Patents

Literature

2124 results about "Textile technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textile Technology. Textile technology is the processing of a raw material – natural products such as wool and cotton, or synthetics like nylon and acrylics – into yarn, thread and fabric. It involves developing new colors, textures and properties such as water and fire resistance.

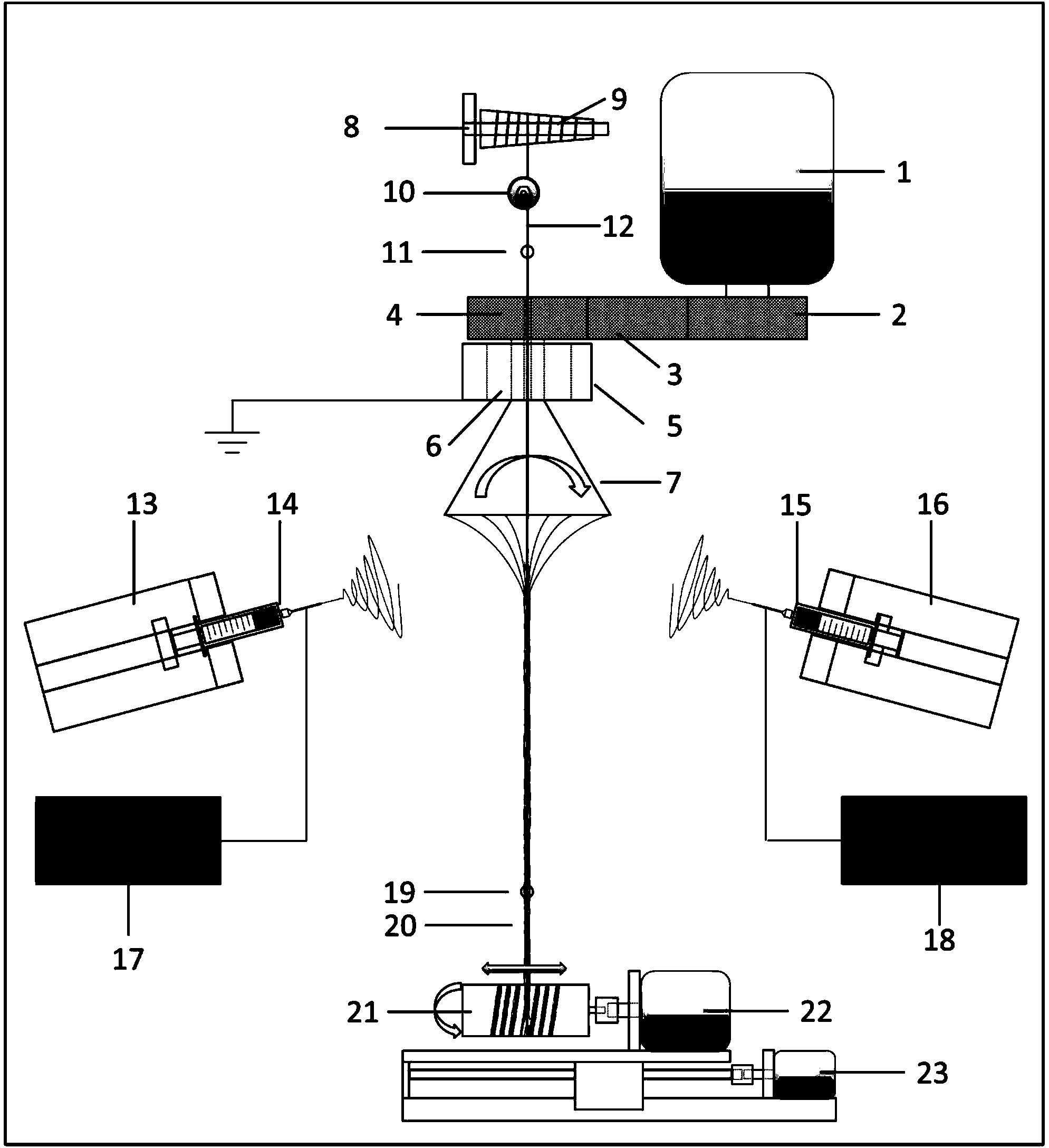

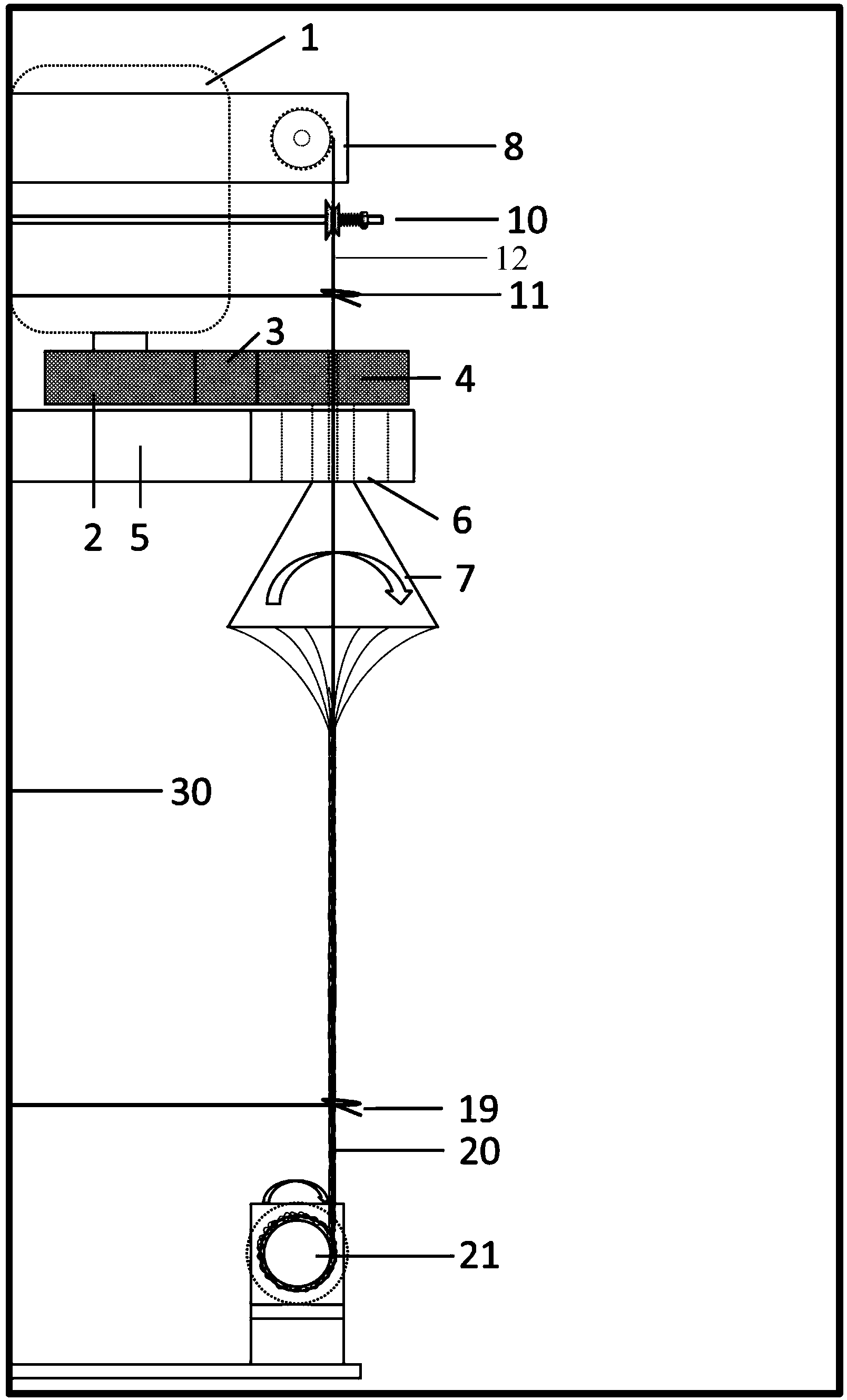

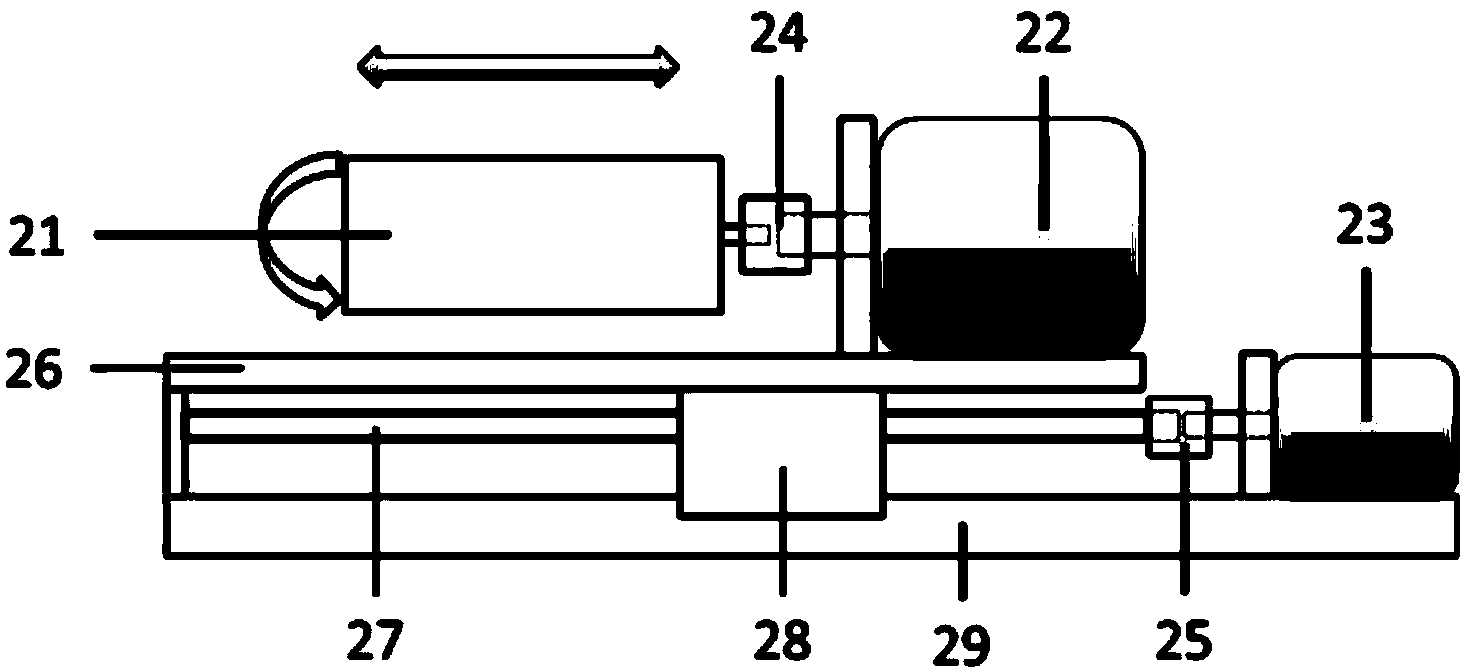

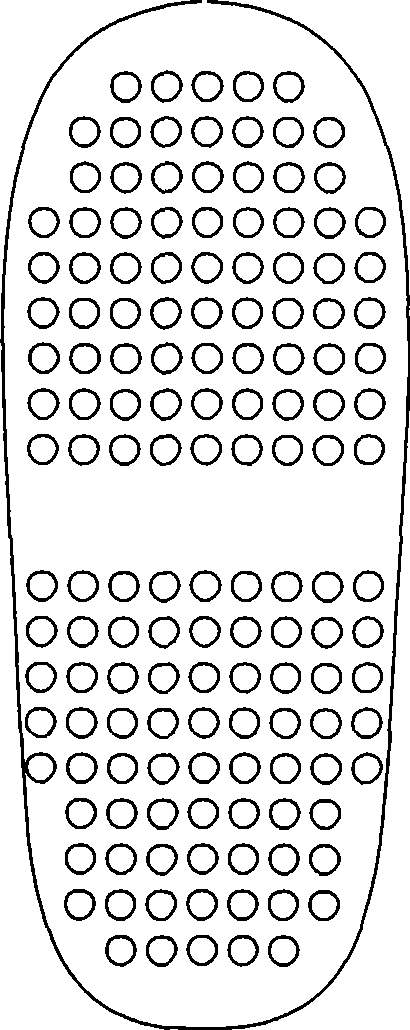

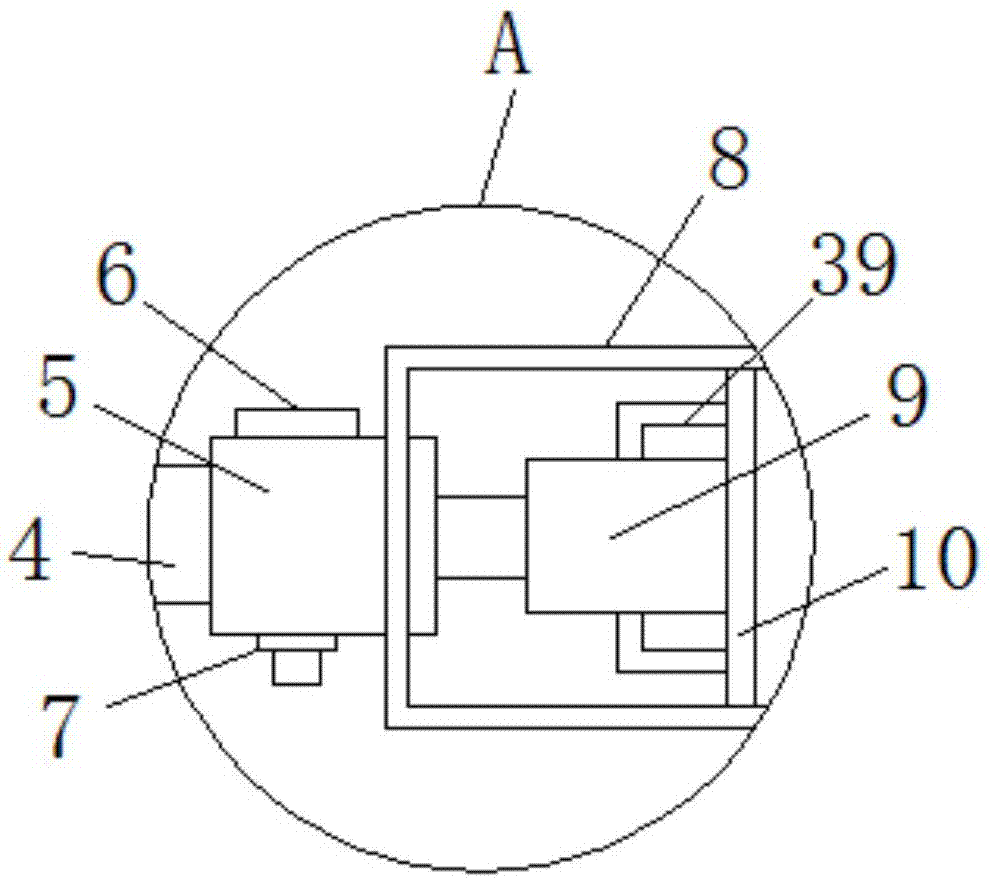

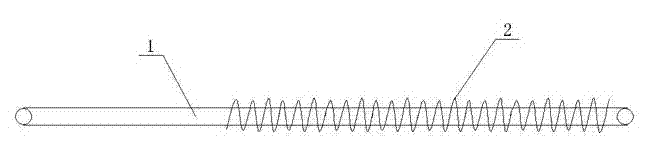

Nano-fiber covering yarn electrostatic spinning device and application thereof

ActiveCN104032423AArrangement structure controllableControllable twistWeft knittingWarp knittingTextile technologyFiber

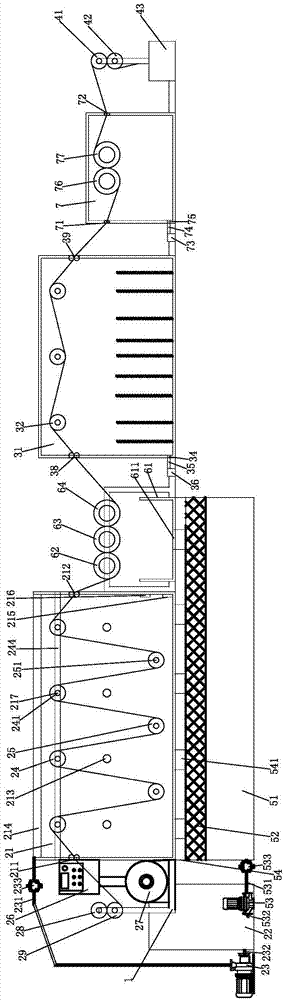

The invention relates to a nano-fiber covering yarn electrostatic spinning device and application thereof. The nano-fiber covering yarn electrostatic spinning device comprises a twisting device, a backing-off device, a winding device, a double-needle electrostatic spinning device and a control system. The invention also provides a method for preparing electrostatic spinning nano-fiber covering yarns. The method comprises the following steps of performing spinning by using prepared spinning liquor through the double-needle electrostatic spinning device; depositing nano-fibers on a metal funnel and core yarns; uniformly winding the nano-fibers on the core yarns moving at constant speed by rotating the metal funnel; and finally forming the nano-fiber covering yarns of which skin layers are nano-fibers. The invention also provides another method for preparing a nano-fiber fabric. The other method for preparing the nano-fiber fabrics comprises the following steps of using water soluble yarns as core yarns; preparing the nano-fiber covering yarns by using the method; preparing a covering yarn fabric by using a textile technology; and dissolving the core yarns to obtain the nano-fiber fabric. The maneuverability is high; the nano-fiber covering yarn electrostatic spinning device is novel in structure; and the nano-fibers on surfaces of the covering yarns are arranged controllably.

Owner:诺一迈尔(山东)医学科技有限公司

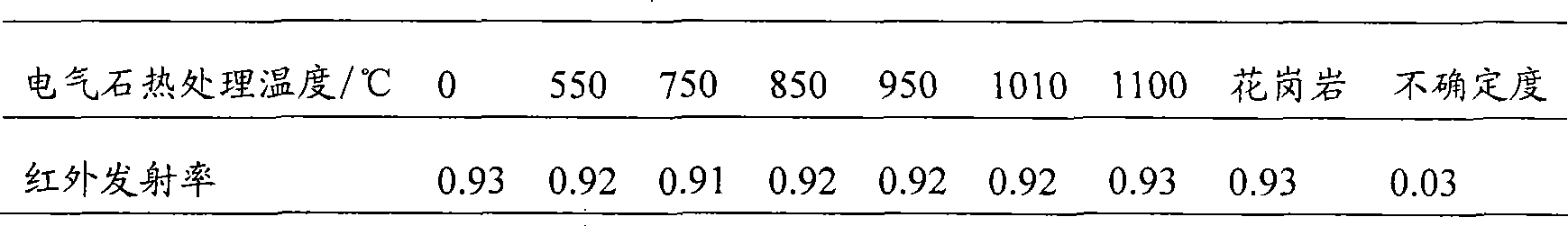

Textile finishing agent with thermal protecting, antibacterial and moisture-keeping functions, and health socks using the same

InactiveCN101476240AStay hydratedAvoid crackingFibre treatmentPanty-hoseTextile technologyHuman body

The invention provides a weaving finishing agent with the functions of emitting far infrared ray, generating air negative ion, resisting bacterium and retaining moisture, which has positive roles to human body health, belonging to the functional textile technology field. The invention further provides the socks applying the weaving finishing agent, which achieves the functions of warming, killing and resisting bacterium, retaining skin moisture, preventing skin seasoning check, promoting blood circulation, promoting metabolism and alleviating fatigue and ache.

Owner:SHENZHEN BAOLI VOGUE TECH

Method for preparing super-hydrophobic fabric through polyphenol modification

ActiveCN106087404AIncrease productivityGood soaping resistanceFibre treatmentTextile technologyIron(III) chloride

