Patents

Literature

22343 results about "Dust control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dust filter bag including a highly porous backing material ply

InactiveUS6706086B2Simple and cost-effective productionCleaning filter meansCombination devicesBursting strengthCellulose fiber

A dust filter bag having a highly porous backing material ply and a method for producing the dust filter bag. The dust filter bag includes at least one filter material ply and at least one backing material ply, the backing material ply possessing an air permeability of at least 900 l / m<2 >x s, a burst strength of at least 70 kPa, a rupture strength longitudinally better than 10 and transversely better than 3 N, a flexural rigidity longitudinally better than 0.5 cN cm<2 >and transversely better than 0.25 cN cm<2>, a basis weight of 30-80 g / m<2 >and a droplet sink-in time of less than 10 minimum. The dust filter bag can be produced by the following steps: mixing fibers including cellulose fibers and fusible fibers into a homogenous fiber mix, processing the fiber mix into a fiber web by wet laying, drying the fiber web, curing the dried fiber web by thermofusion into a backing material ply, processing the backing material ply with a filter material ply into a raw bag, and finishing the raw bag into a dust filter bag.

Owner:NEENAH GESSNER GMBH

Low dust gypsum wallboard

ActiveUS20070048490A1High strengthReduce weightConstruction materialCovering/liningsDust controlSlurry

This invention provides low dust low density gypsum wallboard products having high total core void volumes, corresponding to low densities in the range of about 10 to 30 pcf. The wallboards have a set gypsum core formed between two substantially parallel cover sheets, the set gypsum core preferably having a total void volume from about 80% to about 92%, and made from a slurry including stucco, pregelatinized starch, and a naphthalenesulfonate dispersant. The combination of the pregelatinized starch and the naphthalenesulfonate dispersant also provides a glue-like effect in binding the set gypsum crystals together. The wallboard formulation, along with small air bubble voids (and water voids) provides dust control during cutting, sawing, routing, snapping, nailing or screwing down, or drilling of the gypsum-containing products. This invention also provides a method of making the low dust low density gypsum products including the introduction of soap foam in an amount sufficient to form a total void volume, including air voids, preferably from about 80% to about 92% in the set gypsum core, corresponding to a set gypsum core density from about 10 pcf to about 30 pcf. The wallboards produced by the method generate significantly less dust during working.

Owner:UNITED STATES GYPSUM CO

Resource utilization process of organic hazardous waste

ActiveCN111185460AHarmlessAchieve reductionSolid waste disposalTransportation and packagingFluid phaseSlag

The invention discloses a resource utilization process of organic hazardous waste. The resource utilization process includes the steps that classified storage and treatment of solid-phase, solid-liquid mixing and liquid-phase organic hazardous waste are carried out; solid-phase crushing, grinding and screening treatment is carried out; solid-liquid mixing is carried out after solid-liquid separation, solid-phase grinding and liquid-phase sedimentation separation treatment is carried out; direct liquid-phase sedimentation is carried out; then after solid-liquid mixing, a fluxing agent is addedfor stirring, a stabilizer and a dispersing agent are added for slurrying, the slurry is fed into a gasifier, and the obtained gas is used as fuel gas after being subjected to cooling, dedusting, spraying and desulfuration; slag tapping and vitrification slag discharge are carried out; and waste water is recycled. The resource utilization process has the beneficial effects that solid phase, solid-liquid mixing and liquid-phase comprehensive treatment, harmless treatment and slag discharge are realized.

Owner:杰瑞邦达环保科技有限公司

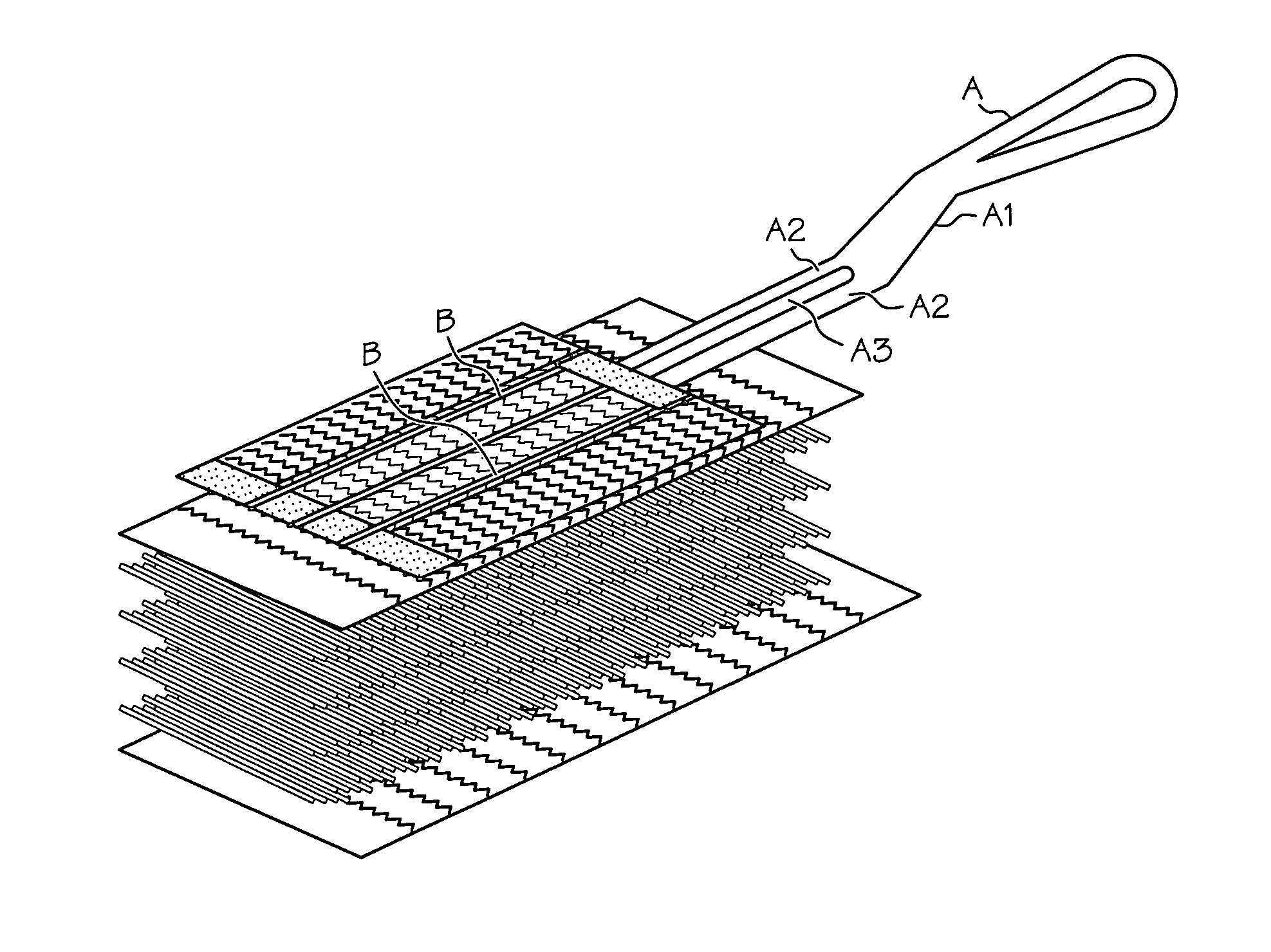

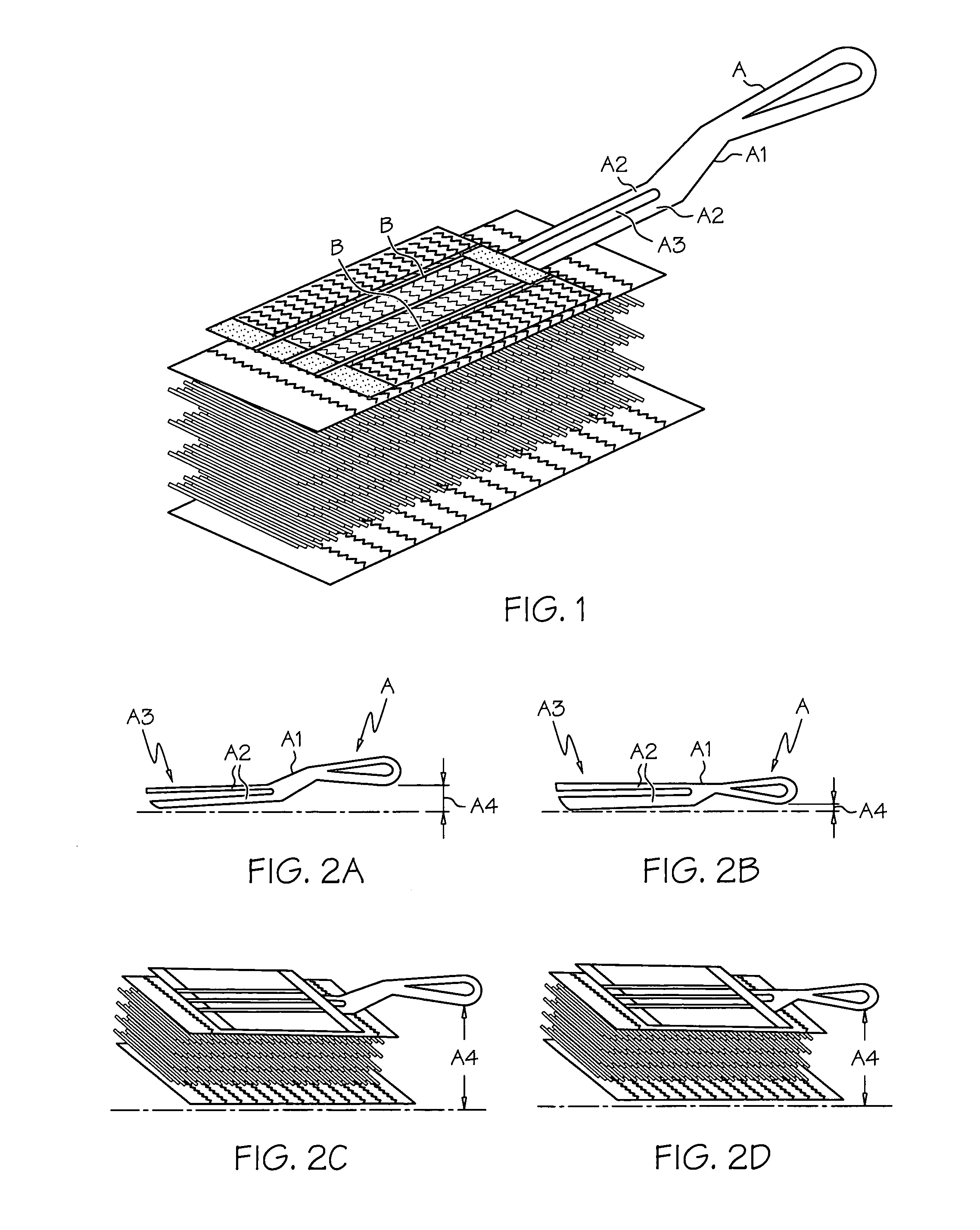

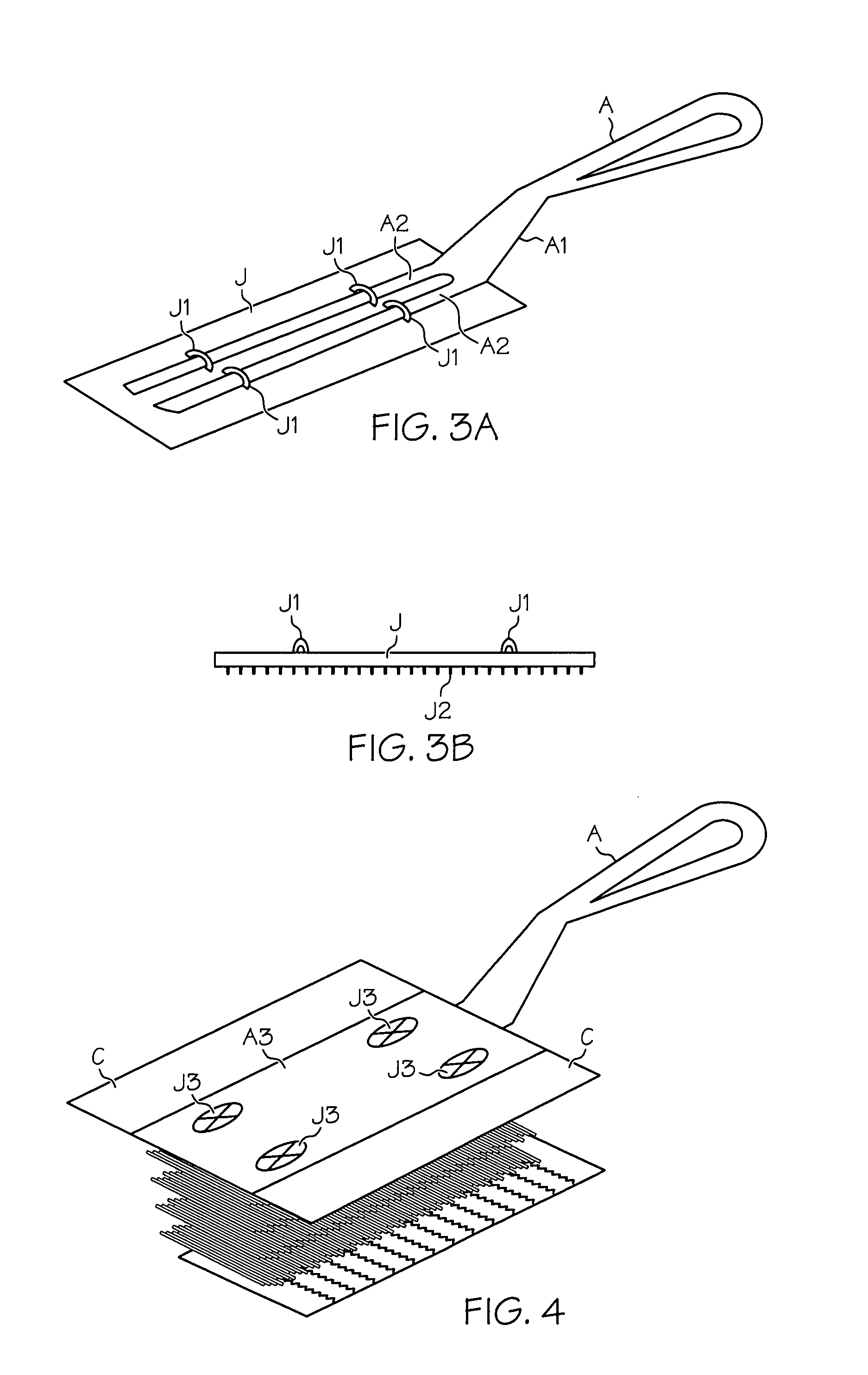

Duster system for damp and dry dusting

A kit duster pad and a cleaning composition said duster pad comprising at least one layer comprising hydrophilic non-woven fibers capable of contacting a surface to be cleaned; and at least one non-woven layer capable of being attached to a handle, wherein the at least one layer comprises at least one free end; and wherein said cleaning composition comprises a solids content at least about 0.5% by weight of the cleaning composition.

Owner:THE PROCTER & GAMBLE COMPANY

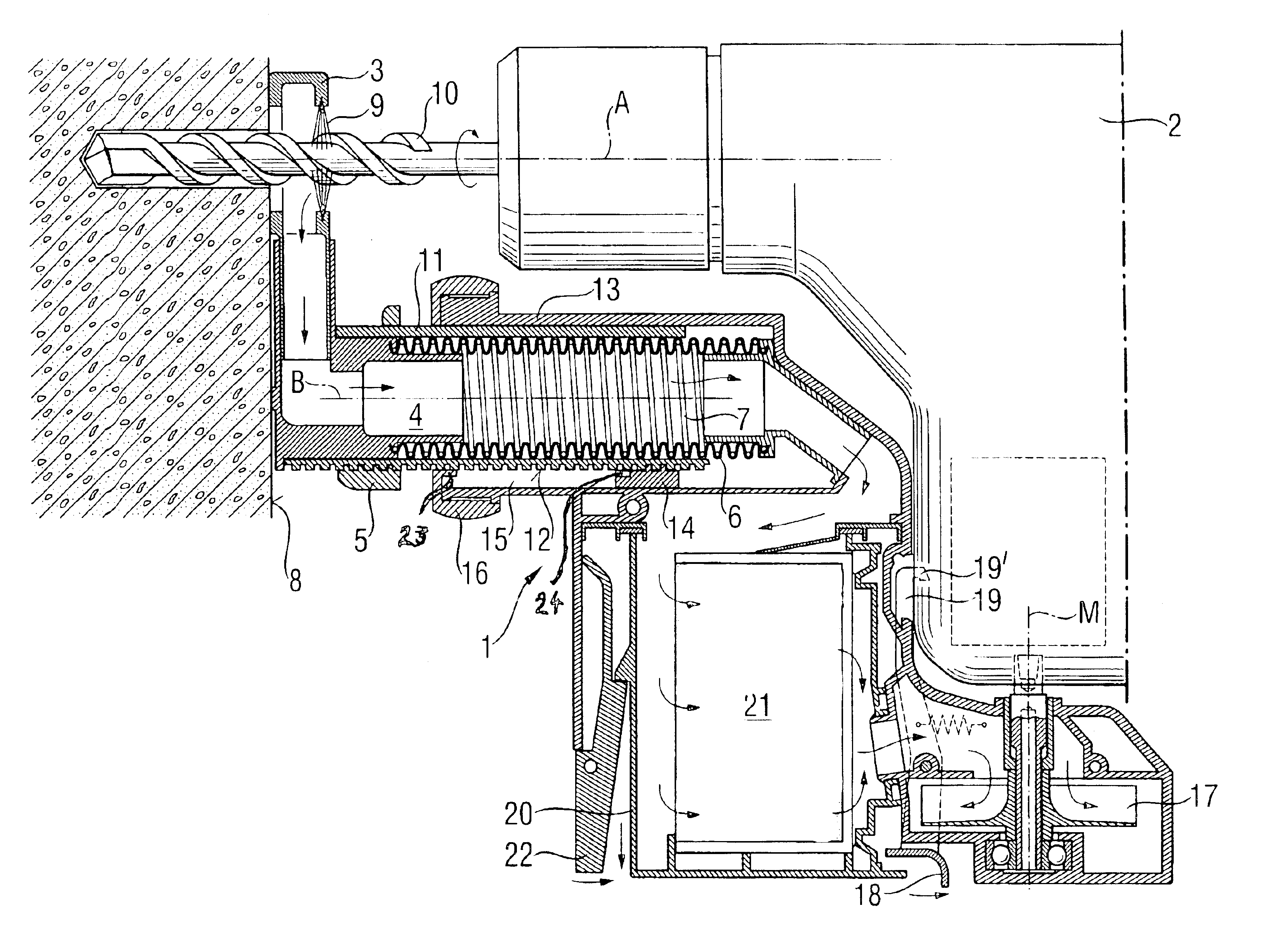

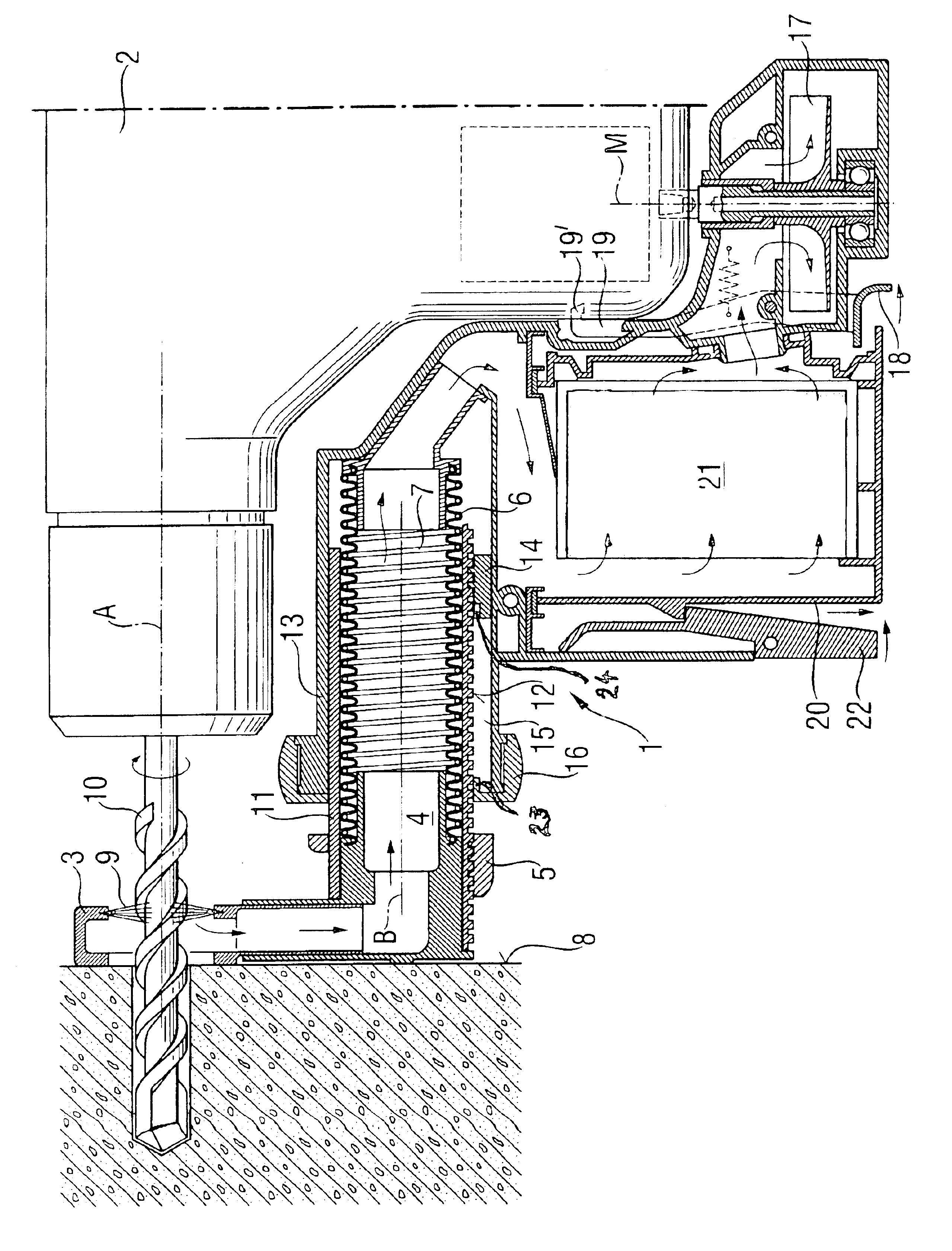

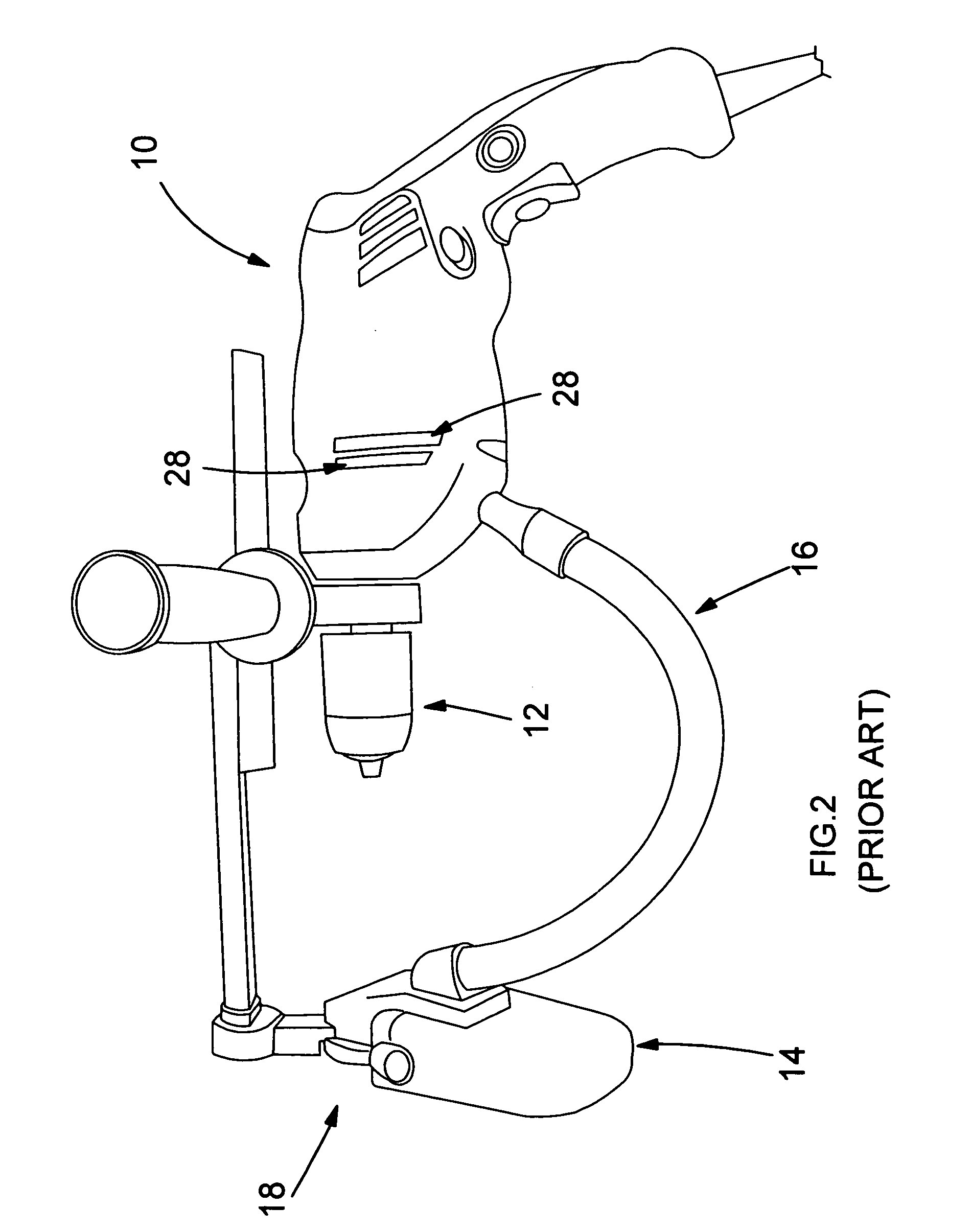

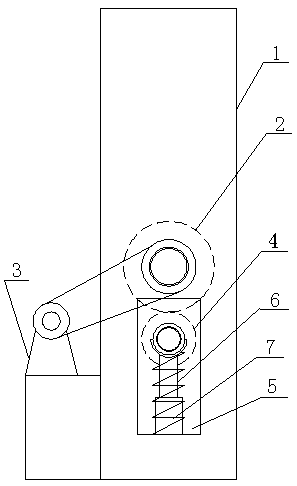

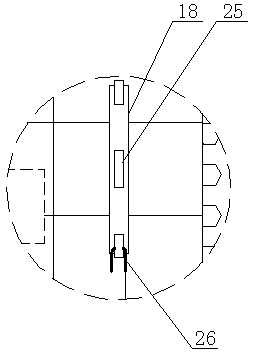

Dust removal unit for a hand tool device

InactiveUS6851898B2Easy to installDrilling/boring measurement devicesThread cutting feeding devicesEngineeringRemoval Units

A dust removal unit (1) includes an adjustable axial depth stop (5) for an at least partially rotatable hand tool device (2) with a radially displaced, rotationally fixed, telescopable, axially limited movable suction tube assembly with a suction tube (4) running parallel to the axis (A) of the tool device (2) and coupled at one end to a suction head (3). The suction tube (4) includes an axially extending pleated bellows (6).

