Patents

Literature

657results about How to "Reduce impact damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for filling and mining after ore caving

ActiveCN102587916AReduce impact damageImprove work efficiencyUnderground miningSurface miningSpelunkingMineral Sources

The invention discloses a method for filling and mining after ore caving, which includes the following steps: exploiting; mining quasi work; cutting work: including excavation of mine collection trench and patio cutting, cutting a patio at one end portion of a rock drilling chamber, cutting the patio by using a vertical deep hole ore falling stage chamber method, and enabling patio cutting to provide sufficient compensation space for actual mining; chamber extraction work: constructing a downward blasthole in the rock drilling chamber, filling and blasting, one-time blasting charging at the entire middle section height of the blasthole, and enabling blasting to adopt one-time lateral blasting and ore removal; filling and maintaining: closing all outlets communicated with a lower mine of the empty area, burying strainer pipes, leading in filling pipelines from the upper portion of the chamber, and filling and maintaining the chamber; and pillar recovery: recovering pillars after filling and maintaining the chamber, and the pillar recovery is the same as the chamber extraction work. The method for filling and mining after ore caving is high in recovery rate of mineral resources, small in blasting impact effect, low in cost and high in production efficiency.

Owner:金建工程设计有限公司

Non-lethal wireless stun projectile system for immobilizing a target by neuromuscular disruption

InactiveUS20070101893A1Reduce impact damageReduce momentumAmmunition projectilesMusical toysSTUNTransformer

A projectile launched from a conventional weapon; upon impact with a human target the projectile attaches to the target and stuns and disables the target by applying a pulsed electrical charge. The electric round is defined as non lethal ammunition directed to incapacitate a human, to prevent him from moving for a short time, to prevent him from committing a crime and to allow authorized personnel to arrest the target. A novel thin film technology transformer and thin film technology battery produce an electrical shock capable of stunning a human being in a device the size of a conventional bullet. The transformer and battery are smaller and lighter than conventional transformers and batteries with similar power output.

Owner:SECURITY DEVICES INT INC

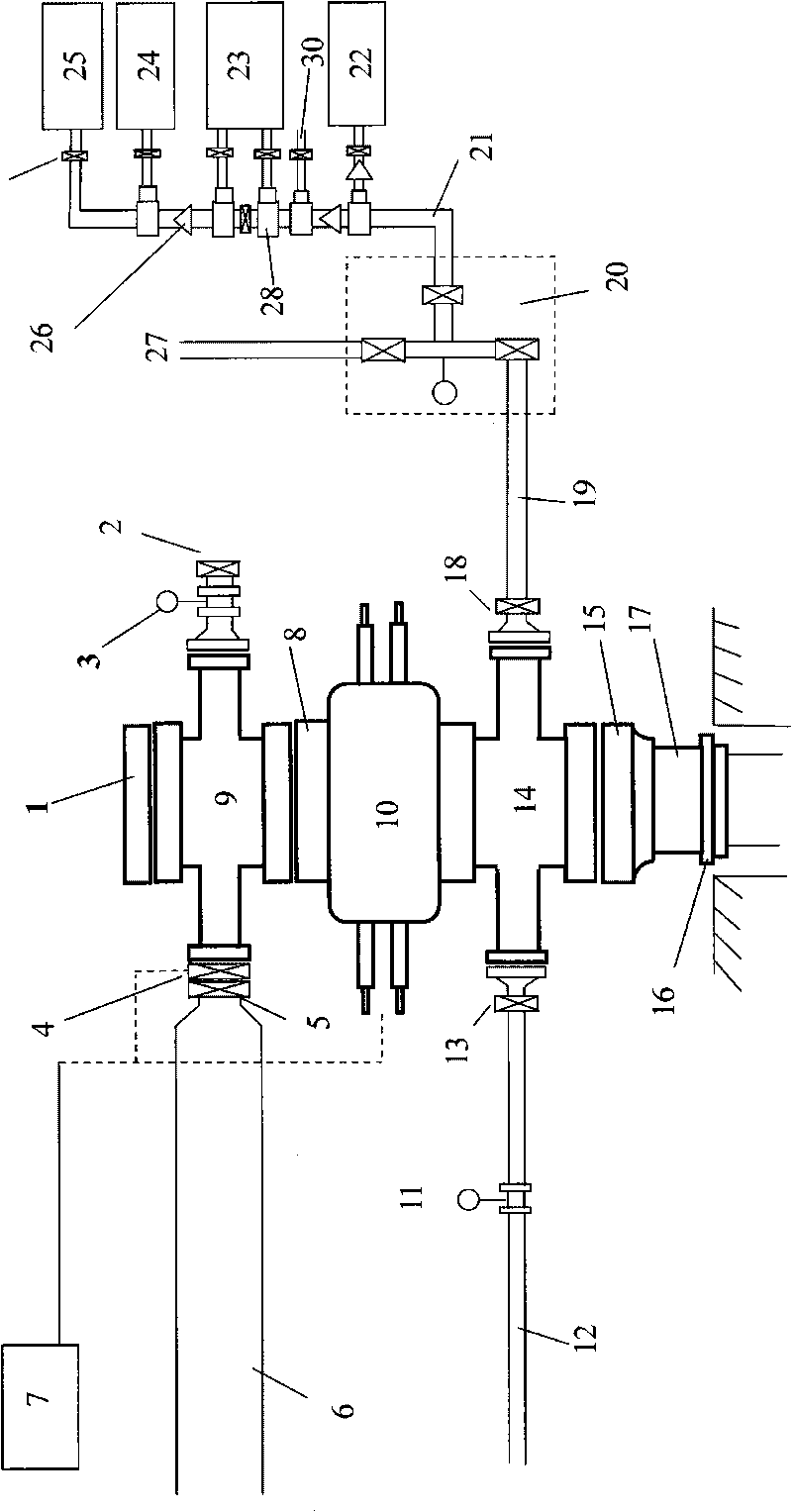

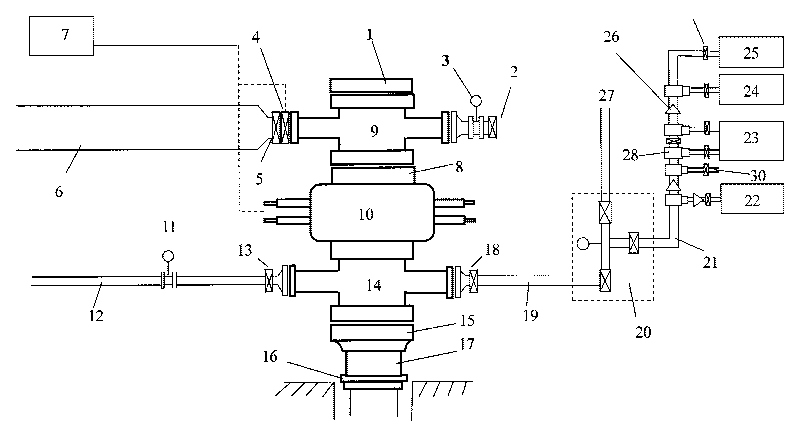

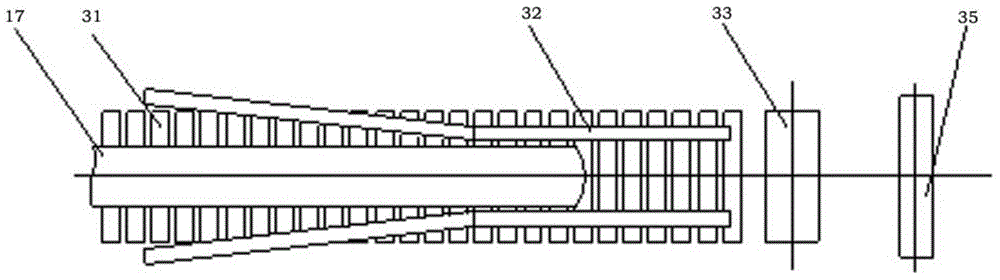

Reverse circulation aerodynamic cavitation method for coalbed methane well and equipment

The invention discloses a reverse circulation aerodynamic cavitation method for a coalbed methane well and equipment. The reverse circulation aerodynamic cavitation method comprises the following steps of: arranging wellhead equipment on a wellhead and sinking a working pipe to a bottom hole; clearly eliminating rock coal dust and water inside the well by using an air compressor in a circulating way; then lifting the working pipe upwards and injecting air / foam by using the air compressor and a supercharger, wherein the air injecting pressure is 3-15 MPa; meanwhile continuously injecting atomized water into the well with the water injecting amount of 3.0-5.0 m<3> each time; opening a hydraulic flat plate gate valve for discharging; after discharging, sinking the working pipe to a coalbed part; injecting the air simultaneously by the air compressor and the supercharger; meanwhile injecting water / foam with the amount of 3.0-10.0 m<3> by using an injection pump for washing the well to thebottom hole; after completing one cycle of discharging and well washing, detecting initial data; closing the air compressor, the supercharger, the injection pump and the hydraulic flat plate gate valve to enable gas inside the well to return freely; measuring the change of gas output of coalbed gas in one hour by using a flow meter; and placing a torch at a discharge port to ignite the gas. The invention improves the construction safety, improves the yield of single well coalbed gas, and saves the construction cost.

Owner:河南省资源环境调查二院

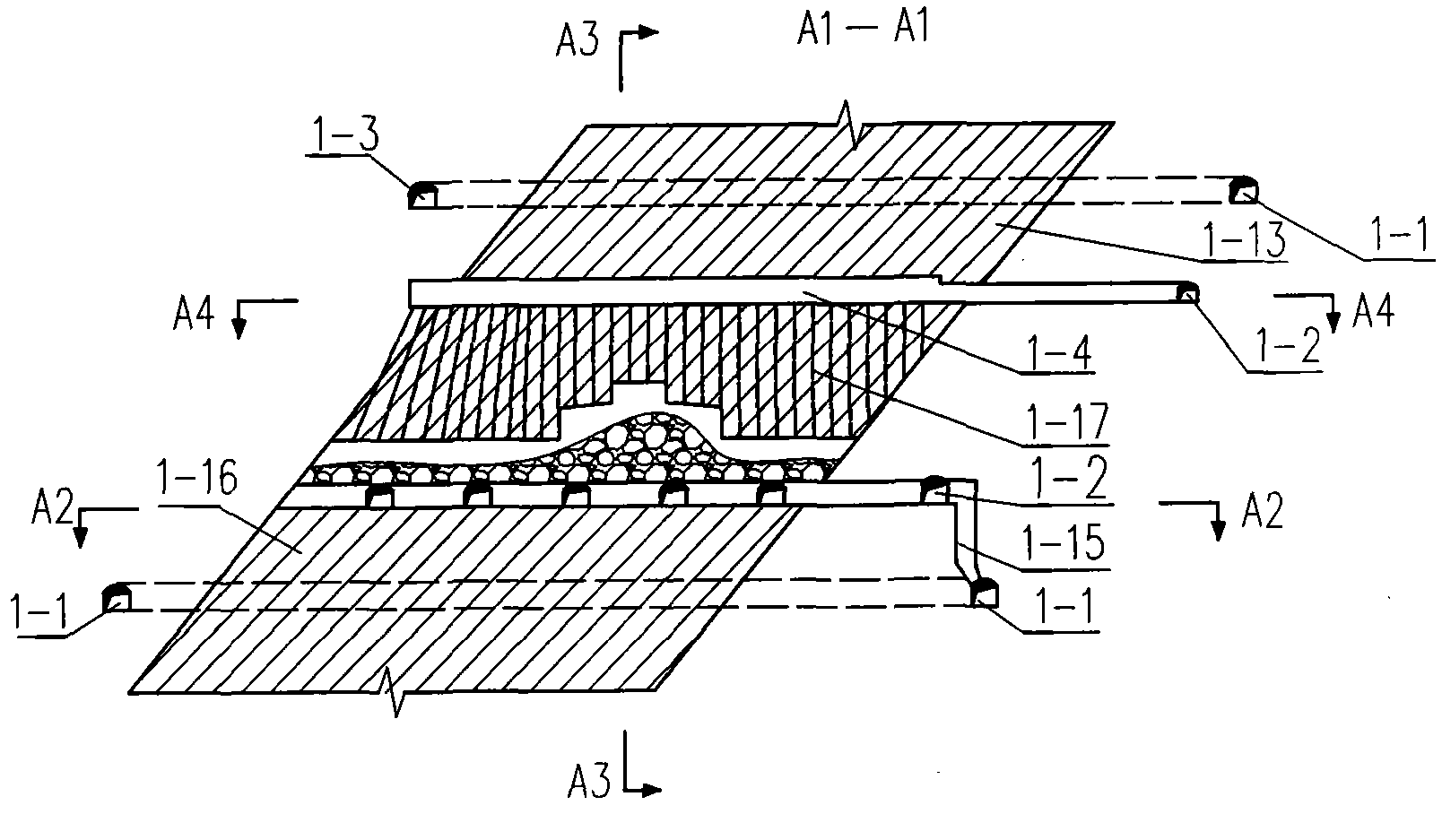

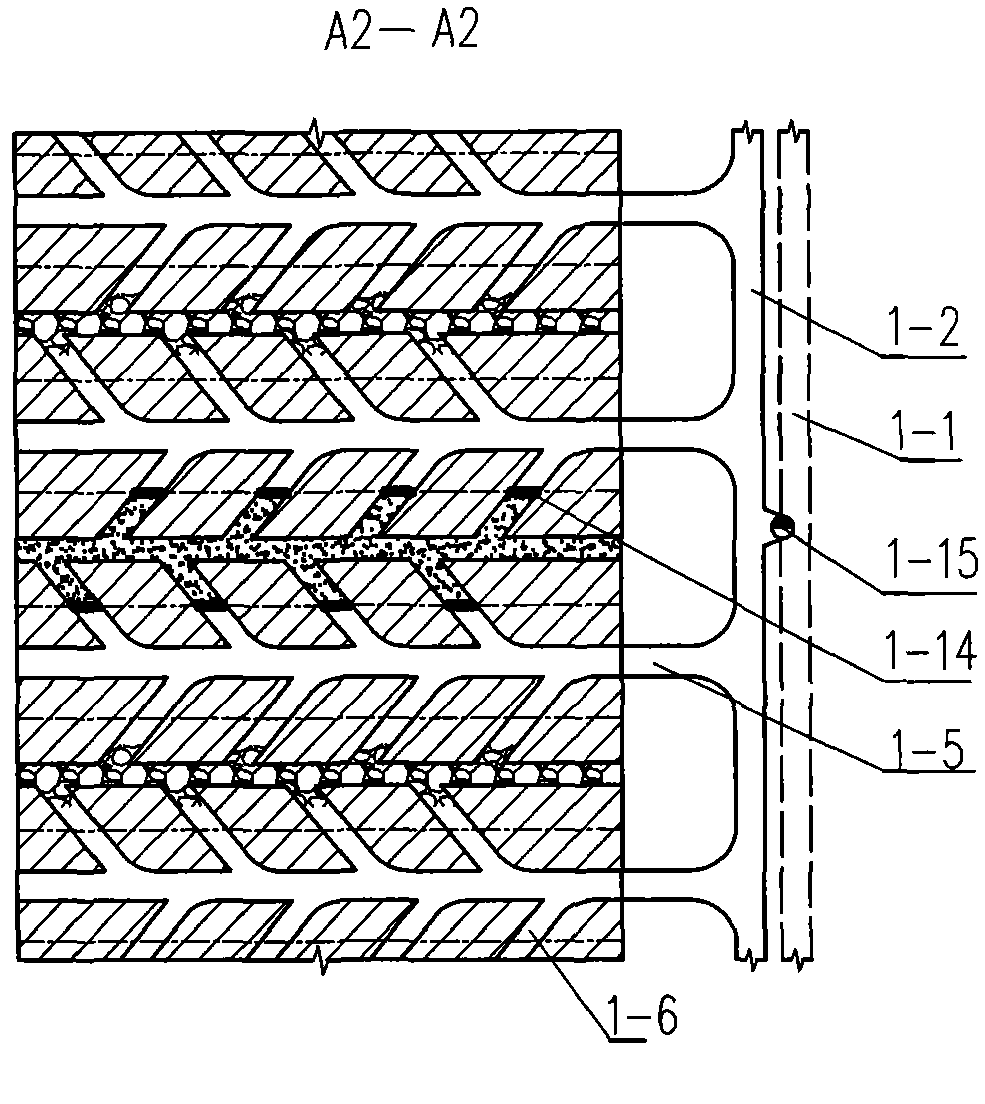

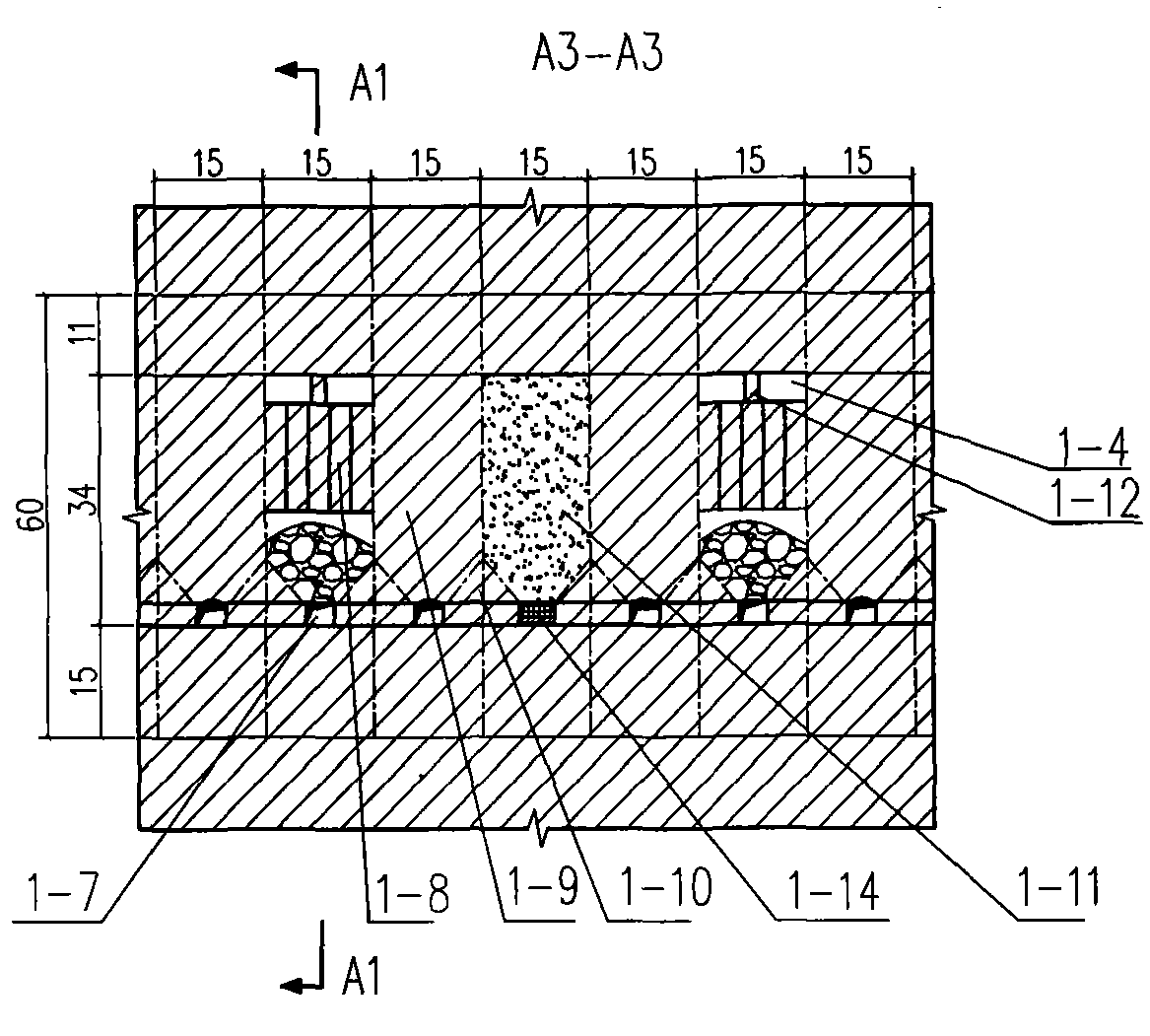

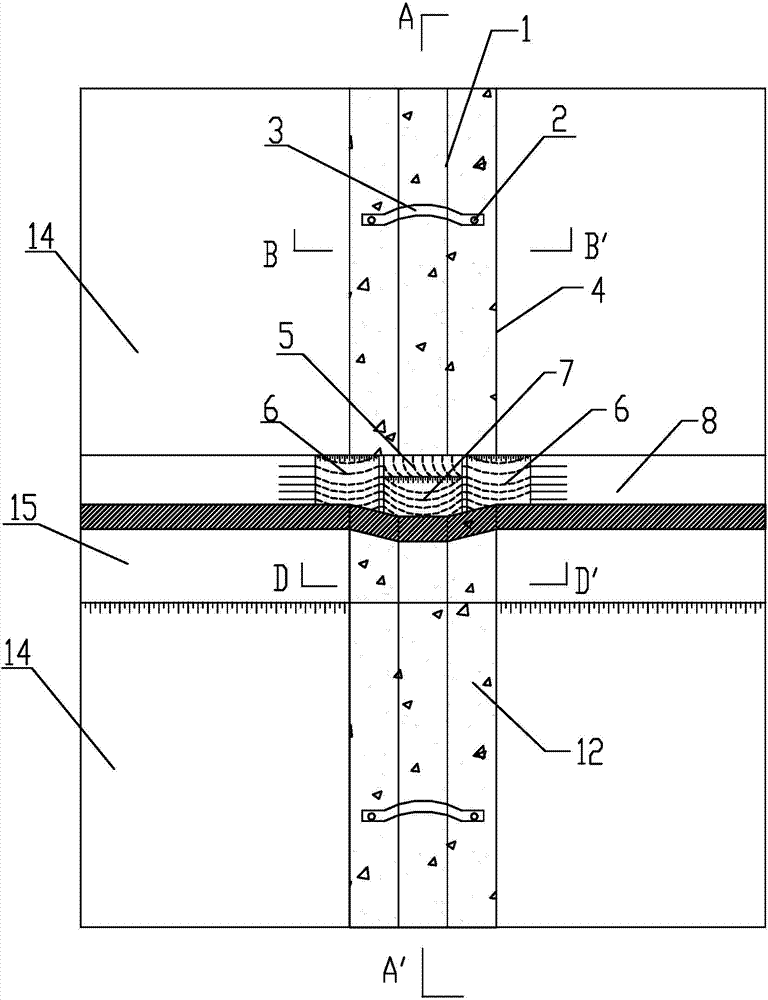

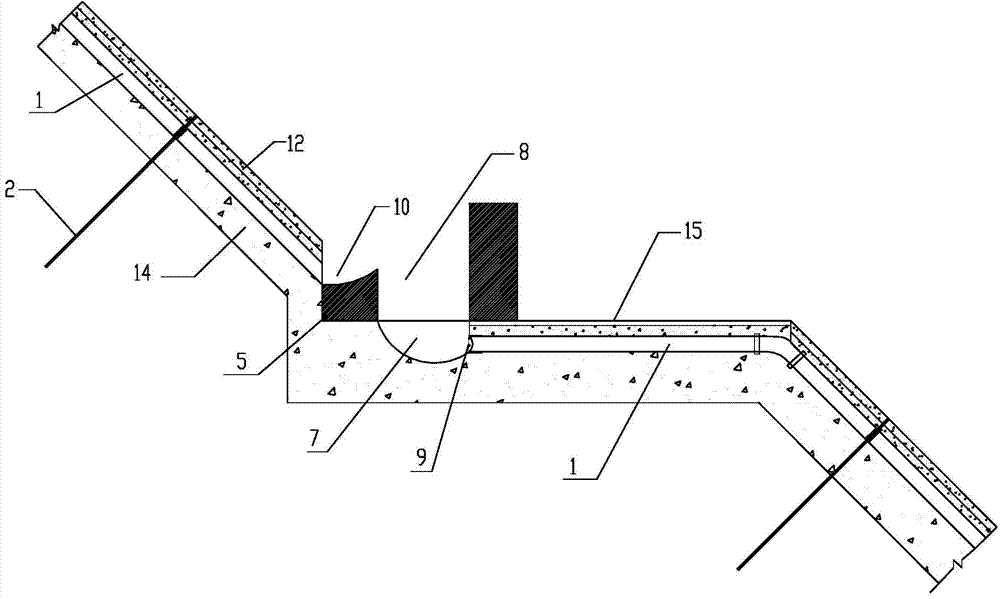

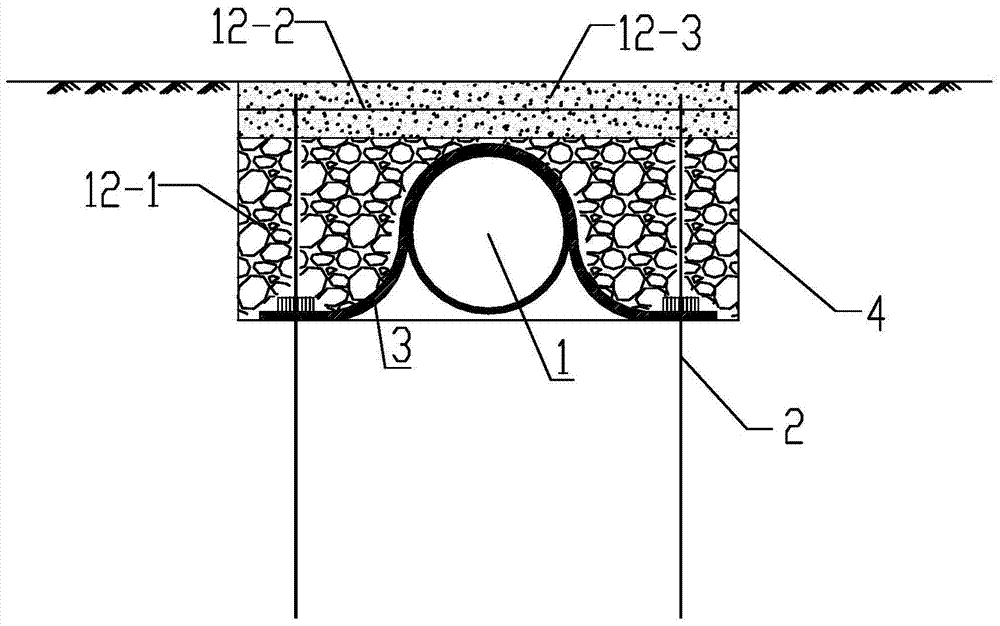

Buried type side slope drainage system and construction method thereof

The invention provides a buried type side slope drainage system and a construction method thereof. The drainage system comprises a plurality of transverse drainage ditches and a plurality of vertical drainage ditches. The vertical drainage ditches are of drainage structures formed in the manner that after a slope is filled or dug according to a design drawing, drainage pipe pre-buried grooves are formed in the positions, corresponding to the vertical drainage ditches, of all levels of side slopes and platforms, drainage pipes are pre-buried in the drainage pipe pre-buried grooves, and protection structures are built on the upper portions of the drainage pipe pre-buried grooves. A force eliminating platform, an accumulating pond and a water collecting pond are built at the joint of the transverse drainage ditches and the vertical drainage ditches, the force eliminating platform is right opposite to water outlets of the drainage pipes in the upper level side slope, and water is led to the collecting pond and the water collecting pond in sequence and then is led into the vertical drainage pipes in the lower level side slope through the water collecting pond. According to the buried type side slope drainage system and the construction method, the constructed drainage system is buried underground, the continuity and attractiveness of side slope protection are not affected, the drainage pipes cannot be damaged by exposing and grinding, the drainage pipes are prevented from being blocked through a multi-layer filtering method, the drainage smoothness is improved, and maintaining cost is reduced.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

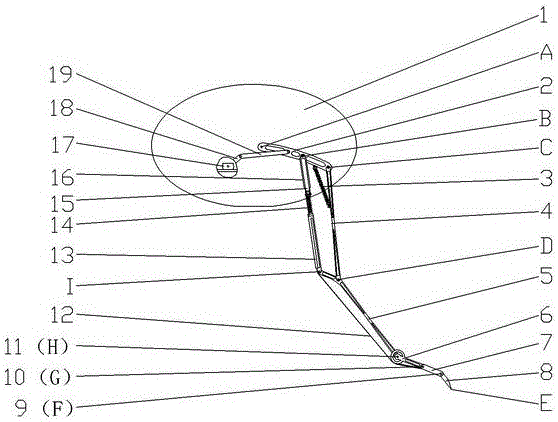

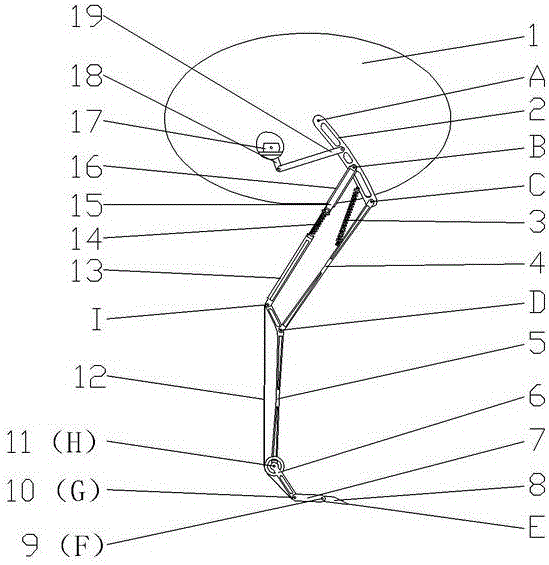

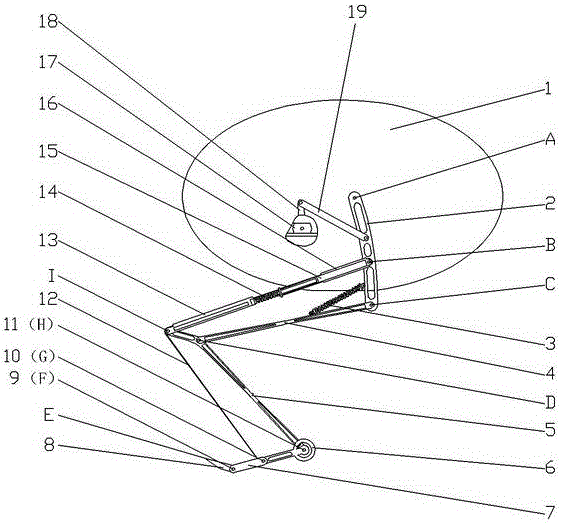

Mechanical leg imitating ostrich hind limb

The invention discloses a bionic mechanical leg imitating the motion function characteristic of an ostrich hind limb. The mechanical leg comprises a body, a hip joint motion mechanism, a knee joint motion mechanism and an ankle joint motion mechanism. The hip joint motion mechanism is composed of a motor and a crank-rocker mechanism, wherein the crank-rocker mechanism comprises a crank, a femur and a connecting rod. The knee joint motion mechanism comprises the femur, a first spring, a tibia, a metatarsus, a brake cable, a lower fibula, a second spring, an air cylinder and an upper fibula. The ankle joint motion mechanism comprises the metatarsus, a first apotelus bone, a second apotelus bone, a third apotelus bone, a third torsional spring, a second torsional spring and a first torsional spring. The ostrich hind limb capable of efficiently moving serves as the bionic prototype, through combination of testing on hind limb motion parameters during running of an ostrich and biological anatomic analysis, the mechanical leg imitating the ostrich hind limb is obtained through optimization design according to the tendon-bone and muscle-tendon interaction mechanism of the ostrich, and the mechanical leg is simple in structure, safe, reliable, low in vibration, and capable of efficiently saving energy.

