Patents

Literature

803 results about "Reverse flotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

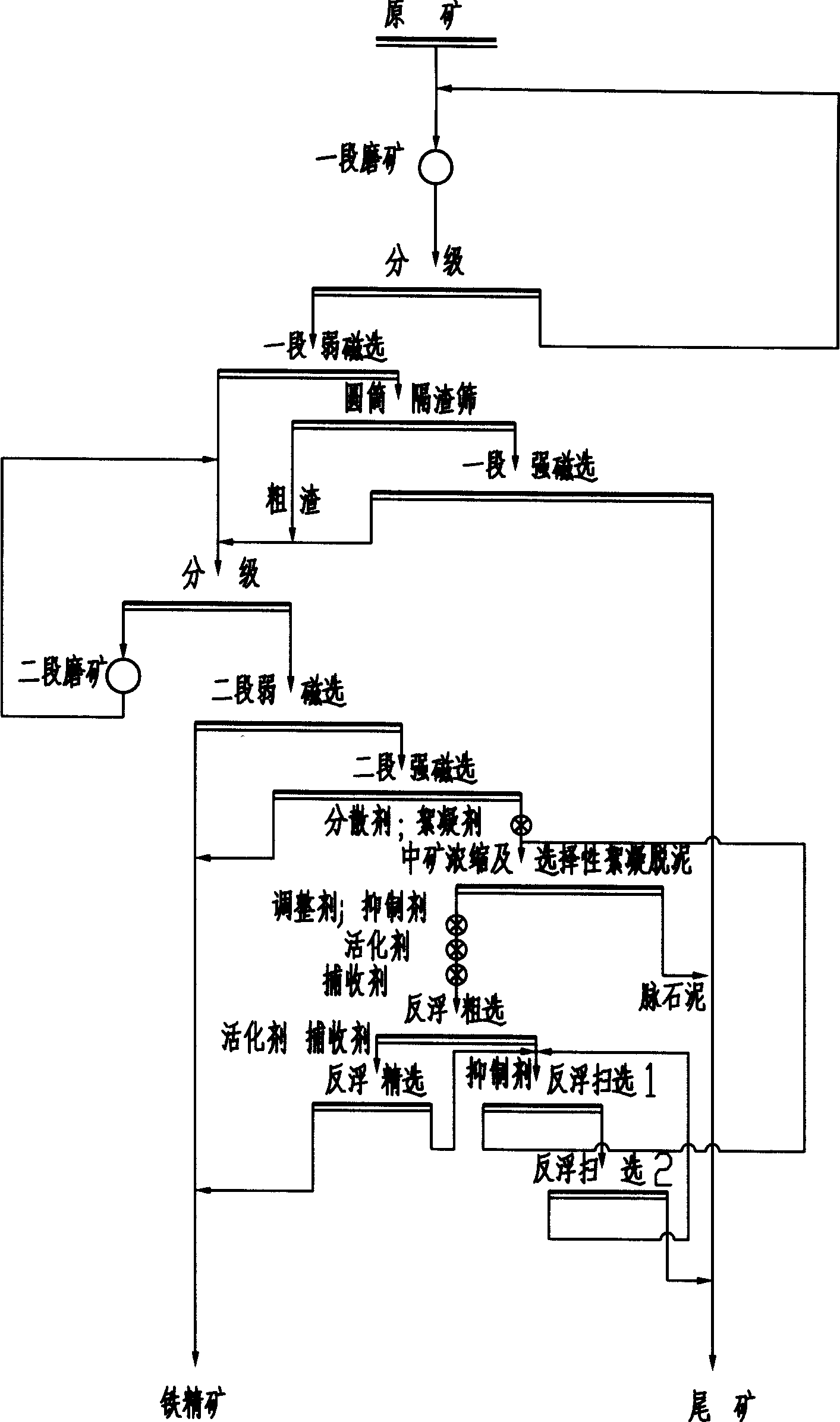

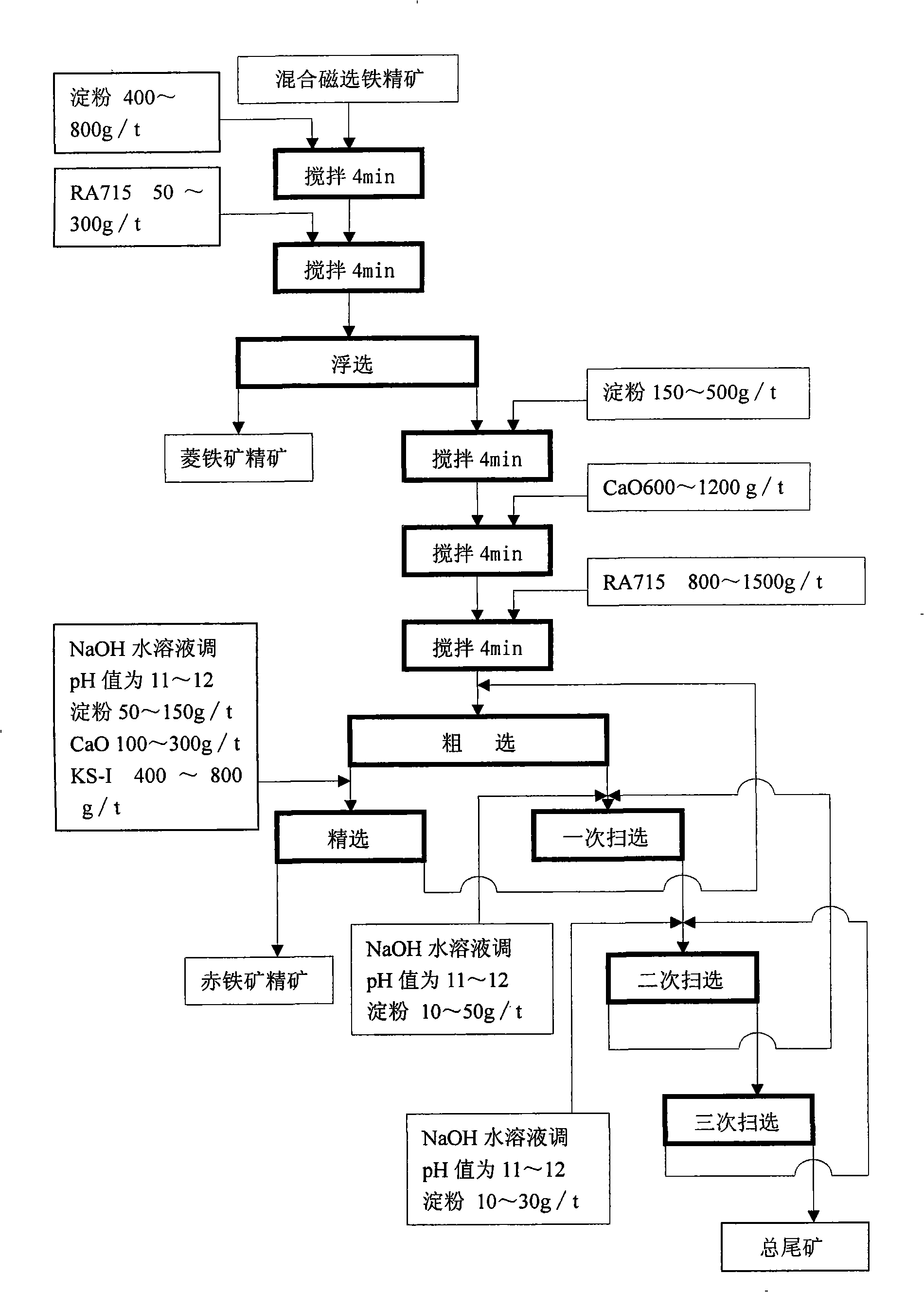

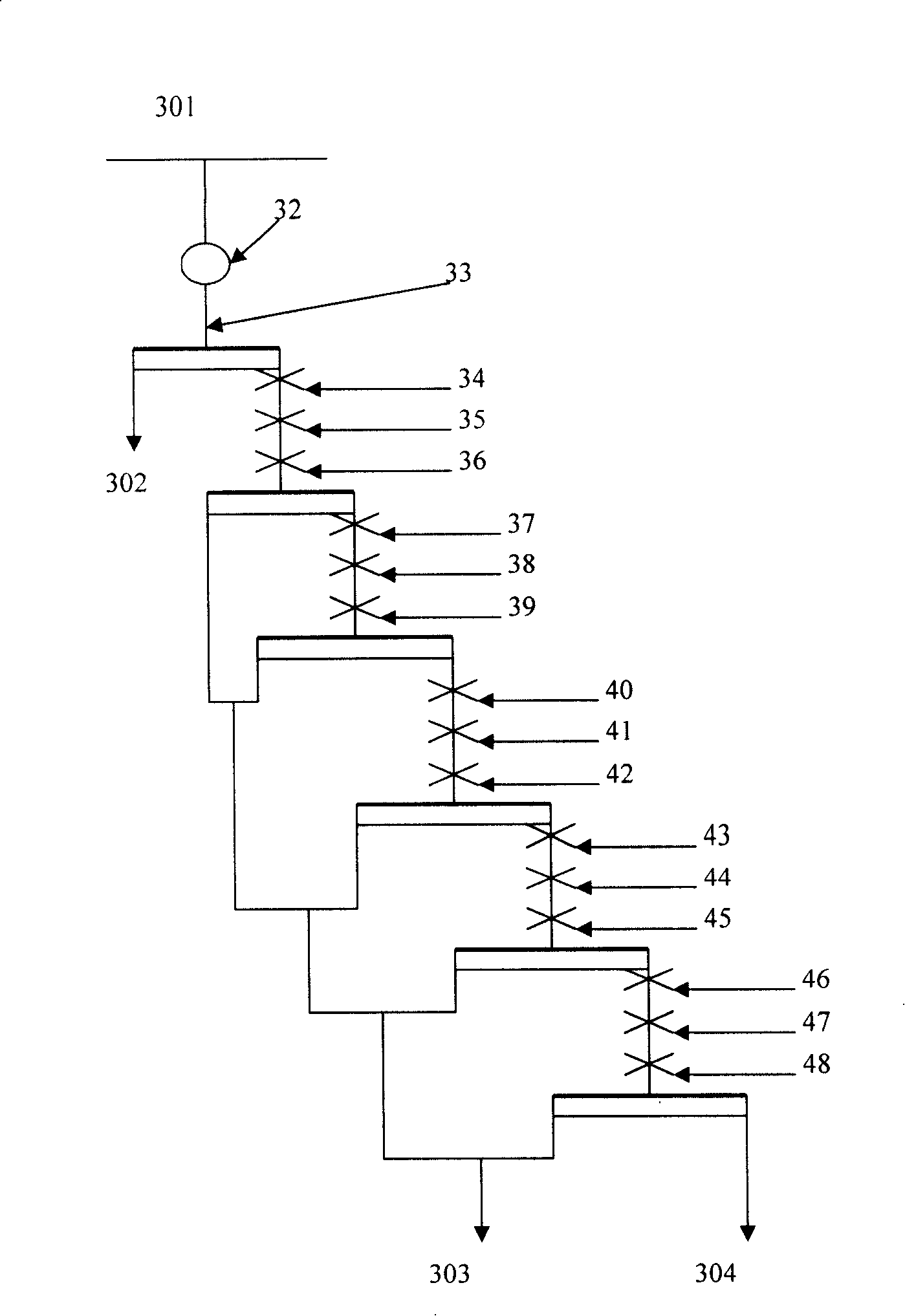

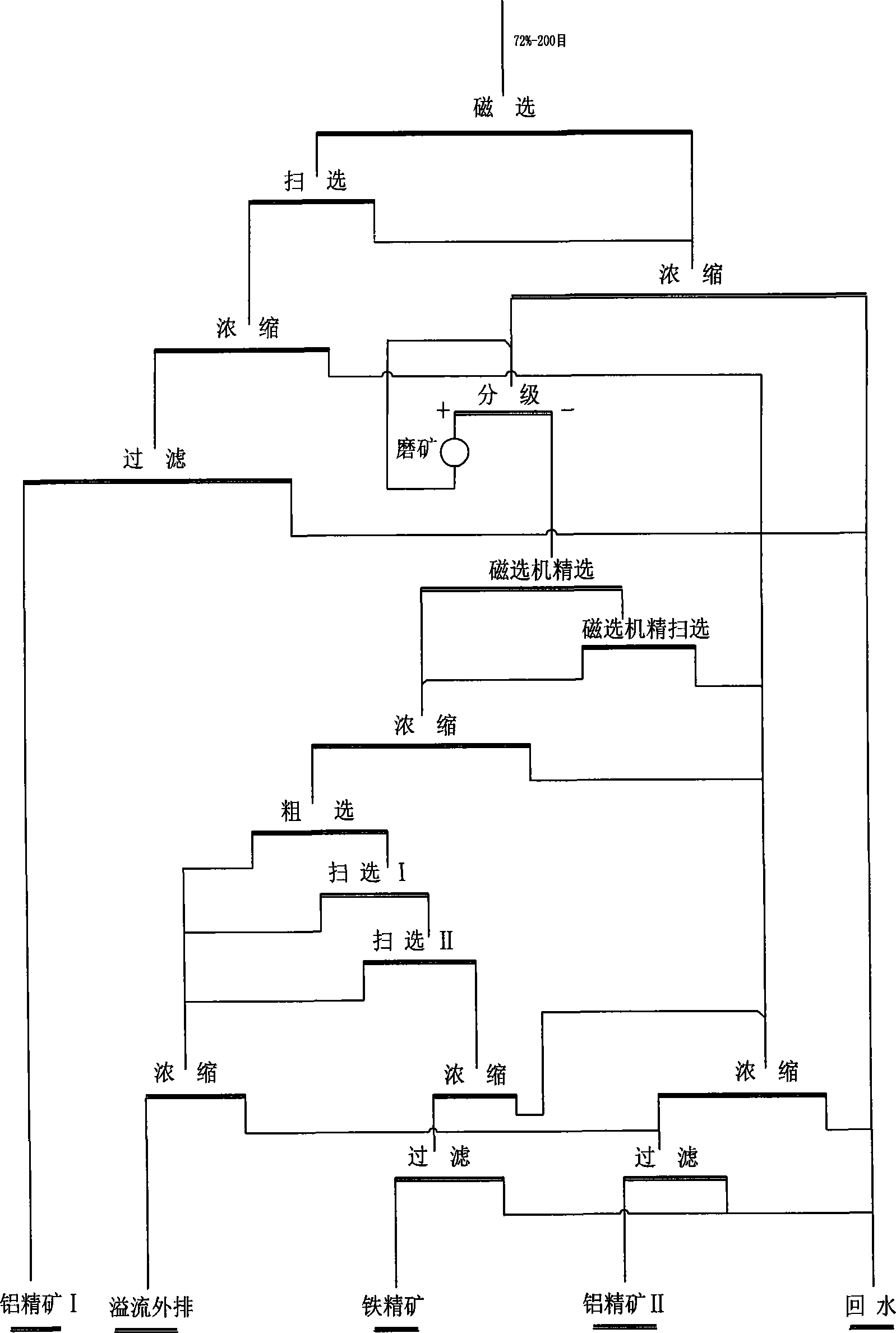

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

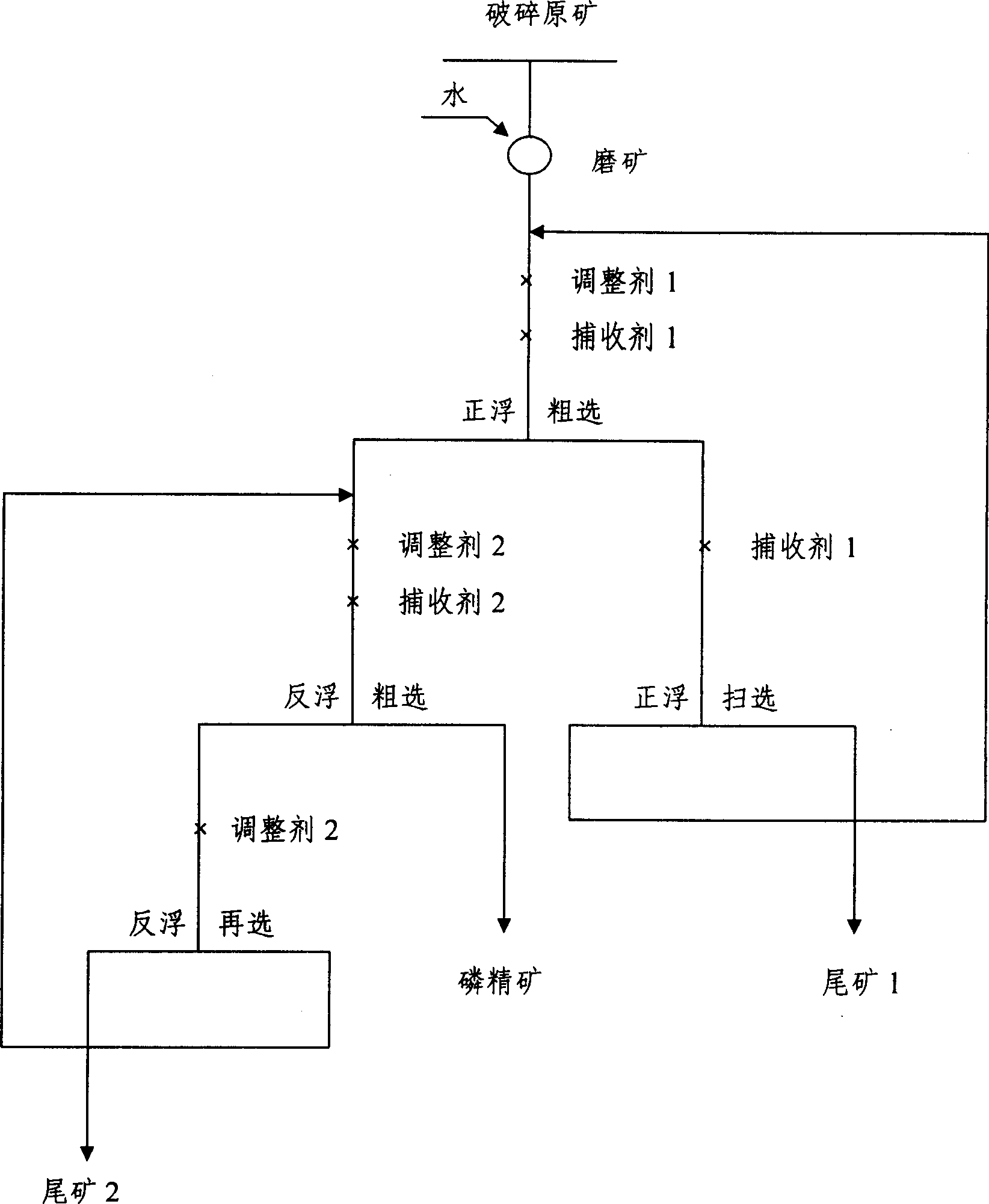

Collophanite direct flotation and reverse flotation technique

The invention relates to a positive-negative floatation technology for cellophane, which comprises the following steps: subjecting siliceous-calcareous collophane ore to breaking and grinding process to dissociate ore monomer; adding water to it get ore pulp with concentration of 20 -50%; Leading the mixture to agitated tank; adding modifying agent sodium silicate and positive collector agent to ore pulp; processing the mixture in positive floating system to get foamed product; adding negative floatation agent inorganic acid and collector agent to the foamed product in negative flotation agitated tank; processing the mixture in negative floating system with carbonate vein mineral negative flotation to get foamed product as negative flotation debris and product in tank as clean ore. The invention can simplify process, deduce cost and recycle the water.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

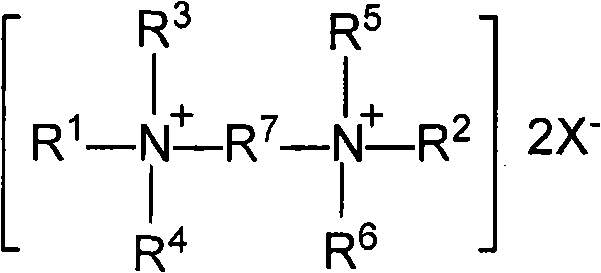

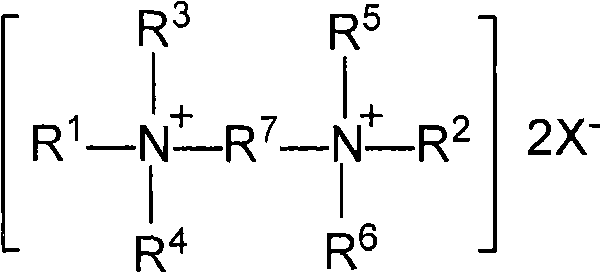

Use of quaternaries compound in floating silicate mineral

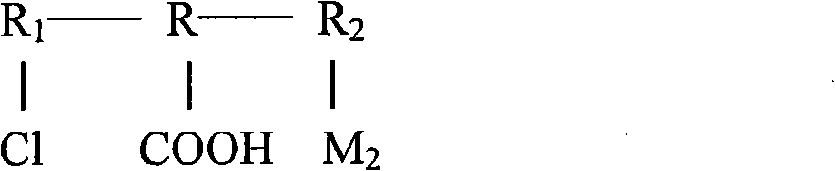

The invention relates to the field that biquaternary ammonium compounds are applied in silicate mineral flotation, and discloses a collector which applies the biquaternary ammonium compound with the constitutional formula shown as the formula I in bauxite or ironstone reverse flotation desiliconization. In the formula I, R<1> and R<2> are alkyls with 6-18 carbon atoms; R<3>, R<4>, R<5> and R<6> are respectively methyl, ethyl, -(CH2CH2O)nH, or -(CH(CH3)CH2O)nH, wherein, n is equal to 1-6; R<7> is alkylene with 2-6 carbon atoms; and X is Cl, Br or I. The collector of the invention has strong ability to collect quartz, kaolinite, illite and pyrophyllite, and is applicable to the silicate mineral separation from the bauxite or ironstone by reverse flotation, the suitable pH range of the flotation pulp is 5-13, and the dosage is equal to 50-500 g / t according to the content change of the silicate mineral in ores.

Owner:CENT SOUTH UNIV

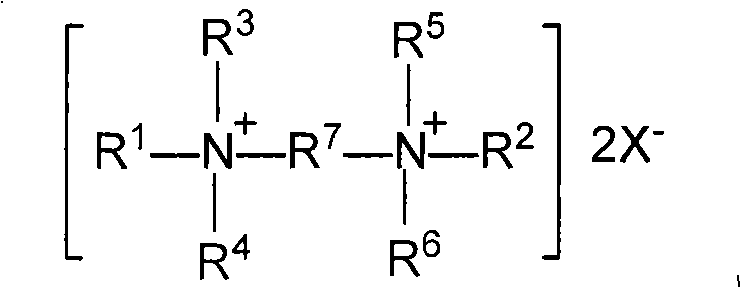

Method of performing chloridizing roasting to synchronously reduce and recover gold and iron from gold concentrate cyanide tailings

The invention provides a method of performing chloridizing roasting to synchronously reduce and recover gold and iron from gold concentrate cyanide tailings, and belongs to the technical field of comprehensive utilization of resources. The method comprises the following steps: performing reverse flotation desilicication preconcentration on the gold concentrate cyanide tailings which comprise 0.5-0.95% of phosphorus, 0.9-1.4% of sulfur, 20-25% of iron, and 3.0-4.5 g / t of gold, drying the obtained concentrate, then mixing the concentrate with a chlorinating agent, a reducing agent, a dephosphorization agent and a desulfurizing agent, pelletizing, performing high temperature chlorination to volatilize gold and synchronously performing deep reduction to remove sulfur and phosphorus, collecting the exhaust gas to recover gold, and then performing crushing, ore grinding, magnetic separation on the roasted pellets to recover iron. With application of the method, a gold product and a sponge iron product can be obtained, wherein the gold recovery rate of the gold product is 92-96%; in the sponge iron product, the iron grade is 90-92.5%, the sulfur content is less than 0.06%, the phosphorus content is less than 0.07%, and the iron recovery rate is 88-93%. Through the reverse flotation preconcentration, the method can reduce the energy consumption of the follow-up treatment process and realize recycling of the low-grade gold and iron in the gold concentrate cyanide tailings.

