesium phosphate transition layer on the surface of the magnesium alloy and to increase bonding strength; thus, a degradable nano acicular hydroxyapatite / magnesium alloy coating composite biomaterial with excellent mechanical property, biocompatibility and corrosion resistance can be obtained. Meanwhile, the method also has the advantages of low cost of raw materials and simple technological operation, etc.

Owner:ZHENGZHOU UNIV

Electrolyte purgative

ActiveUS7993682B2Simply performing their known purgative functionIncreased tonicityBiocideOrganic active ingredientsMagnesium saltPotassium

The invention relates to compositions for use in purgatives, to purgatives comprising such compositions, and to methods for inducing purgation of the colon. The composition may comprise at least one water-soluble sodium salt; at least one water-soluble minimally degradable sugar in an amount, by weight, of from about 1 to about 3 times the weight of sodium ions in said composition; at least one water-soluble potassium salt in an amount, by weight, of from about 0.05 to about 1 time the weight of said sodium salt in said composition; and at least one water-soluble magnesium salt, wherein the weight of magnesium ions in said composition is from 0.1 to about 10 times the weight of sodium ions in said composition.

Owner:RITE PREP PTY LTD AS TRUSTEE FOR THE RITE PREP UNIT TRUST

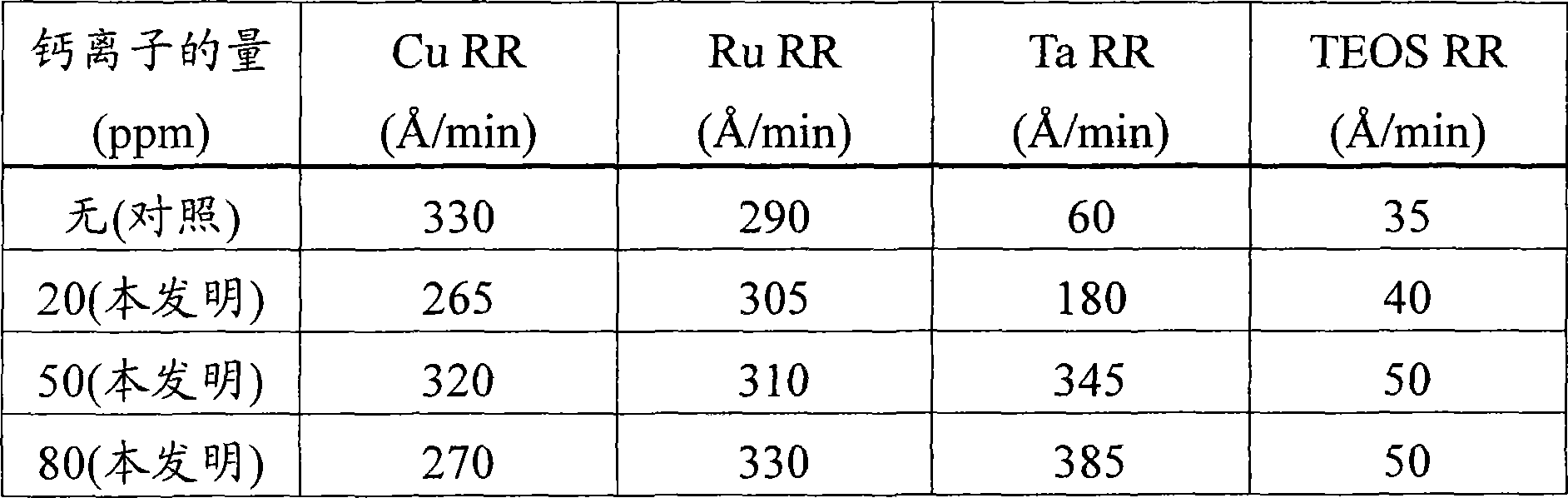

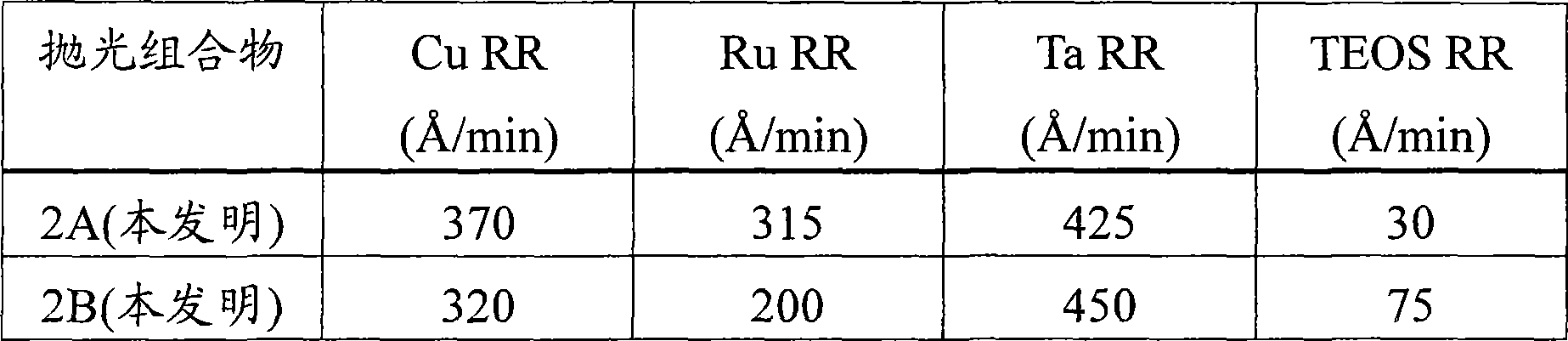

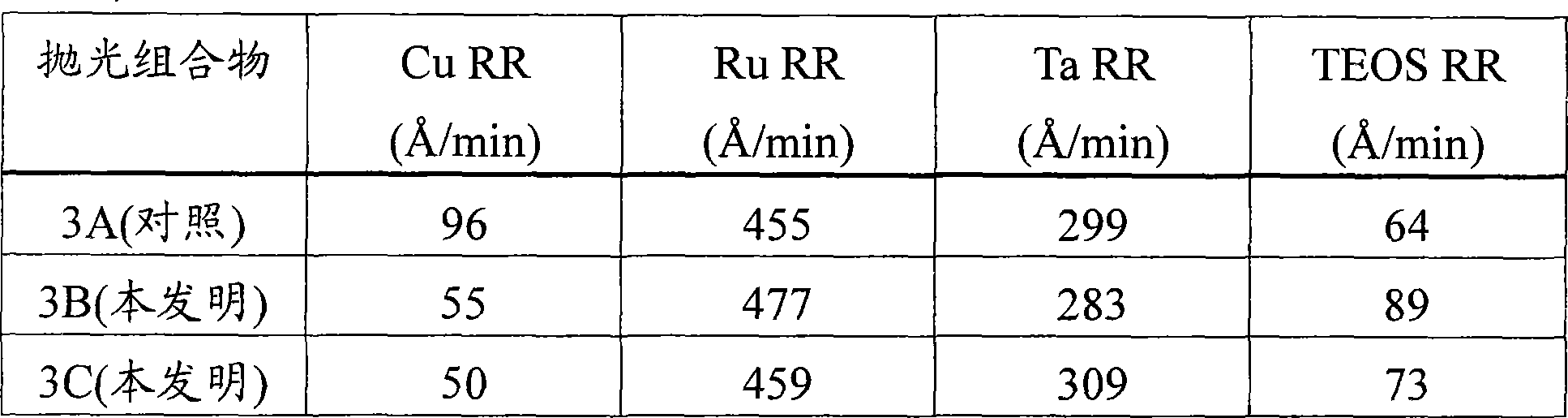

CMP of copper/ruthenium/tantalum substrates

The invention provides a chemical-mechanical polishing composition for polishing a substrate. The polishing composition comprises an abrasive, an oxidizing agent, an amphiphilic nonionic surfactant, calcium ion or magnesium ion, a corrosion inhibitor for copper, and water, wherein the pH of the polishing composition is about 6 to about 12. The invention further provides a method of chemically-mechanically polishing a substrate with the aforementioned polishing composition.

