Patents

Literature

396results about How to "Strong pressing force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

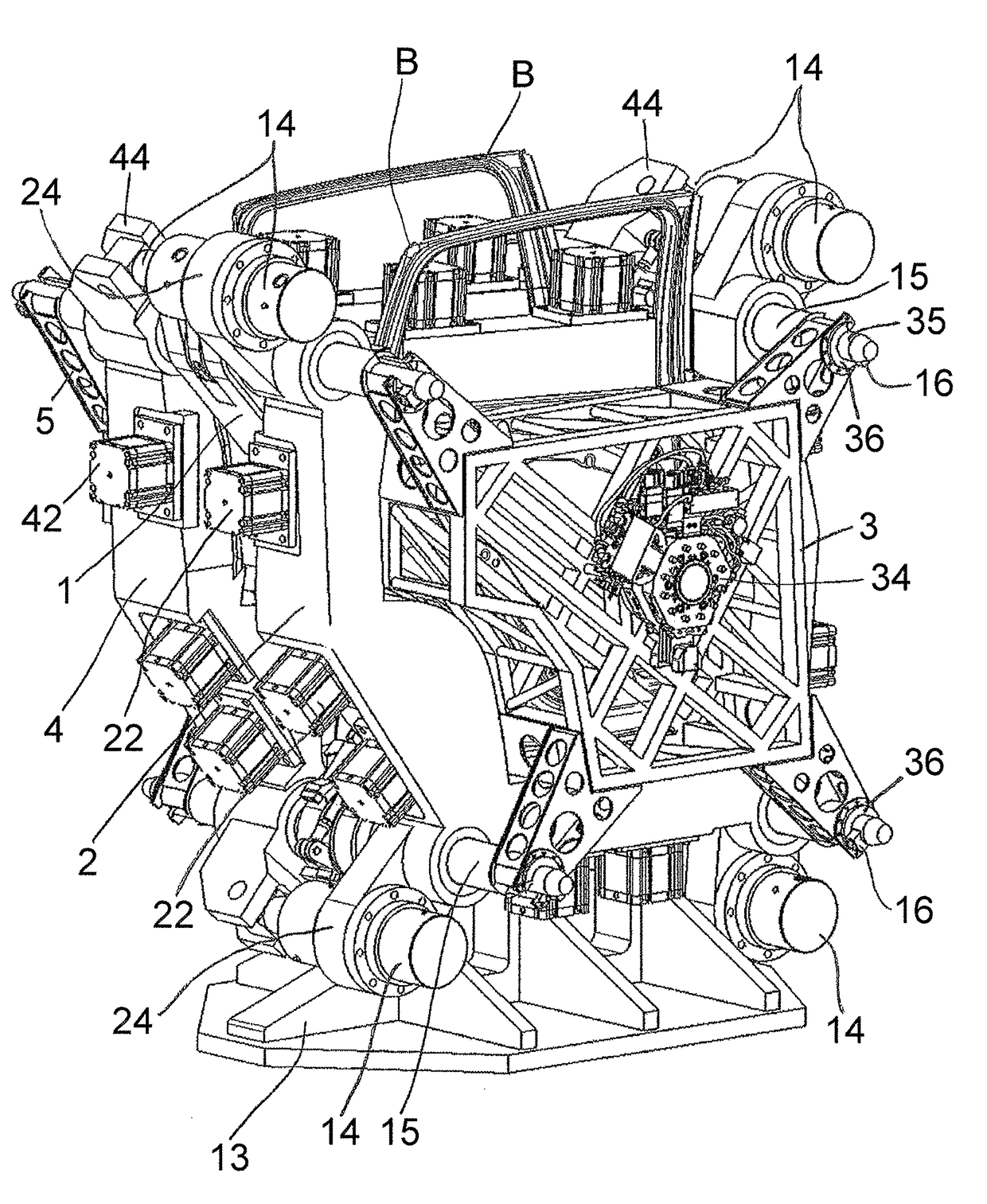

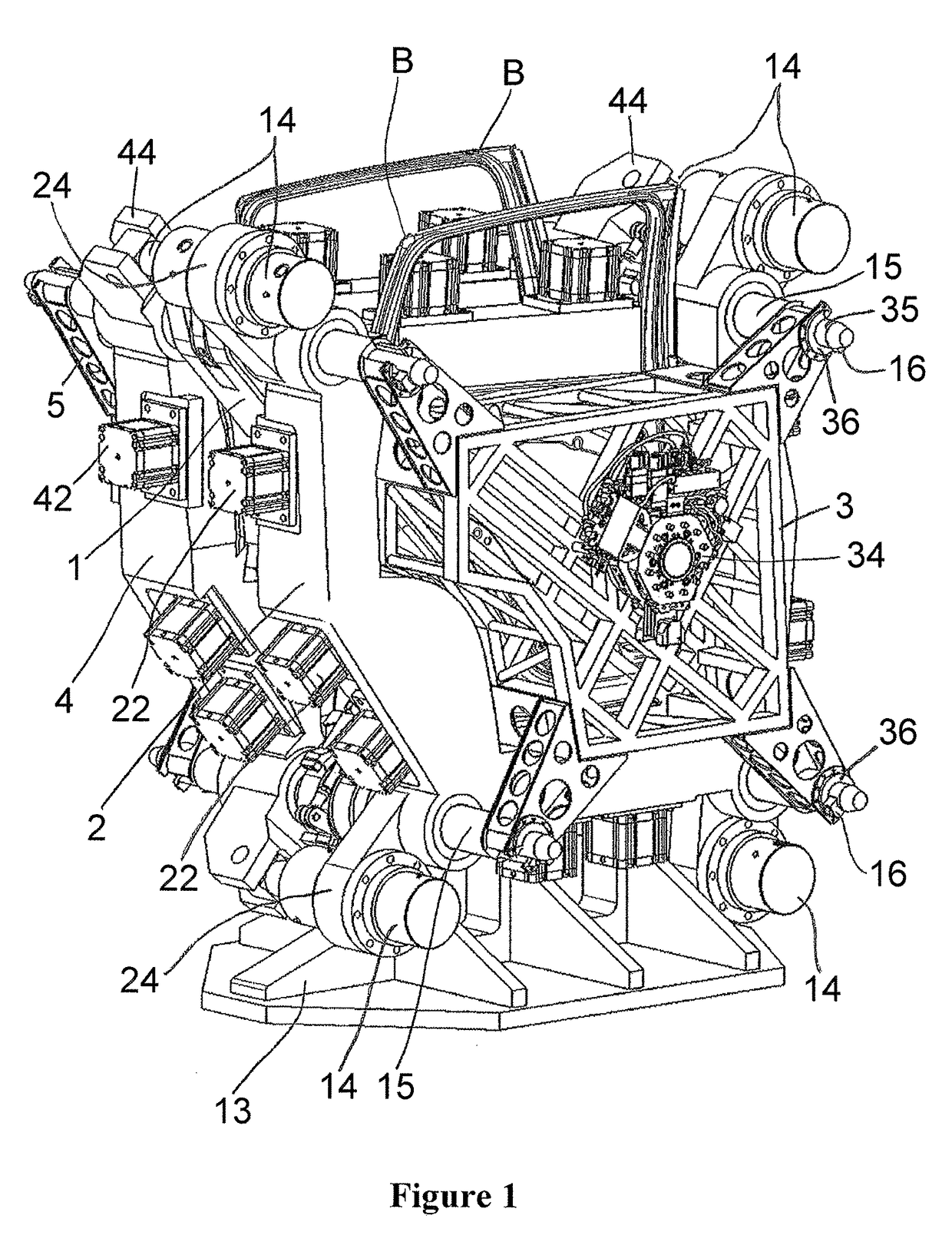

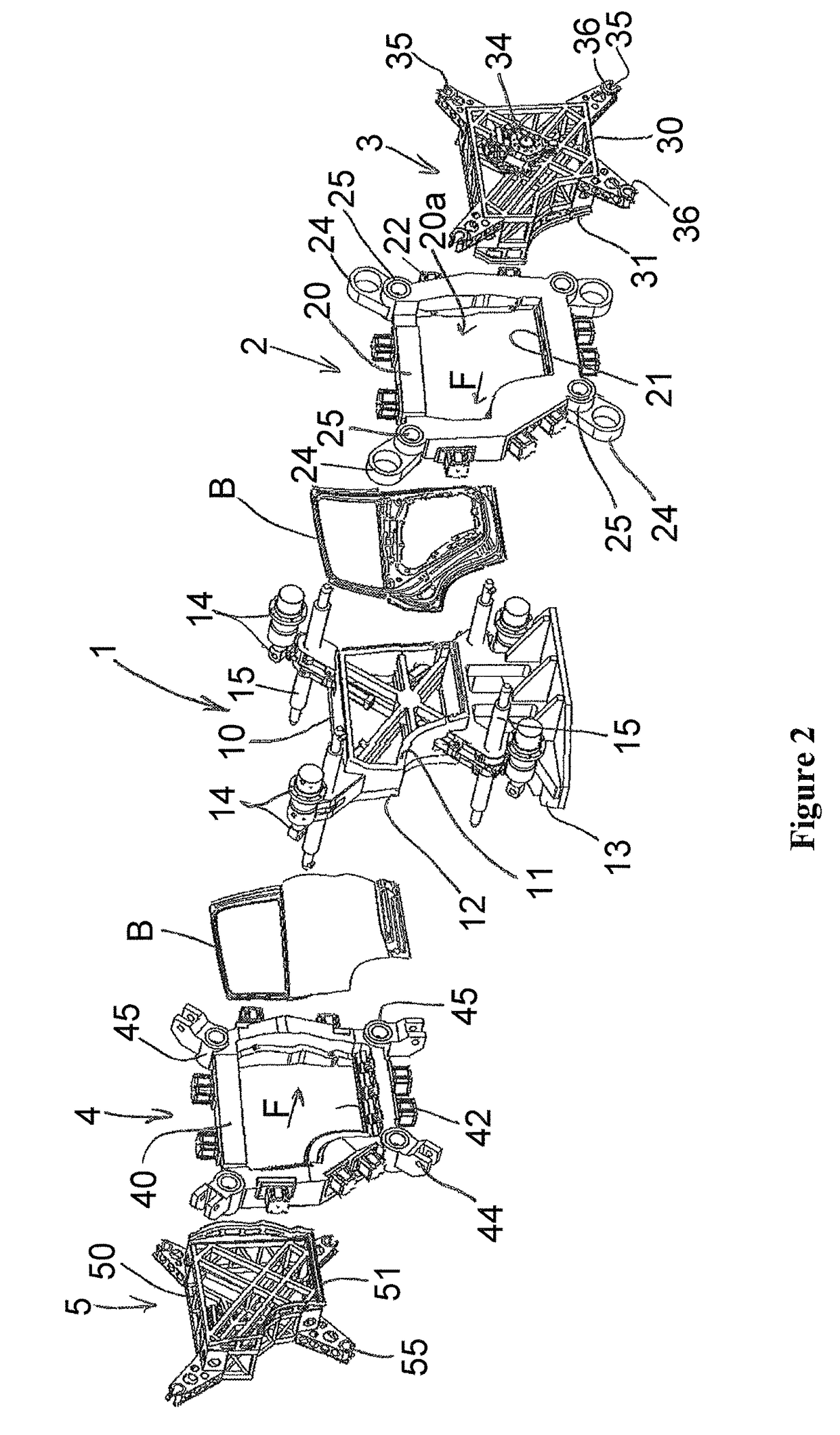

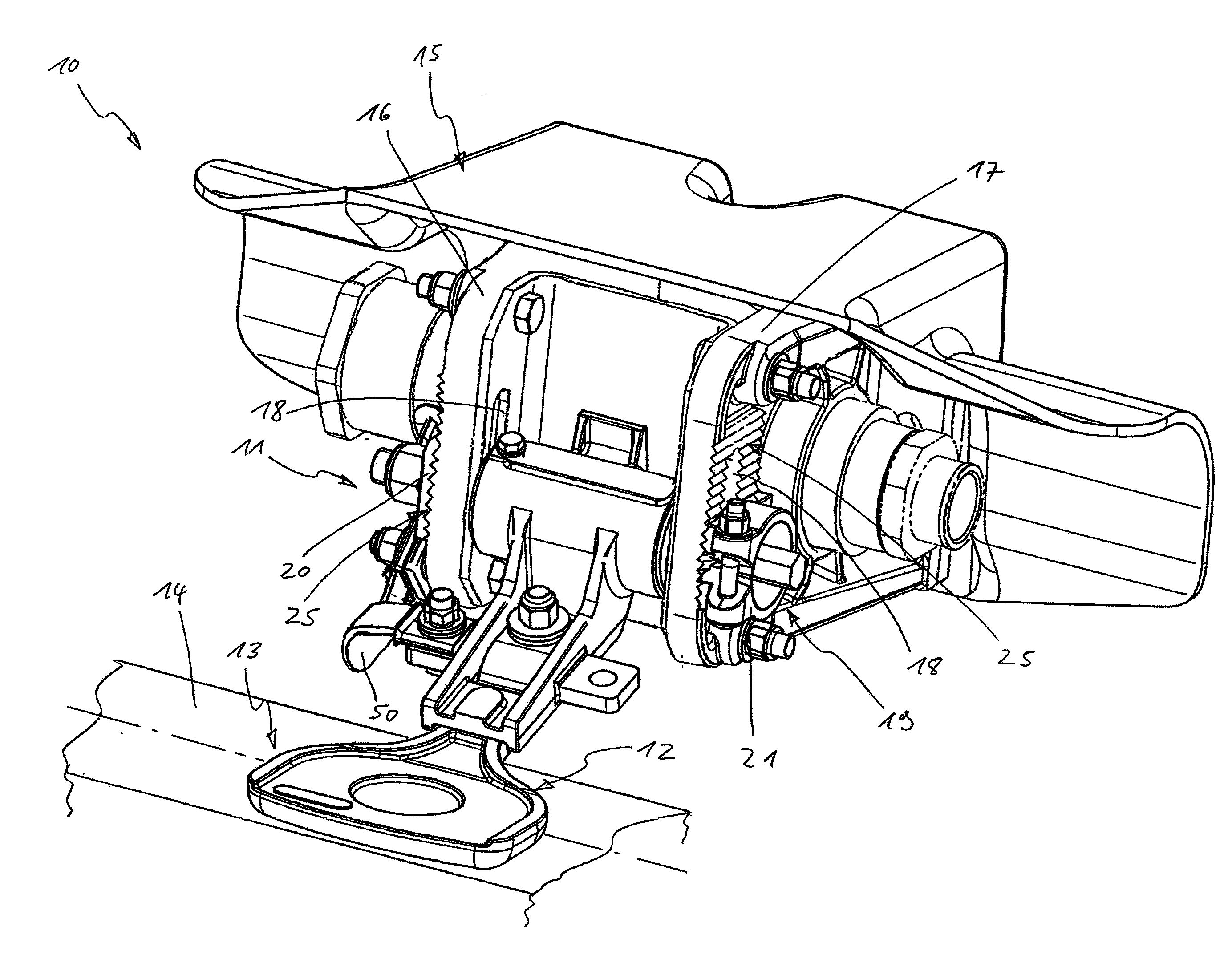

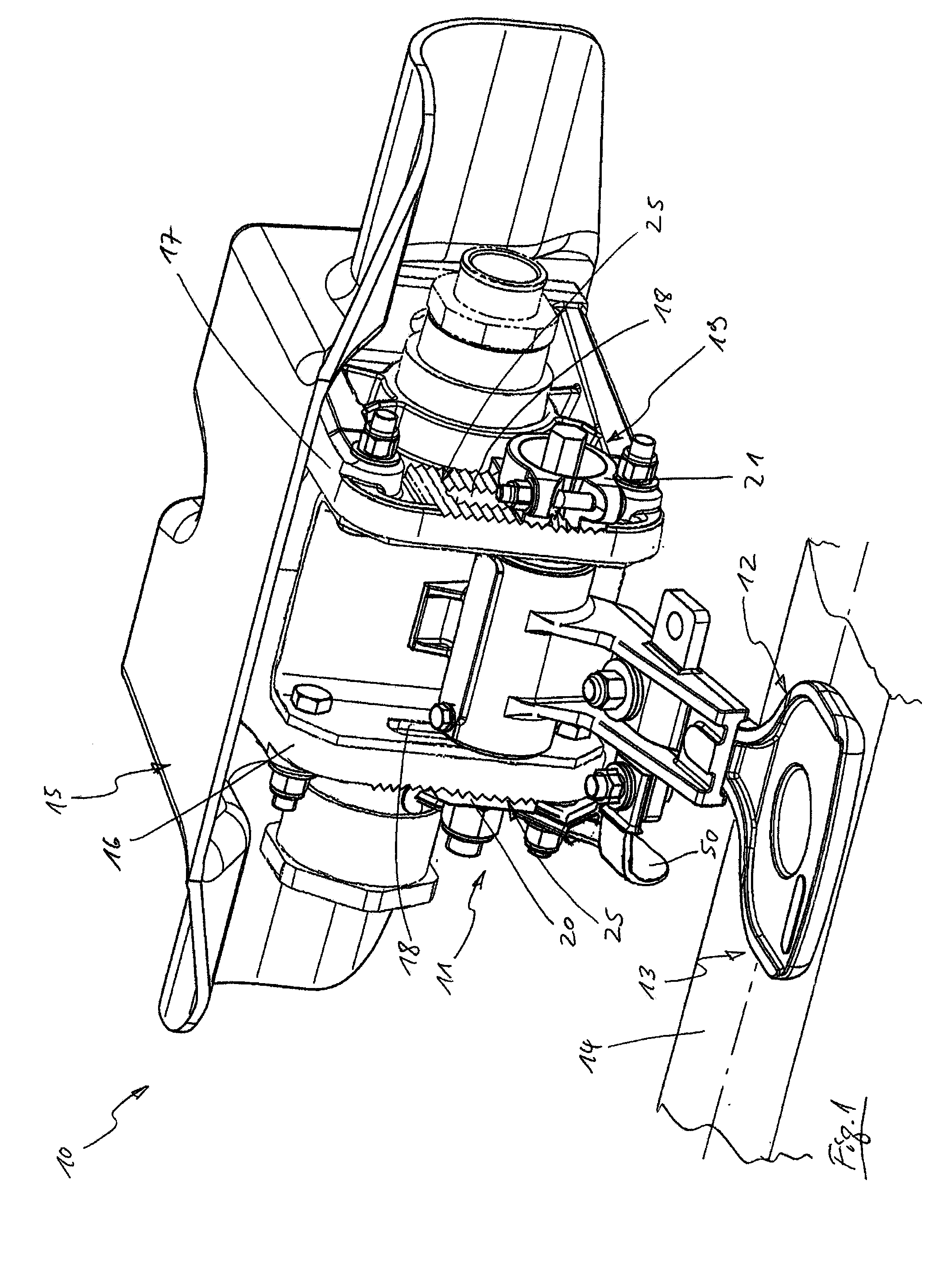

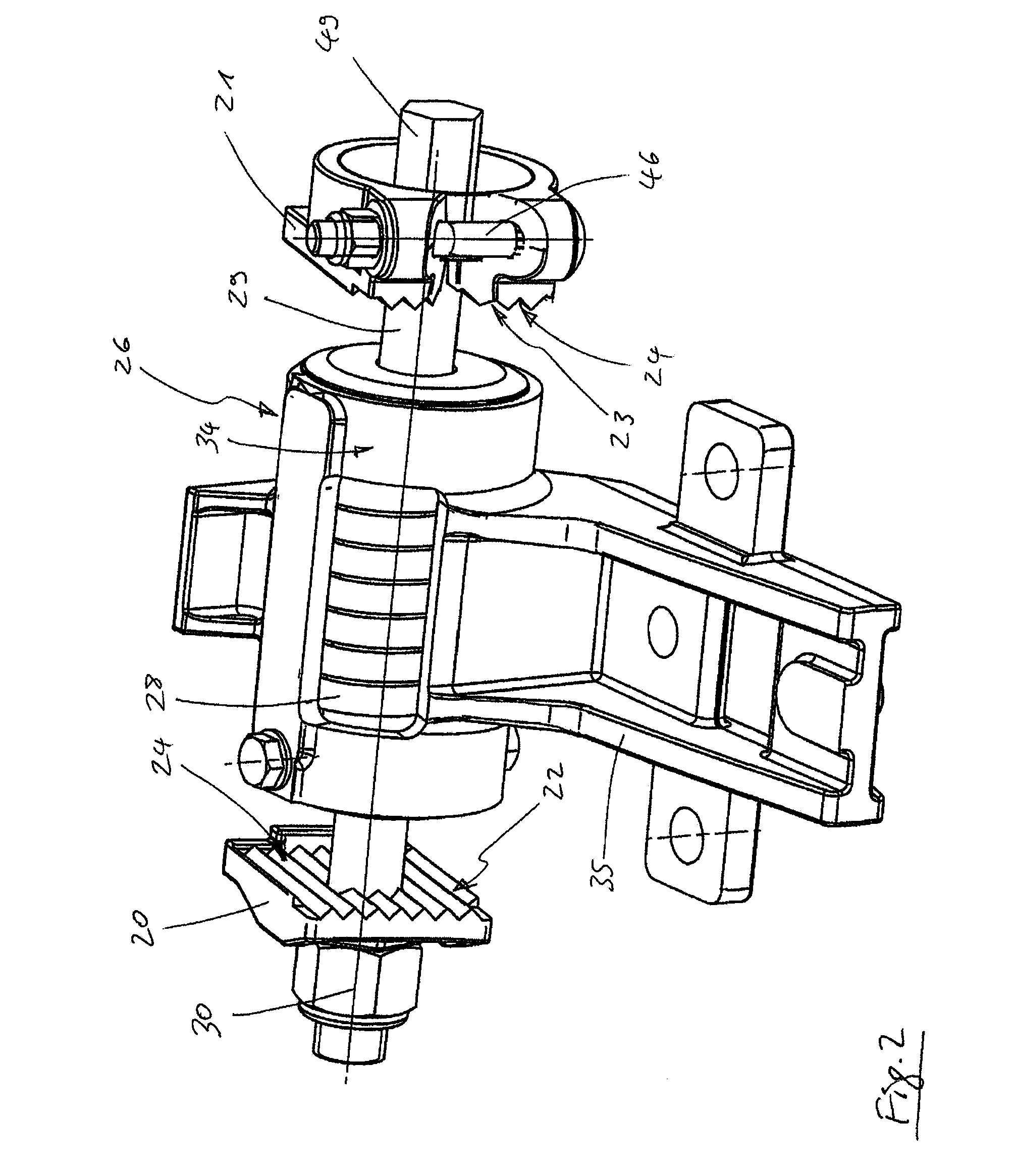

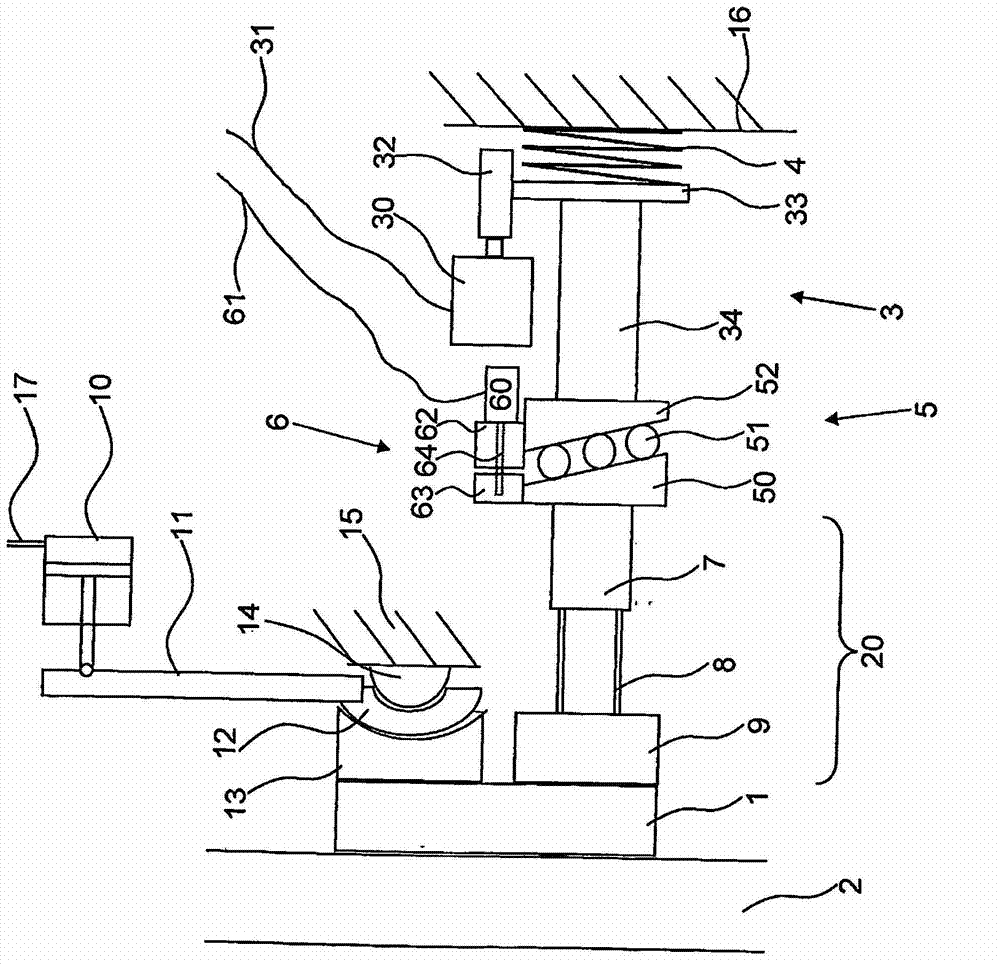

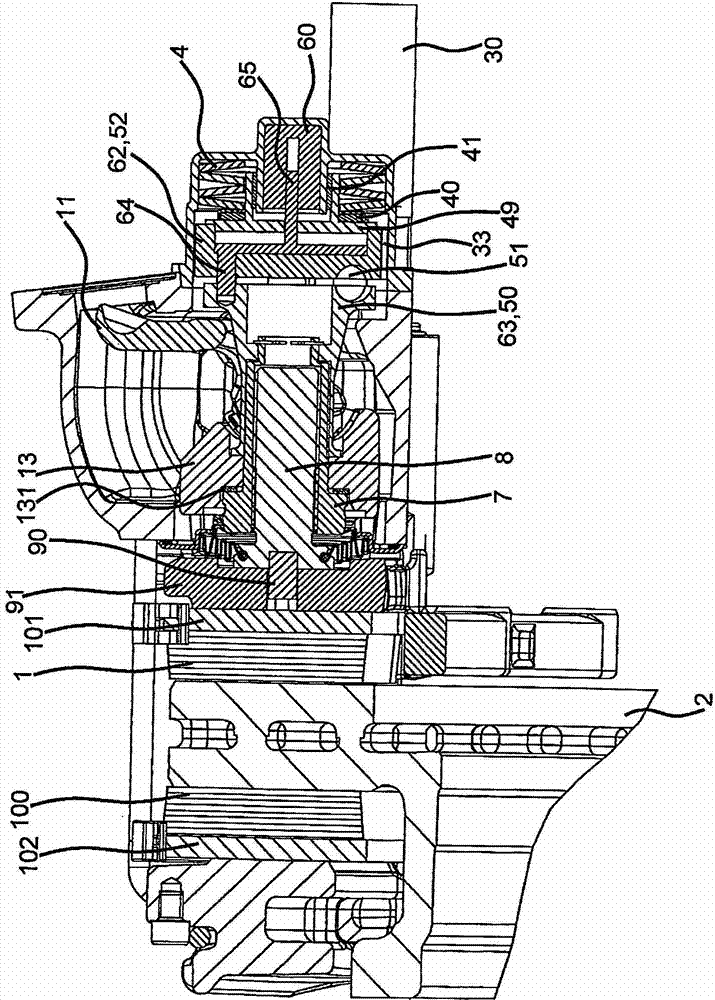

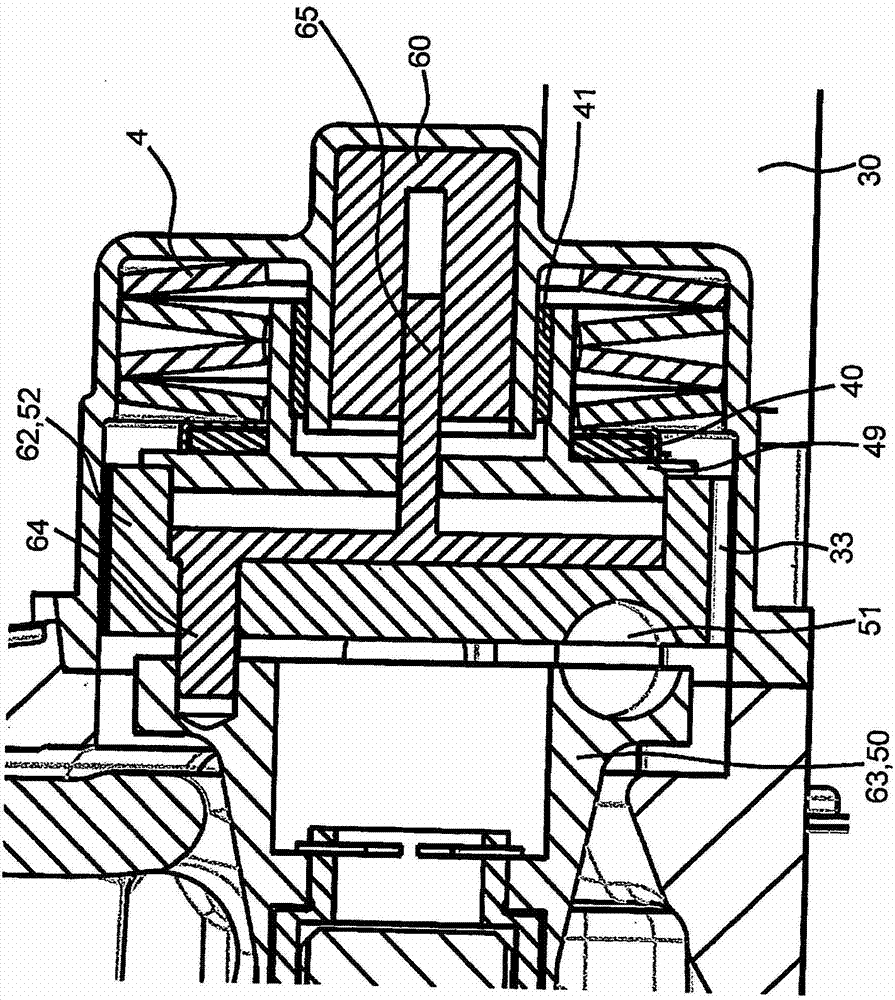

Flanging press

ActiveUS9776234B2Firmly connectedStrong pressing forcePositioning apparatusMetal-working holdersEngineeringFlanging