Owner:JIANGXI YIYUAN REGENERATION RESOURCE CO LTD

Low-temperature-resistant collophanite reverse-flotation collecting agent and method for preparing low-temperature-resistant collophanite reverse-flotation collecting agent

ActiveCN104107762ARealization of Magnesium Removal by Low Temperature Reverse FlotationWide range of raw materialsFlotationFoaming agentPhosphorite

The invention relates to a low-temperature-resistant collophanite reverse-flotation collecting agent. The low-temperature-resistant collophanite reverse-flotation collecting agent is composed of a basic active flotation material, an auxiliary component and water, wherein the basic active flotation material is composed of, by weights, 10 parts to 30 parts of unsaturated sulfonated aliphatic acid and 50 parts to 80 parts of higher aliphatic acid, the auxiliary component is composed of, by mass, 5 parts to 10 parts of surface active agents, 5 parts to 15 parts of foaming agents and 10 parts to 20 parts of inorganic base, and the ratio of the sum of the mass of the basic active flotation material and the mass of the auxiliary component to the mass of the water ranges from 1:1 to 1:10. When the low-temperature-resistant collophanite reverse-flotation collecting agent is used for collophanite flotation, phosphorus concentrate with the low MgO content (1.60%) can be obtained, and the high P2O5 recovery rate (90.03%) can be achieved. The low-temperature-resistant collophanite reverse-flotation collecting agent has the advantages that the range of sources of raw materials is wide, the preparing technology is simple and easy to execute, the stability is high, the environmental friendliness is achieved, and the market promotion value is high.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

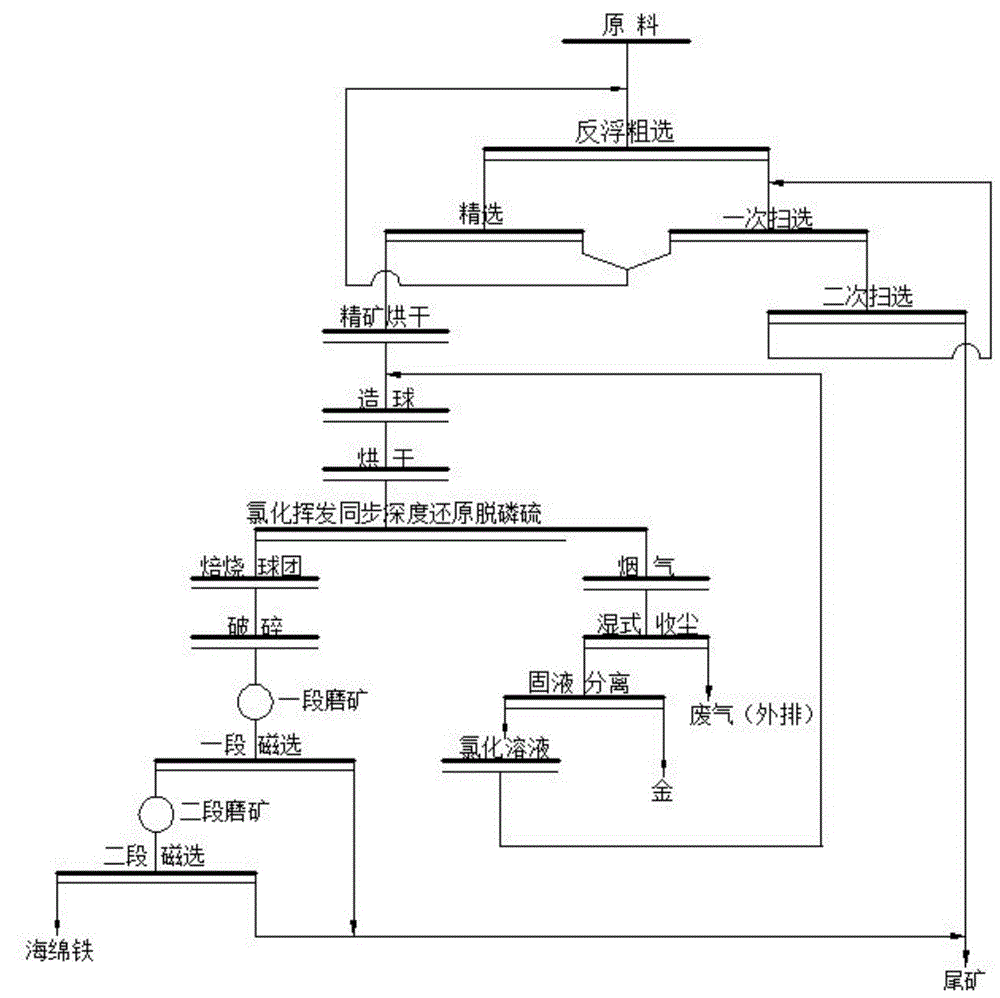

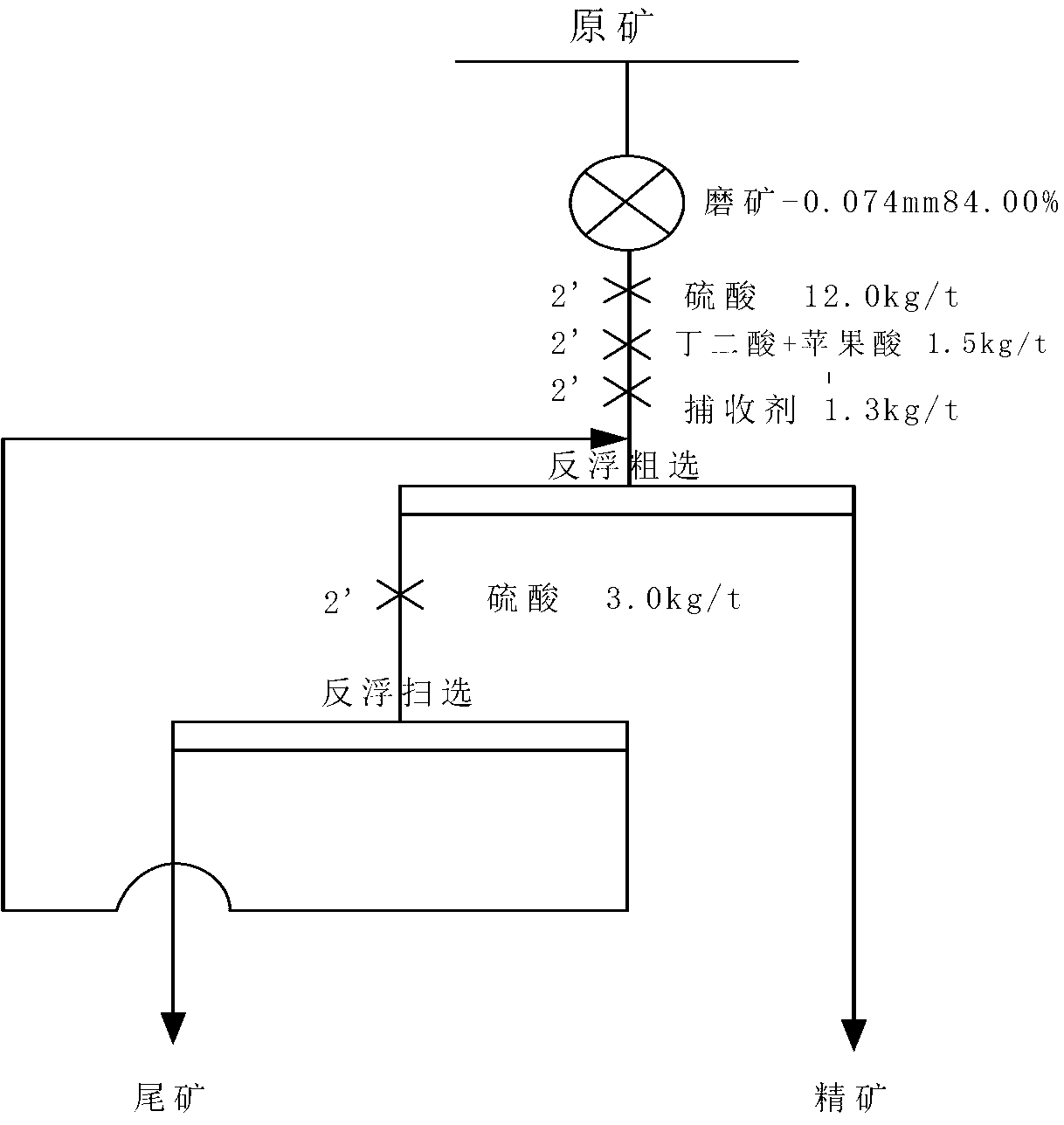

Phosphorite reverse flotation process

ActiveCN103212484ANo pollution in the processEfficient separationFlotationOrganic acidPhosphoric acid

The invention relates to a phosphorite reverse flotation process which comprises the following steps: after carrying out ore crushing, ore grinding and size mixing on phosphorite, enabling the obtained product to enter the reverse flotation process, wherein ore pulp obtained after size mixing is added with sulfuric acid or phosphoric acid to form a regulator and an inhibitor and then is added with micromolecule organic acid to form a combined inhibitor for inhibiting phosphate minerals; carrying out reverse flotation to separate out carbonate minerals by using fatty acids or fatty acid soaps as a collecting agent so as to obtain high-grade low-magnesium phosphate concentrates. The phosphorite reverse flotation process has the following advantage that the micromolecule organic acid inhibitor is adopted to implement effective separation of collophanite and dolomite, so that the grade of the phosphate concentrates is improved, the grade of tailings is reduced and the recovery rate can be improved. Meanwhile, application of phosphoric acid and derivatives thereof to phosphorite reverse flotation is replaced, so that phosphorus resources are saved, service time of phosphate rock resources is prolonged and the defects in the prior art are overcome.

