Patents

Literature

1374 results about "Radial displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Answer Wiki. The radial displacement is the component of a change in position in the radial direction. The radial velocity is the component of a change in position per unit time in the radial direction.

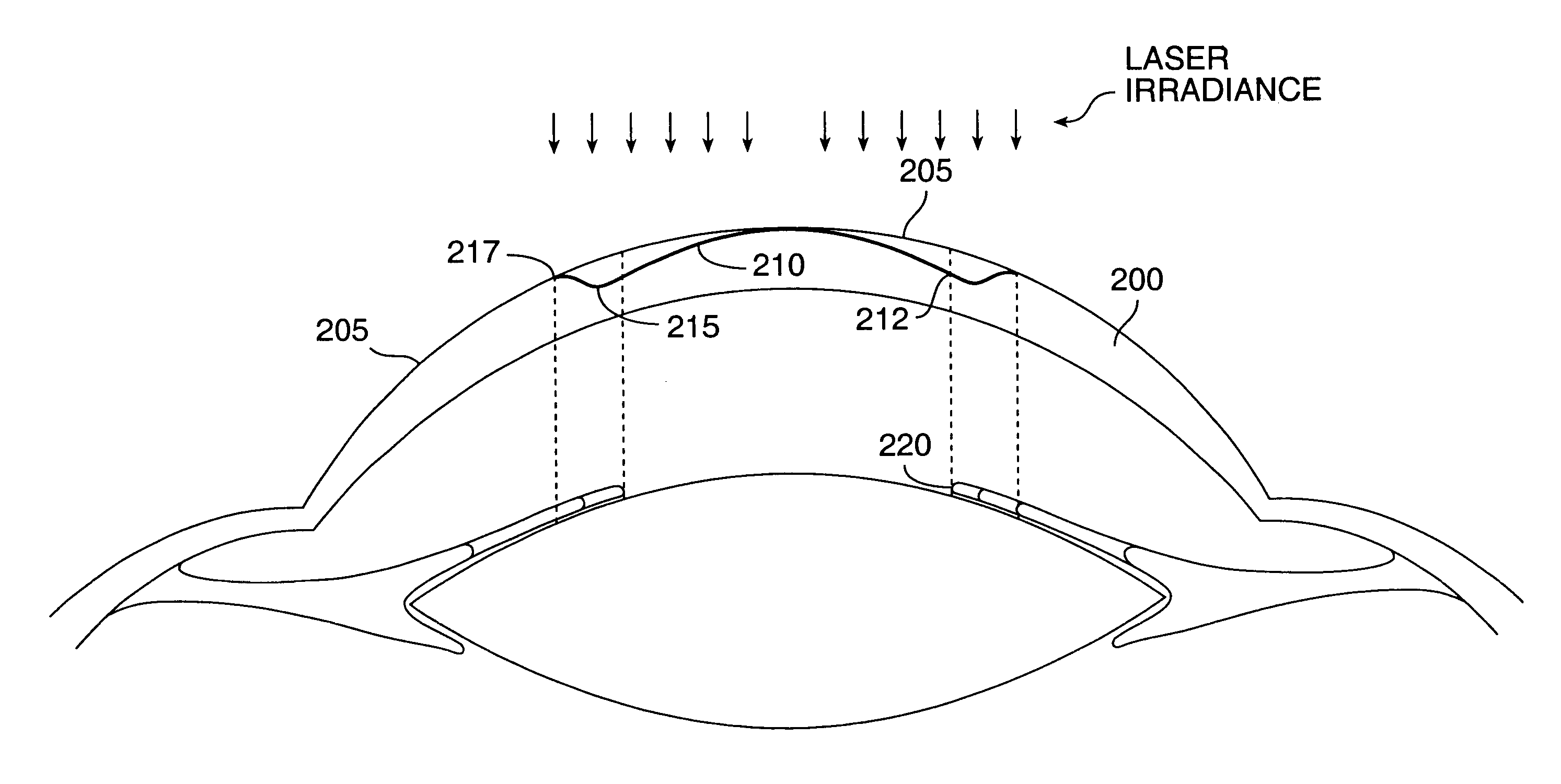

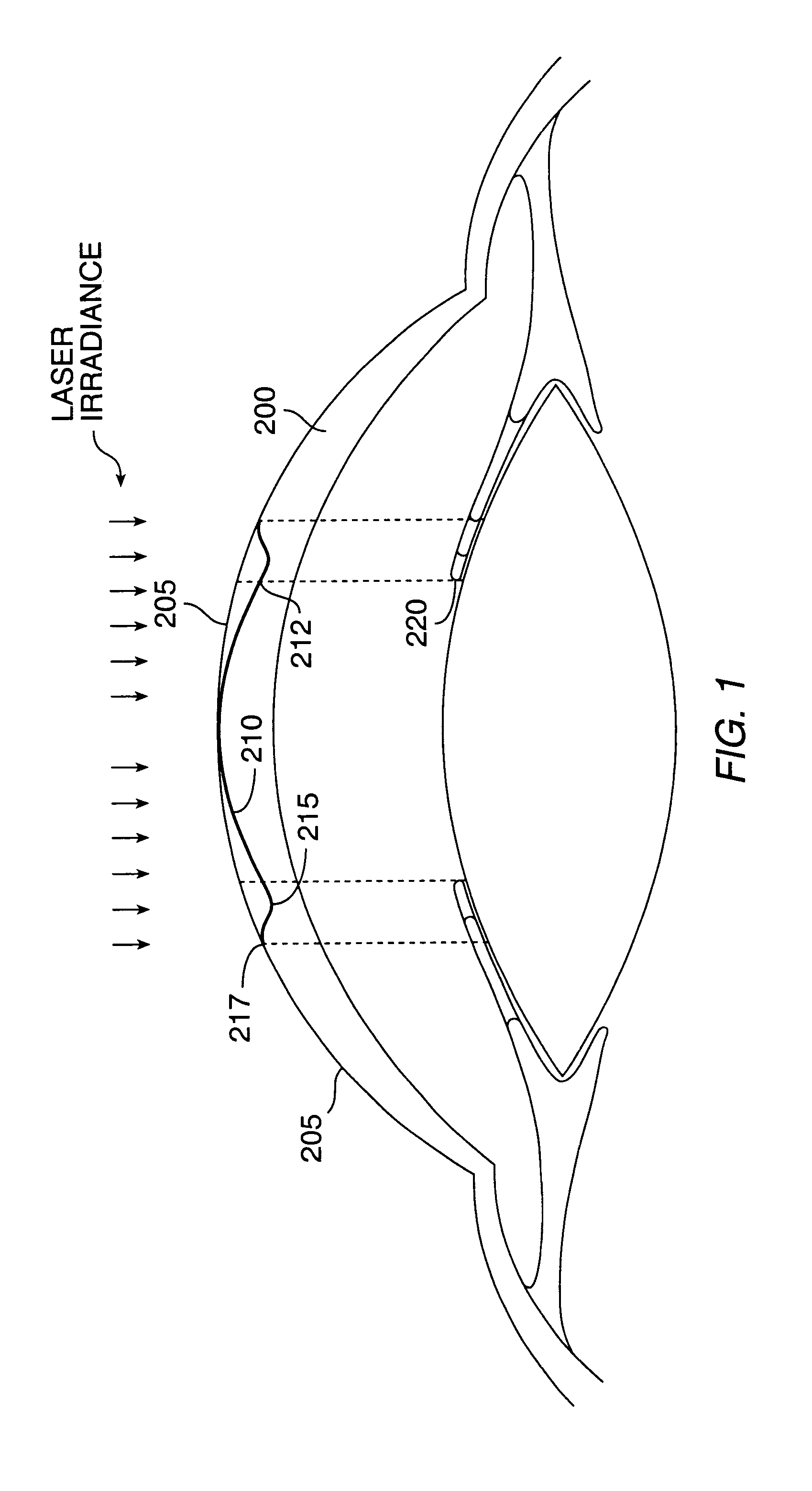

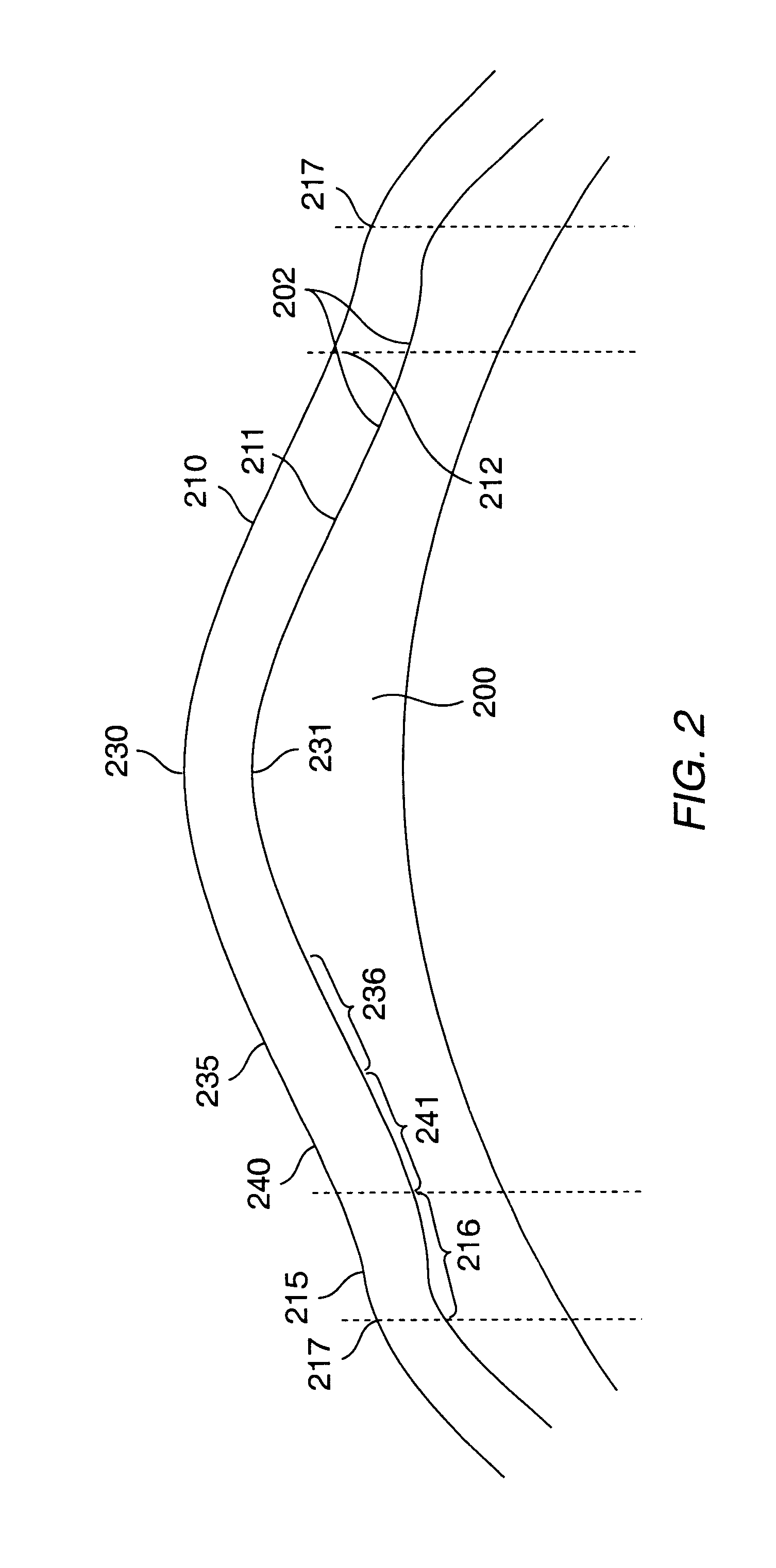

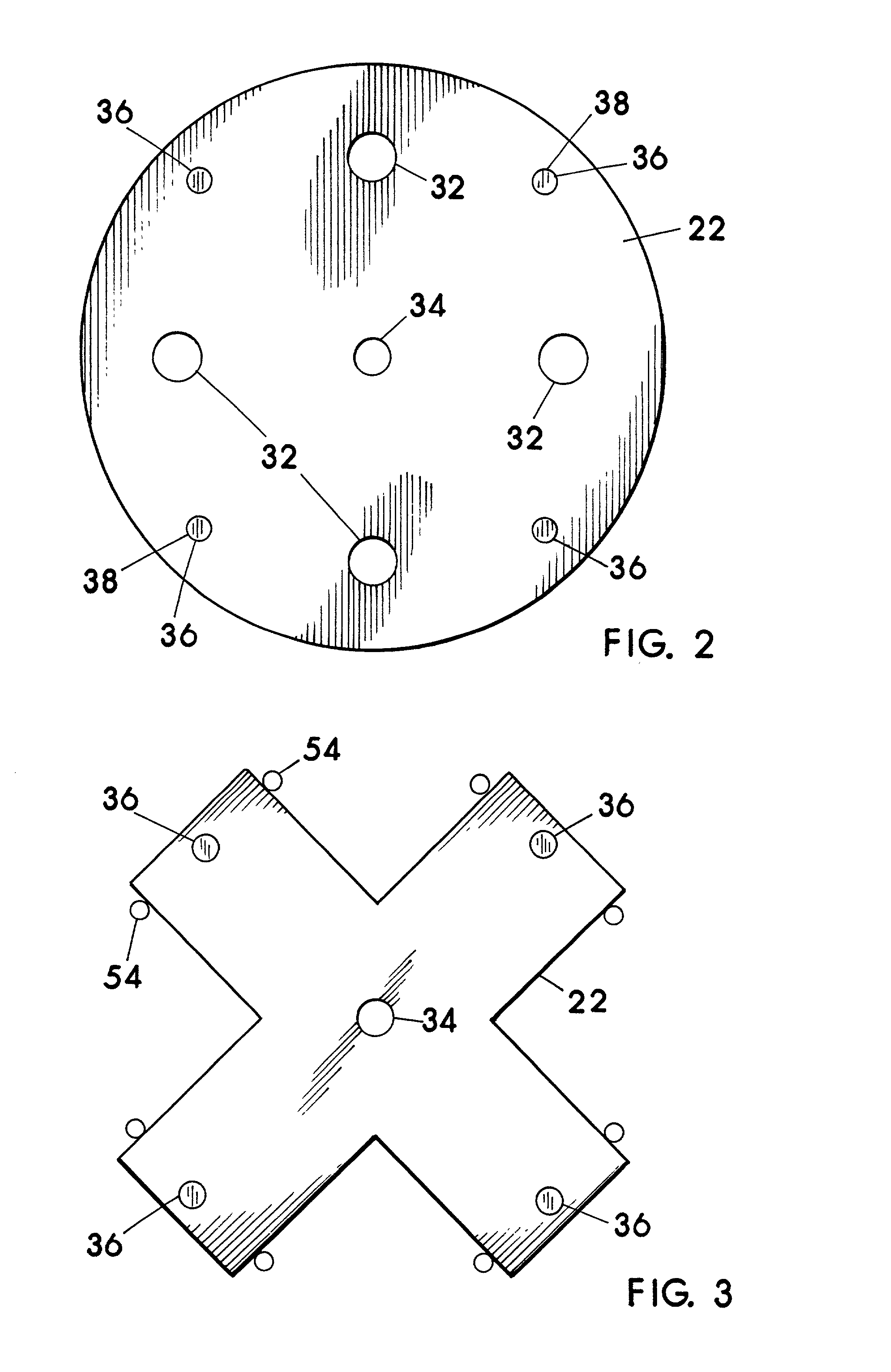

Method and systems for laser treatment of presbyopia using offset imaging

InactiveUS6280435B1Less attractiveReduce discontinuityLaser surgerySurgical instrument detailsWide areaHyperopic astigmatism