Owner:CABOT MICROELECTRONICS CORP

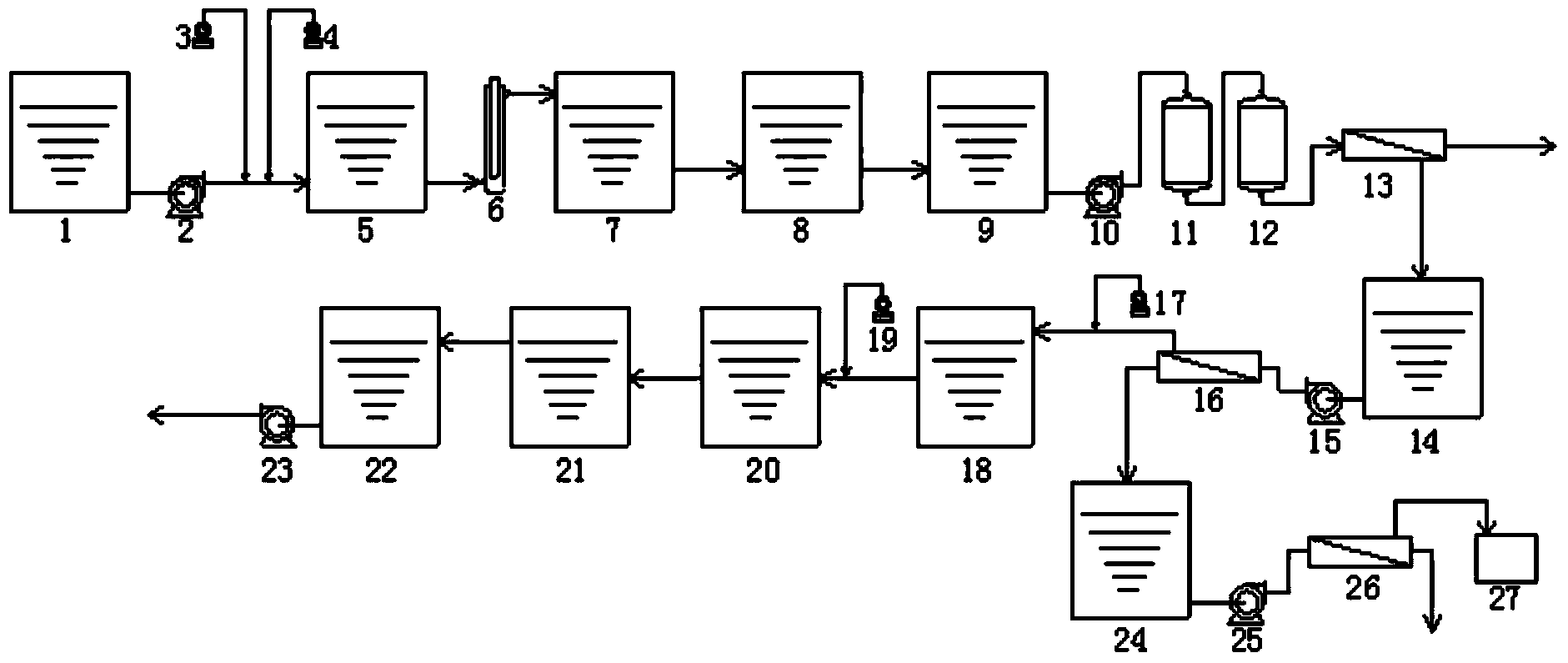

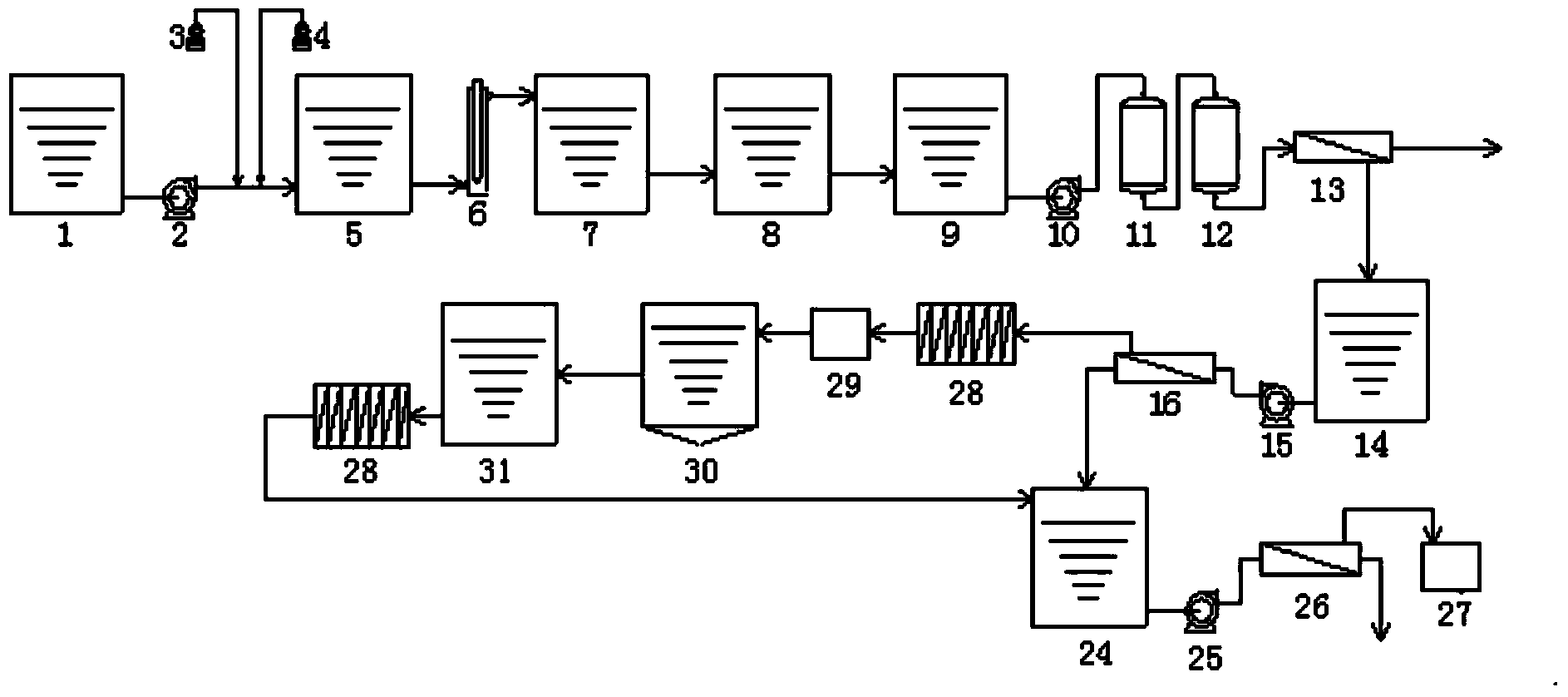

Method and device for zero-emission treatment of high-hardness waste water containing sulfate

ActiveCN104291511AIncrease the concentration factorSave investmentWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentSulfate radicalsIon exchange

The invention belongs to the field of waste water treatment and reclaimed water reuse, in particular to a method and a device for the zero-emission treatment of high-hardness waste water containing sulfate. The method for the zero-emission treatment of high-hardness waste water containing sulfate comprises the following steps: 1) sequentially substituting calcium and magnesium ions in waste water into sodium ions by a double-alkali process and an ion exchange process and simultaneously removing most alkalinity so as to promote sulfate radicals and chlorine ions to be the main components of rest anions in water and promote sodium ions to be the main component of cations; 2) concentrating waste water obtained in step 1) through reverse osmosis and reclaiming produced water; 3) separating and concentrating concentrated water treated by reverse osmosis in step 2) through nanofiltration so as to obtain nanofiltered concentrated water of which the main component is sodium sulfate and nanofiltered produced water of which the main component is sodium chloride; 4) after concentrating the produced water nanofiltered in step 3) through reverse osmosis or positive osmosis, evaporating and concentrating; 5) removing sulfate radicals from the concentrated water nanofiltered in step 3). The concentrating times of waste water is increased as much as possible, and the evaporating quantity of waste water is reduced.

Owner:山东泰禾环保科技股份有限公司

Methods for preserving fresh produce

The present invention pertains to methods of preserving fresh produce with a produce preservative which extends the shelf life of fresh produce, particularly cut fresh produce. The produce preservative preserves the texture, flavor, appearance, crispness, and color of the fresh produce, particularly the exposed surface of the fresh produce. The method comprises the following steps: providing a solution of produce preservative comprising: water, magnesium ions or zinc ions or tin ions; and ascorbate ions, or erythorbate ions; wherein the magnesium ion or zinc ions or tin ions and ascorbate ions are present in a mole ratio of preferably from 0.2:1 to 8:1, more preferably from 0.75:1 to 8:1, more preferably from 1:1 to 4:1, most preferably 1.5:1 to 3:1, applying said produce preservative to the produce; applying said produce preservative to the produce.