The invention discloses a method for preparing super-hydrophobic fabric through polyphenol modification, and belongs to the technical field of weaving. The method comprises dipping fabric successively in a ferric chloride solution and a polyphenol compound solution, so as to obtain fabric of which the surface is modified by a metal-polyphenol layer; then dipping the fabric of which the surface is modified by the metal-polyphenol layer into an ethanol-water mixed solution containing a low-surface-energy substance, reacting for 6-24 h, washing successively by deionized water and absolute ethyl alcohol, and drying the fabric at 40 DEG C in vacuum for 5-10 h, so as to obtain phenol-modified super-hydrophobic fabric. The super-hydrophobic fabric possesses extremely good soaping resistance and efficient endurable hydrophobicity, the static contact angle is still larger than 150 DEG after the fabric is washing for 20 times, the fabric variety is diversified, application is wide, and the preparation technology is simple, green, friendly to environment, low in cost and suitable for large-scale production.

Owner:DONGGUAN YIMAO FILTER MEDIA

Method for producing bidirectional elastic flock suede fabric

InactiveCN101381922AIncrease elasticityWith comfortWeft knittingHeating/cooling textile fabricsFiberTextile technology

The invention discloses a method for producing bidirectional elastic suede knitted fabric, which belongs to the technical field of textile. The method for producing bidirectional elastic suede knitted fabric is characterized by comprising the following sequential steps of selecting raw materials, weft-knitting to obtain grey cloth, cutting the grey cloth, setting white blank, opening fiber, drying-setting, performing first teasing, shearing velvet, dyeing, presetting, performing second teasing, shearing velvet, rubbing off nap and setting a finished product. The invention has the advantages that the method is simple and feasible in industrial production; the raw materials are easy to get and low in cost; and the product is good in quality.

Owner:JIAXING FUSHENGDA DYEING & FINISHING

Machining process of peach skin cotton fabric

InactiveCN102031657APlasticityImprove touch effectBiochemical fibre treatmentTextile treatment by spraying/projectingTextile technologyPulp and paper industry

The invention belongs to the field of textile technology, in particular to a machining process of a peach skin cotton fabric. The machining process of the peach skin cotton fabric provided by the invention comprises the processes of turning and sewing, singeing, cooling and stacking, bleaching again by a jig dyeing machine, drying in a loose mode, sizing, mercerizing by a straight roller, brushing by carbon elements, dyeing by air flow, treating by cellulase in an air flow machine, drying in a loose mode, padding softeners in a loose mode, beating by air flow in a softening machine, tentering, pre-shrinking, and sorting and finishing. In the invention, the pretreatment processes of cooling and stacking and the process of dyeing by air flow are used for achieving the optimal effect of uniform and transparent dyeing; the automatic on-line detection technology is used for tracking the quality and processes to enable the production processes to be controlled at the critical optimal point, and all drying processes are carried out in a loose mode to keep the optimal hand feeling effect; and the processes of brushing by carbon elements, dyeing by air flow, treating by cellulase, beating by air and the like are used for ensuring that the fabric has delicate and plump peach skin hand feeling, plastic elasticity and delicate and clear cloth cover.