Owner:HILTI AG

Flashless rubber floor mat and method

InactiveUS6589631B1Provide stabilityPermit cleaningLiquid surface applicatorsKitchenware cleanersCushioningDust control

A flashless floor mat or product and method are provided. At least one embodiment of this invention relates to a flashless cushioned dust control mat article wherein the mat comprises at least two distinct layers of rubber, one comprising foam rubber, the other comprising solid rubber. The solid rubber layer is present over the foam rubber layer on the side of the mat in which at least one integrated rubber protrusion is present to provide cushioning characteristics. The solid rubber layer acts as a cap or barrier for the foam rubber layer, particularly over the integrated protrusion or protrusions, in order to provide a mat which is resilient, will not easily degrade in its modulus strength after appreciable use and / or washing within industrial cleaning processes, and will not exhibit appreciable cracking or breaking, particularly within the integrated protrusion(s), after standard use for pedestrian traffic. A method of producing such an inventive cushioned floor mat article is also provided.

Owner:MILLIKEN & CO

Functional filter felt for eliminating harmful constituents of fume, preparation method and application method thereof

ActiveCN101518718AExtended service lifePrevent penetrationPhysical/chemical process catalystsDispersed particle separationNonwoven fabricHigh heat

The invention pertains to the technical field of fume purification. The provided functional filter felt for eliminating harmful constituents of fume can realize the desulfurization or denitration of fume when removing dust; the filter felt is made from fiber materials and a functional catalyst in a compound manner; when purifying the harmful constituents of fume, the filter felt filters the dusts in the fume with nonwoven fabrics made from high temperature-resistant fiber material and carries out a catalytic reaction to eliminate nitrogen oxides (NOX) and / or sulfur oxides (SOX) through the functional catalyst contained in the filter felt. The provided filter felt is applicable to fume dedusting devices, fume desulfurization devices and fume denitration devices in power plants, metallurgical plants and chemical plants, in particular to the manufacturing of bag type fume filter. Compared with the prior art, the invention simplifies the fume purifying processes, improves processing efficiency, effectively saves the investment and reduces operational expenses, thus being suitable for the modification of the existing fume dedusting device.

Owner:CHINESE TEXTILE ACAD

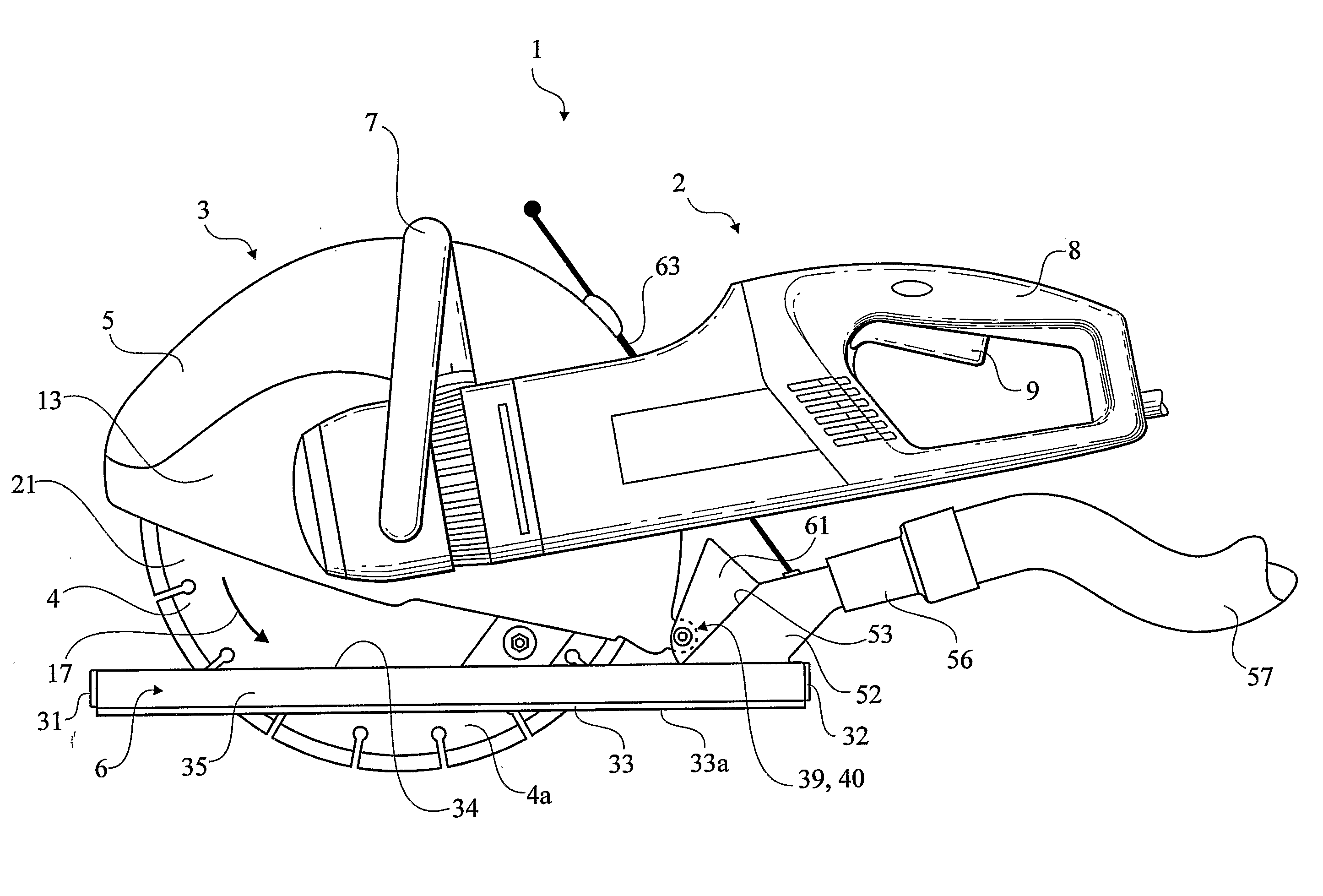

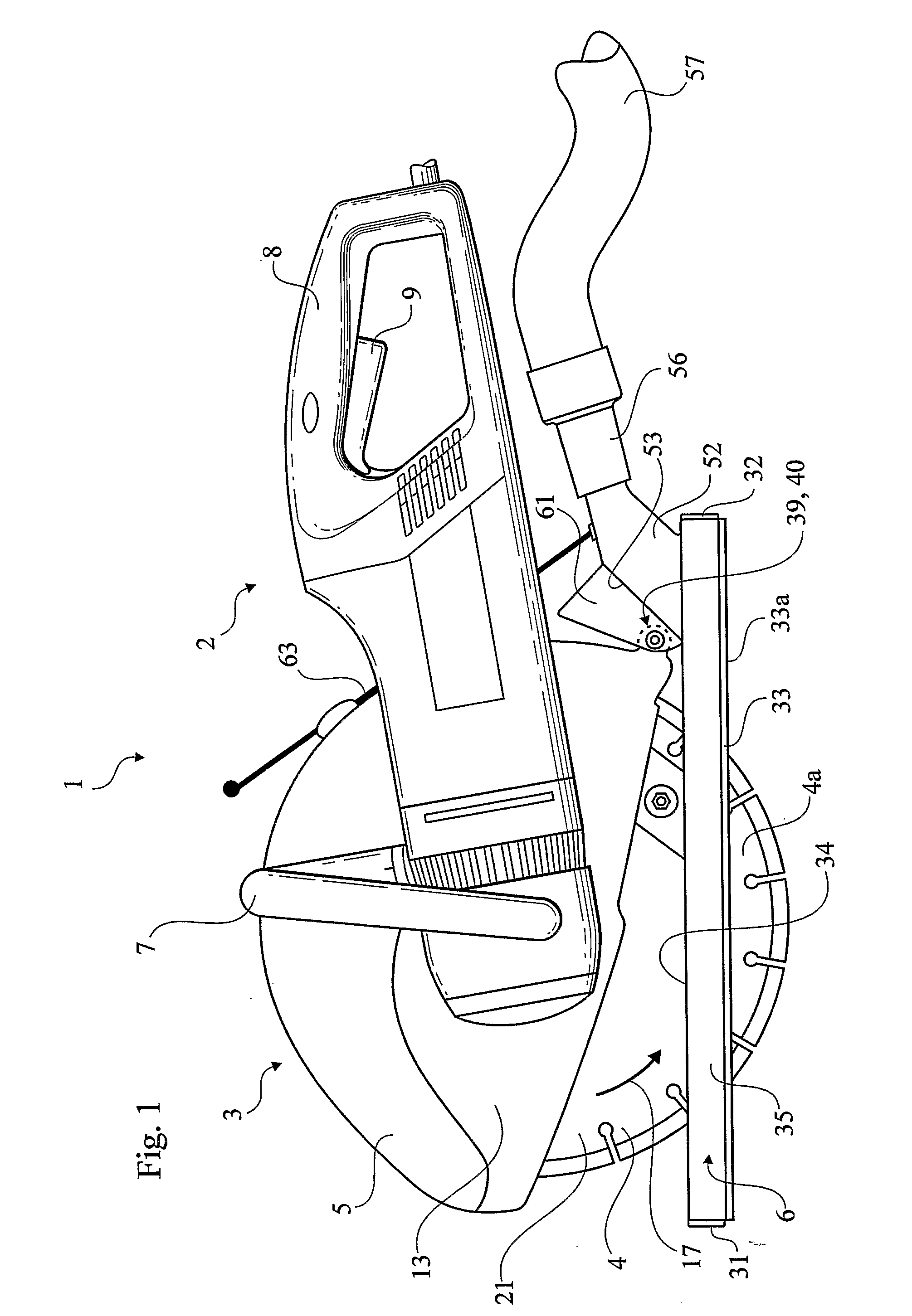

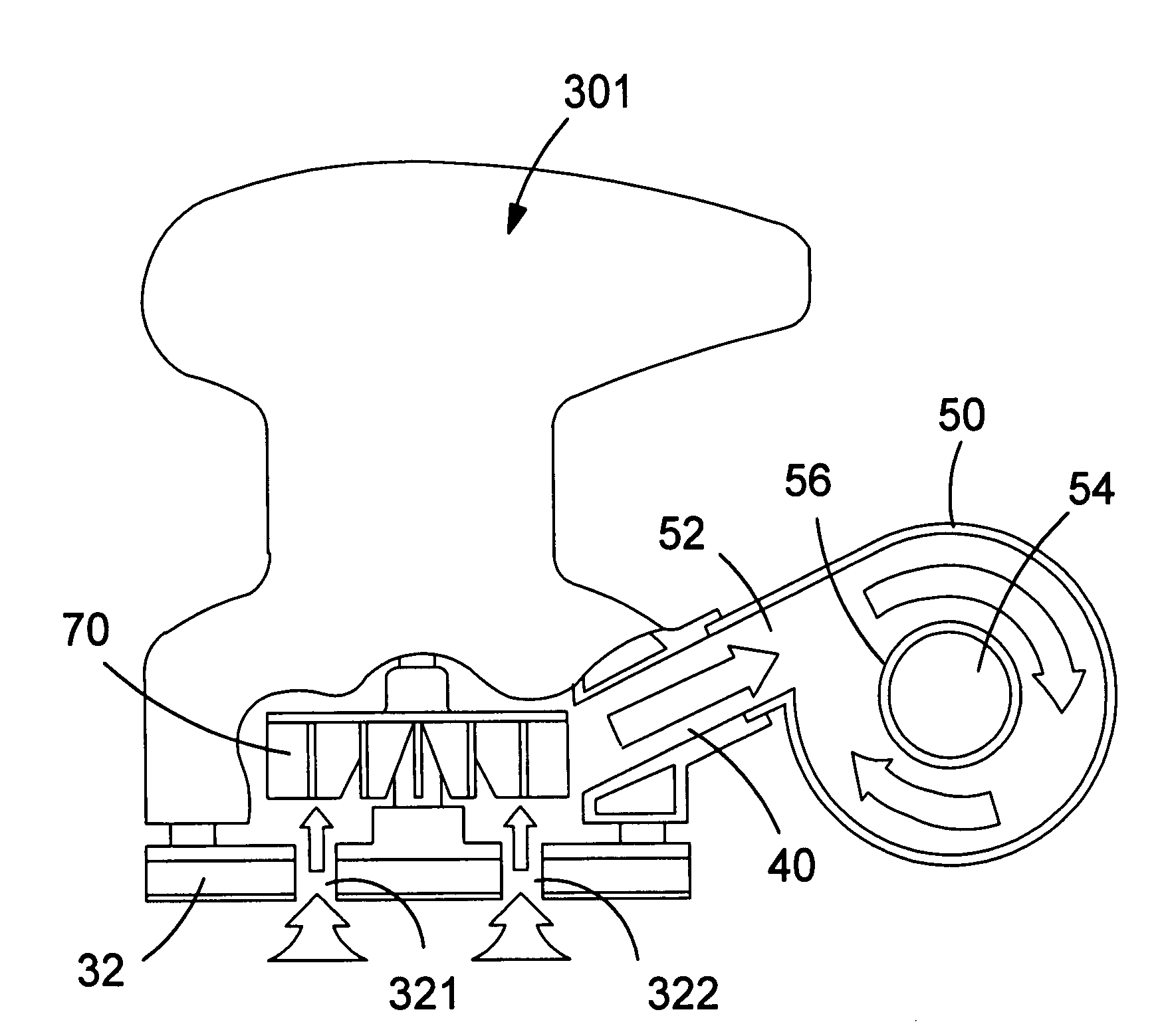

Cutting and Dust Collecting Assembly and Working Machine with Such Assembly

ActiveUS20080163492A1Avoid flyingEfficient collectionMetal sawing devicesMetal sawing accessoriesCircular sawDust control

A cutting and dust collecting assembly comprises a rotatable, circular saw blade (4) having a first side (20), a second side (21), and a cover device (6) with a terminal member (52). The bottom surface (36) of the cover device extends in a plane. A longitudinal passage (45, 46) for the saw blade extends through the cover device from its top surface to its bottom surface. The terminal member comprises a terminal chamber (60) having an inlet (45a), the mouth of which coincides with the plane of said bottom surface. An outlet (58) can be connected to a vacuum source. The direction of rotation of the operating blade is such that the rear part (4a) of the saw blade which has passed beyond the bottom surface of the cover device will move in a direction upwards-rearwards towards the bottom surface. The invention also concerns the cover device, a sealing body belonging to the cover device and a working machine which is provided with the cutting and dust collecting assembly.