Owner:MANTROSE HAEUSER

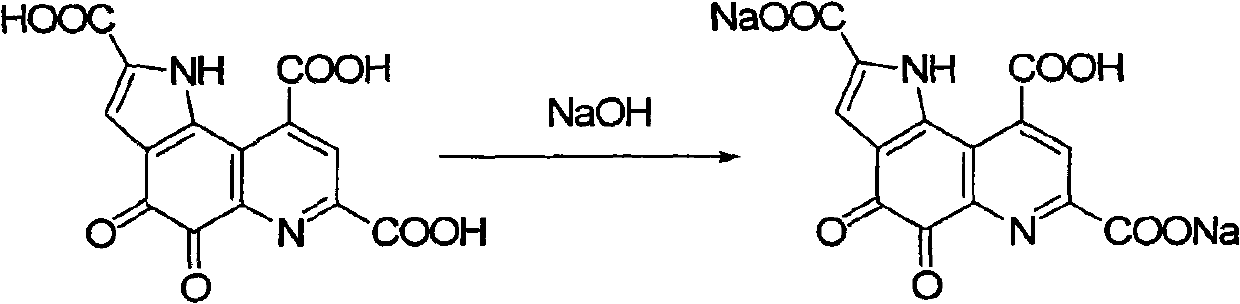

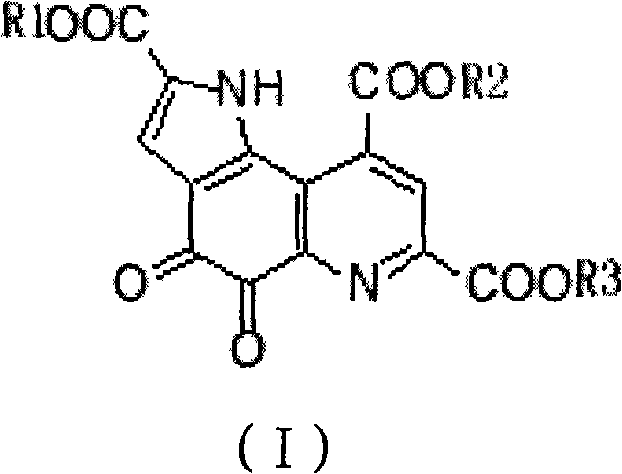

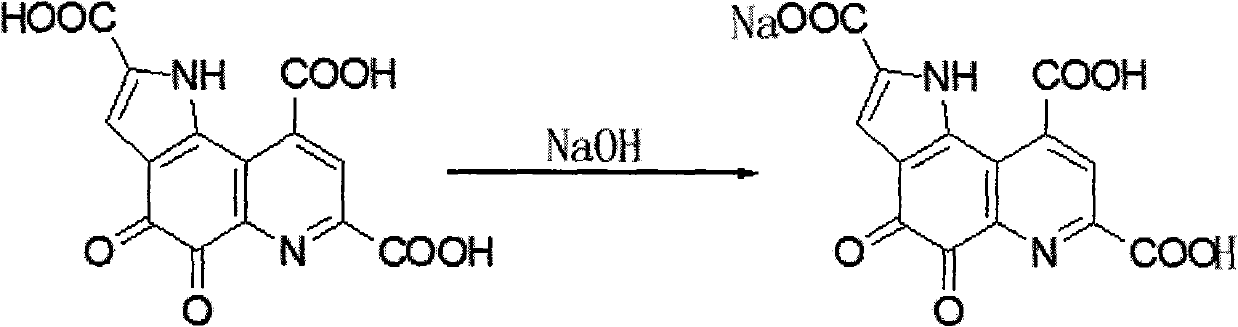

Pyrro-quinoline quinine sodium salt derivative and preparation method thereof

InactiveCN101885725AGood water solubilityMild reaction conditionsOrganic active ingredientsNervous disorderQuinolineStructural formula