Owner:FFT PRODIONSSYST

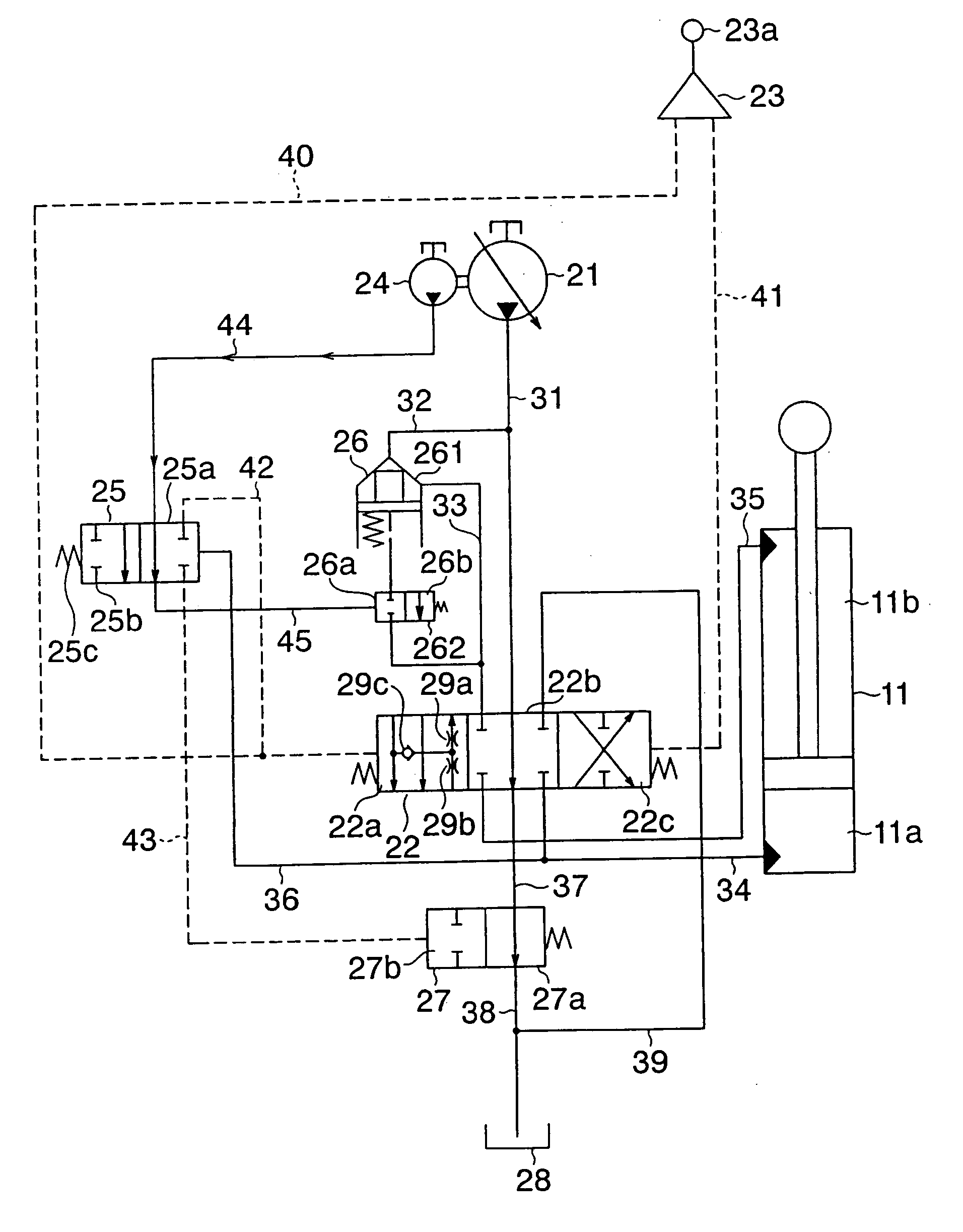

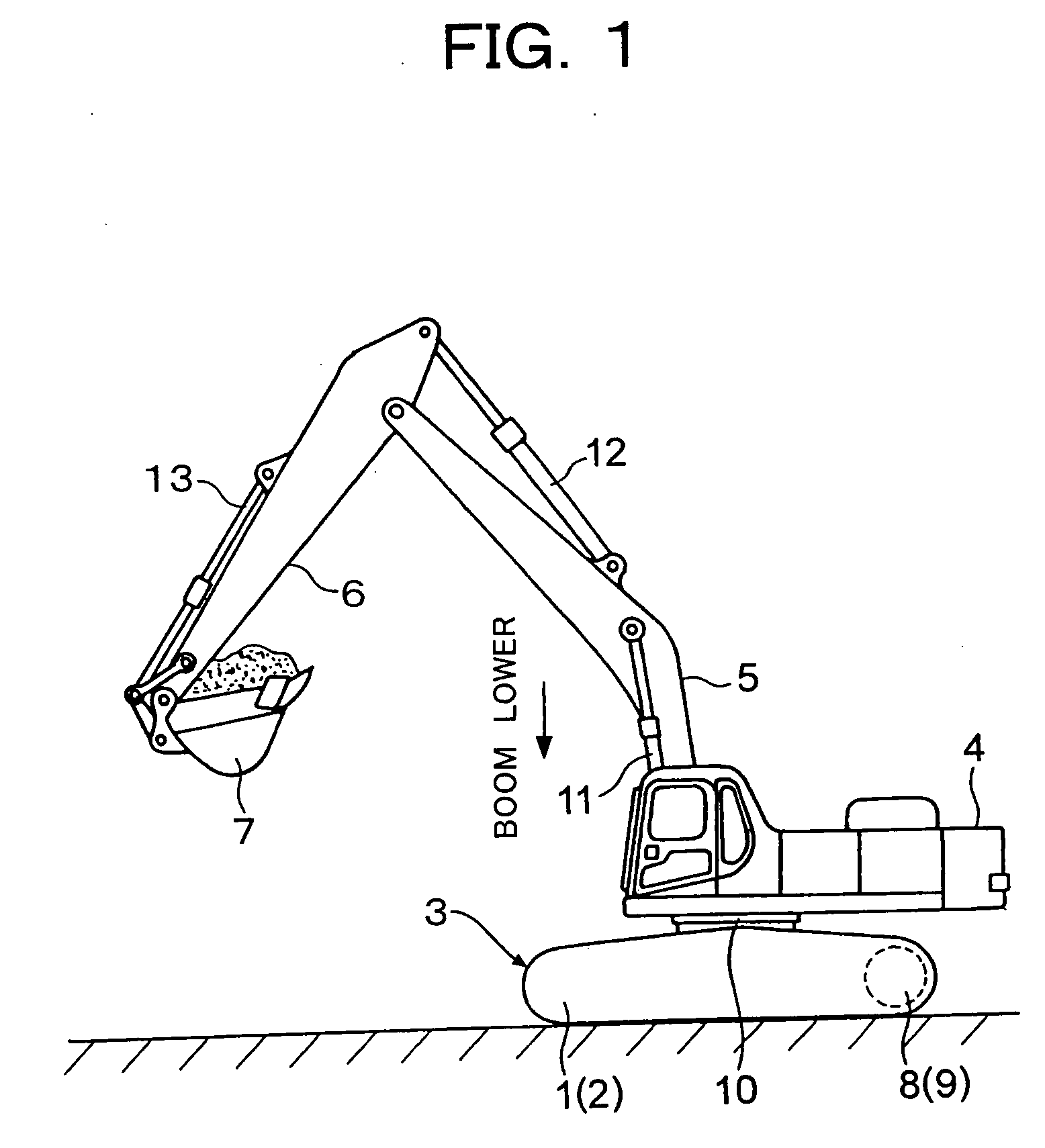

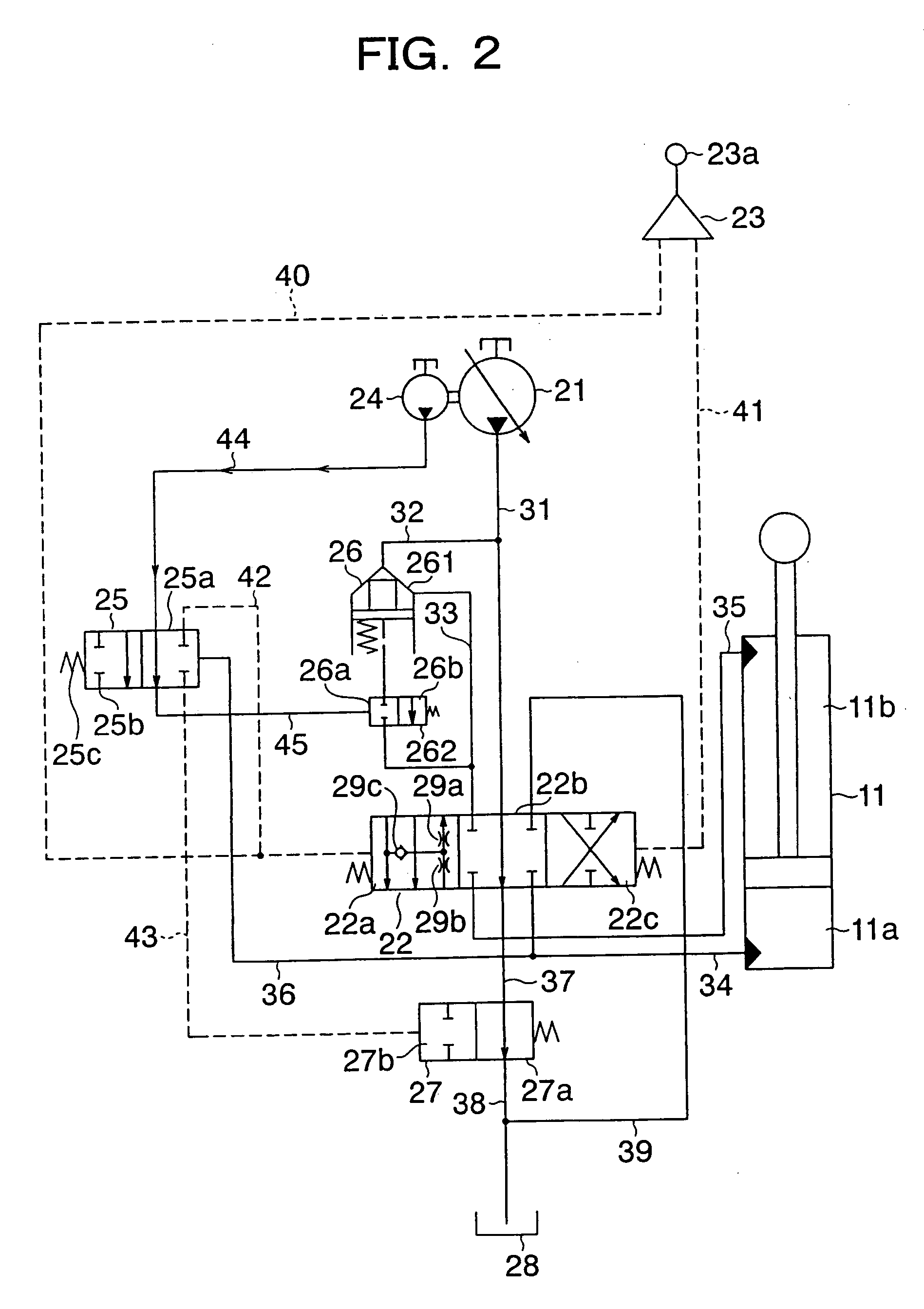

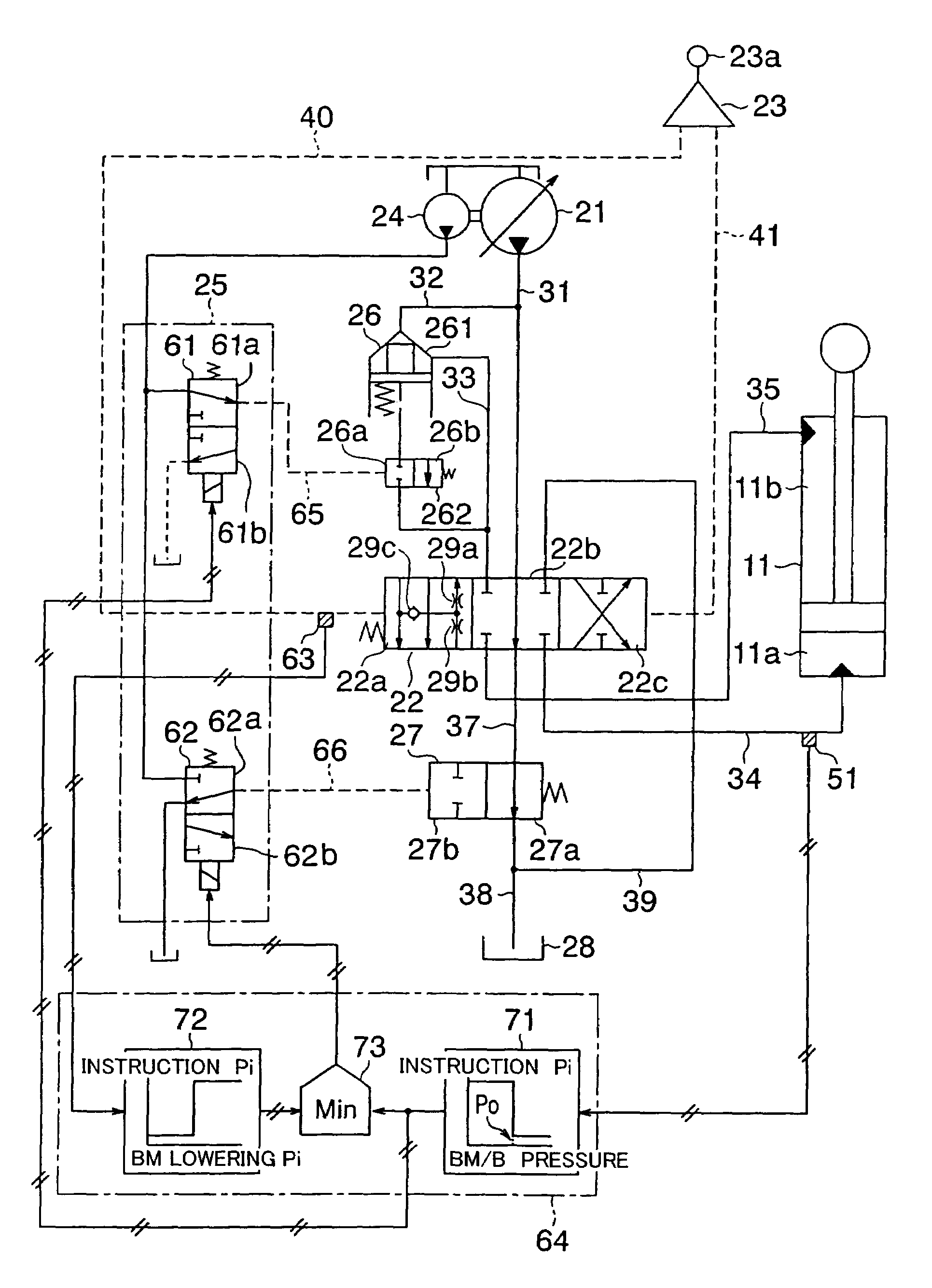

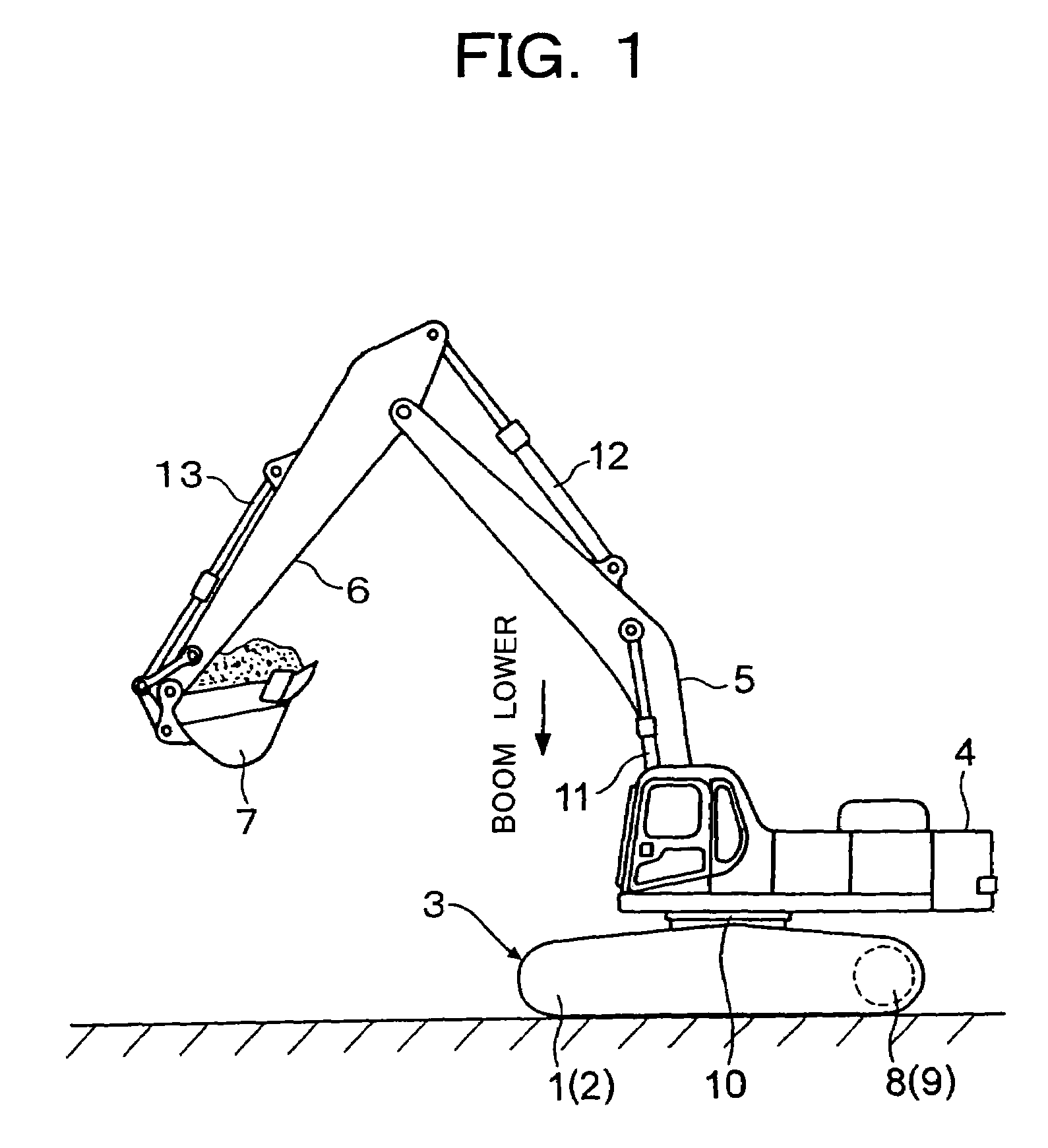

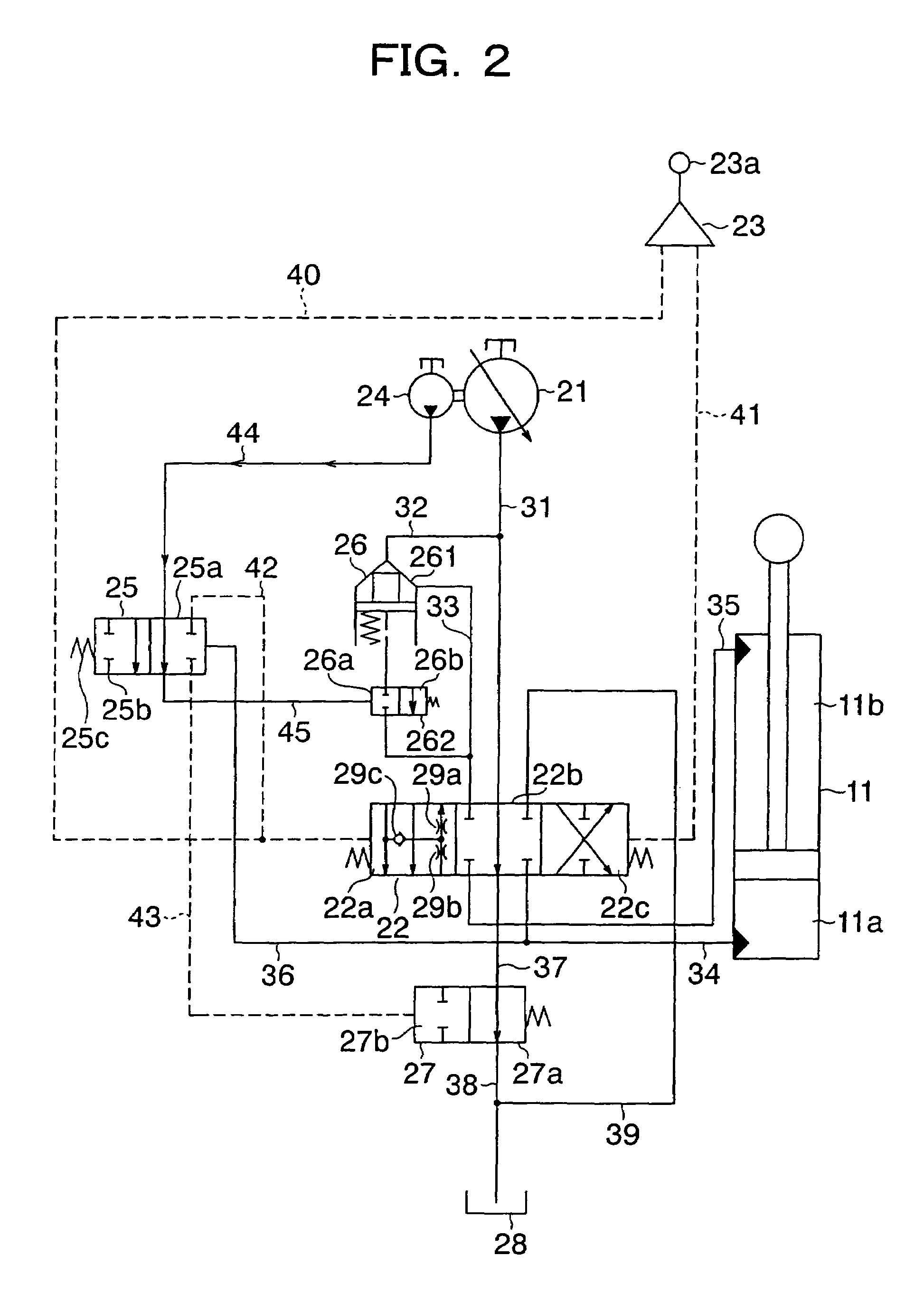

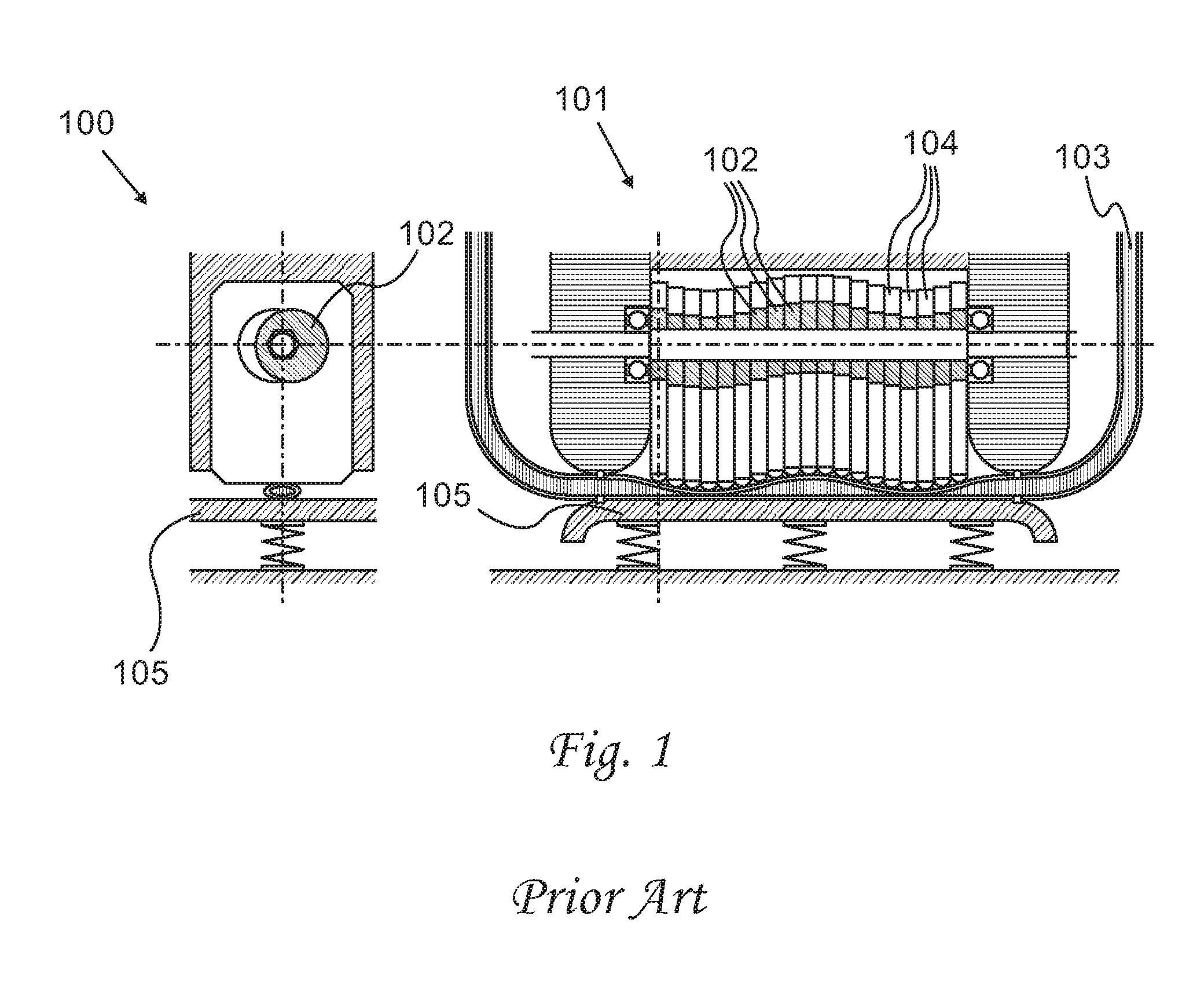

Hydraulic working machine

ActiveUS20060162543A1Reduce consumptionImprove energy efficiencyServomotor componentsServomotorsHydraulic circuitBottom pressure

A hydraulic circuit for a hydraulic working machine is composed of a main pump 21, a boom cylinder 11 arranged for extension or contraction by pressure oil from the main pump 21, a directional control valve 22 for controlling flows of pressure oil to be fed from the main pump 21 to a bottom chamber 11a and rod chamber 12b of the boom cylinder 11, a control unit 23 for performing a change-over control of the directional control valve 22, a pilot pump 24, a jack-up selector valve 25 for controlling a flow of pressure oil delivered from the pilot pump 24, a flow control valve 26 connected on an upstream side of the directional control valve 22 to a meter-in port of the directional control valve 22 such that the flow control valve 26 can be changed over by the jack-up selector valve 25, and a center bypass selector valve 27 connected on a downstream side of the directional control valve 22 to a center bypass port of the directional control valve 22 such that the center bypass selector valve 27 can be changed over by the jack-up selector valve 25. The hydraulic circuit performs a change-over of the jack-up selector valve 25 in accordance with a bottom pressure on the boom cylinder 11.

Owner:NIHON KENKI CO LTD

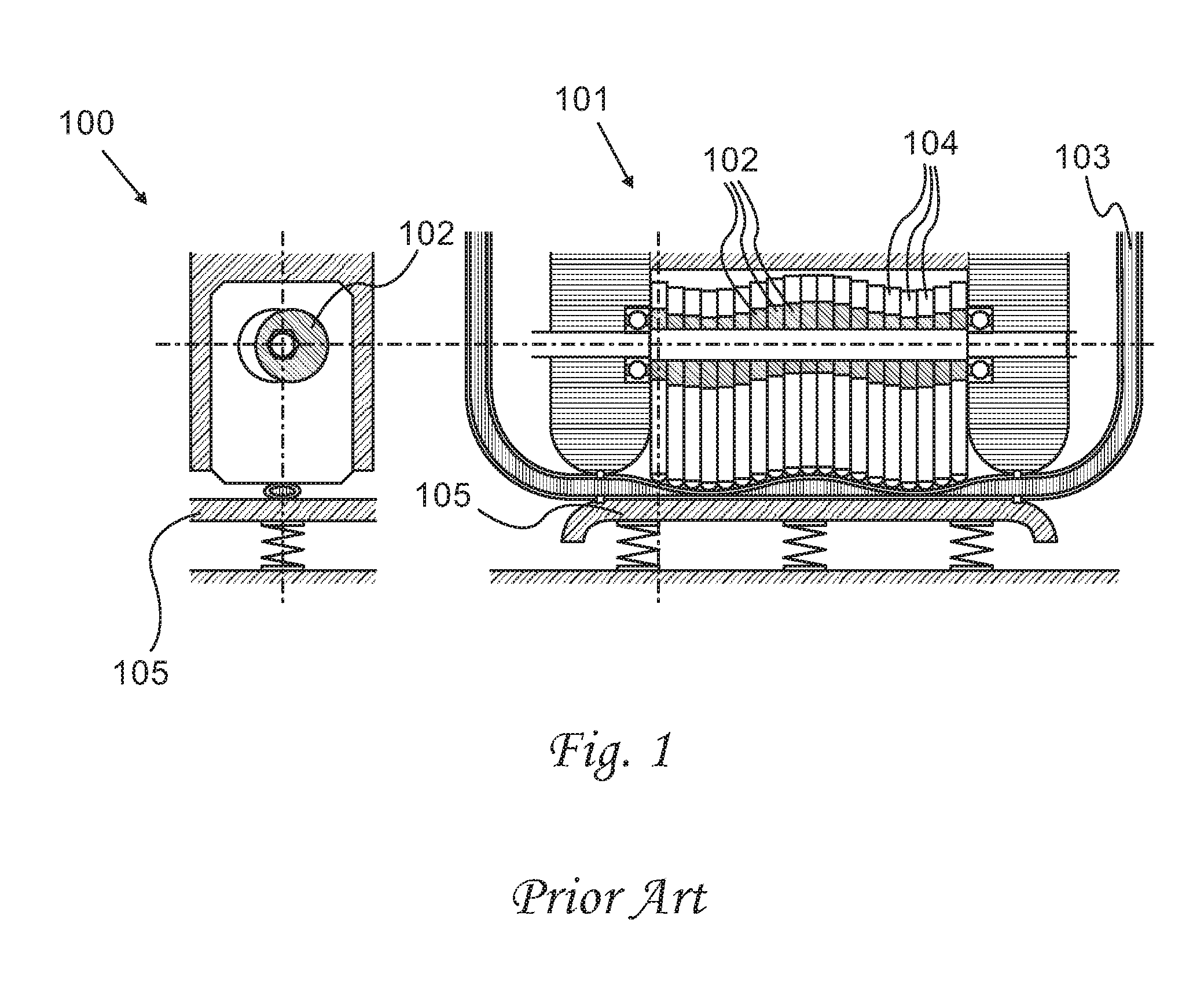

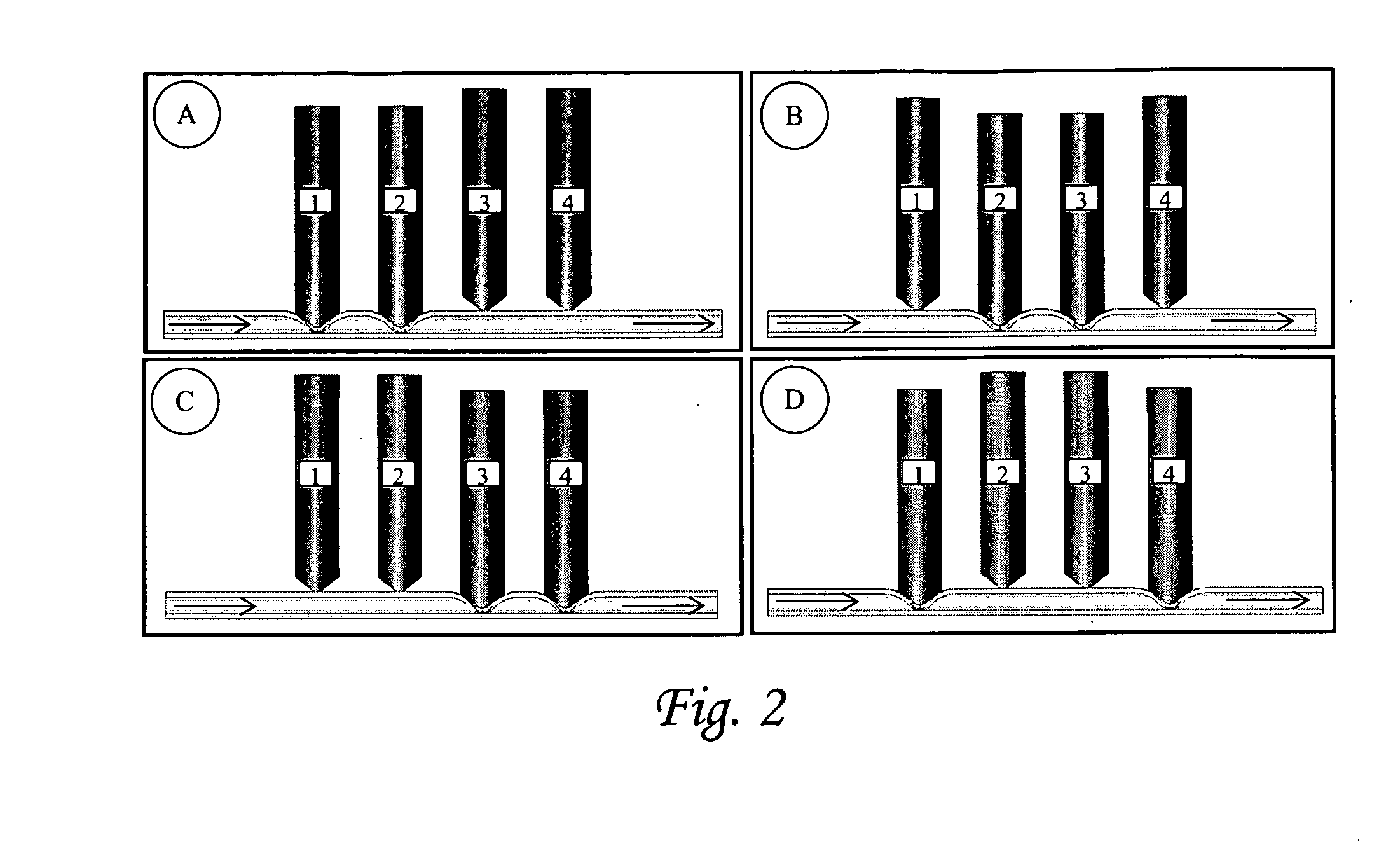

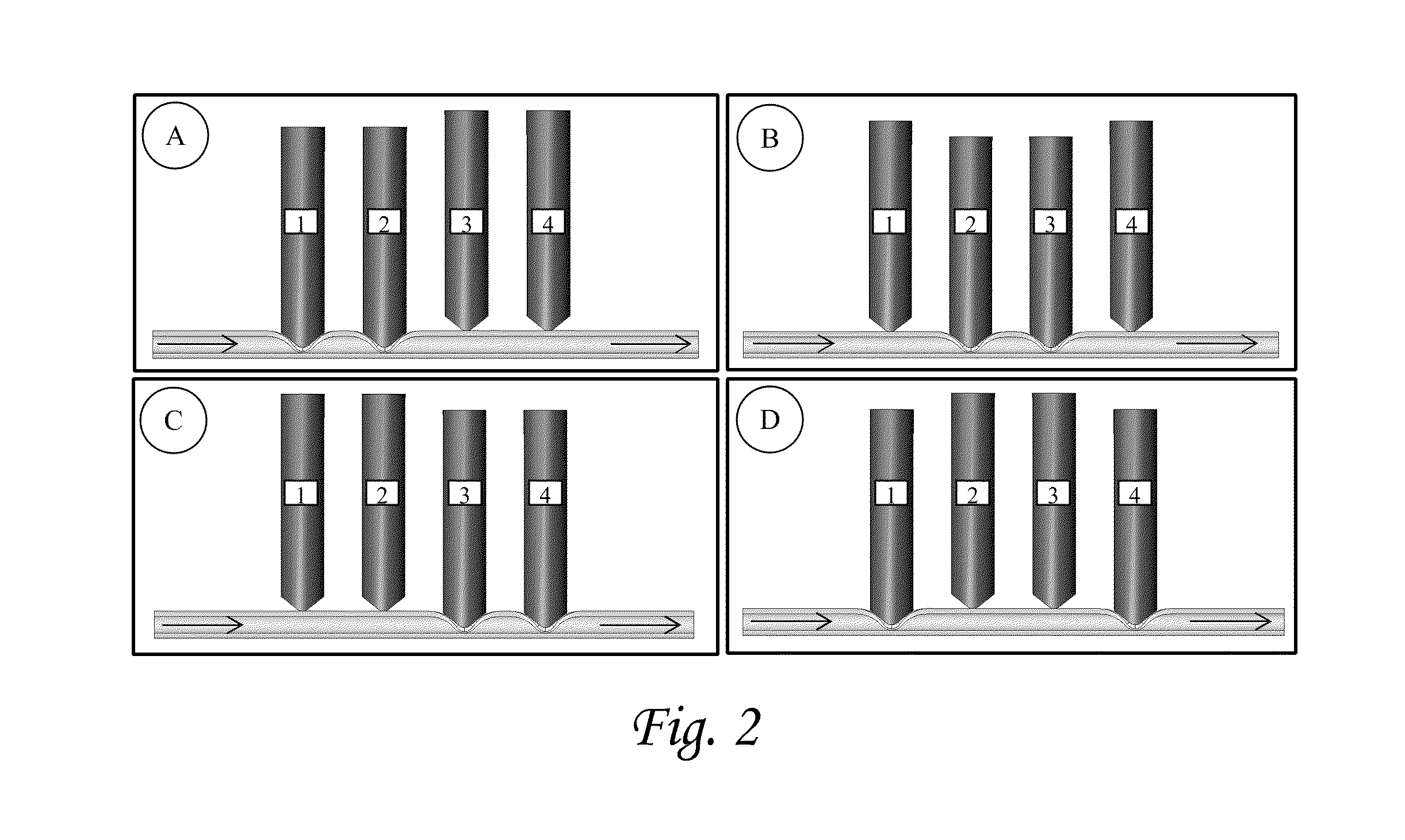

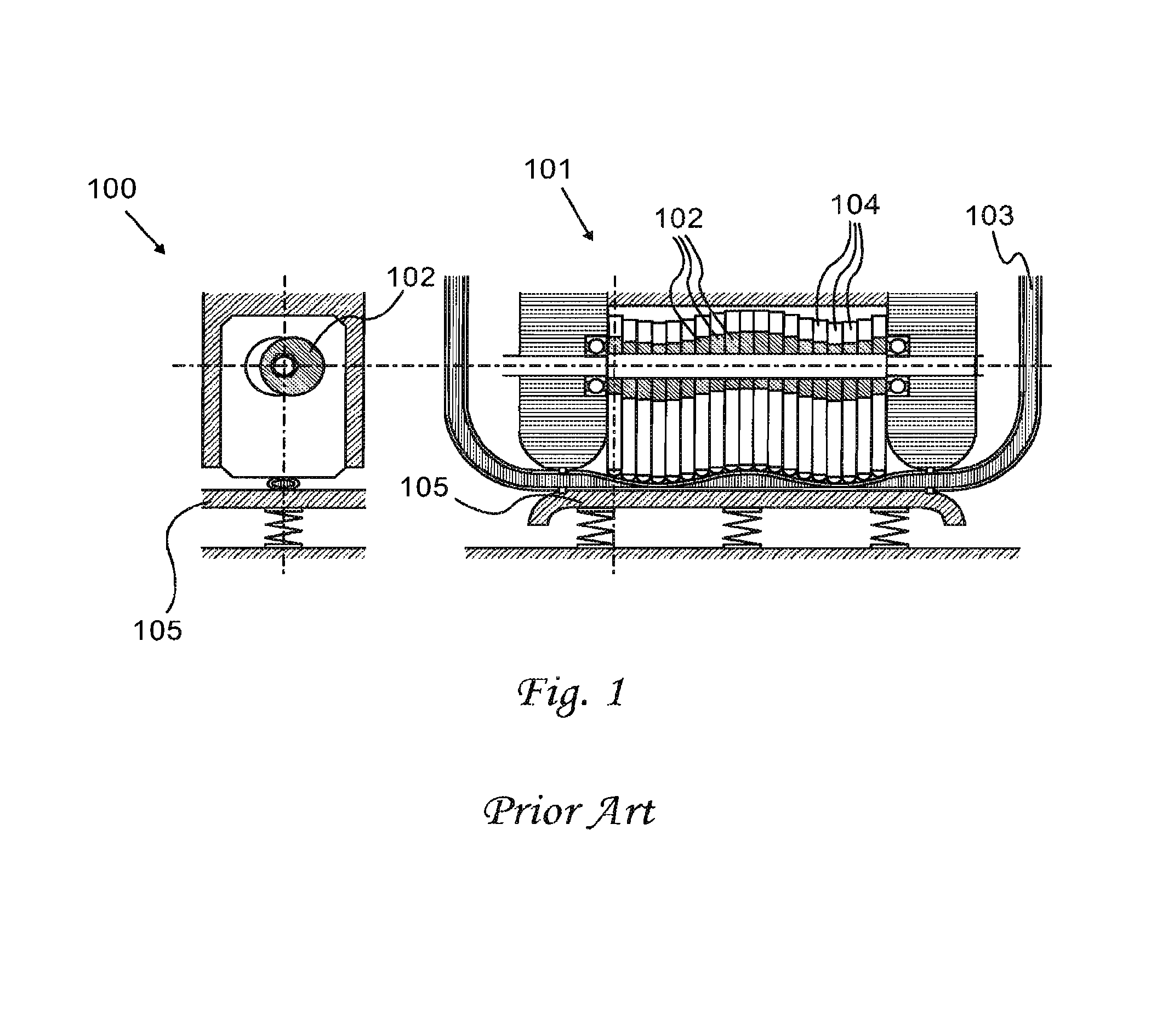

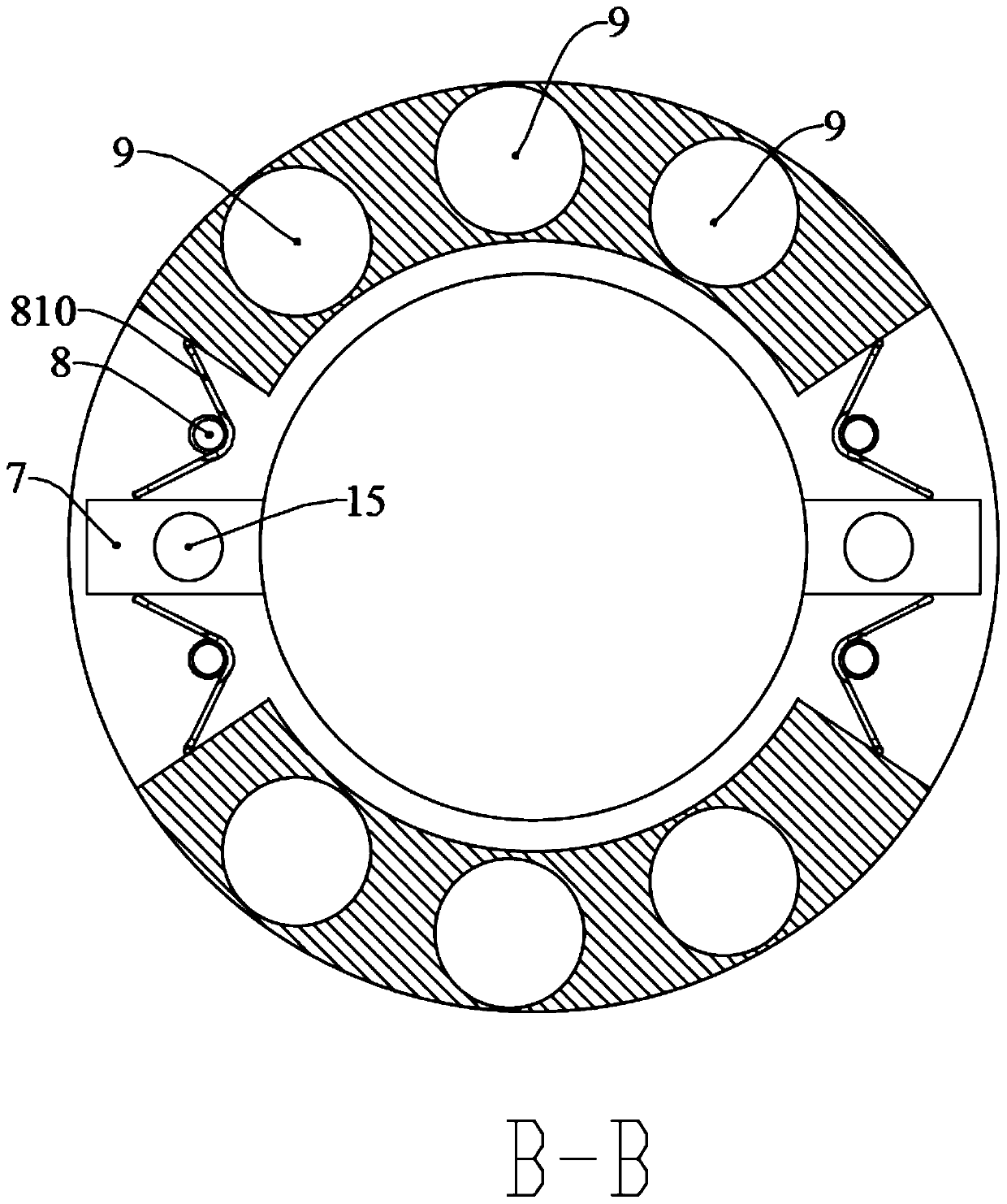

Magnetically balanced finger-type peristaltic pump

ActiveUS20090240201A1Decreasing pump energyOptimize working timeFlexible member pumpsPressure infusionPeristaltic pumpEngineering

A peristaltic pump includes a plurality of effecters, actuated in a periodic manner upon by obstructive forces of a flexible infusion tube so as flow of infusion fluid is provided along said infusion tube, the magnitude of the obstructive forces being dependent upon the displacement of said moving effecters; and a plurality of balancing magnets providing balancing forces upon one or all the moving effecters, the balancing forces at each point along the path of motion of the moving effecters being of approximately equal magnitude to that of the obstructive forces at the point; such that the parasitic output due to work performed against the obstructive forces is approximately zero and yield is maximized.

