Patents

Literature

162 results about "Sulfur product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

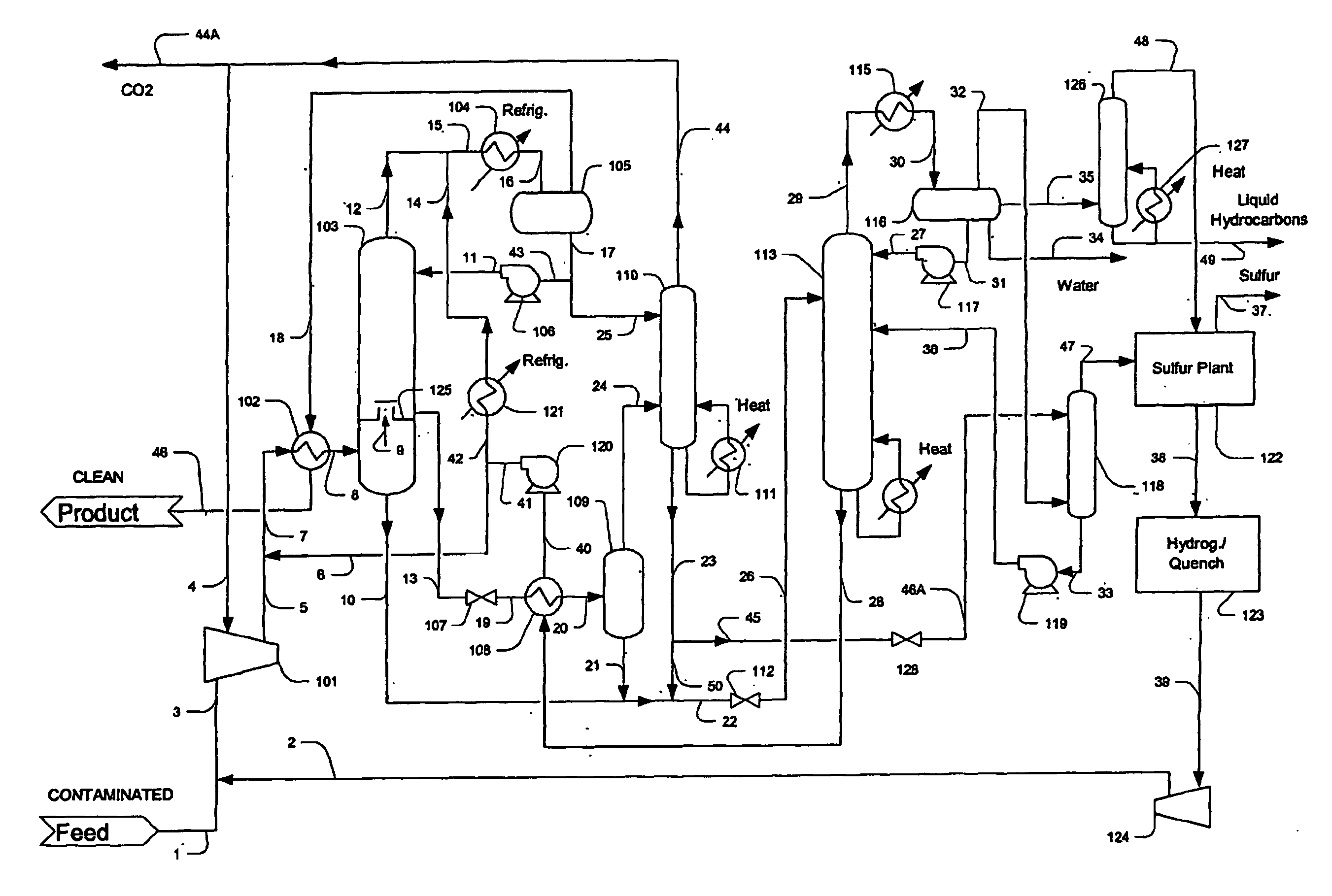

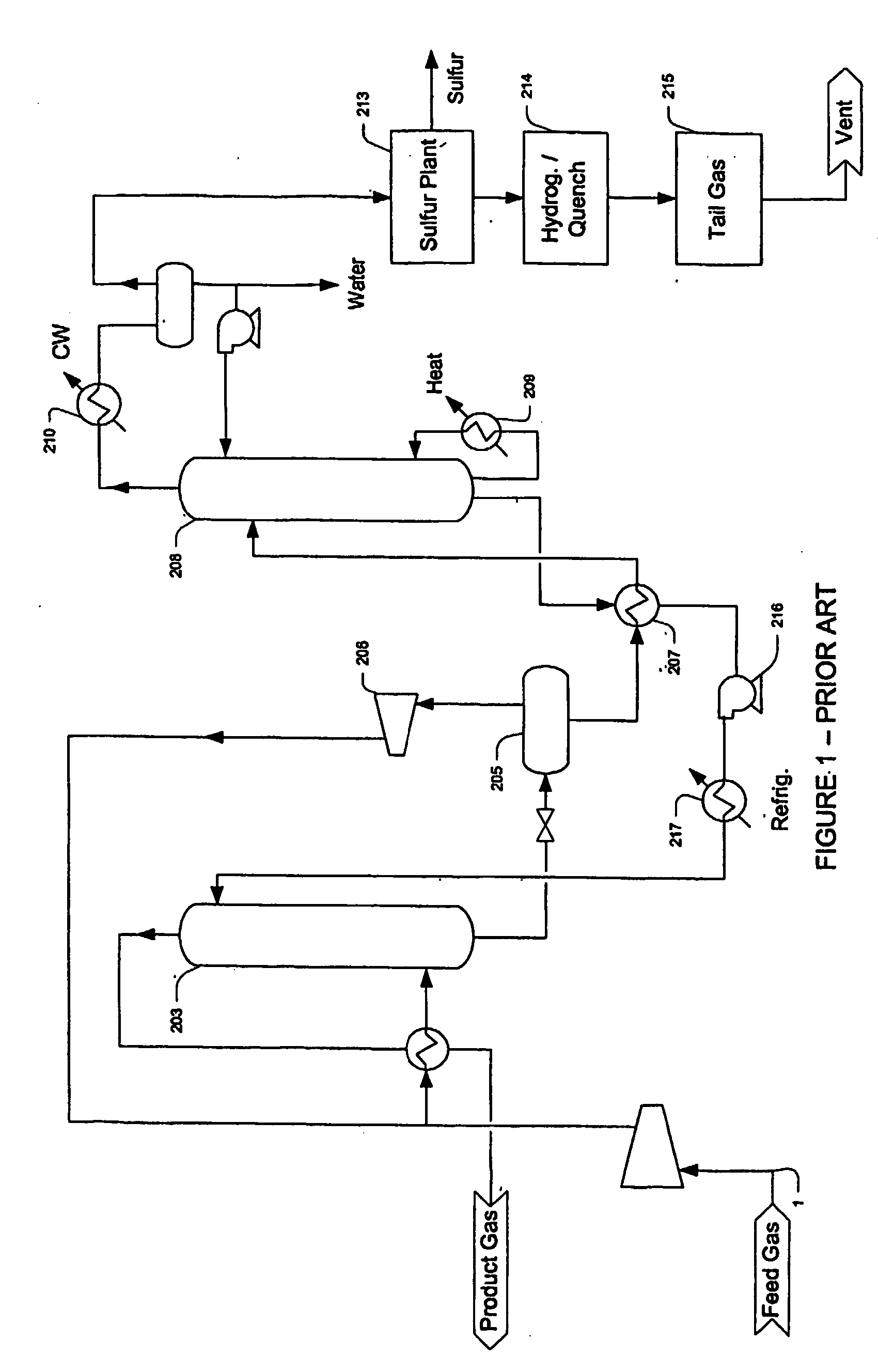

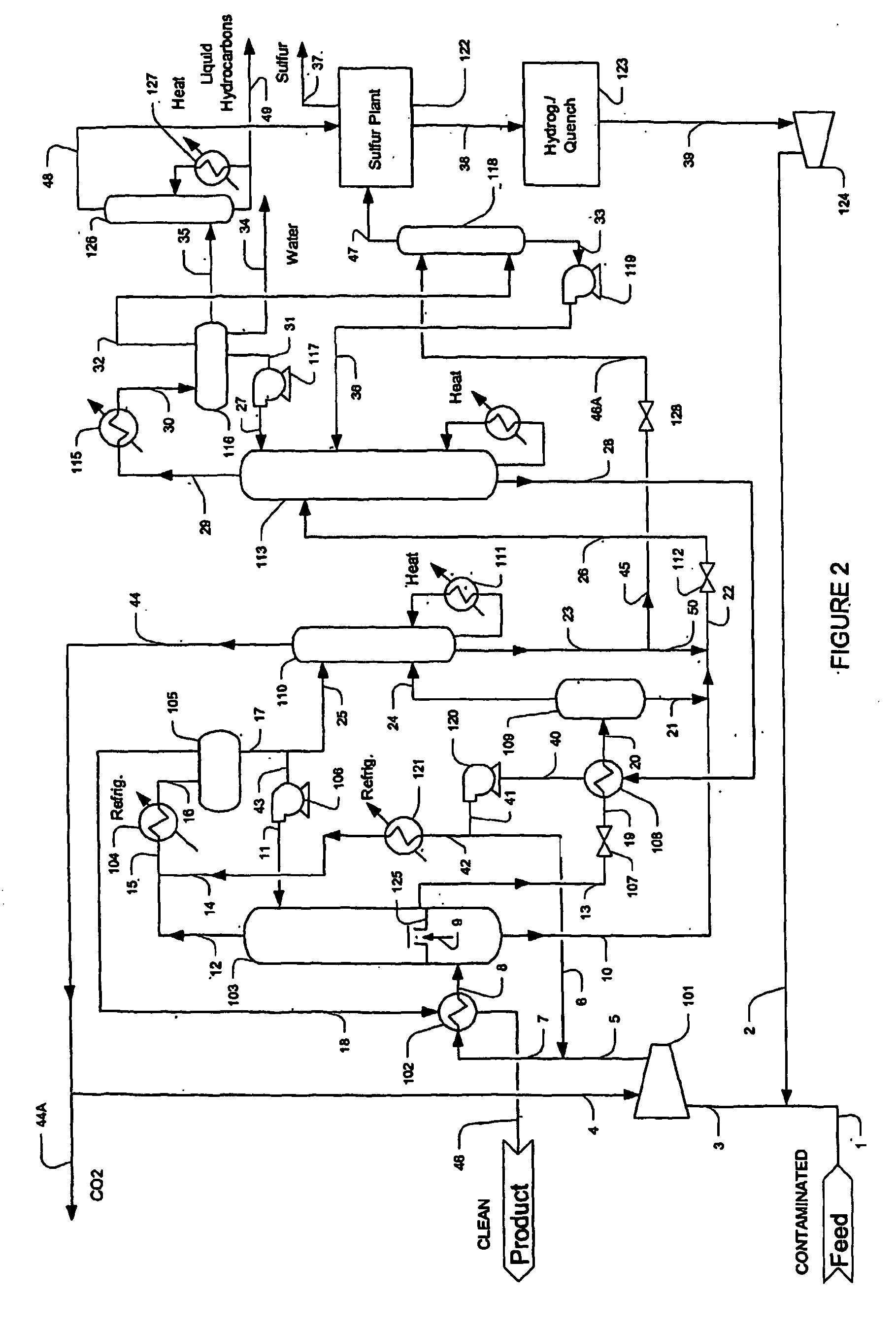

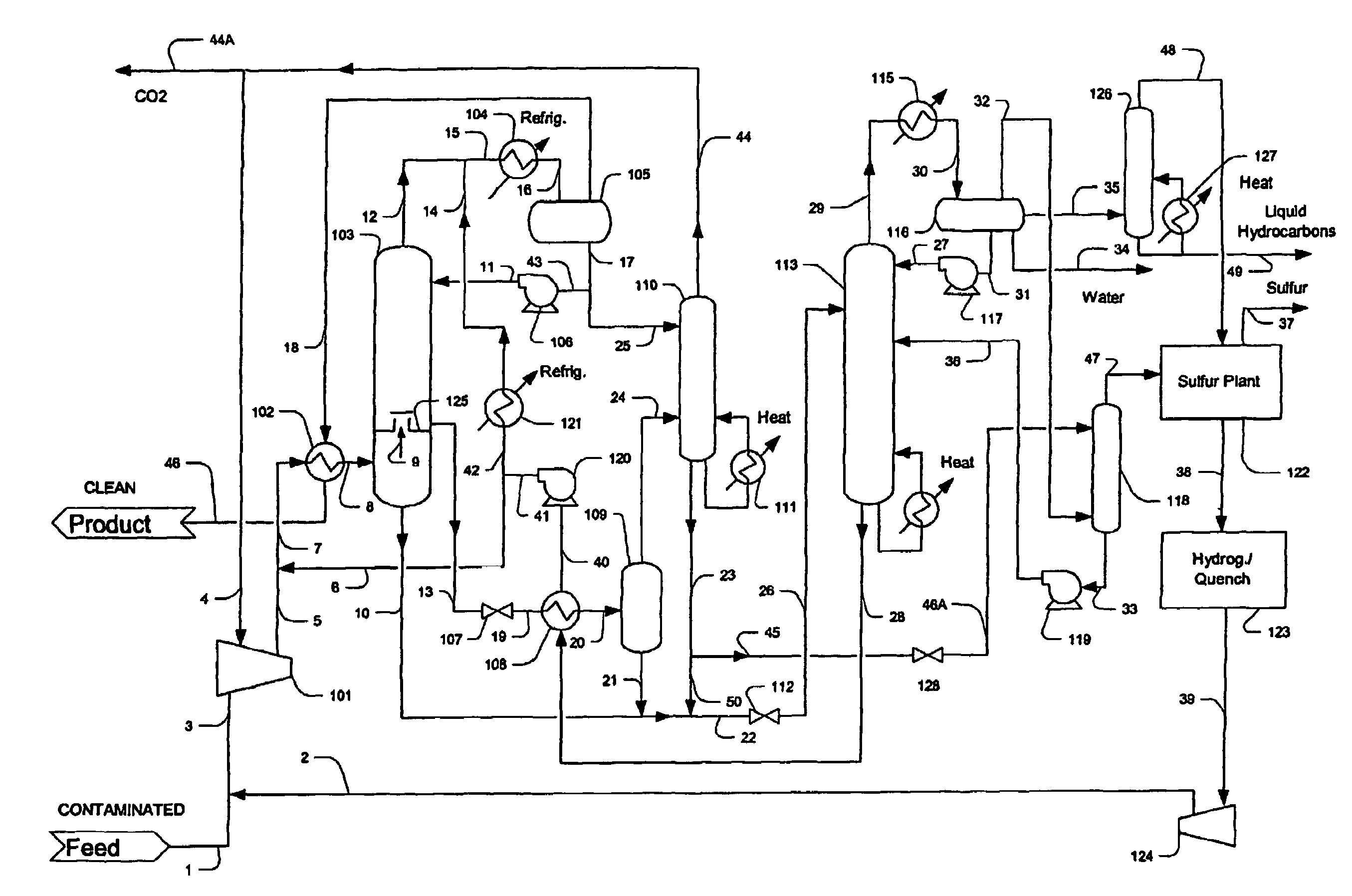

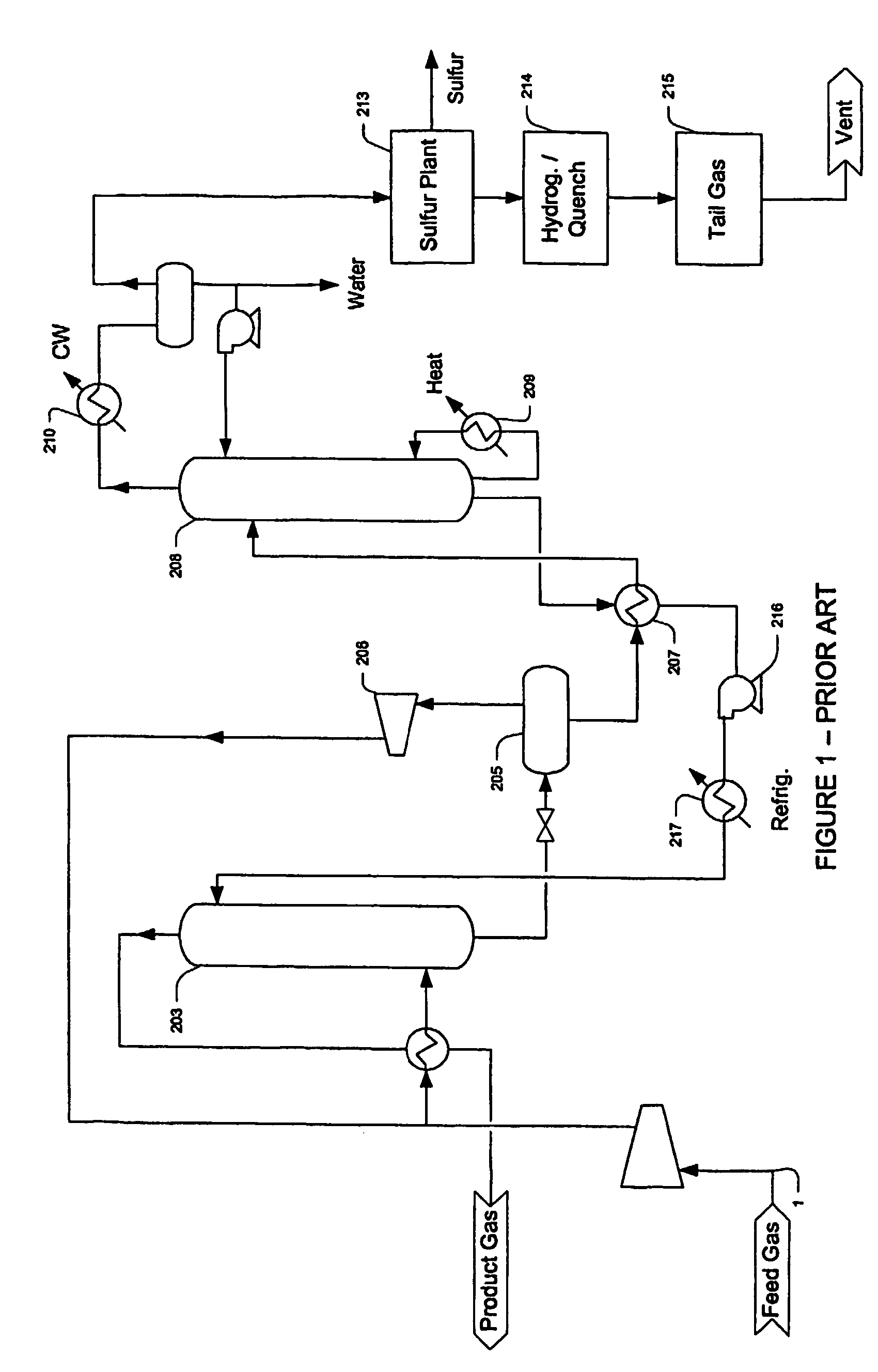

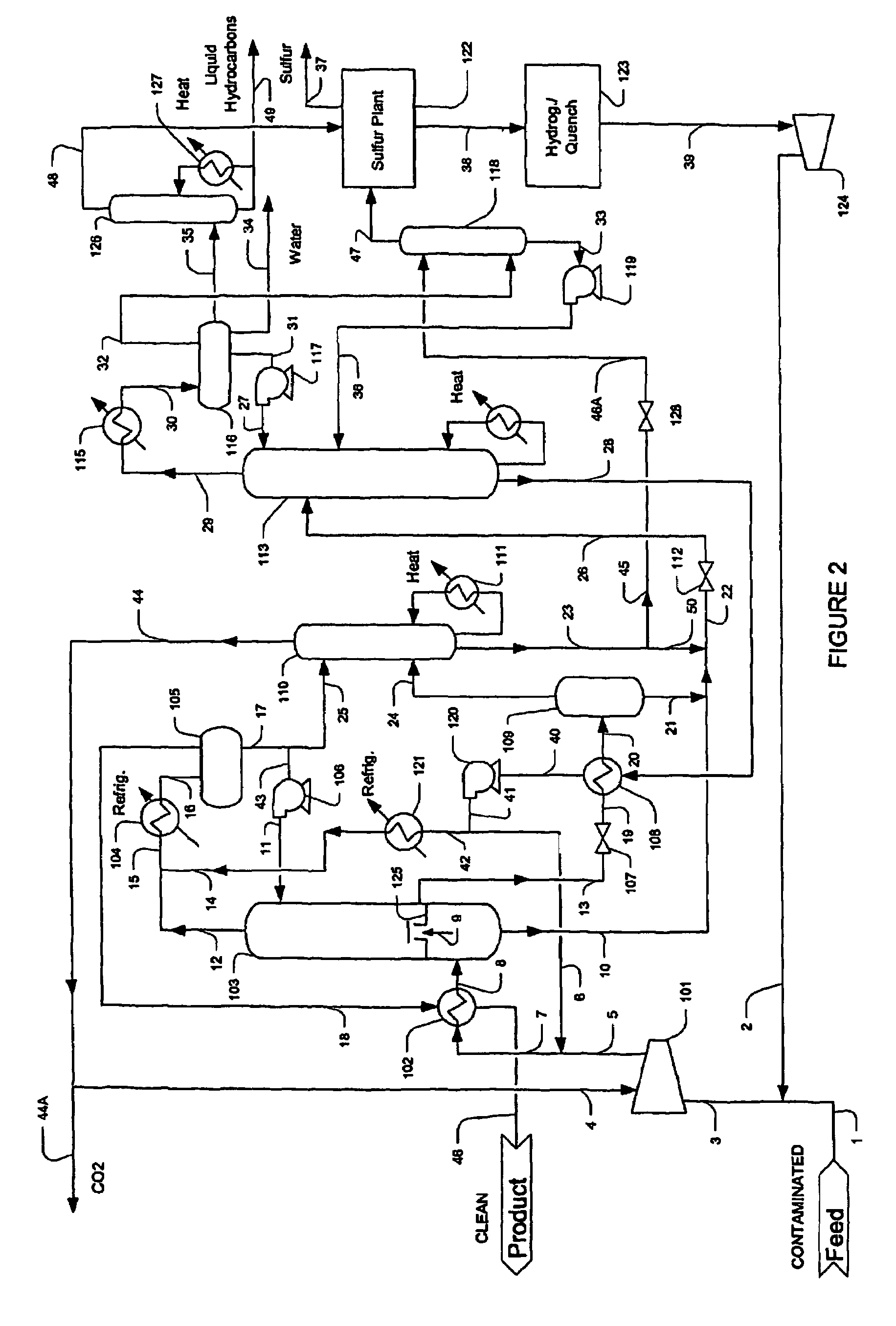

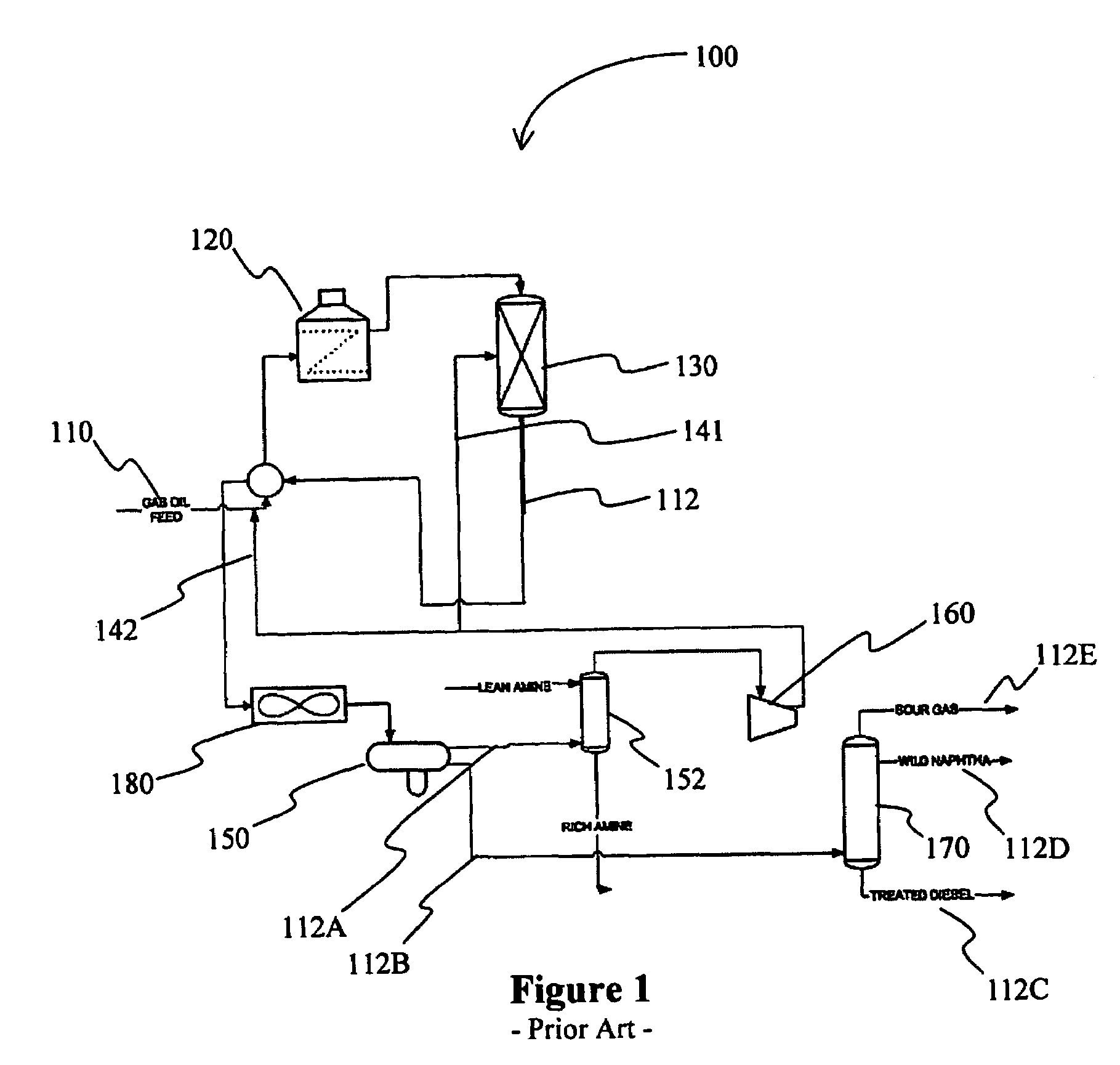

Configurations and methods for acid gas and contaminant removal with near zero emission

InactiveUS20060150812A1Reduce temperature riseEnhance selective absorptionProductsLiquid degasificationWaste streamHydrocotyle bowlesioides

