Patents

Literature

387results about How to "Quick compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

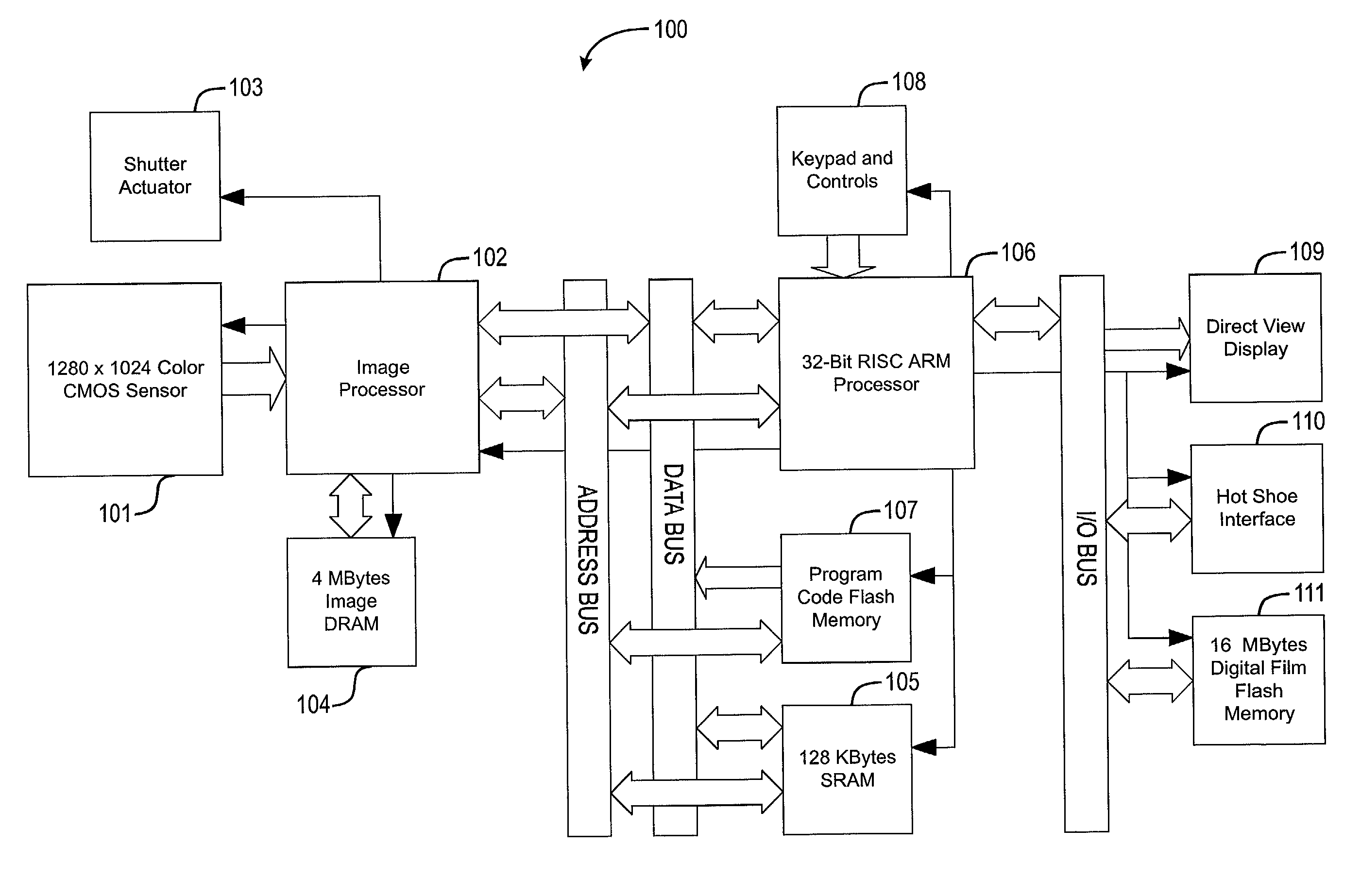

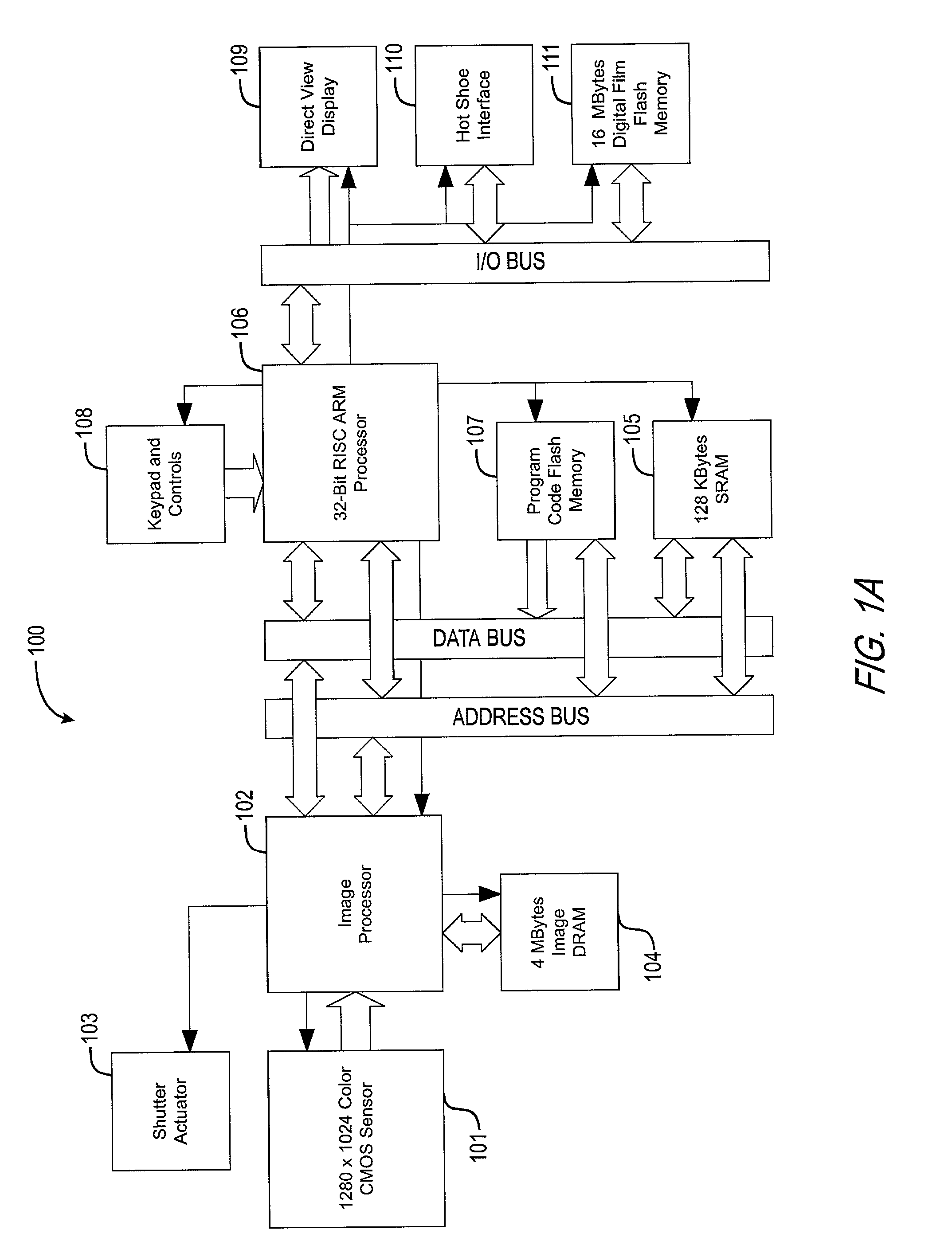

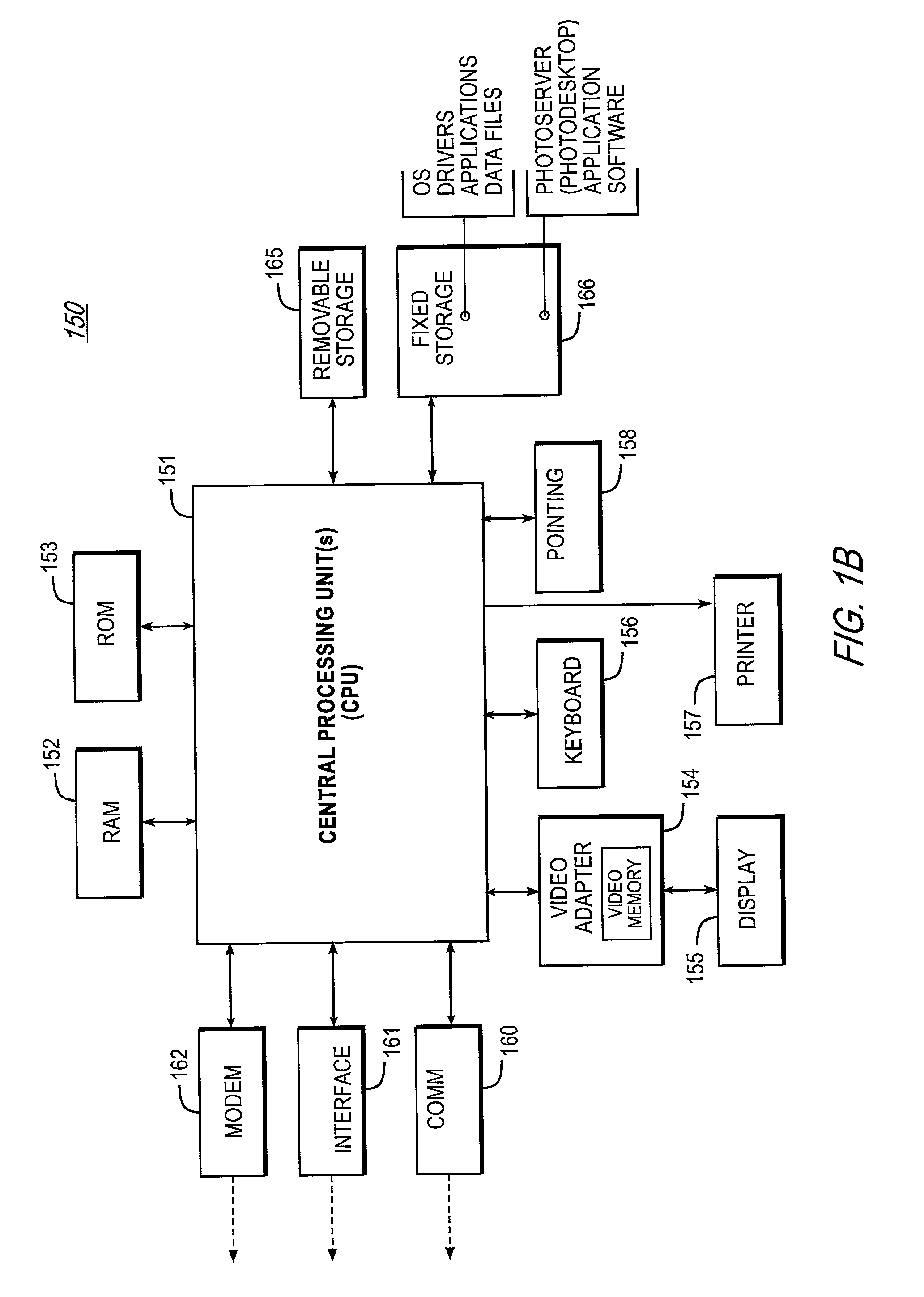

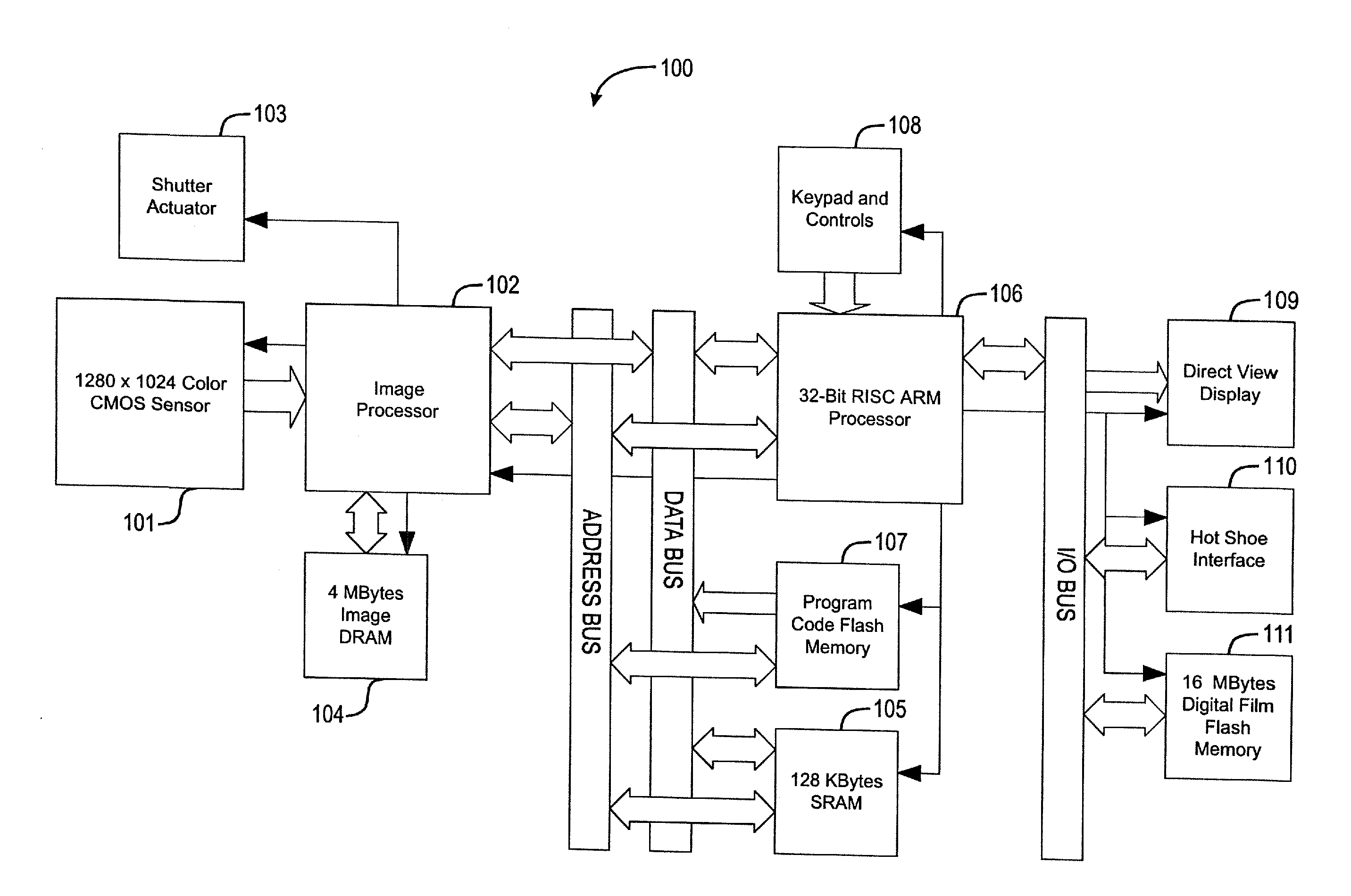

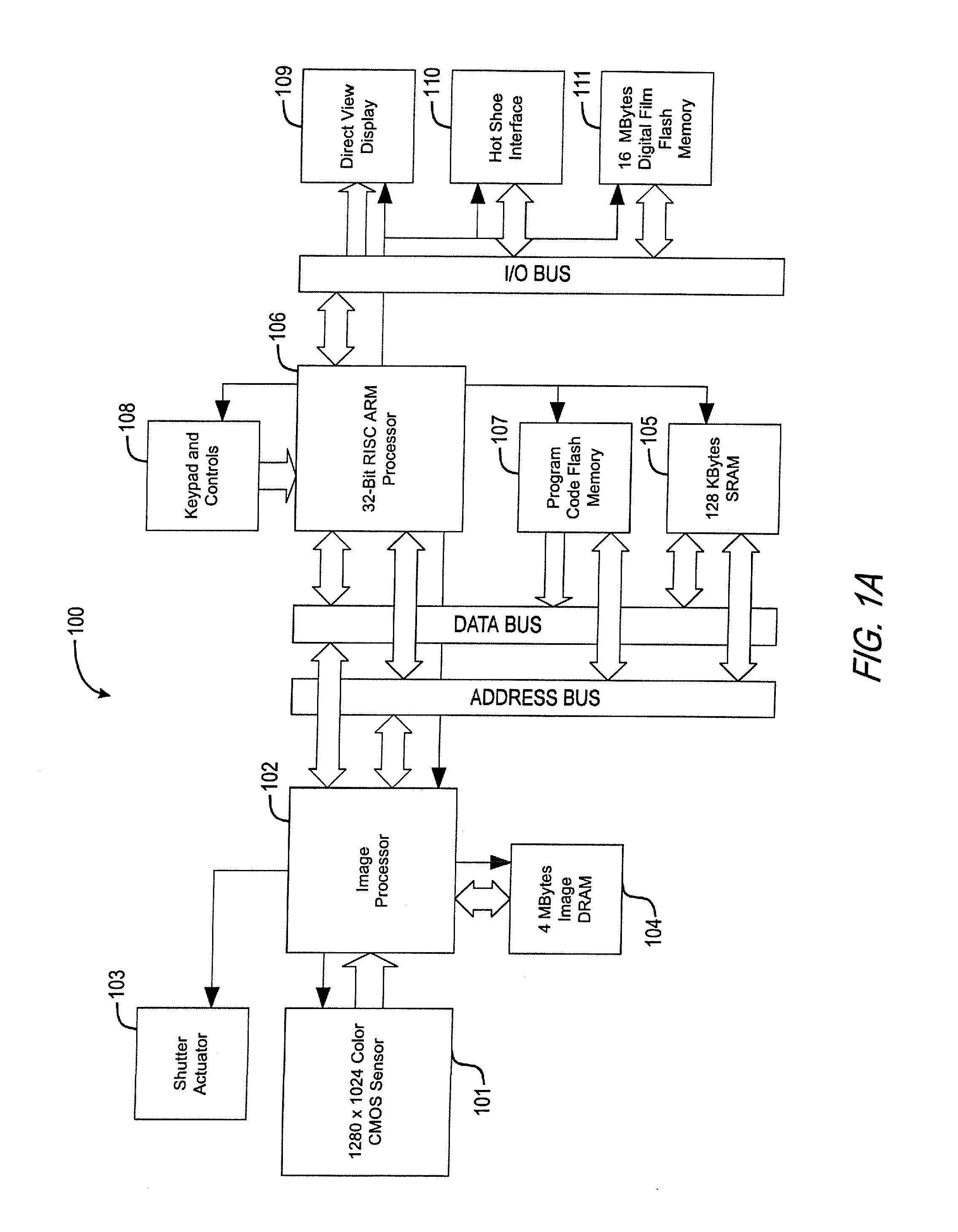

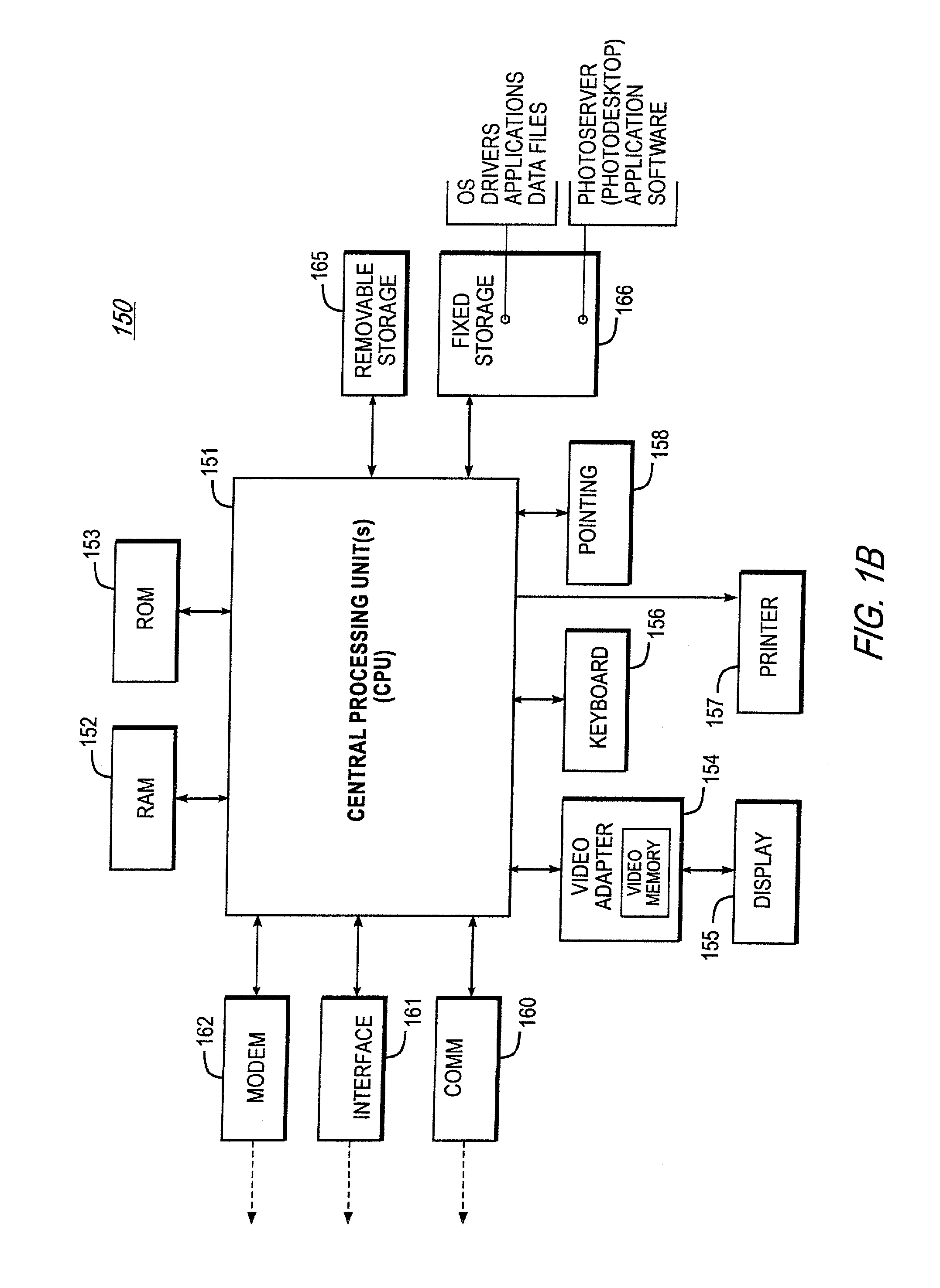

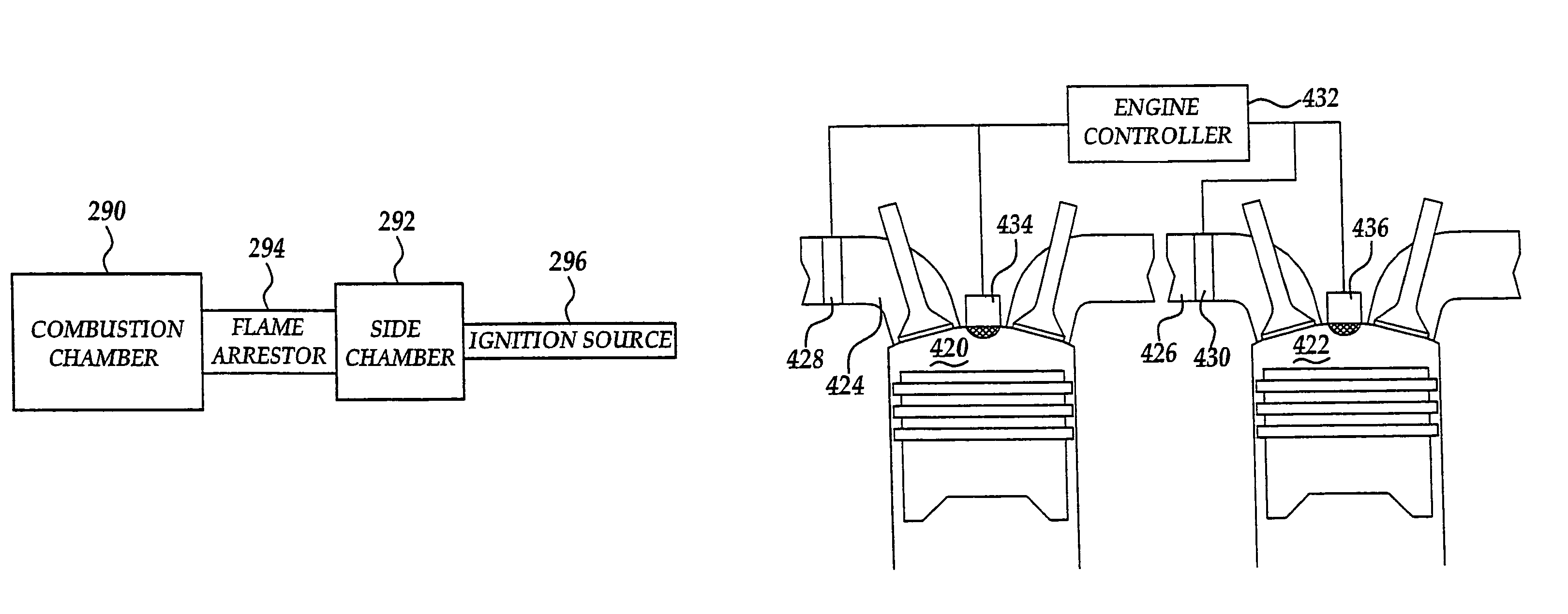

Digital camera device providing improved methodology for rapidly taking successive pictures

InactiveUS7369161B2Extended latencyAvailable storageTelevision system detailsColor television with pulse code modulationLuminosityDigital image

An in-camera two-stage compression implementation is described that reduces the latency between snapshots to a fraction of that otherwise required by other systems that either process complete compression following each snapshot or that incorporate heavy, bulky, and expensive RAM hardware capable of maintaining several raw luminosity records (unprocessed file containing a digital image). In the 1st stage compression the raw luminosity record is quickly, yet partially, compressed to available RAM buffer space to allow a user to expeditiously capture a succeeding image. When the higher-priority processes, the user shooting pictures, and stage one compression subside, a 2nd stage compression, which is slower but more effective, decompresses the earlier partially-compressed images, and re-compresses them for saving in flash memory until they are distributed to a remote platform to be finally converted to the JPEG2000 format.

Owner:RPX CORP

Digital Camera Device Providing Improved Methodology for Rapidly Taking Successive Pictures

InactiveUS20080239093A1Extended latencyAvailable storageTelevision system detailsColor television with pulse code modulationComputer graphics (images)Engineering

An in-camera two-stage compression implementation is described that reduces the latency between snapshots to a fraction of that otherwise required by other systems that either process complete compression following each snapshot or that incorporate heavy, bulky, and expensive RAM hardware capable of maintaining several raw luminosity records (unprocessed file containing a digital image). In the 1st stage compression the raw luminosity record is quickly, yet partially, compressed to available RAM buffer space to allow a user to expeditiously capture a succeeding image. When the higher-priority processes, the user shooting pictures, and stage one compression subside, a 2nd stage compression, which is slower but more effective, decompresses the earlier partially-compressed images, and re-compresses them for saving in flash memory until they are distributed to a remote platform to be finally converted to the JPEG2000 format.