Owner:EITHAN MEDICAL LTD

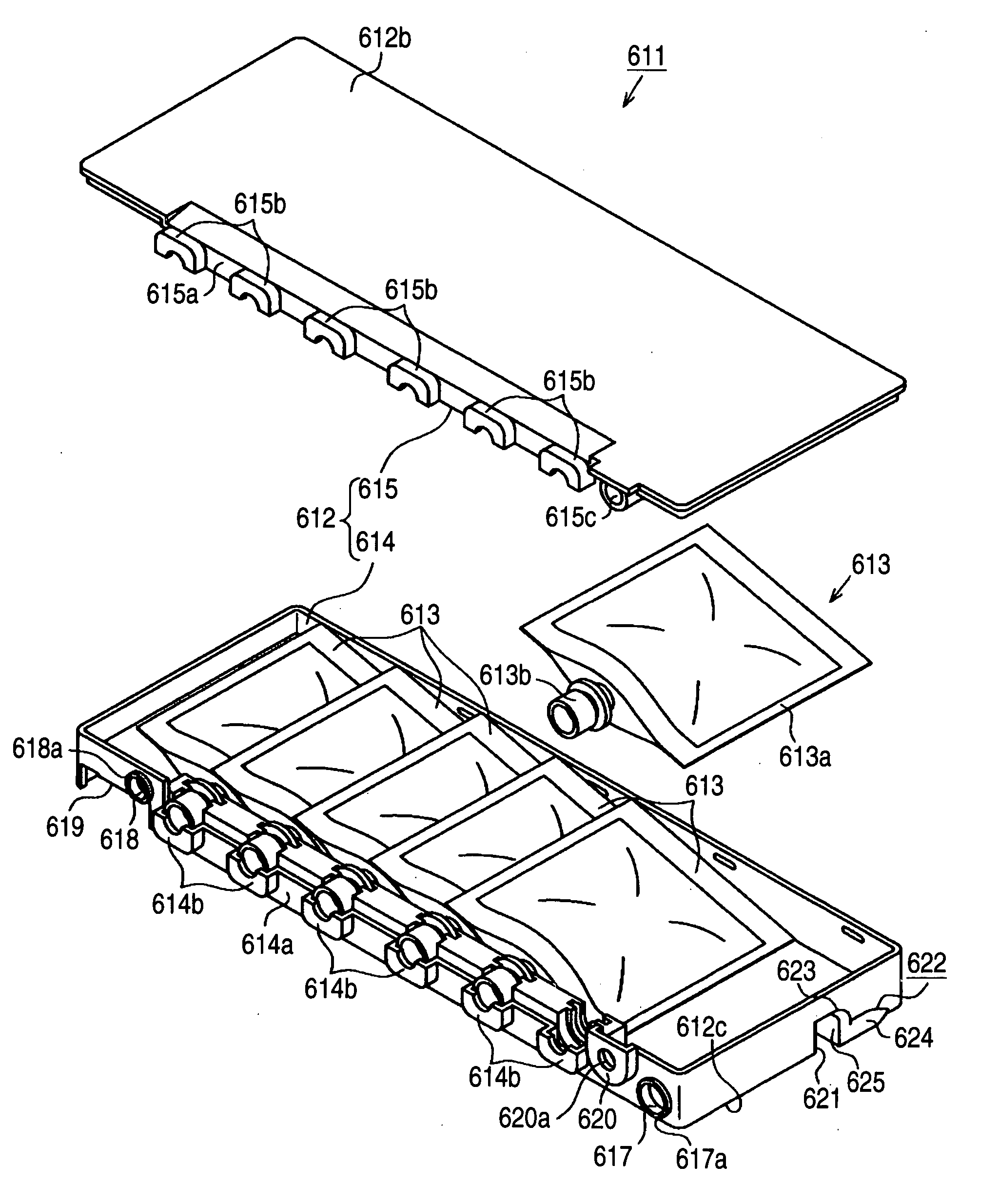

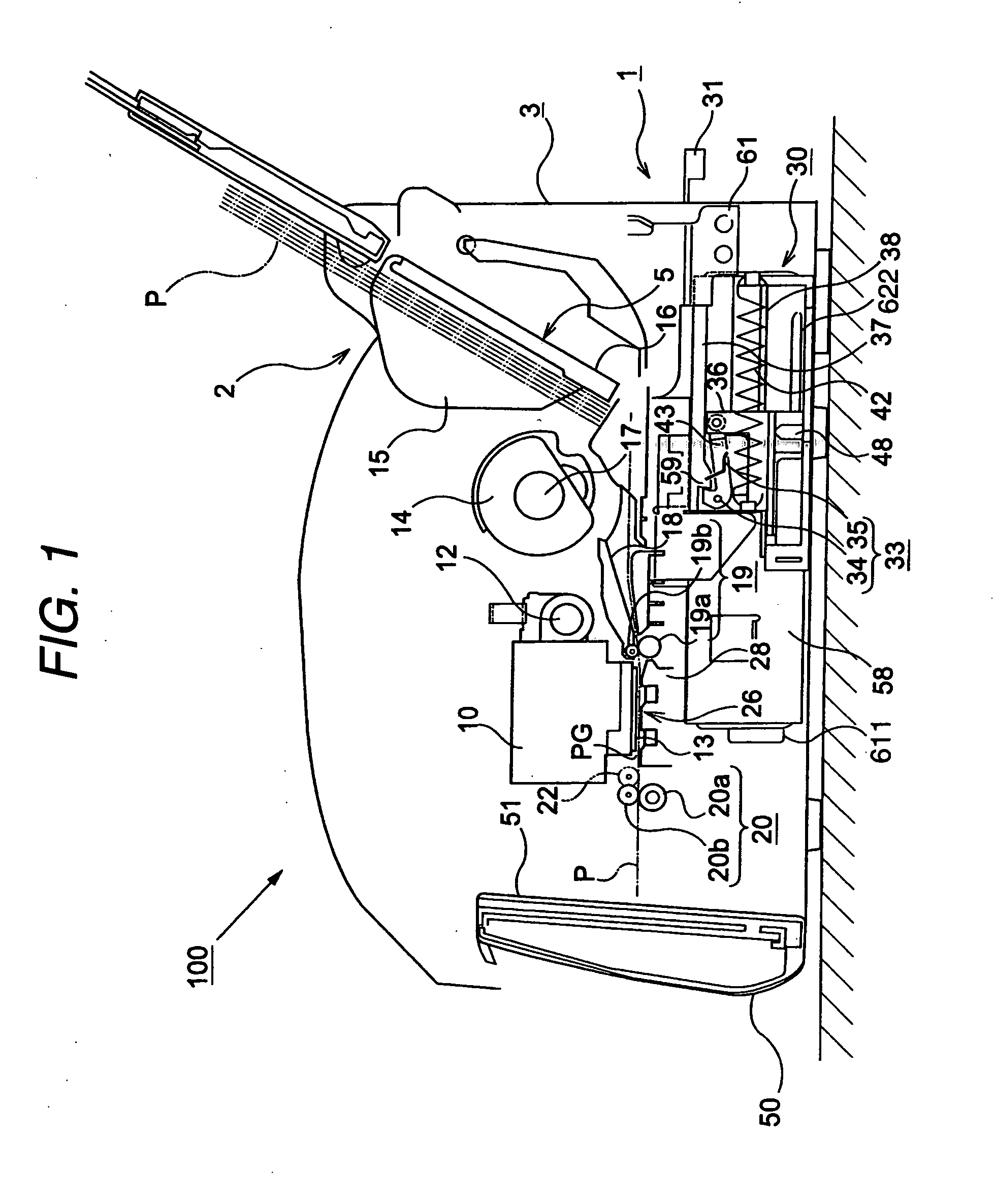

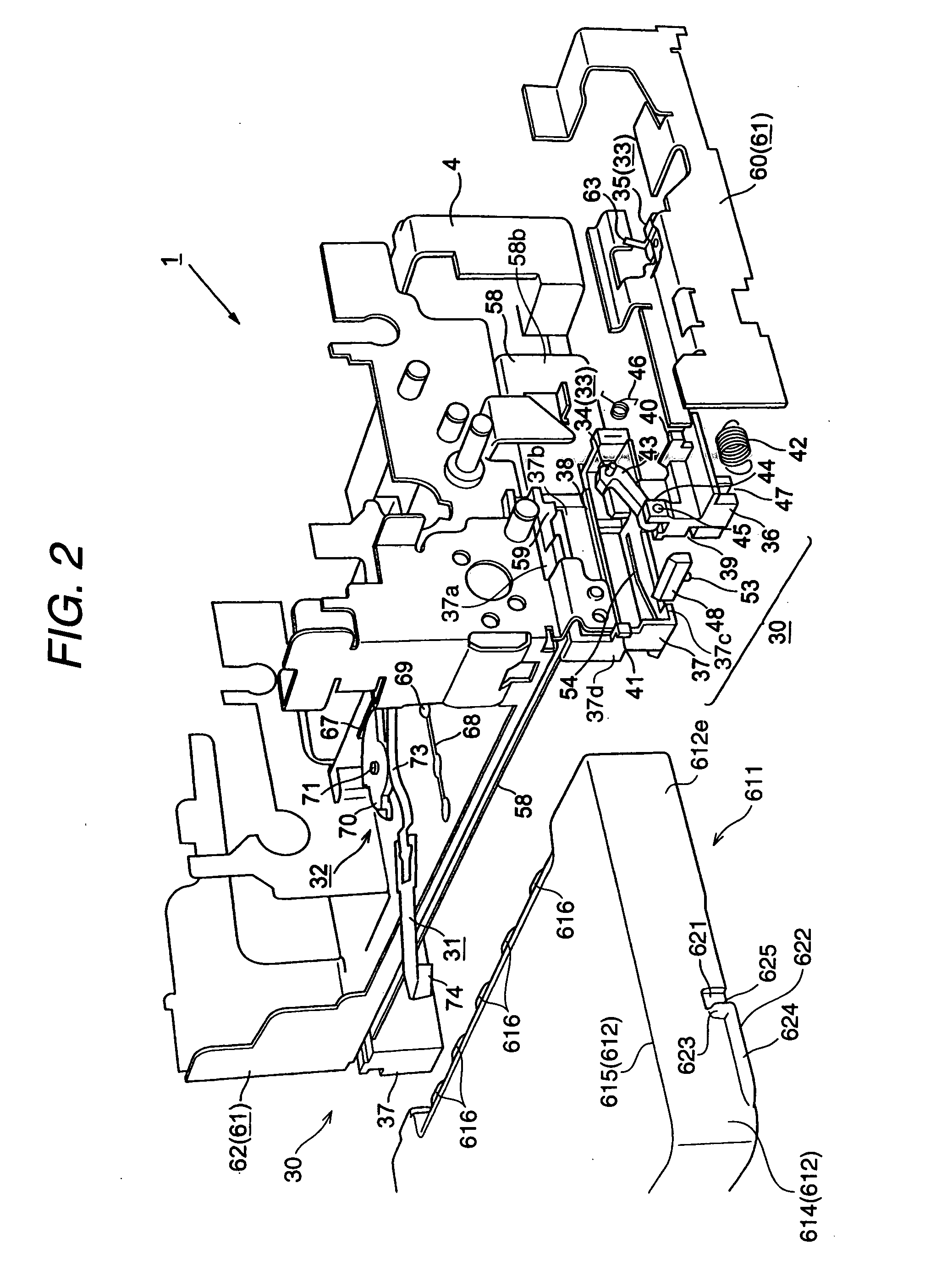

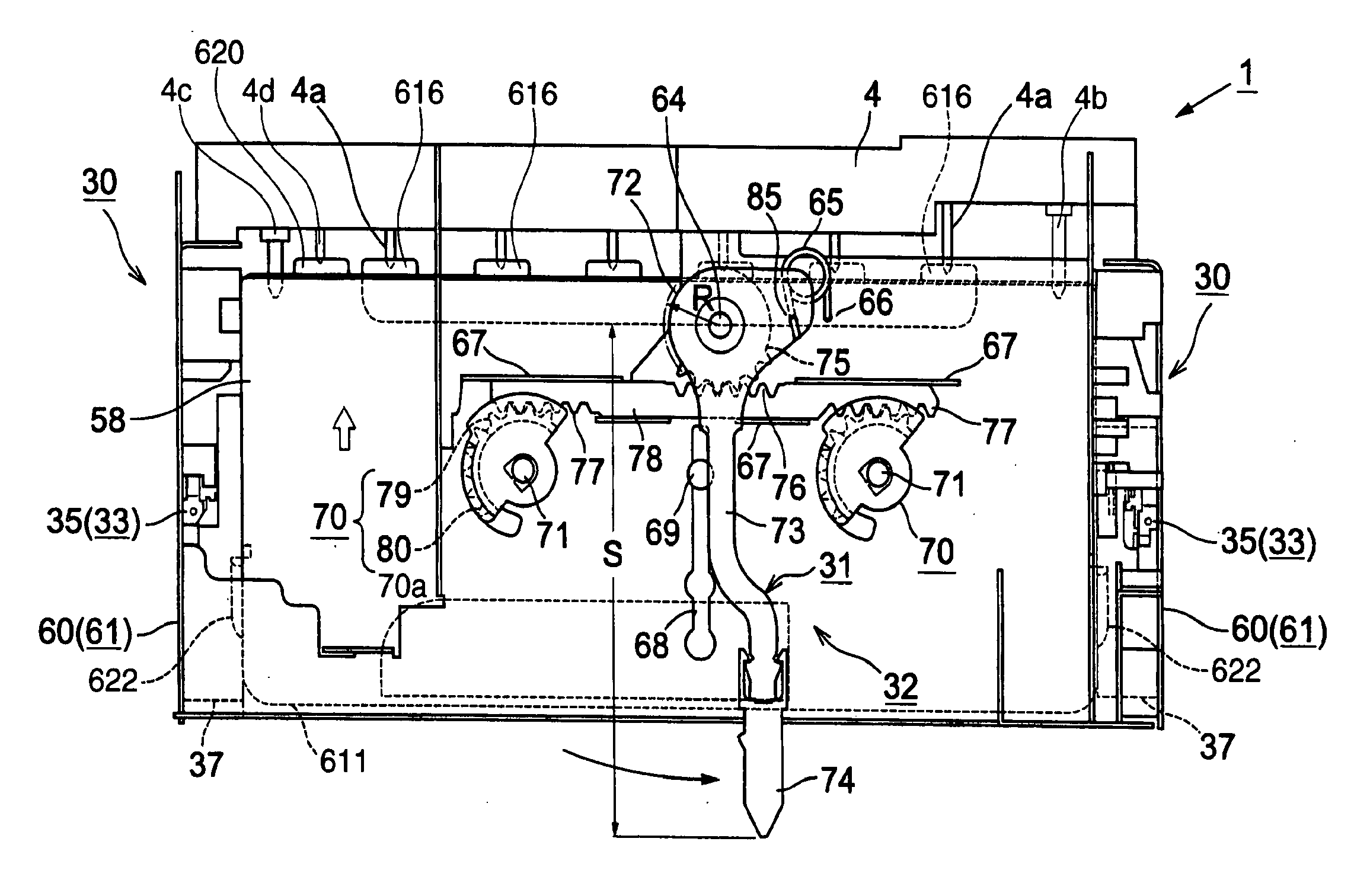

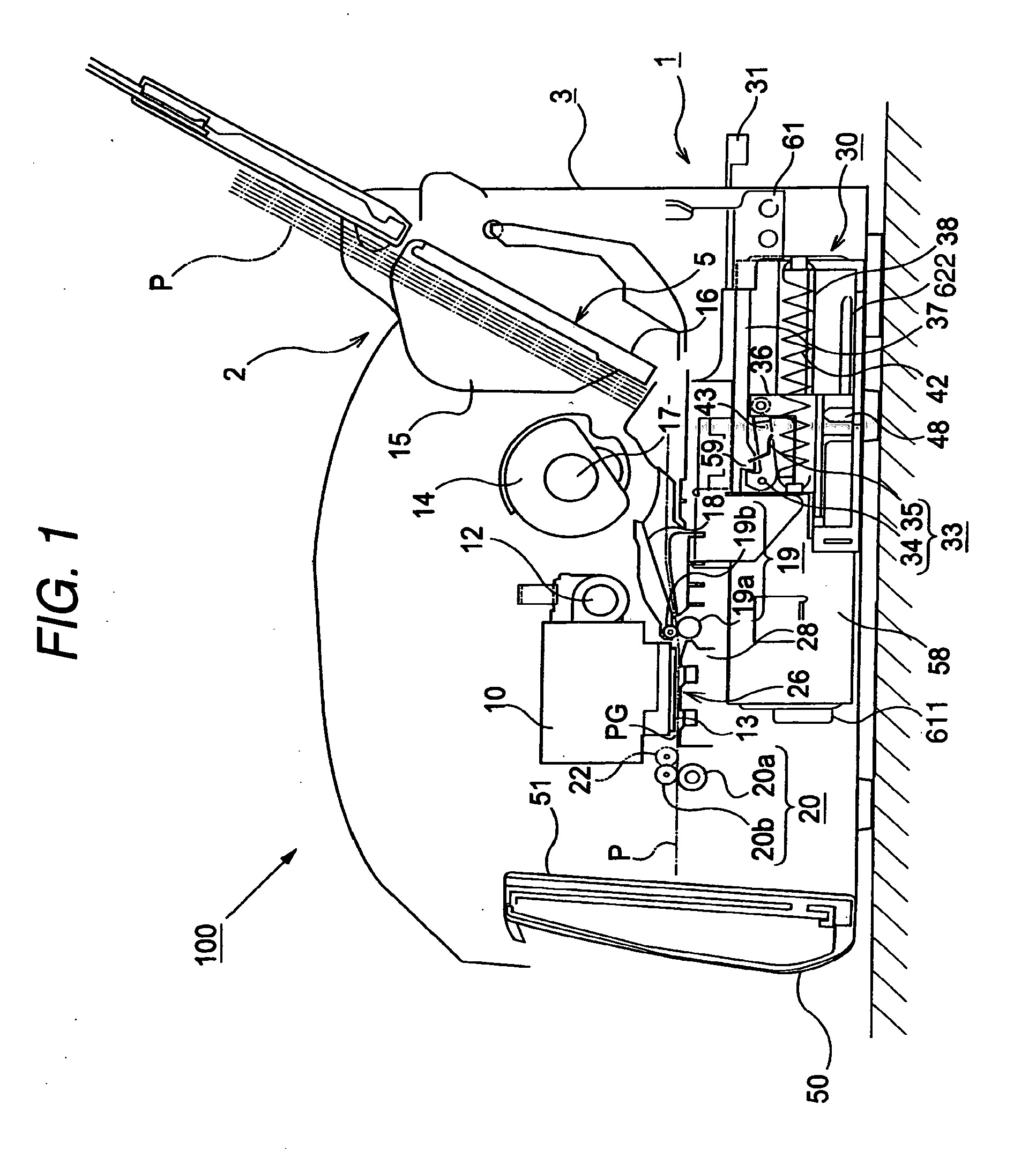

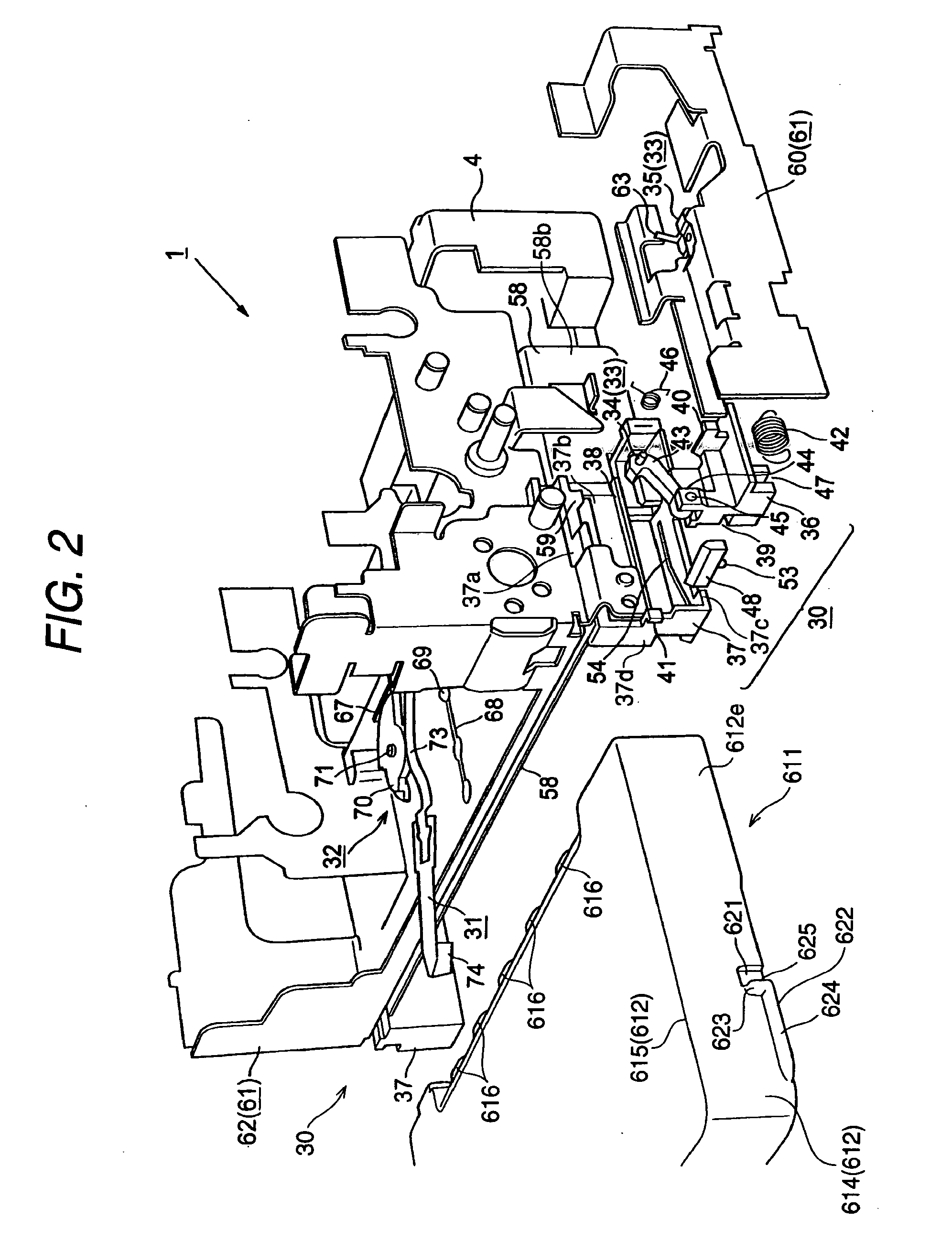

Ink cartridge attachment/detachment device, recording apparatus, liquid ejection apparatus, and liquid container

ActiveUS20050168545A1Accurate insertionAvoid closingRoof coveringOther printing apparatusMechanical engineeringMental detachment

Owner:SEIKO EPSON CORP

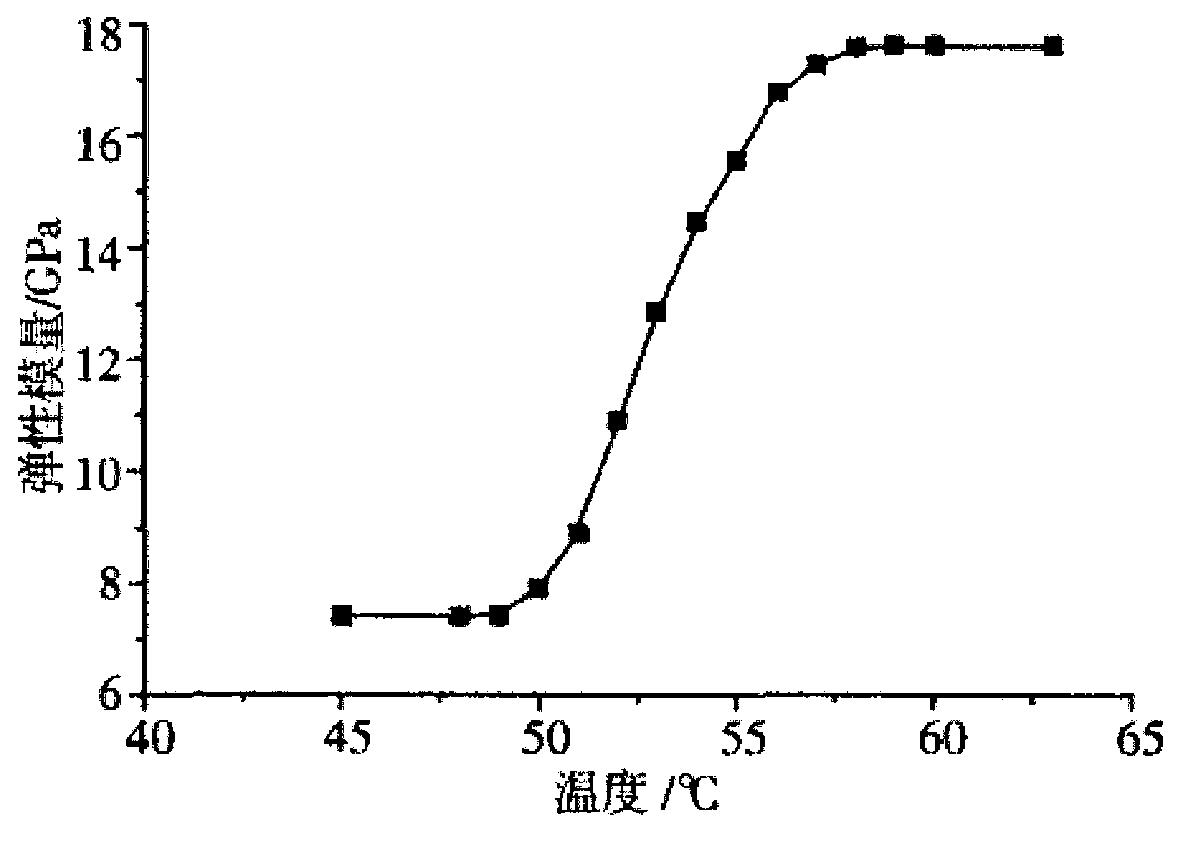

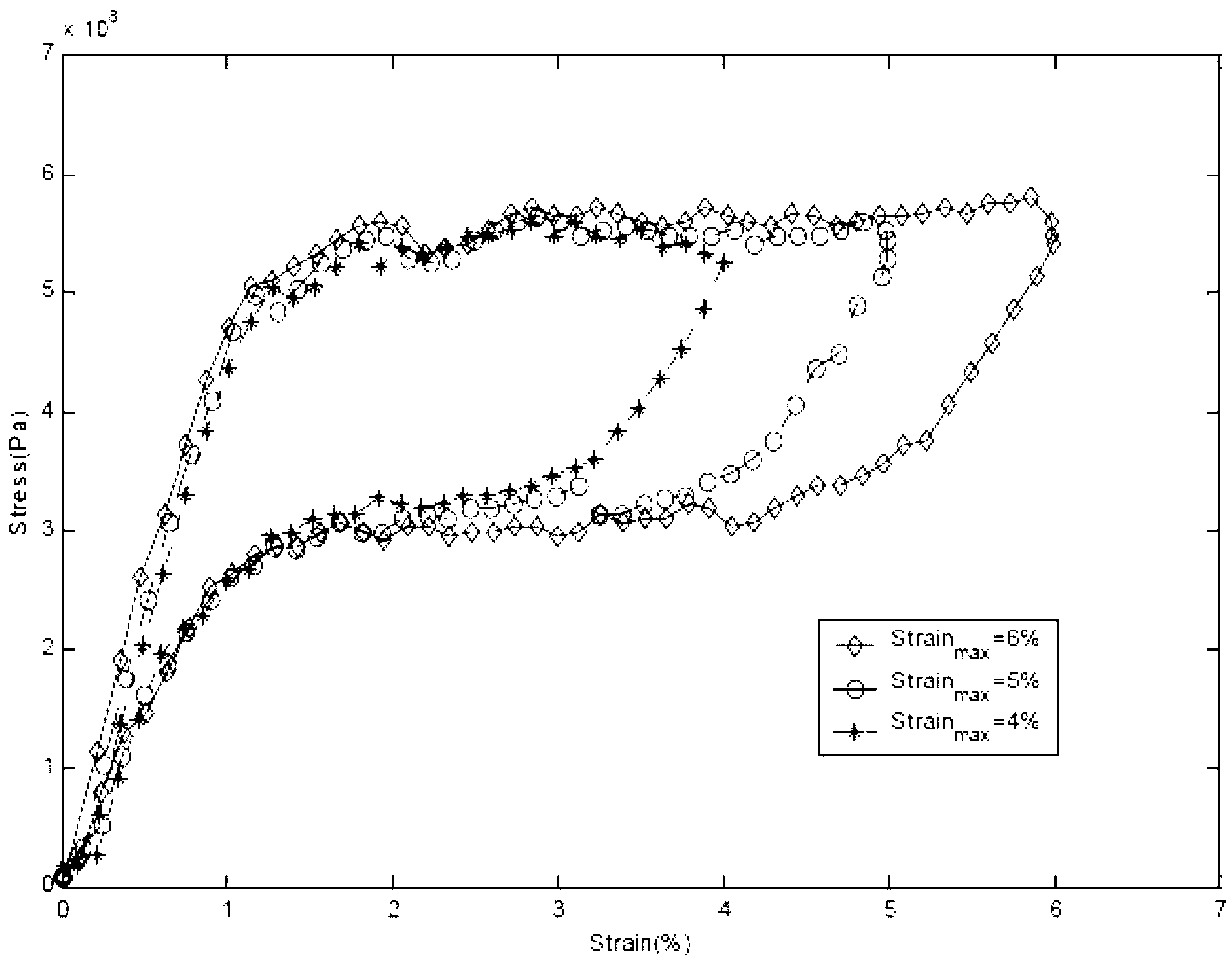

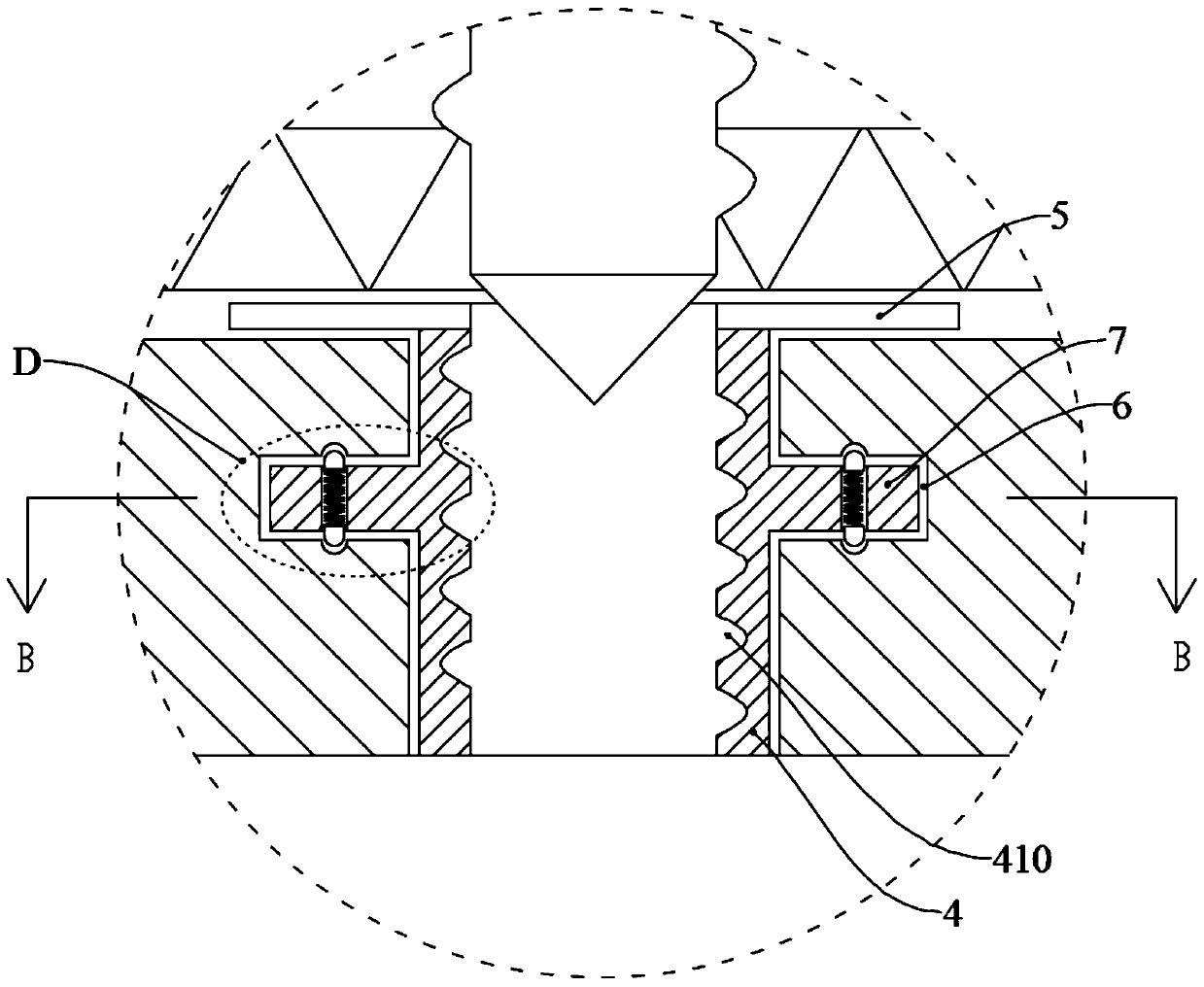

Shape memory alloy (SMA) group rolling rod type large load releasing mechanism

InactiveCN103231813AStrong impact resistanceLarge release loadCosmonautic component separationShape-memory alloyShock resistance

The invention provides a shape memory alloy (SMA) group rolling rod type large load releasing mechanism. A segmented nut of the mechanism is firmly hooped by a hooping cylinder through rolling rods, simultaneously the upper end face and the lower end face of the segmented nut are respectively matched with an end cover and a separating ejector block, so that the segmented nut is a total nut and cannot move vertically. Groove are arranged on the segmented nut, so that when separation is needed, and the hooping cylinder moves downwards to drive the rolling rods to roll downwards and properly enter the grooves of the segmented nut when moving to a certain position, so that the segmented nut can obtain radial displacement. When releasing is finished, the hooping cylinder moves upwards under the effect of an SMA reset spring and simultaneously push the rolling rods out from the grooves, and the segmented nut draws close toward the inside to form an integral thread, so that repeated using function of the mechanism can be achieved, the segmented nut is fit with the separating ejector block through a conical surface, and the separating ejector block is matched with the hooping cylinder through two end faces. The shape memory alloy (SMA) group rolling rod type large load releasing mechanism is strong in shock resistance, releases large load and has the redundancy design and high reliability.