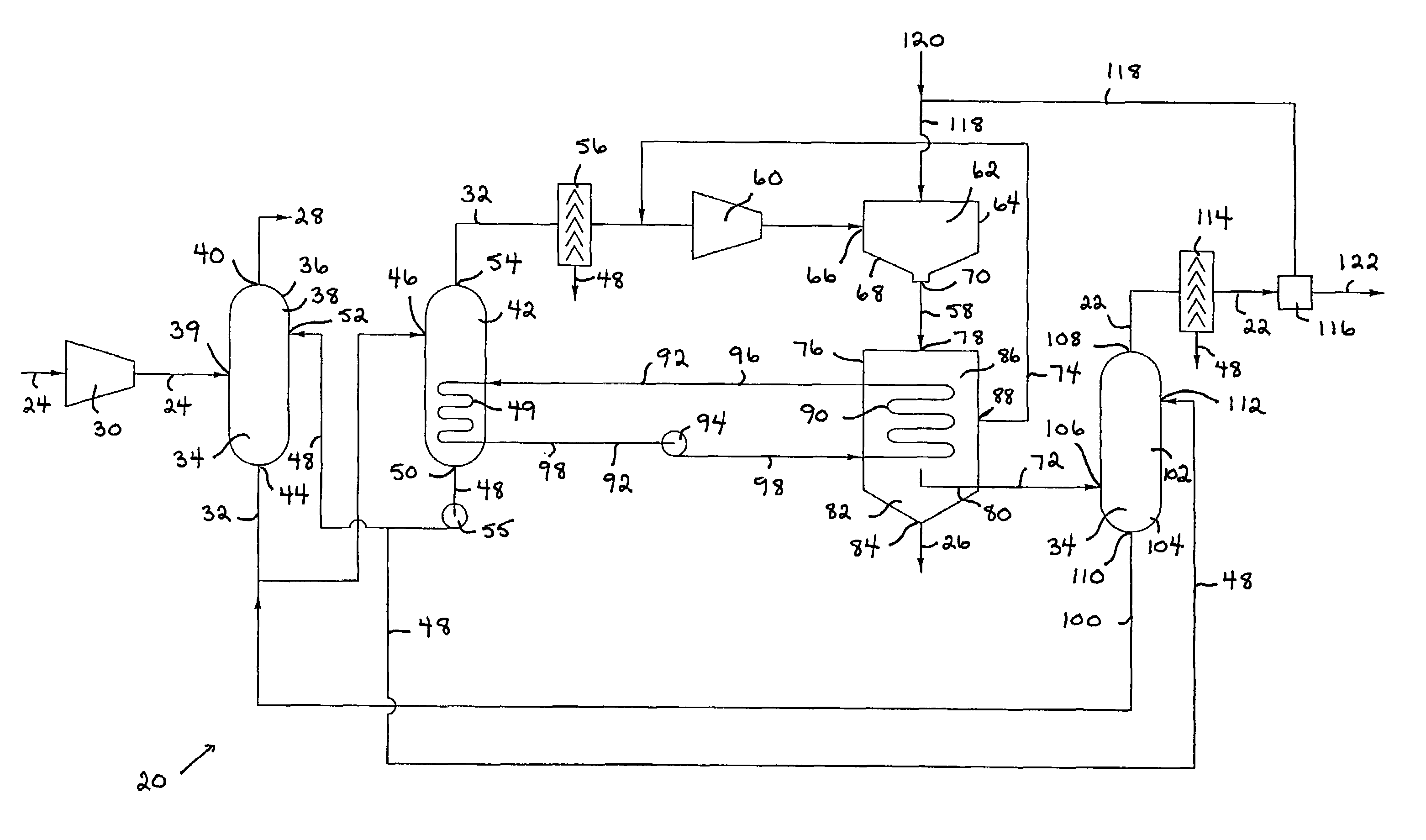

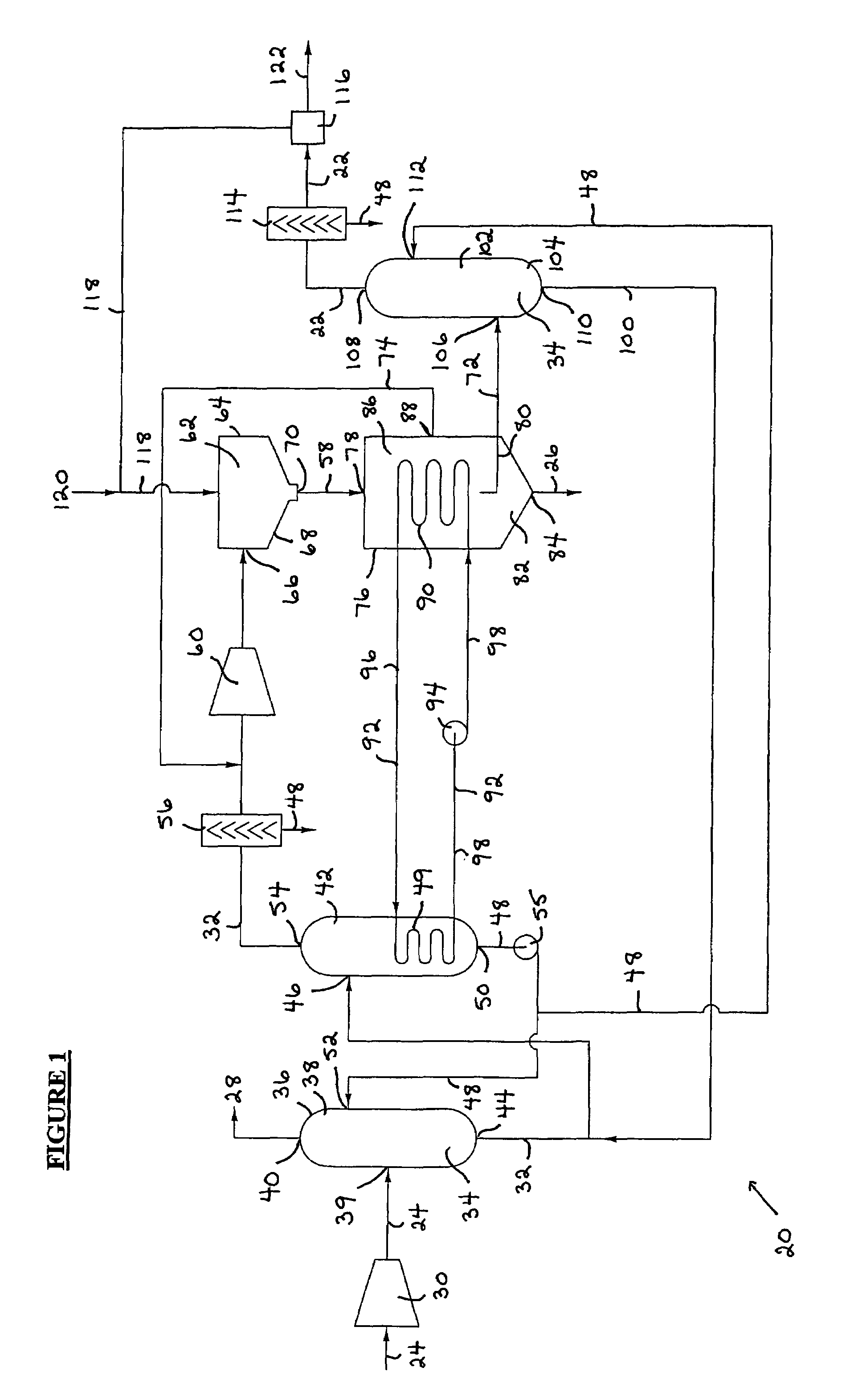

A gas (1) comprising hydrogen sulfide, carbon dioxide, and hydrocarbon contaminants is treated in a plant (FIG. 2) in a configuration in which waste streams are recycled to extinction. In especially preferred aspects of contemplated methods and configurations, hydrogen sulfide and other sulfurous components are converted to a sulfur product (37), carbon dioxide (44A) is separated at a purity sufficient for enhanced oil recovery or sale, and hydrocarbon contaminants are purified to a marketable hydrocarbon product (49).

Owner:FLUOR TECH CORP

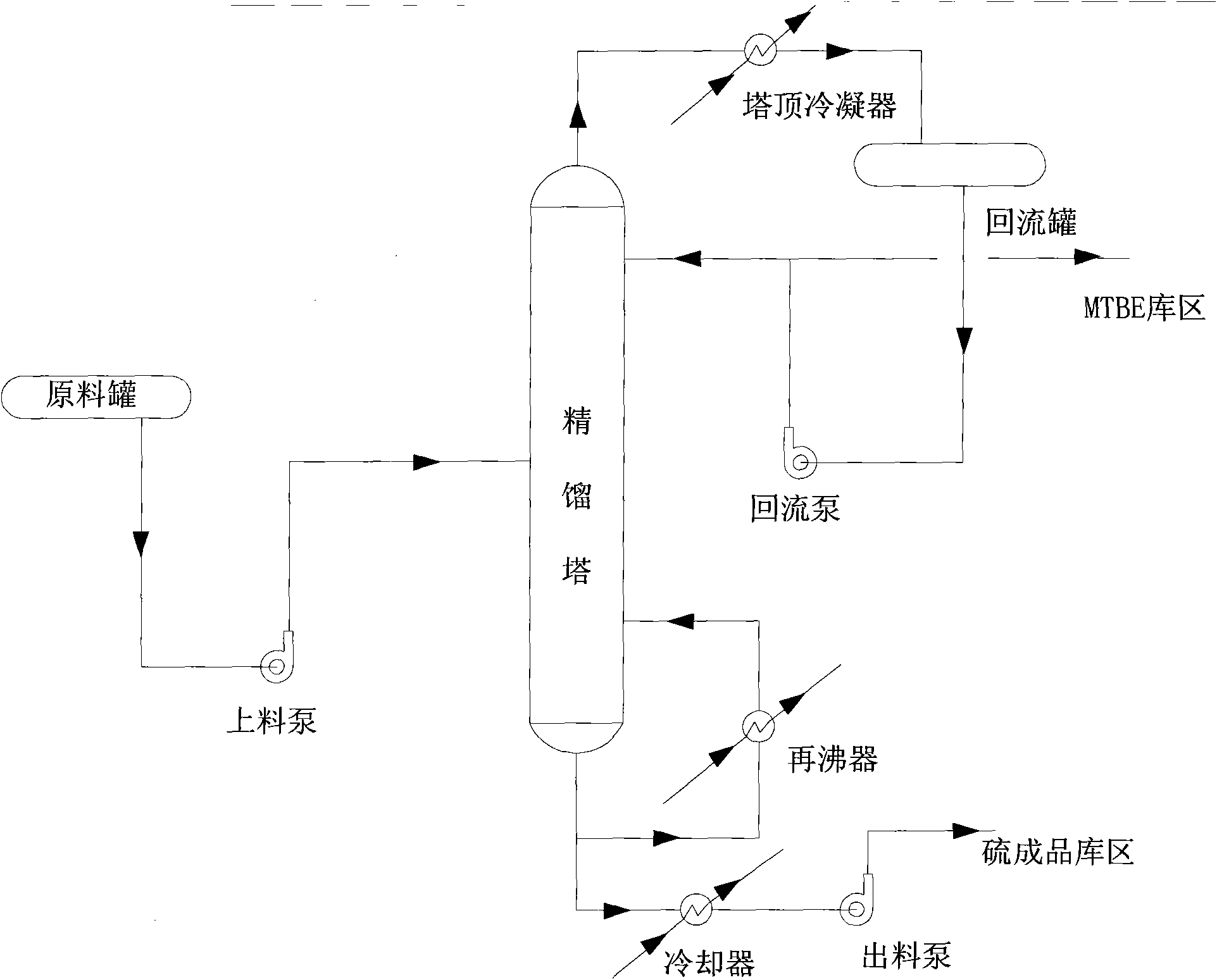

Method for desulphurizing methyl tertiary butyl ether with high sulphur content

InactiveCN101643392ASimple processAdvanced technologyEther separation/purificationPolymer scienceSulfur product

The invention relates to a method for desulphurizing MTBE with high sulphur content, belonging to the field of the refining of methyl tertiary butyl ether (MTBE). The methyl tertiary butyl ether (MTBE) with high sulphur content is placed into a distillation tower and heated by a reboiler, the temperature of a tower kettle is kept between 90 DEG C and 120 DEG C, the pressure of the tower kettle iskept at 0.08+ / -0.02 MPa, the temperature of a tower top is kept between 69 DEG C and 75 DEG C, and the pressure of the tower top is kept at 0.06+ / -0.02 MPa so that a finished product is distilled outof the tower top, a reflux ratio is kept from 1 to 10, and a sulfur product is recycled from a tower bottom. The invention has the advantages of simple process, advanced technology, easy and convenient control operation, little investment, low cost and no three-waste pollution.

Owner:SHANDONG YUHUANG CHEM CO LTD

Configurations and methods for acid gas and contaminant removal with near zero emission

InactiveUS7597746B2Reduce temperature riseEnhance selective absorptionProductsLiquid degasificationHydrocotyle bowlesioidesWaste stream

A gas (1) comprising hydrogen sulfide, carbon dioxide, and hydrocarbon contaminants is treated in a plant (FIG. 2) in a configuration in which waste streams are recycled to extinction. In especially preferred aspects of contemplated methods and configurations, hydrogen sulfide and other sulfurous components are converted to a sulfur product (37), carbon dioxide (44A) is separated at a purity sufficient for enhanced oil recovery or sale, and hydrocarbon contaminants are purified to a marketable hydrocarbon product (49).

Owner:FLUOR TECH CORP

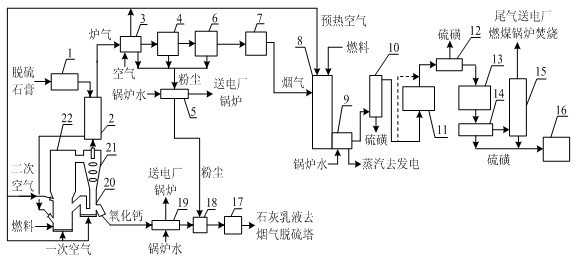

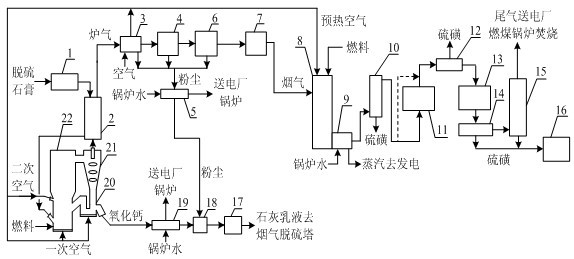

Method for preparing calcium oxide and sulfur by double-atmosphere fluidized roasting of desulfurated gypsum

InactiveCN102303883ASolve the use problemAbundant raw materialsEnergy inputSulfur preparation/purificationDust controlSulfur dioxide

The invention provides a method for preparing calcium oxide and sulfur by double-atmosphere fluidized roasting of desulfurated gypsum, belonging to the technical fields of solid pollutant treatment and in environmental protection chemical production. The method comprises the following steps: drying and dehydrating aged desulfurated gypsum, and then entering a multi-stage suspension heat exchangerfor pre-heating; entering hot-state gypsum into a circulating fluidized bed decomposition furnace, and introducing primary and secondary air for decomposition; cooling discharged hot-state calcium oxide, wherein cooled hot-state calcium oxide is used as a desulfurizer for later use; entering discharged smoke containing sulfur dioxide into the multi-stage suspension heat exchanger; removing calcium oxide dust in cooled hot smoke through multi-stage dust removing equipment; and feeding the smoke without the dust into a high-temperature-resistant high-efficiency filter for further removing the dust, and feeding clean smoke into a sulfur recovery system; and preparing the sulfur product by the processes of hot reduction, catalytic reduction, Clause reaction and the like, and feeding Clause tail gas into a coal burning boiler in a power plant for combustion. The method has the advantages of good environmental protection benefits and strong economic benefits.

Owner:CHINA PETROCHEMICAL CORP +1

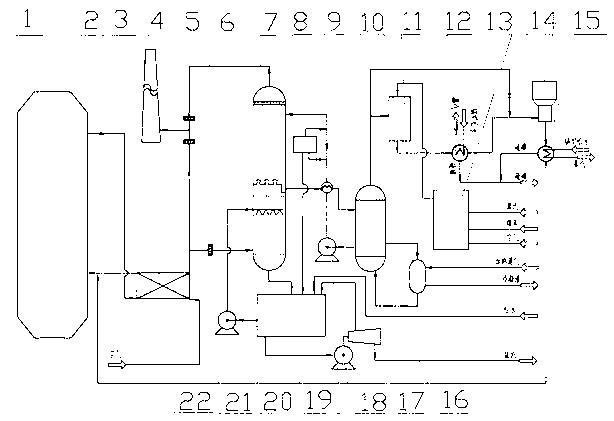

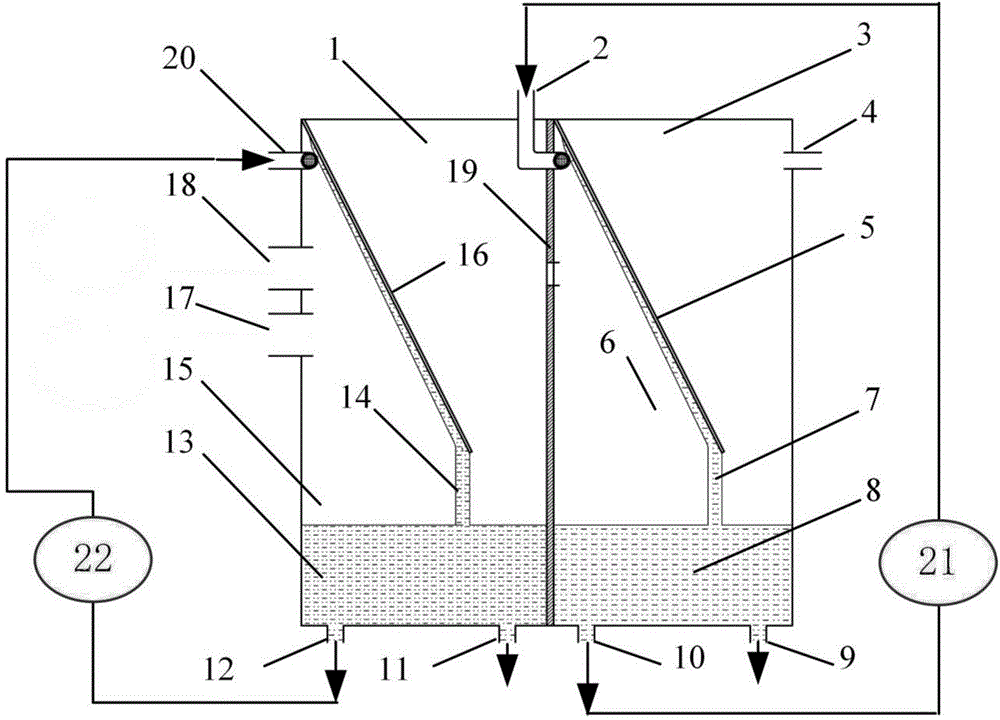

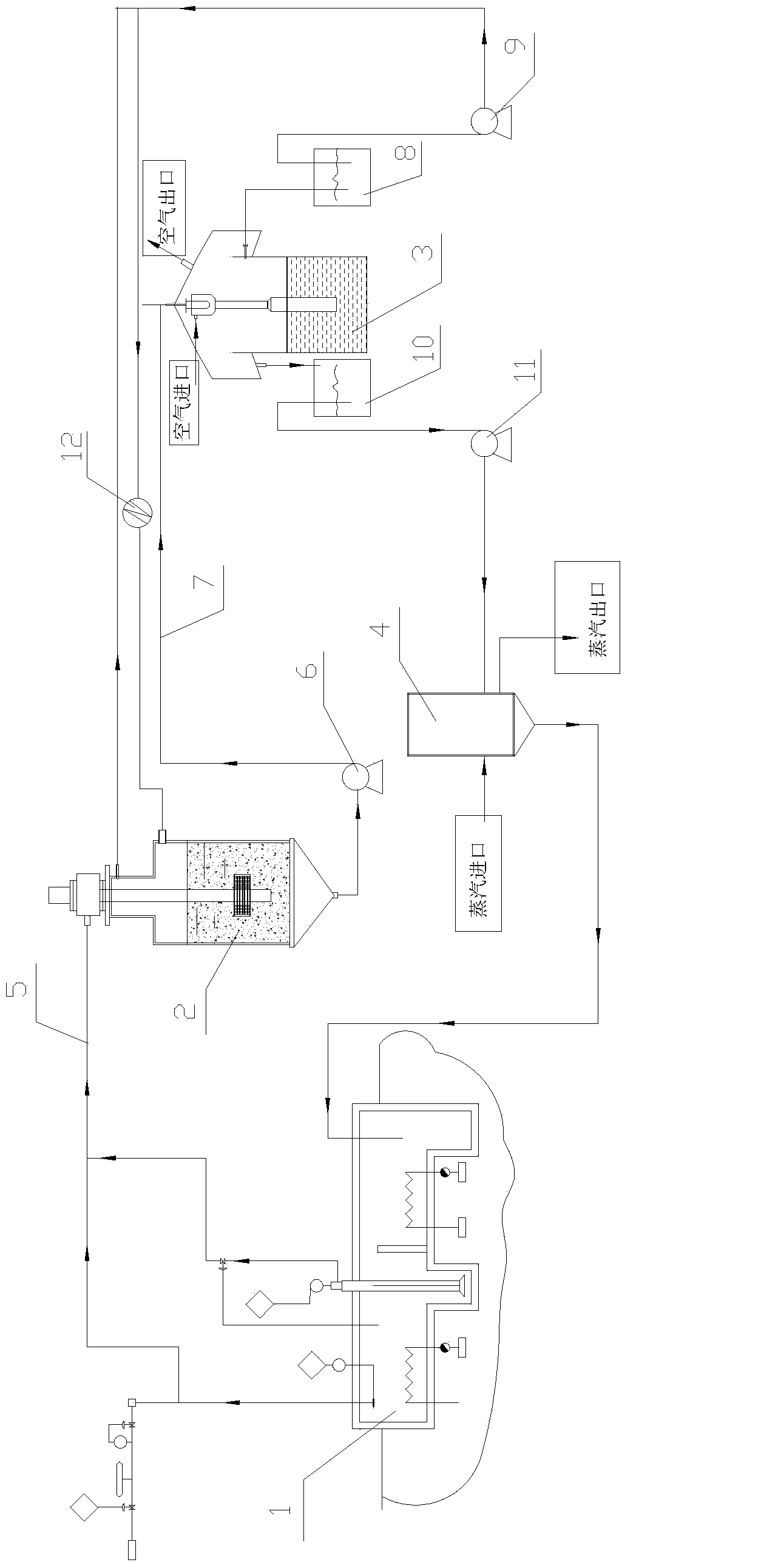

System device and method for recycling sulfur dioxide from fume to prepare sulfur

InactiveCN103303872AEmission reductionImprove performanceEnergy inputSulfur preparation/purificationCooling towerSulfur product

The invention discloses a system device and a method for recycling sulfur dioxide from fume to prepare sulfur. The device comprises three units of an absorption and pyrolysis unit, a reduction unit and a krauss unit, wherein the absorption and pyrolysis unit mainly consists of a cooling tower, an absorbing tower, a purifier, a circulation pump, a regeneration pyrolysis tank and a rich and lean liquid heat exchanger; the reduction unit mainly consists of a mixed gas generation system, a reduction reactor and a sulfur condenser; the krauss unit mainly consists of a krauss reactor and a sulfur condenser. The method comprises the steps that the absorption and pyrolysis unit absorbs and pyrolyzes the fume so as to obtain a pure sulfur dioxide gas, and the reduction unit converts the sulfur dioxide into elementary sulfur through catalysis reaction, wherein the conversion per pass is not less than 95%, and the total conversion is greater than 99.5%. The sulfur dioxide content that the fume is completely discharged is not greater than 50 milligrams per normal cubic meter. The sulfur dioxide is converted into national best grade sulfur products which are stable in property and convenient to store and transport, with high efficiency and low cost, the desulfuration operation cost is lower than the value of a recycled product, and the products can be widely applied to chemistry and thermal power industry.

Owner:陕西华锐迪橡胶科技有限公司

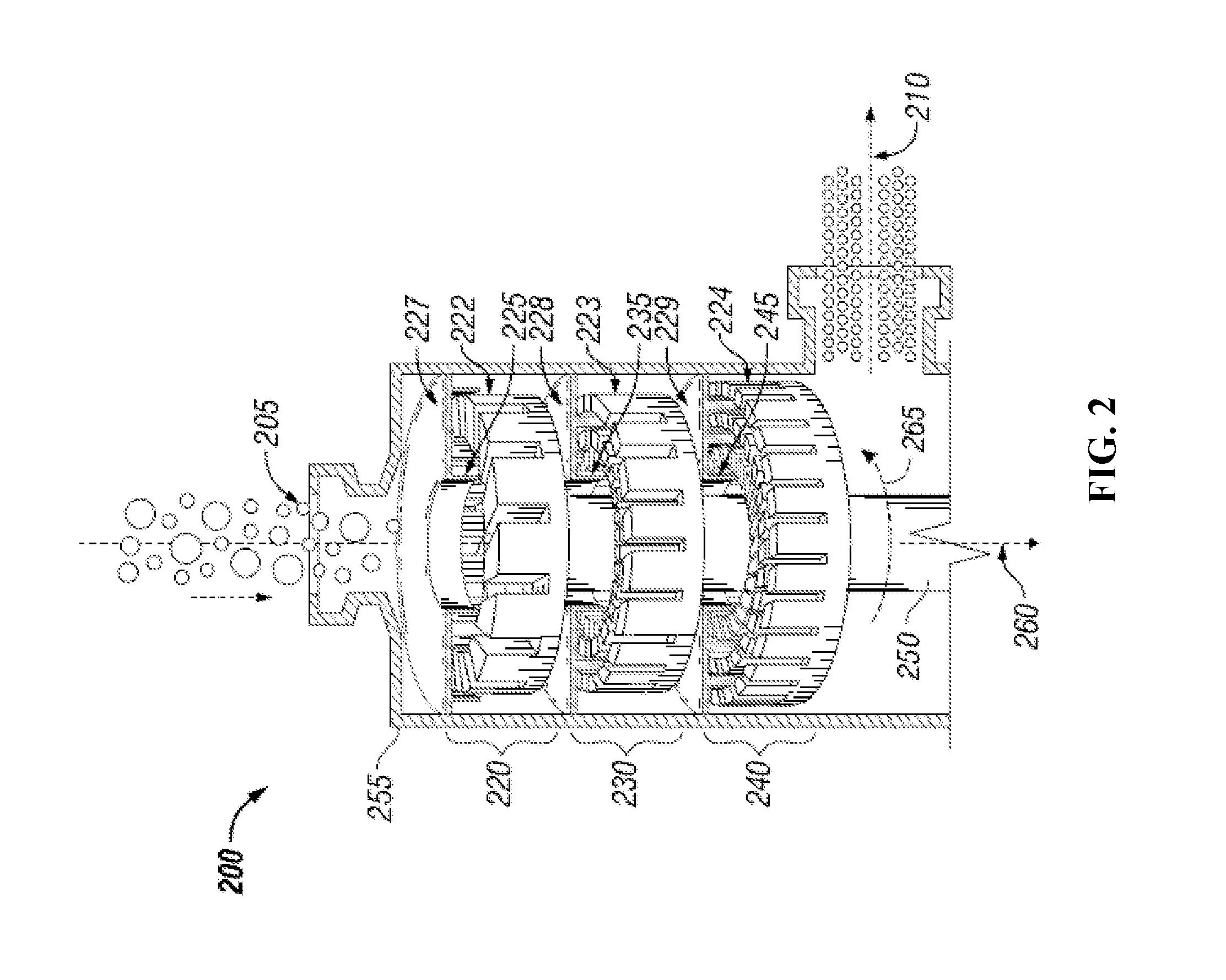

Process and apparatus for converting hydrogen sulfide into hydrogen and sulfur

ActiveUS20050191237A1Improve efficiencyIncrease attractivenessHydrogen productionFuel cellsHydrogenSulfur product

A process and an apparatus for obtaining a hydrogen product and a sulfur product from a feed gas. The feed gas is comprised of hydrogen sulfide, the hydrogen product is comprised of elemental hydrogen and the sulfur product is comprised of elemental sulfur. In the process, a first separating step separates the feed gas to obtain a first purified hydrogen sulfide fraction comprised of at least about 90 percent hydrogen sulfide by volume. A dissociating step dissociates hydrogen sulfide present in the first purified hydrogen sulfide fraction to convert it into a dissociated first purified hydrogen sulfide fraction comprised of elemental hydrogen and sulfur. A second separating step separates the dissociated first purified hydrogen sulfide fraction to obtain a hydrogen rich fraction comprised of elemental hydrogen. The sulfur product may also be obtained from the dissociated first purified hydrogen sulfide fraction. Finally, the hydrogen product is obtained from the hydrogen rich fraction. The apparatus is provided for performing the process.