Owner:JILIN UNIV

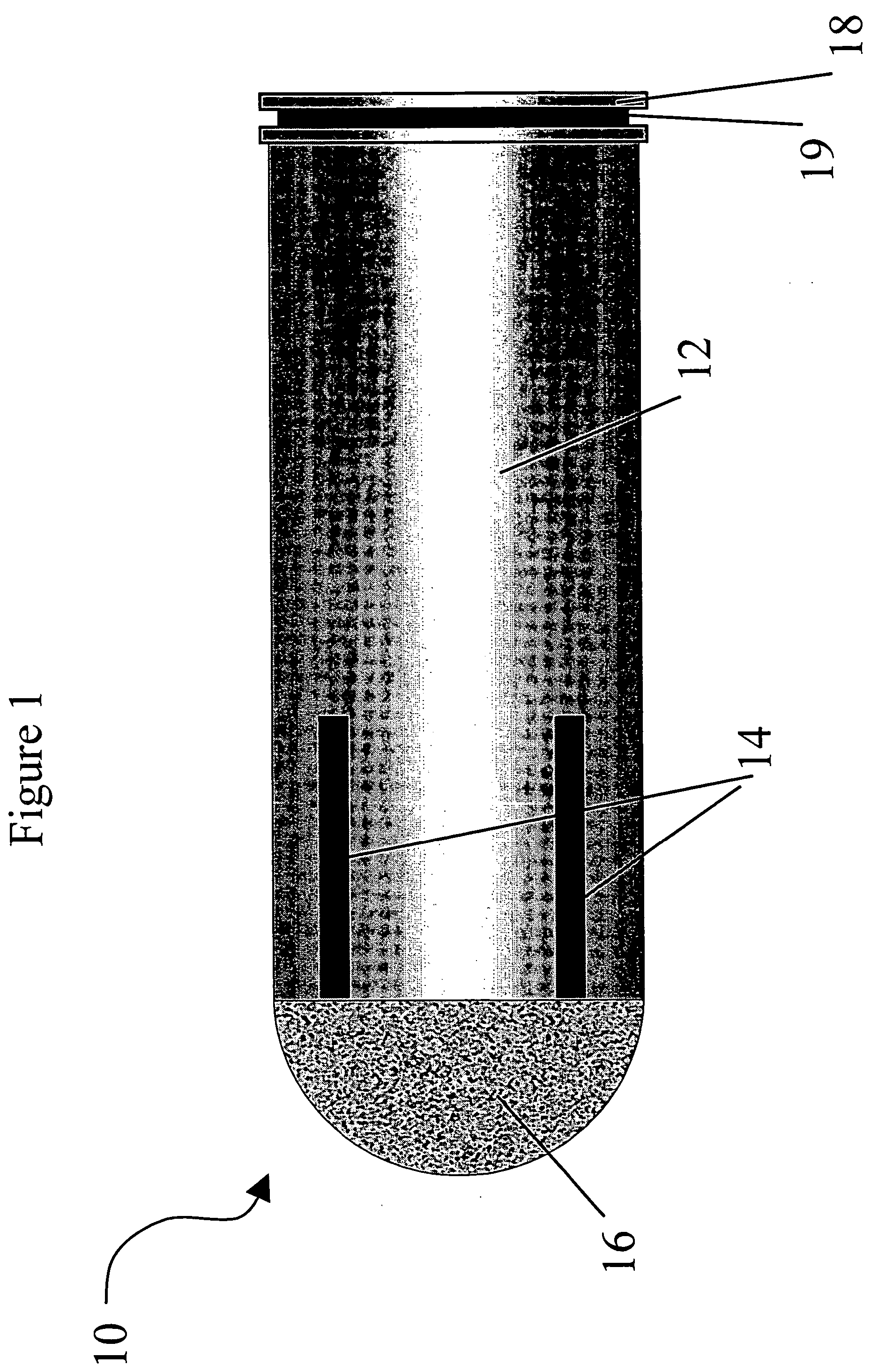

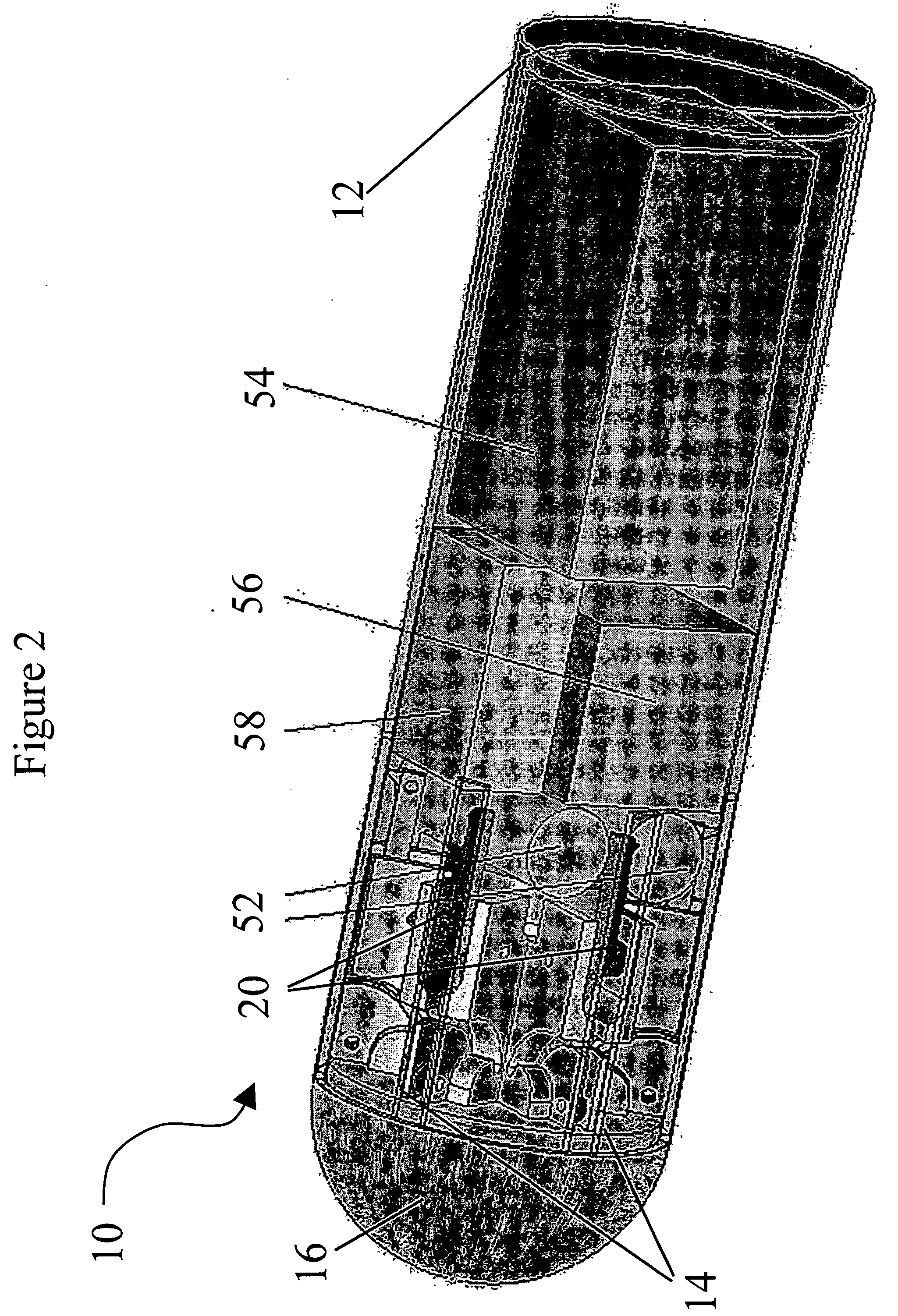

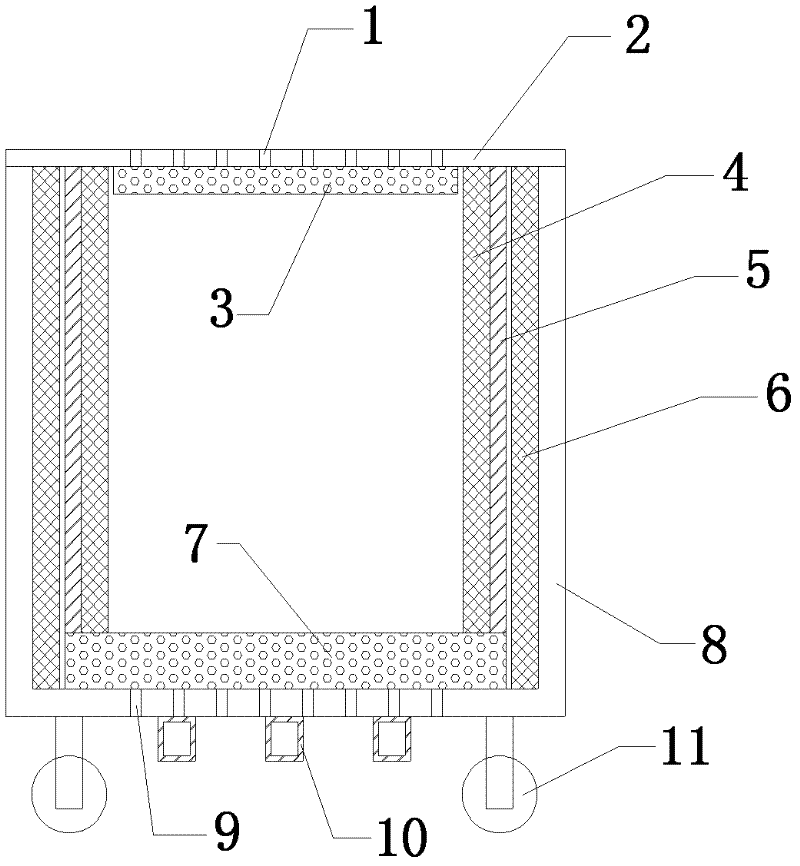

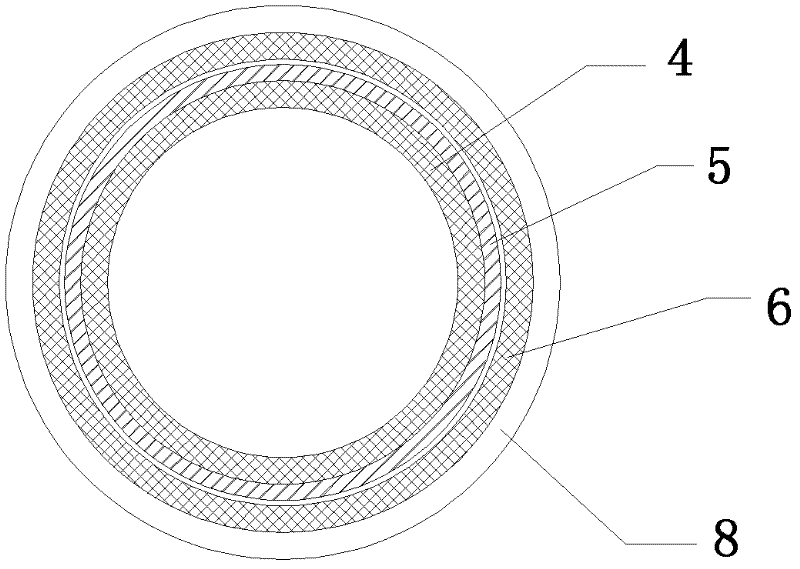

Pressure relief type explosion-proof tank

The invention discloses a pressure relief type explosion-proof tank, which comprises a tank body and a tank bottom, wherein a cover plate with cover plate pressure relief holes is arranged on the top of the tank body; the tank body consists of an inner cylinder and an outer cylinder; the outer cylinder consists of an outer cylinder wall and an outer cylinder buffer layer arranged in the outer cylinder wall; the tank bottom is provided with an outer cylinder wall bottom plate; a buffering base plate is arranged on the upper part of the outer cylinder wall bottom plate, on the inner side of the outer cylinder buffer layer and on the lower part of the inner cylinder; outer cylinder wall pressure relief holes are formed on the outer cylinder wall bottom plate; the inner cylinder consists of an inner cylinder wall and an inner cylinder buffer layer in the inner cylinder wall; a buffering lining plate is arranged on the lower part of the cover plate and on an inner side of the inner cylinder buffer layer; the buffering lining plate and the buffering base plate are made of porous foam metals; the inner cylinder buffer layer and the outer cylinder buffer layer are made of closed pore foam metals; and the thickness of the buffering base plate is greater than that of the buffering lining plate. By the explosion-proof tank, fragments produced through explosion can be prevented from flying out of the tank so as not to damage surrounding equipment and crowd, the internal pressure of the tank body can be reduced through pressure relief, and the safety performance of the explosion-proof tank is improved.

Owner:XI AN JIAOTONG UNIV

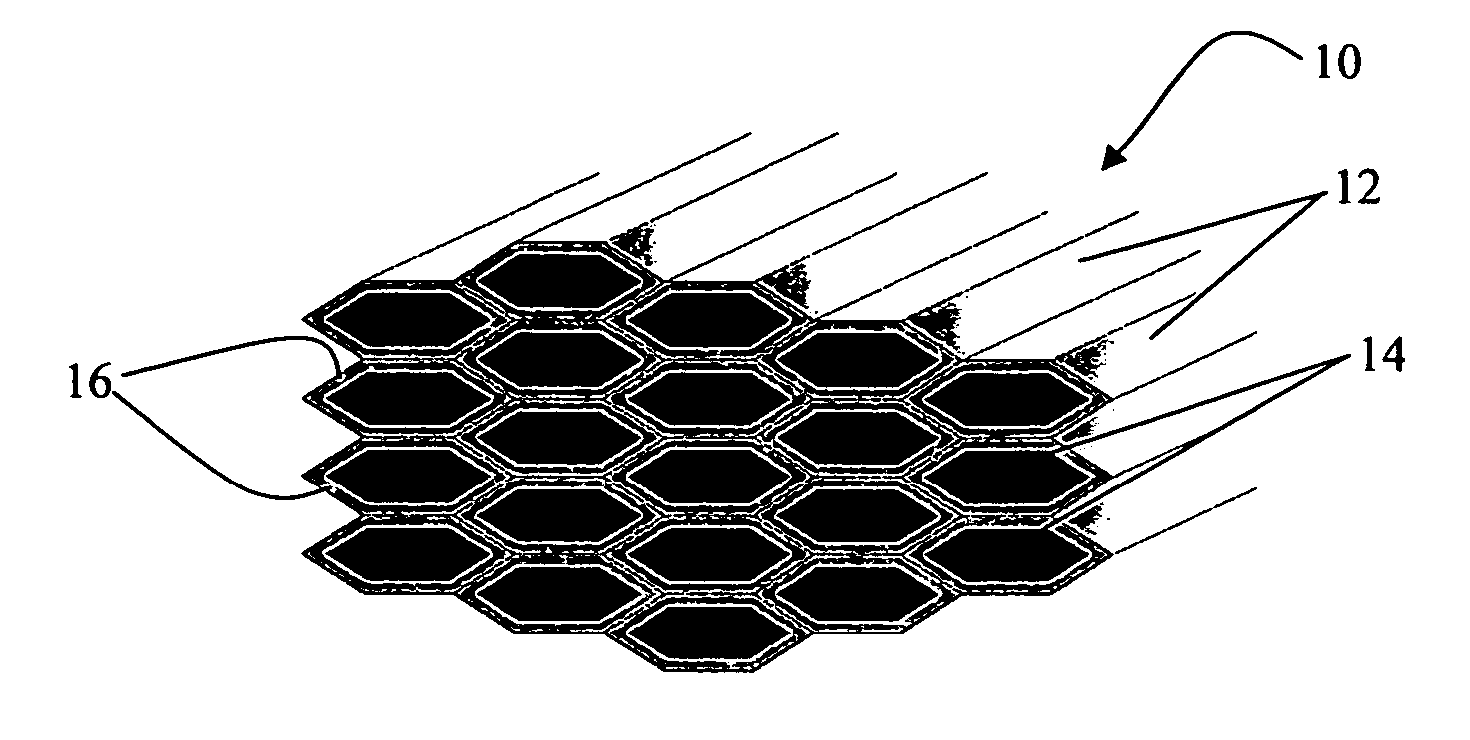

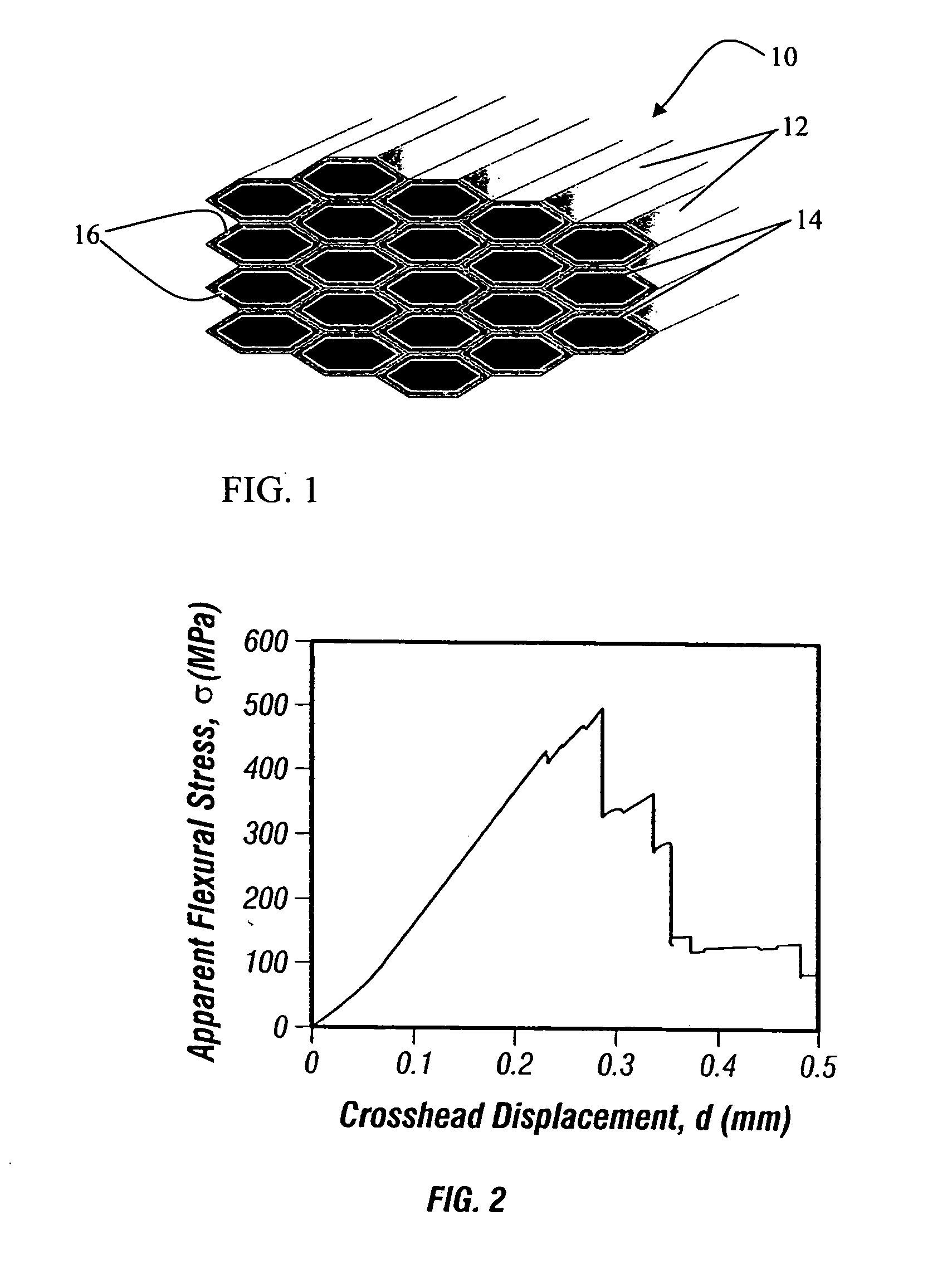

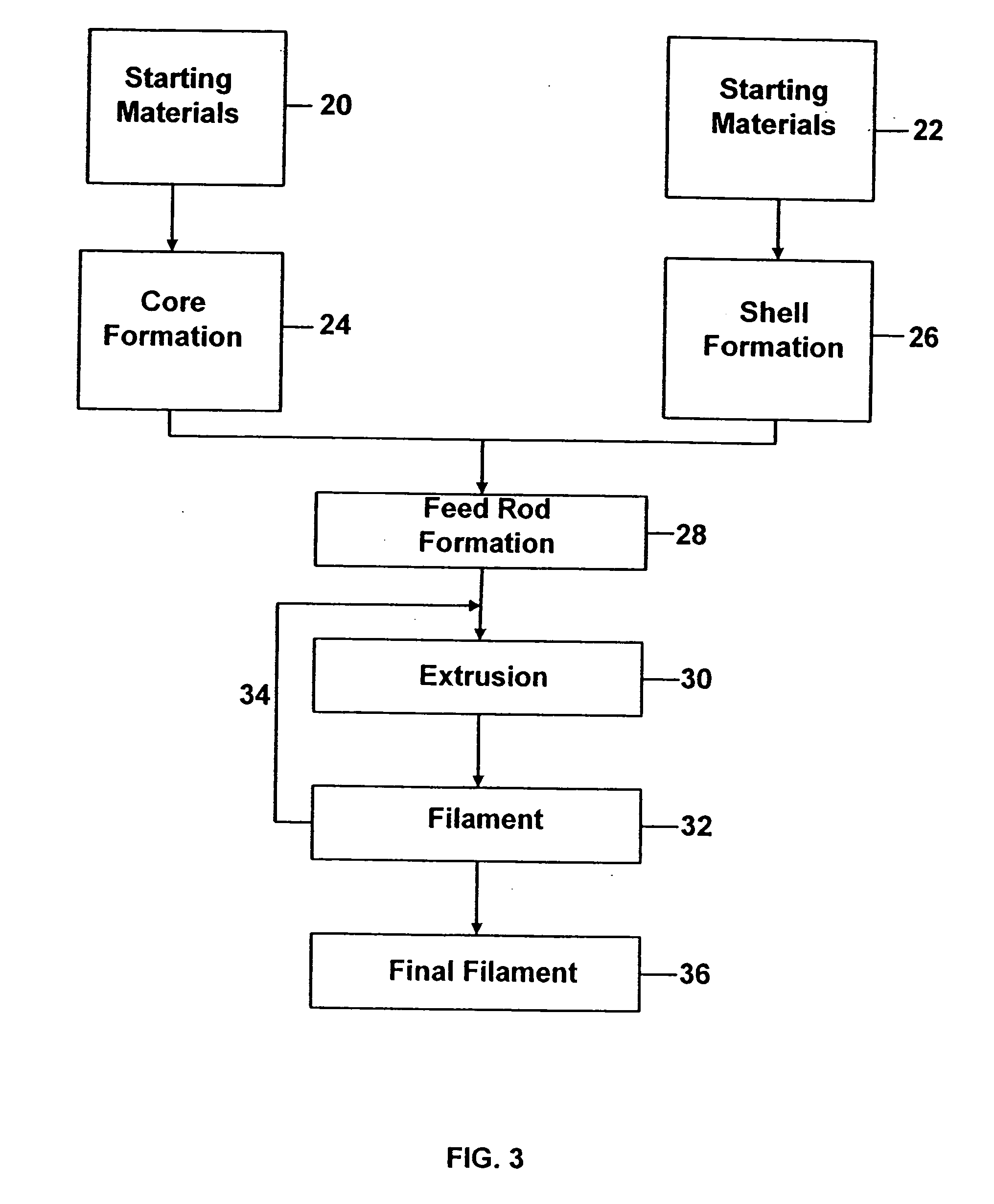

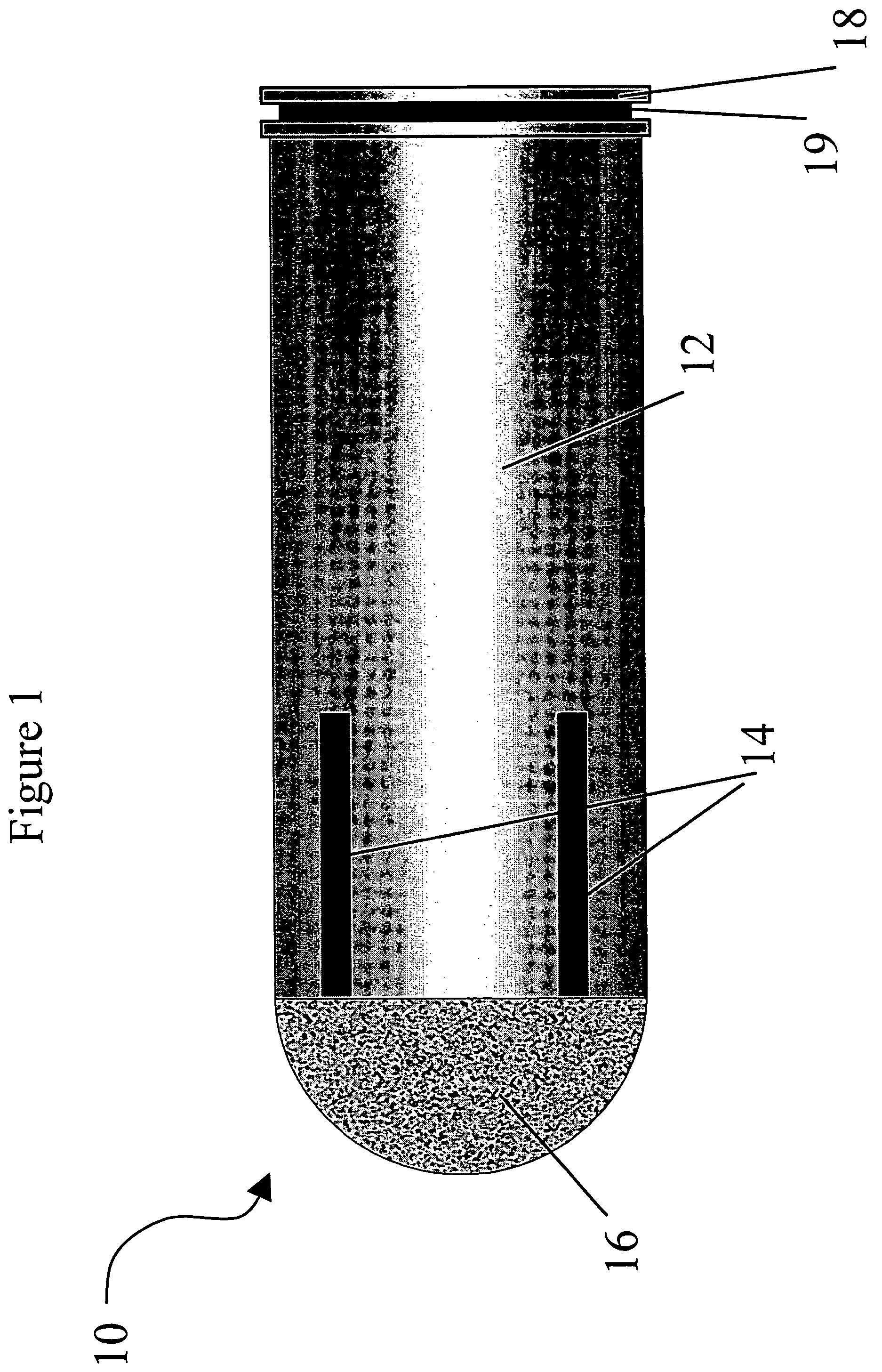

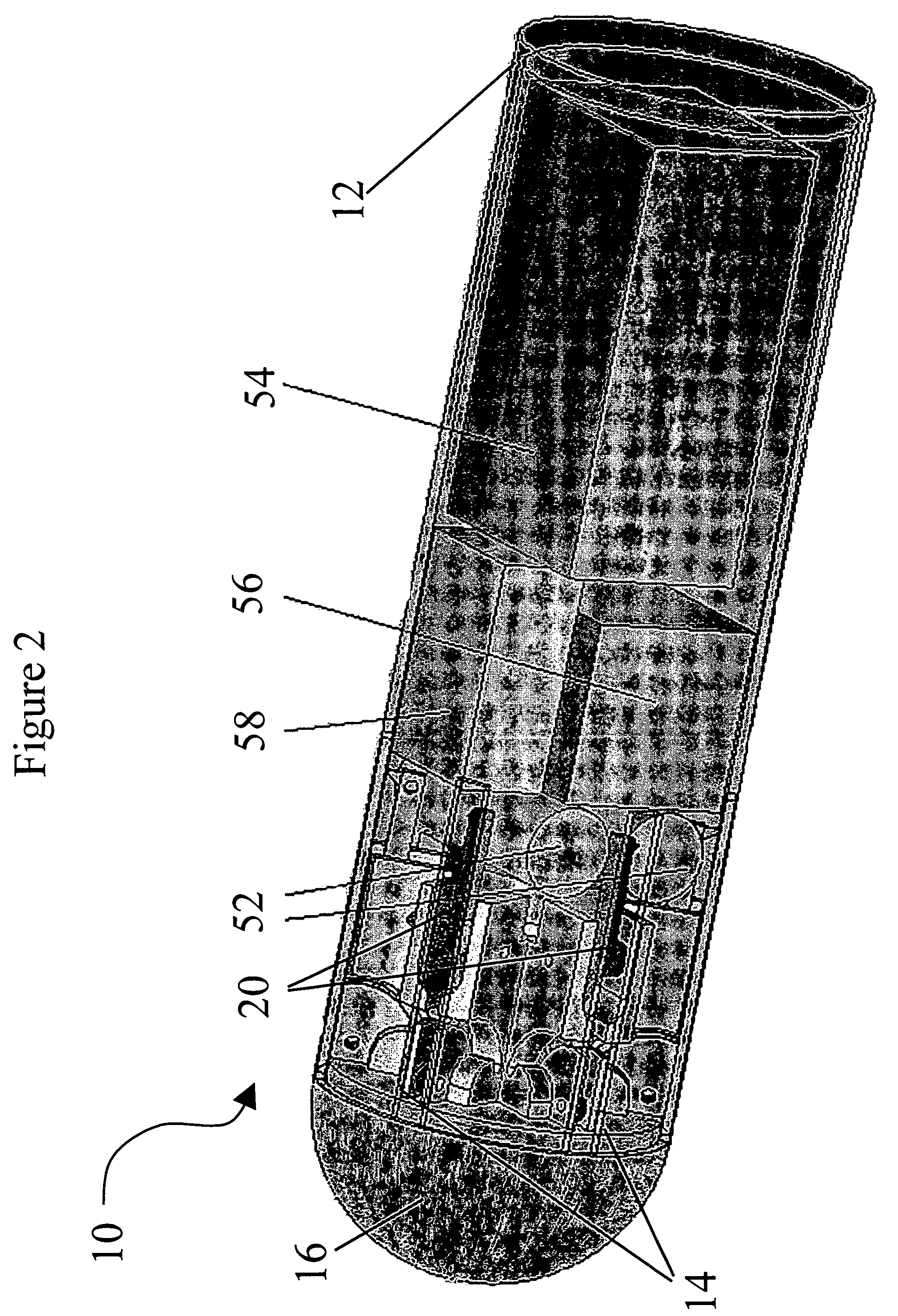

Aligned composite structures for mitigation of impact damage and resistance to wear in dynamic environments

