Patents

Literature

690results about How to "Guaranteed recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resource technology and system for separating salt from high-salinity wastewater

InactiveCN107619144ASolve the problem of pipe blockageReduce energy consumptionMultistage water/sewage treatmentAlkali metal chloridesMirabiliteProduced water

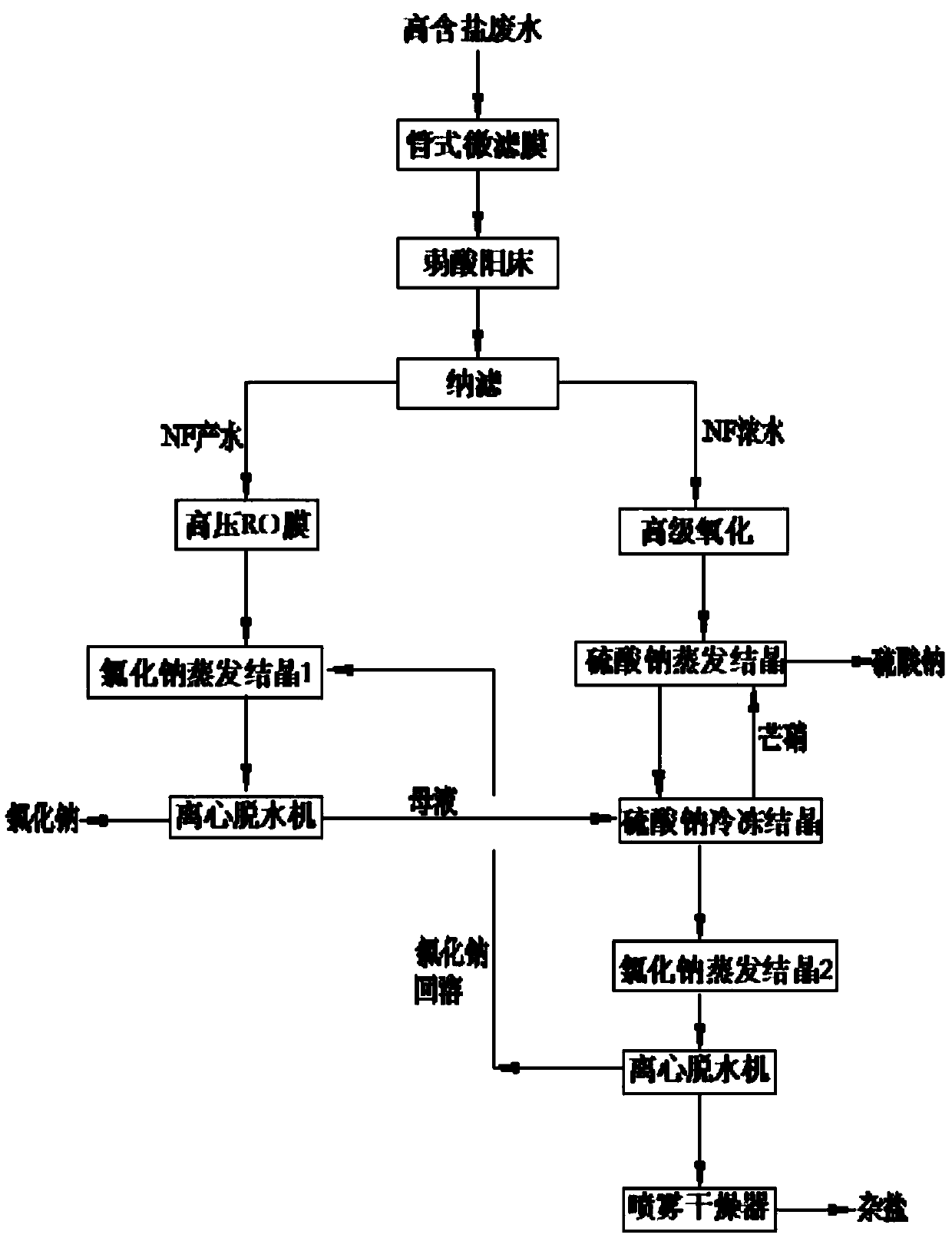

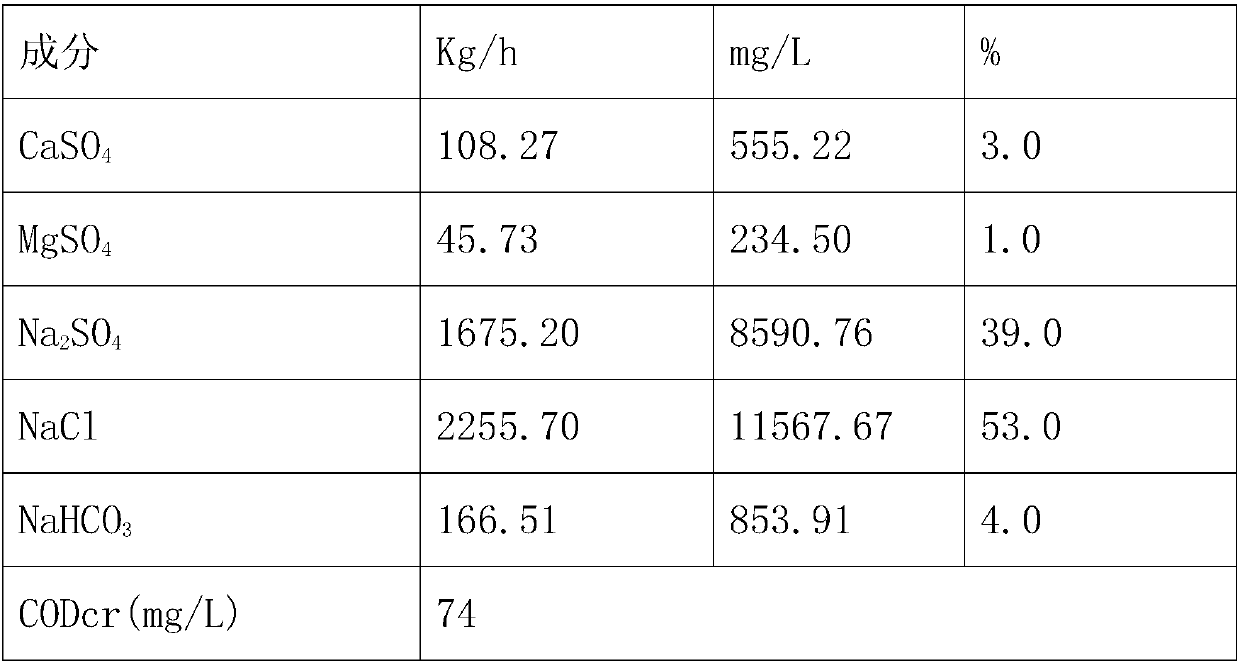

The invention discloses a zero-drainage technology for recycling crystallizing salt from high-salinity wastewater and a treatment system thereof. The treatment system comprises a tubular microfiltration system, a weak acid resin hardness removal system, a nanofiltration membrane salt separating system, a nanofiltration concentrated water oxidizing system, a nanofiltration concentrated water sodiumsulfate evaporating and crystallizing system, a sodium sulfate freezing and crystallizing system and the like. The zero-drainage technology has the advantages that the pretreated wastewater is subject to nanofiltration primary salt separating, the salt component in the produced water is mainly sodium chloride, the sodium chloride with purity no lower than 98.5% is obtained by membrane concentration, evaporating and crystallizing, and the sodium sulfate with purity 99.1% or more is produced by MVR (mechanical vapor recompression) crystallizing after concentrated water oxidizing; a mother liquid after evaporating and crystallizing of sodium sulfate and a mother liquid after nanofiltration evaporating and crystallizing are mixed and frozen, so as to obtain mirabilite, and the mirabilite is converted into anhydrous sodium sulfate after sodium sulfate evaporating and crystallizing; at the premises of ensuring quality, the whole recycling rate of salt reaches 90% or above; finally, a smallamount of mother liquid is sprayed, dried and cured, and the zero-drainage effect of wastewater is realized.

Owner:侯新春 +1

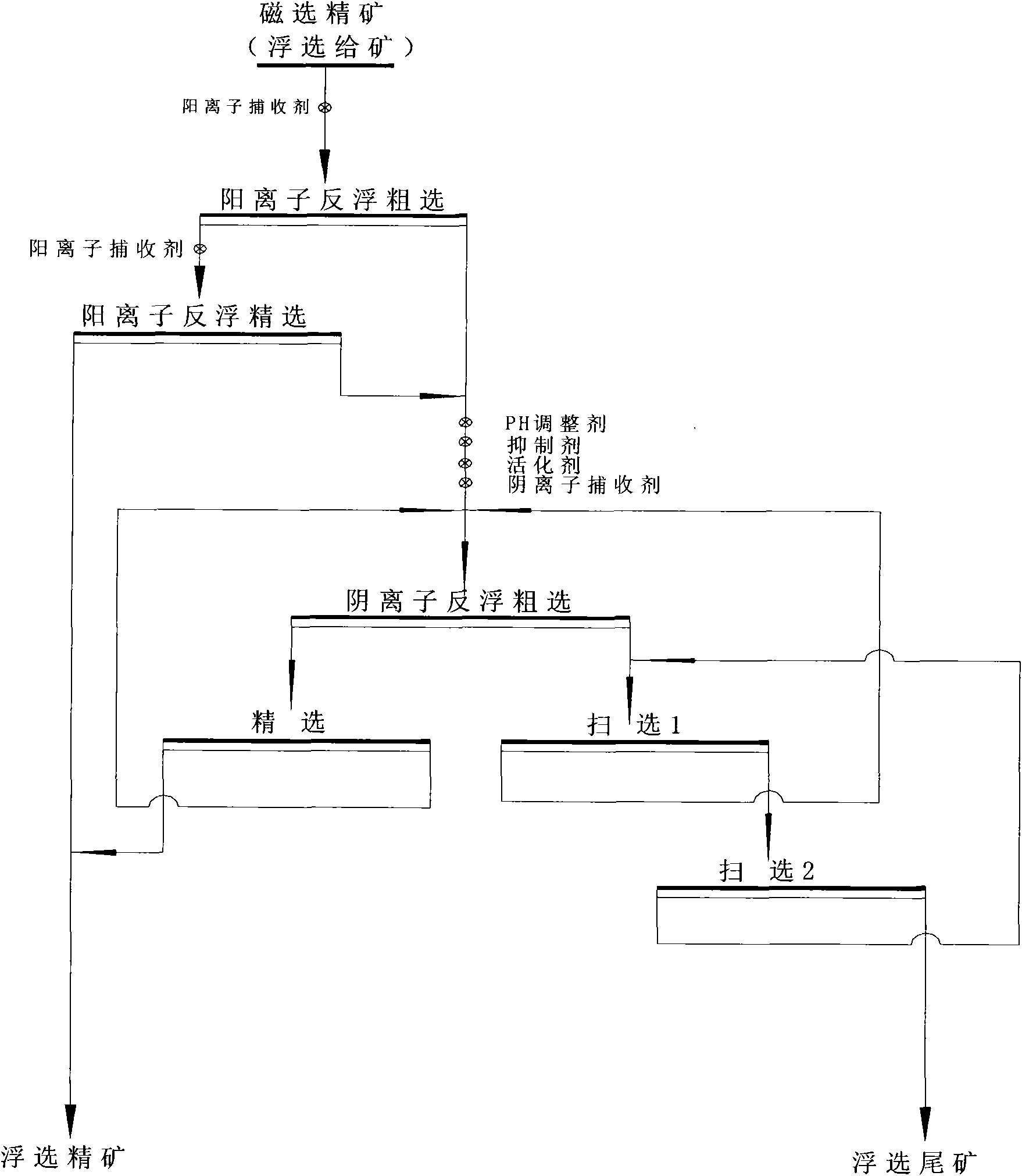

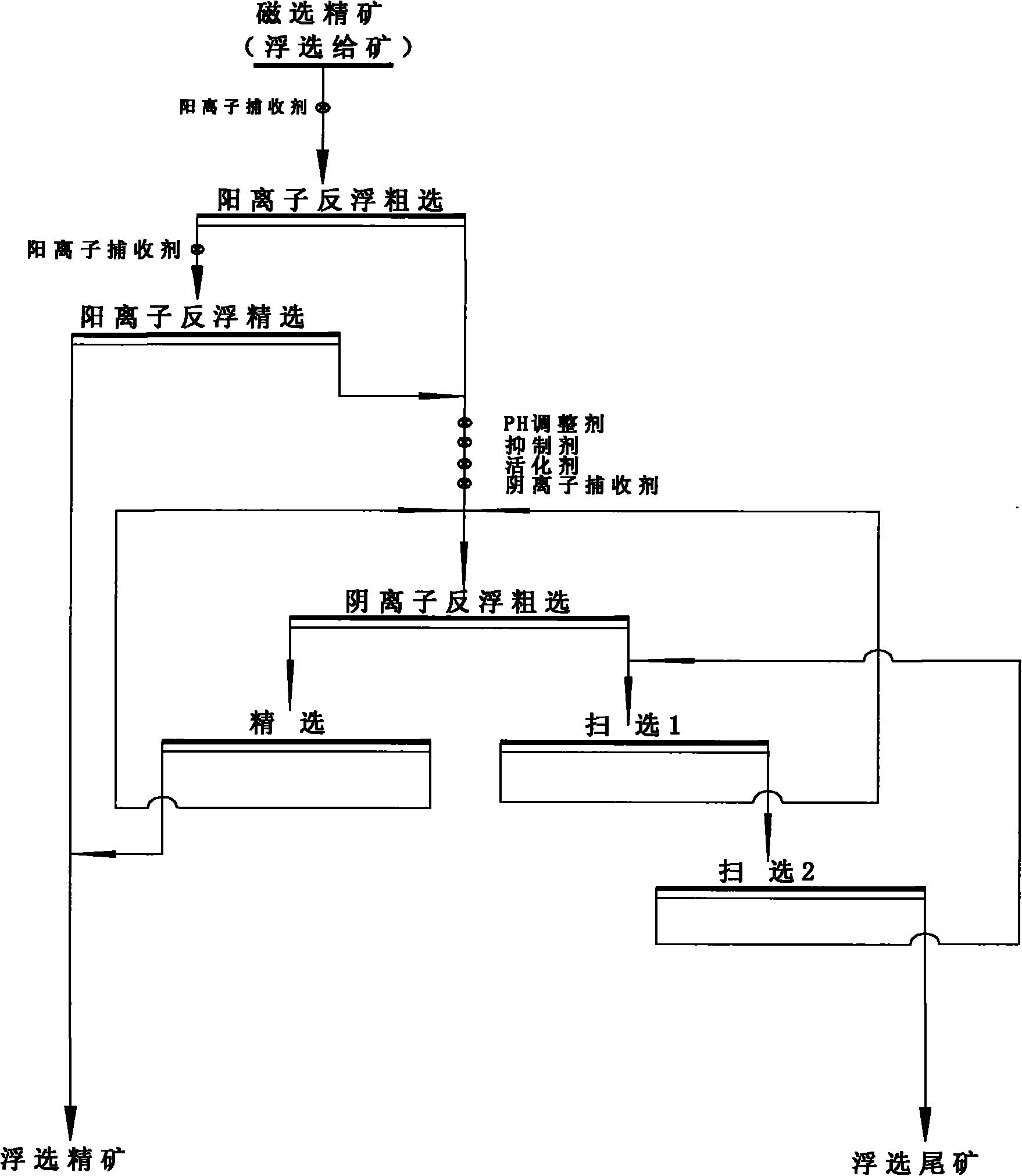

Beneficiation method for producing high-quality iron ore concentrate by low-grade magnetic iron ore

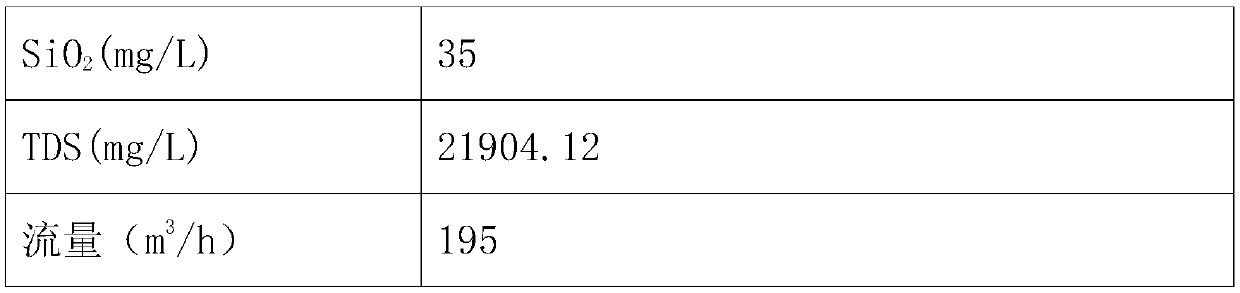

The invention discloses a beneficiation method for producing high-quality iron ore concentrate by low-grade magnetic iron ore, which comprises the following steps that a stage grinding-stage magnetic separation discarding tailing beneficiation process is adopted to produce magnetic separation ore concentrate with the iron ore concentrate grade TFe of 62-66%; a positive ion collector reverse flotation process is adopted on the magnetic separation ore concentrate to obtain positive ion collector reverse flotation iron ore concentrate and middling; a negative ion collector reverse flotation process is adopted on the middling obtained by positive ion collector reverse flotation to obtain negative ion collector reverse flotation iron ore concentrate; and the positive ion collector reverse flotation iron ore concentrate and the negative ion collector reverse flotation iron ore concentrate are combined to obtain the ultimate high-quality iron ore concentrate. The invention has the advantages of high grade of iron ore concentrate, high iron recovery rate, small loss of fine iron minerals, low beneficiation energy consumption and small consumption of medicaments, can relieve the industry difficulty of difficult filtration caused by adding starch into fine concentrate, greatly optimizes concentrate filtration operation, can be used for the sorting of magnetite ore, and can also be used for the sorting of weakly magnetic iron minerals such as hematite and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Method for producing high-purity lithium carbonate by using lithium concentrate

ActiveCN103318925AReduce consumptionGuaranteed RecoveryLithium compoundsLithium sulphatePhysical chemistry

The invention relates to a method for producing high-purity lithium carbonate by using lithium concentrate. The method is characterized by comprising the following steps of: preparing an acid clinker, preparing a mixing size, preparing a lithium sulfate leaching solution, preparing a lithium sulfate purification liquid, preparing a lithium sulfate finishing solution, preparing a sodium carbonate solution, performing primary lithium deposition reaction, preparing a sodium separating mother liquor, preparing excellent lithium carbonate in a sweating manner, and preparing 99.99% of high-purity lithium carbonate. By adopting the method, the principle of removing calcium and magnesium ions is ingeniously utilized in preparation of common lithium carbonate; a fussy procedure of removing calcium and magnesium by ion exchange resin is avoided when the common lithium carbonate is purified to prepare the high-purity lithium carbonate; a method of recycling after separating out sodium sulfate in a freezing manner is adopted to process the primary lithium settling mother liquor; the high-purity lithium carbonate mother liquor in precipitation of the high-purity lithium carbonate is used as an optimal lithium carbonate washing liquor for primary lithium sedimentation after being recycled for a plurality of times. Thus, the method has the characteristics of simple process, high production efficiency, high recovery rate and low production cost.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

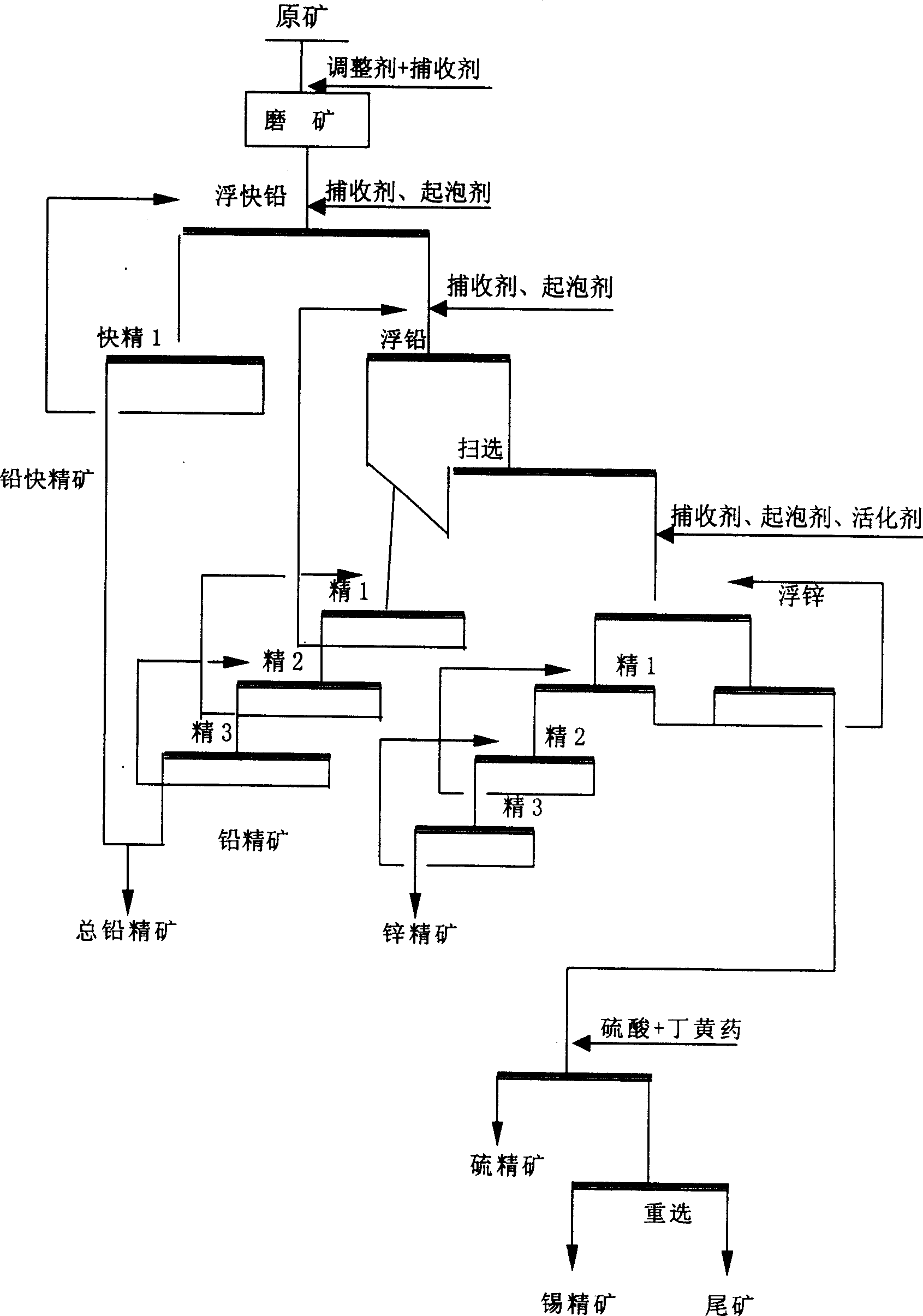

Stepped flotation of tin, lead and zinc sulfide mine

A step floatation technology for the tin-lead-zinc sulfide ore includes such steps as high-alkali high-speed floatation and separation of lead sulfide ore, high-alkali high-Ca floatation and separation of zinc sulfide ore, and floatation of zinc tailings. Its advantages are high grade and recovering rate of lead concentrate, no loss of Ag ore, and simple apparatus.

Owner:黎东明

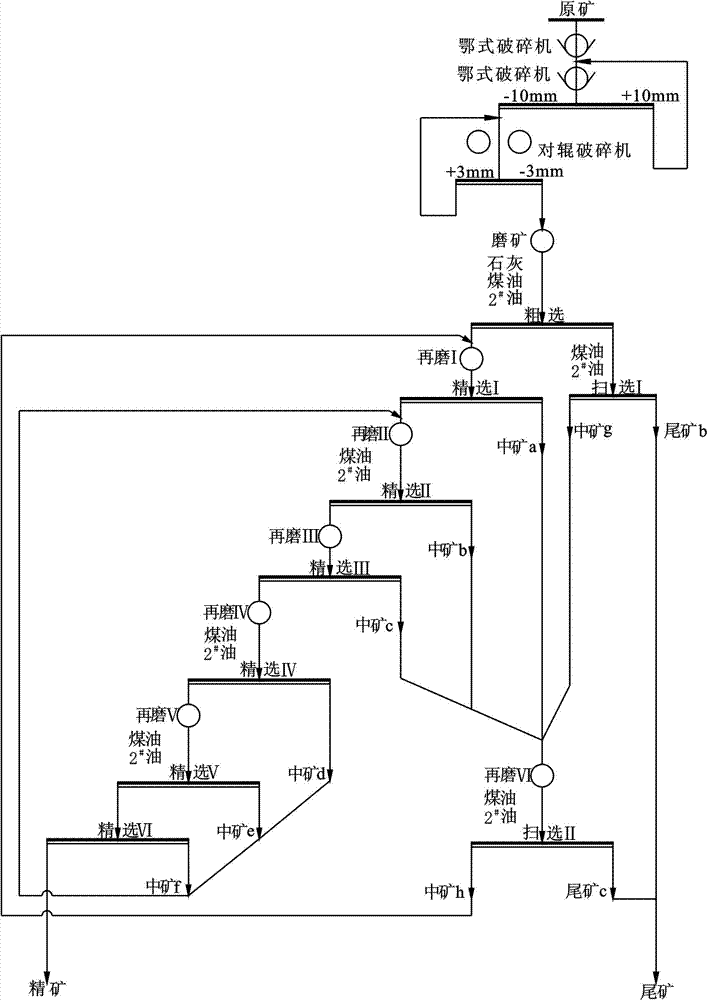

Fine flaky-cryptocrystalline mixed graphite separation technique

The invention discloses a fine flaky-cryptocrystalline mixed graphite separation technique which comprises the following steps: primary rough grinding and rough separation, quintic regrinding and sextic concentrating, and middling centralized processing. According to the technique, in the rough separation step, the grinding fineness is -0.074mm, and the content is 90-95%; in the concentrating step, the regrinding fineness is -0.045mm, and the content is 90-95%; and thus, the graphite monomer is sufficiently dissociated, thereby sufficiently ensuring the fixed carbon content and recovery rate of the concentrated concentrate. The technique adopts gradually decreased low concentrating concentrations in multiple concentrating process to ensure the dispersity of ore slurry, thereby solving thesevere problem of entrapped impurities in floatation foam; and thus, in the final concentrate, the fixed carbon content is 91.35%, and the recovery rate is 91.30%, thereby solving the problems of lowtechnical indexes, low grade, low recovery rate and high cost in the fine flaky-cryptocrystalline mixed graphite concentrate separation, so that the fine flaky-cryptocrystalline mixed graphite ores are utilized in an efficient, economical and reasonable way.