Owner:远安县燎原矿业有限责任公司

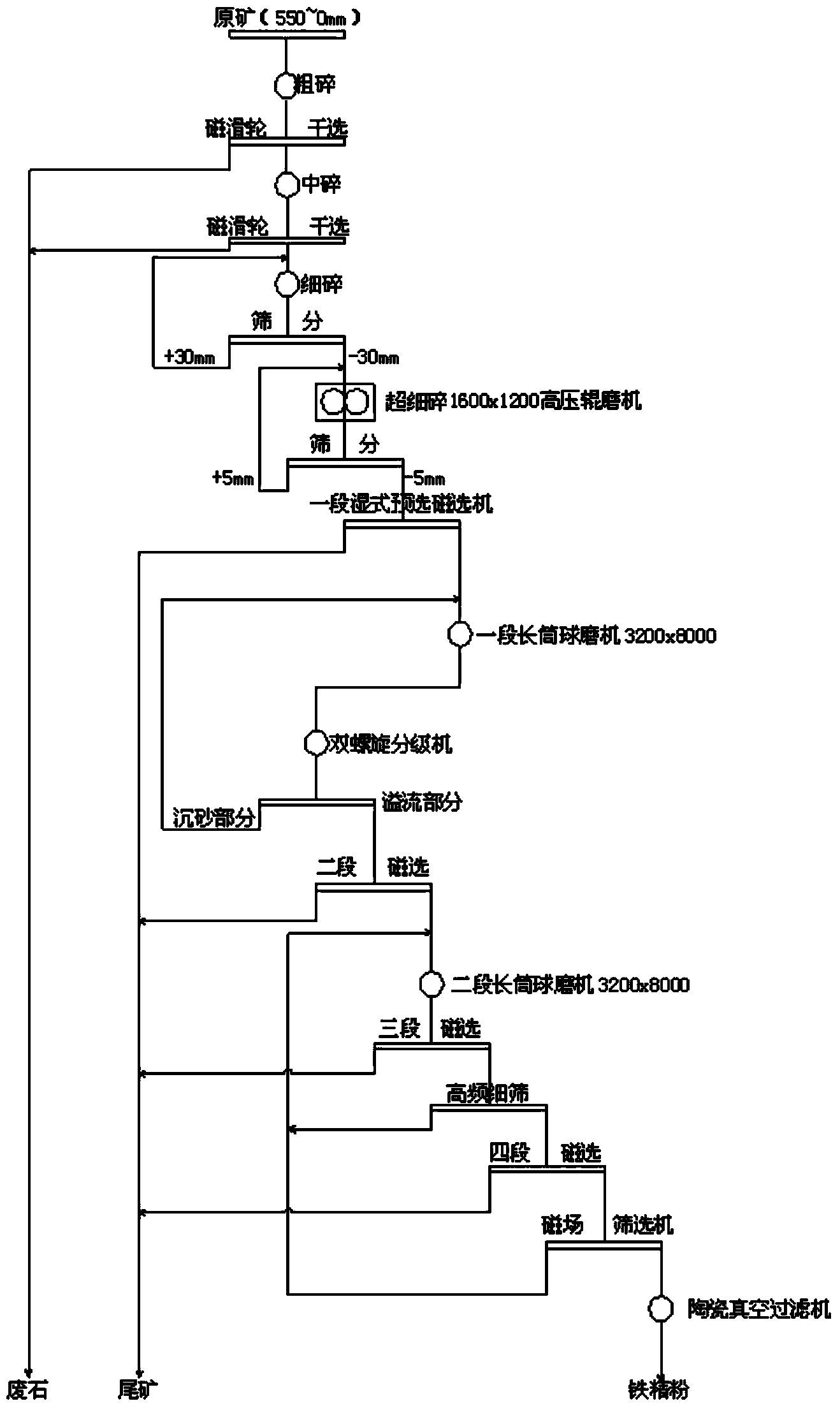

Method for raising iron content and reducing silicon in concentrate by means of low-intensity magnetic separation process

InactiveCN103447144ARealize the purpose of increasing iron and reducing siliconSimple processWet separationOperational costsScreening method

The invention discloses a method for raising iron content and reducing silicon in concentrate by means of a low-intensity magnetic separation process. Aimed at the problems of floatation (reverse flotation) in the prior art in terms of raising iron content and reducing silicon in concentrate, a magnetic field screening method for separation and corresponding crashing and grinding process and equipment are adopted in order to achieve the goal of raising iron content and reducing silicon in concentrate. The method has the advantages of simple process, advanced equipment, low operating cost and remarkable economic benefit.

Owner:安徽大昌矿业集团有限公司

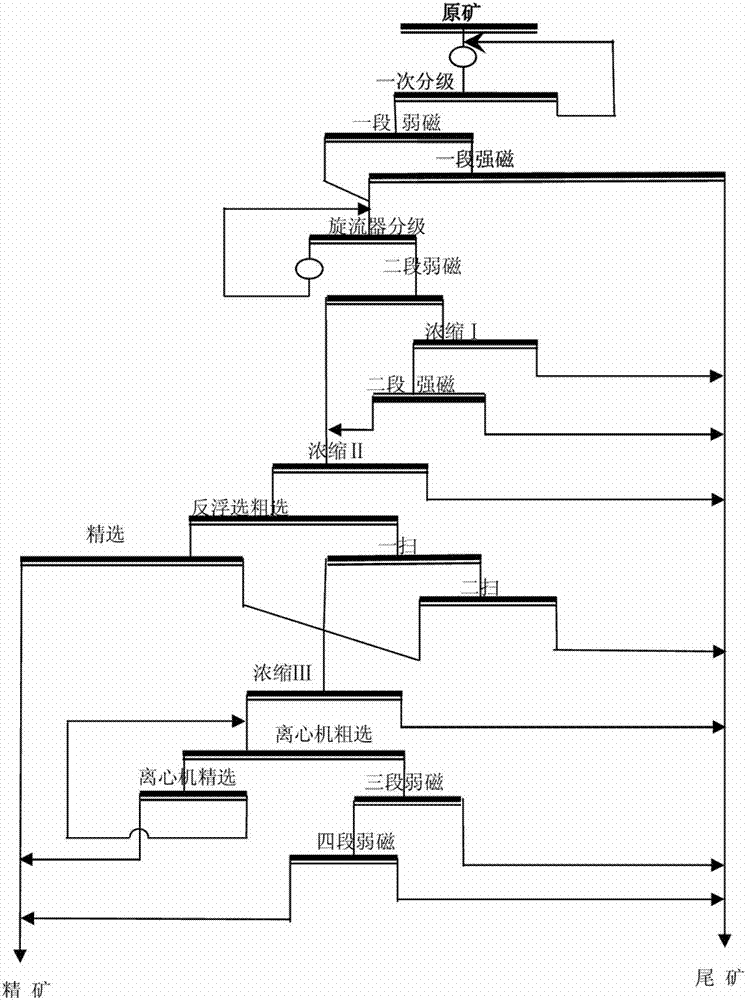

New technology for sorting lean hematite and magnetite orecontaining iron carbonate

The invention relates to a new technology for sorting a lean red magnetite ore containing iron carbonate, which is characterized by comprising the following steps of: enriching and discarding tailings by adopting a 'technology for stage grinding and strong magnetic discarding tailings', thereby obtaining a mixed magnetic concentrate; sorting the mixed magnetic concentrate by adopting an 'open-circuit reverse flotation technology with one-stage roughing, one-stage fining and two-stage scavenging', thereby obtaining a high-grade hematite and magnetite concentrate; adopting a 'close-circuit centrifuge technology with one-stage roughing and one-stage fining' for sorting a high iron carbonate ore enriched in mine obtained by adopting the 'open-circuit reverse flotation technology', thereby obtaining a siderite concentrate; feeding the centrifuge tailings into a weak magnetic machine and sorting; and recycling fine fraction magnetic concentrates. The new technology provided by the inventionhas the advantages that the lean hematite and magnetite ore containing iron carbonate is sorted by adopting a 'combined sorting process flow with stage grinding, strong magnetic discarding tailings, reverse flotation-centrifuge', so that the sorting indexes of the whole iron grade of the obtained comprehensive concentrate being more than 65% and the metal recovery rate being more than 65% are achieved and the maximization of utilization benefit of iron ore resources is realized.

Owner:鞍钢集团矿业设计研究院有限公司

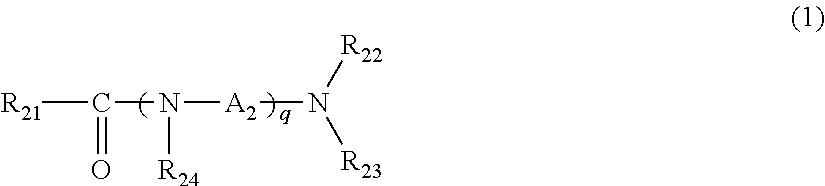

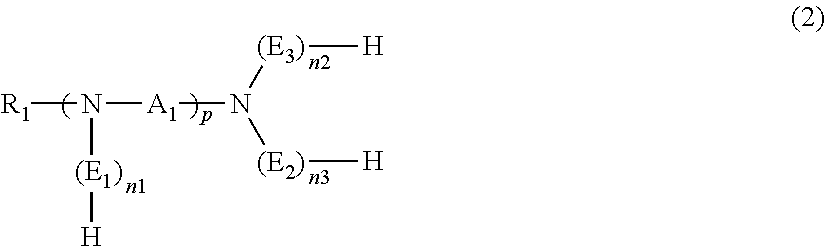

Collectors for ore beneficiation

The present invention relates to fatty amido amine collectors for the beneficiation by flotation of aqueous suspensions of ores, the use of said fatty amido-amine collectors in flotation processes for the beneficiation of ores, more particularly in reverse flotation processes for the beneficiation of silicates containing-ores.

Owner:CECA SA

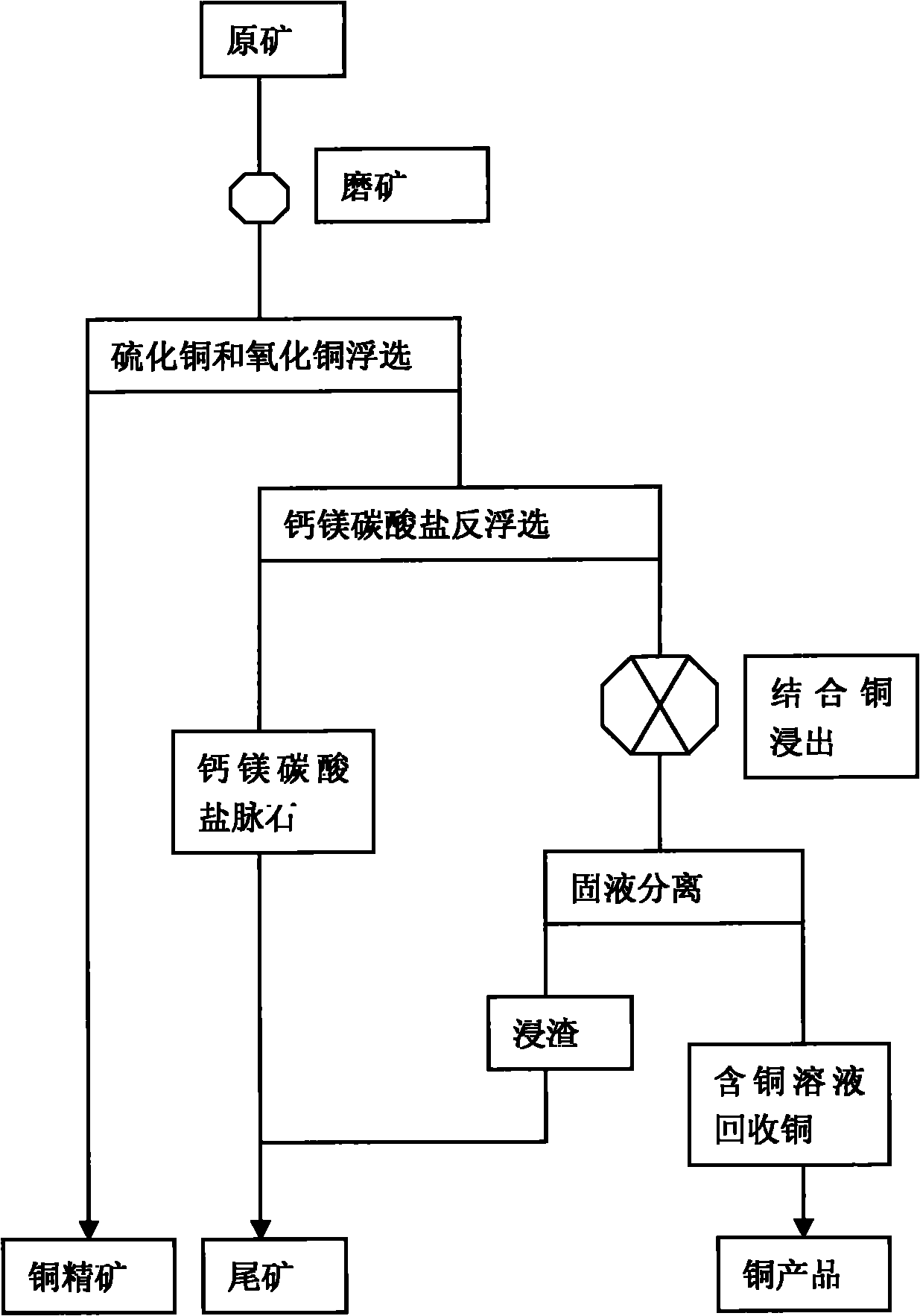

Flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore

ActiveCN101831559AAvoid lostReduce consumptionFlotationProcess efficiency improvementCopper oxideOxygen

The invention relates to a flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore. The flotation and metallurgy method comprises the following steps of: firstly, recovering copper sulfide minerals and free copper oxide minerals in the high-bonding-ratio oxygen-sulfur mixed copper ore with high calcium-magnesium carbonate gangue mineral content by flotation; carrying out reverse flotation on calcium-magnesium carbonate ore in tailings obtained after floatation with fatty acid to obtain middlings containing combined copper and less calcium-magnesium carbonate minerals; then, adding sulphuric acid and stirring to leach out combined copper; and processing a copper-contained solution obtained after solid-liquid separation to obtain a copper product by a metallurgy method. The method combines the flotation and the metallurgy for complementary advantages, efficiently recovers and utilizes high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore resources incapable of being processed at present, lessens the emission of castoff, such as carbon dioxide, magnesium calcium sulfate, and the like and has favorable economic benefits and environmental benefits.

Owner:YUNNAN TIEFENG MINING CHEM NEW TECH CO LTD

Stepped-flotation separation method for iron ore containing carbonas

InactiveCN101274302ANo difficulty returningImprove flotation environmentFlotationMagnetic separationIronstoneHigh intensity

The invention discloses a flotation and separation method of carbonate-bearing iron ore which has fractional steps and is characterized in that the carbonate-bearing iron ore is milled by a ball milling method and pre-separated by adopting low-intensity magnetic separation and high-intensity magnetic separation, and iron ore concentrate that is obtained from the mixed magnetic separation is separated by the flotation technique with fractional steps, which comprises the following steps: in the first step, siderite concentrate is selected under neutral condition by adopting the direct flotation technique; in the second step, the hematite concentrate is selected under strong basicity condition by adopting the reverse flotation technique. The flotation and separation method of the carbonate-bearing iron ore of the invention has smooth process running, the siderite selection in the first step improves flotation environment, and the hematite selection in the second step can finally obtain the hematite concentrate with the iron grade of over 66 percent and the recovery rate of over 62 percent. The flotation and separation method of the carbonate-bearing iron ore of the invention provides an exploiting method of the domestic potential iron ore resources with low iron grade and has important significance to the economical and reasonable exploiting of the carbonate-bearing iron ore.