Owner:AMO MFG USA INC

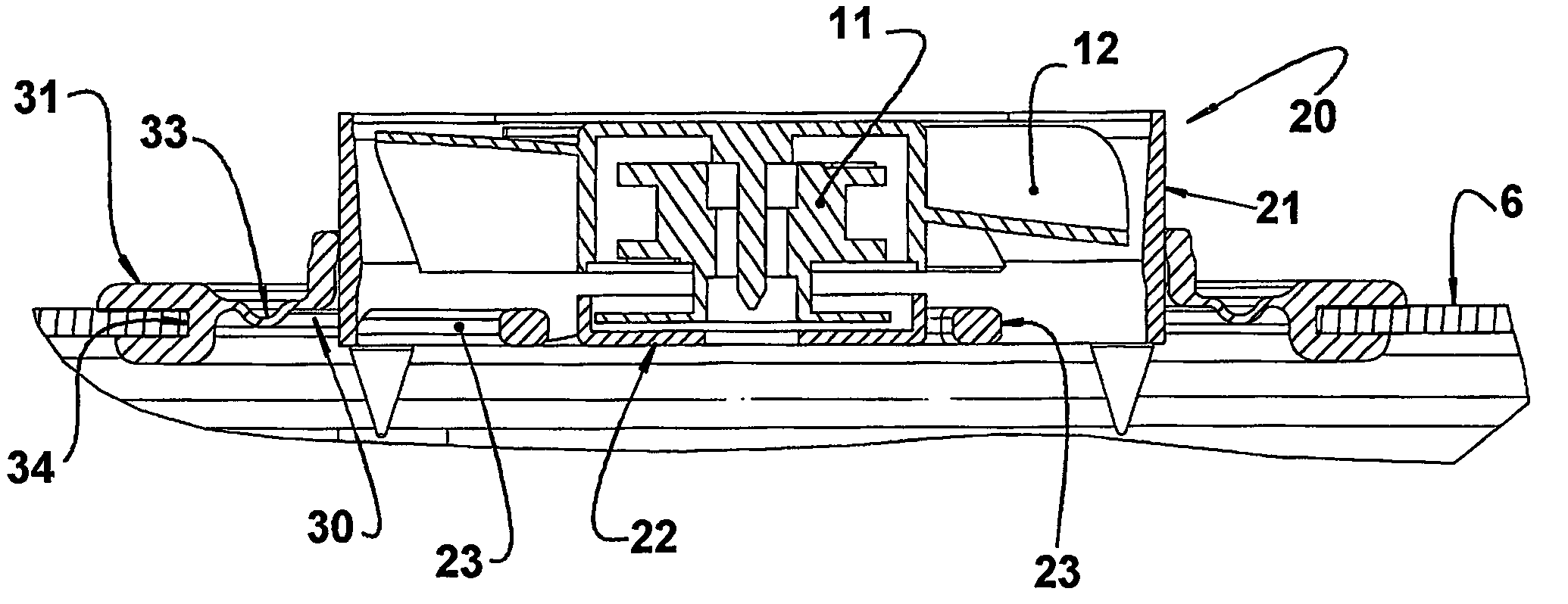

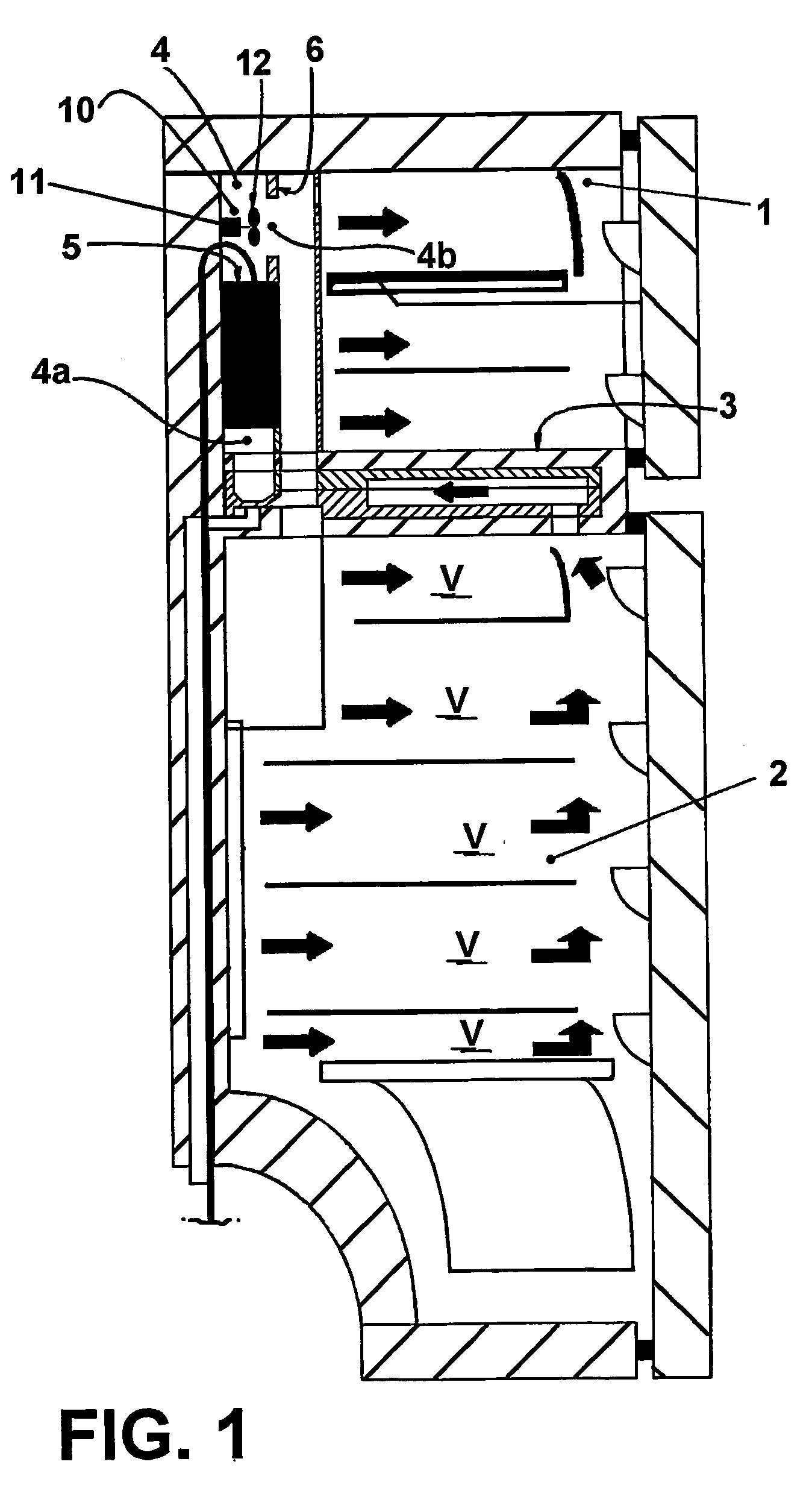

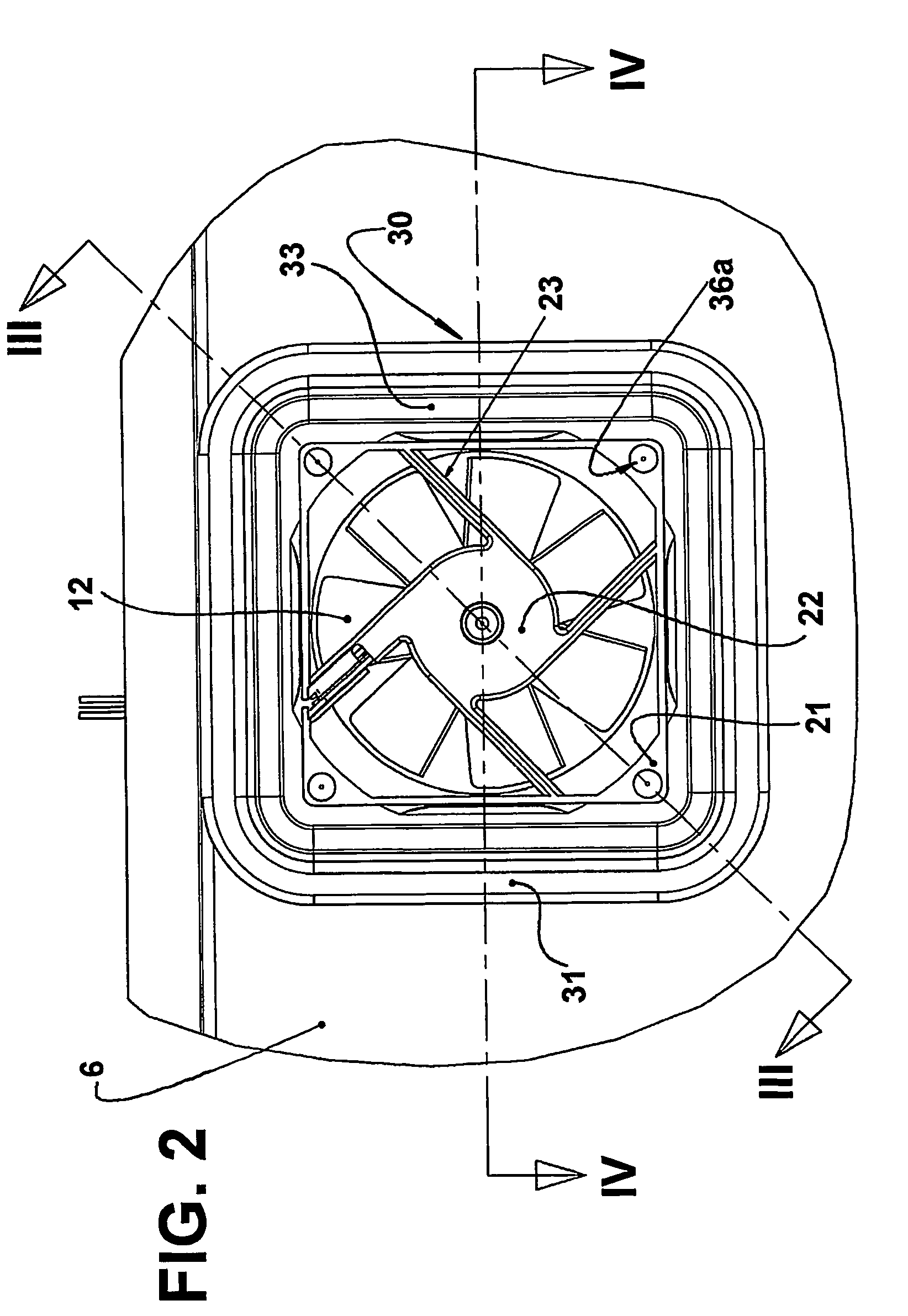

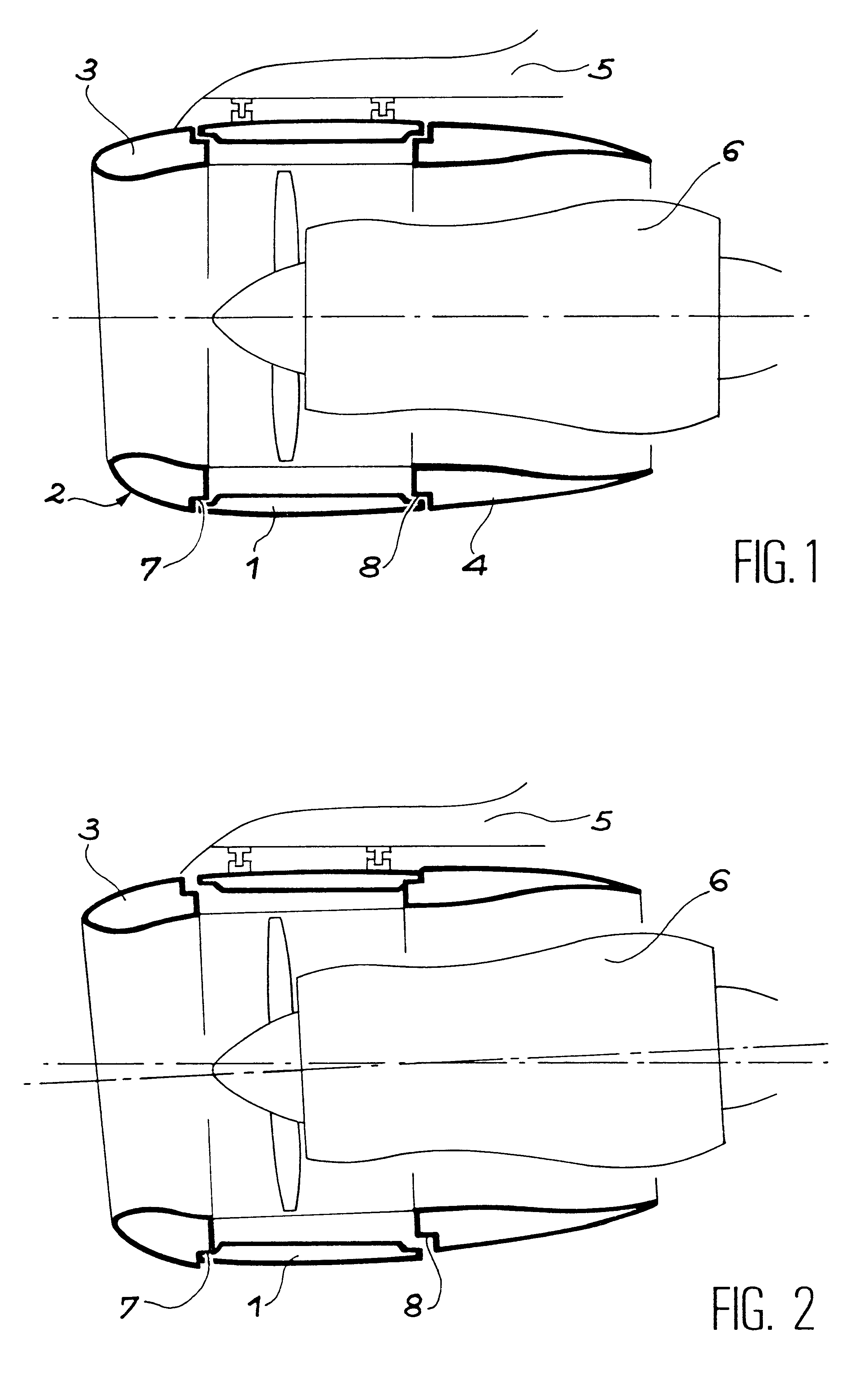

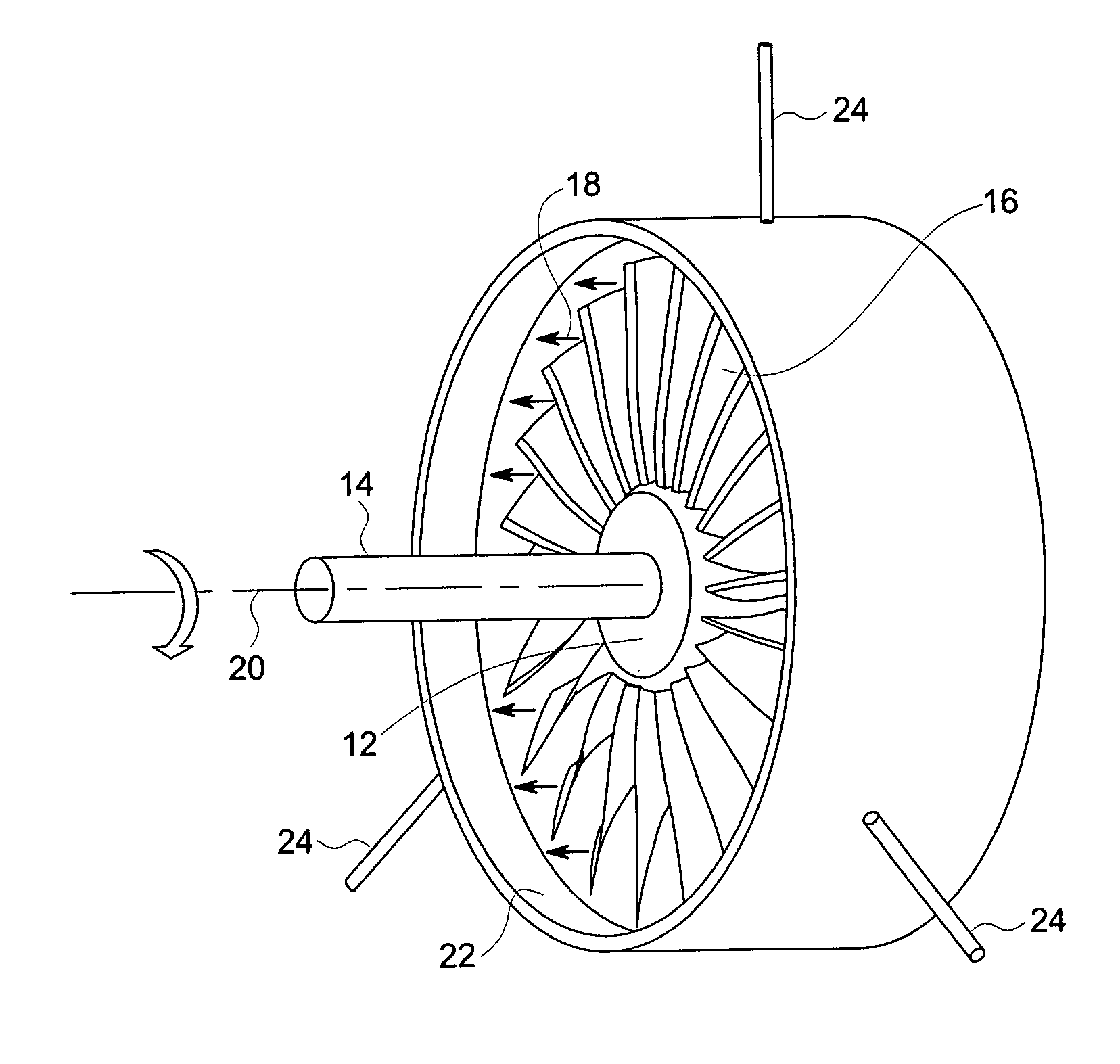

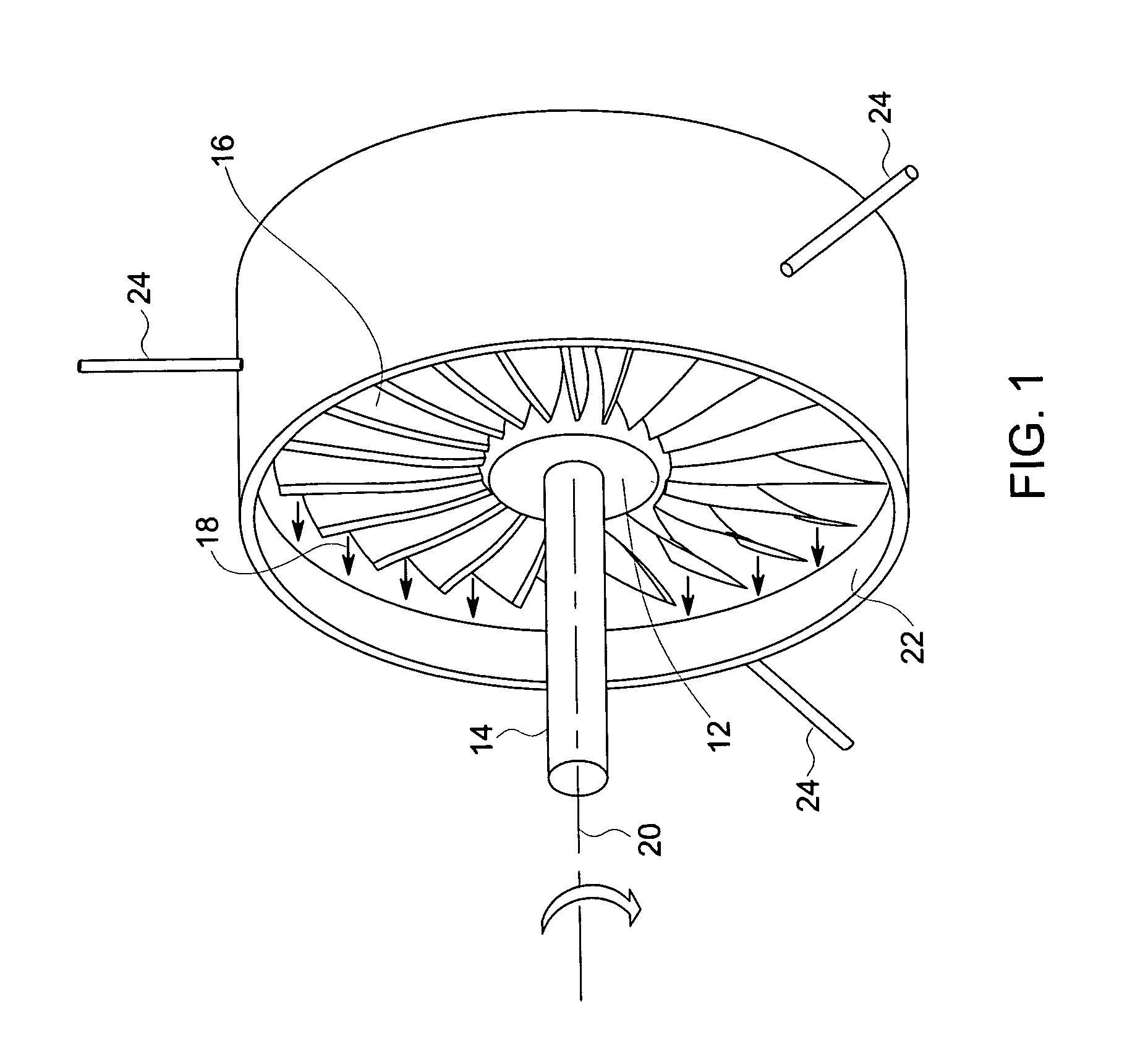

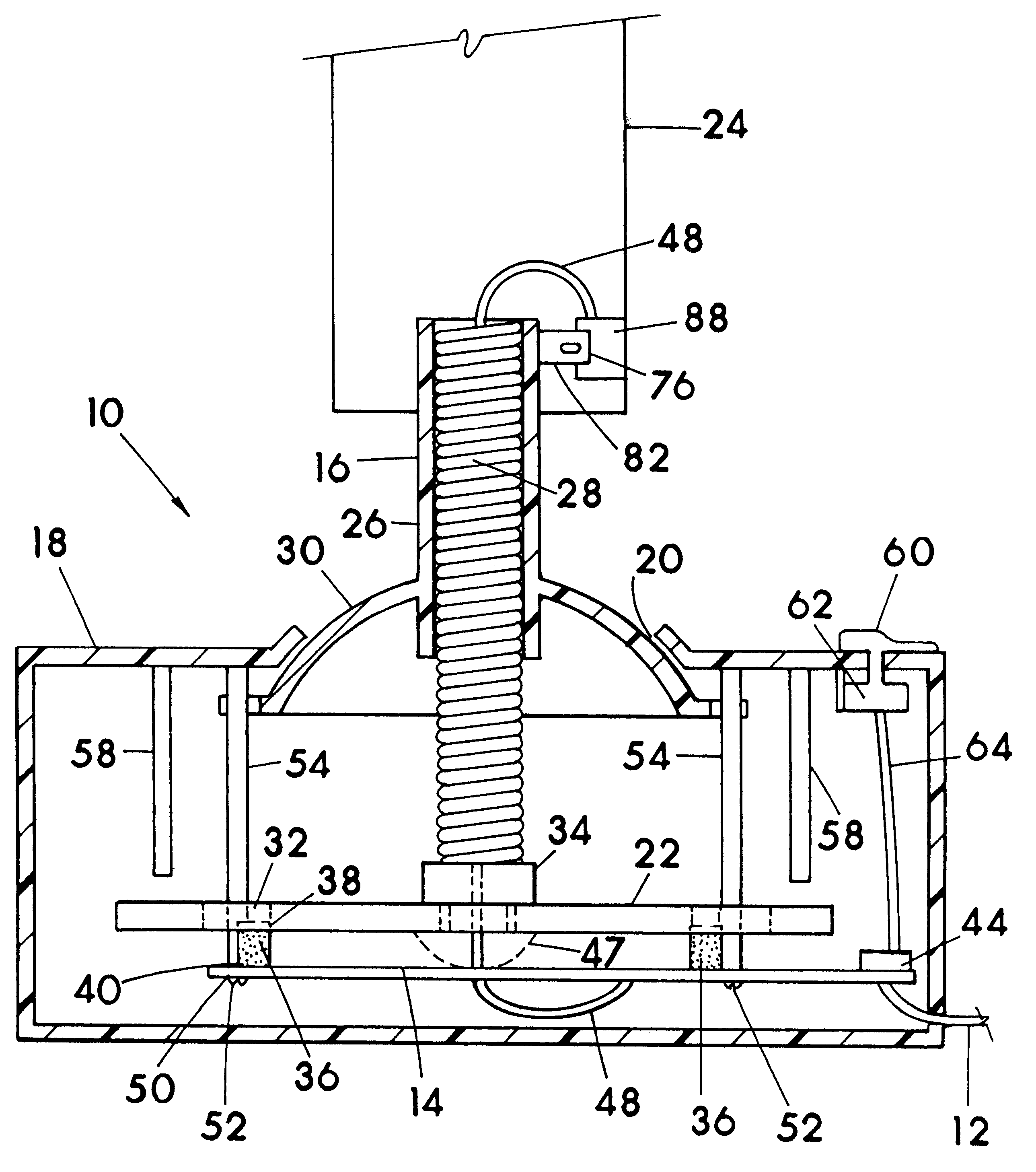

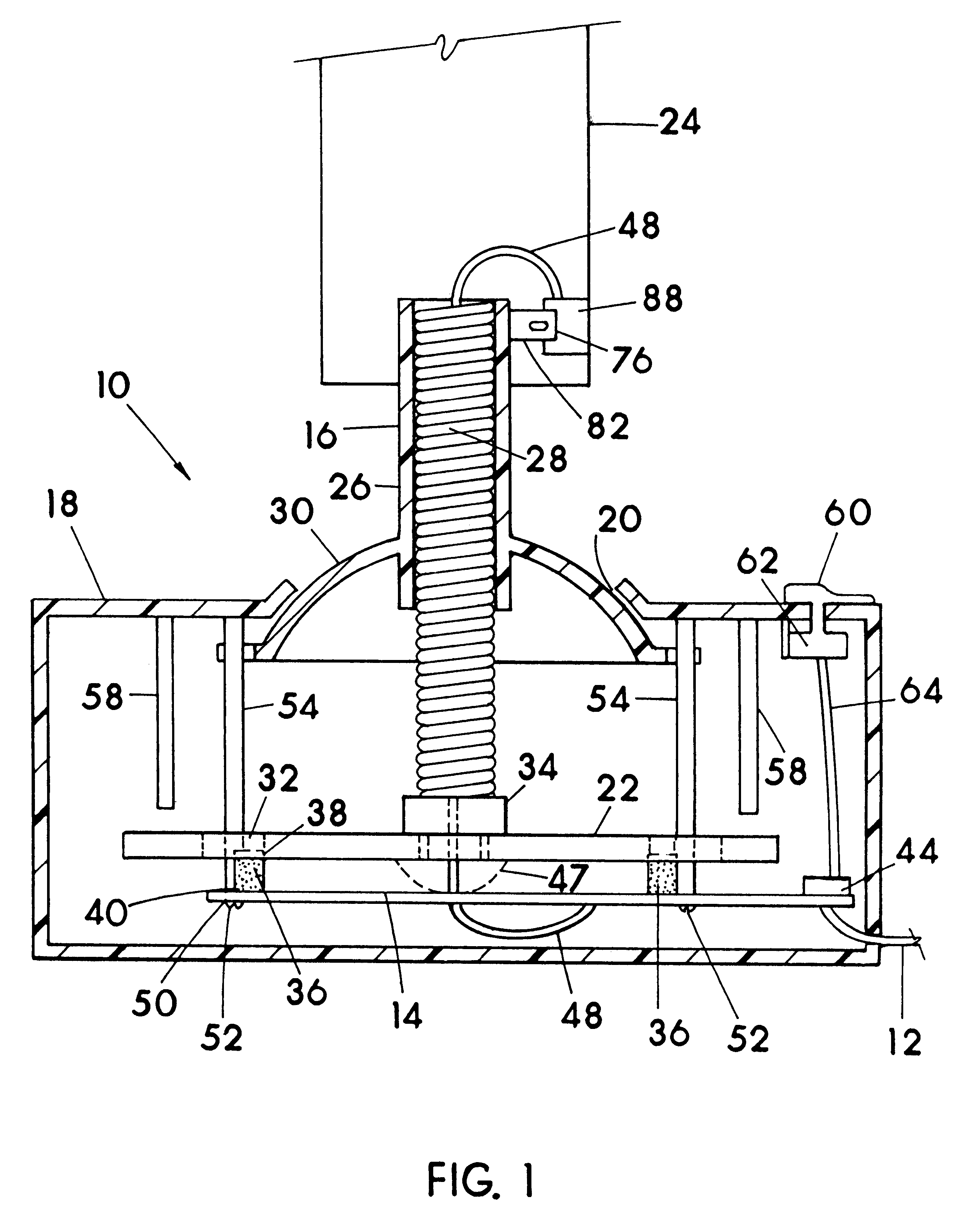

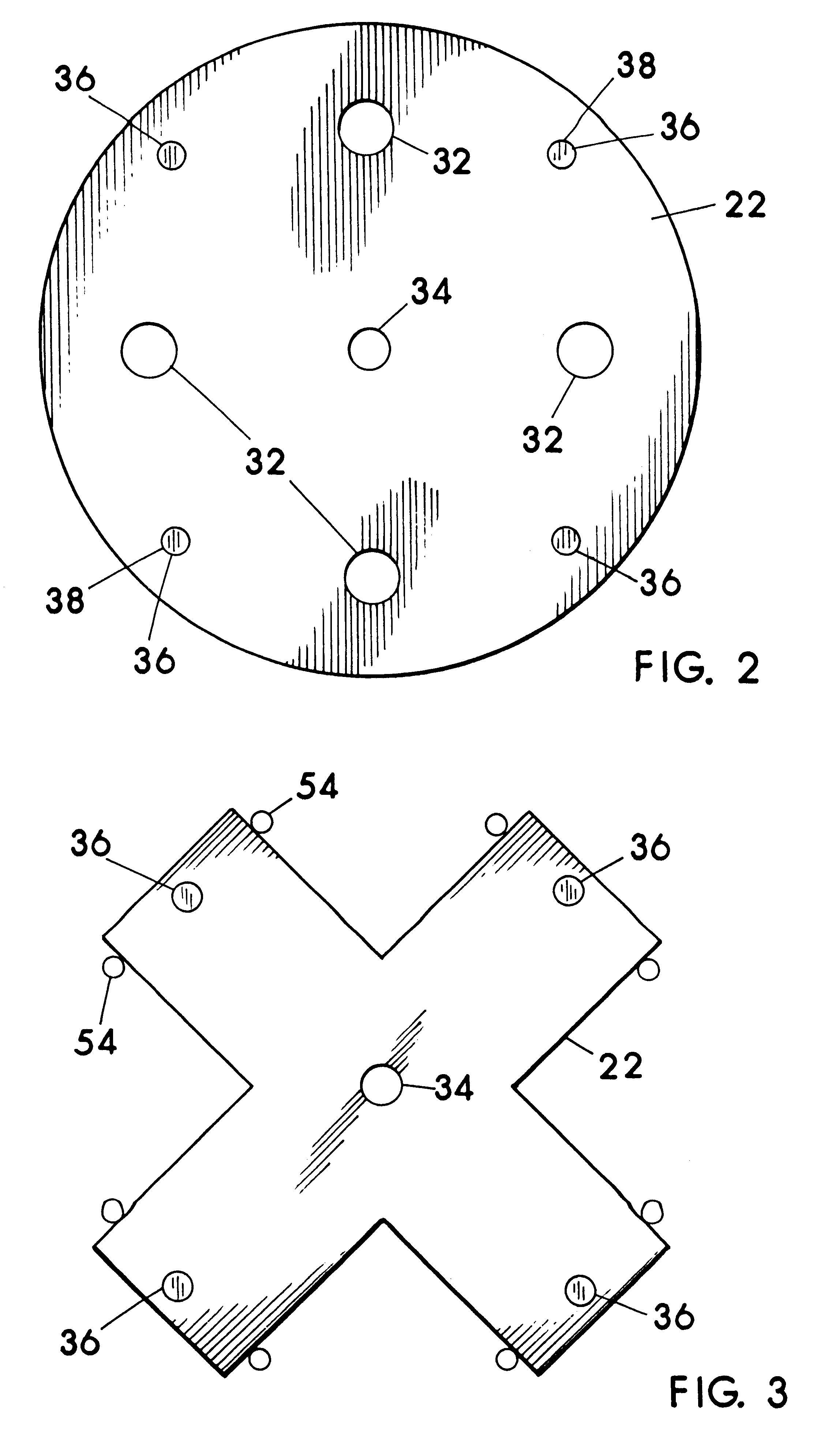

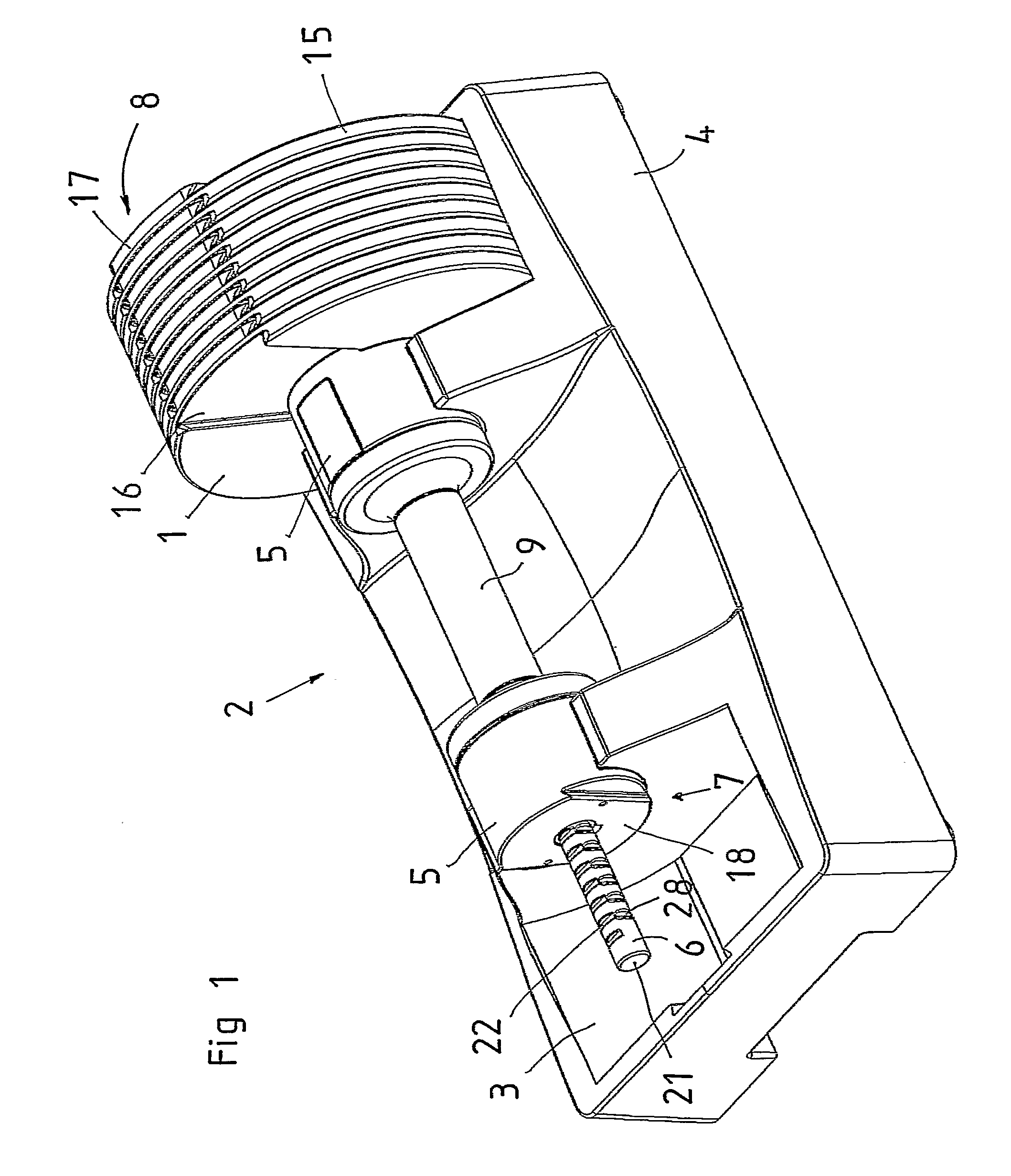

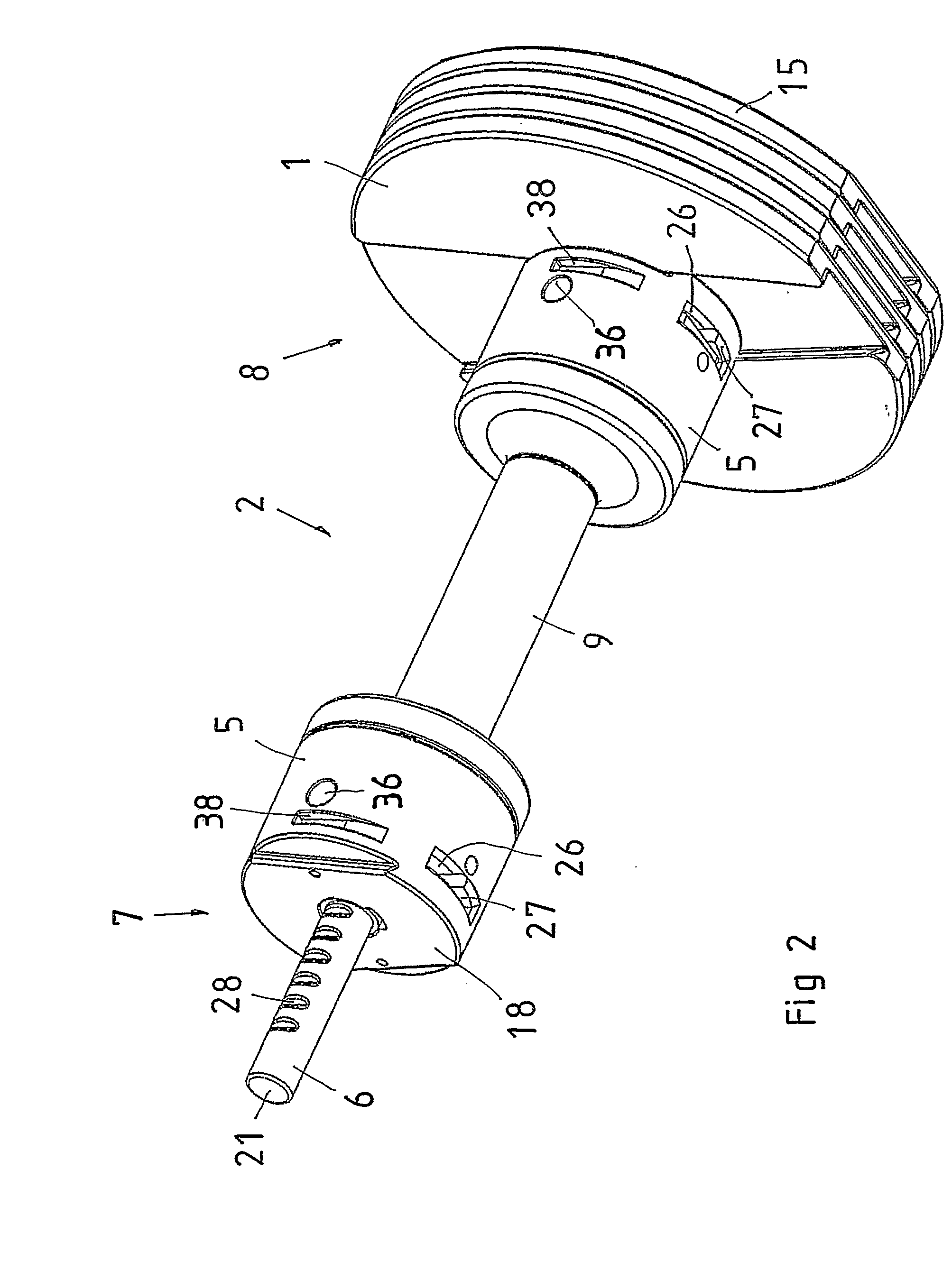

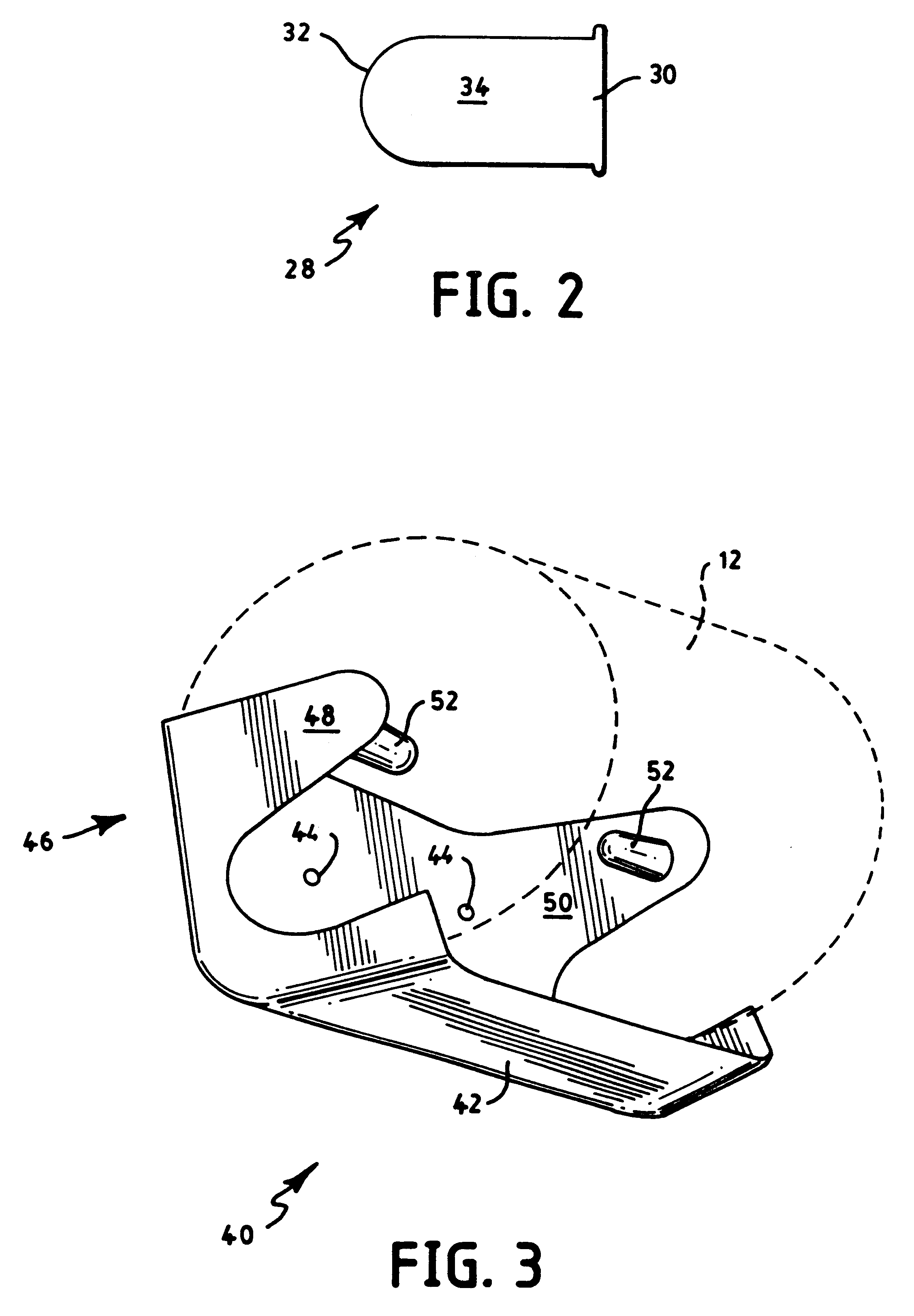

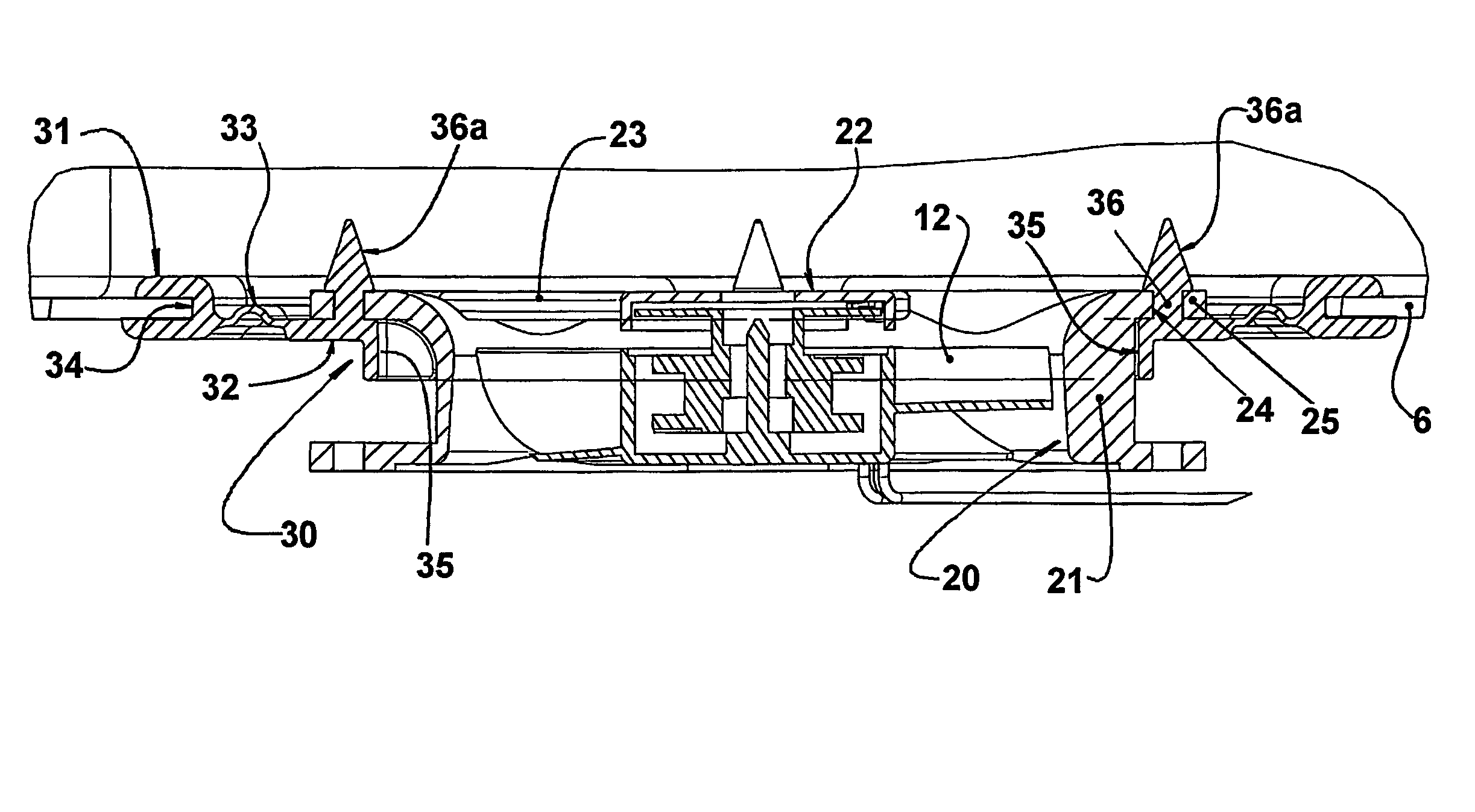

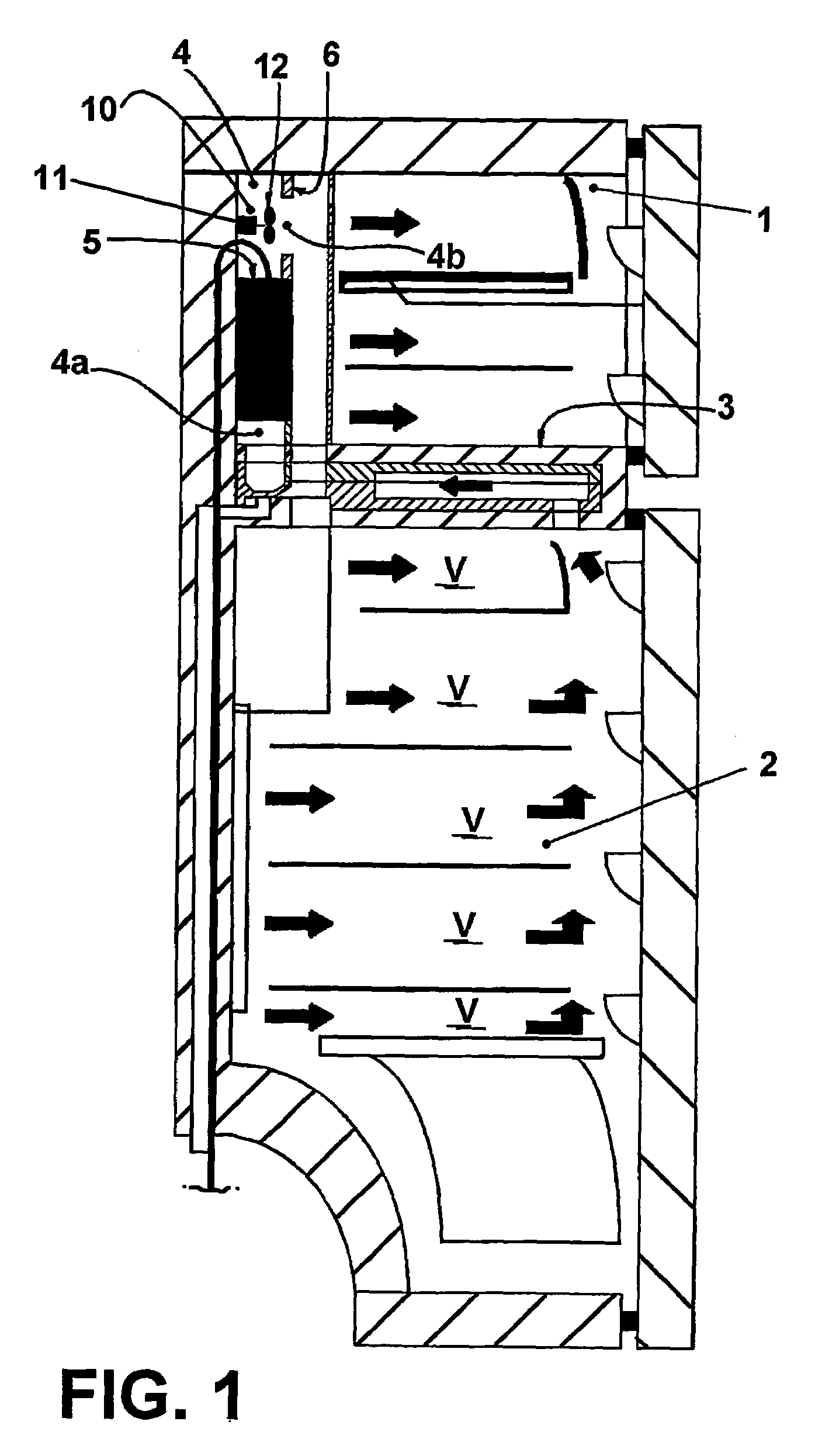

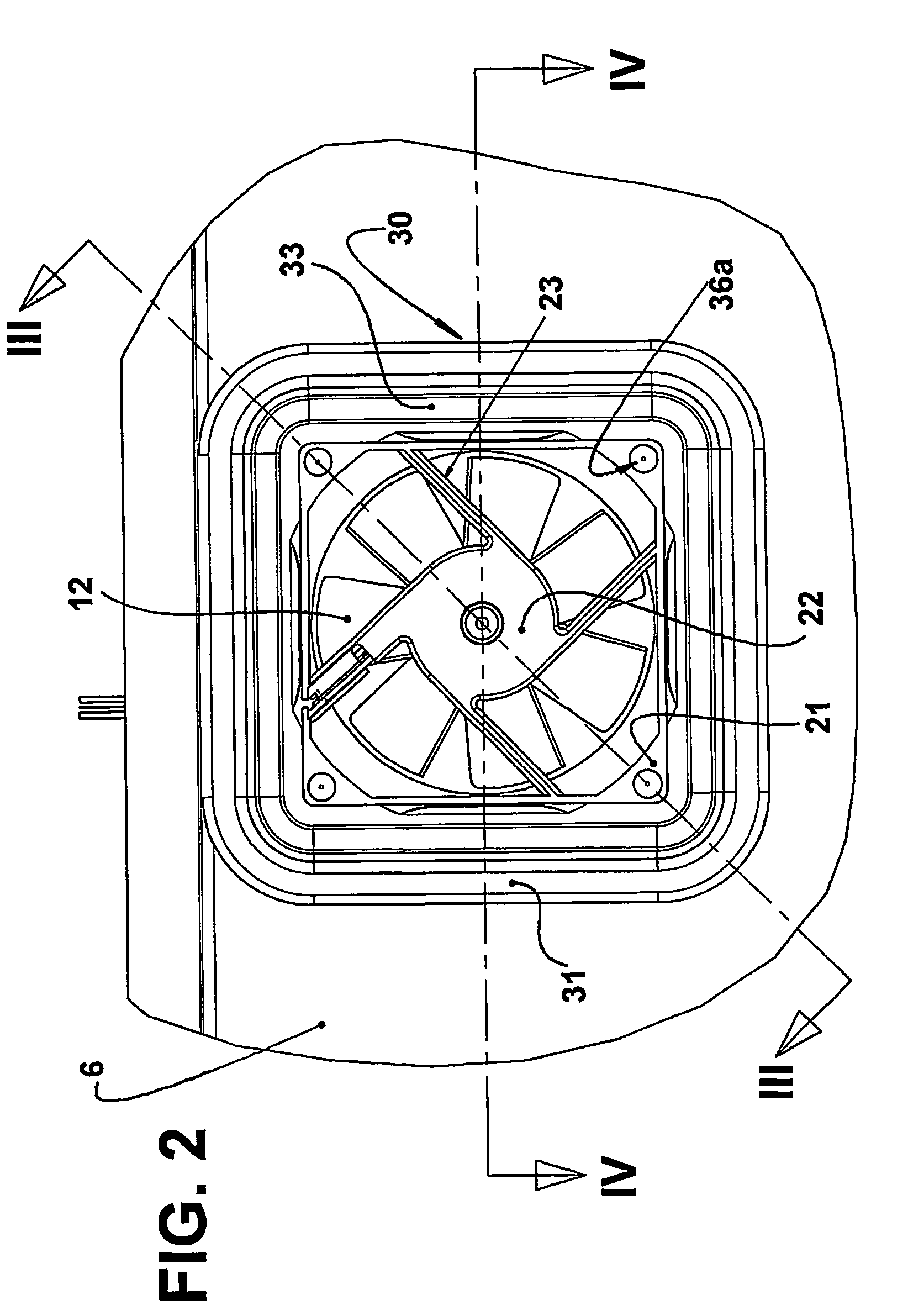

Mounting arrangement for a refrigerator fan

InactiveUS20050173997A1Small radial displacementEasily and rapidly attachedPump componentsInsulation for cooling apparatusIceboxPropeller

A mounting arrangement for a refrigerator fan, comprising an electric motor (11) to whose shaft is affixed a propeller (12) with an axial flow passing through a refrigerated air outlet (4b) provided through an internal divisional wall (6) of the refrigerator; a support frame (20) having a marginal portion (21) and incorporating a central hub (22) in which is affixed the electric motor (11); a flexible support (30) in the form of an annular flange presenting an outer portion (31), which is peripherally and removably affixed to the contour of the refrigerated air outlet (4b), an inner portion (32) provided with a central opening (35) and with retaining means (36), which are removably locked to the marginal portion (21) of the support frame (20); and an annular membrane portion (33) interconnecting the outer portion (31) and the inner portion (32), in order to allow for small relative axial and radial displacements therebetween.

