Patents

Literature

160 results about "Gas lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas lubrication is the process of removing gas from beneath the BOP stack while maintaining constant bottom hole pressure.

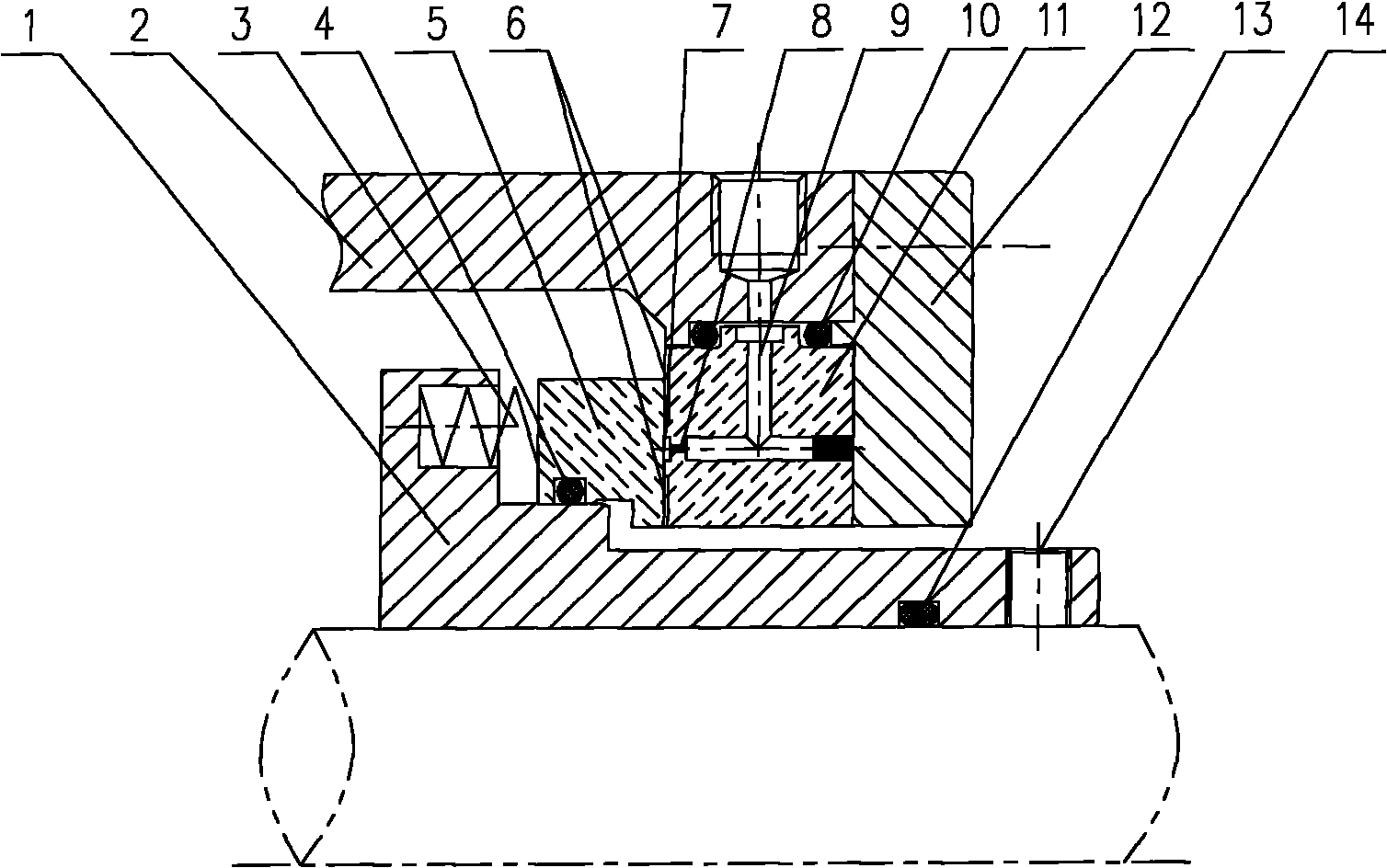

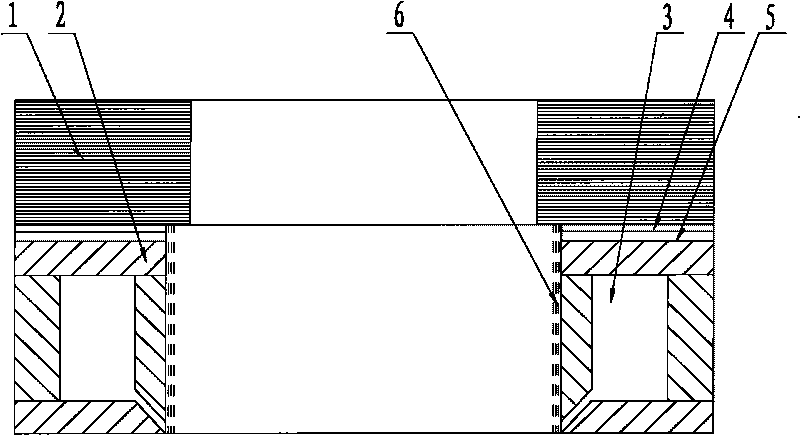

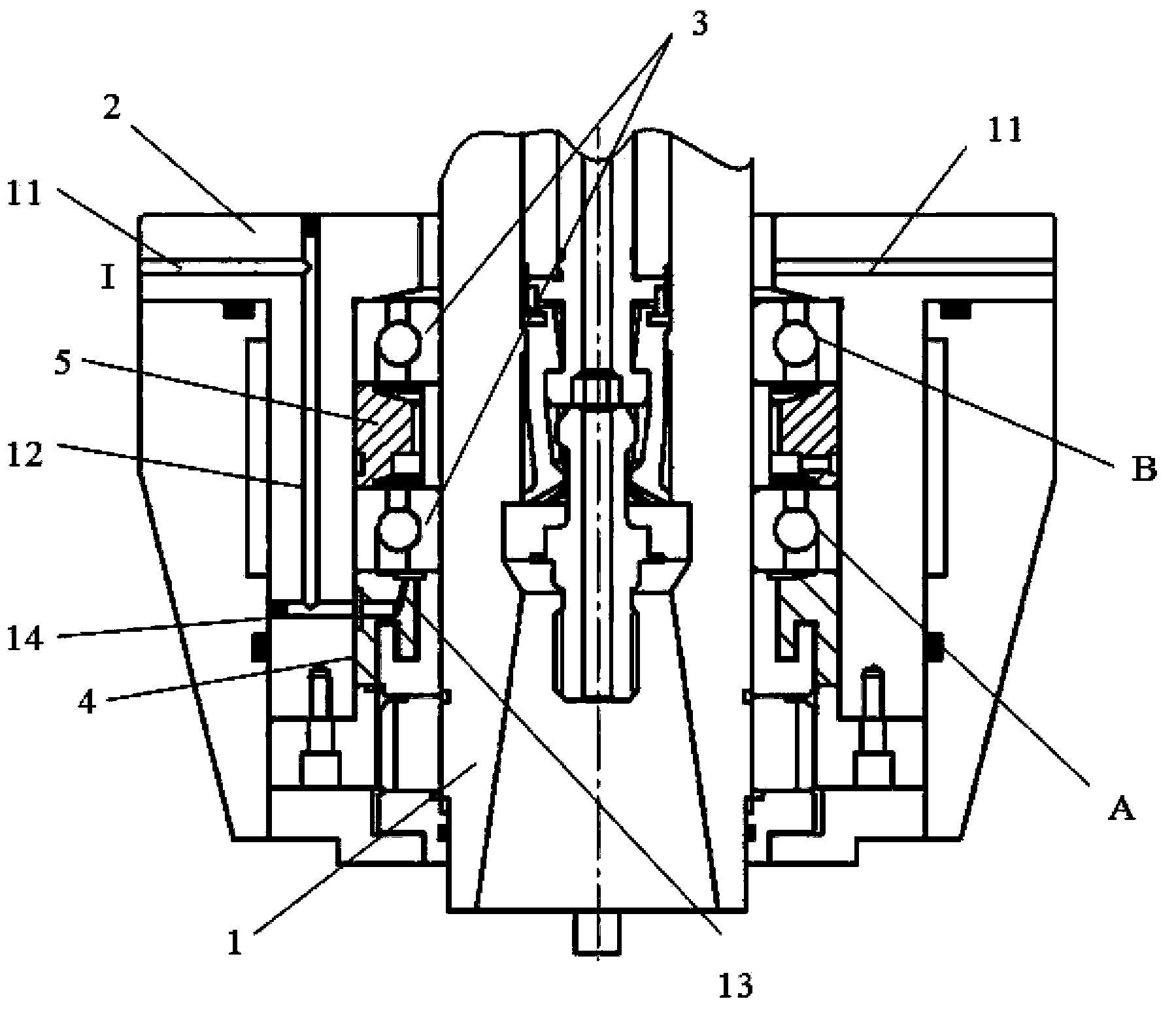

Outside pressurized type dynamic and static pressure gas lubricating and sealing device

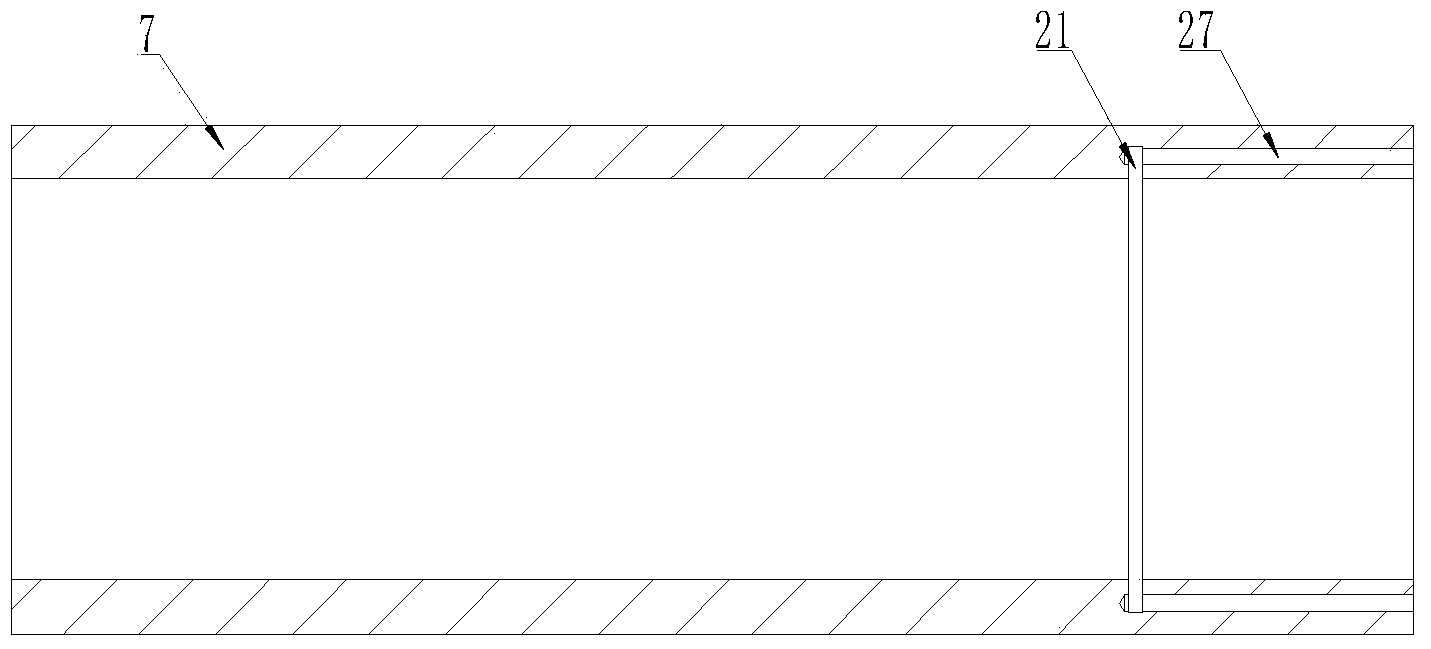

The invention discloses an outside pressurized type dynamic and static pressure gas lubricating and sealing device, which comprises a moving ring (5) and a seal static ring (11), wherein the moving ring (5) is fixed on a moving ring seat (1) and rotates along with a spindle, and the seal static ring (11) is fixed on a seal cavity (2) and a seal end cover (12); channels (9) for introducing outsidepressurized gas from outside are arranged in the seal static ring (11), and the channels (9) of certain numbers are distributed in the seal static ring (11) along circumference; throttle devices (8) are arranged in the channels (9), and pressure equalizing troughs (7) of certain depth are arranged at the outlets of the channels (9); various dynamic pressure troughs (6) having dynamic pressure effects are formed on the end face of the moving ring (5) or the seal static ring (11), and the inside and outside of the pressure equalizing troughs (7) are provided with seal dams not communicated withthe pressure equalizing troughs; and on-line monitoring is realized by adjusting the pressure of the outside pressurized gas. The pressurized type dynamic and static pressure gas lubricating and sealing device greatly lowers resistance moment and power consumption and improves the phenomenon that the traditional end face seal abrasion is severe.

Owner:BEIJING UNIV OF CHEM TECH

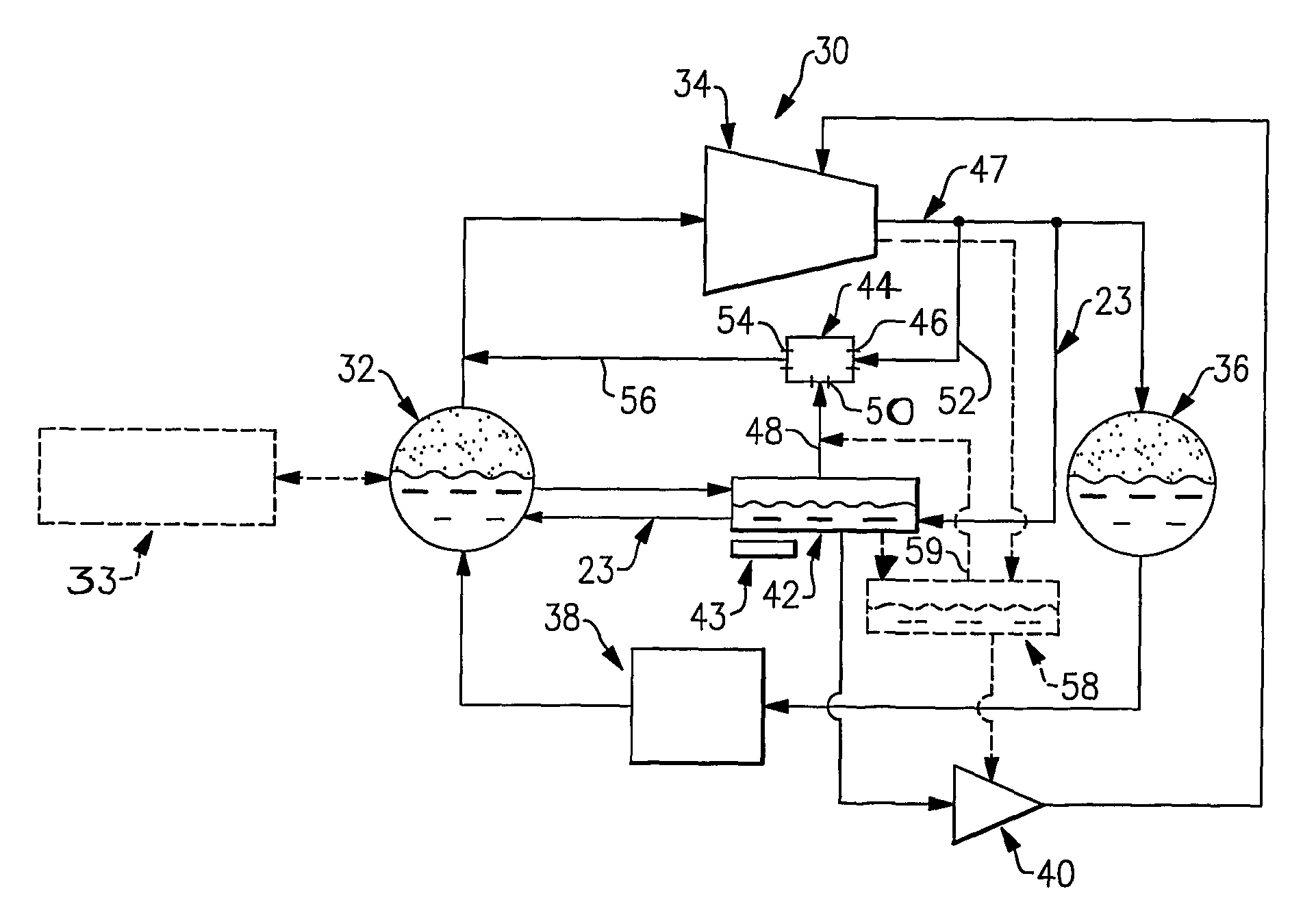

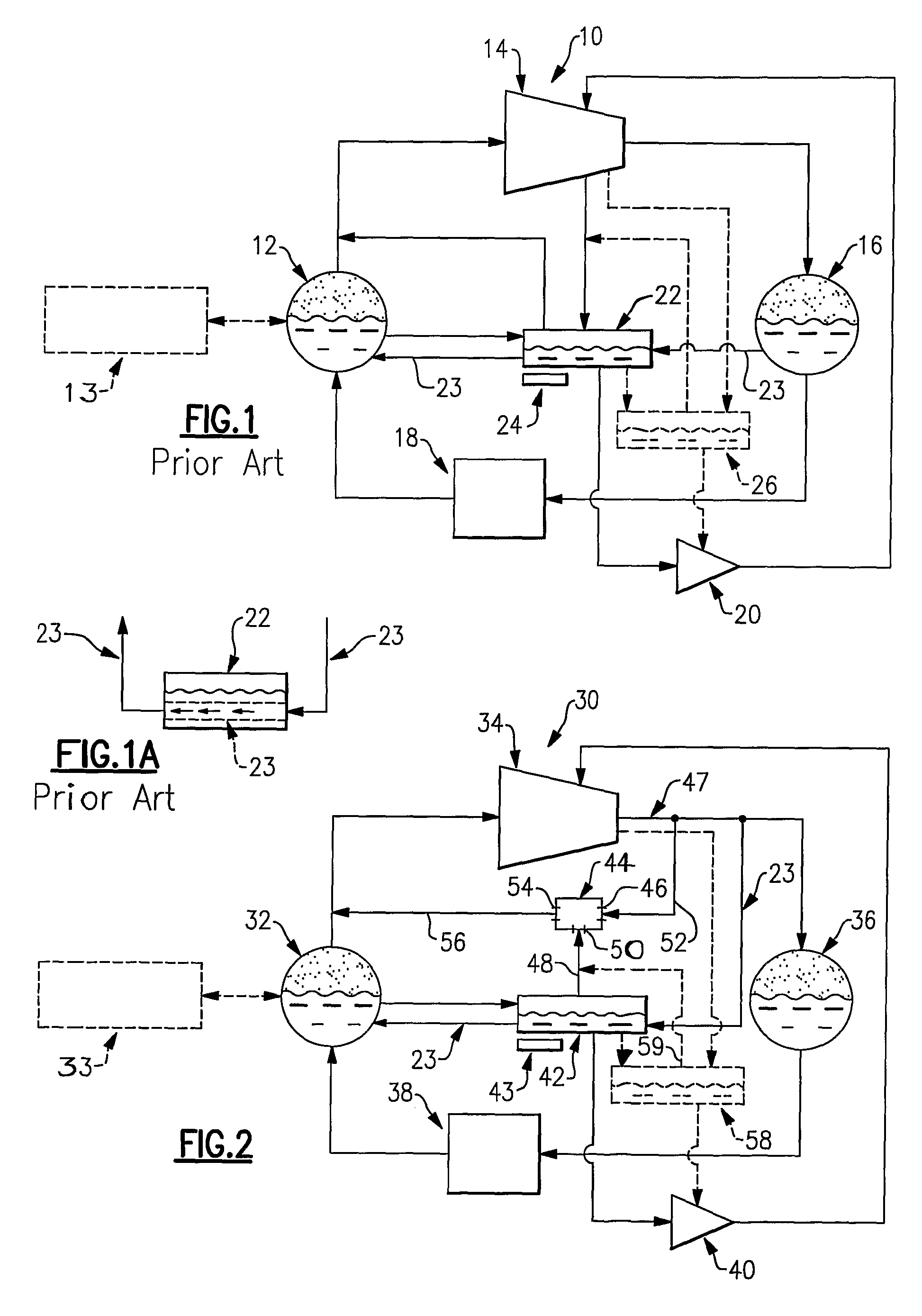

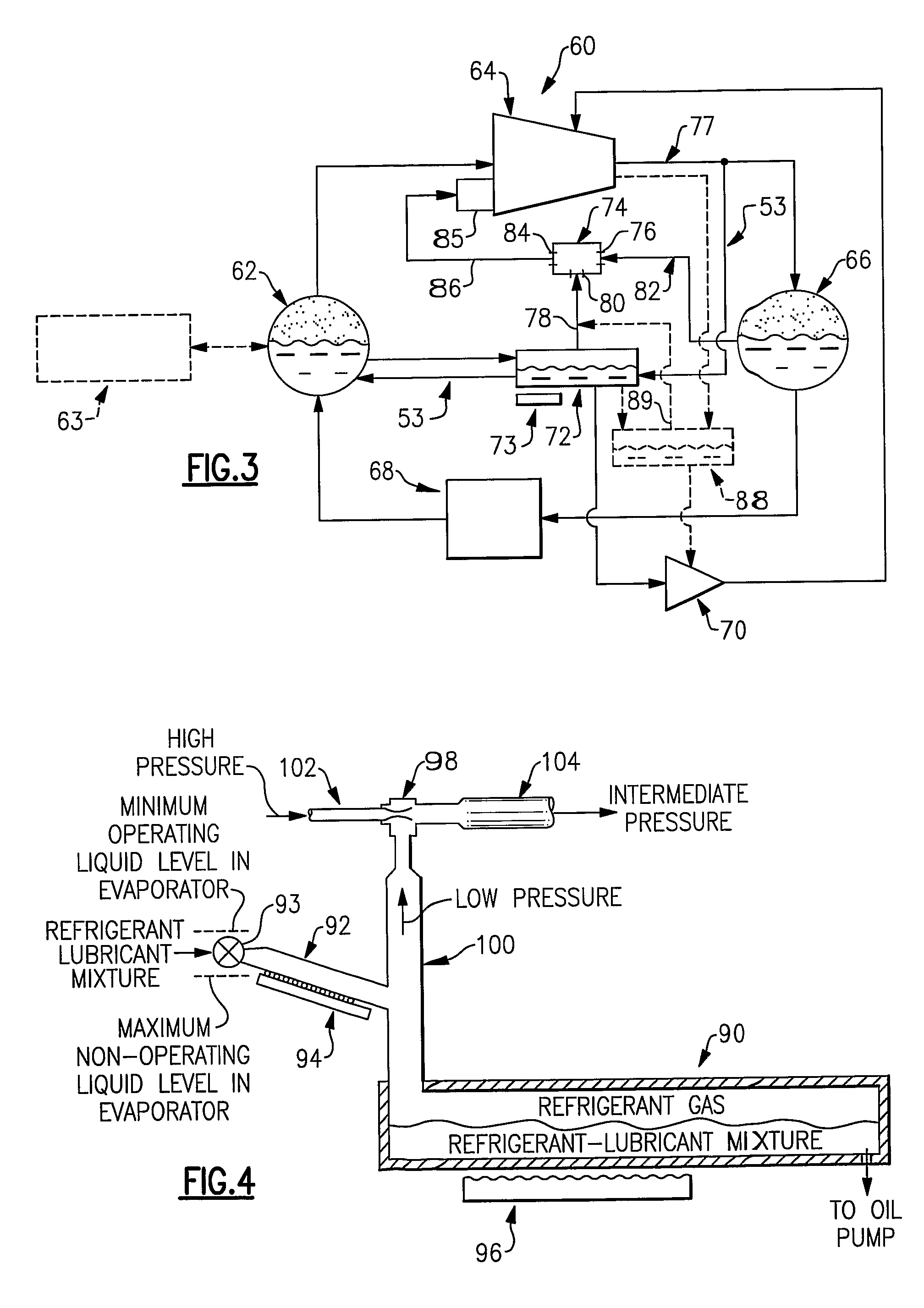

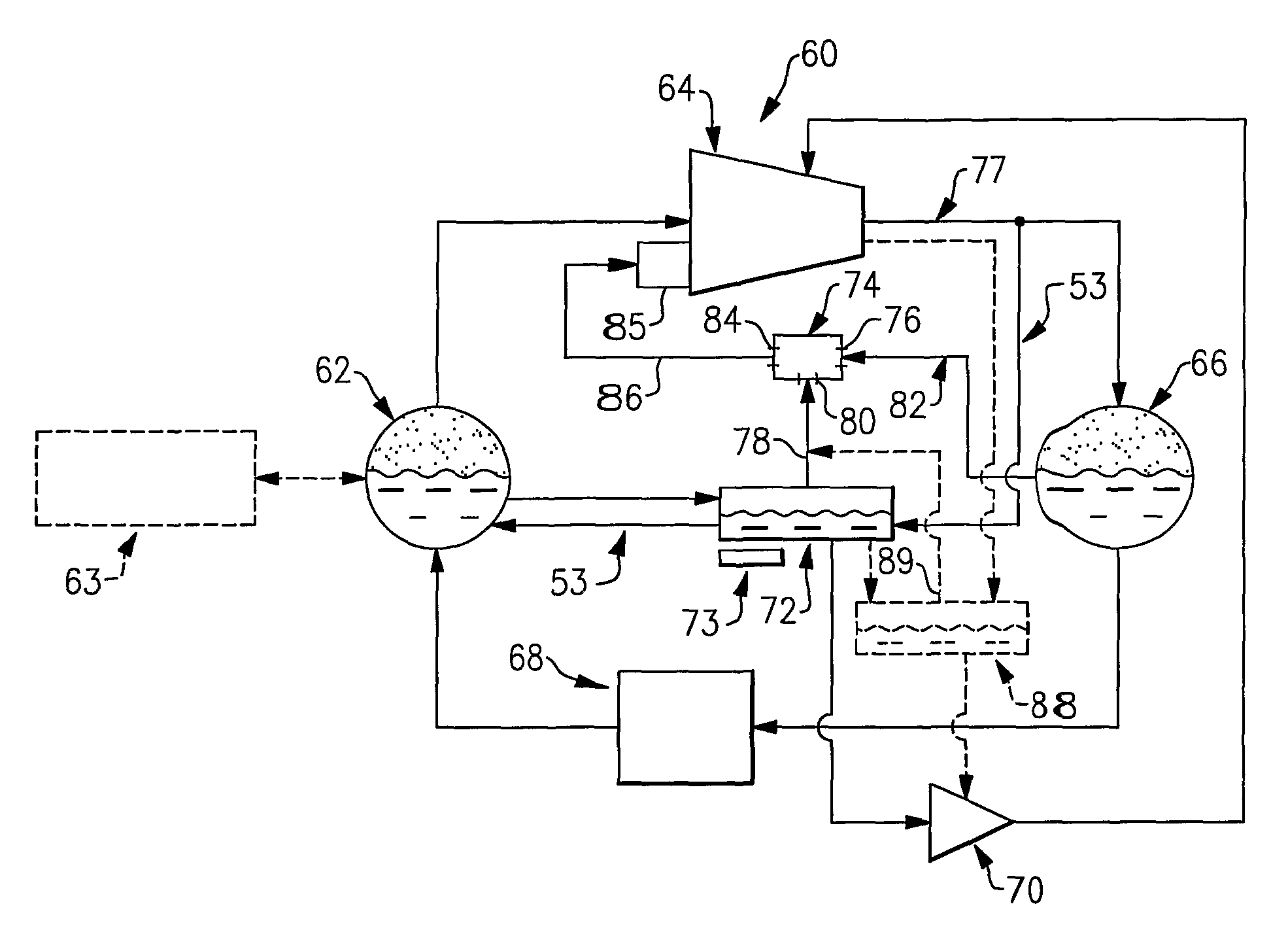

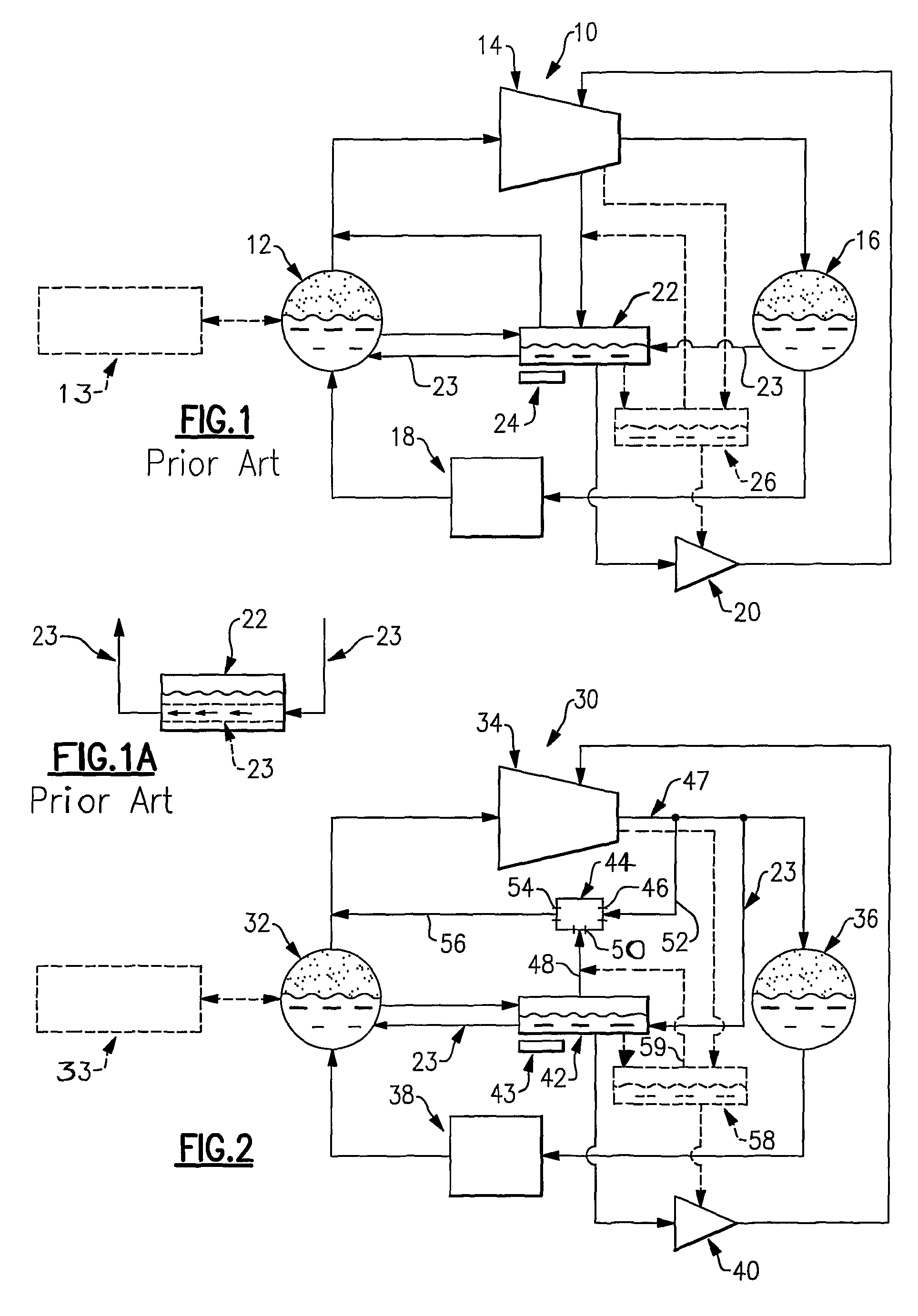

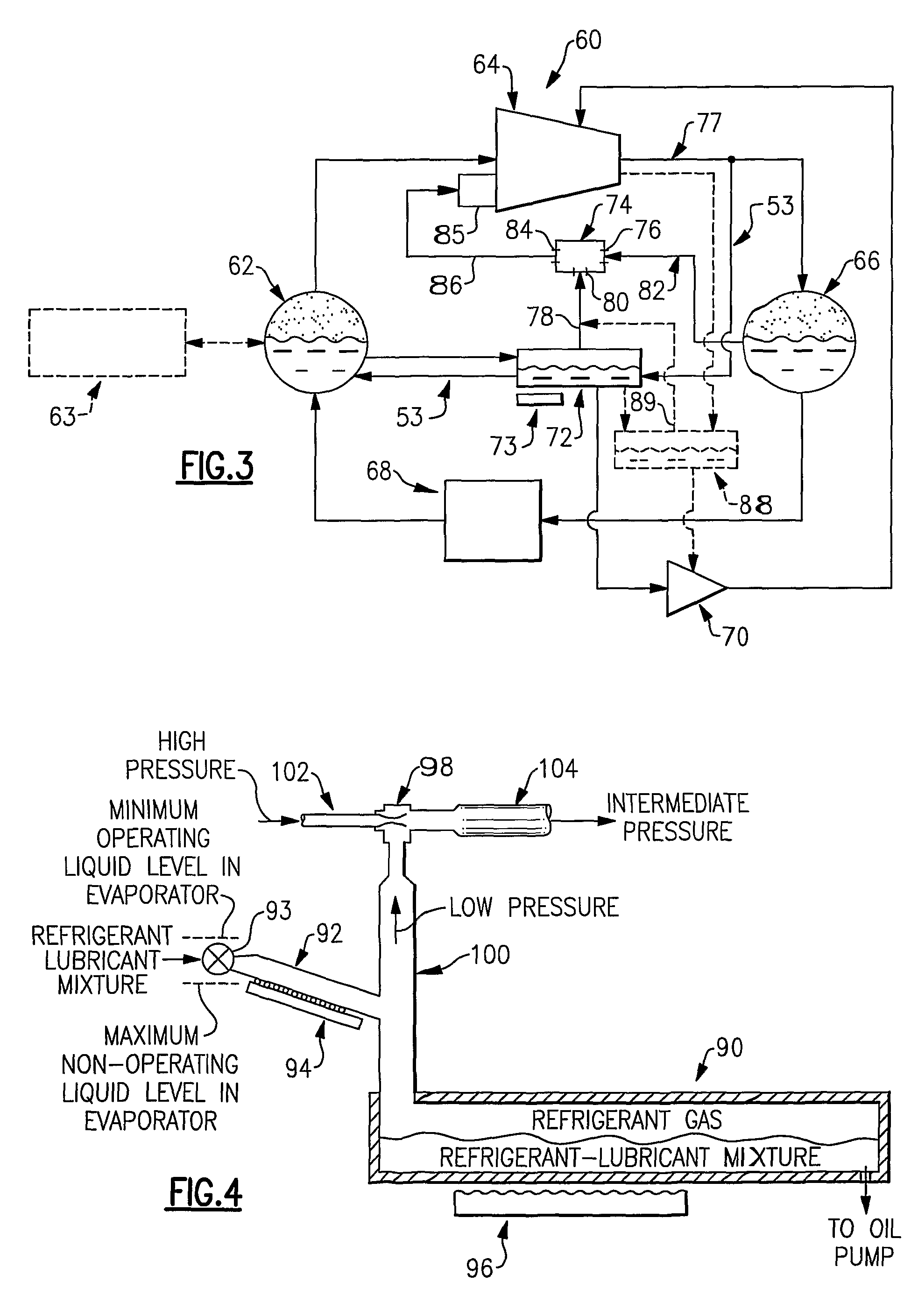

De-Gassing Lubrication Reclamation System

ActiveUS20080210601A1Reduce pressureCompressorCompression machines with non-reversible cycleGas lubricationDecreased pressure

