Patents

Literature

28802results about "Maintainance and safety accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

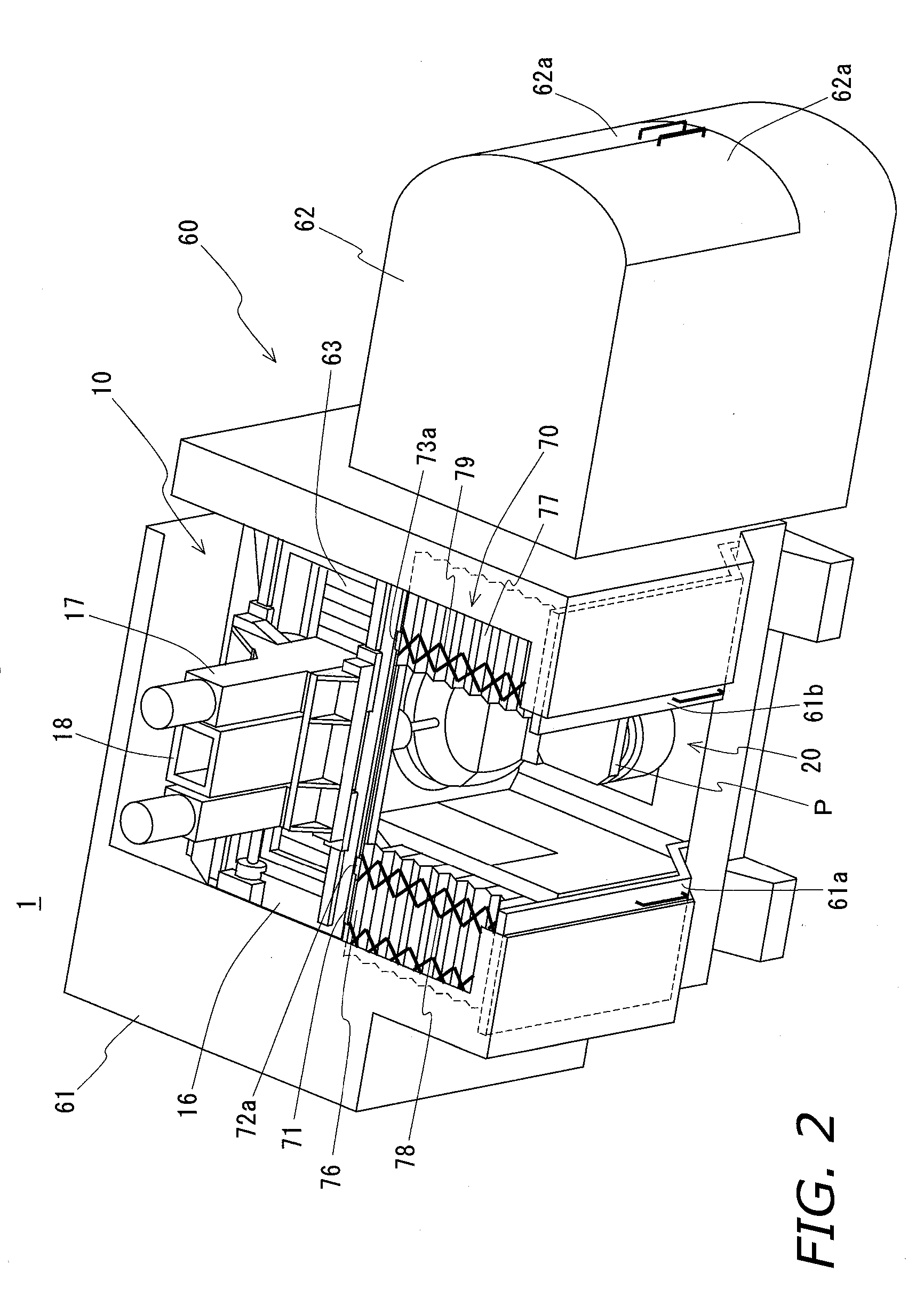

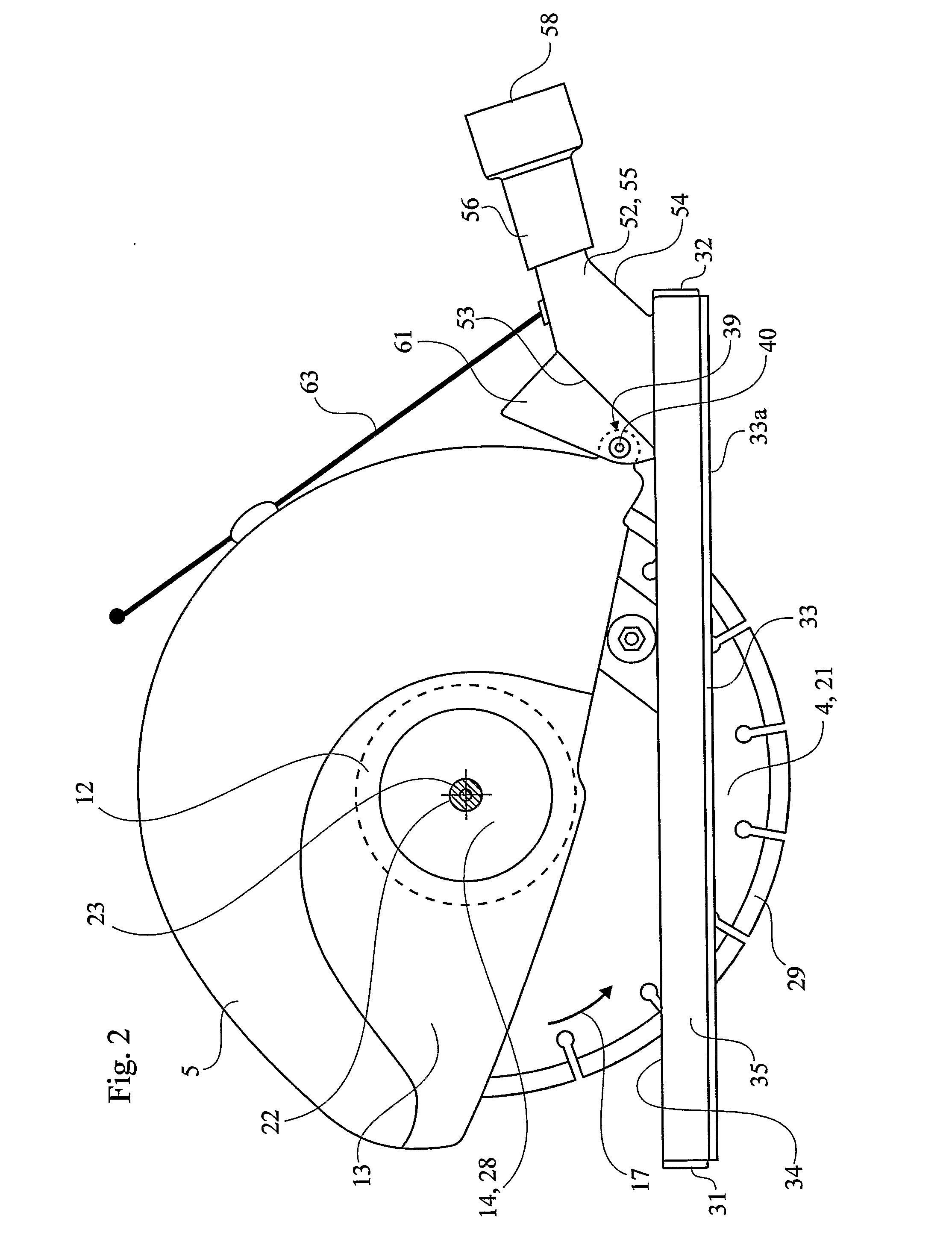

Electric drill apparatus

InactiveUS7121773B2Reduce weight and sizeLow profileDrilling/boring measurement devicesThread cutting machinesRotational axisAnnular cutter

An electric drill apparatus having a low profile is provided which comprises an annular cutter, a motor for rotating the annular cutter, a rotary shaft assembly for rotating the annular cutter attached to its leading end about a rotating, a rotation reduction mechanism disposed between the motor and rotary shaft assembly for transmitting a driving force of the motor to the annular cutter through the rotary shaft assembly, a feed mechanism responsive to an operation of a manual handle, for moving the rotary shaft assembly along with a straight line to advance or retract the annular cutter attached to the rotary shaft assembly with respect to a workpiece, and an adhesion base for securing the electric drill apparatus to the workpiece. The annular cutter has a plurality of cutting blades comprised of cemented carbide tips fixed on its lower end, thereby it is capable of rotating at a high speed. The rotary shaft assembly has a rotating shaft which rotates in a direction different from that of a rotating shaft of the motor, thereby the drill apparatus has a low profile.

Owner:NITTO KOHKI CO LTD

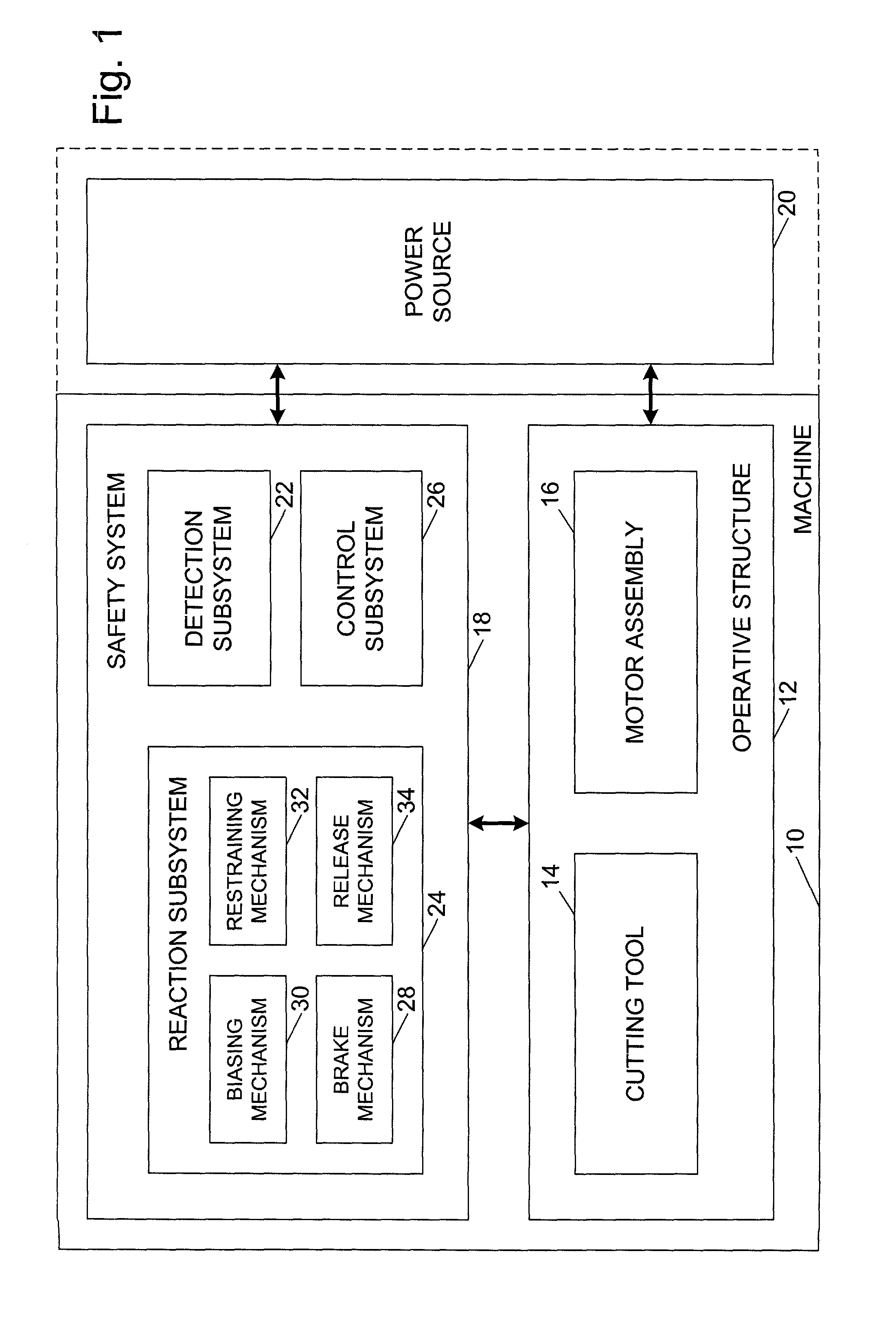

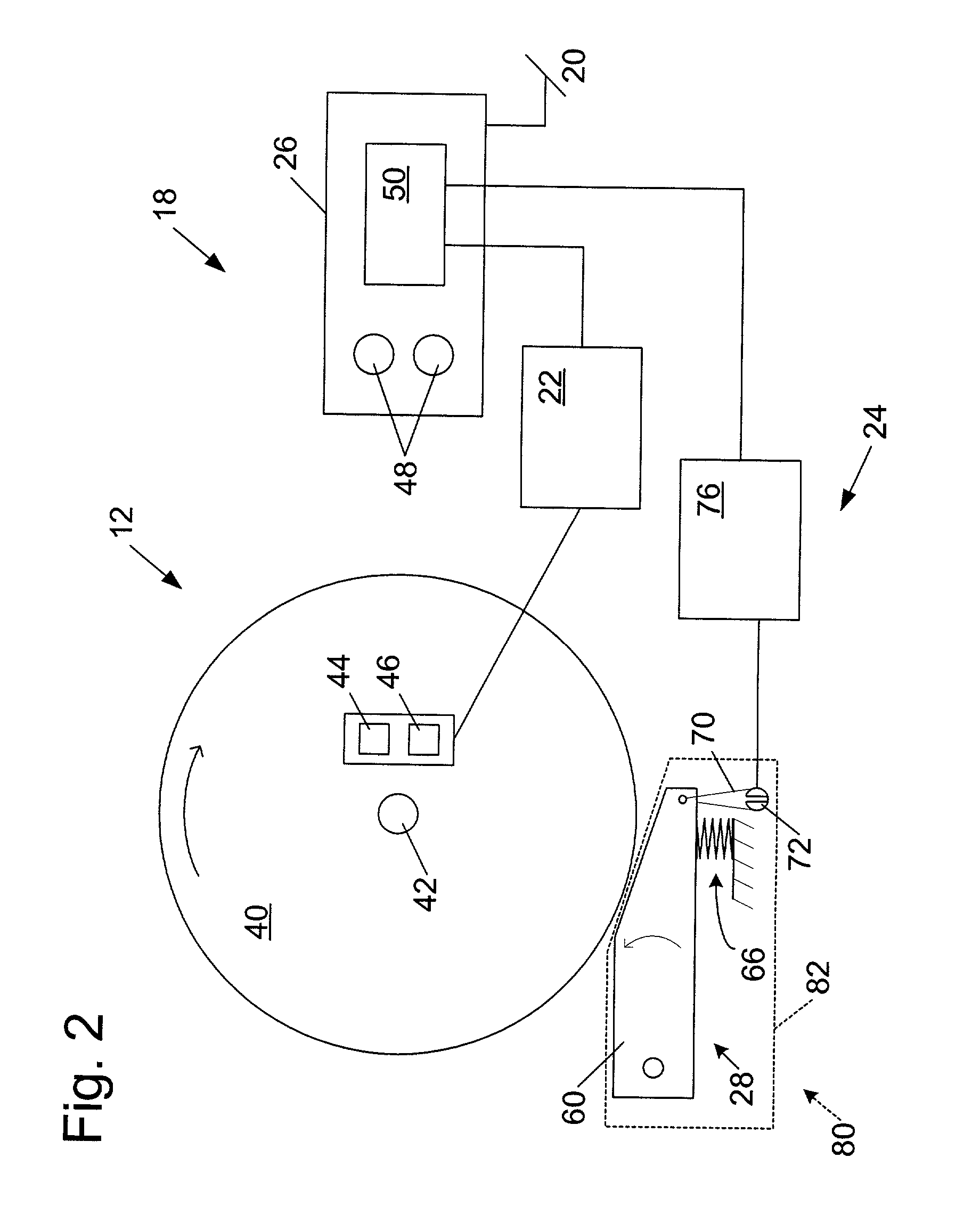

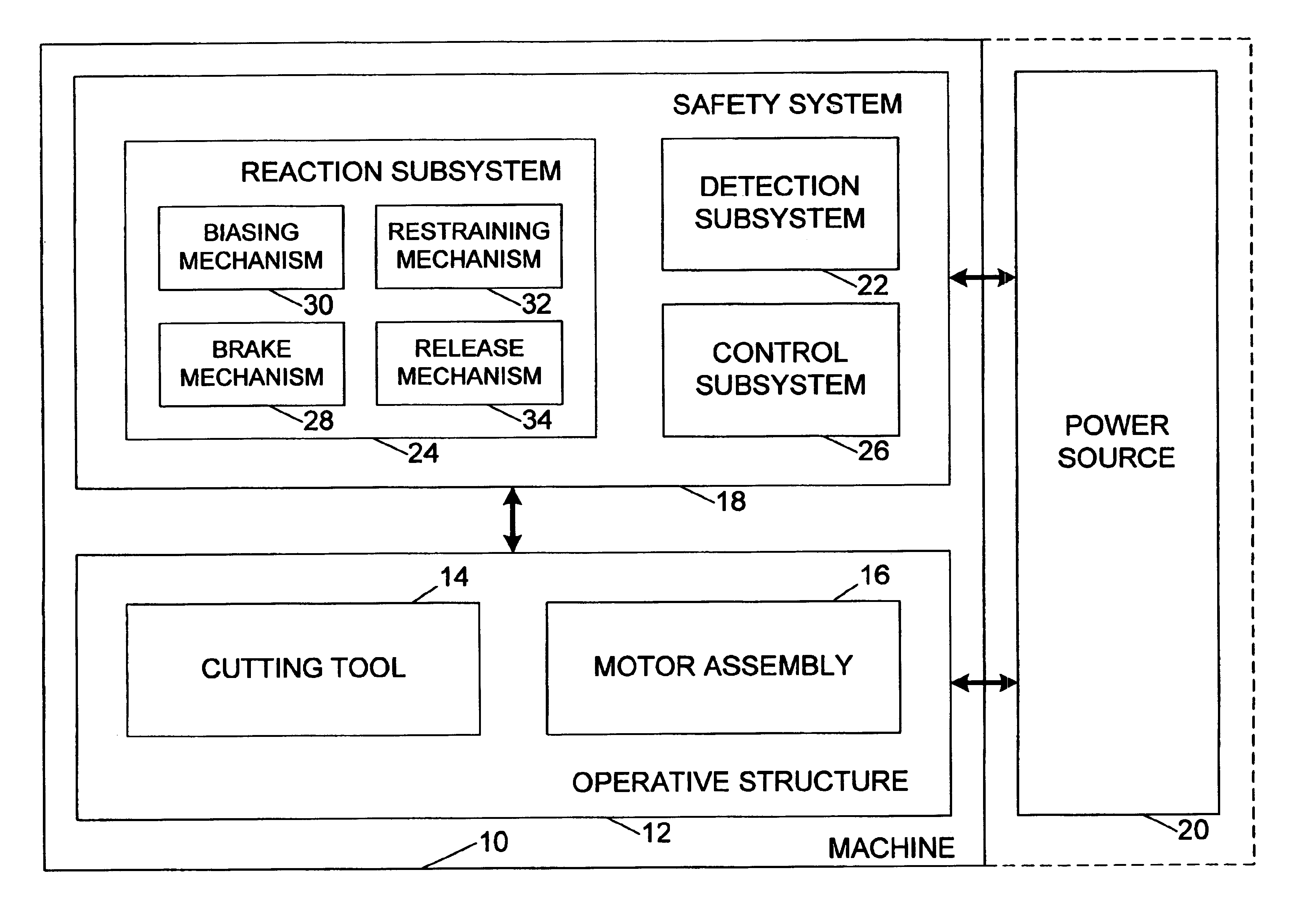

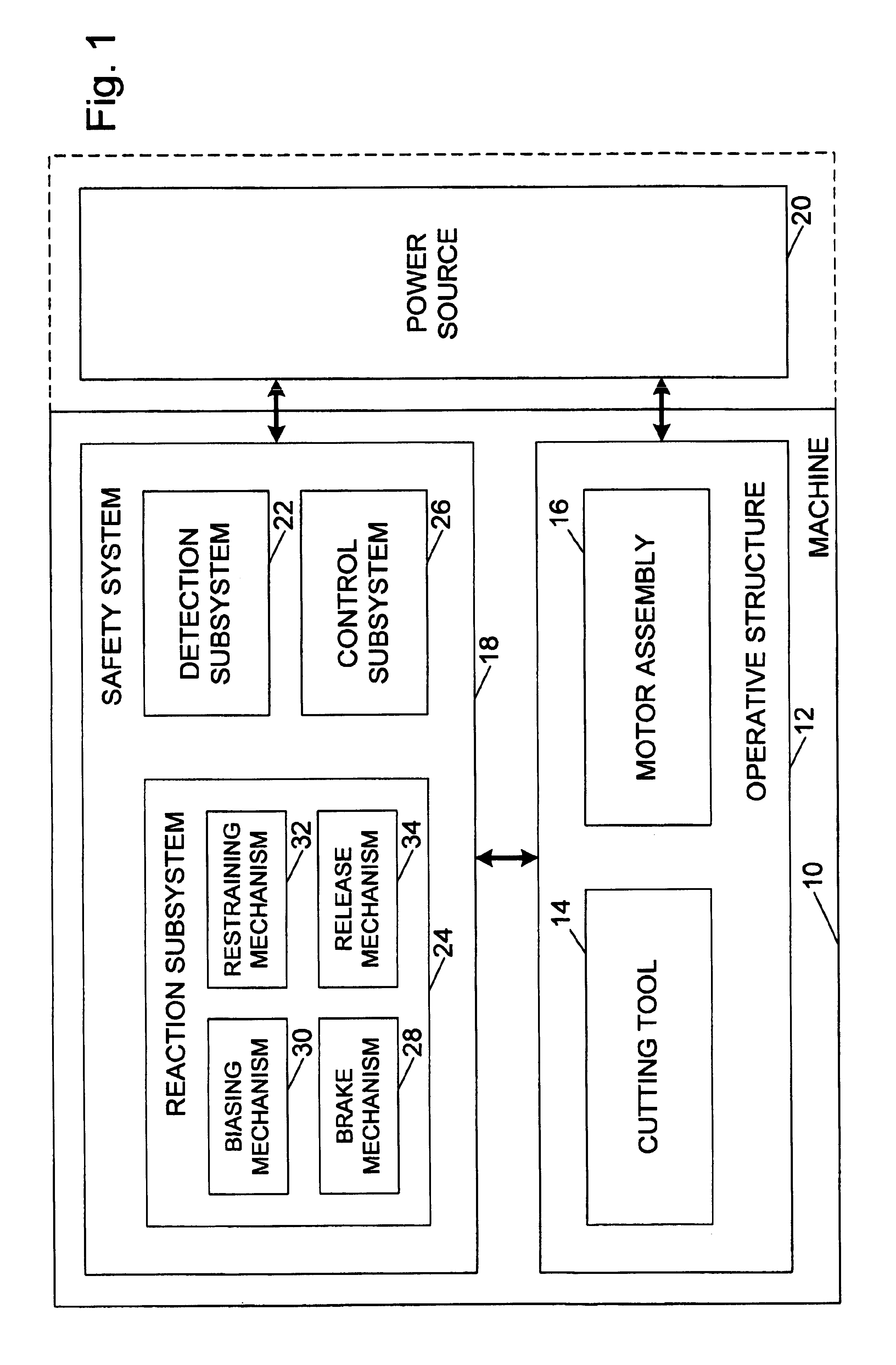

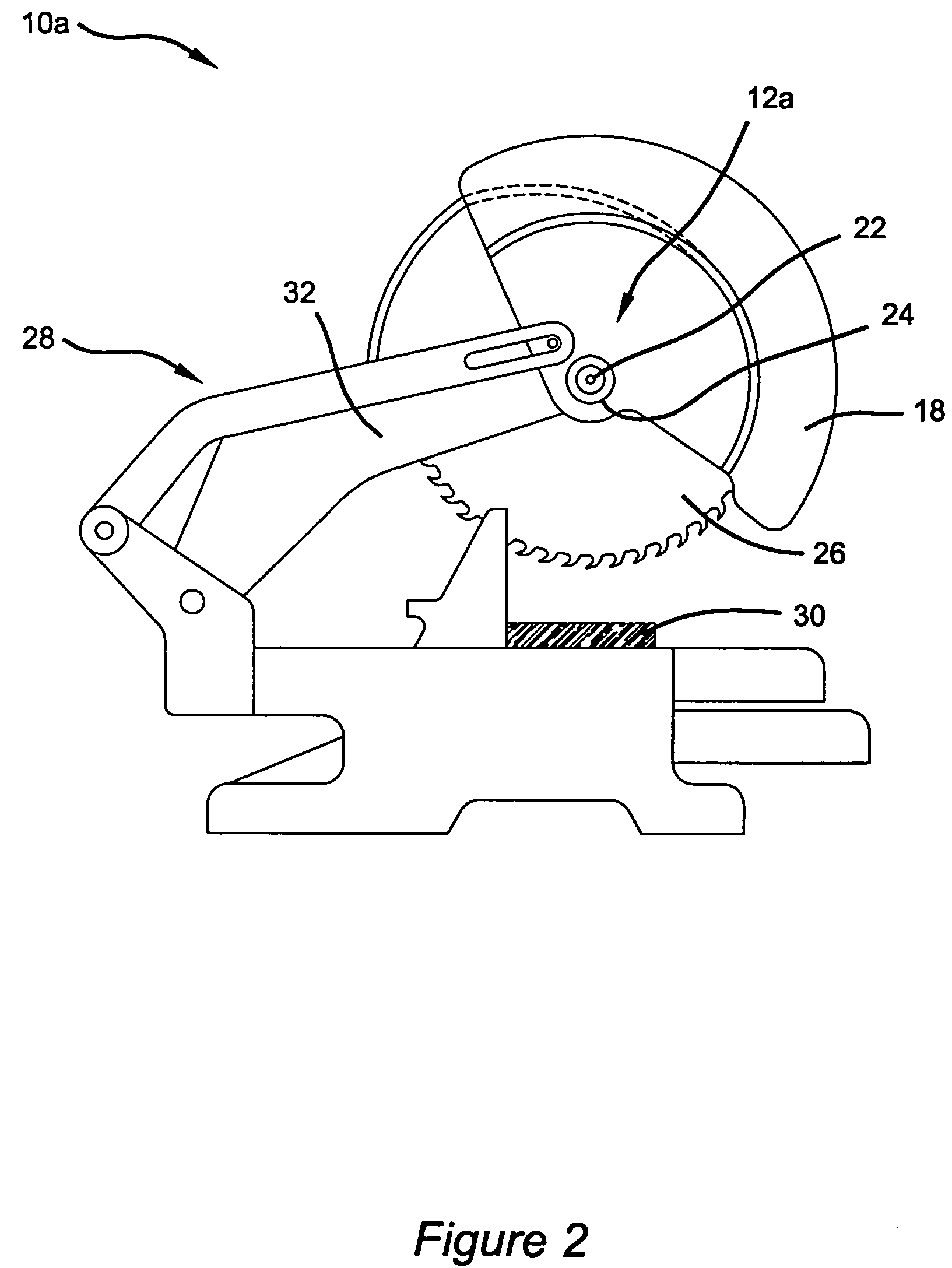

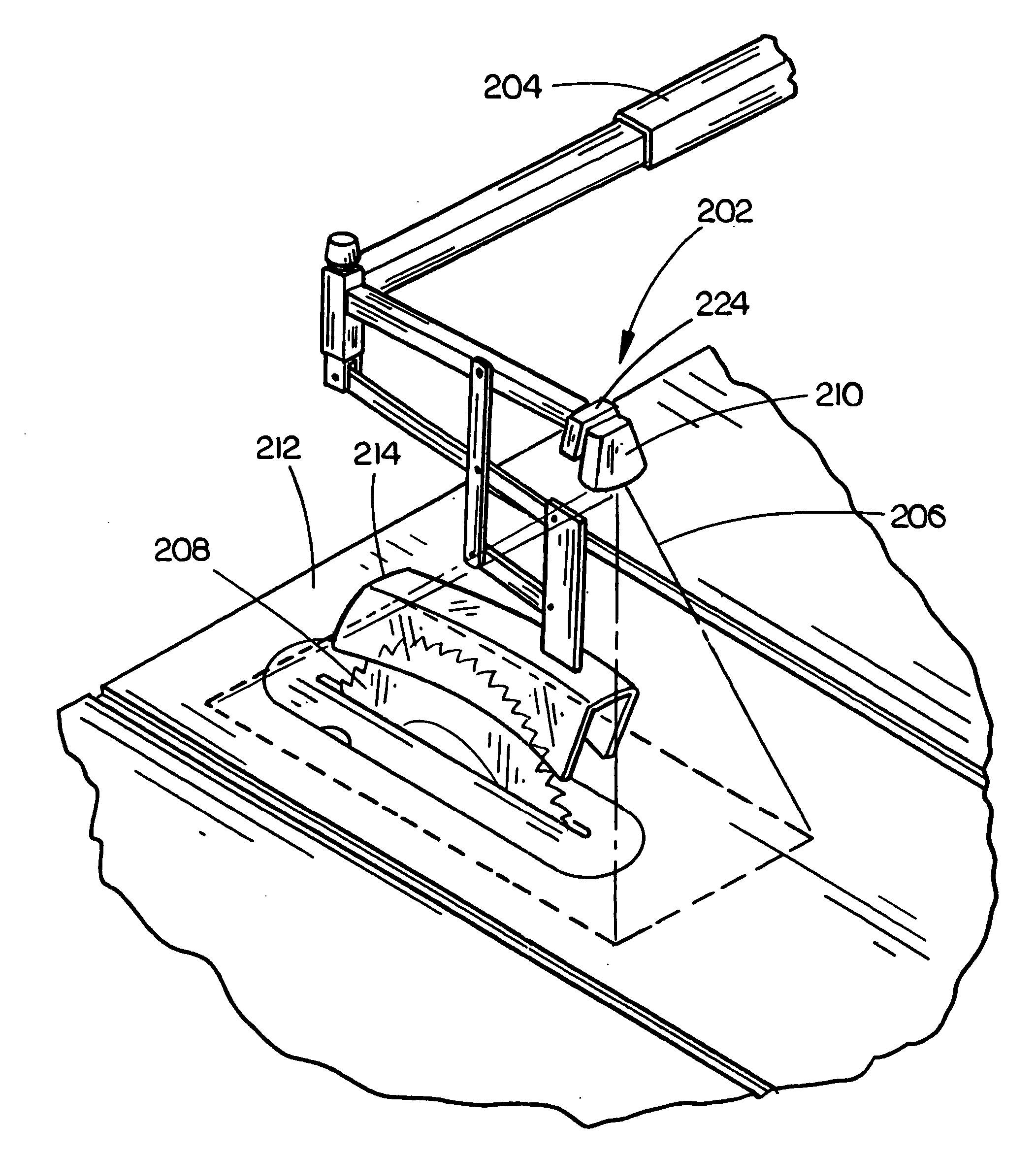

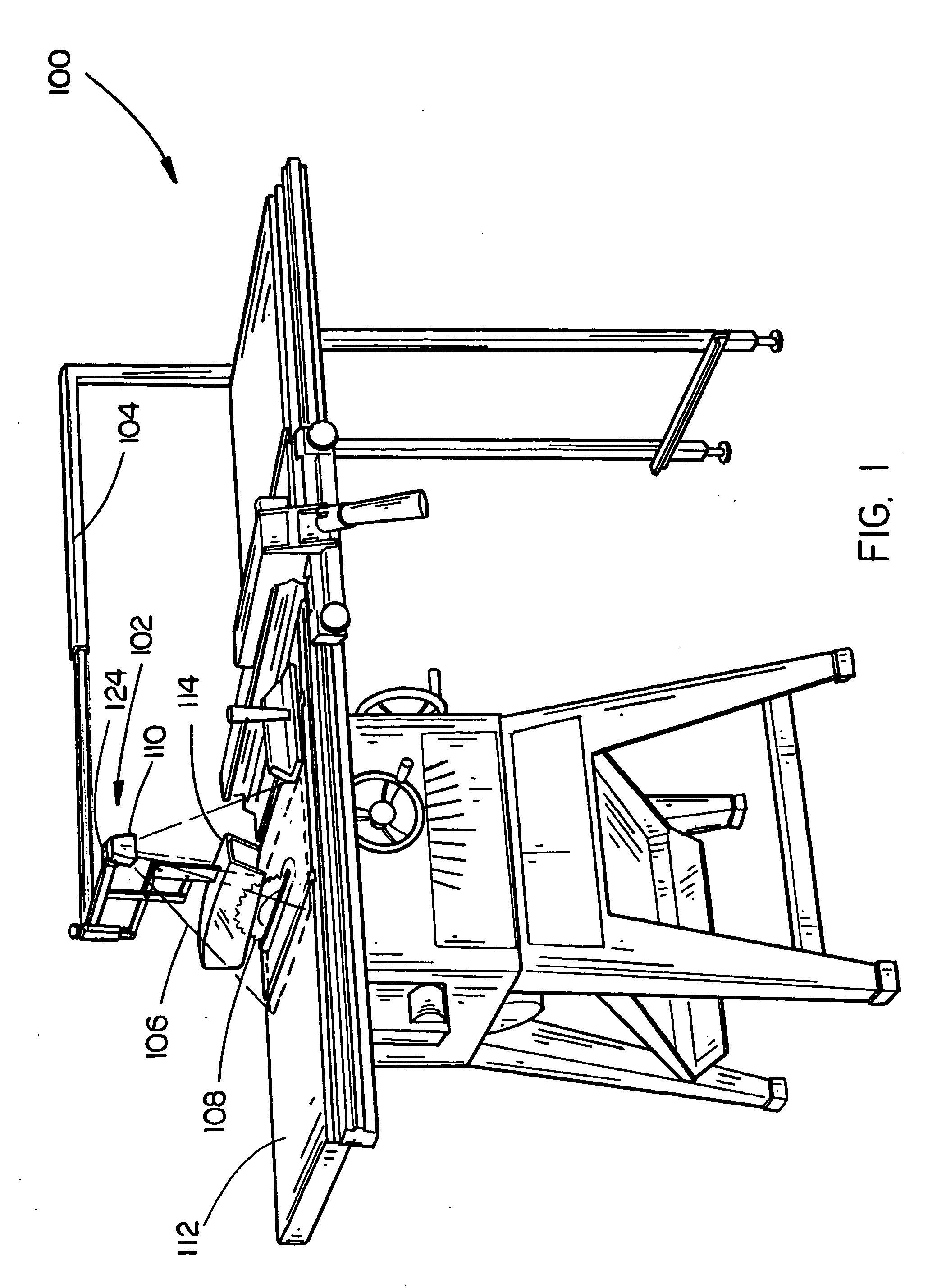

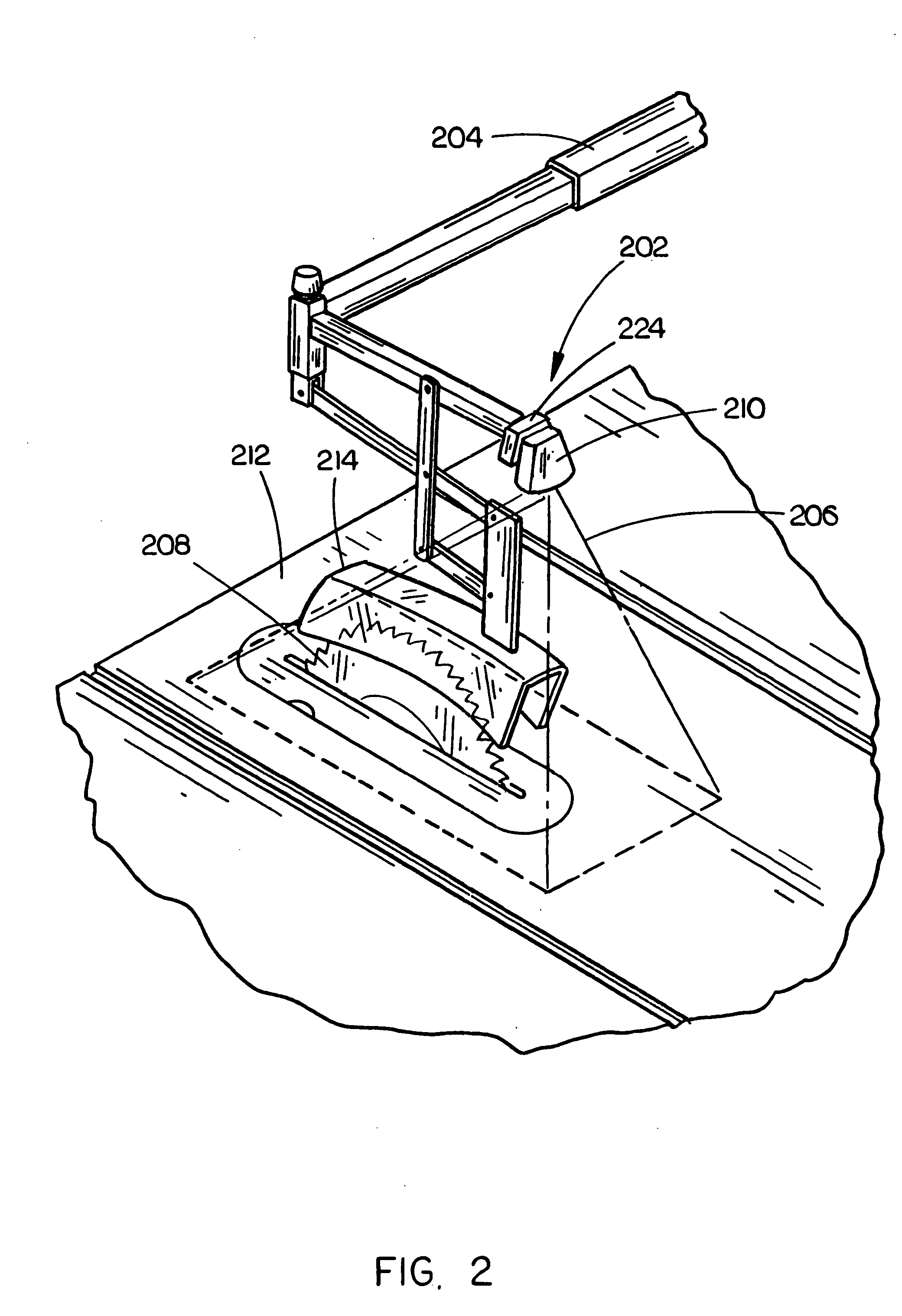

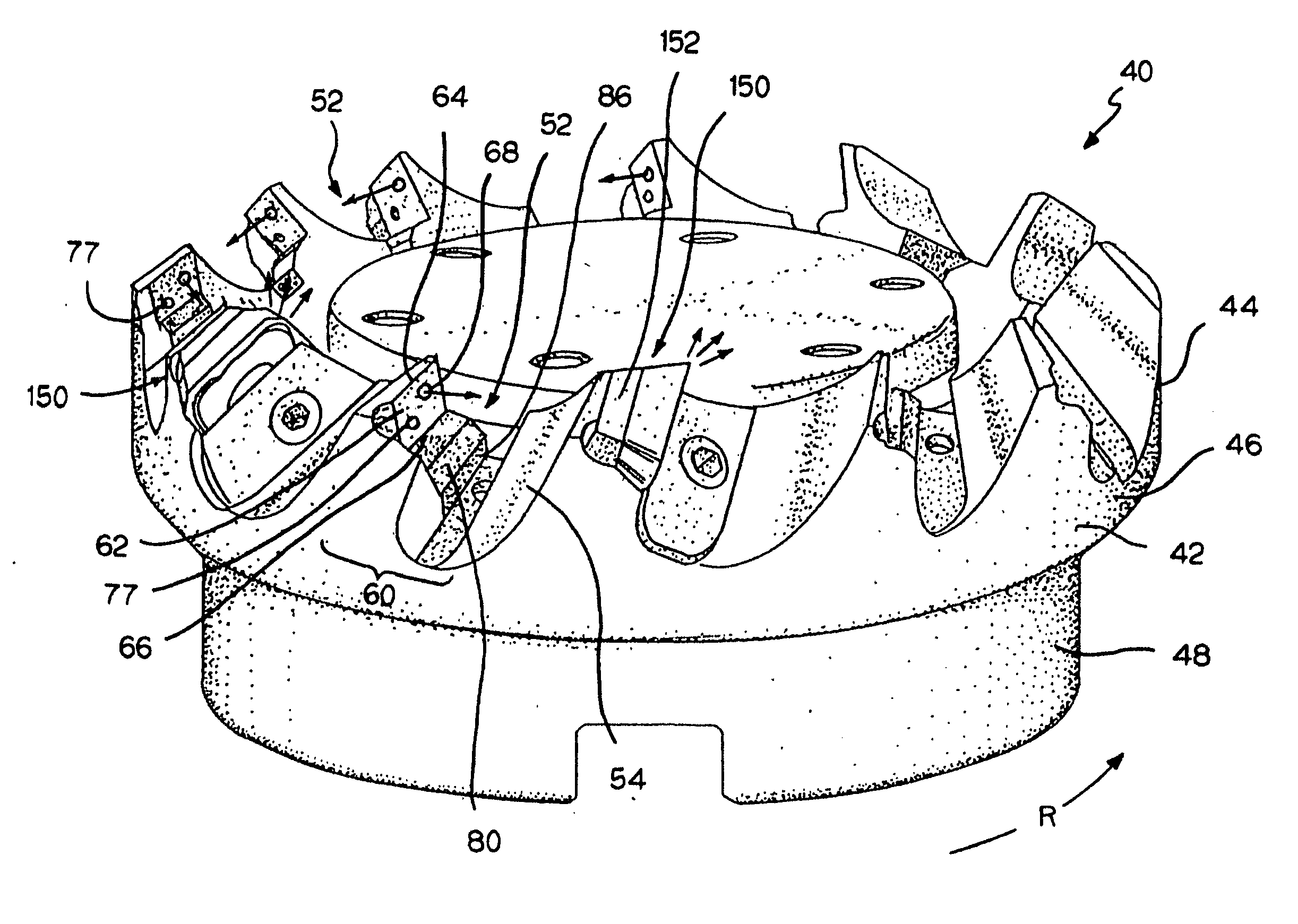

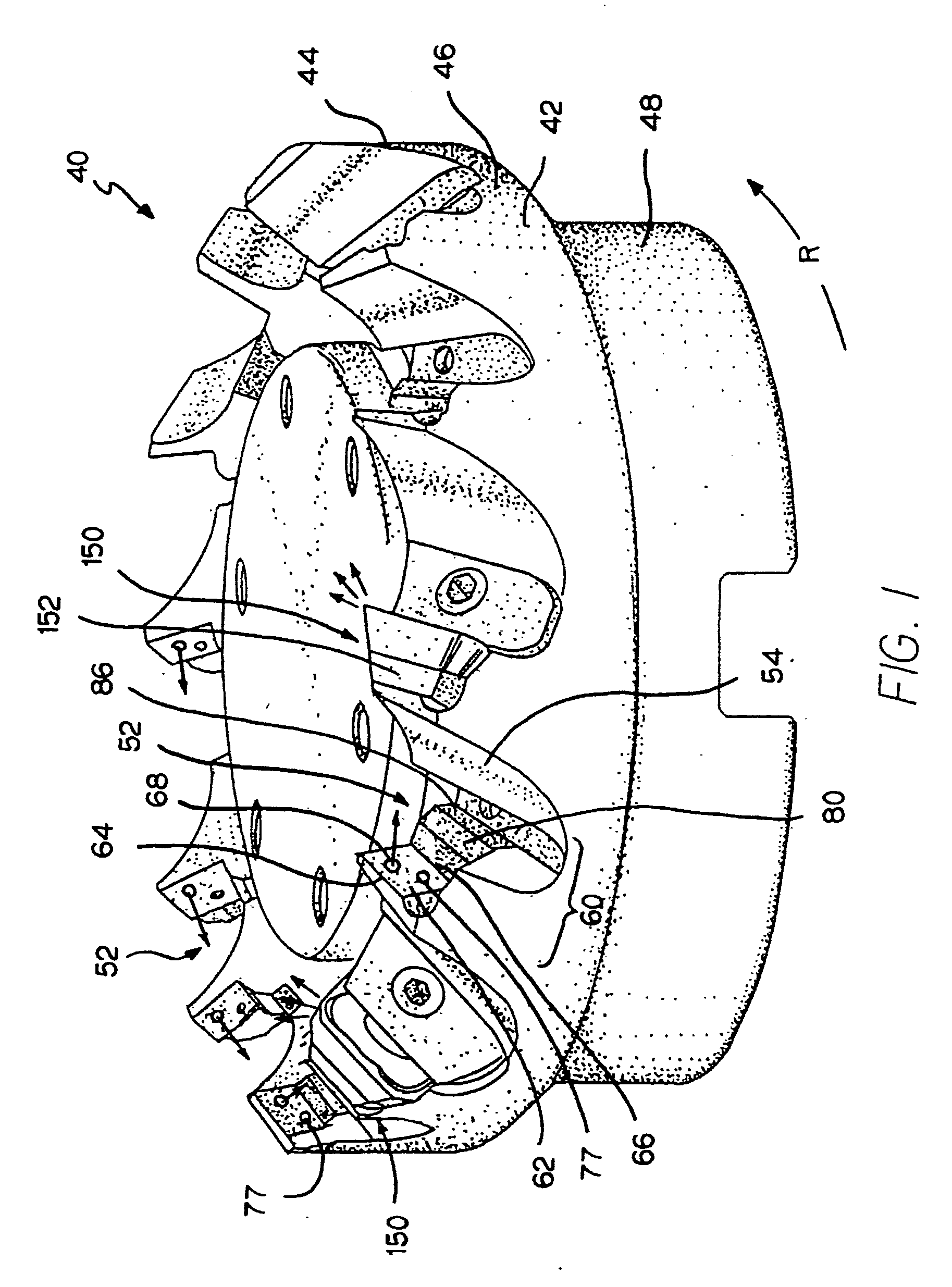

Safety systems for power equipment

Machines with safety systems are disclosed. The machine may take the form of woodworking machines including table saws, band saws, miter saws, hand-held circular saws, pneumatic chop saws, radial-arm saws, jointers, planars, routers and shapers. The machines may include an operative structure configured to perform a task, where the operative structure includes a cutting tool adapted to move in at least one motion, and a safety system adapted to detect the occurrence of an unsafe condition between a person and the cutting tool and for mitigating the unsafe condition. The safety system may include a detection subsystem and a reaction subsystem.

