Method for utilizing comprehensive resource of sulfur-containing solid waste

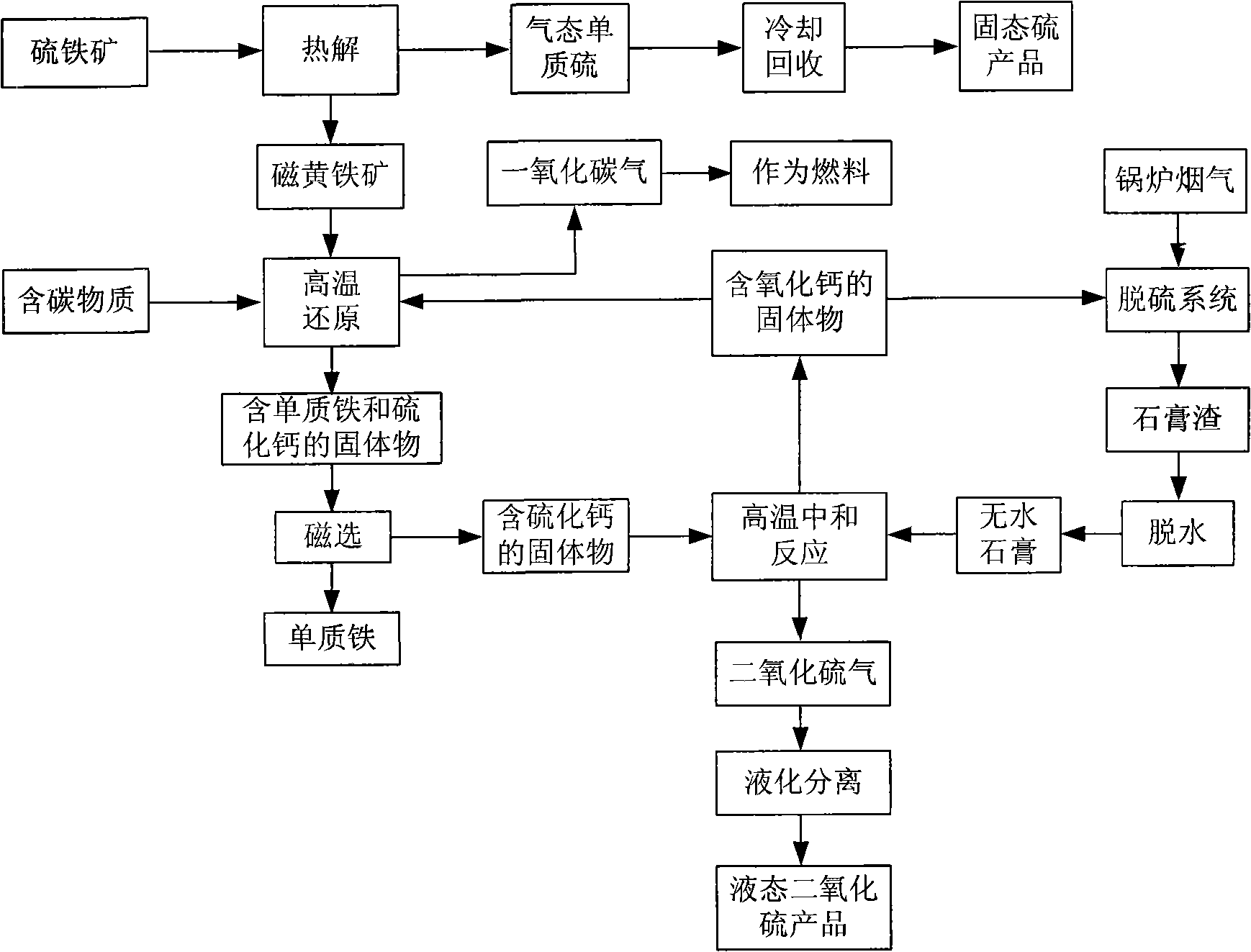

A solid waste and comprehensive resource technology, applied in the field of two types of sulfur-containing solid waste - pyrite and gypsum slag, can solve problems such as difficulty in ensuring the working conditions of fluidized fluidized furnaces, waste of pyrite iron resources, and secondary pollution. To achieve the effect of solving the problems of stacking land, environmental pollution and hidden safety hazards, facilitating the utilization of waste resources, and avoiding the destruction of the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The pyrite with a purity (mass percentage content of iron disulfide) of 70% is crushed to less than 4mm, and sent into a fluidized bed pyrolysis reactor with a temperature of 650°C, and the pyrolysis atmosphere is kept as a neutral atmosphere. For 20 minutes, the flue gas is cooled, and the solid sulfur formed by the condensation of sulfur vapor in the flue gas is collected to obtain elemental sulfur products.

[0044] Mix the solid pyrolysis product discharged from the fluidized bed pyrolysis reactor with anthracite and calcium oxide-containing solids. The molar ratio of ferrous sulfide, carbon, and calcium oxide in the mixture is 1:1:1, and the mixture is pulverized to 4mm or less, send it into a fluidized bed reduction reactor with a temperature of 900°C, keep the reaction atmosphere as a reducing atmosphere, and the reaction time is 30min, and recycle the flue gas containing carbon monoxide as fuel gas to provide heat source for other steps.

[0045] The solid matte...

Embodiment 2

[0048] Pulverize pyrite with a purity (mass percentage content of iron disulfide) of 90% to less than 2mm, and send it into a fluidized bed pyrolysis reactor with a temperature of 750°C, keep the pyrolysis atmosphere as a weakly reducing atmosphere, and stay The time is 10 minutes; the flue gas is cooled, and the solid sulfur formed by the condensation of sulfur vapor in the flue gas is collected to obtain elemental sulfur products.

[0049] The solid pyrolysis product discharged in the fluidized bed pyrolysis reactor is mixed with charcoal and calcium oxide-containing solids. The molar ratio of ferrous sulfide, carbon, and calcium oxide in the mixture is 1: 1.5: 1.5, and the mixture is pulverized to 3mm or less, send it into a fluidized bed reduction reactor with a temperature of 1150°C, keep the reaction atmosphere as a reducing atmosphere, and the reaction time is 20min; the flue gas containing carbon monoxide is recycled as fuel gas to provide heat source for other steps. ...

Embodiment 3

[0053] The pyrite with a purity (mass percentage content of iron disulfide) of 100% is crushed to less than 2mm, and sent into a fluidized bed pyrolysis reactor with a temperature of 850°C, and the pyrolysis atmosphere is kept as a neutral atmosphere. 2 minutes; the flue gas is cooled, and the solid sulfur formed by the condensation of sulfur vapor in the flue gas is collected to obtain elemental sulfur products.

[0054] Mix the solid pyrolysis product discharged from the fluidized bed pyrolysis reactor with coke and calcium oxide-containing solids. The molar ratio of ferrous sulfide to carbon and calcium oxide in the mixture is 1:2:2, and the mixture is pulverized to 2 mm or less, it is sent to a fluidized bed reduction reactor at a temperature of 1000 ° C, and the reaction atmosphere is kept as a reducing atmosphere, and the reaction time is 15 minutes; the flue gas containing carbon monoxide is recycled as fuel gas to provide heat sources for other steps.

[0055] The soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com