Owner:H2S TECH INC

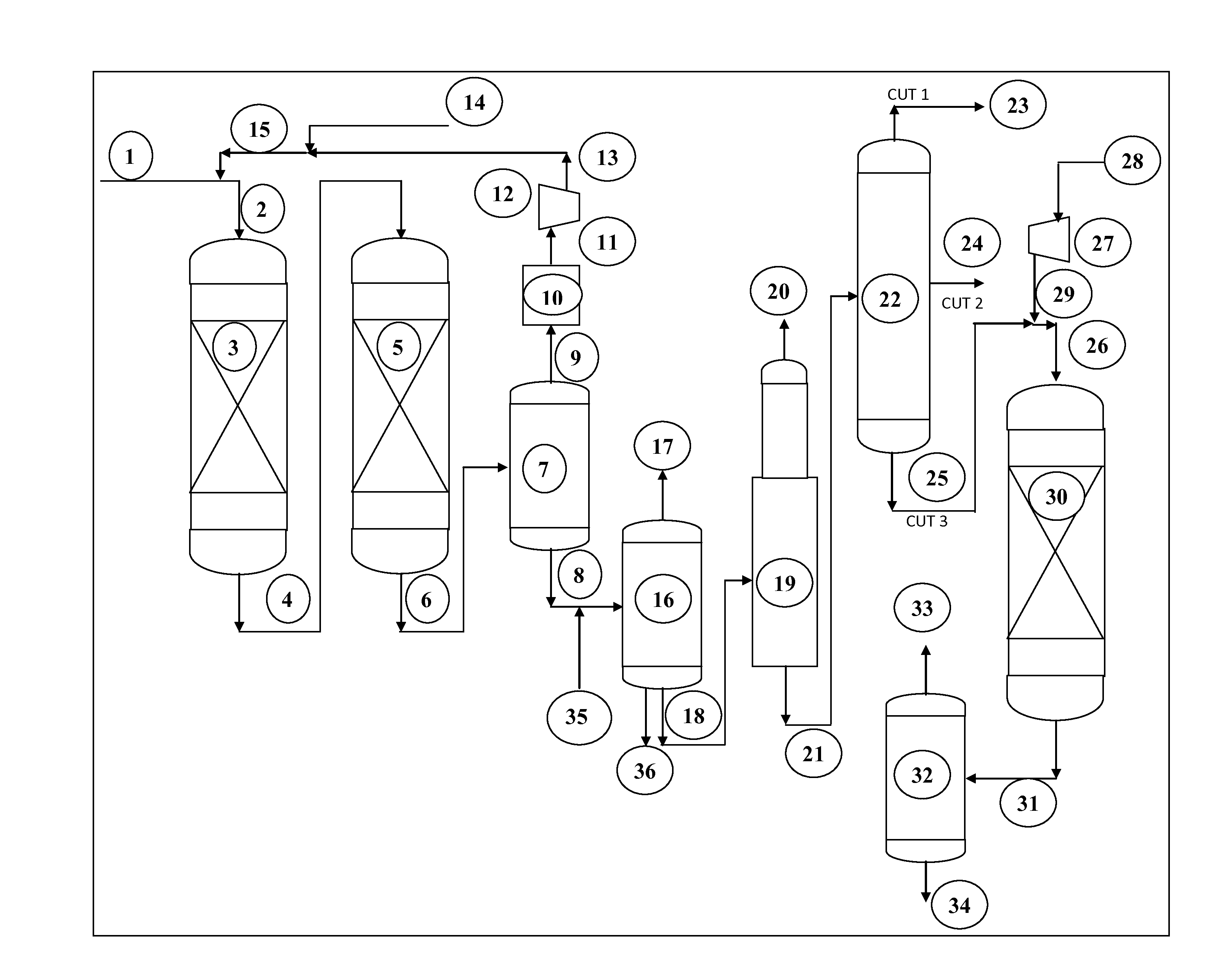

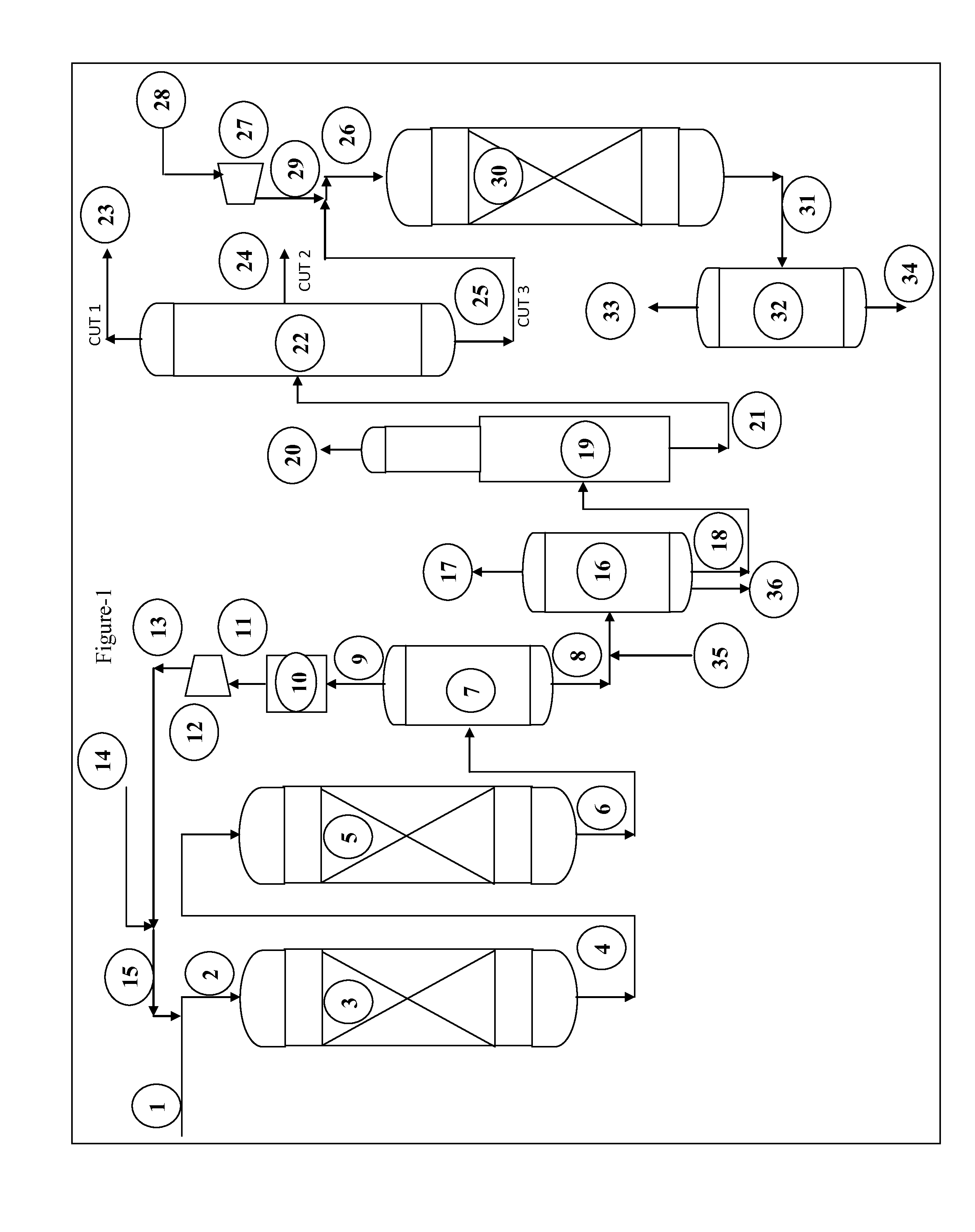

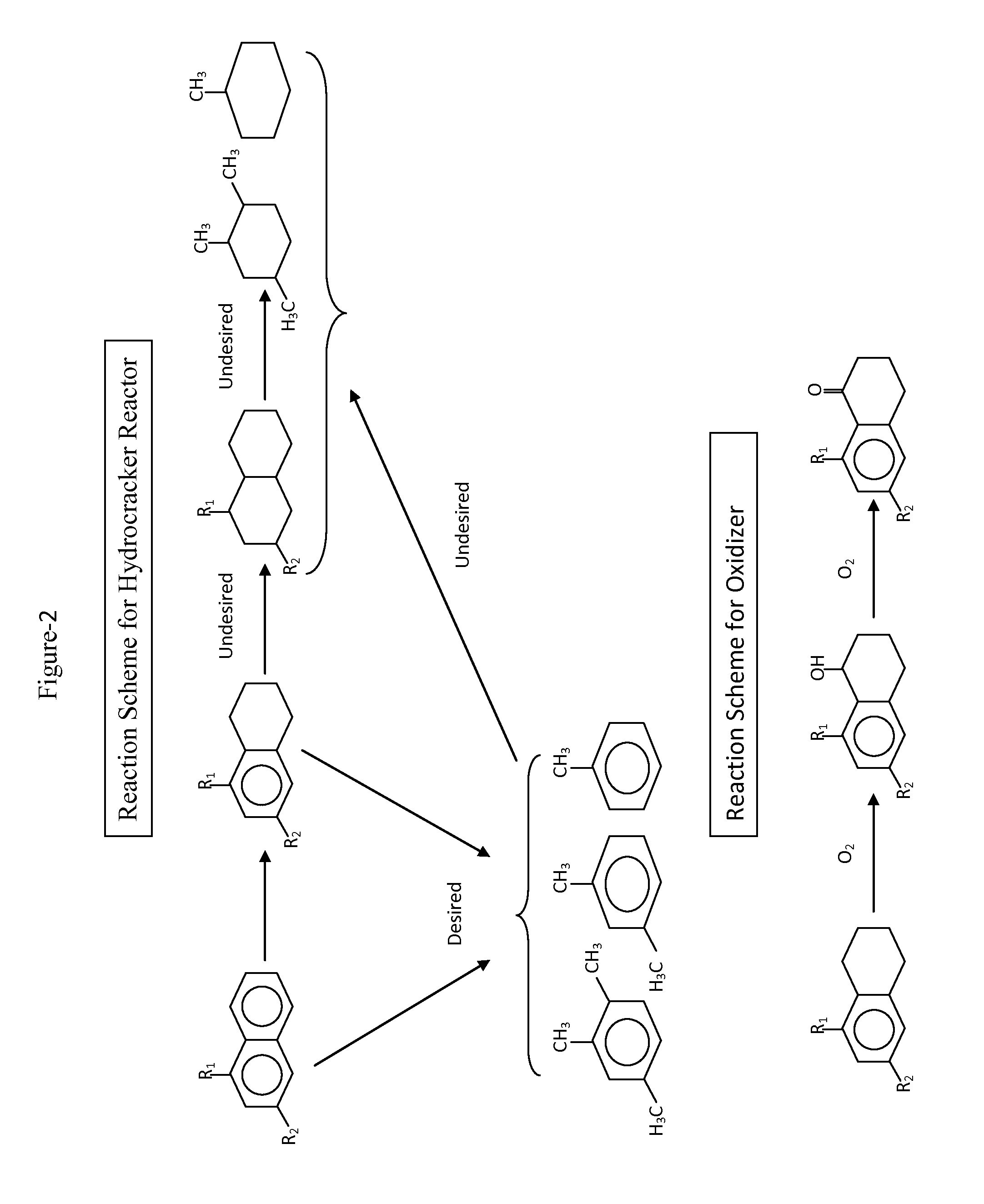

Integrated process for production of high octane gasoline, high aromatic naphtha and high cetane diesel from high aromatic middle distillate range streams

ActiveUS20150267130A1Increase yield & selectivityPreparation by oxidation reactionsOrganic compound preparationCyclic alkaneParaffin wax

An integrated process for production of ultra low sulfur products of high octane gasoline, high aromatic naphtha and high Cetane Diesel from high aromatic middle distillate range streams from any cracker units such as Light Cycle Oil (LCO) stream of Fluid catalytic cracking (FCC) units and comprising of subjecting the feed boiling between 200 to 400° C. and having at least 30 wt % multi-ring aromatics content subjected to hydrotreating for removal of heteroatoms like sulfur and nitrogen and at a pressure sufficient only for saturation of one ring of multi-ring aromatics. The effluent from hydrotreating is subjected to hydrocracking at same pressure of hydrotreating step above for selective opening of saturated ring of multi-ring aromatics. The effluent from hydrocracking is separated in CUT-1 boiling between 35 to 70° C., CUT-2 boiling between 70 to 200° C. in which the monoaromatics and alkylated monoaromatics are concentrated and CUT-3 boiling above 200° C. in which concentration of saturates i.e. paraffins and naphthenes significantly increased. The CUT-3 is selectively oxidized in selective oxidation step in presence of catalyst, an oxidizing agent and operating conditions such that it results in diesel product with more enhanced Cetane.

Owner:INDIAN OIL CORPORATION

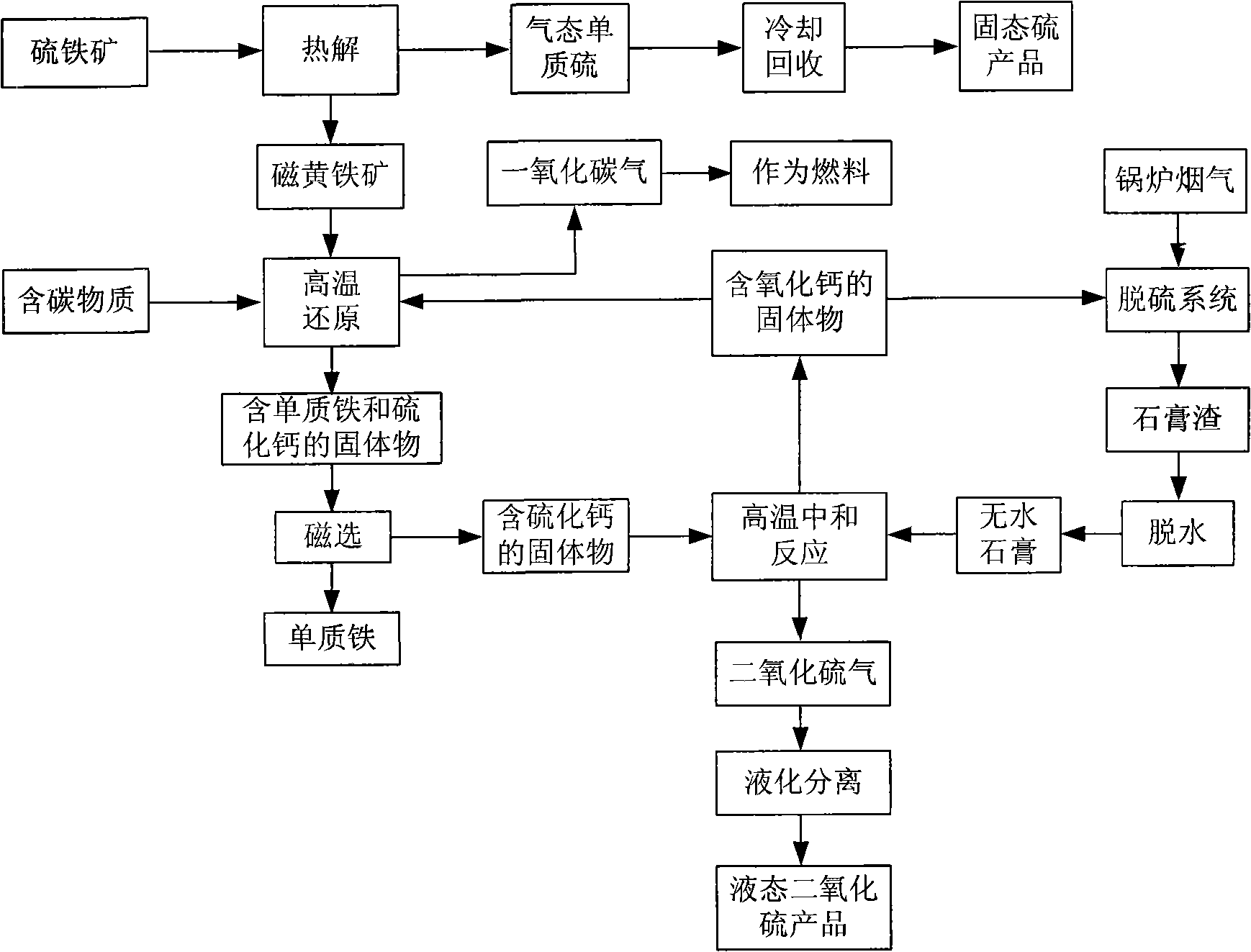

Method for utilizing comprehensive resource of sulfur-containing solid waste

InactiveCN101570341ATo promote metabolismSave resourcesDispersed particle separationSulfur compoundsSulfur containingPollution

The invention discloses a method for utilizing comprehensive resource of sulfur-containing solid waste, which comprises the following steps: (1) pyrolyzing sulfurous iron ore to obtain pyrrhotite and an elemental sulfur product; (2) mixing the pyrrhotite, a carbon-containing substance and a calcium-containing substance to carry out reduction reaction under a high temperature to obtain a solid mixture of elemental iron and calcium sulfide; (3) magnetically separating the solid mixture, and separating and recovering the solid mixture to obtain the elemental iron; (4) mixing and heating the solid containing the calcium sulfide and dehydrated gypsum to obtain tail gas containing SO2 and solid containing calcium oxide; and (5) separating the tail gas containing the SO2 through liquefying to obtain a liquid SO2 product, and using the solid containing the calcium oxide as the calcium-containing substance to participate in the reaction of the step (2) and as flue gas desulfurizing agent for cyclically utilization. The method solves the problems of occupied floor due to the stacking of desulfurization gypsum and coal washing sulfurous iron ore, environment pollution and potential safety hazard, makes full use of calcium, sulfur and iron resources rich in the wastes, and can realize recycling economy and clean production.