Owner:RPX CORP

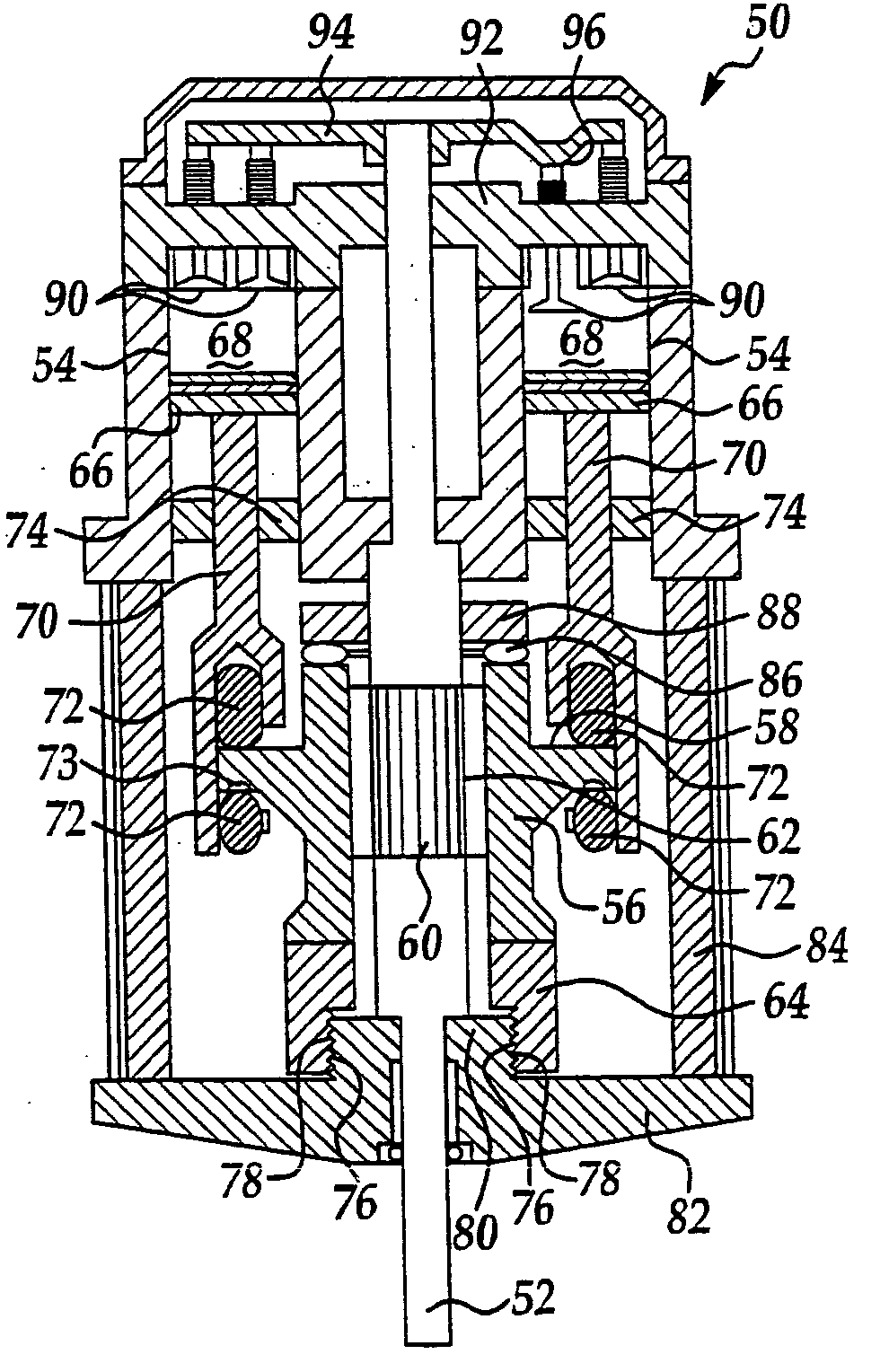

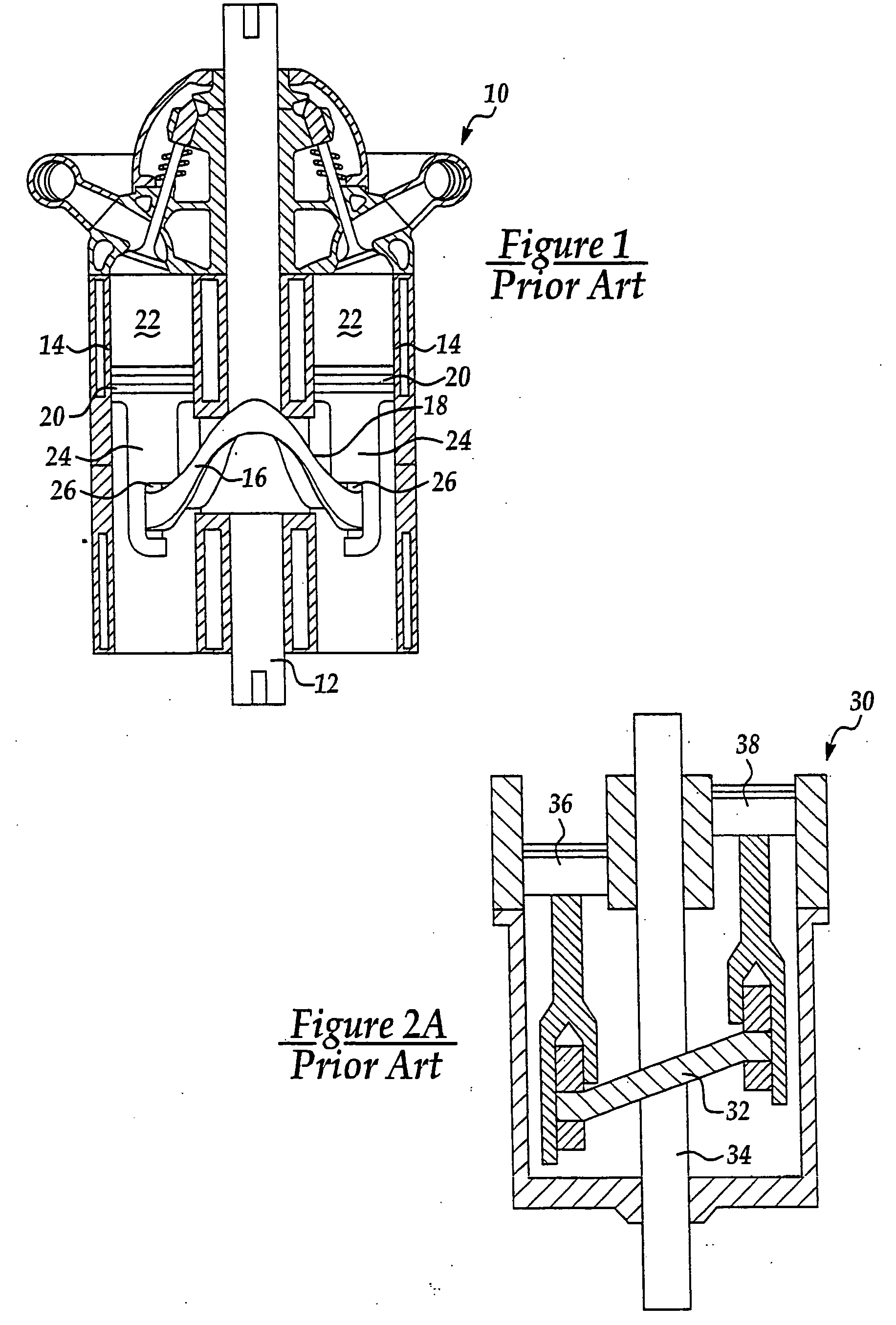

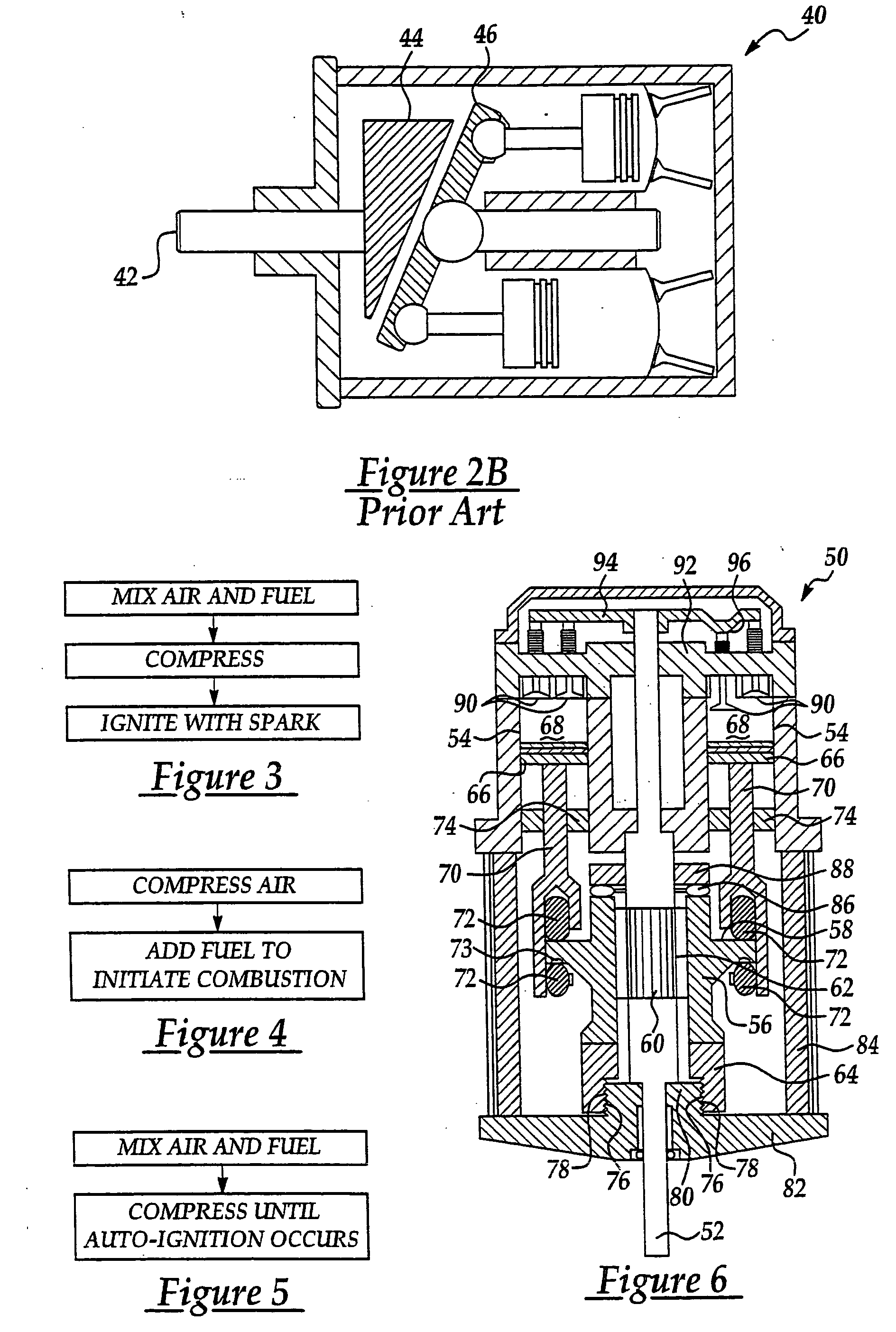

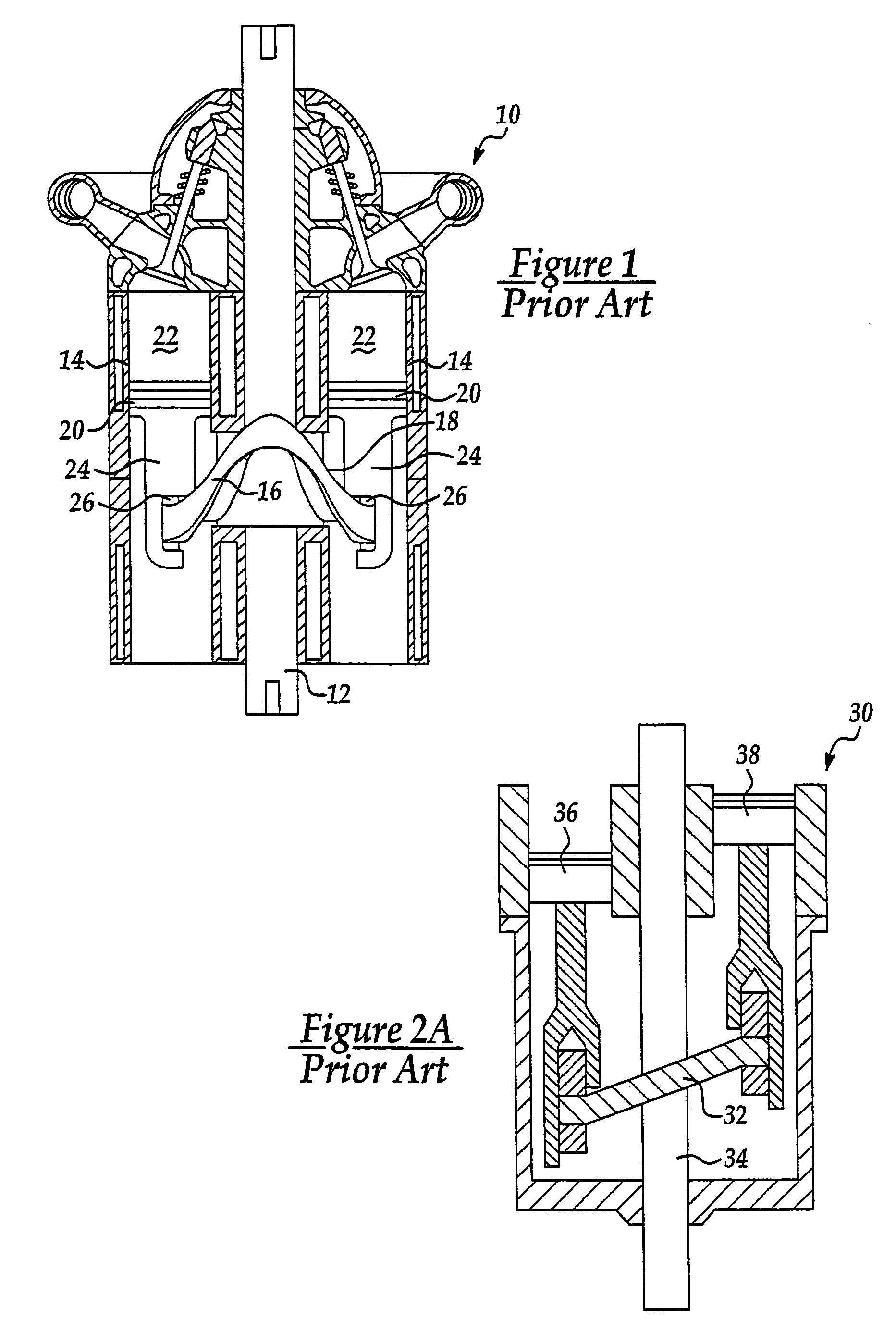

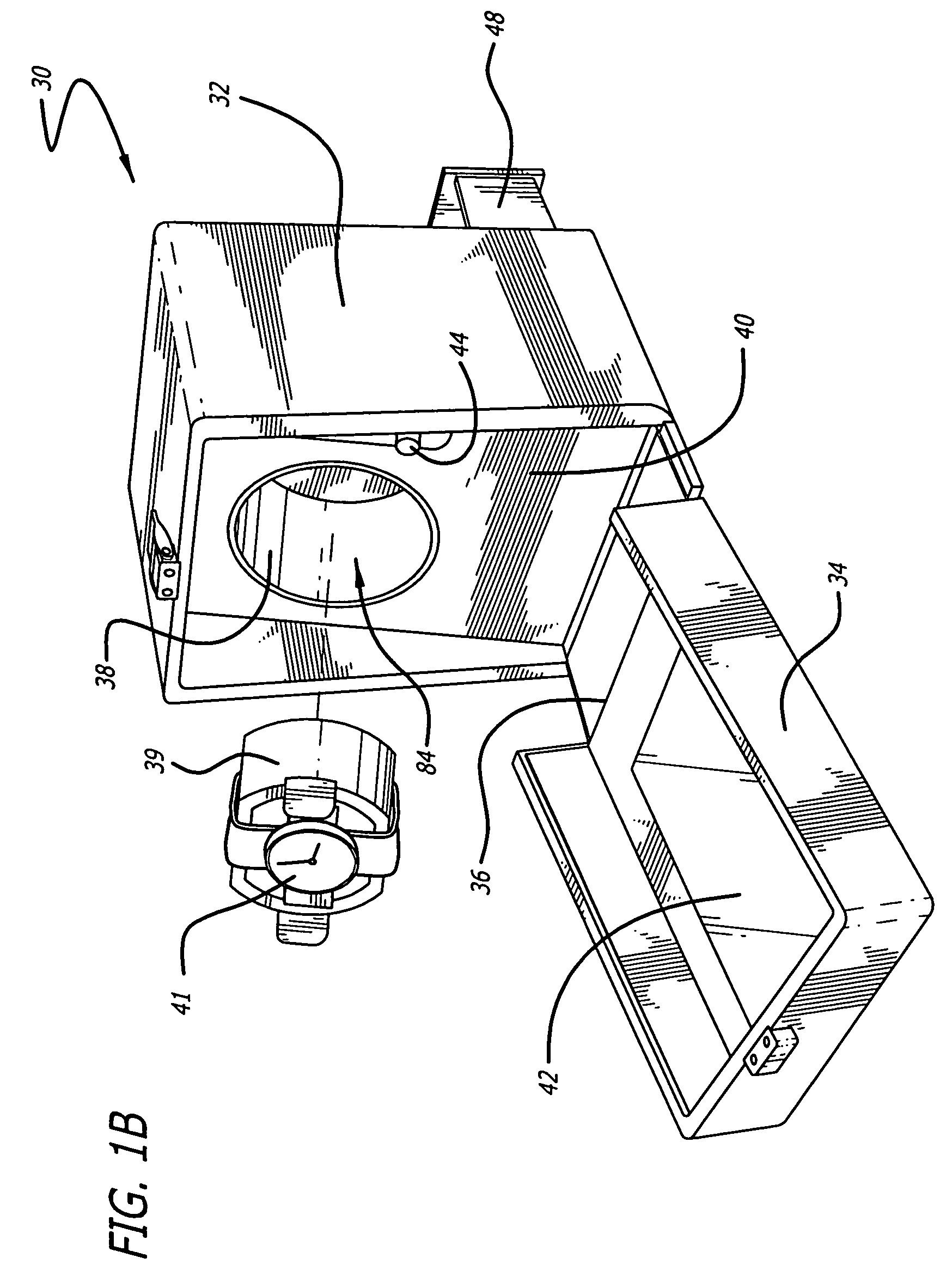

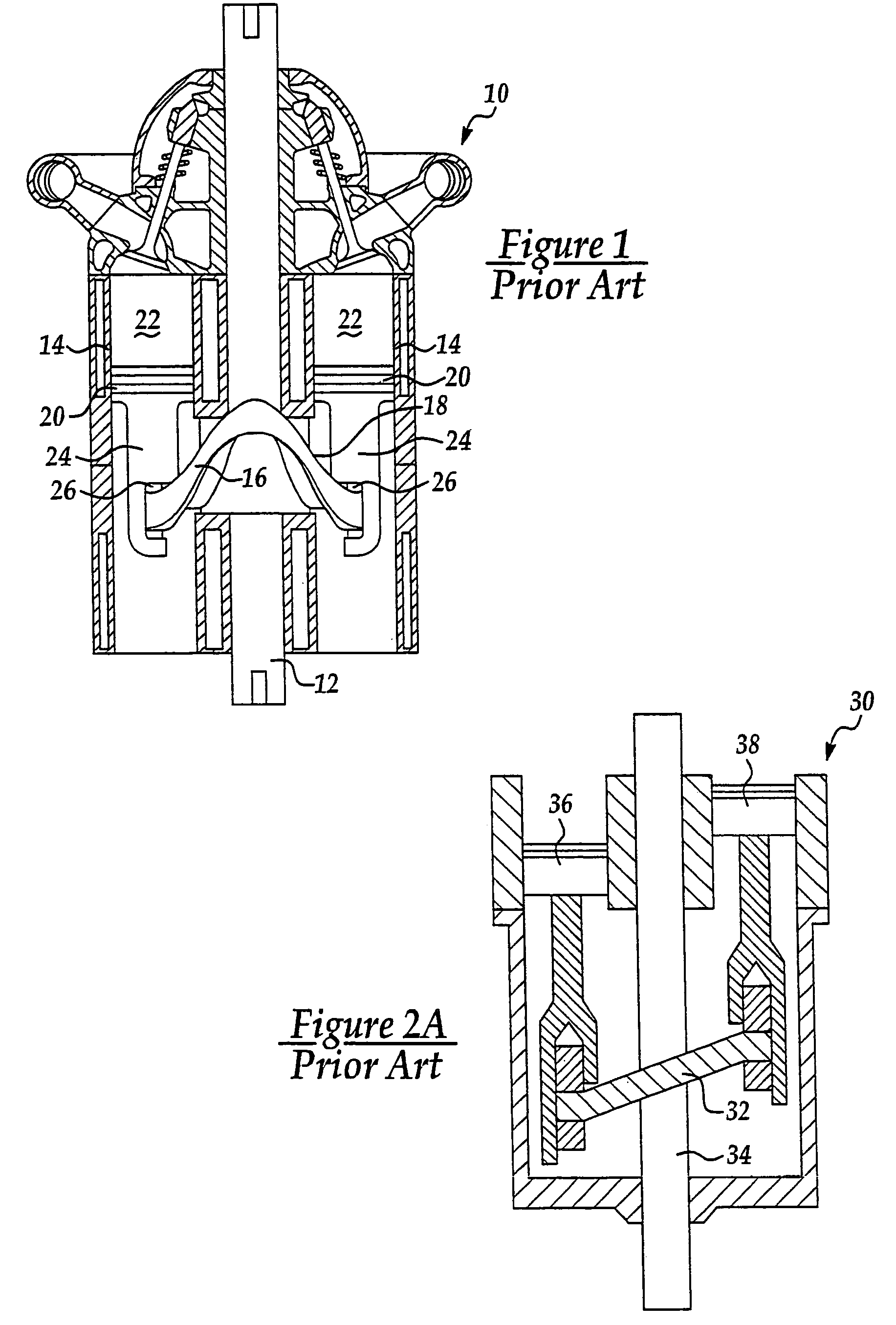

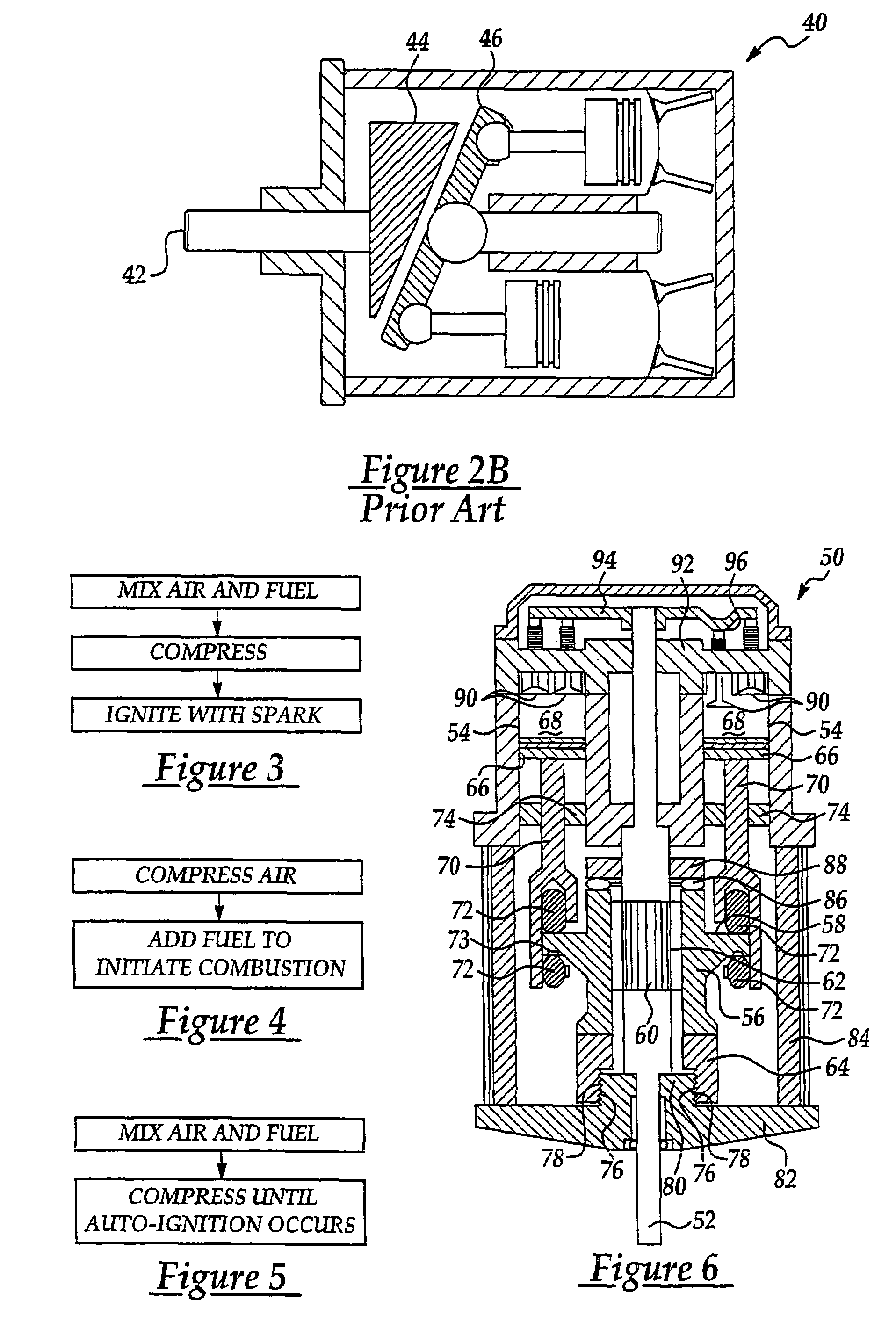

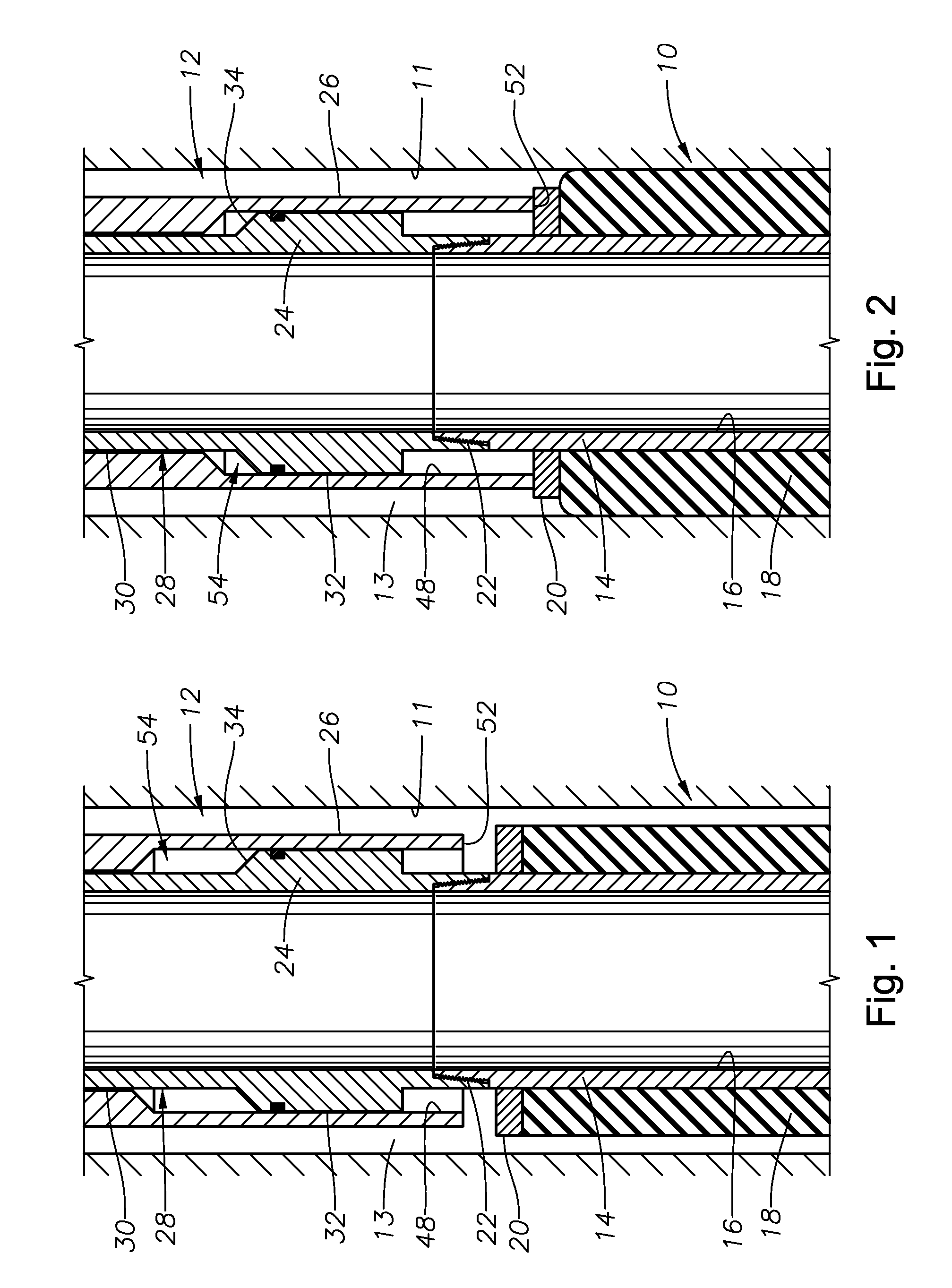

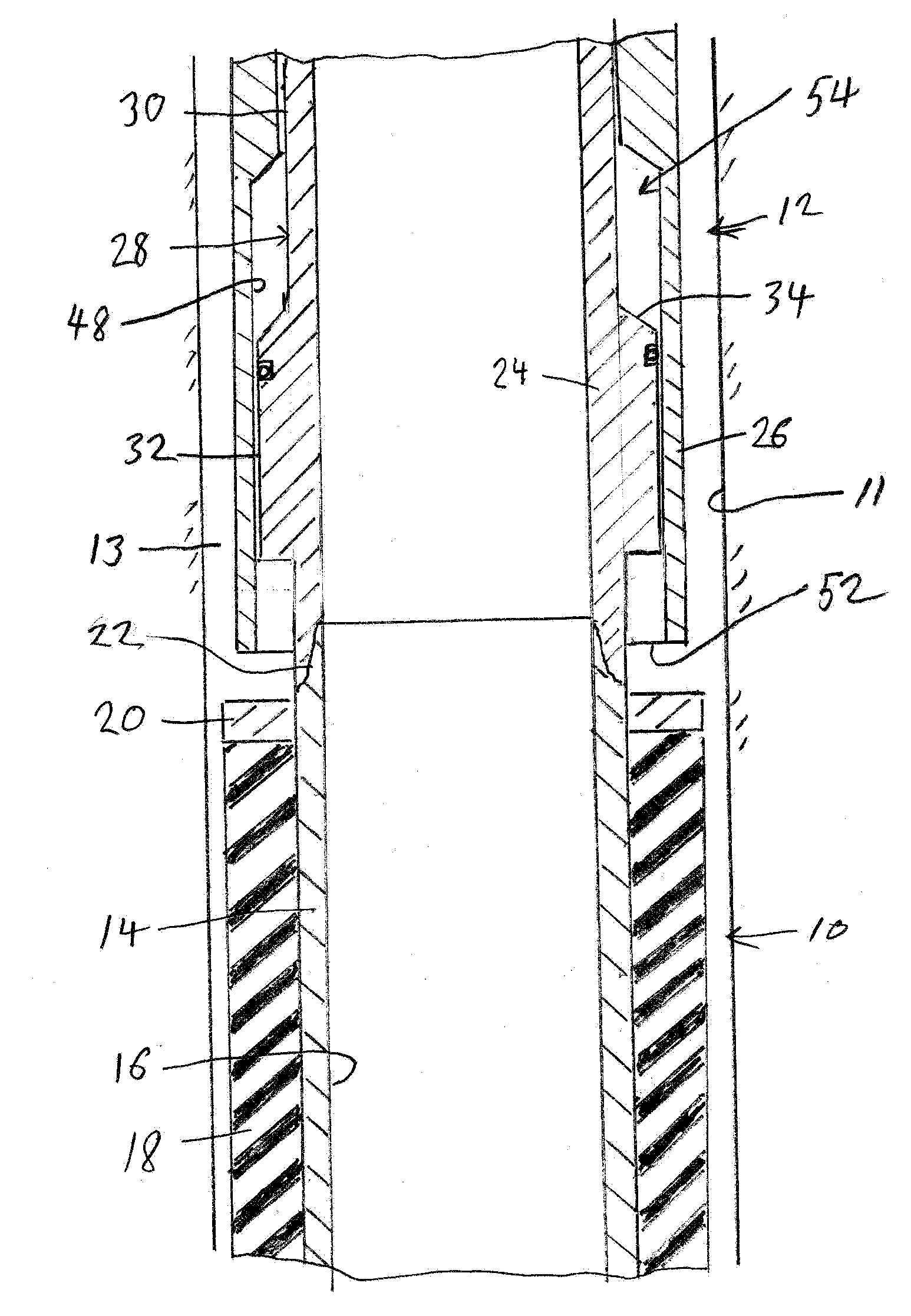

Homogeneous charge compression ignition and barrel engines

InactiveUS20060037567A1Rapidly raise compression levelRapidly increase compression levelInternal combustion piston enginesEngine componentsHomogeneous charge compression ignitionReciprocating motion

A homogenous charge compression ignition barrel engine includes an engine housing with a first and second end. An elongated power shaft is longitudinally disposed in the engine housing and defines a longitudinal axis of the engine. A plurality of cylinders surround the longitudinal axis with each cylinder having a closed end and an open end. Each cylinder has a central axis. The open ends of the cylinders are each generally directed toward the first end of the housing. An intake system is operable to introduce a combustible mixture of air and fuel into each of the cylinders. A track is disposed between the first end of the housing and the open ends of the cylinders such that a portion of the track is disposed generally in alignment with the central axis of each of the cylinders. The track has a cam surface that longitudinally undulates with respect to the open ends of the cylinders. A portion of the cam surface is disposed generally in alignment with the central axis of each of the cylinders. The track and the cylinders are rotatable with respect to each other such that the undulating cam surface moves with respect to the open ends of the cylinders. A piston is moveably disposed in each of the cylinders such that a combustion chamber is defined between the piston and the closed end of the cylinder. Each piston is in mechanical communication with the cam surface of the track such that as the cylinders and the track move with respect to each other, the pistons reciprocate within the cylinders. Each cylinder is operable to compress a combustible mixture until the mixture auto ignites, without the introduction of a spark.

