Patents

Literature

87 results about "Chamber method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manual Chamber Method. The closed chamber method is a widely used technique in quantifying greenhouse gas emissions (GHG). In fact, more than 95% of published emission studies used this method. This approach is low cost and can be implemented in remote sites as it can run without power supply.

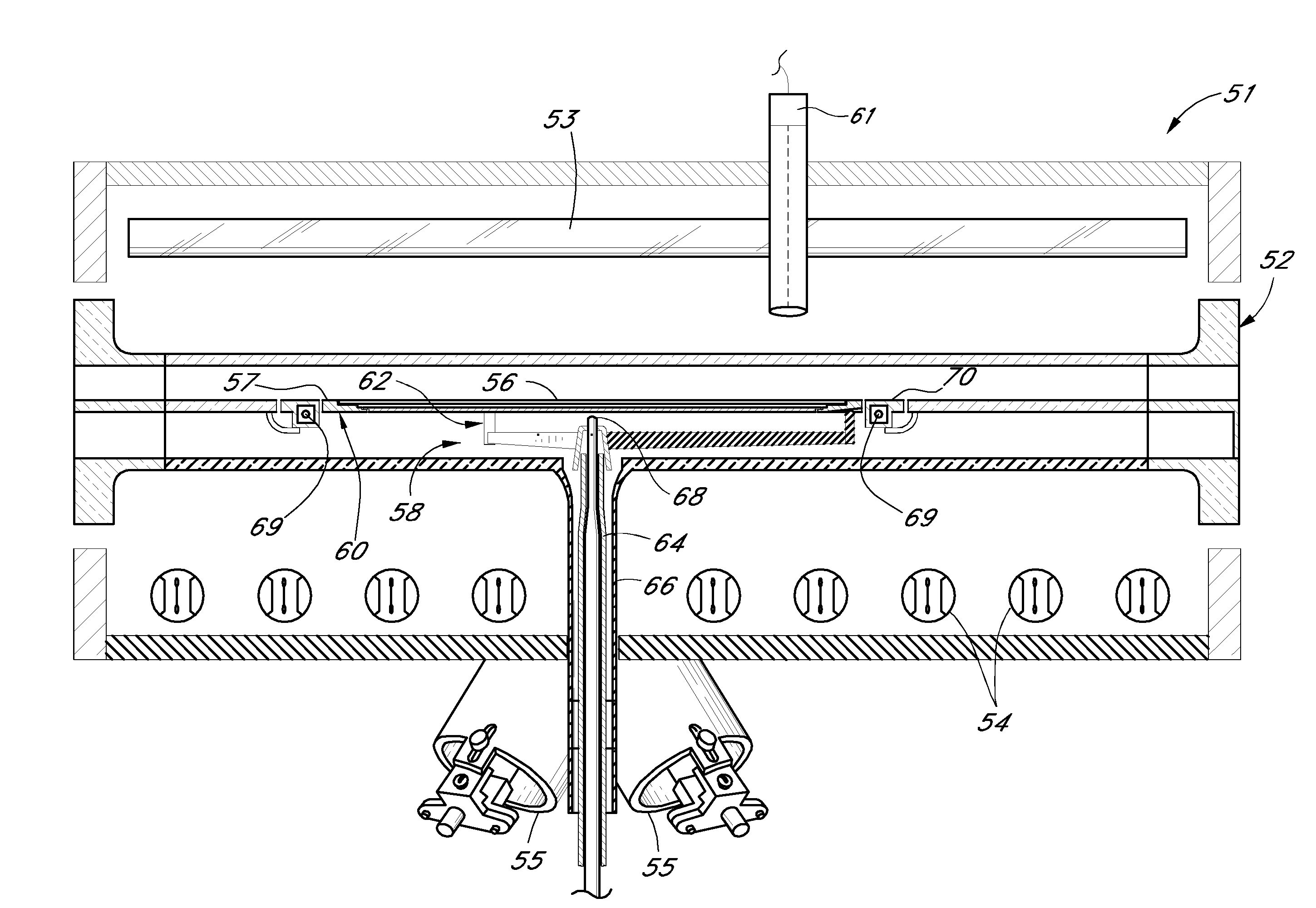

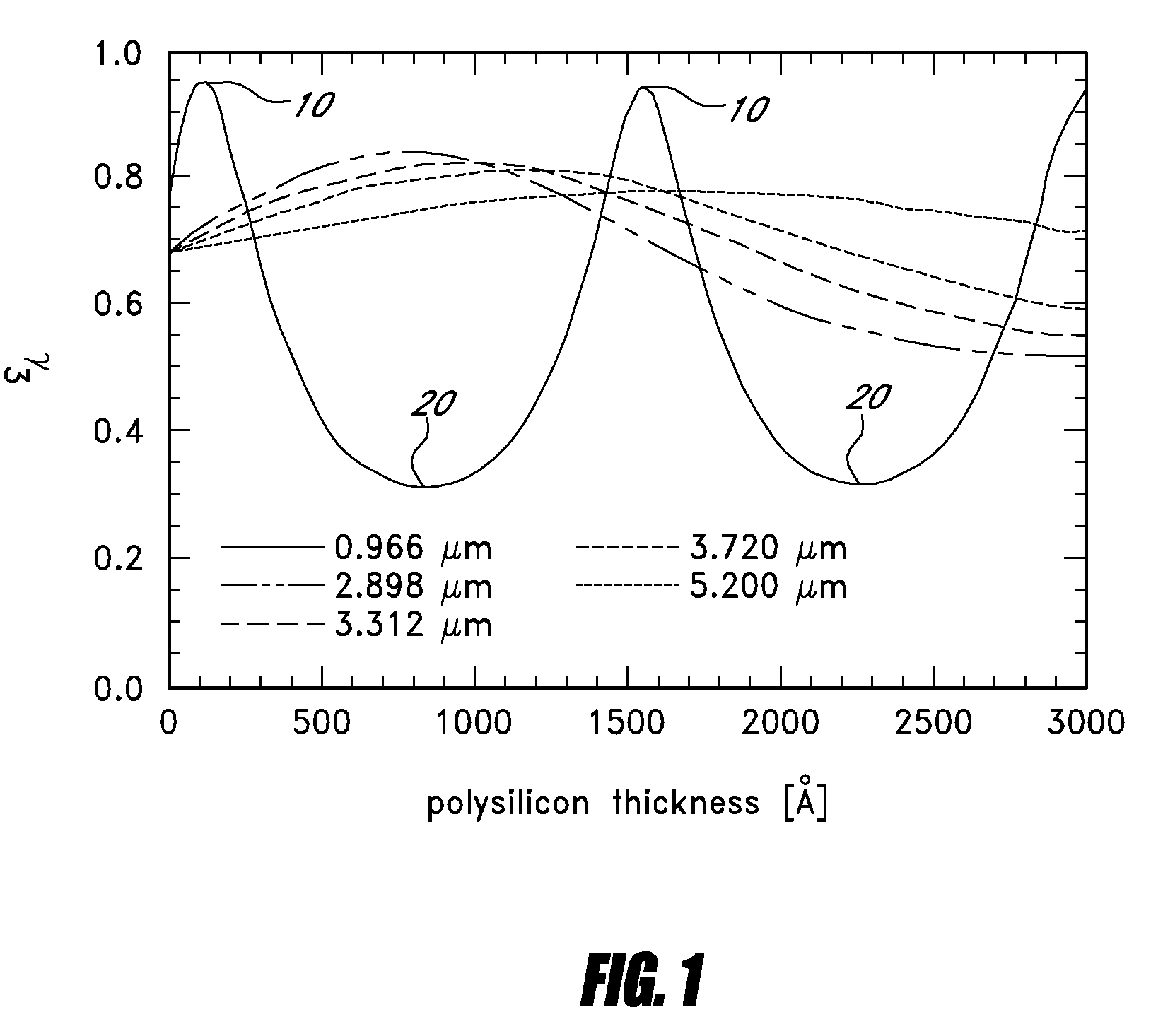

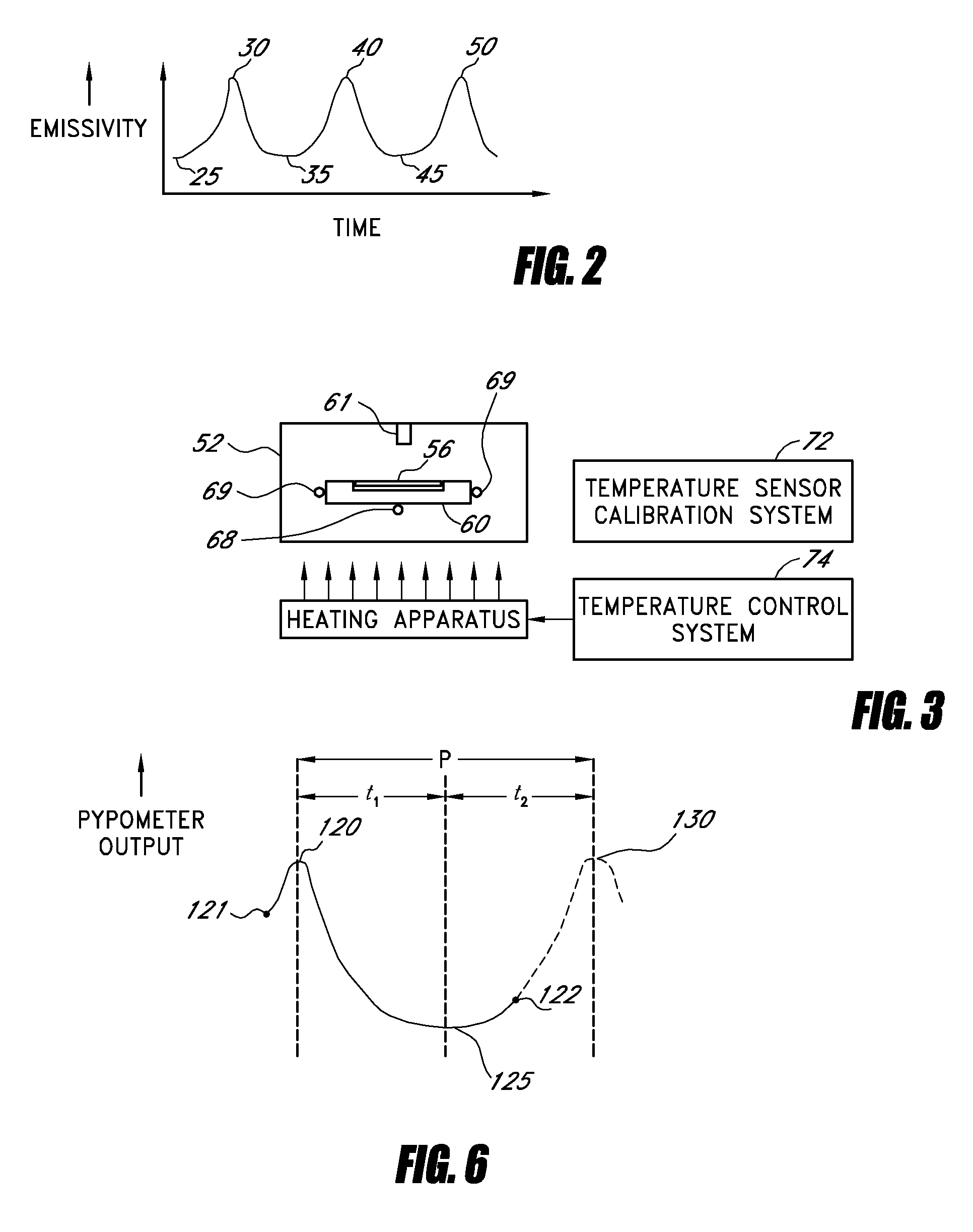

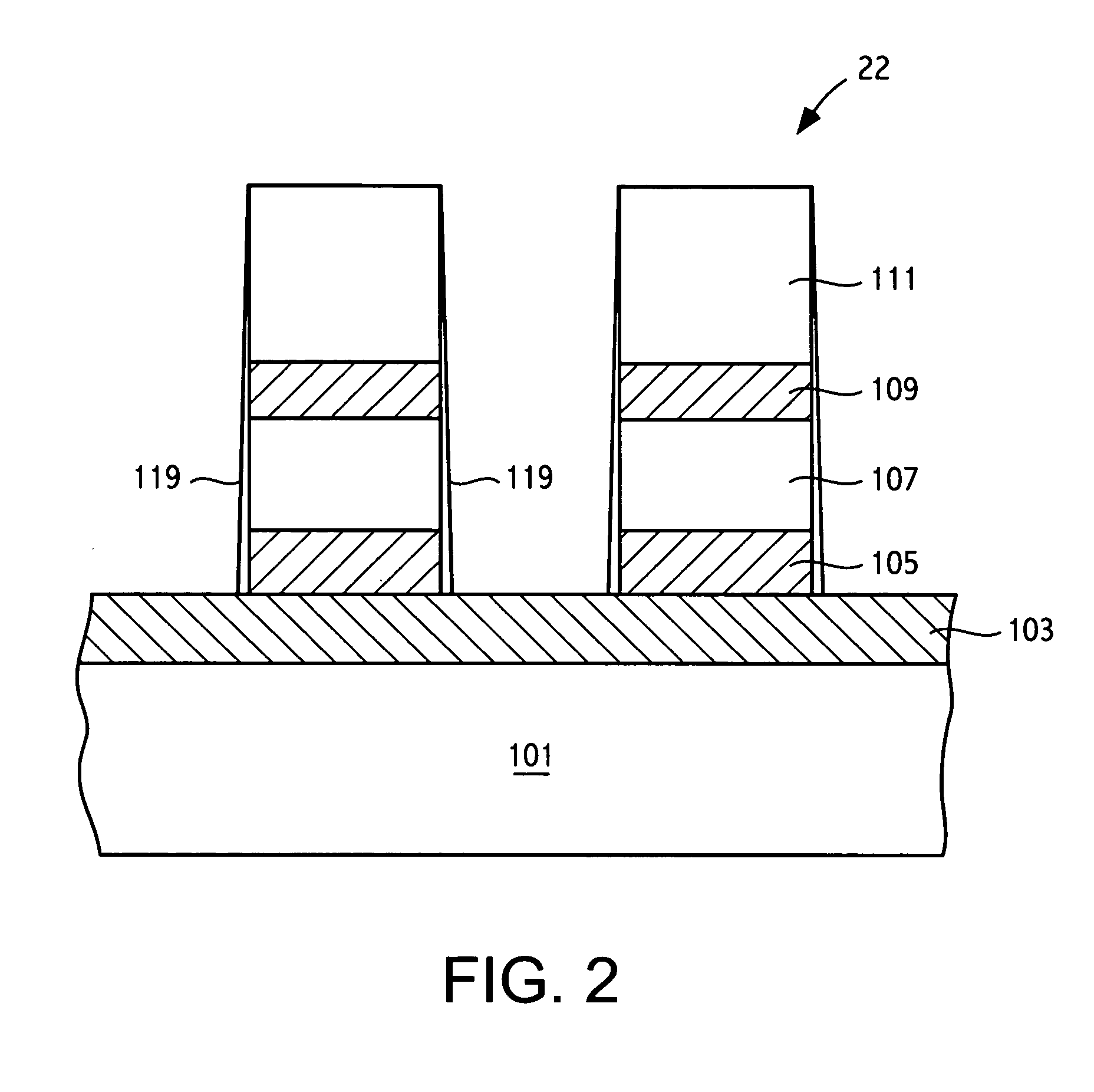

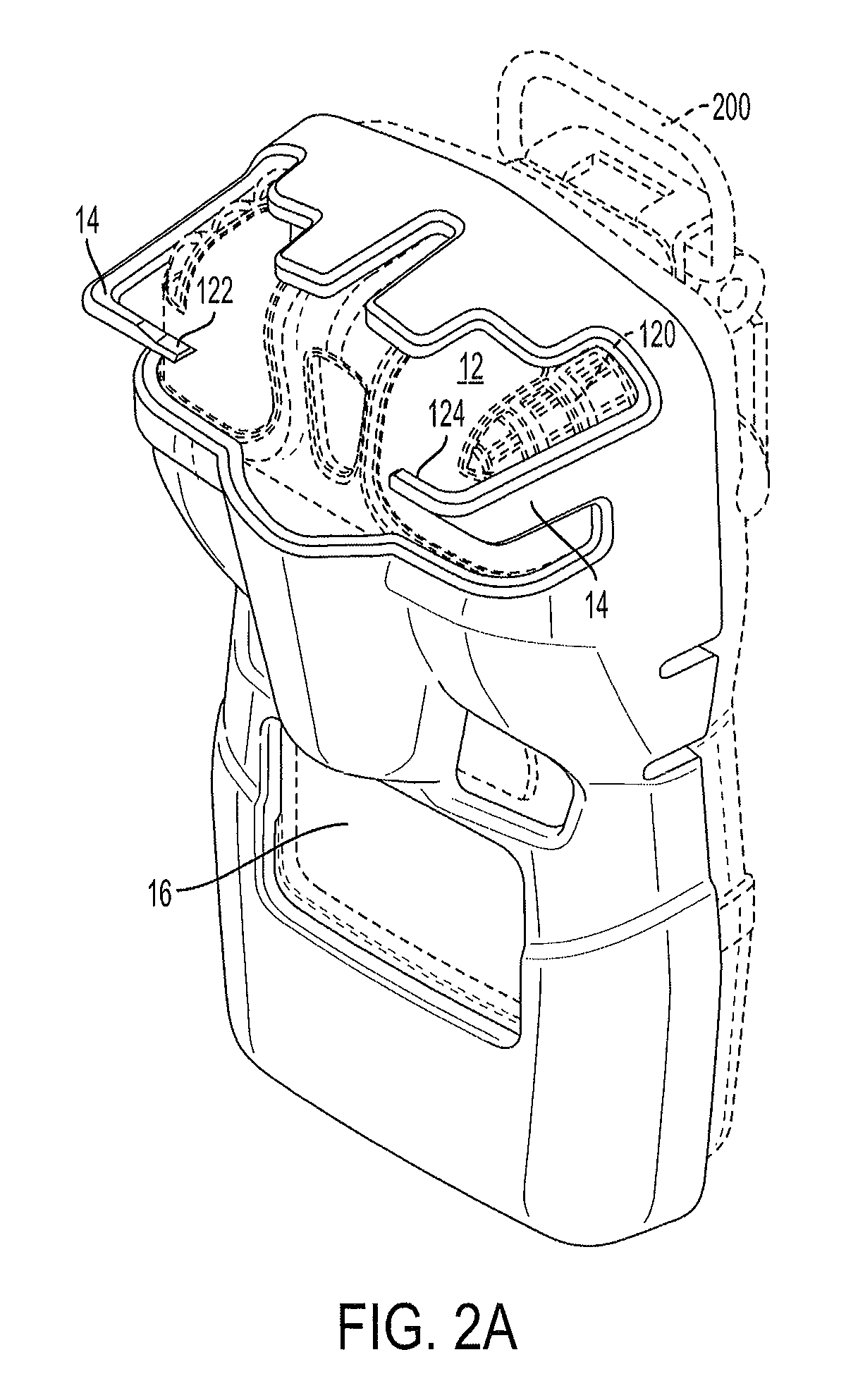

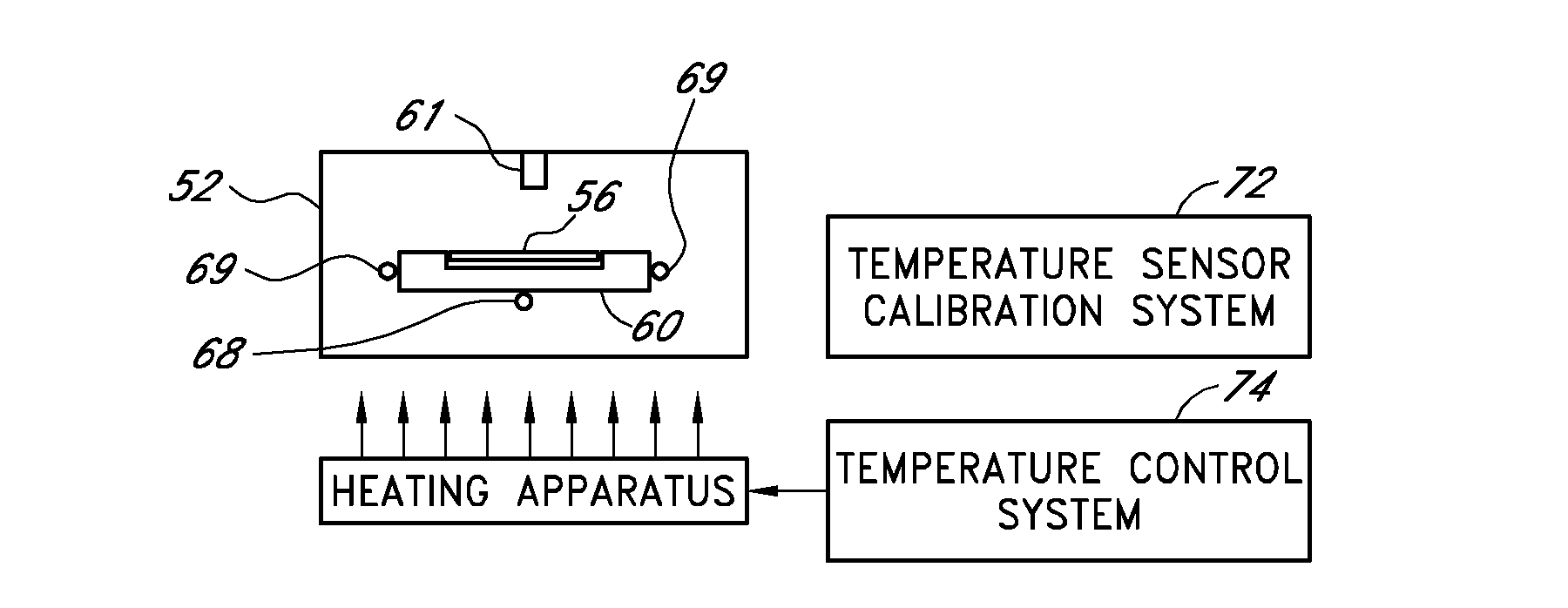

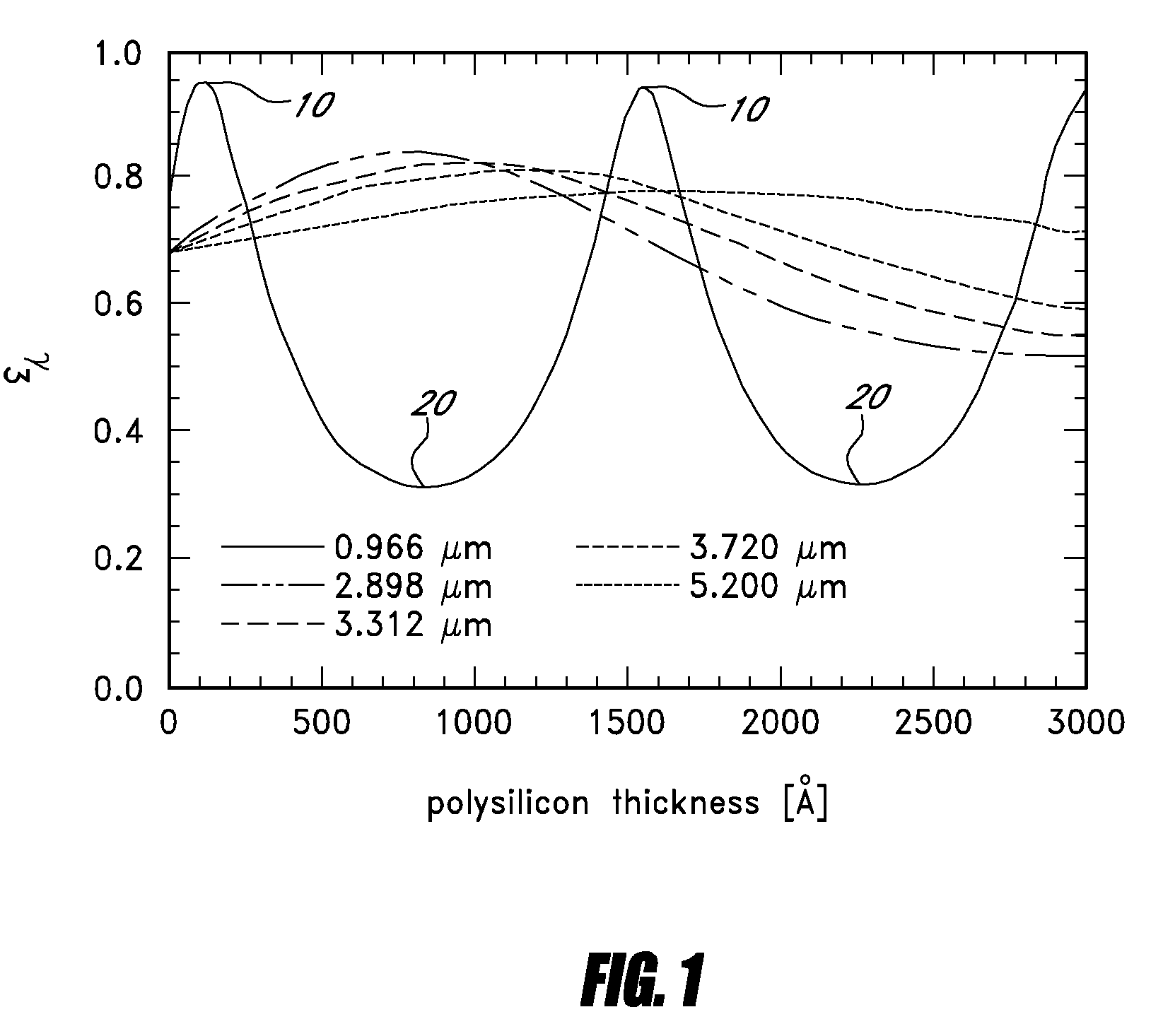

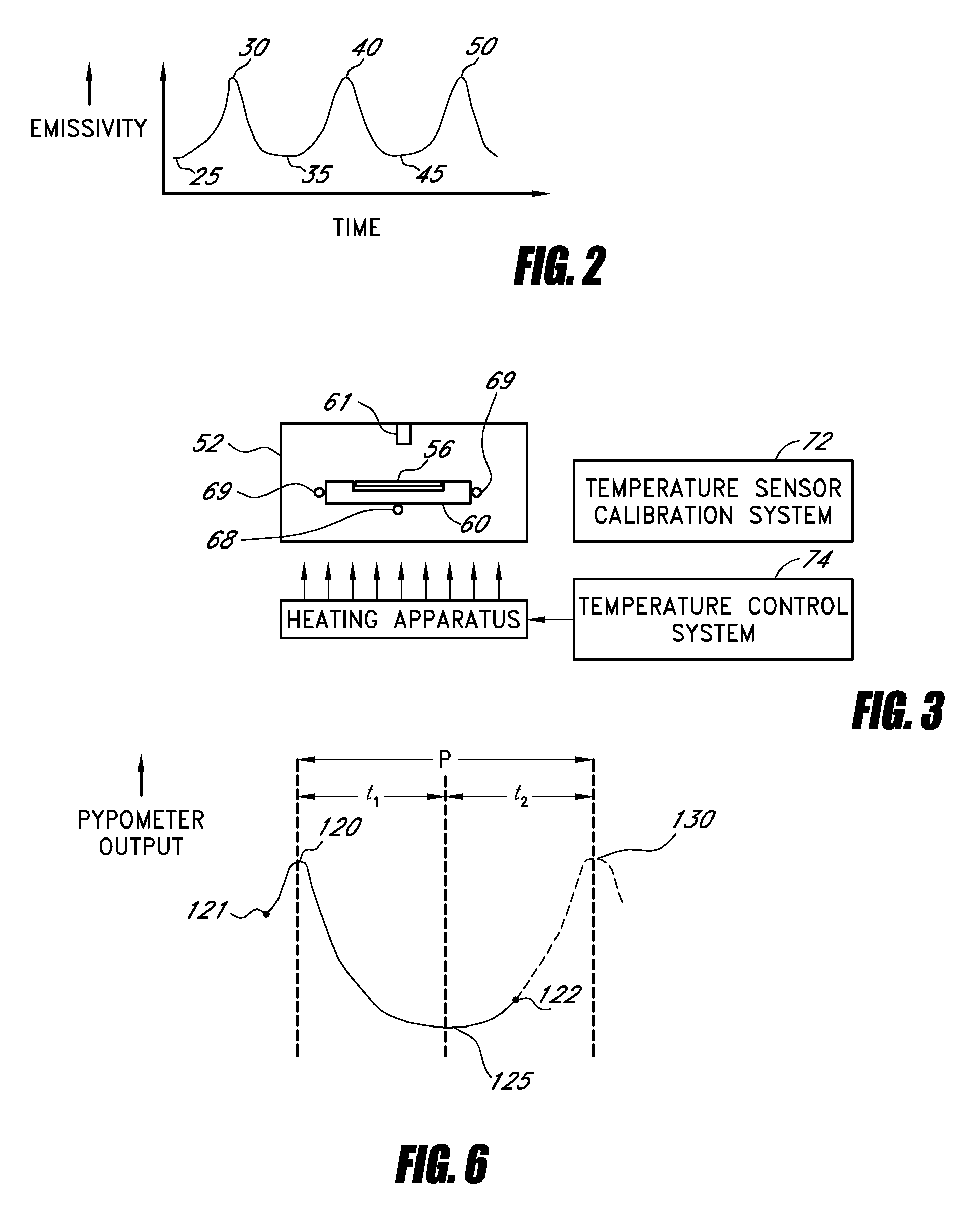

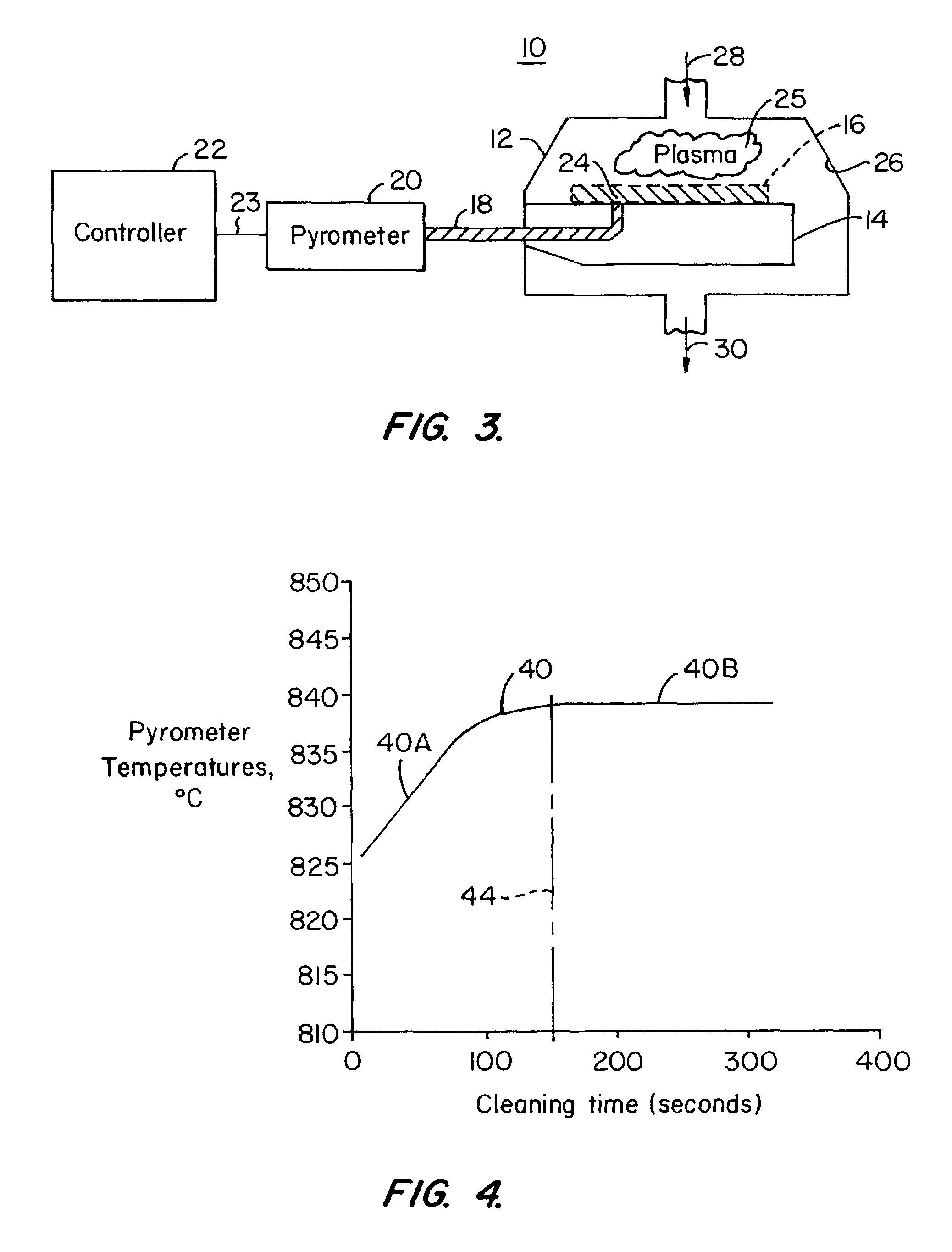

Calibration of temperature control system for semiconductor processing chamber

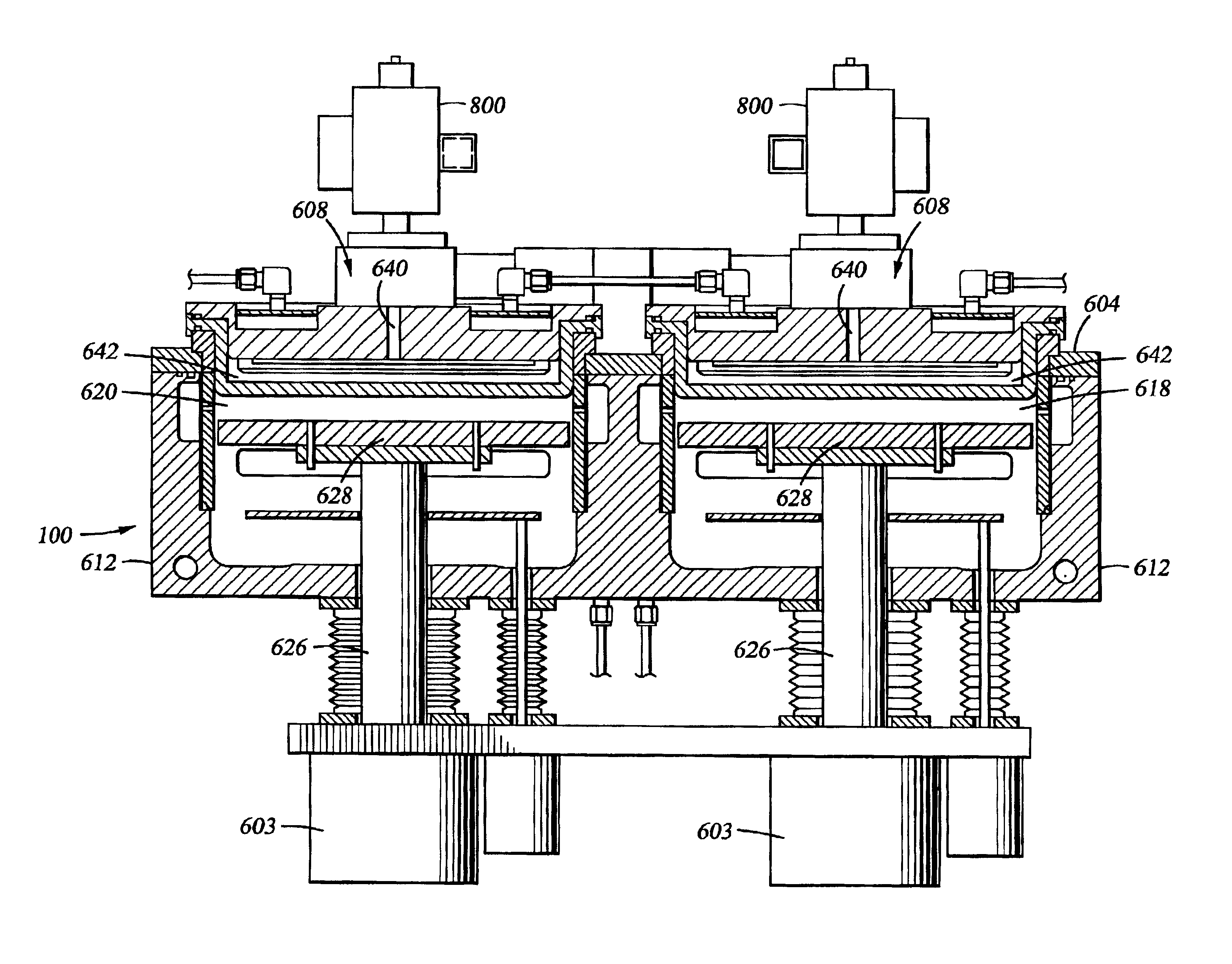

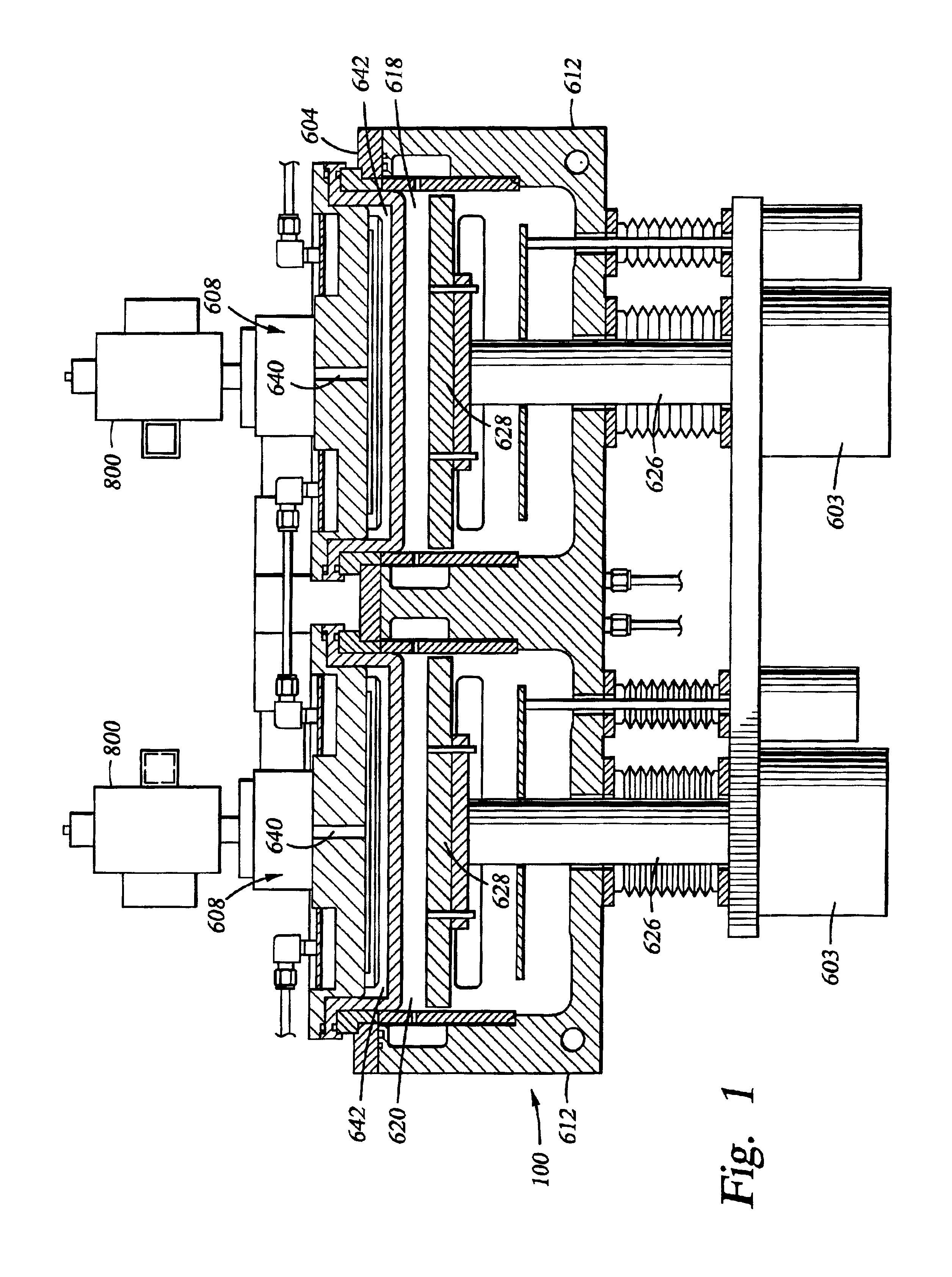

ActiveUS20090147819A1Readily apparentSemiconductor/solid-state device testing/measurementThermometers using electric/magnetic elementsTemperature controlControl system

Methods and systems for calibrating a temperature control system in a vapor deposition chamber. A temperature sensor senses temperature within a semiconductor processing chamber and generates an output signal. A temperature control system controls a chamber temperature by controlling a heating apparatus based on the output signal. A method includes instructing the control system to target a setpoint temperature, and depositing a layer of material onto a surface in the chamber by a vapor deposition process. A variation of a property of the layer is measured while depositing the layer, the property known to vary cyclically as a thickness of the layer increases. The measured property is allowed to vary cyclically for one or more cycles. If there is a difference between a time period of one or more of the cycles and an expected time period associated with the setpoint temperature, the temperature control system is adjusted based on the difference.