Owner:SICHUAN PILOT GRAPHITE PROD

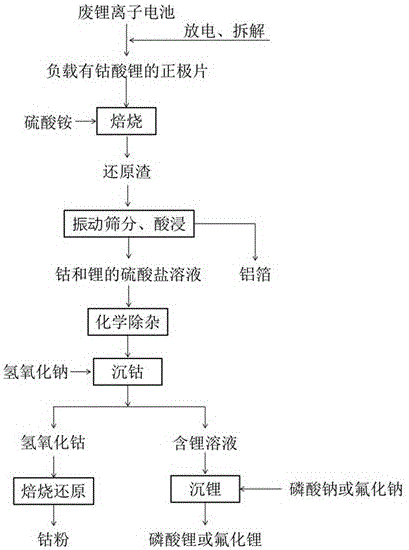

Method for recycling cobalt and lithium from positive plate of waste lithium ion battery

ActiveCN106505270AGuaranteed RecoveryHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementSlagLithium-ion battery

The invention provides a simple and high-efficiency method for recycling cobalt and lithium from a positive plate of a waste lithium ion battery, and relates to a method for recycling cobalt and lithium from the positive plate of the waste lithium ion battery. The method is characterized by comprising the following processes of ammonium sulfate roasting, in which the positive plate of the waste lithium battery is mixed with ammonium sulfate, and high-temperature roasting is performed to obtain reduction roasting slag; screening, in which the reduction roasting slag is vibrated and is screened by a vibration screening machine, and an aluminum foil is separated and removed to obtain reduction slag containing cobalt and lithium; acid leaching, in which the aluminum foil is separated and removed from the reduction roasting slag, is leached in sulfuric acid and is filtered to obtain a sulfate solution containing cobalt and lithium; impurity removal, in which pH of the solution is adjusted by sodium carbonate, and a precipitant is filtered and removed to obtain a lithium-cobalt sulfate mixture solution; cobalt deposition, in which sodium hydroxide is added into the lithium-cobalt sulfate mixture solution, the pH of the solution is controlled to be 7.5-9.5, and filtering is performed to obtain the precipitant, the precipitant is washed with deionized water at 85-95 DEG C, cobalt hydroxide is dried, cobalt hydroxide after being dried is placed in a reduction furnace, and H2 is introduced for reduction to obtain cobalt powder; and lithium deposition, in which pH of a lithium-containing solution is adjusted to 7-8, and an excessive amount of a lithium deposition agent is added to a lithium salt product.

Owner:JINGMEN GEM NEW MATERIAL

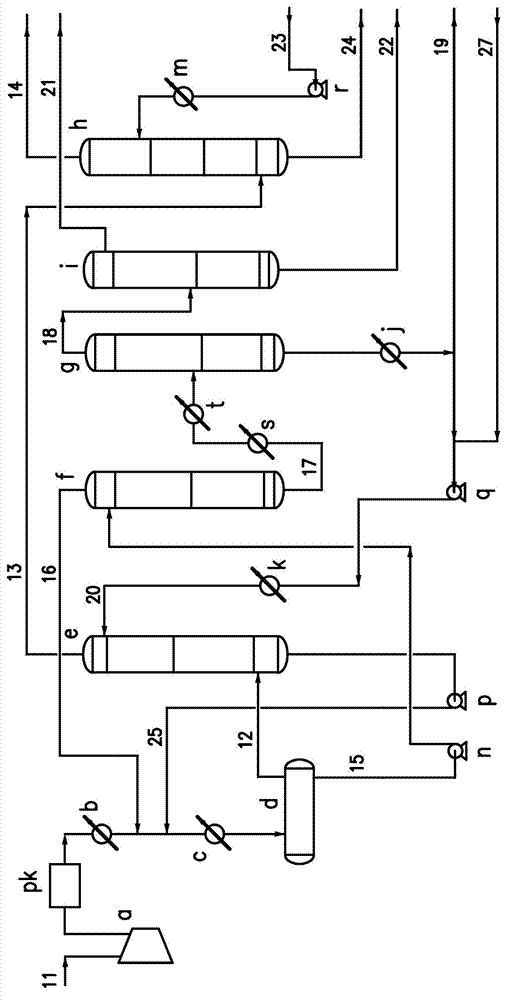

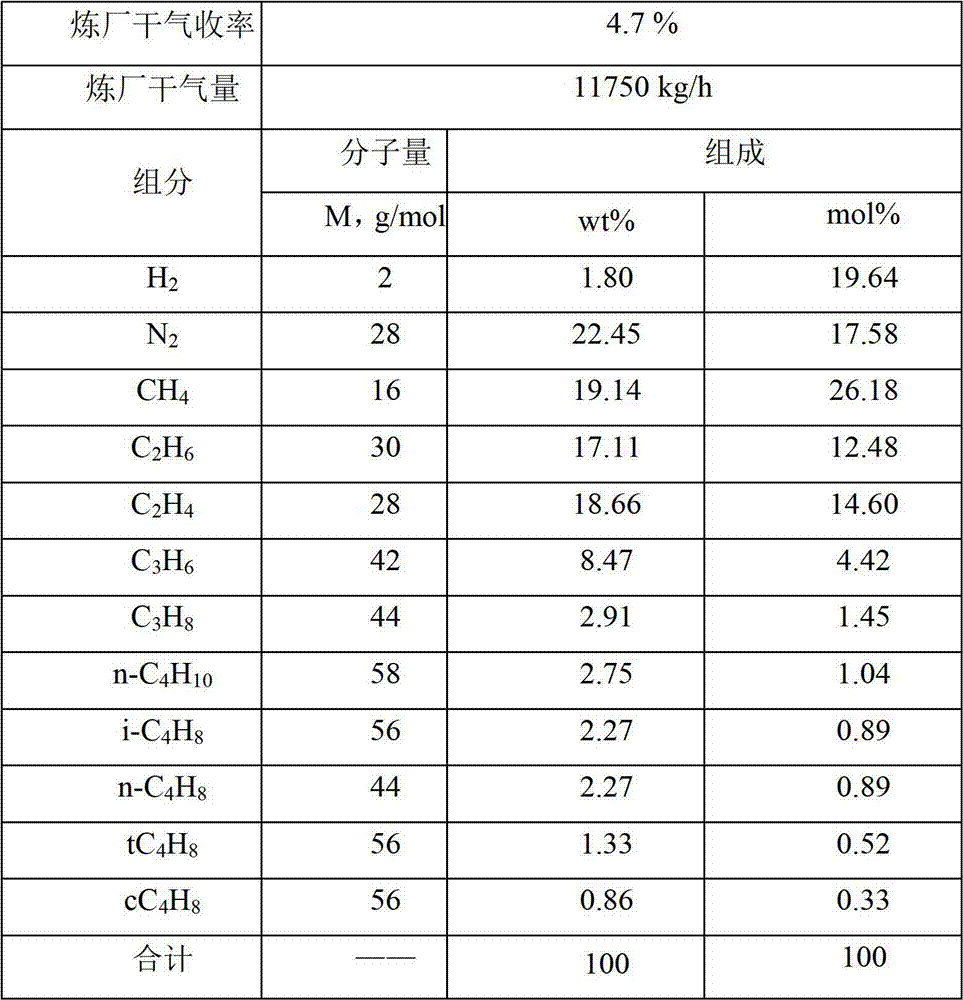

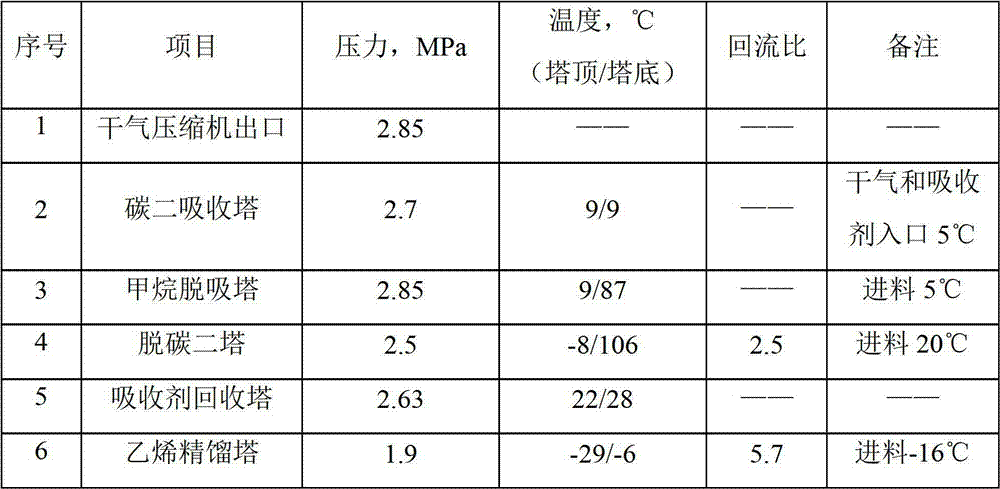

Recovering system and method of C2 in refinery dry gas by compound adsorption method

ActiveCN103588604AModerate operating conditionsGuaranteed RecoveryEthylene productionAbsorption purification/separationFluid phaseProcess engineering

The invention provides a recovering system and a method of C2 in refinery dry gas by a compound adsorption method. The recovering system comprises a compressor, a pretreatment unit, a refinery dry gas cooling unit, a compound adsorption unit and a rectification unit. The adsorption unit comprises a gas-liquid separating tank, a C2 adsorption tower, and a methane desorption tower. The rectification unit comprises a C2 removing tower and an ethylene rectification tower. The refinery dry gas, after being compressed, pretreated and cooled, is subjected to gas-liquid separation to obtain a gas phase and a liquid phase. The gas phase is fed into the C2 adsorption tower and subjected to C2 adsorption by using a C4 mixture or a C5 mixture as an absorbent. The liquid phase is fed into the methane desorption tower, and subjected to methane desorption through stripping. The mixed adsorption oil at the bottom of the C2 adsorption tower and desorption gas at the top of the methane desorption tower are returned to the gas-liquid separation tank after being mixed and cold with the refinery dry gas. Tower bottom of the methane desorption tower is cooled and fed into the C2 removing tower and the ethane rectification tower to be rectified to obtain an ethylene product and an ethane product. The method provided by the invention adopts moderate operating conditions. The ethylene and the ethane both have the high recovering rate and the high purity.

Owner:CHINA PETROCHEMICAL CORP +1

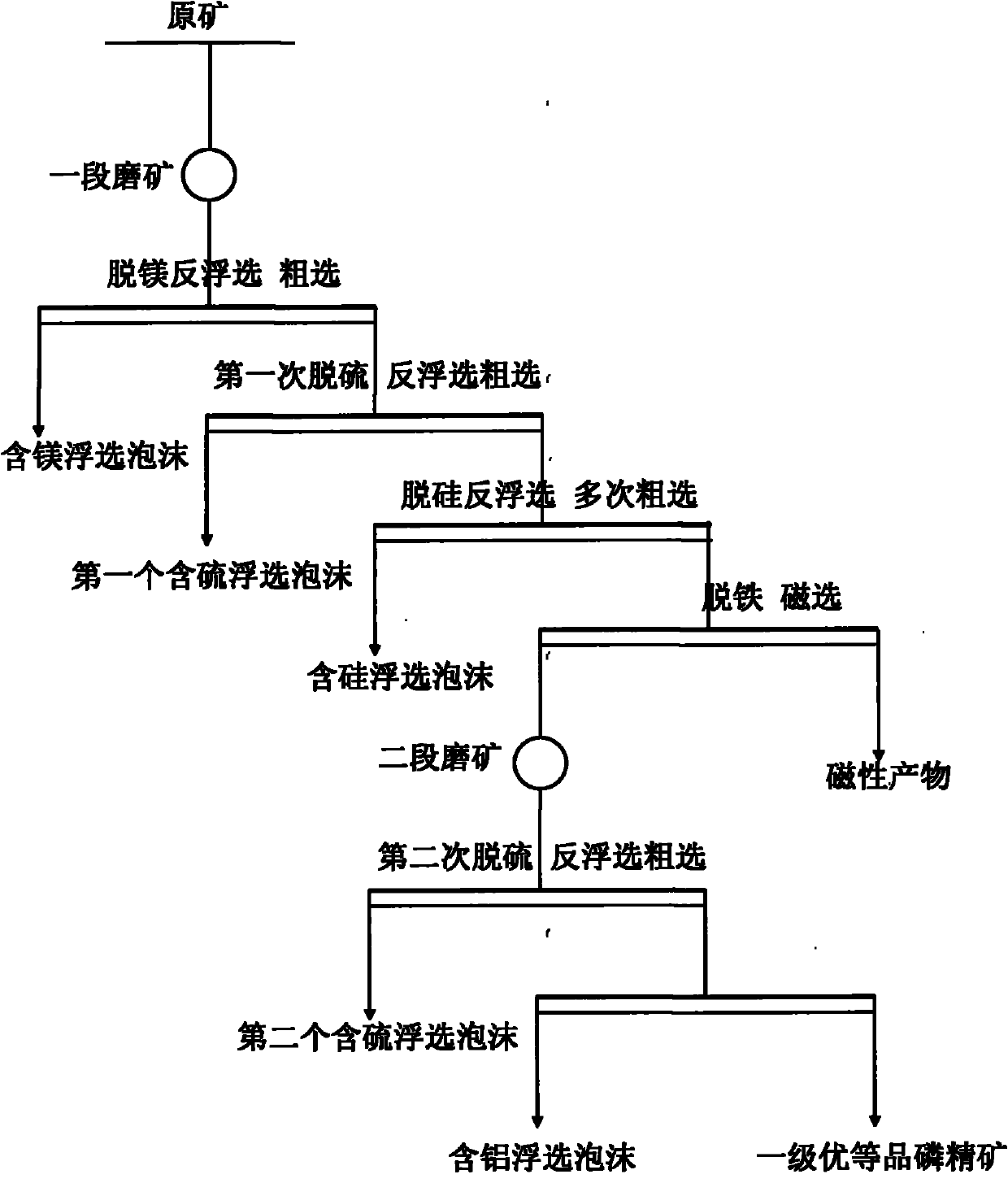

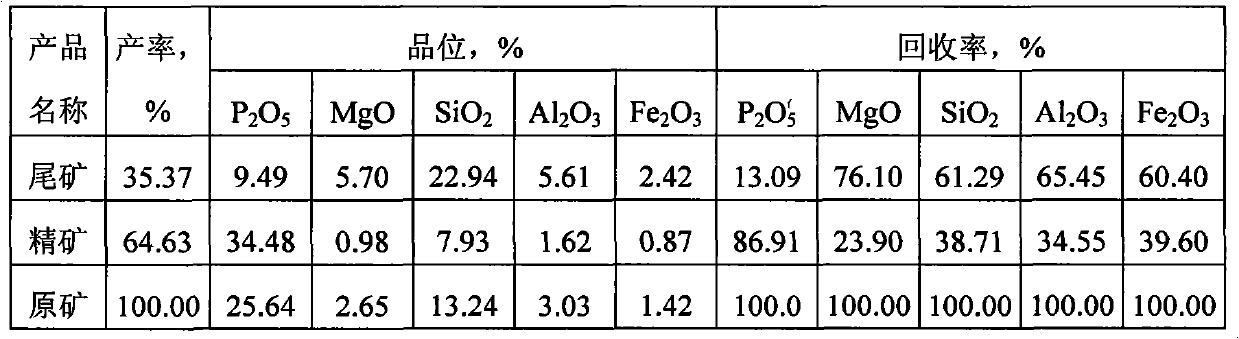

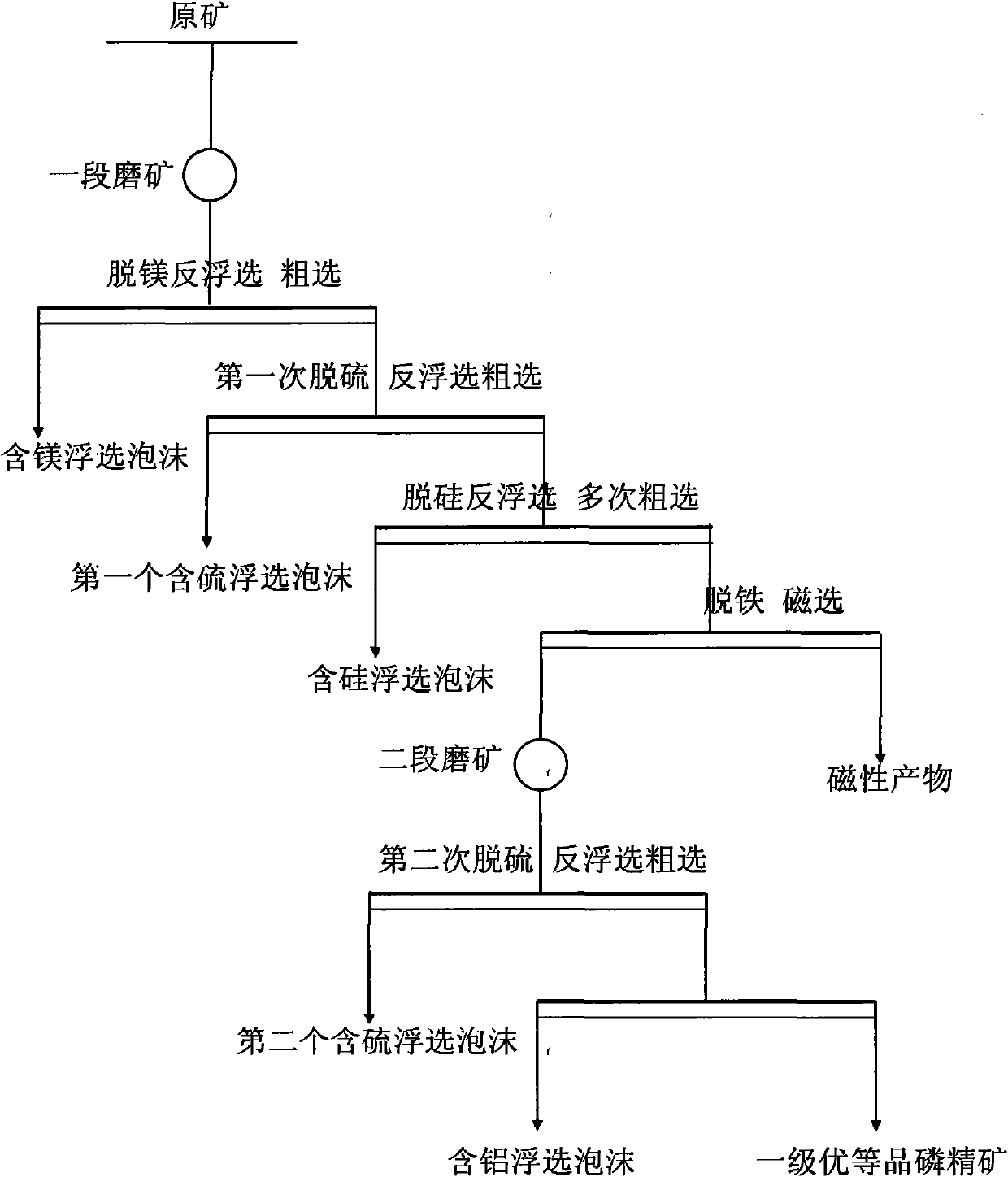

Method for separating collophanite

The invention relates to a method for separating collophanite, which is characterized by comprising the following steps of: (1) coarsely grinding raw collophanite; (2) performing reverse floatation on the grinding product to remove magnesium; (3) reacting floatation base flow of the step (2) with a desulfurization floatation medicament for reverse floatation to remove sulfur; (4) reacting the floatation base flow in the step (3) with a desilicification floatation medicament for reverse floatation to remove silicon; (5) performing intensity magnetic separation on the floatation base flow in the step (4) to remove iron; (6) regrinding a non-magnetic product in the step (5); (7) reacting the grinding product in the step (6) with a desulfurization floatation medicament for reverse floatation to remove sulfur; and (8) reacting the floatation base flow in the step (7) with a dealumnization floatation medicament for reverse floatation to remove aluminum to obtain aluminum-containing floatation foam and the floatation base flow, wherein the floatation base flow is the final phosphorus concentrate. The method can perform floatation at normal temperature and even low temperature to obtain phosphorus concentrate, and has the advantages of high separation property, low energy consumption and effective improvement of the P2O5 recovery rate.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Ore dressing process of oolitic high phosphorus hematite

The ore dressing process of oolitic high phosphorus hematite includes the following steps: roasting crushed oolitic high phosphorus hematite in 80-99 wt% with coal powder as reductant in 1-20 wt% inside a shaft furnace or rotary kiln at 700-1050 deg.c for 0.5-2.5 hr and sealed cooling to room temperature; crushing the roasted hematite, grinding and weak magnetic separation; regulating pH value of the coarse concentrate to 8-12, adding iron ore inhibitor sulfonated starch in 0.5-3.0 kg / ton, activator in 0.2-2.0kg / ton and collecting agent in 0.2-3.0kg / ton and final reverse floatation. The process converts the weak magnetic hematite into strong magnetic mineral, concentrates iron mineral via weak magnetic separation and eliminate P, Si and other impurities in reverse floatation, and can obtain iron concentrate with iron grade higher than 63 %, P content less than 0.15 %, and iron recovering rate over 75 %.