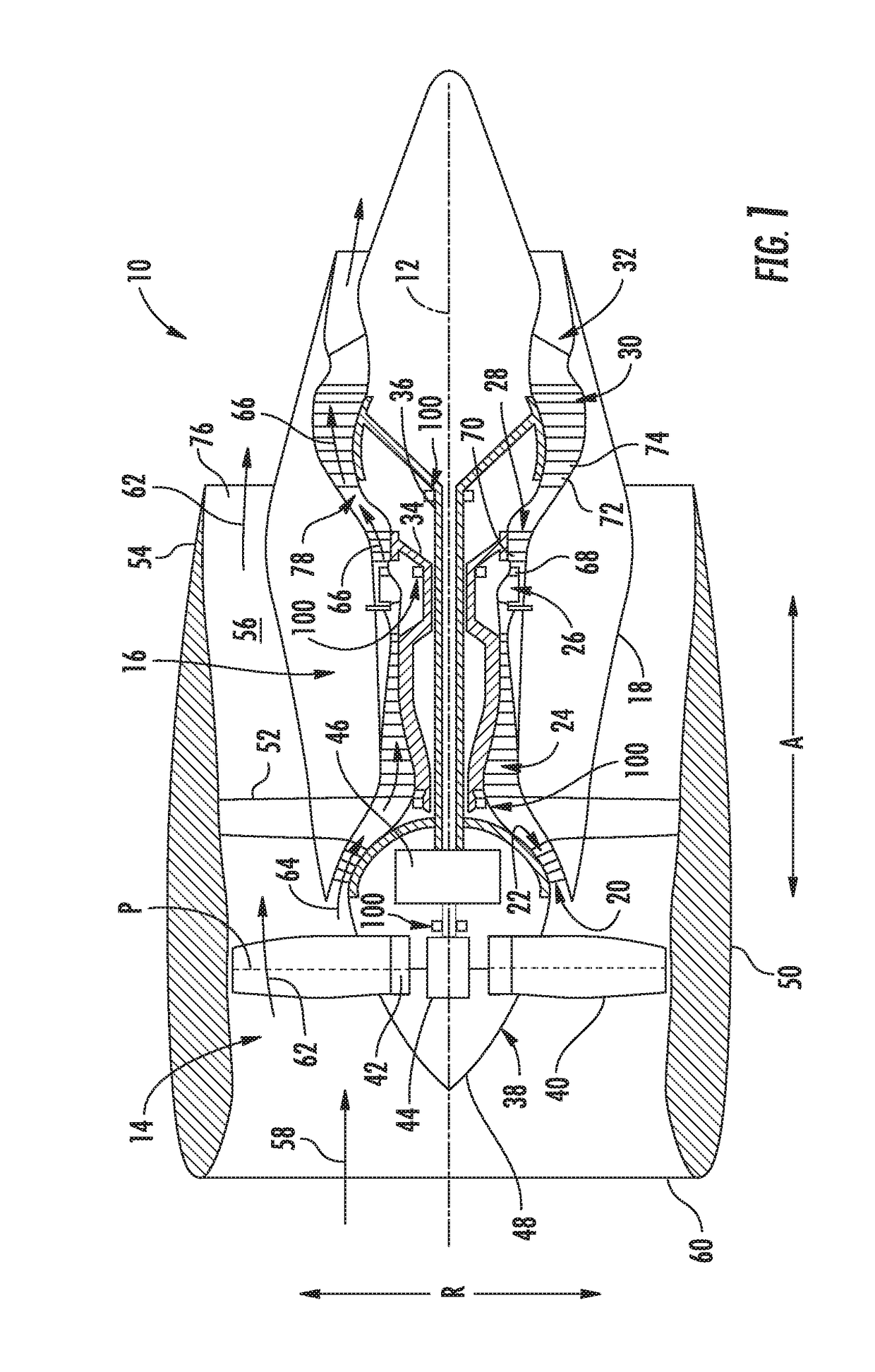

A vapor compression system (10), also known as a chiller, includes a refrigeration loop and a lubrication loop. The lubrication loop includes a lubrication reclamation system that further includes a still (42) and an ejector (44) to reduce a pressure in the still (42). The ejector (44) includes an input portion (46), an output portion 54 and a vent portion (50). The input portion (46), the output portion (54) and the vent portion (50) are in fluid communication with one another. The vent portion (50) of the ejector (44) is positioned in a vent line (48) associated with the still (42). The still (42) primarily contains a mixture of liquid refrigerant and lubricant. The input portion (46) of the ejector receives liquid or gas at a high pressure and expels the liquid or gas through the output portion (54) at an intermediate pressure. As the input fluid at a high pressure flows through the ejector (44), a low pressure is created at the vent portion (50). The reduction in pressure in the vent portion (50) causes a suction pressure within the vent portion (50) associated with the still (44), resulting in a portion of the liquid refrigerant vaporizing, leaving a higher viscosity lubricant.

