Wear-resistant carbon fiber modified polyether-ether-ketone composite material and preparation method thereof

A polyether ether ketone and composite material technology, applied in the field of composite materials, can solve problems such as poor processability and poor impact resistance, and achieve the effects of compact structure, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

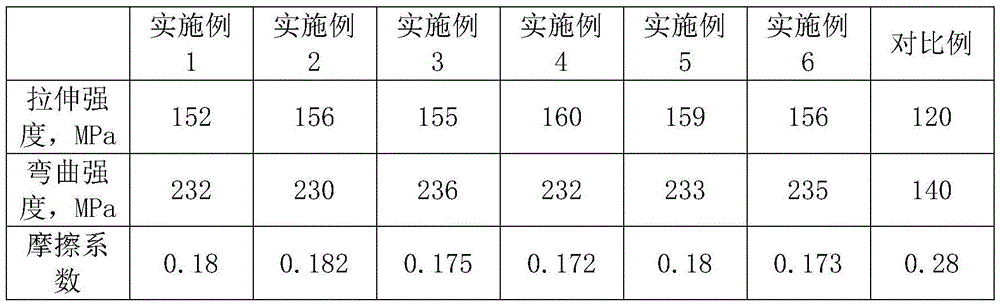

Examples

Embodiment 1

[0033] 40 parts of polyether ether ketone resin, 10 parts of polytetrafluoroethylene resin,

[0034] 8 parts of polyimide resin, 2 parts of carbon fiber,

[0035] 5 parts of vermiculite, 5 parts of parthenolide,

[0036] Potassium feldspar powder 4 parts, compatibilizer 1 part.

[0037] Its preparation method comprises the following steps:

[0038] (1) Mix ether ether ketone resin, polytetrafluoroethylene resin, polyimide resin, carbon fiber, vermiculite, parthenolide, potassium feldspar powder and compatibilizer evenly, knead at 50°C for 10 minutes, get mixed material;

[0039] (2) extruding the mixed material obtained in the step (1) through an extruder to granulate, and drying to obtain a wear-resistant carbon fiber modified polyether ether ketone composite material.

Embodiment 2

[0041] 60 parts of polyether ether ketone resin, 30 parts of polytetrafluoroethylene resin,

[0042] 20 parts of polyimide resin, 5 parts of carbon fiber,

[0043] 10 parts of vermiculite, 15 parts of parthenolide,

[0044] Potassium feldspar powder 8 parts, compatibilizer 2 parts.

[0045] Its preparation method comprises the following steps:

[0046] (1) Mix ether ether ketone resin, polytetrafluoroethylene resin, polyimide resin, carbon fiber, vermiculite, parthenolide, potassium feldspar powder and compatibilizer evenly, knead at 80°C for 30min, get mixed material;

[0047] (2) extruding the mixed material obtained in the step (1) through an extruder to granulate, and drying to obtain a wear-resistant carbon fiber modified polyether ether ketone composite material.

Embodiment 3

[0049] 45 parts of polyether ether ketone resin, 15 parts of polytetrafluoroethylene resin,

[0050] 10 parts of polyimide resin, 3 parts of carbon fiber,

[0051] 6 parts of vermiculite, 7 parts of parthenolide,

[0052] Potassium feldspar powder 5 parts, compatibilizer 1.2 parts.

[0053] Its preparation method comprises the following steps:

[0054] (1) Mix ether ether ketone resin, polytetrafluoroethylene resin, polyimide resin, carbon fiber, vermiculite, parthenolide, potassium feldspar powder and compatibilizer evenly, knead at 60°C for 15 minutes, get mixed material;

[0055] (2) extruding the mixed material obtained in the step (1) through an extruder to granulate, and drying to obtain a wear-resistant carbon fiber modified polyether ether ketone composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com