Owner:WUHAN UNIV OF SCI & TECH

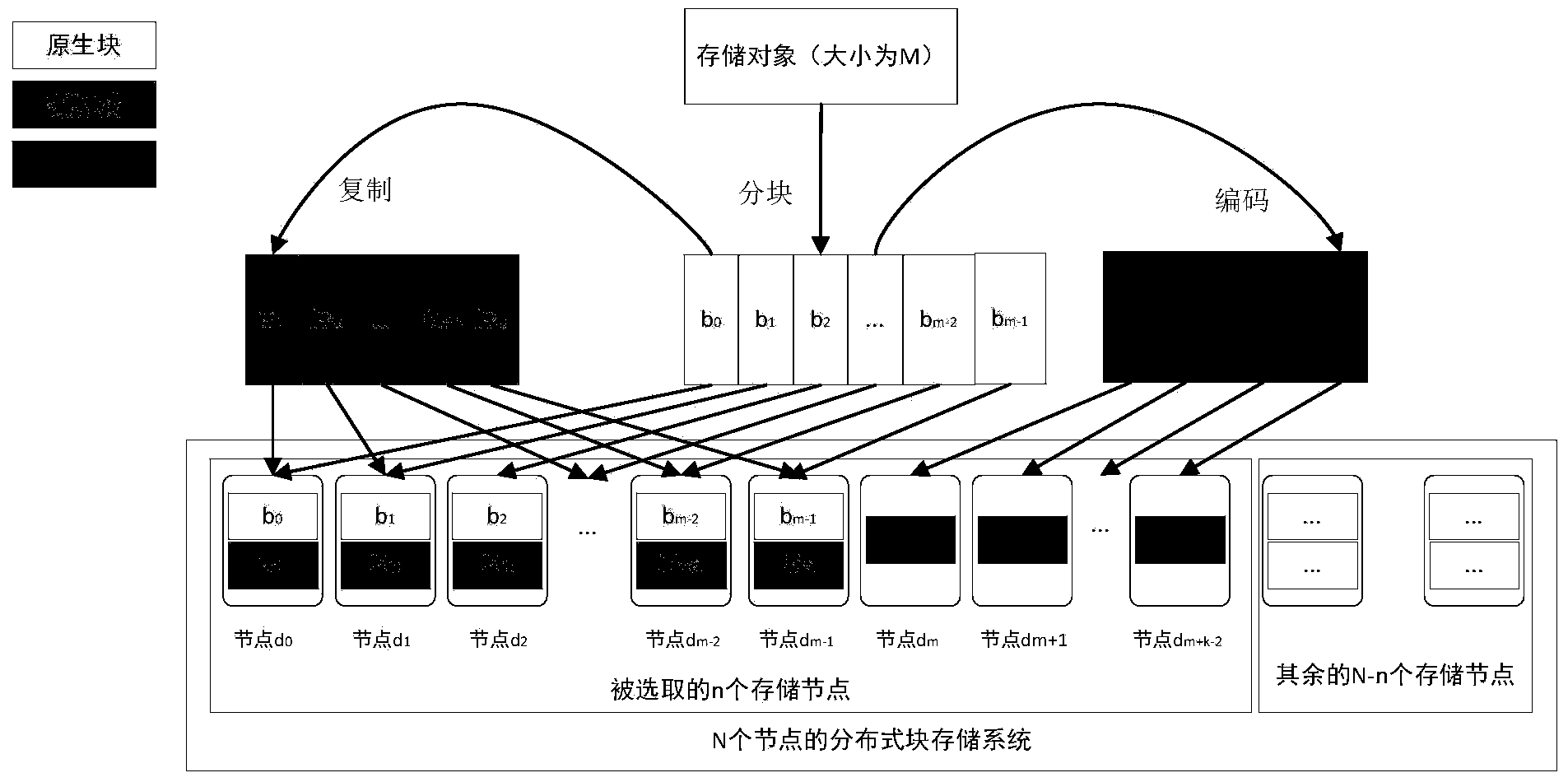

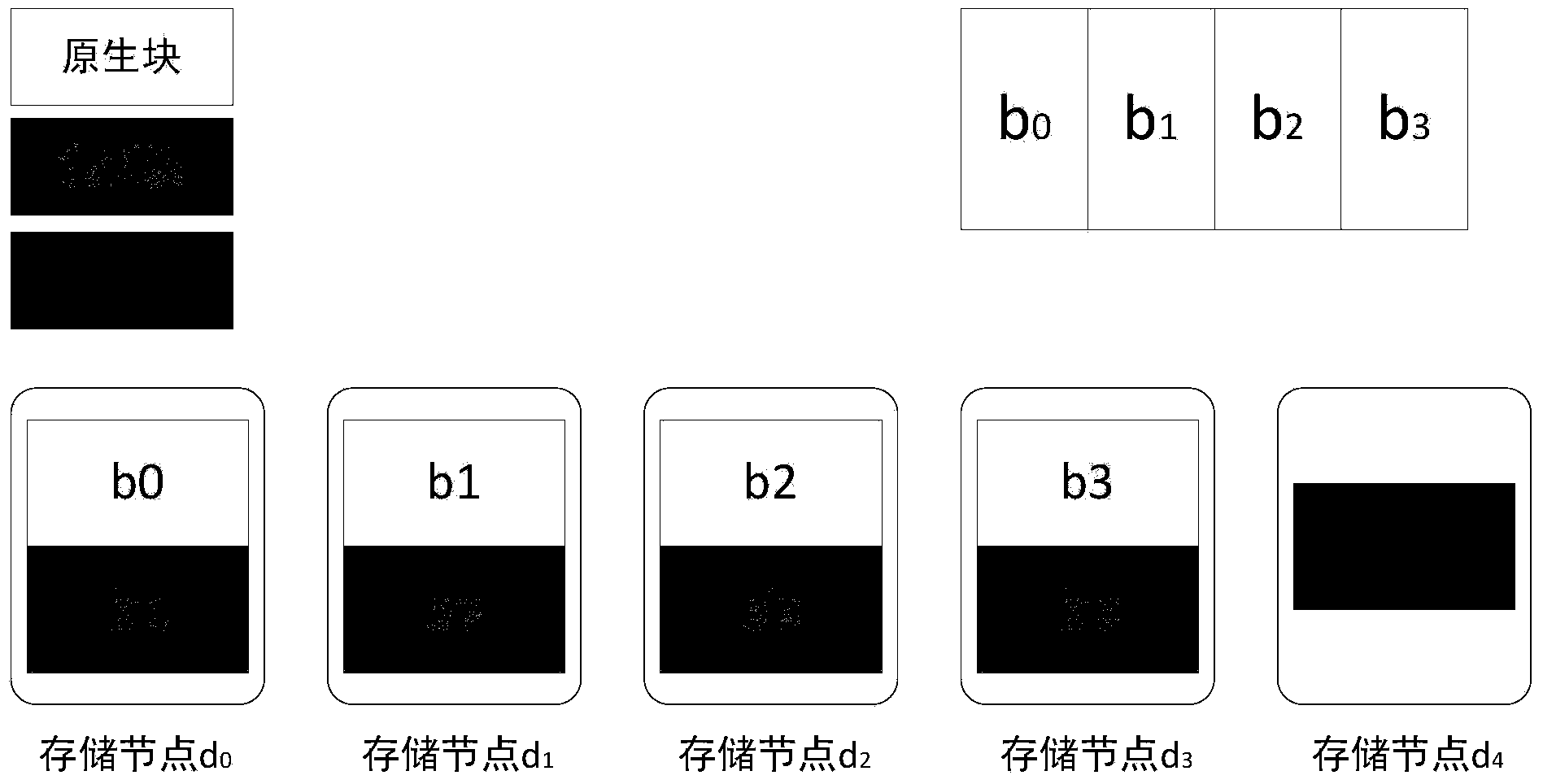

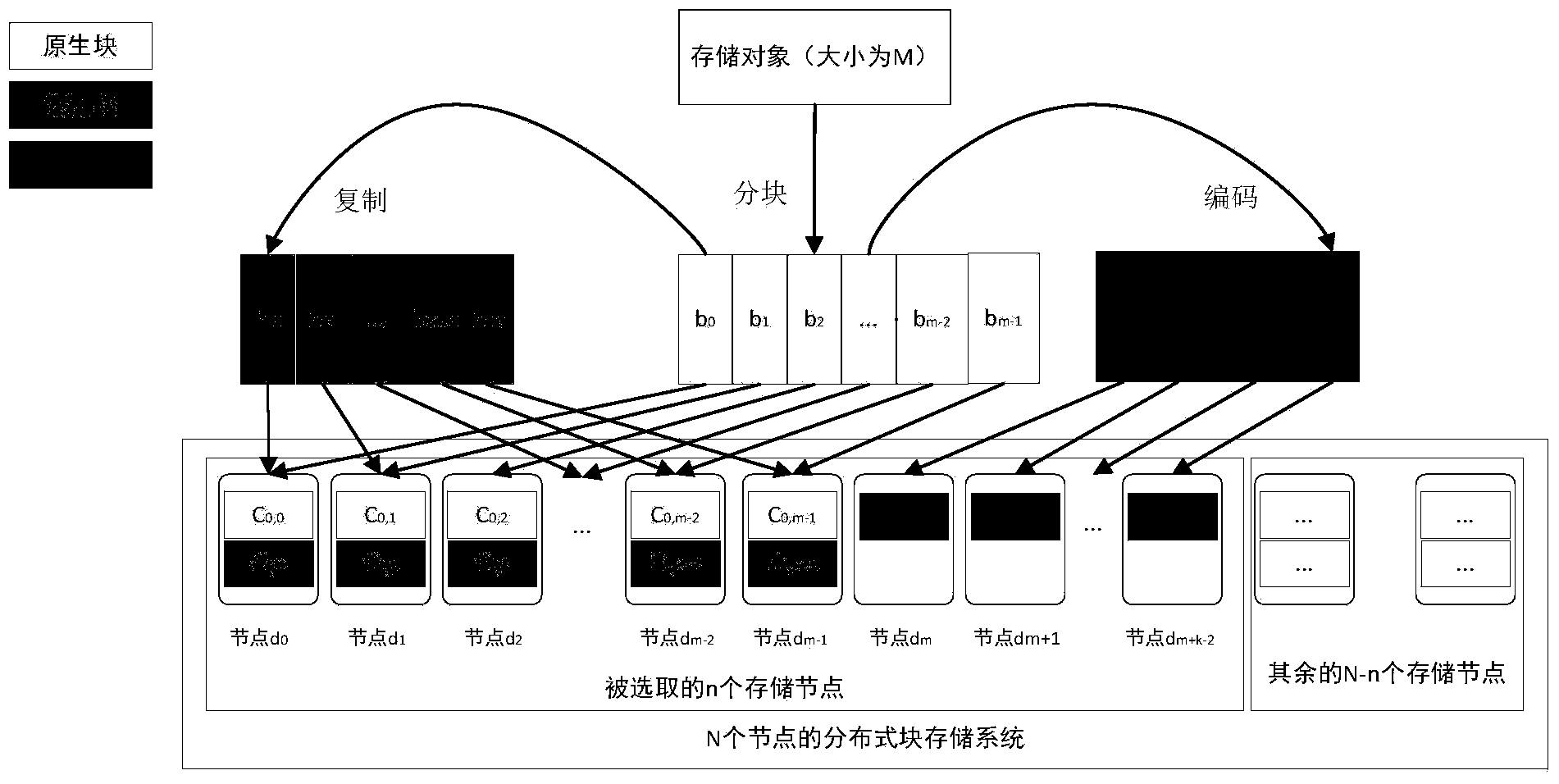

Data recovery method based on error correcting codes in cloud storage

ActiveCN104052576AReduce transfer volumeLighten the computational burdenError preventionData switching networksNetwork communicationCloud storage system

The invention discloses a data recovery method based on error correcting codes in cloud storage, and belongs to the technical filed of cloud storage. According to the method, firstly, data objects are processed in a block mode, and the data blocks, copy blocks and check blocks are stored in all remote storage nodes in a distributed cloud storage system. When the remote storage nodes break down, the data are transmitted to the replacement nodes to be reorganized so as to achieve data recovery through calculation of the storage nodes where the corresponding data blocks are located. According to the data recovery method, by the adoption of the RS check code and the calculation performance of the storage nodes, the data size of the network communication is reduced, data recovery can be achieved in an extremely low bandwidth situation, meanwhile, only one copy block and less check blocks need to be used, and thus storage space is saved.

Owner:HUAZHONG UNIV OF SCI & TECH

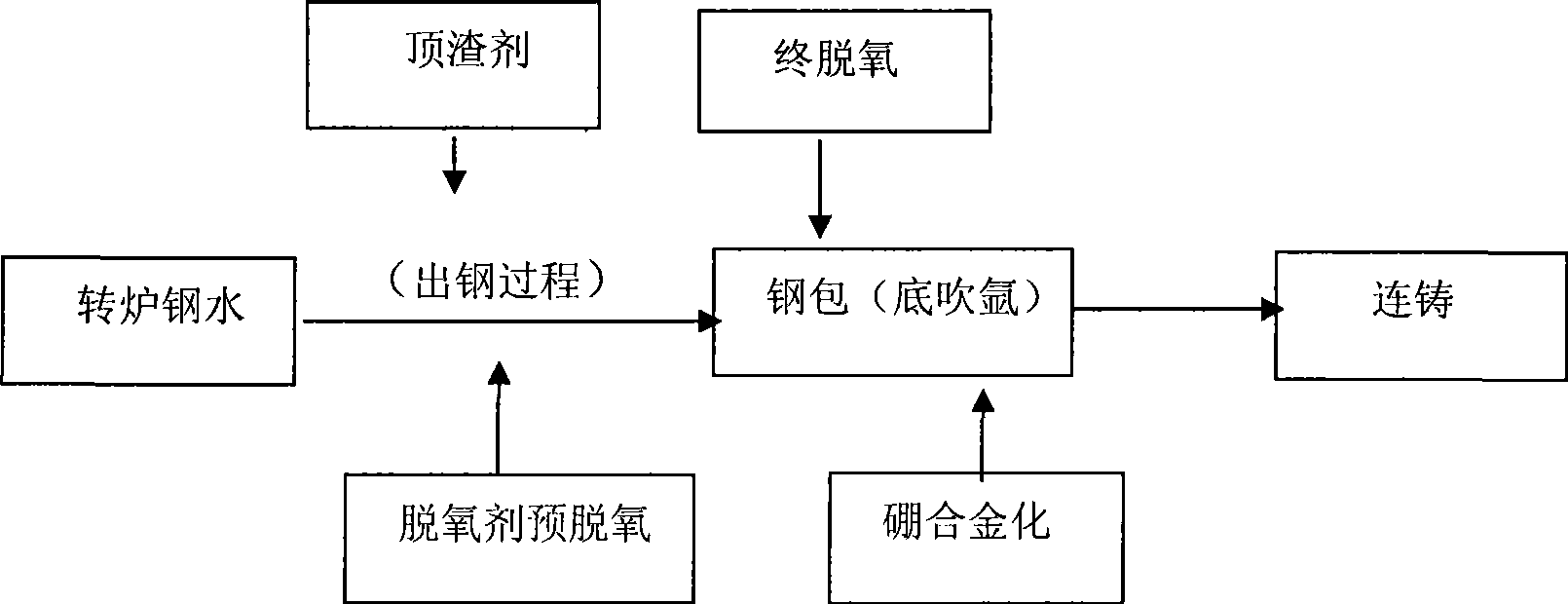

Method for producing boron steel by converter

InactiveCN101503746AAvoid stickinessAvoid water-prone mouthsManufacturing convertersAlloyMolten steel

The invention provides a method for producing boron steel in a converter, which is characterized in that argon subaeration is performed on a ladle in the whole process; a deoxidizer and alloys required by steel grades are begun to be added into the ladle for preliminary deoxidation and alloying under the condition of 1 / 4 tapping, and simultaneously a desulfurizer is added for desulfurization treatment; aluminum is added into the ladle in an argon blowing station for final deoxidation, and ferroboron is added into the ladle when the [O] is controlled to be between 0.0020 and 0.0040 percent; and the ferroboron is coated by an aluminum sheet and added into molten steel. The method has the advantages that: firstly, the method saves the refining procedure of an LF furnace and a vacuum furnace and has low production cost, short production procedure and high production efficiency; secondly, the pourability of the molten steel is good; thirdly, no requirement is put forward as for acid-soluble aluminum in the steel, so that the method solves the problems of pastiness of the molten steel, easy bonding of water gaps, reduction of the steel quality and the like caused by the increase of Al2O3 inclusion due to high acid-soluble aluminum; and fourthly, the recovery rate of boron can reach 60 to 75 percent and the wave range of the yield is small. Moreover, the method has good application prospect.

Owner:新余钢铁股份有限公司

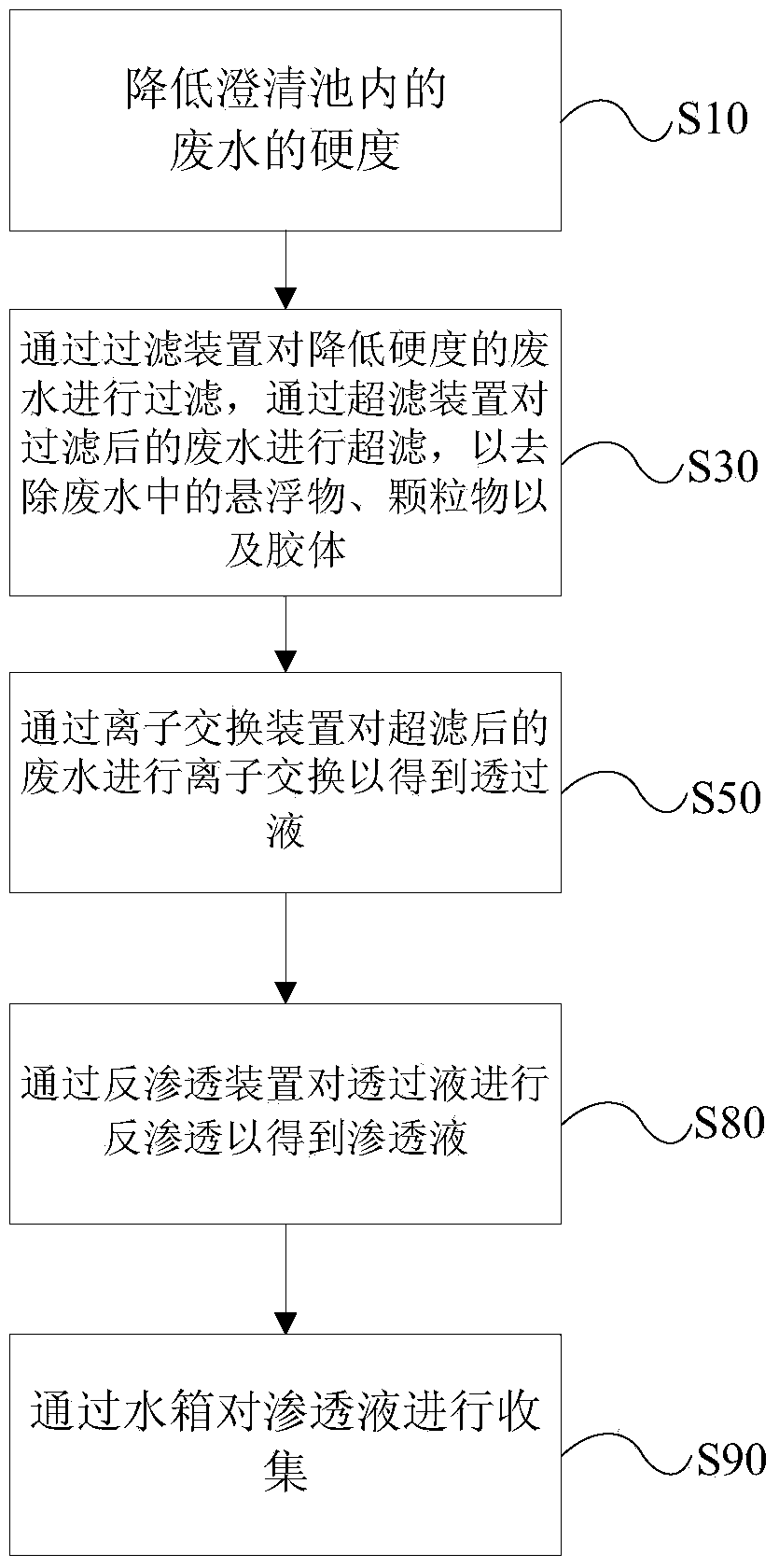

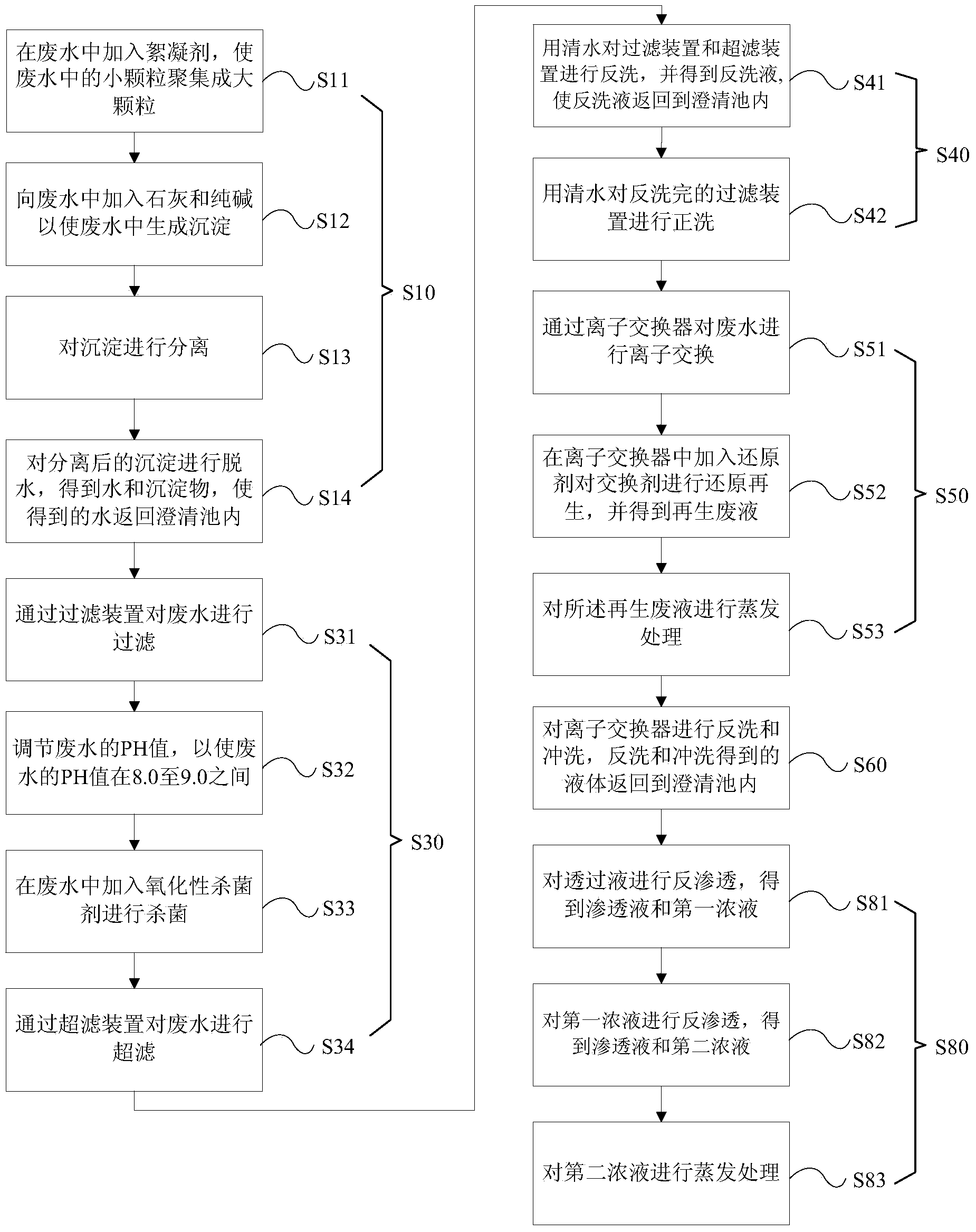

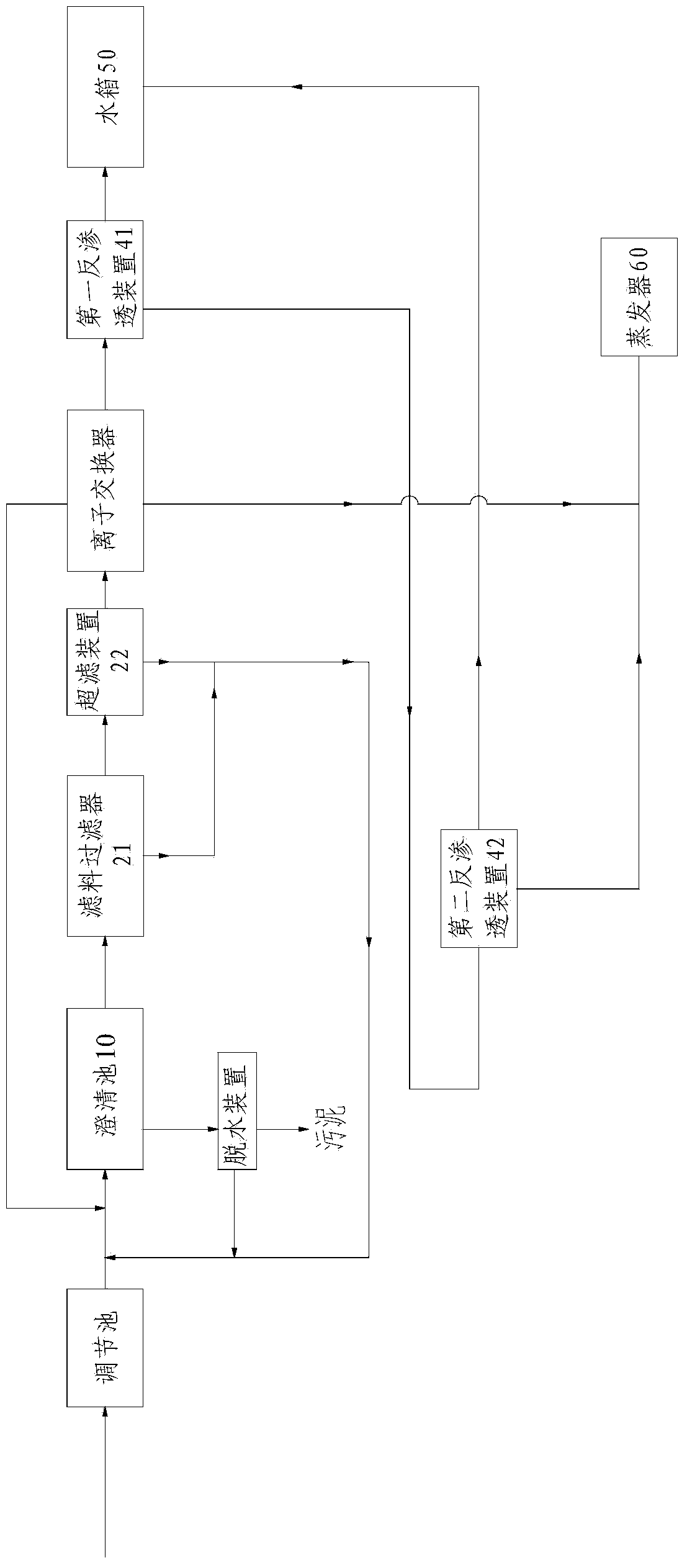

Industrial wastewater recovery method and wastewater recovery system

ActiveCN103539288AGuaranteed recoveryHigh recovery rateMultistage water/sewage treatmentRecovery methodIndustrial waste water

eps: S10, reducing the hardness of wastewater in a settling pond; S30, filtering wastewater with hardness by a filter device and ultra-filtering the filtered wastewater by an ultrafiltration device to remove suspended solids, particles and coeps: S10, reducing the hardness of wastewater in a settling pond; S30, filtering wastewater with hardness by a filter device and ultra-filtering the filtered wastewater by an ultrafiltration device to remove suspended solids, particles and colloids in the wastewater; S50, carrying out ion exchange for the ultra-filtered wastewater by an ion exchange device to obtain a permeable liquid; S80, carrying out reverse osmosis on the permeable liquid by a reverse osmosis to obtain a penetrating fluid; S90, collecting the penetrating fluid by virtue of a water tank. The wastewater recovery method provided by the invention ensures that the reverse osmosis device can be continuously and stably operated with high recovery rate, thereby guaranteeing the wastewater recovery amount.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

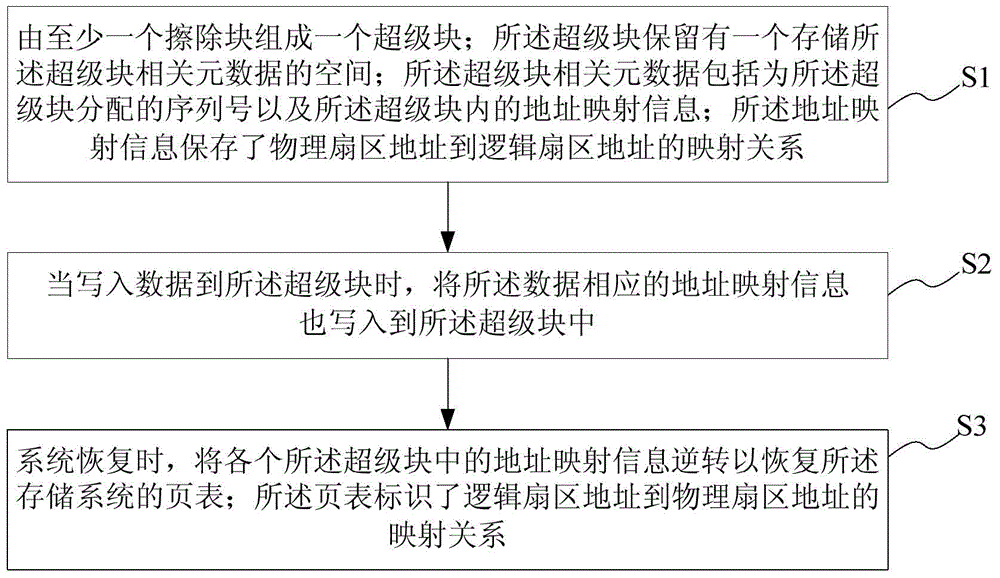

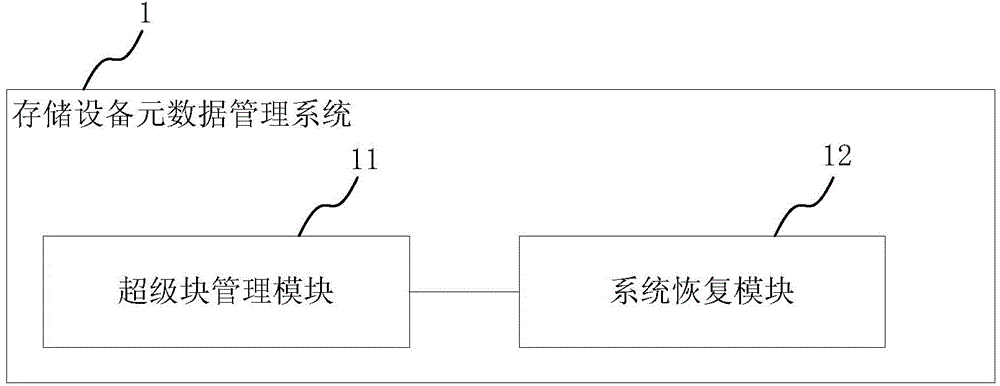

Method and system for managing and processing metadata of storage equipment

ActiveCN104461391AGuaranteed recoveryWork lessInput/output to record carriersMemory adressing/allocation/relocationMetadata managementSystem recovery

The invention provides a method and system for managing and processing metadata of storage equipment. The method comprises the following steps: one or more erase blocks form a superblock; the superblock retains a space for storing superblock-related metadata; the superblock-related metadata comprises a serial number distributed for the superblock and address mapping information in the superblock; the address mapping information stores a mapping relationship from a physical sector address to a logic sector address; when data is written into the superblock, the corresponding address mapping information of the data is also written into the superblock; when a system is recovered, a page table of the storage system is recovered according to the address mapping information of the superblock; the page table marks a mapping relationship from a logic sector address to a physical sector address. Due to the adoption of the technical scheme, the page table can be guaranteed to be completely recovered during startup and the storage equipment can be ensured to normally work when started.