Owner:HUAFANG

Piecedyed jet black fine-spun facing and preparation method thereof

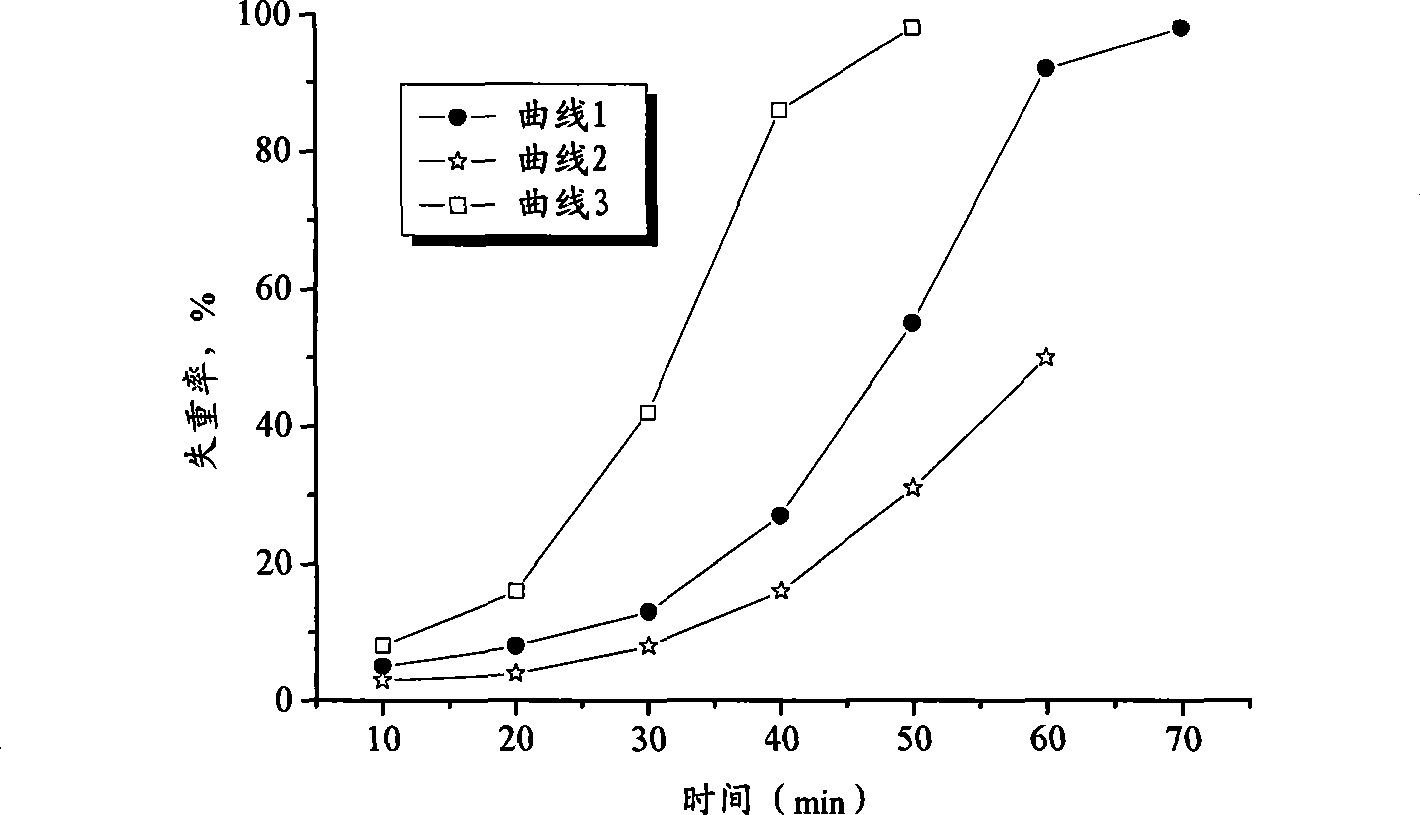

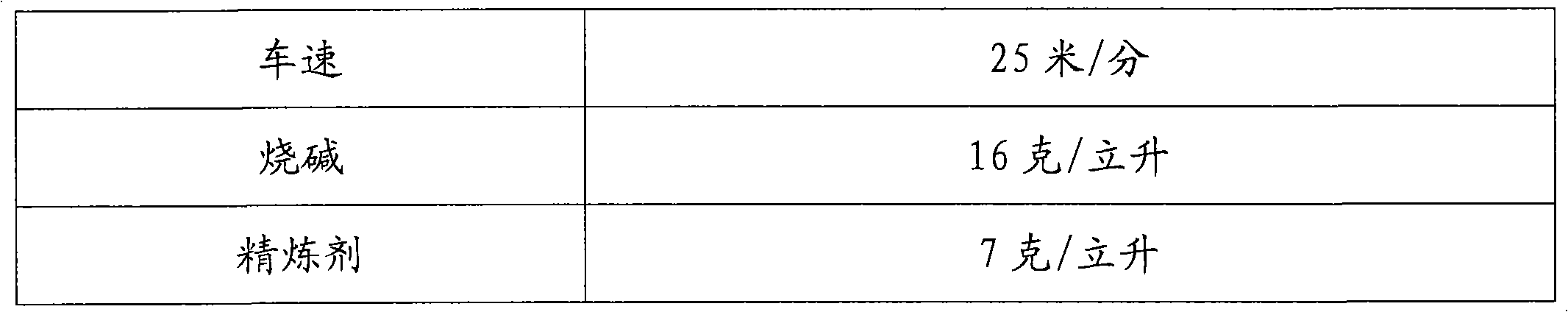

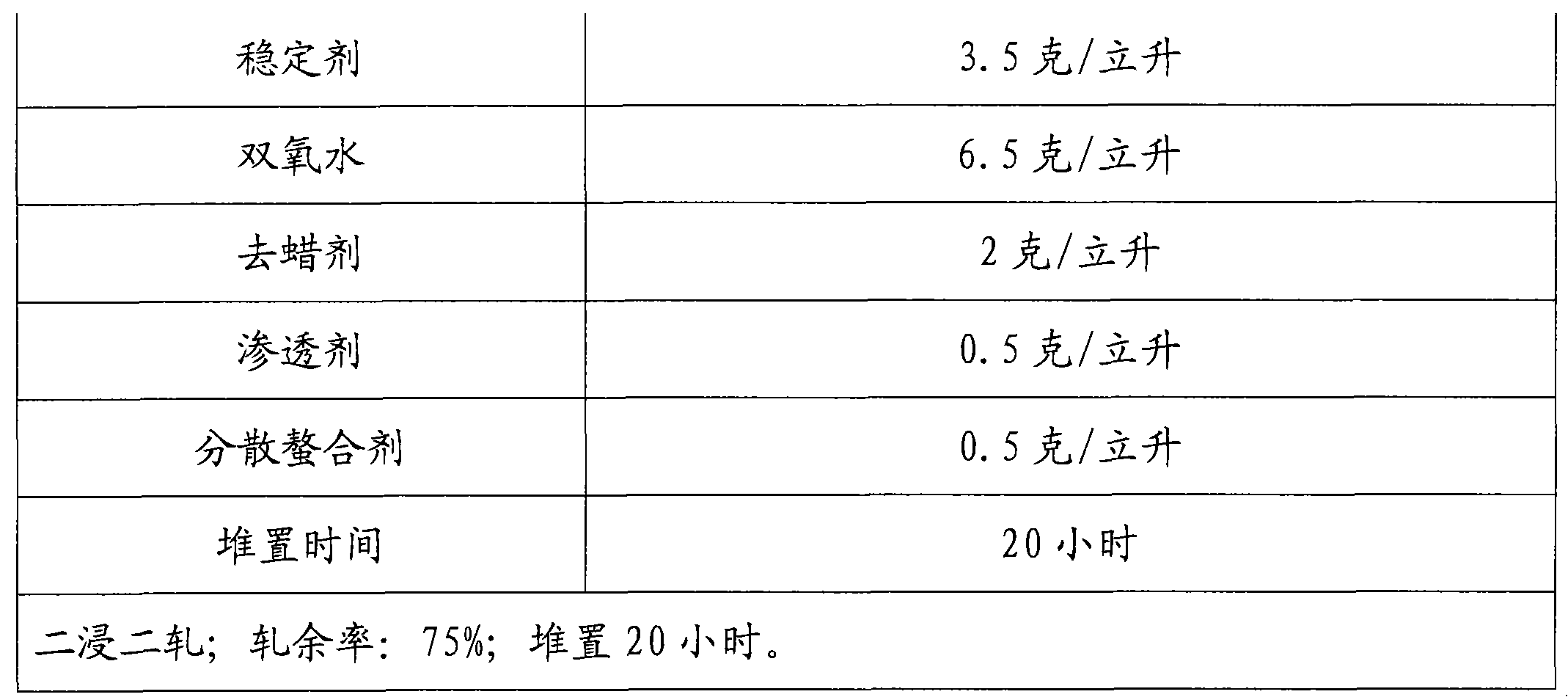

InactiveCN101671950AImprove hydrophilicityImprove dye uptakePhysical treatmentDyeing processTextile technologyNatural fiber

The invention discloses a piecedyed jet black fine-spun facing and a preparation method thereof, and relates to the technical field of wool spinning. Raw fiber used comprises natural wool fiber. The preparation method comprises steps of preparation, spinning, weaving, dyeing, finishing and the like. The method is characterized in that the raw fiber used further comprises wool natural fiber, and non-wool natural fiber or / and chemical fiber blended spinning material. The preparation method comprises a step of wool top chlorination treatment in the preparation step, or fabric chlorination treatment in the step of dyeing and finishing, further comprises steps of low-temperature plasma treatment in the steps of preparation, spinning or dyeing and finishing to generate obvious dyed color to enhance effect, so even jet black wool and blended-spun and fine-spun facing without dyeing defect can be obtained. Detection by a computer color photometer shows that blackness of the facing is deep, L value is up to 3.5-9.5, chromatic aberration between pieces is small, and delta E is equal to or less than 0.5. No expensive piece goods treating machine is needed, and the method has the advantages oflow cost, simple process and stable quality.

Owner:JIANGSU DANMAO TEXTILE

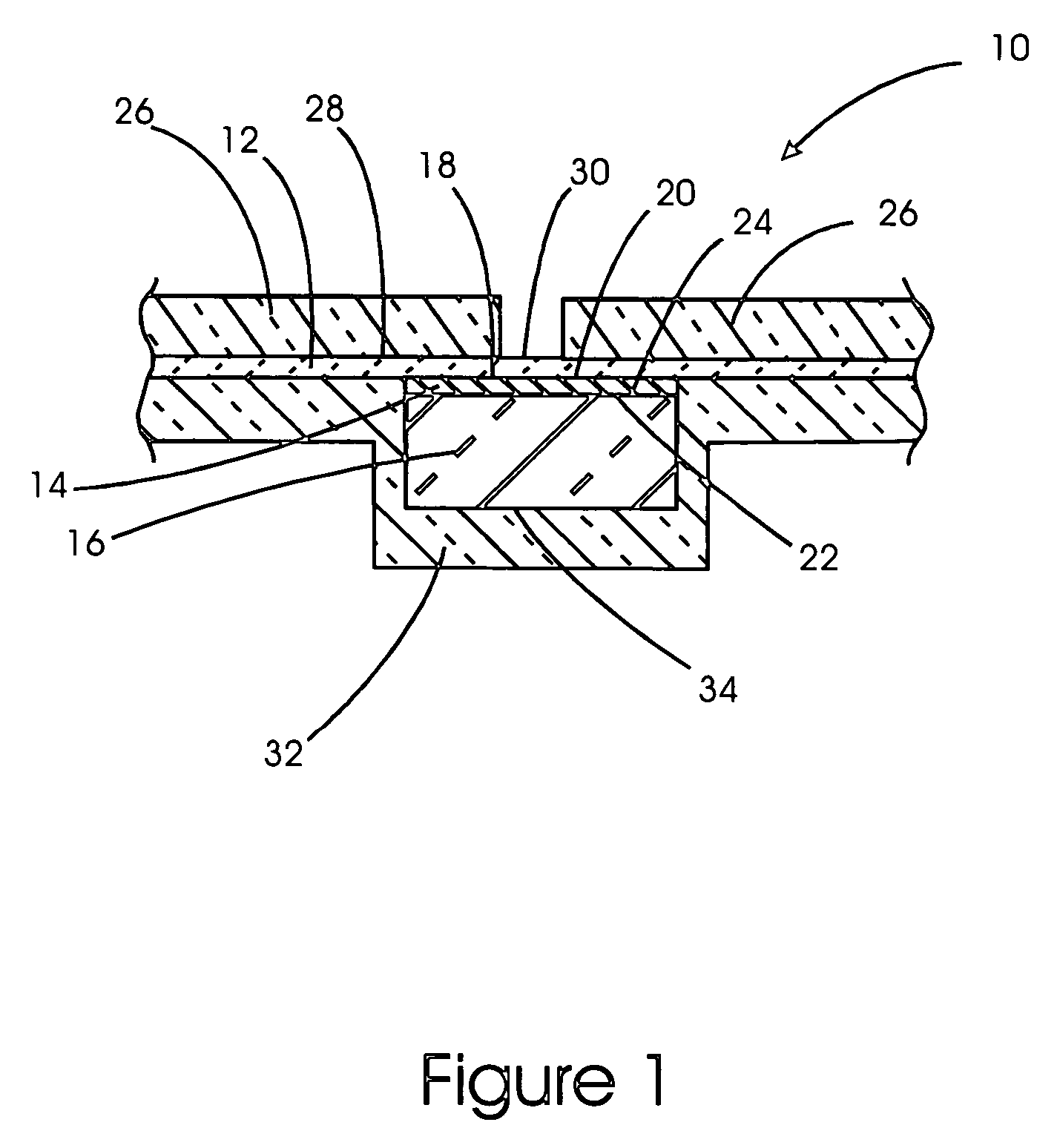

Method for preparing composite artificial blood vessel stent by combined electro-spinning with knitting technique

InactiveCN101264349AIncrease growth activityNot easy to embolismStentsSurgeryTextile technologyHuman body

The invention relates to a preparation method of compound artificial blood vessel support by electrostatic textile and weave technology, which can be described as follows: 6% to 10% (g / ml) polymer spinning solution is prepared; under the control of electrostatic spinning parameter, the prepared solution is used to make nano fiber with electrostatic textile technology; the nano fiber is collected by a roller collecting device to be the inner layer of a tubular support; the fiber materials are woven into tubular form by making use of the textile equipment to be the outer layer of the tubular support; the electrostatically textile inner layer and the woven outer layer are compounded together with the method of hot shaping or coating; with the adoption of biocompatible implant technology, human endothelial cells are implanted on the inner layer of the support and human smooth muscle cells are implanted on the outer layer of the support; after cell culture, the blood support is completed. The preparation method of compound artificial blood vessel support through electrostatic textile and weave technology has the advantages of simplification and time-saving effect, fine growth activity of the prepared artificial blood vessel after being implanted into human body; besides, the smooth muscle can grow along and into the fiber, and adaptability adjustment can be made to the blood vessel according to the condition of the host, leaving less liability for embolization.

