Spherical piezoelectric stator type gyroscope

A technology of electric stator and gyroscope, applied in the direction of rotating gyroscope, etc., can solve the problems of complex system, harsh processing requirements, and difficulty in miniaturization, and achieve the effect of simplifying the overall structure, avoiding interference torque, and being easy to miniaturize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure and working principle of the present invention will be described in detail below with reference to the drawings and specific embodiments.

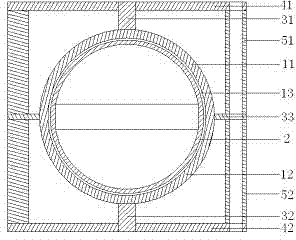

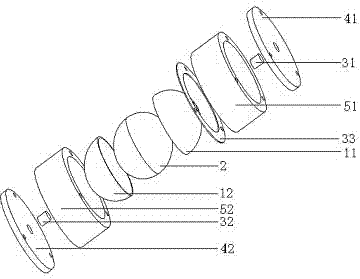

[0020] Such as figure 2 As shown, the present invention provides a spherical piezoelectric stator type gyroscope, including a spherical stator, a spherical rotor and a clamping device, which will be introduced separately below.

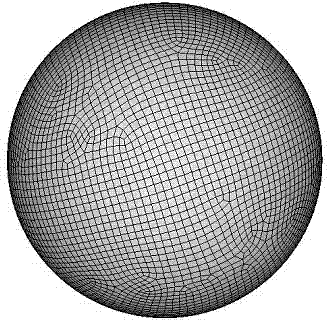

[0021] The spherical stator is directly prepared by piezoelectric material. In this embodiment, for the convenience of installation, the spherical stator is assembled by the first hemispherical piezoelectric stator 11 and the second hemispherical piezoelectric stator 12 by buckling and sealing. An accommodating cavity 13 is formed between the two. The first and second hemispherical piezoelectric stators 11, 12 have the same shape, and both are completely silver-plated on the inner spherical surface, while the outer spherical surface is divided into zones. The divisions can be divided into equal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com