Owner:CARRIER CORP

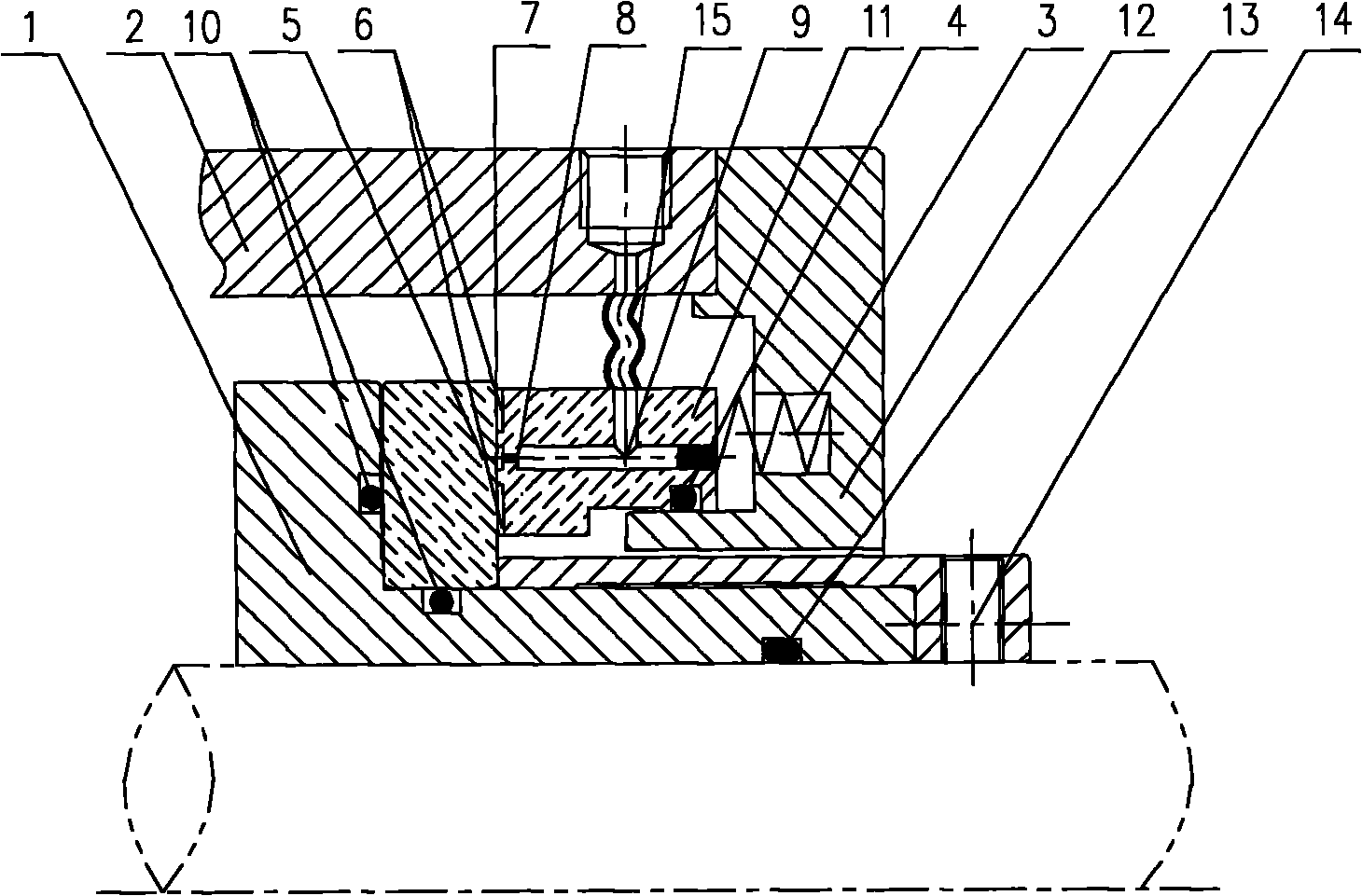

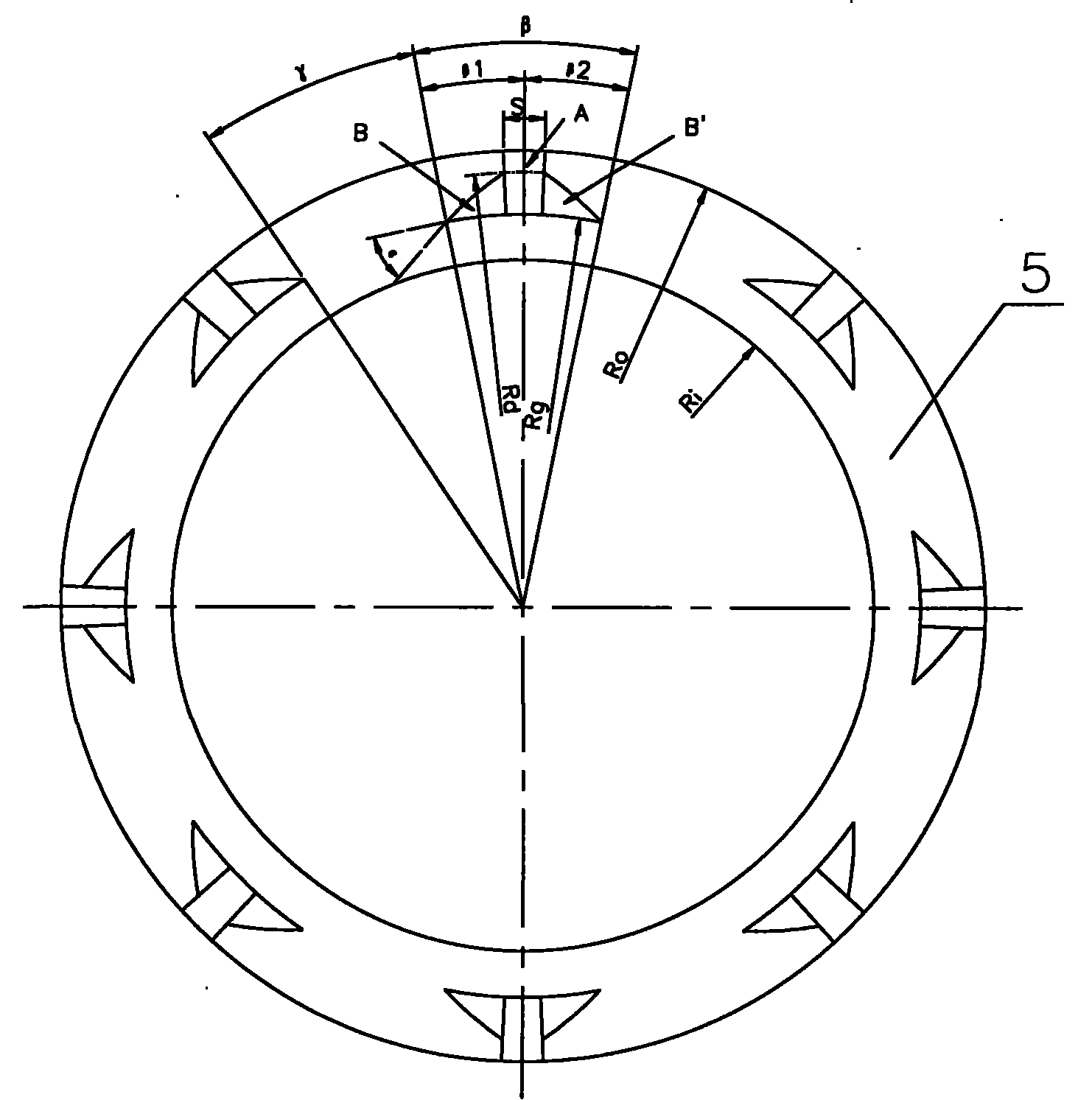

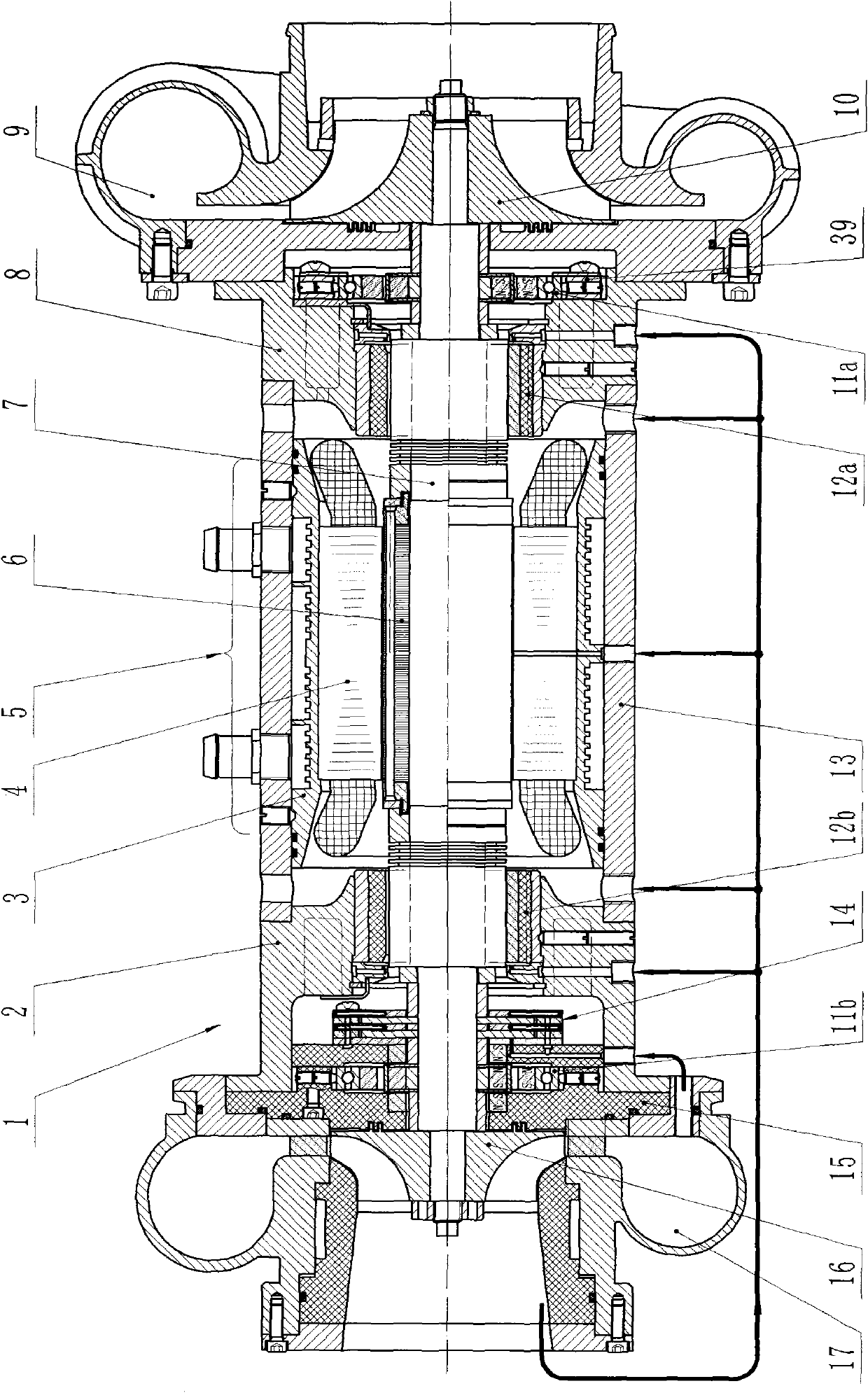

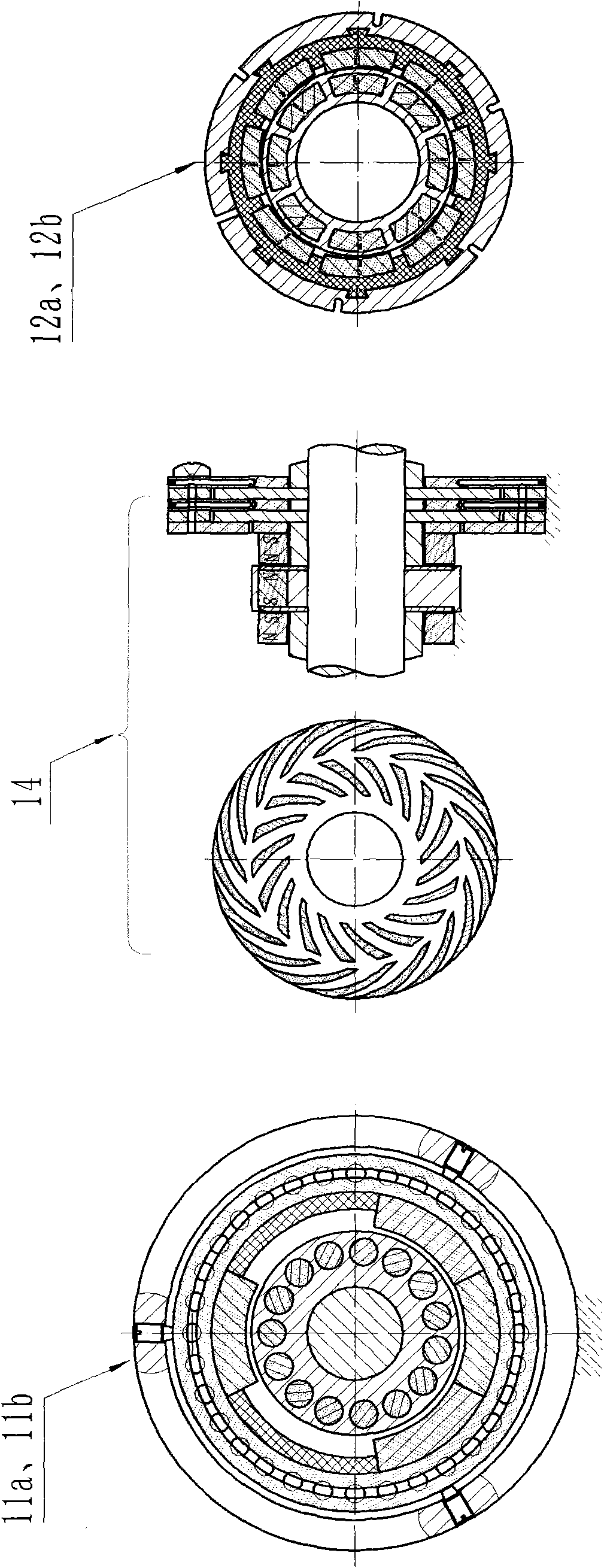

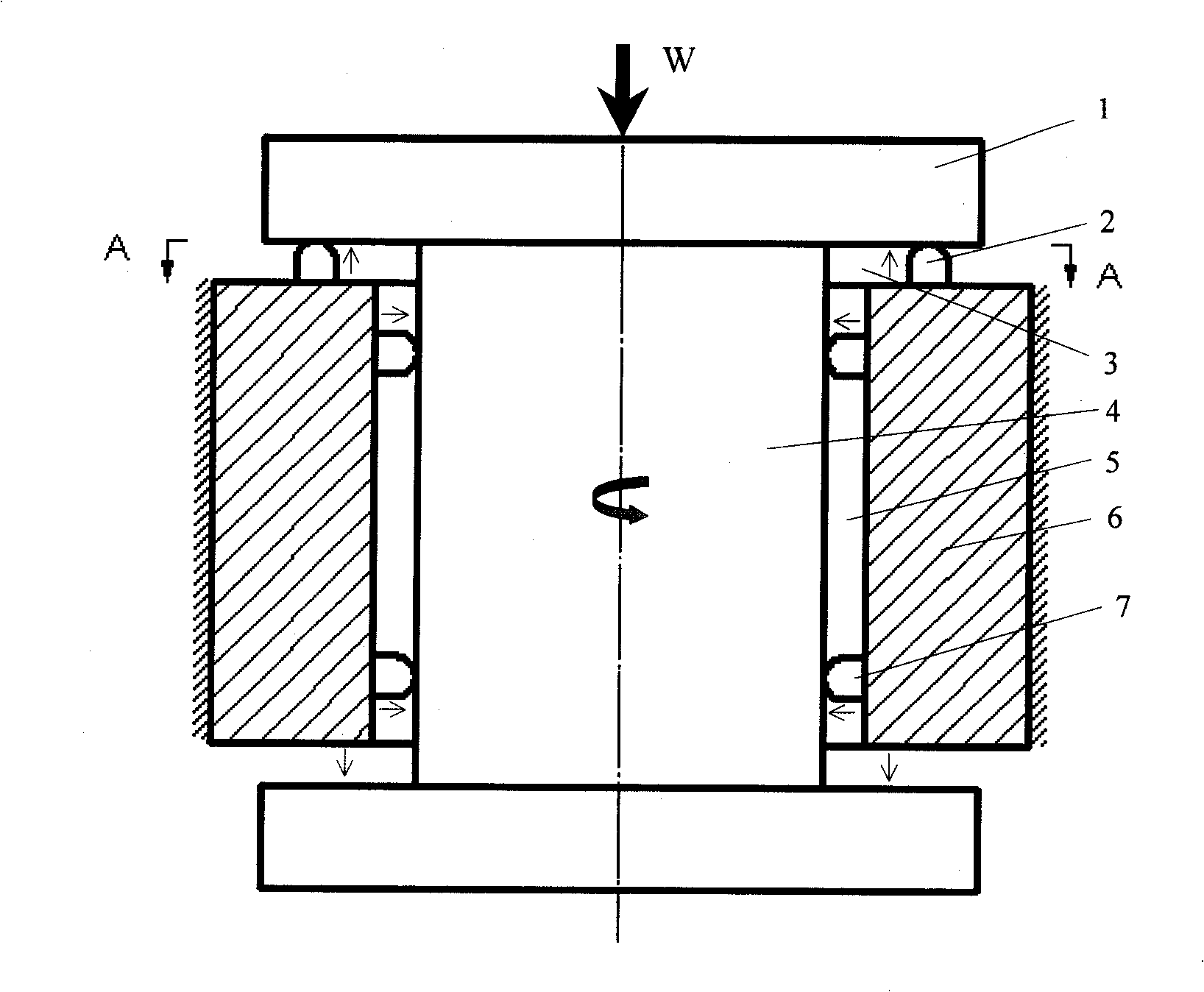

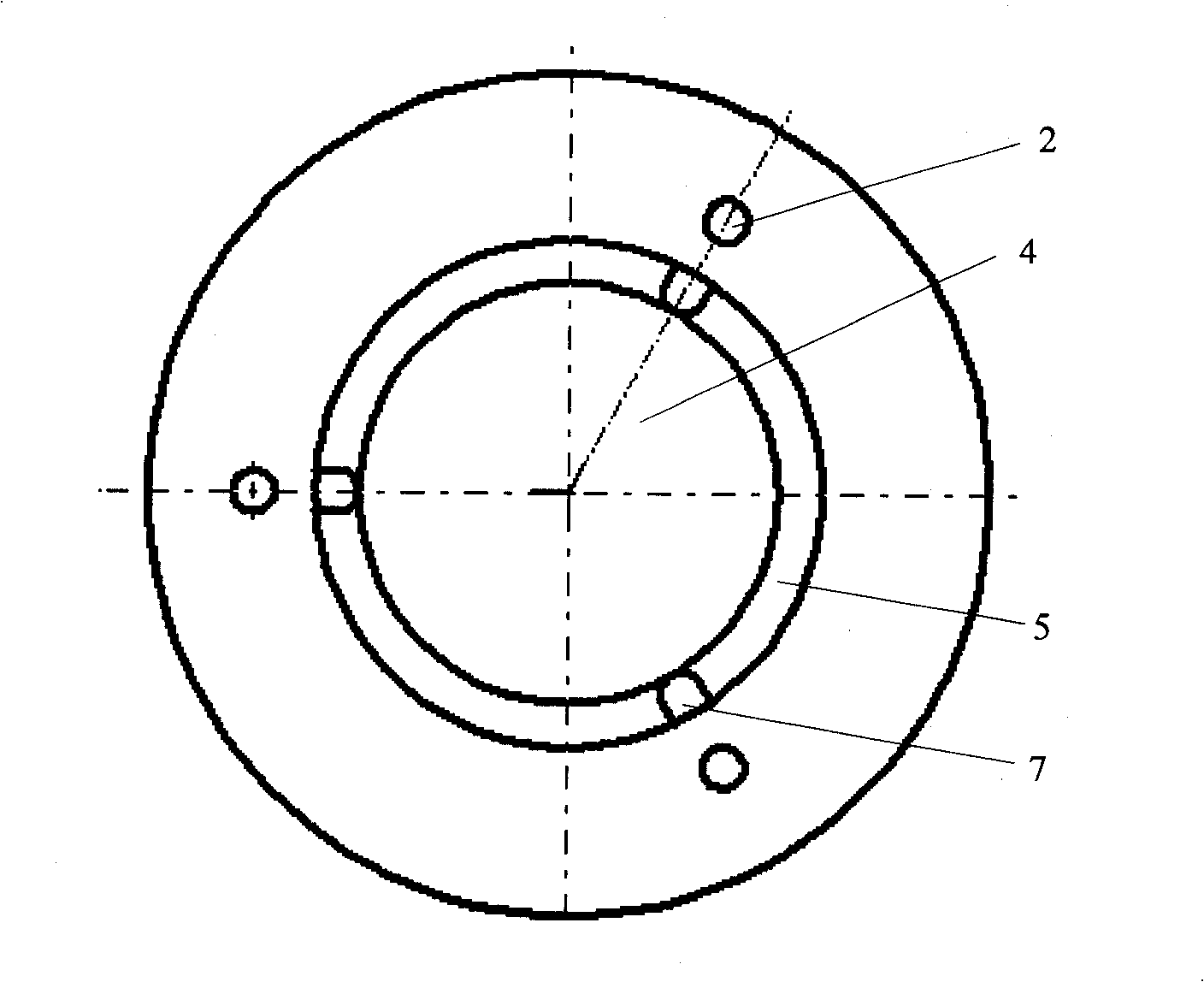

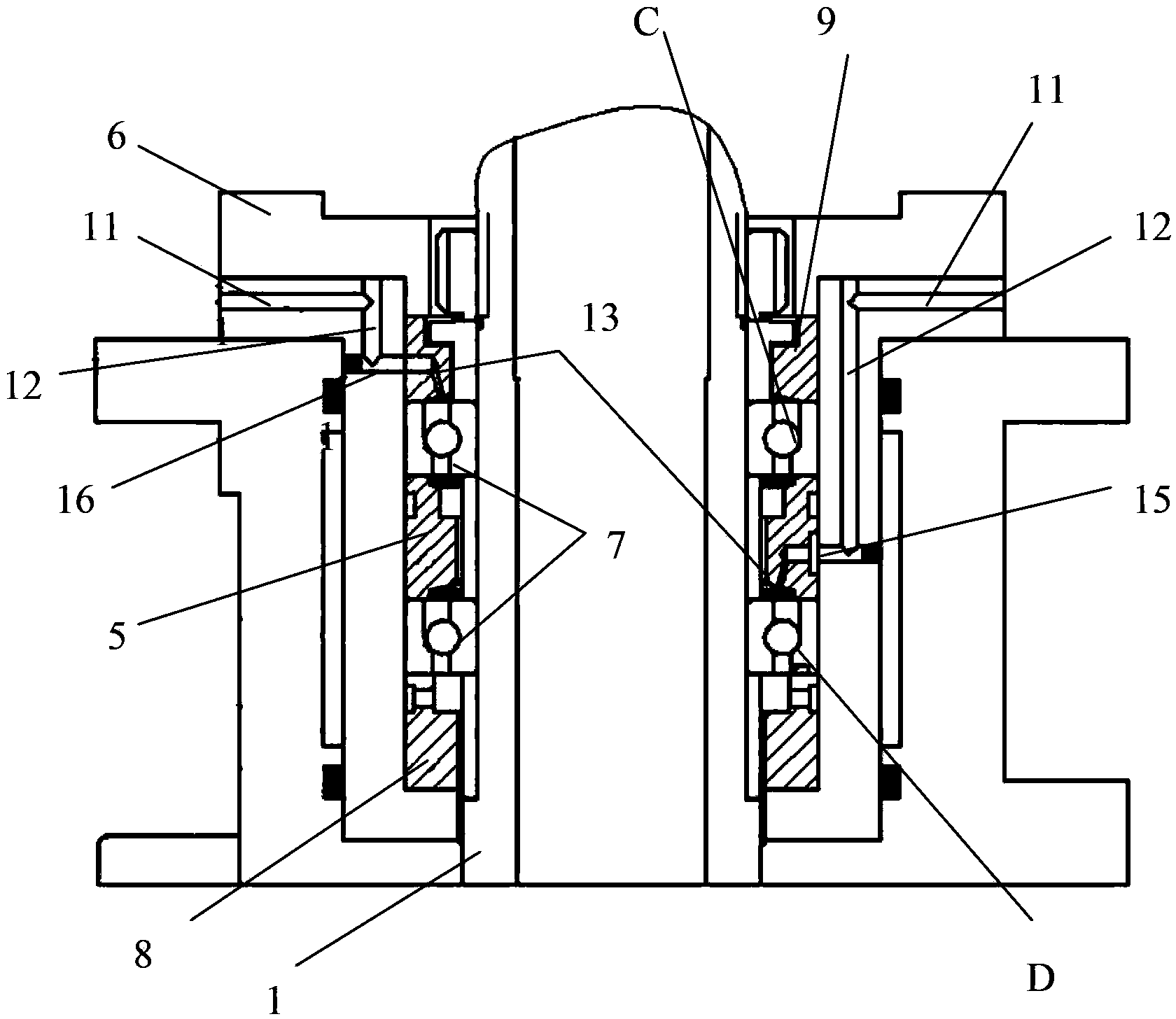

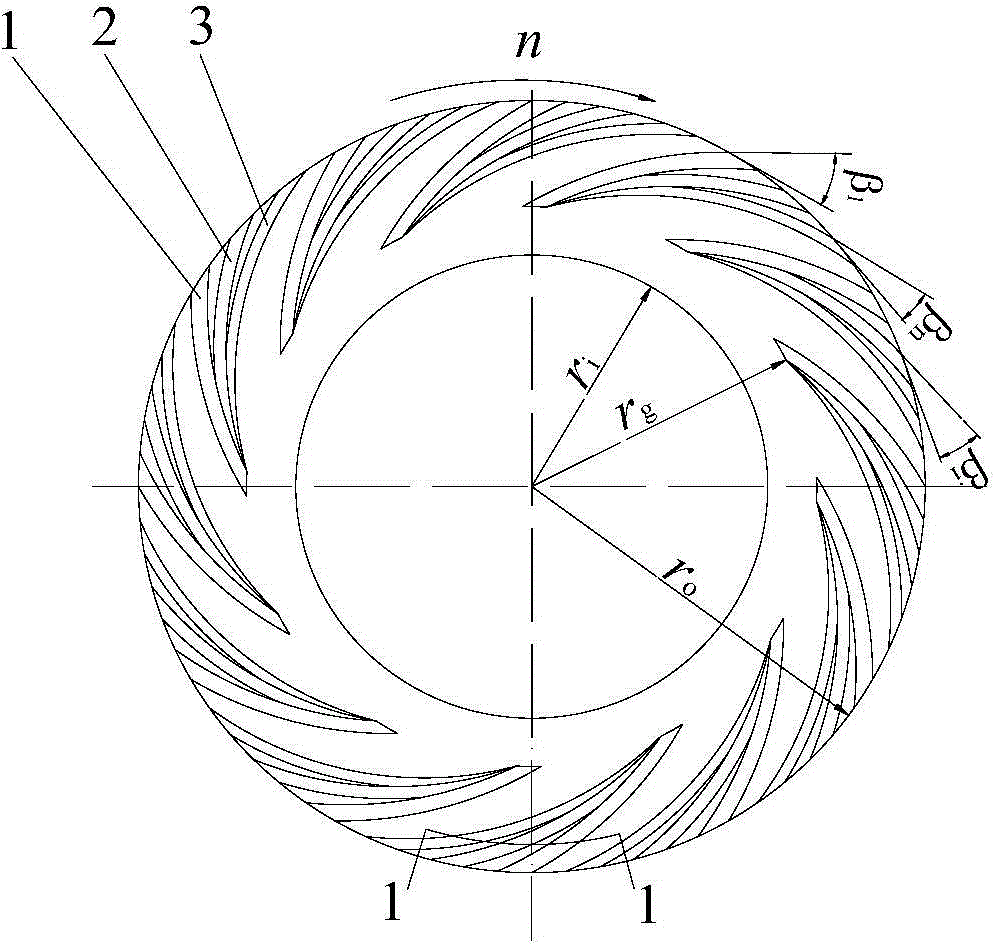

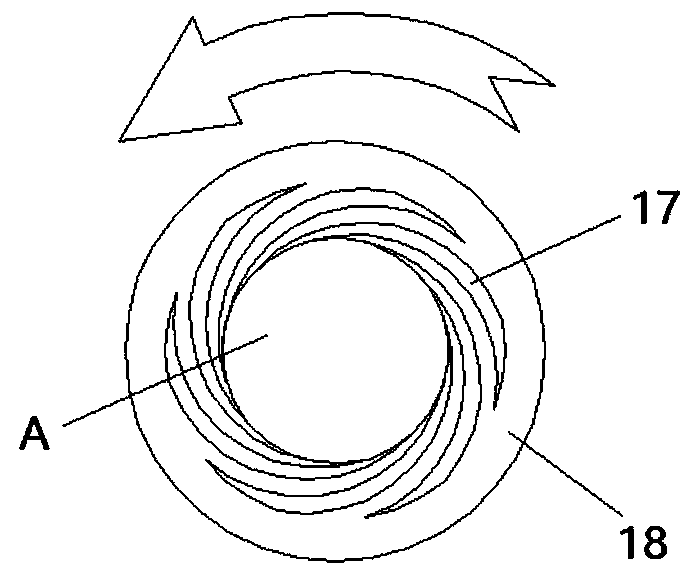

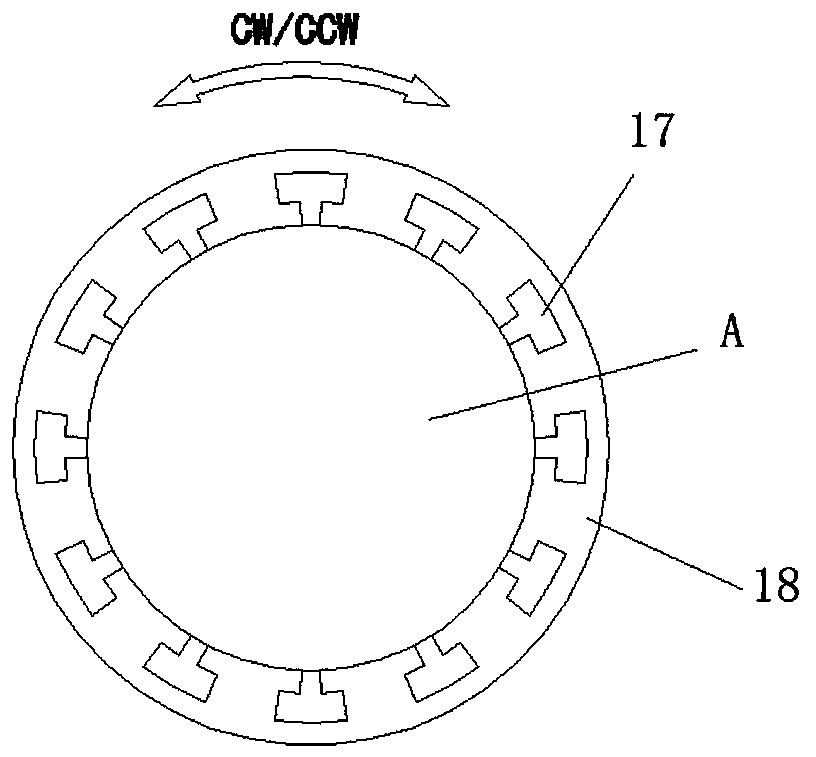

Bilaterally rotary gas lubrication non-contact mechanical seal device

The invention relates to a bilaterally rotary gas lubrication non-contact mechanical seal device, belonging to the technical field of mechanical seal. In the utility of the invention, a seal cavity is arranged in a rotating machinery shell, a rotating shaft passes through a hole on the seal cavity, a fixed component fixes a moving ring on the rotating shaft, and a stationary seal ring is glued with the moving ring; the mechanical seal device of the invention is characterized in that the seal cavity is provided with an elastic element and a thrust ring, wherein the elastic element is positioned between the seal cavity and the trust ring; the thrust ring is glued with the back face of the stationary seal ring, the stationary seal ring and the moving ring are glued with each other under the action of elastic force of the elastic element, and the two gluing faces are sealed end faces; the seal end face of the moving ring or / and the stationary seal ring is provided with slot groups which are distributed along the peripheral direction of the seal end face; and each slot group is composed of a radial air supply slot and a dynamic pressure slot which are distributed on the left and right sides of the air supply slot. The invention has the advantages of simple structure, compact assembly, good tightness, strong carrying capacity, convenient manufacture, bilaterally rotary seal, wide application range and the like.

Owner:天津赛锐特密封技术有限公司

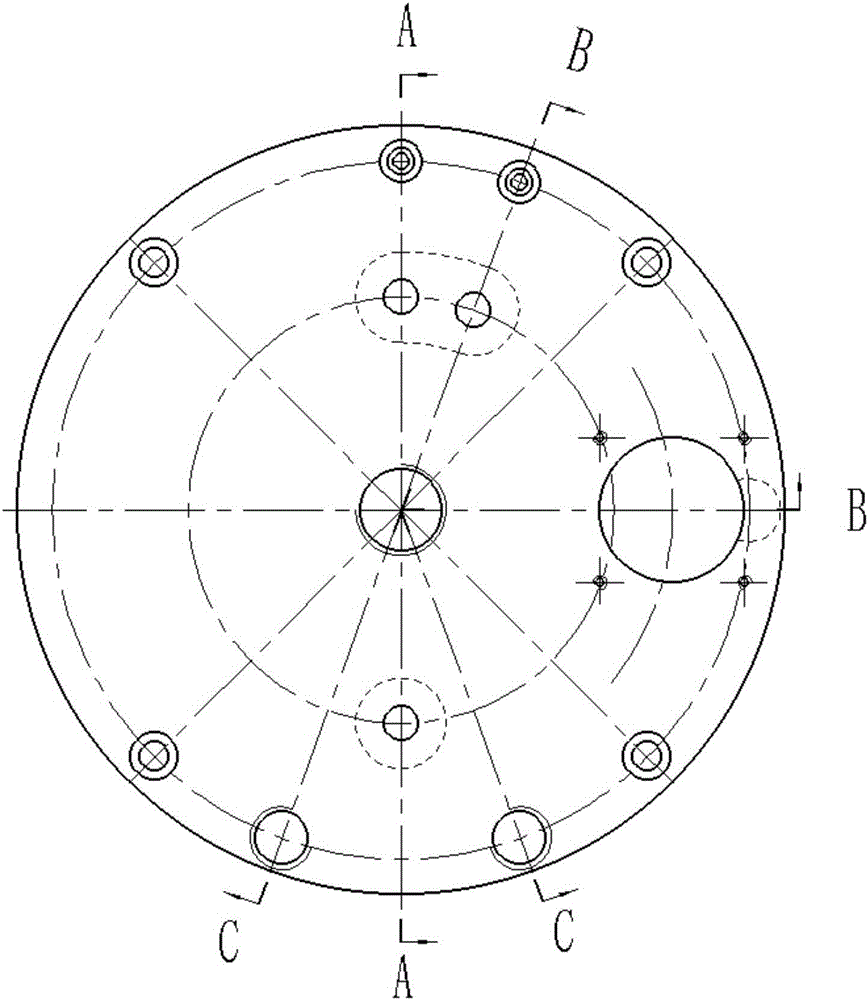

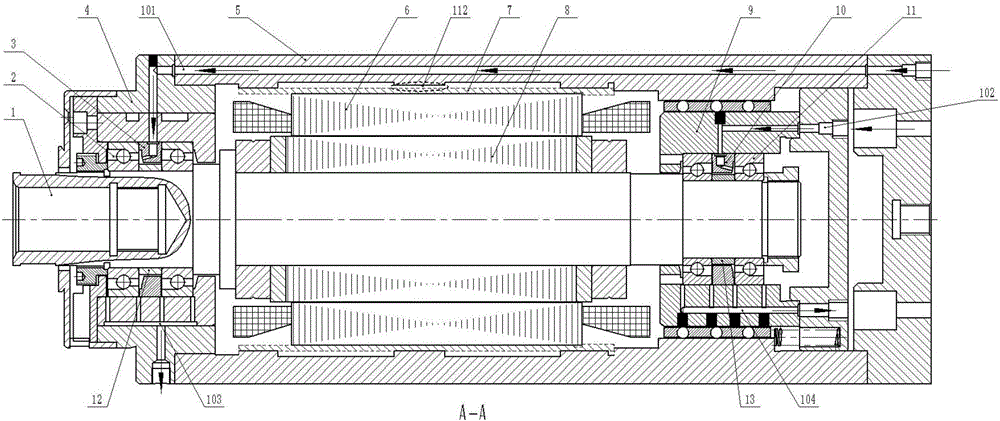

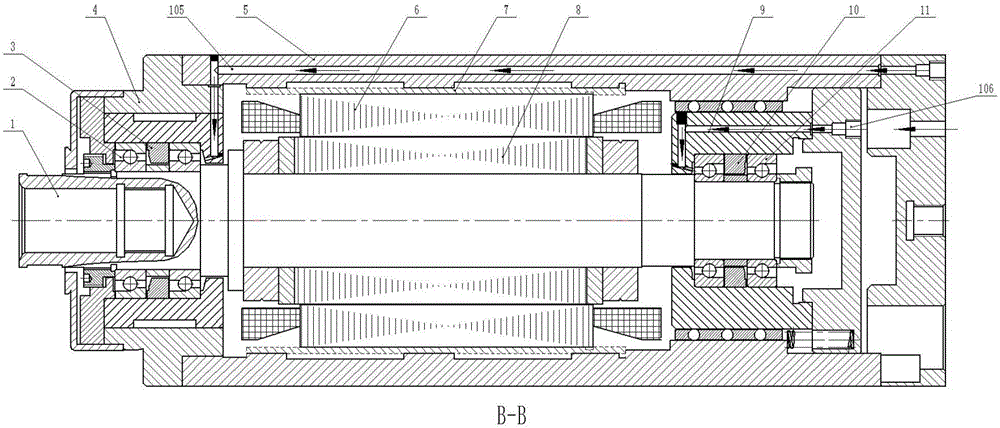

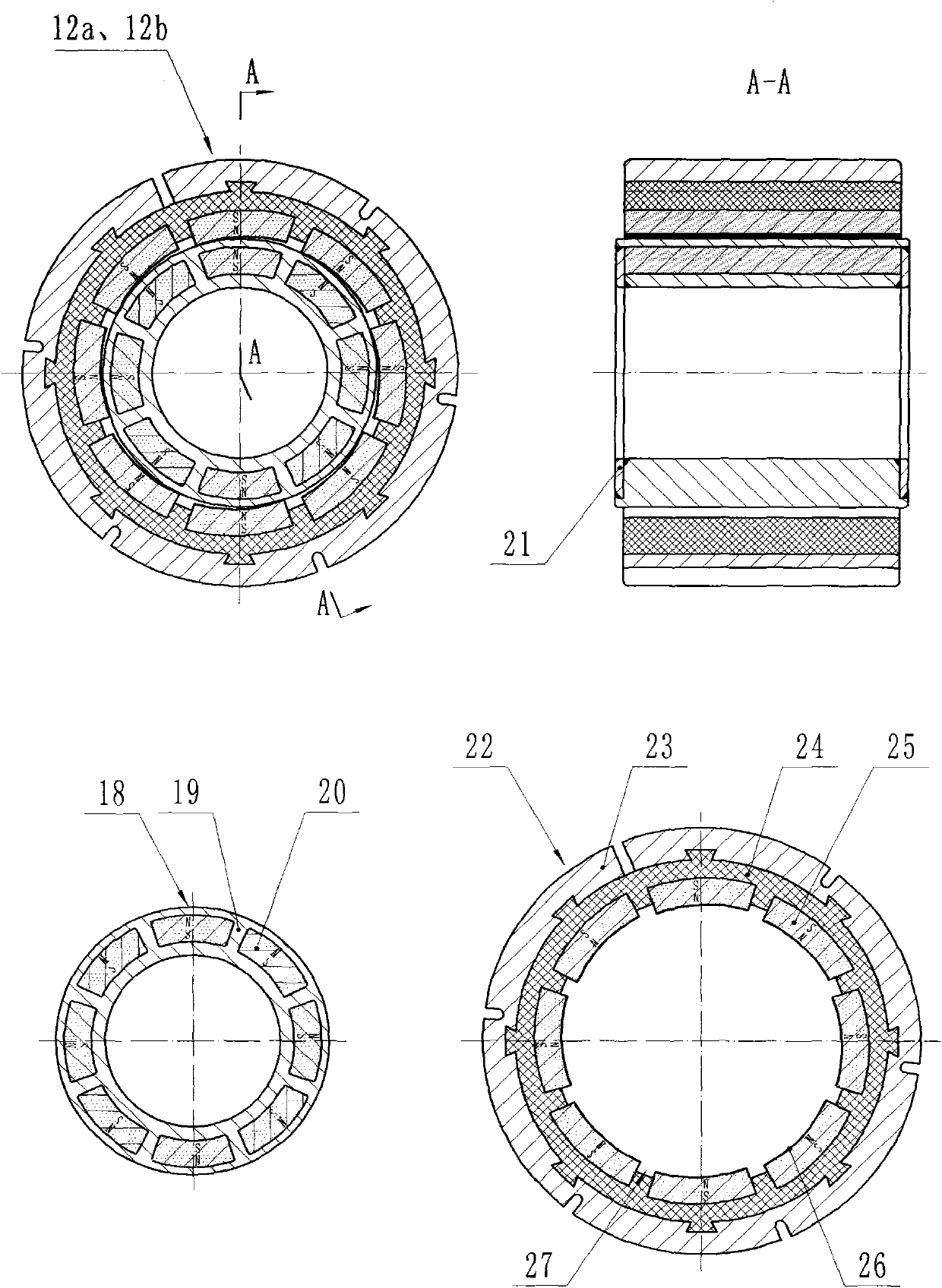

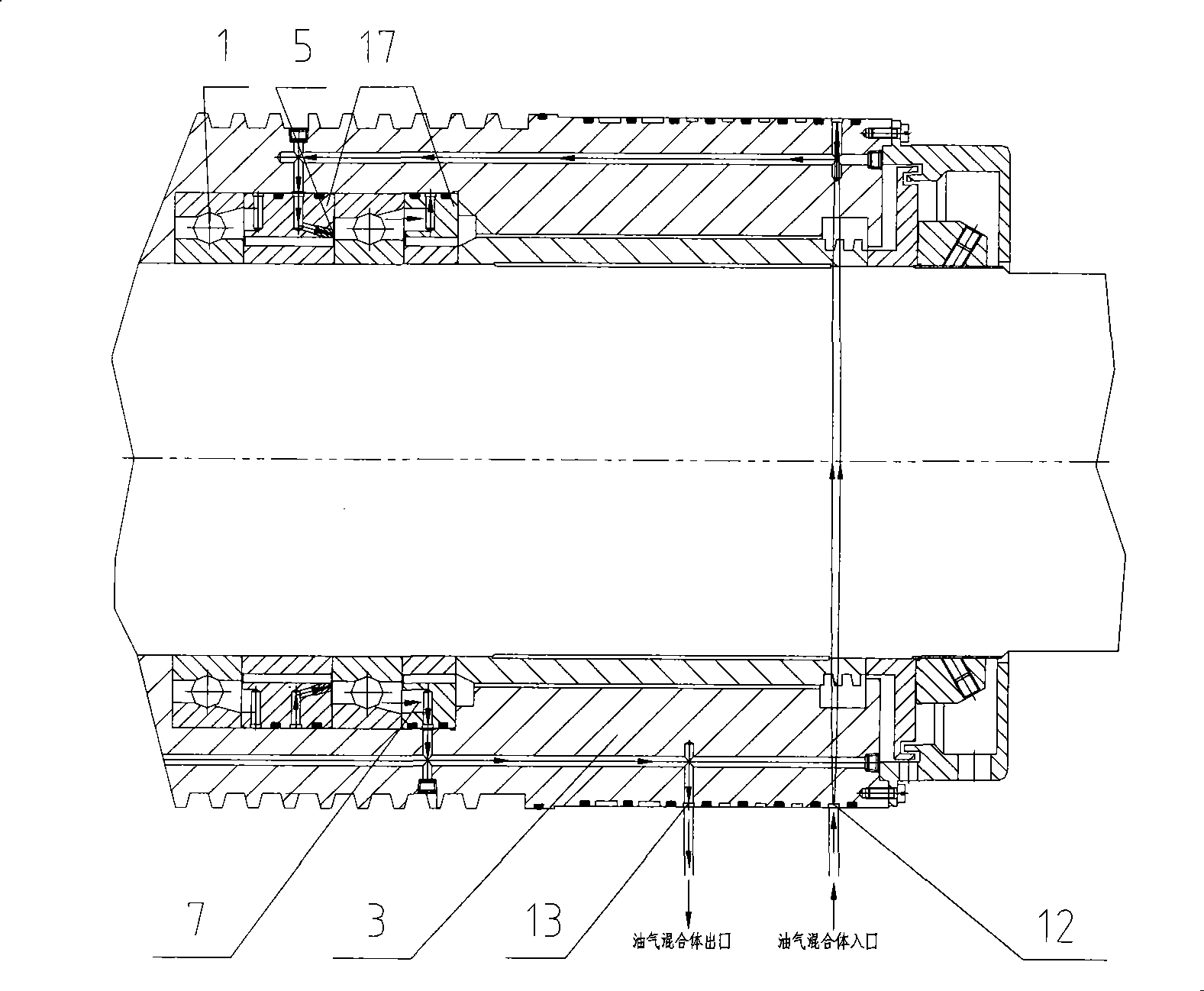

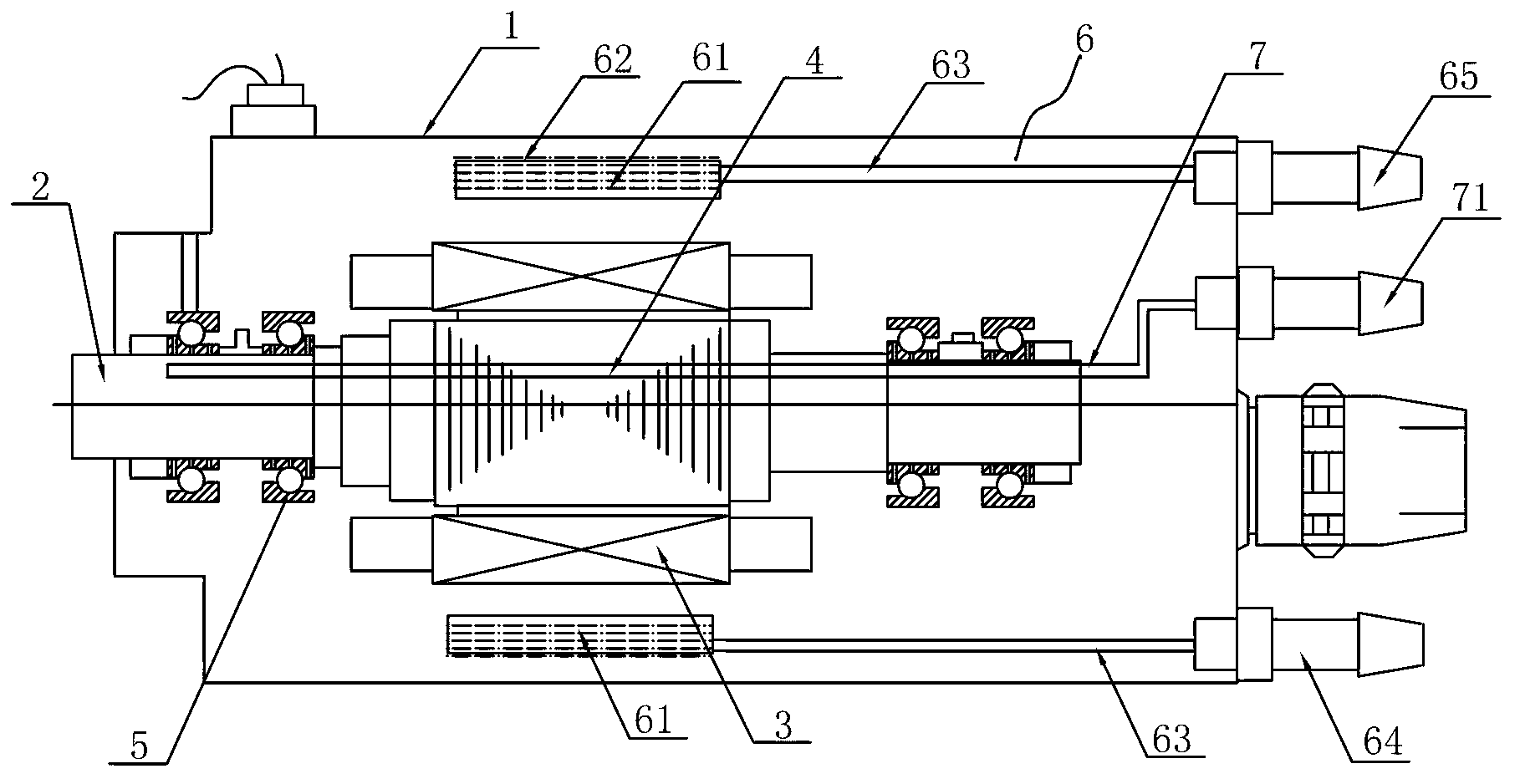

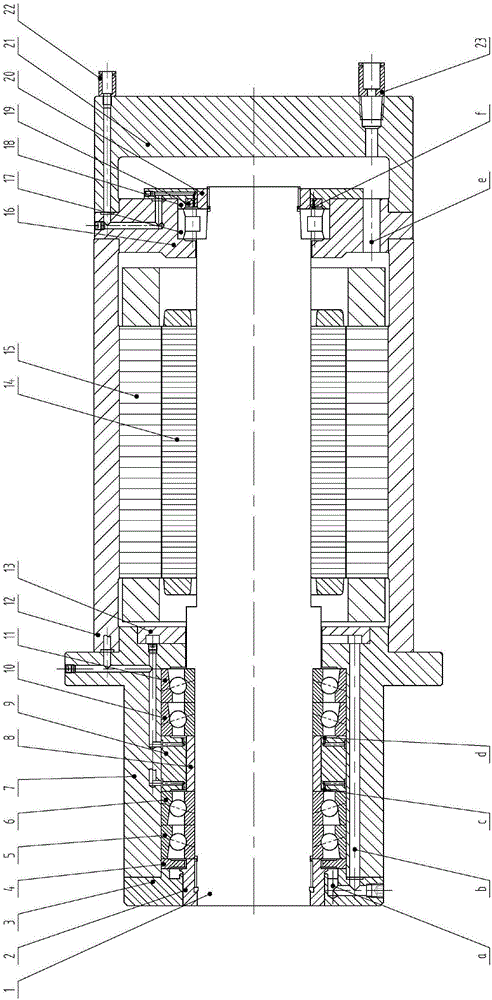

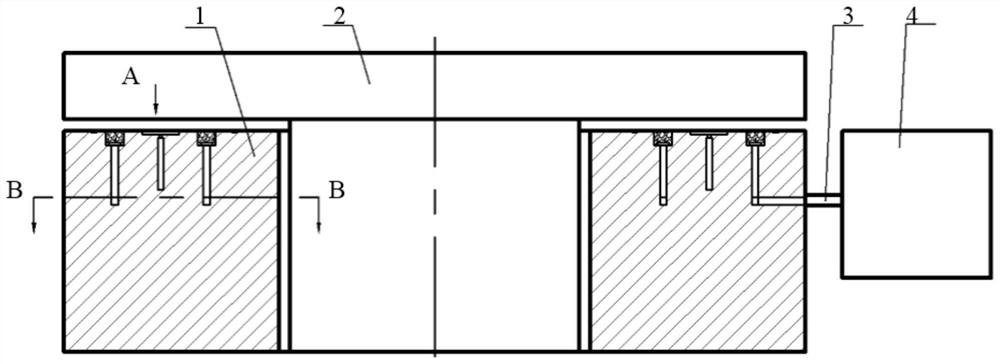

High-speed oil-gas lubrication electric spindle achieving precise oil supplying

ActiveCN106735335AGuaranteed accuracyAchieve reliabilityLarge fixed membersMaintainance and safety accessoriesGas lubricationCentral spindle

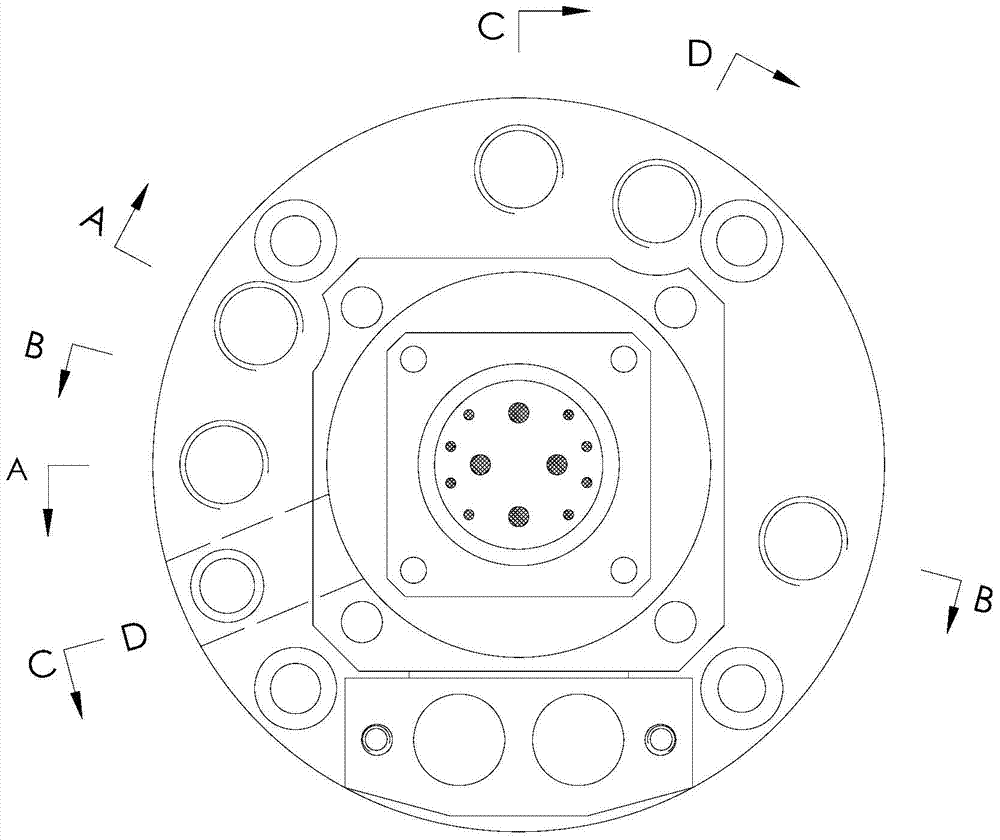

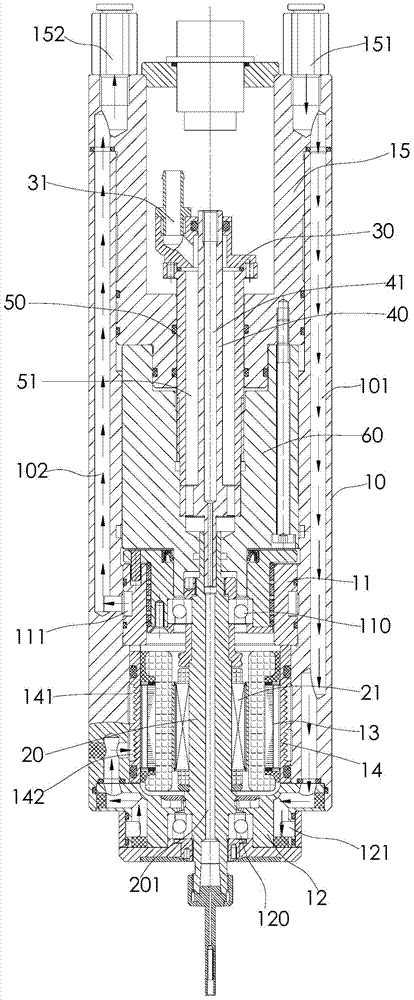

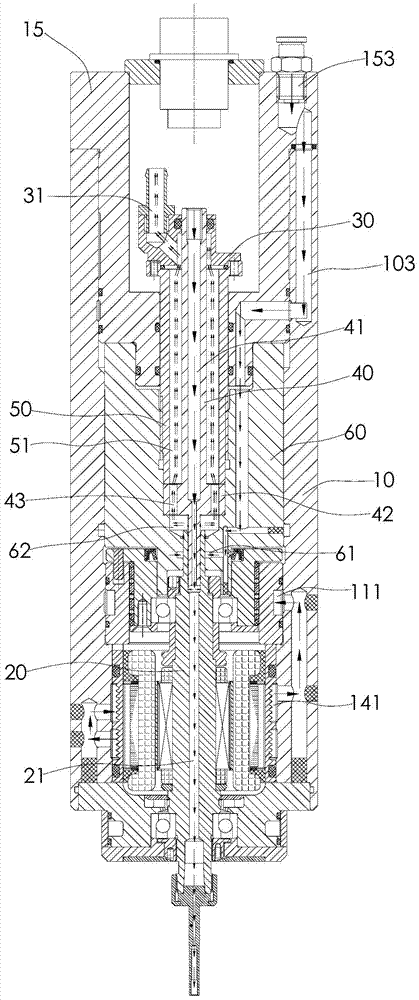

The invention discloses a high-speed oil-gas lubrication electric spindle achieving precise oil supplying, and belongs to the technical field of electric spindles. The overall electric spindle comprises a shell, and a stator is fixed in the shell; a front bearing chamber and a back bearing chamber are connected to the two ends of the shell respectively, and two bearings are connected in series in each bearing chamber, wherein the two bearings are separated through an inner bearing isolation pad and an outer bearing isolation pad; a central spindle is supported by the front bearings and the back bearings and provided with a rotor matched with the stator; each bearing is provided with an oil-gas lubrication oil line; annular cooling grooves are formed in the front bearing chamber and the shell respectively; the bearing shell is provided with oil-gas inlets and an oil-gas outlet, an oil-gas pipeline penetrates through the shell, the bearing chambers and the outer bearing isolation pads, the tail end of the pipeline is provided with an oil-gas nozzle, and each bearing is provided with an independent oil delivery line, an independent nozzle and an independent oil return line. Accordingly, by designing the independent oil-gas lubrication oil lines, nozzles and oil return lines, precise control over oil-gas lubrication parameters of the bearings is achieved, the lubricating effect of the bearings is improved, and the performance of the electric spindle is enhanced.