Owner:DONGHUA UNIV

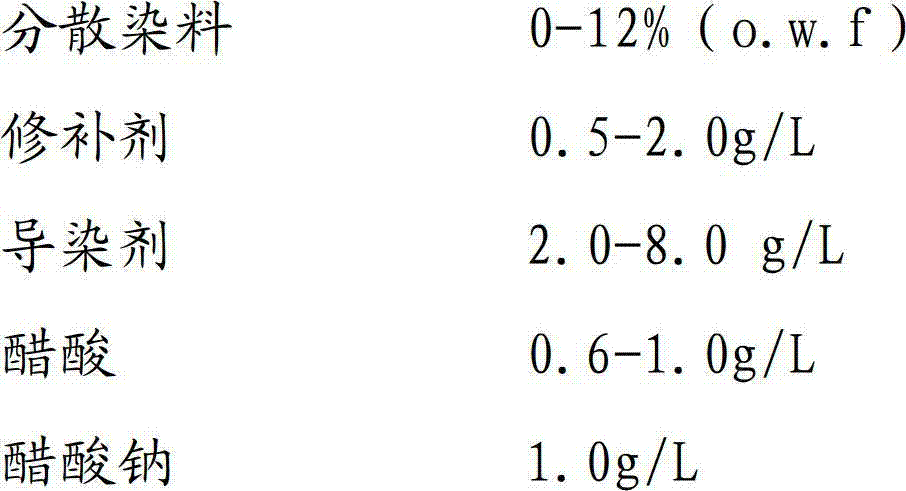

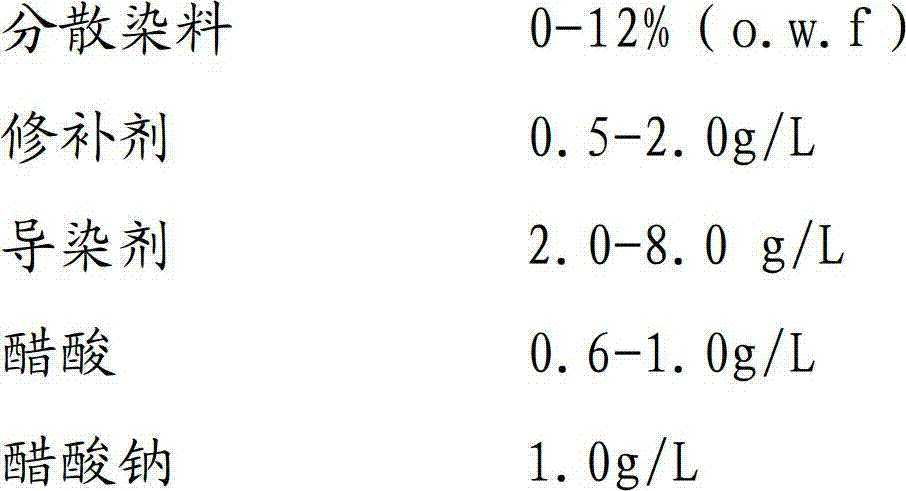

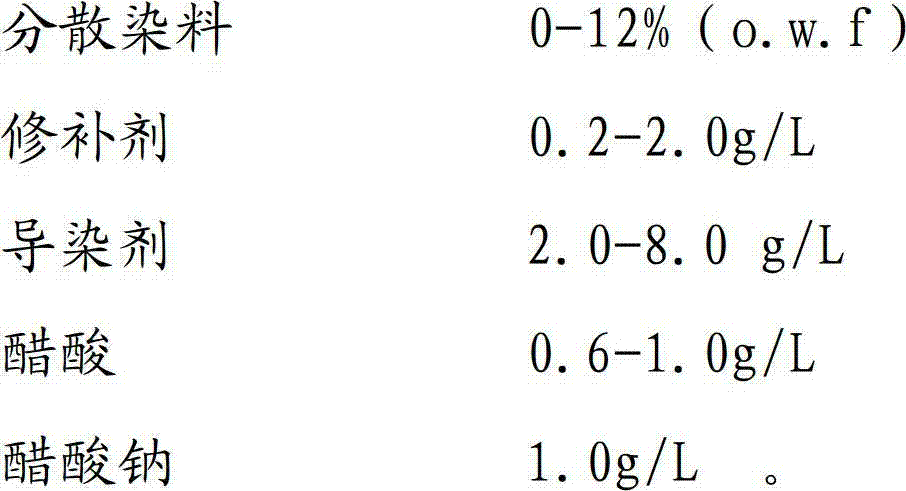

Method for dyeing cheese prepared from polyester-cotton blending stretch yarn

InactiveCN102733207ASolve the problem of shortage of dyed polyester-cotton blended elastic yarnAvoid VulnerabilityBiochemical fibre treatmentDyeing processTextile technologyDisperse dye

The invention belongs to the technical field of spinning and specifically relates to a method for dyeing cheese prepared from polyester-cotton blending stretch yarn. The method comprises the steps of loosen-type spooling, pretreatment, dyeing and washing, reduction clearing, after-treatment, dewatering and drying, and is characterized in that each loosen-type spooling bobbin is 0.6-1.2kg in weight and 0.28-0.42g / cm<3> in density; after a spooling step is completed; a dyeing working procedure is processed; in polyester dyeing process, low-temperature disperse dye is used and subjected to dyeing at 100-128 degrees centigrade for 15-60 minutes; then, the steps of reduction clearing, cotton dyeing, after-treatment, dewatering and drying are carried out. The method has the benefit that in the polyester dyeing process, the low-temperature disperse dye is used and subjected to dyeing at 100-128 degrees centigrade for 15-60 minutes; therefore, the dyed bobbin has the advantages of identical colors and elasticity in interior and exterior and high color one-time success rate, and avoids problems caused by a traditional dyeing method.

Owner:TIANJIN TIANGE TEXTILE

Multifunctional thermal underwear fabric and processing method thereof

InactiveCN102312342AFunction increaseGood warmth retentionWeft knittingFibre treatmentPolyesterTextile technology

The invention relates to a multifunctional thermal underwear fabric and a processing method thereof, belonging to the field of textile technology. The multifunctional thermal underwear fabric comprises a face weave and a bottom weave, wherein the face weave consists of cotton fibers, polyester fibers, spandex fibers, bamboo charcoal fibers, viscose fibers, wool fibers and plant protein fibers; and the bottom weave consists of polyester fibers. The content of the cotton fibers accounts for 34-60 percent of the total components, the content of the polyester fibers accounts for 26-39 percent of the total components, the content of the spandex fibers accounts for 5-6 percent of the total components, the content of the bamboo charcoal fibers accounts for 0.5-6 percent of the total components, the content of the viscose fibers accounts for 1-17 percent of the total components, the content of the wool fibers accounts for 1-5 percent of the total components, and the content of the plant protein fibers accounts for 0.5-7 percent of the total components. The multifunctional thermal underwear fabric has the advantages that the functions of the fabric are expanded by guaranteeing an excellent warmth keeping performance through the cotton fibers, by guaranteeing ideal elasticity through the spandex fibers, by reflecting a good moisture absorbing performance and air permeability through the polyester fibers and by reflecting a good antibiotic property through the bamboo charcoal fibers; and since function processing, baking and secondary ironing processes are increased, the fabric has an aromatic long-lasting effect.

Owner:CHANGSHU MENGXI FURNISHINGS

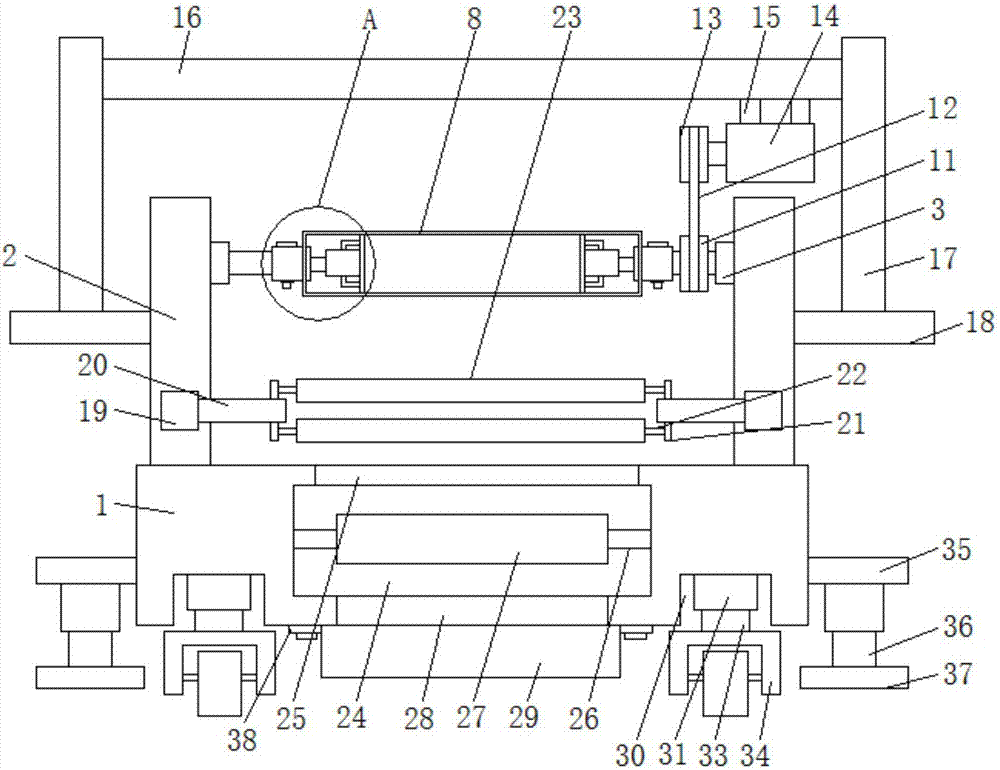

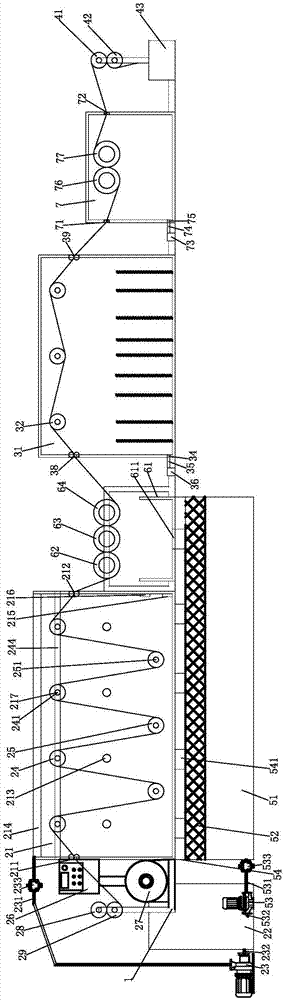

Cloth winding device capable of facilitating winding drum replacement and dust removal

InactiveCN107381168AEasy to change rollsEasy to remove dustCleaning using toolsCleaning using gasesEngineeringConductor Coil

Owner:梅明会

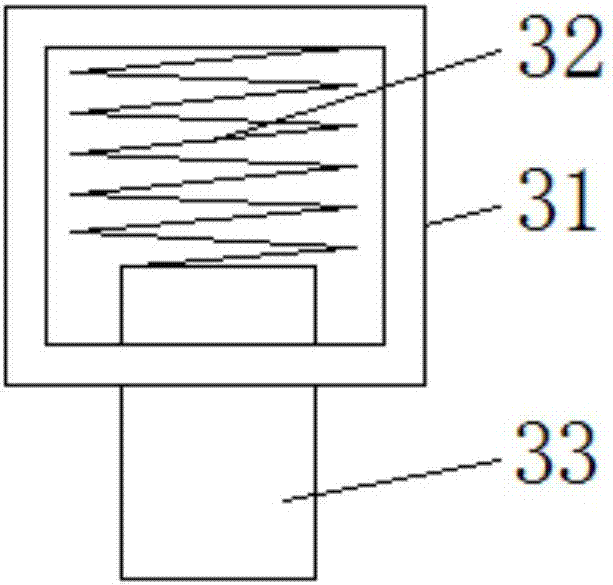

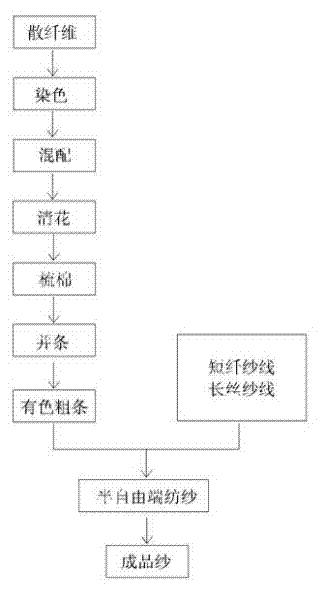

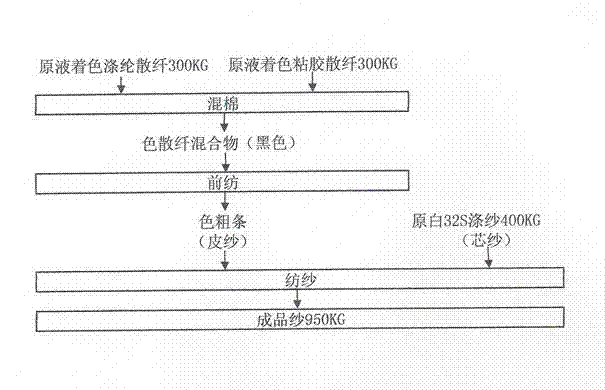

Manufacturing technology for yarn with cowboy style

ActiveCN102493067ASolve the shortcomings of single ingredientsSolve the shortcomings of too single colorYarnTextile technologyManufacturing technology

The invention discloses a manufacturing technology for yarn with a cowboy style, and belongs to the technical field of textile. The manufacturing technology is characterized by comprising the following steps: 1, preparing colored leather yarn, that is, taking various bulk fibers, coloring the bulk fibers, mixing the colored bulk fibers in a certain proportion, and manufacturing the colored leather yarn through a fore-spinning process; 2, selecting heart yarn which is one or more of staple yarn, filament yarn, twisted yarn and air textured yarn; and 3, spinning, that is, feeding the colored leather yarn and the heart yarn into semi-open-end spinning equipment, so as to obtain the yarn with the cowboy style. The yarn prepared by the invention has the advantages that the raw materials are abundant; the colors are various; and the energy consumption and the pollution are low.

Owner:绍兴国周针织科技有限公司

Terylene super fine denier double-faced short floss textile and production method thereof

InactiveCN101760896AAvoid churnSilkyWarp knittingHeating/cooling textile fabricsYarnTextile technology

The invention relates to the textile technology field, in particular to a terylene super fine denier double-faced short floss textile and a production method thereof; the terylene super fine denier double-faced short floss textile is characterized in that: polyester yarns or poly / nylon composite yarns with 0.42dtex and / or 0.58dtex or lower than the specification of the single-fiber fineness are adopted as felted yarn raw material, polyester FDY or polyester DTY with 55.5dtex-111dtex is used as bottom yarns; the invention further discloses a production method of the terylene super fine denier double-faced short floss textile. The terylene super fine denier double-faced short floss textile in the invention has the advantages that: 1) the textile has super smoothness, the single-fiber fineness reaches 0.42dtex and 0.58dtex, the advanced printing and dyeing process is adopted, so as to ensure the super smoothness, really achieve the purpose that the touch sense is more comfortable than the feeling of touching baby skins and have excellent fitting performance; 2) the textile has strong heat retention, the texture structure is compact and can reach 36 stitches per hour; 3) the textile has super long using cycle, the weaving structure is contact without depilation and balling-up, and the anti-tearing strength is high.