Owner:HUSQVARNA AB

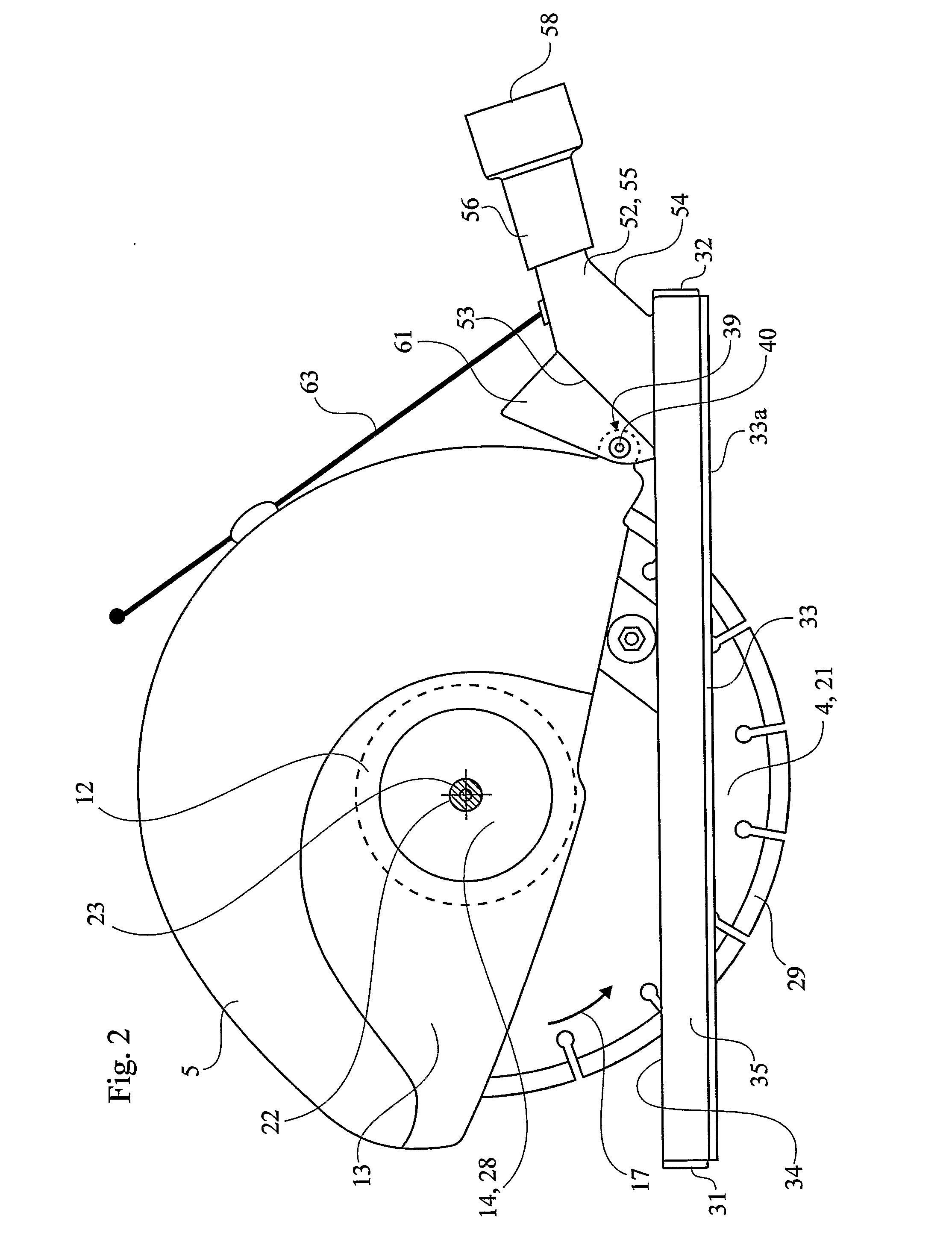

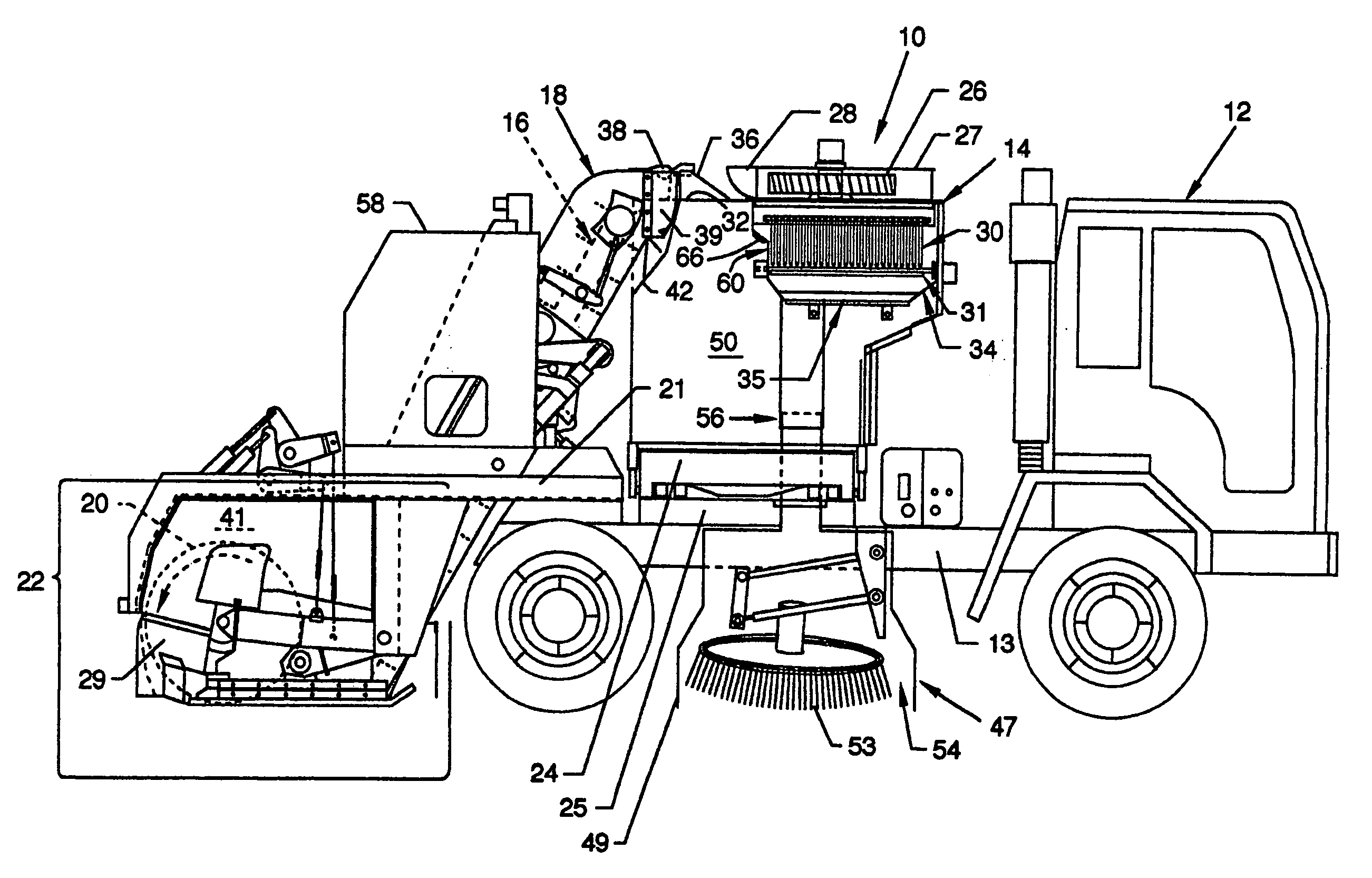

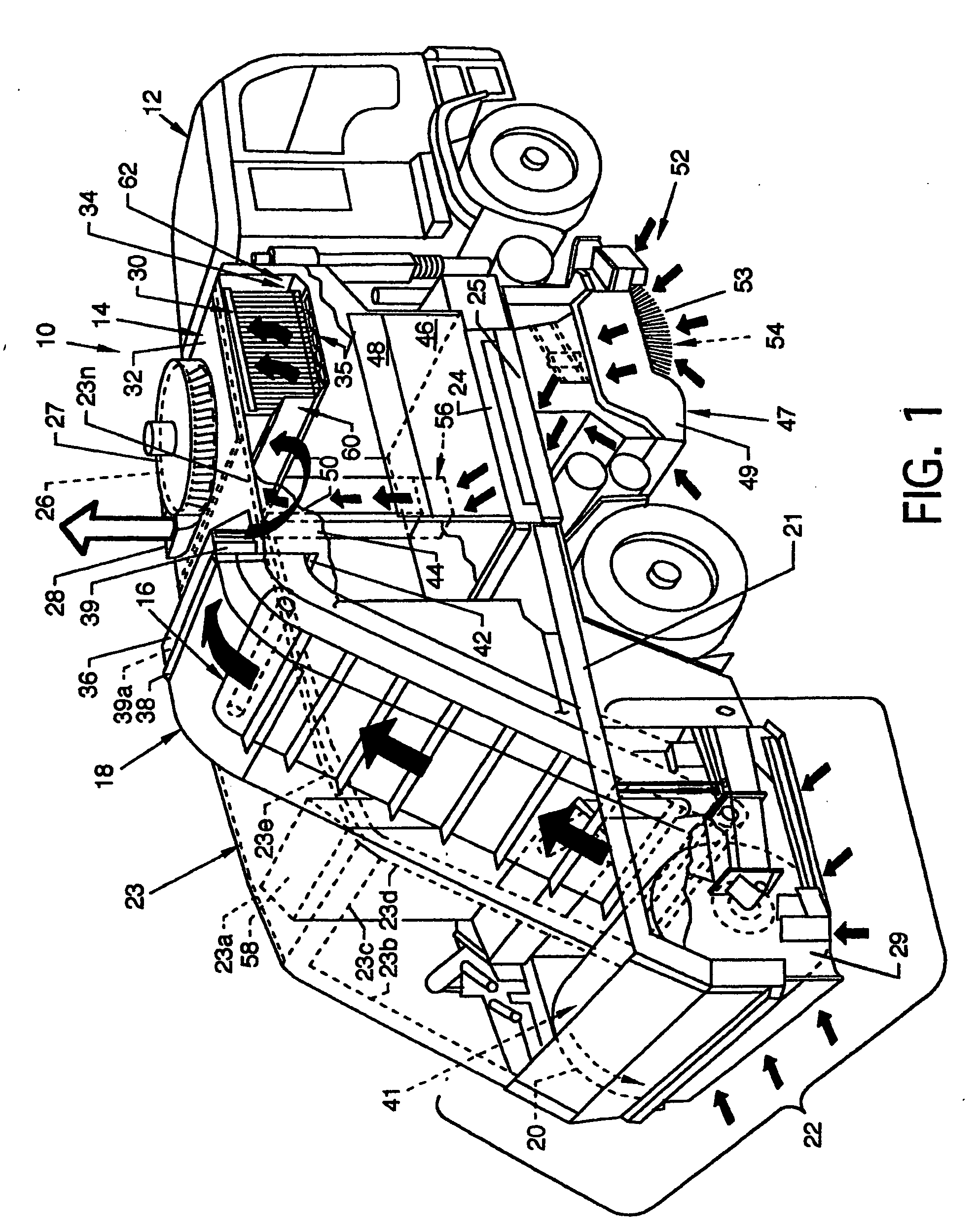

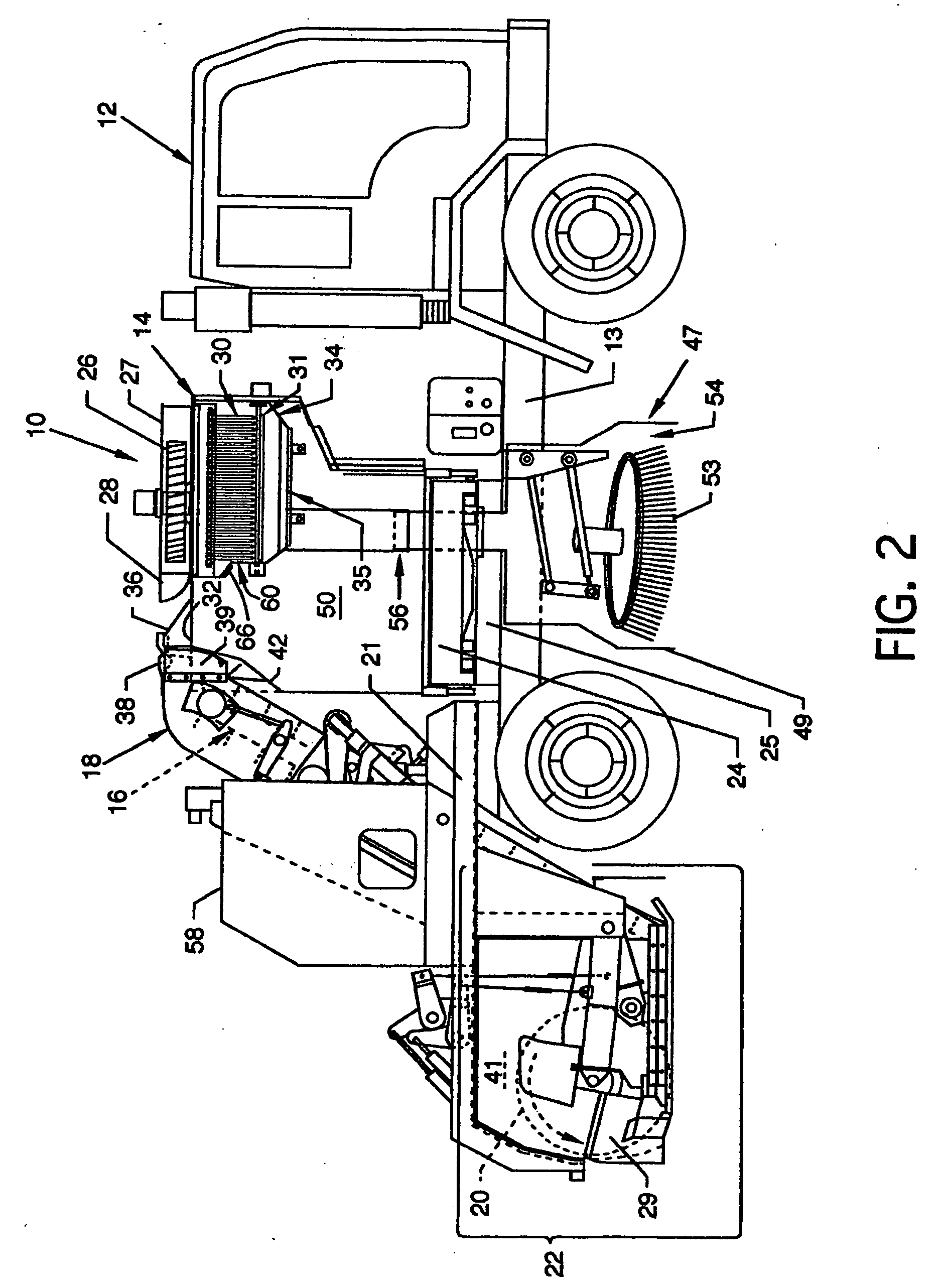

Street sweeper with dust control

Street sweeper having dust control from two or more cleaning heads with one air source where one fan provides vacuum for a centrally located rotating broom which is surrounded by a vacuumized chamber and for a gutter broom which is surrounded by a vacuumized chamber. A plenum having a unique valving system and a filter shaker mechanism provides for filter cleaning and for a dirt and debris path from the plenum to a hopper bottom during filter cleaning.

Owner:ENGEL GREGORY J +1

Process for transporting and quenching coke

ActiveUS8236142B2Emission minimizationMinimize timeCoke quenchingDirect heating destructive distillationDust controlProcess engineering

A method and apparatus for transporting and quenching coke, useful in quenching a batch of coke produced in one of a plurality of coke ovens forming a coke oven battery, is disclosed. A hot car defining a substantially planar receiving surface is positioned adjacent a coke oven of the coke oven battery, and a unitary cake of unquenched coke is placed onto the hot car receiving surface. The hot car and unquenched coke are transported to a transfer station having a dust collection system. A quenching car is positioned at the transfer station adjacent the hot car, under the dust collection system. The unitary cake of unquenched coke is dumped into the quenching car receptacle, thereby separating the unitary cake. At least a portion of the dust generated by separation is collected. The quench car is then transported to a quenching station, where the separated coke is quenched.

Owner:WESTBROOK THERMAL TECH

Azetidinium-functional polysaccharides and uses thereof

The present invention relates to polysaccharides that have been modified by providing azetidinium functionality thereto. Such functionality can be provided by crosslinking a polysaccharide with a resin having azetidinium functional groups. In one or more aspects, the polysaccharide can comprise one or more of starch, guar gum, alginate or derivatives thereof. Polysaccharides having azetidinium functionality according to the present invention are suitable for multiple uses. Such uses include, but are not limited to, removal of one or more solid materials from a liquid, beneficiation of an ore, removal of metallic ions from a liquid; providing oil from bitumen; and removal of mercury from synthetic gypsum. Other uses of the functionalized polysaccharides of the present invention include hydroseeding, dust control and corosion control.

Owner:GEORGIA PACIFIC CHEM LLC

Aerodynamic performance enhancements using discharge plasma actuators

ActiveUS20100329838A1Easy maintenanceImprove performanceWind motor controlPump componentsPerformance enhancementPlasma actuator

The current invention provides significant performance improvements or significant energy savings for fans used in these applications: personal, industrial and automotive cooling, ventilation, vacuuming and dust removal, inflating, computer component cooling, propulsors for unmanned and manned air vehicles, propulsors for airboats, air-cushion vehicles, airships and model aircraft. Additionally, the invention provides higher performance such as higher lift and higher lift efficiency to small air vehicles. These advantages are achieved by using plasma actuators to provide active flow control effectors into thin fan blades and wing.

Owner:GREENBLATT DAVID

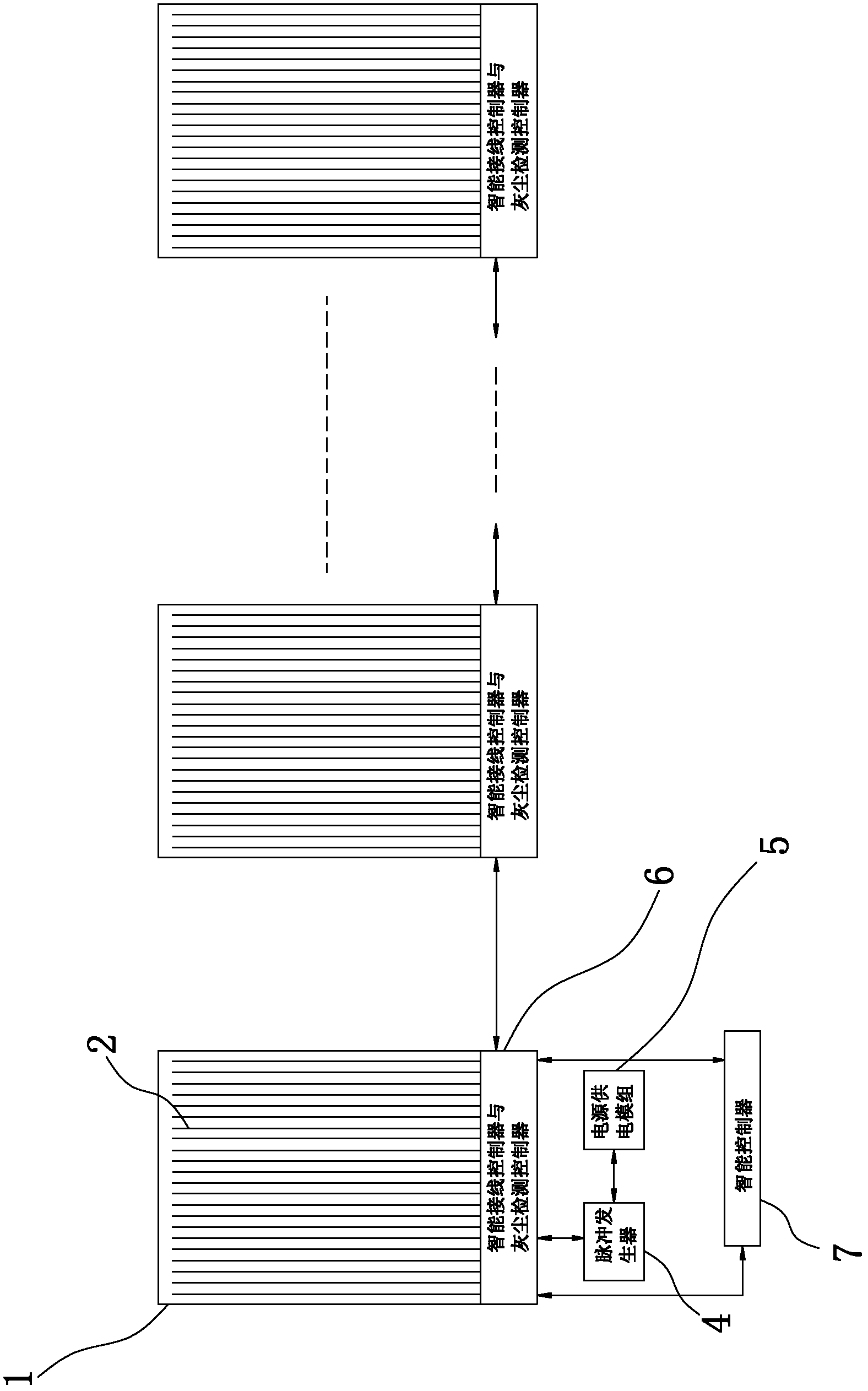

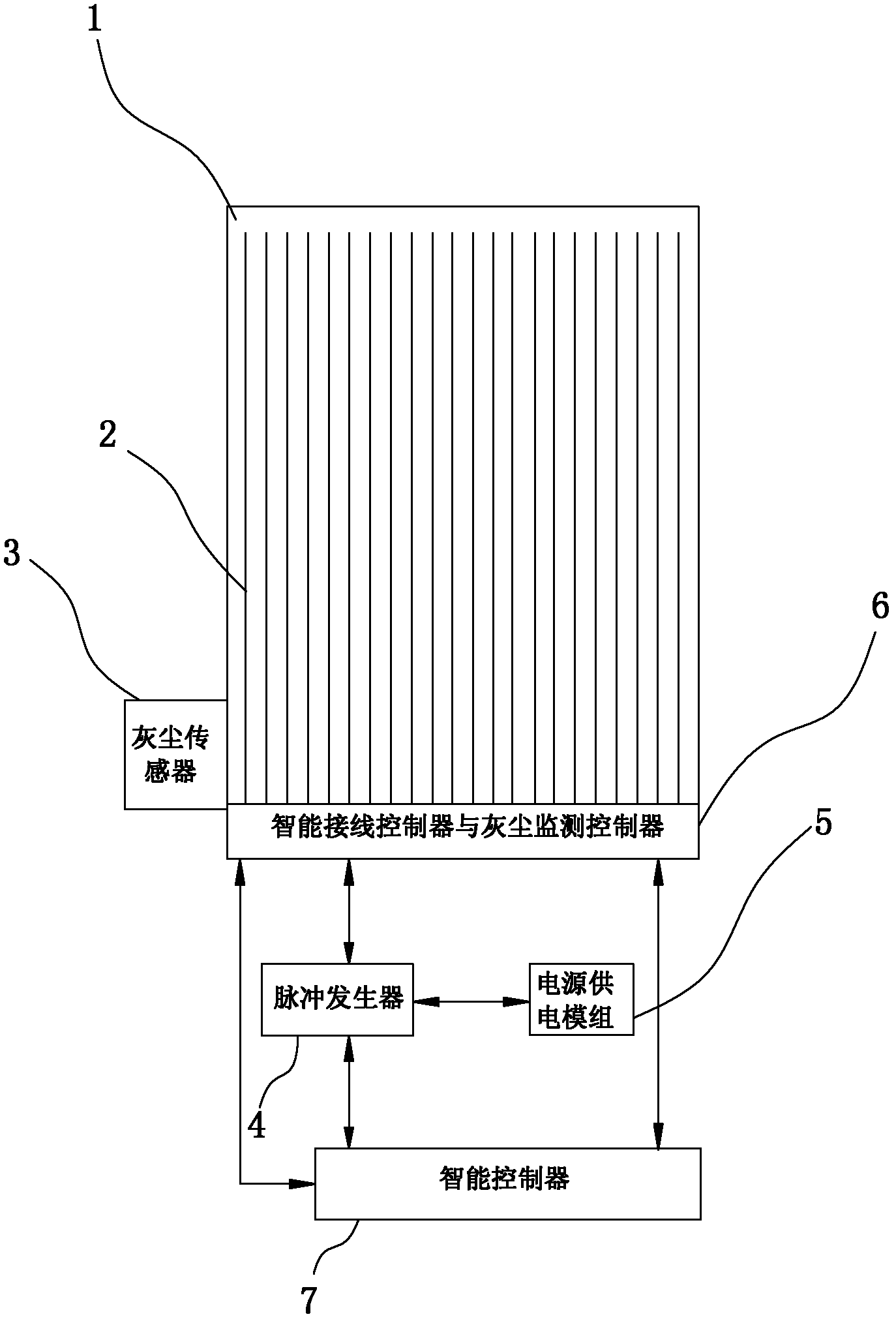

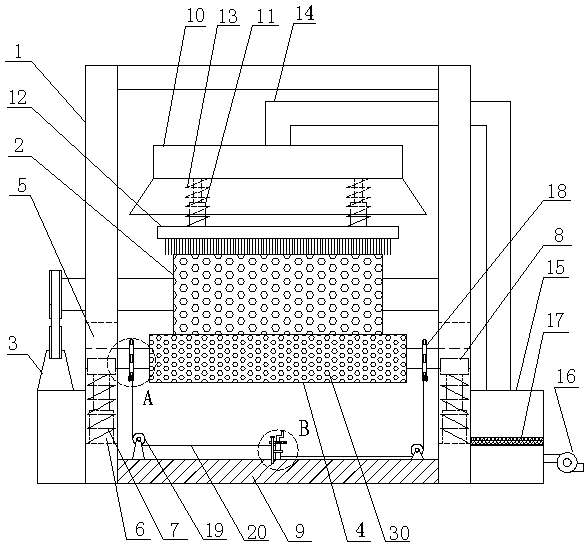

Multi-plane dust removing device

The invention relates to a multi-plane dust removing device comprising a plurality of parallel electrodes attached to each plane needing dust removal and dust monitoring controllers arranged on or near the planes needing dust removal, wherein the electrodes and the dust monitoring controllers corresponding to the multiple planes needing dust removal are respectively cascaded in sequence, the cascaded electrodes are connected with a pulse generator, the pulse generator is electrically connected to a power supply, the pulse generator is further electrically connected with an intelligent controller, the intelligent controller is electrically connected with the cascaded dust monitoring controllers, the dust monitoring controllers are used for feeding dust status signals of the planes needing dust removal back to the intelligent controller, and the intelligent controller is used for outputting a first control signal to the pulse generator. The intelligent controller is used for automatically calculating pulse parameters according to the feedback results of the dust monitoring controllers and further outputting the signal to the pulse generator, and the pulse generator is used for applying different pulse signals to the electrodes on all the planes to generate a varying electromagnetic field so that various types of dust on all the planes can be removed.