Owner:MULTIBRAS SA ELETRODOMESTICOS

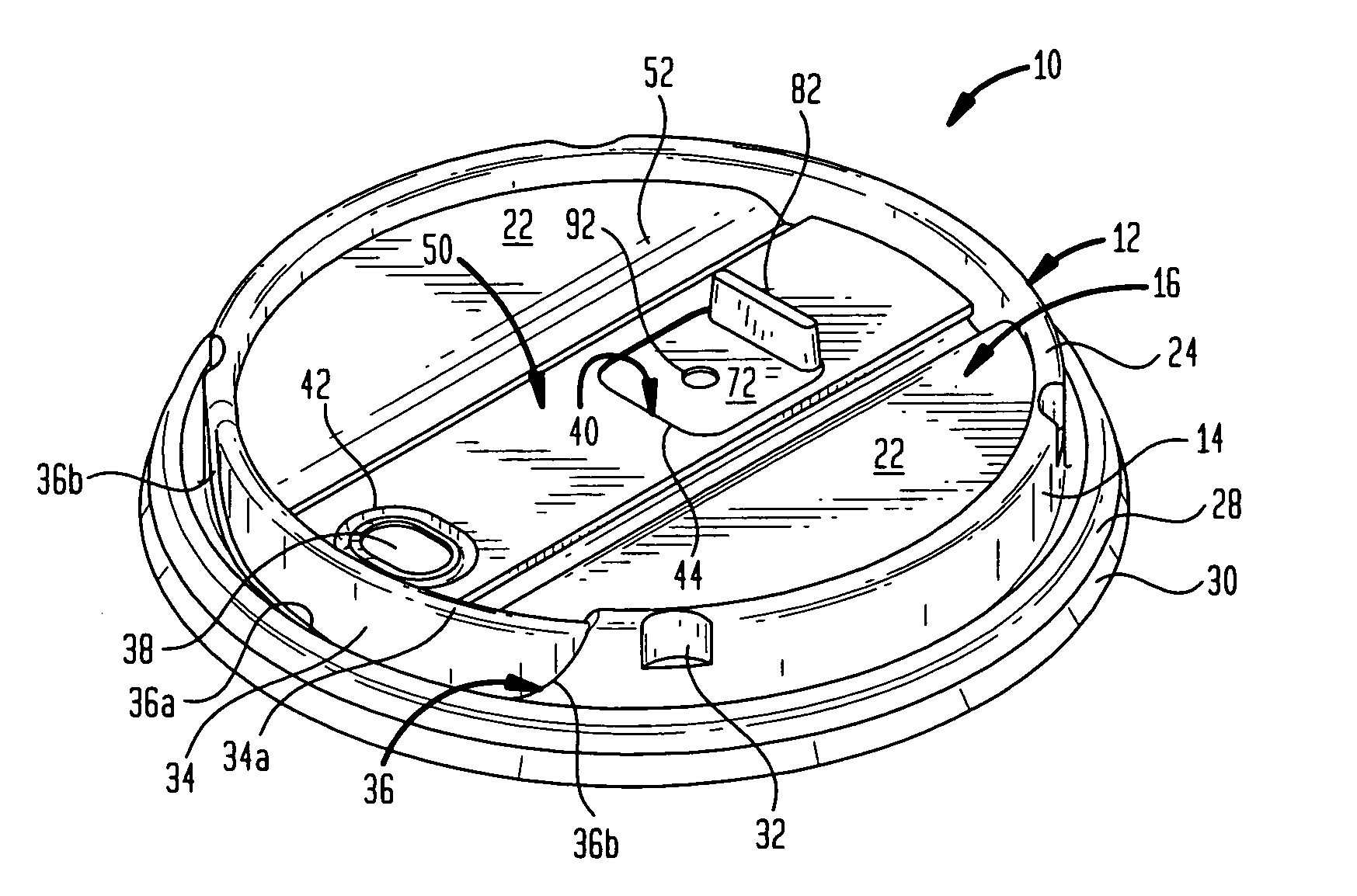

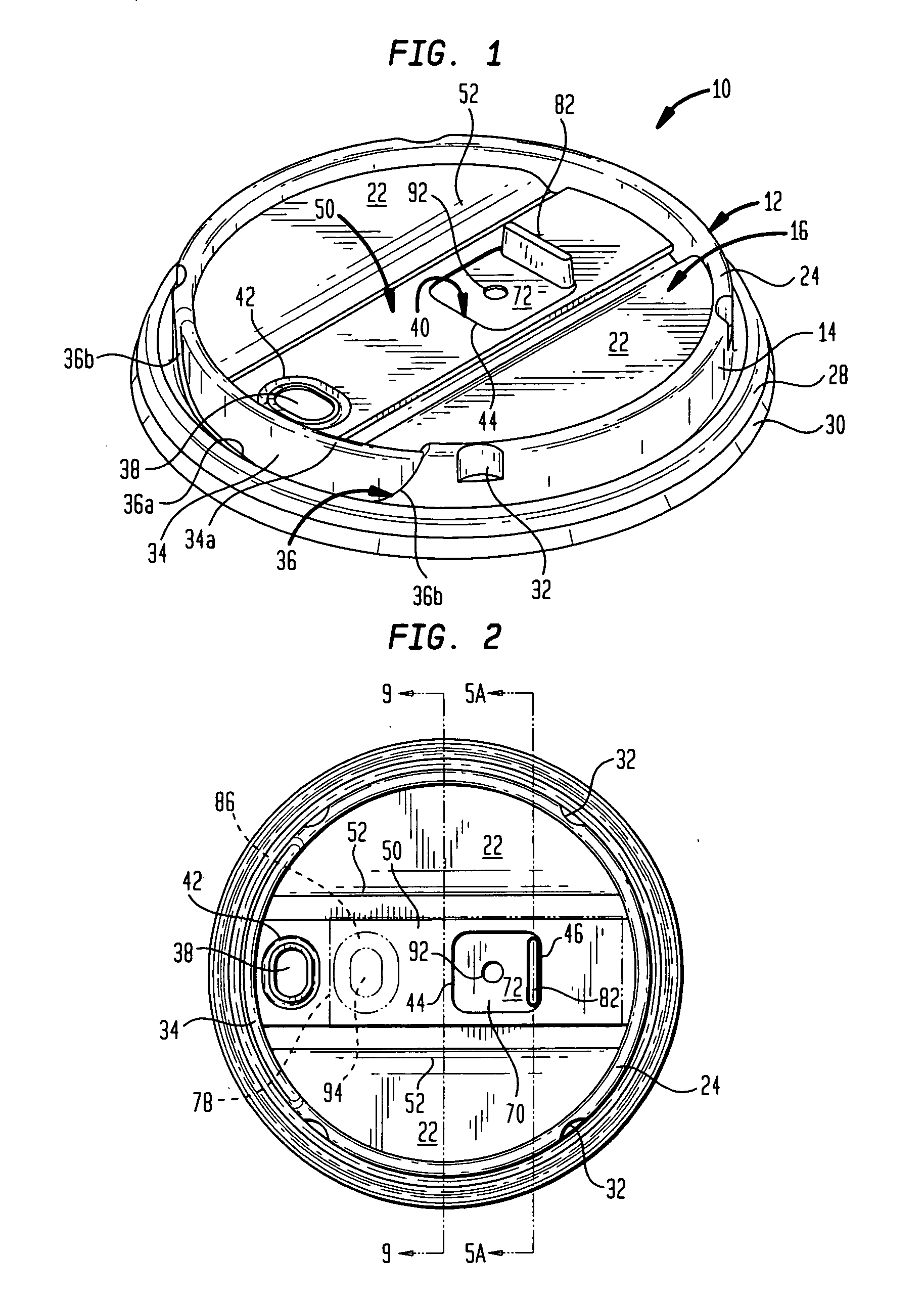

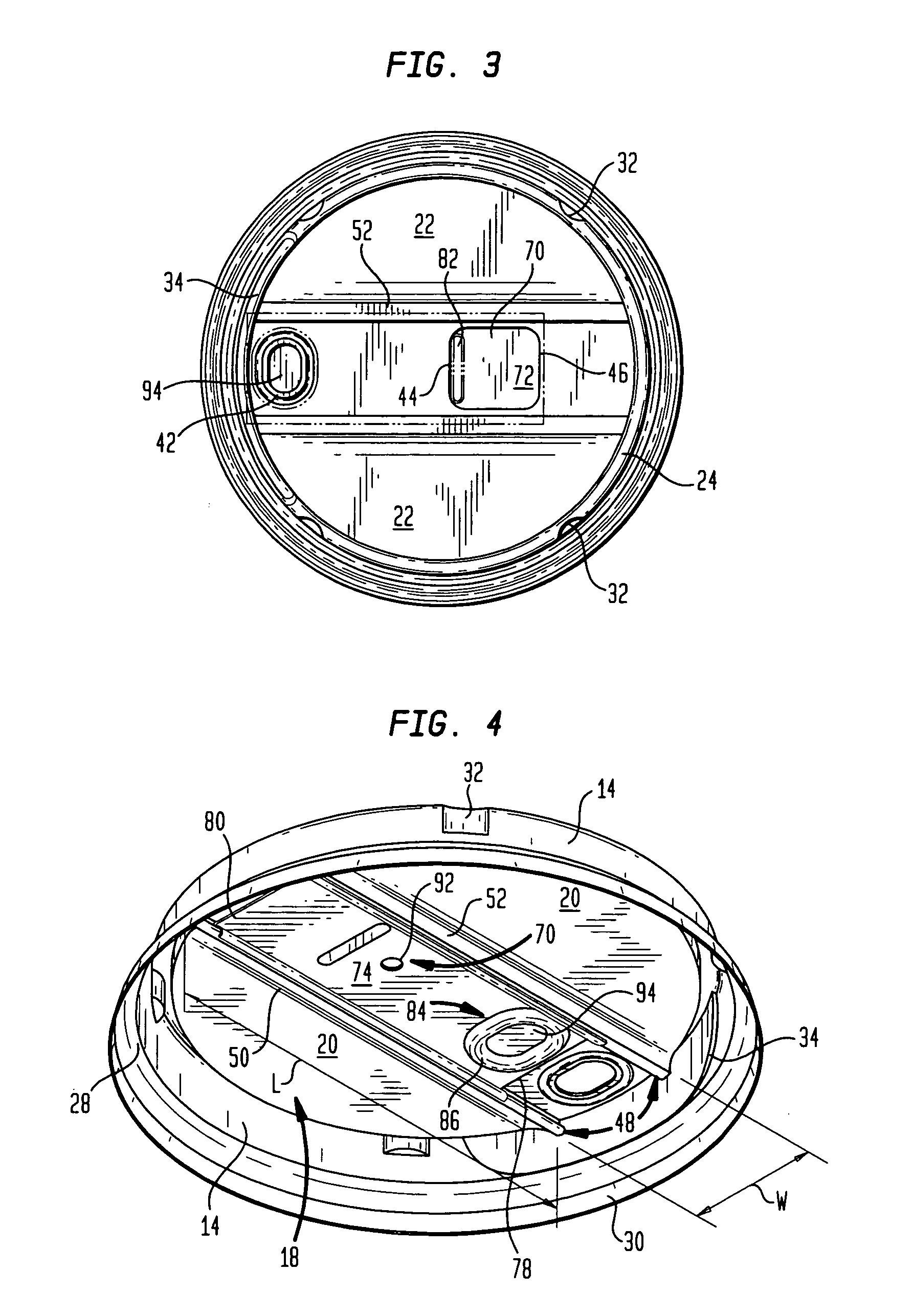

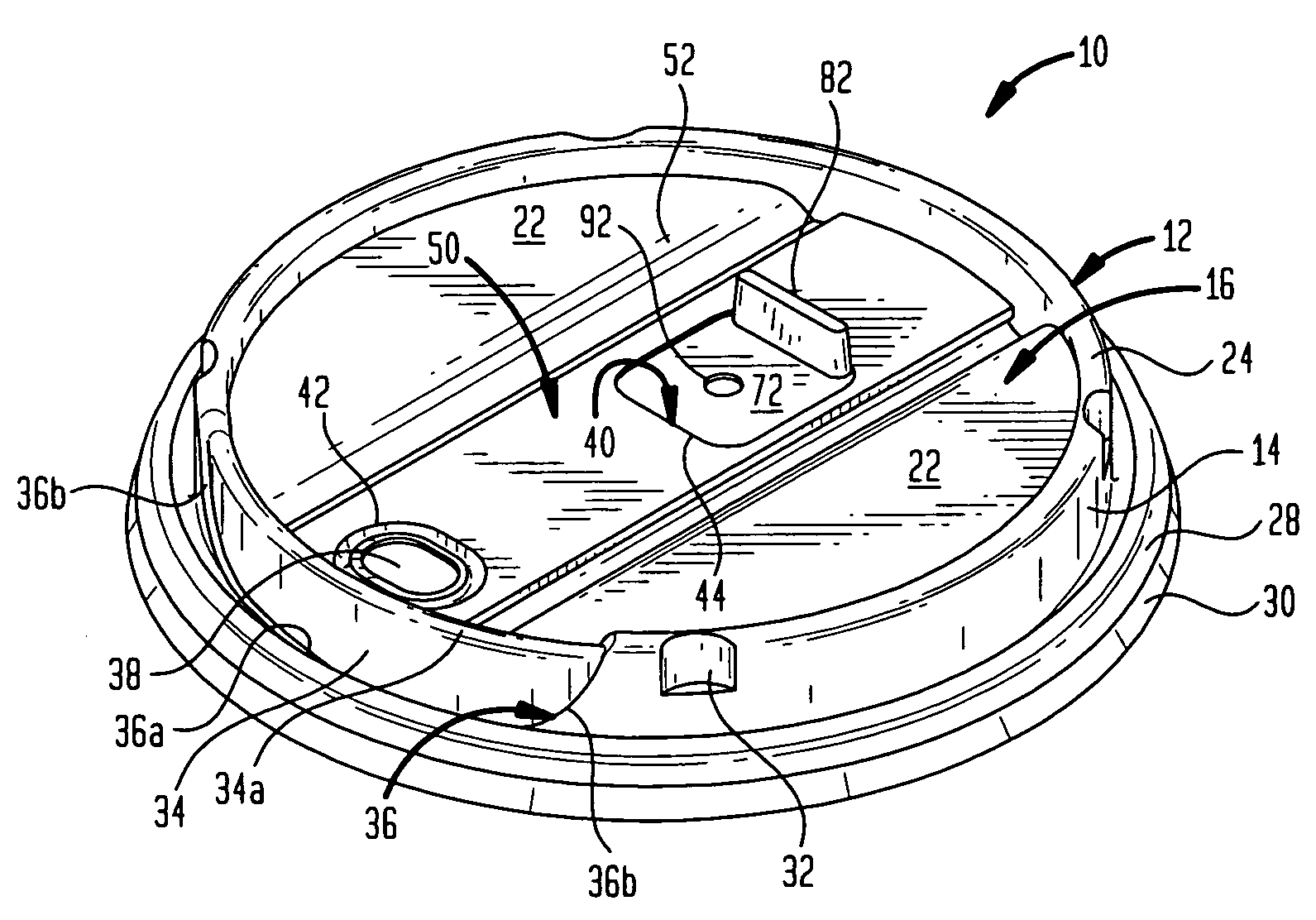

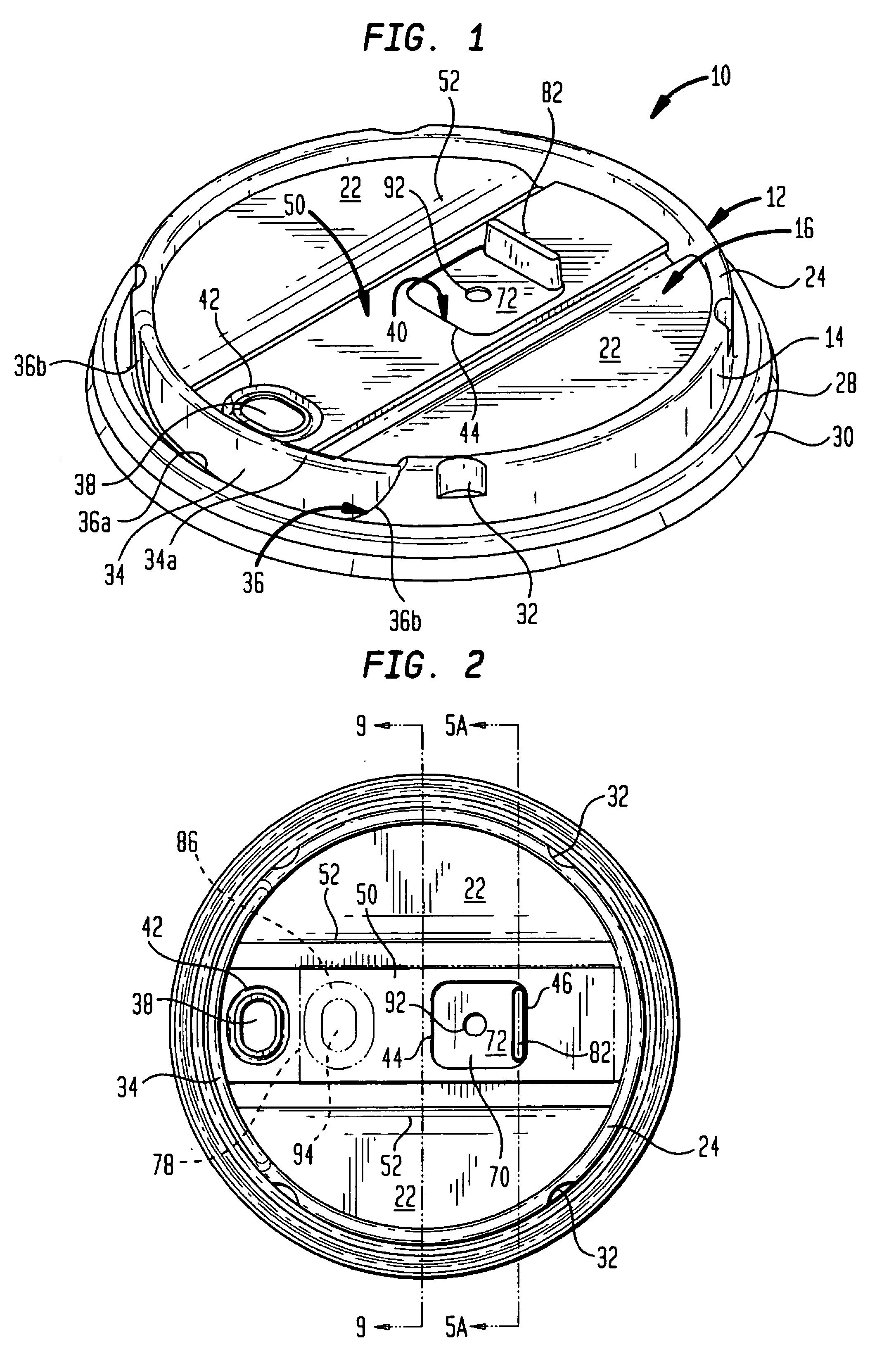

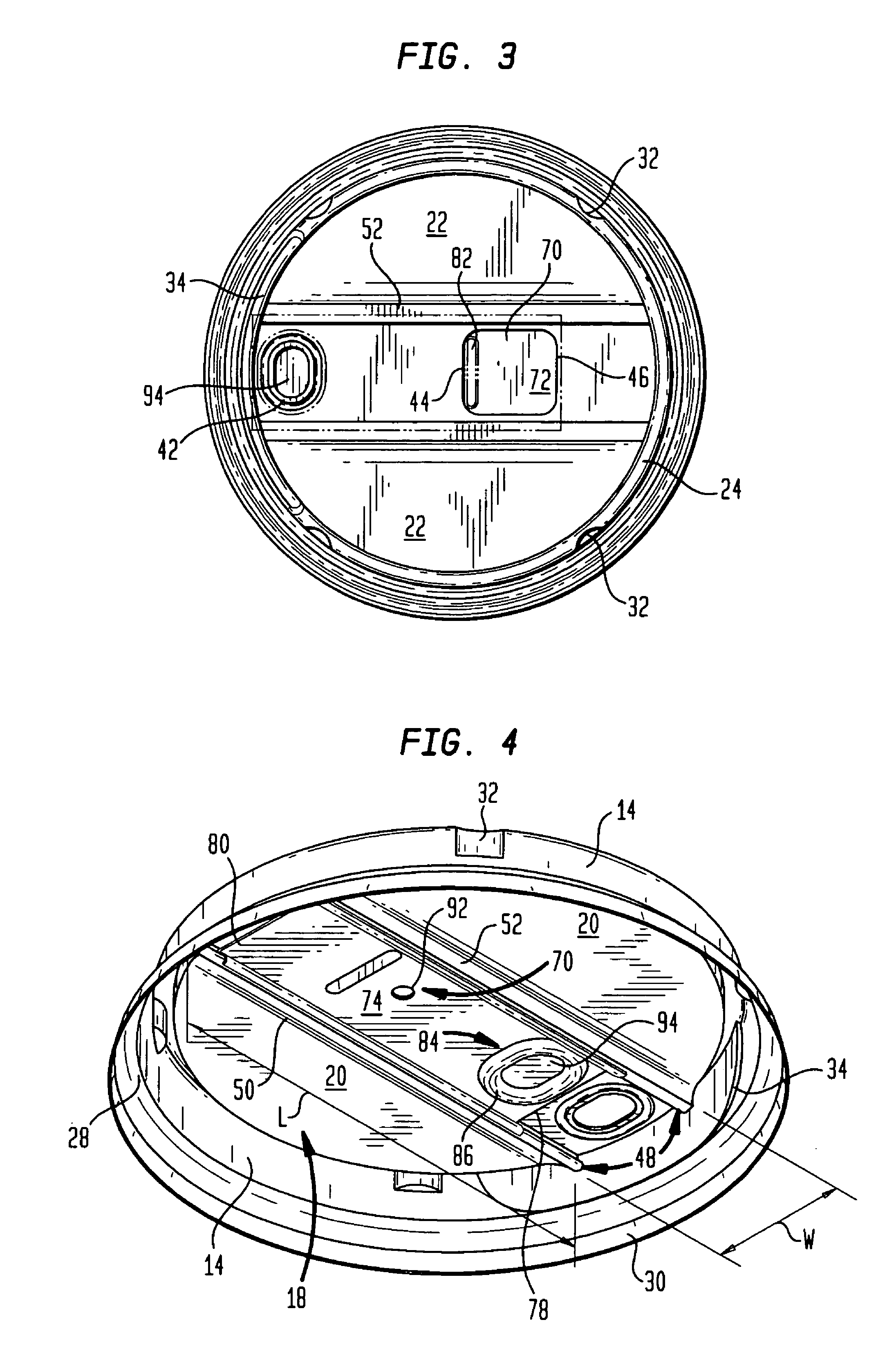

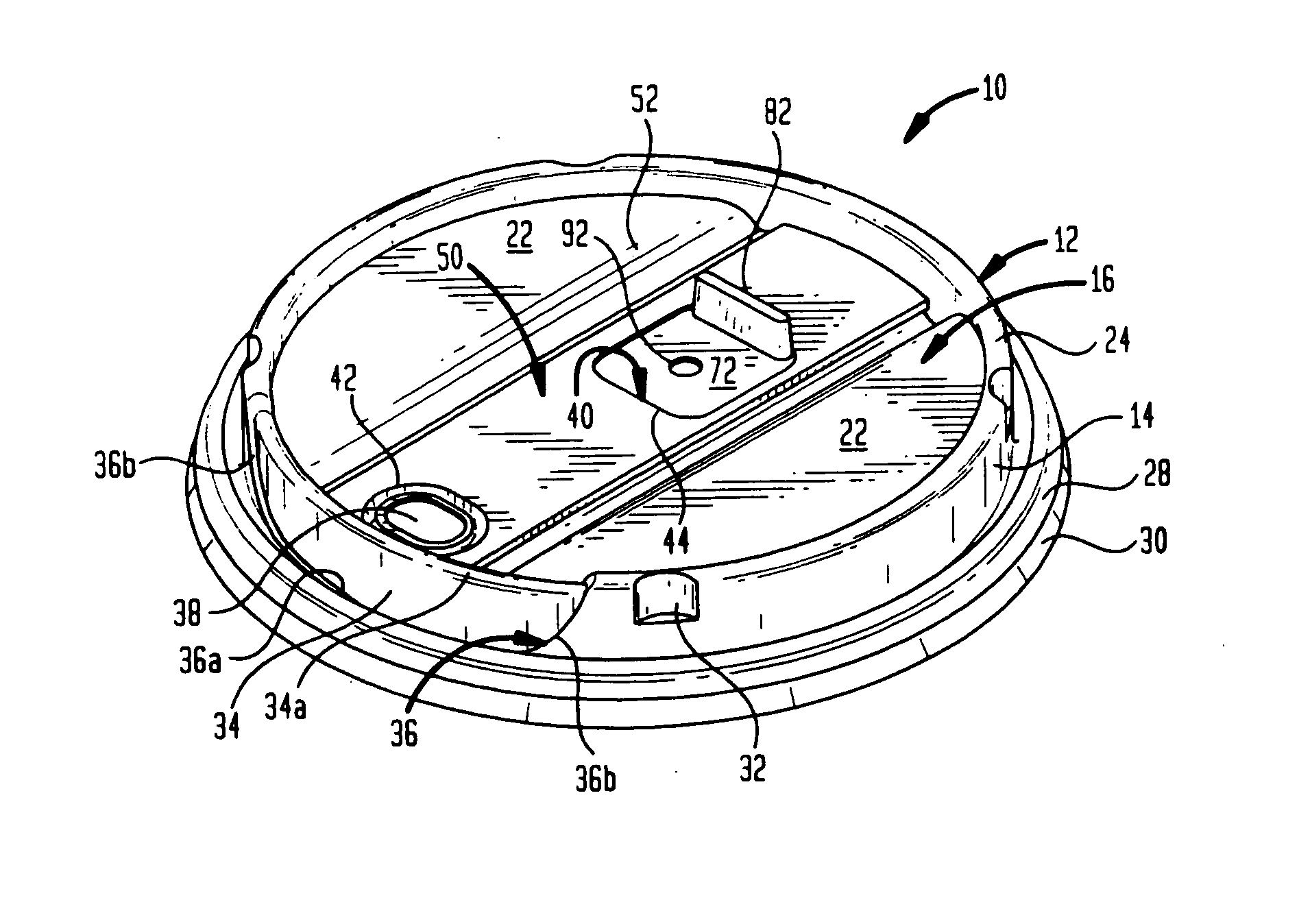

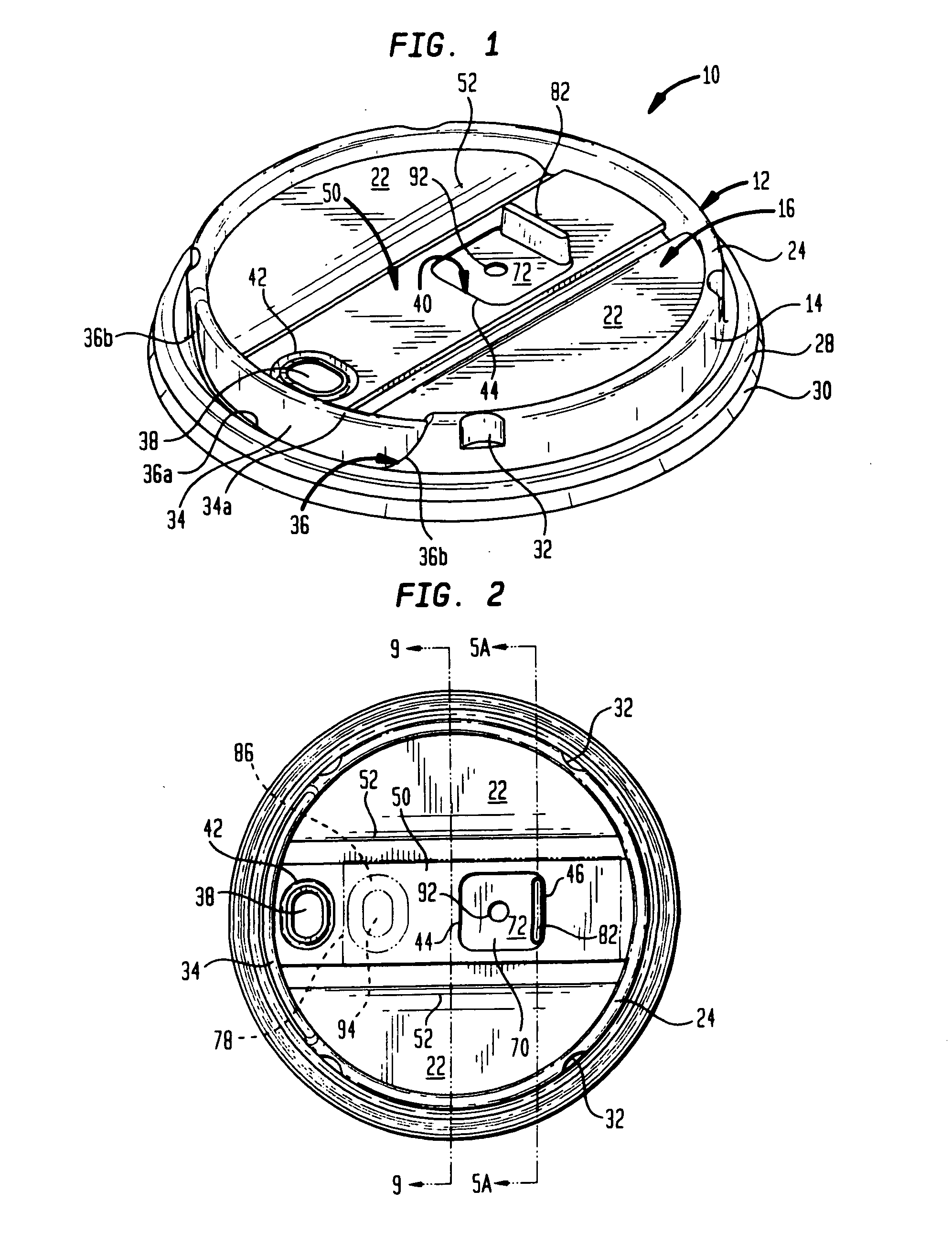

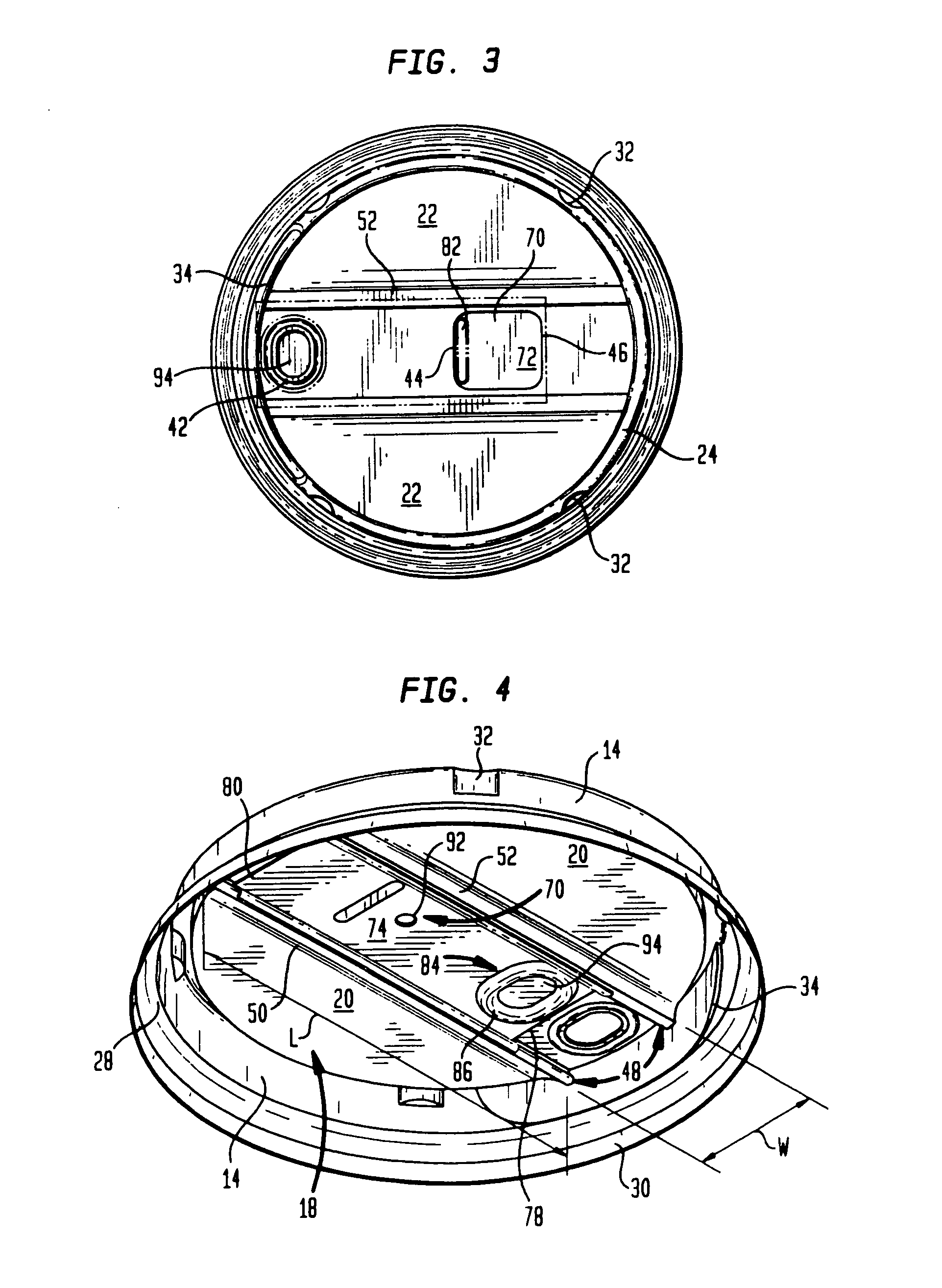

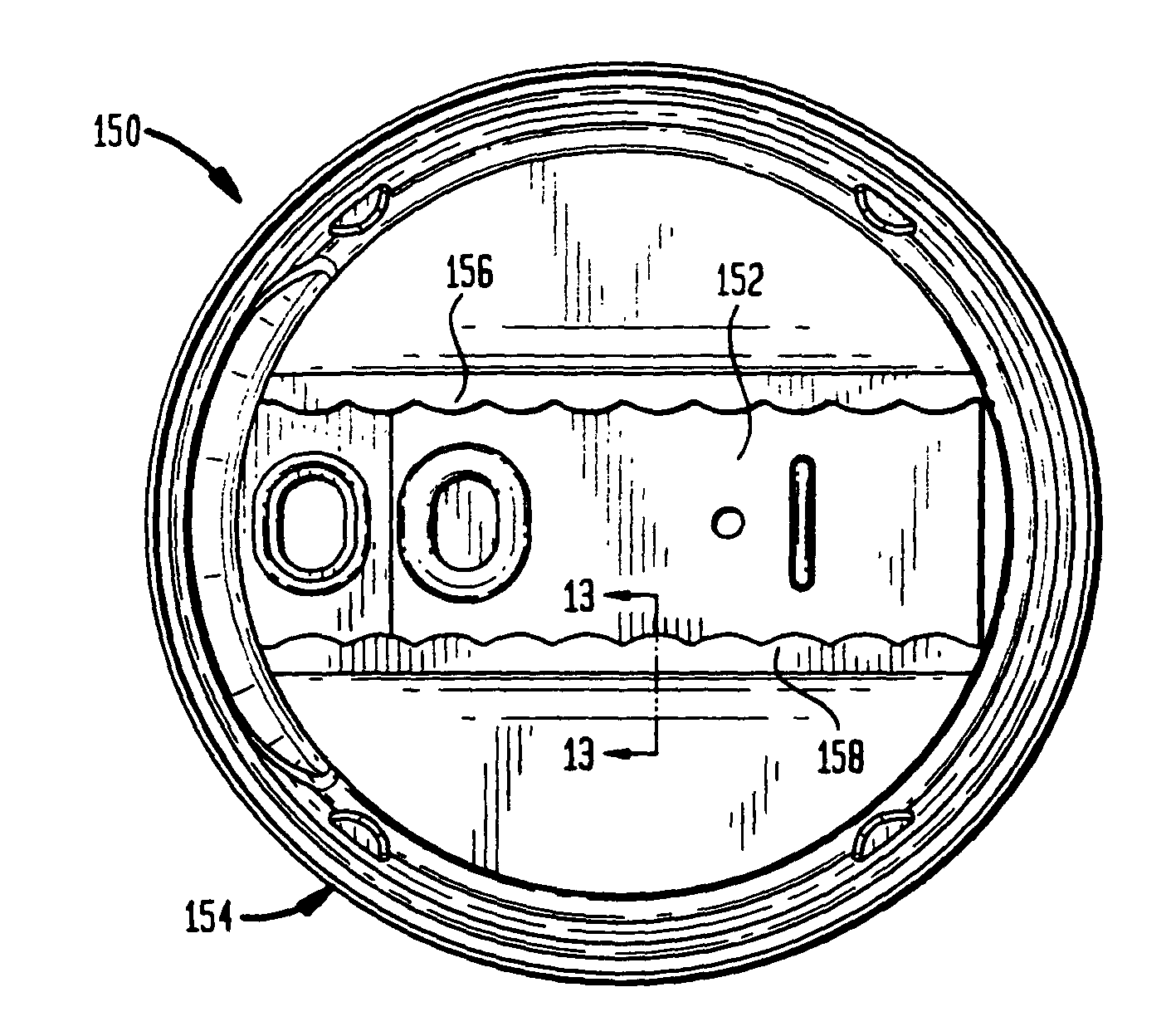

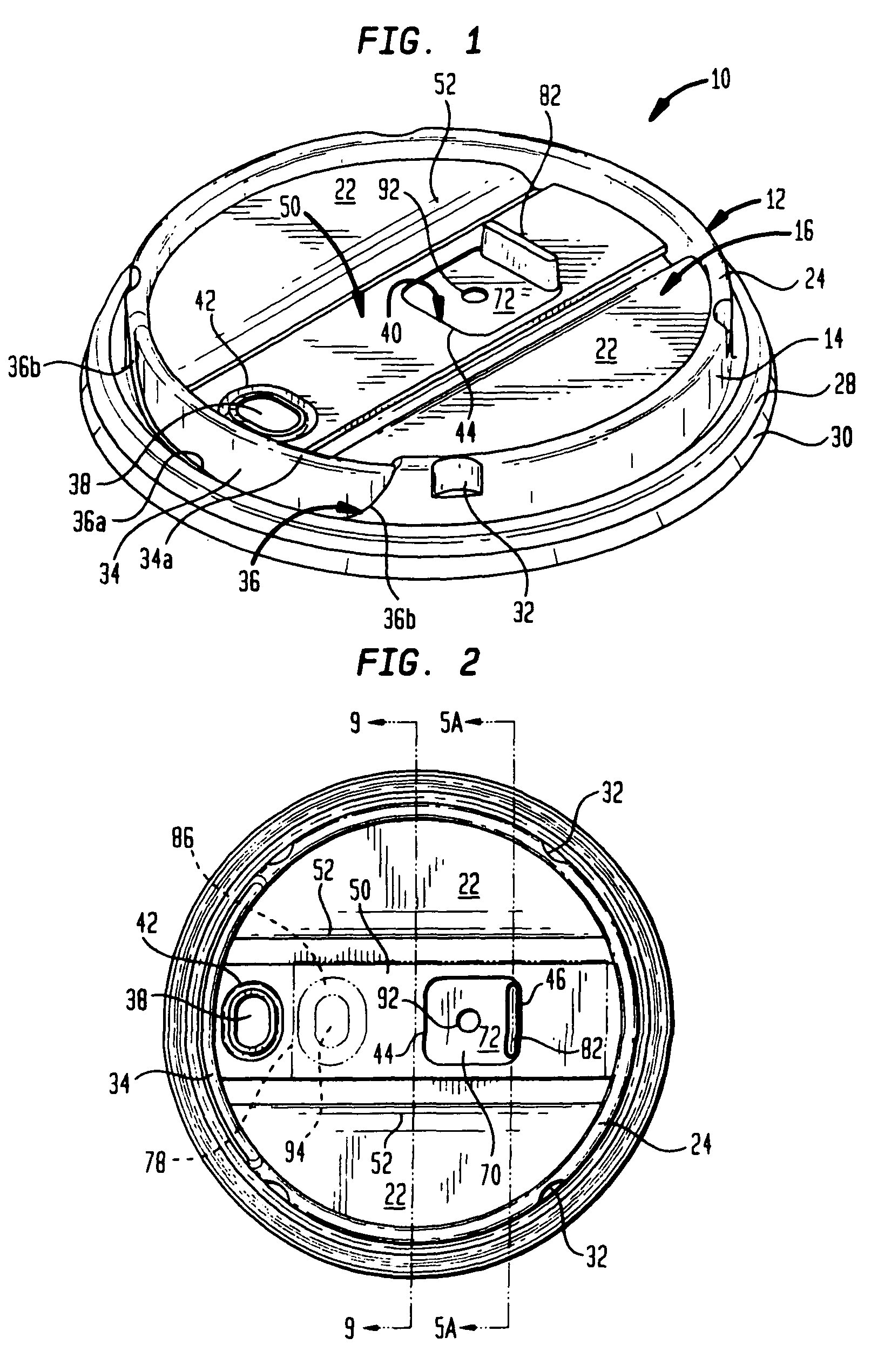

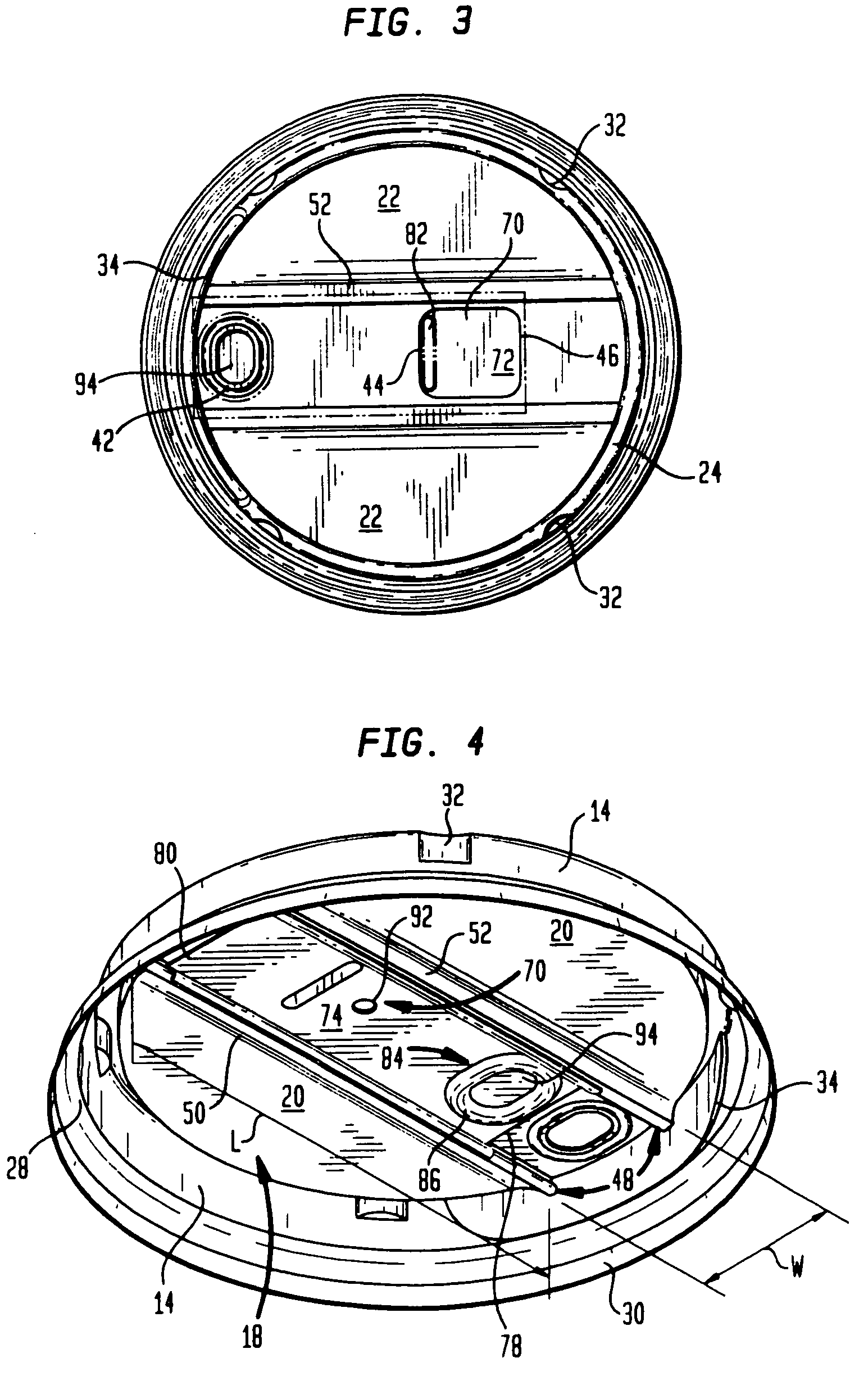

Reclosable cup lid

A reclosable cup lid thermoformed from a polymeric material includes a domed member and an elongate closure panel. The thermoformed domed member is provided with a sidewall and a top wall, the top wall having upper and lower surfaces and a drinking aperture at a periphery of the top wall. The top wall further defines a pair of slide tracks depending from the lower surface of the top wall and also defines a post aperture disposed inwardly with respect to the drinking aperture. The elongate closure panel has opposed engagement edges, an upper surface provided with a post projecting upwardly therefrom, and a drinking aperture sealing area. As assembled, the domed member and elongate closure panel are configured such that the opposed engagement edges of the elongate closure panel are slidingly mounted in the slide tracks for generally radial displacement.

Owner:GPCP IP HLDG LLC

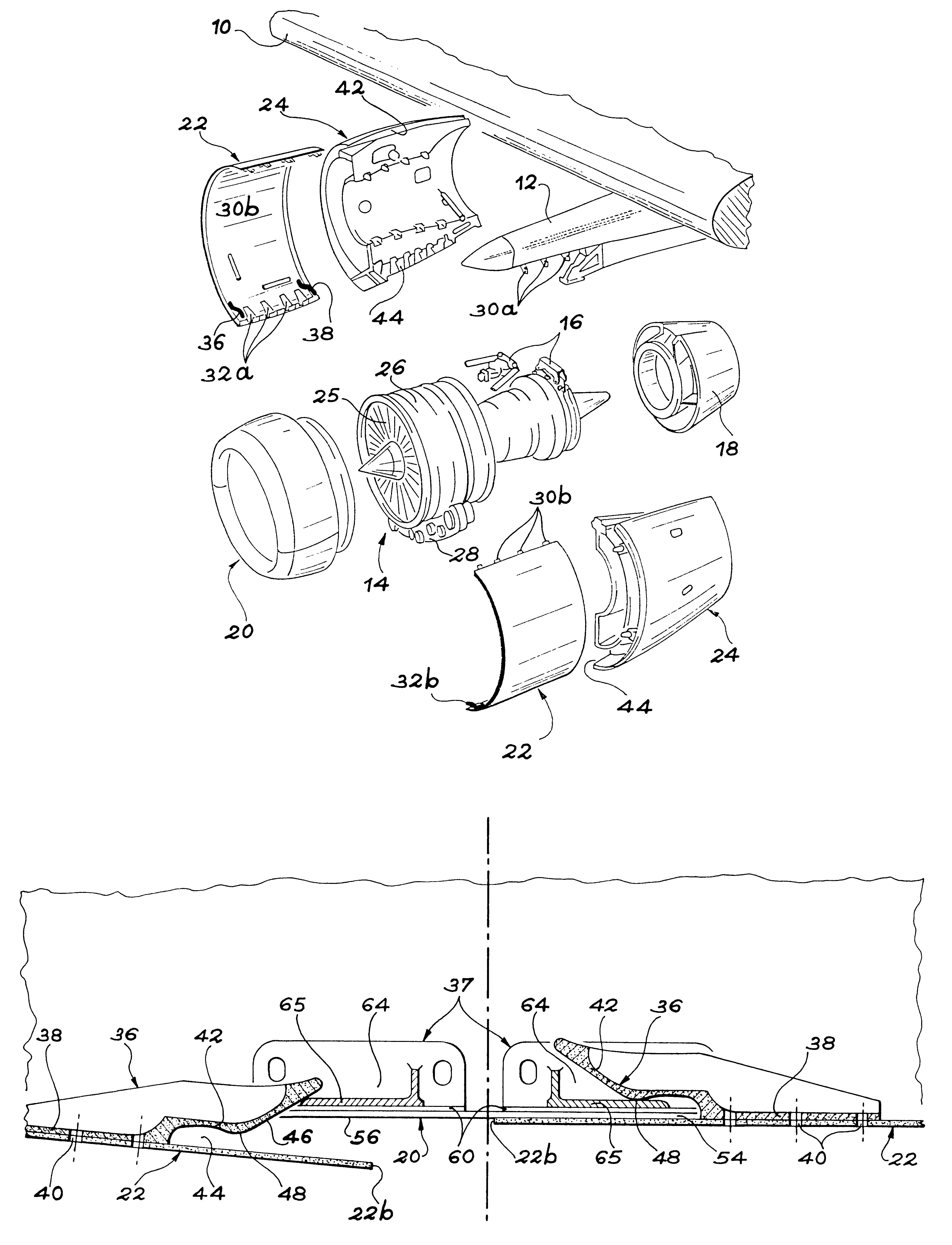

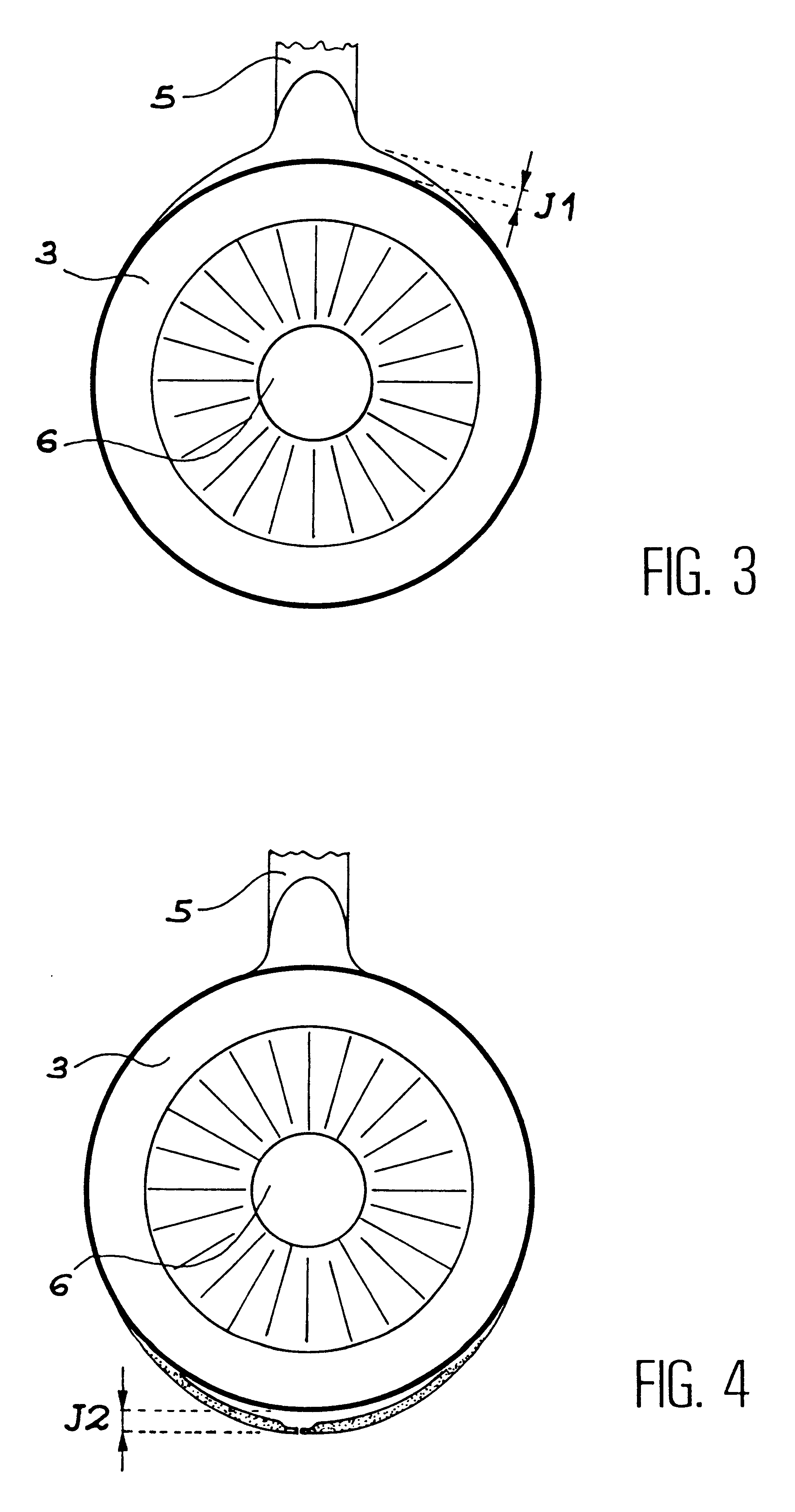

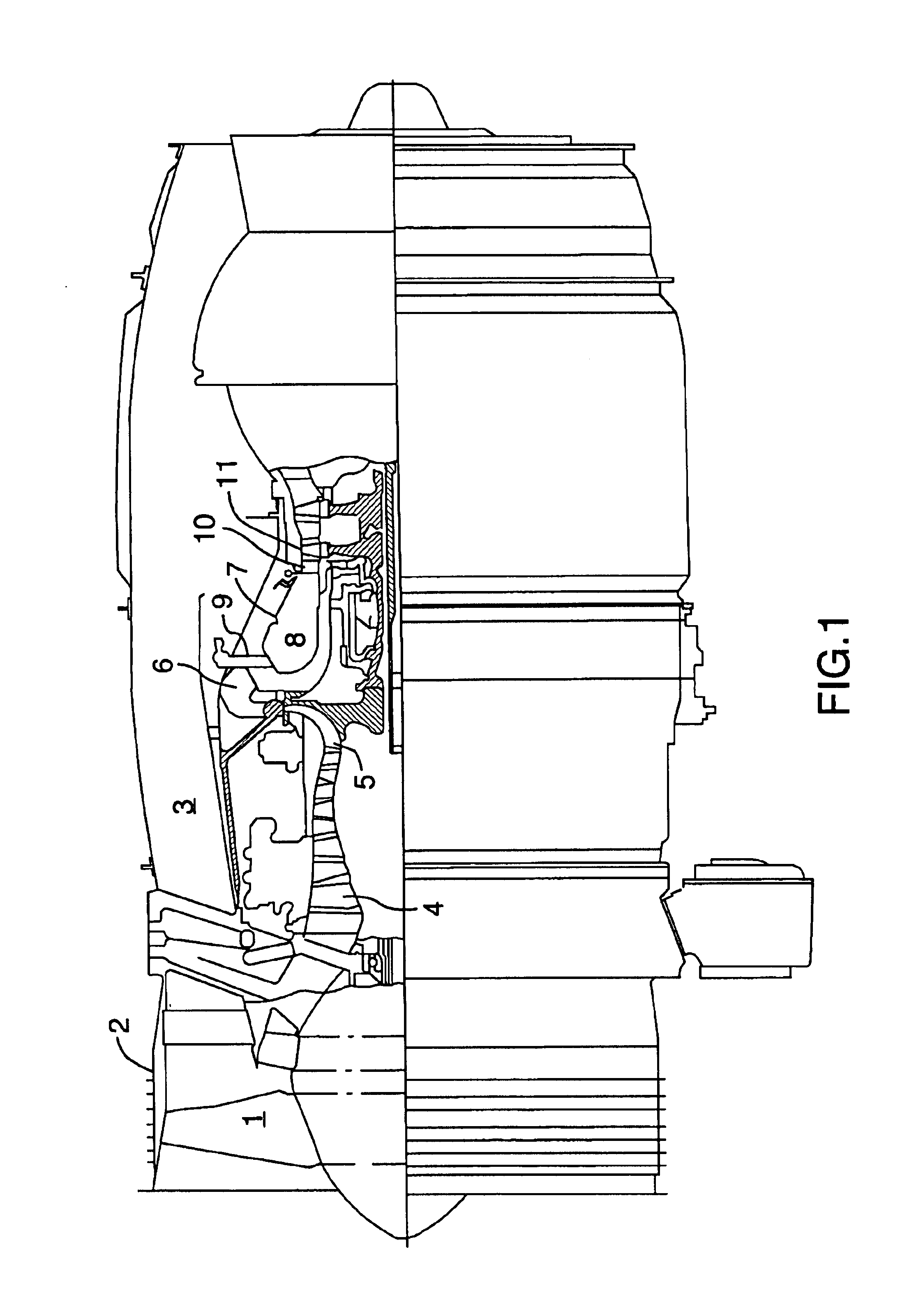

Aircraft propulsion unit fan cowls equipped with maintaining and positioning safety elements

In an aircraft propulsion system, such as a jet engine, the fan cowls (22) are articulated to the support strut or pylon (12) by which the centre or core engine (14) is connected to a wing element (10). The cowls (22) are kept closed by hooked locks (32a, 32b), which connect their lower edges. To eliminate any risk of accidental opening, guide devices (36, 38) are placed between the lower edges of the cowls (22) and structures (20; 24, 26) connected to the centre engine (14), at least at the front of the cowls. The front structure (20) opposes any axial and radial displacement of the cowls.