InactiveUS20060091580A1Improve mechanical propertiesIncrease insensitivityNatural cellulose pulp/paperFilament/thread formingFiberDamage tolerance

Fibrous monolith composites having architectures that provide increased flaw insensitivity, improved hardness, wear resistance and damage tolerance and methods of manufacture thereof are provided for use in dynamic environments to mitigate impact damage and increase wear resistance.

Owner:ADVANCED CERAMICS

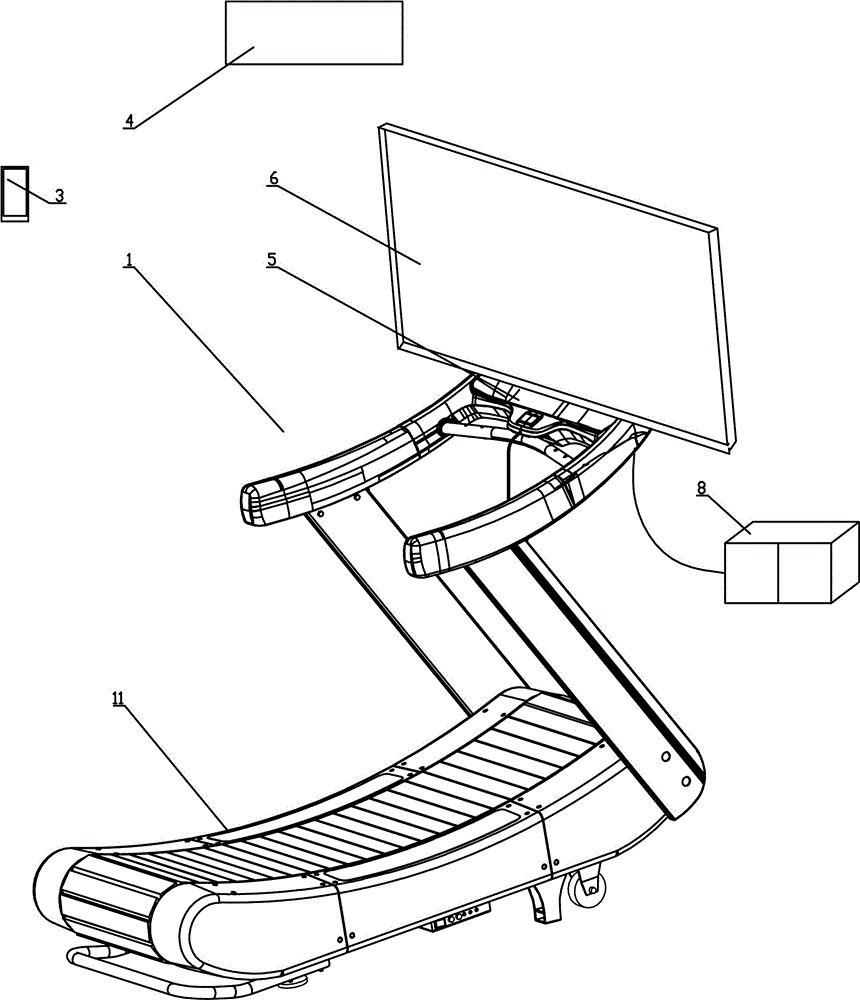

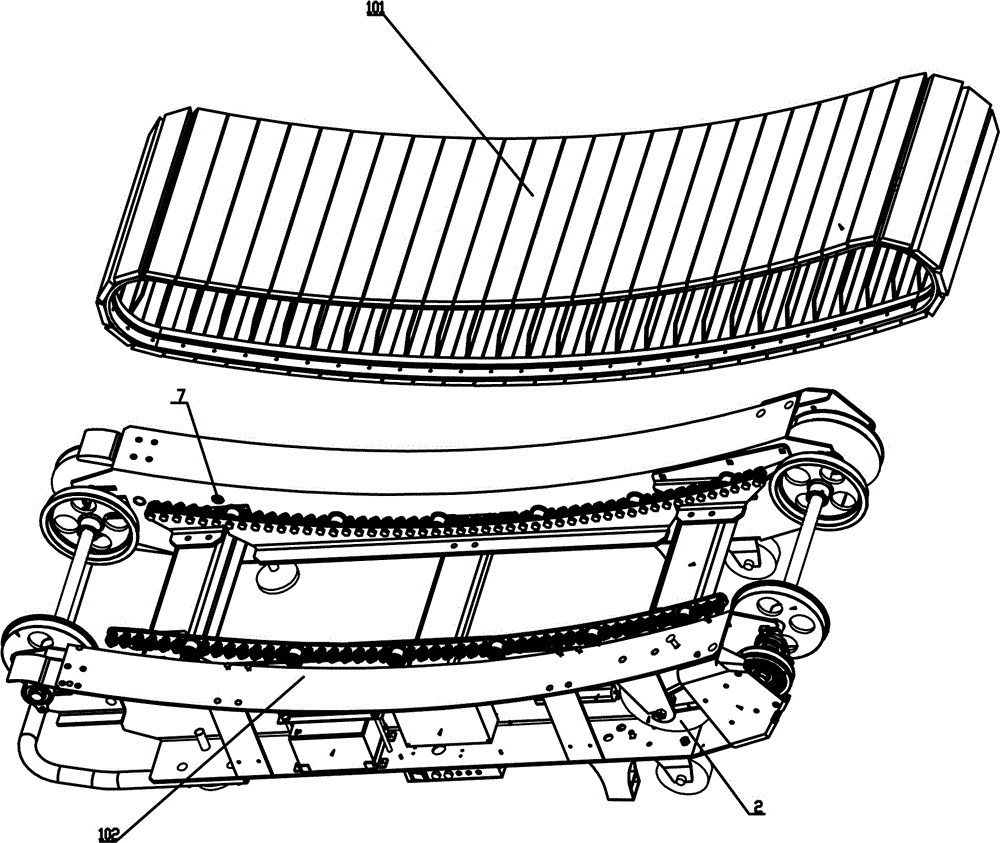

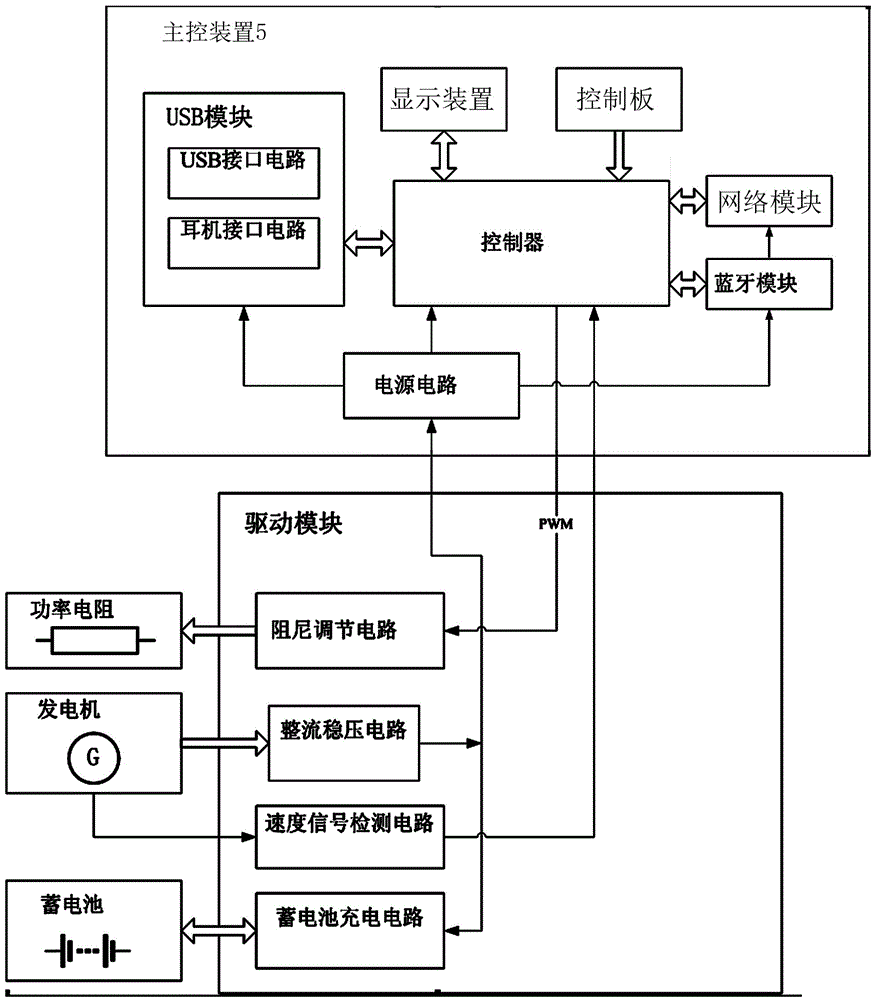

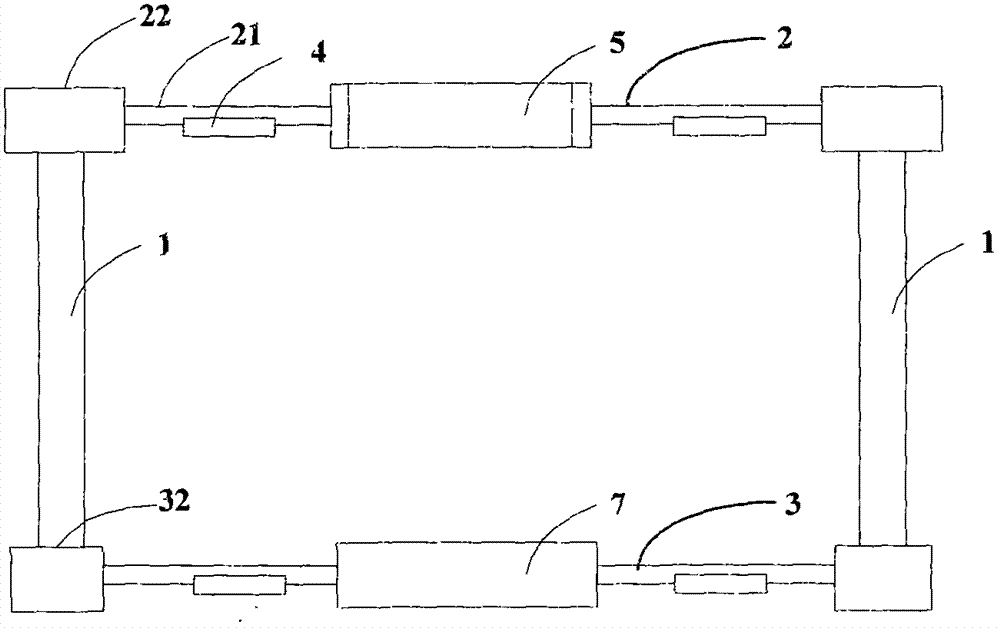

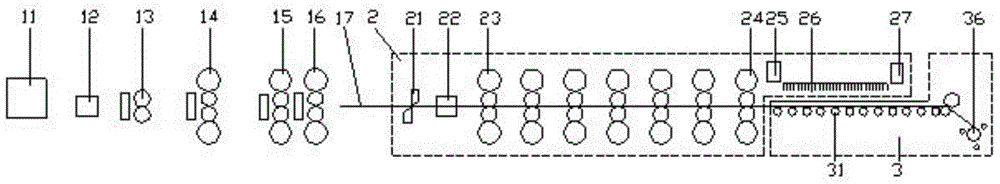

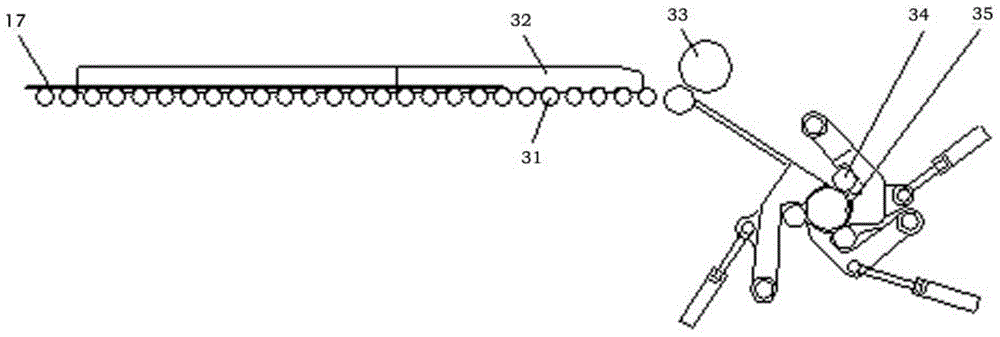

Running machine based on internet and internet competition system

InactiveCN105797311AIncrease the challengeAdd funMovement coordination devicesCardiovascular exercising devicesData informationKnee Joint

The invention provides a running machine based on an internet and an internet competition system. The internet running machine comprises a running platform, a main control device, a network module and a damper, wherein the running machine adopts an arc caterpillar-type running platform of which the front and rear ends are higher and the middle part is lower, initiative running is formed by virtue of the gravity action, the impact injury on knee joints is reduced, the damper can limit the highest motion speed, and the motion safety is further guaranteed. The running speed is correspondingly adjusted by virtue of the foot settling speed of a runner, so that the foundation of a competition is realized. By combining the network module, a mobile terminal and a cloud platform, various participating running machines are interconnected to form a network, so that the running machines distributed in different places in the world can participate in the network competition in real time, the main control device generates a virtual image of each competitor and transmits the virtual image to a virtual-reality terminal, each competitor stands on a corresponding position according to the data information of the corresponding running machine, and a competition result is pushed to the mobile terminal in real time. By virtue of the internet competition, the reality, challenge, fun and sociability of the body building by utilizing the running machine can be improved, and the body building impetus and the body building effect can be improved.

Owner:HUBEI HAISHAN TECH CO LTD

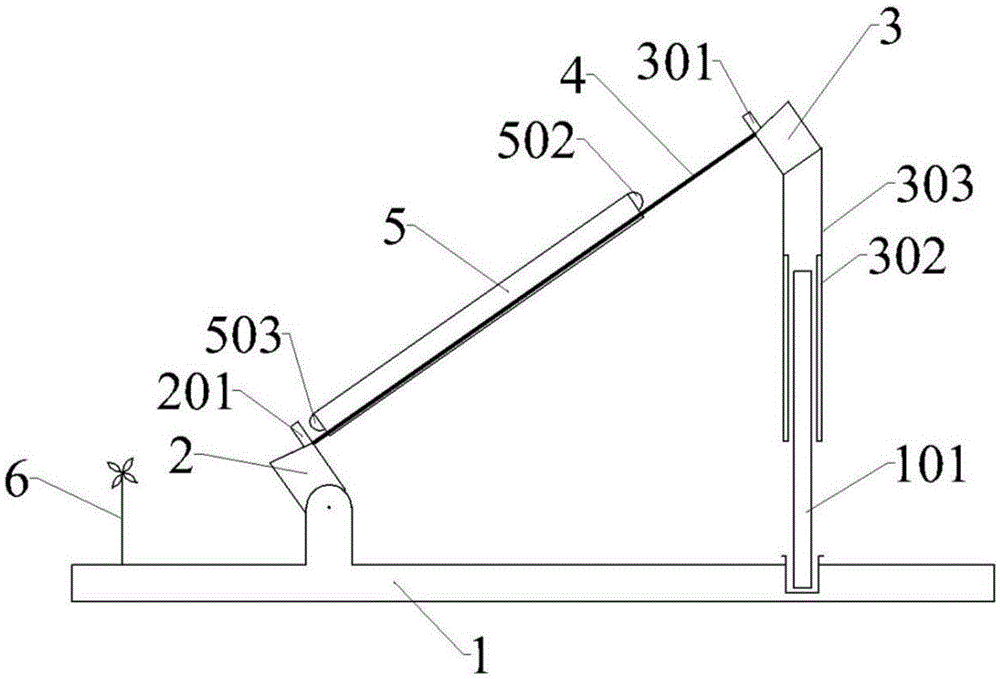

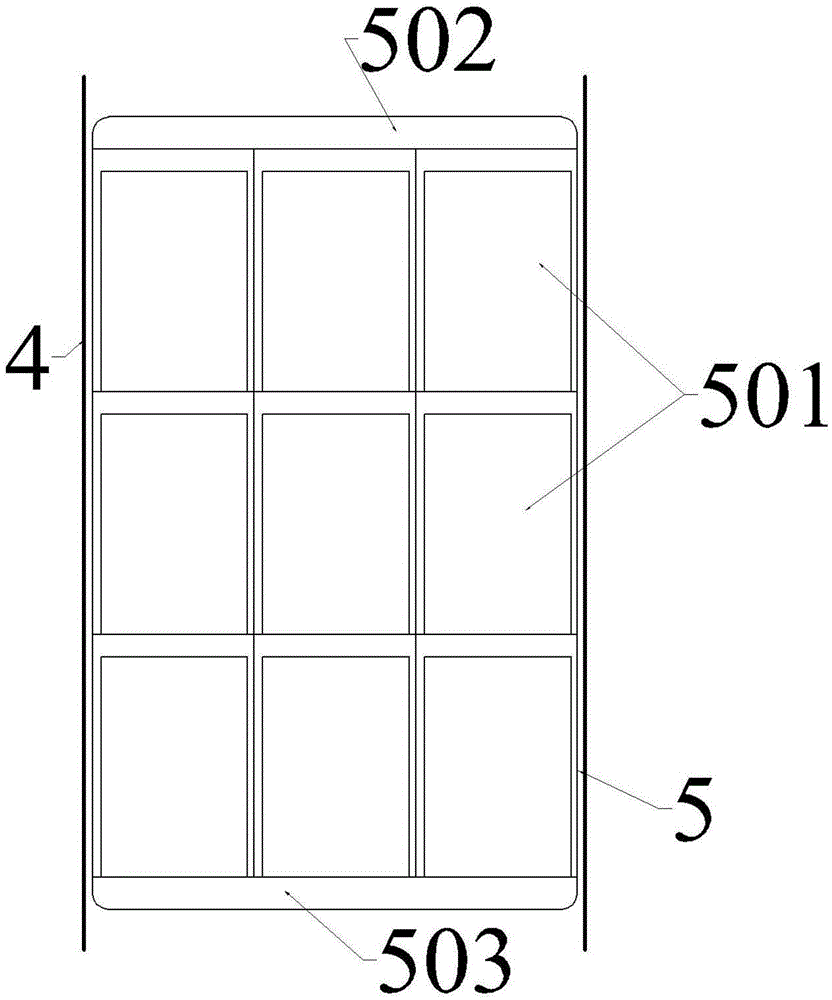

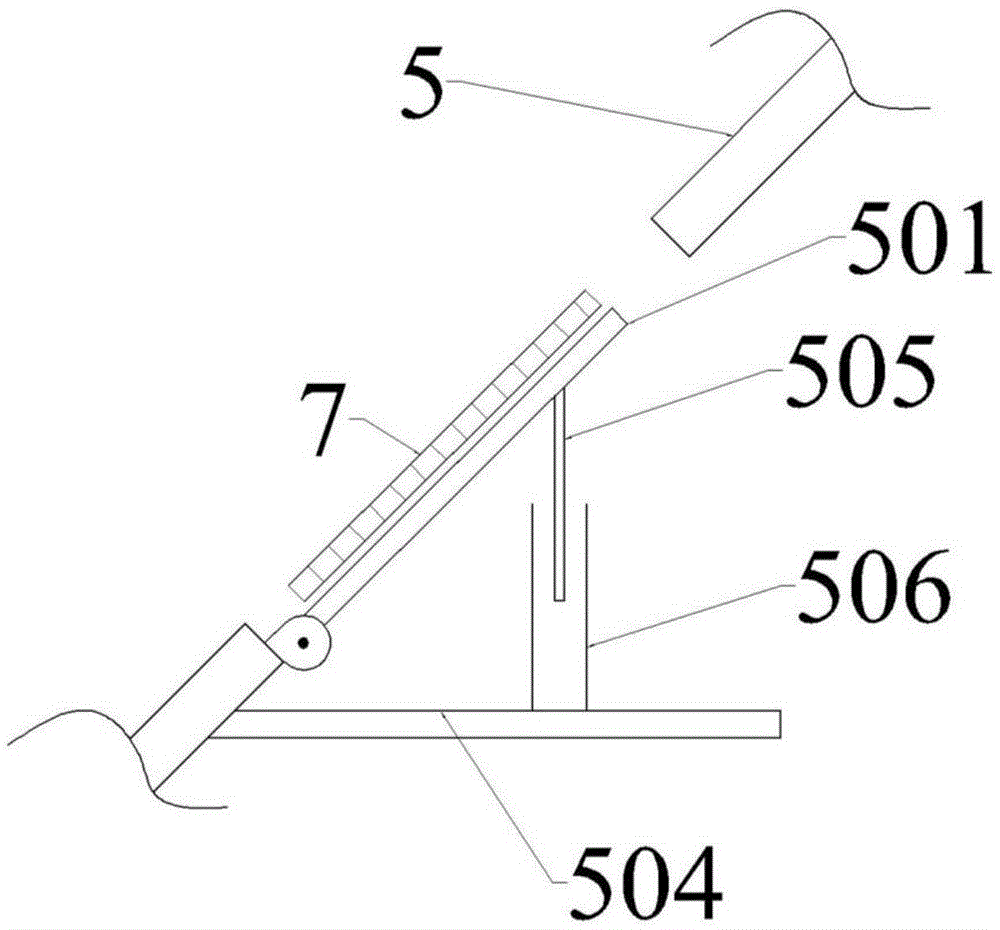

Photovoltaic power generation apparatus

InactiveCN105634388AReduce shockReduce impact damagePhotovoltaic supportsPhotovoltaic energy generationEngineeringSlide plate

The invention discloses a photovoltaic power generation apparatus. The photovoltaic power generation apparatus comprises a base, a first fixed block and a second fixed block, a pair of guide rods and a sliding plate, wherein the lower part of the first fixed block is hinged with the base; a sleeve is fixed at the lower part of the second fixed block; a nut is coaxially fixed in the sleeve; a rotary screw rod is perpendicularly arranged on the base; the screw rod extends into the sleeve and is meshed with the nut; the screw rod rotates under the drive of a motor; the two ends of the pair of the guide rods are connected with the first fixed block and the second fixed block respectively; a sliding groove matched with each guide rod is formed in each of the left and right sides of the sliding plate separately; multiple rectangular mounting openings are formed in the sliding plate in an up-and-down penetration manner; a rectangular plate having the same dimension and shape as the rectangular mounting opening is hinged with the lower edge of each rectangular mounting opening separately; a supporting plate is fixed on the lower edge of each rectangular mounting opening; the lower surface of the rectangular plate and the upper surface of the supporting plate are fixed with the two ends of a telescopic rod; and a solar cell panel is paved on the upper surface of the rectangular plate. The photovoltaic power generation apparatus has excellent windproof and wind-resistant performance.