Owner:承启(上海)能源科技有限公司

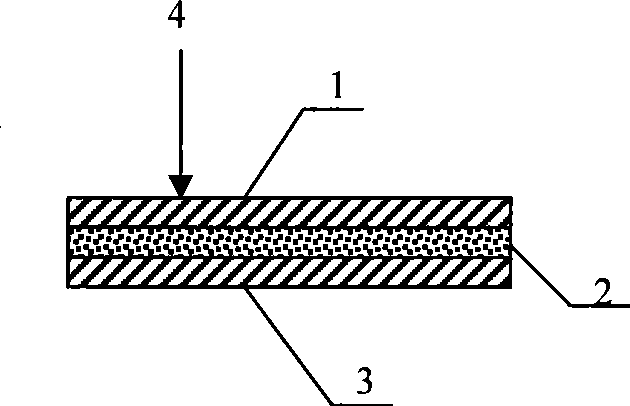

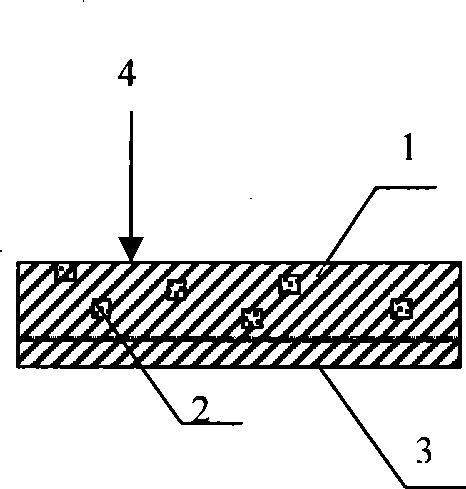

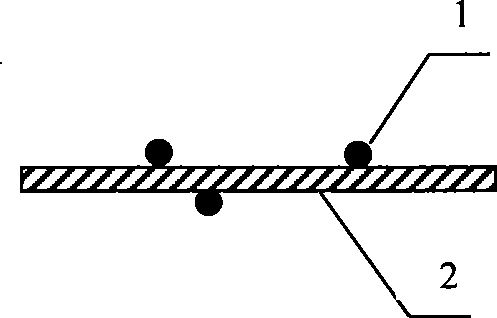

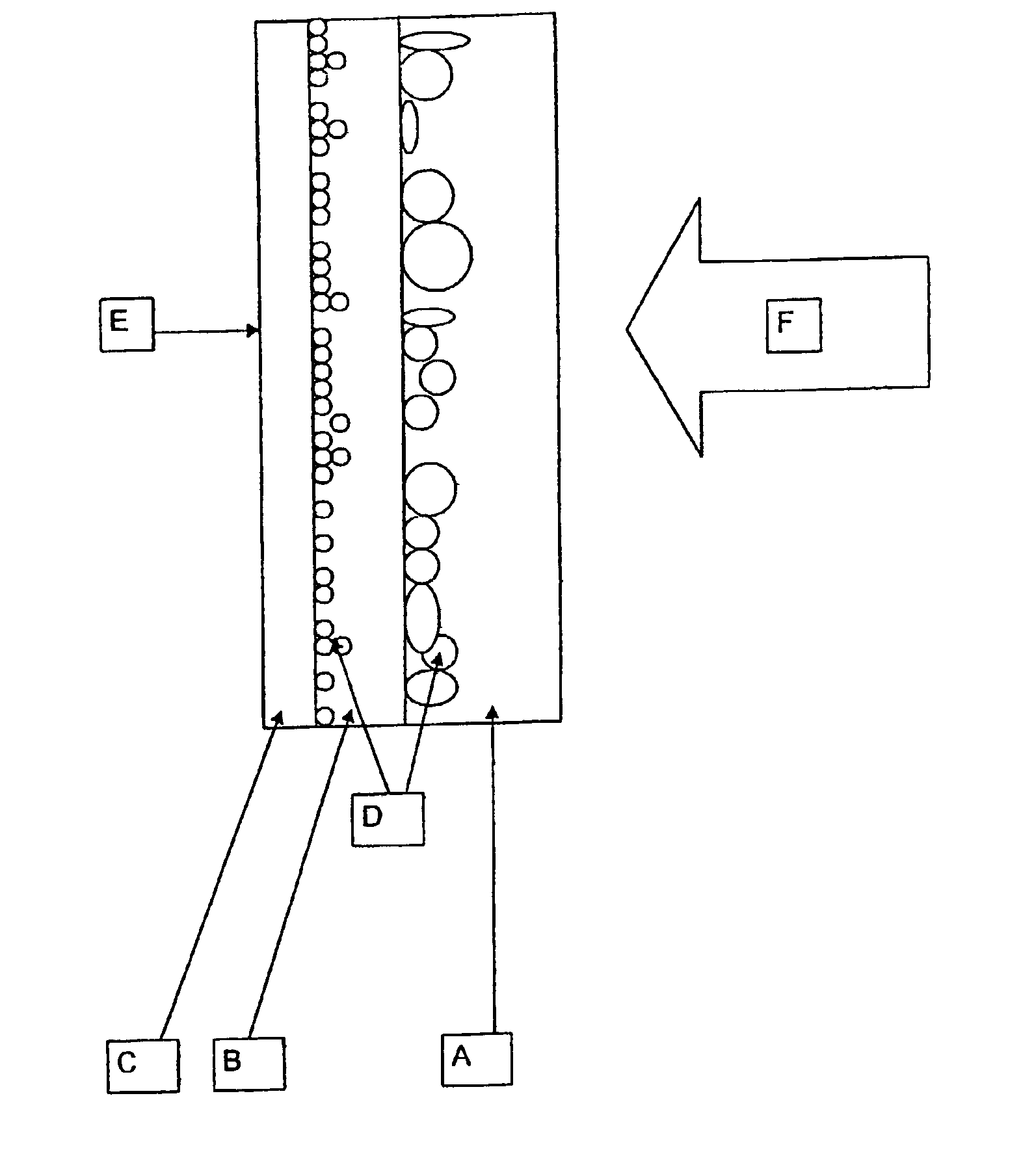

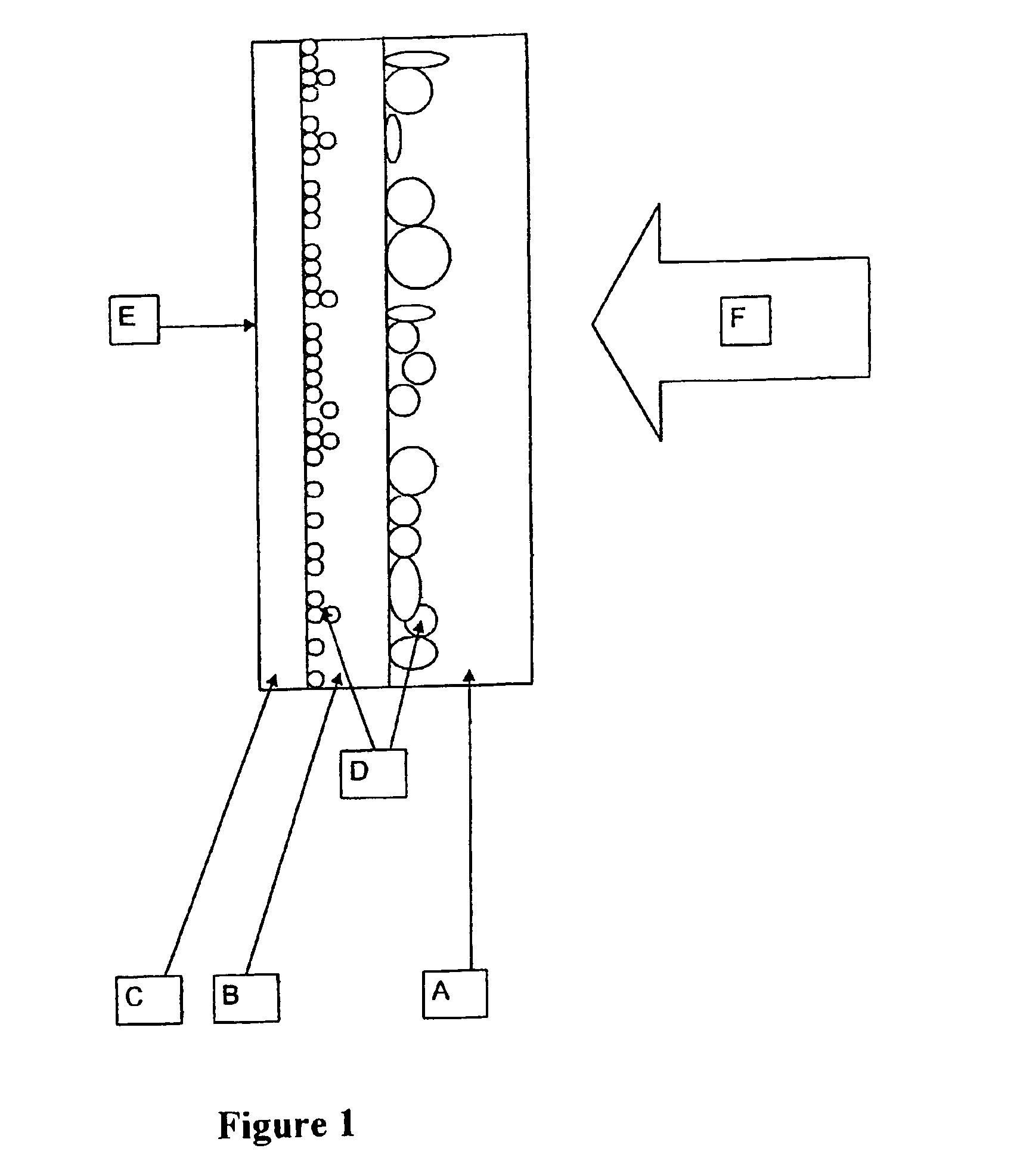

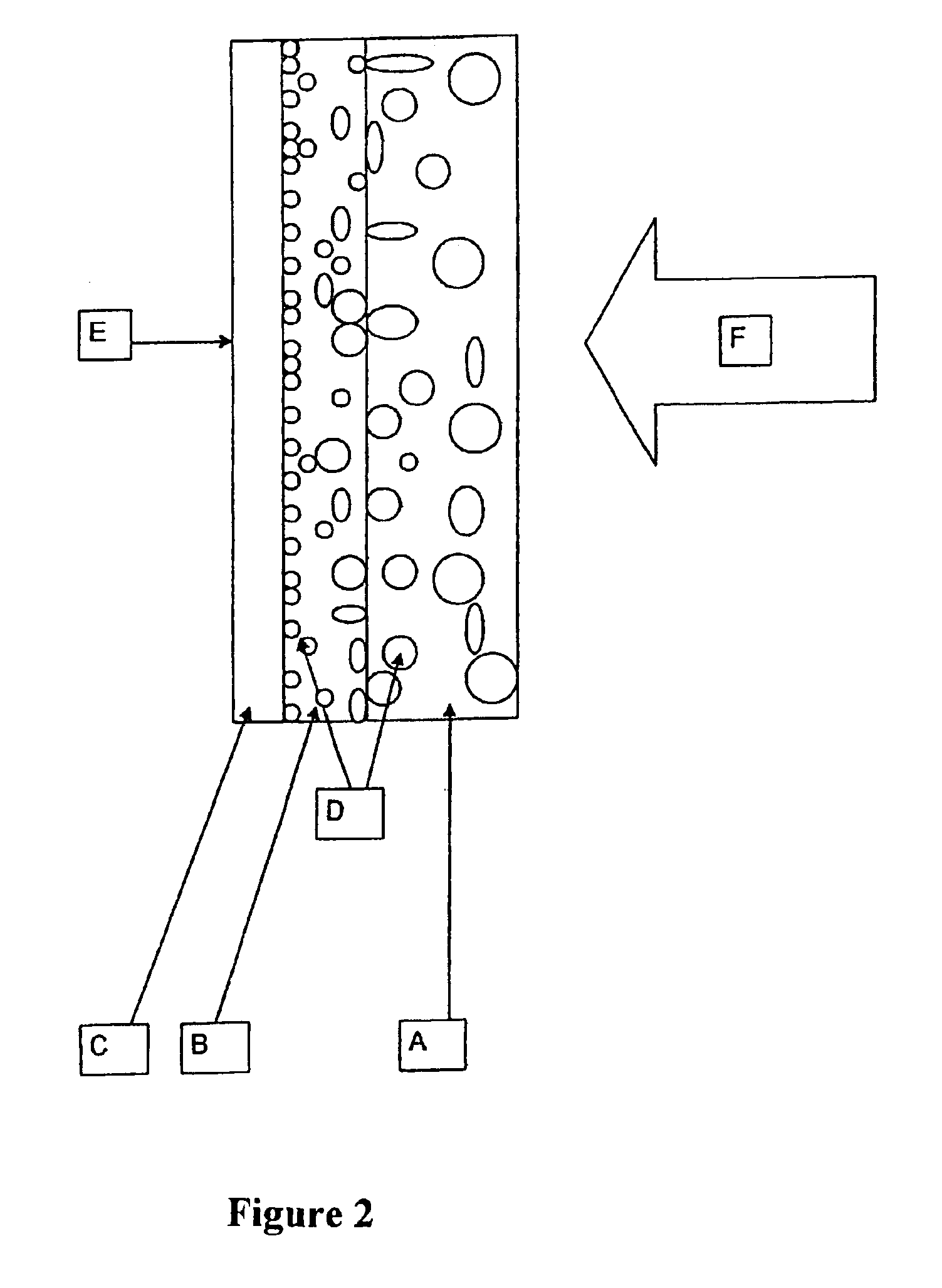

Multi-layer filter structure and use of a multi-layer filter structure

InactiveUS6966939B2Small average pore sizeSmall fiber diameterCleaning filter meansCombination devicesFiber diameterWaste management

The invention describes a multi-layer filter structure and the use of a multi-layer filter structure for the dust removal from gases, wherein a coarse dust filter layer, a fine dust filter layer, and a support layer are disposed behind one another in the direction from the inflow side to the outflow side, and which is designed such that the fiber diameter distribution within the coarse dust filter layer and fine dust filter layer has a gradient, and that the fiber diameters of the coarse dust filter layer and fine dust filter layer continually decrease from the inflow side to the outflow side.This multi-layer filter structure may be used in a filter cassette for industrial dust removal, as well as in a stationary or mobile home dust cleaning device.

Owner:BRANOFILTER +1

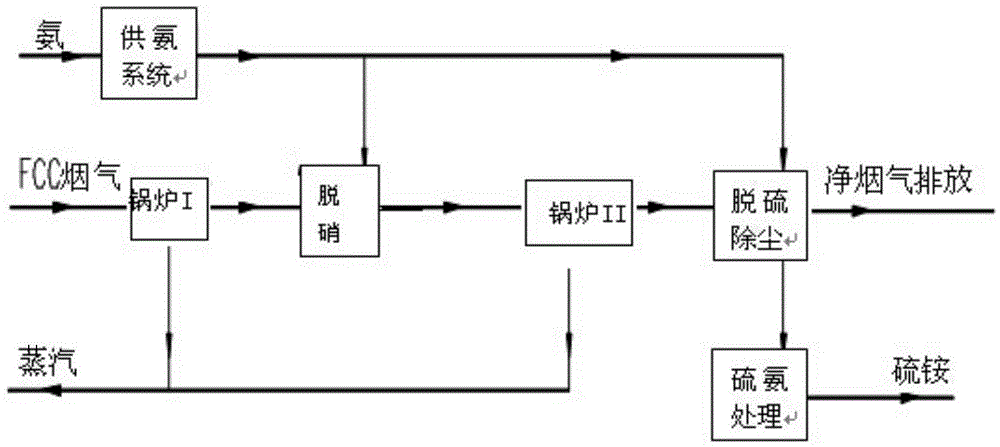

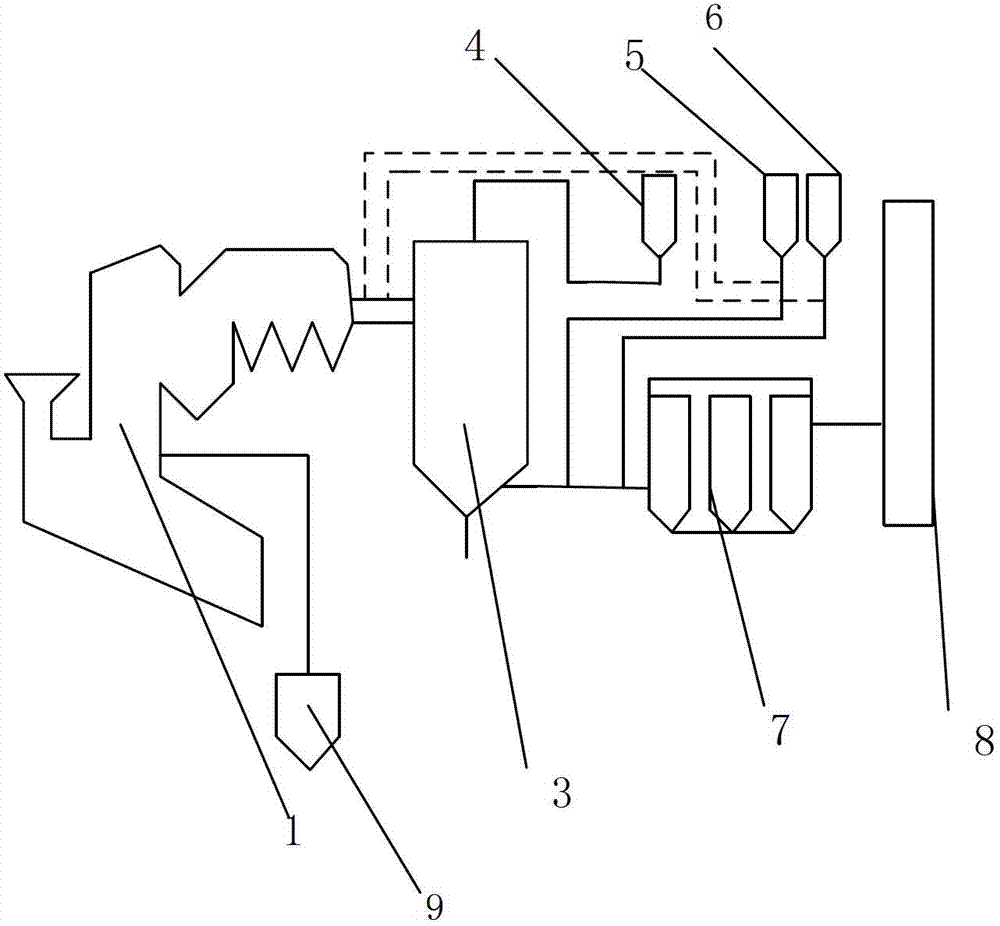

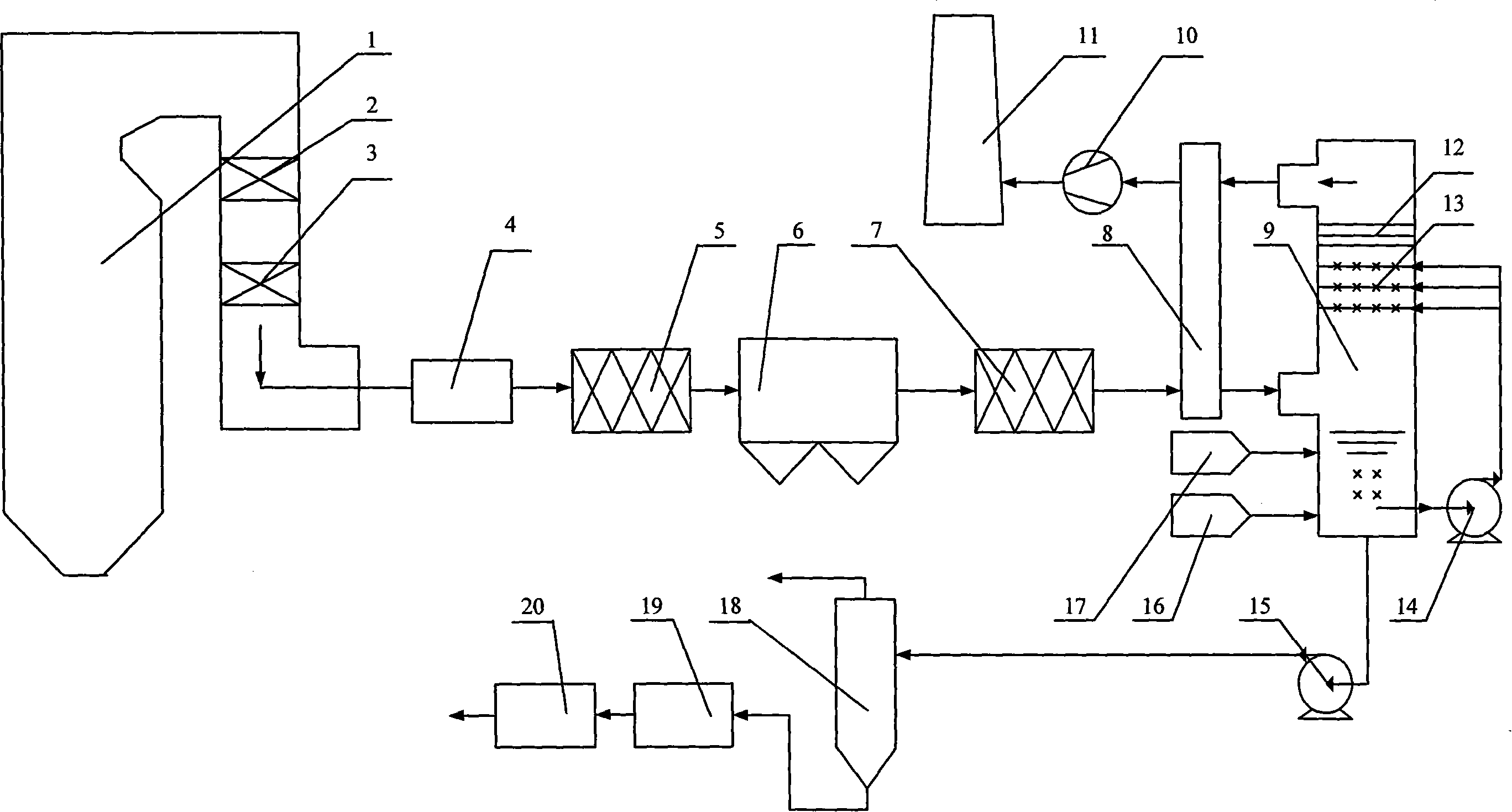

Ammonia desulfurization and denitrification dedusting method and device utilizing catalytic cracking regeneration flue gas

ActiveCN104941423ALess investmentLow running costUsing liquid separation agentEnergy inputNitric oxidePetroleum

The invention relates to an ammonia desulfurization and denitrification dedusting method and device utilizing catalytic cracking regeneration flue gas, comprising the following steps: enabling high-temperature catalyst regeneration flue gas coming from a catalytic cracking unit and containing catalyst dust to firstly enter a waste heat boiler I, reducing the temperature of the flue gas to 280-430 DEG C, wherein the heat of the flue gas is externally supplied by steam produced by the waste heat boiler I; enabling flue gas at temperature of 280-430 DEG C to enter a denitrification device for denitrification and enter a waste heat boiler II through an outlet flue after sufficiently reacting on the surface of a denitrification catalyst in a denitrification reactor; removing sulfur dioxide, nitric oxide and byproduct ammonium sulfate by taking ammonia as a reactant, and removing catalyst dust in the regeneration flue gas to achieve clean gas up-to-standard release; the three waste free release purifying method can be applied to catalytic cracking catalyst regeneration flue gas treatment in oil refining.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