Owner:SOC NATIONALE INDUSTRIELLE AEROSPATIALE SA

Reclosable cup lid with sliding closure member

A reclosable cup lid thermoformed from a polymeric material includes a domed member and an elongate closure panel. The thermoformed domed member is provided with a sidewall and a top wall, the top wall having upper and lower surfaces and a drinking aperture at a periphery of the top wall. The top wall further defines a pair of slide tracks depending from the lower surface of the top wall and also defines a post aperture disposed inwardly with respect to the drinking aperture. The elongate closure panel has opposed engagement edges, an upper surface provided with a post projecting upwardly therefrom, and a drinking aperture sealing area. As assembled, the domed member and elongate closure panel are configured such that the opposed engagement edges of the elongate closure panel are slidingly mounted in the slide tracks for generally radial displacement.

Owner:GPCP IP HLDG LLC

Displacement sensor system and method of operation

A clearance sensing system for a rotating machine includes a plurality of sensor probes disposed within a stationary shroud of the rotating machine. Each of the plurality of sensor probes is adapted to measure a parameter indicative of an axial and a radial displacement of a rotating component within the shroud and to produce a signal that corresponds to the parameter. In certain embodiments, this parameter may include a capacitance between the rotating component and the sensor probe. The clearance sensing system further includes a circuit that receives the signal from each of the plurality of sensor probes and determines (a) the axial displacement of the rotating component within the shroud and (b) a radial displacement of the rotating component relative to the shroud.

Owner:GENERAL ELECTRIC CO

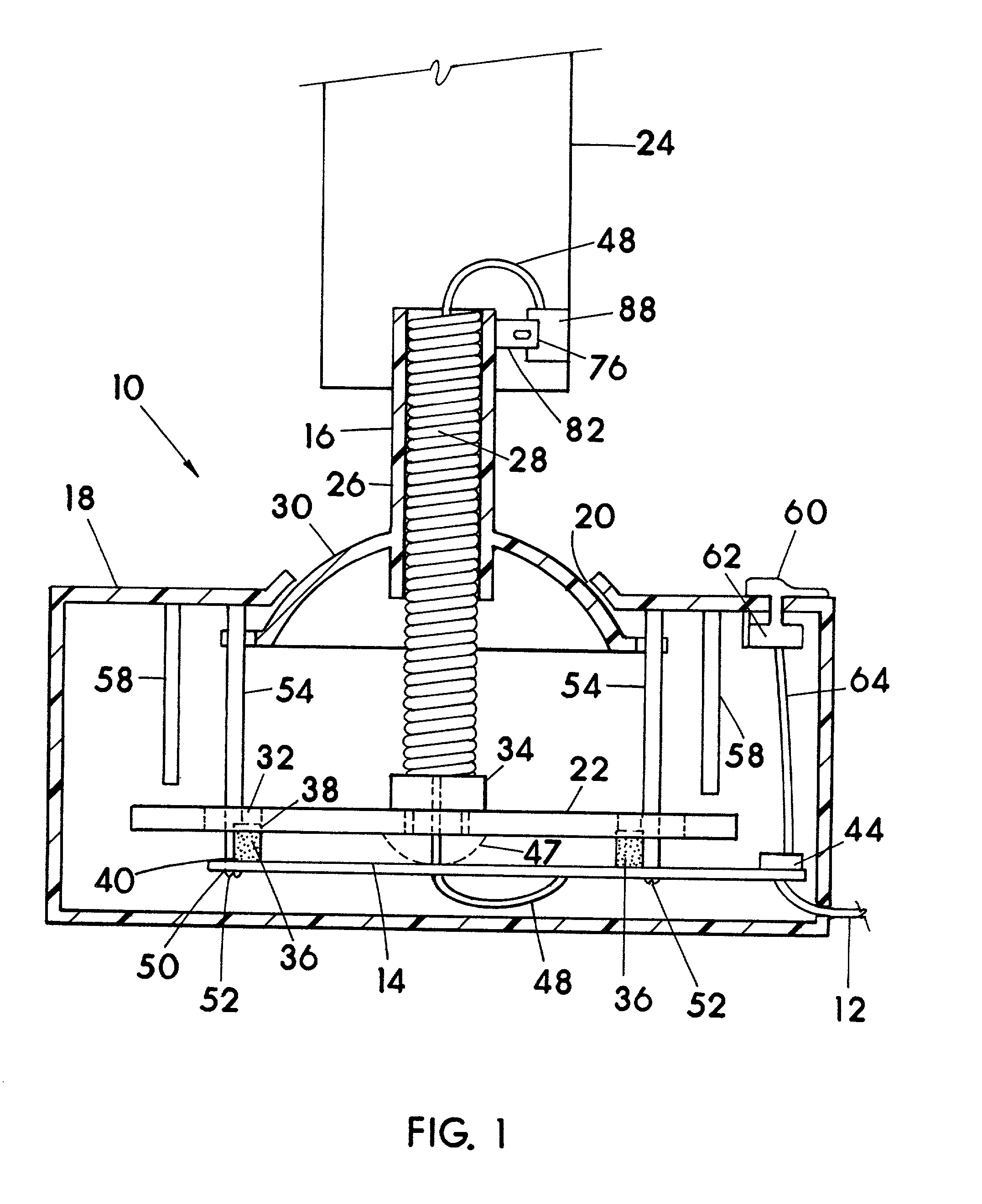

Controller with variable sensor(s)

InactiveUS20020024503A1Manual control with multiple controlled membersCathode-ray tube indicatorsJoystickEngineering

An input device such as a joystick, which utilizes a plurality of individual analog compression-sensitive sensors for detecting direction and magnitude of applied force, such as applied to an arm. The arm is supported to allow substantial radial displacement outward from a resting to a maximum allowed position. The analog sensors are positioned within a compression applicator moveable to apply compression thereto. Resilient structuring is incorporated to provide, once compressing of a sensor starts, substantial disproportionate movement of the arm relative to the moveable compression component. The resilient structuring includes resistance to further deflection in order to increase force to a sensor as the arm is further displaced toward the maximum allowed displacement. The arm, resilient member and moveable component of the compression applicator are integrally molded as one piece of plastics in one embodiment.

Owner:ANASCAPE

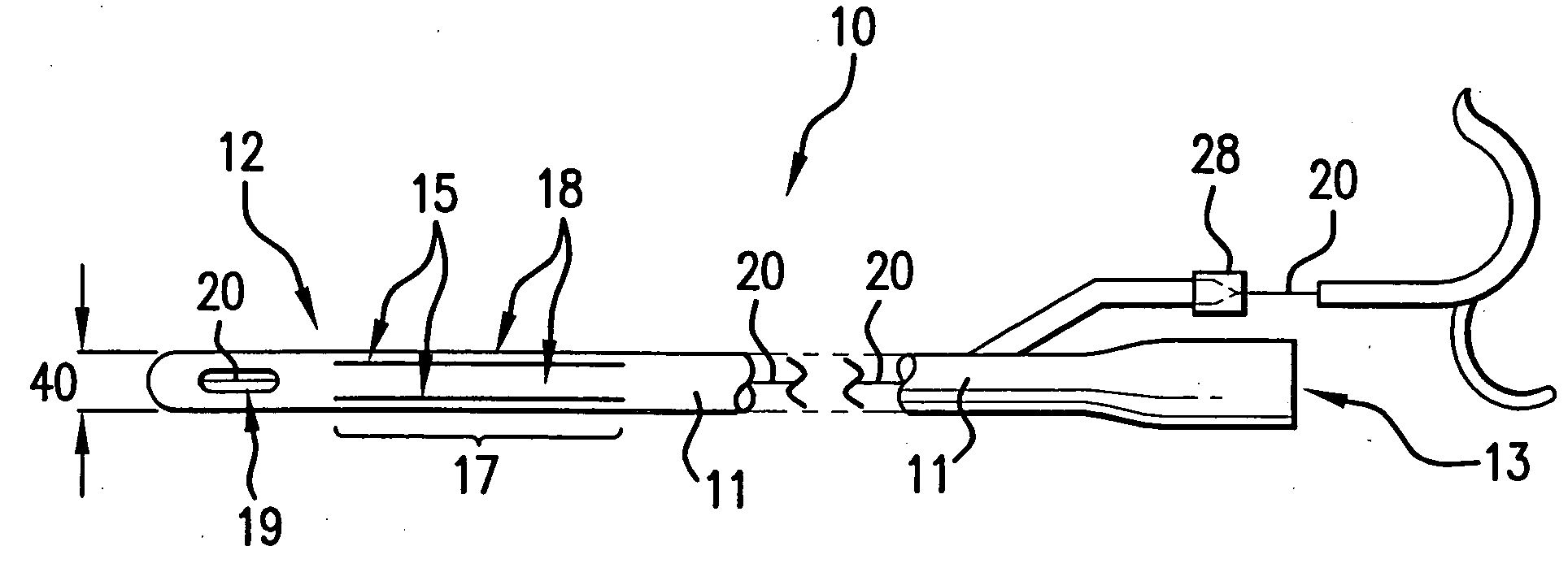

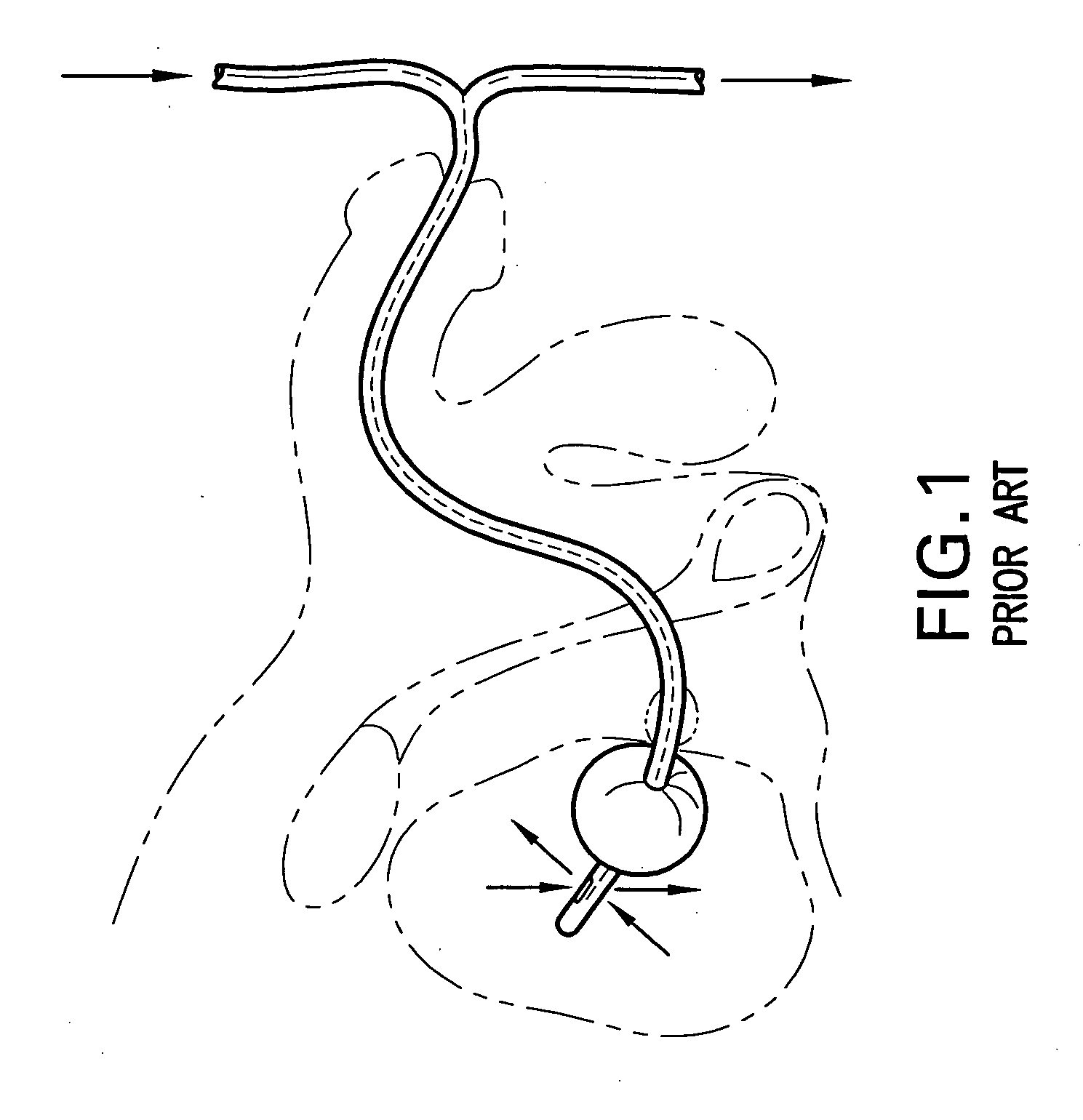

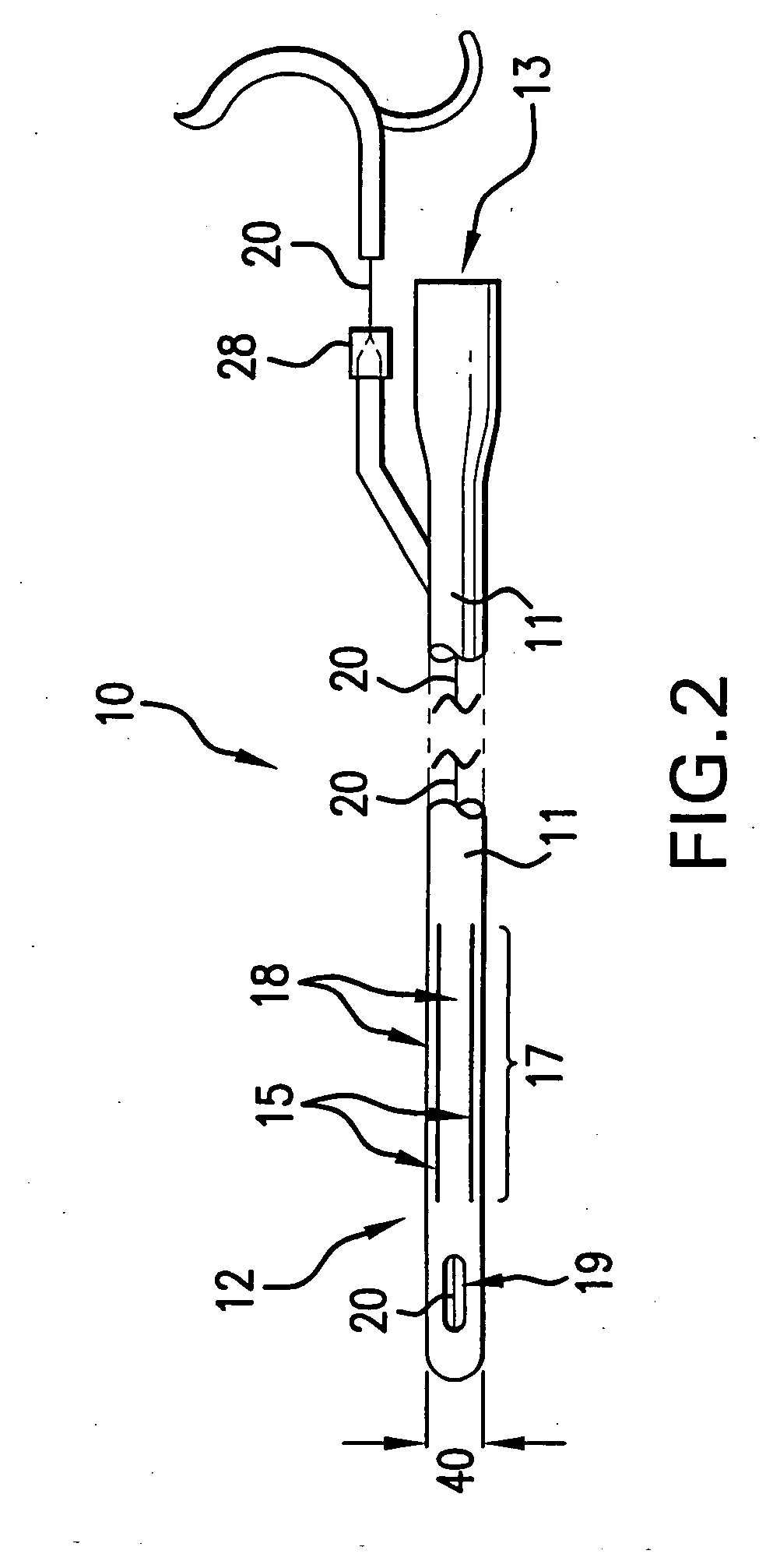

Indwelling urinary catheter

ActiveUS20050101941A1Rigid enoughMinimized contact areaSurgeryWound drainsUrinary drainageResidual urine

The retention balloon of the Foley urinary drainage catheter is replaced by a new self-retaining system. This new self-retaining catheter eliminates the problem of residual urine and also of bladder wall irritation caused by continuous contact with a spherical retention balloon; it also does not rely on a stylet for placement. The new system may use an internal control wire that reversibly foreshortens the proximal end of the catheter thus radially displacing longitudinal strips defined in the proximal catheter to form retention wings. Alternatively, a balloon situated between the longitudinal strips is inflated to force open the retention wings once inside the urinary bladder. Radial displacement of the retention wings widens the spaces between the longitudinal strips, these spaces constituting the drainage apertures which permit complete emptying of the urinary bladder, thereby eliminating a source of bladder irritation. The radially displaced retention wings abut the bladder wall in a non-continuous manner thereby reducing the area of bladder-catheter contact and further reducing bladder wall irritation.

Owner:LOTUS MEDICAL TECH

Reclosable cup lid

A reclosable cup lid thermoformed from a polymeric material includes a domed member and a closure panel. The thermoformed domed member is provided with a sidewall and a top wall, the top wall having upper and lower surfaces and a drinking aperture at a periphery of the top wall. The top wall further defines a pair of engagement tracks depending from the lower surface of the top wall and also defines a post aperture disposed inwardly with respect to the drinking aperture. The closure panel has opposed engagement edges, an upper surface provided with a post projecting upwardly therefrom, and a drinking aperture sealing area. As assembled, the domed member and closure panel are configured such that the opposed engagement edges of the closure panel are slidingly mounted in the engagement tracks for generally radial displacement.