Owner:SAWSTOP HLDG LLC

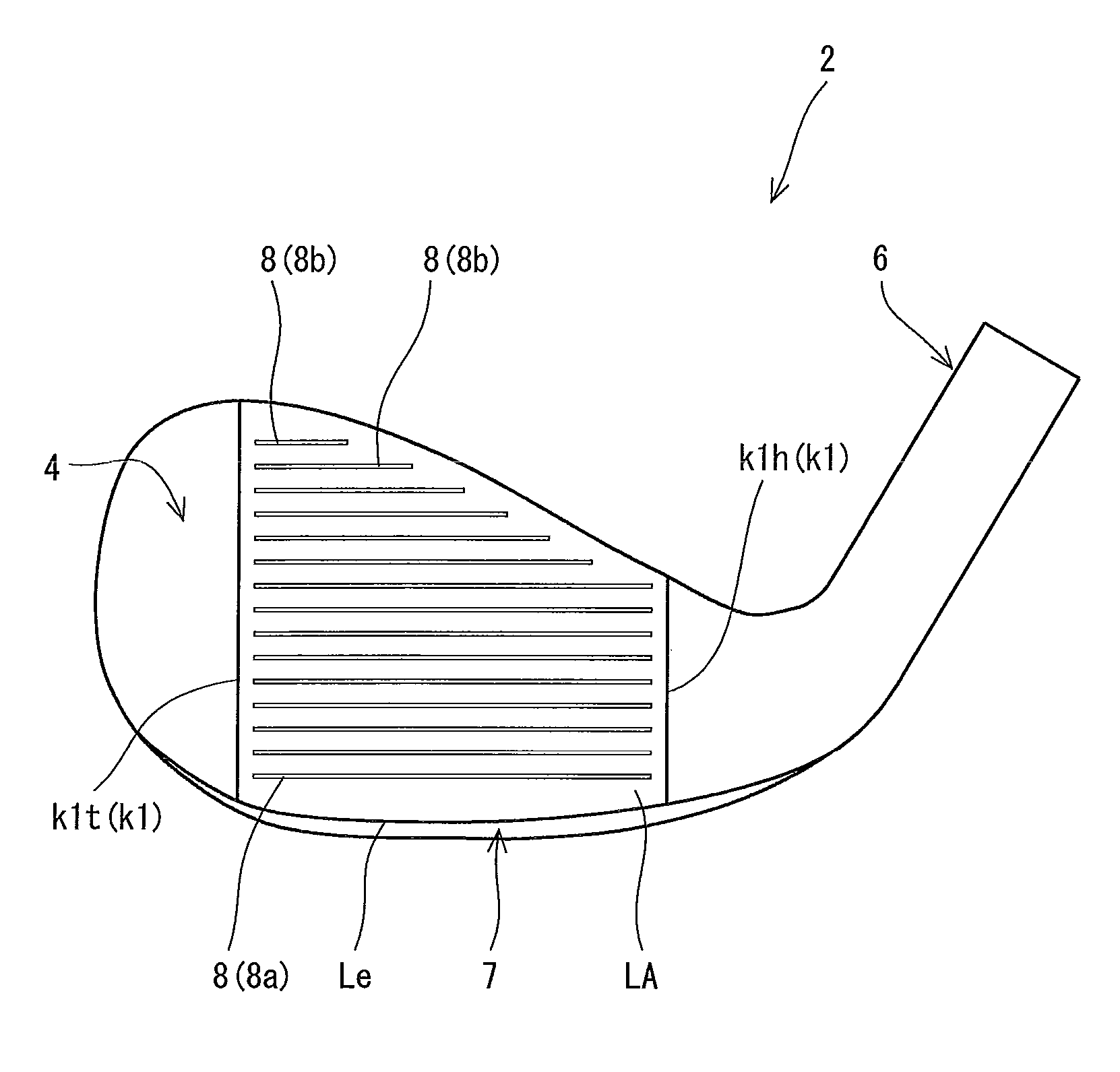

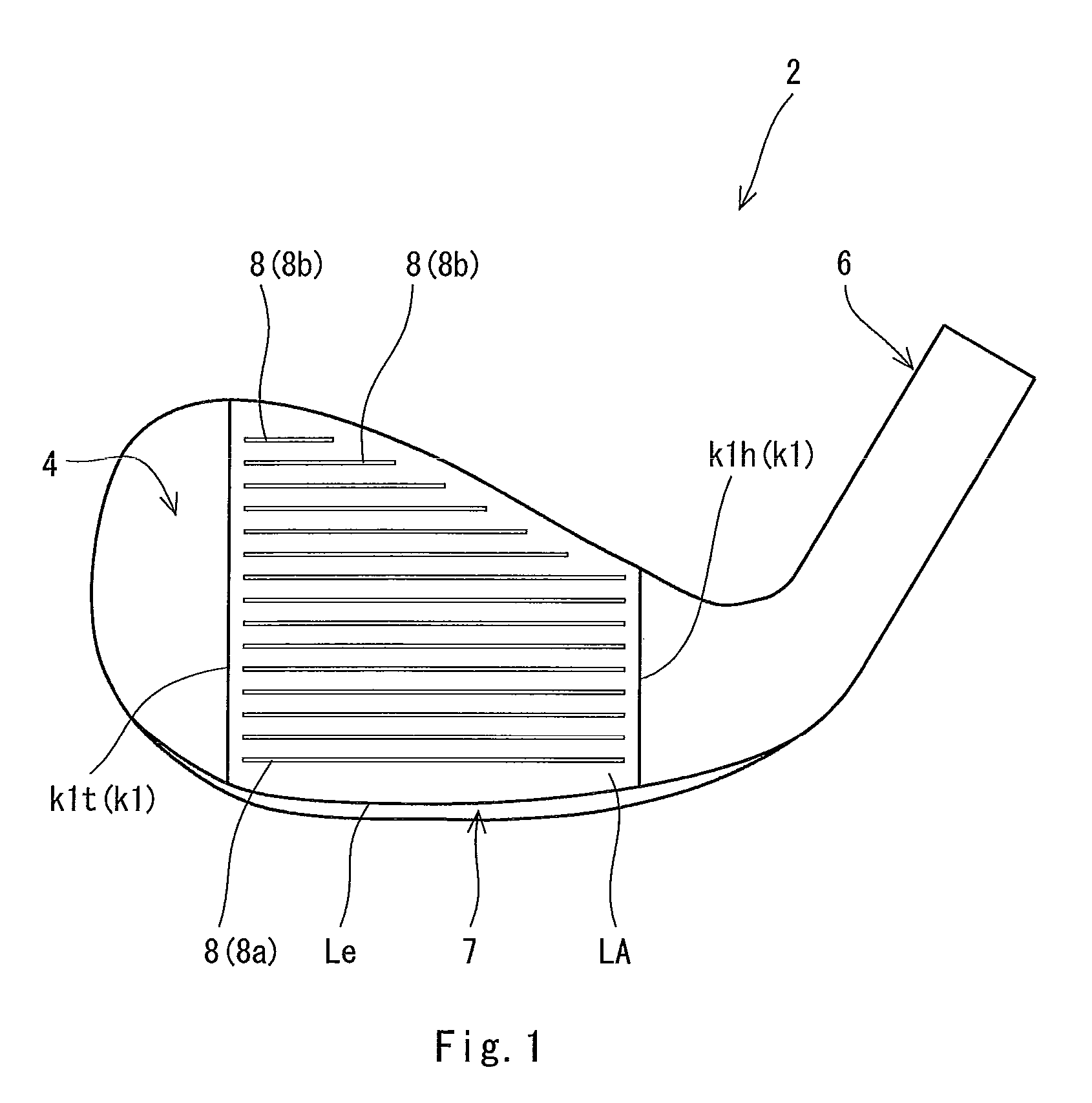

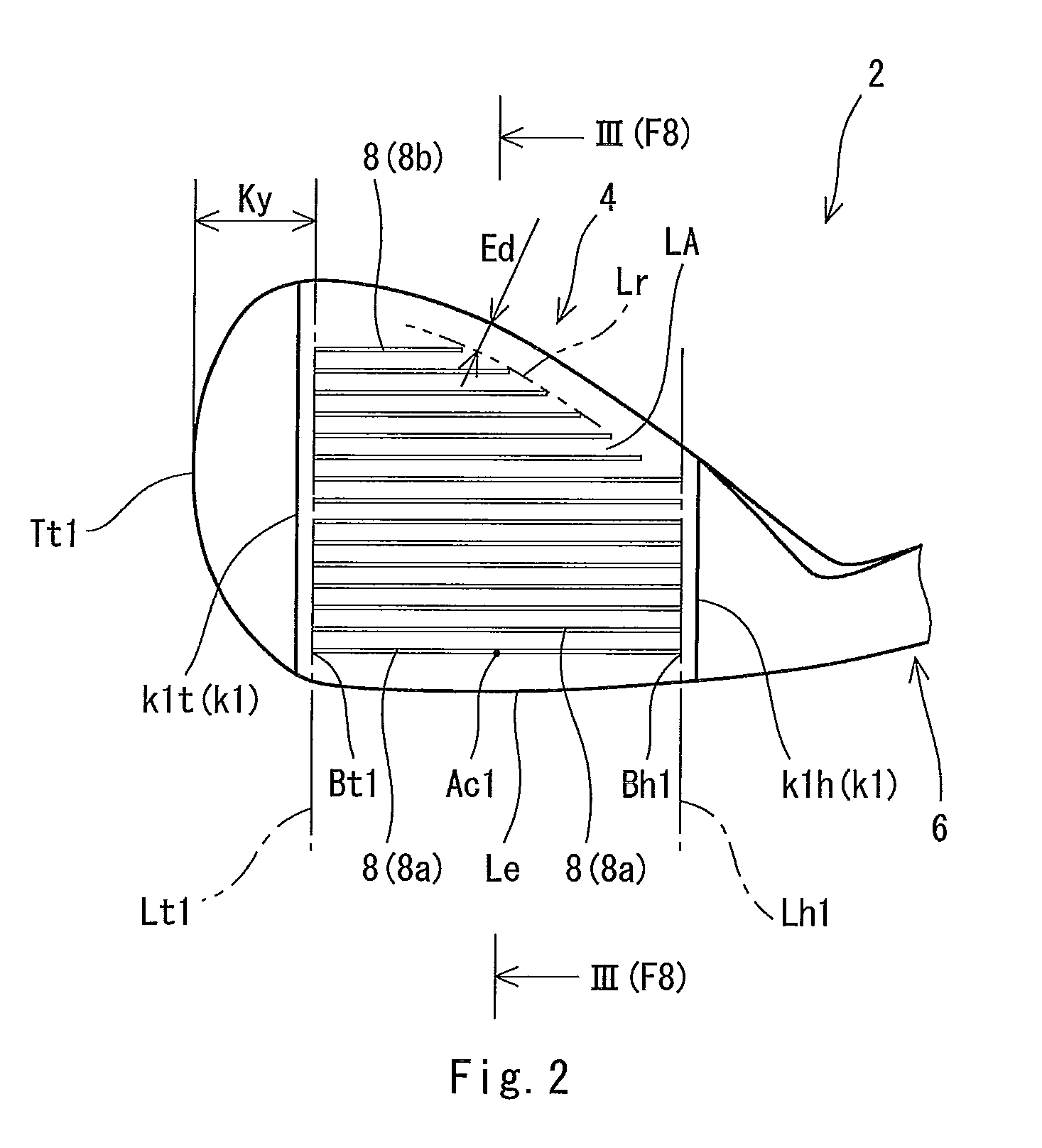

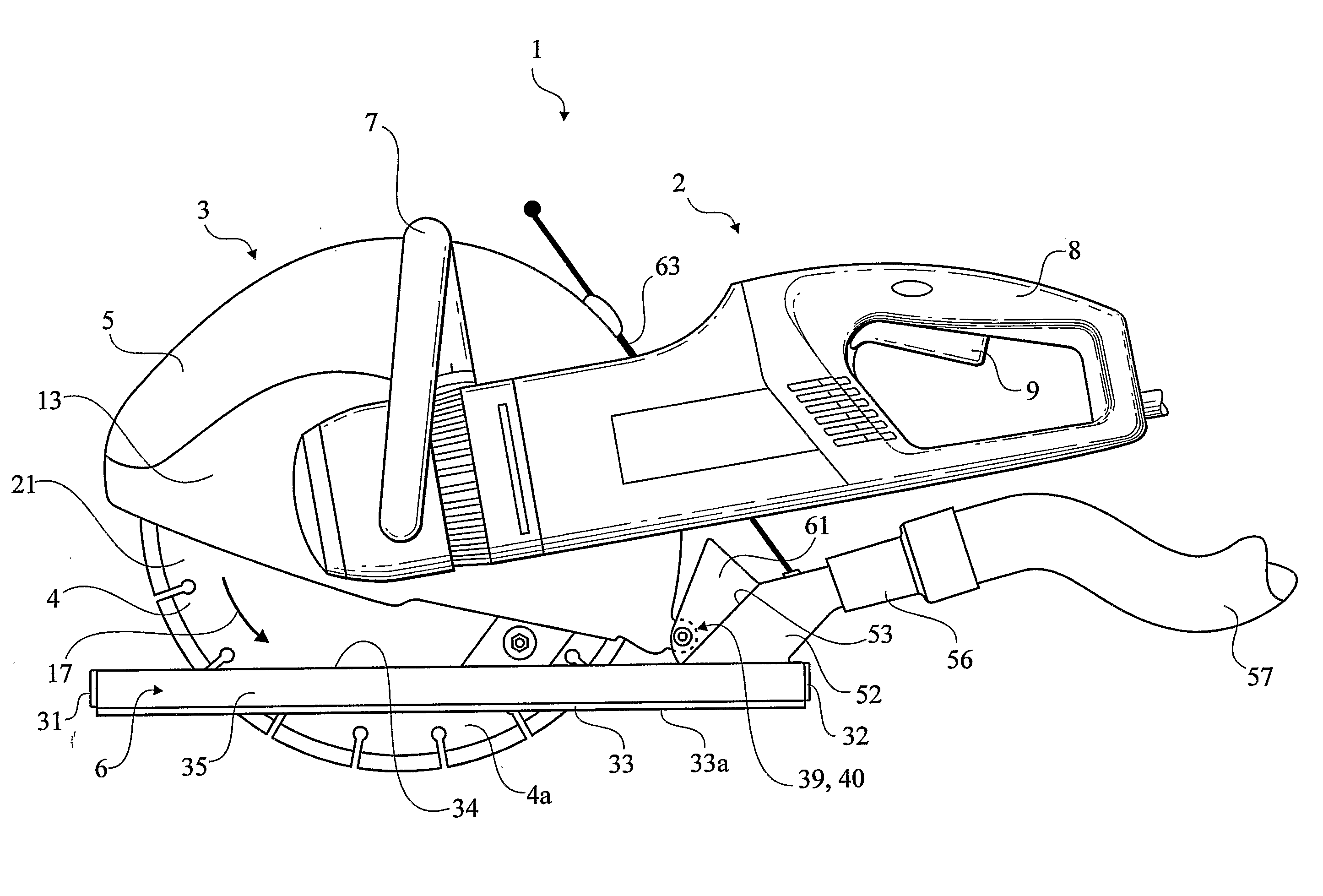

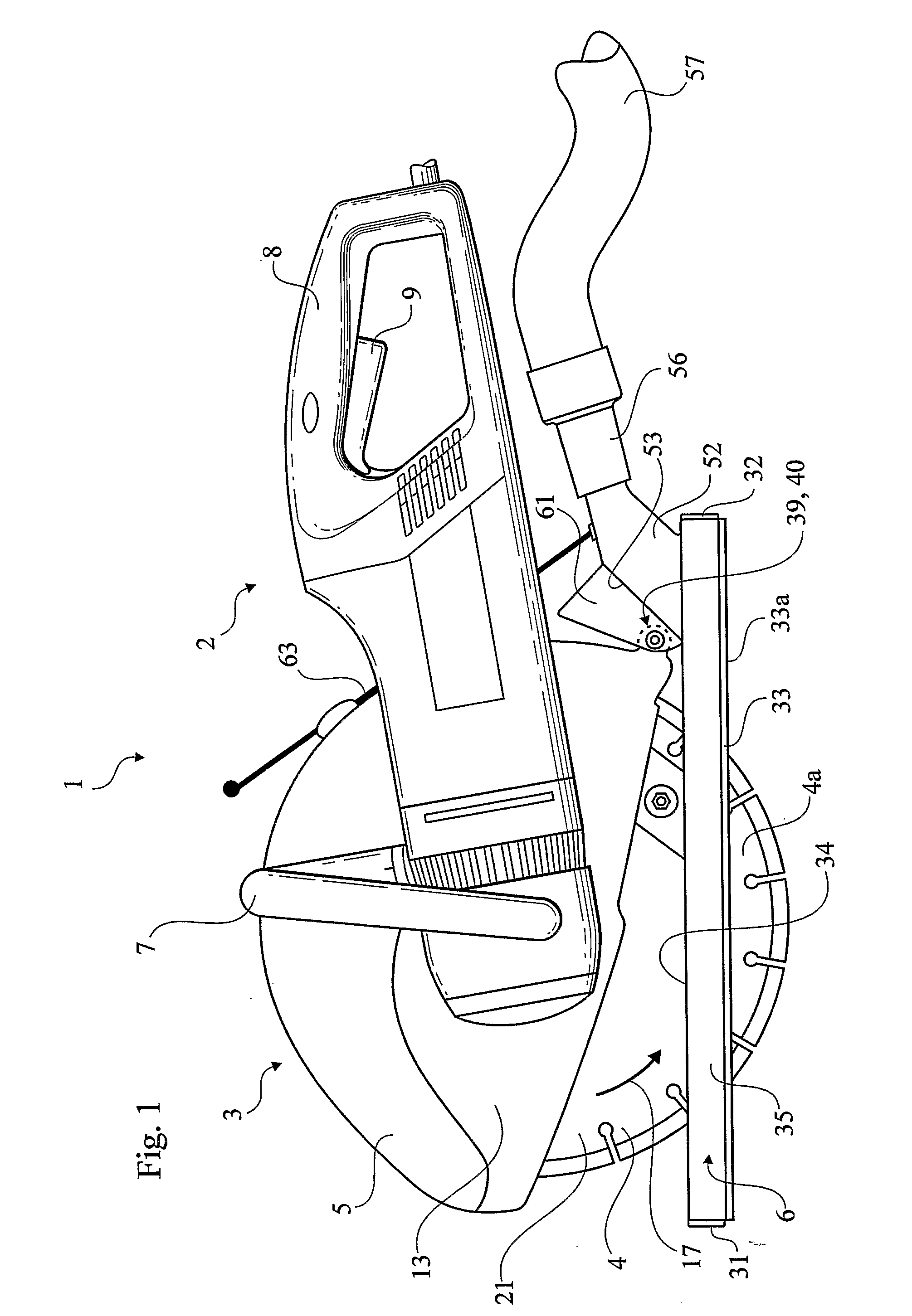

Golf club head

ActiveUS8328662B2Improve the rotation effectDamage suppressionGolf clubsMaintainance and safety accessoriesAlgorithmGolf Ball

A head 2 has a face line 8 having a depth of D1 (mm). When a boundary between a land area and a face line is defined as a point Pa; a point of which a depth is [D1 / 4] (mm) is defined as a point Pb; a point of which a depth is [D1 / 2] (mm) is defined as a point Pc; a point of which a depth is [(D1)×(¾)] (mm) is defined as a point Pd; a point of which a depth is 0.002 (mm) is defined as a point Px; a radius of a circle CL1 passing through three points of the point Pa, the point Pb, and the point Pc is defined as R3 (mm); a straight line passing through the point Pa and the point Px is defined as a straight line Lax; and an angle between the land area and the straight line Lax is defined as θ2 (degree), the radius R3 is 0.2 (mm) or greater and 0.4 (mm) or less, and the angle θ2 is 10 degrees or greater and 50 degrees or less.