Owner:HUAZHONG UNIV OF SCI & TECH

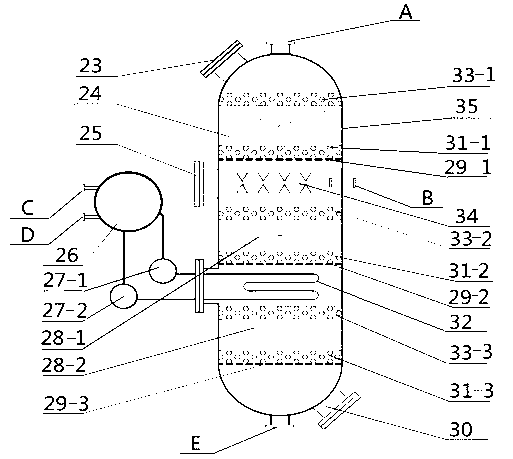

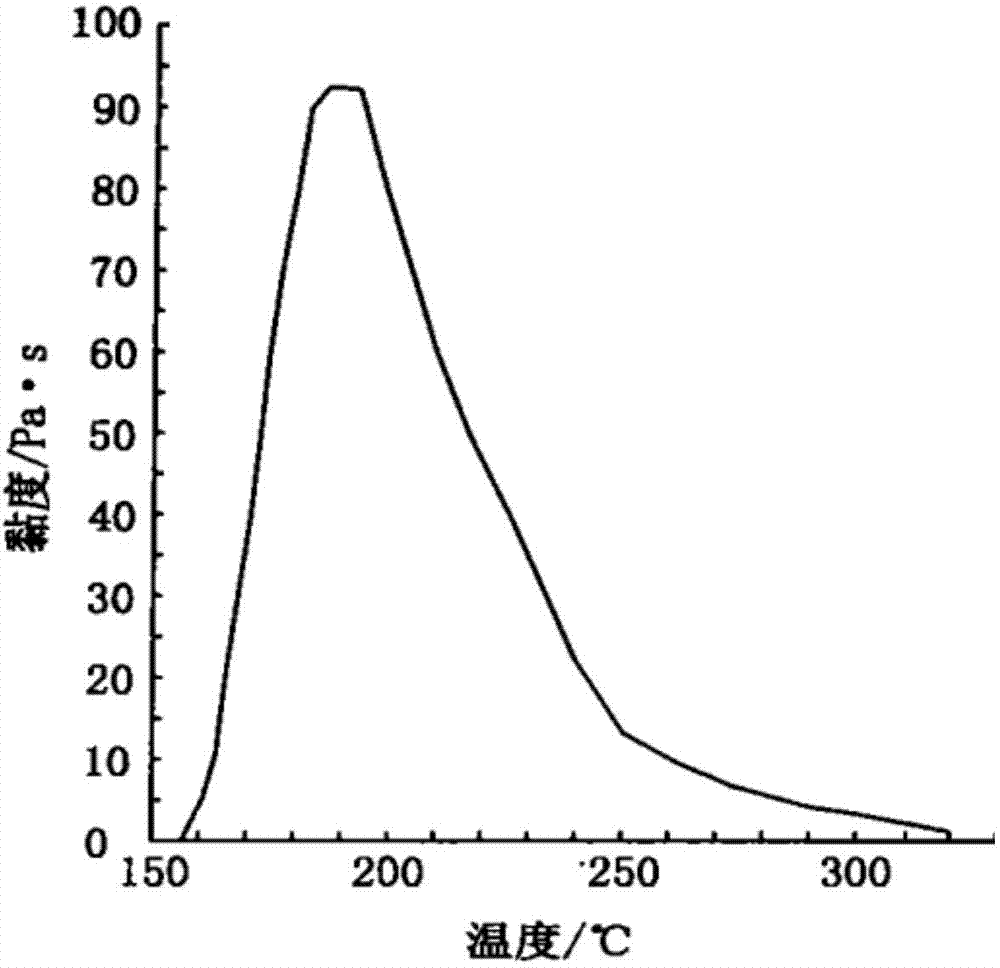

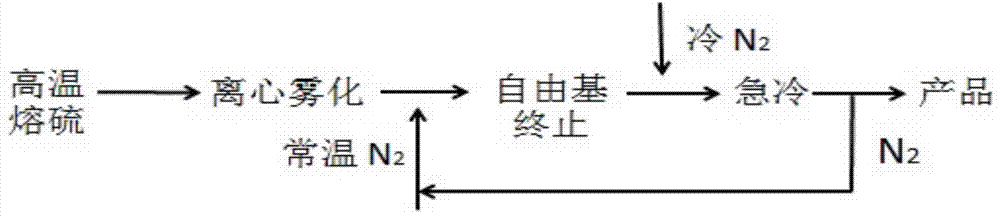

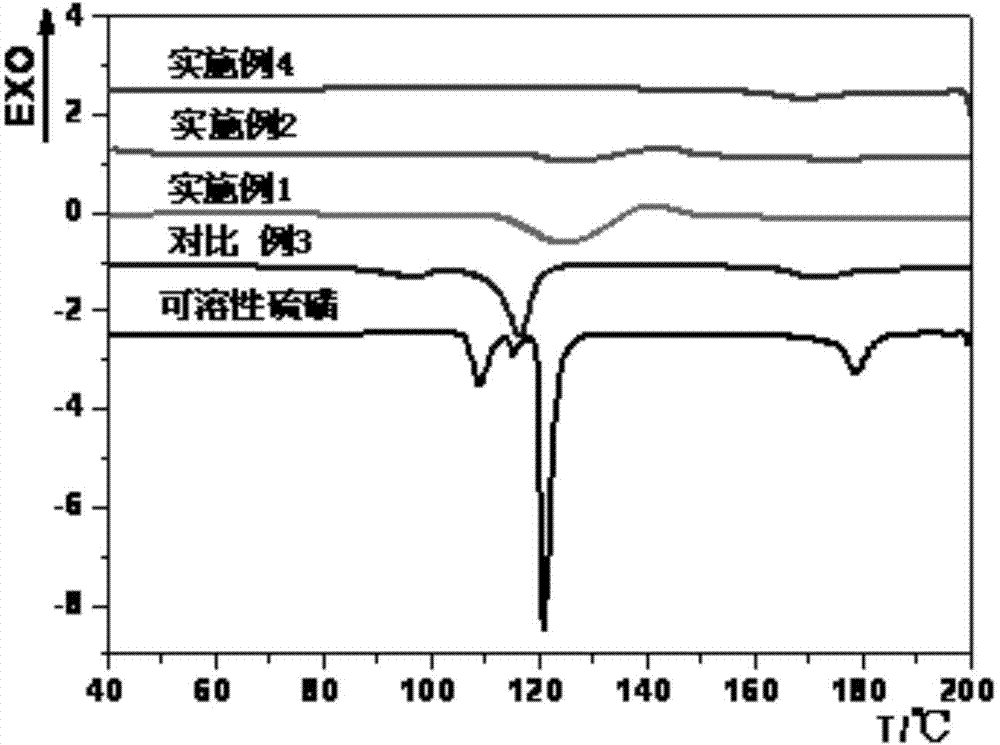

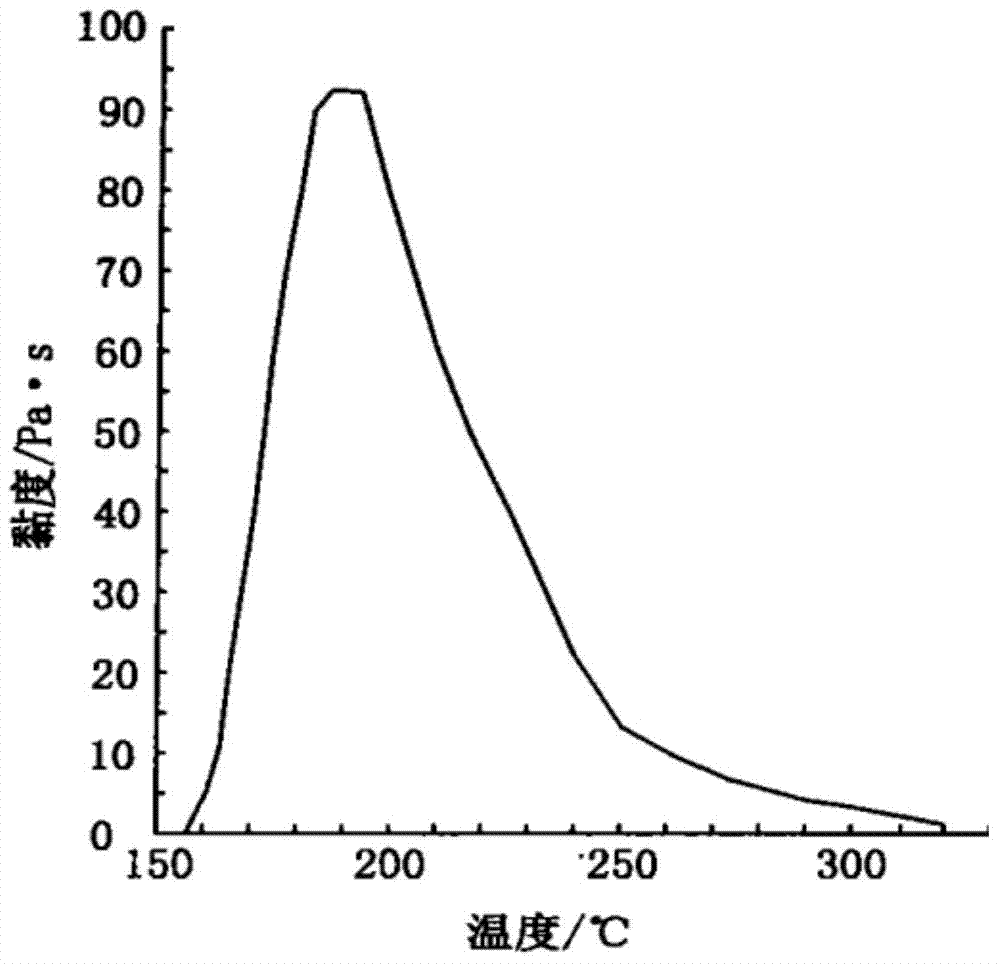

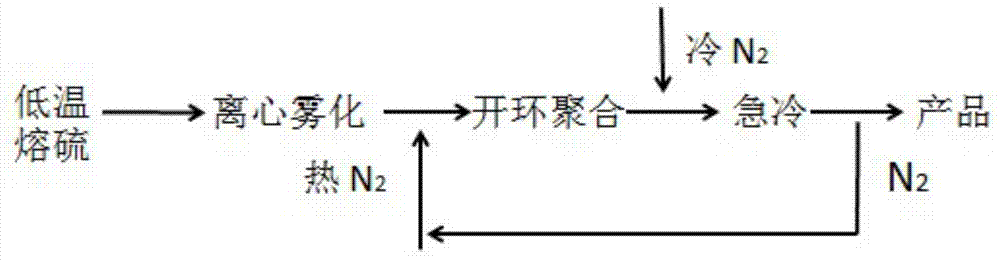

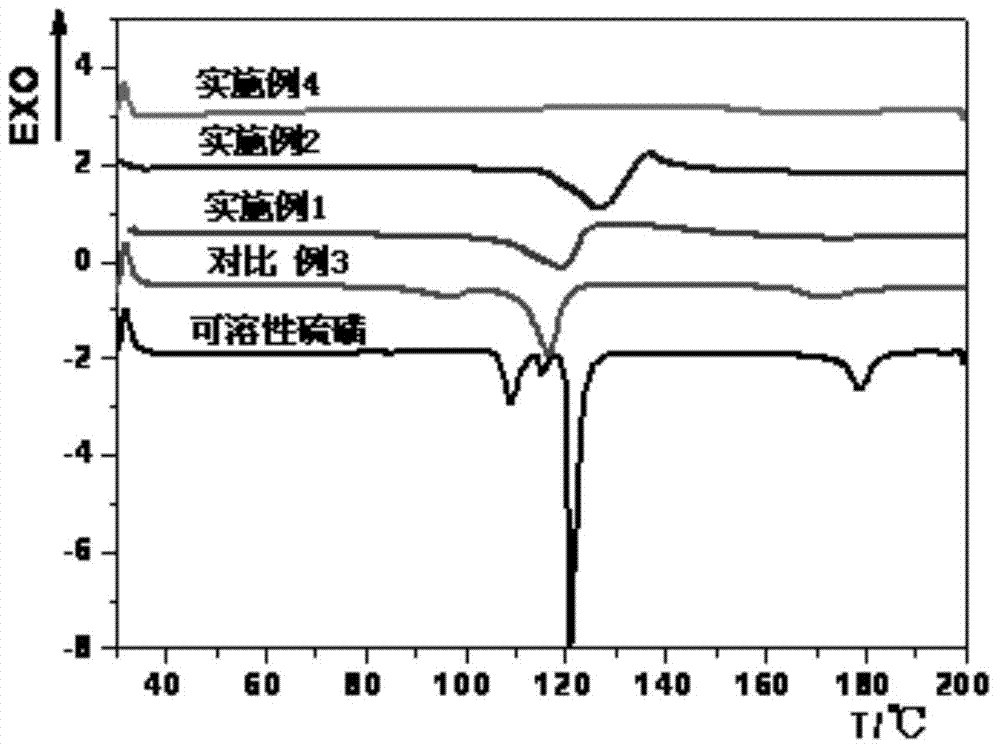

Method for preparation of insoluble sulfur

ActiveCN103539078AIncrease contentSmall particle sizeSulfur preparation/purificationSulfur productDirect effects

The invention relates to a method for preparation of insoluble sulfur. In a production process of insoluble sulfur, rapid cooling is one of very key process steps, realizes an effect of instantly stopping a reversible reaction and further directly affects the content of insoluble sulfur in a product. The method provided by the invention comprises the following steps of directly heating raw material sulfur to 280-400 DEG C, forming a large number of sulfur liquid droplets by centrifugal atomization through an atomizer, and increasing the specific surface area of sulfur; then cooling to 180-240 DEG C by circulating nitrogen at room temperature and keeping for 2-25 seconds; further cooling by circulating cold nitrogen to below 60 DEG C within 2-20 seconds; performing cyclone separation, collecting and packaging to obtain the insoluble sulfur product, wherein the average particle size of the product is 10 mu m-50 mu m; recycling the separated nitrogen. The method provided by the invention has the advantages of high safety in operation, low toxicity, high production efficiency, easiness in industrialization and high stability of prepared insoluble sulfur.

Owner:BEIJING UNIV OF CHEM TECH

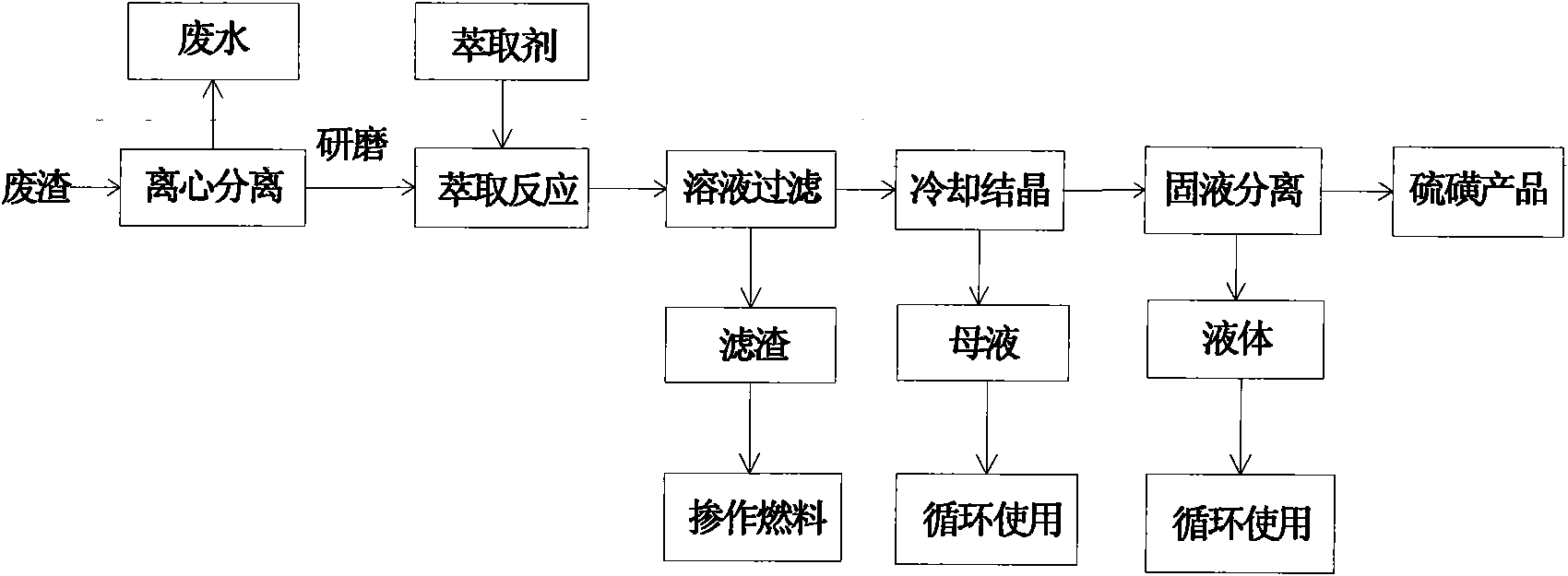

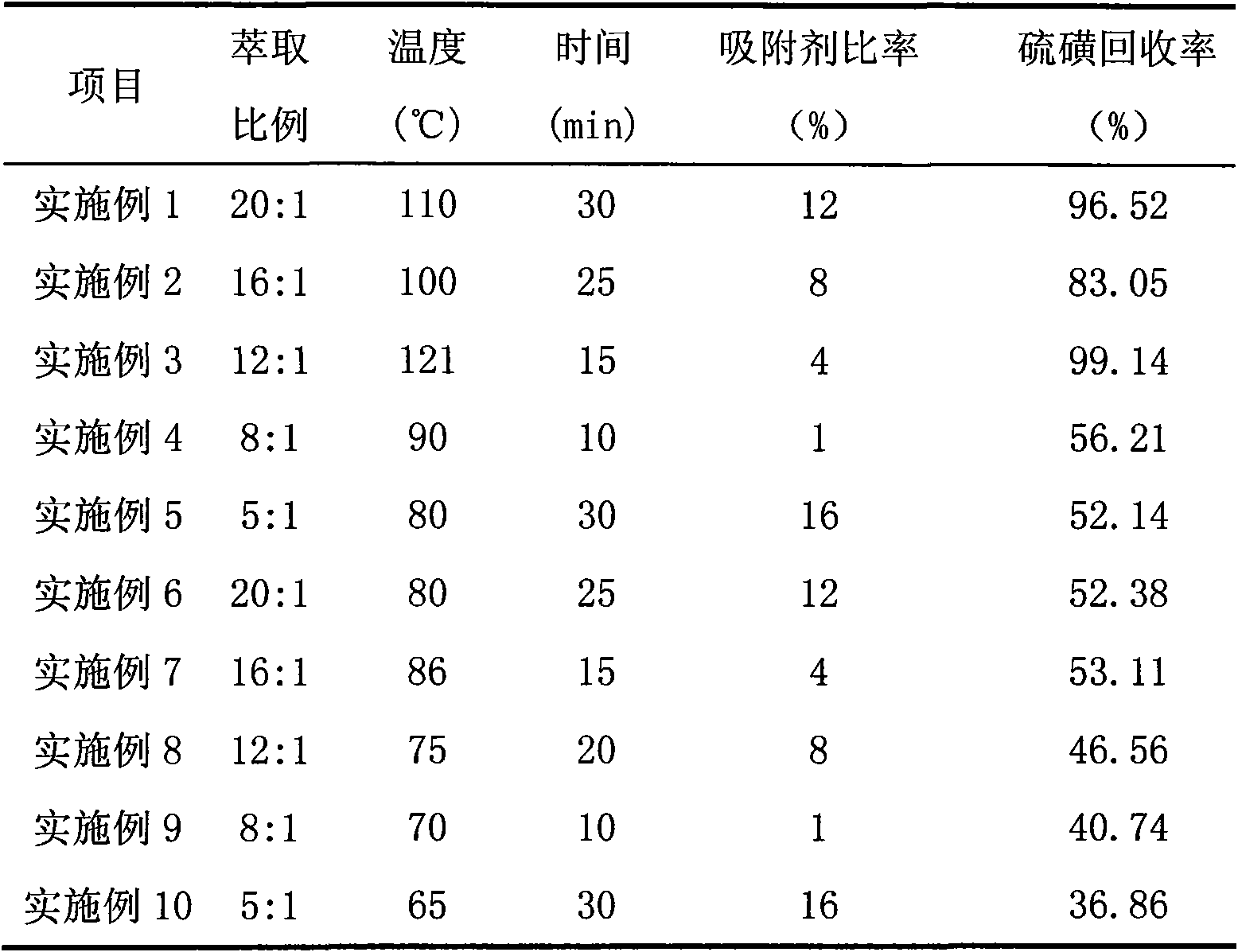

Method for extracting sulfur in sulfur-contained slag by chlorohydrocarbon organic solvent

InactiveCN101618860AImprove solubilitySolve volatileSulfur compoundsSolid solvent extractionFiltrationSlag

The invention relates to a method for extracting sulfur in sulfur-contained slag by chlorohydrocarbon organic solvent. The method adopts the technical scheme that raw sulfur cream sulfur-contained slag is used as a raw material to carry out centrifugal separation, extraction reaction, solution filtration, cooling crystallization and solid-liquid separation to obtain a sulfur product; a great deal of raw sulfur cream sulfur-contained slag produced when gas produced by an iron and steel coking enterprise is purified and desulphurized is used as the raw material; after being ground, the raw material carries out extraction reaction with the organic solvent; the solution carries out heat preservation filtration, the cooling crystallization and the solid-liquid separation to obtain a sulfur product, and the low-price and poison solvent for recovering sulfur is developed. The invention overcomes the defects of resource consumption, corresponding environmental pollution, and the like caused by not adopting an effective processing measure on the sulfur-contained slag in the prior HPF method gas desulphurizing technology and is widely applied to process and recycle the sulfur-contained slag produced in the coking desulphurization process in iron and steel smelting industries.

Owner:HUNAN UNIV OF SCI & TECH

Process and composition for increasing the reactivity of sulfur scavenging oxides

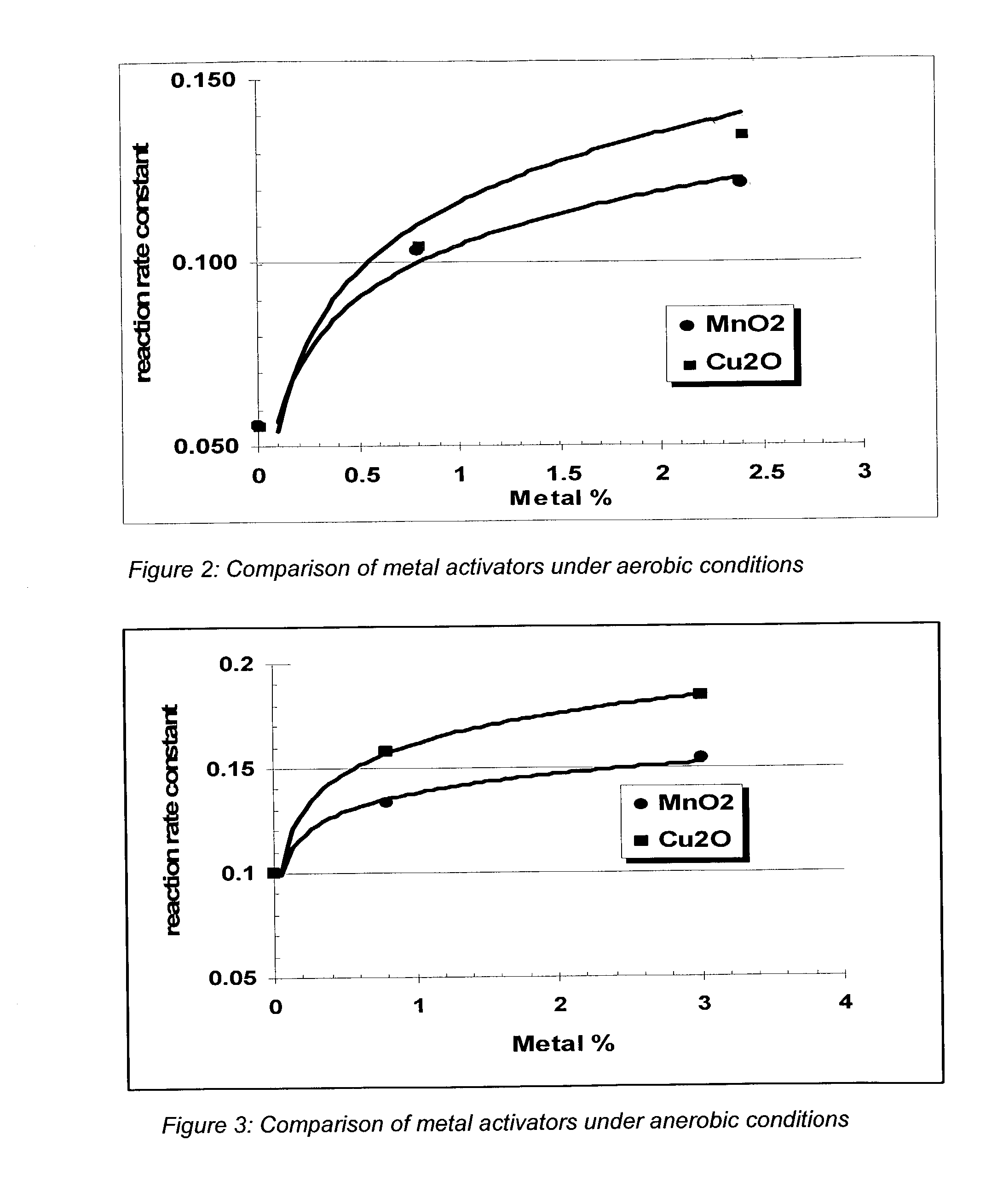

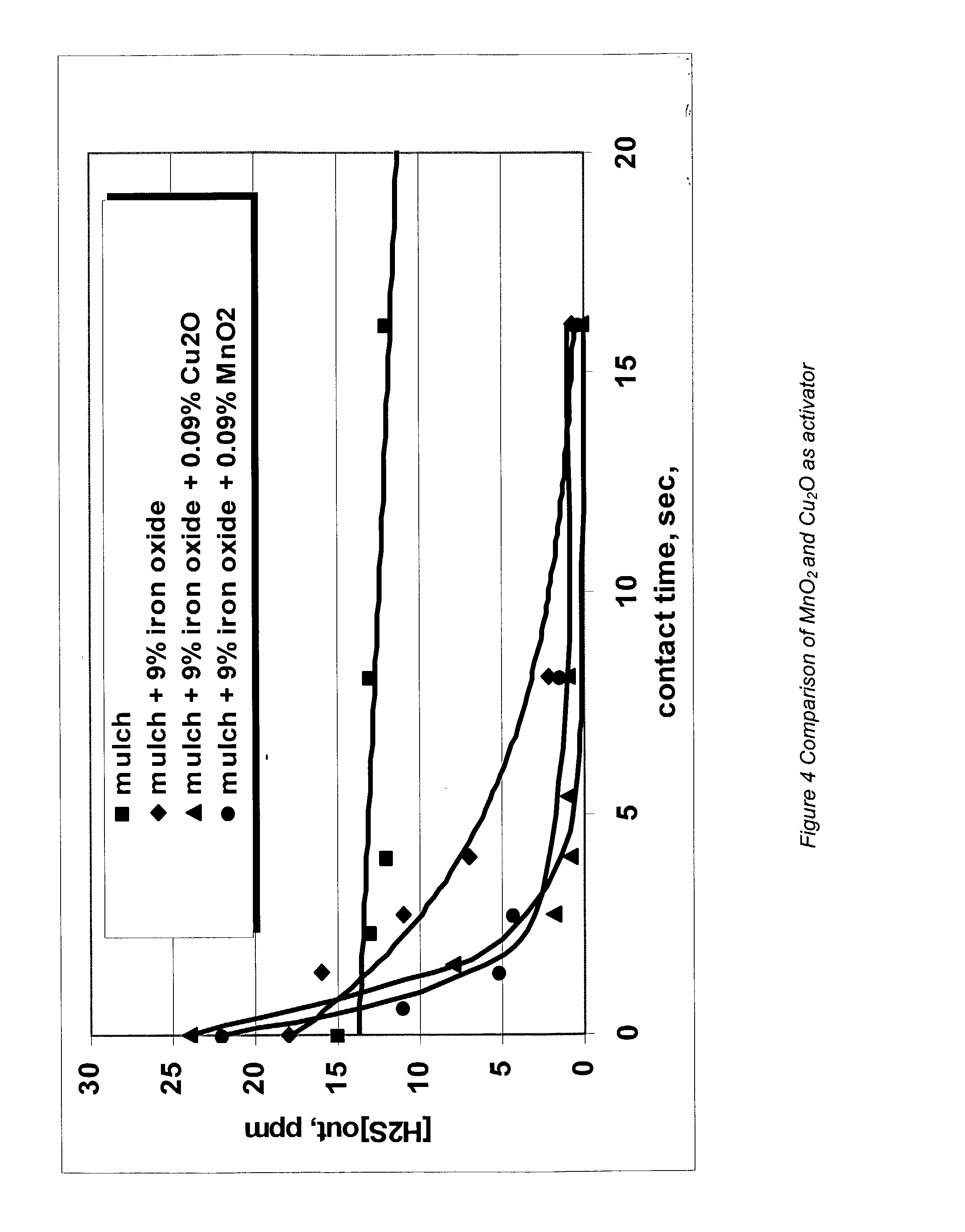

InactiveUS20020182135A1Increase response rateRaise the potentialPhysical/chemical process catalystsOther chemical processesZinc hydroxideManganese oxide

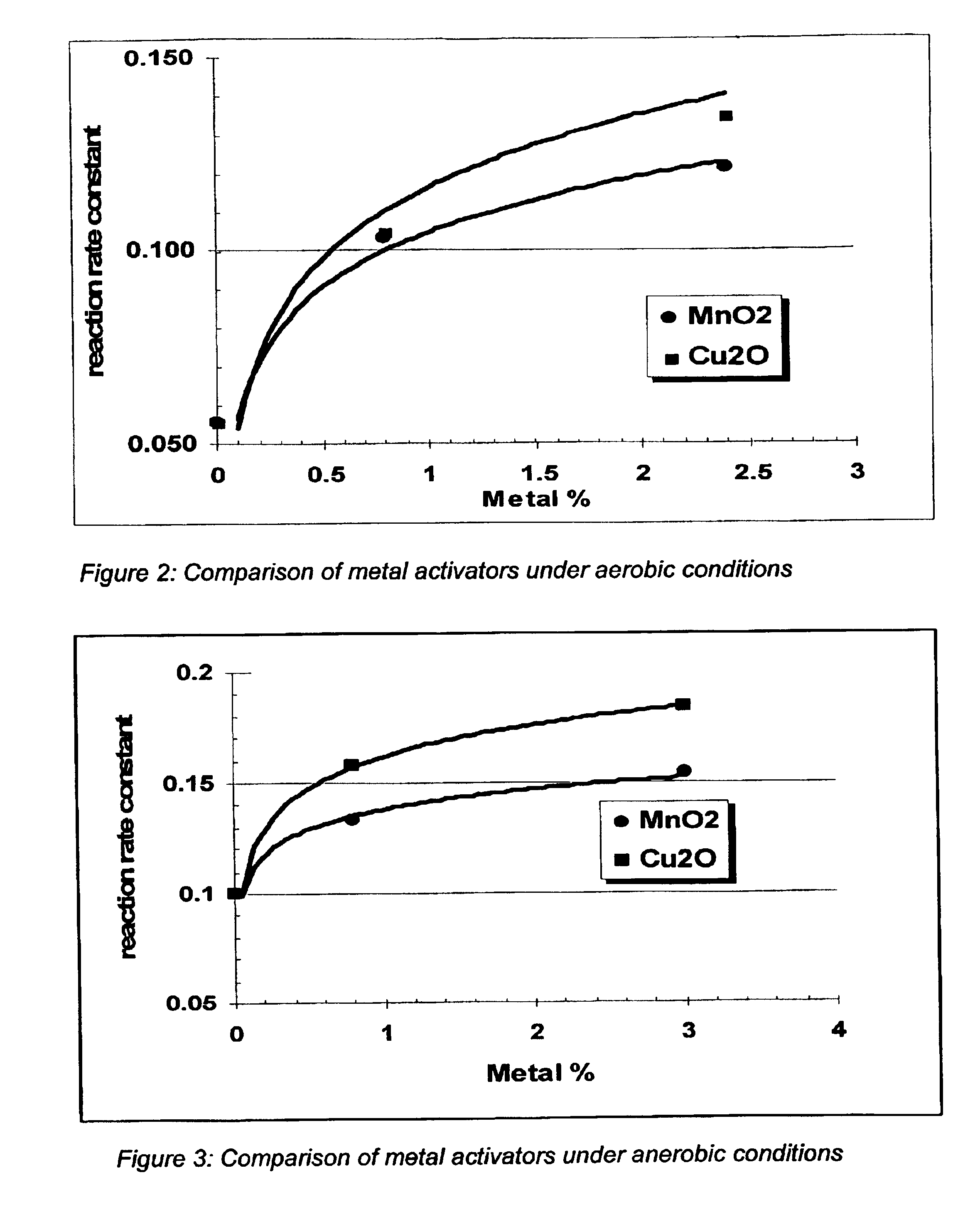

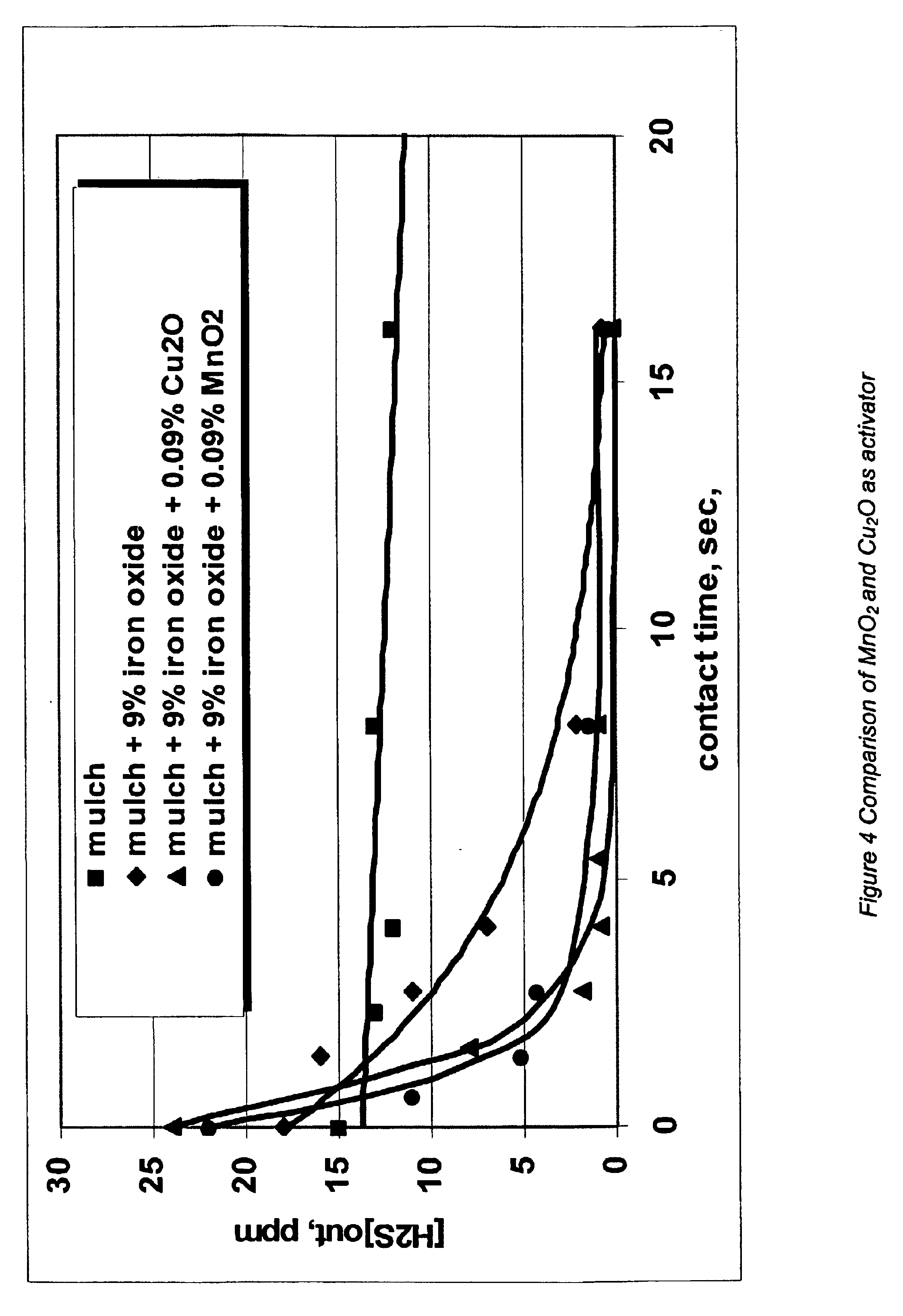

In ridding fluids, including hydrocarbon fluids, both gaseous and liquid, of sulfur compounds including hydrogen sulfide, oxides of sulfur, and thiols, the present invention uses a small quantity of an activator, generally a noble metal oxide, preferably a copper species and / or a manganese species, along with a known oxide product, such as iron oxide, iron hydroxide, zinc oxide, zinc hydroxide, manganese oxide, manganese hydroxide, or combinations thereof, to thoroughly remove sulfur contaminants in a short amount of time. The activator allows for the use of smaller reactor vessels and the production of hydrocarbon fluids substantially free of sulfur products.