Owner:GPCP IP HLDG LLC

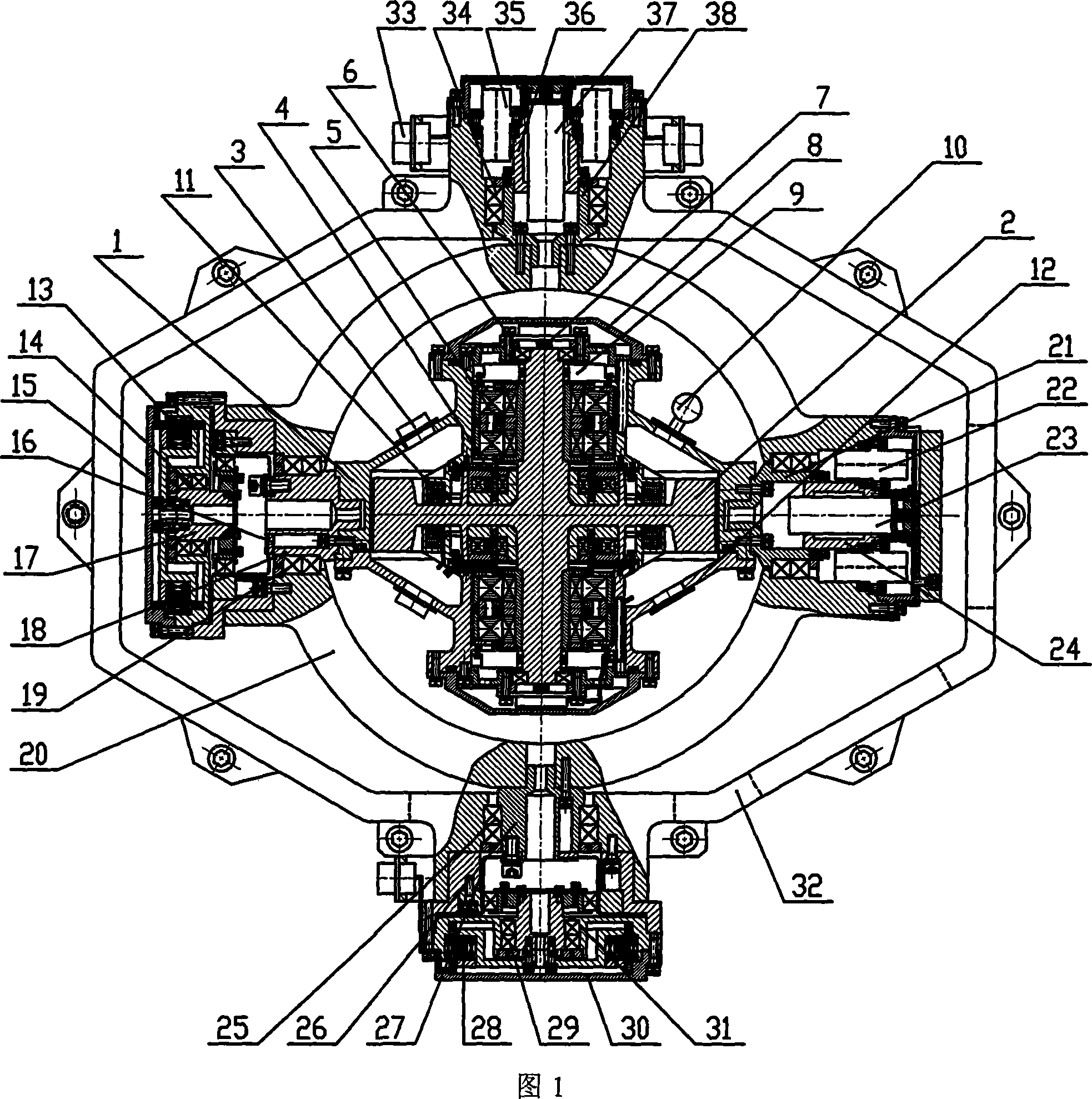

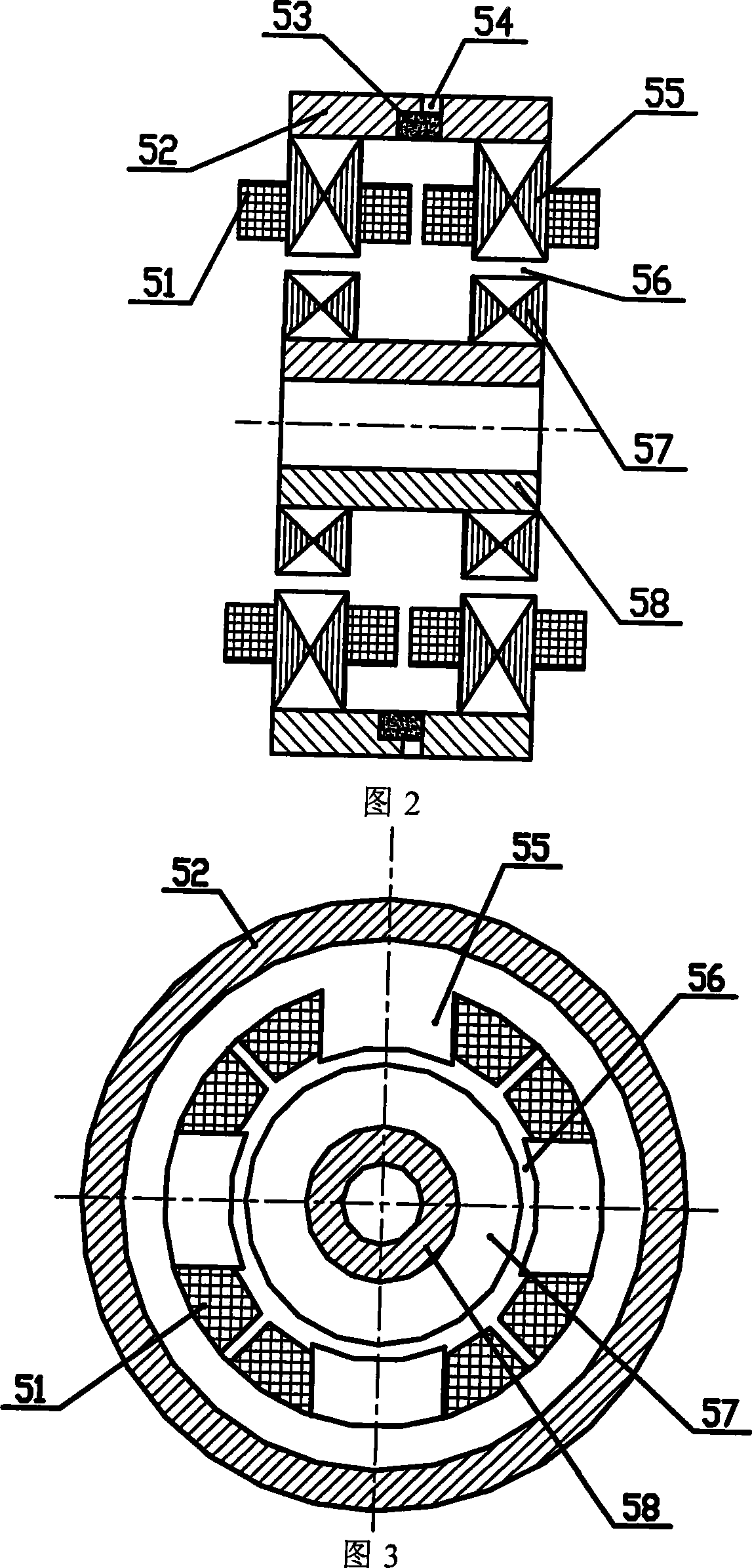

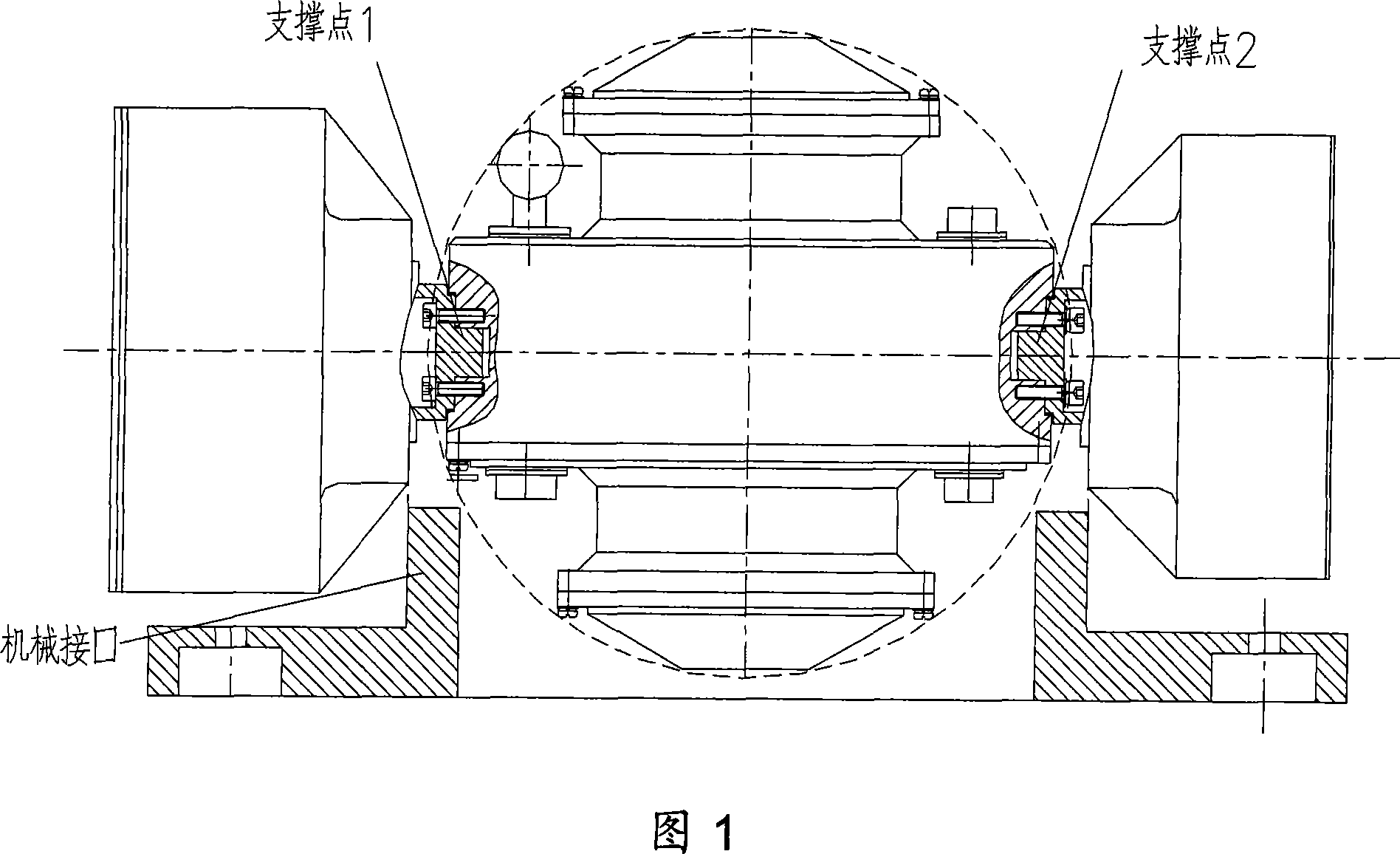

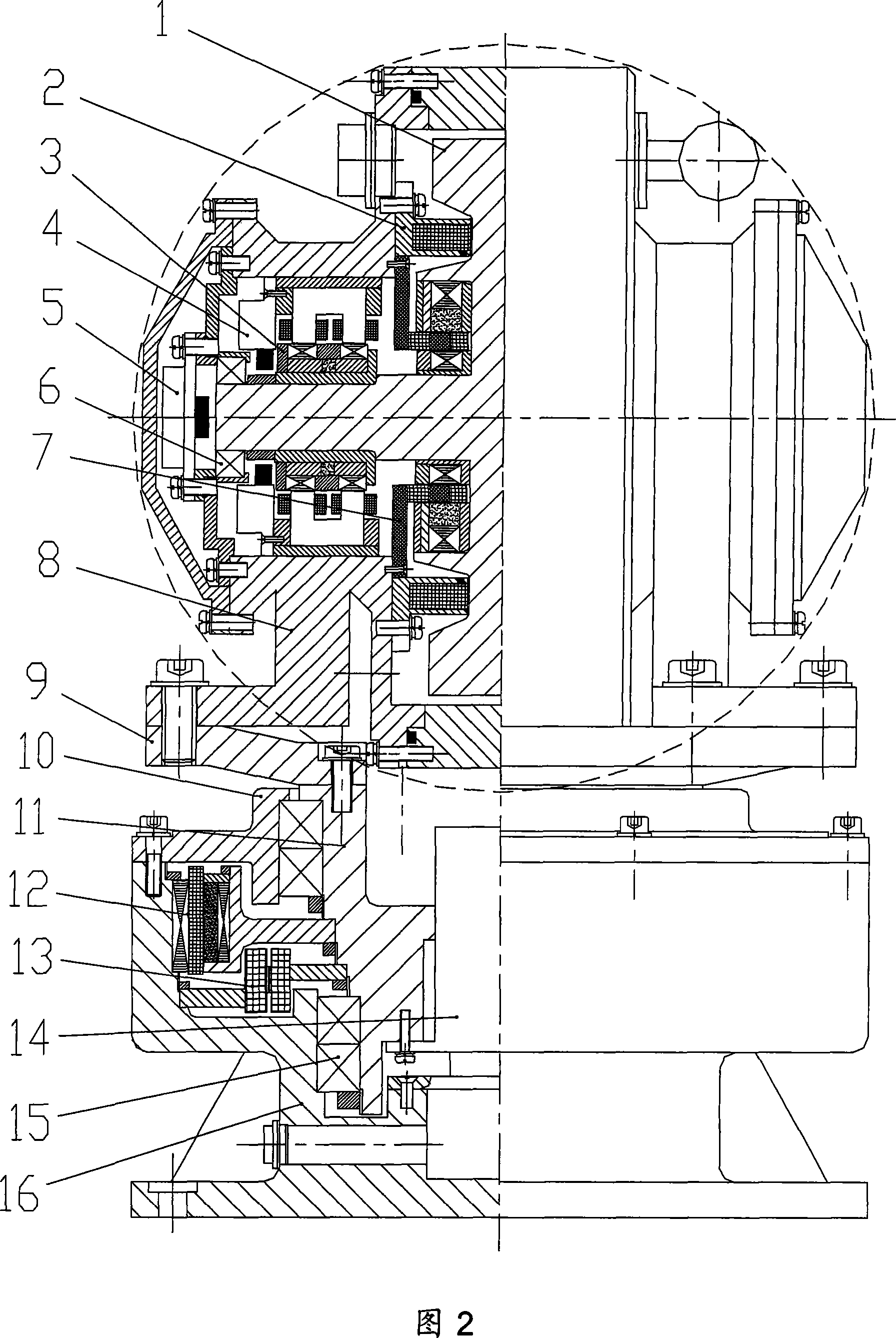

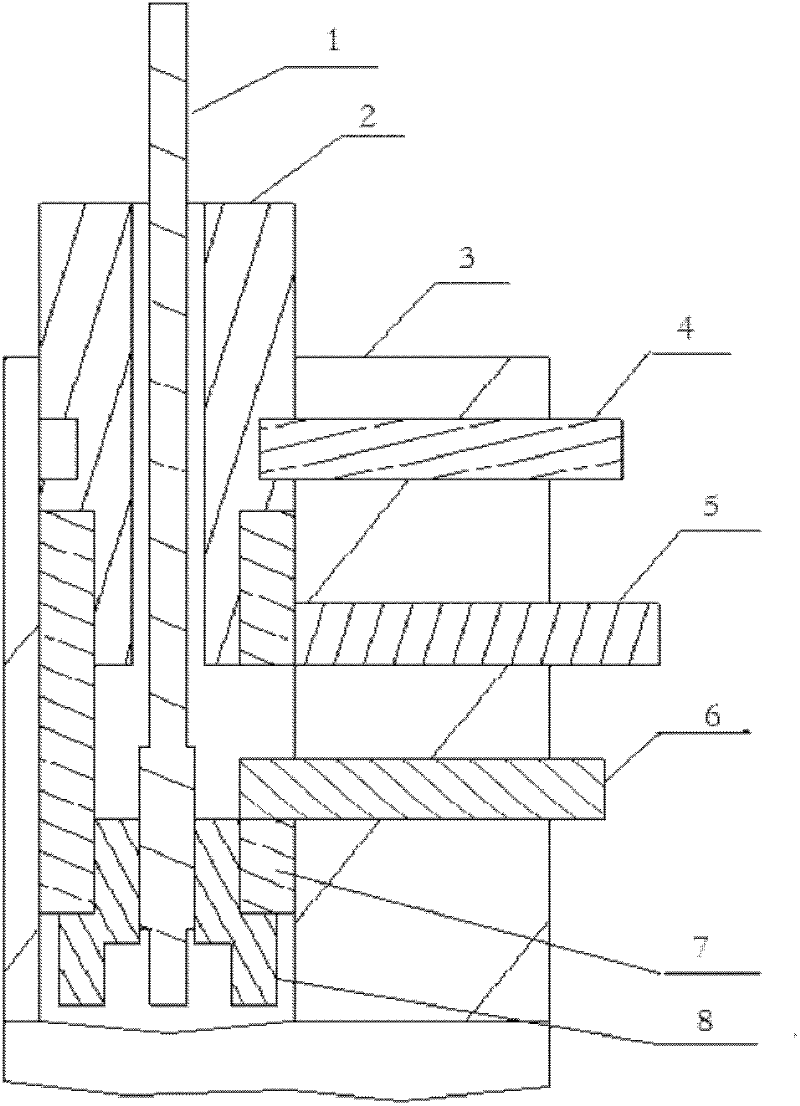

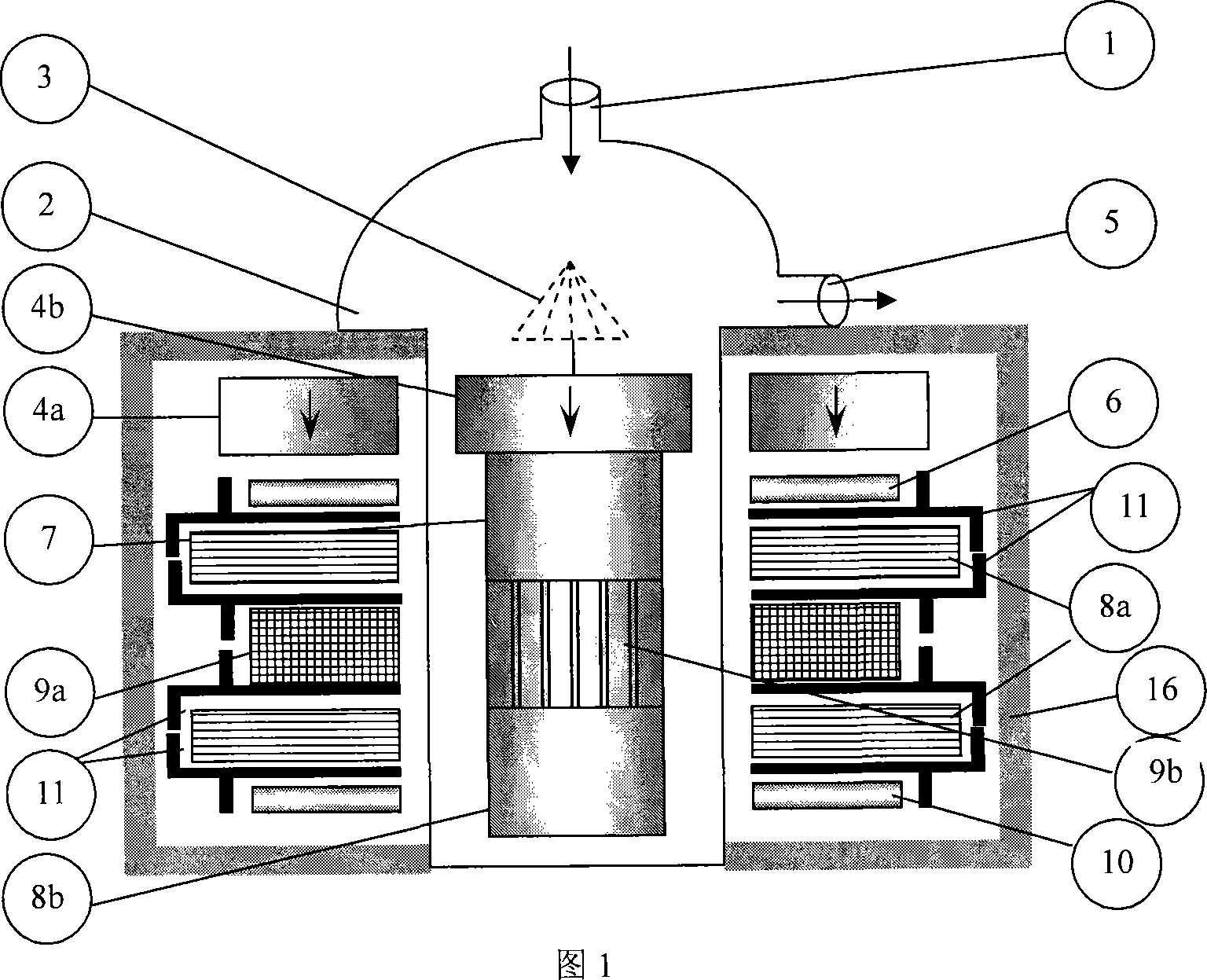

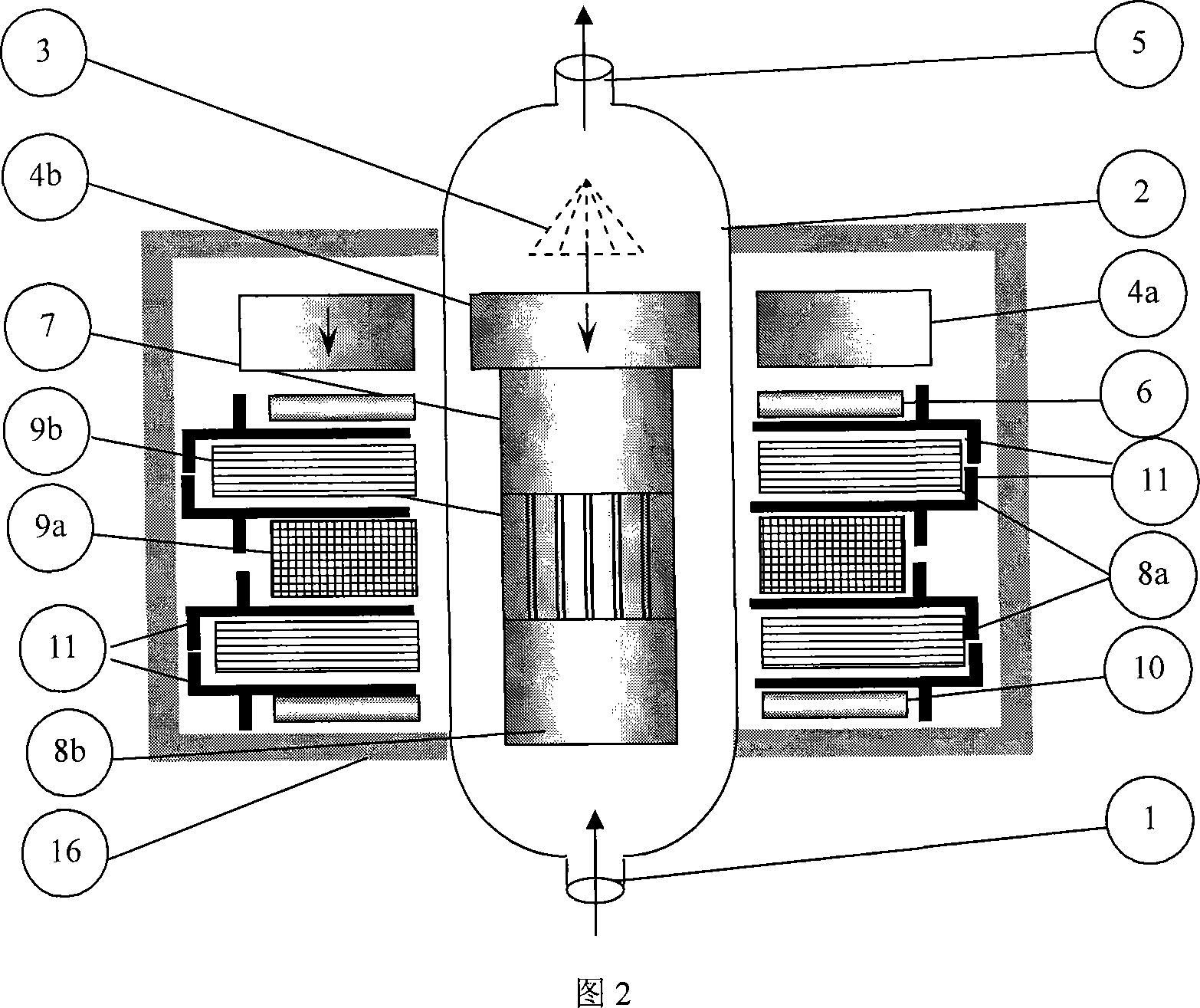

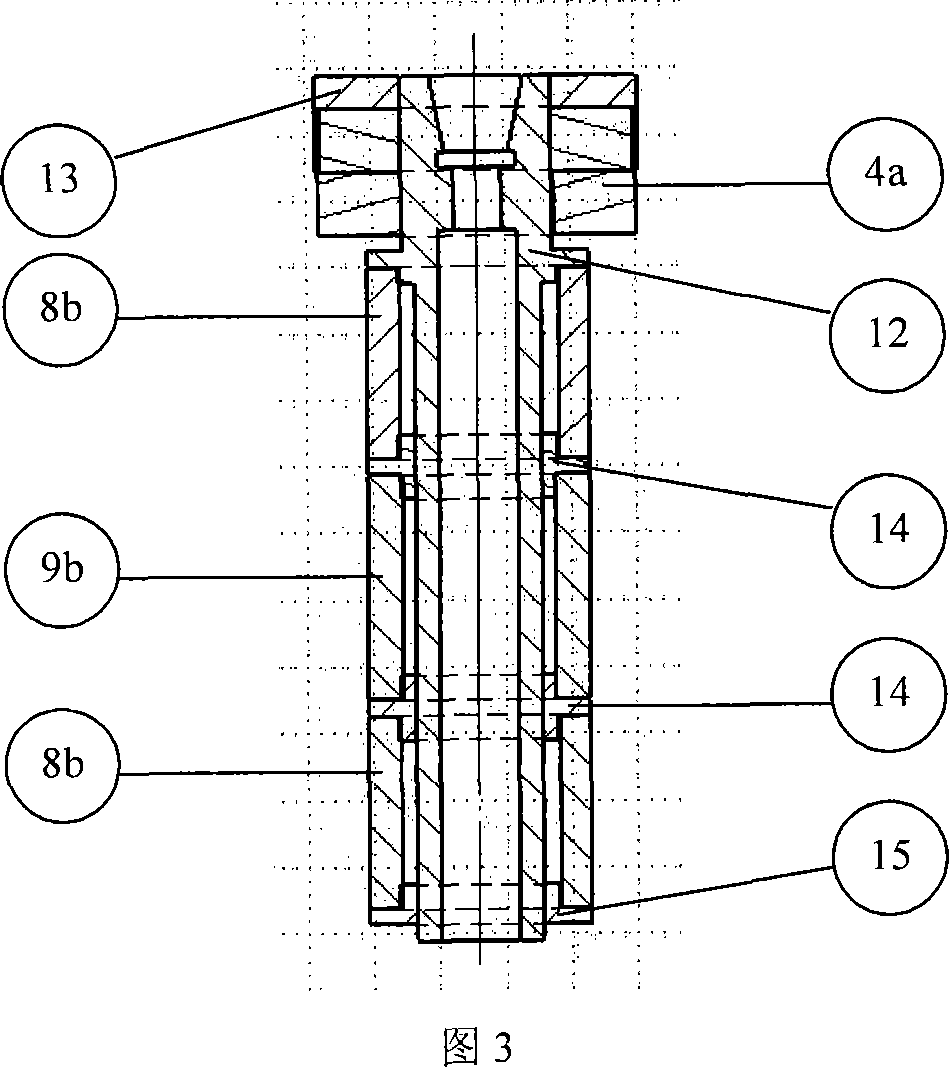

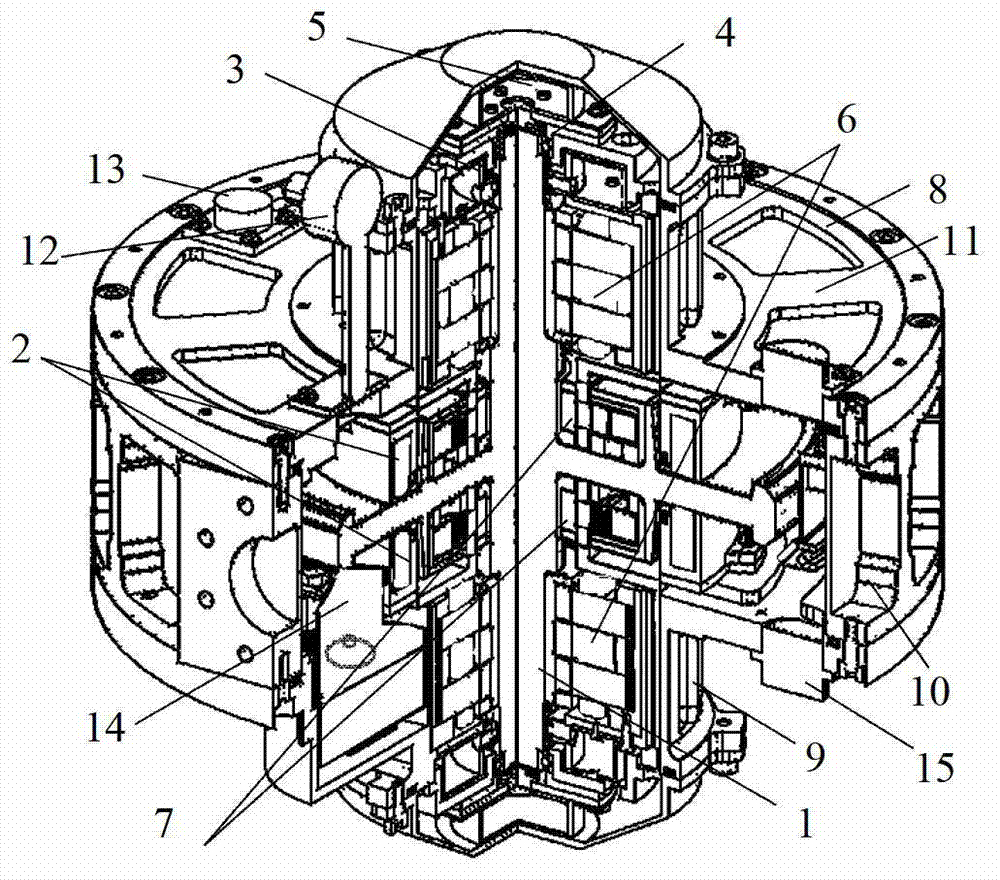

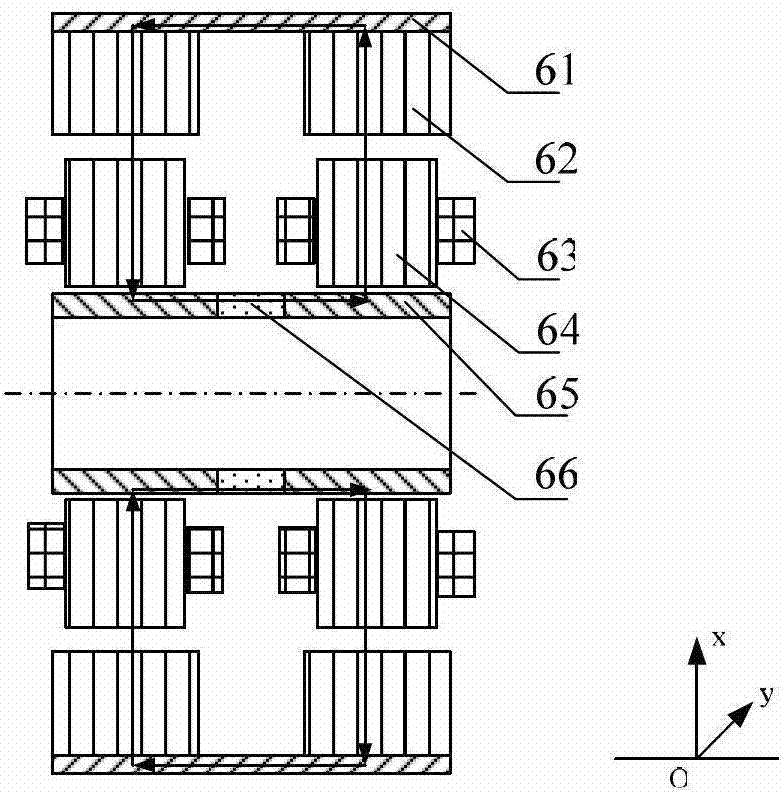

Double-frame magnetic suspension control moment gyro

InactiveCN101219714AReduce volumeReduce weightSpacecraft guiding apparatusAxial displacementMagnetic bearing

The invention relates to a magnetic suspension controlled moment gyro with double frames, essentially consisting of a flywheel, an inner frame system and an outer frame system. The flywheel is arranged in the middle of the magnetic suspension controlled moment gyro with the double frames and essentially comprises a rotary shaft, a radial mixed magnetic bearing, an axial magnetic bearing, a radial displacement sensor, an axial displacement sensor, a high-speed motor and a gyro room; the inner frame system and the outer frame system essentially comprise the frames, a mechanical bearing, a moment motor, a reducer, an angle position sensor, a conductive slip ring a control system; the inner frame system is connected with a shaft hole on one end of the gyro room through the reducer and at the same time the conductive slip ring and the angle position sensor are connected with the shaft hole on the other end of the gyro room; the outer frame system is connected with a shaft hole on one end of the inner frame through the reducer and at the same time the conductive slip ring and the angle position sensor are connected with the shaft hole on the other end of the inner frame. The invention reduces noise, size and weight of the system through the mixed magnetic bearing, and eliminates bearing friction, and thus prolongs life span and promotes control accuracy of the controlled moment gyro.

Owner:BEIHANG UNIV

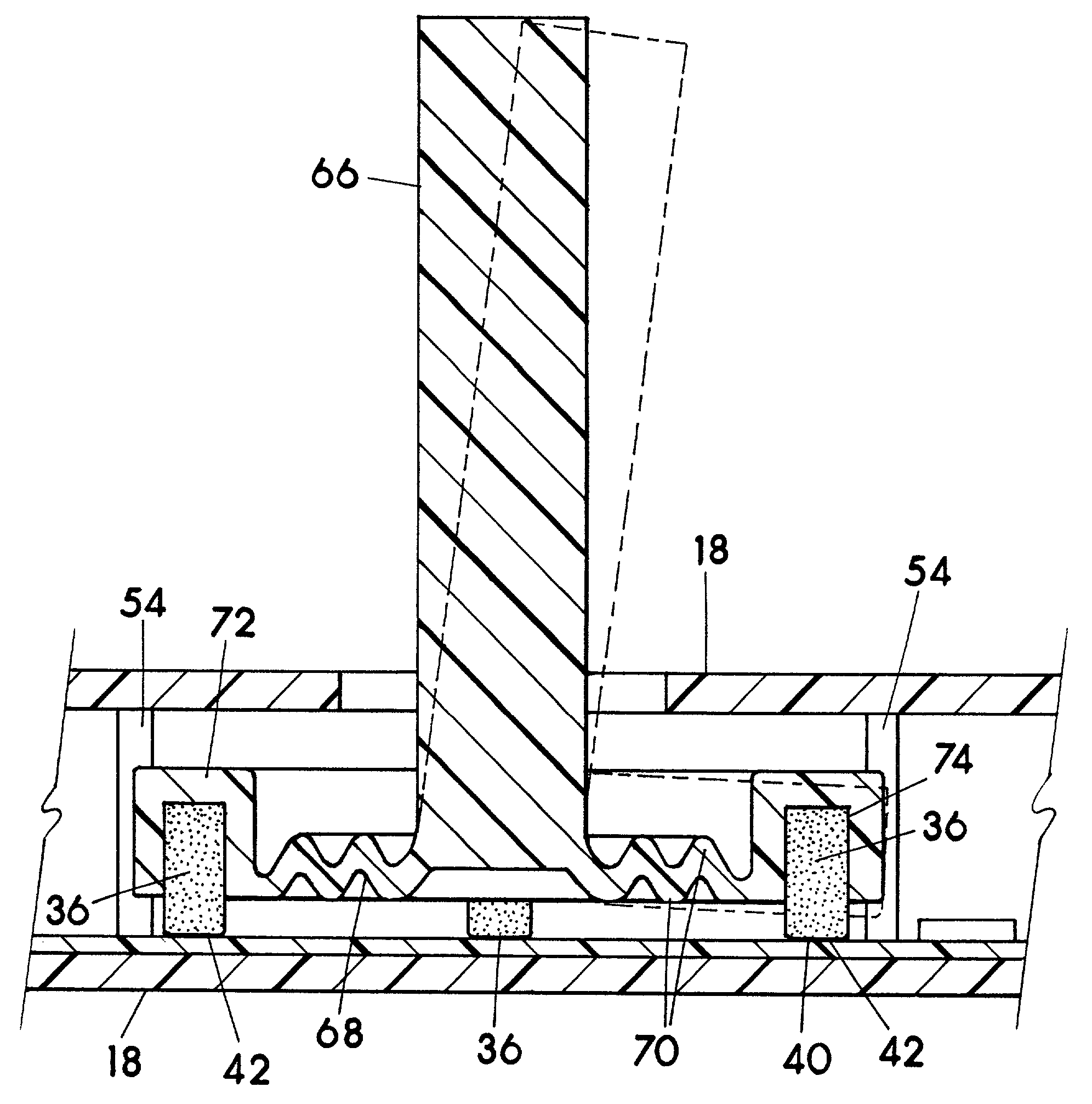

Blade retention scheme using a retention tab

A blade retention system for retaining blade roots in slots of a rotor hub disk, the rotor blade having a radially outward blade tip requiring surface material removal by grinding to acquire a finished ground surface, having a blade root retention tab with an elongated web of thickness less than the gap between the slot and blade root and with at least two deformable protrusions extending radially to a height exceeding said gap, the protrusions adapted to deform under compression radially inwardly on sliding engagement with the blade root in the slot and to exert a reaction force radially outwardly on the blade root of a magnitude sufficient to secure the blade tip during surface removal grinding of the blade tip against radial displacement and against rotational displacement.

Owner:PRATT & WHITNEY CANADA CORP

Reclosable cup lid with sliding member and scalloped track

A reclosable cup lid thermoformed from a polymeric material includes a domed member and a closure panel. The thermoformed domed member is provided with a sidewall and a top wall, the top wall having upper and lower surfaces and a drinking aperture at a periphery of the top wall. The top wall further defines a pair of engagement tracks depending from the lower surface of the top wall and also defines a post aperture disposed inwardly with respect to the drinking aperture. The closure panel has opposed engagement edges, an upper surface provided with a post projecting upwardly therefrom, and a drinking aperture sealing area. As assembled, the domed member and closure panel are configured such that the opposed engagement edges of the closure panel are slidingly mounted in the engagement tracks for generally radial displacement.

Owner:GPCP IP HLDG LLC

Displacement joystick with compression-sensitive sensors

InactiveUS6285356B1Reduce manufacturing costLow costManual control with multiple controlled members2D-image generationJoystickEngineering

A joystick which utilizes a plurality of individual analog compression-sensitive sensors for detecting direction and magnitude of force applied to an arm. The arm is structured and supported to allow substantial radial displacement outward from a resting to a maximum allowed position. The analog sensors are positioned within a compression applicator moveable to apply compression thereto. Resilient structuring is incorporated as a linkage in the arm or between the arm and a moveable component of the compression applicator to provide, once compressing of a sensor starts, substantial disproportionate movement of the arm relative to the moveable compression component. The resilient structuring includes resistance to further deflection to increase force to a sensor as the arm is further displaced toward the maximum allowed displacement. The arm, resilient member and moveable component of the compression applicator are integrally molded as one piece of plastics in one embodiment.

Owner:ANASCAPE +1

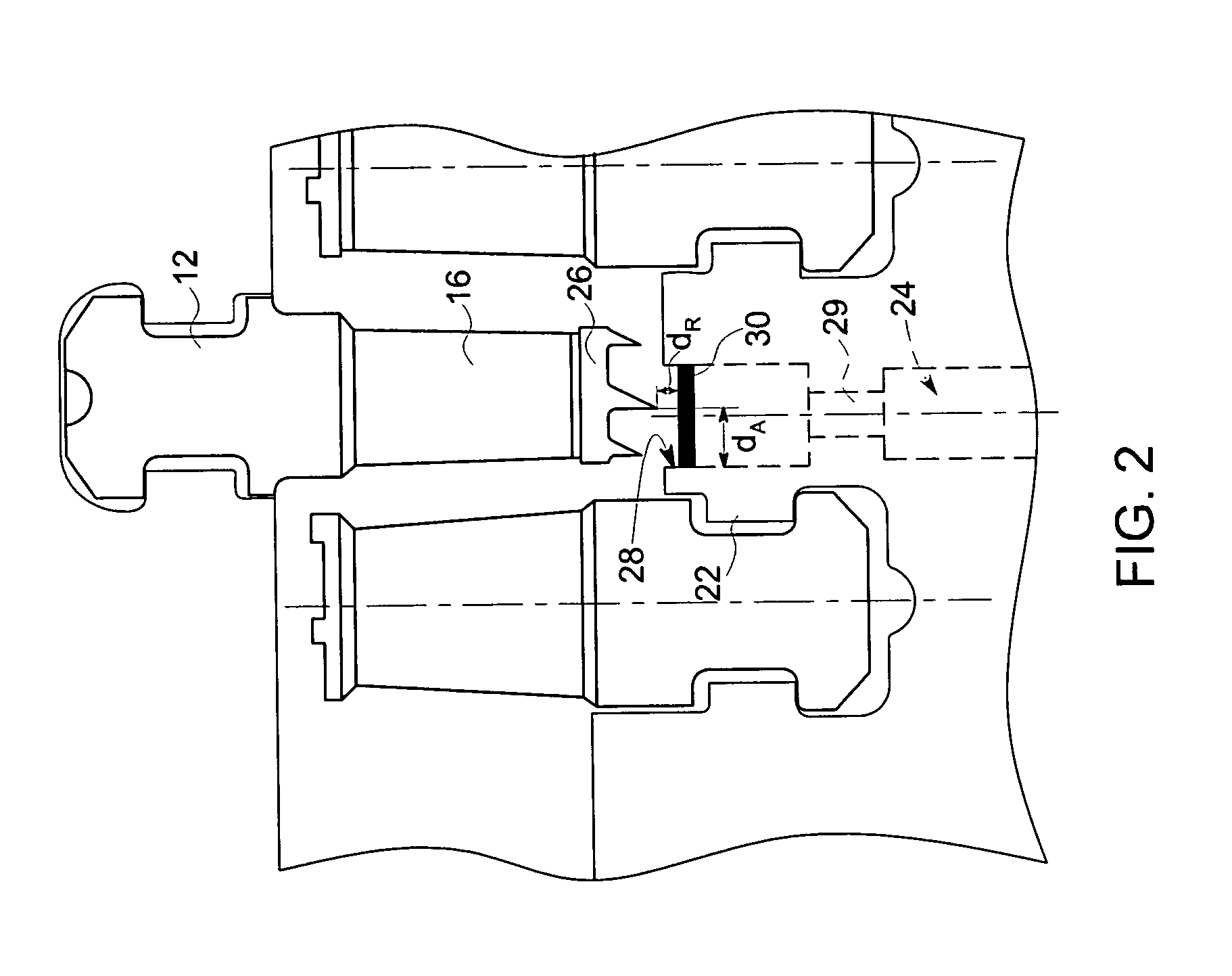

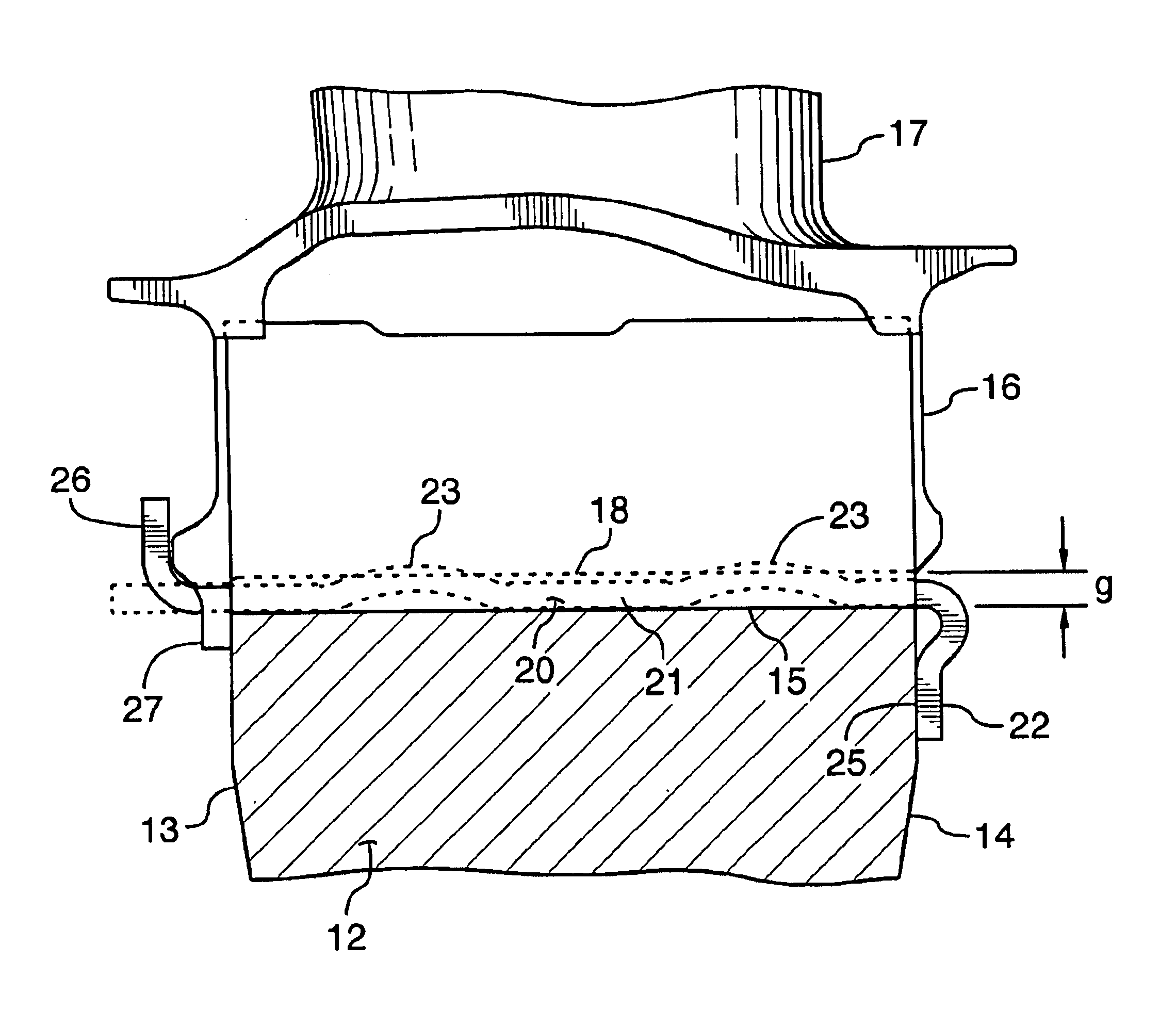

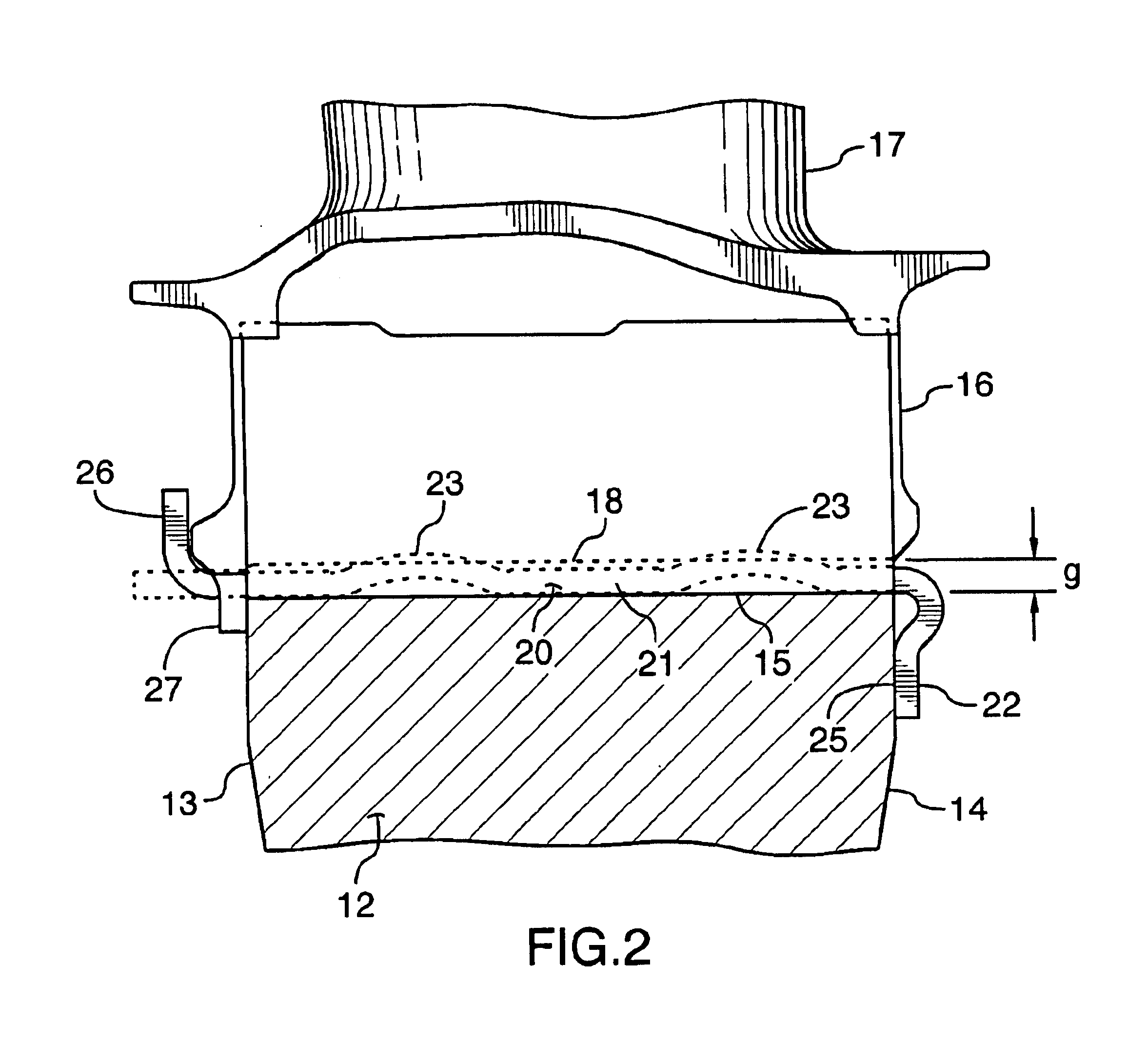

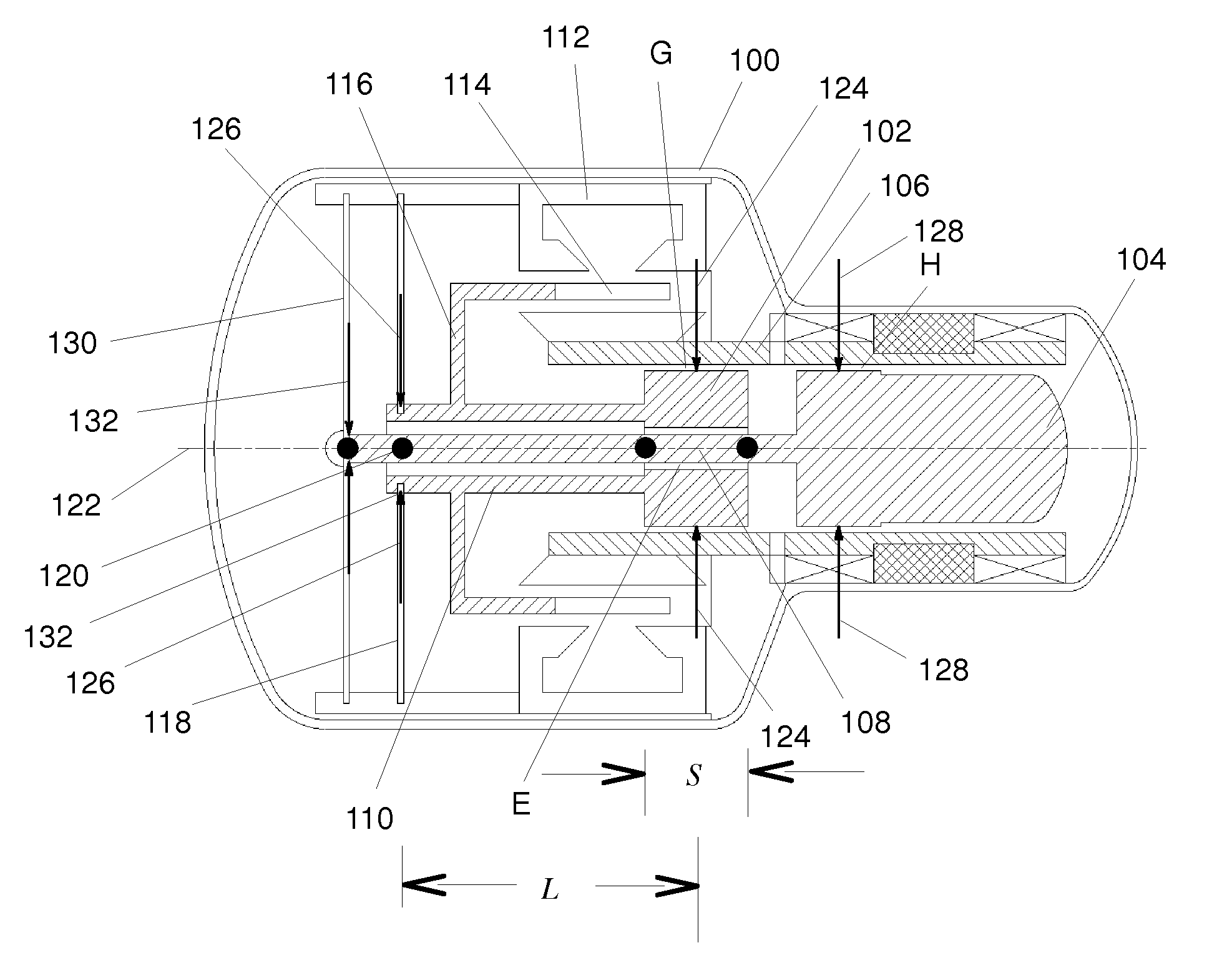

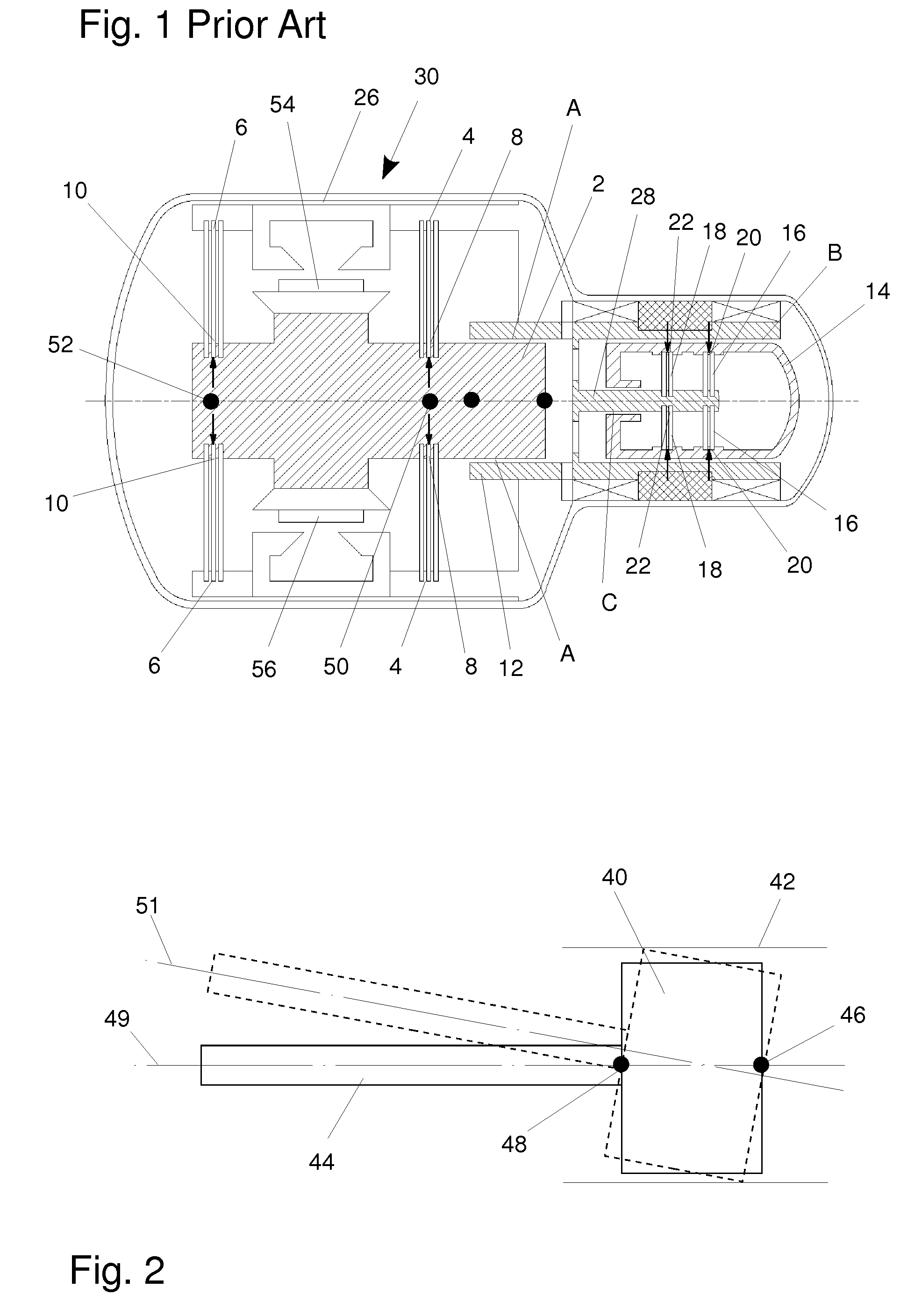

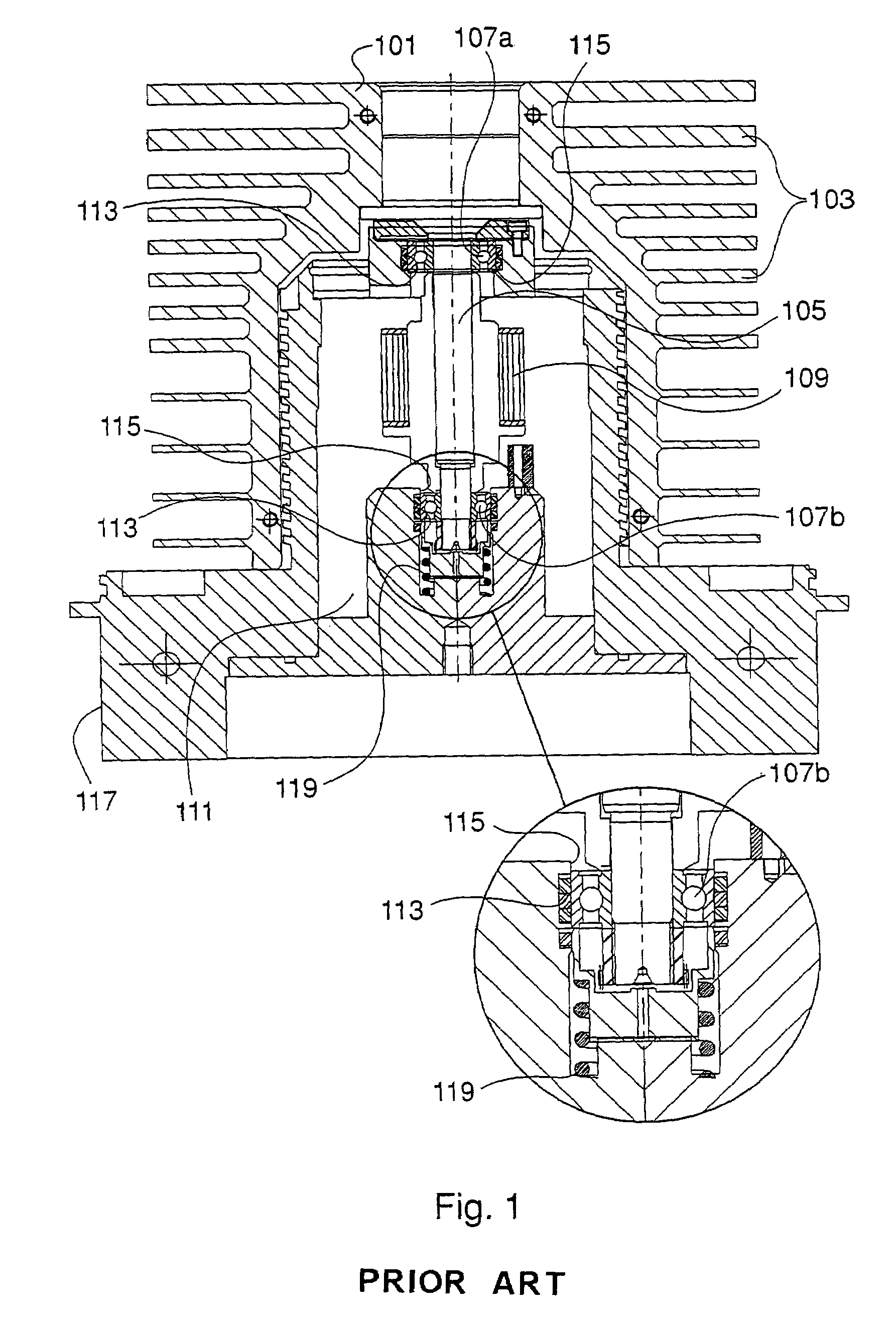

Bearing support system for free-piston stirling machines

ActiveUS20110056196A1Safety/regulatory devicesClosed-cycle gas positive displacement engine plantSupporting systemEngineering

A bearing support system for a piston and its connecting rod in which the bearing system supports the combined piston and connecting rod by only two bearings, a gas bearing at the power piston (or displacer) and a radially acting spring bearing at its connecting rod. The spacing between them meets prescribed relationships and preferably exceeds a calculated value based upon chosen engineering parameters. A non-compliant connecting rod is fixed to an end of a piston which has a clearance seal length in the range of 0.3 times the diameter of the piston and 1.5 times the diameter of the piston. The distance from the gas bearing to the effective point of connection of the radially acting spring bearing to the connecting rod is greater than the seal length of the piston. The allowable off-center distance A for the radial displacement of the fixed connection of the radially acting spring bearing to the connecting rod is considerably greater than the diametrical clearance gap g which illustrates the reduction in the required precision for adjusting the position of the radially acting spring bearing. The piston and connecting rod unit is not supported by additional bearings that introduce additional alignment problems.