Owner:泰安海纳轴研科技有限公司

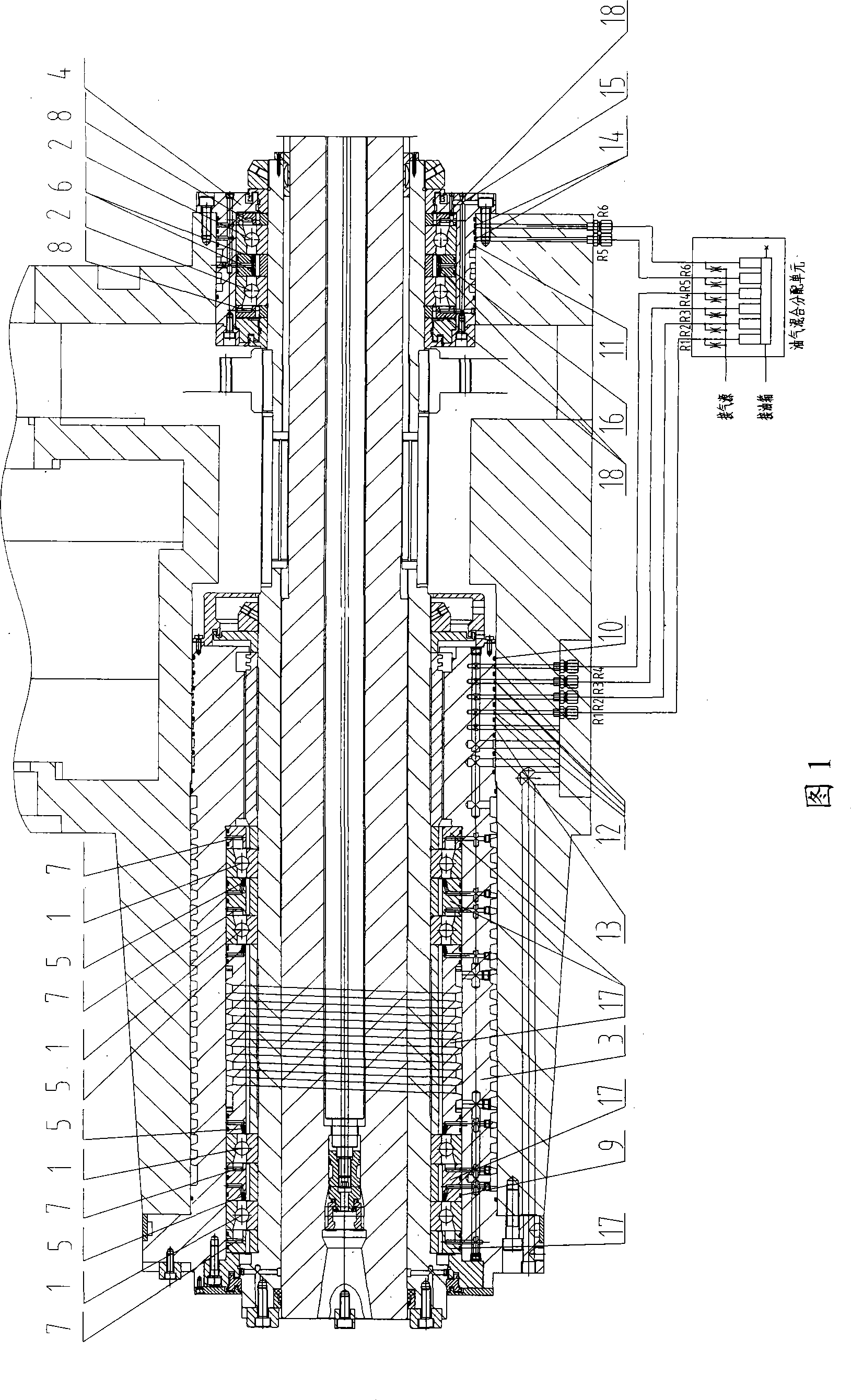

Bearing for air refrigerating machine driven by high-speed motor and the air refrigerating machine

The invention discloses a bearing for an air refrigerating machine driven by a high-speed motor, comprising two elastic support permanent-magnet and air dynamic pressure mixing radial bearings, a permanent magnet and air hydrostatic mixing thrust bearing set, and two self-adaptive refrigerating machine attitude change permanent magnet radial unloading follow-up auxiliary bearings, wherein two radial bearings are disposed on a rotor shaft between the center position of a left bearing pedestal and a right bearing pedestal of a motor housing and the housing, the thrust bearing set and one follow-up auxiliary bearing are both disposed on the rotor shaft between the center position of a turbine heat-insulation cover and the housing, the heat-insulation cover is connected with a left bearing pedestal, another follow-up auxiliary bearing is disposed on the rotor shaft between the center position of the right bearing pedestal outside and the housing, and the right bearing pedestal is connected with a gas compressor. The high-speed motor-driven air refrigerating machine-used bearing integrates the respective advantages of the permanent magnets and gas-lubricated bearings in one bearing, helps to overcome the problem of bearing solid friction at starting and stopping stages of a high-speed motor, is long in service life, and is high in reliability.

Owner:何君 +2

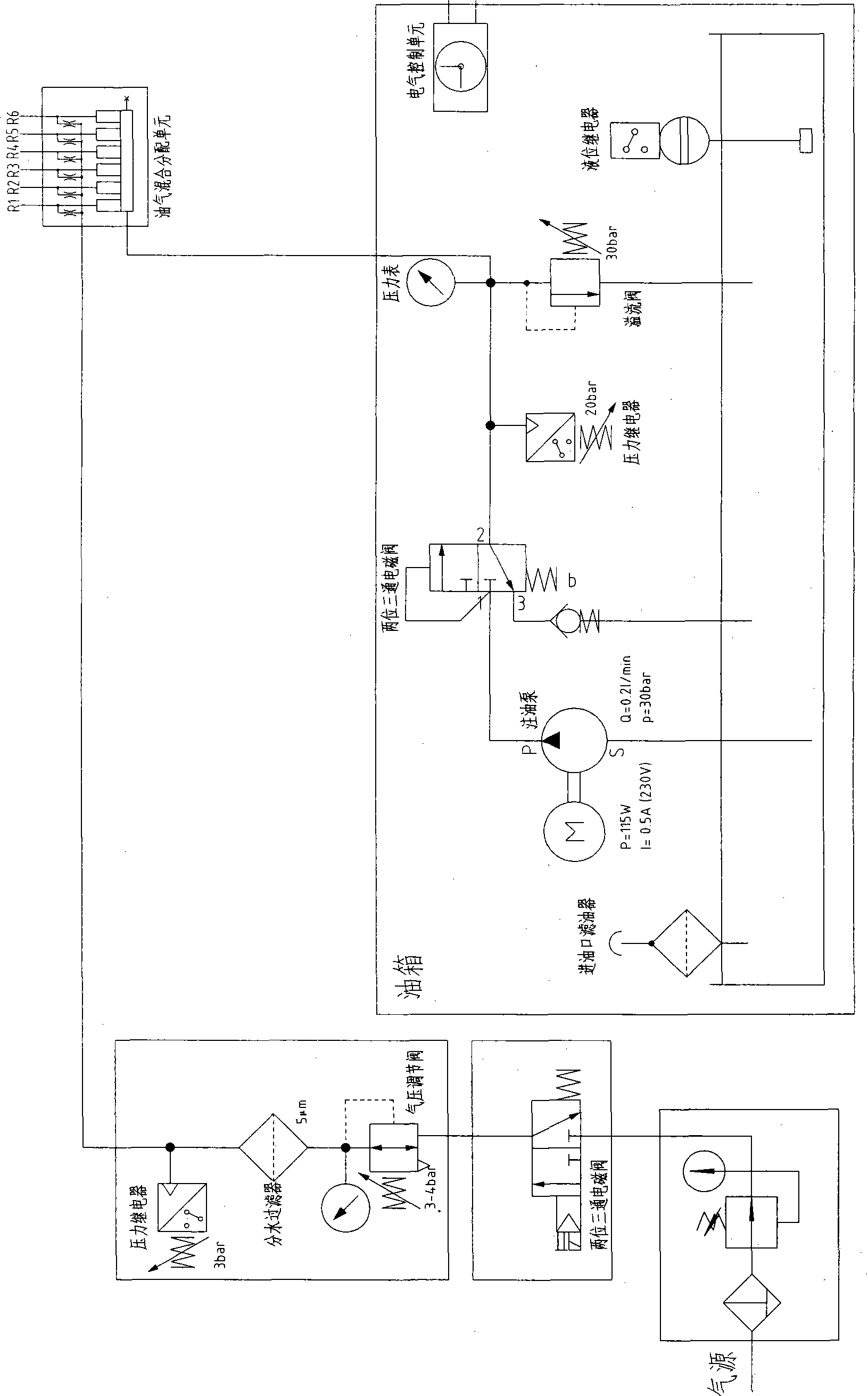

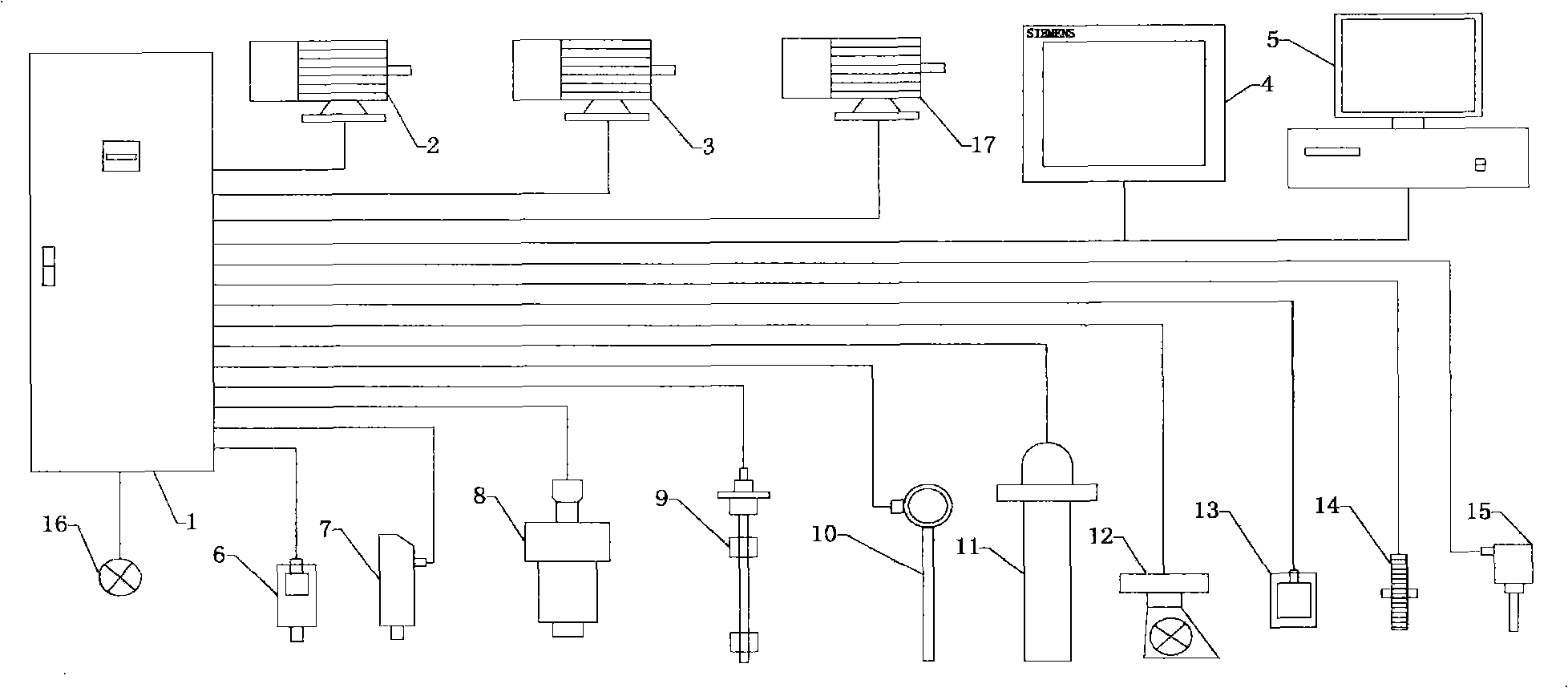

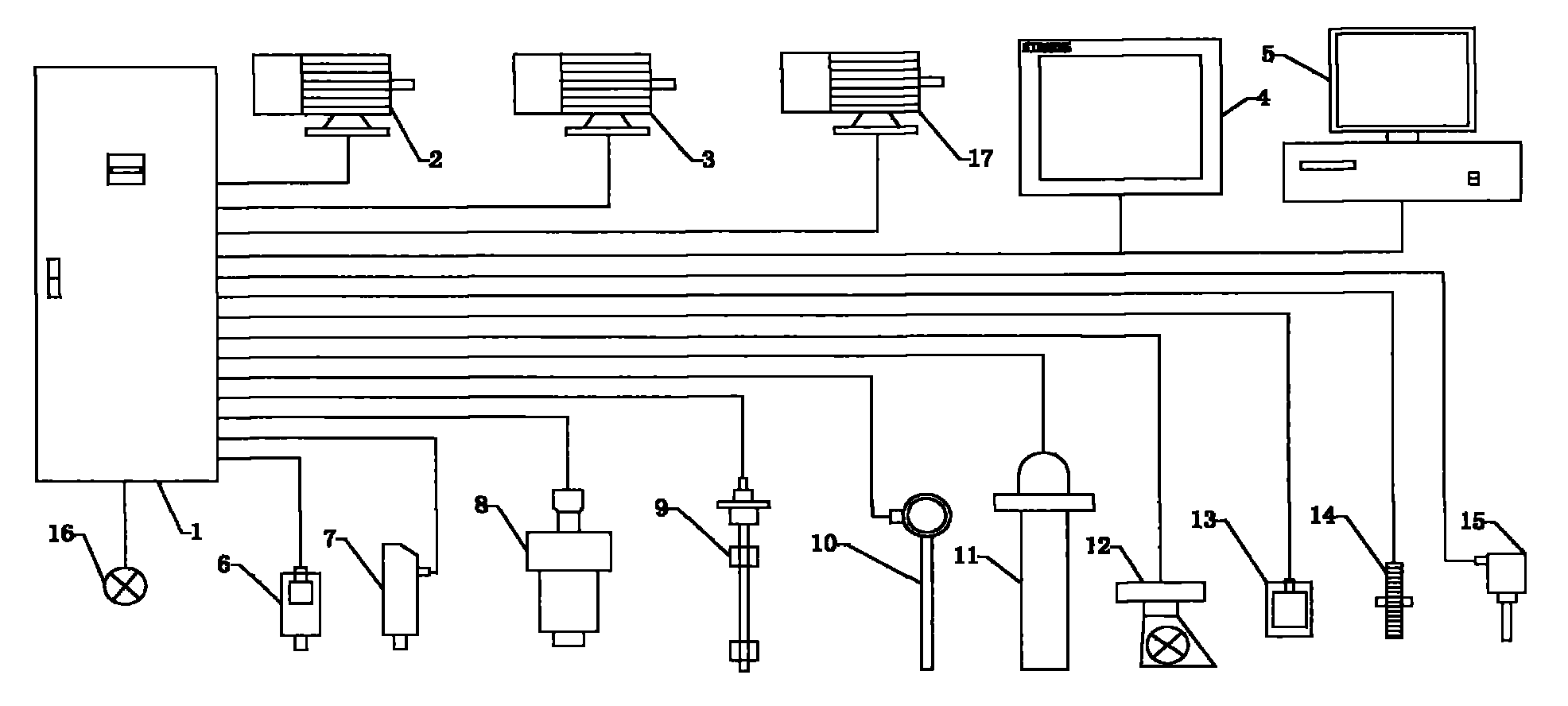

Large-size horizontal machining-center high-speed main-axle oil gas lubricating system

InactiveCN101362300ALow calorific valueSlow heatingMaintainance and safety accessoriesGas lubricationControl signal

The invention relates to an oil-gas lubrication system for a high speed main shaft in a large scale horizontal machining center. The oil-gas lubrication is adopted for the high speed main shaft with the diameter of large than 160 mm, and an external gas source and an external oil tank are arranged. The oil-gas lubrication system is characterized in that the system is composed of an oil-gas generating device and an oil-gas delivery mechanism, wherein, the lubrication circulation and the operation of an oil-filling pump are controlled through the program of an electric control unit inside the oil-gas generating device, the electric control unit is connected with the control system of a machining center through a connecting terminal, and the output of a control signal and the remote control of the oil-gas lubrication are realized; the gas source pipeline of the oil-gas generating device and the oil tank are respectively provided with an inductor and a pressure valve, and the pump is communicated with an oil-gas mixing and distribution unit inside the oil-gas generating device; a plurality of delivery pipelines of the oil-gas mixing and distribution unit are respectively connected with an oil-gas connector arranged at the bottom of a main shaft box, the oil-gas connector is communicated with an oil-gas channel on the bearing sleeve of the main shaft and the oil-gas channel on an annular outer sleeve gasket, and an oil-gas circulation delivery channel from entering the main shaft to being discharged out of the main shaft is formed. The friction coefficient between the inner / outer sleeve gasket and balls of the bearing system can be as low as 0.001 or even lower, simultaneously, the bearing of the main shaft is ensured to run in the required temperature range, the self control design can also ensure that once the running of the lubrication system is abnormal, the automatic shutdown of the machine tool can be implemented.

Owner:ZHONGJIE MACHINE TOOL

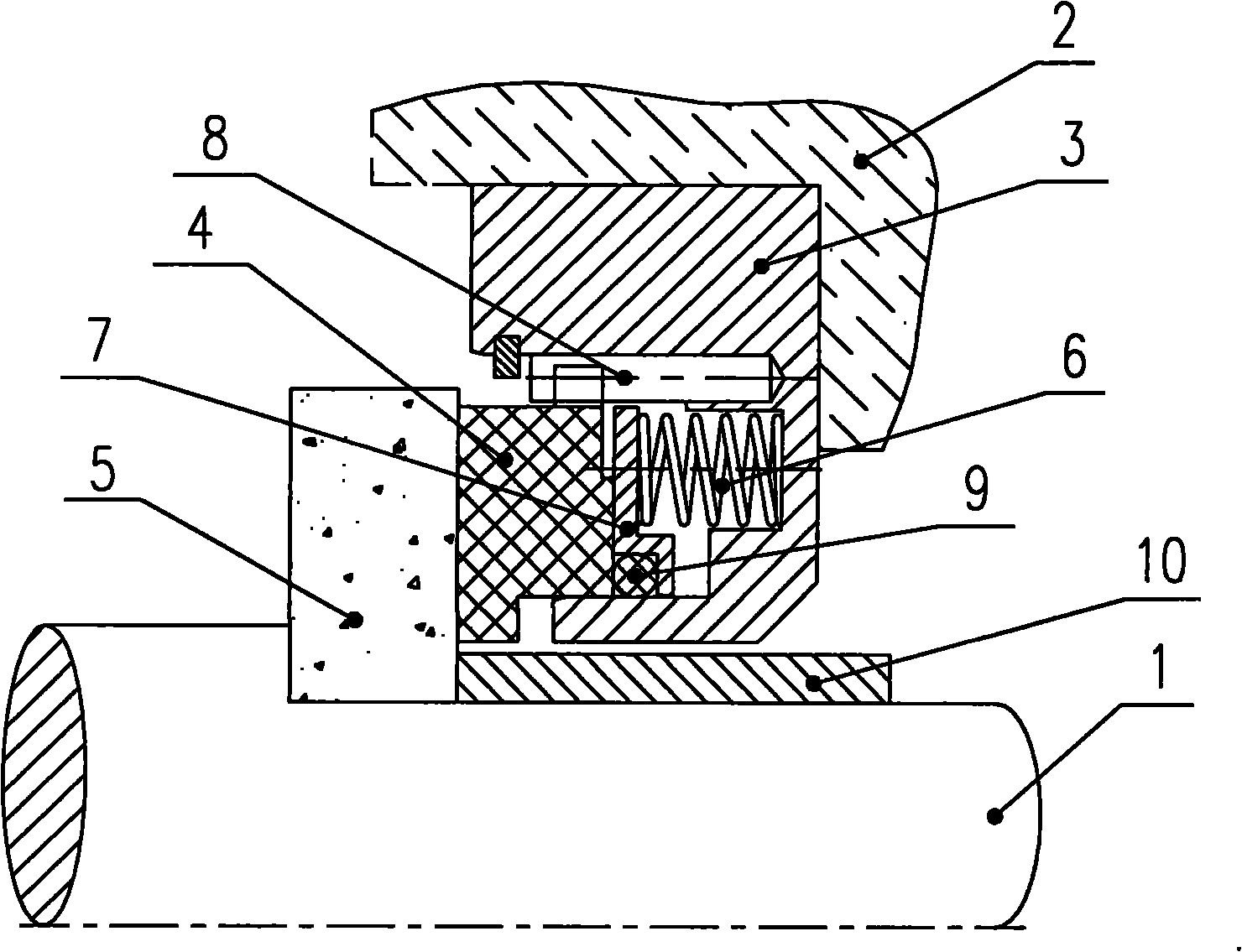

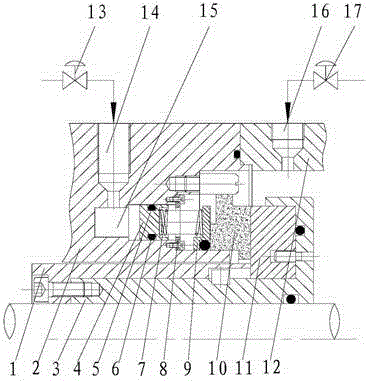

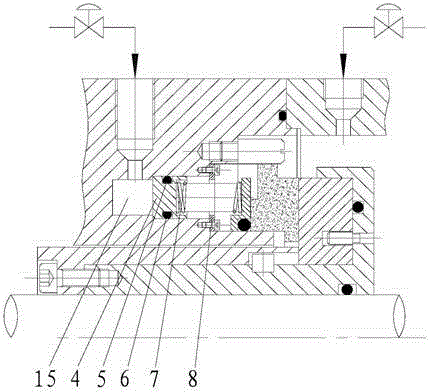

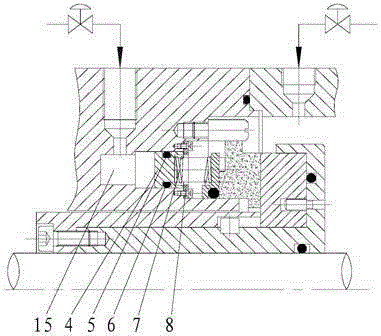

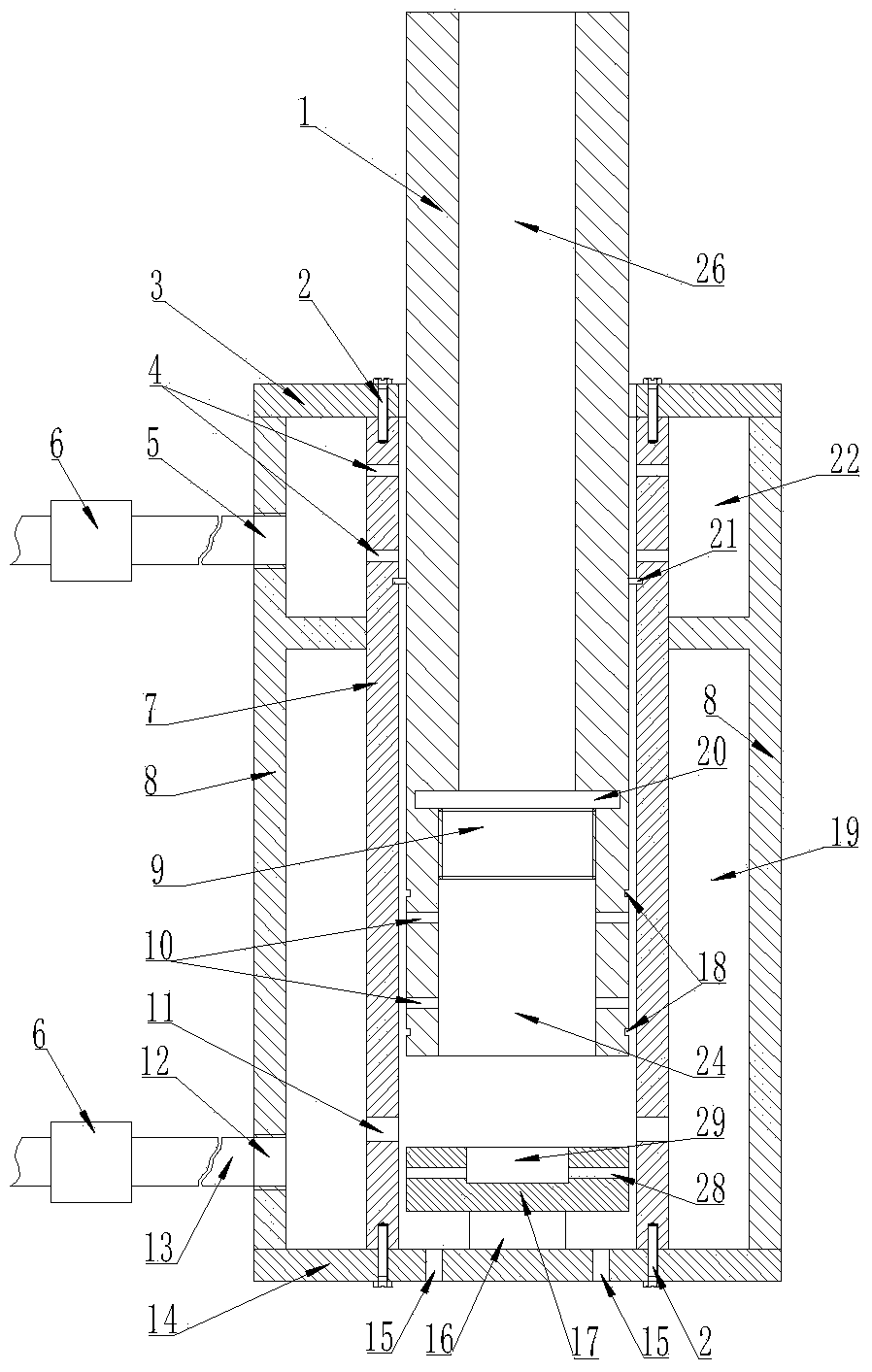

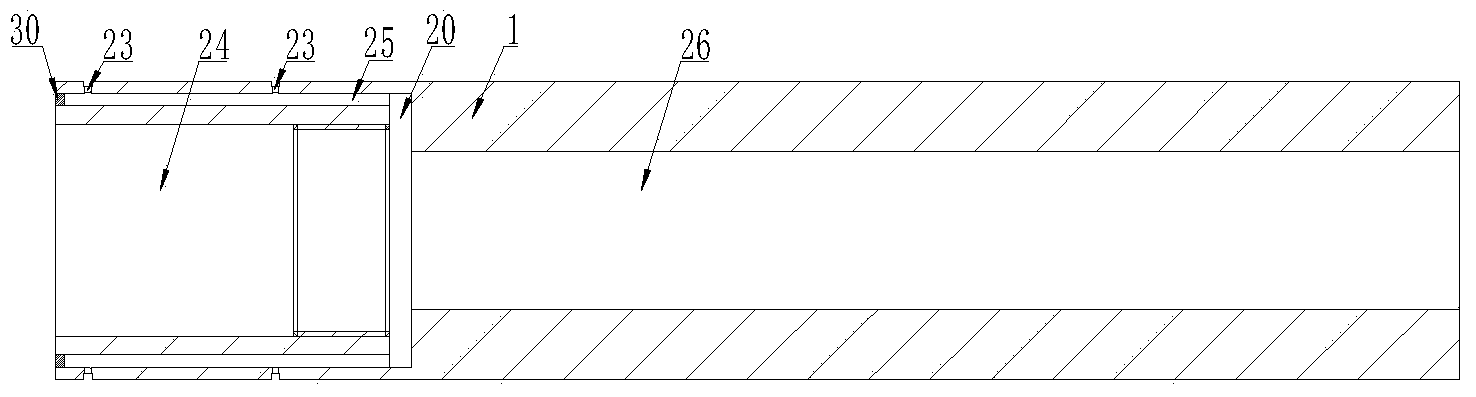

Online adjustable closing force gas lubricating mechanical sealing device

ActiveCN104896104AExtended service lifeImprove use reliabilityEngine sealsGas lubricationMechanical engineering

Provided is an online adjustable closing force gas lubricating mechanical sealing device. The online adjustable closing force gas lubricating mechanical sealing device comprises an axial moving ring positioning ring, a sealing end cover, a moving ring seat, a piston, a working spring, a piston limiting ring, a pushing ring, a static ring, a moving ring and a sealing cavity. The moving ring is fixed to the moving ring seat and rotates along with a shaft. The static ring is arranged on the sealing end cover. A piston cavity is arranged inside the sealing end cover. The sealing end cover is provided with an outer gas supplying channel, and the sealing end cover is communicated with one side of the piston cavity. The working spring is arranged between the other side of the piston and the static ring. The piston moves along the piston cavity in the axial direction to change the compression amount of the working spring. The other side of the piston is exposed inside the sealing cavity. The sealing cavity is communicated with a buffer gas channel. By adjusting the outer gas supplying pressure, the compression amount of the working spring can be adjusted, and therefore online adjusting on the sealing closing force can be achieved.

Owner:ZHEJIANG UNIV OF TECH

Screw groove non-contact leak-less mechanical seal system for centrifugal pump

InactiveCN1492152AGuaranteed uptimeSolution to short lifePump componentsPumpsGas lubricationFriction loss

The present invention relates to mechanical non-contact spiral groove sealing system for centrifugal pump. The sealing system is installed on the rotation shaft of centrifugal pump to form mechanical non-contact sealing system, and the sealing cavity provides the sealing system with buffering fluid with pressure lower than that in pump work cavity. Besides, externally non-contact cylindrical sealing is provided as auxiliary sealing. The non-contact sealing has no friction loss and no leakage, and makes centrifugal pump operate safely and reliably.