Owner:THOMAS ENGINE CO LLC

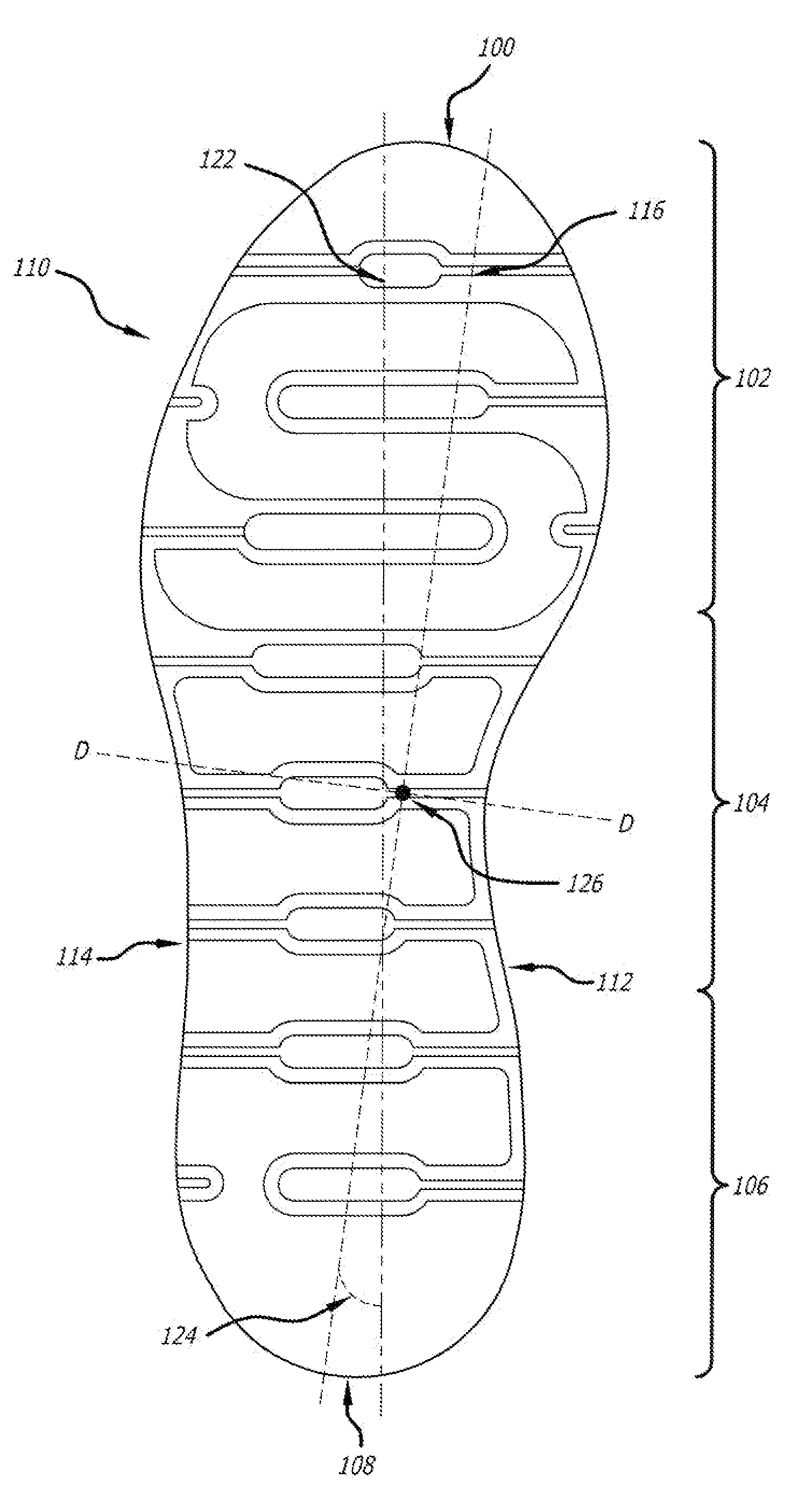

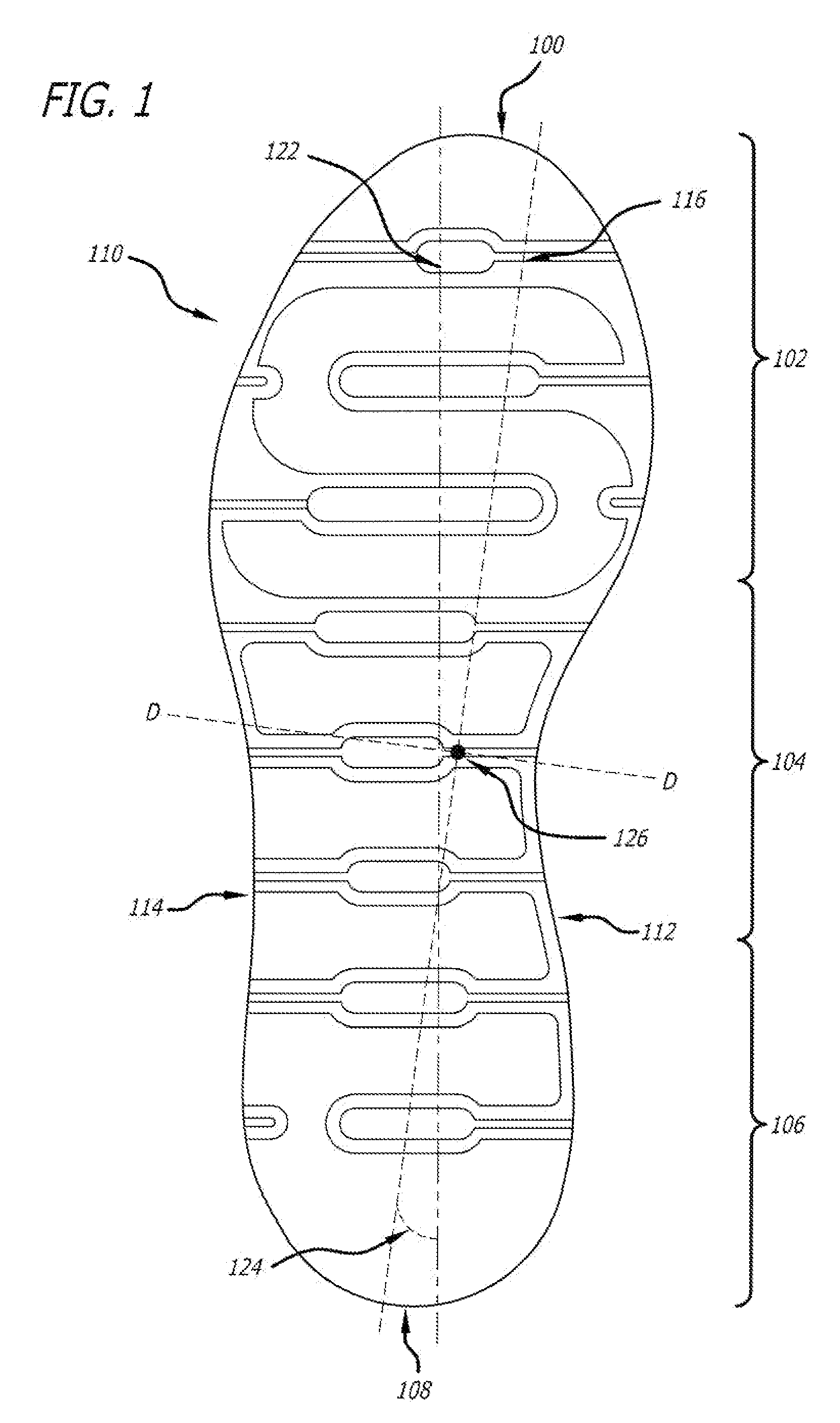

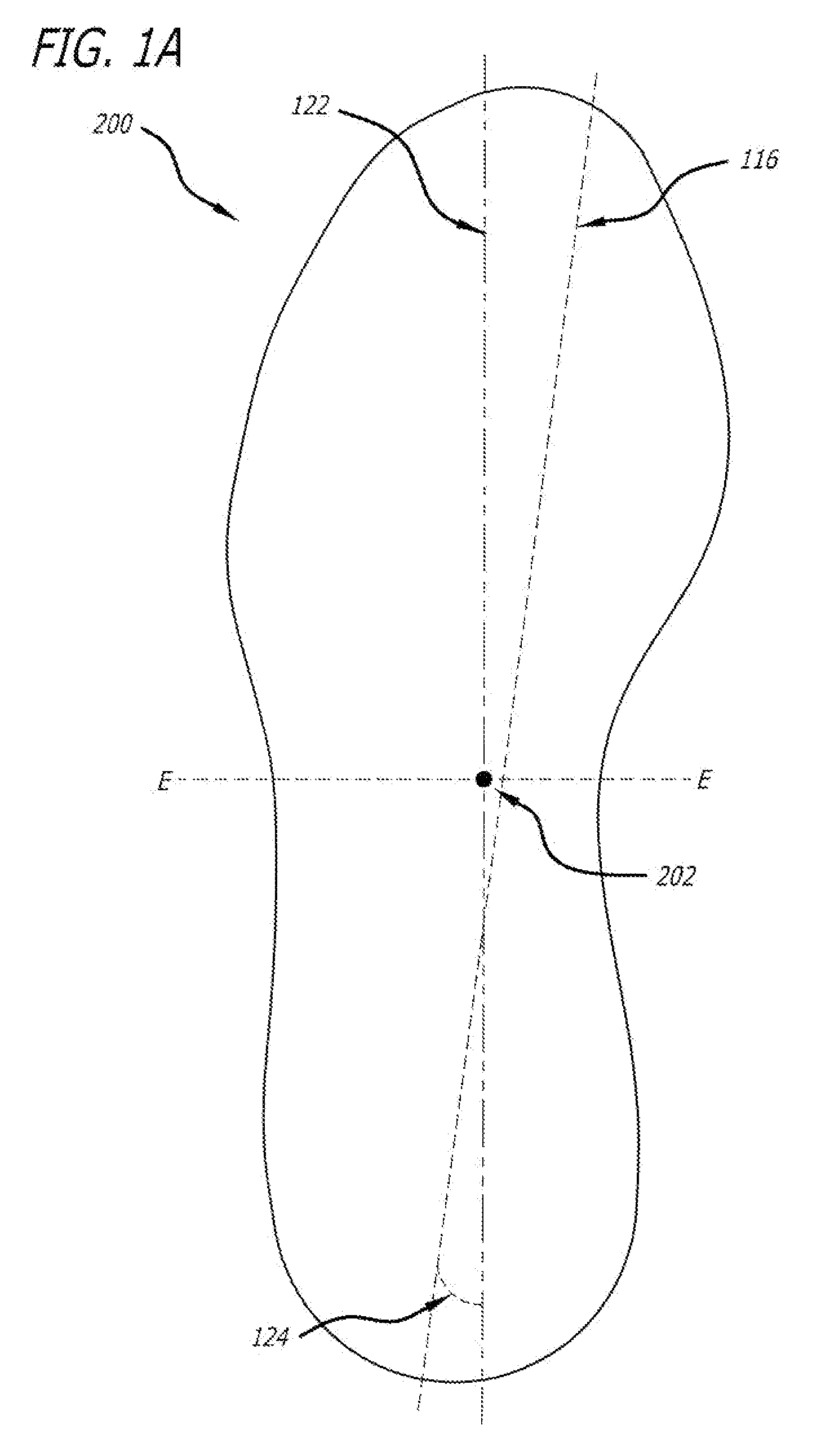

Shoe

A shoe having an upper and a curved sole member, the sole member may be comprised of one unitary piece or a separate midsole and a separate outsole. The curvature results from the sole member tilting along a center of mass axis that extends through a point in the vicinity of the lateral side of the heel region of the sole member to a point in the vicinity of the medial side of forefoot region of the sole member. The center of mass axis runs diagonally along the entire length of the shoe. Due to the curvature, the sole member has a non-uniform thickness. The curvature of the sole member allows the user's foot to be guided in a more natural motion providing more movement efficiency and comfort.

Owner:SKECHERS US II

Homogenous charge compression ignition and barrel engines

InactiveUS6986342B2Rapidly raise compression levelRapidly increase compression levelCasingsInternal combustion piston enginesCombustion chamberReciprocating motion

A homogenous charge compression ignition barrel engine includes an engine housing with a first and second end. An elongated power shaft is longitudinally disposed in the engine housing and defines a longitudinal axis of the engine. A plurality of cylinders surround the longitudinal axis with each cylinder having a closed end and an open end. Each cylinder has a central axis. The open ends of the cylinders are each generally directed toward the first end of the housing. An intake system is operable to introduce a combustible mixture of air and fuel into each of the cylinders. A track is disposed between the first end of the housing and the open ends of the cylinders such that a portion of the track is disposed generally in alignment with the central axis of each of the cylinders. The track has a cam surface that longitudinally undulates with respect to the open ends of the cylinders. A portion of the cam surface is disposed generally in alignment with the central axis of each of the cylinders. The track and the cylinders are rotatable with respect to each other such that the undulating cam surface moves with respect to the open ends of the cylinders. A piston is moveably disposed in each of the cylinders such that a combustion chamber is defined between the piston and the closed end of the cylinder. Each piston is in mechanical communication with the cam surface of the track such that as the cylinders and the track move with respect to each other, the pistons reciprocate within the cylinders. Each cylinder is operable to compress a combustible mixture until the mixture auto ignites, without the introduction of a spark.

Owner:THOMAS ENGINE CO LLC

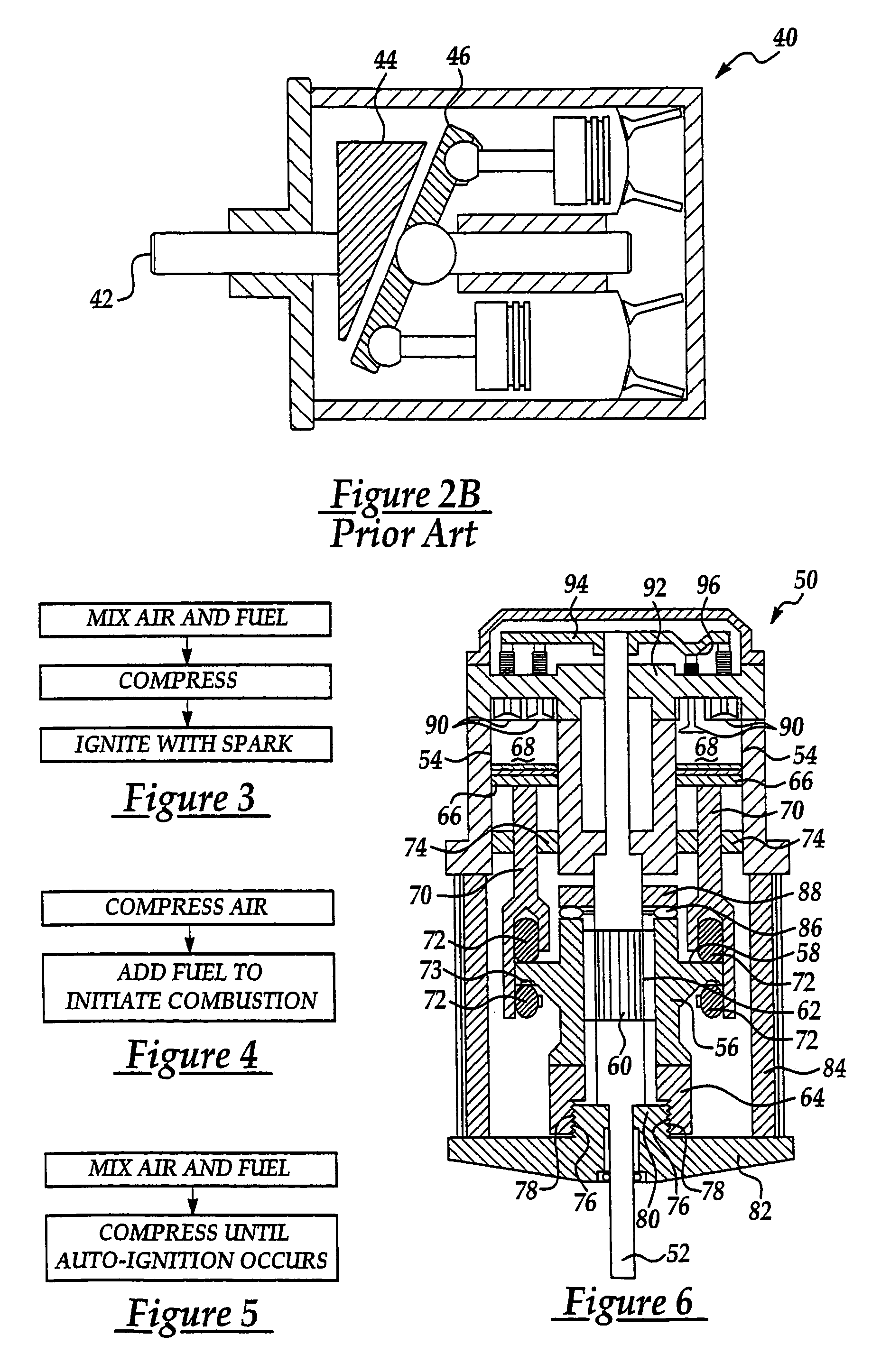

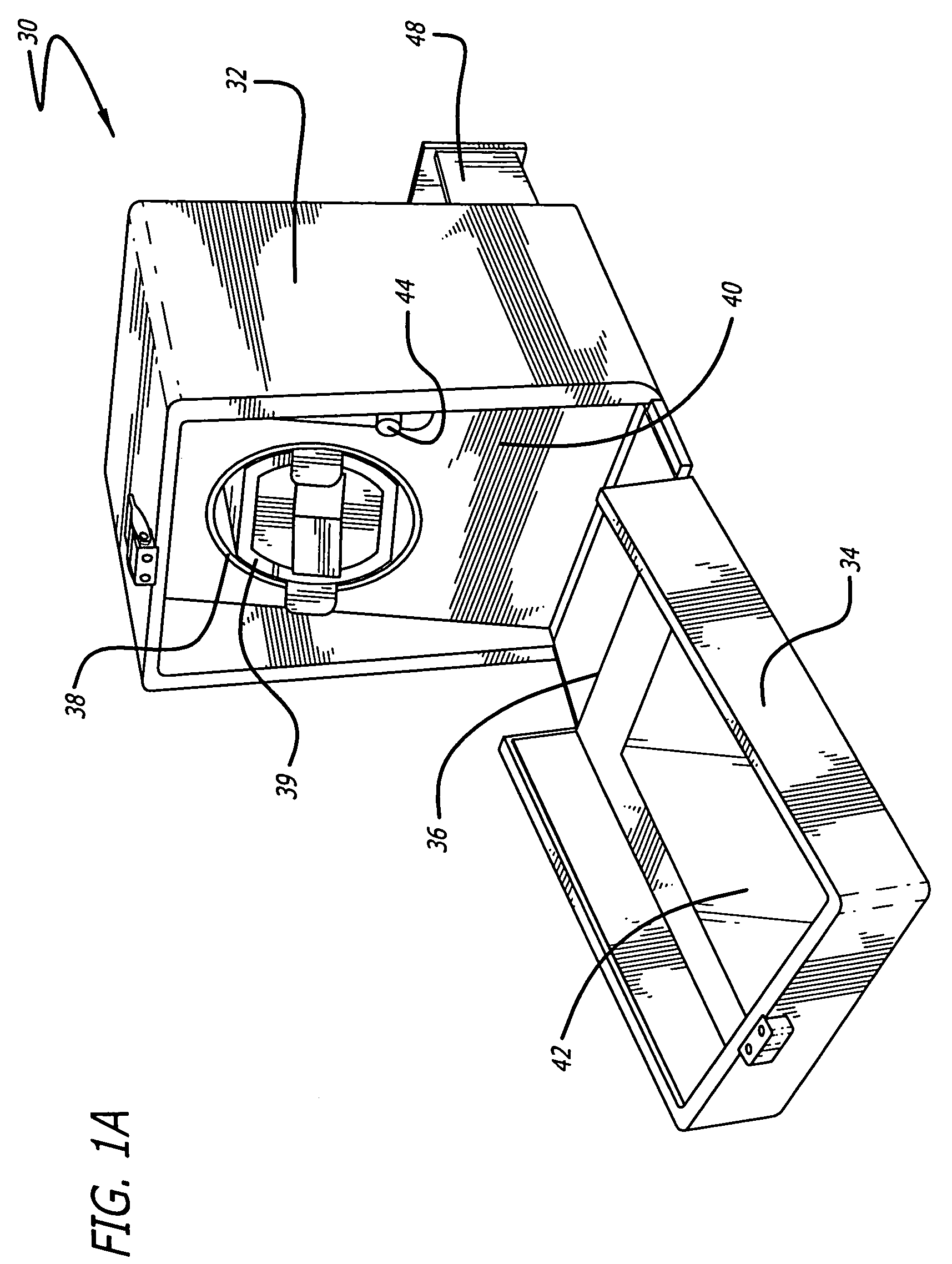

Controllable watch winder for self-winding watches

ActiveUS7575367B2Improve adaptabilityEfficient use ofNormal windingElectric windingMechanical watchMicroprocessor

A controllable watch winder for a self-winding mechanical watch, in which a turntable is provided to hold and rotate the watch, including a programmable microprocessor circuit configured to count the number of rotations executed by the turntable. In one aspect, the watch winder is configured to introduce, after the electronic circuit is activated, a delay period before the turntable commences rotating. In another aspect, the circuit may be configured to interrupt the rotation of the turntable with pauses, to break up the rotation into cyclical sets. The circuit may be configured to automatically predetermine the number of rotations in each set. In yet another aspect, the watch winder may be configured to be manually adjustable, to variably predetermine before use, the number of rotations to be executed by the turntable and the length of any pause between rotations.

Owner:WOLF 1834 +1

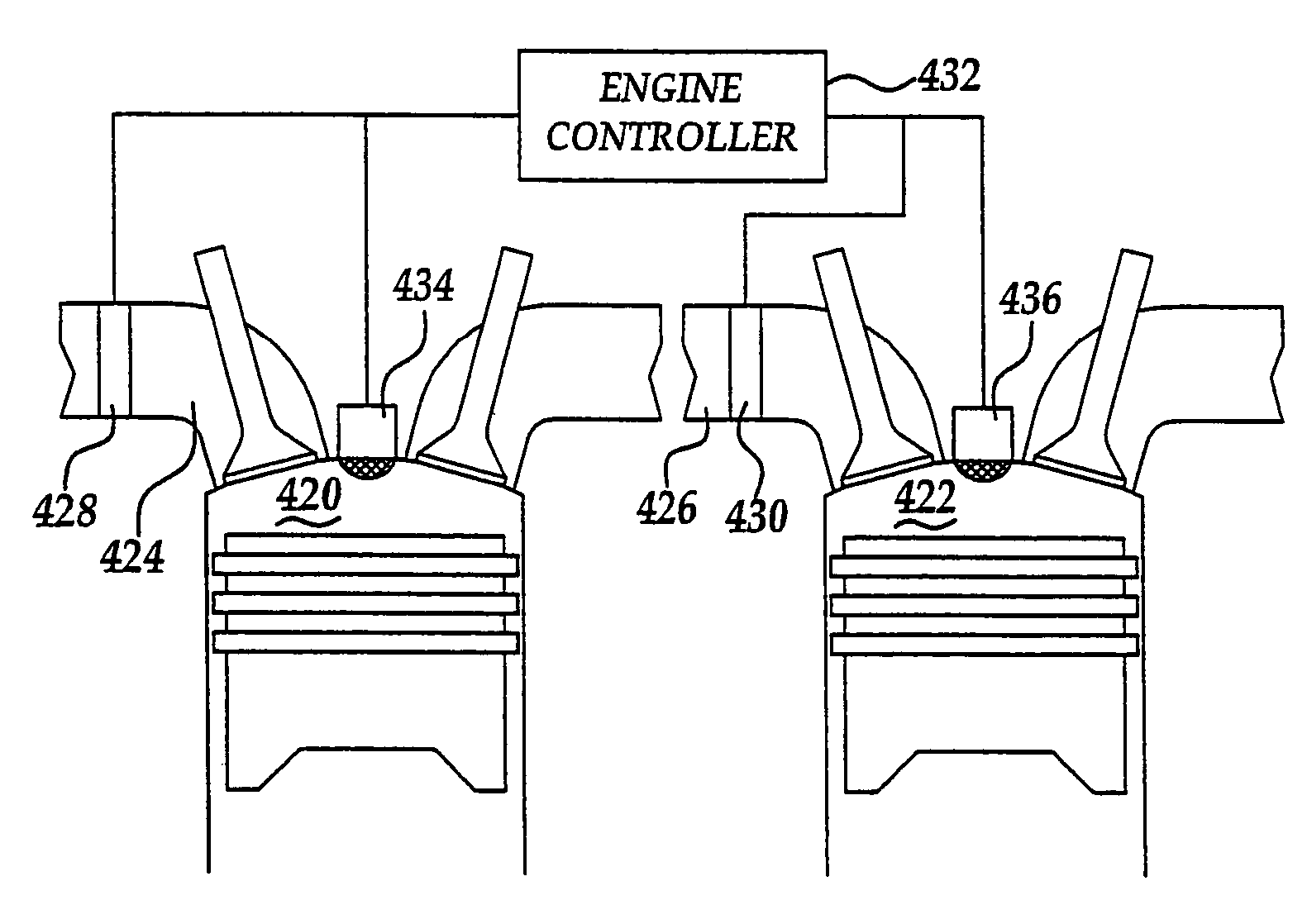

Homogeneous charge compression ignition engine with combustion phasing

InactiveUS7469662B2Rapidly increase compression levelQuick compressionInternal combustion piston enginesEngine componentsPistonAutomotive engineering

The relative combustion phasing of a homogenous charge compression ignition engine is controlled by controlling the introduction of ions and free radicals to cylinders in the engine. The engine has an engine housing with at least a first and second cylinder and an intake system that introduces a combustible mixture of air and fuel to the cylinders. A piston is disposed in each of the cylinders and is operable to compress a combustible mixture until the mixture auto ignites, without the introduction of a spark.