Owner:GLOBAL COOLING

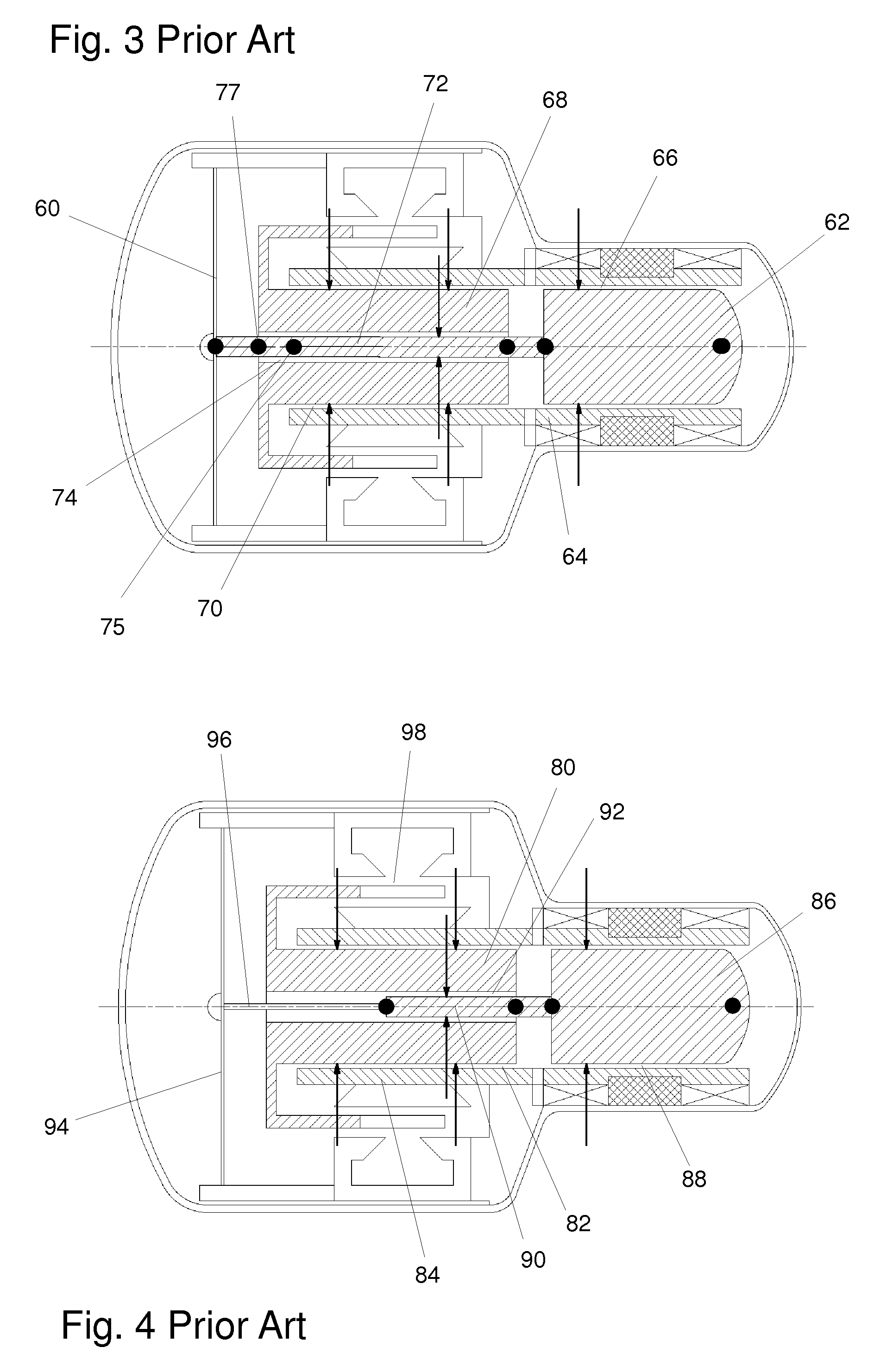

Strut joint for an external fixator

A ball joint for use with an external fixator has a sleeve in engagement with a rod of a strut for the external fixator. A ring insert and a blocking element are provided, having a combined circumferential surface being able to be introduced into a hole of a ring of an external fixator. The ring insert and blocking element have complementary wedge surfaces allowing a relative radial displacement therebetween to enlarge the diameter of the combined circumferential surface for blocking the ball joint inside the hole. Additionally the sleeve comprises a spherical hollow ball portion with concentrical inner and outer spherical portions, wherein the outer spherical portion engages a complementary spherical socket of the blocking element and wherein the inner spherical portion is engaged by a ball nut. A connection element extends through the sleeve, blocking element and ring insert, wherein a radial displacement and axial displacement of the ring insert and blocking element are activated by the connection element.

Owner:STRYKER EURO OPERATIONS HLDG LLC

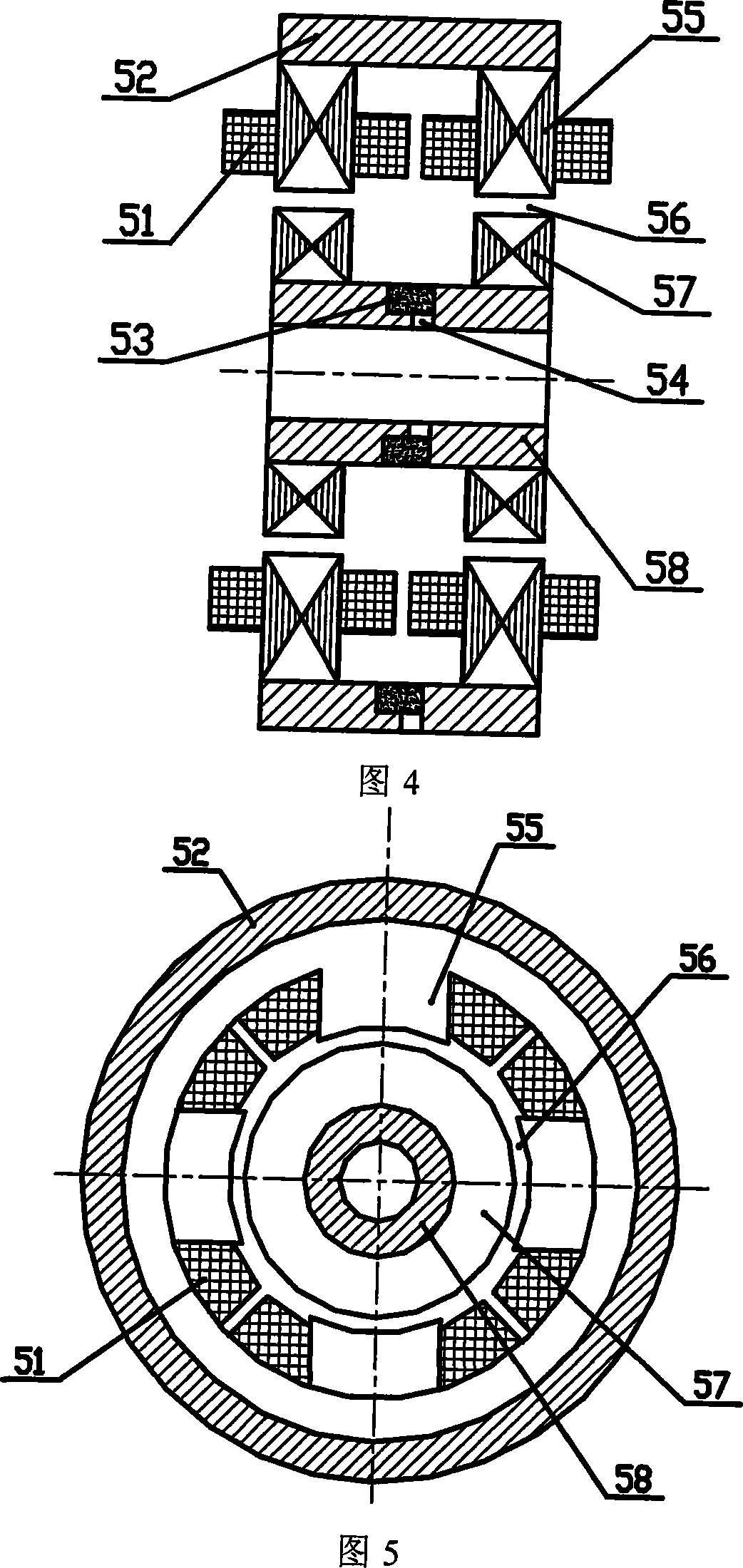

Single end support type magnetic suspension control moment gyro of single framework

InactiveCN101049860AEliminate frictional momentIncrease speedSpacecraft guiding apparatusUltra high speedAxial displacement

A single end supported single-frame magnetic-levitation torque-controlling gyro is composed of magnetically levitated rotor system and frame system. Said magnetically levitated rotor system consists of gyro rotor, axial and radial magnetic bearings, and axial and radial displacement sensors, protecting bearing, drive motor and gyro room. Said frame system comprises frame jointer, end covers, mandrel, torque motor, angular position sensor, electrically conductive slide ring, mechanical bearing, and base. It has high rotation speed and long service life.

Owner:BEIHANG UNIV

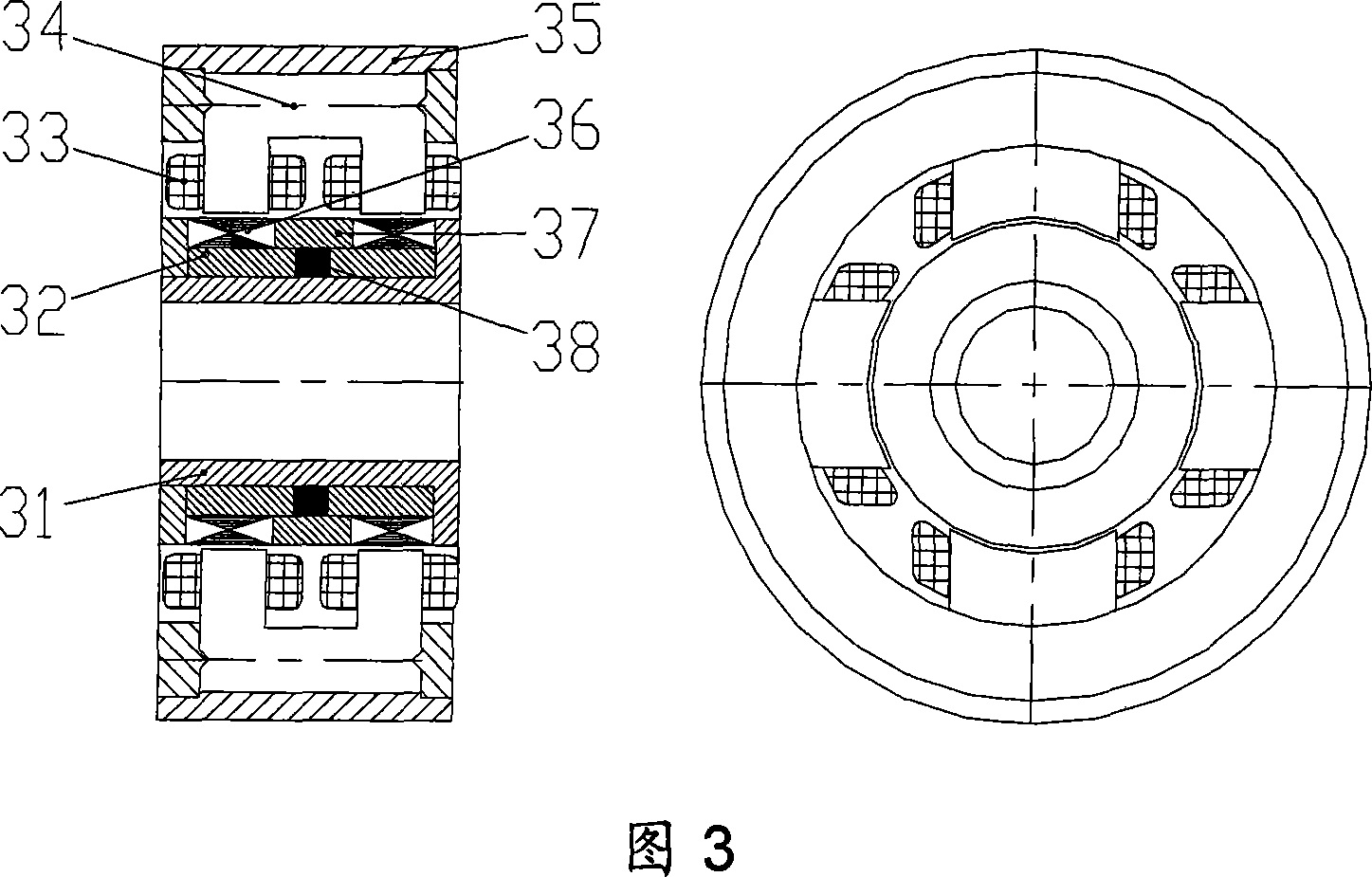

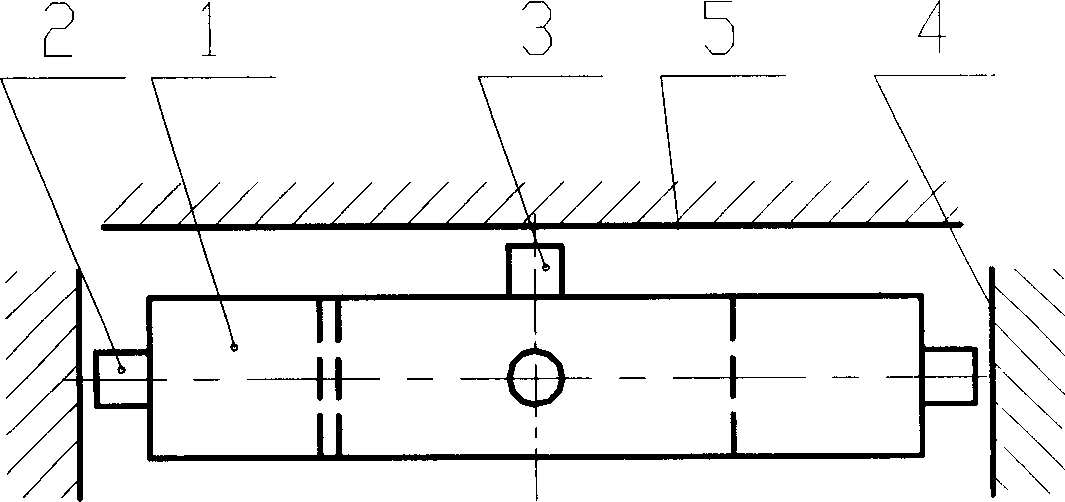

Radial/axial six-position integrated electric eddy transducer

InactiveCN1800773AReduce volumeReduce power consumptionUsing electrical meansAxial displacementAudio power amplifier

This invention relates to a radial and axial six digits integral electric vortex sensor, which characterized in that it is composed of the six digits integral electric vortex pick-off and the probe, wherein between the sensor probe and the probe there forms the radial probe space and the axial probe space, and the said sensor has six channels, whose probes are integrated in a sensor seat with the preamplifier, and the sensor is composed of the radial displacement probe, axial displacement probe, preamplifier, and power information output line, wherein the four radial probes probe the X direction and Y direction displacement information separately, and the axial probes probe the Z direction displacement information, the preamplifier and the probes of the six channels are integrated, which can be designed into the radial and axial six digits integral electric vortex sensor whose probe interfaces are external according to the structure demand. This invention improves the probe precision and stabilization, and reduces the volume and weight of the sensor greatly.

Owner:BEIHANG UNIV

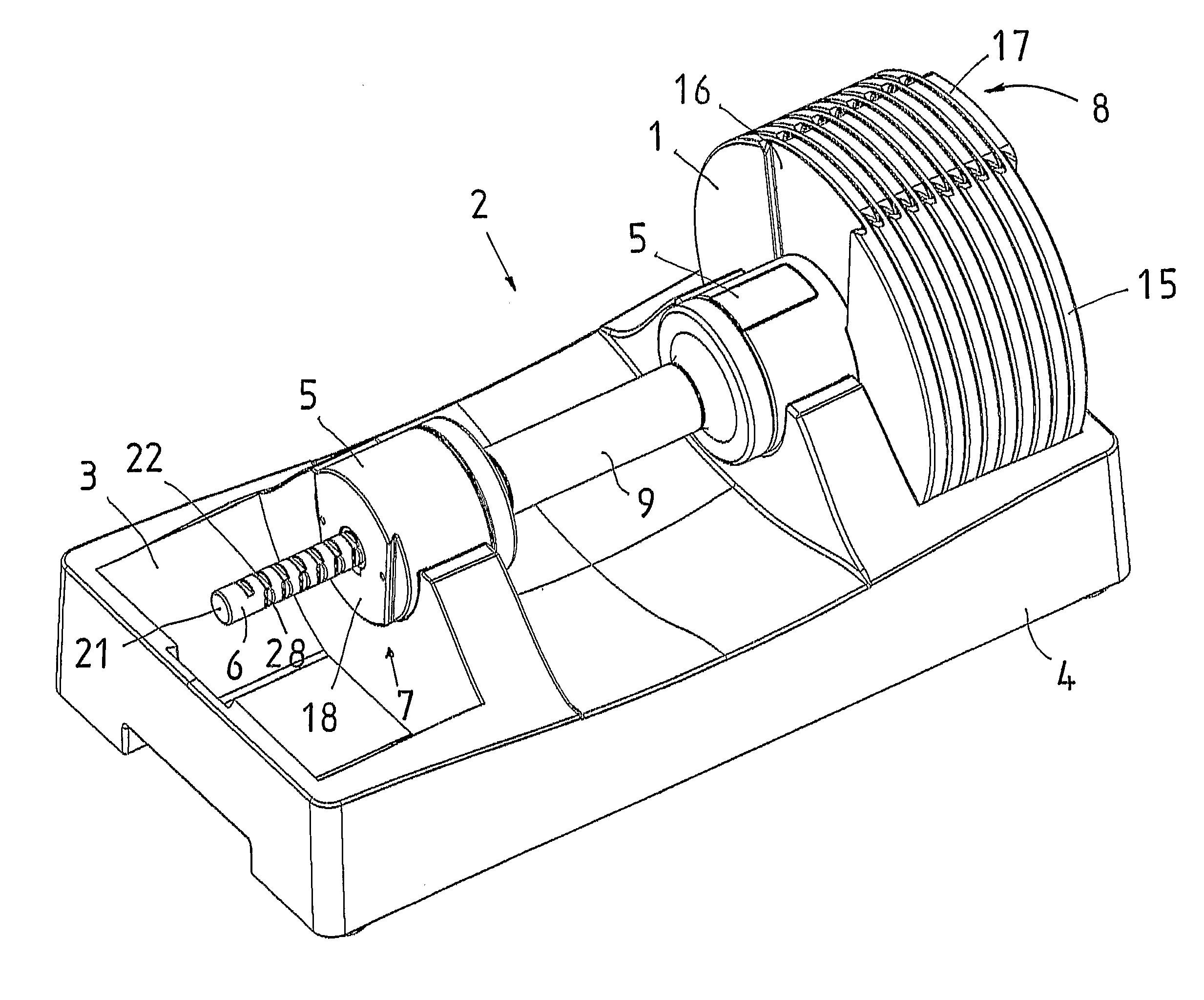

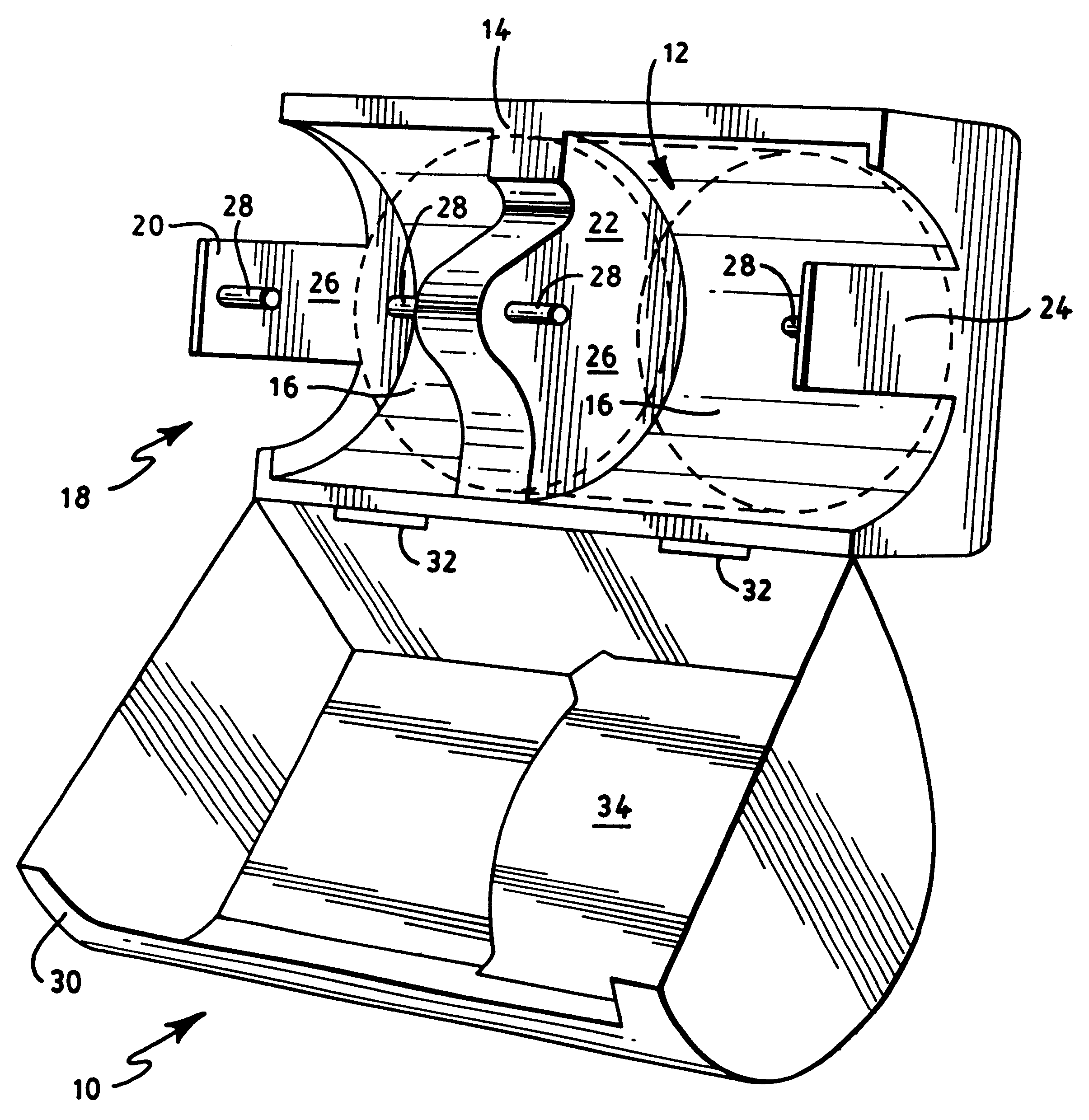

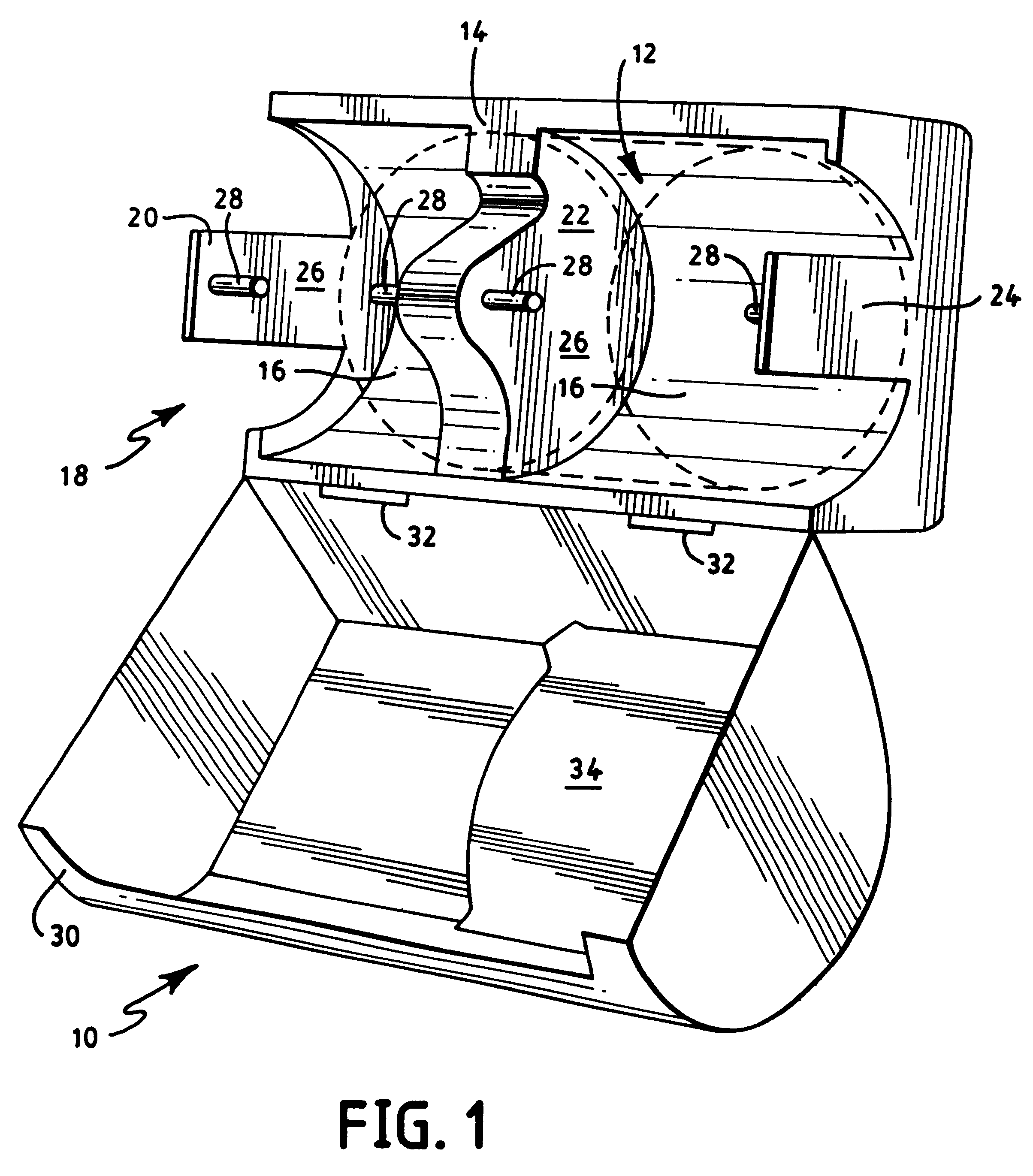

Dumbbell

InactiveUS20100304940A1Drawback can be obviatedSatisfactory mechanical strengthDumb-bellsDumbbellMechanical engineering

A dumbbell with a selectable number of weight disks includes a handle with pins projectable in opposing directions, a base assembly for accommodating two sets of weight disks standing on edge and provided with openings. The projection lengths of the pins are stepwise selectable in order to permit selection of the number of weight disks supported on the handle. Neighbouring weight disks have mutually engaging connecting arrangements which axially interconnect the weight disks but which permit radial separation. The weight disks are planar with a circular, unbroken peripheral edge and with the openings located centrally. All connecting arrangements have a longitudinal centre line which coincides with a diameter line for the weight disks and with the permitted radial displacement direction between two neighbouring weight disks.

Owner:SVENBERG TOMAS

Dispenser for coreless rolls of products

InactiveUS6439502B1Prevent theftPrevent radial displacementFilament handlingDomestic applicationsEngineeringMechanical engineering

A dispenser for a coreless roll product having a pair of depressions defined in the ends of the coreless roll. The dispenser includes: a frame; mounting device for permitting the frame to be mounted to a stationary surface such as a wall; and a coreless roll securing device for securing a coreless roll product for rotation within the frame. The coreless roll securing device includes a pair of cooperating plungers. Each plunger includes: (1) a base, the base being fixed to the frame; (2) a distal end, the distal end having a radius of curvature; and (3) a central shaft, the central shaft connecting the base and the distal end and providing sufficient length so the plunger has a length at least as great as its widest dimension so the plunger is adapted to penetrate a depression defined at an end of a coreless roll product, so radial displacement of the coreless roll with respect to said frame is prevented during use. Also a method for installing a coreless roll of a product.

Owner:KIMBERLY-CLARK WORLDWIDE INC

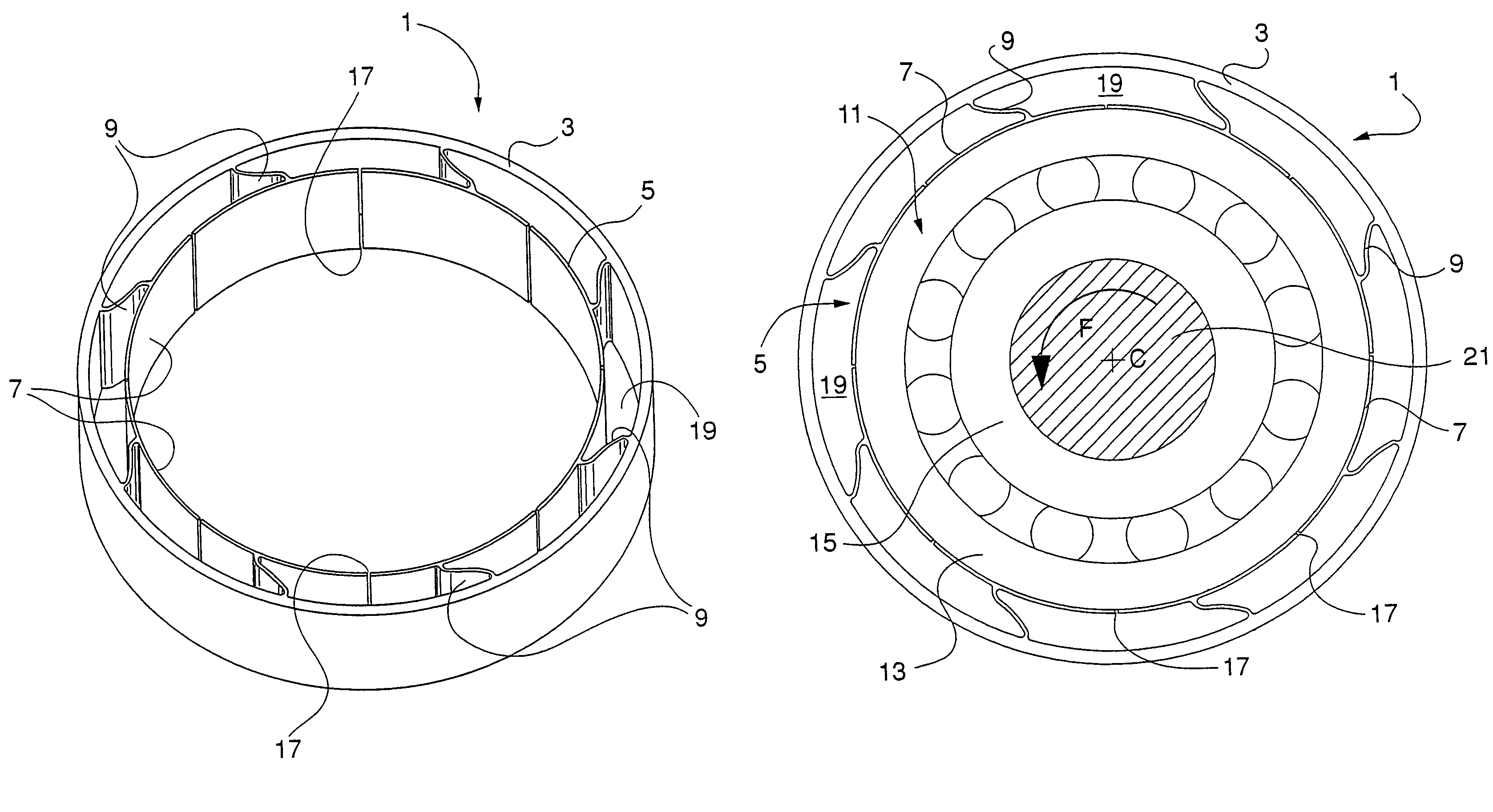

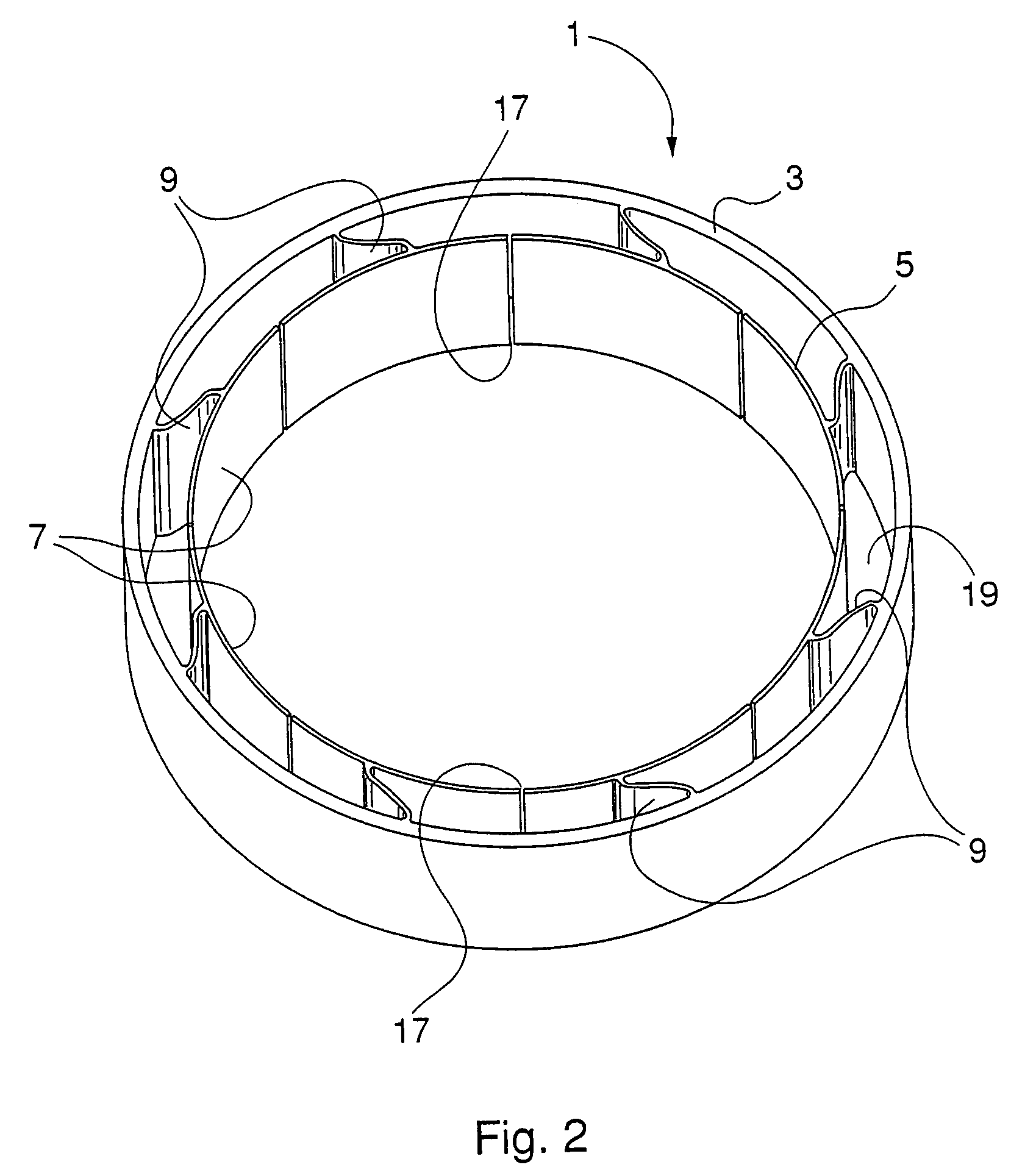

Annular support for rolling bearings

InactiveUS7553123B2Avoid vibrationReduce axial frictionPump componentsNon-positive displacement enginesRolling-element bearingEngineering

Owner:VARIAN SPA

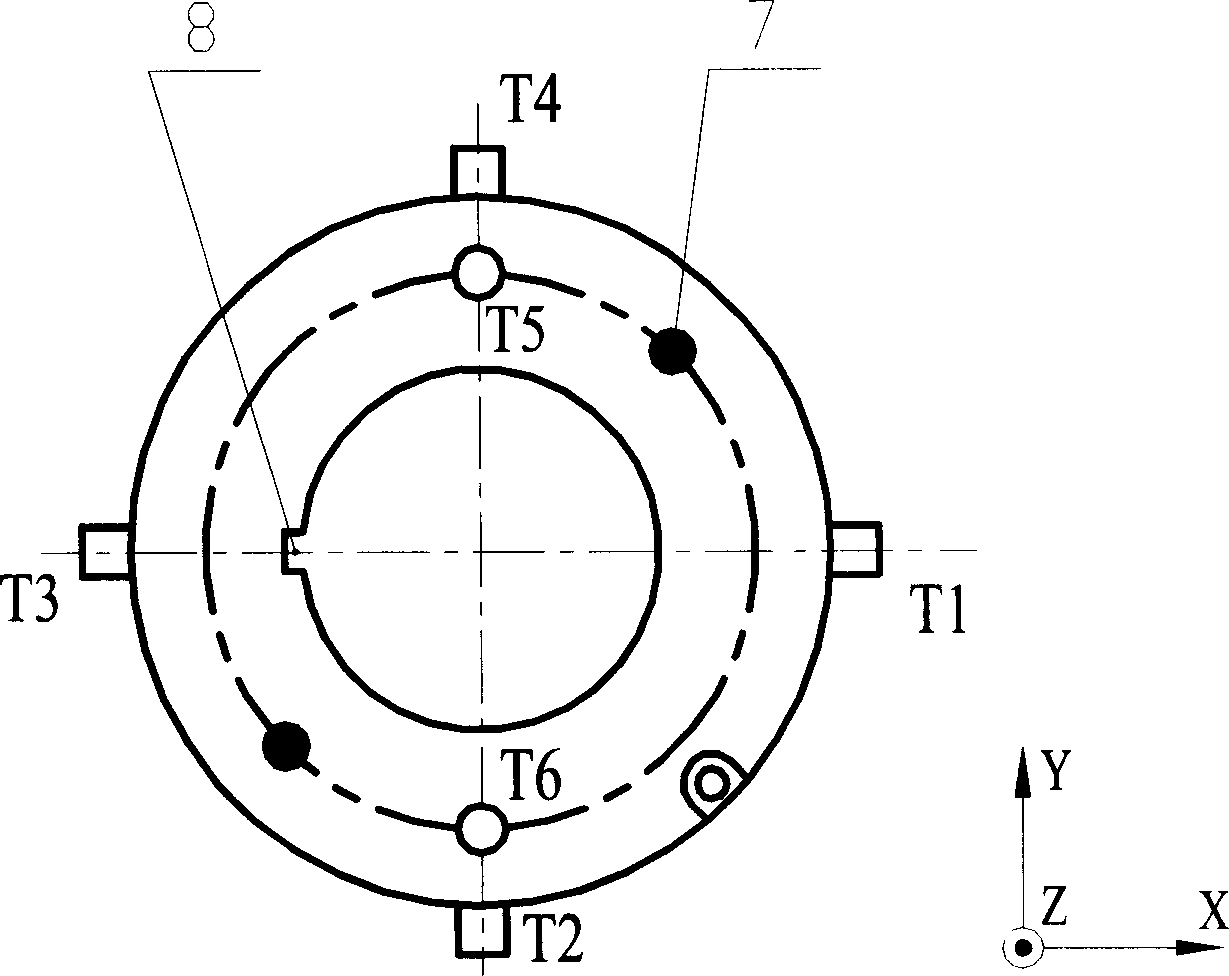

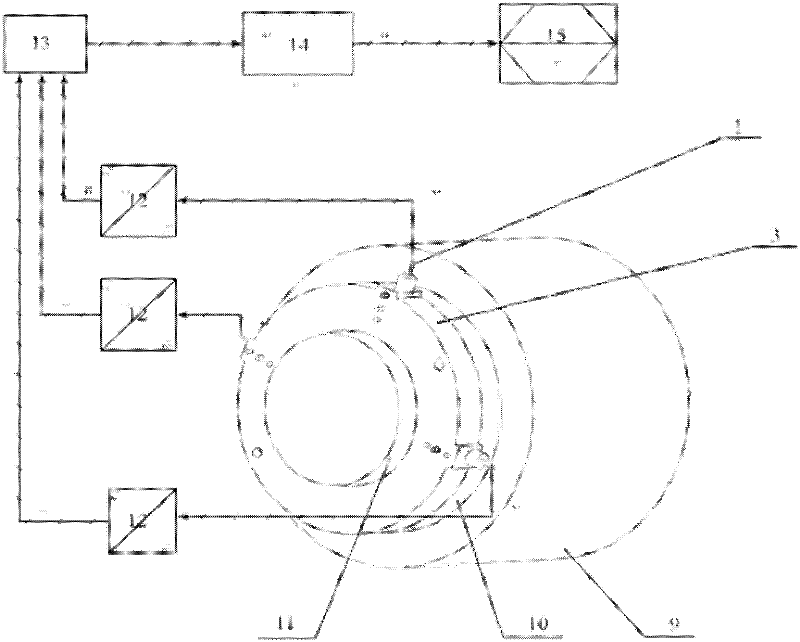

Online monitoring device for radial rotation accuracy of main shaft

ActiveCN102501137AReal-time online monitoringAccurate rotation accuracyMeasurement/indication equipmentsSeparation technologyData acquisition

An online monitoring device for the radial rotation accuracy of a main shaft is disclosed, wherein a monitoring ring is installed at the radial measuring position of the main shaft; three eddy-current displacement sensors are installed on the monitoring ring; the proximitors of the eddy-current displacement sensors are connected with the terminal board of a data acquisition board card; the data acquisition board card is connected to an industrial computer via a PCI (peripheral component interconnection) slot; when the main shaft is in a rotating state, the eddy-current displacement sensors convert the measured voltage signal to a standard voltage signal via the proximitors; the analog signal is converted to a digital signal via a signal conditioning circuit module and an A / D (analog / digital) conversion module on the data acquisition board card, and then the digital signal enters into the industrial computer; the radial displacement signal of the main shaft is obtained by signal acquisition and analysis software; the roundness error of the main shaft is separated out by applying a three-point error separation technology, thereby obtaining the rotation error of the main shaft; and finally the analysis result of the rotation accuracy of the main shaft is displayed. The online monitoring device for the radial rotation accuracy of a main shaft has the advantages of being high in accuracy and convenient in adjustment.