Owner:ANSTEEL GRP MINING CO LTD +1

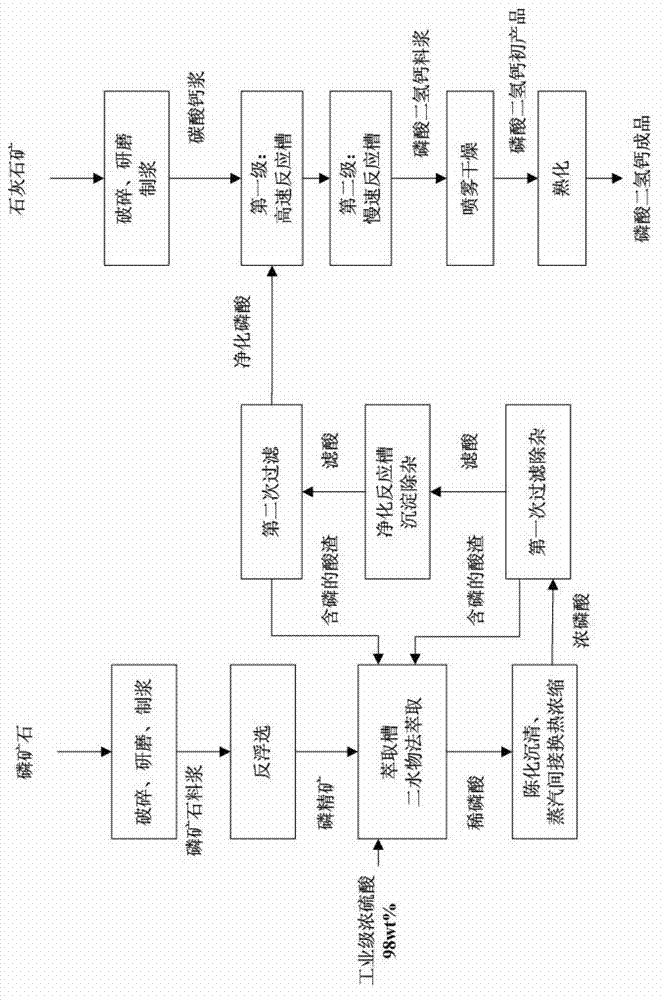

Method for producing feed-grade calcium dihydrogen phosphate from wet-process phosphoric acid

A method for producing feed-grade calcium dihydrogen phosphate from wet-process phosphoric acid comprises the following steps of: pulping by the use of natural phosphate rock and carrying out reverse flotation to obtain phosphate concentrate, extracting for desulphurization by a dihydrate process so as to obtain dilute phosphoric acid, aging, setting and condensing to obtain concentrated phosphoric acid; filtering the concentrated phosphoric acid to remove impurities, extracting acid sludge, filtering acid, setting, removing impurities, carrying out secondary filtration to obtain purified phosphoric acid, and returning filter residue to the extraction step; and grinding limestone mine to obtain a calcium carbonate powder which can pass through a Tyler sieve of -100 meshes and is greater than 95 wt%, adding water to prepare a pulp, performing two stages of high-speed and low-speed reactions between the pulp and the purified phosphoric acid so as to generate a calcium dihydrogen phosphate slurry, and drying and slaking the slurry to obtain a powdered feed-grade calcium dihydrogen phosphate finished product. The method provided by the invention has advantages of high phosphorus yield, good impurity removal effect, low cost, coarse and large crystalllization product and good fluidity. The product is not easy to cake. The method replaces a technological method for producing feed-grade calcium dihydrogen phosphate from hot-process phosphoric acid. The method provided by the invention has advantages of saving energy, reducing emission, decreasing production cost and improving caking property of the calcium dihydrogen phosphate material and material fluidity.

Owner:SINOCHEM YUNLONG

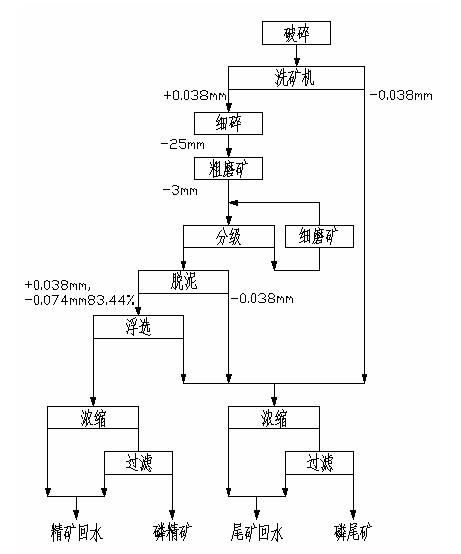

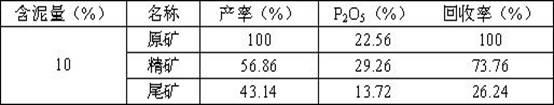

Direct and reverse flotation desliming process of collophanite

The invention discloses a flotation desliming process of collophanite. The flotation desliming process of collophanite comprises the following steps of: scrubbing collophanite crude ore; dividing the crude ore into a coarse fraction part and a fine fraction part according to different particle diameters of particles; feeding the coarse fraction part into a grinding and classification flow after getting the coarse fraction part through an ore washer; feeding into a hydraulic cyclone to deslime for the first time; feeding a settled sand part into a direct and reverse flotation flow after getting the settled sand part through the hydraulic cyclone to obtain flotation concentrate and flotation tailing; removing fine silt from the fine fraction part after getting the fine fraction part throughthe hydraulic cyclone; concentrating and filtering the flotation concentration to obtain finished products phosphate concentrate and concentrate backwater; concentrating and filtering desliming tailing of the ore washer, desliming tailing of the hydraulic cyclone and flotation tailing to obtain phosphorus tailing and tailing backwater; recycling the concentrate backwater and tailing backwater; and returning to each backwater utilization site in the ore washer or a flotation plant. According to the flotation desliming process, the flotation recovery rate and the concentrate grade can be improved, the agent consumption is reduced, and the utilization efficiency of flotation equipment is increased.

Owner:云南三明鑫疆磷业股份有限公司

Collophanite flotation collector and method for preparing same

ActiveCN101797536AStable chemical propertiesGood water solubilityFatty acids production/refiningFlotationSolubilityFatty acid

The invention relates to a collophanite normal-temperature flotation collector, in particular to collophanite flotation collector prepared from natural rubber seed oil fatty acid, belonging to the collector. The invention also relates to a method for preparing the collophanite flotation collector. The collophanite flotation collector comprises natural rubber seed oil fatty acid, tall oil, tributyl phosphate, tween 80, dodecyl benzene sulfonic acid, inorganic base and water. The collophanite flotation collector has stable chemical performance, good water solubility, high flotation speed, suitable viscosity and strong selectivity and collection performance, is easy to diffuse in collophanite pulp, can be used for obverse floatation and reverse flotation and can generate uniform bubbles, obviously shorten the floatation time, improve the concentrate grade and reduce the content of impurities in the concentrate product.

Owner:YUNNAN CHEM RES INST

Reverse/direct flotation technology of collophanite

The invention discloses a reverse / direct flotation technology of collophanite. The technology comprises the following steps of: performing ore reduction, ore grinding and size mixing on the silicon calcium type collophanite; adding a carbonate gangue mineral flotation regulator and fatty-acid soap respectively to perform size mixing; performing reverse flotation on the material after the size mixing, wherein the product in the tank is reverse flotation concentrate; dehydrating the reverse flotation concentrate and adding sodium carbonate so as to adjust the pH value to 8-10; performing closed-loop ore grinding and grading on the base flow; enabling the grading overflow to enter a direct flotation stirring tank, and adding water glass and fatty acid soap into the tank respectively to perform size mixing; performing direct flotation on the material subjected to the size mixing, wherein the direct flotation foam product is direct flotation concentrate; and performing concentration, filtration and drying to obtain the finished product of phosphate concentrate. After dehydration (reagent removal), the technology disclosed by the invention can be used for remarkably reducing the amount of sodium carbonate for neutralizing acid water; the sodium carbonate has a dispersion and grinding aid function, and the over-grinding of the material of direct flotation can be reduced; and the fresh surface and proper size composition generated by the ore grinding are favorable for improving the sorted behavior of the direct flotation and improving the sorting efficiency.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

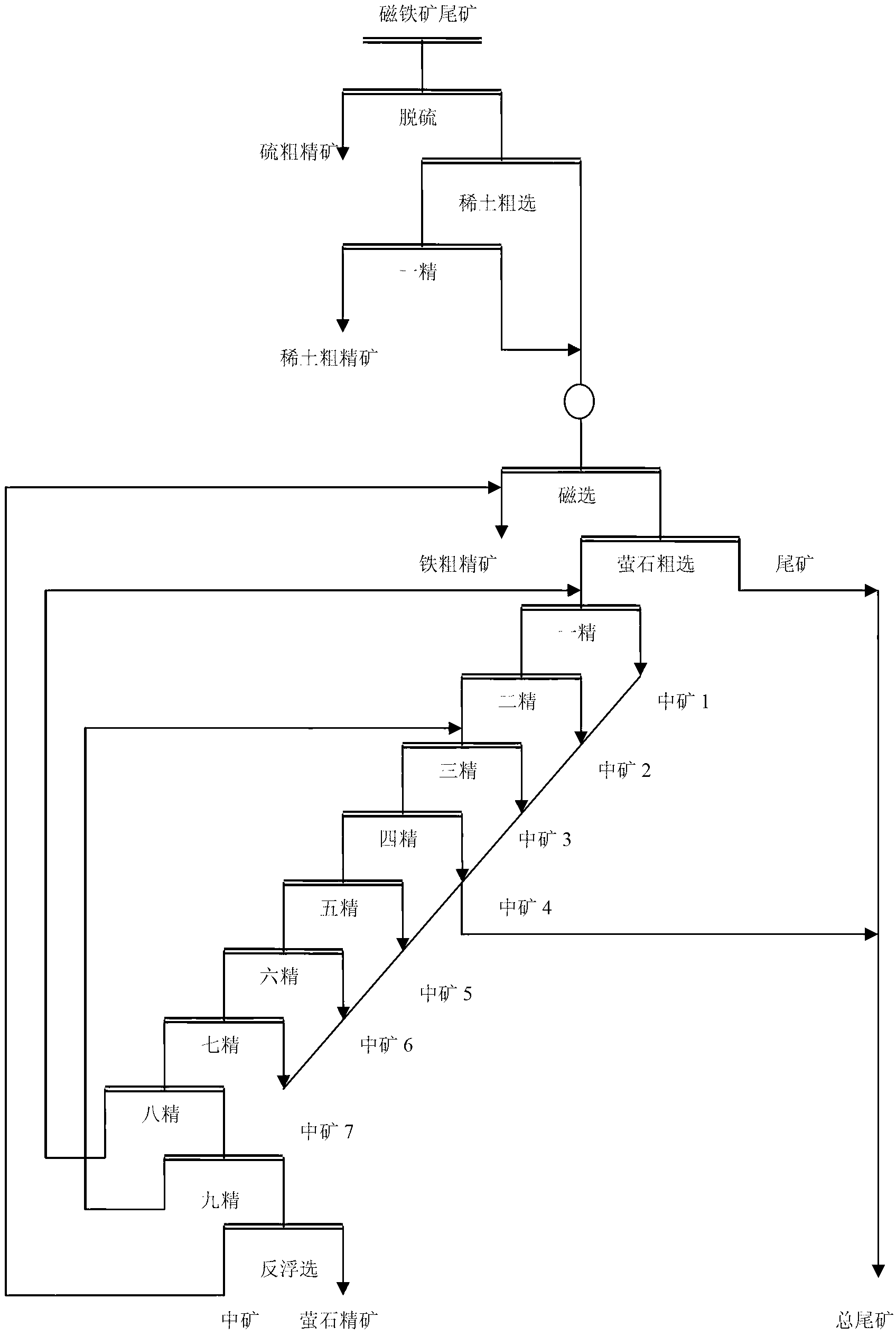

Mineral processing technology for recycling fluorite from baotite, magnetite and tailing

The invention belongs to the technical field of mineral engineering and provides a mineral processing technology for recycling fluorite from baotite, magnetite and tailing. In the tailing, mineral particle size of the fluorite is thin, iron-bearing mineral, rare-earth mineral, gangue mineral and the fluorite mineral are closely symbiotic and floatability of minerals such as rear earth, barite, apatite, calcite and dolomite is close to the fluorite mineral, so that separation of the fluorite mineral is difficult. According to the mineral processing technology for recycling the fluorite from the baotite, the magnetite and the tailing, priority desulfuration, rear earth flotation, ore grinding, iron selection through magnetic separation, fluorite selection through direct flotation and a reverse flotation sorting technology are performed on the magnetite and the tailing to enable pyrite, the rare earth, the iron-bearing mineral and the fluorite to be picked out in sections, efficient, high selective, easy-to-operate inhibitor and collecting agent combination is utilized in sorting of fluorite which is mostly performed monomer separation, so that fine fluorite of high grade and high recovery rate is obtained, a purpose of synthetically recycling valuable minerals is achieved, and effective separation of the fluorite mineral and the gangue mineral is achieved.

Owner:包钢集团矿山研究院(有限责任公司)

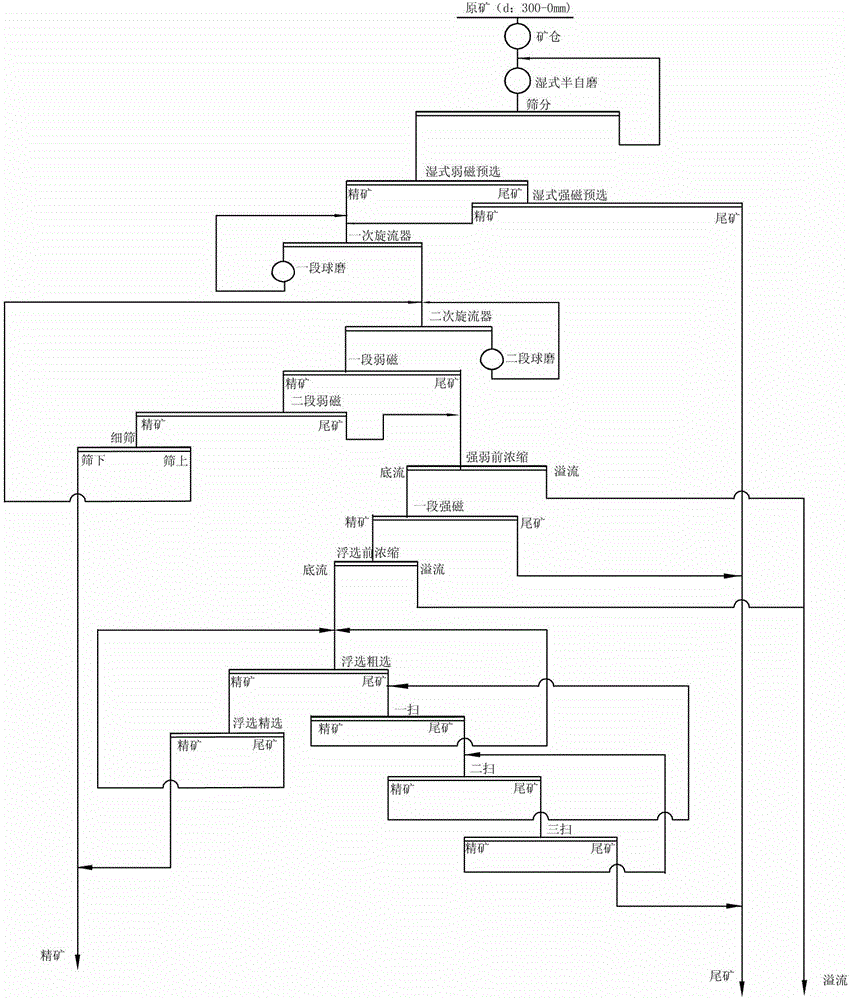

Coarse grain pre-selection and magnetic-floating separation process for mixed ores with embedded micro-fine particles

ActiveCN104874462AReduce the amount of oreReduce dosageSolid separationGrain treatmentsReverse flotationLarge particle

The invention relates to a coarse grain pre-selection and magnetic-floating separation process for mixed ores with embedded micro-fine particles. The coarse grain pre-selection and magnetic-floating separation process is characterized in that a 'half-self-grinding, wet-type pre-selection, continuous ore grinding, weak magnetic-strong magnetic fine screening and re-grinding and strong magnetic reverse flotation' operating system is adopted to sort the mixed ores with embedded micro-fine particles, and iron ore concentrates with grade of 65%-65.5% and yield of 35%-40% are obtained. The coarse grain pre-selection and magnetic-floating separation process has the advantages that 15%-20% large-particle qualified tailings are obtained from the ores through the wet-type pre-selection, the magnetic ores with yield of 15%-20% and grade of higher than 65% can be separated in advance through magnetic-floating separation, the ore feeding amount of separation operation is reduced, the number of flotation machines is decreased, agent using amount is decreased, and ore separation cost is reduced.

Owner:ANSTEEL GRP MINING CO LTD

Method for separating oolitic hematite

InactiveCN101693222AReduce lossesEconomic beneficiation costHigh gradient magnetic separatorsFlotationSulfateReverse flotation

The invention discloses a method for separating oolitic hematite, and the process of the method comprises discarding tailings of ores by intense magnetic separation through stage grinding and stage separation, and de-phosphorizing and increasing iron to the intense magnetic concentrated by reverse flotation. The intense magnetic separation is functioned of concentrating iron minerals and desliming, thereby preventing smile from influencing flotation. The highly-effective regulator is made from sodium carbonate, sodium silicate and sodium hydroxide, the collecting agent is a composite medicine made from hydroximic acid and alkyl sulfate, and the method for separating oolitic hematite is a key technology for the reverse flotation to further upgrade the concentrate of iron ore. The invention has the advantages of simple technological process, low energy consumption, low cost and good product index, and solves the defects in prior art.