Owner:ASM IP HLDG BV

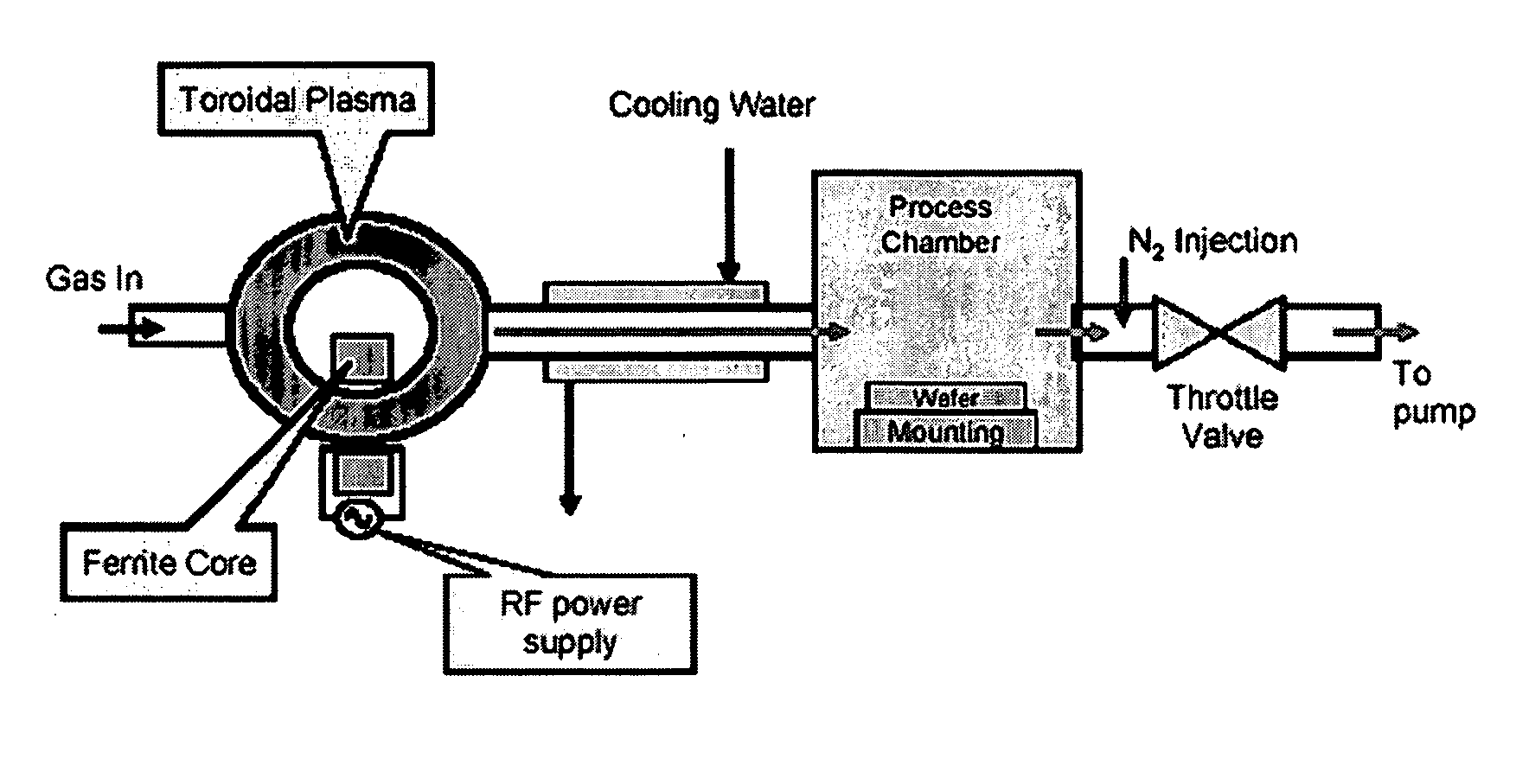

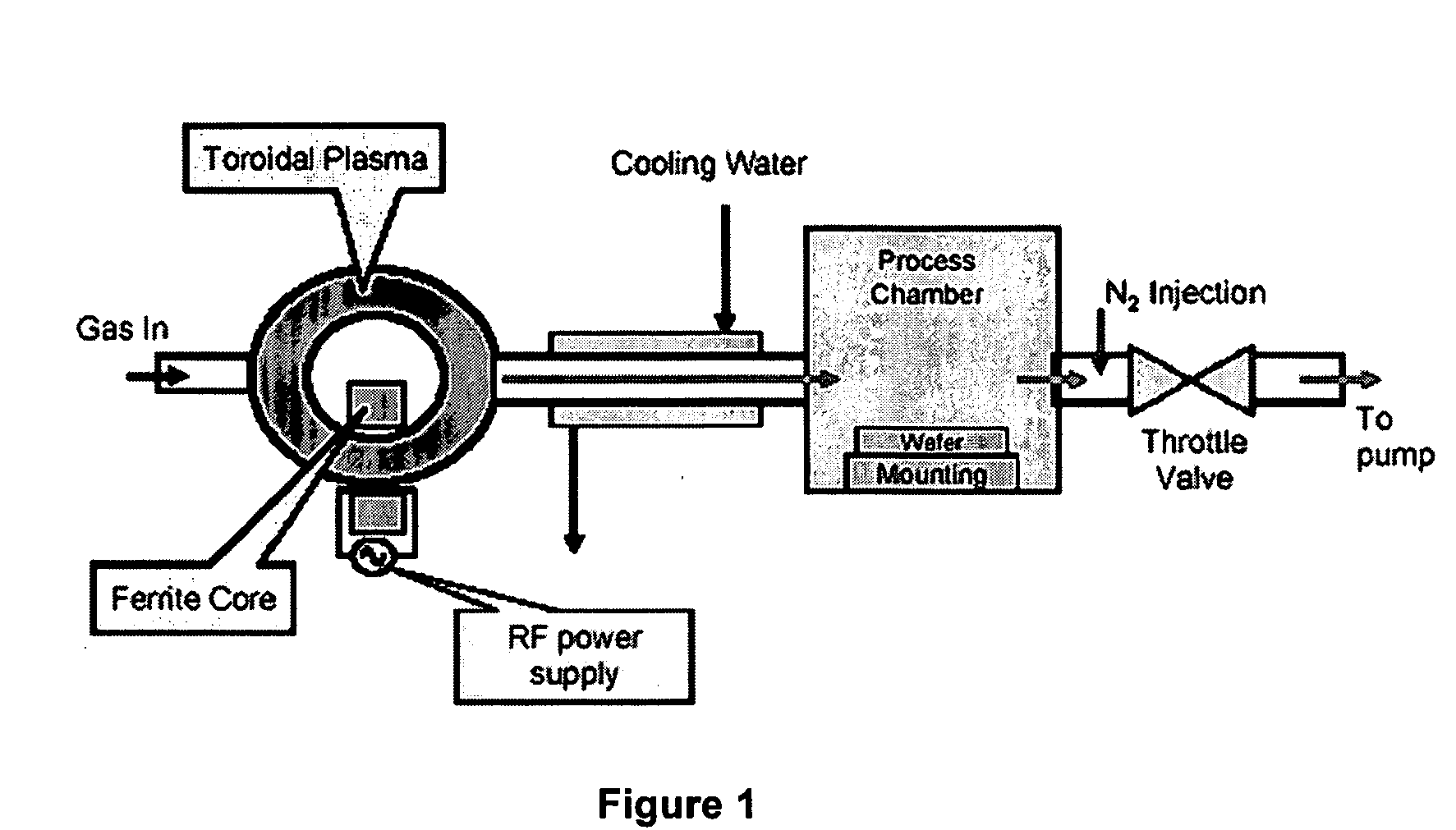

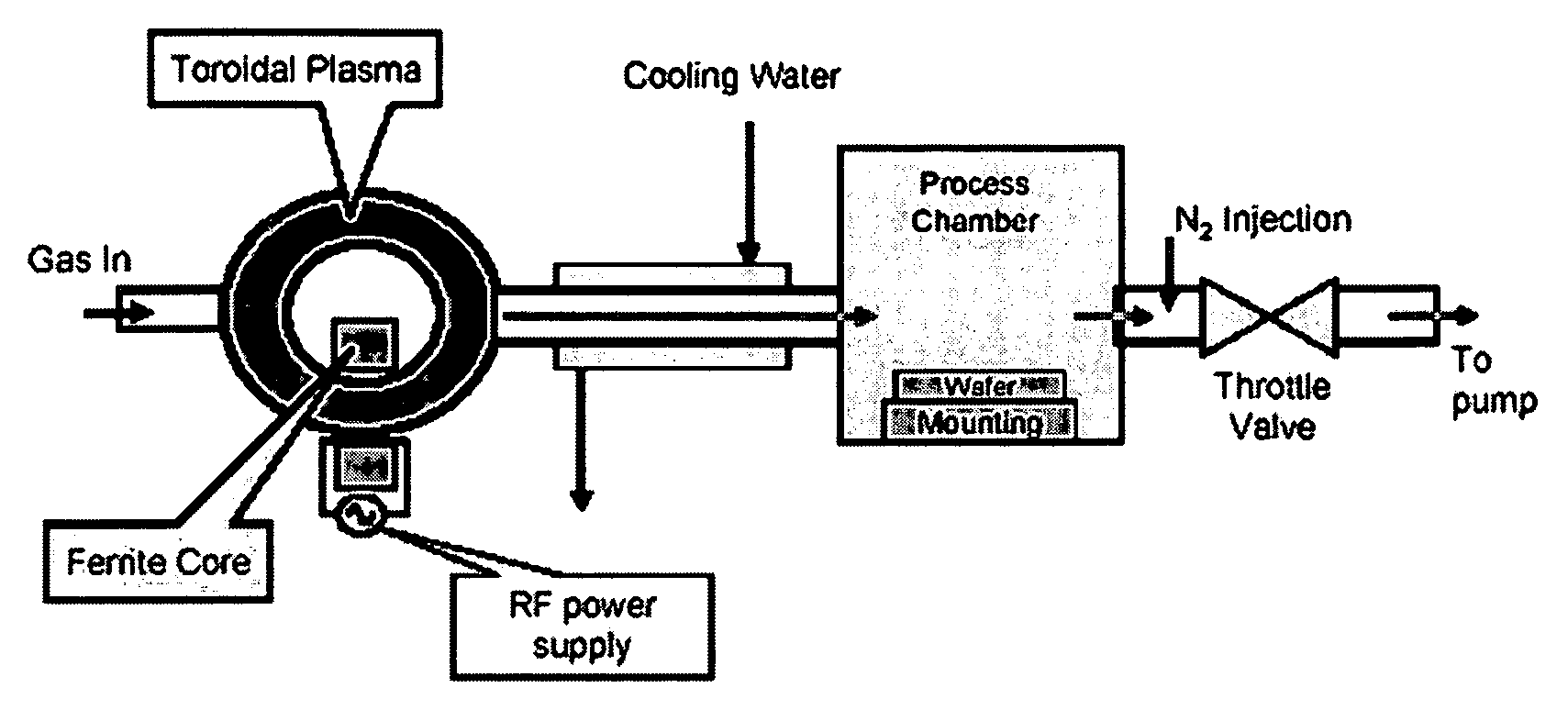

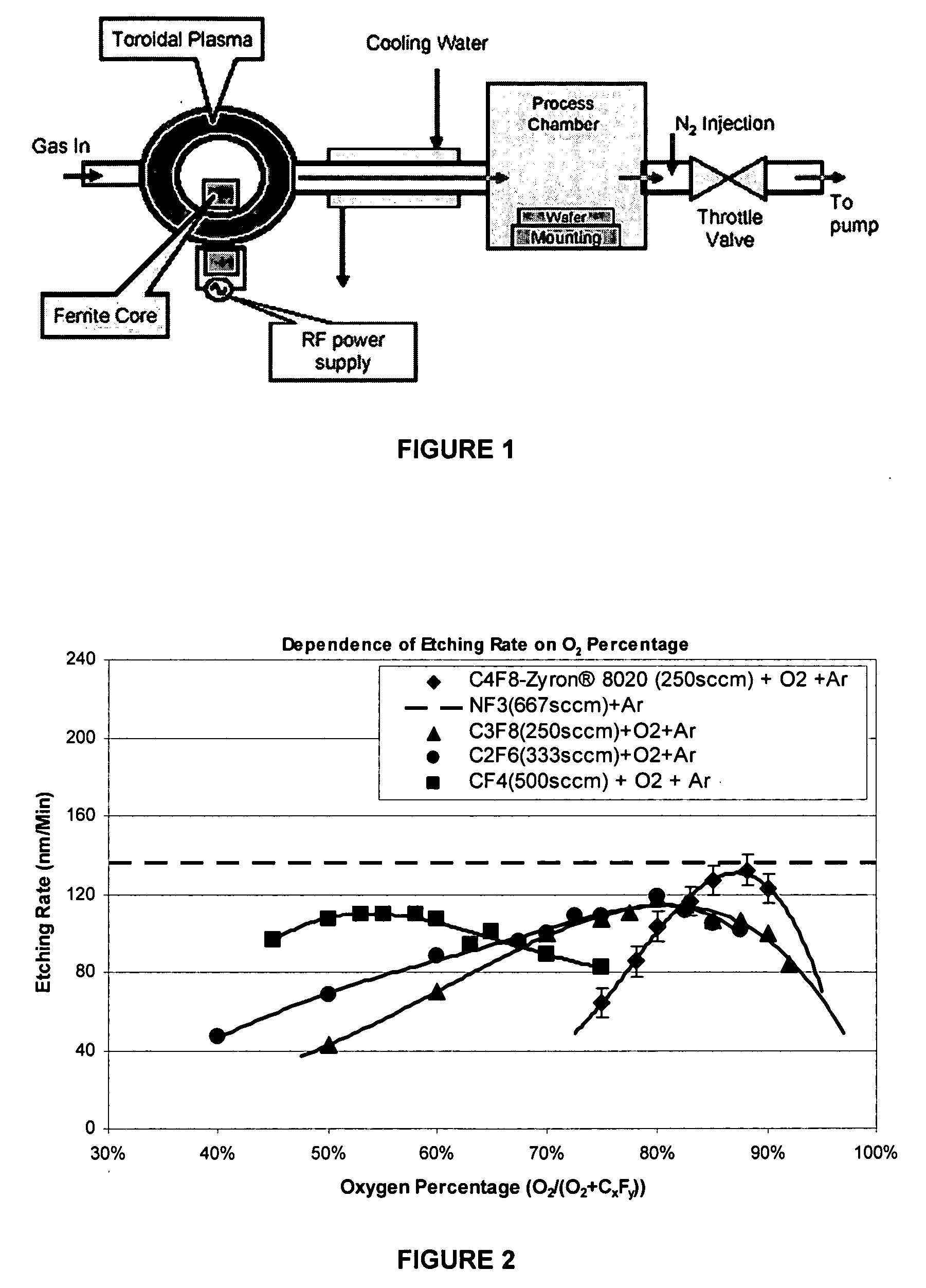

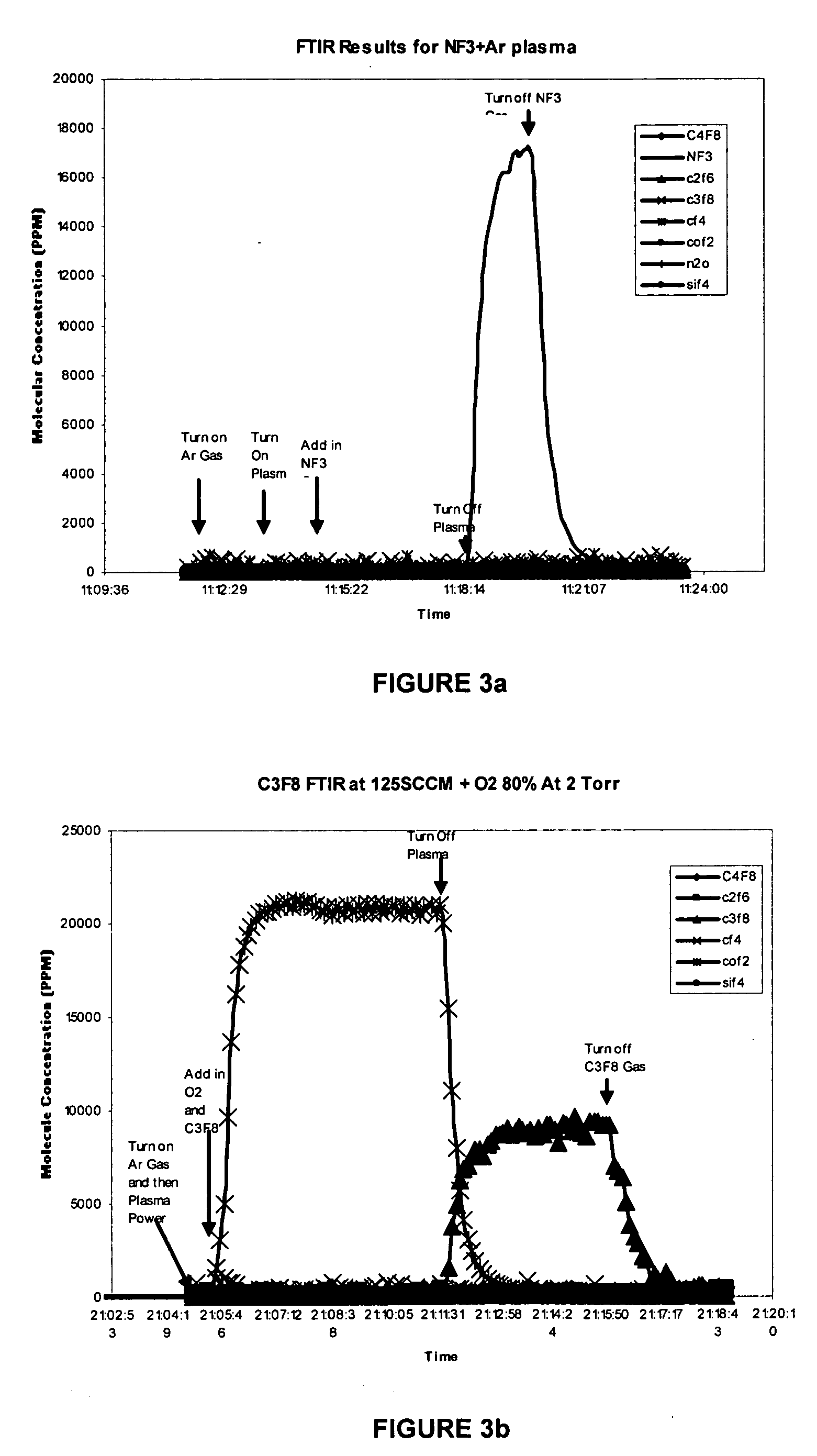

Remote chamber methods for removing surface deposits

The present invention relates to an improved remote plasma cleaning method for removing surface deposits from a surface, such as the interior of a deposition chamber that is used in fabricating electronic devices. The improvement involves a fluorocarbon rich plasma pretreatment of interior surface of the pathway from the remote chamber to the surface deposits.

Owner:MASSACHUSETTS INST OF TECH +1

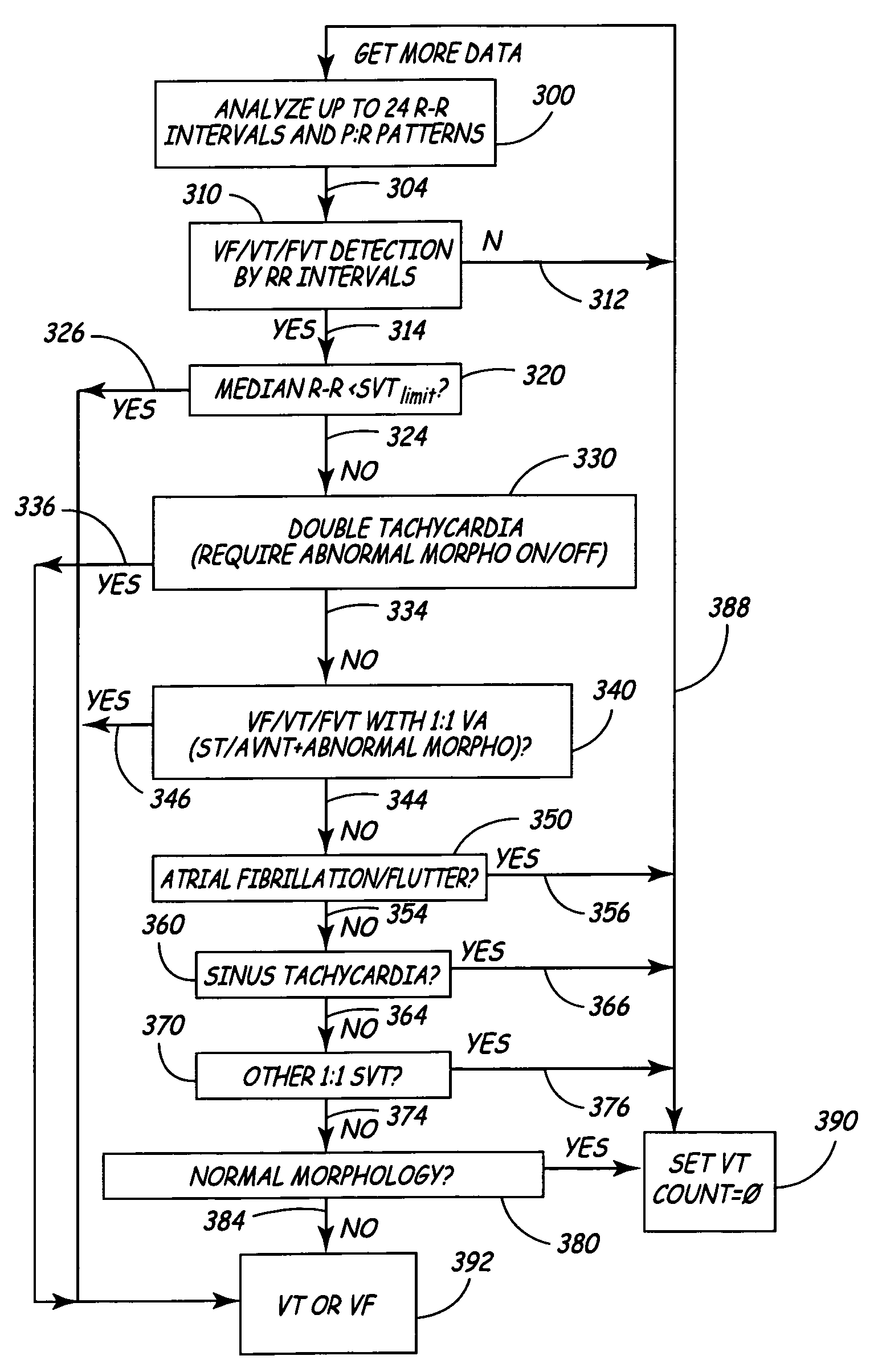

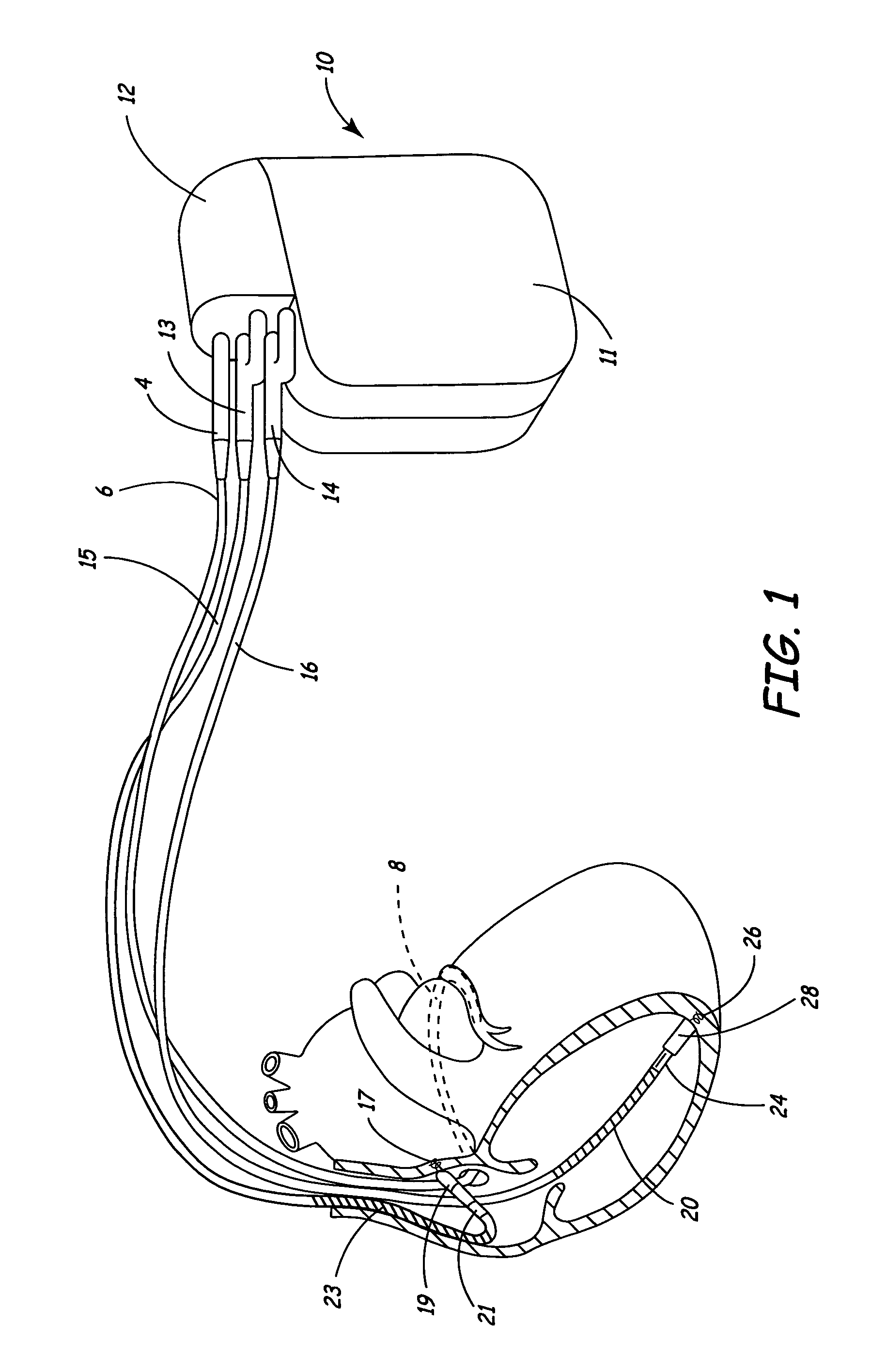

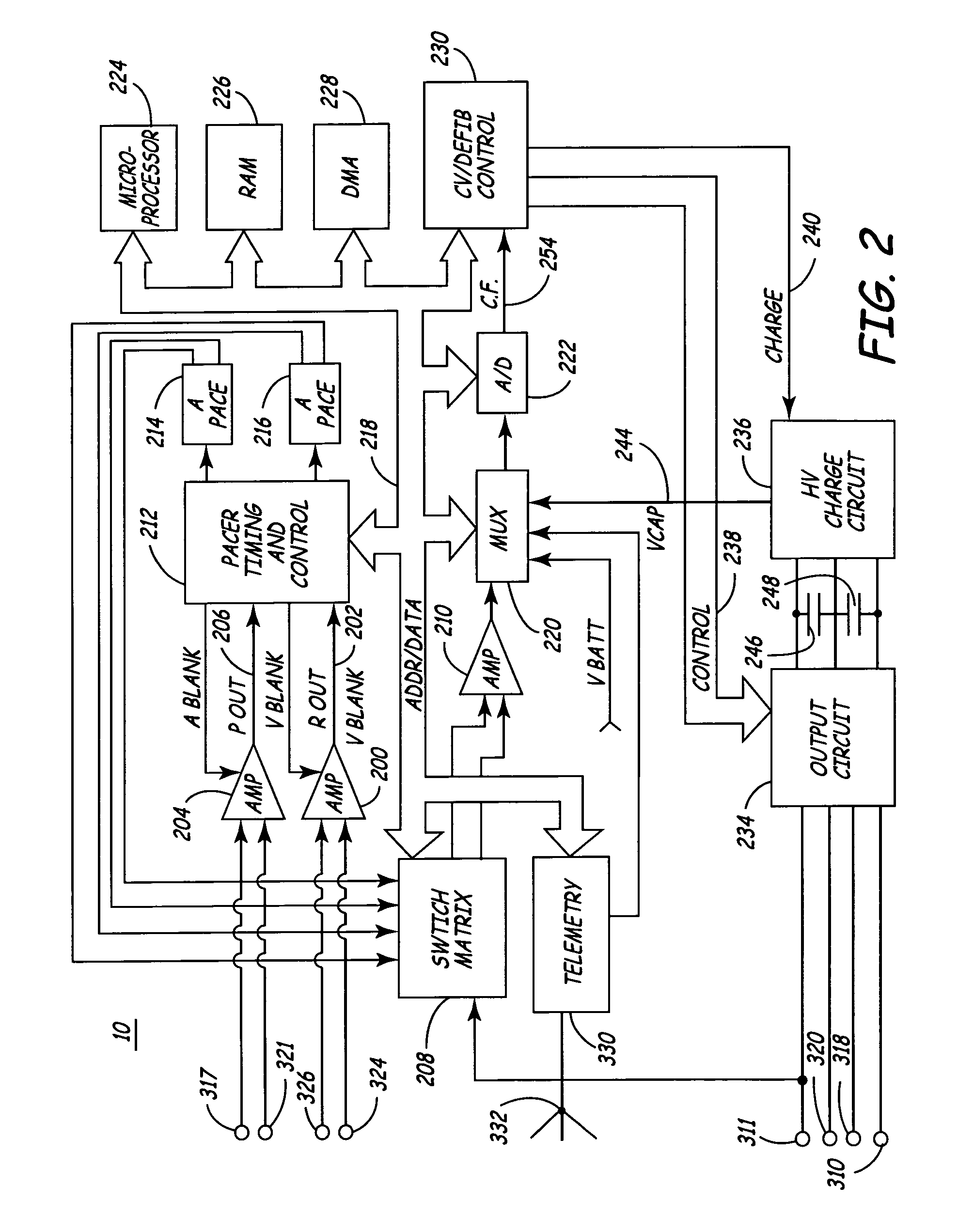

Dual chamber method and apparatus for diagnosis and treatment of arrhythmias

ActiveUS7031771B2Strong specificityEasy to analyzeElectrocardiographyHeart defibrillatorsData miningChamber method

A method and apparatus are provided for improving the detection of certain cardiac rhythms by combining dual chamber interval-related detection methods with electrogram morphology analysis. A prioritized set of rules are defined wherein each rule is directed at identifying a particular arrhythmia or type of arrhythmia. Each rule includes clauses that may be related to sensed event intervals and interval patterns and at least one rule includes at least one clause relating to the EGM morphology.

Owner:MEDTRONIC INC

Methods for wet cleaning quartz surfaces of components for plasma processing chambers

InactiveUS20050274396A1Electric discharge tubesDecorative surface effectsOrganic solventSemiconductor

Methods for wet cleaning quartz surfaces of components for plasma processing chambers in which semiconductor substrates are processed, such as etch chambers and resist stripping chambers, include contacting the quartz surface with at least one organic solvent, a basic solution and different acid solutions, so as to remove organic and metallic contaminants from the quartz surface. The quartz surface is preferably contacted with one of the acid solutions at least two times.

Owner:LAM RES CORP

Method for filling and mining after ore caving

ActiveCN102587916AReduce impact damageImprove work efficiencyUnderground miningSurface miningSpelunkingMineral Sources

The invention discloses a method for filling and mining after ore caving, which includes the following steps: exploiting; mining quasi work; cutting work: including excavation of mine collection trench and patio cutting, cutting a patio at one end portion of a rock drilling chamber, cutting the patio by using a vertical deep hole ore falling stage chamber method, and enabling patio cutting to provide sufficient compensation space for actual mining; chamber extraction work: constructing a downward blasthole in the rock drilling chamber, filling and blasting, one-time blasting charging at the entire middle section height of the blasthole, and enabling blasting to adopt one-time lateral blasting and ore removal; filling and maintaining: closing all outlets communicated with a lower mine of the empty area, burying strainer pipes, leading in filling pipelines from the upper portion of the chamber, and filling and maintaining the chamber; and pillar recovery: recovering pillars after filling and maintaining the chamber, and the pillar recovery is the same as the chamber extraction work. The method for filling and mining after ore caving is high in recovery rate of mineral resources, small in blasting impact effect, low in cost and high in production efficiency.