Owner:MI

Process and apparatus for converting hydrogen sulfide into hydrogen and sulfur

ActiveUS7455828B2Improve efficiencyIncrease attractivenessHydrogen productionFuel cellsSulfur productHydrogen

A process and apparatus for obtaining a hydrogen product and a sulfur product from a feed gas comprised of hydrogen sulfide. In the process, a first separating step separates the feed gas to obtain a first purified hydrogen sulfide fraction comprised of at least about 90 percent hydrogen sulfide by volume. A dissociating step dissociates hydrogen sulfide present in the first purified hydrogen sulfide fraction to convert it into a dissociated first purified hydrogen sulfide fraction comprised of elemental hydrogen and sulfur. A second separating step separates the dissociated first purified hydrogen sulfide fraction to obtain a hydrogen rich fraction comprised of elemental hydrogen. The sulfur product may also be obtained from the dissociated first purified hydrogen sulfide fraction. Finally, the hydrogen product is obtained from the hydrogen rich fraction. The apparatus is provided for performing the process.

Owner:H2S TECH INC

Biomass composite solid forming fuel and preparation method thereof

The invention relates to biological complex shaped fuel and the preparation method. The comprised components of fuel and their proportion are as follows: straw 80- 95 uints, refined coal 5- 20 units and sulfur- fixing agent 0.5- 1uints. The production method comprises following steps: (1) disintegrating straw with water content being 13- 17% into particles with size being smaller than 5mm; (2) disintegrating refined coal with water content being 13- 17% to particles with size smaller than 1mm; (3) mixing said straw, refined coal and sulfur- fixing agent according to said proportion; (4) feeding said mixture into shaping machine, extruding at 110- 150 Deg. C and 105- 120 Mpa, getting granular or block- shaped fuel with density being 1.2- 1.4 g / cm3 and water content being 10- 12%; (5) cooling temperature of got shaped fuel to room temperature, and packing. The fuel is characterized by convenient transportation, easy storage and no sulfur product generation, and it is a sustainable new energy.

Owner:北京盛昌绿能科技股份有限公司

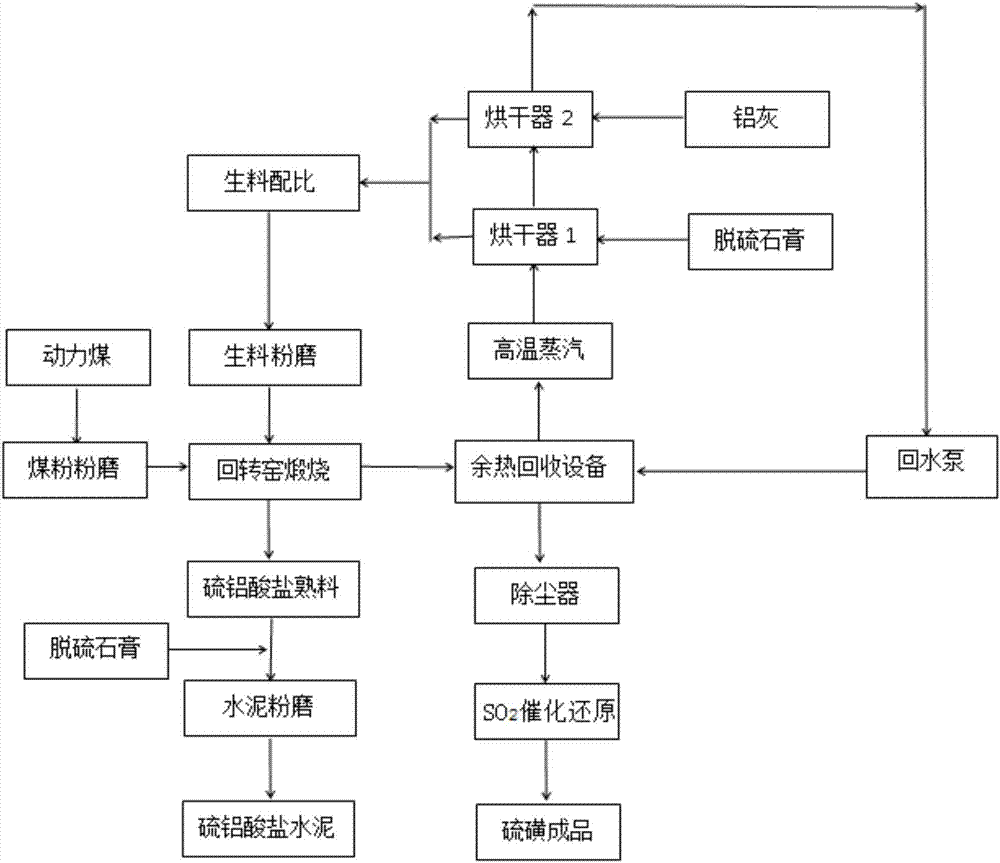

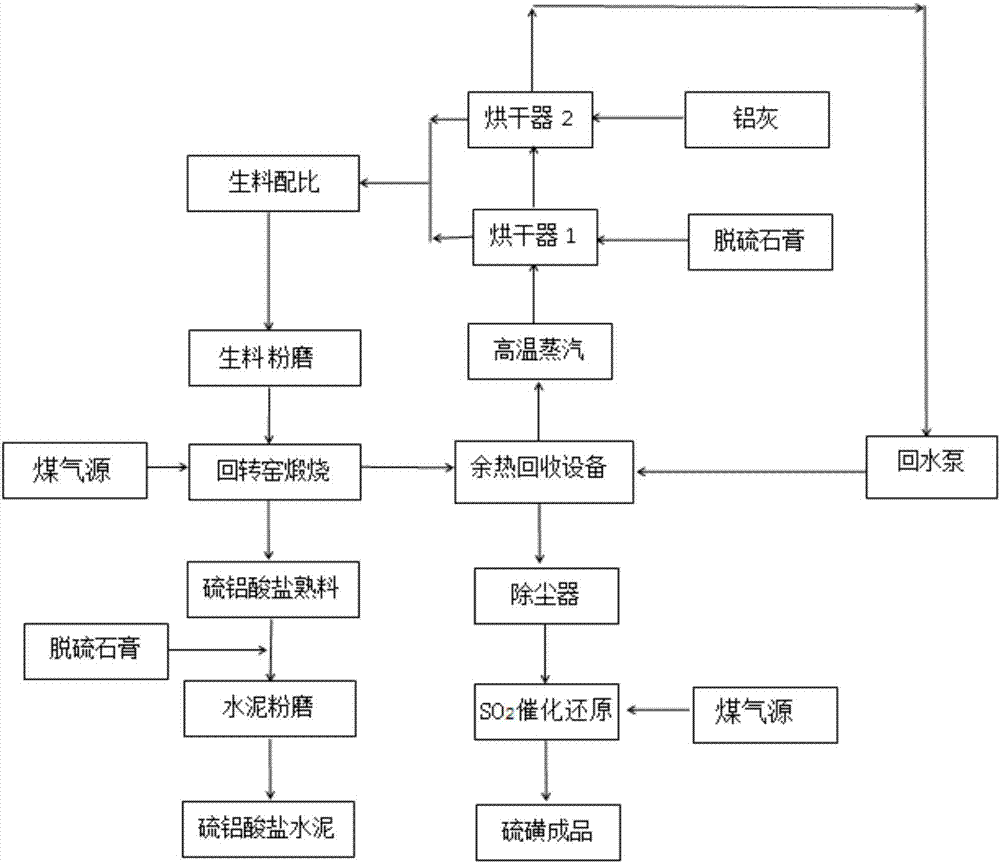

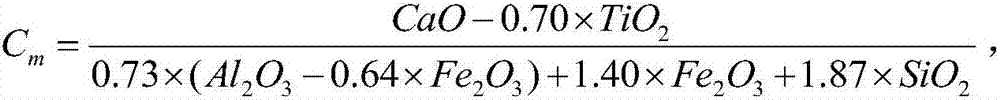

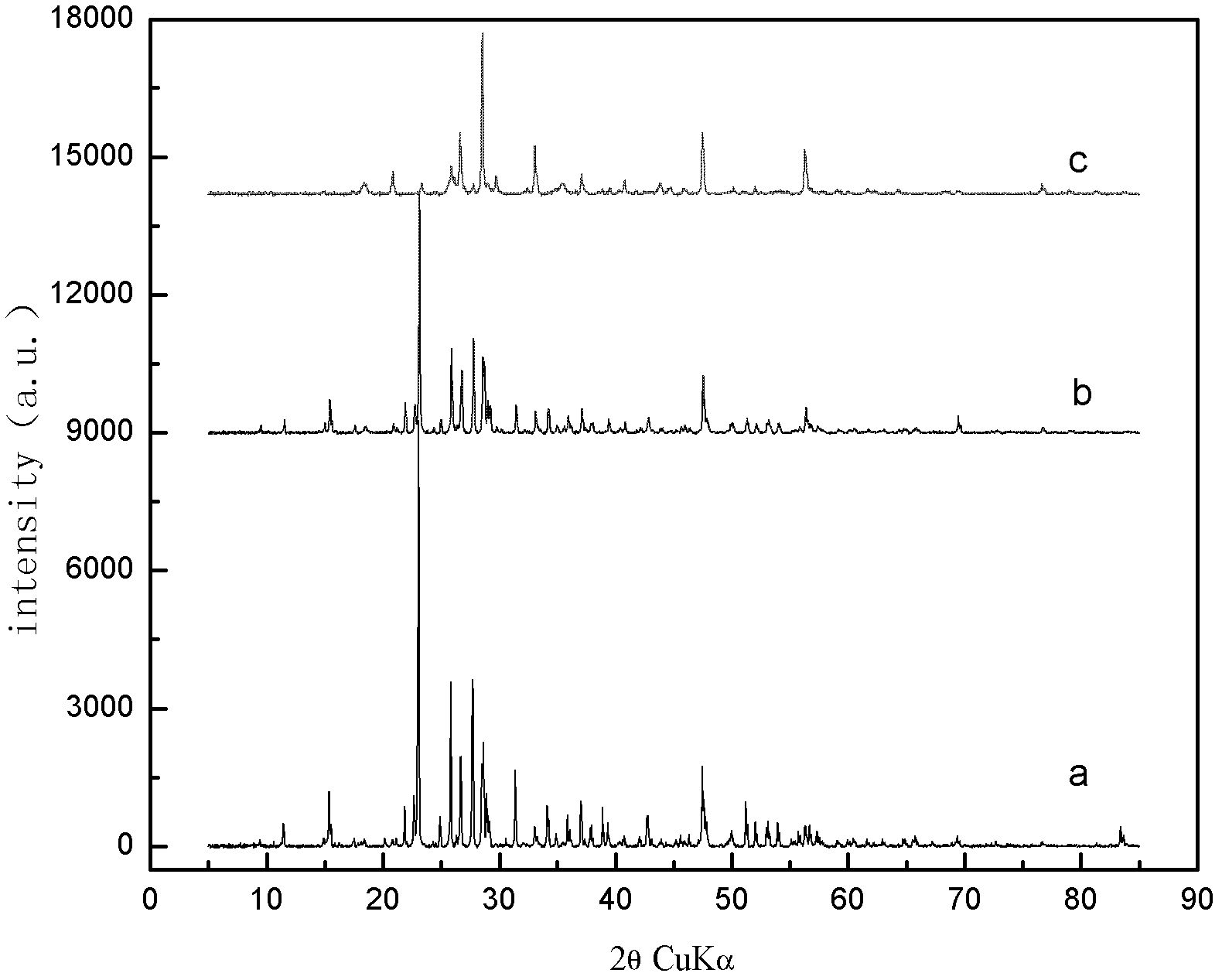

System and method for co-producing sulfo-aluminate cement and sulfur by use of desulfurized gypsum and aluminum ash

ActiveCN107056102AReduce usageMeet the formulation requirementsSulfur preparation/purificationCarbon monoxideCombustionSulfur product

The invention discloses a system and a method for co-producing sulfo-aluminate cement and sulfur by use of desulfurized gypsum and aluminum ash. The method comprises the following steps: (1) drying aluminum ash, and heating desulfurized gypsum for dehydration to obtain semi-hydrated gypsum; (2) mixing aluminum ash with semi-hydrated gypsum according to a preset ratio, pulverizing, and homogenizing; (3) calcining the pulverized and homogenized mixture of aluminum ash and semi-hydrated gypsum while adding coal dust to the mixture, and carrying out oxygen enriched combustion to obtain sulfo-aluminate cement clinker and sulfur dioxide-containing flue gas; (4) mixing sulfo-aluminate cement clinker and desulfurized gypsum according to a ratio, and pulverizing to obtain sulfo-aluminate cement; and (5) dedusting the sulfur dioxide-containing flue gas, and carrying out catalytic reduction to obtain a sulfur product, wherein the mass ratio of aluminum ash to desulfurized gypsum to carbon powder is (33-39):(61-66):1.

Owner:中芈(山东)环保科技有限公司

Method for recovering sulfur from atmospheric-pressure oxygen-rich leached residues of lead-zinc ores

InactiveCN102633233AFast sublimation volatilizationHigh puritySulfur compoundsEnergy inputVacuum pumpSulfur containing

The invention discloses a method for recovering sulfur from atmospheric-pressure oxygen-rich leached residues of lead-zinc ores, and particularly relates to the recovery of sulfur in lead-zinc ore leached residues through vacuum distillation, belonging to the field of reclamation and reuse of solid waste resources. The method comprises the following steps of: placing atmospheric-pressure oxygen-rich leached residues, subjected to drying, milling and screening pretreatment, of lead-zinc ores into a vacuum distillation furnace, heating the residues to 200-400 DEG C, and controlling the pressure of the inside of the furnace to 600-10000 Pa, so that sulfur in the leached residues is sublimated and volatilized; pumping sulfur-containing vapor out of the distillation furnace by a vacuum pump; and cooling the sulfur-containing vapor so as to obtain a sulfur product. After the distillation is completed and the sulfur is completely volatilized, high-boiling-point residues are discharged out of the distillation furnace in a solid powder form. In the whole process, the furnace is internally sealed, thereby avoiding the oxidation and environmental pollution of elemental sulfur. The method is simple in technological process and equipment, high in sulfur recovery rate and product quality, low in energy consumption, strong in adaptability to raw materials and pollution-free, so that the method disclosed by the invention is an economic and efficient sulfur extraction method and can realize the zero discharge of waste smelting residues in a lead-zinc wet process, thus the method has broad application prospects.

Owner:CENT SOUTH UNIV

Process for sulfur scavenging

InactiveUS6887445B2Increase response rateRaise the potentialOther chemical processesDispersed particle separationZinc hydroxideManganese oxide