Owner:GUIZHOU UNIV

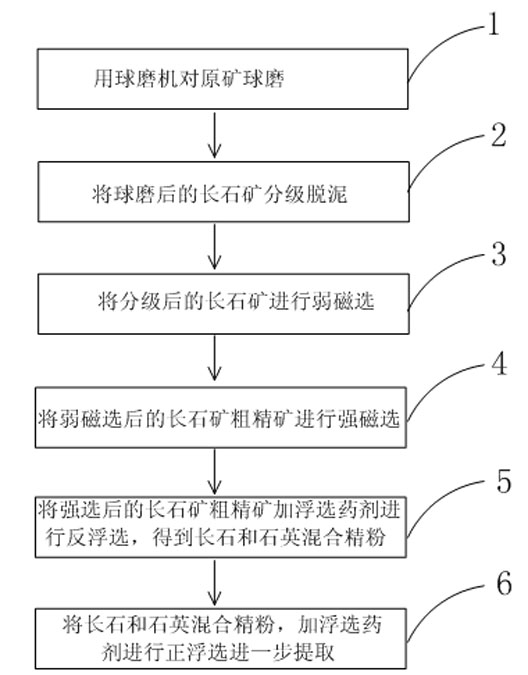

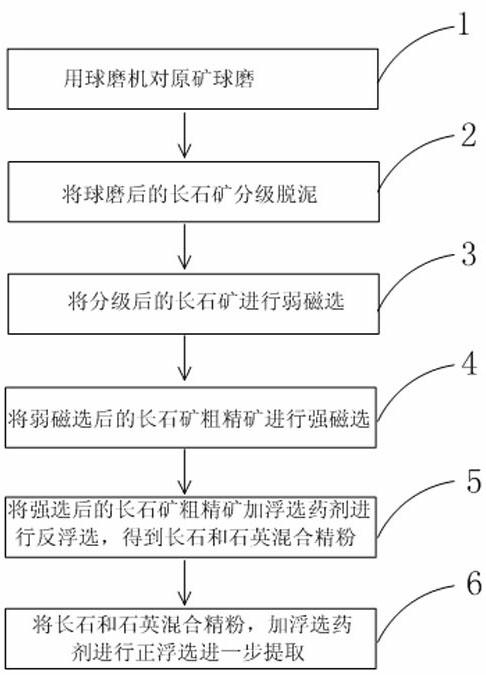

Method for separating and extracting feldspar ore with complex impurity components

InactiveCN102069033AEfficient removalImprove burnt board whitenessWet separationHigh intensityReverse flotation

The invention relates to a method for separating and extracting feldspar ore with complex impurity components, which comprises the following steps of: 1) performing ball milling on the feldspar ore with complex impurity components through a ball mill; 2) performing classification and de-sliming on the milled feldspar ore by using an improved hydraulic classifier; 3) performing low-intensity magnetic separation on the classified feldspar ore through a low-intensity magnetic separator to obtain high-intensity magnetic substances and rough feldspar concentrate for high-intensity magnetic separation; 4) performing high-intensity magnetic separation on the rough feldspar concentrate obtained by the low-intensity magnetic separation through a high-intensity magnetic separator to obtain low-intensity magnetic substances and rough feldspar concentrate for flotation; and 5) performing size mixing and segmentation on the rough feldspar concentrate obtained by the high-intensity magnetic separation, adding a flotation agent, and performing reverse flotation, impurity removal and dehydration through a flotation machine to remove impurities and obtain fine feldspar and quartz mixed powder and flotation water.

Owner:烟台宜陶矿业有限公司

Reverse flotation iron increase and silicon removing method for refractory limonite

InactiveCN101234366AImprove mineral processing recovery rateReduce typesFlotationIron increasedRefractory

The invention discloses an reverse flotation iron extracting and desiliconizing method of rebellious limonite. The procedure of the invention is as following: finely grinding, dispersing and desliming ore; adding sulphuric acid to stir the ore power into paste; adding a certain amount of starch or modified starch, lignosulfonate sulphonic acid and their salt and polyacrylamide with the molecular weight about 10,000 or polyacrylamide inhibitory iron-bearing mineral; adopting cation collector quaternary ammonium salt to reverse flotation and separate ore with silicon range or iron ore in a method of adding a little amount of medicine for many times. The reverse flotation iron extracting and desiliconizing method has the advantages of simple process, few medicine agent varieties, able to obtain high grade iron ore concentrate and good effect of raising ore dressing recovery percentage of limonite.

Owner:CENT SOUTH UNIV

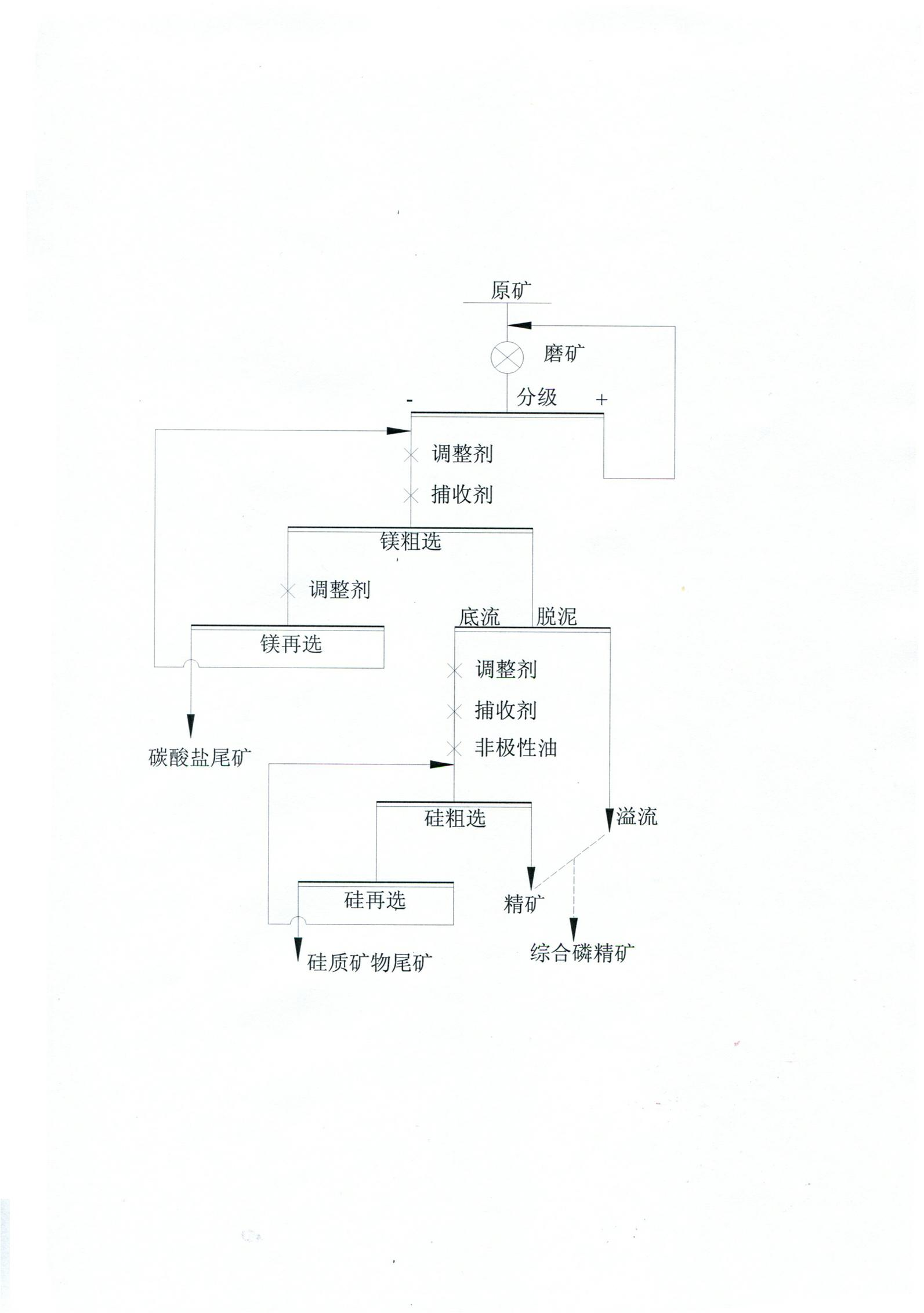

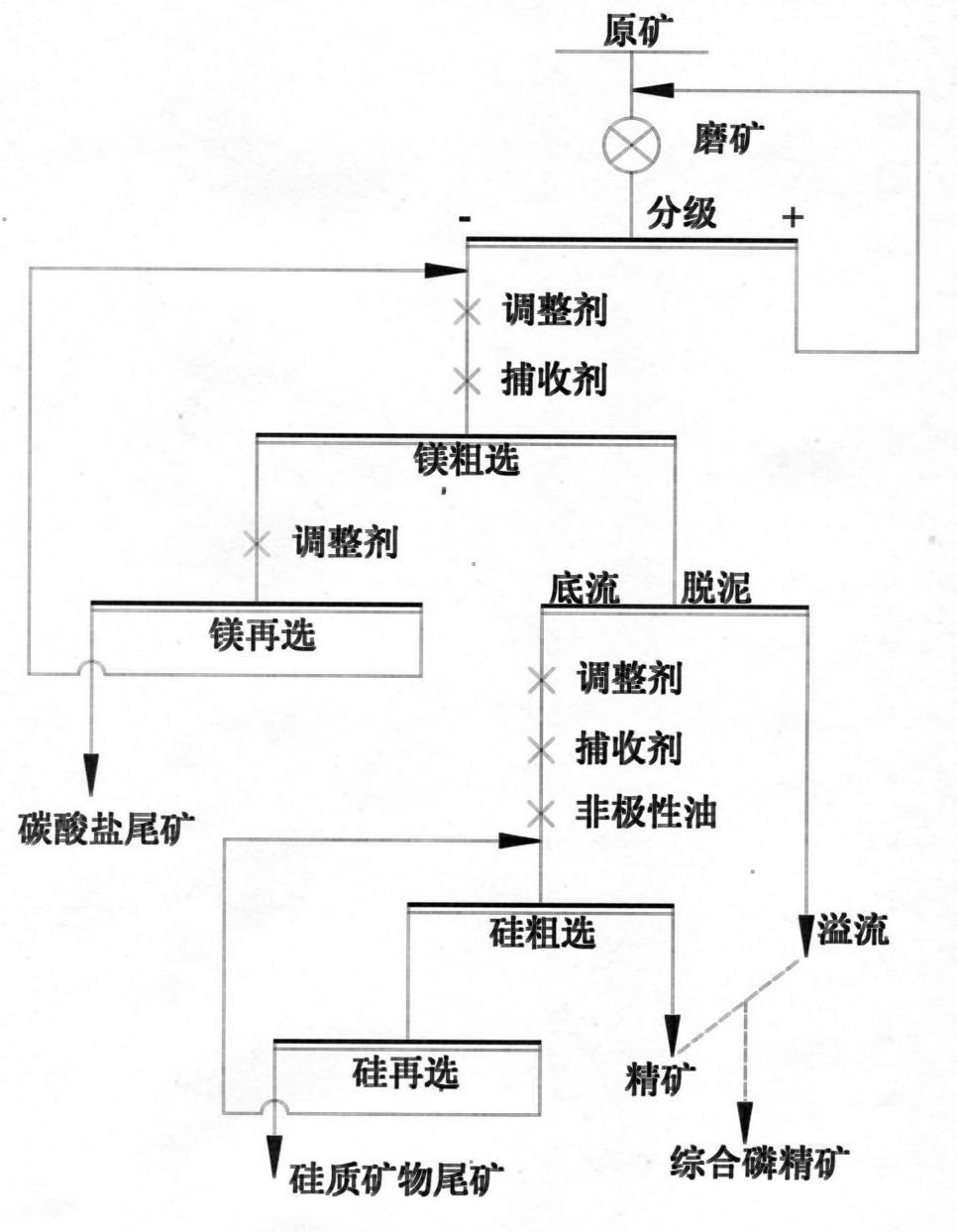

Phosphorite double-reverse flotation process

The invention relates to phosphorite double-reverse flotation process, which comprises reverse flotation de-magging, desliming and pulp mixing and reverse flotation desilicication. The phosphorite double-reverse flotation process is characterized in that ore pulp after reverse flotation de-magging realizes desliming, the concentration of a desliming bottom flow and the content of fine particles are controlled, and reverse flotation desilicication is realized after pulp mixing of the bottom flow. The phosphorite double-reverse flotation process can eliminate or mostly remove interference of slime to reverse flotation desilicication, increases flotation efficiency, more importantly, improves fluidity of flotation foam, and lead phosphorite double-reverse flotation to be engineered.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