Owner:金建工程设计有限公司

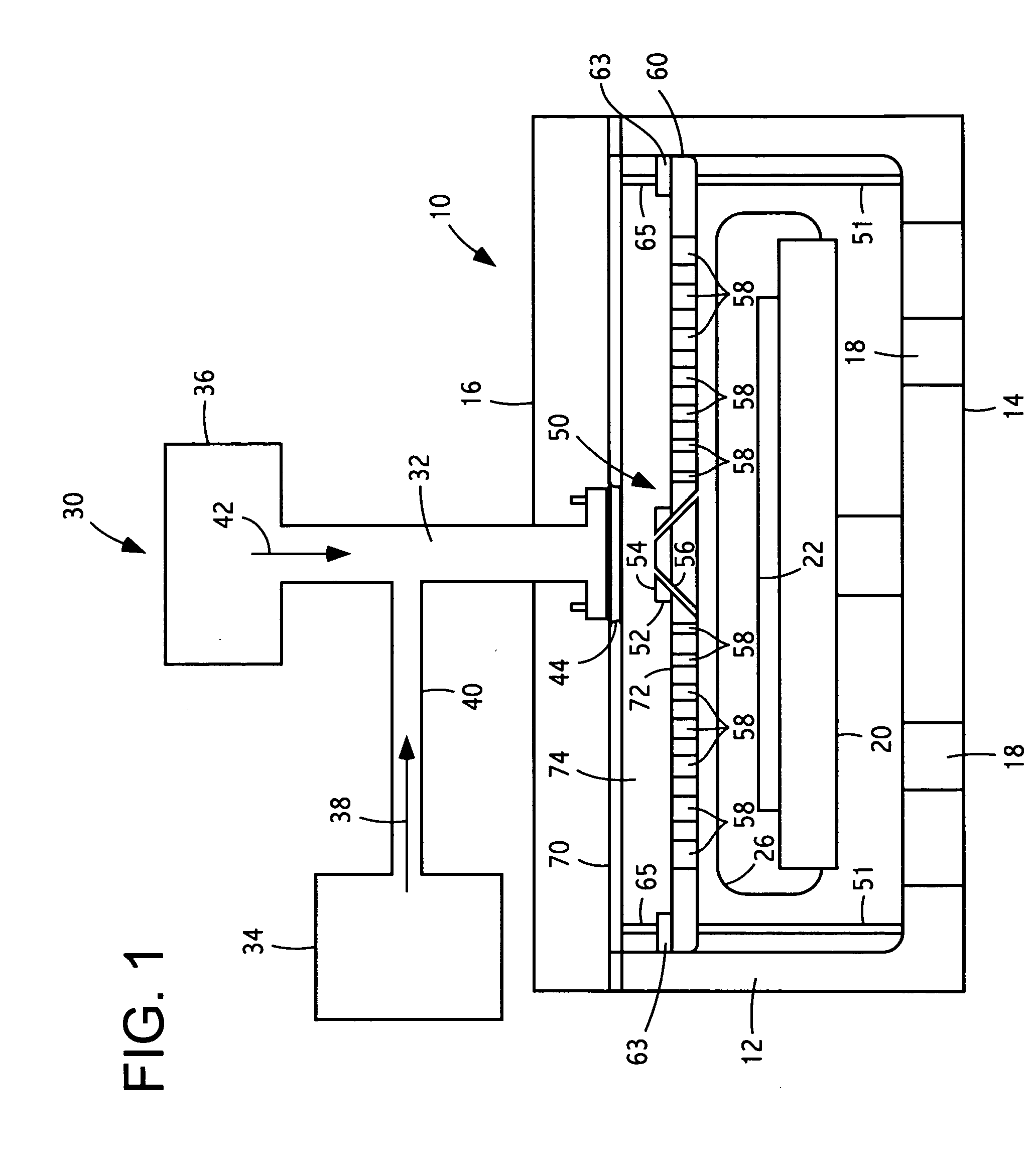

Method of forming a film in a chamber and positioning a substitute in a chamber

InactiveUS6530992B1Liquid surface applicatorsSemiconductor/solid-state device manufacturingMaterials scienceChamber method

Methods and apparatuses of forming a film on a substrate including introducing a pretreatment material into a processing chamber sufficient to form a film as a portion of an inner surface of the processing chamber to inhibit outgassing from that portion of the chamber, introducing a substrate into the chamber, and forming a film on the substrate.

Owner:APPLIED MATERIALS INC

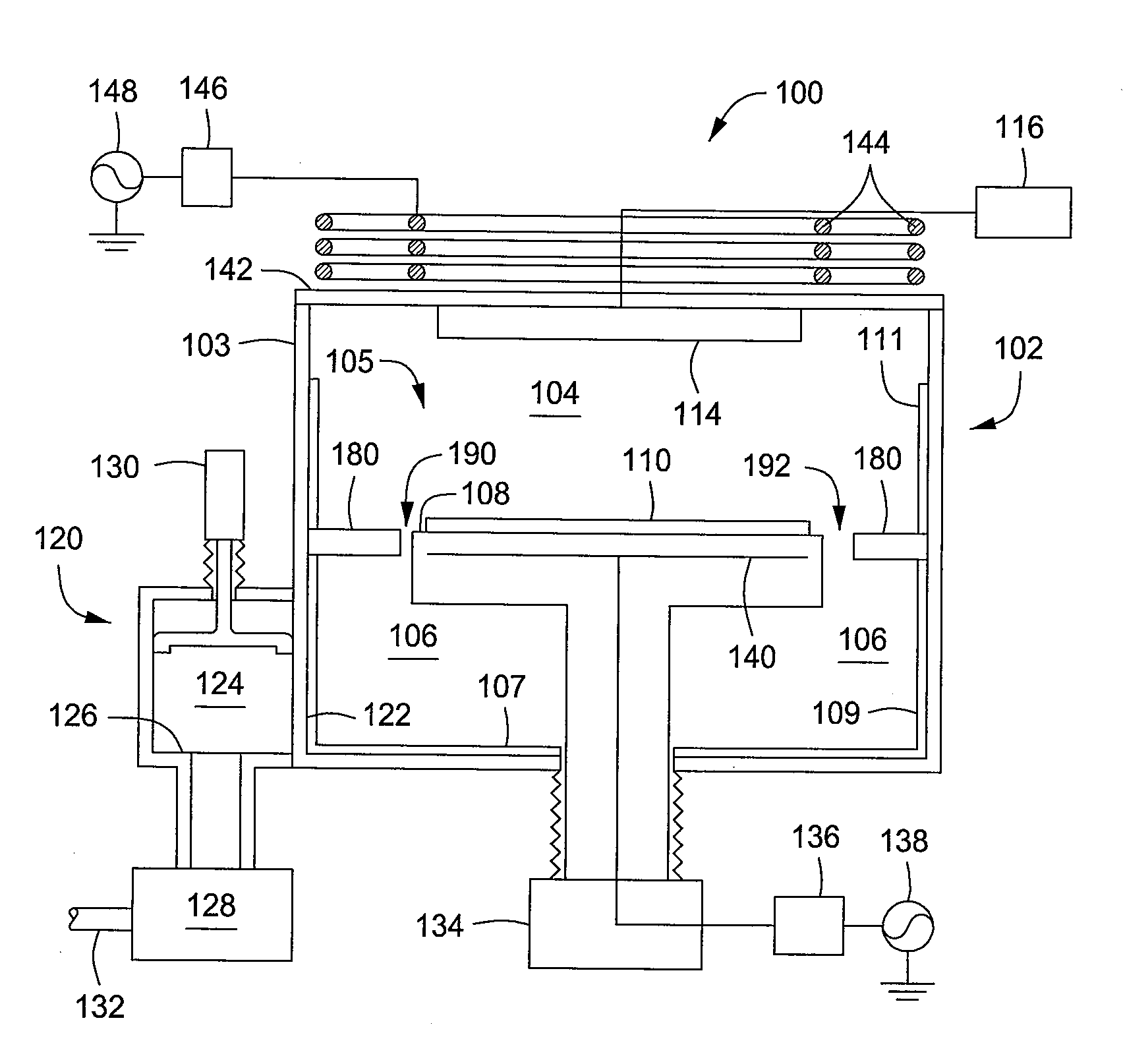

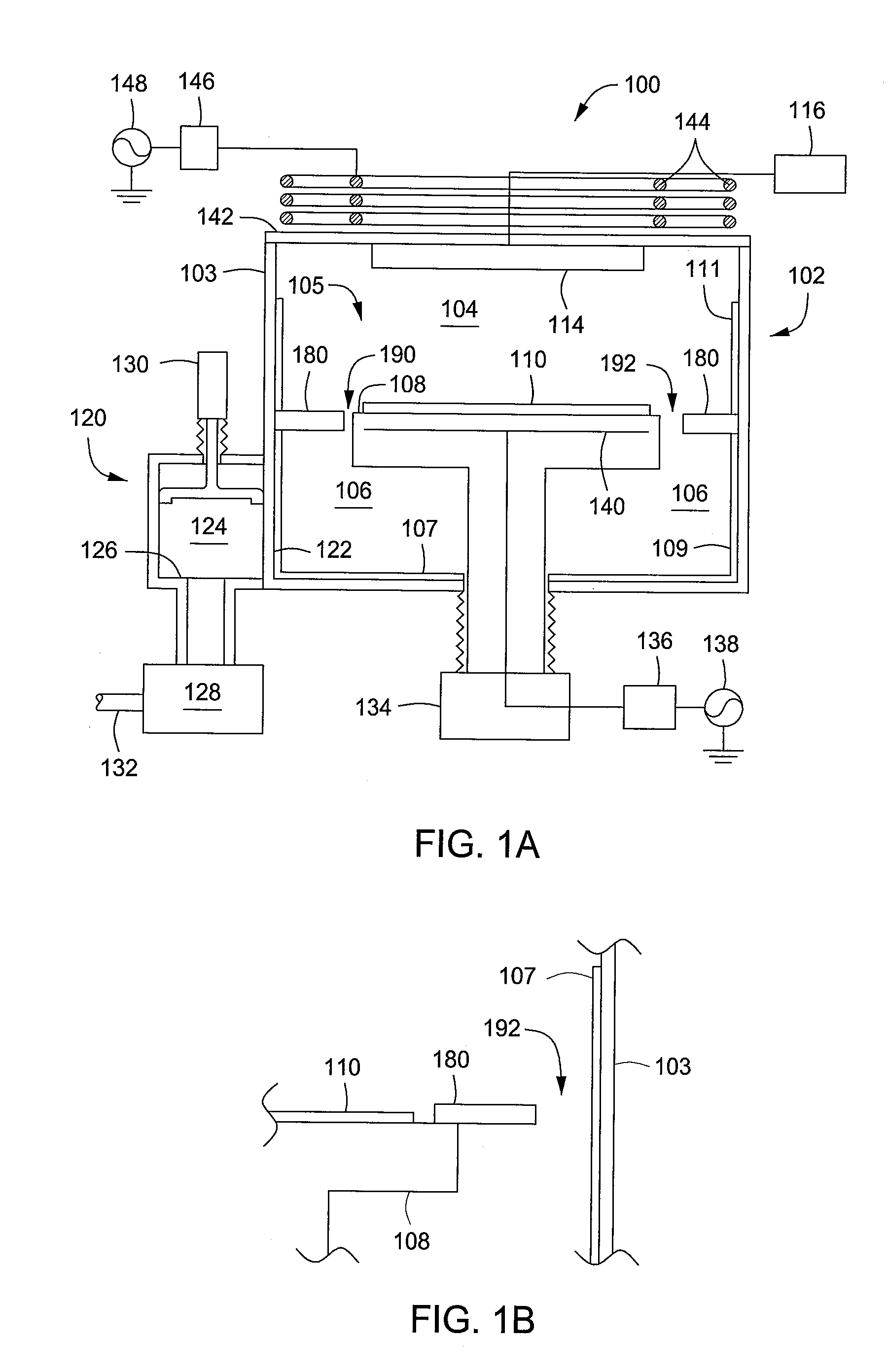

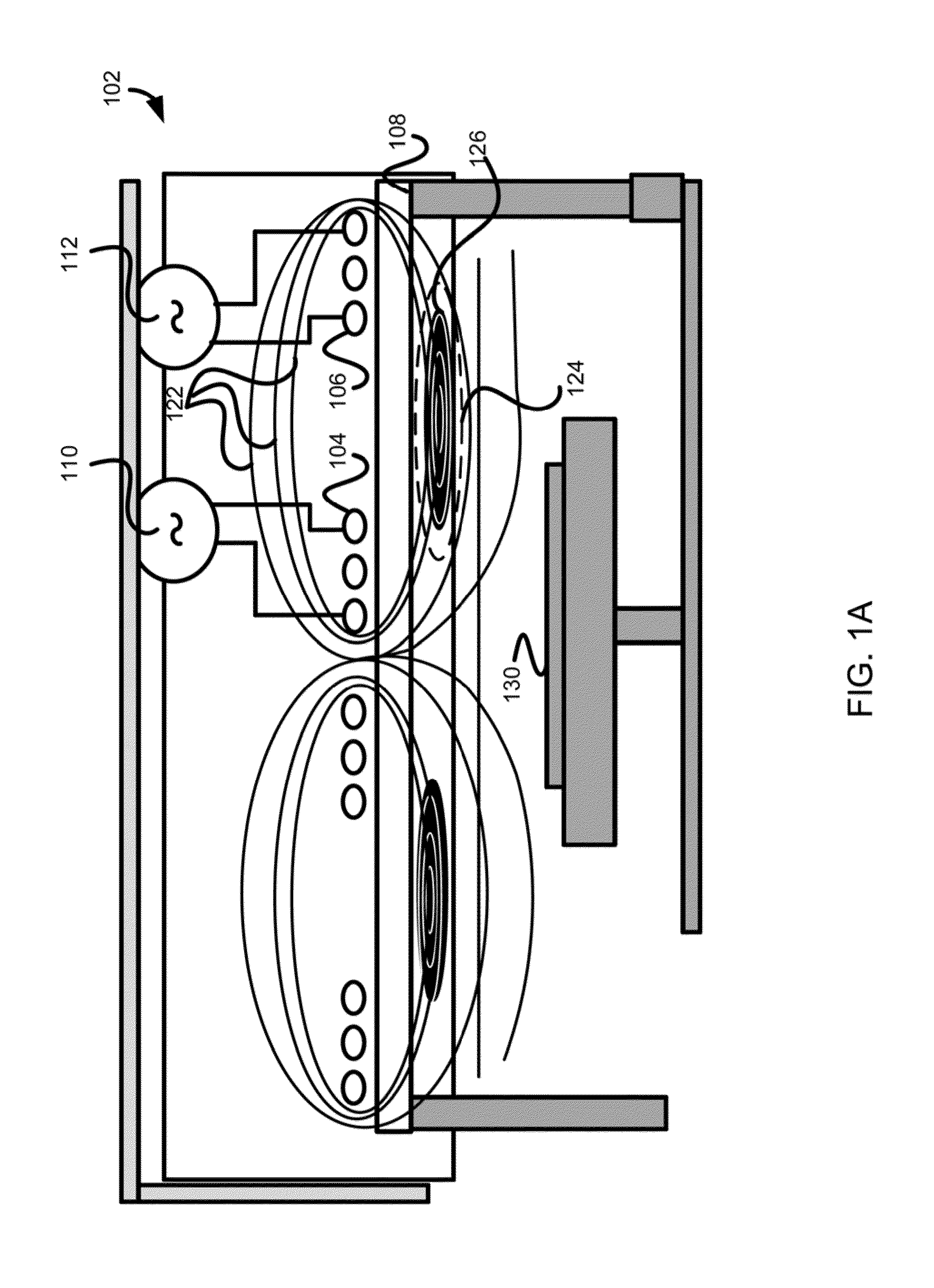

Methods and apparatus for improving flow uniformity in a process chamber

InactiveUS20100081284A1Reduce trafficNon-uniform flowElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

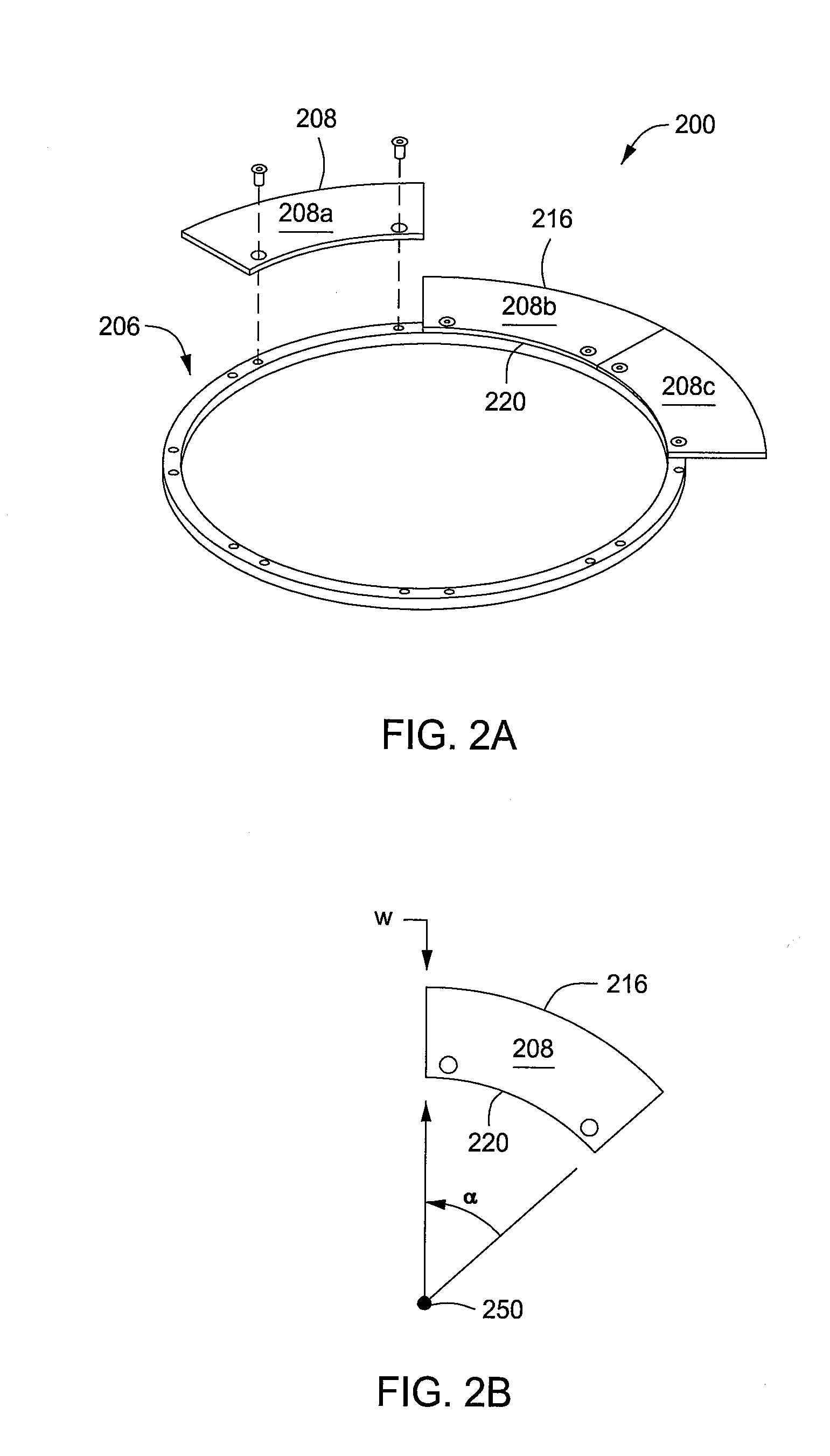

Methods and apparatus for processing substrates are provided herein. In some embodiments, an apparatus for processing a substrate includes a flow equalizer configured to control the flow of gases between a process volume and an exhaust port of a process chamber. The flow equalizer includes at least one restrictor plate configured to be disposed in a plane proximate a surface of a substrate to be processed and defines an azimuthally non-uniform gap between an edge of the at least one restrictor plate and one of either a chamber wall or a substrate support when installed in the process chamber.

Owner:APPLIED MATERIALS INC

Microvolume biochemical reaction chamber

InactiveUS20040101870A1High sensitivityLower the volumeBioreactor/fermenter combinationsBiological substance pretreatmentsReagentChamber method

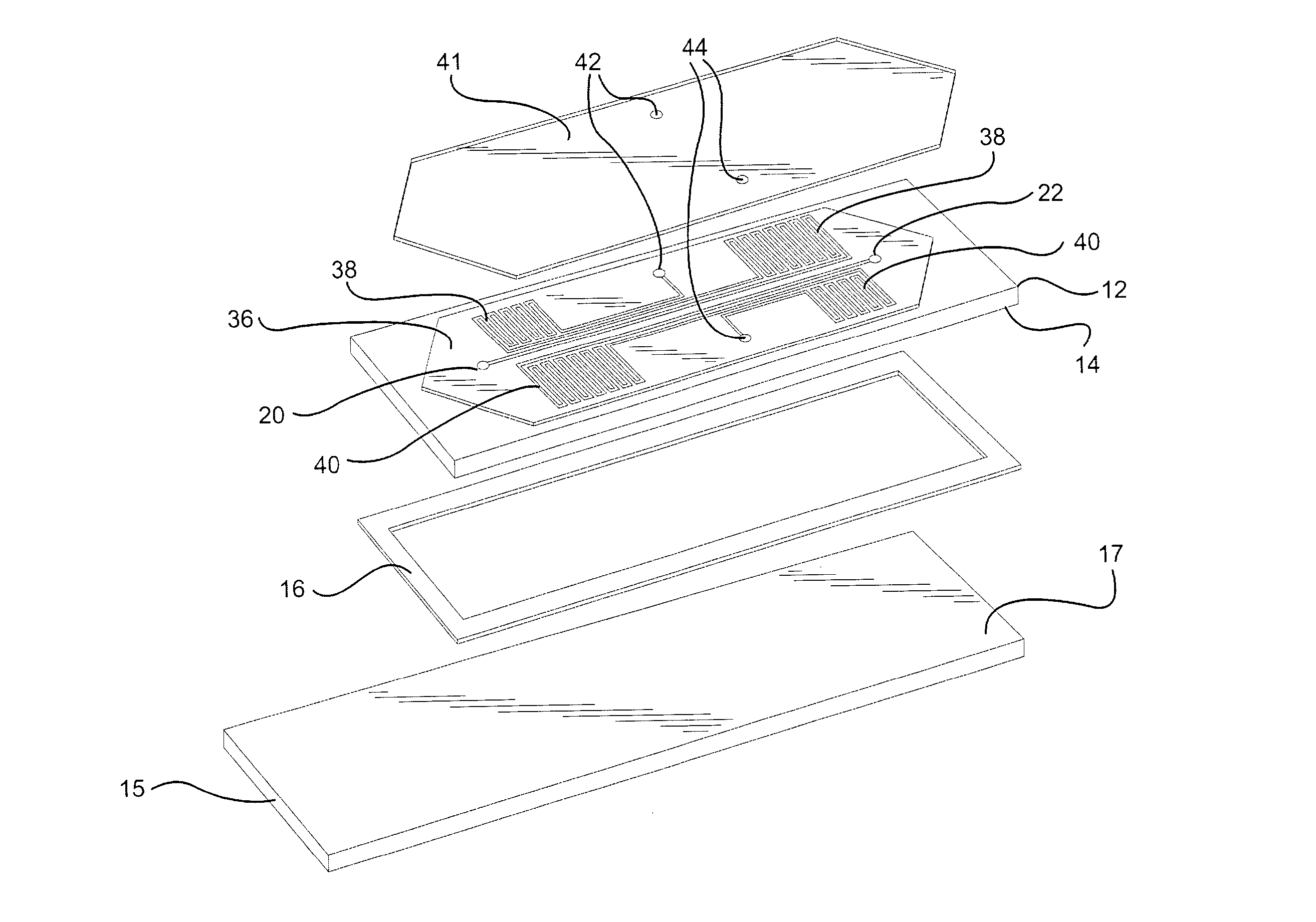

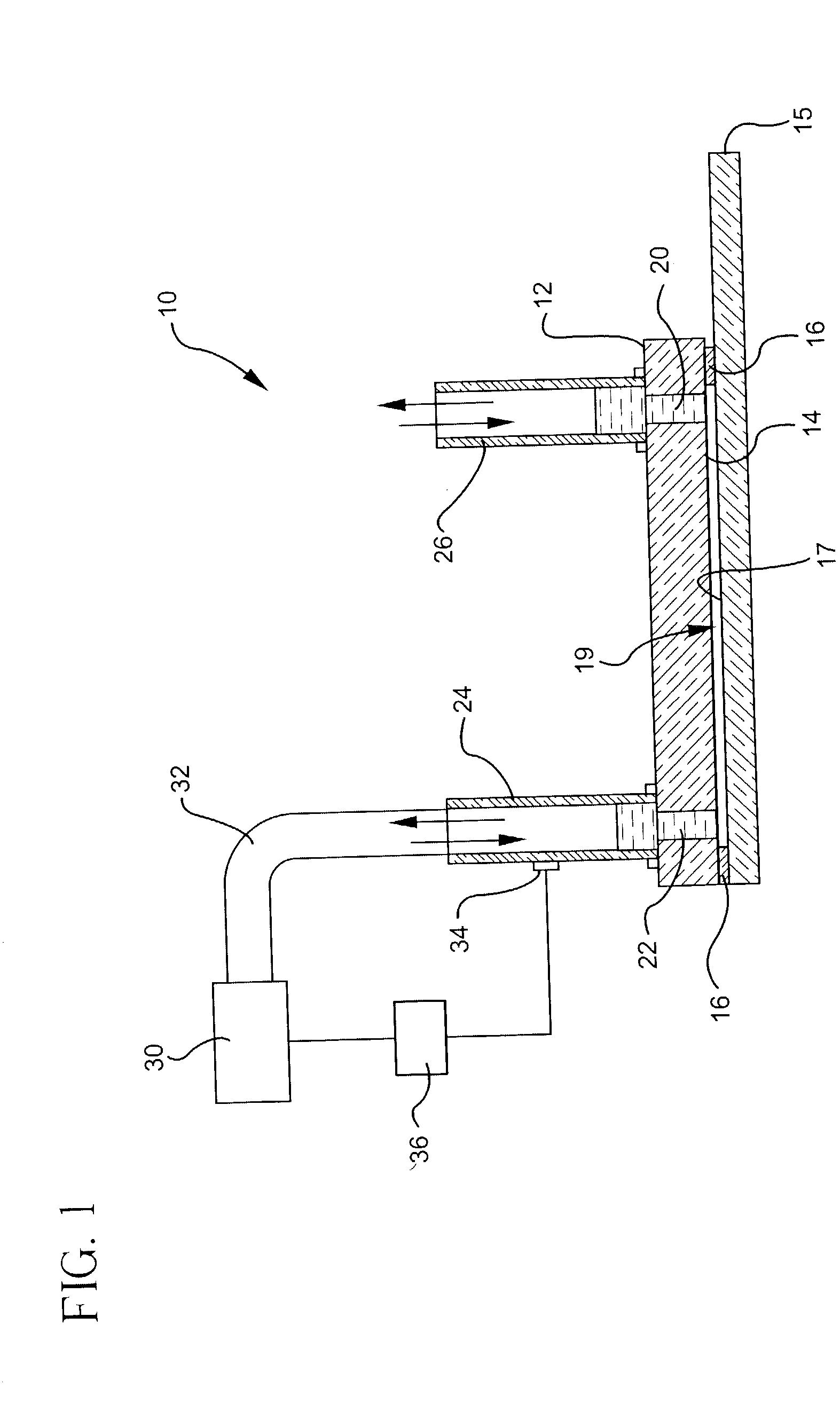

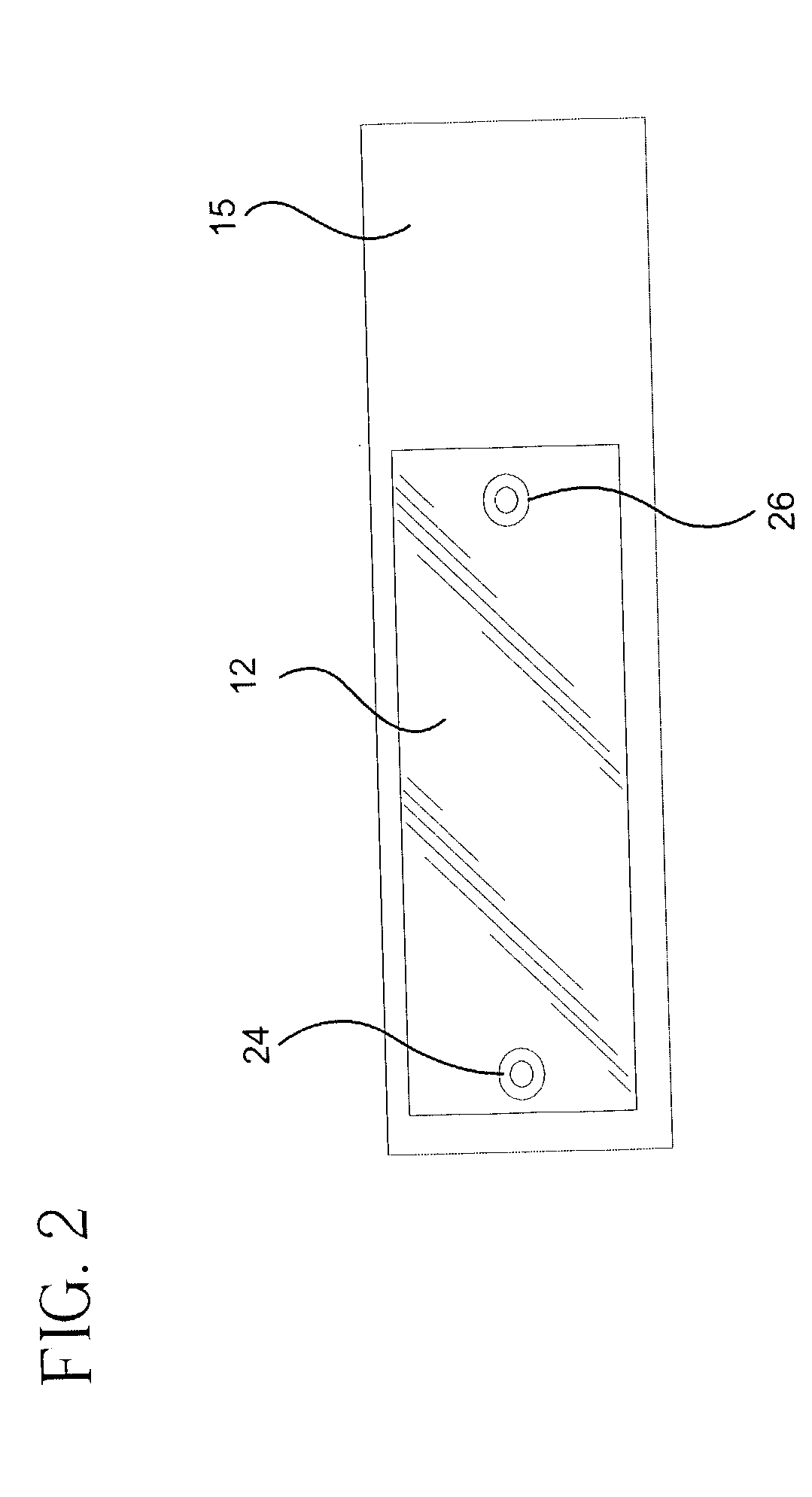

Methods and apparatus for performing biomolecular reactions using microvolumes of reagents are disclosed. The apparatus and methods include a chamber having a height less than 50 microns and means for mixing the extremely small volume of fluid in the chamber. The decreased volumes combined with mixing greatly improved microarray hybridization signal strength.

Owner:CORNING INC

Method for cleaning a process chamber

Methods and apparatus for cleaning deposition chambers are presented. The cleaning methods include the use of a remote plasma source to generate reactive species from a cleaning gas to clean deposition chambers. A flow of helium or argon may be used during chamber cleaning. Radio frequency power may also be used in combination with a remote plasma source to clean deposition chambers.