Owner:BEIHANG UNIV +1

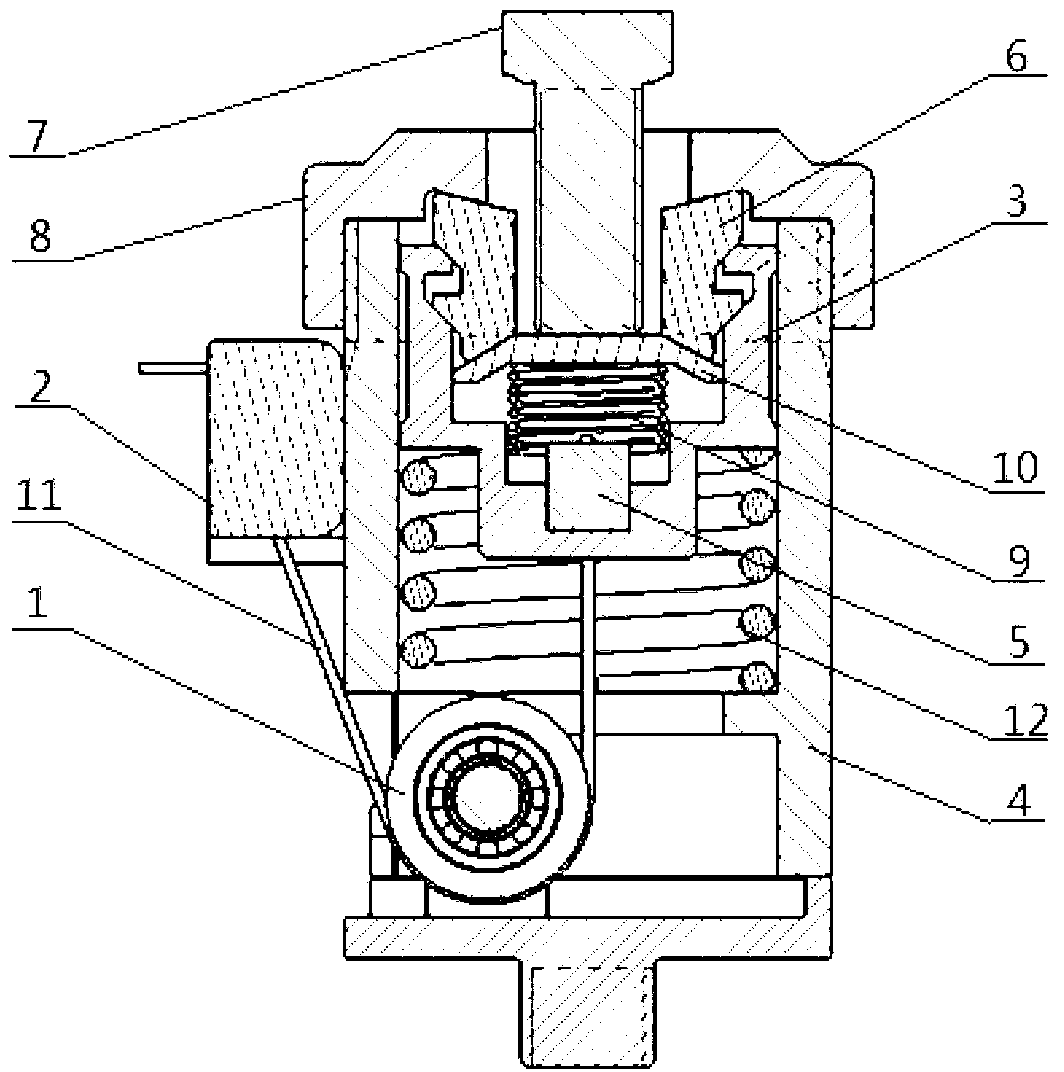

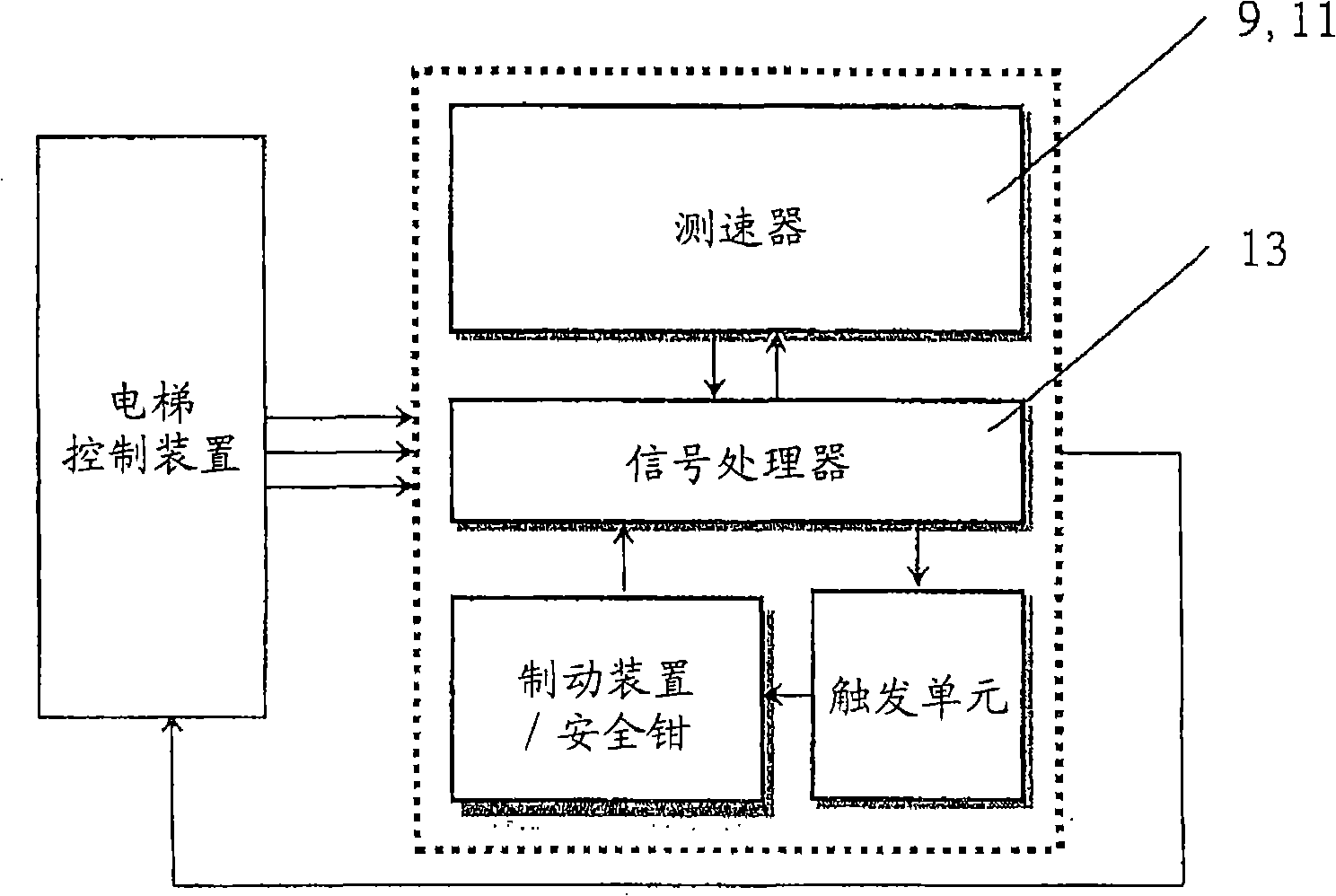

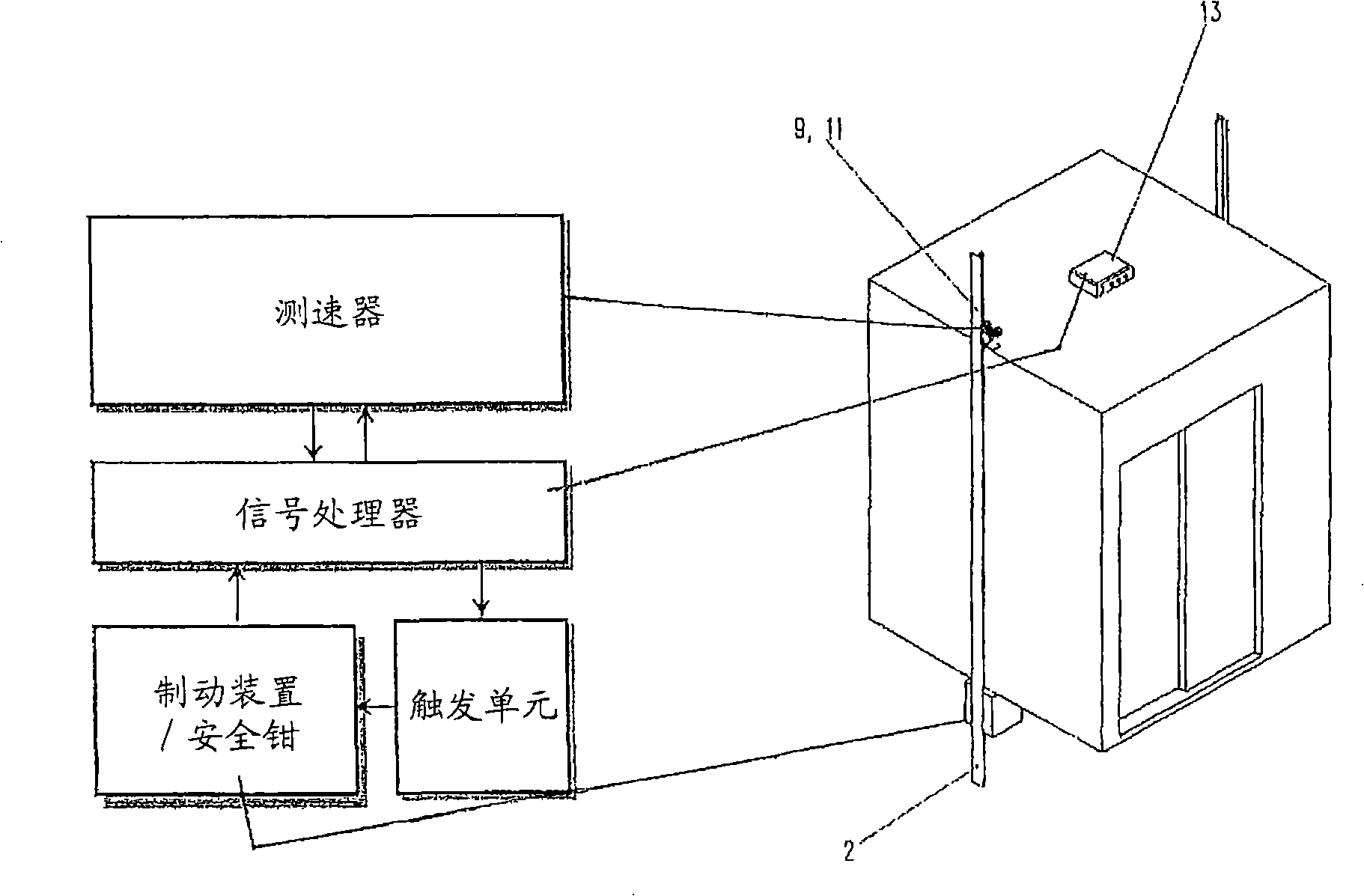

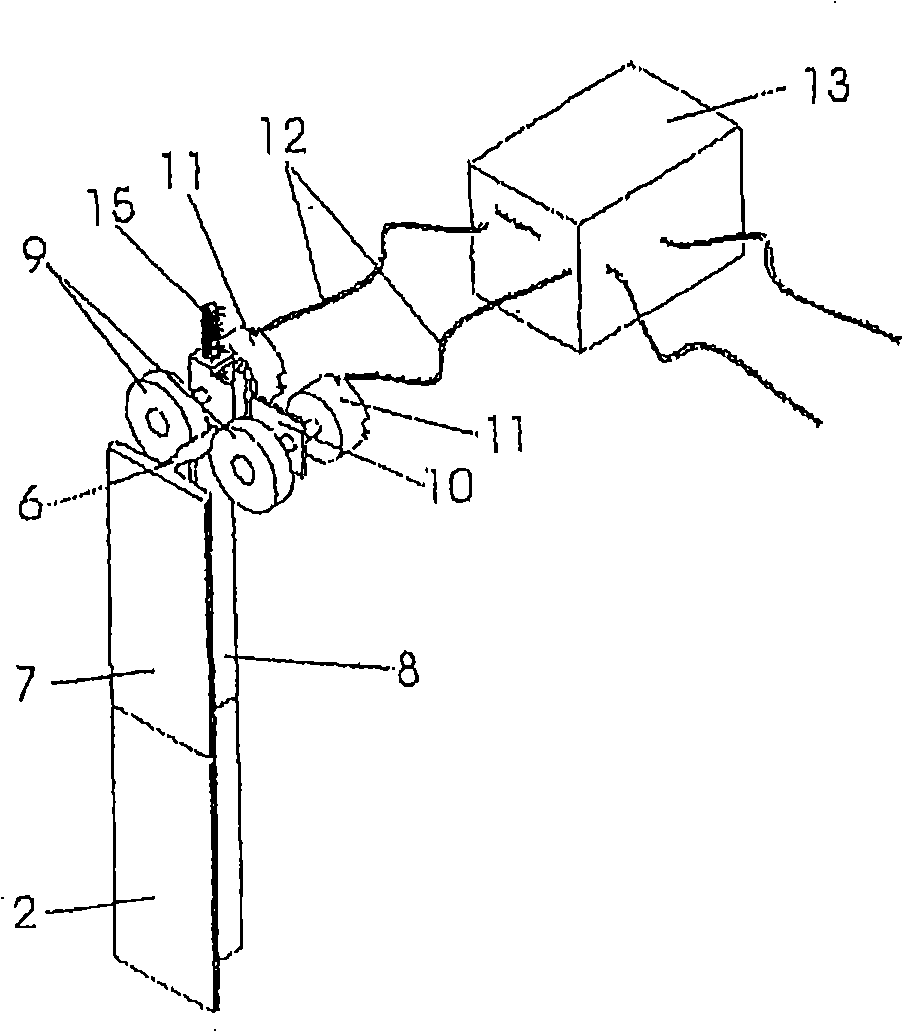

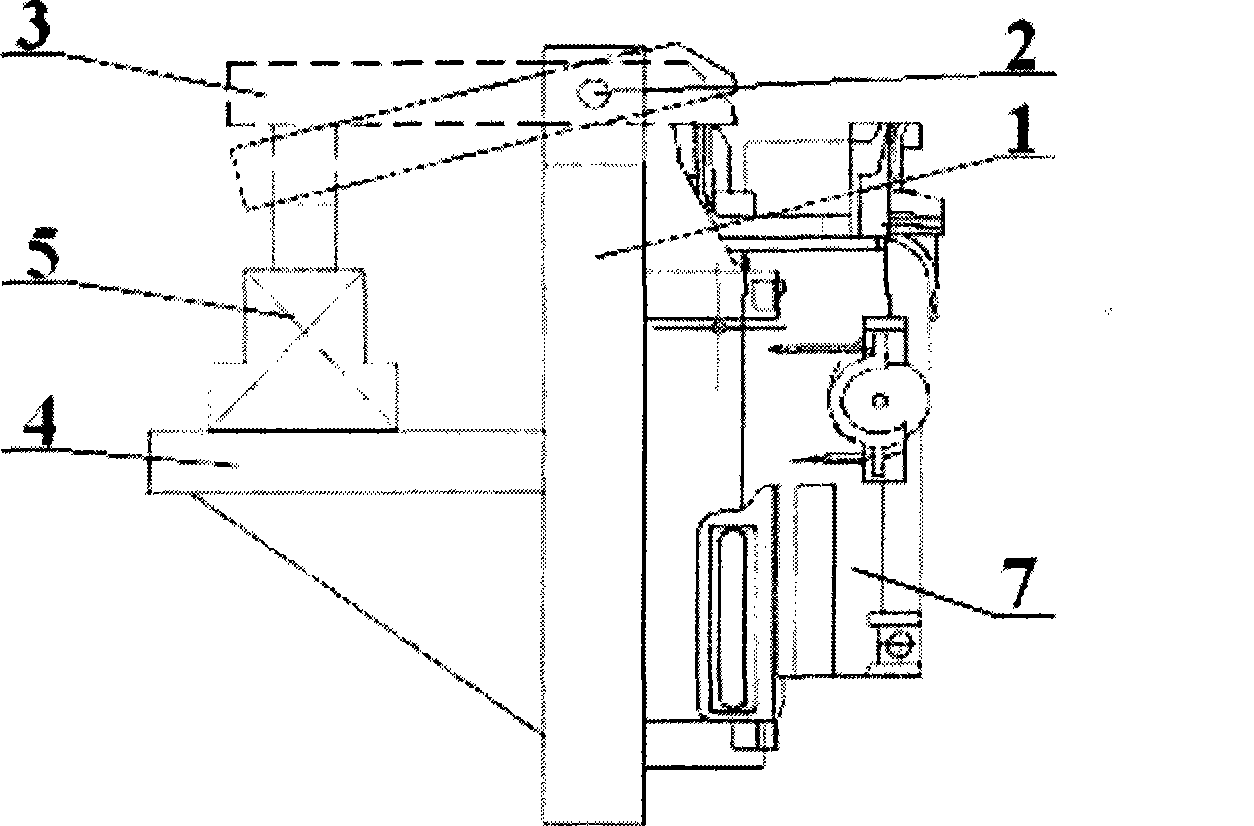

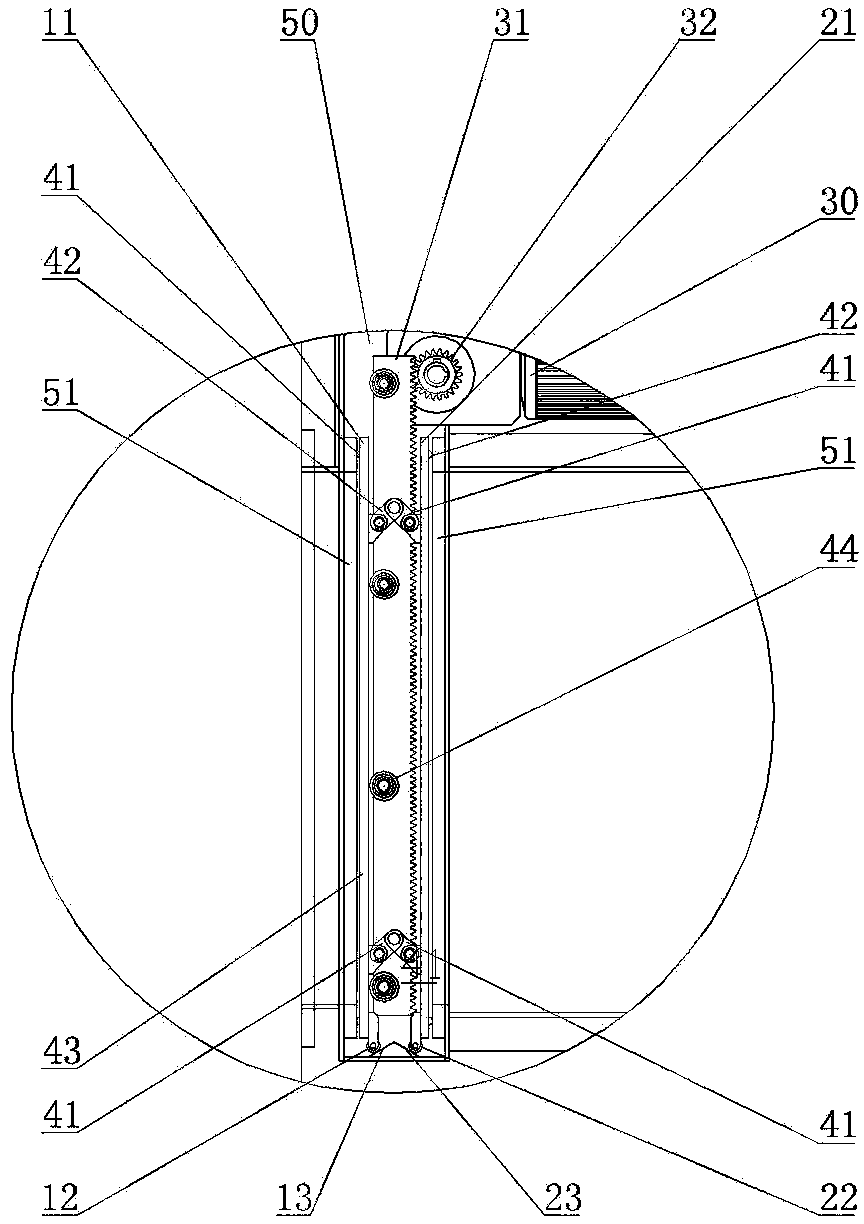

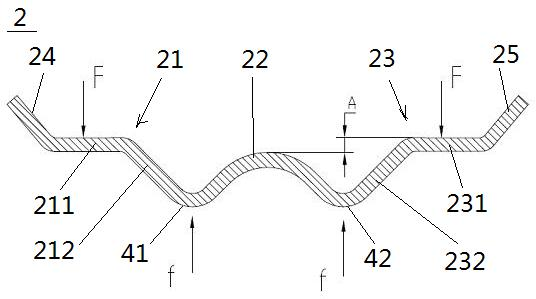

ISG type multifunctional electronic urgent safety clamp

The invention relates to an elevator comprising an elevator car that is guided inside an elevator shaft on guide rails. Said elevator also comprises electronics for inter alia travel control or regulation and an emergency braking device for preventing excess speed of the elevator car. Said emergency braking device has a braking device and a detector unit (11) the signal of which actuates the braking device when the elevator car reaches an excess speed. The detector unit (9, 11) comprises at least two wheels (8) that rest against a guide rail (2), each driving a respective detector (11) the signal of which is a measure for the rotational angle or rotational speed of the corresponding wheel. The electronics are adapted to functionally utilize the detector signal.; For this purpose, at least one detector signal is used during operation of the elevator within the admissible speed range for determining at least travel, speed and / or acceleration variable of the elevator car influencing the operation of the elevator system. The electronics actuate the braking device as soon as at least one of the detectors (11), by way of its detector signal, indicates an excess speed of the elevator car outside the admissible speed range.