Owner:SHANGHAI WEILE TEXTILES CO LTD

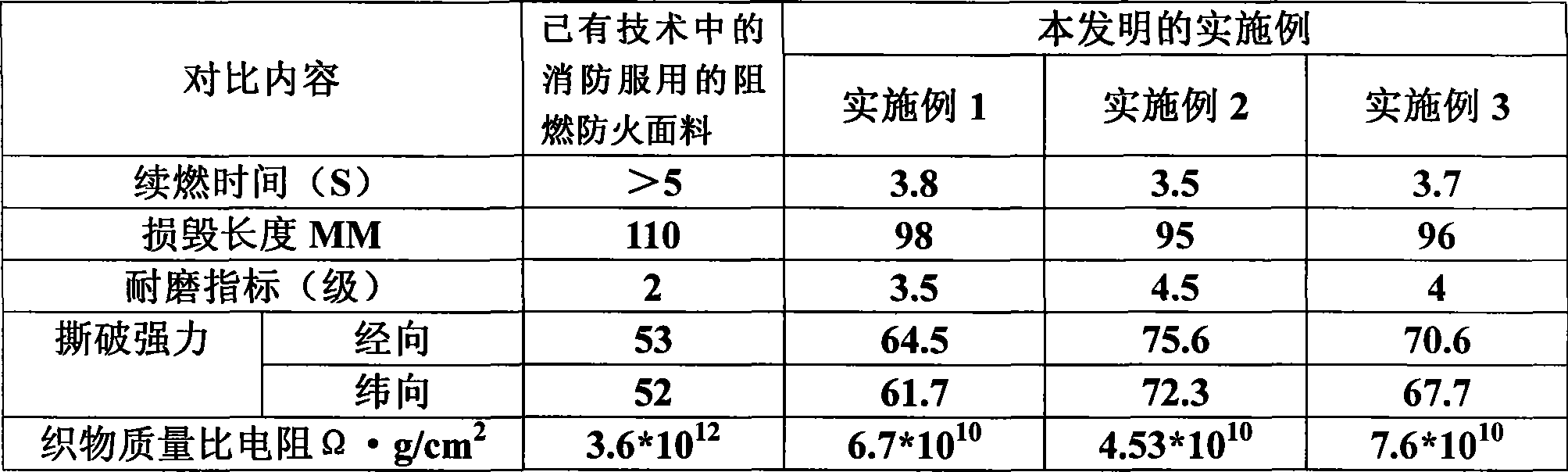

Flame-proof fireproof facing material

InactiveCN101368313AImprove flame retardant performanceShort afterburn timeWoven fabricsTextile technologyEngineering

Disclosed is fire-retardant fabric, belonging to textile technical field. The fire-retardant fabric is composed of warp tissue and weft tissue which are both made of meta-aramid aromatic polyamide fiber, para-aramid fiber and antistatic fiber. The fire-retardant fabric has the advantages of good fire retardant effect, short after-flame time, high wear resistance, high tear strength in both weft and warp and good quality-to-resistance ratio.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

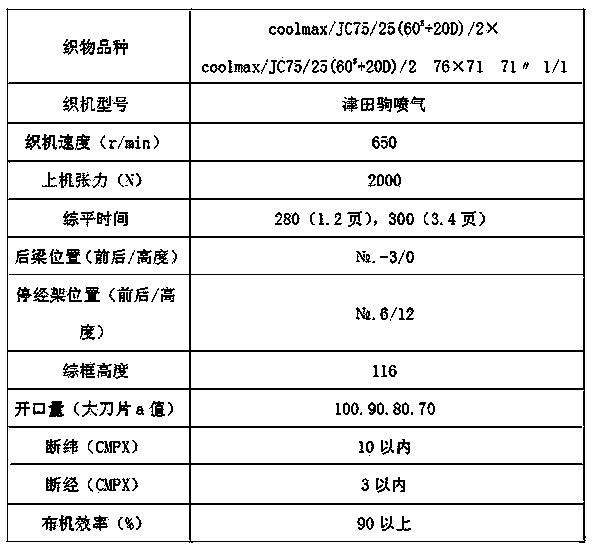

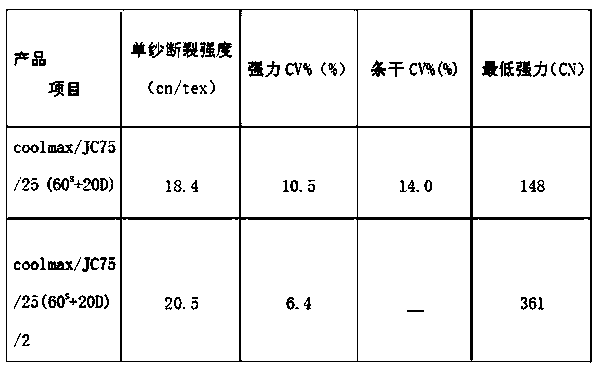

Moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric and production method thereof

The invention provides moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric and a production method of the moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric and belongs to the technical field of textile. 75% of coolmax moisture-absorbing and sweat-releasing modified polyester fibers and 25% of cotton fibers are used as coated fibers, and 20D common polyester filament yarn is composed of covering yarn. Cotton opening and picking, cotton carding and pre-drawing are performed on the coolmax moisture-absorbing and sweat-releasing modified polyester fibers, and primary drawing, secondary drawing, roving, spinning, single yarn winding, yarn twisting and plied yarn winding are performed on the cotton fibers undergoing cotton opening and picking, cotton carding and combing to generate coolmax / JC75 / 25(60S+20D) single yarn and coolmax / JC75 / 25(60S+20D) / 2 plied yarn; the moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric is produced through beaming, slashing, denting, weaving and weave repairing. By means of reasonable scotching and cotton carding processes, two-time drawing mixing and appropriate slashing and weaving processes, the fabric has good moisture-absorbing, sweat-releasing, washable and quick-drying effects and good boney feel.

Owner:JIHUA 3542 TEXTILE CO LTD

Preparation method of polyphenol modified nano-silver carrying antibacterial fabric

ActiveCN105839419ANot easy to loseGood soaping resistanceBiochemical fibre treatmentTextile technologyEnvironmental resistance

The invention discloses a preparation method of polyphenol modified nano-silver carrying antibacterial fabric and belongs to the technical field of textiles. According to the method, after being soaked in a polyphenol compound water solution for a reaction, fabric is air-dried to obtain fabric with the surface coated with a polyphenol compound, and then the fabric is soaked in a silver nitrate water solution for a reaction to obtain the polyphenol modified nano-silver carrying antibacterial fabric. According to the method, the polyphenol compound is used for modifying the fabric, nano-silver particles are generated on the surface of the fabric in an in-situ reduction mode through a redox reaction of polyphenol and silver ions, and meanwhile nano-silver can adhere to the surface of the fabric without loss under the coordination effect of the polyphenol compound on the nano-silver particles. The antibacterial fabric has good soaping resistance and efficient and lasting antibacterial properties, and is not prone to fall off; after 30 times of washing, the sterilizing rate can still reach 95-100%; the fabric is diversified in type, wide in application range, simple in preparation process, environmentally friendly, low in cost and suitable for large-scale production, and selected materials are cheap and easy to obtain.

Owner:DONGGUAN YIMAO FILTER MEDIA

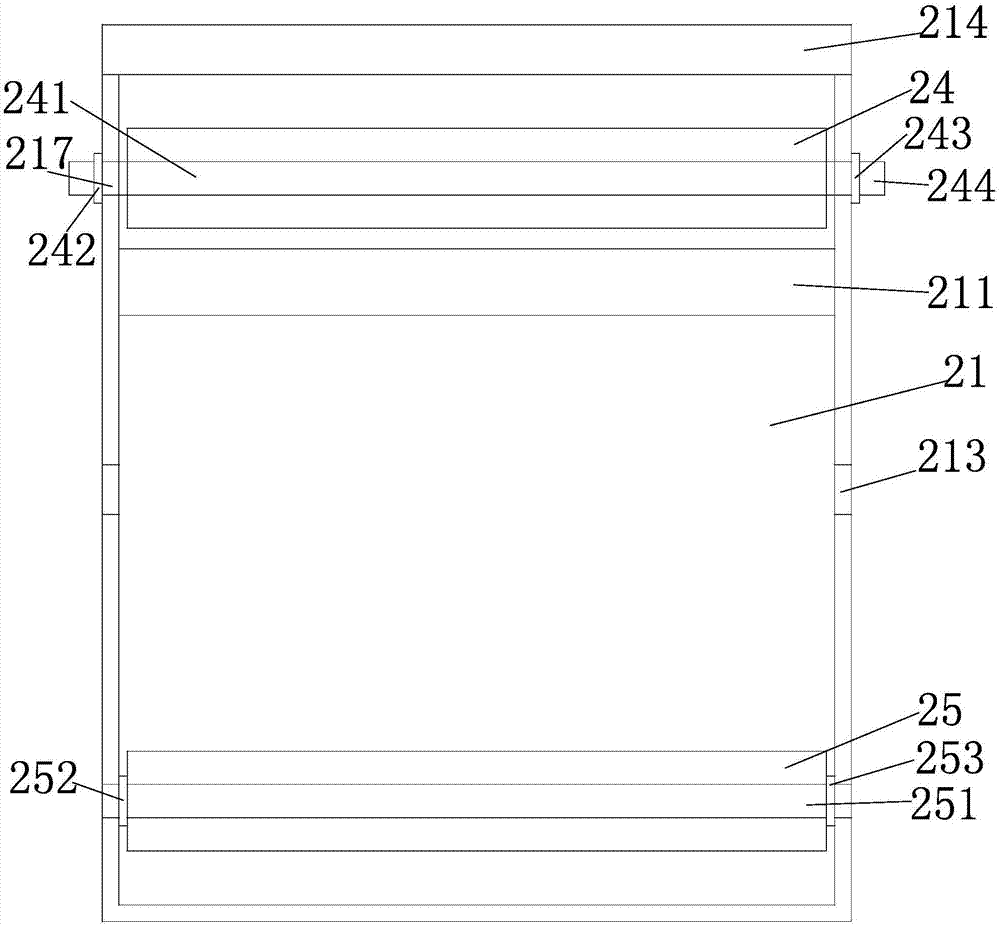

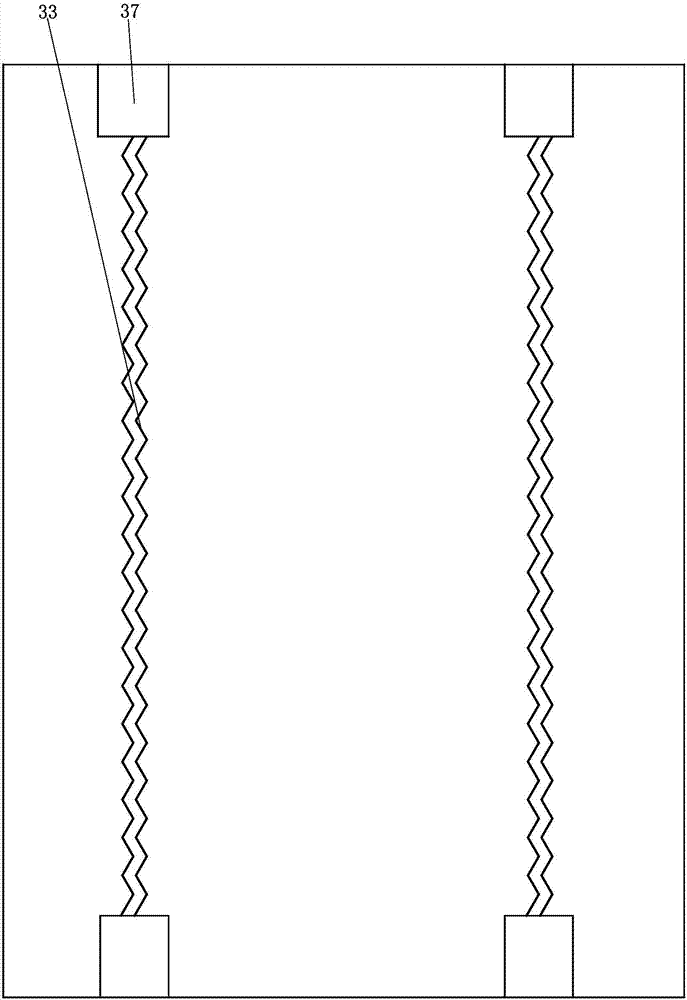

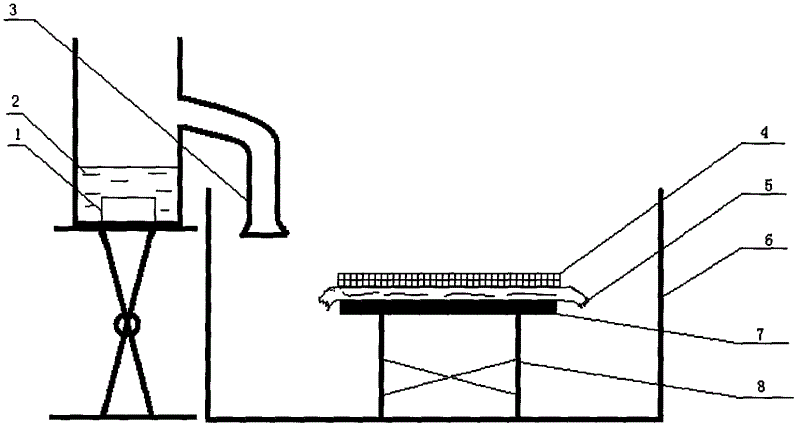

Washing and drying integrated machine for high-end fabric

InactiveCN107090682AWashing to achieveNo wasteSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersTextile technologyWater storage tank