Owner:徐万福

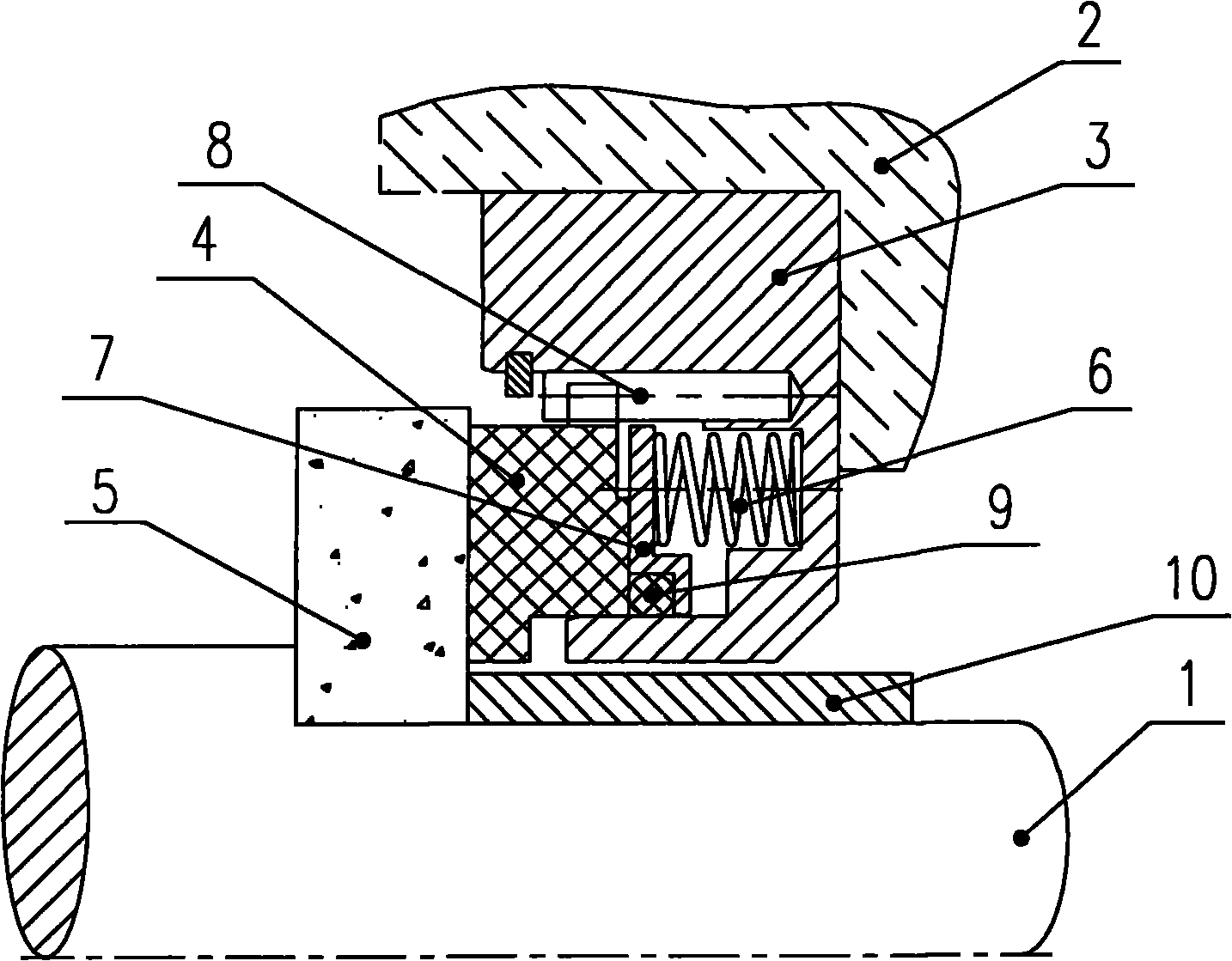

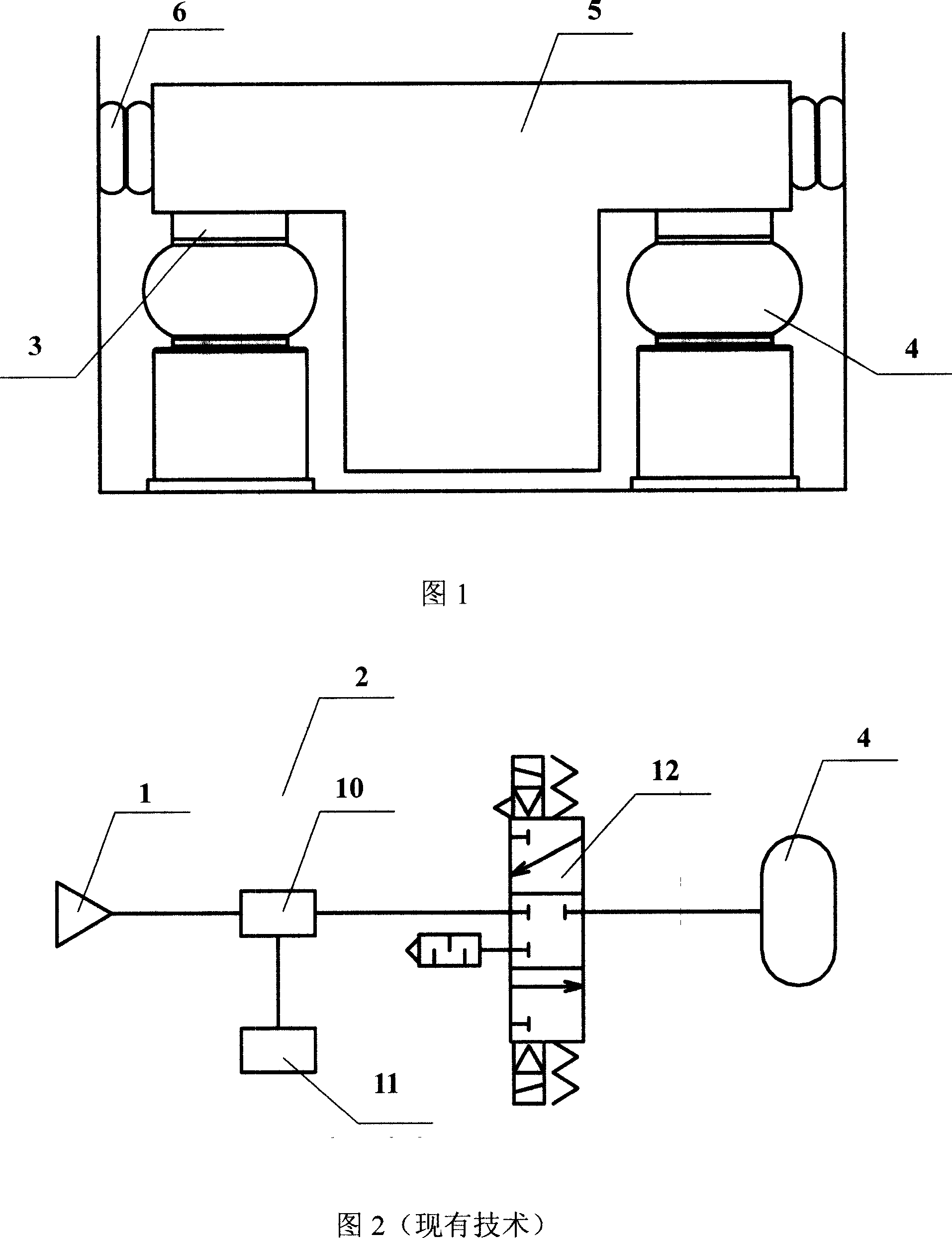

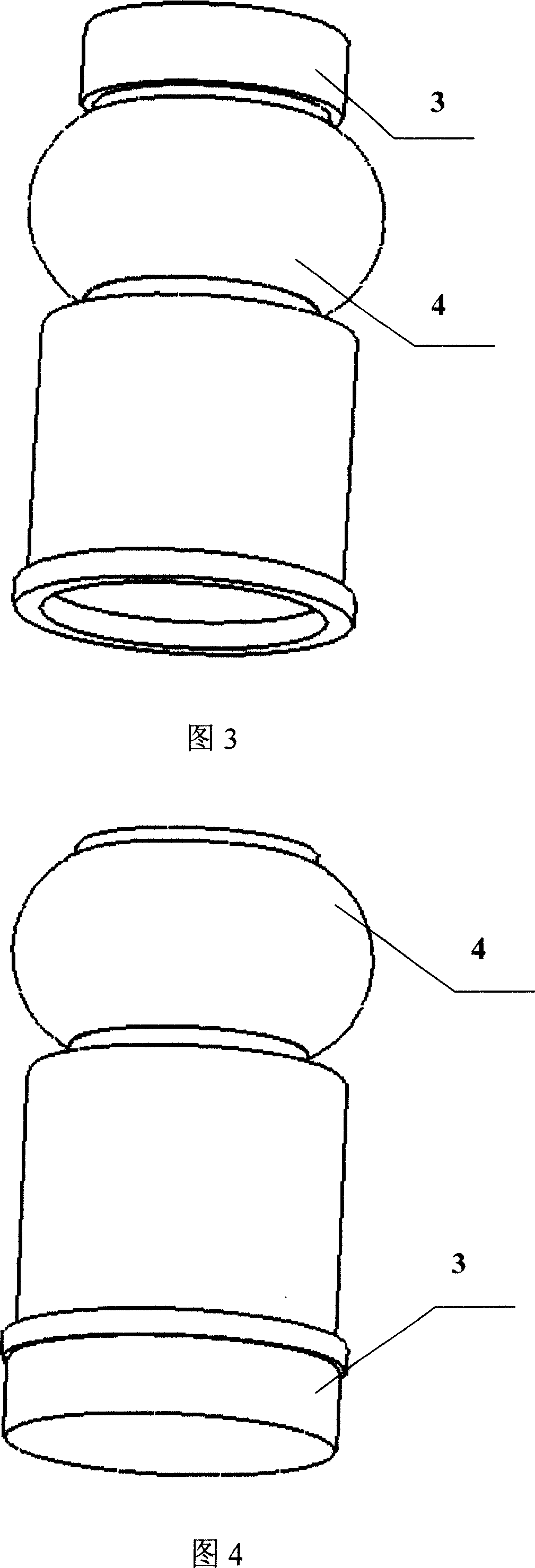

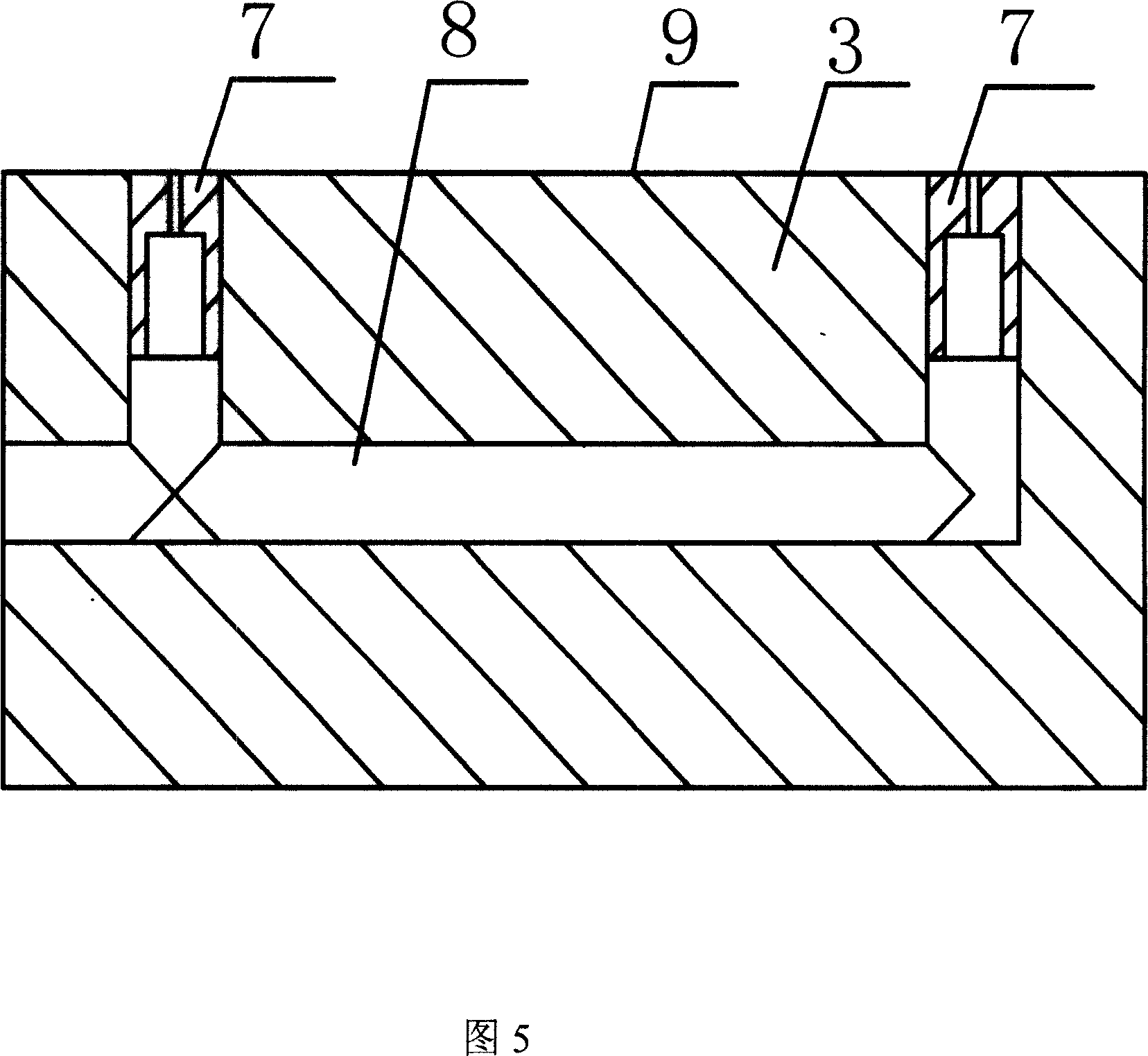

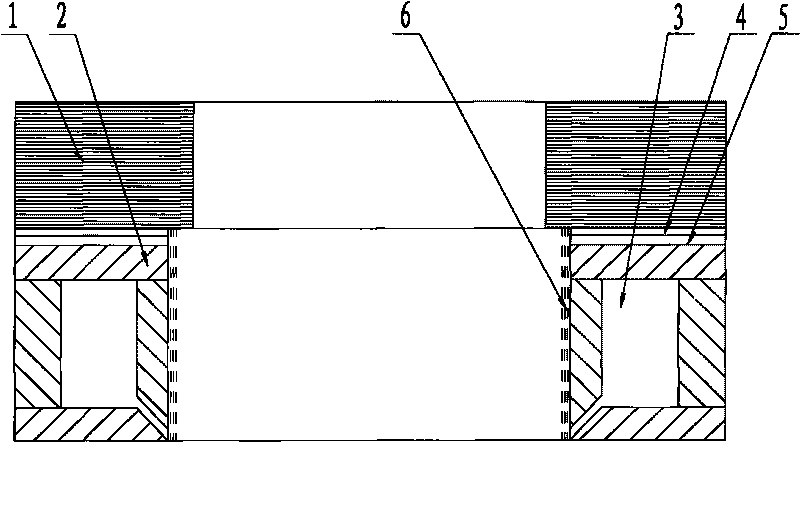

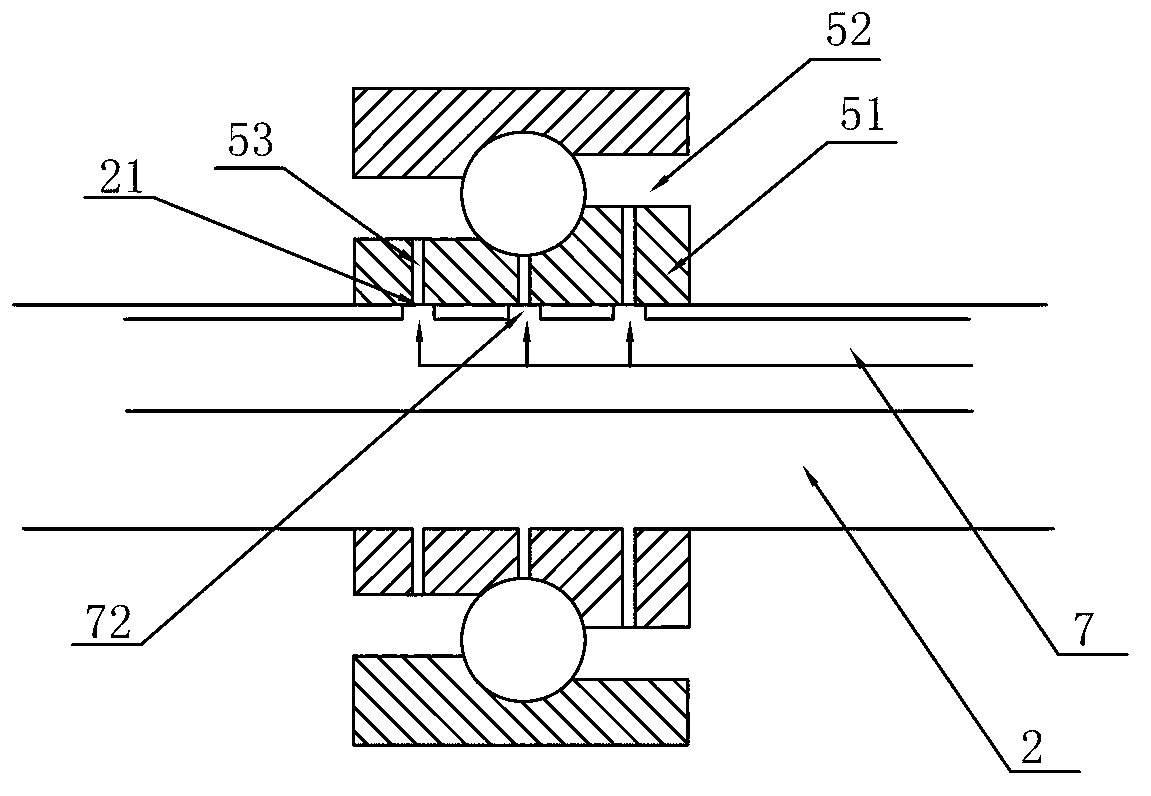

Air spring vibration insulating foundation with gas-film lubrication unit

InactiveCN101096987AGood effectReduce lateral stiffnessNon-rotating vibration suppressionGas lubricationControl system

The invention discloses an air spring vibration isolation base with gas lubricating unit, which is characterized by the following: comprising base (5), a group of air spring (4), air feed system (1), height controlled system (2), a plurality of gas lubricating unit (3)and erection device with low rigidity; connecting the air feed system (1)to the inputting end of the height controlled system (2); connecting the outputting end of the height controlled system (2)to each air spring (4)separately; connecting the gas lubricating unit (3)to the air feed system (1)directly; cascading the gas lubricating unit (3)and the air spring (4); assembling under the base (5)to support the base; layouting erection device (6)with low hardness at the lateral of the base (5). This invention is fit for super air spring vibration isolation base.

Owner:HARBIN INST OF TECH

Method for casting high-strength aluminum alloy round ingot by continuous oil gas lubrication

The invention relates to a method for casting a high-strength aluminum alloy round ingot by continuous oil gas lubrication, which comprises the following steps: firstly, melting an industrial pure aluminum ingot in an induction furnace; after the industrial pure aluminum ingot is molten, controlling the melt temperature at 700-730 DEG C, and adding an industrial pure zinc ingot and an industrial pure magnesium ingot; stirring the melt, heating up to 710-750 DEG C, and adding Al-50Cu, Al-10Zr, Al-10Mn and Al-5Cr intermediate alloy ingots; stirring and transferring the melt to a heat-insulation holding furnace for refining and removing slag; before casting, adding Al-5Ti-B poles into the furnace for thinning the melt; in the semi-continuous casting process, adopting a continuous oil gas lubrication crystallizer; in the casting process, controlling the crystallizer compressed air pressure at 0.1-0.4MPa and the lubrication oil pressure at 0.2-0.8MPa, mixing the compressed air and the lubrication oil, and forming an oil-gas cushion film on the inner wall of the crystallizer; in the initial stage of casting, controlling the casting speed at 10-30mm / min and the cooling water pressure at 0.08-0.1MPa; and after casting for a certain length, gradually increasing the casting speed and the cooling water pressure, and keeping the casting speed and the cooling water pressure constant. The method not only can be used for successfully casting a high-strength aluminum alloy cast ingot, but also can obviously improve surface quality of the cast ingot.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

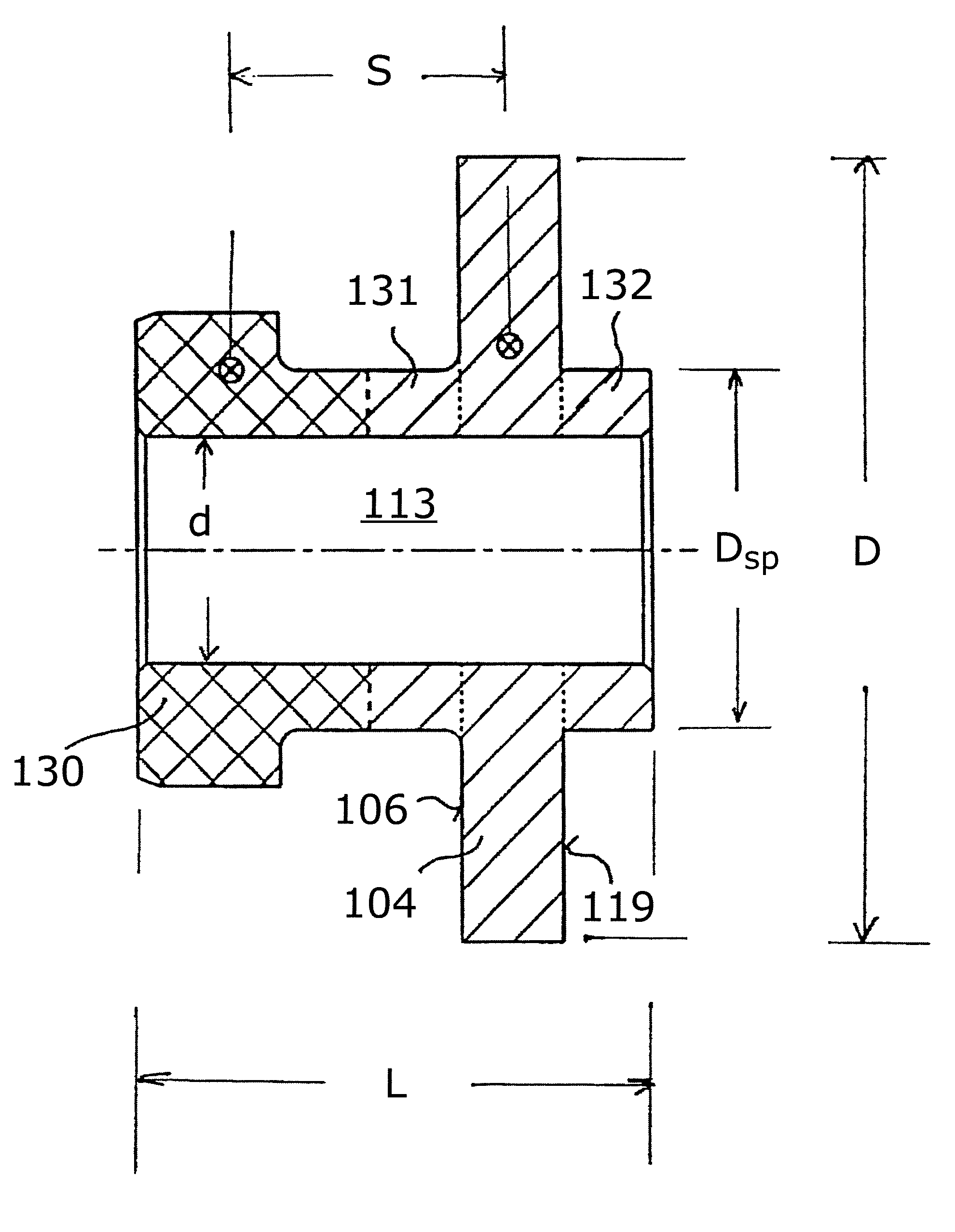

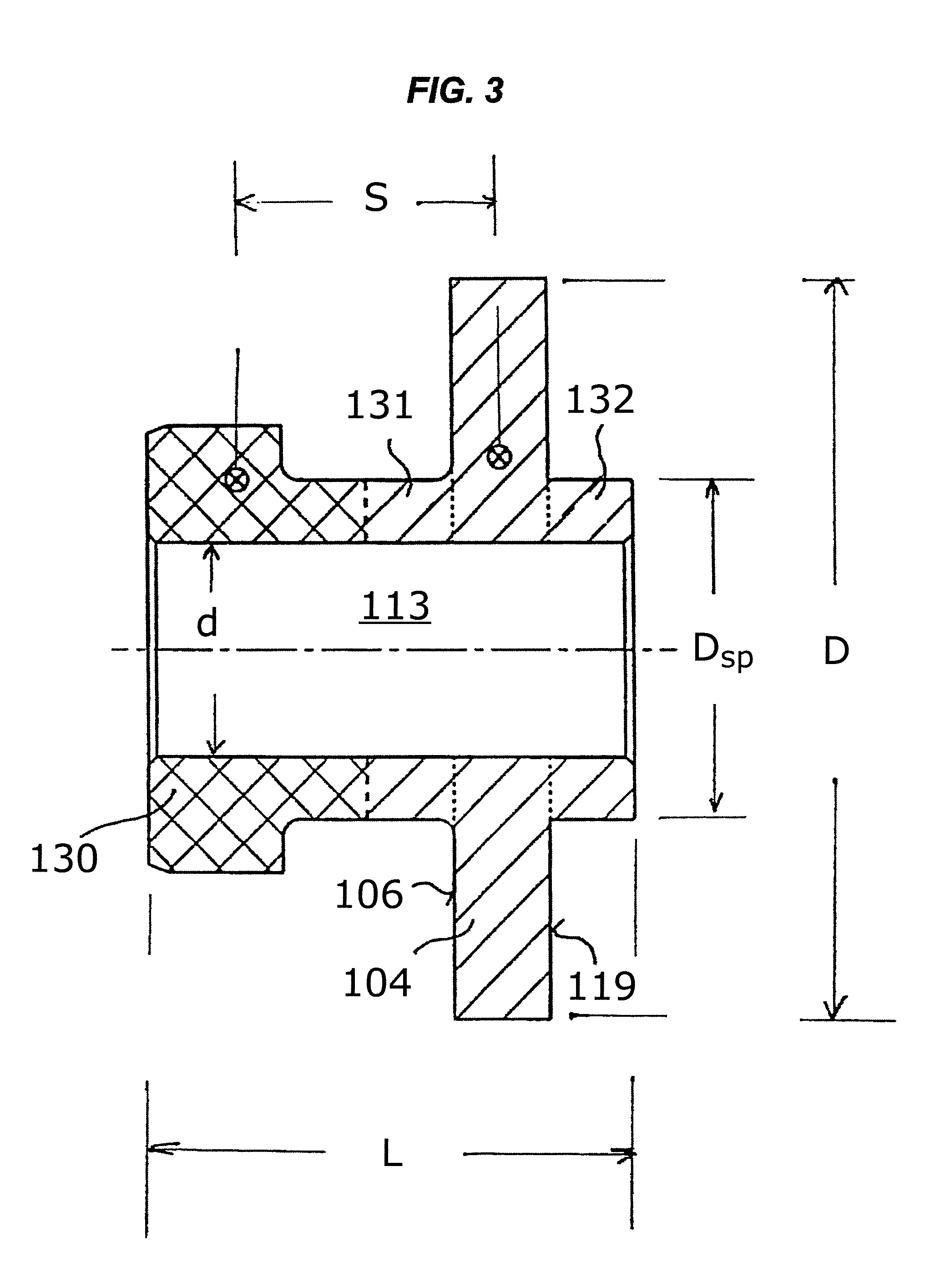

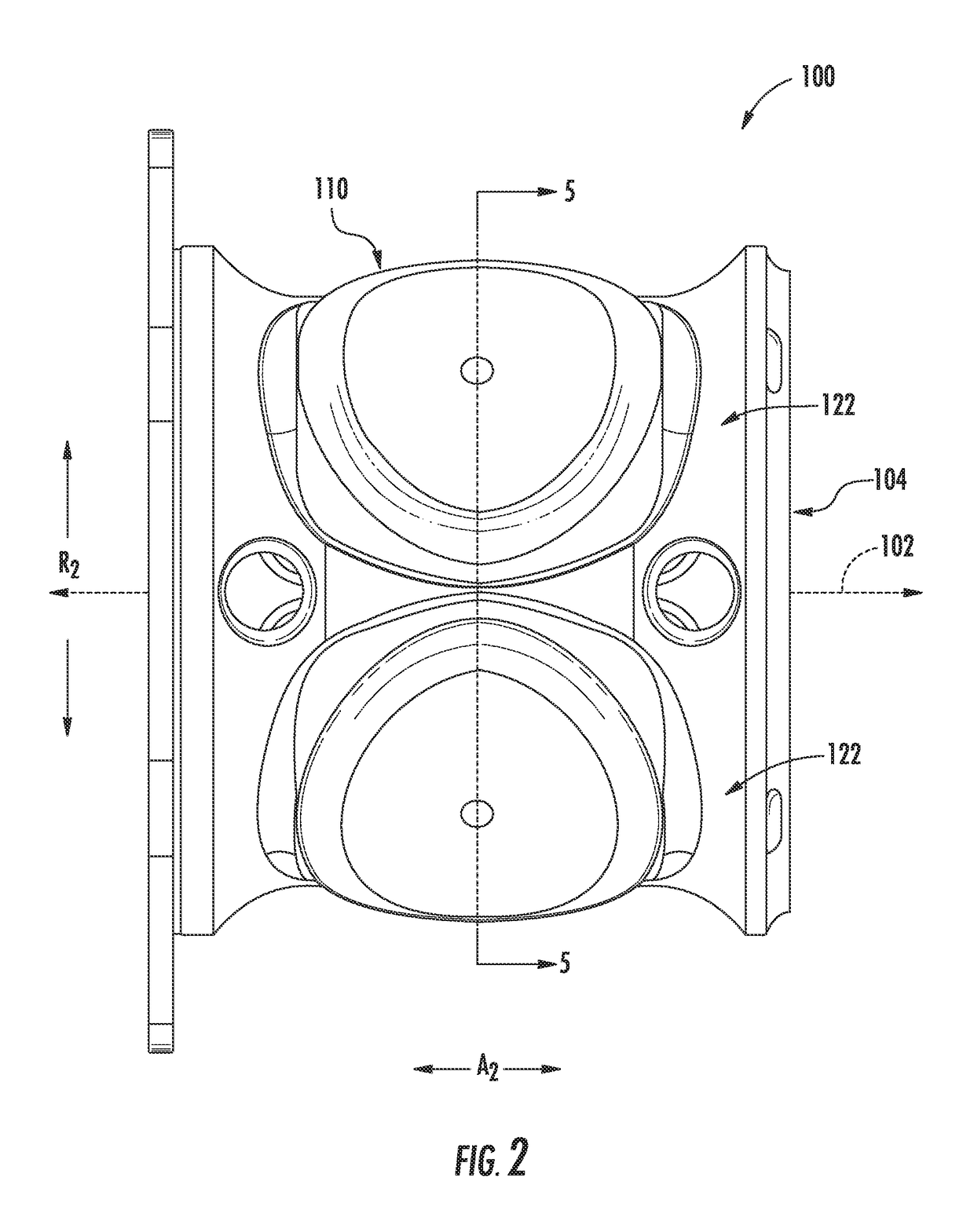

Axial plain bearing assembly

InactiveUS7997802B2Distortion of the thrust ringHighly effectiveEngine sealsShaftsThrust bearingEngineering

An axial plain bearing assembly includes a thrust ring provided for common rotation with a rotary component. The thrust ring has a radial seal face on an end face thereof for co-operating with a radial seal face of a non-rotational seal ring of a gas-lubricated mechanical face seal assembly for sealing said rotary and stationary components against each other. A plurality of peripherally spaced gas-pumping grooves is formed in at least one of the radial seal faces of the thrust and non-rotational seal rings. A mass ring connected with the thrust ring is provided at an axial distance from the thrust ring. The mass ring is configured and adapted to exert a balancing force on the thrust ring under centrifugal forces acting on the mass ring during common rotation of the mass and thrust rings to compensate for thermal distortion of the thrust ring during operation.

Owner:CARL FREUDENBERG KG

Electric control system for oil-gas lubrication

InactiveCN102494236AImprove the lubrication effectImprove automation controlDistribution equipmentGas lubricationControl system

The invention discloses an electric control system for oil-gas lubrication, comprising a PLC (programmable logic controller) main control cabinet of a lubricating main station, a lubricating oil monitoring sensor, a lubricating pump oiling device and an electromagnetic valve, wherein the PLC main control cabinet is provided with a PLC; the lubricating oil monitoring sensor is connected with the PLC main control cabinet and transmits acquired signal data to the PLC controller; and the PLC controls the lubricating pump oiling device and the opening and closing of the electromagnetic valve according to the acquired signal data. After the technical scheme is adopted, the electric control system has the advantages of high automation degree, simplicity and easiness in operation, convenience in maintenance and installation, low energy consumption and perfect alarming.