Owner:南安普敦咨询服务有限公司

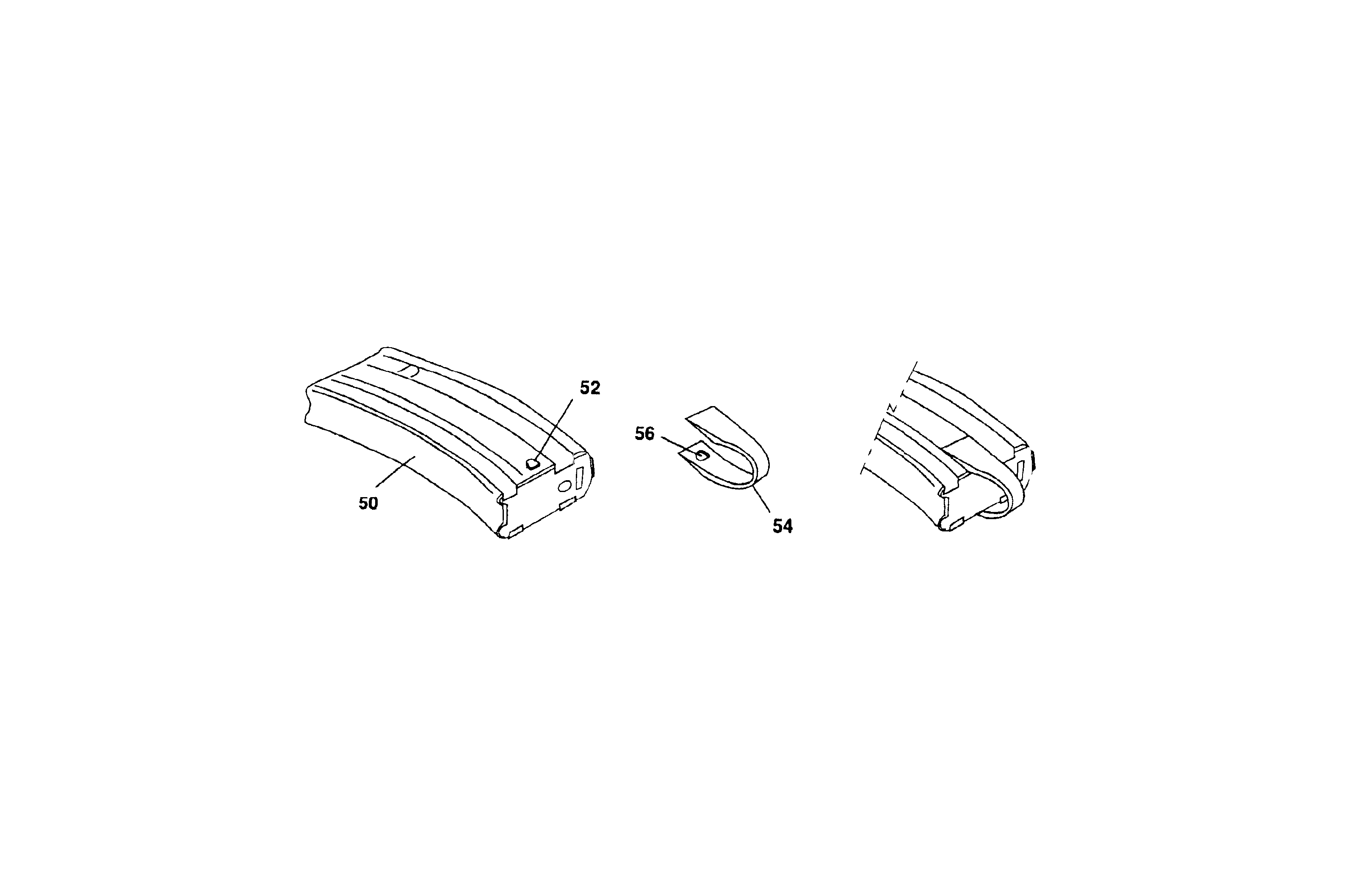

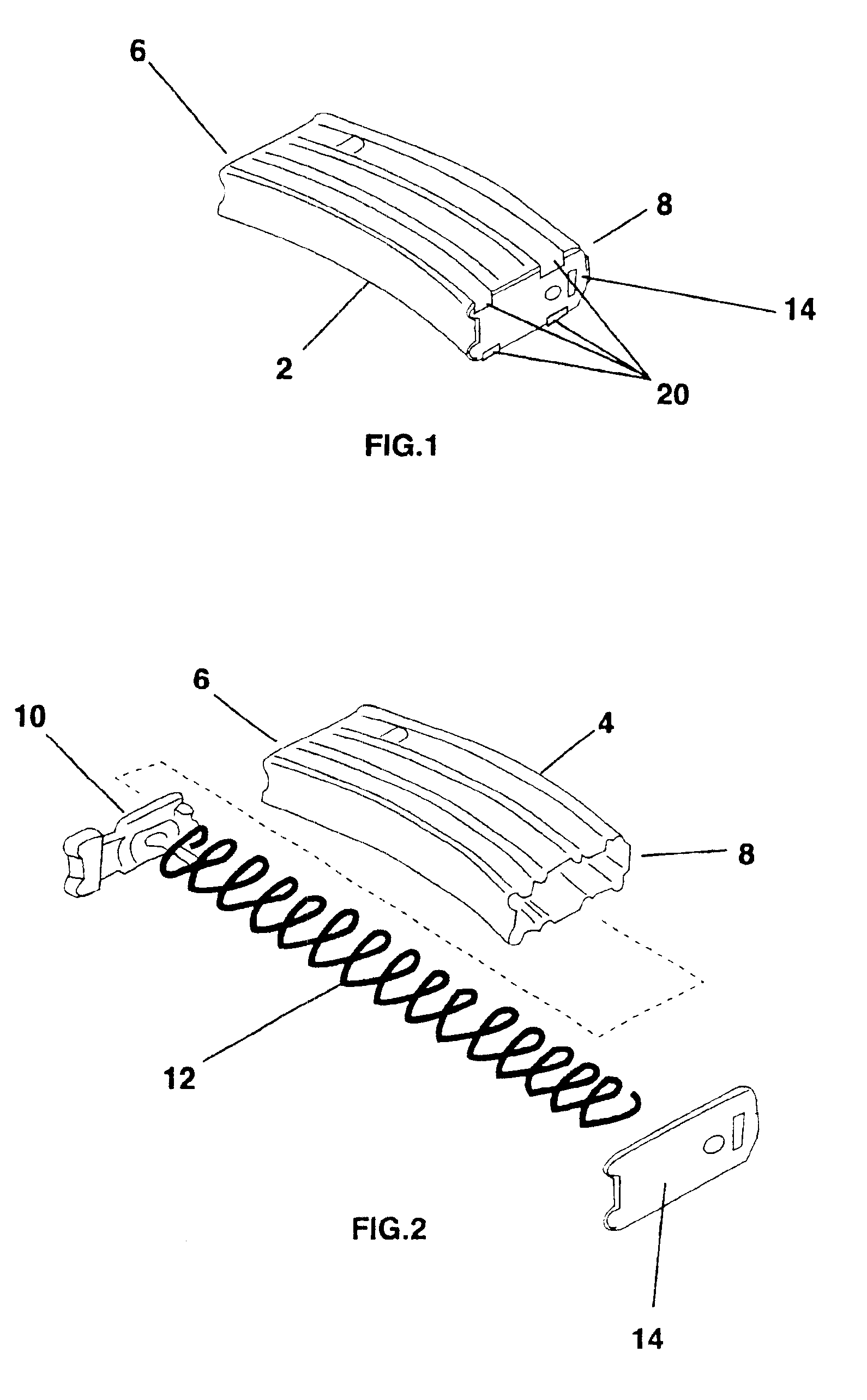

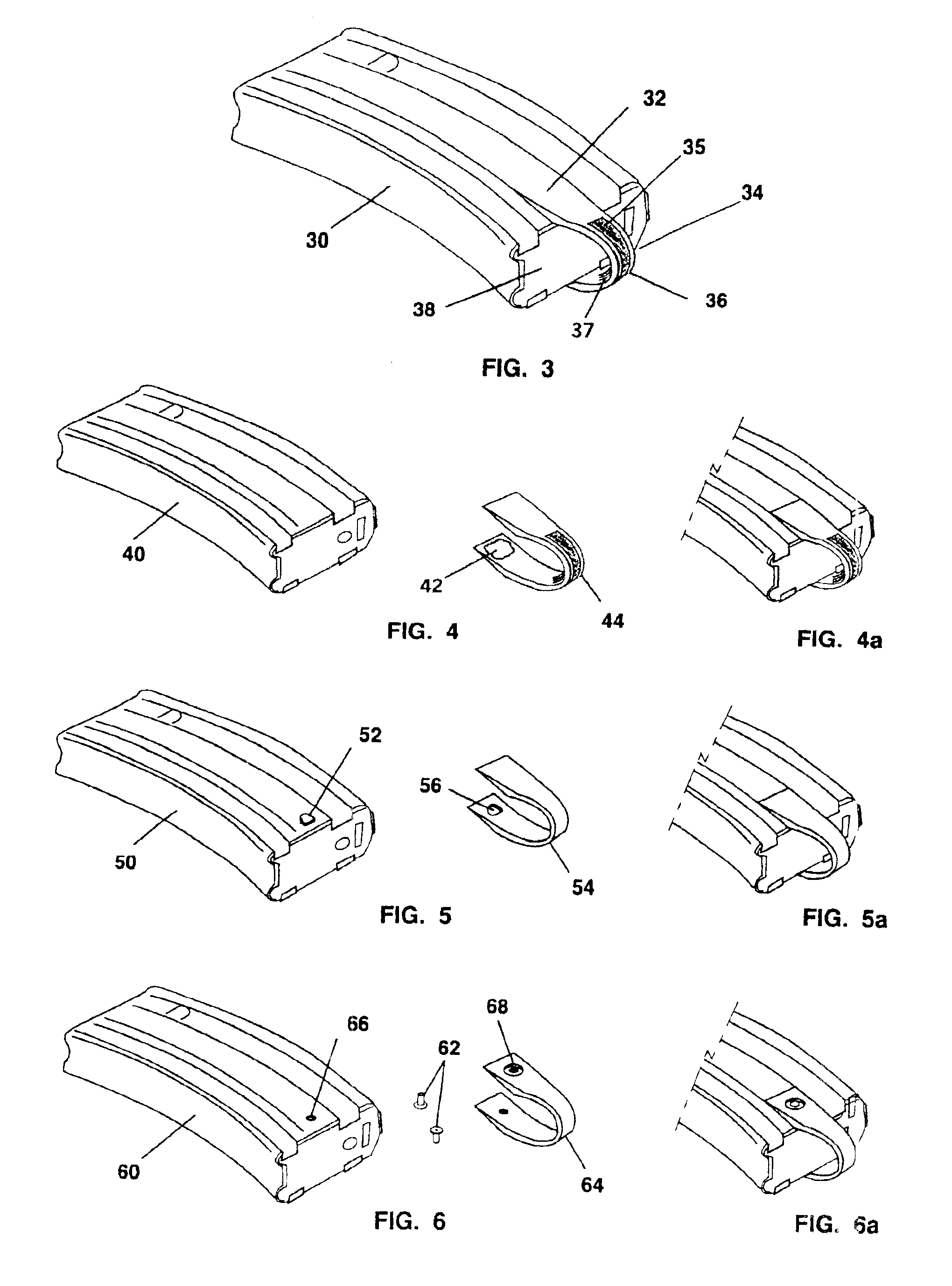

Ammunition magazines with integral handles

InactiveUS6883261B2Reduce impact damageLow failure rateBreech mechanismsAmmunition storageEngineering

Integral extensions to aid in the extraction of ammunition magazines from ammunition pouches are provided in three embodiments. In this embodiment, the sides of an ammunition magazine are extended, either by molding or affixing a handle directly to the sides of the magazine, to provide a handle. This embodiment provides a more steam-lined handle adapted for use specifically in the extraction of magazines from ammunition pouches and other storage means.

Owner:MAGPUL INDUSTRIES

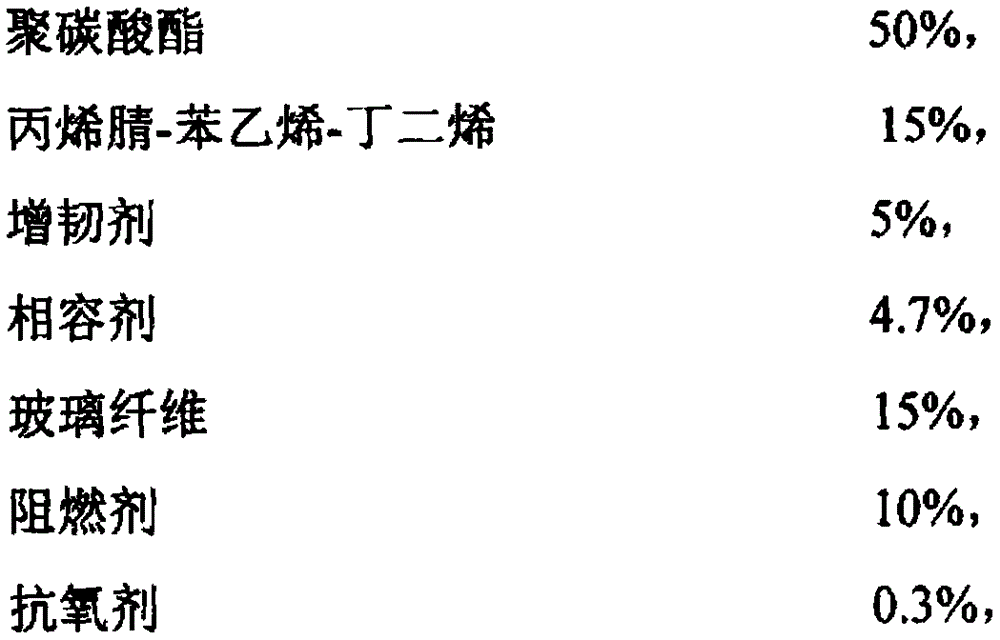

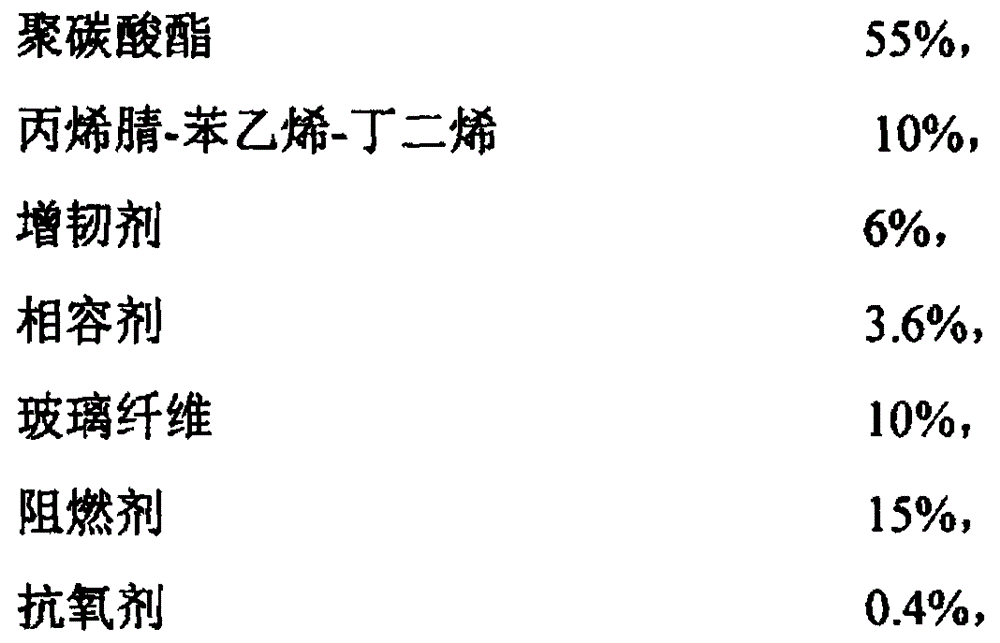

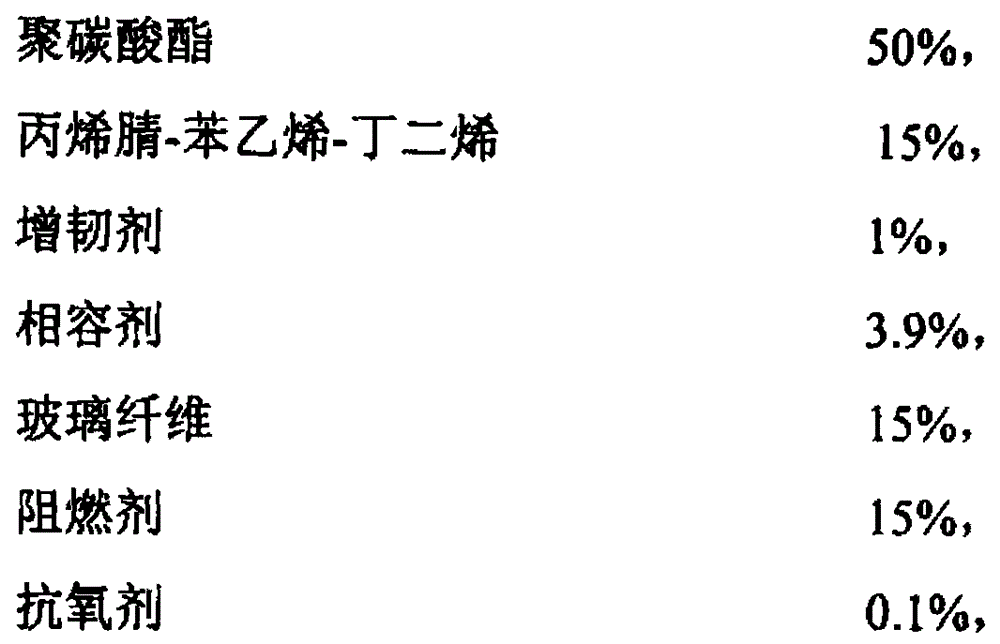

Intumescent flame-retardant reinforced PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) alloy and preparation method thereof

The invention relates to an intumescent flame-retardant reinforced PC (Polycarbonate) / ABS (Acrylonitrile Butadiene Styrene) alloy and a preparation method thereof. The intumescent flame-retardant reinforced PC / ABS alloy is prepared from the following components in parts by weight: 40-60 parts of PC, 10-25 parts of ABS, 1-10 parts of toughening agent, 3-10 parts of compatilizer, 10-20 parts of glass fiber, 10-20 parts of flame retardant and 0.1-0.5 part of antioxidant. The preparation method comprises the steps of proportioning according to the weight ratio, placing other raw materials except for glass fiber into a high-speed mixer to mix for 2-5min, and adding the mixture through a first-section drum of a double-screw extruder; adding glass fiber through a fourth-section drum of the double-screw extruder; and controlling the rotating speed of the double-screw extruder at 300-500r / min, extruding and granulating to prepare the PC / ABS alloy. The vertical combustion grade of the intumescent flame-retardant reinforced PC (Polycarbonate) / ABS alloy is UL94V-0(3.2mm). In addition, the intumescent flame-retardant reinforced PC (Polycarbonate) / ABS alloy is free of pollution during combustion so as to be capable of generating nontoxic gases during combustion, favorable in environment friendliness, little in influence to the mechanical performance of a material and favorable in mechanical performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method and apparatus for diverting material

InactiveUS7258225B2Extended service lifeEasy transferCleaningLoading/unloadingControl mannerEngineering

Owner:MARTIN ENG

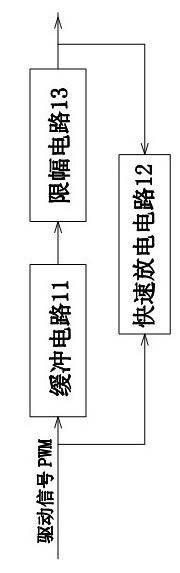

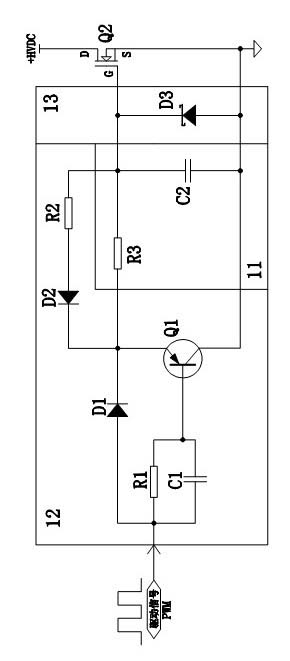

Drive circuit for preventing oscillation of grid drive signals

InactiveCN102231594AExtended opening timeReduce impact damagePower conversion systemsSignal processingElectro magnetic compatibility

The invention relates to a drive circuit for preventing the oscillation of grid drive signals. The drive circuit is characterized by comprising a buffer circuit, an amplitude limiting circuit and a rapid discharge circuit, wherein the buffer circuit receives and processes a drive signal PWM (Pulse Width Modulation) and then outputs the signal to the amplitude limiting circuit; the amplitude limiting circuit processes the received signal and then respectively outputs the signal to the grid of an MOS (Metal Oxide Semiconductor) transistor and the rapid discharge circuit; and the rapid discharge circuit also receives the drive signal PWM. The drive circuit has the advantages of lowering the voltage change rate of the MOS transistor, decreasing the open surge in the opening process, reducing the impact and damage to the MOS transistor, improving the EMC (Electro Magnetic Compatibility) property of the whole switch power supply, decreasing the turnoff loss, effectively avoiding the abnormal oscillation of drive signals, protecting normal working states of the MOS transistor and the circuit, and the like.

Owner:SHUNDE POLYTECHNIC

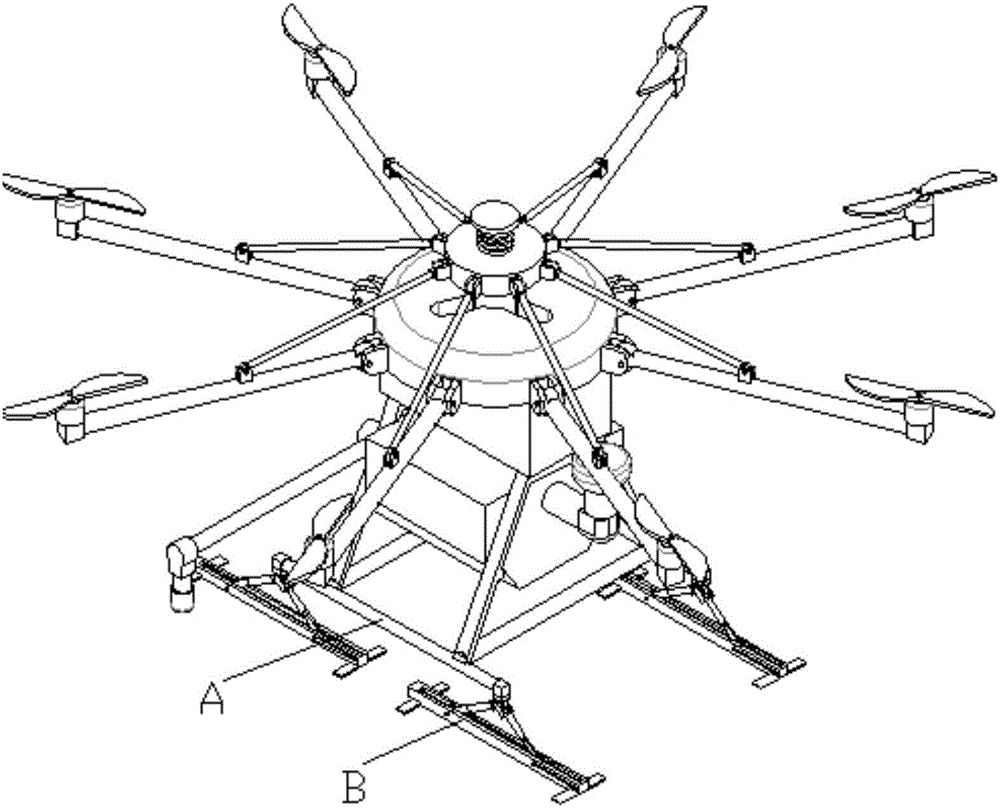

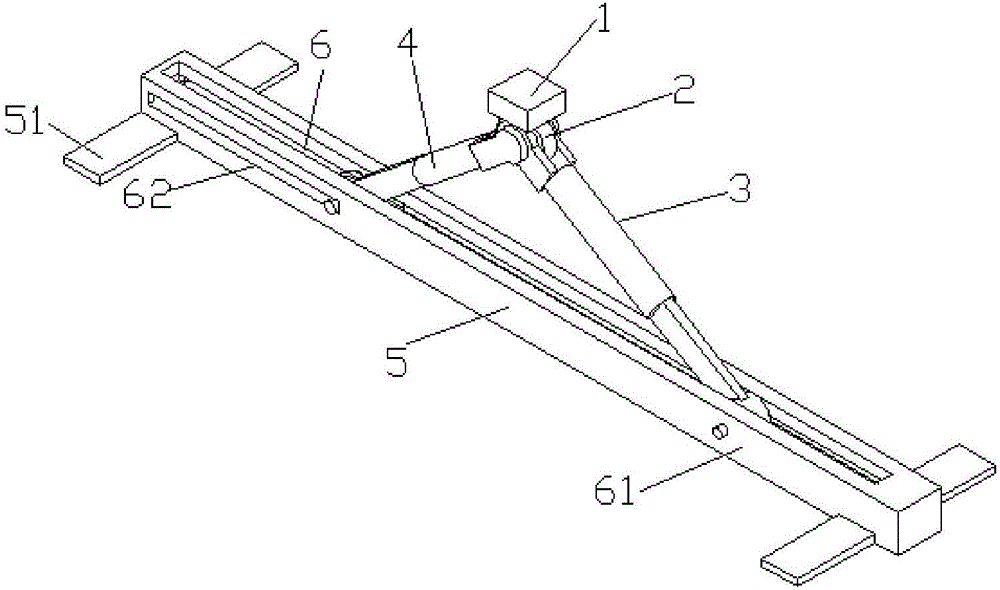

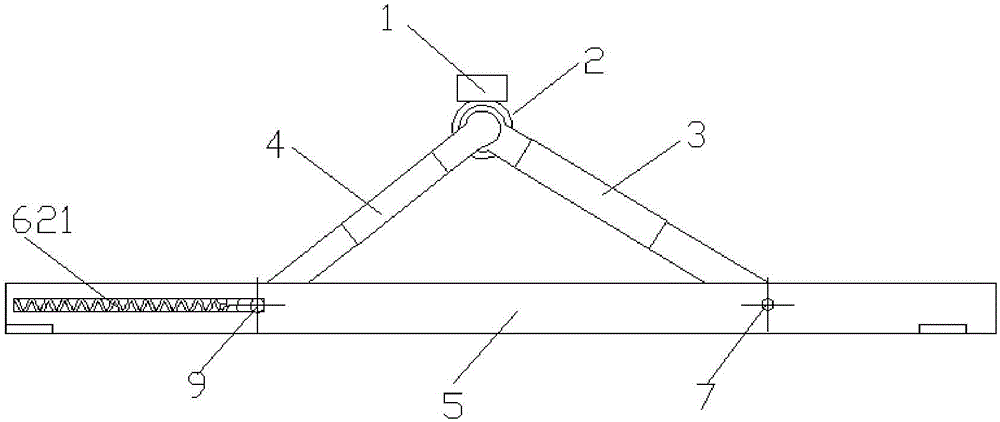

Unmanned aerial vehicle undercarriage for agricultural machinery

InactiveCN106741881AReduce impact damageSimple structureAlighting gearRotocraftAgricultural engineeringAgricultural machinery

The invention provides an unmanned aerial vehicle undercarriage for agricultural machinery. The unmanned aerial vehicle undercarriage comprises buffering units located at the ends of lifting-falling rods, and each buffering unit comprises a fixing block, a shaft connecting block, a fixed connecting rod, a movable connecting rod, a supporting rod and a groove. Each groove is located in the corresponding supporting rod and comprises a fixed area and a movable area, a through groove is formed in side wall of each movable area, an elastic piece and a movable rotary shaft is arranged in each movable area, and a fixed rotary shaft is arranged in each fixed area; the lower end of each fixed connecting rod is rotatably connected with the corresponding groove through the corresponding fixed rotary shaft; and the lower end of each movable connecting rod is rotatably connected with the corresponding groove through the corresponding movable rotary shaft. The unmanned aerial vehicle undercarriage for the agricultural machinery has the beneficial effects that the movable connecting rods, the movable rotary shafts and the springs in the buffering units are matched to complete the buffering effect, the structure is simple, the buffering effect is good, and impacting damage caused to an unmanned aerial vehicle with sprayed liquid during falling is effectively reduced.