Owner:THOMAS ENGINE CO LLC

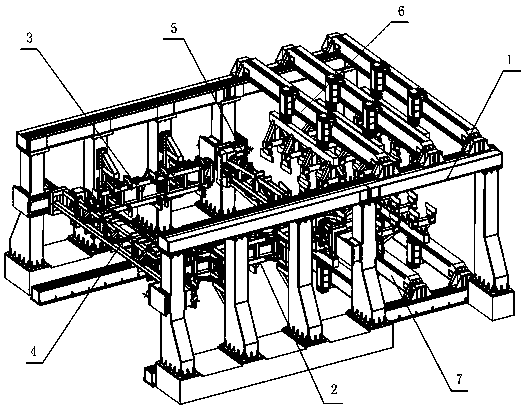

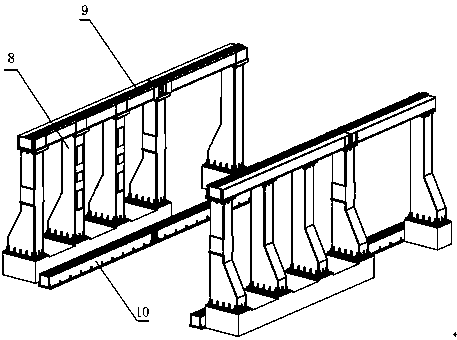

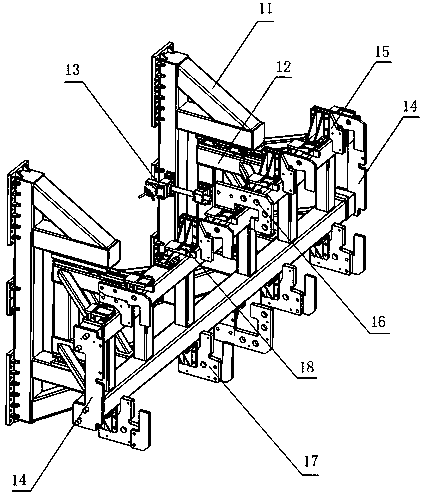

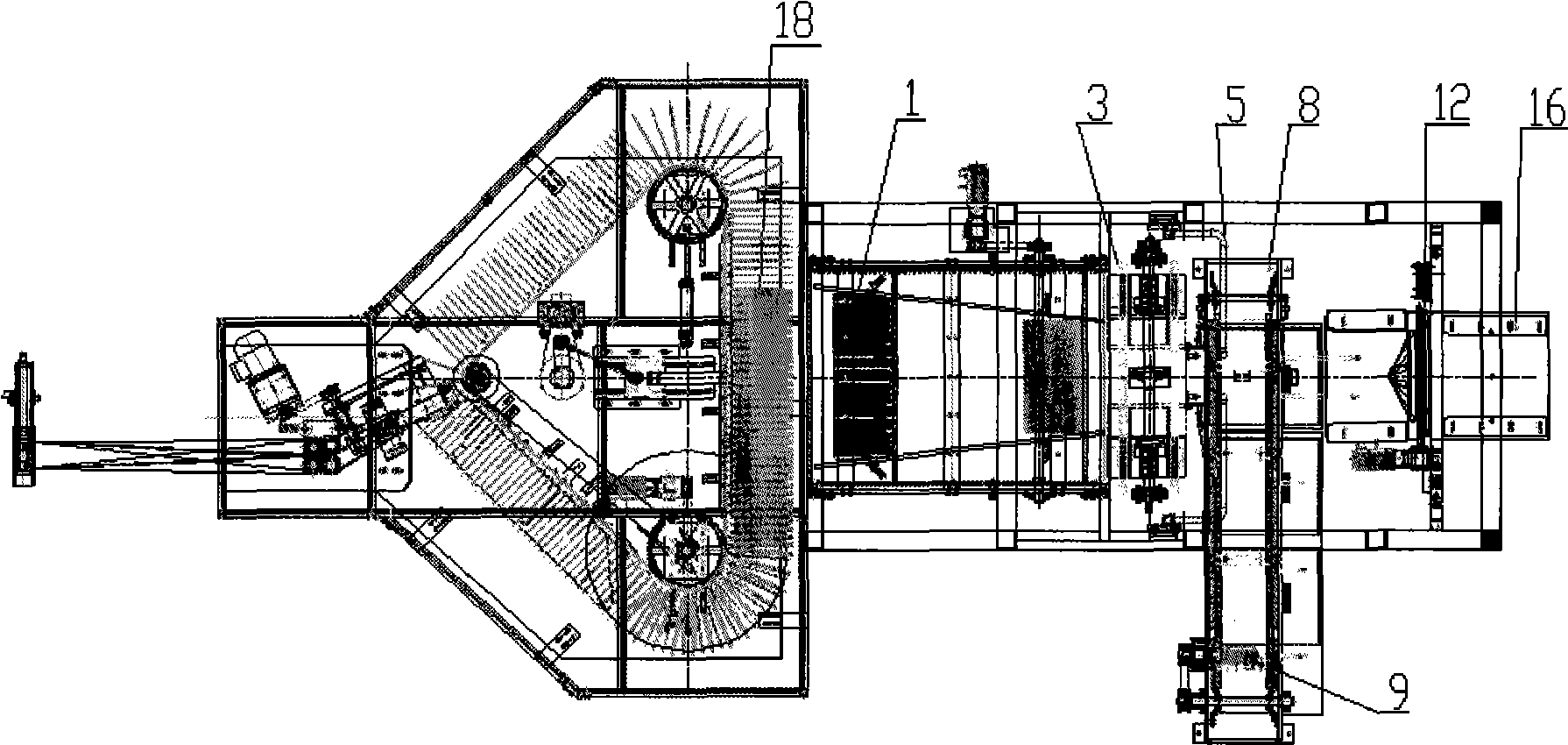

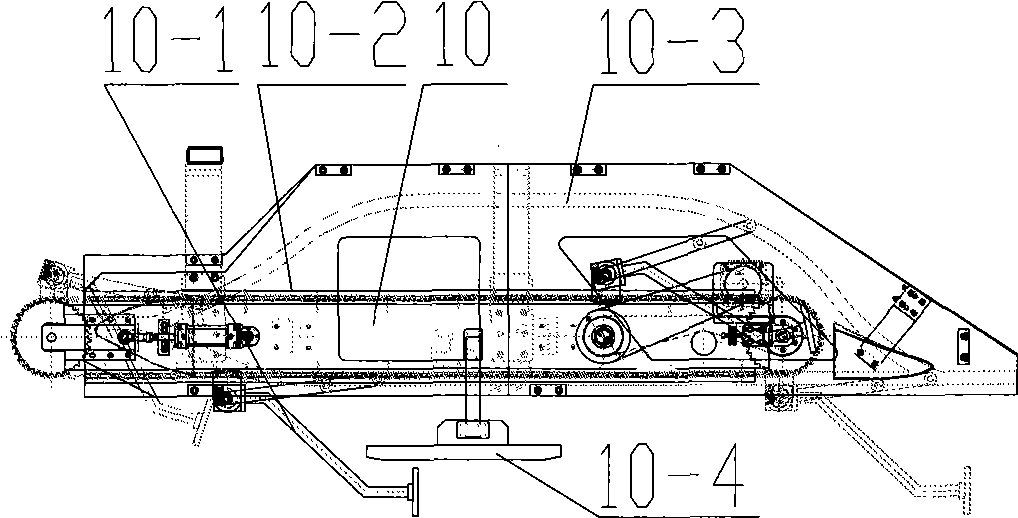

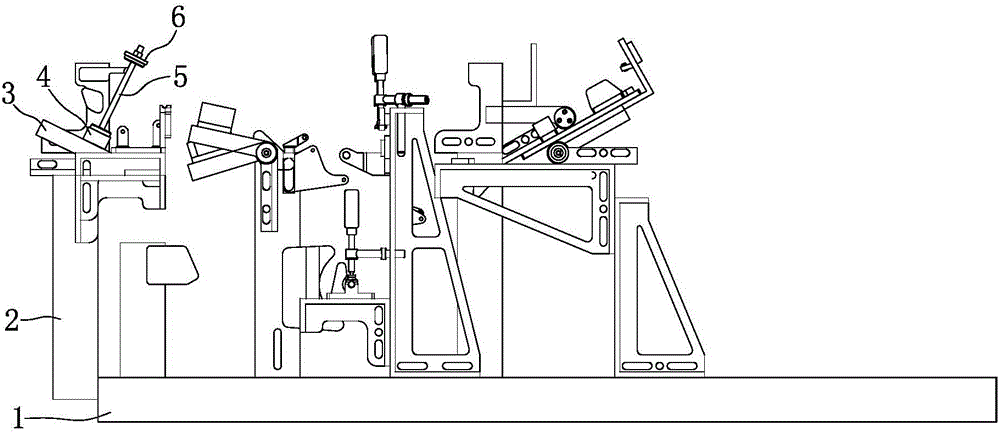

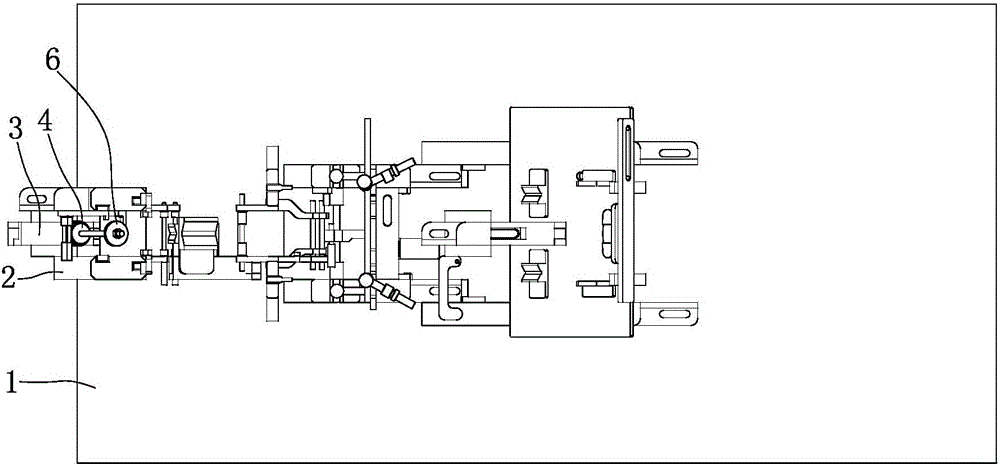

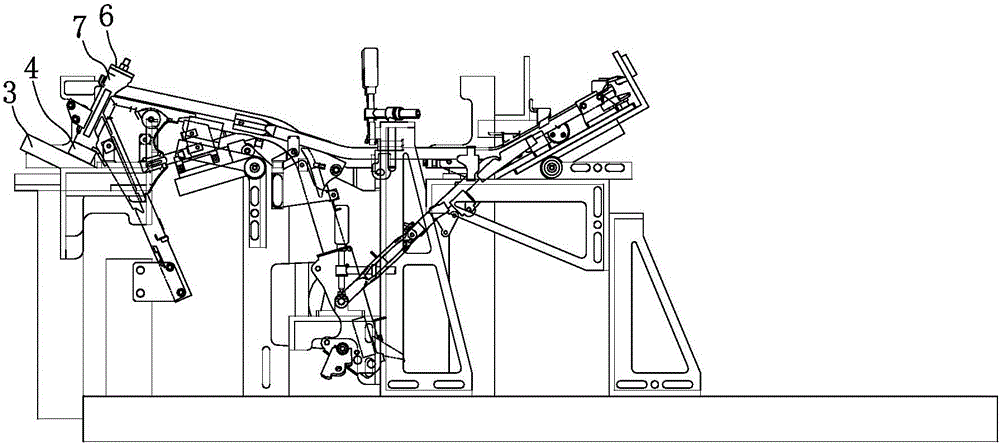

Aircraft center wing box digital assembly positioning system and positioning method

ActiveCN109204873AAchieve precise positioningIncreased versatilityAircraft assemblyAutomatic controlPositioning system

An aircraft center wing box digital assembly positioning system and positioning method are provided. A digital flexible positioning tool is divided into a bed body unit, a front spar positioning unit,a rear spar positioning unit, a left wing rib conformal unit, a right wing rib conformal unit, an upper tooling positioning pressing unit and a lower tooling positioning pressing unit according to functional modules. At first, an automatic positioning method is performed with the skeleton as the reference; skeleton parts such as the front spar, the rear spar and the wing rib of the large-scale central wing box are accurately positioned, and then the upper panel, the low panel and the longitudinal spar are positioned with the skeleton as a reference until the whole positioning process of the central wing box is completed. The digital assembly positioning system and positioning method are capable of accurate positioning, automatic control, multi-functional integration, and flexible design of large-scale center wing boxes.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

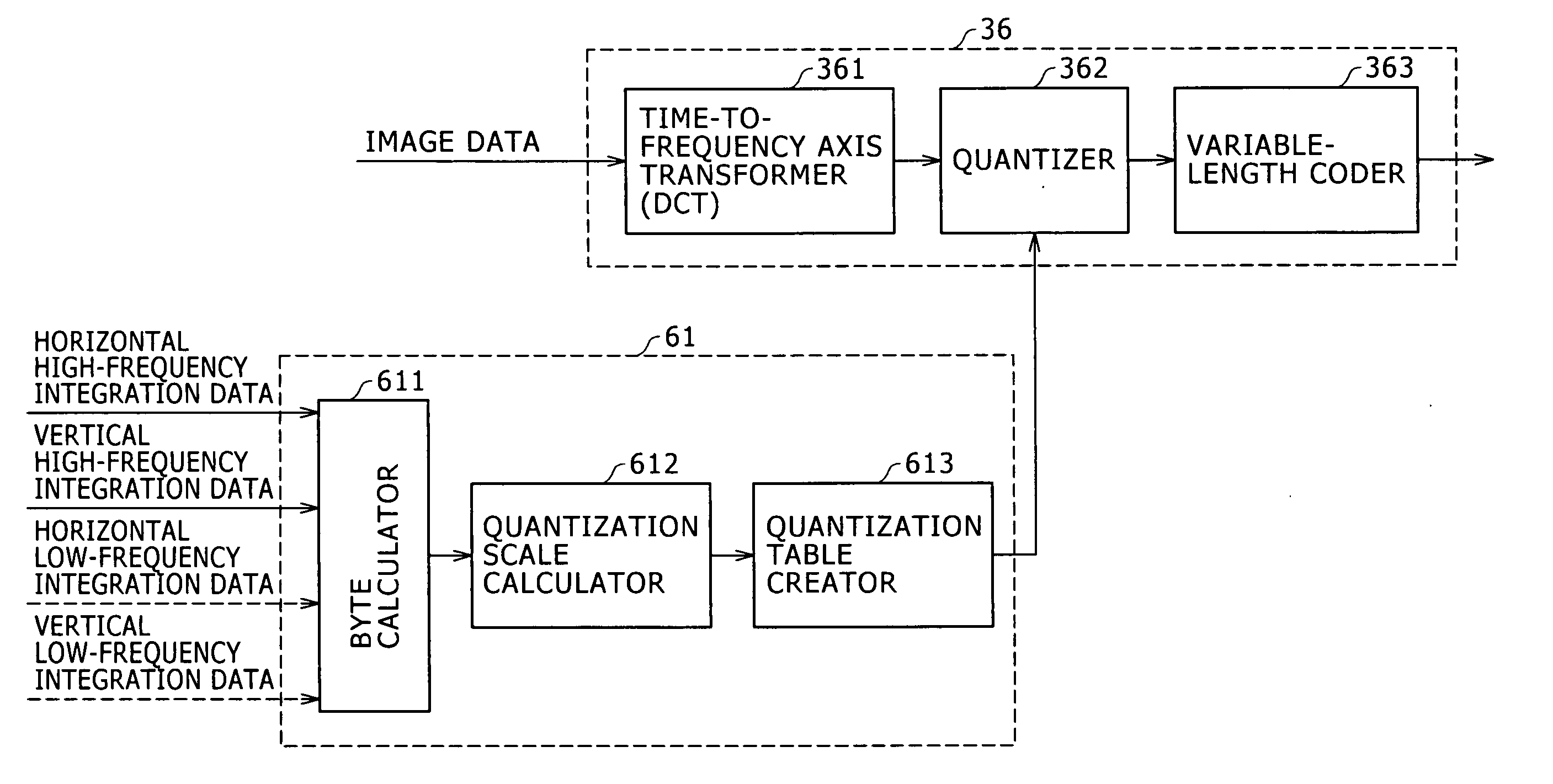

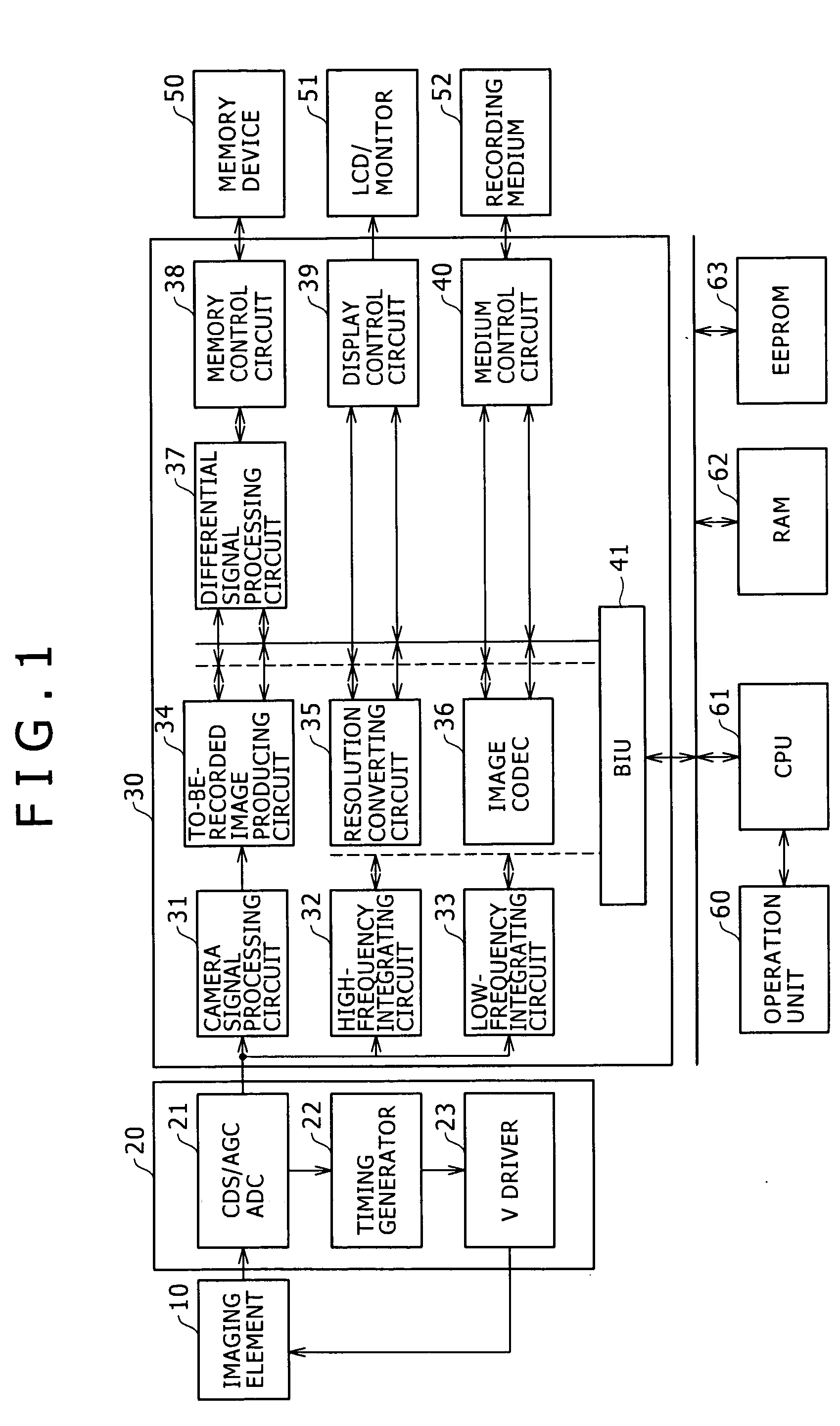

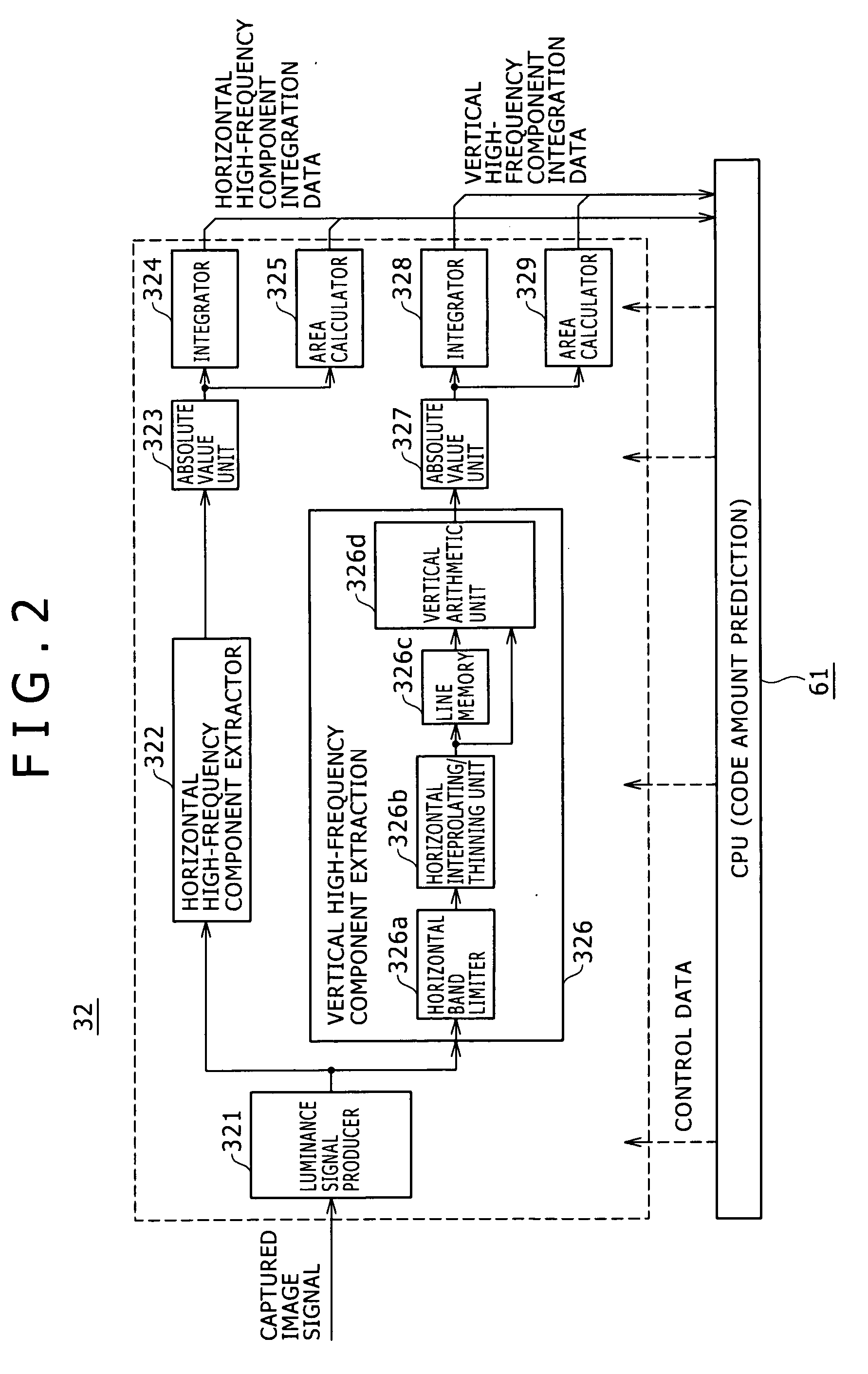

Image compression processing device, image compression processing method, and image compression processing program

InactiveUS20070110328A1Easy to useQuick noteTelevision system detailsPicture reproducers using cathode ray tubesImage compressionImage signal

A high-frequency integrating circuit 32 detects characteristics of horizontal high-frequency components and vertical high-frequency components of the image formed by a processing-target image signal. Based on the detection result, a CPU 61 obtains the number of bits of the after-compression-coding data of the image signal, and calculates the compression rate dependent upon the number of bits. The CPU 61 controls an image codec 36 so that the processing-target image signal is compression-coded through only one time of compression coding processing by use of the calculated compression rate. This configuration allows the image compression processing (compression coding) to be rapidly executed with high accuracy.

Owner:SONY CORP

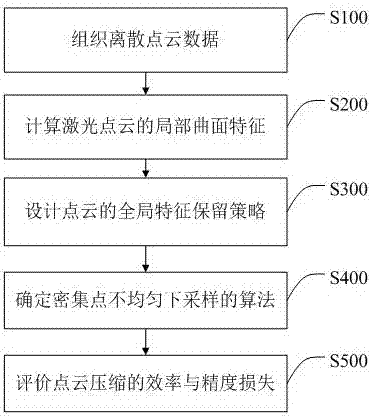

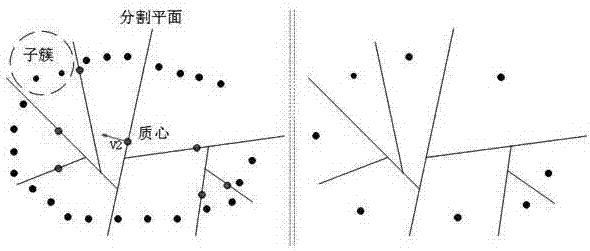

Compression method of airborne high-density laser point clouds, storage device and laser radar

The invention discloses a compression method of airborne high-density laser point clouds, a storage device and a laser radar. The compression method includes the following steps that: spatial indexes are established for discretely distributed point cloud data by using a preset indexing mode; the spatial distribution features of the point clouds of a specific area are obtained through the related theory of a discrete surface, the local surface features of the laser point clouds are calculated; on the basis of data features required by a specific application, a certain quantity of point clouds containing the data features are extracted and reserved, and the point clouds containing the data features are adopted as global features; compression algorithms which are matched with the requirements of the application are screened out from universally applied discrete data down-sampling algorithms, and the compression algorithms are improved so as to be applied to the compression of dense point cloud data; and the selection and design of the compression algorithms are guided by means of point cloud compression algorithm evaluation. According to the compression method of the airborne high-density laser point clouds, the storage device and the laser radar of the invention, an efficient hierarchical segmentation algorithm is adopted, and a large number of dense point clouds are rapidly compressed through using a strategy of reserving boundary points, and therefore, the fast and efficient compression of high-density three-dimensional laser point cloud data which retains topographic features is realized.

Owner:深圳市建设综合勘察设计院有限公司

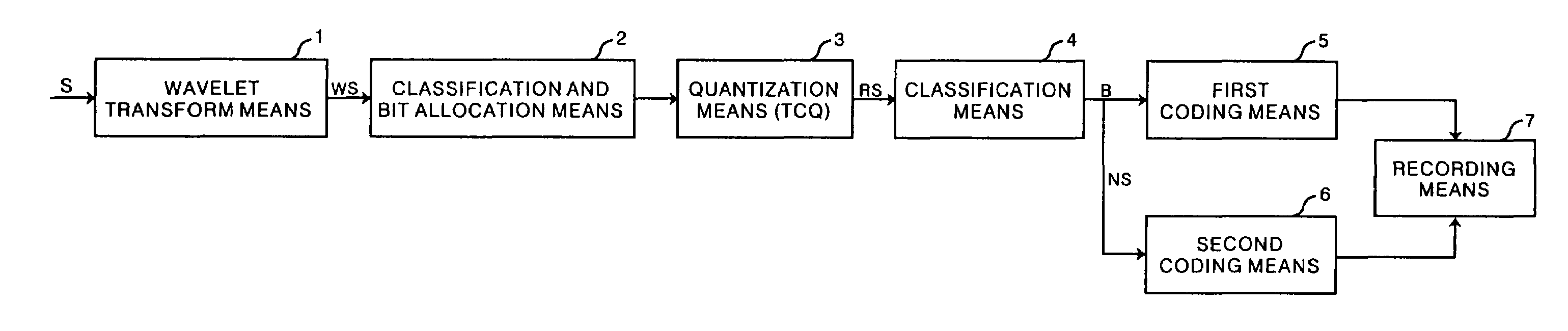

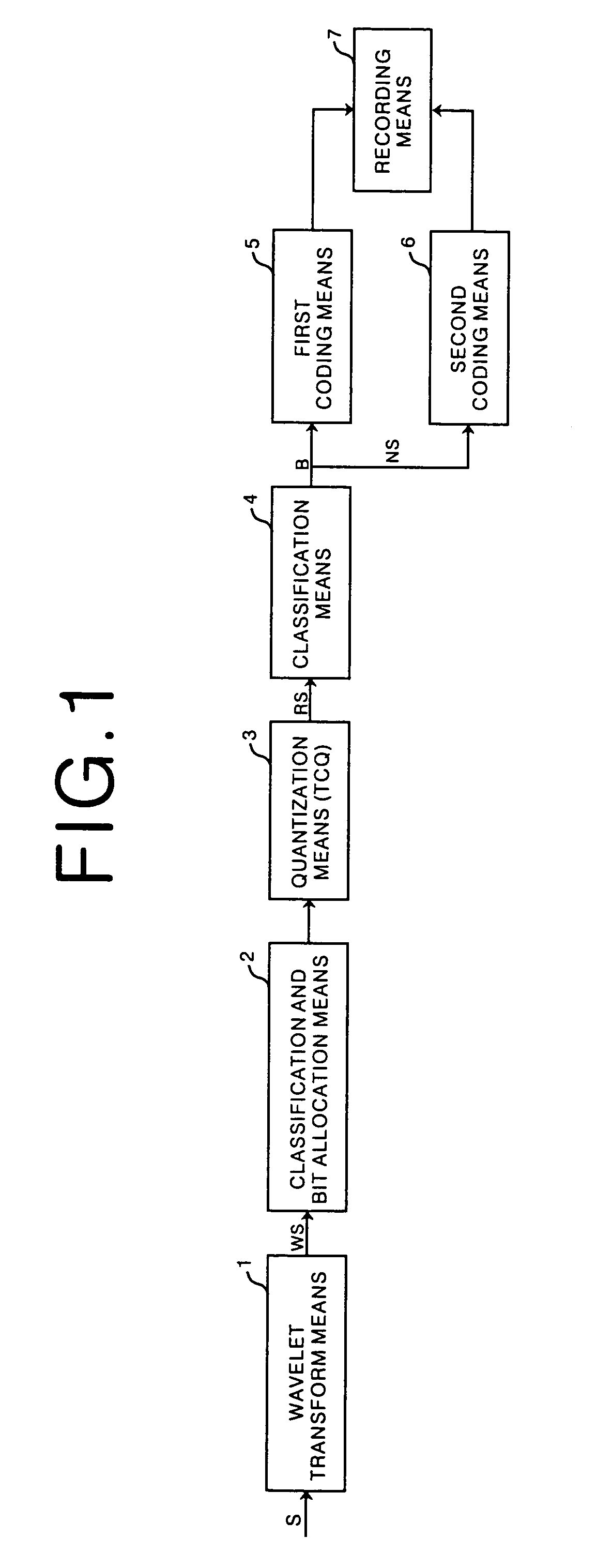

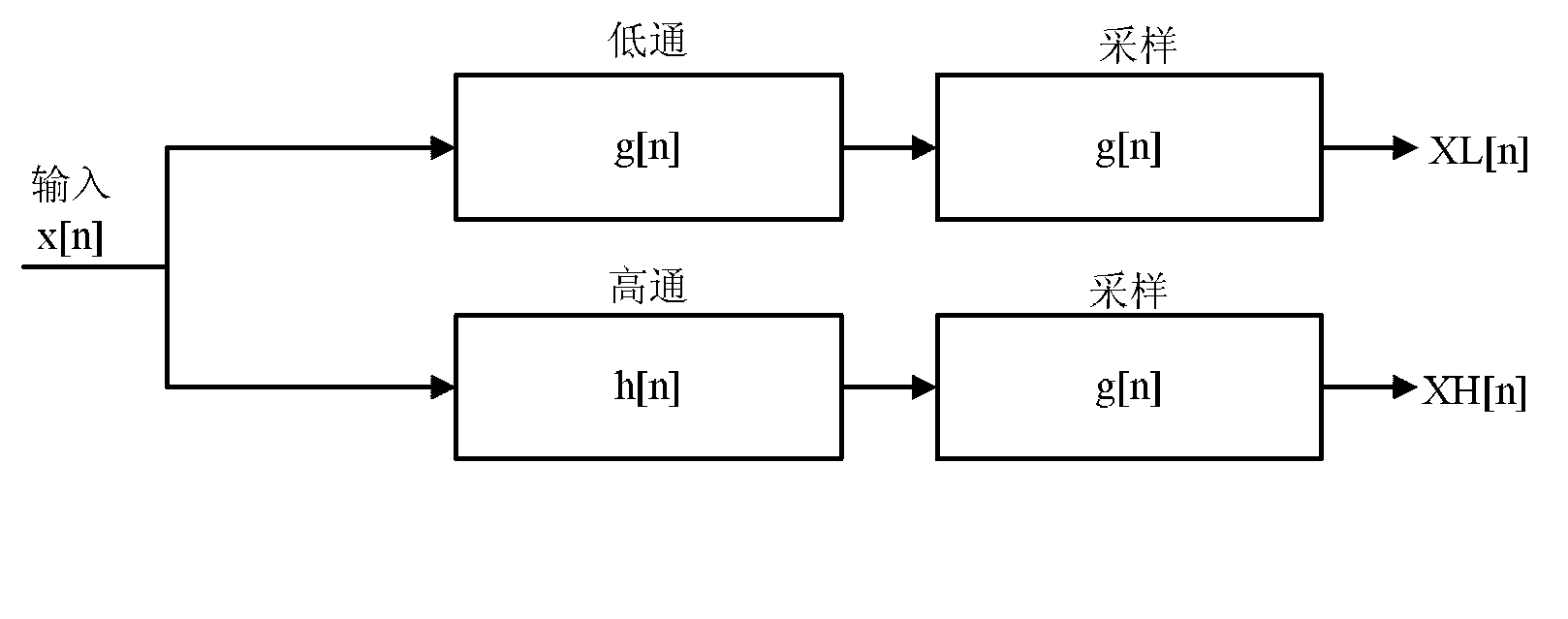

Method, apparatus and recording medium for data compression

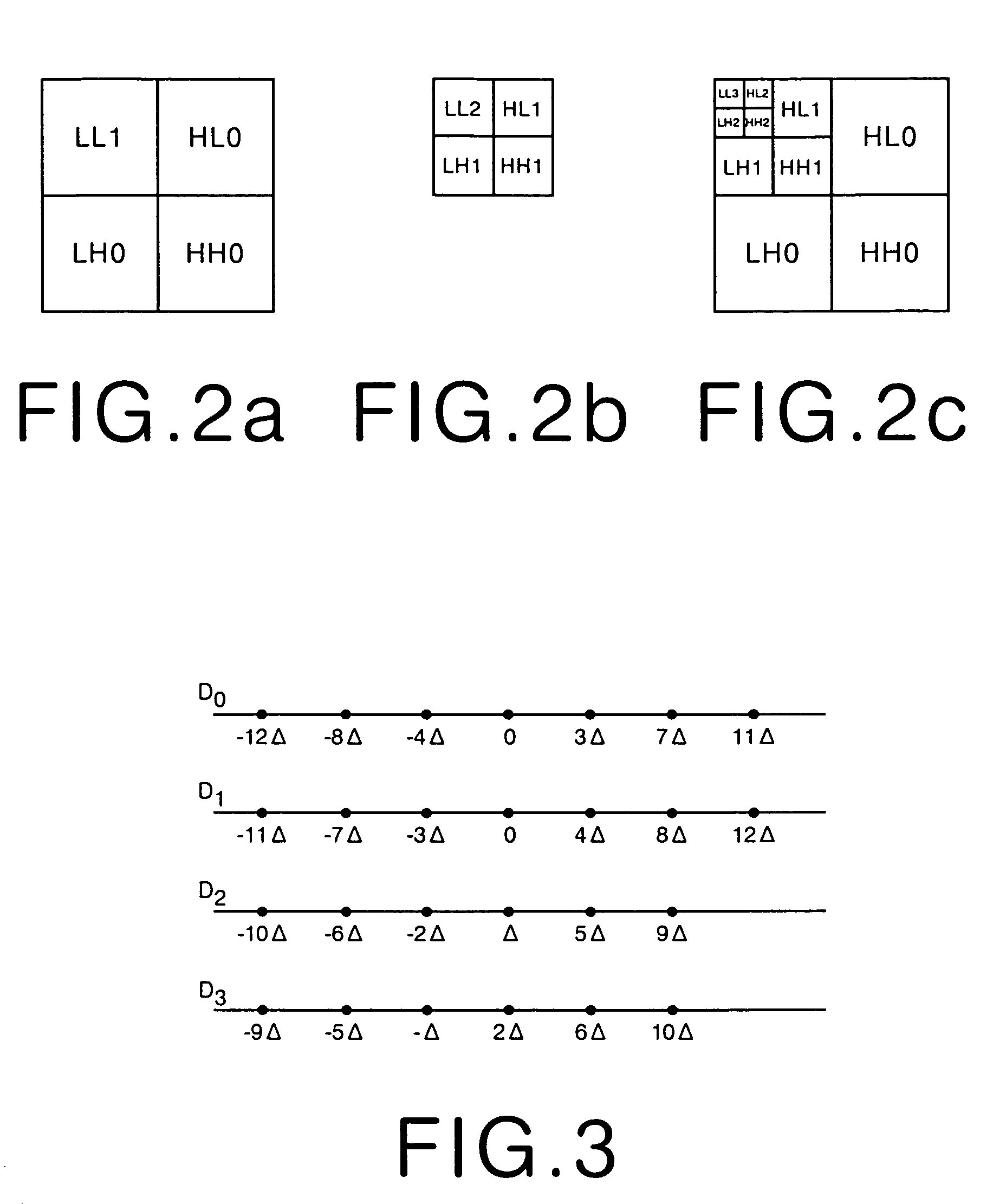

InactiveUS7003171B1Fast and efficient data compressionComputational loadCharacter and pattern recognitionDigital video signal modificationBit allocationBinary classification

Fast and efficient data compression can be carried out. Original image data are subjected to wavelet transform. The obtained wavelet-transformed data are classified and bit allocation is determined. Based on the determined bit allocation, the wavelet-transformed data are quantized and quantized data are obtained. The quantized data are classified into 0 data and non-zero data. Binary classification information data indicating this classification are also obtained. The classification information data are coded according to a coding method having a comparatively simple operation, such as Huffman coding and run length coding. The multi-valued, non-zero data are coded according to a coding method having a high compression efficiency although having a comparatively complex operation, such as universal coding and Golomb-Rice coding.