Owner:YANTAI HUASHUN MACHINERY ENG EQUIP

Friction-free constant force output gas floatation device

ActiveCN103527561AIncrease volumeHigh precisionFluid-pressure actuatorsGas lubricationConstant force

The invention provides a friction-free constant force output gas floatation device which comprises a long piston, a cylinder barrel, a gas storage sleeve and a gas pressure pressing plate. The long piston is installed in the cylinder barrel in a sleeved mode, the gas storage sleeve is installed outside the cylinder barrel in a sleeved mode, the two ends of the gas storage sleeve and the two ends of the cylinder barrel are sealed through end covers and bases, the long piston penetrates through the end covers, the gas pressure pressing plate is installed in the cylinder barrel in a sleeved mode, a force sensor is installed on the lower portion of the gas pressure pressing plate, two gas storage cavities are formed between the gas storage sleeve and the cylinder barrel, the long piston and the cylinder barrel are provided with a first radial direction throttling hole, a second radial direction throttling hole, a first pressure relief tank and a second pressure relief tank respectively, the cylinder barrel and the long piston are lubricated through gas, the magnitude of gas pressure is obtained through the gas pressure pressing plate and the force sensor, the gas storage cavities are increased to store constant pressure gas, and thus constant force output is achieved. The friction-free constant force output gas floatation device is simple in structure, accurate in output force value and good in stability.

Owner:NANTONG YUANZHENG FREEZING EQUIP LTD

Ball high-speed motorized spindle

ActiveCN103752863AHigh running precisionExtended service lifeLarge fixed membersDriving apparatusGas lubricationCore component

A ball high-speed motorized spindle comprises a unit component which comprises a body, a stator fixed in the unit and an upper bearing block and a lower bearing block which are fixedly connected onto the unit. A shaft core component comprises a shaft core and a rotor which is mounted on the outside of the shaft core and matched with the stator. The upper end of the shaft core is pivoted to the upper bearing block through an upper bearing, and the lower end is pivoted to the lower bearing block through a lower bearing. An upper lubrication oil gas inlet, a lower lubrication oil gas inlet and a lubrication oil gas outlet are formed in the body component. Gaps between the upper lubrication oil gas inlet and an upper bearing inner ring and outer ring and the lubrication oil gas outlet are communicated successively. Gaps between the lower lubrication oil gas inlet and a lower bearing inner ring and outer ring and the lubrication oil gas outlet are communicated successively. According to the ball high-speed motorized spindle, channels for delivering oil gas lubrication media to the upper bearing and the lower bearing are arranged in the ball high-speed motorized spindle to deliver oil gas lubrication media to the upper bearing and the lower bearing continuously, so that the lubrication effect is improved.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

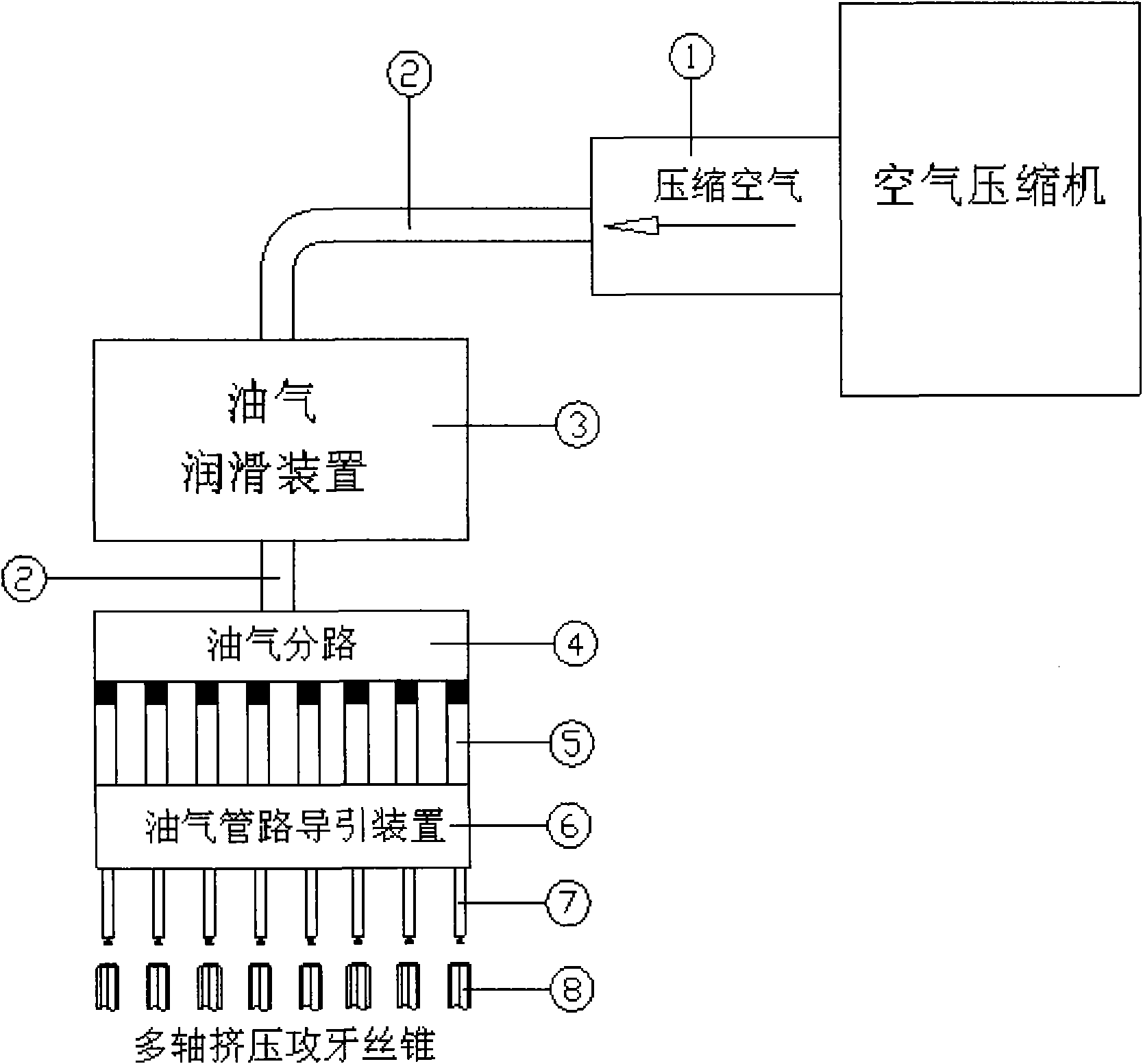

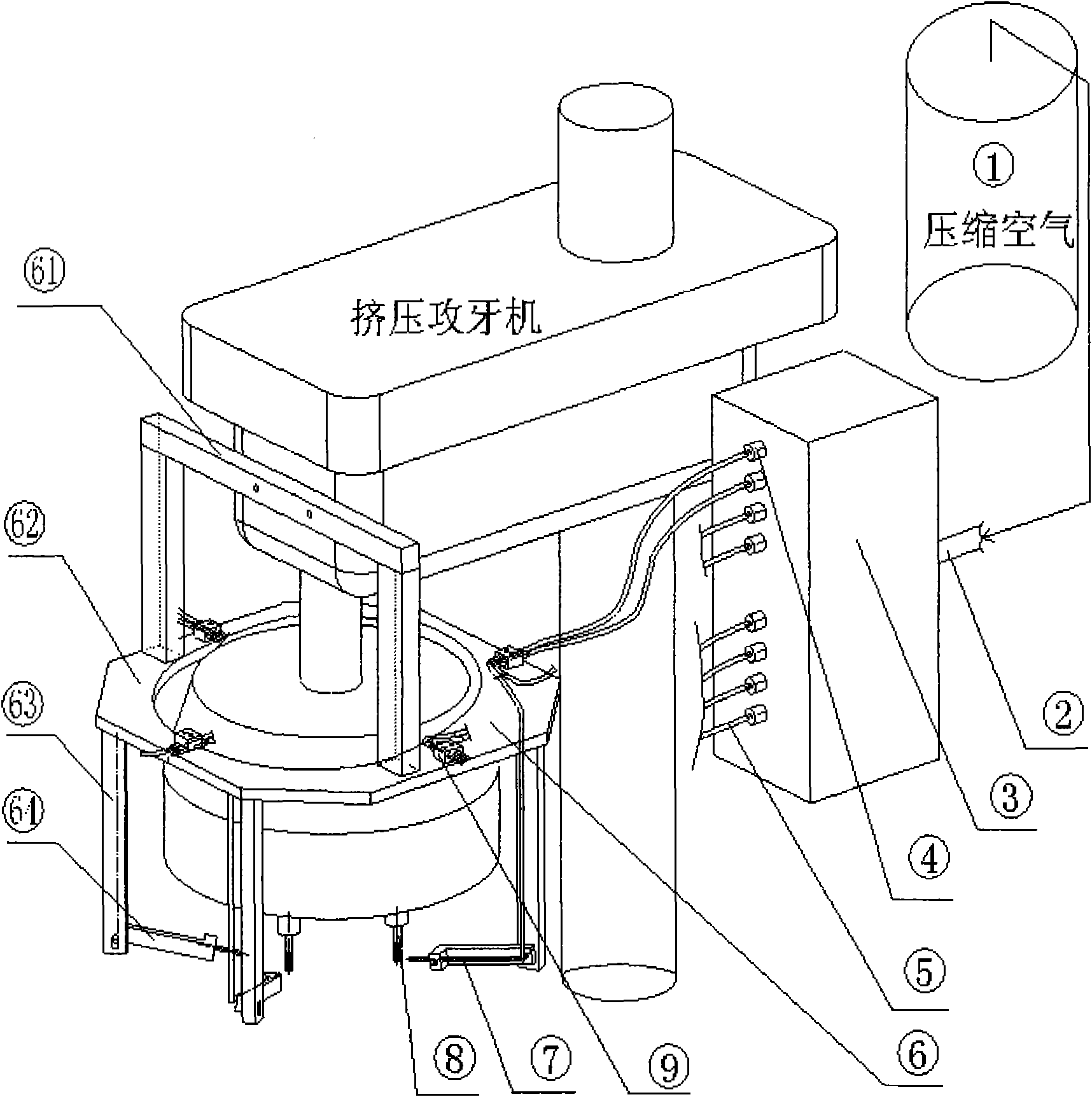

Method and system for lubricating and cooling tapping screw tap

InactiveCN101612708AExtended service lifeLess residual oil stainsThread cutting toolsMaintainance and safety accessoriesGas lubricationEngineering

The invention provides a method and a system for lubricating and cooling a tapping screw tap. The method comprises the following steps: inputting compressed air to an oil-gas lubrication apparatus which distributes the gas-liquid mixture of the input compressed air and lubricant to oil-gas discharge hoses by an oil-gas branching unit; connecting the oil-gas discharge hoses with an oil spray copper pipe by an adapter and adjusting the oil spray copper pipe by an oil-gas pipeline guide apparatus so as to ensure that the nozzle of the oil spray copper pipe closely aims at the working part of an extrusion tapping screw tap of a tapping machine and sprays the lubricant to the extrusion tapping screw tap for lubrication and cooling. The method can achieve the purpose of saving oil, ensure that the extrusion tapping screw tap is not influenced by the quality of the lubricant which is not reused during the production, enhance the service life of the screw tap, leave less oil stains on the product, have no need of an additional oil-removing procedure, satisfy the tact production and improve the operation environment.

Owner:无锡雄伟精工科技有限公司

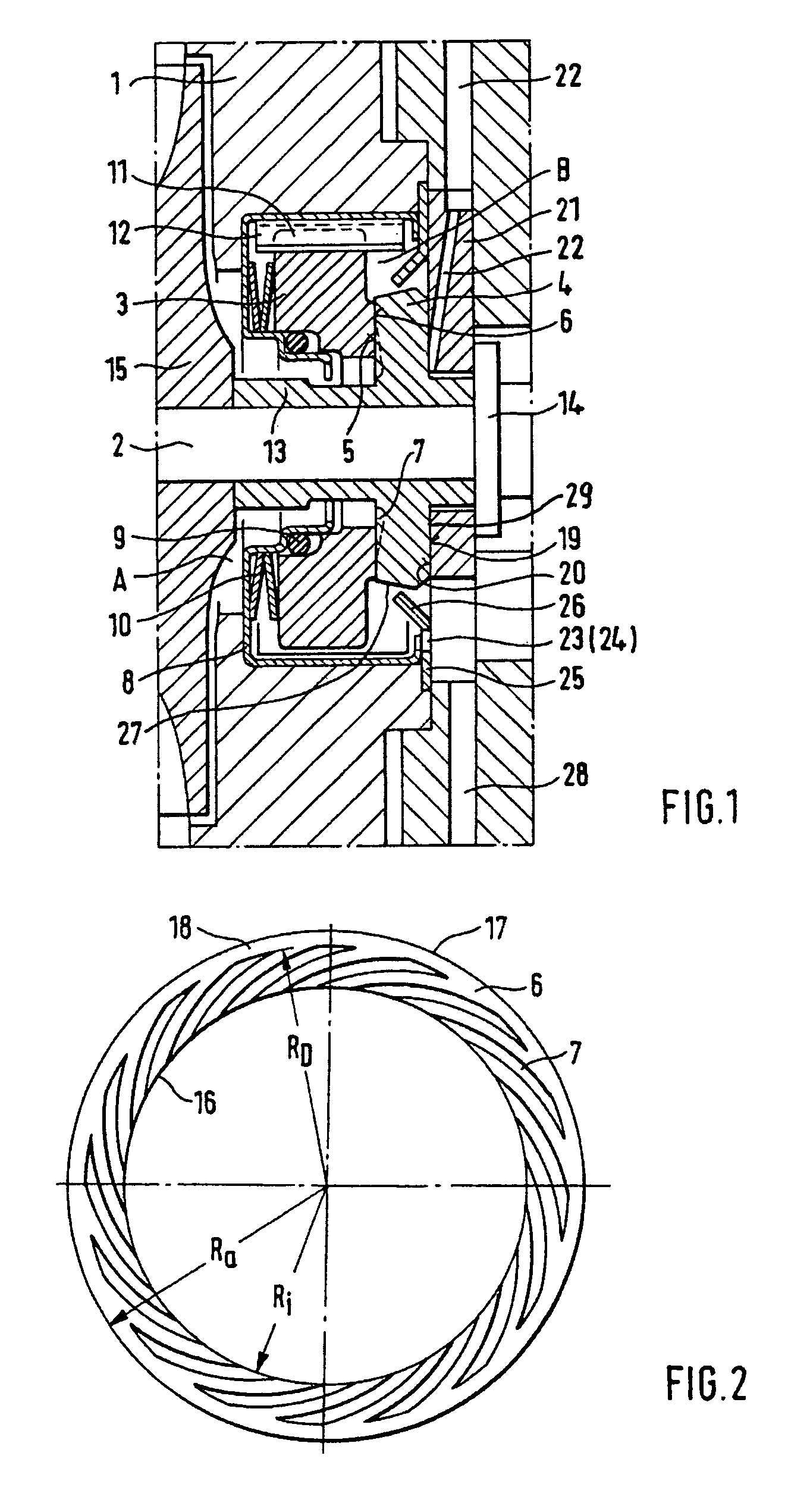

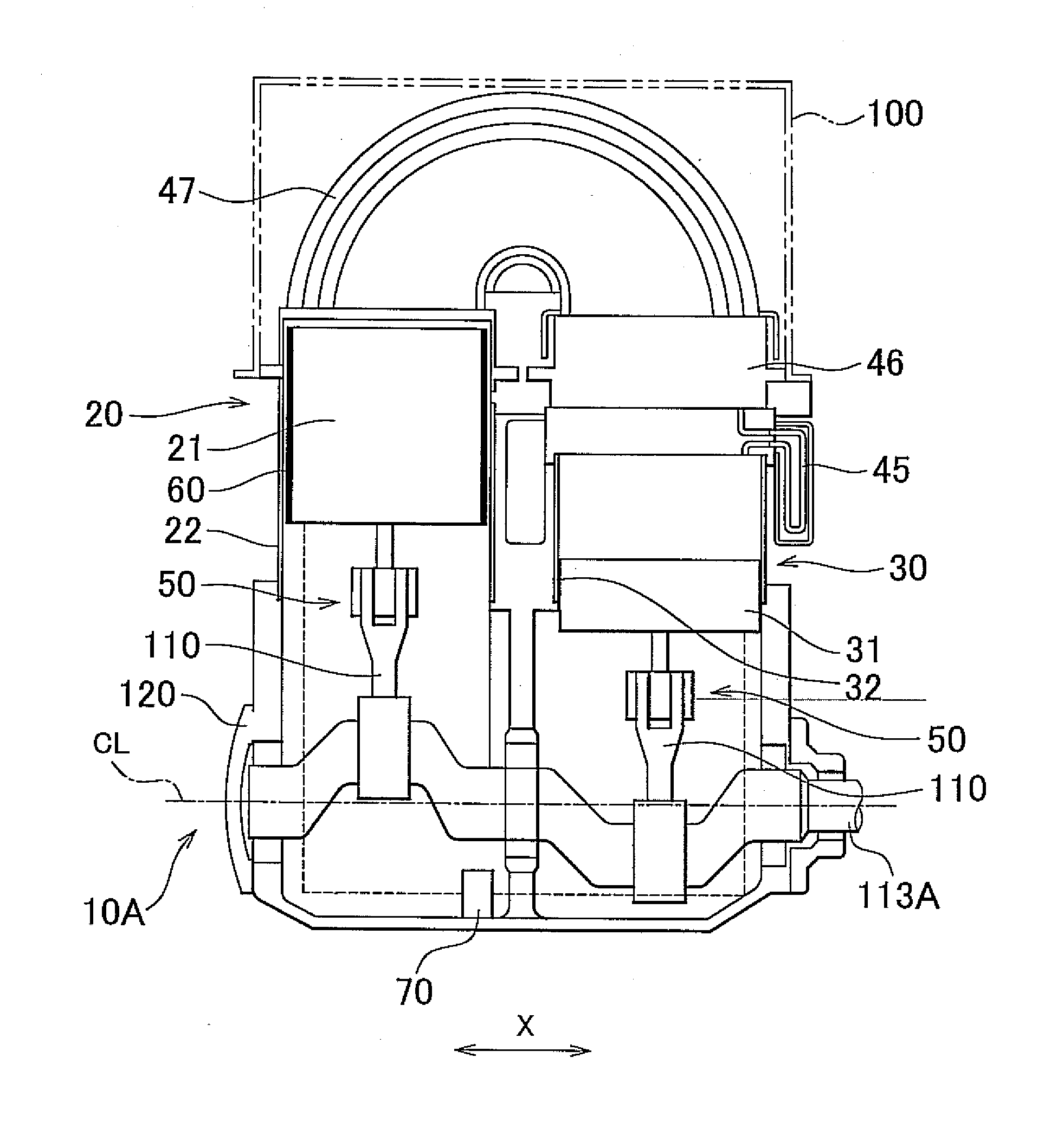

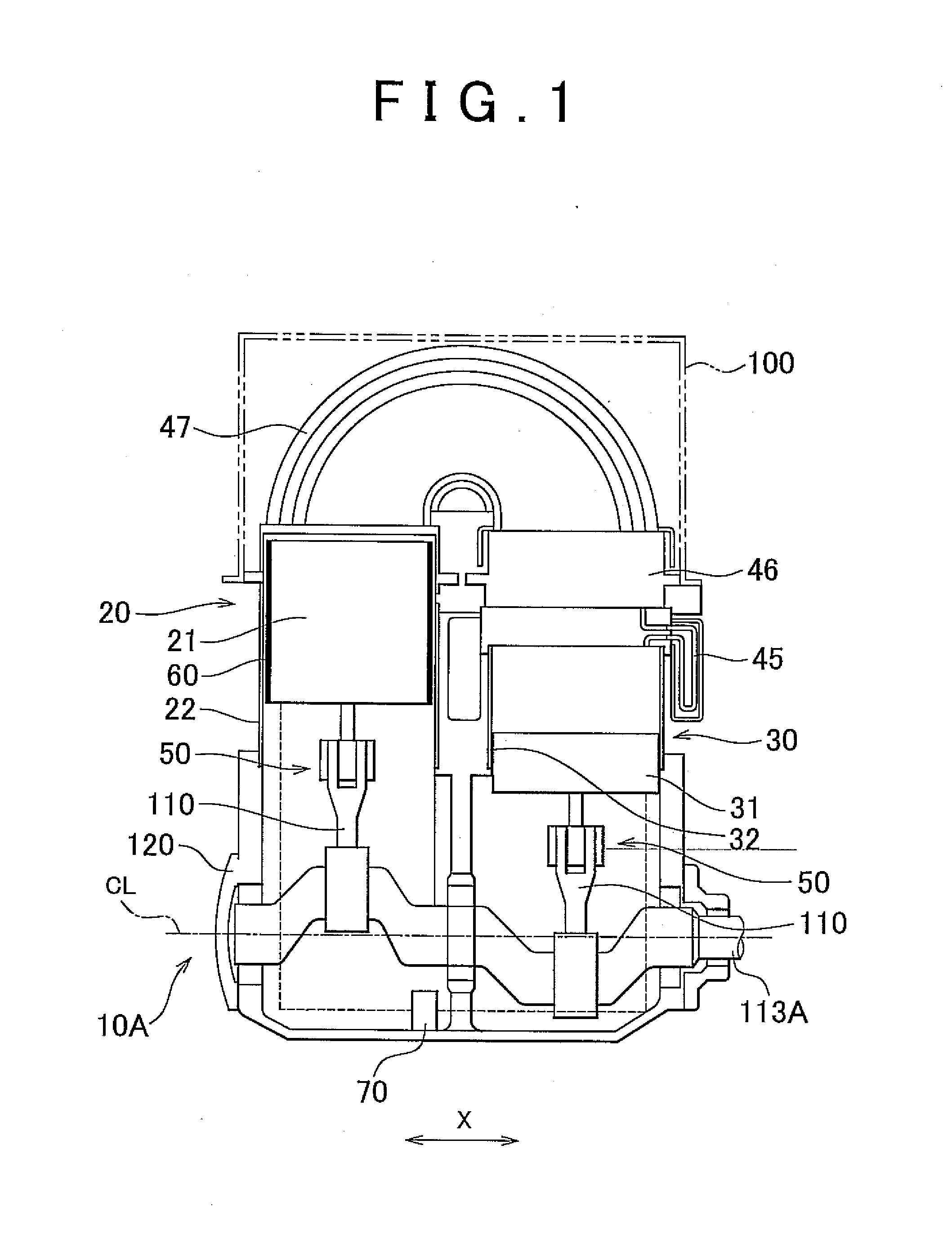

Stirling engine and control method thereof

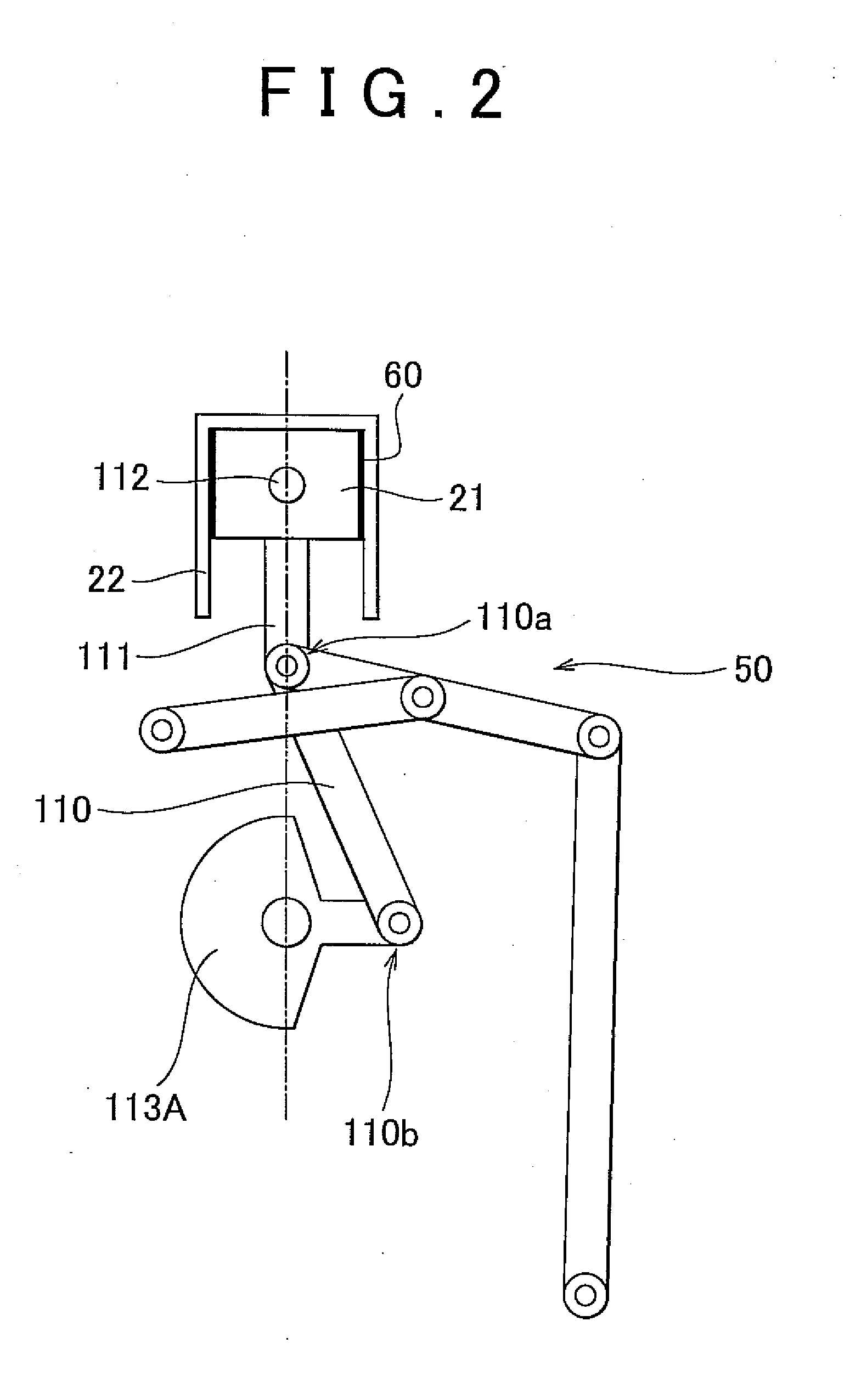

InactiveUS20110232276A1Ensure reliabilityClosed-cycle gas positive displacement engine plantEngine lubricationGas lubricationEngineering

A Stirling engine includes a high-temperature side cylinder and an expansion piston that is subjected to gas lubrication, or more specifically static pressure gas lubrication, relative to the high-temperature side cylinder and has a layer on an outer peripheral surface thereof, the layer being formed from a flexible material having a higher linear expansion coefficient than a base material of the expansion piston, wherein a booster pump and a ECU are provided as a contact avoiding device to prevent the expansion piston from contacting the high-temperature side cylinder when an engine operation is stopped until a temperature of the expansion piston can be suppressed below a predetermined value.

Owner:TOYOTA JIDOSHA KK

De-gassing lubrication reclamation system

Owner:CARRIER CORP

High-speed motor spindle adopting lubrication under loop

InactiveCN102794467AIncrease speedIncrease the spindle speedMaintainance and safety accessoriesGas lubricationEngineering

The invention discloses a high-speed motor spindle adopting lubrication under a loop, which belongs to the technical field of motor spindles. The high-speed motor spindle comprises a spindle casing and a spindle arranged in the spindle casing, wherein bearings are sleeved at the two ends of the spindle respectively; the middle of the spindle is sleeved by a rotor; a stator corresponding to the rotor is arranged in the spindle casing; an oil mist pipe is arranged in spindle and provided with a plurality of nozzles corresponding to lubricating holes of the bearings; through holes are formed in the connecting parts of the spindle and the nozzles of the oil mist pipe; an oil mist inlet connected with the oil mist pipe is formed in the spindle casing; a cooling system is further arranged in the spindle casing of the high-speed motor spindle; and the oil lubrication under the loop or oil gas lubrication under the loop is adopted for the bearings. With the adoption of the lubrication under the loop for the high-speed motor spindle, lubricating oil or oil gas arrives at bearing lubrication areas more easily under the action of a centrifugal force, so that the lubrication effect is better than the effects of ordinary jet lubrication and oil gas lubrication.

Owner:SHAOXING UNIVERSITY

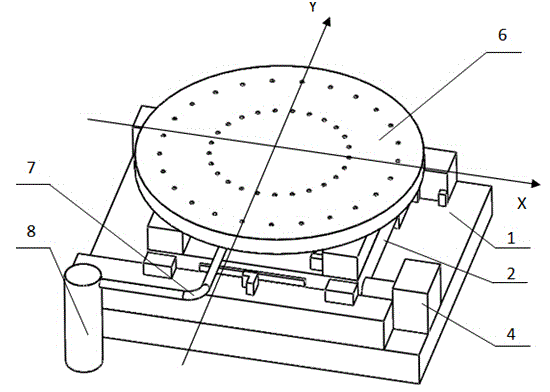

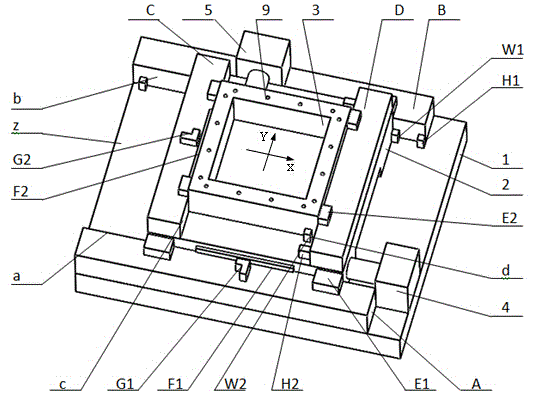

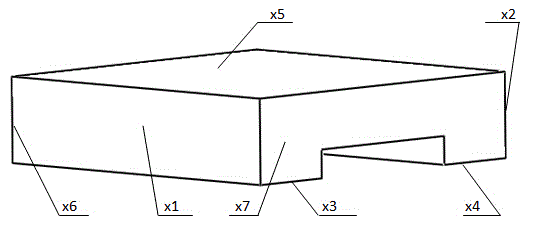

Gas lubrication and friction damping composition type high-rigidity and high-stability two-dimensional adjusting workbench

ActiveCN104400763AImprove linear motion guidance accuracyHigh displacement sensitivityWork benchesGas lubricationSlide plate

The invention discloses a gas lubrication and friction damping composition type high-rigidity and high-stability two-dimensional adjusting workbench and belongs to the technical field of precise instruments and machines. An X-direction gas floatation sliding plate is configured between a base and a Y-direction gas floatation sliding plate; a supporting gas film is formed between a gas flotation working face x5 on the X-direction gas flotation sliding plate and a gas flotation working face y3 on the Y-direction gas floatation sliding plate to support the Y-direction gas flotation sliding plate; a supporting gas film is formed between a gas flotation working face z on the base and gas flotation working faces x3 and x4 on the X-direction gas floatation sliding plate to support the X-direction gas flotation sliding plate; guide rails A and B parallel to each other are fixedly mounted on the gas flotation working face z of the base; guide rails C and D parallel to each other are fixedly mounted on the X-direction gas flotation sliding plate; a friction damping unit E1 is in contact fit with the guide rail A and the guide rail B; a friction damping unit E2 is in contact fit with the guide rail C and the guide rail D. The invention provides a precise plane two-dimensional adjusting device with high rigidity and high positioning stability.

Owner:HARBIN INST OF TECH

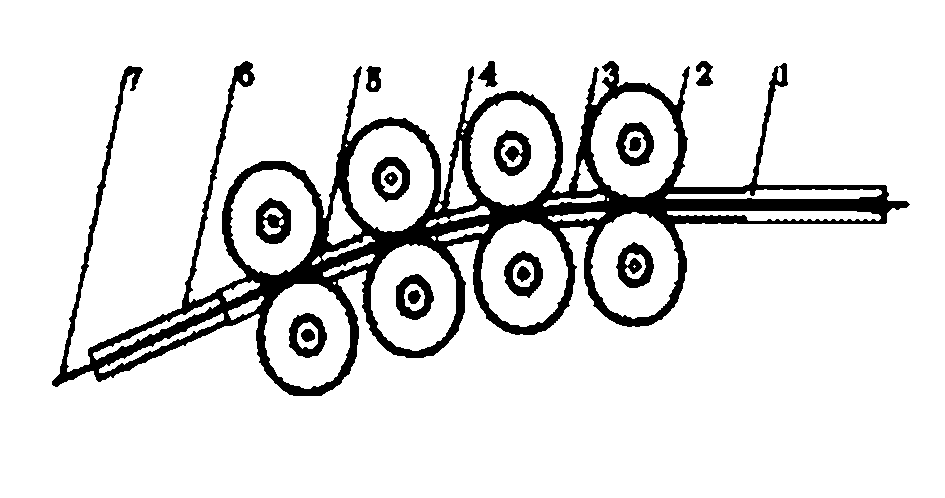

High-speed wire finish-rolling process

InactiveCN101564734ASimple production processLow failure rateGuiding/positioning/aligning arrangementsRoll mill control devicesFailure rateWire rod

The invention discloses a high-speed wire finish-rolling process. Rolling is performed on 28 passes finishing mill 1-17 passes use the pass-free rolling way and the rolling piece is rolled between the two pass-free rollers and the height of the roll gap is the height of the rolling piece and the width of the rolling piece is the breadth of the freely spread rolling piece without gripping and deforming action of the pass sidewall. During rolling, it is only necessary to change the roll gap to adjust the section size of the rolling piece and the rolling adaptability is very strong, thereby optimizing the production process of the wire tandem mill, reducing the guide loss, reducing the oil gas lubrication consume, reducing the failure rate of the roller, increasing the use frequency of the roller and reducing the roller loss, improving the bite of the rolling piece, reducing the roll-changing number during rolling, in order to increase the productivity, save the energy, reduce the consume, ensure the production operate for long period. The high-speed wire finish-rolling process can be used in the same or similar rolling mill in civil with very wide application foreground.