Owner:SUMITOMO RUBBER IND LTD

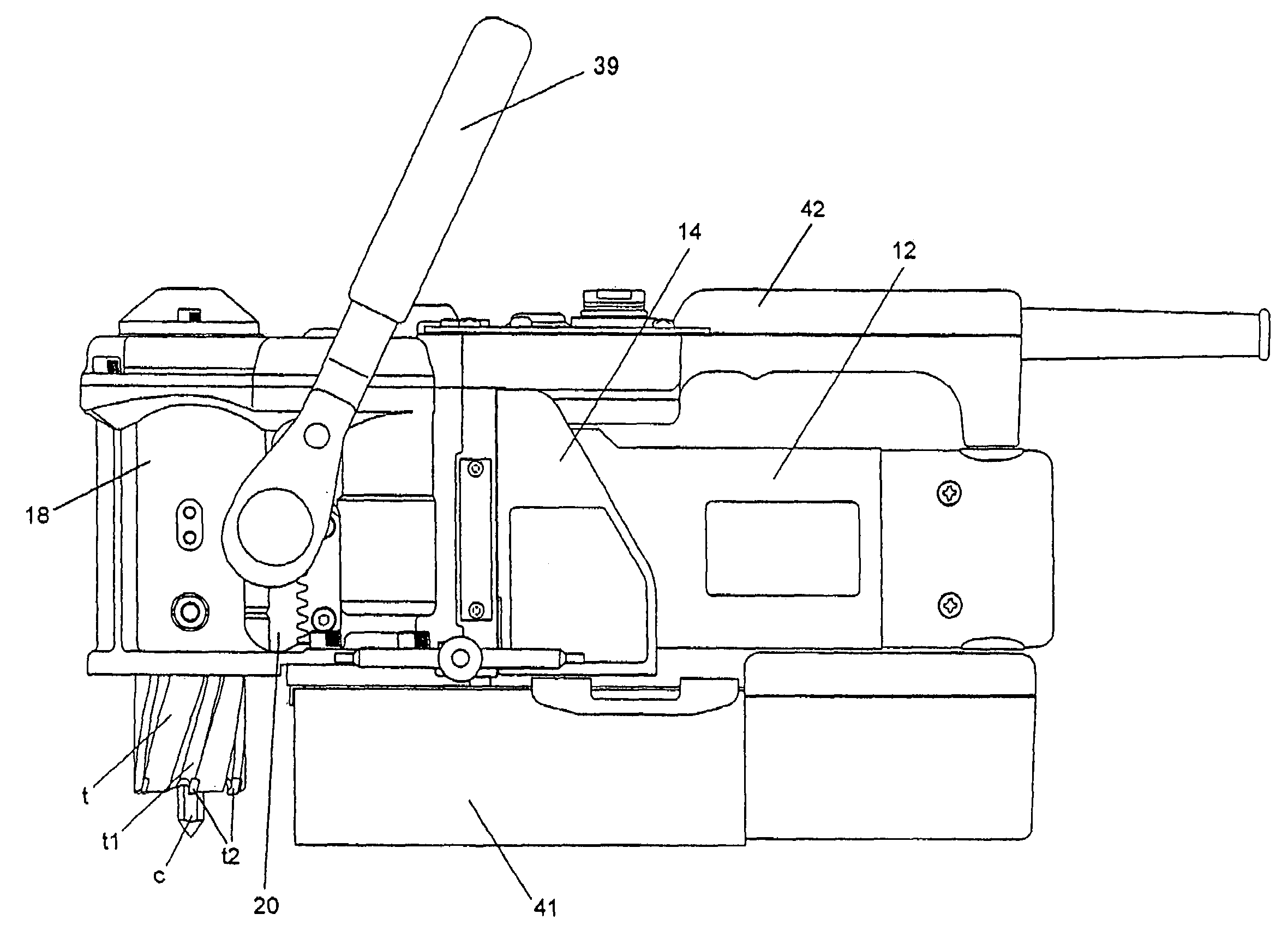

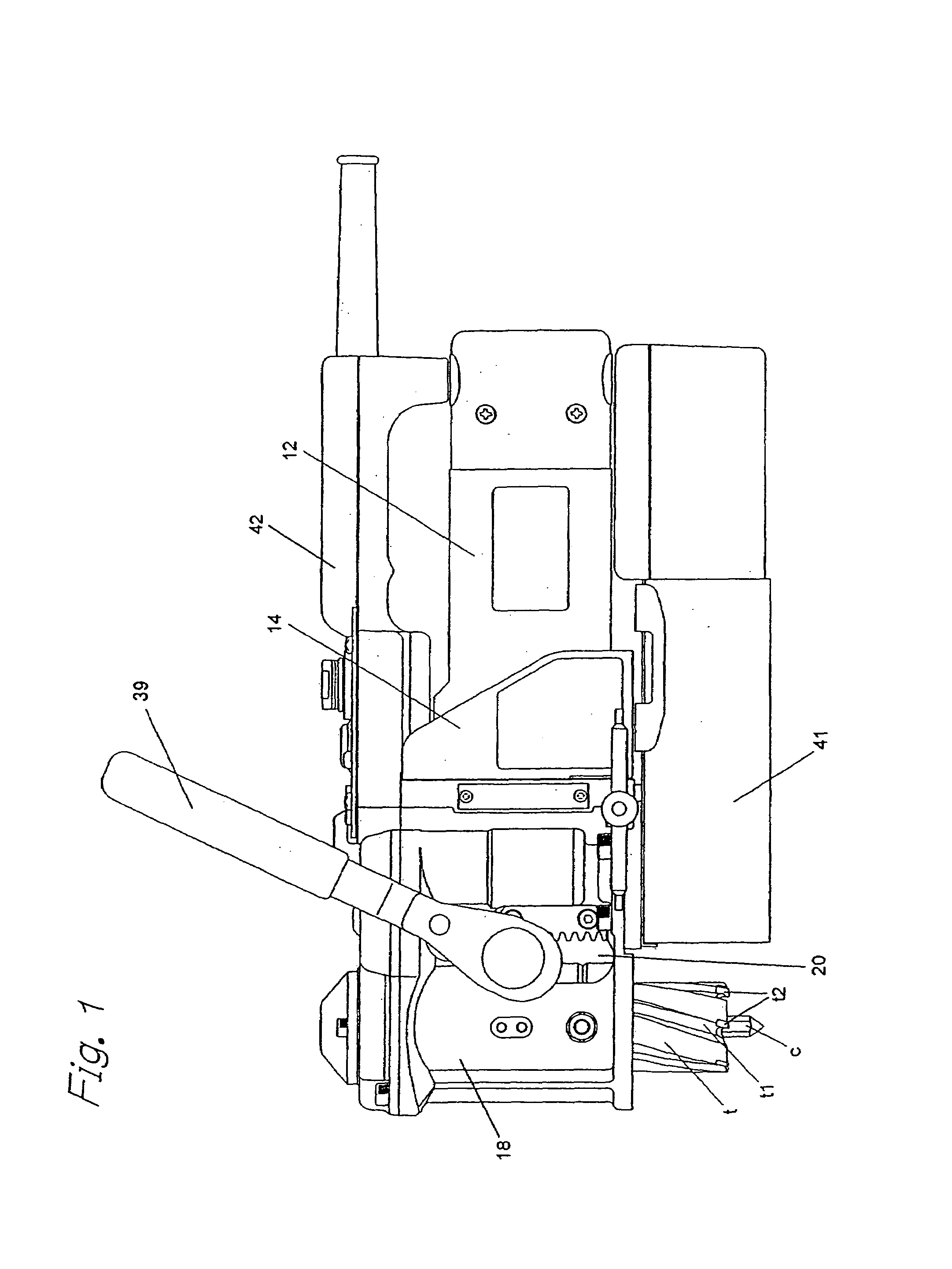

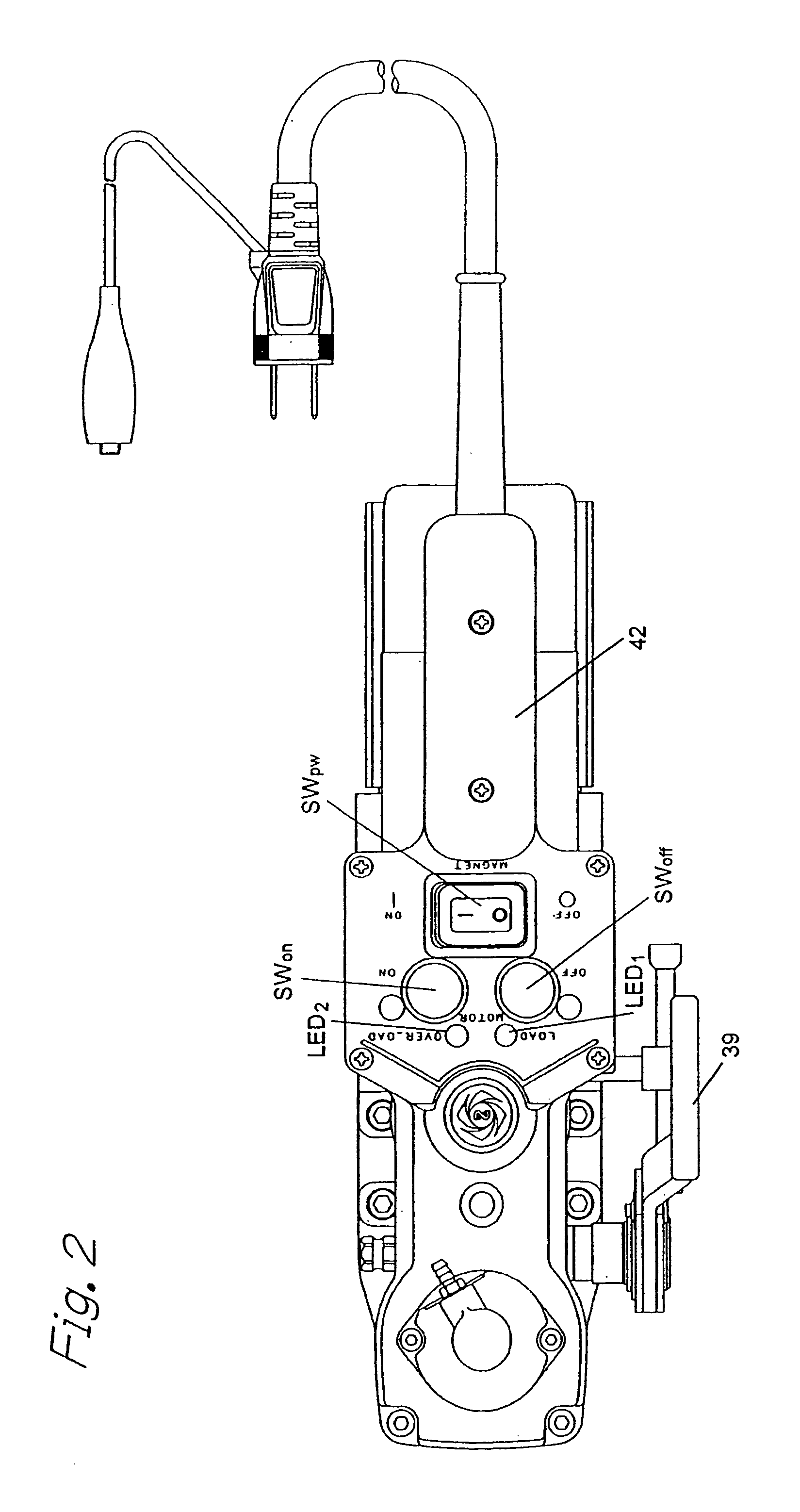

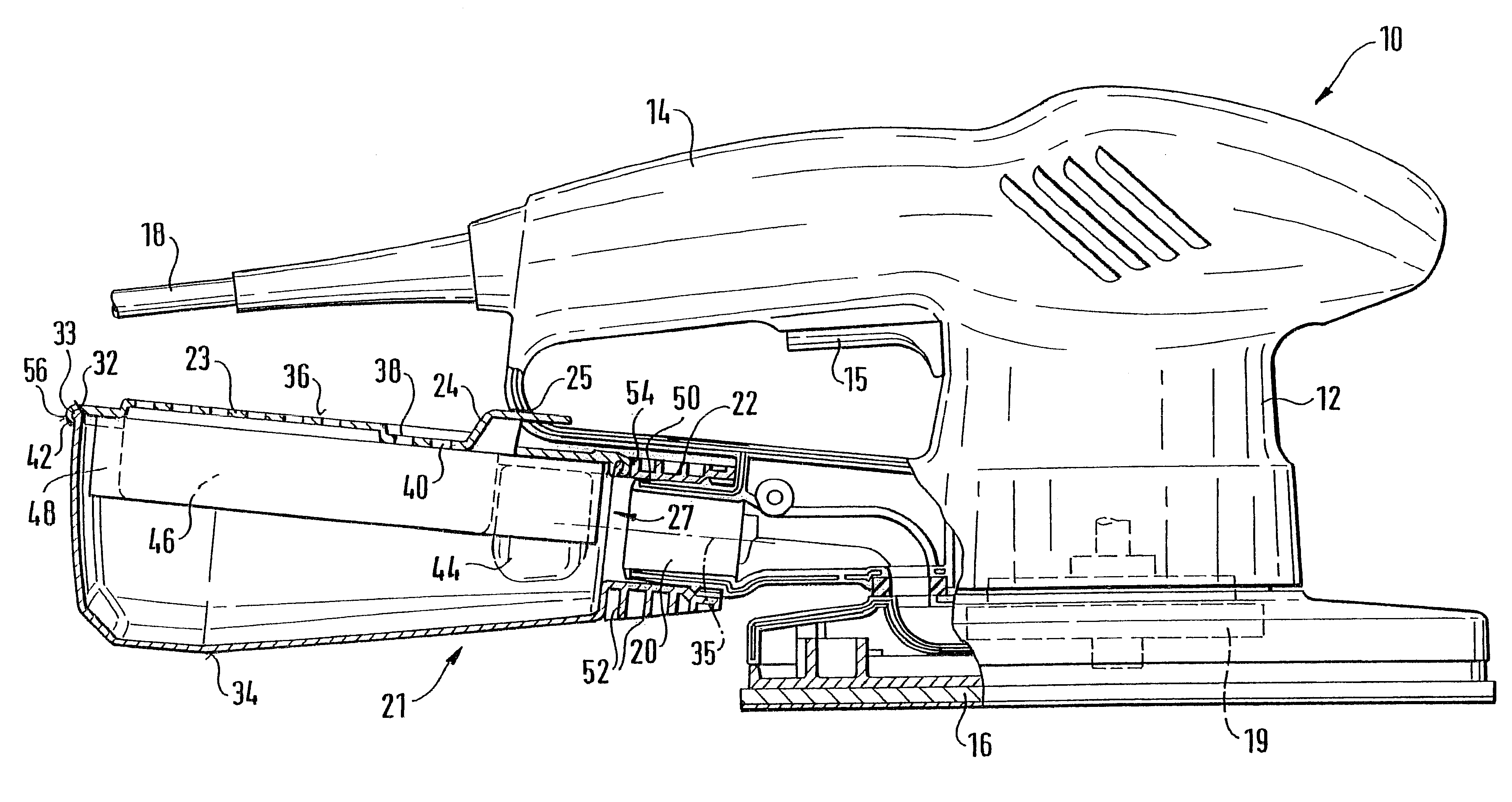

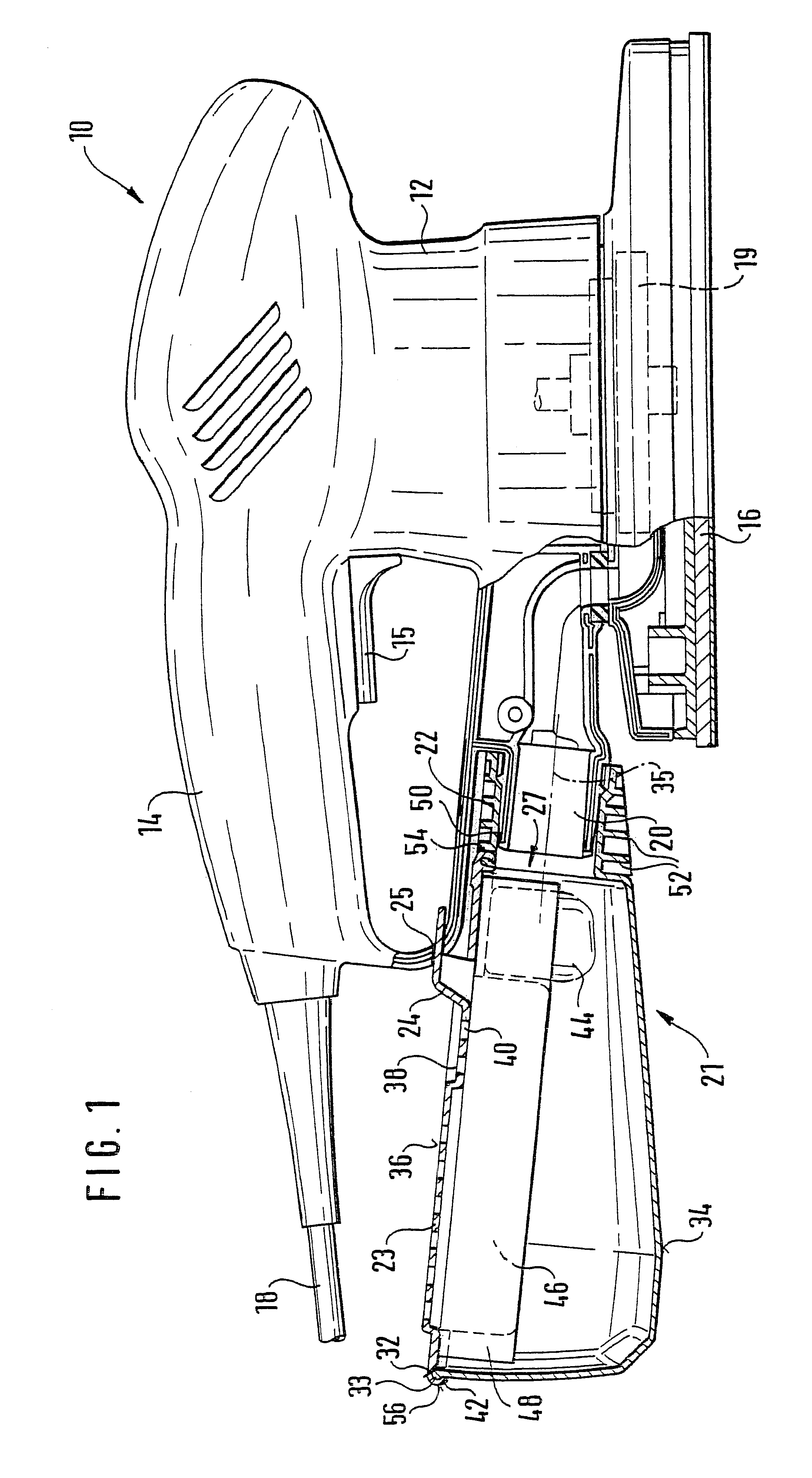

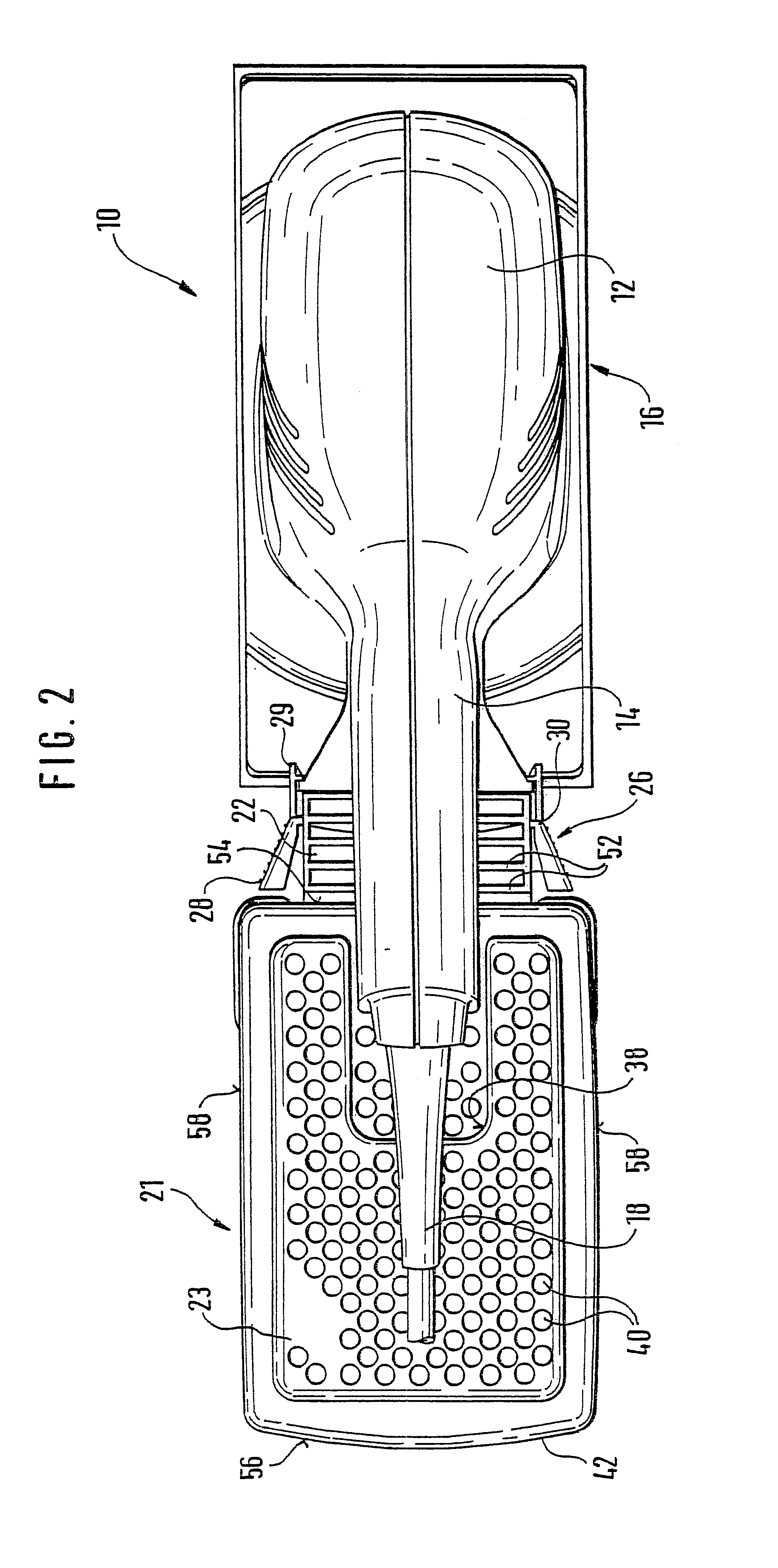

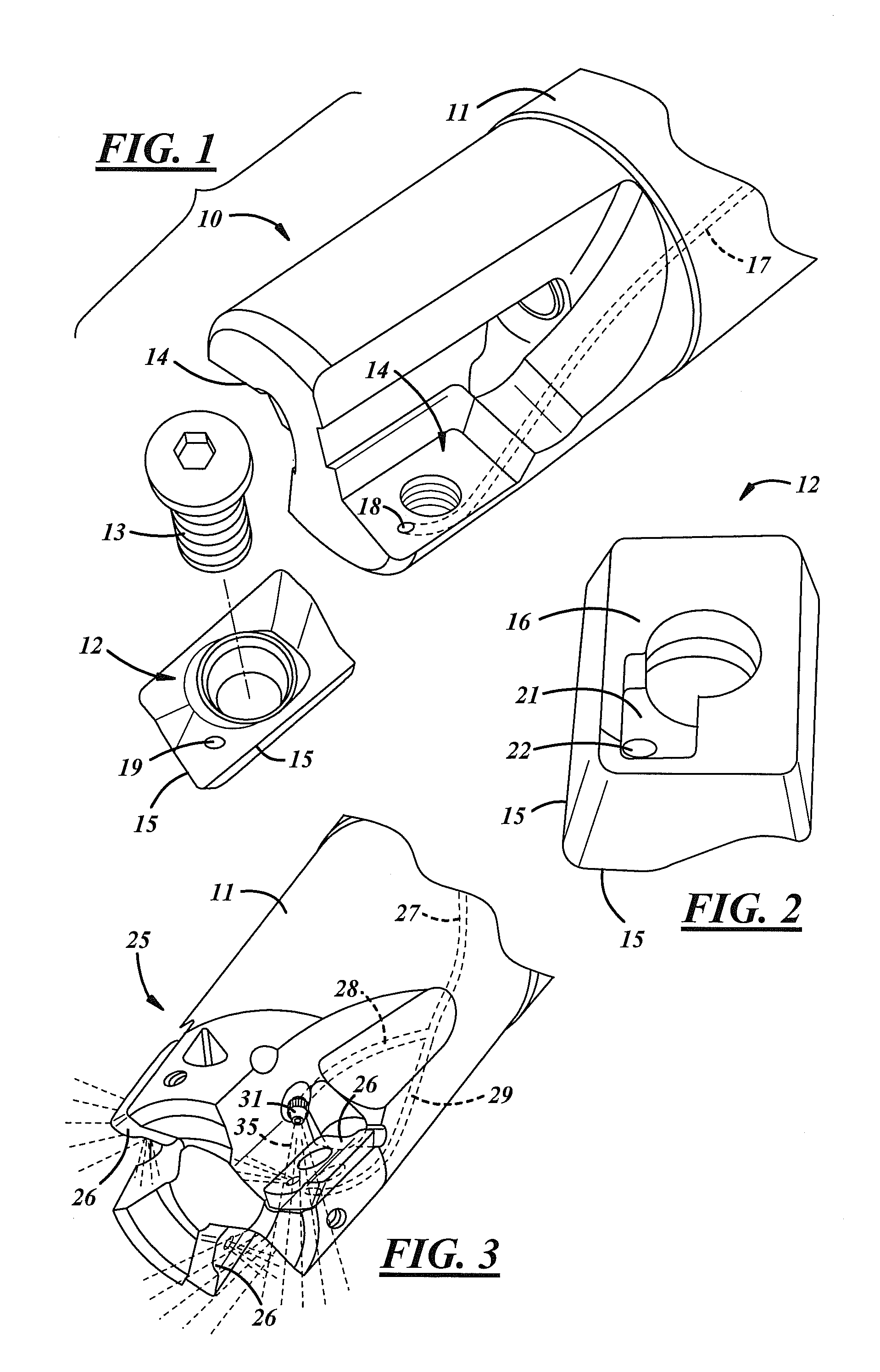

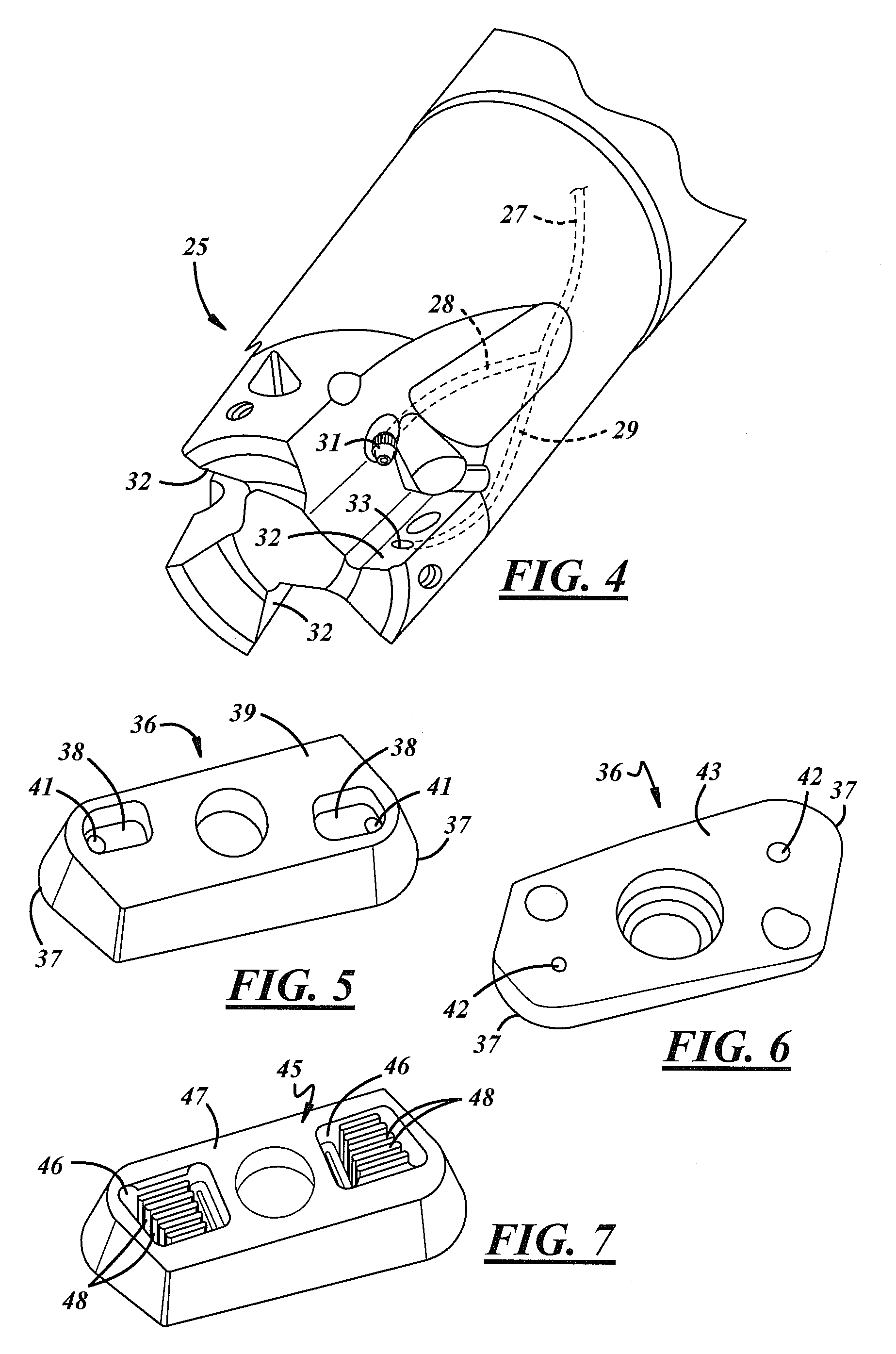

Hand-held machine tool with dust extraction

InactiveUS6514131B1Large filter areaHigh degreePortable grinding machinesMaintainance and safety accessoriesHand heldPower tool

A power tool (10) having a dust suction device (19) integrated into its housing (12) and having an ejection fitting (20) which is connected to the dust suction device (19) and can be detachably fastened with its injection fitting (22) to a dustproof dust box (21) is particularly suitable for containing sanding dust because of a number of side walls (34) of the dust box (21) have air openings (40) and on the inside, support at least one filter element (48), in particular a folded filter, which overlaps the air openings (40).

Owner:ROBERT BOSCH GMBH

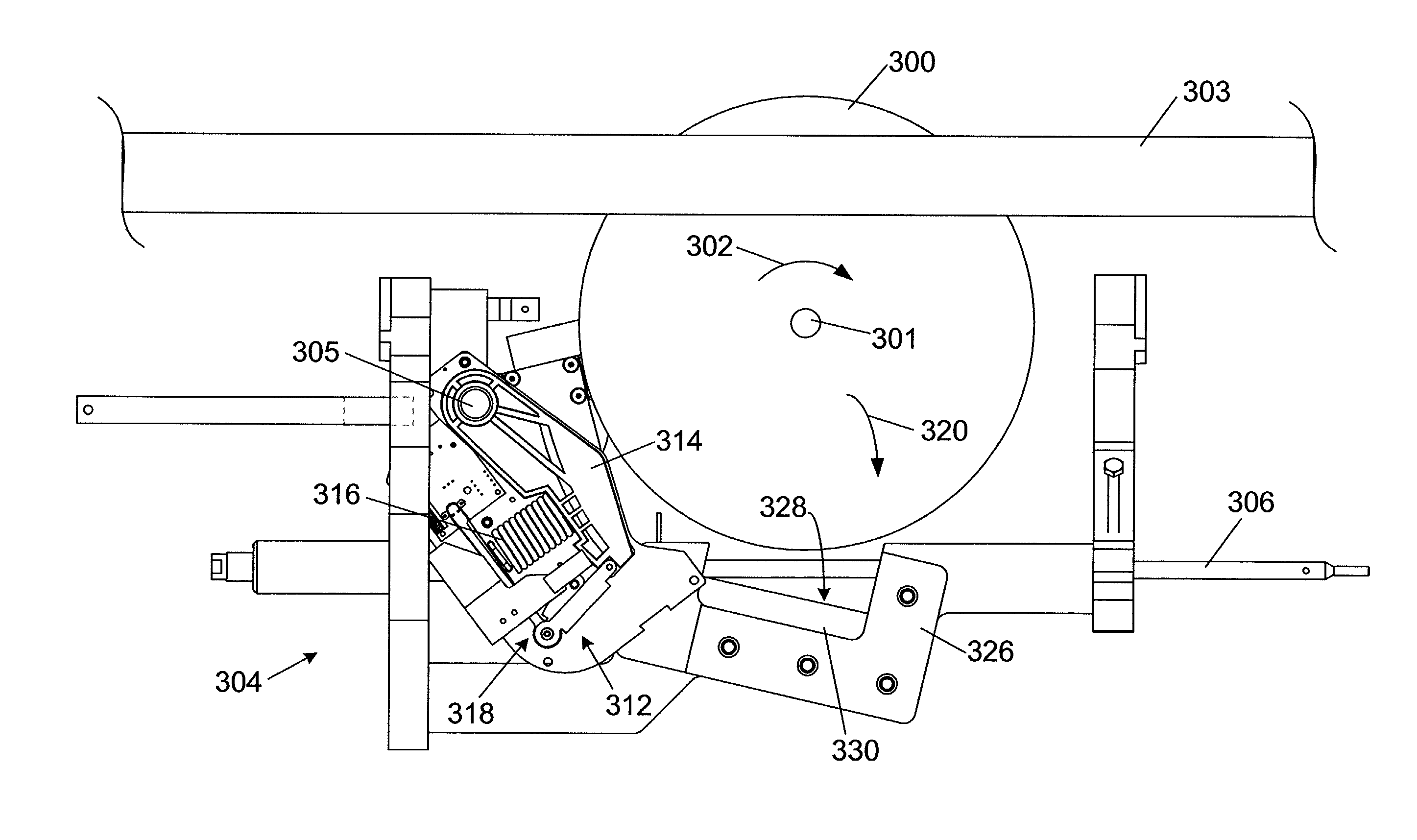

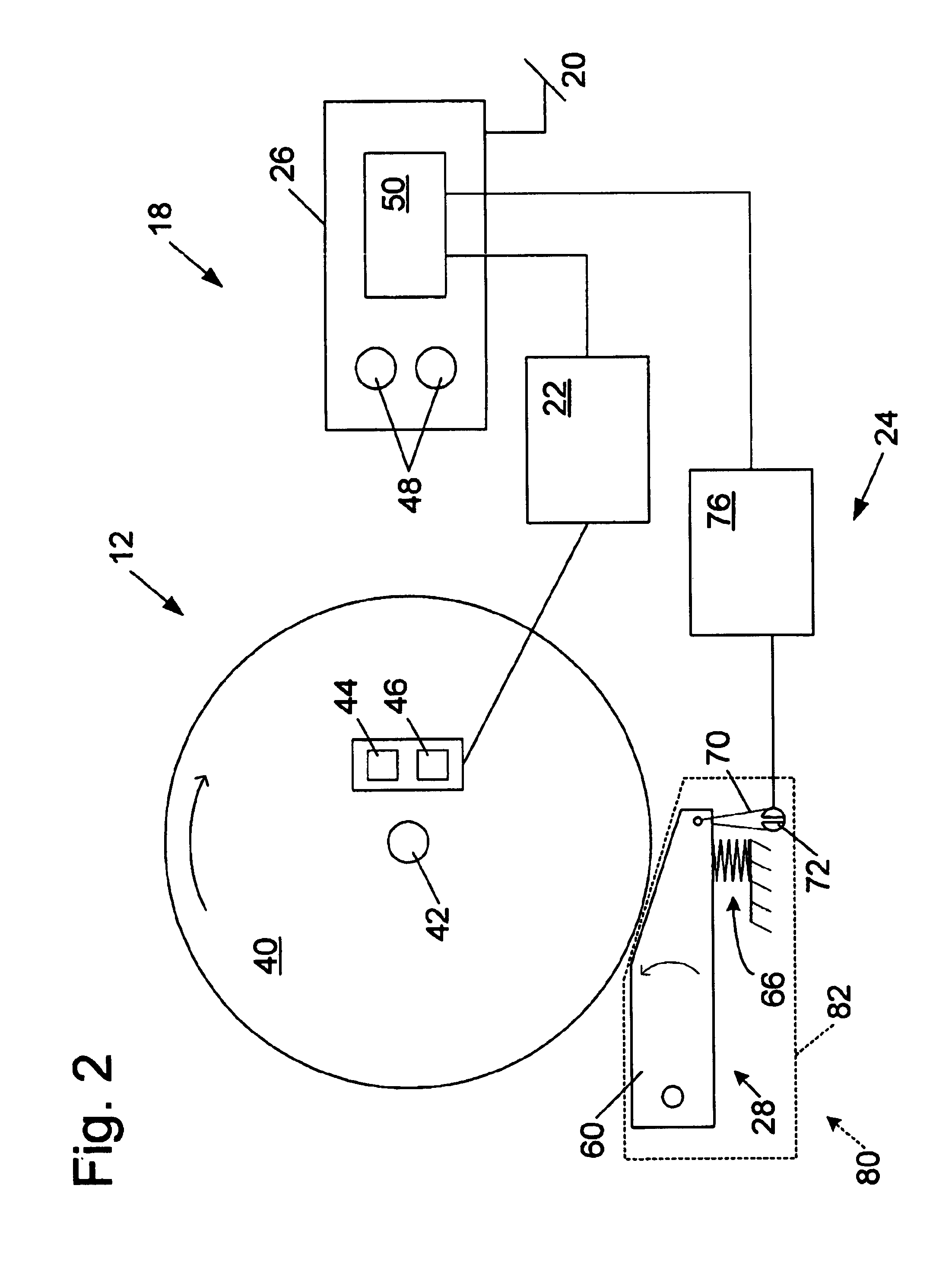

Actuators for use in fast-acting safety systems

Cutting machines with high-speed safety systems, and actuators used in high-speed safety systems, are disclosed. The cutting machines may include a detection system adapted to detect a dangerous condition between a cutting tool and a person. A reaction system performs a specified action, such as stopping the cutting tool, upon detection of the dangerous condition. An actuator may be used to trigger the reaction system to perform the specified action.

Owner:SAWSTOP HLDG LLC

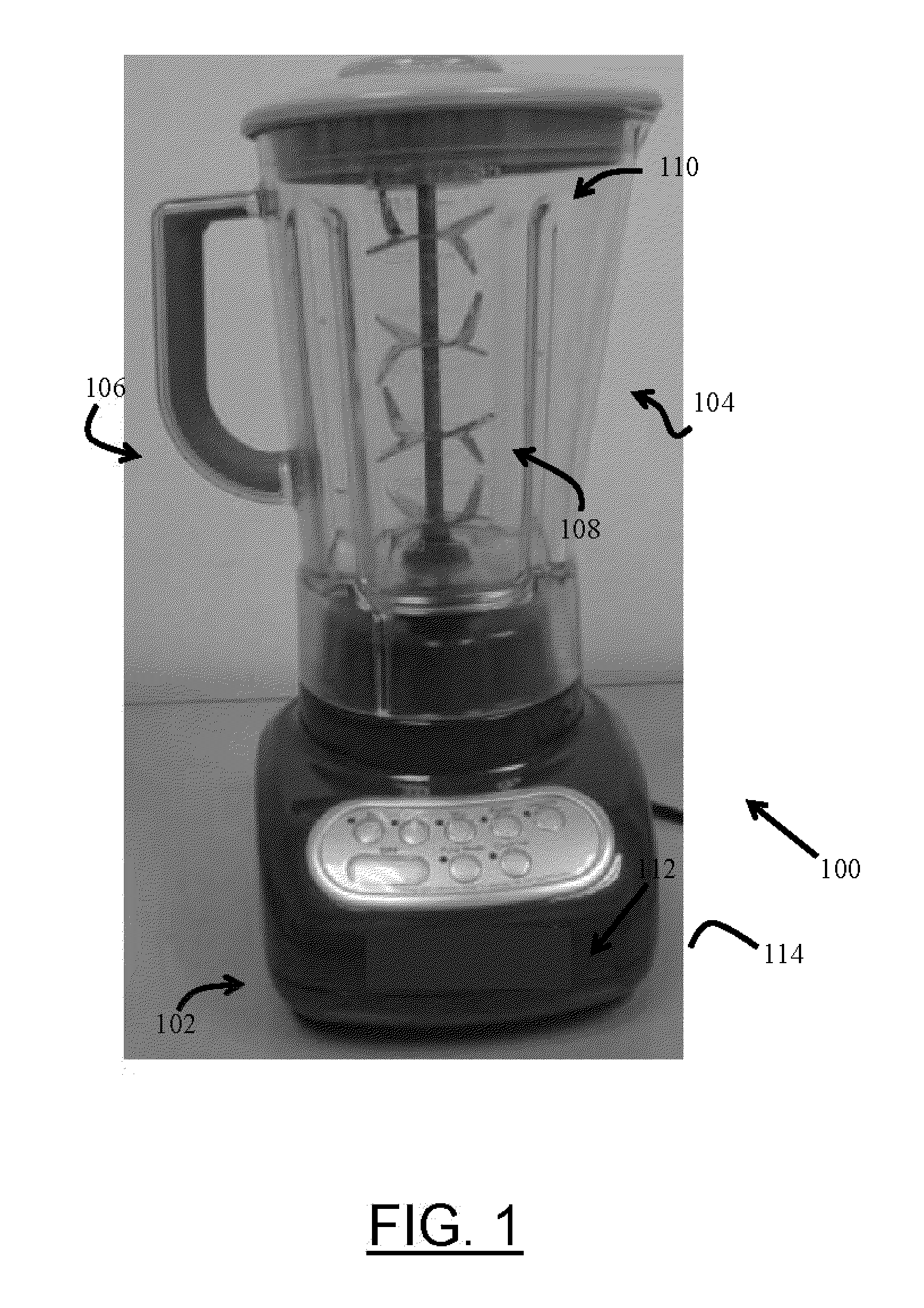

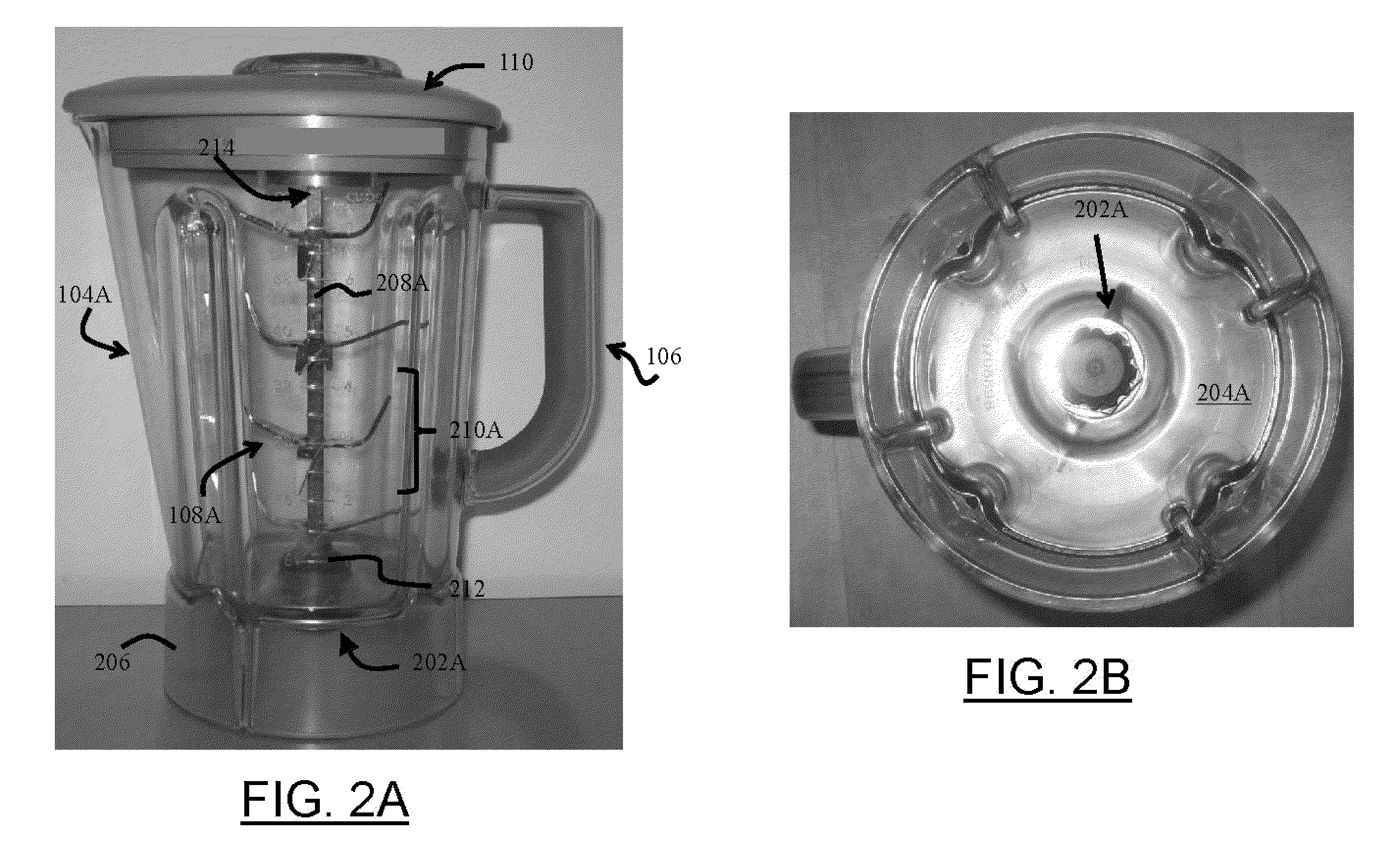

Blender and food processor device

Owner:CARRIERE MARK C

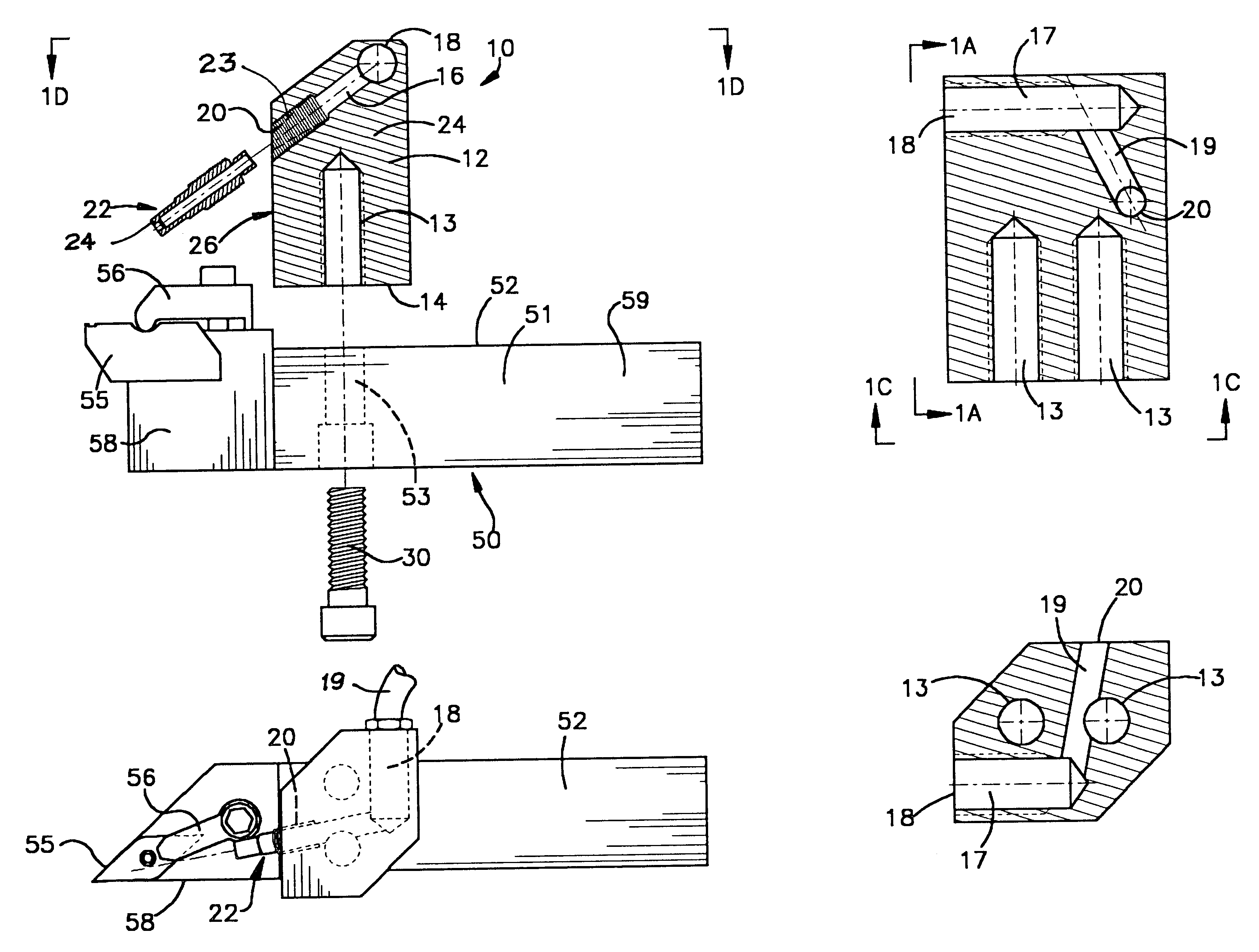

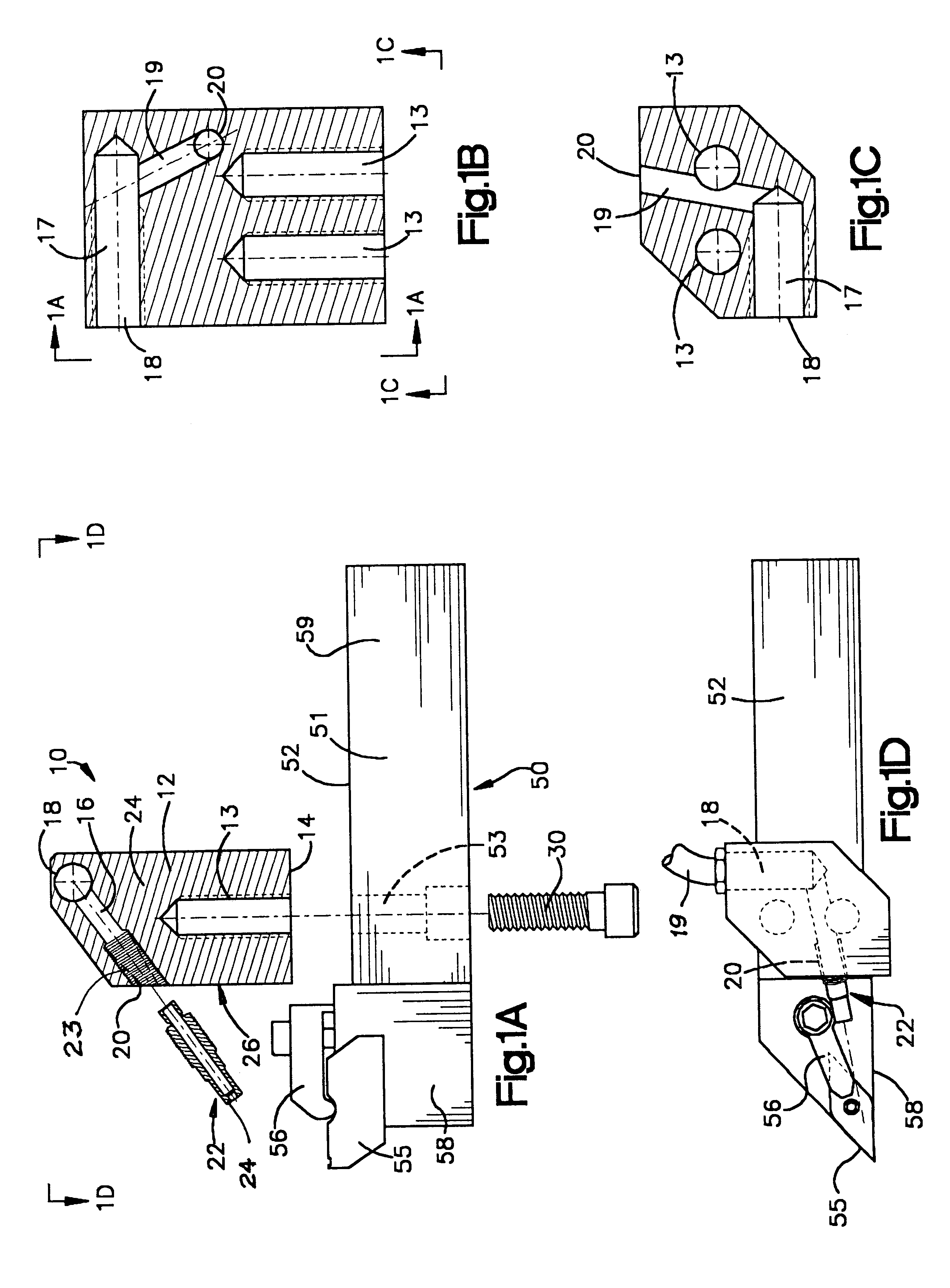

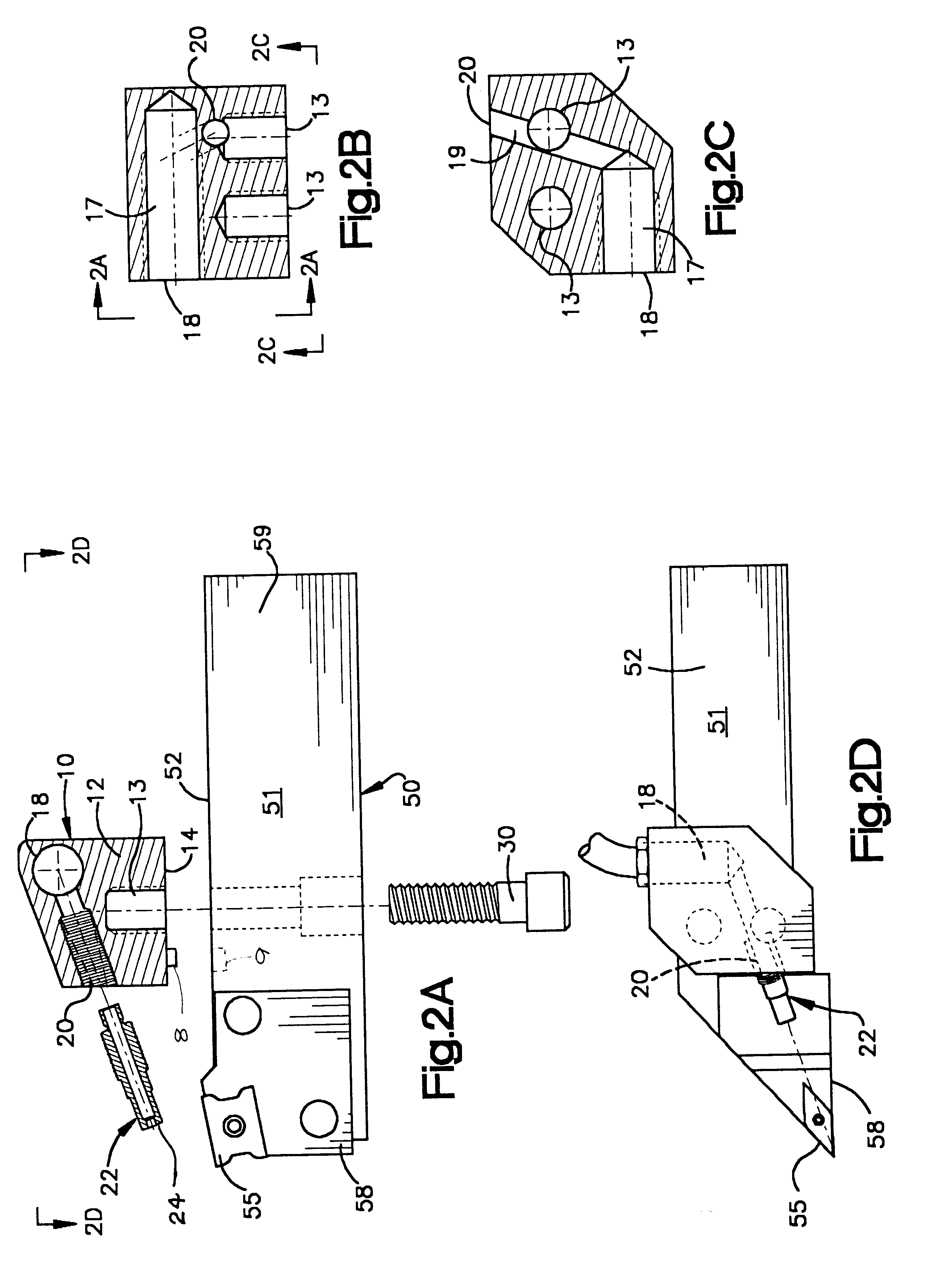

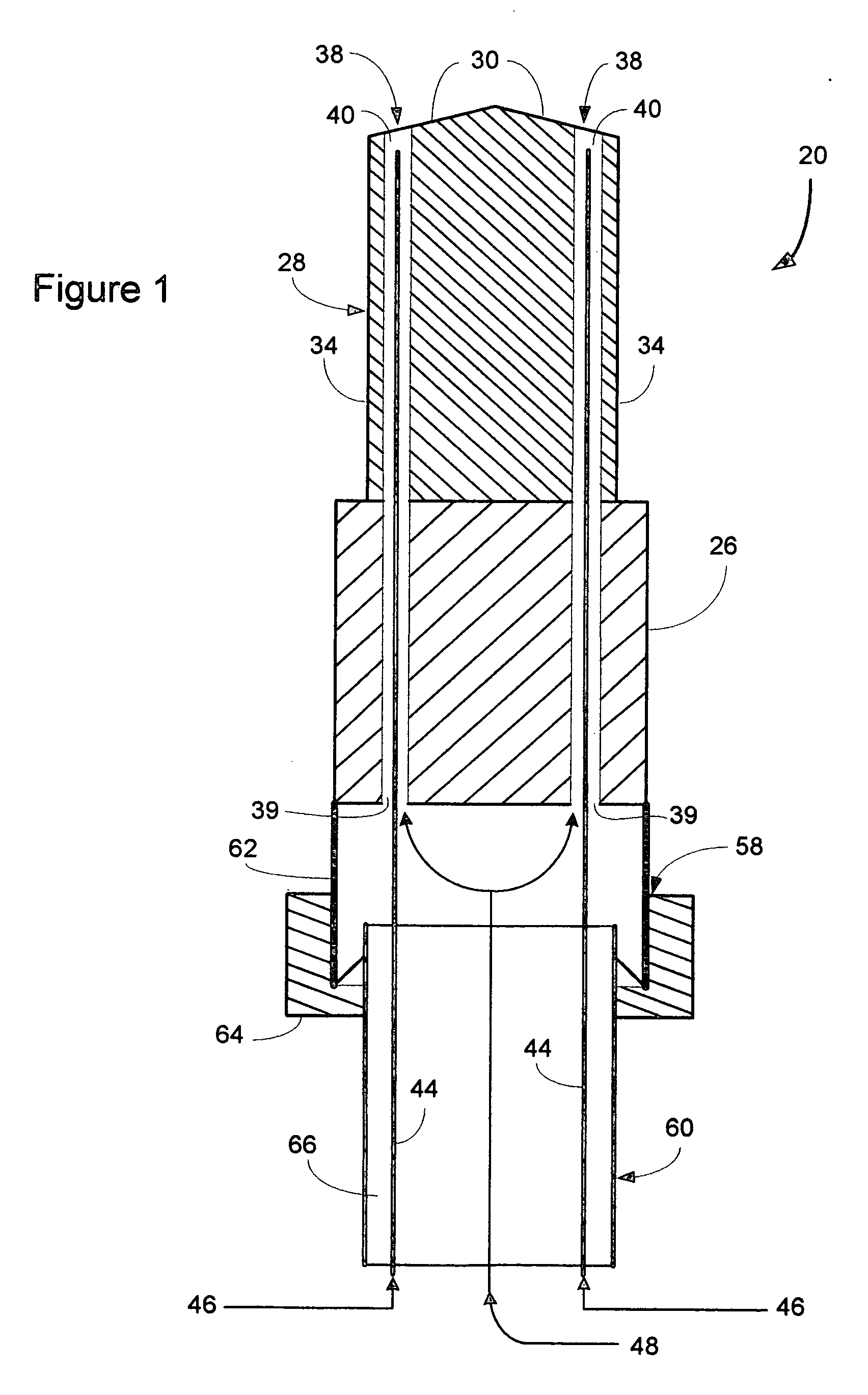

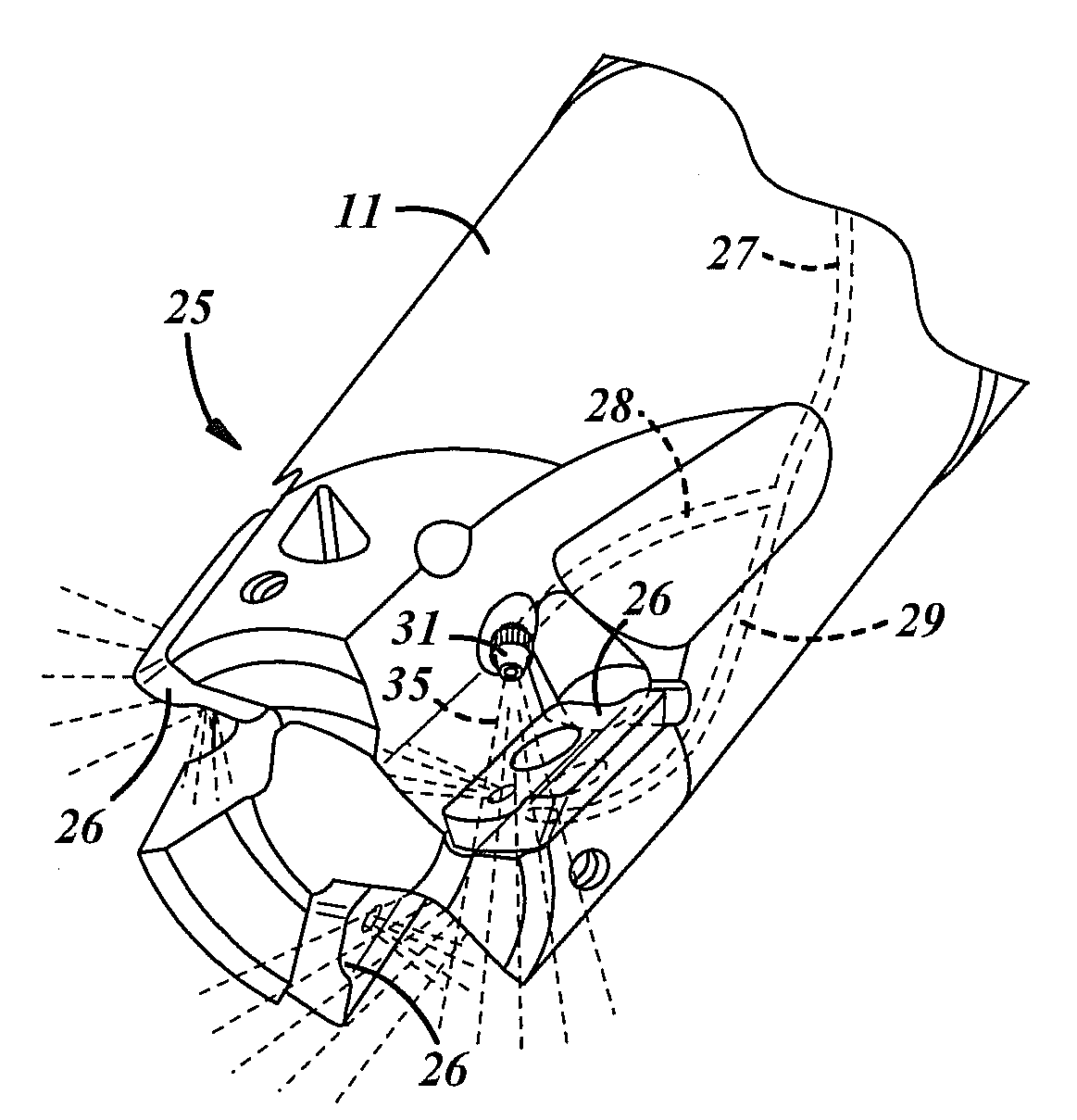

Universal tool holder coolant delivery adapters

InactiveUS6299388B1Increase COOOptimized coolant deliveryTurning toolsShaping cuttersLine tubingSpray nozzle

Universal tool holder coolant delivery adapters have adapter bodies which are removably attachable to a tool holder by at least one fastening device, the adapter located between an attachment end of the tool holder and a distal end of the tool holder, the distal end of the tool holder having a cutting tool attached thereto, the adapter bodies having an internal coolant passageway including an intake port and an exit port, the intake port adapted for attachment to a pressurized coolant supply line and the outlet port adapted for attachment to or configured in the form of a coolant spray nozzle, the coolant spray nozzle being closely positioned and substantially aligned with the cutting interface of the cutting tool and a workpiece.