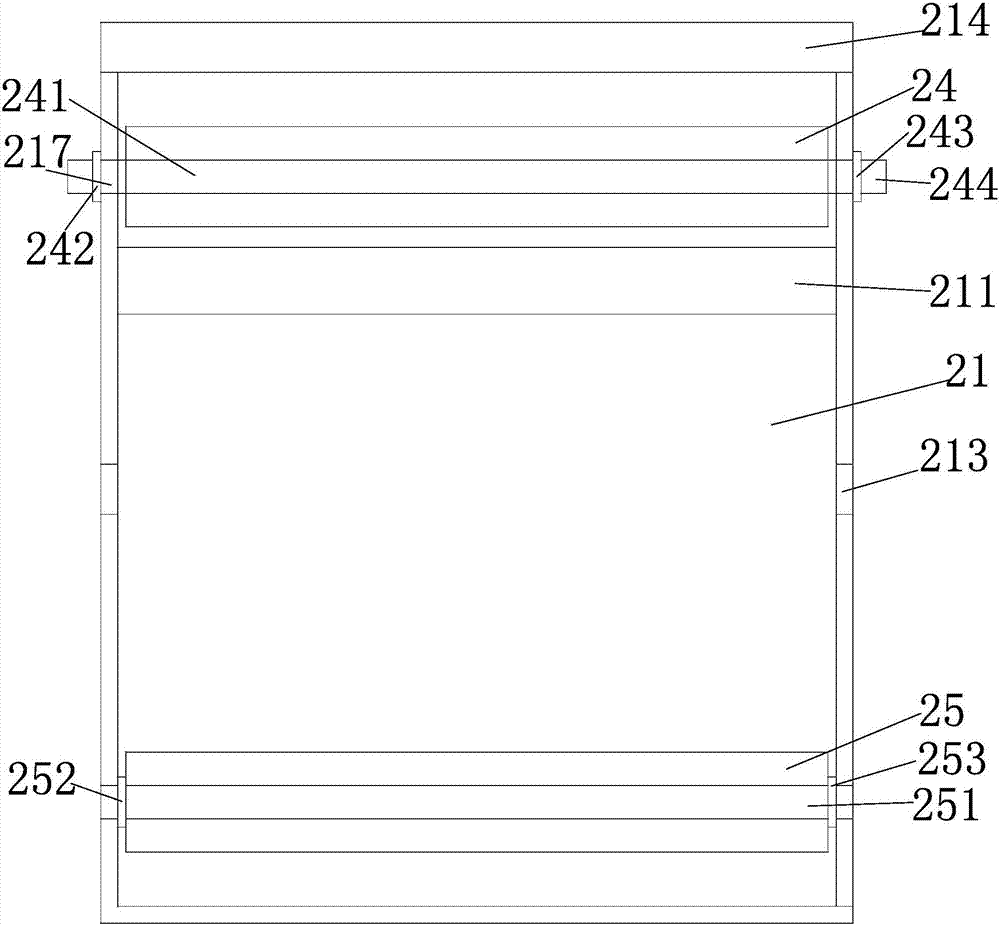

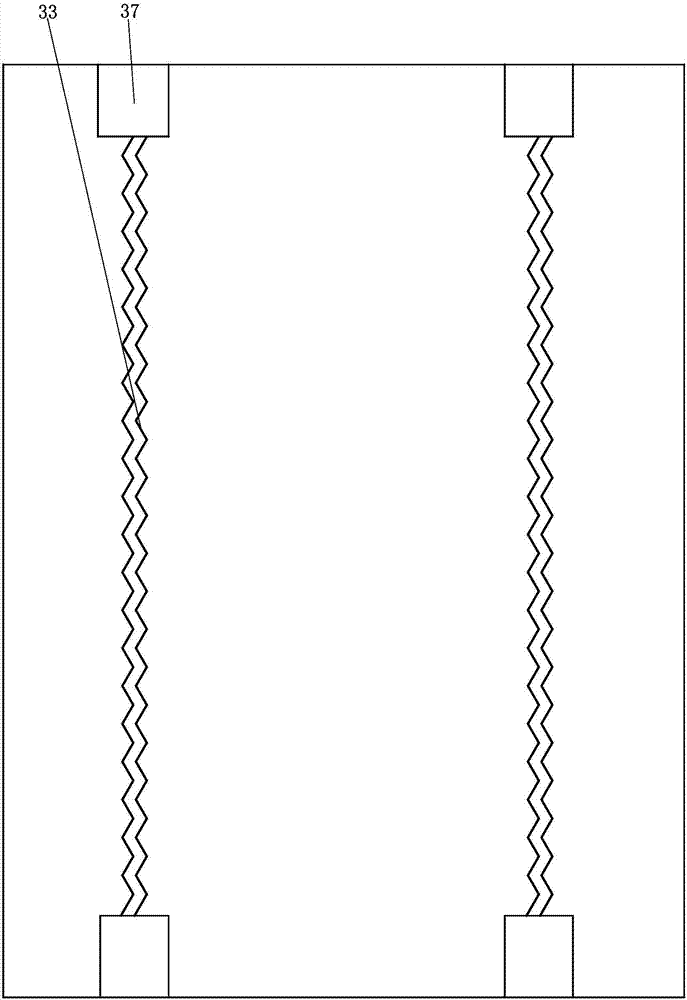

The invention provides a washing and drying integrated machine for high-end fabric, belongs to the technical field of textile and solves the technical problem that the washing and drying effect of an existing washing and drying integrated machine for high-end fabric is not high. The washing and drying integrated machine for the high-end fabric comprises a rack, wherein a washing device for washing the fabric, a drying device for drying the washed fabric, a fabric collecting device for collecting the dried fabric and a wastewater recycling device for recycling wastewater produced during fabric washing are arranged on the rack, the washing device, the drying device and the fabric collecting device are sequentially arranged along the rack, the washing device comprises a washing tank, a water storage tank and a water pump I, multiple upper drums and multiple lower drums are horizontally arranged in the washing tank, multiple overflow ports are formed in the middle of the washing tank, the upper drums are located above the overflow ports, the lower drums are located below the overflow ports, and a nozzle is arranged at the top of the washing tank. The washing and drying effect of the machine is good, and the water resource is saved.

Owner:HAINING MEILI KNITTING CO LTD

Process for producing polyether type easy dyeing spandex fiber

InactiveCN101096779AQuality impactImprove dyeing effectMonocomponent polyurethanes artificial filamentArtifical filament manufactureFiberTextile technology

The invention discloses a preparing method of a new spandex fibre with good dyeing behavior in weaving technique domain, which is characterized by the following: choosing polyurethane solution with polyurethanes or polyurethanes urea as main component; proceeding enlargered chain reaction; spinning; producing spandex fibre; possessing organic compound as enlarged chain agent in mixing amine enlarged chain agent solution. This invention possesses the advantages of high dying ratio, big colour stability and stable productive process.

Owner:YANTAI TAYHO ADVANCED MATERIALS

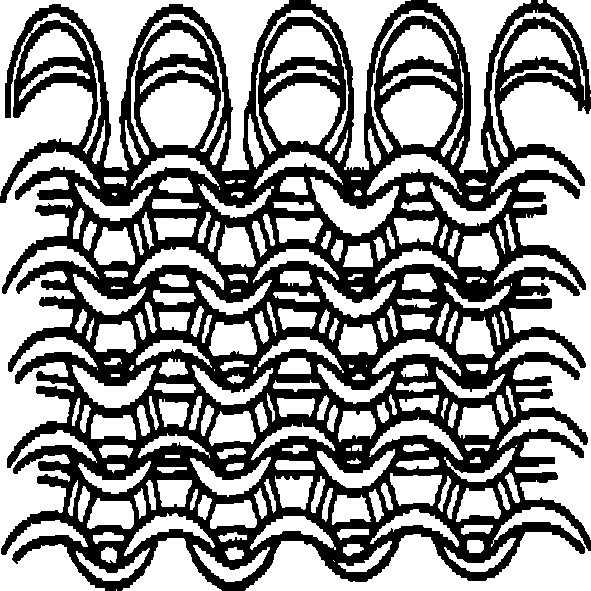

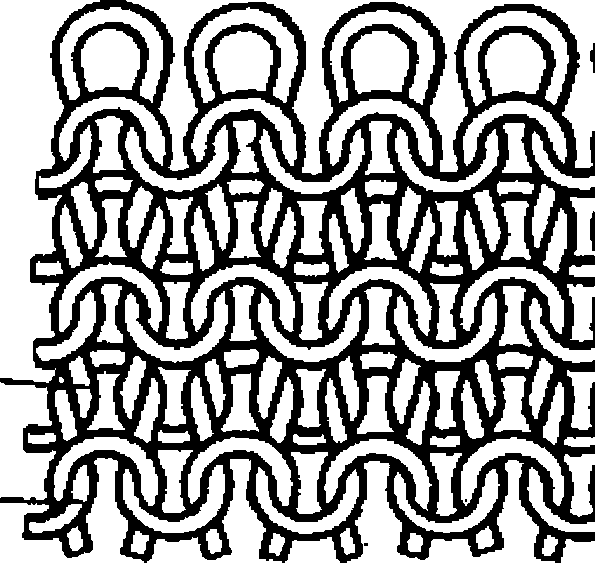

Method for manufacturing seamless knitted dress employing PTT fiber

InactiveCN101177831AGood elasticity and durabilitySoft touchWeft knittingWarp knittingTextile technologyExtensibility

The invention relates to a production method of seamless knitted garments adopting polytrimethylene terephthalate fibre, including the steps of (1) selecting raw materials according to product purposes, requirement of style and performance and characteristics of the raw materials; (2) establishing textile technology and weaving garment blank by a knitting machine; (3) according to colored woven garment and grey garment sorting and making a finishing process flow; (4) confirming key finishing process parameter. The finished PTT seamless knitted garments by adopting the invention have soft texture, good extensibility, good rebound elasticity, and are comfortable and beautiful; the elasticity in particular lasts long; compared with the existing products made of nylon and spandex, the product has incomparable advantage in chlorine fastness, sun fastness and high-temperature processing resistance, etc., which leads possible extended application of the seamless knitted garments to high grade swimwear, sportswear, high temperature printing, etc.

Owner:DONGHUA UNIV +1

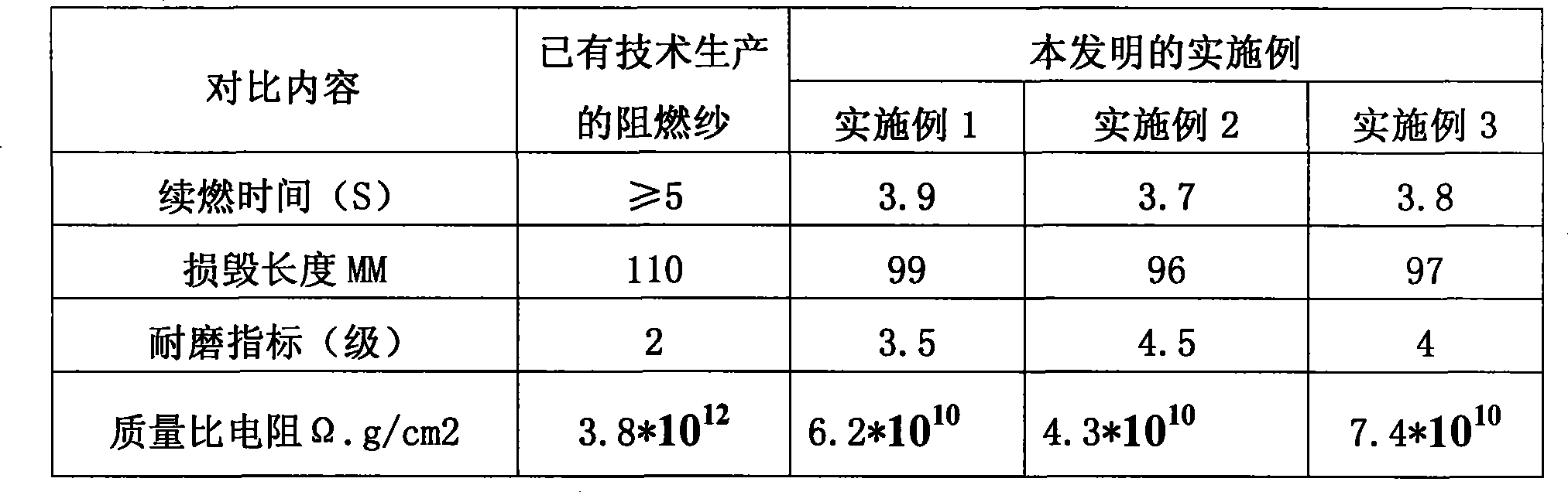

Flame-proof electrostatic resistance yarn and its processing method

InactiveCN101377027AShort afterburn timePermanent and non-fading flame retardancyFibre mixingYarnYarnElectrical resistance and conductance

The invention relates to retardant anti-static yarn and a processing method thereof, which belongs to the technical field of spinning. The yarn is composed of the following materials by the weight percentage: 70 percent to 95 percent of meta aramid fiber, 3 percent to 28 percent of para aramid fiber and 1.5 percent to 4 percent of anti-static fiber. The afterflame time of the retardant anti-static yarn obtained by the disclosed technical proposal is short (shorter than 4S), the damage length is less than 100mm, the wear resistance level is higher than or equal to 3.5, and the mass specific resistance is less than 7.4*10<10>; because of the meta aramid fiber, the para aramid fiber and the anti-static fiber, the retardant and anti-static effect are permanent and do not fade; the recommended process requirements are not harsh and can ensure the technical effect of the retardant anti-static yarn.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

High-grade fabric washing and drying integrated machine with waste water recovery device

InactiveCN107326580ASave waterWashing to achieveMechanical cleaningPressure cleaningTextile technologyWater resources

The invention provides a high-grade fabric washing and drying integrated machine with a waste water recovery device and belongs to the technical field of textiles. The problem that an existing high-grade fabric washing and drying integrated machine cannot fully utilize waste water is solved. The high-grade fabric washing and drying integrated machine with the waste water recovery device comprises a rack, wherein a washing device for washing fabrics, an extrude-drying device for extruding washed fabrics dry, a waste water recovery device for recovering waste water produced during fabric washing, a drying device for drying the washed fabrics and a fabric collecting device for collecting dried fabrics are arranged on the rack, the washing device, the extrude-drying device, the drying device and the fabric collecting device are sequentially arranged along the rack, the waste water recovery device is located below the washing device and the extrude-drying device. The high-grade fabric washing and drying integrated machine achieves the advantages of recycling waste water and improving the utilization rate of water resources.