Owner:欧亚班列(天津)供应链有限公司

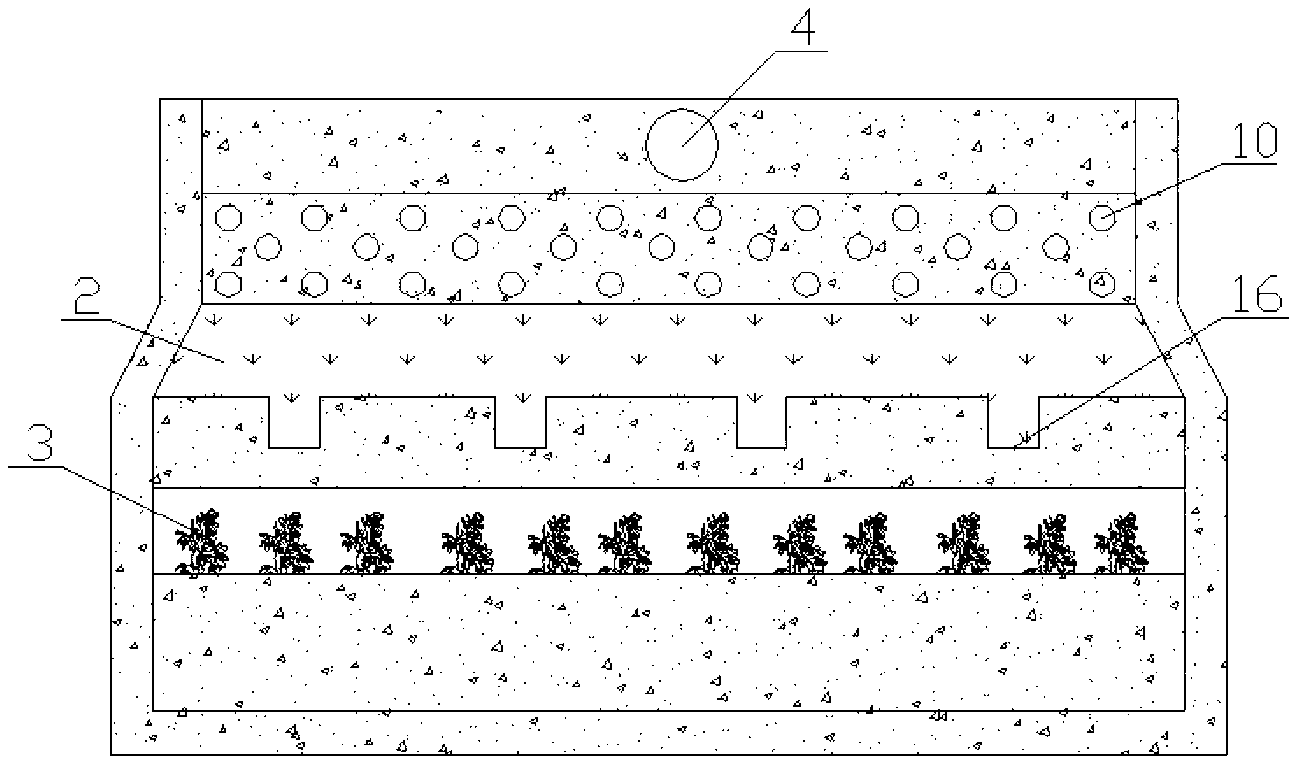

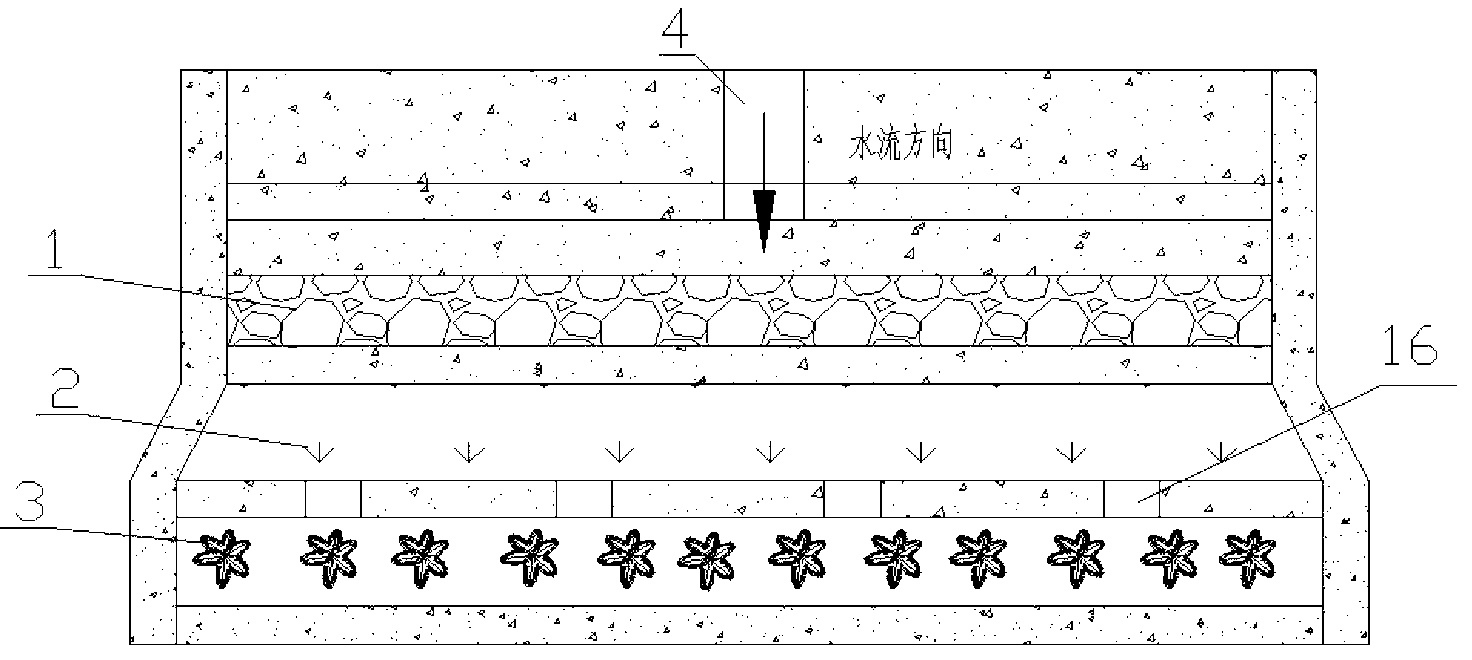

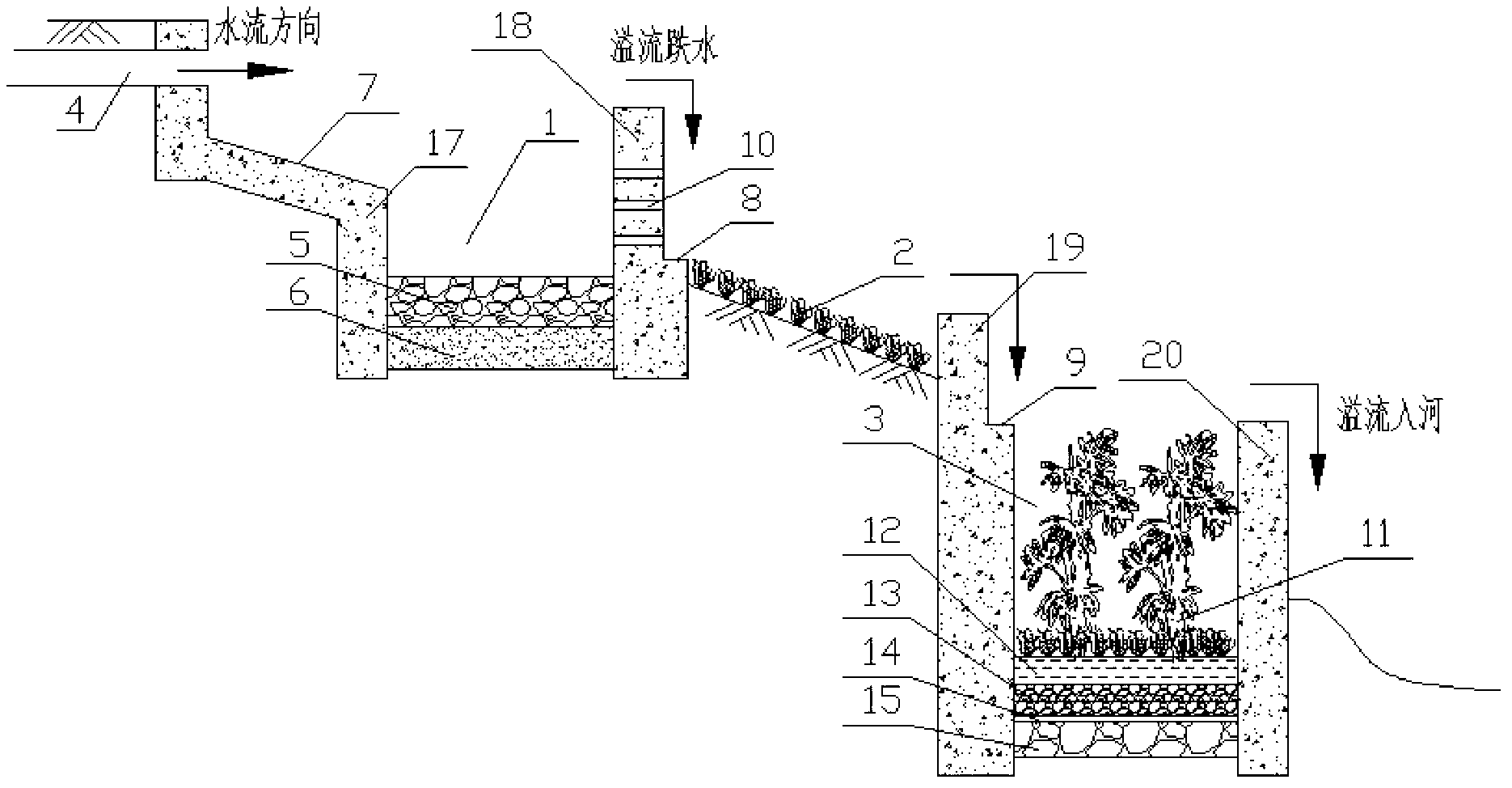

Multidimensional ecological drainage system for intercepting and controlling separate system rainwater pollutants into river

InactiveCN103306360AReduce the risk of polluted runoff directly entering the riverReduce impact damageSustainable biological treatmentSewage drainingEnvironment of AlbaniaWater pipe

The invention discloses a multidimensional ecological drainage system for intercepting and controlling separate system rainwater pollutants into a river. The system is arranged on one side of a river bank and takes a stair-step shape along the river bank; rainwater in pipe networks flows into a first-stage water drop platform by rain-water pipes, enters a storage pond, flows into an ecological buffer zone by a second-stage water drop platform, and lastly flows into a plant growth detention pond; and the first-stage water drop platform and the ecological buffer zone are slope-shaped, and plants are planted in the plant growth detention pond. The system not only ensures drainage, but also reduces the risk that rainwater polluted run-offs directly flow into the river, reduces impact and damage to water quality of the water body in a river channel, effectively controls the pollutants in the river, effectively improves the water environment, and enhances the urban water landscape value.

Owner:TIANJIN UNIV

Water-air vertical crossing vehicle

InactiveCN102963230AReduces impact damageStrong promotion and application valueAircraft convertible vehiclesPropellerAutomotive engineering

The invention discloses a water-air vertical crossing vehicle, which comprises a central support, an aerodynamic device, an underwater power device, an electronic governor, a remote control receiver and a remote controller. The design density of the vehicle is greater than that of water, and the rotational speed of the aerodynamic device is gradually reduced when the vehicle enters water so as to reduce the impact damage to the vehicle; after the vehicle touches the water, the aerodynamic device is turned off, the vehicle is submerged below the water surface by the self-gravity of the vehicle, and then an underwater propeller is started up, so that the vehicle is in a submerged state; and the vehicle goes out of the water by relay propulsion of two-layer power. The water-air vertical crossing vehicle has the several interface-crossing capacity and the continuous navigation ability in multiple media, has the advantages that no auxiliary equipment is needed and the vehicle can be repeatedly used, and has stronger promotion and application values; and by using the layered design, at least one power device of the vehicle separately acts in air or water in the water-air medium crossing process, the situation that the power system works in the water-air two-phase environment is avoided, and the great damage of the water-air mixed environment to blades is prevented.

Owner:空军工程大学

Hot continuous rolling strip thick plate coiling temperature control method

ActiveCN104801551AIncrease the actual coiling temperatureReduce deformation resistanceTemperature control deviceWork treatment devicesTemperature controlThick plate

A hot continuous rolling strip thick plate coiling temperature control method comprises the steps of controlling a finish rolling scale removal box, controlling high-pressure scale removal water behind a finish rolling F1 rack, controlling cooling water between the finish rolling racks F2 and F7 and controlling laminar flow cooling water. The hot continuous rolling strip thick plate coiling temperature control method is characterized in that a first scale removal header pipe and a second scale removal header pipe are arranged in the finish rolling scale removal box, so that one of the first scale removal header pipe and the second scale removal header pipe already performs jet before the head of strip steel arrives, and the other one of first scale removal header pipe and the second scale removal header pipe is used for improving the final rolling temperature of the head of the strip steel by the adoption of a strip steel head delay jet method. In the steps of controlling high-pressure scale removal water behind the finish rolling F1 rack and controlling the cooling water between the finish rolling racks F2 and F7, a strip steel head delay jet avoiding method is adopted to improve the final rolling temperature of the head of the strip steel. In the step of controlling the laminar flow cooling water, a strip steel head delay jet avoiding method is adopted to improve the coiling temperature of the head of the strip steel. According to the method, actual coiling temperature of the head of a thick plate within 500mm length range can be effectively improved; deformation resistance of the head of the thick plate can be effectively reduced, scrap steel coiling accidents of the thick plate can be decreased; impact damage of the thick plate to the roller face and a mechanical device can be effectively reduced, and indentation defects of a clamping-delivering roller and a coiling aiding roller of a coiling machine and faults of the mechanical device of the coiling machine can be decreased.

Owner:BAOSHAN IRON & STEEL CO LTD

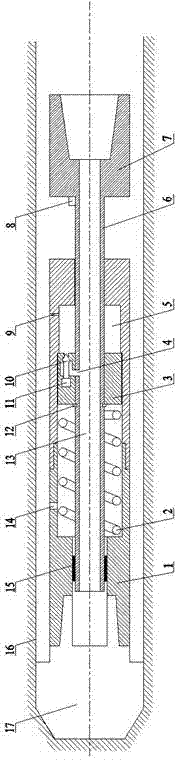

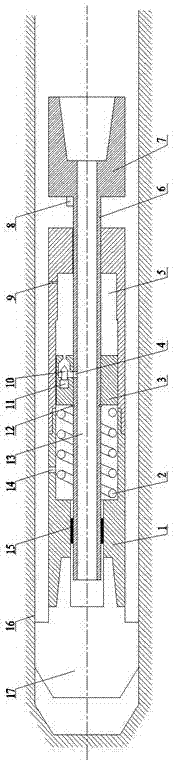

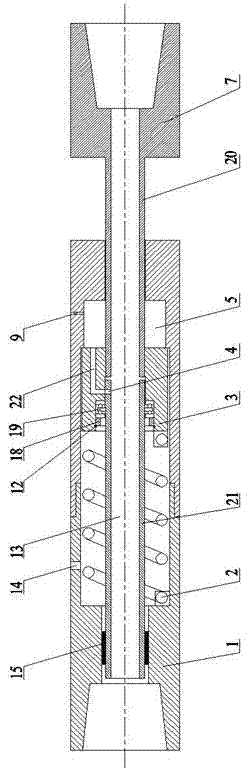

Device used for weakening stick-slip vibration of downhole drilling tool and control method of device

ActiveCN103485726AReduce impact damageExtended service lifeEarth drilling toolsDrill bitsWell drillingPetroleum oil

The invention relates to a device used for weakening the stick-slip vibration of a downhole drilling tool and a control method of the device in petroleum and gas drilling operation. According to the technical scheme, the device is installed between a drill bit and the downhole drilling tool; the device is provided with an outer sleeve, wherein a piston, a spring and a spline are installed in the sleeve; the size of a sleeve cylinder is controlled to drive the outer sleeve to move axially relative to a hollow shaft so that the drill bit can be separated from a downhole. According to the device used for weakening the stick-slip vibration of the downhole drilling tool and the control method of the device, when the torque at the drill bit can not reach a value required by rock breaking, the drill bit is lifted by a certain distance so as to reduce the torque required by rock breaking, the situation that the drill bit stops rotating temporarily and releases energy instantaneously, namely the stick-slip vibration is prevented from happening, the drill bit can keep drilling under a normal operating condition so as to reduce damage of the stick-slip vibration to drill bit teeth, and the service life of the drill bit is prolonged; the damage of the stick-slip vibration to the drill bit can be mitigated, the penetration rate can be increased, energy loss can be reduced, the rock breaking efficiency is improved, no extra process is added, and the device and the control method of the device are convenient to implement, safe and reliable.

Owner:SOUTHWEST PETROLEUM UNIV

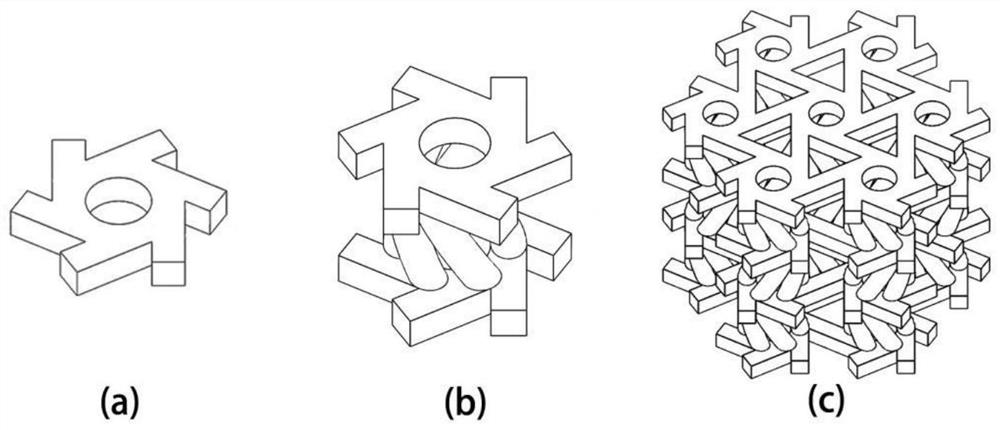

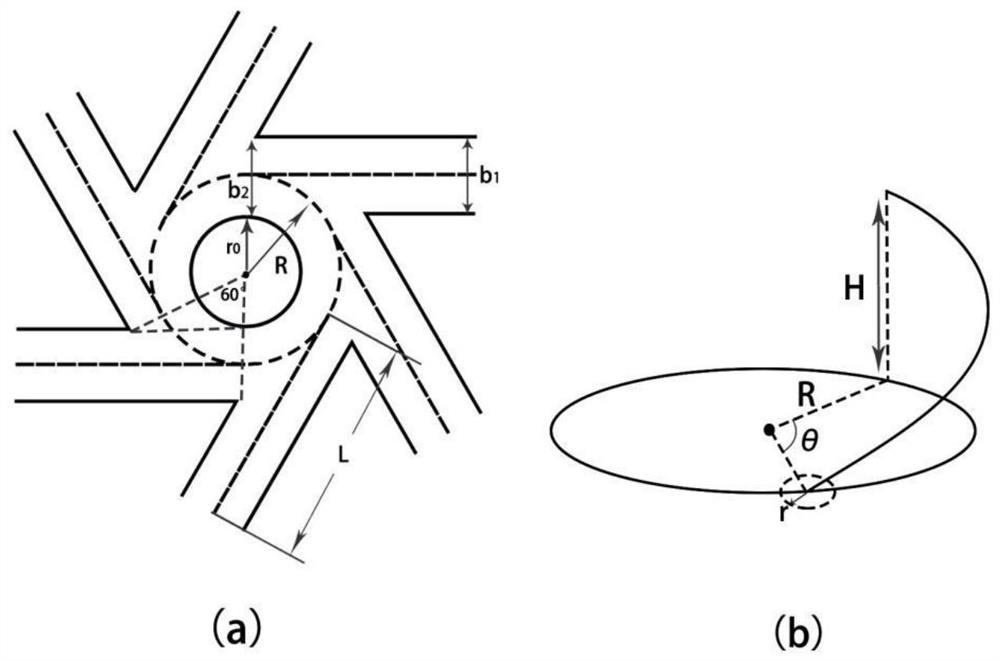

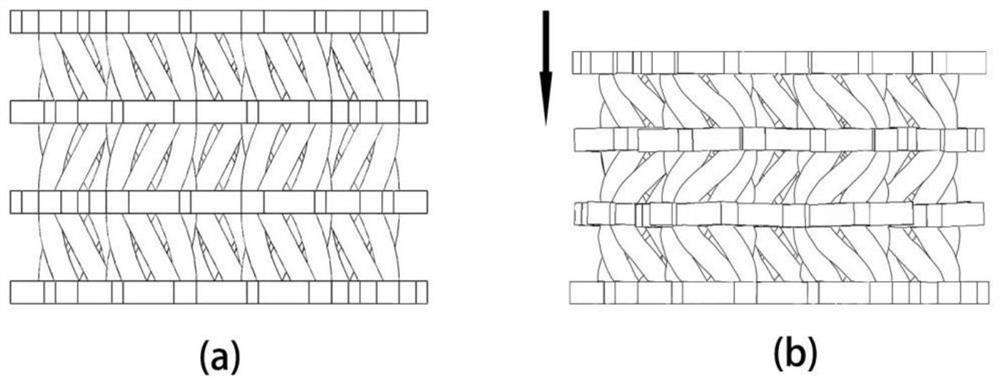

Novel three-dimensional chiral negative Poisson ratio multi-cell energy absorption structure

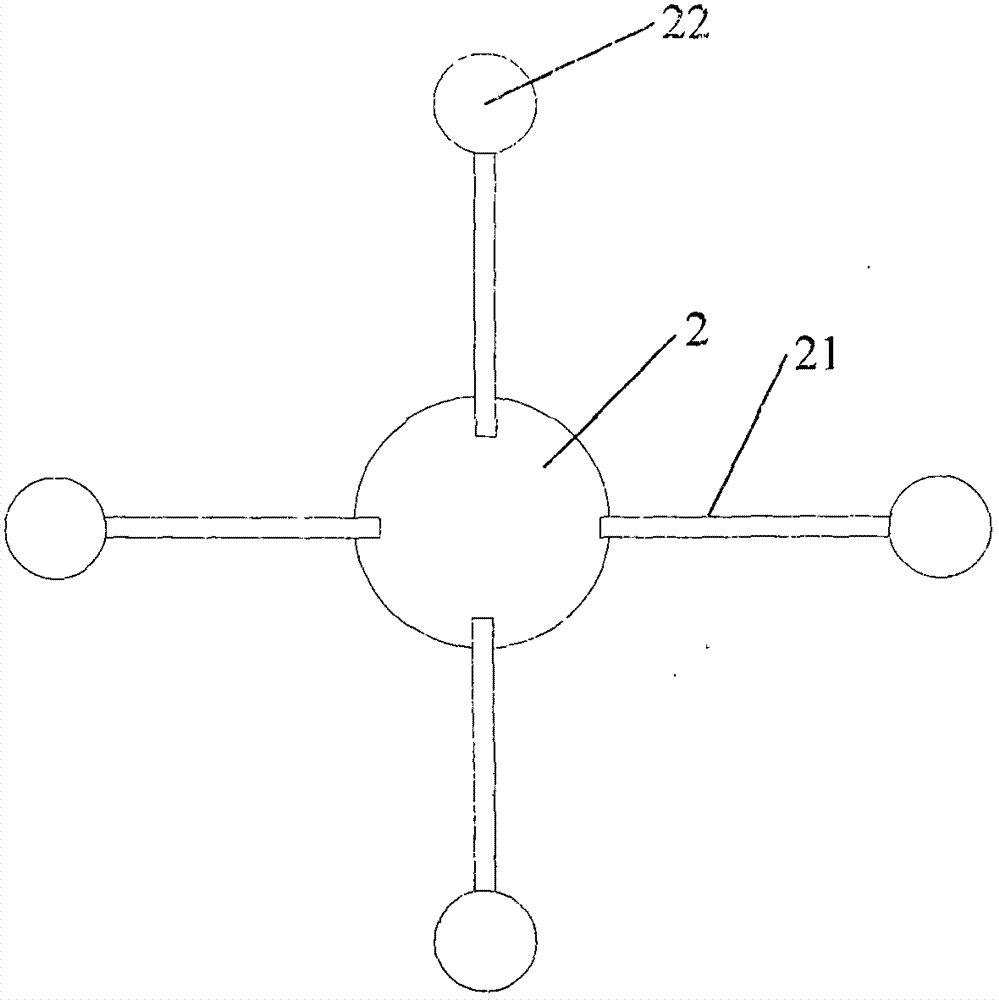

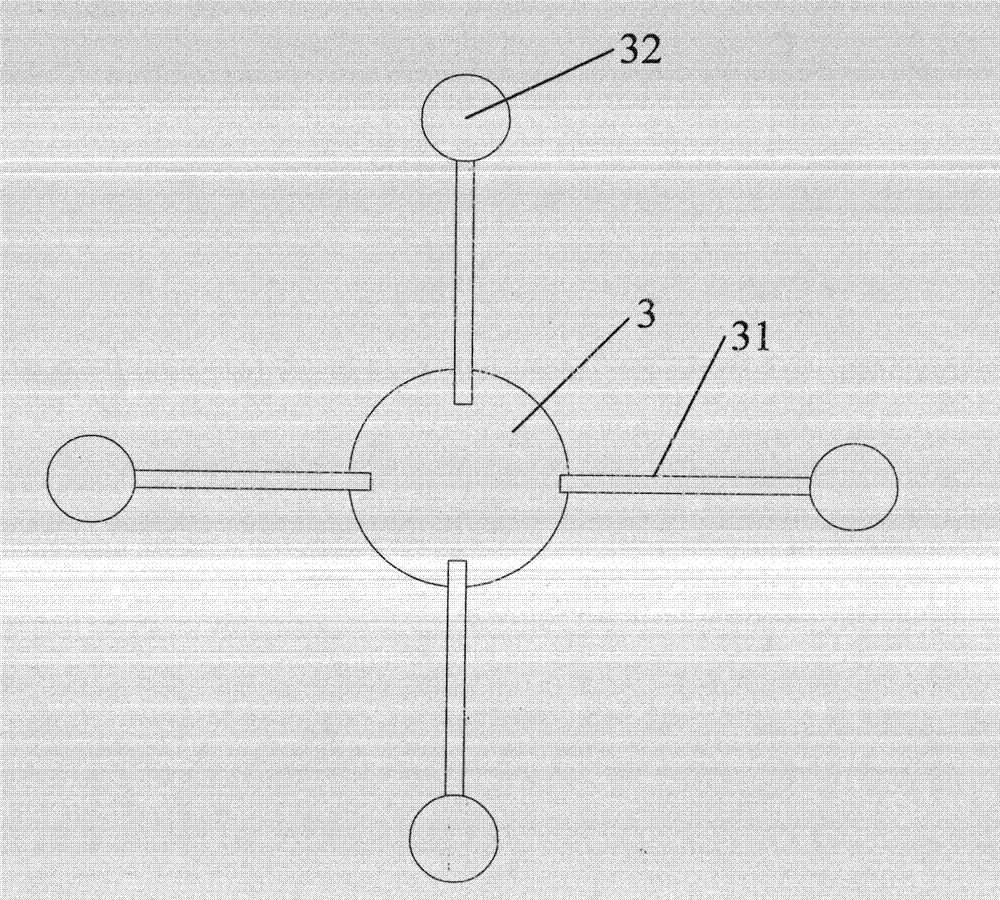

The invention discloses a novel three-dimensional chiral negative Poisson ratio multi-cell energy absorption structure. The structure comprises a plurality of energy absorption layers which are stacked in sequence, wherein the energy absorption layer comprises a plurality of hexagonal chiral structure unit cells; each hexagonal chiral structure unit cell comprises a central circular ring, first tosixth connecting rods; the rotation directions of the hexagonal chiral structure unit cells in the energy absorption layer are the same, and the first to sixth connecting rods of the adjacent hexagonal chiral structure unit cells are correspondingly connected to form an array; the hexagonal chiral structure unit cells of the adjacent energy absorption layers are in one-to-one correspondence and opposite in rotation direction, and interlayer spiral supporting structures are arranged between the hexagonal chiral structure unit cells corresponding to the adjacent energy absorption layers. By means of stacking of the micro structures, elastic displacement of the structure before reaching the yield limit is improved to a great extent, initial impact force is absorbed by means of large displacement, residual impact is absorbed by means of large counter force, and the structure has great advantages in absorption of centralized, repeated and small-magnitude impact energy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Production method of explosion inhibiting material

InactiveCN1904103ACrystallization changes and uniformImprove bending effectRoll mill control devicesMetal rolling arrangementsChemical compositionSludge

This invention relates to the process of a kind of explode restrain material. chemical composition of it includes Si 0.1-0.6,Fe 0.2-0.7,Cu 0.05-0.1,Mn 0.6-1.2,Zn 0.05- 0.1,Ti 0.03-0.12,Na 0.02-0.07,and Al the rest .the process includes steps as follows: melt, de-sludge and de-airing, make body, milling, first anneal, hot press, cold press, second anneal, stamp to open the sew, tension.