Owner:SHANNON SYST

Method for extracting platinum-palladium out of copper anode mud

ActiveCN103305699ASimple configurationEasy to operateProcess efficiency improvementPlatinumProcess equipment

The invention discloses a method for extracting platinum-palladium out of copper anode mud. The method is characterized in that the platinum-palladium is extracted by employing a secondary gold dust chlorination gold leaching liquid, and the method comprises the following process steps of: firstly, carrying out sulfation roasting on the copper anode mud, carrying out primary chlorination gold leaching, carrying out sulfur dioxide gas reduction so as to obtain a primary reduction liquid, and subsequently carrying out zinc powder replacement so as to enrich gold, silver, platinum and palladium into secondary gold powder; secondly, dissolving the secondary gold powder, removing the impurities, filtering the obtained filtered residue, carrying out secondary chlorination gold leaching, adding ammonium chloride and a reduction inhibitor sodium chlorate into the filtered liquid, and reacting so as to obtain platinum and palladium precipitate; and finally reducing the filtered liquid by using a liquid sulfur dioxide to leach the gold. The method is simple in process equipment arrangement and convenient to operate; the recycling rate of the gold in the copper anode mud is increased; and meanwhile the platinum-palladium is effectively enriched in platinum-palladium concentrate.

Owner:SHANDONG HUMON SMELTING

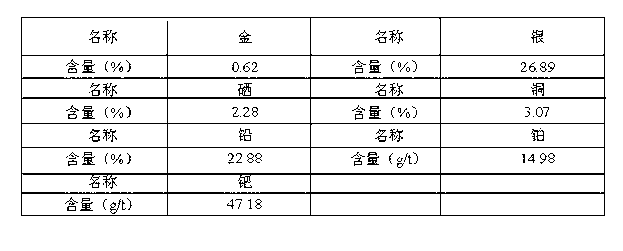

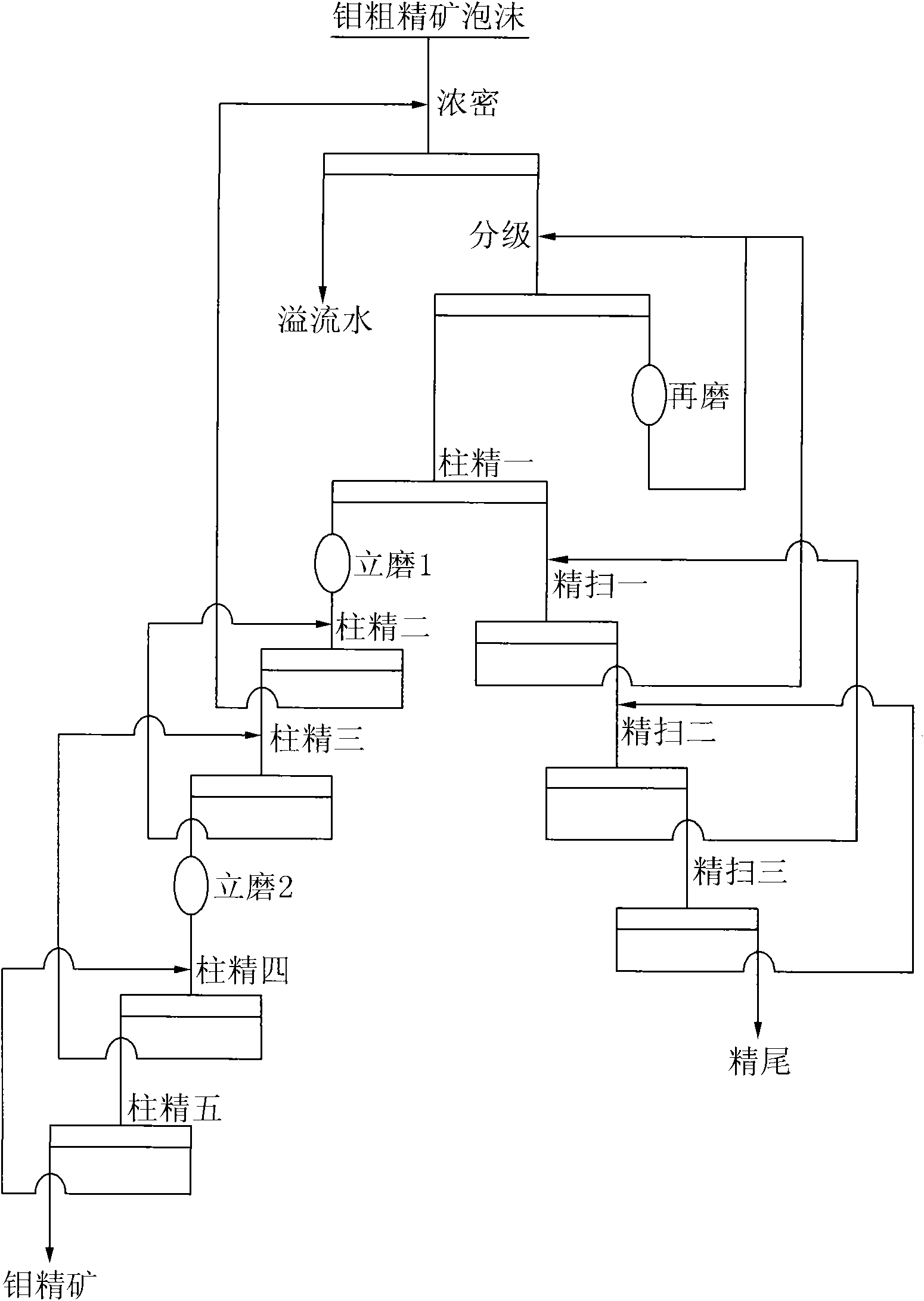

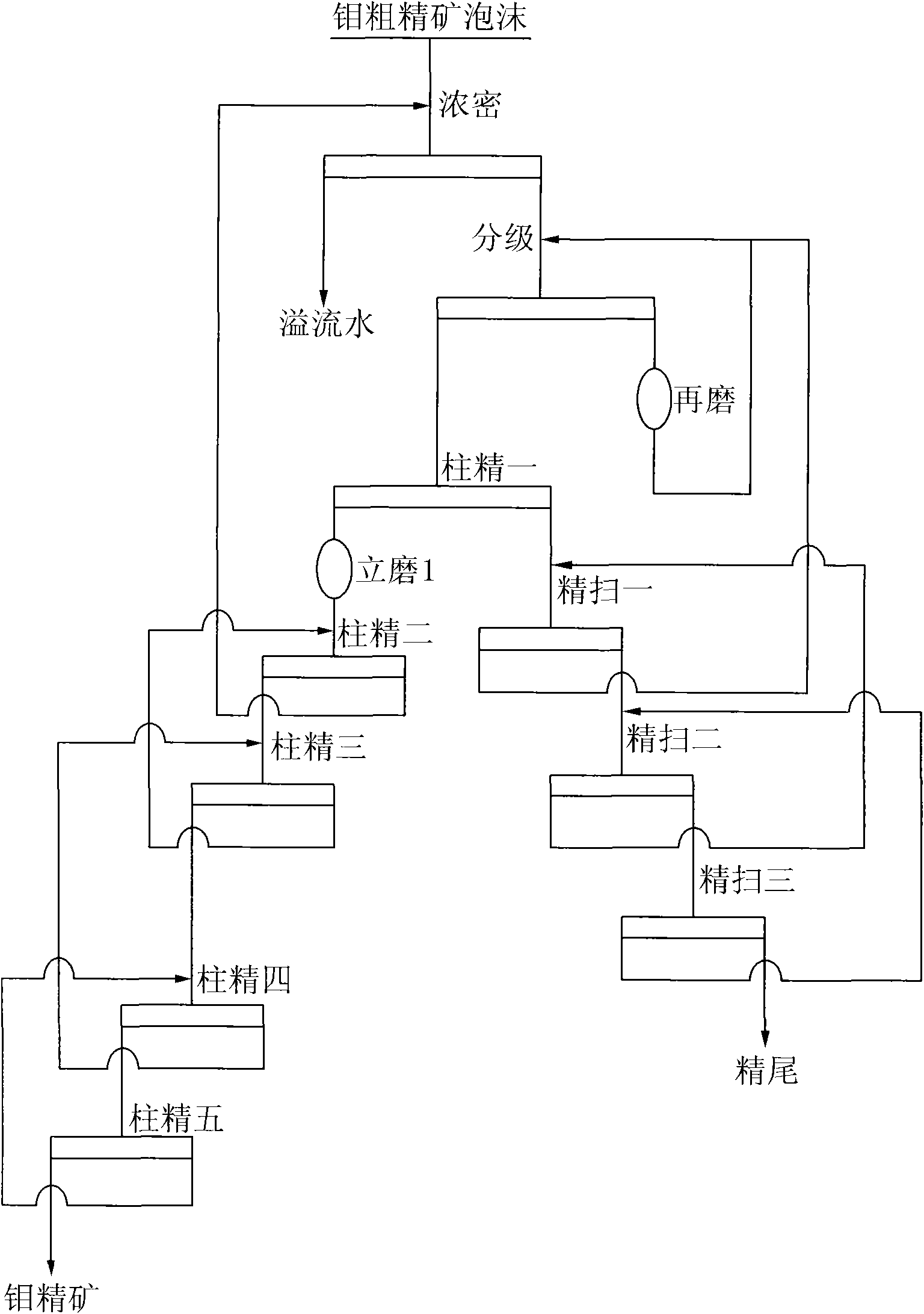

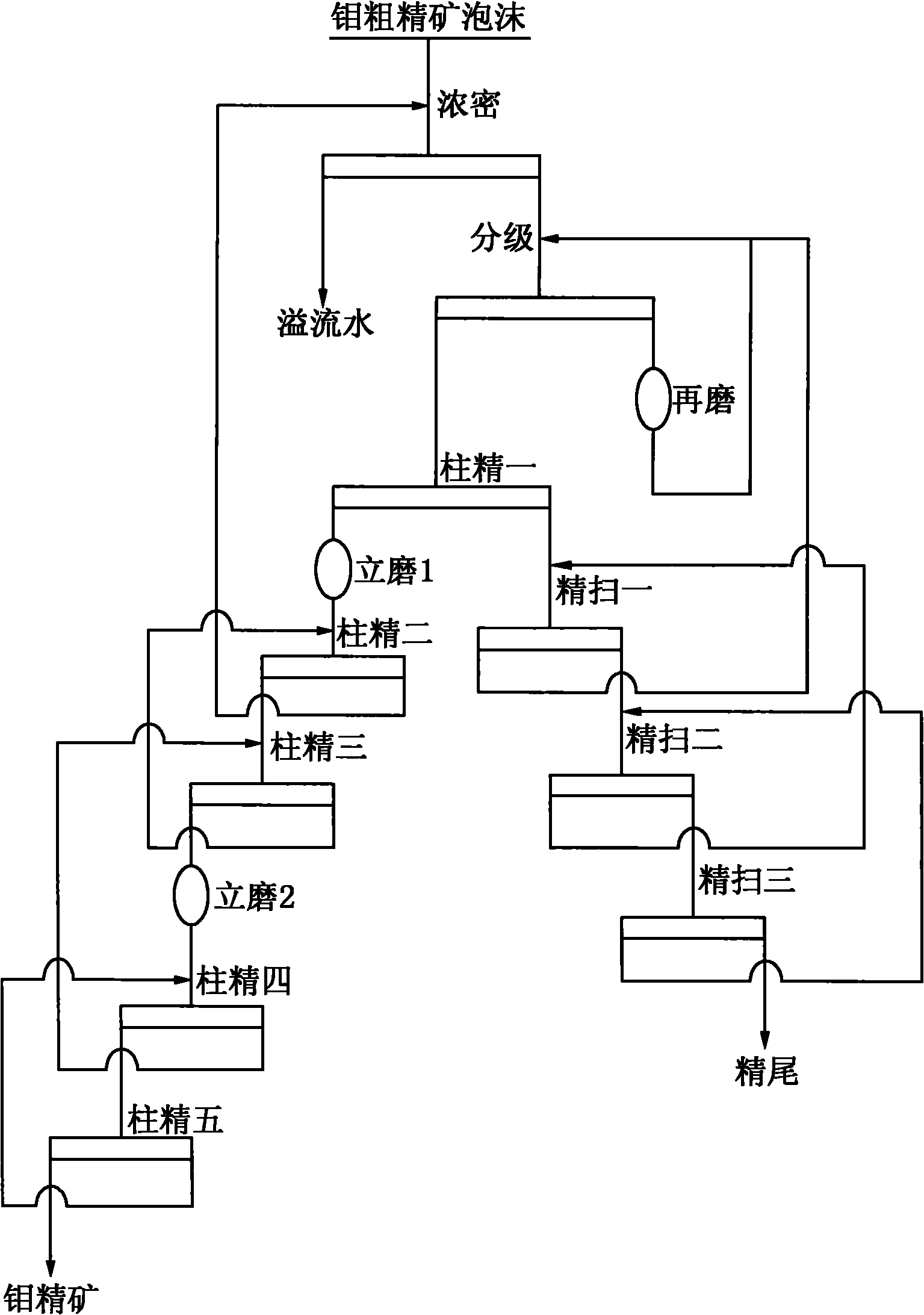

Production technology of high-grade molybdenum concentrate

ActiveCN101773871AReduce pollutionIncrease feed concentrationFlotationWet separationBall millReagent

The invention discloses a production technology of high-grade molybdenum concentrate, which comprises the following steps: rough molybdenum concentrate is obtained by roughing crude molybdenum ore, the rough molybdenum concentrate is concentrated and removed reagent through a thickener, underflow enters a hydraulic swirler to be graded previously, overflow after the grading enters a primary flotation column to be selected, the underflow after the grading enters a horizontal ball grinding mill to be reground, and after the regrinding, the ore discharge enters the hydraulic swirler to be regraded; selected concentrate from the primary flotation column is cleaned by a vertical ore mill to enter a secondary and a tertiary flotation columns to be selected, and the selected concentrate from thetertiary flotation column directly enters or enters a quartic or a quintic flotation columns to be selected after being cleaned by a second section of the vertical ore mill to obtain the high-grade molybdenum concentrate; the selected tailings from the primary flotation column is tertiary scavenged by a flotation machine, and the scavenged concentrate tailings from the tertiary scavenging enters the next procedure. The technology adopts the flotation columns and the flotation machine, so the flow is short, the agent system is simple, the adaptability of the crude ore is strong, and the molybdenum concentration ratio is high, the molybdenum concentrate has high grade, large yield and high recycling rate so as to provide excellent raw material to the following molybdenum chemical engineering and further processing.

Owner:JINDUICHENG MOLYBDENUM CO LTD

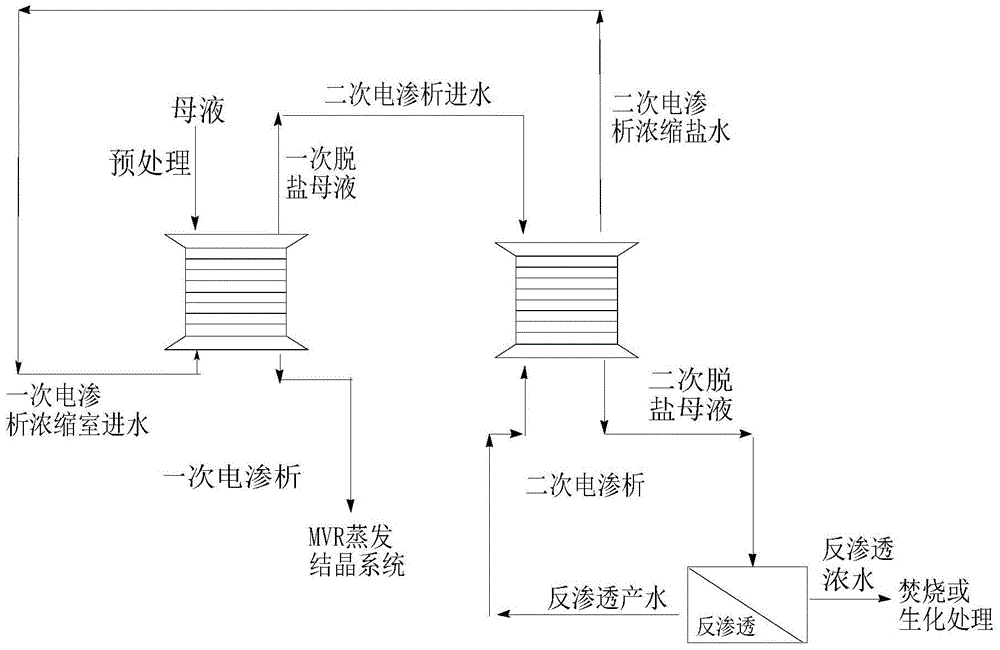

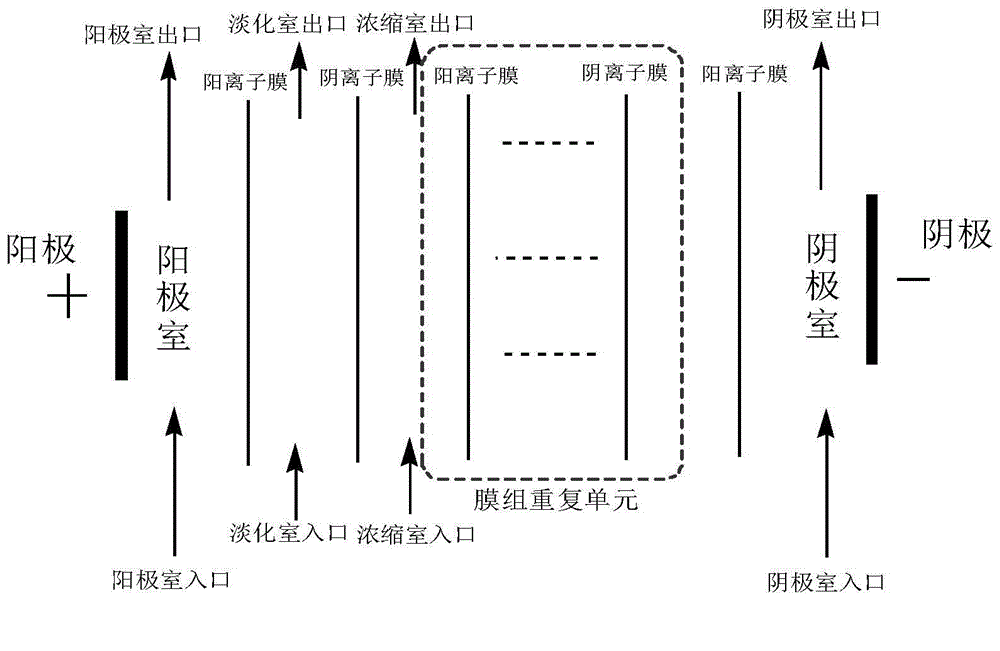

Method for treating cefalexin enzyme-process synthesizing mother liquor wastewater

ActiveCN104058537ASolve the real problemFix bugsGeneral water supply conservationDispersed particle separationReverse osmosisWastewater

The invention discloses a method for treating cefalexin enzyme-process synthesizing mother liquor wastewater. The mother liquor wastewater is treated by adopting an electroosmosis integrated reverse osmosis system, wherein the electroosmosis integrated reverse osmosis system consists of primary electroosmosis equipment, secondary electroosmosis equipment, a reverse osmosis device and crystallization equipment. The method disclosed by the invention adopts a reverse osmosis technology to recycle water resources in secondary electroosmosis desalted mother liquor, and to recycle the water to an electroosmosis system as the secondary electroosmosis system concentration room inlet water, realizes comprehensive utilization of wastewater resources, minimizes environmental influences and lowers treatment cost.

Owner:浙江佰辰低碳科技有限公司

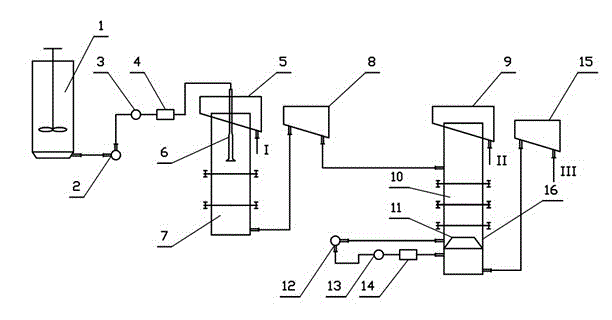

Novel flotation column serial connection test system for improving flotation granularity upper limit

The invention relates to a novel flotation column serial connection test system for improving the flotation granularity upper limit. The equipment of the system comprises a fed material stirring barrel, a feeding pump, a feeding pressure meter, a froth generator, a primary-section foam enriching chamber, a lower catheter, a spray type flotation column chamber, a primary-section tailing box, a secondary-section foam enriching chamber, a column flotation chamber, a rotary flow sorting chamber, a circulation ore pulp pump, a circulation pressure meter, a froth generator, a secondary-section tailing box and an FCMC cyclo-microfroth flotation column, wherein a spray type flotation column and the FCMC cyclo-microfroth flotation column are connected in series by the system, and the primary-section tailing is used as secondary-section fed materials. The system is favorable for the static fast flotation of preference flotation of coal with good flotation performance and the strong power efficient recovery of difficult-to-sort coal, in addition, the problem of high-concentration coal slime flotation can be perfectly solved, the recovery rate of coarse particle coal slime can be improved, and the problem of coarse particle running of coarse particle flotation can be solved.