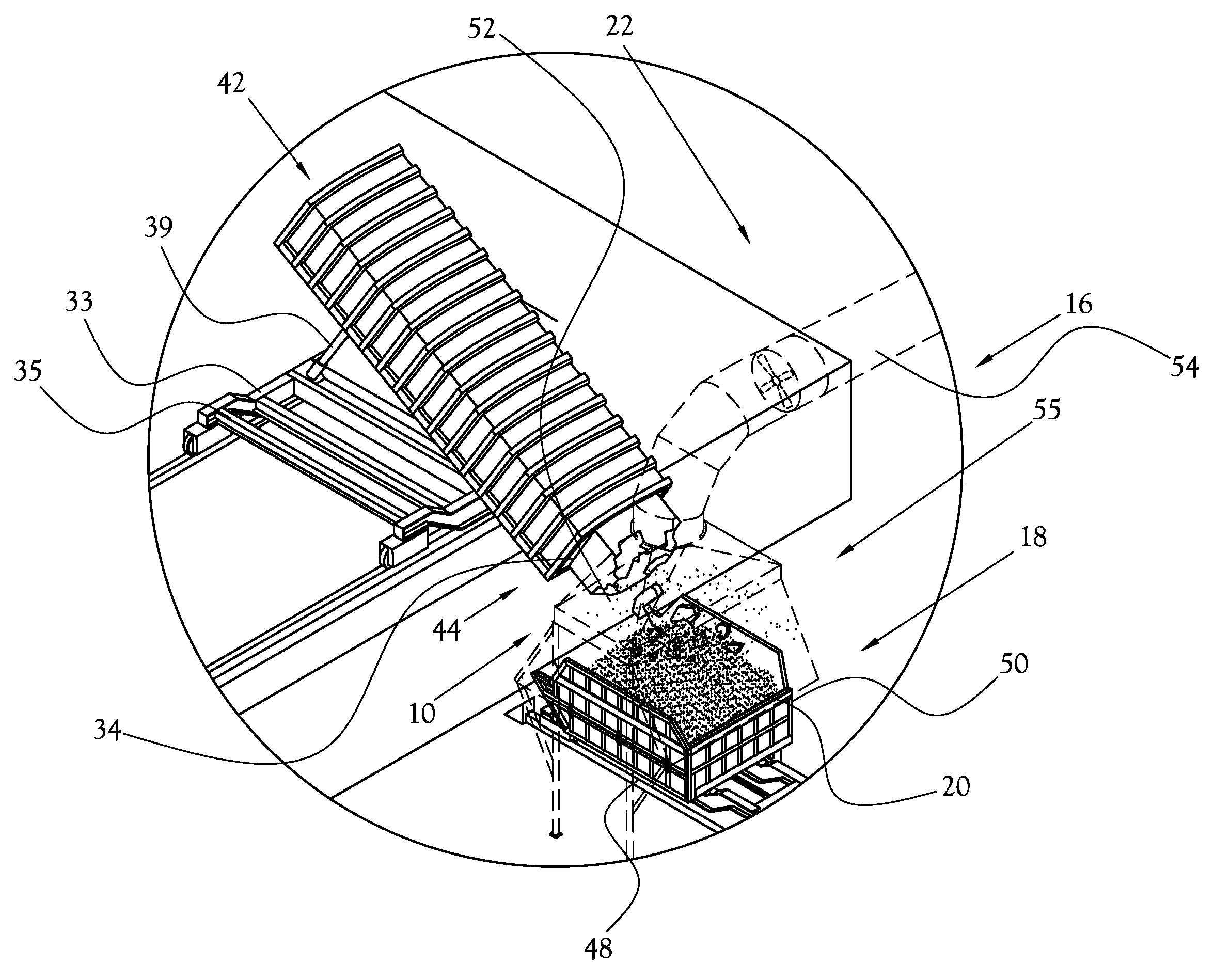

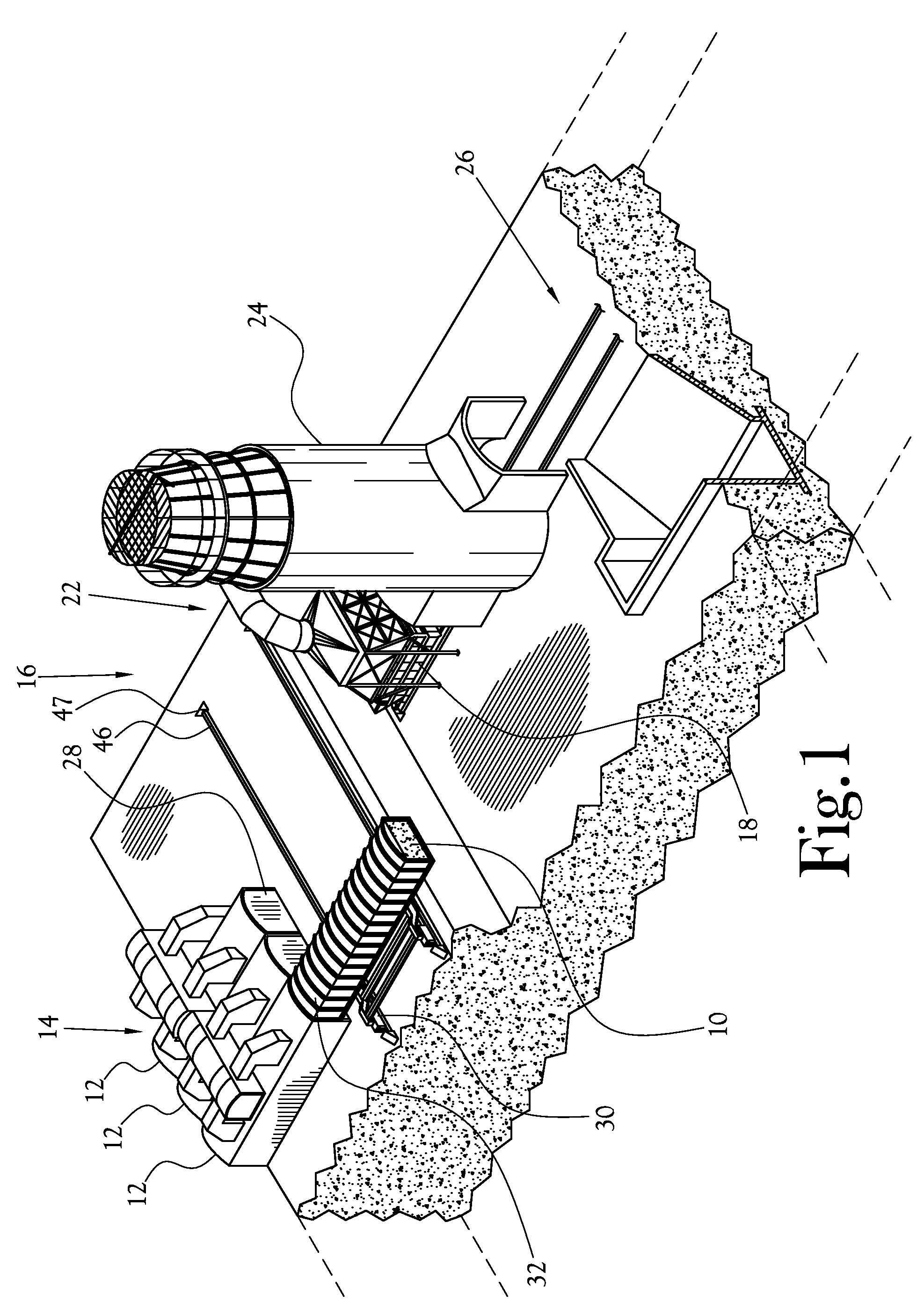

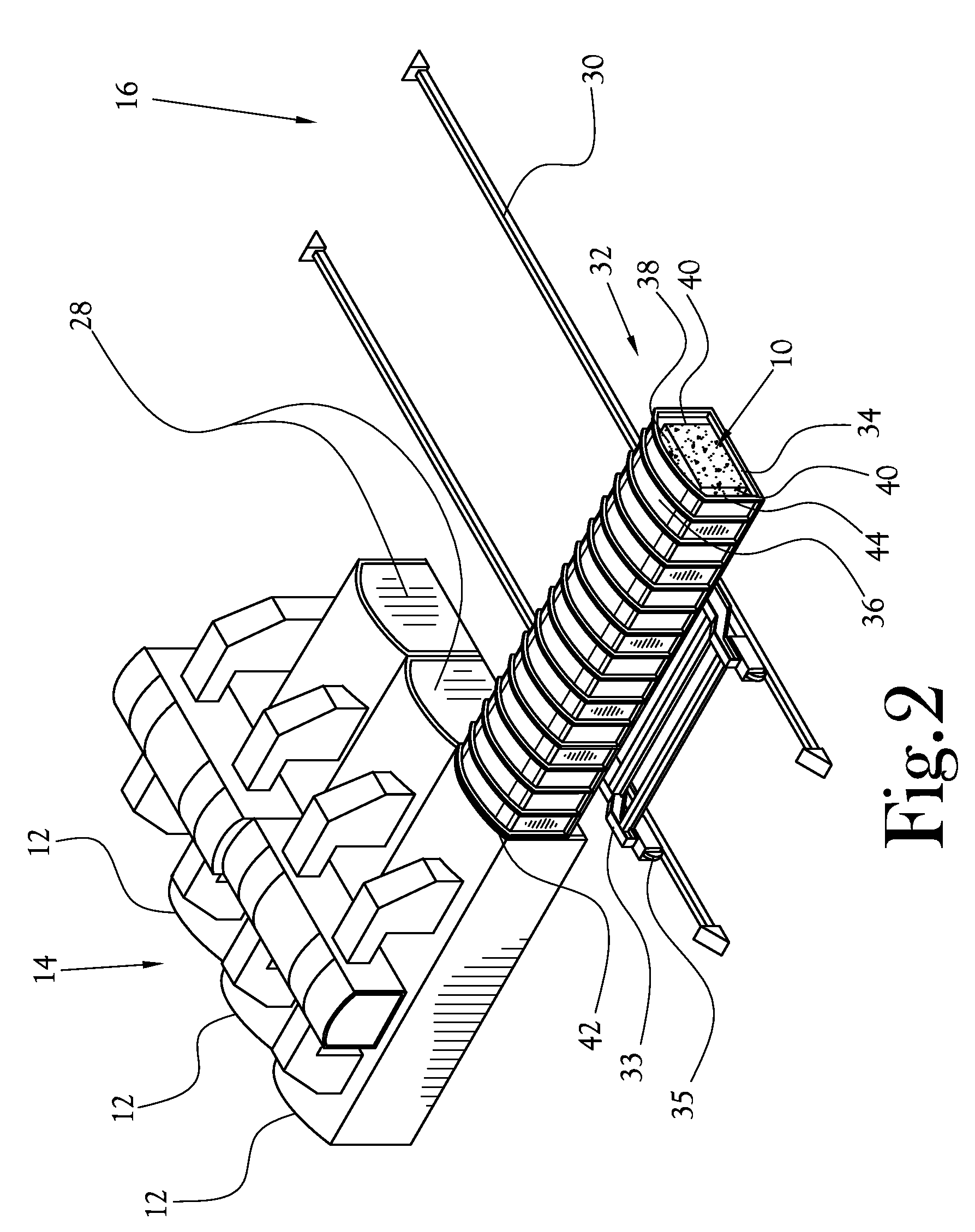

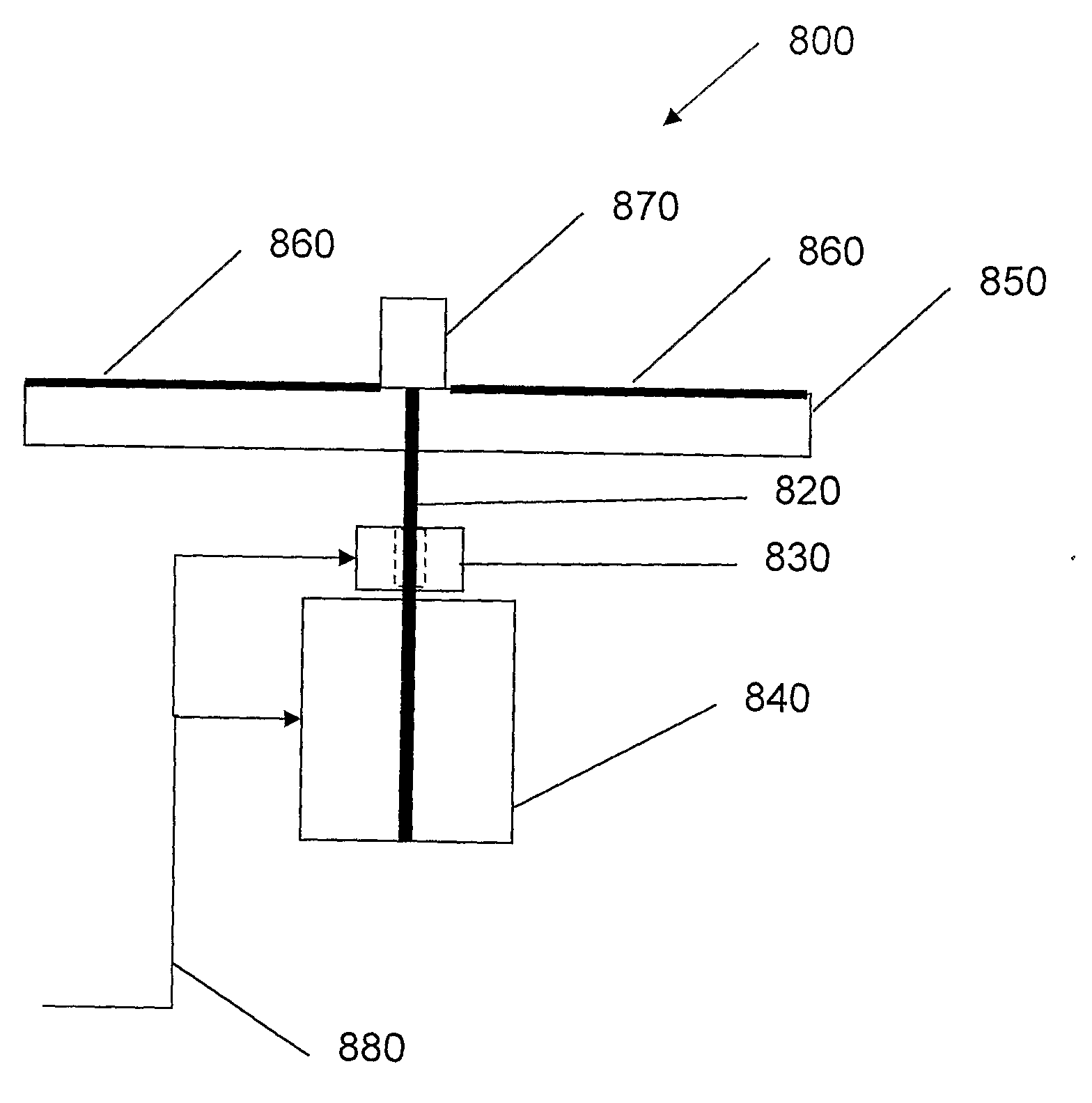

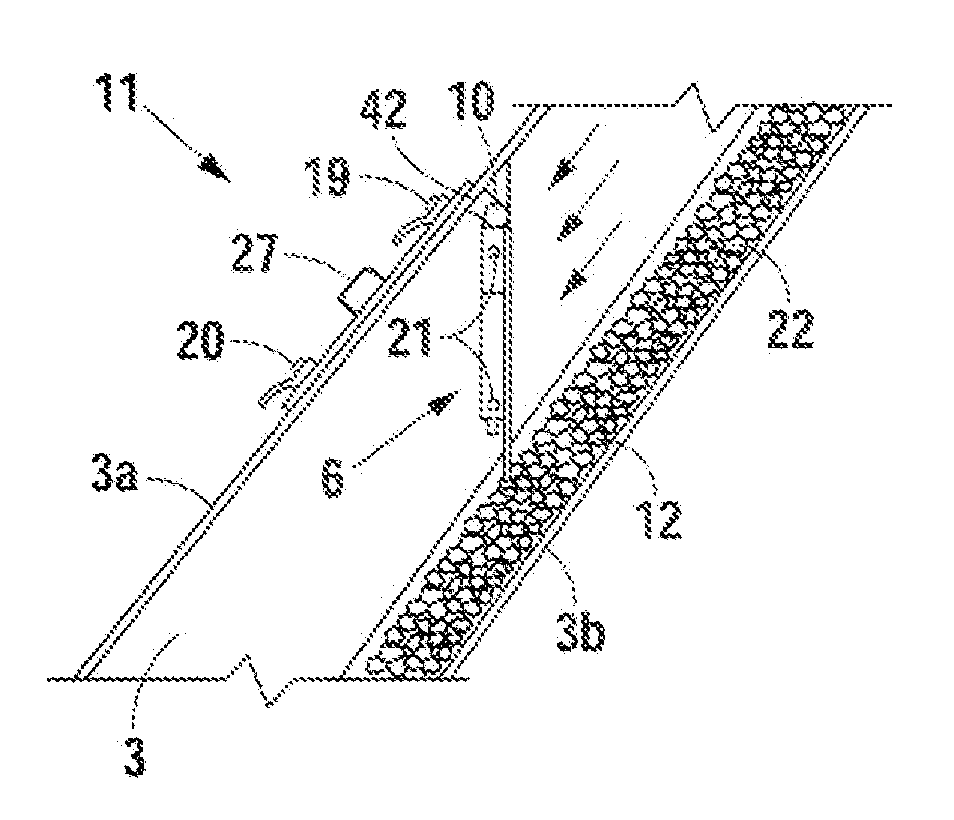

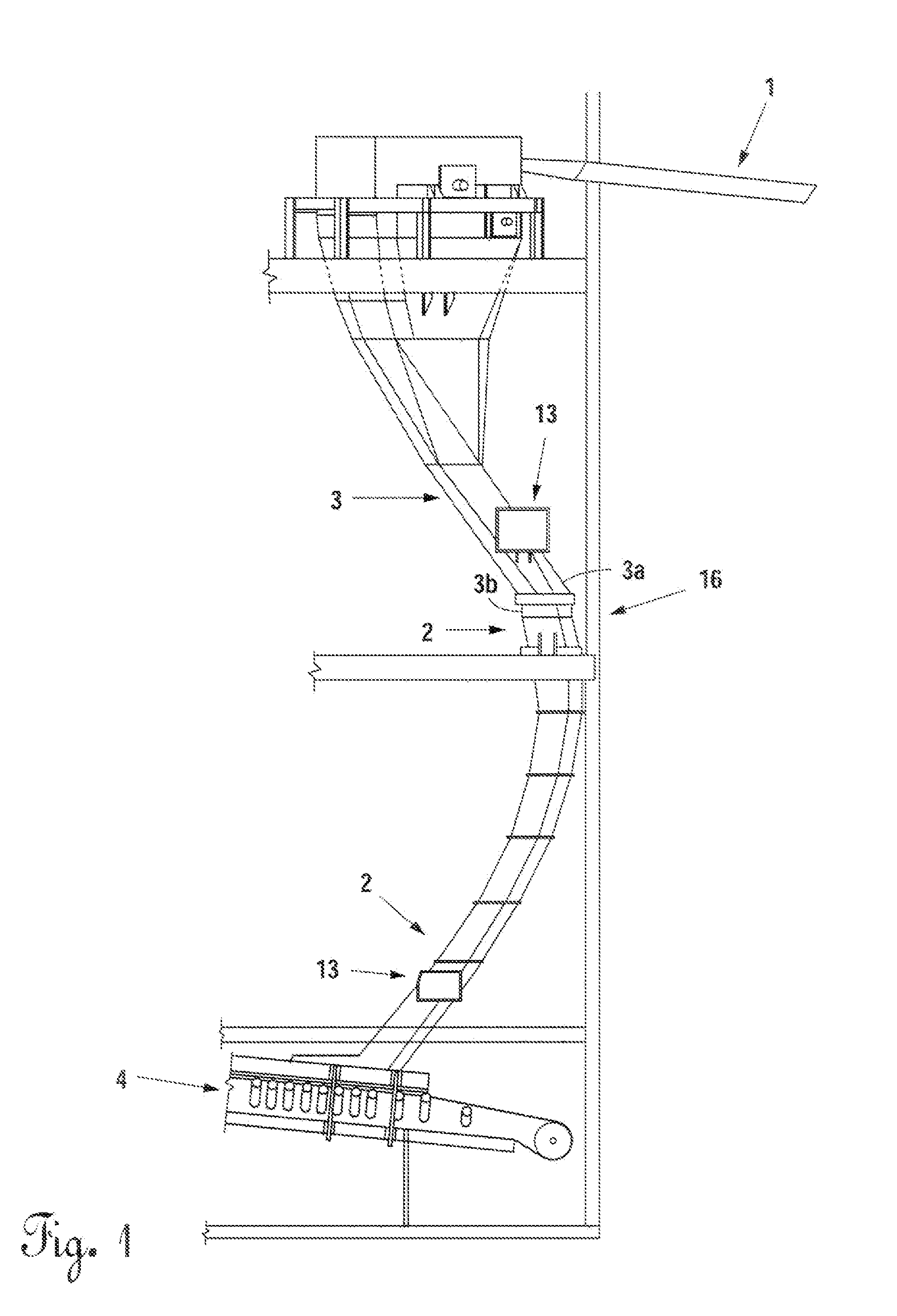

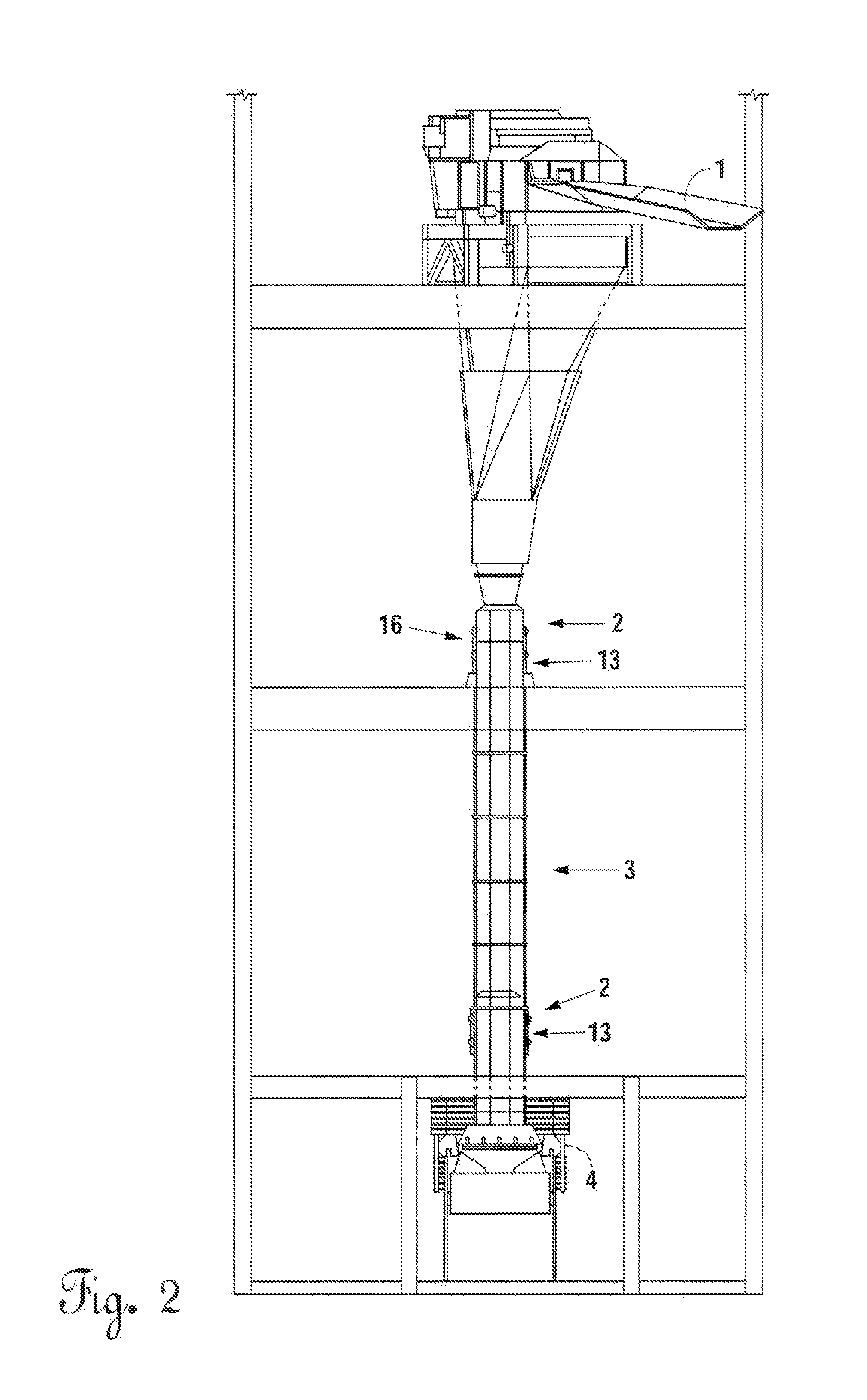

Apparatus and Method for Passive Dust Control in a Transfer Chute

InactiveUS20120090956A1Minimize air flowReduce dust emissionsLoading/unloadingConveyor partsTransfer systemDust control

A dust control apparatus and method for a bulk material handling transfer system having a chute comprising a pathway there through for handling varying volumes of bulk material flowing through the chute using gravity flow. A self-adjusting air restrictor gate is mounted in the chute for engaging the upper surface of flowing bulk material through the chute for restricting the air pathway during material volume flow variations to reduce dust emissions. The gate member contacts the upper surface of flowing bulk material and moves up and down in response to the flow of bulk material through the chute to restrict the flow of air to reduce dust. A counterweight mechanism and a damper helps maintain controlled contact of the air restrictor gate with the upper surface of bulk material flowing through the chute.

