High-productivity thin film deposition device and thin film batch production method

A thin film deposition device, high-yield technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of increasing vacuuming time and vacuuming amount, reducing production efficiency, increasing costs, etc., to achieve improved Product quality, overall production capacity improvement, and the effect of production capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

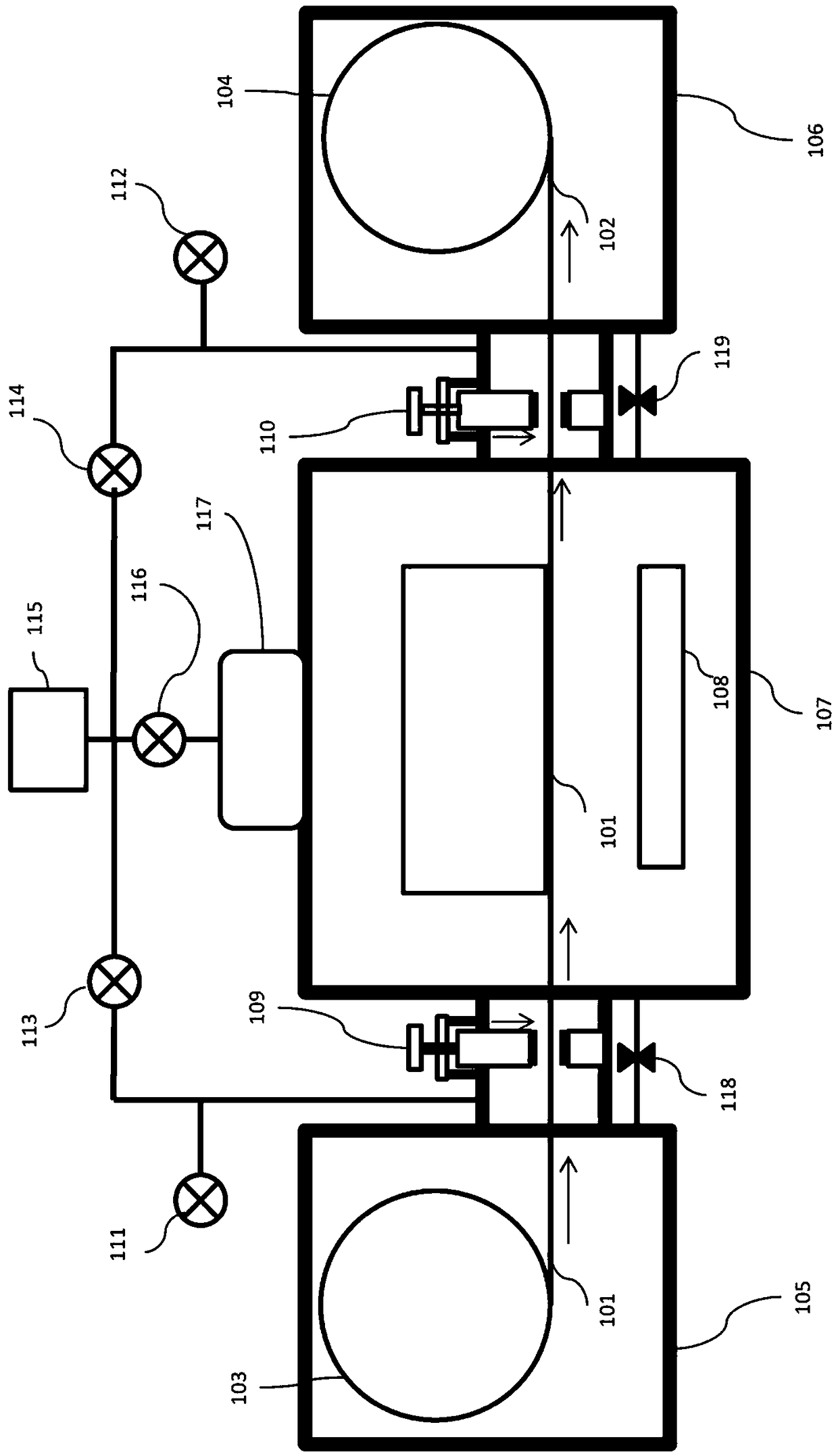

[0039] Such as figure 1 As shown, this embodiment relates to a high-yield thin film deposition device, including: a raw tape reel chamber 105, a product tape reel chamber 106, and at least one deposition chamber 107 with a deposition source 108;

[0040]The original base tape reel 103 and the product base tape reel 104 are arranged in the original tape reel chamber 105 and the product tape reel chamber 106, and the original base tape reel 103 and the product base tape reel 104 are connected to the tape transport system. In this example, a deposition chamber 107 is provided. In actual use, a plurality of deposition chambers can be set and one of the deposition chambers has a deposition source while the other deposition chambers do not have a deposition source. The original tape reel chamber 105 is connected to the deposition chamber 107 through the first base tape vacuum lock 109, and the deposition chamber 107 passes through a second base tape vacuum lock 110 is connected to t...