Owner:FUJIFILM HLDG CORP +1

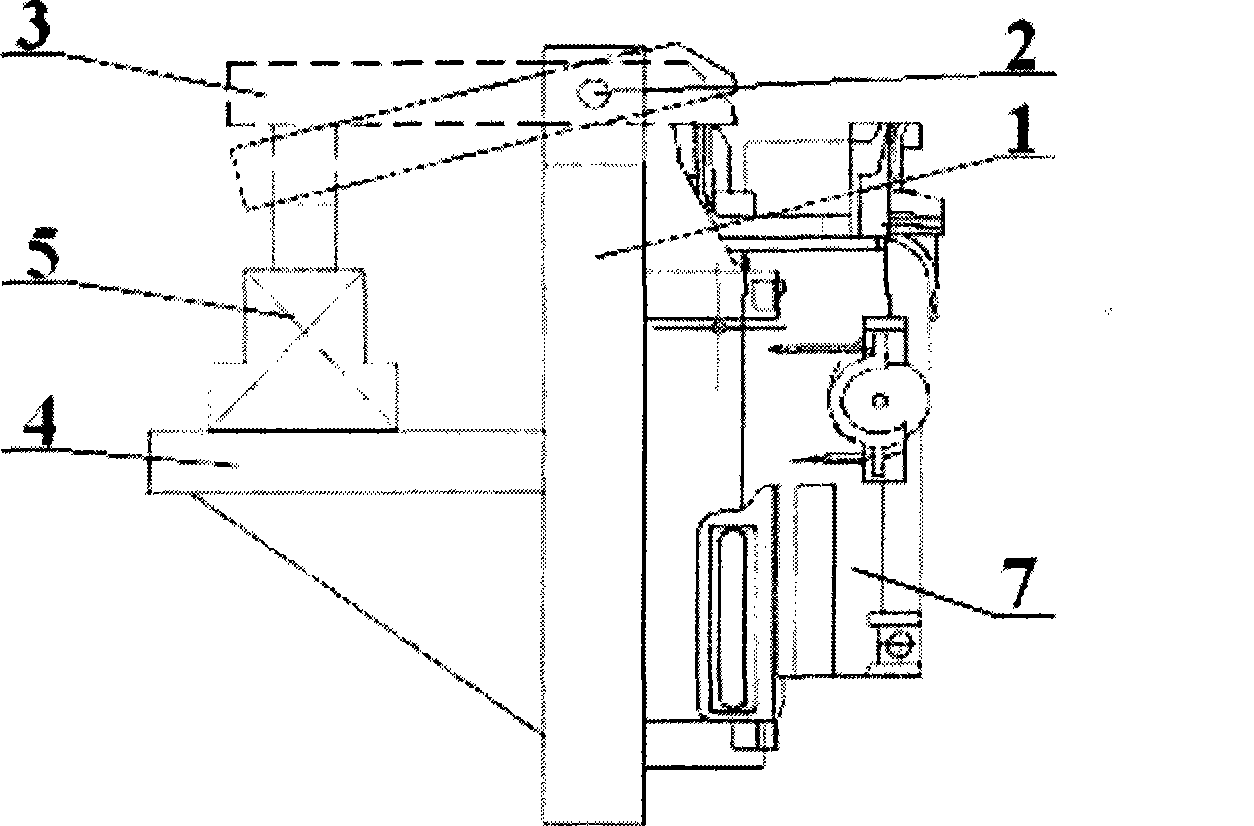

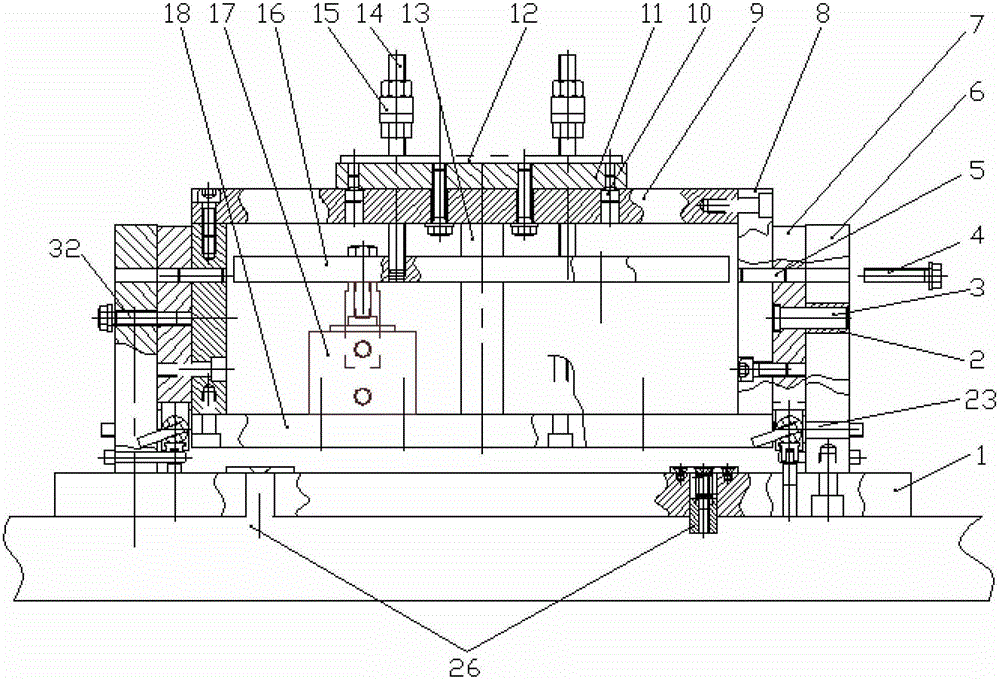

Pneumatic lever type clamping structure

InactiveCN101434040AStrong pressing forceEfficient compressionPositioning apparatusMetal-working holdersHigh rateGyration

The invention discloses a pneumatic lever type clamp structure. A pressure plate (3) is a lever structure, and the gyration center of the pressure plate is hinged with a clamp body (1) through a lever fulcrum (1); and under the state that a workpiece (7) is tightly clamped, one end of the pressure plate (3) is connected with a piston rod on a cylinder (5), while the other end is contacted with the clamped workpiece (7). With the technical proposal, pressing force of the cylinder can be increased through an arm of the lever structure by the lever principle when the cylinder is adopted, so that the processing workpiece can be pressurized conveniently and more effectively. The invention has a simple structure, can effectively improve the efficiency of processing parts, can realize stable processing tempo, and has the advantages of high rate of finished products and safe and convenient use.

Owner:THIXOMAG TECHNOLOGH WUHU

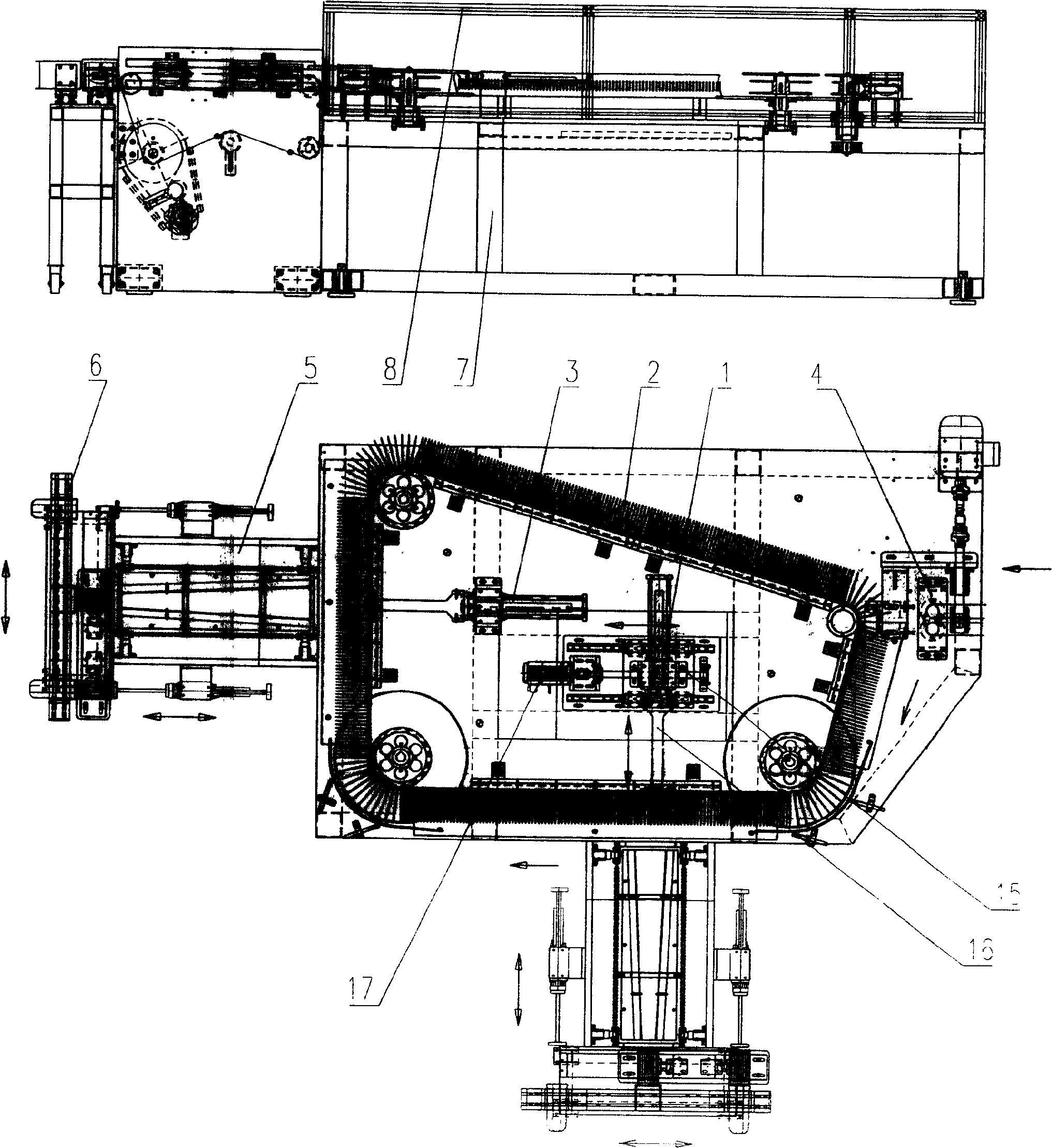

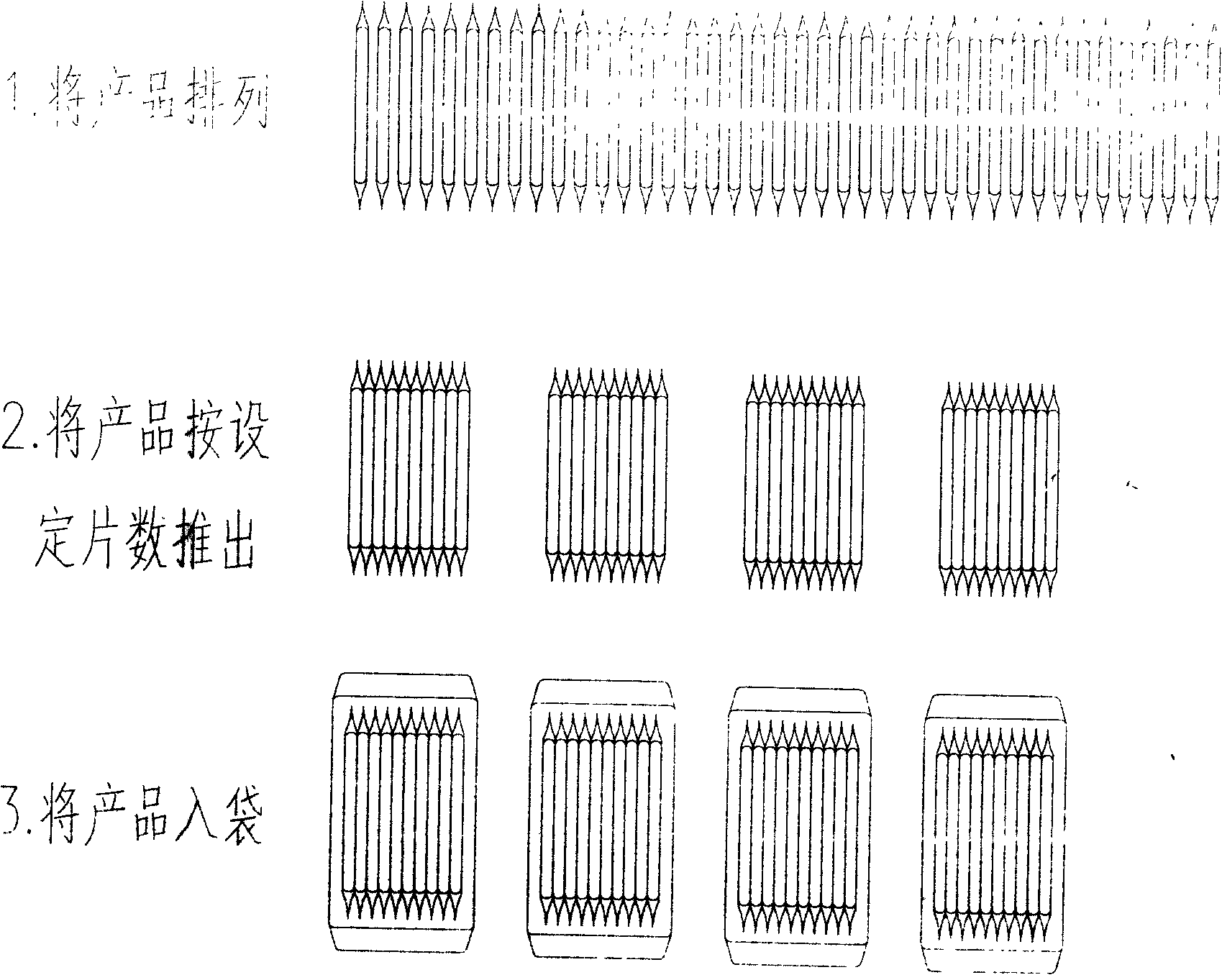

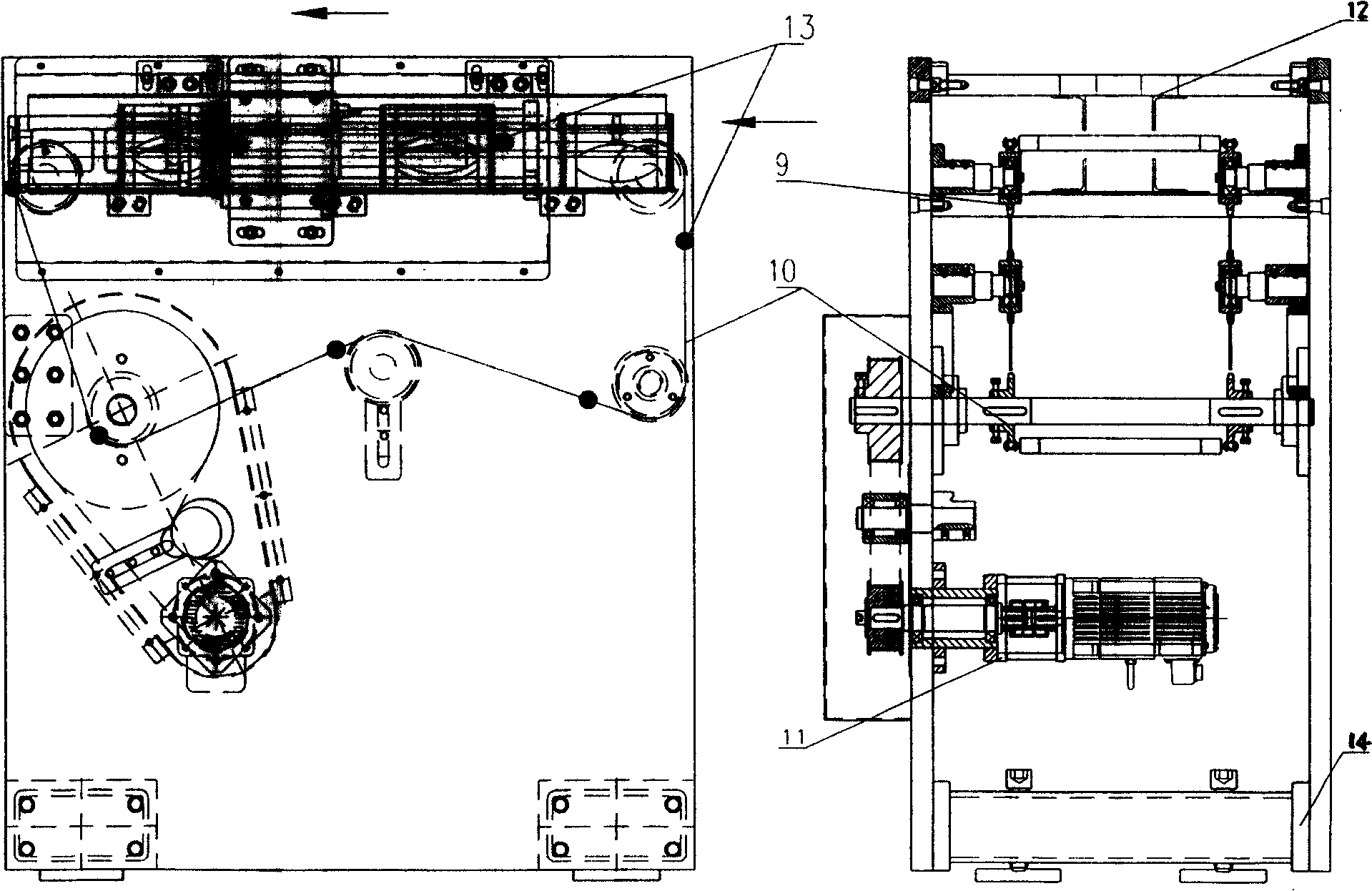

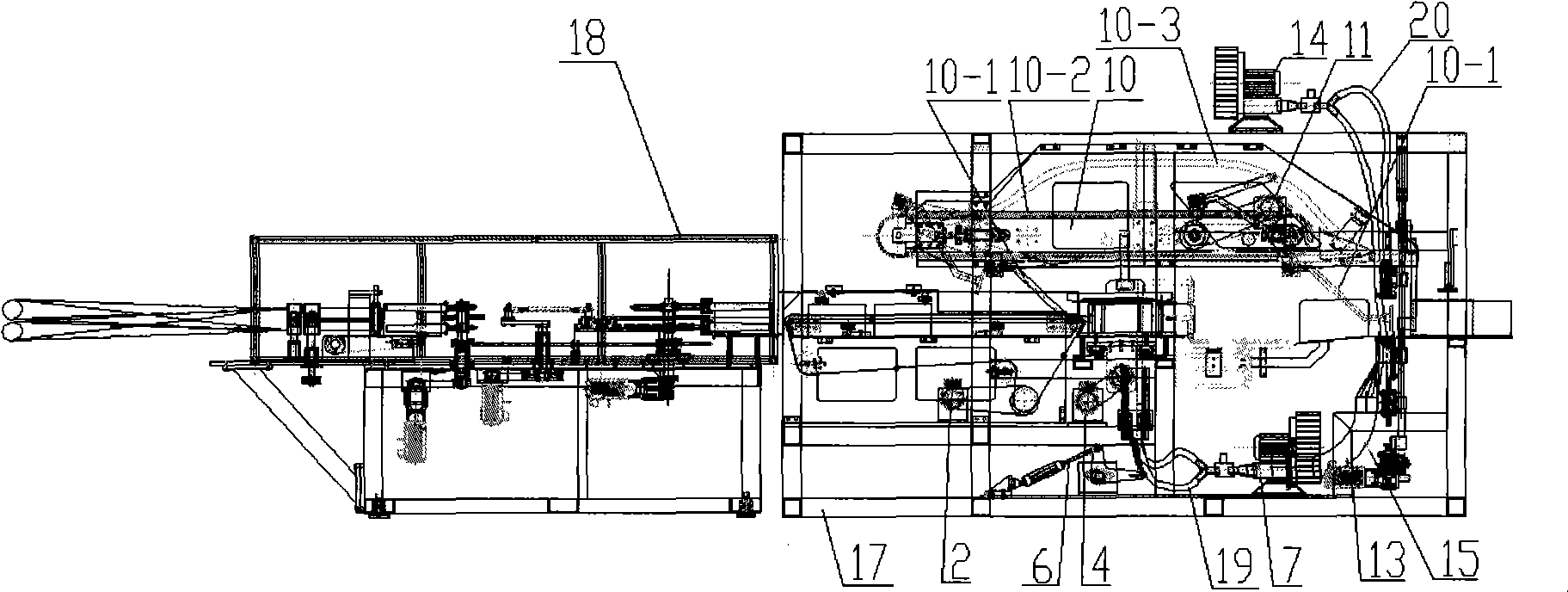

Sanitary towel production line high-speed buck stacker and stacking method

The invention relates to a device capable of stacking sanitary napkins at high speed and a method. A group ejecting mechanism I is composed of guide rails, an ejecting cylinder assembly and a motor drive assembly. The two guide rails are located on a frame, the ejecting cylinder assembly is located on the two guide rails, the motor drive assembly is located between the two guide rails, and a driving shaft in the motor drive assembly is connected with the cylinder assembly and drives the cylinder assembly to move back and forth along the guide rails. A group ejecting mechanism II formed by a cylinder assembly is located on the frame. Two clamping output devices are composed of a chain supporting mechanism, a push rod circulation mechanism, a power unit, a clamping device, a push rod device and a frame, wherein the chain supporting mechanism inside the frame is driven by the power unit, the clamping device on the frame is located between two chains of the chain supporting mechanism, the push rod circulation mechanism on the chain supporting mechanism is driven by and synchronously moves with the chain supporting mechanism, and two ends of the push rod device are respectively connected with the push rod circulation mechanism and driven by the push rod circulation mechanism.