Owner:CHINA UNIV OF MINING & TECH

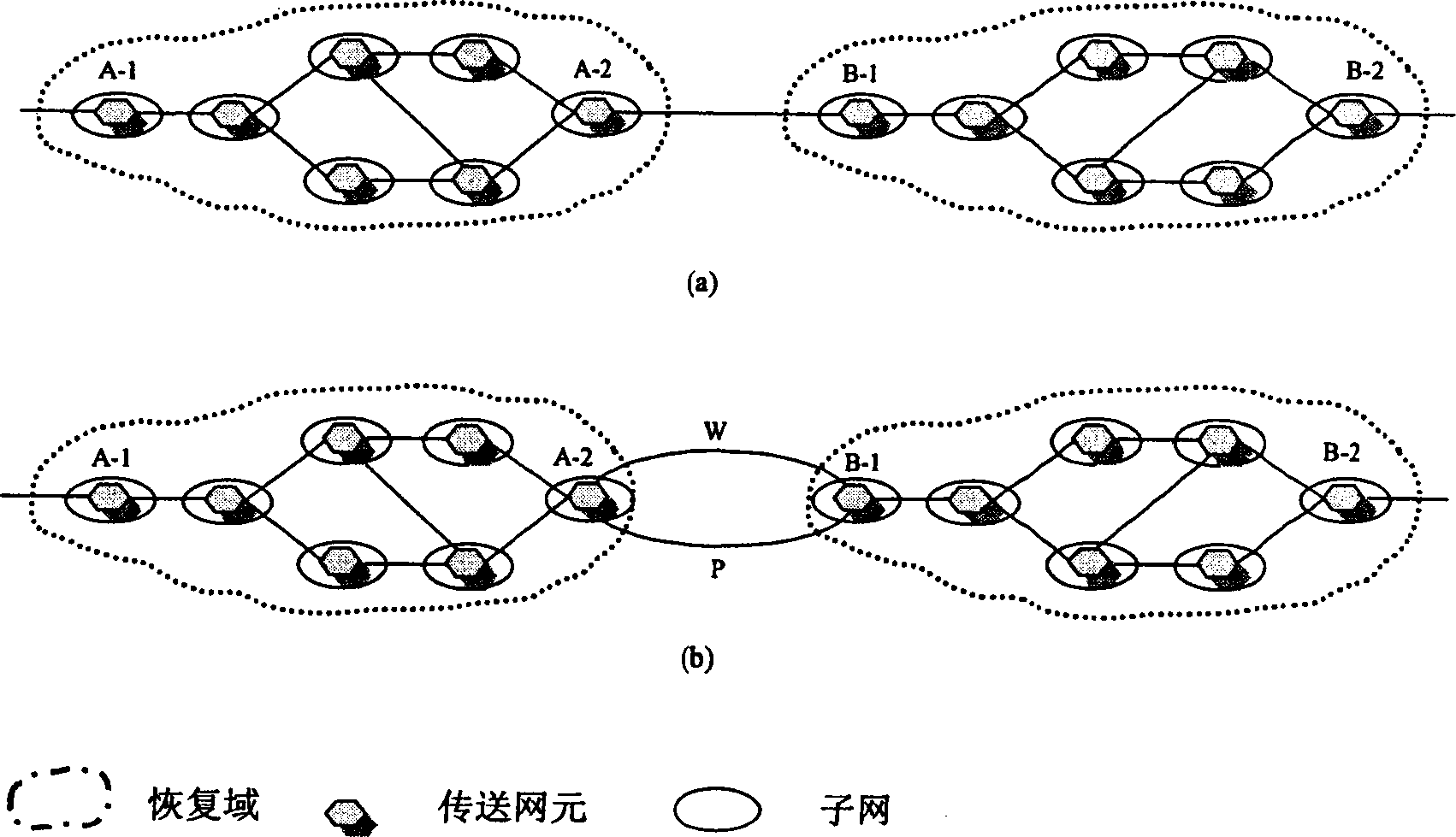

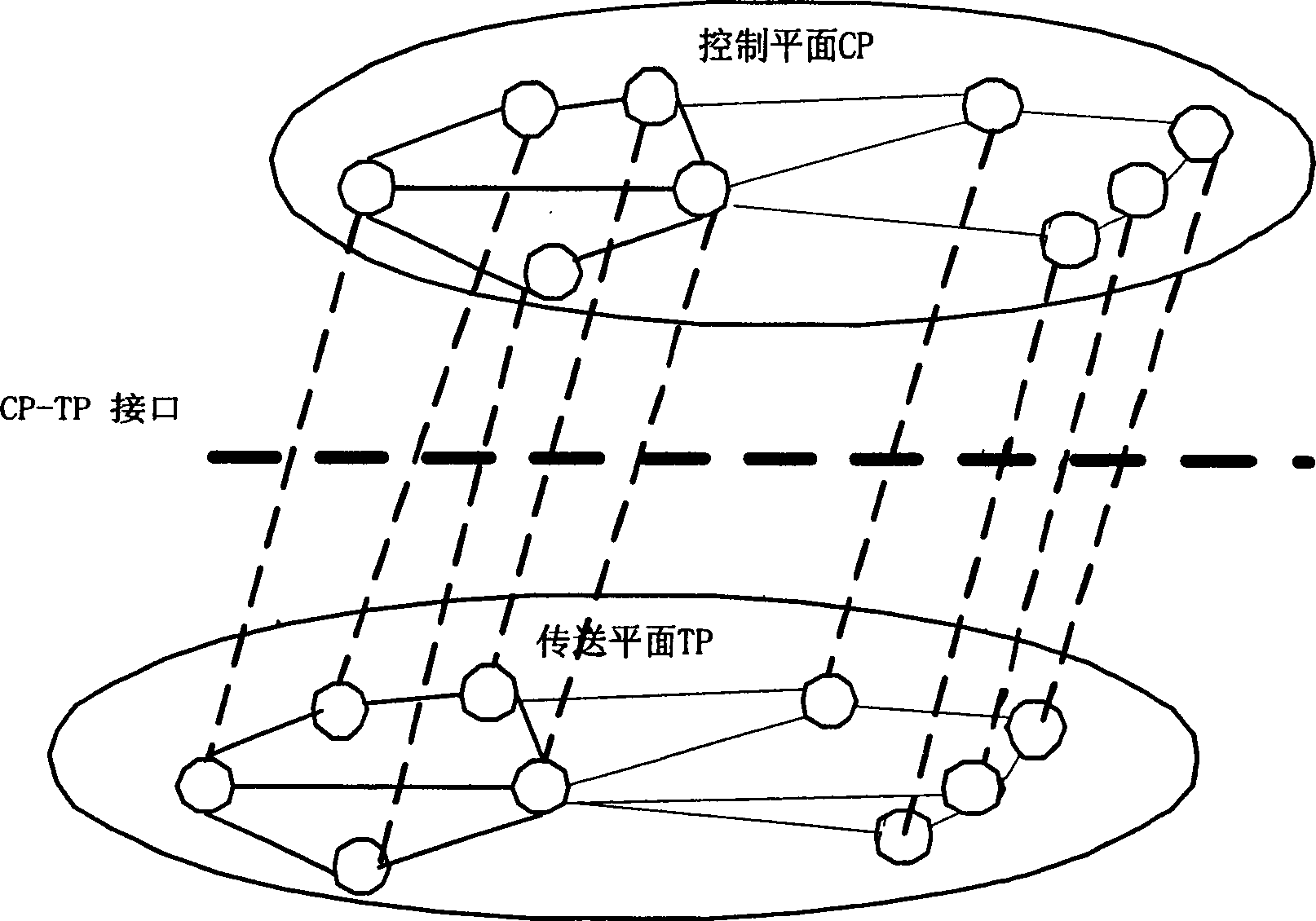

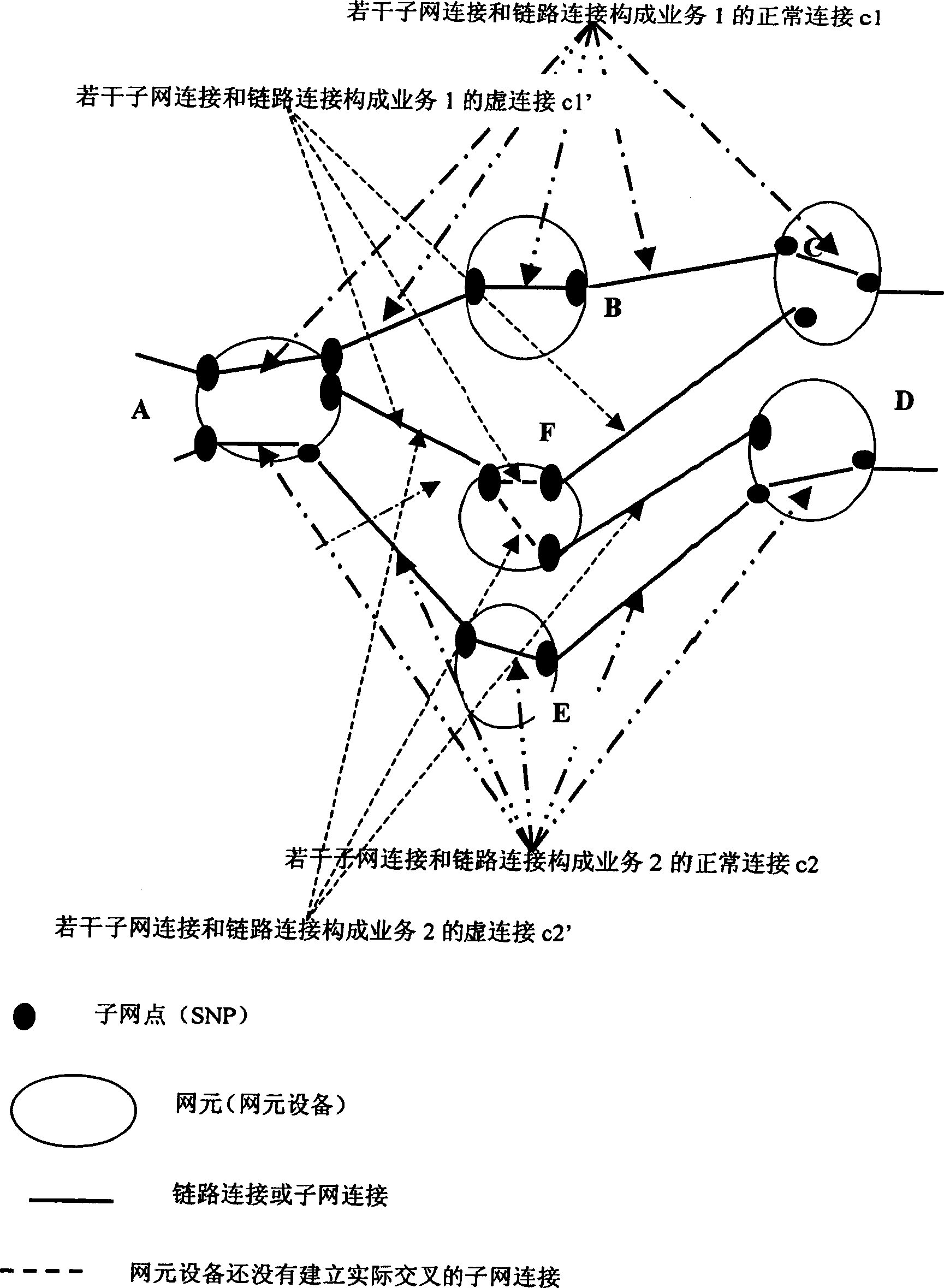

Method of network fault recovery crossing over connections in multiple domains

ActiveCN1798051AOptimized useRational use of large resourcesData switching networksRouting control planeProtection mechanism

Its system consists of: a transmission platform including a network composed of multi net elements that are used to assign and build links, and to build connection between subnets; and a control platform including multi control nodes. Each net element in the transmission platform corresponds to a control node. The invention can automatically build the static or dynamic protective connection used to recover the inter-domain failure by building cross-domain normal connection, determining intra-domain protection mechanism, and determining inter-domain protection mechanism.

Owner:ZTE CORP

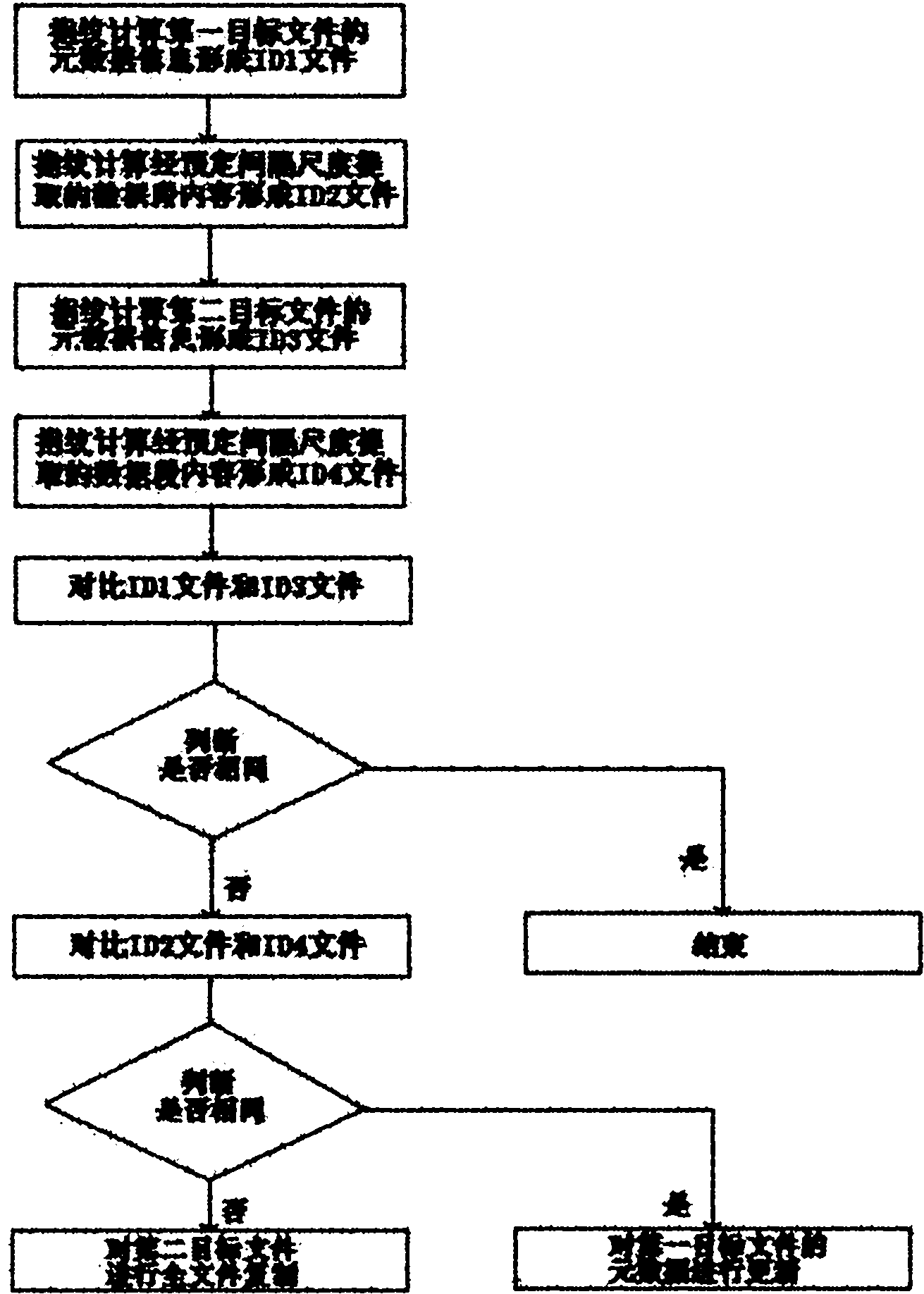

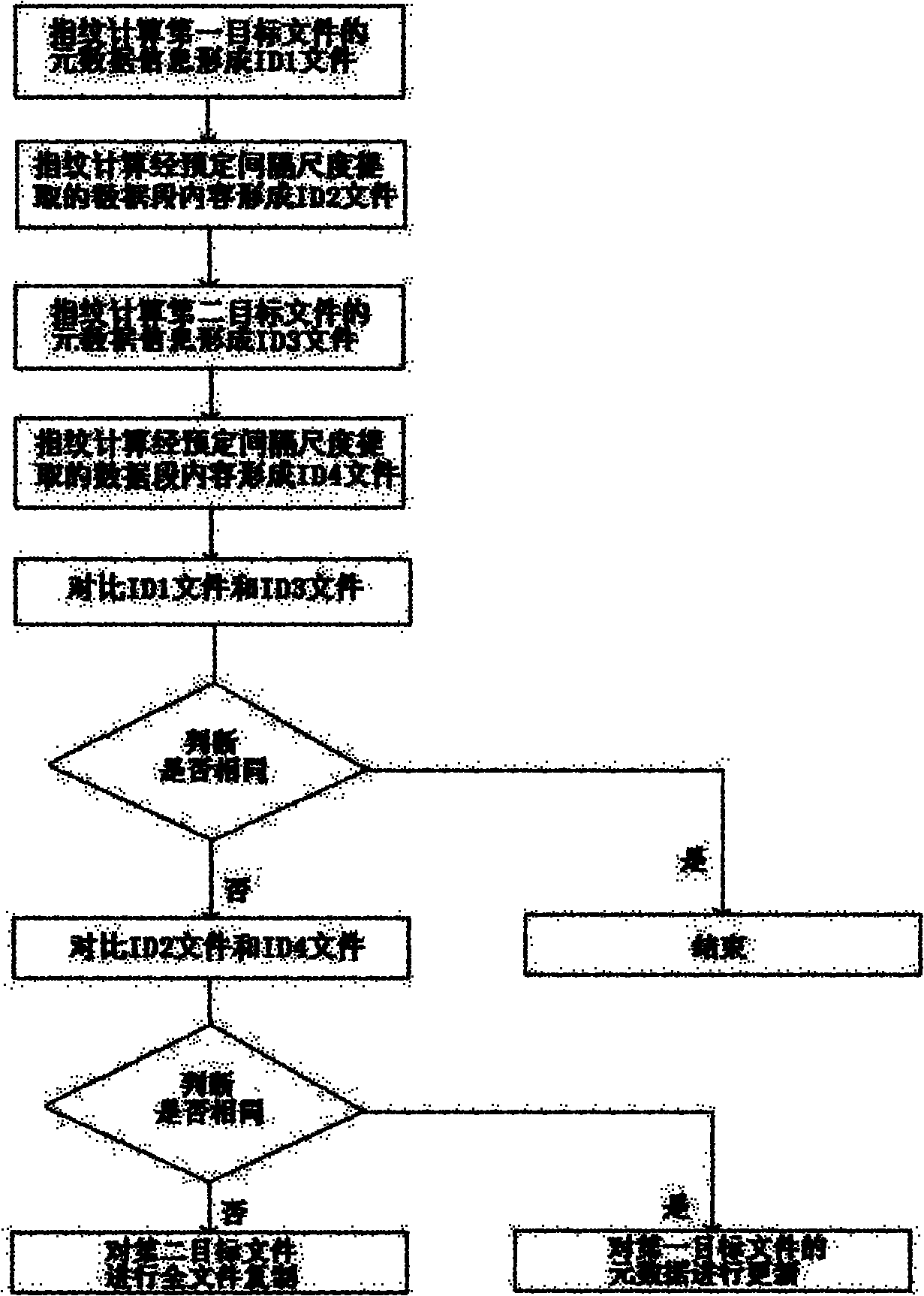

File data replication method for quick deduplication

InactiveCN102033962AImprove replication efficiencyGuaranteed deduplicationSpecial data processing applicationsData segmentReplication method

The invention discloses a file data replication method for quick deduplication. The method comprises the following steps of: before a first target file in a storage medium is wholly replicated to a target file directory for the first time, performing fingerprint calculation on metadata information of the first target file to form identity (ID1) by a processor, extracting contents of a plurality of file data segments from the first target file according to an interval with preset size and performing the fingerprint calculation to form ID2, performing the fingerprint calculation on the metadata information of a second target file to form ID3, and extracting contents of a plurality of file data segments from the second target file according to an interval with preset size and performing the fingerprint calculation to form ID4; comparing the ID1 with the ID3; if the ID1 is the same as the ID3, saving replication; if the ID1 is different from the ID3 and the ID2 is the same as the ID4, updating metadata of the first target file; and if the ID2 is different from the ID4, wholly replicating the second target file.

Owner:COMMUNICATION UNIVERSITY OF CHINA

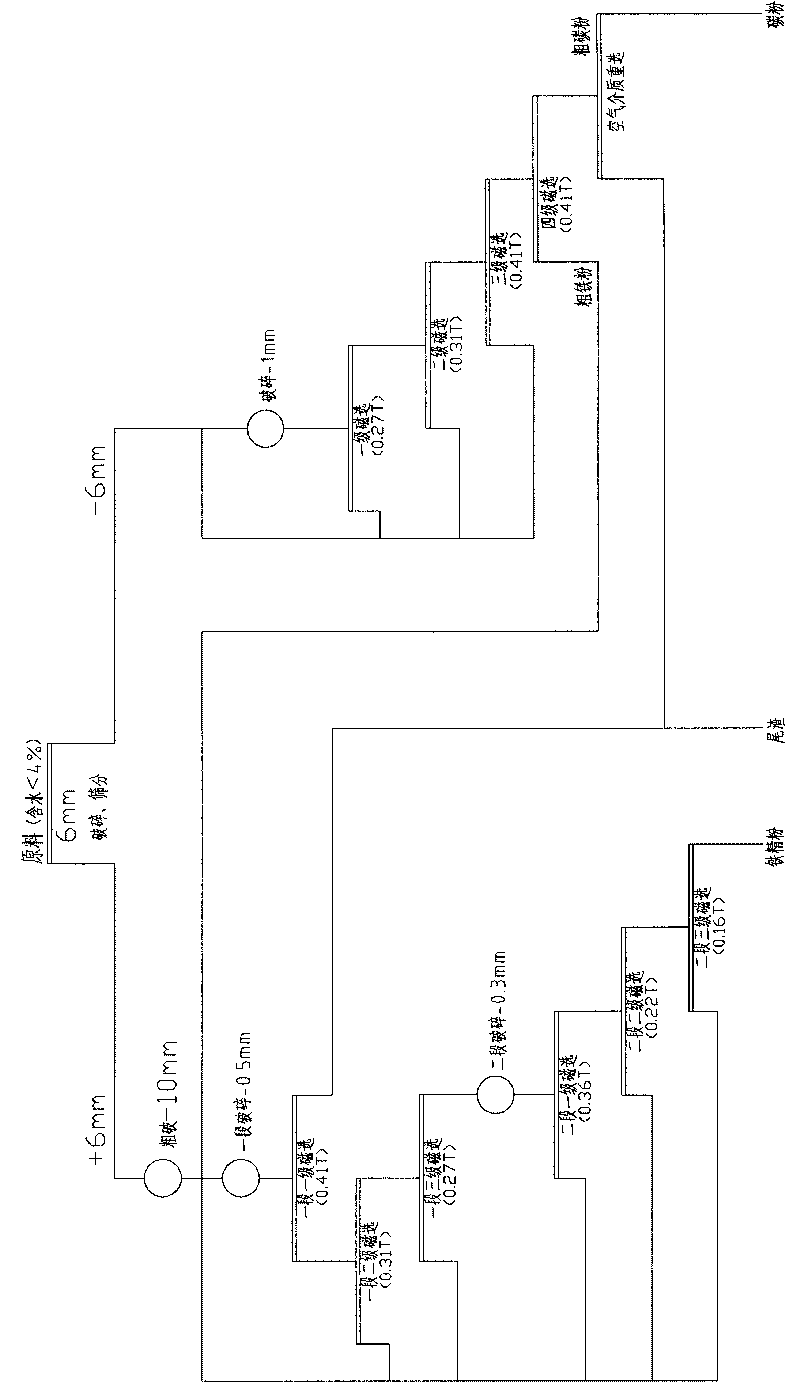

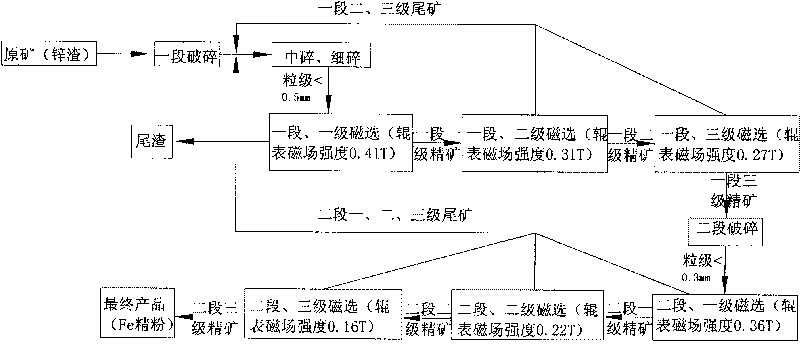

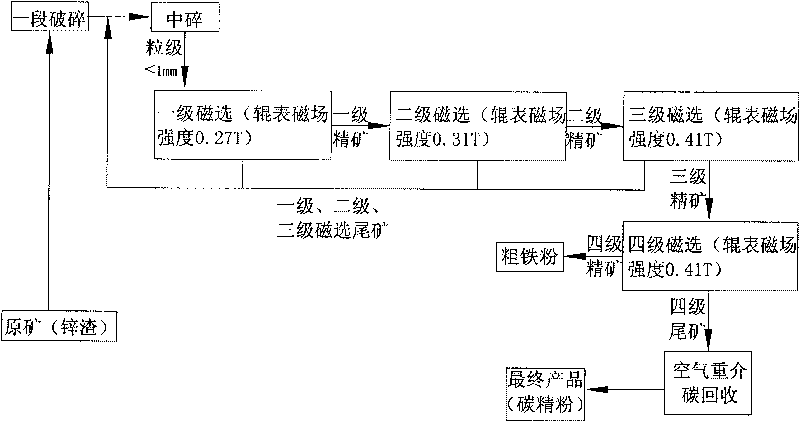

Kiln slag processing technology of zinc volatilizing kiln

The invention relates to a kiln slag processing technology of a zinc volatilizing kiln, which is characterized by comprising the technological steps of crude crushing and prescreening, medium crushing and fine crushing, two-section and three-stage magnetic separating Fe fined powder, four-stage magnetic separating and re-separating carbon refined powder by an air medium. The invention has the advantages of simple technology, high production efficiency, stable product quality and low energy consumption and enhances the utilization rate of resources, the Fe content of the finally separated Fe refined powder can be about 60%, and the Fe refined powder according with the national requirements can be separated without secondary processing.