Owner:BROBST STEVEN HAYS

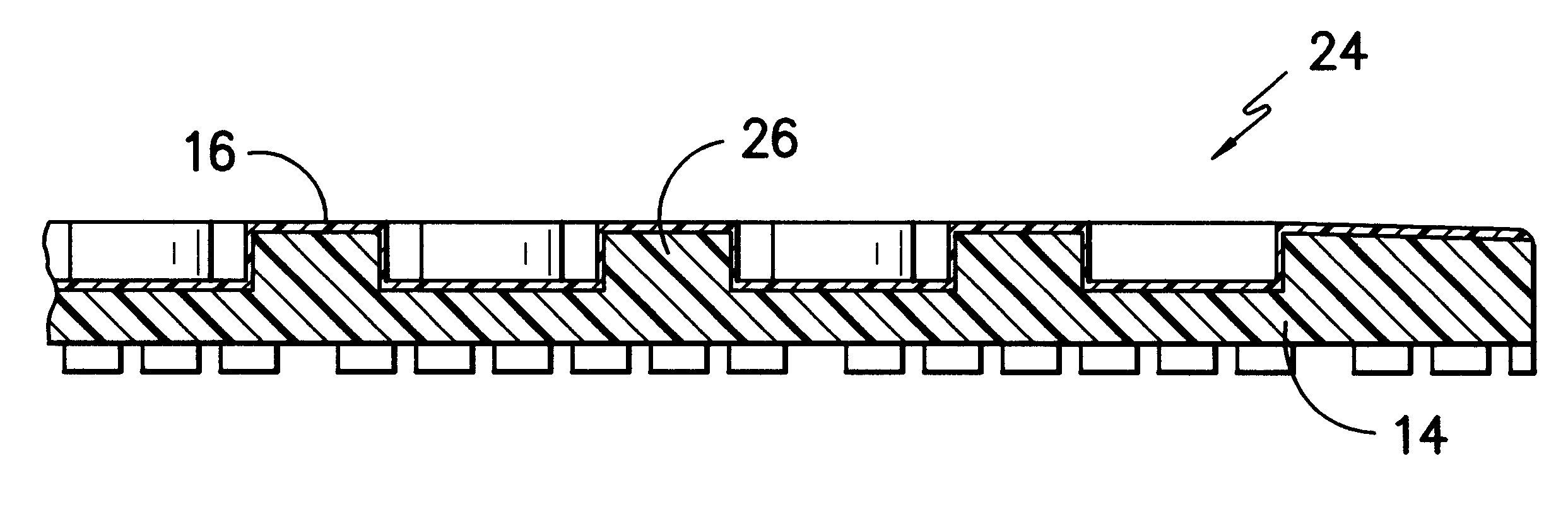

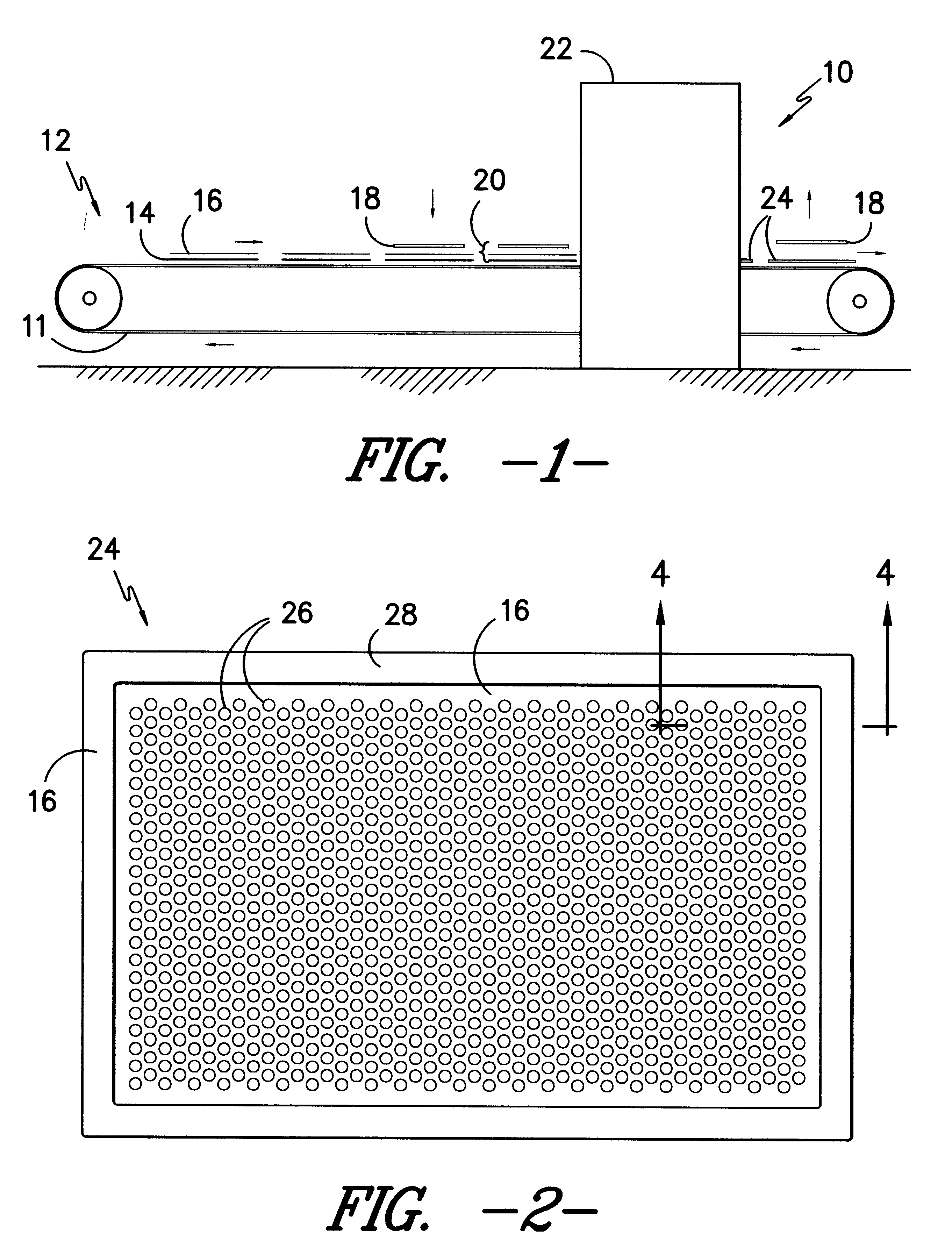

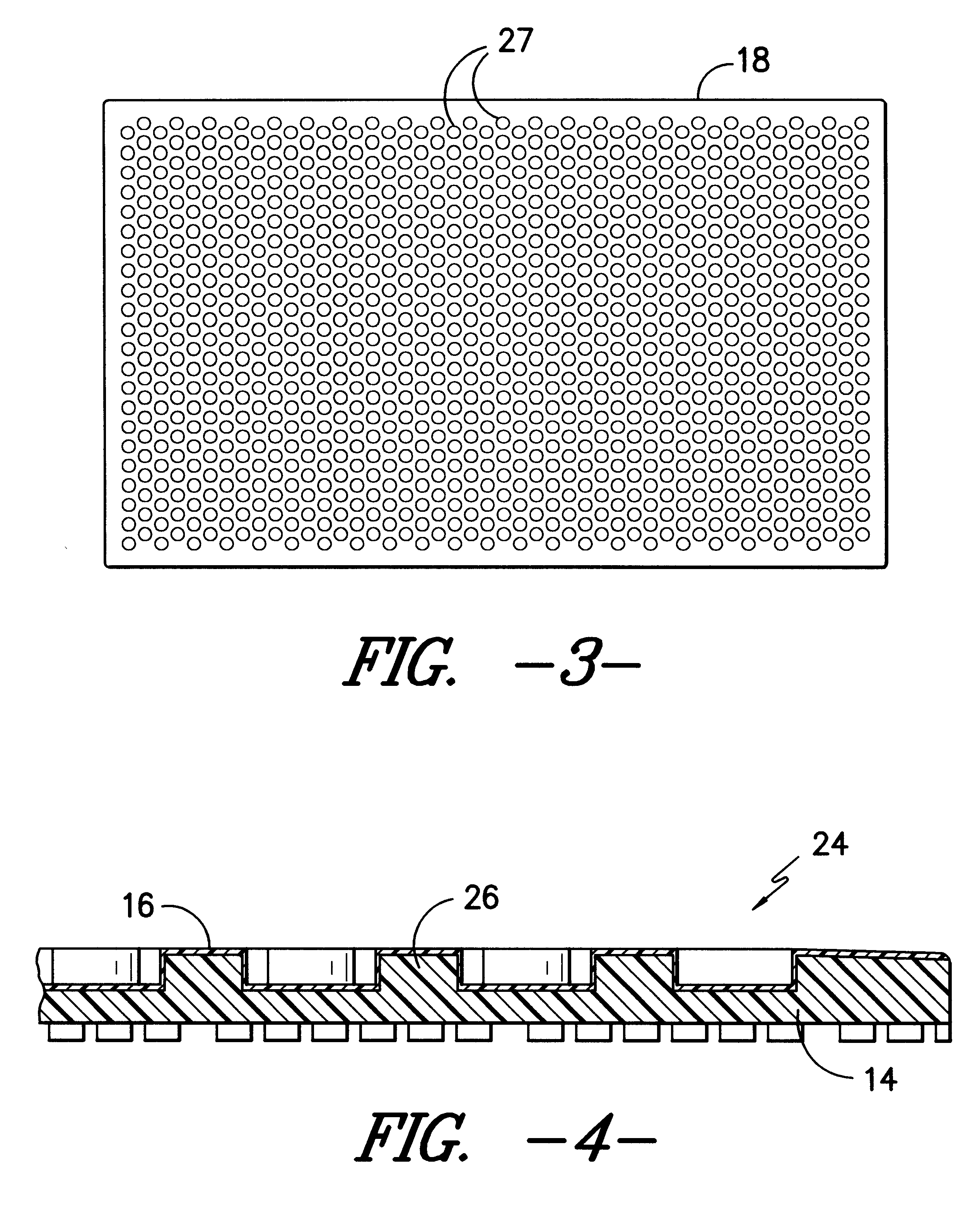

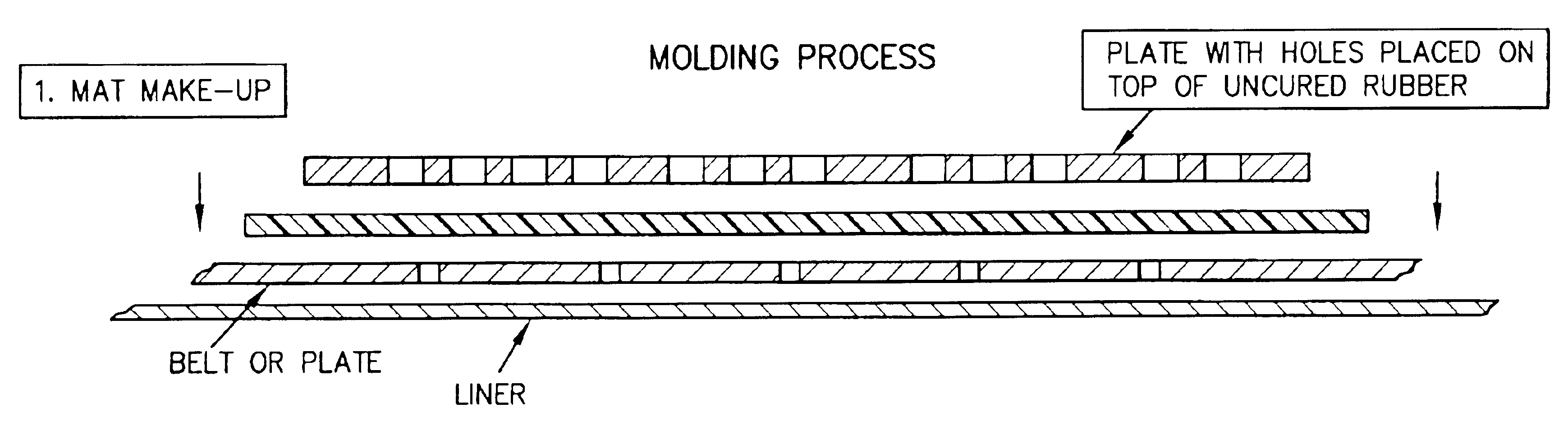

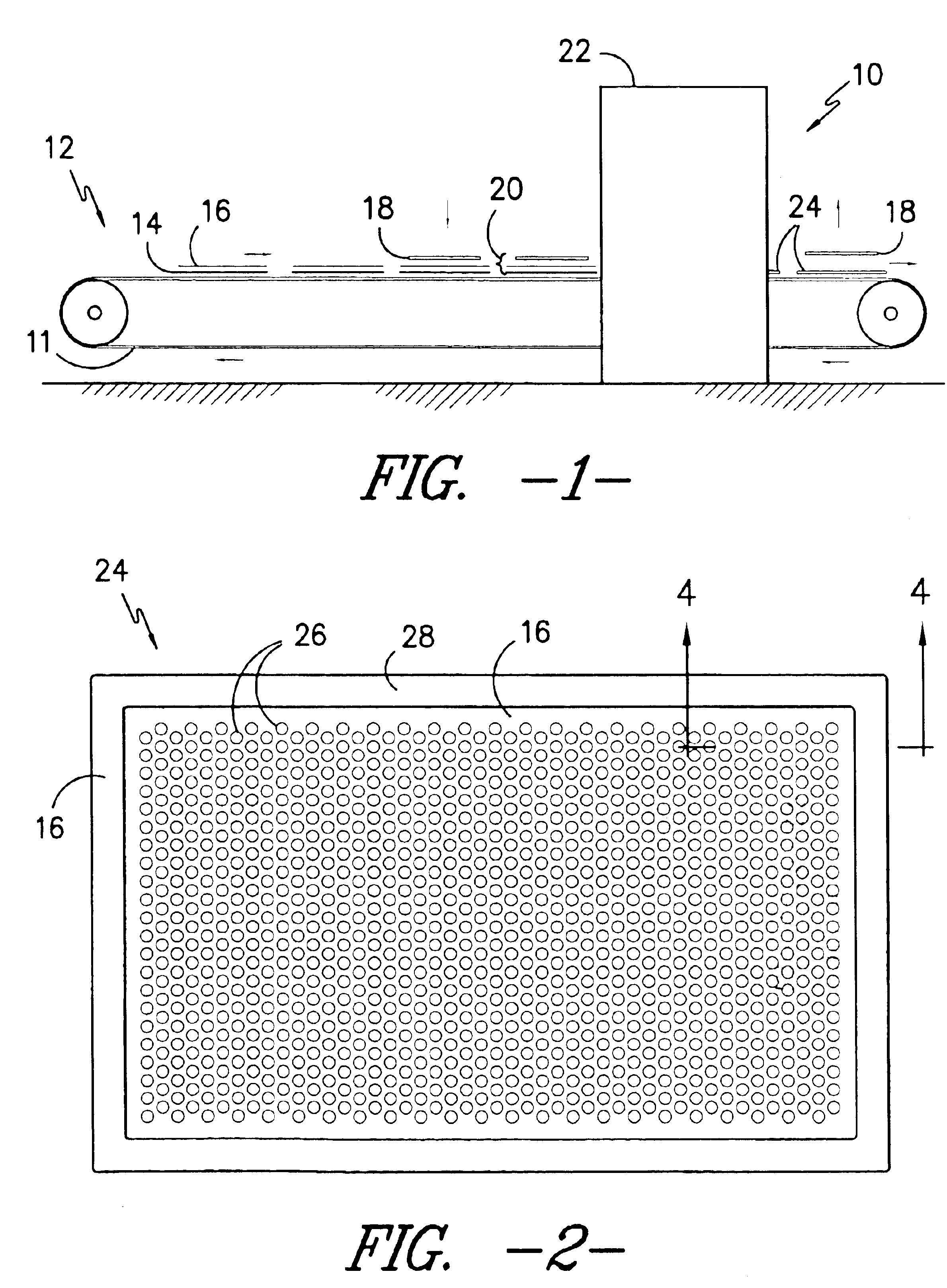

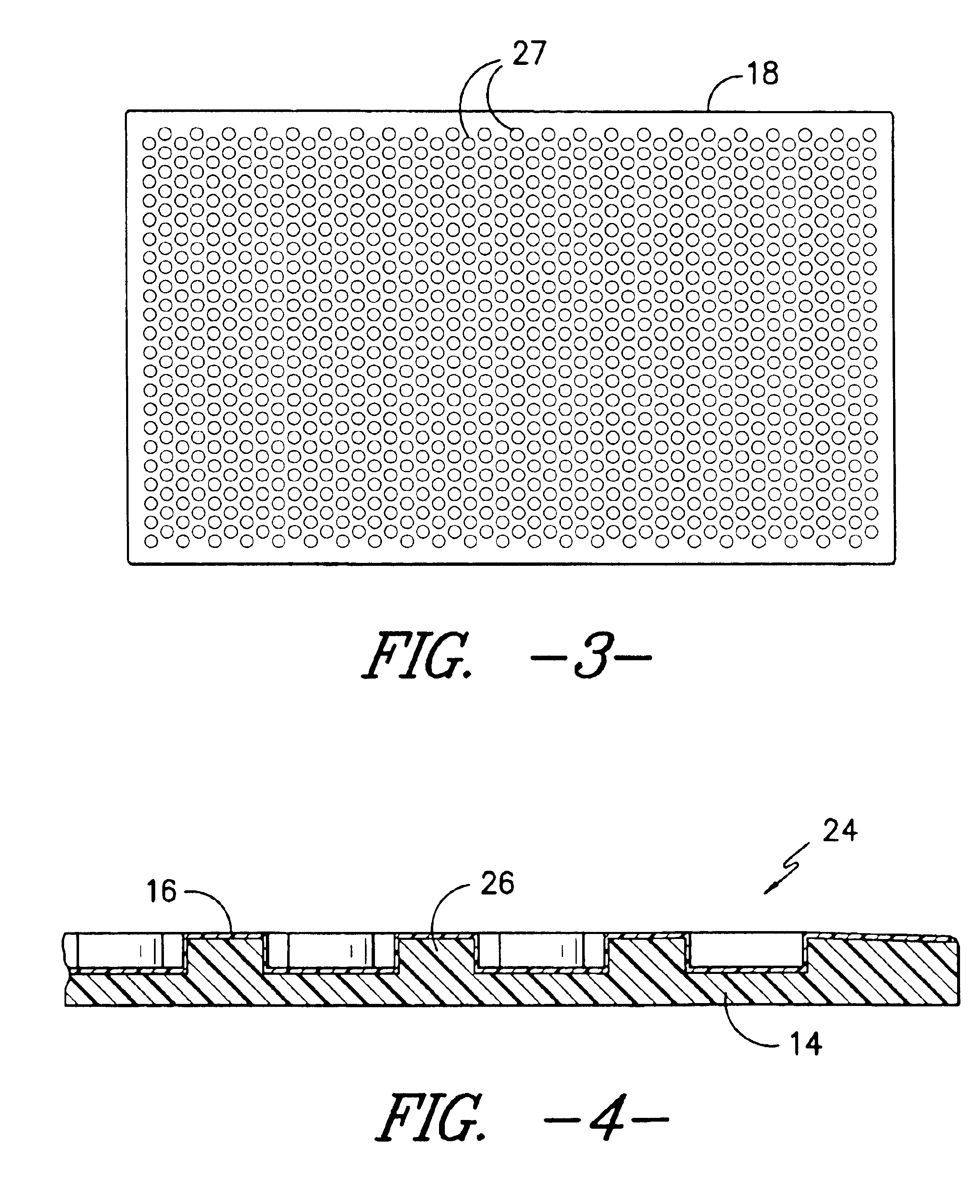

Cushioned rubber floor mat article and method

InactiveUS6921502B1Improving non-slip characteristicImprove featuresWood working apparatusFlat articlesCushioningDust control

At least one embodiment of this invention relates to a cushioned dust control mat article wherein the mat comprises at least two distinct layers of rubber, one comprising foam rubber, the other comprising solid rubber. The solid rubber layer is present over the foam rubber layer on the side of the mat in which at least one integrated rubber protrusion is present to provide cushioning characteristics. The solid rubber layer acts as a cap or barrier for the foam rubber layer, particularly over the integrated protrusion or protrusions, in order to provide a mat which is resilient, will not easily degrade in its modulus strength after appreciable use and / or washing within industrial cleaning processes, and will not exhibit appreciable cracking or breaking, particularly within the integrated protrusion(s), after standard use for pedestrian traffic. A method of producing such an inventive cushioned floor mat article is also provided.