Owner:WITTUR

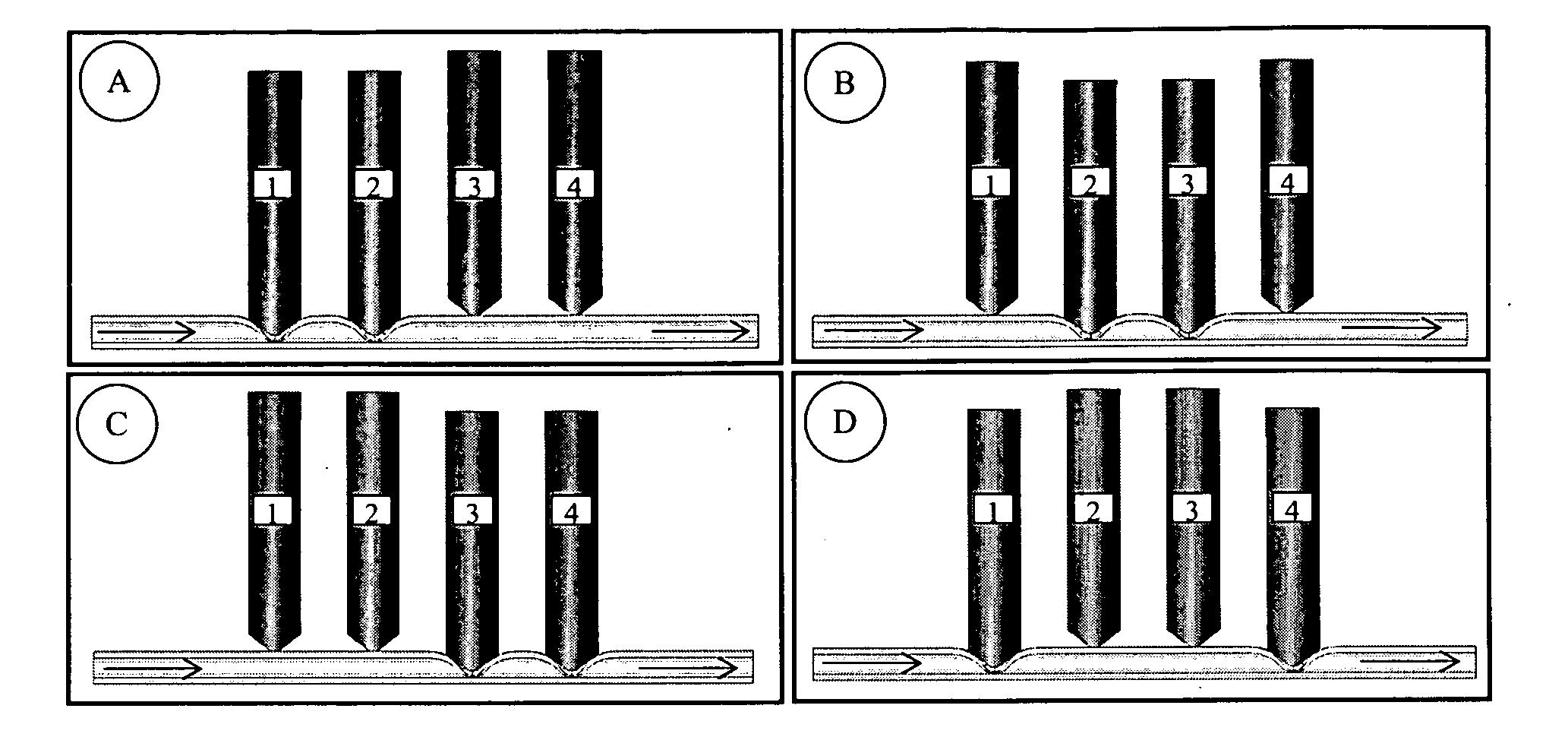

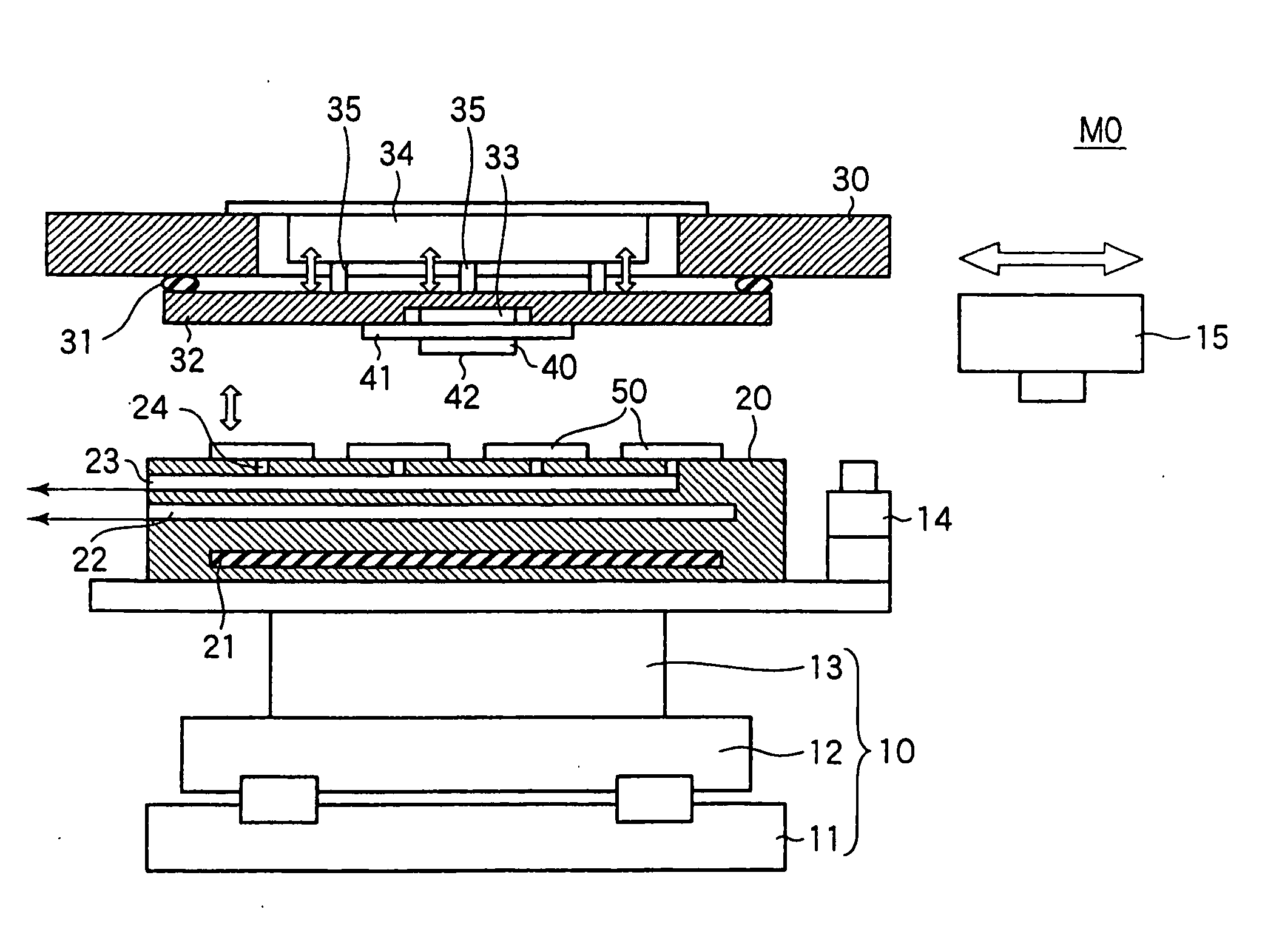

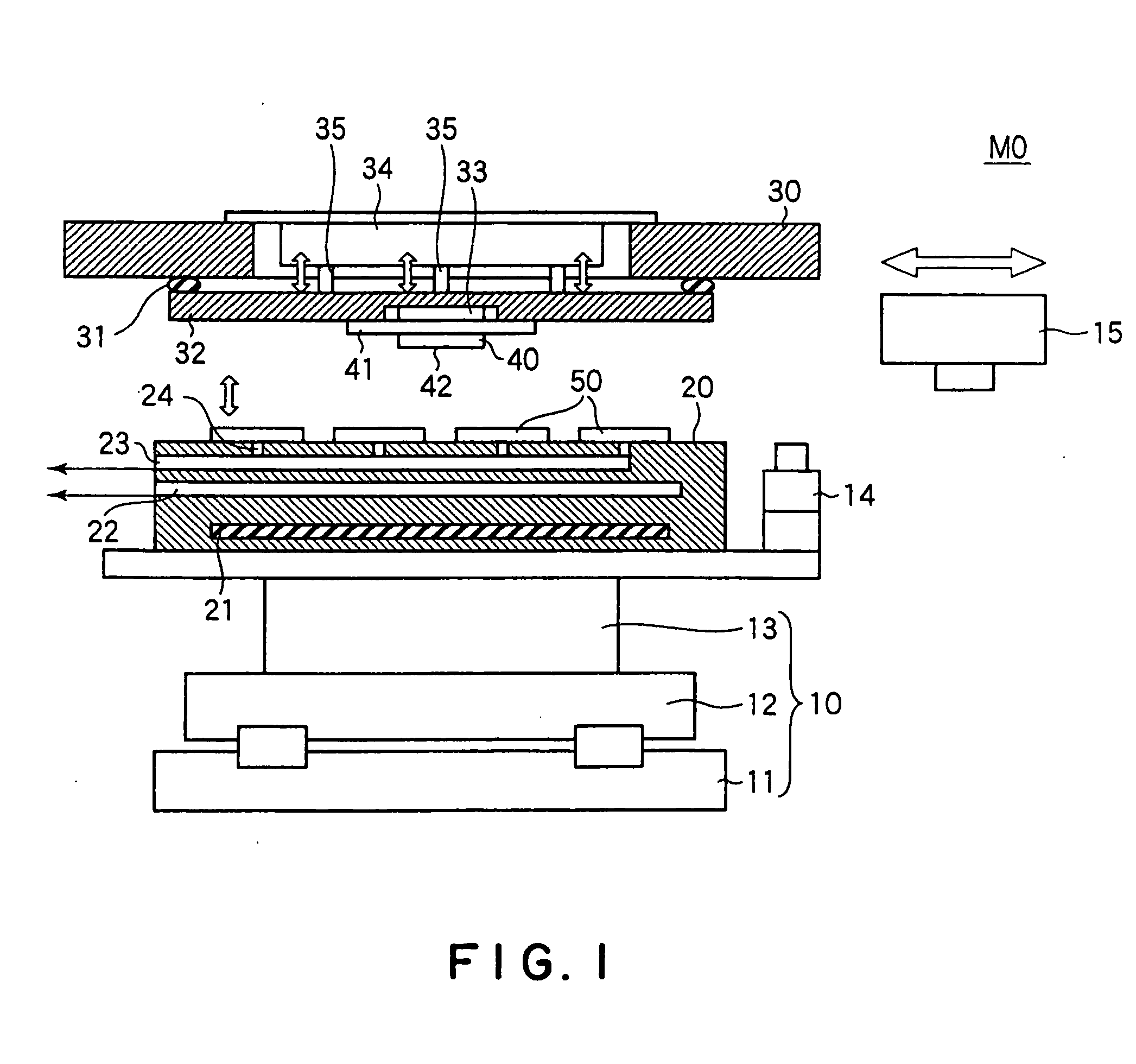

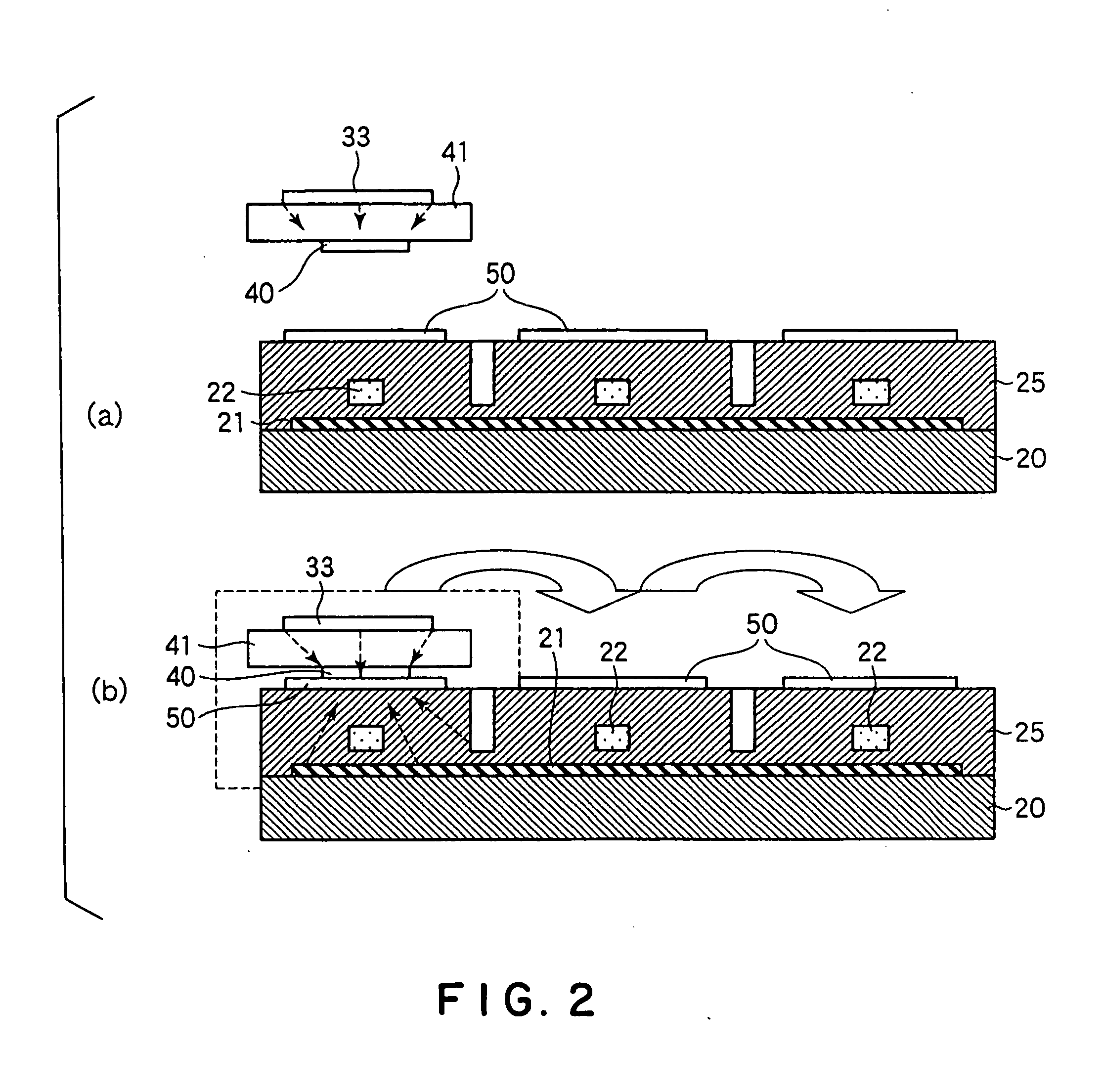

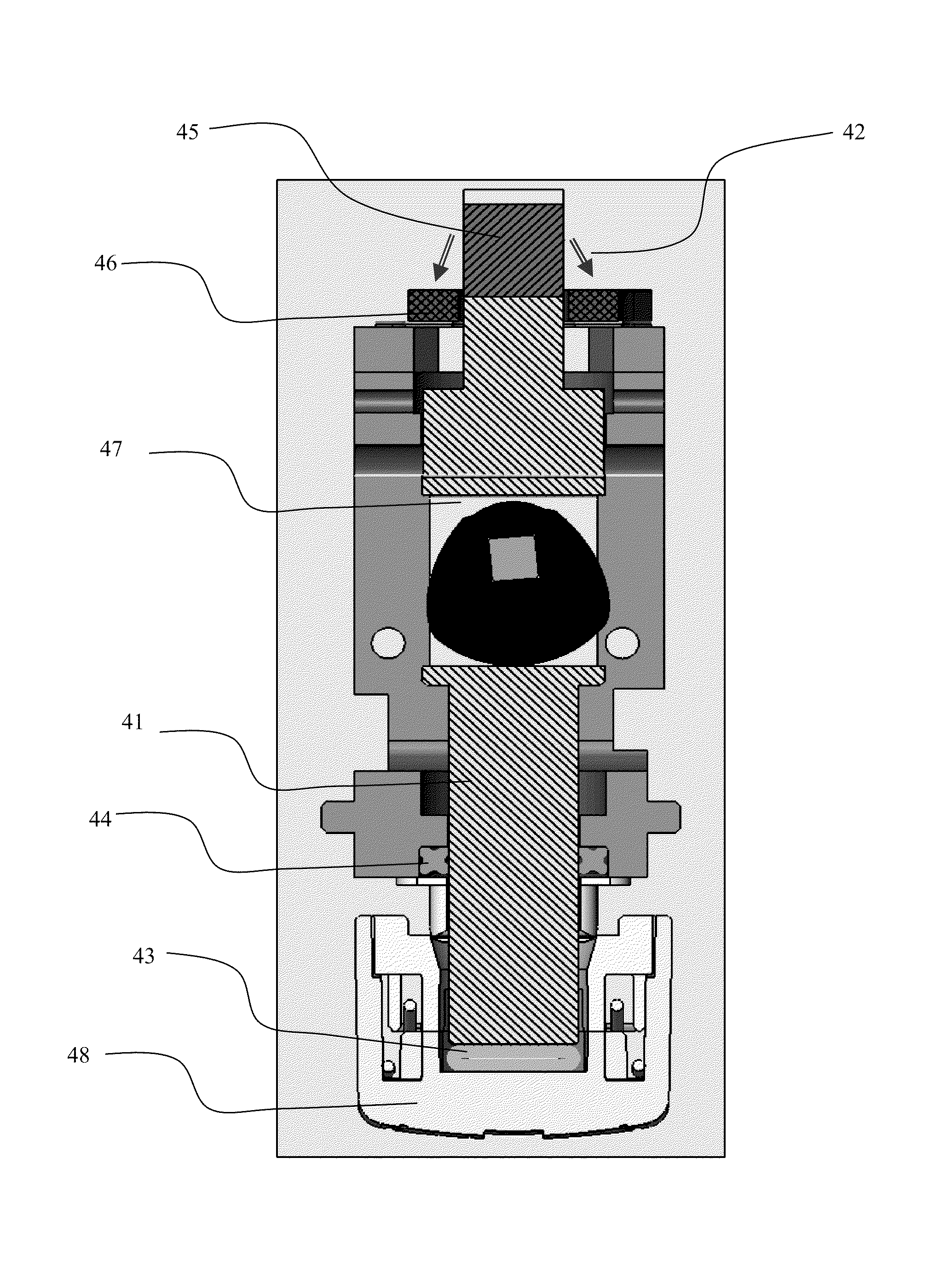

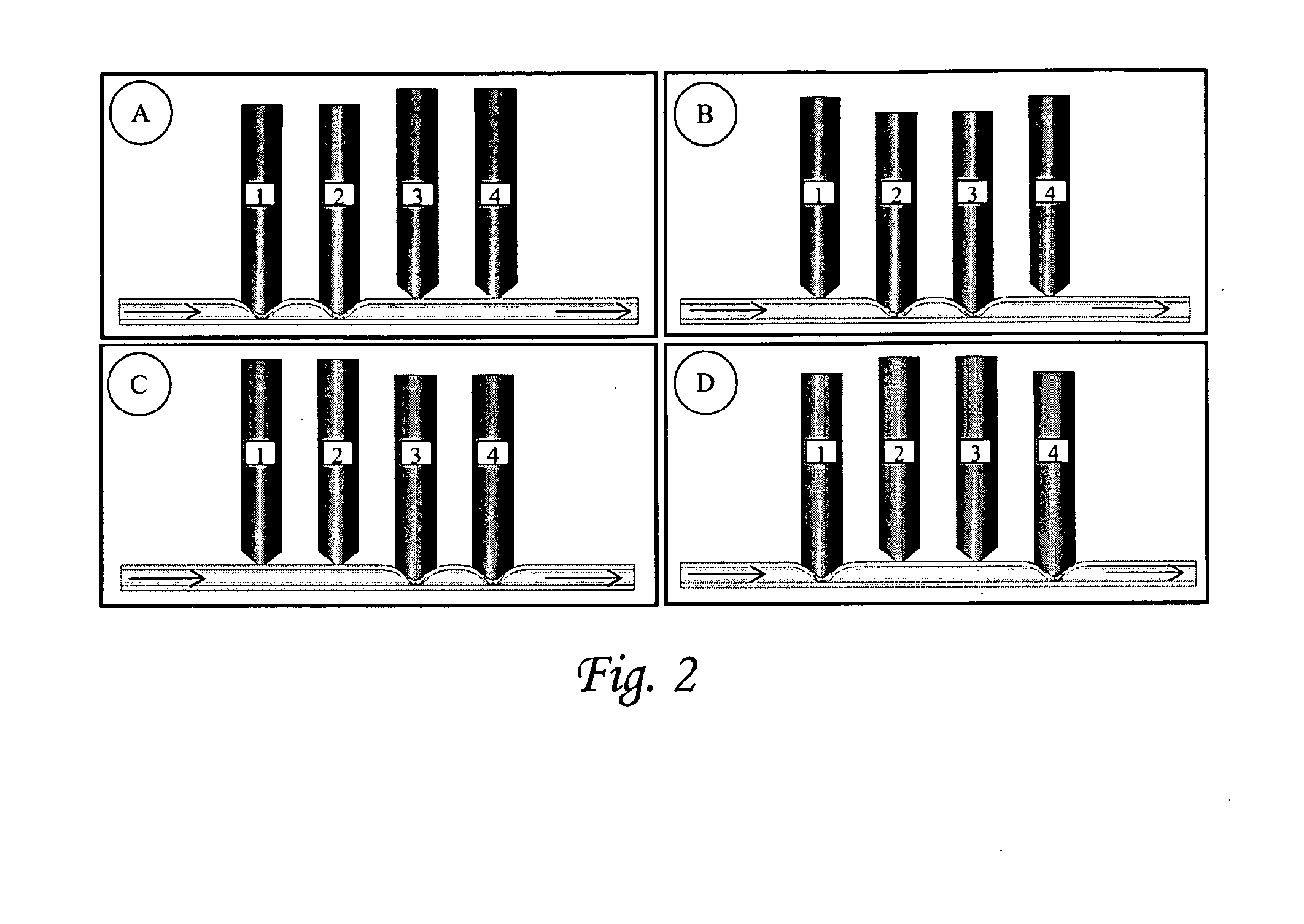

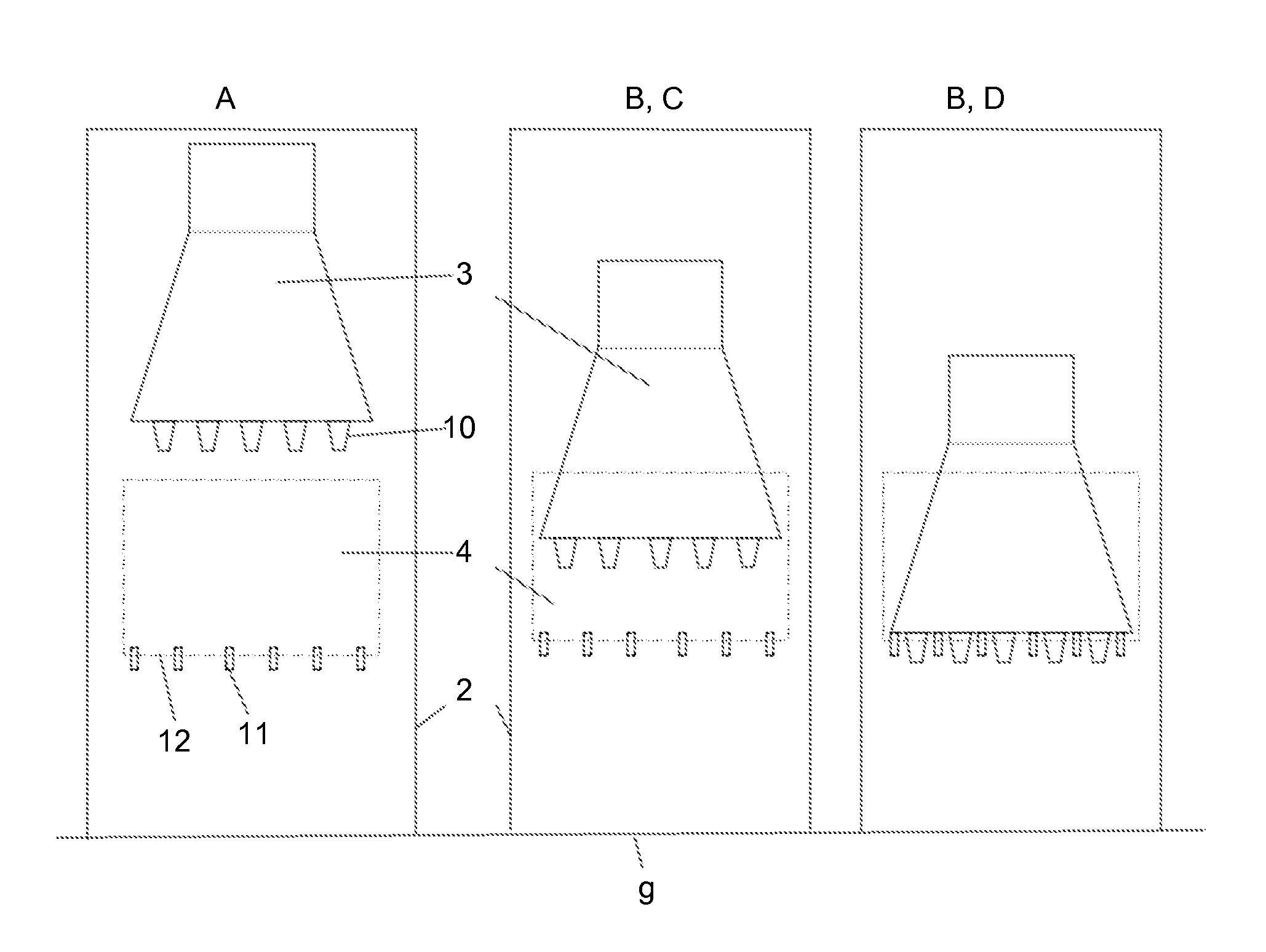

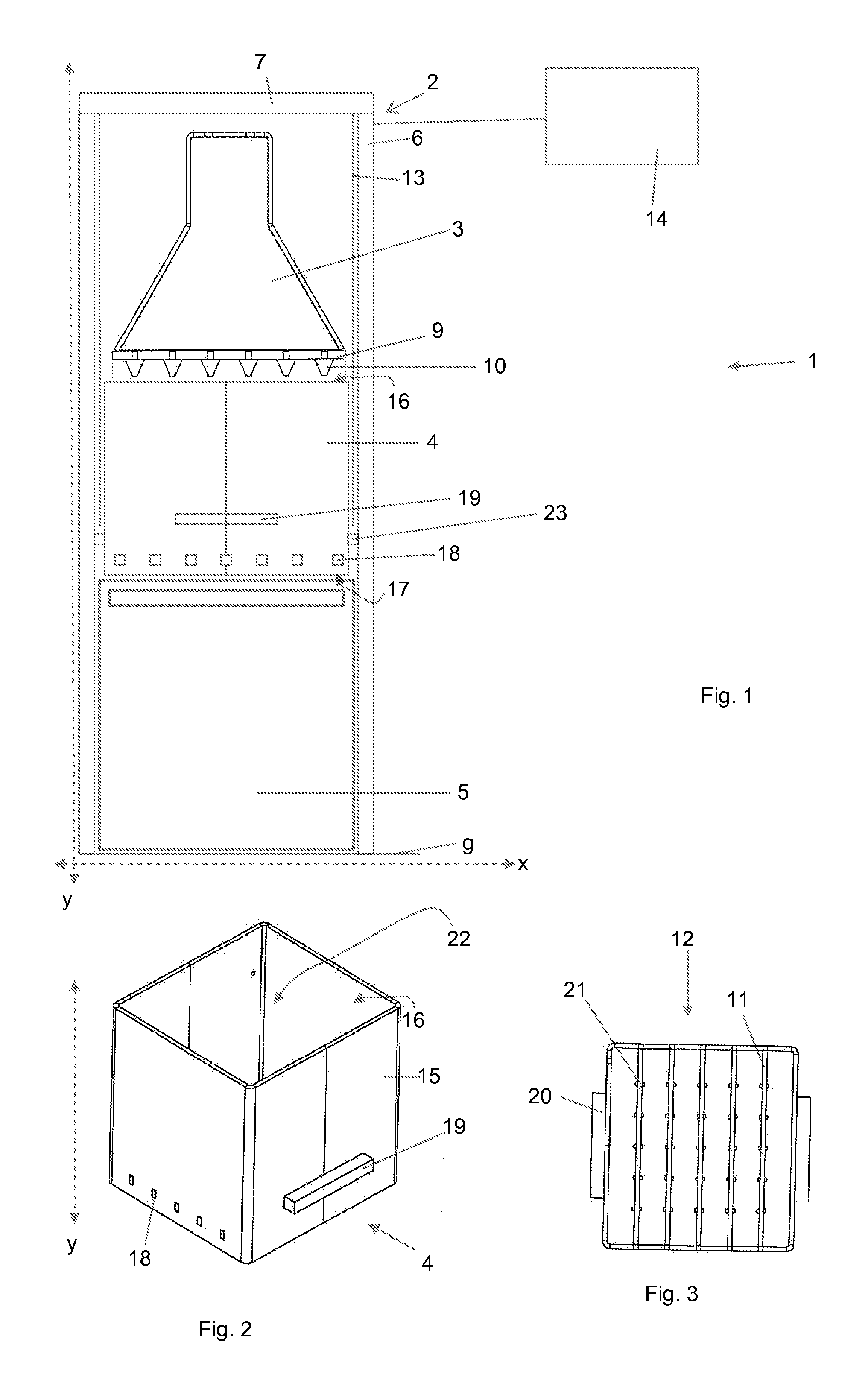

Imprinting method and imprinting apparatus

InactiveUS20070093079A1High positioning accuracyImprove throughputDecorative surface effectsSemiconductor/solid-state device detailsMechanical engineeringPrincipal plane

An imprinting method of the present invention is to press a mold member (40) having thereon a mold pattern onto a film carried on a principal plane of a substrate (50) as an object to be processed, so as to transfer the mold pattern to the film. A plurality of substrates (50) are fixed on a chuck stage (20). One of the substrates (50) can be selectively heated by a heater (21) and a cooling line (22). The mold member (40) is fixed on a head plate (30) which is disposed to be opposed to the chuck stage (20). The selectively heated substrate (50) and the mold member (40) are positioned relative to each other, and the mold member (40) is pressed onto a film on the substrate (50). By repeating this operation, all the substrates (50) are imprinted.

Owner:TOKYO ELECTRON LTD

Non-fire-worker-driven two-stage compressing releasing mechanism

ActiveCN108298112AHeavy loadImprove vibration resistanceCosmonautic vehiclesCosmonautic component separationEngineeringDriven element

The invention provides a non-fire-worker-driven two-stage compressing releasing mechanism. Pretightening force applied to the mechanism can be accurately measured by means of strain gages; in the compressing state, a separating cap is limited by upper balls; a releasing pin is clamped by lower balls; the positions of the upper balls are determined by the separating cap, an upper retainer and the releasing pin; the positions of the lower balls are determined by the releasing pin, a sliding block and a lower retainer; and the sliding block is compressed by an anti-impact spring. During releasing, a non-fire-worker-driven element is powered on to start working to drive the sliding block to upwards move, after the sliding block upwards moves by a certain distance, the lower balls enter a groove of the sliding block, the releasing pin is unclamped and moves downwards under the effect of a driving spring, then the upper balls are unrestrained and fall into a groove of the releasing pin, theseparating cap is separated, and thus releasing is completed. In this mechanism, a plurality of spherical pairs are adopted, the influence of moment transferring on the part cooperation relationship and the releasing reliability is avoided, and meanwhile the mounting accuracy requirement is reduced; and control is convenient, vibration resistance is high, the borne load is large, and reliability is high.

Owner:北京深空动力科技有限公司

Pressure Plate Assembly And Method For Power Transmission

ActiveUS20130081915A1Precise positioningStrong pressing forceRailway vehiclesPower current collectorsPower flowCoil spring

A pressing device for a current collector moves a contact shoe unit is movable relative to a current rail. The pressing device includes a rocker unit and a spring unit. The spring unit having a helical spring rotatably biasing rocker unit is rotatable such that the contact shoe unit is movable into a sliding contact position in only one direction spring unit.

Owner:SCHUNK BAHN UND INDTECHN

Hydraulic working machine

ActiveUS7562615B2Reduce consumptionImprove energy efficiencyServomotor componentsServomotorsHydraulic circuitEngineering

A hydraulic circuit for a hydraulic working machine is composed of a main pump 21, a boom cylinder 11 arranged for extension or contraction by pressure oil from the main pump 21, a directional control valve 22 for controlling flows of pressure oil to be fed from the main pump 21 to a bottom chamber 11a and rod chamber 12b of the boom cylinder 11, a control unit 23 for performing a change-over control of the directional control valve 22, a pilot pump 24, a jack-up selector valve 25 for controlling a flow of pressure oil delivered from the pilot pump 24, a flow control valve 26 connected on an upstream side of the directional control valve 22 to a meter-in port of the directional control valve 22 such that the flow control valve 26 can be changed over by the jack-up selector valve 25, and a center bypass selector valve 27 connected on a downstream side of the directional control valve 22 to a center bypass port of the directional control valve 22 such that the center bypass selector valve 27 can be changed over by the jack-up selector valve 25. The hydraulic circuit performs a change-over of the jack-up selector valve 25 in accordance with a bottom pressure on the boom cylinder 11.

Owner:NIHON KENKI CO LTD

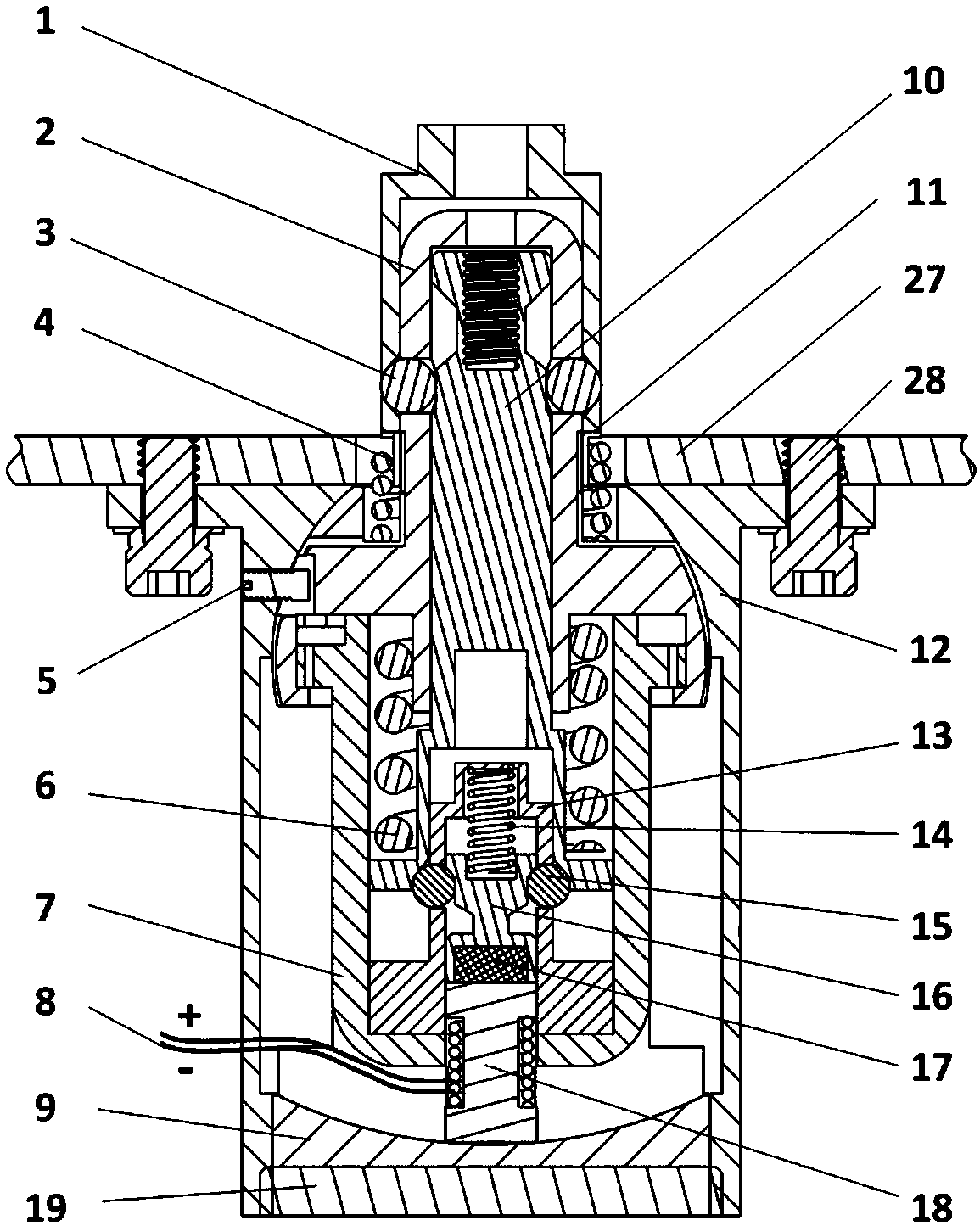

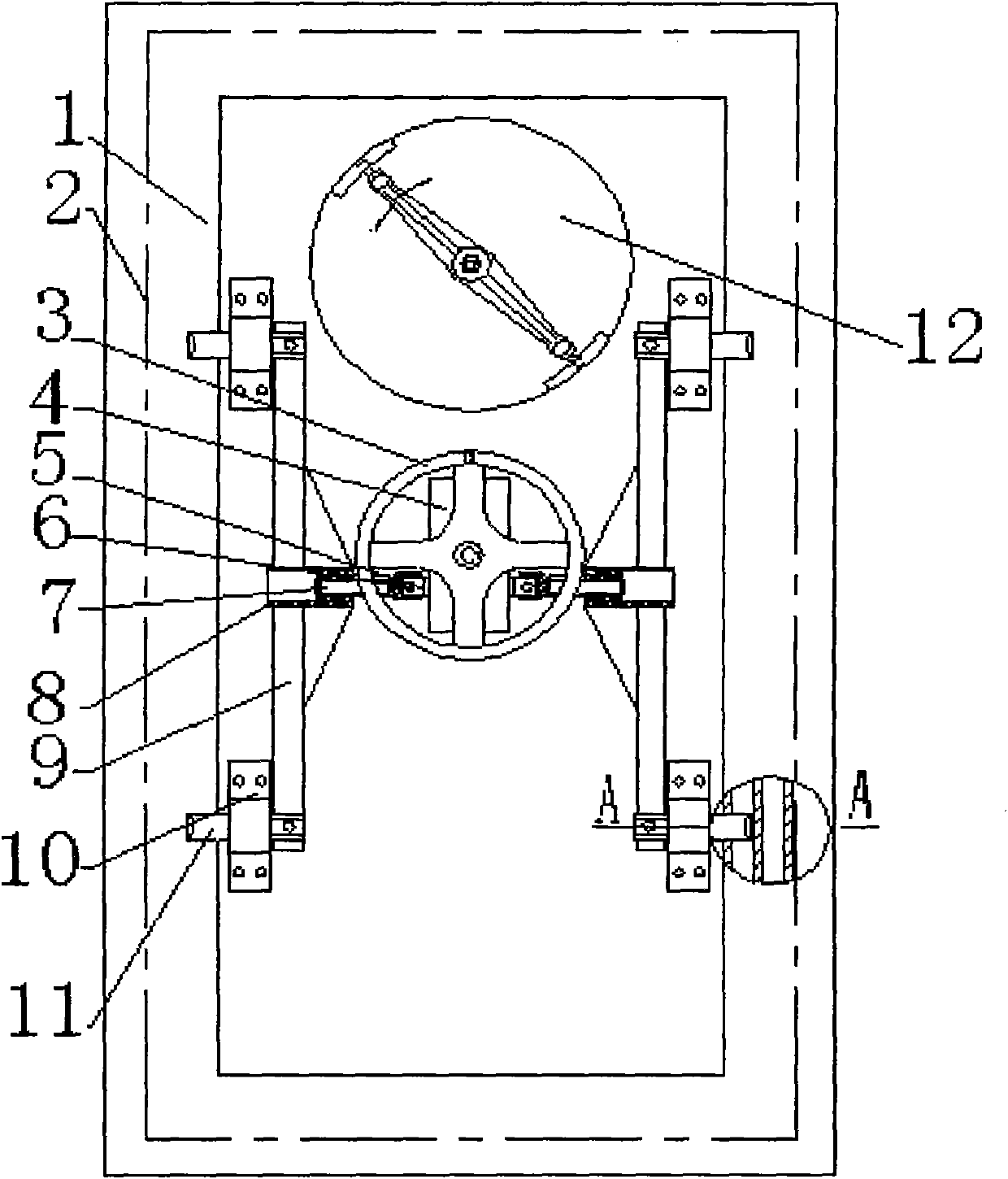

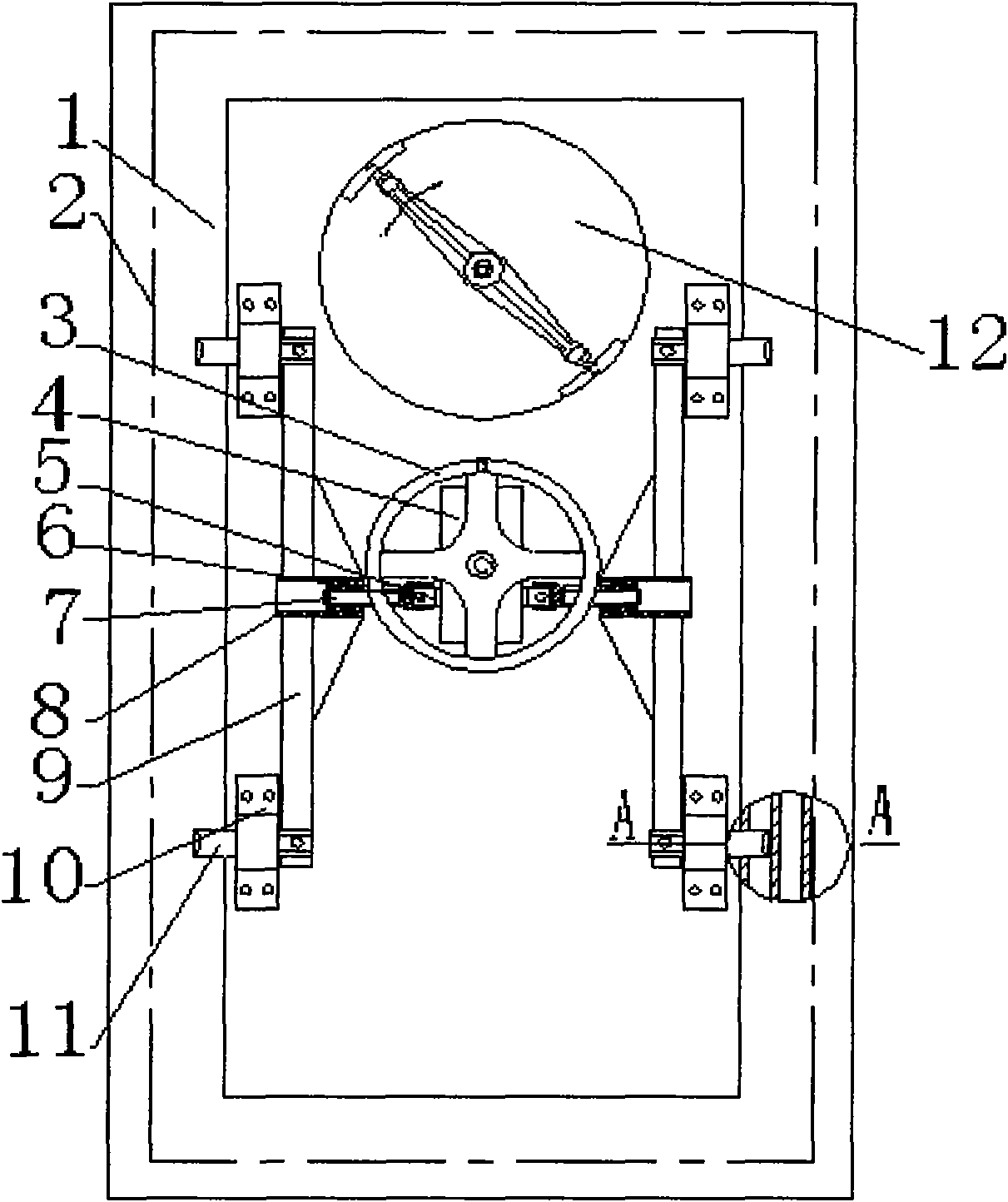

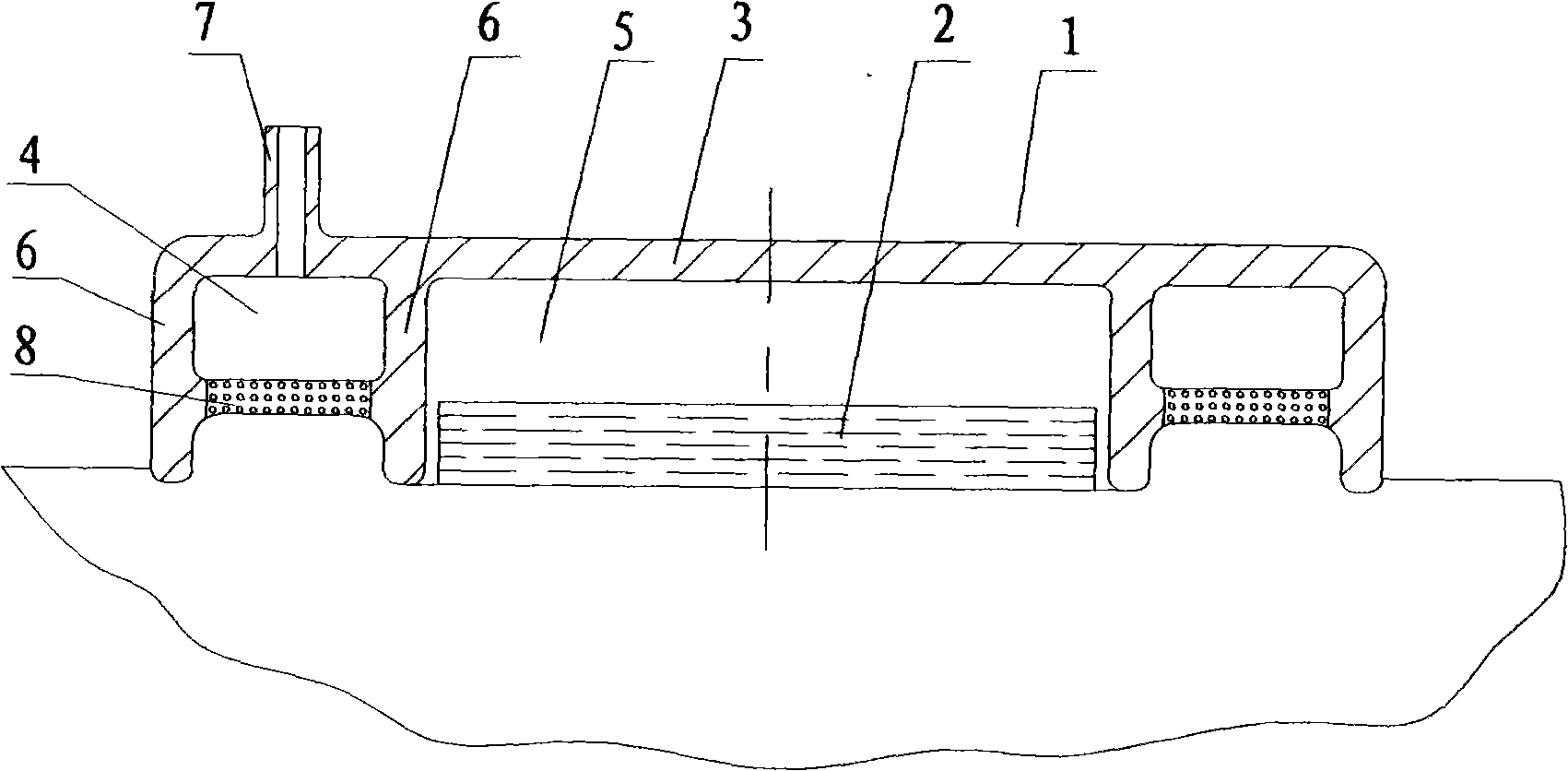

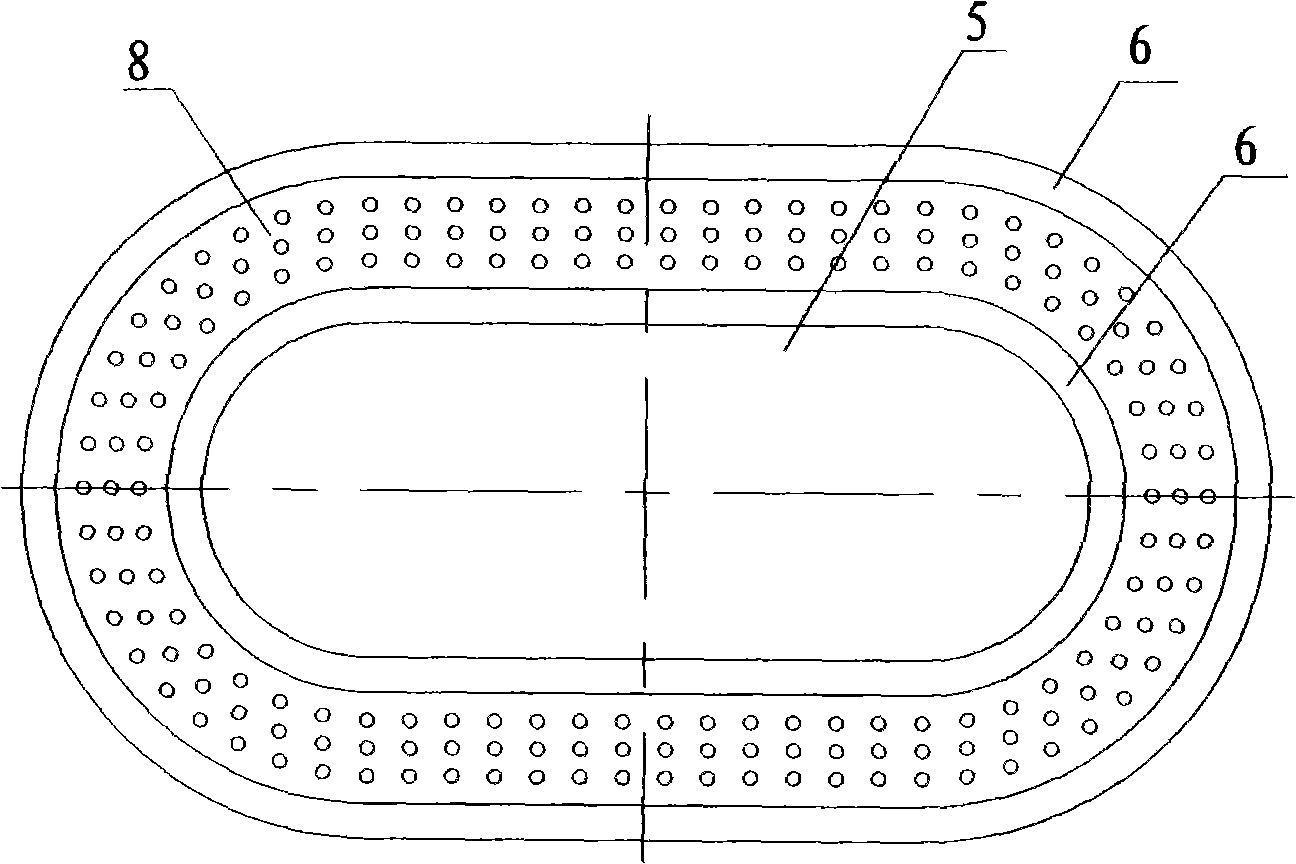

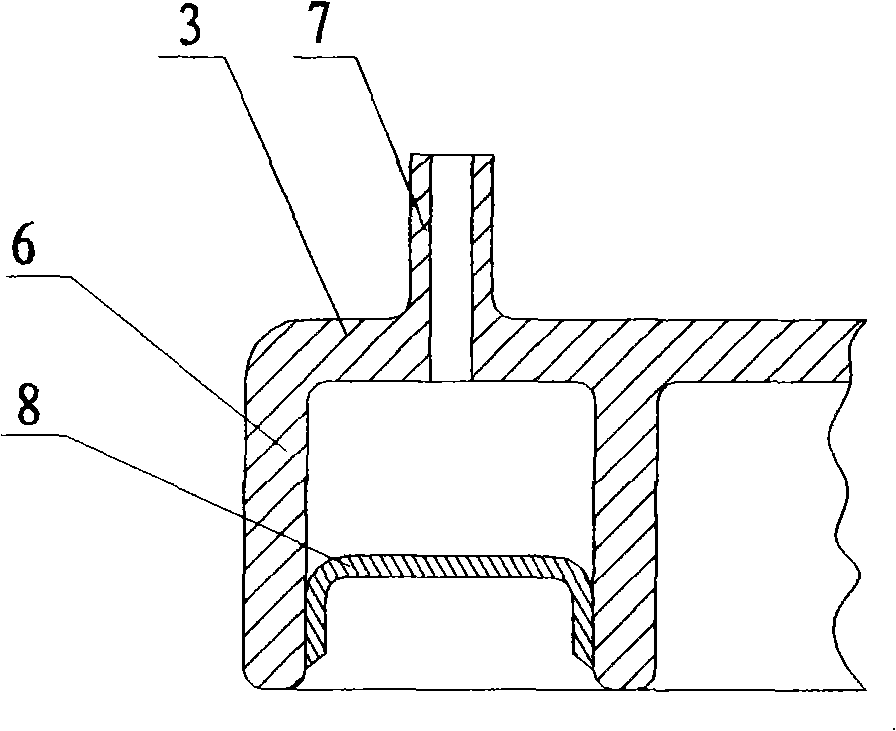

Sealing door of mining rescue capsule

InactiveCN101949254AStrong pressing forceImprove the sealing effectConstruction fastening devicesSealing arrangementsEngineeringMechanical engineering

The invention discloses a sealing door of a mining rescue capsule. The sealing door comprises a door panel, a decelerating mechanism, a locker mechanism, a transmission mechanism, a clamping and pressing plate, a seal ring pressing member and a seal ring, wherein two bearing plates and an oblique pressing plate of the seal ring pressing member are fixed on a door frame in the way that the bearing plates are engaged with the oblique pressing plate; a mounting groove for the seal ring is formed between the bearing plates and the oblique pressing plate; the clamping and pressing plate is fixed along the periphery of the door panel; the middle upper part of the door panel of the mining sealing door is provided with an emergency exit with an emergency door; the locker mechanism is provided with two sets of lead screws, connecting rods, locking seats and locking heads; a worm wheel and worm transmission mechanism is shared by the two sets of lead screws, connecting rods, locking seats and locking heads; the two lead screws are reverse in rotation direction; and the two ends of each connecting rod are connected with the two locking heads respectively. The sealing door realizes full sealing and provides more chance for personnel to escape; the pressing force to the seal ring is increased and the sealing effect of the sealing door is improved by pressing four points of the seal ring; and the sealing door has the characteristics of simple and reliable structure, convenience of use and low cost.