Owner:SLABE MACHINE PROD

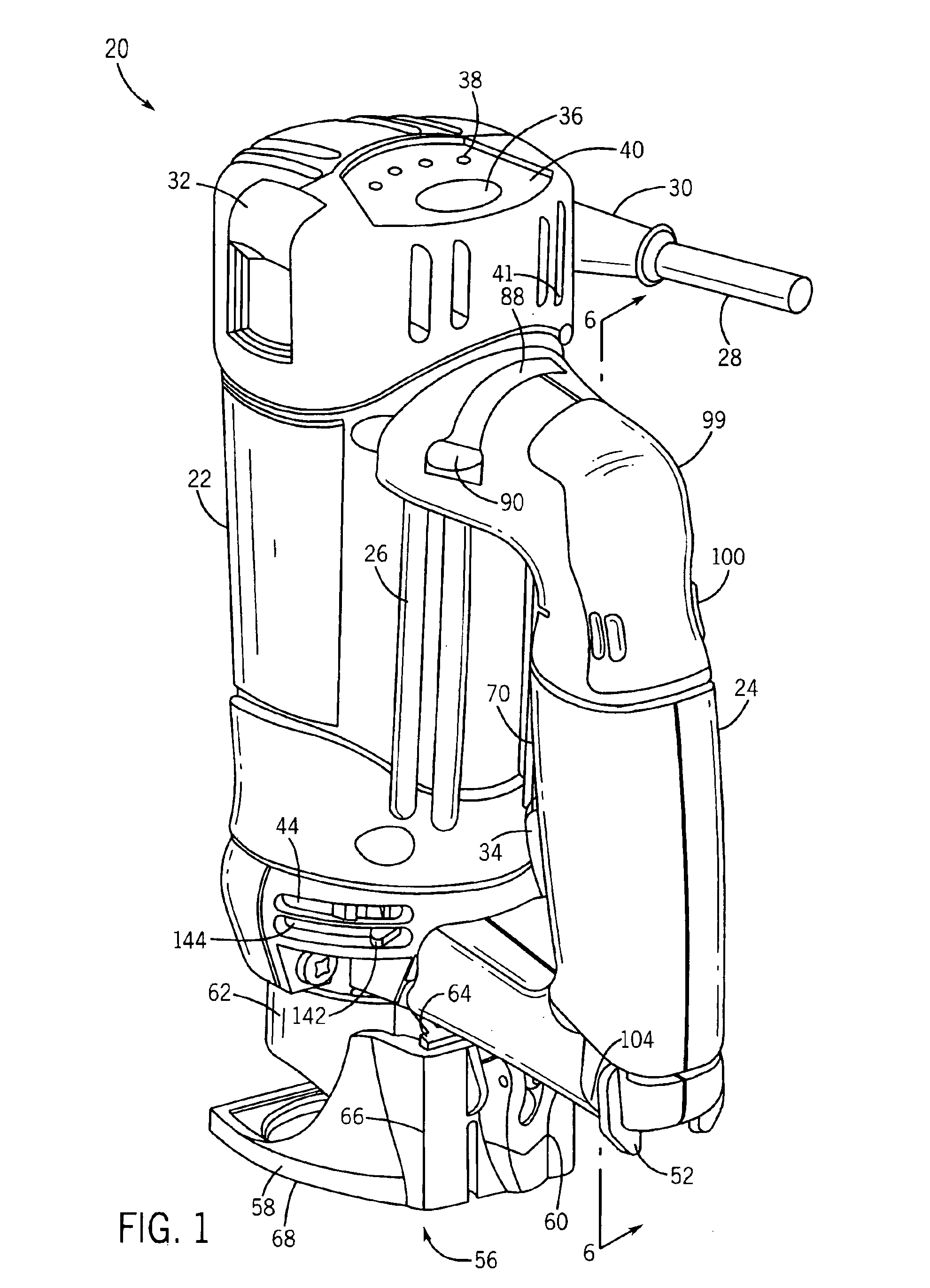

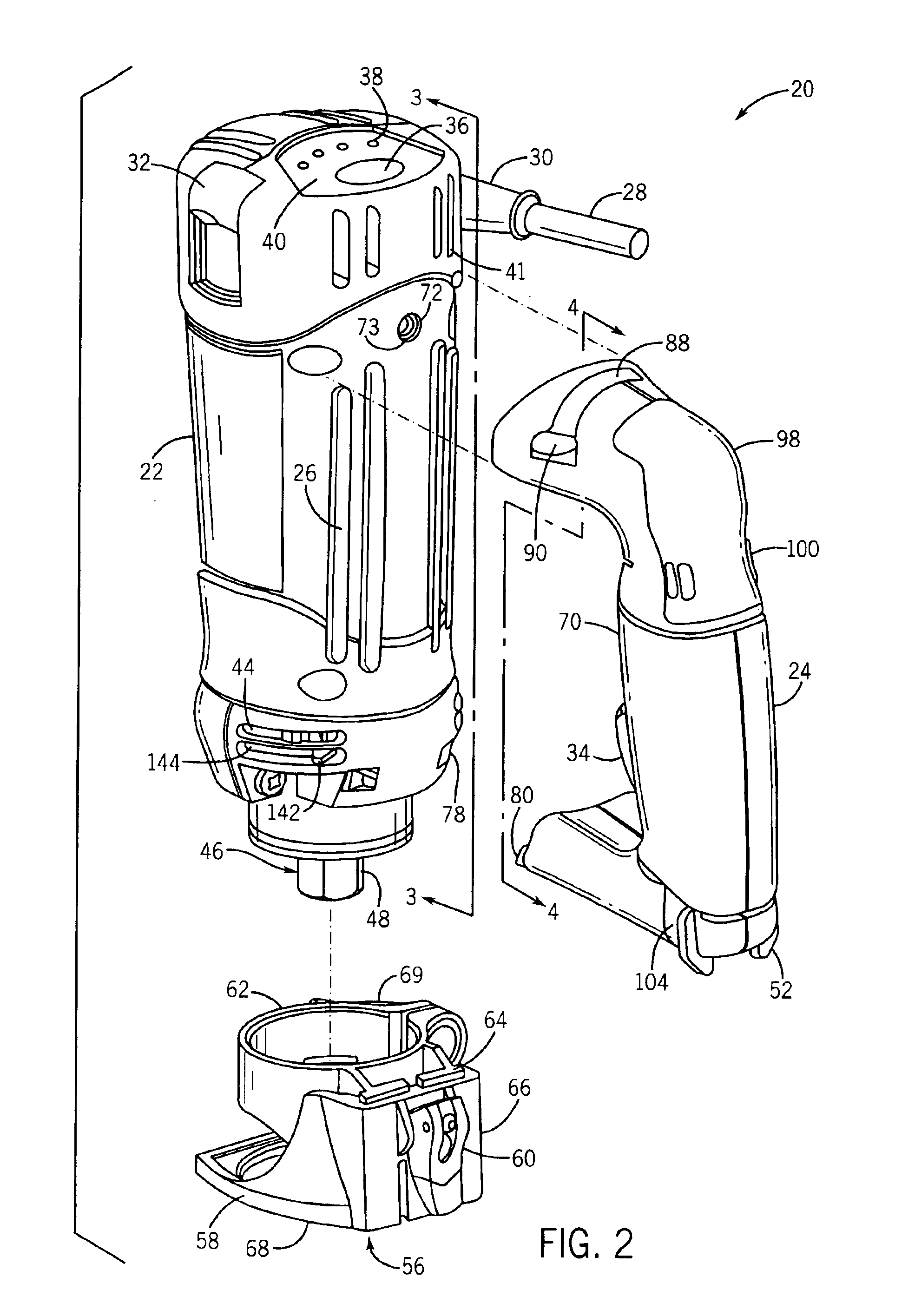

Power tool safety mechanisms

A sensing mechanism (12) for detecting user contact with an active portion (26) of the power tool (10) is provided. In addition, a safety mechanism (14) for preventing prolonged user contact with the active portion (26) of a power tool (10) is provided. The safety mechanism (14) is configured to actuate upon receipt of a signal from the sensing mechanism (12). According to a first aspect, the safety mechanism (14) is arranged to rapidly displace the active portion (26) away from a user extremity. Alternatively, according to a second aspect, the safety mechanism (14) is arranged to rapidly urge an extremity of the user away from the active portion (26) of the power tool (10).

Owner:BLACK & DECKER INC

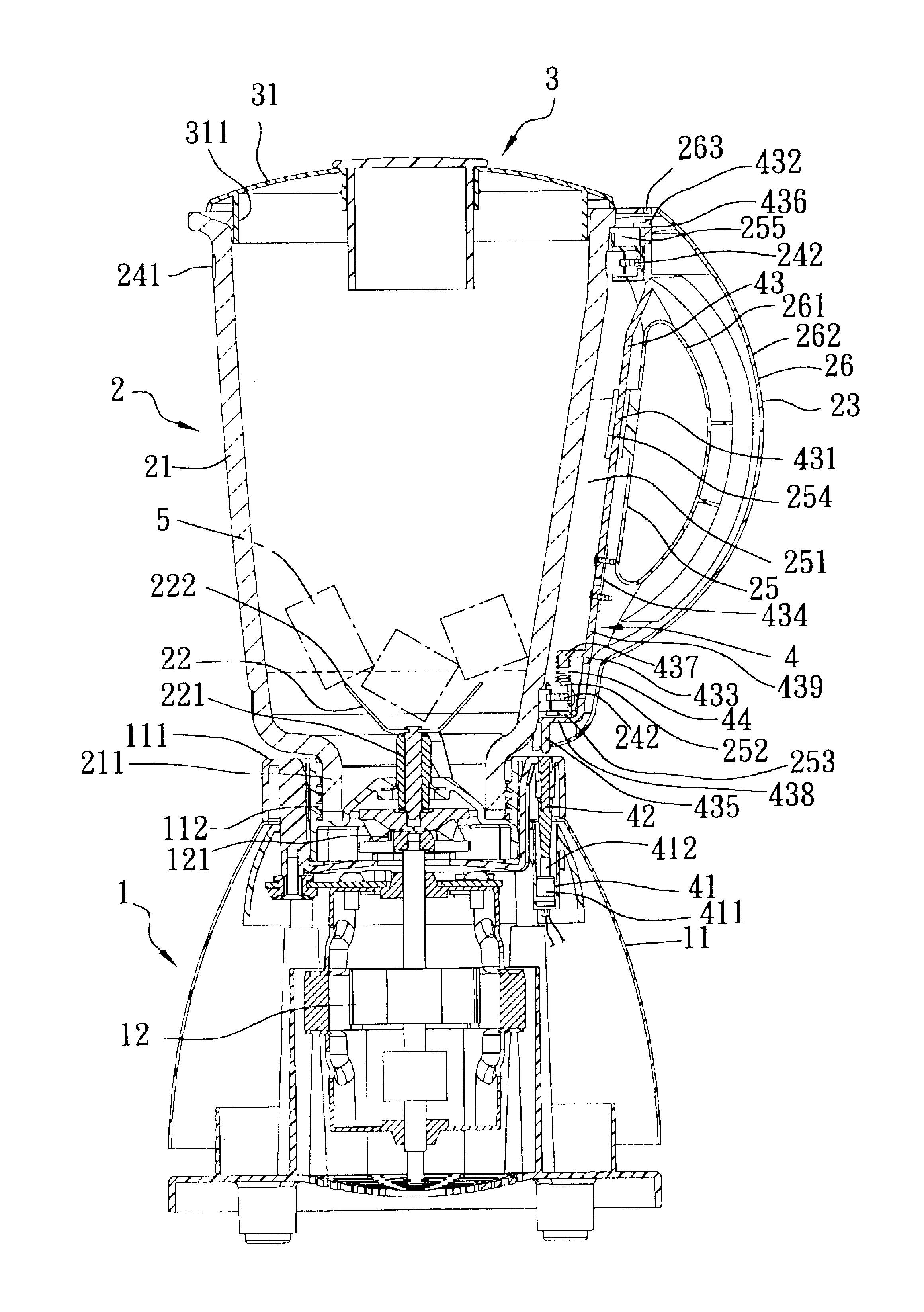

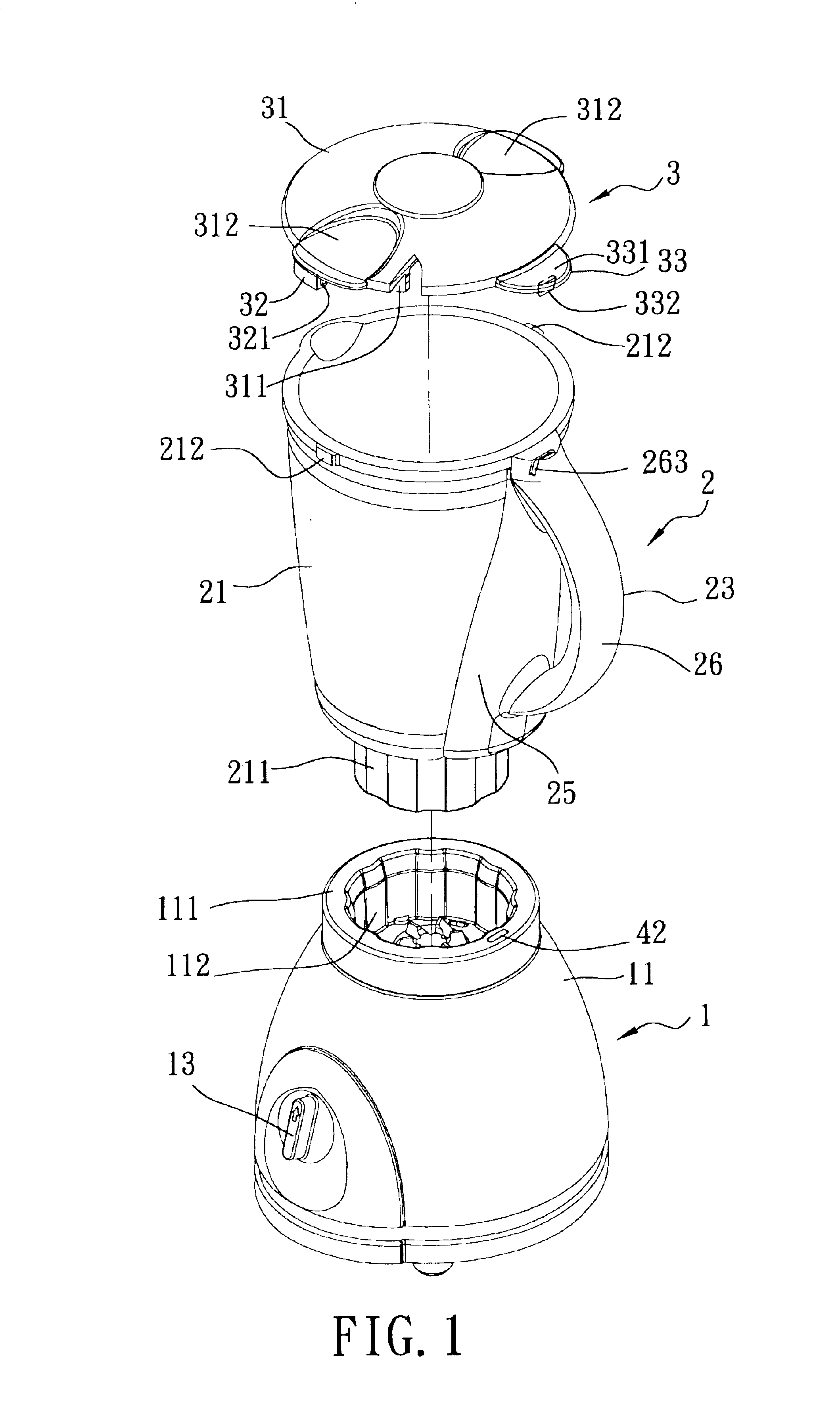

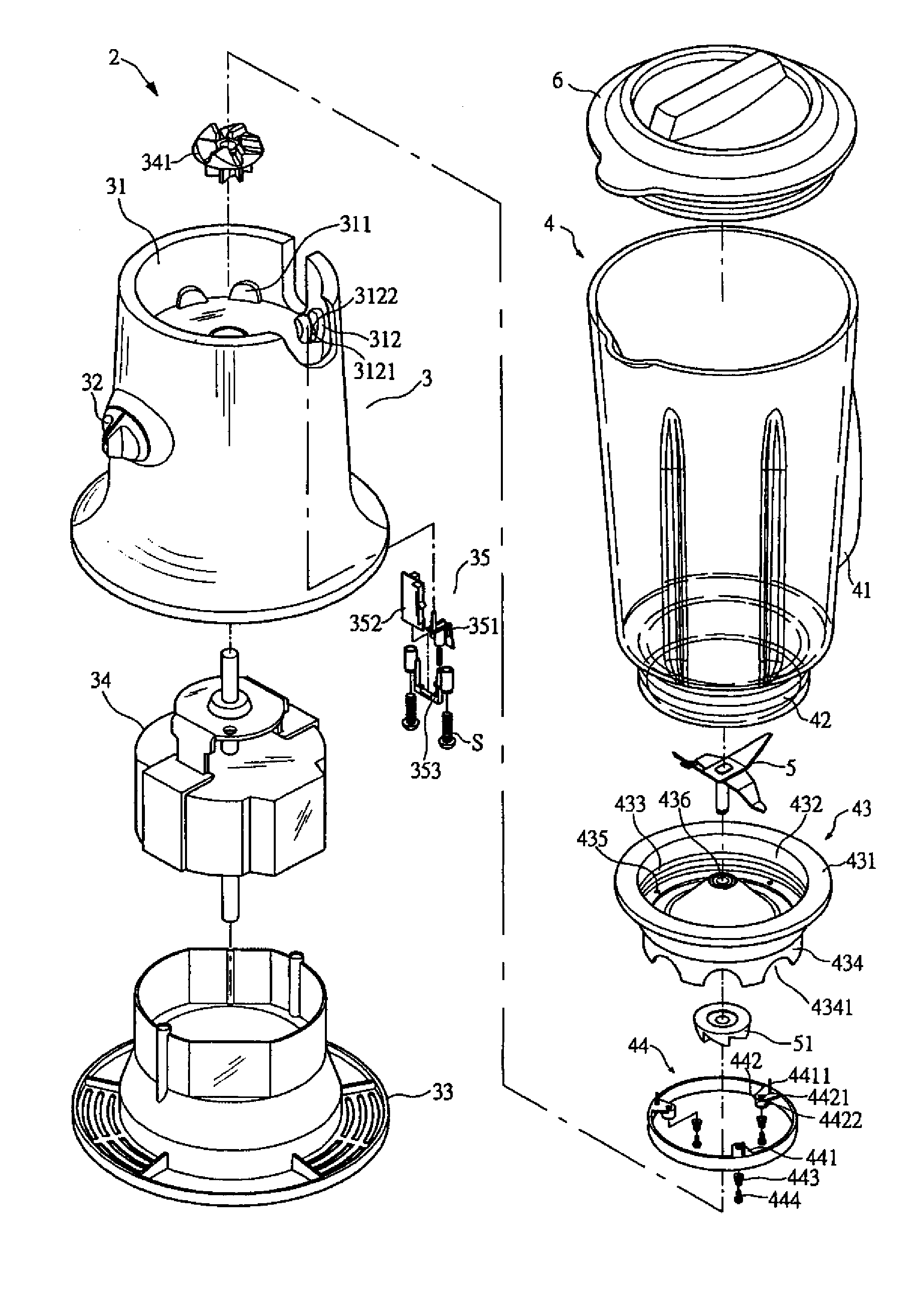

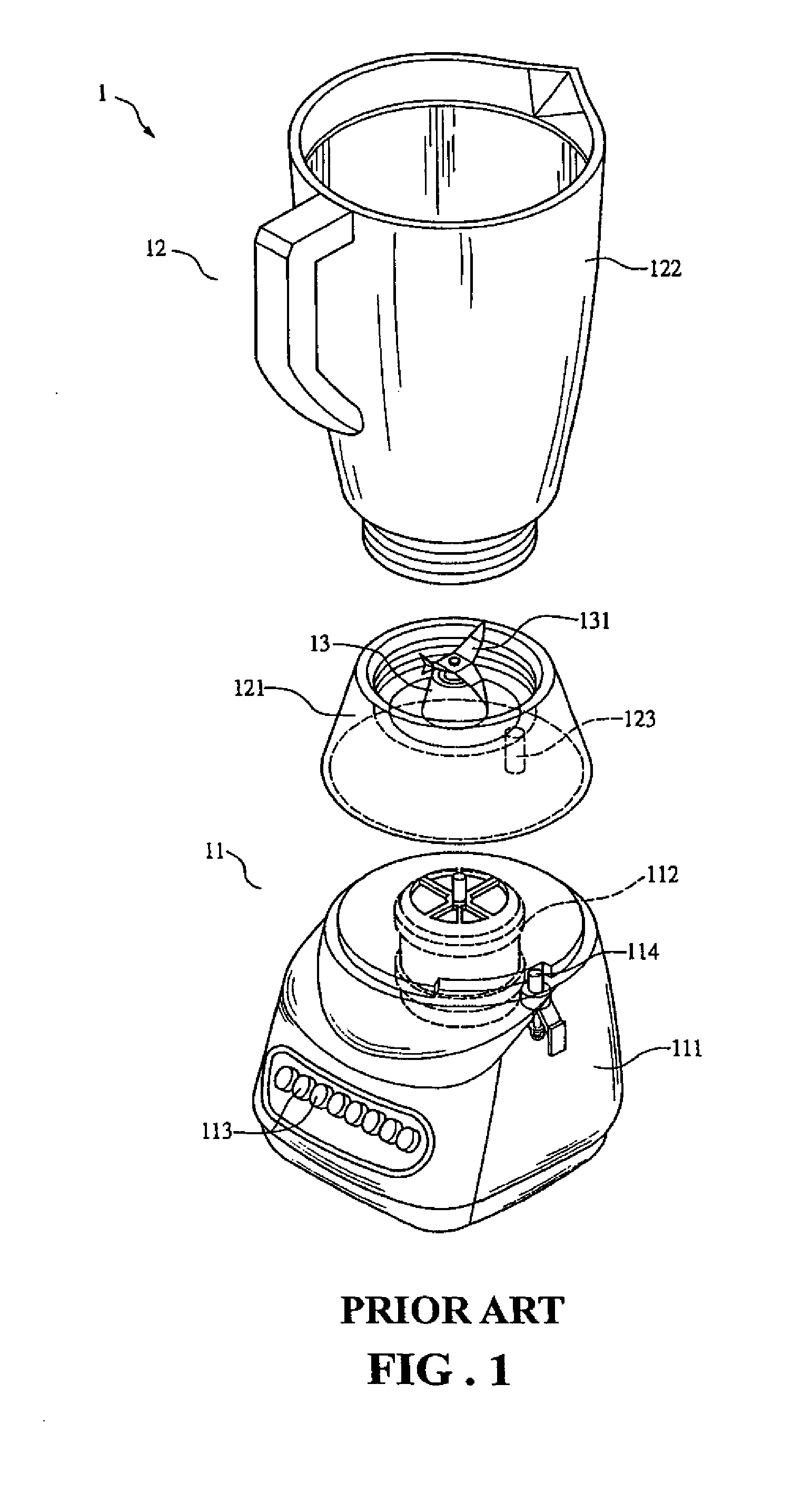

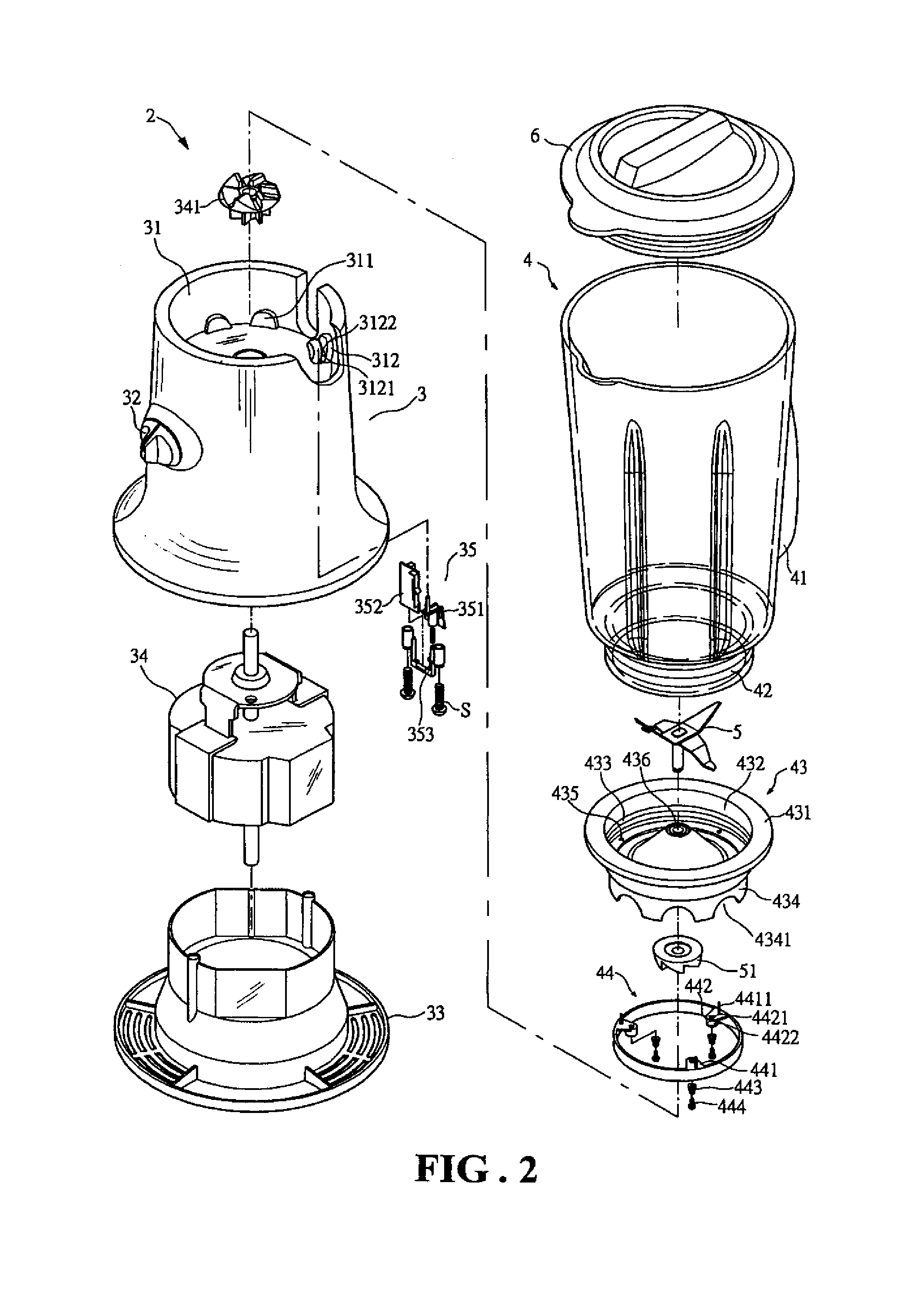

Blender having a top cover provided with a switch actuating block

A blender includes a motor base, a container, and a top cover. The motor base includes a motor unit having a blade driving section, and a contact switch unit connected electrically to the motor unit. The contact switch unit includes a press button that is depressible so as to permit activation of the motor unit. The container has a container bottom provided with a cutting blade unit that is coupled to the blade driving section so as to be driven rotatably by the motor unit. The container has a spring-loaded push rod unit mounted movably thereon. The push rod unit has a bottom rod section associated with the press button of the contact switch unit, and a top rod section depressible by a switch actuating block of the top cover so as to move the push rod unit against biasing action from a deactivating position to an activating position.

Owner:EUPA INT CORP

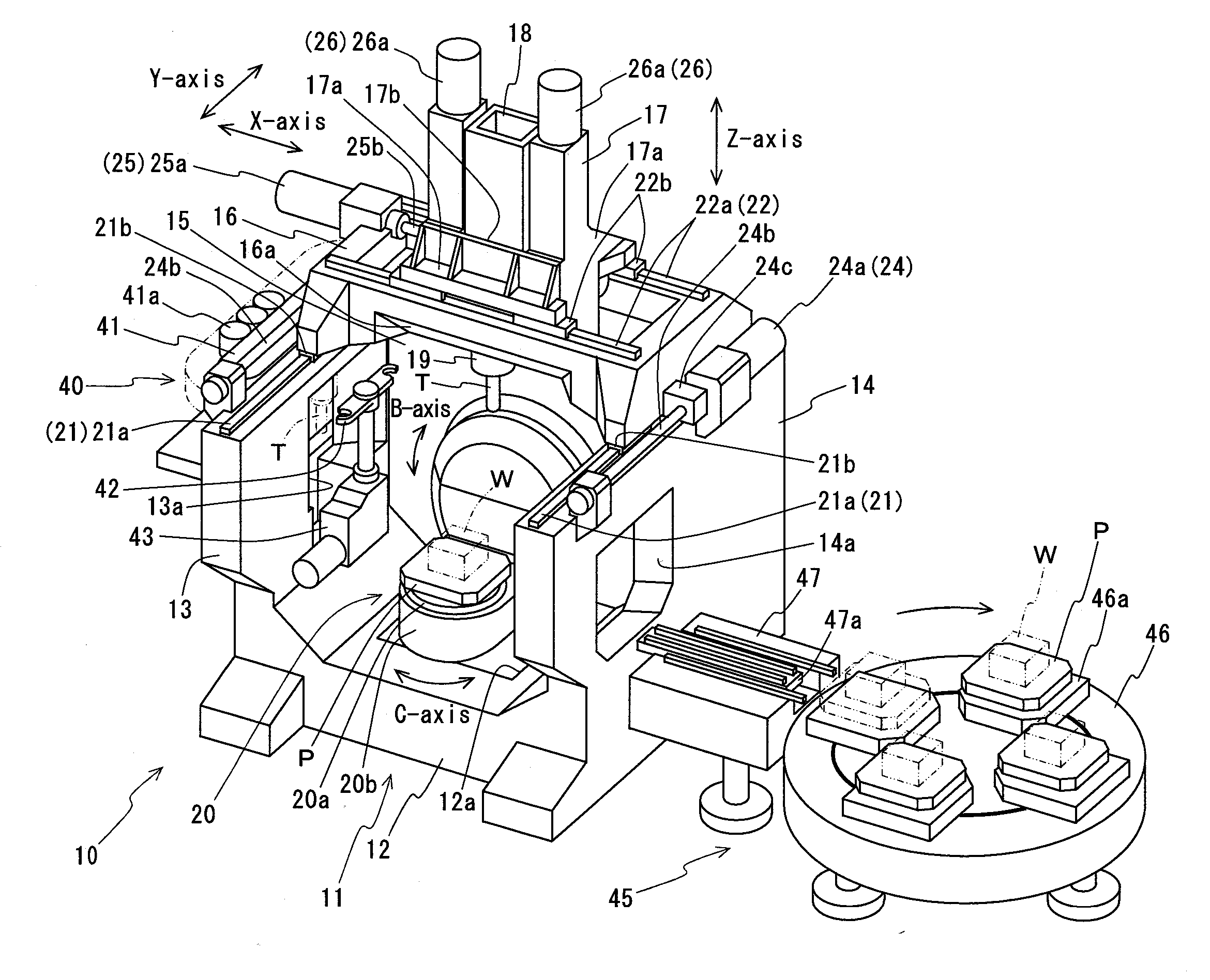

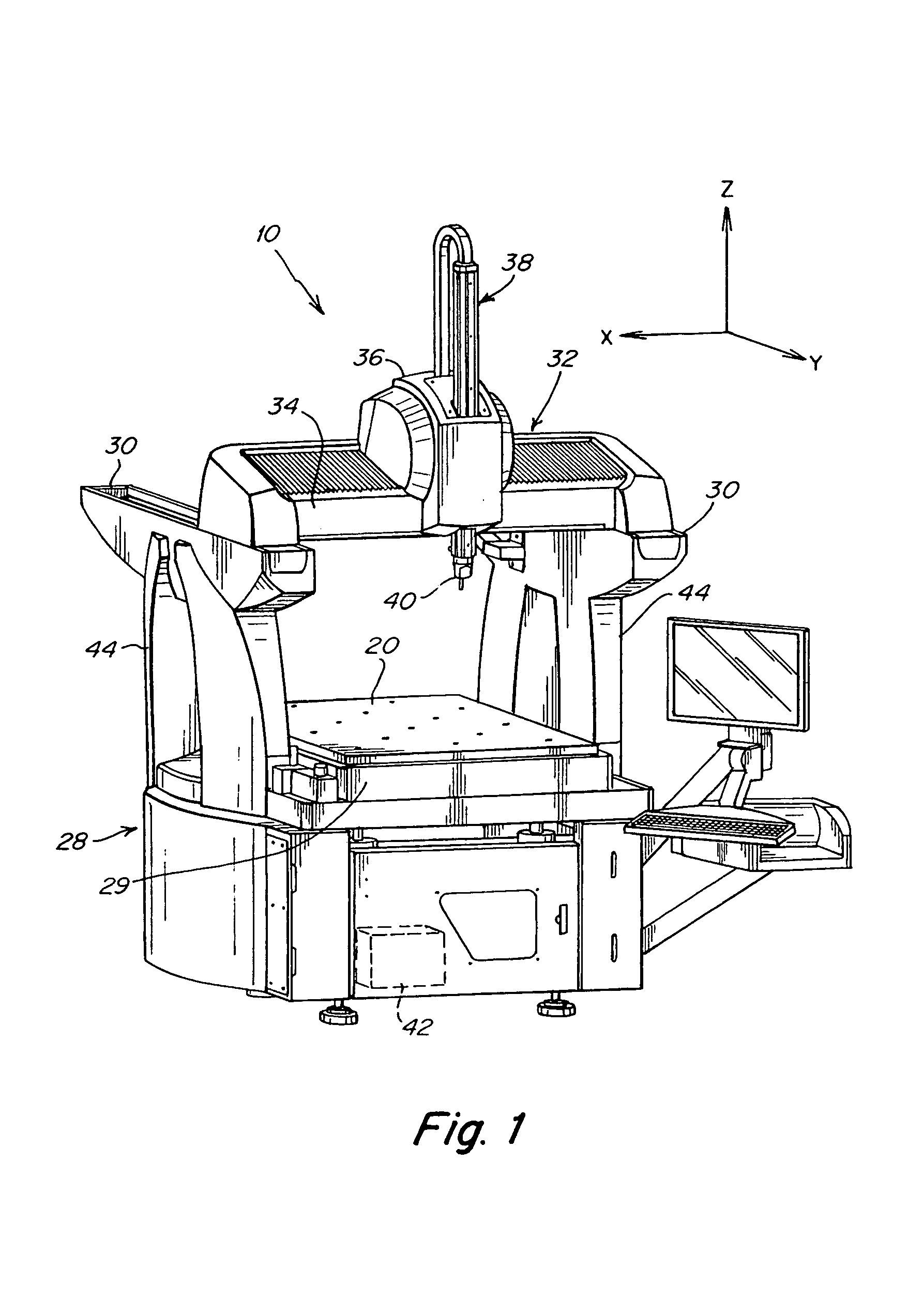

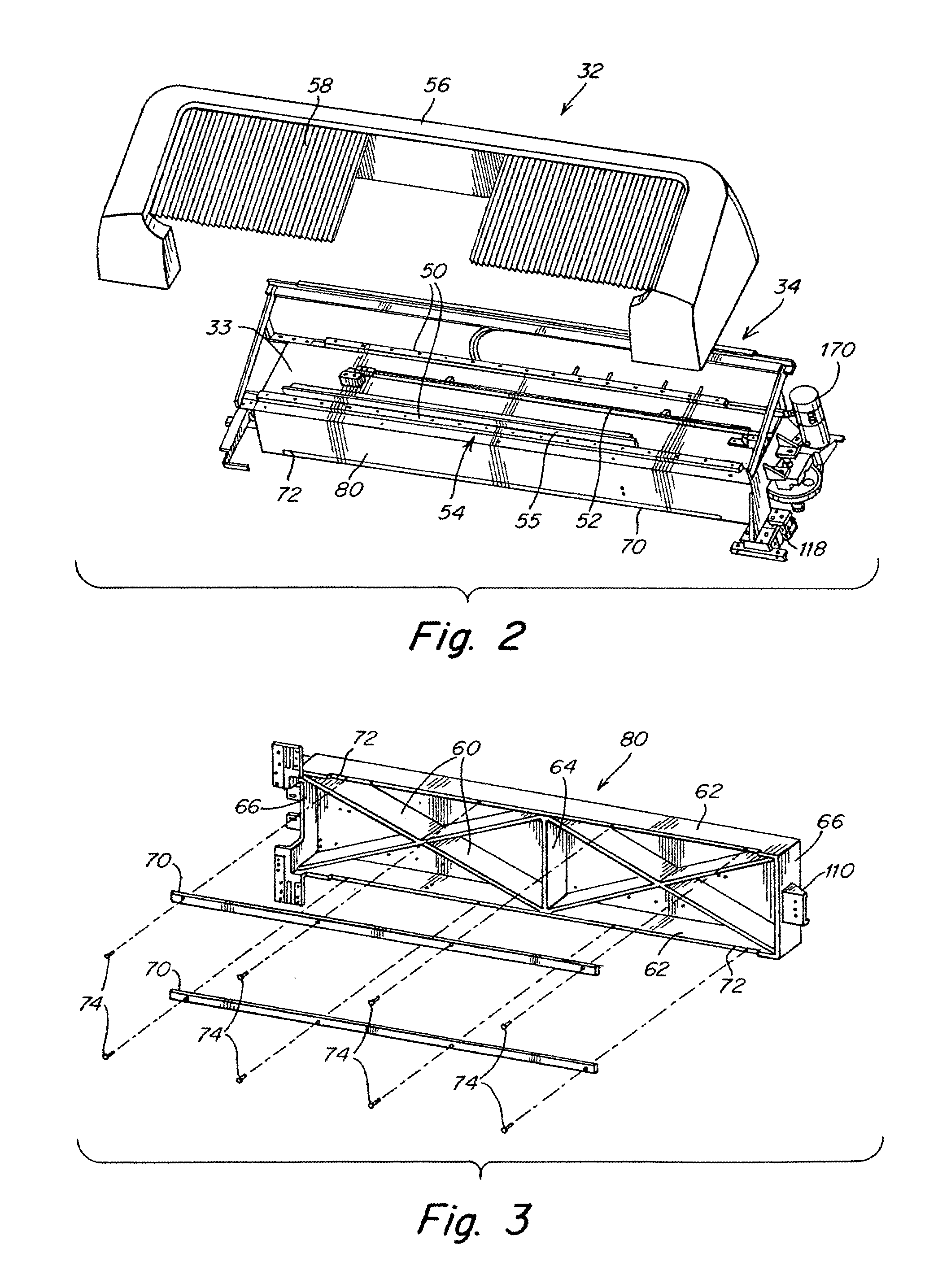

Machine Tool

ActiveUS20060270540A1Easy maintenanceReduce manufacturing costPlaning/slotting machinesMilling machinesFree rotationSaddle shape

Machine tool simplifying maintenance, reducing manufacturing costs, and enabling high precision machining. The machine tool is equipped with: a bed furnished with a rectangular base, right and left sidewalls provided standing either side of the base, and a rear sidewall provided standing along the back of the base; a table disposed in the space surrounded by the three sidewalls; a first saddle shaped in the form of a rectangular frame shape, provided free to shift back and forth supported on the tops of the left and right sidewalls; a second saddle penetrated by a perpendicular through-hole and arranged free to shift sideways inside the first saddle frame; and a spindle head arranged free to shift perpendicularly inside the through-hole in the second saddle; and a main spindle arranged over the table and supported by the spindle head free to rotate centered on its axis.