Owner:XI AN JIAOTONG UNIV +1

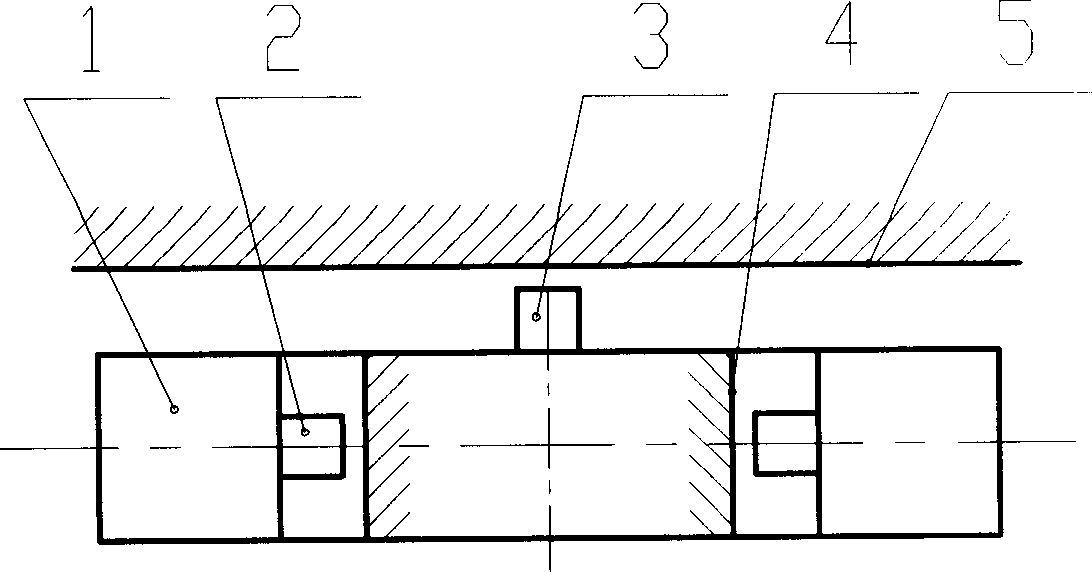

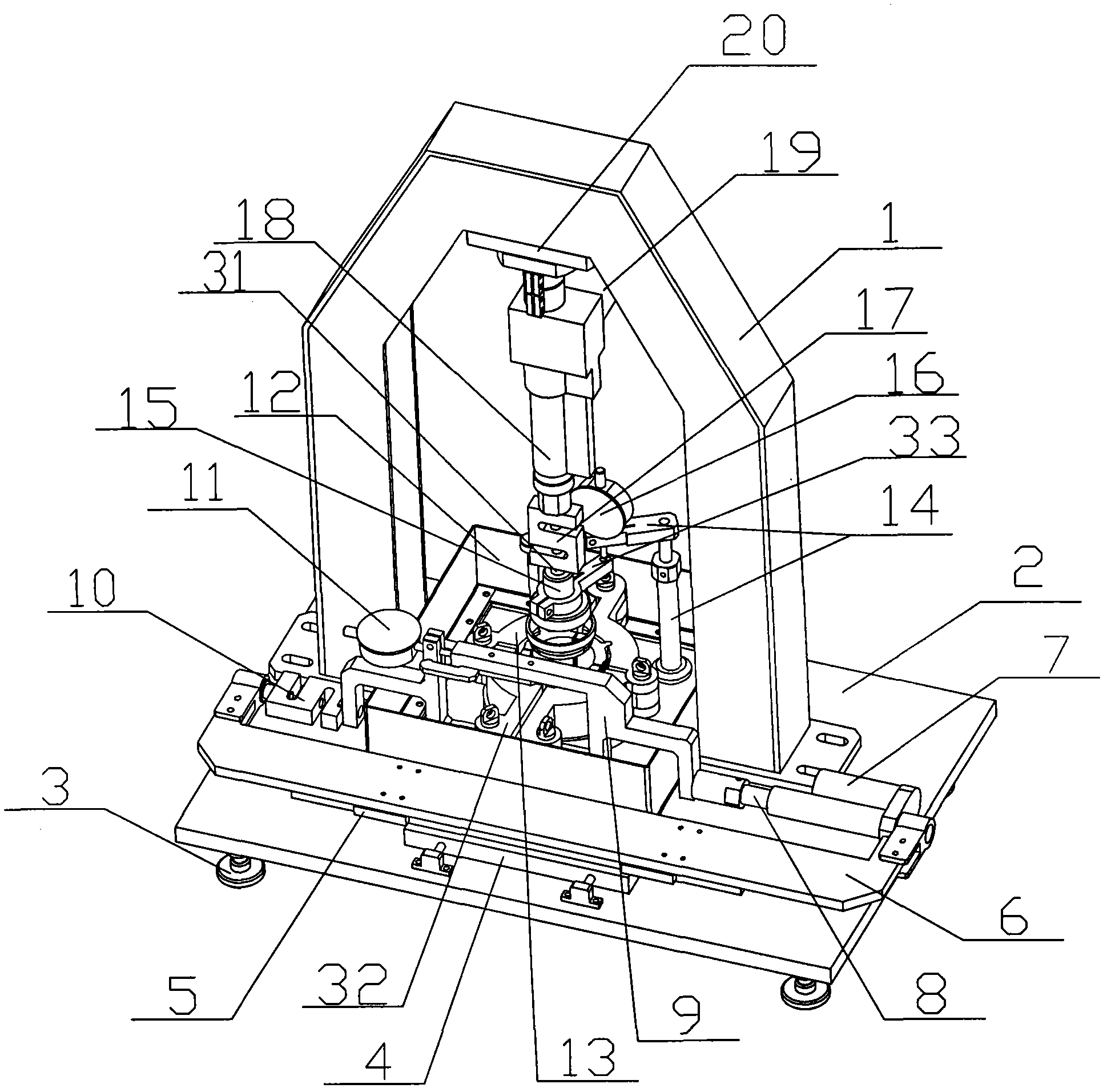

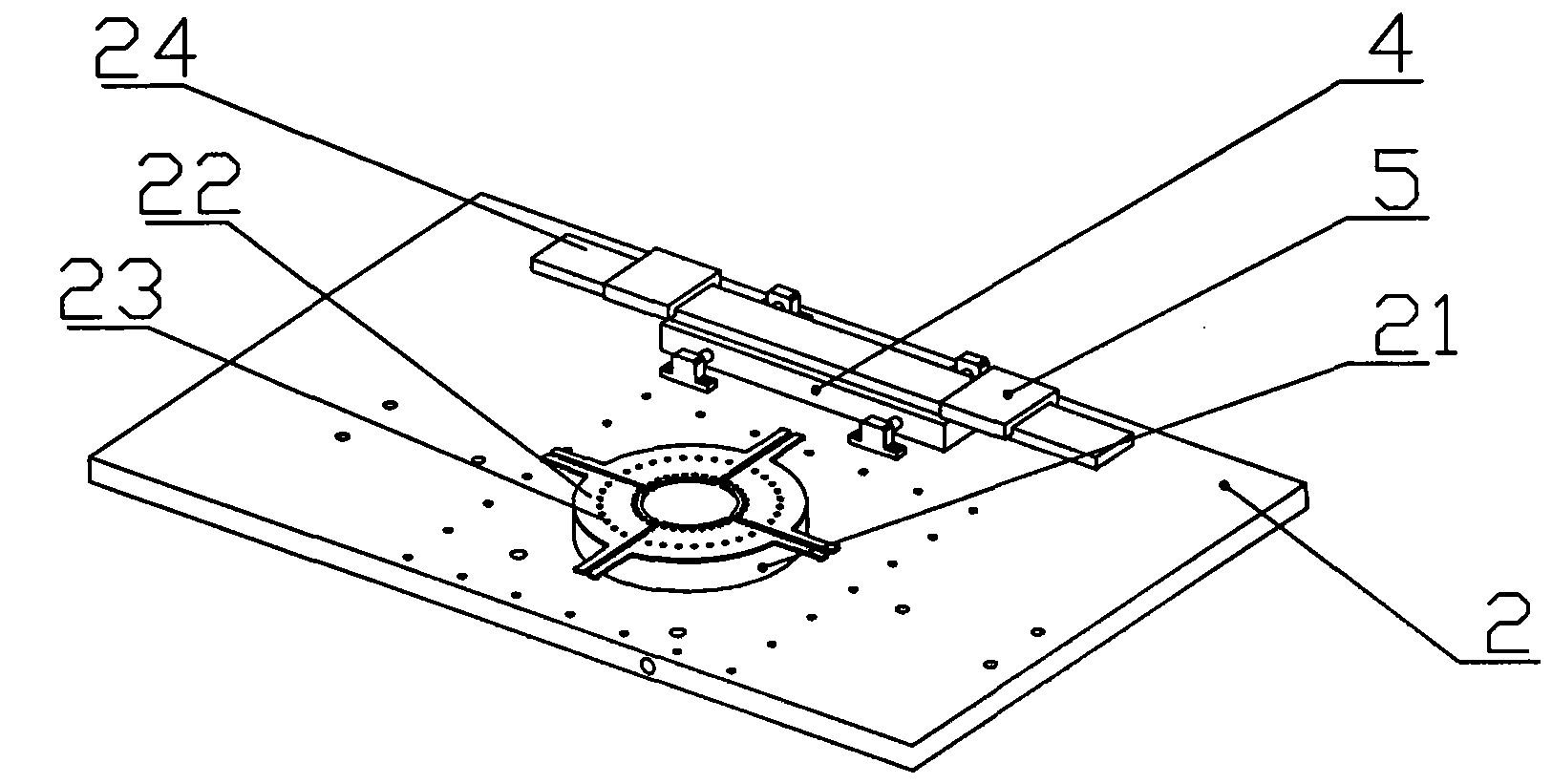

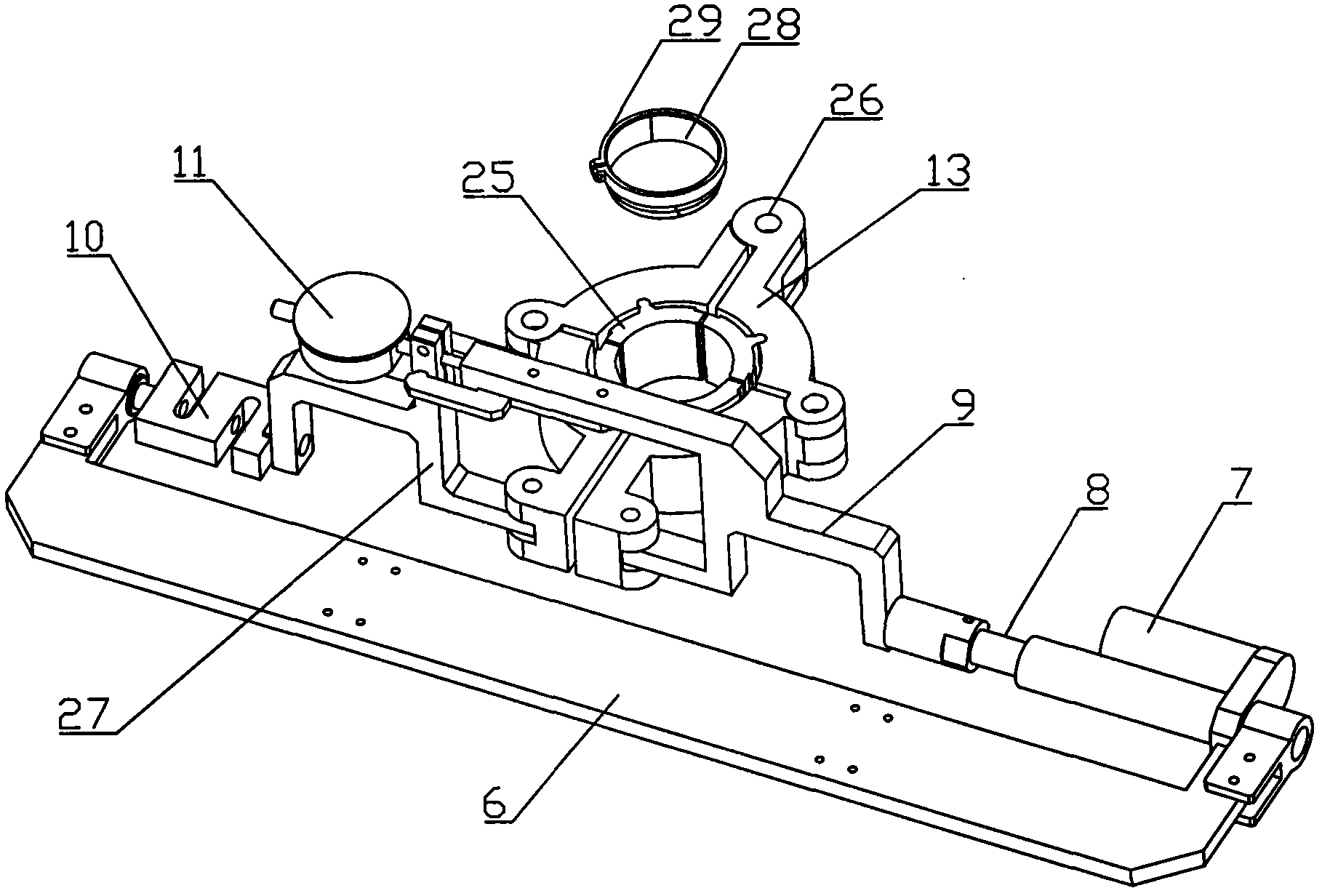

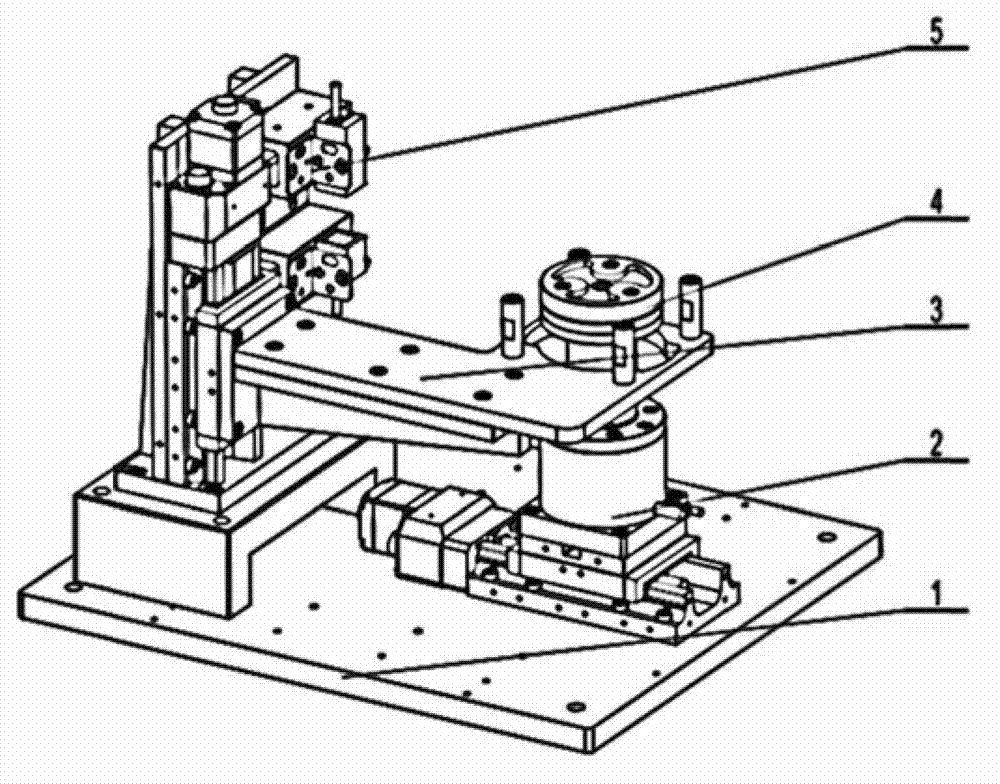

Tester for soil vertical and radial expansive deformation and expansive force relation

InactiveCN102636427ASolve the above deficienciesOvercome deficienciesEarth material testingUsing mechanical meansData acquisitionTester device

The invention discloses a tester for testing soil vertical and radial expansive force and expansive deformation. The tester comprises a frication force reducing device, a sample protecting ring component, a confining pressure and radial deformation testing component, a vertical pressure and deformation testing component and a data acquirer. The friction force reducing device is located in a soaking tank; the sample protecting ring component is placed on the friction force reducing device at the center of the soaking tank; and the data acquirer is connected with sensors in the vertical pressure and deformation testing component and the confining pressure and radial deformation testing component via data lines, and transmits acquired data to a computer. The tester can be used for testing vertical and radial expansive forces in a sample saturation process when vertical and radial displacements are not changed and obtaining the change law of the vertical and radial expansive forces, testing vertical and radial expansive forces under the condition of different vertical displacements in the sample saturation process when the radial displacement is changed or not changed, and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

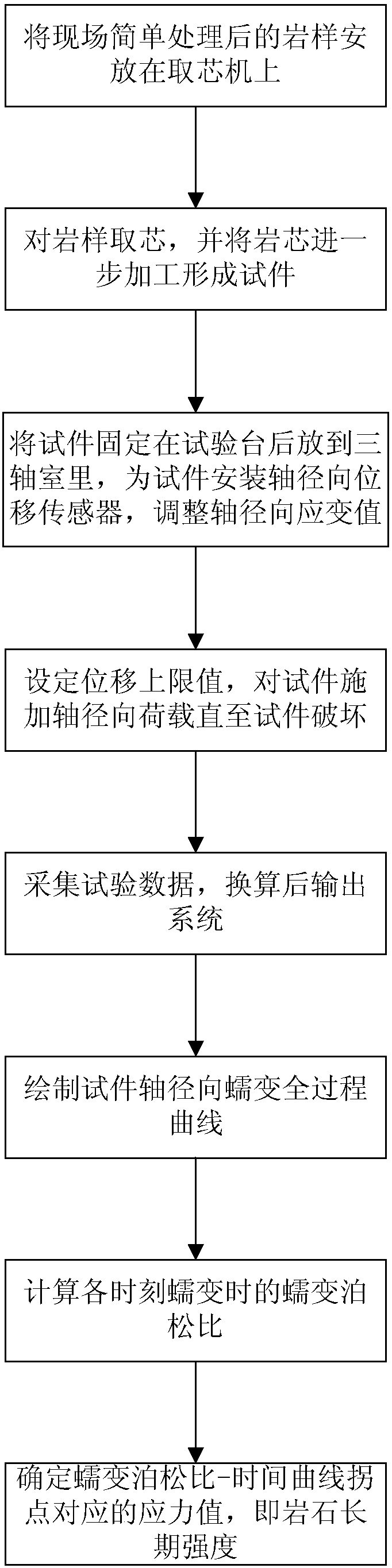

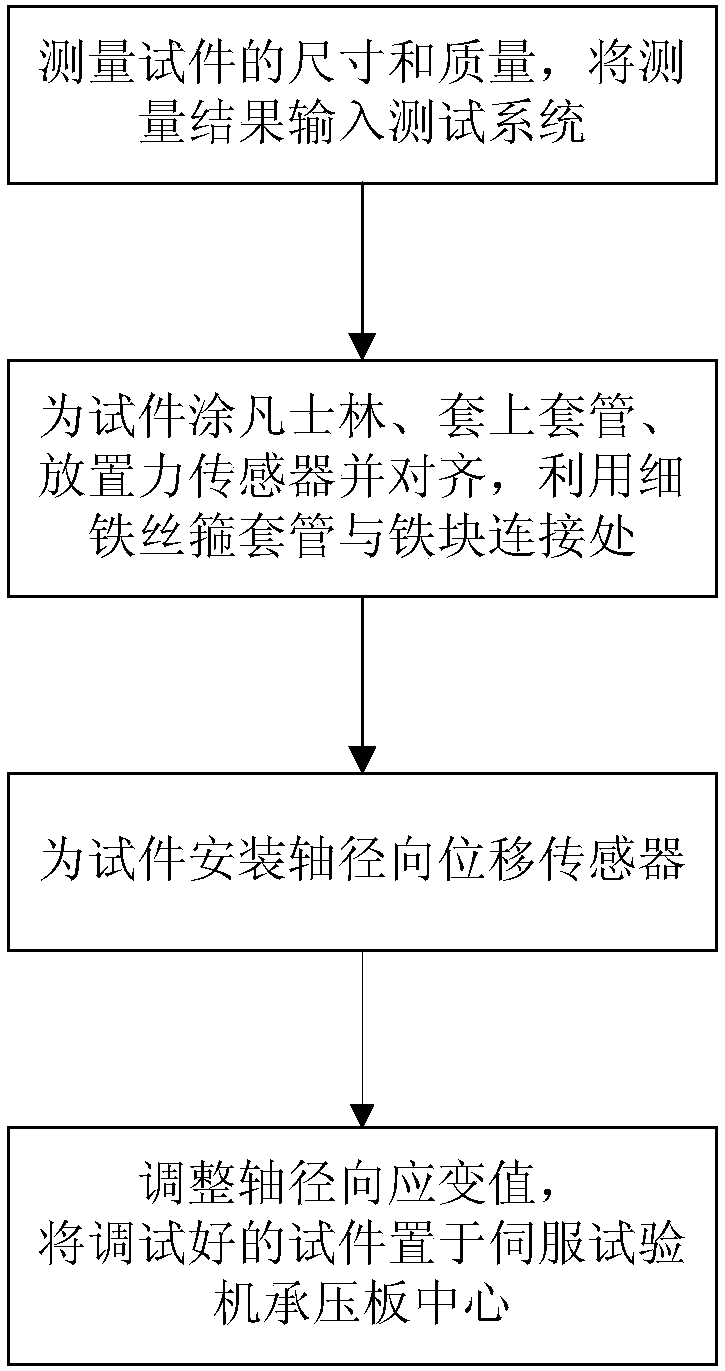

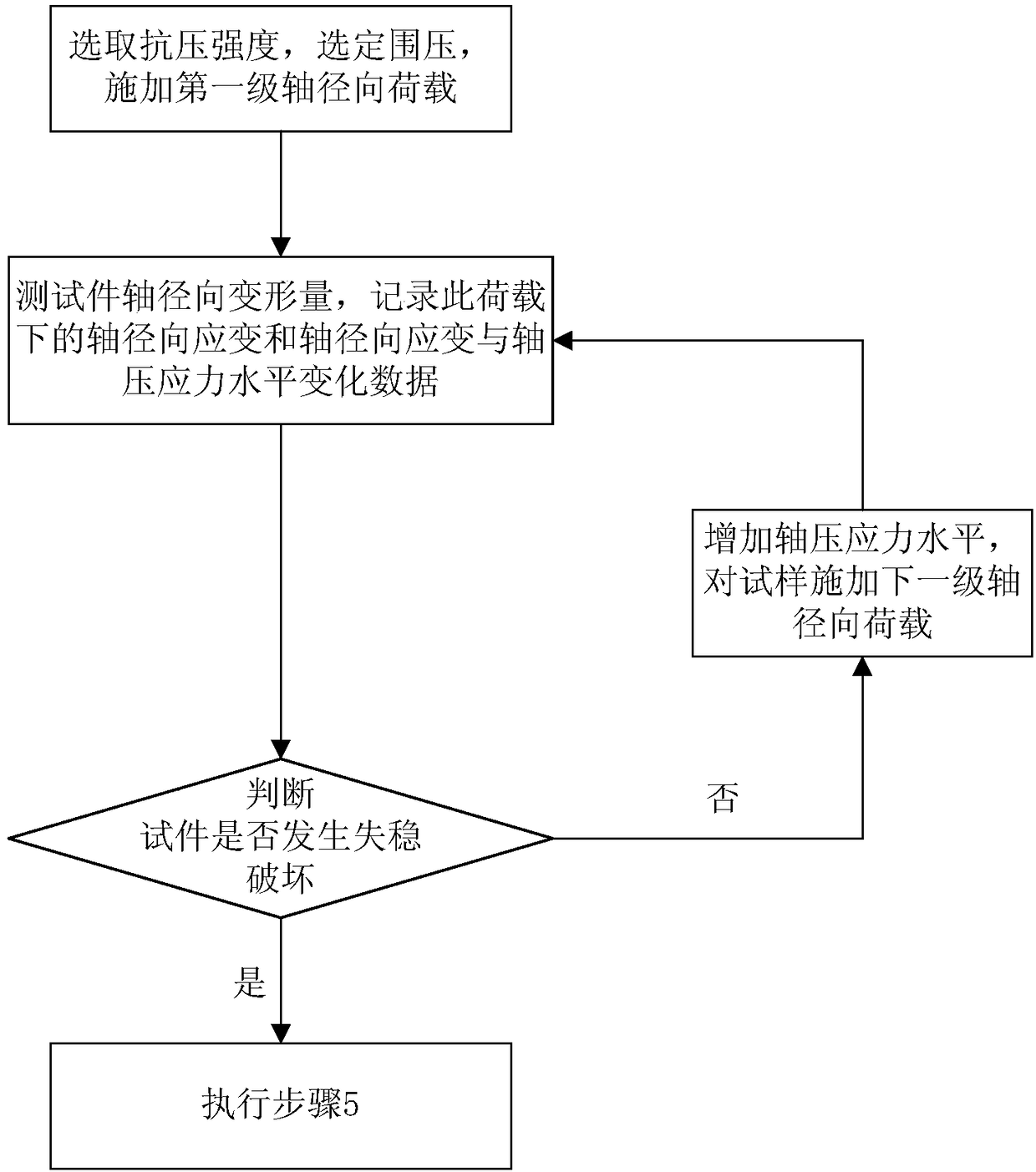

Method of determining long-term strength in rock creep tests

InactiveCN108152137AImprove accuracyMaterial strength using tensile/compressive forcesRock engineeringRock core

The invention provides a method of determining long-term strength in rock creep tests, and relates to the technical field of rock mechanics. The method includes coring field rock samples; processing rock cores to form test pieces; mounting and adjusting axial and radial displacement sensors for the test pieces; applying axial and radial load to the test pieces until the text pieces are destroyed;acquiring test data, and converting and outputting the test dada; plotting axial and radial creep curves of the test pieces; computing creep Poisson ratios at various moments; determining the long-term strength of rock. The method for determining the long-term strength in the rock creep tests has the advantages that influence of axial and radial deformation in the rock creep procedures on the performance of the rock is comprehensively considered according to actual ductile dilation deformation of the rock, the creep time is segmented, creep Poisson ratio -time curves are plotted, the long-termstrength of the rock is determined according to stress corresponding to data of inflection points of the curves, accordingly, the timeliness of the rock can be effectively reflected by the solved long-term strength, subjective judgment can be eliminated, and the method is simple and reliable, is high in accuracy and is easy to popularize and apply to actual rock engineering.

Owner:LIAONING TECHNICAL UNIVERSITY

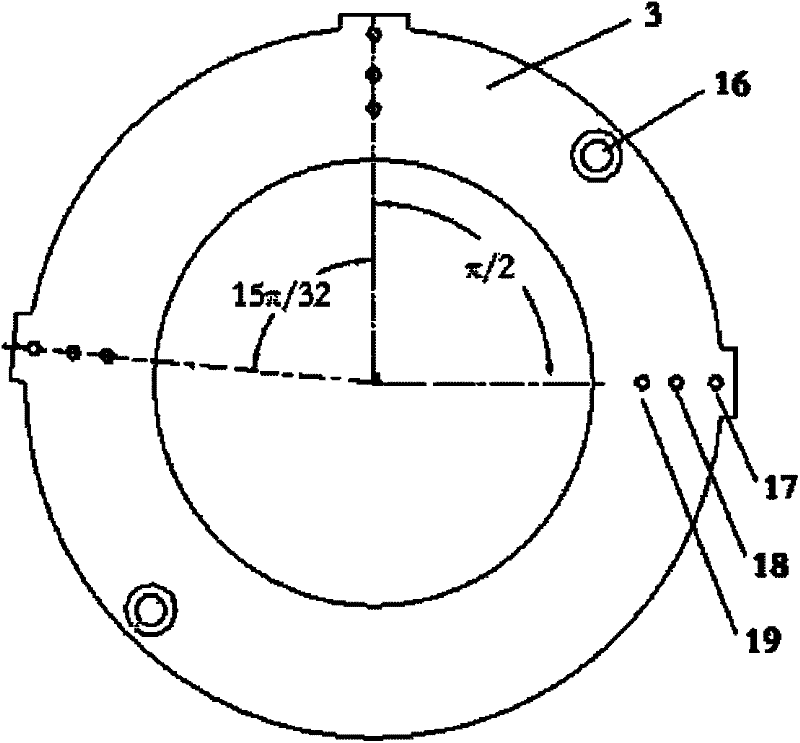

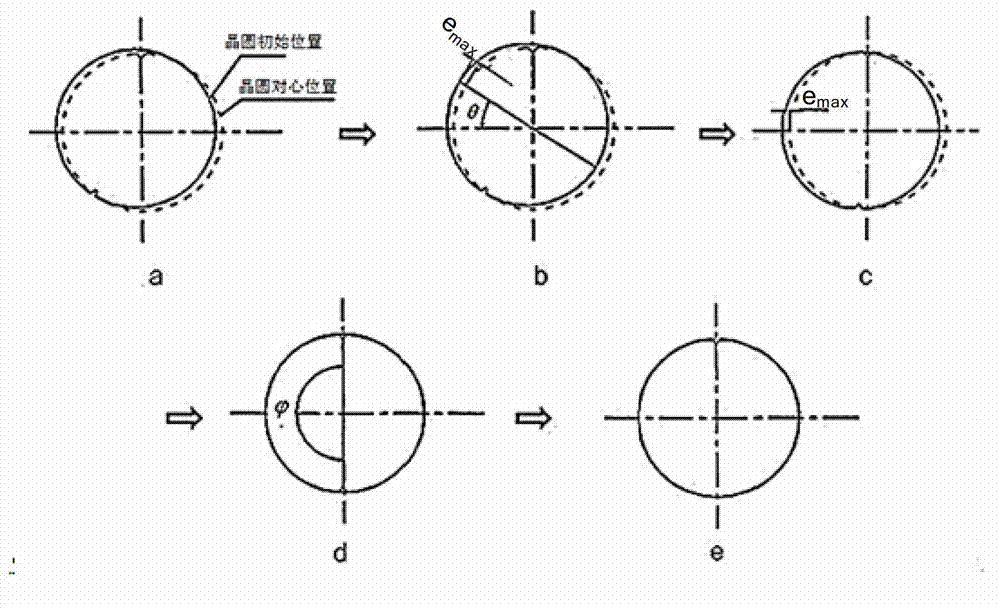

Wafer pre-alignment method

InactiveCN103050427AIncrease the number of sampling points for a weekDoes not take up space sizeSemiconductor/solid-state device manufacturingMathematical modelEngineering

The invention provides a wafer pre-alignment method, which comprises the following steps of: calculating shape center position coordinates of a wafer, radial displacement maximum offset emax and an included angle of a radial displacement maximum offset part and horizontal Y direction by using a high-accuracy laser transmitting sensor according to one-circumference data of the edge of the wafer; driving the wafer to rotate at an angle so as to position the radial displacement maximum offset emax and the horizontal Y direction on a straight line, thereby finishing shape center positioning of the wafer; and accurately positioning a notch of the wafer according to a shape center algorithm. According to the wafer pre-alignment method, the edge of the wafer is detected by using a light transmitting sensor, and the positions of a shape center and the notch of the wafer are determined by using the shape center algorithm, so that the accuracy of the positioning method is effectively improved, the time and the space occupied by a pre-alignment are reduced, and the cost is reduced.

Owner:SHANGHAI JIAO TONG UNIV

Magnetic suspension manual heart pump

The invention relates to a magnetic suspension artificial heart pump, comprising a frame, a motor, a magnetic bearing and a blood pump blade wheel, wherein, the blood pump blade wheel, a motor rotor and a magnetic bearing rotary magnetic ring form a combined rotor to be mounted in a blood separating sheath with blood inlet and outlet, a motor stator, a fixed magnetic ring of the magnetic bearing and a radial displacement sensor combine a combined stator to be arranged at an outer ring of the blood separating sheath to be fixed with the frame. The invention realizes magnetic suspension on the rotor, with reliable operation, and uses blood separating sheath to avoid polluting blood from heart pump most. The invention has compact structure, small volume, better integration, long service life, and better transplant property.

Owner:SHANGHAI UNIV

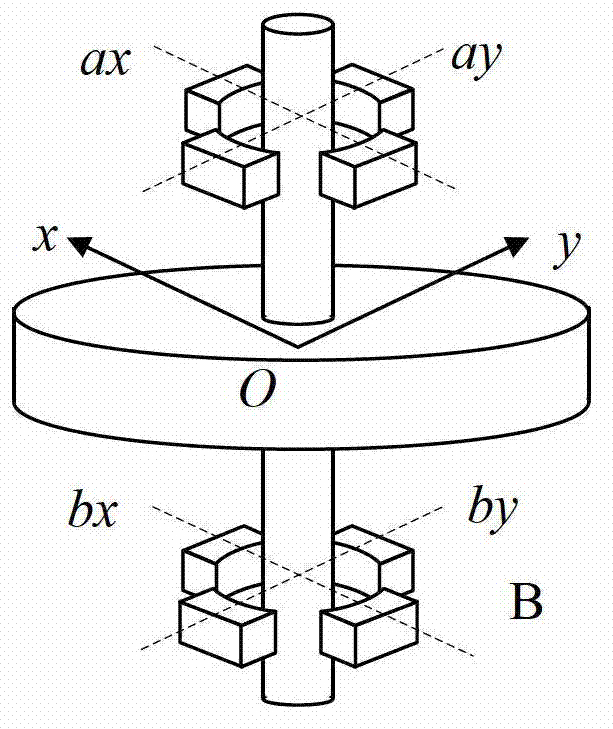

Five-freedom active magnetic bearing type dual-axis angular rate gyroscope

ActiveCN103196436ASmall drift rateAvoid disturbance torqueRotary gyroscopesAxial displacementGyroscope

The invention discloses a five-freedom active magnetic bearing type dual-axis angular rate gyroscope. The five-freedom active magnetic bearing type dual-axis angular rate gyroscope consists of rotors, a radial magnetic bearing, an axial magnetic bearing, a protection bearing, a radial displacement sensor, an axial displacement sensor, a driving motor, gyroscope cases and a circuit system. By using position feedback information of the rotors of the radial sensor and the axial sensor relative to the gyroscope cases, the circuit system regulates the coil winding current of the radial magnetic bearing and the axial magnetic bearing in real time, so that the five-freedom fully-active suspension of the rotors is realized, and the rotors are driven by the driving motor to rotate at a high speed so as to generate an angular momentum. When the attitude of an external rotor is changed, the coil winding current is correspondingly changed, and the magnitude of external input angular rate is calculated according to a linear relationship between the coil winding current and the input angular rate. The five-freedom active magnetic bearing type dual-axis angular rate gyroscope is applicable to the field of high-accuracy angular rate measurement application, and has the characteristics of small zero offset, low output noise, high resolution and the like.

