Method for separating collophanite

A beneficiation method, collophosite technology, applied in flotation, solid separation, etc., to achieve the effects of reducing energy consumption and dosage of chemicals, high selectivity, and simplifying the drug system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

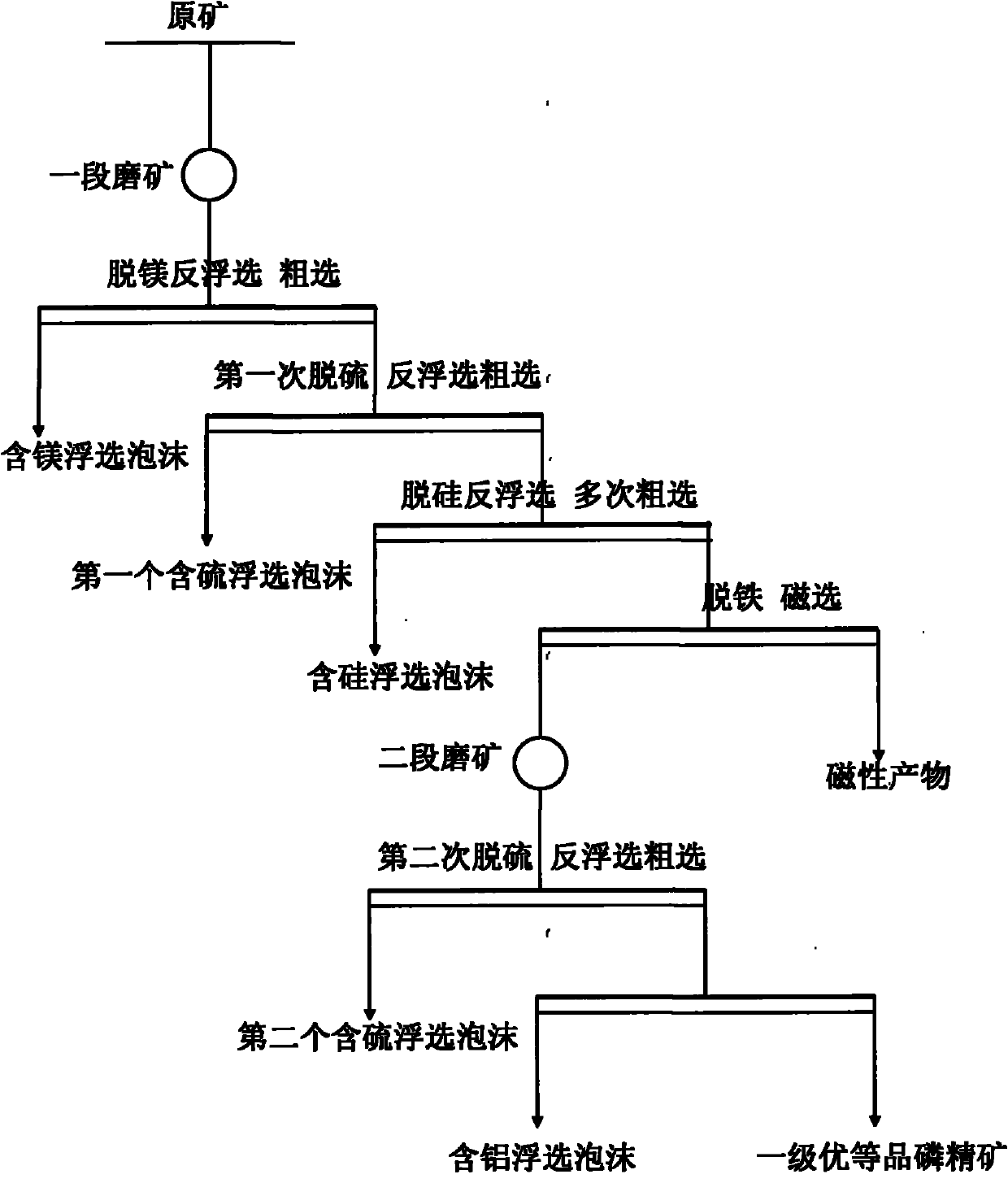

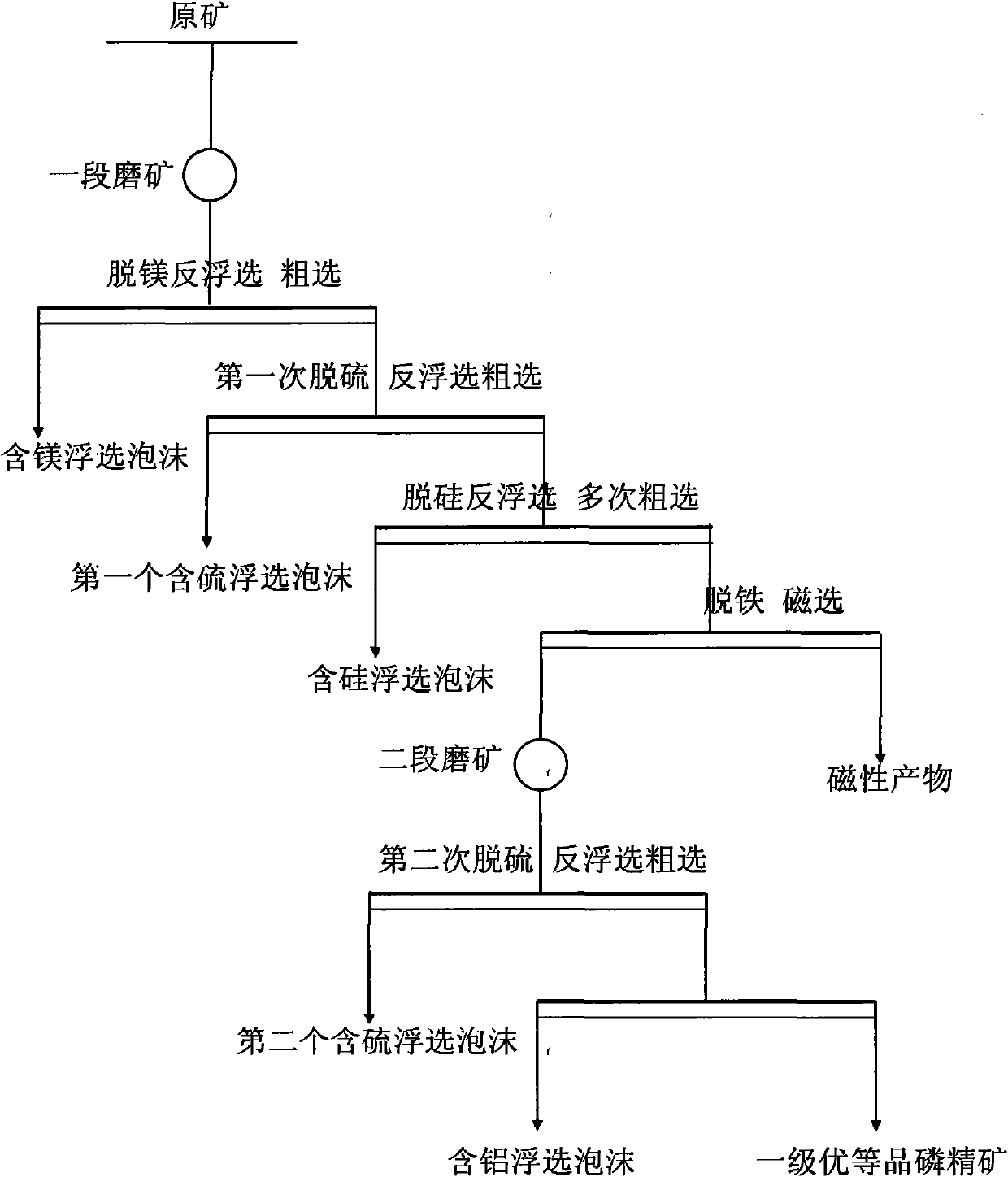

Method used

Image

Examples

Embodiment 1

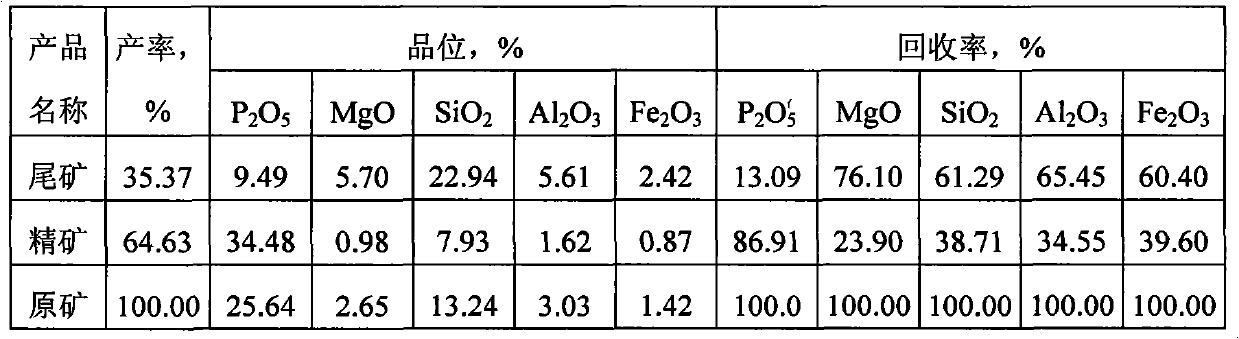

[0043] Silica colloidal ore P 2 o 5 25.64%, MgO 2.65%, SiO 2 13.24%, Al 2 o 3 3.03%, Fe 2 o 3 1.42%. The process of beneficiation and impurity removal includes: coarse grinding of the raw ore (grinding fineness -0.074mm grain size accounts for 45%), adding water to control the pulp concentration to 35%; Sulfuric acid 10kg / t, stearic acid 350g / t, roughing for 6 minutes once, the flotation foam is tailings containing magnesium, and the pulp in the tank is further removed from sulfur (pyrite); the pulp in the tank is reverse flotation for the first time The chemical system used for desulfurization is: xanthate 50g / t, roughing for 6 minutes once, the flotation foam is the first