Control device and method for locking torque of dynamic pressure motor

A locking torque, dynamic pressure motor technology, applied in the directions of portable mobile devices, manufacturing tools, manufacturing stator/rotor bodies, etc., can solve the problems affecting the quantitative control of locking torque, mutual interference, and unfixed motors, and achieve effective results. The effect of locking torque control, low technical level requirements and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further elaborated below in conjunction with embodiment.

[0053] The invention provides a locking torque control device and method of a miniature dynamic pressure motor, which can accurately and effectively realize the locking torque control of the motor.

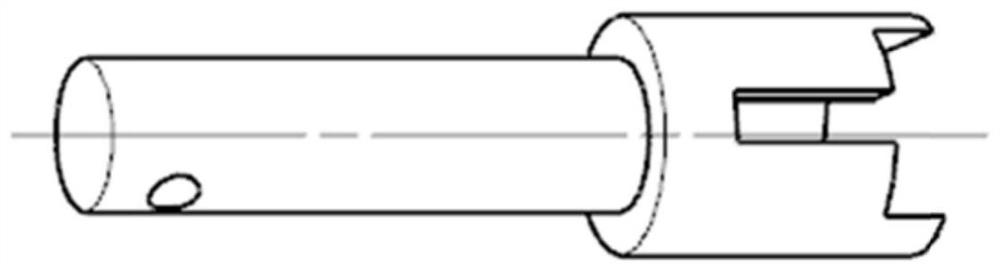

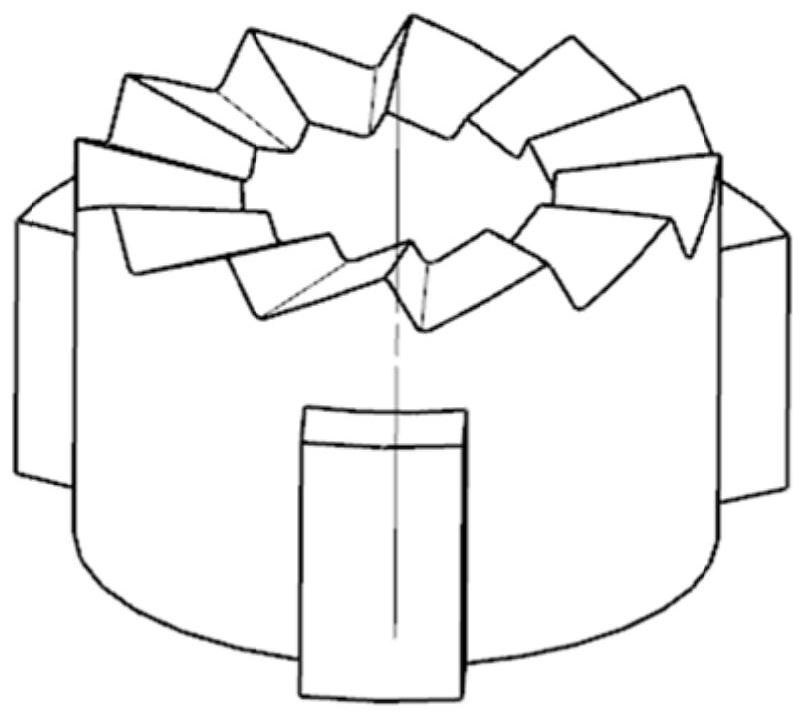

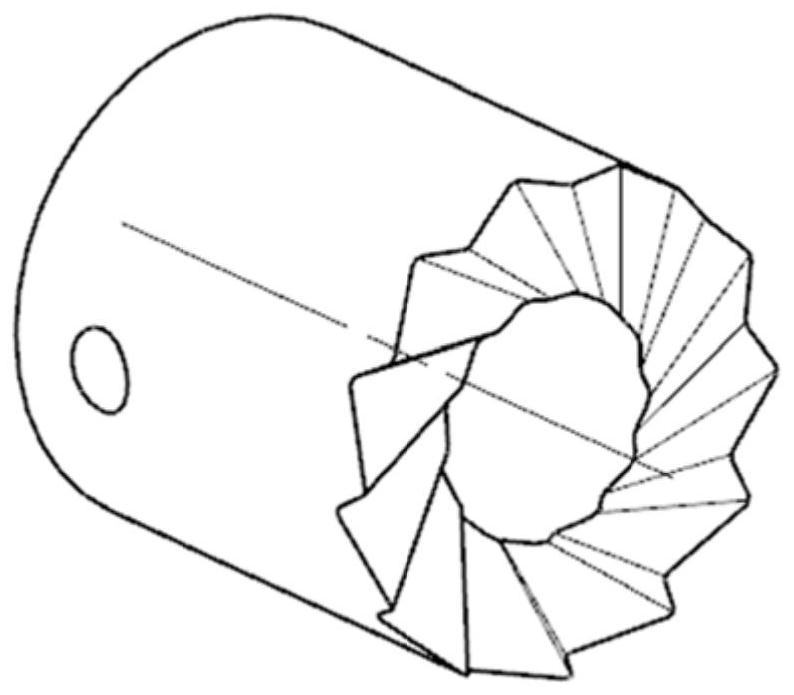

[0054] Such as Figure 1 to Figure 12 As shown, a dynamic pressure motor locking torque control device provided by the present invention includes an interface assembly 1, a first card seat 2, a second card seat 3, a screw cover 4, a pin, a ball 6, a first gasket 7, Second liner 9, spring 8, top wire 10, shell 11;

[0055] The shell is a cylindrical structure with a disc in the middle. One end of the cylinder is the interface shaft end. There is a cylindrical cavity with openings at both ends inside the cylinder. There is a hole in the cross section of the middle of the cylindrical cavity. The partition, the ball 6 is located in the hole in the middle of the partition, can rotate freel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com