Owner:APPLIED MATERIALS INC

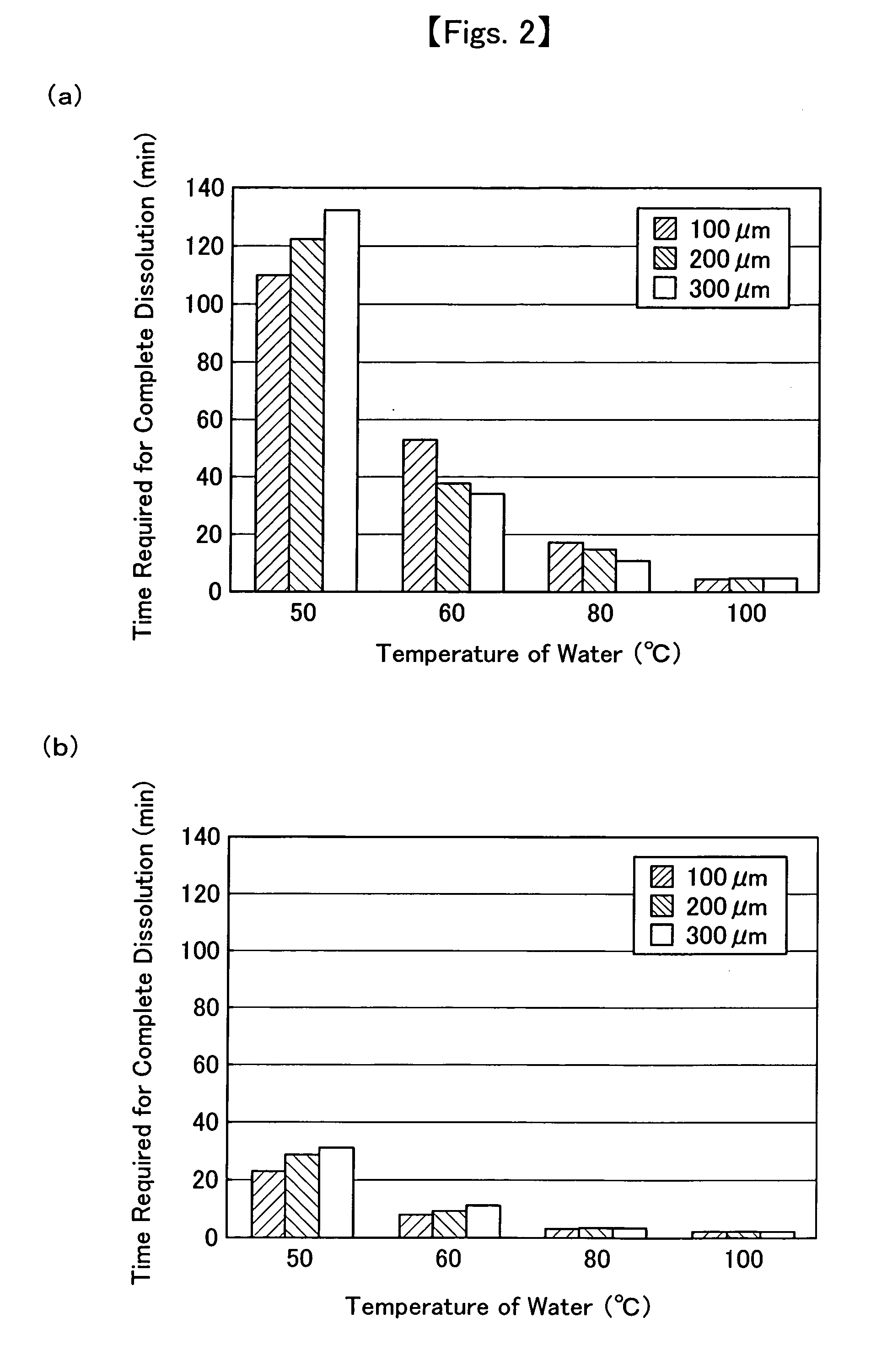

A1 composite material being crumbled with water, a1 film and a1 power comprising the material and methods for preparation thereof, constitutional member for film-forming chamber method for recovering film-forming material

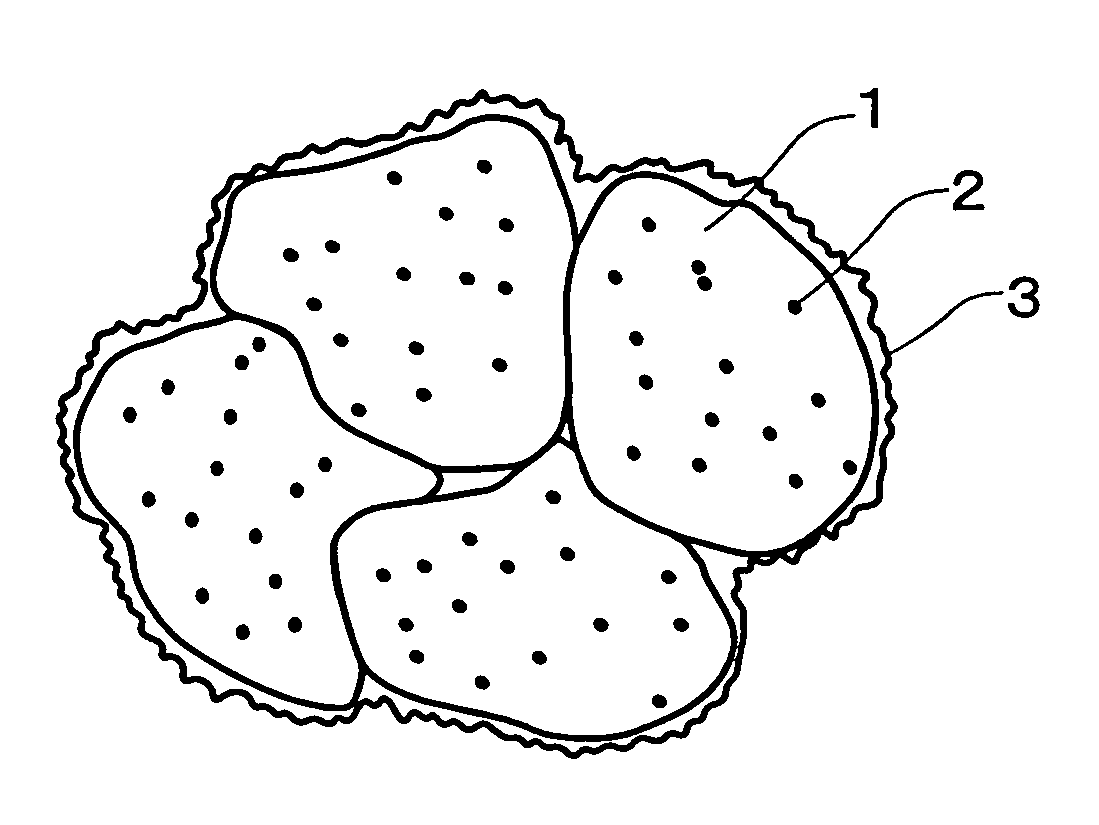

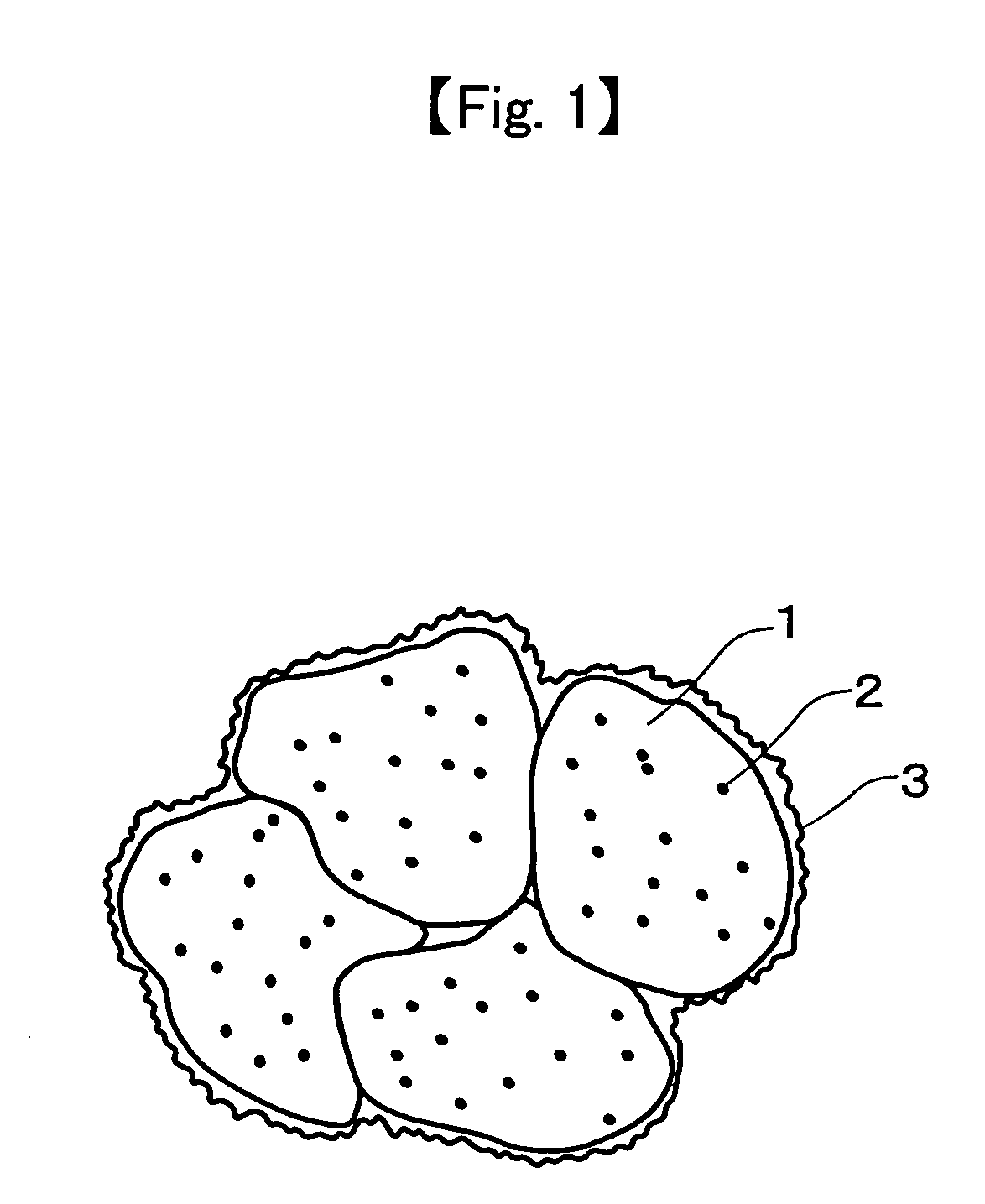

ActiveUS20060240271A1Efficiently be disintegratedEfficiently be collapsedLiquid surface applicatorsMolten spray coatingAl powderMetallurgy

In An Al composite material collapsible in the presence of moisture, the external surface of small pieces or powder constructed from a single or a plurality of crystalline grains of Al or an Al alloy is covered with a film of a low melting point metal or alloy selected from the group consisting of In, Sn, combinations of In and Sn, and alloys thereof. The content of the foregoing low melting point metal or alloy ranges from 0.1 to 20% by mass on the basis of the total mass of the composite material. A material obtained by adding a low melting point metal in an amount specified above to, for instance, Al and then fusing and melting the resulting mixture is quenched and solidified within a non-oxidizing atmosphere to thus form an Al composite material. An Al film, an Al spray-coated film and Al powder can be prepared from the foregoing Al composite material. A component member for a film-forming chamber is also provided, which is provided with a water-collapsible Al film on the surface thereof. Film-forming operations are continued over a long period of time using the component member for a film-forming chamber provided with the water-collapsible Al film and then film-forming materials can be recovered from the component member on which the film-forming materials are deposited in a substantial thickness.

Owner:ULVAC INC

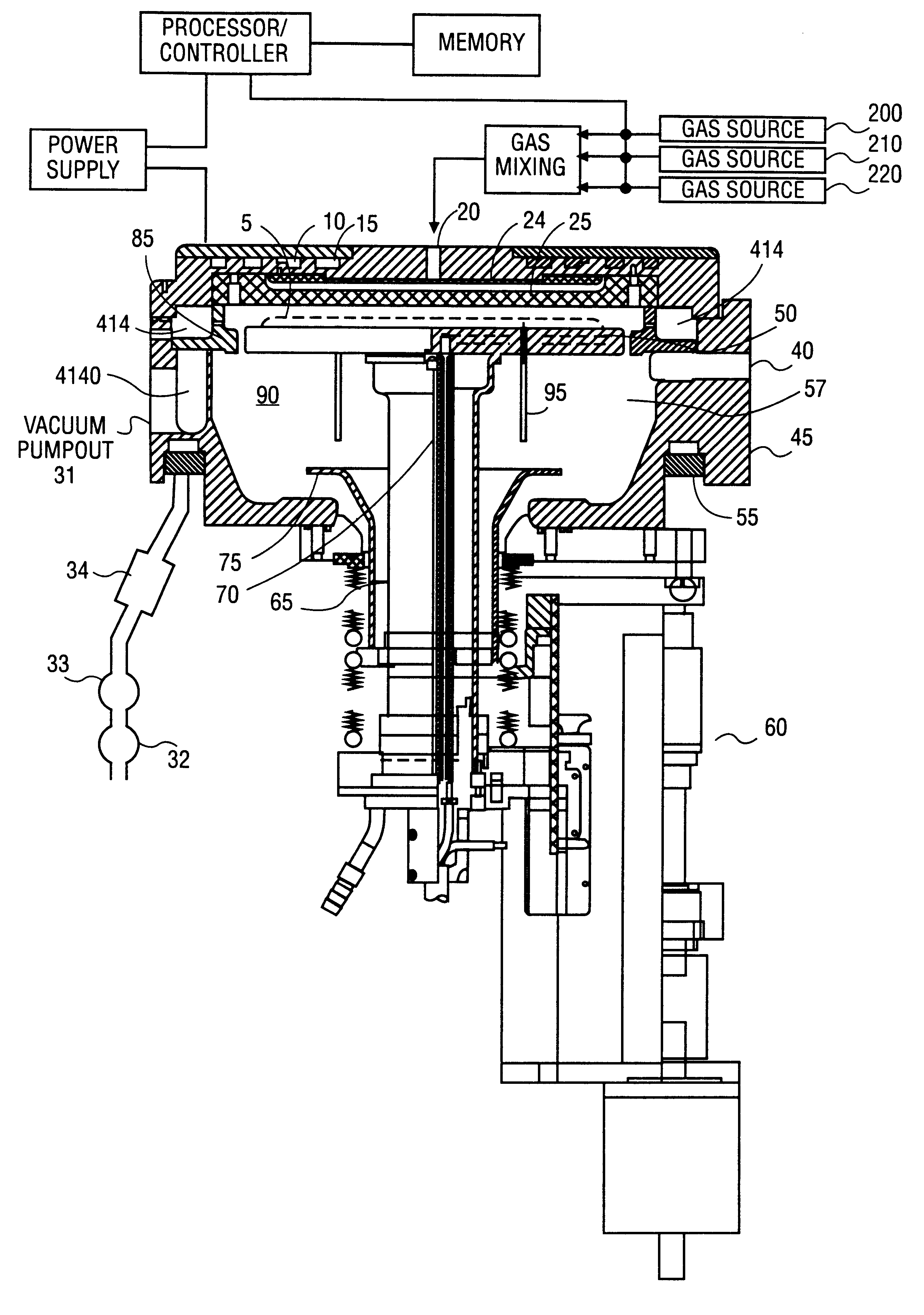

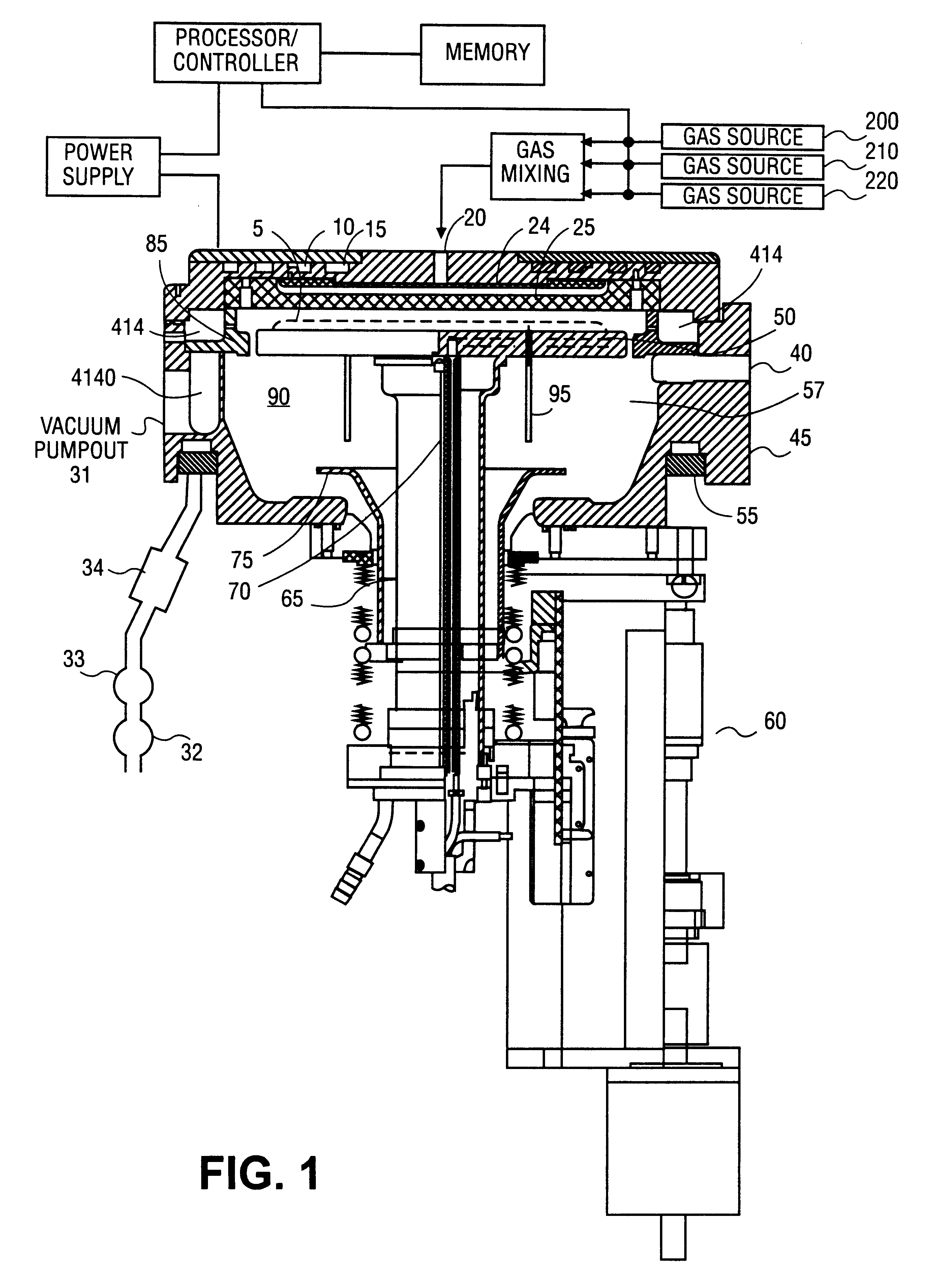

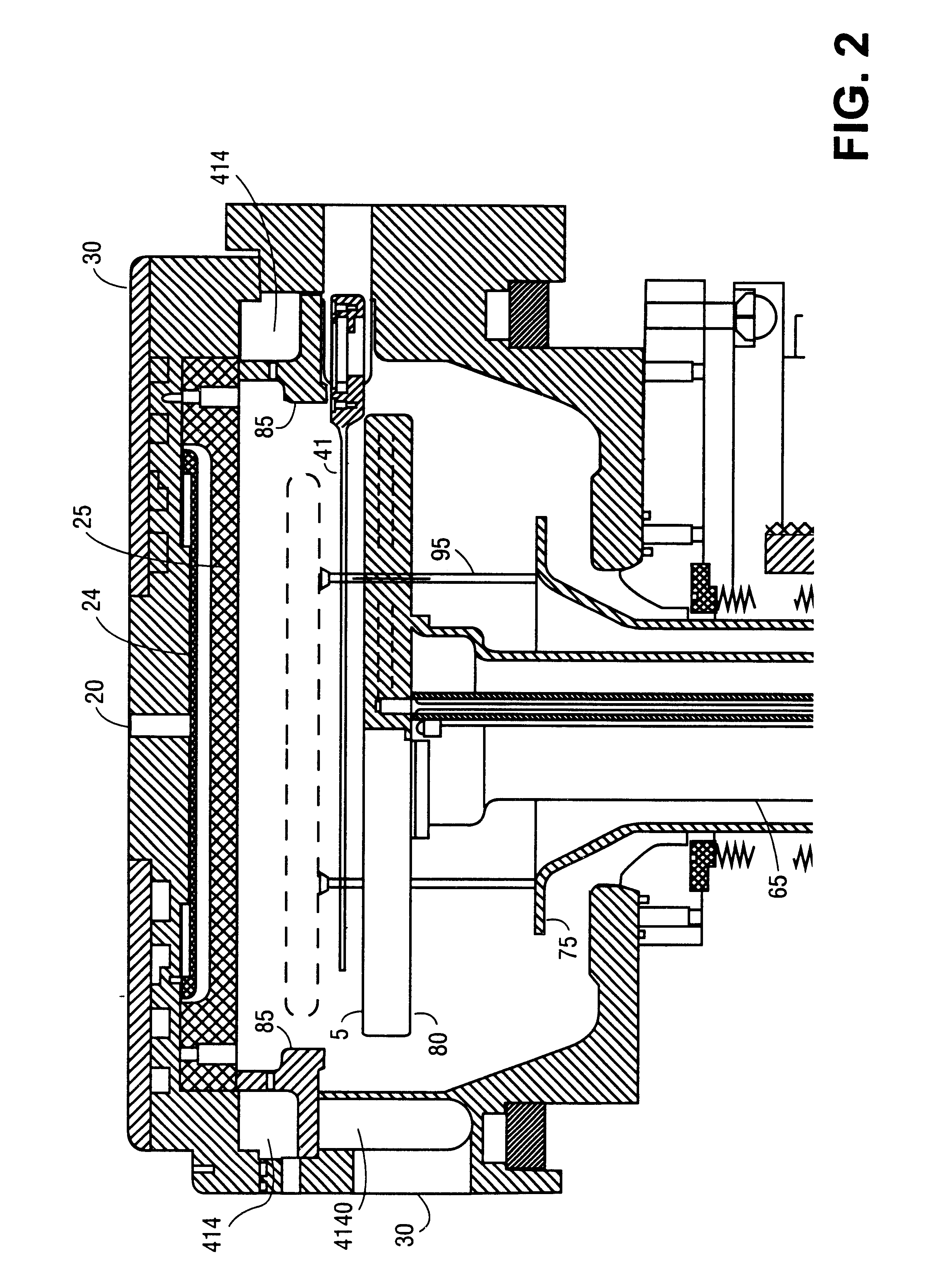

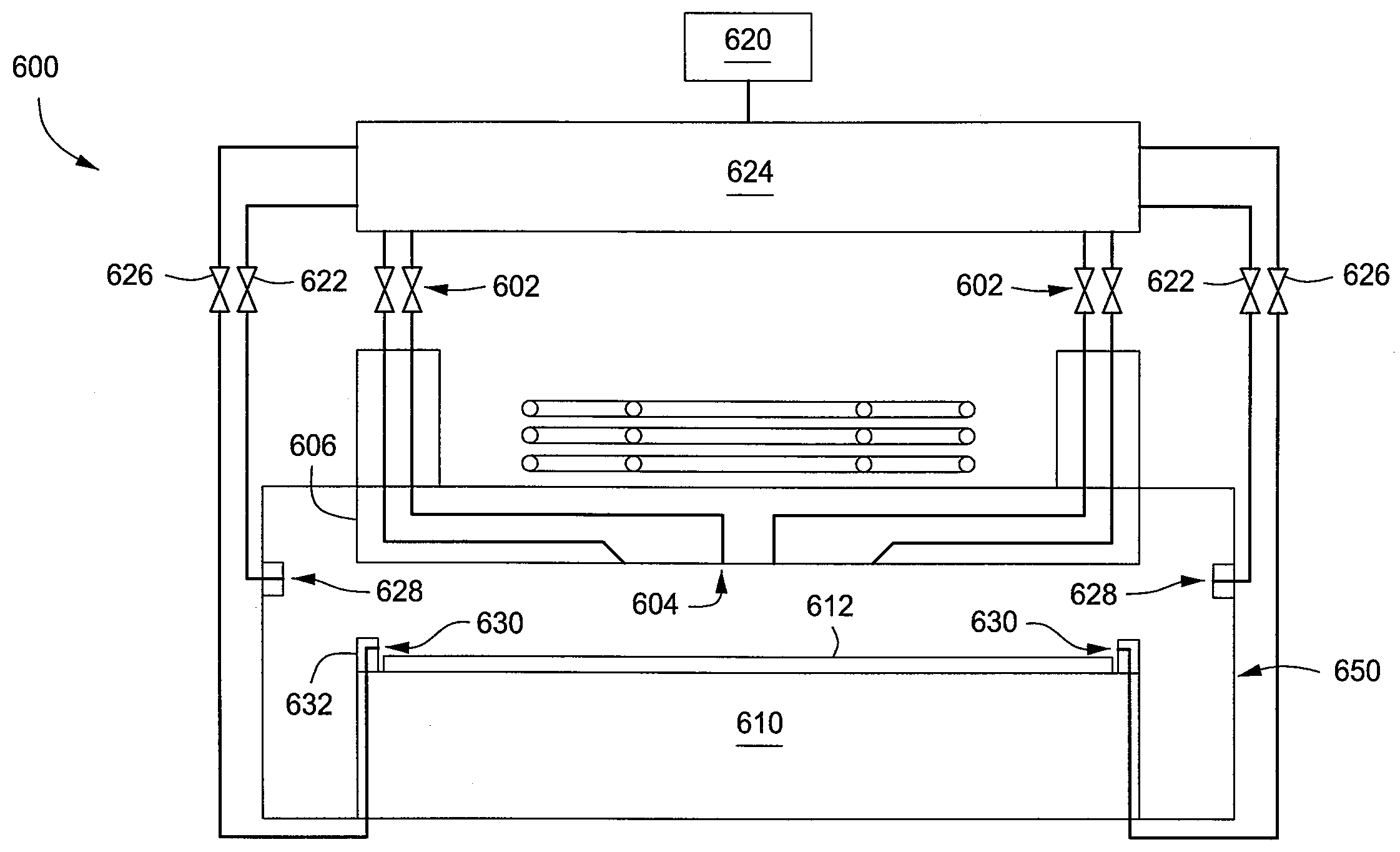

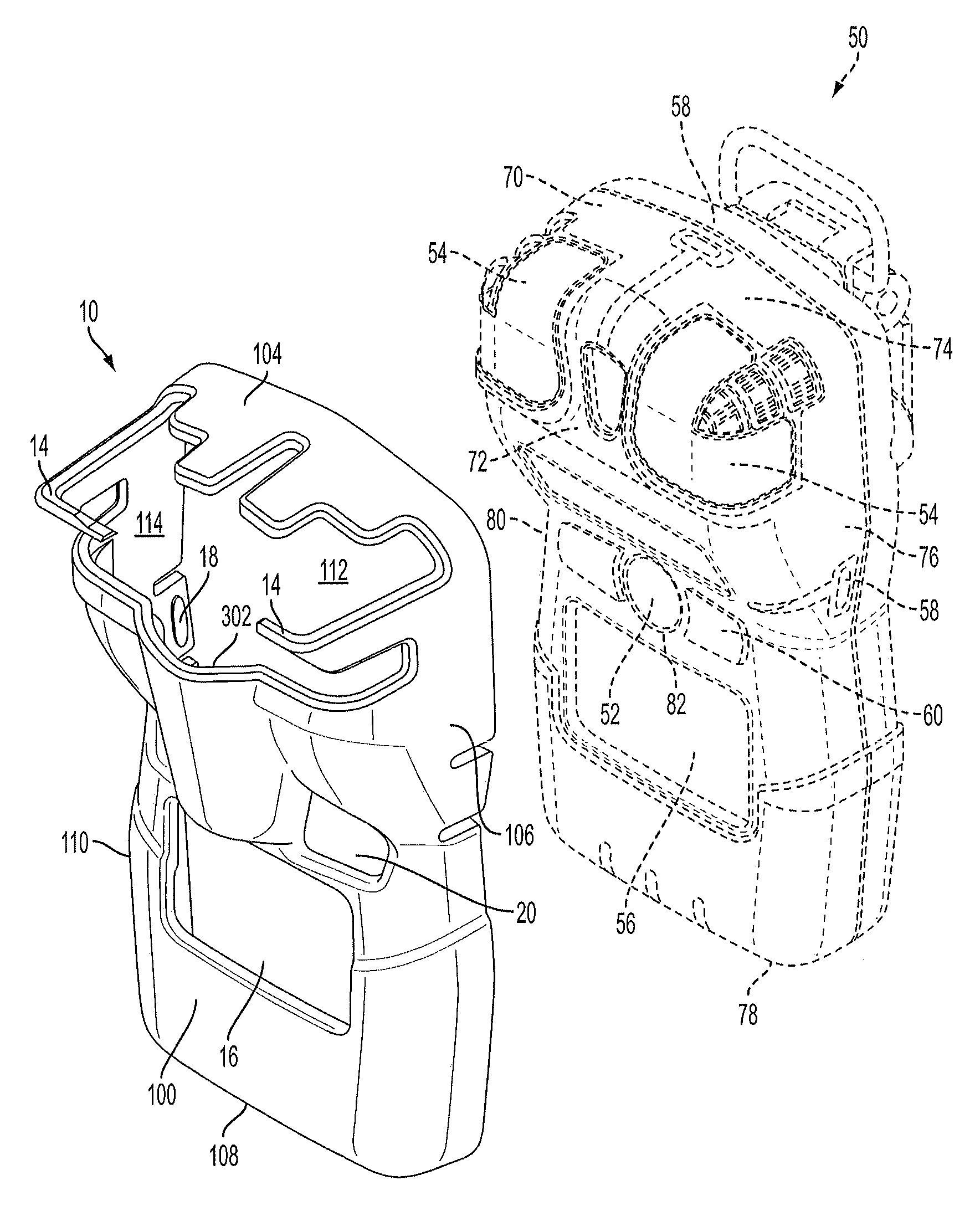

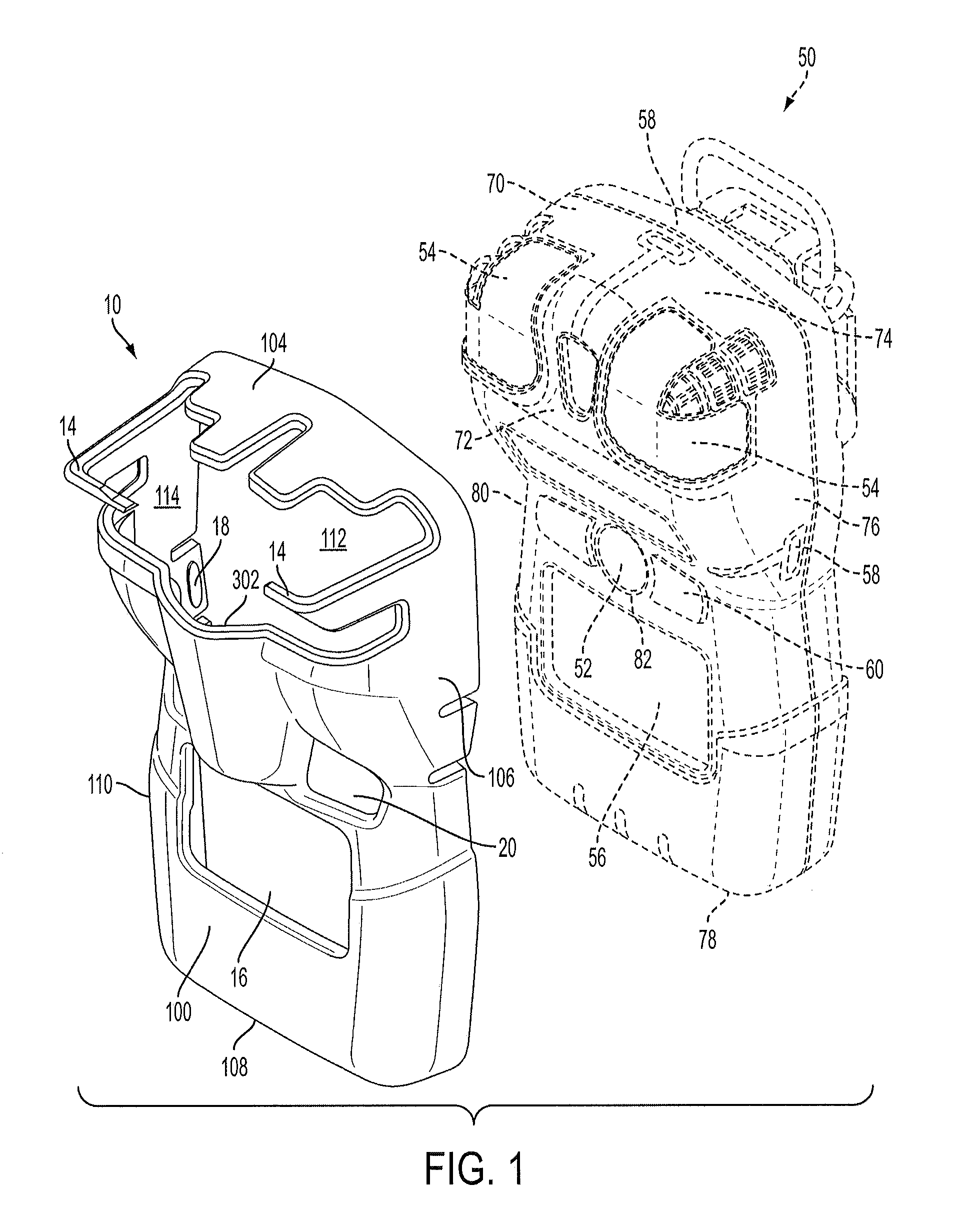

Process gas delivery for semiconductor process chamber

ActiveUS20100048032A1Increase the sectionSemiconductor/solid-state device manufacturingMultiple way valvesEngineeringProduct gas

Methods and apparatus for a gas delivery assembly are provided herein. In some embodiments, the gas delivery assembly includes a gas inlet funnel having a first volume and one or more gas conduits; each gas conduit having an inlet and an outlet for facilitating the flow of a gas therethrough and into the first volume, wherein each gas conduit has a second volume less than the first volume, and wherein each gas conduit has a cross-section that increases from a first cross-section proximate the inlet to a second cross-section proximate the outlet, wherein the second cross-section is non-circular. In some embodiments, each conduit has a longitudinal axis that intersects a central axis of the gas inlet funnel.

Owner:APPLIED MATERIALS INC

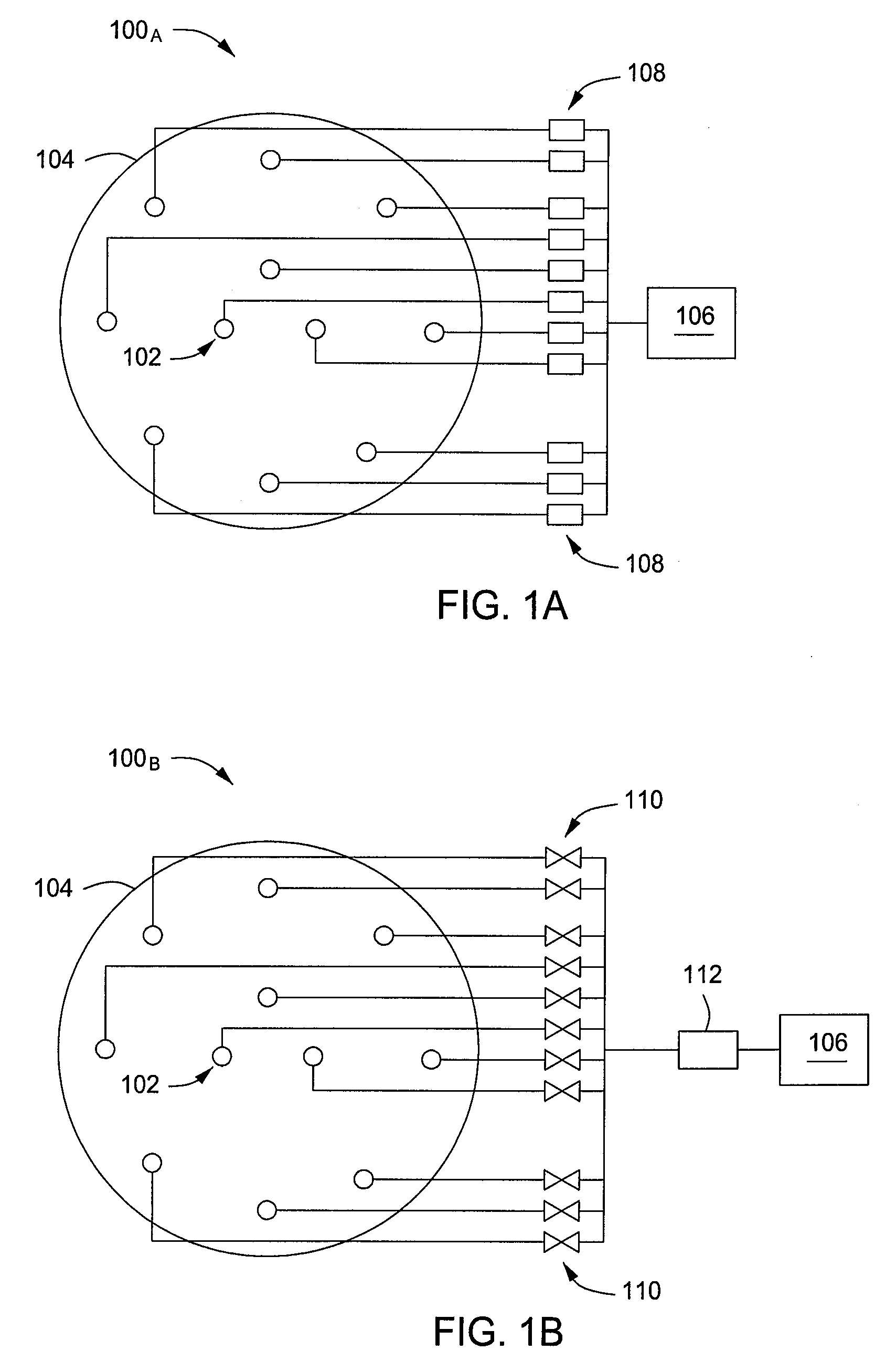

Method and apparatus for controlling gas injection in process chamber

Methods and apparatus for processing substrates are provided herein. In some embodiments, a gas distribution apparatus may include a plurality of gas inlets configured to deliver a process gas to a process chamber; and a plurality of flow controllers having outlets coupled to the plurality of gas inlets for independently controlling the flow rate through each of the plurality of gas inlets. The gas distribution apparatus may be coupled to a process chamber for controlling the delivery of one or more process gases thereto.