sulfur-containing tailings, and the pulp in the tank is further desiliconized; the pulp in the tank is reverse flotation and desiliconized roughing for 4 times , 4 minutes each time, the reagent system for each roughing is: dodecylamine 35g / t, the flotation foam is merged into silicon-containing t...

Embodiment 2

[0047] Silica colloidal ore P 2 o 5 25.80%, MgO 2.78%, SiO 2 13.54%, Al 2 o 3 3.12%, Fe 2 o 3 1.35%. The process of beneficiation and impurity removal includes: coarse grinding of the raw ore (grinding fineness -0.074mm grain size accounts for 55%), adding water to control the pulp concentration to 35%; Sulfuric acid 10kg / t, oleic acid 350g / t, roughing for 6 minutes once, the flotation foam is tailings containing magnesium, and the pulp in the tank is further desulfurized (pyrite); the pulp in the tank is desulfurized by reverse flotation for the first time The chemical system used is: xanthate 50g / t, roughing for 6 minutes once, the flotation foam is the first sulfur-containing tailings, and the pulp in the tank is further desiliconized; the pulp in the tank is reverse flotation desiliconized roughing for 4 times, 4 minutes each time, the reagent system for each roughing is: dodecylamine 35g / t, the flotation foam is merged into silicon-containing tailings, the slurr...

Embodiment 3

[0051] Silica colloidal ore P 2 o 5 24.84%, MgO 2.87%, SiO 2 14.32%, Al 2 o 3 3.23%, Fe 2 o 3 1.26%. The process of beneficiation and impurity removal includes: rough grinding of raw ore (grinding fineness -0.074mm grain size accounts for 65%), adding water to control the pulp concentration to 35%; Sulfuric acid 10kg / t, oleic acid 350g / t, roughing for 6 minutes once, the flotation foam is tailings containing magnesium, and the pulp in the tank is further desulfurized (pyrite); the pulp in the tank is desulfurized by reverse flotation for the first time The chemical system used is: xanthate 50g / t, roughing for 6 minutes once, the flotation foam is the first sulfur-containing tailings, and the pulp in the tank is further desiliconized; the pulp in the tank is reverse flotation desiliconized roughing for 4 times, 4 minutes each time, the reagent system for each roughing is: dodecylamine 35g / t, the flotation foam is merged into silicon-containing tailings, the slurry in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com