Owner:王季庄 +1

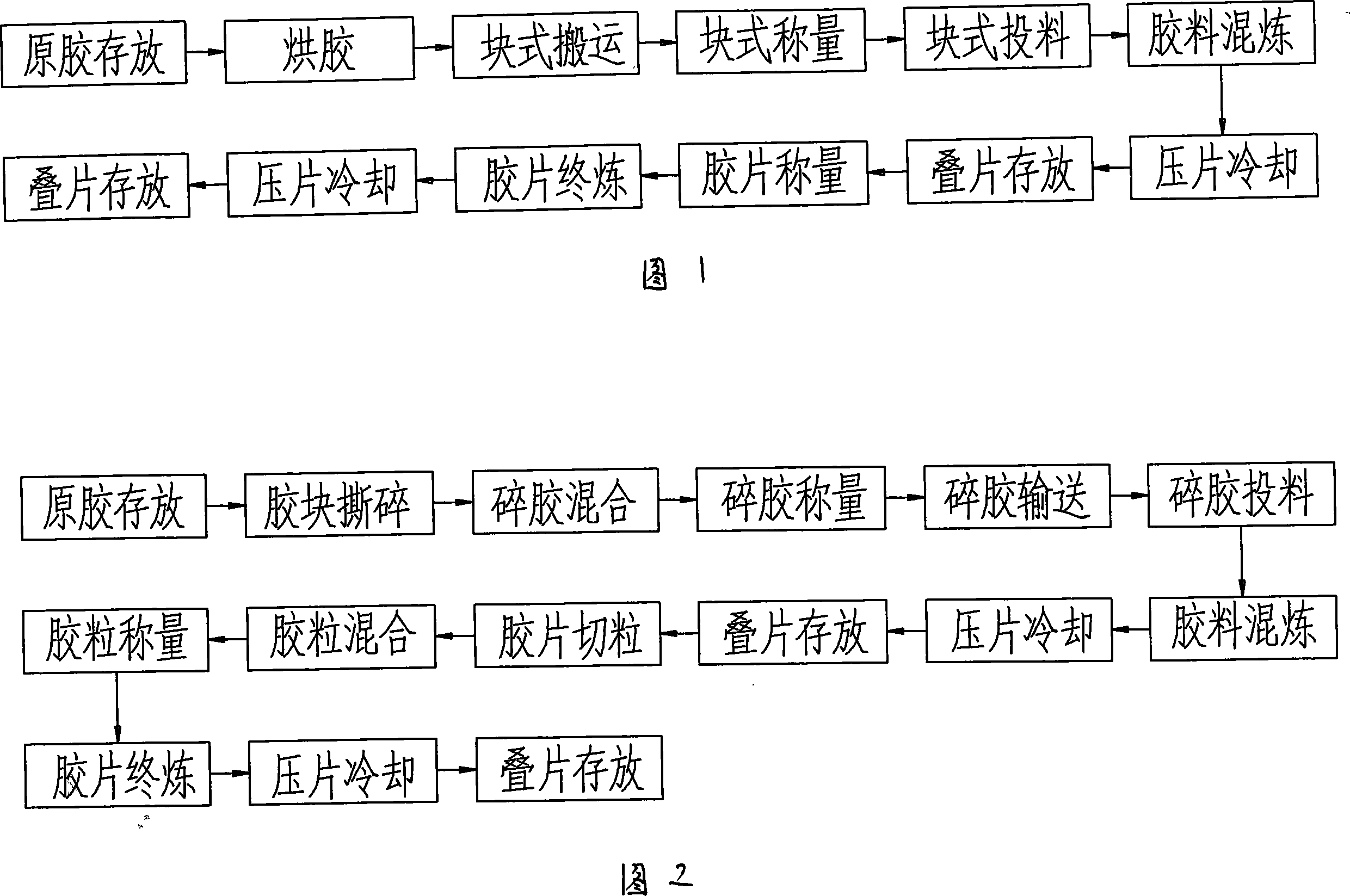

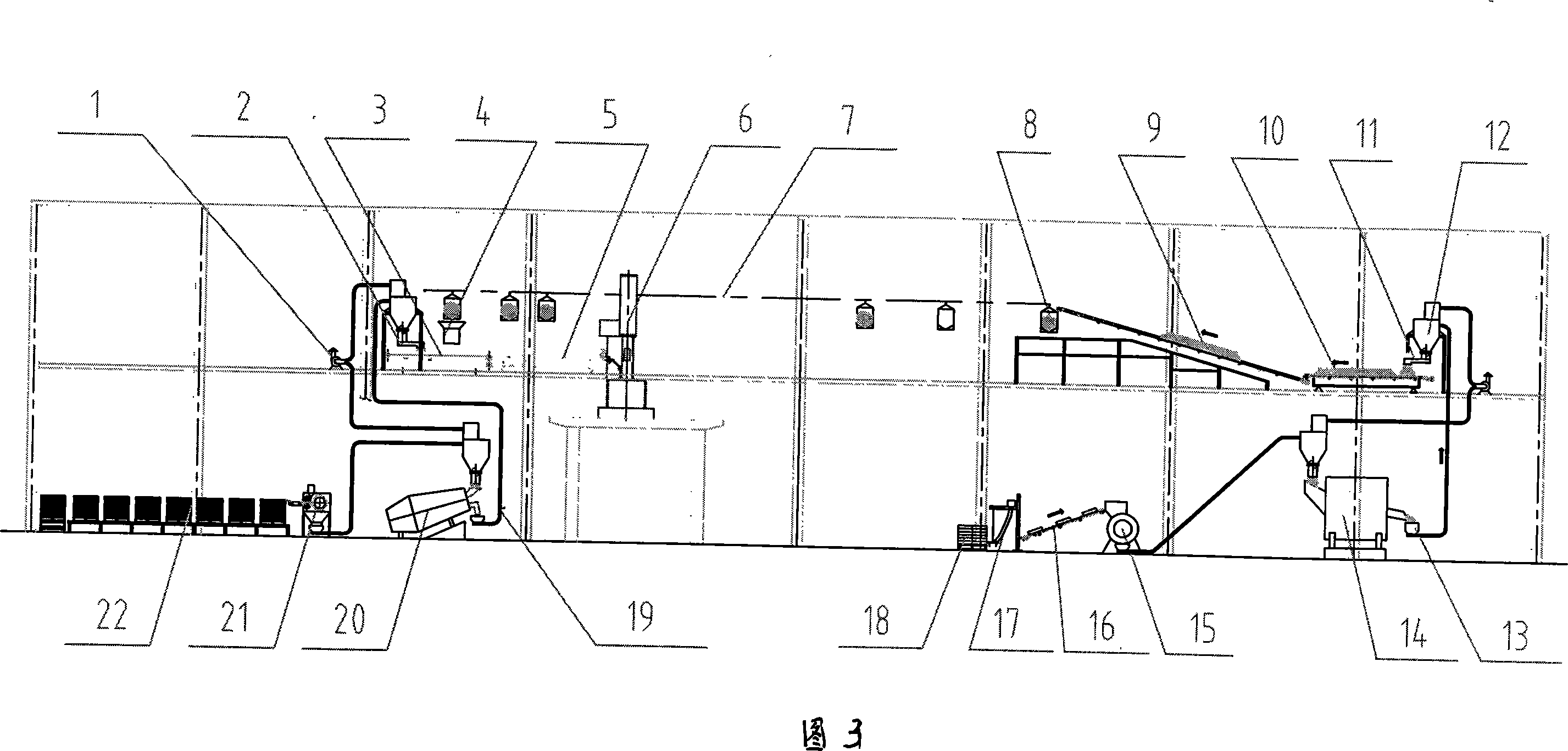

Broken glue feeding rubber mixing technique

ActiveCN101214705AStable and uniform qualityIncrease the level of automationRubber materialEngineering

The present invention relates to a cuttings-feeding rubber mixing technique, which belongs to the field of rubber-processing machines. The technique includes the following steps: (1) the storage of raw rubber, (2) the ripping of rubber blocks, (3) the weighing of cuttings, (4) the conveying of the cuttings, (5) the charging of the cuttings, (6) the mixing of the rubber material, (7) sheeting and cooling, (8) the stacking and storing of rubber sheets, (9) the granulating of the rubber sheets, (10) the mixing of rubber particles, (11) the weighing of the rubber particles, (12) the final mixing of rubber sheets, (13) sheeting and cooling, and (14) the stacking and storing of the rubber sheets. By the ripping of the rubber blocks, the granulating of the mother rubber sheets and two times of uniform mixings, the present invention realizes the uniform mixings of multiple batches of materials, so that the quality of the rubber material is more uniform and stable, and therefore the banburying effect is more ideal, and the following effects are achieved: The uniformity and stability of rubber mixing is improved, the efficiency of rubber mixing is increased, the impact damage of equipement is abated, and the automatization degree of material flowing is increased.

Owner:TRIANGLE TIRE

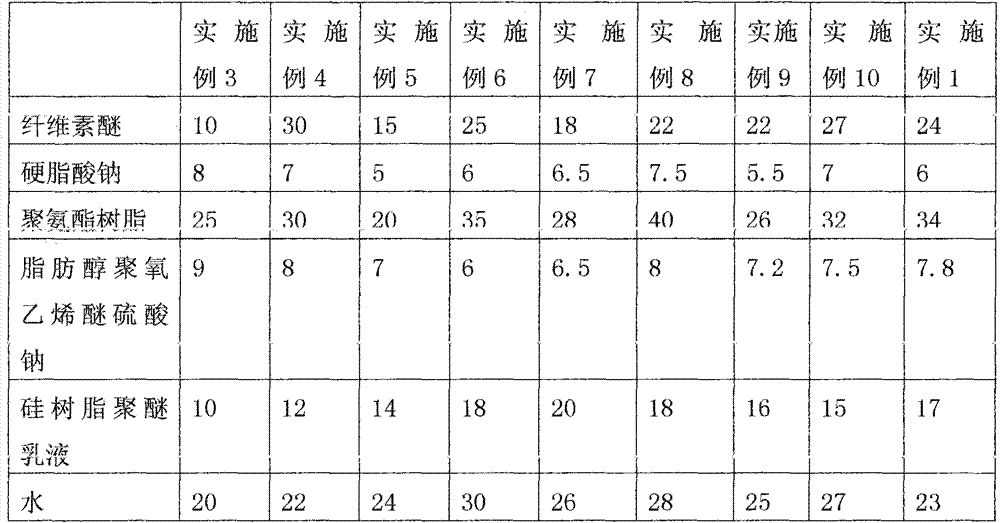

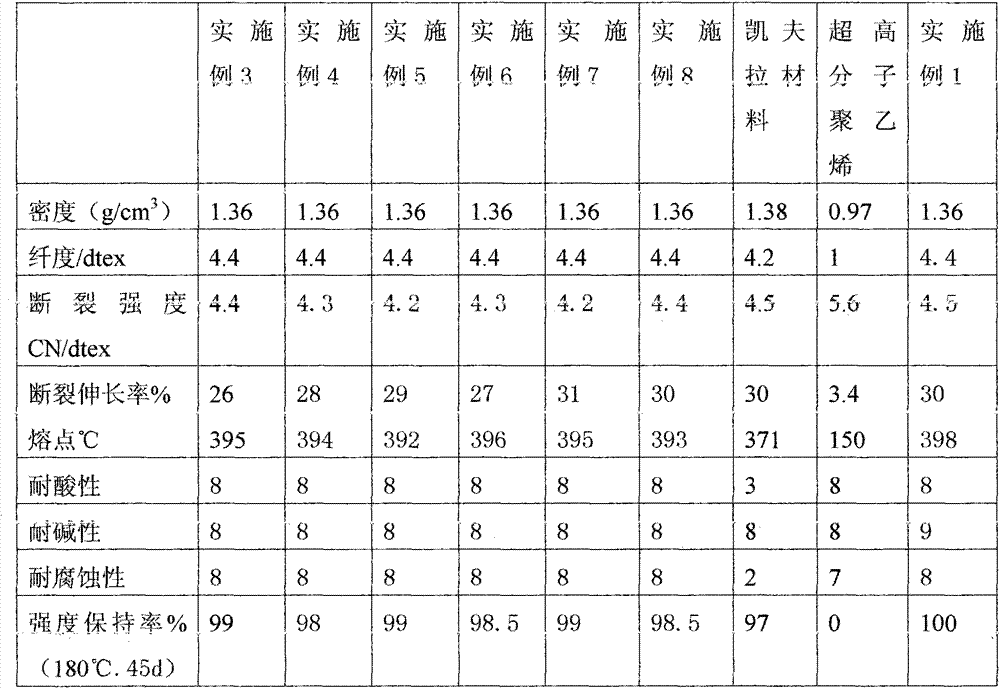

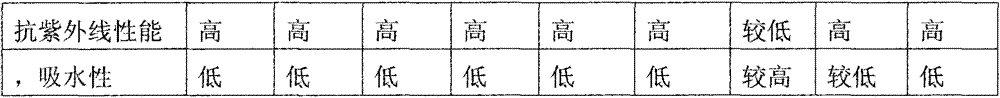

Composite flexible bulletproof material

InactiveCN104748624AGood effectHigh strengthFibre typesHeating/cooling textile fabricsFiberVulcanization

A flexible composite bulletproof material overcomes the defects that an existing bulletproof material is poor in impact force resistance, short in service life and poor in damp-proof performance. The flexible composite bulletproof material is manufactured according to the following processes that A, processed Kevlar fibers and fibers made of ultra-high molecular weight polyethylene are blended and woven into a composite Kevlar fiber layer; B, the woven composite Kevlar fiber layer is heated to 150-200 DEG C through infrared rays in a vacuum environment, and then vulcanization reaction is conducted at the temperature ranging from 200 DEG C to 450 DEG C; C, the reacted composite Kevlar fiber layer is woven, another composite Kevlar fiber layer is crocheted, the step two is repeated, and each composite Kevlar fiber layer and another composite Kevlar fiber layer are staggered by 0.25-0.5 wired tube; D, the step three is repeated many times, and then carbonization treatment is conducted on the lower surface of the multiple layers of woven composite Kevlar fiber layers. The flexible composite bulletproof material is strong in impact force resistance, good in bulletproof effect, long in service life, good in damp-proof performance, and suitable for being popularized and applied.

Owner:杨晓波

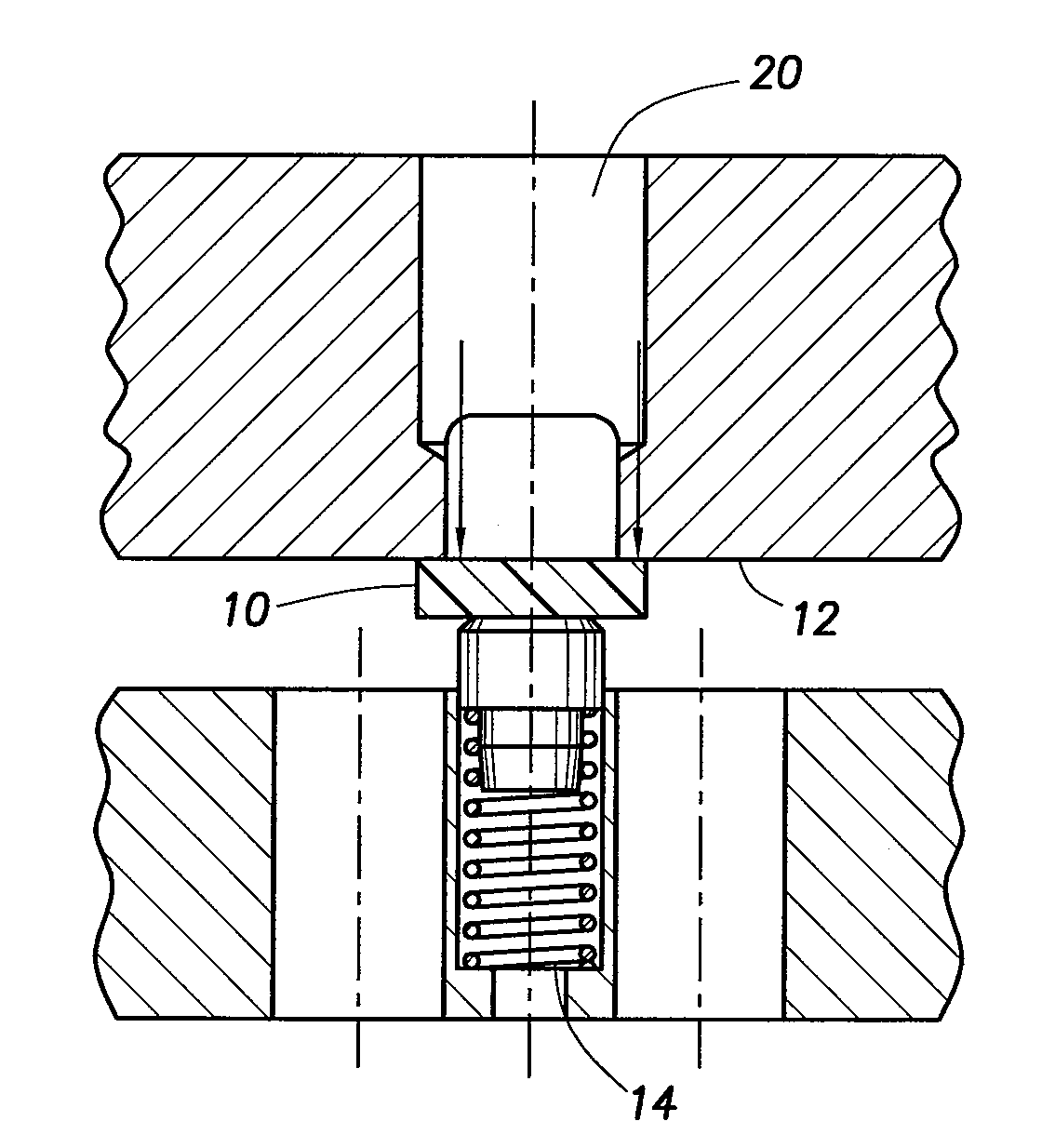

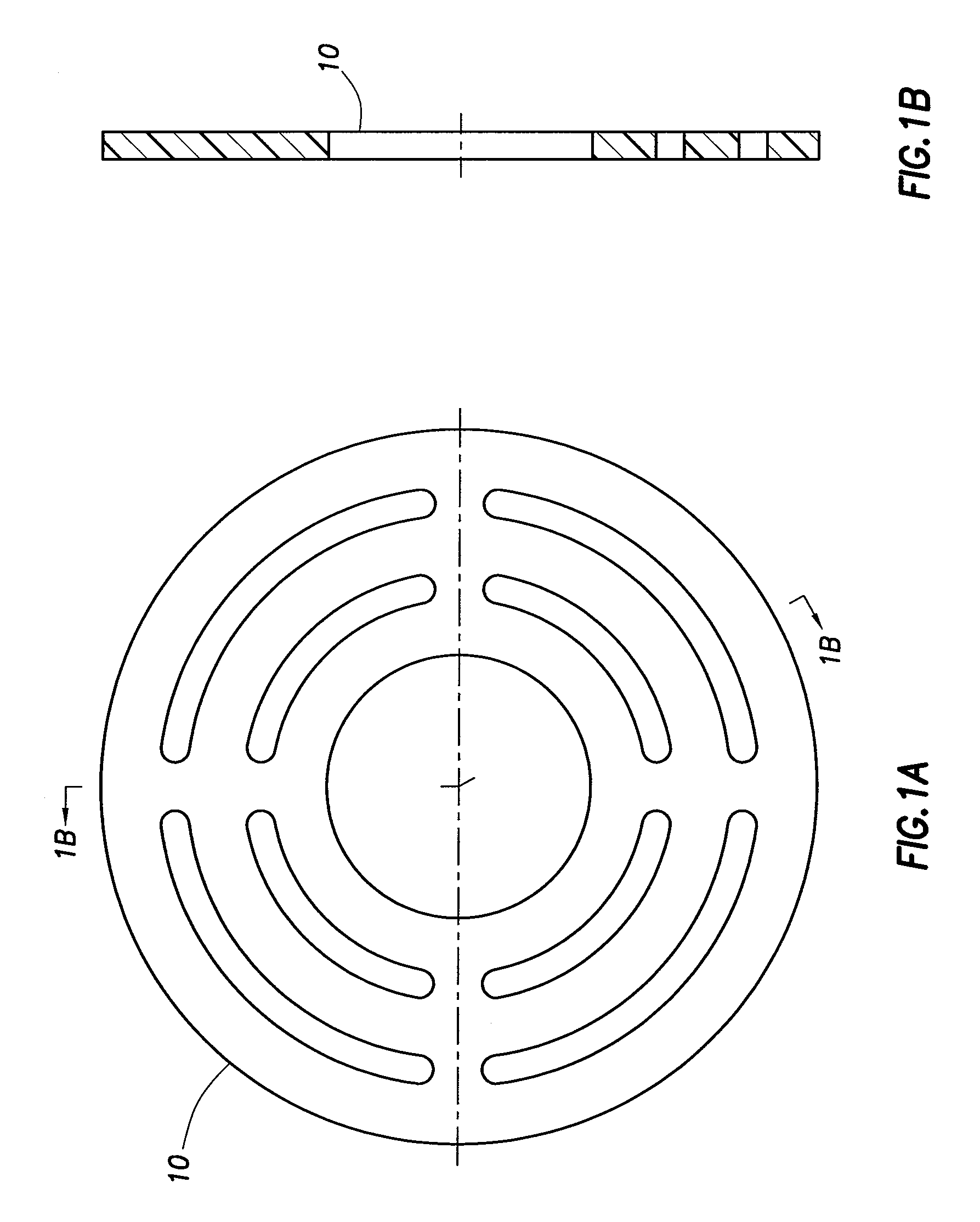

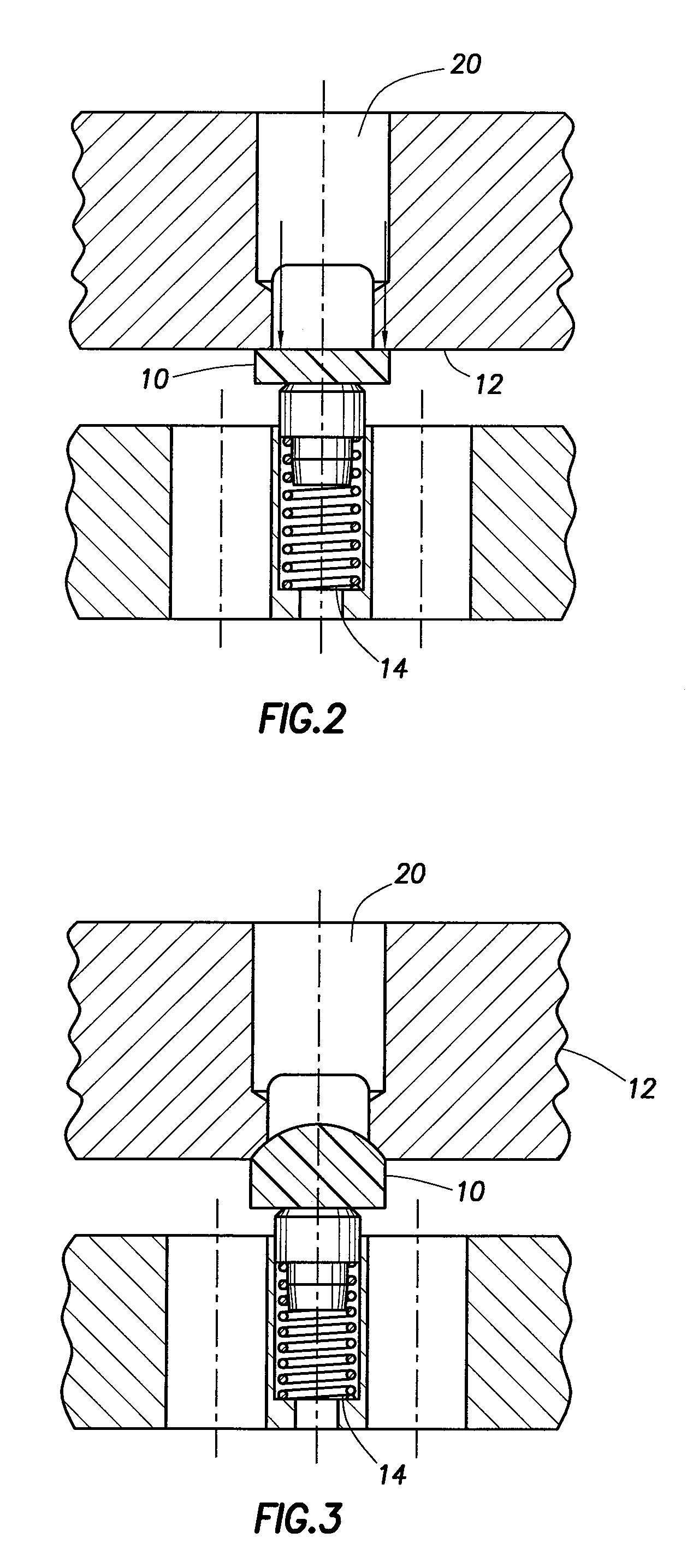

Elastomeric Sealing Element for Gas Compressor Valve

InactiveUS20090014678A1Gas tight sealReduce impact damageEngine sealsPositive displacement pump componentsAxial compressorElastomer

This invention relates to the use of elastomers with the sealing element of reciprocating gas compressor valves to increase the reliability of the gas tight seal within the reciprocating gas compressor valve and to increase the useful life of reciprocating gas compressor valve. The elastomeric material is either used as a coating layer on the sealing element of the reciprocating gas compressor valve, or as the entire sealing element. The elastomeric material acts as a cushion to reduce the wear on the sealing element, provides a superior gas tight seal, and is more tolerant of entrained dirt or liquids in the gas stream thereby increasing the operable life of the reciprocating gas compressor valve. Reducing the mean time between reciprocating gas compressor valve failures results in longer reciprocating gas compressor run times for the user, increased revenue generation for the user and safer operation of said equipment.