Owner:HANGZHOU CREATOR MACHINERY MFG

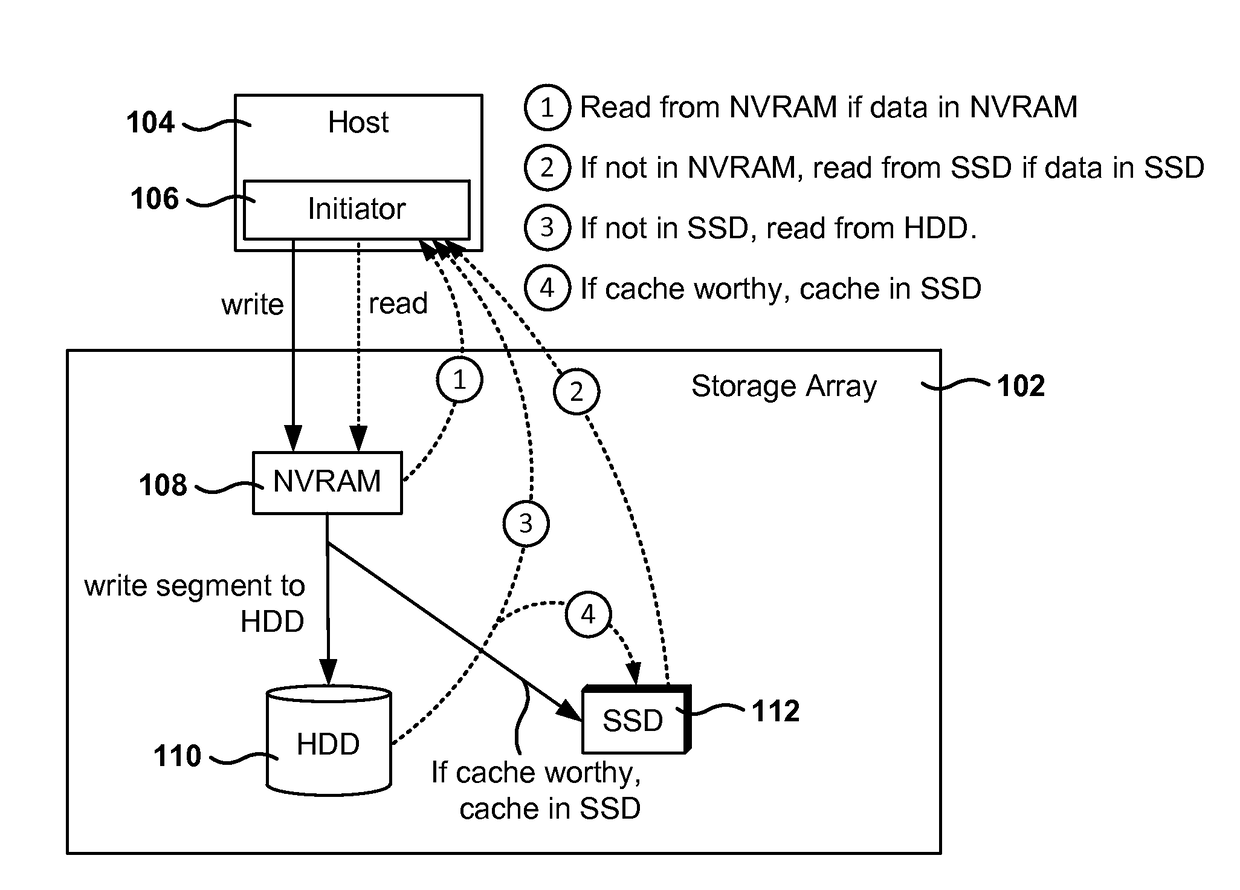

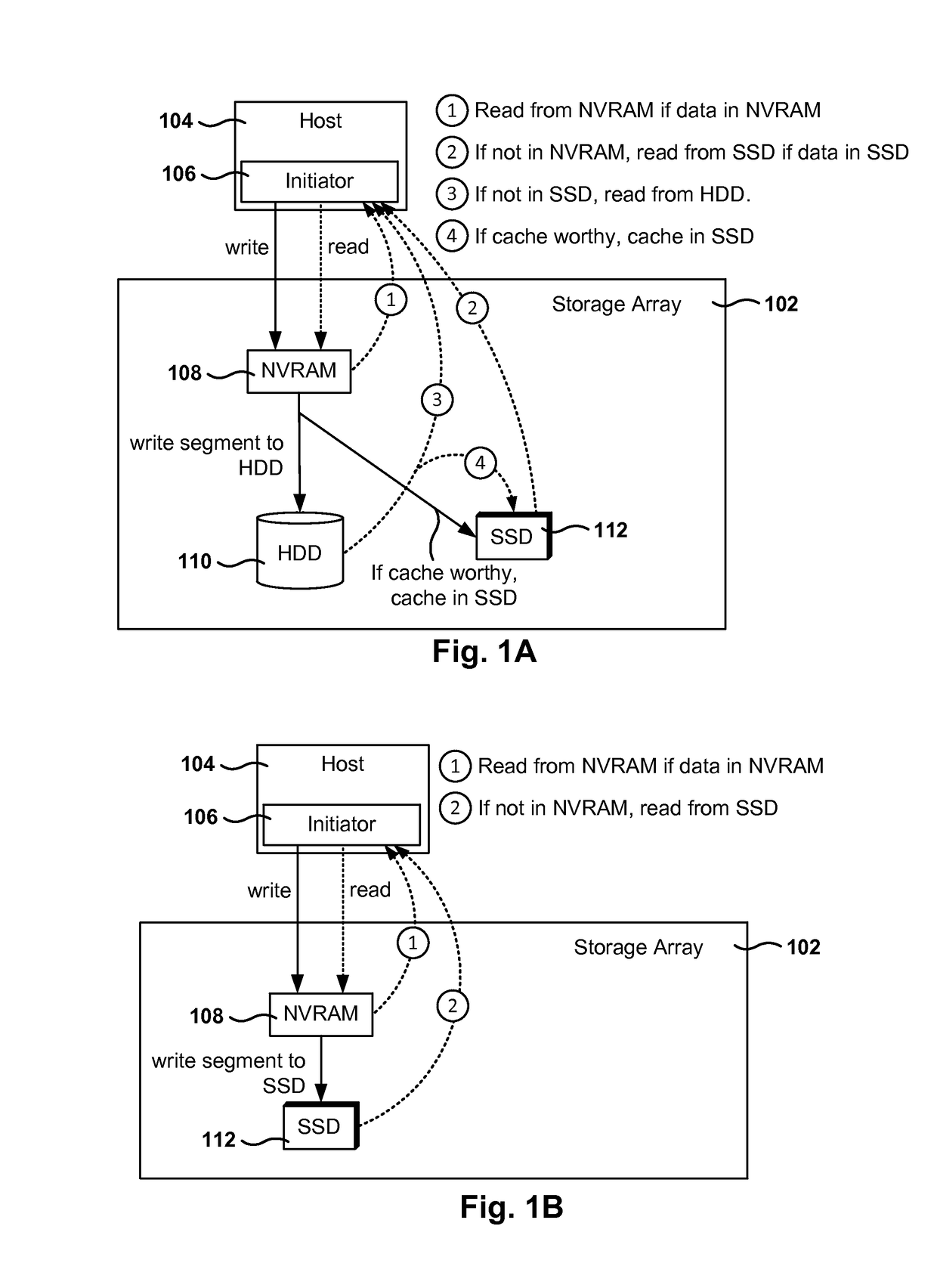

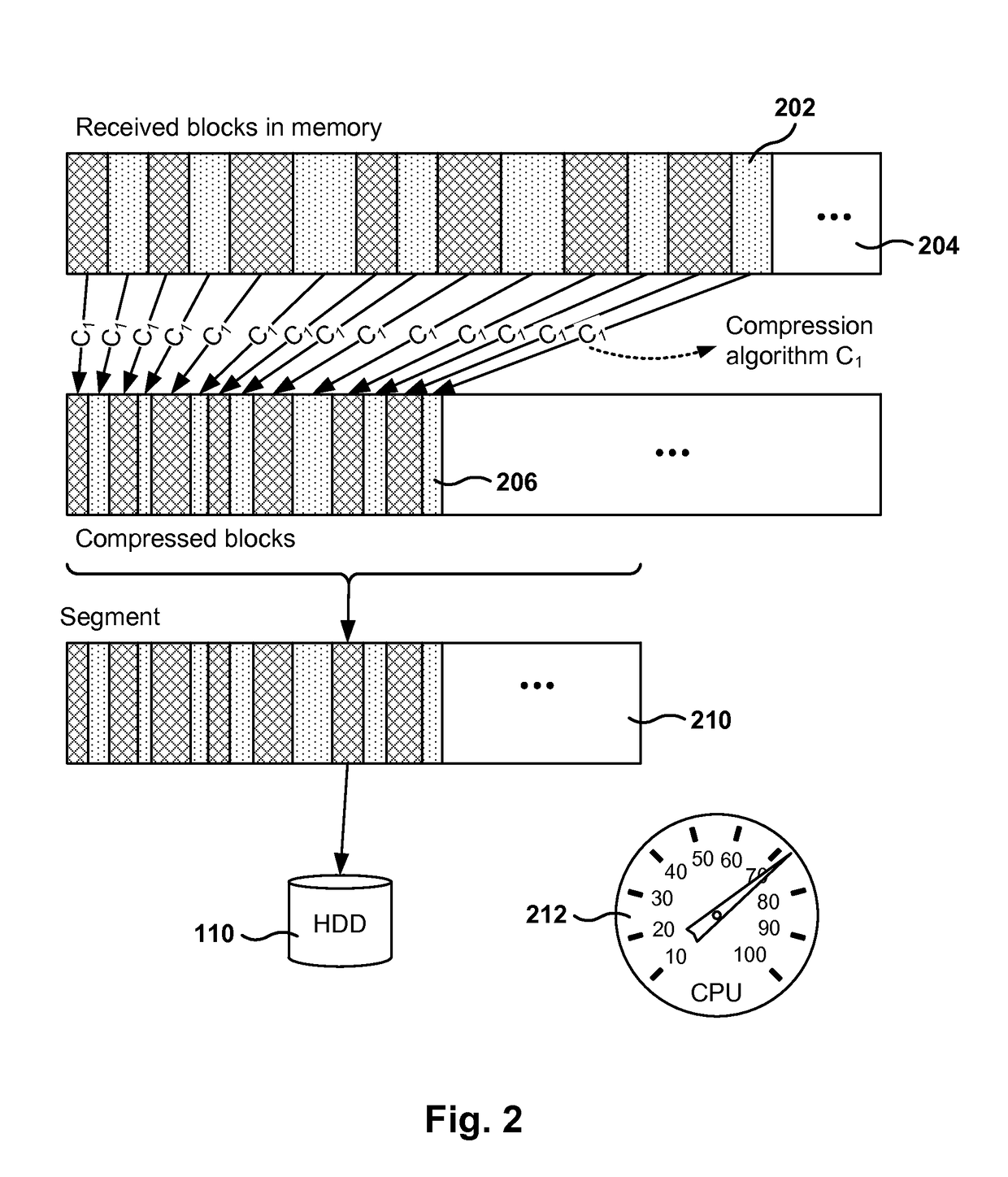

Dynamic adaptive compression in network storage device

ActiveUS20170123704A1Efficient compressionQuick compressionInput/output to record carriersCode conversionAdaptive compressionParallel computing

Methods, systems, and computer programs are presented for dynamic adaptive compression in a storage device. One method includes operations for setting a percentage factor for utilizing a first and a second compression algorithms, and for receiving incoming blocks in the memory of the storage device. The incoming blocks are compressed before being sent to permanent storage, where a portion of the incoming blocks are compressed with the first compression algorithm based on the percentage factor, and the remainder is compressed with the second compression algorithm. Further, the method includes determining that a processor utilization rate, of a processor in the storage device, is below a first predetermined threshold, and decreasing, in response to the determining, the percentage factor to decrease the portion of the incoming blocks that are compressed with the first compression algorithm, while the remainder of the incoming blocks is compressed with the second compression algorithm.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

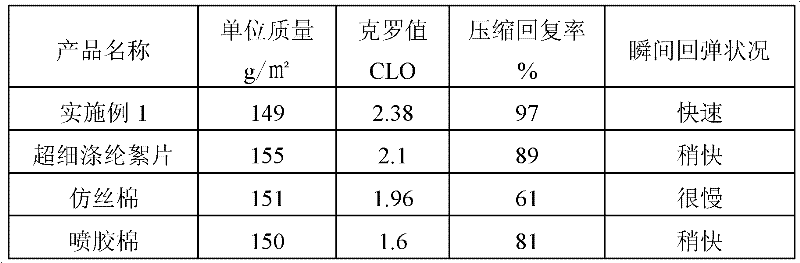

Rapid high-rebound high-heat-preservation floccus flake and preparation method thereof

The invention discloses a rapid high-rebound high-heat-preservation floccus flake and a preparation method thereof. The elastic heat-preservation floccus flake is prepared by processing raw materials of superfine polyster fiber, hollow fiber with triangular or special-shape holes therein, composite elastic fiber, viscose fiber, polyster fiber with common properties and hollow fiber with a round inner part. The floccus flake is prepared by blending novel high-performance fiber, special fiber, functional fiber and the conventional fiber in different ratios. The obtained floccus flake has the characteristics of quick and high rebound resilience and high heat preservation. The floccus flake meets requirements on lightness of a sleeping bag, compression and rebound, heat preservation, comfortability and the like. The product overcomes the defects of the heat-preserving floccus flake in the conventional sleeping bag, and increases heat preservation ratio and compression resilience ratio.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

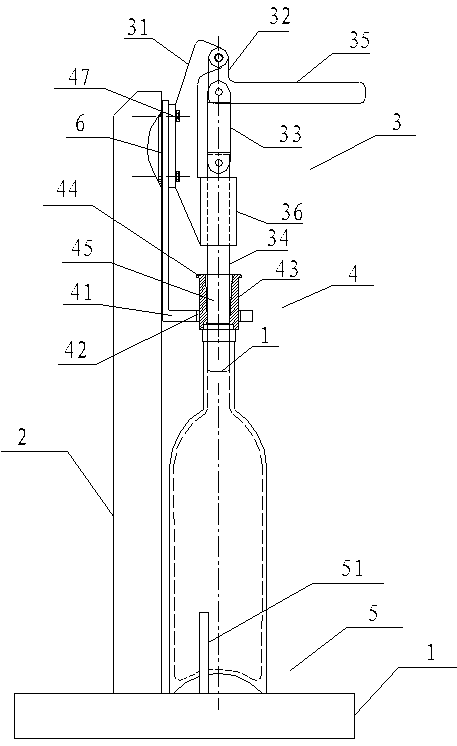

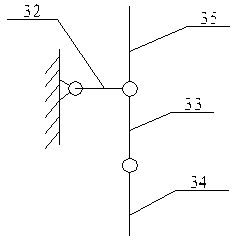

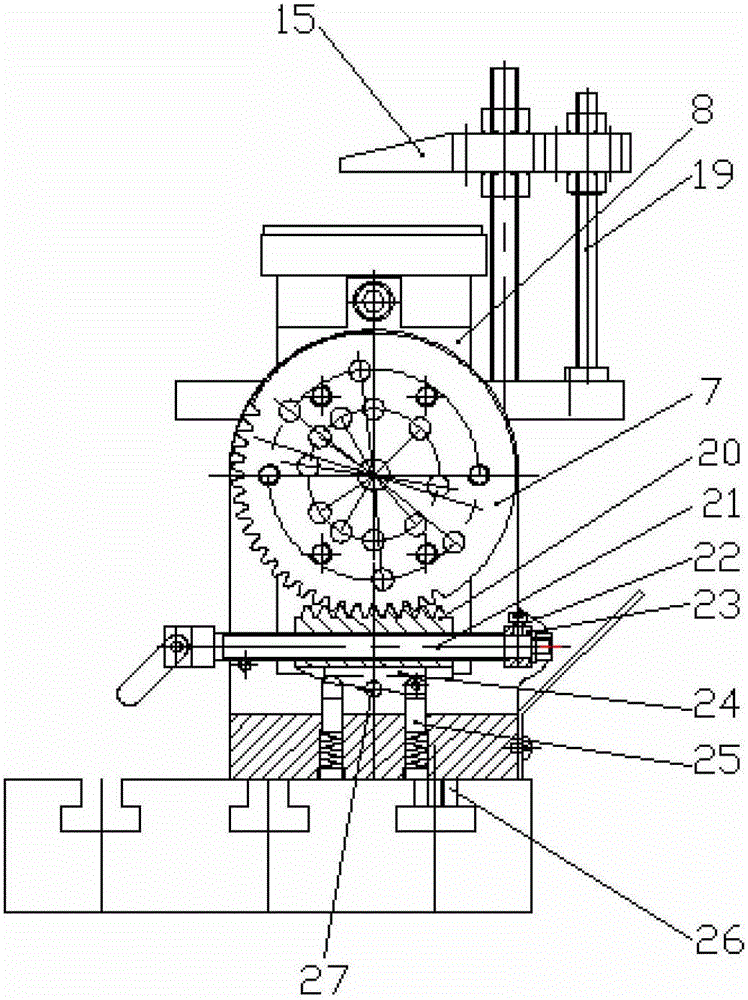

Cork pressing device

InactiveCN103159151AQuick compressionGuaranteed to press in correctlyThreadless stopper insertionEngineeringMechanical engineering

The invention discloses a cork pressing device. The cork pressing device comprises a support base plate and a support vertical plate, wherein the support base plate and the support vertical plate are mutually perpendicular. The support vertical plate is provided with a cork pressing mechanism, and a cork guide mechanism arranged below the cork pressing mechanism. The support base plate is provided with a locating mechanism used for fixing objects to be pressed. Centers of the cork pressing mechanism, the cork guide mechanism and the locating mechanism are collinear. The cork pressing mechanism is a crank-link mechanism. The support vertical plate is further provided with a slotted hole used for adjusting the height of the cork pressing mechanism. By rotating a crank, a cork can be pressed fast, operation is simple and convenient, much time and labor do not need to be consumed, and sealing efficiency is improved. By arranging the cork guide mechanism, the cork can be pressed correctly. Meanwhile, by arranging the locating mechanism, the objects to be pressed can be located accurately. By arranging the slotted hole used for adjusting the height of the cork pressing mechanism in the support vertical plate, adjustment can be carried out according to the height of the objects to be pressed. The cork pressing device is strong in genenrality.

Owner:苏州微纳过滤设备有限公司

Pants products packing device and method

ActiveCN101508351APrevent poppingReliable heat sealingWrapper twisting/gatheringPackaging automatic controlEngineeringRelative motion

The invention relates to a pants-type product packing machine capable of packaging and sealing a plurality of pants-type products after precompression gas exhaust and rapid compression, and a packing method. The packing machine comprises a stander, a sealing cutting device and a waste material recovery device, wherein a movable precompression device is in shape of a contraction passage of which two sides are provided with two sets of mutually symmetrical annular chain driving mechanisms driven by a precompression servomotor; a product compressor is positioned at an outlet of the contraction passage 1, and the precompression servomotor drives a double-ended guide screw which drives two compression plates thereon to perform quick relative motions so as to compress the pants-type products; product bag-opening devices are positioned at the outlet of the product compressor and packaging bags are conveyed to the outlet of the compressor through a movable cylinder, and the product bag-opening devices at two sides of the outlet of the contraction passage suck the bag openings of the packaging bags open; a bag conveyor is positioned at the outlet of the product bag-opening device and is driven to move by a bag conveying servomotor; and the sealing cutting device is positioned at the outlet of the bag conveyor.

Owner:ZHEJIANG YONGCHUANG MACHINERY

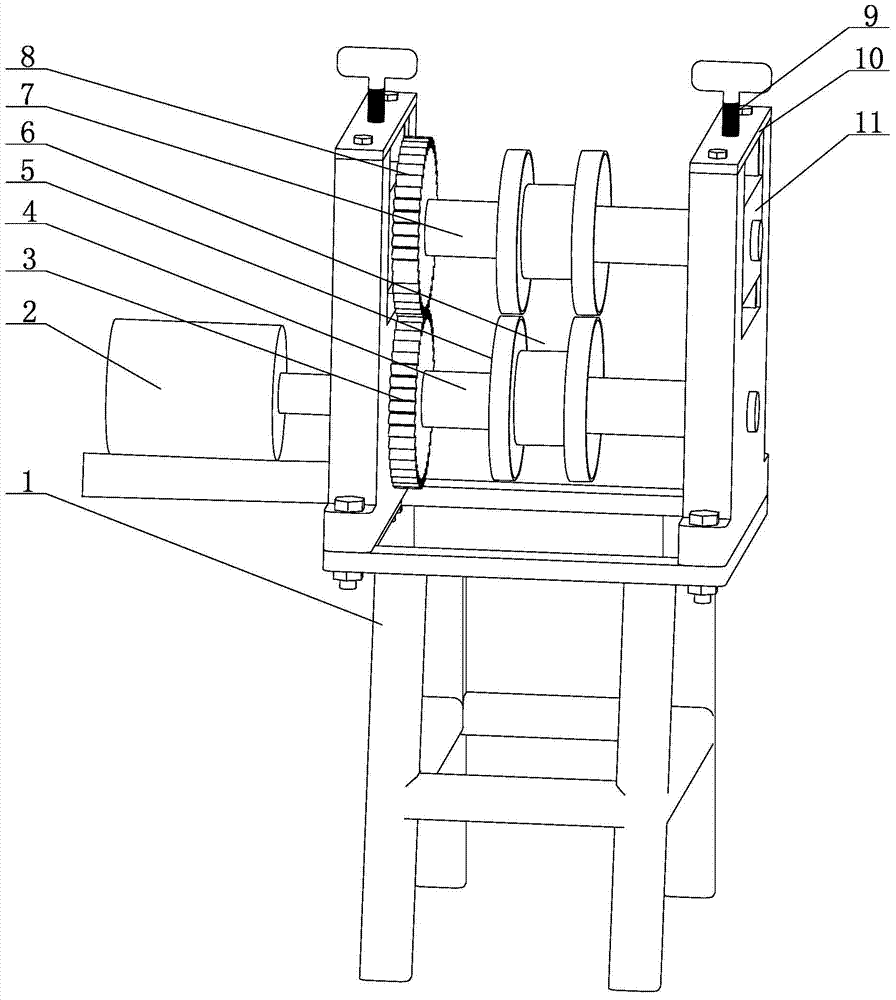

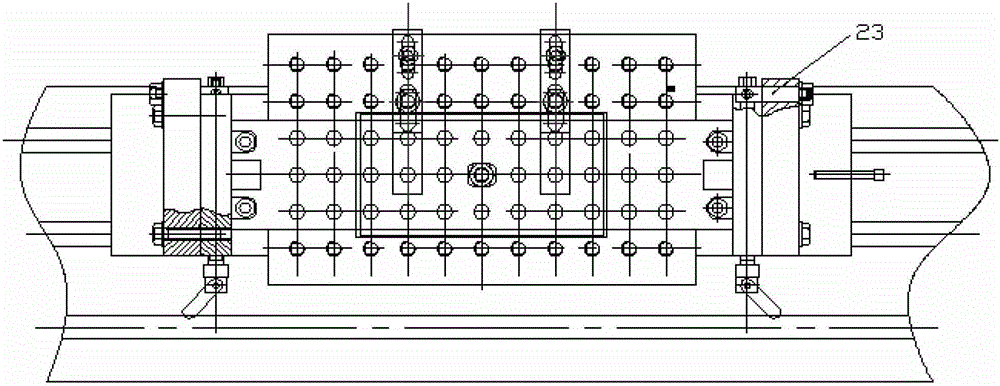

Adjustable stranded cable wire pressing device

InactiveCN104715861AReasonable structureQuick compressionCable/conductor manufactureGear wheelDrive shaft

The invention, which belongs to the field of cable processing equipment, and particularly relates to an adjustable stranded cable wire pressing device, which comprises a rack and a driving shaft and a driven shaft arranged on the rack, wherein one end of the driving shaft is connected with a motor, and the other end is provided with a first gear; the first gear is engaged mutually with a second gear arranged at one end of the driven shaft; both the driving shaft and the driven shaft are provided with rolling wheels; positions of the two rolling wheels are corresponding vertically; the circumference of the rolling wheel is provided with an annular groove; and the upper part of the rack is provided with two driven shaft height adjustment devices which are symmetrical horizontally. According to the device, the structure is reasonable; the rolling wheel on the driven shaft can be adjusted to move vertically via the driven shaft height adjustment devices; the device can thus be applied to cables of different diameters; the application range is wide; in the case of operation, the motor can drive the two rolling wheels to rotate; the annular grooves of the upper rolling wheel and the lower rolling wheel are matched for action to vertically squeeze the cable; the wire in the stranded cable can be quickly pressed and rolled, and the operation is simple and convenient.

Owner:淄博思科电子技术开发有限公司

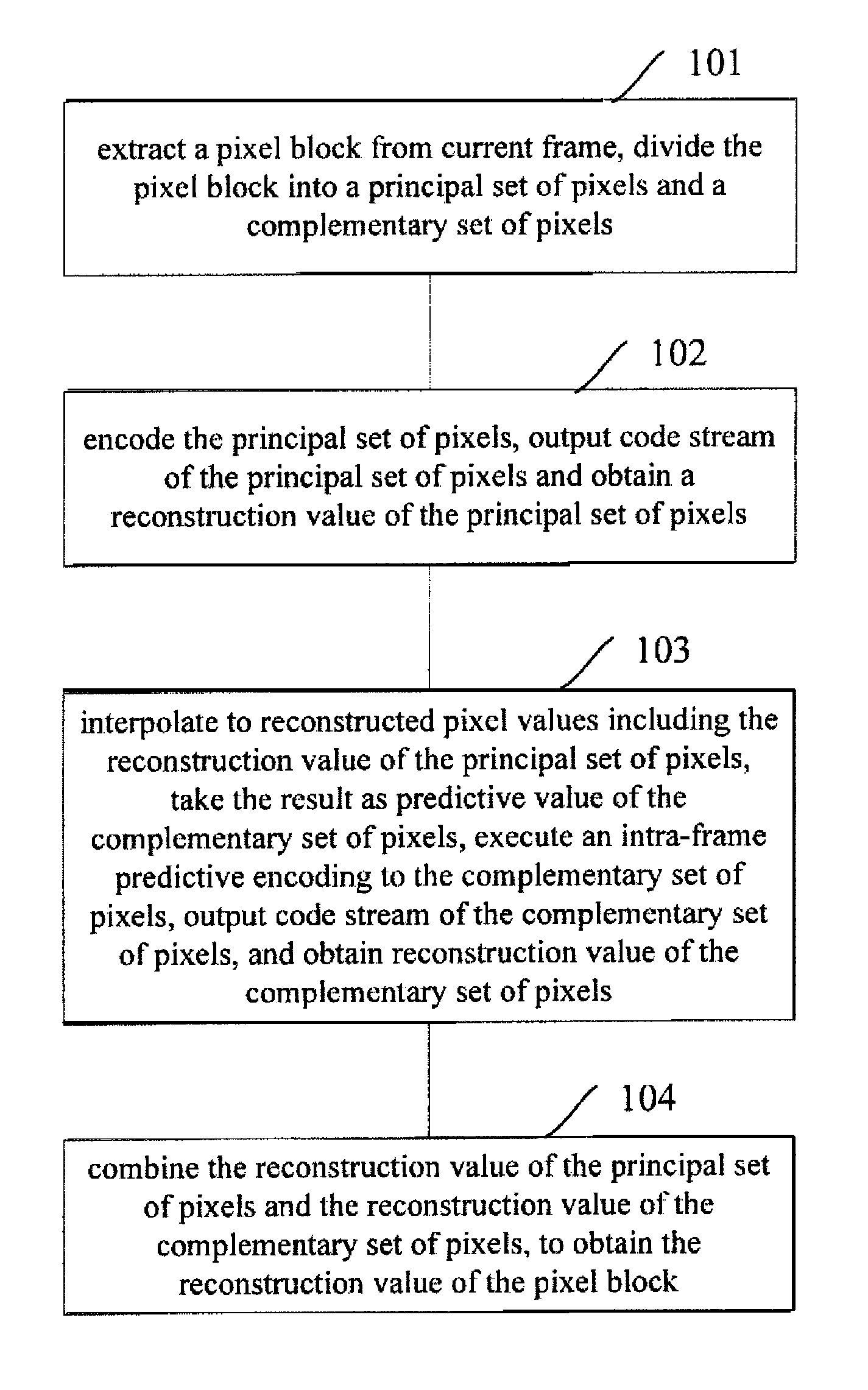

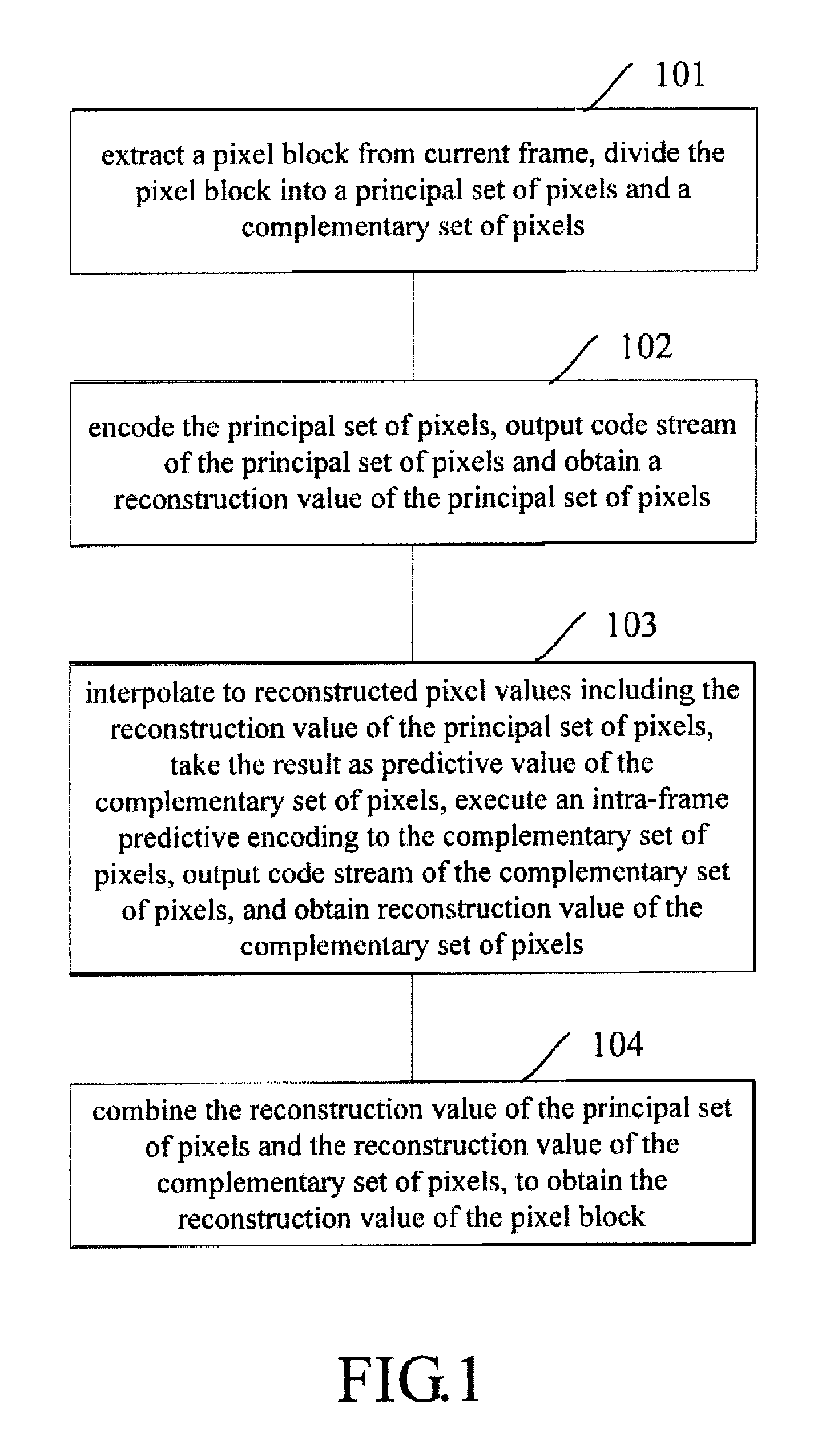

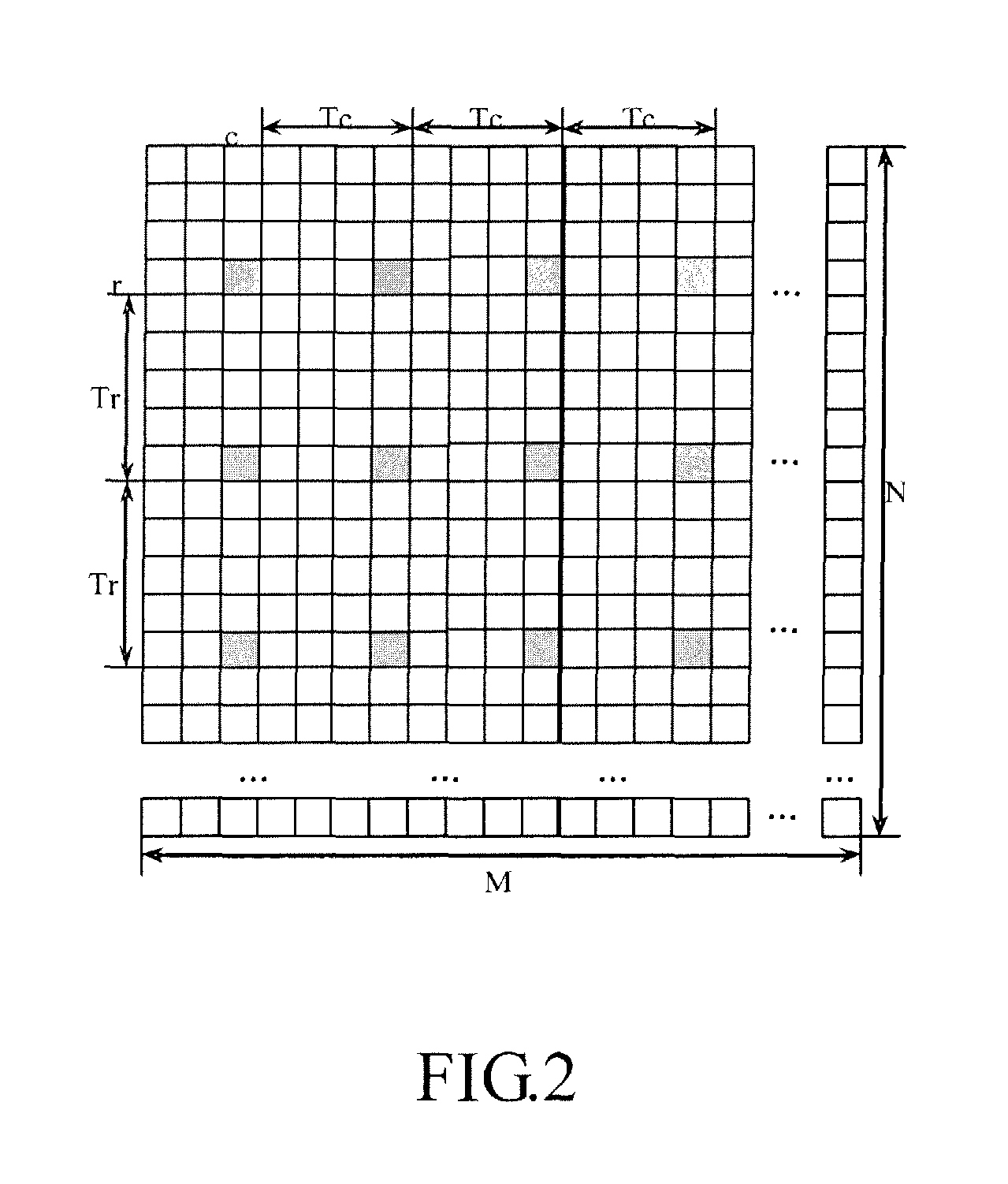

Method and device for video predictive encoding

ActiveUS8654845B2Improve compression efficiencyReduce overheadColor television with pulse code modulationPulse modulation television signal transmissionComputer hardwareVideo prediction