Owner:CHONGQING IRON & STEEL CO LTD

Gas/ solid two-phase composite gyration basic method and device

InactiveCN101338790AOvercome the shortcomings of not being able to take care of these features at the same timeImprove carrying capacityBearingsGas lubricationGas phase

The present invention relates to a gas phase / solid phase composite gyration benchmarking method and a device, which belong to the technical field of precision gyration benchmarking. The method compositely uses the gas lubricating and error averaging technology and the solid supporting and damping technology, the method applies axial solid support in the axial anti-thrust gaseous film of a gas-floated shafting to form a composite supporting mode with the primary solid support and the subsidiary gas support or the primary gas support and the subsidiary solid support or the gas support and the solid support which are the equivalent in order to notably enhance the axial rigidity and bearing capacity of the gas-floated shafting. Applying radial solid support in the radial gaseous film of the gas-floated shafting, the method utilizes the slight elastic deformation of elastic elements to dissipate the medium / high-frequency micro-vibration energy of a mainshaft and the stored deformation energy and static friction characteristic of the elastic elements to enhance positioning damp in order to increase positioning precision. In the device, the solid elastic elements are respectively assembled in the axial anti-thrust gaseous film and the radial gaseous film. The method can establish a gyration benchmark which also takes high precision, high rigidity, high support, low vibration and high displacement sensitivity into consideration.

Owner:HARBIN INST OF TECH

Oil-gas lubrication pipeline in main shaft structure

ActiveCN103350237AEvenly lubricatedImprove cooling efficiencyMaintainance and safety accessoriesGas lubricationMachining

The invention discloses an oil-gas lubrication pipeline in a main shaft structure. Each group of bearings is provided with at least one group of oil inlet pipelines correspondingly, the terminal ends of each group of oil inlet pipelines are aligned to the inner rings of the bearings, each group of bearings is provided with three groups of oil inlet pipelines correspondingly, and the three groups of oil inlet pipelines form angles of 120 degrees mutually. A plurality of groups of oil inlet pipelines are correspondingly arranged on each group of bearings, and the oil inlet pipelines are uniformly distributed and arranged, so that uniform lubrication of the main shaft structure is ensured, and the heat dissipation efficiency is improved. The pipeline structure is suitable for application of a main shaft high-speed five-axis precision vertical machining center, and can effectively ensure that lubricating oil can be continuously conveyed in a small-dose and multiple-times manner, so that the bearings are always at an optimal lubrication state. Meanwhile, a lubricating oil film with certain bearing capacity can be formed, and the oil-gas lubrication pipeline has a good antifriction effect. Moreover, through oil-gas lubrication, compressed air can enable the bearings to well radiate heat, so that the bearings can be effectively cooled.

Owner:SUZHOU SUXIANG ROBOT INTELLIGENT EQUIP CO LTD

Oil-gas lubrication structure of high-speed electric main shaft

InactiveCN106695450AExtend your lifeReduce the temperatureMaintainance and safety accessoriesBall bearingGas lubrication

The invention discloses an oil-gas lubrication structure of a high-speed electric main shaft. The oil-gas lubrication structure comprises a main shaft rotor, a motor rotor and a motor stator. The motor stator is sleeved with a stator sleeve and a front gland with an oil inlet and used for front end sealing. The main shaft rotor is sleeved with a first angular contact ball bearing and a second angular contact ball bearing. The first angular contact ball bearing and the second angular contact ball bearing are sleeved with a front bearing sleeve with a first through hole. An inner spacer ring and an outer spacer ring are arranged between the first angular contact ball bearing and the second angular contact ball bearing. A front flow dividing ring is arranged between the front bearing sleeve and the motor rotor. A first oil spraying opening is formed in the outer spacer ring. Oil gas enters the first angular contact ball bearing from the first oil spraying opening, then sequentially passes through the oil inlet of the front gland, the first through hole of the front bearing sleeve and a radial groove of the front flow dividing ring, finally passes through a gap between the front bearing sleeve and the main shaft rotor and then is discharged. The oil-gas lubrication structure has the beneficial effects that lubricating and cooling of the bearings are conducted, and meanwhile the temperature of a motor is decreased.

Owner:SHENZHEN SUFENG TECH +2

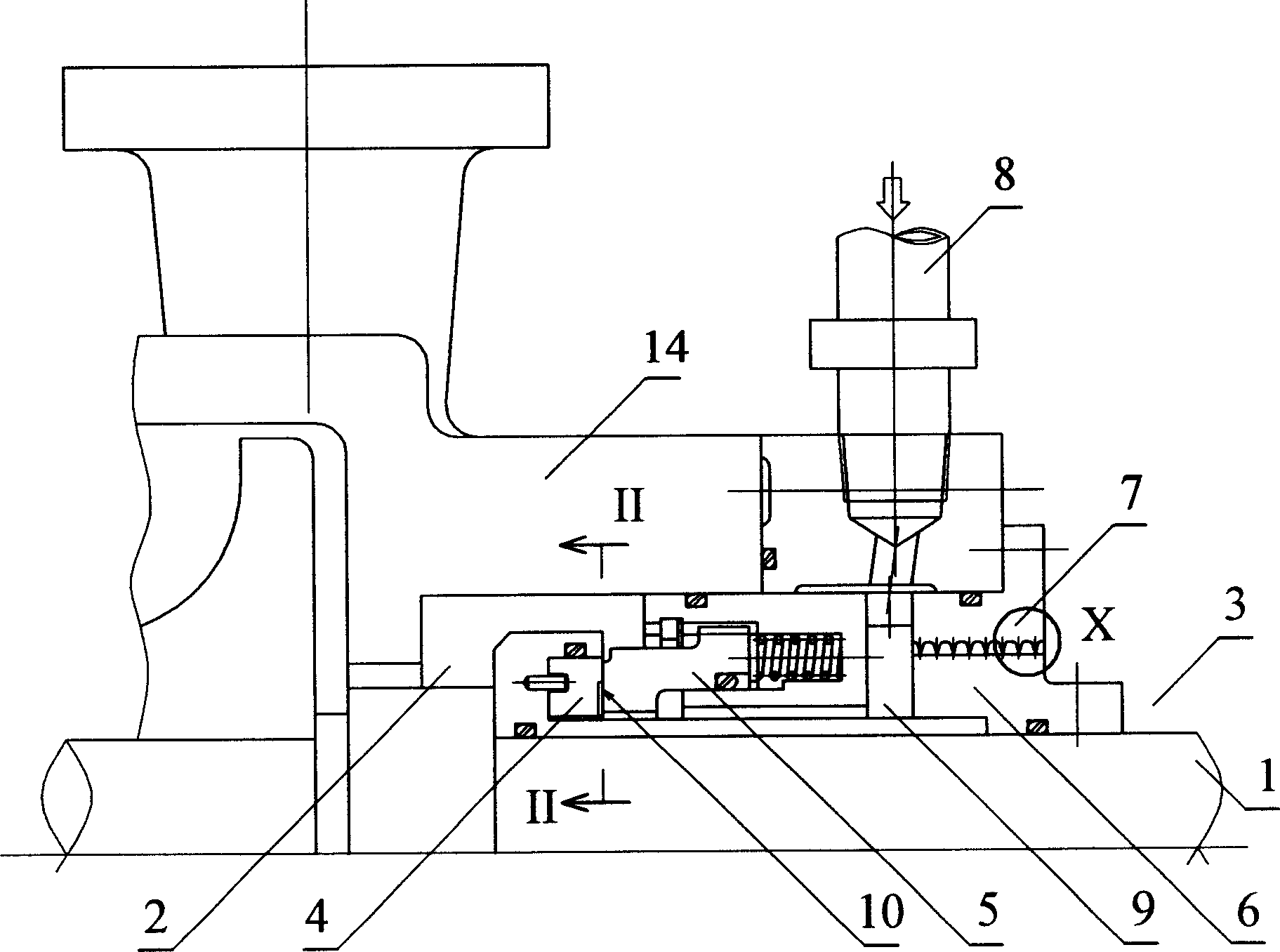

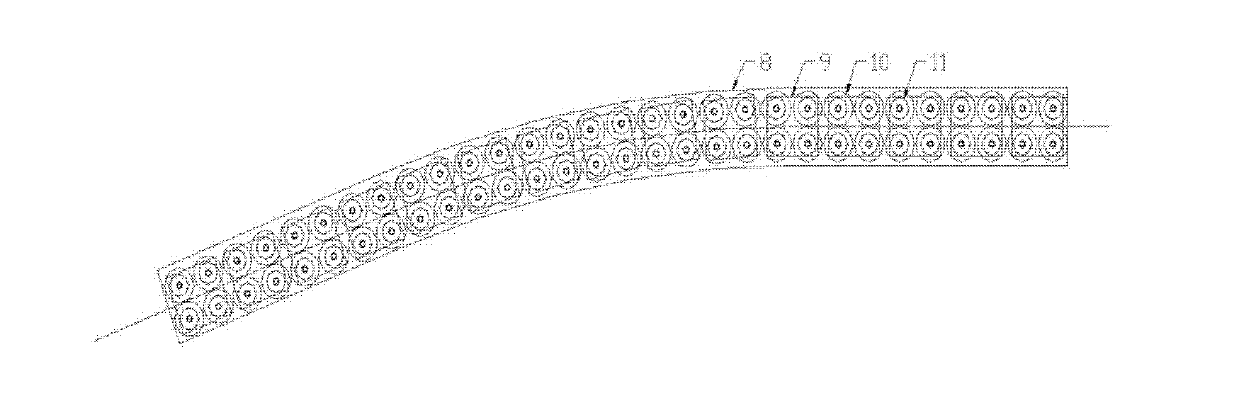

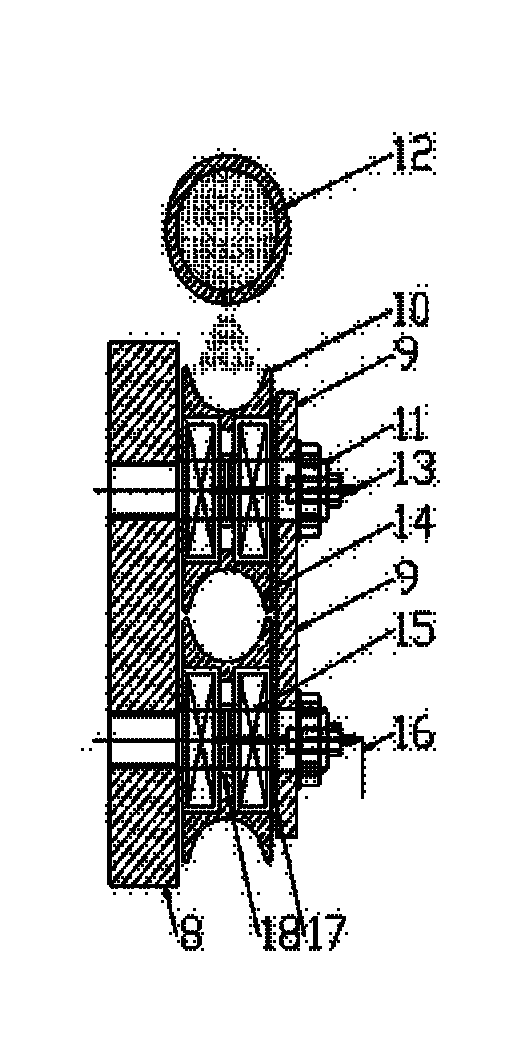

Novel rolling prebending device

InactiveCN103157662AEliminate scratchesImprove surface qualityMetal rolling arrangementsWire rodGas lubrication

The invention discloses a novel rolling prebending device. An all-guide-roller structure is adopted to solve the problem that an existing power prebending device can scratch the surfaces of wire rods. A major structure of the novel rolling prebending device is formed by a base plate (8), a clamp plate (9) and guide rollers (10). Every four guide rollers (10) are fixed between the clamp plate (9) and the base plate (8) through guide roller shafts (11) to form one group. A plurality of groups are connected to form a prebending path. A group of guide roller bearings (15) and an oil distributing ring (18) are arranged in each guide roller (10). A cooling water pipe (12) is additionally arranged above the guide rollers (10). Water retaining rings (17) are installed on two sides of each guide roller bearing (15). An oil-gas lubrication connector (13) is installed at an opening end of each guide roller shaft (11). An outer end of the each oil-gas lubrication connector (13) is communicated with a hosepipe (16) of an oil-gas lubrication device. An inner end of each oil-gas lubrication connector (13) is communicated with a middle oilhole and the oil distributing ring (18) in each guide roller shaft (11). The prebending path comprises an inlet straight line AB section, a bending curve BC section and an outlet straight line CD section. The novel rolling prebending device basically eliminates scratches of the wire rods generated in the prebending device. The surface quality of the wire rods is obviously improved.

Owner:DONGBEI SPECIAL STEEL GROUP

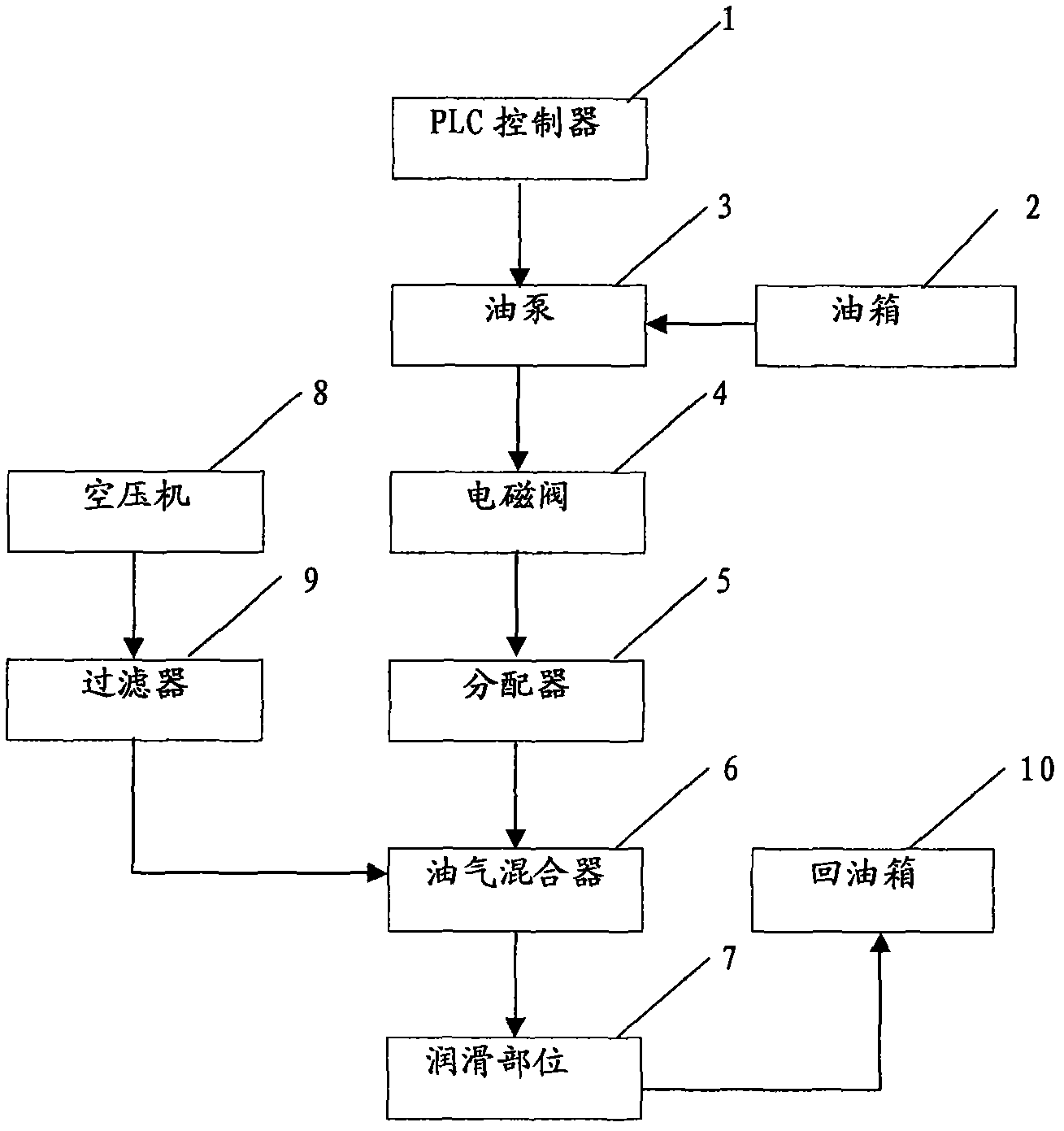

Oil-gas lubrication method

InactiveCN103836319AReduce fuel consumptionStrong conveying capacityEngine lubricationGas lubricationPositive pressure

The invention discloses an oil-gas lubrication method. The method comprises the steps that first, a PLC control system controls an entire oil-gas lubrication process and is sequentially connected with an oil pump, an electromagnetic valve, a distributor, an oil and gas mixer, a lubrication part and an oil return box; second, an oil box is connected with the oil pump; third, an air compressor is connected with the oil and gas mixer through a filter. The oil-gas lubrication method has the advantages that oil consumption (1 / 8-1 / 10 of that of oil-mist lubrication) is low, the adaptability (150-680 cst / 40 DEG C) to lubricating oil viscosity is wide, oil mist conveying capacity (conveying air pressure is 2-10 bar, and air flow speed is 30-80 m / s) is high, conveying distance (capable of achieving 100m) is long, the sealing effect on a bearing is good (the positive pressure in the bearing is 0.3-0.8 bar), the service life of the bearing is long (the service life is prolonged by 2-4 times), emission of oil mist is avoided, and the environment is not polluted, thereby having high popularization value.

Owner:TIANJIN YIBO STEEL MAKING

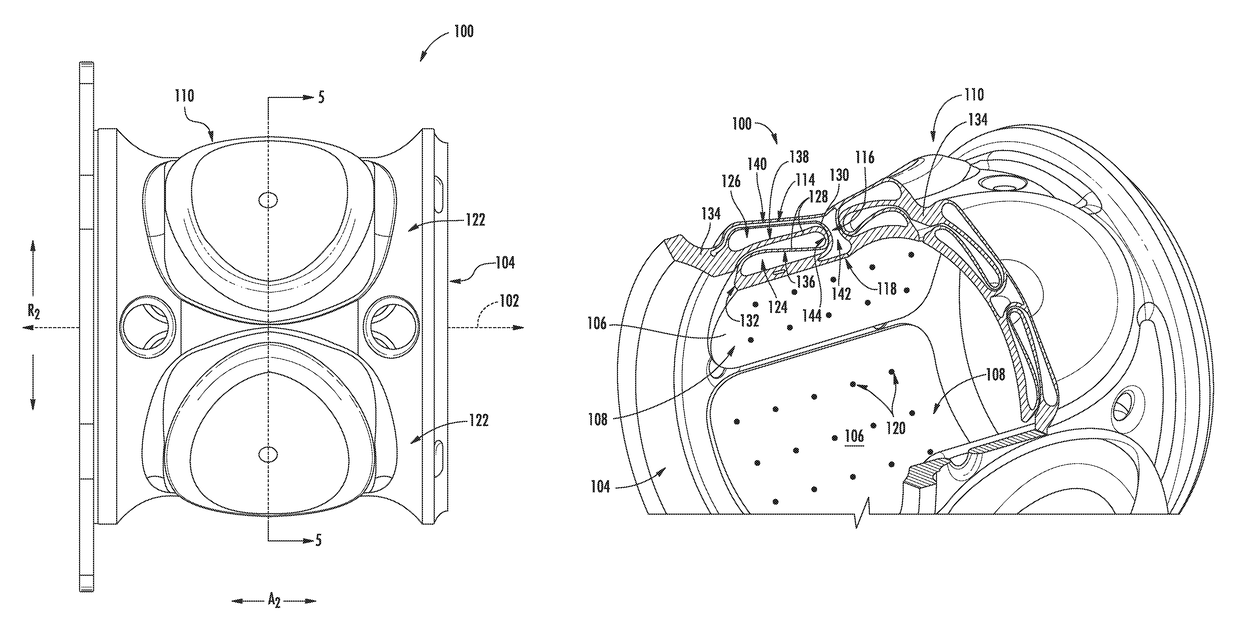

Fluid-filled damper for gas bearing assembly

ActiveUS10066505B2SpringsSprings/dampers functional characteristicsPillow block bearingGas lubrication

The present disclosure is directed to a gas-lubricated bearing assembly for a gas turbine engine and method of damping same. The bearing assembly includes a bearing pad for supporting a rotary component and a bearing housing attached to or formed integrally with the bearing pad. The bearing housing includes a first fluid damper cavity, a second fluid damper cavity in restrictive flow communication with the first fluid damper cavity via a restrictive channel configured as a clearance gap, and a damper fluid configured within the first and second fluid damper cavities. More specifically, the damper fluid of the present disclosure is configured to withstand the high temperature environment of the engine. Thus, the bearing housing is configured to transfer the damper fluid from the first fluid damper cavity to the second fluid damper cavity via the restrictive channel in response to a force acting on the bearing pad.