Owner:DMG MORI SEIKI CO LTD

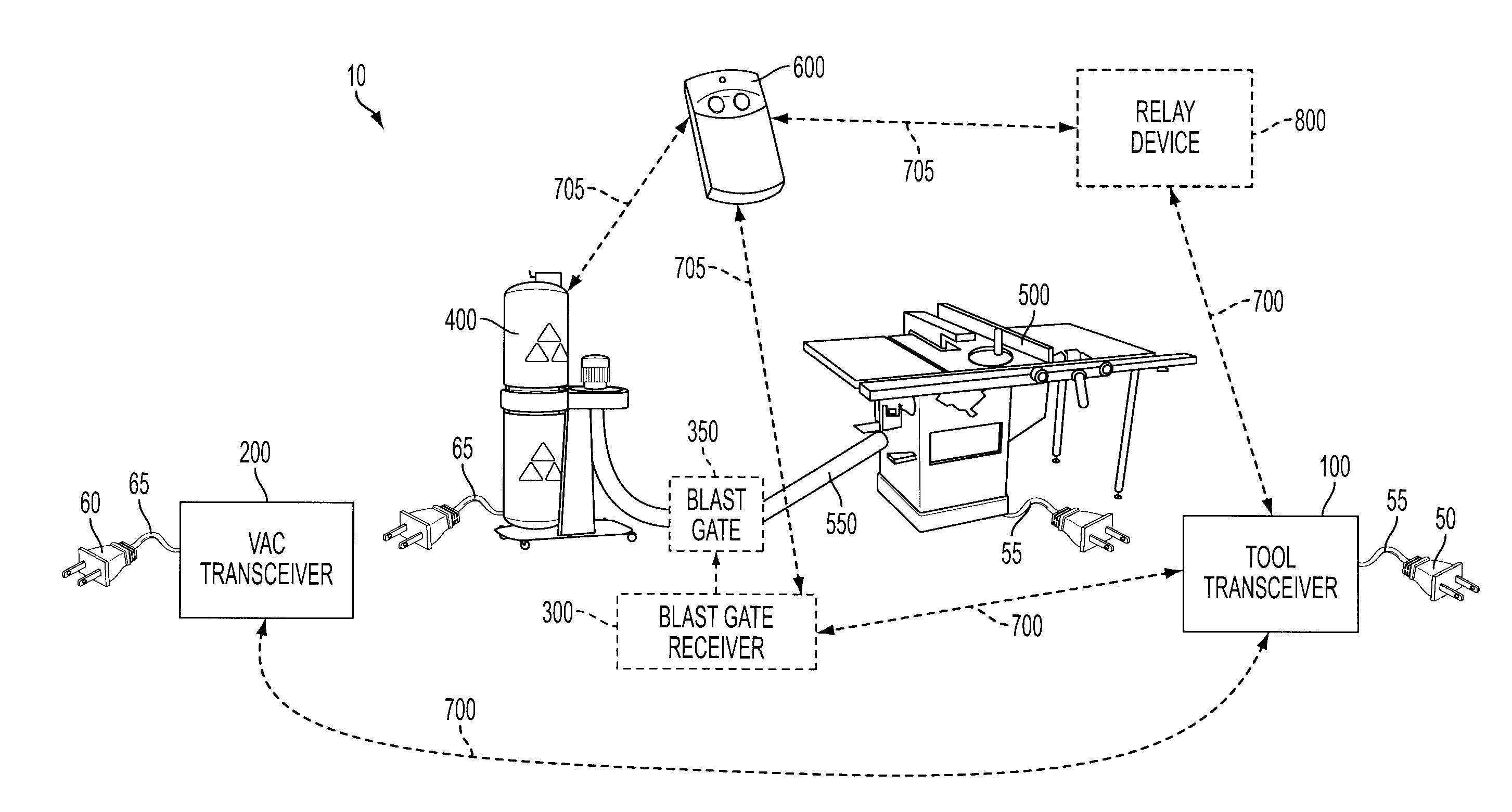

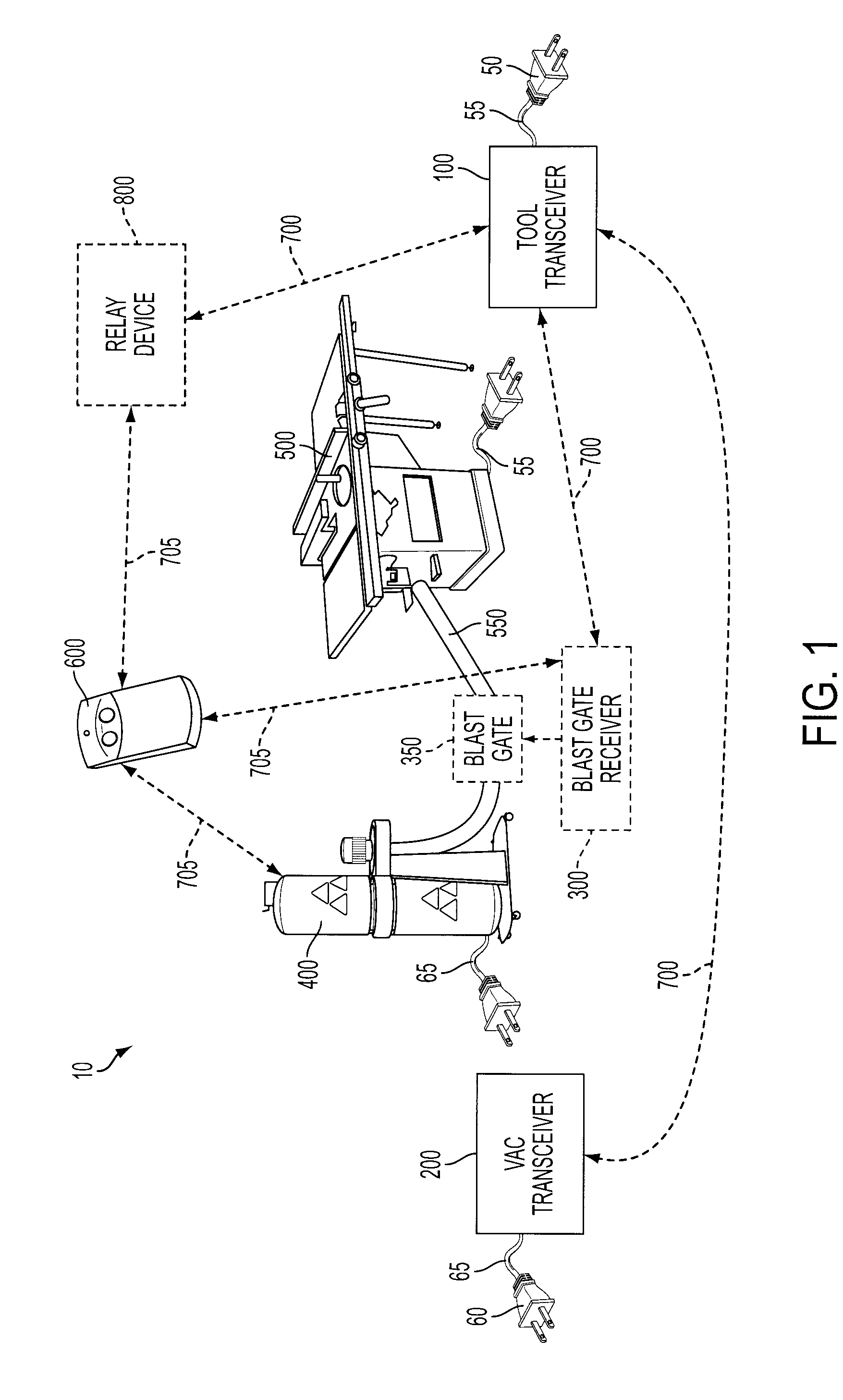

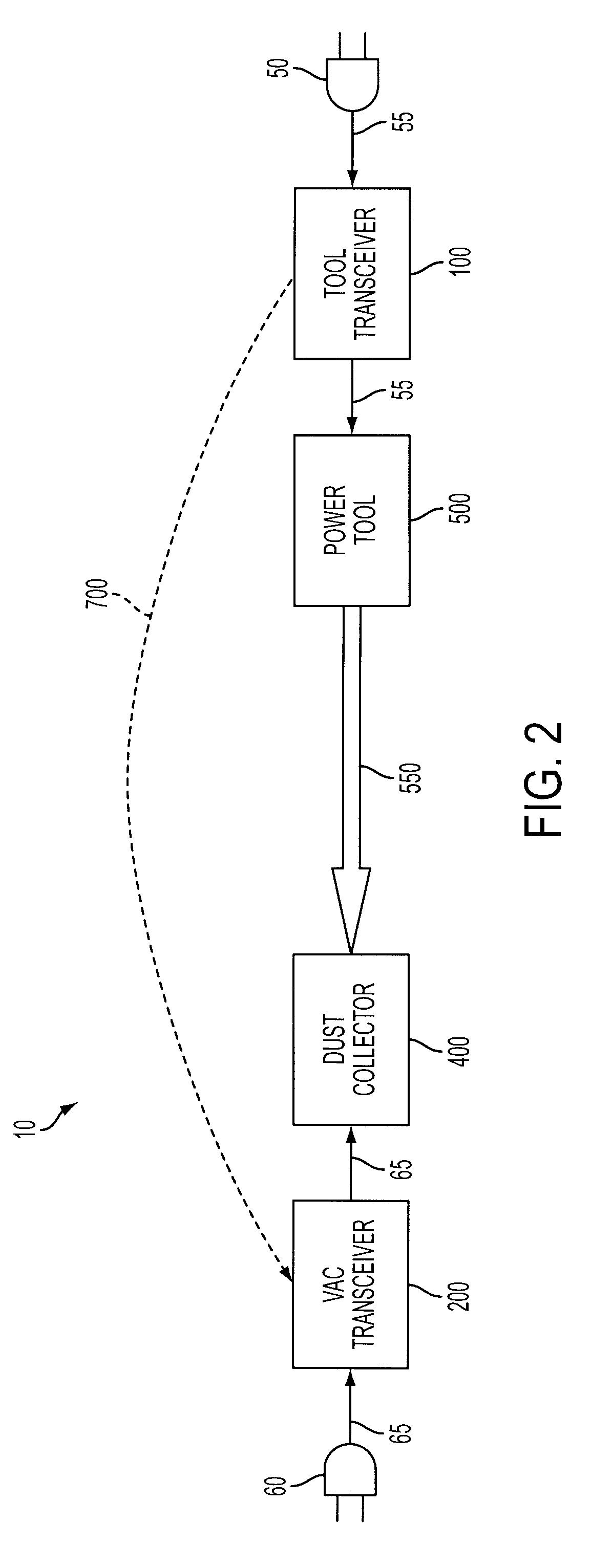

Wireless particle collection system

InactiveUS20100199453A1Metal sawing accessoriesDispersed particle filtrationCollection systemUnique identifier

A wireless particle collection system includes a dust collector and at least one power tool coupled to the dust collector. The power tool is associated with a unique identifier contained in a wireless signal transmitted from the power tool upon an activation event of the tool. The unique identifier is recognized by the dust collector, and the dust collector activates or de-activates upon receipt of the wireless signal.

Owner:CHANG TYPE INDAL

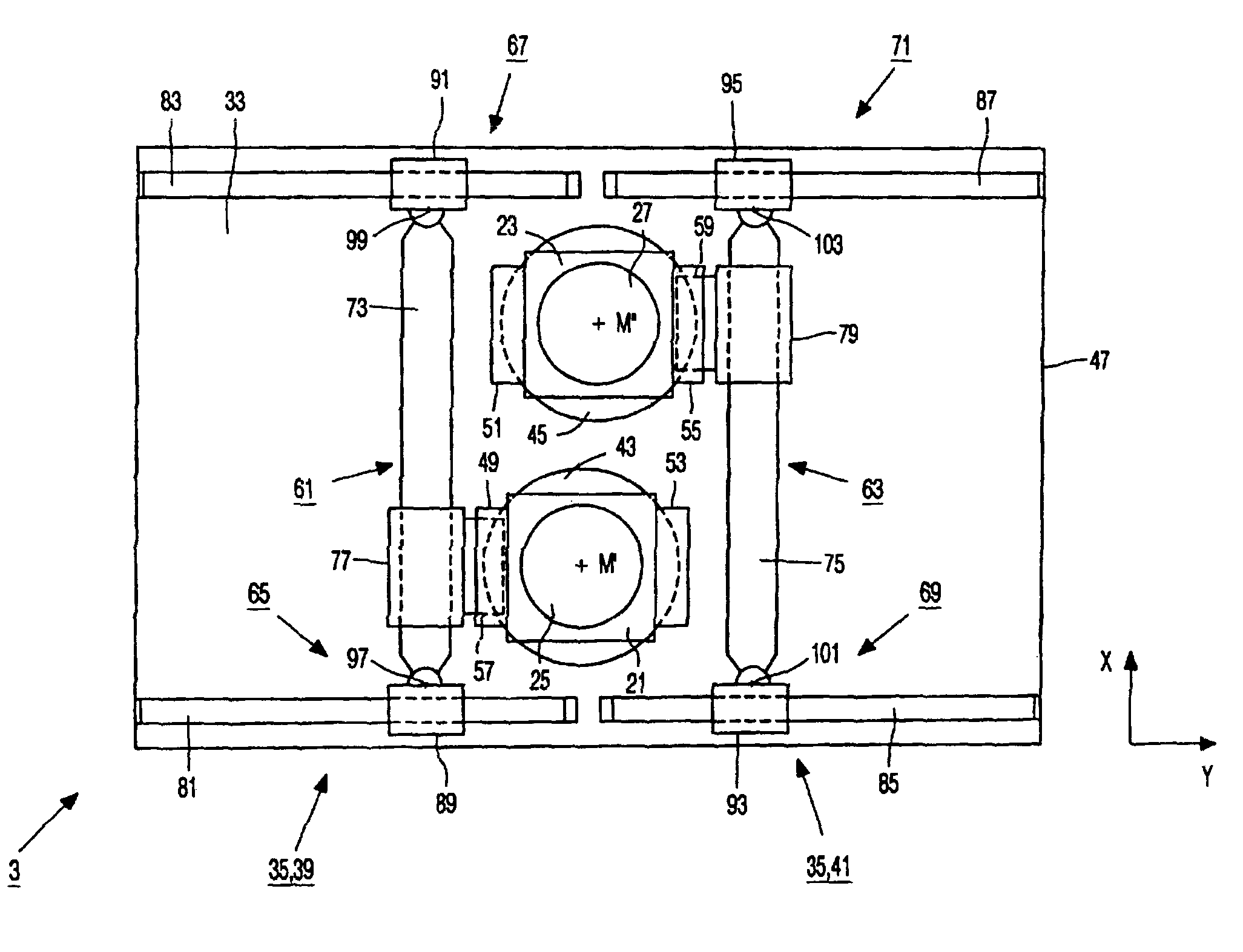

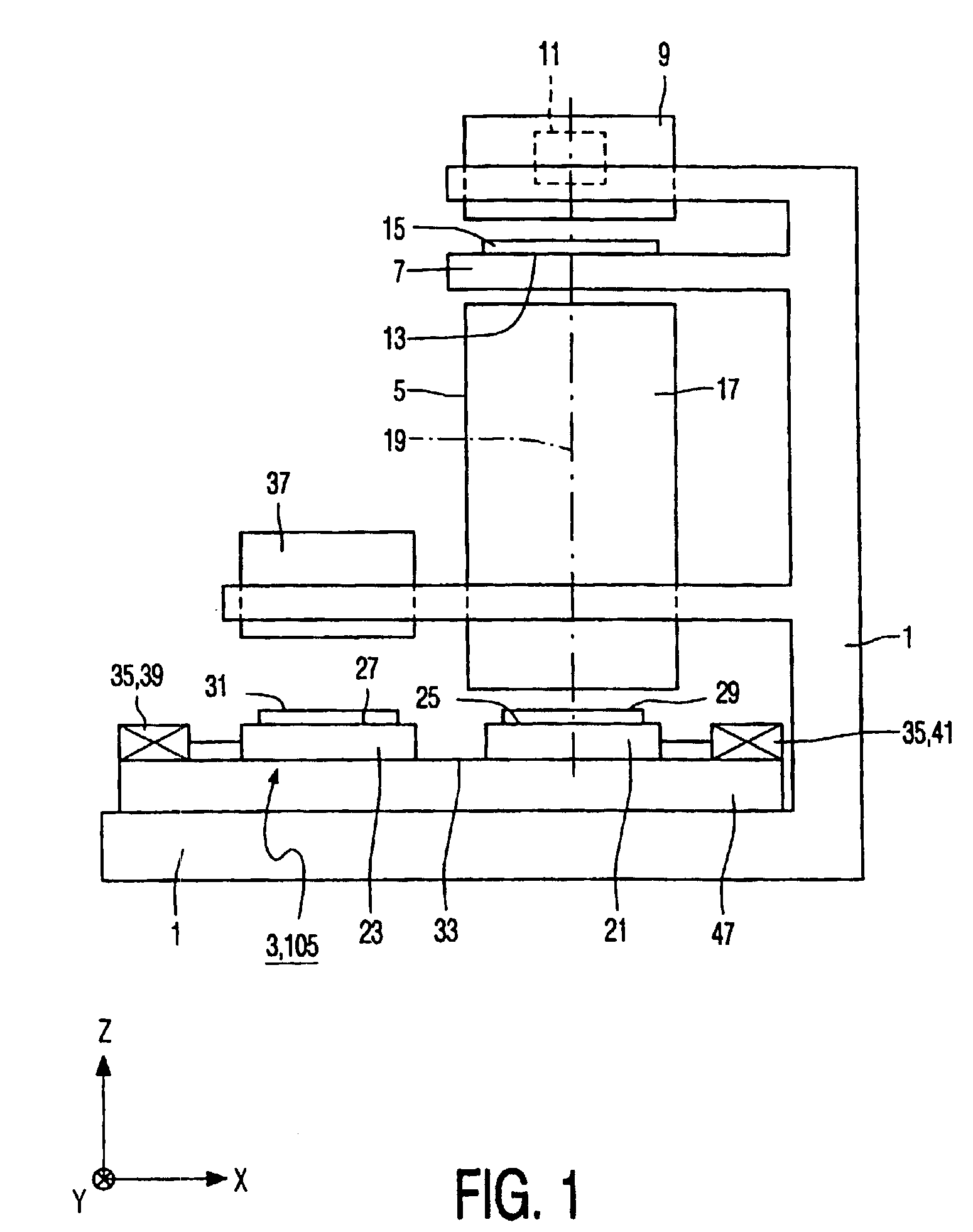

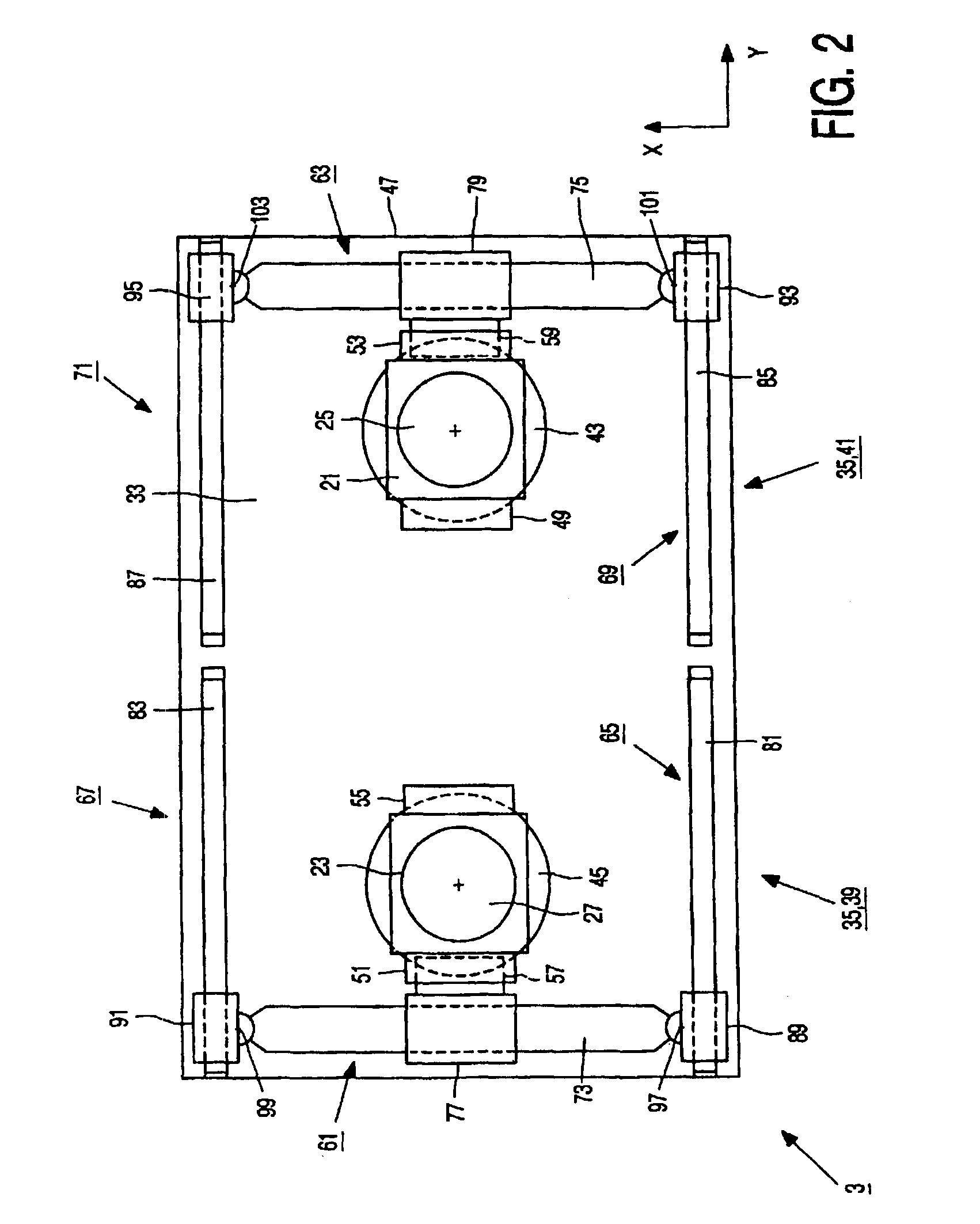

Positioning device having two object holders

InactiveUSRE40043E1Easy to adjustEasy constructionSemiconductor/solid-state device manufacturingInstrumental componentsEngineeringSemiconductor

A positioning device has first and second object holders that are guided over a guiding surface extending parallel to an X-direction and parallel to a Y-direction perpendicular to the X-direction and which are displaceable over the guiding surface from a first position into a second position by means of a displacement system. The displacement system includes a first displacement unit and a second displacement unit to which the object holders can be alternately coupled. The first displacement unit is suitable for carrying out a first series of positioning steps of the first object holder in the first position and for displacing the first object holder from the first position into an intermediate position between the first and second positions. The second displacement unit is suitable for carrying out a second series of positioning steps of the second object holder in the second position, simultaneously with and independently of the first displacement unit, and for displacing the second object holder from the second position into the intermediate position. In the intermediate position, the object holders are exchanged, after which the first series of positioning steps can be carried out by the first displacement unit with the second object holder in the first position and the second series of positioning steps can be carried out by the second displacement unit with the first object holder in the second position. The positioning device is suitable for use in a lithographic device to carry out an exposure process with a first semiconductor substrate in an exposure position and, simultaneously therewith and independently thereof, a characterization process with a second semiconductor substrate in a characterization position.

Owner:ASML NETHERLANDS BV

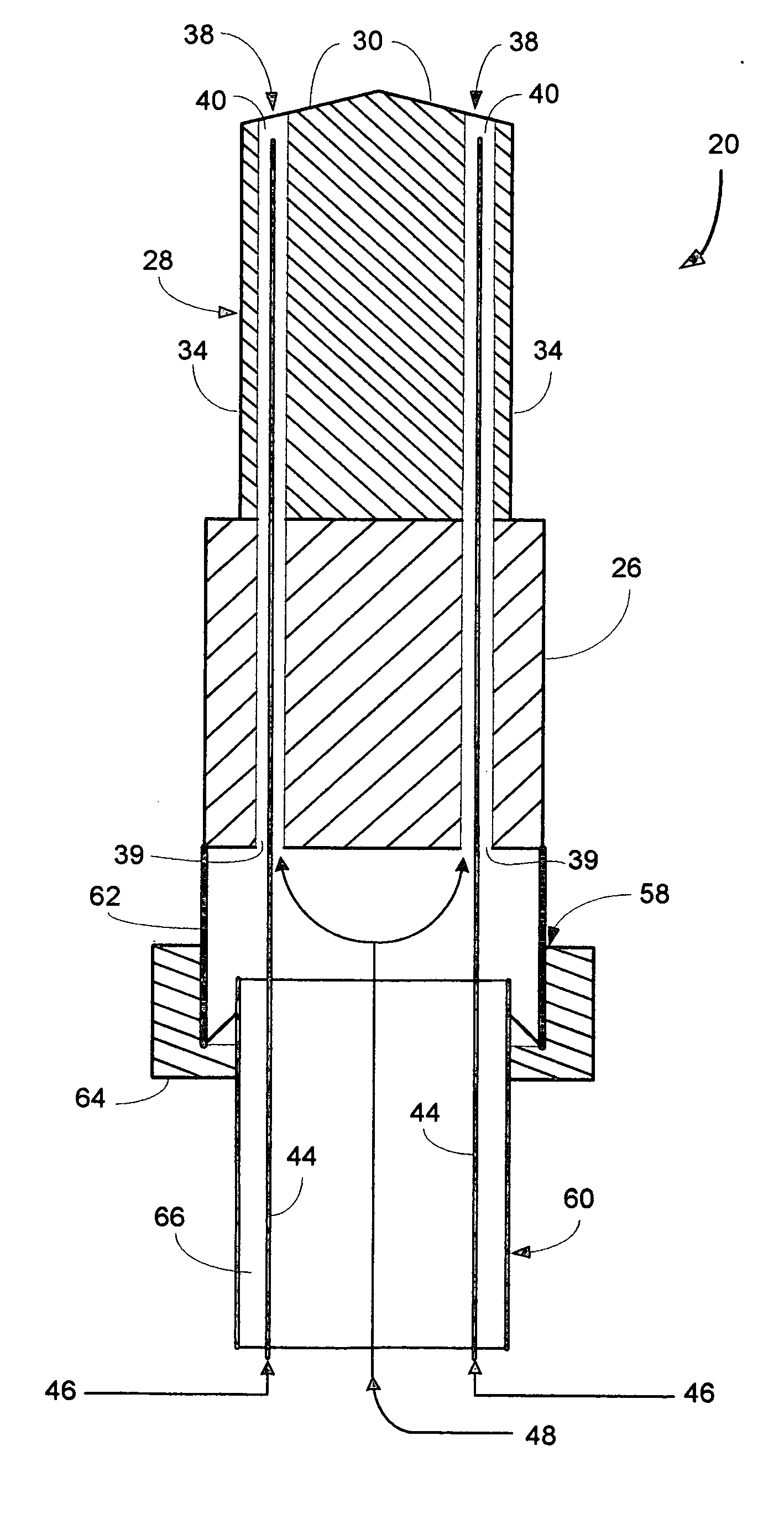

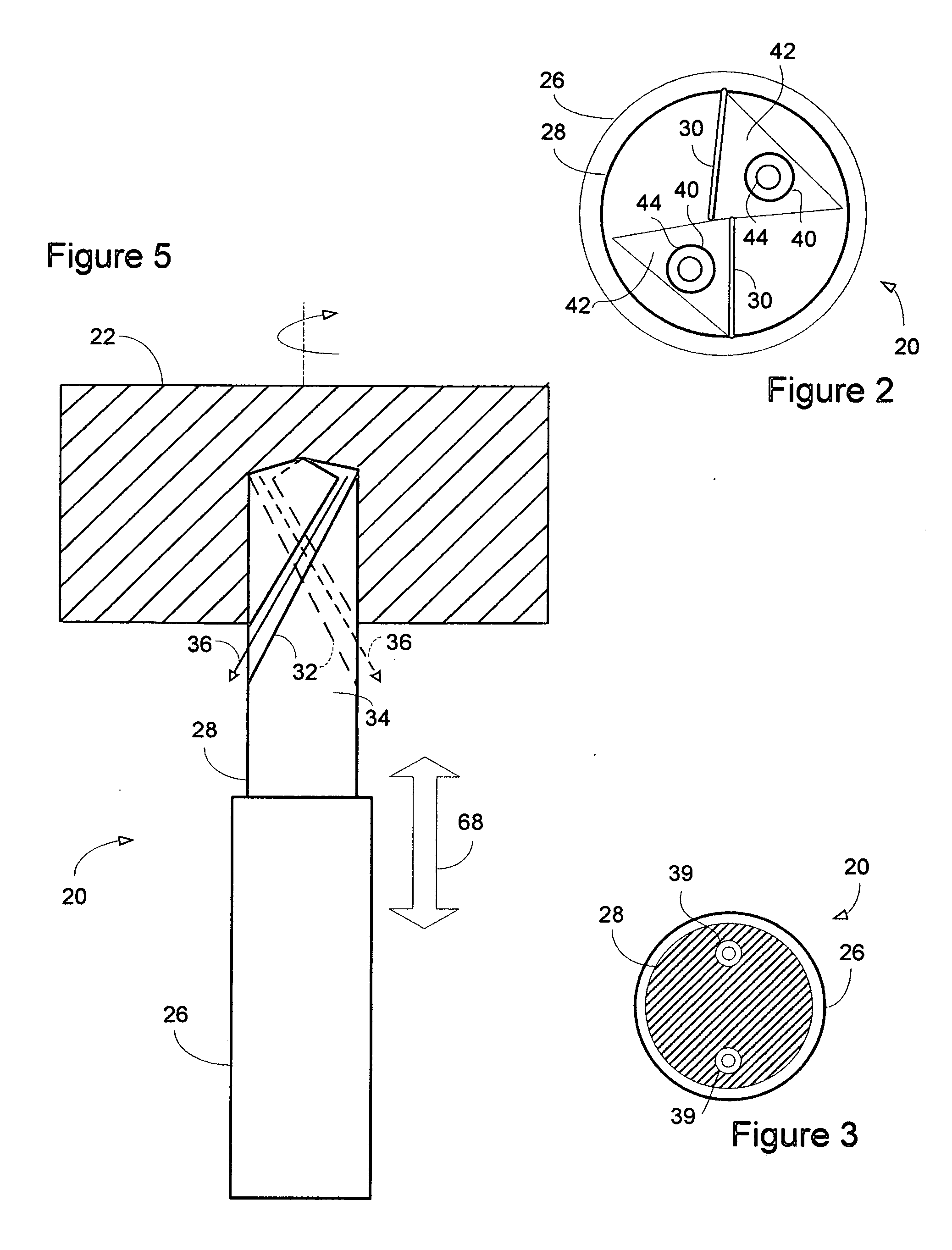

Device for applying cryogenic composition and method of using same

A device of the present invention for applying a cryogenic composition includes a machining tool or tool holder having a channel positioned therethrough and a capillary tube positioned within the channel. A dense cryogenic fluid is passed through the capillary tube while a diluent or propellant fluid is passed through the channel. The diluent or propellant fluid flows within the channel and about the capillary tube. Upon exiting the capillary tube, the dense fluid admixes with the diluent or propellant fluid to form a cryogenic composite fluid or spray. The cryogenic composite fluid or spray is selectively directed onto a substrate for cooling or lubrication purposes, or onto the machining tool for cooling purposes.

Owner:COOL CLEAN TECH

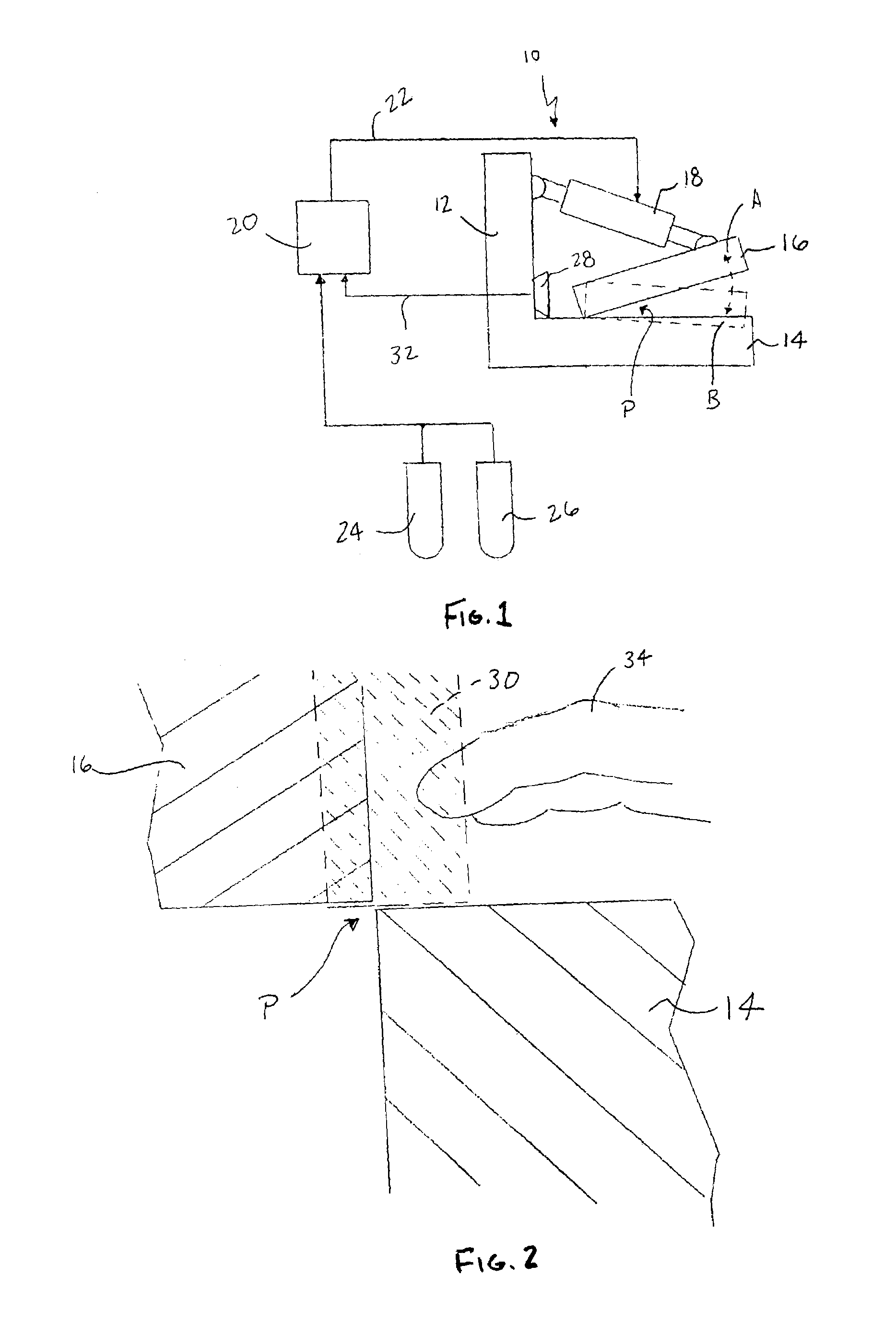

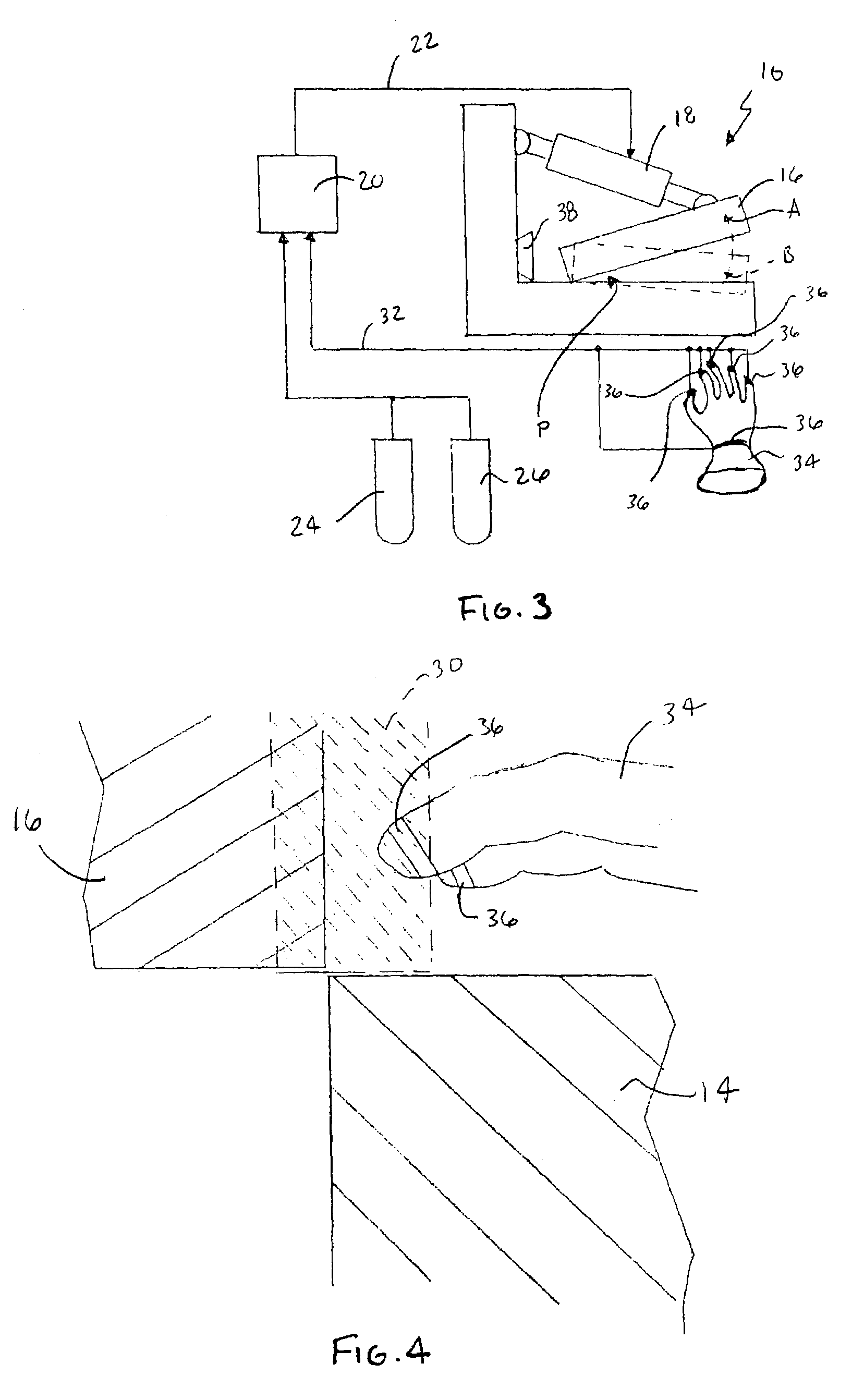

Optical proximity device for power tools

The present invention is directed to a power tool including a working element for performing a task. A light source is arranged to project a beam of light adjacent the working element. A detector, such as an electro-optic type detector, is communicatively coupled to the power tool such that the detector is capable of detecting the presence of a human body part in the beam of light. If a body part is detected, the detector may communicate to stop operation of the working element.

Owner:BLACK & DECKER INC

Tool for chip removing machining and having fluid-conducting branch ducts

InactiveUS6595727B2The effect is outstandingManufactured in simple and inexpensiveMilling cuttersTurning toolsEngineeringBranch Duct

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Chip removing machining of a workpiece while applying high pressure cooling liquid

The chip removing machining of a workpiece is performed by a cutting tool which includes a cutting insert. In order to cool the cutting insert, one or more over-cooling nozzles is arranged for directing a jet of cooling liquid downwardly toward a contact area between the workpiece and a chip surface of the cutting insert. A sub-cooling nozzle is arranged for directing a jet of cooling liquid upwardly toward a contact area between the workpiece and a flank surface of the cutting insert. A jet of cooling liquid can be emitted from only the over-cooling nozzle, or from only the sub-cooling nozzle, or from both of those nozzles simultaneously.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Safety device for blender

InactiveUS7318666B1Reduce riskUnexpected operationRotary stirring mixersBalingEngineeringMechanical engineering

A blender includes a base forming a receiving space in which a positioning seat is formed. The positioning seat defines a through hole. The base houses a motor that is connected to a safety switch. The safety switch has a bar extending through the through hole of the positioning seat. A container has a lower end releasably mounted to a retainer. A movable member is received in the retainer and has pegs extending through the retainer to be engageable and depressible by the lower end of the container when the container is mounted to the container retainer. The container is positionable in the receiving space, and the depressed movable member is fit into the positioning seat to depress downward the bar of the safety switch to thereby actuate the safety switch supplying the power to the motor.