Owner:HENAN POLYTECHNIC UNIV

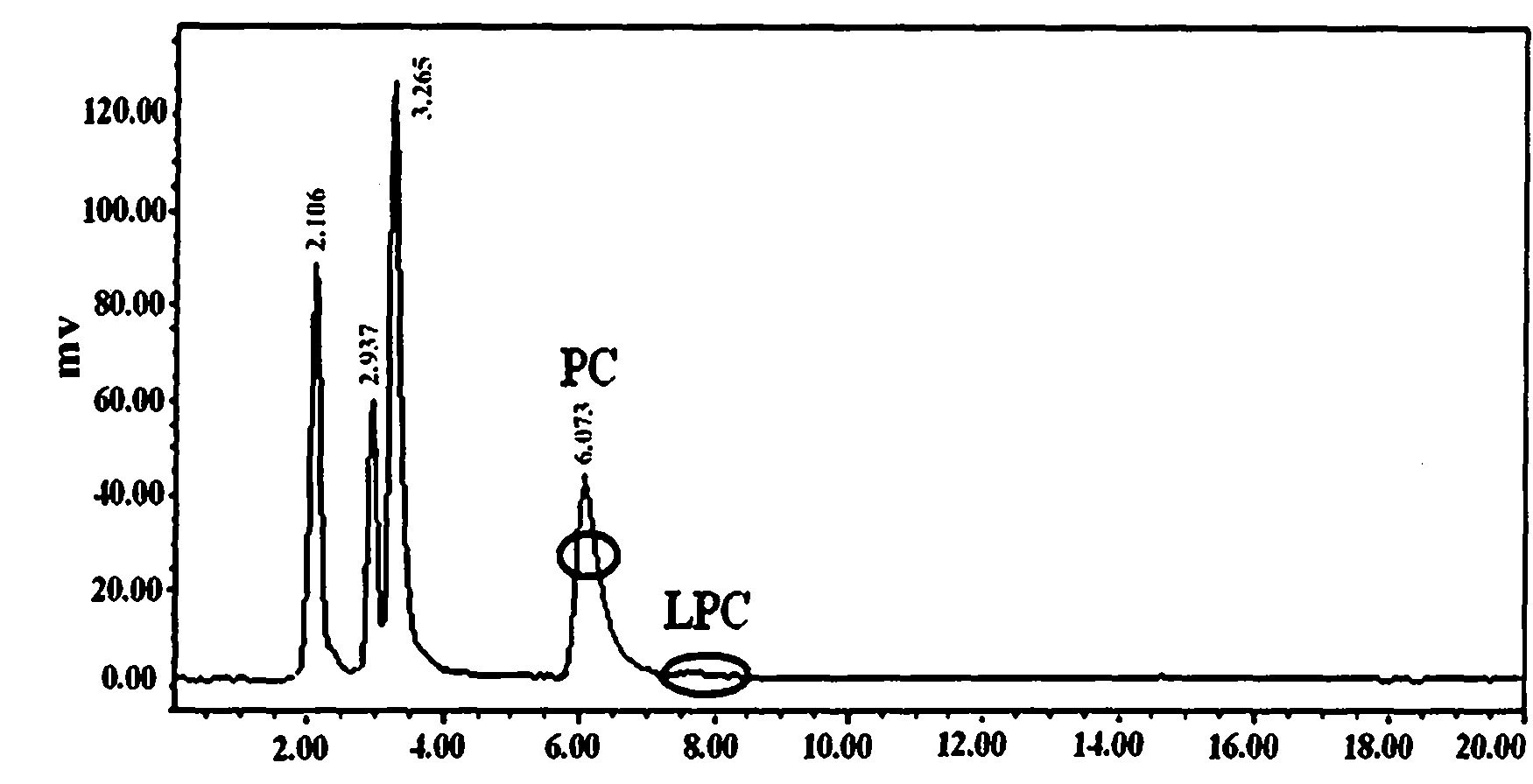

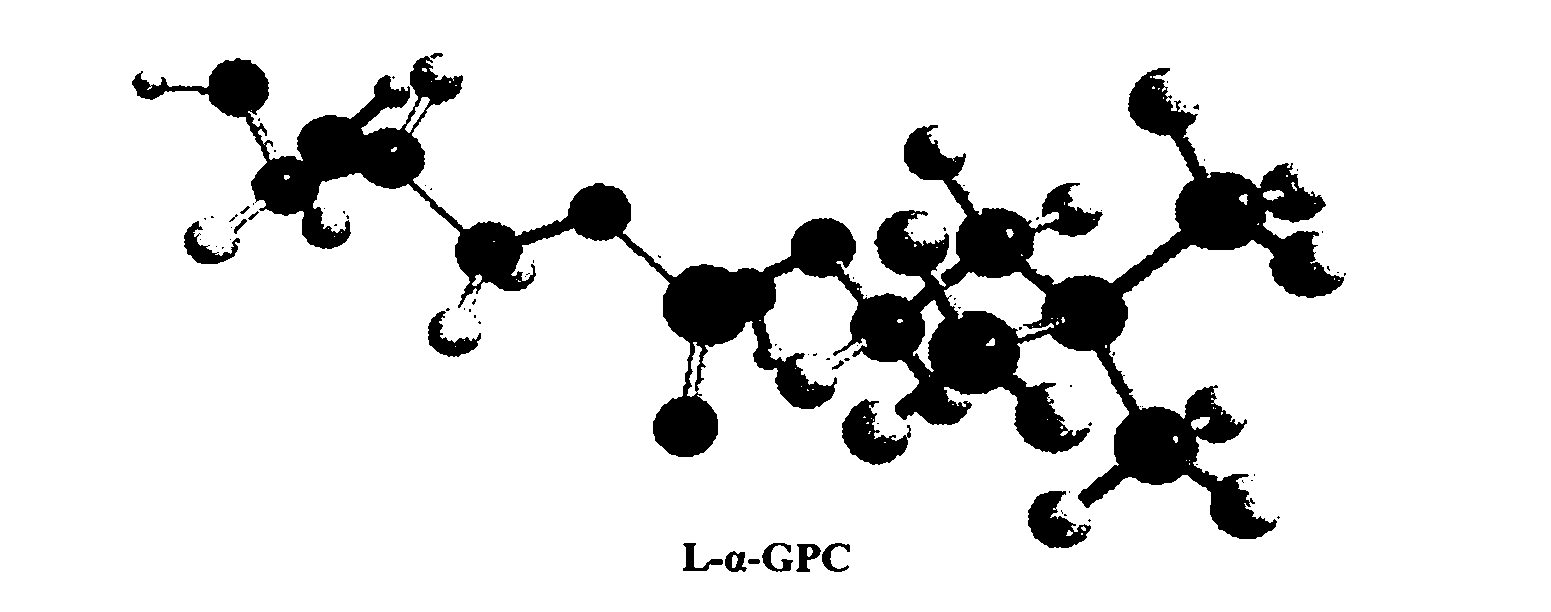

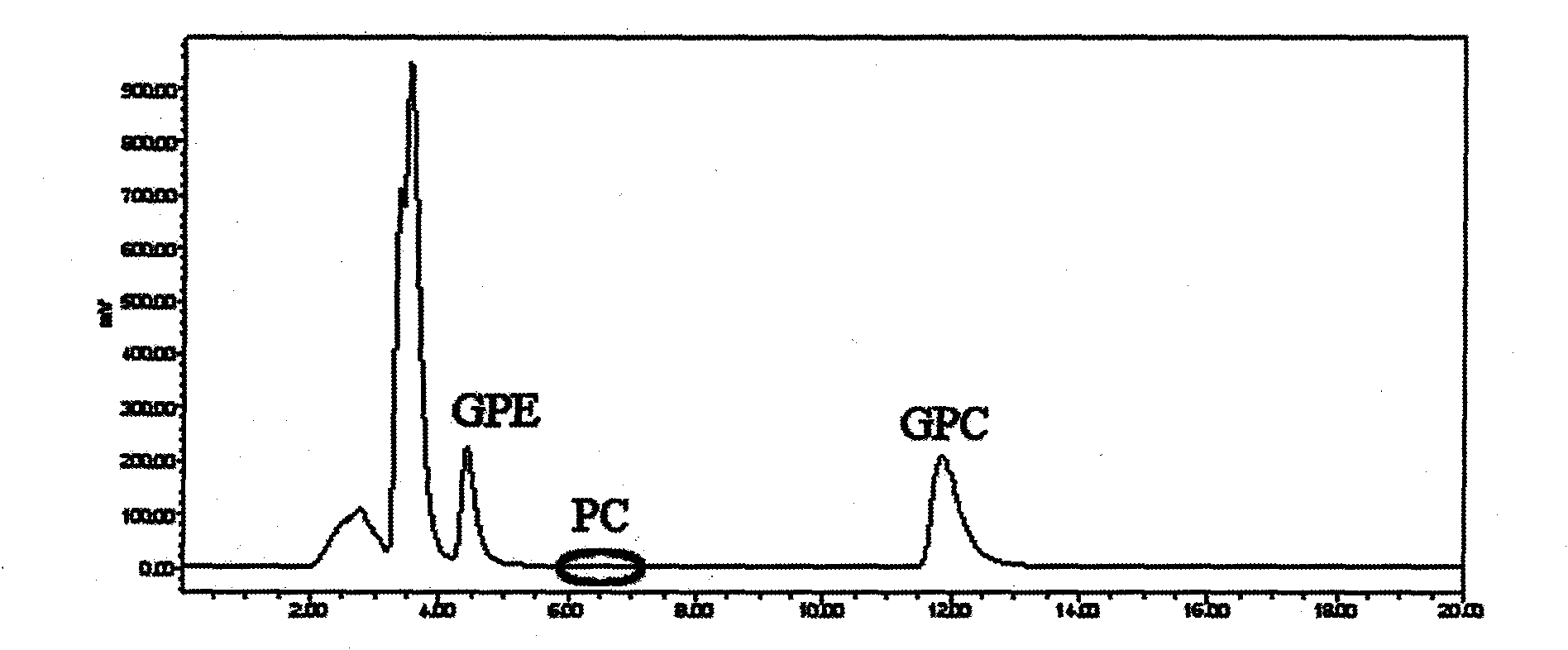

Method for separating and purifying L-alpha-glycerophosphorylcholine (L-alpha-GPC) by silica gel column chromatography

ActiveCN102093410ALow costGuaranteed optical activityFermentationPhosphorus organic compoundsChromatographic separationPurification methods

The invention discloses a method for separating and purifying L-alpha-GPC by silica gel column chromatography, which belongs to the technical field of lipid development and application and comprises the following steps: removing Ca<2+> and Cl<-> from enzymatic hydrolysis reaction solution serving as a raw material by using ion exchange resin, converting a water phase into an alcohol phase, separating L-alpha-GPC from glycerol polyglycidyl ether (GPE), lysophosphatidylcholine (LPC) and other byproducts, decolorizing by active carbon, and dewatering through vacuum concentration to obtain a colorless and transparent product; directly passing alcoholysis reaction solution serving as a raw material through a silica gel column for separation, removing Na<+> by cation exchange resin, decolorizing by active carbon, and dewatering through vacuum concentration to obtain a product. According to the test of the indexes of the product, the chemical purity is 99.6 percent, the optical purity ee is 99 percent, and the melting point (mp) is 142 to 143 DEG C (wherein C is equal to 2.6, the H2O content is 16 percent, and the pH value is 5.8). The invention provides a new way of thought and a new method for separating and purifying L-alpha-GPC, and realizes the application of the silica gel column chromatographic separation and purification method in lipid science.

Owner:JIANGNAN UNIV +1

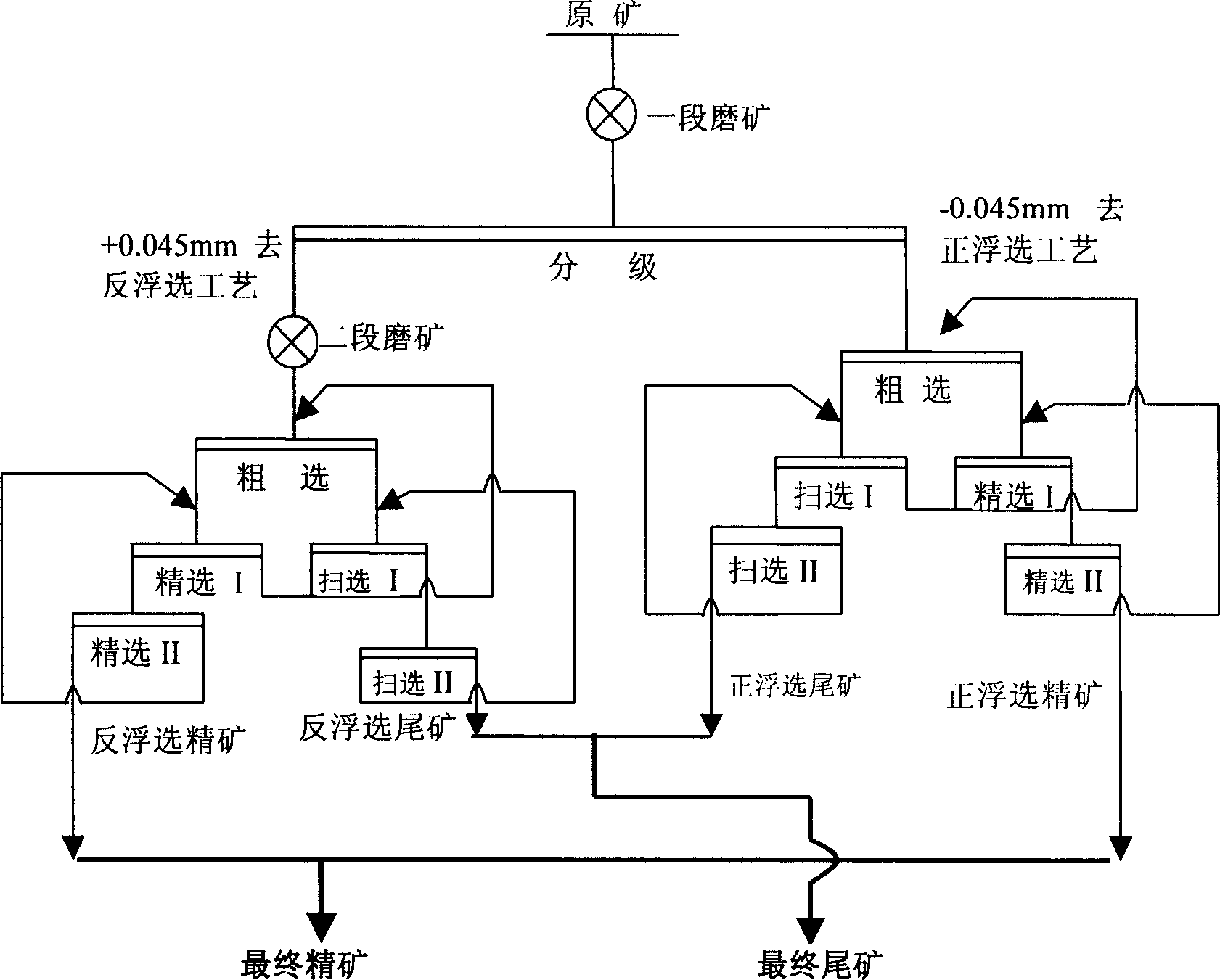

Parallel floatation process of desilionization for bauxite

InactiveCN1869258AEfficient separationIncrease production capacityFlotationProcess efficiency improvementEngineeringMaceral

The invention relates to a parallel floatation selecting method for bauxite desilication that adopts one section or two sections grinding technology to take classification to the bauxite pulp to gain raw and fine class product. The fine class product adopts positive floatation technology, and the raw class product adopts reverse floatation technology after taking or not taking second grinding. The positive floatation mine and the reverse floatation mine could be mixed to form final fine mine, and the positive floatation tail mine and the reverse floatation tail mine would be mixed to form final tail mine. The invention has great advantages and has wide application prospect.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

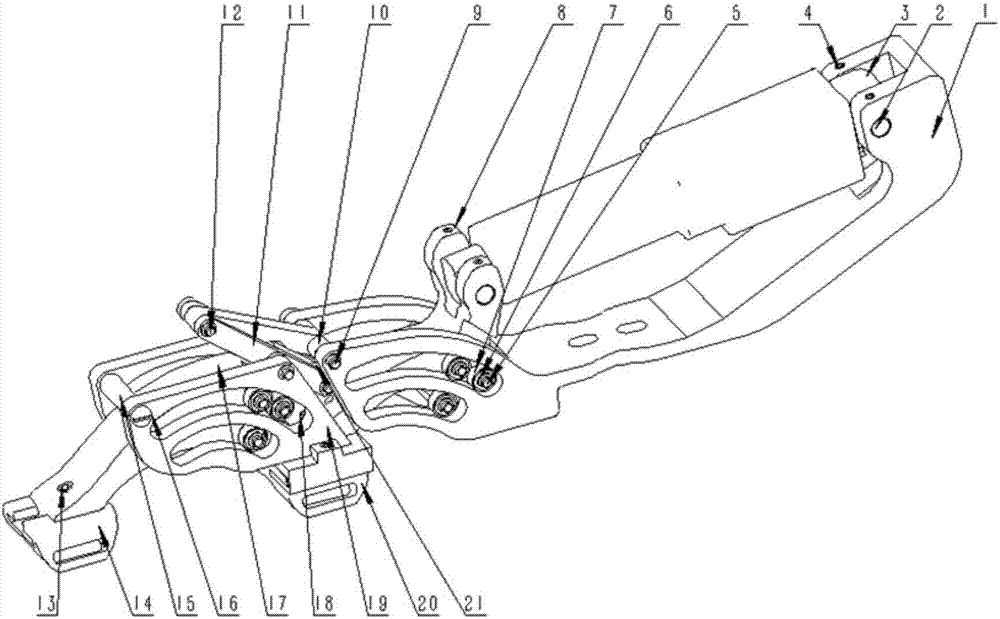

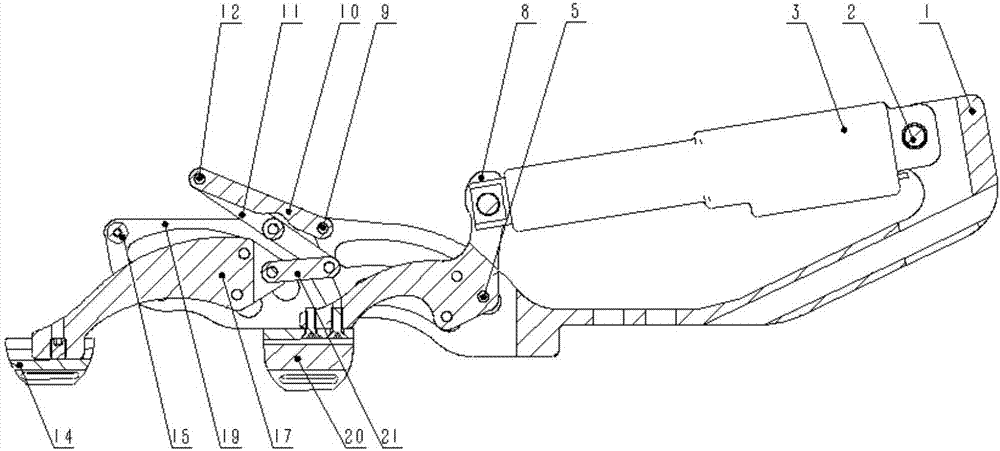

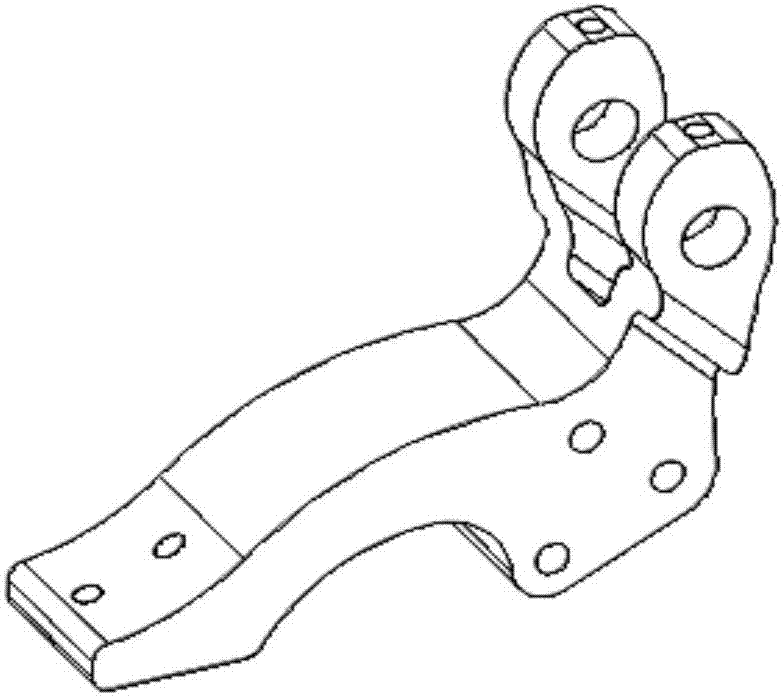

Hand rehabilitation training device with wrist rehabilitation training function

InactiveCN107361994AEasy to controlAchieve bendingChiropractic devicesPhysical medicine and rehabilitationMulti link

The invention discloses a device for hand rehabilitation training with the function of wrist rehabilitation training, which effectively solves the problems in the prior art that the training device is bulky and not easy to carry, and has the advantages of simple structure, easy operation and high functionality. As follows: the device includes at least one two-joint finger training mechanism and a wrist training mechanism; wherein, each two-joint finger training mechanism includes a power drive source fixed by the joint bracket of the finger near the end of the finger, and the push rod of the power drive source is connected to the finger near the end of the finger. The joint driving part is connected to control the rear joint of the human finger; the finger proximal end joint support, the finger proximal finger end joint driving part is fixed by the finger proximal finger end joint support and the finger proximal finger end joint support defines the position of the finger proximal finger end joint driving part The moving path is the far fingertip joint support of the finger, and the multi-link mechanism is connected with the finger far fingertip joint support.

Owner:山东海天智能工程有限公司

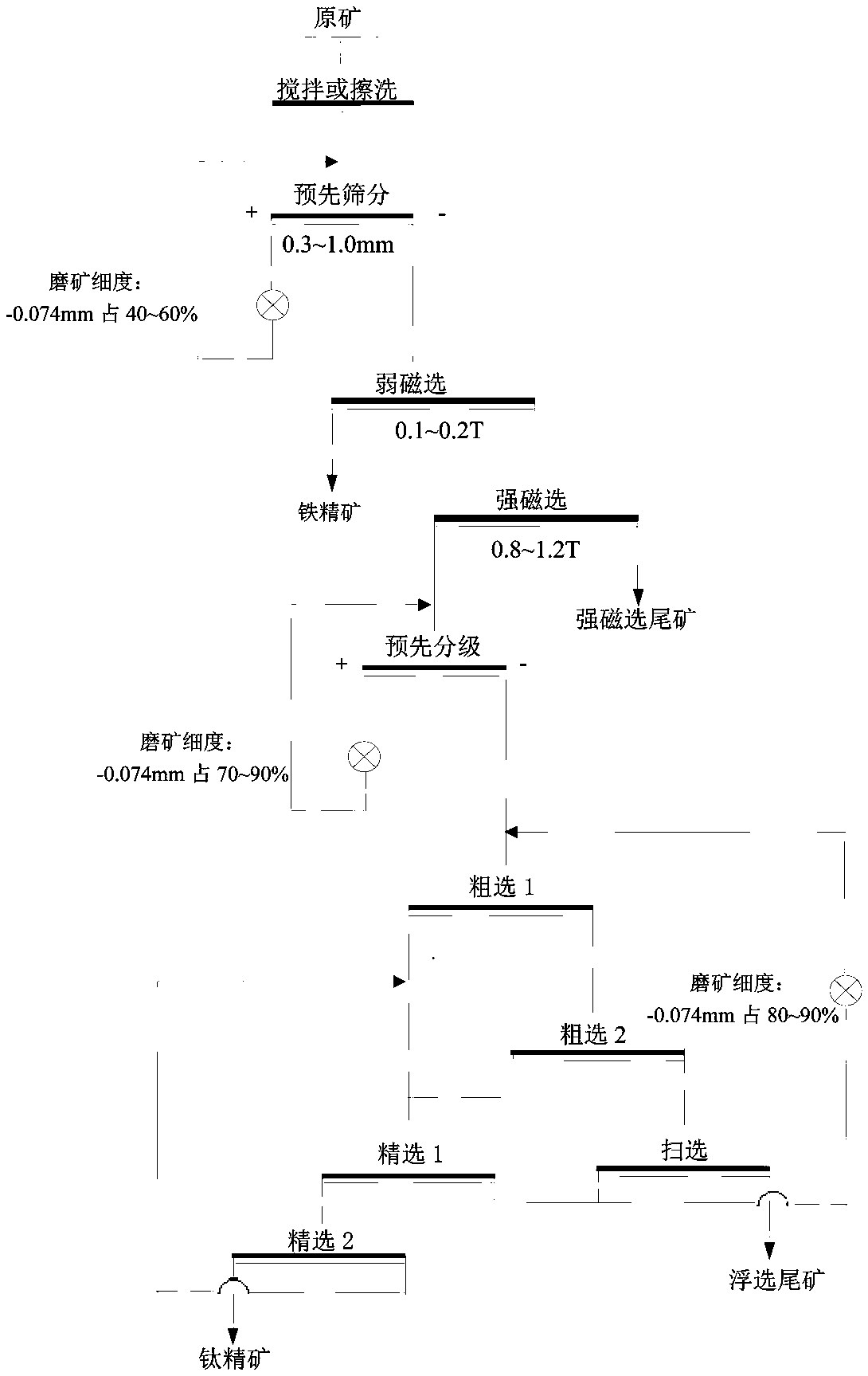

Weathering type ilmenite beneficiation treatment method

The invention discloses a weathering type ilmenite beneficiation treatment method. The beneficiation treatment method comprises the following steps that A prescreening is carried out; B, low intensitymagnetic separation is carried out; C, high intensity magnetic separation is carried out; D, preliminary classification is carried out; and E, flotation is carried out. According to the weathering type ilmenite beneficiation treatment method, the titanium recovery rate is effectively improved, titanium concentrate and iron ore concentrate are obtained at the same time, the technology is simple, the technological process is easily operated, and popularization is facilitated. Beneficiation according to the technical scheme is adopted, the particle size of monomer separation fine-fraction ilmenite in raw ore is protected, and excessive abrasion is avoided; the high intensity magnetic separation technology is used for discarding tailings, the follow-up handling quantity is greatly reduced, and the ore grinding cost and the beneficiation cost are reduced; and an environment-friendly collecting agent KM221 which is good in selectivity, low in cost, non-poisonous and harmless is adopted forflotation recovering of ilmenite ore, fine fraction titanium resources which are difficult to recover through the traditional technological process are effectively recovered, and the weathering type ilmenite resource using rate is improved.