Owner:APPLIED MATERIALS INC

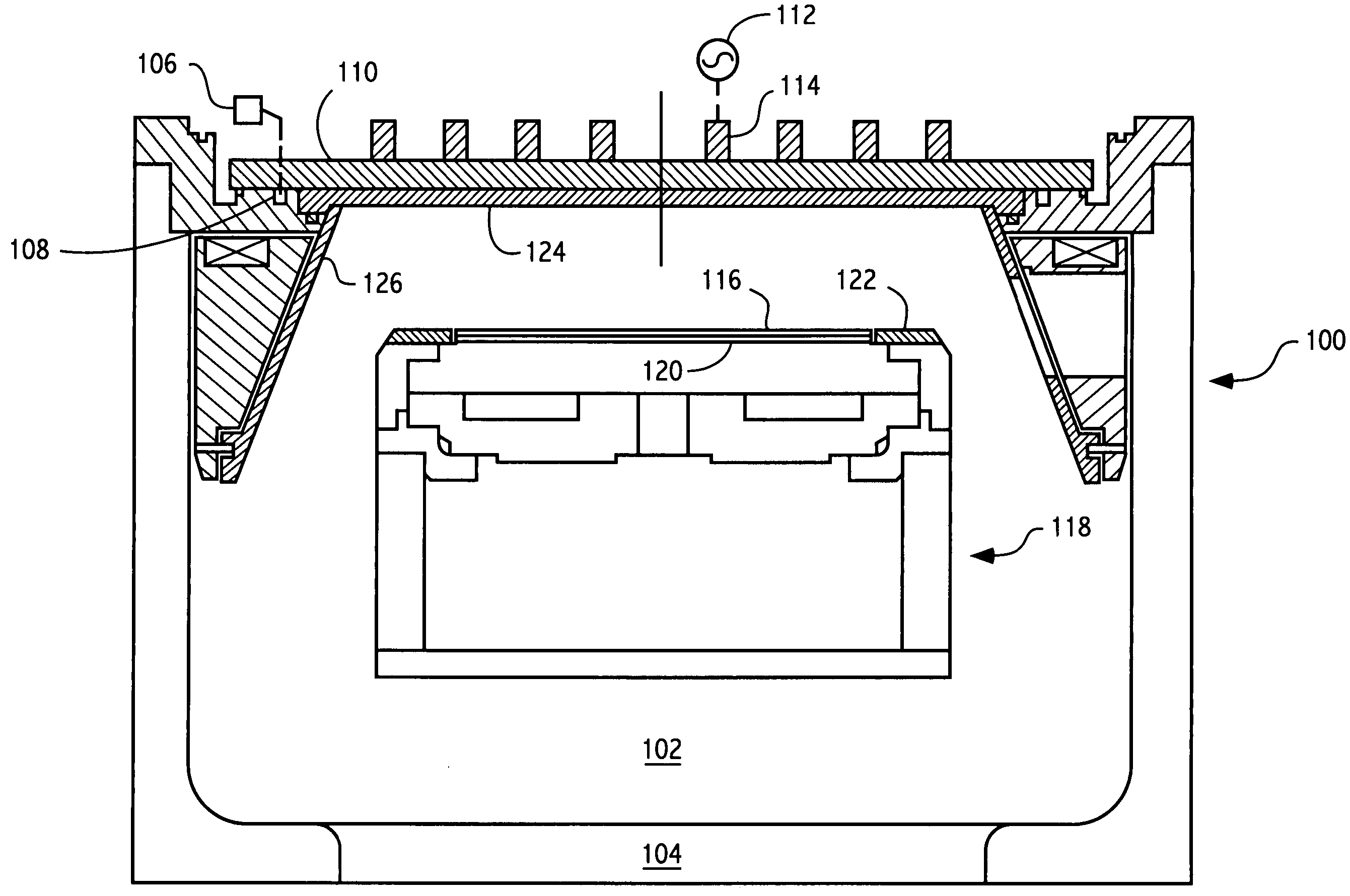

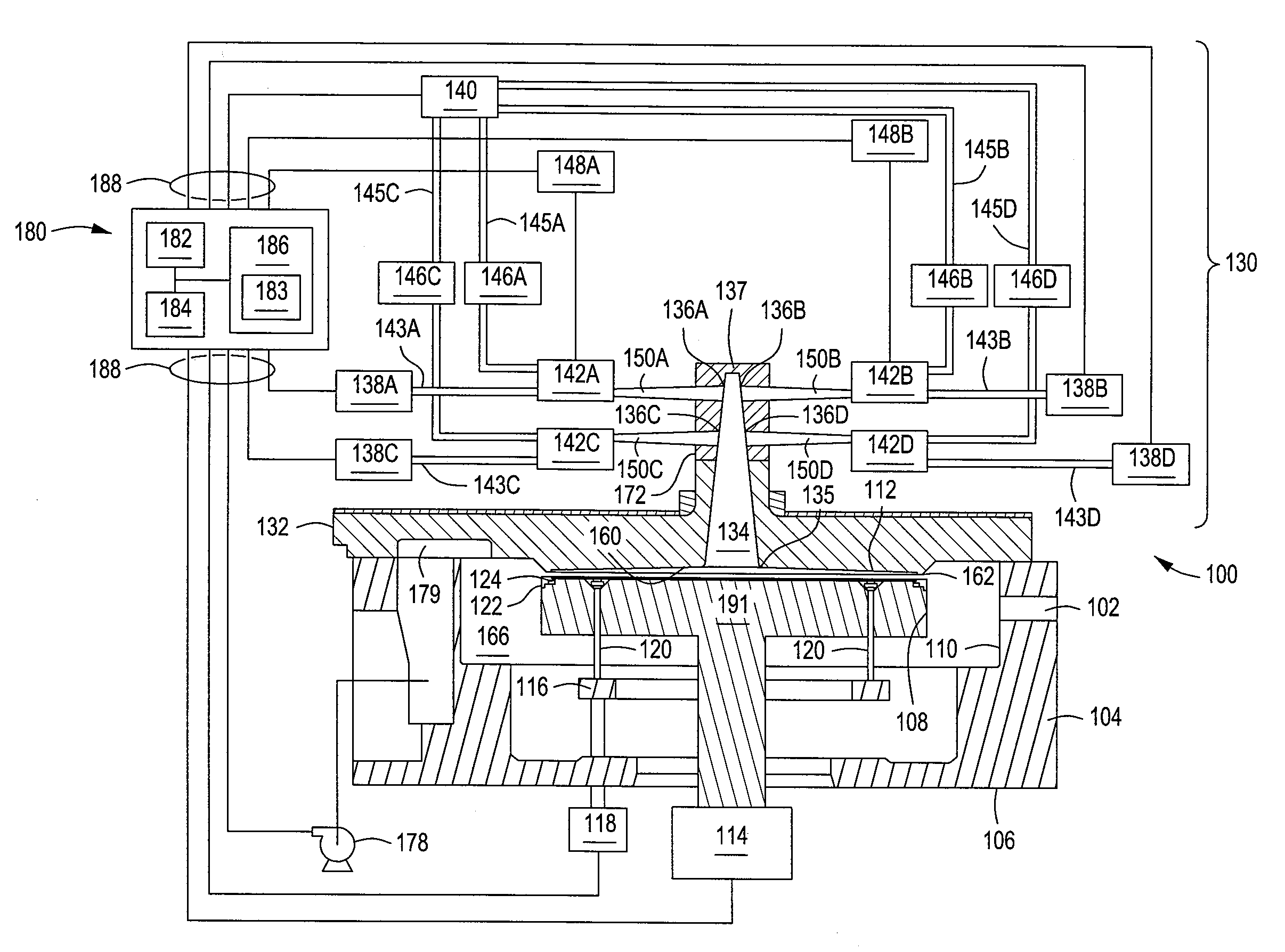

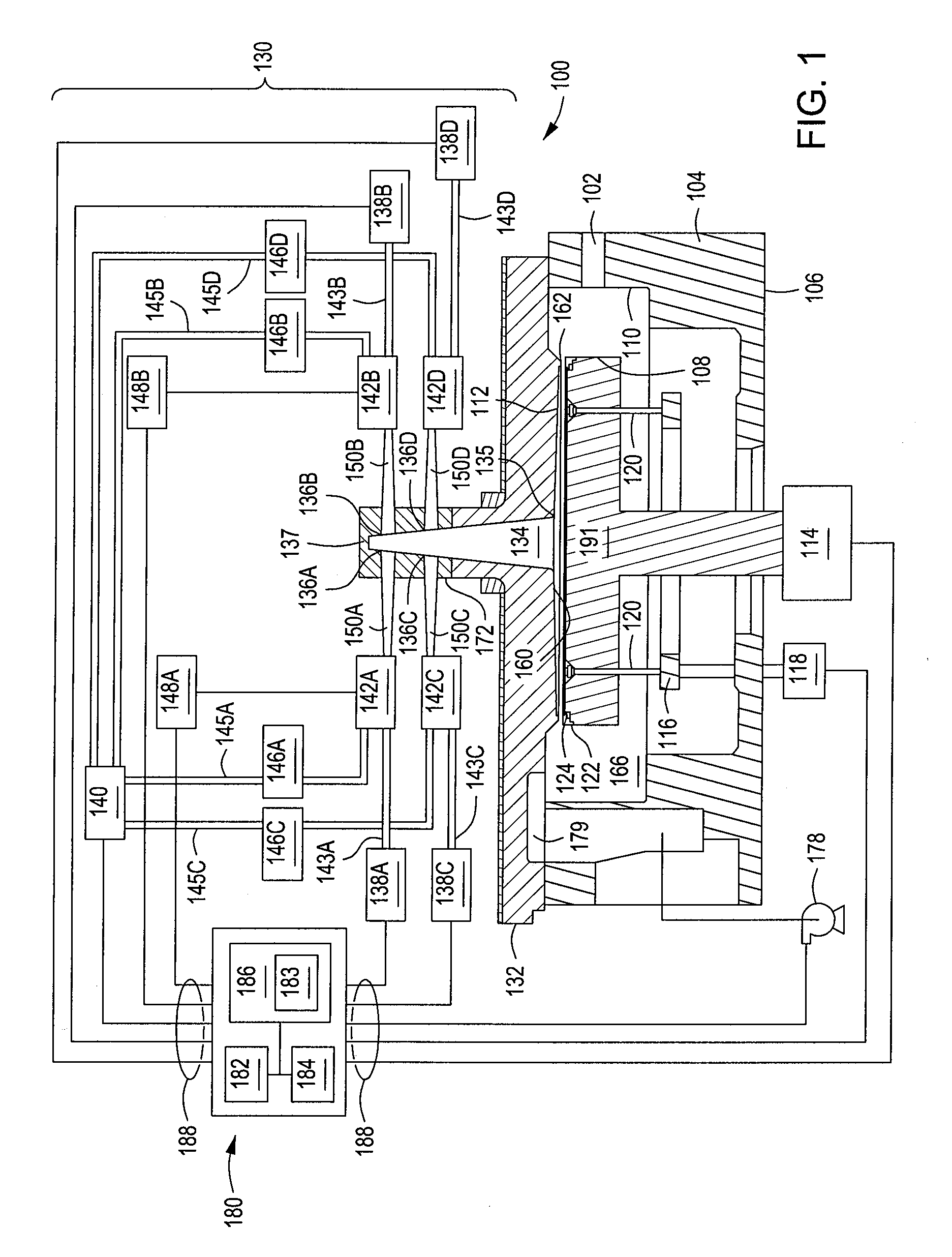

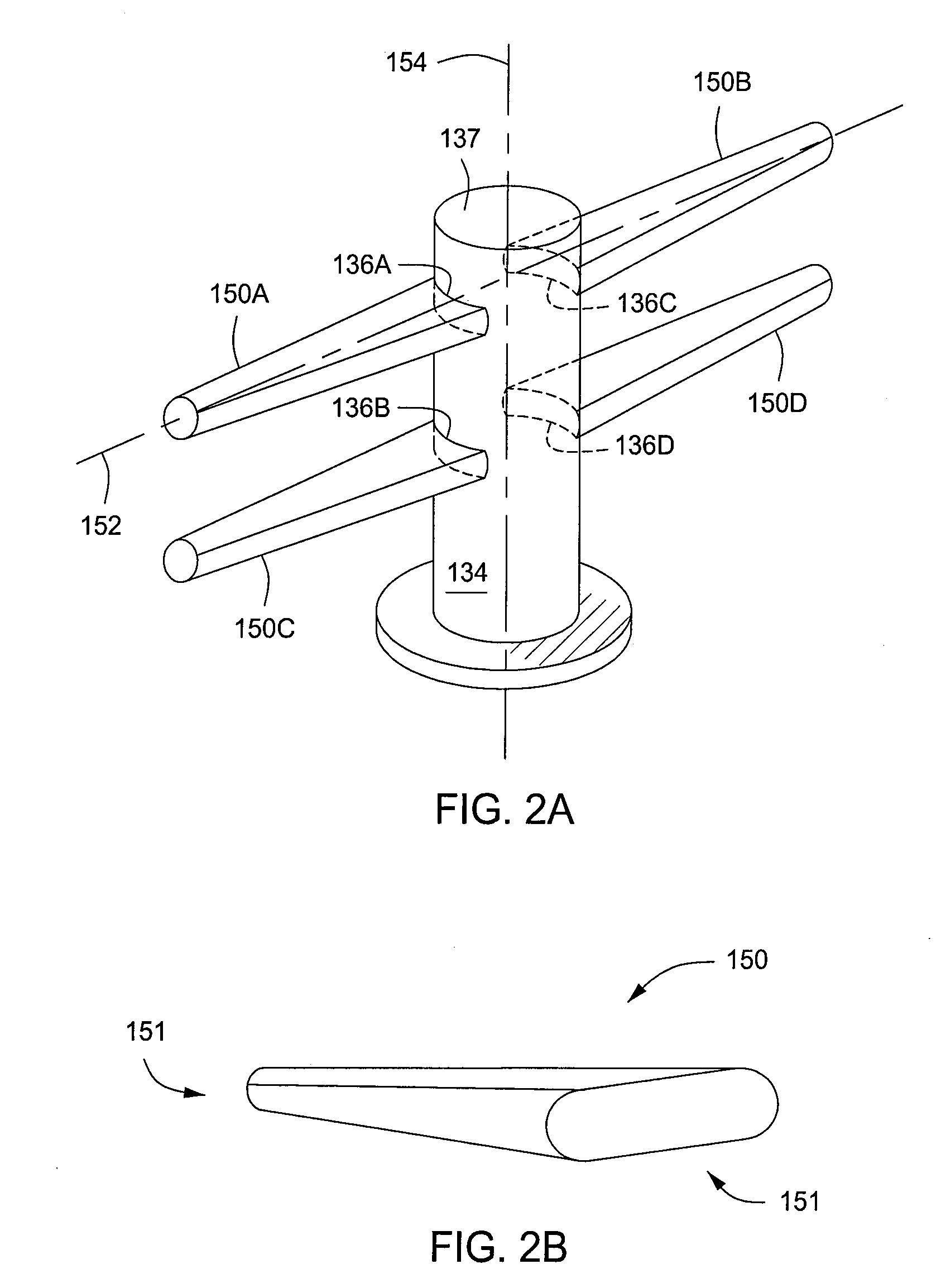

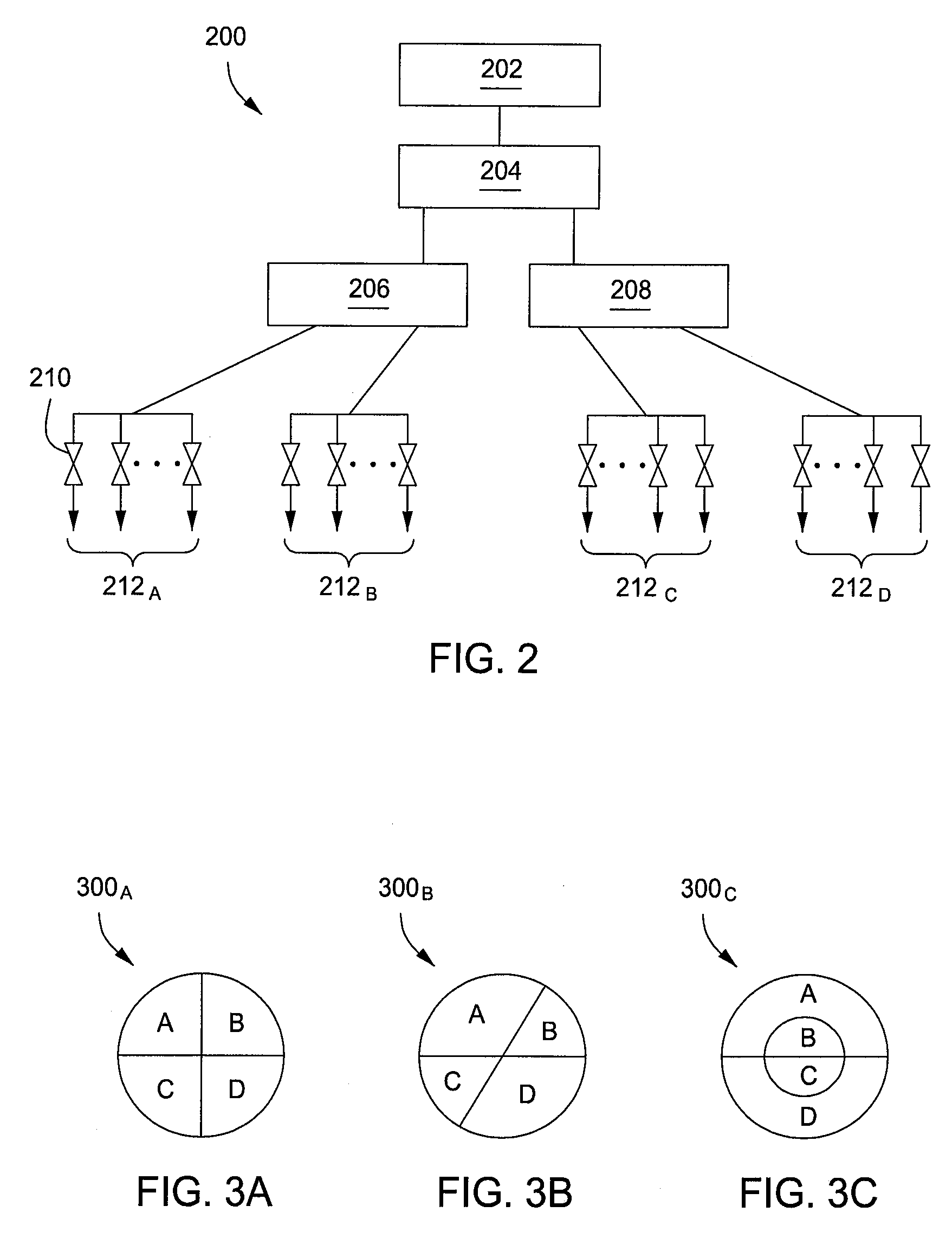

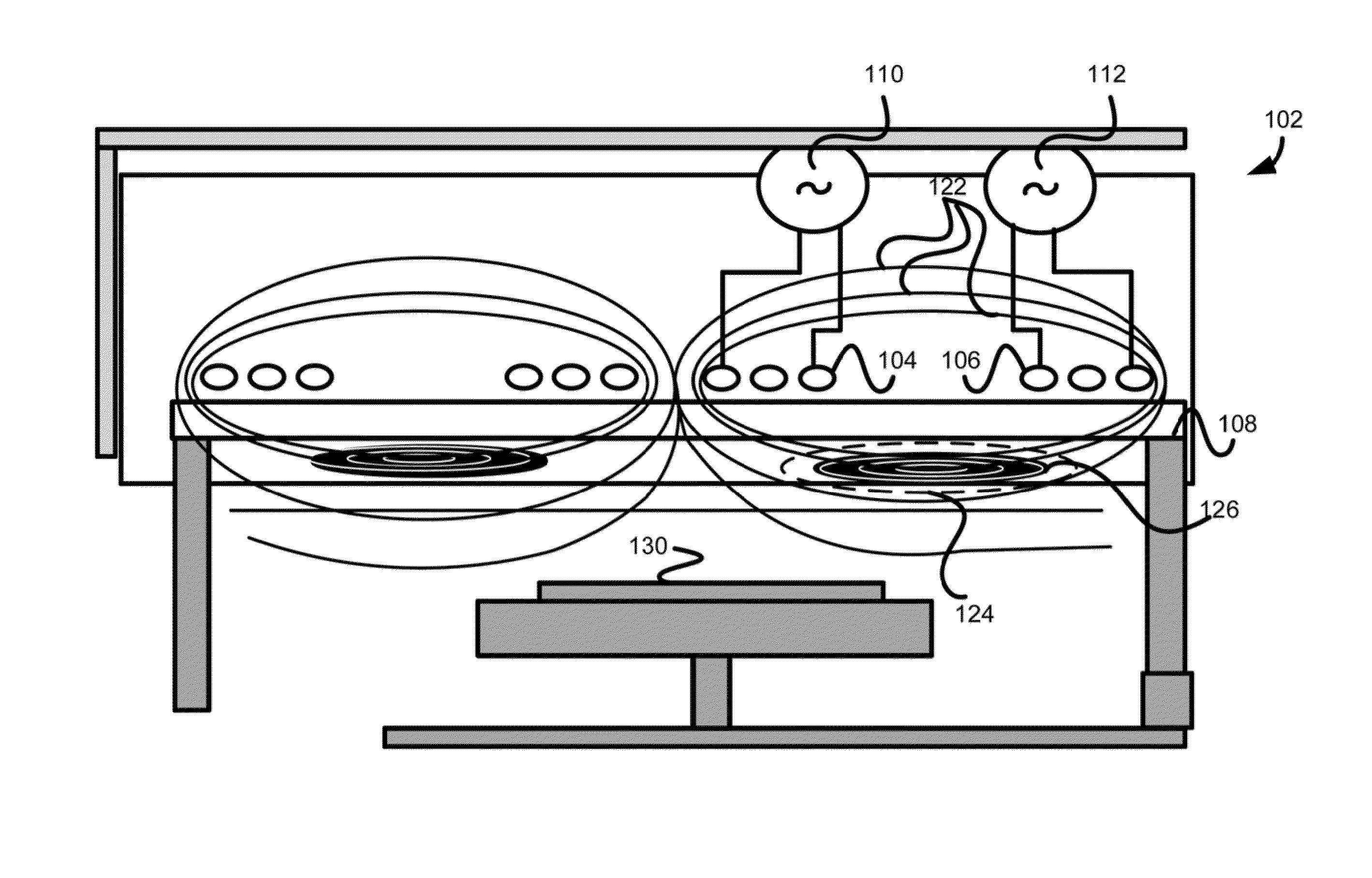

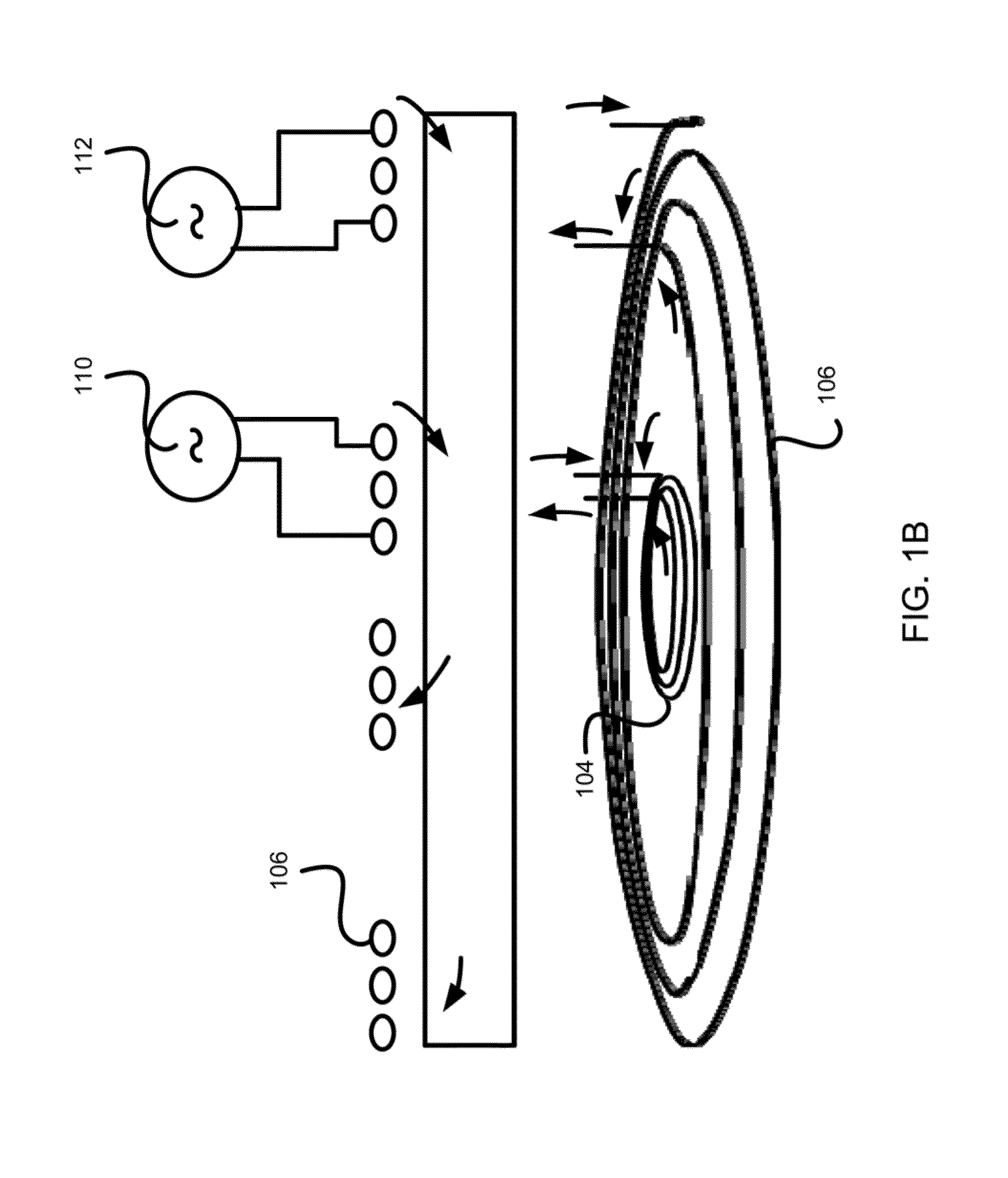

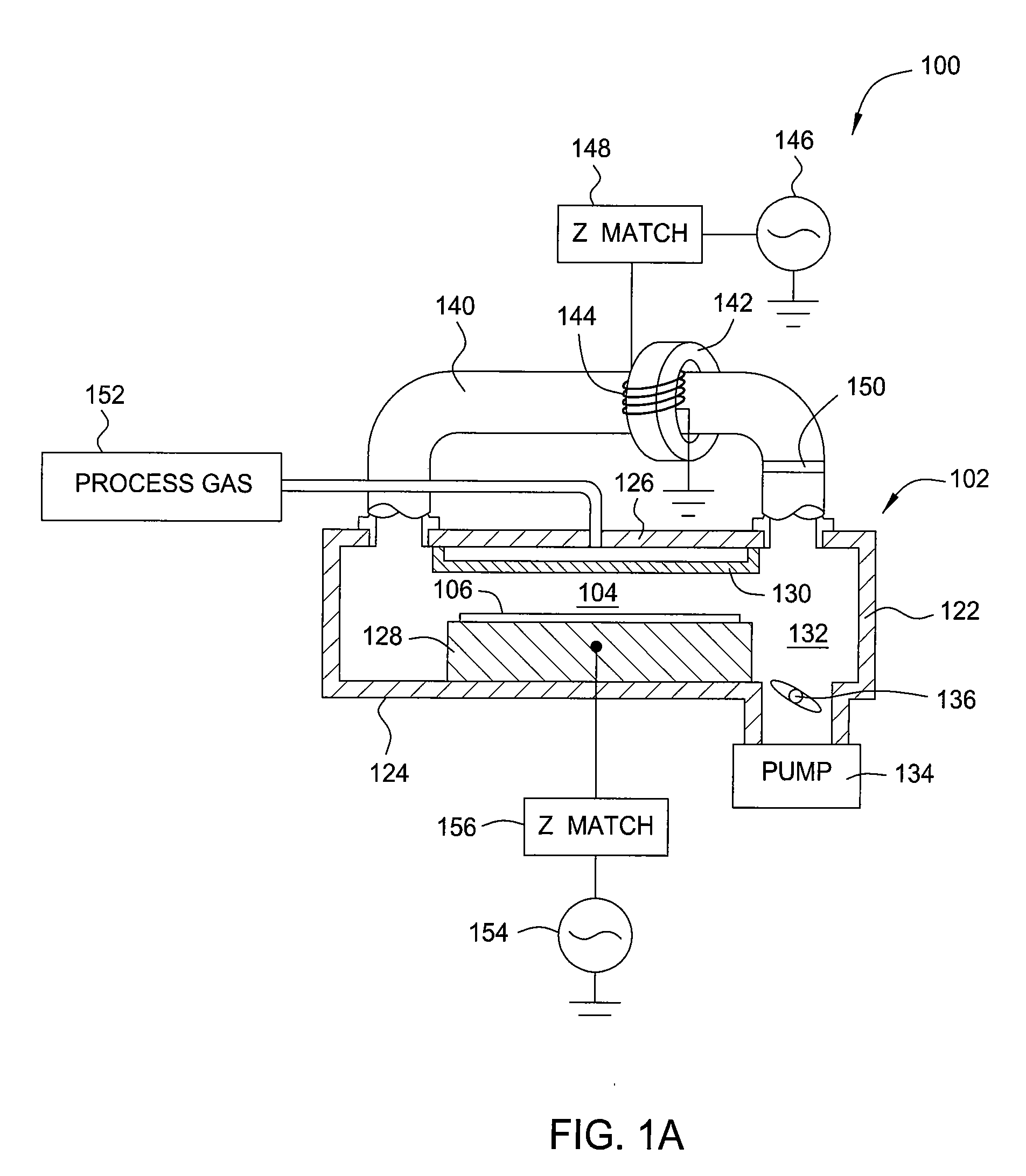

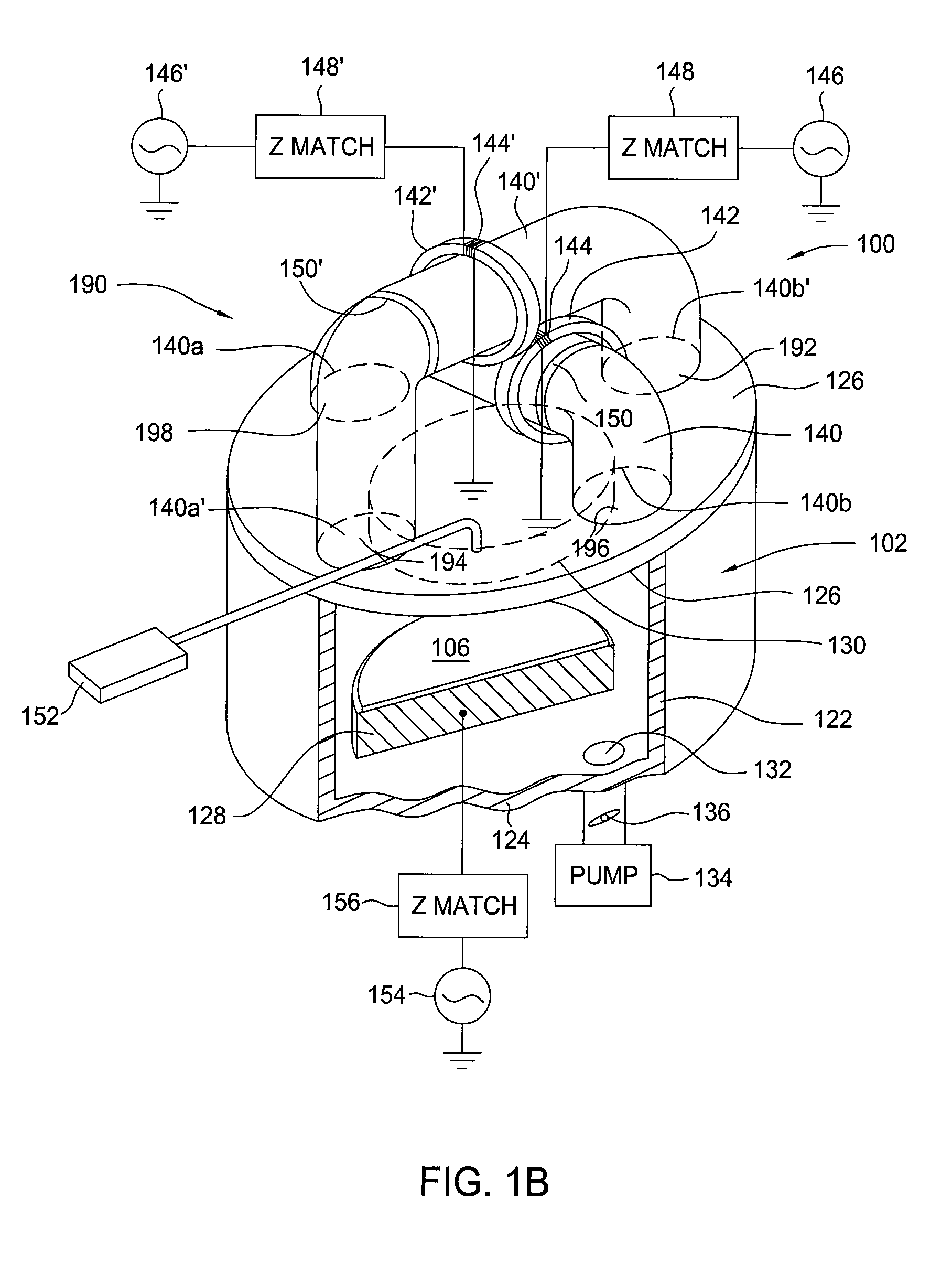

Methods and apparatuses for controlling plasma in a plasma processing chamber

InactiveUS20130256271A1Electric discharge tubesDecorative surface effectsPower flowInductively coupled plasma

Methods and apparatus for controlling plasma in a plasma processing system having at least an inductively coupled plasma (ICP) processing chamber are disclosed. The ICP chamber employs at least a first / center RF coil, a second / edge RF coil disposed concentrically with respect to the first / center RF coil, and a RF coil set having at least a third / mid RF coil disposed concentrically with respect to the first / center RF coil and the second / edge RF coil in a manner such that the third / mid RF coil is disposed in between the first / center RF coil and the second / edge RF coil. During processing, RF currents in the same direction are provided to the first / center RF coil and the second / edge RF coil while RF current in the reverse direction (relative to the direction of the currents provided to the first / center RF coil and the second / edge RF coil) is provided to the third / mid RF coil.

Owner:LAM RES CORP

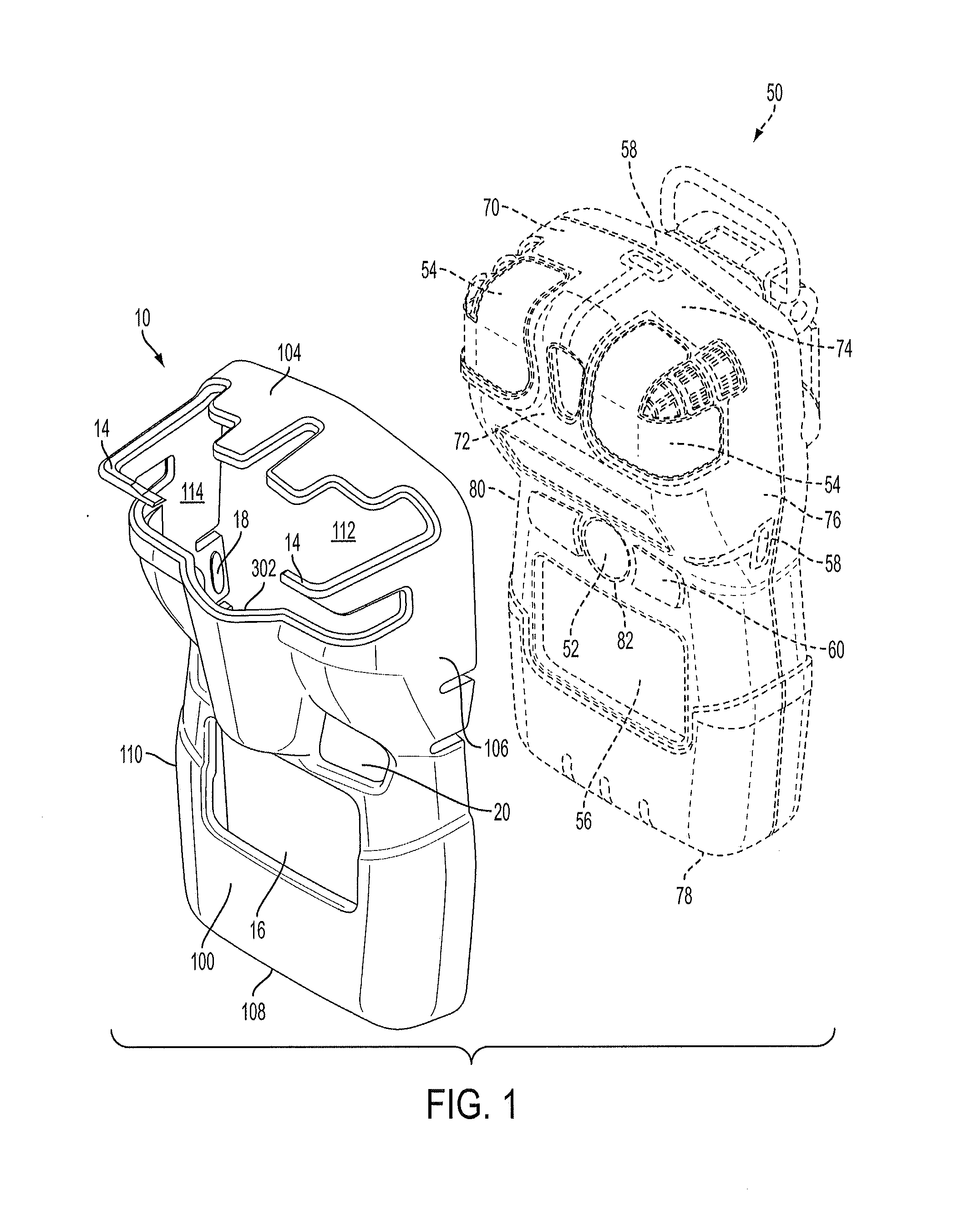

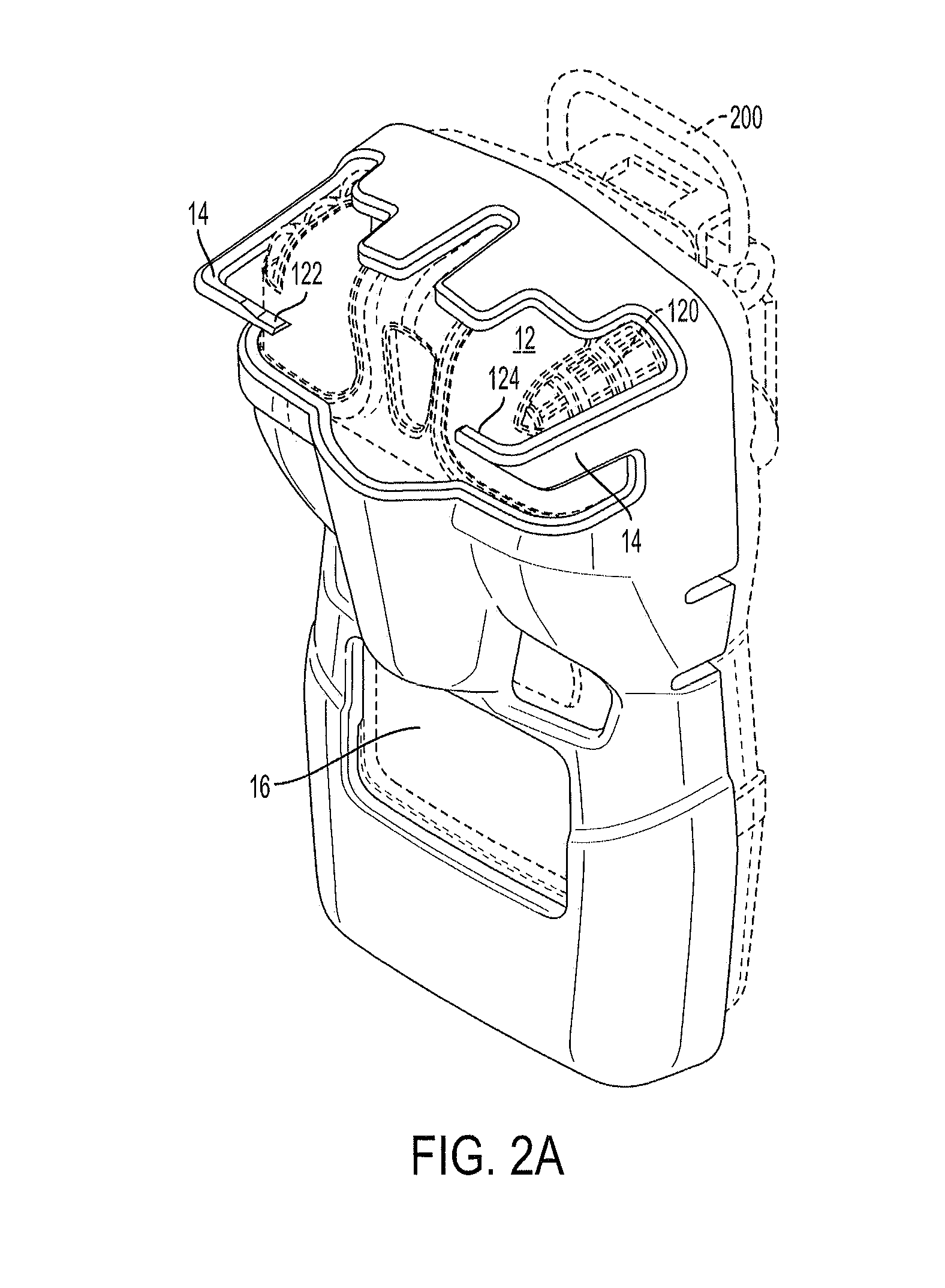

Alarm enhancing protective cover for safety instruments with optional calibration chamber

ActiveUS9064386B2Enhances the audible alarm of the deviceDetect signal easilyGas analyser calibrationAlarmsEngineeringVisual perception

Owner:INDUSTRIAL SCIENTIFIC CORPORATION

Calibration of temperature control system for semiconductor processing chamber

ActiveUS8047706B2Semiconductor/solid-state device testing/measurementThermometers using electric/magnetic elementsTemperature controlGas phase

Methods and systems for calibrating a temperature control system in a vapor deposition chamber. A temperature sensor senses temperature within a semiconductor processing chamber and generates an output signal. A temperature control system controls a chamber temperature by controlling a heating apparatus based on the output signal. A method includes instructing the control system to target a setpoint temperature, and depositing a layer of material onto a surface in the chamber by a vapor deposition process. A variation of a property of the layer is measured while depositing the layer, the property known to vary cyclically as a thickness of the layer increases. The measured property is allowed to vary cyclically for one or more cycles. If there is a difference between a time period of one or more of the cycles and an expected time period associated with the setpoint temperature, the temperature control system is adjusted based on the difference.

