New technology for sorting lean hematite and magnetite orecontaining iron carbonate

A technology of magnetite ore and iron carbonate, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of inability to meet the separation and utilization of Guanbaoshan iron ore, fine particle size, etc., to avoid overgrinding, improve Metal recovery rate, the effect of reducing the amount of regrinding and selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

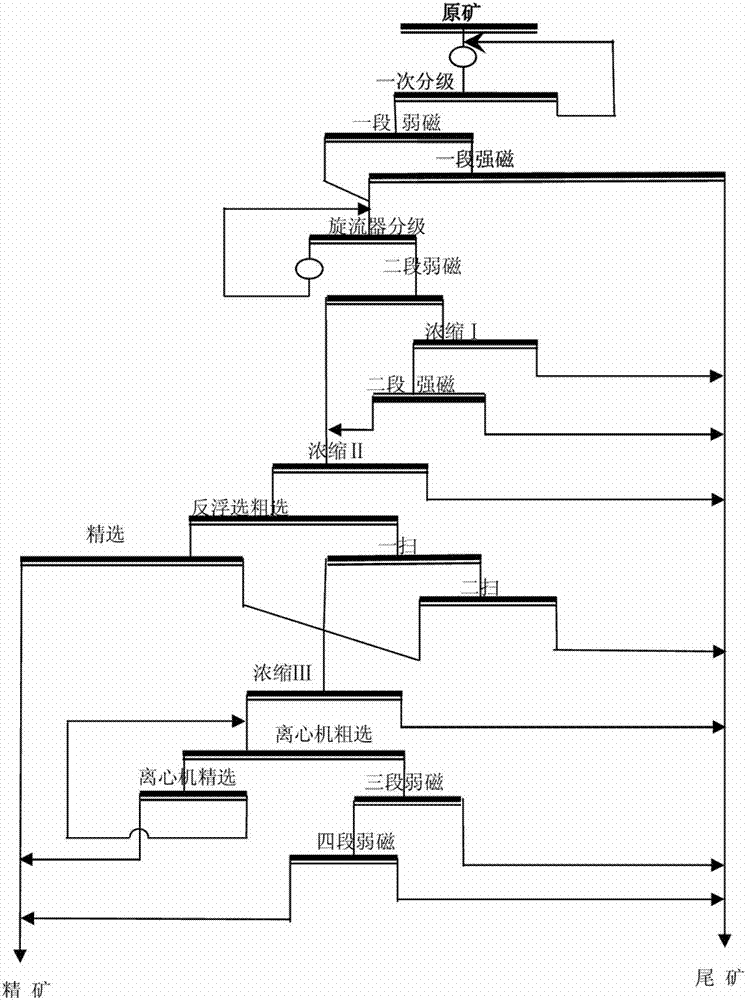

[0020] Such as figure 1 As shown, the new process for sorting iron carbonate-poor hematite magnetite ores of the present invention is characterized in that: first adopt "stage grinding, strong magnetic tailings throwing process" to enrich and throw tails, and obtain mixed magnetic separation concentrate; then adopt " One-stage roughing, one-stage beneficiation and two-stage scavenging open-circuit reverse flotation process" sorting mixed magnetic separation concentrate to obtain high-grade hematite concentrate; Iron carbonate minerals are separated by "one-stage roughing and one-stage selection closed-circuit centrifuge process" to obtain siderite concentrate, and the tailings of the centrifuge are sent to the weak magnetic machine for separation to recover fine-grained magnetic concentrate. Proceed as follows:

[0021] 1) Crush the iron carbonate-poor hematite magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com