Owner:中船重工西安东仪科工集团有限公司

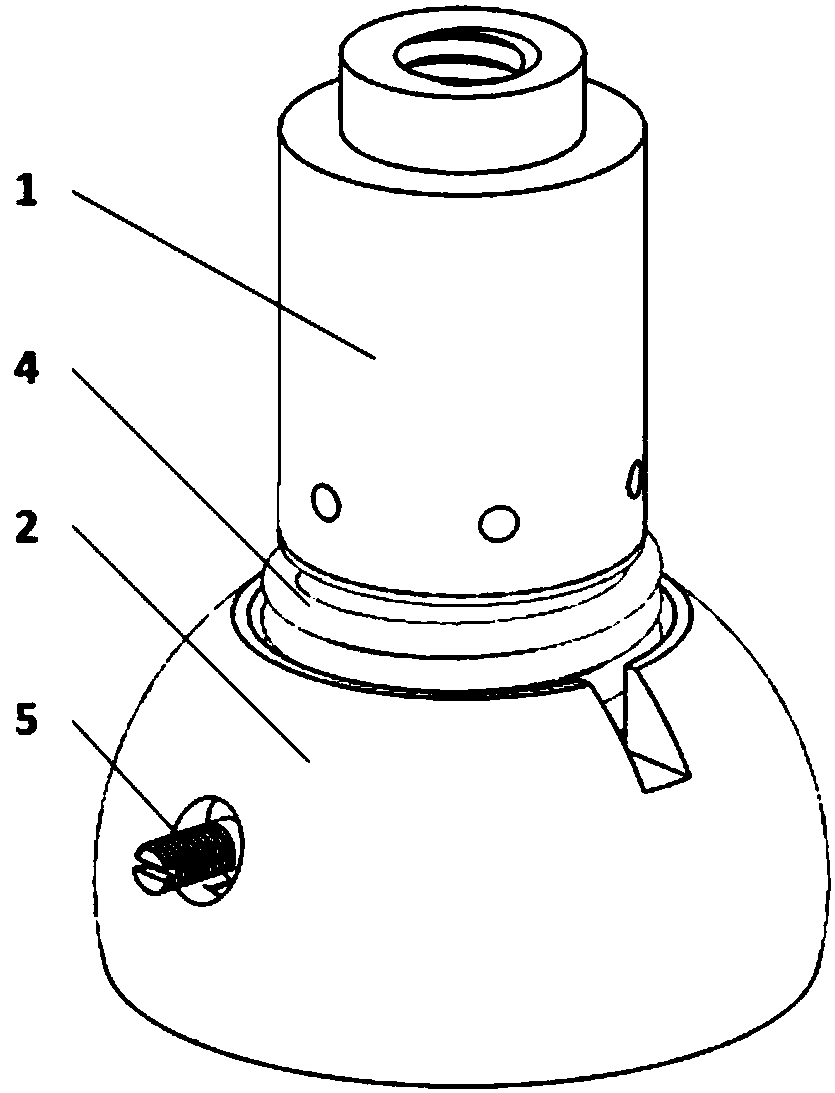

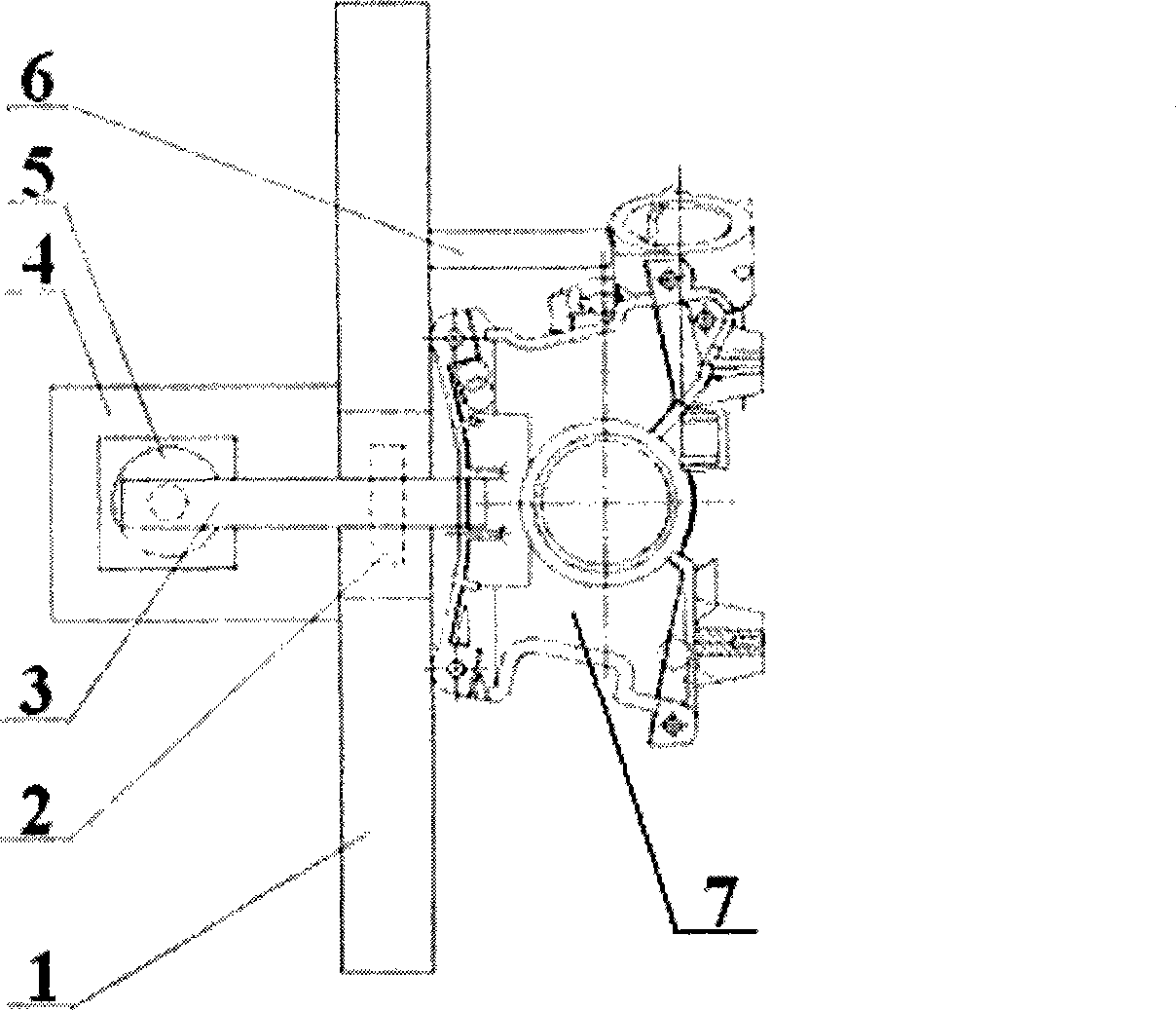

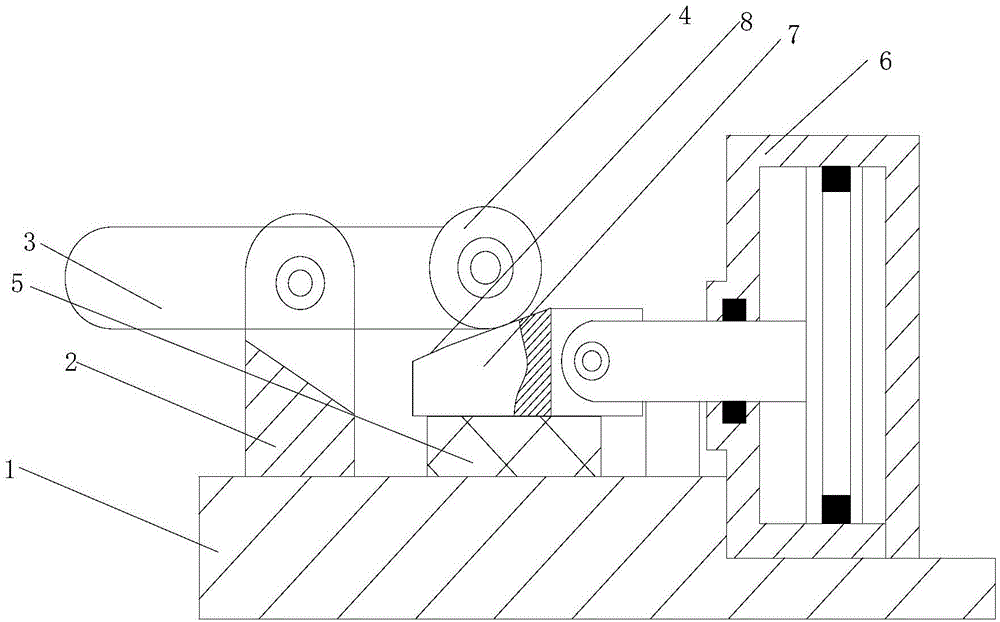

Pneumatic lever type clamping structure

InactiveCN101434040AStrong pressing forceEfficient compressionPositioning apparatusMetal-working holdersHigh rateGyration

The invention discloses a pneumatic lever type clamp structure. A pressure plate (3) is a lever structure, and the gyration center of the pressure plate is hinged with a clamp body (1) through a lever fulcrum (1); and under the state that a workpiece (7) is tightly clamped, one end of the pressure plate (3) is connected with a piston rod on a cylinder (5), while the other end is contacted with the clamped workpiece (7). With the technical proposal, pressing force of the cylinder can be increased through an arm of the lever structure by the lever principle when the cylinder is adopted, so that the processing workpiece can be pressurized conveniently and more effectively. The invention has a simple structure, can effectively improve the efficiency of processing parts, can realize stable processing tempo, and has the advantages of high rate of finished products and safe and convenient use.

Owner:THIXOMAG TECHNOLOGH WUHU

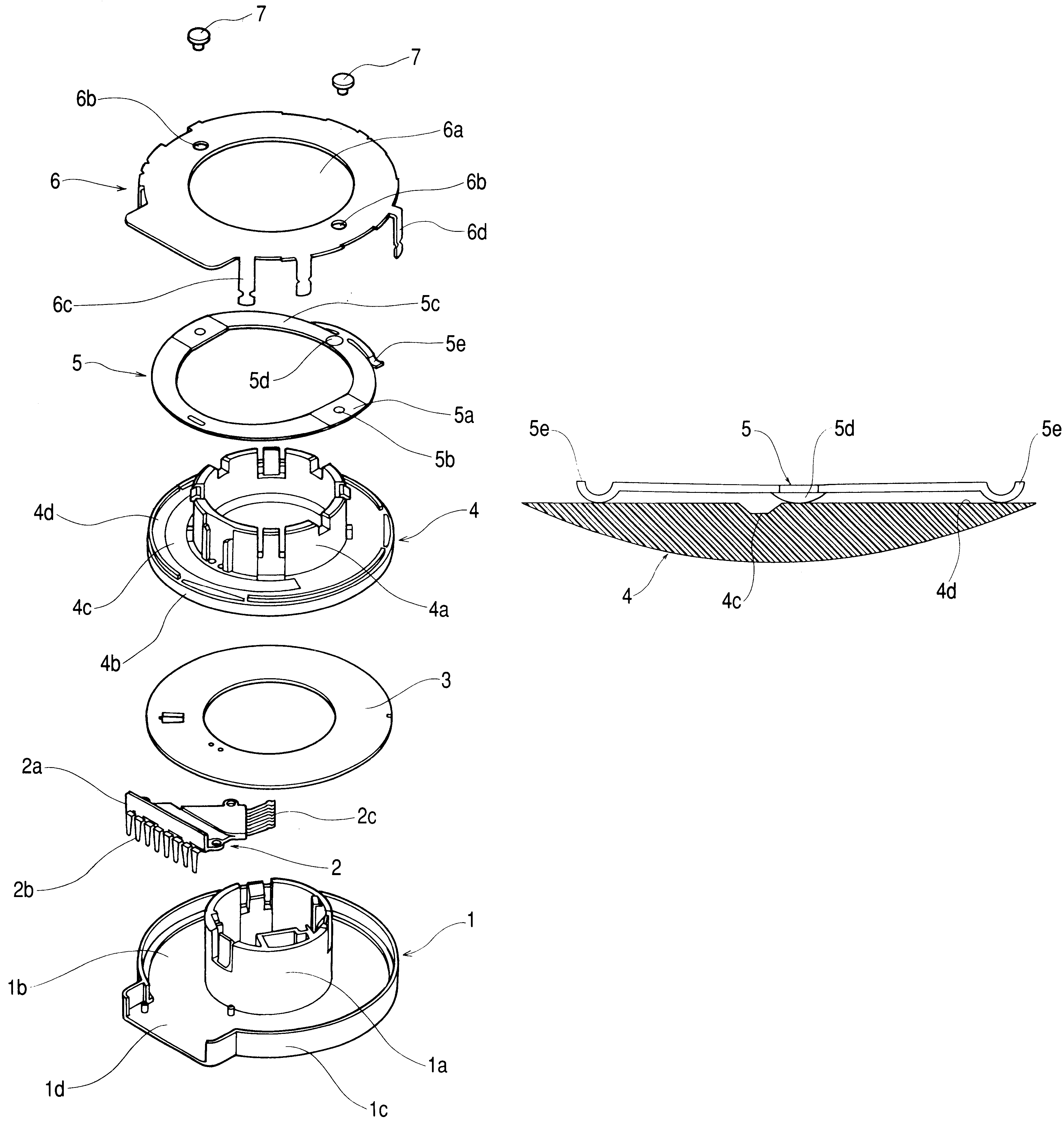

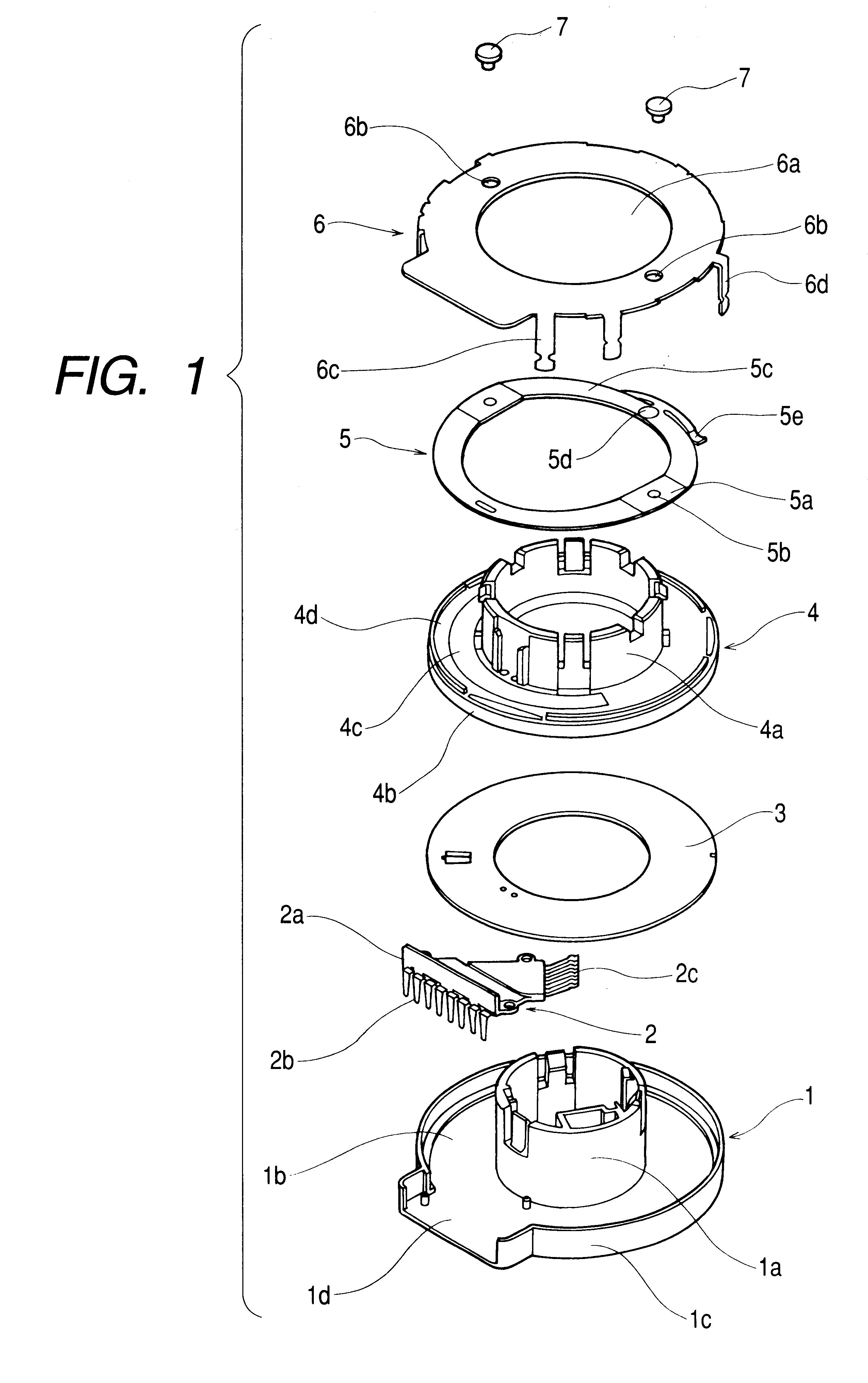

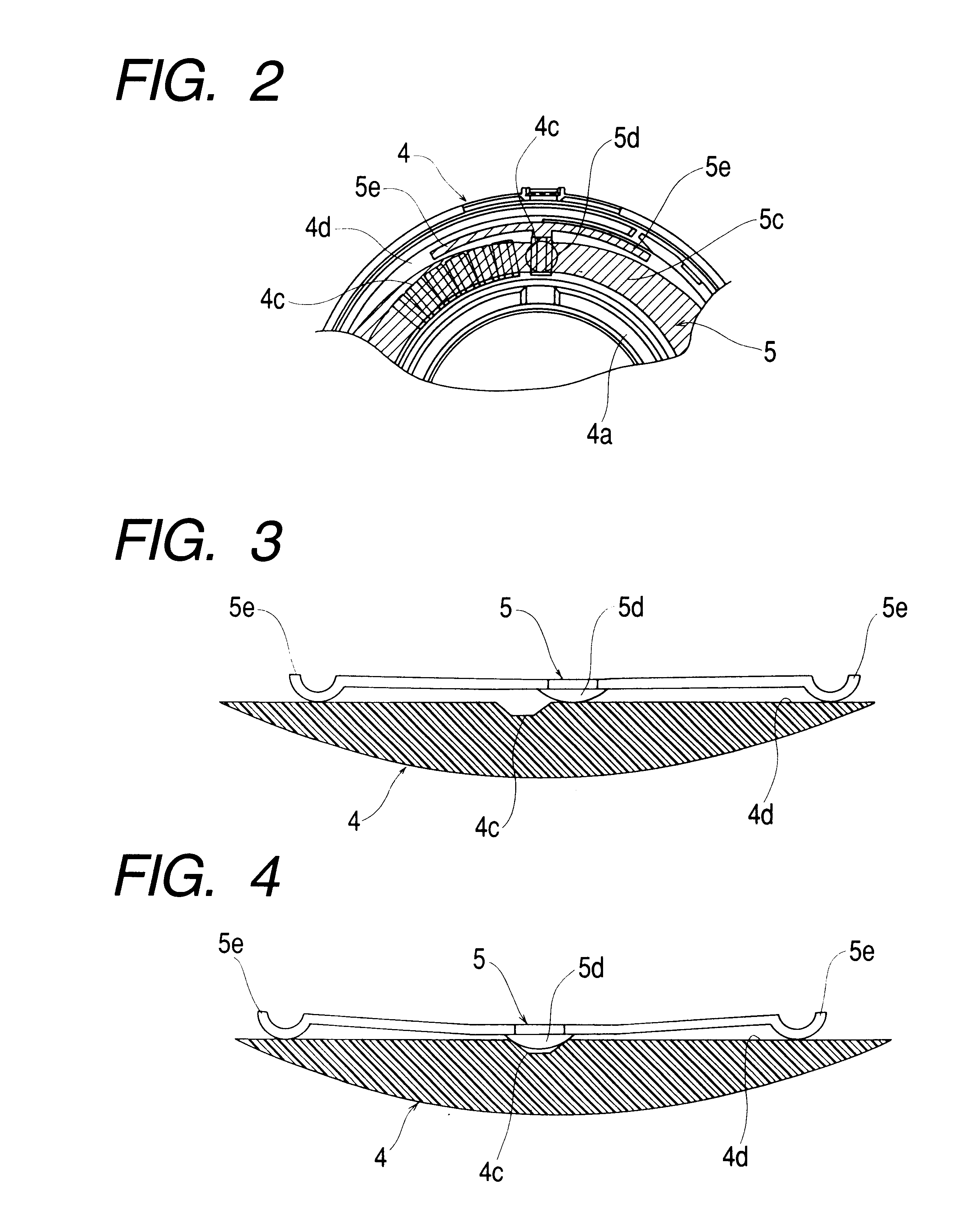

Rotary switch having click mechanism

InactiveUS6506984B2Span of the auxiliary spring can be sufficiently ensuredWell formedContact driving mechanismsResisitors with sliding contactRotary switchEngineering

A switch device reduces a switching sound (an impinging sound) at the time of manipulation with a constitution of a click mechanism which uses a spring member having a projection which is brought into slide contact with a cam surface formed of plateaus and valleys. The switch device includes a manipulating member having a cam surface which is formed of plateaus and valleys arranged contiguously and alternately and a spring member having the projection and generating a click feeling when the projection is brought into slide contact with the plateaus and the valleys of the cam surface. The spring member is provided with an auxiliary spring which is brought into slide contact with the manipulating member corresponding to the slide contact of the projection with the plateaus and the valleys of the cam surface. An auxiliary spring receiving portion with which the auxiliary spring is brought into slide contact is formed in the vicinity of the cam surface.

Owner:ALPS ALPINE CO LTD

Magnetically balanced finger-type peristaltic pump

ActiveUS8535025B2Yield maximizationStrong pressing forceFlexible member pumpsPressure infusionPeristaltic pumpEngineering

A peristaltic pump includes a plurality of effecters, actuated in a periodic manner upon by obstructive forces of a flexible infusion tube so as flow of infusion fluid is provided along said infusion tube, the magnitude of the obstructive forces being dependent upon the displacement of said moving effecters; and a plurality of balancing magnets providing balancing forces upon one or all the moving effecters, the balancing forces at each point along the path of motion of the moving effecters being of approximately equal magnitude to that of the obstructive forces at the point; such that the parasitic output due to work performed against the obstructive forces is approximately zero and yield is maximized.

Owner:EITHAN MEDICAL LTD

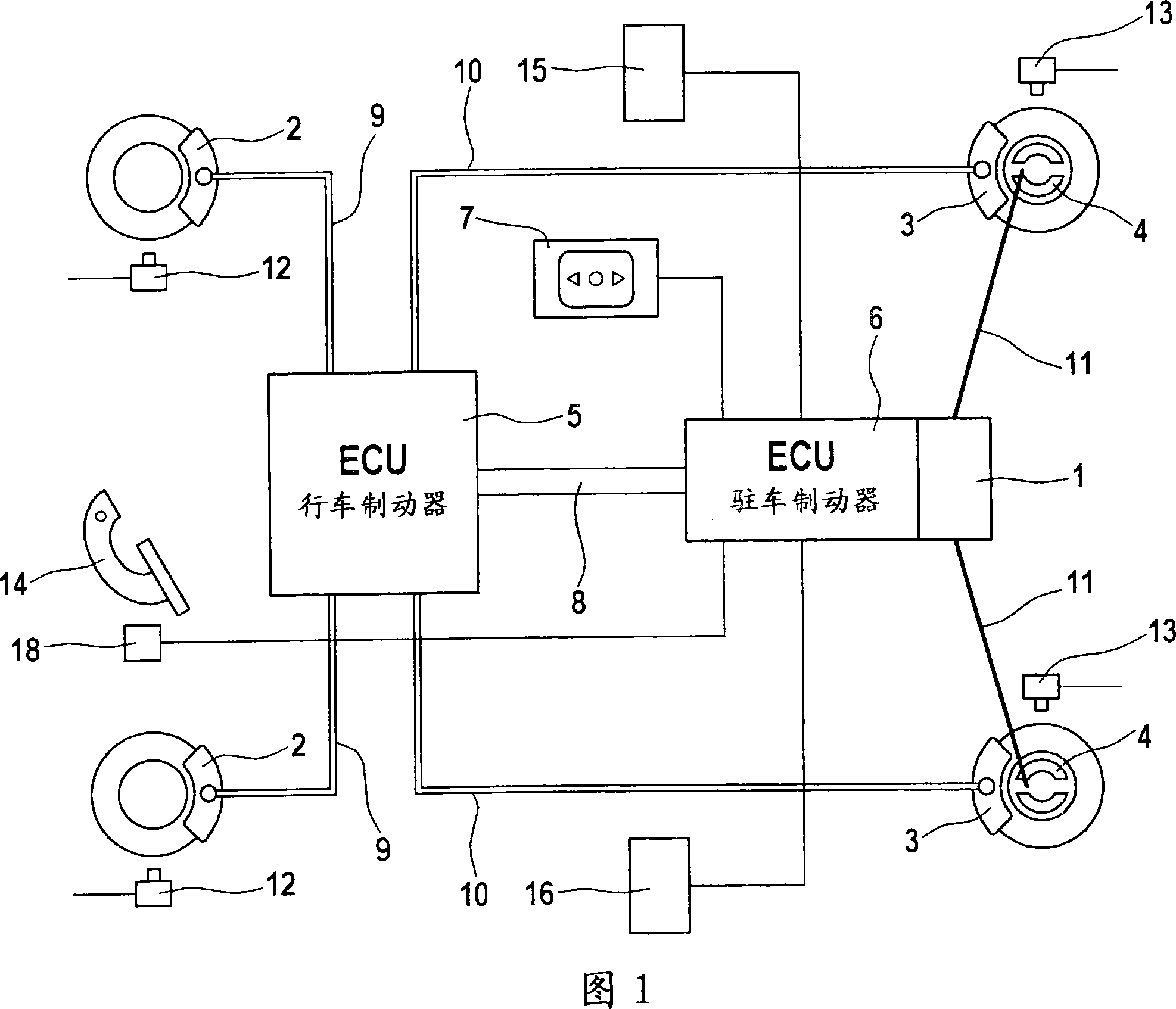

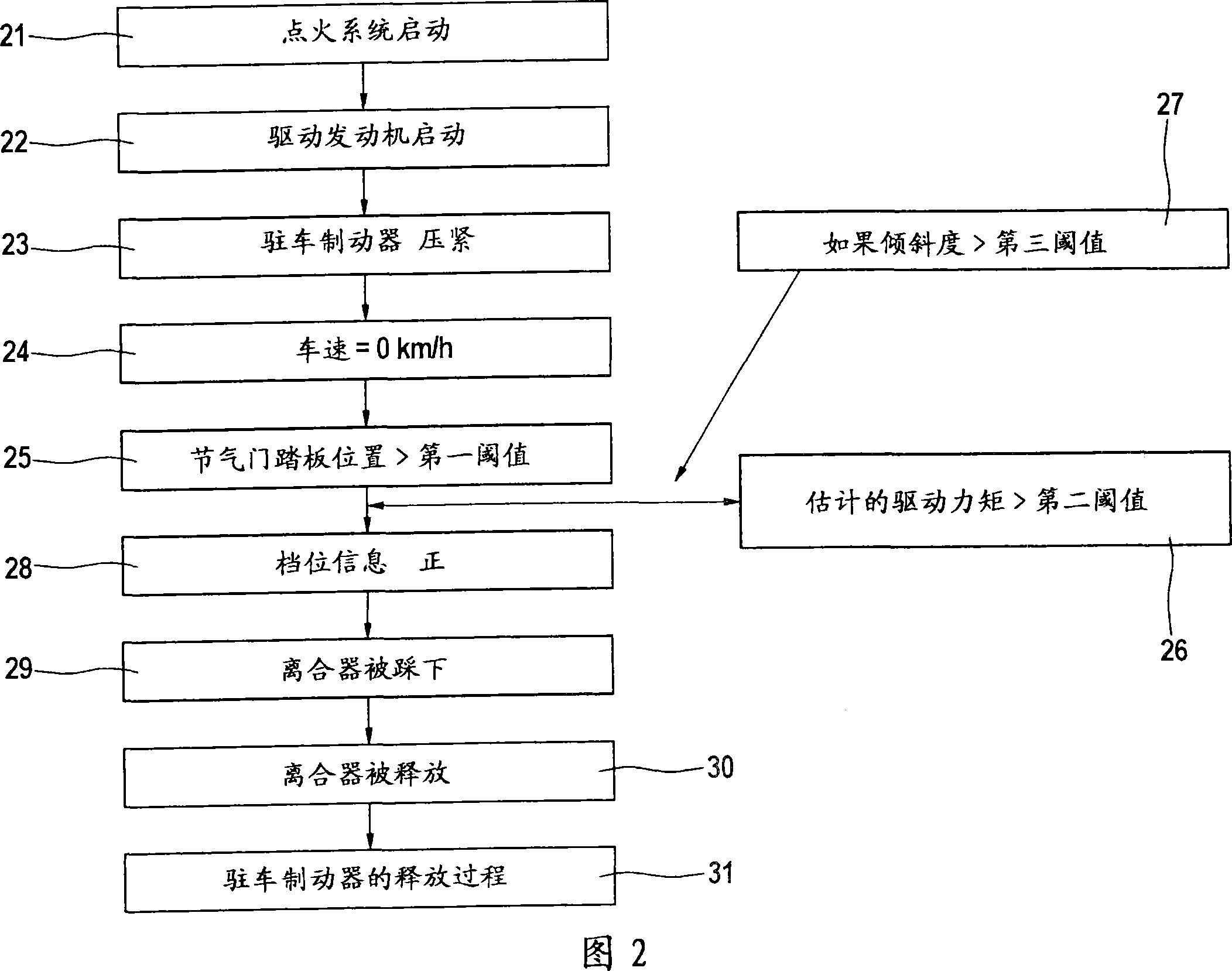

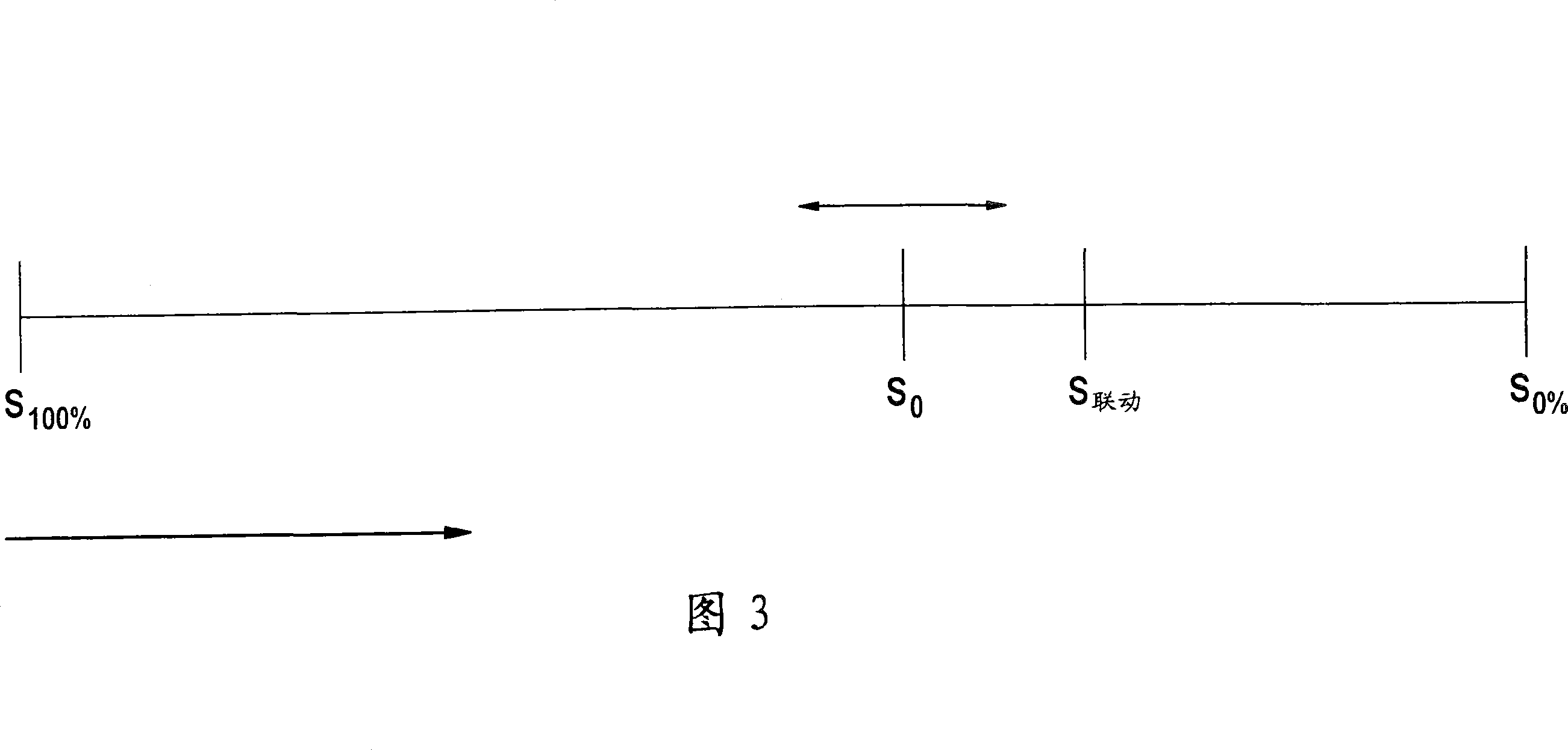

Method for operation of a braking system for a motor vehicle

InactiveCN1993257AIncrease the pressing forceStrong pressing forceBraking action transmissionAutomatic initiationsAutomotive engineeringDrive motor

The invention relates to a method for operation of an electromechanically-operated parking brake for motor vehicles with a drive motor provided with a mechanical manual gearbox, essentially comprising an operating element, an electronic controller, provided with wheel rotational speed values from wheel rotational speed sensors, at least one unit for generation of an application force and braking devices applied by the unit on at least one axle, whereby the electronic controller operates the unit, after recognition of a starting procedure for the motor vehicle, in the manner of a release process for the parking brake. According to the invention, a release process for the parking brake, after recognition of a starting process, may be configured to be as convenient as possible, whereby, on recognition of a starting process and before carrying out the release process for the parking brake, the electronic controller 6a operates the unit 1 such as to reduce the application force to a slope-dependent holding force.

