Oil-gas lubrication structure of high-speed electric main shaft

A high-speed electric spindle and oil-air lubrication technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as strong frictional heat, burns, and failure to work normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

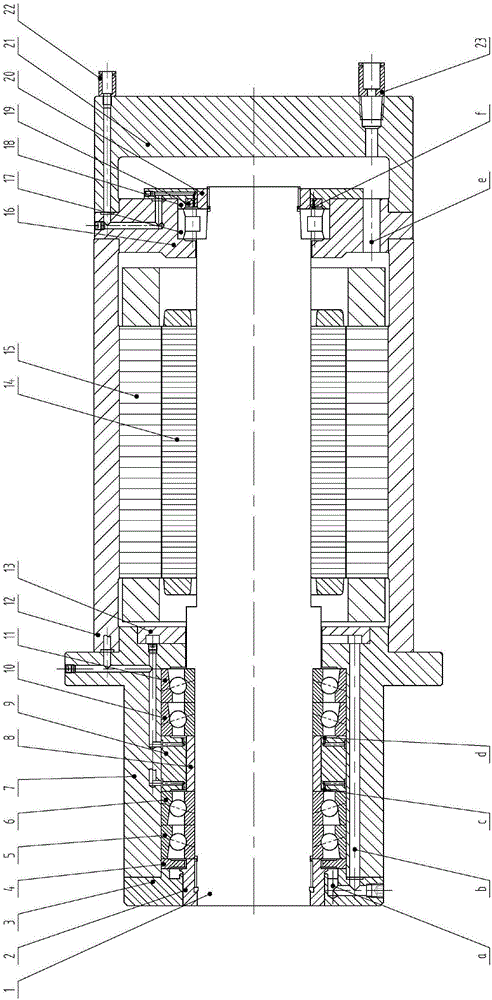

[0022] refer to figure 1 , the present invention relates to an oil-air lubrication structure for a high-speed electric spindle, which includes a spindle rotor 1, a front lock nut 2, a front gland 3, an adjustment ring 4, an angular contact ball bearing 5, an angular contact ball bearing 6, and a front bearing sleeve Barrel 7, inner spacer ring 8, outer spacer ring 9, angular contact ball bearing 10, angular contact ball bearing 11, stator sleeve 12, front splitter ring 13, motor rotor 14, motor stator 15, rear bearing sleeve 16, single row Cylindrical roller bearing 17, rear gland 18, rear splitter ring 19, rear lock nut 20, rear cover 21, push-in connector 22, and push-in connector 23.

[0023] The oil gas of angular contact ball bearings 5 and 6 enters from the oil injection port c of the outer spacer ring 9, after lubricating the bearings, it enters the oil inlet a of the front gland through the gap between the front lock nut 2 and the adjustment ring 4, and then enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com