Owner:BEIHANG UNIV

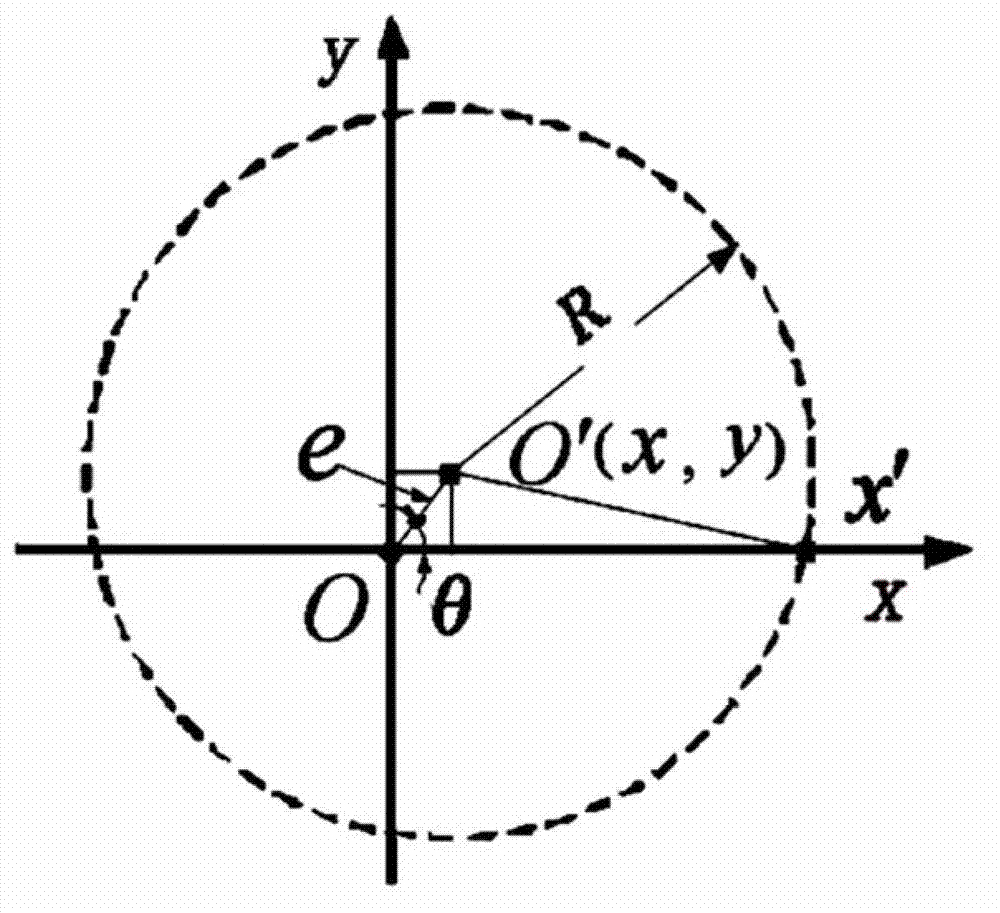

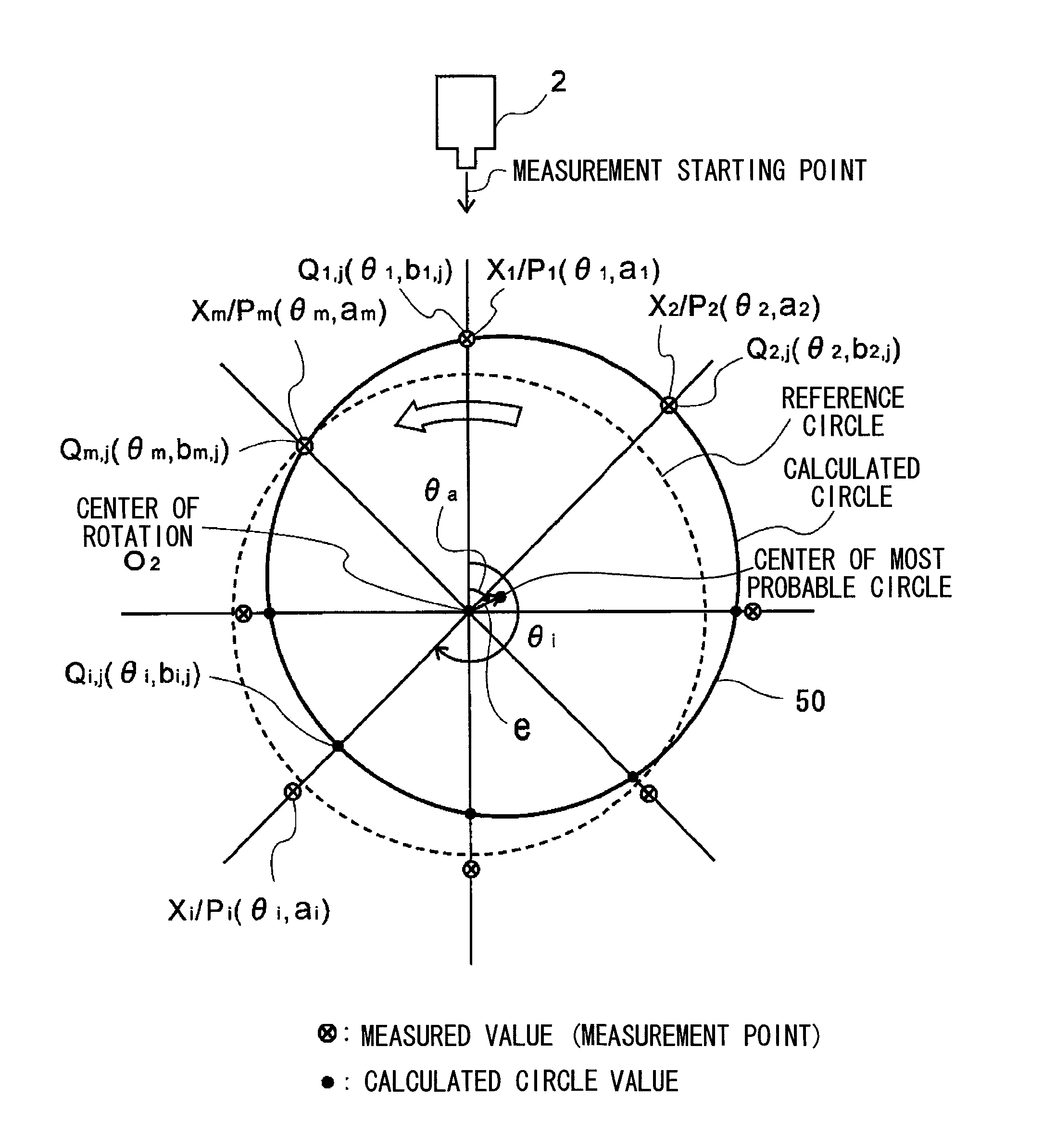

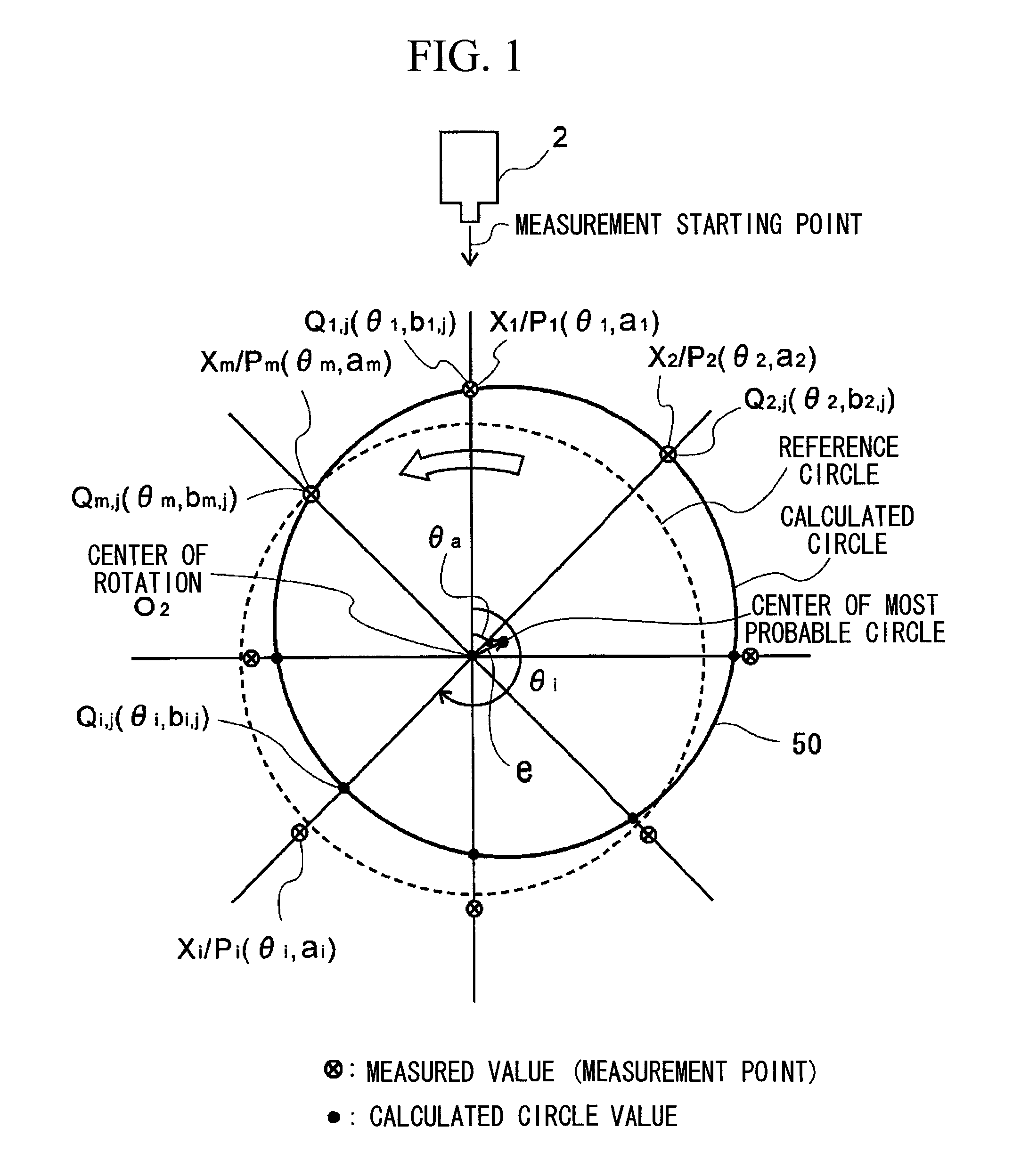

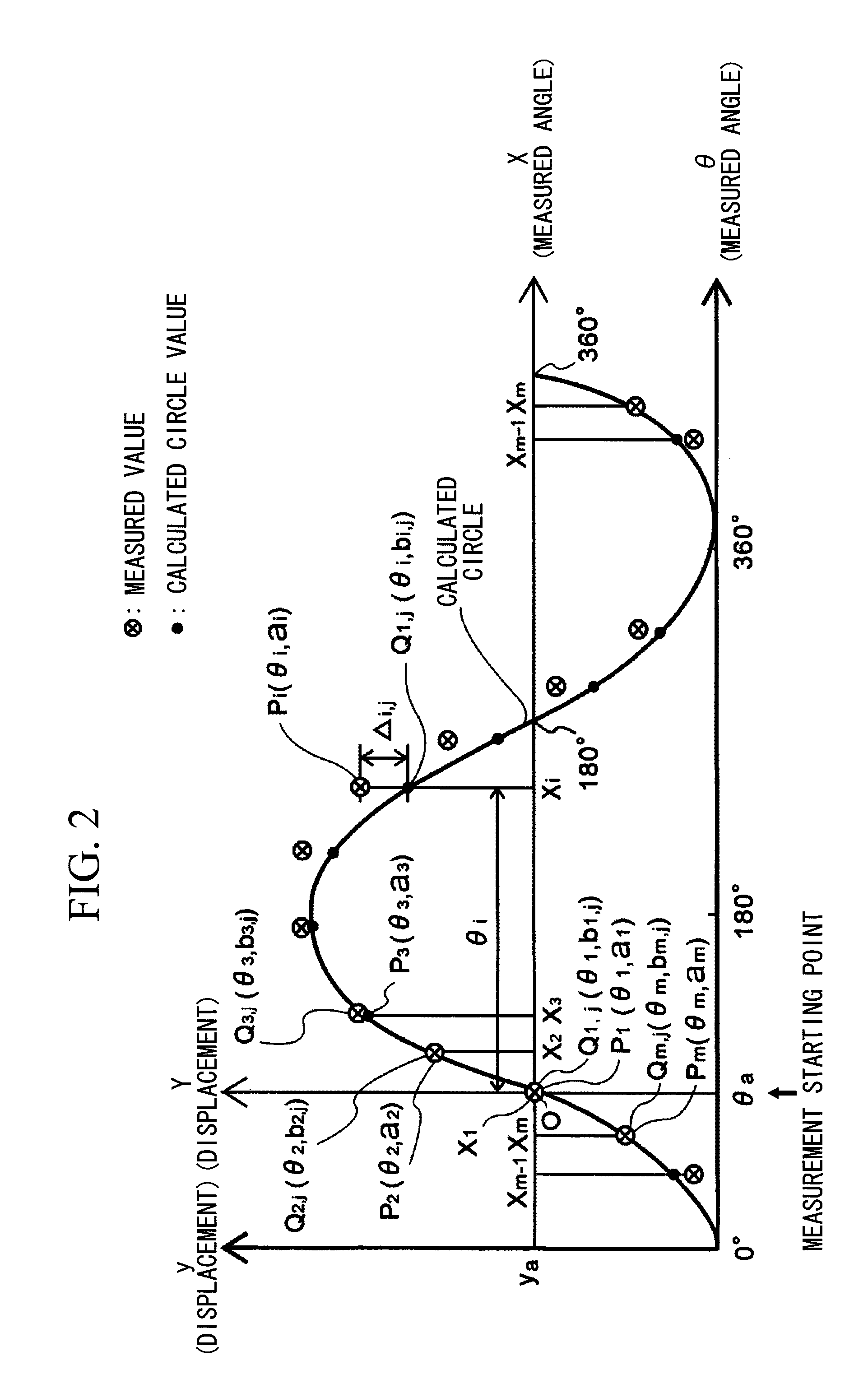

Method and system for calculating misalignment of rotational body

ActiveUS8306776B2Quick and reliable maintenanceElectrical/magnetic diameter measurementsIncline measurementMeasurement pointRepeating circle

In a method of calculating misalignment of a rotational body, radial displacement values are measured using a displacement gauge. A calculation part performs the steps of deriving radial displacement amounts of the rotational body for at least four or more measurement points along an outer surface while rotating the rotational body, selecting three arbitrary points to calculate a circle, calculating circle values for all the measurement points, calculating differences between the calculated circle values and the radial displacement amounts as error amounts, summing the error amounts to derive a total error amount, repeating circle calculation for different combinations and calculating a total error amount for each calculated circle, selecting a circle with a minimum total error amount as a most probable circle, and calculating deviation between the center of the most probable circle and the center of rotation of the rotational body.

Owner:MITSUBISHI POWER LTD

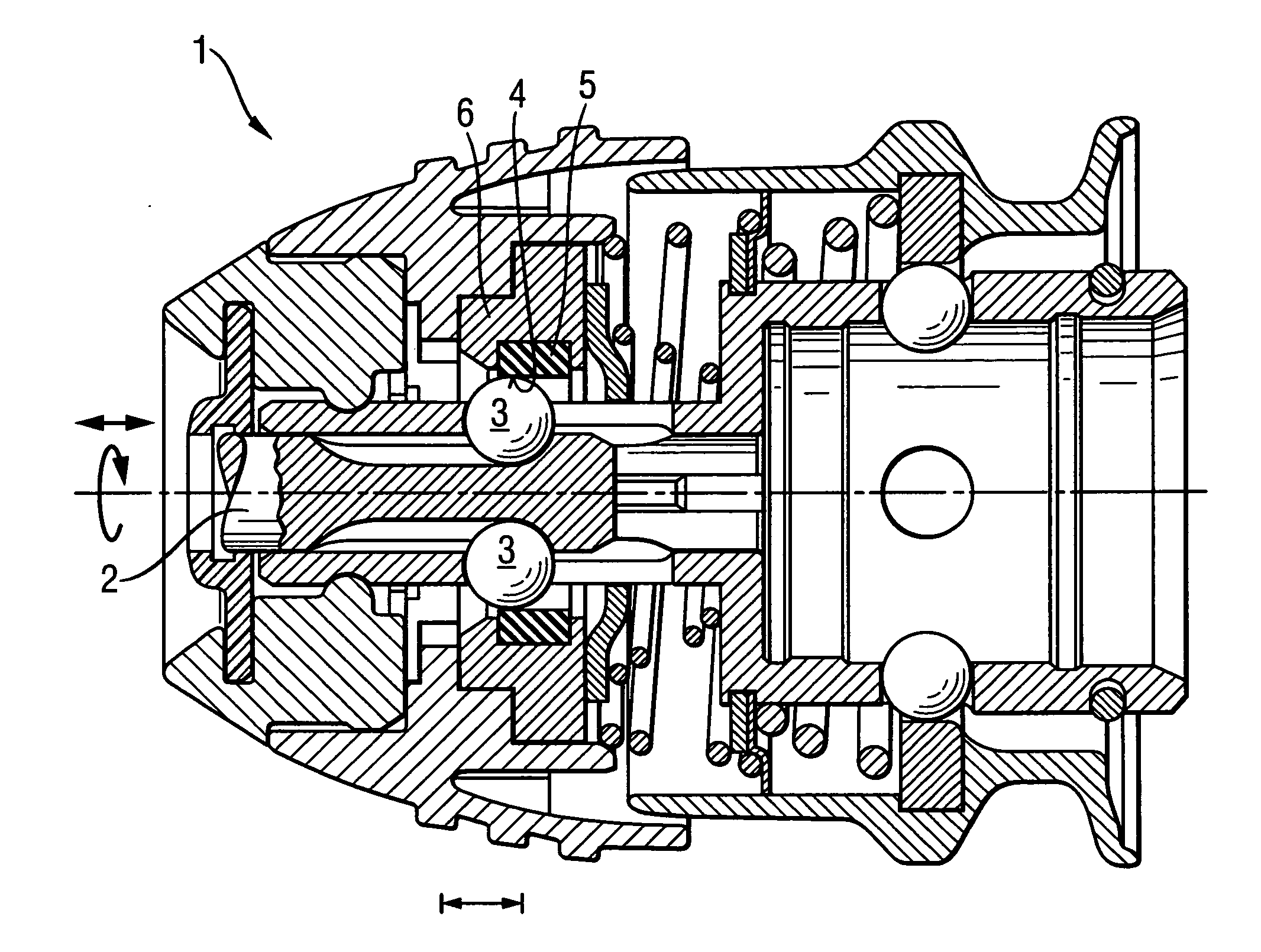

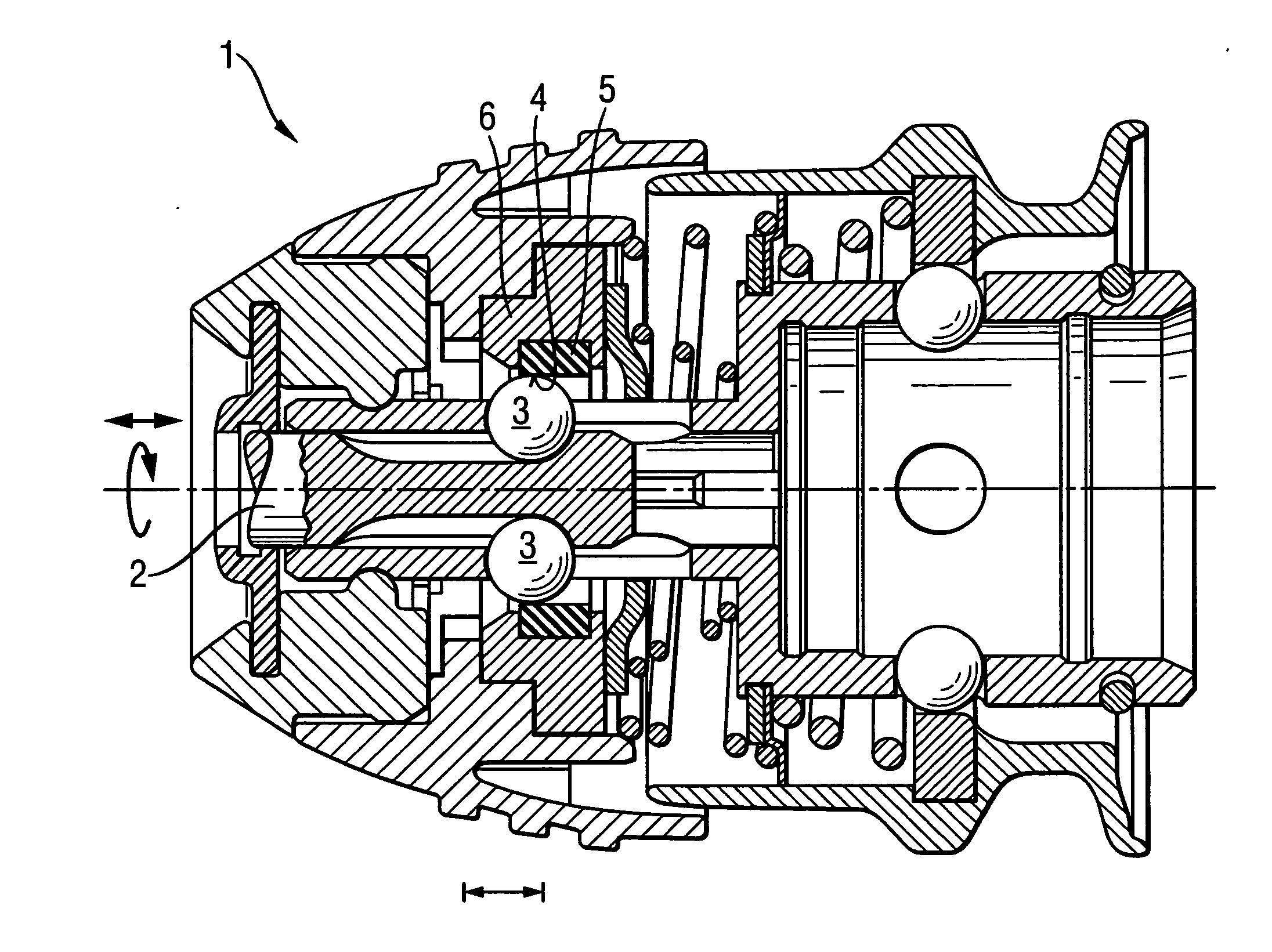

Chuck

InactiveUS20070024013A1High strengthImprove rigiditySleeve/socket jointsPortable percussive toolsEngineeringMechanical engineering

A chuck for a percussively driven working tool includes at least one radially displaceable, locking member (3) and a locking element (5, 6) for blocking radial displacement the at least one locking member outwardly. The locking member has a locking surface (4) located radially adjacent to the at least one locking member (3) and formed as a radially damping surface.

Owner:HILTI AG

Mounting arrangement for a refrigerator fan

InactiveUS7317267B2Easily and quickly assembled and disassembledImprove performancePump componentsStands/trestlesPropellerEngineering

A mounting arrangement for a refrigerator fan, comprising an electric motor (11) to whose shaft is affixed a propeller (12) with an axial flow passing through a refrigerated air outlet (4b) provided through an internal divisional wall (6) of the refrigerator; a support frame (20) having a marginal portion (21) and incorporating a central hub (22) in which is affixed the electric motor (11); a flexible support (30) in the form of an annular flange presenting an outer portion (31), which is peripherally and removably affixed to the contour of the refrigerated air outlet (4b), an inner portion (32) provided with a central opening (35) and with retaining means (36), which are removably locked to the marginal portion (21) of the support frame (20); and an annular membrane portion (33) interconnecting the outer portion (31) and the inner portion (32), in order to allow for small relative axial and radial displacements therebetween.

Owner:MULTIBRAS SA ELETRODOMESTICOS

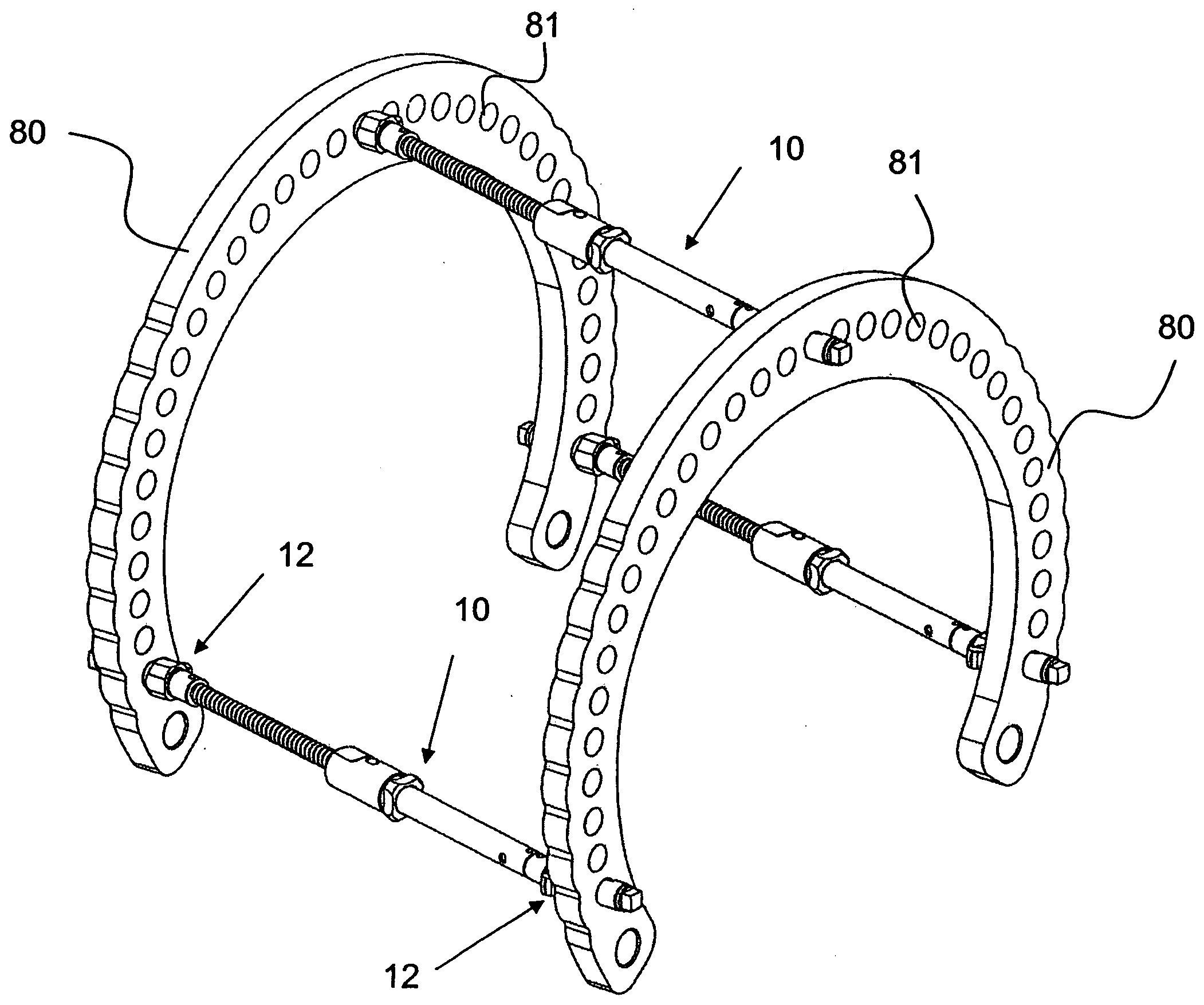

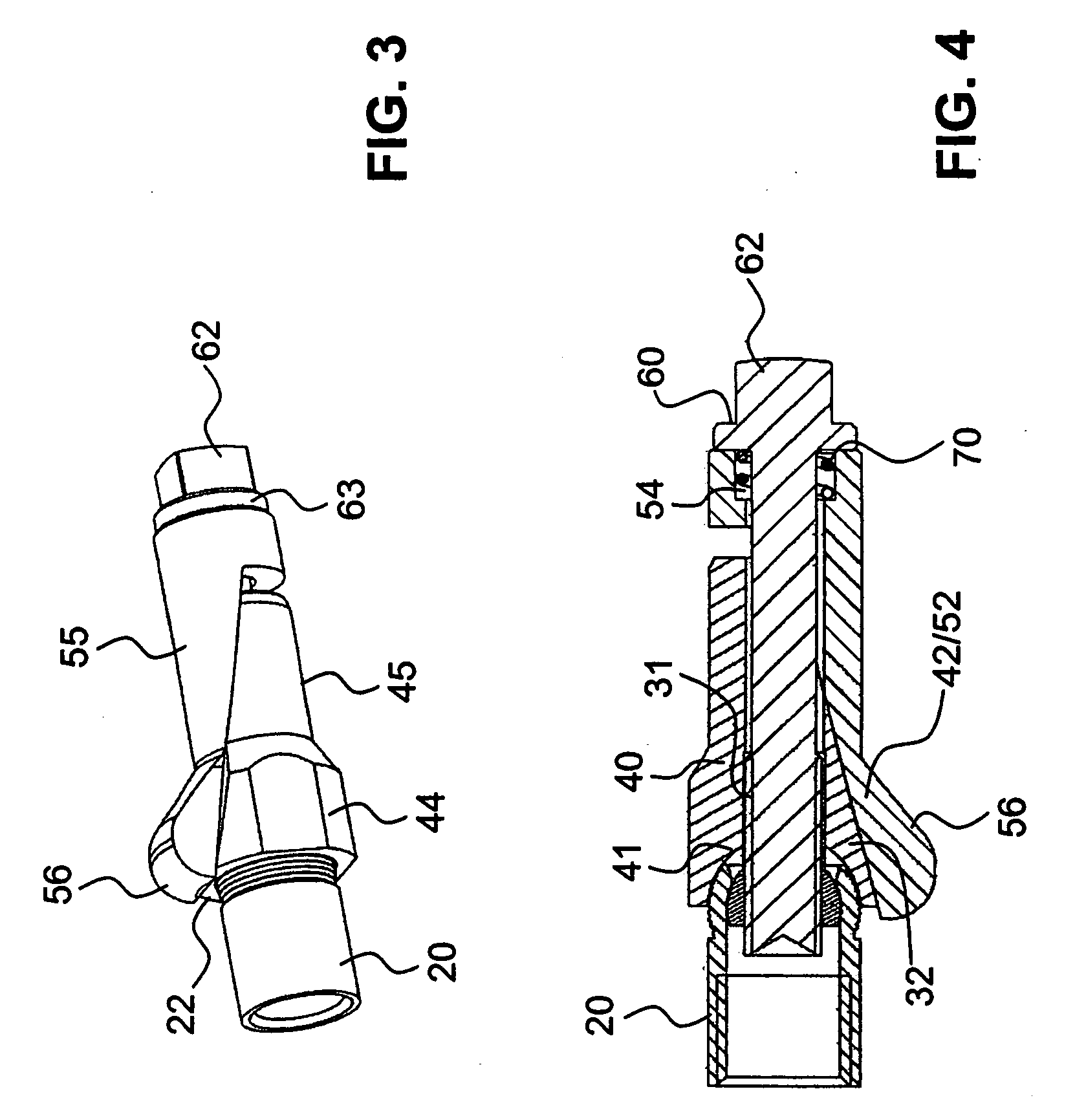

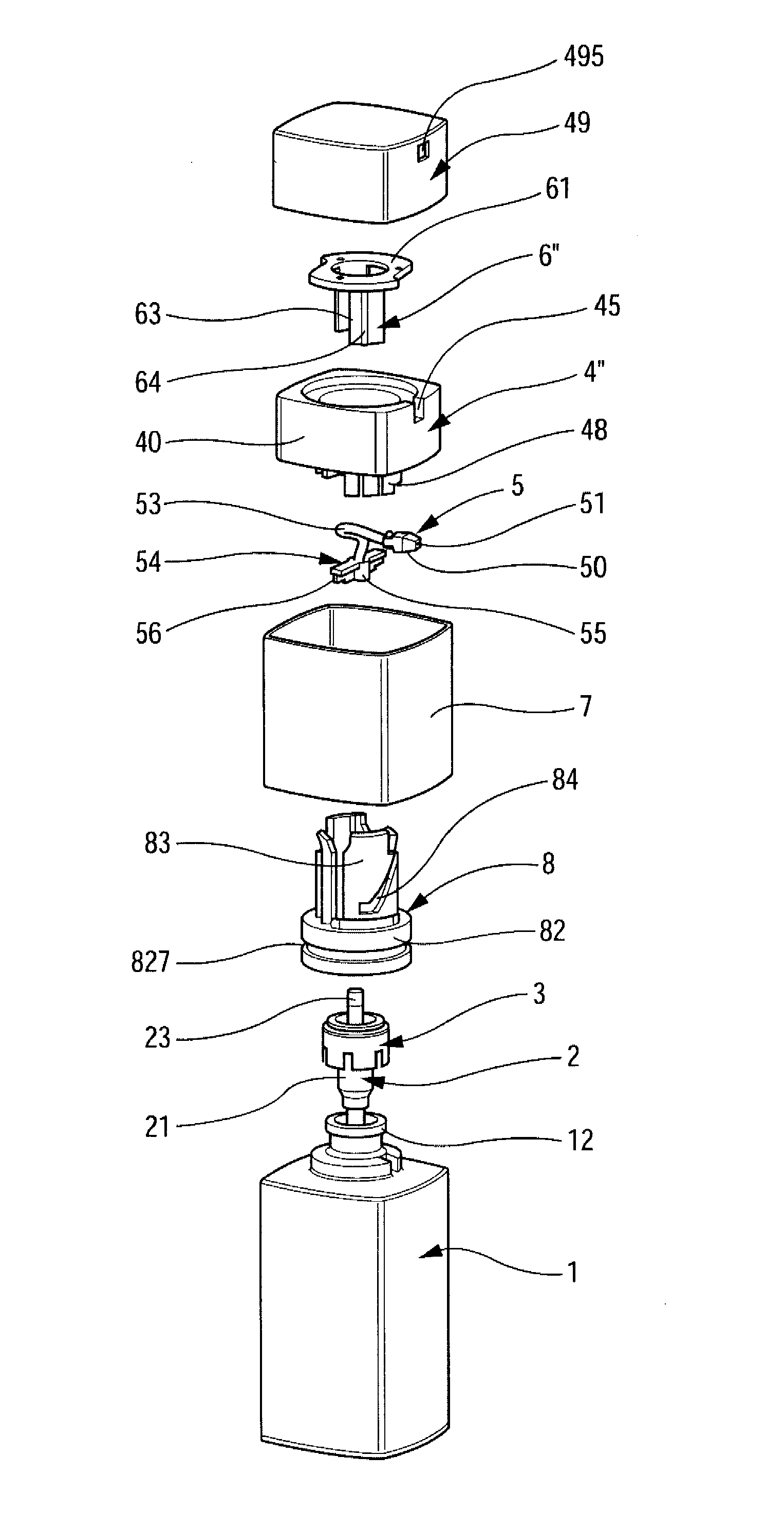

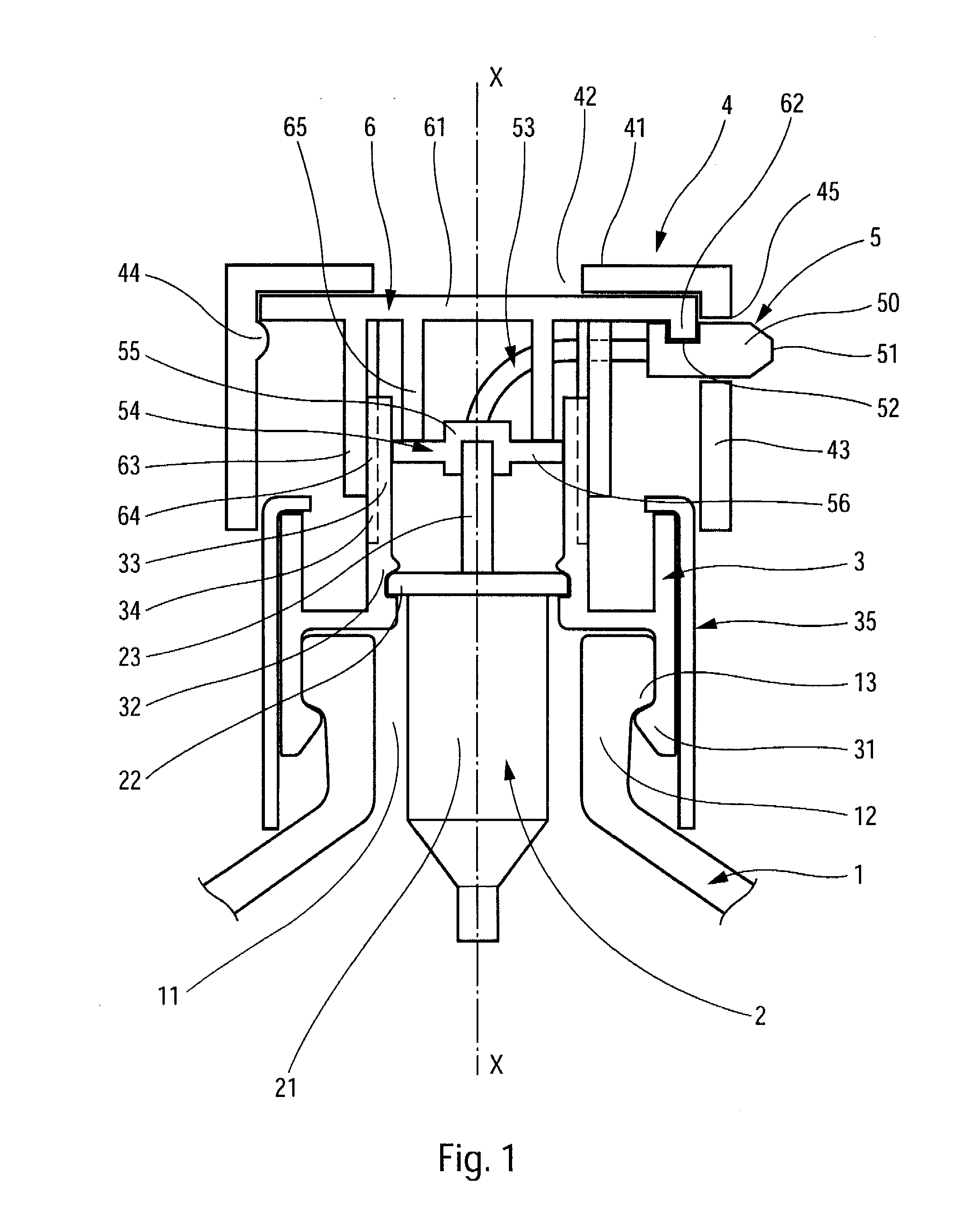

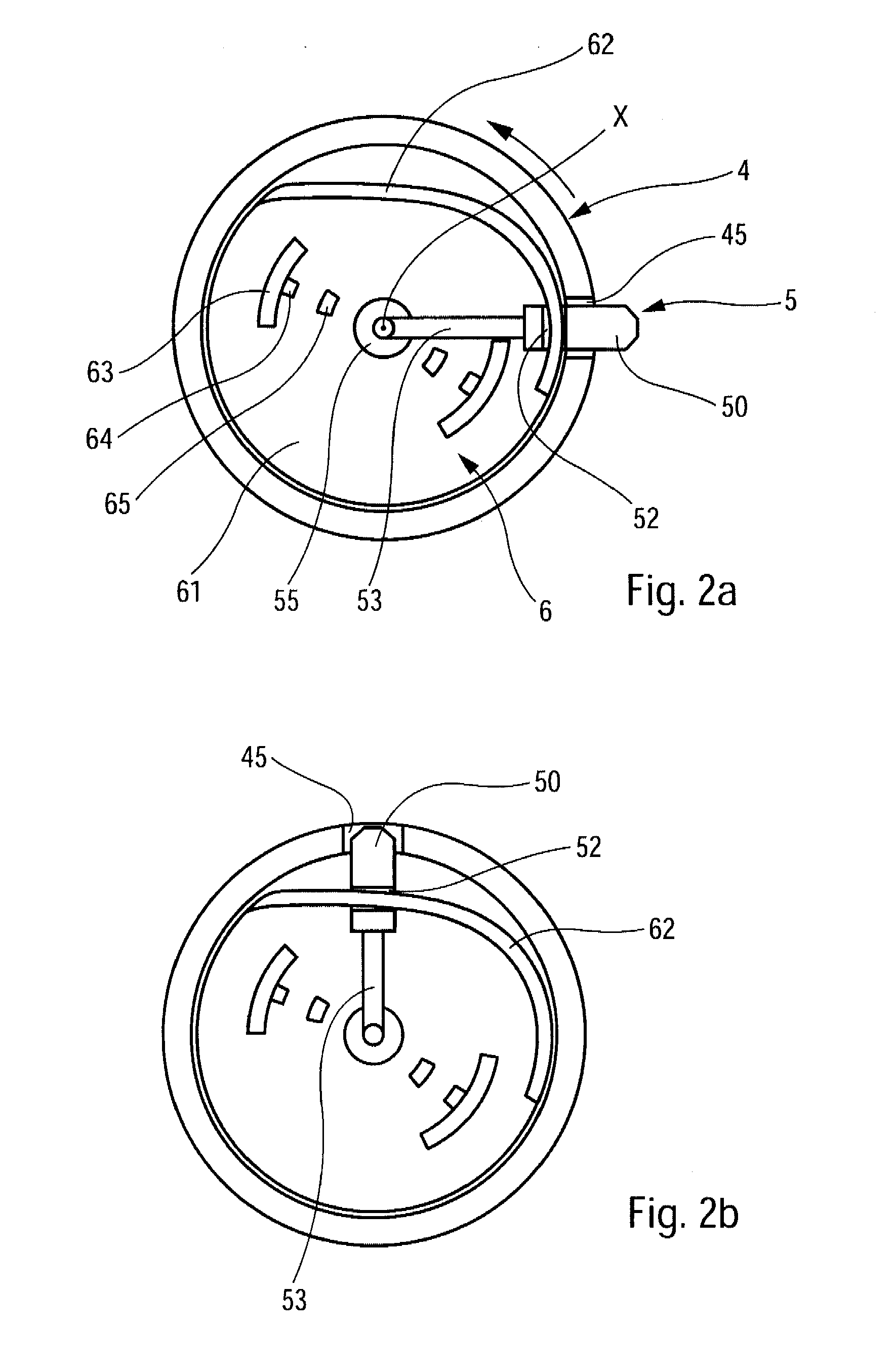

Fluid dispenser

InactiveUS20080116232A1Good deformation propertiesClosuresLiquid flow controllersAxial displacementEngineering

A fluid dispenser comprising:a fluid reservoir (1) provided with an opening (11);a fluid dispenser member (2), such as a pump or a valve, said member comprising a body (21) and an actuator rod (23) that is displaceable down and up along an axis X;a fastener ring (3) for fastening the dispenser member on the opening of the reservoir;a pusher (4; 4′; 4″) that is axially displaceable down and up so as to displace the actuator rod (23); anda dispenser endpiece (50) defining a dispenser orifice (51);displacement means (6, 4; 6′, 7; 6″, 7, 4″) that are suitable for displacing the endpiece (50) both in turning about the axis X and in radial translation, the radial distance between the endpiece and the axis X varying as the endpiece turns about said axis X, such that the endpiece is displaceable between an extended position remote from the axis X and a retracted position close to the axis X, the displacement means comprising a rotary actuator member (4; 7) that turns about the axis X, the endpiece (50) being constrained to turn with said actuator member, and a cam path (62) that is prevented from turning relative to the reservoir (1), the radial distance between the path (62) and the axis X varying along the path, the endpiece (50) being engaged with the cam path in such a manner that it follows the cam path while it is being turned by the actuator member (4; 7),the fluid dispenser being characterized in that the cam path (62) is formed by a cam element (6″) that is mounted on a ferrule (8) that is mounted in stationary manner relative to the reservoir (1), the cam element (6″) being prevented from turning relative to the ferrule (8), but being capable of being displaced axially, the pusher (4″) being in engagement with the ferrule (8) via a second threaded cam path (84), the pusher (4″) being turned by the actuator member (7), the pusher (4″) being displaced axially relative to the ferrule (8) and to the actuator member (7) by following the second threaded cam path (84) while said pusher is being turned by the actuator member, such that turning the actuator member simultaneously causes the rotary axial displacement of the pusher and the rotary radial displacement of the endpiece.

Owner:APTAR FRANCE SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com