Owner:LIN KUAN CHIH

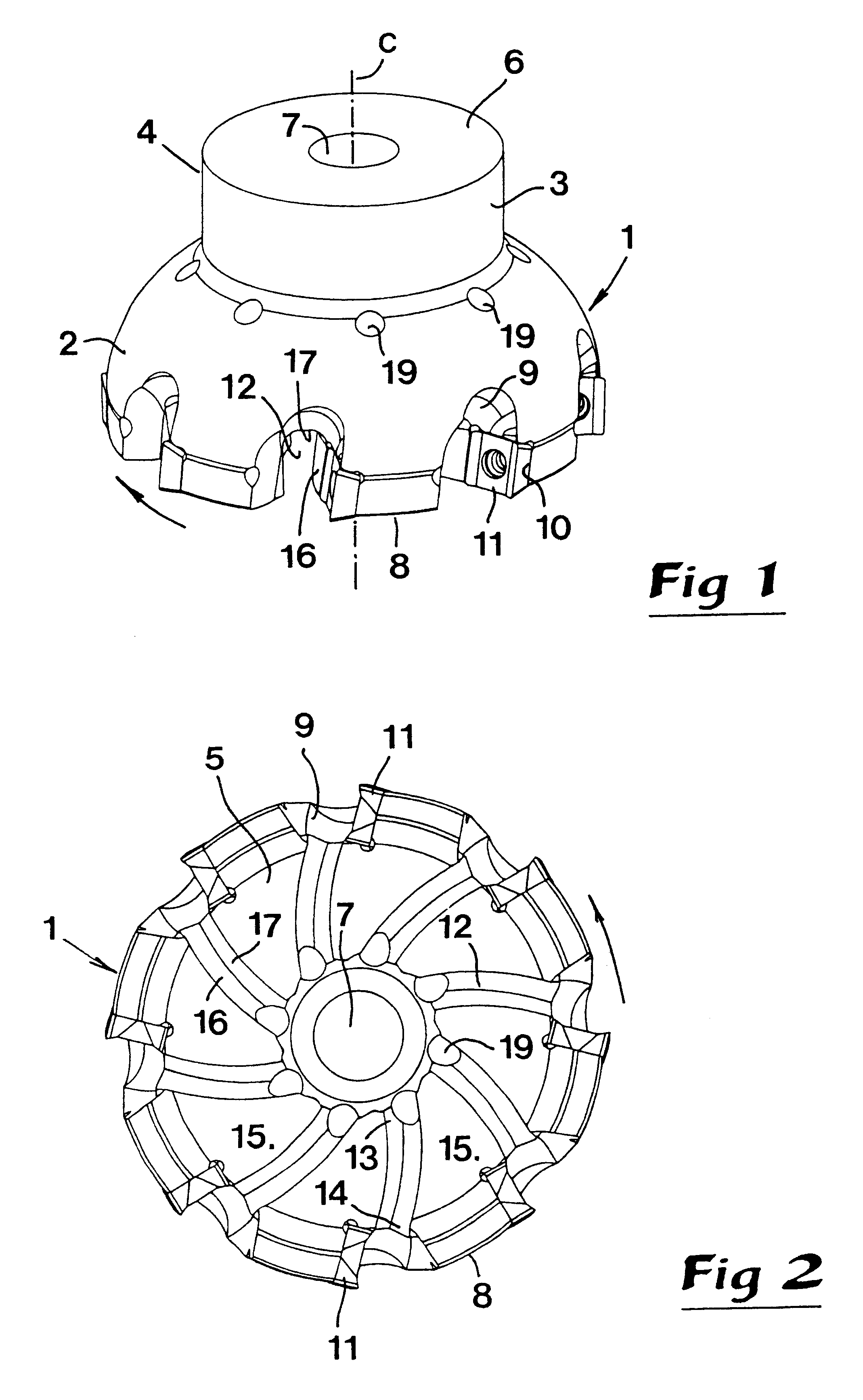

Milling cutter and milling insert with coolant delivery

A cutting insert for use in chipforming and material removal from a workpiece wherein coolant is supplied to the cutting insert from a coolant source. The cutting insert includes at least one discrete cutting location and at least one distinct internal channel that corresponds to the cutting location. The internal channel has an inlet to receive coolant and an outlet to exit coolant. The outlet is proximate to the cutting location, and the inlet is radial inward of the outlet.

Owner:KENNAMETAL INC

Indirect Cooling of a Rotary Cutting Tool

ActiveUS20100272529A1Dissipate energyMinimization requirementsTransportation and packagingMilling cuttersWorking fluidEngineering

An indirect cooling system for a rotating cutting tool uses a cryogenic coolant that is delivered to a cavity formed on the back surface of the cutting element, providing cooling near the cutting edge of the element. Because the total flow rate of the working fluid is low (less than 0.08 Liters / min / cutting edge), the fluid can be safely vented to atmosphere from the cavity, and as a result, no specialized coolant recovery or ventilation equipment is needed. The cavity may be formed with fins to enhance the heat transfer between the cutting element and the coolant, and coolant may additionally be sprayed directly onto the exterior surface of the element to cool the tool-chip interface. The indirect cooling system may be used for hard to machine metals and composites, as well as the machining of conventional materials without the use of traditional cutting fluids.

Owner:5ME LLC

Cordless hand held power tool with powered accessory

Owner:BLACK & DECKER INC

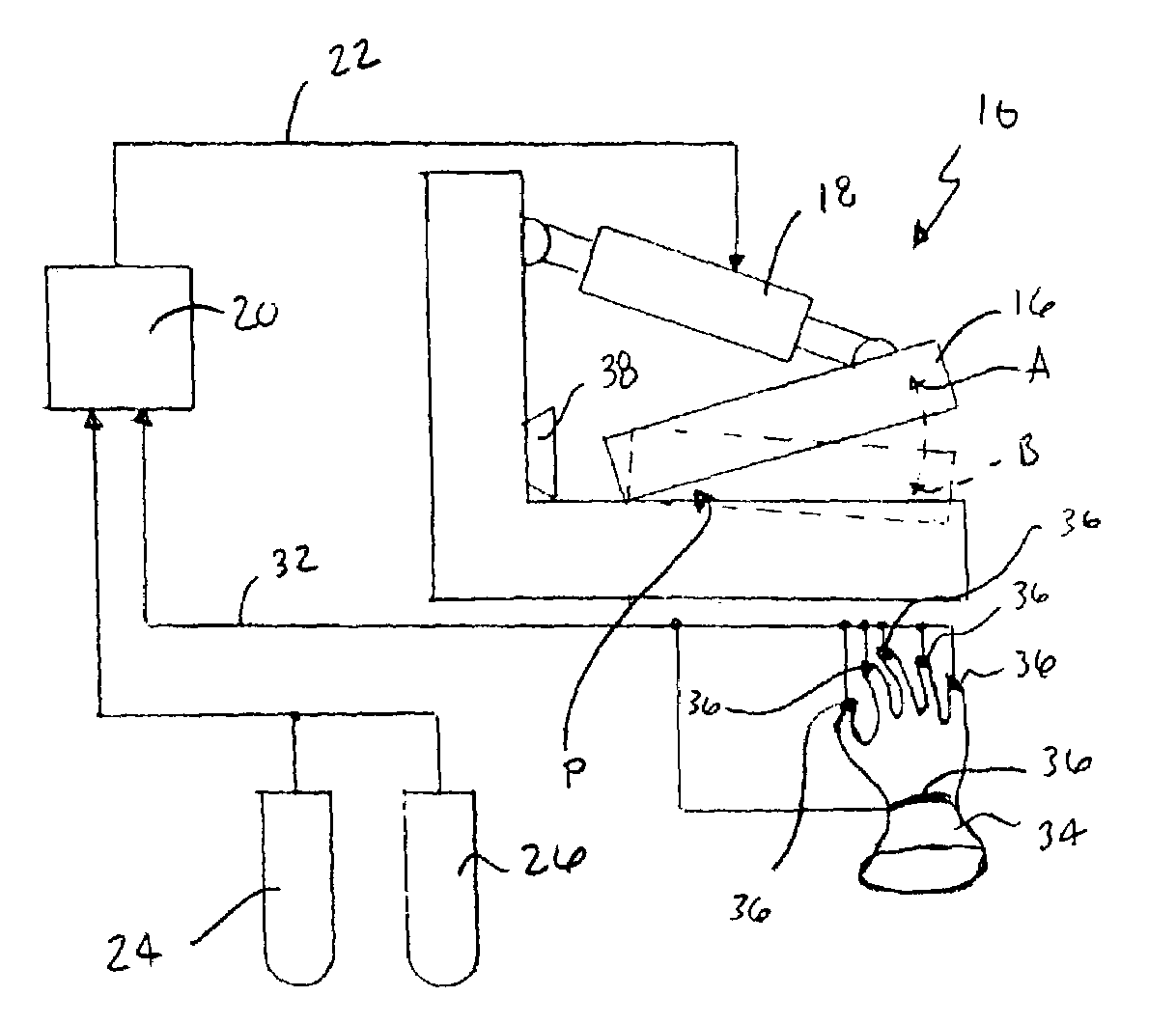

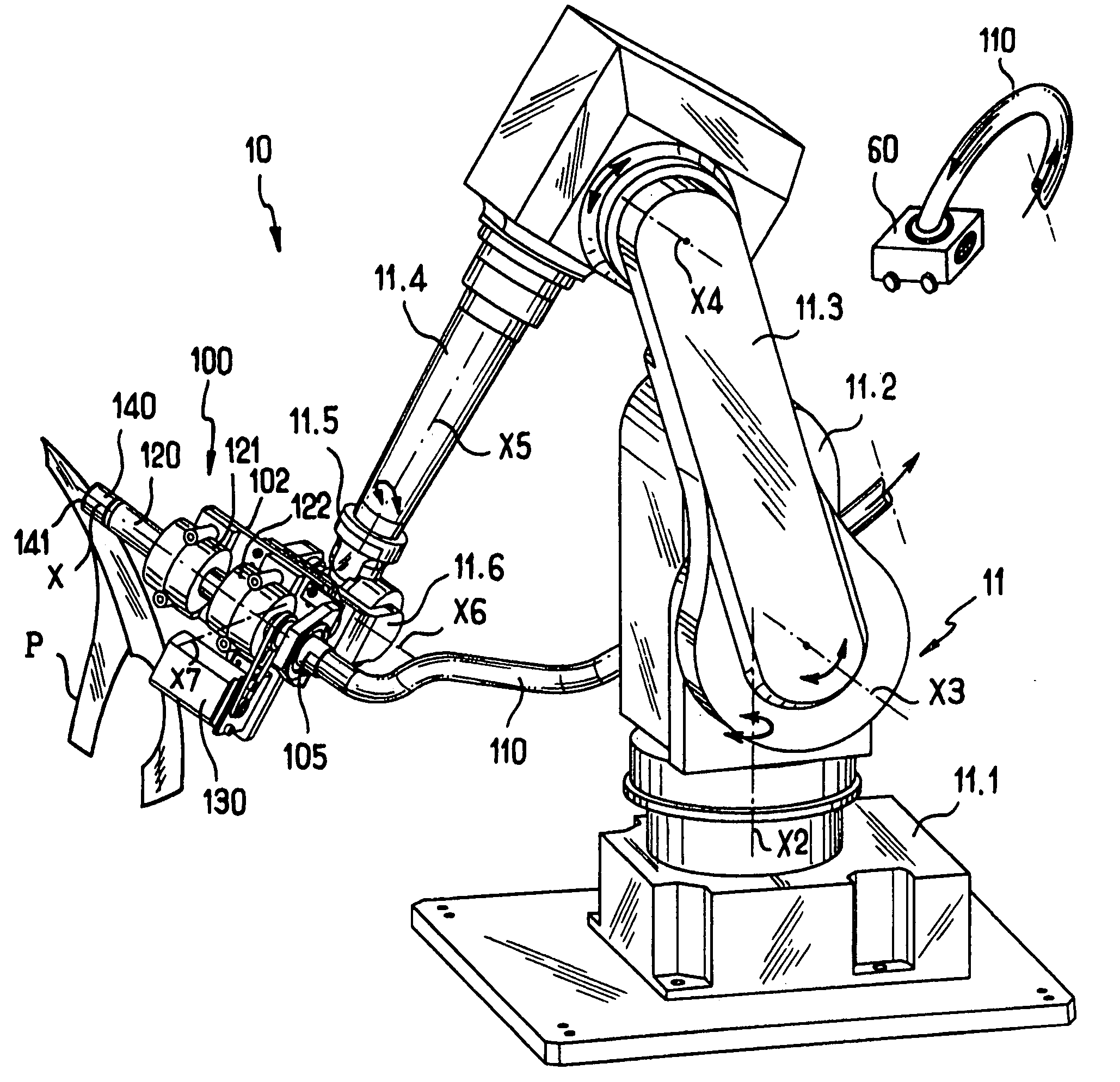

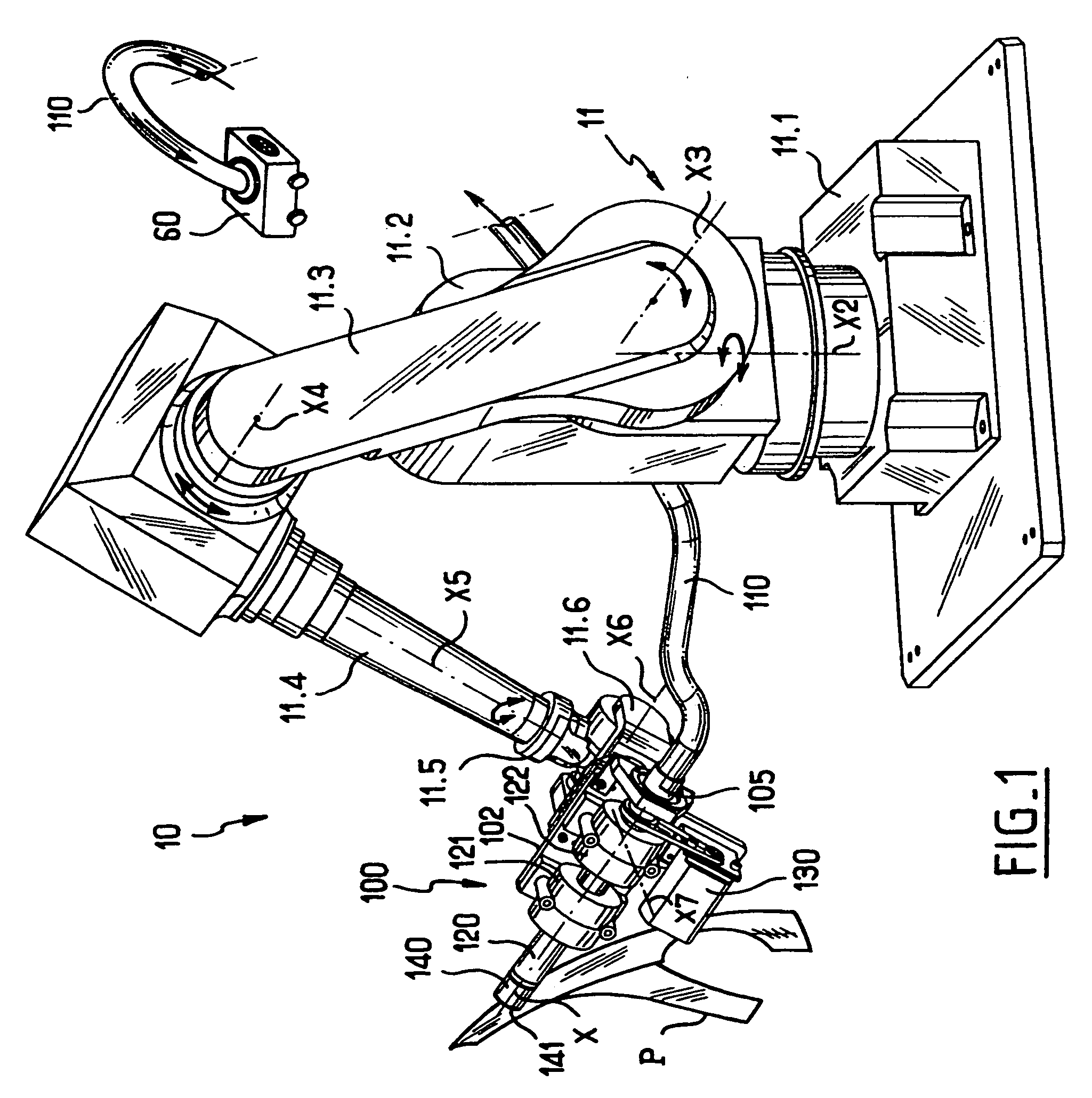

Safety-shutoff device for a manually fed processing machine

InactiveUS6979813B2Operational securityDc network circuit arrangementsMaterial analysis by optical meansComputer scienceFeed processing

An intrusion detection system for altering the operation of an associated machine when an appropriate intrusion is detected, the system comprising: a first detector to detect the presence of a first distinguishing property and to selectively produce an intrusion signal when the first distinguishing property associated with an object is detected within a danger zone approximate a pinch point of a machine, wherein an area approximate the pinch point of the machine does not exhibit the first distinguishing property; and, a controller, operatively coupled to the intrusion detector and the machine, for controlling the operation of the machine, wherein the controller generates a corrective action signal directed toward the machine when intrusion signals are received from the intrusion detector.

Owner:AVRIL JOHN G

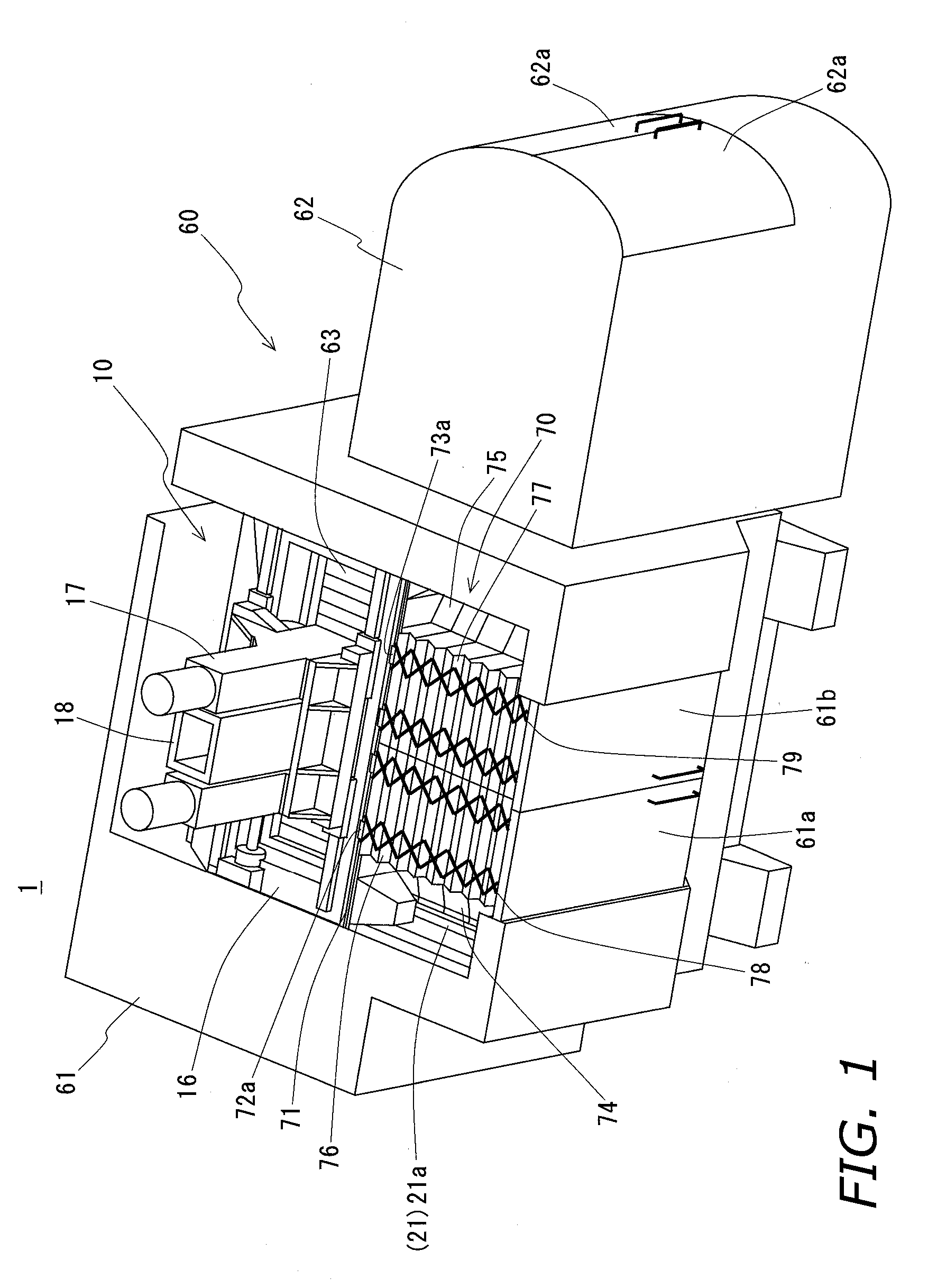

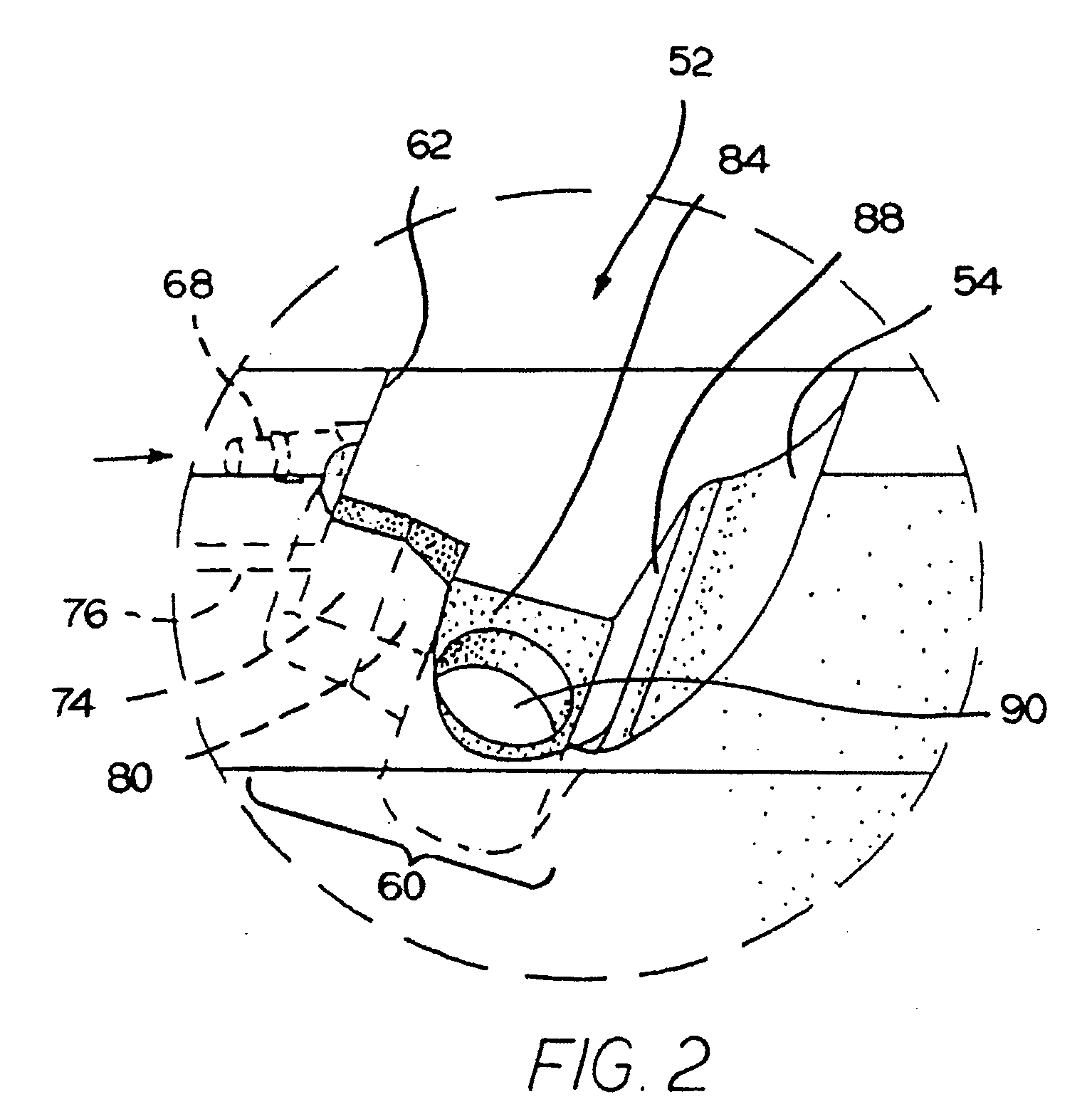

Cutting and Dust Collecting Assembly and Working Machine with Such Assembly

ActiveUS20080163492A1Avoid flyingEfficient collectionMetal sawing devicesMetal sawing accessoriesCircular sawDust control

A cutting and dust collecting assembly comprises a rotatable, circular saw blade (4) having a first side (20), a second side (21), and a cover device (6) with a terminal member (52). The bottom surface (36) of the cover device extends in a plane. A longitudinal passage (45, 46) for the saw blade extends through the cover device from its top surface to its bottom surface. The terminal member comprises a terminal chamber (60) having an inlet (45a), the mouth of which coincides with the plane of said bottom surface. An outlet (58) can be connected to a vacuum source. The direction of rotation of the operating blade is such that the rear part (4a) of the saw blade which has passed beyond the bottom surface of the cover device will move in a direction upwards-rearwards towards the bottom surface. The invention also concerns the cover device, a sealing body belonging to the cover device and a working machine which is provided with the cutting and dust collecting assembly.

Owner:HUSQVARNA AB

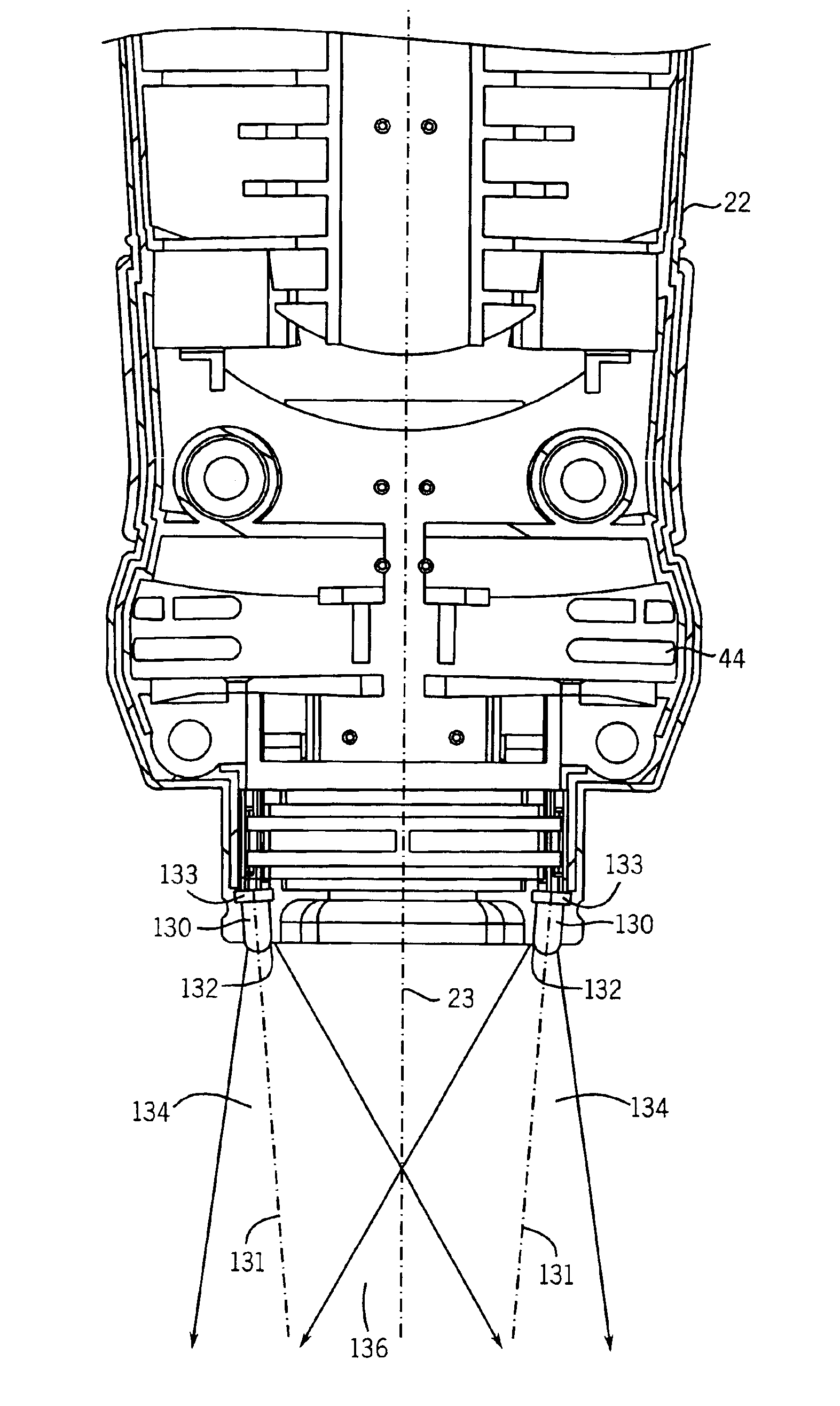

Power tool with light emitting diode

A rotary cutting tool includes a housing and a motor provided within the housing for rotating a cutting accessory coupled to the rotary cutting tool. The rotary cutting tool also includes a plurality of light emitting diodes for illuminating a point of cut of the rotary cutting tool. Each of the plurality of light emitting diodes have a central longitudinal axis, and at least one of the light emitting diodes is couple to the housing such that the central longitudinal axis of the light emitting diode is not parallel to a rotation axis of the cutting accessory.