Owner:DELAWARE CAPITAL FORMATION

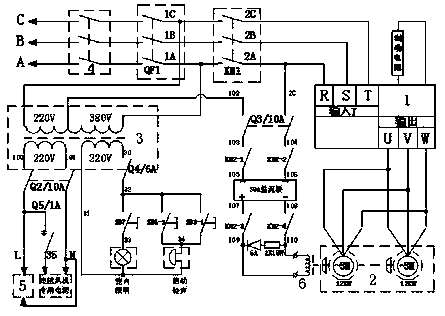

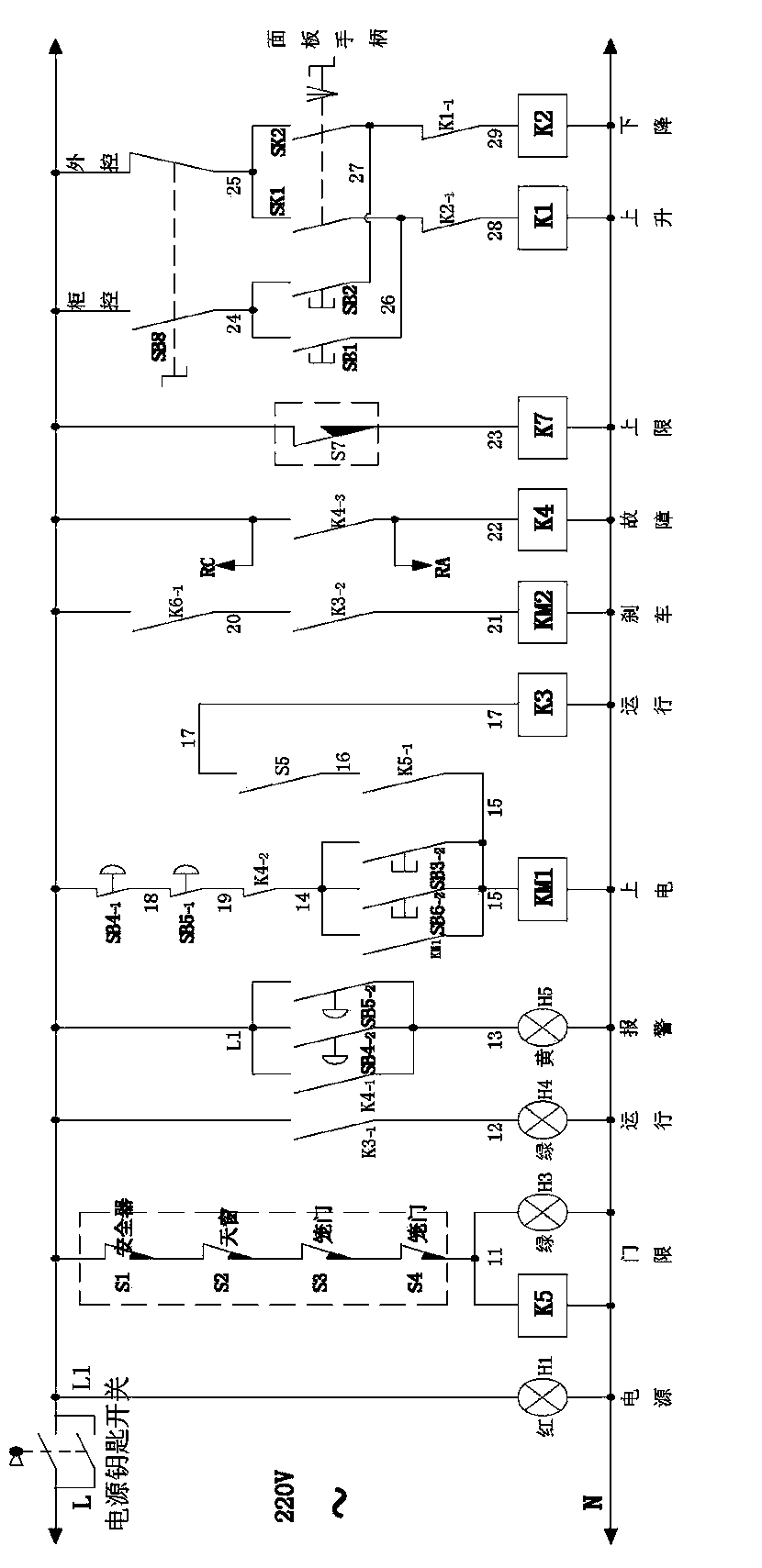

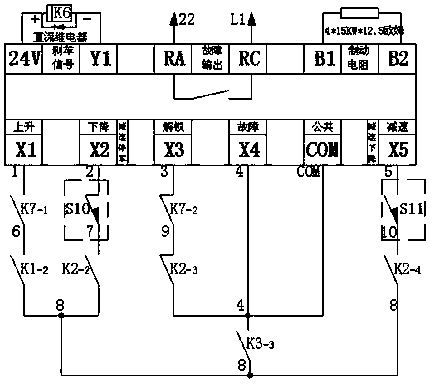

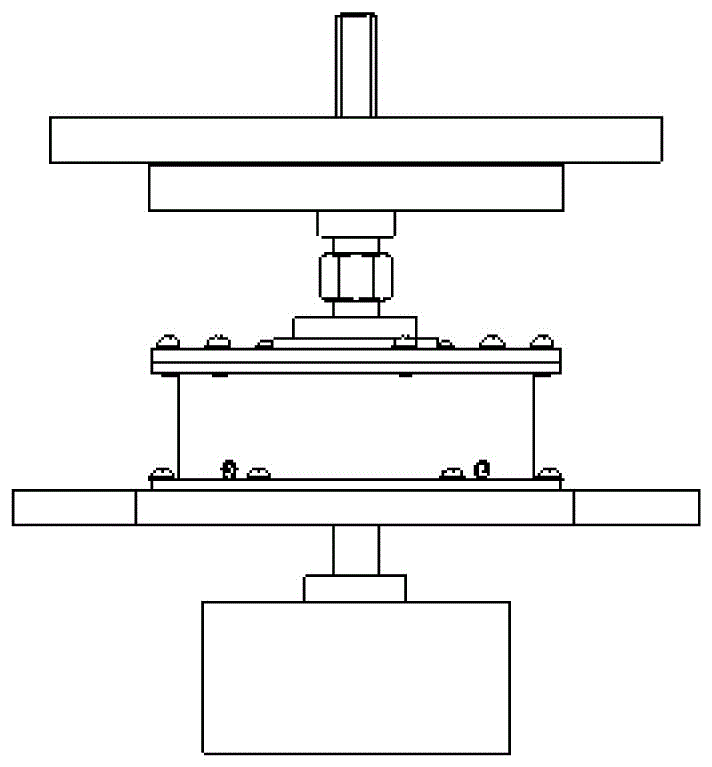

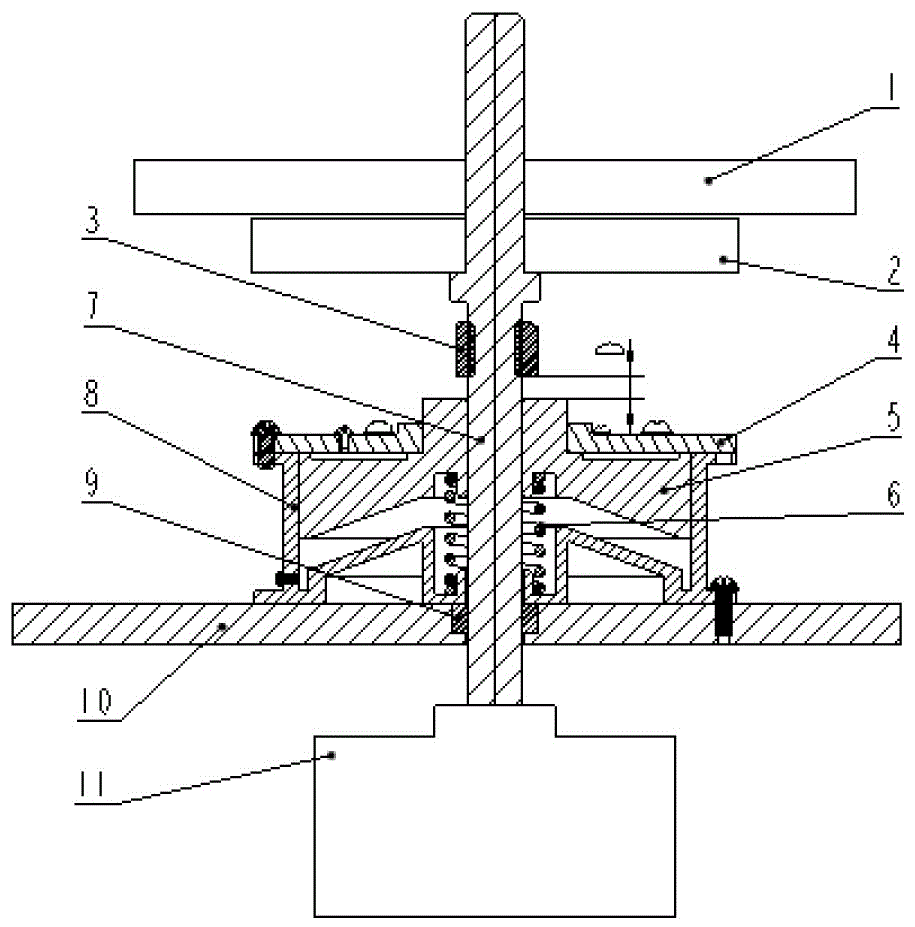

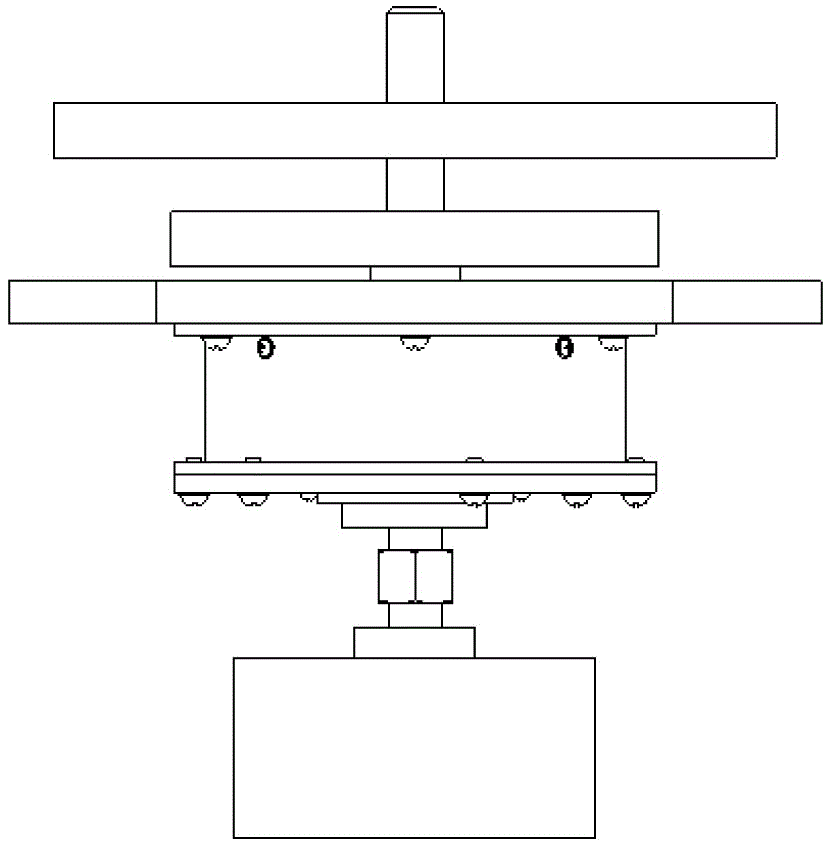

Frequency converting control system for building hoist and control method for frequency converting control system

The invention discloses a frequency converting control system for a building hoist. The system comprises a limit switch, an over-current protection control switch, a phase-sequence control switch, a main alternating-current contactor, a control transformer, a vector control type frequency converter and a control loop, wherein the limit switch is connected to a power input end of the frequency converting control system and controls make and break of a power source of the frequency converting control system; the over-current protection control switch is in circuit connection to one end, which is connected to the frequency converting control system, of the limit switch; the phase-sequence control switch, the main alternating-current contactor and the control transformer are respectively in circuit connection with the over-current protection control switch; an input end of the vector control type frequency converter is in circuit connection with the main alternating-current contactor; an output end of the vector control type frequency converter is in circuit connection with a motor of the building hoist; and the control loop is in circuit connection with the transformer. The vector control type frequency converter is specially used for the hoist, control software in the vector control type frequency converter is specially designed for professionalism of the building hoist, the frequency converting control system also has impact feeling of the original power frequency control system during running, impact damage on mechanical equipment is reduced, and drivers and passengers of the building hoist feel comfortable.