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

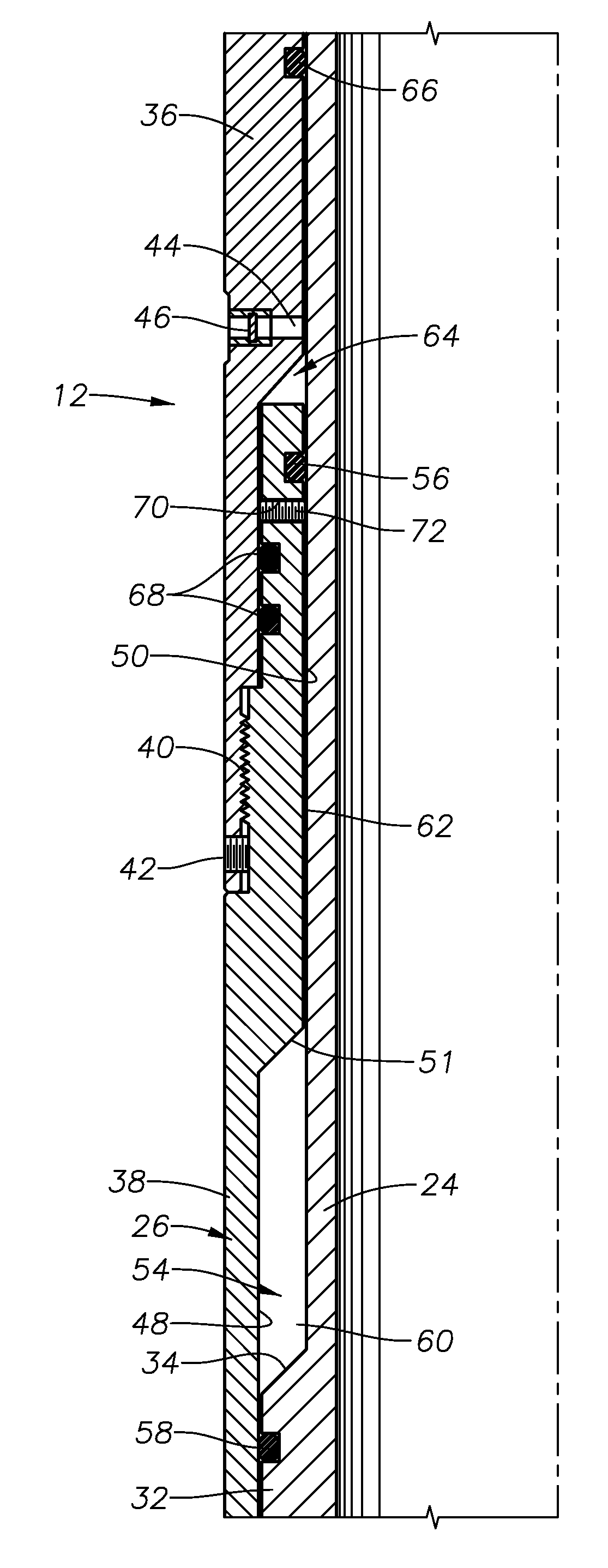

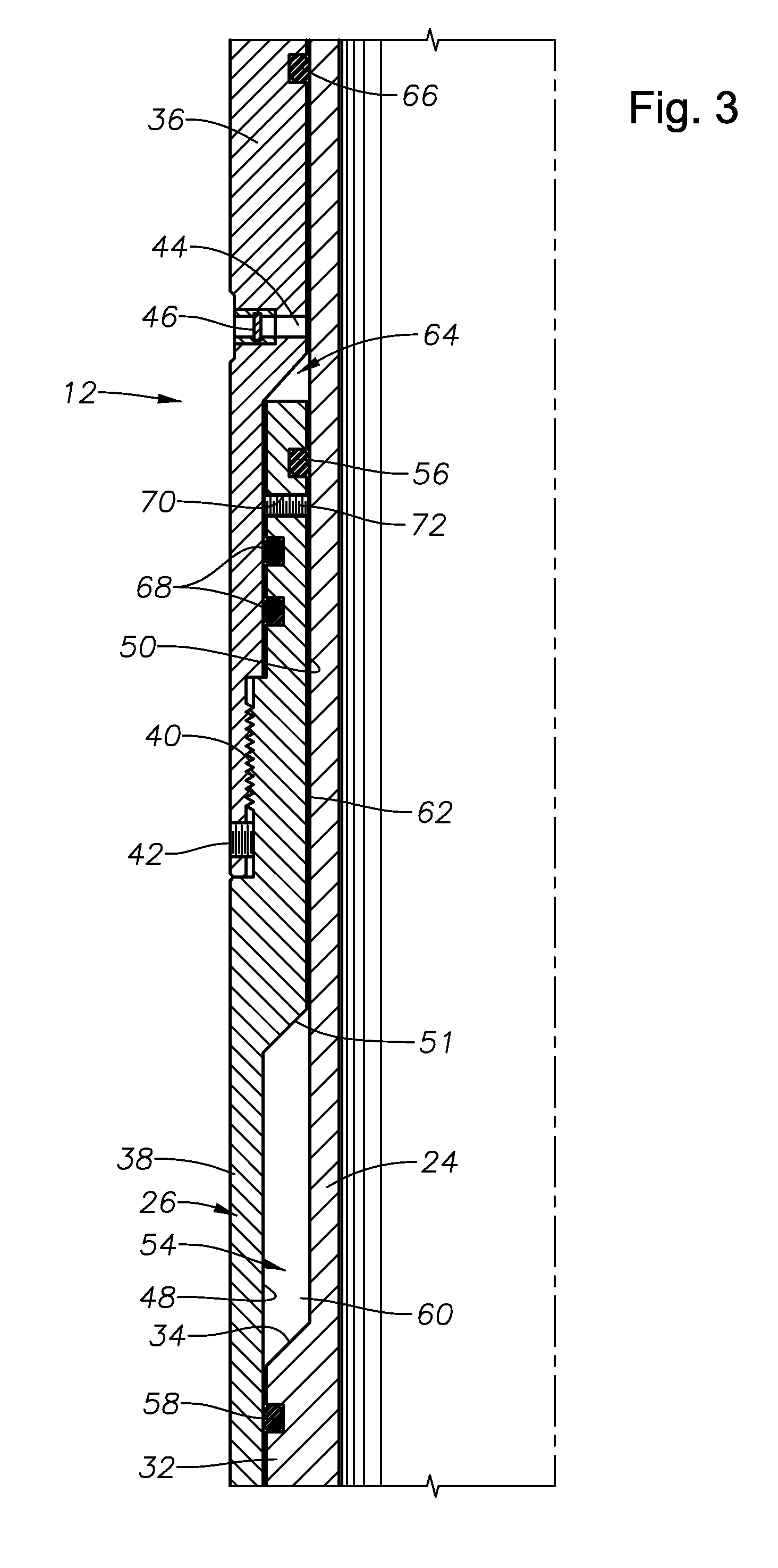

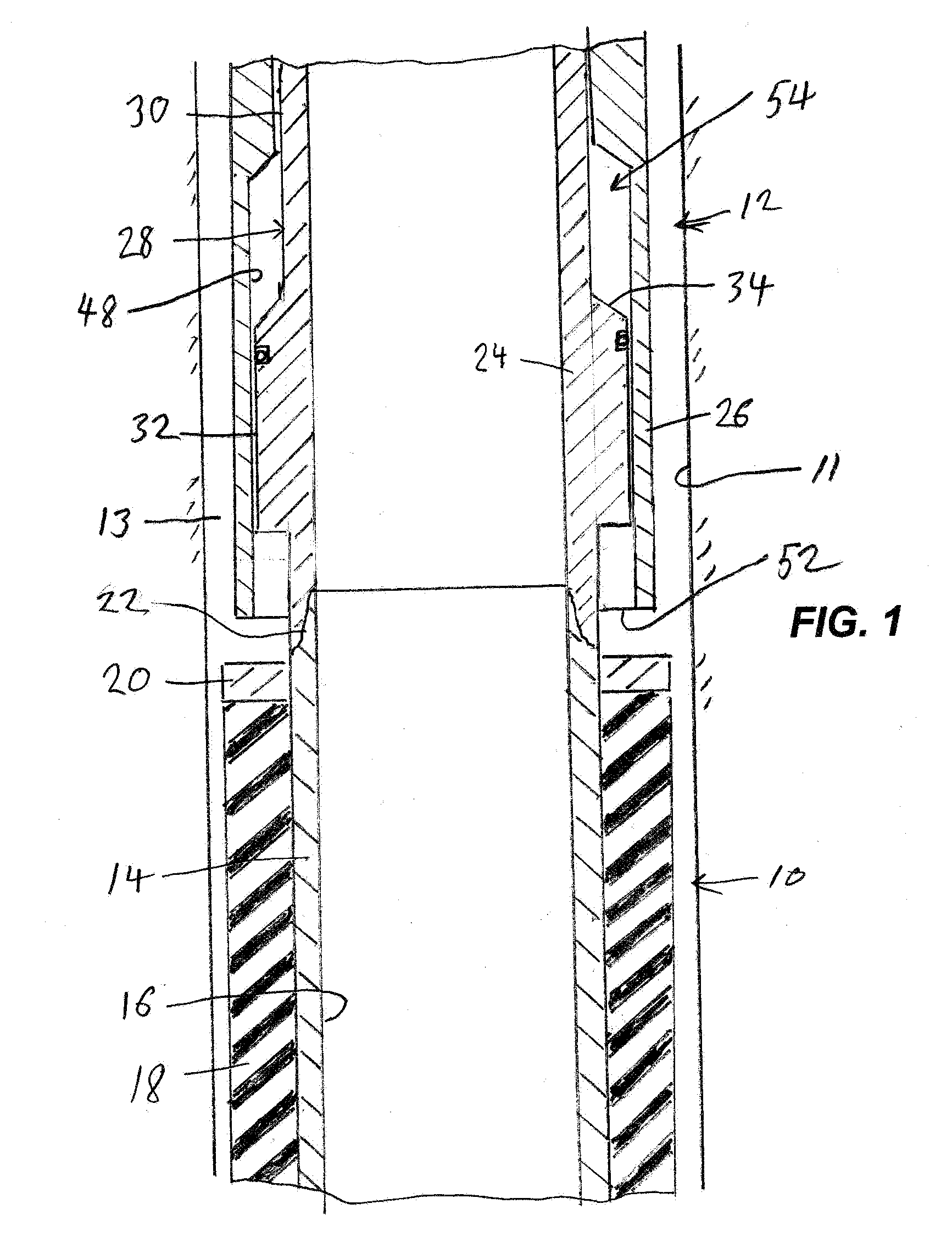

Controlled pressure equalization of atmospheric chambers

ActiveUS7913770B2Quick compressionFluid removalWell/borehole valve arrangementsControl mannerEngineering

Methods and devices for equalizing an atmospheric chamber within a well tool in a controlled manner following the operation of setting the well tool. A packer setting tool has a setting mechanism with an atmospheric chamber and an equalization assembly to permit the pressure differential between the atmospheric chamber and the surrounding annulus to be substantially equalized.

Owner:BAKER HUGHES INC

Controlled Pressure Equalization of Atmospheric Chambers

ActiveUS20090321081A1Quick compressionIncrease the length of timeFluid removalWell/borehole valve arrangementsControl mannerEngineering

Methods and devices for equalizing an atmospheric chamber within a well tool in a controlled manner following the operation of setting the well tool. A packer setting tool is described having a setting mechanism with an atmospheric chamber and an equalization assembly to permit the pressure differential between the atmospheric chamber and the surrounding annulus to be substantially equalized.

Owner:BAKER HUGHES INC

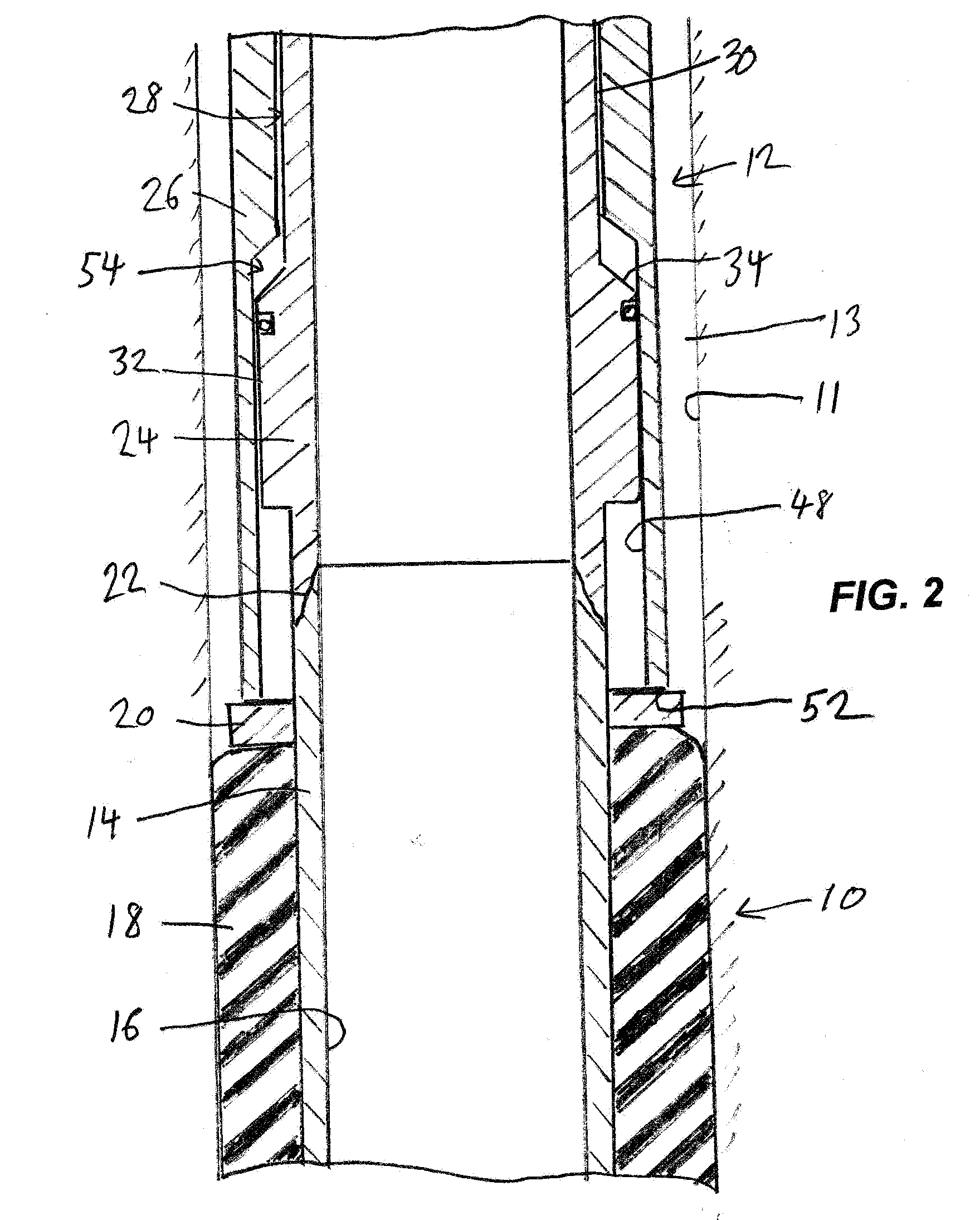

Improved fast video summarization method and system

ActiveCN105025360AQuick compressionSave time at workSelective content distributionWork periodVisual technology

The invention discloses an improved fast video summarization method and system and belongs to the digital image processing technology and computer vision technology field. According to the method and system of the invention, the summarization system is innovatively improved in that frequency-relatively slowed down background update, frame skip type target extraction and collision type target ordering are adopted, and therefore, higher-level requirements of today's society for the summarization system can be satisfied. The improved fast video summarization system not only has a moving target accurately locking ability of an original video summarization system, but also can perform summarization more quickly and greatly compress video time, and therefore, storage pressure can be reduced, and working time can be decreased.

Owner:JIANGXI HONGDU AVIATION IND GRP

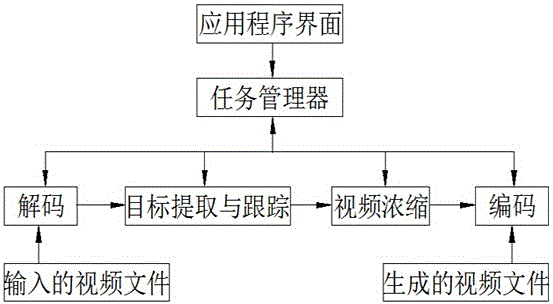

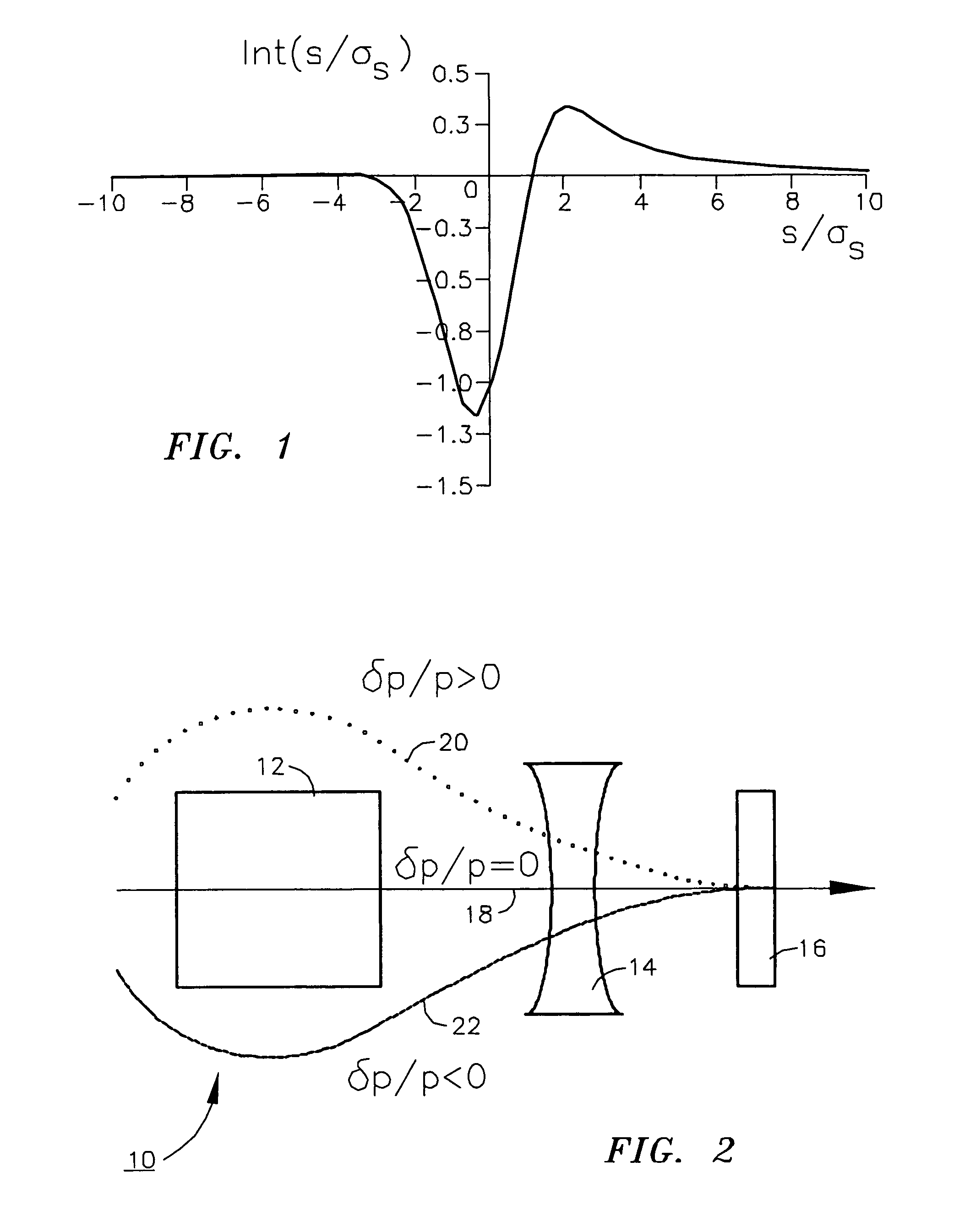

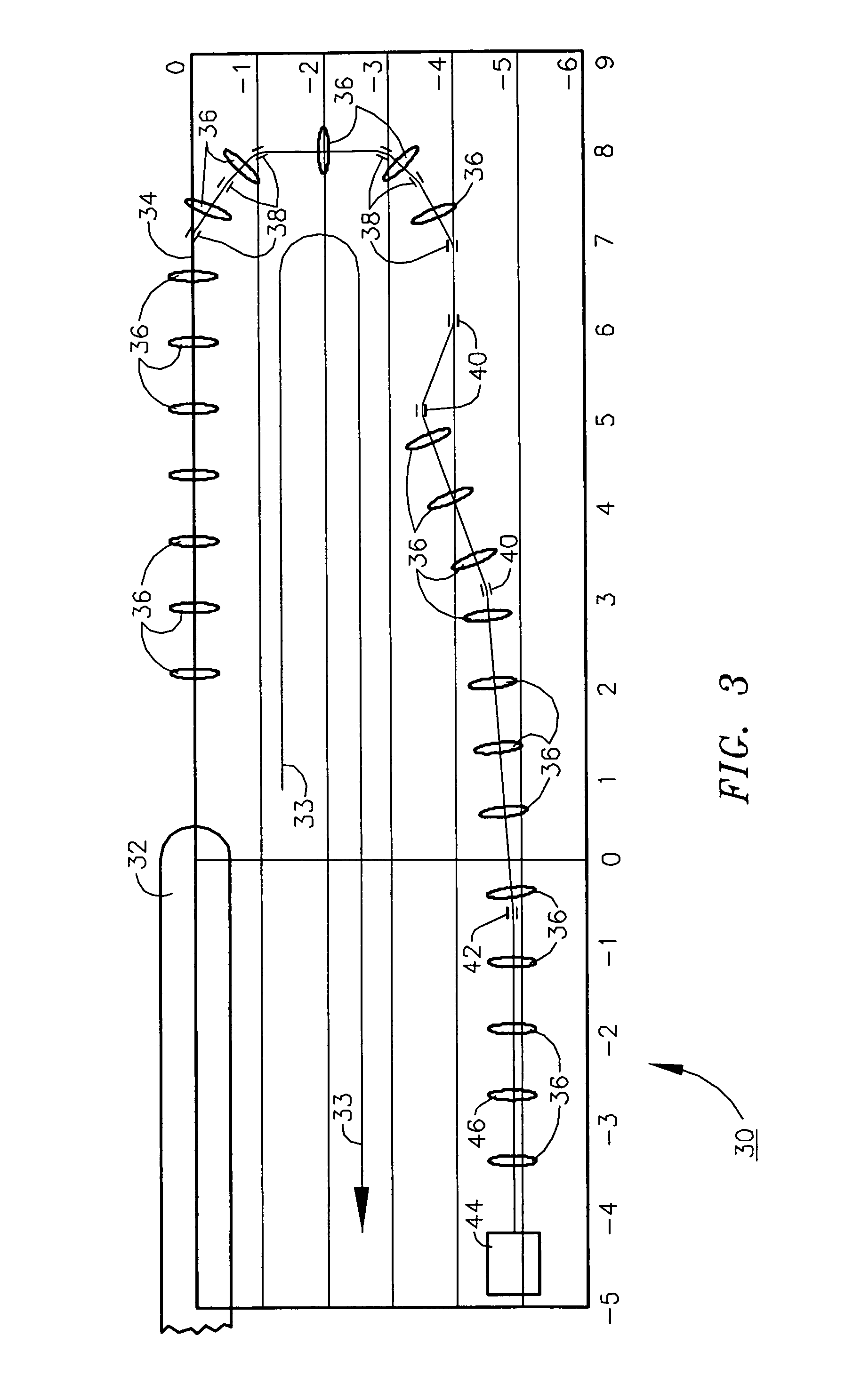

Method of controlling coherent synchroton radiation-driven degradation of beam quality during bunch length compression

InactiveUS8217596B1Prevent degradationQuick compressionLaser detailsBeam/ray focussing/reflecting arrangementsTransport systemLight beam

A method of avoiding CSR induced beam quality defects in free electron laser operation by a) controlling the rate of compression and b) using a novel means of integrating the compression with the remainder of the transport system: both are accomplished by means of dispersion modulation. A large dispersion is created in the penultimate dipole magnet of the compression region leading to rapid compression; this large dispersion is demagnified and dispersion suppression performed in a final small dipole. As a result, the bunch is short for only a small angular extent of the transport, and the resulting CSR excitation is small.

Owner:JEFFERSON SCI ASSOCS LLC

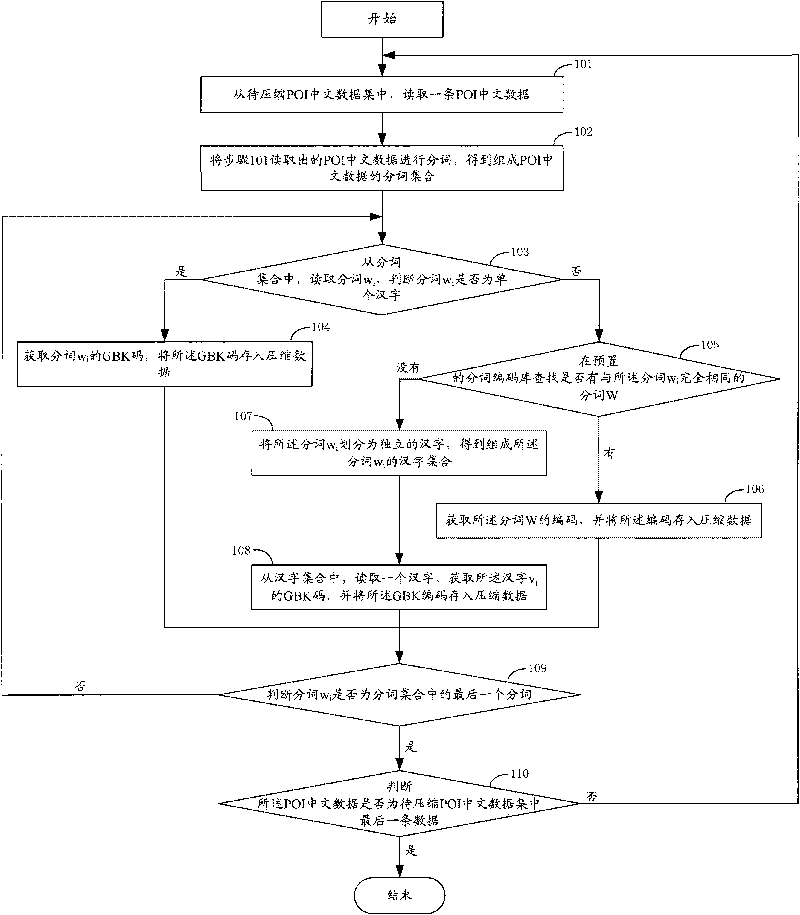

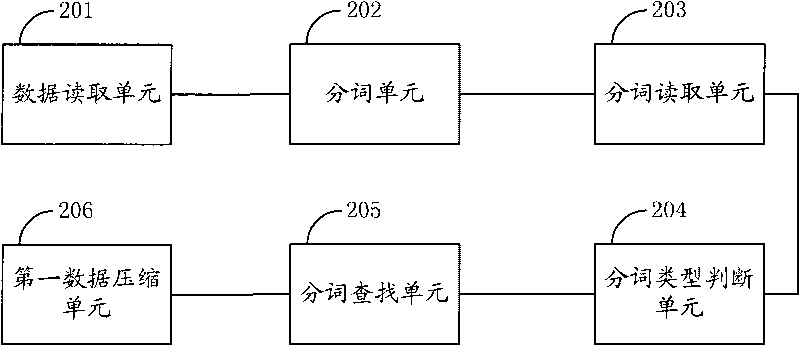

Chinese data compression method and Chinese data decompression method and related devices

ActiveCN101751451ACompressed greatlyQuick compressionSpecial data processing applicationsSpeech recognitionData compression

The invention discloses a Chinese data compression and a Chinese data decompression method and related devices. The Chinese data compression method comprises the following steps: in the step A, reading Chinese data to be compressed; in the step B, carrying out word segmenting on the Chinese data to obtain a word set composing the Chinese data; in the step C, reading a word from the word set, if the word consists of more than two Chinese characters, searching the word in a preset word code library, if the word is searched, acquiring a code of the word from the word code library and storing the code into compression data, wherein the code at most occupies two bytes of storage space in the compression data; and repeating the step C until all the word in the word set are processed. The Chinese data compression technology provided by the invention can realize great compression of the Chinese data. The decompression method for the Chinese compression data, which is provided by the invention, can realize rapid decompression of the compression data.