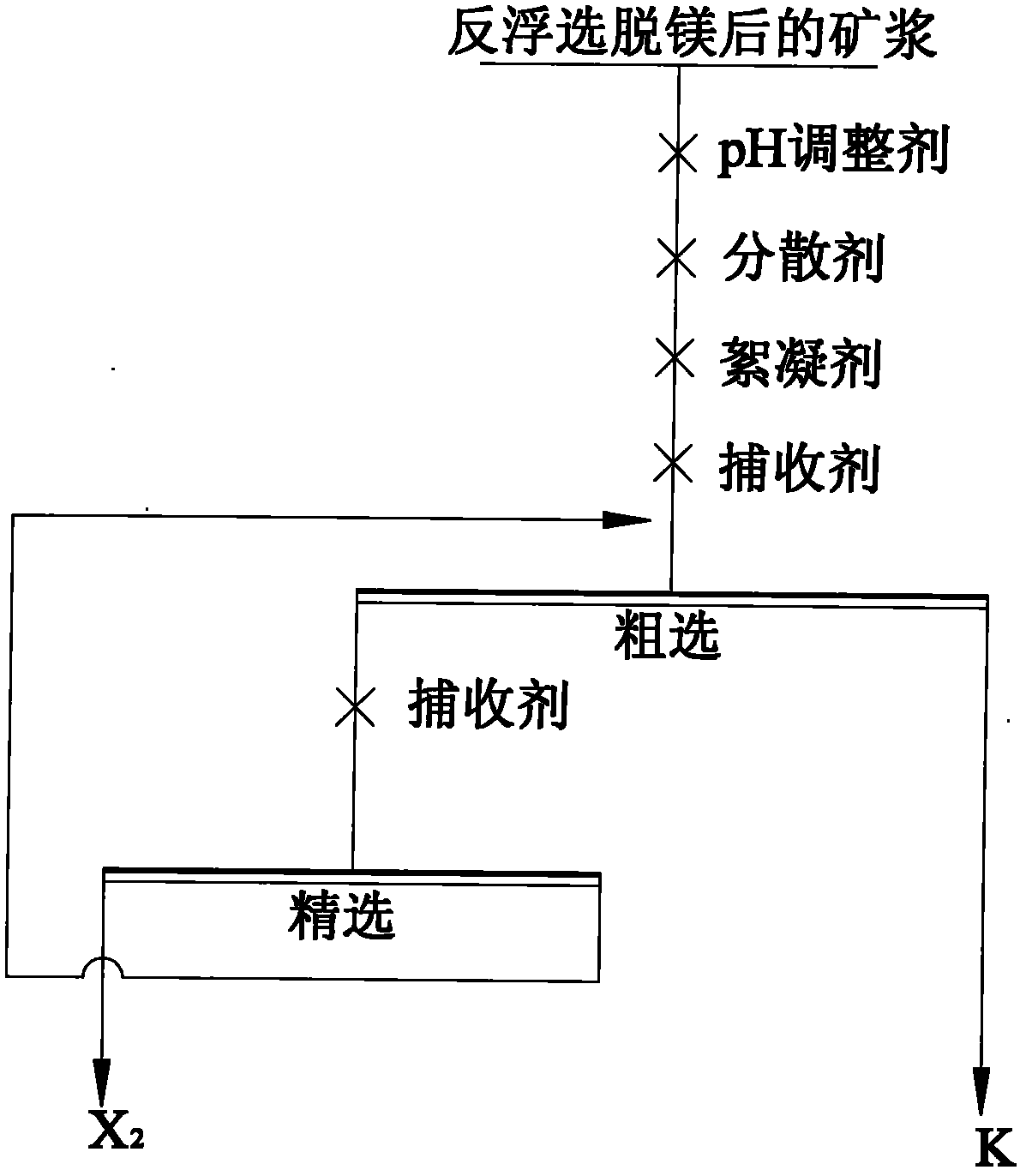

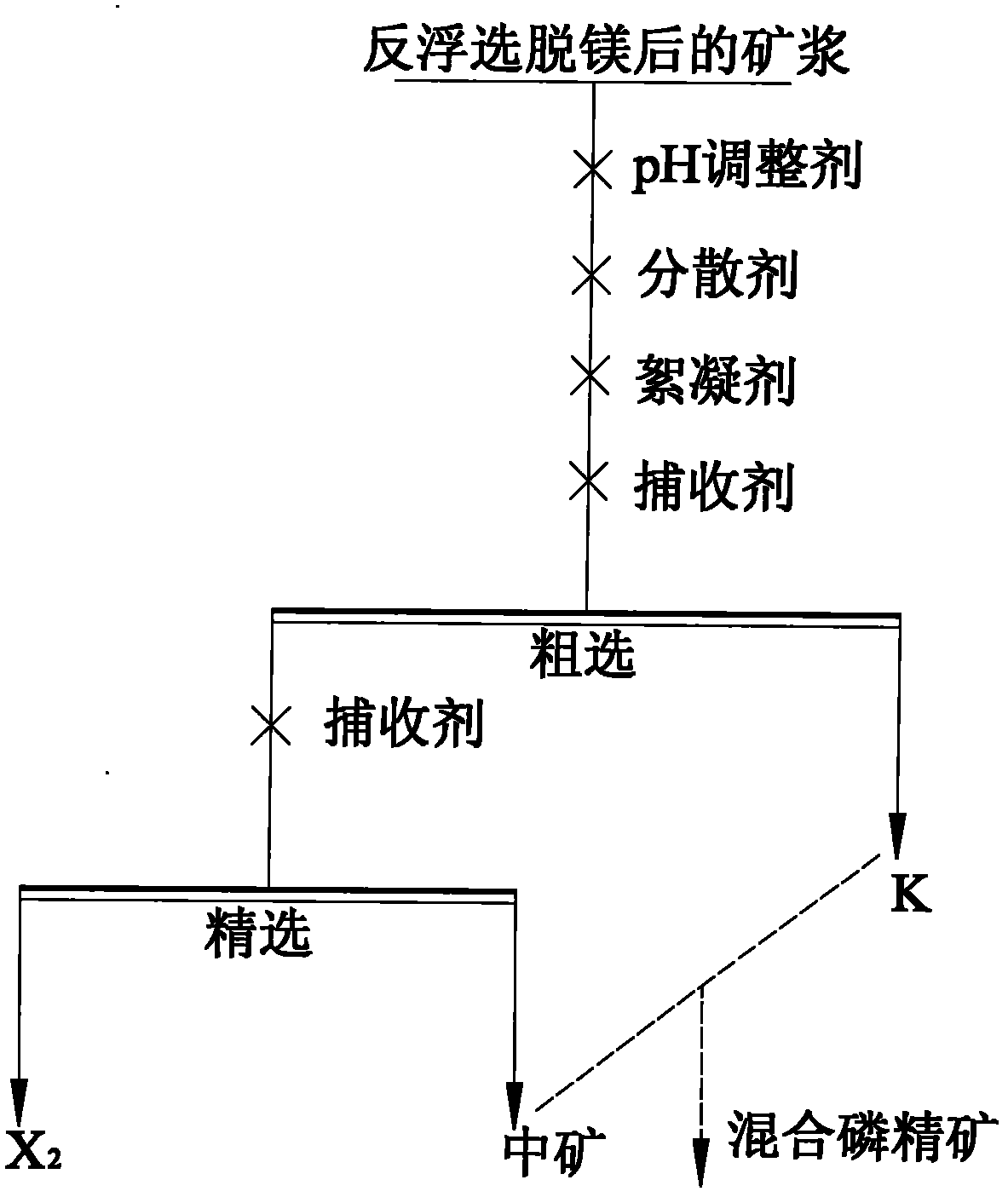

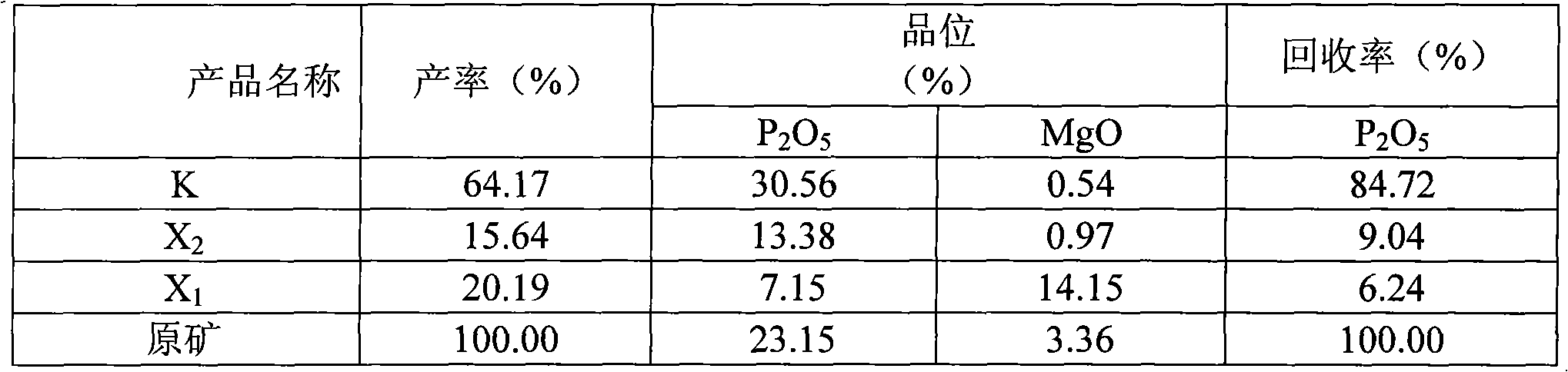

Selective flocculation reverse flotation desilication process of collophanite containing primary slime

The invention relates to a selective flocculation reverse flotation desilication process of collophanite containing primary slime. The process comprises the following steps of: adding a modifier sodium hydroxide or sodium carbonate to the pulp obtained after the collophanite containing primary slime is subjected to the reverse flotation demagging till the pH value of the slurry is between 9.5 and10.5; then, adding a dispersant water glass or alkali metal phosphate, a flocculant anionic starch and a collector ethers propylamine or alkyl diaminopropane for roughing and obtaining concentrate ina roughing groove; and adding a collector to roughed foam, concentrating, using concentrated foam as tailing, returning middling in a concentrating groove for roughing or mixing with the concentrate in the roughing groove into mixed phosphor concentrate, wherein flotation machine impellers have the rotating speed of 1900-2400 rounds / min. In the process provided by the invention, the anti-flotation separation of siliceous gangue of quartz class is realized by adjusting the pH value of the slurry, adding various agents and selectively flocculating and inhibiting the collophanite according to the surface acting force of the various medicaments on the collophanite surface, and the optimal separation effect is achieved through adjusting the rotating speed of the flotation machine impellers.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

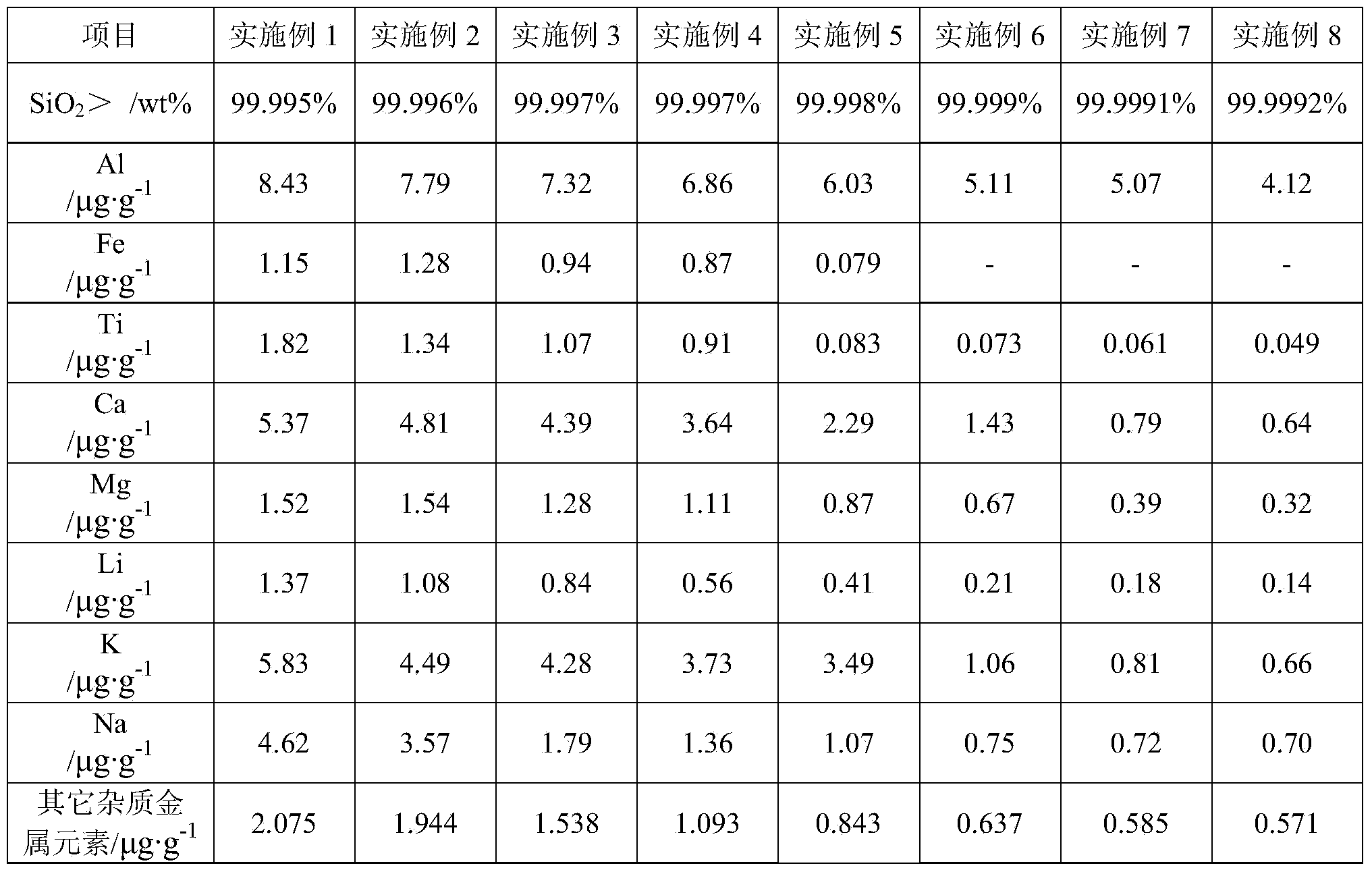

Method for preparing ultralow-metallic-element ultrahigh-purity quartz through mixed acid hot-pressing leaching reaction

ActiveCN103539133AReduce mineral contentIncreased contact surface areaSilicaPurification methodsChemical reaction

The invention relates to a method for preparing ultralow-metallic-element ultrahigh-purity quartz through mixed acid hot-pressing leaching reaction. The method is characterized by comprising the following steps of crushing and classifying; performing magnetic separation; performing three-section preferential reverse flotation; performing roasting and water quenching; performing hot-pressing leaching, namely putting a product of roasting and water quenching in a reaction kettle, and performing hot-pressing acid leaching reaction in a mixed acid system while stirring, wherein the reaction temperature is 120-400 DEG C, the reaction pressure is 0.5-15.0MPa, the reaction time is 0.5-8h, and the mixed acid system for the hot-pressing leaching chemical reaction is a mixed solution of HF, HNO3 and HCl; after hot-pressing acid leaching, filtering and washing the product until the product is neutral, and drying to obtain the ultralow-metallic-element ultrahigh-purity quartz. The purification method is simple in process and easy to operate; the ultralow-metallic-element ultrahigh-purity quartz of which the SiO2 content reaches 99.995wt%, preferably 99.999wt%, can be prepared by the method.

Owner:陕西合兴硅砂有限公司

Collophane low-temperature reverse flotation collector and preparation method thereof

InactiveCN101983776ALow concentrate MgO contentReduce the cost of beneficiationFlotationPhosphoriteReverse flotation

The invention relates to a collophane low-temperature reverse flotation collector and a preparation method thereof. The collector is prepared by mixing basic substance with water in a weight ratio of 1:20-100, wherein the basic substance comprise the following components by weight percent: 90-95% of higher fatty acid soap with the fatty acid content of no less than 40% and 5-10% of terpenol. The collector is characterized in that the grade of the selected crude ore is low, the applicable scope is wide, the recovery rate of the concentrate is high, the MgO content of the concentrate is low and the cost of ore dressing is low. Compared with the prior art, the gelation of the collector is difficult to appear below 10 DEG C, the flotation index is qualified and the collector can adapt to the low-temperature flotation.