Owner:CREDO TECH CORP

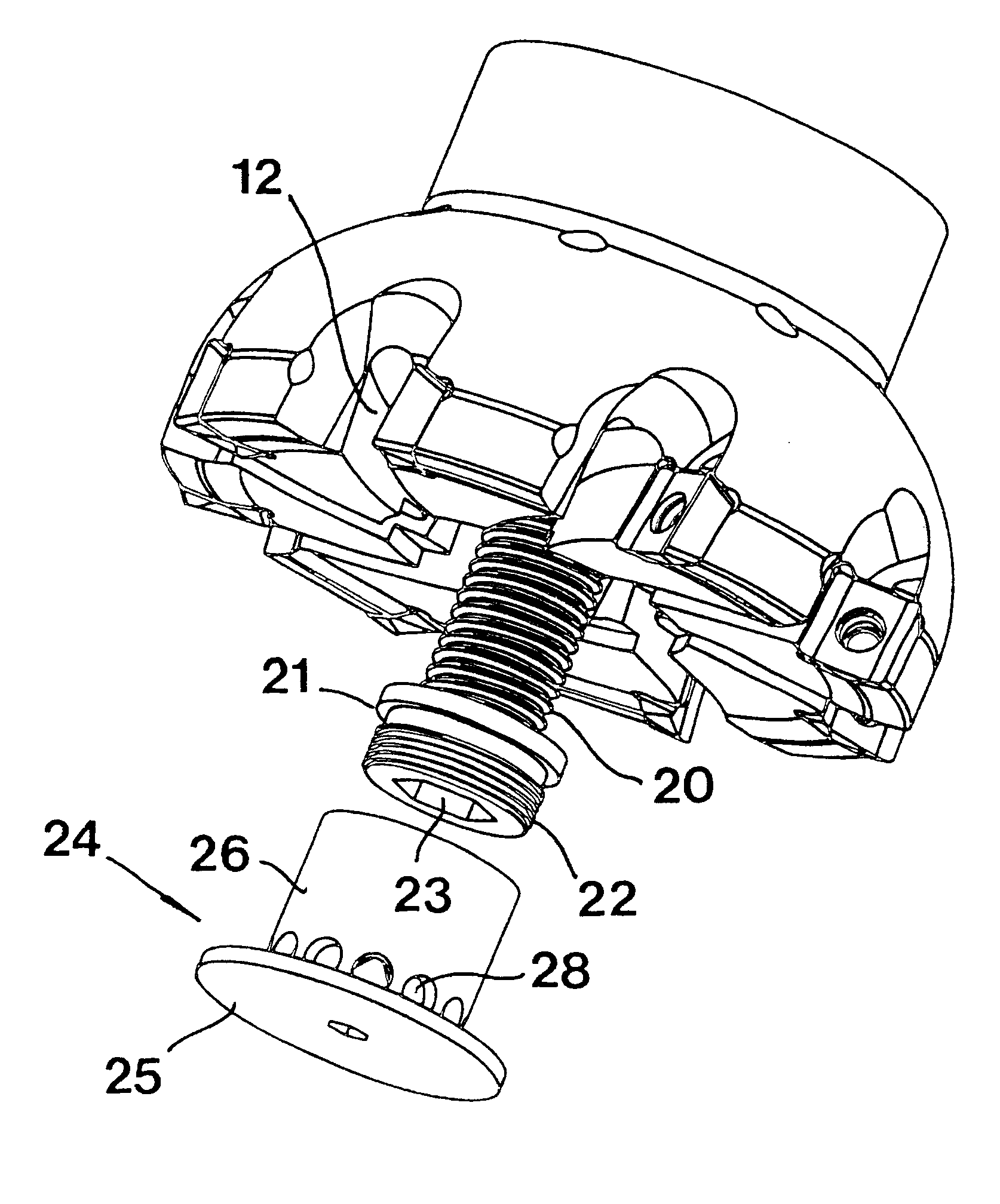

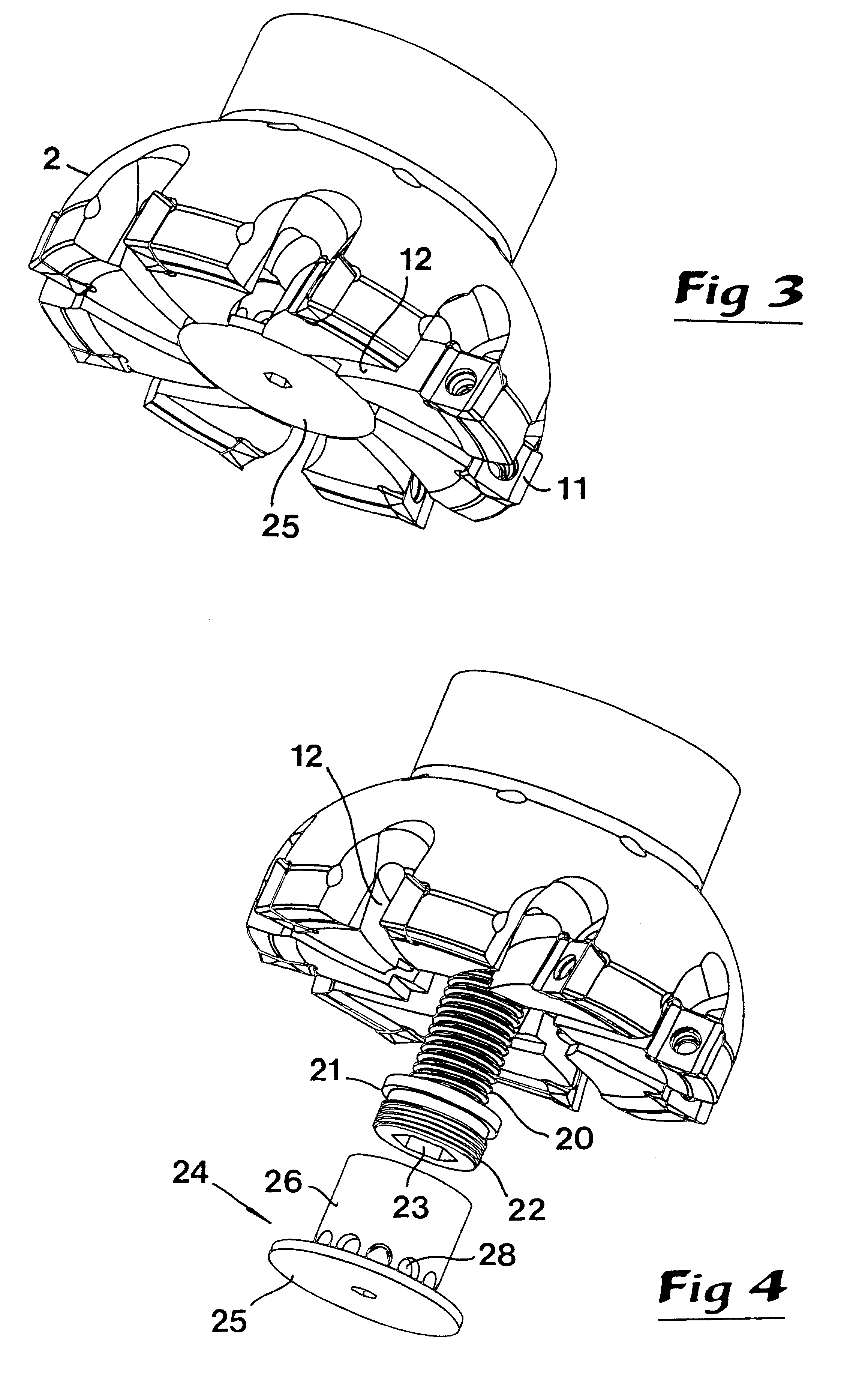

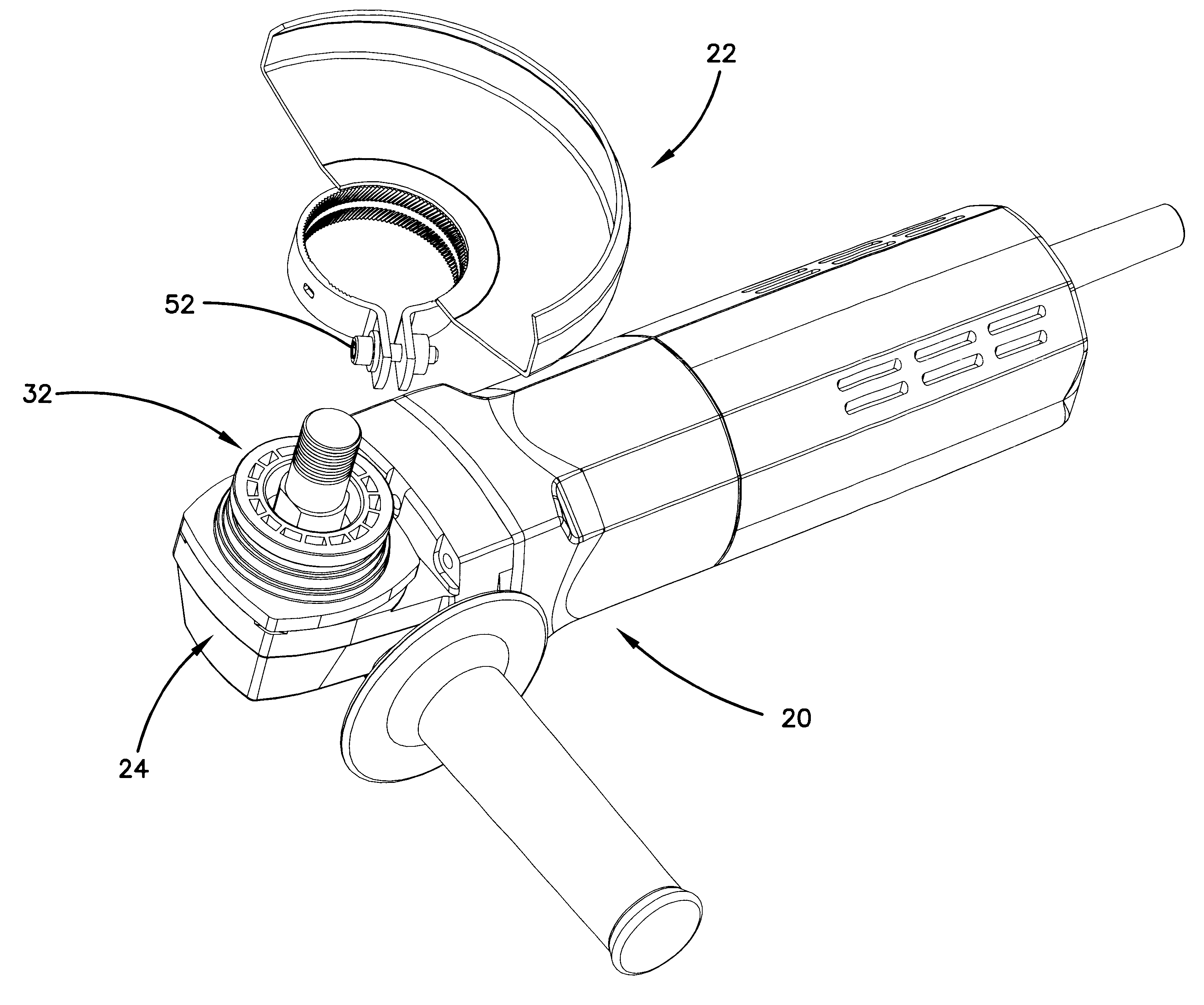

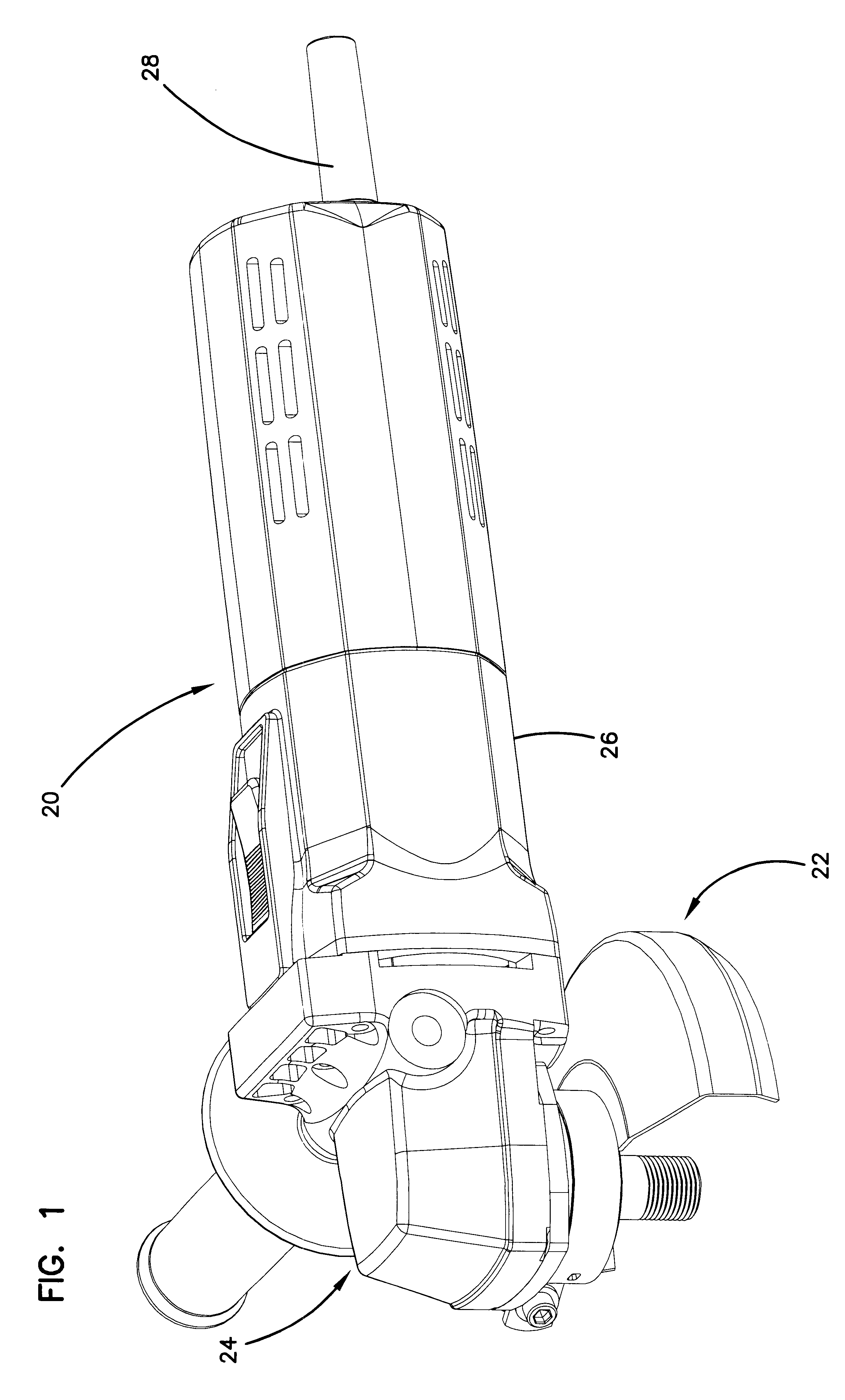

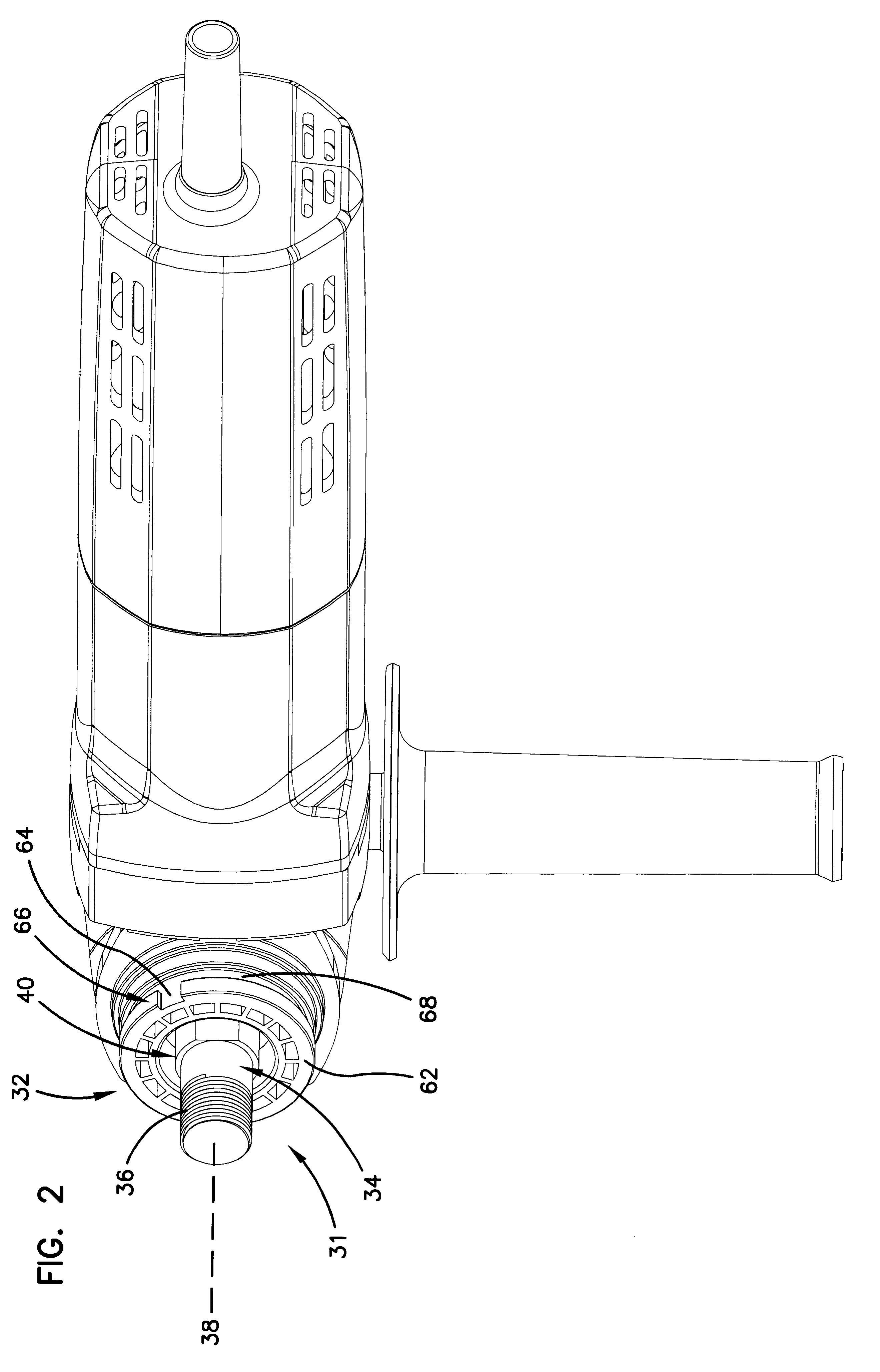

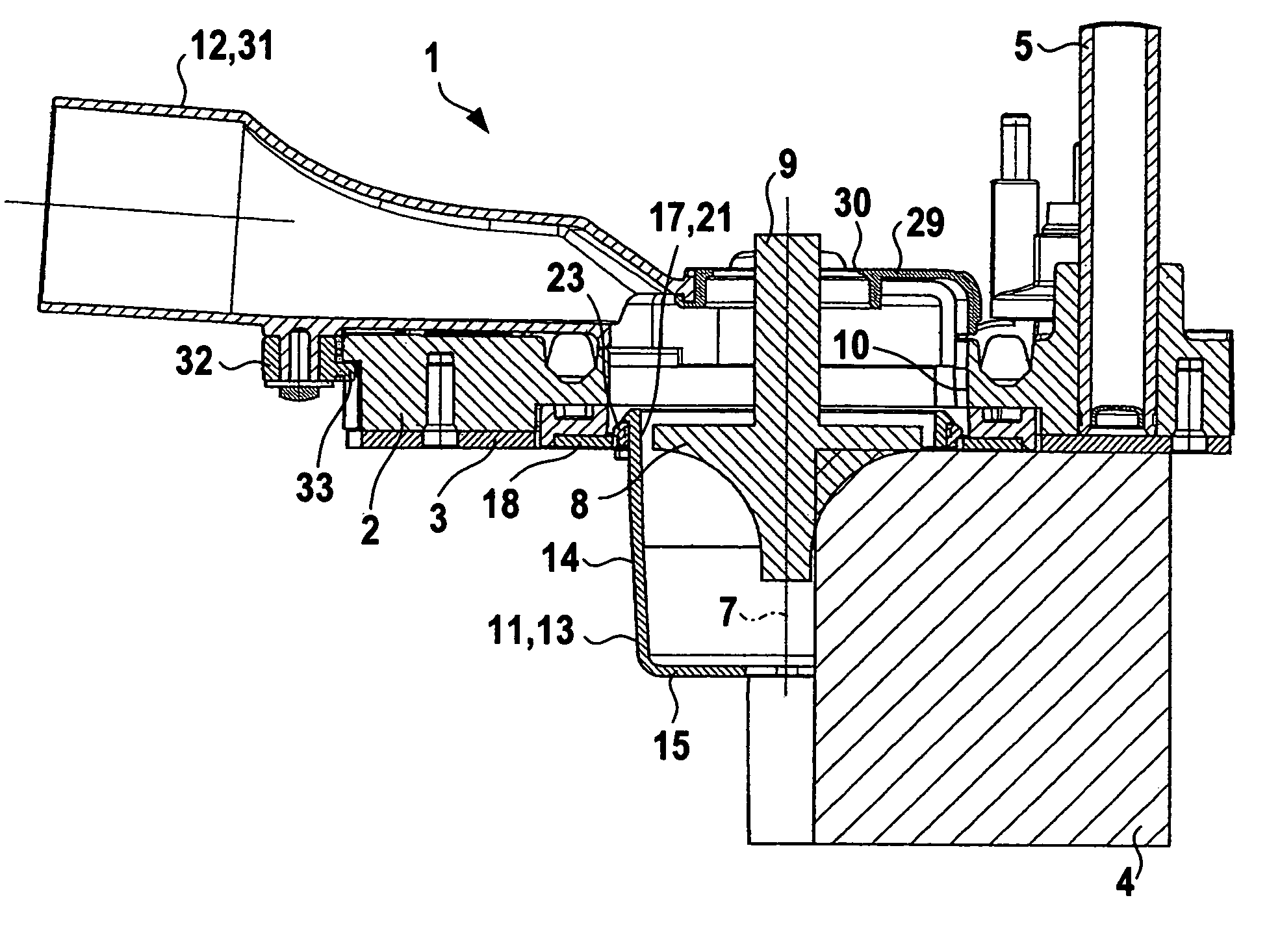

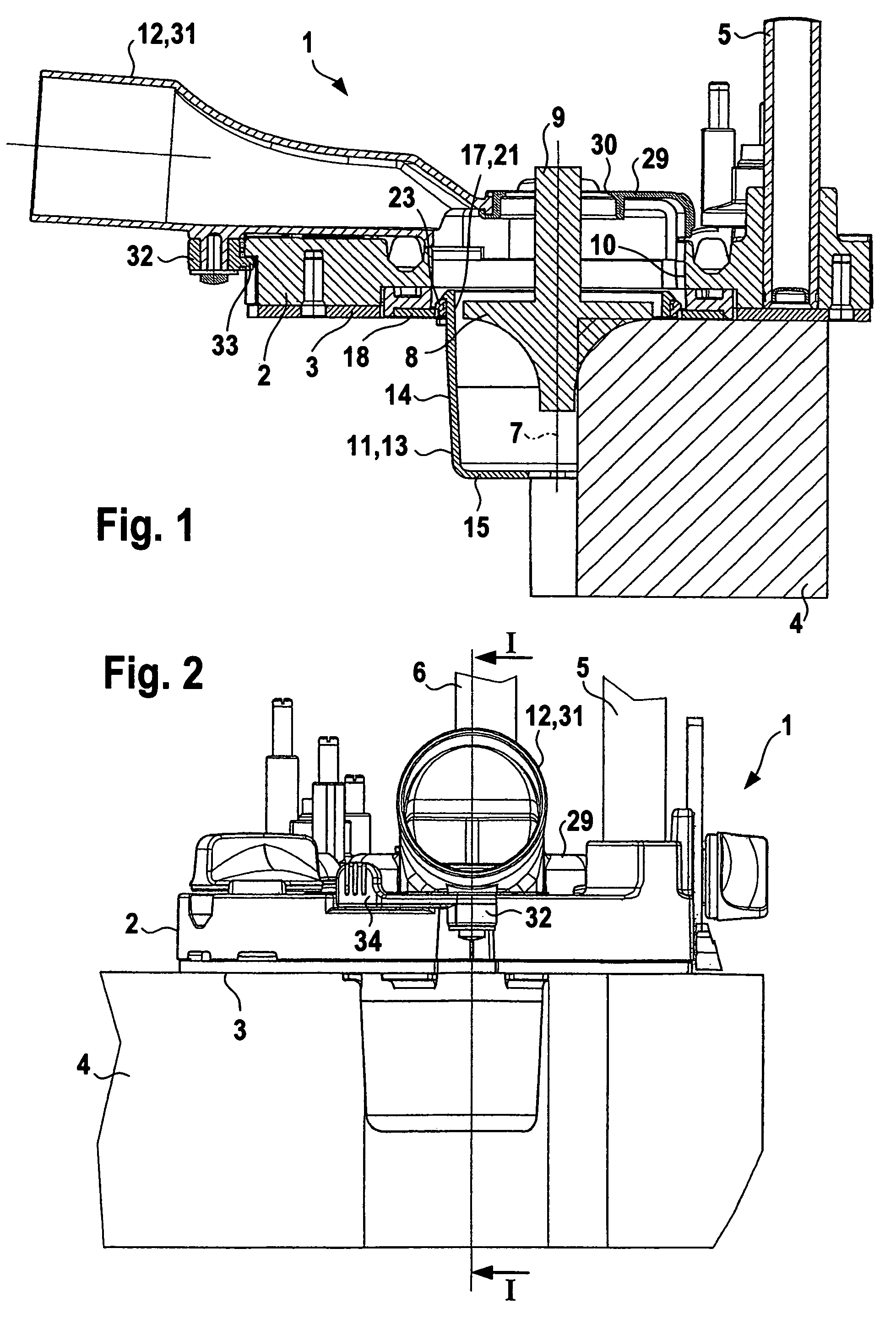

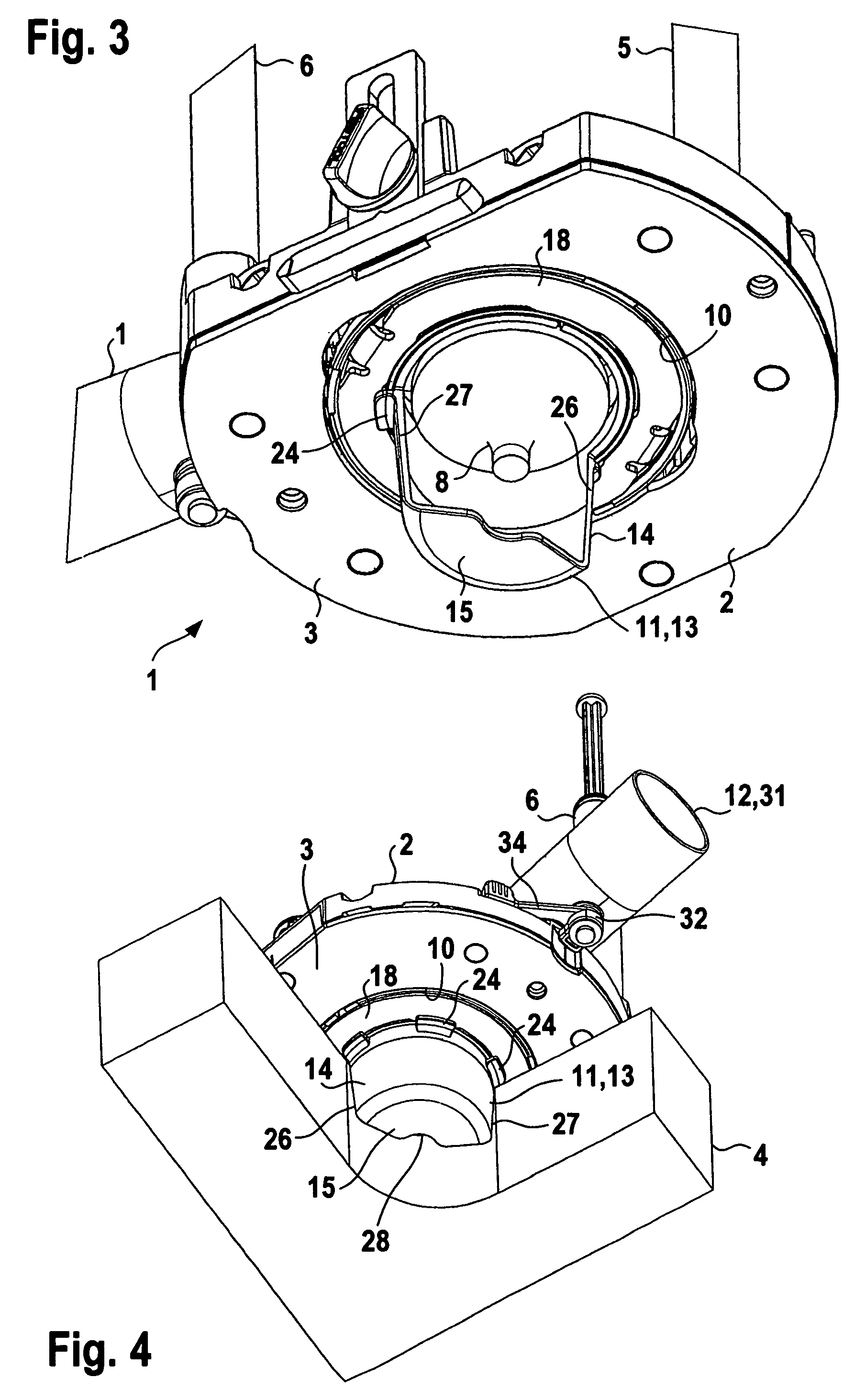

Guard attachment system with knurled clamp ring

InactiveUS6464573B1Portable grinding machinesMaintainance and safety accessoriesHand heldEngineering

A removable guard for a hand-held power tool. The guard is configured to cover an area proximate a spindle assembly of the tool between the spindle assembly and a user of the tool. The guard is further configured to be securely mounted to a semi-elastic lower bearing housing supporting the spindle assembly of the tool. The guard, when mounted to the semi-elastic lower bearing housing of the tool, and when in use during operation of the tool, must remain functional under conditions of flying debris, such as under conditions of an exploding, rotating abrasive grinding wheel mounted on the spindle assembly of the tool.The guard includes a clamp ring depending from a guard hood. The clamp ring's inner circumferential portion has at least a partially-knurled surface, whereby when securely tightened around the semi-elastic lower bearing housing, the at least partially-knurled surface of the clamp ring inner circumferential portion compresses into the semi-elastic lower bearing housing to securely mount the guard to the tool.

Owner:BLACK & DECKER INC

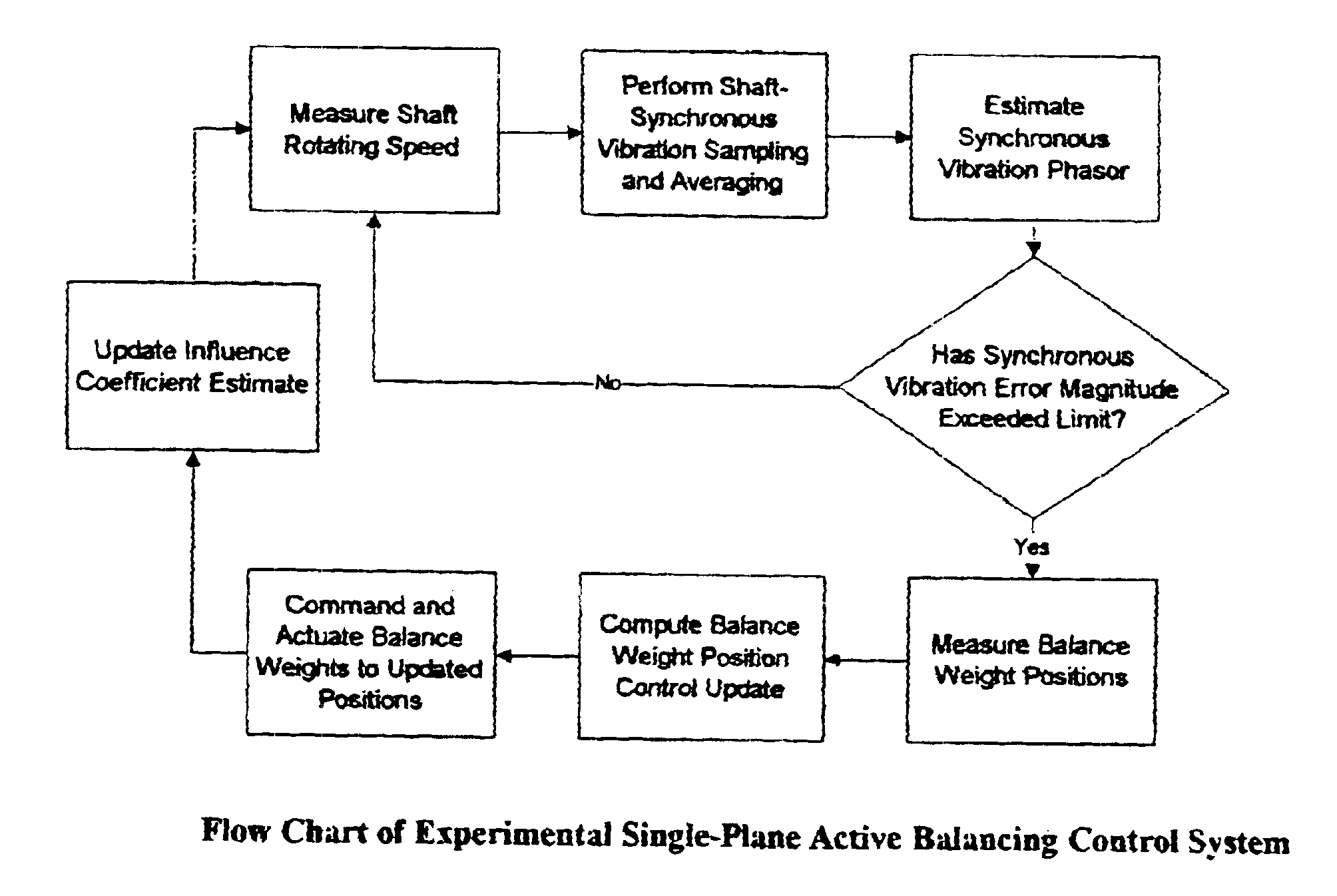

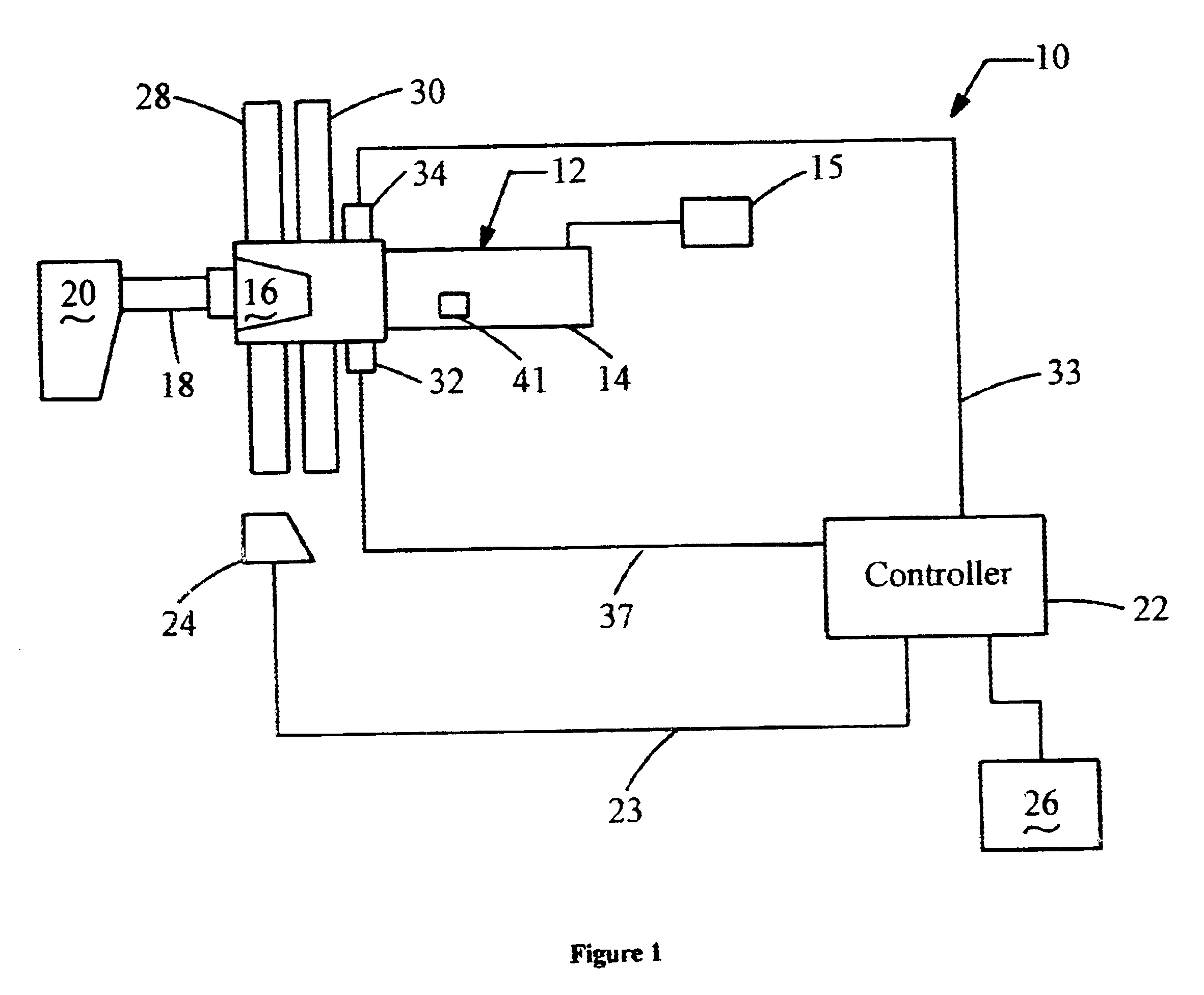

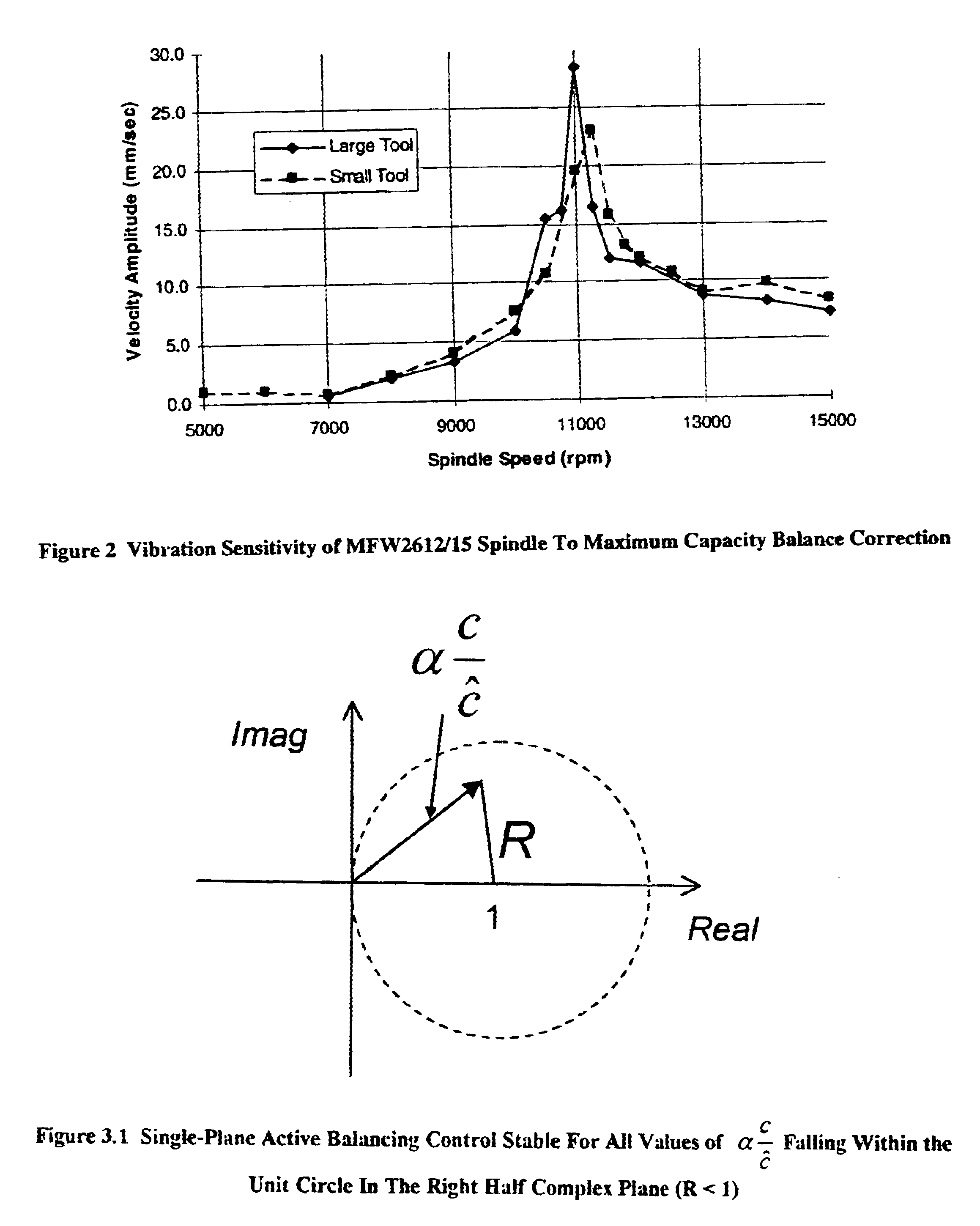

Method and apparatus for balancing

InactiveUS6618646B1Overcomes drawbackImprove vibrationSampled-variable control systemsComputer controlEngineeringShort terms

A balancer assembly 10 which automatically provides balancer limits, which achieves a balancing state while substantially minimizing short term vibration increases and which provides for multi-plane balancer dithering.

Owner:LORD CORP

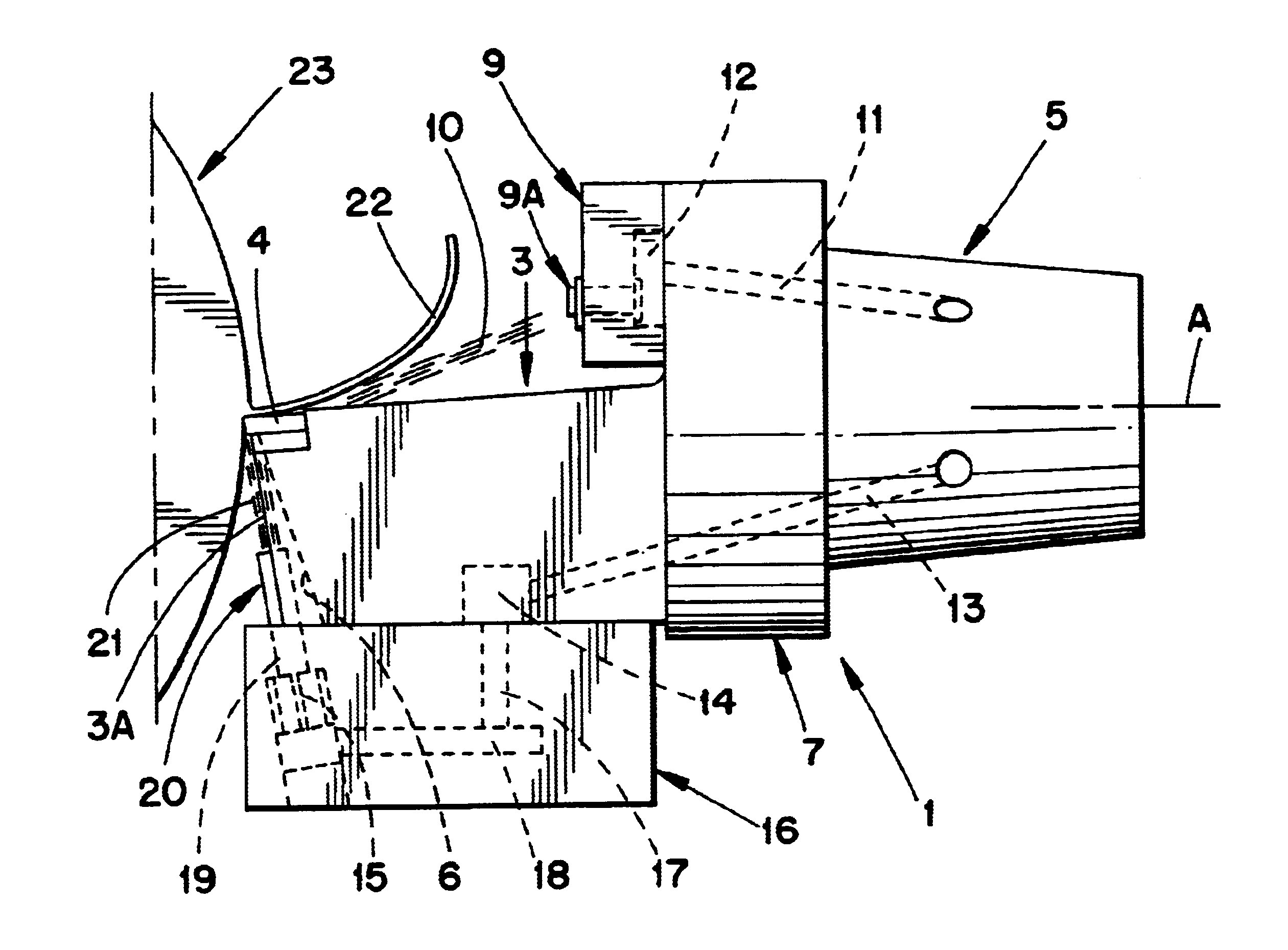

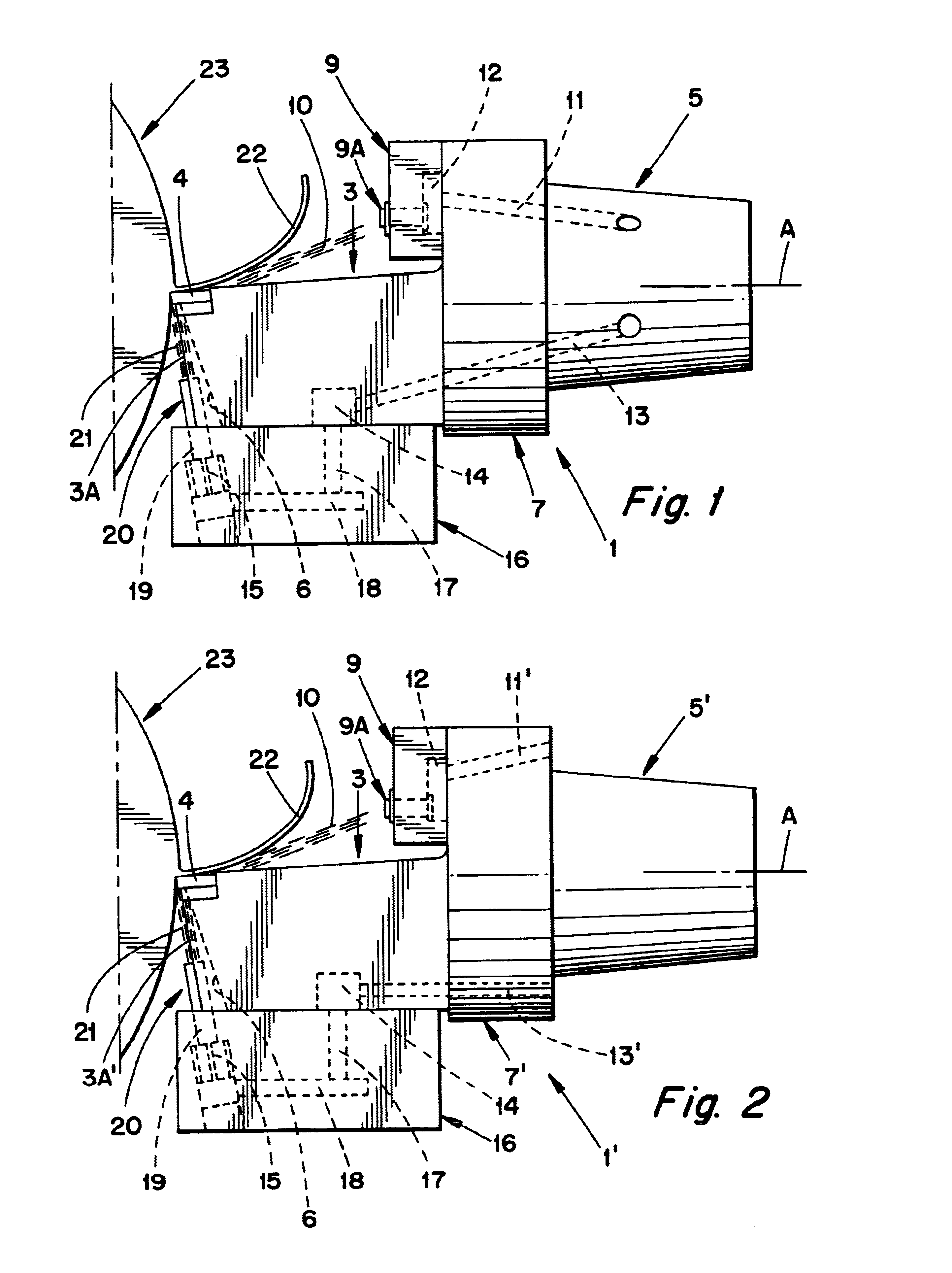

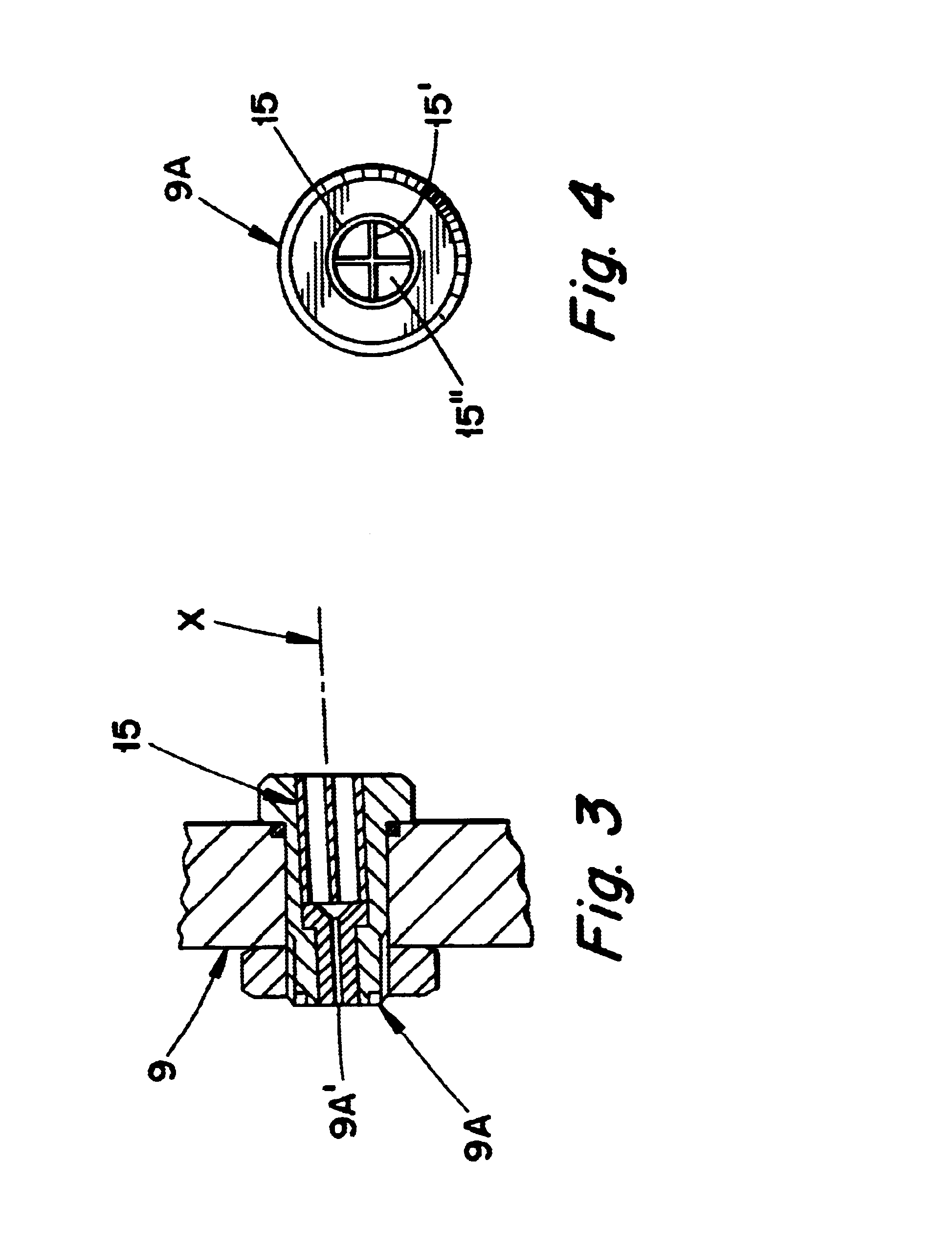

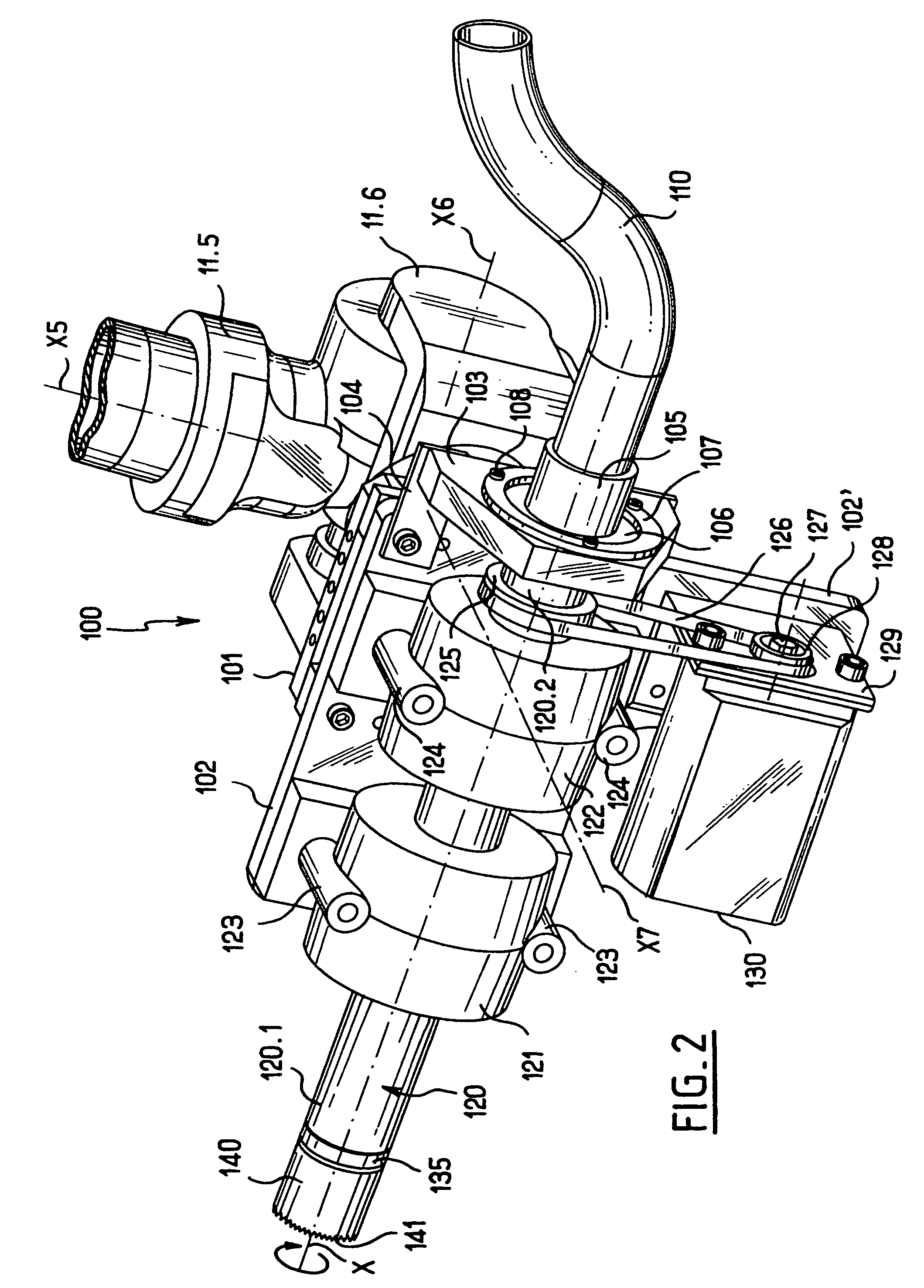

Machining mechanical parts with a hollow cylindrical tool

ActiveUS20060291970A1Simple processAvoid high frequency noiseThread cutting feeding devicesDrilling rodsWood shavingsMechanical components

The present invention relates to a device for machining mechanical parts by means of a hollow cylindrical tool presenting a distal end with a free edge that is shaped to perform machining when said tool is rotated about its axis. In accordance with the invention, the hollow cylindrical tool is fitted internally with a transverse member forming a shaving-breaker, and said hollow cylindrical tool is secured axially to a distal end of a hollow cylindrical spindle, said hollow cylindrical spindle being mounted to rotate about its own axis on a support plate, and being driven externally by rotary drive means mounted on said support plate, and said hollow cylindrical spindle having a proximal end facing and directly adjacent to a hollow cylindrical endpiece secured to said support plate and connected to a suction hose, such that the machining shavings can be evacuated internally by passing successively through the hollow cylindrical tool going round the transverse member forming a shaving-breaker, through the hollow cylindrical spindle, through the hollow cylindrical endpiece, and through the suction hose.