Owner:CONTINENTAL TEVES AG & CO OHG

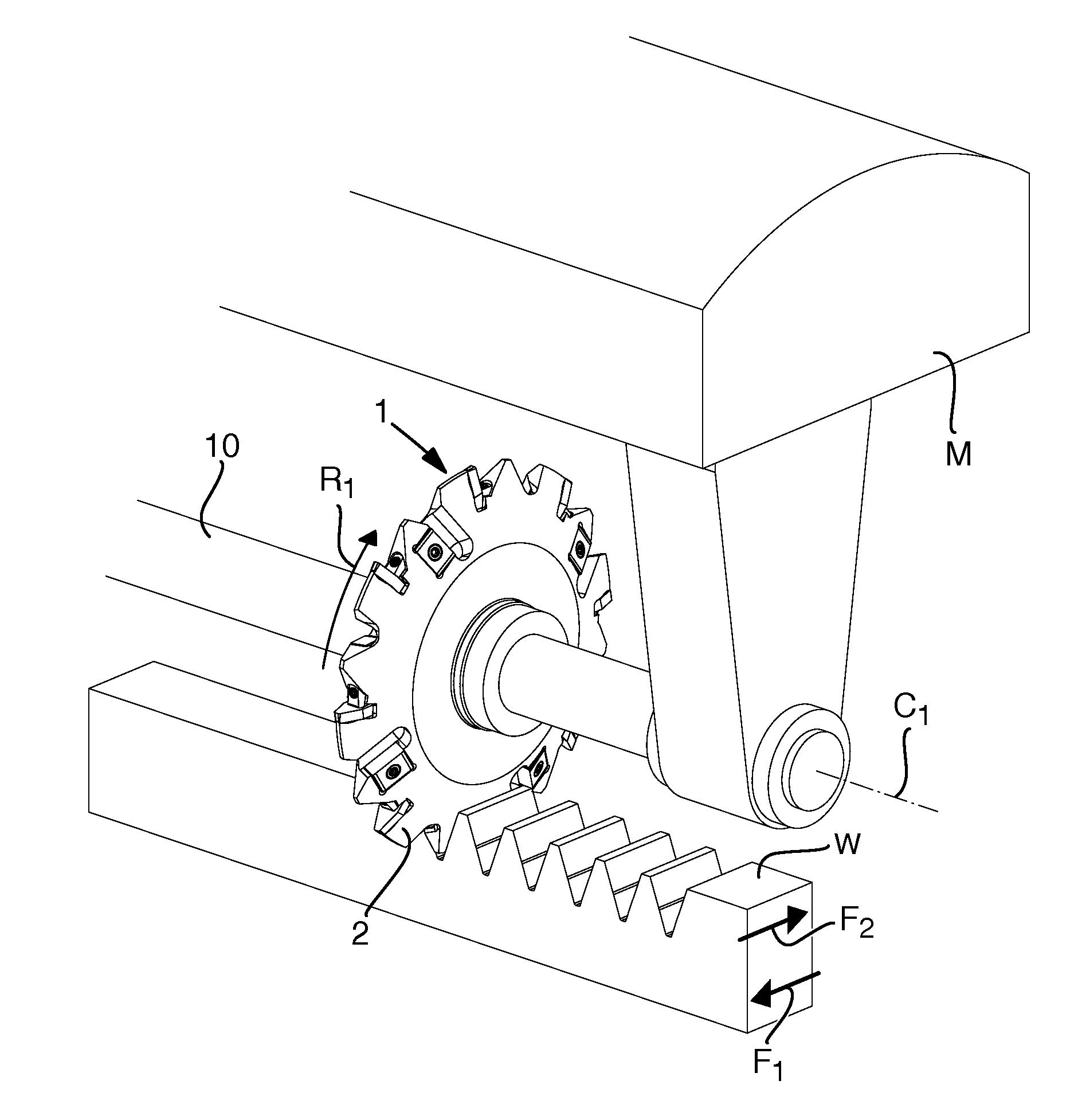

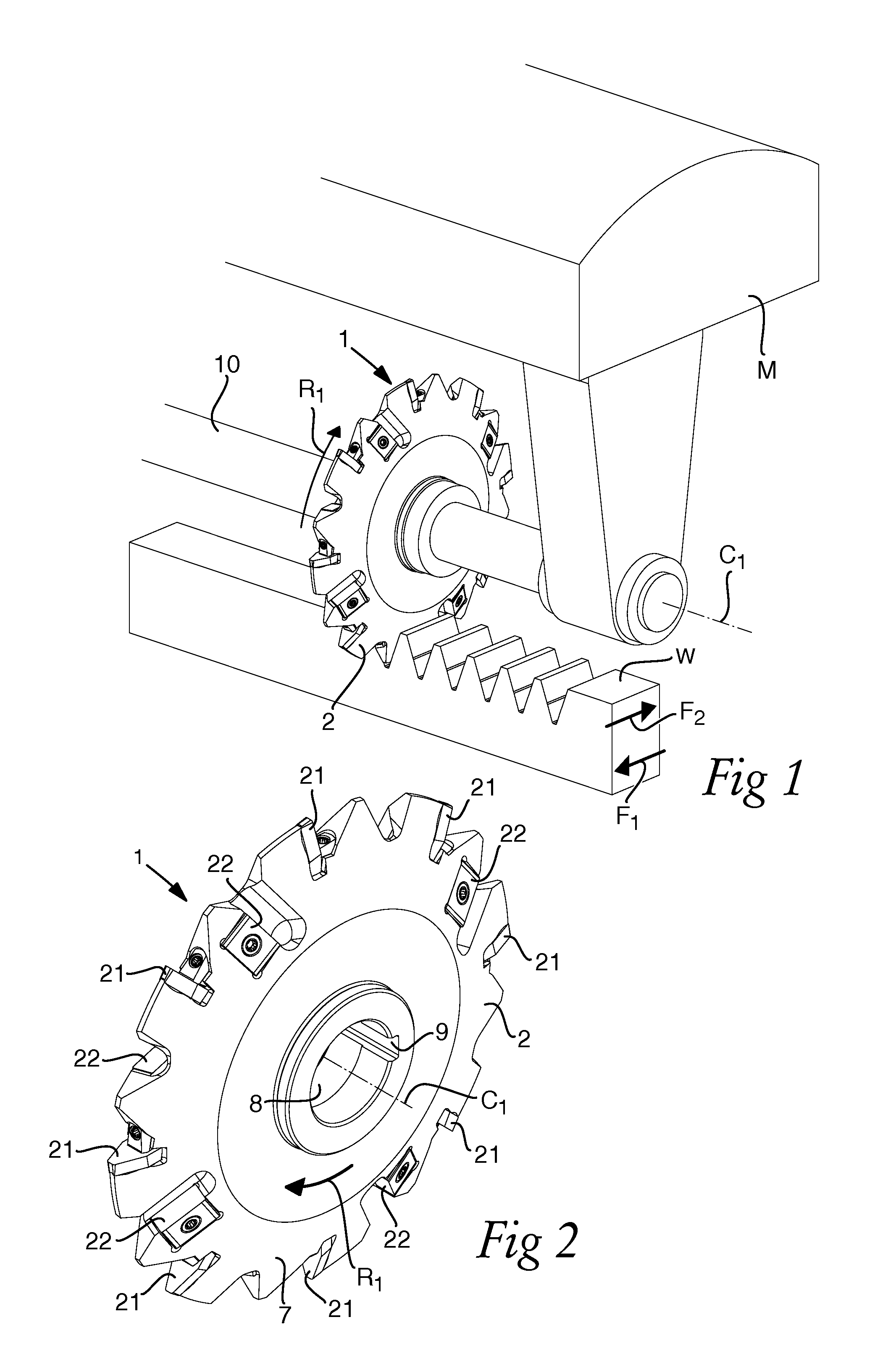

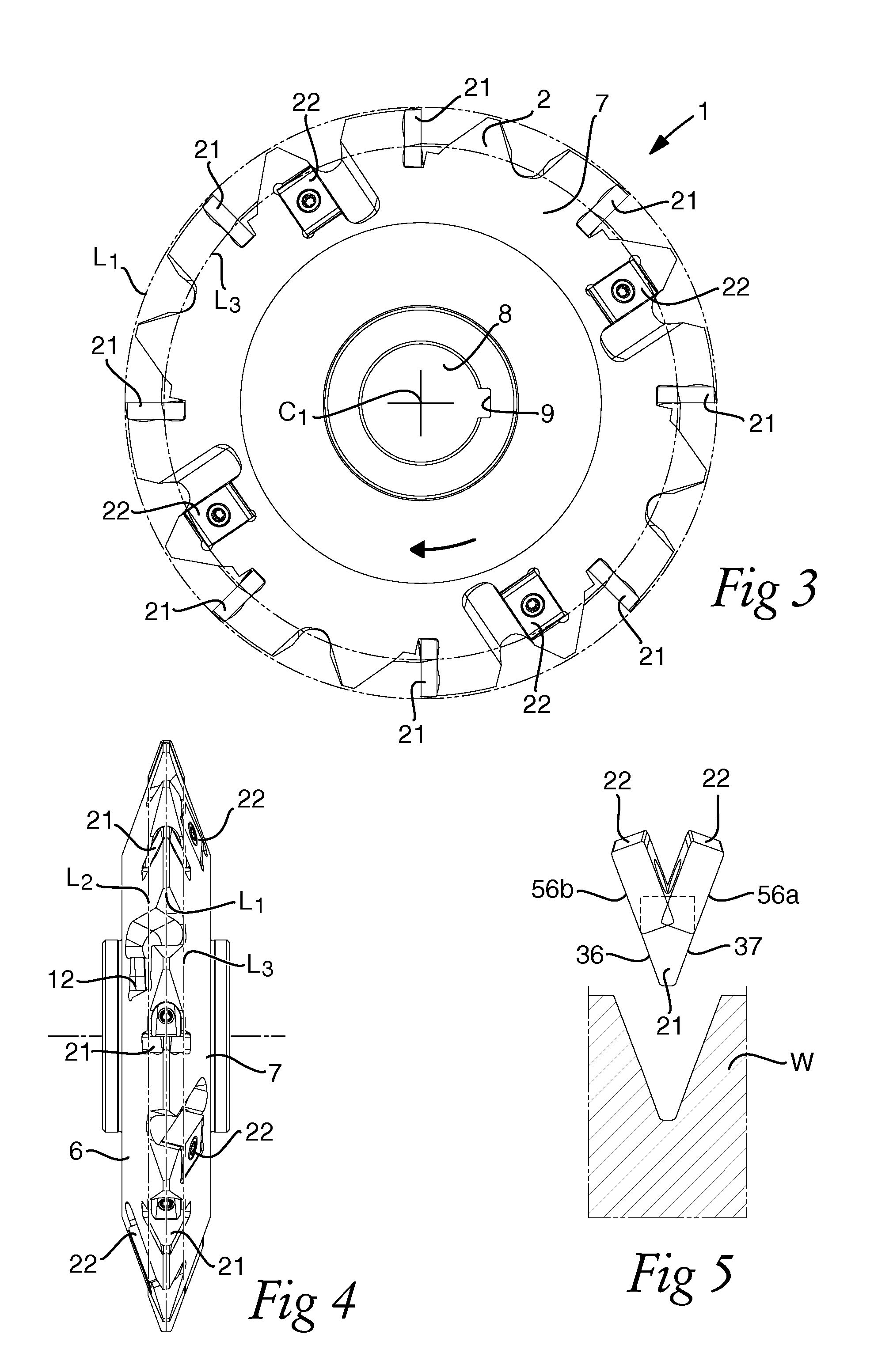

Milling tool as well as set of milling inserts of a milling tool

InactiveUS20130294851A1High strengthFine surfaceThread cutting toolsTransportation and packagingMilling cutterEngineering

A milling tool for slot milling includes a tool body and a plurality of separated first seats, which form root insert seats for root inserts arranged one after the other along a first line and a plurality of separated flank insert seats that includes a plurality of second seats for flank inserts . The plurality of second seats is arranged one after the other along a second line on a primary side of the root insert seats. A plurality of third seats for flank inserts is arranged one after the other along a third line on a secondary side of the root insert seats. Each flank insert seat includes a bottom surface, an inner side surface, and an outer side surface. Each flank insert includes an under side, an opposite upper side, and a circumferential edge side that forms a rake face connecting the upper side and the underside.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

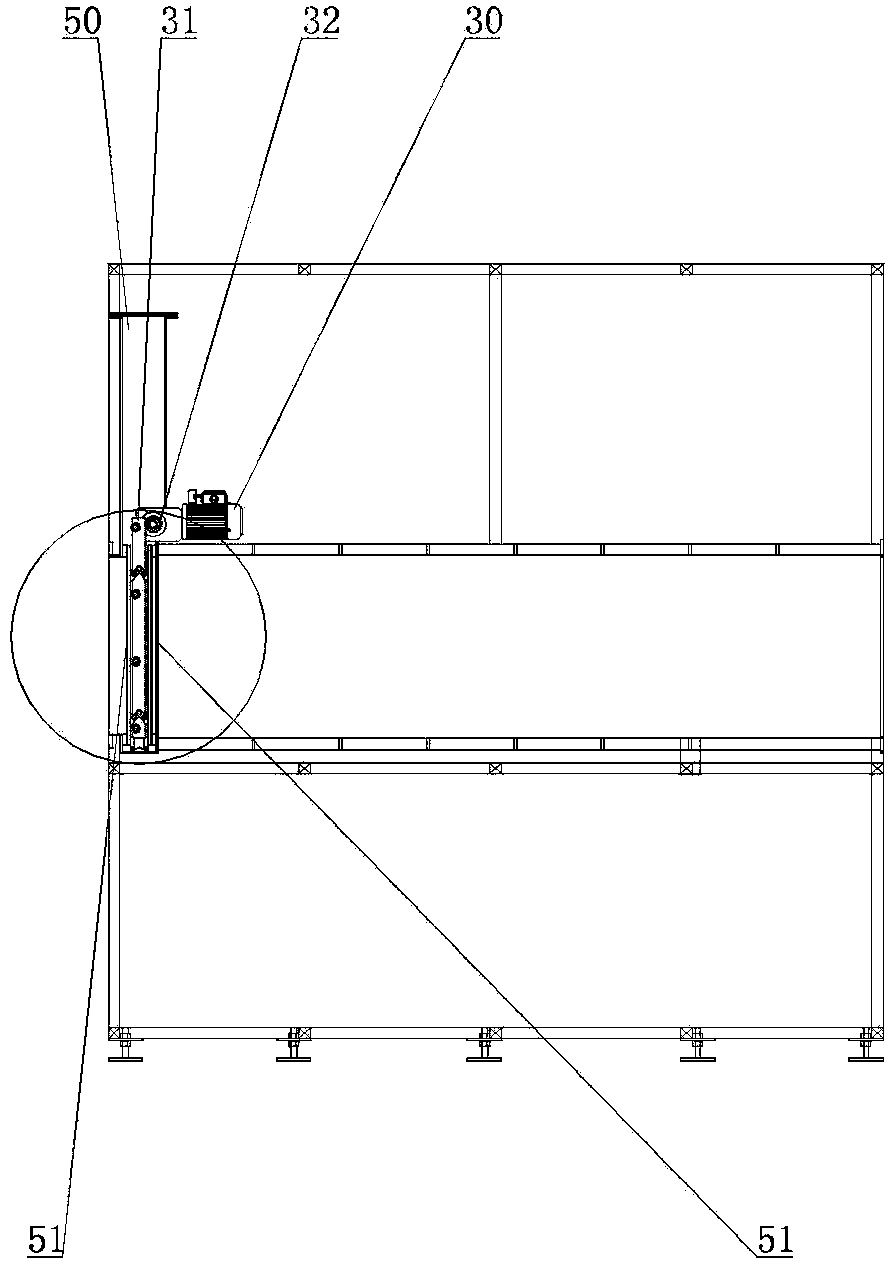

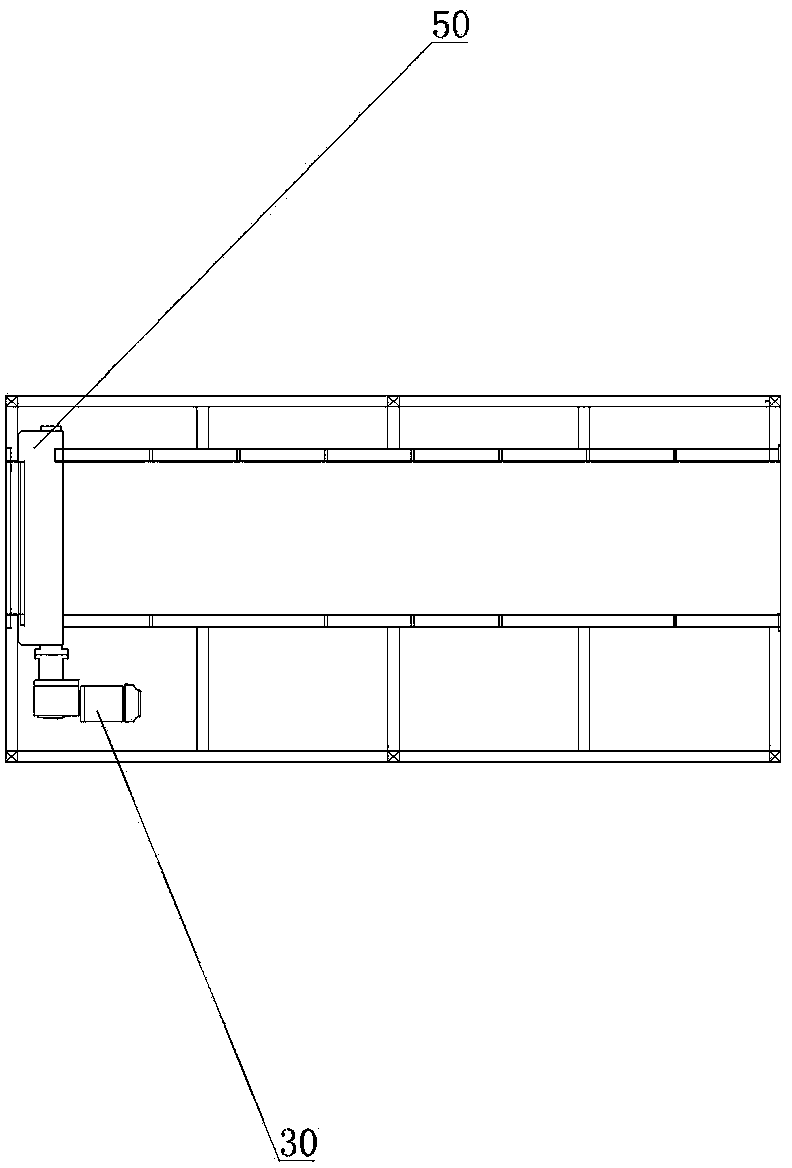

Automatic sealing door

InactiveCN104358494AAchieve sealingGuaranteed sealing performanceDrying chambers/containersSealing arrangementsEngineeringMechanical engineering

An automatic sealing door comprises a first door plate and a second door plate which are arranged in parallel, wherein an elevating mechanism for lifting the first door plate and the second door plate is arranged between the first door plate and the second door plate; at least two articulation pieces are arranged between the first door plate and the elevating mechanism; one end of each of the two articulation pieces is hinged to the first door plate, and the other ends of the articulation pieces are hinged to the elevating mechanism; at least two articulation pieces are arranged between the second door plate and the elevation mechanism; one end of each of the two articulation pieces is hinged to the second door plate, and the other ends of the articulation pieces are hinged to the elevation mechanism; first rolling wheels are arranged at the lower end of the first door plate; a first inclined plate with a left lower end and a higher right end is arranged below the first rolling wheels; second rolling wheels are arranged at the lower end of the second door plate; a second inclined plane with a left higher end and a right lower end is arranged below the second rolling wheels. The automatic sealing door with the structure provided by the invention can realize seamless connection between vacuum drying equipment of a vacuum drying system.

Owner:SHENZHEN TIME HIGH TECH EQUIP

Magnetically balanced finger-type peristaltic pump

ActiveUS20140005631A1Yield maximizationStrong pressing forceFlexible member pumpsMedical devicesPeristaltic pumpEngineering

A peristaltic pump includes a plurality of effecters, actuated in a periodic manner upon by obstructive forces of a flexible infusion tube so as flow of infusion fluid is provided along said infusion tube, the magnitude of the obstructive forces being dependent upon the displacement of said moving effecters; and a plurality of balancing magnets providing balancing forces upon one or all the moving effecters, the balancing forces at each point along the path of motion of the moving effecters being of approximately equal magnitude to that of the obstructive forces at the point; such that the parasitic output due to work performed against the obstructive forces is approximately zero and yield is maximized.

Owner:EITHAN MEDICAL LTD

Punching device for paperboard

PendingCN110000855AReduce punching processPlay the role of support limitMetal working apparatusPunchingPaperboard

The invention discloses a punching device for paperboard, belongs to the technical field of paper punching devices and aims to solve the problem that waste chips generated when the paperboard is punched in an existing way cannot be completely separated from the paperboard. The punching device comprises a workbench, wherein a plurality of receding holes penetrate through the workbench, and a plurality of punching needles are arranged above the workbench; a reinforcing rib is arranged at the lower end of any punching needle; a sleeve is arranged in any receding hole; spiral guide grooves matchedwith the reinforcing ribs are formed in the inner wall of the sleeves in the height direction; the upper ends of the sleeves extend out of the receding holes to be connected with a plurality of blades; a storage groove is formed in the middle of each receding hole; positioning blocks are symmetrically connected to the outer wall of the sleeves; positioning columns are arranged on two sides of anypositioning block, and the positioning columns are sleeved with torsion springs; one end of each torsion spring is connected with the corresponding positioning block, and the other end of each torsion spring is connected with the inner wall of the corresponding storage groove; and a plurality of chip removal grooves penetrate through the periphery of any receding hole.

Owner:武威福民汇科技开发有限公司

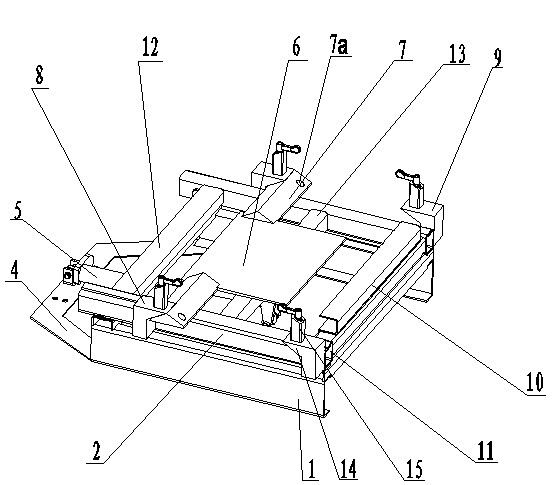

Adjustable steel tube joint closing device

InactiveCN104148873AWill not deviate in direction,Those who don't slip outWelding/cutting auxillary devicesAuxillary welding devicesOperation safetySteel tube

The invention provides a novel steel tube machining device, and particularly relates to an adjustable steel tube joint closing device which comprises a base, a press-fitting roller fixing seat, a first press-fitting roller, a second press-fitting roller, a third press-fitting roller and a lifting support. By means of the adjustable steel tube joint closing device, press-fitting adjustment can be carried out from multiple angles, prominent load bearing capacity and press-fitting precision are achieved, the novel press-fitting rollers can be better attached to the surfaces of tubes to be machined, press-fitting force is accurate and uniform, tube joint closing efficiency and quality can be effectively improved, operation is easy, and operation safety risks are effectively lowered.

Owner:江苏振光电力设备制造有限公司

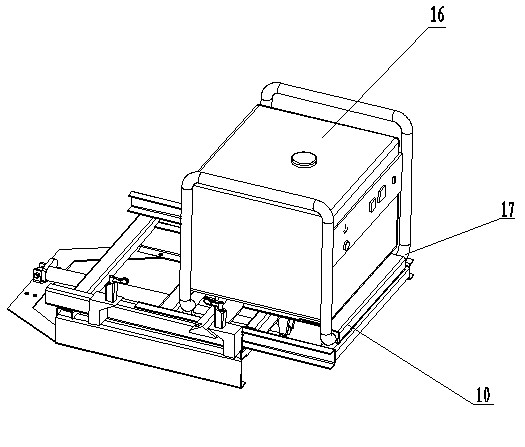

Electric push-pull type vehicle-mounted generator bracket

InactiveCN102222999ARealize automatic push and pullRetain manual operation functionSupports/enclosures/casingsPush and pullPush pull

The invention discloses an electric push-pull type vehicle-mounted generator bracket. Front ends of two side beams of a lower bracket are connected with push rod fixing plates; two sliding chutes are correspondingly arranged above the two side beams of the lower bracket; an upper bracket is mounted in the two sliding chutes; the upper bracket slides in the two sliding chutes back and forth; an electric push rod is arranged between each push rod fixing plates and the upper bracket; one end of the electric push rod is hinged with a support on the push rod fixing plate, and the other end of the electric push rod is hinged with a support fixed below the bracket; a groove-shaped limiting bar of which the notch faces forward is fixed above the rear end of the upper bracket; the upper bracket is provided with a generator fixing plate; two sides of the generator fixing plate are connected with upper bracket fixing blocks; the two upper bracket fixing blocks are lapped on the two sides of the upper bracket; the upper bracket fixing blocks move back and forth along the sliding chutes with the upper bracket; and the upper bracket fixing blocks are limited back and forth by front and rear fixing blocks arranged on the outer sides of the two sliding chutes. Labor is saved to push and pull the bracket; and a generator is reliably fixed and convenient to assemble and disassemble.

Owner:CHONGQING JINGUAN AUTOMOBILE MFR

Device and method for crushing glass objects

InactiveUS20150001324A1Guaranteed continuous useStrong pressing forceGlass recyclingGrain treatmentsEngineeringStructural engineering

Owner:NORDIC RECYCLE GRP

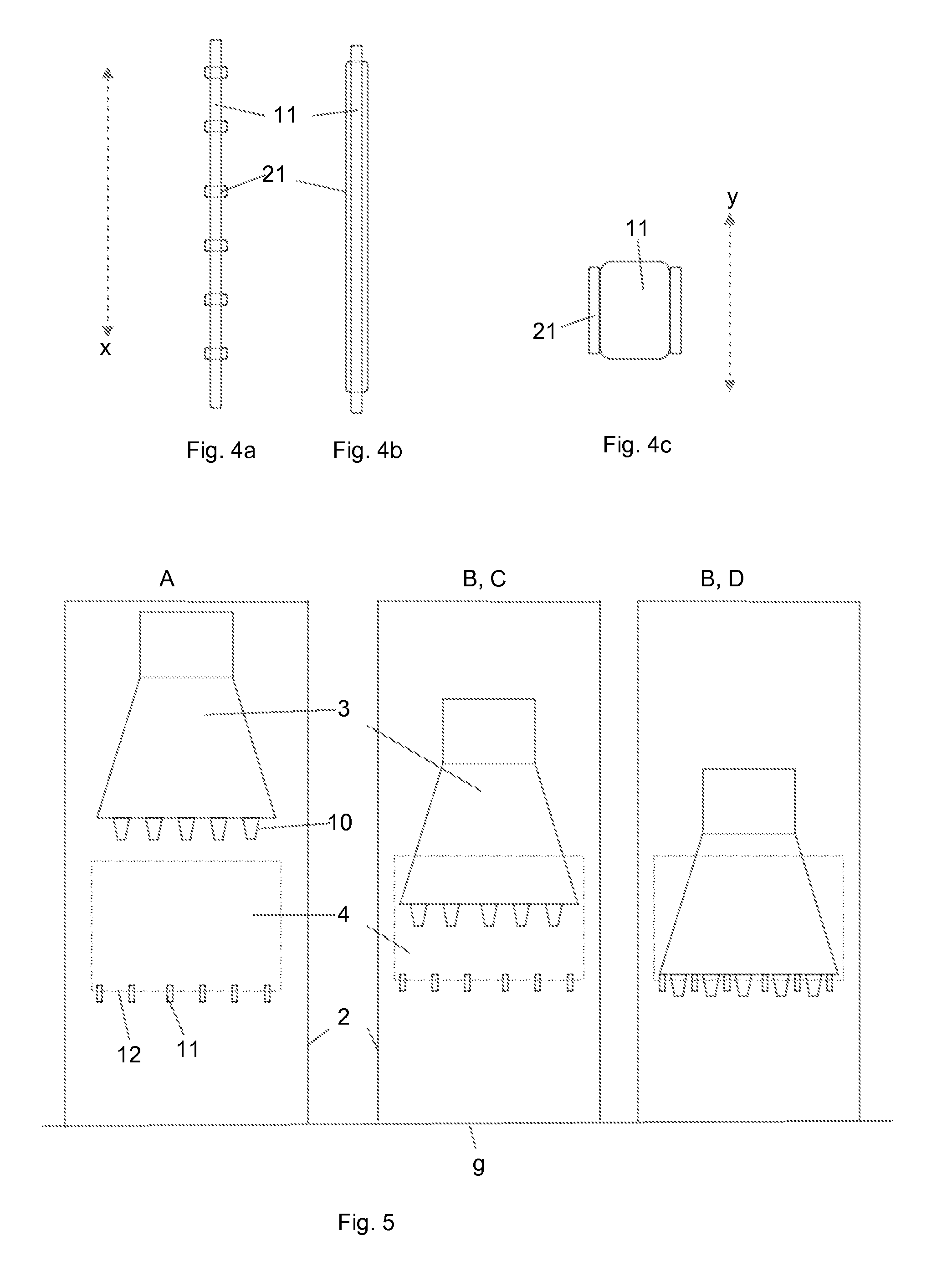

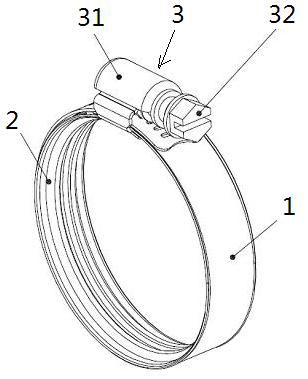

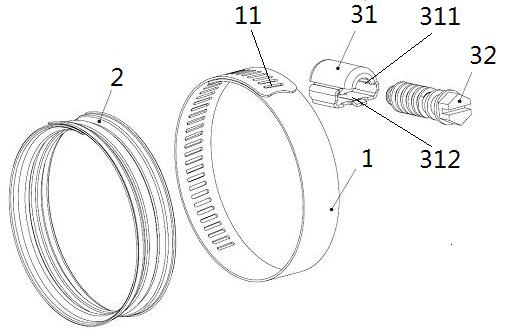

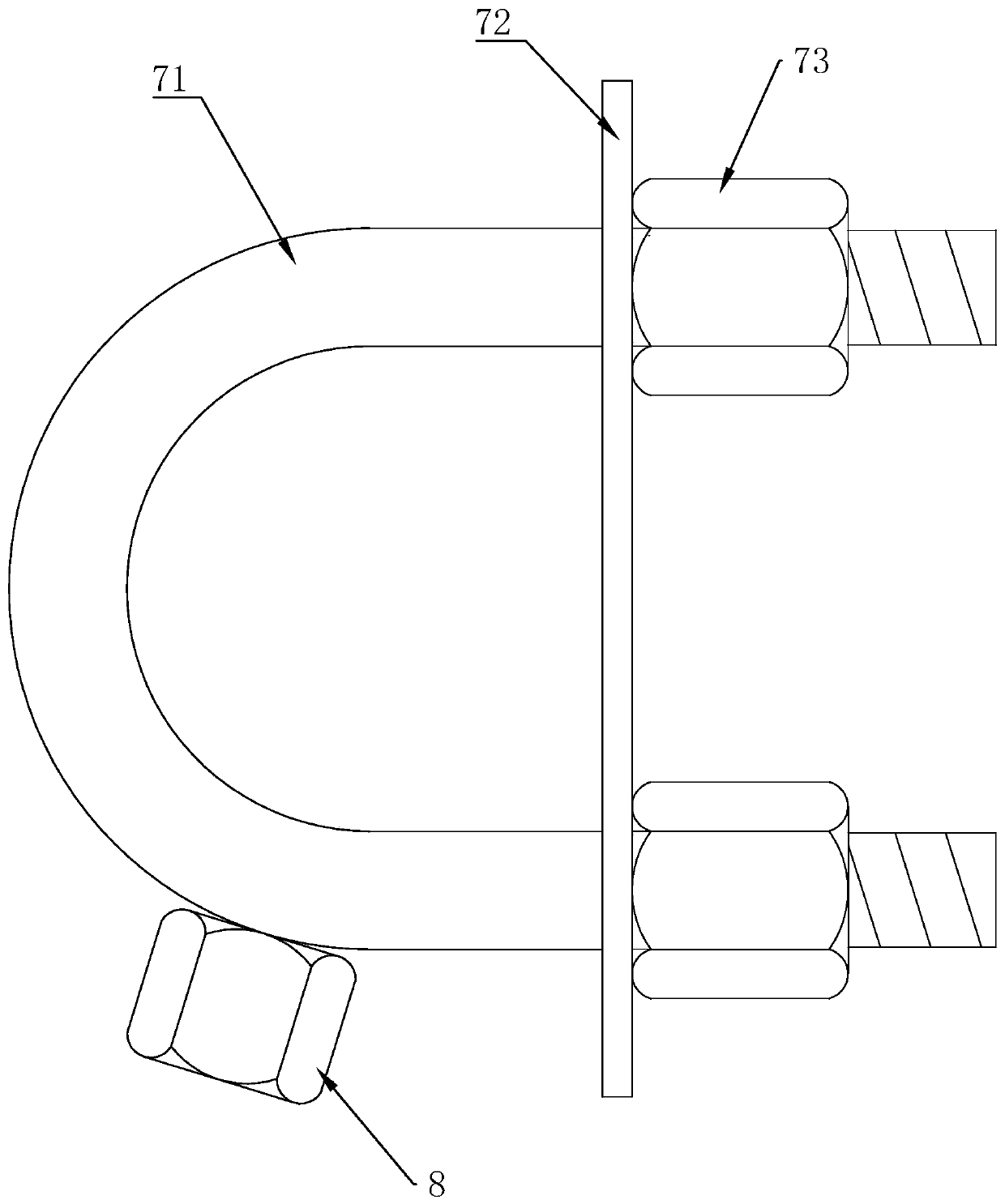

Double clamping groove lining hoop

InactiveCN102691839AGood technical effectReduce the stress areaHose connectionsTransverse forceTemperature difference

The invention discloses a double clamping groove lining hoop which comprises a hoop strip and a locking component, and is characterized by further comprising a lining adhered to the inner wall of the hoop strip; the lining is a double clamping groove lining comprising a first edge, a second edge and a third edge; the first edge and the third edge are symmetrically arranged; the first edge as well as the third edge comprises a transverse forced part and an inward-tilted supporting part in smooth connection with one end of the transverse forced part; the second edge is an arch part; and the two ends of the second edge are in smooth connection with the bottom of the supporting part of the first edge and the bottom of the supporting part of the third edge respectively in a circular arc-shaped manner to form two convex ridges protruding in the inner diameter direction. As the two convex ridges are arranged on the elastic lining of the hoop, when two pipes are connected through a hose pipe, the two convex ridges form double clamp grooves to reduce the stress area and enlarge pressing force to clamp the hose pipe, so as to ensure firm clamping and eliminate the impacts of poor sealing and leakage caused by high temperature difference variation of a pipeline. The double clamping groove lining hoop has advantages of convenience and fastness in construction and stable system.

Owner:WENZHOU KEBODA AUTO PARTS +2

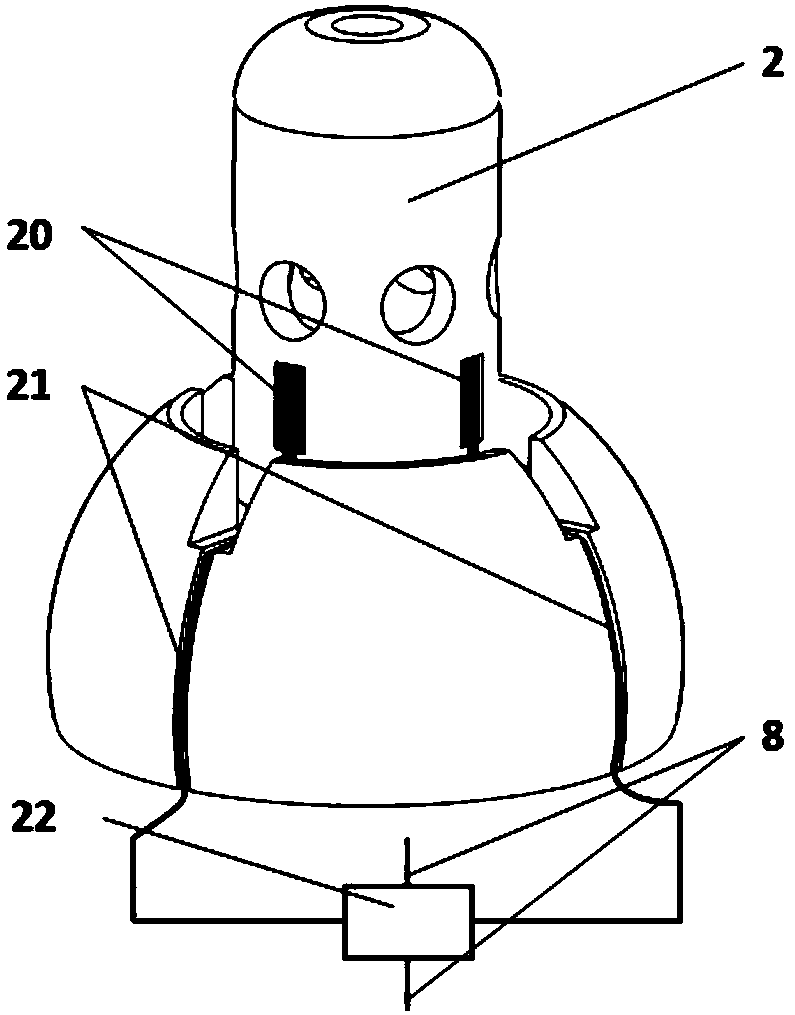

Transdermal drug delivery device

ActiveCN101284157AIncrease motivationSo as not to damageMedical devicesMedical applicatorsDrug treatmentBiomedical engineering

The invention discloses a percutaneous drug-delivery device, comprising an application disk (1) stuck to skin, and a drug cushion (2) arranged under the lower part of the application disk (1). The upper part of the application disk (1) is a top surface (3); an outer-ring cavity (4) with a downward opening and a central cavity (5) are arranged under the top surface (3); an annular side wall (6) is arranged between the outer-ring cavity (4) and the central cavity (5); the outer-ring cavity (4) is communicated with a negative pressure source through a negative pressure passage port (7) of the top surface (3); the drug cushion (2) is arranged in the central cavity (5); the outer-ring cavity (4) is divided into an upper cavity and a lower cavity by a permeability clapboard (8), wherein, the upper cavity is communicated with the negative pressure source through the negative pressure passage port (7), and the lower cavity is open downwards. When being combined with drug therapy, the percutaneous drug-delivery device increases the percutaneous drug-delivery force, and also can form the well seal on the human skin surface.