Owner:HUBEI FORBON TECH

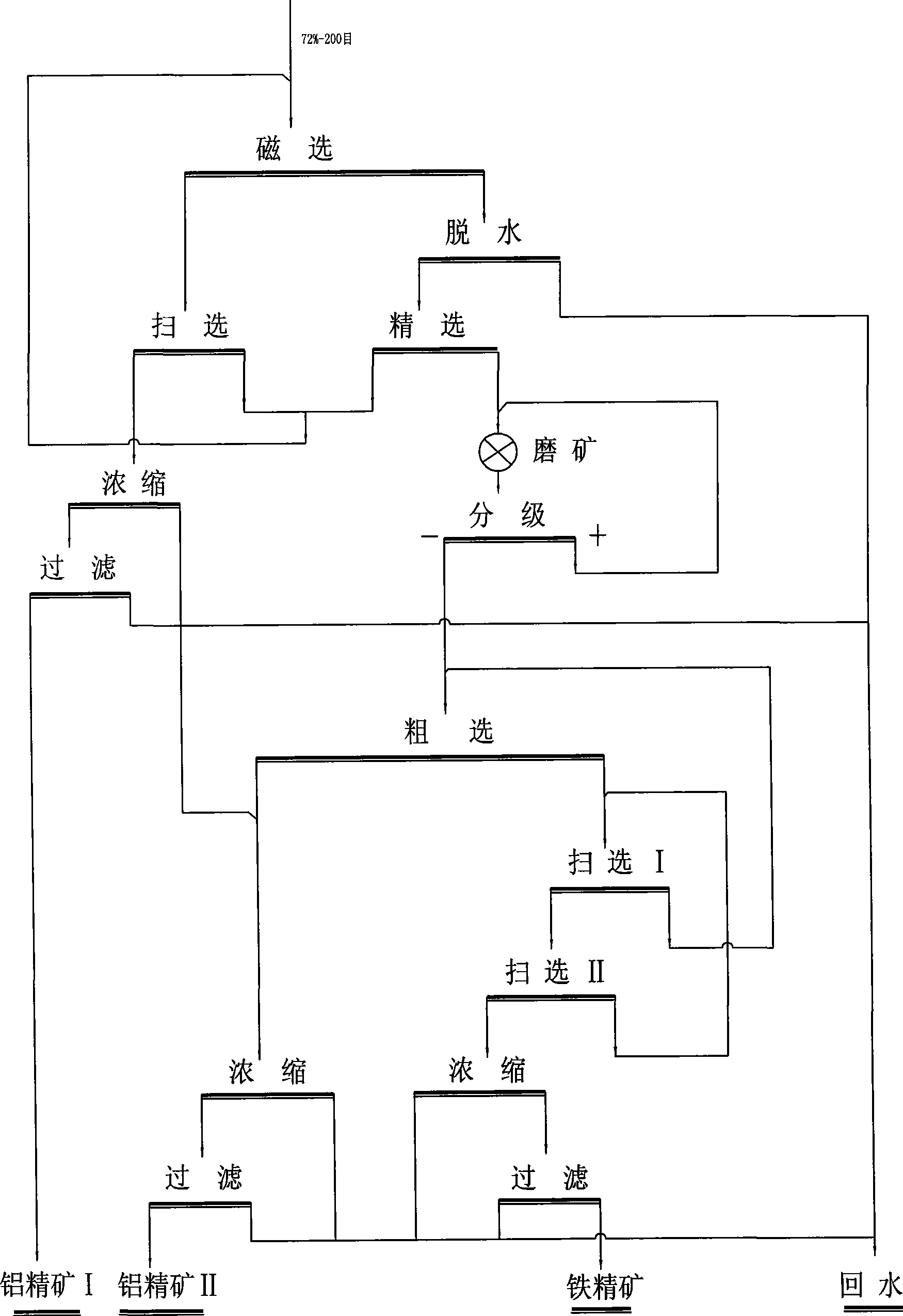

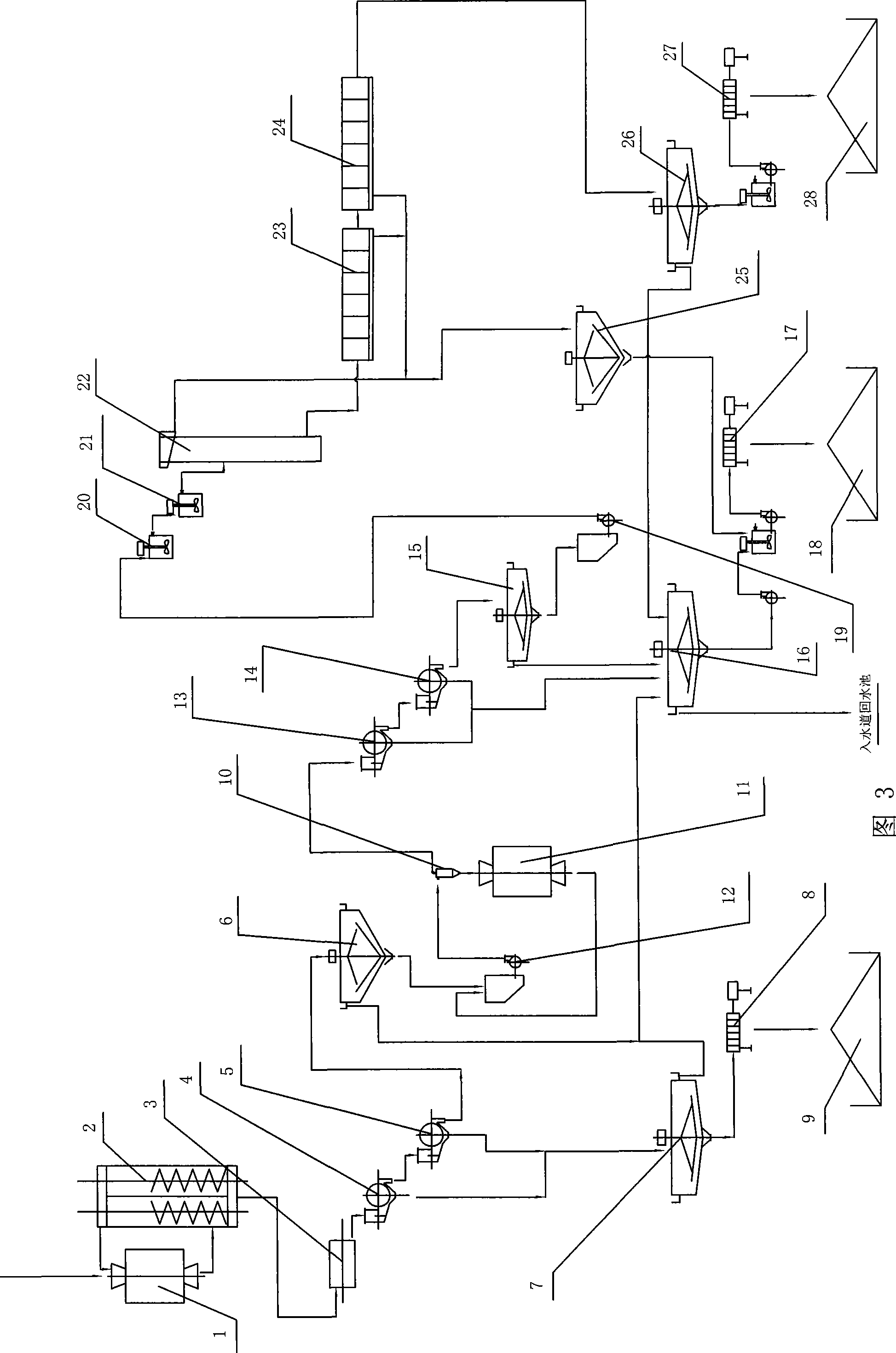

High iron bauxite dressing method

ActiveCN101417260AQuality improvementLower iron contentHigh gradient magnetic separatorsFlotationProduction rateReverse flotation

The invention provides a beneficiation method for high iron bauxite. The invention adopts strengthening magnetic separating-anionic reverse flotation flow, stage grinding and stage magnetic separating. Under the condition of ensuring the magnetic separating iron concentrate recovery rate, strengthening magnetic separating has the priority to obtain higher quality aluminum concentrate one and high grade iron rough concentrate, thus improving the selection grade of the reverse flotation and opening circuit fully in the reverse flotation process, a reverse flotation rougher flotation device adopts a flotation column with large charge and fine even bubbles, thus obtaining iron concentrate with higher quality. In addition, the beneficiation method optimizes and reduces the production rate of material entering reverse flotation operation, and achieving the purposes of energy saving and consumption reducing.

Owner:中铝国际南方工程有限公司

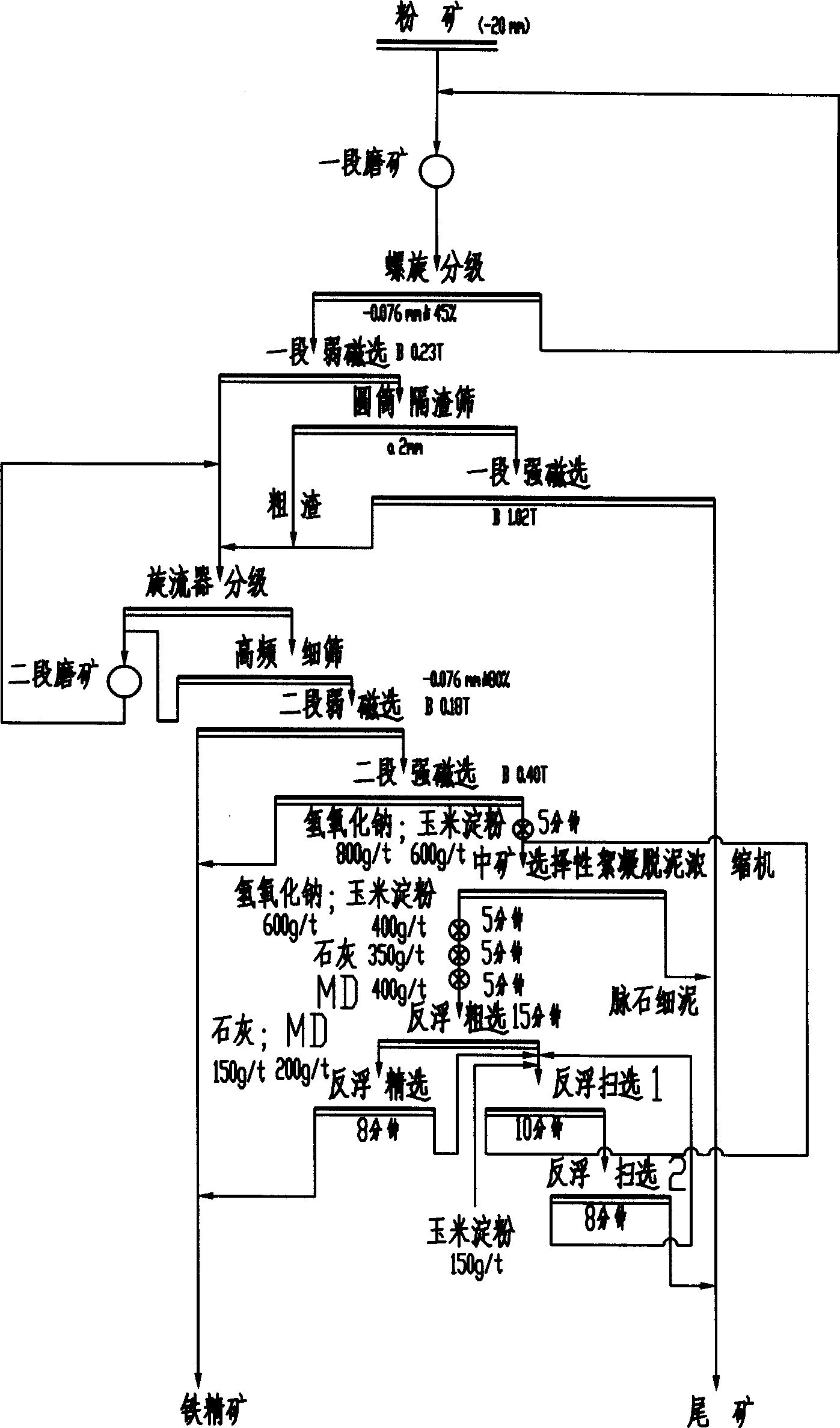

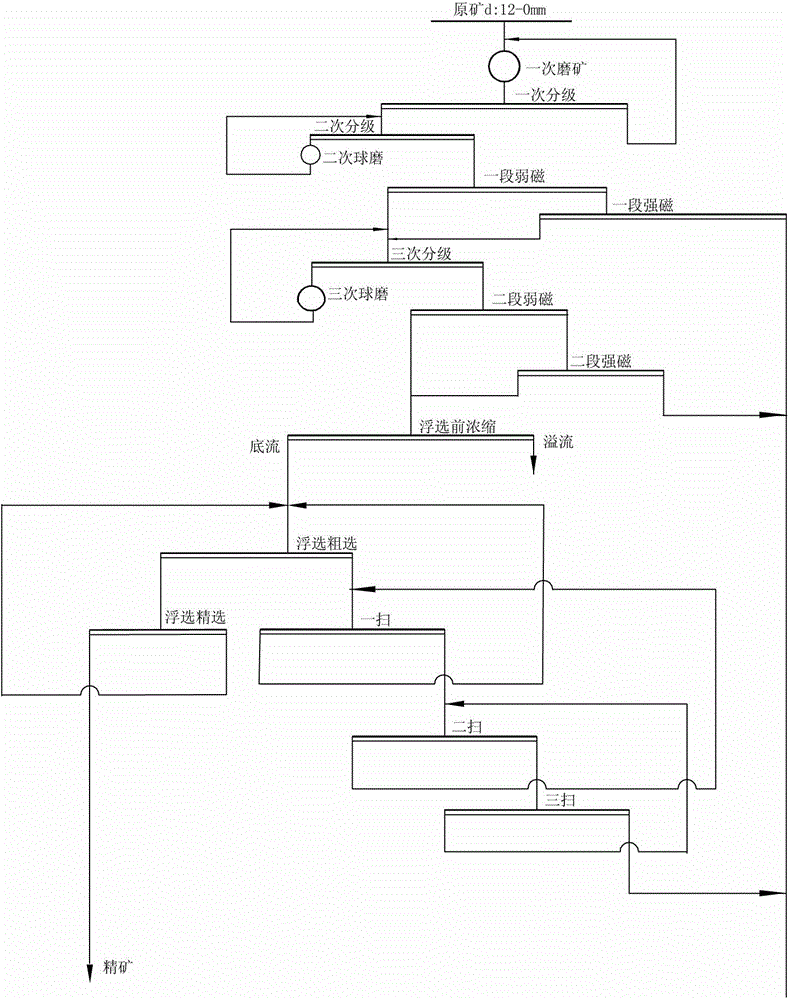

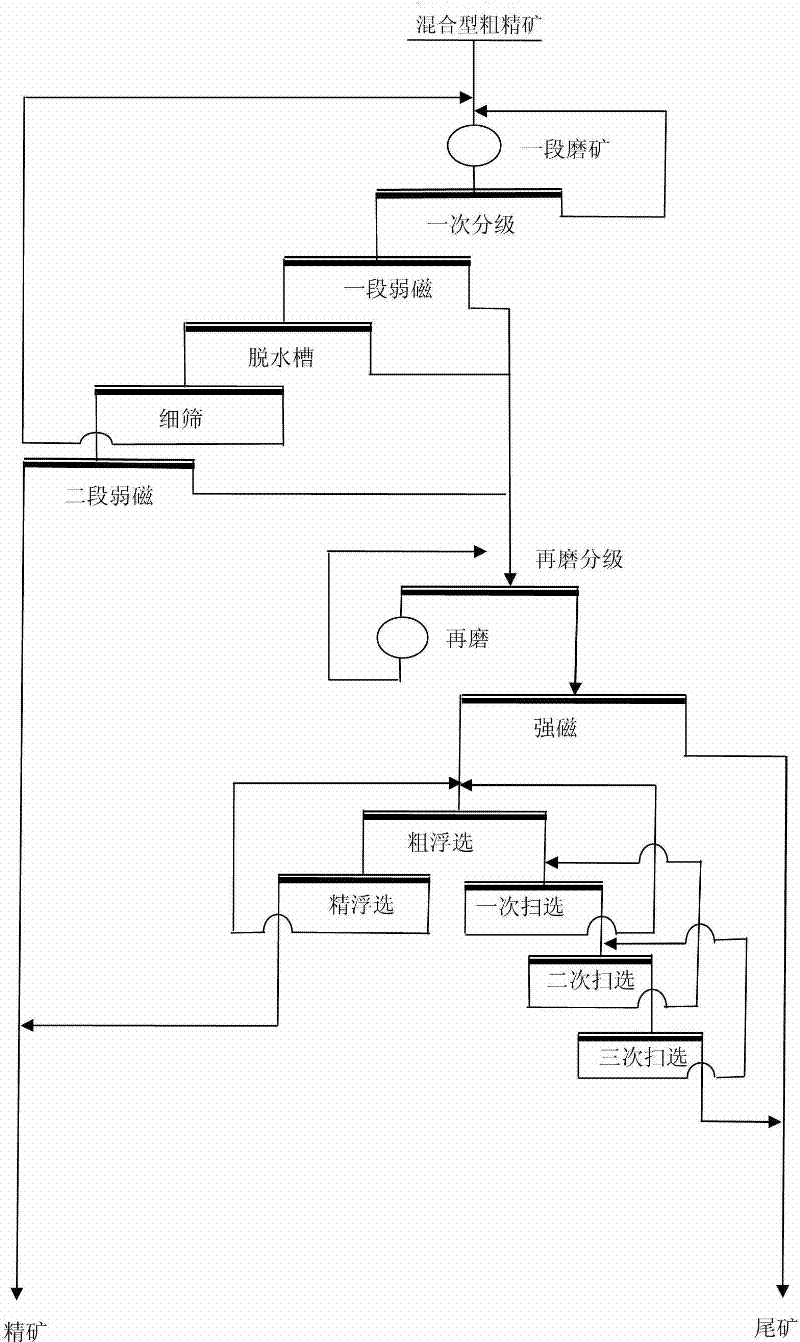

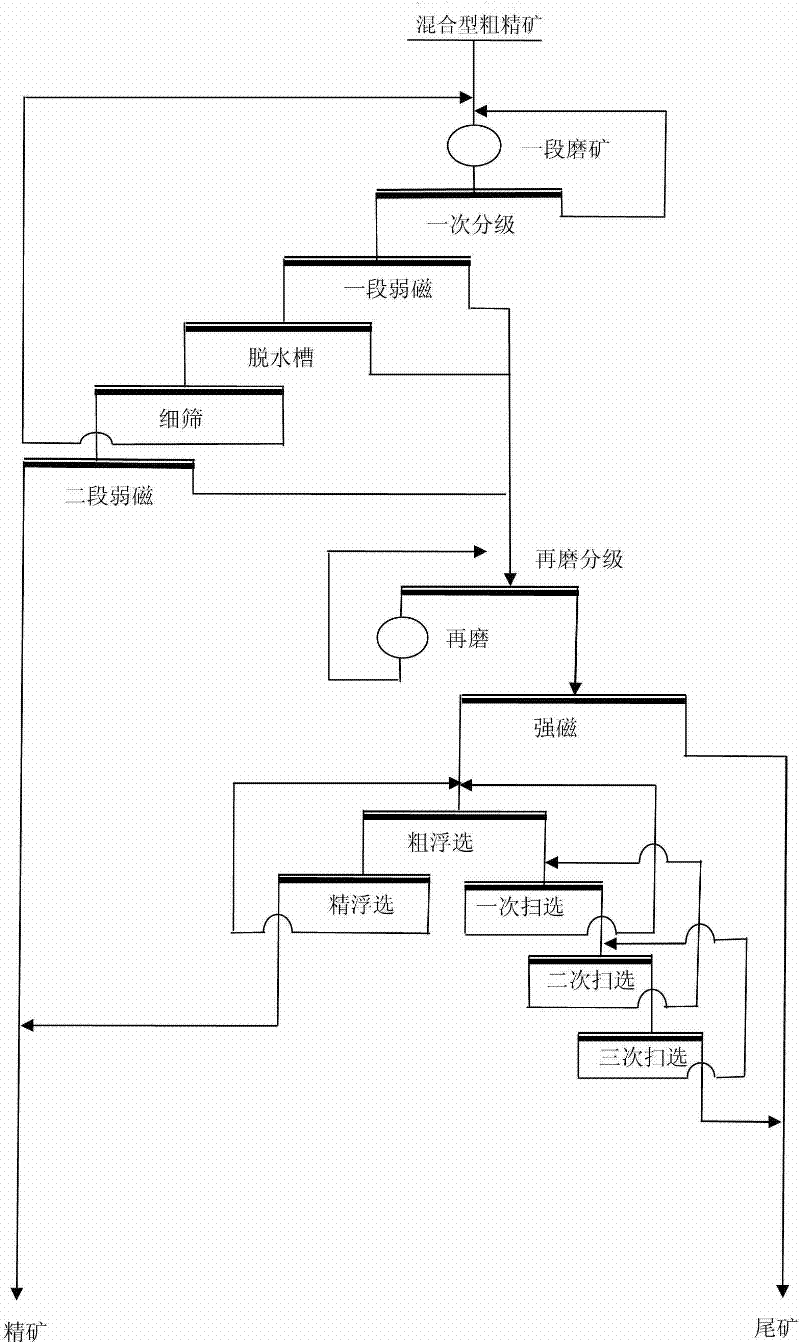

Mineral separation process for magnetic hematite rough concentrates

ActiveCN102441481ATo achieve the purpose of increasing iron and reducing siliconSolve the technical problems of improving the quality of coarse and concentrated oresFlotationMagnetic separationHybrid typeEngineering

The invention relates to a mineral separation process for magnetic hematite rough concentrates, which comprises the following steps of: feeding the magnetic hematite rough concentrates into a closed circuit grinding system; once grading, overflowing and feeding into weak magnetism at first section; feeding the concentrates in the weak magnetism at the first section into a dewatering tank; feedingthe concentrates in the dewatering tank into a fine sieve; returning rough particle products on the sieve into the first section for grinding; feeding fine particle products under the sieve into weakmagnetism at second section; mixing tailings in the weak magnetism at the second section, tailings in the weak magnetism at the first section and tailings in the dewatering tank to obtain low intensity magnetic separation tailings; concentrating the low intensity magnetic separation tailings by a concentrating machine; feeding into a closed circuit regrinding system; grading, overflowing and feeding again into strong magnetism; concentrating strong magnetic concentrates by the concentrating machine; feeding into a negative ion reverse flotation process including one-time rough separation, one-time fine separation and three-time scavenging; combining the strong magnetic tailings with the floatation tailings to obtain final tailings; and combining the concentrates in the weak magnetism at the second section with the flotation concentrates to obtain final concentrates. The mineral separation process provided by the invention is simple, high-efficiency, particularly low-cost, good in effect and high in concentrate quality and metal recovery rate, and realizes high-efficiency utilization of resources.