Owner:MILLIKEN & CO

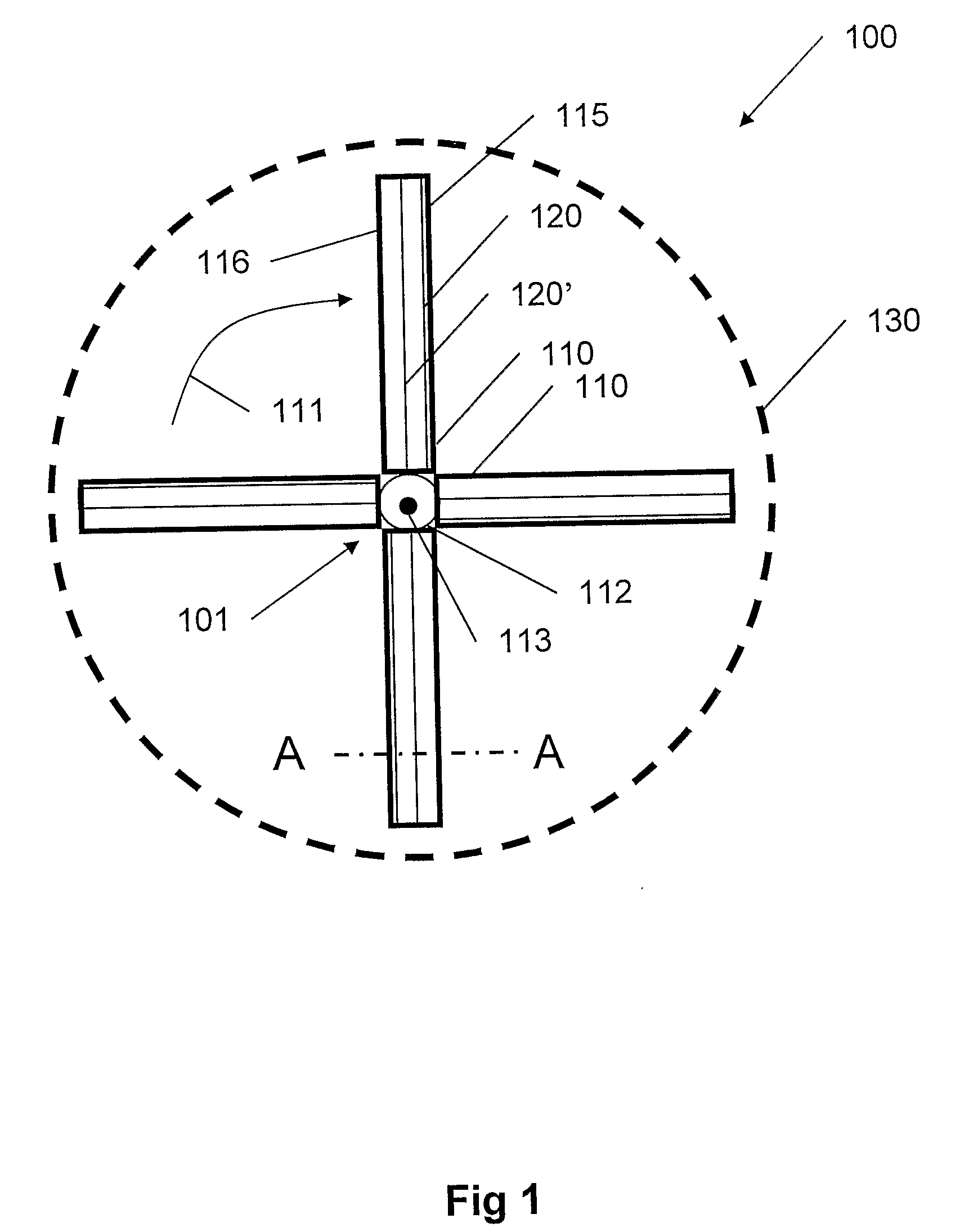

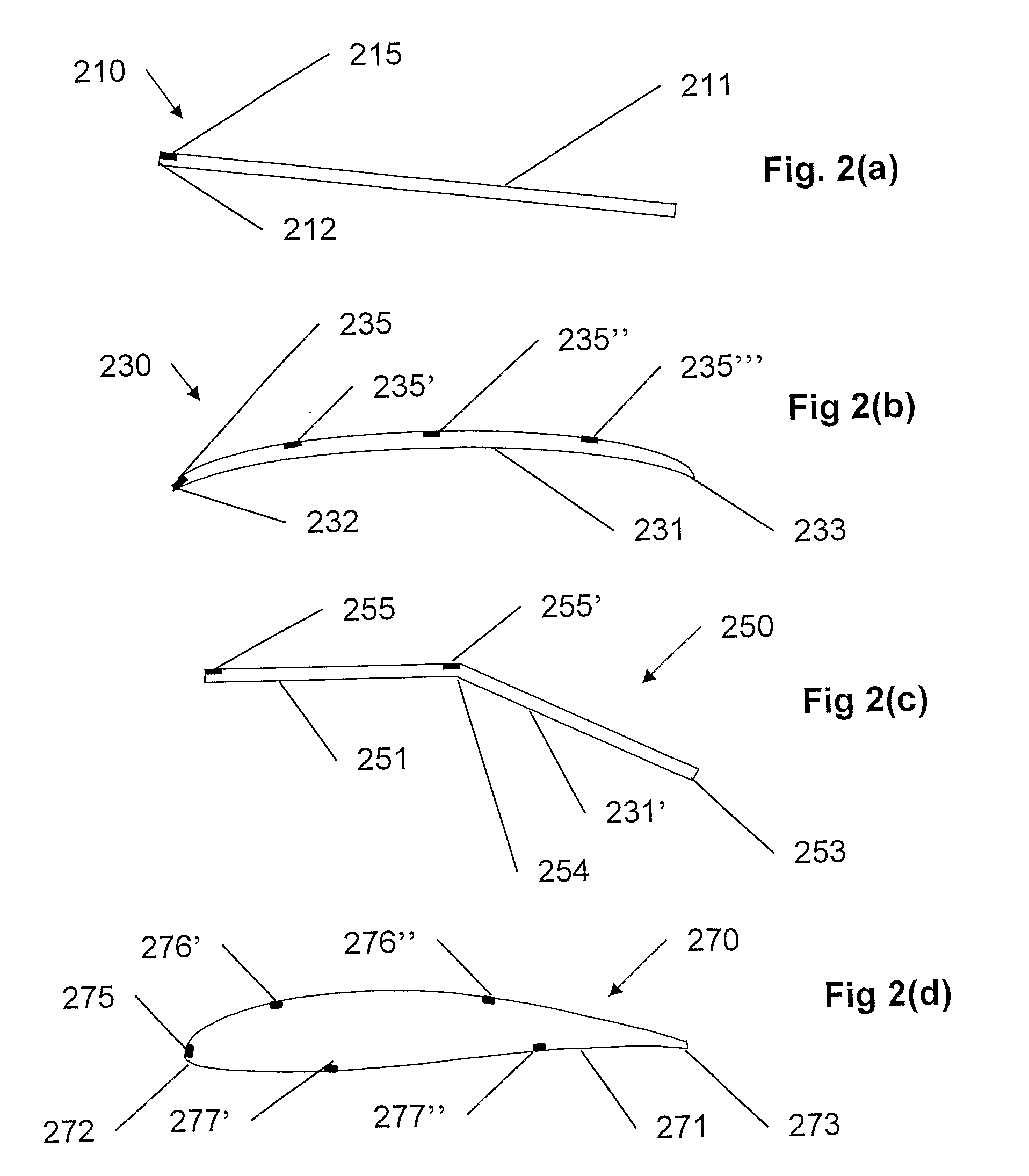

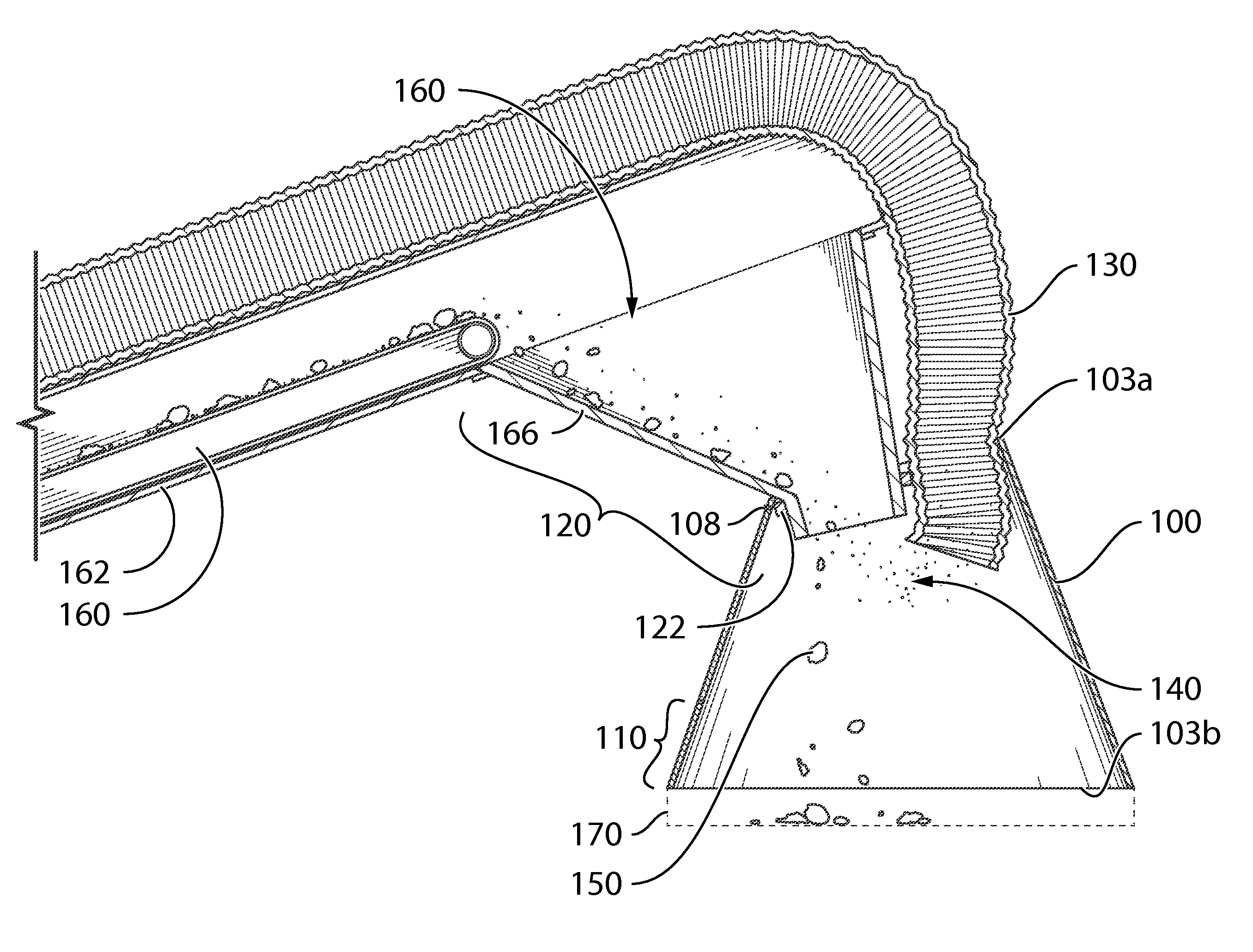

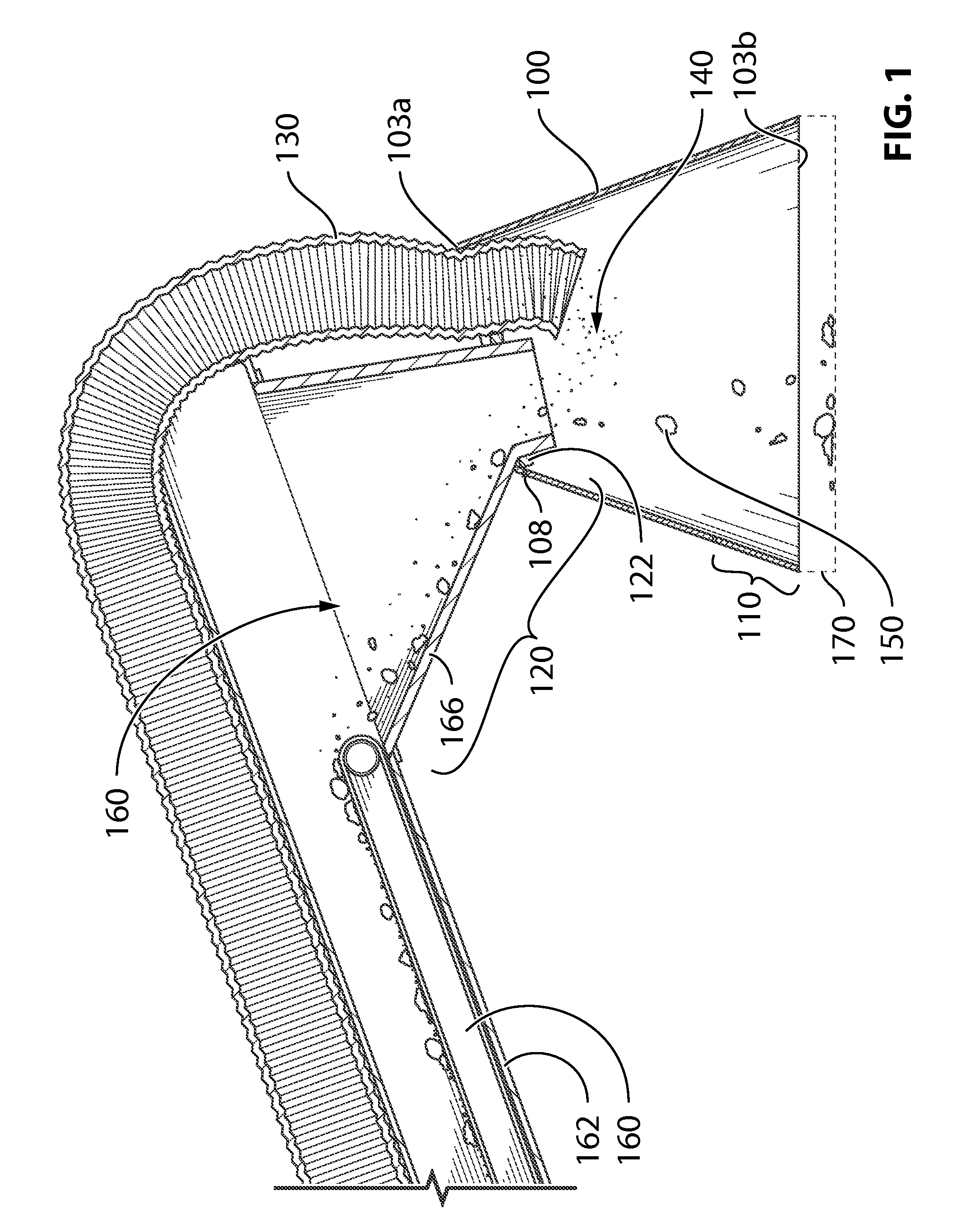

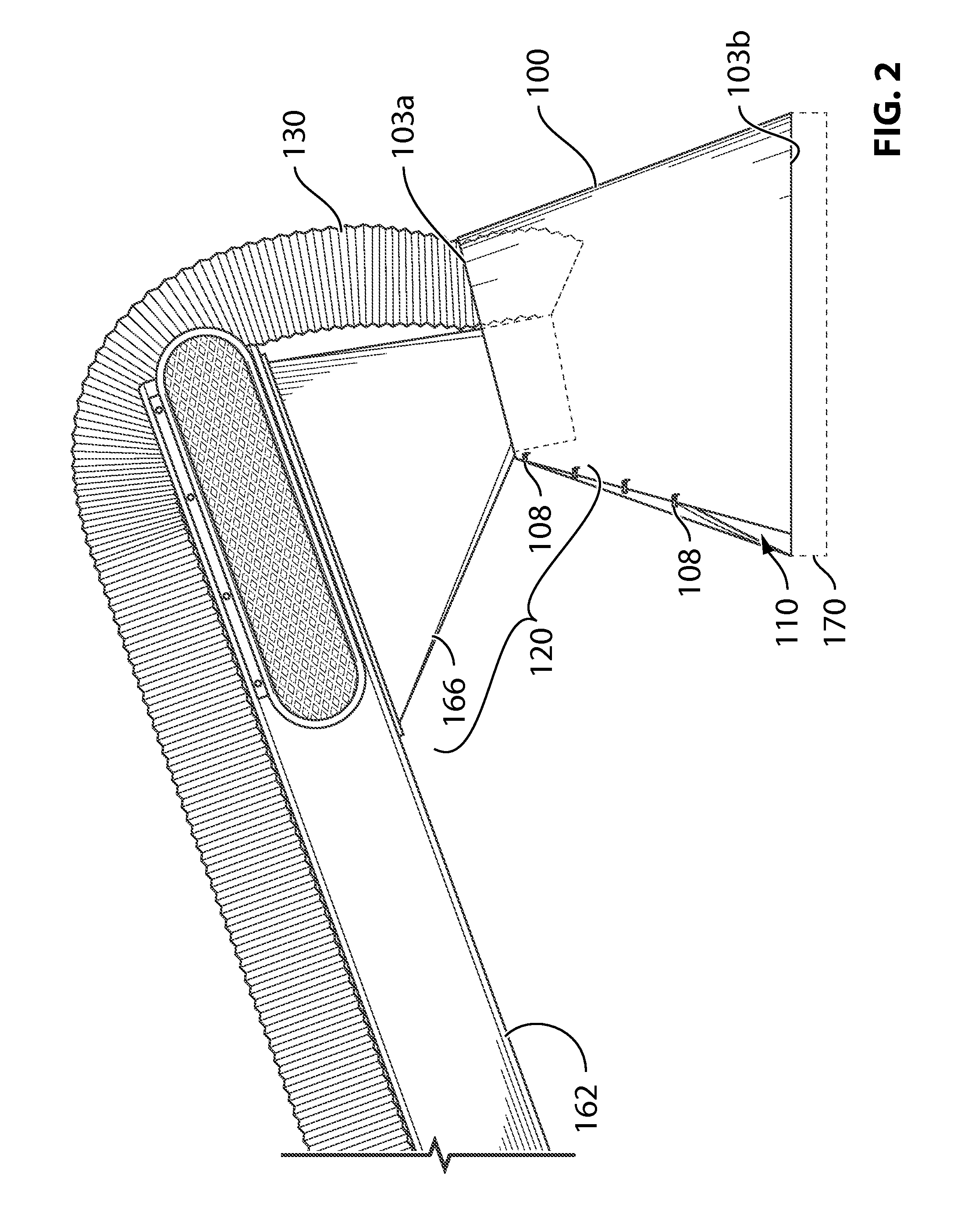

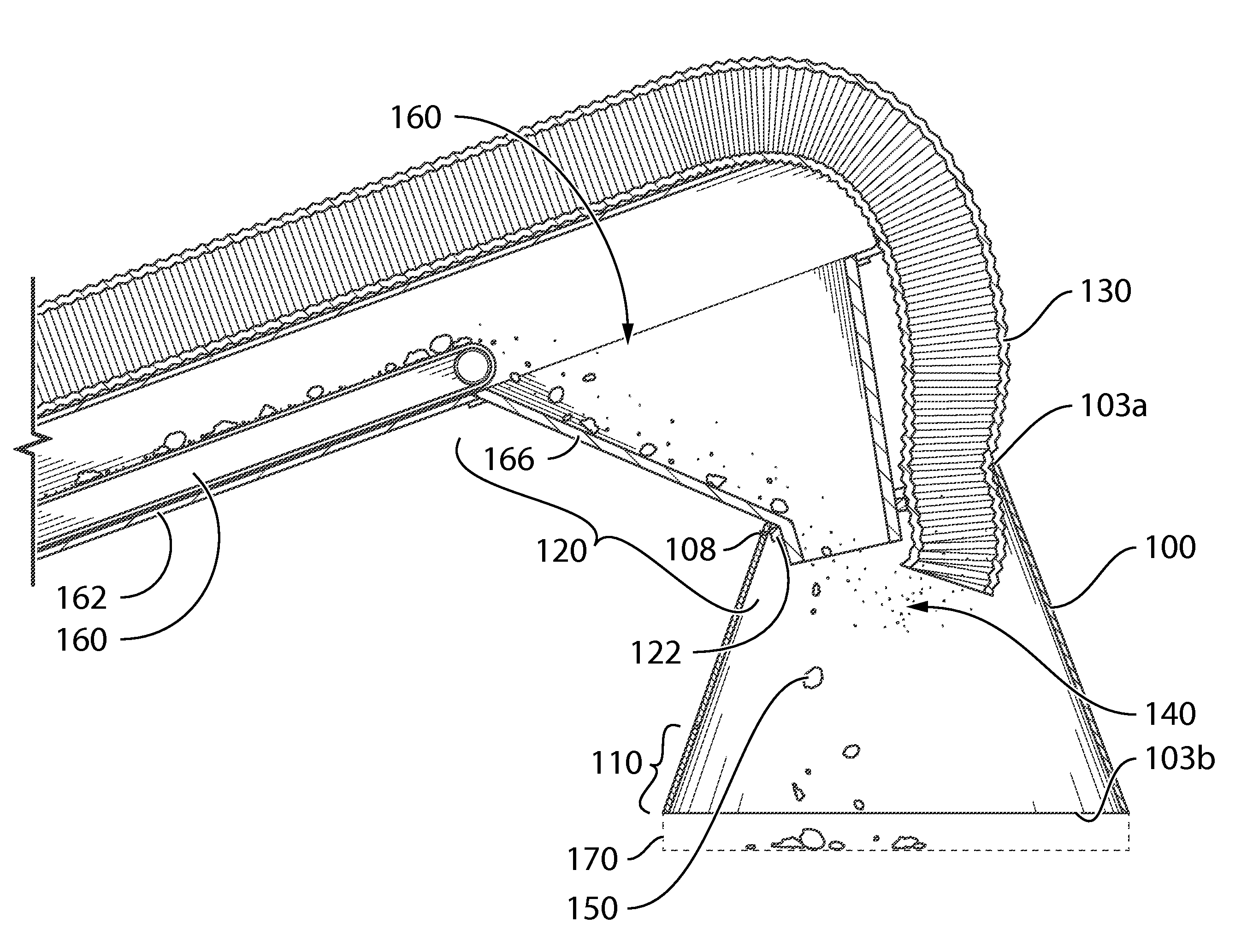

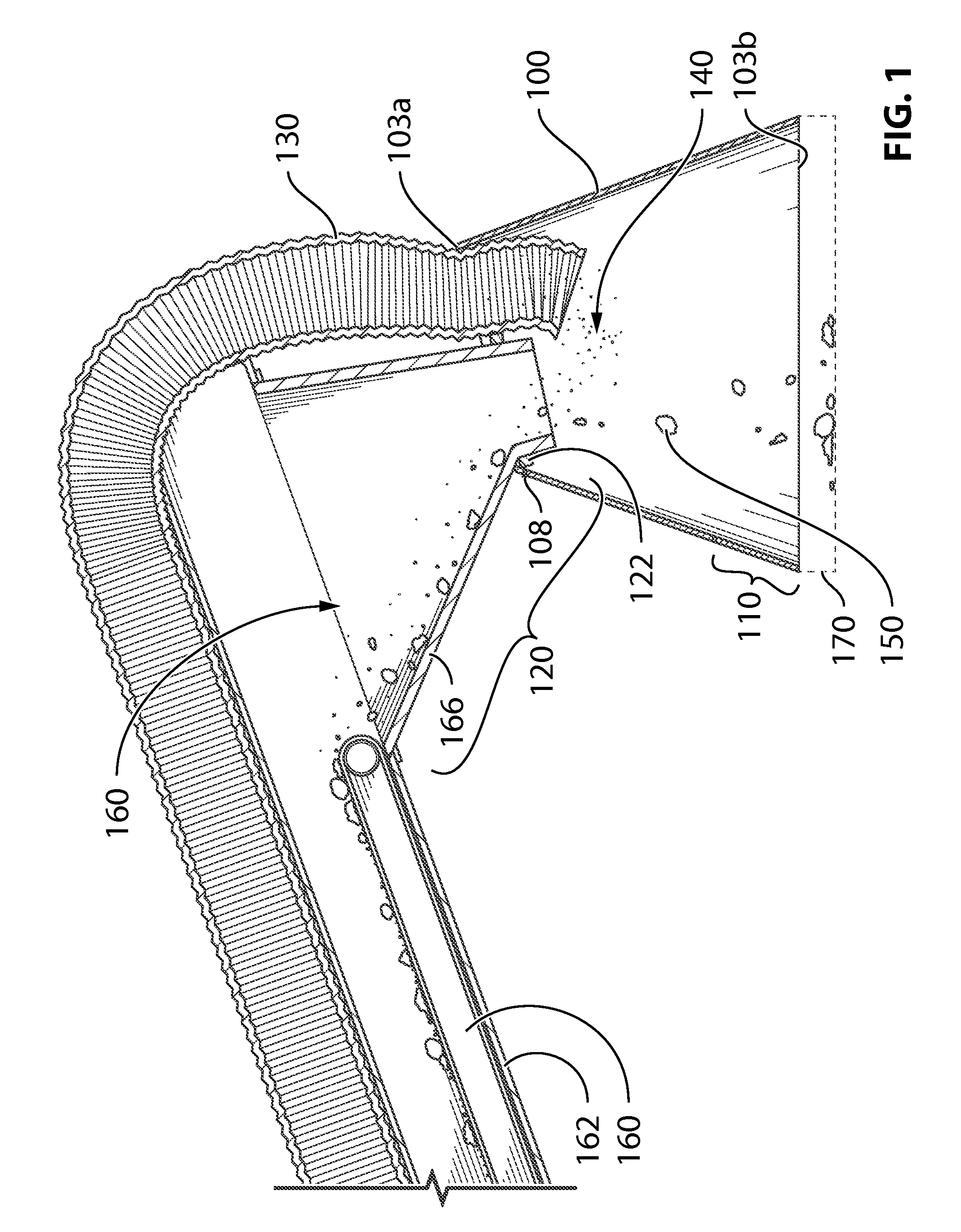

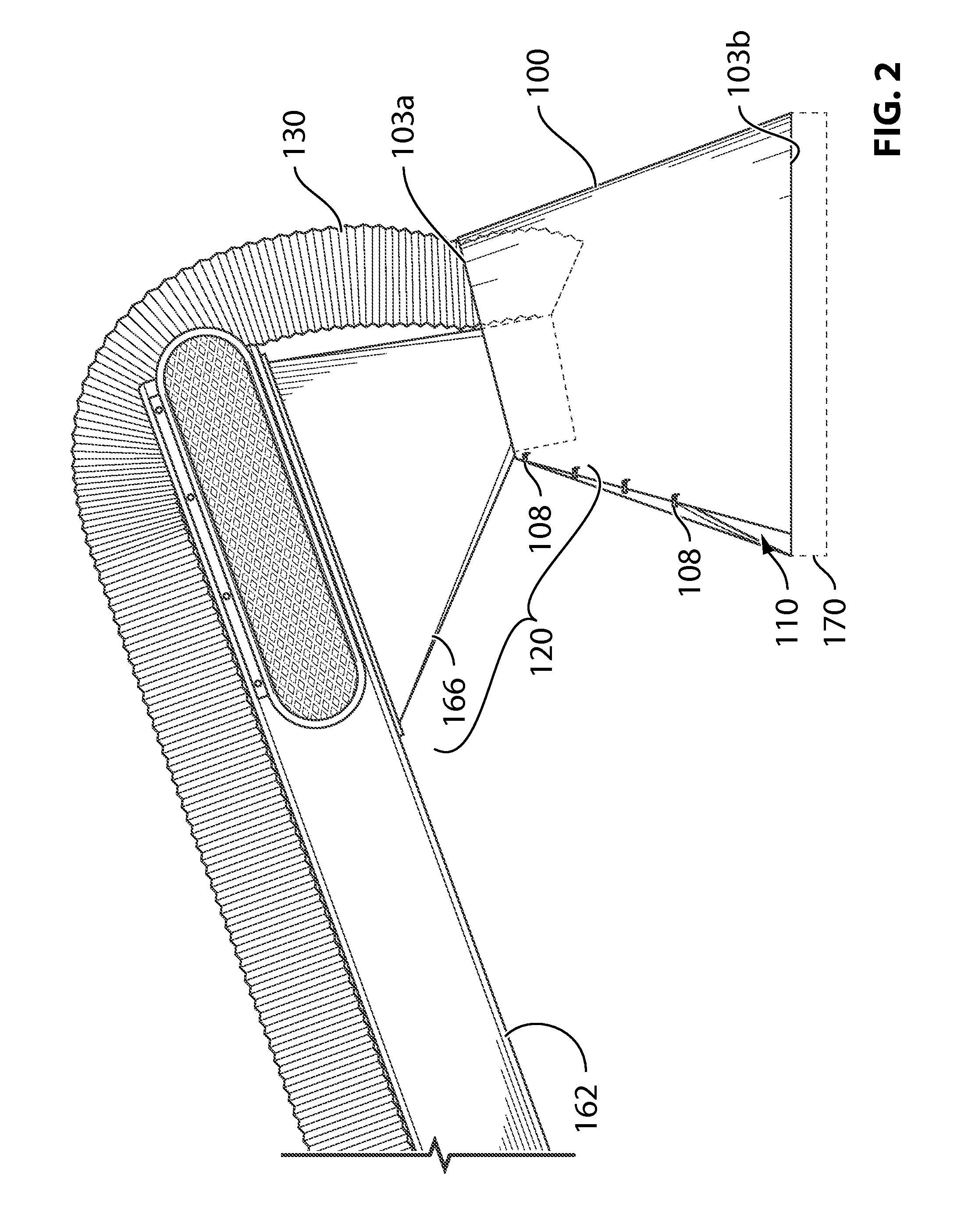

Nose Cone for Dust Control

Preferred nose cones 100 associatable with a tail spout 120 of a sand handler and a vacuum hose 130 of a vacuum system are described herein. A method for containing respirable and / or inhalable particles 140 created in an industrial process is also disclosed herein.

Owner:ASSOC RES - EDC

Nose cone for dust control

Preferred nose cones 100 associatable with a tail spout 120 of a sand handler and a vacuum hose 130 of a vacuum system are described herein. A method for containing respirable and / or inhalable particles 140 created in an industrial process is also disclosed herein.

Owner:ASSOC RES - EDC

Methods and compositions for dust control and freeze control

ActiveUS20060284137A1Avoid dustAvoid it happening againLiquid surface applicatorsOther chemical processesTransesterificationTG - Triglyceride

Dust control and / or freeze control compositions and methods of using the compositions are provided. In an embodiment, the present invention provides methods of utilizing the dust control and / or freeze control products. For example, the method can comprise preventing the agglomeration of particulate material comprising coal and the adhesion thereof to surfaces in subfreezing weather. The method can also comprise preventing dust formation from particulate material handling processes. The dust control and / or freeze control compositions can comprise one or more glycerin by-products derived from a biodiesel manufacturing process. The dust control and / or freeze control compositions can also comprise one or more glycerin by-products of transesterification reactions involving triglycerides.

