Five-freedom active magnetic bearing type dual-axis angular rate gyroscope

A technology of active magnetic bearings and rate gyroscopes, applied in rotating gyroscopes and other directions, can solve the problems of poor gyroscope bandwidth and sensitivity adjustment ability, low gyroscope anti-overload ability, and large gyroscope drift rate, etc., to achieve small gyroscope drift rate and convenient gyroscope Bandwidth and sensitivity, the effect of solving disturbance torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples.

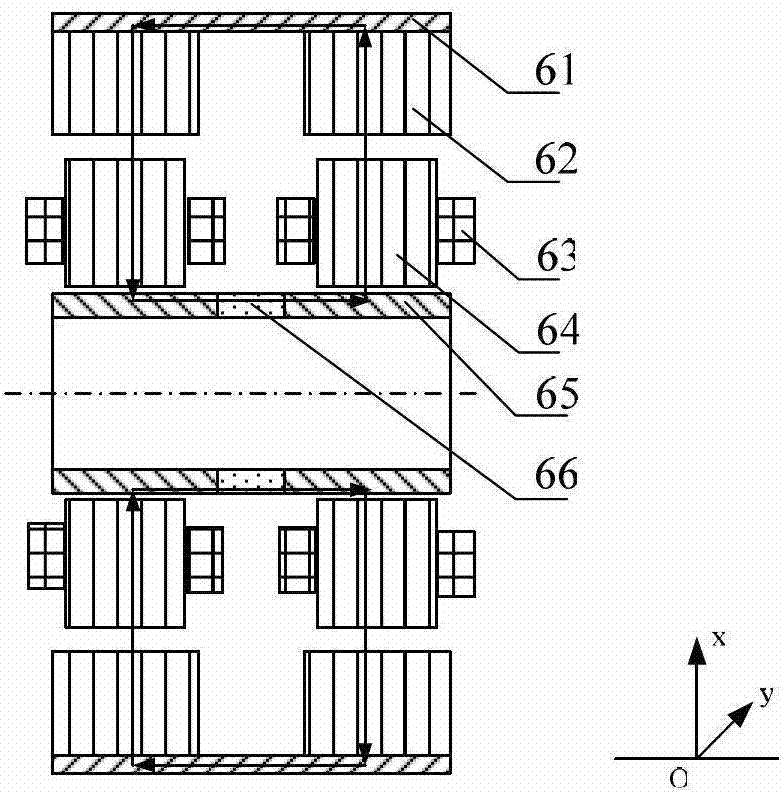

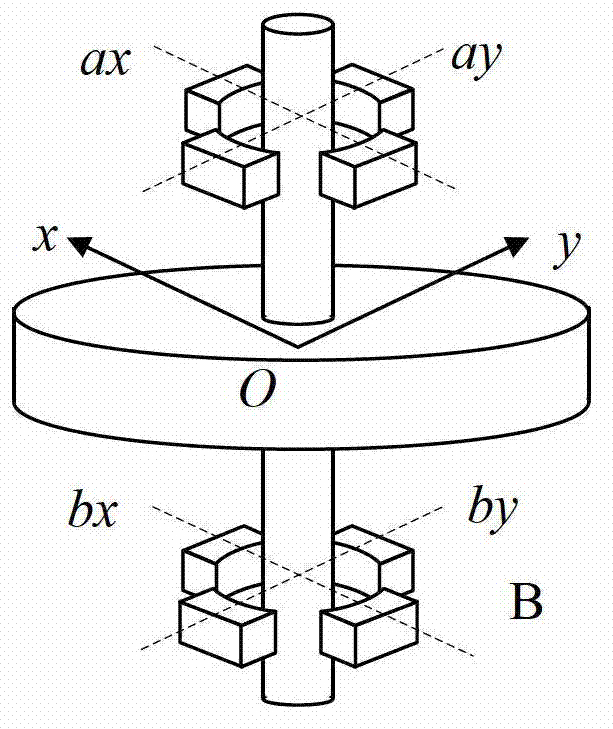

[0018] The present invention uses the electromagnetic torque of the radial magnetic bearing to offset the gyro torque of the high-speed magnetic levitation rotor. Because the electromagnetic torque is equal to the gyro torque in the steady state, the external input angular rate and the electromagnetic torque are in a linear relationship, and the current torque is driven by the coil current Generated, the magnitude of the external input angular rate can be calculated by detecting the driving current of the coil.

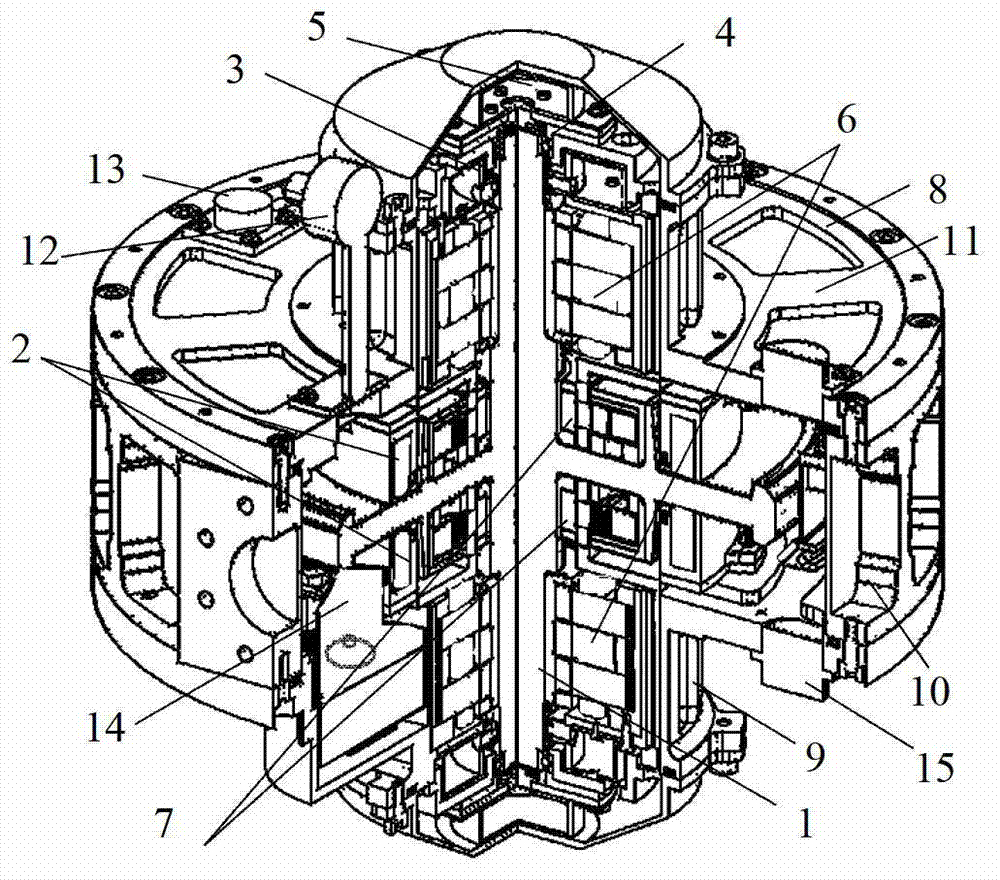

[0019] Such as figure 1 As shown, the driving motors 7 implemented in the present invention need to be used in pairs and be located in the middle of the rotor 1, the axial magnetic bearings 2 need to be used in pairs and be located outside the driving motor 7, and the radial magnetic bearings 6 need to be used in pairs and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com