Owner:HAINING MEILI KNITTING CO LTD

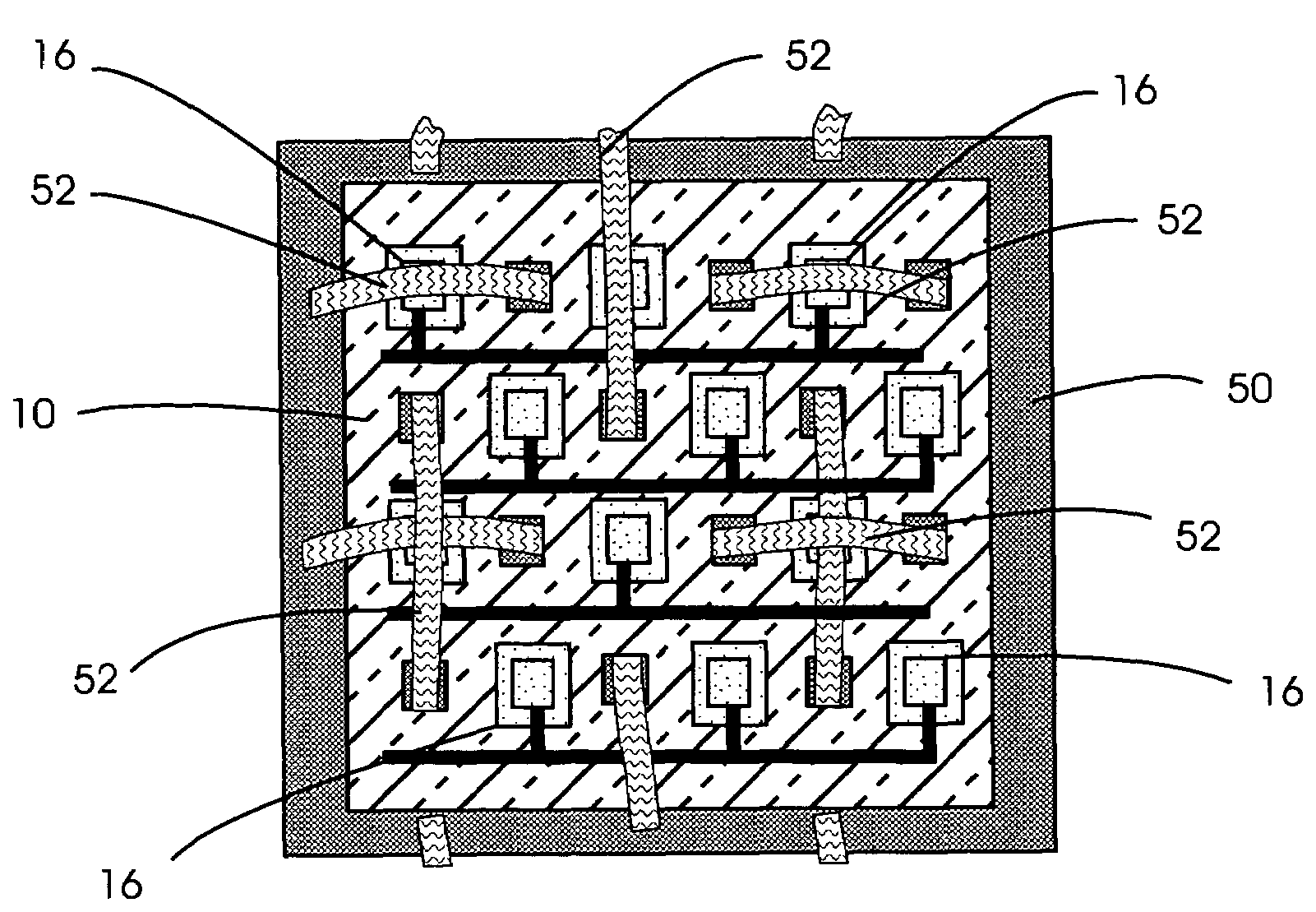

Intelligent textile technology based on flexible semiconductor skins

Owner:WAYNE STATE UNIV

Bamboo carbon fiber underwear fabric and manufacture method thereof

InactiveCN101532204AFully reflect the decomposition of odorFully reflect the functionWeft knittingYarnFiberTextile technology

The invention relates to a bamboo carbon fiber underwear fabric and a manufacture method thereof, belonging to the technical field of textiles. The bamboo carbon fiber underwear fabric consists of a lining layer and an external layer, and is characterized in that the lining layer consists of bamboo carbon fibers and cotton fibers according to the weight ratio of 15-30:70-85; the external layer consists of cotton fibers, Newdal fibers and polyurethane elastic fibers according to the weight ratio of 43-54:40-54:3-6. The manufacture method comprises that: the bamboo carbon fibers and the cotton fibers, the cotton fibers and the Newdal fibers are respectively spun into Sirospun blended yarns; the Sirospun blended yarns are interwoven with polyurethane elastic fibers to form a knitted underwear fabric; and the knitted underwear fabric forms a final finished product, namely the bamboo carbon fiber underwear fabric through dyeing, drying, sanding and shaping treatment. The fabric and the manufacture method have the advantages that the bamboo carbon fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, and has functions of good odor decomposition, smell elimination and the like.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

Fabric used for making warm underclothes

InactiveCN101002633AExcellent Texture and HygroscopicitySoft-touch texture and hygroscopicityHeating/cooling textile fabricsCircular knitting machinesPolyesterYarn

A fabric for heat-insulating underwear is composed of the surface structure made of polyester fibers and substrate made of polyurethane cored cotton yarn. Its productive method includes such steps as weaving by dual-surface loom, pre-treating, and dyeing, finishing, post-treating, scotching, pre-fixating shape, napping, combining, shearing, ironing, swinging, and fixating shape.

Owner:常熟市东方染整有限公司

Production method for pure cotton single direction wet guiding functional nonwovens

InactiveCN102619083AHandling method is convenientImprove siphon effectVegetal fibresTextile technologySiphon

The invention relates to a production method for pure cotton single direction wet guiding functional nonwovens, which belongs to the technical field of textile. The production is a treatment method which is free of pollution, convenient and fast and comprises placing the pure cotton nonwovens in an atomization microbead environment with the water repellent effect, enabling atomization microbeads to slowly permeate from one sides of the nonwovens to the other sides of the nonwovens to obtain the single face water repellent effect of the pure cotton nonwovens to enable water repellent components in the pure cotton nonwovens to be distributed in graded mode, forming the good siphon effect, and producing the single direction wet guiding function. The method can effectively solve the problem that during the water repellent treatment process of the pure cotton nonwovens, due to the fact that the pure cotton nonwovens are thin, a water repellency finishing agent easily permeates to the other sides of the nonwovens, enables the both sides of the nonwovens to have the water repellent effect, and the single face water repellent function of the nonwovens. The prepared pure cotton nonwovens has the ideal single direction wet guiding function and are suitable for being used in medical and health products.

Owner:WUHAN TEXTILE UNIV

Multe-component hemp blended spinning products and textile technology thereof

InactiveCN1483873AAnti-mold and antibacterialMoisture-absorbing and breathableWoven fabricsYarnFiberPolyester

The present invention relates to a multicomposition hemp blended spinning products and its technology. It is made from four fibres of hemp, yak cashmere, polyester fiber and modal as raw material, and its linear density is 9.7-200 tex, and its total compactness is 30%-99.5%. Its spinning technology includes the following steps: hemp and yak cashmere, dressing (A1860), pre-drawing (A272F) model and polyester fibre, dressing (FA201A), pre-drawing (FA304) mixed drawing first pass, mixed drawing second pass, roving (FA401), spinning (P7501), coning, warping, sizing, weaving and fabric finishing.

Owner:山西绿洲纺织有限责任公司

Preparation method and application of ceiba fiber in spinning and weave field

InactiveCN1990946AMake up for the light weightMake up yifeihuaFibre treatmentLiquid/gas/vapor textile treatmentTextile technologyFiber

The invention relates to an assistant agent, ceiba fiber treated by the assistant agent, the treating method, the manufacturing method and application of the ceiba fiber in spinning and textile, belonging to spinning technology area. Said assistant agent comprises 30-55 parts of acrylate, 30-50 parts of amylum, 15-25 parts of polyvinyl alcohol, and 150-600 parts of water. The former treating method of said ceiba fiber is that every components of said assistant agent are mixed to form mixed solution of assistant agent; the mixed solution is heated to 60-80DEG C; ceiba fiber with 30-35 times weight of the mixed solution is added and mixed evenly; the ceiba fiber is treated in self-formation for 10-20 minutes by the water steam with 80DEG C in mixing material room so that the mixed solution of assistant agent sprays on the surface of ceiba fiber in uniformity and it is dried; the former treatment is finished. After said treatment burr is formed on the surface of ceiba fiber and cohesive force can be enhanced greatly. The ceiba fiber not only can be spun with other fiber together but also spun by itself.

Owner:戴建荣 +1

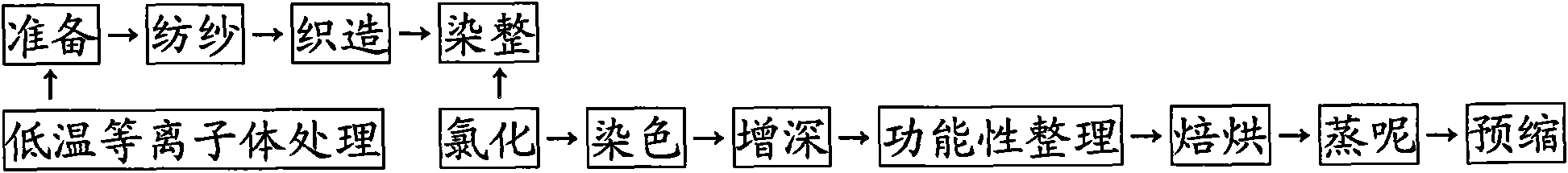

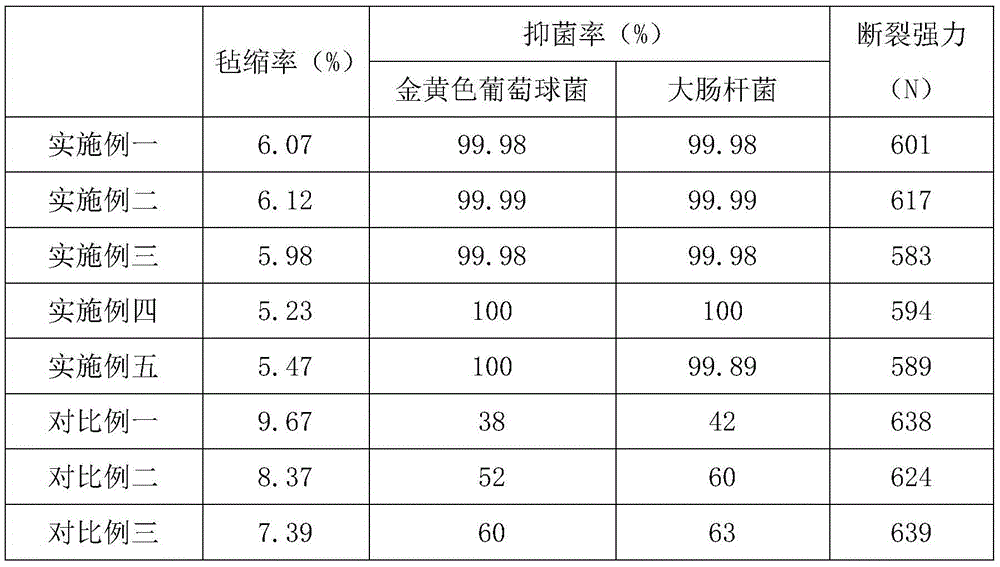

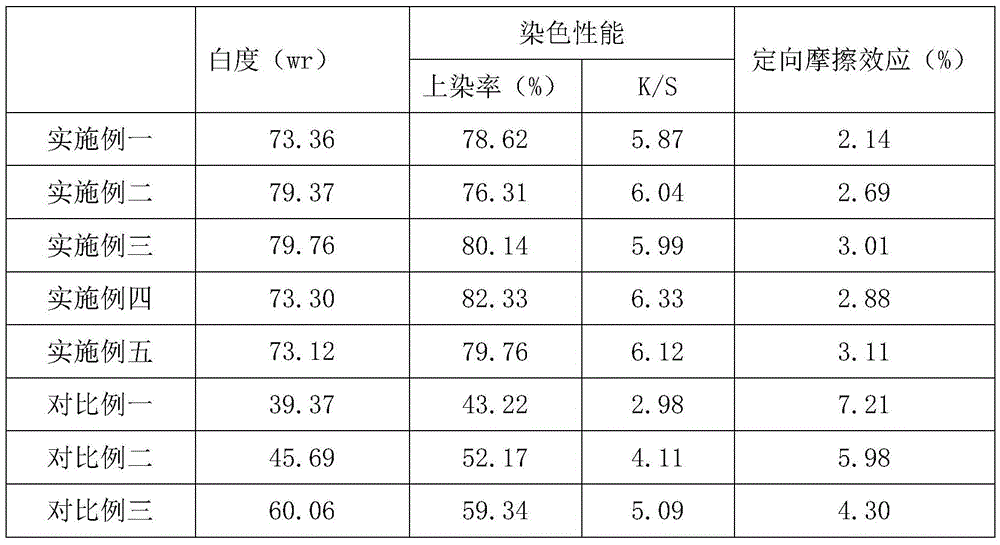

Antibacterial and anti-felting wool fabric finishing method

InactiveCN105544198AImprove antibacterial propertiesPrevent intrusionBiochemical treatment with enzymes/microorganismsShrinking resistant fibresTextile technologyFriction effect

Owner:海阳英伦纺织有限公司

Moisturizing skin care warm-keeping knitted fabric and production technology thereof

ActiveCN104047102AHas skin care and moisturizing functionWith warm functionSucessive textile treatmentsWeft knittingTextile technologyPolymer science

The invention relates to the textile technical field, in particular to moisturizing skin care warm-keeping knitted fabric and a production technology thereof. The production technology comprises the following processing steps of a, spinning, b, weaving and c, dyeing and finishing. In the step of spinning, acrylic fibers including arginine and common viscose fibers are spun into siro spinning blended yarns, the proportion of the acrylic fibers in the blended yarns is 50%-80%, the proportion of the viscose is 50%-20%, the yarn count of the yarns is 40-80 S / 1, and the twist coefficient of the yarns is 330-370. In the step of weaving, the siro spinning blended yarns and spandex are interwoven, the linear density of the spandex is 15-40 D, a weft knitting circular weft knitting machine is used for weaving knitted gray cloth, and the tissue is plaiting tissue. In the step of dyeing and finishing, the following processes of pre-shaping, dyeing, soaping, cloth drying, cloth bottom sanding and shaping are included. The produced fabric has the skin care moisturizing function, the moisturizing skin care function cannot be weakened along with repeated washing, and the fabric has the warm-keeping function and is suitable for being worn in autumn and winter in which the air humidity is low.