Embodiment 2

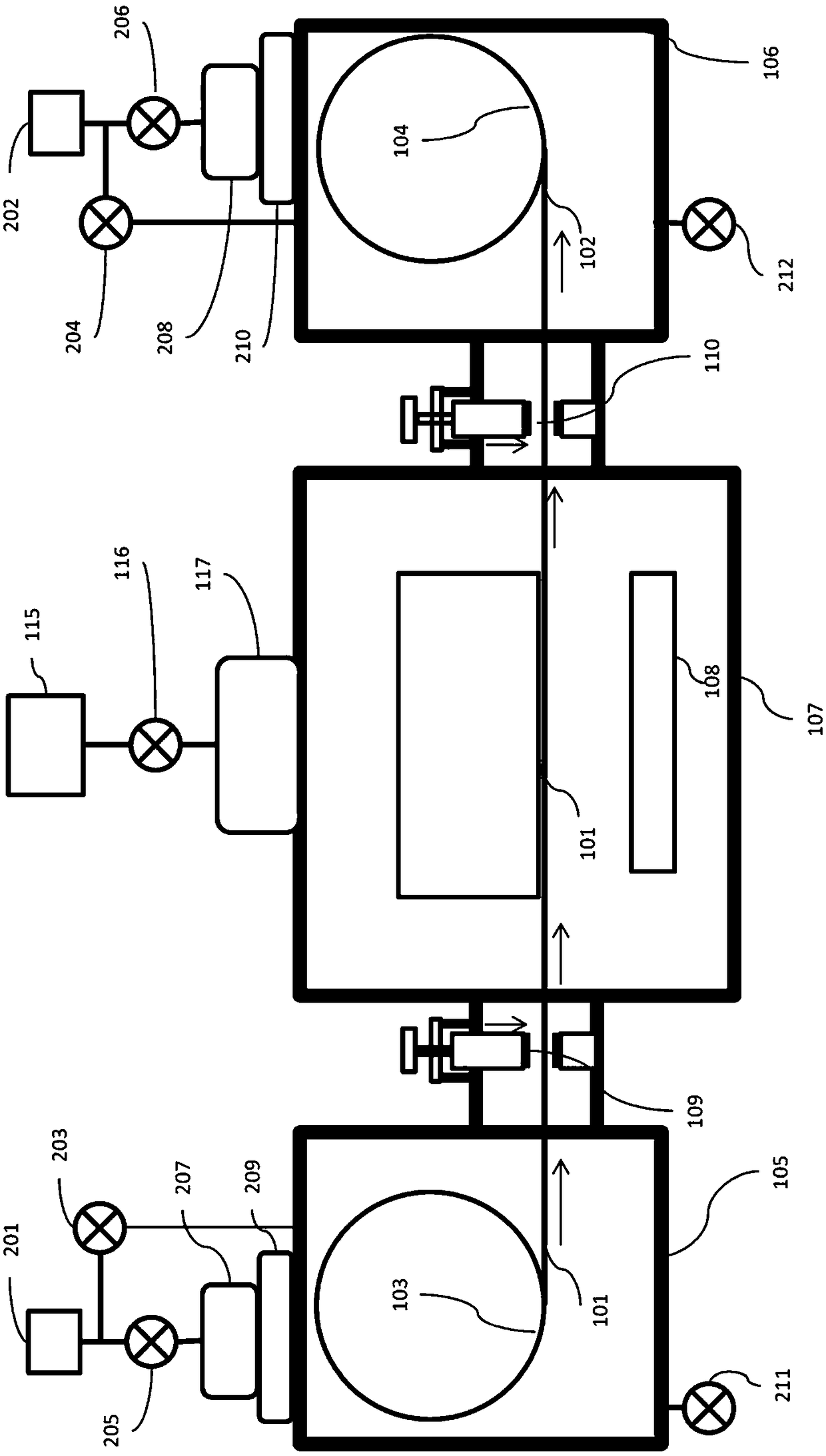

[0061] Such as figure 2 As shown, this embodiment relates to a high-capacity thin film deposition device. The difference from Embodiment 1 is that in Embodiment 2, the original tape reel chamber 105 and the product tape reel chamber 106 have independent vacuuming devices. There is no need to stop sputtering between depositions, minimizing the time between depositions, further increasing productivity.

[0062] Specifically, the original tape reel cavity 105 is connected to the second high vacuum pump 207 through the first high vacuum valve 209, and the second high vacuum pump 207 is connected to the second rough vacuum pump 201 through a pipeline. A first support valve 205 is provided between the vacuum pumps 201, a second rough vacuum pump 201 is connected to the original tape reel chamber 105 through a pipeline and a fourth rough valve 203 is arranged on the pipeline;

[0063] The product tape reel cavity 106 is connected to the third high vacuum pump 208 through the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com