Owner:MI

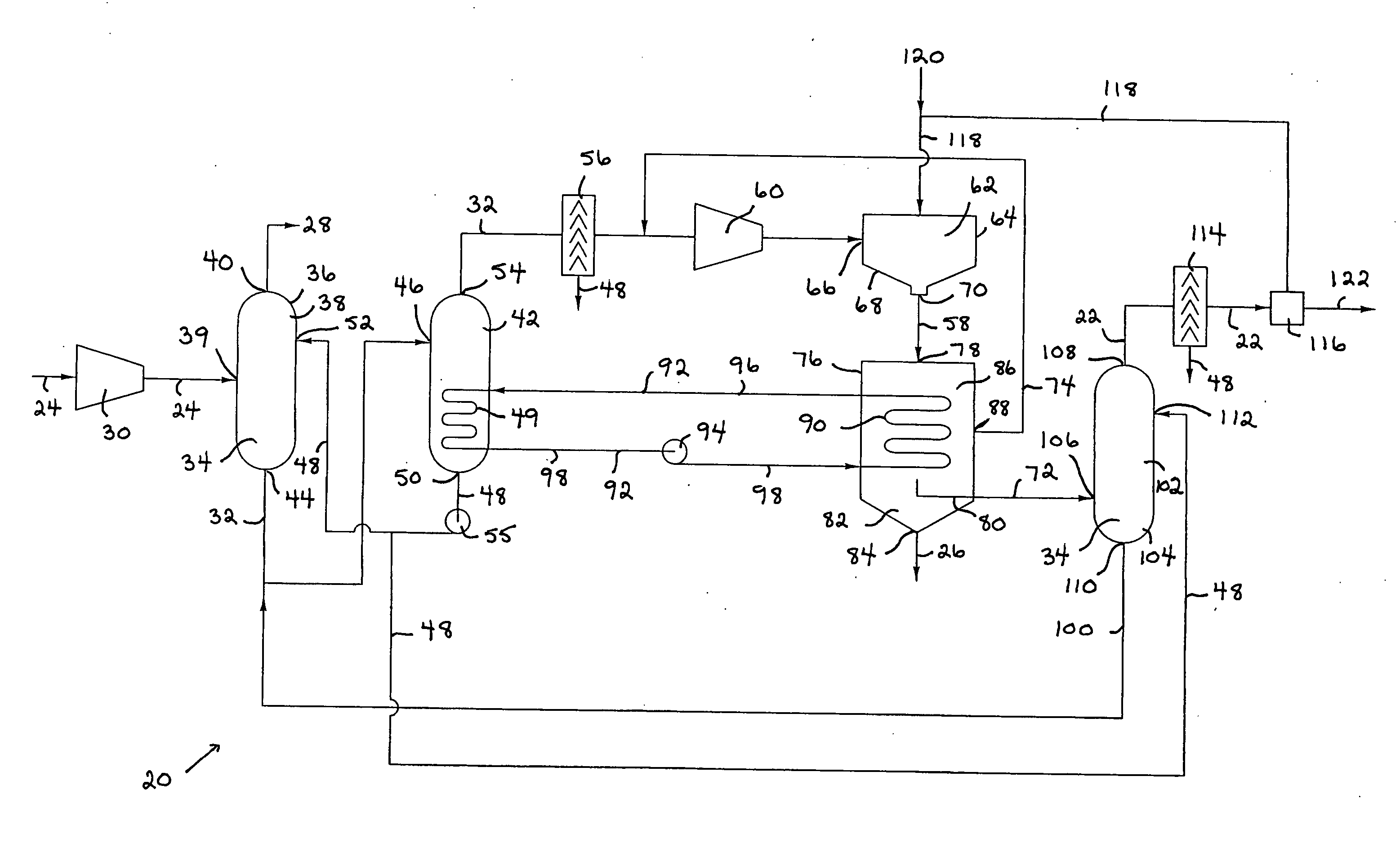

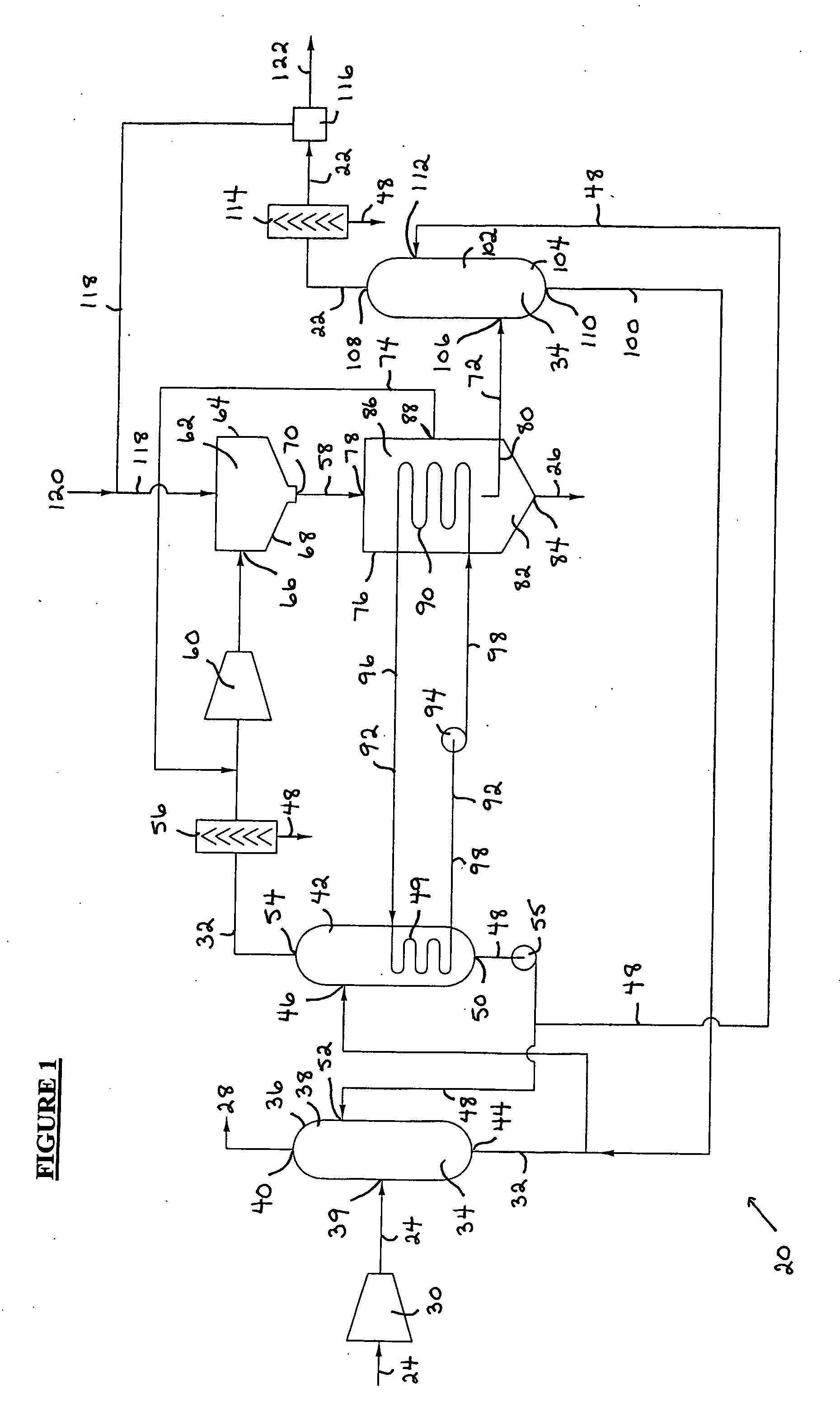

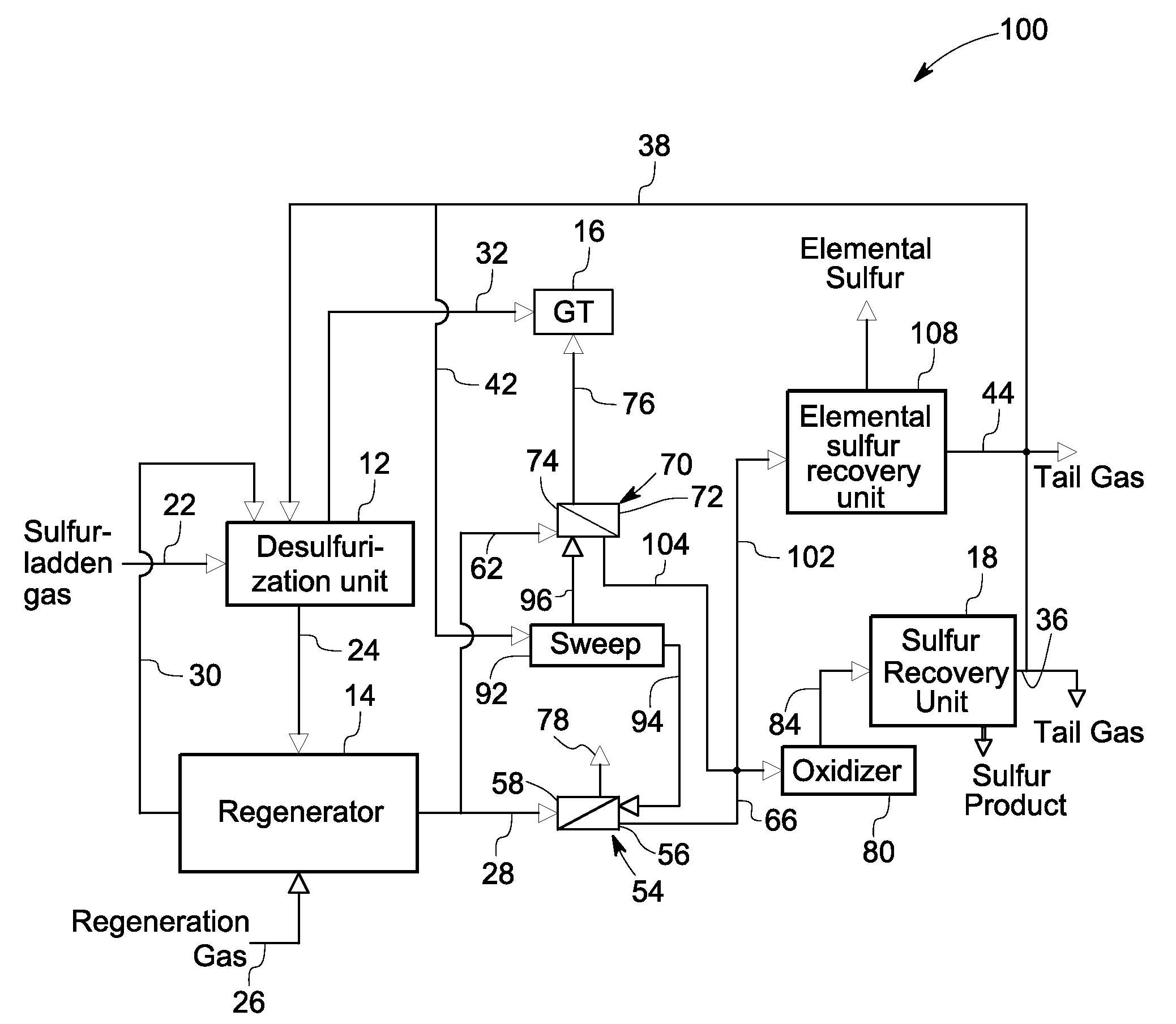

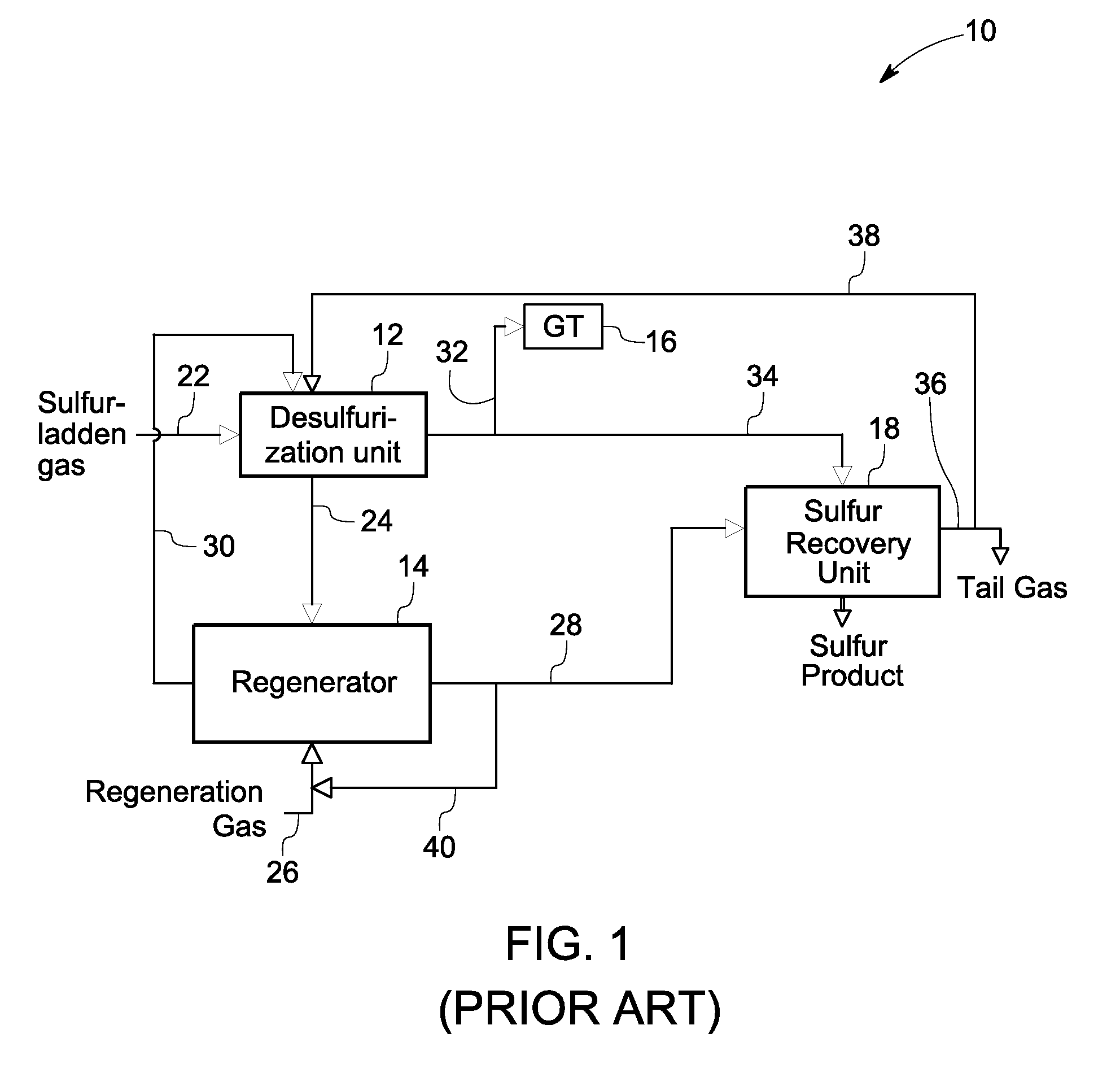

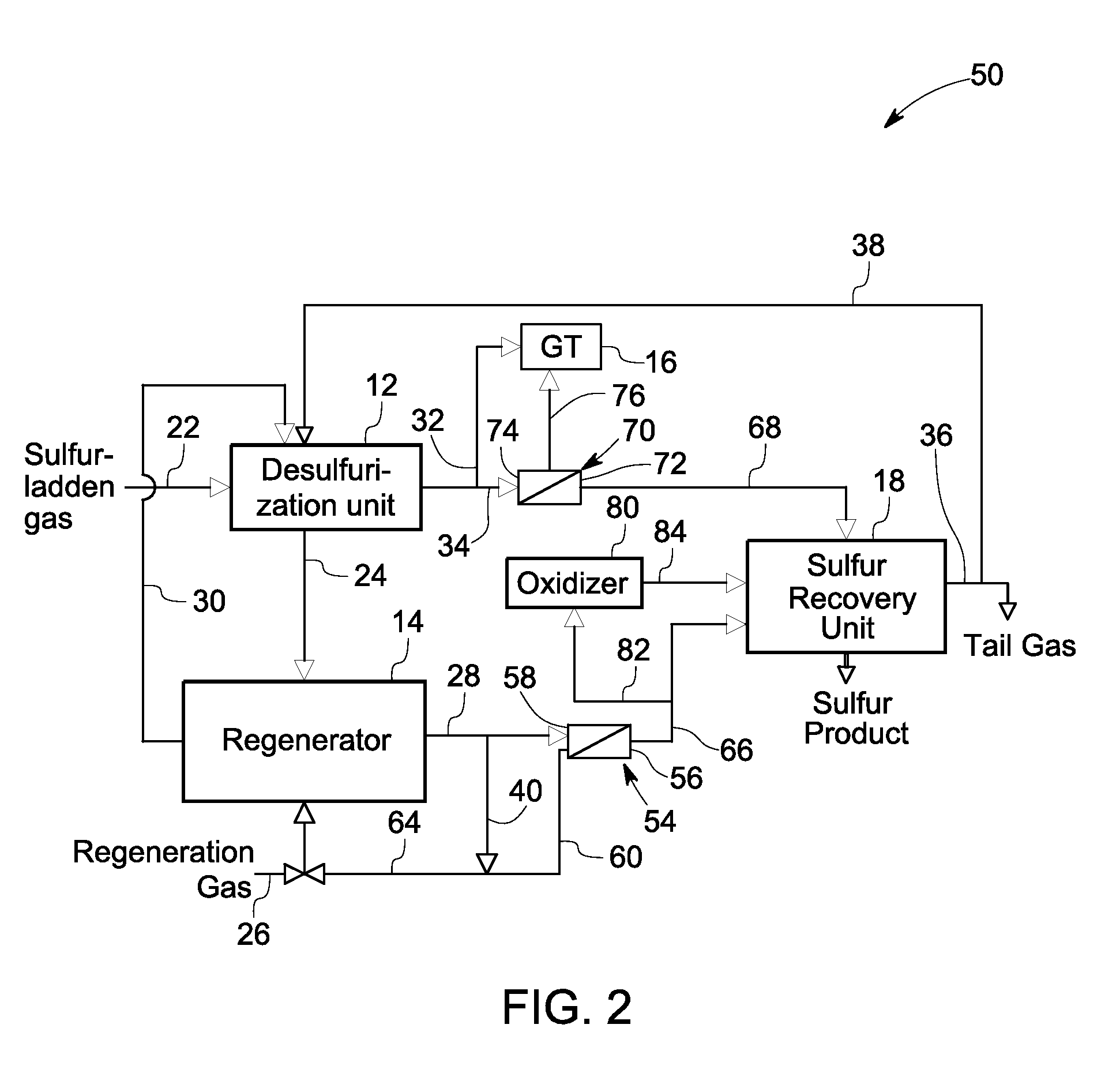

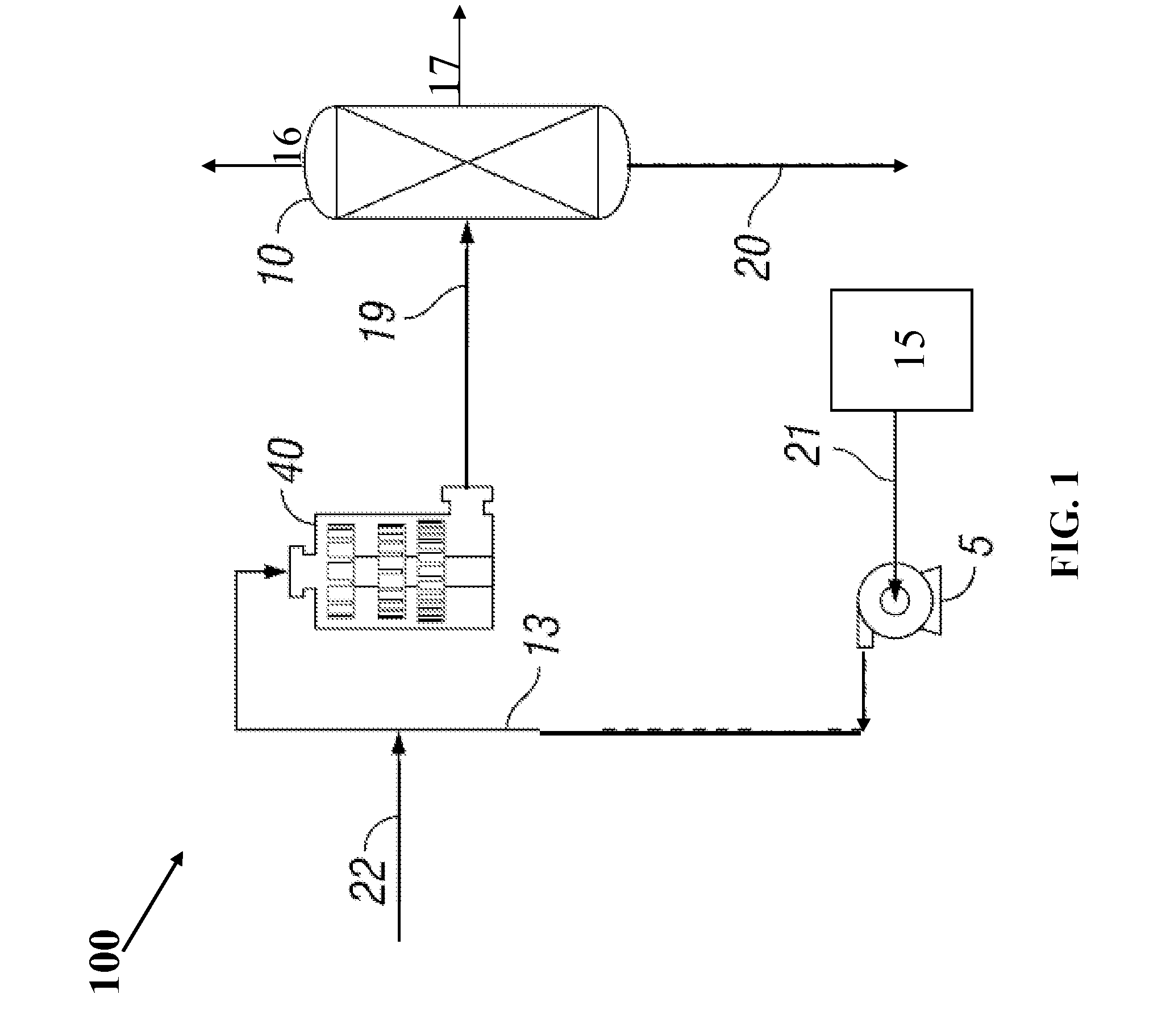

System and method for sulfur recovery

ActiveUS20110033370A1Reduce the amount requiredImprove efficiencyCombination devicesExhaust apparatusSulfur productProduct gas

Disclosed herein are various types of systems and methods for the efficient production of sulfur from a sulfur-laden gas. The system described herein includes a desulfurization unit, a regenerator receiving sulfurized mass from the desulfurization unit, a sulfur recovery unit, a sulfur track in fluid communication with the regenerator and the sulfur recovery unit, and a sulfur concentrator on a sulfur track. The sulfur stream coming out of the regenerator is concentrated using the sulfur concentrator and converted into a sulfur product at the sulfur recovery unit.

Owner:AIR PROD & CHEM INC

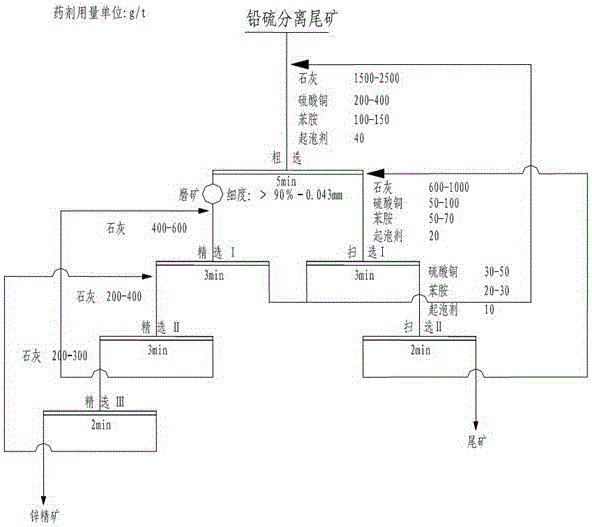

Method for recycling sphalerite from separated tailings of lead-sulfur bulk concentrate

InactiveCN106552715AImprove the level of comprehensive utilizationRelieve stressFlotationSulfur productFoaming agent

The invention discloses a method for recycling sphalerite from separated tailings of lead-sulfur bulk concentrate. The method for recycling the sphalerite from the separated tailings of the lead-sulfur bulk concentrate comprises the steps that firstly, water is added to the separated tailings of the lead-sulfur bulk concentrate, and the mass percent concentration of a pulp is adjusted to be 25%-32%; secondly, an appropriate amount of lime is added so that the pH value of the pulp can be adjusted, and pyrite is inhibited at the same time; thirdly, copper sulfate is added as an activating agent to activate the sphalerite; and finally, a collecting agent, aniline, and a foaming agent are added for flotation of the sphalerite, the flotation procedure comprises one-time rough flotation, two-time scavenging and three-time concentration (after the concentrate obtained through rough flotation is ground to the extent that the ores reaching the grain level of >-0.043 mm account for 90%, concentration is conducted ), and effective concentration of the sphalerite is achieved. According to the sphalerite obtained through the method, the zinc grade is higher than 40%, and the recovery rate of zinc is higher than 80%. By the adoption of the method for recycling the sphalerite from the separated tailings of the lead-sulfur bulk concentrate, the zinc lost in the lead-sulfur separated tailings, namely sulfur products, can be well recycled, the comprehensive recovery rate of zinc is improved, and the economic benefits of a concentrating plant are increased.

Owner:KUNMING UNIV OF SCI & TECH

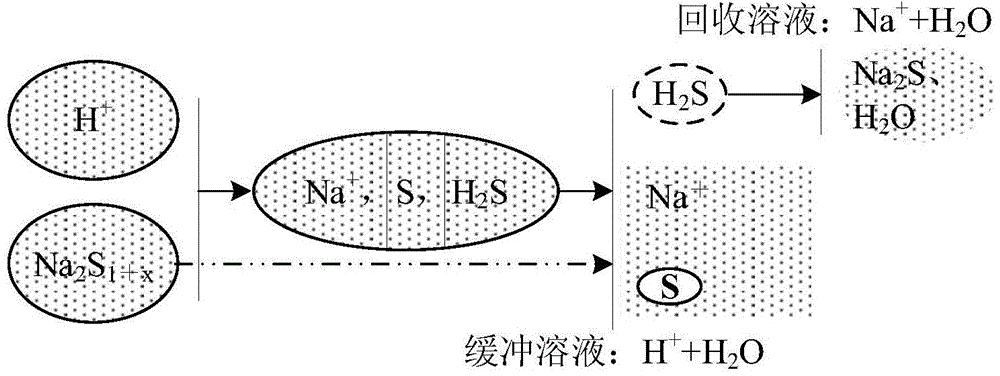

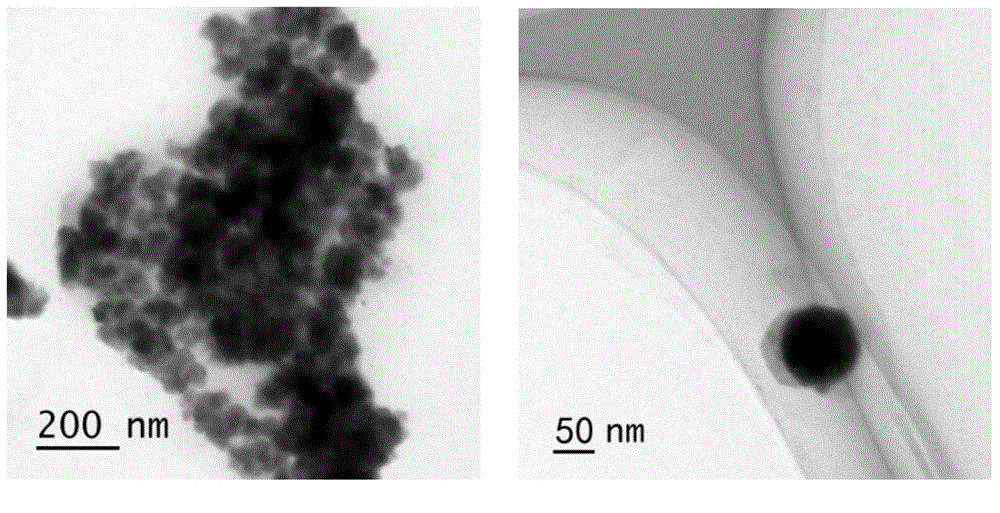

Method for nano sulfur atomization synthesis

InactiveCN104944381AGood size uniformityGood shape consistencySulfur preparation/purificationGas phaseChemical products

The invention discloses a method for nano sulfur atomization synthesis. The method concretely comprises respectively atomizing a starting material solution and a precipitant solution which are prepared well, controlling gas flow and liquid drop dimension of an atomizer, reacting to synthesize nano sulfur; scattering and precipitating the nano sulfur in a buffer solution and absorbing by-product gas phase through a recycling liquid; filtering the buffer solution through centrifugal separation to obtain nano sulfur sediment products, and performing washing and drying to obtain nano sulfur products; and evaporating and drying the remaining buffer solution and the recycling liquid to obtain reaction by-product chemical sodium salt. Through gas flow atomization, fog drips containing starting materials and fog drips containing a precipitant collide and are mixed with each other, the reaction occurs in the scale range of the fog drips; due to the limitation of the fog drip scale and concentration, the sizes of the products are far smaller than those of the fog drips, and the size uniformity and shape consistency of the obtained products are good. Reacting exhaust gas is fully absorbed through the waste gas recycling liquid and then discharged, and reacting by-products are high-purity sulphurizing salt or sulfite chemical products and are free of environmental pollution.

Owner:XIAN UNIV OF TECH

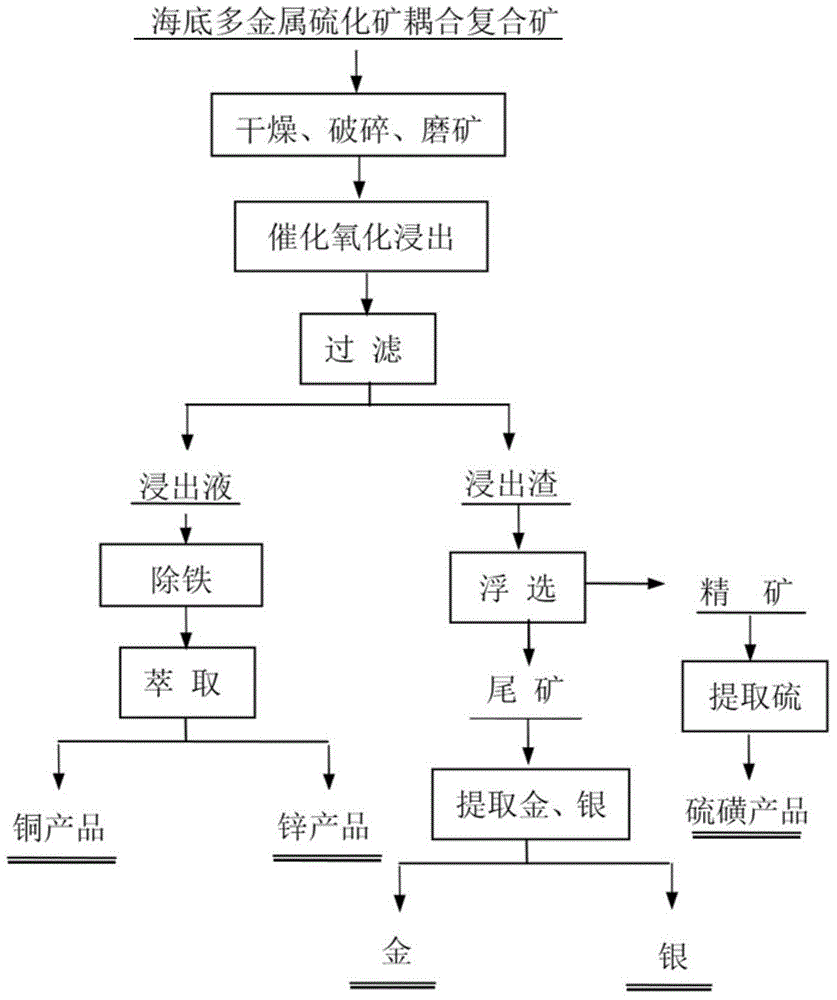

Method for extracting valuable metal from seabed multi-metal sulfide mineral coupling complex ore

ActiveCN104785357AReduce consumptionSimple processWet separationPregnant leach solutionSulfur product

The invention discloses a method for extracting valuable metal from seabed multi-metal sulfide mineral coupling complex ore. The method comprises the steps of obtaining leaching liquid containing copper and zinc and leaching slag containing sulfur, gold and silver through catalysis, oxidation and leaching; exacting copper products and zinc products out of the leaching liquid, and exacting sulfur products, gold products and silver products out of the leaching slag. By means of the method, valuable elements including copper, zinc, gold, silver and sulfur in the seabed multi-metal sulfide mineral coupling complex ore can be recycled comprehensively, the method has the advantages that the multipurpose utilization rate is high, the recycling rate is high, the process is simple, the cleanliness is achieved, and energy is saved, and the method is effective in processing new resources in the seabed multi-metal sulfide mineral coupling complex ore.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Separating agent for separating sulfur from sulfur-containing system and method for separating sulfur

ActiveCN105084319AEasy to prepareNo pollutionSulfur preparation/purificationBulk chemical productionSulfur productEconomic benefits

The invention discloses a method for separating sulfur from a sulfur-containing system. The method comprises that a composition containing a Fe-based ionic liquid, a solvent and a surfactant is employed, the composition promotes agglomeration of sulfur simple substance in a sulfur-containing system, and therefore small-particle sulfur generated in a sulfur-containing system rapidly grows into a sulfur particle with relatively large particle size at a relatively low temperature, and the sulfur product generated in the desulphurization technology is easy for sedimentation and recovery, and is prevented from depositing on a reactor wall or blocking a pipe. Also, investment reutilization is realized and economic benefit is increased.