Owner:ANSTEEL GRP MINING CO LTD

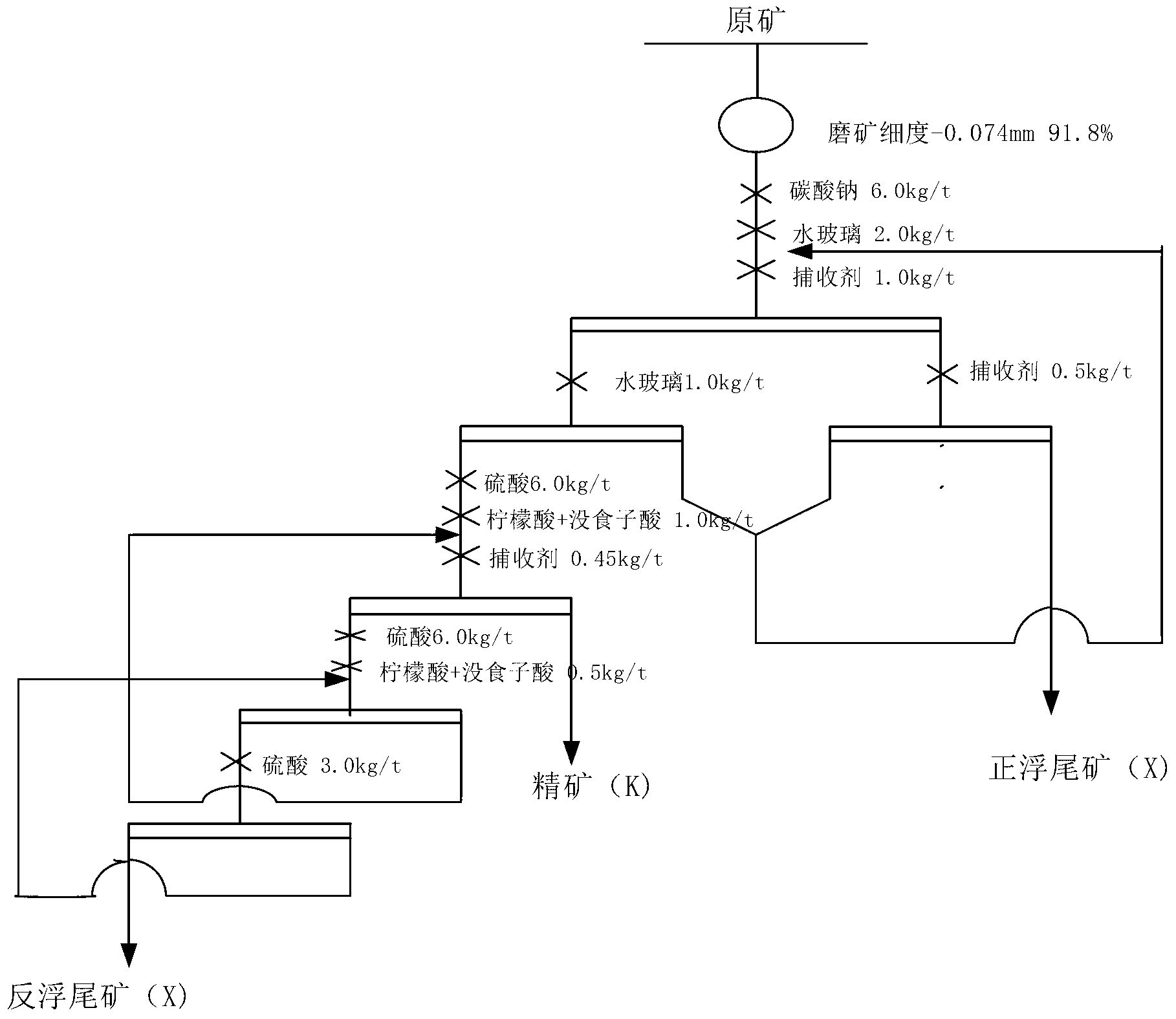

Branch flotation technology for silicon calcium collophanite

The invention relates to a branch flotation technology for collophanite, which comprises the following steps: crushing and grinding silicon calcium collophanite ores, and then adding water and mixing into slurry, and guiding the slurry to flow into a flotation groove; adding a regulator and a collecting agent for mixing the slurry, and then pouring into a reverse flotation system for performing reverse flotation, wherein products in the groove are reverse flotation concentrates; grading the reverse flotation concentrates into coarse fraction and fine fraction; pouring the coarse fraction partinto a desilicification reverse flotation groove, adding a desilicification regulator and a desilicification collecting agent for mixing the slurry, and then pouring into a desilicification system for performing reverse flotation, wherein products in the groove are desilicification reverse flotation concentrates; pouring the fine fraction part into a normal flotation groove, adding a normal flotation pH (Potential of Hydrogen) regulator, the regulator and the collecting agent for mixing the slurry, and then performing normal flotation, wherein foam products of the normal flotation are normal flotation concentrates; mixing the normal flotation concentrates with the desilicification reverse flotation concentrates, thereby forming the final phosphorus concentrates; and concentrating, filtering and drying, thereby obtaining phosphorus concentrates. The branch flotation technology for collophanite has the advantages that the separation efficiency is high, the technic index is excellent, the content of MgO in the obtained phosphorus concentrates is lower, the quality of the concentrates is high, and the comprehensive cost of the final product of the phosphor concentrates is lower.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Compound maghemite ore dressing method

ActiveCN106076606AAdvantages of beneficiation methodIndicators are stableWet separationMaghemiteHigh intensity

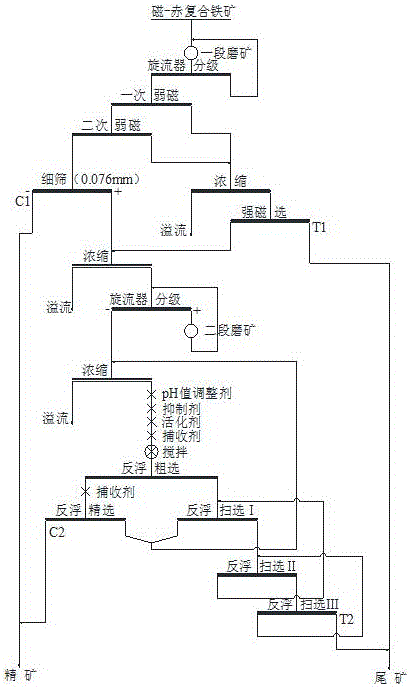

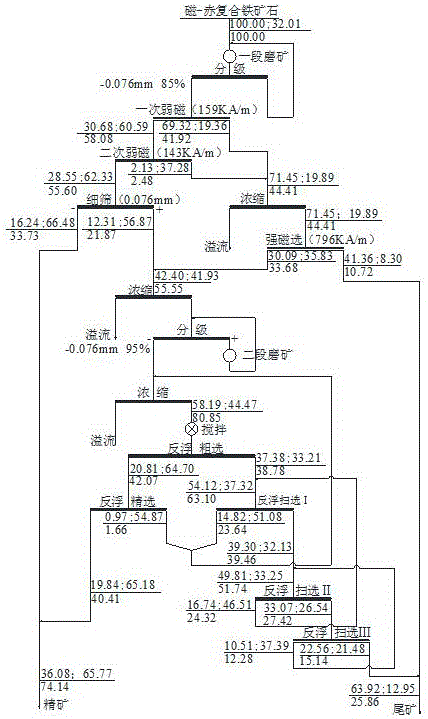

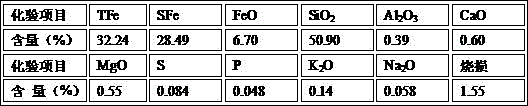

The invention discloses a compound maghemite ore dressing method. The compound maghemite ore dressing method comprises the following steps: feeding compound maghemite ore into an ore grinding-grading-low-intensity magnetic separation operation segment to obtain low intensity magnetic separation concentrate and low-intensity magnetic separation tailings; feeding the low-intensity magnetic separation concentrate into a fine sieving operation segment to obtain finely-sieved concentrate C1; feeding the low-intensity magnetic separation tailings into a high-intensity magnetic separation operation segment, and throwing out high-intensity magnetic separation tailings T1 to obtain high-intensity magnetic separation concentrate; combining coarse fraction low-intensity magnetic separation concentrate with the high-intensity magnetic separation concentrate, and feeding the mixture into a pre-grading-two-stage ore grinding-reverse flotation operation segment to obtain reverse flotation concentrate C2, and throwing out reverse flotation concentrate T2. In the method, staged ore grinding and high-intensity tailing throwing are adopted, so that discarding as soon as possible is realized; the low-intensity magnetic separation concentrate is obtained by fine sieving, so that collection as soon as possible is realized; oversize finely-sieved and high-intensity coarse concentrate is ground, so that the amount of ore ground at a second segment is lowered greatly, and energy-saving and consumption lowering are facilitated; an oversize finely-sieved product is reground and floated, so that the flotation grade is raised, and the adaptability of negative ion reverse floatation to ore characteristic fluctuation is improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

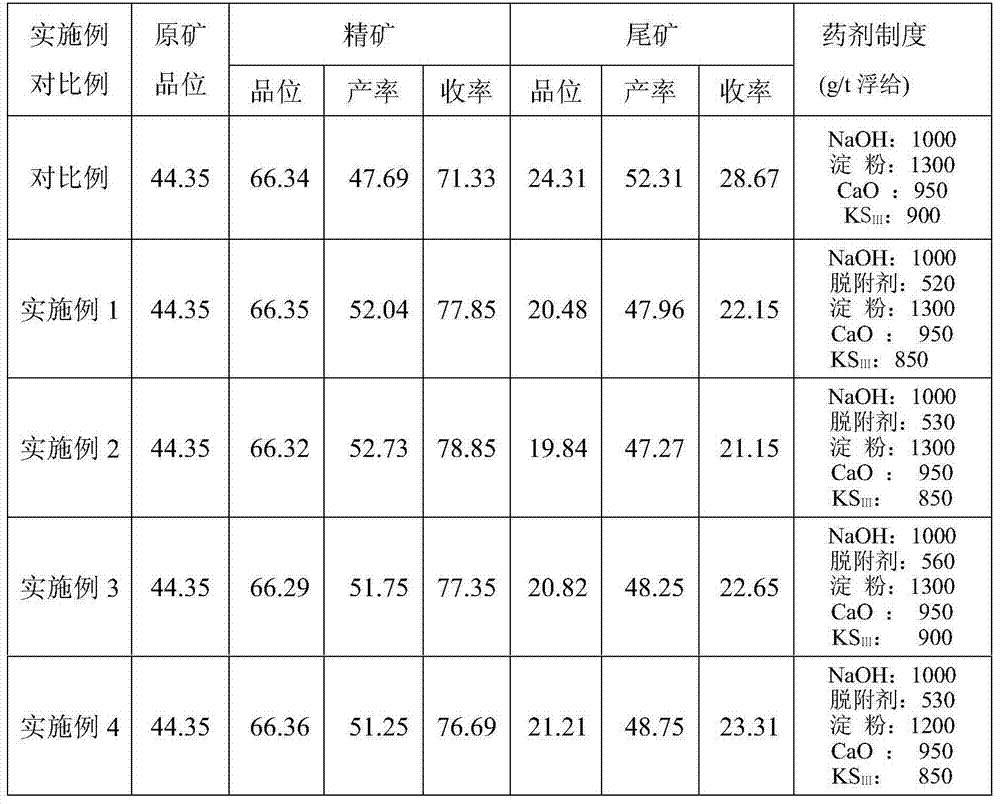

Agent for reverse flotation of iron ore and combination use method

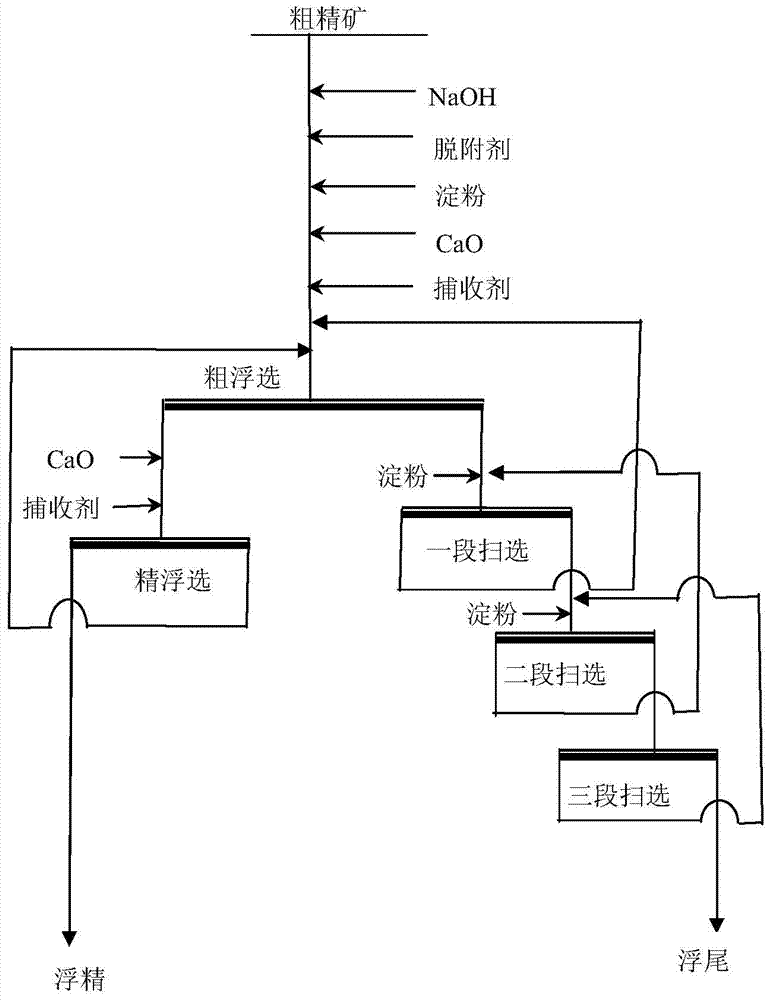

The invention provides an agent for reverse flotation of iron ore and a combination use method. The agent is composed of pH regulator sodium hydroxide, desorption agents, inhibitor causticity corn starch, activator calcium oxide and fatty acid collectors and is characterized in that the desorption agents are composed, by weight, of 40-42 parts of water glass, 4-6 parts of carboxymethyl cellulose and 7-9 parts of polycarboxylate. When the desorption agents are used, all raw material components are dissolved respectively according to the weight proportion and mixed, water is added, and therefore a desorption agent solution with the mass concentration of 0.04-0.06% is prepared. The desorption agents are applied to a reverse flotation process including one-time rough separation, one-time fine separation and three-time scavenging and a stage agent addition manner is adopted, so that the selective inhibition function on iron minerals by inhibitors in an original reverse flotation process is obviously enhanced, selectivity of the collectors is obviously enhanced, the tailing grade is reduced, the metal recovery rate is improved, fine-grain metal losses are reduced, emission reduction, yield increasing and efficiency increasing are achieved, the resource utilization rate is improved, and a new approach is provided for improvement of the micro-fine-particle iron ore reverse flotation technical index.

Owner:ANSTEEL GRP MINING CO LTD

Composite modified starch as hematite reverse flotation inhibitor and preparation method thereof

The invention discloses composite modified starch as a hematite reverse flotation inhibitor and a preparation method thereof. The composite modified starch comprises 100 weight portions of raw material starch, 0.5-10 weight portions of sodium hypochlorite as an oxidizing agent, 1.2-7.0 weight portions of sodium hydrosulphite, 0.2-1.2 weight portions of sodium nitrite as esterification reagents, 0.5-3.5 weight portions of 3-chloro-2-hydroxypropyl-trimethyl quaternary ammonium salt as a cationic reagent, 3.0-7.0 weight portions of caustic alkali, and 25-40 weight portions of water. The composite modified starch contains carboxylic groups, sulfonic anions, and quaternary ammonium cations, and has the advantages of cold water solubility and low viscosity, and has the advantages of increasing the yield of hematite concentrate, improving the filtering conditions of iron ore pulp, and the like.

Owner:GUANGXI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com