The invention relates to a pyrro-quinoline quinine (PQQ) sodium salt derivative and a preparation method thereof, belonging to the field of pharmacy. In the preparation method, PQQ is used as a raw material, and an acid-base neutralization reaction with PQQ is carried out in a basic solvent of sodium hydroxide to prepare the PQQ sodium salt derivative represented in the structural formula (I), wherein R1, R2 and R3 can be identical or different and respectively represents H, ammonium ion (NH3), potassium ion, sodium ion, magnesium ion, calcium ion or zinc ion, and at least one of R1, R2 and R3 is sodium ion. The invention has mild reaction conditions, easy product refining and purification, simple preparation steps and high yield more than 80%. The PQQ sodium salt derivative has the functions of inhibiting GSK-3 activity, reducing senile pigment formation in a transgenic mouse brain, reducing tau protein phosphorylation and the like. Thus, the PQQ sodium salt derivative can be medically used for treating senile dementia and other diseases.

Owner:SHANGHAI RIXIN BIOTECHNOLOGY CO LTD

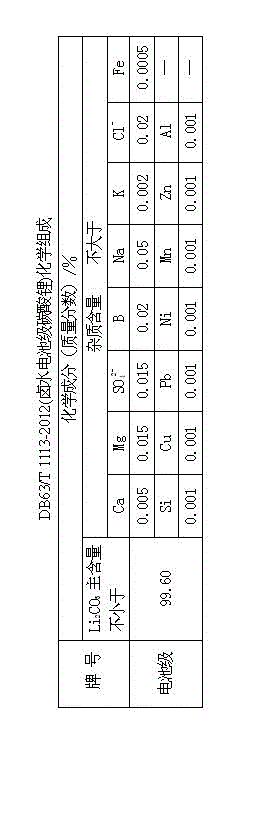

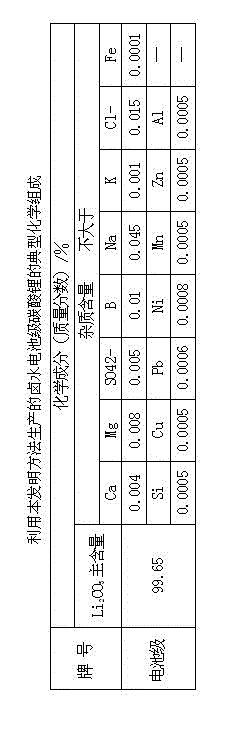

Method for preparing battery-level lithium carbonate by using salt lake brine

ActiveCN102976367ALow impurity indexImprove product qualityLithium carbonates/bicarbonatesLithium carbonatePhysical chemistry

The invention provides a method for preparing battery-level lithium carbonate by using salt lake brine. The method uses salt lake brine in Qinghai as a raw material and uses an ion selectivity separation device to transfer magnesium and lithium ions in the raw material of the brine under the effect of an electric field; when the raw material of the brine passes through a separation membrane with selectivity, monovalent ions, such as the lithium ions and sodium ions can pass through, but divalent ions, such as magnesium ions and calcium ions can be separated, so that lithium-enrichment brine with a low ratio of magnesium to lithium is obtained after the separation; impurities, such as Ca<2+>, K<+>, SO4<2-> and Mg<2+>, in the lithium-enrichment brine with the low ratio of the magnesium to the lithium can be deeply removed; an auxiliary material of a pure alkali solution can be purified; the lithium-enrichment brine after deep removal of the impurities is subjected to three-effect evaporation and concentration after neutralizing with acid; alkali is added into the concentrated lithium-enrichment brine at a certain temperature for lithium sedimentation; and finally, the finished product of the battery-level lithium carbonate can be obtained by drying and cooling after filter press, washing and centrifugal separation washing are carried out. The battery-level lithium carbonate meets the requirements of the local standard DB63 / T1113-2012 (brine battery lithium carbonate) in the Qinghai Province.

