Shape memory alloy (SMA) group rolling rod type large load releasing mechanism

A release mechanism and large load technology, applied in the docking device of aerospace vehicles, etc., can solve the problems of low impact resistance, small release load, no redundant design, etc., achieve strong impact resistance, large release load, and improve unlocking reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

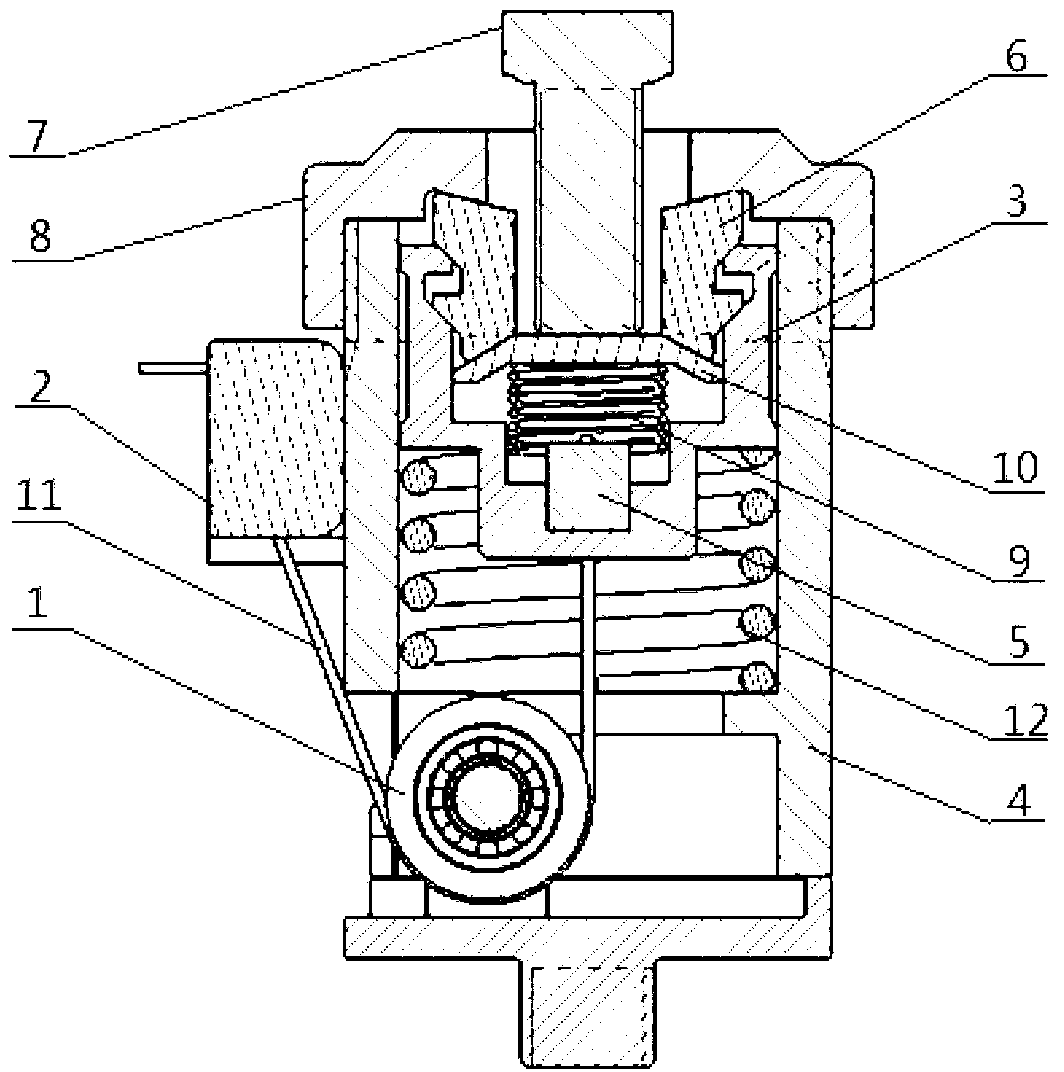

[0041] The specific structure of the present invention is as Figure 5 shown.

[0042] Such as Figure 5 As shown, the split nut 16 of the present invention is tightly hooped by the hoop 13 through the rolling rod 17, and the rolling rod 17 is restricted in its spatial position by the cage (not shown in the figure), while the upper and lower end surfaces of the split nut 16 are respectively Cooperate with end cap 8 and separation top block 10, so that split nut 16 becomes a complete nut and cannot move up and down.

[0043] Such as Figure 5 As shown, there is a groove on the split nut 16. When separation is required, the hoop 13 moves downward, driving the roller 17 to roll down, and moves to a certain position, just entering the groove of the split nut 16. Make the split nut 16 obtain radial displacement; after the release, the hoop 13 mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com