Owner:江苏三上机电制造股份有限公司

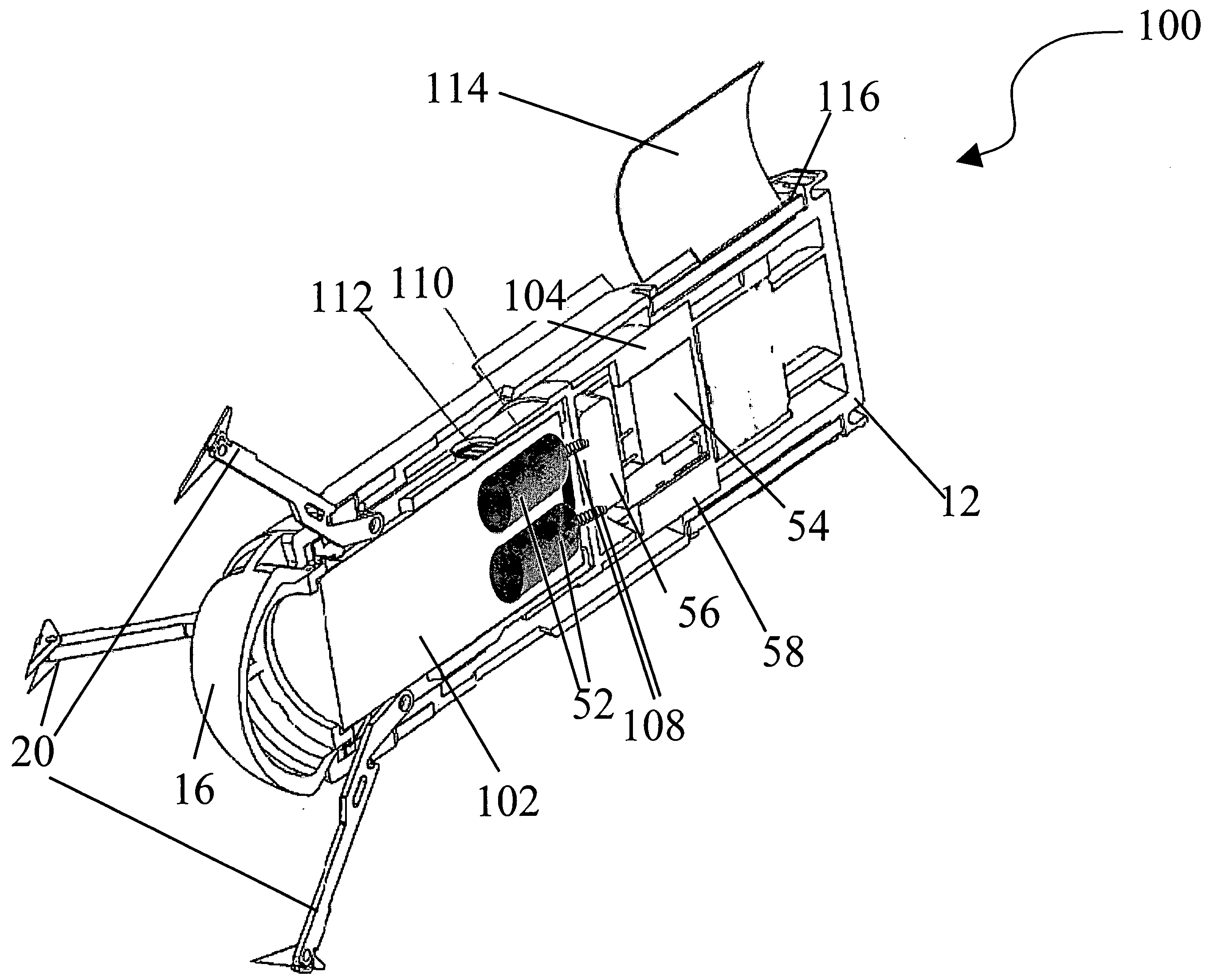

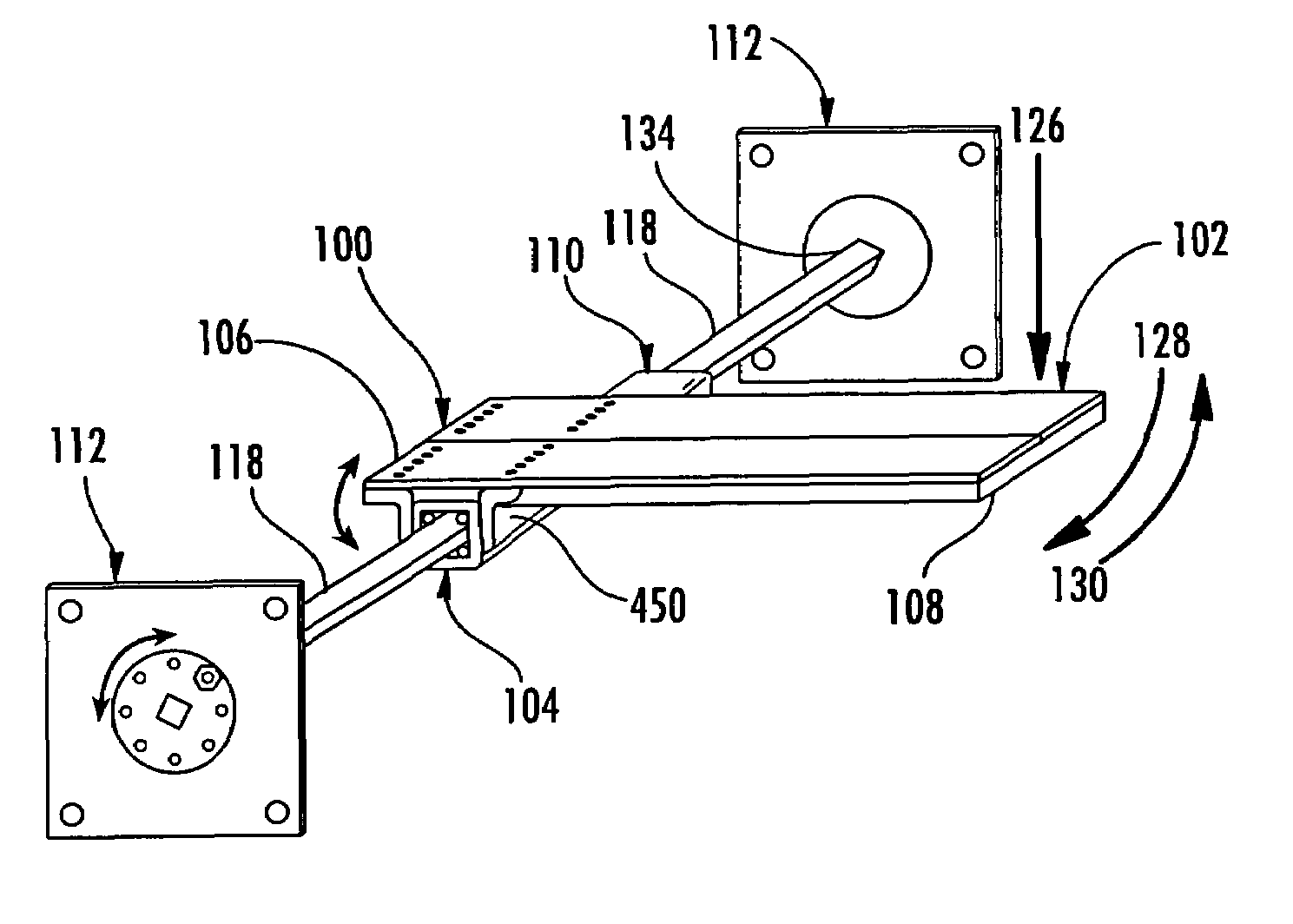

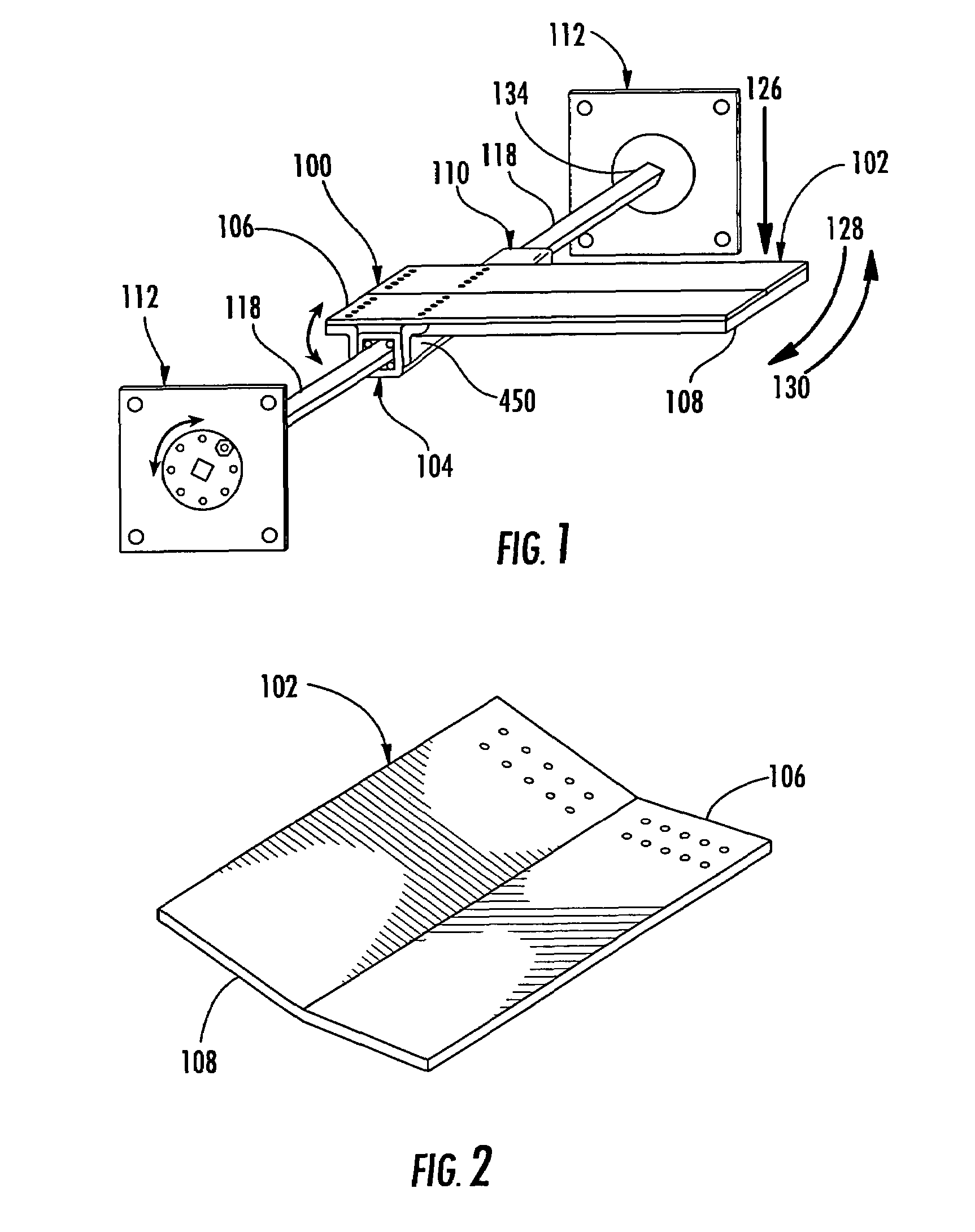

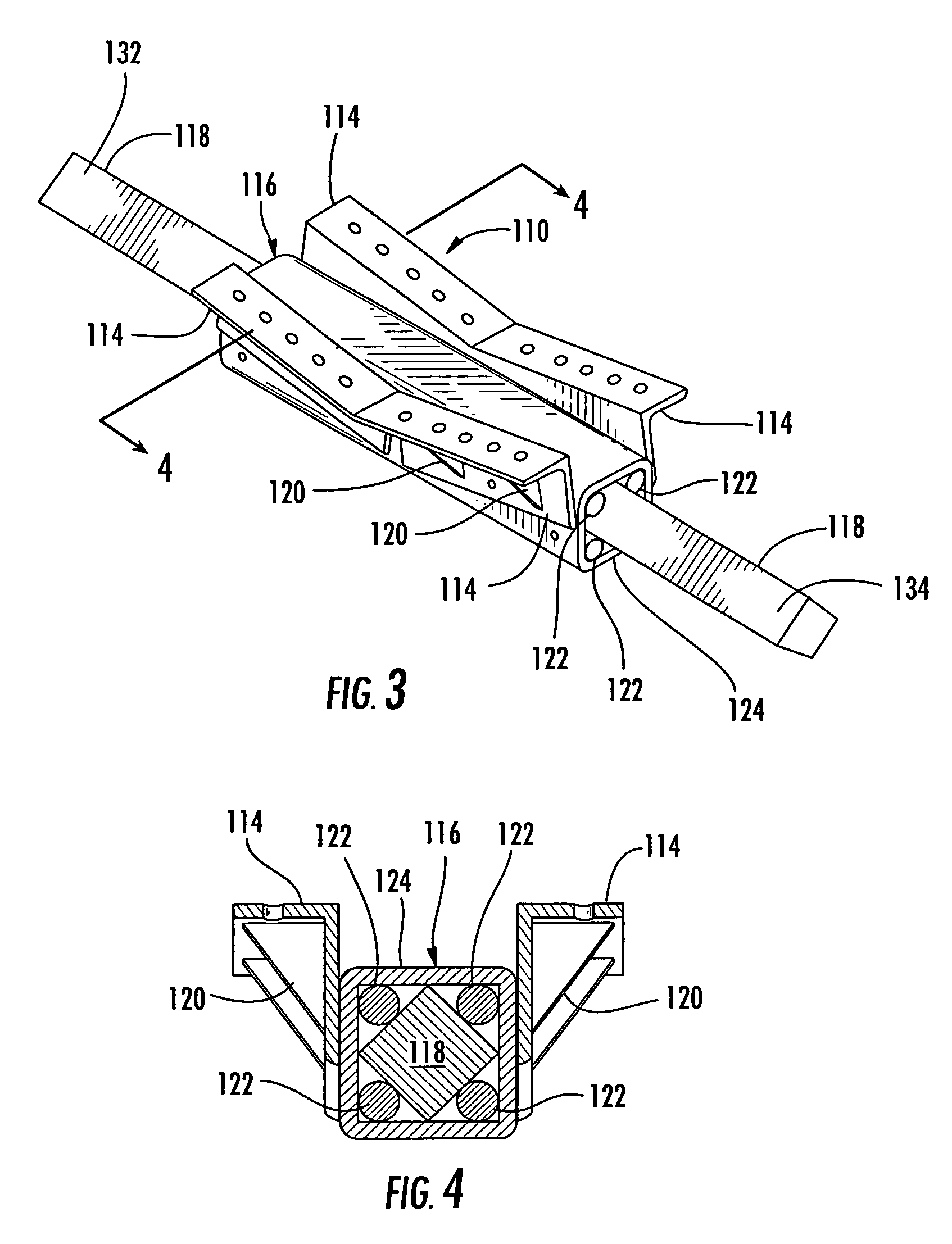

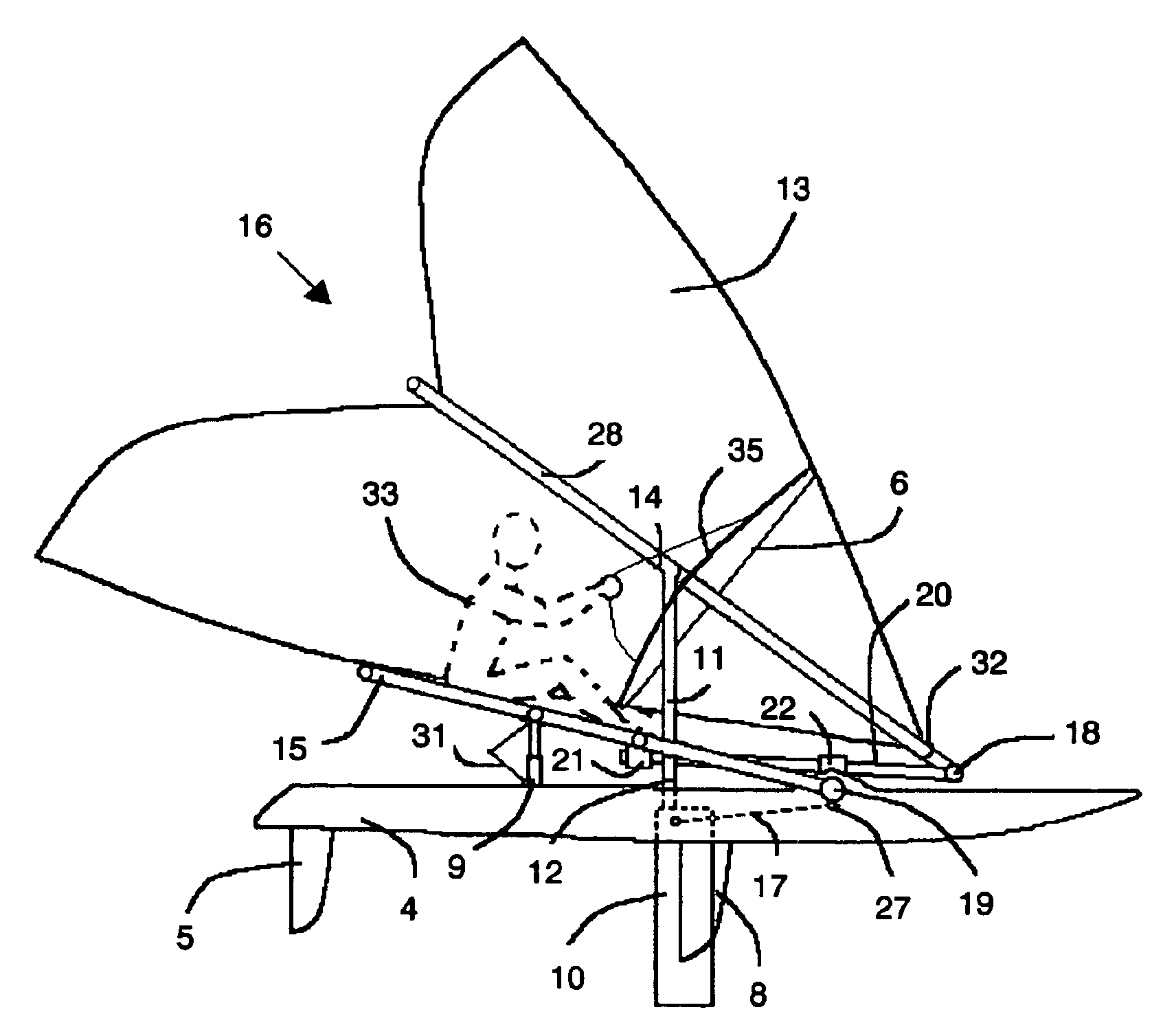

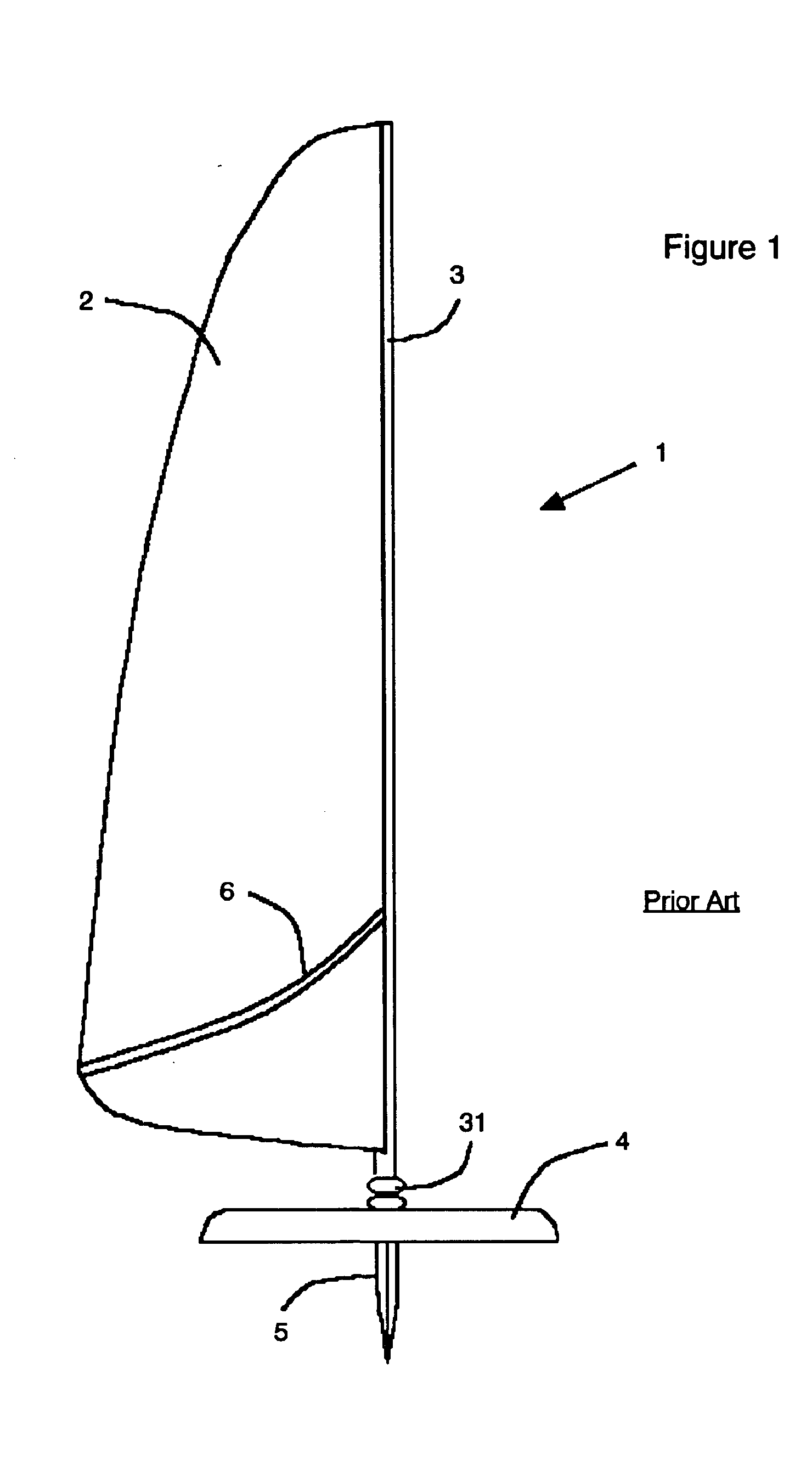

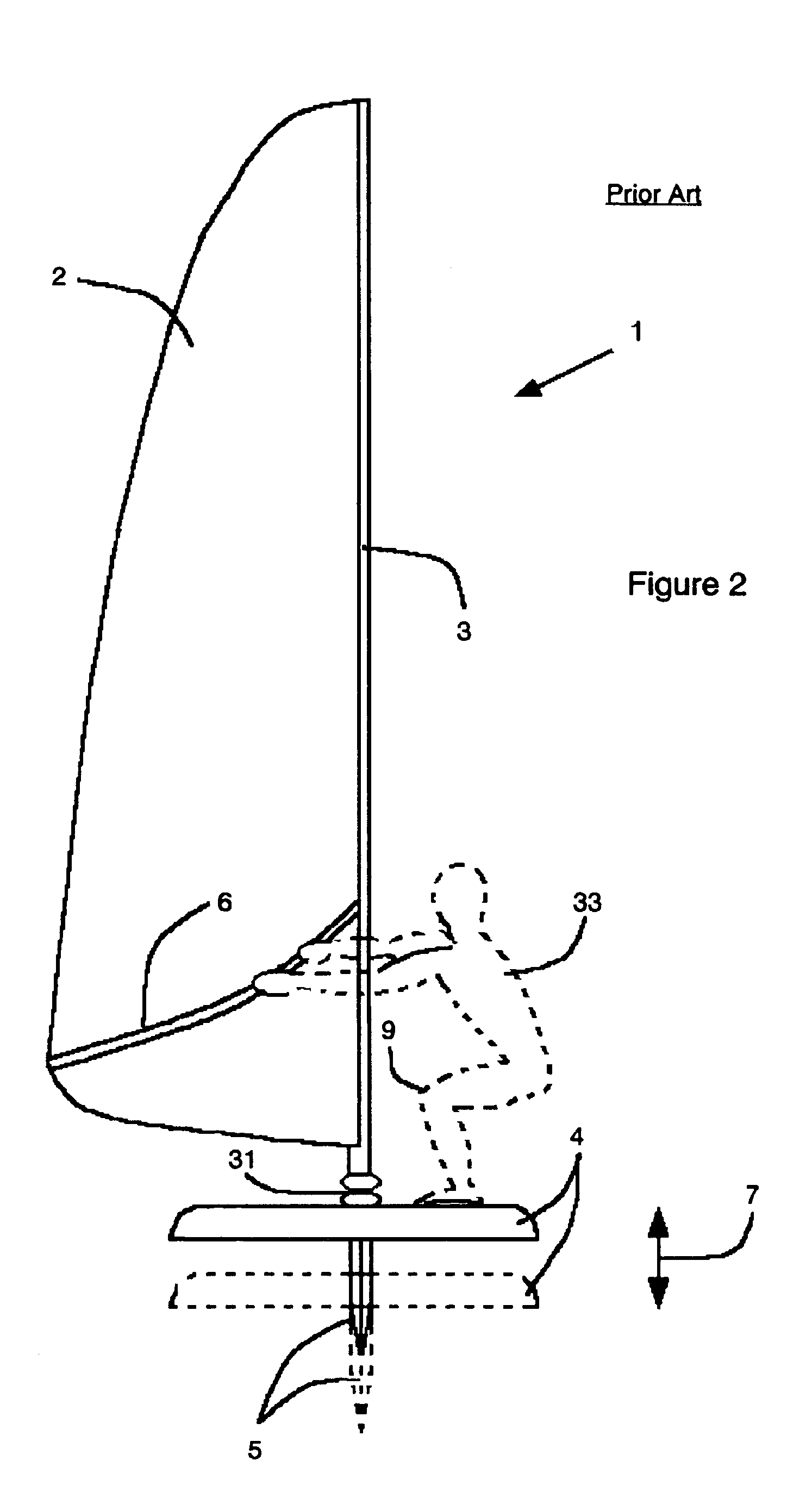

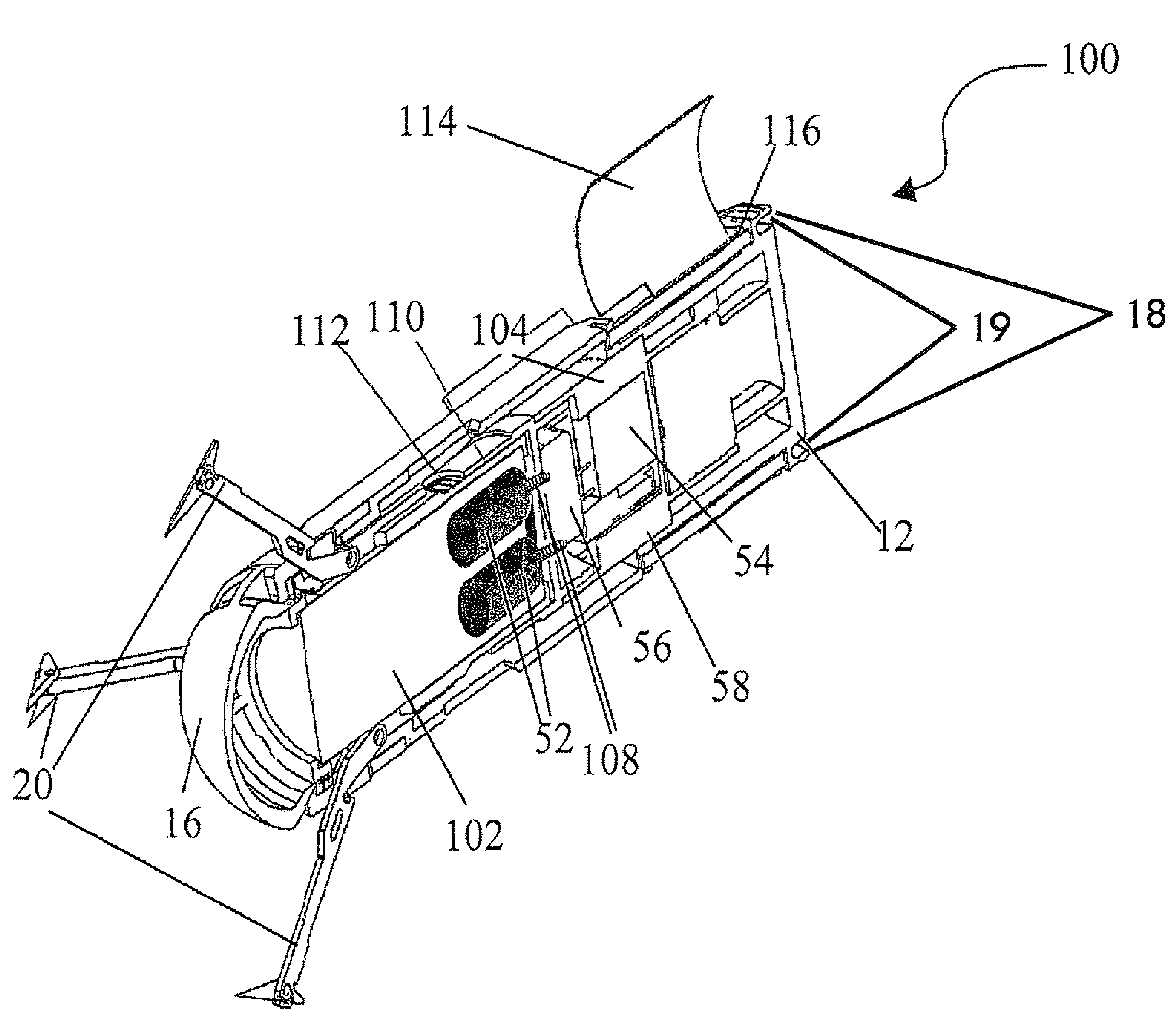

Windsurfing catamaran with dynamic shock dampened rig centering keel and hull support

InactiveUS6923131B2Easy to operateIncrease resistanceWater sport boardsVessel superstructuresMarine engineeringKeel

A windsurfing catamaran with a self-stabilizing wing. The wing is moved to the correct position by counter balancing water pressure from a rotating central keel connected to a central mast. The keel rotates in the opposite direction of the wing when the wing is moved off center by wind. The keel rotates such that a greater surface area is presented to water flow striking the keel. Water pressure on the keel offsets wind pressure on the sails and returns the keel and mast back to an upright position. This increases stability, lift, driving force, and speed. A central catamaran platform provides hinged struts and shock absorbers between the rear end of the central platform and planing hulls to reduce impact damage. The hinged struts and shock absorbers reduce water drag and the braking effect of repeated hull impacts with water resulting in a further increase in speed.

Owner:PETROVICH ENRIQUE

Non-lethal wireless stun projectile system for immobilizing a target by neuromuscular disruption

InactiveUS8342098B2Avoid impact damageSlowing projectileAmmunition projectilesMusical toysSTUNTransformer

A projectile launched from a conventional weapon; upon impact with a human target the projectile attaches to the target and stuns and disables the target by applying a pulsed electrical charge. The electric round is defined as non lethal ammunition directed to incapacitate a human, to prevent him from moving for a short time, to prevent him from committing a crime and to allow authorized personnel to arrest the target. A novel thin film technology transformer and thin film technology battery produce an electrical shock capable of stunning a human being in a device the size of a conventional bullet. The transformer and battery are smaller and lighter than conventional transformers and batteries with similar power output.

Owner:SECURITY DEVICES INT INC

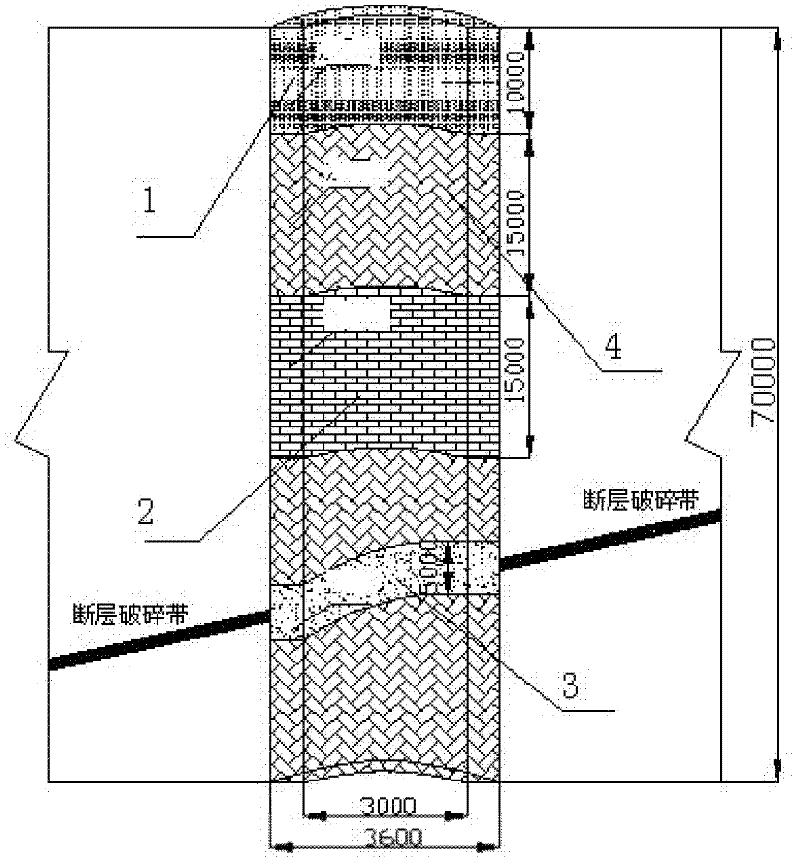

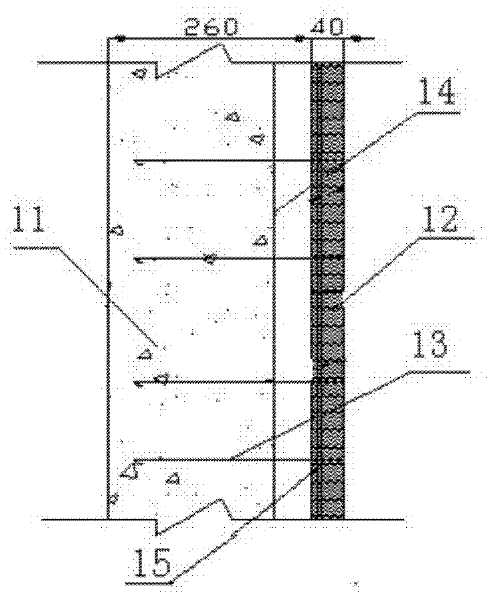

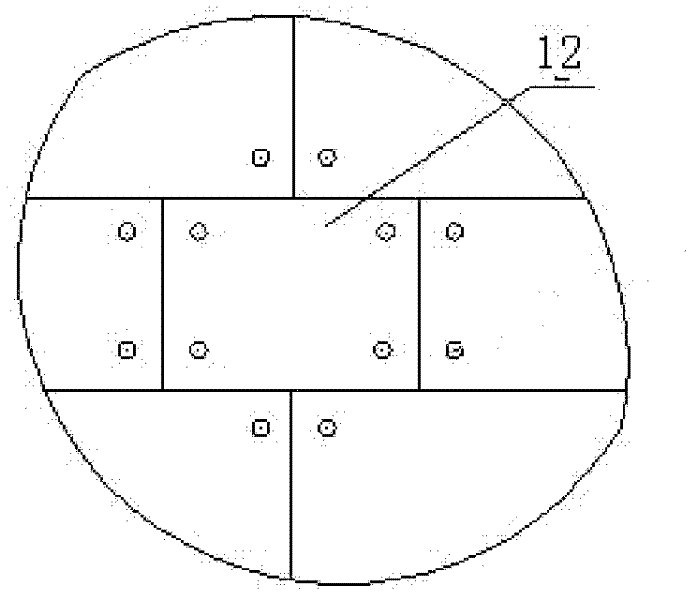

Method for reinforcing drop shaft in underground mine producing area

InactiveCN102226397AEasy to deform and shrinkShock absorbing effectAnchoring boltsShaft liningRock engineeringFracture zone

The invention relates to a method for reinforcing a drop shaft in an underground mine producing area and belongs to the field of metal mine and rock engineering reinforcement. The method is characterized in that the movement track of ores in the drop shaft during the ore discharge process is fully considered, model experiments and theoretical analysis method are adopted for determining the property of impact action and an impact failure region to the well wall generated by the ores according to the height of the drop shaft and the diameter of the drop shaft, the drop shaft is hereby divided into four stress regions, namely a first impact failure region, a second impact failure region, a fault fracture zone region and a wear-out failure region, and different forms are further adopted for reinforcement. The method is especially applicable to reinforcement of the drop shafts in the producing areas under soft and broken surrounding rock conditions, can be used for significantly prolonging the service life of the drop shaft and has the advantages of safety in construction, simpleness and low cost.

Owner:UNIV OF SCI & TECH BEIJING

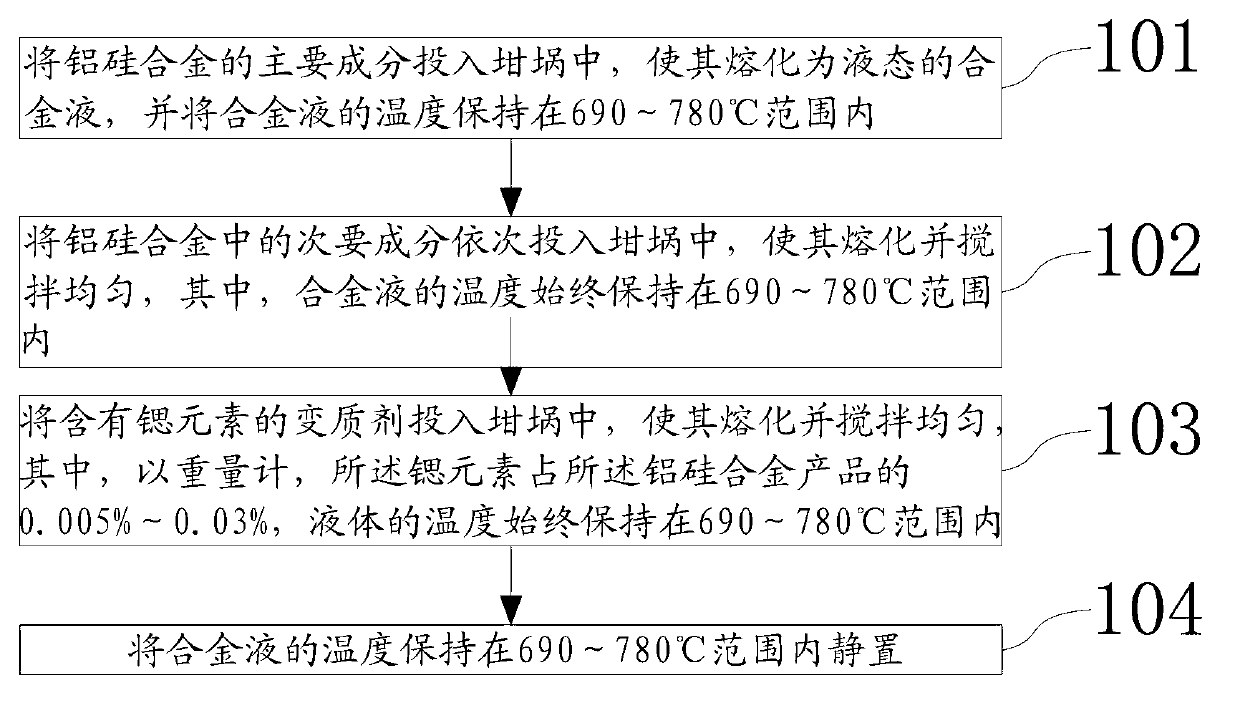

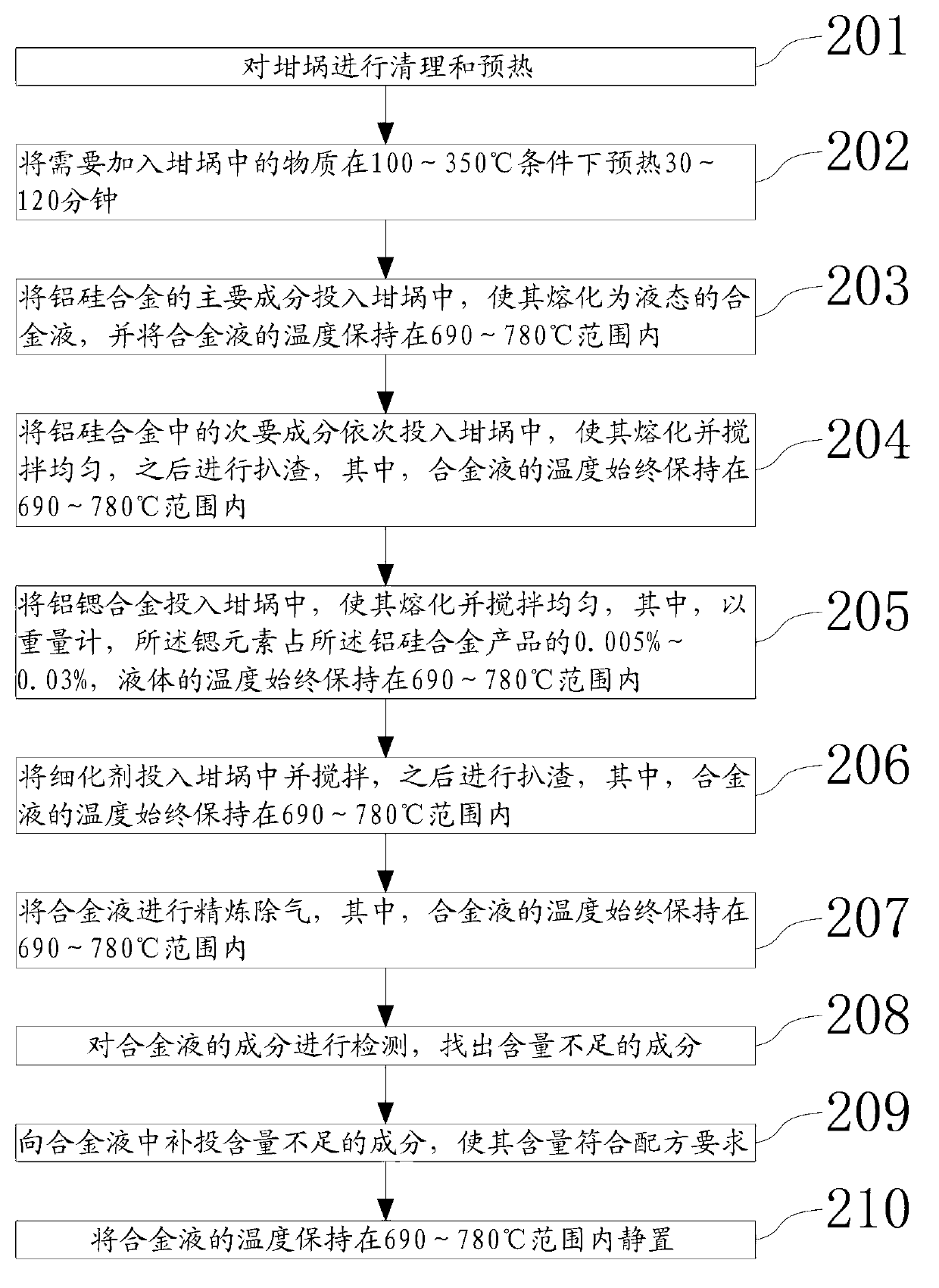

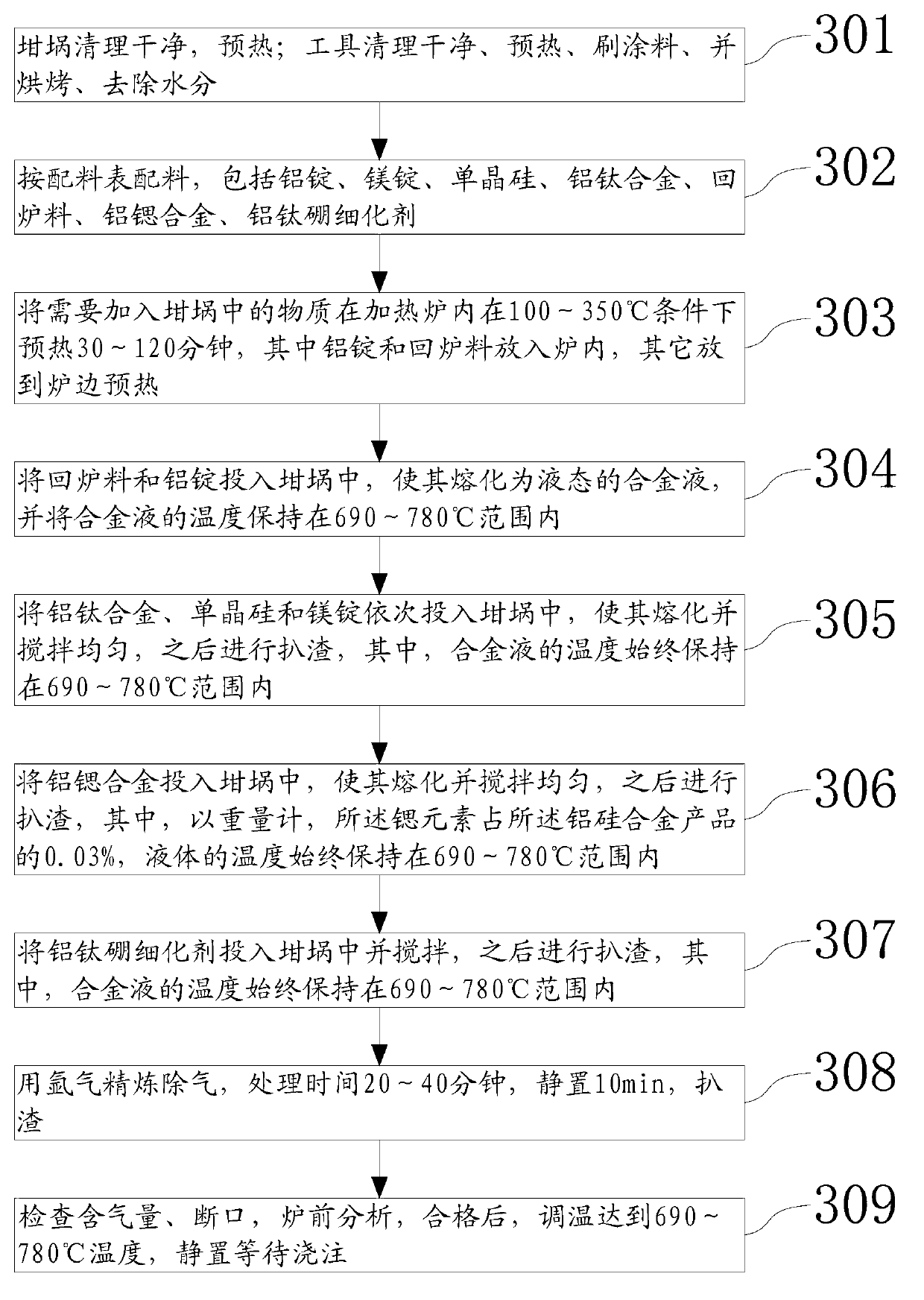

Stable operation method for restraining deteriorated alusil alloy strontium from inhaling

The invention relates to the field of metal alloy refining, in particular to a stable operation method for restraining deteriorated alusil alloy strontium from inhaling, which comprises the following steps of inputting main components of alusil alloy into a crucible so as to be melted into alloy liquid, and keeping the temperature of the alloy liquid between 690 and 780 DEG C; sequentially inputting secondary components of the alusil alloy into the crucible so as to be melted and evenly mixed, inputting alterant with element of strontium into the crucible so as to be melted and evenly mixed, wherein according to weight, the element of strontium is 0.005%-0.03% of alusil alloy product, the temperature of the liquid is always kept between 690 and 780 DEG C; and keeping the temperature of the alloy liquid between 690 and 780 DEG C, and standing. According to the method, alloy liquid can be effectively prevented from inhaling, and the alloy liquid with the strontium deteriorated can be guaranteed to be valid for more than 7 hours.

Owner:闫卫平

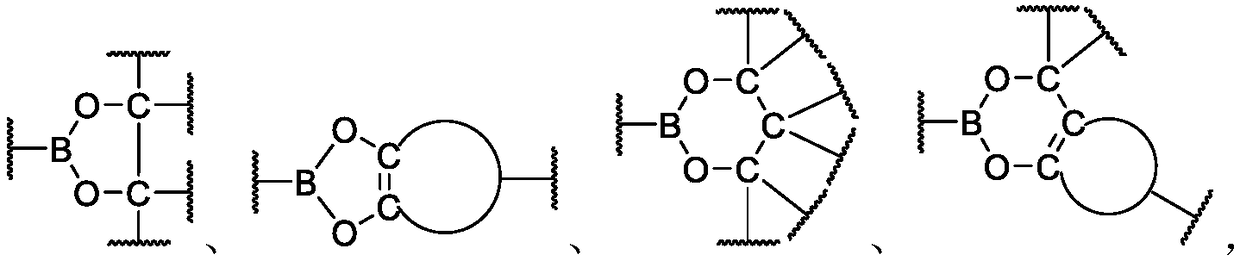

Energy-absorbing method based on dynamic polymer

InactiveCN108341944ADynamicImprove energy absorptionFibre treatmentPolyether coatingsCross-linkHydrogen

The invention discloses an energy-absorbing method based on a dynamic polymer. The method employs a dynamic polymer containing a cyclic organic borate bond and an optional supramolecular hydrogen bondfor energy-absorption, wherein the cyclic organic borate bond exists as a polymeric chain joint and / or cross-linked chain joint for the dynamic polymer and is a necessary condition for the formationor maintenance of the structure of the dynamic polymer. Due to dynamic reversibility of the cyclic organic borate bond, the dynamic polymer has an energy dissipation characteristic; as an energy-absorbing material, the dynamic polymer can provide the good functions of damping, shock absorption, sound insulation, noise abatement, impact resistance and the like; and the dynamic polymer is especiallyapplicable to the body protection of people during exercises, daily life and working, the body protection of the military police, explosion prevention, protection in airborne landing and aerial delivery, collision prevention of automobiles, anti-impact protection of electronic products and electric appliances, etc.

Owner:厦门逍扬运动科技有限公司

Gas buffer device for high-speed repulsion mechanism

ActiveCN106356211AMovement characteristics have no effectSolve the break buffer problemContact vibration/shock dampingCircuit breakerPiston

The invention discloses a gas buffer device for a high-speed repulsion mechanism. The gas buffer device for the high-speed repulsion mechanism comprises a support plate and a cavity fixedly arranged on the support plate, wherein a piston and a spring located under the piston are arranged in the cavity. The gas buffer device for the high-speed repulsion mechanism also comprises a mechanism moving rod penetrating through a central axis of the support plate, the cavity, the piston and the spring, wherein a striking ring is fixed onto the mechanism moving rod and is located above the piston; one end of the mechanism moving rod is connected with a moving contact of a circuit breaker; the other end of the mechanism moving rod is connected with a mechanism lock catch unit. The gas buffer device for the high-speed repulsion mechanism provided by the invention solves the buffer problem of the high-speed mechanism, the damage caused by the impact force on the mechanism during a buffer process is greatly reduced, and the service life and the operation stability of the high-speed mechanism are improved; through changing an arrangement manner, the buffer device can be used for closing buffer of the high-speed mechanism.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com