Owner:ASM IP HLDG BV

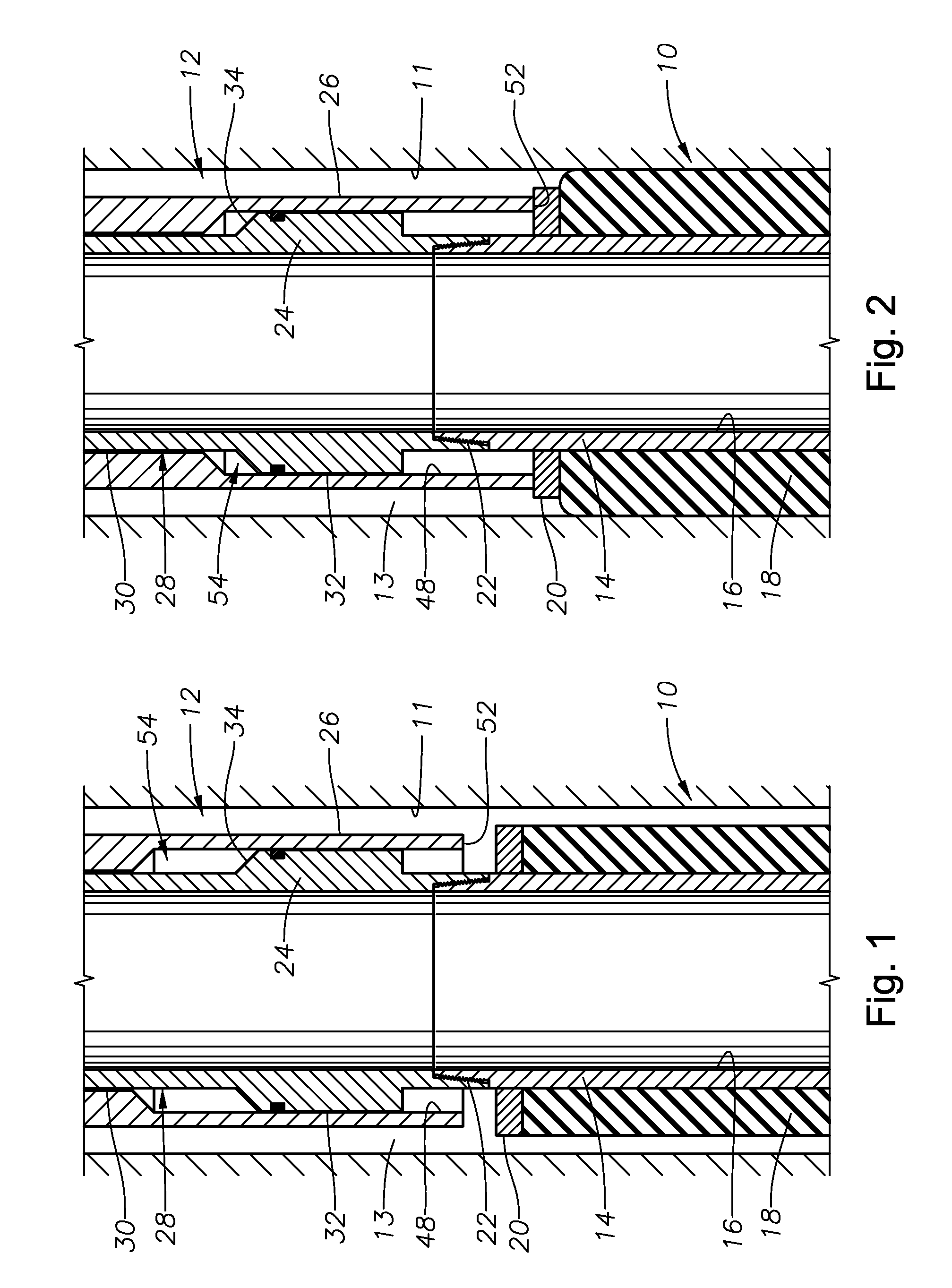

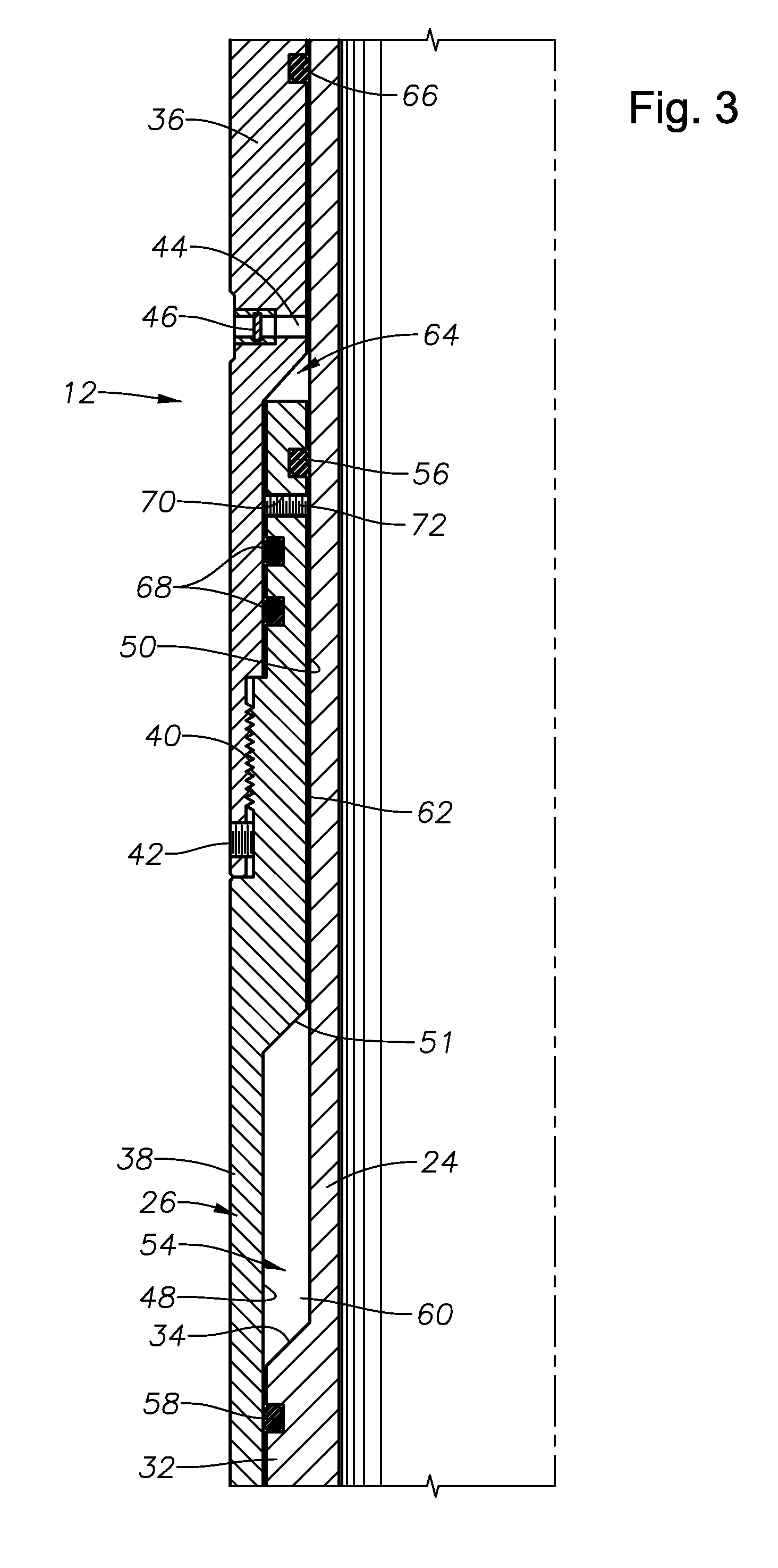

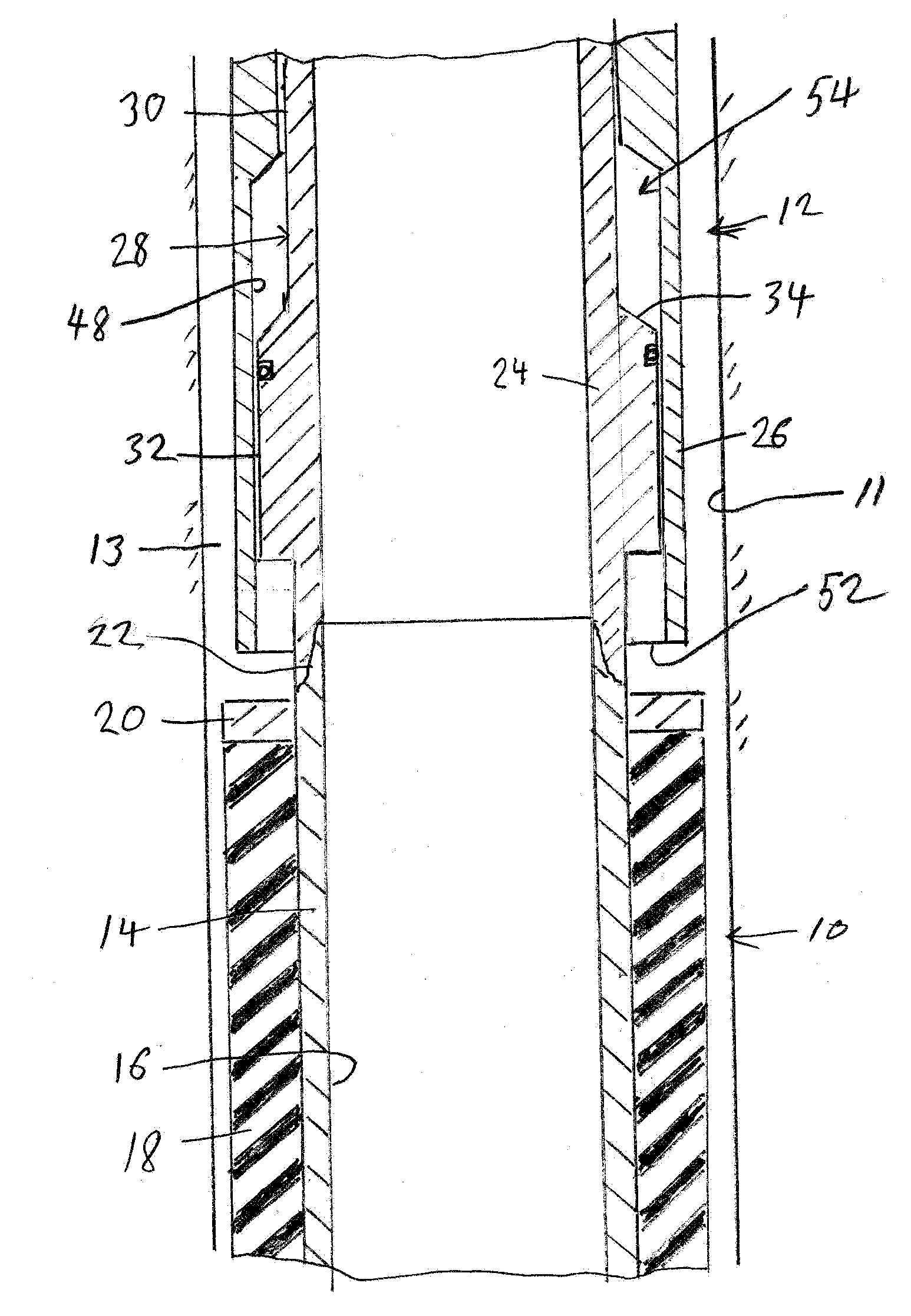

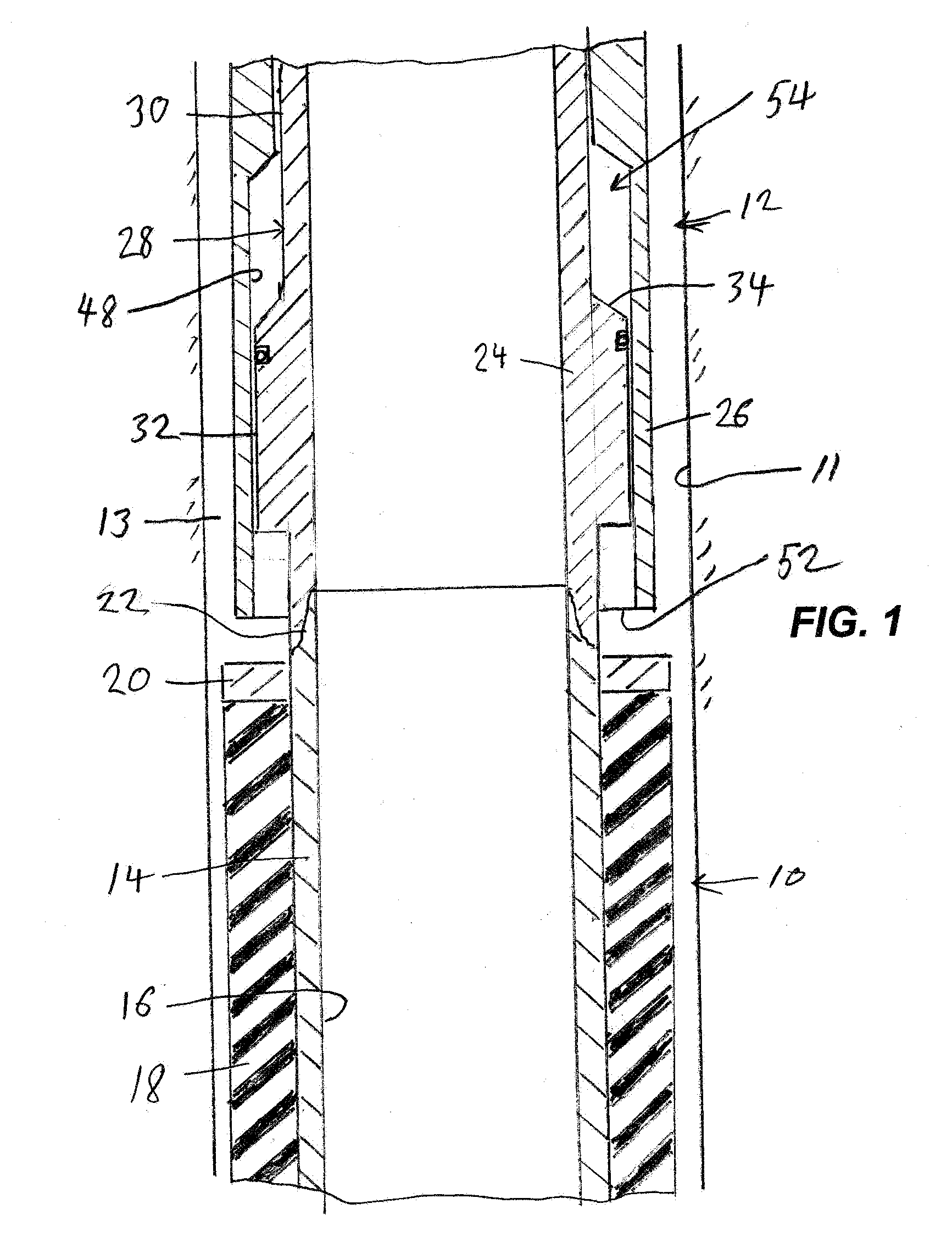

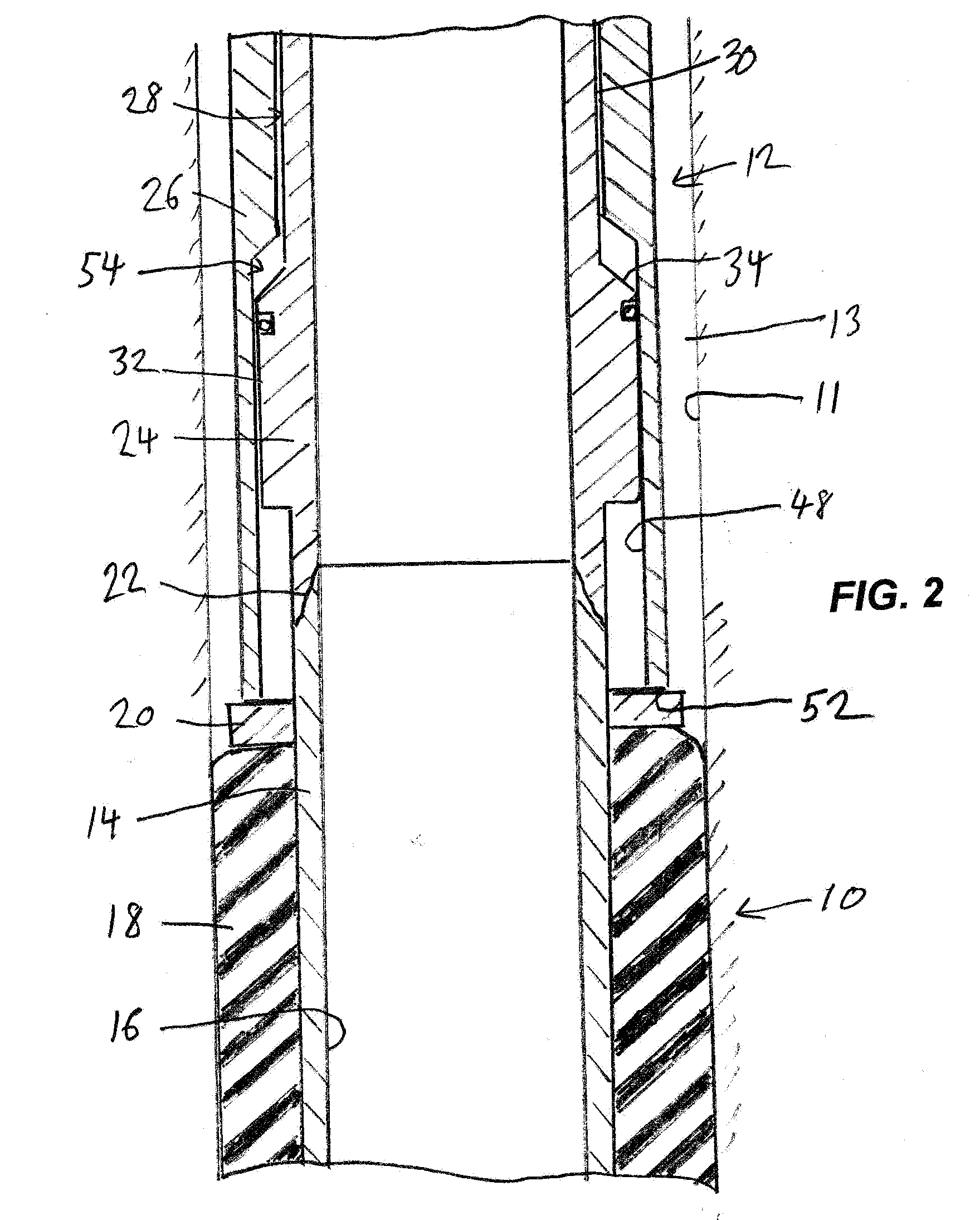

Controlled pressure equalization of atmospheric chambers

ActiveUS7913770B2Quick compressionFluid removalWell/borehole valve arrangementsControl mannerEngineering

Methods and devices for equalizing an atmospheric chamber within a well tool in a controlled manner following the operation of setting the well tool. A packer setting tool has a setting mechanism with an atmospheric chamber and an equalization assembly to permit the pressure differential between the atmospheric chamber and the surrounding annulus to be substantially equalized.

Owner:BAKER HUGHES INC

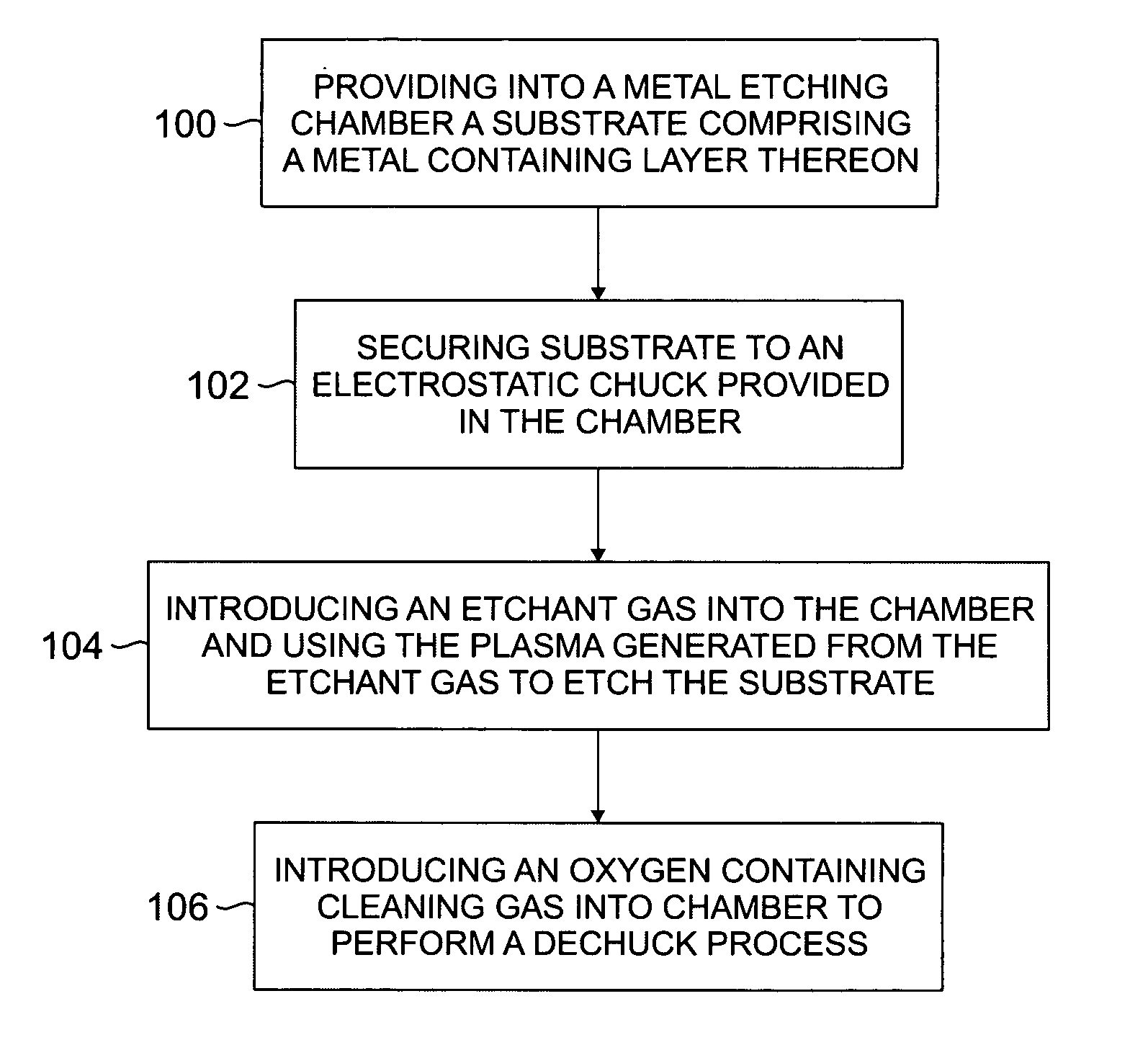

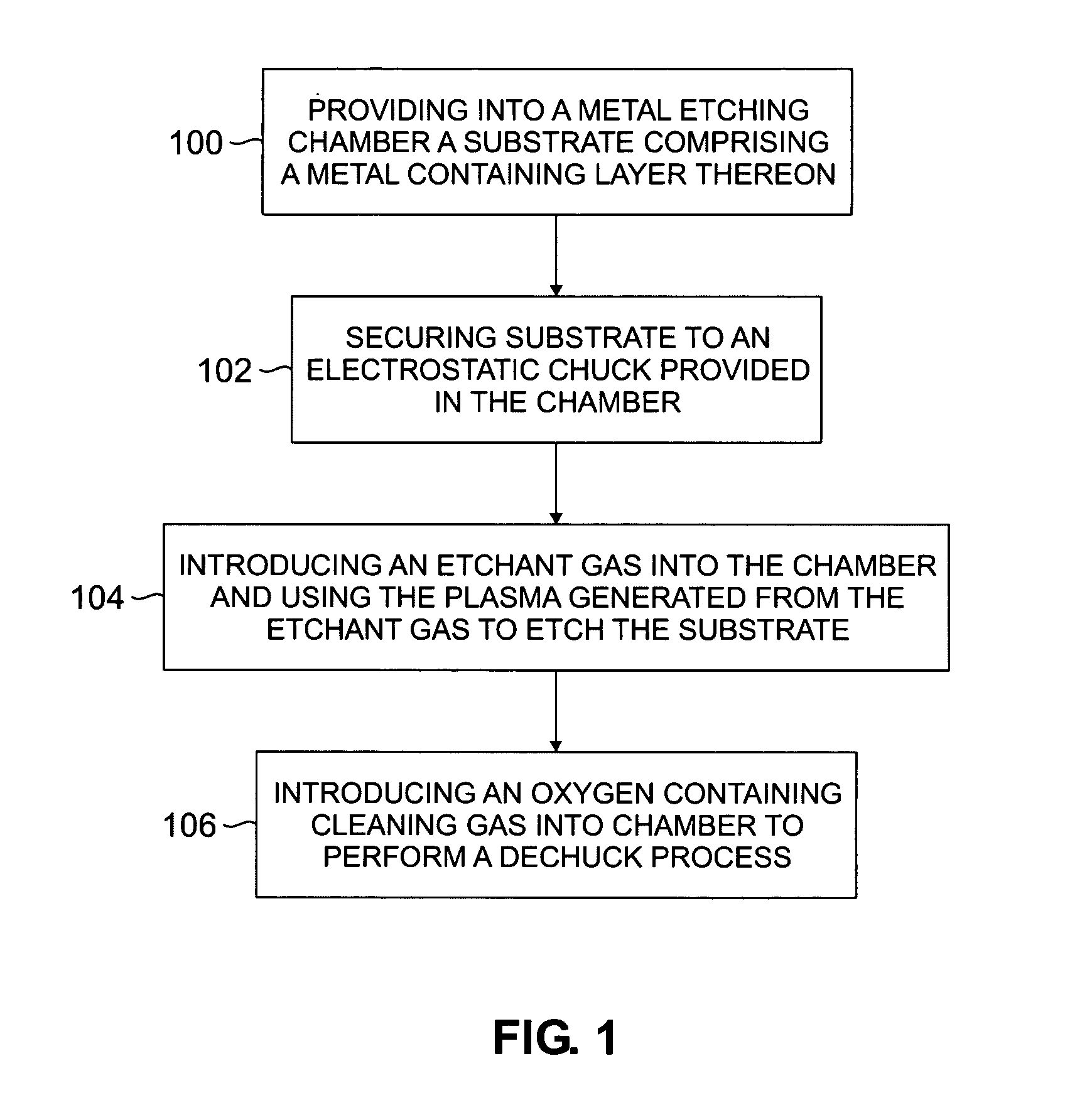

Methods for cleaning processing chambers

InactiveUS20050066994A1Diminish wasted production timeEnhances sidewall polymer removalElectric discharge tubesHollow article cleaningEngineeringOxygen

Methods for metal etching substrates in IC manufacturing, and methods for cleaning processing chamber and substrates are disclosed herein. The disclosed methods reduce the frequency of conventional wet-cleaning processes that must be periodically conducted to clean etchant residues accumulated on the walls of the processing chamber. In an exemplified embodiment, the subject methods utilize an oxygen-containing gas during the dechuck process which reacts with, softens, burns and / or removes etchant residue present on the chamber walls and substrate.

Owner:AGERE SYST INC

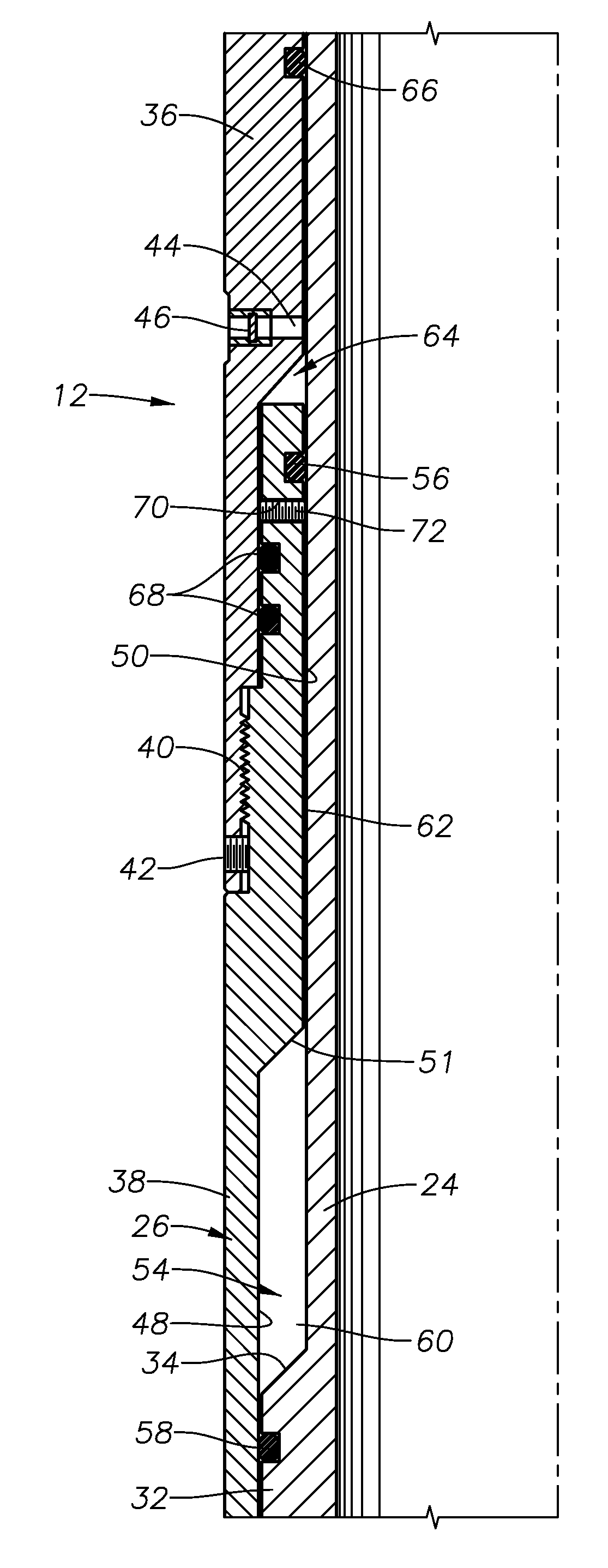

Controlled Pressure Equalization of Atmospheric Chambers

ActiveUS20090321081A1Quick compressionIncrease the length of timeFluid removalWell/borehole valve arrangementsControl mannerEngineering

Methods and devices for equalizing an atmospheric chamber within a well tool in a controlled manner following the operation of setting the well tool. A packer setting tool is described having a setting mechanism with an atmospheric chamber and an equalization assembly to permit the pressure differential between the atmospheric chamber and the surrounding annulus to be substantially equalized.

Owner:BAKER HUGHES INC

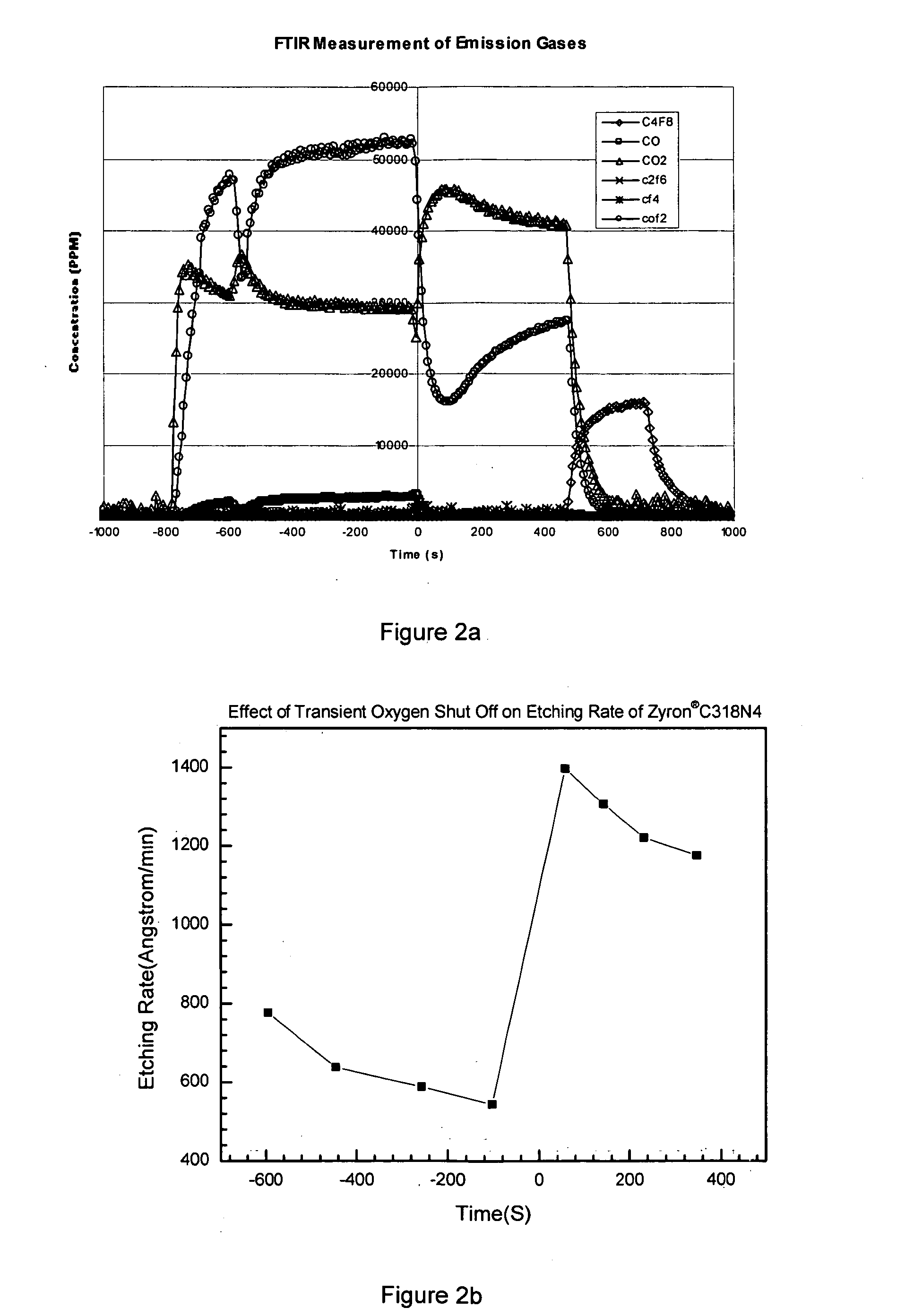

Remote chamber methods for removing surface deposits

InactiveUS20050258137A1Decorative surface effectsSemiconductor/solid-state device manufacturingNeutral temperatureRemote plasma

The present invention relates to an improved remote plasma cleaning method for removing surface deposits from a surface, such as the interior of a deposition chamber that is used in fabricating electronic devices. The improvement involves using an activated gas with high neutral temperature of at least about 3,000 K. The improvement also involves optimizing oxygen to fluorocarbon ratios for better etching rates and emission gas control.