Owner:BEIJING SINOHANFANG PHARMA SCI &TECH

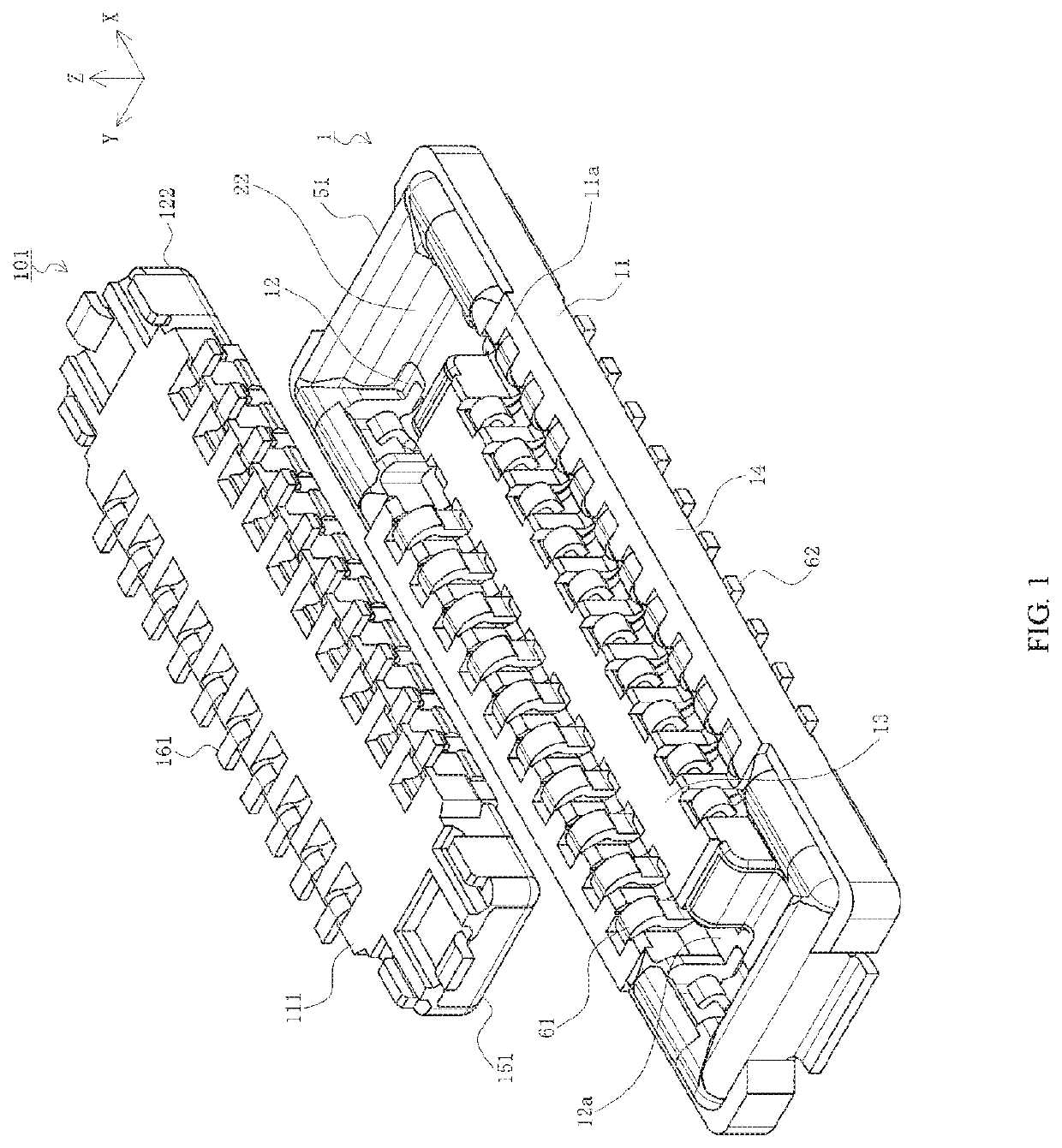

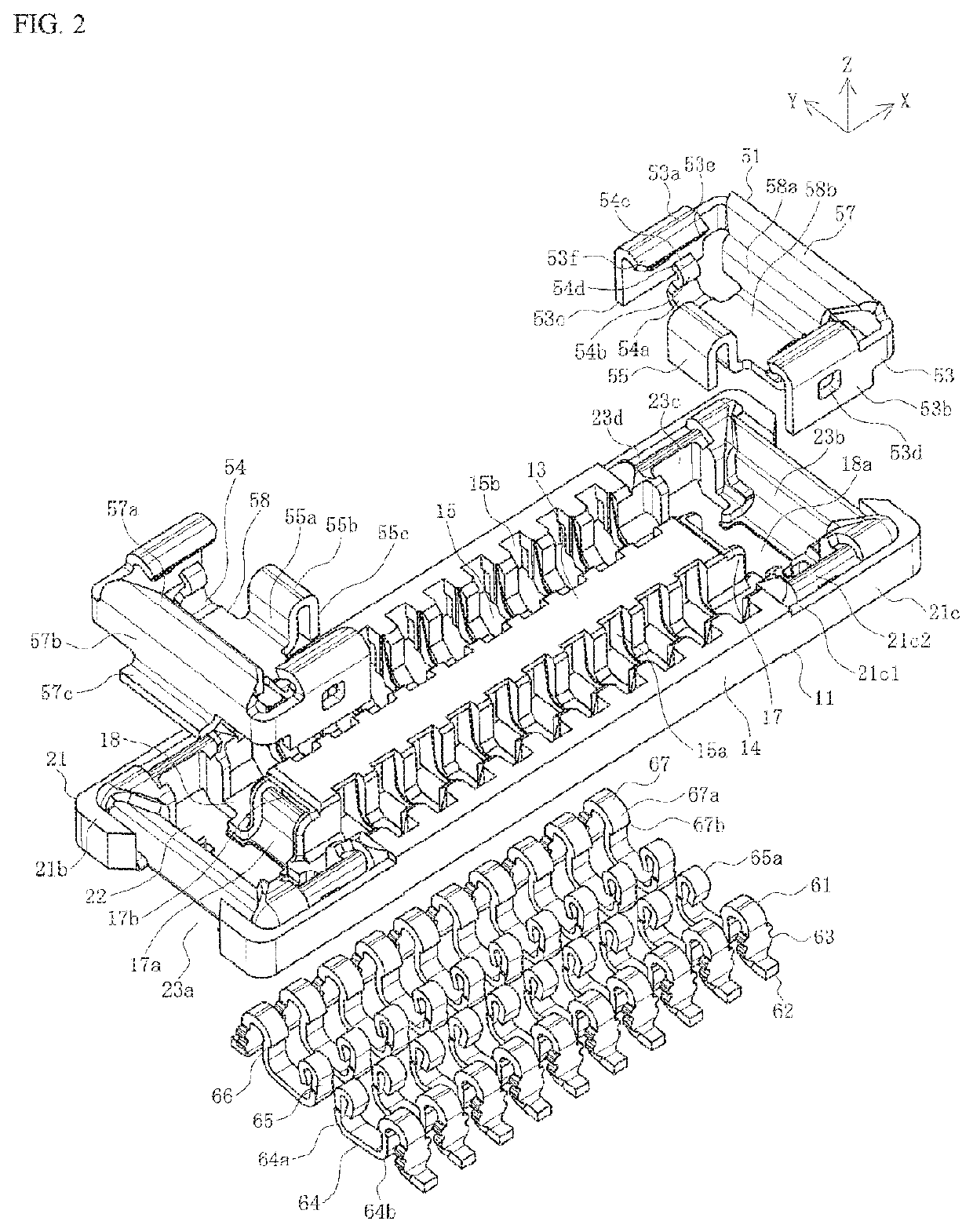

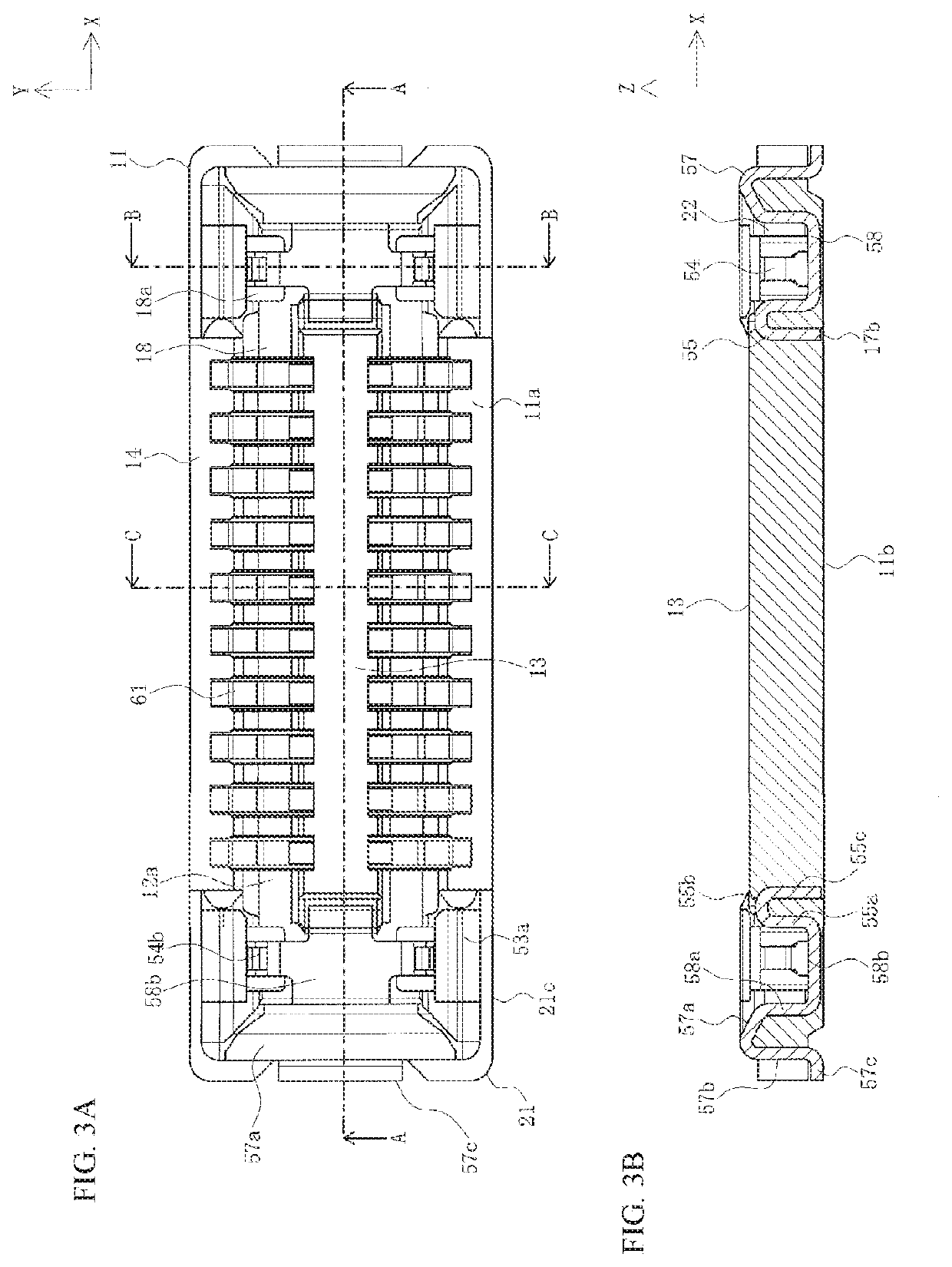

Connector and connector assembly

ActiveUS20200358213A1Improve reliabilityStrong pressing forceEngagement/disengagement of coupling partsCoupling contact membersEngineeringStructural engineering

A connector body includes mating guide parts having mating recesses into which counterpart mating guide parts are inserted, the reinforcing bracket includes a body part attached to end wall parts of the mating guide parts, and a pair of left and right connection arms connected to both ends of the body part, the connection arms extending to the longitudinal center of the connector body and being attached to side wall parts of the mating guide parts, the connection arm includes a side plate part and a side wall upper cover part connected to an upper end of the side plate part, at least a part of the outside of the side plate part is covered with an outside part of the side wall part, and the side wall upper cover part is curved such that a tip faces the mating recess and covers at least a part of the upper surface of the inside part of the side wall part.

Owner:MOLEX INC

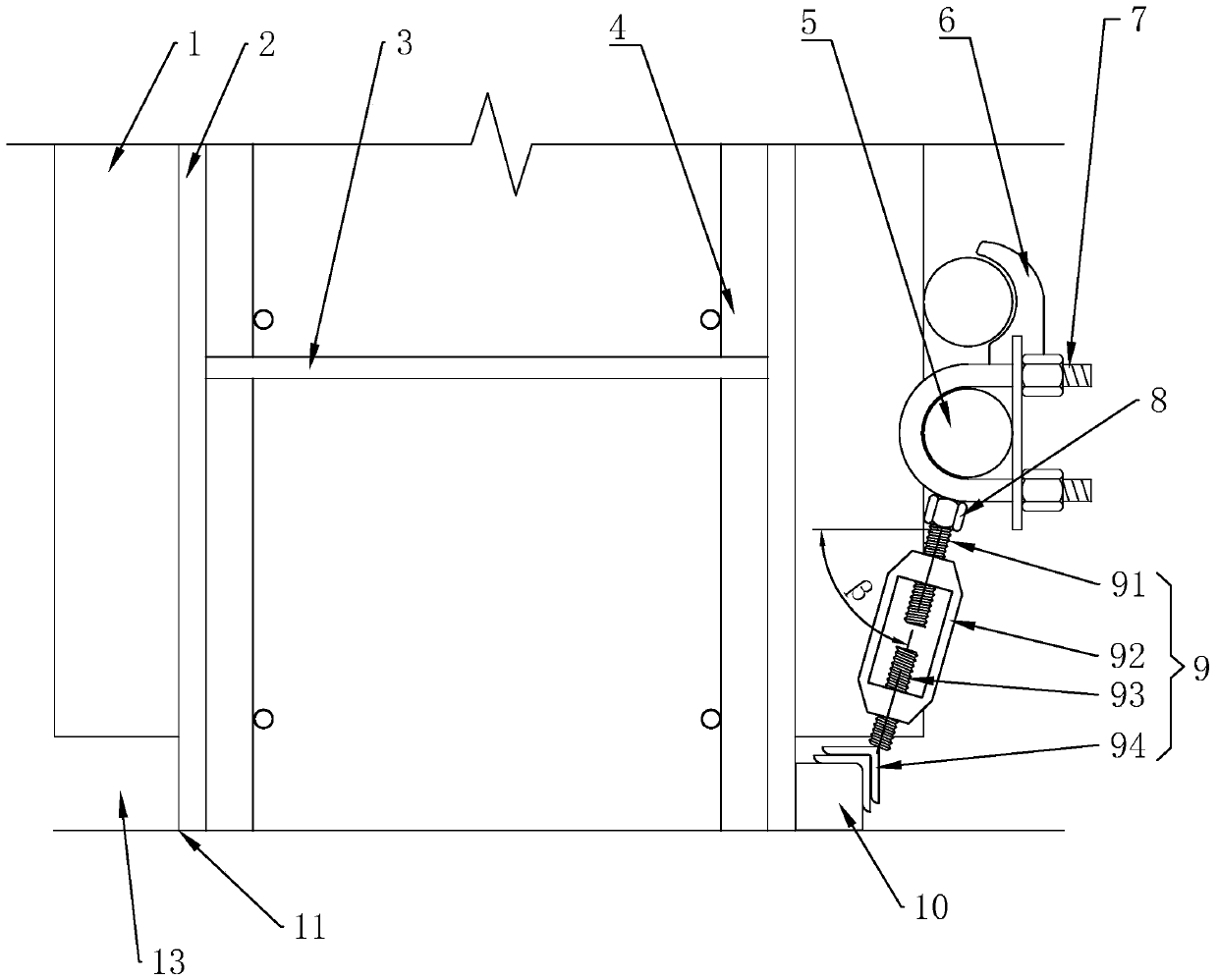

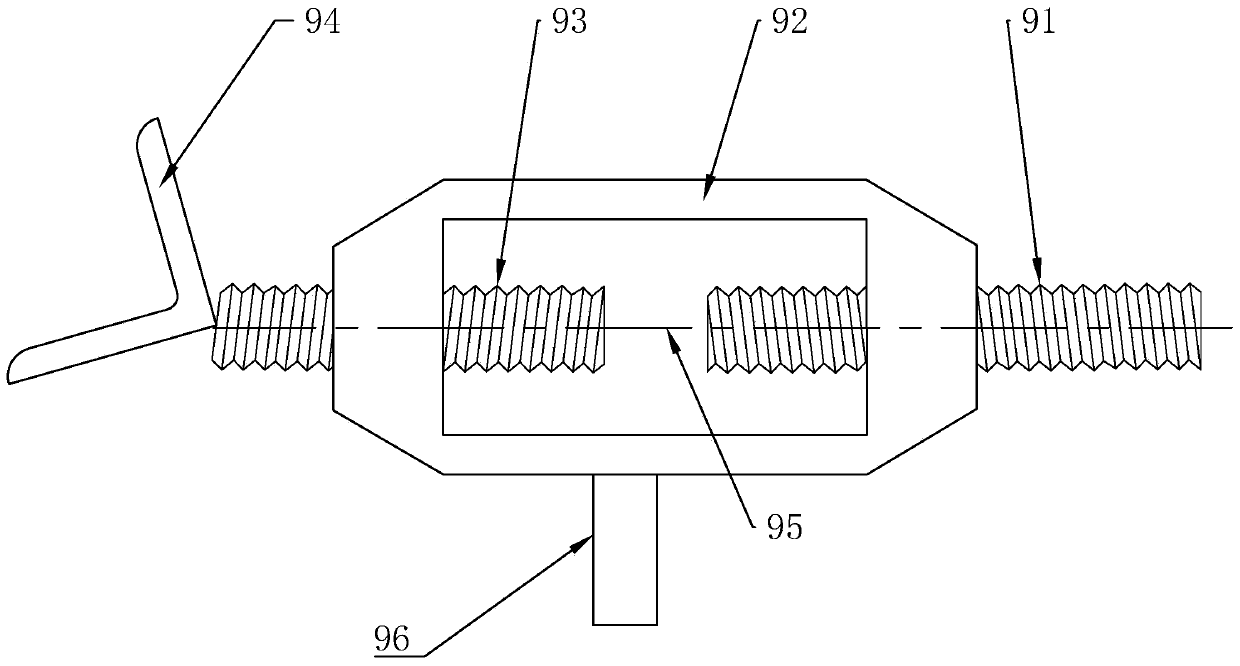

Wall template bottom plugging device, template supporting system and formwork construction method

PendingCN111502247AAdjust the forceAchieve reuseForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemArchitectural engineering

The invention relates to a wall template bottom plugging device, a template supporting system and a formwork construction method, and relates to the technical field of building construction template structures, installation and protection. The wall template bottom plugging device comprises a locker, a grouting stop structure, and an adjusting structure respectively connected with the locker and the grouting stop structure, wherein the grouting stop structure comprises a flexible sealing body; the adjusting structure comprises an adjusting frame, a first adjusting screw rod and a second adjusting screw rod with one ends being respectively in threaded connection with the adjusting frame, and a first connecting body for tightly pressing the grouting stop structure; the rotation directions ofthe first adjusting screw rod and the second adjusting screw rod are opposite; and the central axes of the first adjusting screw rod and the second adjusting screw rod are collinear, and are inclinedtowards a part to be plugged. The template supporting system comprises the wall template bottom plugging device detachably connected with a steel pipe main keel on the bottommost part. The formwork construction method adopts the template supporting system. According to the wall template bottom plugging device, the template supporting system and the formwork construction method provided by the invention, the technical problem of a poor grouting stop effect of a plugging device in the prior art can be solved, and an effect on tightly plugging is achieved.

Owner:中铁十六局集团城市建设发展有限公司 +1

Ink cartridge attachment/detachment device, recording apparatus, liquid ejection apparatus, and liquid container

InactiveUS20080136879A1Big ratioLittle powerRoof coveringOther printing apparatusLiquid jetEngineering

Owner:SEIKO EPSON CORP

Press mounting fixture

InactiveCN104440305AFully automatedThe arc structure is stableWork clamping meansPositioning apparatusMechanical engineeringEngineering

Owner:常州依丝特纺织服饰有限公司

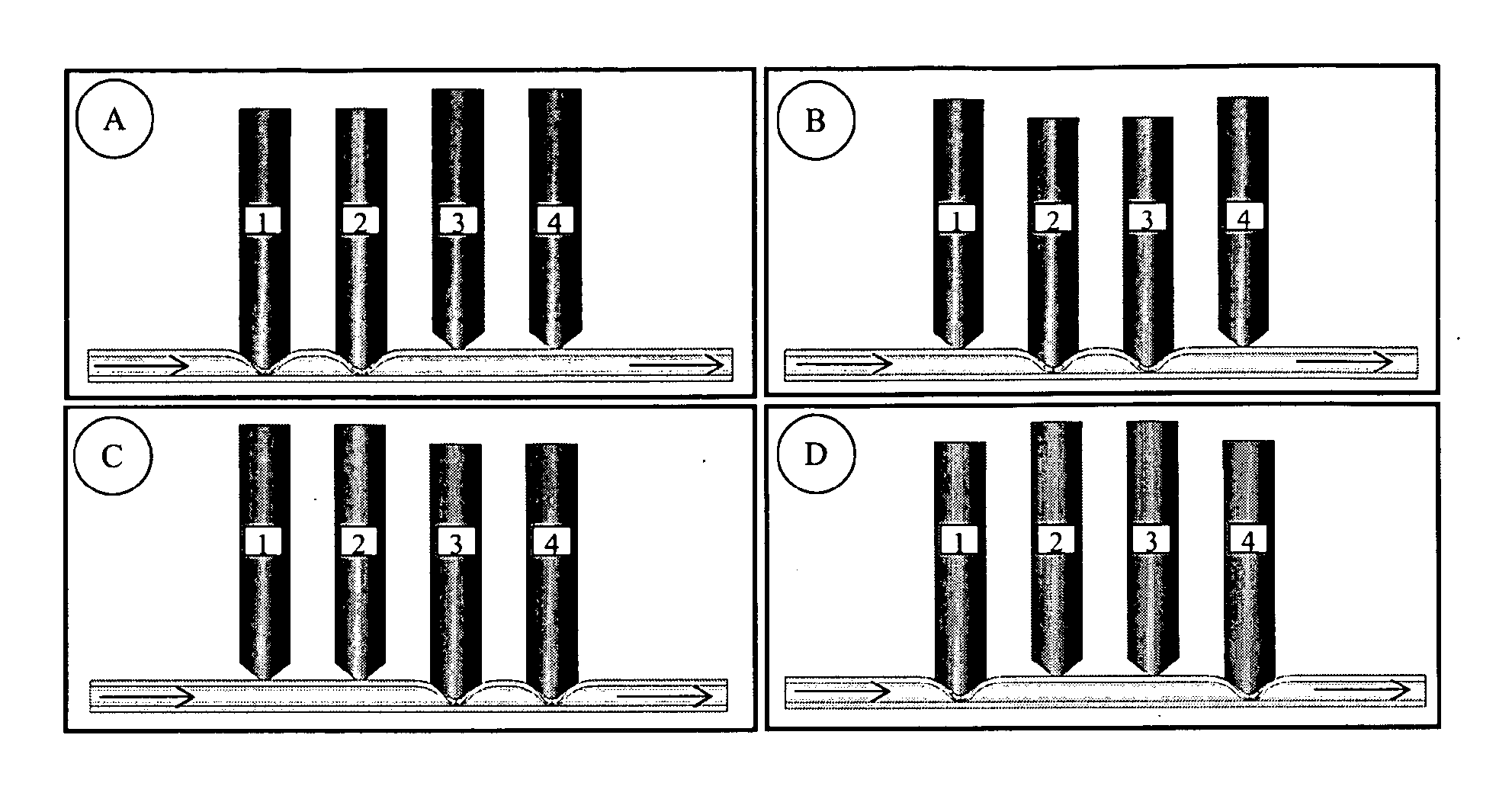

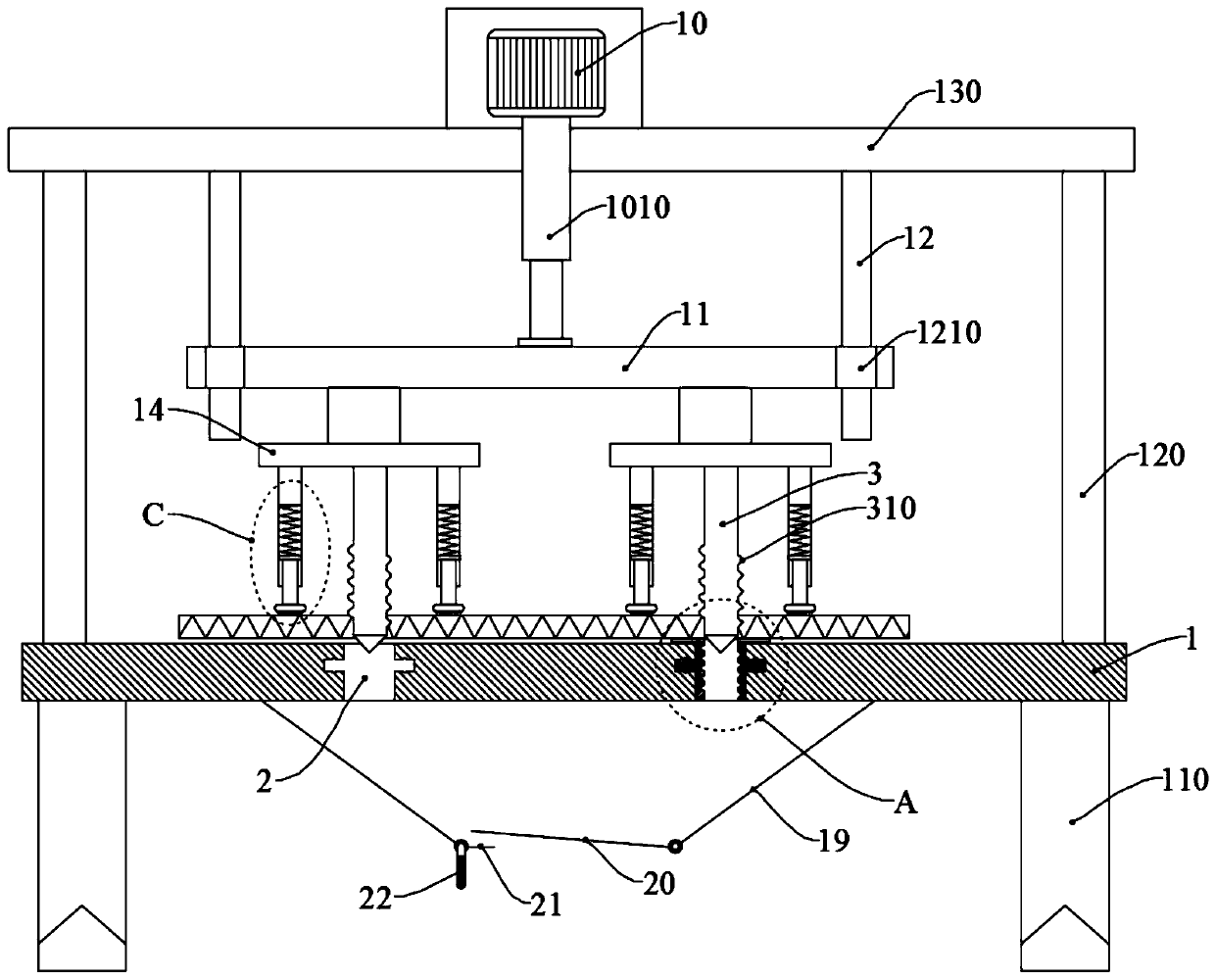

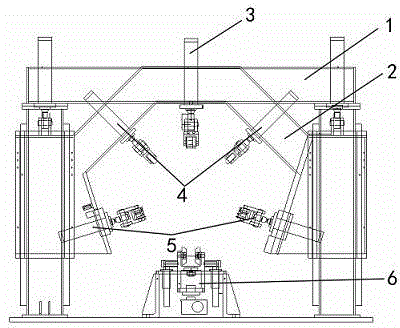

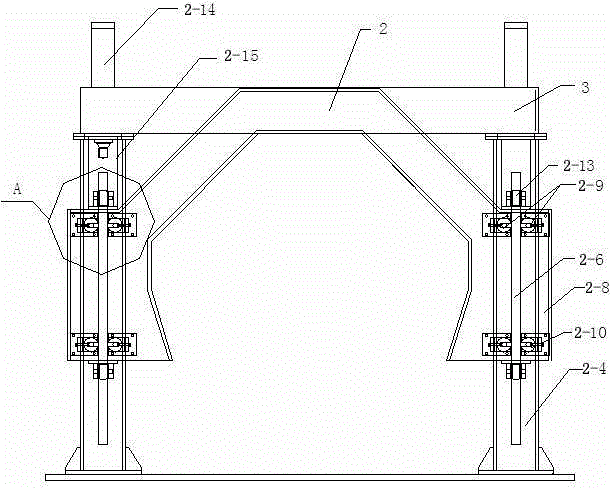

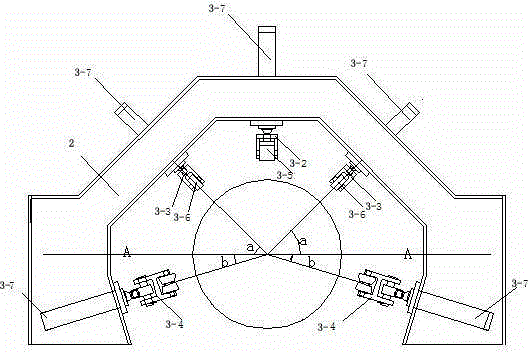

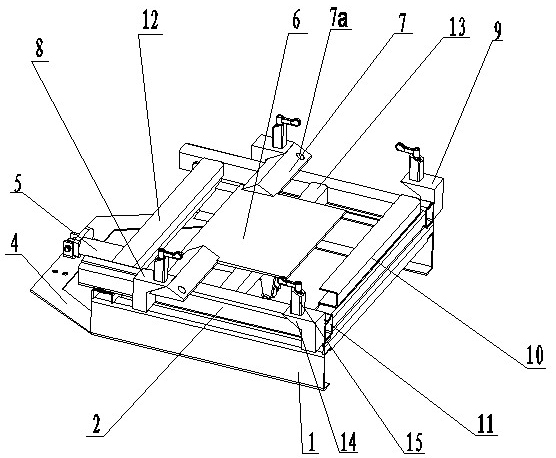

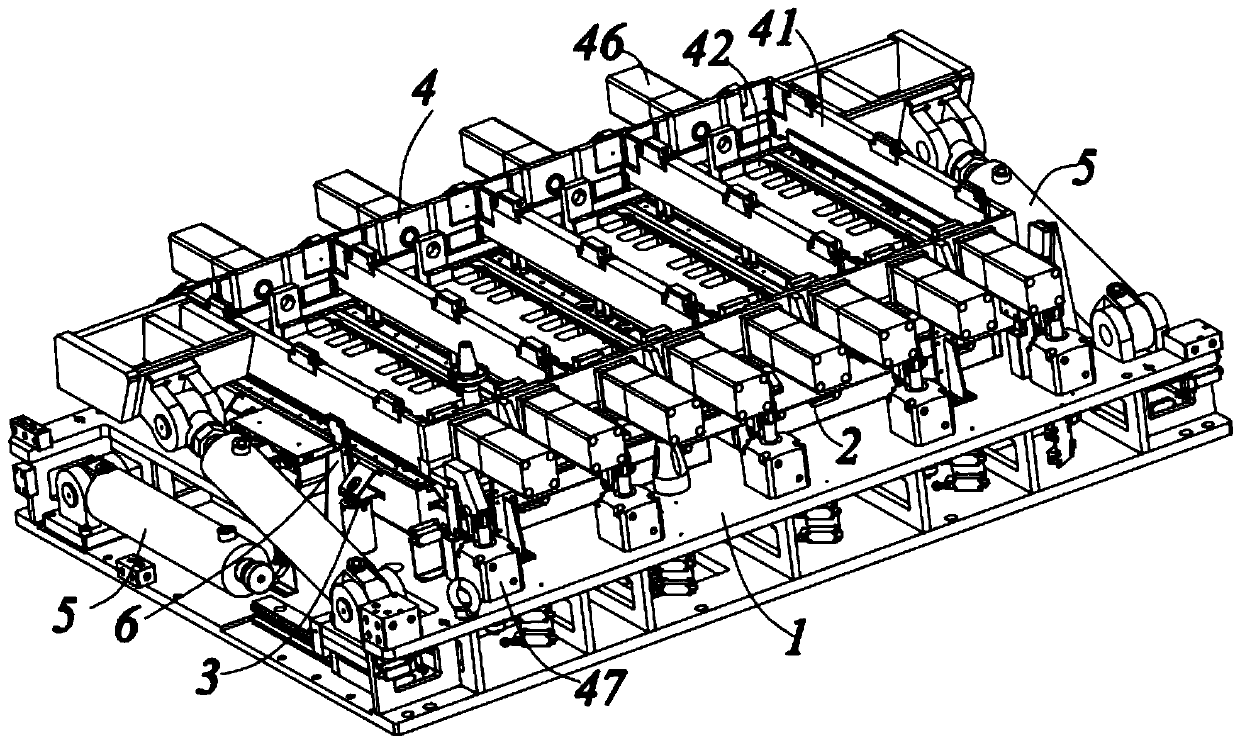

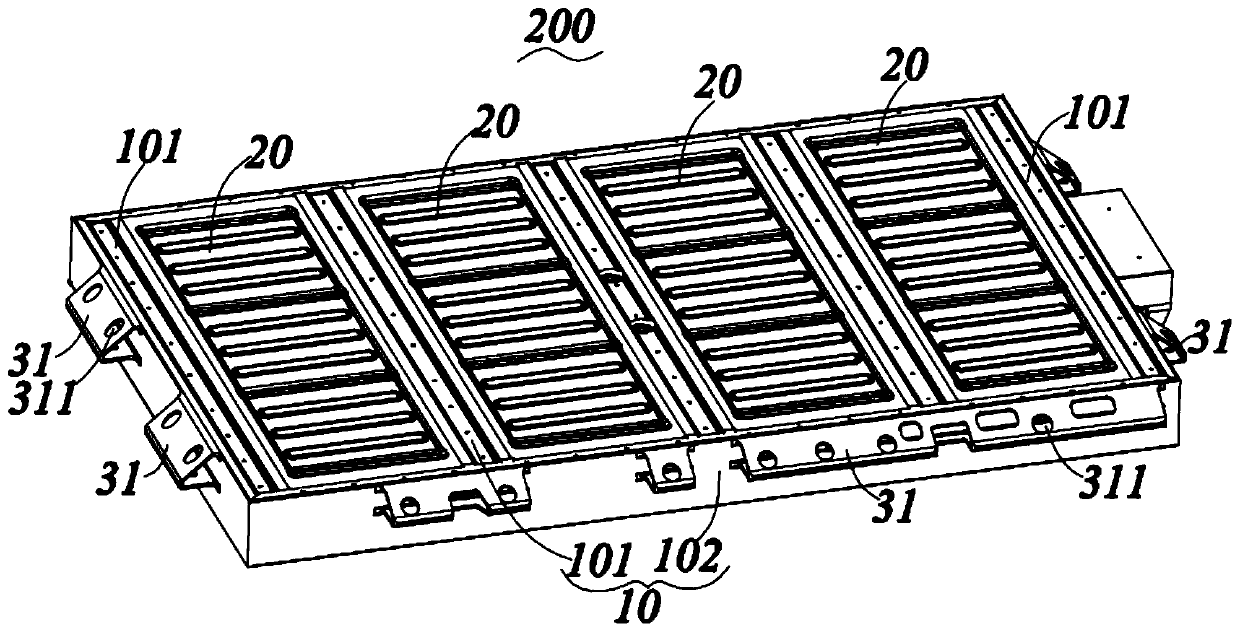

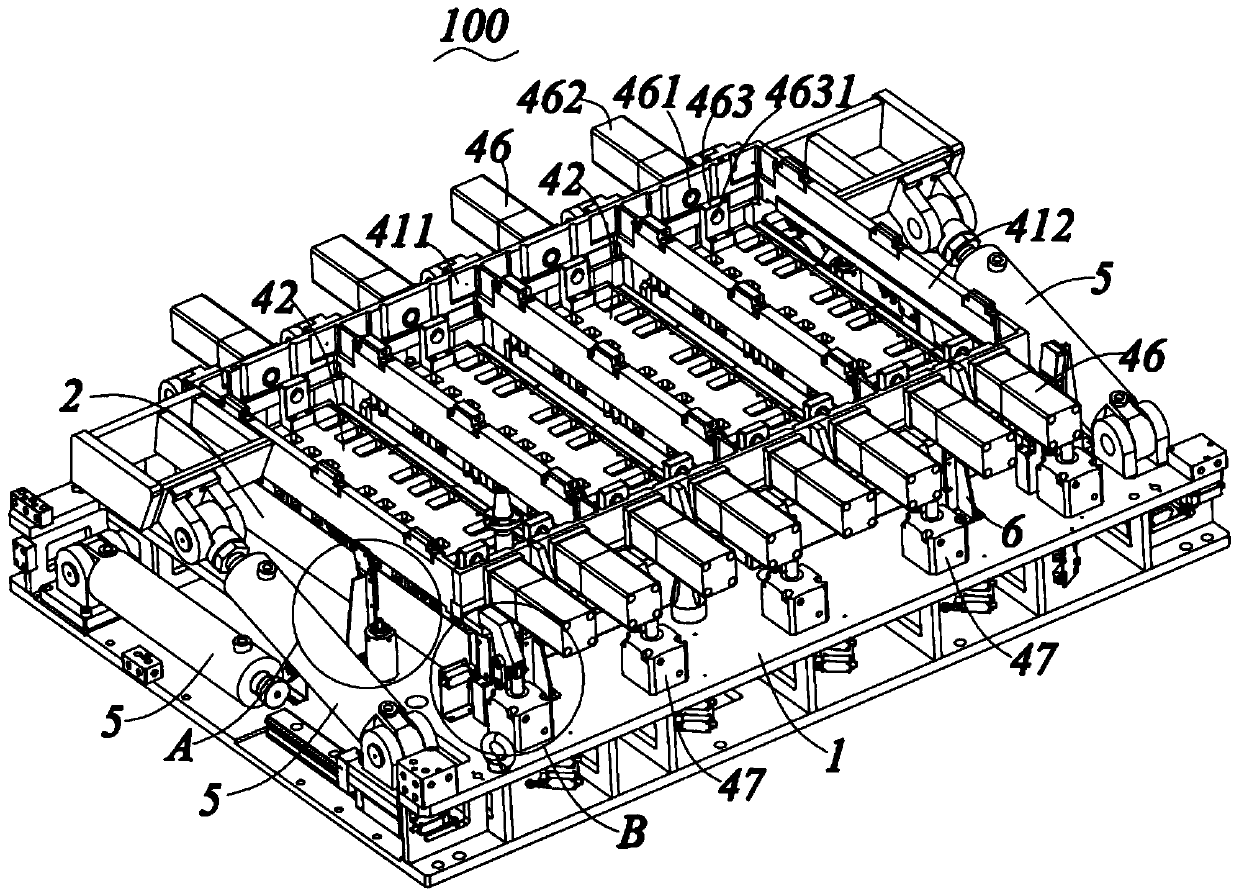

Clamp for friction stir welding

PendingCN110193659APrecise positioningStrong pressing forceWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingBraced frame

The invention provides a clamp for friction stir welding. The clamp is used for clamping a frame and aluminum plates to be welded, wherein the frame comprises a plurality of cross beams which are arranged in parallel and are arranged at intervals and longitudinal beams connecting the end parts of the plurality of cross beams in sequence; the clamp used for friction stirring welding comprises a base, a positioning structure, a pressing mechanism, a turnover driving mechanism, wherein a supporting frame is arranged on the base and is used for supporting the frames and the aluminum plates; the positioning structure is arranged between the base and the frames so as to locate the frames; the pressing mechanism is rotationally connected to the base to press the frames and the aluminum plates; and the turnover driving mechanism is fixed on the base and is used for driving the pressing mechanism to turn over. The frames are accurately positioned, it is guaranteed that the frames and the aluminum plates are completely positioned, and the influence of welding quality caused by positioning problems is avoided; and meanwhile, the manual operation is reduced, the welding efficiency is improved,the pressing mechanism can provide enough press force, so that gaps between the frames and the aluminum plates are prevented from changing during a welding process, and the welding quality is furtherimproved.

Owner:JIANGSU BEIREN ROBOT SYST CO LTD

Pneumatic wheel brake for a vehicle

ActiveCN102959269ASimple structureCompact structureBraking element arrangementsAxially engaging brakesEngineeringCompressed air

The invention relates to a pneumatic wheel brake for a vehicle, wherein the wheel brake has at least one brake lever (11) that can be operated by a compressed air cylinder (10) and a brake application device (20) that can be operated by the brake lever (11), wherein by means of said brake application device a first brake element (1) can be pressed against a second brake element (2) when the brake lever (11) is operated, and the wheel brake has an actuating device (3) that can be driven by an electric motor, wherein by means of said actuating device force can be applied to at least parts (7, 8, 9) of the brake application device (20), at least when the brake lever (11) is not operated, and thereby the first brake element (1) can be pressed against the second brake element (2). Furthermore, the wheel brake has a spring accumulator element (4), which is arranged outside the compressed air cylinder (10), wherein force can be applied to the spring accumulator element (4) by the actuating device (3) that can be driven by an electric motor and force can be applied to at least parts (7, 8, 9) of the brake application device (20) by the spring accumulator element, at least when the brake lever (11) is not operated, and thereby the first brake element (1) can be pressed against the second brake element (2).

Owner:ZF CV SYST EURO BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com