Owner:ROMER INC

Dust extractor device for a router

ActiveUS7290967B2Maximum effectivenessSpace minimizationMulti-purpose machinesProfiling/shaping machinesEngineeringFoot boards

A dust extractor device of a router has rotatable dust trap part able to be connected with a foot plate of the router and arranged to the side of the routing tool underneath the foot plate, such dust trap part being open toward the routing tool. The foot plate has an access opening for the routing tool. The dust trap part is constituted by an extractor hood with a hood casing at least essentially centered on the axis of rotation and a hood floor. The hood casing and the hood floor extend in the peripheral direction through an angle equal to or less than 180°. The extractor hood is open at its top side and opens into the access opening. The top end region of the extractor hood is rotatably supported on a holder, which is detachably secured to the foot plate and in the position of use extends around the access opening. The top side of the access opening is provided with a covering means, which is detachably attached to the foot plate and covers the access opening, such covering means having in it an access opening for the routing tool. The connection means is, in the position of use, in open connection with the access opening.

Owner:FESTOOL GMBH

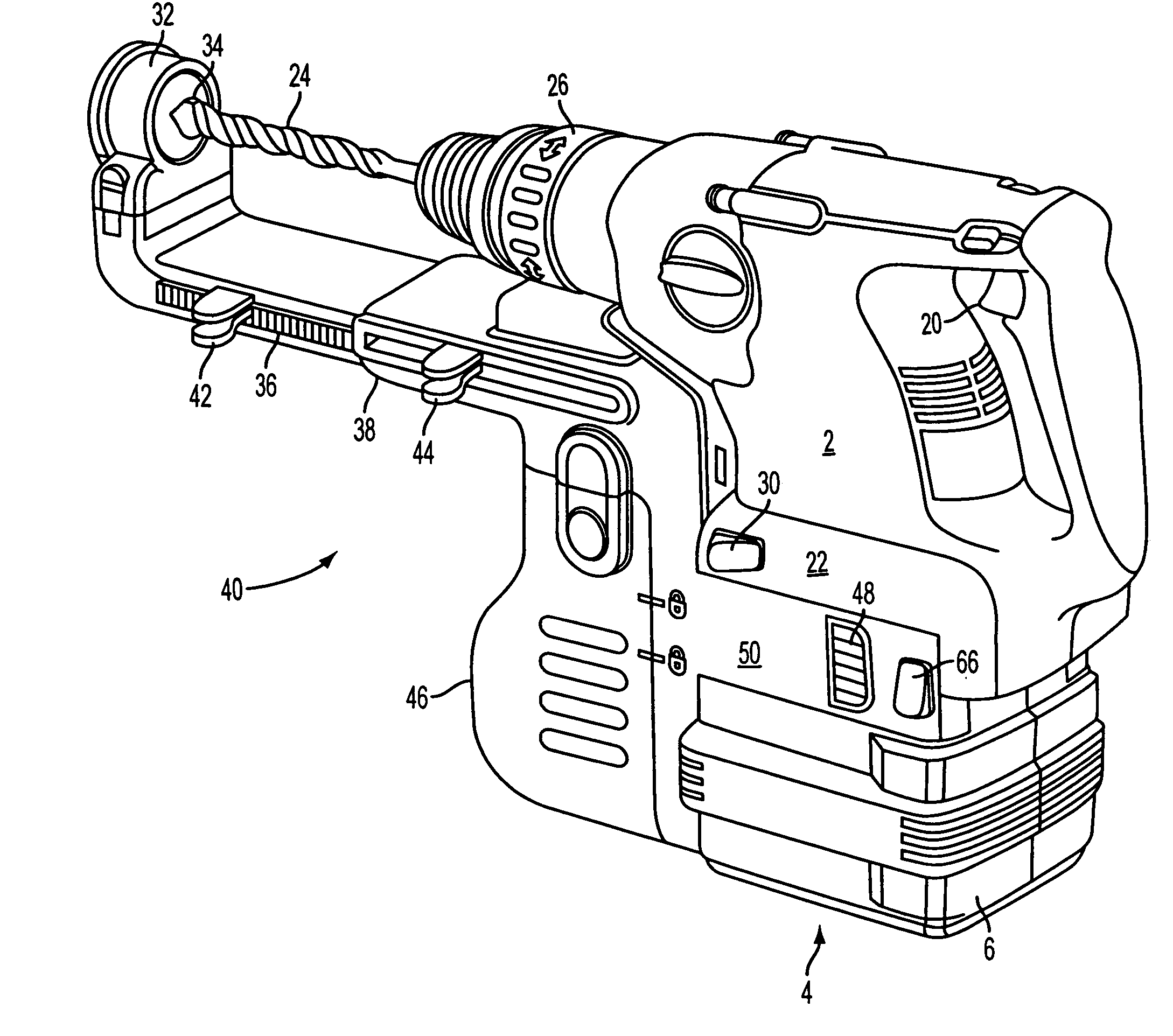

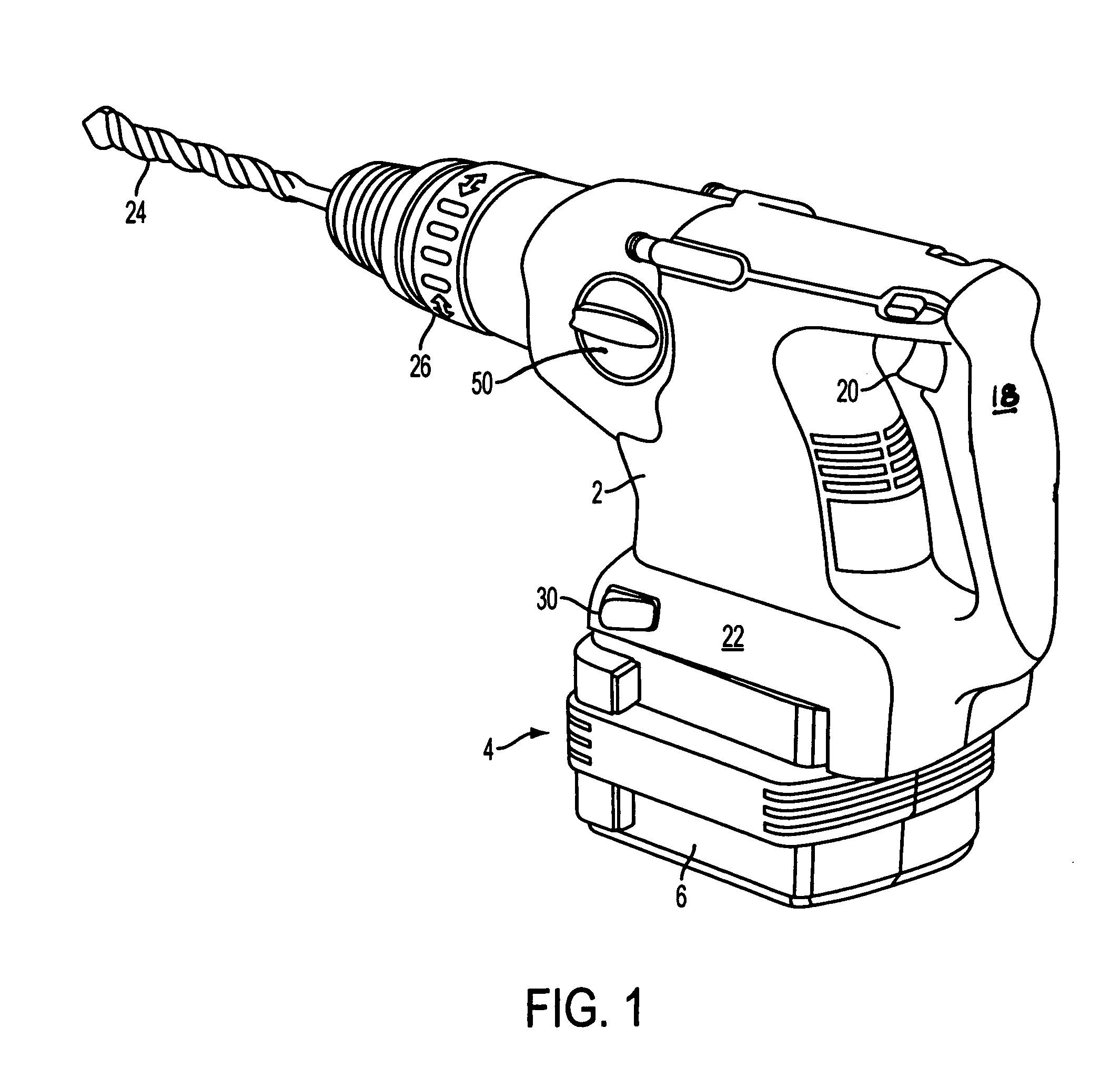

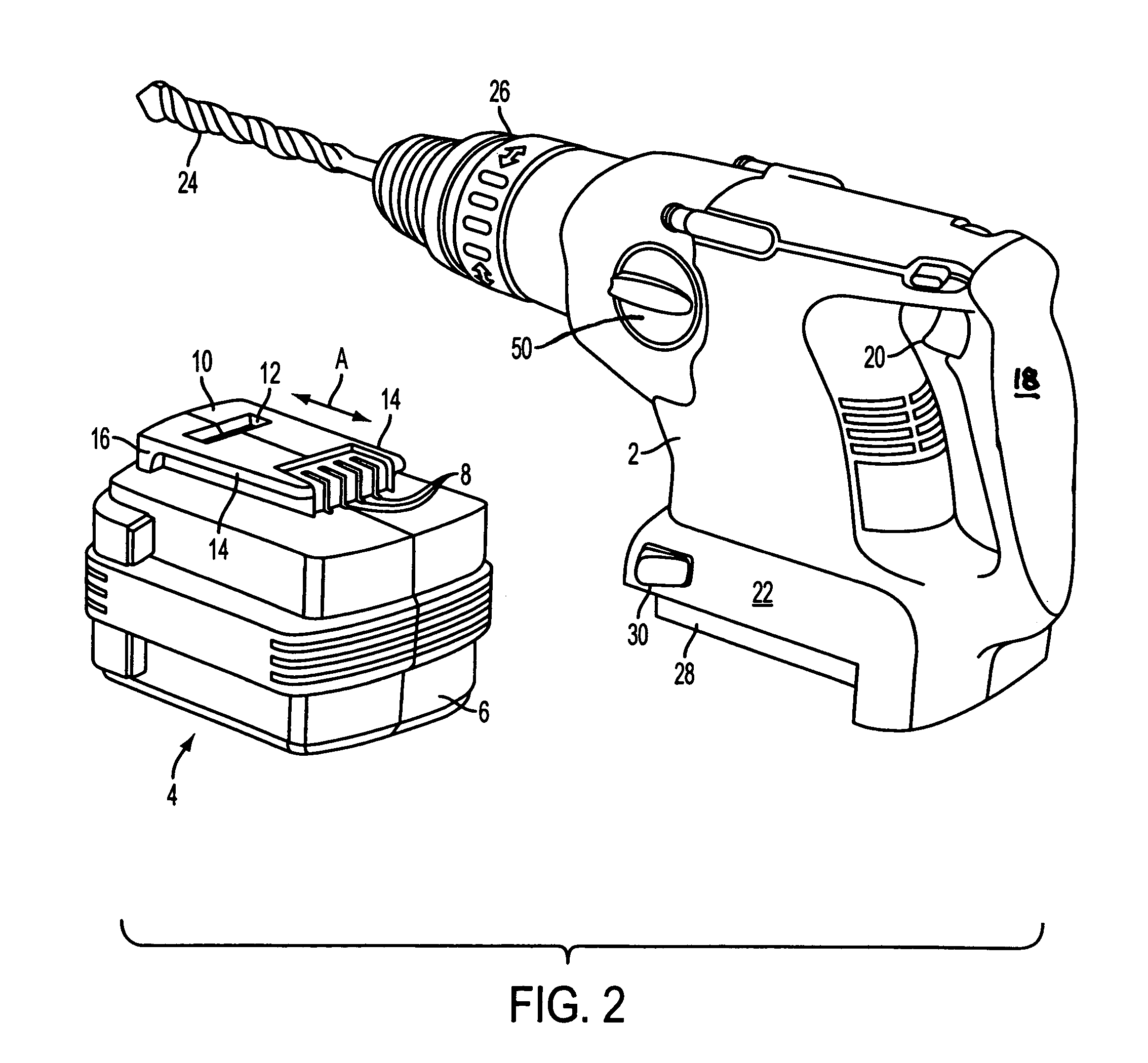

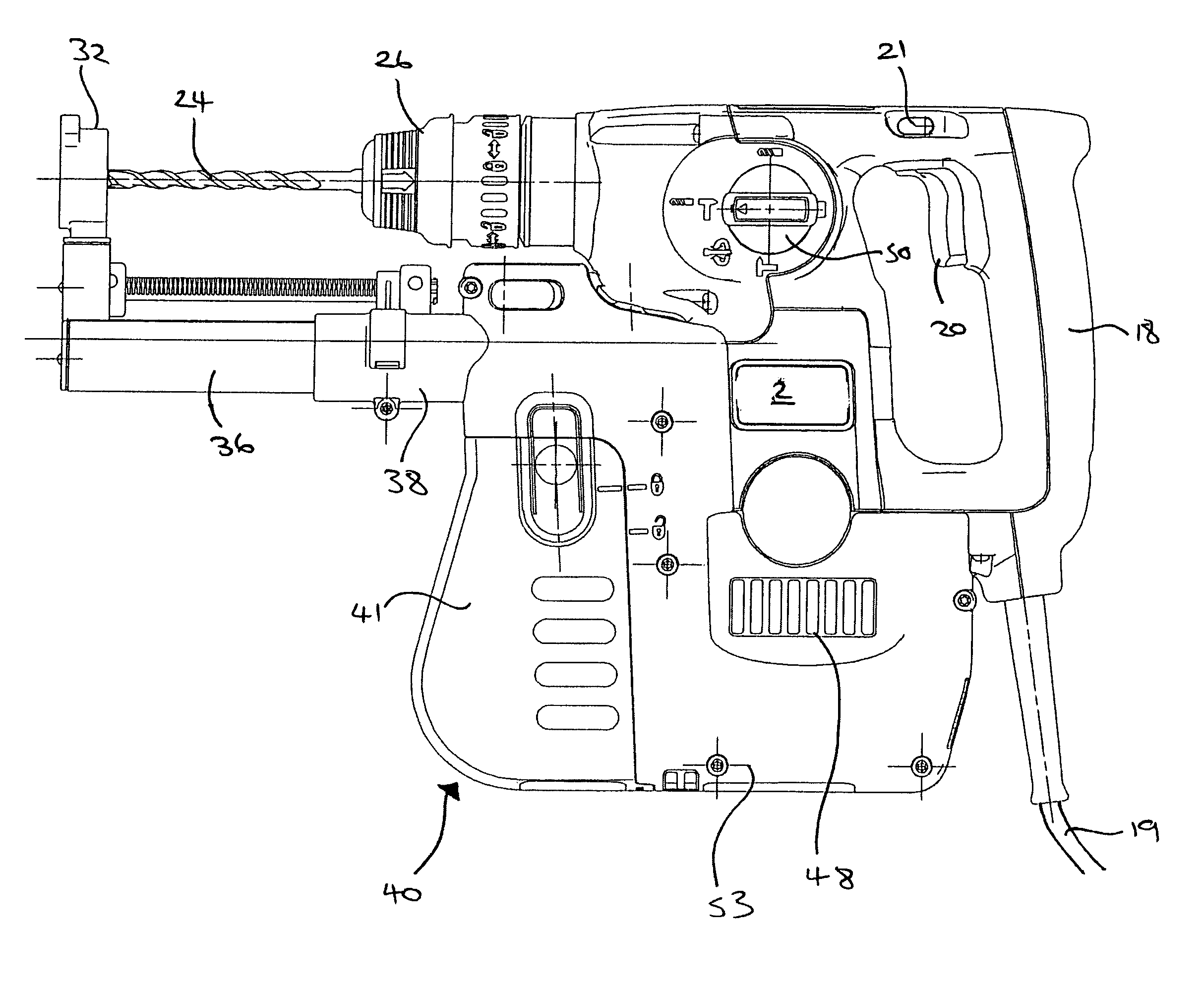

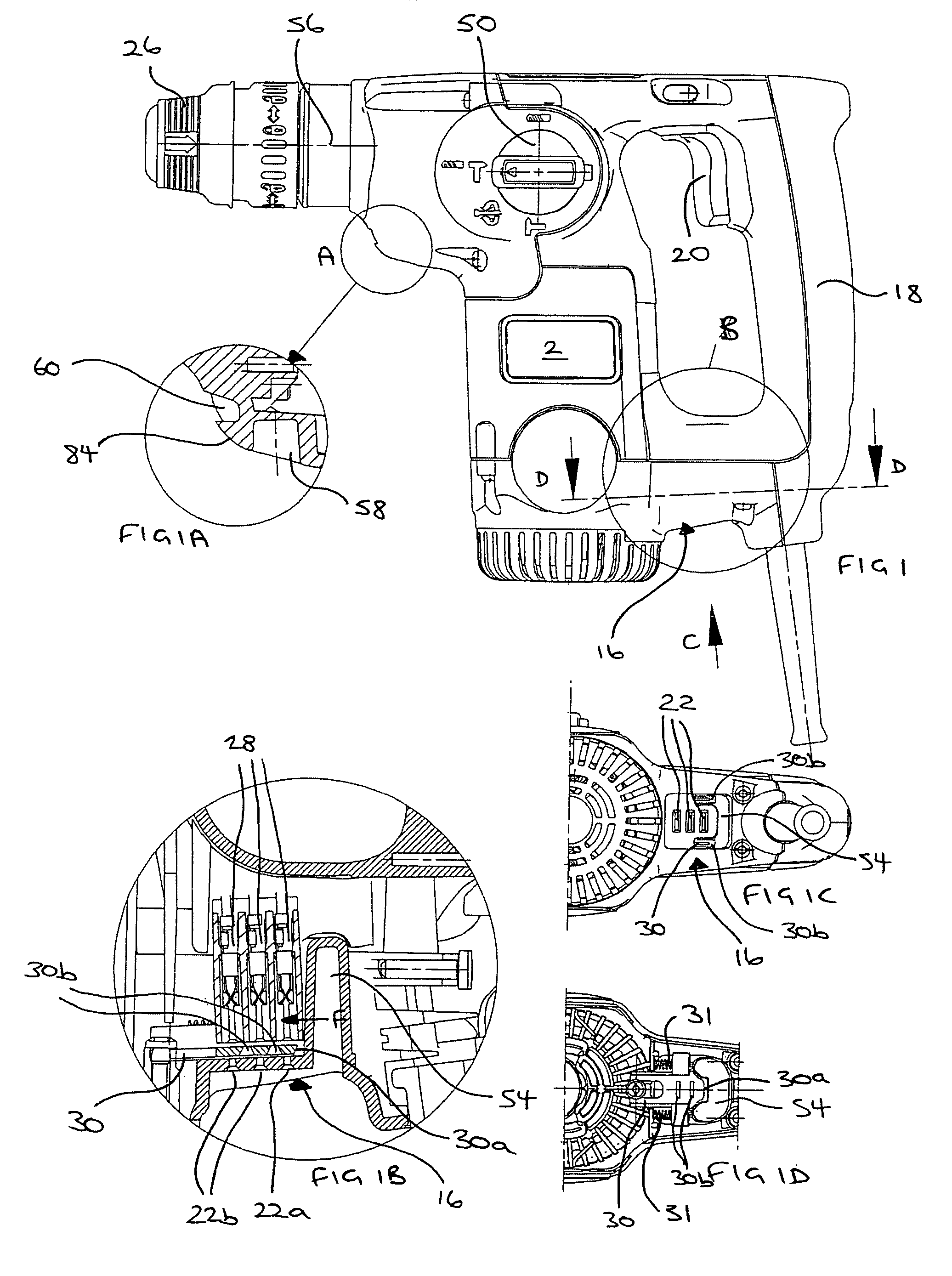

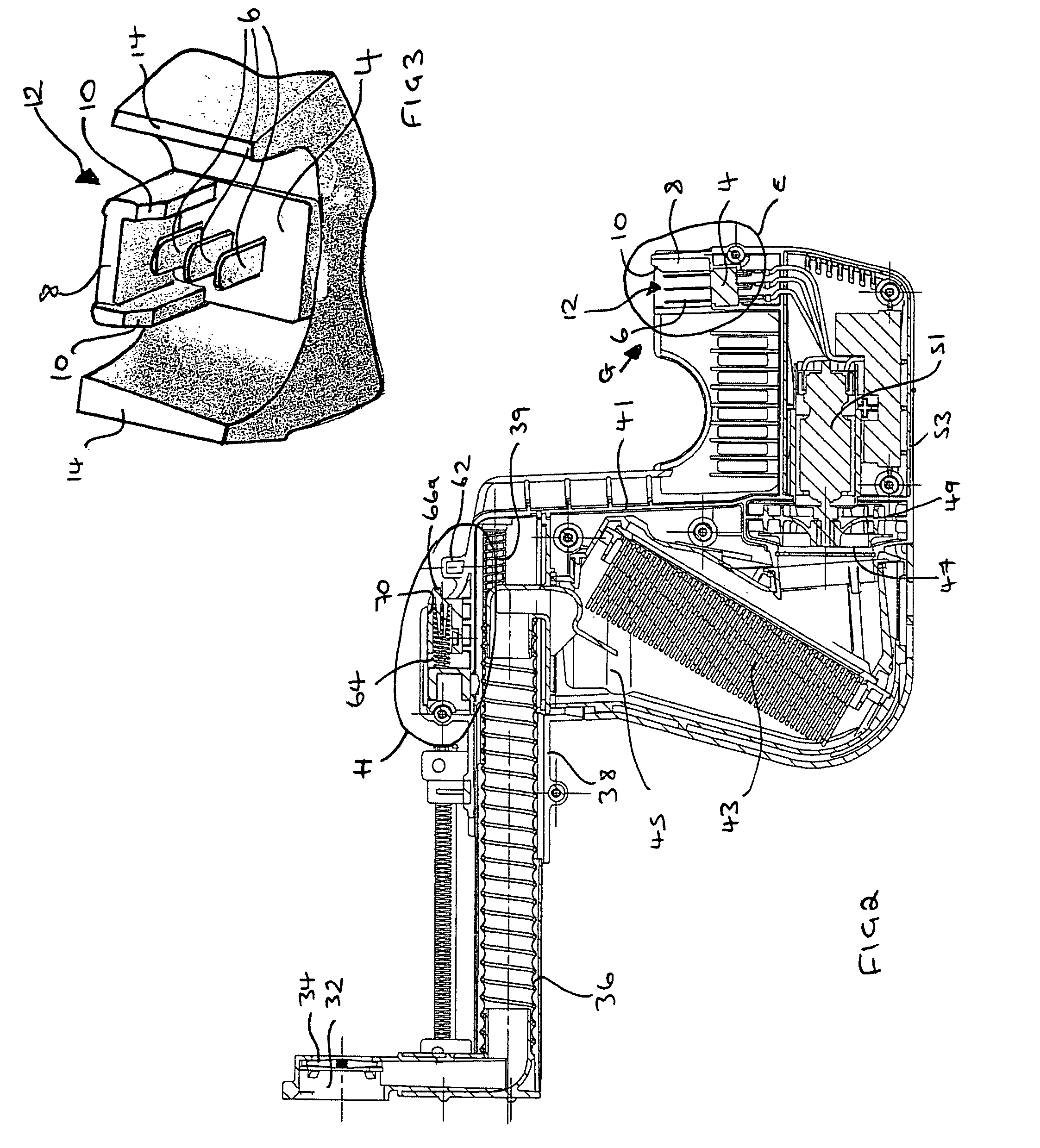

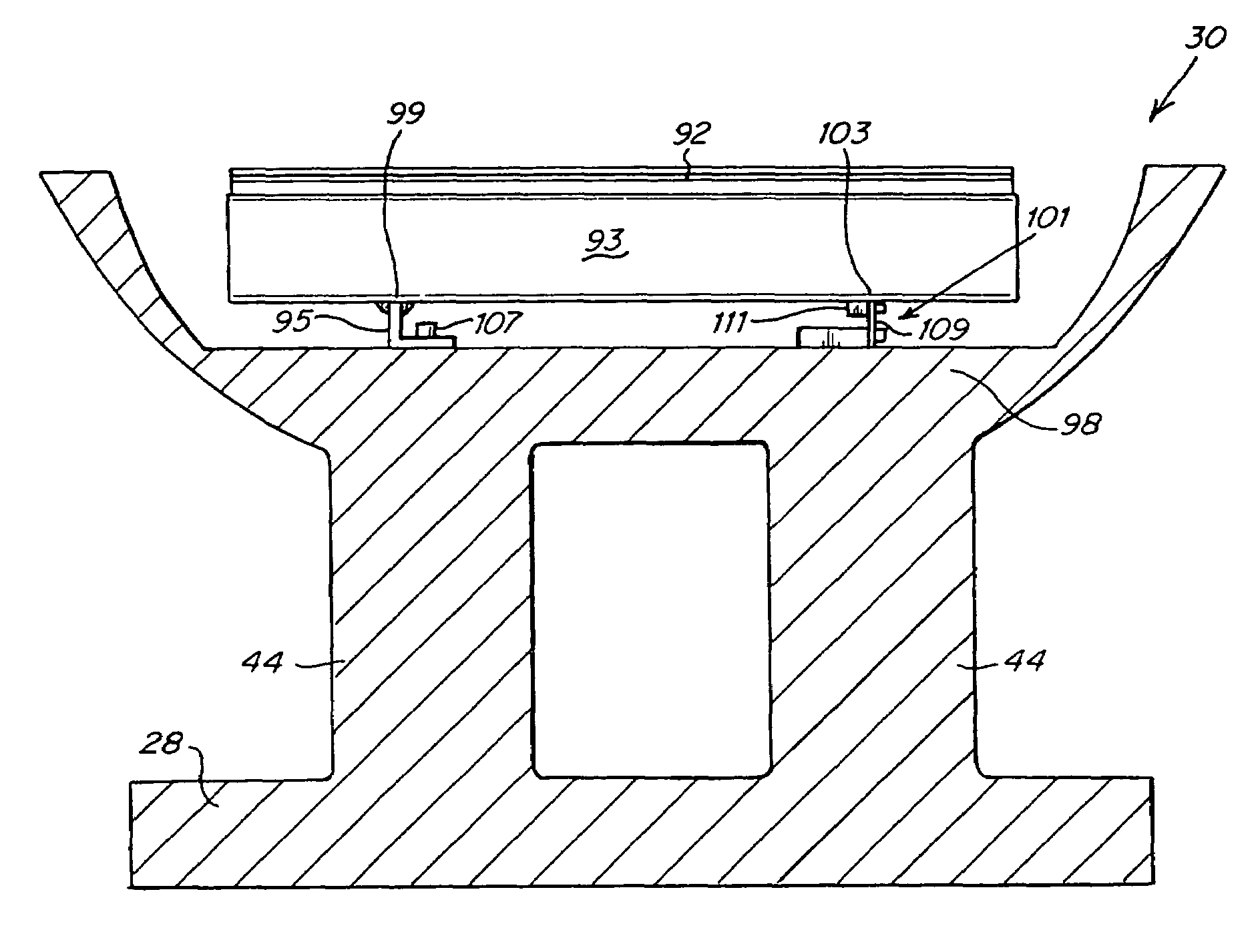

Hand held drilling and/or hammering tool with dust collection unit

InactiveUS7017680B2Efficient processEasy to installThread cutting feeding devicesDrilling rodsHand heldElectrical connection

Owner:BLACK & DECKER INC

Temperature compensation system for a coordinate measuring machine

ActiveUS7191541B1Minimize movementWalking sticksMetal working apparatusCouplingCoordinate-measuring machine

A machine, such as a coordinate measuring machine, having a component or element movable with respect to a support structure along rails or guideways, wherein the rails have a coefficient of thermal expansion that is different from that of the support structure to which they are attached. Differential thermal expansion and contraction of the rails with respect to the support structure may be accommodated without binding or distortion of the rails by coupling each guideway to the support structure at two different points. Typically, the coupling at the first point is rigid and prevents any movement of the rail with respect to the support structure. The second coupling includes a flexible component that permits movement of the rail with respect to the support structure in a direction of movement of the element or component. This flexible component may be a leaf spring. In another embodiment, the first coupling may also be flexible. A method is also disclosed for accommodating differential thermal expansion and contraction of the rail with respect to the support structure by providing first and second couplings between the rail and support structure wherein at least the second coupling includes a flexible component that permits movement of the rail with respect to the support structure in a direction generally parallel to the direction of movement of the machine element.

Owner:HEXAGON TECH CENT GMBH

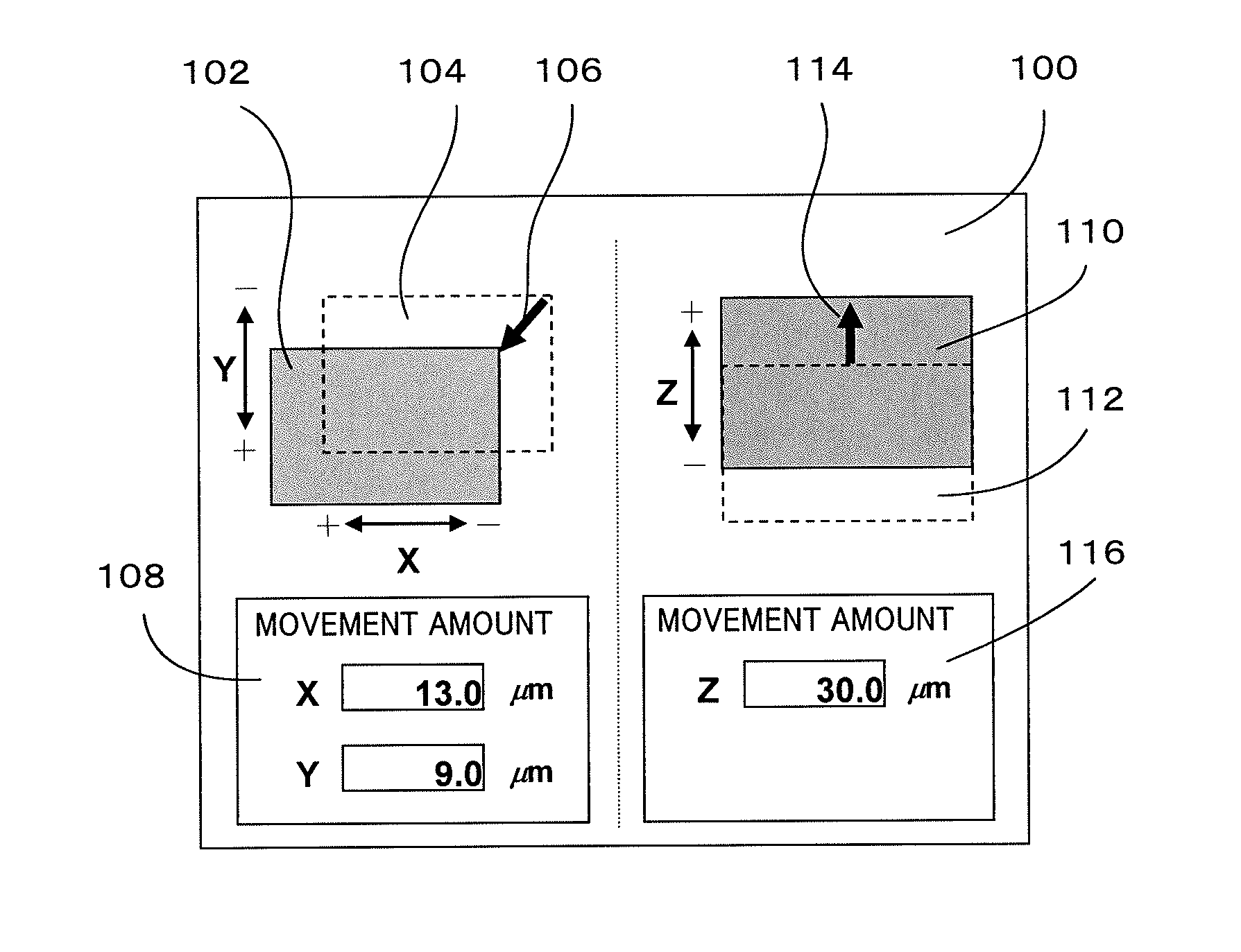

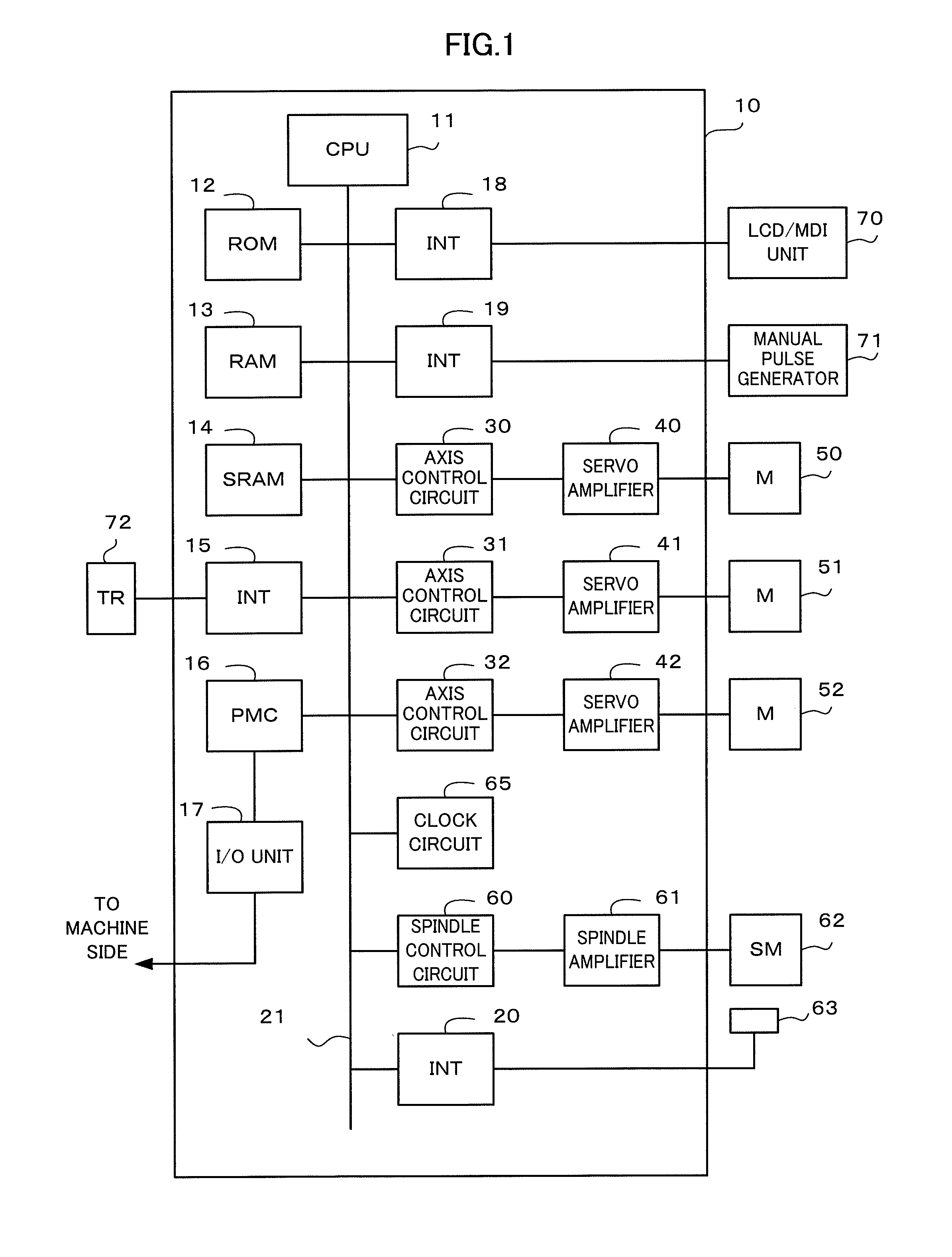

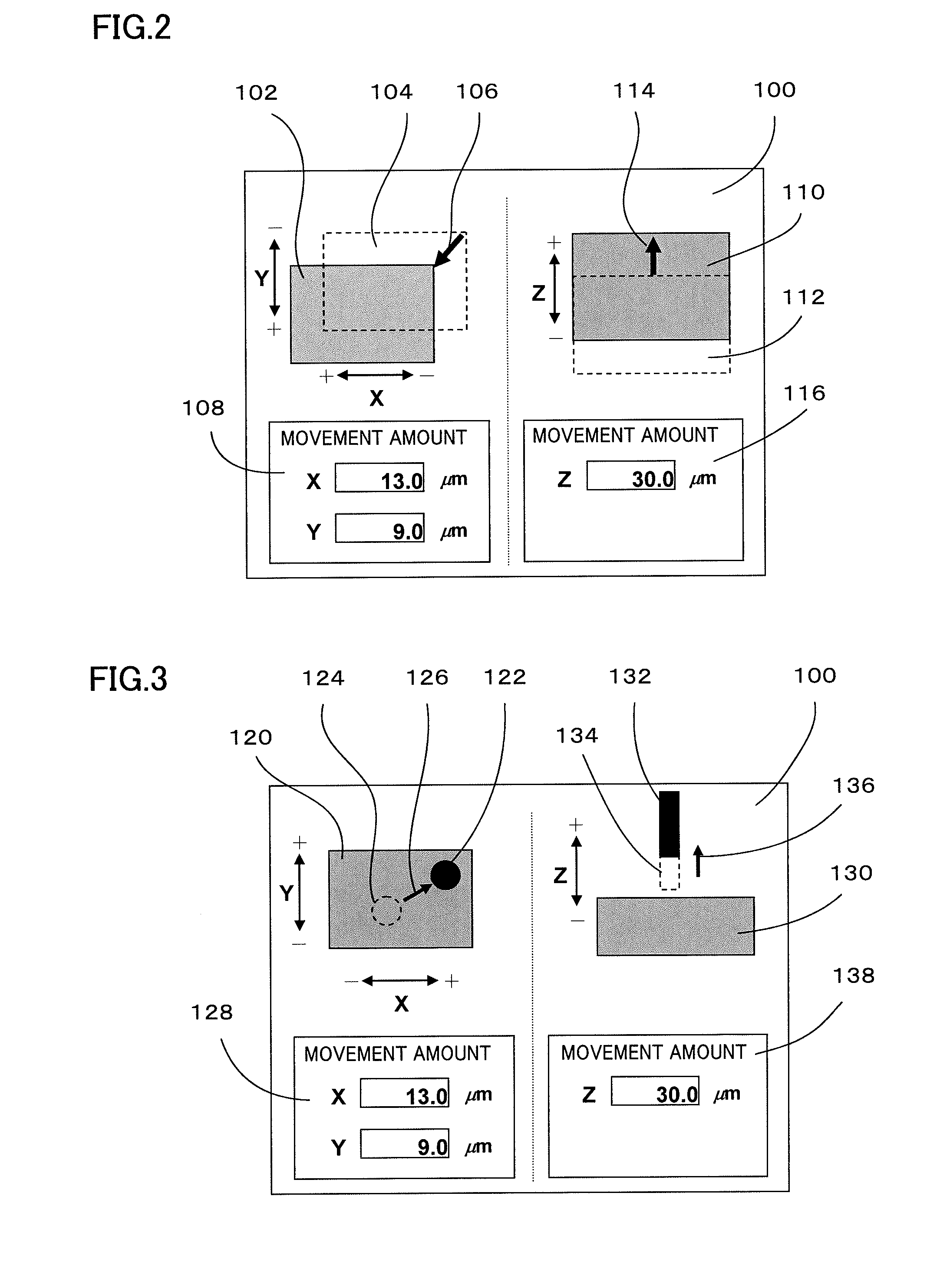

Themal dispalcement compensating device of machine tool

ActiveUS20140074299A1Reduce setting errorsReduce errorsProgramme controlSampled-variable control systemsControl theoryThermal displacement

A position command value is compensated by predicting a thermal displacement amount of each part of a machine tool and adding a thermal displacement compensation amount which cancels the predicted thermal displacement amount to the position command value of a feed axis. This thermal displacement compensation amount is adjusted from the error amount between this compensated position command value and an actual machining point. Upon adjustment of this thermal displacement compensation amount, it is possible to determine whether to increase or decrease the thermal displacement amount based on a direction in which an operator moves a tool image or a workpiece image on a screen.

Owner:FANUC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com