Owner:KUNMING METALLURGY INST

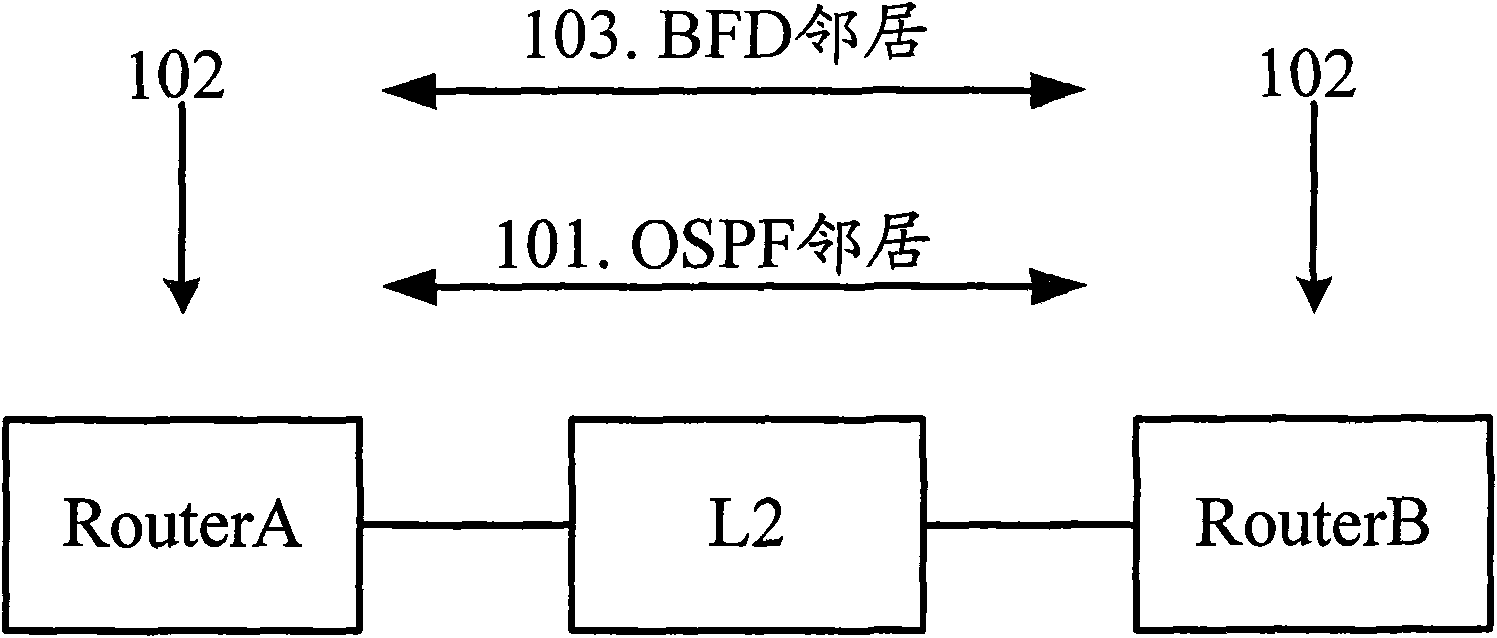

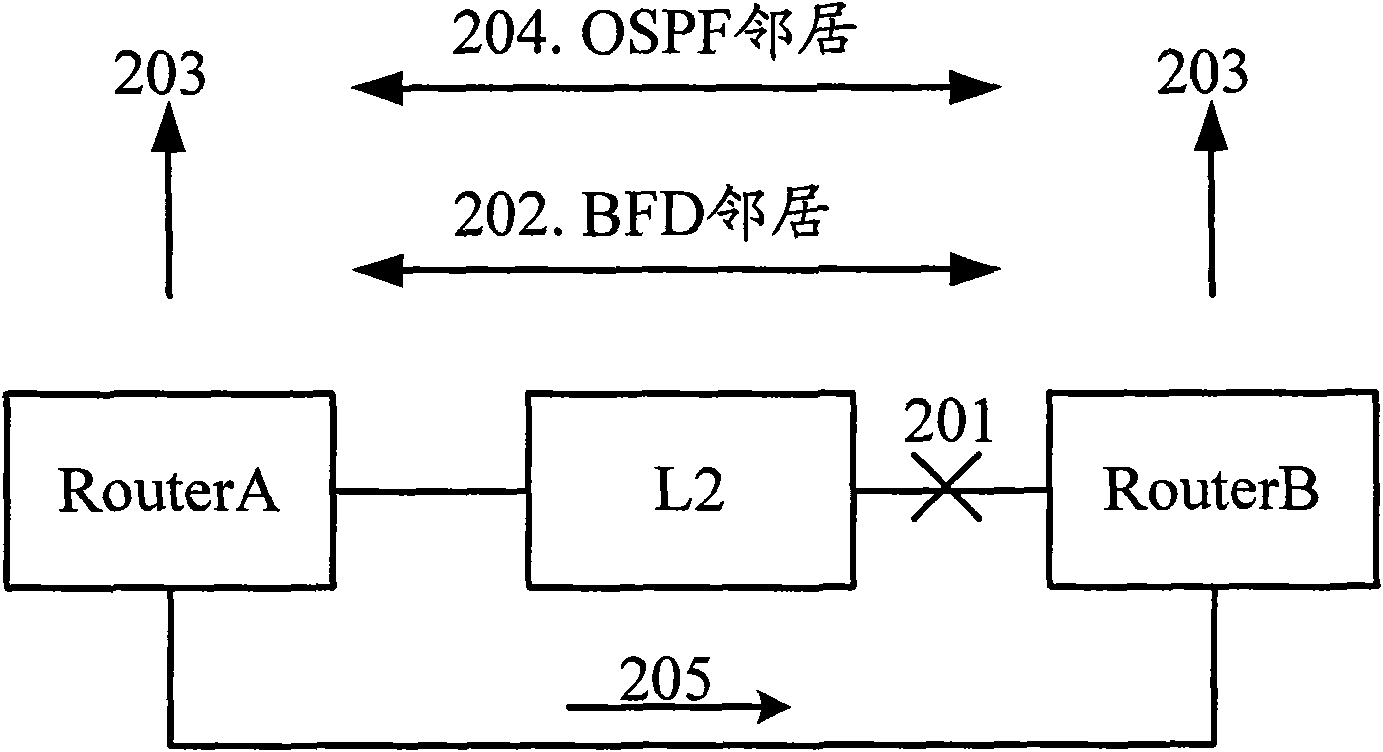

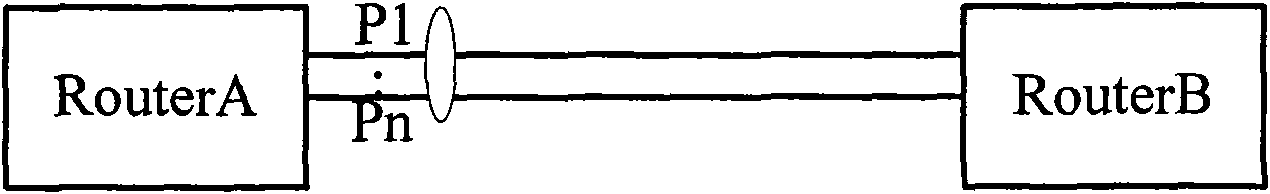

Method, system and device for ensuring BFD conversation stability on the scene of multilink direct connection

ActiveCN101610535AAvoid oscillationReduce the impactNetwork traffic/resource managementConnection managementTraffic capacityComputer hardware

The invention discloses a method for ensuring BFD conversation on the scene of multilink direct connection, which is applied in a system comprising a transmitting end device and a receiving end device, wherein the transmitting end device and the receiving end device are communicated by at least two directly-connected chains. The method comprises the following steps: the transmitting end device transmits BFD protocol messages with the same sequence number to the receiving end device respectively through at least two directly-connected chains, wherein each BFD protocol message carries the sequence number, and the sequence numbers are increased progressively after each message is transmitted in the current conversation; and the sequence number of the BFD protocol messages is detected after the receiving end device receives the BFD protocol messages, the first message with the same sequence number is processed, and the follow-up messages with the same sequence number are discarded. The invention can realize the stability of the BFD conversation and the upper application protocol when a part of ports or chains go wrong on the scene of multilink direct connection, thus ensuring the stable operation of traffic flow.

Owner:北京华三通信技术有限公司

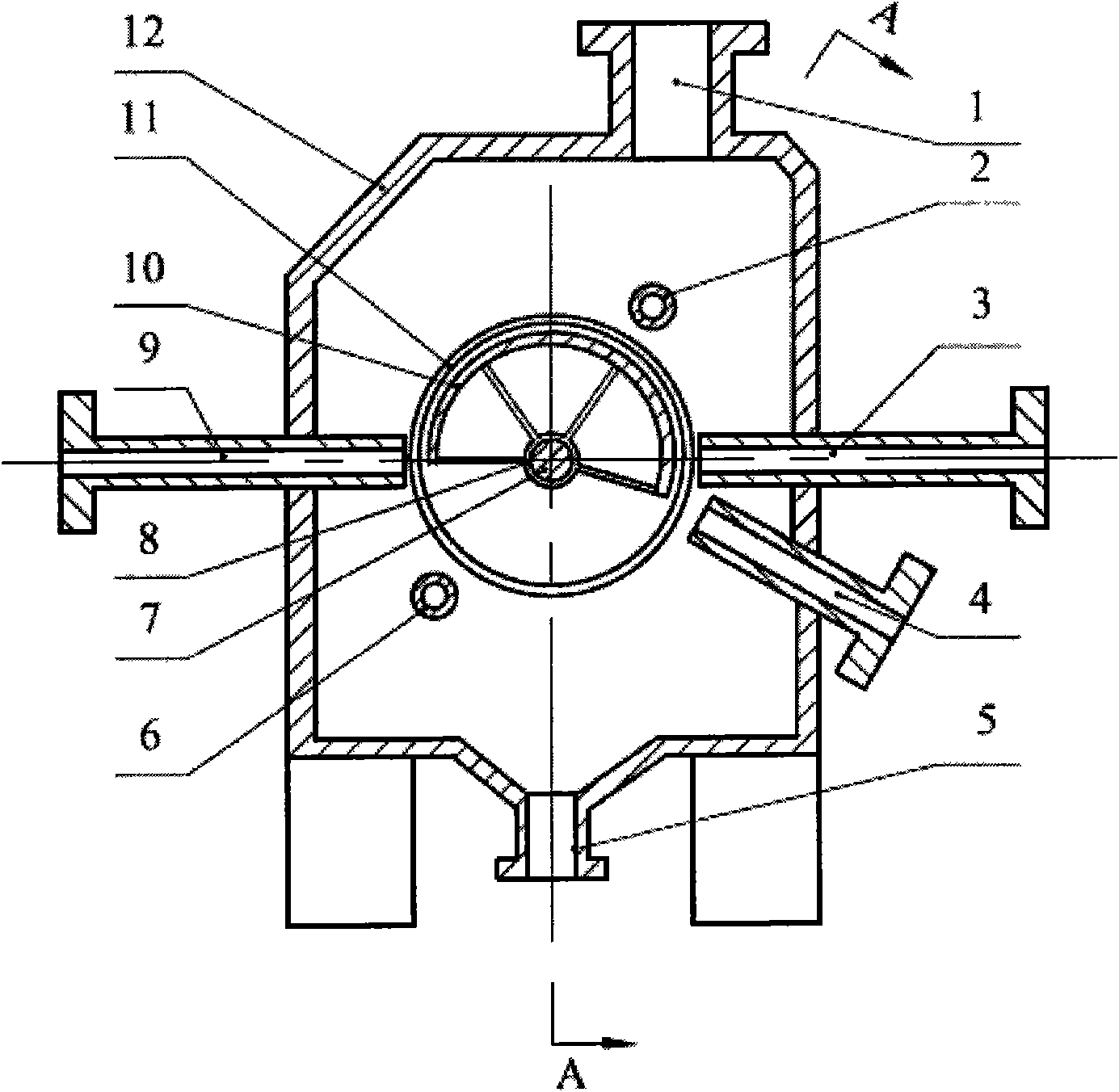

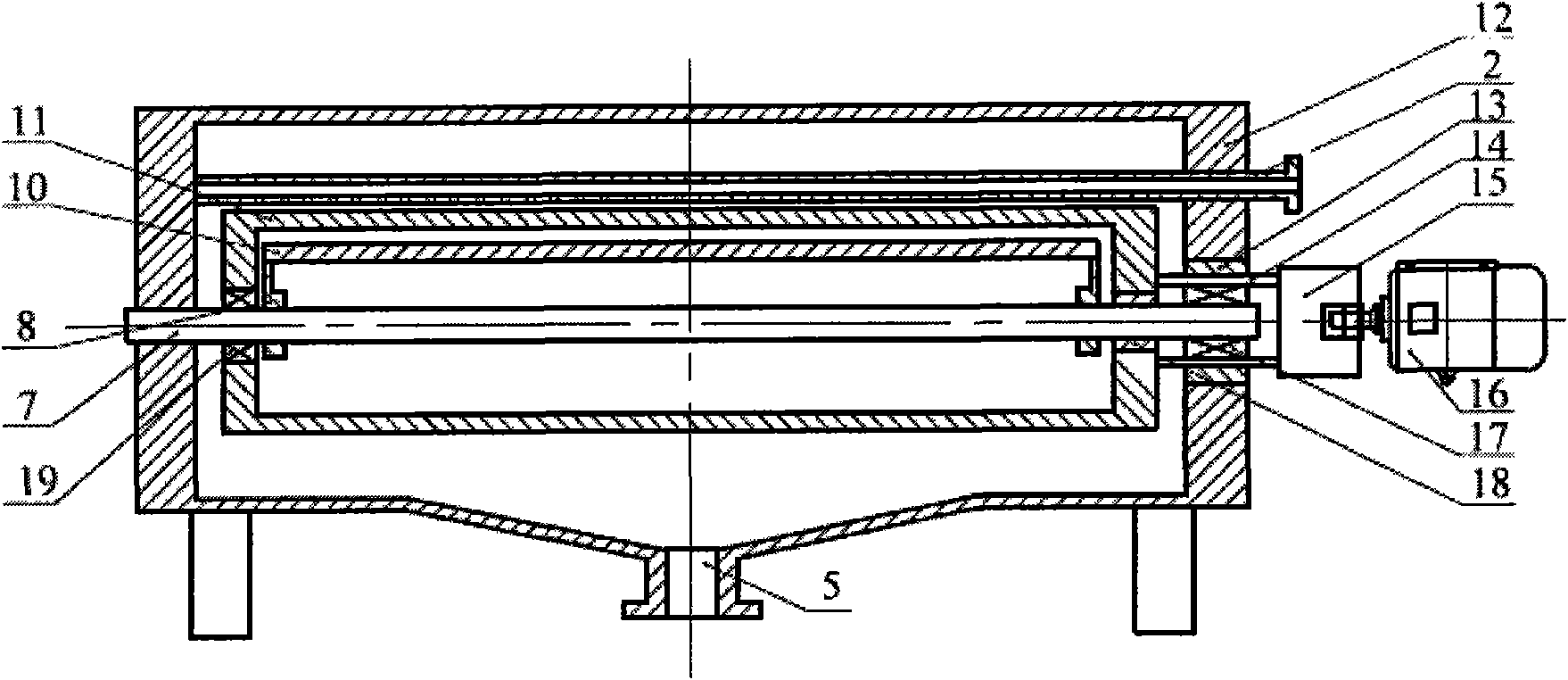

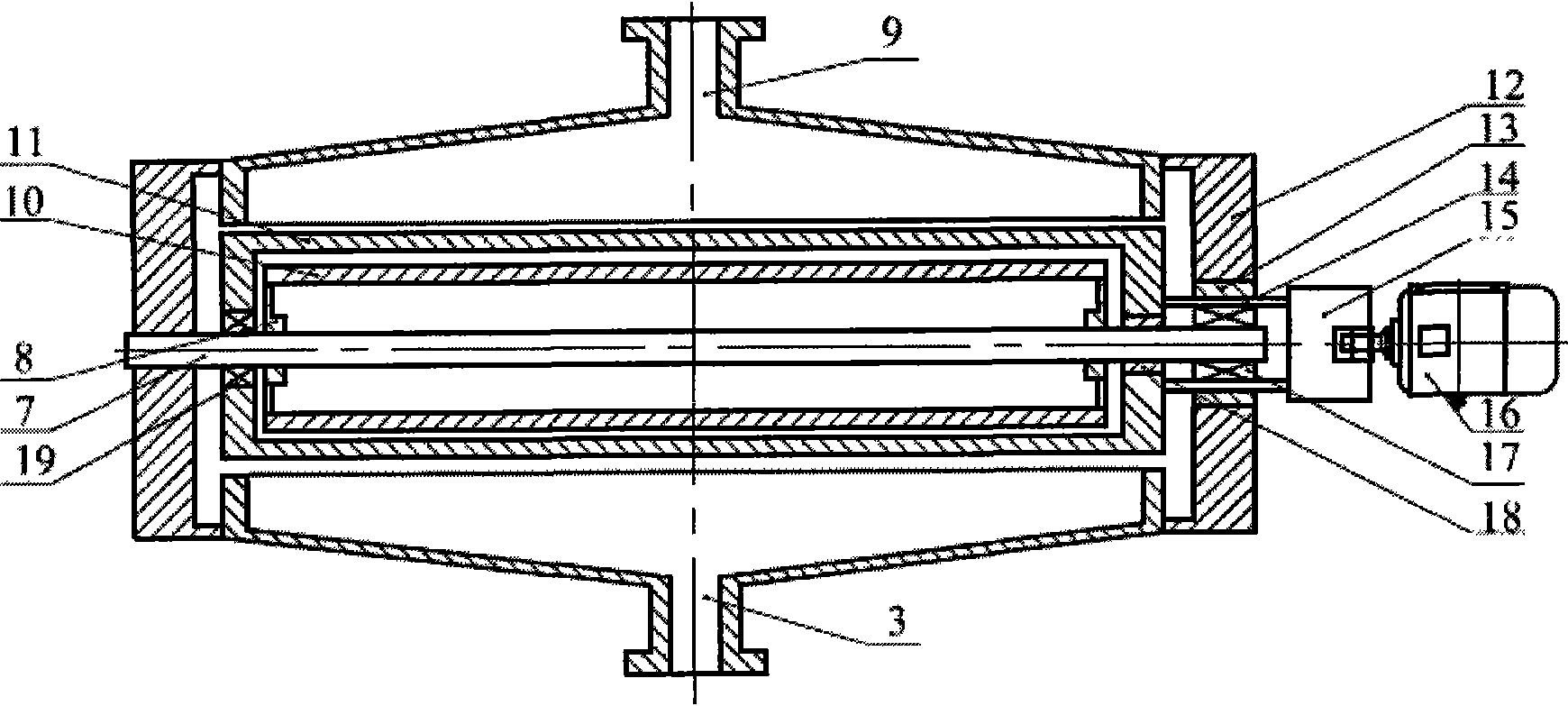

Micro powder dry-type magnetic separator

InactiveCN101596492AGood iron removal effectSolve sorting difficultiesMagnetic separationProcess efficiency improvementMagnetic separatorEngineering

The invention relates to a micro powder dry-type magnetic separator; the technical proposal is that: the two ends of a magnetic rotary drum (11) are respectively arranged on a fixing shaft (7) concentrically by a left end bearing (19) and a right end shaft liner (18), the right side of the magnetic rotary drum (11) is connected with a hollow shaft (14), a motor (16) is connected with the hollow shaft (14) by a speed reducer (15), a magnetic system (10) is concentrically arranged in the magnetic rotary drum (11), the upper right part and the bottom left part of the magnetic rotary drum (11) are respectively provided with one to two first air duct (2) and a second air duct (6) along the axial direction, a row of air outlet holes are uniformly opened on the first air duct (2) and the second air duct (6) towards to one side of the magnetic rotary drum (11), a sealing type machine shell (12) above the magnetic rotary drum (11) is provided with a tailings outlet (1), the sealing type machine shell (12) at the left side of the magnetic rotary drum (11) is provided with a first middling outlet (9), and the sealing type machine shell (12) at the bottom right part of the magnetic rotary drum (11) is provided with a second middling outlet (4). The micro powder dry-type magnetic separator has the characteristics of high separating purity of high recovery rate of magnetic products.

Owner:WUHAN UNIV OF SCI & TECH +1

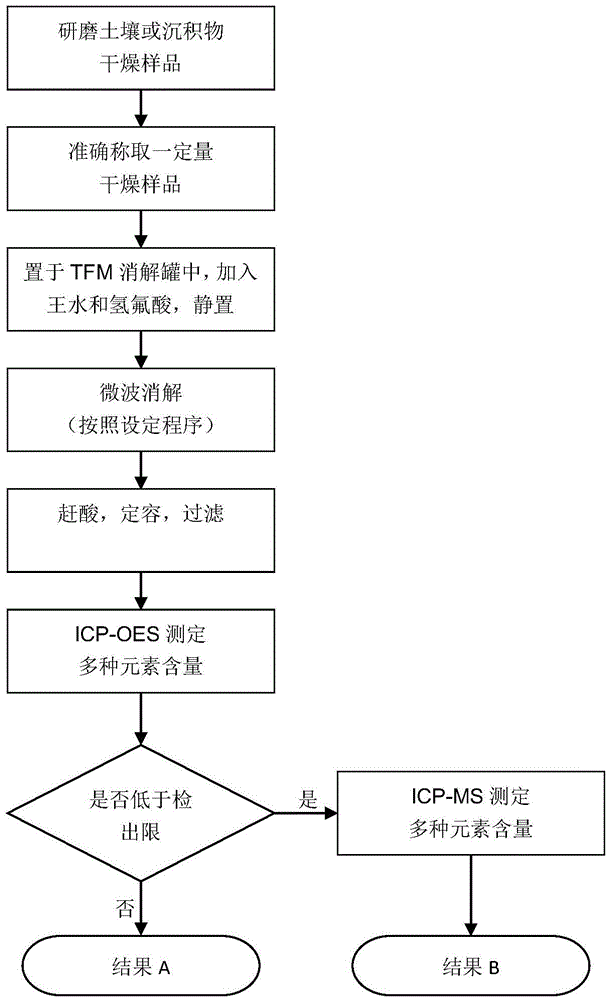

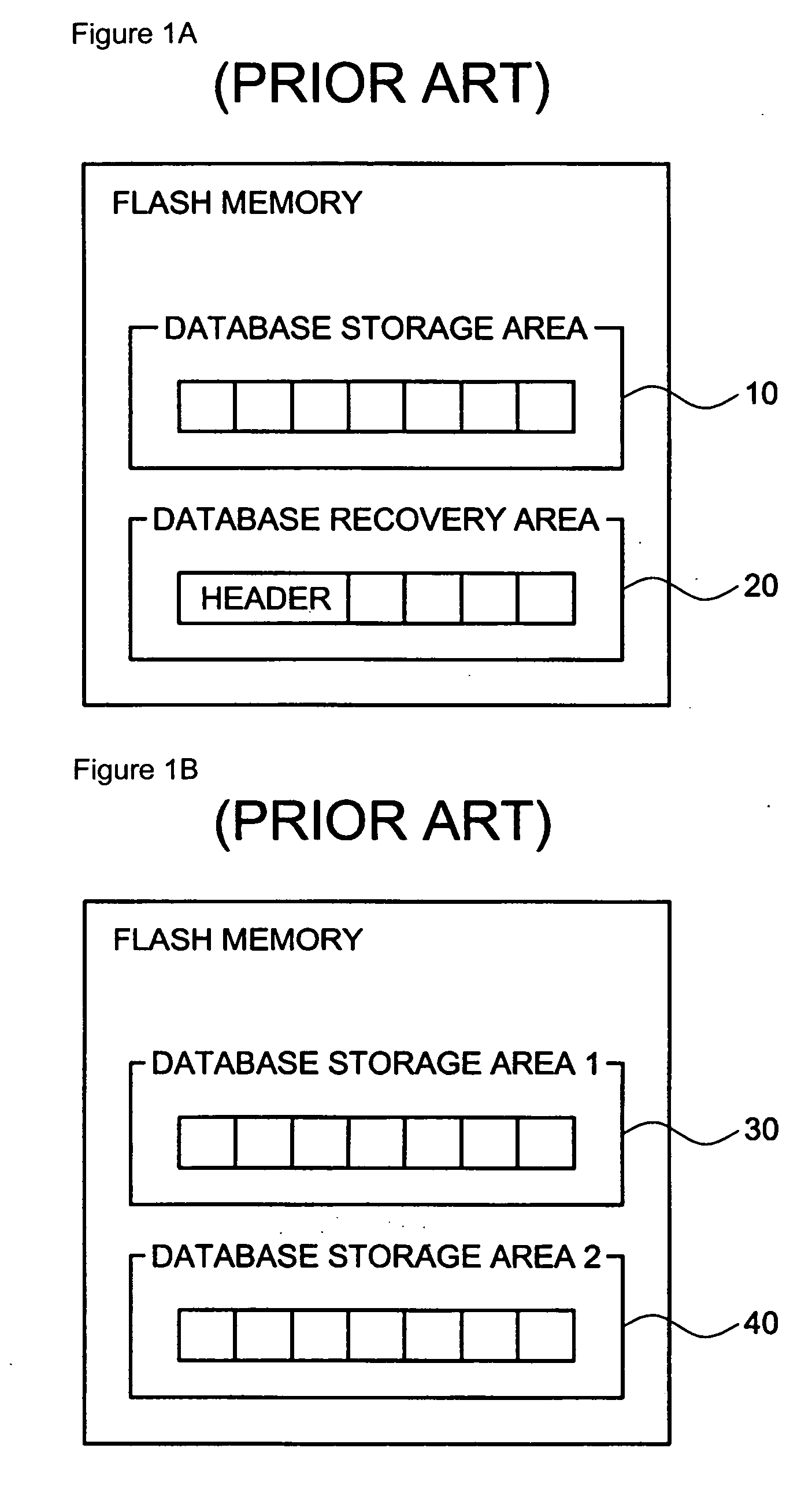

Method for simultaneously determining contents of various elements in soil or deposits

InactiveCN105606590AShorten digestion timeReduced measurement timePreparing sample for investigationMaterial analysis by electric/magnetic meansManganeseDigestion