Owner:ALIBABA (CHINA) CO LTD

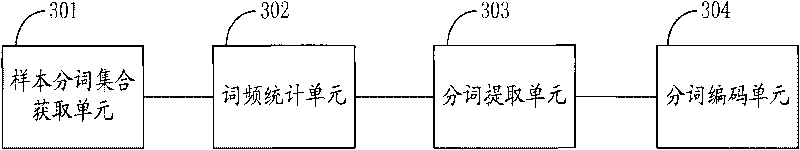

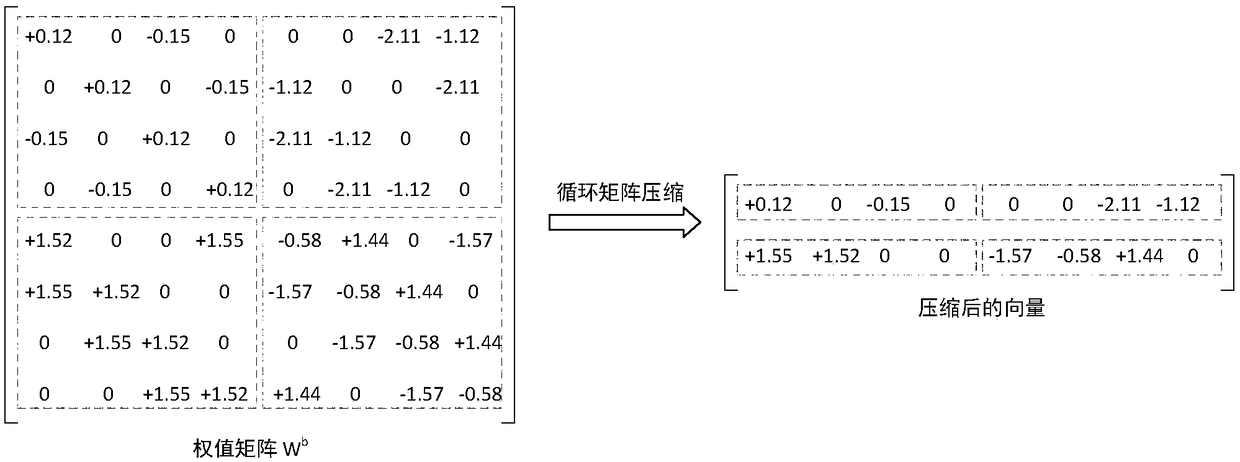

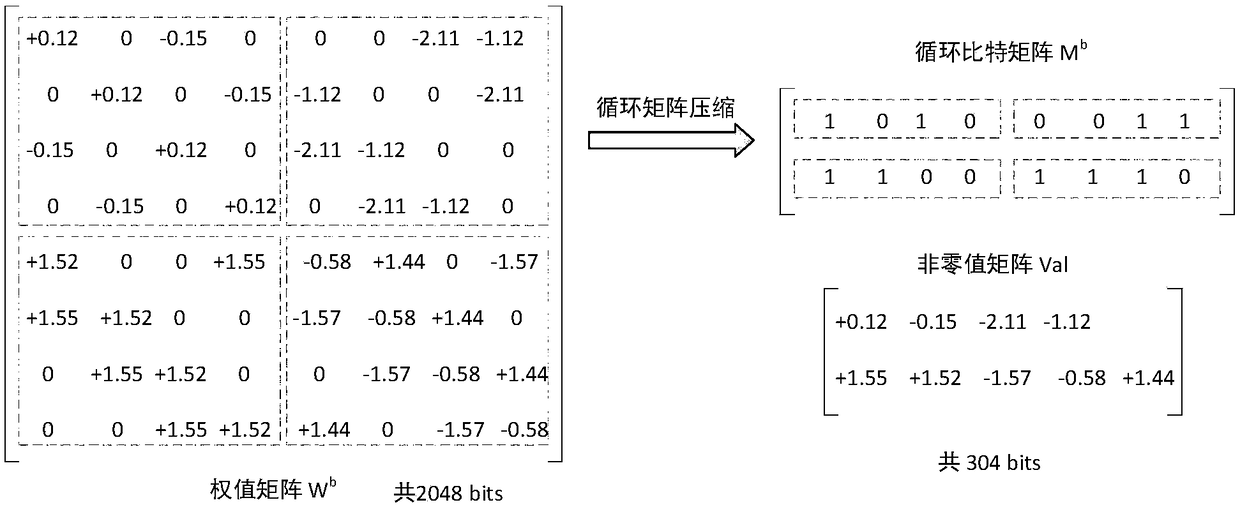

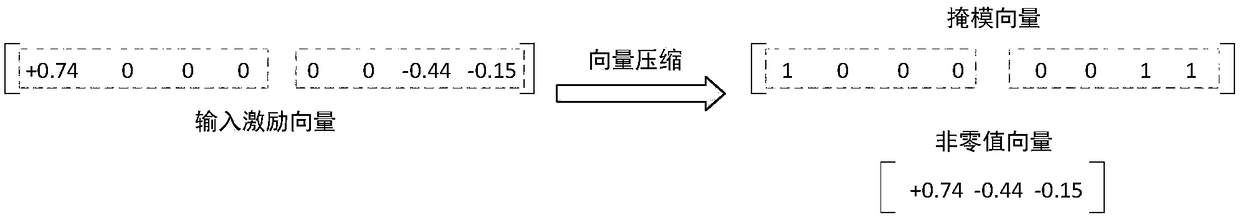

Coding and decoding method based on block cyclic sparse matrix neural network

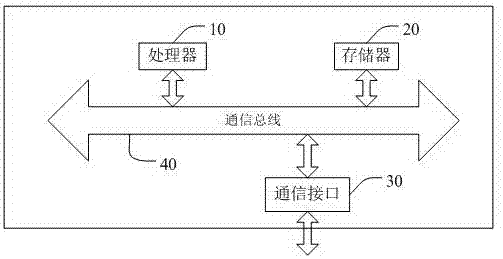

ActiveCN109245773AReduce storage requirementsImprove throughputCode conversionBiological neural network modelsSparse matrixCirculant matrix

The invention relates to a coding and decoding method based on a block cyclic sparse matrix neural network, and the method comprises the steps: compressing and coding a fully connected neural networkwith a block cyclic sparse weight matrix; using the cyclic property and sparsity of the weight matrix to design a coding method using a mask matrix and a non-zero value list; using the sparsity of theinput excitation to design a coding method using a mask vector and a non-zero value list. The method makes full use of the characteristics of the mask matrix and the cyclic matrix, and employs a hardware-friendly decoding method. The beneficial effects are that the method performs the simultaneous compressing and coding of a sparse input excitation vector and the weight matrix, effectively reduces the storage space required for the data and the number of storage accesses required to carry the data in the operation process. In the process of neural network operation, the method can effectivelyreduce the energy consumed by the memory access, brings convenience to a processor for skipping unnecessary operations, and improves the throughput of a hardware system.

Owner:NANJING UNIV

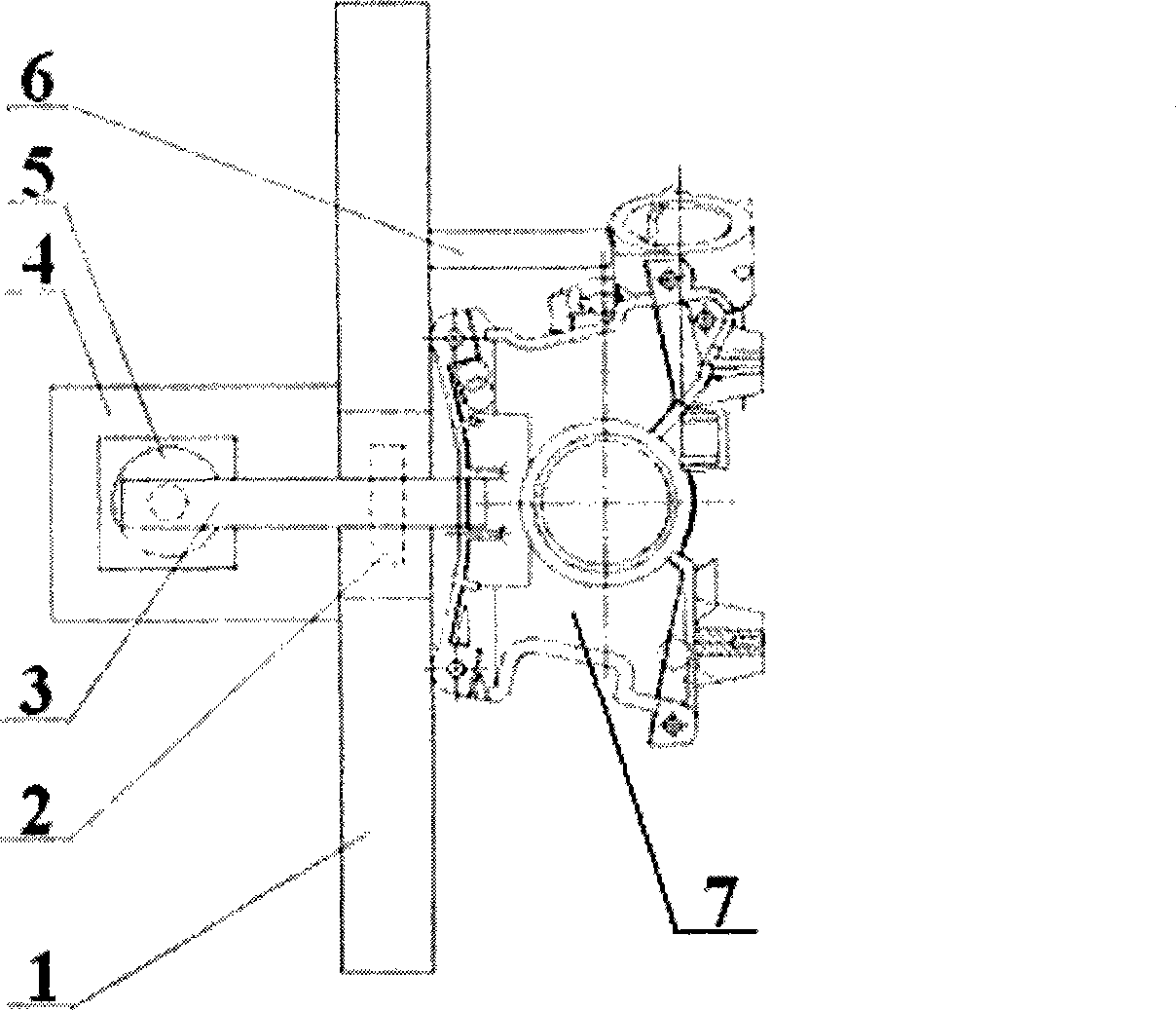

Headstock pipe positioning device of motorcycle frame welding tool

InactiveCN104985372AGuaranteed accuracyPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHeadstock

The invention discloses a headstock pipe positioning device of a motorcycle frame welding tool. A front square box (2) is arranged at the front end of a working platform (1); the bottom end of the front square box (2) is fixed to the working platform (1); an angle device (3) is installed at the top end of the front square box (2) and provided with a positioning boss (4) with a positioning rod (5); the axis of the positioning rod (5) and the axis of the positioning boss (4) coincide; a pressing plate (6) is installed at the upper end of the positioning rod (5) in a sleeving mode and can be locked by a nut. The headstock pipe positioning device of the motorcycle frame welding tool is reasonable in design, simple in structure, accurate in positioning, rapid in compression, convenient, flexible and variable to disassemble and good in universality, has the complete interchangeability and can meet various needs.

Owner:力帆科技(集团)股份有限公司

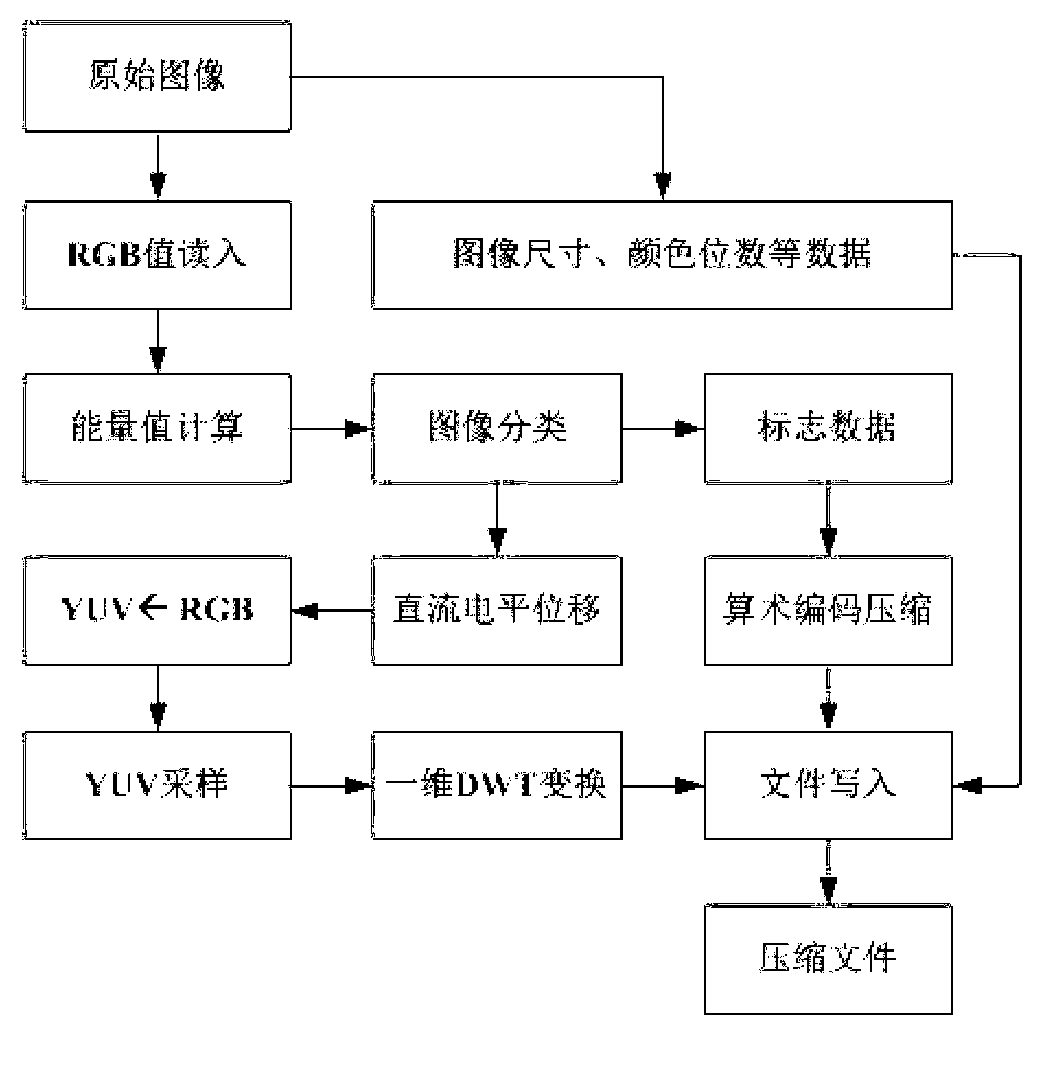

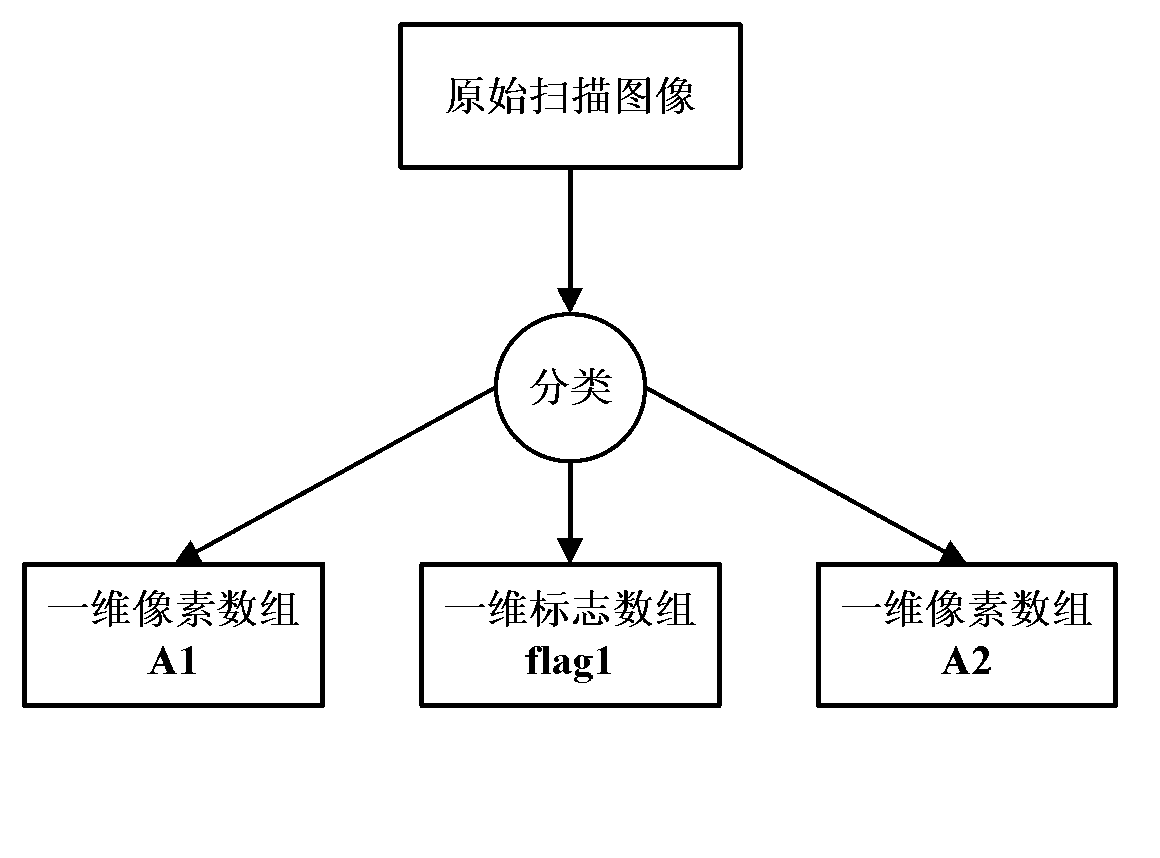

Method for compressing and decompressing single picture

ActiveCN103024393AReduce data volumeReduce lossesColor television with pulse code modulationTelevision systemsArray data structureGray level

The invention discloses a method for compressing and decompressing a single picture. The method includes creating at least one flag array, classifying pixels of a scanned picture into N types to be stored in the N array according to the preset mode, and recording storage positions of the pixels in the designation array; subjecting the pixels in the N array to direct-current level displacement; converting the scanned picture into YUV (luma and chroma) color space if the scanned picture is a colored picture of RGB (red, green and blue) mode; subjecting each array of the N array to one-dimensional wavelet transform according to each pixel component; and compressing the flag array, writing data into files according to preset sequence to obtain the compressed picture. Compression speed can be increased by classifying color or gray level of the picture by utilizing picture energy as criteria according to a mode of binary tree, picture information loss can be reduced to the greatest extent, high compression is realized and data quantity of the picture is greatly decreased.

Owner:京北方信息技术股份有限公司

Material compressor and material compression method

The invention discloses a material compressor and a material compression method, belonging to the field of machinery. The material compressor comprises a horizontal pre-pressing mechanism, a vertical compression mechanism, a compression box body and a horizontal compression and pushing mechanism positioned in the compression box body, wherein the horizontal pre-pressing mechanism is arranged on the rear upper part of the compression box body and communicated with the compression box body; the vertical compression mechanism is arranged at the upper end of the compression box body; the lower surface of a compression head of the vertical compression mechanism is higher than the upper surface of a pushing plate of the horizontal pre-pressing mechanism when moving to the highest point, and is lower than the lower edge of the pushing plate of the horizontal pre-pressing mechanism when moving to the lowest point; the lower surface of the vertical compression mechanism and the compression box body form a compression cavity; and the compression box body is used for bearing compressed materials. According to the invention, a vertical compression port and a feed port are separated due to the arrangement of the vertical compression mechanism and the horizontal pre-pressing mechanism; the materials are horizontally pre-pressed by the horizontal pre-pressing mechanism and then vertically compressed by the vertical compression mechanism, so that the materials can be conveniently received, the material receiving speed is increased, and quantitative feeding is facilitated.

Owner:聂忠海

Rapid-positioning and pneumatic-compressing universal fixture capable of slightly adjusting inclination angle

ActiveCN103143967ARapid positioningQuick compressionPositioning apparatusMetal-working holdersBody angleEngineering

The invention discloses a rapid-positioning and pneumatic-compressing universal fixture capable of slightly adjustable inclination angle, which comprises a bracket mounted on a workbench, wherein a box body is rotationally connected with the bracket; a flat fixture is fixed on a top plate of the box body and used for mounting a workpiece; the box body is provided with a pneumatic compressing mechanism for compressing the workpiece; and a box body angle adjustment device is arranged between the box body and the bracket. The universal fixture can rapidly position and press the workpiece when medium and small parts are machined; the inclination angle of the fixture can be adjusted; and the universal fixture has the advantages of good universality, high positioning accuracy, good self-locking property, and the like.

Owner:钱汝玉

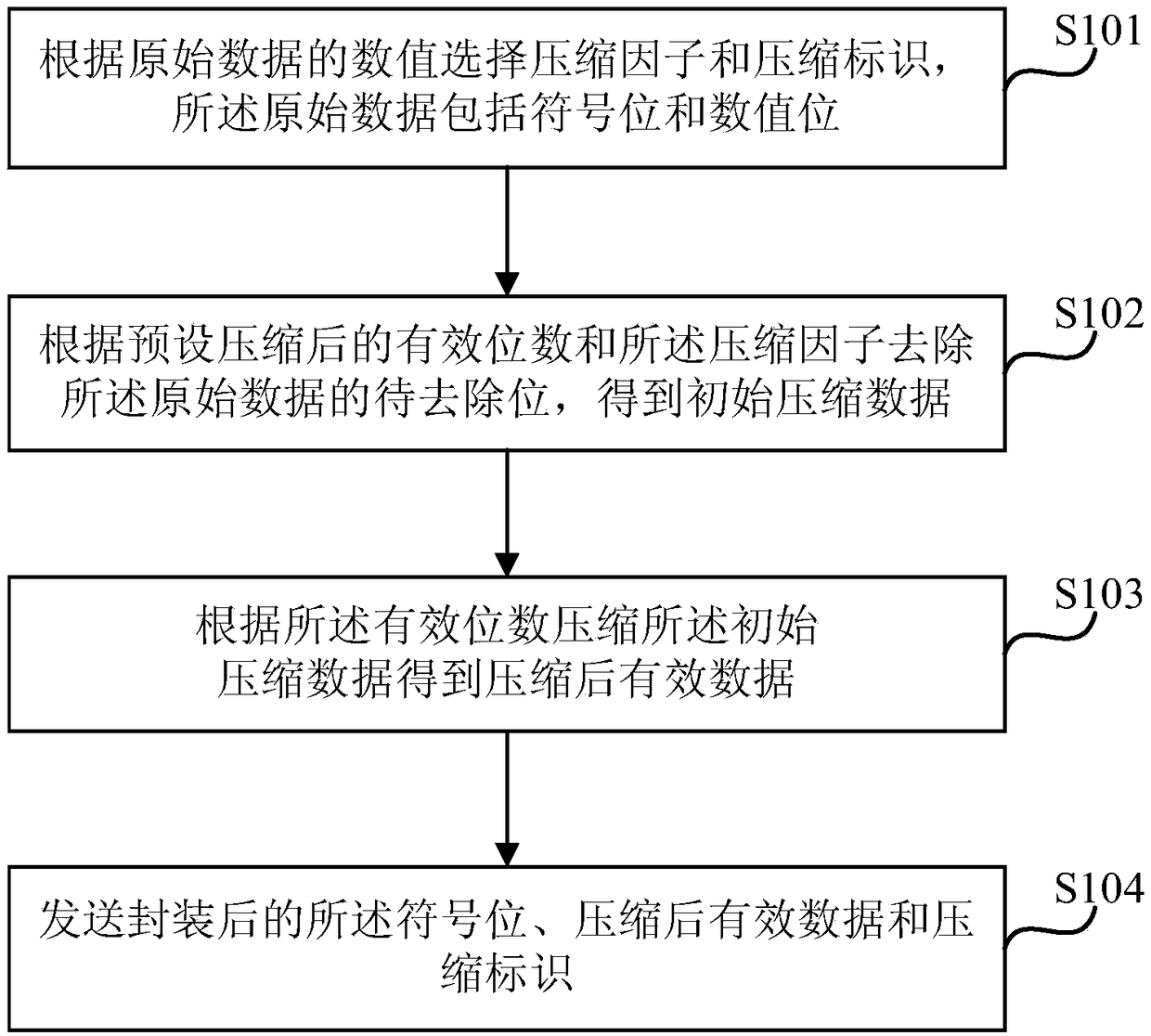

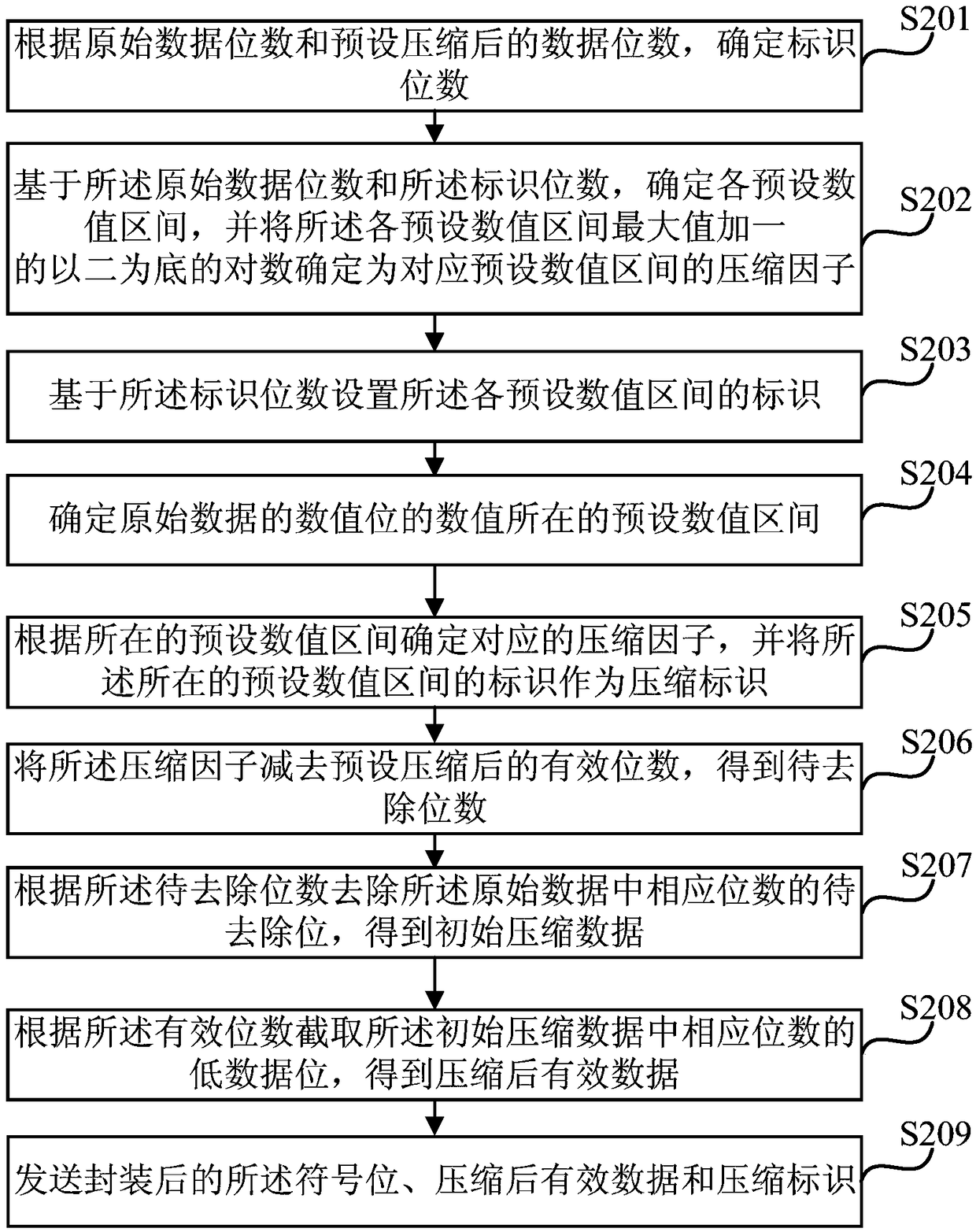

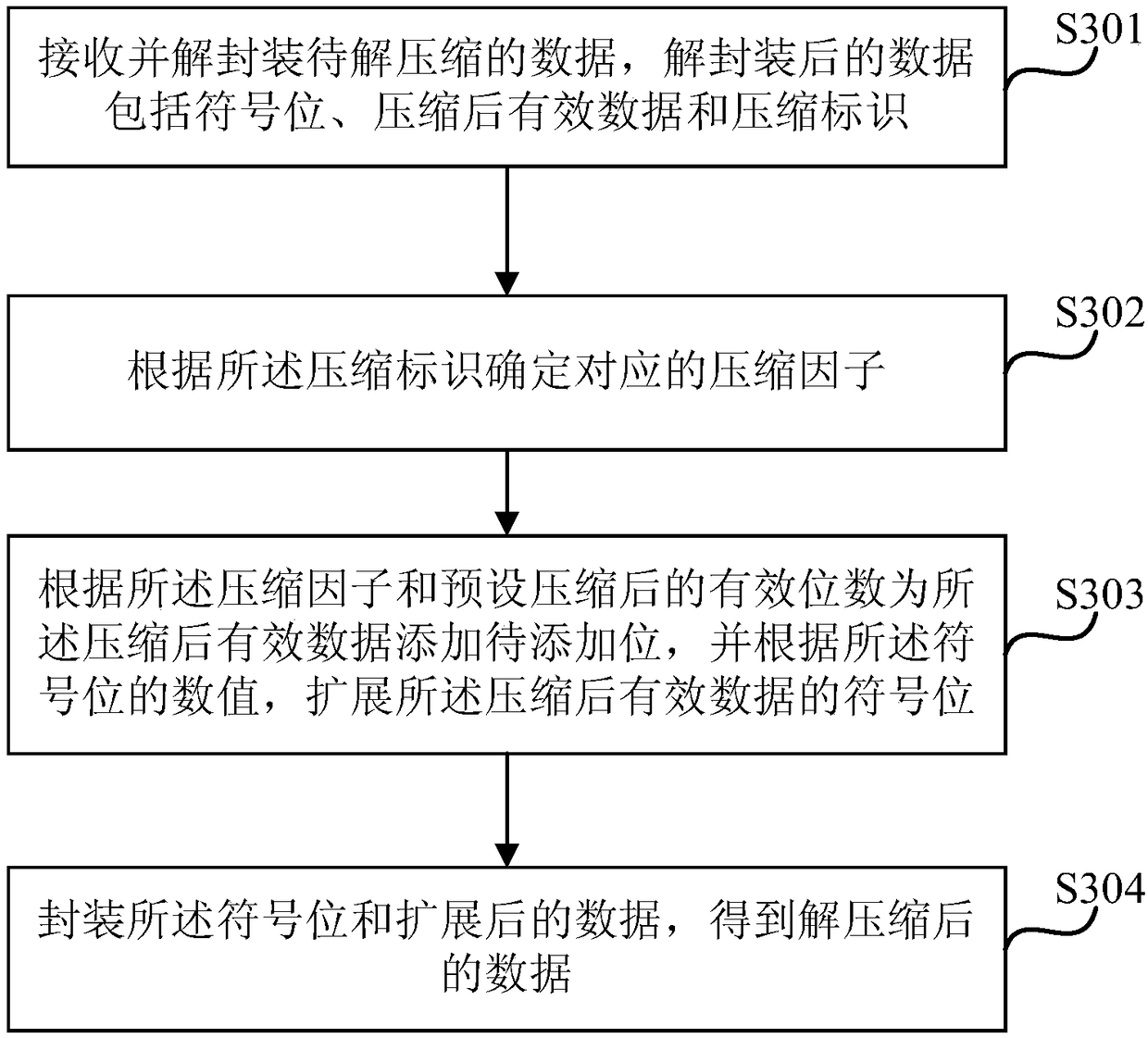

Data transmitting and receiving method and device

ActiveCN108616927AExtended sign bitQuick compressionNetwork traffic/resource managementTransmissionData compressionOriginal data

The invention discloses a data transmitting and receiving method and device. The method comprises the steps that the compression factor and the compression identifier are selected according to the numerical value of the original data, wherein the original data include the sign bit and the numerical bit; the bit to be removed of the original data is removed according to the preset compressed effective number of bits and the compression factor so as to obtain the initial compression data; the initial compression data are compressed according to the effective number of bits so as to obtain the compressed effective data; and the packaged sign bit, the compressed effective data; and the compression identifier are transmitted. With application of the method, the original data can be rapidly compressed so that the problem of excessively high data transmission pressure caused by high transmission data volume can be solved, the data compression time can be effectively reduced, implementation issimpler, resource occupation is low and the data transmission form is simple and feasible.

Owner:RUN TECH CO LTD BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com