Owner:BEIJING UNIV OF CHEM TECH

Process for removing organic sulfur in low-temperature condition

InactiveCN101318099AEfficient removalNo pollutionDispersed particle separationHigh concentrationSulfur product

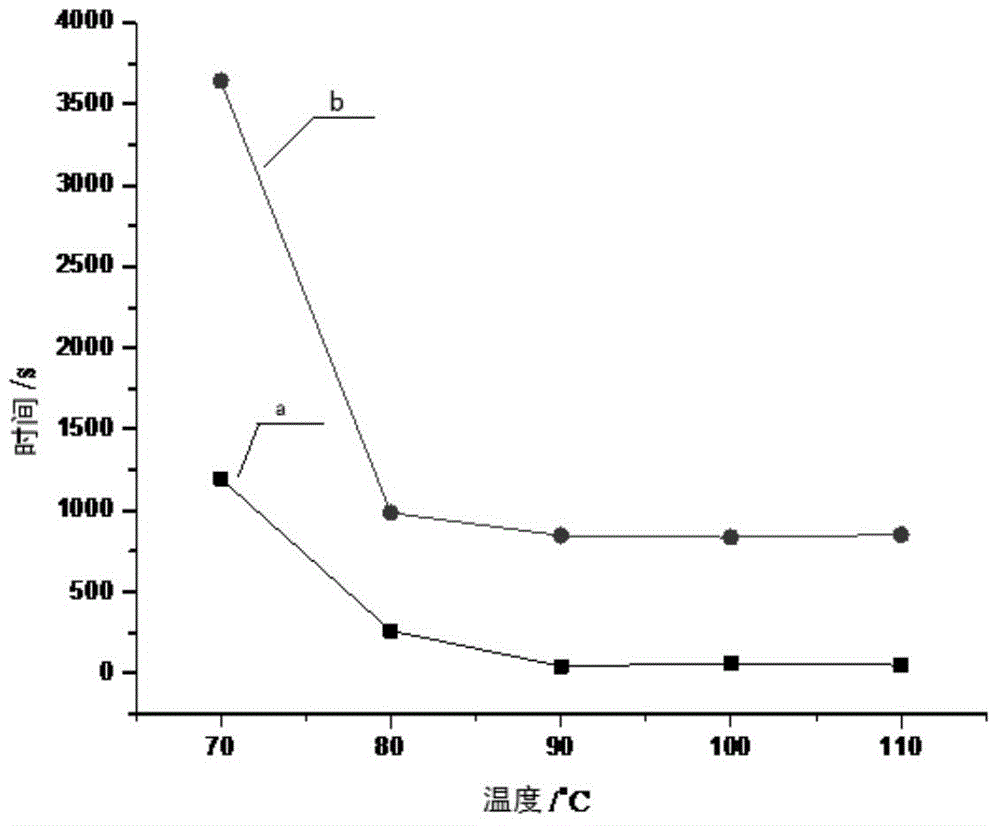

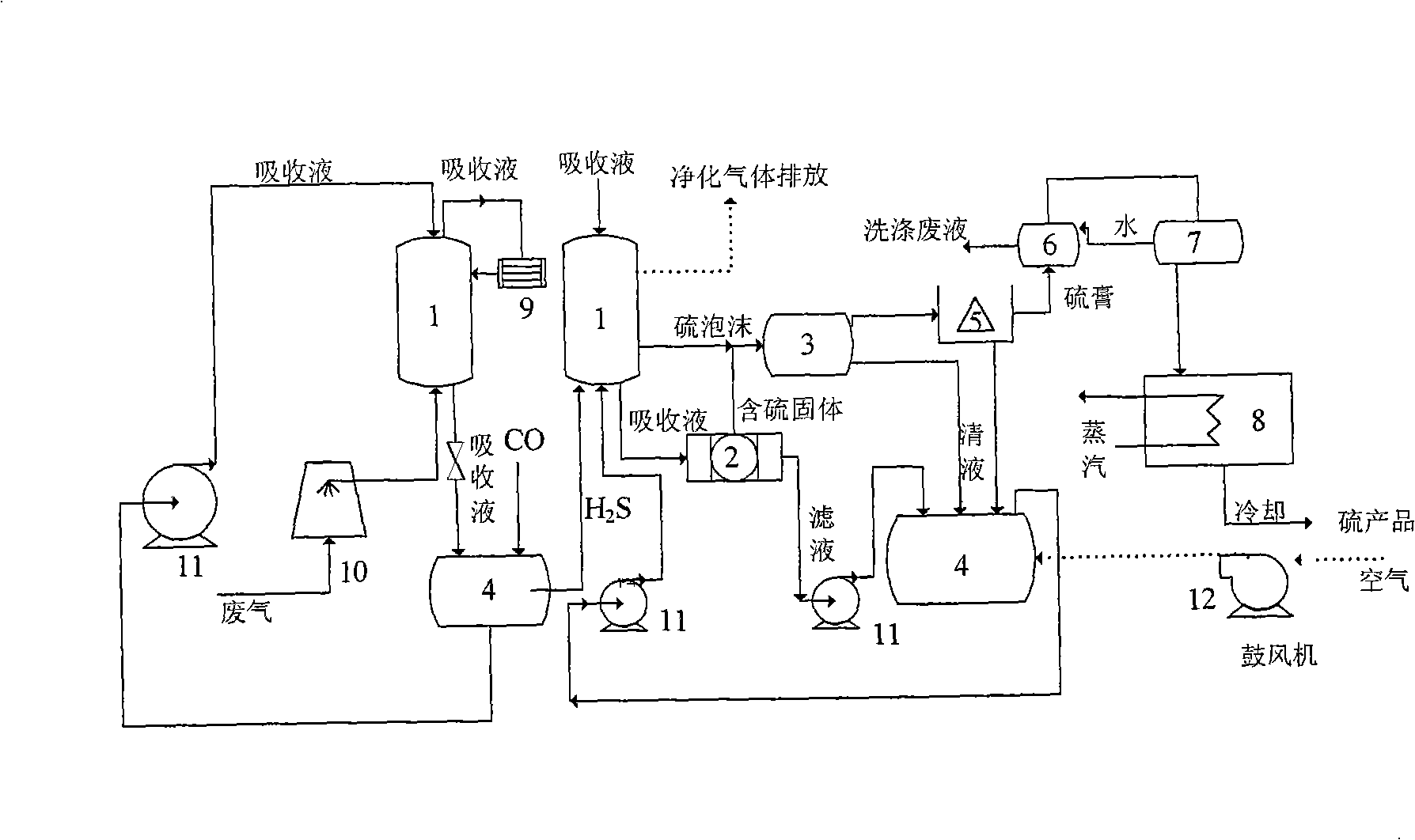

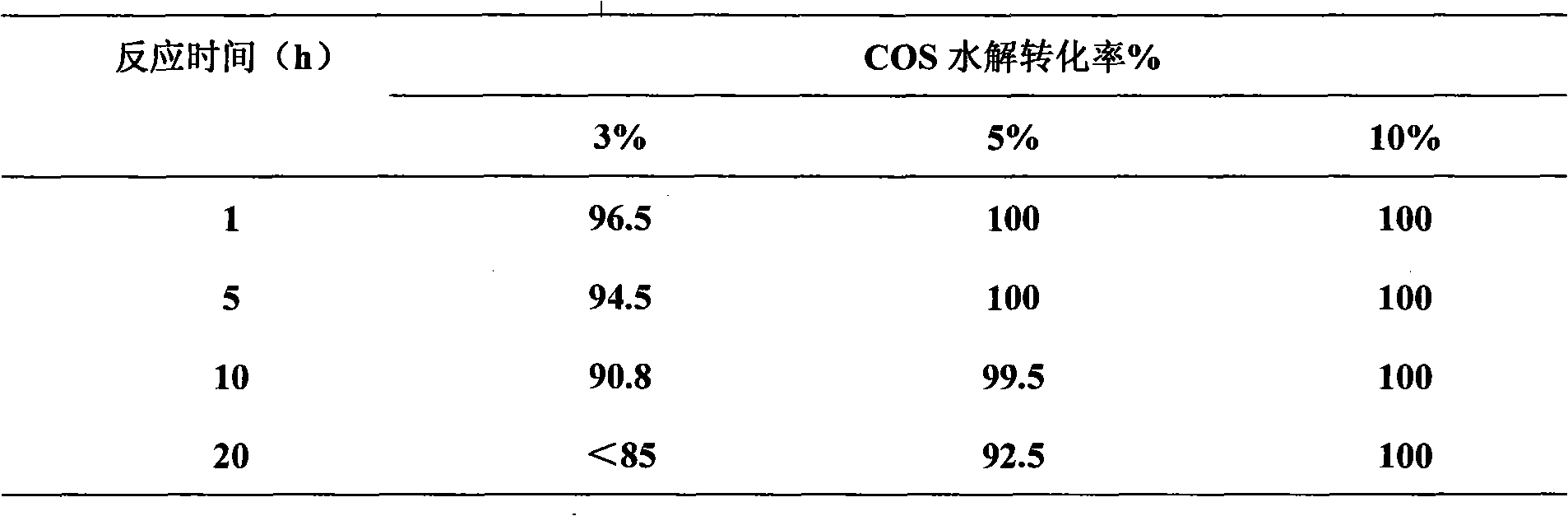

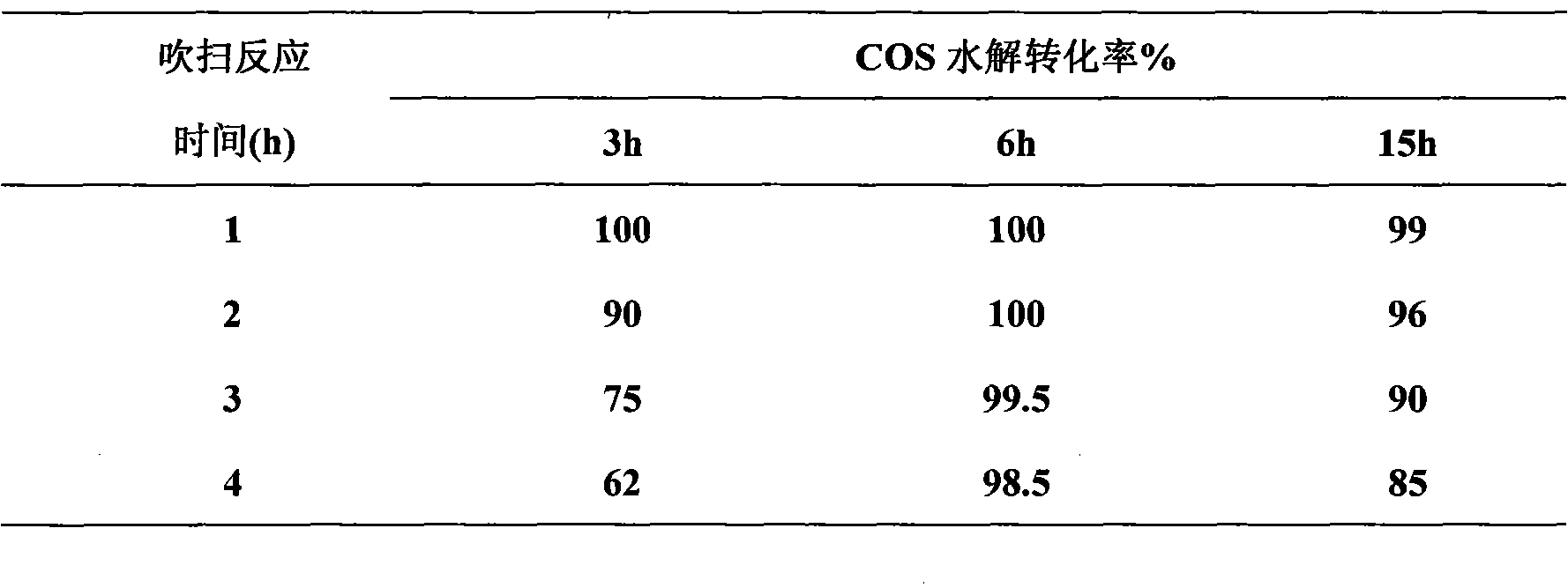

The invention provides a technological method for desorbing organic sulphur at low temperatures; wherein, the organic sulphur is hydrolyzed into H2 and CO2 and H2S is absorbed after being cooled by waste gas and absorbed by absorbing fluid for organic sulphur; the absorbing fluid for organic sulphur is regenerated by aerating gaseous CO, and the regenerated H2S is then aerated into H2S absorbing liquid so as to regenerate the H2S absorbing liquid in the air-blow method; the sulfur product can be obtained after the sulfur generated in the regeneration process goes through working procedures of centrifugal separation, washing, dehydration and fusion. The invention has the advantages that sulphur in the high-concentration organic sulphur waste gas can be effectively desorbed, with an absorbing and purifying efficiency more than 95 percent; meanwhile, the used catalysts, namely, the absorbing liquid for organic sulphur and H2S absorbing liquid are guaranteed for regeneration; the simple substance of sulphur absorbed by the catalyst can be effectively recycled at the same time of regeneration. The invention has simple process, small investment, low running cost and simple operation, requires low labor intensity, and does not pollute the environment.

Owner:KUNMING UNIV OF SCI & TECH

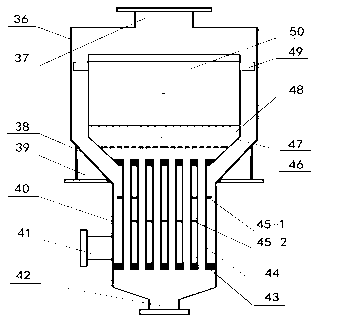

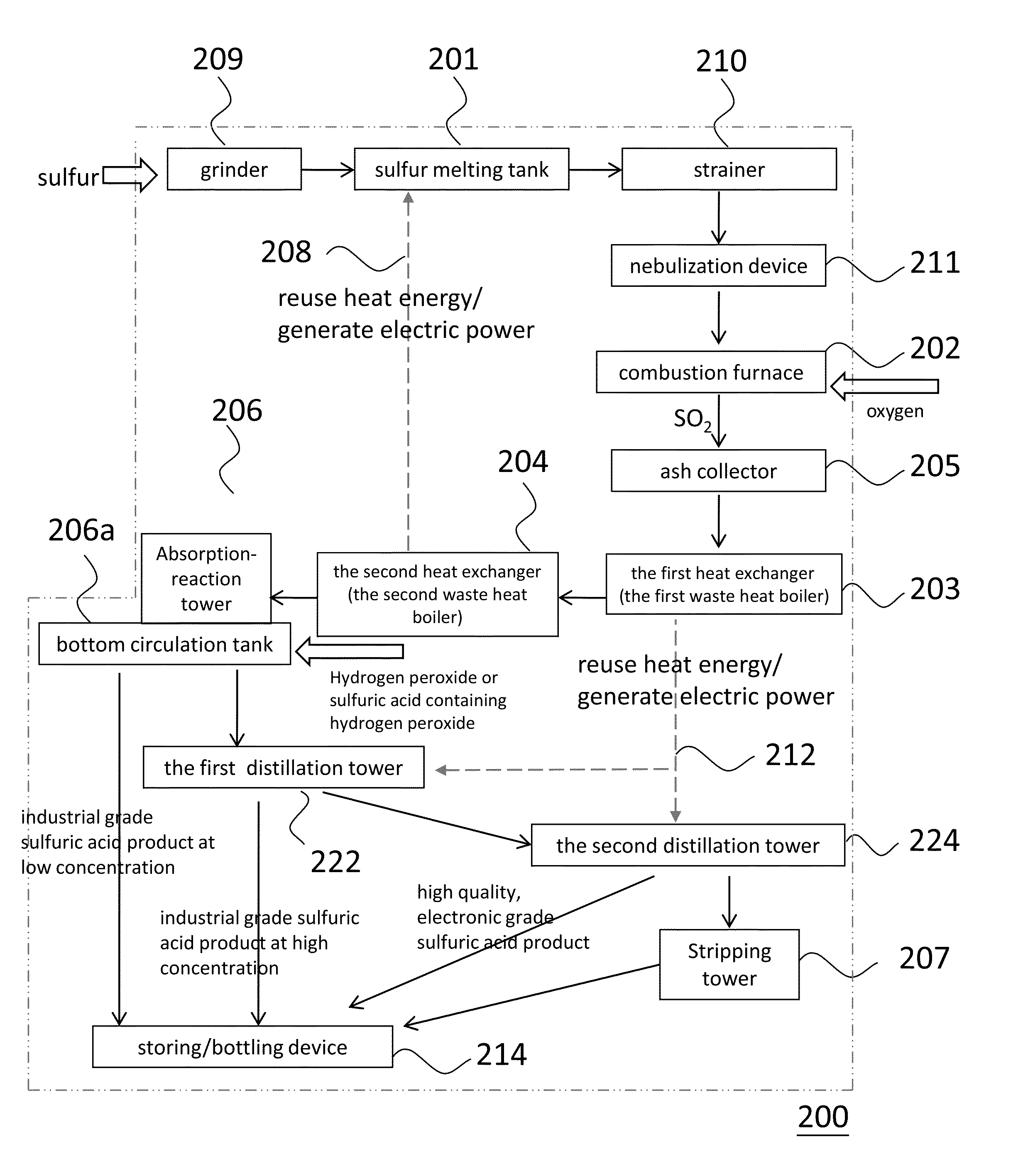

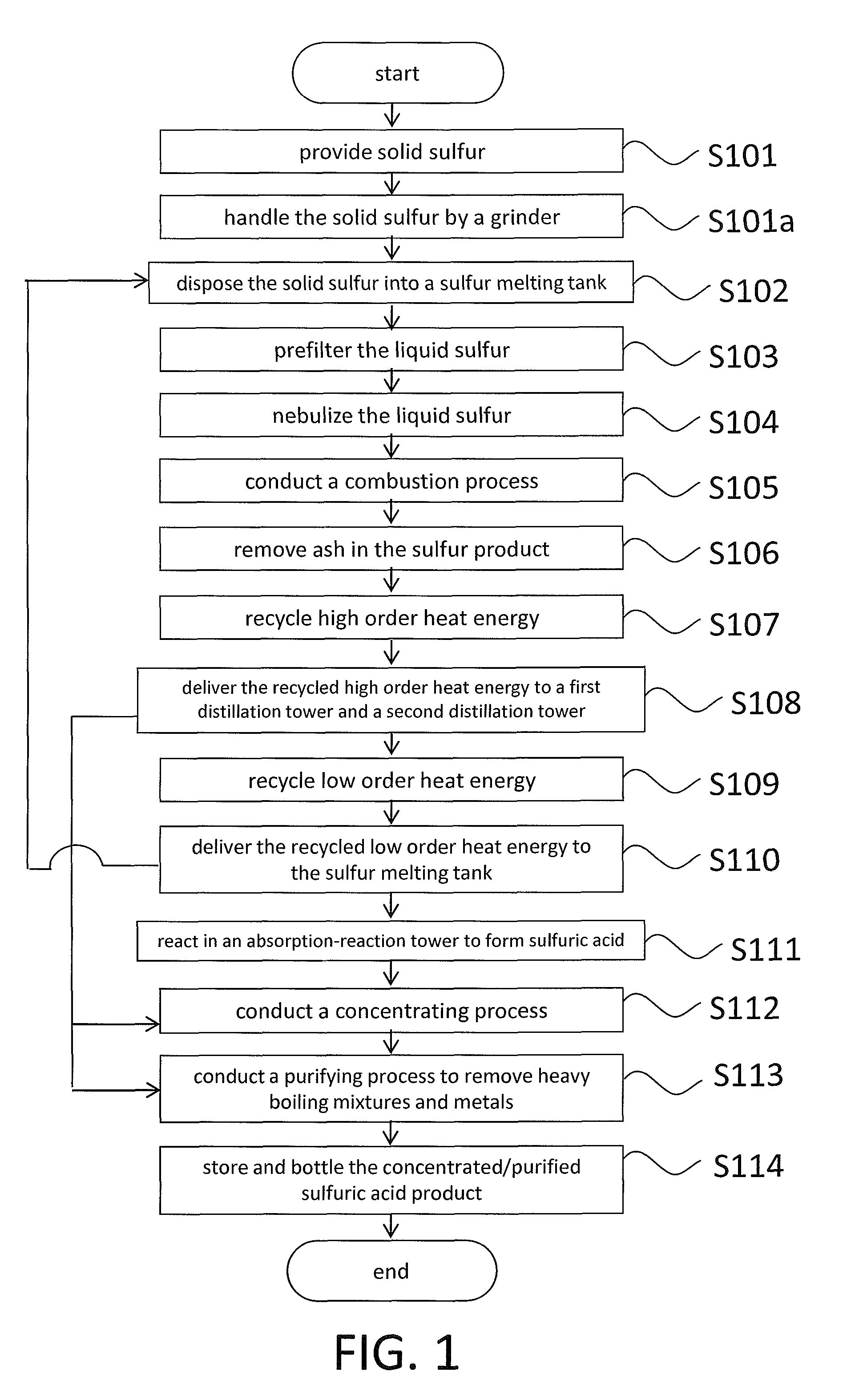

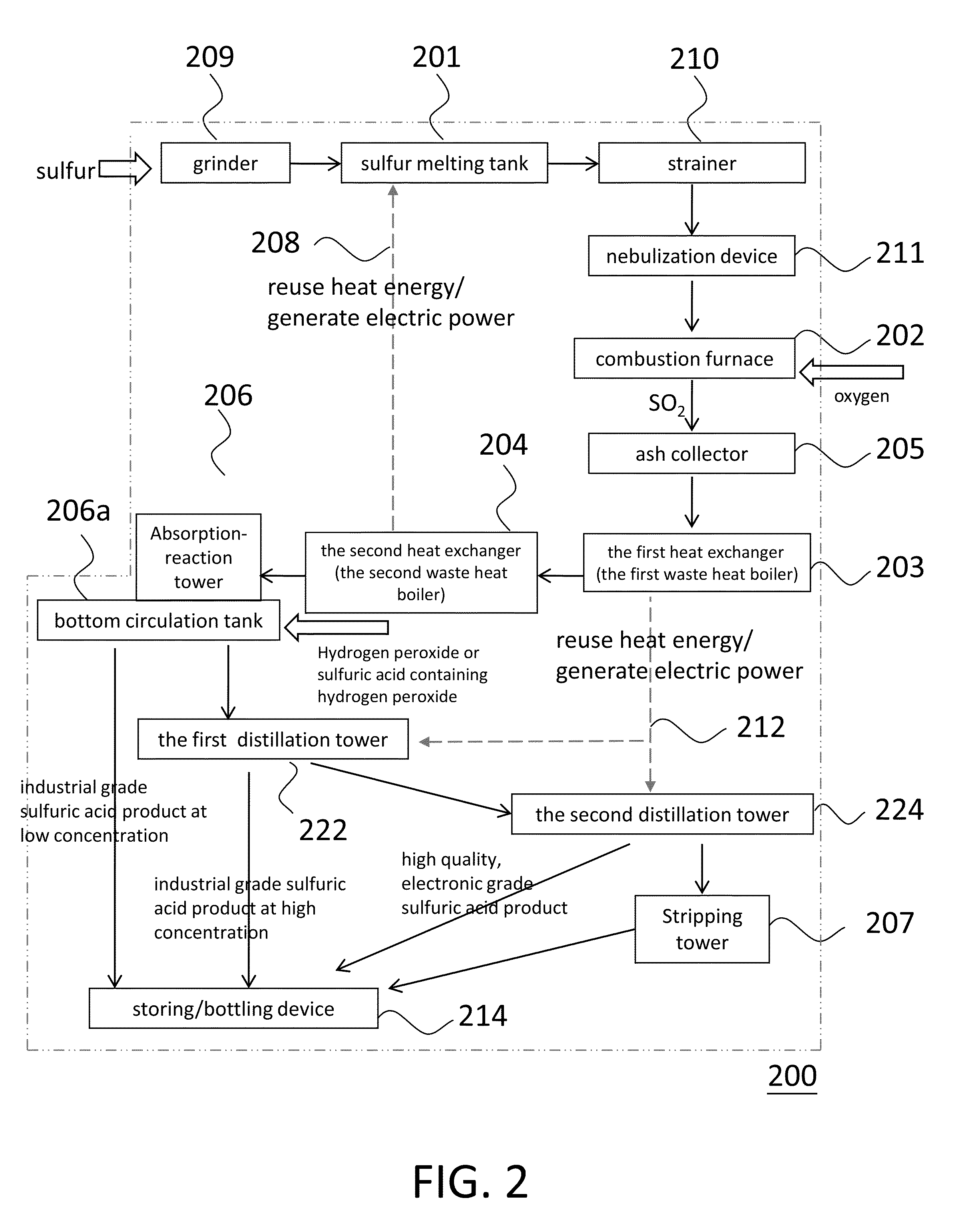

Method, apparatus and system for making sulfuric acid

ActiveUS8916127B1Reduce power consumptionResolution problemGaseous chemical processesSulfur-dioxide/sulfurous-acidMelting tankSulfur

A method for making sulfuric acid comprises: providing solid sulfur, melting the solid sulfur into liquid sulfur in a sulfur melting tank, burning the sulfur to generate a sulfur product, recycling high order heat energy generated from burning the sulfur and providing the high order heat energy to a distillation tower, recycling low order heat energy generated from burning the sulfur and providing the low order heat energy to the sulfur melting tank, providing hydrogen peroxide or sulfuric acid containing hydrogen peroxide into an absorption-reaction tower for reacting to produce a sulfuric acid product, and concentrating or purifying the sulfuric acid product to improve its concentration or purity.

Owner:GREEN AMERICA ENTERPRISES

Method for one-step preparation of insoluble sulfur

ActiveCN103539079AImprove production safetySave energySulfur preparation/purificationEnvironmental resistanceSulfur product

The invention relates to a method for one-step preparation of insoluble sulfur. In a production process of insoluble sulfur, rapid cooling is one of very key process steps, realizes an effect of instantly stopping a reversible reaction and further directly affects the content of insoluble sulfur in a product. The method provided by the invention comprises the following steps of directly heating raw material sulfur to 120-150 DEG C, forming a large number of sulfur liquid droplets by centrifugal atomization through an atomizer, and increasing the specific surface area of sulfur; then heating to 180-240 DEG C by circulating hot nitrogen for ring-opening polymerization, and keeping for 2-25 seconds; further cooling by circulating cold nitrogen, and cooling to below 60 DEG C at 2-20 seconds; performing cyclone separation, collecting and packaging to obtain the insoluble sulfur product, wherein the average particle size of the product is 10 mu m-50 mu m; recycling the separated nitrogen. The method provided by the invention has the advantages of simple process, safety, environmental friendliness and low cost.