Owner:QINGHAI LITHIUM IND

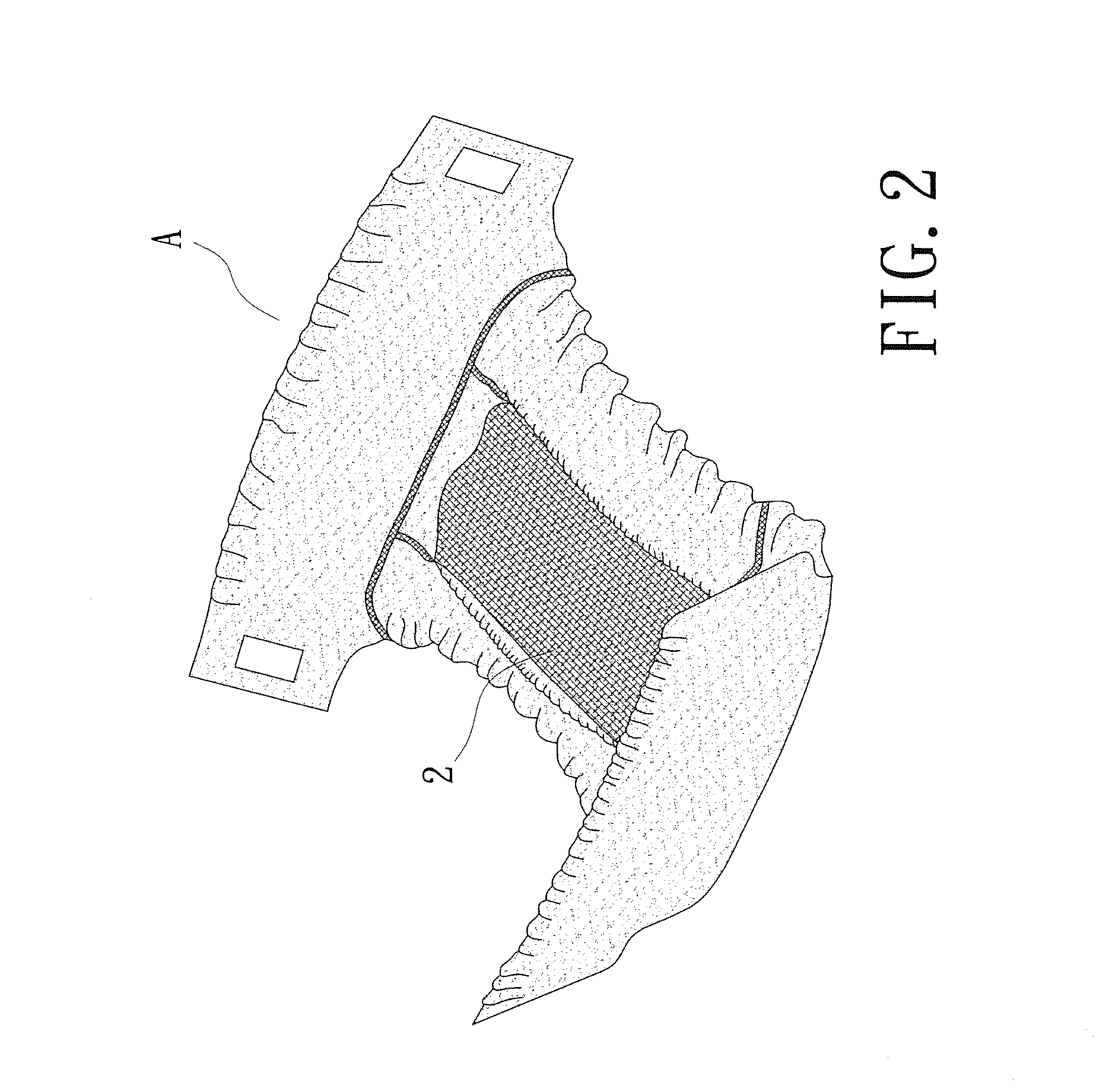

Sanitary product structure for human body with functions of sterilization and deodorization

InactiveUS20150164680A1Improve the bactericidal effectImprove securityNon-surgical orthopedic devicesBaby linensAluminum IonPlatinum

The invention relates to a sanitary product structure for human body with functions of sterilization and deodorization. It comprises a main body and at least one metal ion layer with the functions of sterilization and deodorization. The metal ion layer is at least disposed on the surface of the main body, wherein the metal ion layer is a cover layer composed of germanium ions, molybdenum ions, magnesium ions, manganese ions, chromium ions, vanadium ions, zinc ions, silicon ions, platinum ions, aluminum ions, selenium ions, calcium ions, titanium ions or any combinations thereof. Accordingly, the human body sanitary product has the effects of sterilization and deodorization.

Owner:CHEN TENG LAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com