The invention relates to detection technology for element contents, and provides a method for simultaneously determining contents of arsenic, cadmium, lead, vanadium, zinc, manganese and phosphor in soil or deposits. The method mainly comprises the following steps: (1) 0.1g of a grinded drying soil sample is accurately weighed and placed in a TFM microwave digestion pot, a certain proportion of aqua regia and hydrofluoric acid are added, and a solution is allowed to stand; (2) an appropriate microwave digestion program is set, and microwave digestion is carried out for the solution in the step (1); (3) after the microwave digestion program ends, an acid-driving device is used for heating and evaporating the digestion solution in the step (2) to a dry state, and total transfer, volumetric flask preparation, and filtering are carried out; (4) ICP-OES is used for determining contents of arsenic, cadmium, lead, vanadium, zinc, manganese and phosphor in the clear liquor in the step (3); (5) ICP-MS is used for determining contents of elements in the clear liquor in the step (3) which do not reach detection limits in the step (4) once more. The method has the advantages of simple steps, simplified operation, saved soil samples, reduced personal error, minimized environment interference, and improved working environments.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

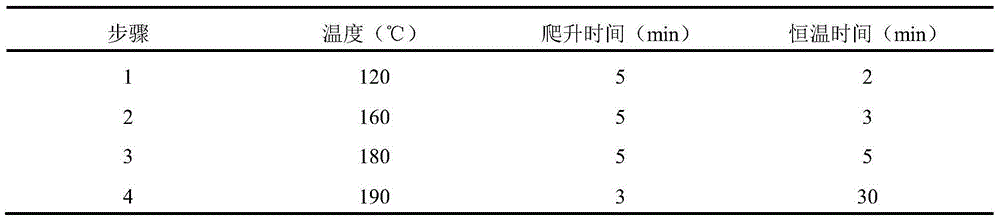

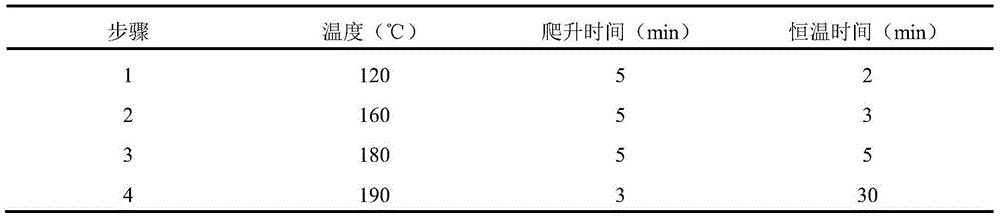

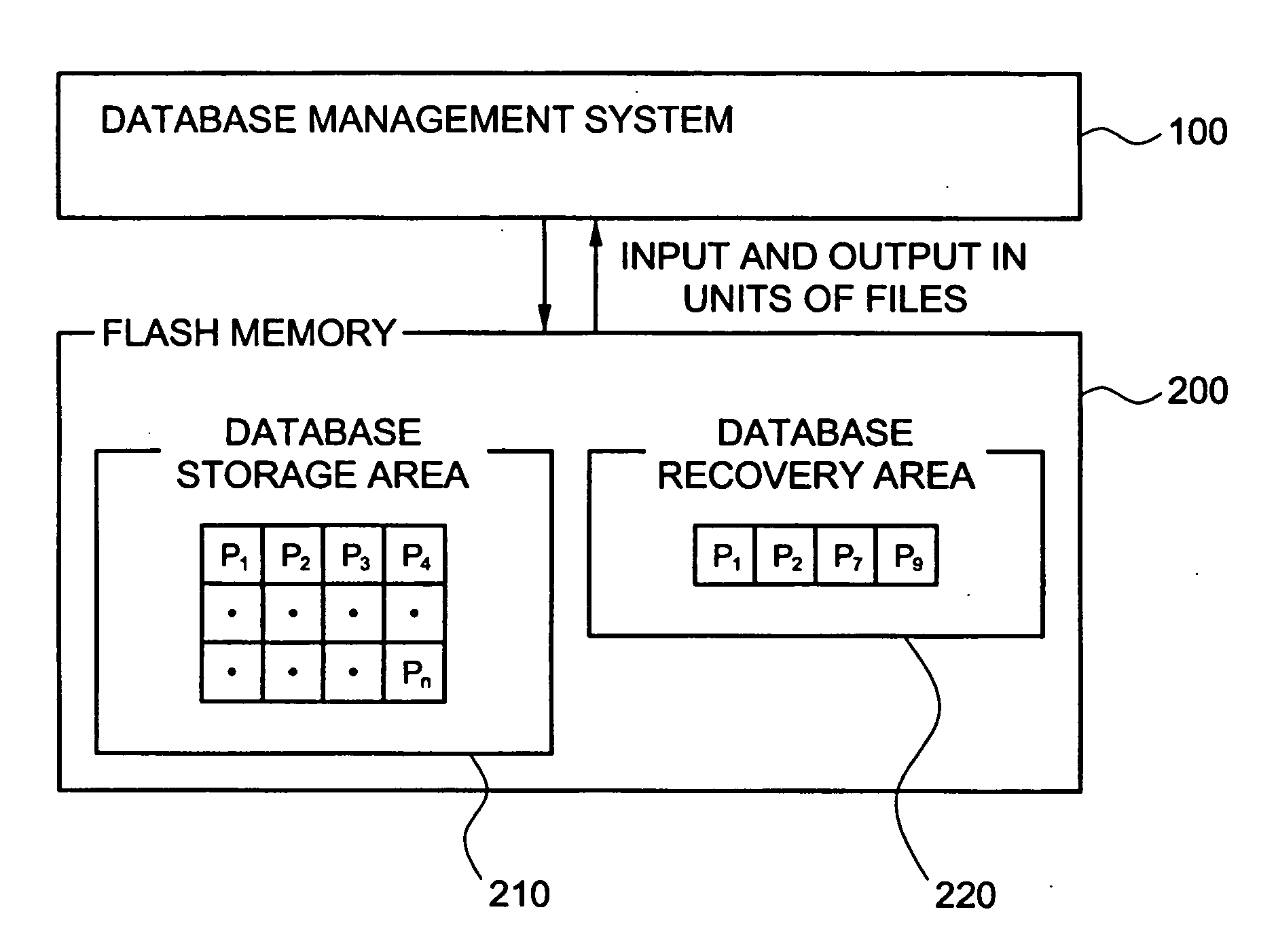

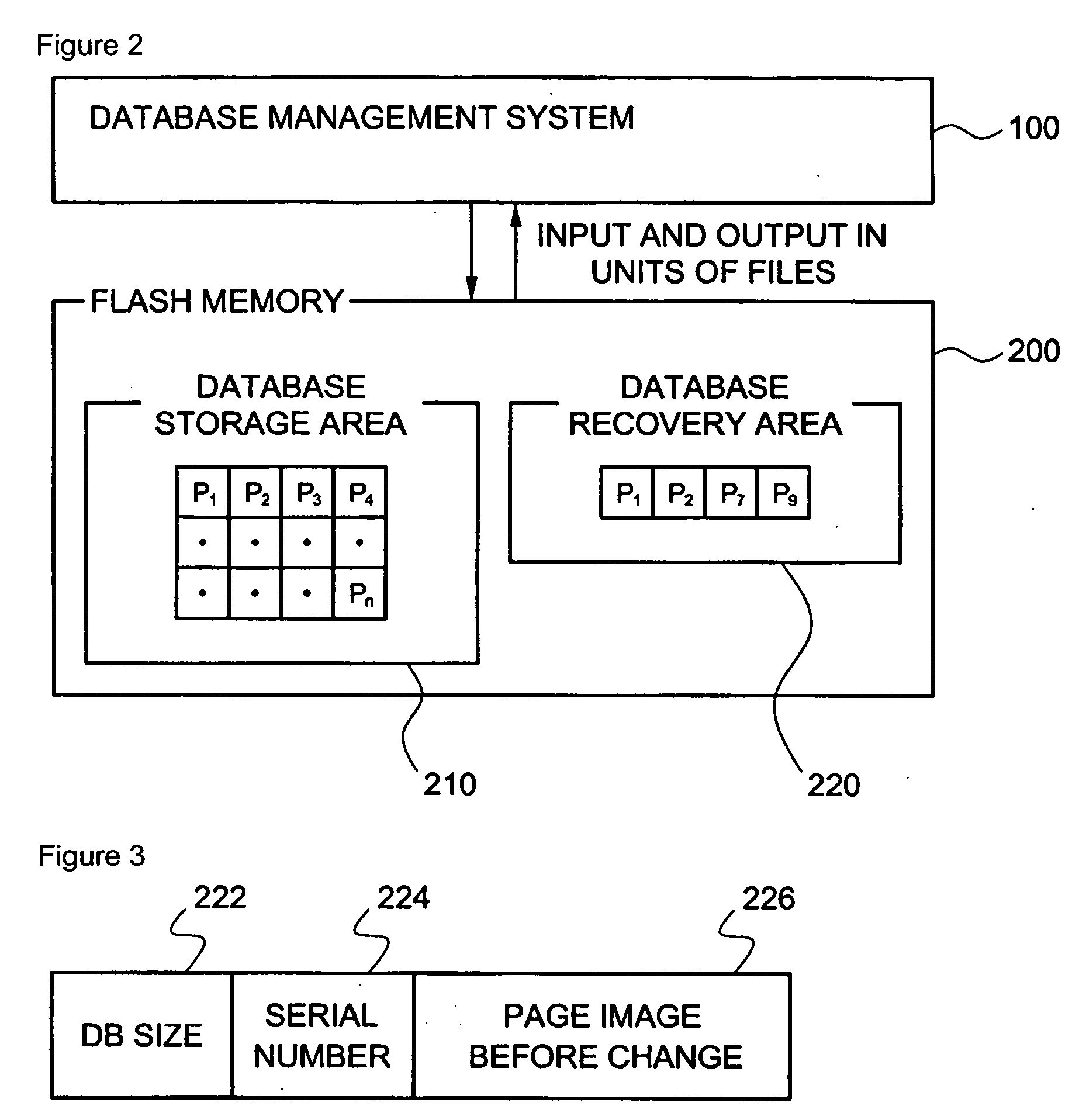

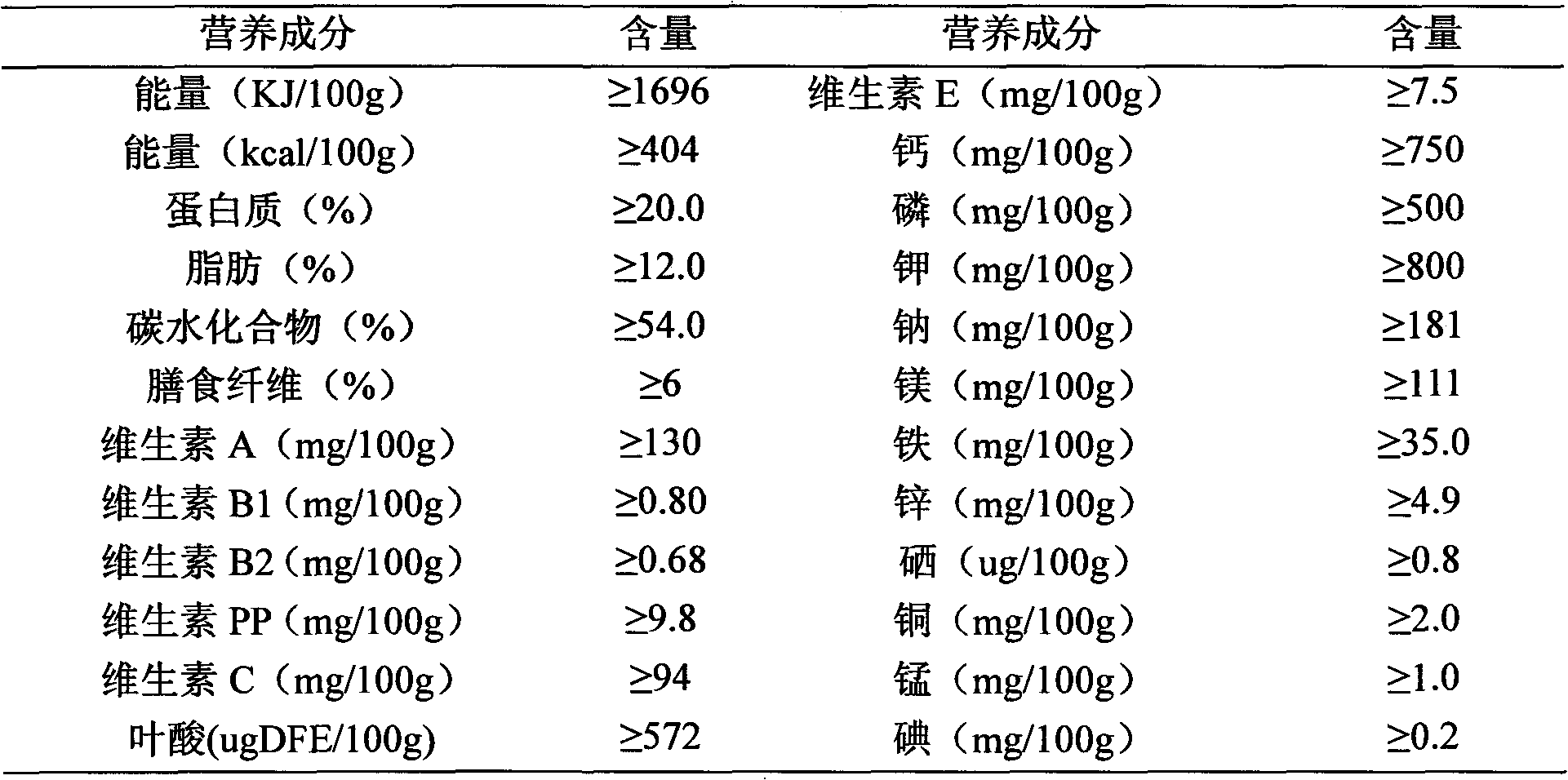

Method of efficiently recovering database

InactiveUS20060200500A1Increase in sizeGuaranteed RecoveryMemory loss protectionError detection/correctionPage countImage storage

A method of efficiently recovering a database that can be applied to a mobile communication terminal employing a flash memory as a storage medium is provided. In the flash memory, a database (DB) storage area and a DB recovery area are separately allocated. Images of pages in the DB storage area that are objects to be changed are sequentially read and stored in a memory buffer, and the original images of the pages before change are assigned sequential serial numbers and backed up in the DB recovery area. Then, the images of the pages in the memory buffer are changed according to a transaction. This series of jobs is performed with respect to all pages that are the objects of change. Then, each page in the DB storage area that is the object of the change is updated with a corresponding changed page in the memory buffer. If the mobile communication terminal is abnormally terminated without successfully performing this update, when the terminal is booted again, it is confirmed whether or not the serial number of the last page in the DB recovery area matches the total number of pages stored in the DB recovery area. If the serial number matches the total number, with the original image of the page before modification stored in the DB recovery area, the corresponding page in the DB storage area is recovered.

Owner:FUSIONSOFT

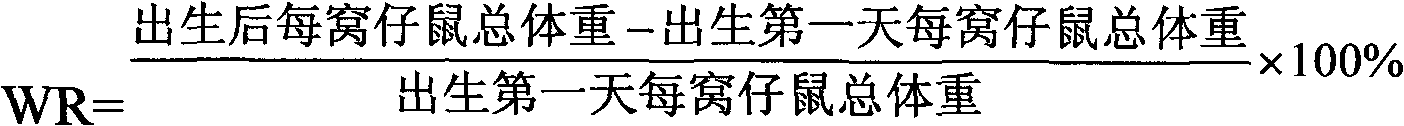

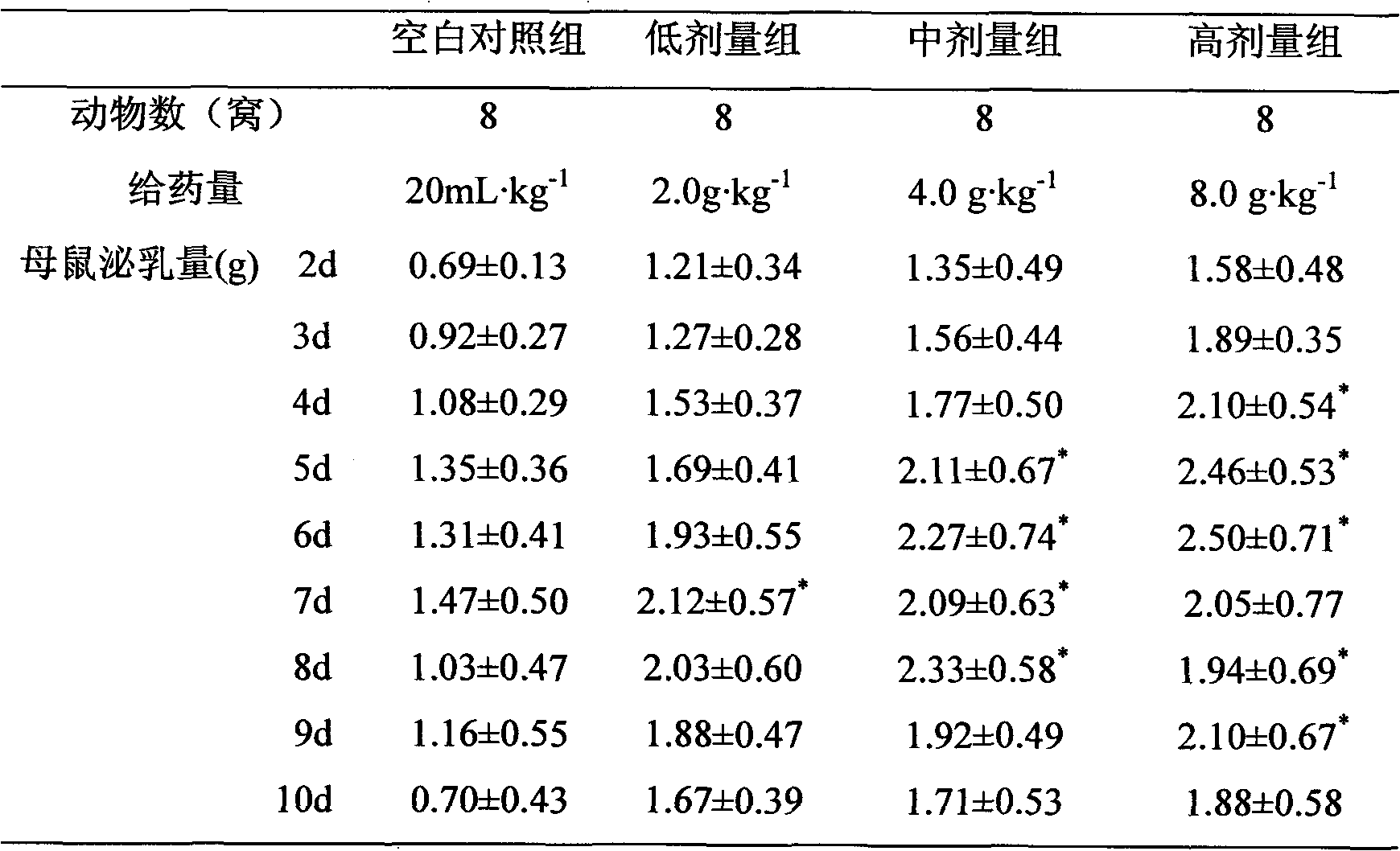

Functional nutriment for promoting lactation and recuperation of postpartum women and preparation method thereof

ActiveCN101791125AAdapt to breastfeeding needsHigh nutritional valueOrganic active ingredientsAlgae medical ingredientsPost-pregnancy depressionPhosphopeptide

The invention discloses a functional nutriment for promoting lactation and recuperation of postpartum women, which is characterized by comprising the following raw materials: marine proteins, papaya, calcium preparations, dried marine algae powder, jujube powder, olive oil, casein phosphopeptides and active probiotics. The functional nutriment is powder, an effervescent tablet or suspension. The invention also discloses a method for preparing the functional nutriment into different forms. The functional nutriment is basically suitable for the postpartum women, has reasonably prepared nutrient components, enhances the effects of the active components, has high quality proteins, is abundant in unsaturated fatty acid, has certain galactagogue effect, is easy to digest and absorb, can improve the immunity of the body and promote recuperation of the body, has certain effect on stabilizing the emotion, is beneficial to relieving postpartum depression and better ensures recuperation and the health of the postpartum women while promoting lactation, and the predigesting and comprehensively balanced nutrition of the functional nutriment is beneficial to organic regulation of the body functions of the postpartum women.

Owner:泡一泡生物科技(浙江)有限公司

Data packet transmission method for multimedia broadcasting service

InactiveCN101370165AGuaranteed recoveryResume applicableSpecial service provision for substationRadio/inductive link selection arrangementsMultimedia Broadcast Multicast ServiceBroadcast service

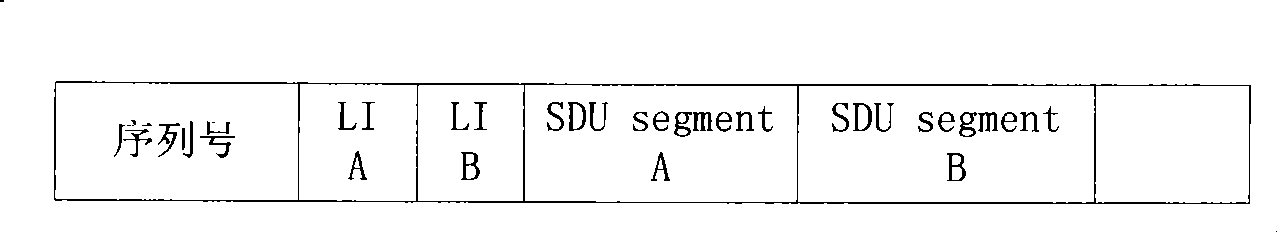

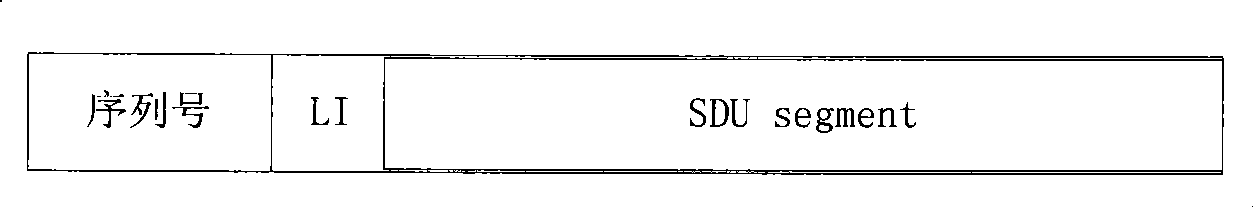

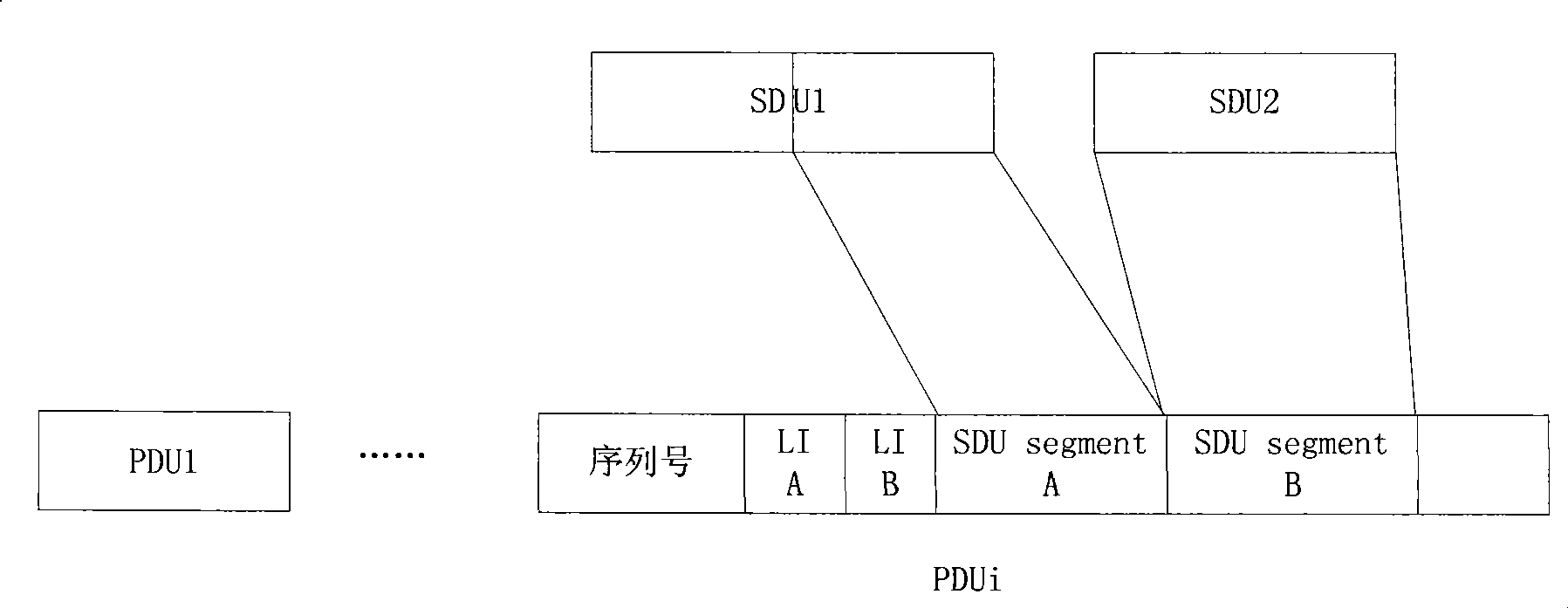

The invention discloses a method for transmitting data package in multimedia broadcast service so that system can recover content according to data package loss, in order to ensure synchronicity of received content. The transmitting method comprises: when packaging service data unit (SDU), according to ending segment of each SDU, carrying length indicator LI of ending segment of the SDU in package data unit (PDU) head, for indicating length of the SDU ending segment; when receiving the PDU, reading SDU data according to LI in the PDU package head, when the LI in the PDU head is used for indicating length of the SDU ending segment, determining starting position of the next SDU starting segment after the SDU ending segment in the same PDU according to length of the LI.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com