Owner:MASSACHUSETTS INST OF TECH

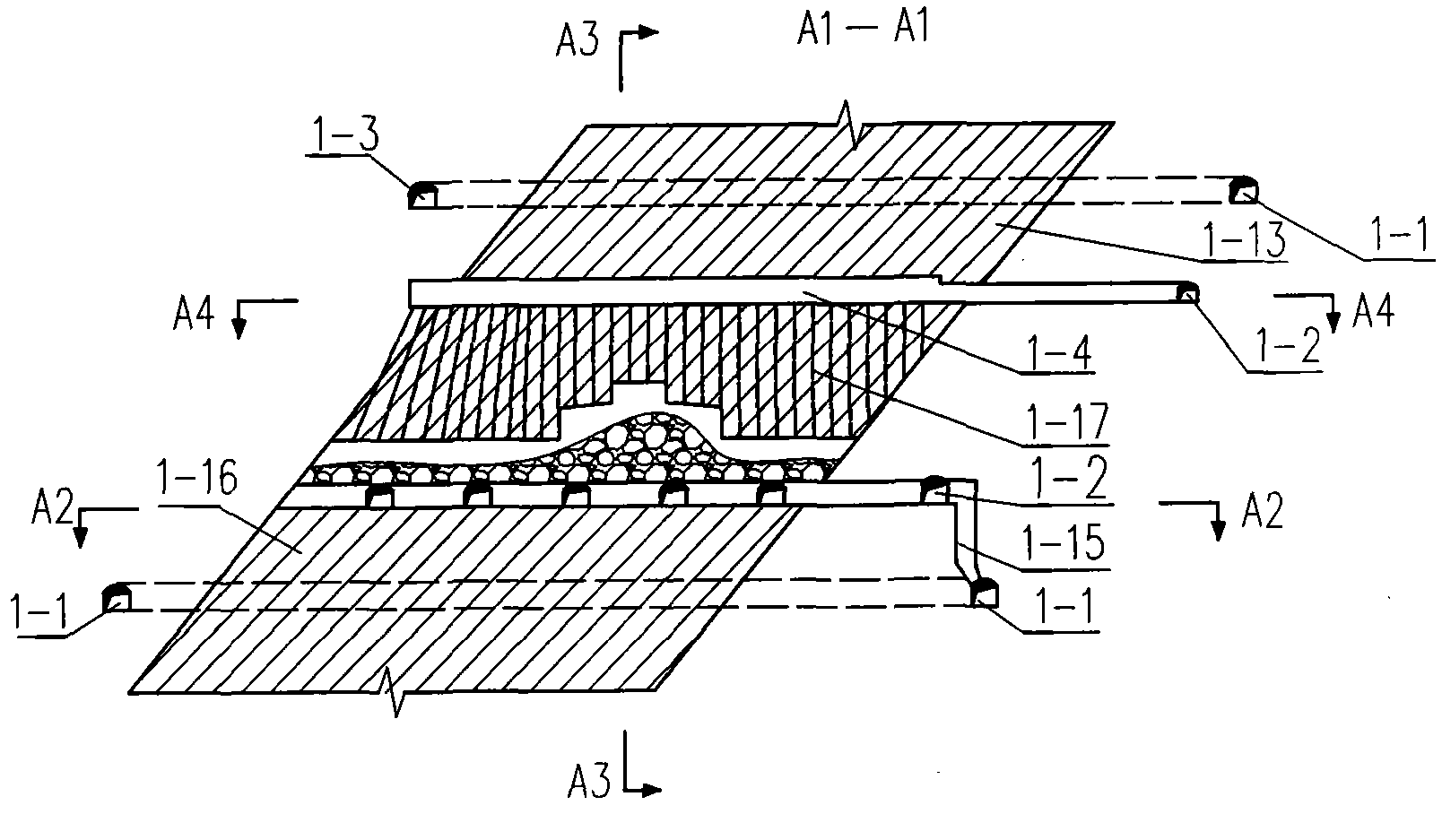

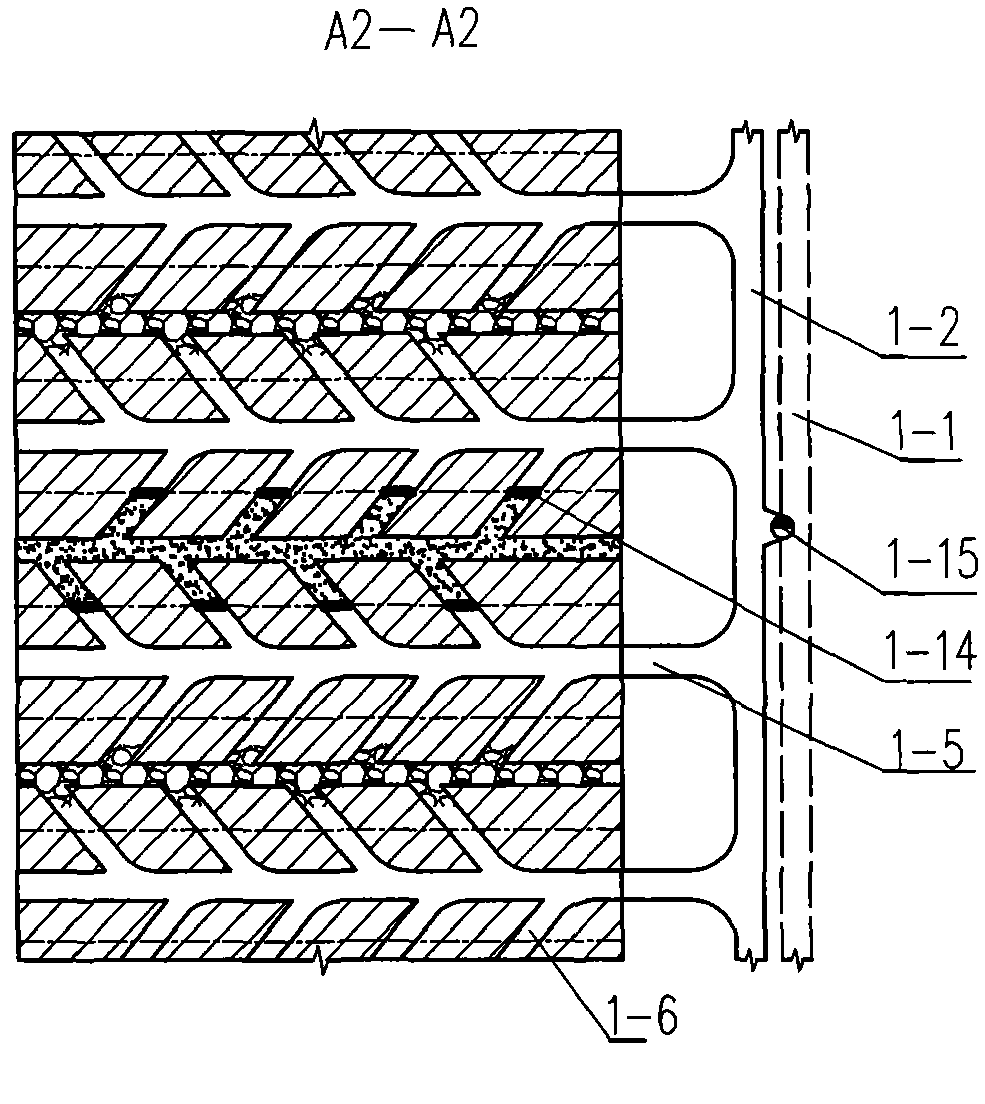

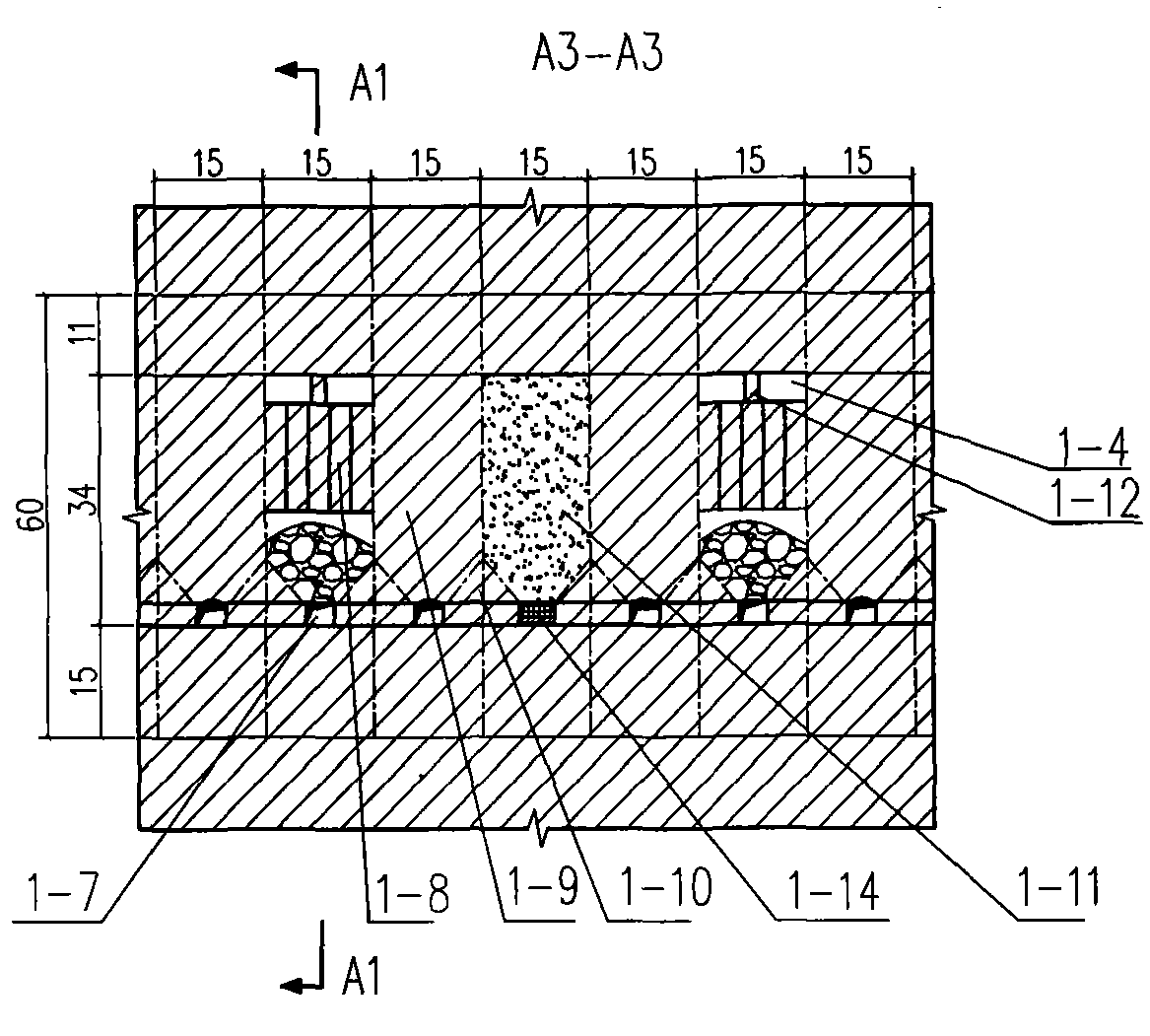

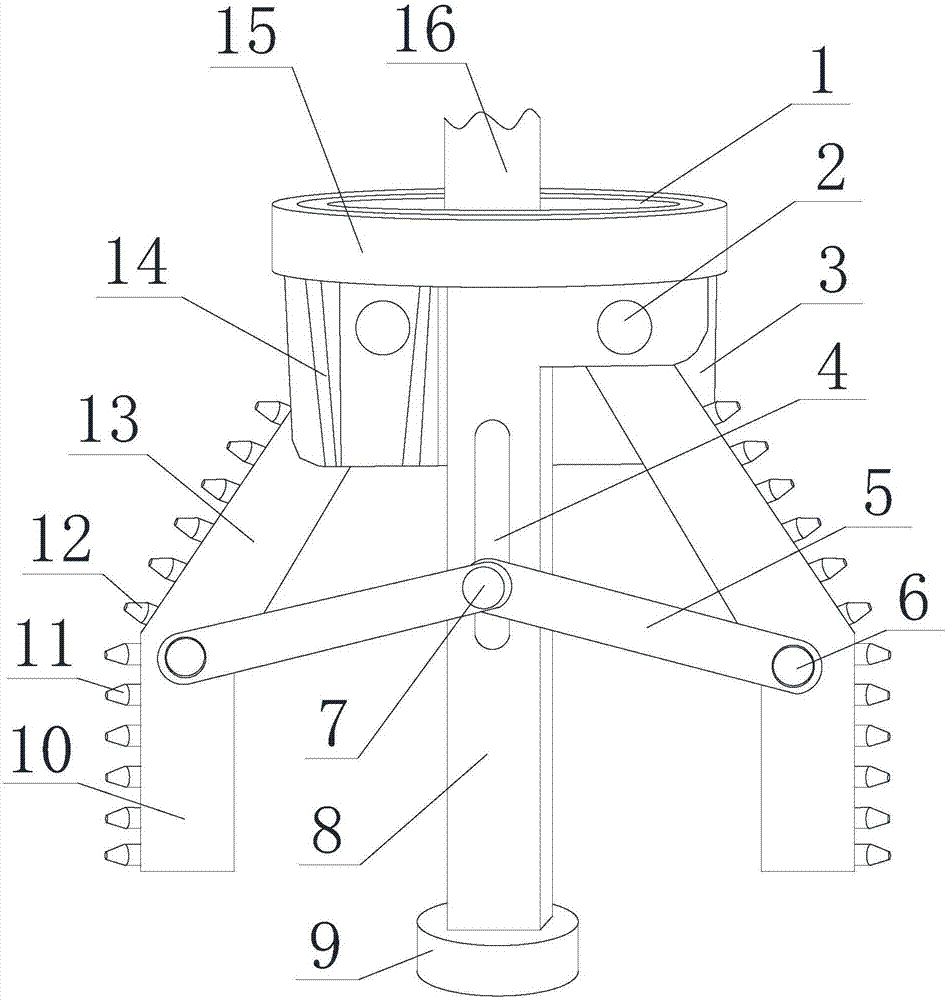

Chambering method of chambering equipment on construction site

InactiveCN106869797AImprove stabilityReduce the reducing rangeDrill bitsDrilling without earth removalEngineeringChamber method

The invention discloses a hole reaming method for hole reaming equipment on a construction site. A connecting rod is gradually lowered under the action of a power mechanism, the connecting arm rotates around the pin shaft 2 and the pin shaft 1, and the scraping mechanism rotates around the connecting pin, so that The connecting arm is horizontal, and the reaming equipment rotates around its axis, so that the scraping teeth scrape the wall of the original pile hole. After the scraping mechanism is expanded to the maximum state, the hole formed by scraping is formed; the connecting rod is gradually raised by the action of the power mechanism. The connecting arm rotates around pin 2 and pin 1, and the scraping mechanism rotates around the connecting pin, so that the connecting arm tilts from the horizontal state, and the scraping mechanism shrinks to the minimum state; the reaming equipment is pulled out along the original pile hole to the hole outside. The diameter of the hole expanded by this reaming method is high in longitudinal depth, and the diameter reduction range at the bottom of the hole and the original diameter of the pile hole is reduced, so that the bearing force after grouting is increased, the stability of the upper building can be maintained, and the reaming efficiency is high. And it can protect the security of the equipment.

Owner:CHINA MCC5 GROUP CORP

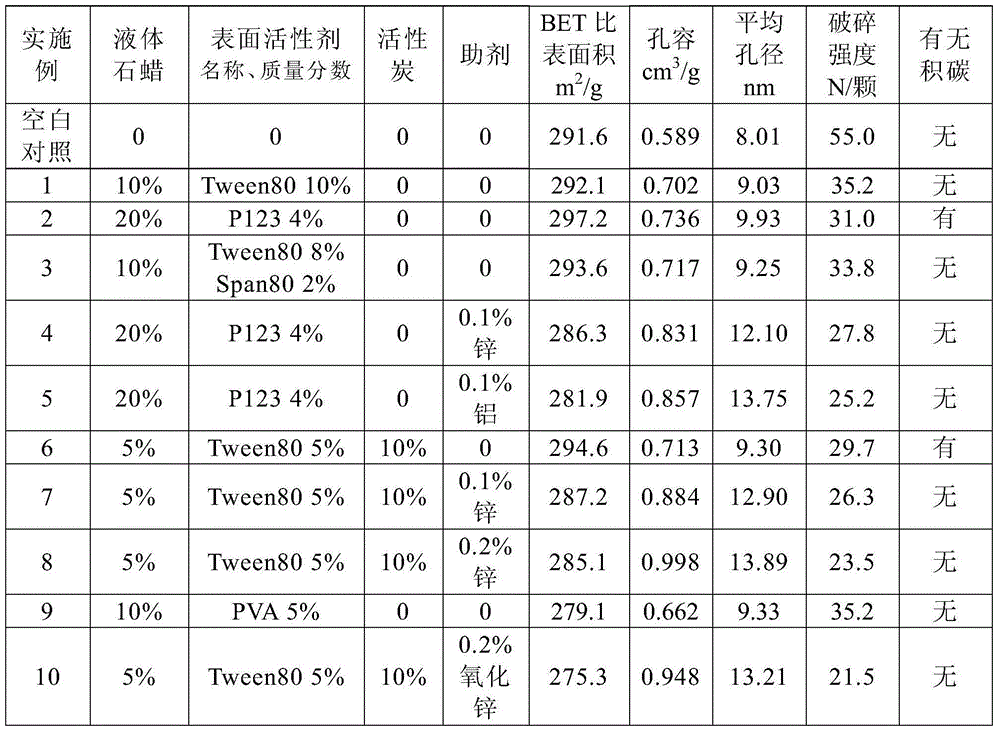

Chambering method for spherical aluminum oxide particles

ActiveCN104891539ASolve the problem of incomplete combustion of carbon depositsExcellent hole expandabilityAluminium oxides/hydroxidesParaffin waxAdjuvant

The invention discloses a chambering method for spherical aluminum oxide particles. The method comprises the following steps of: dispersing pseudo-boehmite powder by adding water to obtain pseudo-boehmite turbid liquid; adding liquid paraffin, a surfactant and active carbon into the pseudo-boehmite turbid liquid and performing homogenizing emulsification to form emulsified turbid liquid, wherein the mass ratio of the liquid paraffin to the pseudo-boehmite is 0.02-0.2, the mass ratio of the surfactant to the liquid paraffin is 0.2-1, and the mass ratio of the active carbon to the pseudo-boehmite is 0-0.1; adding an adjuvant, in an amount which is 0.1 to 0.5 percent of the mass of the pseudo-boehmite, into the emulsified turbid liquid and performing homogenizing dispersion; after performing homogenizing dispersion, adding soluble alginate aqueous solution at the mass concentration of 1.5 to 4.0% into the emulsified turbid liquid to prepare suspension pulp; dropwise adding the suspension pulp into aqueous solution of aluminum, calcium, barium, copper, zinc, manganese or cobalt metal ion at the concentration of 0.1 to 2.0 mol / L and treating for 10 to 120 min to obtain formed spheres; and drying and roasting to obtain the products. The method provided by the invention has the advantages that dispersibility is high; carbon deposition is low; and the prepared spherical aluminum oxide has high average aperture and specific surface area.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Alarm enhancing proective cover for safety instruments with optional calibration chamber

ActiveUS20140091939A1Detect signal easilyIncrease awarenessSubstation equipmentGas analyser calibrationEngineeringVisual perception

Owner:INDUSTRIAL SCIENTIFIC CORPORATION

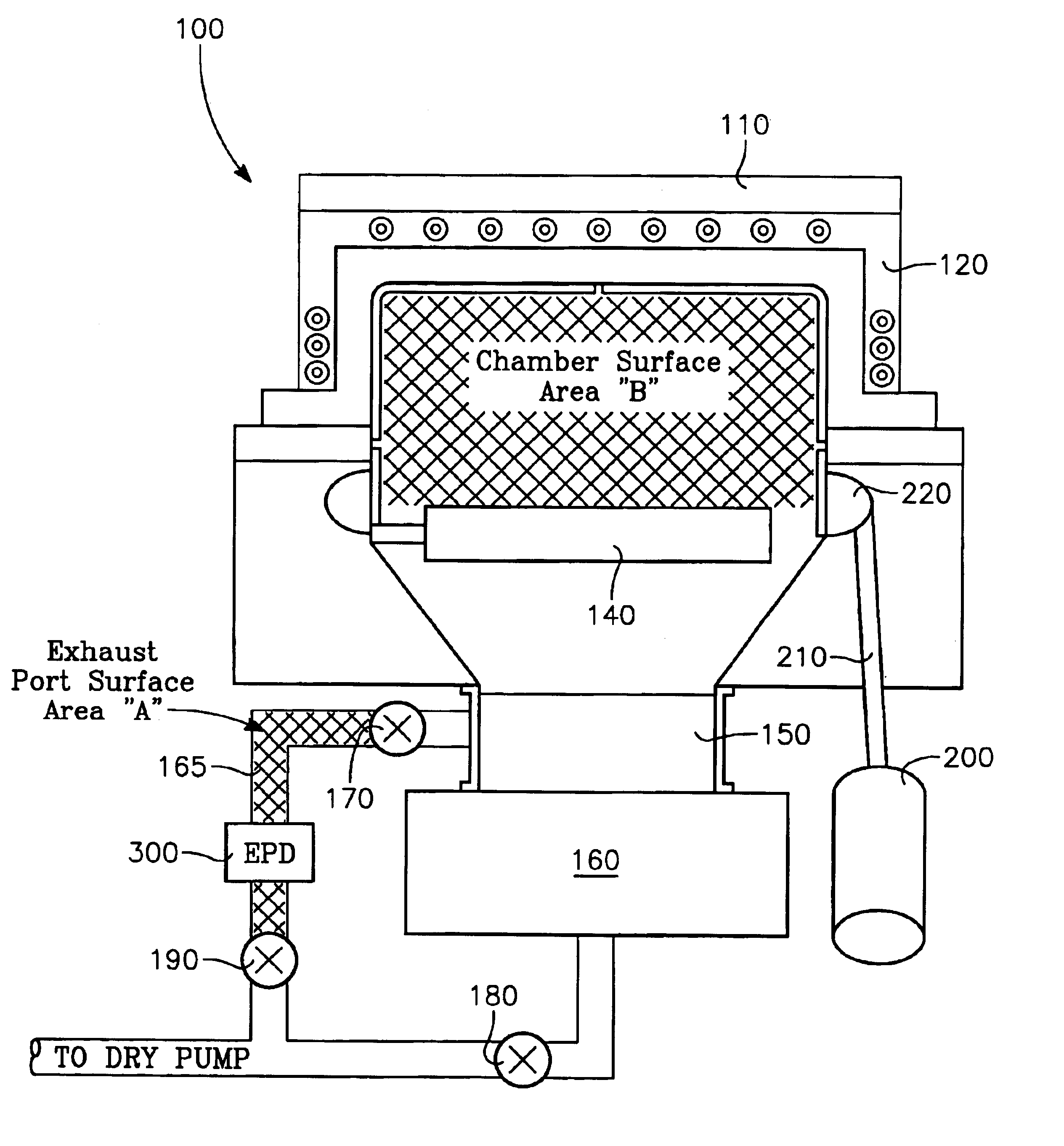

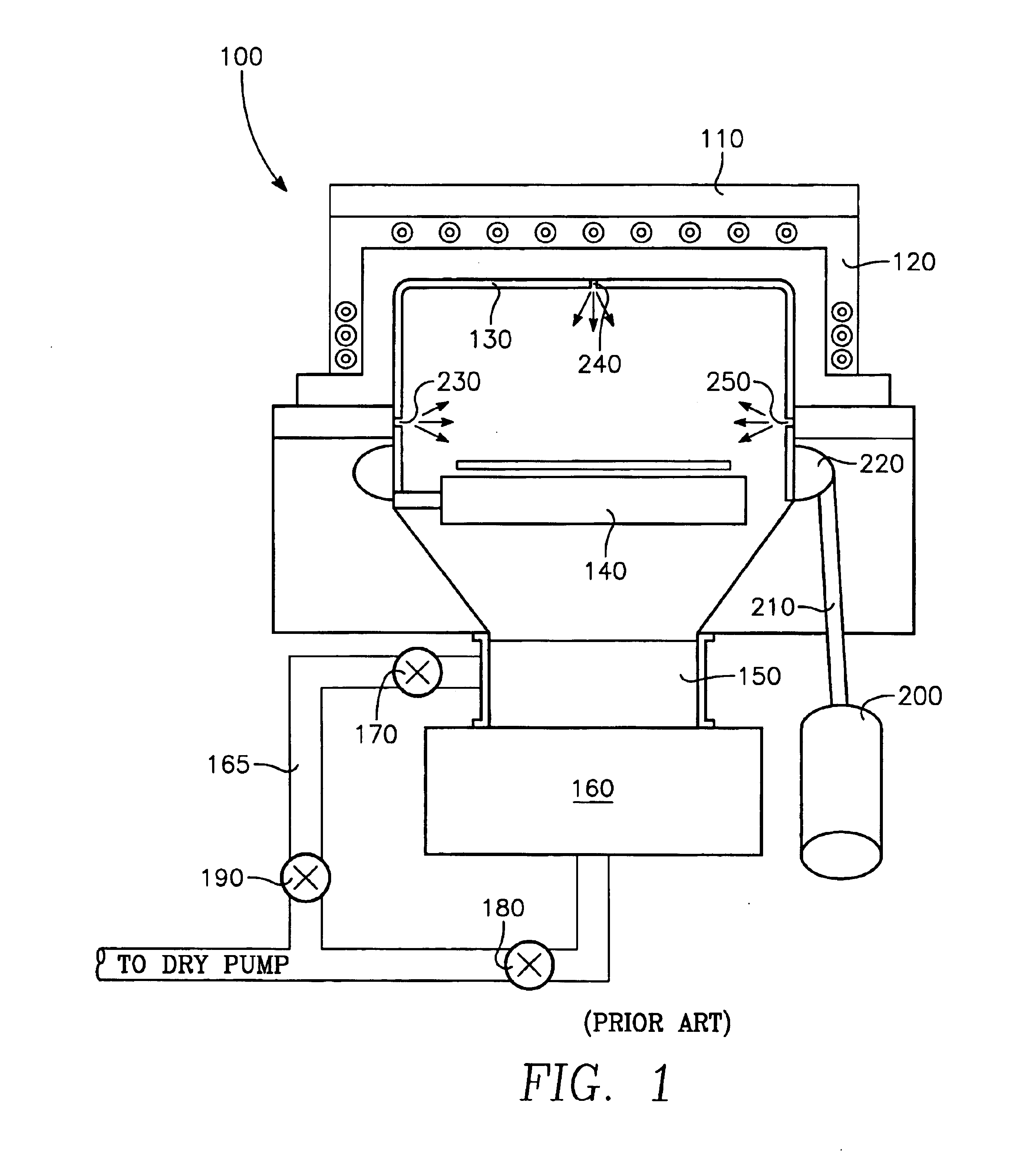

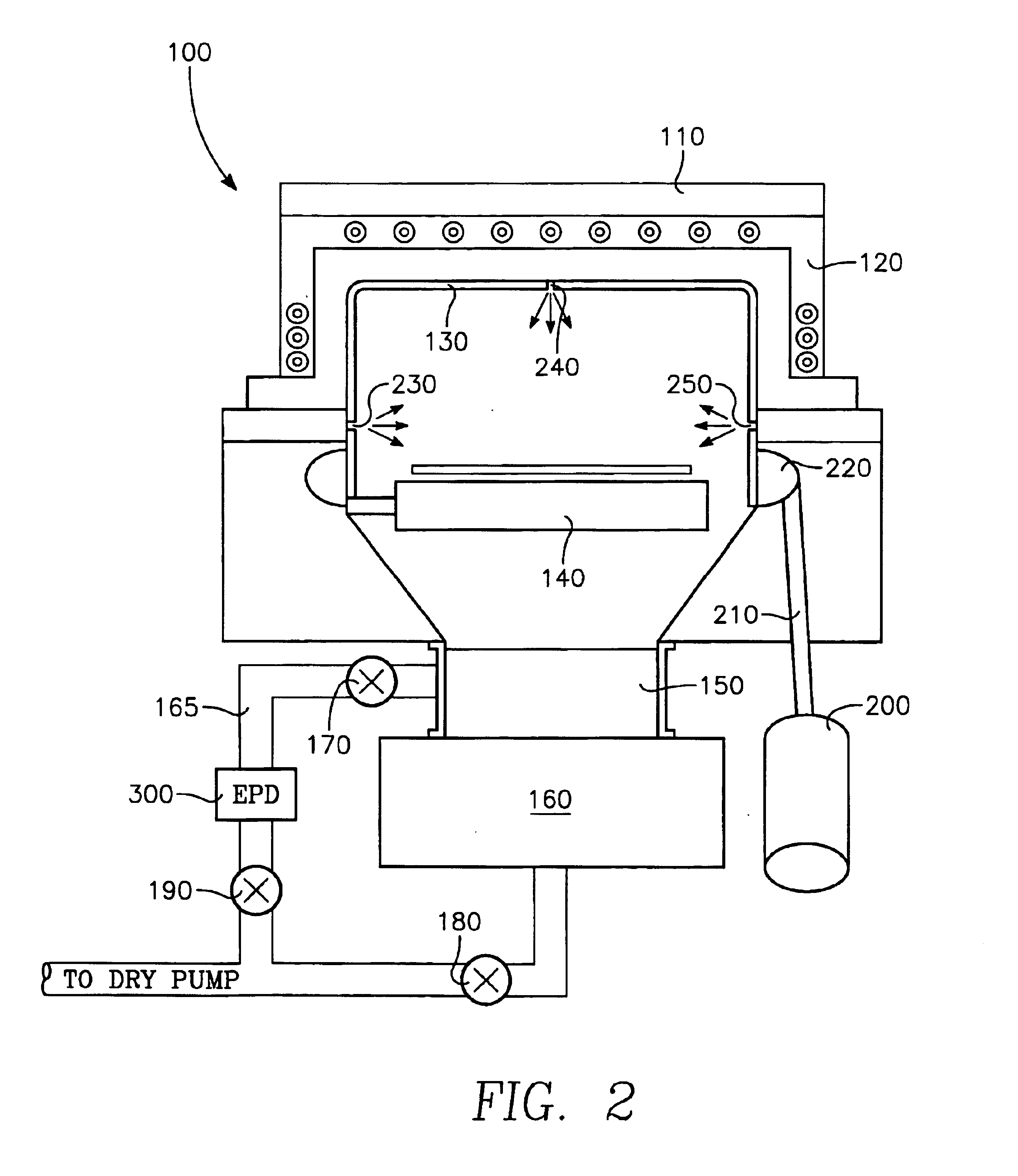

Process endpoint detection in processing chambers

InactiveUS6878214B2Semiconductor/solid-state device testing/measurementElectric discharge tubesEngineeringDirect radiation

Method and apparatus for determining an endpoint of a cleaning process running in a chamber. In particular, one embodiment of the present invention is a method that includes steps of: (a) directing radiation absorbed by a byproduct of the cleaning process into an exhaust line of the chamber; (b) detecting a measure of absorbance of the radiation by the byproduct; and (c) determining the endpoint when the measure of absorbance falls within a predetermined window.

Owner:APPLIED MATERIALS INC

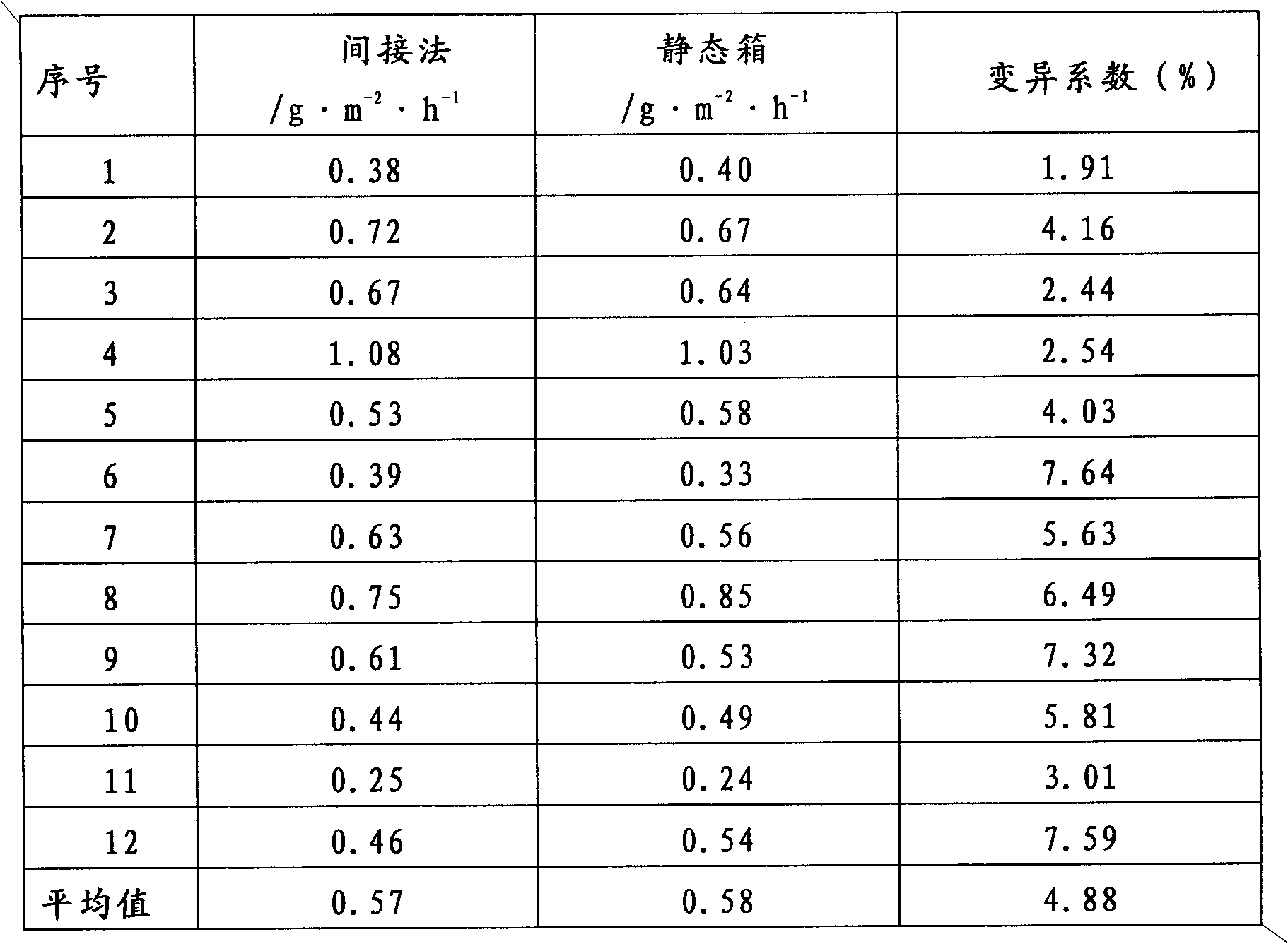

Indirect determination method of forest soil respiration

The invention relates to an indirect determination method of forest soil respiration, which comprises the following five steps: 1) selecting sample points; 2) sampling soil samples; 3) determining the content of dissolved organic carbon (DOC) in soil; 4) establishing the linear relation, wherein the linear relation functional expression between the soil respiration and the DOC is that: Y is equal to 0.003X plus 0.1266; and 5) actually measuring the forest soil respiration quantity, substituting the content of the DOC (unit: mg / kg) in the forest soil to be measured into the functional expression in the step 4) as X, and calculating Y which is the quantity of carbon dioxide released from the soil respiration, wherein the unit is g / m<2> / h. The method can calculate the forest soil respiration quantity by determining the dissolved organic carbon in the soil; compared with the static chamber method, the method can reduce the field workload, reduce the determination cost, be capable of carrying out batch analysis, improve the determination working efficiency, realize a small range of numerical errors and have good reliability.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method of improving vacuum quality in semiconductor processing chambers

Methods of removing gaseous phase contaminants from a processing chamber, such as a PVD chamber, are provided. In one aspect, a method of removing gaseous phase water from a processing chamber is provided that includes placing a heated substrate that has a titanium film in the processing chamber to dissociate a first portion of the gaseous phase water into hydrogen and oxygen and capture some of the oxygen in, the titanium film. The dissociated hydrogen and uncaptured oxygen are pumped from the processing chamber and the substrate is removed from the processing chamber. Pump down times and test wafer consumption may be reduced.