Owner:GUANGDONG SMART TEAM TEXTILES TECH

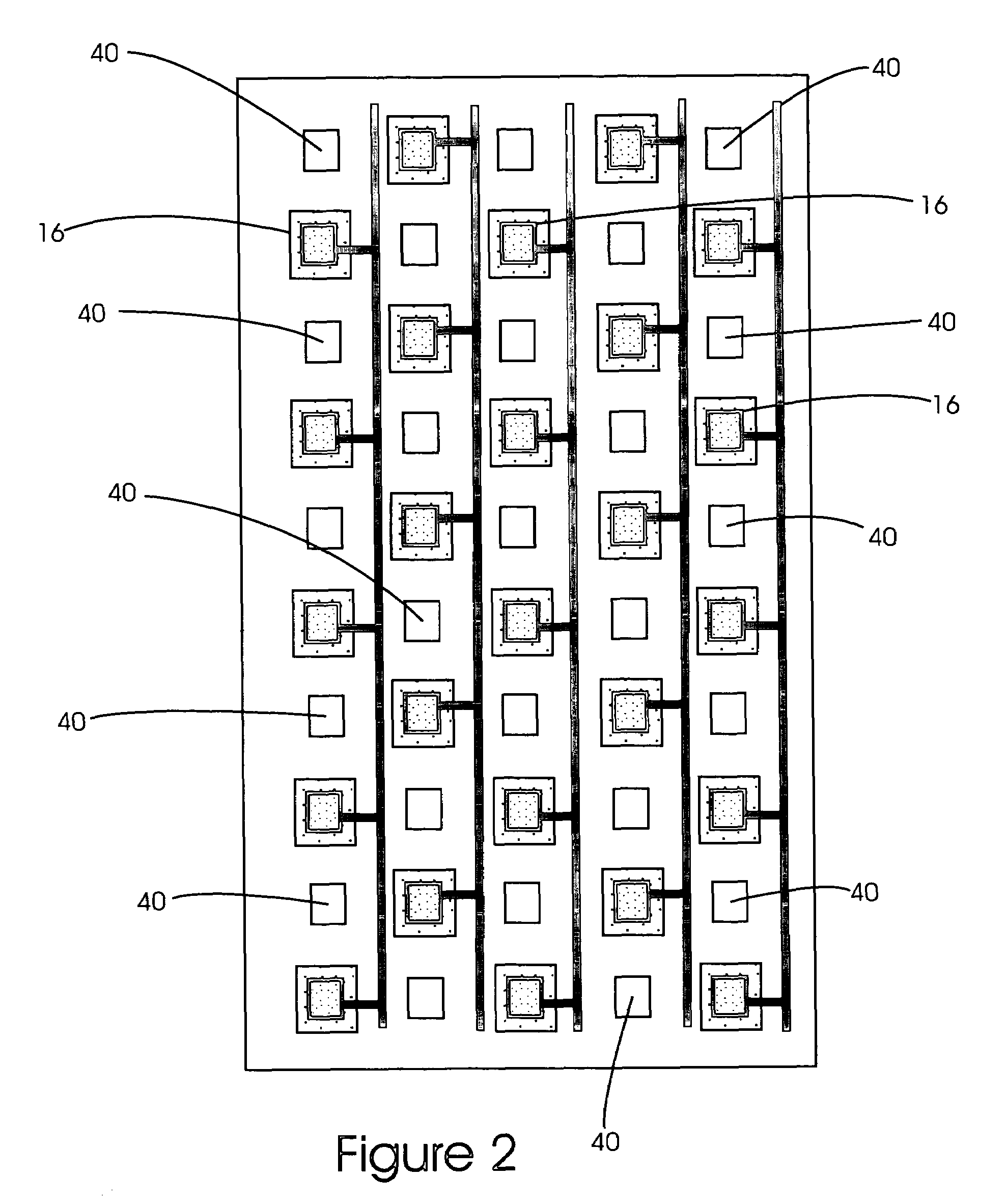

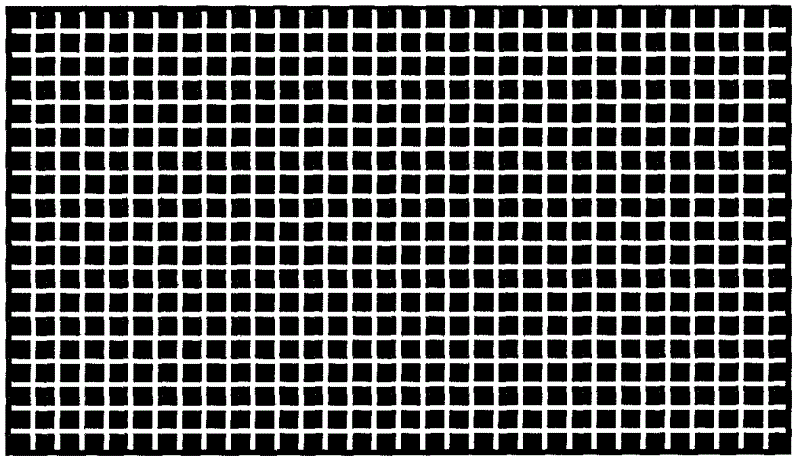

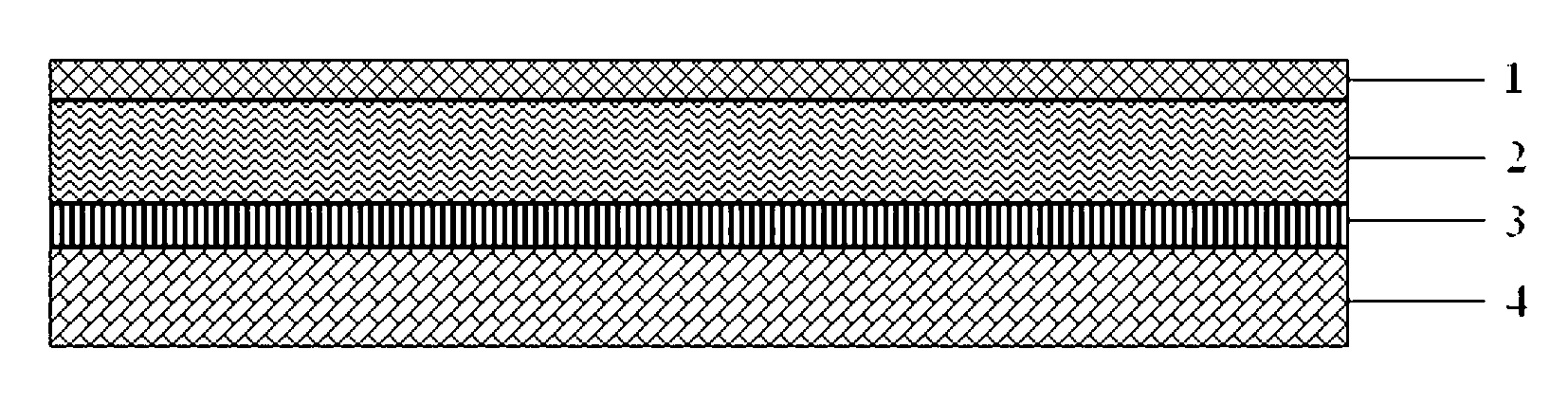

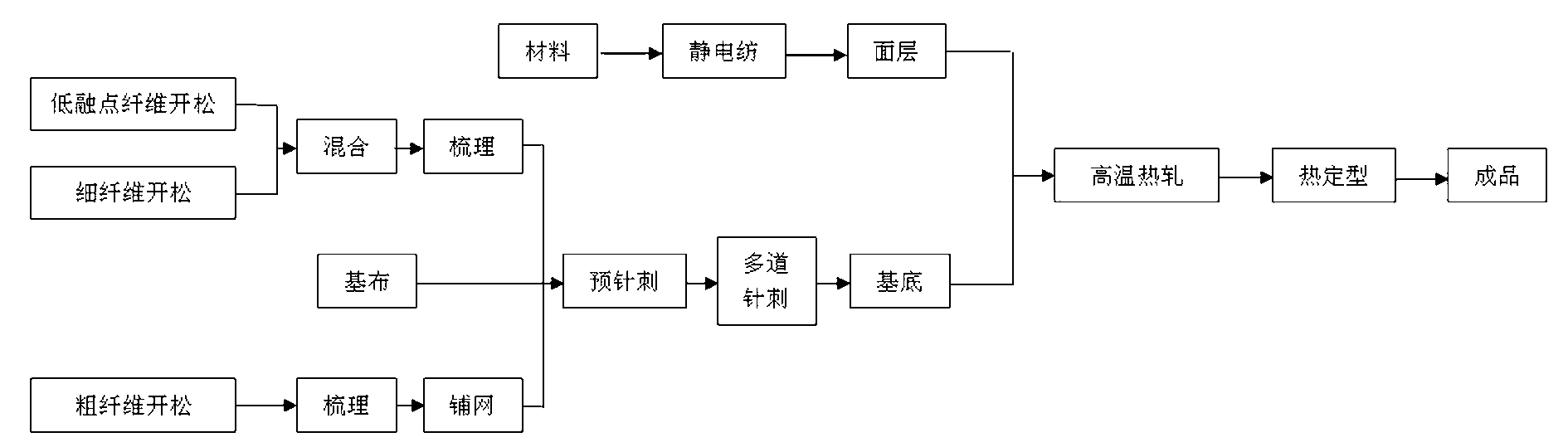

Fabrication method of needling/spunlace and electrostatic spinning compound filtering material

ActiveCN103071339AReduce resistanceImprove filtering effectLayered productsFiltration separationTextile technologyBreaking strength

The invention belongs to the technical field of textile, and particularly relates to a fabrication method of a needling / spunlace and electrostatic spinning compound filtering material. The method comprises the steps of fabricating a high-performance filtering material substrate by a needling method or a spunlace method, fabricating a high-performance filtering material surface layer by electrostatic spinning, placing the fabricated filtering material surface layer on the filtering material substrate, compounding by hot rolling at a temperature that is equal to or higher than a melting point of a low melting point fiber within 20 DEG C, and fabricating the high performance filtering material. The warpwise breaking strength of the fabricated high-performance filtering material is greater than or equal to 900N / 5cm, and the weftwise breaking strength of the high-performance filtering material is greater than or equal to 1200N / 5cm. According to the method, the novel high-performance filtering material is fabricated by a high-strength needling / spunlace filtering material and a high-filtration-performance electrostatic spinning fiber layer; the novel high-performance filtering material is high in filter efficiency, low in resistance, and high in breaking strength; the low-melting point fiber is mixed on the upper surface layer of the needling / spunlace filtering material to fabricate a needling / spunlace felt substrate; the felt substrate is compounded with the electrostatic spinning surface layer by the hot rolling; and a stable structure of the filtering material is formed by heat setting.

Owner:孙熙

Coffee cashmere fabric and manufacturing method thereof

The invention discloses a coffee cashmere fabric and a manufacturing method of the coffee cashmere fabric, and aims to provide the warming, comfortable, light and thin coffee cashmere fabric and the manufacturing method thereof. The technical key points of the fabric are that: the fabric consists of the following raw materials in percentage by weight: 13.3 percent of carbon fiber, 29.1 percent of terylene, 19.8 percent of lenzing viscose fiber, 3 percent of spandex and 34.8 percent of normal viscose fiber; and the manufacturing method comprises the following steps of: feeding pure viscose yarn in a first path, terylene in a second path and coffee carbon fiber and lenzing viscose fiber blended yarn in a third path; sequentially and circularly arranging weft yarns; forming two loops by using different thread lengths to form approximate loops on one side of a texture; forming an air retaining layer; and finally dyeing and tidying. The fabric and the method belong to the technical field of textile.

Owner:上海缀菱纺织品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com