Owner:ECOLAB USA INC

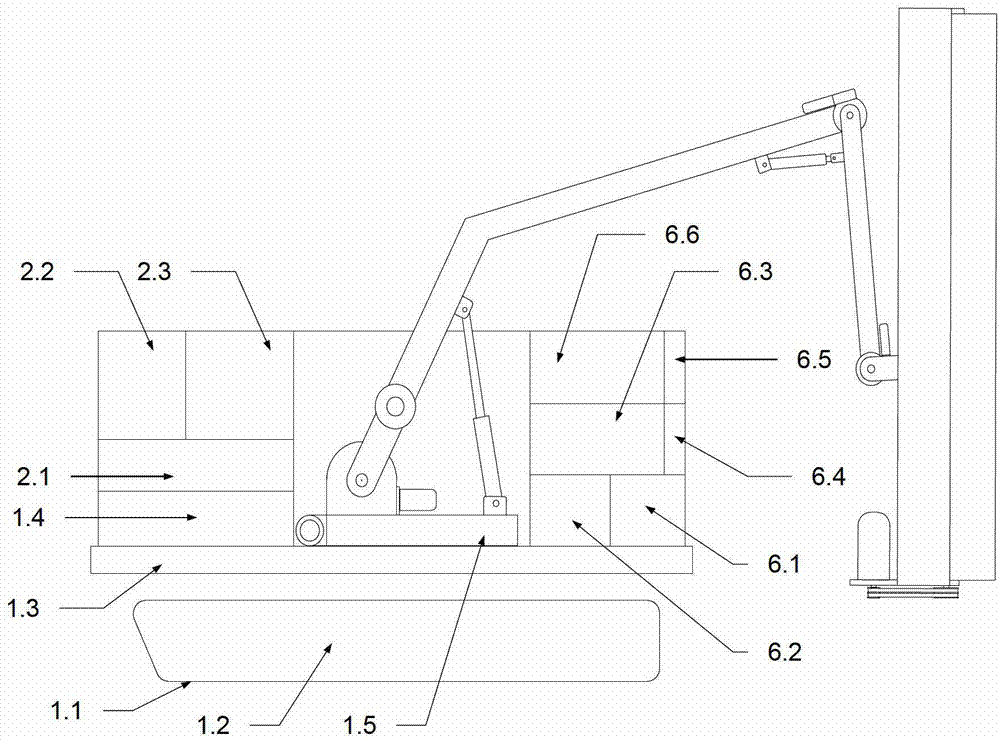

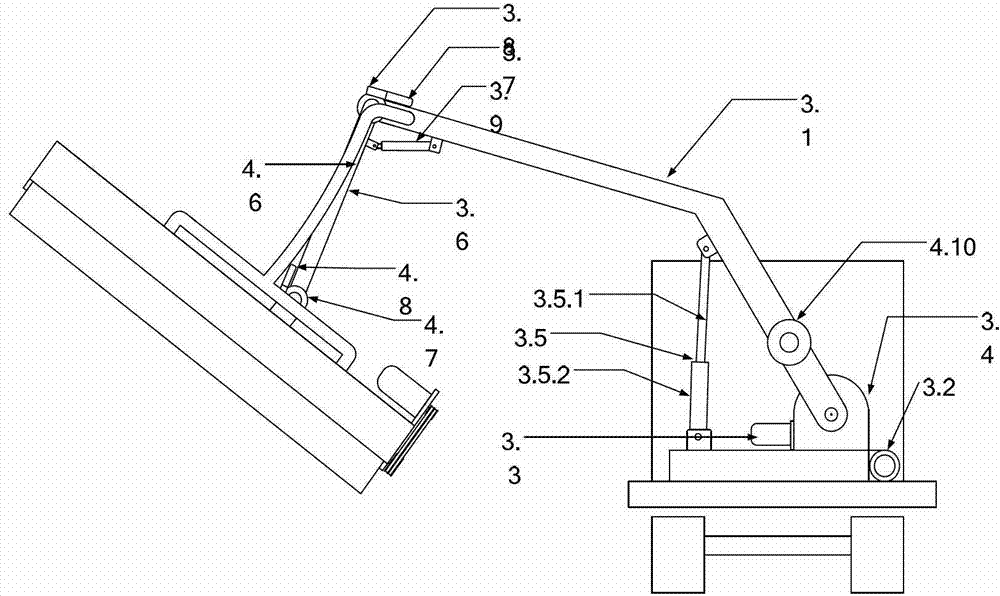

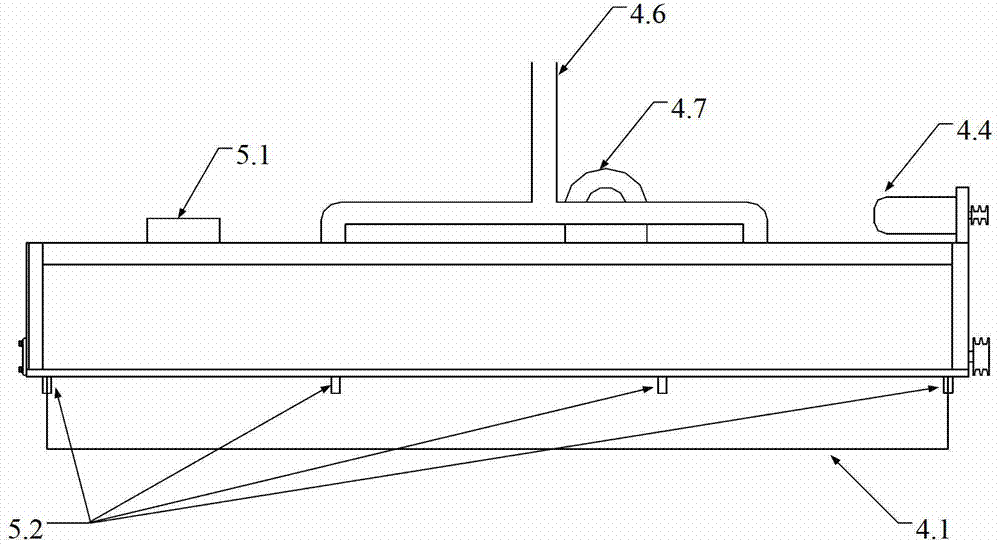

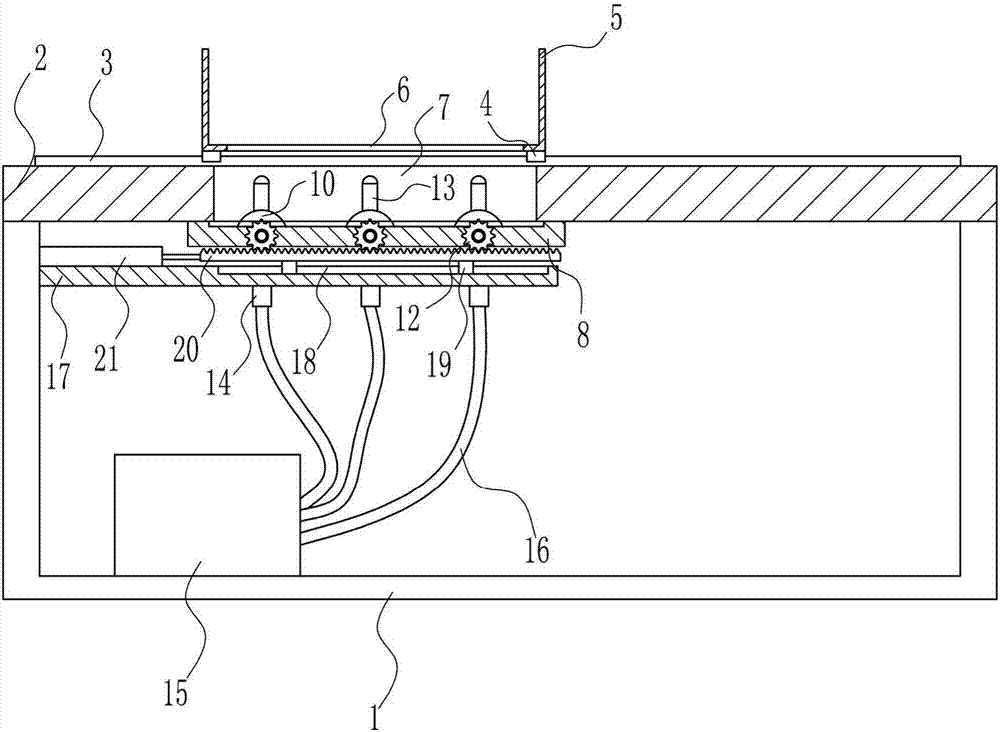

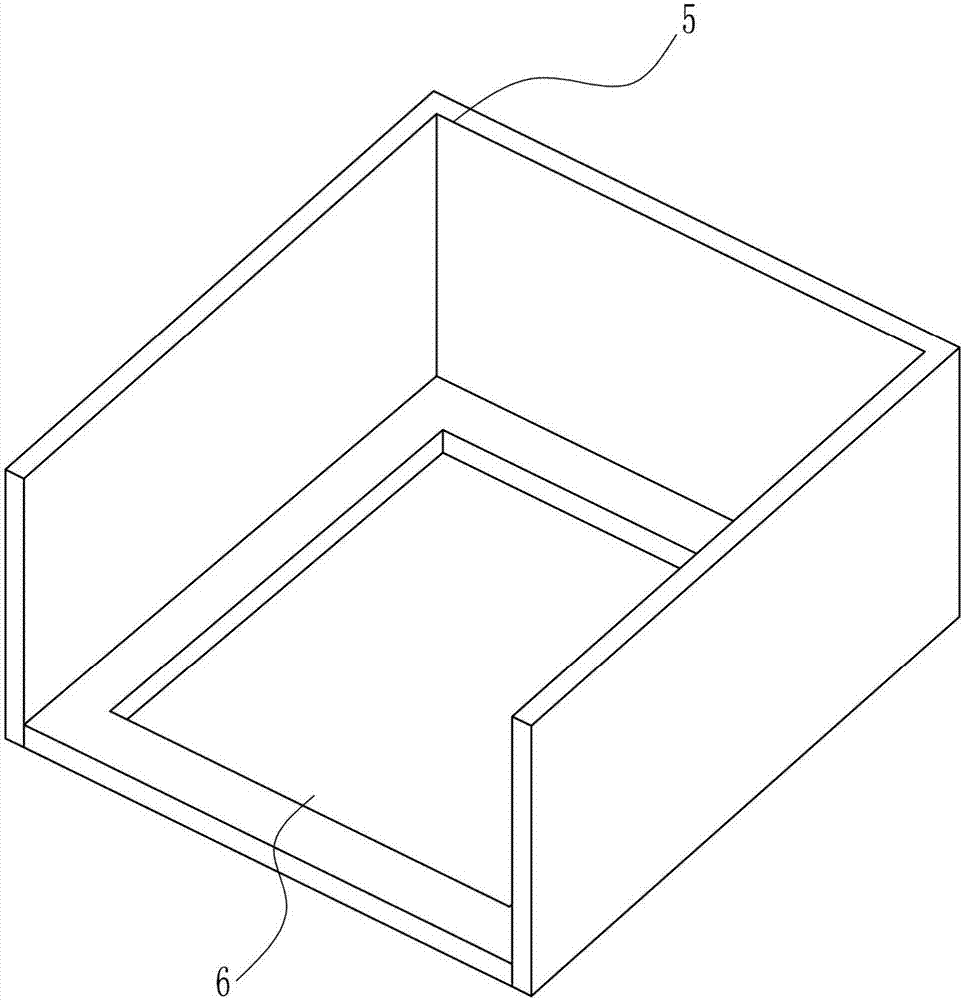

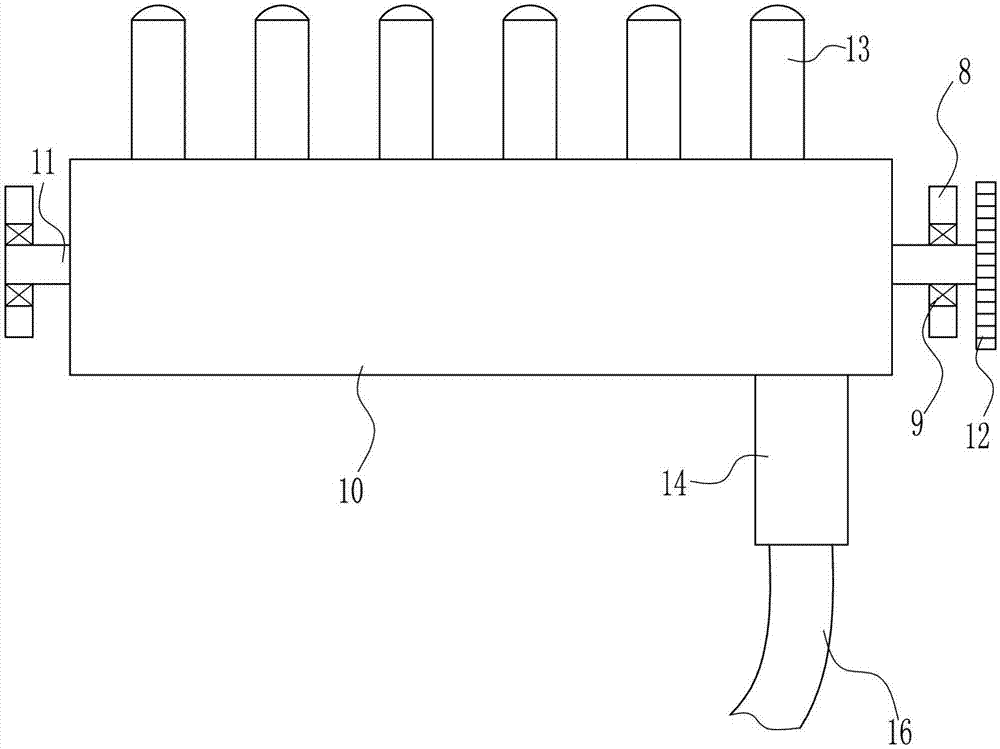

Full-automatic intelligent cleaning device of photovoltaic power station modules

The invention relates to a full-automatic intelligent cleaning device of photovoltaic power station modules, in particular to a high-efficiency dust-cleaning device for various long or short square photovoltaic modules of a large-scale photovoltaic power station. The full-automatic intelligent cleaning device of the photovoltaic power station modules comprises a cleaning car, an electromechanical braking system and an intelligent control system. The electromechanical braking system comprises a power supply unit, a support arm unit and a cleaning unit. The electromechanical braking system has the functions of cleaning and dust-cleaning with a plurality of degrees of freedom according to the surfaces of the photovoltaic modules. The intelligent control system comprises a perception unit, a processing unit and a remote control unit and can achieve full-automatic, real-time and remote controlled high-accuracy control of the cleaning car and a cleaning mechanism. The full-automatic intelligent cleaning device of the photovoltaic power station modules enables the cleaning device to be intelligentized, can carry out one-time high-accuracy dust-cleaning to the various long or short square under different road conditions, is safe, stable, reliable and full-automatic, and effectively solves the technical problems that cleaning is excessively dependent on manpower to supervise and the cleaning efficiency of the large-scale photovoltaic power station is low in the prior art.

Owner:北京安必信金属制品有限公司

Dust extraction for power tools

ActiveUS7497886B2Throughput of air through the dust extraction system andImprove performanceEdge grinding machinesCombination devicesAtmospheric airPower tool

There is also provided a dust extraction module for use with a power tool, the dust extraction module having: a dust collection chamber (50) having an inlet (52) connectable in fluid communication with an outlet (44) of a dust-extracting duct (40) of the power tool, and having an outlet (54) in fluid communication with atmospheric air; and a filter (60) locatable in fluid flow between the outlet of the dust collection chamber and the atmospheric air; wherein the dust collection chamber (50) has a substantially circular cross section, the inlet (52) to the dust collection chamber is at the perimeter of the circle and the outlet (54) of the dust collection chamber is from the middle of the circle.

Owner:BLACK & DECKER INC

Special formulations for the removal of mercury and other pollutants present in combustion gases

InactiveUS20080182747A1Efficient removalRemoving the flue gas borne pollutantsGas treatmentOther chemical processesParticulatesDust control

The invention provides compositions to remove mercury and other pollutants from a fluid stream, particularly flue gases containing them. The compositions are mixtures of compounds selected from two or more different groups of compounds. One of the compositions can simultaneously remove mercury and condition the dust for better removal of the dust by an ESP if an ESP is the device of choice for dust control. This composition is a mixture selected from the group of halides other than fluoride and chloride, and mixture thereof, and that selected from a group of nitrates. In the other invention, the composition consists of a mixture of selected polyhydroxy compound or compounds, ammonium sulfate, halides other than fluoride and chloride, and mixture thereof. The composition can be liquid or dry powder and can be injected ahead of the particulate control device as a mist when the formulation is a liquid or as a powder when dry. Methods are provided for applying the formulations.

Owner:SINHA RABINDRA K

Novel fabric rolling machine

InactiveCN107697695AEasy to assemble and disassembleEasy maintenanceCleaning using toolsCleaning using gasesEngineeringMechanical engineering

The invention discloses a novel fabric rolling machine which comprises a rack; the rack is provided with a winding roll and a motor used for driving the winding roll to rotate; a pressure roll is arranged under the winding roll; the two ends of the pressure roll are movably installed in chutes which are arranged on the two sides of the rack respectively; a telescopic rod A is vertically installedin each chute and is provided with a spring A in a sleeved manner; a mounting seat is arranged at the top end of each telescopic rod A; the pressure roll is rotationally connected with the mounting seats; a base is arranged at the bottom end of the rack and is provided with pressure roll lifting regulation device; and a dust removal mechanism is arranged above the winding roll. The novel fabric rolling machine provided by the invention can ensure automatic smoothing to be realized when a fabric is wound, realizes automatic regulation without being limited by a diameter of the pressure roll andcan also suck dust and thread ends adhered to the fabric.

Owner:SUQIAN SHENLONG HOME TEXTILE

Dust control unit used after assembling of mainframe box of computer

InactiveCN106944416AAvoid inhalationAvoid driftingDirt cleaningDigital processing power distributionDust controlBolt connection

The invention belongs to the field of computer assembly, in particular to a dust removal device after assembly of a computer main case. The technical problem to be solved by the present invention is to provide a dust removal device after assembly of the computer main case which can reduce the labor intensity, improve the dust removal efficiency and improve the quality of the case. In order to solve the above-mentioned technical problems, the present invention provides such a dust removal device after the computer main case is assembled, which includes a first bracket, a workbench, a first slide rail, a first slider, a placement frame, a support plate, and a first bearing seat , main air pipe, rotating shaft, gear, air spray head, joint, etc.; the top of the first bracket is provided with a workbench, and the top of the workbench is horizontally connected with the first slide rail by means of bolt connection. The present invention blows air to the cabinet by swinging the air spray head left and right to blow away the dust in the cabinet, so that the dust in the cabinet can be removed, the labor intensity can be reduced, and the dust removal efficiency can be improved.

Owner:汪国栋

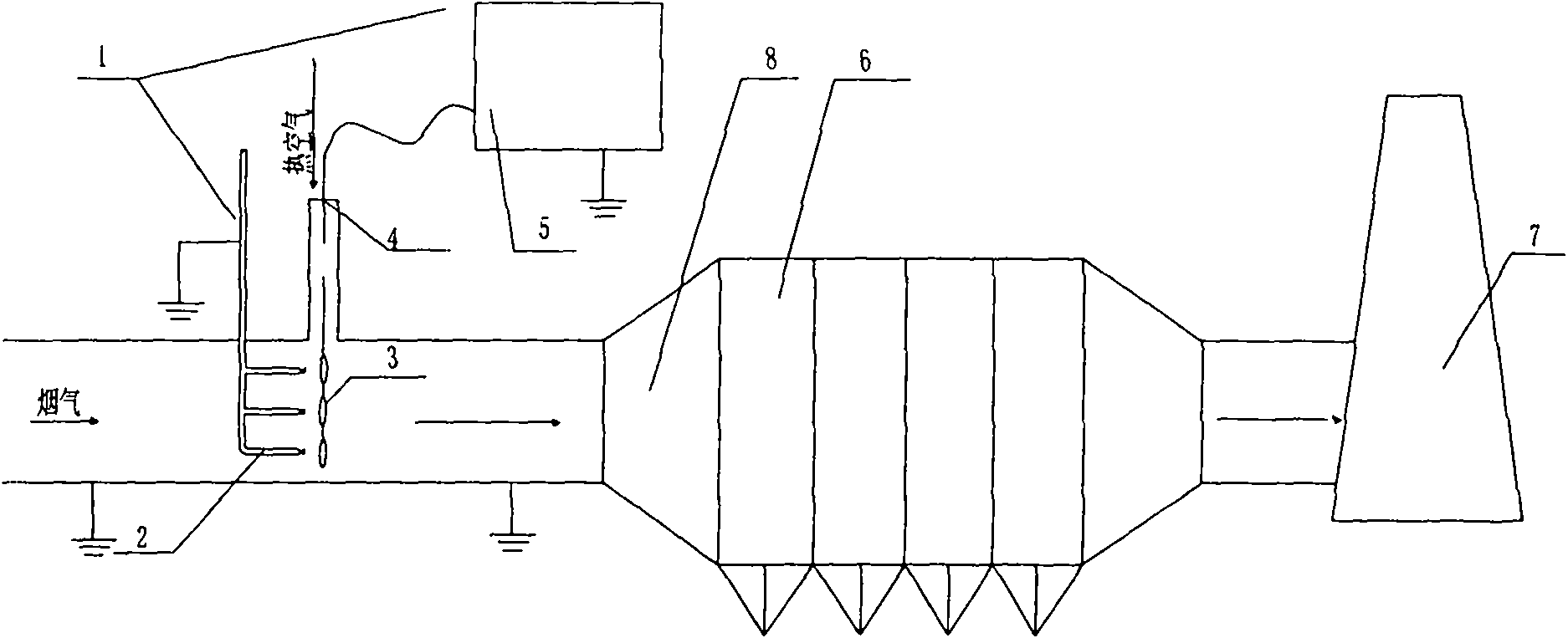

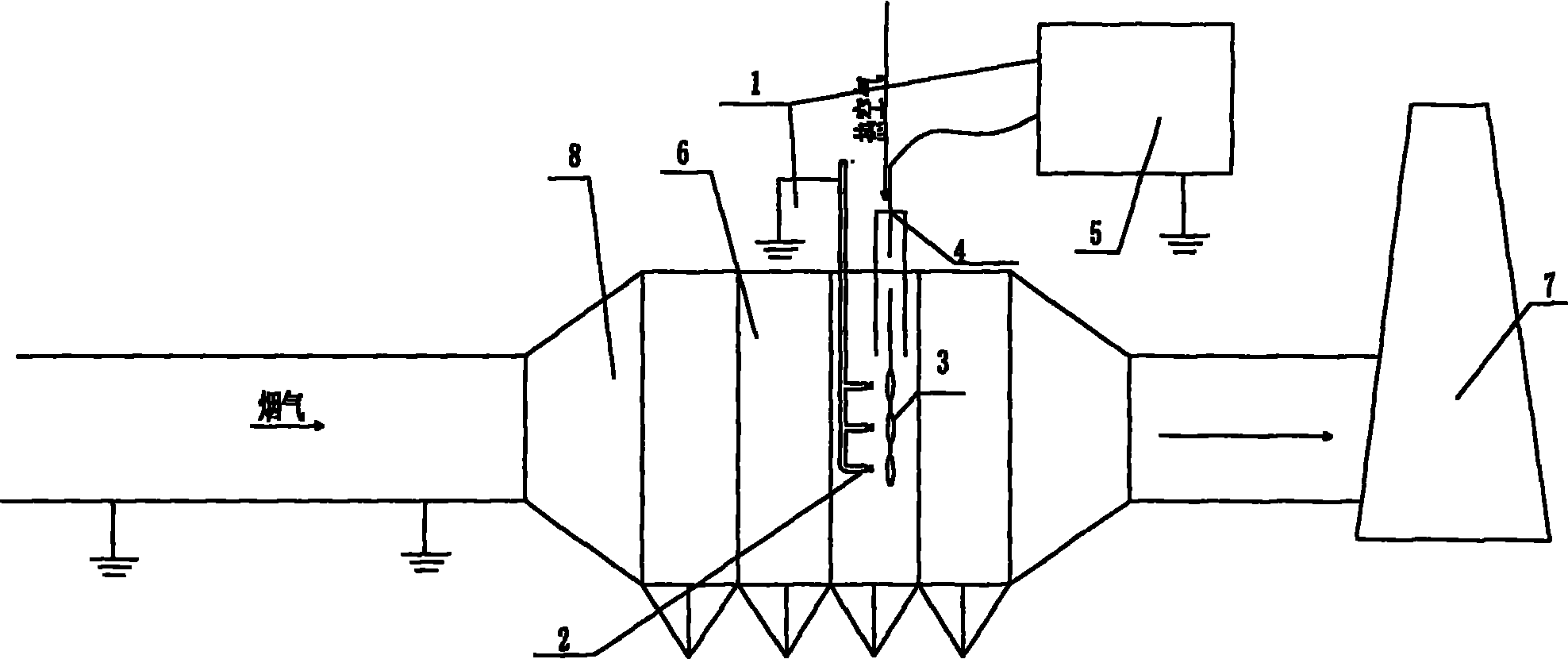

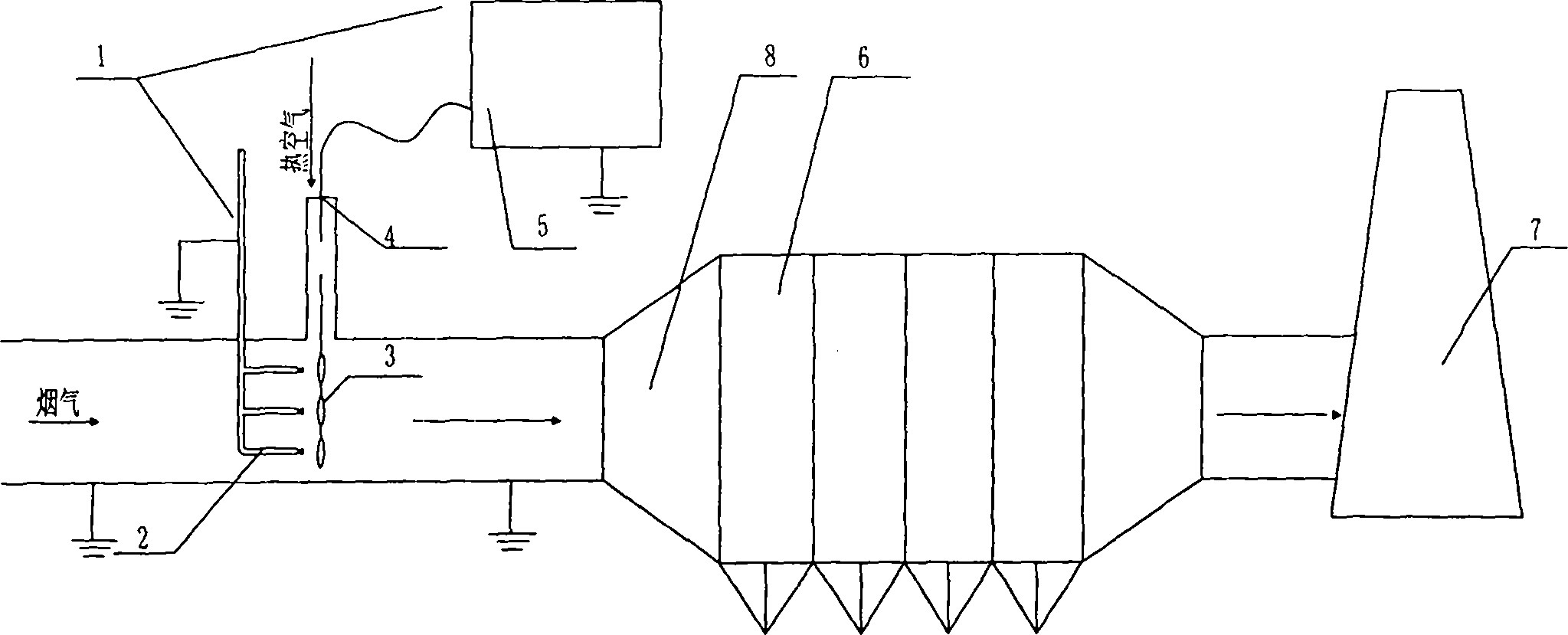

Synergistic spray charging and electrostatic dust collecting method and device

InactiveCN102145316AIncreased viscosityPromote reunionElectrostatic separationElectrostatic precipitatorDust particles

The invention relates to a synergistic spray charging and electrostatic dust collecting method by which a water spray charging device is combined with an electrostatic dust collector, flue gas is conditioned by using water spray, agglomeration of dust particles is promoted and the charging characteristic of the dust particles is improved through charging drops containing an agglomerating agent, thus the dust collection efficiency of the electrostatic dust collector is increased, the fine dust collecting efficiency is higher than 90 percent, and the concentration of smoke dust at an outlet is lower than 50 milligrams per cubic meter. The invention also discloses a synergistic spray charging and electrostatic dust collecting device which comprises the electrostatic dust collector and the water spray charging device, wherein the electrostatic dust collector is arranged on a flue; and the water spray charging device is arranged on a flue in front of an inlet of the electrostatic dust collector, or on a gradually expanded section of the inlet or on a position of a bottom second-stage or third-stage electric field in the electrostatic dust collector. The water spray charging device comprises a dual-fluid atomizing nozzle and a corona ring, wherein the dual-fluid atomizing nozzle is arranged at the front part of the corona ring, an insulator is arranged outside the upper end of the corona ring, and the corona ring is connected with a high-voltage power supply through a wire. The synergistic spray charging and electrostatic dust collecting device has a simple structure, low cost and high dust collecting efficiency.

Owner:SHANDONG UNIV

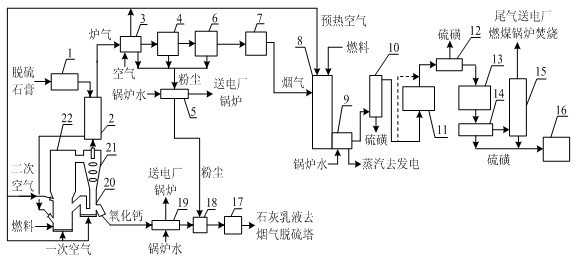

Method for preparing calcium oxide and sulfur by double-atmosphere fluidized roasting of desulfurated gypsum

InactiveCN102303883ASolve the use problemAbundant raw materialsEnergy inputSulfur preparation/purificationDust controlSulfur dioxide

The invention provides a method for preparing calcium oxide and sulfur by double-atmosphere fluidized roasting of desulfurated gypsum, belonging to the technical fields of solid pollutant treatment and in environmental protection chemical production. The method comprises the following steps: drying and dehydrating aged desulfurated gypsum, and then entering a multi-stage suspension heat exchangerfor pre-heating; entering hot-state gypsum into a circulating fluidized bed decomposition furnace, and introducing primary and secondary air for decomposition; cooling discharged hot-state calcium oxide, wherein cooled hot-state calcium oxide is used as a desulfurizer for later use; entering discharged smoke containing sulfur dioxide into the multi-stage suspension heat exchanger; removing calcium oxide dust in cooled hot smoke through multi-stage dust removing equipment; and feeding the smoke without the dust into a high-temperature-resistant high-efficiency filter for further removing the dust, and feeding clean smoke into a sulfur recovery system; and preparing the sulfur product by the processes of hot reduction, catalytic reduction, Clause reaction and the like, and feeding Clause tail gas into a coal burning boiler in a power plant for combustion. The method has the advantages of good environmental protection benefits and strong economic benefits.

Owner:CHINA PETROCHEMICAL CORP +1

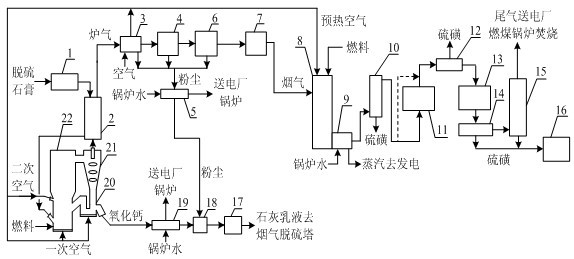

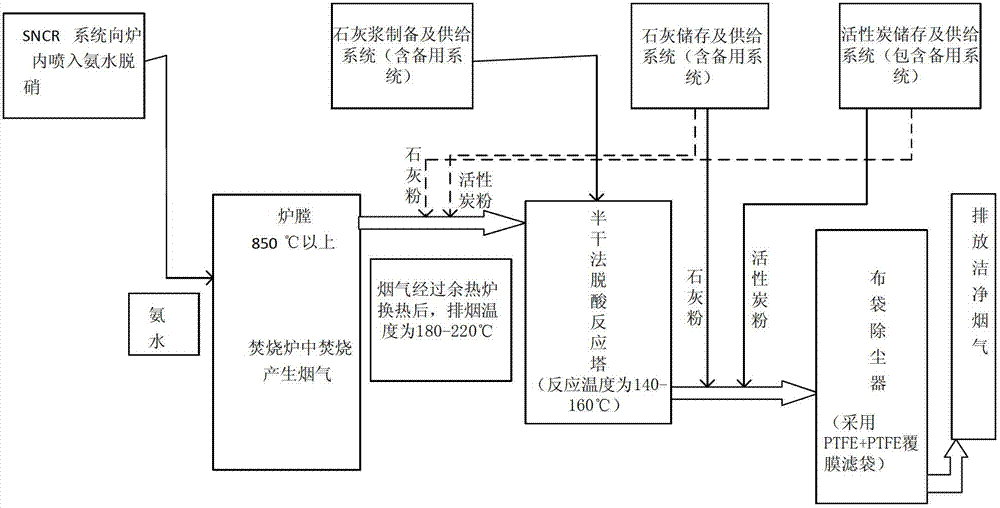

Method and device for fume purification treatment in waste incineration

InactiveCN102728194AControllable investment costControllable operating costsDispersed particle filtrationActivated carbonOperational costs

The invention relates to a method and a device for fume purification treatment in waste incineration. The method comprises steps of denitration, semidry-method deacidification, dry-method deacidification, activated carbon adsorption and cloth-bag dust removing; in the semidry-method deacidification step, a temperature reducing water system which is independent from lime slurry is adopted to control the deacidification reaction temperature to be 140-160 DEG C; and the dry lime powder for the dry-method deacidification and the activated carbon powder for the activated carbon absorption can be injected prior to the semidry-method deacidification or injected after the semidry-method deacidification. The device aims at analyzing and improving the prior art and further inspecting after the improvement; indexes in fume discharge can reach the standard 2000 of the European Union continuously and stably; furthermore, the investment and operation cost are controllable and lower; the process is simple; the operation management is convenient; and no secondary liquid pollution is caused.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +3

Cyclic fluidized bed active coke desulfurating and sulfur reutilization method

InactiveCN1435273ALow priceHigh mechanical strengthDispersed particle separationSulfur preparation/purificationFluidized bedFlue gas

A desulfurizing process with circulating fluidized bed for the flue gas at 70-200 deg.C containing SO2 and NOx is characterized by that said flue gas and the active coke as desulfurizing agent are continuously fed in the reactor of desulfurizing tower for removing dust, SO2 and NOx, the clean flue gas flows in chimney for exhausting it, the active coke is regenerated then in regenerating tower for further using it in desulfurizing tower, and SO2 is reduced to become sulfur to be recovered. Its advantages are high desulfurizing efficiency, low cost and water consumption, and no secondary pollution.

Owner:国家电站燃烧工程技术研究中心 +3

Wet-type ammonia process flue gas purifying technique for jointly removing multipollutant and system thereof

InactiveCN101108303ASimple processSmall footprintDispersed particle separationAir quality improvementChemistryProcess systems

A damp ammonia smoke and gas purifying techniques and system which deprives plurality kinds of infectant is provided. The technique uses the dual functions of high gradient magnetic field and grain conglobation accelerator firstly, which makes small grains in smoke and gas reunite large grains. Then deprives the reunited large grains by a static dedusting device, adopts oxydol to proceed oxidation on nitric oxide in the smoke and gas to convert to nitrogen dioxide, finally adsorbs sulfur dioxide and nitrogen dioxide in smoke and gas by damp ammonia smoke and gas purifying techniques. The system is composed of a high gradient magnetic field generator, a grains conglobation accelerator spaying device, a static dust catcher, an oxidant spaying device and a reaction adsorption tower which are laid in series one by one. A draining opening of the reaction adsorption tower can be connected with an outgrowth process system which is composed of a rotary stream separator, an evaporator and a desiccator. The invention can improve the utilization rate of absorbent effectively, deprives the respirable grains, oxysulfide and nitrogen oxides in smoke and gas, and has simple technics, simplified system and low investment and operating cost.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com