Owner:GENERAL ELECTRIC CO

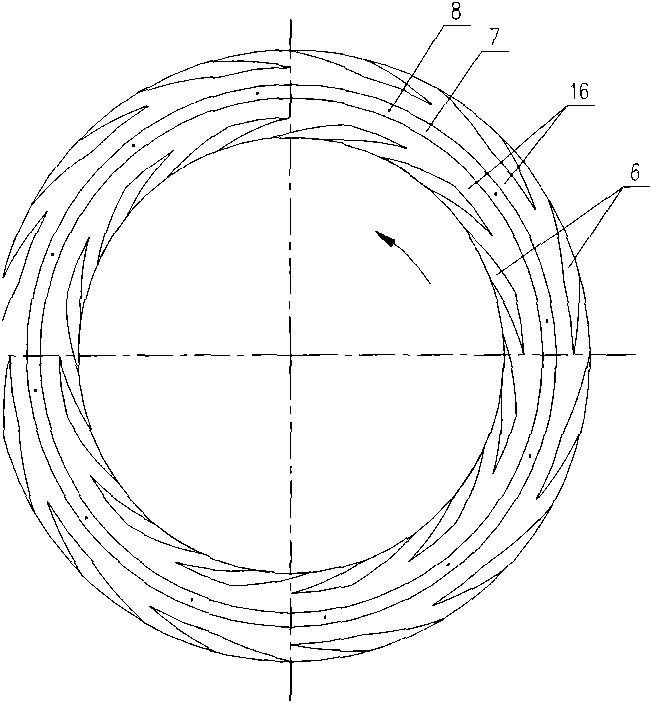

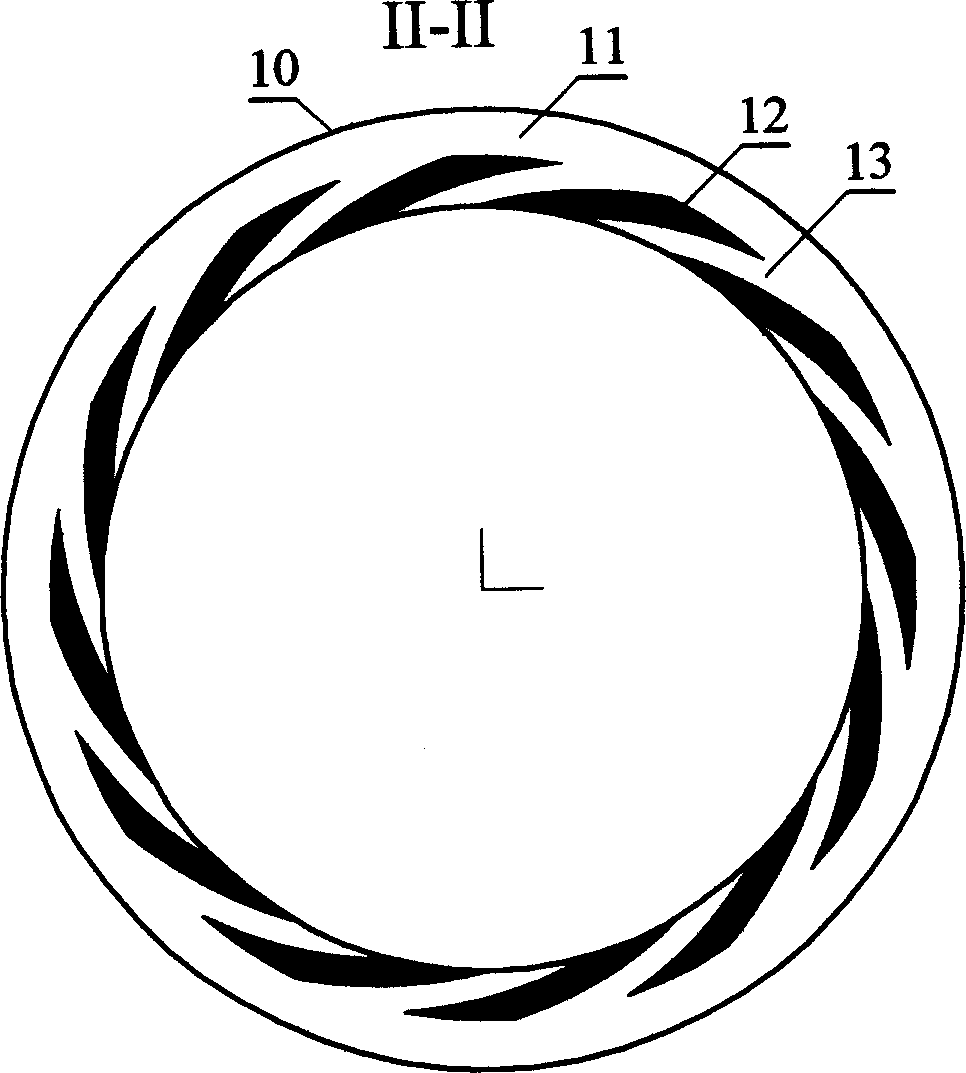

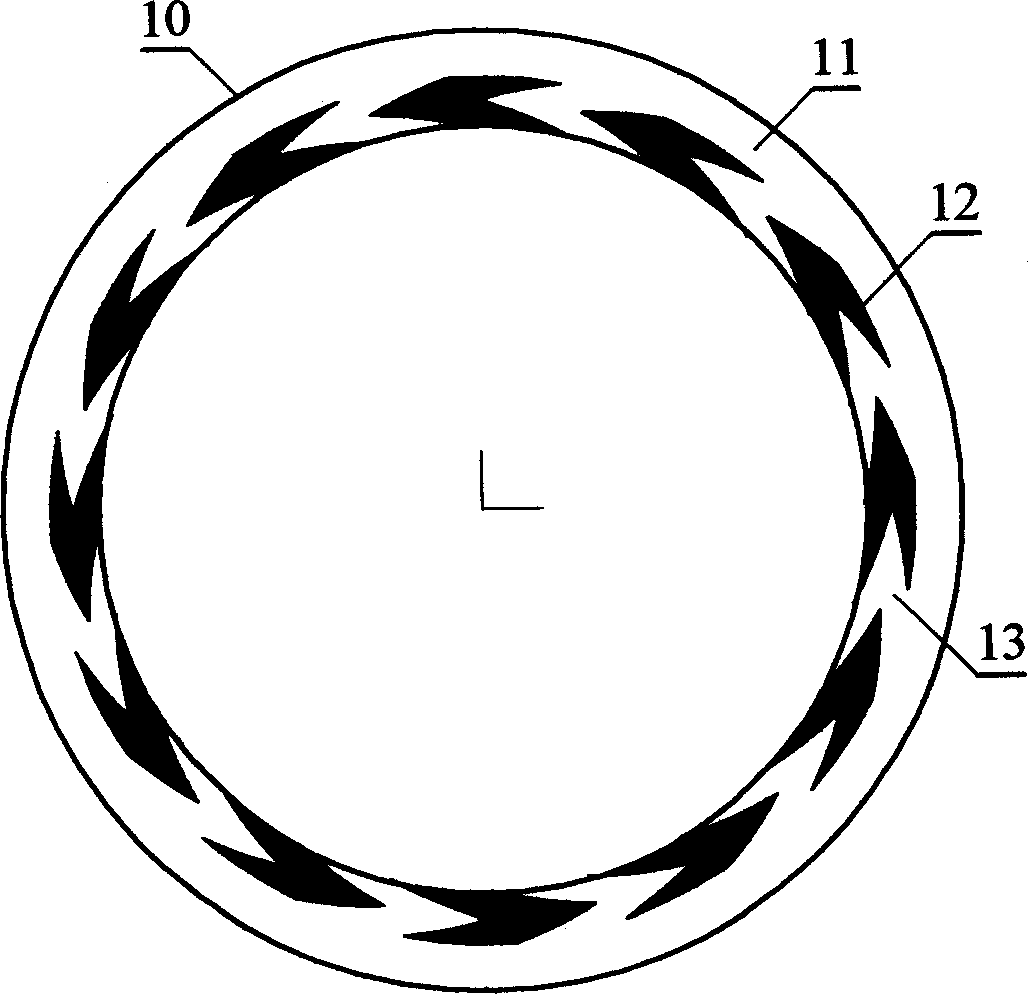

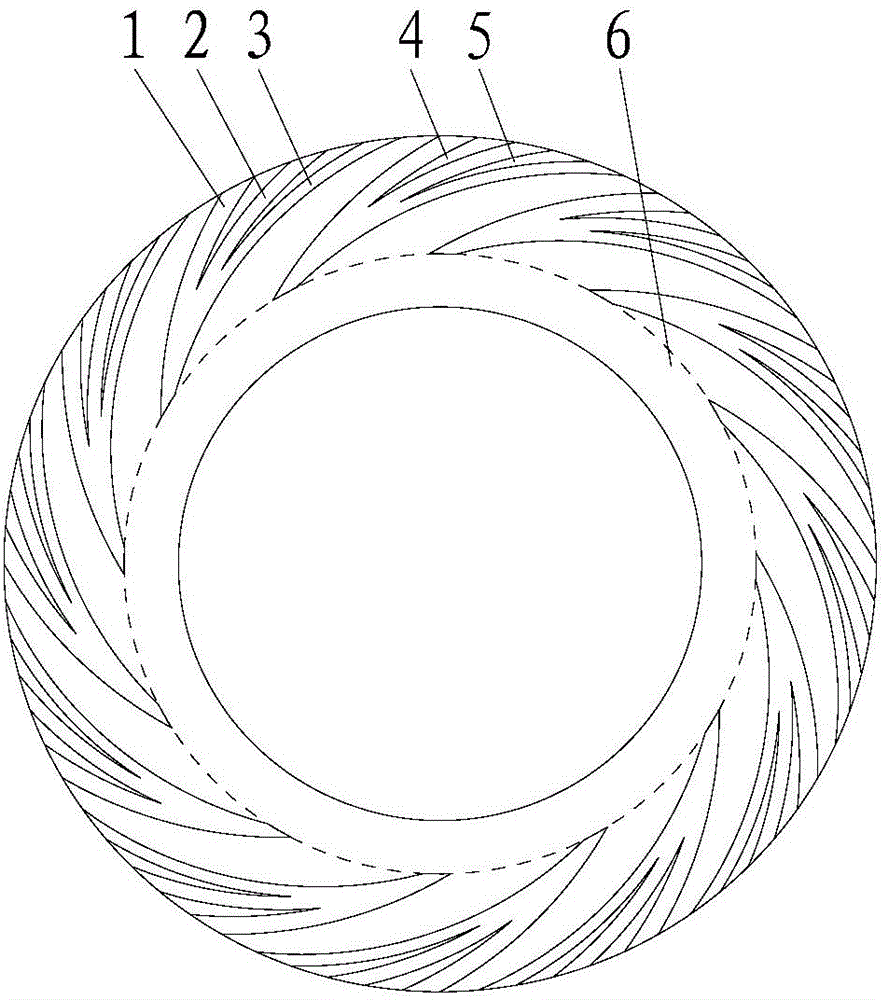

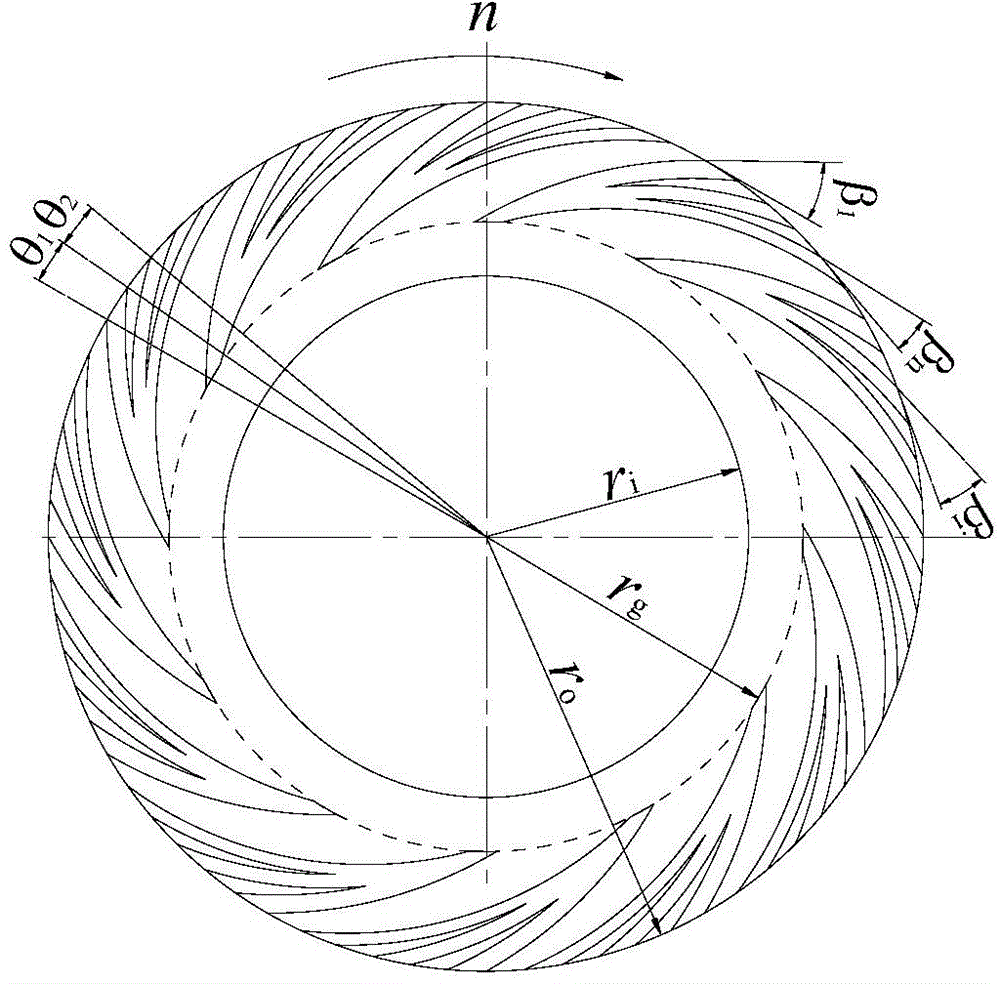

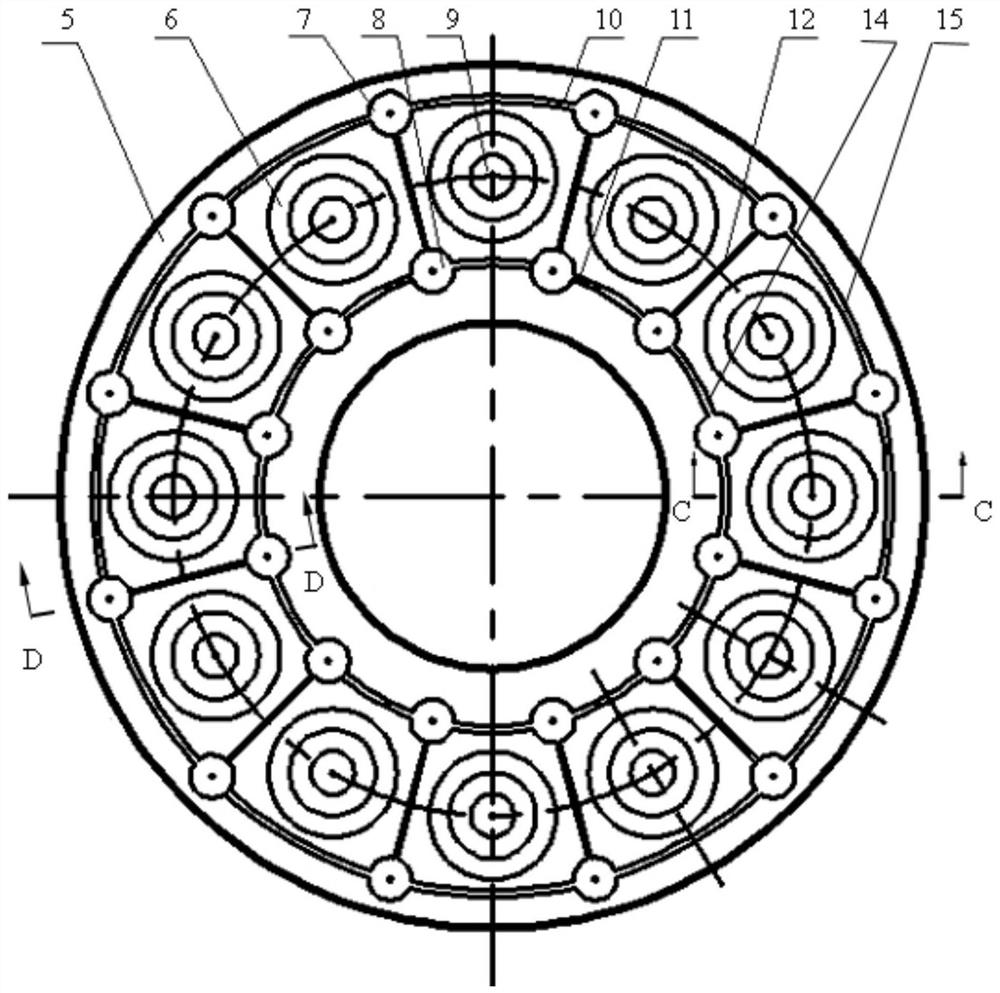

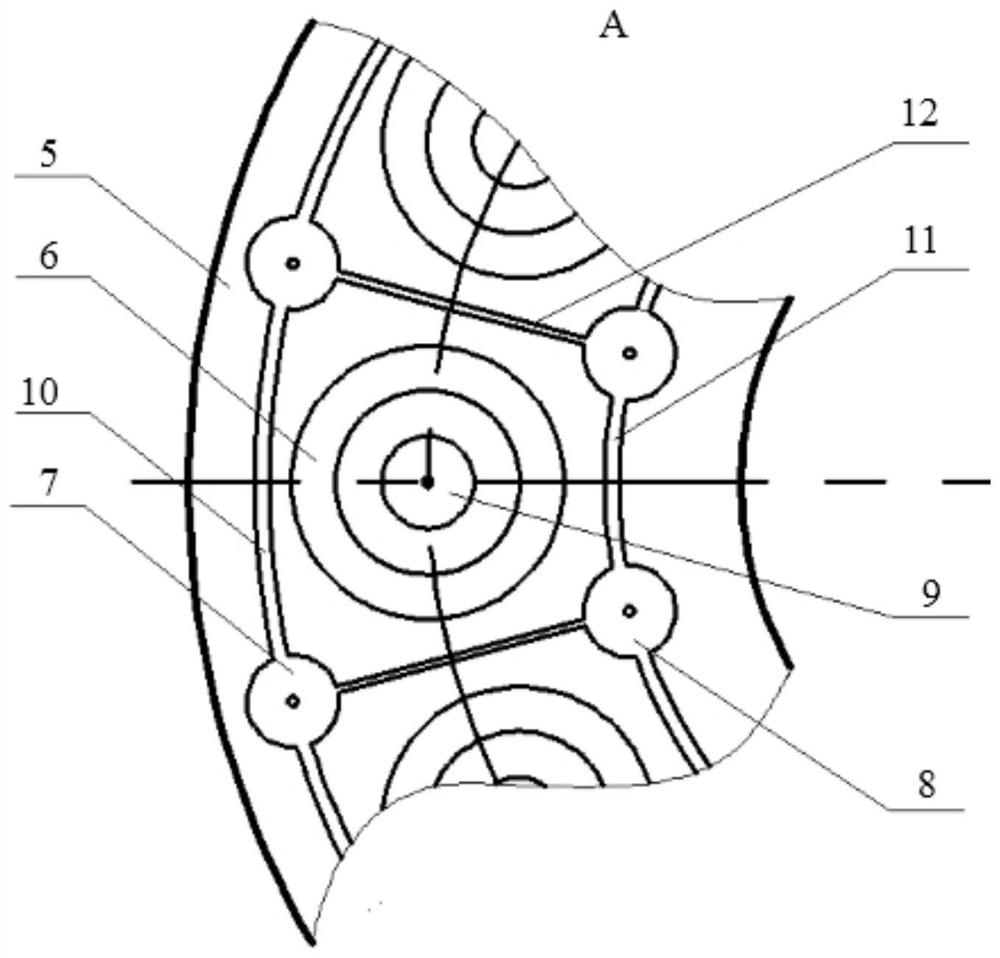

Gas lubrication cluster spiral groove end face mechanical sealing structure

InactiveCN104896099AStrong convergence propertiesImprove compression performanceEngine sealsLow speedGas lubrication

A gas lubrication cluster spiral groove end face mechanical sealing structure comprises a moving ring and a stationary ring of a mechanical seal. One side of the end face of the moving ring and one side of the end face of the stationary ring are high-pressure sides, namely, upper streams, and the other side of the end face of the moving ring and the other side of the end face of the stationary ring are low-pressure sides, namely, lower streams. A plurality of cluster spiral grooves symmetrically distributed along the circumference of the end face are formed in the end face of at least on sealing ring of the moving ring or the stationary ring, the cluster spiral grooves are formed by combining a plurality of micro spiral grooves with different spiral angles in the circumferential direction of the end face, the micro spiral grooves in the same cluster spiral groove are separated by a sealing weir free of grooves on the high-pressure side, the groove roots of the micro spiral grooves in the same cluster spiral groove are overlaid and communicated to a whole on the lower-pressure side, and sealing dams are arranged on the down streams of the cluster spiral grooves. Through the convergence configuration of bionic high-speed flyer wings and the alula structure of flyer wing front edges, the gas lubrication cluster spiral groove end face mechanical sealing structure has a high flow guide effect and compression function on fluid media, the low-speed start and stop characteristic, high-speed running stability and sealing performance of the seal can be improved, the high-speed disturbance rejection capacity of the seal is improved, and end face abrasion is avoided.

Owner:ZHEJIANG UNIV OF TECH

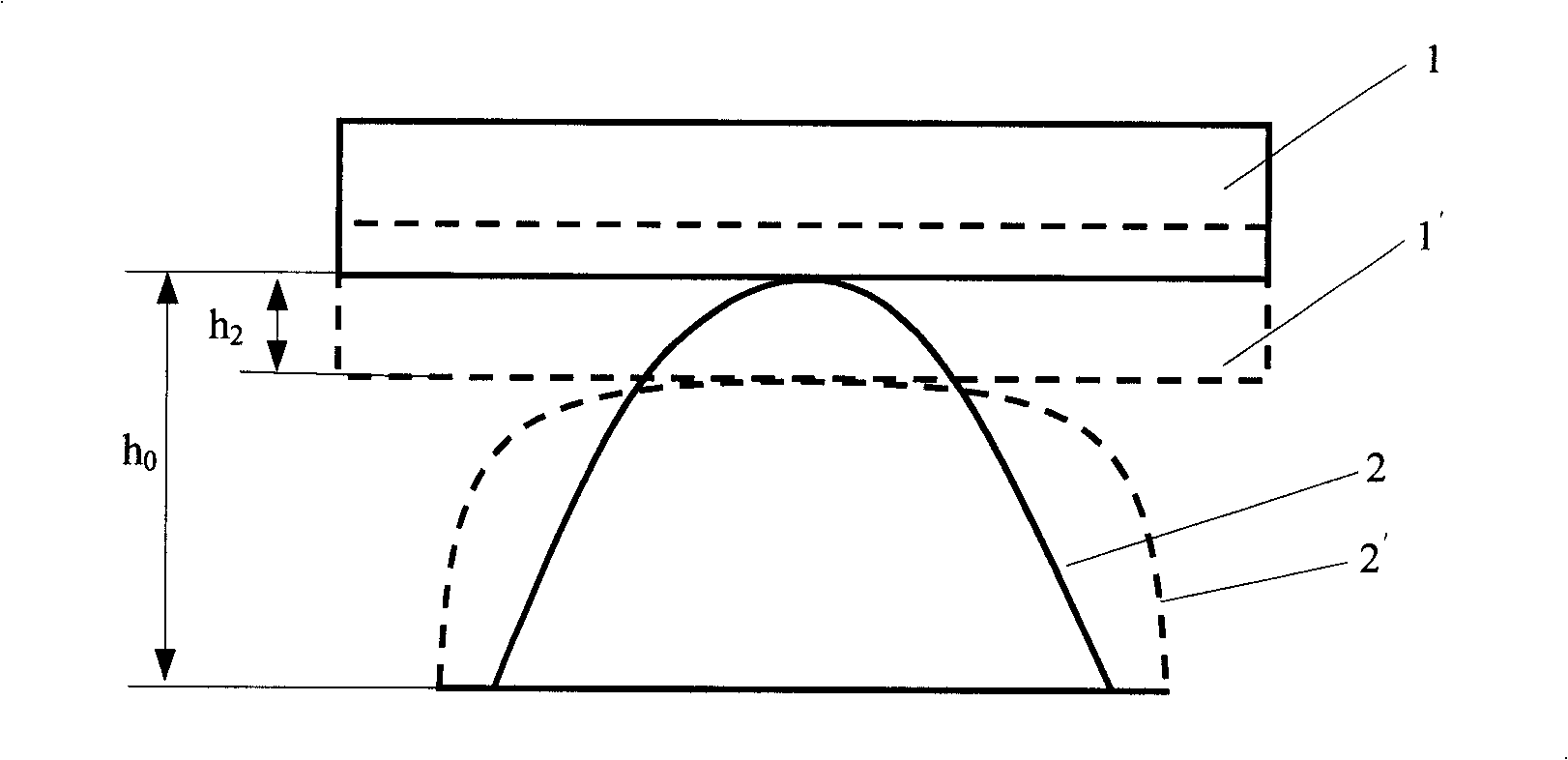

Static pressure air floatation thrust bearing based on multi-ring belt exhaust

The invention discloses a static pressure air floatation thrust bearing based on multi-ring exhaust, and belongs to the technical field of gas bearings and gas lubrication. According to the static pressure air floatation thrust bearing, through a combined type flow control structure of small hole throttling at an air film inlet and porous throttling at an exhaust inlet, the effect of homogenizing pressure is achieved while it is guaranteed that the air flow is not lost, and the rigidity of the bearing is improved; small hole throttling is adopted in a throttler in the thrust bearing, diffusion flow of the throttler is guided in three different modes, namely first-stage pressure equalizing, second-stage pressure equalizing and porous ring pressure control, and the adjustable composite diffusion flow can improve the bearing capacity and rigidity of the bearing; according to the multi-ring exhaust structure in the thrust bearing, a gas film far away from a natural pressure boundary has a stable and adjustable pressure boundary, so that the static pressure gas thrust bearing has better self-adaptability and can adapt to various gas supply conditions and variable loads, the bearing, rigidity and stability of the static pressure gas bearing are considered, and the purpose that one shaft has multiple purposes is achieved.

Owner:BEIJING UNIV OF TECH

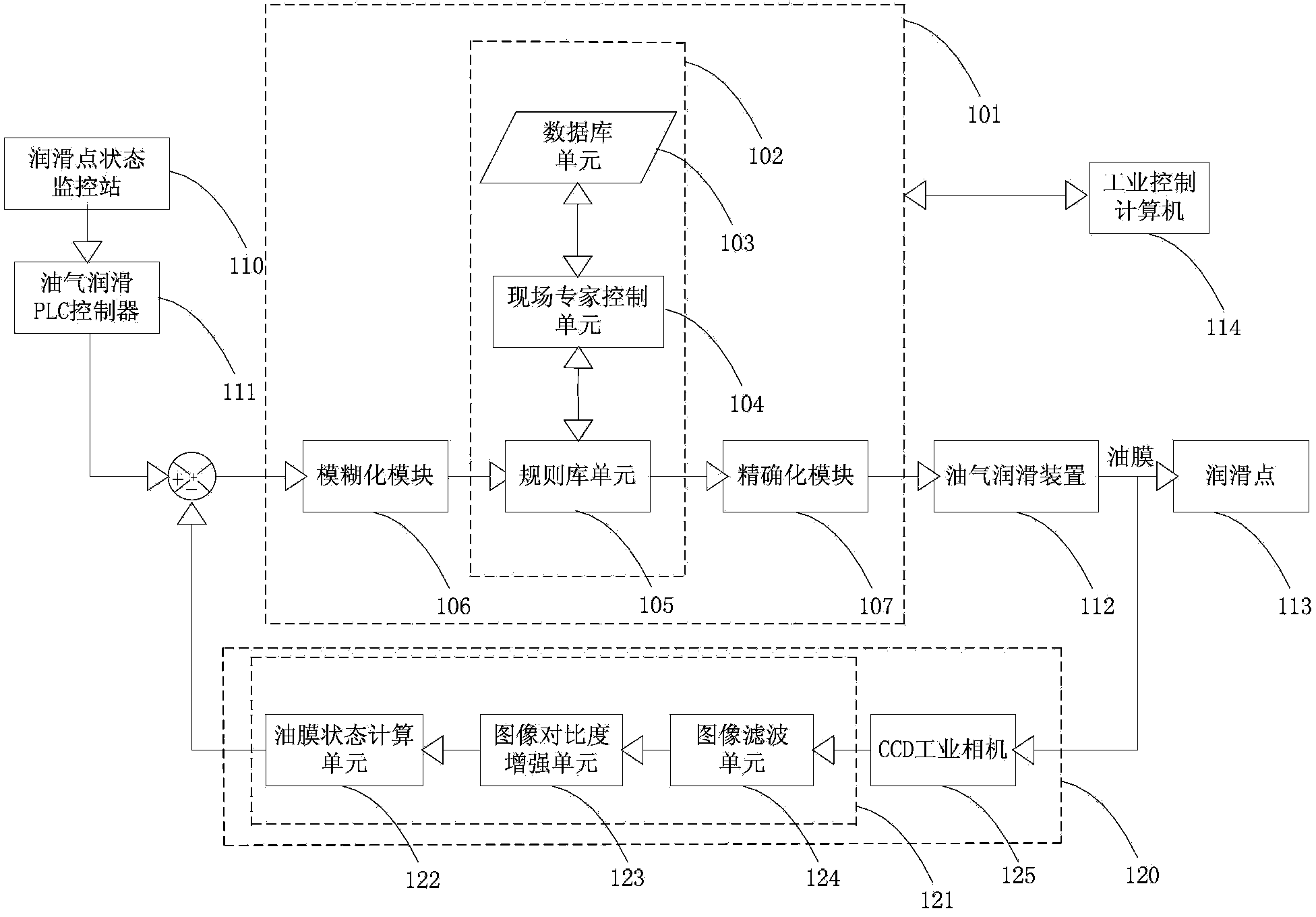

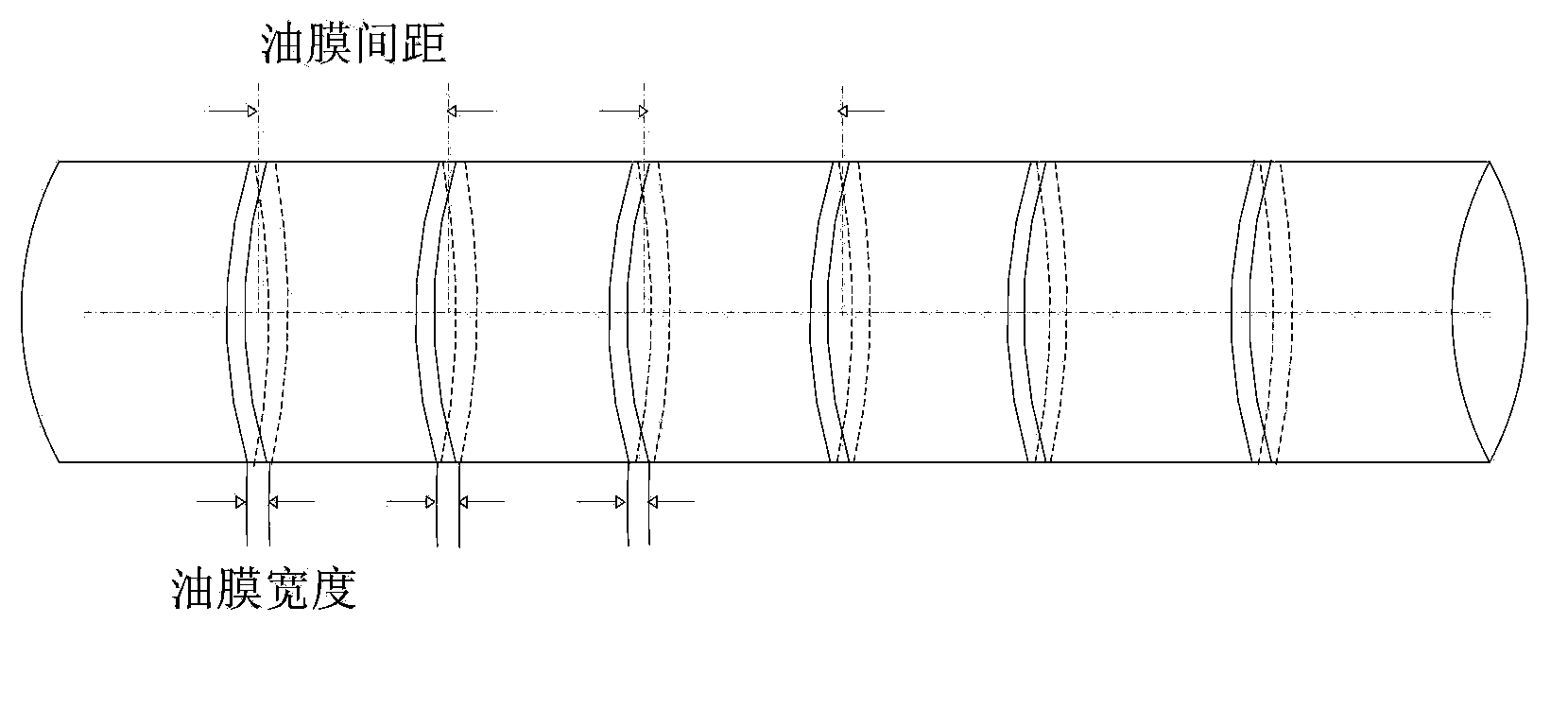

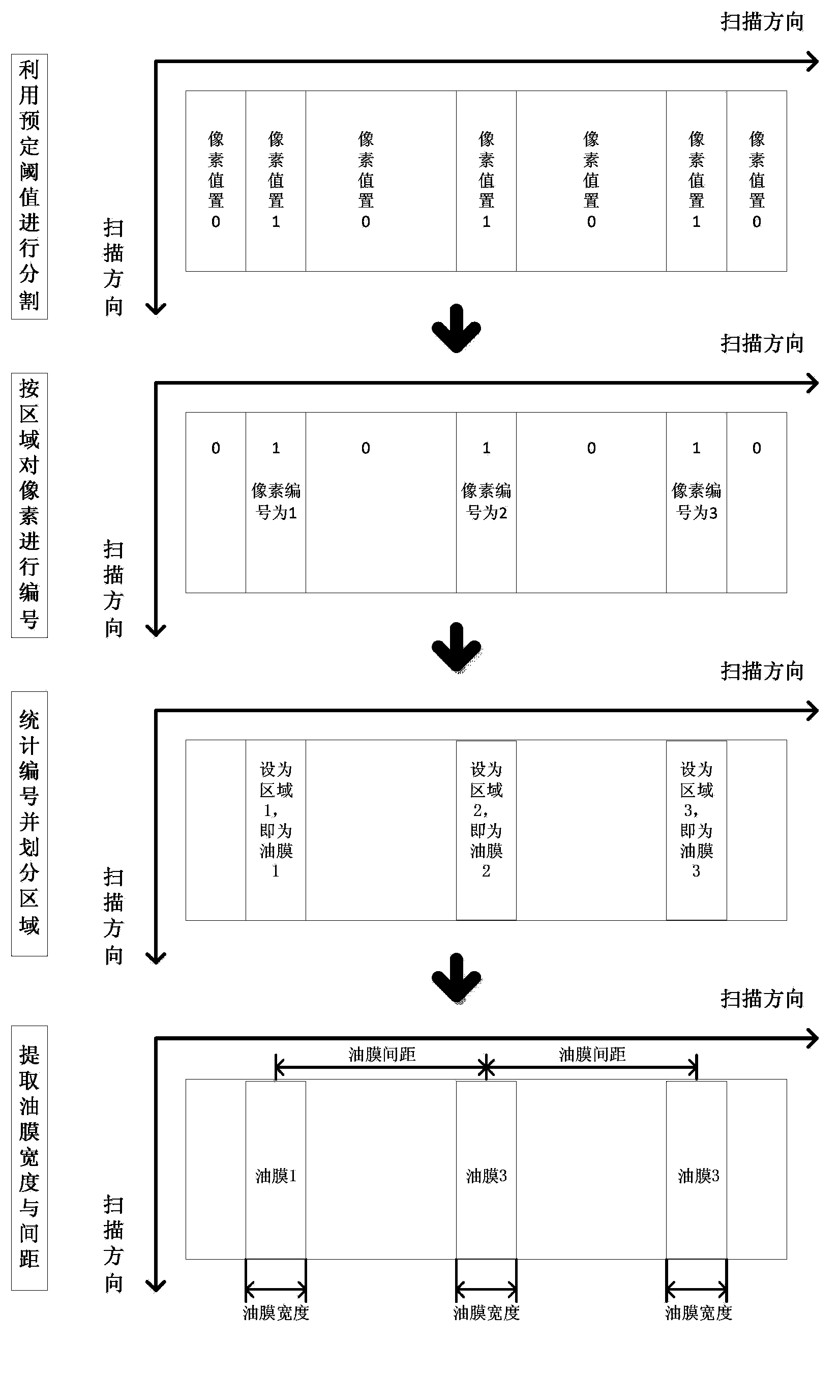

Intelligent oil-gas lubrication monitoring system and method

ActiveCN103899901ASolve wasteOvercome the problem that the adjustment accuracy cannot be guaranteedLubrication elementsGas lubricationMonitoring system

The invention discloses an intelligent oil-gas lubrication monitoring system. The intelligent oil-gas lubrication monitoring system comprises a lubrication point state monitoring station, an oil-gas lubrication PLC, an industrial control computer, an intelligent vision sensor and a fuzzy controller, the fuzzy controller is used for processing oil-gas supply quantity parameter set values from the oil-gas lubrication PLC and oil film state data from the intelligent vision sensor, providing the oil-gas supply quantity parameter adjustment amount, adjusting oil-gas supply parameters of an oil-gas lubrication device, and evaluating whether the oil film state data meet predefined requirements, and therefore oil films meeting the predefined requirements of oil-gas lubrication are sprayed to all lubrication points. According to the intelligent oil-gas lubrication monitoring system, the intelligent vision sensor is used for directly collecting and processing oil film images, the corresponding oil film state data are extracted from pixels of the oil film images, and oil film state indexes are evaluated through the fuzzy controller and therefore meet the predefined requirements of oil-gas lubrication better. The invention further discloses an intelligent oil-gas lubrication monitoring method.

Owner:上海重矿连铸技术工程有限公司

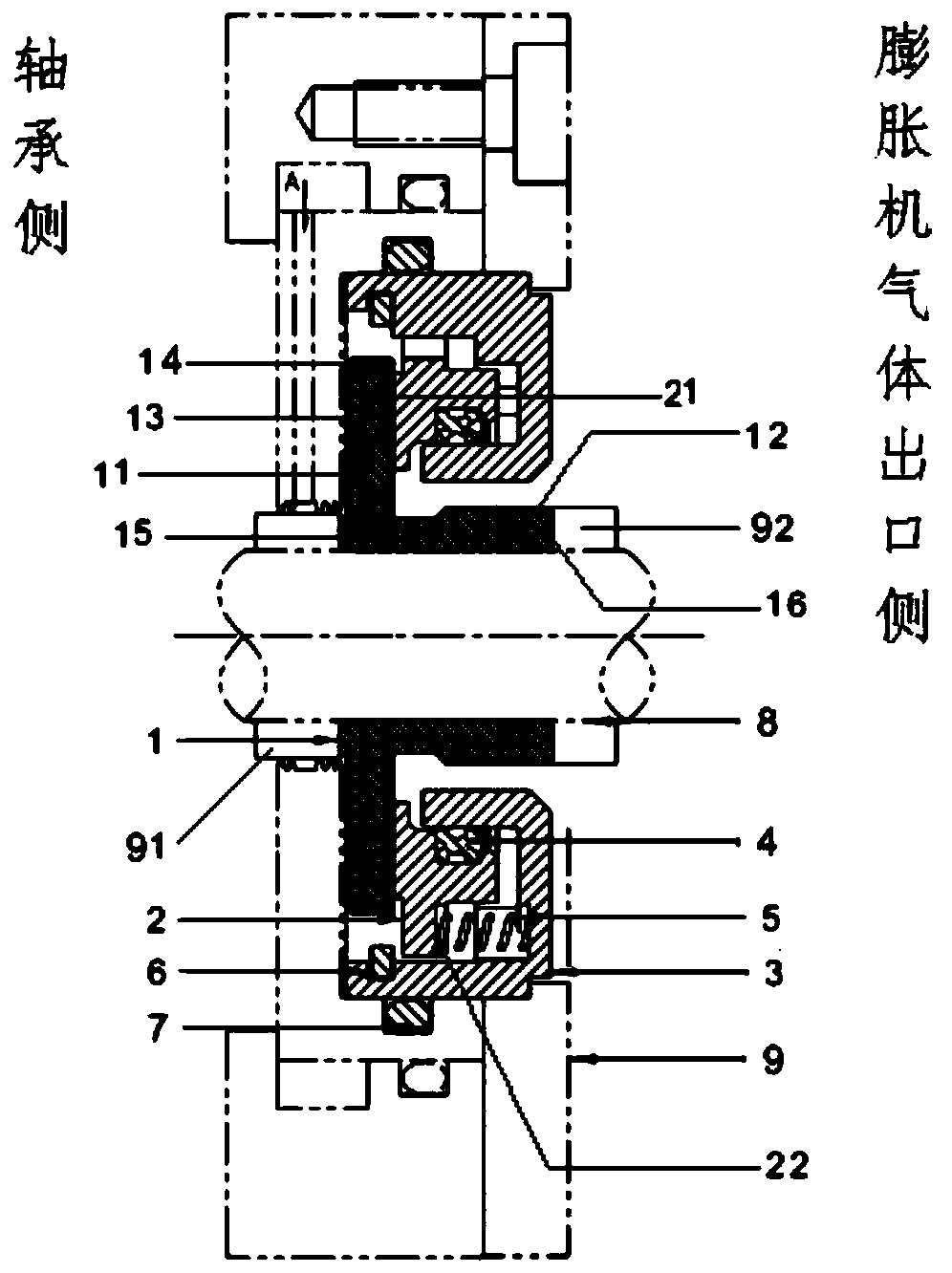

Gas lubrication hydrodynamic sealing device used for miniature high-speed turbo expander

PendingCN111188653AIncrease stiffnessGuaranteed zero leakageLeakage preventionMachines/enginesImpellerGas lubrication

The invention discloses a gas lubrication hydrodynamic sealing device used for a miniature high-speed turbo expander. The miniature high-speed turbo expander comprises a shell, wherein a main shaft and an impeller component are arranged in the shell; the impeller component is fixed on the main shaft; a bearing component is arranged out of the impeller component; the bearing component is sheathed to the main shaft; the sealing device is positioned between the impeller component and the bearing component and comprises a movable ring and a static component; the movable ring is sheathed to the main shaft; two ends of the movable ring are clamped between the impeller component and the bearing component; the static component is fixed on the shell; one end surface of the static component and themovable ring form a sealing surface; an end surface, which is laminated with the static component, on the movable ring is provided with a fluid hydrodynamic groove. Compared with the prior art, the sealing device disclosed by the invention is applied to the high-speed turbo expander, the zero leakage of bearing side lubricating oil to an exit side of the expander can be realized, and in addition,the internal gas loss of the expander is extremely small.

Owner:上海优赛密封科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com