Owner:BEIJING UNIV OF CHEM TECH

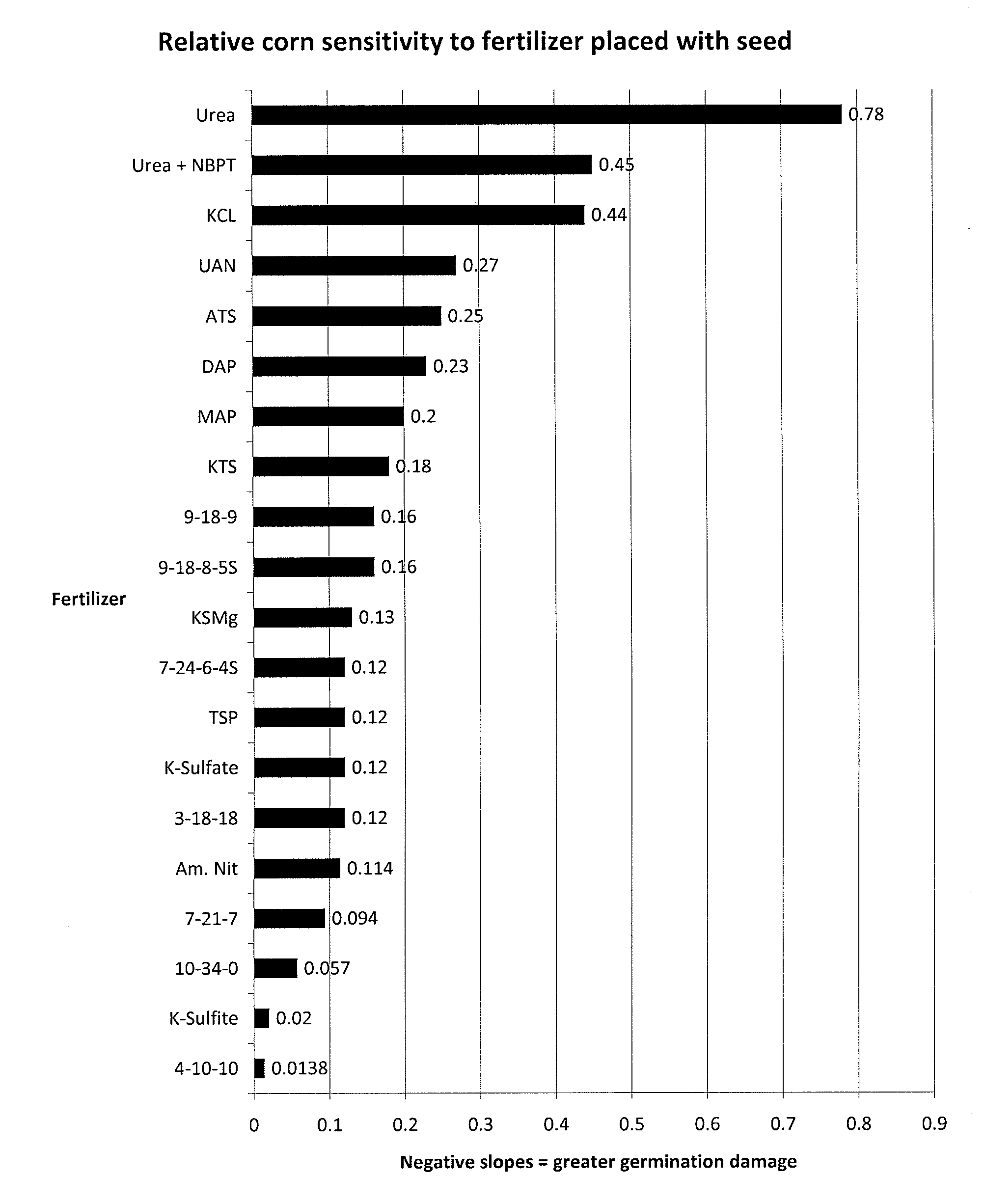

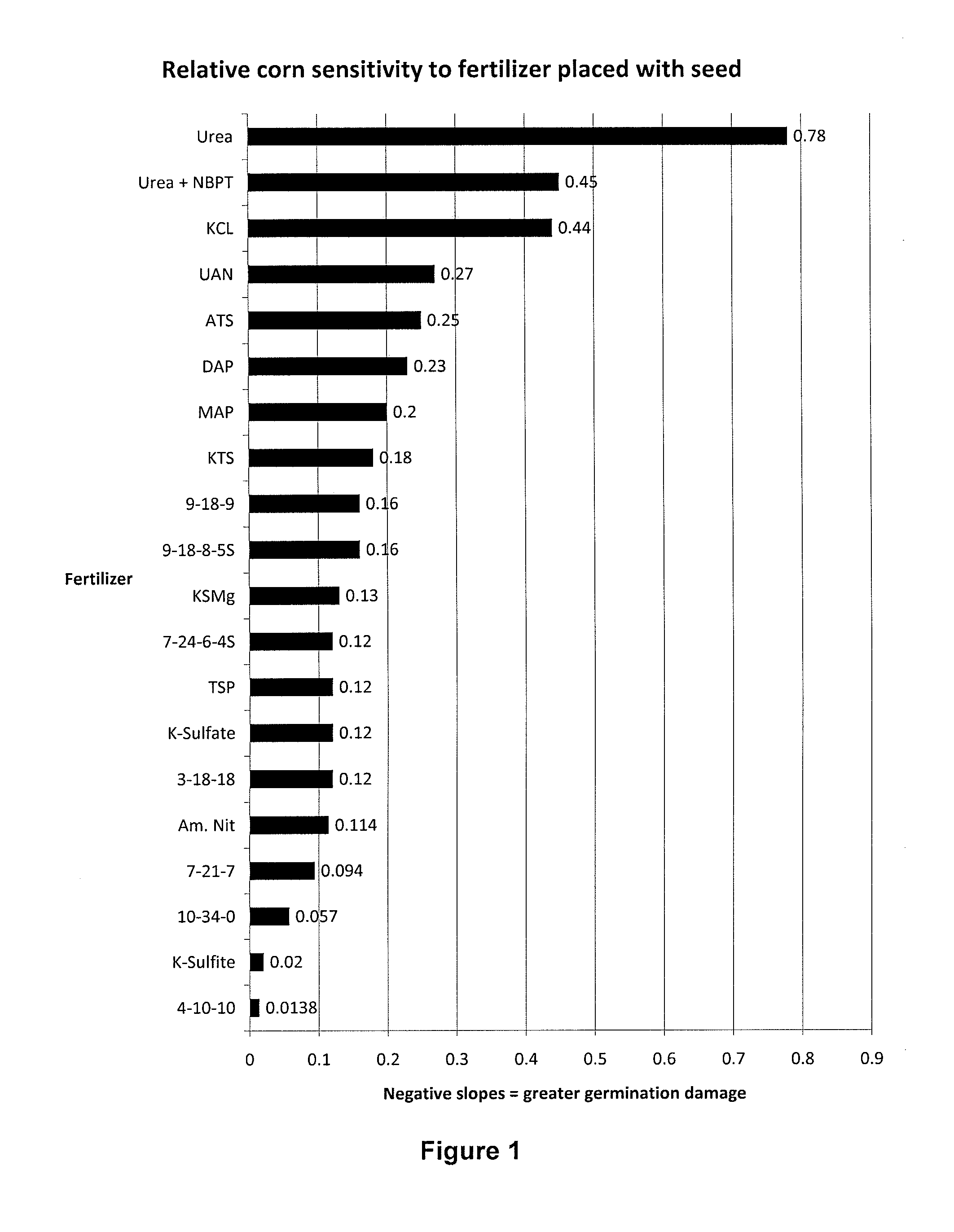

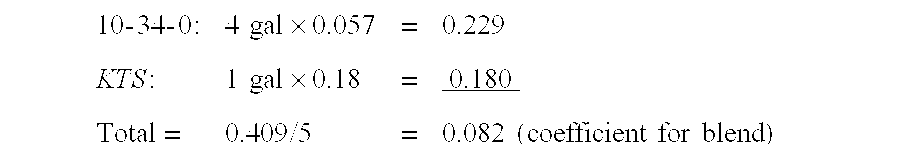

Potassium sulfite/potassium bisulfite (ks/kbs) liquid as starter, side-dress, broadcast, foliar and fertigation fertilizers

ActiveUS20120255335A1Low indexReduce drug damageBiocideSulfite preparationSulfur productPhytotoxicity

The present invention provides a new liquid fertilizer comprised of potassium sulfite and potassium bisulfite, with neutral to slightly alkaline pH, relatively lower salt index and potentially lower phytotoxicity damage compared to other sources of potassium and sulfur products applied in equal amounts as a starter fertilizer. More specifically, the present invention further relates to methods for fertilizing using a composition of potassium sulfite and potassium bisulfite, particularly as a starter fertilizer, in-furrow fertilizer, side dress fertilizer, and for foliar, broadcast, soil injection and fertigation applications. The fertilizer composition is comprised primarily of potassium sulfite (with the fertilizer grade of 0-0-23-8S).

Owner:TESSENDERLO KERLEY INC

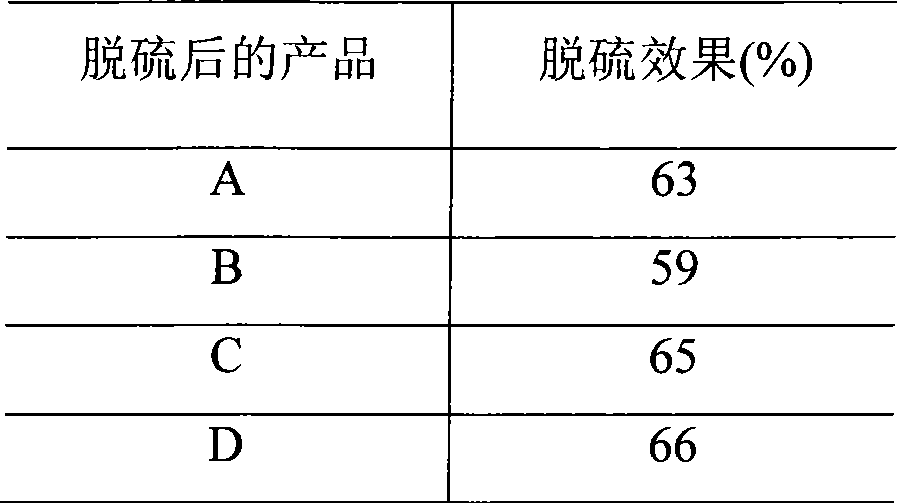

Method for removing sulfide from oil products with high aromatic hydrocarbon content

InactiveCN101381625ALow costSimple methodTreatment with plural serial refining stagesConcentration ratioPhosphoric acid

The invention provides a method for removing sulfides in a high aromatic hydrocarbon content oil product. The method comprises the following steps: 1) the mixed liquid of monatomic organic low-carbon acid and inorganic acid, vitriol acid salt or acid salt of phosphoric acid with the mol concentration ratio of 1 to between 4 and 9 to 2 is prepared, the mixed acid prepared is mixed with an oxidant according to the volume ratio of between 10 to 1 and 1 to 5, and the mixed solution is mixed with raw oil according to the volume ratio of between 1 to 8 and 9 to 1 to form an oil-water two phase medium; 2) the medium is subjected to emulsion breaking and split phase; and 3) by a composite extractant consisting of a polar solvent in which the aromatic hydrocarbon is not dissolved and water, the oil product after oxidation is subjected to extraction, the polar solvent is mixed with the water according to the volume ratio of between 2 to 1 and 1 to 4 to obtain the composite extractant, and the sulfides in the oil product are removed to obtain a low-sulfur product. The method can be applied to the desulfating process of heavy oil and the high aromatic hydrocarbon content oil product, and the method also has the advantages of low cost, simple method, good desulfating effect and no secondary pollution, and meets the requirement of an environment-friendly chemical engineering process.

Owner:TIANJIN UNIV

Crude oil desulfurization

ActiveUS20120111769A1Low costReduce usageRefining with non-metalsTransportation and packagingInorganic saltsChemistry

A method of removing sulfur from sour oil by subjecting sour oil having a first sulfur content to high shear in the presence of at least one desulfurizing agent to produce a high shear treated stream, wherein the at least one desulfurizing agent is selected from the group consisting of bases and inorganic salts, and separating both a sulfur-rich product and a sweetened oil product from the high shear-treated stream, wherein the sulfur-rich product comprises elemental sulfur and wherein the sweetened oil product has a second sulfur content that is less than the first sulfur content. A system for reducing the sulfur content of sour oil via at least one high shear device comprising at least one rotor and at least one complementarily-shaped stator, and at least one separation device configured to separate a sulfur-rich product and sweetened oil from the high shear-treated stream.

Owner:HRD CORP +1

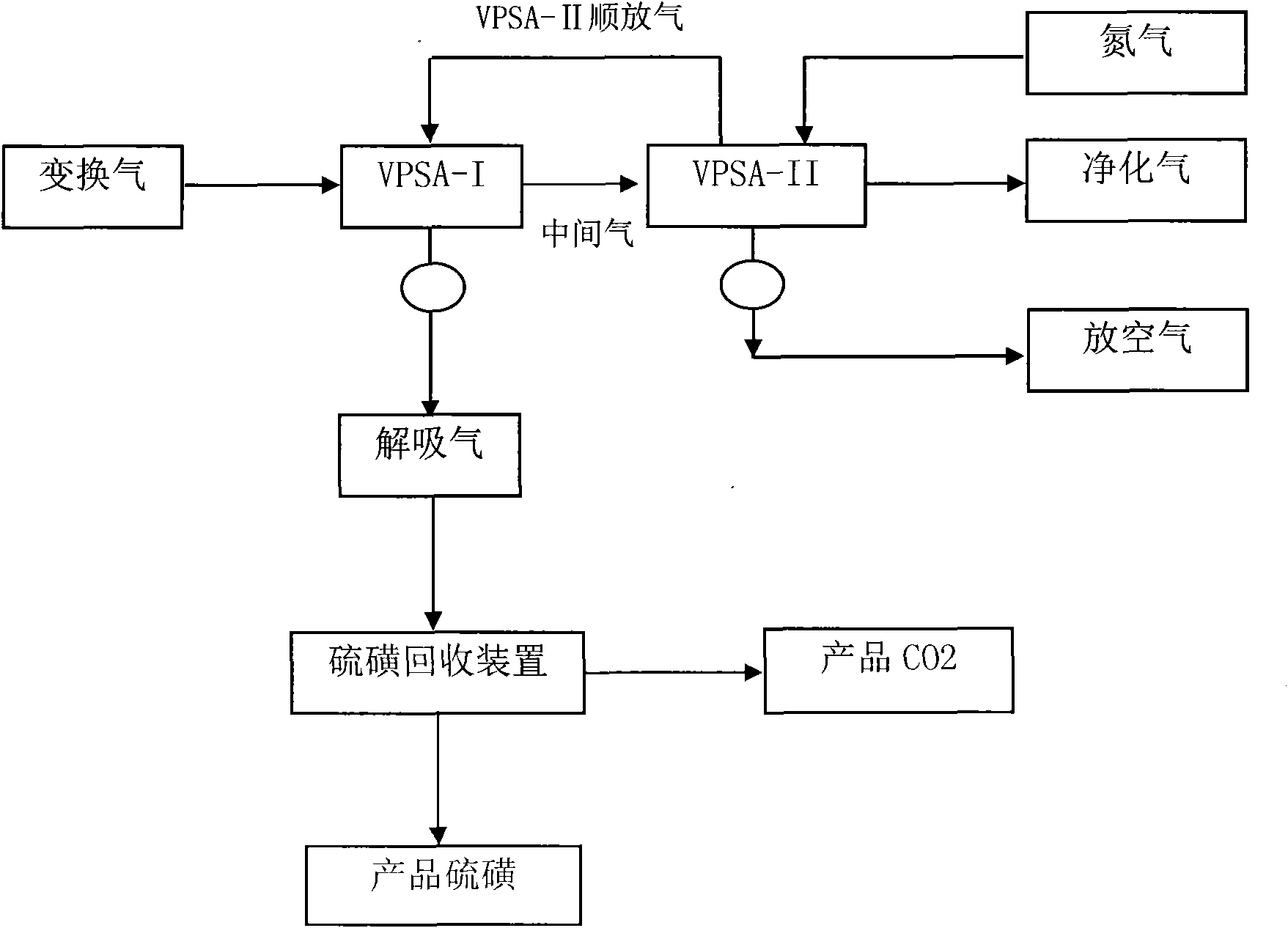

Process flow for removing CO2 and H2S in gas mixture

ActiveCN101653688AHigh recovery requirementsAchieve recyclingDispersed particle separationBy adsorptionSocial benefitsHigh concentration

The present invention provides a process flow for removing CO2 and H2S in gas mixture. The invention is characterized in that the process flow satisfies the high recovery rate requirement to the effective component in the purifying process of the gas mixture which contains the impurities of CO2 and H2S, satisfies the high recovery rate requirement to the effective component in the purifying process of the gas mixture which comprises CO2 and H2S, and realizes the recovery of sulfur product and high-concentration CO2 thereby effectively increasing the economic and social benefit of the gas mixture purifier.

Owner:成都华西工业气体有限公司

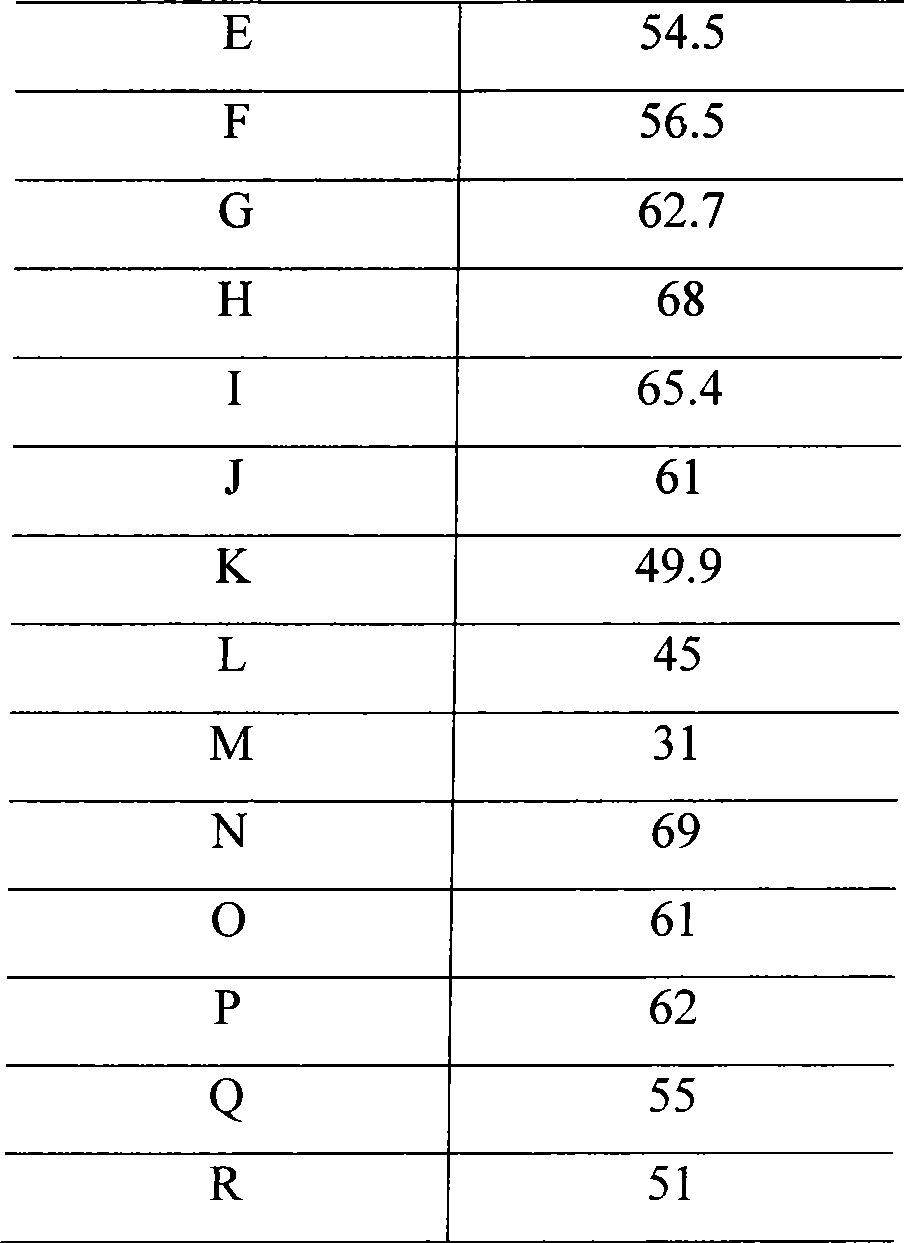

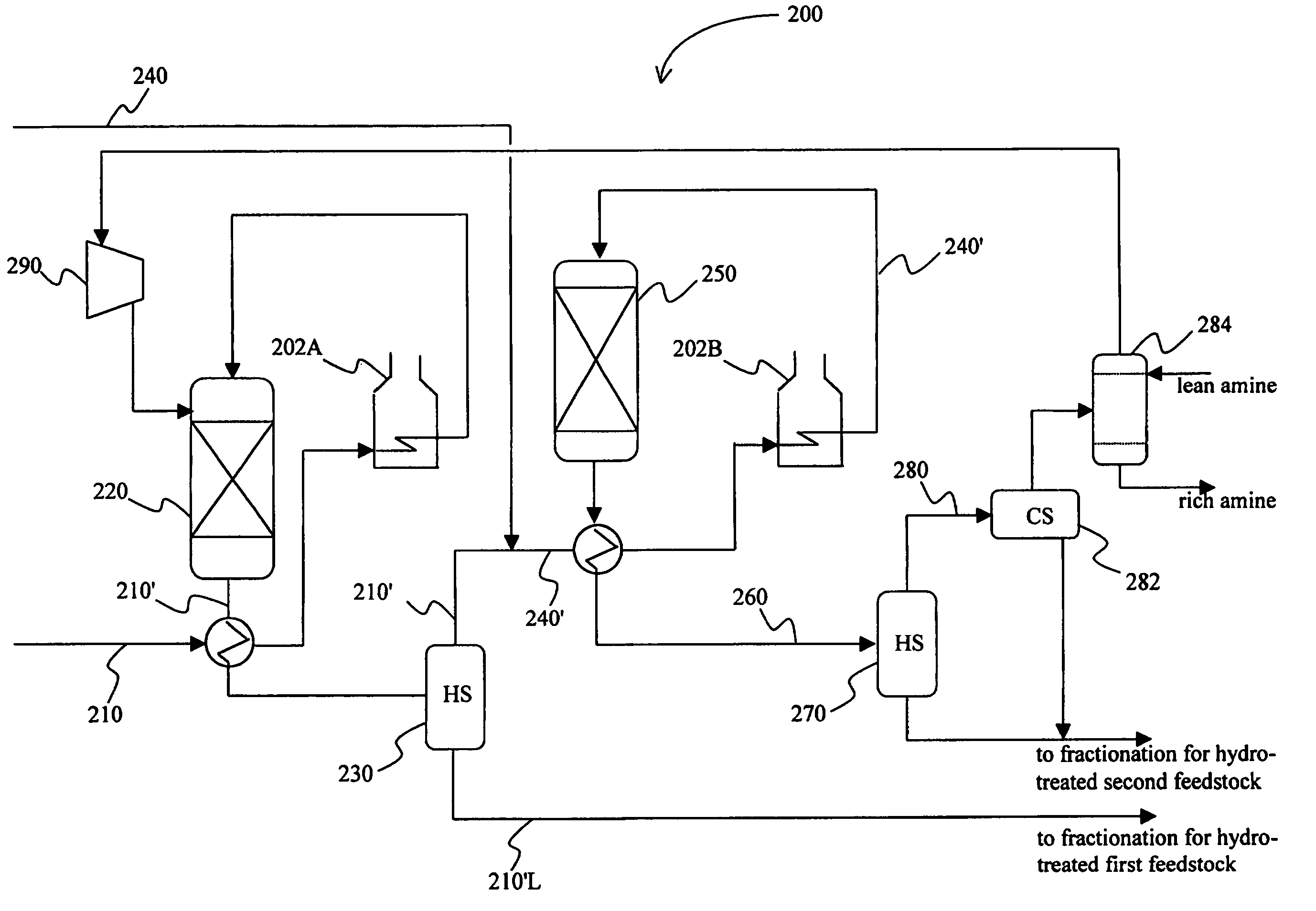

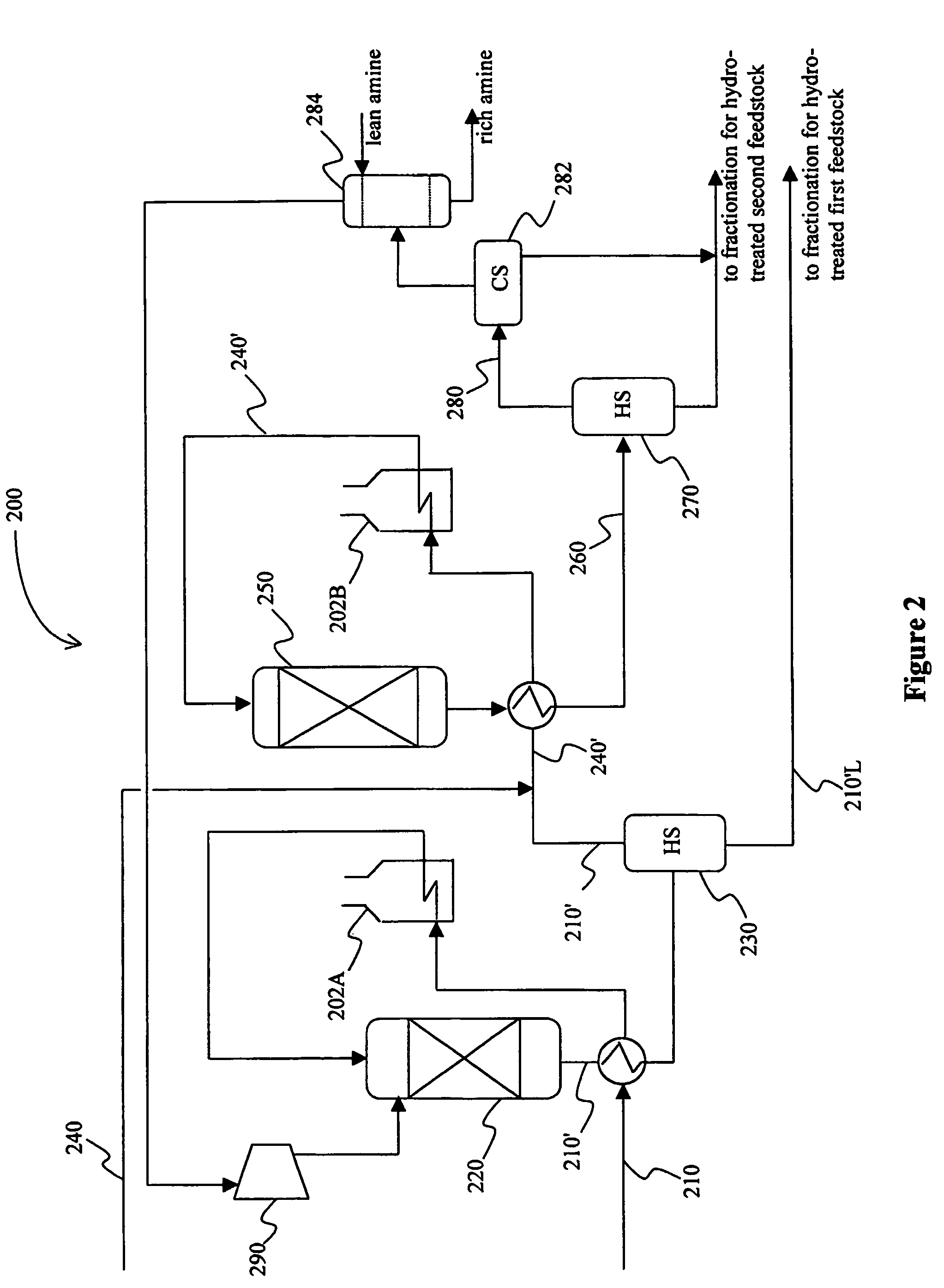

Combined hydrotreating and process

InactiveUS7238274B2Thermal non-catalytic crackingDistillation regulation/controlSulfur productChemistry

First (210) and second (240) feedstocks are hydrotreated in an integrated hydrogenation plant (200) using a hot separator (230) that provides a vapor stream containing at least some of the hydrotreated first feedstock (210), wherein the second feedstock (240) is mixed with the vapor stream at a position downstream of the separator (240) and upstream of the a second hydrotreating (250) reactor to form a mixed second feedstock that is fed into the second hydrotreating reactor (250) to produce a ultra-low sulfur product.

Owner:FLUOR TECH CORP

Technology and device for recovering volatile tail gas in sulfur collection pit of sulfur device of oil refinery

ActiveCN103585883AReduce concentrationReduce energy consumptionDispersed particle separationIncinerator apparatusPtru catalystSulfur product

The invention relates to a technology and device for recovering tail gas in a sulfur collection pit, in particular to a technology and device for recovering the volatile tail gas in the sulfur collection pit of a sulfur device of an oil refinery. The technology comprises the steps as follows: firstly, a water jacket is used for condensing volatile gas and elemental sulfur in the sulfur collection pit, and condensed sulfur substance returns to the sulfur collection pit; the volatile gas in a supergravity settling reactor is absorbed by a desulfurization solution under the action of a catalyst, and is oxidized into elemental sulfur; and then the desulfurization solution containing elemental sulfur and part of hydrogen sulfide is oxidized and regenerated in a jet regenerator, elemental sulfur is subjected to flotation, returns to a sulfur melting kettle and generates a sulfur product, meanwhile, purified gas is fed into the supergravity settling reactor, discharged out from the upper part of the settling reactor and fed into a combustion furnace finally, and residual sulfur and sulfur components are removed. Therefore, the volatile gas is recovered, the sulfur product is generated, furthermore, the quantity of sulfur fed into the combustion furnace is reduced, the emission reduction of sulfur dioxide is realized, and the energy consumption of the combustion furnace is reduced.

Owner:JIANGSU WISDOM ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com