Owner:GLOBALFOUNDRIES INC

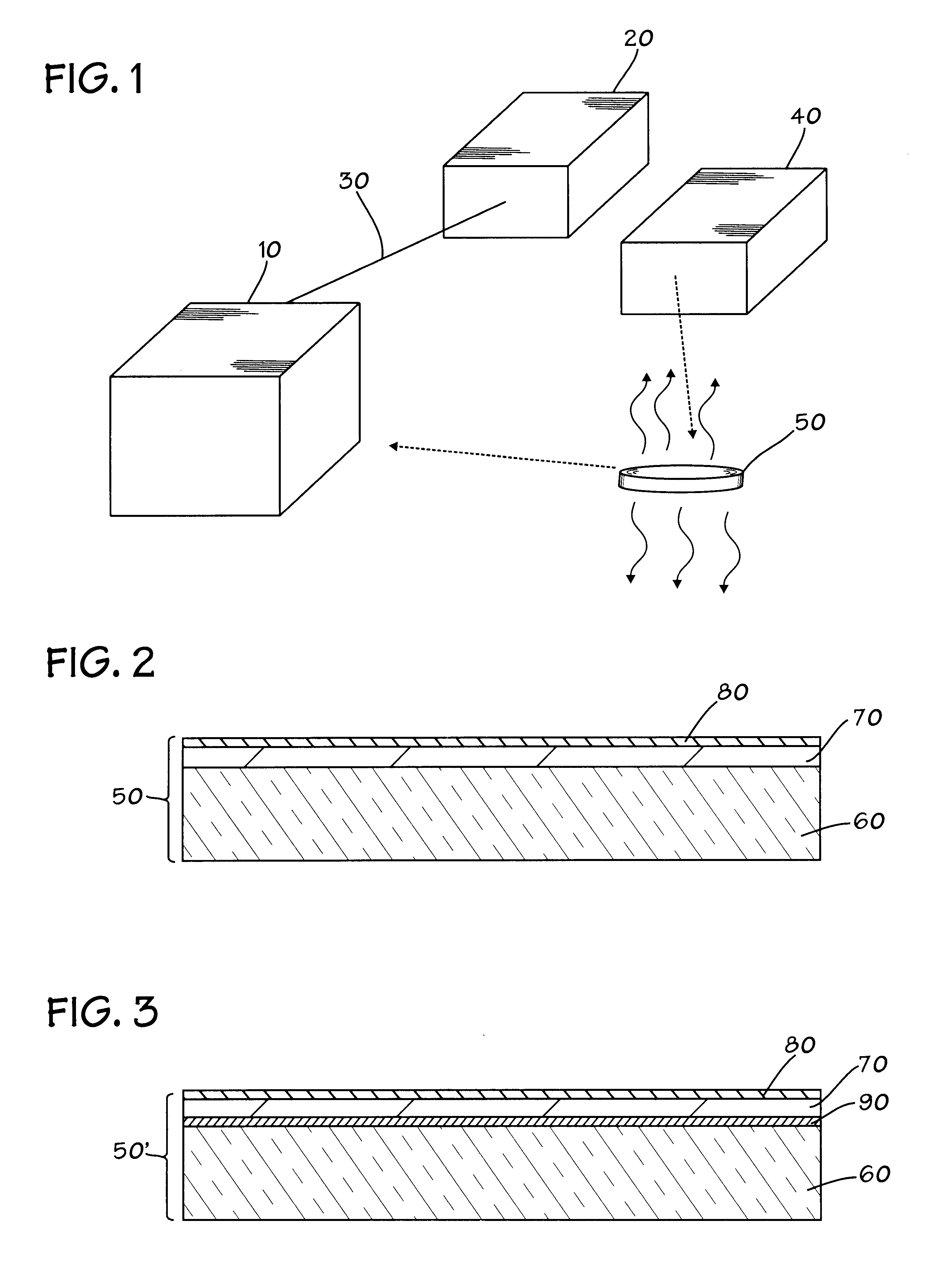

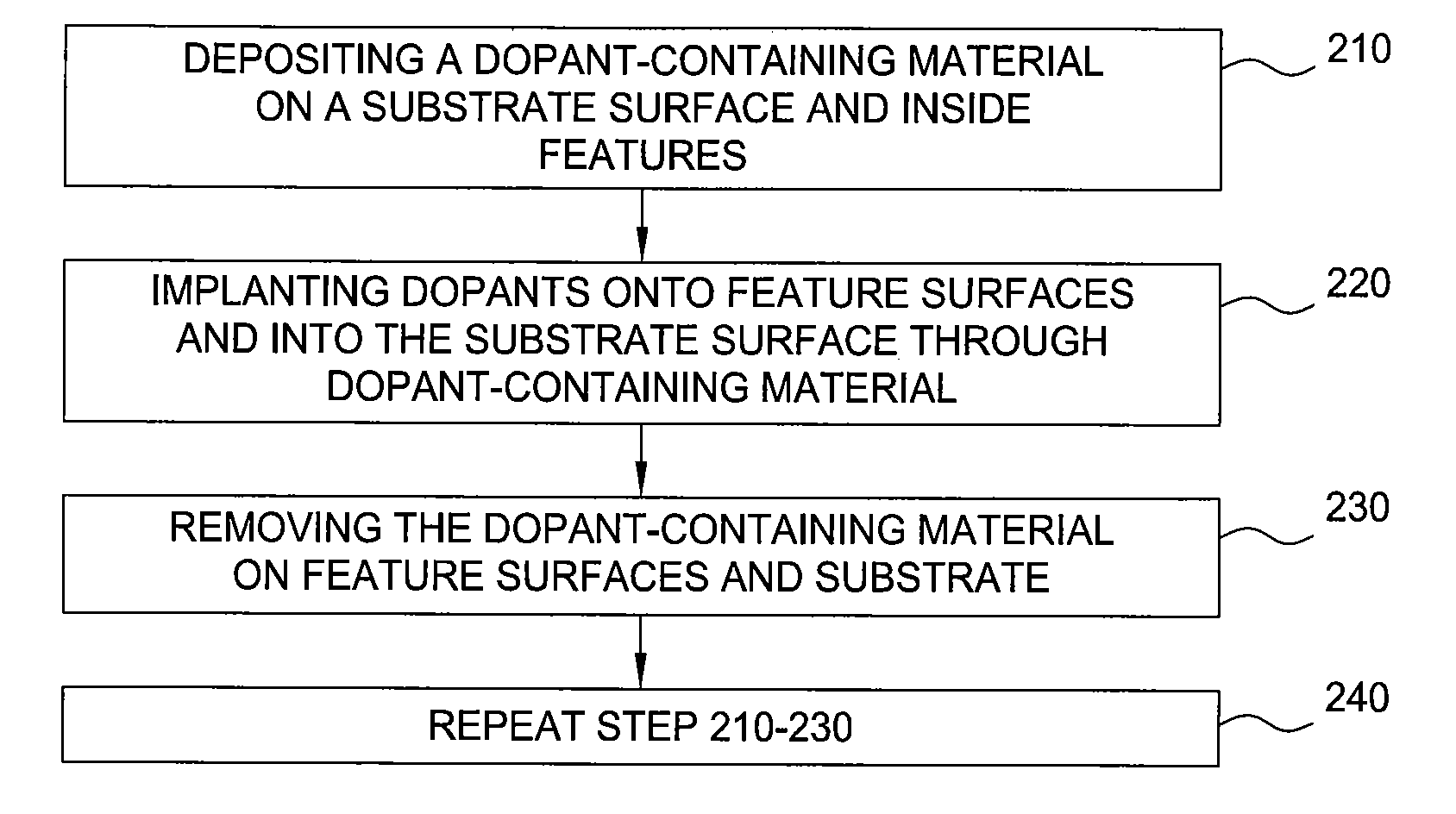

Conformal doping in p3i chamber

InactiveUS20100112793A1Electric discharge tubesSemiconductor/solid-state device manufacturingPlasma-immersion ion implantationSubstrate surface

Methods for implanting ions into a substrate by a plasma immersion ion implanting process are provided. In one embodiment, a method for implanting ions into a substrate includes providing a substrate into a processing chamber, the substrate comprising substrate surface having one or more features formed therein and each feature having one or more horizontal surfaces and one or more vertical surfaces, generating a plasma from a gas mixture including a reacting gas adapted to produce ions, depositing a material layer on the substrate surface and on at least one horizontal surface of the substrate feature, implanting ions from the plasma into the substrate by an isotropic process into at least one horizontal surface and into at least one vertical surface, and etching the material layer on the substrate surface and the at least one horizontal surface by an anisotropic process.

Owner:APPLIED MATERIALS INC

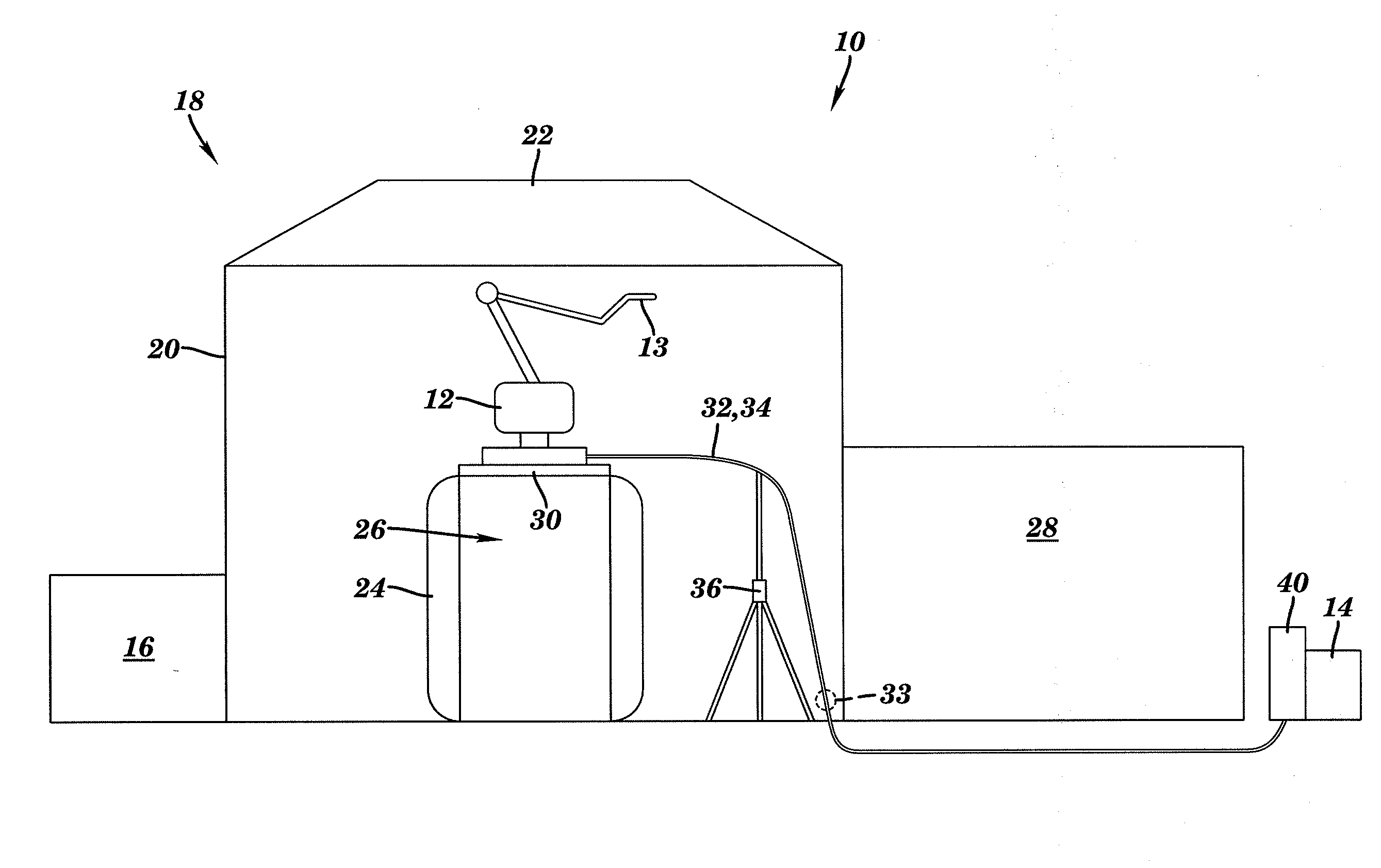

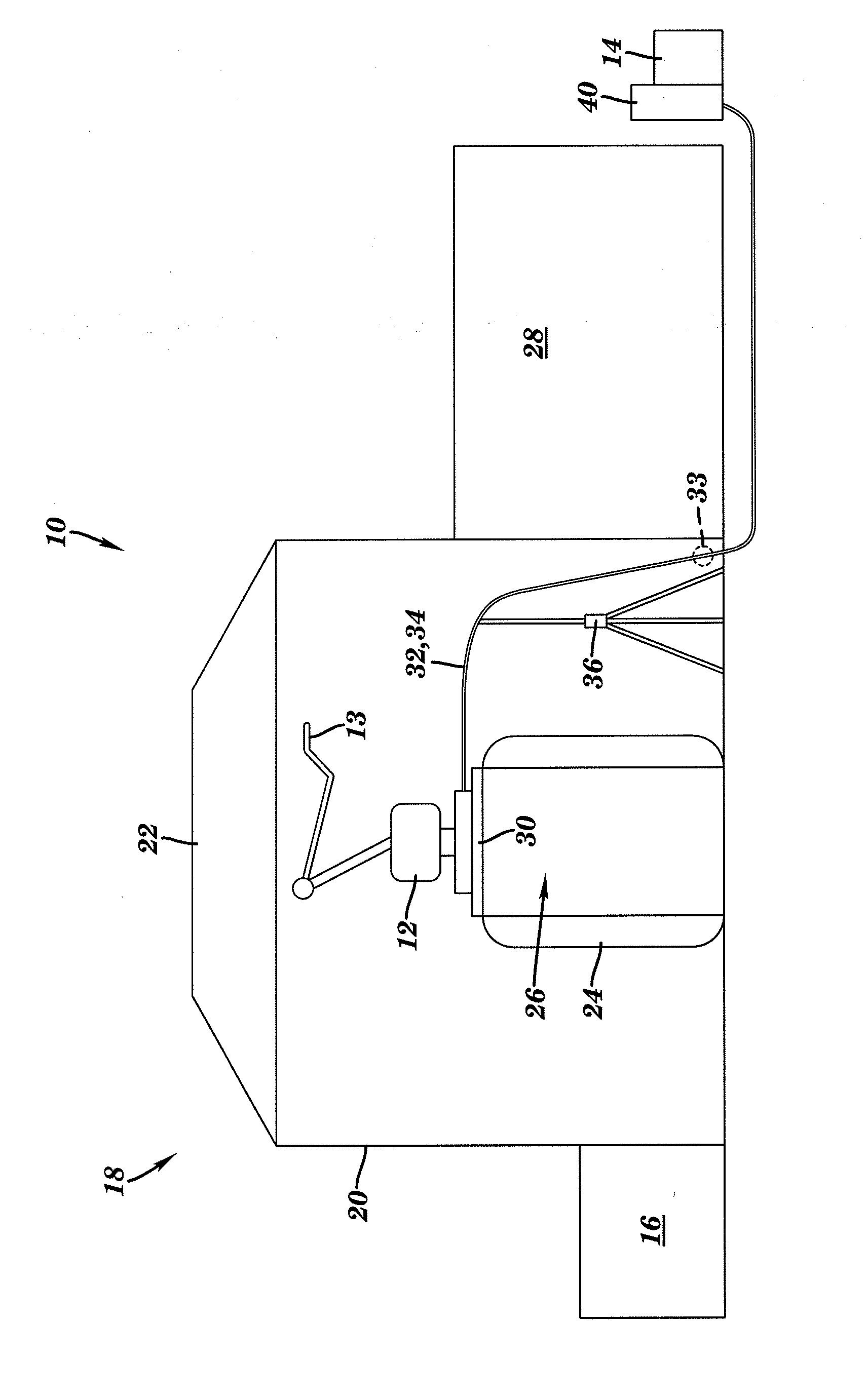

Method and apparatus for removing material from a surface of a metal processing chamber

Methods and apparatus for removing condensed metal from the surfaces of metal processing chambers, such as, a vacuum induction metal (VIM) furnaces having, for example, condensed Mg or Ti, are disclosed. The methods and apparatus provide a robotic arm end positioned in the furnace having a nozzle operatively connected to a source of dry ice. The robotic arm end directs a stream of dry ice particles against the surface of the furnace to displace condensed metal. The displaced metal is collected for reuse or disposal. Aspects of the invention provide a safe and automated process for cleaning process chambers and recovering metal that can typically be dangerous when performed by conventional methods.

Owner:MARS METALS

Method for cleaning a process chamber

InactiveUS20050211265A1Electrostatic cleaningChemical vapor deposition coatingRemote plasmaCombined use

Methods and apparatus for cleaning deposition chambers are presented. The cleaning methods include the use of a remote plasma source to generate reactive species from a cleaning gas to clean deposition chambers. A flow of helium or argon may be used during chamber cleaning. Radio frequency power may also be used in combination with a remote plasma source to clean deposition chambers.

Owner:APPLIED MATERIALS INC

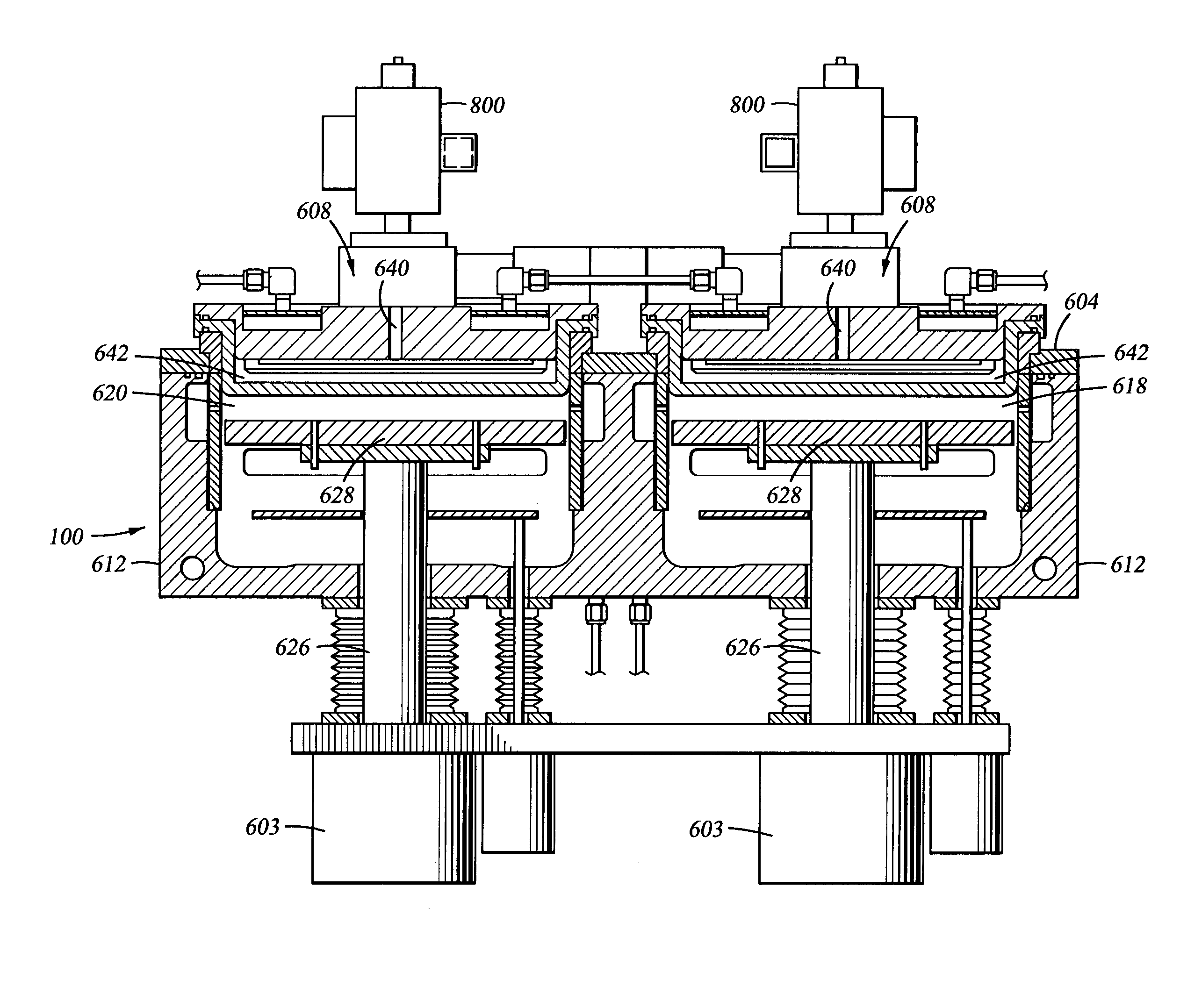

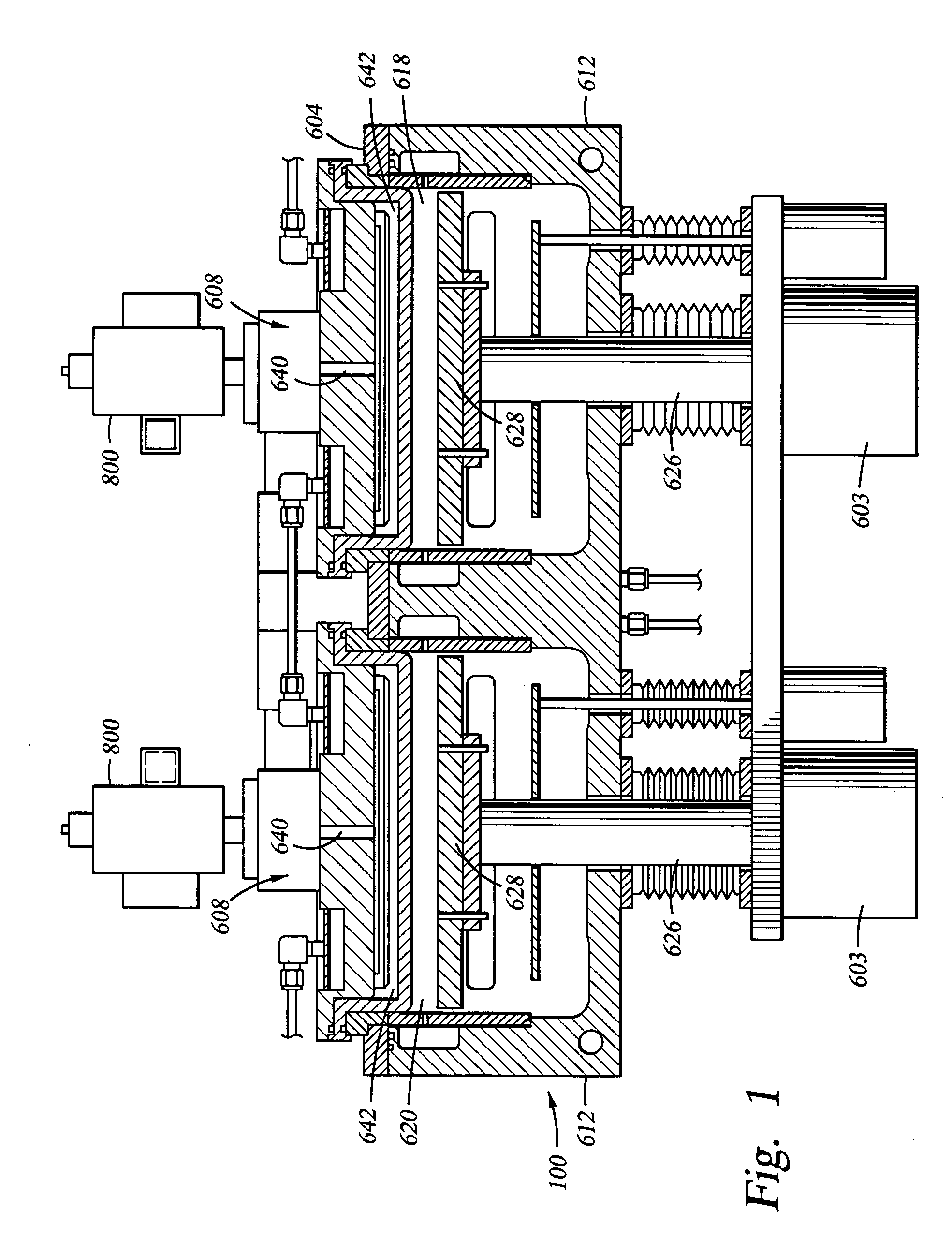

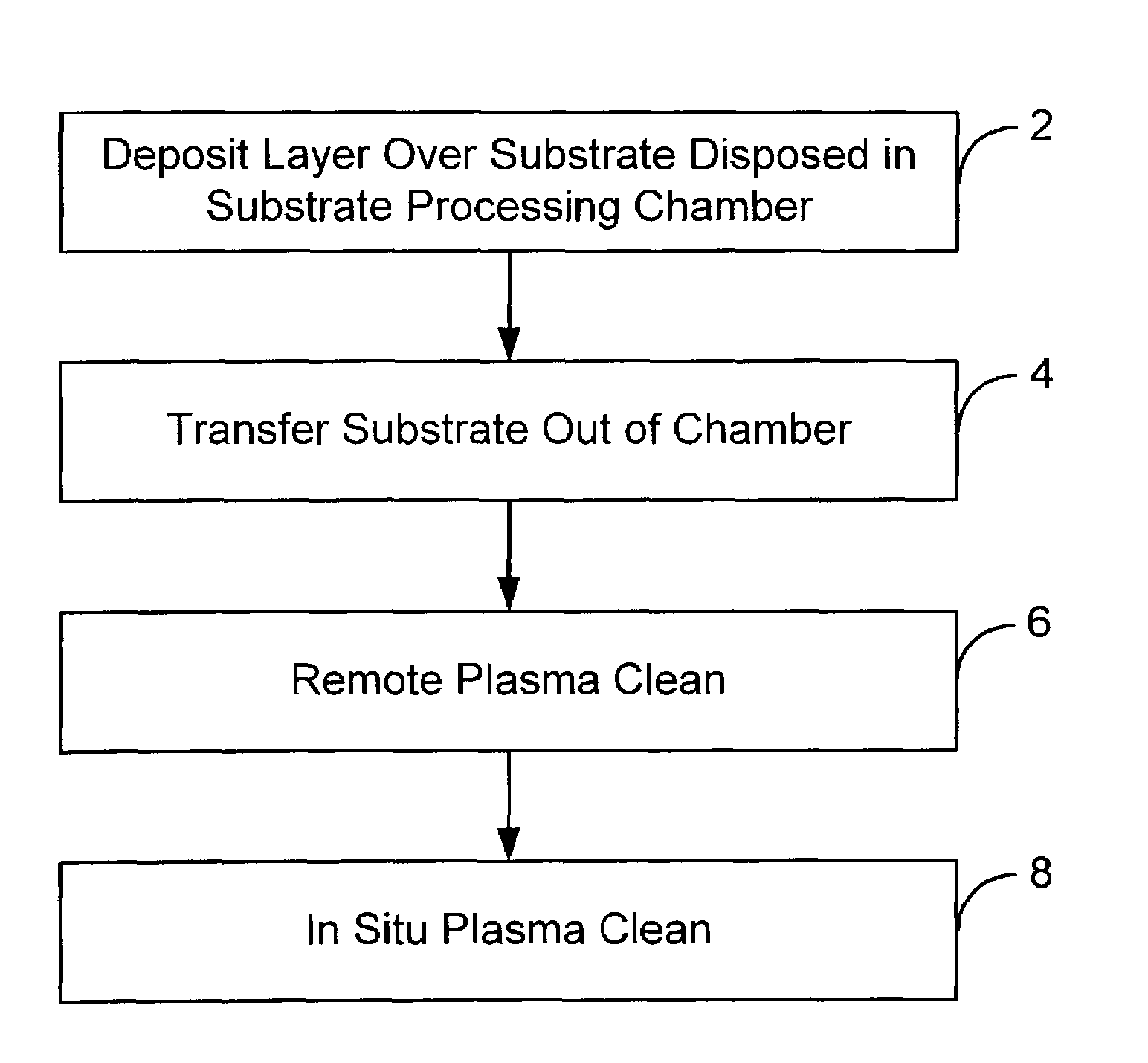

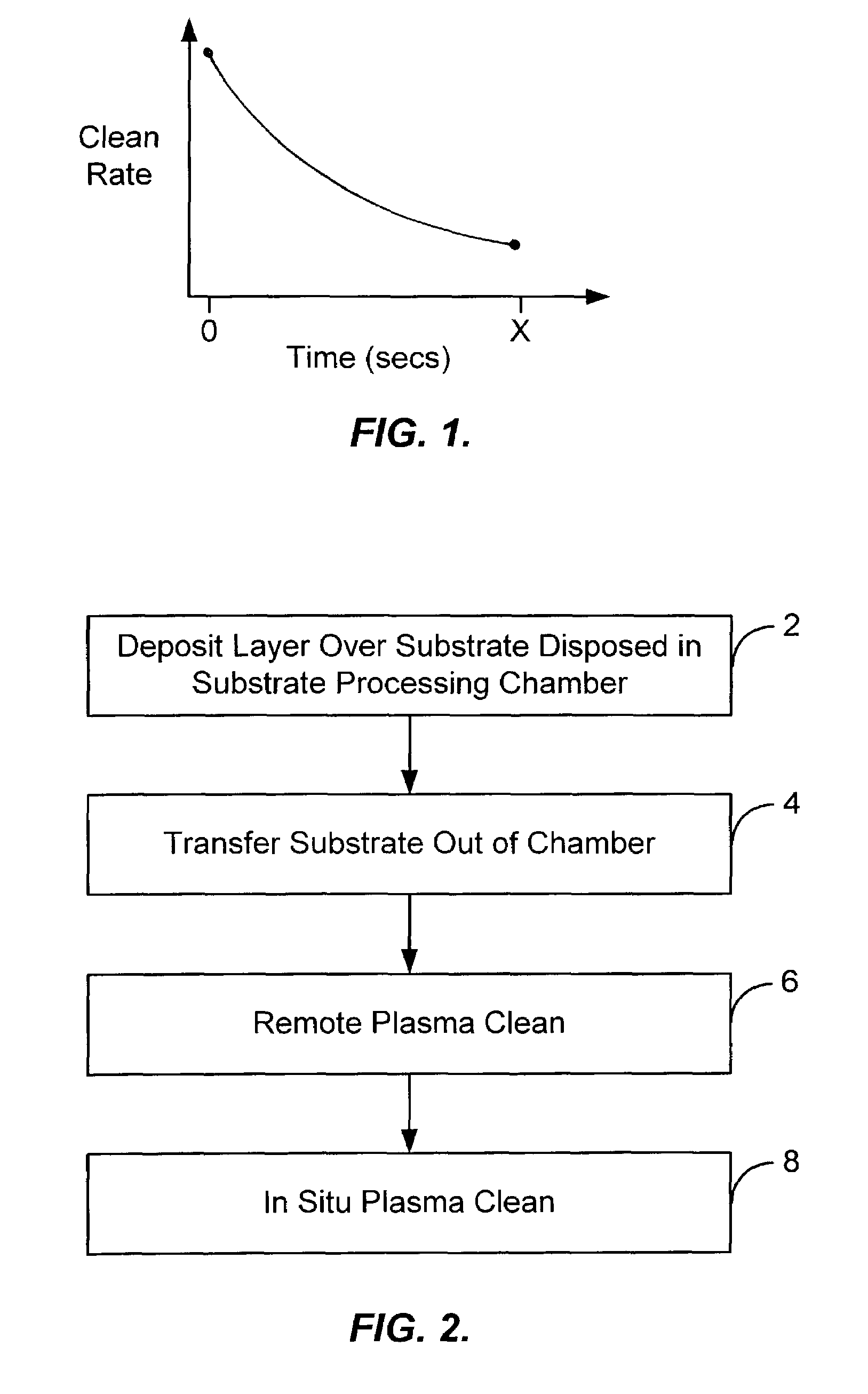

Chamber clean method using remote and in situ plasma cleaning systems

A process for removing unwanted deposition build-up from one or more interior surfaces of a substrate processing chamber. According to one embodiment the process comprises performing a substrate processing operation on the substrate within the substrate processing chamber and then transferring the substrate out of the substrate processing chamber; flowing a first etchant gas into a remote plasma source, forming reactive species from the etchant gas and transporting the reactive species into the substrate processing chamber to remove a first portion of the unwanted deposition build-up; and thereafter, flowing a second etchant gas into the substrate processing chamber and forming a plasma within the substrate processing chamber from the second gas in order to remove a second portion of the unwanted deposition build-up.

Owner:APPLIED MATERIALS INC

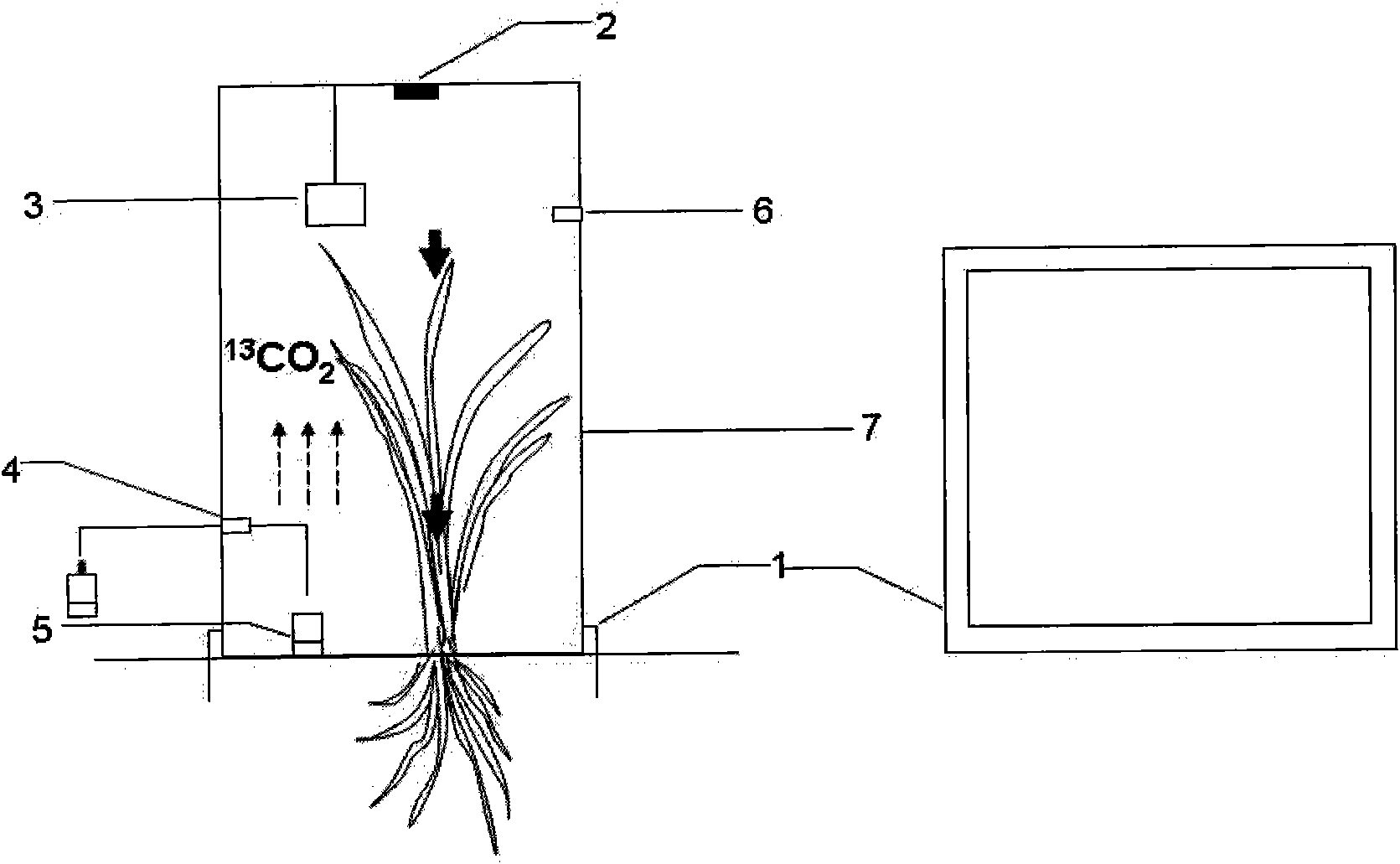

Method for detecting greenhouse gas emission of transgenic rice

InactiveCN102053133AAccurately evaluate emission differencesComponent separationGenetically modified riceBiology

The invention discloses a method for detecting greenhouse gas emissions of transgenic rice, which integrates the 13C stable carbon isotope labeling technique and the static-chamber sampling technique to detect the difference in greenhouse gas emission between transgenic rice and parents. The method comprises the following steps: (1) making a closed-type 13C stable carbon isotope labeled chamber; (2) labeling with 13C stable carbon isotope; (3) collecting gas samples by the static-chamber method; and (4) detecting by isotope ratio mass spectrometry. The method can accurately evaluate the difference in greenhouse gas emission between transgenic rice and the control group, and provides a powerful technical basis for setting the standards of commercial release of transgenic rice in China.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com